Page 1

INSTALLATION INSTRUCTIONS

CommerCial Gas or eleCtriC Dryer

moDels

mDe18CsaG, mDG18CsaG, mDe18mNaG, mDG18mNaG

INSTRUCTIONS D’INSTALLATION

sèChe-liNGe À Gaz ou ÉleCtrique À usaGe CommerCial

moDèles

mDe18CsaG, mDG18CsaG, mDe18mNaG, mDG18mNaG

INSTRUCCIONES DE INSTALACIÓN

seCaDora a Gas o elÉCtriCa ComerCiale

moDelos

mDe18CsaG, mDG18CsaG, mDe18mNaG, mDG18mNaG

ISTRUZIONI D’INSTALLAZIONE

asCiuGatriCe a Gas o elettriCa CommerCiale

moDelli

mDe18CsaG, mDG18CsaG, mDe18mNaG, mDG18mNaG

www.maytagcommerciallaundry.comW10474275A

Page 2

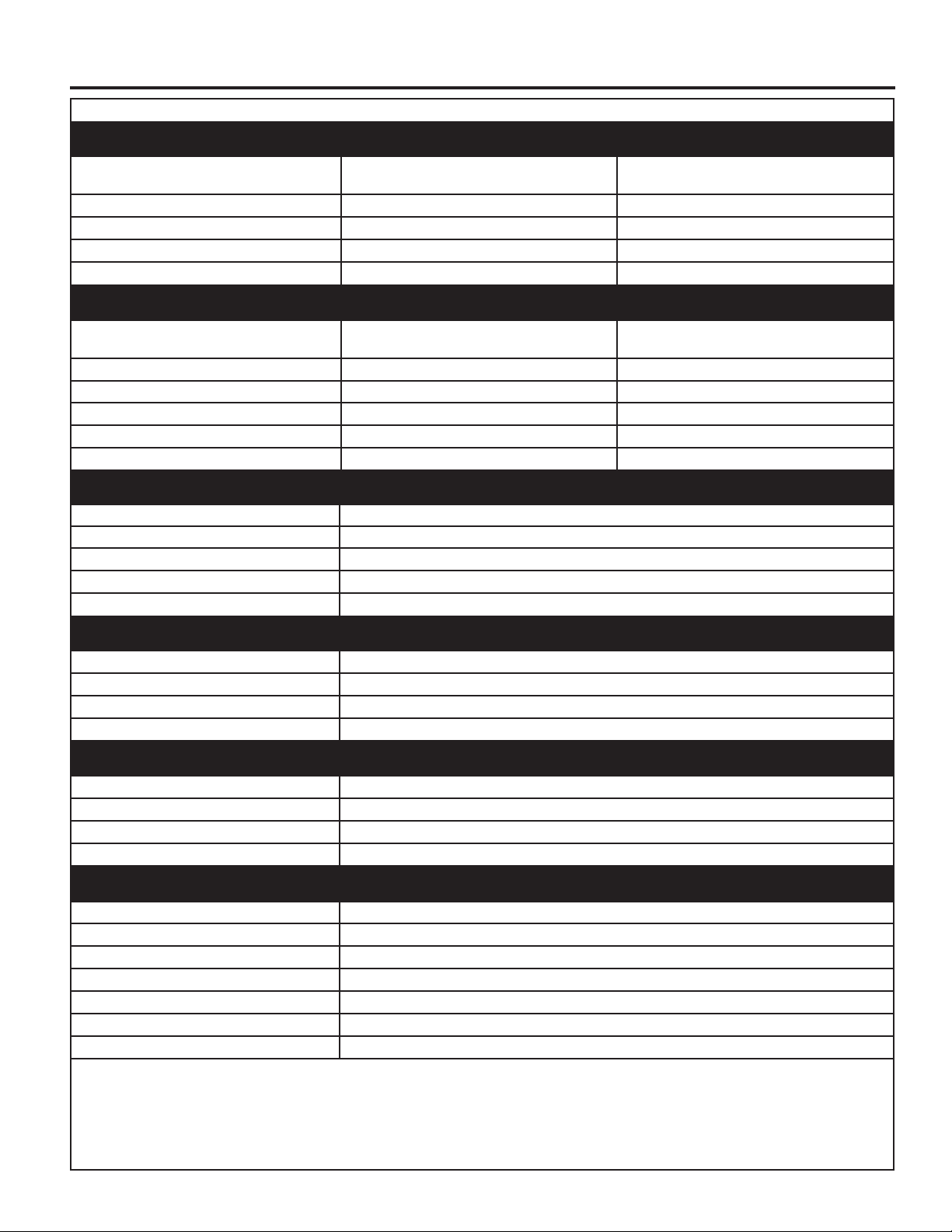

TABLE OF CONTENTS

Page

Dryer Safety ..........................................................................................................3

Dryer Disposal ................................................................................................... 6

Tools & Parts ....................................................................................................... 7

Dimensions/Clearances .............................................................................. 8

Dryer Installation Requirements ............................................................. 9

Electric Dryer Installation Requirements ......................................... 10

Gas Dryer Installation Requirements ................................................ 11

Dryer Venting Requirements .................................................................. 13

Gas Supply Connection ............................................................................ 15

Installing Leveling Legs .............................................................................. 16

Leveling ...............................................................................................................17

Complete Installation .................................................................................. 18

Reversing Dryer Door Swing ................................................................... 19

Maintenance Instructions ......................................................................... 20

If You Need Assistance .............................................................................. 20

Technical Specifications – Gas Dryer ................................................. 21

Warranty ............................................................................................................. 22

ÍNDICE

Página

Seguridad de la secadora ......................................................................... 43

Eliminación de la secadora ...................................................................... 46

Herramientas y piezas ................................................................................47

Dimensiones y espacios libres ............................................................. 48

Requisitos de instalación de secadora ............................................ 49

Requisitos de instalación de secadora eléctrica ........................ 50

Requisitos de instalación de secadora a gas ............................... 51

Requisitos de ventilación de la secadora ....................................... 53

Conexión del suministro de gas .......................................................... 56

Instalación de las patas niveladoras................................................... 57

Nivelación .......................................................................................................... 58

Complete la instalación ............................................................................. 59

Cómo invertir el sentido de apertura de la puerta ....................... 60

Instrucciones de mantenimiento .......................................................... 61

Si necesita ayuda .......................................................................................... 61

Especificaciones técnicas – secadora a gas ................................. 61

Garantía ............................................................................................................... 62

TABLE DES MATIÈRES

Page

Sécurité du sèche-linge ........................................................................... 23

Élimination du sèche-linge ................................................................... 26

Outils et pièces ............................................................................................ 27

Dimensions/Distances de dégagement ........................................ 28

Exigences d’installation pour le sèche-linge ................................ 29

Exigences d’installation pour le sèche-linge électrique ......... 30

Exigences d’installation pour le sèche-linge à gaz ................... 31

Exigences concernant l’évacuation

du sèche-linge ............................................................................................. 33

Raccordement à la canalisation de gaz ......................................... 35

Installation des pieds de nivellement ............................................. 36

Nivellement .....................................................................................................37

Achever l’installation ..................................................................................38

Inversion du sens d’ouverture de la porte ......................................39

Instructions d’entretien .............................................................................40

Si vous avez besoin d’assistance .......................................................40

Fiche technique – sèche-linge à gaz .................................................41

Garantie .............................................................................................................42

INDICE

Pagina

Sicurezza dell’asciugatrice ........................................................................ 63

Eliminazione dell’asciugatrice ................................................................ 66

Attrezzi e componenti ..................................................................................67

Dimensioni/spazi ......................................................................................... 68

Requisiti dell’installazione dell’asciugatrice .................................. 69

Requisiti dell’installazione dell’asciugatrice elettrico ............... 70

Requisiti dell’installazione dell’asciugatrice a gas ..................... 71

Requisiti di scarico dell’asciugatrice ................................................. 73

Collegamento di alimentazione del gas .......................................... 75

Installazione dei piedini di regolazione ............................................. 76

Livellamento ......................................................................................................77

Completamento dell’installazione ....................................................... 78

Invertire il senso di apertura dello sportello ................................... 79

Istruzioni di manutenzione ........................................................................ 80

Se avete bisogno dell’assistenza ......................................................... 80

Dati tecnici – asciugatrice a gas ........................................................... 81

Garanzia ............................................................................................................. 83

2

Page 3

DRYER SAFETY

■ It is recommended that the owner post, in a prominent location, instructions for the customer’s use in the event the customer smells

gas. This information should be obtained from your gas supplier.

■ Post the following warning in a prominent location.

FOR YOUR SAFETY

1. DO NOT USE OR STORE PETROL OR OTHER FLAMMABLE MATERIALS IN THIS APPLIANCE OR NEAR THIS APPLIANCE.

2. DO NOT SPRAY AEROSOLS IN THE VICINITY OF THIS APPLIANCE WHILE IT IS IN OPERATION.

3. DO NOT MODIFY THIS APPLIANCE.

3

Page 4

DRYER SAFETY

IMPORTANT: When discarding or storing your old clothes dryer, remove the door.

4

Page 5

DRYER SAFETY

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of fire, electric shock, or injury to persons when using the dryer, follow basic precautions, including

the following:

■ Read all instructions before using the dryer.

■ This dryer is intended only for drying clothes and textiles

that have been washed in water. Do not use for any other

purpose.

■ WARNING: If you smell gas, do not use the dryer or any

electrical equipment nearby. Warn other people to clear the

area. Contact the dryer owner immediately.

■ Do not place items exposed to cooking oils in your dryer.

Items contaminated with cooking oils may contribute to a

chemical reaction that could cause a load to catch fire.

■ If it is unavoidable that fabrics that contain vegetable or

cooking oil or that have been contaminated by hair care

products be placed in a tumble dryer, they should first be

washed in hot water with extra detergent – this will reduce,

but not eliminate the hazard.

■ Do not dry articles that have been previously cleaned in,

washed in, soaked in, or spotted with petrol, dry-cleaning

solvents, other flammable, or explosive substances as they

give off vapors that could ignite or explode.

■ Items that have been soiled with substances such

as acetone, alcohol, petrol, kerosene, spot removers,

turpentine, waxes, and wax removers should be washed

in hot water with extra detergent before being dried

in the dryer.

■ Do not dry unwashed items in the dryer.

■ Do not use this dryer if industrial chemicals have been used

for cleaning. The possible presence of residual quantities

of aggressive or decomposed chemicals in the load may

produce damage to the dryer and harmful fumes.

■ Do not allow children to play on or in the dryer. Close

supervision of children is necessary when the dryer is used

near children.

■ This dryer is not intended for use by persons (including

children) with reduced physical, sensory, or mental

capabilities, or lack of experience or knowledge, unless they

have been given supervision or instruction concerning use

of the dryer by a person responsible for their safety.

■ Before the dryer is removed from service or discarded,

remove the door to the dryer compartment.

■ Do not reach into the dryer if the drum is moving.

■ Do not open door while dryer is in operation. It will stop.

■ When loading or re-loading the dryer, avoid touching hot

metal parts of the drum (burn risk).

■ If drum rotation is blocked due to trapped textiles,

disconnect the dryer from the electrical supply before gently

removing the blockage.

■ If the dryer is not heating, or appears to be defective or

damaged, do not use it. Contact the owner.

■ Do not install or store the dryer where it will be exposed to

the weather.

■ Do not tamper with controls.

■ Clean dryer lint screen before or after each load.

■ Do not use this dryer without the lint screen in place.

