MB 4550 General Information

Chapter

1

General Information

This service manual contains information useful for troubleshooting, repairing,

adjusting, and maintaining a Tektronix Phaser

Printers. This manual includes troubleshooting guides, adjustment procedures,

a field replaceable units (FRU) list and assembly/disassembly procedures for

selected FRUs. To ensure complete understanding of the product, we

recommend participation in Phaser 540 service training.

®

540 and Phaser

®

540 Plus Color

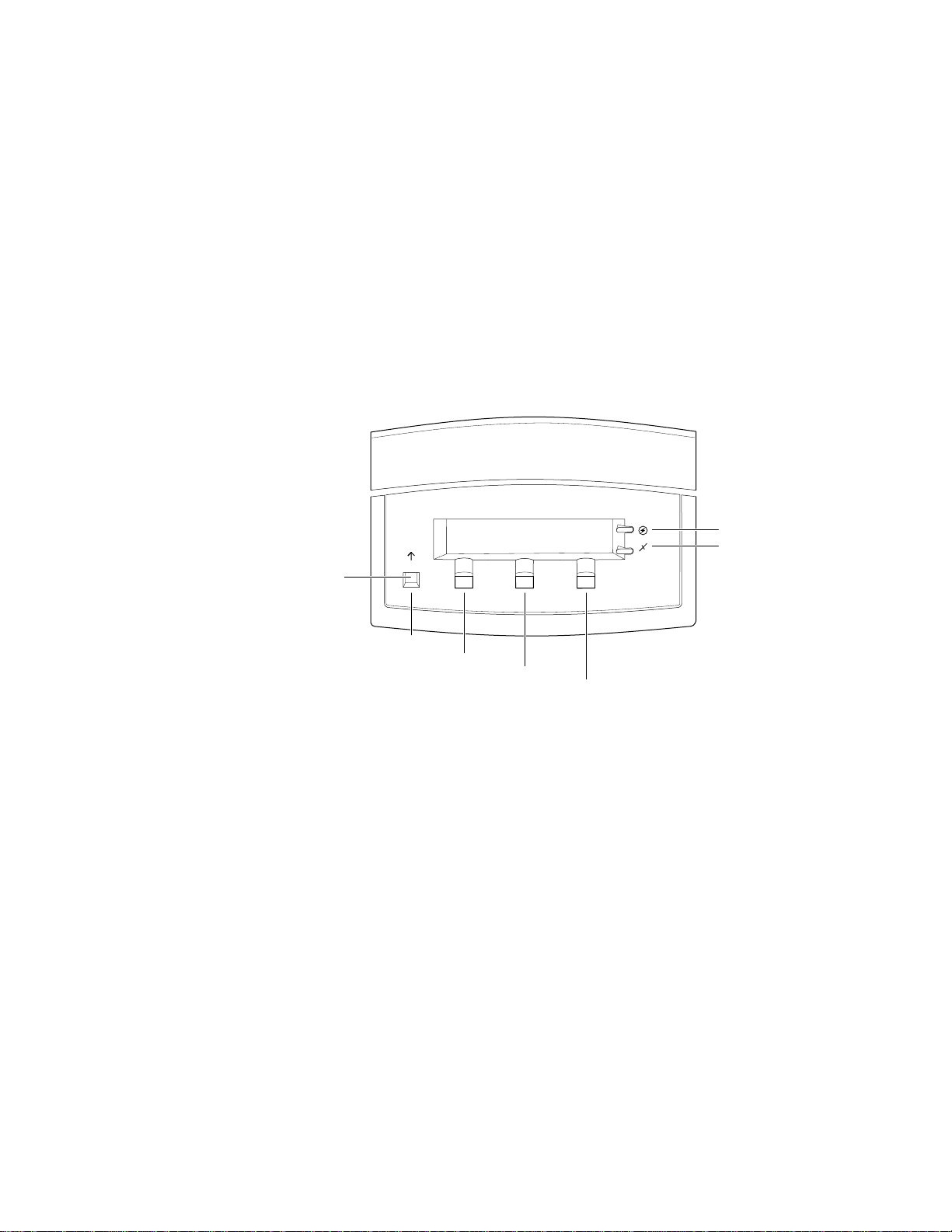

Figure 1-1 The Phaser 540 Color Printer

9013-01

Service Manual

1-1

General Information

1

The Phaser 540 Color Printers

The Phaser 540 and Phaser 540 Plus Color Printers both combines a color laser,

continuous-tone print engine with an image processor supporting Adobe’s

PostScript Level 2 page description language (version 2015). The image

processor features a bi-directional parallel interface for host communication.

Optional network adapter cards to the image processor allow the printer to

communicate on networks using LocalTalk, serial, Ethernet or Token Ring

protocols. The Ethernet network card supports EtherTalk, Novell and TCP/IP.

With the Token Ring network card, the Phaser 540 Plus supports Toten Ring

protocols. The network cards are sometimes referred to as “smart cards”

because each houses its own processor for executing specific on-board protocols;

only data is transferred from the installed smart card to the printer’s image

processor board.

The printers each comes standard with 20 Mbytes of RAM which can be

supplemented with one or two additional 16-Mbyte RAM SIMMs. The printer

contains 39 standard, built-in fonts. The printer features a SCSI-compatible

interface to connect to an external hard disk drive for additional font storage.

An orderable option, the Phaser CopyStation can also be connected to the

printer’s SCSI port to give the printer the ability to optically copy color images.

The printer supports printing on A- and A4-sized paper and transparency film

from an A or A4-size tray. An optional two-tray second feeder (called the Lower

Tray Assembly) is available. The printer also supports manual feeding. The

Phaser 540 Plus also supports Legal-size paper in its Legal-size tray.

The printer prints at a user-selectable resolution of 300 dots-per-inch or

600 dots-per-inch. Color printing is at either 4 or 16 levels of color depending on

the amount of memory installed in the printer. After being idle for one hour the

printer switches into its Energy Star mode where it consumes less than 45 watts

of power. It “awakens” upon receiving data at any of its ports. The printer also

features a closed-loop image density sensor system that allows it to

auto-calibrate its color imaging so printing output remains consistent over the

life of the print engine and its consumable supplies.

RAM and printer capabilities

With additional RAM memory the printer’s capabilities increase:

■

With standard 20 Mbytes of RAM, the printer has a frame buffer of 16

Mbytes, an I/O buffer of 100 kbytes, an image pipeline color cache of

500 kbytes, and PostScript virtual memory of 3.6 Mbytes. With

standard 20 Mbytes of RAM, the printer can print 300 dpi

continuous-tone and 600 dpi bi-level images.

1-2

Phaser 540 Color Printer

With 36 Mbytes of RAM, the printer has a frame buffer of 32 Mbytes,

■

an I/O buffer of 100 kbytes, an image pipeline color cache of 500

kbytes, and PostScript virtual memory of 3.6 Mbytes. With 36 Mbytes

of RAM the printer can print 300 or 600 dpi continuous-tone images

and has faster data throughput. With the additional RAM in the

Phaser 540 Plus, the scan-to-print start time of the Phaser CopyStation

is reduced to about 65 seconds.

■

With a maximum 52 Mbytes of RAM, the printer has a frame buffer of

32 Mbytes, an I/O buffer of 1 Mbytes, and image pipeline color cache

of 2 Mbytes, and PostScript virtual memory of 16.8 Mbytes.

