McCulloch Pro Mac 8000i Owner's Manual

AWICCULLOCH

CHIPPER/SHREDDER

UK OWNER’S MANUAL

READ CAREFULLY

o

a

287

.,

WARNING: TO REDUCE THE POTENllAL FOR ANY INJURY, COMPLY WITH THE FOLLOWfNG SAFETY

INSTRUCTIONS. FAILURE TO COMPLY WfTH THE lNSTRUCTfONS MAY RESULT IN PERSONAL INJURY.

m

.. ..

●

TRAINING

Read this owner’s manual carefully in its entirety before

attempting to assemble or operate this machine. Be

completely familiar with the controls and the proper use of

this machine before operating it. Keep this manual in a

safe place for future and regular reference or for ordering

replacement parts.

Children must never be allowed to op”erate this

equipment.

No one should operate this unit while intoxicated or while

taking medication that impairs the senses or reactions.

lWs equipment should never be operated in the vicinity of

children, pets or other persons.

Never run your machine in an enclosed area as the

exhaust from the engine contains carbon monoxide,

which is an odorless, tasteless and deadly poisonous gas.

Never place your hands or any part of your body or

clothing inside the feeding chamber, discharge. chute, or

near any moving part while the machine or engine is

running.

Hit is necessary for any reason to inspect or repair the

feeding chambers or any part of the machine where a

moving part can come in contact with your body .or

clothing, stop the machine, allow itto cool, disconnect the

spark plug wire from the spark plug and move it away from

the spark plug before attempting such inspection or

repair.

PREPARATION

Wear safety goggles, work gloves and shoes while

operating the chipper/shredder. Do not wear loose

cbthing or jewelry.

Operate chipper/shredder only on a level surface.

Do not operate the chipper/shredder on a paved or gravel

surface.

Before starting the chipper/shredder, check that all

screws, nuts, bolts and all other fasteners are properly

secured. Replace all damaged or unreadable warning

and operating decals.

Check fuel level before starting engine. Gasoline is highly

flammable; handle with care. Use only an approved

container.

Do not fill fuel tank indoors, when engine is running, or

until engine is allowed to cool. Do not smoke.

Reinstall fuel cap on tank and fuel container. Wipe the unit

clean of any spilled fuel.

oPERAmoN

Before starting the machine, operators shall make certain

that the cutting chamber is empty.

When feeding material into this equipment, be extremely

careful that pieces of metal, rocks, bottles, cans or other

foreign objects are not included. Personal injury or

damage to the machine could result.

INING:Thisunitis

red or grass~vered fand unless the engine’s exhaust system is equipped with a

@rk arrester is used, it should be maintained in effecdve workhg order by the operator.

e ~te of CStfofia the above is required by law (Section 4442 of the Cafifomia Pubfk Resources Coda). other states may have similar iaws

ml laws appfy on federal lands. A spark amester for the mufffer is available through your nearest engine authorized service dealer.

equipped with an internal combustion engine and should not be used on or near any unimproved foreskovered, brush-

n tfre cumng mecnamsm stnf(es any fore~n otqact or n

your machine should stari making an unusual noise or

vibration, immediately stop the engine, disconnect the

spark plug wire from the spark plug and move it away from

the spark plug. Allow the machine to stop and take the

following steps:

. Insf%t for damage.

Replace or repair any damaged parts.

Check for any loose parts and tighten to assure continued

safe operation.

The engine must be kept clean of debris and other

●

accumulations.

Do not allow an accumulation of processed material to

●

build up in the discharge area as this will prevent proper

discharge and can restilf in kti-back from feed opening.

Never place your hands or any other part of your body or

●

clothing inside the feeding chamber, dis~arge chute or

near any moving part while the engine.isrunning.

Keep all guards and deflectors in p!ace and in good

●

working condition to assure continued safe operation.

Always stand clear of the discharge area when operating

●

this machine.

Keep your face and body back from the feed opening to

●

avoid accidental bounce back of any material.

●

Do not over-reach. Keep proper balance and footing at all

times.

The engine governor settings on your machine must not

●

be altered, changed, or tampered with. The governor

controls the maximum safe: operating speeds and

protects the engine and all rnovmg parts from damage

caused by over-speed. Authorized service personnel

should perform these adjustments if a problem exist.

Do not transport machine while engine is running.

●

Do not operate engine if air cleaner or cover directly over

●

carburetor air :intake is removed, except for adjustment.

Removal,of stih~rts could create afire hazard.

ff chipperlshredder becomes clogged the operator must

●

shut-off engine, and disconnect SPSAplug before clearing

debris.

MAINTENANCE AND STORAGE

When this equipment is stoppad for servicing, inspection,

●

storage or to change an accessory, make sure the spark

plug wire is disconnected from the spark plug and moved

away from the spark plug. The machine should be

allowed to cool down before making such inspection,

adjustments, service, etc. Maintain your machine with

care and keep it clean for the best and continued safe

operation. Authorized service shall be sought if a problem

exists.

Do not use flammable solutions to clean the air filter.

●

When not in use, your machine should be stored out of

●

the reach of children. Keep where gasoline fumes will not

reach anopen flame or spark. For long periods of storage,

refer to the “Storage- secti?n of this manual.

spark arrester meeting applicable local or state laws (if any)

. . . ..

. . . . . ..

1

288

D

SAFETVRULES

TABLE OF CONTENTS .................................................