■ Do not repair or replace any part of the dryer or attempt any

servicing unless specifically recommended in this Installation

Instructions or in published user-repair instructions that you

understand and have the skills to carry out.

■ Do not use fabric softeners or products to eliminate static

unless recommended by the manufacturer of the fabric

softener or product.

■ Do not use heat to dry articles containing foam rubber or

similarly textured rubber-like materials.

■ The final part of a tumble dryer cycle occurs without heat

(cool-down cycle) to ensure that the articles are left at a

temperature that ensures that the items will not be damaged.

■ WARNING: Never stop a tumble dryer before the end of

the drying cycle unless all items are quickly removed and

spread out so that the heat is dissipated. (Avoids risk of

spontaneous combustion).

■ In case of electrical supply failure, remove the load quickly

and spread it out to avoid risk of spontaneous combustion.

■ Keep area around the exhaust opening and adjacent

surrounding areas free from the accumulation of lint, dust,

and dirt.

■ The fresh air ventilation openings into the room and into the

dryer must not be blocked or sealed.

■ Emergency stop control: The mains plug should be removed

in an emergency.

■ The interior of the dryer and dryer exhaust vent should be

cleaned periodically by qualified service personnel.

■ See “Electrical Requirements” section for earthing

instructions.

SAVE THESE INSTRUCTIONS

5

Page 6

DRYER DISPOSAL

MODEL NOMENCLATURE:

MDG – Maytag Gas CS – Coin Operated

MDE – Maytag Electric MN – Non-Pay

18 – Model Type Number

6

Page 7

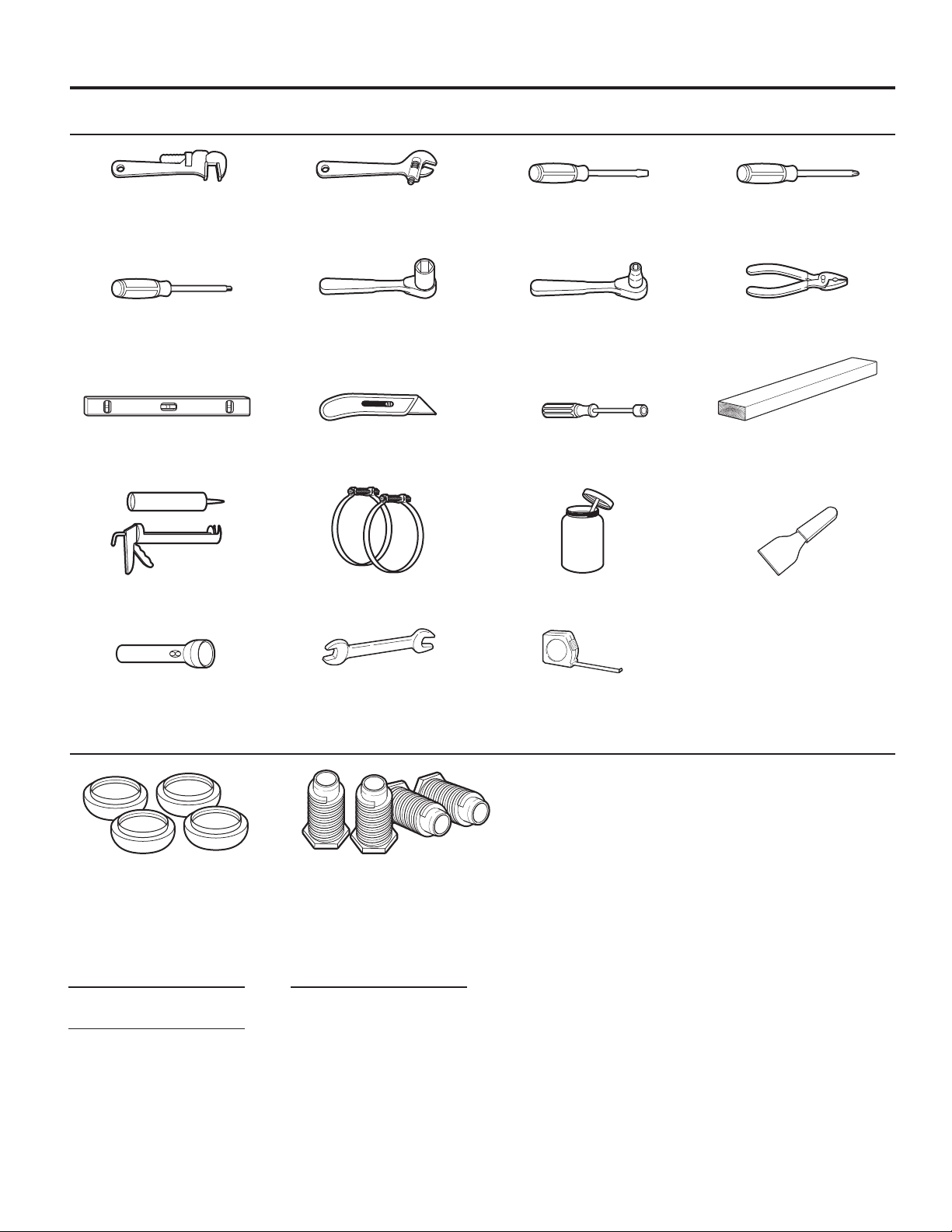

TOOLS & PARTS

Tools Needed:

203 mm (8") 203 mm (8") or 254 mm (10") Flat-Blade Screwdriver Phillips Screwdriver

or 254 mm (10") Adjustable Wrench

Pipe Wrench that opens to 25 mm ( 1")

Torx®† T-20®† Security 25 mm (1") Hex-Head 8 mm ( 5⁄16") Socket Wrench Pliers (that open to

Screwdriver or Bit Socket Wrench 39 mm [19/16"])

Level Utility Knife 6 mm (1/4") Nut Driver 686 mm (27")

Wood Block

Caulk Gun and Caulk Vent Clamps Pipe-Joint Compound Putty Knife

(for installing new exhaust vent) Suitable for Gas Type

Flashlight (optional) 25 mm (1") Ruler or Measuring Tape

Open-End Wrenches

Parts Supplied:

Foot Boots (4) Leveling Legs (4)

NOTE: The circuit diagram for this dryer is located inside the lower

front panel, within the Tech Sheets.

Technical Specifications:

220 – 240 V, 50 Hz. AC

4575W

Total mass: 68 kg max.

Clothes Capacity:

9 kg max.

NOTE: Sound Pressure Level, Lpa: 58 dBA

(uncertainty, Kpa: +/–10 dBA).

†® TORX and T20 are registered trademarks of Acument Intellectual Properties, LLC.

7

Page 8

DIMENSIONS/CLEARANCES

(1")

(0")

Dimensions

Side View Back View

889 mm

(35")

743 mm

(291/4")

648 mm

(251/2")

210 mm

1

(8

/4")

83 mm

(31/4")

38 mm

1

(1

/2")

140 mm

(5

1

/2")

686 mm

(27")

Electric

343 mm

(131/2")

Gas

279 mm

(11")

102 mm

(4" dia)

889 mm

(35")

(electric models)

940 mm

(37")

(gas models)

1048 mm

1

(41

/4")

25 mm

(1")

260 mm

1

/4")

(10

330 mm

(13")

83 mm

(31/4")

Bottom Exhaust

178 mm

(7")

359 mm

1

/8")

(14

Clearances

Recessed Front View Closet Side View

8

381 mm

(15")

0 mm

(0")

0 mm

(0")

25 mm

356 mm

(14")

0 mm

Page 9

DRYER INSTALLATION REQUIREMENTS

(Australia and New Zealand – for full details of installation requirements refer to AS/NZS 5601.1)

Location Requirements

Recessed Area and Closet Installation Instructions

This dryer may be installed in a recessed area or closet. For

recessed area and closet installations, minimum clearances

can be found on the warning label on the rear of the dryer

or in “Dimensions/Clearances.”

The installation spacing is in millimeters and is the minimum

allowable. Additional spacing should be considered for ease

of installation, servicing, and compliance with local codes and

ordinances.

If closet door is installed, the minimum unobstructed air opening in

the top and bottom is required. Louvered doors with equivalent air

openings are acceptable.

The dryer must be exhausted outdoors.

No other fuel-burning appliance may be installed in the same closet

as the dryer.

Your dryer can be installed in a basement, laundry room, or

recessed area.

This dryer is not intended for installation in a mobile home.

Companion appliance location requirements should also be

considered.

IMPORTANT: Do not install or store the dryer where it will be

exposed to the weather. Proper installation is your responsibility.

You will need:

■ An earthed electrical outlet located within 1.8 m (6 ft.) of

where the power cord is attached to the back of the dryer.

See “Electrical Requirements.”

■ A level floor with a maximum slope of 25 mm (1") under entire

dryer. Installing the dryer on soft floor surfaces, such as carpets

or surfaces with foam backing, is not recommended.

Dryer installation clearances

■ The location must be large enough to allow the dryer door

to be fully opened.

■ Additional spacing should be considered for ease of installation

and servicing. The door opens more than 180°.

■ Additional clearances might be required for wall, door, and floor

moldings.

■ Additional spacing of 25 mm (1") on all sides of the dryer

is recommended to reduce noise transfer.

When installing a dryer:

IMPORTANT: Observe all governing codes and ordinances.

■ Check code requirements: Some codes limit or do not

permit installation of clothes dryers in garages, closets,

or sleeping quarters. Contact your local building inspector.

NOTE: For installation in Australia and New Zealand, install

dryer in accordance with AS/NZS 5601.1 and local governance

codes.

■ Gas Dryers only: Make sure that lower edges of the cabinet,

plus the back and bottom sides of the dryer, are free of

obstructions to permit adequate clearance of air openings for

combustion air. See “Recessed Area and Closet Installation

Instructions” below for minimum spacing requirements.

NOTE: For installation in Australia and New Zealand, refer to

AS/NZS 5601.1 for ventilation requirements.

Front

View

Closet

Door

9

Page 10

ELECTRIC DRYER INSTALLATION REQUIREMENTS

Electrical Requirements

IMPORTANT: Observe all governing codes and ordinances.

This dryer is supplied without an electric cord and plug. It must be

connected by a competent electrician to a single-phase electricity

supply at the voltage shown on the dataplate, using a suitable

fixed wiring installation in accordance with local and national

wiring regulations.

■ A 3-wire circular cord of minimum conductor size 2.5 mm2

cross-section area should be used.

■ A 25A (minimum) supply fuse should be used, and a switch

having a contact separation in both poles that provides full

disconnection under over-voltage category III conditions must

be incorporated into the fixed wiring in accordance with local

wiring regulations. The dryer should be positioned so that the

disconnection switch is clearly visible and easily accessible to

the user. This disconnection switch also provides the function

of an emergency stop control for the user.

■ A cord clamp bush is provided on the dryer, and should be

tightened on completion of wiring. The electrical mains terminals

are located behind the small rear access panel (terminal block

cover), and connections should be made in accordance with the

terminal markings. Remember to replace the terminal access

panel (terminal block cover).

NOTE: In accordance with the European EMC Directive

(2004/108/EC), the maximum electrical supply system impedance

to which the electric dryer should be connected is declared to be

0.054 Ohm + j0.034 Ohm.

NOTE: Electrical safety standards: The manufacturer has chosen

compliance with IEC/EN.60335 standards as the most appropriate

for this product.

This is 3-wire appliance which must be earthed.

If codes permit and an additional earth bond wire is used, it is

recommended that a qualified electrician determine that the earth

bond path is adequate.

