Page 1

Washer Installation Instructions

Instructions d’installation de la laveuse

Table of Contents

WASHER SAFETY .............................................................1

INSTALLATION REQUIREMENTS ....................................2

Tools and Parts .................................................................... 2

Location Requirements ...................................................... 3

Drain System ....................................................................... 4

Electrical Requirements ..................................................... 4

INSTALLATION INSTRUCTIONS ......................................5

Before you start: Remove shipping materials .................. 5

Connect Drain Hose ............................................................ 5

Connect Inlet Hoses ............................................................ 6

Level Washer ....................................................................... 7

COMPLETE INSTALLATION CHECKLIST .......................9

INSTALLATION NOTES

Date of purchase: _________________________________

Date of installation: _______________________________

Installer: ________________________________________

Model number: ___________________________________

Serial number: ___________________________________

Table des matières

SÉCURITÉ DE LA LAVEUSE .............................................9

EXIGENCES D'INSTALLATION .........................................9

Outillage et pièces ............................................................... 9

Exigences d'emplacement ................................................ 10

Système de vidange .......................................................... 10

Spécications électriques ................................................. 11

INSTRUCTIONS D’INSTALLATION .................................12

Avant de commencer : Retirer

le matériel d’expédition ..................................................... 13

Raccordement du tuyau de vidange.................................14

Raccordement des tuyaux d’alimentation ....................... 14

Mise à niveau de la laveuse ............................................... 15

LISTE DE VÉRIFICATION

POUR INSTALLATION TERMINÉE ..................................16

NOTES CONCERNANT L'INSTALLATION

Date d'achat : _____________________________________

Date d'installation : ________________________________

Installateur : ______________________________________

Numéro du modèle : ________________________________

Numéro de série : __________________________________

WASHER SAFETY

W10240438C

Page 2

INSTALLATION REQUIREMENTS

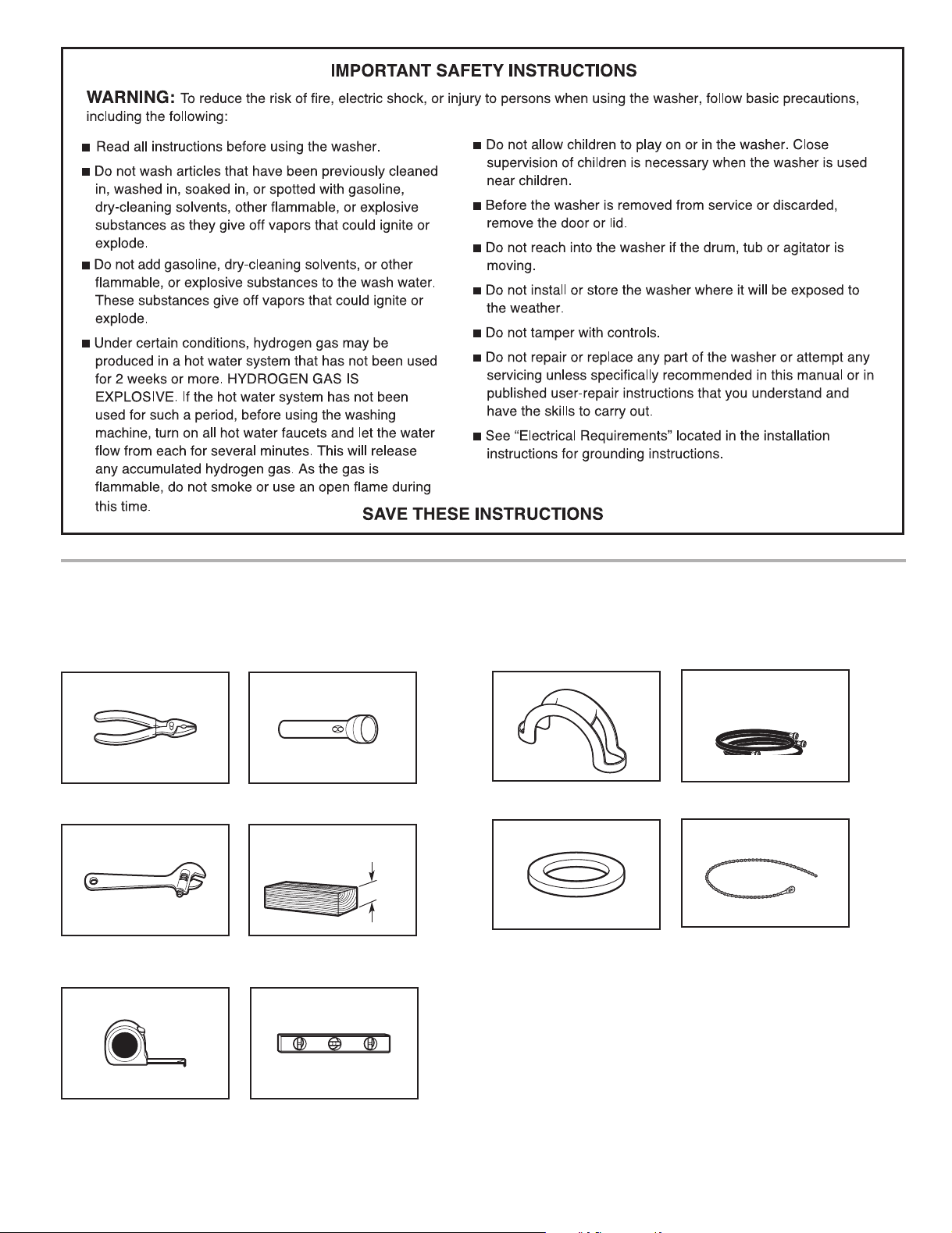

TOOLS AND PARTS

Gather the required tools and parts before starting installation.

Tools needed:

Pliers that open to 1 9/16"

(39.5 mm)

Adjustable or open end

wrench 9/16" (14 mm)

Flashlight (optional)

4" min

(102 mm)

Wood block

Parts supplied (located in the washer basket):

Drain hose form

Flat inlet hose washers (4)

Water inlet hoses (2)

Removable Tie Strap

Tape measure or ruler Level

2

Page 3

Alternate parts: (Not supplied with washer)

Your installation may require additional parts. To order, please

refer to the phone number or website on the back page of your

“Use and Care Guide”.