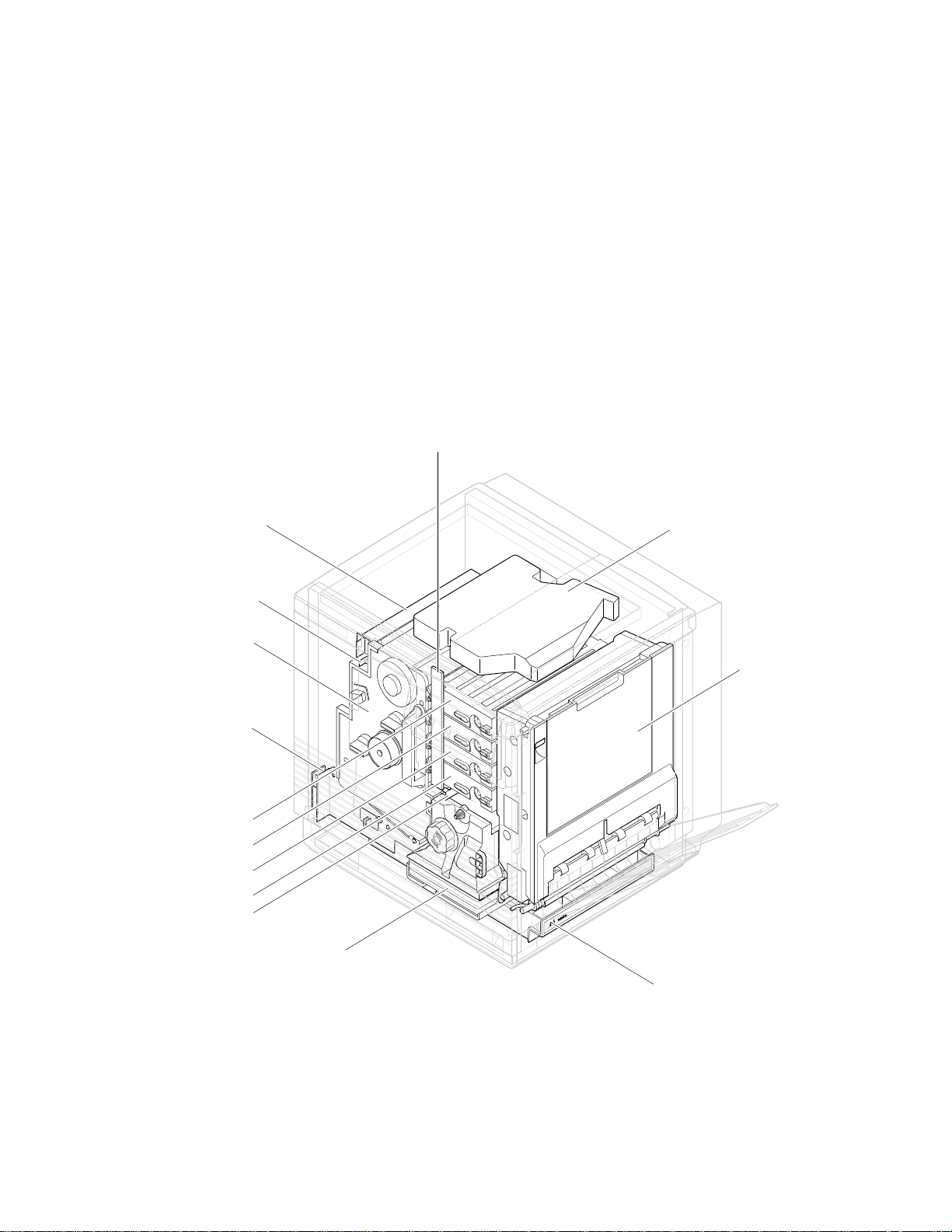

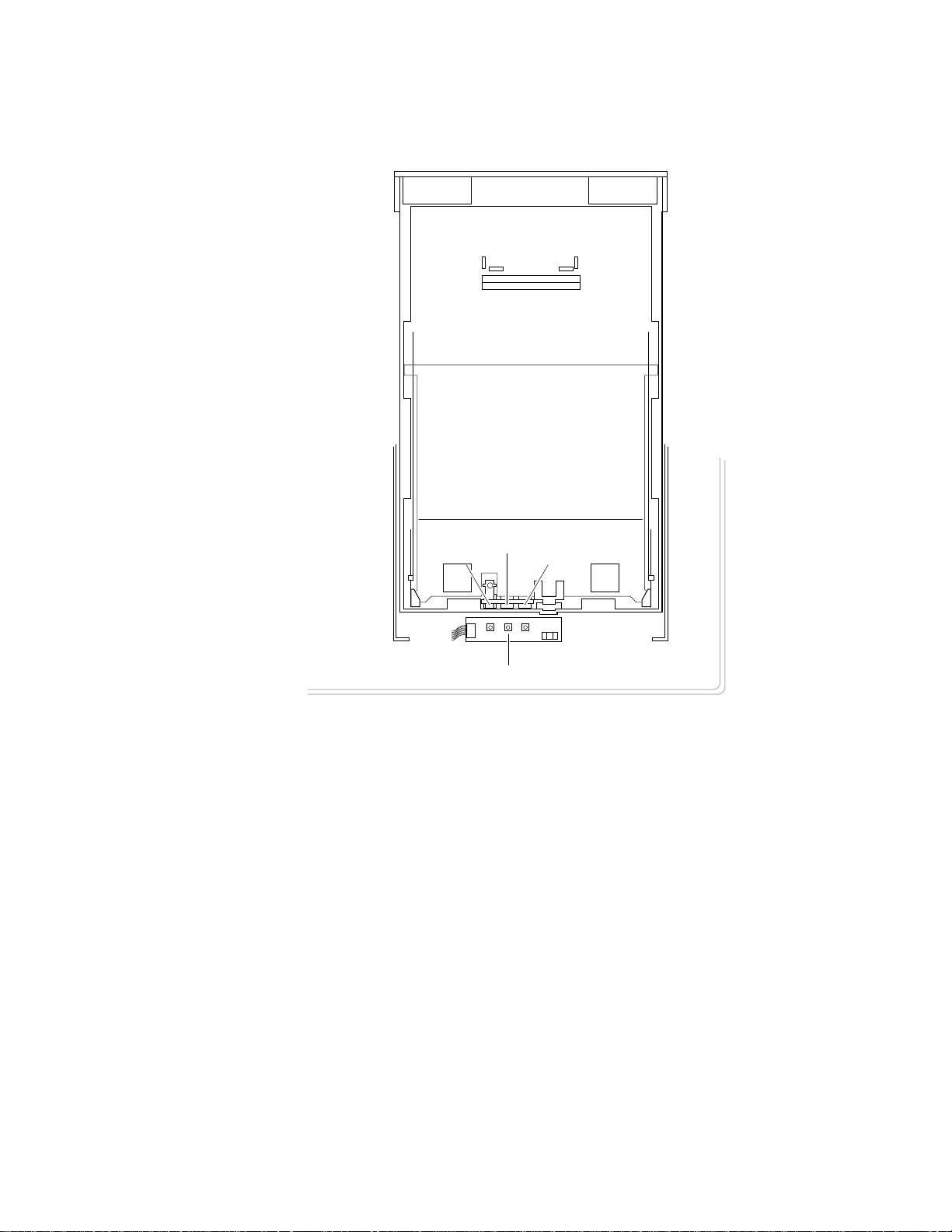

Print engine assemblies

Toner level

sensor board

General Information

1

Pre-exposure lamp

Imaging unit

Paper feeder

Black toner cartridge

Yelllow toner cartridge

Magentatoner cartridge

Cyan toner cartridge

Pre-transfer lamp

Ozone filter

Fuser

Laser scanner

Toner cartridge

selector/paper

exit unit

ER

P

A

P

A4

Paper tray

9013-02

Figure 1-2 Print engine major components

Service Manual

1-3

General Information

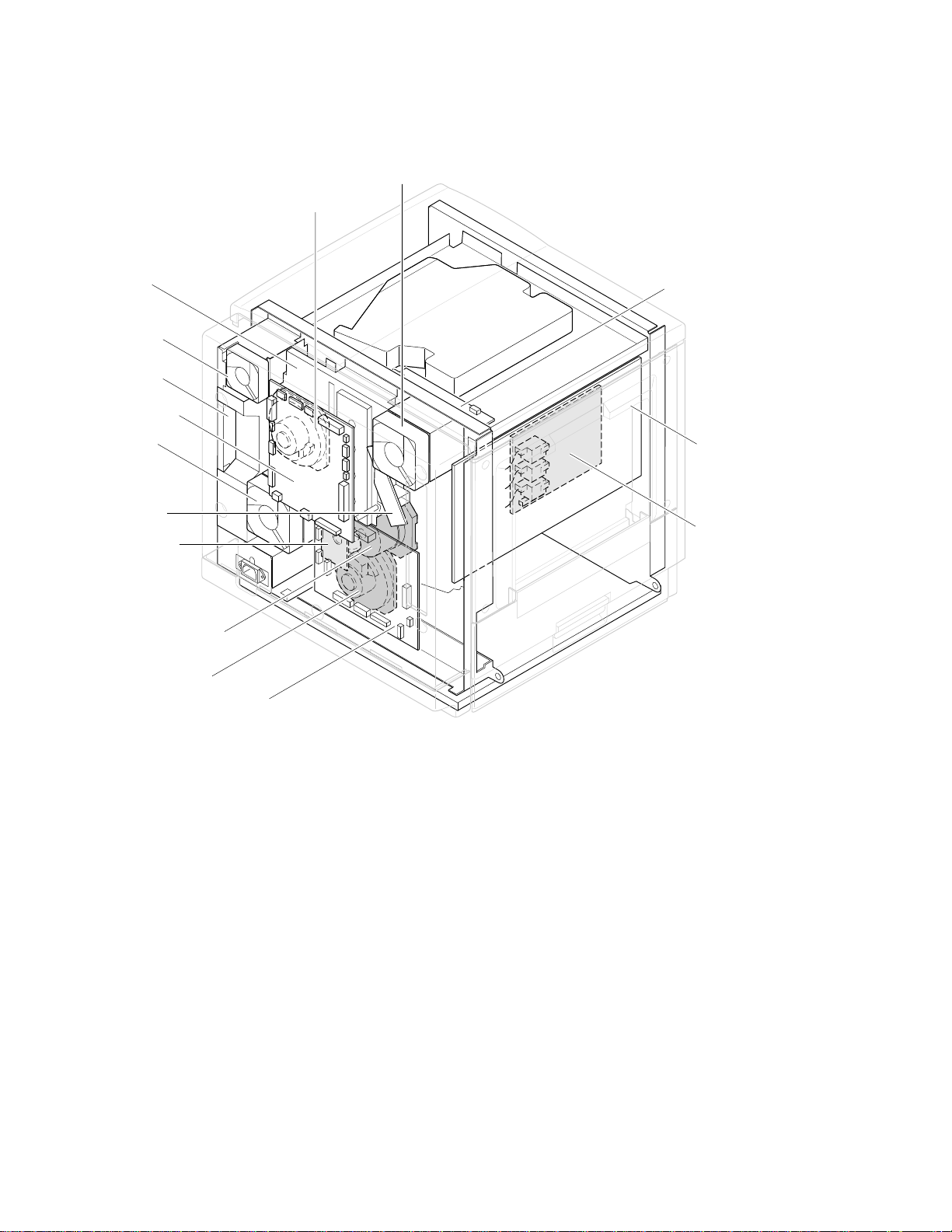

1

Toner cartridge

drive unit

Power

supply fan

Power

supply unit

Engine

control board

Fuser fan

Charger

sensor board

Cleaning board

Toner

cartridge

motor

Ozone fan

Laser driver board

Image processor

board

High voltage board

Main motor

Paper feed motor

Engine driver board

Figure 1-3 Print engine components (continued)

9013-03

1-4

Phaser 540 Color Printer