ASSEMBLY

OPERATION

MAINTENANCE .............................................................

..............................................................

..................................................................

................................................................

4-5

8-8

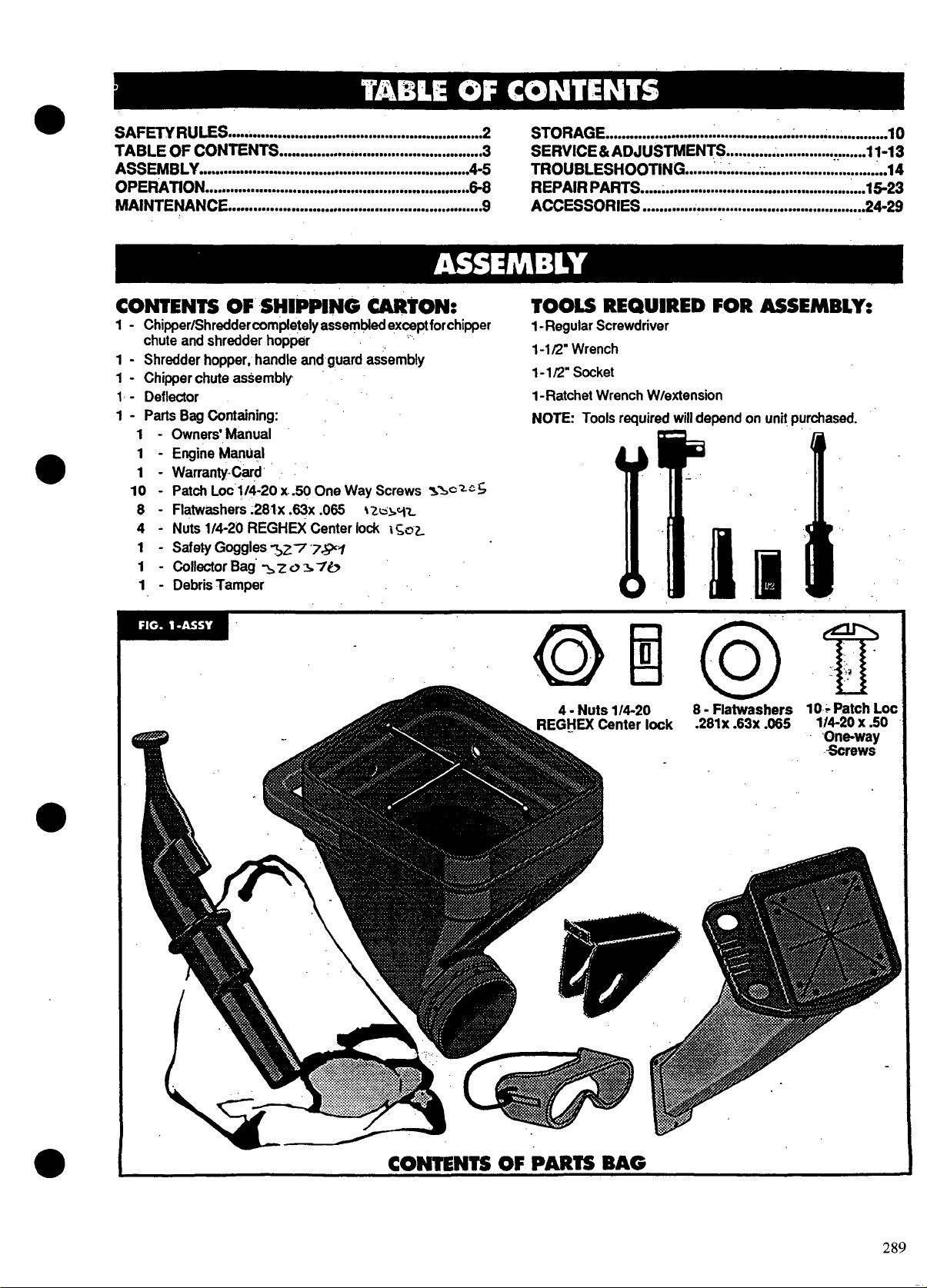

CONTENTS OF SHIPPING CARTON:

1 - Chipper/Shreddercompletely assern~ed exceptforchipper

chute and shredder hopper “

1 - Shredder hopper, handle and guard assembly

1- Chipper chute assembly

1 - Deflector

1 - Parts Bag Containing:

1 - Owners’ Manual

1

- Engine Manual

1 - Warranty-Cwd’ ~

10 - Patch Loc 1/4-20x.50 One Way Screws %%oZ55

8 - Flatwashers .281x .~x .085 ~2tis.qz

4

- Nuts 1/4-20 REGHEX Center lock i @L

1 - %fety Goggles ~z7 ‘7~7

1 - Collector Bag’ zz o 37ti

1 - Debris Tamper

2

3 SERVICE&ADJUSTMENTS

9

STORAGE

TROUBLESHOOTING - ““ 14

REPAIRPARTS

ACCESSORIES ......................................................

.....................................................................

.................................................

.......................................................

TOOLS REQUIRED FOR ASSEMBLY:

l-Regular Screwdriver

1-1/2” Wrench

1-1/2’ Socket

1-Ratchet Wrench W/extension

NOTE Tools required will depend on unit Purchased.