If you have: You will need:

Laundry tub or Sump pump system (if not already

standpipe taller available)

than 96" (2.4 m)

1" (25 mm) 2" (50 mm) diameter to 1" (25 mm)

diameter standpipe diameter Standpipe Adapter Kit,

Part Number 3363920 and

Connector Kit, Part Number 285835

Overhead sewer Standard 20 gal. (76 L) 39” (990 mm)

tall drain tub or utility sink, sump

pump, and connectors (available from

local plumbing suppliers)

Floor drain Siphon Break Kit, Part Number 285834

Drain Hose, Part Number 8318155

Connector Kit, Part Number 285835

Spacing for recessed area or closet installation

All dimensions show recommended spacing allowed, with tested

spacing of 0" (0 mm) clearance on sides.

■ Additional spacing should be considered for ease of

installation and servicing.

■ Additional clearances might be required for wall, door, and

oor moldings.

■ Additional spacing should be considered on all sides of the

washer to reduce noise transfer.

■ For closet installation, with a door, minimum ventilation

openings in the top and bottom of the door are required.

Louvered doors with equivalent ventilitation openings are

acceptable.

■ Companion appliance spacing should also be considered.

3"*

(76 mm)

17"*

(432 mm)

14"* max.

(356 mm)

48 in.2*

(310 cm2)

Water faucets 2 longer water ll hoses:

beyond reach of 6 ft. (1.8 m), Part Number 76314

ll hoses 10 ft. (3.0 m), Part Number 350008

Lint clogged drain Drain protector, Part Number 376031

LOCATION REQUIREMENTS

Select proper location for your washer to improve performance

and minimize noise and possible “washer walk”. Install your

washer in a basement, laundry room, closet, or recessed area.

Proper installation is your responsibility.

You will need:

■ A water heater set to deliver 120°F (49°C) water to the washer.

■ A grounded electrical outlet located within 4 ft. (1.2 m) of

where the power cord is attached to the back of the washer.

See “Electrical Requirements”.

■ Hot and cold water faucets located within 3 ft. (900 mm)

of the hot and cold water ll valves, and water pressure

of 20-100 psi (138-690 kPa) for best performance.

■ Level oor with maximum slope of 1" (25 mm) under entire

washer. Installing the washer on carpet is not recommended.

■ A sturdy oor to support the washer weight (washer, water,

and load) of 315 lbs (143 kg).

IMPORTANT: Do not operate, install, or store washer where

it will be exposed to water, weather, or at temperatures below

32° F (0° C). Some water can remain in washer and can cause

damage in low temperatures. See your “Use and Care Guide”

for information on winterizing.

1"

(25 mm)

* Required spacing

27 1/2"

(699 mm)

Front view

1"

(25 mm)

1"

(686 mm)

(25 mm)

Side view

27"

5"*

(127 mm)

24 in.2*

(155 cm2)

Closet door

with vents

3"*

(76 mm)

3

Page 4

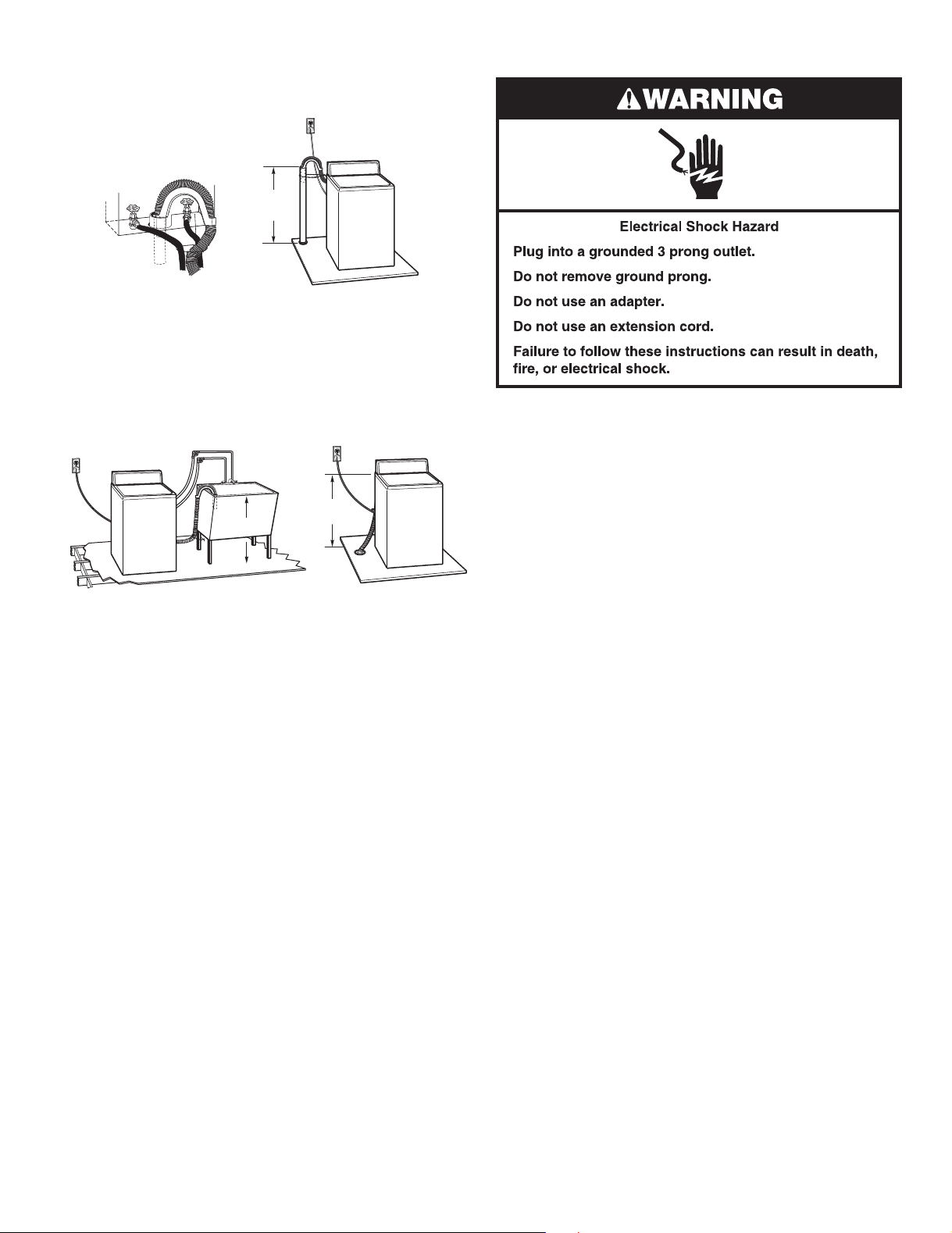

DRAIN SYSTEM

Drain system can be installed using a oor drain, wall standpipe,

oor standpipe, or laundry tub. Select method you need.

