Page 1

Operating, Servicing, and Safety

Manual

Model # 900

90° Hydraulic Bender

CAUTION: Read and Understand

These Operating, Servicing, and

Safety Instructions, Before Using

This Machine.

1-800-467-2464

10 Cooperative Way Wright City, MO 63390

P.O. Box 110 Foristell, MO 63348

1-636-745-7757 Fax 1-636-745-2874

www.mittlerbros.com

REV 1 March 10 2011

Page 2

• Safety Pg.3

• Hydraulic Safety Pre cautions Pg.4

• Hydraulic System Oper ation Pg.5

• Machine Set up Pg.6

- 2 -

Table of Contents

• Operation Pg.7

• Math Formulas Pg.8-11

• Technical D iagram Pg.12

• Optional Equipment Pg.13-15

• Maintenance Pg.16

Page 3

- 3 -

SAFETY

The purpose of the safety section of this manual is to inform operators and

maintenance personnel of the precautions to be taken while operating or servicing the

machine. The following are a few basic guidelines to follow, but as with any type of

machinery good judgment and a safe attitude should be applied at all times.

1. Always disconnect power, lock-out and tag-out machine per OSHA regulations before

attempting to service this machine.

2. Always wear safety glasses or other approved eye protection while operating or

servicing the machine.

3. Keep all body parts and any foreign objects away from moving parts. Do not reach

into the machine without first disconnecting all power sources.

4. Do not attempt to override any safety device on the machine.

5. Do not operate the machine if it has been damaged or is not operating properly.

6. Do not wear jewelry (watches, rings, necklaces, etc.), or loose fitting clothing while

operating or servicing the machine.

7. The machine should only be operated or serviced by properly trained, authorized

personnel.

8. Replacement parts should have the same specification and operation as the original

parts on the machine.

9. Before starting the machine be sure it is set up properly.

10. The machine and work area should be kept neat and clean.

11. Do not operate or service any machine while under the influence of drugs or alcohol.

NOTE: THESE SAFETY RULES ARE FOR YOUR BENEFIT TO HELP PREVENT INJURY TO

YOURSELF AND/OR YOUR CO-WORKERS. REVIEW ALL SETUP AND OPERATING

PROCEDURES, WHETHER COVERED OR NOT, IN THIS MANUAL TO HELP INSURE SAFE

OPERATION OF THE MACHINE.

Page 4

- 4 -

HYDRAULIC SAFETY PRECAUTIO NS

WARNING

General Operation

• All WARNING statements must be carefully observed to help prevent personal injury.

• Before operating the pump, all hose connections must be tig ht en ed with the proper tools. Do not over

tighten. Connections should only be tightened securely and leak-free. Over tightening can cause

premature thread failure or high pressure fittings to split at pressures lower than their rated capacities.

• Should a hydraulic hose ever rupture, burst, or need to be disconnected, immediately shut off the

pump and release all pressure. Never attempt to grasp a leaking pressurized hose with your hands.

The force of escaping hydraulic fluid could cause serious injury.

• Do not subject the hose to potential hazard such as fire, sharp surfaces, extreme heat or cold or

heavy impact. Do not allow the hose to be altered or kink, twist, curl, crush, cut, or bend so tightly that

the fluid flow within the hose is blocked or reduced. Periodically inspect the hose for wear, because

any of these condition’s can damage the hose and possibly result in personal injury.

• Do not use the hose to move attached equipment. Stress can damage hose and possibly cause

personal injury.

• Hose material and coupler seals must be compatible with the hydraulic fluid used. Hoses also must

not come in contact with corrosive materials such as creosote-impregnated objects and some paints.

Consult the manufacturer before painting a hose. Hose deterioration due to corrosive materials can

result in personal injury. Never paint the couplers.

• Inspect machine for wear, damage, and correct function before each use. Do not use machinery that

is not in proper working order, but repair or replace it as necessary.

• Replace worn or damaged safety decals.

• Modification of a product requires written Power Team authorization.

• Use only components with the same pressure rating when assembling a system or machine.

Pump

• Do not exceed the hydraulic pressure rating noted on the pump data plate or tamper with the internal

high pressure relief valve. Creating pressure beyond the rated pressure can result in personal injury.

• Before replenishing the fluid level, retract the system to prevent overfilling the pump reservoir. An

overfill can cause personal injury due to excess reservoir pressure create when cylinders are

retracted.

Air Supply

• Shut off and disconnect the air supply when the pump is not in use or before breaking any

connections in the system.

