Model A-P3

(Machine Code: G065)

SERVICE MANUAL

November 6th, 2001

Subject to change

!

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the printer and peripherals,

make sure that the printer power cord is unplugged.

2. The wall outlet should be near the printer and easily accessible.

3. Note that some components of the printer and the paper tray unit are

supplied with electrical voltage even if the main power switch is turned off.

4. If any adjustment or operation check has to be made with exterior covers off

or open while the main switch is turned on, keep hands away from electrified

or mechanically driven components.

5. The inside and the metal parts of the fusing unit become extremely hot while

the printer is operating. Be careful to avoid touching those components with

your bare hands.

HEALTH SAFETY CONDITIONS

Toner and developer are non-toxic, but if you get either of them in your eyes by

accident, it may cause temporary eye discomfort. Try to remove with eye drops

or flush with water as first aid. If unsuccessful, get medical attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The printer and its peripherals must be installed and maintained by a

customer service representative who has completed the training course on

those models.

2. The NVRAM on the system control board has a lithium battery which can

explode if replaced incorrectly. Replace the NVRAM only with an identical

one. The manufacturer recommends replacing the entire NVRAM. Do not

recharge or burn this battery. Used NVRAM must be handled in accordance

with local regulations.

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do not incinerate toner bottles or used toner. Toner dust may ignite suddenly

when exposed to an open flame.

2. Dispose of used toner, developer, and organic photoconductors in

accordance with local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used lithium batteries in or der to dispose of them later, do not

put more than 100 batteries per sealed box. Storing larger numbers or not

sealing them apart may lead to chemical reactions and heat build-up.

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair of

laser-based optical units in the field. The optical housing unit can only be repaired

in a factory or at a location with the requisite equipment. The laser subsystem is

replaceable in the field by a qualified Customer Engineer. The laser chassis is not

repairable in the field. Customer engineers are therefore directed to return all

chassis and laser subsystems to the factory or service depot when replacement of

the optical subsystem is required.

!

WARNING

Use of controls, or adjustment, or performance of procedures other than

those specified in this manual may result in hazardous radiation exposure.

!

WARNING

WARNING: Turn off the main switch before atte mpting any of the

procedures in the Laser Unit section. Laser beams can seriously damage

your eyes.

Caution Labels

LASER-3.WMF

G065RLW.WMF

LASER-1.WMF

Lithium Batteries (Memory Back-up)

!

CAUTION

The danger of explosion exists if a battery of this type is incorrectly

replaced. Replace only with the same or an equivalent type recommended

by the manufacturer. Discard used batteries in accordance with the

manufacturer’s instructions.

Warning Concerning Copyright

Many documents are copyrighted. Such documents may not be reproduced by

copying or in any other form without the express permission of the copyright holder.

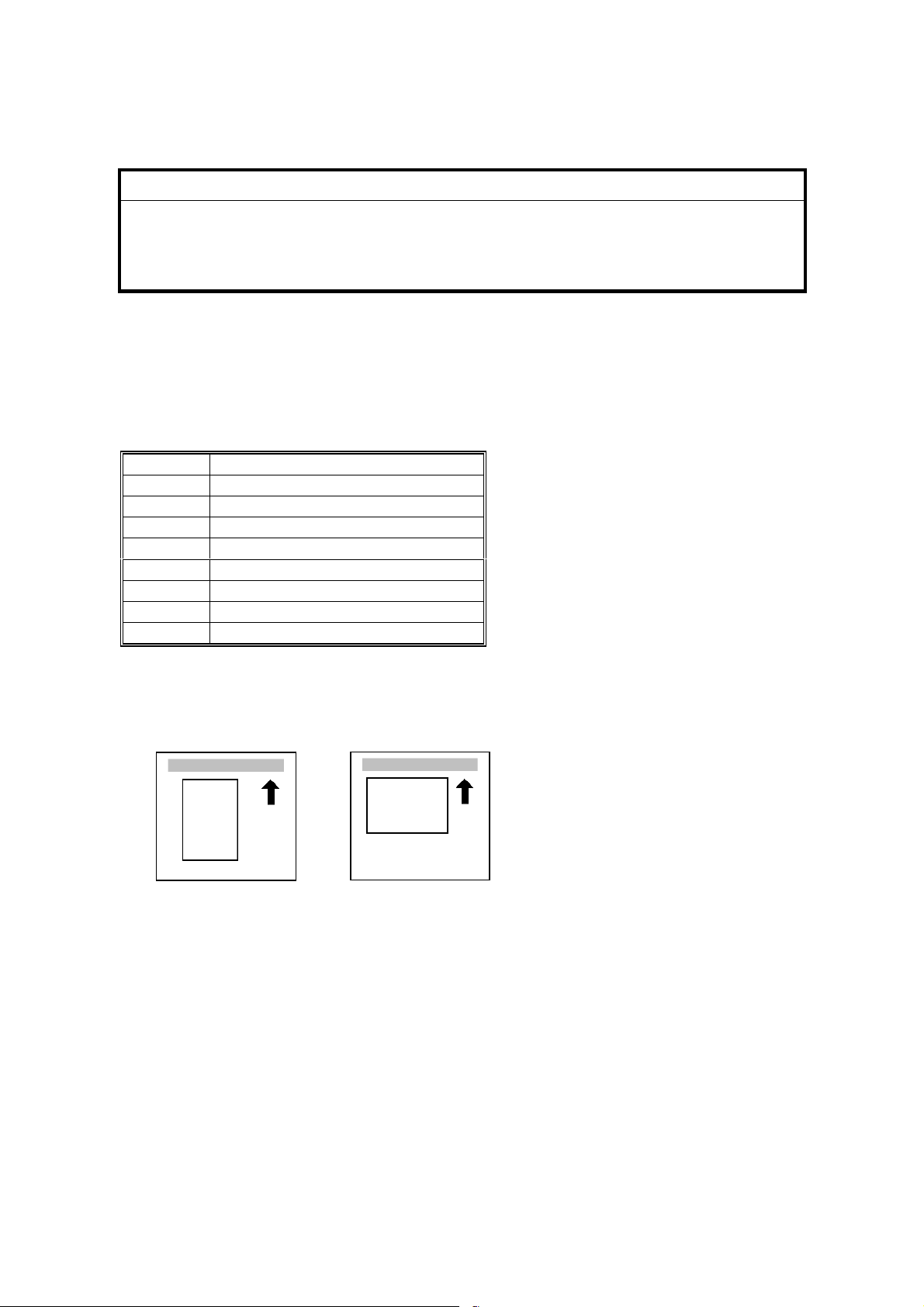

Conventions in this Manual

This manual uses several symbols and some simple abbreviations.

Symbol What it means

☛

!

"

#

$

%

HP Home Position

T/S Transfer/Separation

Refer to section number

See Core Tech Manual for details

Screw

Connector

E-ring

C-ring

The following notations are used in text to describe the direction of paper feed:

lengthwise and sideways. The annotations “SEF” and “LEF” denote “Short Edge

Feed” and “Long Edge Feed’. (The arrows indicate the direction of paper feed.)

Lengthwise (SEF) Sideways (LEF)

TABLE OF CONTENTS

1. INSTALLA TION .......................................................................... 1-1

1.1 INSTALLATION REQUIREMENTS...........................................................1-1

1.1.1 ENVIRONMENT...............................................................................1-1

1.1.2 MACHINE LEVEL.............................................................................1-1

1.1.3 MACHINE SPACE REQUIREMENTS.............................................. 1-2

1.1.4 POWER REQUIREMENTS..............................................................1-3

1.2 MACHINE INSTALLATION .......................................................................1-3

1.3 OPTIONAL UNIT INSTALLATION.............................................................1-3

1.4 SYMBOLS USED IN TEXT .......................................................................1-3

1.5 LCT INSTALLATION (A683)......................................................................1-4

1.5.1 ACCESSORY CHECK......................................................................1-4

1.5.2 INSTALLATION PROCEDURE........................................................1-5

1.6 BRIDGE UNIT INSTALLATION (B397).....................................................1-7

1.6.1 ACCESSORY CHECK......................................................................1-7

1.6.2 INSTALLATION PROCEDURE........................................................1-8

1.7 1000-SHEET FINISHER INSTALLATION (A681)....................................1-10

1.7.1 ACCESSORY CHECK....................................................................1-10

1.7.2 INSTALLATION PROCEDURE......................................................1-11

1.8 3000-SHEET FINISHER INSTALLATION (A697)....................................1-14

1.8.1 ACCESSORY CHECK....................................................................1-14

1.8.2 INSTALLATION PROCEDURE......................................................1-15

1.9 PUNCH UNIT INSTALLATION (A812)....................................................1-19

1.9.1 ACCESSORY CHECK....................................................................1-19

1.9.2 INSTALLATION PROCEDURE......................................................1-20

1.10 MAILBOX INSTALLATION (G909)........................................................1-23

1.10.1 ACCESSORY CHECK..................................................................1-23

1.10.2 REQUIREMENT OPTIONS FOR MAIN MACHINE......................1-23

1.10.3 INSTALLATION PROCEDURE....................................................1-24

1.11 BRIDGE UNIT FOR MAILBOX INSTALLATION (G912) .......................1-27

1.11.1 ACCESSORY CHECK..................................................................1-27

1.11.2 INSTALLATION PROCEDURE....................................................1-28

2. PREVENTIVE MAINTENANCE SCHEDULE.............................. 2-1

2.1 PM TABLES ..............................................................................................2-1

2.1.1 PM TABLES FOR THE PRINTER....................................................2-1

2.1.2 PM TABLES FOR OPTIONS............................................................2-3

3. REPLACEMENT AND ADJUSTMENT........................................ 3-1

3.1 GENERAL CAUTIONS..............................................................................3-1

3.1.1 LASER UNIT ....................................................................................3-1

3.1.2 USED TONER..................................................................................3-1

3.2 SPECIAL TOOLS AND LUBRICANTS......................................................3-2

3.2.1 SPECIAL TOOLS.............................................................................3-2

3.2.2 LUBRICANTS...................................................................................3-2

i

3.2.3 SYMBOLS USED IN TEXT...............................................................3-2

3.3 FRONT DOOR ..........................................................................................3-3

3.4 DUPLEX UNIT...........................................................................................3-3

3.5 UPPER RIGHT COVER............................................................................3-4

3.6 BY-PASS TRAY UNIT...............................................................................3-5

3.7 REAR COVERS ........................................................................................3-6

3.7.1 REAR UPPER COVER.....................................................................3-6

3.7.2 REAR LOWER COVER....................................................................3-6

3.8 LEFT COVERS..........................................................................................3-7

3.8.1 LEFT UPPER COVER......................................................................3-7

3.8.2 OPERATION PANEL........................................................................3-8

3.8.3 PAPER OUTPUT TRAY...................................................................3-9

No Bridge Unit Installed........................................................................3-9

Bridge Unit Installed..............................................................................3-9

3.9 LASER UNIT........................................................................................... 3-10

3.9.1 CAUTION DECAL LOCATIONS.....................................................3-10

3.9.2 LASER UNIT ..................................................................................3-11

3.9.3 POLYGON MIRROR MOTOR........................................................3-12

3.9.4 LASER SYNCHRONIZATION DETECTOR....................................3-13

3.9.5 LD UNIT..........................................................................................3-13

Laser Beam Pitch Adjustment.............................................................3-14

3.10 PCDU....................................................................................................3-15

3.10.1 PHOTOCONDCUTOR CLEANING/DEVELOPMENT UNIT.........3-15

3.10.2 DRUM...........................................................................................3-16

3.10.3 PICK-OFF PAWLS.......................................................................3-17

3.10.4 CHARGE ROLLER AND CLEANING ROLLER ............................3-18

3.10.5 DRUM CLEANING BLADE...........................................................3-19

3.10.6 ID SENSOR..................................................................................3-20

3.11 DEVELOPMENT................................................................................... 3-21

3.11.1 DEVELOPMENT UNIT.................................................................3-21

3.11.2 DEVELOPMENT FILTER............................................................. 3-22

3.11.3 DEVELOPMENT ROLLER...........................................................3-23

3.11.4 DEVELOPER................................................................................3-24

3.11.5 TD SENSOR.................................................................................3-26

3.12 TRANSFER UNIT..................................................................................3-27

3.12.1 TRANSFER BELT UNIT...............................................................3-27

3.12.2 TRANSFER BELT........................................................................3-28

3.12.3 CLEANING BLADE/TONER OVERFLOW SENSOR....................3-29

Transfer Belt Cleaning Blade..............................................................3-29

Toner Overflow Sensor.......................................................................3-29

3.13 PAPER FEED........................................................................................3-30

3.13.1 PICK-UP, SEPARATION, AND FEED ROLLERS ........................3-30

3.13.2 LOWER RIGHT COVER...............................................................3-31

3.13.3 RELAY/UPPER PAPER FEED AND LOWER PAPER FEED

CLUTCHES..................................................................................3-32

3.13.4 UPPER PAPER FEED UNIT FOR TRAY 1..................................3-33

3.13.5 LOWER PAPER FEED UNIT FOR TRAY 2.................................3-34

3.13.6 PAPER END/PAPER LIFT/RELAY SENSORS............................3-35

3.13.7 REGISTRATION SENSOR...........................................................3-36

ii

3.13.8 TRAY LIFT MOTOR.....................................................................3-38

3.13.9 FEED/DEVELOPMENT MOTOR..................................................3-39

3.14 FUSING.................................................................................................3-40

3.14.1 FUSING UNIT...............................................................................3-40

3.14.2 FUSING UNIT EXIT GUIDE .........................................................3-41

3.14.3 HOT ROLLER STRIPPERS .........................................................3-41

3.14.4 FUSING LAMPS...........................................................................3-42

Left Side..............................................................................................3-42

Right Side...........................................................................................3-43