39"

(990 mm)

Wall standpipe Floor standpipe

The standpipe drain requires a minimum diameter standpipe

of 2" (51 mm). The minimum carry-away capacity can be no less

than 17 gal. (64 L) per minute. A 2" (51 mm) diameter to 1" (25 mm)

diameter standpipe adapter kit is available. See “Tools and Parts”.

The top of the standpipe must be at least 39" (990 mm) high

and no higher than 96" (2.4 m) from the bottom of the washer.

28"

39"

(990 mm)

Laundry Tub Floor

The laundry tub drain system needs a minimum 20 gal. (76 L)

capacity laundry tub. The top of the laundry tub must be at least

39" (990 mm) above the oor and no higher than 96" (2.4 m) from

the bottom of the washer.

The oor drain system requires a siphon break that may

be purchased separately. See “Tools and Parts”. The siphon

break must be a minimum of 28" (710 mm) from the bottom

of the washer. Additional hoses might be needed.

(710 mm)

ELECTRICAL REQUIREMENTS

■ A 120 volt, 60 Hz., AC only, 15- or 20-amp, fused electrical

supply is required. A time-delay fuse or circuit breaker on

a separate circuit serving only this washer is recommended.

■ This washer is equipped with a power supply cord having

a 3 prong grounding plug.

■ To minimize possible shock hazard, the cord must be

plugged into a mating, 3 prong, grounding-type outlet,

grounded in accordance with local codes and ordinances.

If a mating outlet is not available, it is the personal

responsibility and obligation of the customer to have the

properly grounded outlet installed by a qualied electrician.

■ If codes permit and a separate ground wire is used, it is

recommended that a qualied electrician determine that

the ground path is adequate.

■ Do not ground to a gas pipe.

■ Check with a qualied electrician if you are not sure

the washer is properly grounded.

■ Do not have a fuse in the neutral or ground circuit.

4

Page 5

INSTALLATION INSTRUCTIONS

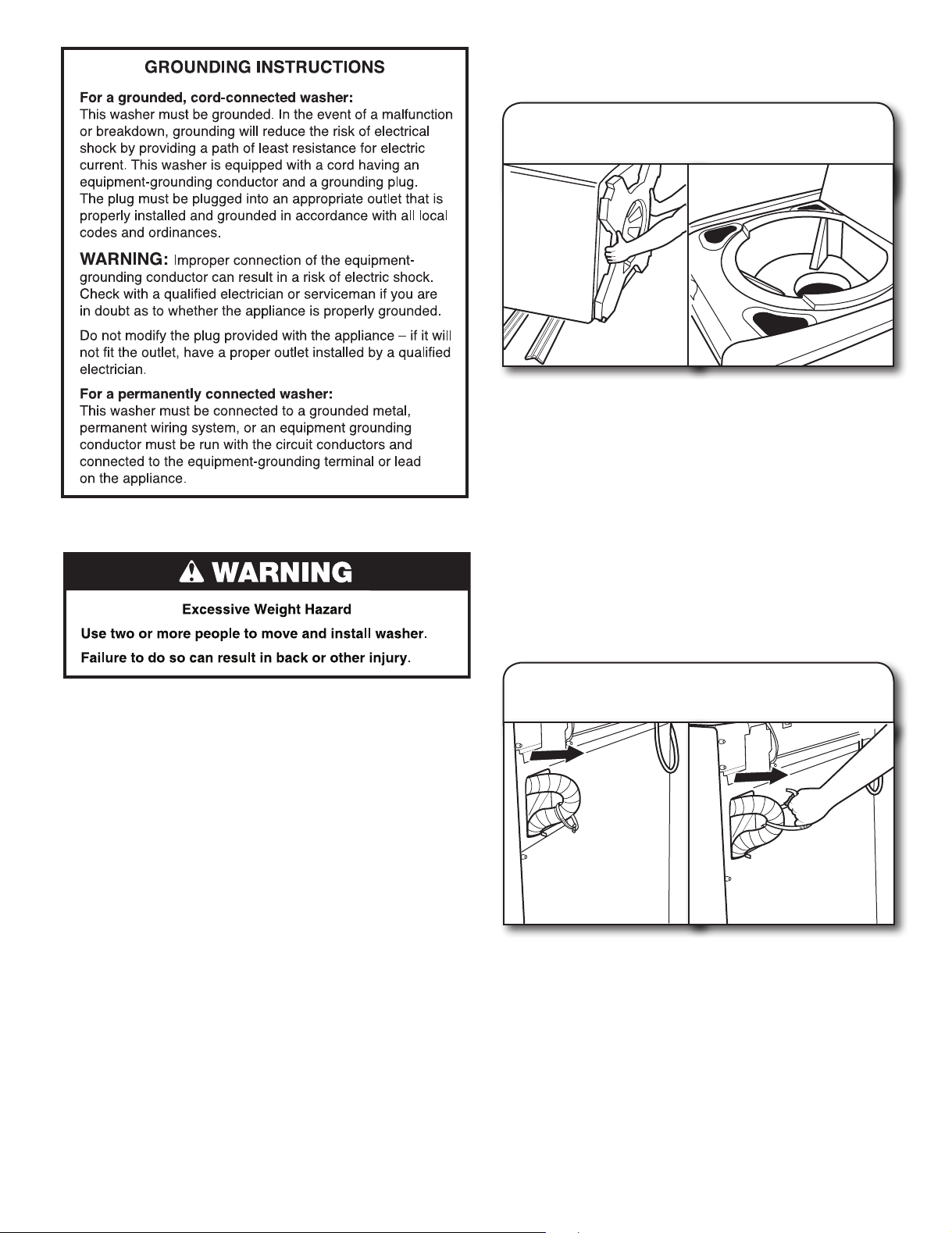

REMOVE SHIPPING BASE

AND PACKING RING

1. Remove shipping base

and packing ring

Place cardboard supports from shipping carton on oor

behind washer for support. Secure the lid with tape. Using

two or more people, tip the washer onto its back and place

on cardboard supports. Remove foam shipping base. Then,

set washer back upright, and remove the tape from the lid

so that you can open the lid and remove the foam packing

ring from the washer tub.