PREPARATION & SET-UP

Air Supply Hook-Up

Remove the thread protector from the air inlet of the pump. Select and install the threaded fittings

which are compatible with your air supply fittings. The air supply should be 20 CFM (.57 M3/min.) and

100 PSI (7 BAR) at the pump to obtain the rated hydraulic pressure. Air pressure should be regulated

to a maximum of 140 PSI (9 BAR). Secure your pump fitting to the air supply.

WARNING: If improperly used, pressurized equipment can be potentially hazardous. Therefore:

• Hydraulic connections must be securely fastened before building pressure in the system.

• Release all system pressure before loosening any hydraulic connection in the system.

Venting the Reservoir

To improve hydraulic fluid delivery and increase useable hydraulic fluid capacity, remove shipping

plug and install filler/vent cap before using the pump.

Page 5

- 5 -

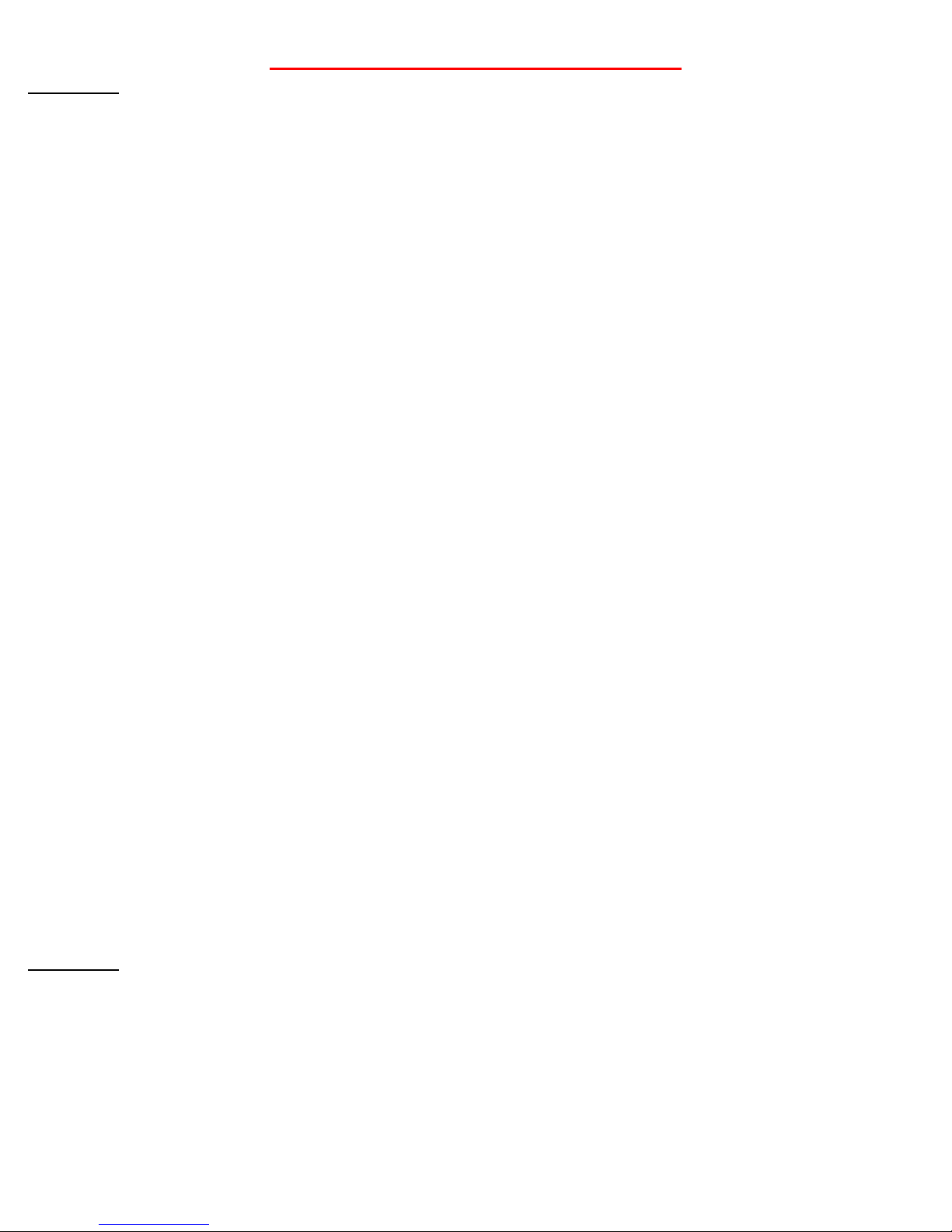

RED Plug should

Pump Assembly

Air

TOE END

HEEL END

Push Down to

Female End

Male End

Retainer Collar

HYDRAULIC SYSTEM

1. Remove the RED Plug in the pump assembly and replace with the

supplied BLACK plug. This is the reservoir venting system

and damage or inoperabilit y may result if not chang ed out.