Recommended Earthing Method

It is your responsibility to contact a qualified electrical installer

to ensure that the electrical installation is adequate and in

conformance with all local codes and ordinances.

10

Page 11

GAS DRYER INSTALLATION REQUIREMENTS

Electrical Requirements

IMPORTANT: Observe all governing codes and ordinances.

You will need an earthed electrical outlet located within 610 mm

(2 feet) of either side of the dryer.

This dryer is supplied/fitted with an electrical supply cord and plug.

It should be connected to electrical supply socket at the voltage

shown on the rating plate. The minimum supply fuse capacity

should be 10A. The dryer must be positioned so that the plug is

clearly visible and accessible. This plug also provides the function

of an emergency stop control for the user. If the fitted plug is not

used, the electrical connection must be carried out by a competent

electrician in accordance with local or national codes.

If the supply cord is damaged, it must be replaced with a specially

terminated cord by an authorized service agent or a similarly

competent person in order to avoid a hazard.

Do not use an adapter.

Do not use an extension cord.

NOTE: In accordance with the European EMC Directive

(2004/108/EC), the maximum electricity supply system impedance

to which the gas dryer should be connected is declared to be

0.054 Ohm + j0.034 Ohm.

NOTE: Electrical safety standards: The manufacturer has chosen

compliance with IEC/EN.60335 standards as the most appropriate

for this product.

EARTHING INSTRUCTIONS

SAVE THESE INSTRUCTIONS

Using the universal cord included with this dryer:

The gas dryer is equipped with a universal cord with

interchangeable plugs.

1. To use the universal cord, select the plug end that fits your

electrical outlet, and plug it into the adapter on the supply cord.

2. Secure the plug end in place on the cord by aligning the 2 cover

halves over the cord adapter and clipping them together.

If codes permit and an additional earth bond wire is used, it is

recommended that a qualified electrician determine that the earth

bond path is adequate.

11

Page 12

GAS DRYER INSTALLATION REQUIREMENTS

Gas Supply

Supply line requirements:

Provide a rigid gas supply line to the dryer location. It should be

minimum 12.5 mm (1/2") ID. When acceptable to the gas supplier

and local codes, 10 mm (3/8") ID rigid supply line may be used for

lengths under 6.1 m (20'). Pipe-joint compounds resistant to the

action of L.P. gas must be used.

NOTE: For installation in Australia and New Zealand, refer to

AS/NZS 5601 for pipe sizing details. All piping is to be in

accordance with AS/NZS 5601.1 – Gas Installations.

Gas connection to the dryer itself should be made by means

of a flexible gas hose suitable for the appliance and gas category

in accordance with national installation regulations. If in doubt,

contact the gas supplier. It should be minimum 10 mm (3/8") ID.

A means of restraint should be used between the dryer and the

wall to avoid straining of the rigid gas supply when the dryer

is moved. An appropriate length of chain and a wall hook is

recommended.

The dryer gas inlet connection is a 3/8" NPT thread. An adapter is

supplied for conversion to standard ISO.228-1 thread (3/8" BSP).

Check for leaks by using an approved noncorrosive leak-detection

solution. Bubbles will show a leak. Correct any leak found. A

IMPORTANT: Observe all governing codes and ordinances.

In Australia and New Zealand, refer to AS/NZS 5601.1 – Gas

Installations.

Gas Supply

Before installation, check that the local gas distribution conditions,

nature of gas and pressure, and the adjustment of the appliance

are compatible. Burner information will be found on the model/

serial rating plate in the door recess of the dryer. If this information

does not agree with the type of gas available, see your dealer.

Natural Gas:

This dryer is factory adjusted for use with NATURAL GAS (G20),

and no further adjustment should be required at installation.

L.P. Gas:

This dryer is also certified for use with L.P. (propane or butane)

gases with appropriate conversion. No attempt shall be made to

convert the appliance from the gas specified on the model/serial

rating plate for use with a different gas without consulting the

serving gas supplier.

Conversion must be done by a competent service technician.

Gas conversion kit (European Country), part number W10233219,

is available for purchase from your dealer. Gas conversion kit

(Australia), part number W10315369, is available for purchase

from your dealer. Full instructions are supplied with the kit.

Natural Gas (France/Belgium):

This dryer is also certified for France/Belgium for use with G20/

G25 gases (20 mbar/25 mbar) with appropriate conversion.

No attempt should be made to convert this appliance from the

gas specified on the gas rating label for use with a different gas

without consulting the serving gas supplier. Gas conversion must

be done by a qualified gas service technician. Conversion kit, part

number (W10181947) is available for purchase from your dealer.

Full instructions are supplied with the kit.

pressure measurement tapping is provided on the gas valve within

the dryer, accessible after removal of the lower front panel.

The dryer must be disconnected from the gas supply piping

system during any pressure testing of that system.

12

Page 13

DRYER VENTING REQUIREMENTS

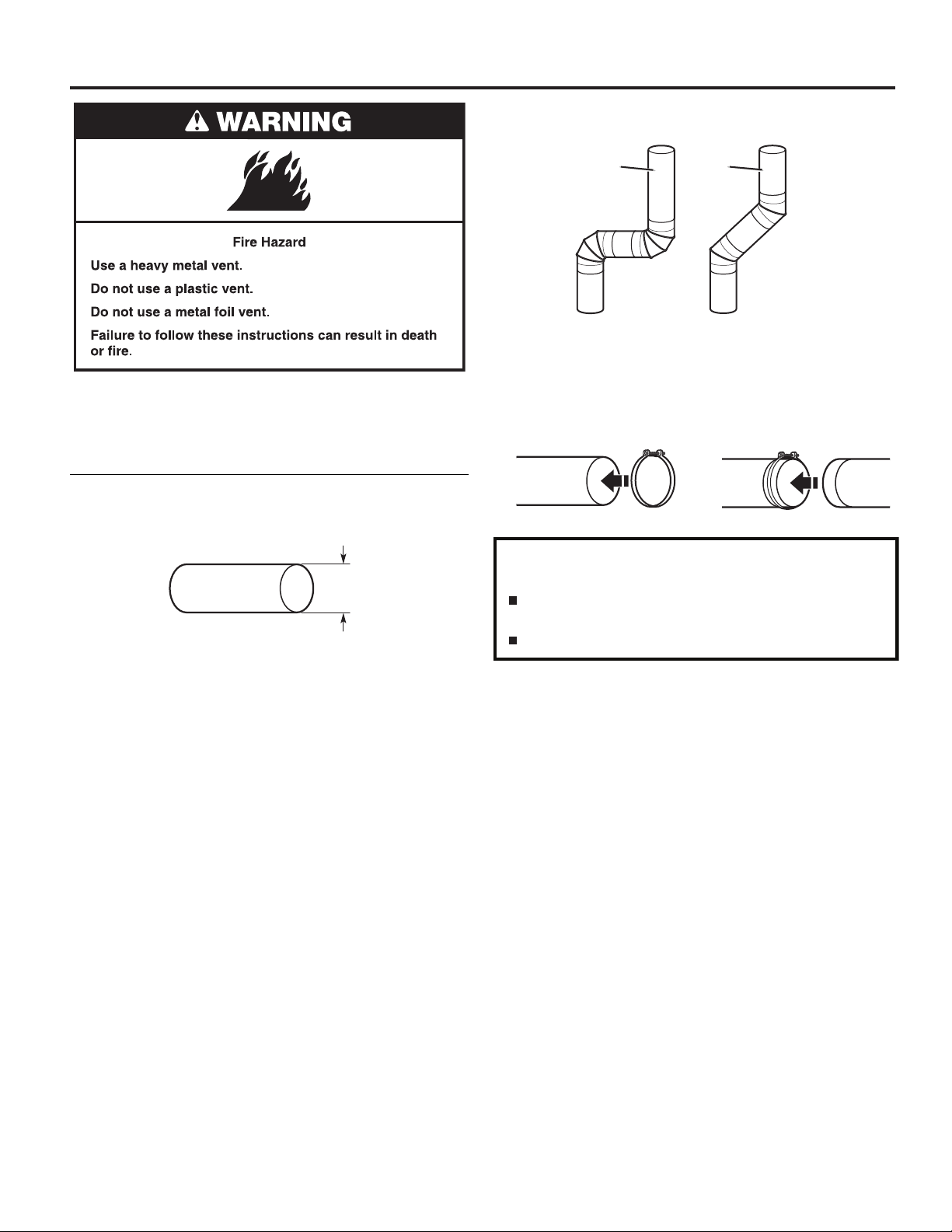

Elbows:

■ 45° elbows provide better airflow than 90° elbows.

WARNING: To reduce the risk of fire, this dryer MUST BE

EXHAUSTED OUTDOORS.

IMPORTANT: Observe all governing codes and ordinances.

In Australia and New Zealand, refer to AS/NZS 5601.1 – Gas

Installations.

Dryer exhaust must not be connected into any gas vent, chimney,

wall, ceiling, attic, crawlspace, or a concealed space of a building.

Only rigid or flexible metal vent shall be used for exhausting.

102 mm

(4")

102 mm (4") Heavy, Metal Exhaust Vent

Good

Better

Clamps:

■ Use clamps to seal all joints.

■ Exhaust vent must not be connected or secured with screws

or other fastening devices that extend into interior of duct and

catch lint. Do not use duct tape.

Improper venting can cause moisture and lint to collect

indoors, which may result in:

Moisture damage to woodwork, furniture, paint, wallpaper,

carpets, etc.

Housecleaning problems and health problems.

■ Only a 102 mm (4") heavy, metal exhaust vent and clamps may

be used.

■ Do not use plastic or metal foil vent.

Rigid metal vent:

■ Recommended for best drying performance and to avoid

crushing and kinking.

Flexible metal vent: (Acceptable only if accessible to clean)

■ Must be fully extended and supported in final dryer location.

■ Remove excess to avoid sagging and kinking that may result in

reduced airflow and poor performance.

■ Do not install in enclosed walls, ceilings, or floors.

■ The total length should not exceed 2.4 m (7

3

⁄4 ft.).

NOTE: If using an existing vent system, clean lint from entire length

of the system and make sure exhaust hood is not plugged with

lint. Replace plastic or metal foil vents with rigid metal or flexible

metal vents. Review “Vent System Chart” and if necessary, modify

existing vent system to achieve best drying performance.

13

Page 14

DRYER VENTING REQUIREMENTS

Vent Hoods

102 mm (4") Diameter Exhaust Hoods

Exhaust hood must be at least 305 mm (12") from the ground or

any object that may be in the path of the exhaust (such as flowers,

rocks, bushes, or snow).

Box Hood Louvered Hood Angled Hood

Vent System Length

Maximum Vent Length/Vent Connection

Maximum length of vent system depends upon the type of vent

used, number of elbows, and type of exhaust hood.

Vent System Chart (Rigid Metal Vent)

No. of Box and Angled

90˚ Turns Louvered Hood Hood

0 39.6 m (130 ft.) 39.3 m (129 ft.)

1 38.1 m (125 ft.) 36.3 m (119 ft.)

2 35.1 m (115 ft) 33.2 m (109 ft.)

3 32.3 m (106 ft.) 30.5 m (100 ft.)

4 29.9 m (98 ft.) 28.0 m (92 ft.)

For vent systems not covered by the vent specification chart,

see your parts distributor.

Provision must be made for enough air for combustion and

ventilation. (Check governing codes and ordinances.) See

“Recessed Area and Closet Installation Instructions” in the

“Location Requirements” section.