NOTE: Keep foam packing ring in case you need to move

the washer in the future.

Before you start: remove shipping materials.

It is necessary to remove all shipping materials for proper

operation and to avoid excessive noise from washer.

NOTE: To avoid oor damage during installation, set the washer

onto cardboard before moving across the oor.

IMPORTANT:

■ Be sure the foam shipping base has been removed from the

bottom of the washer as directed in the “Remove Shipping

Base and Packing Ring” section.

■ If foam shipping base has not been removed, be sure lid is

secured with tape before laying washer on its back.

■ Removing the foam shipping base is necessary for proper

operation.

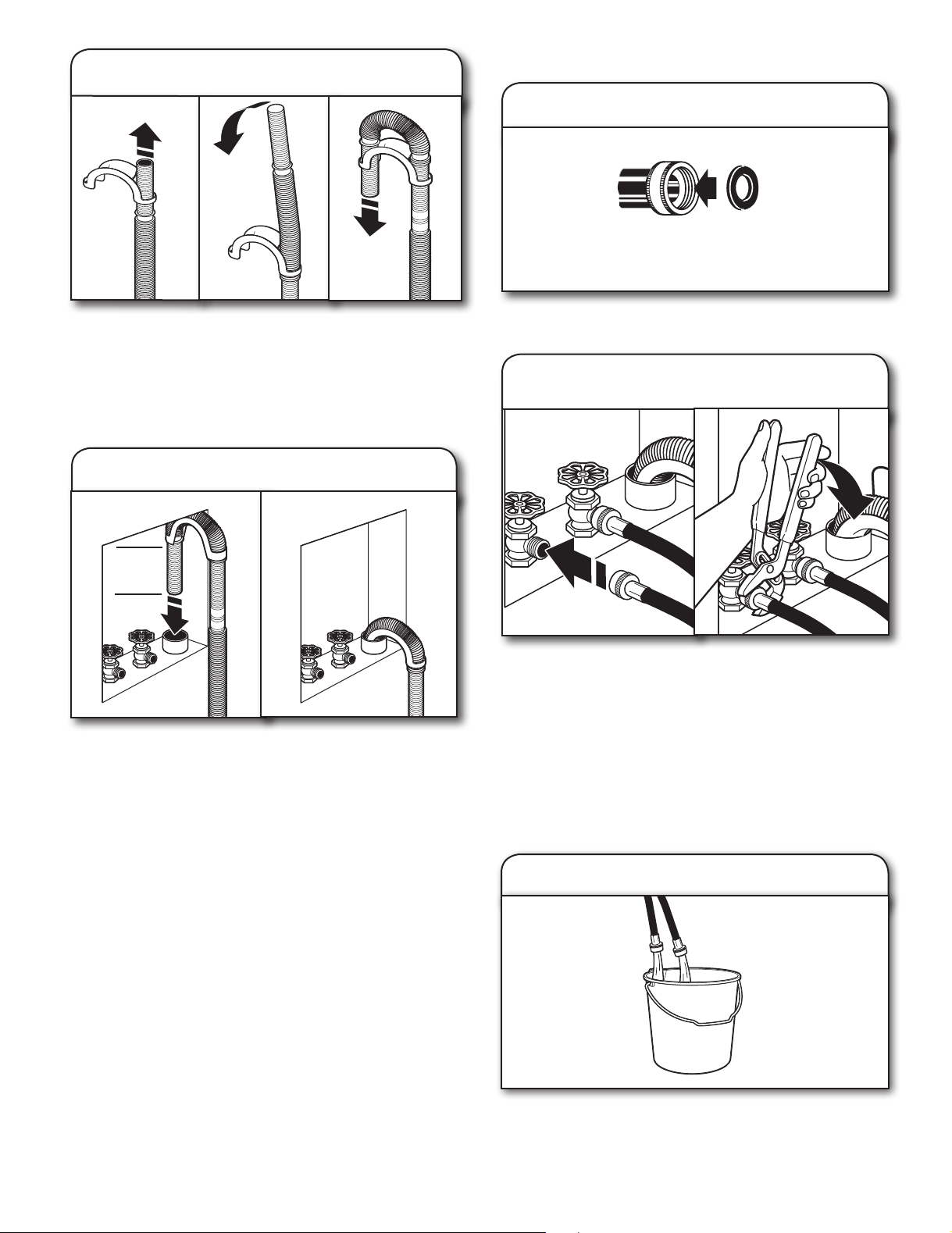

CONNECT DRAIN HOSE

IMPORTANT: Proper connection of the drain hose helps

to avoid water leakage and damage to your oors. The drain

hose is connected to your washer and is stored inside the

washer cabinet.

1.

Remove drain hose from washer

cabinet

Gently pull hose out of back of washer cabinet from top until

end emerges.

IMPORTANT: Do not force excess drain hose back into rear

of washer.

5

Page 6

2. Connect drain hose form

CONNECT INLET HOSES

Insert new at washers

1.

A B

A. Coupling

B. Washer

For a laundry tub or standpipe drain, connect the drain hose

form. For a oor drain, do not install drain hose form. You

may need alternate parts with separate directions. See

“Tools and Parts” to determine what you may need.

Feed hose into one end of form. Bend hose and feed through

other side, anchoring form on smooth sections of hose. The

hose must extend 4 1/2" (114 mm) beyond the form.

3. Place drain hose in standpipe

4.5"

(113 mm)

Place hose into standpipe (shown in picture) or over side

of laundry tub.

IMPORTANT: To keep drain water from going back into

the washer:

■ Do not force excess drain hose into standpipe. Hose

should be secure but loose enough to provide a gap

for air.

■ Do not lay excess hose on the bottom of the laundry

tub.

Insert new at washers into each end of the inlet hoses.

Firmly seat the washers in the couplings.

Connect inlet hoses to water

2.

faucets

Make sure the washer basket is empty. Attach the hose

labeled hot to hot water faucet. Screw on coupling by hand

until it is seated on washer. Use pliers to tighten couplings

an additional two-thirds turn. Repeat this step with the hose

labeled cold for the cold water faucet. Both hoses must

be connected for washer to work properly.

