Page 1

Service

This manual is to be used by qualified appliance

technicians only. Maytag does not assume any

responsibility for property damage or personal

injury for improper service procedures done by

an unqualified person.

This Base Manual covers general information

Refer to individual Technical Sheet

for information on specific models

This manual includes, but is

not limited to the following:

Freestanding

Double Oven

Gas Range

MGR6775ADB/Q/S/W

MGR6875ADB/Q/S/W

16023415

August 2004

©2004 Maytag Services

Page 2

Important Information

Pride and workmanship go into every product to provide our customers with quality products. It is possible, however,

that during its lifetime a product may require service. Products should be serviced only by a qualified service

technician who is familiar with the safety procedures required in the repair and who is equipped with the proper tools,

parts, testing instruments and the appropriate service information. IT IS THE TECHNICIANS RESPONSIBILITY TO

REVIEW ALL APPROPRIATE SERVICE INFORMATION BEFORE BEGINNING REPAIRS.

Important Notices for Servicers and Consumers

!

To avoid risk of severe personal injury or death, disconnect power before working/servicing on appliance to avoid

electrical shock.

To locate an authorized servicer, please consult your telephone book or the dealer from whom you purchased this

product. For further assistance, please contact:

WARNING

Customer Service Support Center

CAIR Center

Web Site Telephone Number

WWW.MAYTAG.COM ............................................. 1-800-688-9900

CAIR Center in Canada ........................................... 1-800-688-2002

Recognize Safety Symbols, Words, and Labels

DANGER!

DANGER—Immediate hazards which WILL result in severe personal injury or death.

WARNING!

WARNING—Hazards or unsafe practices which COULD result in severe personal injury or death.

CAUTION!

CAUTION—Hazards or unsafe practices which COULD result in minor personal injury, product or property

damage.

2 16023415 ©2004 Maytag Services

Page 3

Table of Contents

Important Information .................................................... 2

Safety Information

Safety Practices for Servicer .................................... 4

Servicing .................................................................. 4

Receiving Oven ........................................................ 5

Using the Oven ........................................................ 5

Baking, Broiling, and Roasting ................................. 6

Connecting Range to Gas ........................................ 6

Electrical Requirements ........................................... 6

Extension Cord ........................................................ 6

Product Safety Devices ............................................ 6

General Information

Cooking Nomenclature ............................................. 7

Specifications .......................................................... 8

Placement of the Oven ............................................. 8

Location of Model Number ........................................ 8

Model Identification .................................................. 8

Service ..................................................................... 8

Parts and Accessories ............................................. 8

Extended Service Plan ............................................. 8

Grounding ................................................................ 9

Range Description ................................................... 10

Troubleshooting Procedures

Control System Troubleshooting ............................. 11

Component Troubleshooting .................................... 14

Component Testing Procedures ................................... 17

Quick Test Mode.....................................................22

Disassembly Procedures

Moving and/or Replacing Range ..............................24

Leveling Legs .......................................................... 24

Anti-Tip Bracket ...................................................... 24

Top Burner .............................................................. 24

Side Panel .............................................................. 24

Maintop Removal ..................................................... 24

Top Surface Valve and Spark Switch .......................24

Shut-Off Valve ......................................................... 24

Top Burner Lower Assembly ................................... 24

Manifold and Top Burner .......................................... 24

Oven Sensor ........................................................... 25

Electronic Clock......................................................25

Oven Light Replacement ......................................... 25

Oven Door(s)

Door Removal ...................................................... 25

Door Replacement ............................................... 25

Gasket and Door Disassembly ............................ 26

Lower Latch Assembly ............................................ 27

Upper Latch Assembly ............................................ 27

Oven Door Hinge ..................................................... 28

Regulator ................................................................ 28

Gas Valve ............................................................... 28

Door Plunger ........................................................... 28

Spark Module .......................................................... 28

Convection Assembly ..............................................28

Oven Racks ............................................................ 29

Rack Positions .......................................................29

Oven Cavity Components (Gas) .............................. 29

Appendix A

Installation Instructions ......................................... A-2

Appendix B

Use and Care Model MGR6775AD* ...................... B-2

Use and Care Model MGR6875AD* .................... B-12

Care and Cleaning ............................................... B-23

Appendix C

LP Conversion ....................................................... C-2

©2004 Maytag Services 16023415 3

Page 4

Important Safety Information

Recognize this symbol as a safety precaution.

!

WARNING

!

If the information in this manual is not followed exactly,

a fire or explosion may result causing property

damage, personal injury or death.

Do not store or use gasoline or other flammable vapors

or liquids in the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Extinguish any open flame.

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire

department.

Installation and service must be performed by an

authorized installer, service agency or gas supplier.

WARNING!

Due to the nature of cooking, fires can occur as a

result of overcooking or excessive grease. Although a

fire is unlikely, if one occurs proceed as follows:

Oven Fires

1. Do not open the oven door.

2. Turn all controls to the OFF position.

3. As an added precaution turn off the electricity at

the main circuit breaker or fuse box and the gas

at the main supply valve.

4. Allow the food or grease to burn itself out in the

oven.

If smoke or fire persist call the local fire department.

To avoid risk of property damage or personal injury do

not obstruct the flow of combustion or ventilation air to

the oven.

To avoid risk of electrical shock, serious personal

injury or death: Verify the oven has been properly

grounded and always disconnect the electrical supply

before servicing this unit.

WARNING

!

To avoid risk of electrical shock, property damage,

personal injury or death; verify wiring is correct, if

components were replaced. Verify proper and complete

operation of unit after servicing.

This gas appliance contains or produces a chemical or

chemicals which are known to the state of California to

cause cancer, birth defects or other reproductive harm.

To reduce the risk from substances in the fuel or from

fuel combustion make sure this appliance is installed,

operated, and maintained according to the instructions

in this manual.

NOTE: The maximum gas supply pressure for these

models must not exceed 14 inches W.C.P.

Safety Practices for Servicer

Safe and satisfactory operation of gas ranges depends

upon its design and proper installation. However, there is

one more area of safety to be considered:

Servicing

Listed below are some general precautions and safety

practices which should be followed in order to protect

the service technician and consumer during service and

after service has been completed.

1. Gas smell—Extinguish any and all open flames and

open windows.

2. Turn gas off—Service range with gas turned off

unless testing requires it.

3. Checking for gas leaks—Never check for leaks

with any kind of open flame. Soap and water solution

should be used for this purpose. Apply solution to

suspected area and watch for air bubbles which

indicates a leak. Correct leaks by tightening fittings,

screws, connections, applying approved compound,

or installing new parts.

4 16023415 ©2004 Maytag Services

Page 5

Important Safety Information

4. Using lights—Use a hand flashlight when servicing

ranges or checking for gas leaks. Electric switches

should not be operated where leaks are suspected.

This will avoid creating arcing or sparks which could

ignite the gas. If electric lights are already turned on,

they should not be turned off.

5. Do not smoke—Never smoke while servicing gas

ranges, especially when working on piping that

contains or has contained gas.

6. Check range when service is completed—After

servicing, make visual checks on electrical

connection, and check for gas leaks. Inform

consumer of the condition of range before leaving.

7. Adhere to all local regulations and codes when

performing service.

Receiving Oven

• Installer needs to show consumer location of the range

gas shut-off valve and how to shut it off.

• Authorized servicer must install the range, in

accordance with the Installation Instructions.

Adjustments and service should be performed only by

authorized servicer.

• Plug range into a 120–volt grounded outlet only. Do

not remove round grounding prong from the plug. If in

doubt about grounding of the home electrical system,

it is consumers responsibility and obligation to have an

ungrounded outlet replaced with a properly grounded

three-prong outlet in accordance with the National

Electrical Code. Do not use an extension cord with

this appliance.

• Insure all packing materials are removed from the

range before operating it, to prevent fire or smoke

damage should the packing material ignite.

• Ensure range is correctly adjusted by a qualified

service technician or installer for the type of gas

(Natural or LP). Some ranges can be converted for

use with Natural or LP gas.

• With prolonged use of a range, high floor

temperatures could result. Many floor coverings will not

be able to withstand this kind of use. Never install

range over vinyl tile or linoleum that cannot withstand

high temperatures. Never install range directly over

carpeting.

Using the Oven

• Do not leave children alone or unattended where a

range is hot or in operation. They could be seriously

burned.

• Do not allow anyone to climb, stand or hang on the

door. They could damage the range and cause severe

personal injury.

• Wear proper apparel. Loose fitting or hanging garments

should never be worn when using oven. Flammable

material could ignite if brought in contact with flame or

hot oven surfaces which may cause severe burns.

• Never use range for warming or heating a room. This

may cause burns, injuries, or a fire.

• Do not use water on grease fires.

• Do not let grease or other flammable materials collect

in or around range.

• Do not repair or replace any part of range unless it is

recommended in this manual.

• Use only dry potholders. Moist or damp potholders

used on hot surfaces may result in a burn from steam.

Do not let a potholder touch the flame. Do not use a

towel or a bulky cloth as a potholder.

• Never leave range unattended while cooking.

Boilovers can cause smoking and may ignite.

• Only certain types of glass/ceramic, earthenware, or

other glazed utensils are suitable for oven use.

Unsuitable utensils may break due to sudden

temperature change.

• Use care when opening oven door. Let hot air or

steam escape before removing or replacing food.

• Do not heat unopened food containers in oven.

Buildup of pressure may cause a container to burst and

result in injury.

• Keep range vent ducts unobstructed.

• Place oven racks in desired location while oven is cool.

If a rack must be moved while oven is hot, use a dry

potholder.

• Do not use aluminum foil to line oven bottom or racks.

Aluminum foil can cause a fire and will seriously affect

baking results, and damage to porcelain surfaces.

• Do not touch interior surfaces of oven during or

immediately after use. Do not let clothing or other

flammable materials come in contact with bake or broil

burners.

• Other areas of the oven can become hot enough to

cause burns, such as vent openings, window, oven

door and oven racks.

• To avoid steam burns, do not use a wet sponge or cloth

to wipe up spills on hot cooking area.

• Do not store combustible or flammable materials, such

as gasoline or other flammable vapors and liquids near

or in oven.

• Do not clean oven door gasket located on back of the

door. Gasket is necessary to seal the oven and can be

damaged as a result of rubbing or being moved.

• Do not drape towels or any materials on oven door

handles. These items may ignite causing a fire.

CAUTI ON

!

Do not store items of interest to children in cabinets

above range. Children may climb on oven to reach

these items and become seriously injured.

©2004 Maytag Services 16023415 5

Page 6

Important Safety Information

Baking, Broiling, and Roasting

• Do not use oven area for storage.

• Stand back from range when opening door of a hot

oven. Hot air or steam can cause burns to hands,

face, and eyes.

• Do not use aluminum foil anywhere in the oven. This

could result in a fire hazard and damage the range.

• Use only glass cookware appropriate for use in gas

ovens.

• Always remove broiler pan from oven when finished

broiling. Grease left in pan can catch fire if oven is

used without removing grease from the broiler pan.

• Meat that is close to the flame may ignite when

broiling. Trim any excess fat to help prevent excessive

flare-ups.

• Make sure broiler pan is placed correctly to reduce any

possibility of grease fires.

• Should a grease fire occur in the broiler pan, turn off

oven, and keep oven door closed until fire burns out.

Connecting Range to Gas

Install manual shut-off valve in gas line for easy

accessibility outside range. Be aware of the location of

the shut-off valve.

Electrical Requirements

120-volt, 60 Hertz, 15 amp, individual circuit which is

properly grounded, polarized and protected by a circuit

breaker or fuse.

Extension Cord

Due to possible pinching during installation, extension

cords should not be used on products.

Extension cords will adversely affect the performance of

spark system.

Gas Burner Orifices Universal orifices are

used on most valves.

They must be adjusted

or set for the type of gas

being used Natural

LP.

After servicing a valve or

orifice verify it is

adjusted properly before

completing service.

Oven Safety Valve Oven valve is designed

to be a safety valve. Two

basic designs are used

in gas ranges.

Hydraulic type valve

Electric type valve

Both types are safety

valves because they are

indirectly operated by

the oven thermostat,

which controls a pilot

flame or electric ignitor,

to open and close the

oven valve.

Grounded Oven Frame Ground prong on power

cord is connected to the

frame, usually a green

lead fastened by a

screw. In addition, any

part or component

capable of conducting

an electric current is

grounded by its

mounting.

or

Product Safety Devices

Safety devices and features have been engineered into

the product to protect consumer and servicer. Safety

devices must never be removed, bypassed, or altered in

such a manner as to defeat the purpose for which they

were intended.

Listed below are various safety devices together with the

reason each device is incorporated in the gas ranges.

Pressure Regulator Maintains proper and

steady gas pressure for

operation of oven

controls. Regulator must

be set for the type of

gas being used Natural

or LP. After servicing

regulator, make certain it

is set properly before

completing service.