..................................

la

10

11-13

15-23

24-29

CONTENTS OF PARTS BAG

289

—

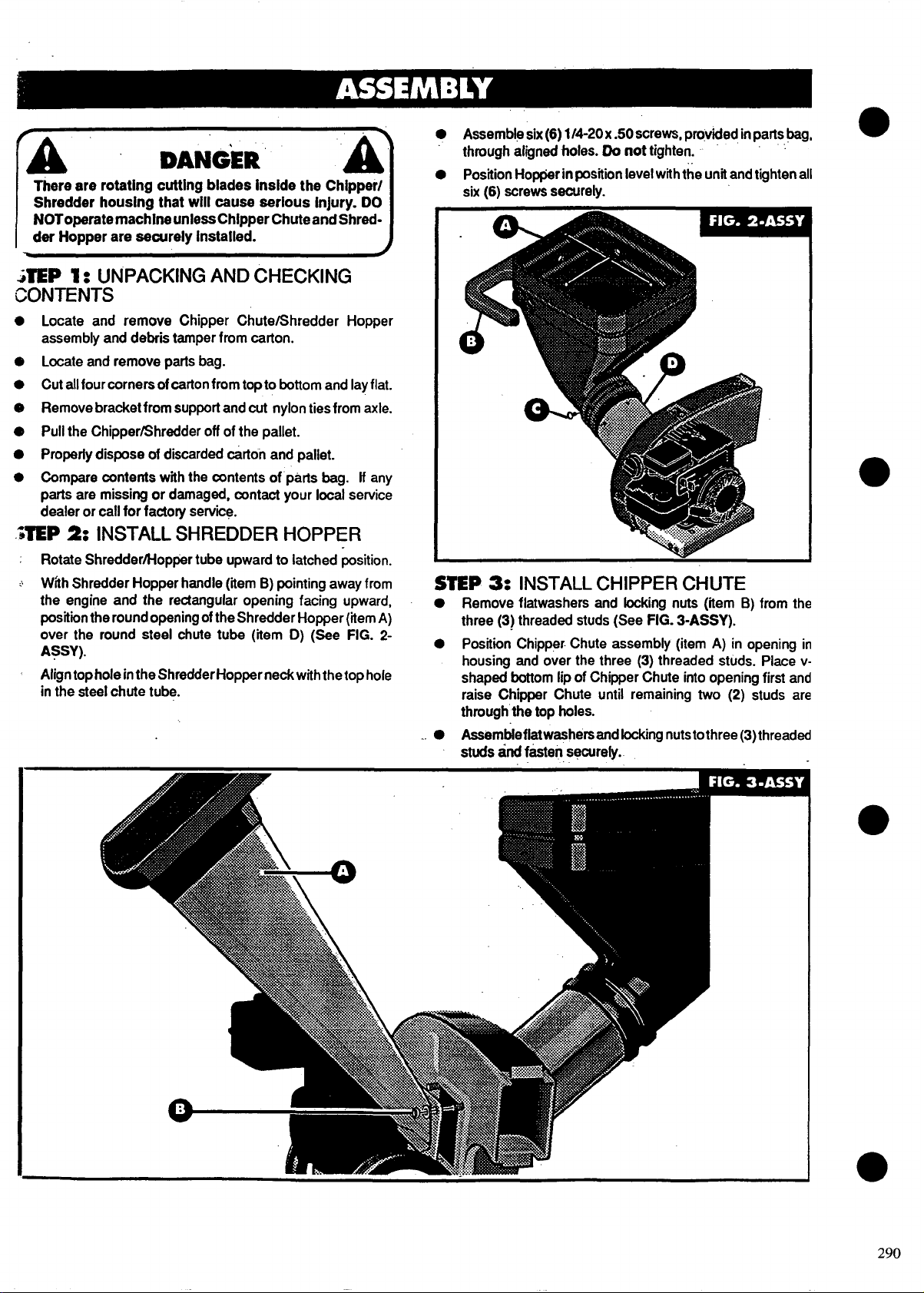

DANGER

There are rotating cutting blades inside the Chipper/

Shredder housing that will cause serious injury. DO

NOToperatemachlns unlessChlpperChuteand Shredder Hopper are seourely installed.

A

J~P 1: UNPACKING AND CHECKING

CONTENTS

Locate and remove Chipper Chute/Shredder Hopper

assembly and debrii tamper from carton.

Locate and remove parts bag.

Cut allfour corners ofcarton from top to bottom and layflat.

Remove bracket from supportandcut nylon ties from axle.

Pull the Chipper/Shredder off of the pallet.

Properfy dispose of discarded c&ton and pallet.

Compare contents with the contents of parts bag. If any

parts are missing or damaged, corrtaot your local service

dealer or call for factory service.

.$TEP2: INSTALL SHREDDER HOPPER

Rotate Shredder/1-foppsr tube upward to latched position.

~ With Shredder Hopper handle (iem B) pointing away from

the engine and the rectangular opening facing upward,

positiintheround opening of the Shredder Hopper (item A)

over the round steel chute tube (item D) (See FIG. 2ASSY).

Align top hole inthe ShredderHopperneck withthe top hole

in the steal chute tube.

● Assemble six(6) l/4-20x .50screws, pm,videdinparts bag,

through afignsd holes. Do not tighten. “” ““

● Position Hopper in position levelwith the unit and tighten all

six (6) screws seourely.

STEP 3: INSTALLCHIPPER CHUTE

● Remove flatwashers and locking nuts (iem B) from the

three (3) threadad studs (See FIG. 3-ASSY).