IMPORTANT: Do not overtighten or use tape or sealants

on valve when attaching to faucets or washer. Damage

can result.

HELPFUL TIP: Make note of which hose is connected

to hot water to help in attaching hoses to washer correctly.

3. Clear water lines

Run water for a few seconds through hoses into a laundry

tub, drainpipe, or bucket to avoid clogs. Water should run

until clear. Check the temperature of the water to make sure

that the hot water hose is connected to the hot water faucet

and the cold water hose is connected to the cold water faucet.

6

Page 7

4. Connect inlet hoses to washer

6. Secure drain hose

Laundry Tub Standpipe Wall

Attach hot water hose to hot water inlet valve. Screw coupling

by hand until it is snug. Use pliers to tighten couplings an

additional two-thirds turn. Repeat with cold water inlet valve.

Both hoses must be connected for washer to work properly.

IMPORTANT: Do not overtighten or use tape or sealants on

valve when attaching to faucets or washer. Damage can result.

NOTE: To reduce risk of hose failure, replace the hoses every

5 years. Record hose installation or replacement dates for

future reference.

■ Periodically inspect and replace hoses if bulges, kinks,

cuts, wear, or leaks are found.

5. Check for leaks

4.5"

(114 mm)

A

Secure drain hose to laundry tub leg, drain standpipe, or inlet

hoses for wall standpipe with removable tie strap (A). This will

help reduce the chance of drain water splashing on the oor.

4.5"

(114 mm)

A

4.5"

(114 mm)

A

LEVEL WASHER

IMPORTANT: Leveling your washer properly reduces excess

noise and vibration.

1. Move washer to nal location

Turn on water faucets to check for leaks from faucet and at

washer connection. A small amount of water may enter washer.

You will drain this in a later step.

Move the washer to its nal location. Rock the washer back

and forth to check whether all four feet are stable and in rm

contact with the oor. If the washer rocks, your model may

be one that comes with 3 feet preset at the factory. It will

be necessary to adjust the right front foot to level the washer.

If all 4 feet were preset at the factory, minor adjustments may

be needed to level the washer on your oor.

2. Adjust front leveling foot

For washers with an adjustable right front foot, lower the right

front foot until it contacts the oor. Using pliers, rotate the foot

up to an additional 1 1/2 turns.

7

Page 8

3. Check levelness of washer

Place level here

Place level here

Check the levelness of the washer. First, place a level

on the lid near the console. Then place the level on the side

of the washer in the crease between the top of the washer

and the cabinet.

4. Adjust levelness of washer

If the washer is not level, move

the washer out slightly, tip back

and prop up the front of the washer with a wood block.

Adjust the right front foot by loosening the locknut

with a 9/16" or 14 mm open-end wrench, then twisting

the foot up or down as needed.After the washer is level,

make sure all 4 feet are in rm contact with the oor

by gently rocking it back and forth and side to side. Adjust

the feet if necessary, then using the wrench again, turn

the locknuts counterclockwise on the foot to tighten

to the washer cabinet.

HELPFUL TIP: You may have to adjust the back feet to level

the washer. If you are installing the washer in a tight or hard

to reach area, you may have to move the washer out to reach

the feet comfortably. You may wish to lock the back feet

before moving the washer back into place.

IMPORTANT: If the locknuts are not tight against the washer

cabinet, the washer may vibrate.

Not Level LEVEL Not Level

5.

Plug into a grounded

3 prong outlet

8

Page 9

COMPLETE INSTALLATION

CHECKLIST

■ Check electrical requirements. Be sure you have correct

electrical supply and recommended grounding method.

See “Electrical Requirements”.

■ Check that all parts are now installed. If there is an extra

part, go back through steps to see what was skipped.

■ Check that you have all of your tools.

■ Keep the foam packing ring from the washer tub for future

relocation of the washer. Dispose of/recycle all packaging

materials.

■ Check that both water faucets are on.

■ Check for leaks around faucets and inlet hoses.

■ Remove lm from console and any tape remaining

on washer.

■ Check that washer is plugged into a grounded

3 prong outlet.

■ Read “Washer Use” in your “Use and Care Guide”.

■ To test and clean your washer, measure 1/2 of normal

recommended amount of High Efciency (HE) powdered

or liquid detergent for a medium-size load and pour it into

detergent dispenser. Close lid. Press POWER. Select

a normal cycle and press Start. Allow it to complete

one whole cycle.

9

Page 10

SÉCURITÉ DE LA LAVEUSE

10

Page 11

EXIGENCES D’INSTALLATION

OUTILLAGE ET PIÈCES

Rassembler les outils et composants nécessaires avant

d’entreprendre l’installation.

Outillage nécessaire :

Autres pièces : (Non fournies avec la laveuse)

Il se peut que l’installation nécessite des pièces supplémentaires.

Pour commander, consulter le numéro de téléphone sans frais

ou le site Web sur la page arrière du “Guide d’utilisation et

d’entretien”.

Si vous avez : Il vous faudra :

Évier de buanderie Système de pompe de puisard

ou tuyau de rejet (si non déjà disponible)

à l’égout plus

haut que 96" (2,4 m)

Pince - ouverture jusqu’à

19/16" (39,5 mm)

Clé plate ou clé à molette

de 9/16" (14 mm)

Mètre-ruban ou règle Niveau

Lampe de poche

(facultative)

4" min

(102 mm)

Cale en bois

Pièces fournies (dans le panier de la laveuse) :

Tuyau de rejet Ensemble pour adaptateur de 2"

à l’égout de 1" (25 mm) (50 mm) à 1" (25 mm) de diamètre

de diamètre pour tuyau de rejet à l’égout; pour

tuyau de rejet à l’égout; pièce

numéro 3363920 et ensemble

de connexion; pièce numéro 285835

Égout surélevé Tuyau rigide d’évacuation standard

de 20 gal. (76 L) de 39" (990 mm)

de haut ou évier de décharge, pompe

de puisard et connecteurs (disponibles

chez les vendeurs de matériel

de plomberie locaux)

Égout au plancher Ensemble de brise-siphon, pièce

numéro 285834; Tuyau d’évacuation,

pièce numéro 8318155; Ensemble

de raccord, pièce numéro 285835

Robinets d’eau 2 tuyaux d’admission d’eau plus longs :

hors d’atteinte 6 pi (1,8 m) – Pièce numéro 76314

des tuyaux 10 pi (3,0 m) – Pièce numéro 350008

d’admission

Système d’évacuation Protecteur de canalisation, pièce

obstrué par de la numéro 376031

charpie

Bride de retenue pour

tuyau de vidange

Rondelles plates pour

tuyau d’arrivée d’eau (4)

Tuyaux d’admission

d’eau (2)

Attache de xation

amovible

11

Page 12

EXIGENCES D’EMPLACEMENT

Le choix d’un emplacement approprié pour la laveuse

en améliore le rendement et réduit au minimum le bruit

et le “déplacement” possible de la laveuse. La laveuse

peut être installée dans un sous-sol, une salle de buanderie,

un placard ou un encastrement.