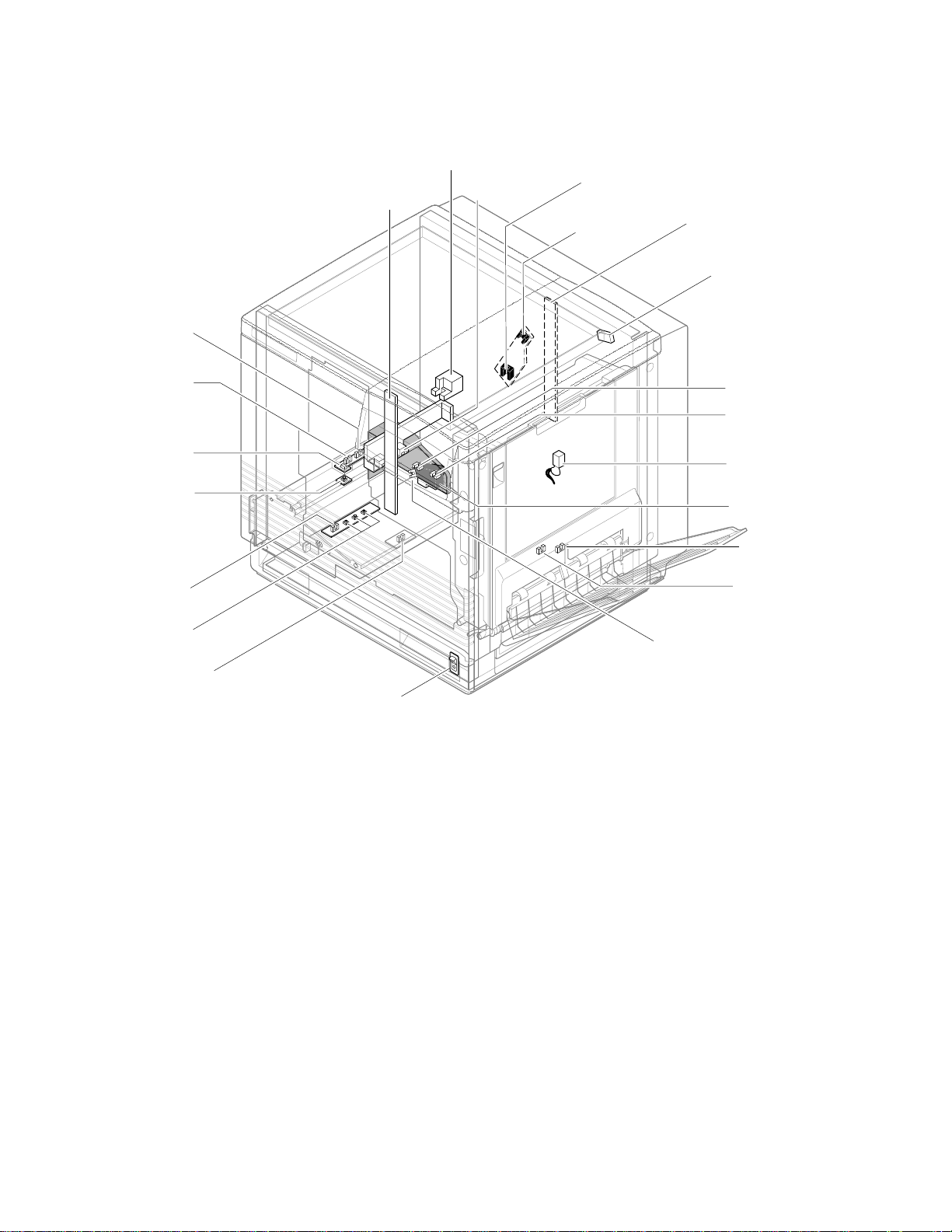

Manual feed

sensor

Registration

sensor

Transparency

sensor

(transmitter)

Transparency

sensor

(receiver)

Toner level

sensors

(transmitters)

Accumulator belt

home position sensor

Image density

sensor

Scorotron

charger

sensor

Pre-transfer

charger

sensor

General Information

Toner level sensors

(receivers) are mounted

inside the toner cartridge

driver unit

Front right door

opened switch

Transfer waste

bin sensor

Transfer roller

position sensor

Fuser-installed

switch

Left door opened

switch

1

Paper low

sensor*

Paper tray

type sensors

Paper jam

sensor

*Unused by image processor

Power switch

Figure 1-4 Print engine sensor, switch and solenoid locations

These sensors are not illustrated:

■

The photoconductive belt position sensor. This optical sensor marks

the home position of the photoconductive belt. It is mounted inside

the customer-replaceable imaging unit.