. Positiin Chipper. Chute assembly (item A) in opening in

housing and over the three (3) threaded sttids. Place vshapsd bottom lip of Chipper Chute into opening first and

raise Chipper Chute until remaining two (2) studs are

through the top holes.

● Assem~efletwashersand locking nutstothree (3)threaded

..

studs and f&ten securely.

●

290

c)

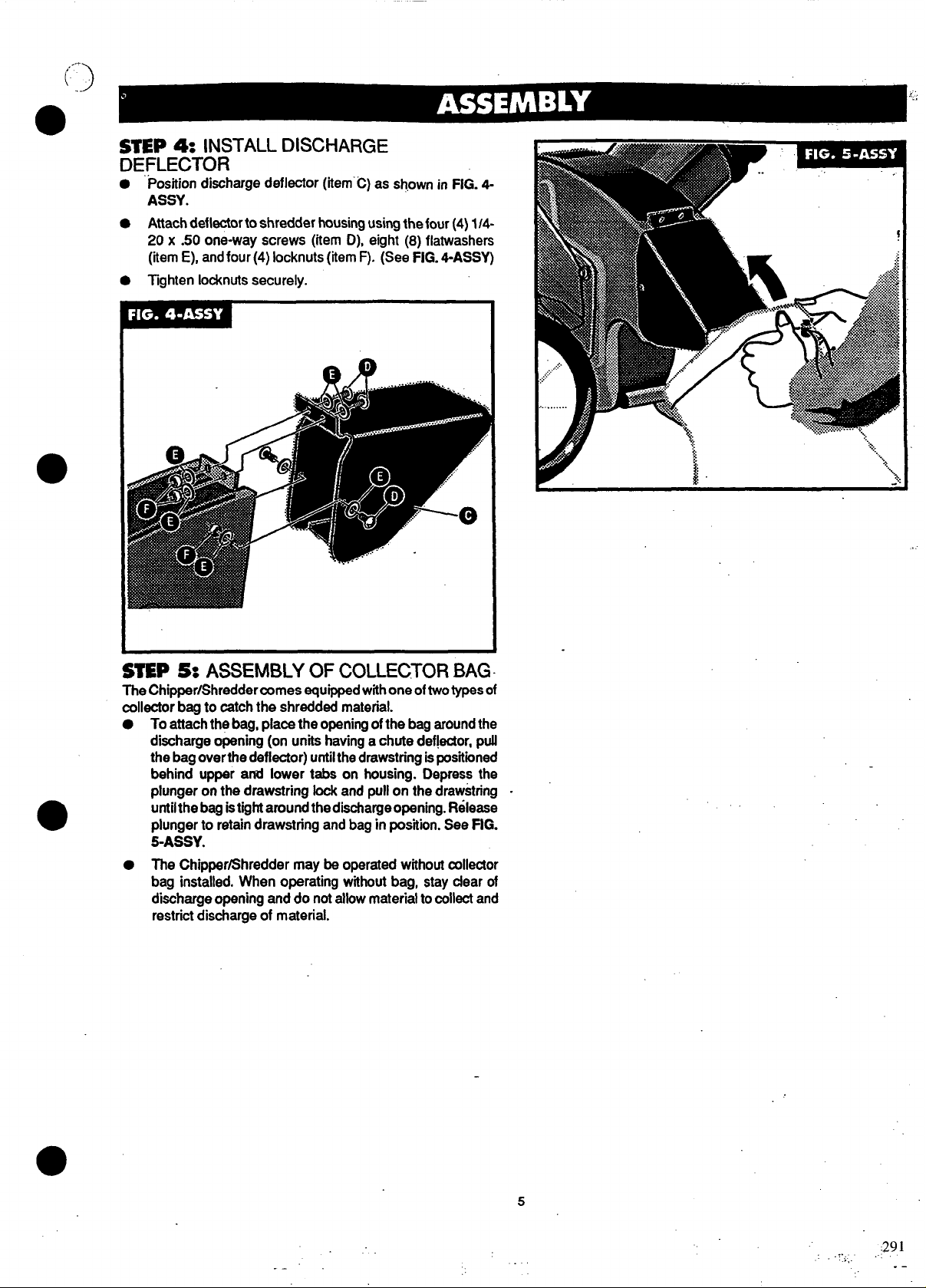

STEP 4: INSTALL DISCHARGE

DEFLECTOR

● “Positiondischarge deflector (item C) as shown in FIG. 4-

iassY.

. Attach deflector to shredder housingusing the four (4) l/4-

20 x .50 one-way screws (item D), eight (8) fiatwashers

(iem E), andfour(4) locknuts (item F). (See FIG. 4-ASSY)

● Tighten locknuts securely.

STEP 5: ASSEMBLY OF COLLECTOR BAG

The Chipper/Shreddercomes equippedwith one oftwotypes of

collector bag to catch the shredded material.

To atta~h the bag, place the opening of the bag around the

discharge opening (on units having a chute deflector, pull

the bag overthe deflector) untilthe drawstring is positioned

behind upper and lower tabs on housing. Depress the

plunger on the drawstring lock and pull on the drawstring

untilthe bag istight around the discharge opening. Release

plunger to retain drawstring and bag in position. See FfG.

5-ASSY.

The Chipper/Shredder may be operated without collector

bag installed. When operating without bag, stay dear of

discharge opening and do not allow material to collect and

restrict discharge of material.

,4

.-. .