6 16023415 ©2004 Maytag Services

If any ground wire,

screw, strap, nut, etc. is

removed for service, or

any reason, it must be

reconnected to its

original position with

original fastener before

the appliance is put into

operation again.

Failure to do so can

create a possible shock

hazard.

Page 7

General Information

This manual provides basic instructions and suggestions

for handling, installing and servicing gas ranges.

The directions, information, and warnings in this manual

are developed from experience with, and careful testing

of the product. If the unit is installed according to this

manual, it will operate properly and will require minimal

servicing. A unit in proper operating order ensures the

consumer all the benefits provided by clean, modern gas

cooking.

Cooking Nomenclature

M E R 6 8 7 5 A A W

Brand

A Amana

C Magic Chef

G Graffer &

Sattler

H Hardwick

J Jenn-Air

M Maytag

N Norge

U Universal

Y Crosley

This manual contains information needed by authorized

service technicians to install and service gas ranges.

There may be, however, some parts which need further

explanation. Refer to the Installation Instructions, Use

and Care, Technical Sheets or the toll-free technical

support line.

Color

A Almond on Almond

B Black

C Brushed Chrome

H Traditional White

L Traditional Almond

P Prostyle

Q Monochromatic Bisque

S Stainless

T Traditional Bisque

W White on White

F Frost White (True Color White)

N Natural Bisque (True Color Bisque)

Fuel

B Butane

D Dual Fuel

E/J Electric

G Gas, Natural

L Liquid Propane

M Microwave

P Standing Pilot

X No Fuel

W Warming Drawer

Product Type

A Accessory/Cartridge

C Cooktop Updraft/Countertop

D Downdraft Cooktop or Warming Drawer

E Eyelevel Range

G Grill

L Range (20")

M Range (36")

P Drop In (24")

Q Wall Oven (27")

R Range, Free-Standing (30")

S Slide-In (30")

T Range Hood

V OTR

W Wall Oven

Y RV Range

Z RV Top

Listing

A UL/AGA

C CSA/CGA/CUL

D Dual Listed

G 220-240 V / 50-60 Hz

M Military Model

P PSB Approved

(Singapore)

X Export 120 V / 60 Hz

Production Code

This identifies the

production version.

Feature Content

1000-3999 Brands

4000-6999 Maytag/Amana

7000-9999 Jenn Air

©2004 Maytag Services 16023415 7

Page 8

General Information

Specifications

Refer to individual Technical Sheet for specification

information.

Placement of the Oven

This freestanding range must be placed in the kitchen or

comparable room. All safety guidelines must be followed

(see Chapter 2) and free air flow around the range is

essential.

Do Not Block Air Vents

All air vents must be kept clear during cooking. If air

vents are covered during operation, the oven may

overheat. If this occurs, a sensitive, thermal safety device

automatically removes power to the oven, rendering the

oven inoperable. The oven will remain in this state until it

has sufficiently cooled.

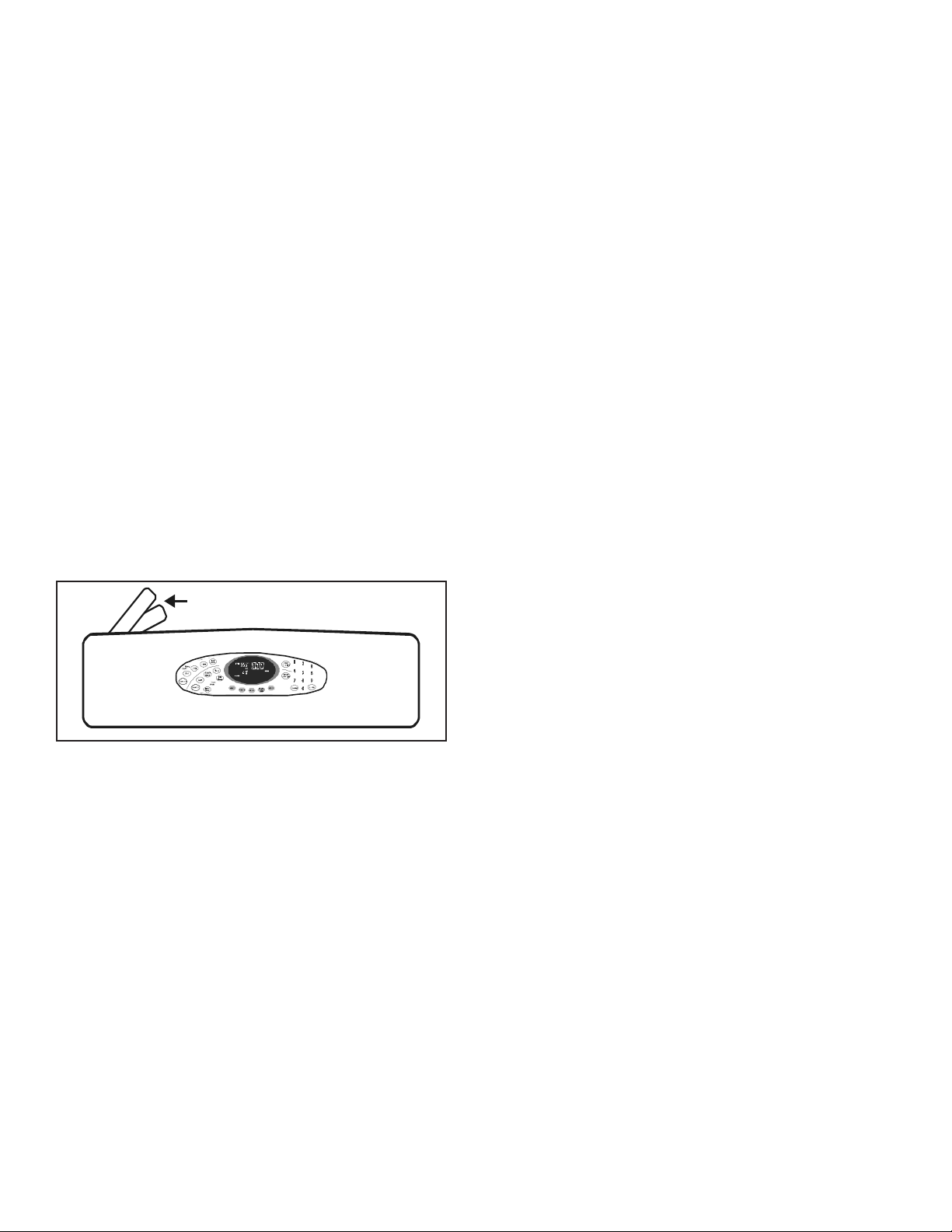

Location of Model Number

To request service information or replacement parts, the

service center will require the complete model, serial, and

manufacturing number of your freestanding range. The

number can be found on a metal tag located on the back

of the control panel. Reach behind the top left corner of

the control panel and rotate the tags up to view the data.

Service

Keep a copy of sales receipt for future reference or in

case warranty service is required. To locate an authorized

servicer:

• For Maytag product call 1-800-462-9824 or visit the

Web Site at www.maytag.com

• For product in Canada call 1-866-587-2002 or visit the

Web Site at www.maytag.com

Warranty service must be performed by an authorized

servicer. We also recommend contacting an authorized

servicer, if service is required after warranty expires.

Parts and Accessories

Purchase replacement parts and accessories over the

phone. To order accessories for your product call:

• For Maytag product call 1-800-688-9900 or visit the

Web Site at www.maytag.com

• For product in Canada call 1-866-587-2002 or visit the

Web Sites at www.maytag.com

Extended Service Plan

We offer long-term service protection for this new oven.

• Dependability PlusSM Extended Service Plan is

specially designed to supplement Maytag’s warranty.

This plan covers parts, labor, and travel charges.

Call 1-800-925-2020 for information.

Location of Model

and Serial N umb er

Model Identification

Complete enclosed registration card and promptly return.

If registration card is missing:

• For Maytag product call 1-800-688-9900 or visit the

Web Site at www.maytag.com

• For product in Canada call 1-866-587-2002 or visit the

Web Site at www.maytag.com

When contacting provide product information located on

rating plate. Record the following:

Model Number: ___________________

Manufacturing Number: ___________________

Serial or S/N Number: ___________________

Date of purchase: ___________________

Dealer’s name and address: ___________________

8 16023415 ©2004 Maytag Services

Page 9

General Information

Grounding

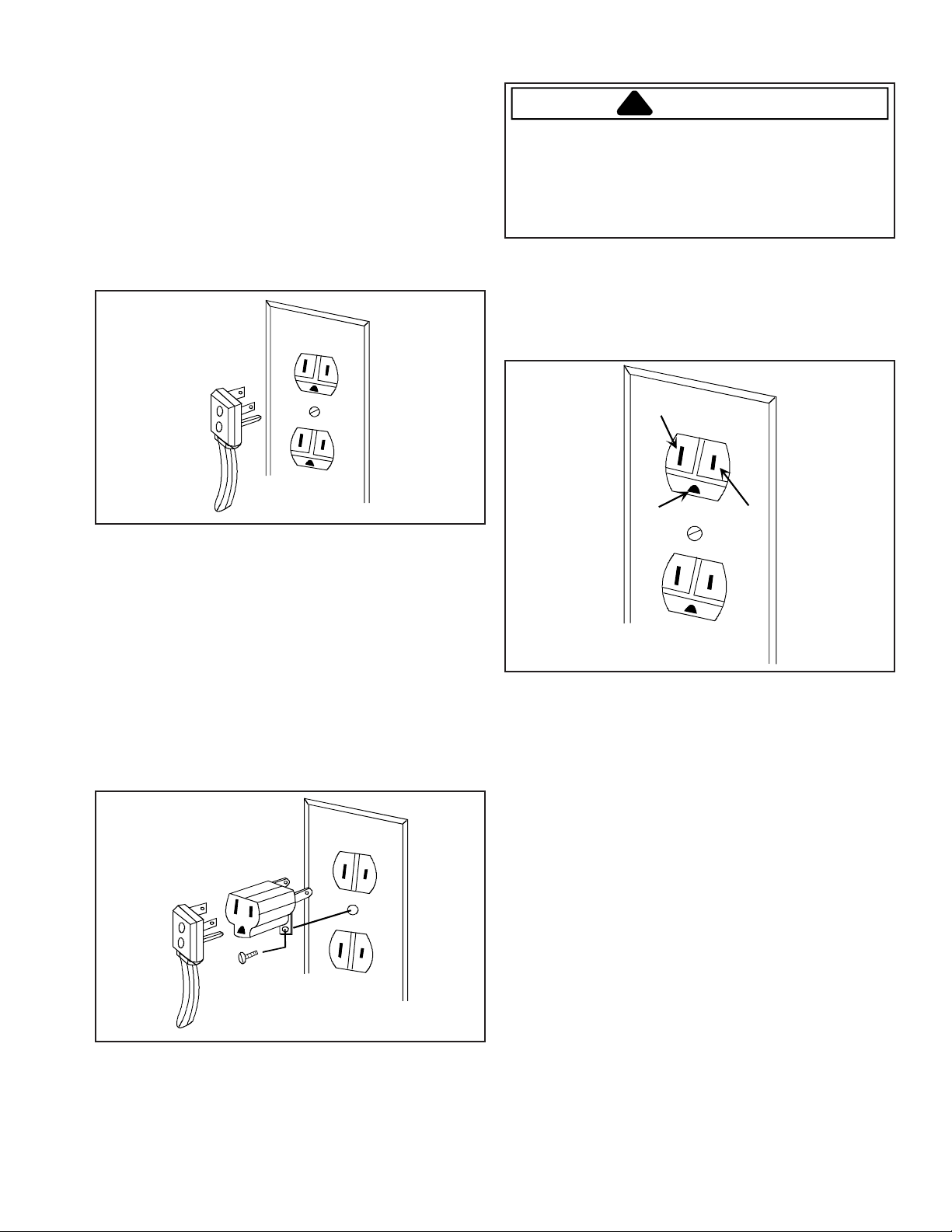

NOTE: This appliance must be properly grounded, for

personal safety.

Power cord on this appliance is equipped with a threeprong grounding plug. This matches standard three-prong

grounding wall receptacle to prevent possibility of electric

shock from this appliance.

Consumer should have wall receptacle and circuit

checked by qualified electrician to verify receptacle is

properly grounded.

WARNING

!

Attaching adapter ground terminal to wall receptacle

cover screw does not ground appliance unless the

cover screw is metal and not insulated, and wall

receptacle is grounded through the house wiring.

Consumer should have circuit checked by a qualified

electrician to verify receptacle is properly grounded.

When disconnecting power cord from adapter, always

hold adapter with one hand. If this is not done, adapter

ground terminal is very likely to break with repeated use.

Should this happen, DO NOT USE appliance until a

proper ground has been established.

Neutral Wire

Ground

Hot Line

It is the consumers responsibility to replace standard twoprong wall receptacles with properly grounded three-prong

wall receptacles.

DO NOT, UNDER ANY CIRCUMSTANCES, CUT OR

REMOVE THE THIRD (GROUND) PRONG FROM

POWER CORD.