3.14.5 THERMISTORS AND THERMOSTATS.......................................3-44

3.14.6 HOT ROLLER/PRESSURE ROLLER...........................................3-45

3.15 BY-PASS TRAY....................................................................................3-47

3.15.1 COVER REPLACEMENT.............................................................3-47

3.15.2 BY-PASS FEED/PICK-UP ROLLER.............................................3-48

3.15.3 BY-PASS SEPARATION ROLLER REPLACEMENT...................3-49

3.15.4 PAPER END SENSOR/PICK-UP SOLENOID..............................3-50

3.15.5 PAPER SIZE SENSOR BOARD REPLACEMENT.......................3-51

3.15.6 BY-PASS TABLE REMOVAL.......................................................3-52

3.15.7 PAPER FEED CLUTCH REPLACEMENT....................................3-53

3.16 DUPLEX UNIT.......................................................................................3-54

3.16.1 DUPLEX COVER REMOVAL.......................................................3-54

3.16.2 DUPLEX ENTRANCE SENSOR REPLACEMENT....................... 3-55

3.16.3 DUPLEX EXIT SENSOR REPLACEMENT ..................................3-56

3.17 DRIVE AREA.........................................................................................3-57

3.17.1 REGISTRATION/TRANSFER BELT CONTACT CLUTCHES......3-57

3.17.2 MAIN MOTOR..............................................................................3-58

3.17.3 FUSING/EXIT MOTOR.................................................................3-59

3.17.4 FUSING/EXIT CLUTCH................................................................3-60

3.17.5 TONER SUPPLY MOTOR............................................................3-61

3.18 PRINTED CIRCUIT BOARDS...............................................................3-62

3.18.1 HIGH VOLTAGE POWER SUPPLY.............................................3-62

3.18.2 I/O BOARD...................................................................................3-63

3.18.3 BICU BOARD...............................................................................3-64

3.18.4 PSU..............................................................................................3-64

3.19 HARD DISK/CONTROLLER BOARD ....................................................3-65

To Format the HDD.............................................................................3-65

3.20 PRINTING ADJUSTMENTS..................................................................3-66

3.21 PARALLELOGRAM IMAGE ADJUSTMENT .........................................3-67

4. TROUBLESHOOTING ................................................................ 4-1

4.1 SERVICE CALL CONDITIONS.................................................................4-1

4.1.1 SUMMARY.......................................................................................4-1

4.1.2 SC CODE DESCRIPTIONS .............................................................4-2

4.2 ELECTRICAL COMPONENT DEFECTS ................................................4-13

4.2.1 SENSORS......................................................................................4-13

4.2.2 SWITCHES.....................................................................................4-14

4.3 BLOWN FUSE CONDITIONS.................................................................4-15

4.4 LEDS.......................................................................................................4-15

iii

BICU...................................................................................................4-15

4.5 TEST POINTS.........................................................................................4-15

Controller Board..................................................................................4-15

5. SERVICE TABLES...................................................................... 5-1

5.1 SERVICE PROGRAM MODE....................................................................5-1

5.1.1 ENTERING AND LEAVING THE SERVICE PROGRAM MODE......5-1

5.2 PRINTER CONTROLLER SERVICE MODE.............................................5-2

5.2.1 CONTROLLER SERVICE MODE MENUS.......................................5-2

5.2.2 BIT SWITCH PROGRAMMING........................................................5-2

5.2.3 PRINTER CONTROLLER BIT SWITCH SETTINGS........................5-3

5.3 PRINTER ENGINE SERVICE MODE........................................................5-4

Leaving the SP Mode.............................................................................5-5

5.3.1 SERVICE PROGRAM MODE TABLES............................................5-6

1. Feed (SP1000-00)..............................................................................5-6

2. Drum (SP2000-00) ...........................................................................5-10

3. Process (SP3000-00).......................................................................5-20

4. HDD (SP4000-00) ............................................................................5-21

5. Mode (SP5000-00)...........................................................................5-21

6. Peripherals (SP6000-00)..................................................................5-25

7. Data Log (SP7000-00)......................................................................5-26

5.3.2 TEST PATTERN PRINTING...........................................................5-29

Test Pattern Table: SP2902-03 Printing Test Patterns.......................5-30

5.3.3 INPUT CHECK...............................................................................5-31

Table 1: By-pass Feed Table Paper Size ...........................................5-34

5.3.4 OUTPUT CHECK...........................................................................5-35

SP5804 Output Check Table.............................................................. 5-36

5.3.5 MEMORY ALL CLEAR: SP5801 ....................................................5-37

5.3.6 SMC PRINT OUT LISTS: SP5990..................................................5-38

5.4 SOFTWARE DOWNLOAD......................................................................5-39

5.4.1 DOWNLOADING THE SOFTWARE...............................................5-39

5.4.2 POWER FAILURE DURING SOFTWARE DOWNLOAD................5-40

5.5 SELF-DIAGNOSTIC MODE....................................................................5-41

5.5.1 SELF-DIAGNOSTIC MODE AT POWER ON.................................5-41

Self-Diagnostic Test Flow...................................................................5-41

5.5.2 DETAILED SELF-DIAGNOSTIC MODE.........................................5-42

5.6 DIP SWITCHES.......................................................................................5-43

Controller: DIP SW2 ...........................................................................5-43

I/O Board: DIP SW101........................................................................5-43

6. DETAILED SECTION DESCRIPTIONS ...................................... 6-1

6.1 OVERVIEW...............................................................................................6-1

6.1.1 COMPONENT LAYOUT...................................................................6-1

Paper Path............................................................................................6-2

DRIVE LAYOUT ...................................................................................6-3

6.2 BOARD STRUCTURE...............................................................................6-4

6.2.1 BLOCK DIAGRAM............................................................................6-4

6.2.2 CONTROLLER.................................................................................6-6

iv

6.3 PRINTING PROCESS OVERVIEW...........................................................6-8

Drum Charge........................................................................................6-8

Laser Exposure.....................................................................................6-8

Development.........................................................................................6-8

Image Transfer .....................................................................................6-9

Separation ............................................................................................6-9

ID Sensor..............................................................................................6-9

Cleaning................................................................................................6-9

Quenching ............................................................................................6-9

6.4 LASER EXPOSURE................................................................................6-10

6.4.1 OVERVIEW....................................................................................6-10

6.4.2 AUTO POWER CONTROL (APC)..................................................6-11

6.4.3 DUAL BEAM WRITING..................................................................6-12

6.4.4 LASER BEAM PITCH CHANGE MECHANISM..............................6-13

6.4.5 LD SAFETY SWITCHES................................................................6-14

6.5 PHOTOCONDUCTOR UNIT (PCU)........................................................6-15

6.5.1 OVERVIEW....................................................................................6-15

6.5.2 DRIVE MECHANISM......................................................................6-16

6.5.3 DRUM PAWLS...............................................................................6-16

6.5.4 DRUM TONER SEALS...................................................................6-16

6.6 DRUM CHARGE .....................................................................................6-17

6.6.1 OVERVIEW....................................................................................6-17

6.6.2 CHARGE ROLLER VOLTAGE CORRECTION..............................6-18

Correction for Environmental Condi tions ............................................6-18

Correction for Paper Width and Thickness (By-pass Tray only) .........6-19

6.6.3 ID SENSOR PATTERN PRODUCTION TIMING............................6-20

6.6.4 DRUM CHARGE ROLLER CLEANING..........................................6-21

6.7 DEVELOPMENT.....................................................................................6-22

6.7.1 OVERVIEW....................................................................................6-22

DRIVE MECHANISM..........................................................................6-23

6.7.3 DEVELOPER MIXING....................................................................6-23

6.7.4 DEVELOPMENT BIAS...................................................................6-24

Mechanism .........................................................................................6-24

Correction for Paper Width and Thickness (By-pass Tray only) .........6-24

6.7.5 TONER SUPPLY............................................................................6-25

Toner Bottle Replenishment Mechanism............................................6-25

Toner Supply Mechanism...................................................................6-26

Toner Density Control.........................................................................6-26

Sensor Control Mode..........................................................................6-27

Image Pixel Count Mode.....................................................................6-27

6.7.6 TONER NEAR END/END DETECTION.........................................6-28

Standard Method................................................................................6-28

Adjustable Near-end Warning Method................................................6-28

6.7.7 TONER END RECOVERY .............................................................6-29

6.7.8 TONER SUPPLY WITH ABNORMAL SENSORS..........................6-29

6.8 DRUM CLEANING AND TONER RECYCLING.......................................6-30

6.8.1 DRUM CLEANING..........................................................................6-30

6.8.2 TONER RECYCLING.....................................................................6-30

6.9 PAPER FEED..........................................................................................6-31

v

6.9.1 OVERVIEW....................................................................................6-31

6.9.2 PAPER FEED DRIVE.....................................................................6-32

6.9.3 PICK-UP/SEPARATION ROLLER RELEASE................................6-32

6.9.4 PAPER LIFT...................................................................................6-33

6.9.5 PAPER END DETECTION.............................................................6-34

6.9.6 PAPER REGISTRATION................................................................6-34

6.9.7 PAPER SIZE DETECTION.............................................................6-35

6.9.8 PAPER HEIGHT DETECTION.......................................................6-36

6.10 BY-PASS TRAY....................................................................................6-37

6.10.1 OVERVIEW..................................................................................6-37

6.10.2 BY-PASS TRAY OPERATION .....................................................6-38

6.10.3 BY-PASS PAPER SIZE DETECTION ..........................................6-39

6.11 DUPLEX UNIT.......................................................................................6-40

6.11.1 OVERVIEW..................................................................................6-40

6.11.2 DUPLEX DRIVE LAYOUT............................................................6-41

6.11.3 DUPLEX BASIC OPERATION .....................................................6-42

Larger than A4 Lengthwise/LT Lengthwise (SEF) ..............................6-42

Up to A4 Lengthwise/LT Lengthwise (SEF)........................................6-42

6.11.4 DUPLEX UNIT FEED IN AND EXIT MECHANISM.......................6-43

Feed-in................................................................................................6-43

Inversion and Exit...............................................................................6-43

6.12 IMAGE TRANSFER AND PAPER SEPARATION.................................6-44

6.12.1 OVERVIEW..................................................................................6-44

6.12.2 BELT DRIVE MECHANISM..........................................................6-45

6.12.3 TRANSFER BELT UNIT CONTACT MECHANISM......................6-45

6.12.4 IMAGE TRANSFER AND PAPER SEPARATION

MECHANISM................................................................................6-46

6.12.5 TRANSFER BELT CHARGE........................................................6-47

Mechanism .........................................................................................6-47

Correction for Paper Width and Thickness .........................................6-48

Transfer Currents to Leading Edge and Image Areas ........................6-49

6.12.6 TRANSFER BELT CLEANING MECHANISM..............................6-50

6.13 IMAGE FUSING AND PAPER EXIT......................................................6-51

6.13.1 OVERVIEW..................................................................................6-51

6.13.2 FUSING DRIVE............................................................................6-52

6.13.3 FUSING ENTRANCE GUIDE SHIFT MECHANISM.....................6-52

6.13.4 EXIT GUIDE PLATE AND DE-CURLER ROLLERS.....................6-53

6.13.5 PRESSURE ROLLER...................................................................6-53

6.13.6 CLEANING MECHANISM ............................................................6-53

6.13.7 FUSING TEMPERATURE CONTROL..........................................6-54

Temperature Control...........................................................................6-54

Fusing Idling Temperature..................................................................6-55

6.13.8 OVERHEAT PROTECTION .........................................................6-55

6.14 ENERGY SAVER MODE ......................................................................6-56

vi

SPECIFICATIONS..................................................................... SPEC-1

1. GENERAL SPECIFICATIONS.............................................................SPEC-1

2. SUPPORTED PAPER SIZES..............................................................SPEC-2

3. SOFTWARE ACCESSORIES.............................................................SPEC-3

3.1 PRINTER DRIVERS....................................................................SPEC-3

3.2 UTILITY SOFTWARE..................................................................SPEC-3

4. MACHINE CONFIGURATION.............................................................SPEC-4

4.1 SYSTEM COMPONENTS...........................................................SPEC-4

4.2 INSTALLABLE OPTION TABLE..................................................SPEC-5

5. OPTIONS............................................................................................SPEC-6

5.1 BRIDGE UNIT .............................................................................SPEC-6

5.2 1000-SHEET FINISHER..............................................................SPEC-6

5.3 3000-SHEET FINISHER..............................................................SPEC-7

5.4 LARGE CAPACITY TRAY (LCT).................................................SPEC-8

5.5 MAILBOX.....................................................................................SPEC-8

5.6 PAPER TRAY UNIT.....................................................................SPEC-8

vii

6 November, 2001 INSTALLATION REQUIREMENTS

1. INSTALLATION

1.1 INSTALLATION REQUIREMENTS

1.1.1 ENVIRONMENT

1. Temperature Range: 10°C to 32°C (50°F to 89.6°F)

2. Humidity Range: 15 % to 80 % RH

3. Ambient Illumination: Less than 1,500 lux (do not expose to direct sunlight).

4. Ventilation: 3 times/hr/person

5. Avoid areas which are exposed to sudden temperature changes. This includes:

1) Areas directly exposed to cool air from an air conditioner.

2) Areas directly exposed to heat from a heater.

6. Do not place the machine in an area where it will be exposed to corrosive

gases.

7. Do not install the machine at any location over 2,500 m (8,125 ft.) above sea

level.

8. Place the machine on a strong and level base. (Inclination on any side should

be no more than 5 mm.)