The photoconductive belt toner disposal bin full sensor. It is mounted

■

inside the customer-replaceable imaging unit. This ultrasonic sensor

determines if one of the imaging unit’s two waste toner bins is full

which, if true, would impair print quality. Under ordinary

circumstances, neither waste toner bin should fill up before the

imaging unit’s life is expired.

Paper-exit

sensor

Fuser-exit

sensor

Paper-empty

sensor

9013-04

The logic state of paper low sensor is not monitored or used by the image

processor.

Service Manual

1-5

General Information

1

Front panel

These front panel features are found on the printer:

■

A two-line, 24-character LCD and two LEDs

Four push buttons

■

LCD

The LCD serves two purposes: displaying current controller and print

engine status information and displaying an interactive menu. Status

information includes controller status such as

Printing . Print engine status includes messages such as Out of paper ,

Paper Jam , and Out of toner . The interactive menu can only be entered

while the print engine and controller are idle. The interactive menu allows the

user to review and change certain NVRAM, I/O ports and peripheral

parameters. Using the front panel to review and change parameters is discussed

in Chapter 9, “Checks and Adjustments.”

Ready , Receiving data and

Buttons

cancel an operation while in the interactive menu. The functions of Buttons 2, 3

and 4 are defined by the particular menu or function being displayed on the

LCD display. The bottom row of the LCD labels the current function of each

button.

In addition, pressing the buttons as you turn on the printer enables certain

diagnostic modes:

■

■

■

The Chapter 9 topic, “Resetting NVRAM” on page 9-9 explains how to use the

front panel buttons to reset the NVRAM to its factory default values.

Button 1, the left-most button, is labeled the Exit key and is used to

Pressing and holding Button 1, as you turn on the printer, skips

power-up diagnostics (except for a brief kernel test) and proceeds to

PostScript startup.

Pressing and holding Button 2, as you turn on the printer, executes

extended diagnostics.

Pressing and holding Button 3, as you turn on the printer, executes

interactive service tests. These are described in “Printer

self-diagnostics” on page 9-6.

1-6

Phaser 540 Color Printer

On

General Information

LEDs

The Power LED indicates the printer has +5 VDC available for its logic

control boards.

The

Error LED has three indications:

■

Off indicates that no errors have been detected.

■

indicates a warning to the user. An explanatory message, such as

Low Paper , is displayed on the LCD.

Blinking indicates an error has been detected. An error message, such

■

Paper Jam at Output , is displayed on the LCD. Error codes

as,

are listed and explained in the Section 6 topic, “Error messages” on

page 6-19.

1

Exit

Exit

Button 1

Button 2

Button 3

Button 4

Figure 1-5 The front panel and its functions

Power

Error

9013-06

Service Manual

1-7

General Information

1

Rear panel

Connectors

The rear panel of the Phaser 540 printer features the host interface connectors to

the printer. It includes the following connectors:

Standard parallel (high-density connector).

■

■

SCSI high-density connector (font hard disk drive or

Phaser CopyStation only).

With the addition of a network card, the printer can feature either of these

groups of connectors:.

■

ThinNet (10base2) and Twisted Pair (10baseT) Ethernet connectors.

This is Option P1 and P2.

■

RS-232 serial and LocalTalk connectors. This is Option P2

Unshielded Twisted Pair (10baseT) and shielded Twisted Pair (DB-9)

■

Token Ring connectors. This is Option P4.

The figure below illustrates the rear panel.

Parallel

Smart card slot

for network card

Phaser™ Share

Ethernet Card

10Base2

Link

RX

TX

10Base-T

LocalTalk/Serial Card

Phaser™ Share

Serial LocalTalk®

RS-232

serial

LocalTalk

1-8

Figure 1-6 The Phaser 540 rear panel

Phaser 540 Color Printer

SCSI

Option

P1

P2

Option

P3

9013-05

on

on

Network card LEDs

The Ethernet network card has two LED indicators:

■

■

Note

General Information

TX indicator (yellow); blinks while data is transmitted to the host. The

LED is off while no data is being sent.

Twisted Pair (10baseT). RX indicator (green); blinks while the

network card is receiving data. The LED is

being received. If the LED is

hardware) has occurred at the network hub.

ThinNet (10base2). RX indicator (green); blinks while the network

card is receiving data. The LED is

received. If the LED is

has occurred at the network hub.

Do not use both Ethernet connectors at the same time. If both are used

the 10base2 line is ignored.

on steady , then a problem (probably hardware)

off steady , then a problem (probably

off stead y while no data is being

on steady while no data is

1

Test print button

The Token Ring network card has two LED indicators:

■

Connection (yellow); off when the printer is not inserted into the Token

blinks while the printer is attemping to insert itself into the Token

Ring,

Ring,

Ring Speed (green); off when the card is set for 4 megabits per second

■

(MBPS),

When both LEDs blink, a network card failure has occured.

■

In the center of the rear cabinet panel is the test print button. Pressing this

button while the printer is idle causes the print engine to print a built-in test

print. The print is made independently of the image processor board.

when the printer is properly inserted in the ring.

when the card is set for 16 MBPS.

Service Manual

1-9

General Information

On

1

Health LED

A health LED indicates the status of the image processor board. The health LED

is mounted on the image processor board and is viewable through the grill

behind the manual feed tray. (The grill is the removable RAM SIMM options

cover.) Once the PostScript code is loaded into memory and the image processor

is initialized and running, the image processor blinks the LED at a one-second

rate.

Blinking (at a steady rate): The printer is operating normally. The LED

■

blinks irregularly during power-up self-diagnostics.

If a soft error occurs, the image processor board operates, but in a

reduced capacity. Soft failures include failure of expansion memory

SIMMs or any of the interface ports. When a soft error occurs, the

printer automatically prints a startup page listing the error.

■

or Off : A hard error condition has occurred that would keep the

image processor board from operating.

Media tray type sensing

The combinations of the three tray sensors “tell” the print engine what type of

paper tray is installed. The tray sensors are located on the left-side interior of

the paper tray slot. Sensor actuators are attached to the bottom end of the tray to

close the appropriate sensor. There are four tray types:

■

Letter (A-size) paper

Letter (A-size) transparency film

■

■

Metric Letter (A4-size) paper

■ Metric Letter (A4-size) transparency film

■ Legal-size paper (Phaser 540 Plus)

Table 1-1 Tray switch sensor combinations

Left switch Middle switch Right switch Tray type

Closed Open Open Letter (A-size) paper

1-10

Closed Closed Open Letter (A-size) transparency film

Open Open Closed Metric Letter (A4-size) paper

Closed Open Closed Metric Letter (A4-size) transparency film

Open Closed Open Legal-size paper

Phaser 540 Color Printer

General Information

1

Sensor actuators

Middle

Left

Right

Tray sensors

Figure 1-7 Tray switch sensors and actuators

9013-40

Service Manual

1-11

1

General Information

Specifications

Table 1-2 Physical dimensions

Dimensions Specification

Height:

Width: 48.3 cm (19 in.) With output tray: 69.6 cm (27.4 in.)

Depth: 48.3 cm (19.5 in.)

45.7 cm (18 in.) With Lower Tray Assembly: 68.6 cm (27 in.)

Weight: Approximately 53.3 kgs (117 lbs.) with Lower Tray Assembly

and consumables installed.

Approximately 39.1 kgs (86.2 lbs.) without Lower Tray

Assembly.

Table 1-3 Printer clearances

Clearances Specification

Top: 7.6 cm (3 in.)