5

..291

,,.,

,,.,

.-

c)

,\:-,.

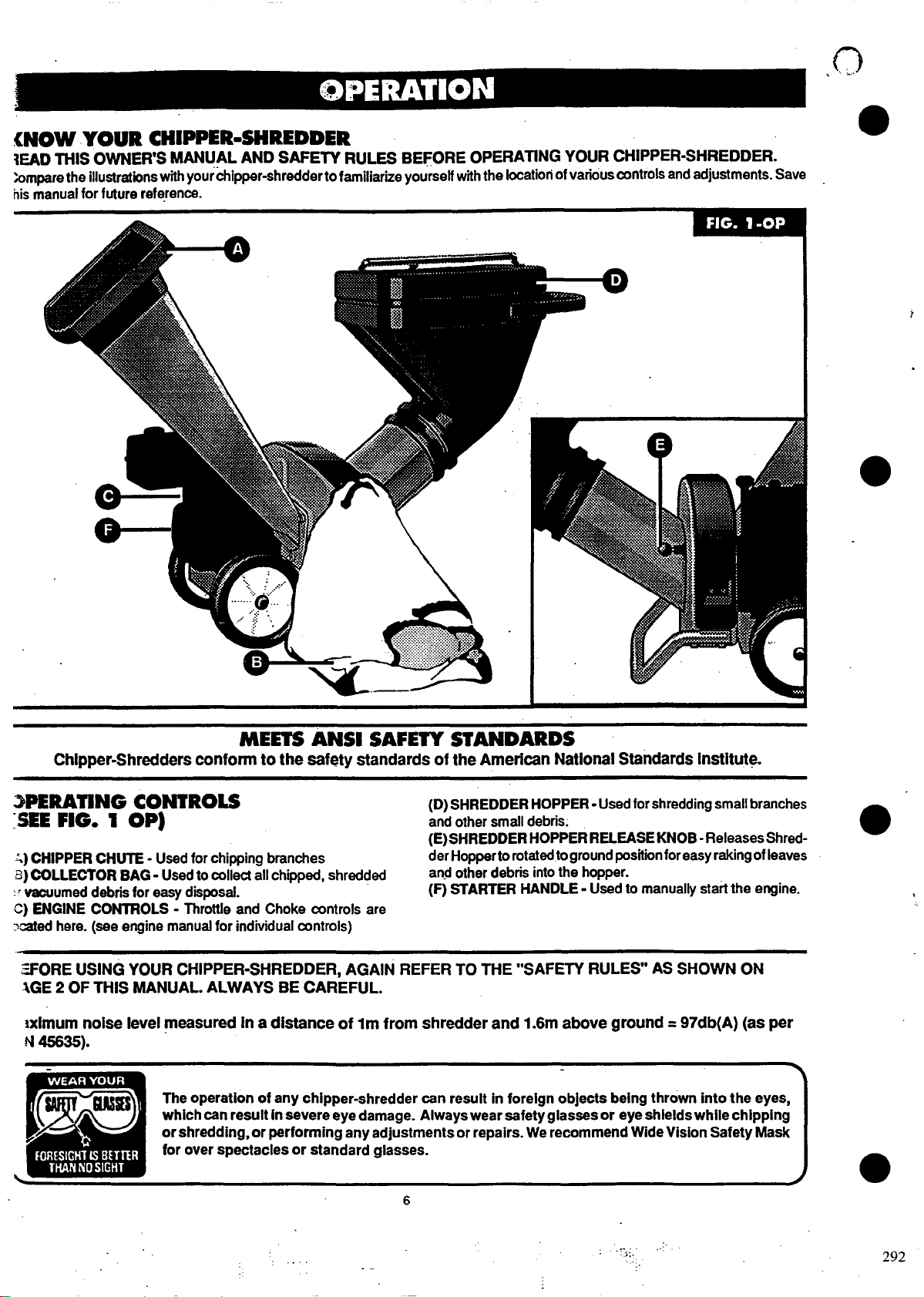

<NOW YOUR CIMPPER-SHREDDER

WAOTHIS OWNER’S MANUALAND SAFETY RULES BEFORE OPERATING YOUR CHIPPER-SHREDDER.

hnpare the illustrations with yourchippar-shradderto familiarize yoursetf with the Iocat”mriofvarkius controls and adjustments. Save

hismanual for future reference.

●

MEEK ANSI SAFETY STANDARDS

Chipper-Shredders conform to the safety standards of the American National Standards Institute.

3PERAllNG CONTROLS

(D) SHREDDER HOPPER -Used forshredding small branches

SEE FIGe 1 OP) and other small debris.

(E)SHREDDER HOPPER RELEASE KNOB -Releases Shrad-

:) CHIPPER CHUTE- Usad forchippingbranches

2) COLLECTOR BAG- Used to collect all chipped, shredded

:‘ vacuumed debrisfor easydisposaf.

C) ENGINE CONTROLS - Throttle and Choke controls are

xatad here.(see enginemanualfor ind”widualcontrols)

*ORE

XGE 2 OF THIS MANUAL. ALWAYS BE CAREFUL.