A 102 mm (4") outlet hood is preferred. However, a 64 mm (21⁄2")

outlet exhaust hood may be used. A 64 mm (21⁄2") outlet creates

greater back pressure than other hood types. For permanent

installation, a stationary vent system is required.

Connect Vent

1. If connecting to existing vent, make sure the vent is clean.

2. Using a 102 mm (4") clamp, connect vent to exhaust outlet

in dryer.

Vent Collar

12" min.

305 mm min.

(305 mm)

(12")

3. Tighten hose clamp with Phillips screwdriver.

4. Make sure the vent is secured to exhaust hood with

a 102 mm (4") clamp.

5. Move dryer into final position. Do not crush or kink vent.

Make sure dryer is level.

NOTE: Do not remove vent collar.

14

Page 15

DRYER VENTING REQUIREMENTS

If an Exhaust Hood Cannot be Used Multiple Dryer Venting

The outside end of main vent should have a sweep elbow directed

downward.

* Minimum clearance above any

accumulation of snow, ice, or

debris such as leaves

If main vent travels vertically through the roof, rather than through

wall, install a 180° sweep elbow on end of vent at least 610 mm

(2 ft.) above surface of roof.

The opening in wall or roof shall have a diameter 13 mm (1⁄2")

larger than vent diameter. Vent should be centered in opening.

Do not install screening over end of vent for best performance.

A main vent can be used for venting a group of dryers. The main

vent should be sized to remove 5663 l/min. (200 CFM) of air per

dryer. Large-capacity lint screens of proper design may be used in

main vent if checked and cleaned frequently. The room where the

dryers are located should have make-up air equal to or greater than

CFM of all the dryers in the room.

Back-draft dampers are available from your distributor and should

be installed in the vent of each dryer to keep exhausted air from

returning into dryers and to keep exhaust in balance within main

vent. Unobstructed return air openings are required.

Although usually each single-load dryer should have an

unobstructed outdoor air opening of 154 cm2 (24 in.2) (based on

6.5 cm2 [1 in.2] per 252 kcal [1,000 Btu]), common make-up air

openings are also acceptable. Set up common openings so the

make-up air is distributed equally to all of the dryers. Keep in mind

that the coverage area must be increased by 33% to account for

the use of registers or louvers over the openings. Also, make-up air

openings should not be installed near the location where exhaust

vents exit the building.

Each vent should enter the main vent at an angle pointing in

the direction of the airflow. Vents entering from the opposite side

should be staggered to reduce the exhausted air from interfering

with the other vents.

30˚ max.

Make Gas Connection

air ow

Air Flow

The maximum angle of each vent entering the main vent should be

no more than 30°.

Keep air openings free of dry cleaning fluid fumes. Fumes create

acids which, when drawn through the dryer heating units, can

damage dryers and items being dried.

A clean-out cover should be located on the main vent for periodic

cleaning of the vent system.

GAS SUPPLY CONNECTION (on some models)

3. Open the shut-off valve in the gas supply line and make sure

the dryer has its own gas supply opened.

4. Test all connections by brushing on an approved noncorrosive

leak-detection solution. Bubbles will show a leak. Correct any

leaks found.

1. Remove red cap from gas pipe on back of dryer.

2. Connect gas supply to dryer. If the flexible gas hose has 10 mm

(3/8") BSP thread, use the supplied conversion thread adapter.

Use pipe-joint compound resistant to the action of L.P. gas for

gas connections.

If necessary for service, open the toe panel. Use a putty knife

to press on the 2 toe panel locks located at the top of the toe

panel. Pull downward on the toe panel to open. Toe panel

is hinged at the bottom.

15

Page 16

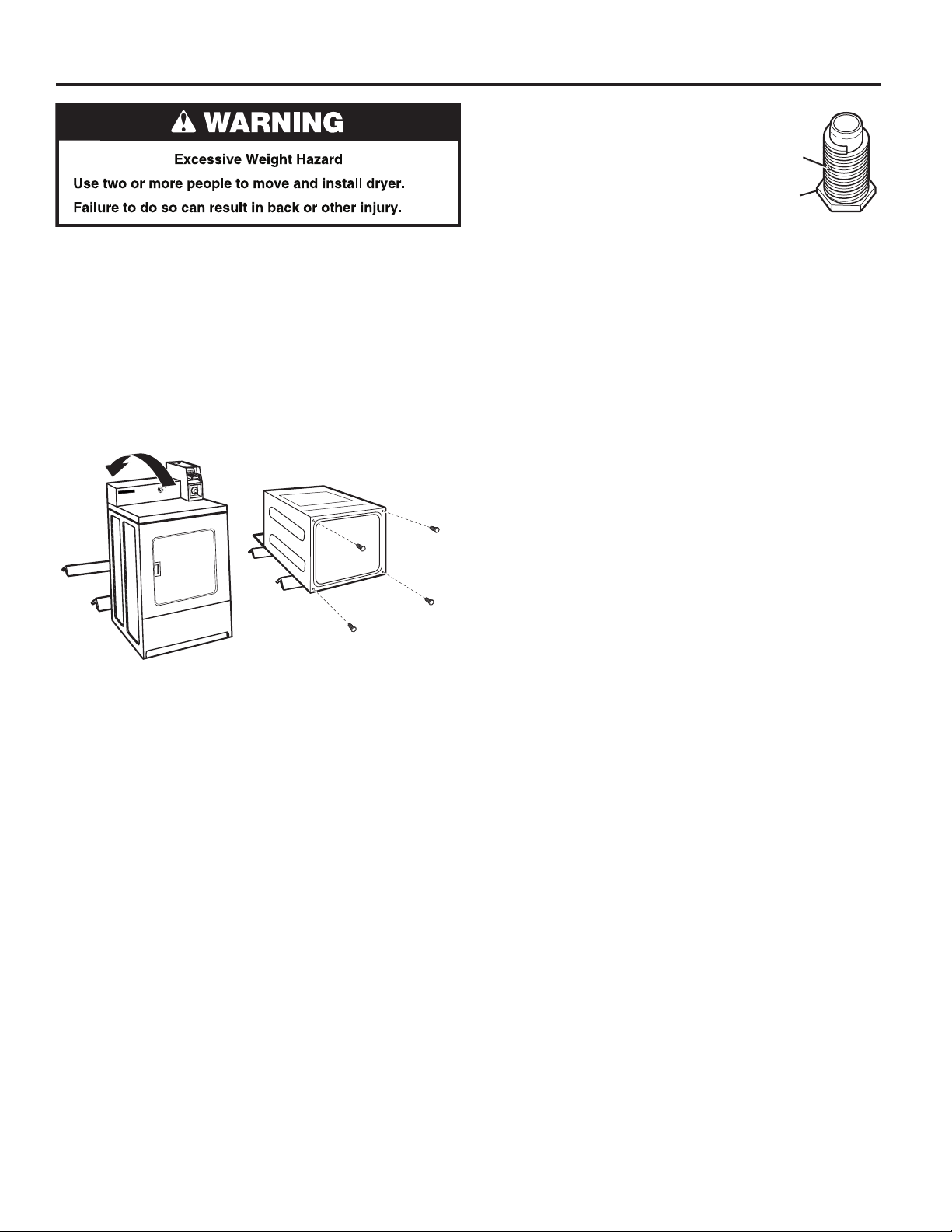

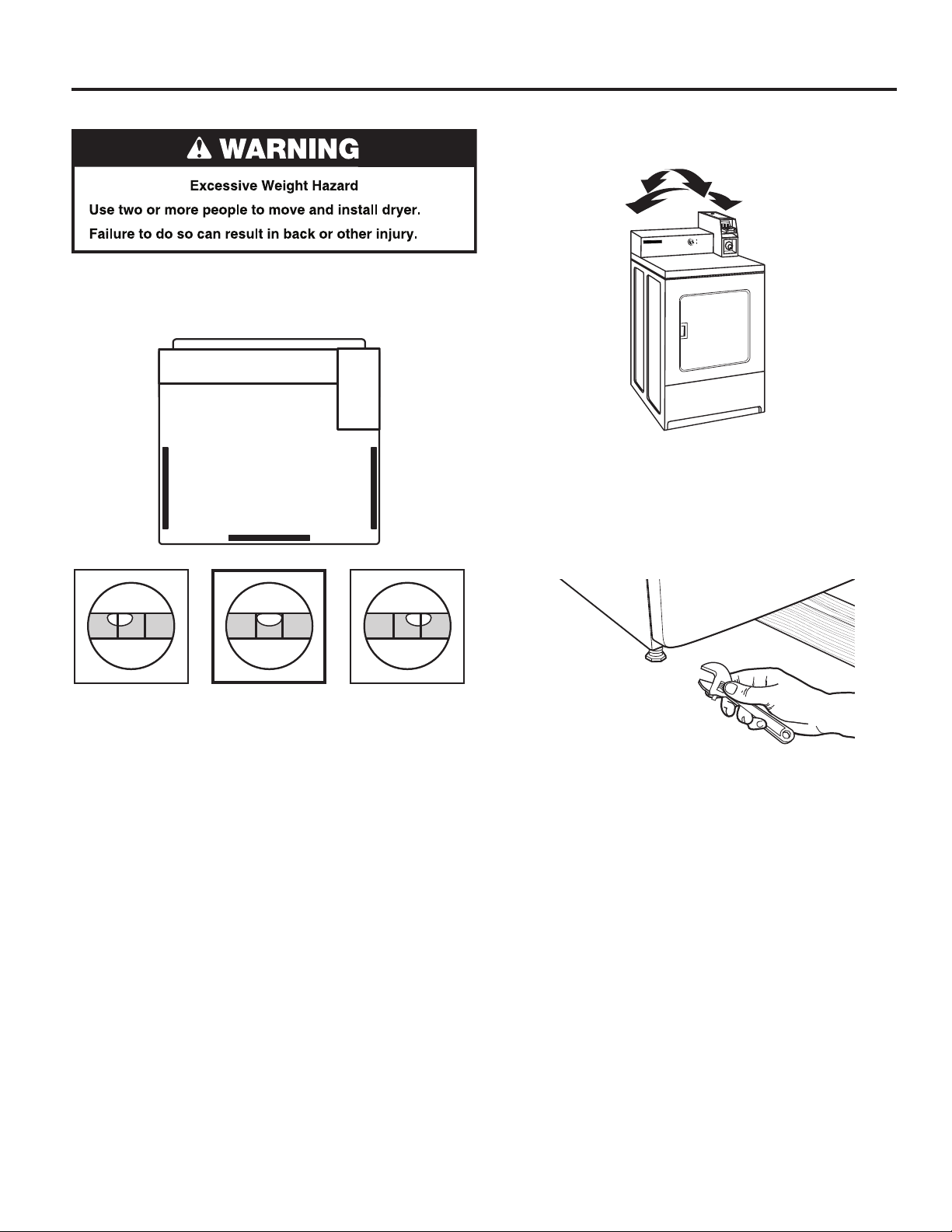

INSTALLING LEVELING LEGS

1. Prepare dryer for leveling legs

NOTE: Slide dryer onto cardboard or hardboard before moving to

avoid damaging floor covering.

Using two or more people, move dryer to desired installation

location.

Take tape off front corners of dryer. Open dryer and remove

the literature and parts packages. Wipe drum interior with a damp

cloth to remove any dust.

Take two cardboard corners from the dryer carton and place them

on the floor in back of the dryer. Firmly grasp the body of the dryer

and gently lay it on its back on the cardboard corners.