For 15 amp circuits only, do not use an adapter on 20

amp circuit. Where local codes permit, a TEMPORARY

CONNECTION may be made to a properly grounded twoprong wall receptacle by the use of a UL listed adapter

(available at most hardware stores).

Larger slot on adapter must be aligned with larger slot in

the wall receptacle to provide proper polarity.

NOTE: Circuit tester can be used to verify voltage at

outlet. Connect one lead to hot line and the

other lead to ground. Circuit tester should light.

©2004 Maytag Services 16023415 9

Page 10

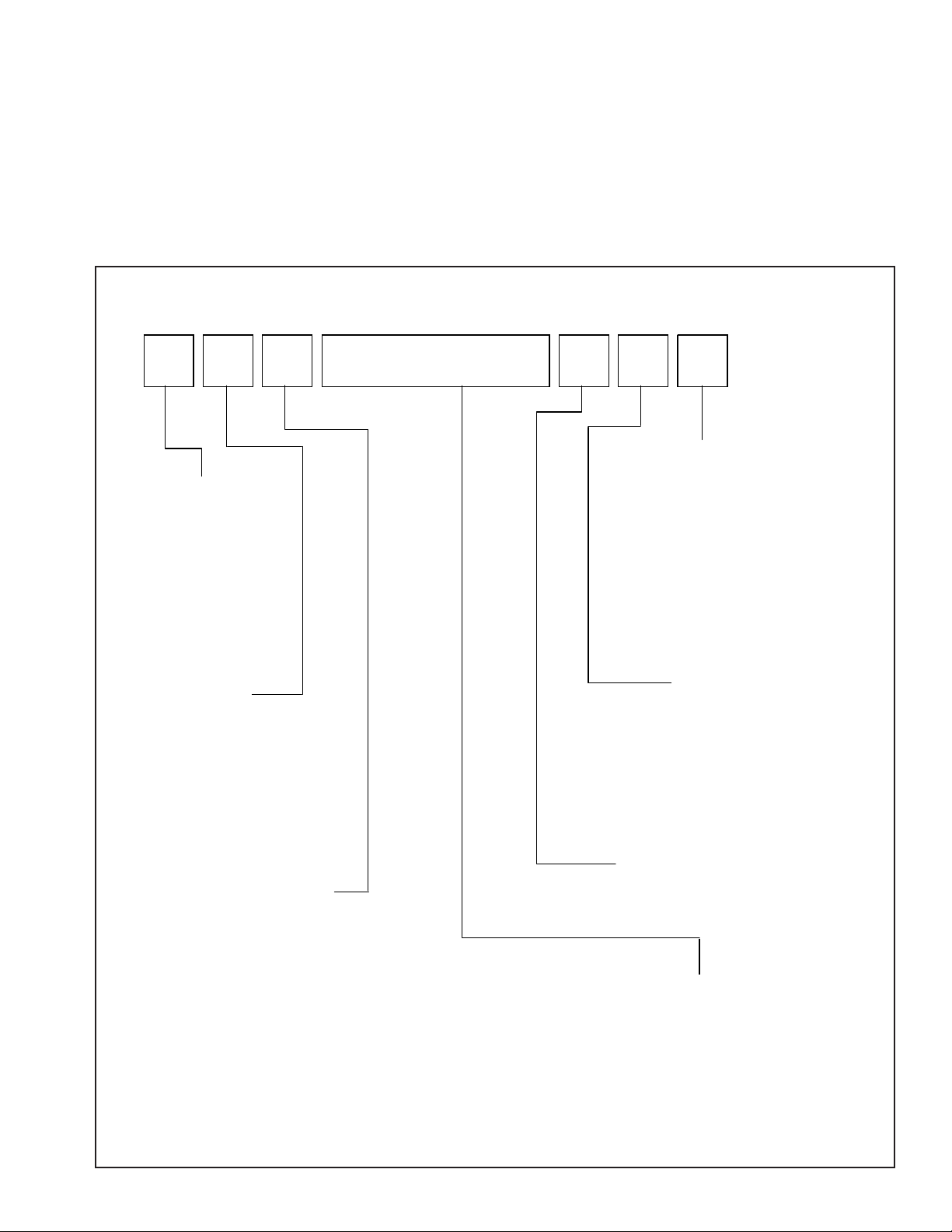

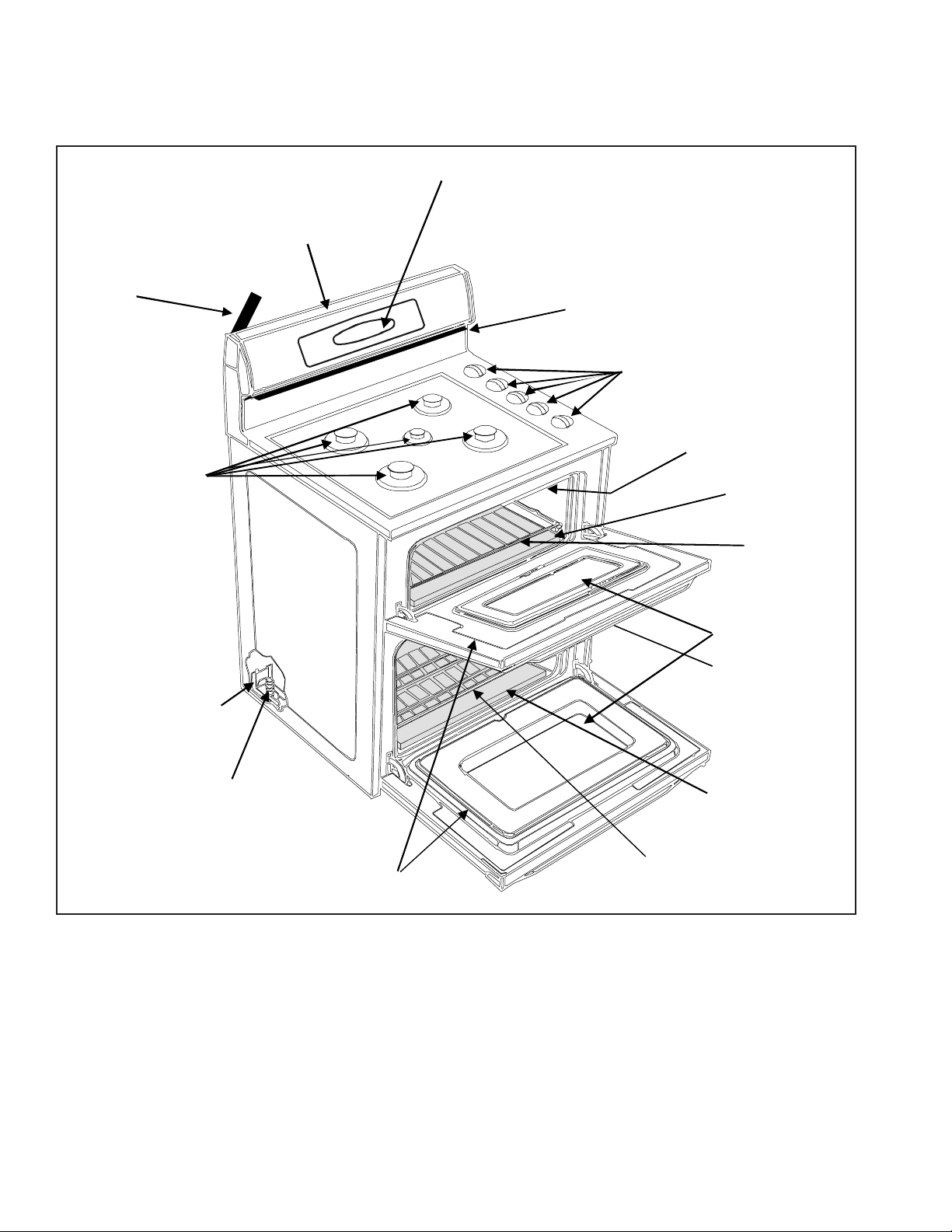

Range Description

Backguard

Data Plate

Surface Burners

Electronic Oven Control

Oven Vent

Surface Controls

Broiler

Bake Burner

Anti-Tip Bracket

Leveling Leg

Oven Rack

Oven Window

Broiler

Bake Burner

Oven Racks

Door Gasket

10 16023415 ©2004 Maytag Services

Page 11

Troubleshooting Procedures

!

To avoid risk of electrical shock, personal injury or death; disconnect power and gas to oven before servicing,

unless testing requires power and/or gas.

!

• Verify proper grounding before checking for trouble.

• Be careful of the high voltage circuit.

• Discharge the high voltage capacitor.

• When checking the continuity of the switches or of the high voltage transformer, disconnect one lead wire from

these parts and then check continuity with the AC plug removed. To do otherwise may result in a false reading

or damage to your meter.

• Do not touch any part of the circuit on the printed circuit board, since static electric discharge may damage the

control panel. Always touch yourself to ground while working on this panel to discharge any static charge built

up on your body.

WARNING

CAUTION

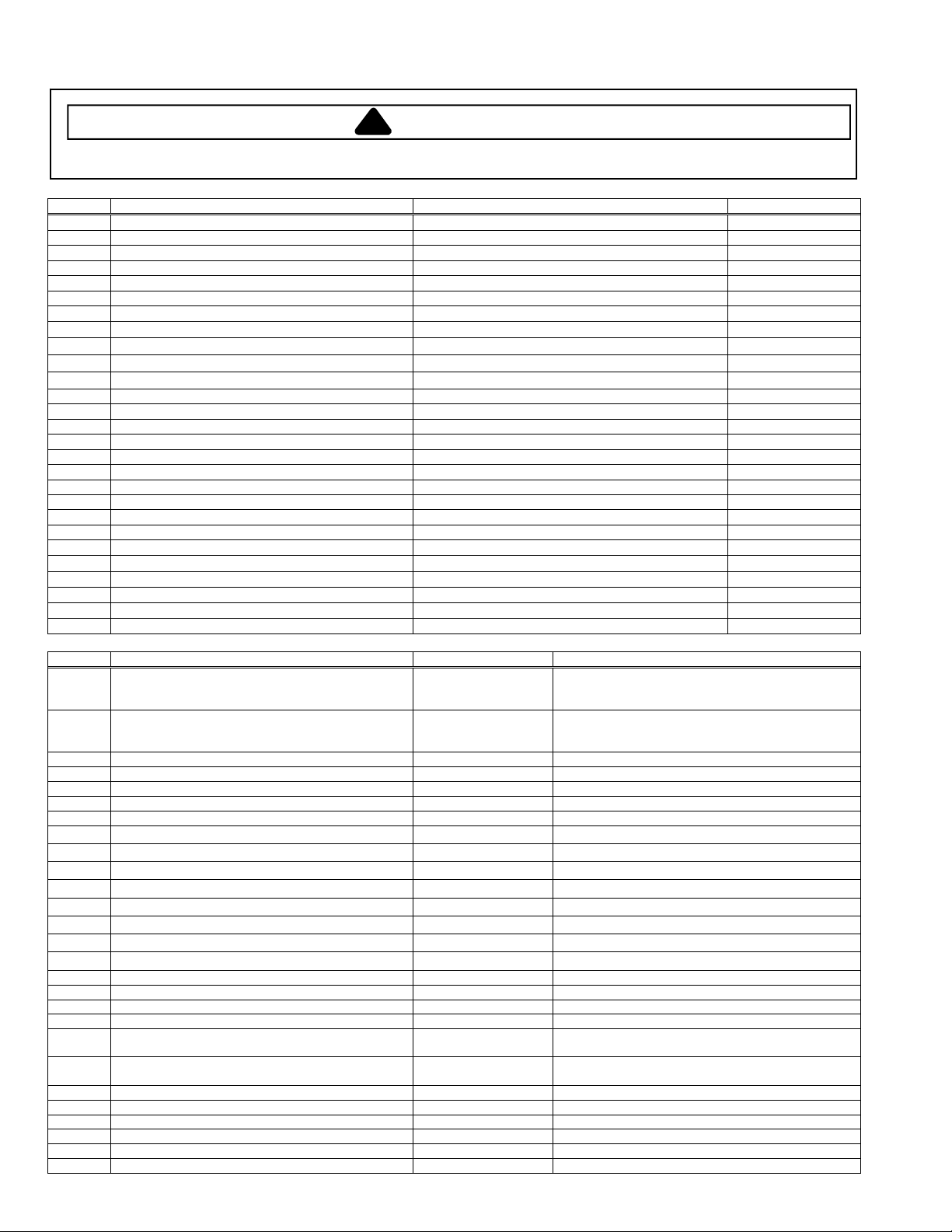

Control Systems Troubleshooting

Description of Error Codes

The Diagnostic Code Display Mode allows viewing of the error diagnostic codes.

Each error code consists of four digits. The following table describes the function of each digit.