C’est à l’utilisateur qu’incombe la responsabilité de réaliser

une installation correcte.

Il vous faudra :

■ Un chauffe-eau réglé pour fournir de l’eau à 120°F (49°C)

à la laveuse.

■ Une prise électrique reliée à la terre située à 4 pi (1,2 m)

maximum de l’emplacement de la prise du cordon électrique

se trouvant à l’arrière de la laveuse. Voir “Spécifications

électriques”.

■ Des robinets d’eau chaude et d’eau froide situés à 3 pi

(900 mm) maximum des valves de remplissage d’eau

chaude et d’eau froide, et une pression d’eau de

20-100 lb-po2 (138-690 kPa) pour une performance optimale.

■ Un plancher de niveau avec une pente maximale de 1"

(25 mm) sous l’ensemble de la laveuse. L’installation

de la laveuse sur de la moquette ou un tapis n’est pas

recommandée.

■ Un plancher robuste pour supporter la laveuse avec

un poids total (laveuse, eau et charge) de 315 lb (143 kg).

IMPORTANT : Ne pas installer, remiser ou faire fonctionner

la laveuse à un emplacement où elle sera exposée à de l’eau,

des intempéries ou à des températures inférieures à 32° F

(0° C). Une certaine quantité d’eau peut rester dans la laveuse

et causer des dommages à des températures basses. Consulter

le “Guide d’utilisation et d’entretien” pour plus d’informations

sur l’hivérisation.

Espacement pour une installation

dans un encastrement ou dans un placard

Toutes les dimensions indiquent le dégagement autorisé,

avec un dégagement testé de 0" (0 mm) de chaque côté.

■ Prévoir davantage d’espace pour faciliter l’installation

et l’entretien.

■ Des espaces supplémentaires peuvent être requis pour

les moulures de porte et de plancher et pour les plinthes.

■ Un espace supplémentaire doit être envisagé de tous

les côtés de la laveuse an de réduire le transfert de bruit.

■ Pour une installation dans un placard avec porte, on doit

prévoir des ouvertures minimums d’entrée d’air en haut

et en bas de la porte. Les portes à claire-voie offrant

des ouvertures équivalentes de passage de l’air sont

acceptables.

■ Il faut aussi prendre en compte l’espace requis entre

les appareils voisins.

14"* max.

(356 mm)

48 in.2*

17"*

(432 mm)

1"

(25 mm)

*Espacement requis

27 1/2"

(699 mm)

Vue de face

1"

(25 mm)

27"

1"

(686 mm)

(25 mm)

Vue latérale

(310 cm2)

(155 cm2)

5"*

(127 mm)

24 in.2*

Porte de

placard

avec orices

d’entrée d’air

3"*

(76 mm)

3"*

(76 mm)

12

Page 13

SYSTÈME DE VIDANGE

Le système de vidange peut être installé à l’aide d’un conduit

d’évacuation au plancher, un tuyau rigide de rejet à l’égout

mural, un tuyau rigide de rejet à l’égout au plancher

ou un évier de buanderie. Sélectionner la méthode à utiliser.

39"

(990 mm)

Tuyau rigide de rejet Tuyau rigide de rejet à

à l’égout mural l’égout au plancher

Le système de rejet à l’égout nécessite un tuyau de diamètre

minimum de 2" (51 mm). La capacité minimale d’acheminement

ne doit pas être inférieure à 17 gal. (64 L) par minute. Un

adaptateur de 2" (51 mm) à 1" (25 mm) de diamètre est disponible

pour le tuyau de rejet à l’égout. Voir “Outillage et pièces”.

Le sommet du tuyau de rejet à l’égout doit être au moins à 39"

(990 mm) de hauteur et au maximum à 96" (2,4 m) de la base

de la laveuse.

28"

39"

(990 mm)

Évier de buanderie Plancher

Le système de vidange doit comporter un évier de buanderie

d’une capacité minimale de 20 gal. (76 L). Le sommet de l’évier

doit être au moins à 39" (990 mm) au-dessus du sol et au

maximum à 96" (2,4 m) de la base de la laveuse.

Le système de vidange au plancher nécessite un brise-siphon

qui peut être acheté séparément. Voir “Outillage et pièces”.

Le brise-siphon doit être au moins à 28" (710 mm) de la base

de la laveuse. Des tuyaux supplémentaires peuvent être requis.

(710 mm)

SPÉCIFICATIONS ÉLECTRIQUES

■ Une alimentation de 120 volts, 60 Hz, CA seulement,

de 15 ou 20 ampères, protégée par un fusible est requise.

On recommande d’utiliser un fusible ou un disjoncteur

temporisé ainsi qu’un circuit distinct pour cette laveuse.

■ Cette laveuse comporte un cordon d’alimentation électrique

à trois broches pour liaison à la terre.

■ Pour minimiser les risques de choc électrique, on doit

brancher le cordon sur une prise de courant de conguration

correspondante, à 3 alvéoles, reliée à la terre et installée

conformément aux codes et règlements locaux. Si une

prise de courant de conguration correspondante n’est

pas disponible, le client a la responsabilité et l’obligation

de faire installer par un électricien qualié une prise

de courant correctement reliée à la terre.

■ Si les codes le permettent et si l’on utilise un conducteur

distinct de liaison à la terre, il est recommandé qu’un

électricien qualié vérie la qualité de la liaison à la terre.

■ Ne pas utiliser une tuyauterie de gaz pour le raccordement

à la terre.