Left: 7.6 cm (3 in.)

Right: 10.2 cm (4 in.) for handling the output tray

Front: Unlimited for removal of consumable

Rear: 15.3 cm (6 in.) for connecting computer cable and pow er cord

Bottom: No obstruction under printer that could block its cooling vents.

Mounting surface

flatness:

Within 2 degrees of horizontal with all four feet in contact with

the table surface.

1-12

Phaser 540 Color Printer

General Information

Table 1-4 Functional specifications

Characteristic Specification

Printing process Electro-photographic, four color (CMYK) transfer printing

1

Color medium Four toner cartridges each contain one of four colors: cyan,

Addressability Standard mode: 300 x 300 dots-per-inch text and graphics

Printing speed Time from paper-load to paper-eject:

Minimum printing

margins

Usable paper A-size (letter) and A4-size (Metric letter) and Legal-size of a

Paper tray capacity 250 sheets using 20-lb. paper. 100 sheets of transparency

magenta, yellow or black. The toner is a nonmagnetic,

monocomponent contact medium.

Enhanced mode: 600 x 600 dpi text and graphics

Four-color 3.5 pages per minute at 300 dpi

paper: 1.75 pages per minute at 600 dpi

Monochrome: 14 pages per minute at 300 dpi

7 pages per minute at 600 dpi

Four-color transparency: 1.3 pages per minute at 300 dpi

Print times do not include image processing time, which can

vary depending on image complexity.

All sides, 5 mm (0.2 ins.).

good quality, or premium laser printer or copier paper.

film. The optional Lower Tray Assembly also uses trays with

the same capacity.

Table 1-5 Electrical specifications

Characteristic Specification

Primary line voltages 87 to 128 VAC (115 VAC or 100 VAC nominal); 174 to 260

Primary voltage

frequency range

Power consumption 60 watts (fuser off), 850 watts (fuser on) during Ready state,

Primary voltage fusing 110 VAC configuration – 10 amp

Secondary DC voltages Image processor:

RF emissions Both 110 and 220 VAC-configured instruments pass these

VAC (220 VAC nominal)

47 to 63 Hz

950 watts during Warm-up state, 45 watts during Energy Star

state

220 VAC configuration – 6.3 amp

+ 5 VDC ± 0.25 (1A minimum, 6 A maximum)

± 12 VDC ± 0.6 (100 mA max)

Print engine:

+ 5V ± .25 (2.2 A max)

+ 12V ± .25 (0.4 A max)

- 12V ± .25 (0.1 A max)

+ 24V ± .25 (3.0 A max)

standards: FCC Part 15 Class B

VDE Class B

EN55022 (CISPR 22) Class B

VCCI (CISPR 22) Class B

Service Manual

1-13

1

General Information

Table 1-6 Environmental specifications

Characteristic Specification

Temperature

Operating

Non-operating

Storage

Humidity

Operating

Non-operating

10o to 32.5o C (50oto 91oF)

o

0

to 40o C (32o to 104o F)

o

-20

to 60o C (-4

o

to 140o F)

Media should be acclimated 24 hours before using in the

printer.

10 to 80% relative humidity, non-condensing

10 to 90% relative humidity, non-condensing

Media should be acclimated 24 hours before using in the

printer.

Altitude

Operating

Non-operating

Vibration/shock

Operating

Non-Operating

(vibration)

Non-operating (shock)

Acoustic Noise

(operating)

o

0 to 2500 m (8,000 ft.) at 25

C

0 to 15000 m (50,000 ft.)

(Fuser maximum 4000 m (13,300 ft.)

May drop any side or corner 50 mm (2 in.) without impairment

of subsequent operation.

On five mutually perpendicular axes: 0.5 g, 25-minute sweep,

5 to 200 to 5 Hz, 100 to 200 sec./sweep cycle. No resonant

frequencies below 50 Hz.

30 g, trapezoidal flared pulse, 20 msec each axis.

Aver age sound le vel (LEQ) is less than 53 dbA. Peak noise in

standby mode is 47 dbA.

1-14

Phaser 540 Color Printer

Regulatory specifications

The printer is a recognized component in conformance with the following

regulatory standards:

■ The packaged product meets ASTM D4169-86 and ASTM D4728-87

Transportation Standards.

■ Listed UL 1950 Information Processing and Business Equipment.

■ Certified CSA C22.2 No. 950 Safety of Information Technology

Equipment, Including electrical Business Equipment.

■ GS licensed IEC 950 (1991) Second Edition; EN60950 Information

Processing and Business Equipment.

■ VDE 0871/6.78 (Class B) Regulation for the Radio Frequency Interface

Suppression of High Frequency Apparatus and Installations.

■ VDE 0875, Regulation for RFI Suppression of Electrical Equipment

and Installations

General Information

1

■ EN55022 (CISPR 22) Class B

VCCI (CISPR 22) Class B

■ FCC Class B (for 115 VAC equipment) pursuant to Sub-part J

of Part 15.

Service Manual

1-15

Service Manual

Phaser

®

540 and Phaser

Color Printers

®

540 Plus

Warning

The following servicing instructions are for

use by qualified service personnel only. To

avoid personal injury, do not perform any

servicing other than that contained in

operating instructions unless you are qualified

to do so.

This printing June 1995

070-9013-01

Copyright

©

1995 by Tektronix, Inc., Wilsonville, Oregon. Printed in the United States of America. All rights

reserved. Contents of this publication may not be reproduced in any form without permission of Tektronix, Inc.

This instrument, in whole or in part, may be protected by one or more U.S. or foreign patents or patent applications.

Information provided upon request from Tektronix, Inc., P.O. Box 1000, Wilsonville, Oregon 97070-1000.

If acquired subject to FAR or DFARS, the following shall apply:

Unpublished — rights reserved under the copyright laws of the United States.

■

■

Restricted Rights Legend — Use, duplication or disclosures by the government is subject to restrictions as set forth

in subparagraph (c) (1)(ii) of the Rights in Technical Data and Computer Software at DFARS 252.227-7013, or in

subparagraph (c) (2) of the Commercial Computer Software – Restricted Rights clause at FAR 52.227-19, as

applicable. Tektronix, Inc., P.O. Box 1000, Wilsonville, Oregon 97070-1000.

Tektronix

®

is a registered trademark of Tektronix, Inc. TekColor™ and Photofine™ are trademarks of Tektronix, Inc.

Phaser™ is a trademark of Tektronix, Inc. for color printers and related products.

Adobe™ and PostScript™ are trademarks of Adobe Systems, Incorporated which may be registered in certain

jurisdictions.

EtherTalkg

®

is a registered trademark of Apple Computer, Incorporated.

Times™, Helvetica™, and Palatino™ are trademarks of Linotype-Hell AG and/or its subsidiaries.

Micronta

Microsoft

®

is a registered trademark of Radio Shack.

®

and Microsoft Windows® are registered trademarks of Microsoft Corporation.

®

Novell

OS/2

PANTONE

and NetWare

®

is a registered trademark of International Business Machine Corporation.

®

* Colors generated by the Phaser 540 and 540 Plus Color Printers are four-color process simulations and

®

are registered trademarks of Novell, Inc.

may not match PANTONE-identified solid color standards. Use current PANTONE Color Reference Manuals for

accurate colors.

PANTONE Color simulations are only obtainable on these products when driven by qualified Pantone-licensed

software packages. Contact Pantone, Inc. for a current list of qualified licensees.

* Pantone, Inc.’s check-standard trademark for color reproduction and color reproduction materials.

© Pantone. Inc., 1988.

TCP/IP is a trademark of FTP Software. Copyright (c) 1986, 1987, 1988, 1989 by FTP Software, Inc. All rights

reserved. PC/TCP for DOS is based on a set of programs originally designed and developed by the Massachusetts

Institute of Technology. FTP Software has made extensive modifications and enhancements to the M.I.T. programs.