2. Attach the hydraulic hose to the pump. Be sure to use a

quality thread sealer on both connections

3. Attach an air line fitting for your shop air to other end of the

pump.

be changed to

BLACK Plug

Hydraulic Hose

Connector

Release Pressure

4. Push the pump foot pedal to the release position (TOE END) to

relieve all internal pressure.

5. Push the MALE hose end, from the pump, into the FEMALE

Cylinder fitting.

6. Thread the retainer collar hand tight. NOTE: This procedure will insure that the male & female fittings

positively seat against each other, eliminating any possibility of air locking. CAUTION Failing to follow

this procedure may cause the cylinder to not retract and / or leak.

BLEED THE CYLINDER

7. Connect a compressed air supply (90PSI) to the pump.

8. Elevate the pump and hose above the cylinder.

9. Push the hydraulic pump pedal HEEL END to actuate the

cylinder. Run the cylinder out about half way. Release the pump

by pressing on the TOE END of the pedal. Repeat this process

three or four times or until the ram cylinder movement is smooth.

Retract

Pump

Page 6

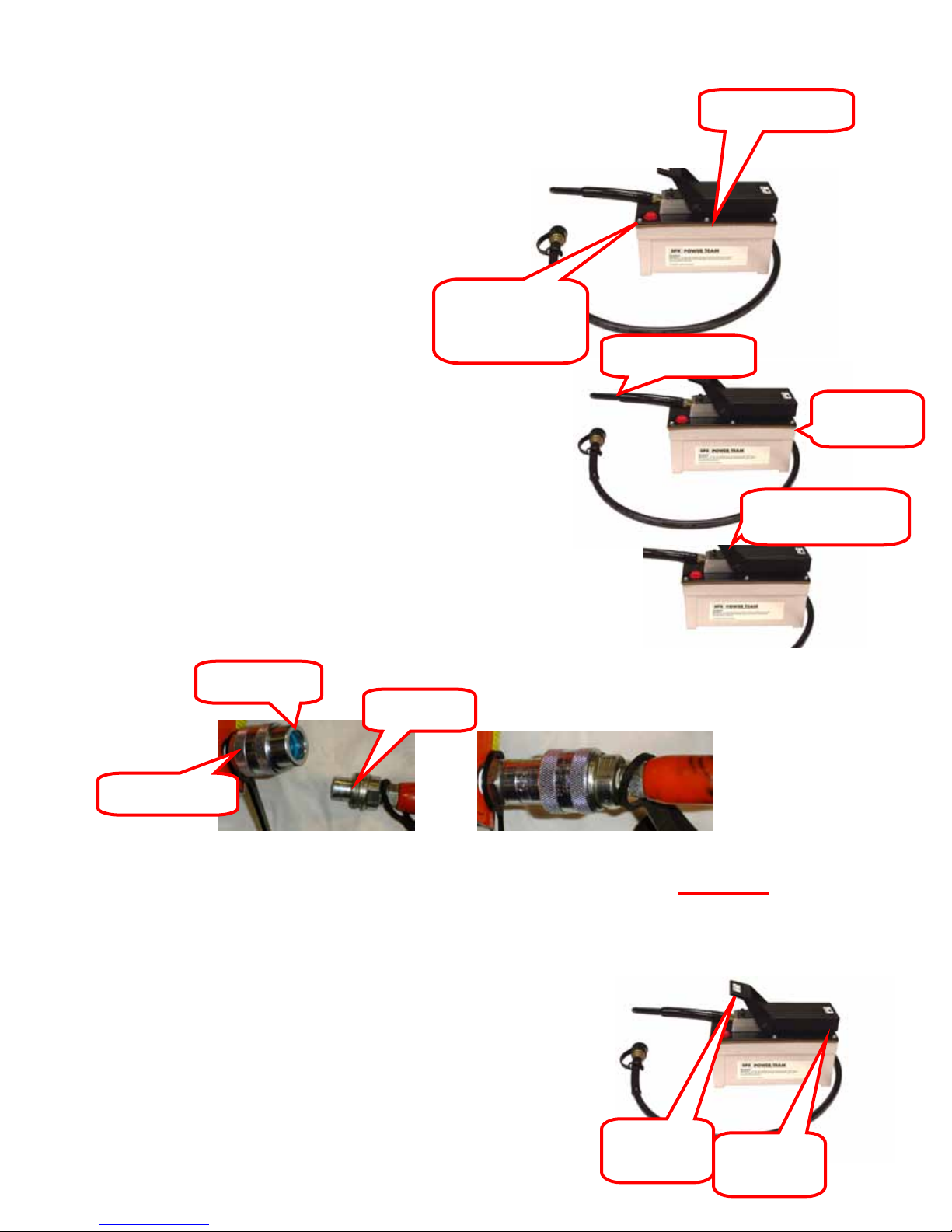

#12 Follow Bar

#13 Roller

#10 Saddle

#5 & #8 Clevis Pin

#7 Clevis

#9 & #11 Saddle Pin

#16 Female Hydraulic

#3 & #15 Roller Pin

#4 & #14 Upper Frame

#16

Release

Pump

MACHINE SETUP

Coupler

1. Remove machine from packaging.

- 6 -

2. Place machine on table or floor.

3. Remove roller pin.

4. Rotate upper frame out of the way.

Pressure

5. Remove clevis pin.

6. Remove bender shoe & follow bar from packaging.

7. Insert shoe into clevis.

AIR / HYDRAULIC PUMP

Note: Shoe can be installed to rotate in either direction

to complete the bends.

8. Insert clevis pin.

9. Remove saddle pin from adjustable saddle.

10. Place saddle on to shoe as shown.

11. Insert saddle pin into saddle and shoe.

CAUTION: Be sur e pin is completely through bottom saddle ar m.

12. Place follow bar on to machine as shown.

Pressure

Hydraulic

Coupler

13. Slide roller as close as possible to follow bar.

Note: Lubri cate (oil) rol ler Top / Bottom and I nside Diameter

14. Close the upper frame.