2. Screw in leveling legs

Examine leveling legs and find diamond

marking. Screw legs into leg holes by

hand. Use an adjustable wrench or

25 mm (1") hex-head socket wrench

to finish turning legs until diamond

marking is no longer visible. Then fit

a covered foot boot over each leg foot.

To protect the floor, use a large piece of cardboard from the dryer

carton. Stand dryer up on the cardboard. Slide the dryer until

it is close to its final location. Leave enough room for electrical

connection and to connect the exhaust vent.

Diamond

Marking

Foot

16

Page 17

LEVELING

Leveling your dryer properly reduces excess noise and vibration.

1. Remove cardboard from beneath dryer. Place a level on top

edges of dryer, checking each side and front. If not level, tip

dryer and adjust legs up or down as shown in Step 3, repeating

as necessary.

2. Grip dryer from top and rock back and forth, making sure all four

legs are firmly on floor. Repeat, rocking dryer from side to side.

If dryer rocks, go to Step 3 and adjust leveling legs.

3. If dryer is not level, use a 25 mm or 1" open-end or adjustable

wrench to turn the leveling leg counterclockwise to lower the

dryer or clockwise to raise the dryer. Recheck levelness of dryer

and that all four legs are firmly in contact with the floor. Repeat

as needed.

HELPFUL TIP: You may want to prop up front of dryer about

102 mm (4") with a wood block or similar object that will support

weight of dryer.

Not Level LEVEL Not Level

17

Page 18

COMPLETE INSTALLATION

1. Check the electrical requirements. Be sure that you have the

correct electrical supply and the recommended earthing method.

See “Electrical Requirements.”

2. Check that all parts are now installed. If there is an extra part,

go back through the steps.

3. Check that you have all of your tools.

4. Dispose of/recycle all packaging materials.

WARNING

Electric Shock Hazard

This dryer must be earthed.

Securely tighten all electrical connections.

Failure to do so can result in death, fire, or

electric shock.

5. Plug into an earthed outlet, or connect power.

6. Check dryer operation (some accumulated time may be

on the timer due to factory testing). Close dryer door. Insert

coins in slide and press slide in slowly. (Operating time will

accumulate per number of coins and type of timing cam used.)

Push START button. Using a full heat cycle (not the air cycle), let

the dryer run for at least five minutes. Dryer will stop when time

is used up.

NOTE: Dryer door must be closed for dryer to operate. When

door is open, dryer stops, but timer continues to run. To restart

dryer, close door and push START button.

7. Gas Models only: Open the dryer door. Check that the inside of

the dryer is warm. If the burner does not ignite and you can feel

no heat inside the dryer, shut off dryer for five minutes. Check

that all supply valve controls are in “ON” position and that the

electrical cord is plugged in. Repeat five-minute test.

8. If drying time is too long, make sure that the lint screen is clean

and that there are no obstructions to airflow in the dryer vent

system.

9. Restart the dryer and allow it to complete a full heat cycle

(not air cycle) to make sure it is working properly.

18

Page 19

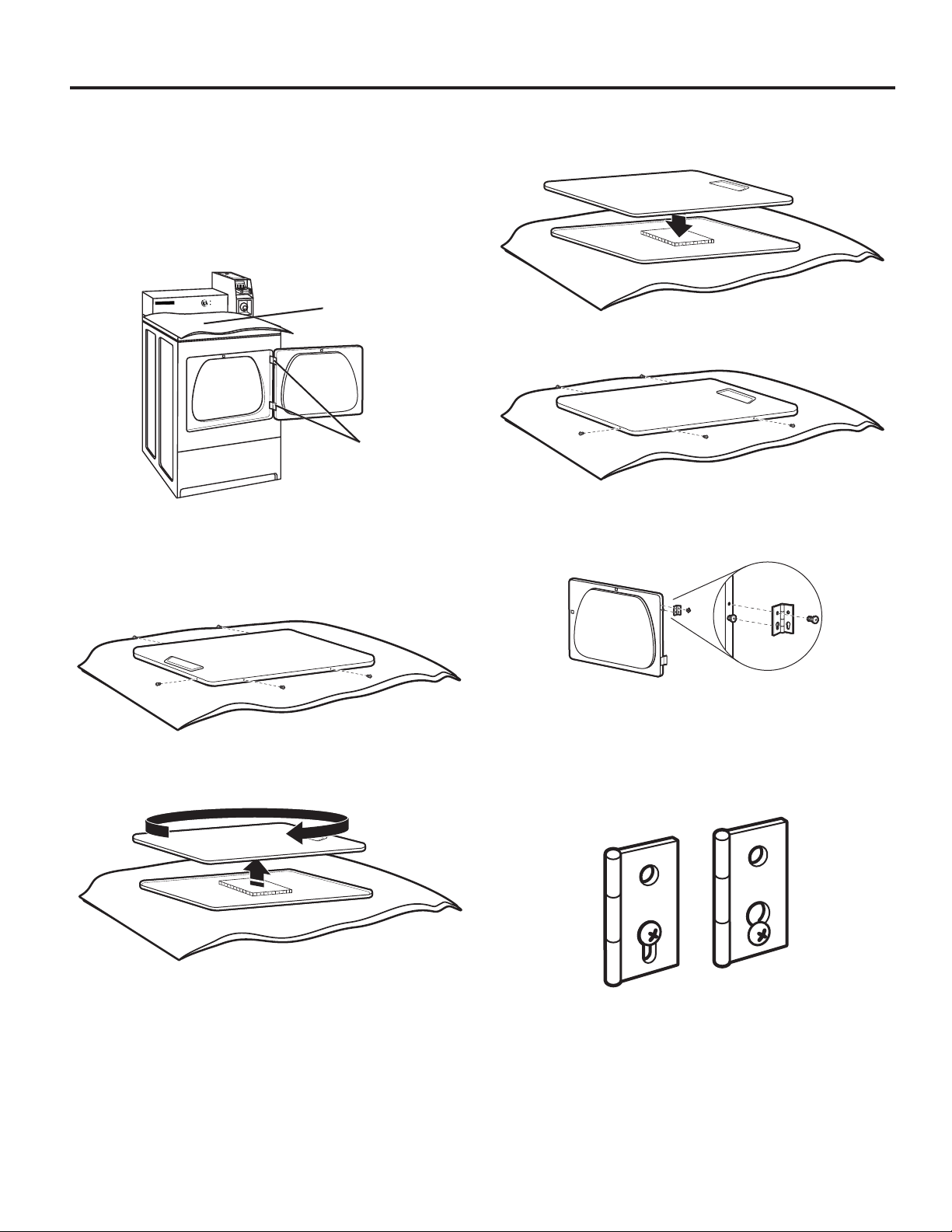

REVERSING DRYER DOOR SWING (OPTIONAL)

You can change your door swing from a right-side opening

to left-side opening, if desired.

Remove the Door Assembly

1. Place a towel or soft cloth on top of dryer or work space to

avoid scratching of the surface.

2. Open dryer door. Remove bottom screws from cabinet side of

hinges. Loosen (do not remove) top screws from cabinet side

of hinges.

Towel

Hinges

3. Lift door until top screws in cabinet are in large part of hinge

slot. Pull forward off screws. Set door (handle side up) on top

of dryer. Remove top screws from cabinet.

4. Remove screws attaching hinges to door.

5. Remove screws at top, bottom, and side of door (5 screws).

7. Be certain to keep cardboard spacer centered between doors.

Reattach outer door panel to inner door panel so handle is on

the side where hinges were just removed.

8. Reattach screws at top, bottom, and side of door (5 screws).

9. Attach door hinges to dryer door so that larger hole is at the

bottom of the hinge and the hinge pin is toward the door front.

6. Holding door over towel on dryer, grasp sides of outer door and

gently lift to separate it from inner door. Do not use a putty knife

to pry apart. Do not pull on door seal or plastic door catch.

10. Remove the 4 screws that attach 2 plugs on the left side.

Attach plugs to right side using the same 4 screws.

11. Insert screws into bottom holes on left side of cabinet. Tighten

screws halfway. Position door so large end of door hinge slot

is over screws. Slide door up so screws are in bottom of slots.

Tighten screws. Insert and tighten top screws in hinges.

12. Close door and check that door strike aligns with door catch.

If needed, slide door catch left or right within slot to adjust

alignment.

19

Page 20

MAINTENANCE INSTRUCTIONS

GPO, Schorndorf

GPO, Schorndorf

■ Clean lint screen before and after each cycle.

■ Removing accumulated lint:

From inside the dryer cabinet:

Lint should be removed every 2 years or more often, depending

on dryer usage. Cleaning should be done by a qualified person.

From the exhaust vent:

Lint should be removed every 2 years, or more often, depending

on dryer usage.

■ Keep area around dryer clear and free from combustible

materials, petrol, and other flammable vapors and liquids.

■ Keep dryer area clear and free from items that would obstruct

the flow of combustion and ventilation air.

IF YOU NEED ASSISTANCE

If you need help, contact the dealer from whom you purchased the

appliance, or a Maytag designated service company. When calling,

please know the purchase date and the complete model and serial

number of your appliance. This information will help us to better

respond to your request.

If dryer does not operate, check the following:

■ Electrical supply is connected.

■ Circuit breaker is not tripped or house fuse is not blown.

■ Door is closed. Listen closely to hear the door switch activate.

■ Controls are set in a running or “on” position.

■ START button has been pushed firmly.

■ For gas dryers, check that gas supply shut-off valves are set in

open position.

EU - DECLARATION OF CONFORMITY

CE - DECLARATION DE CONFORMITE

WE (nous):

BAUKNECHT HAUSGERÄTE GmbH, D-73614 Schorndorf

representing (représentant):

declare under our sole responsibility that the product

déclarons sous notre propre respon sabilité que le produit

dryer Maytag MDE18CS

(séche linge):

Whirlpool XCEM2763

to which this declaration relates is in conformity with the following standard(s) or other

normative document(s)

auquel se référe cette déclaration est con forme aux normes suivantes ou autres documents normatifs

EN 60335-1: 2002+A1+A2+A11+A12+A13+A14+A15

EN 60335-2-11: 2010

EN 62233: 2008+Ber.1: 2008

EN ISO 10472-1: 2008

EN ISO 10472-4: 2008

EN 55014-1: 2006+A1:2009+A2:2011 (Test method > 30 MHz: Disturbance power)

EN 55014-2: 1997+A1:2001+A2:2008

EN 61000-3-12: 2005

EN 61000-3-11: 2000

following the provisions of Directive(s

suivant les previsions des Directives:

2006/42/EC Machinery Directive

2006/95/EC Low Voltage Directive

2004/108/EC Electromagnetic Compatibility Directive

2011/65/EU RoHS Directive

Schorndorf, 14.10.2013

Place and date:

lieu et date

Name and signature of aurthorised p erson

Nom et signature de la personne autorisée

WHIRLPOOL EUROPE S.r.l I-21025 COMERIO

Maytag MDE18MN

(CEE Directive Machine)

(CEE Directive RoHs)

Year of CE Marking (Année d’apposition du marquage CE): 2013

):

(CEE Directive Basse Tension)

Micael Zirondi Karl-Dieter Klingenst ein

Director PDC FC EMEA Product Approval

(CEE Directive Compatibilité Electro-magnétique)

20

EU - DECLARATION OF CONFORMITY

CE - DECLARATION DE CONFORMITE

WE (nous):

BAUKNECHT HAUSGERÄTE GmbH, D-73614 Schorndorf

representing (représentant):

declare under our sole responsibility that the product

déclarons sous notre propre respon sabilité que le produit

dryer Maytag MDG18CS

(séche linge):