TokenTalk® is a registered trademark of Apple Computer, Incorporated.

TORX™ is a trademark of TEKTRON.

The X Window System™ is a trademark of Massachusetts Institute of Technology.

Other marks are trademarks or registered trademarks of the companies with which they are associated.

TE/JG

Users safety summary

Terms in manual:

Power source:

conductor and ground. Use only the specified power cord and connector. Refer to a qualified service technician for

changes to the cord or connector.

Operation of product:

product. Do not operate without the covers and panels properly installed. Do not operate in an atmosphere of

explosive gases.

Safety instructions:

Terms on product:

cover the hazardous area. Also applies to a hazard to property including the product itself.

DANGER A personal injury hazard exists in the area where you see the sign.

Care of product:

power cord or plug is frayed or otherwise damaged, if you spill anything into the case, if product is exposed to any

excess moisture, if product is dropped or damaged, if you suspect that the product needs servicing or repair, and

whenever you clean the product.

Ground the product:

necessary, contact a licensed electrician to install a properly grounded outlet.

Symbols as marked on product:

CAUTION Conditions that can result in damage to the product.

WARNING Conditions that can result in personal injury or loss of life.

Does not apply more than 250 volts RMS between the supply conductors or between either supply

Avoid electric shock by contacting a qualified service technician to replace fuses inside the

Read all installation instructions carefully before you plug the product into a power source.

CAUTION A personal injury hazard exists that may not be apparent. For example, a panel may

Disconnect the power plug by pulling the plug, not the cord. Disconnect the power plug if the

Plug the three-wire power cord (with grounding prong) into grounded AC outlets only. If

DANGER high voltage:

Protective ground (earth) terminal:

Use caution. Refer to the manual(s) for information:

!

Laser use caution. Refer to the manual(s) for information:

WARNING:

cause an electrical shock. Electrical product may be hazardous if misused.

If the product loses the ground connection, usage of knobs and controls (and other conductive parts) can

Service safety summary

For qualified service personnel only:

Do not service alone:

Do not perform internal service or adjustment of this product unless another person capable of

Refer also to the preceding Users Safety Summary.

rendering first aid or resuscitation is present.

Use care when servicing with power on:

Dangerous voltages may exist at several points in this product. To avoid

personal injury, do not touch exposed connections and components while power is on.

Disconnect power before removing the power supply shield, soldering, or replacing components.

Do not wear jewelry:

Remove jewelry prior to servicing. Rings, necklaces, and other metallic objects could come into

contact with dangerous voltages and currents.

Power source:

This product is intended to operate from a power source that will not apply more than 250 volts rms

between the supply conductors or between either supply conductor and ground. A protective ground connection by

way of the grounding conductor in the power cord is essential for safe operation.

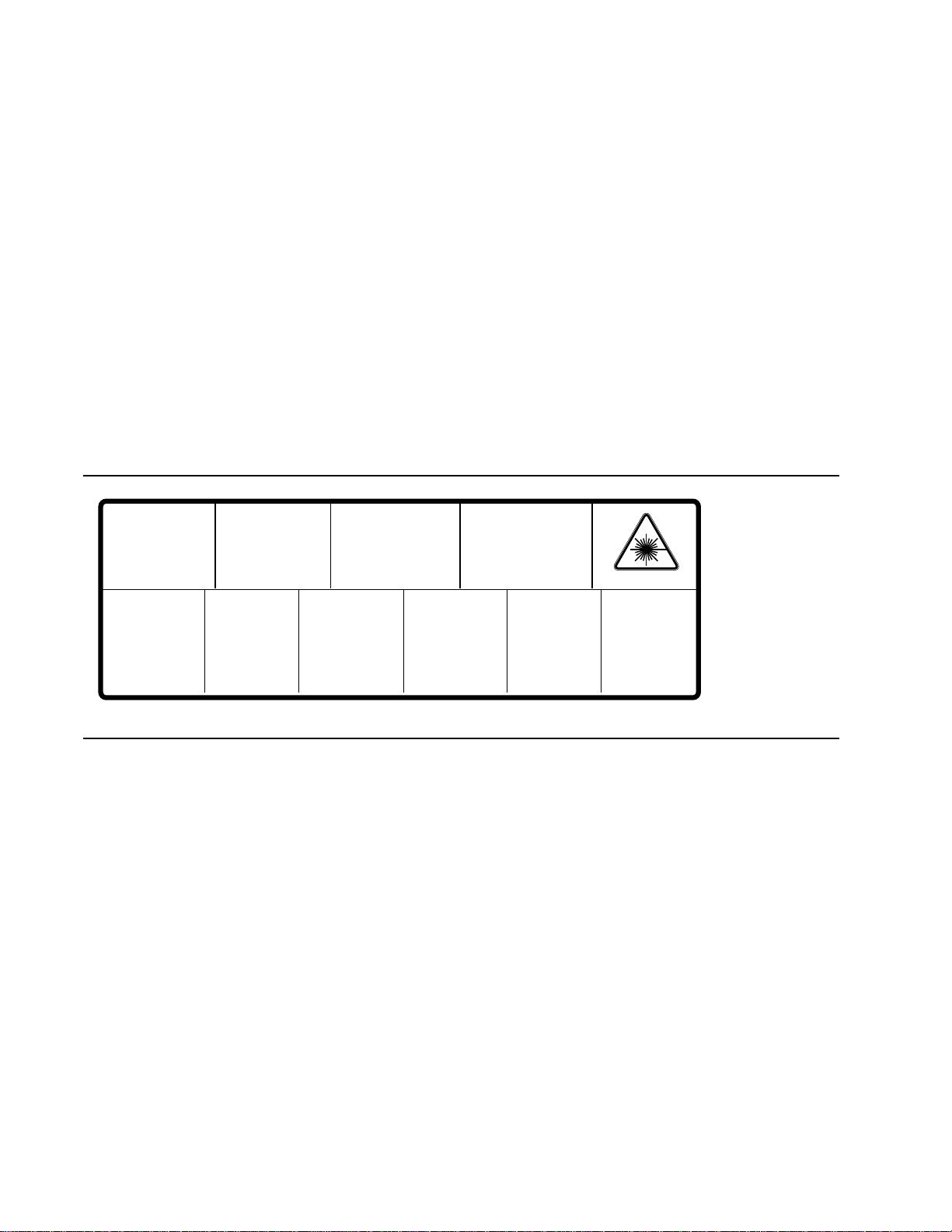

This product is certified under IEC 825 as a Class 1 Laser Product.

DANGER:

Invisible laser radiation

when open and interlock

defeated.

AVOID DIRECT

EXPOSURE TO BEAM.

PELIGRO:

Cuando se abre y se

invalida el bloqueo, se

producen radiaciones

invisibles de láser.

EVITESE LA

´

EXPOSICION

DIRECTA A TALES

RAYOS.

CAUTION:

Invisible laser radiation

when open and

interlocks defeated.

AVOID DIRECT

EXPOSURE TO BEAM.

VARNING:

Osynlig laser-

strálning när denna

del är öppnad och

spärrar är

urkopplade.

STRÅLEN

ÄR FARLIG.

VORSICHT:

Unsichtbare Laserstrahlung,

wenn Abdeckung geöffnet

und Sicherheitsverriegelung

überbrückt.

NICH DEM STRAHL

AUSSETZEN.

VAROI:

Näkymätön

avattaessa ja

suojalukitus

ohitettaessa olet

alttiina lasersäteilylle.

ÄLÄ KATSO

SÄTEESEN.

ATTENTION:

Rayonnement laser invisible

dangereux en cas

d'ouverture et lorsque

la sécurité est neutralisée.

EXPOSITION DANGEREUSE

AU FAISCEAU.

VARNING:

Osynlig laserstrálning

när denna del är

öppnad och spärrar är

urkopplade.

BETRAKTA EJ

STRÅLEN.