~xlmum

N4S63!5).

h

USING YOUR CHIPPER-SHREDDER, AGAIN REFER TO THE “SAFETY RULES AS SHOWN ON

noise level measured in a distance of Im from shredder and 1.6m above ground = 97db(A) (as per

The operation of any chipper-shredder can result in foreign objects being thrown into the eyes,

which can resuft insevere eye damage. Always wear safety glasses or eye shields while chipping

or shredding, or performing any adjustments or repairs. We recommend WideVision Safety Mask

for over spectacles or standard glasses.

derHopparto rotatadtogroundpositiinforeasy rakingofleaves

and other debris intothe hopper.

(F) STARTER HANDLE - Used to manuallystafi the engine.

. .

6

..... ..:

.

.-

..:.

292

—

;.,,..

.....

..

●

●

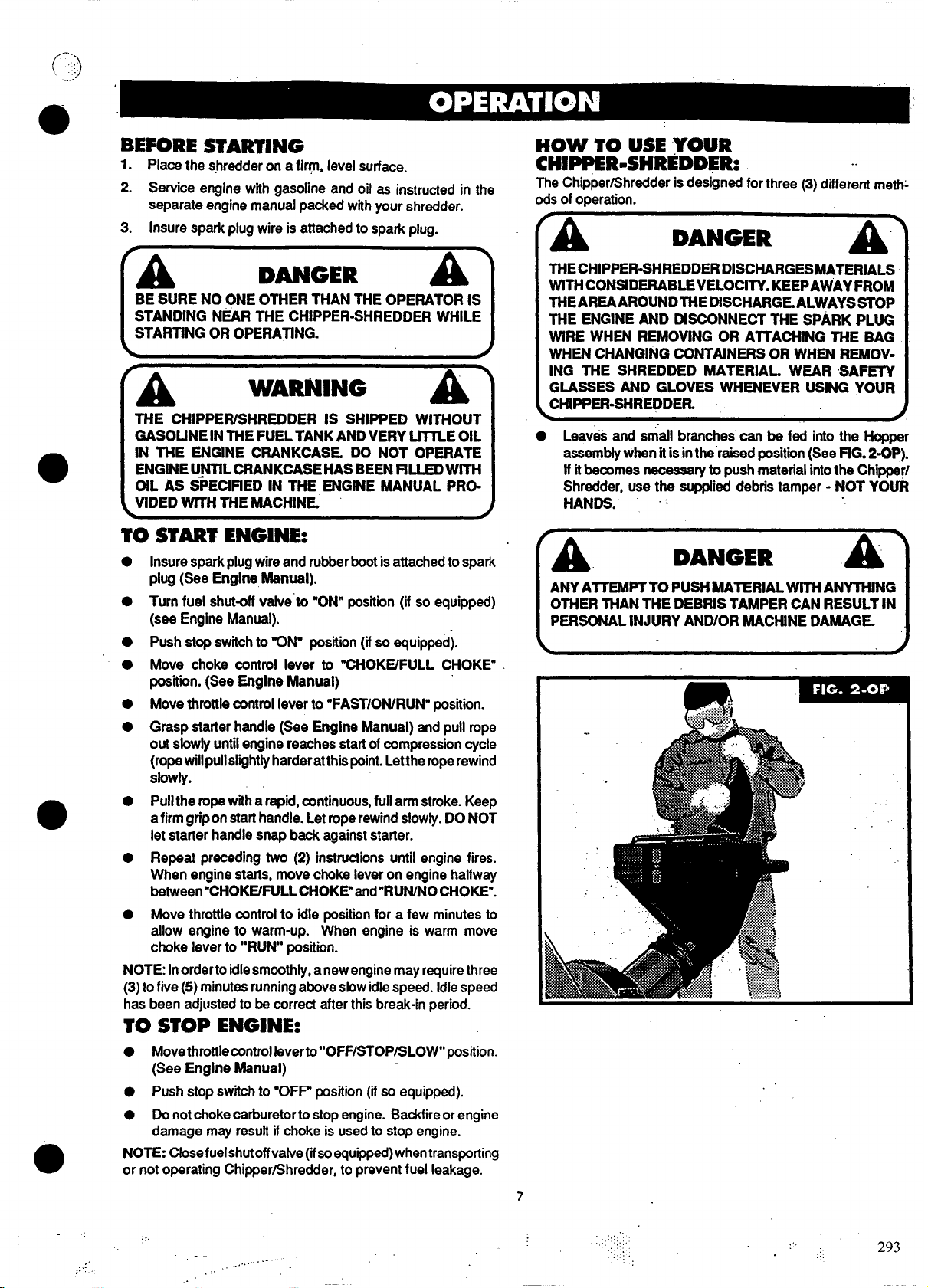

BEFORE STARTING

1. Place the shredder on a firm, level surface.

2. Service engine with gasoline and oil as instructed in the

separate engine manual packed with your shredder.

3. Insure spark plug wire is attached to spark plug.

fA

BE SURE NO ONE OTHER THAN THE OPERATOR IS

STANDING NEAR THE CHIPPER-SHREDDER WHILE

STARTING OR OPERATING.

I

r

A

THE CHIPPEWSHREDDER IS SHIPPED WITHOUT

GASOUNEIN THE FUEL TANK AND VERY LlllLE OIL

IN THE ENGINE CRANKCASE. DO NOT OPERATE

ENGINE U.~L CRANKCASE HAS BEEN HUED WITH

OIL AS SPECIFfED IN THE ENGINE MANUAL PRO-

VIDED WfTH THE MACHINE.

DANGER

WARNING

A“

.

A

TO START ENGIN&

●

Insure spark plug wire and rubber boot is attached to spark

plug (See

Turn fuel shutdf valve to ‘ON” position (if so equipped)

●

EngineManual).