Whirlpool XCGM2763

to which this declaration relates is in conformity with the following standard(s) or other

normative document(s)

auquel se référe cette déclaration est con forme aux normes suivantes ou autres documents normatifs

EN 60335-1: 2012

EN 60335-102: 2006+A1:2010 incl. Corr 1&2

EN 62233: 2008+Ber.1: 2008

EN ISO 10472-1: 2008

EN ISO 10472-4: 2008

EN 55014-1: 2006+A1:2009+A2:2011 (Test method > 30 MHz: Disturbance power)

EN 55014-2: 1997+A1:2001+A2:2008

EN 61000-3-2:2006+A1:2009+A2:2009

EN 61000-3-3:2008

following the provisions of Directive(s

suivant les previsions des Directives:

2006/42/EC Machinery Directive

2006/95/EC Low Voltage Directive

2009/142/EC Gas Appliances Directive

2004/108/EC Electromagnetic Compatibility Directive

2011/65/EU RoHS Directive

Schorndorf, 14.10.2013

Place and date:

lieu et date

Name and signature of aurthorised p erson

Nom et signature de la personne autorisée

WHIRLPOOL EUROPE S.r.l I-21025 COMERIO

Maytag MDG18MN

(CEE Directive Machine)

(CEE Directive RoHs)

Year of CE Marking (Année d’apposition du marquage CE): 2013

):

(CEE Directive Basse Tension)

(CEE Directive relative aux appareils à gaz)

(CEE Directive Compatibilité Electro-magnétique)

Micael Zirondi Karl-Dieter Klingenst ein

Director PDC FC EMEA Product Approval

Page 21

TECHNICAL SPECIFICATIONS – GAS DRYER

220–240V~50Hz 1ph 3A max. IP24 Clothes capacity: 9.0 kg max. Sound pressure level, Lpa: 58 dBA (uncertainty, Kpa: +/-10 dBA) Total mass: 68 kg max.

Factory set for NATURAL GAS: Injector size: 2.2 mm Heat input gross: 5.9 kW

Country: CH, CZ, CY, ES, GB, GR,

HR, IE, IT, PT, SI, SK, TR

European Gas Category:

Gas Flow Rate: .562703 m3/hr 0.562703 m3/hr

Supply Pressure (G20): 20 mbar 20 mbar

Factory Adjusted Pressure: 7.4 mbar 7.4 mbar

With LP Gas Conversion Kit: Injector size: 1.25 mm Heat input gross: 6.4 kW

European Country: CH, CZ, CY, ES, GB, GR, HR,

European Gas Category:

Butane Supply Pressure (G30): 28–30 mbar 30 mbar

Adjusted Pressure: N/A N/A

Propane Supply Pressure (G31): 37 mbar 30 mbar

Adjusted Pressure: N/A N/A

With France/Belgium NATURAL GAS conversion kit: Injector size 1.65 mm Heat input gross: 5.9 kW

European Country: FR, BE

European Gas Category:

Supply Pressure (G20): 20 mbar

Supply Pressure (G25): 25 mbar

Adjusted Pressure: N/A

II

2H3+

IE, IT, PT, SI, SK, TR

II

2H3+

I

2E+

CY, CZ, DK, EE, FI, GR, HU,

IT, NO, RO, SE, SK, TR

II

2H3B/P

CY, CZ, DK, EE, FI, GR, HU,

IT, NO, RO, SE, SK, TR

II

2H3B/P

Factory set for Australia/New Zealand NATURAL GAS: Injector size: 2.2 mm Heat input gross: 5.9 kW

Country: AS, NZS

Supply Pressure (G20) minimum 1.13 kPa

Adjusted Pressure (Test Point Pressure): 0.74 kPa

Nominal Hourly Gas Consumption 21.1 MJ/h

With Australia LG Gas Conversion Kit: Injector Size: 1.40 mm Heat input gross: 6.54 kW

Country: AS, NZS

Propane Supply Pressure: 2.75 kPa

Adjusted Pressure: 2.75 kPa

Nominal Hourly Gas Consumption: 23 MJ/h

Factory set for NATURAL GAS: Injector size: 2.2 mm Heat input gross: 5.0 kW

Country: NL

European Gas Category:

Gas Flow Rate: 0.562703 m3/hr

Supply Pressure (G25): 25 mbar

Factory Adjusted Pressure (G25) : 7.4 mbar

Supply Pressure (G30/G31): 30 mbar

Factory Adjusted Pressure (G30/G31): N/A

NOTE: Conversion kit: From Natural Gas to LP Gas - Europe: Whirlpool Part No. W10233219.

Conversion kit: From Natural Gas to LP Gas - Australia: Whirlpool Part No. W10315369.

Conversion kit: From Natural Gas to Natural Gas - France/Belgium: Whirlpool Part No. W10181947.

Manufacturer: Whirlpool Corporation, Benton Harbor, Michigan 49022, U.S.A.

Manufacturing Site: Whirlpool Corporation, 1300 Marion-Agosta Rd., Marion, OH, 43302, U.S.A.

EU Representatives: Maytag UK Ltd., 2 St. Annes Blvd., Redhill, RH1 1AX, UK & Bauknecht Hausgeräte GmbH, D-73614 Schorndorf, Germany

II

2L3B/P

21

Page 22

MAYTAG® COMMERCIAL WASHER, DRYER, STACKED DRYER/

DRYER, COMMERCIAL STACK LAUNDRY, AND MULTI-LOAD COIN

OPERATED COMMERCIAL WASHERS AND DRYERS WARRANTY

LIMITED WARRANTY ON PARTS

For the first five years from the date of purchase, when this commercial appliance is installed, maintained and operated according to

instructions attached to or furnished with the product, Maytag brand of Whirlpool Corporation (thereafter “Maytag”) will pay for factory

specified parts or original equipment manufacturer parts to correct defects in materials or workmanship. Proof of original purchase date is

required to obtain service under this warranty.

ITEMS MAYTAG WILL NOT PAY FOR

1. All other costs including labor, transportation, or custom duties.

2. Service calls to correct the installation of your commercial appliance, to instruct you how to use your commercial appliance, to replace

or repair fuses, or to correct external wiring or plumbing.

3. Repairs when your commercial appliance is used for other than normal, commercial use.

4. Damage resulting from improper handling of product during delivery, theft, accident, alteration, misuse, abuse, fire, flood,

acts of God, improper installation, installation not in accordance with local electrical or plumbing codes, or use of products not

approved by Maytag.

5. Pickup and Delivery. This commercial appliance is designed to be repaired on location.

6. Repairs to parts or systems resulting from unauthorized modifications made to the commercial appliance.

7. The removal and reinstallation of your commercial appliance if it is installed in an inaccessible location or is not installed

in accordance with published installation instructions.

8. Chemical damage is excluded from all warranty coverage.

9. Changes to the building, room, or location needed in order to make the commercial appliance operate correctly.

10. Repairs made by a non-Whirlpool authorized service technician.

DISCLAIMER OF IMPLIED WARRANTIES; LIMITATIONS OF REMEDIES

CUSTOMER’S SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY SHALL BE PRODUCT REPAIR AS PROVIDED

HEREIN. IMPLIED WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE, ARE LIMITED TO ONE YEAR OR THE SHORTEST PERIOD ALLOWED BY LAW. WHIRLPOOL SHALL NOT BE LIABLE

FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. SOME STATES AND PROVINCES DO NOT ALLOW THE EXCLUSION OR

LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, OR LIMITATIONS ON THE DURATION OF IMPLIED WARRANTIES

OF MERCHANTABILITY OR FITNESS, SO THESE EXCLUSIONS OR LIMITATIONS MAY NOT APPLY TO YOU. THIS WARRANTY

GIVES YOU SPECIFIC LEGAL RIGHTS AND YOU MAY ALSO HAVE OTHER RIGHTS, WHICH VARY FROM STATE TO STATE OR

PROVINCE TO PROVINCE.

If you need service, please contact your authorized Maytag® Commercial Laundry distributor. To locate your authorized Maytag®

Commercial Laundry distributor, or for web inquiries, visit www.MaytagCommercialLaundry.com.

1/11

For written correspondence:

Maytag® Commercial Laundry Service Department

2000 M-63 North

Benton Harbor, Michigan 49022 USA

22

Page 23

SECURITE DU SECHE-LINGE

■ On recommande que le propriétaire place les instructions à l’usage du client en un lieu bien visible, au cas où le client percevrait une

odeur de gaz. Ces renseignements doivent être obtenus auprès de votre fournisseur en gaz.

■ Placer l’avertissement qui suit à un endroit bien visible.

POUR VOTRE SECURITE

1. NE PAS UTILISER OU REMISER D’ESSENCE OU AUTRES MATÉRIAUX INFLAMMABLES DANS CET APPAREIL MÉNAGER

O U À PROXIMITÉ DE CELUI-CI.

2. NE PAS VAPORISER D’AÉROSOLS À PROXIMITÉ DE CET APPAREIL MÉNAGER LORSQU’IL EST EN FONCTIONNEMENT.

3. NE PAS MODIFIER CET APPAREIL MÉNAGER.

23

Page 24

SECURITE DU SECHE-LINGE

IMPORTANT : Pour mettre l’ancien sèche-linge au rebut ou pour la remiser, enlever la porte.

24

Page 25

SECURITE DU SECHE-LINGE

IMPORTANTES INSTRUCTIONS DE SÉCURITÉ

AVERTISSEMENT : Pour réduire les risques d’incendie, de choc électrique ou de blessures lors de l’utilisation

du sèche-linge, suivre les précautions fondamentales dont les suivantes :

■ Lire toutes les instructions avant d’utiliser le sèche-linge.

■ Ce sèche-linge est conçue uniquement pour le séchage

de vêtements et de textiles ayant été nettoyés à l’eau.

Ne pas l’utiliser à toute autre fin.

■ AVERTISSEMENT: Si l’on détecte une odeur de gaz,

ne pas utiliser le sèche-linge ou tout autre équipement

électrique situé à proximité. Avertir les autres personnes

qu’elles doivent évacuer cette zone. Contacter

le propriétaire du sèche-linge immédiatement.

■ Ne pas placer des articles exposés aux huiles de cuisson

dans votre sèche-linge. Les articles contaminés par des

huiles de cuisson peuvent contribuer à une réaction

chimique qui pourrait causer à la charge de s’enflammer.

■ Si on doit absolument placer des tissus qui contiennent de

l’huile végétale ou de cuisson ou qui ont été contaminés par

des produits de soin des cheveux dans un sèche-linge, faut

d’abord les laver dans de l’eau chaude avec un supplément

de détergent; ceci réduira le danger, sans toutefois

l’éliminer.

■ Ne pas faire sécher des articles qui ont été nettoyés ou

lavés avec de l’essence ou imbibés d’essence, solvants

de nettoyage à sec, ou autres substances inflammables ou

explosives; ces substances peuvent émettre des vapeurs

susceptibles de s’enflammer ou d’exploser.

■ Les articles qui ont été souillés avec des substances

comme de l’acétone, de l’alcool, du pétrole, du kérosène,

des détachants, de la térébenthine, des cires et des

décapants pour cire doivent être lavés à l’eau chaude avec

un supplément de détergent avant d’être séchés dans le

sèche-linge.

■ Ne pas faire sécher dans le sèche-linge des articles

nonlavés.

■ Ne pas utiliser ce sèche-linge si l’on a utilisé des produits

chimiques industriels pour le nettoyage. La présence

éventuelle de quantités résiduelles de produits chimiques

corrosifs ou décomposés dans la charge peut endommager

le sèche-linge et produire des fumées toxiques.