Digit Description

Primary System: 1 – Local to the control circuit board

1st

2nd

3rd Secondary System: Sequential numbering

4th

3 – Sensor or meat probe

4 – Control input

9 – Door lock

Measurable: d – Diagnostic: measurable parameter

c – Control related, replace control

Oven Cavity: 1 – Upper oven (or single cavity oven)

2 – Lower oven

c – Control specific

Diagnostic Code Display Mode may be activated by pressing and holding the

power-up. Diagnostic Code Display Mode may be entered only when applying power to the control.

©2004 Maytag Services 16023415 11

AUTOSET

pad for 3 seconds at

Page 12

Troubleshooting Procedures

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power and gas to oven before servicing,

unless testing requires power and/or gas.

Diagnostic Code Checking

Code Description When Checked Detection

1c1c Shorted key Always 1 minute

1c2c Keyboard tail disconnected Always 1 minute

1c31 Cancel key circuit problem Always 20 seconds

1c32 Cancel key circuit problem Always 20 seconds

1c6c EEPROM error When accessing EEPROM 3 tries

1c7c Control not calibrated Always 3 tries

1c8c Cooking program error Cook or clean programmed 3 tries

1d11

1d12

1d21

1d22

Runaway temp (650°F), door unlocked

Runaway temp (650°F), door unlocked

Runaway temp (950°F), door locked

Runaway temp (950°F), door locked

Latch unlocked 1 minute

Latch unlocked 1 minute

Latch locked 1 minute

Latch locked 1 minute

3d11 Sensor open Cook or clean active 20 seconds

3d12 Sensor open Cook or clean active 20 seconds

3d21 Sensor shorted Cook or clean active 20 seconds

3d22 Sensor shorted Cook or clean active 20 seconds

4d11 Door switch position failure Clean or keyboard Lockout active 1 minute

4d12 Door switch position failure Clean or keyboard Lockout active 1 minute

4d21 No reverse airflow fan rotation (no/low RPM) Clean or Cook programmed 1 minute

4d31 Reverse airflow fan state (on when should be off) Suppose to be OFF 1 minute

4d51 Door switch circuit failure Convect, Clean or Keyboard Lockout programmed 1 minute

4d52 Door switch circuit failure Convect, Clean or Keyboard Lockout programmed 1 minute

9d11 Latch will not lock Latch should be locked

9d12 Latch will not lock Latch should be locked

9d21 Latch will not unlock Latch should be unlocked

9d22 Latch will not unlock Latch should be unlocked

9d31 Latch state unknown, both locked and unlocked Latch should be locked or when lock attempted

9d32 Latch state unknown, both locked and unlocked Latch should be locked or when lock attempted

See Note

See Note

See Note

See Note

See Note

See Note

6

6

6

6

6

6

Diagnostic Code Handling

Code Measurable What is Displayed Action Taken By Control

1c1c Keypress Nothing

1c2c Keyboard loop improper value Nothing

1c31

1c32

1c6c No response from EEPROM Nothing

1c7c Calibration value out of range “CAL” in the time digits

1c8c CRC invalid Nothing Cancels active cook function

1d11

1d12

1d21

1d22

3d11

3d12

3d21

3d22

4d11 Door switch not closed when door is locked

4d12 Door switch not closed when door is locked

4d21 No reverse airflow fan rotation (no/low RPM) Nothing Disables all cook function for cavity

4d31 Reverse airflow fan state (on when should be off) Nothing No action

4d51 Door switch not open or closed Nothing

4d52 Door switch not open or closed Nothing

9d11 Lock switch not closed

9d12 Lock switch not closed

9d21 Unlock switch not closed

9d22 Unlock switch not closed

9d31 Latch both locked and unlocked

9d32 Latch both locked and unlocked

Cancel key improper value

Cancel key improper value

Sensor resistance > 2237

Sensor resistance > 2237

Sensor resistance > 2787

Sensor resistance > 2787

Sensor resistance > Infinite

Sensor resistance > Infinite

Sensor resistance > 0

Sensor resistance > 0

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

BAKE flashes 3 Disables all outputs for cavity 1

BAKE flashes 3 Disables all outputs for cavity 1

BAKE flashes

BAKE flashes

BAKE flashes

BAKE flashes

BAKE flashes

BAKE flashes

BAKE flashes

BAKE flashes

Nothing Disables Clean and Lockout functions

Nothing Disables Clean and Lockout functions

LOCK flashes

LOCK flashes

LOCK flashes

LOCK flashes

LOCK flashes

LOCK flashes

Disables audible for affected key depression

Disables all outputs

Disables lights and timers

Disables audible for key depression

Disables all outputs 1

Disables lights and timers

Disables all outputs

Completely disables oven

3

Disables all cook function for cavity

3

Disables all cook function for cavity

3

Disables all cook function for cavity

3

Disables all cook function for cavity

3

Disables all cook function for cavity

3

Disables all cook function for cavity

3

Disables all cook function for cavity

3

Disables all cook function for cavity

Disables Convect, Clean, and Lockout functions

Turn off light and disable light from door switch

Disables Convect, Clean, and Lockout functions

Turn off light and disable light from door switch

3

Disables Clean and Lockout functions 4

3

Disables Clean and Lockout functions 4

3

Disables Clean and Lockout functions 4

3

Disables Clean and Lockout functions 4

3

Disables Clean and Lockout functions 4

3

Disables Clean and Lockout functions 4

1, 2

1

4

5

5

4, 5

4, 5

12 16023415 ©2004 Maytag Services

Page 13

Troubleshooting Procedures

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power and gas to oven before servicing,

unless testing requires power and/or gas.

NOTES:

1

“Action Taken” applies as long as the condition exists. If the condition goes away, the control recovers.

2

If there is a cook function or timer active, the function continues. The user cannot edit the function, and [Cancel] will cancel the cook

mode.

3

Flash rate: 0.2 seconds on, 0.1 second off. Pressing any key will clear the display until the fault clears and is re-triggered.

4

“Action Taken” applies until there is a POR (Power On Reset [“hard reset”]).

5

If the control believes the door is locked, it will attempt to unlock it when the function cancels and the cavity temperature cools.

6

Special conditions for latch faults (9dxx):

• A known good unlock position is defined as when the unlock switch reads closed and lock switch reads open.

• A known good lock position is defined as when the unlock switch reads open and lock switch reads closed.

• A faulted switch means the switch input is reading an invalid state, neither open nor closed.

• Once a latch fault occurs, latch movement is disabled until there is a POR. An error tone will sound if a function requiring a

faulted latch is attempted.

• If at POR, the latch is not at a known good unlock position:

• If the latch is at a good lock position, it will attempt to unlock when the RTD (Resistance Temperature Device)

temperature is below 400°F.

• If the latch is not at a good lock position, the control will fault.

• If a latch fault occurs while the RTD is above the lock temperature, the latch will not try to move, but the fault is still logged

to EEPROM after the first stage of detection.

• The Display column for latch faults applies 1) If the latch was moving when the fault occurred; 2) If the latch is already in a

known locked state when the fault occurs.

• LOCK flashes after a fault is detected and until the unlocked position is achieved. The unlock position may be

identified by a successful unlock switch closure, or as the result of timing when the unlock switch is not

functioning properly.

• If the last known good position was unlock (e.g. baking, or idle) and a latch fault occurs, the motor is never moved. The

fault is logged to EEPROM and is not seen by the user.

• Latch fault detection is in two stages. The first stage is to allow the control to recover without moving the latch. After this:

• If the latch was previously at a known good unlock position, the latch will not move and the control will fault.

• If the control was previously in a known good lock position:

• If the RTD is below 400°F, the latch will attempt to recover to it’s proper position (up to three

revolutions). If it cannot, the control will fault and the latch will move to a calculated unlock position.

• If the RTD is at or above 400°F, the control will fault. When the RTD cools to below 400°F, the control

will attempt to recover to a good unlock position (up to three revolution). If it cannot, the control will fault

and the latch will move to a calculated unlock position.

• Note: If the unlock position cannot be found, this may result in a second fault, the first fault occurring

when the latch request was locked, and the second when the latch request is unlocked.

• If the latch is moving when the fault occurs, the control will bypass the first stage of detection and immediately try

to find it’s proper position. If it cannot, the control will fault and the latch will move to a calculated unlock position.

• Affected DLBs (Double Line Breaks) and loads are disabled during detection.

• If the control is in a known good unlock position and the lock switch becomes faulted:

• The control will not fault.

• If a function requiring latch movement is attempted while the lock switch is faulted, the control will sound an error

tone and the function will be disabled.

• If the control is in a known good lock position and the unlock switch becomes faulted:

• The control will not fault.

• After the function is canceled and unlock is attempted, the control will attempt to unlock the latch according to

the procedures in these notes.

©2004 Maytag Services 16023415 13

Page 14

Troubleshooting Procedures

!

To avoid risk of electrical shock, personal injury or death; disconnect power and gas to oven before servicing,

unless testing requires power and/or gas.