(seeEngine Manual).

●

Push stop switch to “ON” position (if so equipped).

Move choke control lever to “CHOKIVFULL CHOKE”

●

positiin. (See Engine Manual)

Move throttle control lever to ‘FAST/ON/RUN” positiin.

●

Grasp starter handle (See Engine Manual) and pull rope

●

out slowly until engine reaches start of compression cycle

(rope willpullslightly harderatthispoint. Letlhe roperewind

slowly.

Pull the rope with a rapid, continuous, full arm stroke. Keep

●

afirm grip on start handle. Let rope rewind slowly. DO NOT

let starter handle snap back against starter.

Repeat preceding two (2) instructions until engine fires.

●

When engine starts, move choke lever on engine halfway

between ‘CHOKE/FULLCHOKE” and“RUN/NOCHOKE”.

Move throttle control to idle positiin for a few minutes to

allow engine to warm-up. When engine is warm move

choke lever to “RUN positiin.

NOTE Inorderto idlesmoothly, anew engine may require three

(3)to five (5) minutes running above slow idle speed. Idlespeed

has been adjusted to be correct after this break-in period.

TO STOP ENG9NE:

● Movethrottle control leverto*’OFF/STOP/SLOW position.

(See Engine Manual)

● Push stop switch to “OFF position (ifso equipped).

● Do not choke carburetor to stop engine. Backfire or engine

damage may result if choke is used to stop engine.

NOTE: Closefuelshutoff valve (ifsoequipped)when transporting

or not operating Chipper/Shredder, to prevent fuel leakage.

HOW TO USE YOUR

CH9PPER-SHREDDER:

The Chipper/Shredder is designed for three (3)different meth-

ods of operation.

A

THECHIPPER-SHREDDER DISCHARGESMATERIALS

WITH CONSIDERABLE VELOCITY. KEEPAWAYFROM

THEAREAAROUND THE DISCHARGE ALWAYS STOP

THE ENGINE AND DISCONNECT THE SPARK PLUG

WfRE WHEN REMOVING OR AITACHING THE BAG

WHEN CHANGING CONTAINERS OR WHEN REMOVING THE SHREDDED MATERIAL. WEAR SAFETY

GLASSES AND GLOVES WHENEVER USING YOUR

CHIPPER-SHREDDER

● Leaves and small branches can be fed into the Hopper

assembly when it is inthe raised positiin (See FfG. 2-OP).

If it becomes necessary to push material intothe Chipper/

Shredder, use the suppfied debris tamper - NOT YOUR

●

A.

ANY ATTEMPT TO PUSH MATERIAL WITH ANYTHfNG

OTHER THAN THE DEBRfS TAMPER CAN RESULT IN

PERSONAL INJURY AND/OR MACHINE DAMAGE.

+

DANGER

DANGER .

..

A-

A’

4

..:

;.,

.-

,., .,..-.. .

;.,’.

:,:.

‘.:

,. :::

,:.

293

-.