ADVARSEL:

Usynlig laserstràling

ved abning når

sikkerhedsafbrydere

er ude af funktion.

UNDGÅ UD

ÆTTELSE FOR

STRÅLING.

Class 3B

ADVARSEL:

Usynlig laserstraling

nar deksel åpnes og

sikkerhedslas brytes.

UNNGÅ

EKSPONERING

FOR STRÅLEN.

PJQT4521ZA

9008-78

Index

A

Adobe PostScript Level 2

antistatic mat

authorization code, TCP/IP

automatic color correction

8-1

1-2

5-16

8-27

B

BBS

4-10

block diagram of printer

5-2

C

cleaning the printer

clearances, printer

communication parameters

serial and parallel ports

communication setup

configuration page

description

configuring a Novell server for the printer

configuring TCP/IP

connecting the printer to a Token Ring

network

connecting the printer to an Ethernet network

connecting the printer to the Macintosh

connecting the printer to the PC

connectors

rear panel

Customer Support Hotline

2-14

1-8

2-9

2-3

7-1

2-20

2-31

,

2-10

2-8

4-10

2-9

2-8

2-30

D

driver and communication setup

2-20

E

electronic bulletin board service

Engine diagnostics (interactive)

engine failure codes

EuroHAL, automated fax system

6-19

4-10

9-7

4-8

2-9

F

field replaceable units list

Font Downloader Utility

front panel

description

front panel menu

front panel, messages

FRUs

removal and replacement

1-6

9-2

6-19

A-1

2-11

8-1

G

Graphics Supplies Order Desk

2-3

H

HAL, automated fax system

hard error

health LED

Highly Automated Library (HAL)

1-10

1-10

4-7

I

image processor

2-3

9-5

4-4

troubleshooting

image processor board

theory

imaging unit sensitivity to light

interface cables

5-18

J

Jams

6-11

K

key operator

training

4-1

L

laser electrophotography

laser printing, theory

7-2

5-9

laser scanner

Laserwriter Utility

Lubrication

2-11

5-4

5-4

,

2-4

4-7

Service Manual

Index-1

M

Macintosh

connecting the printer

printing

using the Error Handler Utility

Measuring power supply voltages

Media problems

Microsoft Windows

standard PostScript printer driver

3-1

6-8

2-8

3-4

6-3

2-24

N

network card, installing

normal power-up self-test, image processor

Novell configuration

Novell Netware verification

null modem cable

2-29

2-30

8-26

3-7

O

OS/2 connection verification

OS/2 Version 2, Tektronix driver

OS/2 Version 2.0, loading drivers

3-6

2-25

2-25

P

paper path

6-8

jams

3-5

1-2

1-2

5-6

5-4

5-17

6-1

2-9

2-1

7-1

5-15

6-24

3-8

5-6

Paper picking,theory

PC

connecting the printer

using the Error Handler Utility

PC verification

Phaser 540

description

photoconductive belt

PostScript Level 2

power supply

verifying

power supply theory

power-up sequence

pre-exposure during laser printing

pre-installation interview

preventive maintenance

print modes, description

print quality problems

6-3

9-6

printcap file

printer

troubleshooting

printer page description file

printing from a Machintosh

printing test prints

2-29

6-1

9-4

3-4

3-1

R

RAM and printer capabilities

RAM SIMMs, installing

rear panel

connector

description

registration, checking

regulatory standards

removal procedures

required tools, disassembly

resetting NVRAM, image processor

1-8

1-8

9-10

1-15

8-1

1-2

8-24

8-1

9-9

S

safety interlock 6-5

printer

1-10

2-11

2-11

9-6

6-3

1-10

2-1

4-10

6-9

2-25

2-13

4-7

SCSI address

SCSI hard disk drive, installing on the

self-test modes

image processor

self-test print

sensing media

Service Option S0

service support, calling

skewed copy

soft error

Standard Windows PostScript driver

updating

startup page

description

supplies, ordering

Index-2

Phaser 540 Color Printer

T

TCP/IP, configuring 2-31

TCP/IP, enabling

TCP/IP, verification of printing

TekColor

terminator, SCSI

Test Pattern Generator

test patterns

testing the print engine

theory of laser printing

Timeouts, Windows

toner cartridges during printing

Transmission Retry, Windows

tray sensors

troubleshooting

troubleshooting the printer

2-20

3

using

descriptions

image processor

8-27

2-11

B-1

6-2

5-4

2-23

2-23

1-10

9-5

6-1

U

using the Error Handler utility

for Macintosh

3-8

for PC

for workstation

3-4

3-10

3-9

5-10

V

verifying a PC can print 3-5

verifying a workstation can print

verifying and printing using the TCP/IP

protocols

3-9

3-9

W

Windows 3.1 driver verification 3-5

Windows 3.1, Tektronix driver

Windows printer driver

configuring

installing

workstation

connecting the printer

using the Error Handler Utility

workstation verification

wrinkled print

2-22

2-21

6-28

2-21

2-9, 2-10

3-10

3-9

Service Manual

Index-3

Appendix

D

Test Pattern Generator

The Test Pattern Generator contains PostScript scripts to start test patterns for a

number of Tektronix color printers. It allows you to test a printer as if it were

receiving a file from a host computer. The test patterns are generated by the

printer's image processor and then printed by the print engine.

Note

The Test Pattern Generator should contain firmware version 1.2 or

higher.

Service Manual

D-3

1.

2.

3.

4.

D

Test Pattern Generator

To use the Test Pattern Generator, do the following:

Select a test pattern to be printed using the Test Pattern Generator's

five DIP switches. The following tables lists the available test

patterns.

Plug the Test Pattern Generator onto the printer's parallel port. Use

the parallel cable adapter (013-0299-00) to convert between the Test

Pattern Generator’s Centronics-style connector and the printer’s

new-style, high-density parallel port connector. You do not have to

turn the printer off; you can plug in the Test Pattern Generator “hot.”

Press the Test Pattern Generator's START button. Its green LED

flashes as you press the button.

The printer will print the transmitted print file. The front panel

displays the message “Waiting for data,” with the READY light

flashing, for five minutes after a test print has been sent to the printer.

However, you do not have to wait five minutes before sending

another test print from the Test Pattern Generator; the printer will

accept another test print.

Besides print files, the test pattern generator also allows you to turn off and on

the printer's startup page.

Additionally, the Test Pattern Generator lets you set up a printer for printing

from a 4511A Network Interface. To do so, just select the appropriate DIP switch

setting.

Table D-1 Test Pattern Generator DIP Switch settings for Phaser 540

Pattern or function 1 2 3

Print quality test pattern On On On On On

Blank sheet Off On On On On

Engine Pattern 1

(100%)