WARNING

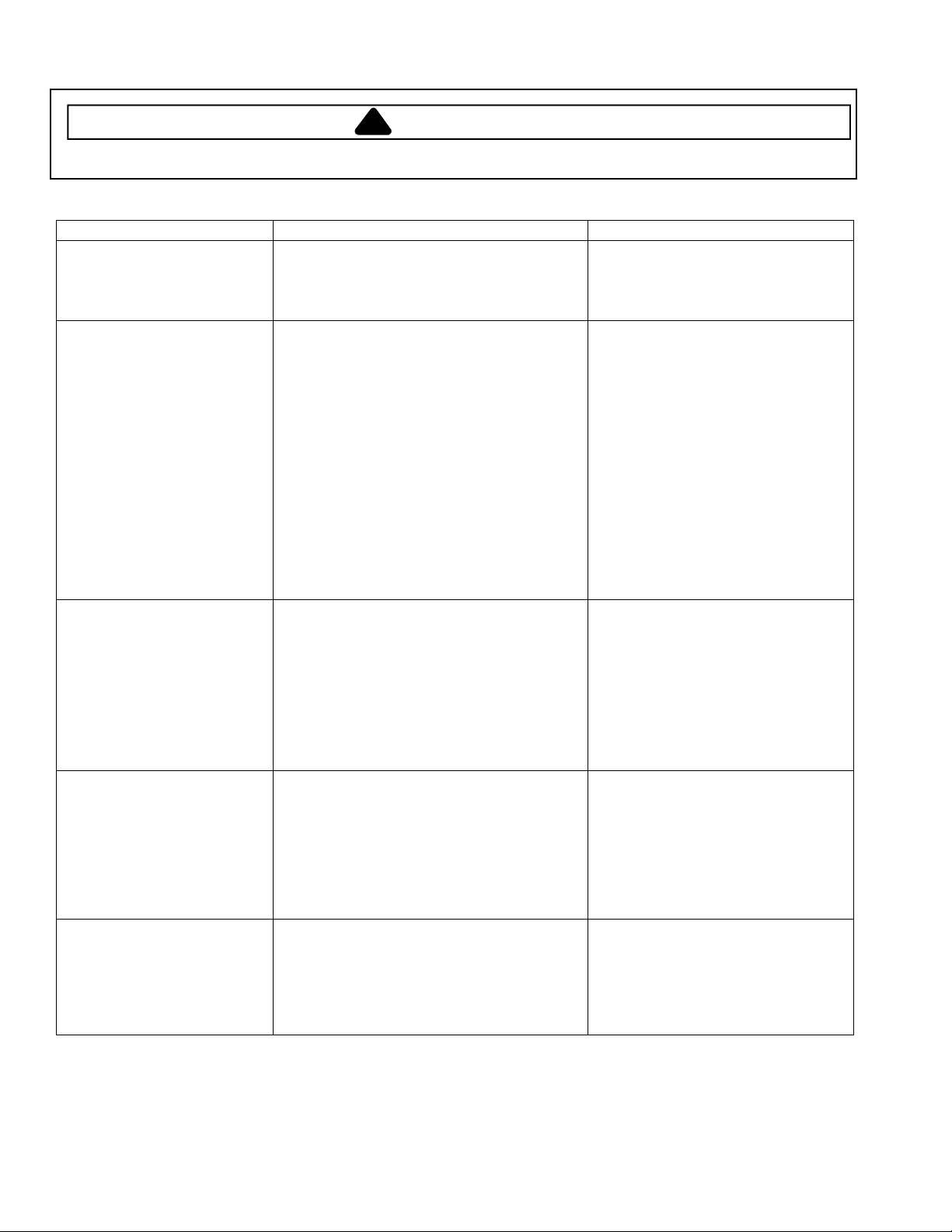

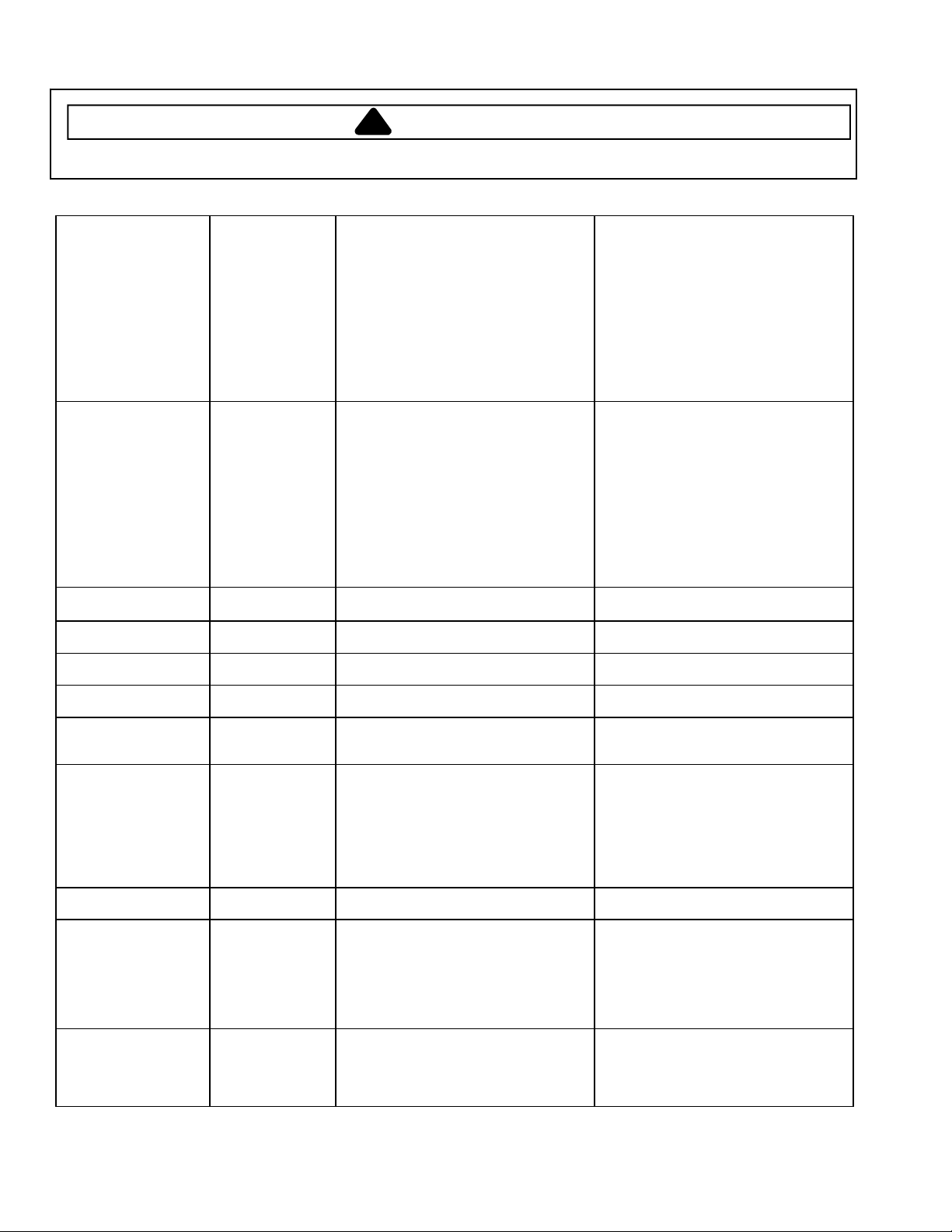

Component Troubleshooting

Problem Possible Cause Correction

Burners will not ignite; no

spark at top burner.

Burner will not ignite. No

spark to burner ignitors when

burner knob is rotated to

“LITE” position.

No spark or only random

spark at one ignitor.

Unit continues to spark after

knob is turned to OFF

position.

No oven operation in bake or

broil.

Poor ground on burner cap..........................

Weak or failed spark module.......................

Low gas pressure ........................................

No 120 VAC to range ..................................

Micro switch contacts not closing ................

Faulty wiring. Bad connection at burner

electrode and electrode socket ...................

Inoperative spark module ............................

Electrode dirty. Burner cap dirty ..................

Cracked or broken electrode, electrode

wire or electrode socket...............................

Check for cracked ignitor or pinched ignitor

wire .............................................................

Poor continuity to burner cap.......................

Bad ground connection or lack of continuity

to ground or ignitor ......................................

Cracked or broken ignitor extension lead....

Shorted valve switch/harness......................

Switch has slipped off the valve ..................

No voltage to control....................................

No voltage from control ...............................

Loose wire connection or broken wire .........

• Clean burner cap.

• Replace spark module.

• Verify pressure 4” WCP for

natural, 10” WCP for LP.

• Verify voltage at wall outlet.

• Check wiring against appropriate

wiring diagram. Verify all

terminals and connections are

correct and tight. Check micro

switch contacts.

• Check wiring against appropriate

wiring diagram. Verify all

terminals and connections are

correct and tight.

• Check module according to

testing procedures information.

• Clean electrode or burner cap.

• Replace electrode.

• Replace ignitor lead or electrode.

• Clean burner cap and lead.

• Tighten ground connection and

correct any breaks in ground path

from ignitor path to unit ground

path.

• Replace ignitor lead.

• Replace switch/harness. If

shorting is caused by excessive

spillovers, customer education is

advised.

• Carefully reposition switch on

valve and rotate from OFF to

high, several times to verify

switch is not broken.

• Check for 120 VAC at control. If

no voltage check power source.

• Check 120 VAC to ignitor, if no

voltage, replace control.

• Verify all connections are clean

and tight, replace broken wire.

14 16023415 ©2004 Maytag Services

Page 15

Troubleshooting Procedures

!

To avoid risk of electrical shock, personal injury or death; disconnect power and gas to oven before servicing,

unless testing requires power and/or gas.

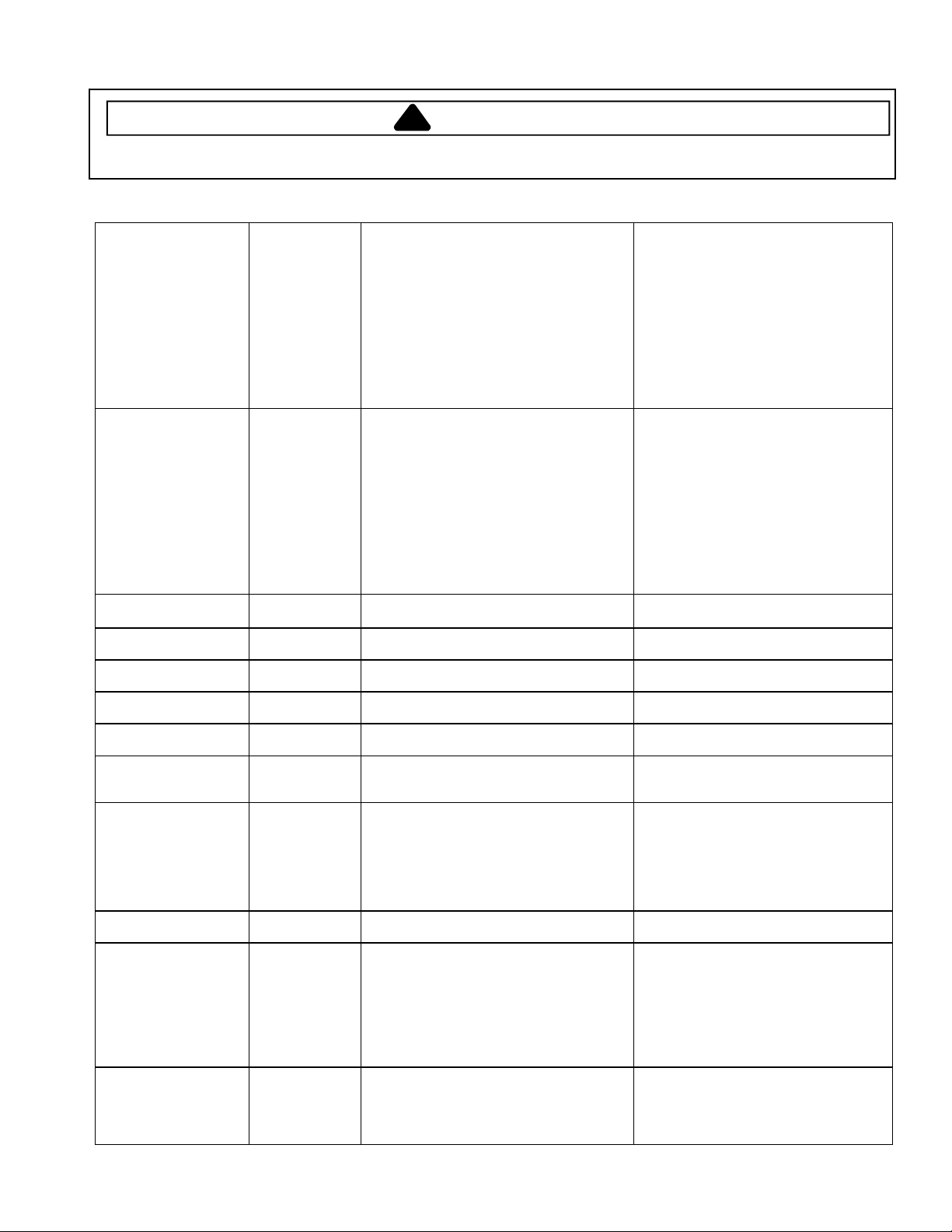

Problem Possible Cause Correction

Failed ignitor. ...............................................

Gas pressure too high .................................

No gas flows to burner.

Ignitor glows red.

Gas flows to bake/broil

burner, but burner does not

light.

Broil burner shuts off shortly

after the start of self-clean

operation. Bake and broil

functions operate normally.

Fan motor does not operate.

Failed gas valve...........................................

Loose wire connection or broken wire .........

Ignitor positioned too far from burner ..........

Dirt or grease in orifice or burner.................

Insufficient gas pressure .............................

Power outage ..............................................

Power outage ..............................................

Control Error................................................

No power to fan motor.................................

Failed fan motor or winding/frozen shaft .....

WARNING

• Check ignitor current draw, 3.2 –

3.6 Amps. Replace ignitor, if it

fails test.

• Check for correct gas pressure.

Natural gas pressure should be 4"

WCP and LP gas pressure should

be 10" WCP.

• Check gas valve for continuity.

• Verify all connections are clean

and tight, replace broken wire.

• Reposition ignitor closer to

bake/broil burner.

• Clean orifice or burner.

• Check for correct gas pressure.

Natural gas pressure should be 5"

WCP and LP gas pressure should

be 10" WCP.

• Verify power is present at unit.

Verify that the circuit breaker is

not tripped.

• Replace household fuse, but do

not fuse capacity.

• Verify power is present at unit.

Verify that the circuit breaker is

not tripped.

• Replace household fuse, but do

not fuse capacity.

• See “Control Systems

Troubleshooting.”

• Check for 120 VAC supplied at

fan motor. If no voltage is

present, check for broken or

loose wiring between fan motor

and relay board. If voltage is

present at fan motor, go to the

next step.

• Check motor winding for

continuity. Check for a frozen

motor shaft. Check for broken

wiring between motor and neutral

terminal block.

©2004 Maytag Services 16023415 15

Page 16

Troubleshooting Procedures

.

.

.

.

.

.

.

.

.

.

.

.

.

!

To avoid risk of electrical shock, personal injury or death; disconnect power and gas to oven before servicing,

unless testing requires power and/or gas.

Problem Possible Cause Correction

Failed oven lamp ....................................

Failed wiring............................................

Oven light does not operate.

Self-clean cycle not working

Oven door will not unlock

Oven smokes/odor first few

times of usage

Failure Codes

Part or all of the appliance

does not work

Failed light socket...................................

Failed light plunger/switch ......................

Programming error .................................

Oven is self-cleaning ..............................

Oven is still hot .......................................

Normal ....................................................

Electronically Controlled .........................

Power Outage.........................................

Improperly set oven controls ..................

Oven door locked ...................................

Delayed cooking/cleaning.......................

WARNING

• Check lamp and replace is necessary.

• Check for broken, loose or dirty

connections.

• Check light socket for continuity.

• Check plunger/switch for continuity.

Check wiring diagram for application.

• Shut off power to oven for five

minutes by switching off circuit

breaker. Reset circuit breaker and try

oven again.

• Allow cycle to complete.

• Door will not unlock until unit has

cooled to safe temperature. Do not

force door open, this will void

warranty. Blow cool air on door latch

area to quicken process.

• Minor smoking and/or odor is normal

the first few times of oven usage.

• Ventilate area well and perform selfclean cycle.

• See Testing Procedures for

diagnostic checks.

• Check power supply/circuit breaker

• Verify oven controls are properly set

• Verify oven door is unlocked after a

self-clean cycle

• Verify oven is not set for delayed

cooking or cleaning program

16 16023415 ©2004 Maytag Services

Page 17

Testing Procedures

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power and gas to oven before servicing,

unless testing requires power and/or gas.