A

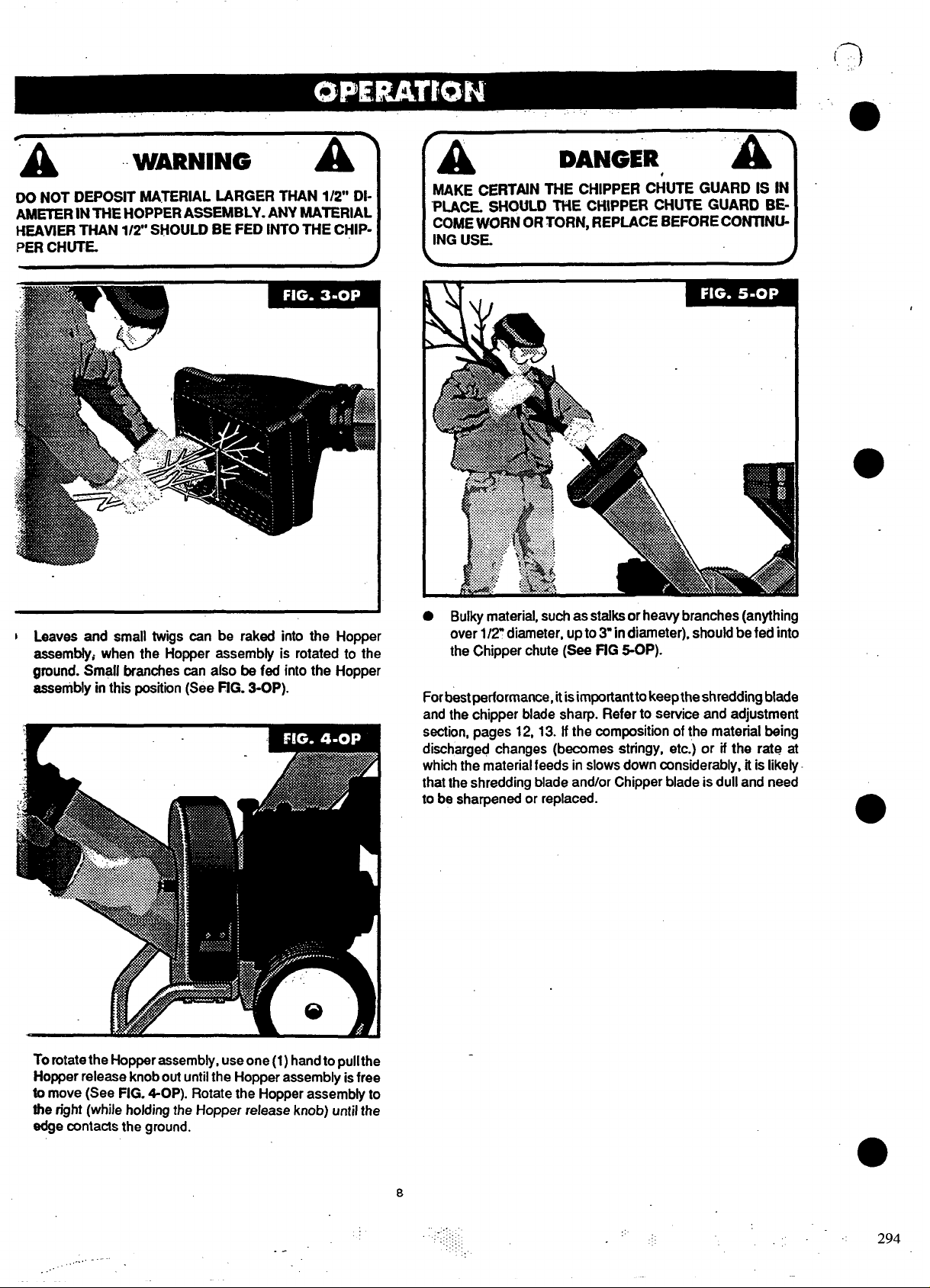

DO NOT DEPOSIT MATERIAL LARGER THAN 1/2” Dl-

AMETER IN THE HOPPER ASSEMBLY. ANY MATERIAL

HEAVIER THAN 1/2” SHOULD BE FED INTO THE CHIPPER CHUTE.

WARNING

r

A

MAKE CERTAIN THE CHIPPER CHUTE GUARD IS IN

PLACE. SHOULD THE CHIPPER CHUTE GUARD BE-

COME WORN OR TORN, REPLACE BEFORE CONTINUING USE.

I

DANGER

A

I Leaves and small twigs can be raked into the Hopper

assemblyi when the Hopper assembly is rotated to the

ground. Small branches can also be fed into the Hopper

assembly in this position (See FIG. 3-OP).

I

● Bulky material, such as stalks or heavy branches (anything

over 1/2” diameter, up to 3“ in diameter), should be fed into

the Chipper chute (See flG 5-OP).

Forbestperformance, it isimportanttokeepthe shredding blade

and the chipper blade sharp. Refer to service and adjustment

section, pages 12, 13. If the composition of the material being

discharged changes (becomes stringy, etc.) or if the rate at

which the material feeds in slows down considerably, it is likely

that the shredding blade and/or Chipper blade is dull and need

to be sharpened or replaced.

●

Torotatethe Hopper assembly, use one (1) hand to pullthe

Hopper release knob out untilthe Hopper assembly isfree

to move (See FIG. 4-OP). Rotate the Hopper assembly to

the right (while holding the Hopper release knob) until the

edge contacts the ground.

.-

.,-.. ...

8

,.

,::.

294

DANGER

NEVERSTOREYOUR CHIPPER-SHREDDER INDOORS

OR IN AN ENCLOSED, POORLY VENTILATED AREA

IF GASOUNE REMAINS IN THE TANK. FUMES MAY

REACH AN OPEN FiAM~ SPARK OR PILOT UGHT

FROM A FURNACEj WATER HEATER, CLOTHES

DRYER, CIGAREITEj ETC.

TOprevent engine damage ifchipper-shredderis not used for

awe than30 days, follow the steps below.

NOT12GASOLINE MUST BE REMOVED OR TREATED TO

PREVENT GUM DEPOSITS FROM FORMING IN THE TANK,

FILTER, HOSE AND CARBURETOR DURING STORAGE.

AEODURINGSTORAGE, ALCOHOL-BLENDED GASOLINE

THAT USES ETHANOL OR METHANOL (SOMETIMES

CALLEDGASOHOL) ATIRACTS WATER. IT ACTS ON THE

GASOLINE TO FORM ACIDS WHICH DAMAGE THE ENGINE.

A

To remove gasoline,run engine “untiltankisemptyandengine w

stops. if you do not want to remove gwdine,agasstabilizer

such as STA-BIL may be added to any gasoline left in the tank

to minimize gum deposits and ac”ds. If thetankis almost empty,

mixstabifiierwith fresh gasoline inaseparatecontainerand add

some to the tank.

container.Thenrun

Iizer is added to allow mixture to reach carburetor. Store

chipper-shredder in safe piace. See warning above.

Thefollowing stepsshould beteken to prepare yourshredderfor

storage.

. Clean unit thorougitly, including engine.

● Refer to engine manual for correct engine storage

instruct”mns.”

● Carefully inspect unit and repiace any worn, damaged, or

missing parts and tghten any ioose fasteners

● if storing in an unventilated or metal storage shed, coat

metal parts with a ~ghtoil or sifiine to prevent rusting.

● Store Chipper/Shredder in a dry, clean are% out of the ●

reach of children.

Alwaysfollow instructionson stsibiiizer

engine at feast 10 minutes after etabf-

.—.

. .

..

—.— .——-—.

10

:’:

‘. :,”

2,6:

.,

!

~~

Loading...

Loading...