■ Ne pas laisser des enfants jouer sur ou à l’intérieur

du sèche-linge. Bien surveiller les enfants lorsque

le sèche-linge est utilisé à proximité d’enfants.

■ Ce sèche-linge n’est pas conçu pour une utilisation par

des personnes (notamment des enfants) aux capacités

physiques, sensorielles ou mentales réduites, ou manquant

d’expérience ou de connaissances, à moins qu’elles soient

supervisées par une personne responsable ou aient reçu

des instructions adaptées pour utiliser le sèche-linge en

toute sécurité.

■ Avant de retirer le sèche-linge pour un dépannage ou pour

le jeter, ôter la porte du compartiment du sèche-linge.

■ Ne pas tenter d’atteindre un article à l’intérieur de la cuve

du sèche-linge lorsque le tambour est en mouvement.

■ Ne pas ouvrir la porte lorsque le sèche-linge est

en marche. Il s’arrêtera.

■ Lors du chargement ou du rechargement du sèche-linge,

éviter de toucher les parties métalliques chaudes du

tambour (risque de brûlure).

CONSERVEZ CES INSTRUCTIONS

■ Si la rotation du tambour est entravée par des tissus

coincés, déconnecter le sèche-linge de l’alimentation

électrique avant de retirer la source d’obstruction avec

précaution.

■ Ne pas utiliser le sèche-linge s’il ne chauffe pas, s’il semble

défectueux ou endommagé. Contacter le propriétaire.

■ Ne pas installer ou remiser ce sèche-linge à un endroit

où il serait exposée aux intempéries.

■ Ne pas modifier les organes de commande.

■ Nettoyer le filtre à charpie avant et après chaque charge.

■ Ne pas utiliser ce sèche-linge si le filtre à peluches

n’est pas installé.

■ Ne pas réparer ou remplacer un composant quelconque du

sèche-linge, ni entreprendre une opération de service, si ce

n’est spécifiquement recommandé dans ce manuel ou dans

un manuel d’instructions de réparations destiné à l’utilisateur;

il est alors essentiel que la personne concernée comprenne

ces instructions et soit compétente pour les exécuter.

■ Ne pas utiliser un produit assouplissant de tissu ou des

produits pour éliminer la statique à moins qu’ils ne soient

recommandés par le fabricant du produit assouplissant de

tissu ou du produit.

■ Ne pas utiliser la chaleur pour faire sécher des articles

fabriqués avec du caoutchouc mousse ou de matériaux

semblables.

■ La dernière partie d’un programme de séchage

par culbutage a lieu sans chaleur (programme de

refroidissement) pour faire en sorte que les articles

soient laissés à une température qui garantit que les articles

ne seront pas endommagés.

■ AVERTISSEMENT: Ne jamais arrêter le séchage par

culbutage avant la fin du programme de séchage sauf

si tous les articles sont retirés rapidement et répartis pour

une dissipation de la chaleur (permet d’éviter le risque de

combustion spontanée).

■ En cas de coupure de l’alimentation électrique, retirer

rapidement la charge et l’étaler pour éviter tout risque

de combustion spontanée.

■ Ne pas laisser la charpie, la poussière, ou la saleté

s’accumuler autour du système d’évacuation ou autour de

l’appareil.

■ Les ouvertures de ventilation pour l’arrivée d’air frais dans

la pièce et dans le sèche-linge ne doivent pas être obstruées

ou scellées.

■ Commande d’arrêt d’urgence : En cas d’urgence, la prise

d’alimentation secteur doit être retirée.

■ Un nettoyage périodique de l’intérieur du sèche-linge et du

conduit d’évacuation doit être effectué par une personne

qualifiée.

■ Voir la section “Spécifications électriques” dans les

instructions d’installation pour les instructions de mise

à la terre.

25

Page 26

ELIMINATION DU SECHE-LINGE

NOMENCLATURE DES MODÈLES :

MDG – Maytag gaz CS – Module de commande électronique avec chute de pièce activé

MDE – Maytag électrique MN – Module de commande électronique sans paiement

18 – Numéro de type du modèle

26

Page 27

OUTILS ET PIECES

Outillage nécessaire :

Clé à tuyau Clé à molette de 203 mm (8") Tournevis à lame plate Tournevis Phillips

de 203 mm (8") ou 254 mm (10") (ouverture

ou 254 mm (10") jusqu’à 25 mm [1"])

Tournevis isolé ou foret Clé à douille hexagonale Clé à douille de 8 mm (5/16") Pince (ouverture

Torx®† T-20®† de 25 mm (1") jusqu’à 39 mm [19/16"])

Niveau Couteau utilitaire Tourne-écrou de 6 mm (1/4") Cale de bois de

686 mm (27")

Pistolet à calfeutrage et Brides de conduit Composé d’étanchéité Couteau à mastic

composé de calfeutrage des tuyauteries résistant au type

(pour l’installation d’un nouveau de gaz utilisé

conduit d’évacuation)

Lampe de poche Clés plates de 25 mm (1") Règle ou mètre ruban

(facultative)

Pièces fournies :

Patins (4) Pieds du sèche-linge (4)

REMARQUE : Le schéma de circuits de ce sèche-linge se trouve

à l’intérieur du panneau inférieur avant, dans les fiches techniques.

Caractéristiques techniques :

220 – 240 V, 50 Hz. AC

4575W

Poids total : 68 kg max.

Capacité de buanderie :

9 kg max.

BRUIT : Niveau de pression acoustique, LpA : 58 dBA

(incertitude, KpA: +/–10 dBA).

†® TORX et T20 sont les marques déposées de Acument Intellectual Properties, LLC.

27

Page 28

DIMENSIONS/DISTANCES DE DEGAGEMENT

(1")

(0")

(

)

Dimensions

Vue latérale Vue arrière

889 mm

(35")

25 mm

(1")

260 mm

1

/4")

(10

743 mm

(291/4")

648 mm

(251/2")

210 mm

1

(8

/4")

83 mm

(31/4")

38 mm

1

(1

/2")

140 mm

(5

1

/2")

686 mm

Électricité

Electric

343 mm

(131/2")

Gaz

Gas

330 mm

(13")

(27")

279 mm

(11")

102 mm

(4" dia)

889 mm

(35")

(modèles

(electric models)

électriques)

(modèles à gaz)

(gas models)

83 mm

31/4"

1048 mm

(411/4")

940 mm

(37")

Évacuation par le bas

178 mm

(7")

359 mm

1

/8")

(14

Distances de dégagement

Encastrement, vue avant Placard, vue latérale

381 mm

(15")

356 mm

(14")

28

0 mm

(0")

0 mm

(0")

25 mm

0 mm

Page 29

EXIGENCES D’INSTALLATION POUR LE SECHE-LINGE

Exigences de l’emplacement

Le sèche-linge peut être installé dans un sous-sol, une salle de

buanderie ou un encastrement.

Ce sèche-linge n’est pas destiné pour l’installation dans une

maison mobile.

Il faut aussi prendre en compte les exigences d’emplacement des

appareils voisins.

IMPORTANT : Ne pas installer ou remiser le sèche-linge dans un

endroit où elle sera exposée aux intempéries. C’est à l’utilisateur

qu’incombe la responsabilité de réaliser une installation correcte.

Il vous faudra :

■ Une prise électrique reliée à la terre située à moins de

1,8 m (6 pi) de la prise du cordon électrique se trouvant

à l’arrière du sèche-linge. Voir “Spécifications électriques”.

■ Un plancher de niveau ayant une pente maximale de

25 mm (1") sous l’ensemble du sèche-linge. L’installation

du sèche-linge sur des surfaces de sol molles, telles que

tapis ou surfaces avec sous-couche en mousse n’est pas

recommandée.

Distances de dégagement pour l’installation pour

le sèche-linge

■ L’emplacement doit être assez grand pour permettre d’ouvrir

complètement la porte du sèche-linge.

■ Prévoir davantage d’espace pour faciliter l’installation

et l’entretien. La porte s’ouvre à plus de 180°.

■ Un espace supplémentaire peut être requis pour les moulures

de porte et de plancher et pour les plinthes.

■ Un espace supplémentaire de 25 mm (1") de tous les côtés du

sèche-linge est recommandé pour réduire le transfert du bruit.

Lors de l’installation d’un sèche-linge :

IMPORTANT : Observer les dispositions de tous les codes

et règlements en vigueur.

■ Vérifier les exigences des codes : Certains codes limitent ou

n’autorisent pas l’installation d’un sèche-linge dans un garage,

un placard ou une chambre à coucher. Communiquer avec

l’inspecteur en bâtiments local.

■ Sèche-linges à gaz seulement : S’assurer que les rebords

inférieurs de la caisse ainsi que les côtés arrière et inférieurs du

sèche-linge, sont bien dégagés pour permettre une évacuation

adéquate de l’air de combustion. Voir la section “Instructions

d’installation dans un encastrement ou un placard” ci-dessous

pour connaître les distances de dégagement minimales.

Instructions d’installation dans un encastrement ou un placard

Ce sèche-linge peut être installé dans un encastrement ou un

placard. Pour les installations dans un encastrement ou un placard,

les distances de dégagement minimales sont indiquées sur

l’étiquette d’avertissement à l’arrière du sèche-linge ou à la section

“Dimensions/Distances de dégagement”.

Les dimensions d’installation sont en millimètres et constituent

le minimum applicable. Un espace supplémentaire peut être

nécessaire pour faciliter l’installation, l’entretien et pour observer

les codes et règlements locaux.

Si une porte de placard est installée, une ouverture d’évacuation

de l’air minimale est nécessaire dans les parties supérieure

et inférieure. Les portes à claire-voie offrant des ouvertures

équivalentes sont acceptables.

Le sèche-linge doit être évacué à l’extérieur.

Aucun autre appareil utilisant un combustible ne doit être installé

dans le même placard.

310 cm2

(48 po2)

Vue de

face

155 cm

(24 po2)

Porte du

placard

2

76 mm

(3 po)

76 mm

(3 po)

29

Page 30

EXIGENCES D’INSTALLATION POUR LE SECHE-LINGE ELECTRIQUE

Spécifications électriques

MPORTANT : Respecter les dispositions de tous les codes et

règlements en vigueur.

Ce sèche-linge est livré sans cordon d’alimentation électrique et

sans prise. Il doit être raccordé par un électricien compétent à

une source d’alimentation électrique monophasée, de tension telle

qu’indiquée sur la plaque signalétique en utilisant un câblage fixe

approprié, conformément aux règlements locaux et nationaux.

■ Un cordon circulaire à 3 fils avec des conducteurs d’au moins

2,5 mm2 de section doit être utilisé.

■ Un fusible de 25A (minimum) doit être utilisé sur l’alimentation

et un sectionneur bipolaire sur les deux lignes doit être

incorporé dans le câblage fixe pour assurer une déconnexion

totale en cas de survoltage de catégorie III, conformément aux

règlements locaux en matière de raccordement. Le sèche-linge

doit être placé de façon à ce que le sectionneur soit clairement

évident et facilement accessible pour l’utilisateur.

Ce sectionneur remplit également la fonction de commande

d’arrêt d’urgence pour l’utilisateur.

■ Une garniture de serre-fil pour le d’alimentation est fournie

avec le sèche-linge et doit être serrée une fois le câblage

terminé. Les bornes de raccordement au secteur se trouvent

derrière le petit panneau d’accès arrière (couvercle du boîtier

de connexion), et les connexions doivent être réalisées

conformément au marquage des bornes. Ne pas oublier de

remettre en place le panneau d’accès du boîtier de connexion

(couvercle du boîtier de connexion).