Component Testing

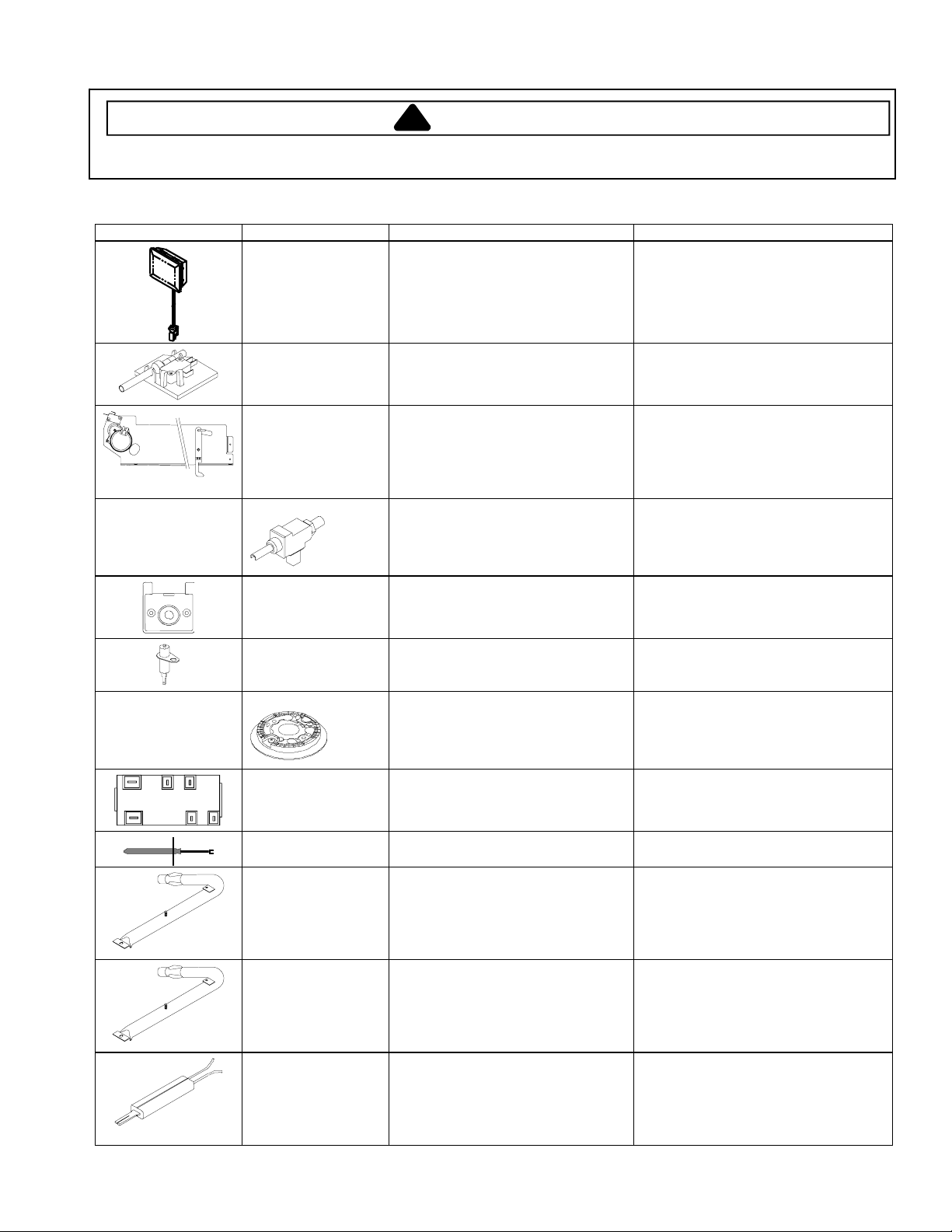

Illustration Component Test Procedure Results

5 K btu

9.2 K btu

16 K btu

12 K btu (Model

MGR6875AD*)

5 K btu

9.2 K btu

16 K btu

12 K btu (Model

MGR6875AD*)

L

AB

A1

Oven light housing Disconnect connector and test

resistance of terminals.........................

Measure voltage at oven light: .............

Door plunger switch Remove switch from unit and measure

the following points:

C NO ................................................

Autolatch assembly

with switch

Disconnect wires and test for

continuity per wiring diagram.

Refer to Parts Manual for correct

autolatch switch associated with the

correct manufacturing number.

270° valve

Verify gas is supplied.

Adjust set screw for simmer control.

Spark 270° switch

Test for voltage at terminals.................

Disconnect wiring and check for

Spark ignition

electrode

continuity in LITE position....................

Test for resistance of spark lead..........

Test ignitor to chassis ..........................

Top surface burner

Verify gas is supplied ...........................

Verify burner cap is positioned

correctly.

Spark module 4 + 0 Test for voltage at terminals L and N ...

B1N

Check polarity and ground ...................

Temperature sensor Measure resistances............................

Bake burner Verify gas is supplied.

Orifice adjusted for Natural or LP.........

Check for obstructions or

contamination in ports..........................

Broil burner Verify gas is supplied.

Orifice adjusted for Natural or LP.........

Check for obstructions or

contamination in ports..........................

Ignitor Test for voltage at terminals.................

Test for the amount of amperage in the

circuit ...................................................

(Ignitor may glow but not have

sufficient amperage to open valve).

Verify bulb is properly installed.

Indicates continuity with bulb installed.

120 VAC, refer to wiring diagram for

terminal identification. If no voltage is

present at light, check wiring/switches.

Plunger in continuity, Plunger out infinite.

See wiring diagram for schematic layout.

Access assembly by removing left side

panel.

120 VAC

Continuity in LITE position.

Continuity

No continuity from ignitor to chassis.

Check for obstructions in burner ports.

120 VAC

See wiring diagram

Approximately 1100 Ω at room

temperature 75°F.

Set for Natural Gas from the factory

Adjust as necessary.

Replace if punctured or torn.

Set for Natural Gas from the factory

Adjust as necessary.

Replace if punctured or torn.

120 VAC

3.2 − 3.6 Amps If not replace.

©2004 Maytag Services 16023415 17

Page 18

Testing Procedures

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power and gas to oven before servicing,

unless testing requires power and/or gas.

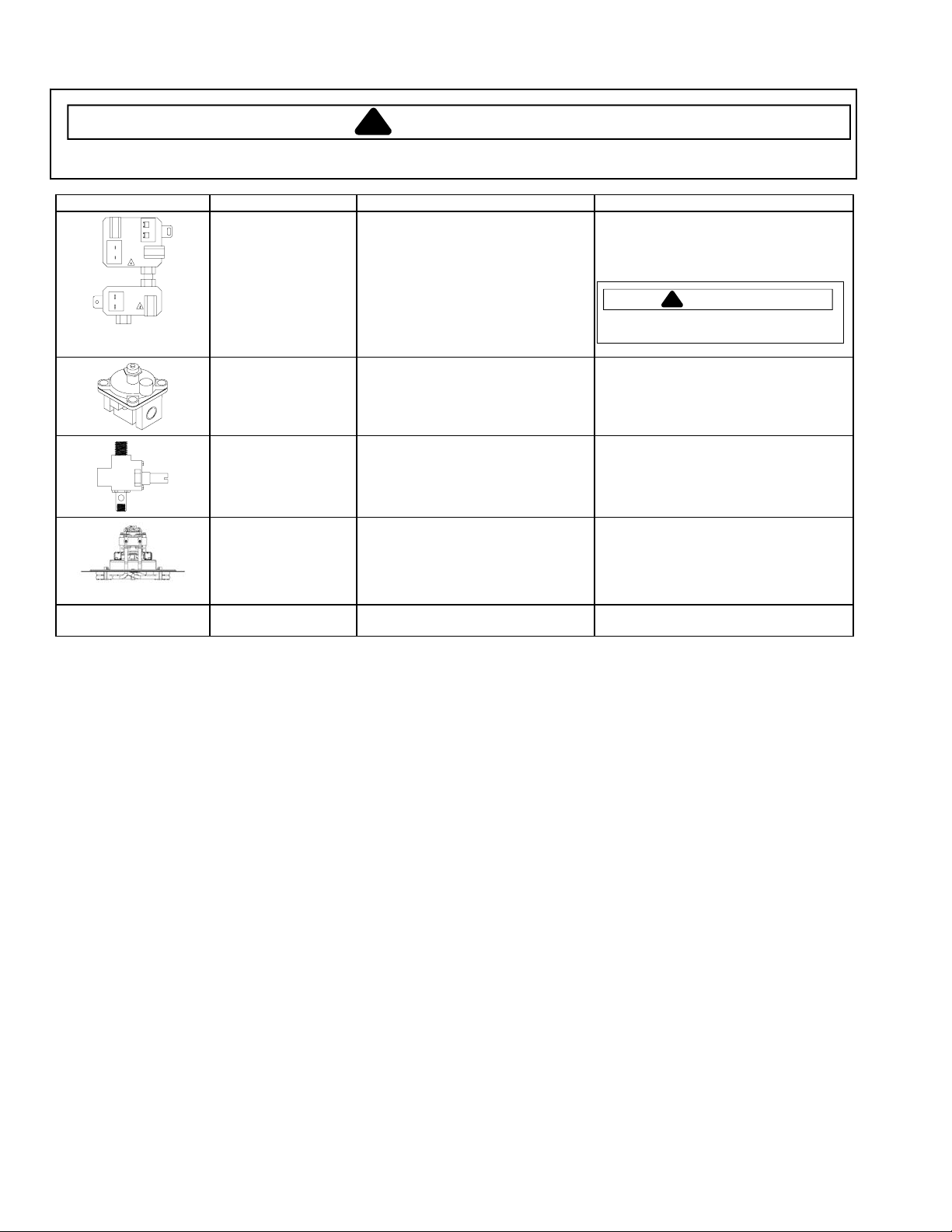

Illustration Component Test Procedure Results

Model MGR6875AD*

Power cord 3-wire Verify resistance of wires to

Triple thermal valve Disconnect wiring to valve.

Pressure regulator Verify gas pressure (W.C.P.).

Shut off valve Check to verify gas supply is turned

Convection Assembly

Convection Element

Convection Motor

Measure resistance on upper and

lower bake circuit.................................

Measure resistance on broil circuit......

If on LP service verify proper gas

supply conversion.

on.

Located on surface valve manifold

near maintop upsweep.

Measure voltage..................................

Remove wires, check resistance.........

Check motor windings to ground .........

terminals.

Continuity, If not replace.

Continuity, If not replace.

WAR NI NG

!

Do not attempt to open valve with

120 VAC.

5" Natural

10" LP/propane

Gas ON .... slot at 9 o’clock position

Gas OFF... slot at 12 o’clock position

120 VAC.

Approximately 28 to 33 Ω.

No continuity.

Approx. 900 RPM.

Continuity

18 16023415 ©2004 Maytag Services

Page 19

Testing Procedures

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power and gas to oven before servicing,

unless testing requires power and/or gas.

Illustration/Component Test Procedure Results

Control Panel Assembly

Model MGR6875AD*

Continuity is indicated as follows:

1000 – 6600 Ω for Cancel pad

1000 – 10000 Ω for All other pads

Pad

1

2

3

4

5

6

7

8

9

0

Lower Cancel

Upper Cancel

Conv Bake

Delay

Clock

Favorite

Lower Clean

Upper Clean

Lower Bake

Lower Light

Upper Keep Warm

Upper Light

Autoset

Lower Keep Warm

Conv Roast

Upper Bake

Timer 2

Cook & Hold

Upper Broil

Timer 1

Trace

14 & 16

17 & 16

16 & 8

7 & 6

8 & 17

7 & 14

6 & 15

5 & 14

6 & 14

8 & 14

1 & 2

11 & 12

4 & 15

5 & 6

5 & 16

5 & 7

5 & 15

7 & 16

8 & 15

7 & 15

7 & 17

15 & 16

14 & 17

8 & 16

5 & 4

4 & 14

4 & 7

6 & 16

14 & 15

4 & 16

Measurement

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Model MGR6775AD* Membrane and Overlay

©2004 Maytag Services 16023415 19

Page 20

Testing Procedures

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power and gas to oven before servicing,

unless testing requires power and/or gas.