15. Note: Lubricate (oil) Pin Outside Diameter Insert roller pin through the upper

frame, roller, & lower frame.

CAUTION: Be sur e pin is completely through lower frame arm.

16. Machine is now ready for use.

Page 7

- 7 -

#2 Bend Start Point

#3 Tubing Through the Saddle

#4 Roller

Male

Coupler

#9 Release

#4 & #7

AIR / HYDRAULIC PUMP

#5 Shoe Start Point

#8 Reference Scale

#10 Follow Bar

#10 Saddle

#10 Saddle Pin

OPERATION

Pump

Pressure

Pressure

1. Insert tubing into channel in the shoe, follow bar, and

adjustable s addle.

CAUTION: B e sure roll er pin is completely through lower

frame

2. Align the be nd start p oint marked on tubing t o the bend st art

point on th e bender sh oe.

3. Make sure that tubing is sticking all the way through the adjustable

CAUTION: Be sure pin is completely through bottom saddle arm.

saddle.

4. Tighten adj ustable sad dle ”V” bl ock against tubing.

5. Align the fr ont edge of the follo w bar with t he bend star t point of t he bending s hoe.

6. Press the foot pedal on the hydraulic pump, using short bursts until the bending shoe and follow

bar are clos e to the ro ller.

7. Check your tubing to make sure that your tubing start point is still aligned with the shoe start point.

8. Now make your bend by pressing down on the foot pedal heel on the hydraulic unit until the

desired angl e is reached.

9. It usually is nec essary to bend tub ing past the desire d angle a few degre es to account for tubi ng

spring back . Note: Rec ord locatio n of referenc e scale po inter to ref erence sc ale to assist in

completing f uture bend s to same de gree of be nd with sam e tubing material, size, and wall

thickness. T hen you ca n bend the n ext pieces to that sam e referenc e scale m ark.

10. When desir ed angle is r eached, pr ess hydraul ic pump f oot pedal to e to release pressure .

11. Turn adjus table saddl e knob count erclockwis e to remove saddle pin, saddle and follow bar.

12. Repeat thes e steps wi th each add itional be nd.

Hydraulic

Page 8

- 8 -

CORRECTED MATHEMATICAL FORMULA

FOR HYDRAULIC TUBING BENDER

WHEN USING INSTRUCTION VIDEO

The following formula should be used to determine the start point for each required bend.