9. Do not place the machine where it may be subjected to strong vibrations.

Installation

1.1.2 MACHINE LEVEL

Front to back: Within 5 mm (0.2") of level

Right to left: Within 5 mm (0.2") of level

1-1

INSTALLATION REQUIREMENTS 6 November, 2001

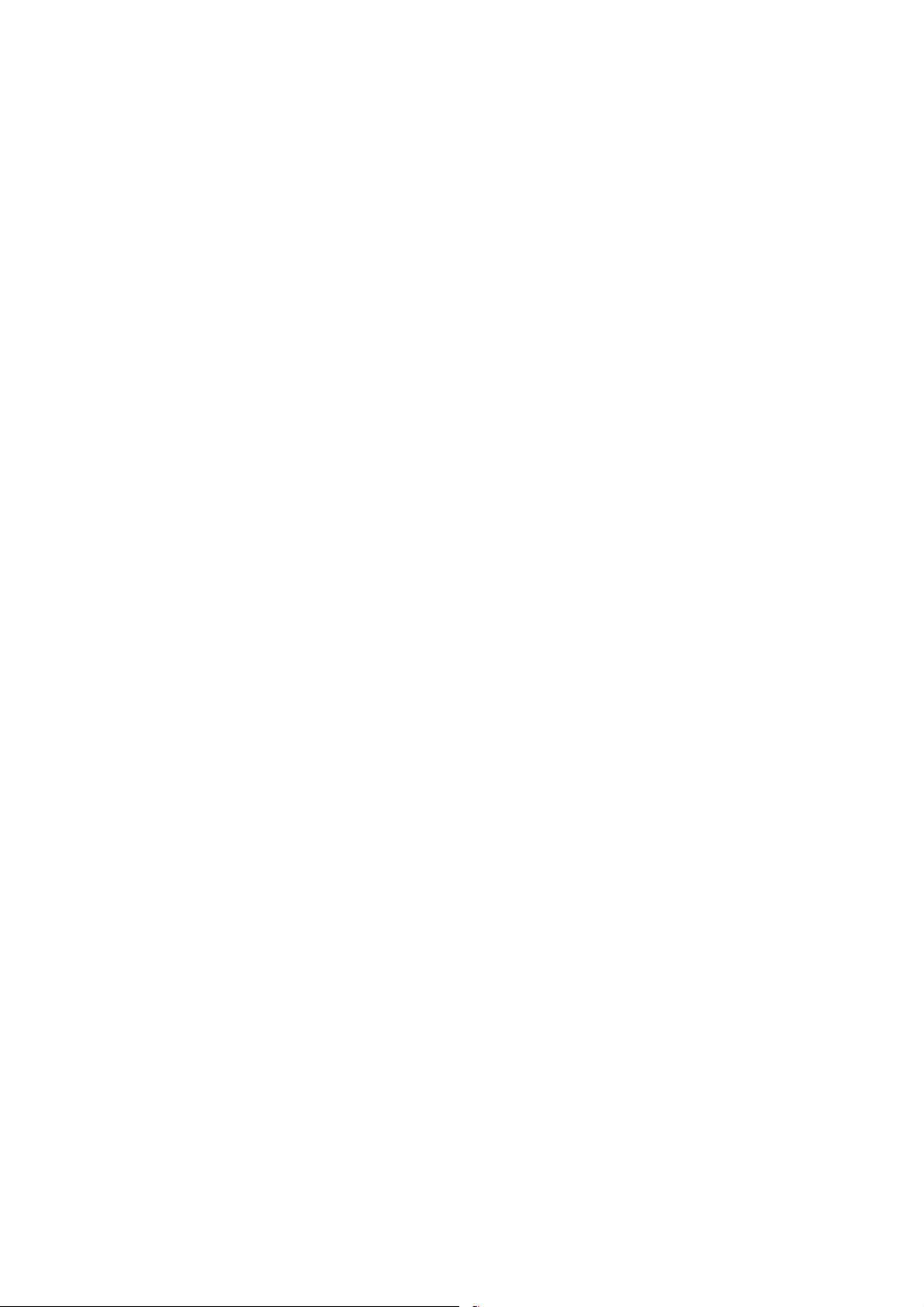

1.1.3 MACHINE SPACE REQUIREMENTS

Place the printer near the power source, providing clearance as shown:

C

A: In Front: > 75 cm (29.6")

B: Left: > 10 cm (4")

C: To Rear: > 10 cm (4")

D: Right: > 45 cm (17.8")

B

G065I000.WMF

G065I001.WMF

630 mm (24.8")

540 mm (21.3")

A

360 mm (14.2")

530 mm (20.9")

D

625 mm (24.6")

G065I002.WMF

970 mm (38.2")

625 mm (24.6")

720 mm (28.4")

600 mm (23.6")

1320 mm (52")

G065I003.WMF

The 75 centimeters recommended for the space at the fron t is for pu lling out the

paper tray only. If an operator stands in front of the printer, more space is required.

1-2

6 November, 2001 MACHINE INSTALLATION

1.1.4 POWER REQUIREMENTS

!

CAUTION

1. Make sure the plug is firmly inserted in the outlet.

2. Connect the printer to an independent power source. Avoid connecting

the printer to a power supply shared with another machine.

3. Always ground the machine.

1. Input voltage level: 120 V, 60 Hz: More than 12 A

220 V ~ 240 V, 50 Hz/60 Hz: More than 8 A

2. Permissible voltage fluctuation: ±10%

3. Do not set anything on the power cord.

1.2 MACHINE INSTALLATION

Refer to the Operating Instructions for details.

1.3 OPTIONAL UNIT INSTALLATION

Installation

The following options are available for this machine. Refer to the Operating

Instructions for how to install these options.

• PTU (Paper Tray Unit)

• 64/128/256 MB DIMMs

• HDD (Hard Disk)

• IEEE 1394

1.4 SYMBOLS USED IN TEXT

Screw: ! Connector: "

1-3

LCT INSTALLATION (A683) 6 November, 2001

1.5 LCT INSTALLATION (A683)

1.5.1 ACCESSORY CHECK

Check the quantity and condition of the accessories in the box against the following

list:

Description Q’ty

1. Joint Pin................................................................................. 2

2. Stepped Screw - M3x18......................................................... 4

3. Magnet Cover........................................................................ 1

4. NECR (-17, -27 machines)..................................................... 1

5. Installation Procedure............................................................ 1

1-4

6 November, 2001 LCT INSTALLATION (A683)

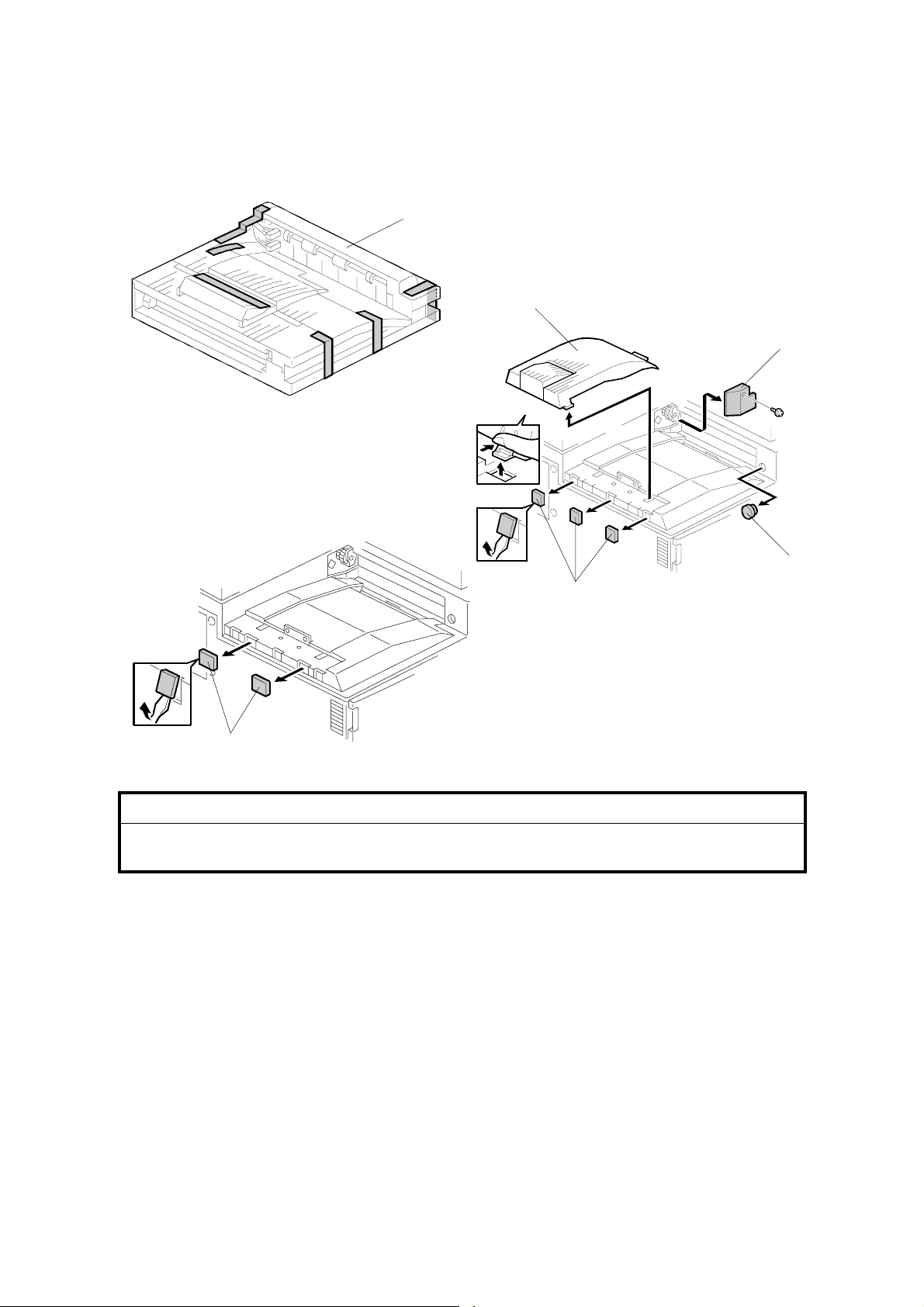

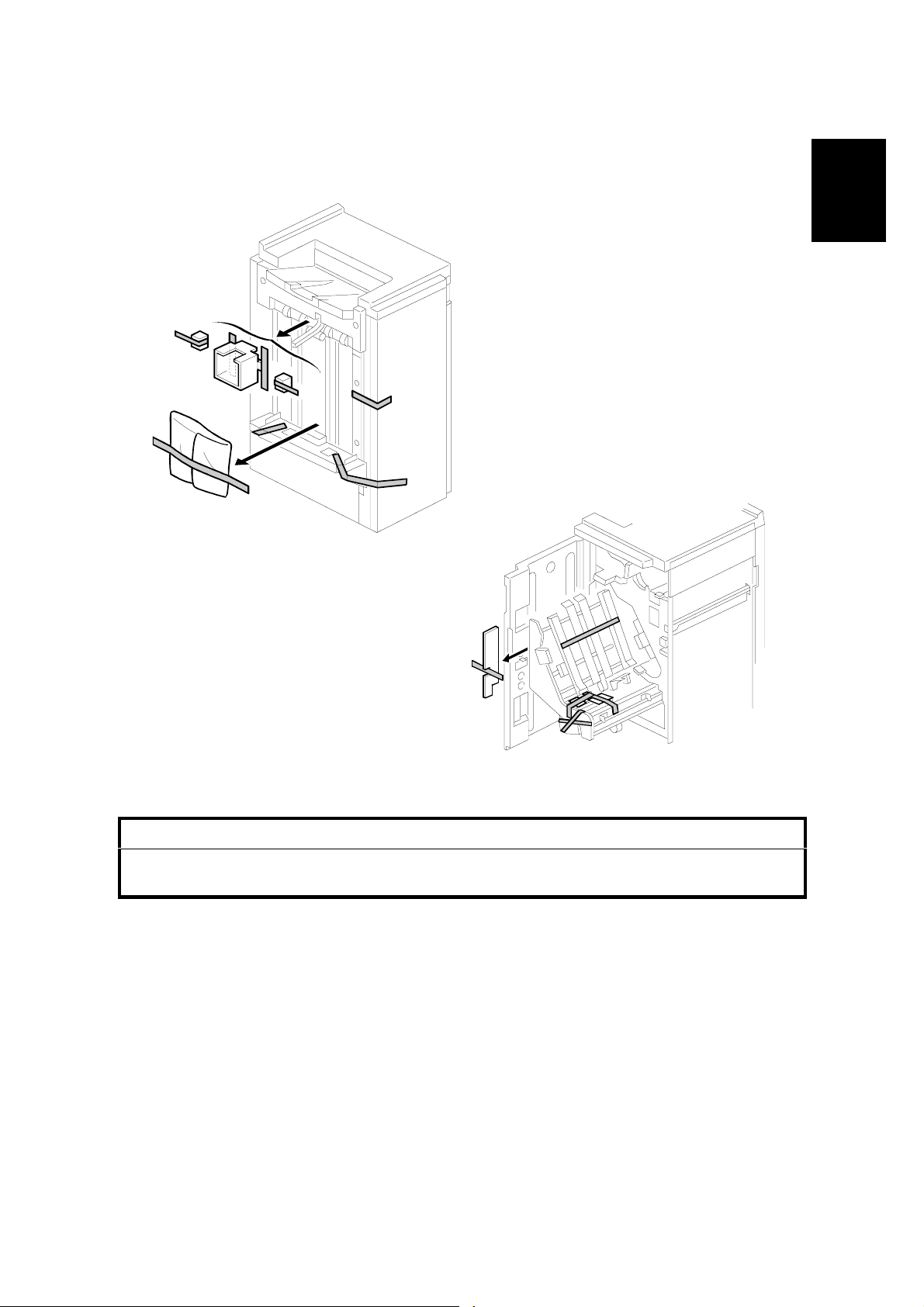

1.5.2 INSTALLATION PROCEDURE

A683I501.WMF

Installation

A683I604.WMF

!