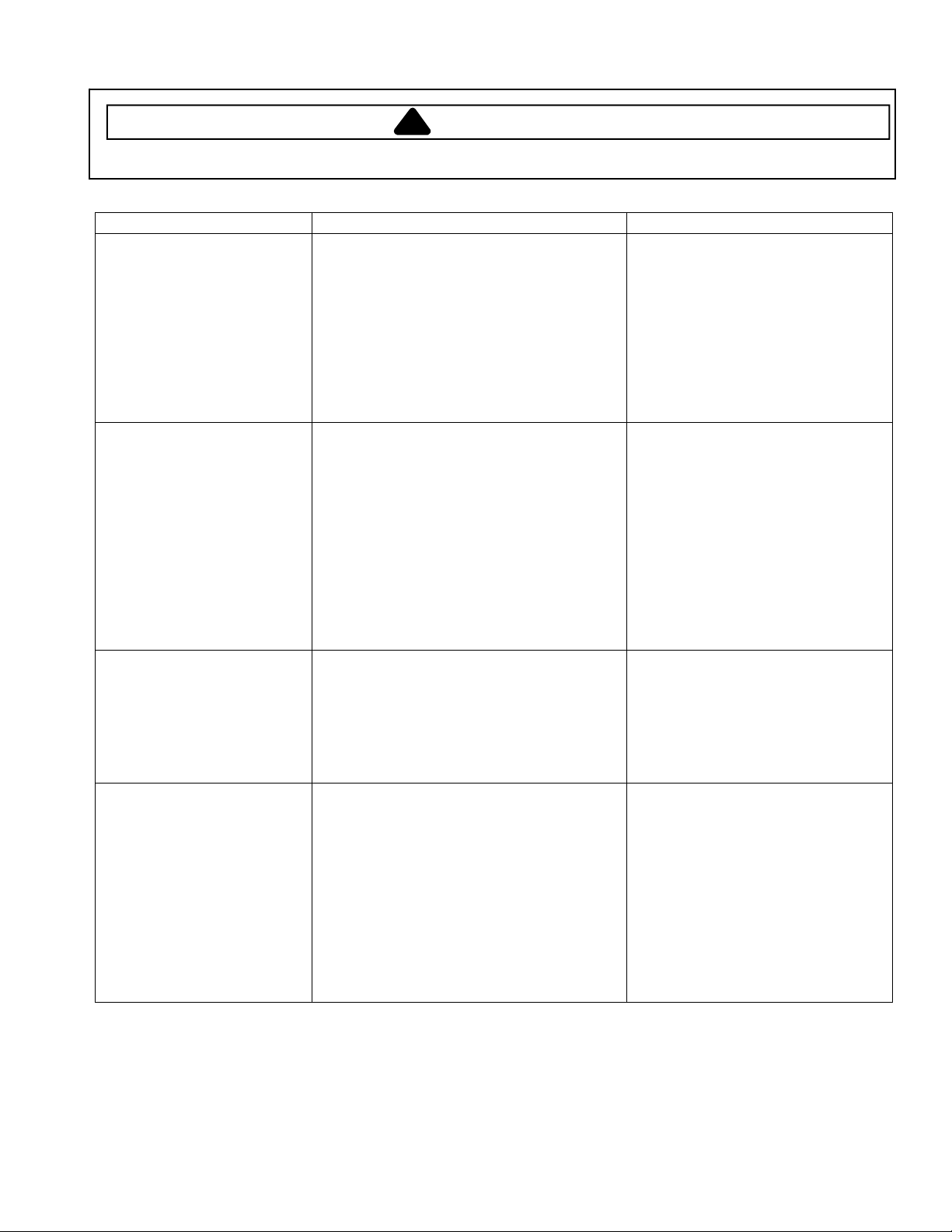

H2 Control Testing (Model MGR6875AA*)

H2 Controlled

Model MGR6875AD*

H2 Controlled

Model MGR6875AD*

H2 Controlled

Model MGR6875AD*

H2 Controlled

Model MGR6875AD*

H2 Controlled

Model MGR6875AD*

H2 Controlled

Model MGR6875AD*

H2 Controlled

Model MGR6875AD*

H2 Controlled

Model MGR6875AD*

H2 Controlled

Model MGR6875AD*

H2 Controlled

Model MGR6875AD*

H2 Controlled

Model MGR6875AD*

Oven temperature

adjustment

(Upper Oven)

Oven temperature

adjustment

(Lower Oven)

Temperature

display

Clock Display

24 Hour Clock

Factory Default

Twelve hour off Control will automatically cancel any

Sabbath Mode

Beeper Volume

Child lock out

Diagnostic Code

Display

Press

Upper Bake

Enter

550

Immediately press and hold

pad for 3 seconds.

Adjust oven from -35° to +35° (-37.2° to

+ 1.6° C) in 5° F (2.7° C) increments by

pressing

adjusting the oven, move temperature 5°

F (2.7° C) each time. W ait 4 seconds for

the data entry timer to expire to accept

the change. Temperature adjustment is

retained even through a power failure.

Press

Enter

Immediately press and hold

pad for 3 seconds.

Adjust oven from -35° to +35° (-37.2° to

+ 1.6° C) in 5° F (2.7° C) increments by

pressing

adjusting the oven, move temperature 5°

F (2.7° C) each time. W ait 4 seconds for

the data entry timer to expire to accept

the change. Temperature adjustment is

retained even through a power failure.

Press and hold

Upper Bake

Press and hold

Clock

Press and hold

Favorite

Press and hold

Upper Keep Warm

cooking operation and remove all relay

drives 12 hours after the last pad touch.

Hold

activate Sabbath mode.

Hold

disable Sabbath mode.

Hold

3 seconds to adjust beeper loudness.

Press and hold

& Hold

display where the temperature normally

appears. “LOCK” will display flashing

while door is locking.

To reactivate the control, press and hold

Cancel

Press and hold

Autoset

See “Quick Test Mode.”

Cycle through the codes using the

number pads 1 through 5.

on the digit-pad.

Autoset

Lower Bake

550

on the digit-pad.

Autoset

pads for 3 seconds.

pads for 3 seconds.

Clock

pad for 3 to 5 seconds to

Clock

pad for 3 to 5 seconds to

Upper Cancel

pads for 3 seconds. “OFF” will

and

pads for 3 seconds.

pad.

Upper Bake

pad. To avoid over

pad.

Lower Bake

pad. To avoid over

Upper Cancel

pads for 3 seconds.

Upper Cancel

Upper Cancel

Upper Cancel

pads for 3 seconds.

and

Upper Cancel

Cook & Hold

Upper Cancel

and

and

and

and

Delay

and

for 3 seconds.

and

pads for

Cook

While increasing or decreasing oven

temperature, this does not affect selfcleaning temperature.

While increasing or decreasing oven

temperature, this does not affect selfcleaning temperature.

This mode enables the user to indicate

°F or °C on the display.

Allows clock to be toggled On or OFF.

Allows the time on the clock to be

toggled from 12 hour or 24 hour display.

Allows the clock to be reset to factory

settings.

See Sabbath mode to disable.

“SAbbAth” will display for 5 seconds,

then change to “SAb” (displayed in Temp

area).

All pad inputs are disabled except for

CANCEL and CLOCK pads.

This mode disables the normal 12 hour

shutoff to allow operation of the bake

mode for a maximum of 72 hours.

Volume settings are Low, Medium and

High.

This is a safety feature that can be used

to prevent children from accidentally

programming the oven. It disables the

electronic oven control.

Child lockout features must be reset after

a power failure.

The last 5 diagnostic codes will be stored

in the non-volatile memory.

See “Description of Error Codes” for

explanation.

16023415 ©2004 Maytag Services

20

Page 21

Testing Procedures

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power and gas to oven before servicing,

unless testing requires power and/or gas.

H3 Control Testing (Model MGR6775AA*)

H3 Controlled

Model MGR6775AD*

H3 Controlled

Model MGR6775AD*

H3 Controlled

Model MGR6775AD*

H3 Controlled

Model MGR6775AD*

H3 Controlled

Model MGR6775AD*

H3 Controlled

Model MGR6775AD*

H3 Controlled

Model MGR6775AD*

H3 Controlled

Model MGR6775AD*

H3 Controlled

Model MGR6775AD*

H3 Controlled

Model MGR6775AD*

H3 Controlled

Model MGR6775AD*

H3 Controlled

Model MGR6775AD*

Oven

temperature

adjustment

(Upper Oven)

Oven

temperature

adjustment

(Lower Oven)

Temperature

display

Factory Default

Clock Display

24 Hour Clock

Demo

Twelve hour off Control will automatically cancel any

Sabbath Mode

Beeper Volume

Child lock out

Diagnostic

Code Display

Press

Upper Bake

Enter

550

Immediately press and hold

pad for 3 seconds.

Adjust oven from -35° to +35° (-37.2° to +

1.6° C) in 5° F (2.7° C) increments by

pressing

over adjusting the oven, move temperature

5° F (2.7° C) each time. W ait 4 seconds

for the data entry timer to expire to accept

the change. Temperature adjustment is

retained even through a power failure.

Press

Enter

Immediately press and hold

pad for 3 seconds.

Adjust oven from -35° to +35° (-37.2° to +

1.6° C) in 5° F (2.7° C) increments by

pressing

over adjusting the oven, move temperature

5° F (2.7° C) each time. W ait 4 seconds

for the data entry timer to expire to accept

the change. Temperature adjustment is

retained even through a power failure.

Press and hold

Bake

Press and hold

pads for 3 seconds.

Press and hold

pads for 3 seconds.

Press and hold

pads for 3 seconds.

Press and hold

pads for 3 seconds.

cooking operation and remove all relay

drives 12 hours after the last pad touch.

Hold

Sabbath mode.

Hold

Sabbath mode.

Oven must be in BAKE mode before

enabling SABBATH.

Hold

seconds to adjust beeper loudness level.

Press and hold

Hold

display where the temperature normally

appears. “LOCK” will display flashing while

door is locking.

To reactivate the control, press and hold

Cancel

seconds.

Press and hold

for 3 seconds within 5 minutes of power up.

See “Quick Test Mode.”

Cycle through the codes.

on the digit-pad.

More+ or Less-

Lower Bake

550

on the digit-pad.

More+ or Less-

pads for 3 seconds.

Clock

pad for 5 seconds to activate

Clock

pad for 5 seconds to disable

Upper Cancel

pads for 3 seconds. “OFF” will

and

pad.

pad.

Upper Cancel

Upper Cancel

Upper Cancel

Upper Cancel

Upper Cancel

and

Upper Cancel

Cook & Hold

Upper Cancel

Upper Bake

pads. To avoid

Lower Bake

pads. To avoid

and

and

and

and

and

More+

pads for 3

and

pads for 3

and

Upper

Warm

Clock

Delay

Less -

Cook &

Timer

While increasing or decreasing oven

temperature, this does not affect selfcleaning temperature.

While increasing or decreasing oven

temperature, this does not affect selfcleaning temperature.

This mode enables the user to indicate

°F or °C on the display.

Allows the clock to be reset to factory

settings.

Allows clock to be toggled On or OFF.

Allows the time on the clock to be

toggled from 12 hour or 24 hour display.

Enters a demonstrative sales mode.

See Sabbath mode to disable.

“SAb” displays and flashes for 5

seconds.

All pad inputs are disabled except for

CANCEL and CLOCK pads.

This mode disables the normal 12 hour

shutoff to allow operation of the bake

mode for a maximum of 72 hours.

Volume settings are Low, Medium and

High.

This is a safety feature that can be used

to prevent children from accidentally

programming the oven. It disables the

electronic oven control.

Child lockout features must be reset after

a power failure.

The last 5 diagnostic codes will be stored

in the non-volatile memory.

See “Description of Error Codes” for

explanation.

©2004 Maytag Services 16023415 21

Page 22

Testing Procedures

!

To avoid risk of electrical shock, personal injury or death; disconnect power and gas to oven before servicing,

unless testing requires power and/or gas.

WARNING

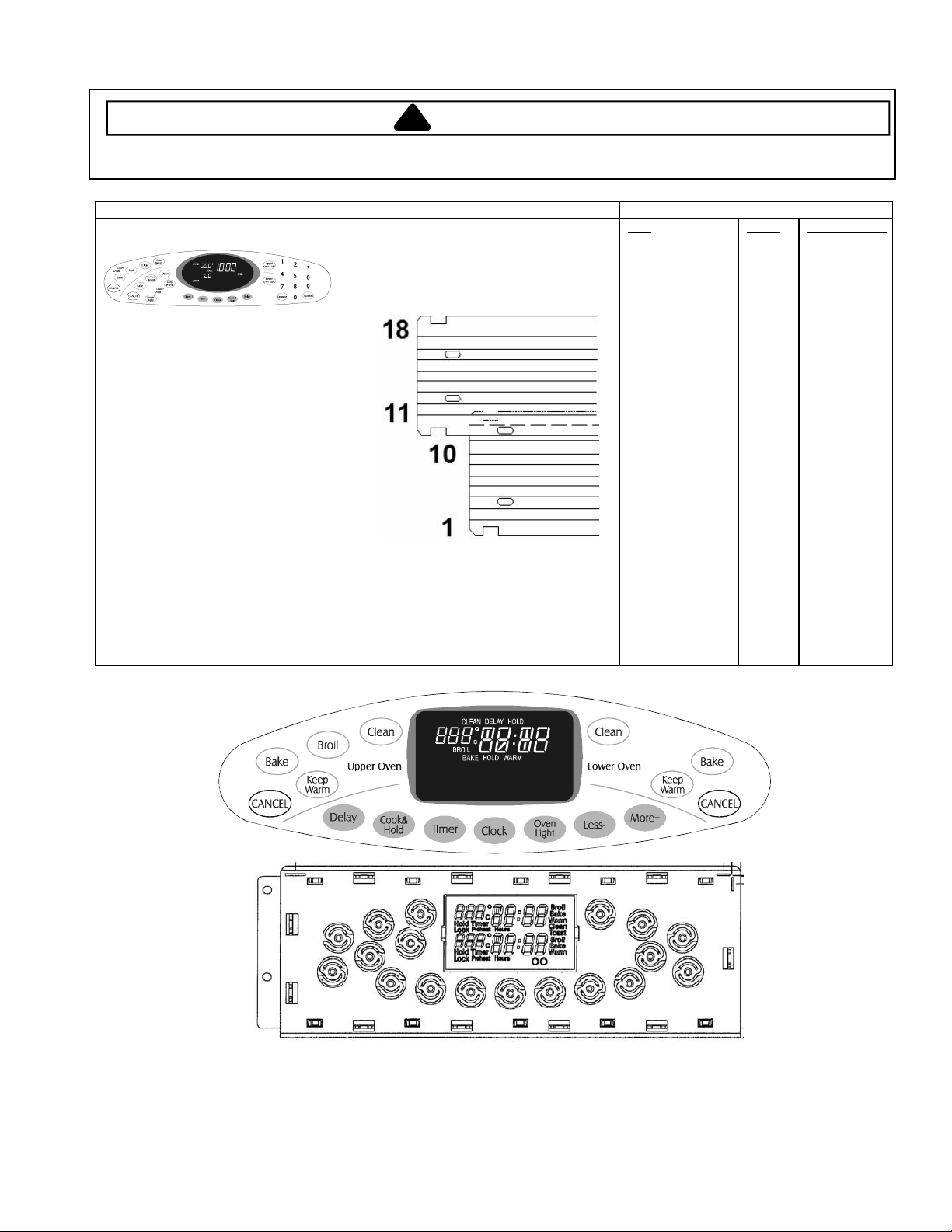

“Quick Test” Mode for Electronic Range Control

Follow the procedure below to perform the Electronic Range Control (ERC) quick test. Instructions must be entered

within 32 seconds of each other (via the touch pad) or the ERC will exit the quick test.