The example will be for a Double Bevel Bend

L1 = 26 25 degree angle

L2 = 15 65 degree angle

L3 = 39 65 degree angle

L4 = 15 25 degree angle

L5 = 26

Bend #1 Start Point:

L1 – ½ developed length (DL25) – ½ (Gain)

26” – ½ (3.064”) – ½ (.050)

26” – 1.532” - .025” = 24.448

Bend #2 Start Point:

L1 + L2 – Gain 1 – ½ (DL65) – ½ (Gain 2)

26 + 15 - .050 –1/2 (7.941) – ½ (.973”)

26 + 15 - .050 – 3.9705 - .48895 = 36.491

Bend #3 Start Point:

L1 + L2 + L3 – Gain 1 – Gain 2 – ½ (DL65) – ½ (Gain 3)

26 + 15 + 39 - .050” - .978 – ½(7.941) – ½ (.972”)

26 + 15 + 39 - .050” -.978 – 3.9705 - 0. 48 6 = 74.5 15

Bend #4 Start Point:

L1 + L2 + L3 + L4 – Gain 1 – Gain 2 – G ain 3 – ½ (DL25) – ½ (Gain 4)

26 + 15 + 39 + 15 -.050 - .978 - .978 –1/2 (3.054) – ½ (0.497)

26 + 15 + 39 + 15 - .050 - .978 - .978 – 1.527 – 0.025 = 91.442

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

Page 9

- 9 -

Degree

of Bend

Degree

of Bend

1

.0000

31

.0136

61

.1134

2

.0000

32

.0150

62

.1196

3

.0000

33

.0165

63

.1260

4

.0000

34

.0181

64

.1327

5

.0000

35

.0197

65

.1397

6

.0001

36

.0215

66

.1469

7

.0001

37

.0234

67

.1544

8

.0003

38

.0254

68

.1622

9

.0003

39

.0276

69

.1703

10

.0005

40

.0298

70

.1787

11

.0006

41

.0322

71

.1874

12

.0008

42

.0347

72

.1964

13

.0010

43

.0373

73

.2058

14

.0013

44

.0400

74

.2156

15

.0015

45

.0430

75

.2257

16

.0018

46

.0461

76

.2361

17

.0022

47

.0493

77

.2470

18

.0026

48

.0527

78

.2582

19

.0031

49

.0562

79

.2699

20

.0036

50

.0600

80

.2891

21

.0042

51

.0637

81

.2944

22

.0048

52

.0679

82

.3074

23

.0055

53

.0721

83

.3208

24

.0062

54

.0766

84

.3347

25

.0071

55

.0812

85

.3491

26

.0079

56

.0860

86

.3640

27

.0090

57

.0911

87

.3795

28

.0100

58

.0963

88

.3955

29

.0111

59

.1018

89

.4121

30

.0126

60

.1075

90

.4292

GAIN F ACTORS

Degree of

Bend

Multiplier

Multiplier

Multiplier

GAIN = GAIN FACTOR FOR DEGREE OF BEND X RADIUS

FIND THE GAIN FOR AN 85 DEGREE BEND

GAIN = .3491 X 7 = 2.4437 OR 2 7/16

EXAMPLE:

USING A 7 INCH RADIUS

Page 10

-- 10 --

DEVELOPED LENGTH

DEVELOPED LENGTH = .0175 X DEGREE OF BEND X RADIUS

EXAMPLE:

FIND THE DEVELOPED LENGTH OF A 70 DEGREE

BEND USING AN 8 INCH RADIUS.

DEVELOPED LENGTH = .0175 X 70 X 8 = 9.80 OR 9 13/16

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

Page 11

-- 11 --

Degree

Bend

Degree

Bend

1

57.30

25

2.37

2

28.65

26

2.28

3

19.11

27

2.20

4

14.33

28

2.13

5

11.47

29

2.06

6

9.57

30

2.00

7

8.21

31

1.94

8

7.18

32

1.89

9

6.39

33

1.84

10

5.76

34

1.79

11

5.24

35

1.74

12

4.81

36

1.70

13

4.45

37

1.66

14

4.13

38

1.62

15

3.86

39

1.59

16

3.63

40

1.56

17

3.42

41

1.52

18

3.24

42

1.49

19

3.07

43

1.46

20

2.92

44

1.44

21

2.79

45

1.41

22

2.67

46

1.39

23

2.56

47

1.37

24

2.46

48

1.35

TABLE FOR OFFSET MULTIPLIER

of

Multiplier

of

Multiplier

DISTANCE BETWEEN BENDS = OFFSET MULTIPLIER FOR

DEGREE X OFFSET HEIGHT

EXAMPLE:

FIND THE DISTANCE BETWEEN BENDS FOR A

15 INCH OFFSET USING 25 DEGREE BENDS.

DISTANCE BETWEEN BENDS = 2.37 X 15 = 35.55 OR 35 9/16

Page 12

-12-

ITEM NO. QTY. PART NO.