CAUTION

A683I500.WMF

[A]

Switch off the main machine and unplug its power cord before starting the

following procedure.

NOTE: The Paper Tray Unit (G520) must be installed before installing the LCT.

1. Unpack the LCT and remove the tapes.

2. Open the right cover [A] of the paper tray unit.

3. Open the lower right cover [B] and cut the holding band [C].

NOTE: When cutting the hold i ng band, the upper part of the band should be

cut as shown. Otherwise, paper jams may occur.

[C]

[B]

4. Remove the right lower cover.

1-5

LCT INSTALLATION (A683) 6 November, 2001

[A]

[E]

[B]

[D]

[C]

A683I503.WMF

5. Install the joint pins [A].

6. Push the release lever [B] and slide the LCT to the right (front view).

7. Hang the LCT [C] on the joint pins, then secure the brackets [D] (! x 4).

8. Return the LCT to the previous position and connect the LCT cable [E].

9. Open the LCT cover and load the paper.

10. Turn on the ac switch and check the LCT operation.

1-6

6 November, 2001 BRIDGE UNIT INSTALLATION (B397)

1.6 BRIDGE UNIT INSTALLATION (B397)

1.6.1 ACCESSORY CHECK

Check the quantity and condition of the accessories in the box against the following

list:

Description Q’ty

1. Stepped Screw ...................................................................... 2

2. Connector Cover.................................................................... 1

3. Exit Mylar............................................................................... 2

4. Installation Procedure............................................................ 1

Installation

1-7

BRIDGE UNIT INSTALLATION (B397) 6 November, 2001

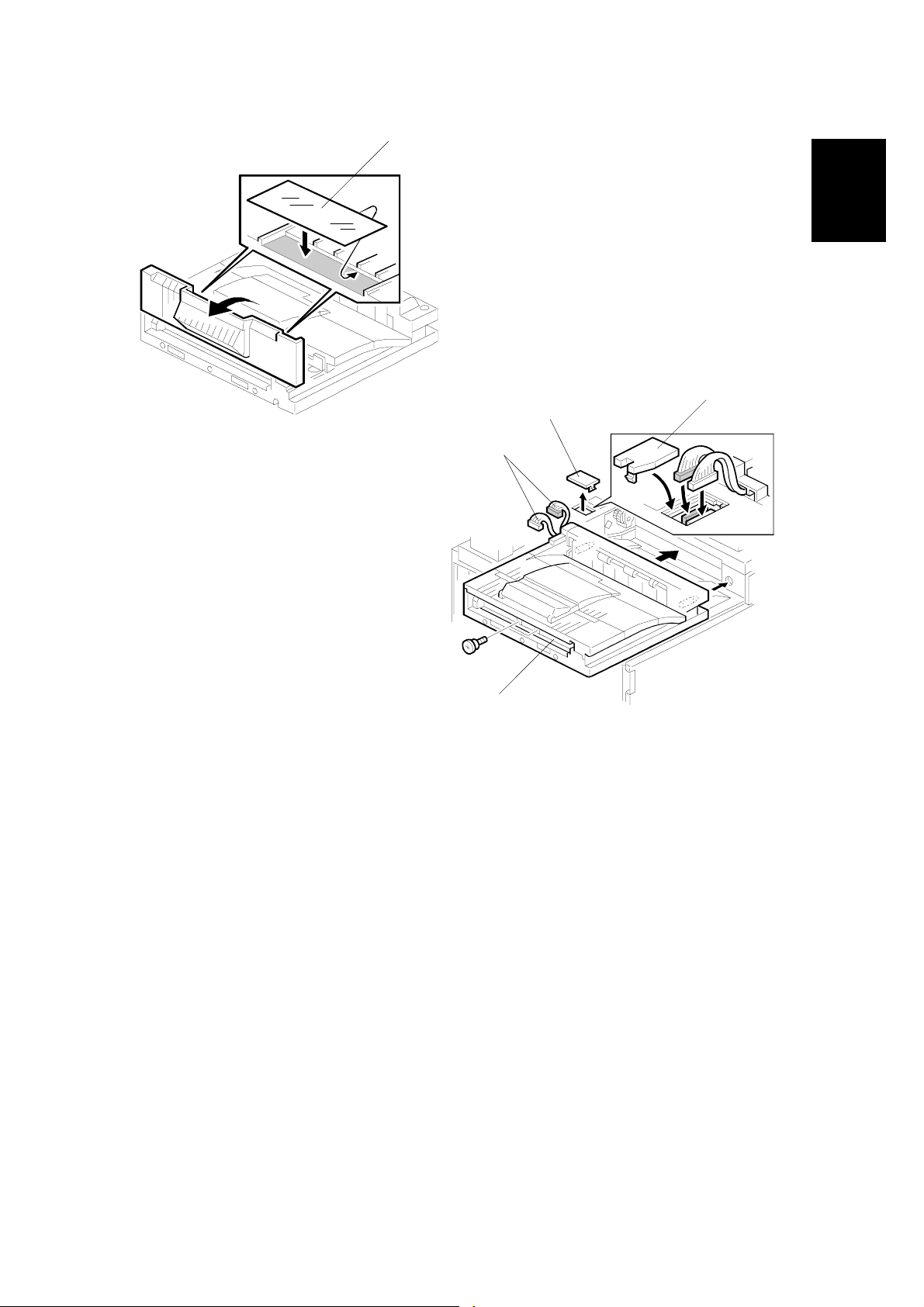

1.6.2 INSTALLATION PROCEDURE

[A]

[B]

[E]

B397I401.WMF

B397I407.WMF

!

CAUTION

[D]

[C]

B397I500.WMF

Switch off the main machine and unplug its power cord before starting the

following procedure.

1. Unpack the bridge unit [A] and remove all tapes and shipping retainers.

2. Remove the inner tray [B].

3. On the side of the machine, remove the three small covers [C].

If the optional external output tray (A825) will be installed (instead of a

finisher), do Step 4.

[F]

4. Remove the two small covers [D].

5. Remove the cover [E] (! x 1)

6. Remove the cap [F].

7. Remove the paper height sensor (! x 2, " x 1)

1-8

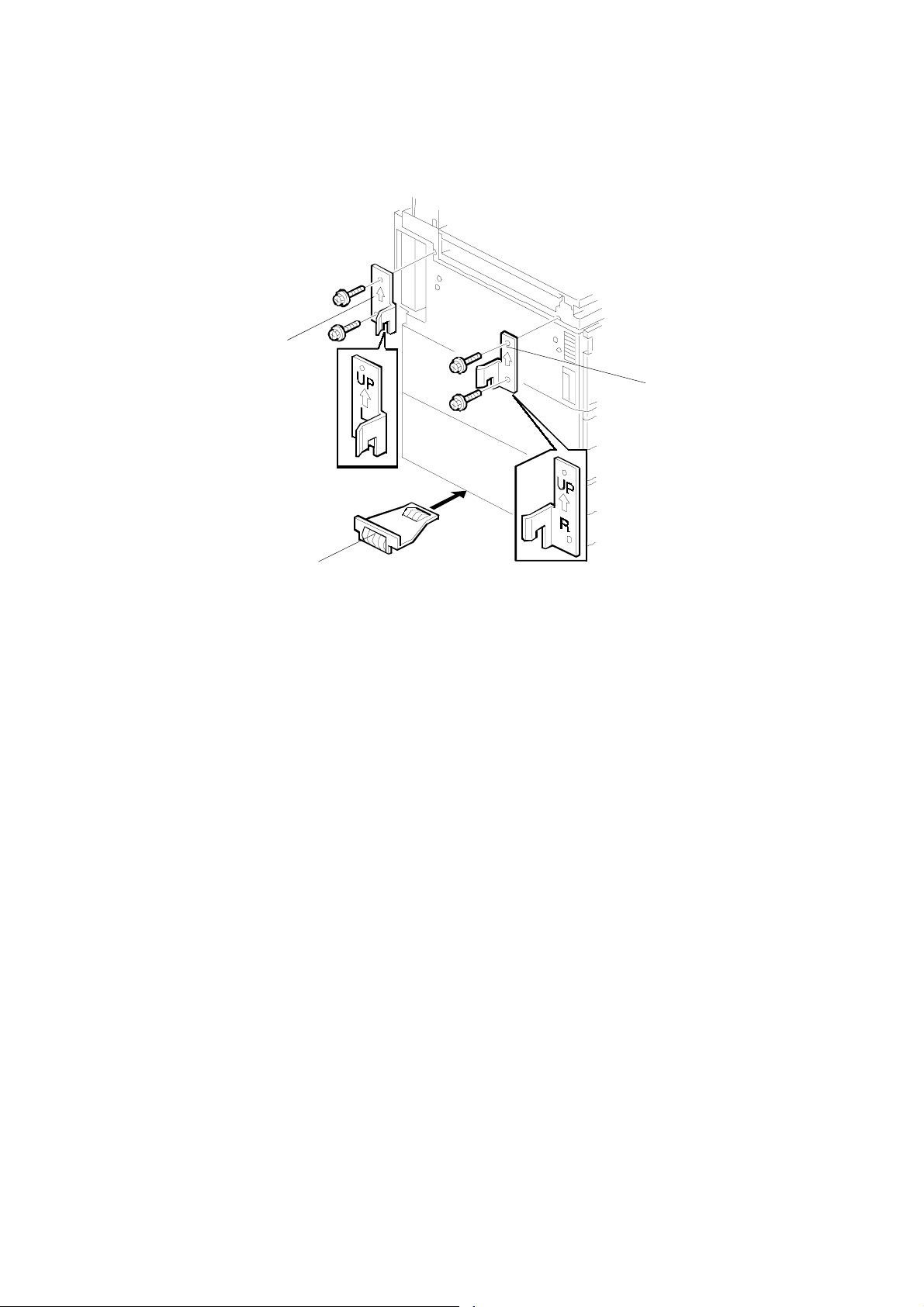

6 November, 2001 BRIDGE UNIT INSTALLATION (B397)

[A]

[E]

B397I402.WMF

[B]

[D]

Installation

[C]

B397I444.WMF

8. If an optional finisher is to be installed, attach two mylars [A] to the bridge unit.

9. Remove the cover [B].

10. Install the bridge unit [C] (! x 2).

11. Connect the bridge unit I/F harnesses [D] (" x 2).

12. Install the connector cover [E].

13. Turn on the main switch and check the bridge unit operation (make sure that

there are no paper jams).

1-9

1000-SHEET FINISHER INSTALLATION (A681) 6 November, 2001

1.7 1000-SHEET FINISHER INSTALLATION (A681)

1.7.1 ACCESSORY CHECK

Check the quantity and condition of the accessories in the box against the following

list:

Description Q’ty

1. Front Stand............................................................................ 1

2. Rear Stand............................................................................. 1

3. Knob Screw ........................................................................... 1

4. Screw - M4x12....................................................................... 6

5. NECR (-17 machine) ............................................................. 1

6. Installation Procedure............................................................ 1

7. Screw - M4x10....................................................................... 1

8. Tray ....................................................................................... 1

9. Snap ring ............................................................................... 1

1-10

6 November, 2001 1000-SHEET FINISHER INSTALLATION (A681)

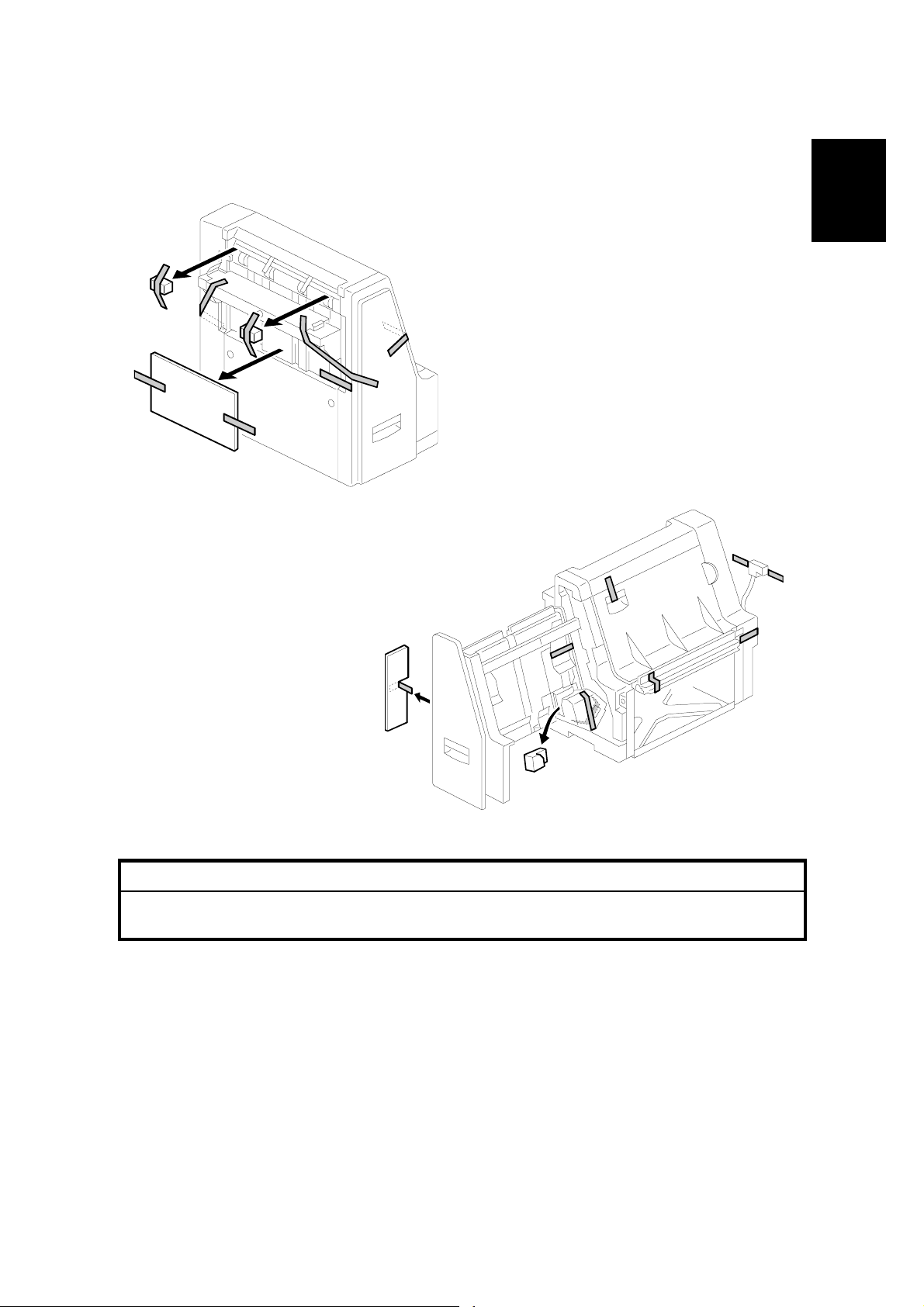

1.7.2 INSTALLATION PROCEDURE

A681I701.WMF

Installation

A681I702.WMF

!