1. Press and hold the

2. Once the control has entered the “Quick Test” mode, release both pads.

3. Press each of the following pads indicated in the table below.

NOTE: Press the applicable pad once to activate the associated response.

Press the applicable pad a second time to deactivate the associated response.

UPPER CANCEL

Display will indicate the following:

Pad Response

BAKE ................................... Bake DLB and Bake relay activated

BROIL.................................. Broil DLB and Broil relay activated

KEEP WARM ...................... Bake DLB and Broil DLB activated

CONVECT BAKE ................ Convection Fan on low speed

CONVECT ROAST ............. Convection Fan on high speed

CLEAN................................. MDL relay activated

COOK & HOLD.................... Displays last diagnostic code

FAVORITE........................... Displays EEPROM version number

TIMER ................................. Displays main code version number

CLOCK ................................ All display segments illuminated

OVEN LIGHT....................... Oven light activated

CANCEL .............................. Exit Quick Test mode

1........................................... Even segments on

2........................................... Odd segments on

3........................................... Convection Ring activated; Convection Ring DLB activated

4........................................... N/A

5........................................... N/A

6........................................... N/A

7........................................... N/A

8........................................... N/A

9........................................... N/A

AUTOSET............................ Steps through last 5 diagnostic codes

and

BROIL

pads for 3 seconds.

Setup Options (0)

displayed the

Control

Function

12 hour shut-off 1 12 HR Energy Saver ON 12 HR Energy Saver OFF

Timer beeps 2 Timer Reminder Beeps for 5 Min. Timer Reminder Beeps for 30 Min.

Cook time beeps 3 Cook Time Reminder Beeps for 30 Min. Cook Time Reminder Beeps for 5 Min.

Control lock 4 Control Unlocked Control Locked

Scroll speed 5 Medium Speed Fast Speed Slow Speed

Volume level 6 6 bars 1 to 8 bars

Temp C/F 7 Degrees F Degrees C

Language 8 English French, Spanish

Default 9 Press AUTO SET for Factory Settings N/A

Display On/Off Clock Clock Display is ON Clock Display is OFF

16023415 ©2004 Maytag Services

22

pad is pressed “Press Desired Pad for Selection” will scroll in the display. When a feature is

AUTO SET

pad is used to toggle the options. Use the chart below to identify the available options.

Pad

Selection

Default Option Additional Options

No Timer Reminder Beeps

No Cook Time Reminder Beeps

Page 23

Testing Procedures

.

.

.

.

.

.

.

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power and gas to oven before servicing,

unless testing requires power and/or gas.

Component Test Procedure Results

Electronic

range control

Engineering

Test Mode

Fault codes

accessed

through

Engineering

Test Mode

Test Mode

Oven

temperature

adjustment

F1−1 –Upper Oven >650°F with door unlocked ............................

F1−2 –Lower Oven >650°F with door unlocked ............................

F1−3 –Upper Oven >950°F with door locked................................

F1−4 –Lower Oven >950°F with door locked................................

F1−7 –Membrane switch is not responding ..................................

F3−1 –Upper sensor is shorted at (< 100 Ω) or

open at (>5 K Ω) ..............................................................

F3−2 –Lower sensor is shorted at (< 100 Ω) or

open at (>5 K Ω) ..............................................................

Press

BAKE

Enter 100°F using the number pads.

Immediately push and hold

approximately 3 seconds.

This mode can also be entered by pressing the hidden pad

for 3 second located to the left of the lower oven light pad.

F0−0 –No fault.................................................................

F1−5 –Upper hardware failure within control....................

F1−6 –Lower hardware failure within control....................

F1−8 –Shorted key in membrane switch..........................

F1−9 –Internal communication errors within control.........

F1−A –Upper latch switches............................................

F1−B –Lower latch switches............................................

F1−C –Upper door switch................................................

F1−D –Lower door switch................................................

F1−E –Sensor input not calibrated ..................................

F1−H –EEPROM error.....................................................

F1−L –Temp in ovens are the same for long period ........

F1−N –Internal voltage on control not working.................

F9−1 –Upper lock switch is not correct............................

F9−2 –Upper unlock switch is not correct........................

F9−3 –Control does not see upper door lock ...................

4 –Lower lock switch is not correct ............................

F9−

F9−5 –Lower unlock switch is not correct........................

F9−6 – Control does not see lower door lock...................

EE –Control cannot read E-PROM. Unit will shut down.

This mode must be activated within the first 5 minutes of

power up.

Press BROIL and CANCEL pad for approximately 3 seconds.

If oven temperature is greater than 400°F, the Test Mode

cannot be activated or will abort if active.

Press and hold individual pads for 4 seconds to activate.

Display will have dashes in all segments to indicate the mode is

active.

Push

Enter 550°F using the number pads.

Immediately push and hold

approximately 3 seconds.

To decrease or increase oven temperature. Push

pad until negative or positive numbers appear. Oven can be

adjusted from -35° to +35° F (-37.2° to + 1.6° C). To avoid over

adjusting oven, move temperature -5° F (2.7° C) each time.

Push

pad.

BAKE

pad.

OVEN CANCEL

BAKE

BAKE

button.

pad for appropriate oven

pad for appropriate oven

AUTO SET

Check actual upper oven temperature,

if > 650°F check sensor.

Check actual lower oven temperature,

if > 650°F check sensor.

Check actual upper oven temperature,

if > 950°F check sensor.

Check actual lower oven temperature,

if > 950°F check sensor.

Check membrane switch for connection or damage.

Check upper sensor, harness, and connections

Check upper sensor, harness, and connections

Used to view the actual oven temperature for both ovens at all

times, even when an oven function is active.

This mode will also display the current fault code for 5

seconds in the time digits.

Default from factory

Replace control

Replace control

Check membrane connection

Replace control

Check latch wire harness

Check latch wire harness

Check lock wire harness

Check lock wire harness

Verify sensor is operating properly

Replace control

Verify sensor is operating properly

Replace control

Check lock wire harness, and lock switch

Check lock wire harness, and lock switch

Check lock wire harness, and lock switch

Check lock wire harness, and lock switch

Check lock wire harness, and lock switch

Check lock wire harness, and lock switch

Disconnect power for 60 seconds. If EE reappears, replace ERC

Upper Bake: Energizes upper bake element

Lower Bake: Energizes lower bake element

Upper Broil: Energizes upper broil element

Convection Bake: Energizes convection fan

Upper Oven Light: Energizes upper oven light

Lower Oven Light: Energizes lower oven light

Upper Clean: Energizes upper motorized door lock

Lower Clean: Energizes lower motorized door lock

Stop Time: Energizes Beeper

Cook Time: Displays error codes

Timer 1: Energizes ROM version

Timer 2: Energizes EEPROM version

Keep Warm: Cooling Fan

Clock: All display segments light

If functions do not perform as specified, replace ERC

While increasing or decreasing oven temperature, this does not

affect self-cleaning temperature.

Holds offset through power outage.

©2004 Maytag Services 16023415 23

Page 24

Disassembly Procedures

WARNING!

Moving and/or Replacing Range

1. Turn off electrical power and gas supply to the range.

2. Slide range forward from installation position.

3. Unplug power cord and disconnect gas line from unit.

4. Replace range using Installation Instructions.

NOTE: When placing range into installation position

verify anti-tip bracket(s) are engaged.

Leveling Legs

• Some floors are not level.

• For proper baking, your range must be level.

• Leveling legs are located on each corner of the base

of the range.

• Place a level horizontally on an oven rack and check

front-to-back and side-to-side. Level by turning the

legs.

Anti-Tip Bracket

When ever range is moved or replaced for safety reasons

this bracket must be engaged.

Anti-Tip Bracket

To avoid risk of electrical shock, personal injury, or death:

disconnect electrical and gas supply before servicing.

Maintop Removal

1. Disconnect power before servicing.

2. Remove surface burner control knobs by grasping

knob and raising knob straight upward.

3. Remove screws securing infinite switch bracket to

maintop.

4. Remove screws securing burner assemblies to

maintop.

5. Remove screws securing maintop to chassis.

Screws are located in the front left and right corners

with the upper oven door open.

6. Remove screws securing ground strap to chassis.

7. Raise and remove maintop from unit.

8. Reverse procedures to reassemble.

Top Surface Valve and Spark Switch

1. Remove maintop, see "Maintop Removal" procedure.

(Perform steps 1 – 6.)

2. Remove spark switch(es) by pulling upward off valve.

3. Remove wires from spark switch by depressing

release arm.

4. Remove bolt(s) securing surface valve(s) to

manifold. Located on the bottom of manifold.

5. Reverse procedures to reassemble.

NOTE: Perform gas leak test.

Leveling Leg

Top Burner

1. Disconnect power before servicing.

2. Remove screws securing burner to burner lower

assembly.

3. Reverse procedures to reassemble.

Side Panel

NOTE: Removal of range from installation position is

required.

1. Disconnect power before servicing.

2. Remove range from installation position, see "Move

and/or Replacing Range" procedure.

3. Remove maintop, see "Maintop Removal" procedure.

(Perform steps 1 – 6.)

4. Remove screws securing right side panel at the top

and back of panel.

5. Pull side panel outward away from rear of range,

then lift upward on the side panel to release from

slotted clips located in front and set aside.

6. Reverse procedures to reassemble.

Shut-Off Valve

1. Remove maintop, see "Maintop Removal" procedure.

(Perform steps 1 – 6.)

2. Remove screws securing back panel to chassis.

3. Disconnect tubing to shut-off valve.

4. Remove bolt securing shut-off valve to manifold.

5. Reverse procedures to reassemble.

NOTE: Perform gas leak test.

Top Burner Lower Assembly

1. Remove maintop, see "Maintop Removal" procedure.

(Perform steps 1 – 6.)

2. Disconnect tubing from lower assembly.

3. Reverse procedures to reassemble.

NOTE: Perform gas leak test.

Manifold and Top Burner

1. Remove maintop, see "Maintop Removal" procedure.

(Perform steps 1 – 6.)

NOTE: If replacing manifold only, skip step 2.

2. Loosen and disconnect fittings securing surface

burner tubing to burner assembly and manifold.

3. Remove bolt(s) securing surface valve(s) to

manifold.

4. Remove bolt securing shut-off valve from manifold.

5. Disconnect tubing from manifold to the regulator.

6. Reverse procedures to reassemble.

NOTE: Perform gas leak test.

24 16023415 ©2004 Maytag Services

Page 25

Disassembly Procedures

WARNING!

Oven Sensor

The oven sensor is located inside oven cavity, attached

to the upper left rear wall of the cavity.

1. Disconnect power before servicing.

2. Open oven door and remove screws securing sensor

to oven cavity.

NOTE: Gently pull wiring through cavity wall.

3. Disconnect sensor at connector block and remove.

4. Reverse procedures to reassemble.

NOTE: Verify connect is pushed through the insulation.

Electronic Clock

1. Disconnect power before servicing.

2. Remove vent deflector by removing screws located on

the underside of the control panel.

3. Remove screws securing backguard panel to

backguard housing. (Screws are located on the

bottom and back side of control panel.)

4. Lift control panel up, tilt forward, and lay panel on a