REMARQUE : Conformément à la directive européenne CEM

(2004/108/EC), l’impédance maximale du système d’alimentation

électrique auquel le sèche-linge électrique doit être connecté est

de 0,054 Ohm + j0,034 Ohm.

REMARQUE : Normes de sécurité électriques : Pour ce produit, le

fabricant a estimé que la mise en conformité avec les normes IEC/

EN.60335 était la plus appropriée.

Cet appareil est un sèche-linge à 3 conducteurs

qui doit être relié à la terre.

Si les codes le permettent et si un conducteur supplémentaire

de mise à la terre est utilisé, il est recommandé qu’un électricien

qualifié inspecte le parcours du fil de mise à la terre.

Méthode recommandée pour la mise à la terre

Il incombe à l’utilisateur de contacter un électricien qualifié afin

de veiller à ce que l’installation électrique soit réalisée de façon

adéquate et en conformité avec les exigences de tous les codes

et règlements locaux.

30

Page 31

EXIGENCES D’INSTALLATION POUR LE SECHE-LINGE A GAZ

Spécifications électriques

IMPORTANT : Respecter les dispositions de tous les codes et

règlements en vigueur.

Une prise électrique avec liaison à la terre située à 610 mm (2 pi)

maximum de l’un des côtés du sèche-linge est nécessaire.

Ce sèche-linge est équipé d’un cordon d’alimentation électrique et

d’une fiche. Il doit être connecté à une prise électrique de tension

tel qu’indiqué sur la plaque signalétique. La capacité minimale

du fusible d’alimentation doit être de 10A. Le sèche-linge doit

être installé de façon à ce que la fiche soit clairement évidente

et accessible. Cette fiche remplit également la fonction de

commande d’arrêt d’urgence pour l’utilisateur. Si la fiche d’origine

n’est pas utilisée, la connexion électrique doit être effectuée par

un électricien compétent conformément aux codes locaux et

nationaux.

Si le cordon d’alimentation est endommagé, il doit être remplacé

par un cordon à embout spécifique par un agent d’entretien

autorisé ou une personne de compétence similaire afin d’éviter

tout danger.

Ne pas utiliser d’adaptateur.

Ne pas utiliser de câble de rallonge.

REMARQUE : Conformément à la directive européenne CEM

(2004/108/EC), l’impédance maximale du système d’alimentation

électrique auquel le sèche-linge à gaz doit être connecté est de

0,054 Ohm + j0,034 Ohm.

REMARQUE : Normes de sécurité électriques : Pour ce produit,

le fabricant a estimé que la mise en conformité avec les normes

IEC/EN.60335 était la plus appropriée.

INSTRUCTIONS DE MISE A LA TERRE

Ce sèche-linge a été conçu pour être raccordé au

secteur et mis à la terre ; la mise à la terre est donc impérative:

En cas disfonctionnement ou de panne, la mise à la terre

réduira le risque de choc électrique en offrant au courant

électrique une voie de moindre résistance. Ce sèche-linge

est alimenté par un cordon électrique comportant un

conducteur de liaison à la terre et une che de mise à la terre.

La che doit être branchée sur une prise de courant

appropriée correctement installée et reliée à la terre

conformément à tous les codes et règlements locaux.

Un raccordement inapproprié

AVERTISSEMENT :

du conducteur de liaison à la terre peut causer un risque

de choc électrique.

En cas de doute concernant la qualité de la liaison à la terre

du sèche-linge, consulter un électricien qualié, un agent

ou personnel d’entretien. Ne pas modier la che fournie

avec ce sèche-linge : Si elle ne correspond pas à la prise

de sortie, faire installer une prise appropriée par un

électricien qualié.

CONSERVEZ CES INSTRUCTIONS

À l’aide du cordon universel fourni avec ce sèche-linge :

Ce sèche-linge à gaz est équipé d’un cordon universel avec des

fiches interchangeables.

1. Pour utiliser le cordon universel, sélectionner la fiche amovible

qui correspond à votre prise de courant et brancher dans

l’adaptateur placé sur le cordon d’alimentation.

2. Fixer la fiche amovible sur le cordon en alignant les deux moitiés

de couvercle sur l’adaptateur et en les emboîtant.

Si les codes le permettent et si un conducteur supplémentaire

de mise à la terre est utilisé, il est recommandé qu’un électricien

qualifié inspecte le parcours du fil de mise à la terre.

31

Page 32

EXIGENCES D’INSTALLATION POUR LE SECHE-LINGE A GAZ

Alimentation en gaz

Exigences concernant le conduit d’alimentation :

AVERTISSEMENT

Risque d'explosion

Connecter ce sèche-linge à une canalisation

d’alimentation en gaz réglementée. La pression

de gaz doit être conforme aux exigences techniques

(voir dernière page).

Installer un robinet d'arrêt.

Bien serrer tous les raccords de la ligne de gaz.

En cas de connexion au gaz propane, demander à

une personne qualiée de s'assurer que la pression

d’alimentation en gaz est correcte.

Le non-respect de ces instructions peut causer

un décès, une explosion ou un incendie.

IMPORTANT : Se conformer à tous les codes et réglements

en vigueur.

Alimentation en gaz

Avant d’effectuer l’installation, vérifier que les caractéristiques

de distribution, la nature et la pression de gaz locales ainsi

que le réglage de l’appareil sont compatibles. Les informations

concernant le brûleur se trouvent sur la plaque signalétique située

sur la paroi interne de la porte du sèche-linge. Si l’information

ne correspond pas au type de gaz disponible, consulter votre

revendeur.

Gaz naturel :

Ce sèche-linge est configuré en usine pour une utilisation au

GAZ NATUREL (G20) et aucun réglage supplémentaire n’est

nécessaire lors de l’installation.

Gaz propane :

Ce sèche-linge est également homologué pour une utilisation

avec des gaz de pétrole liquéfié (propane ou butane) après

conversion appropriée. Ne pas tenter de convertir l’appareil pour

une utilisation avec un gaz différent de celui indiqué sur la plaque

signalétique sans consulter le fournisseur de gaz au préalable.

La conversion doit être effectuée par un réparateur qualifié.

La trousse de conversion, numéro de référence W10233219,

est disponible à l’achat chez votre revendeur. Des instructions

accompagnent cette trousse.

Gaz naturel (France/Belgique) :

Ce sèche-linge est également homologué par la France/Belgique

pour une utilisation avec un gaz G20/G25

avec une conversion appropriée. Il ne faut pas essayer de convertir

ce sèche-linge à partir du gaz indiqué sur l’étiquette d’indice

de gaz vers un gaz différent sans consulter le fournisseur de gaz.

La conversion d’un gaz à un autre doit être faite par un technicien

qualifié de service de gaz. L’ensemble de conversion (numéro

de pièce W10181947) peut être acheté chez votre marchand.

Des instructions complètes sont fournies avec l’ensemble.

(20 mbar/25 mbar)

Installer un conduit rigide d’alimentation en gaz à l’emplacement

du sèche-linge. Le diamètre interne minimal du conduit doit être

de 12,5 mm (1/2"). Lorsque les codes locaux et votre fournisseur

de gaz l’autorisent, un diamètre interne de conduit rigide de

10 mm (3/8") peut être utilisé pour des longueurs inférieures

à 6,1 m (20 pi.). Une pâte d’étanchéité pour joints résistant

à l’action du gaz propane doit être utilisée.

Le raccordement au gaz du sèche-linge lui-même doit être effectué

au moyen d’un conduit de gaz flexible qui convienne à l’appareil et

corresponde à la catégorie de gaz, conformément aux règlements

d’installation nationaux. En cas de doute, contacter le fournisseur

de gaz. Le diamètre interne doit être d’au moins 10 mm (3/8").

Un dispositif de fixation doit être installé entre l’appareil et le

mur afin d’éviter que la canalisation d’alimentation en gaz rigide

ne subisse de tension lors d’un déplacement de l’appareil. Il est

recommandé d’utiliser une longueur de chaîne appropriée et un

crochet mural.

Le raccord du conduit d’alimentation en gaz du sèche-linge est

un filetage conique NPT de 3/8". Un adaptateur est fourni pour

la conversion à un filetage standard (3/8" BSP) selon la norme

ISO.228-1.

Vérifier l’absence de fuites en utilisant une solution de détection

non-corrosive homologuée. L’apparition de bulles indique la

présence d’une fuite. Réparer toute fuite éventuelle. Un dispositif

de mesure de la pression est fourni avec le robinet de gaz à

l’intérieur du sèche-linge; on peut y accéder après avoir retiré

le panneau avant inférieur.

Le sèche-linge doit être déconnecté du système d’alimentation

en gaz lors de tout test de pression.

32

Page 33

EXIGENCES CONCERNANT L’EVACUATION DU SECHE-LINGE

Coudes :

■ Les coudes à 45° permettent une meilleure circulation de l’air

que les coudes à 90°.

AVERTISSEMENT : Pour réduire le risque d’incendie,

ce sèche-linge doit ÉVACUER L’AIR À L’EXTÉRIEUR.

IMPORTANT : Observer les dispositions de tous les codes

et règlements en vigueur.

Le conduit d’évacuation du sèche-linge ne doit pas être raccordé

à une évacuation de gaz, une cheminée, un mur, un plafond, un

grenier, un vide sanitaire ou un vide de construction. Seul un

conduit d’évacuation métallique rigide ou souple doit être utilisé

pour le système d’évacuation.

102 mm

(4")

Conduit d’évacuation en métal lourd de 102 mm (4")

■ Utiliser uniquement un conduit d’évacuation en métal lourd de

102 mm (4") et des brides de serrage.

■ Ne pas utiliser de conduit de plastique ou de métal très mince.

Conduit métallique rigide :

■ Recommandé pour une performance de séchage idéale afin

d’éviter tout écrasement ou déformation.

Conduit métallique flexible : (Acceptable uniquement si son

accès reste facile pour le nettoyage)

■ Doit être entièrement déployé et soutenu à l’emplacement

d’installation final du sèche-linge.

■ Enlever tout excès de conduit flexible pour éviter tout

affaissement et déformation susceptible de réduire la capacité

d’évacuation et le rendement.

■ Ne pas installer le conduit métallique flexible dans des cavités

fermées de mur, plafonds ou planchers.

■ La longueur totale ne doit pas dépasser 2,4 m (7

3

⁄4 pi).

REMARQUE : Lors de l’utilisation d’un système d’évacuation

existant, nettoyer et éliminer la charpie sur toute la longueur du

système, et veiller à ce que le clapet d’évacuation ne soit pas

obstrué par de la charpie. Remplacer tout conduit de plastique ou

en aluminium par un conduit métallique rigide ou souple. Consulter

à nouveau le “Tableau des systèmes d’évacuation” et modifier le

système d’évacuation existant au besoin pour obtenir un meilleur

séchage.

Bon

Mieux

Brides de serrage :

■ Utiliser des brides pour sceller tous les joints.

■ Le conduit d’évacuation ne doit pas être raccordé ou fixé avec

des vis ou tout autre dispositif de serrage qui se prolongerait à

l’intérieur du conduit et retiendrait la charpie. Ne pas utiliser de

ruban adhésif pour conduit.

Une mauvaise évacuation de l'air peut causer de

l'humidité et une accumulation de charpie à l'intérieur de

la maison, ce qui peut provoquer :