CAUTION

Switch off the main machine and unplug its power cord before starting the

following procedure.

NOTE: The bridge unit (B397) and paper tray unit (G520) must be installed before

installing this finisher.

If the mailbox (G909) will be installed, first install the mailbox, then the

bridge unit for the mailbox (G912), and finally install the finisher.

1. Unpack the finisher and remove the tapes and retainers.

1-11

1000-SHEET FINISHER INSTALLATION (A681) 6 November, 2001

[A]

[C]

[B]

A681I704.WMF

[D]

[E]

A681I705.WMF

2. Fasten [A] (! x 2) loosely.

3. Hang the front stand [B] and rear stand [C] on the screws installed in step 2.

4. To secure the front and rear stands tighten [A] (! x 2) and secure the stands

(! x 4).

5. At the front, use handle [D] to pull out the stapler unit.

6. Remove the locking lever [E] (! x 1).

7. Align the finisher on the stands, and lock it in place by pushing the locking

lever.

8. Secure the locking lever (! x 1) and push the stapler unit into the finisher.

1-12

6 November, 2001 1000-SHEET FINISHER INSTALLATION (A681)

[F]

[C]

[A]

Installation

[D]

A681I706.WMF

[E]

[B]

9. Secure the finisher [A] (! x 1).

10. Adjust the securing knobs [B] under the front and rear stands until the finisher

is perpendicular to the floor.

11. Install the shift tray [C] (snap ring x 1).

NOTE: Make sure that the three pegs [D] fit into the slots [E] properly.

12. Connect the finisher cable [F] to the main machine.

13. Turn on the main power switch and check the finisher operation.

1-13

3000-SHEET FINISHER INSTALLATION (A697) 6 November, 2001

1.8 3000-SHEET FINISHER INSTALLATION (A697)

1.8.1 ACCESSORY CHECK

Check the quantity and condition of the accessories in the box against the following

list:

Description Q’ty

1. Front joint bracket.................................................................. 1

2. Rear joint bracket................................................................... 1

3. Entrance guide plate.............................................................. 1

4. Shift tray................................................................................. 1

5. Shift tray guide....................................................................... 1

6. Staple position decal.............................................................. 1

7. Screw - M3x6......................................................................... 2

8. Screw - M4x14....................................................................... 4

9. Screw - M3x8......................................................................... 4

10. Cushion ................................................................................. 1

11. Upper grounding plate........................................................... 1

12. Lower grounding plate........................................................... 2

13. NECR (-17 machine)............................................................. 1

14. Installation procedure ............................................................ 1

1-14

6 November, 2001 3000-SHEET FINISHER INSTALLATION (A697)

1.8.2 INSTALLATION PROCEDURE

Installation

A697I506.WMF

A697I507.WMF

!

CAUTION

Unplug the main machine power cord before starting the following

procedure.

NOTE: The bridge unit (B397) and paper tray unit (G520) must be installed before

installing this finisher.

If the mailbox (G909) will be installed, first install the mailbox, then the

bridge unit for the mailbox (G912), and finally install the finisher.

1. Unpack the finisher and remove the tapes.

1-15

3000-SHEET FINISHER INSTALLATION (A697) 6 November, 2001

[B]

[A]

[C]

A697I558.WMF

2. Install the front joint bracket [A] and rear joint bracket [B] (! x 2 ea.).

3. Peel off the backing of the double-sided tape that is attached to the lower

grounding plate [C].

4. Attach one lower grounding plate to the center position of the paper tray unit as

shown.

1-16

6 November, 2001 3000-SHEET FINISHER INSTALLATION (A697)

[B]

Installation

[A]

[C]

A697I559.WMF

5. Attach the cushion [A] at the position [B].

6. Install the entrance guide plate [C] (! x 2).

1-17

3000-SHEET FINISHER INSTALLATION (A697) 6 November, 2001

[C]

A697I534.WMF

[G]

[D]

[B]

[A]

[F]

A697I550.WMF

[E]

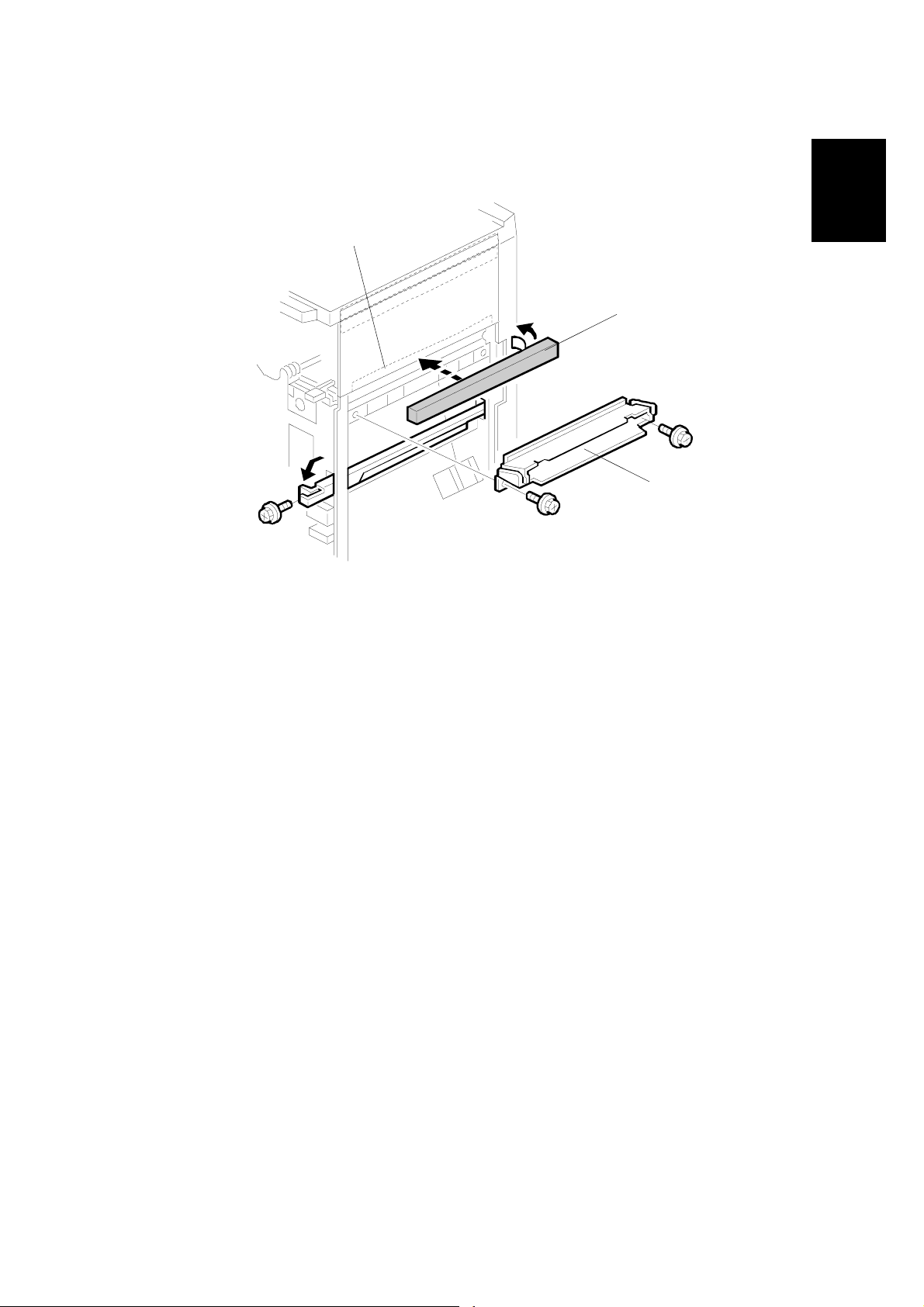

7. If the customer requires the punch unit, install it now, before attaching the

finisher to the machine. See ‘Punch Unit Installation’.

8. Open the front door of the finisher, and remove the screw [A] that secures the

locking lever [B]. Then pull the locking lever.

9. Align the finisher on the joint brackets, and lock it in place by pushing the

locking lever.

NOTE: 1) Before securing the locking lever, make sure that the top edges of

the finisher and the copier are parallel fro m front to rear as show n

[C].

2) Secure the locking lever (! x 1) and close the front door.

10. Install the shift tray guide [D] on the shift tray. If the customer does not wish to

install it on the shift tray, store it at the location [E].

NOTE: The shift tray guide helps to properly stack exiting paper. However, it

reduces the capacity of the shift tray by 50, from 3,000 to 2,950.

11. Install the shift tray [F] (! x 4).

12. Connect the finisher cable [G] to the main machine.

13. Turn on the main power switch and check the finisher operation.

1-18

6 November, 2001 PUNCH UNIT INSTALLATION (A812)

1.9 PUNCH UNIT INSTALLATION (A812)

1.9.1 ACCESSORY CHECK

Check the quantity and condition of the accessories in the box against the following

list:

Description Q’ty

1. Spacer - 2 mm....................................................................... 1

2. Spacer - 1 mm....................................................................... 2

3. Stepped screw - Short........................................................... 1

4. Stepped screw - Long............................................................ 1

5. Punch unit knob..................................................................... 1

6. Spring.................................................................................... 1

7. Harness - Long...................................................................... 1

8. Harness - Short...................................................................... 1

9. Hopper................................................................................... 1

10. Punch position decal.............................................................. 1

11. Tapping screw - M4x10.......................................................... 2

Installation

12. Screw with flat washer - M4x6............................................... 1

13. NECR..................................................................................... 1

1-19

PUNCH UNIT INSTALLATION (A812) 6 November, 2001

1.9.2 INSTALLATION PROCEDURE

[A]

[D]

[B]

A812I761.WMF

[C]

A812I763.WMF

!

CAUTION

Unplug the copier power cord and remove the 3,000-sheet finisher from the

copier before starting the following procedure.

1. Unpack the punch unit and remove the shipping retainers [A] (! x 4) and [B] (!

x 1).

2. Open the front door and remove the hopper cover [C] (! x 2).

3. Remove the finisher rear cover (! x 2) and remove the transport guide plate

[D] (! x 4).

1-20

6 November, 2001 PUNCH UNIT INSTALLATION (A812)

Installation

[A]

[B]

A812I510.WMF

[D]

[C]

4. Install the spacer [A] (thickness = 2 mm).

NOTE: There are three spacers in the accessory box. Do not lose the other

two spacers (1-mm) because they are used for adjusting the punch

hole position.

A812I765.WMF

5. Install the punch unit [B] and secure it with a long stepped screw [C].

6. Install the punch unit knob [D] (! x 1).

7. Secure the rear of the punch unit (! x 2).

1-21

PUNCH UNIT INSTALLATION (A812) 6 November, 2001

A812I767.WMF

A812I512.WMF

[A]

[E]

[B]

[C]

[D]

A812I511.WMF

[F]

8. Install the sensor bracket [A] (! x 1, spring x1).

9. Connect the harnesses [B].

NOTE: 1) The harness binders [C] must not be between the harness clamps [D].

2) The harness binder [E] must be positioned to the left of the harness

clamp.

10. When a three-punch-hole unit is installed: Turn on switch 1 of DIP SW 100

on the finisher control board.

11. Slide the hopper [F] into the finisher.

12. Reassemble the finisher and attach the 3000-sheet finisher to the copi er, then

check the punch unit function.

1-22

6 November, 2001 MAILBOX INSTALLATION (G909)

1.10 MAILBOX INSTALLATION (G909)

1.10.1 ACCESSORY CHECK

Check the quantity and condition of the accessories in the box against the following

list:

Description Q’ty

1. Front joint bracket.................................................................. 1

2. Rear joint bracket................................................................... 1

3. Exit guide mylar..................................................................... 1

4. Proof tray attachment............................................................ 1

5. Upper grounding plate........................................................... 1

6. Lower grounding plate........................................................... 2

7. Cushion ................................................................................. 1

8. Tapping screw - M4x14.......................................................... 4

9. Bin decals.............................................................................. 1

10. Installation procedure ............................................................ 1

Installation

1.10.2 REQUIREMENT OPTIONS FOR MAIN MACHINE

When the mailbox is going to be ins talled on this printer, the following options must

be installed first.