■ En cas de doute quant à la qualité de la liaison à la terre

de la laveuse, consulter un électricien qualié.

■ Ne pas installer un fusible dans le conducteur neutre

ou le circuit de liaison à la terre.

13

Page 14

RETRAIT DE LA BASE

D’EXPÉDITION

ET DE L’EMBALLAGE EN ANNEAU

1. Retrait de la base d’expédition

et de l’emballage en anneau

Placer des supports de carton de la boîte d’emballage

en carton sur le sol derrière la laveuse. Fixer le couvercle

avec du ruban adhésif. À l’aide de deux personnes ou plus,

incliner la laveuse sur sa partie arrière et la placer sur les

supports de carton. Ôter la base d’expédition en mousse.

Remettre ensuite la laveuse debout et retirer le ruban adhésif

du couvercle de façon à pouvoir ouvrir le couvercle et retirer

l’emballage en anneau de la cuve de la laveuse.

INSTRUCTIONS D’INSTALLATION

Avant de commencer : Retirer le matériel d’expédition.

Il est nécessaire de retirer tout le matériel d’expédition pour

un fonctionnement correct et pour éviter que la laveuse

ne fasse trop de bruit.

REMARQUE : Pour éviter d’endommager le plancher durant

l’installation, installer la laveuse sur un carton avant de la

déplacer sur le sol.

IMPORTANT :

■ Vérier que la base d’expédition en mousse a été retirée

de la partie inférieure de la laveuse tel qu’indiqué dans

“Retrait de la base d’expédition et de l’emballage

en anneau”.

■ Si la base d’expédition en mousse n’a pas été retirée,

vérier que le couvercle est bien immobilisé avec

du ruban adhésif avant de faire reposer la laveuse

sur sa partie arrière.

■ Le retrait de la base d’expédition en mousse

est nécessaire au bon fonctionnement de l’appareil.

REMARQUE : Conserver l’anneau de l’emballage en mousse

en cas de déplacement ultérieur de la laveuse.

RACCORDEMENT DU TUYAU

D’ÉVACUATION

IMPORTANT : Un bon raccordement du tuyau d’évacuation

permet d’éviter les fuites d’eau et les dommages au plancher.

Le tuyau de vidange est connecté à la laveuse et est remisé

à l’intérieur de la caisse de la laveuse.

1.

Libérer le tuyau de vidange

de la caisse de la laveuse

Libérer le tuyau de vidange de la caisse de la laveuse.

IMPORTANT : Ne pas forcer l’excédent du tuyau de vidange

dans l’arrière de la laveuse.

14

Page 15

2. Raccordement de la bride

de retenue pour tuyau de vidange

RACCORDEMENT DES TUYAUX

DE VIDANGE

Insérer les rondelles plates neuves

1.

A B

A. Raccord

B. Rondelle

Pour un système d’évacuation par l’évier de buanderie ou le

tuyau rigide de rejet à l’égout, xer le support de xation pour

tuyau d’évacuation. Pour un système d’évacuation au plancher,

ne pas installer le support de xation pour tuyau d’évacuation.

Des pièces supplémentaires avec des directives distinctes

seront peut-être nécessaires. Voir “Outils et pièces” pour

déterminer les outils nécessaires.

Introduire le tuyau d’évacuation dans l’une des extrémités

du support. Replier le tuyau et l’introduire dans l’autre côté en

xant le support sur les parties lisses du tuyau. Le tuyau doit

être étiré de 4½" (114 mm) au-delà du support.

3. Placer le tuyau de vidange dans

le tuyau de rejet à l’égout

4.5"

(113 mm)

Insérer les rondelles plates neuves dans chaque extrémité

des tuyaux d’arrivée d’eau. Insérer fermement les rondelles

dans les raccords.

Connecter les tuyaux d’arrivée

2.

d’eau aux robinets

S’assurer que le panier de la laveuse est vide. Fixer le tuyau

dont l’étiquette porte la mention “hot” (chaud) au robinet

d’eau chaude. Visser le raccord à la main pour qu’il repose

sur la rondelle. Serrer les raccords de deux tiers de tour

supplémentaires à l’aide d’une pince. Répéter cette étape

avec le tuyau portant la mention « cold » (froide) pour le robinet

d’eau froide. Les deux tuyaux doivent être raccordés pour que

la laveuse fonctionne correctement.

Placer le tuyau dans le tuyau de rejet à l’égout (illustré

à l’image) ou par-dessus le côté de l’évier de buanderie.

IMPORTANT : Pour empêcher l’eau de vidange de reuer

dans la laveuse :

■ Ne pas forcer l’excédent du tuyau de vidange dans

le tuyau rigide de rejet à l’égout. Le tuyau doit être bien

immobilisé, tout en permettant le passage d’air.

■ Ne pas mettre l’excédent du tuyau de vidange dans

le fond de l’évier de buanderie.

IMPORTANT : Ne pas serrer excessivement ni utiliser

de ruban adhésif ou de dispositifs d’étanchéité lors

de la xation des robinets ou de la machine. Cela pourrait

entraîner des dommages.

CONSEIL UTILE : Repérer quel tuyau est raccordé

à l’eau chaude pour permettre une xation correcte des

tuyaux à la laveuse.

15

Page 16

3. Purger les canalisations d’eau

5. Vérier l’absence de fuites

Faire couler de l’eau dans les tuyaux de l’évier de buanderie,

le tuyau rigide de rejet à l’égout ou le seau pendant quelques

secondes pour éviter toute obstruction. On doit laisser couler

l’eau jusqu’à ce qu’elle soit limpide. Vérier la température

de l’eau pour s’assurer que le tuyau d’eau chaude est

connecté au robinet d’eau chaude et que le tuyau d’eau

froide est connecté au robinet d’eau froide.

4. Connecter les tuyaux d’arrivée

d’eau à la laveuse

Fixer le tuyau d’eau chaude au robinet d’arrivée d’eau chaude.

Visser le raccord à la main jusqu’à ce qu’il soit bien serré.

Serrer les raccords de deux tiers de tour supplémentaires

à l’aide d’une pince. Répéter pour le robinet d’eau froide.

Les deux tuyaux doivent être raccordés pour que la laveuse

fonctionne correctement.