Service print 1 Off Off On On On

Blank sheet On On Off On On

Engine pattern 2 (50%) Off On Off On On

Service print 2 On Off Off On On

Enable startup page Off Off Off On On

Disable startup page On On On Off On

On Off On On On

45

D-4

Phaser 540 Color Printer

Appendix

C

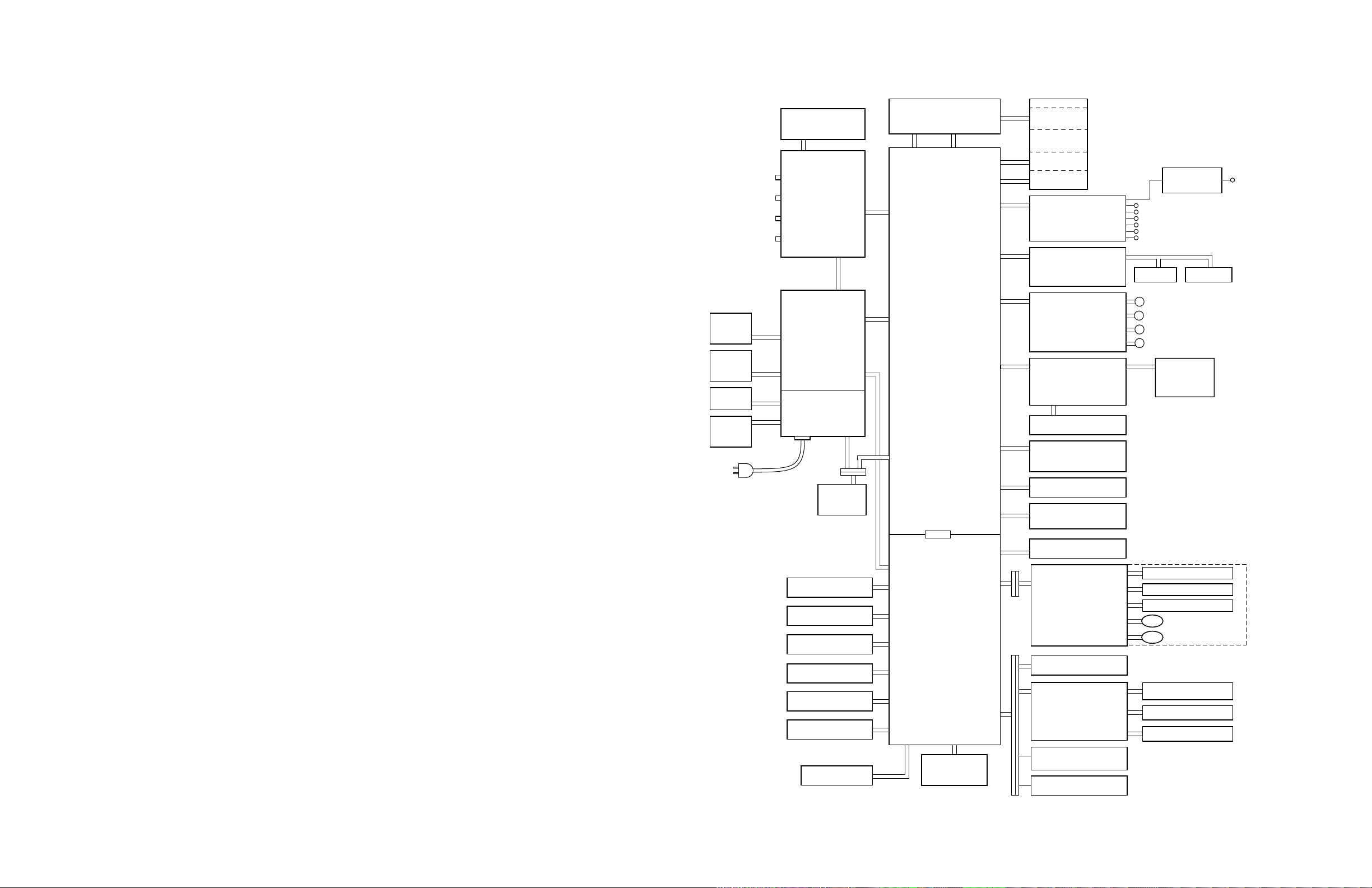

Wiring Diagram

Power

supply

fan

Door-

open

switch

Power

switch

Fuser-

installed

sensor

SCSI

Parallel

Serial

Network

card

Front panel

J24

J11

Image

J3

processor

J12

J4

CN 853

CN 851

CN 802

CN 804

J22

CN 854

Power

supply

J21

CN 855

CN 852

CN 805

Laser driver board

CN 501

CN 1

CN 5

CN 12

CN 503

CN 8CN 3

Engine

control

board

CN502

CN 11

CN 16

CN 4

CN 9

CN 7

CN 6

CN 13

CN 540

Laser

scanner

CN 1

CN 570

CN 701

High voltage

power supply

board

CN 627

Image density

sensor connector

CN 619

Toner cartridge

level sensor

(Receiver) and

roller clutch

board

CN 625

Charger unit

sensor board

CN 624

Imaging unit

CN 632

Accumulator belt

position sensor

Toner cartridge

sub bias board

FTR Orange

DEV Yellow

STR Black

CHG Red

PTC White

GRID Blue

CN 628

BK sensor

CN 620

CN 621

CN622

CN623

CN 626 CN 630

B

Y

M

C

Pre-exposure

lamp

CMY sensor

Fuser

Left door closed

sensor

Fuser fan

Paper-feed motor

Developer cartridge

drive motor

Main motor

Cleaning board

Paper tray switches

CN 618

CN 307

CN 312

CN 304

CN 306

CN 305

CN 313

CN 302

CN 311

CN 2

CN 301

Engine

driver

board

CN 310

Optional

lower tray

assembly

CN 14

CN 17

CN 303

CN 309

CN 308

Ozone fan

Toner cartridge level

(transmitter) sensor

Pre-transfer lamp

CN 601

Paper

feeder

Exit tray full

CN 617

sensor

CN 611

Exit roller

sensor board

Toner cartridge

CN 615

movement sensor

CN 616

Cam motor

board

CN 603

CN 604

CN 602

CN 606

CN 605

CN 614

CN 612

CN 613

Paper-pick sensor

Transp sensor

Registration sensor

Transfer roller solonoid

Registration clutch

Fuser exit

CN 610

sensor

Switchback solenoid

Face switching solenoid

9013-52

Figure C-1 Wiring diagram

Service Manual

C-1

Contents

1 General Information

The Phaser 540 Color Printers 1-2

RAM and printer capabilities 1-2

Print engine assemblies 1-3

Front panel 1-6

Rear panel 1-8

Network card LEDs 1-9

Test print button 1-9

Health LED 1-10

Media tray type sensing 1-10

Specifications 1-12

Regulatory specifications 1-15

2 Installing the Printer and Drivers

Pre-install questions for customers 2-2

Unpacking 2-5

Printer inventory 2-5

Accessory box 2-5

Setting up the printer 2-7

Installing SIMM memory 2-7

Installing a network card 2-7

Cabling the printer 2-8

Connecting the printer to a Macintosh 2-8

LocalTalk connection to a Macintosh 2-8

Ethernet connection to a Macintosh 2-8

Connecting the printer to a PC 2-9

Direct connection to a PC 2-9

Networked connection using the Ethernet port 2-9

Networked connection using the Token ring port 2-9

Connecting the printer to a workstation 2-10

Direct connection to the workstation 2-10

Networked connection to a workstation 2-10

Networked connection using the Token Ring port 2-10

Connecting an optional SCSI hard disk drive to the printer 2-11

Connecting the optional CopyStation to the printer 2-12

Turning on the printer 2-13

The startup page 2-13

The configuration page 2-14

Service Manual

xv

Driver and communication set up 2-20

Loading the Macintosh driver 2-20

Installing the Tektronix driver for Windows 3.1 2-21

If you have other Tektronix printer drivers already installed 2-21

Configuring the Tektronix Windows printer driver 2-22

Updating the standard Microsoft Windows PostScript driver 2-24

Installing the printer driver for OS/2 Version 2 2-25

Configuring the printer's serial port for a PC 2-27

Using printcap to configure a workstation for the printer's serial port 2-29

Configuring a Novell NetWare server for the printer 2-30

Configuring TCP/IP on a UNIX host 2-31

3 Verifying the Printer and Host Connections

Macintosh verification 3-1

Selecting the printer via the Chooser 3-1

Printing the directory from a Macintosh 3-3

Verifying that an application communicates to the printer 3-4

Using the Error Handler utility 3-4

PC verification 3-5

DOS connection verification 3-5

Windows 3.1 driver verification 3-5

OS/2 connection verification 3-6

Novell NetWare verification 3-7

Send a print file to the printer 3-7

Using the Error Handler utility 3-8

Workstation verification 3-9

Verifying connection and printing using TCP/IP protocols 3-9

Using the Error Handler utility 3-10

xvi

Phaser 540 Color Printer

Loading...

Loading...