• Bridge unit type 450 (B397)

• Paper tray unit - PS430 (G520)

1-23

MAILBOX INSTALLATION (G909) 6 November, 2001

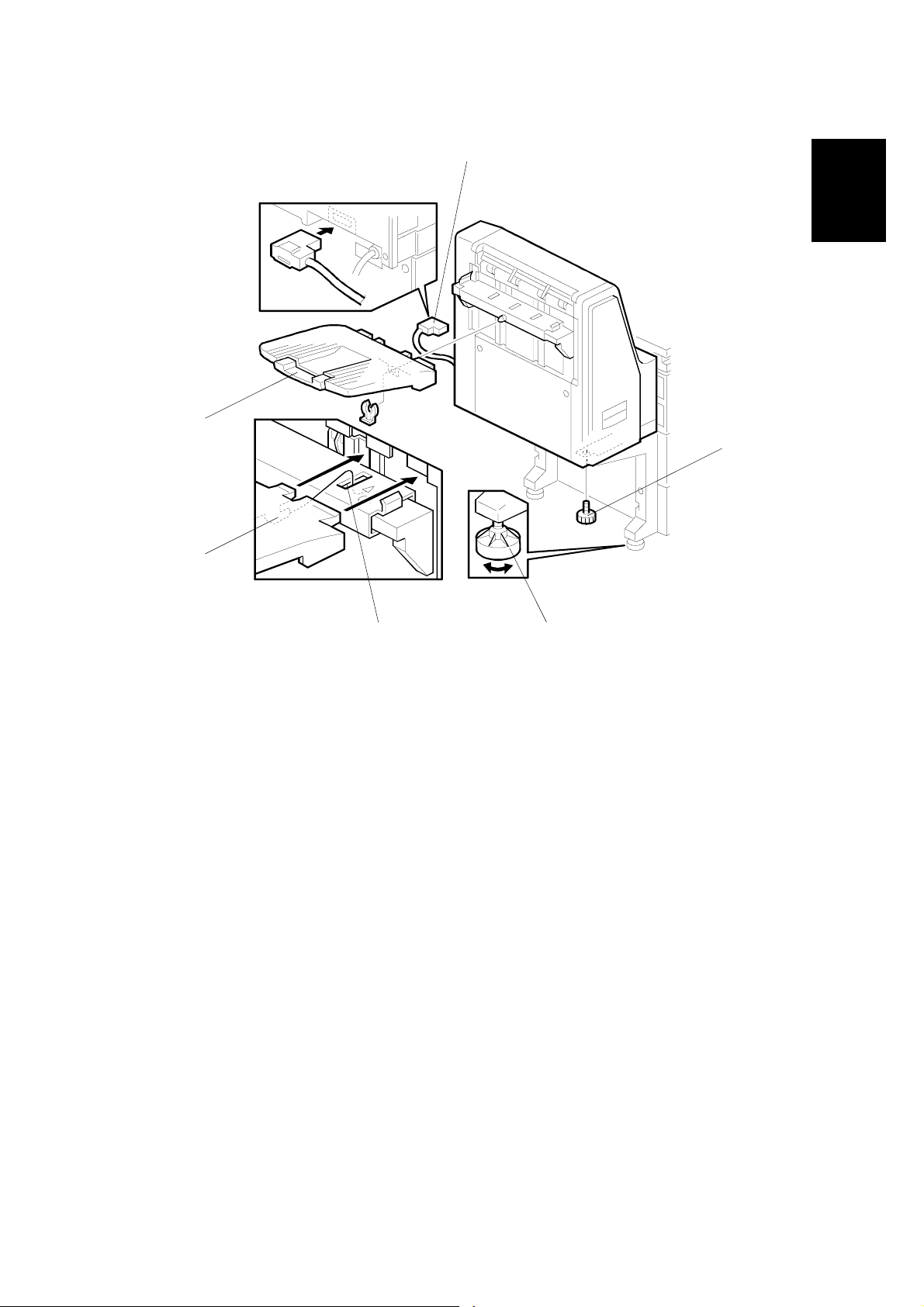

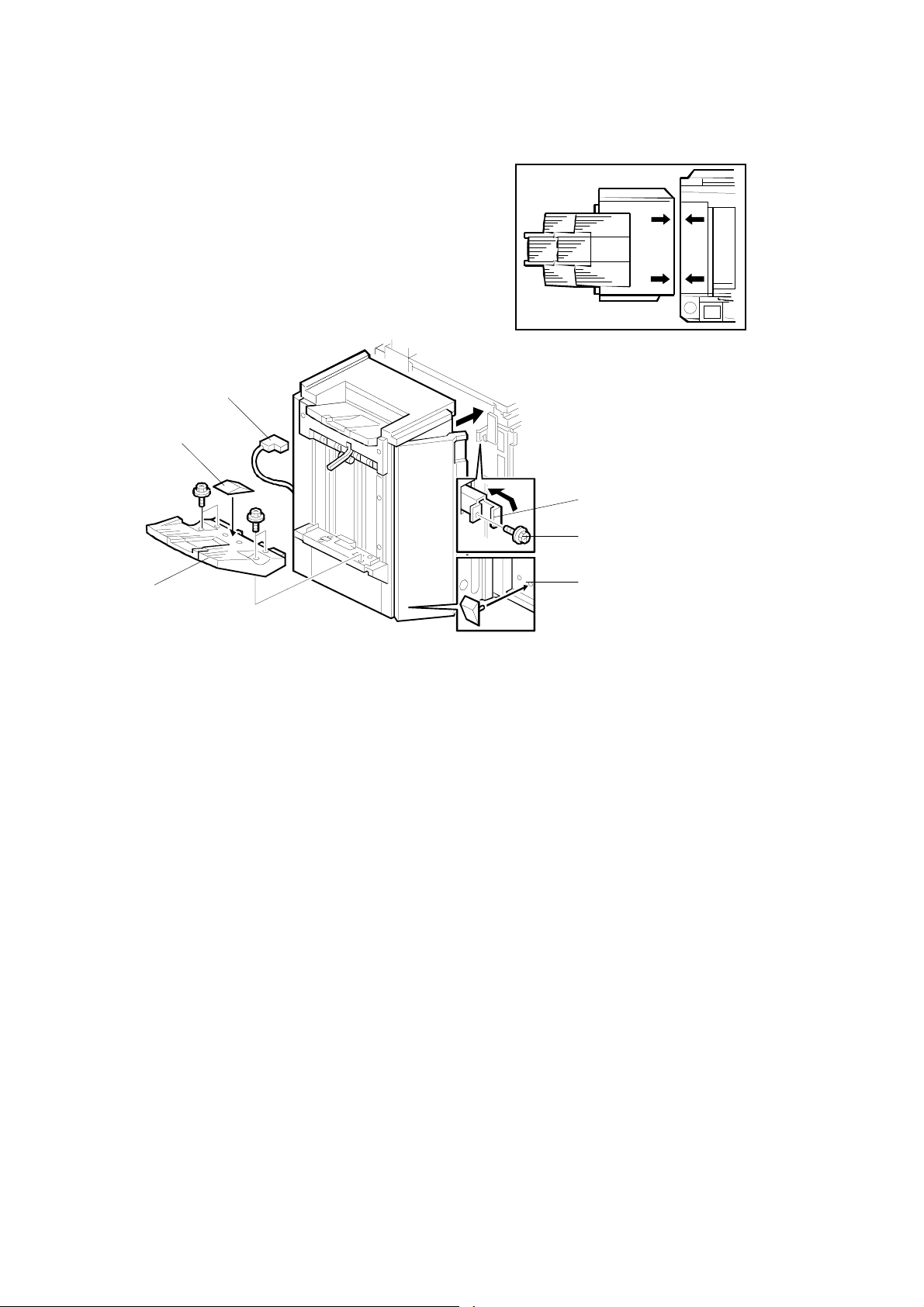

1.10.3 INSTALLATION PROCEDURE

G909I500.WMF

[B]

[A]

[C]

G909I559.WMF

!

CAUTION

Unplug the main machine power cord before starting the following

procedure.

NOTE: If a finisher will be installe d, f irst install this mailbox, then the bridge unit for

the mailbox (G912), and finally install the finisher.

1. Unpack the finisher and remove the pieces of tape.

2. Attach the front joint bracket [A] and rear joint bracket [B] to the main machine

(! x 2 ea.).

3. Peel off the backing of the double-sided tape that is attached to the lower

grounding plate [C].

4. Attach one lower grounding plate to the center of the bottom edge of the paper

tray unit as shown.

1-24

6 November, 2001 MAILBOX INSTALLATION (G909)

[B]

[A]

[C]

Installation

[D]

[E]

G909I550.WMF

5. Attach the cushion [A] to the position [B].

6. Open the front cover [C] of the mailbox, and remove the screw [D] that secures

the locking lever [E]. Then pull the locking lever.

1-25

MAILBOX INSTALLATION (G909) 6 November, 2001

[B]

G909I503.WMF

[A]

[C]

G909I552.WMF

7. Align the mailbox on the joint brackets, and lock it in place by pushing the

locking lever [A].

8. Secure the locking lever (! x 1) and close the front door.

9. Connect the mailbox cable [B] to the main machine.

10. Peel off the backing of the double-sided tape that is attached to the proof tray

attachment [C].

11. Install the proof tray attachment on the proo f tray .

12. Turn on the main switch and check the mailbox operation.

1-26

6 November, 2001 BRIDGE UNIT FOR MAILBOX INSTALLATION (G912)

1.11 BRIDGE UNIT FOR MAILBOX INSTALLATION (G912)

1.11.1 ACCESSORY CHECK

Check the quantity and condition of the accessories in the box against the following

list:

Description Q’ty

1. Guide plate bracket............................................................... 1

2. Cable..................................................................................... 1

3. Cover switch.......................................................................... 1

4. Grounding bracket................................................................. 1

5. Finisher shielding plate.......................................................... 1

6. Screw - M4x8 ........................................................................ 9

7. Screw - M4x4 ........................................................................ 4

8. Screw - M3x6 ........................................................................ 2

Installation

1-27

BRIDGE UNIT FOR MAILBOX INSTALLATION (G912) 6 November, 2001

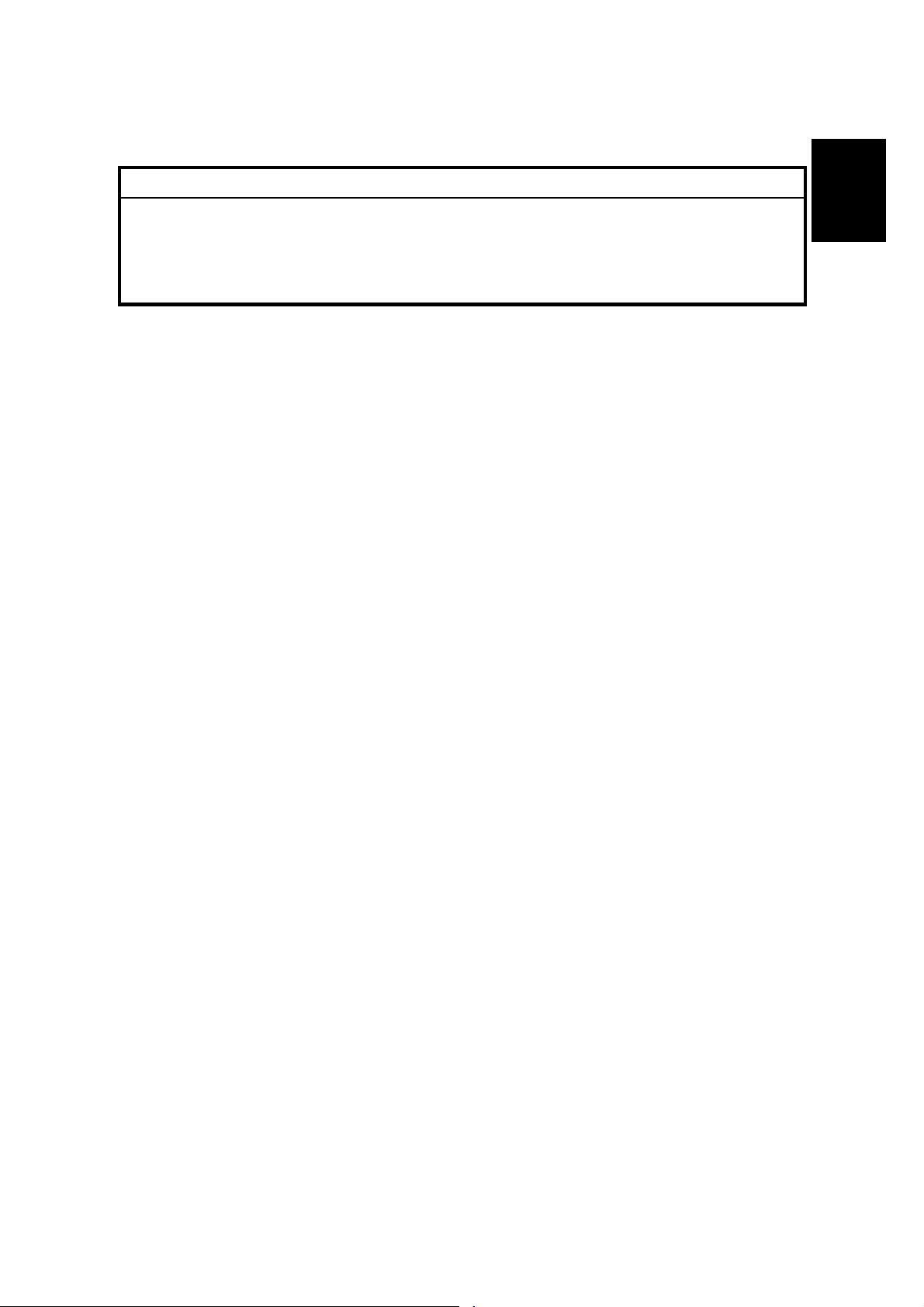

1.11.2 INSTALLATION PROCEDURE

[A]

[D]

G912I506.WMF

!