1 1

900-003 Cylinder Mount Block

2 1 900-002 Lower Frame

3 1 900-005 Upper Frame

4

1

900-004 Shoe Clevis

5 1 900-007 Follow Bar Roller

6 1

900-018 Scale Pointer

7

1

900-502 Hydraulic Cylinder

8

1

900-008-C Hinge Pin

9 1 900-008-

A Roller Pin

10 1 900-008-B Clevis Pin

11 1 900-006 Clevis Adapter

12 2 05/8-11x1-1/2 Hex Head

13 1 Delrin

14

1

5/16-18x1/4 Set Screw

15 2 1/4-20x1/2 Button Head

16 1 1/4-20x1/4 Set Screw

17 1 Roll Pin

1-800-467-2464 www.mittlerbros.com

5

9

3

8

14

16

13 7 1

6

12

2

15

17

11

10

4

Page 13

-13-

Optional Equipment

Adjustable Saddles for 90 & 180 Hydraul ic Benders

Saddle eliminates the need fo r individual saddles for each tubi ng size. Two sizes

handle 5/8” to 1-3/4” Round & Sq uare Tubing.

• Easy Release “V” Block eliminates Stuck Saddle from tube spring back

• Securely holds each tube, eliminates tube creep

• Easier Bend-to-Bend Alignment with light pressure on tube

2500-300

2500-301

2500-302

Advantages

Adjustable Saddle, Small 5/8" t o 1-3/8"

Adjustable Saddle, Medium 1-1/2 to 1-3/4

Adjustable Saddle, Large 2" OD

Pumps

900-504-6 Air Hydraulic Pump, 6' Hose & Fitting

900-508-6 Electric Hydraulic Pump, Hose & Fittings 6'

900-D Digital Read Out for 90° Hydraulic Tube Bender

900-500-DVD Tubing Bending DVD for 90 Degree Hydraulic Tube Bender

Page 14

-14-

Bend Protractors

2100-4 4" Protractor Assembly

2100-5 5" Protractor Assembly

2100-6

2100-7 7" Protractor Assembly

2100-8 8" Protractor Assembly

2100 4" Thru 8" Protractor Set

6" Protractor Assembly

Page 15

-15-

BEND-TECH EZ

Designed for simple 2d parts!

900-510 Bend-Tech EZ Software

BEND-TECH EZ-3D

Designed for 3d bending, with 360 d egree part rotation!

900-511 Bend-Tech EZ-3D Software

BEND-TECH PRO

Full 3d Assembly & Manufacturing I nstructions, plus all EZ featur es!

900-512 Bend-Tech Pro Software

900-513 Bend-Tech SE Software

Page 16

-16-

Air Hydraulic Pump

Electric Hydraulic Pump

The fluid level should be 1/2 inch (12.7 mm) from the filler /

vent cap with all cylinders retracted.

The fluid level should be 1-3/4 inch (44.5 mm) from the filler /

vent cap with all cylinders retracted.

SPX Power Team

Enerpac

Mobil DTE 24 Hydraulic Oil is Compatible with Enerpac Components

MAINTENANCE

Inspecting The Hydraulic Fluid Level

Check the fluid level in the reservoir after every 10 hours of use. Drain and replenish the reservoir with Power Team

hydraulic fluid after every 300 hours of use approximately.

For pumps with a 105 cubic inch (1.71) reservoir capacity

For Machines With:

Orange & White Cylinder with Black Letters

White & Black Pump

Use: AW 46 - Non Foaming Hydraulic Fluid

or

Flame Out # 220 Fire Resistant Hydraulic Fluid

Refilling The Reservoir

If additional fluid must be added to reservoir, use only manufacturer suggested hydraulic fluid.

Clean the entire area around the filler plug before adding fluid to the reservoir.

Remove the filler plug and insert a clean funnel with filter.

The cylinder must be fully retracted and the air supply disconnected when adding the fluid to the reservoir.

For pumps with a 2 gallon (7.61) reservoir capacity

Yellow Cylinder with Black Letters

Yellow & Black Pump

Use: ISO 7 HF 101 Gal

or

ISO 32 HF 100 Qt.

or

Loading...

Loading...