IMPORTANT : Ne pas serrer excessivement ni utiliser

de ruban adhésif ou de dispositifs d’étanchéité lors de la

xation des robinets ou de la machine. Cela pourrait entraîner

des dommages.

REMARQUE : Pour réduire le risque de défaillance des

tuyaux, remplacer les tuyaux tous les 5 ans. Inscrire la date

d’installation ou de remplacement des tuyaux pour référence

ultérieure.

■ Inspecter périodiquement les tuyaux et les remplacer

en cas de renement, de déformation, de coupure, d’usure

ou si une fuite se manifeste.

Ouvrir les deux robinets pour vérier l’absence de fuite au

niveau du robinet et du raccordement des rondelles. Une petite

quantité d’eau peut entrer dans la laveuse. Vous effectuerez

une vidange lors d’une étape ultérieure.

6. Immobiliser le tuyau de vidange

Évier de buanderie Tuyau rigide Mur

de rejet à l’égout

4.5"

(114 mm)

A

Fixer le tuyau d’évacuation au pied de l’évier de buanderie,

au tuyau rigide de rejet à l’égout ou aux tuyaux d’arrivée d’eau

pour le tuyau de rejet à l’égout mural avec l’attache de xation

amovible (A). Ceci aidera à réduire le risque d’éclaboussement

d’eau sur le plancher.

4.5"

(114 mm)

A

4.5"

(114 mm)

A

16

Page 17

MISE À NIVEAU DE LA LAVEUSE

IMPORTANT : L’établissement correct de l’aplomb

de la laveuse permet de réduire un niveau sonore et des

vibrations excessifs.

1. Déplacer la laveuse à son

emplacement nal

3. Vérier le bon aplomb

de la laveuse

Placer le niveau

à cet endroit

Déplacer la laveuse à son emplacement nal. Pousser

la laveuse d’avant en arrière pour vérier que les quatre

pieds sont stables et en contact ferme avec le plancher.

Si la laveuse bascule, ce modèle de laveuse correspond

peut-être à celui qui est livré avec 3 pieds préréglés à l’usine.

On doit alors régler le pied avant droit pour établir l’aplomb

de la laveuse. Si les 4 pieds sont préréglés à l’usine, de petits

réglages seront peut-être nécessaires pour mettre la laveuse

d’aplomb sur le plancher.

2. Ajuster les pieds de nivellement

avant

Pour las laveuses avec un pied avant droit réglable, abaisser

le pied avant droit jusqu’à ce qu’il soit en contact avec

le plancher. À l’aide d’une pince, faire pivoter le pied vers

le haut d’un tour et demi supplémentaire.

Placer le niveau

à cet endroit

Vérier le bon aplomb de la laveuse. Placer d’abord un niveau

sur le couvercle près de la console. Puis, placer le niveau

sur le côté de la laveuse dans l’espace situé entre la partie

supérieure de la laveuse et la caisse.

Pas d’aplomb D’APLOMB Pas d’aplomb

17

Page 18

4. Régler le bon aplomb

de la laveuse

Si la laveuse n’est pas d’aplomb,

déplacer légèrement la laveuse pour la dégager, l’incliner

vers l’arrière et soulever l’avant de la laveuse avec une cale

de bois. Régler le pied avant en desserrant l’écrou de blocage

à l’aide d’une clé plate de 9/16" ou 14 mm puis faire tourner

le pied vers le haut ou vers le bas selon le besoin.

Une fois la laveuse d’aplomb, s’assurer que les 4 pieds

sont en contact ferme avec le plancher en la faisant

doucement pivoter d’avant en arrière et d’un côté à l’autre.

Régler les pieds de nivellement si nécessaire puis utiliser

à nouveau la clé et tourner les écrous de blocage dans

le sens antihoraire sur les pieds pour serrer les pieds contre

la caisse de la laveuse.

CONSEIL UTILE : Il faudra peut-être régler les pieds arrière

pour établir l’aplomb de la laveuse. Si l’on installe la laveuse

dans un endroit exigu ou difcile d’accès, il faudra peut-être

dégager la laveuse de l’emplacement pour pouvoir avoir

pleinement accès aux pieds. Il peut être utile de bloquer

les pieds arrière avant de réinstaller la laveuse dans son

emplacement.

IMPORTANT : Si les écrous de blocage ne sont pas bien

serrés contre la caisse de la laveuse, la laveuse peut vibrer.

5.

Brancher l’appareil sur une prise

à 3 alvéoles reliée à la terre

18

Page 19

LISTE DE VÉRIFICATION POUR

INSTALLATION TERMINÉE

■ Consulter les spécications électriques. S’assurer de

disposer d’une source d’électricité appropriée, et d’une

liaison à la terre conforme à la méthode recommandée. Voir

“Spécications électriques”.

■ Vérier que toutes les pièces sont maintenant installées. S’il

reste une pièce, passer en revue les différentes étapes pour

découvrir laquelle aurait été oubliée.

■ Vérier la présence de tous les outils.

■ Conserver l’anneau de l’emballage en mousse de la cuve en

cas de réinstallation ultérieure de la laveuse. Éliminer/recycler

tous les matériaux d’emballage.

■ Vérier que les robinets d’eau sont tous les deux ouverts.

■ Vérier qu’il n’y a pas de fuite autour des robinets et des

tuyaux d’arrivée d’eau.

■ Ôter la pellicule protectrice de la console et tout ruban adhésif

resté sur la laveuse.

■ Vérier que la laveuse est branchée sur une prise

de courant à 3 alvéoles reliée à la terre.

■ Lire la section “Utilisation de la laveuse” dans le “Guide

d’utilisation et d’entretien”.

■ Pour tester et nettoyer votre laveuse, mesurer la moitié

de la quantité normale recommandée de détergent Haute

Efcacité (HE) en poudre ou liquide pour une charge

de taille moyenne et la verser dans le distributeur de

détergent. Fermer le couvercle. Appuyer sur POWER

(mise sous tension). Sélectionner un programme normal

et appuyer sur Start (mise en marche). Laisser un

programme complet s’effectuer.

19

Page 20

W10240438C

© 2012 Whirlpool Corporation. ® Registered Trademark/TM Trademark of Whirlpool, U.S.A. 01/12

All rights reserved MC Marque de commerce/ MD Marque Déposée de Whirlpool, U.S.A. Printed in U.S.A.

Tous droits réservés Imprimé en É.-U.

Loading...

Loading...