CAUTION

[A]

[B]

G909I508.WMF

Unplug the main machine power cord before starting the following

procedure.

[E]

[C]

NOTE: The bridge unit for the mailbox must be installed when both the mailbox

and a finisher will be installed. Install the mailbox first, then this bridge unit,

and finally the finisher

1. Unpack the bridge unit and remove the shipping retainers [A].

NOTE: Do not remove the protective sheet [B] at this time.

2. Remove the mailbox if it has been installed.

3. Remove the rear cover [C] of the mailbox (! x 8).

4. Remove the proof tray unit [D] (! x 6, " x 1).

5. Remove the cover [E].

1-28

6 November, 2001 BRIDGE UNIT FOR MAILBOX INSTALLATION (G912)

G912I503.WMF

[D]

[A]

[F]

[B]

Installation

[C]

G912I504.WMF

[E]

G912I505.WMF

[D]

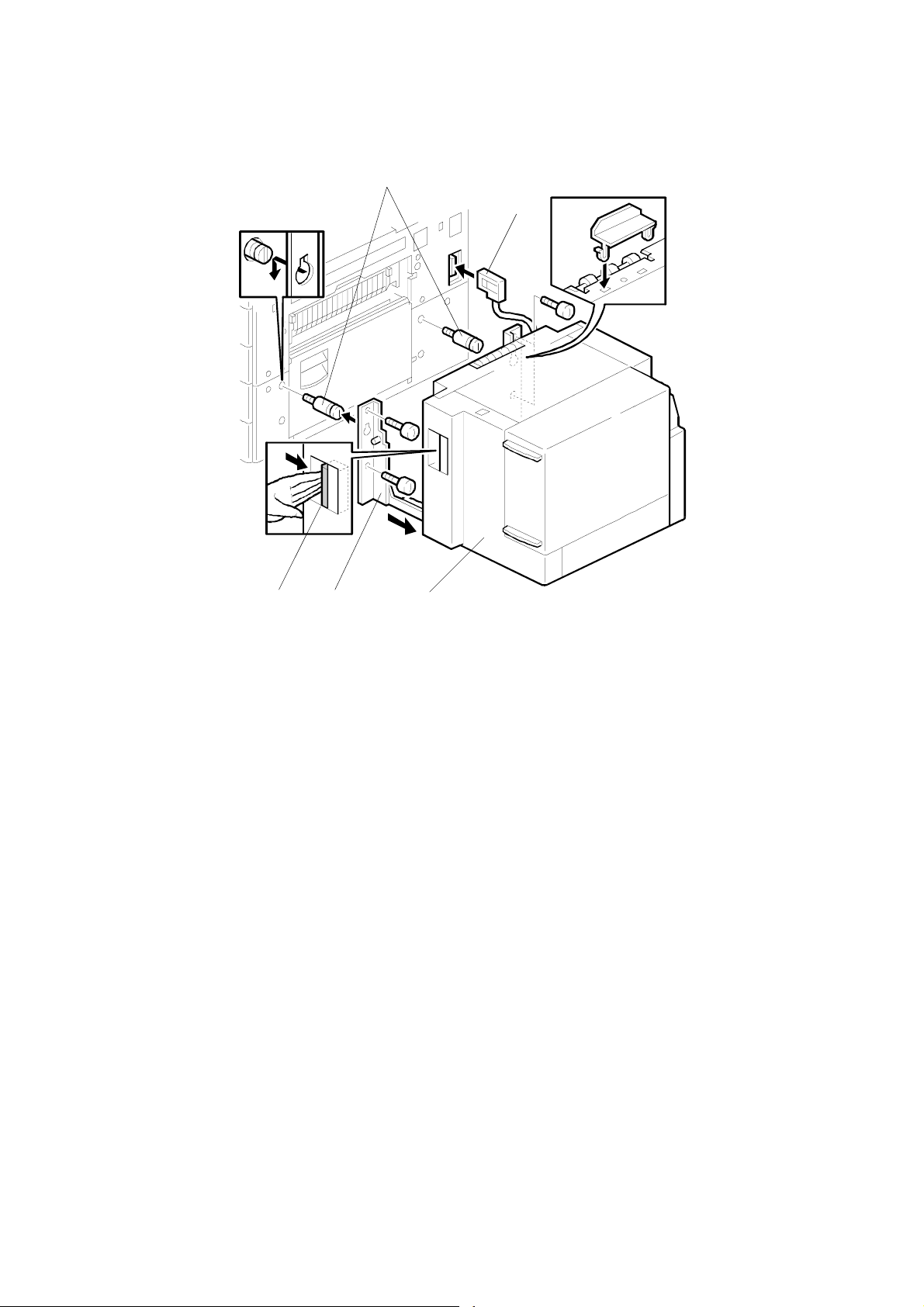

6. Open the left front cover [A] of the mailbox, and remove the inner plate [B] (! x

3).

7. Install the guide plate bracket [C] (! x 4 - M4x4).

8. Route the cable [D] and clamp it as shown.

9. Connect the cover switch [E] to the cable then install the cover switch (! x 2 M4x8).

10. Remove the paper guide plate [F] (! x 2).

1-29

BRIDGE UNIT FOR MAILBOX INSTALLATION (G912) 6 November, 2001

[B]

G912I501.WMF

[F]

G912I508.WMF

[A]

[C]

[D]

[E]

G912I507.WMF

[H]

[G]

[H]

11. Pull up the tab [A] of the protective sheet.

NOTE: 1) Do not remove the protective sheet at this time.

2) Make sure that all mylars are held between the two folded halves of

the protective sheet.

12. Turn over the bridge unit [B] and insert the protective sheet [C] into the gap [D]

between the paper guides, then put the bridge unit on the mailbox [E].

NOTE: When holding the bridge unit, do not touch the timing belt. Otherwise

the timing belt may come off the gear.

13. Remove the tape [F] for the protective sheet.

14. Open the upper paper guide [G] then pull out the protective sheet [H].

NOTE: Check that all mylars are set into the gap between the paper guides.

1-30

6 November, 2001 BRIDGE UNIT FOR MAILBOX INSTALLATION (G912)

[C]

G912I509.WMF

[C]

[B]

[B]

[D]

[A]

[E]

Installation

[B]

[B]

G912I513.WMF

[G]

G912I510.WMF

[F]

15. Secure the bridge unit [A] (! x 4 - M4x8).

16. Route the cables [B] through the openings [C].

17. Route the solenoid harness [D] through the opening [E].

18. Connect the cables to the solenoid and sensors and clamp the cable as shown.

19. Reinstall the rear cover and proof tray unit.

20. Install the mailbox on the main machine (refer to the Mailbox Installation

procedure for more detail).

If installing the 3000-sheet finisher (A697), do steps 21 to 25.

21. Install the front joint bracket [F] and rear joint bracket [G] which are contained in

the finisher’s accessory box.

1-31

BRIDGE UNIT FOR MAILBOX INSTALLATION (G912) 6 November, 2001

[B]

G912I502.WMF

[A]

[C]

G912I512.WMF

22. Remove the seal [A].

23. Attach the grounding bracket [B] (! x 3 - M4x8).

24. Attach the shielding plate [C] to the finisher (! x 2 - M3x8).

25. Attach the finisher to the mailbox (refer to the finisher installation procedure).

26. Turn on the main switch of the main machine and check the bridge unit

operation. (Select a print mode that uses the finisher.)

1-32

6 November, 2001 PM TABLES

2. PREVENTIVE MAINTENANCE SCHEDULE

2.1 PM TABLES

2.1.1 PM TABLES FOR THE PRINTER

Two maintenance kits are provided for customers.

NAME CONTENTS

Maintenance Kit Type 4510 A PCDU (Photo Conductor Cle ani ng/Development Unit)

Maintenance Kit Type 4510 B Fusing Unit and Transfer Unit

Components marked with an asterisk (*) should be inspected, serviced, and

replaced without the maintenance kits.

NOTE: Amounts mentioned as the PM interval indicate the number of prints.

Symbol key: C: Clean, R: Replace, L: Lubricate, I: Inspect

EM 150K 300K 450K NOTE

PCDU

DRUM (OPC) AREA

Charge Roller* R R R

Cleaning Roller* R R R

Quenching Lamp C Dry cloth

Pick-off Pawl s* R R R

Spurs C C C Dry cloth or alcohol

ID Sensor

CCC

Perform SP3001-02 after

blower brush cleaning.

Preventive

Maintenance

CLEANING UNIT

Drum Cleaning Blade* R R R

Cleaning Entrance Seal

Side Seal I I I

DEVELOPMENT

Development Drive Gears I I I Replace every 5 PM (750 K)

Development Filter* R R R

Developer* I R I

Entrance Seal I I I

Side Seal I I I

Development Roller C C C Dry cloth

CCC

Blower brush, replace if

required.

2-1

PM TABLES 6 November, 2001

EM 150K 300K 450K NOTE

PAPER FEED

Registration Roller CCCCWater or alcohol.

Paper Feed Roller* I R R R

Separation Roller* I R R R

Pick-up Roller* I R R R

Paper Feed Roller

(By-pass feed table)*

Separation Roller

(By-pass feed table)*

Pick-up Roller

(By-pass feed table)

Paper Feed Guides C C C Water or alcohol.

Relay Rollers C C C Water or alcohol.

Bottom Plate Pad C C C Water or alcohol.

Bottom Plate Pad

(By-pass feed)

Registration Sensor C C C Blower brush

Paper Feed Roller Gear

(By-pass feed)

I RRR

I RRR

I RRR

CCC

LLL

Check counter value for each

(SP7204). If ≥ 150 K, replace

roller. After replacing the roller,

do SP7816 to reset counter.

Water or alcohol.

Silicone Grease G-50 1. *

DUPLEX UNIT

Upper Transport Roller C C C Water or alcohol.

Lower Transport Roller C C C Water or alcohol.

TRANSFER BELT UNIT

Transfer Belt* CRRRDry cloth

Transfer Belt Cleaning

Blade*

Transfer Belt Rollers C C C Dry cloth

Entrance Seal C C C Dry cloth

Transfer Entrance GuideCCCCDry cloth

Used Toner Tank I C C C Empty the tank.

FUSING UNIT/PAPER EXIT

Fusing Entrance and Exit

Guide Plates

Hot Roller* R R R

Pressure Roller* R R R

Fusing Thermistors* R R R

Cleaning Roller C C C Water or alcohol.

Cleaning Roller Bushings L L L Grease: Barrierta JFE 55/2

Hot Roller Strippers* C R C Water or alcohol.

Paper Exit Guide Ribs C C C Water or alcohol.

Exit Sensor C C C Blower brush

RRR

CCC

Water or alcohol.

DRIVE

Drive Belts I Replace if necessary

2-2

6 November, 2001 PM TABLES

2.1.2 PM TABLES FOR OPTIONS

NOTE: Amounts mentioned as the PM interval indicate the number of prints.

Symbol key: C: Clean, R: Replace, L: Lubricate, I: Inspect

EM 150K 300K 450K NOTE

PAPER TRA Y UNIT G520

Paper Feed Rollers R R R

Pick-up Rollers R R R

Separation Rollers

RRR

Relay Rollers C C C Dry or damp cloth

Bottom Plate Pad C C C Dry or damp cloth

EM 150K 300K 450K NOTE

LCT A683

Paper Feed Roller

RRR

Pick-up Roller* R R R

Separation Roller* R R R

Bottom Plate Pad C C C Dry or damp cloth

Check counter with SP7204. I f

≥ 150 K, replace roller. After

replacing the roller, do SP7816

to reset counter.

Check counter with SP7204. I f

≥ 150 K, replace roller. After

replacing the roller, do SP7816

to reset counter.

Preventive

Maintenance

EM 150K 300K 450K NOTE

1000-SHEET/3000- SHE ET FINI SH E R

Rollers C Water or alcohol.

Brush Roller (A681) IIIIReplace if required.

Discharge Brush CCCCDry cloth

Sensors C Blower brush

Jogger Fences IIIIReplace if required.

Punch Waste Hopper IIIIEmpty hopper.

* Note: Lubricate the paper feed clutch

gear [A] with Silicone Grease

G501 every P.M.

[A]

2-3

G065P500.WMF

6 November, 2001 GENERAL CAUTIONS

3. REPLACEMENT AND ADJUSTMENT

3.1 GENERAL CAUTIONS

!

CAUTION

To avoid damage to the transfer belt, drum, or development unit when it is

removed or re-installed, never turn off either power switch while electrical

components are active.

!

CAUTION

Turn off the main power switch and unplug the machine before attempting

any of the procedures in this section.

3.1.1 LASER UNIT

1. Do not loosen the screws that secure the LD drive board to the laser diode

casing. Doing so would throw the LD unit out of adjustment.

Adjustment

Replacement

2. Do not adjust the variable resistors on the LD unit, as they are adjusted in the

factory.

3. The polygon mirror and F-theta lenses are very sensitive to dust. Do not open

the optical housing unit.

4. Do not touch the glass surface of the polygon mirror motor unit with bare

hands.

5. After replacing the LD unit, do the laser beam pitch adjustment. Otherwise, an

SC condition will be generated.

3.1.2 USED TONER

1. Dispose of used toner in accordance with local regulations. Never throw toner

into an open flame, for toner dust may ignite.

3-1

SPECIAL TOOLS AND LUBRICANTS 6 November, 2001

3.2 SPECIAL TOOLS AND LUBRICANTS

3.2.1 SPECIAL TOOLS

Part Number Description Q’ty

A2309003 Adjustment Cam – Laser Unit 1

A2309004 Positioning Pin – Laser Unit 1

A2309352 Flash Memory Card – 4MB 1

A2309351 Case – Flash Memory Card 1

G0219350 Parallel Loopback Connector 1

3.2.2 LUBRICANTS

Part Number Description Q’ty

A2579300 Grease Barrierta S552R 1

52039501 Silicone Grease G-501 1

3.2.3 SYMBOLS USED IN TEXT

Screw: ! Connector: " C-clamp (snap ring): # E-clamp: $

3-2

6 November, 2001 FRONT DOOR

3.3 FRONT DOOR

[A]

[B]

1. Open front door.

2. Front door. Left pin [A], right pin [B].

3.4 DUPLEX UNIT

[B]

[A]

G065R951.WMF

[C]

[D]

Adjustment

Replacement

G065R003.WMF

1. Connector cover [A] (! x 1)

2. Duplex connectors [B] (" x 2)

3. Duplex support arm [C] (# x 1)

4. Duplex unit [D]

NOTE: Grip the duplex unit with both hands, slowly rotate it towards you and

then lift up.

3-3

UPPER RIGHT COVER 6 November, 2001

3.5 UPPER RIGHT COVER

[C]

[B]

[A]

G065R945.WMF

NOTE: Work carefully to avoid damaging the development roller.

1. Duplex unit (☛ 3.4)

2. Transfer belt unit (☛ 3.12.1)

3. Metal support arm [A] (! x 1)

4. Band support arm [B] (loop fastener)

5. Connector [C] (" x 1)

6. Upper right cover (# x 1, bushing x 1)

3-4

6 November, 2001 BY-PASS TRAY UNIT

3.6 BY-PASS TRAY UNIT

[B]

[C]

[D]

[A]

G065R952.WMF

Use this procedure to remove the complete by-pass tray unit from the machine. If

you wish to remove only the table, or some of the components of this unit, ☛ 3.15.

1. Duplex unit (☛ 3.4)

2. Left cover [A] (! x 1)

3. Right cover [B] (! x 1)

4. Connectors [C] (" x 2)

5. By-pass unit [D] (! x 4)

NOTE: After removing the screws, lift to unhook the by-pass tray unit from the

frame of the machine.

Adjustment

Replacement

3-5

REAR COVERS 6 November, 2001

3.7 REAR COVERS

3.7.1 REAR UPPER COVER

[B]

[A]

G065R953.WMF

1. Left corner cover [A] (! x 2)

2. Rear upper cover [B] (! x 2)

3.7.2 REAR LOWER COVER

[A]

G065R954.WMF

1. Rear lower cover [A] (! x 4)

3-6

6 November, 2001 LEFT COVERS

3.8 LEFT COVERS

3.8.1 LEFT UPPER COVER

[A]

Adjustment

Replacement

[B]

1. Rear left corner cover [A] (! x 2)

2. Left upper cover [B] (! x 4)

G065R955.WMF

3-7

LEFT COVERS 6 November, 2001

3.8.2 OPERATION PANEL

[A]

[D]

[B]

[C]

G065R919.WMF

!

WARNING

The fusing unit below the cover is hot. Allow the machine to cool for a few

minutes before you begin the procedure.

1. Fusing unit cover [A] (caps x 2, ! x 2)

NOTE: Insert the tip of a screwdriver into the slot to release the plastic hook

and lift. Exert very little pressure to avoid breaking the hooks.

2. After removing the screws, slide cover [B] forward to remove it.

NOTE: Before re-installing the cover, open the duplex unit and carefully insert

the brackets on the bottom of the cover into the slots [C].

3. Operation panel [D] (! x 2, " x 2)

NOTE: Turn over the fusing unit cover and pull off the operation panel to

expose the connector.

3-8

6 November, 2001 LEFT COVERS

3.8.3 PAPER OUTPUT TRAY

[B]

[A]

G065R920.WMF

No Bridge Unit Installed

1. Sub copy tray [A]

2. Paper sensor ass’y [B] (! x 2)

[D]

[E]

[C]

G065R921.WMF

Adjustment

Replacement

3. Cover [C] (! x 1)

4. Paper output tray [D] (! x 3)

5. If the duct on the bottom of the paper output tray base hangs up on the vertical

support [E] below, reach under and pull the duct up over the support.

Bridge Unit Installed

1. Bridge unit [A] (! x 2, " x 2)

2. Paper output tray [B] (! x 3)

3. If the duct on the bottom of the paper output tray base hangs up on the vertical

support [E] below, reach under and pull the duct up over the support.

3-9

LASER UNIT 6 November, 2001

3.9 LASER UNIT

!

WARNING

Turn off the main power switch and unplug the machine before attempting

any of the procedures in this section. Laser beams can seriously damage

your eyes.

3.9.1 CAUTION DECAL LOCATIONS

Two caution decals are located in the laser section as shown below. (See the next

page for removal instructions.)

LASER-1.WMF

G065RLW.WMF

3-10

G060R951.WMF

LASER-3.WMF

6 November, 2001 LASER UNIT

3.9.2 LASER UNIT

[B]

[D]

G065R211.WMF

[C]

[B]

[A]

[F]

Adjustment

Replacement

[G]

G065R962.WMF

!

WARNING

[E]

Turn off the main power switch and unplug the machine before attempting

this procedure. Laser beams can seriously damage your eyes.

1. Open the front door and raise the toner bottle holder handle [A].

2. Front door (pins [B] x 2)

3. Inner cover [C] (! x 2, " x 2)

4. Shield glass [D]

5. Shield plate [E] (! x 2)

6. Laser unit connectors [F] (" x 5, " x 1 flat cable)

NOTE: Hold the LD board securely when disconnecting connectors.

7. Laser unit [G] (! x 2)

NOTE: When sliding out the laser unit, do not hold the LD board. Hold the

laser unit casing.

3-11

LASER UNIT 6 November, 2001

3.9.3 POLYGON MIRROR MOTOR

[A]

[B]

G065R994.WMF

1. Laser unit (☛ 3.9.2)

2. Laser unit cover [A] (! x 4, 2 hooks)

3. Polygon mirror motor [B] (! x 4, " x 1)

4. After replacing the motor, do the image adjustment. (☛ 3.20)

G065R201.WMF

3-12

6 November, 2001 LASER UNIT

3.9.4 LASER SYNCHRONIZATION DETECTOR

[A]

G065R206.WMF

1. Laser unit (☛ 3.9.2)

Adjustment

Replacement

2. Laser synchronization detector [A] (! x 1, " x 1).

3.9.5 LD UNIT

[A]

1. Laser unit (☛ 3.9.2)

G065R513.WMF

2. LD unit [A] (! x 3, " x 1)

NOTE: To avoid damaging the LD board, hold it securely when disconnecting

the connectors. Hold the laser unit casing.

3. After replacing the LD board, perform SP2109 to adjust the laser beam pitch

(described on the next page).

3-13

LASER UNIT 6 November, 2001

Laser Beam Pitch Adjustment

After replacing the LD board, do the laser beam pitch adjustment. There are two

procedures: one for 400 dpi, and one for 600 dpi. These use the following SPs.

SP2110 Test Mode Dpi (0: 400 dpi, 8: 600 dpi)

SP2109-01 LD Beam Pitch Adjustment – 400 dpi

SP2109-02 LD Beam Pitch Adjustment – 600 dpi

SP2109-03 LD Beam Pitch Adjustment – 400 dpi Initial Setting

SP2109-04 LD Beam Pitch Adjustment – 600 dpi Initial Setting

NOTE: If you do not have an SMC Report for reference, print the SMC Report so

you can look up and match the SP numbers below with the correct name.

1. Set SP2110 to 0 (for 400 dpi), or to 8 (for 600 dpi).

2. Execute SP2109-08 to reset all the beam pitch data.

3. For SP2109-01 input 144.

NOTE: The entry “144” is only a starting reference value that will allow the

machine to operate. It is only a starting point for adjustment.

4. Execute SP2109-03.

5. Print the test pattern onto A3 (11" x 17") paper using SP2902-03 no.15. (☛ 5

Service Tables, 5.1.2 Test Pattern Printing (SP2902).

6. On the test pattern write 144, the value of SP2109-01.

7. Change the value of SP2109-01 and then print another test pattern, repeating

steps 2 to 6. Print about 5 patterns with different values for SP2109-01 (e.g. 48,

96, 192, 240).

8. Check these test patterns. If the laser beam pitch is not correct, the image

looks like a black vertical stripe pattern (see the diagrams below).

NOTE: For example, if the pattern made with the value 192 has fewer obvious

stripes than the other printouts, the correct value is near 192.

9. Fine adjustment: Do steps 2 to 6 to adjust the laser beam pitch position until

thin lines are of uniform thickness (no stripes should appear on the printout).

NOTE: In step 3, input a value estimated to be correct (e.g., if 192 was the

closest, try 182), then do steps 4 and 5, then if necessary go back to

step 2 and try another value.

10. After adjusting the laser beam pitch for 400 dpi, adjust it for 600 dpi, using the

same procedure as for 400 dpi (use the SP modes for 600 dpi). Laser beam

pitch for 600 dpi should be 24 ~ 48 more than for 400 dpi.

Adjustment not complete

Adjustment complete

G065R553.WMFG065R552.WMF

3-14

6 November, 2001 PCDU

3.10 PCDU

3.10.1 PHOTOCONDCUTOR CLEANING/DEVELOPMENT UNIT

[B]

[A]

G065R905.WMF

[C]

Adjustment

Replacement

[C]

[D]

[E]

G065R906.WMF

1. Open the front door.

2. Lower the by-pass tray, open the duplex unit, and open the transfer unit right

cover.

3. Release the PCDU lock [A].

4. Hold the PCDU by the handle [B] and pull out slowly.

5. Remove the screws [C] (! x 3).

6. Pull the PCU horizontally then up [D] to separate it from the development unit

[E].

7. Cover the drum with a clean sheet of paper to protect it from exposure to light.

Assembly

1. With the PCU slightly offset, set it on top of the development unit, then carefully

slide it horizontally to ensure that the end of the toner supply shutter at the

toner supply port opens.

2. Check the exposed spring on the back of the PCDU.

• If the spring is spread open, the supply port is open.

• If the spring is not open, the supply port is shut. Slide the PCU back and

engage it correctly.

NOTE: If the supply port remains closed, no toner will reach the drum.

3-15

PCDU 6 November, 2001

3.10.2 DRUM

[C]

[B]

[A]

[D]

[E]

G065R907.WMF

G065R908.WMF

G065R304.WMF

1. PCDU (☛ 3.10.1)

CAUTION: Never touch the drum surface with bare hands.

2. Remove the toner cap [A] and use it to cover the toner port [B].

3. Turn the PCU upside down and remove the lower cover [C] (! x 2, pawls x 3)

4. Press at ➀ to release the charge roller [D], release the charge roller ➁, press

the drum [E] to the front, and then remove the drum ➂.

5. SP adjustments.

Charge Roller Bias Adjustment

2001-01

ID Sensor Initial Setting 3001-02 Initializes the ID sensor.

Image Transfer Current – Image Face 2301 01

Image Transfer Current – Image Back 2301 02

Image Transfer Current – Lead Edge Face 2301 03

Image Transfer Current – Image Face By-pass 2301 04

3-16

Set to the standard value

to ensure carrier is not

attracted to the drum.

Set to the default

settings.

6 November, 2001 PCDU

3.10.3 PICK-OFF PAWLS

[A]

Adjustment

Replacement

[B]

G065R305.WMF

1. Remove the drum. (☛ 3.10.2)

2. Pawl assembly [A]

3. Pick-off pawl [B] (spring x 1, spur x 1)

Pick-off pawl position adjustment

If the pick-off pawl has marked the drum with a line, adjust the position by:

• Changing the spur position.

• Changing the pick-off pawl assembly position

3-17

PCDU 6 November, 2001

3.10.4 CHARGE ROLLER AND CLEANING ROLLER

[B]

[C]

[D]

1. Remove the drum. (☛ 3.10.2)

2. Two snap rings [A] (# x 2)

3. Charge roller holder [B]

4. Charge roller [C]

NOTE: Do not touch the charge roller.

5. Cleaning roller [D].

6. SP Adjustment:

Charge Roller Bias Adjustment

Image Transfer Current - Image Face 2301 01

Image Transfer Current - Image Back 2301 02

Image Transfer Current - Lead Edge Face 2301 03

Image Transfer Current - Image Face By-pass 2301 04

2001-01

[A]

G065R500.WMF

Set to the standard value

(–1,480 V) to ensure

carrier is not attracted to

the drum.

Set to the default

settings.

3-18

6 November, 2001 PCDU

3.10.5 DRUM CLEANING BLADE

[A]

Adjustment

Replacement

1. Remove the drum. (☛ 3.10.2)

2. Remove the charge roller. (☛ 3.10.4)

3. Remove the drum cleaning blade [A] (! x 2).

G065R307.WMF

3-19

PCDU 6 November, 2001

3.10.6 ID SENSOR

[A]

[B]

G065R991.WMF

[C]

1. PCDU (☛ 3.10.1)

2. Fusing unit (☛ 3.14.1)

3. Development unit (☛ 3.11.1)

4. PCDU rail [A] (! x 2, " x 1)

5. ID sensor bracket [B] (! x 1, " x 1)

6. ID sensor [C] (! x 1)

7. Perform the ID sensor initial setting with SP3001-2 (☛ 5. Service Tables)

3-20

6 November, 2001 DEVELOPMENT

3.11 DEVELOPMENT

3.11.1 DEVELOPMENT UNIT

[A]

[B]

Adjustment

Replacement

G065R202.WMF

1. PCDU. (☛ 3.10.1)

NOTE: Spread paper on a clean flat surface that is free of pins, paper clips,

staples, screws or any other metal objects.

2. Separate the PCU [A] and development unit [B] (! x 3).

3. Set the development unit on the spread paper, and cover the exposed drum

with a clean piece of paper.

4. SP adjustment if you are temporarily installing a used development unit for test

purposes:

Vref Manual Set SP2220 Set TD Sensor reference voltage to 4.0 V.