Maytag MAT14PDAGW0 Installation Guide

COMMERCIAL WASHER iNSTALLATiON iNSTRUCTiONS

220-240-VOLT, 50-HZ MODELS

iNSTRUCTiONS D'INSTALLATION

DU LAVE-LINGE COMMERCIAL

MODI_LES 220-240 V, 50 HZ

LAVADORA COMERCIAL INSTRUCCIONES DE INSTALACION

MODELOS DE 220 Y 240 VOLTIOS, 50 HZ

LAVATRICE COMMERCIALE ISTRUZIONI D'INSTALLAZIONE

MODELLI A 220-240 V, 50 HZ

MAT14PD

W10045627A

www.maytagcom merciaNaund ry.com

Table of Contents

WASHER SAFETY ..................................................................... 3

WASHER DISPOSAL ................................................................. 3

iNSTALLATiON REQUIREMENTS ............................................ 4

Tools and Parts ................................................................... 4

Location Requirements ....................................................... 4

Drain System ....................................................................... 5

Electrical Requirements ...................................................... 5

Table des mati res

SECURITE DU LAVE-LINGE ................................................... 14

_eLIMINATION DU LAVE-LINGE ............................................. 14

EXlGENCES D'INSTALLATION .............................................. 15

Outillage et pieces ............................................................. 15

Exigences d'emplacement ................................................ 15

Systeme de vidange .......................................................... 16

Specifications _lectriques ................................................. 16

P

Indite

INSTALLATION iNSTRUCTiONS .............................................. 6

Remove Shipping Strap ...................................................... 6

Connect the Hoses ............................................................. 6

Level the Washer ................................................................. 7

Complete Installation .......................................................... 8

Operating Tips ..................................................................... 8

ELECTRONIC CONTROLS SETUP ........................................... 9

WARRANTY .............................................................................. 13

iNSTRUCTiONS D'INSTALLATION ........................................ 17

Enlever la sangle d'exp_dition .......................................... 17

Raccordement des tuyaux ................................................ 17

R_glage de I'aplomb du lave-linge .................................... 18

Achever I'installation .......................................................... 19

Conseils d'utilisation ......................................................... 19

PARAM_eTRAGE DES COMMANDES _eLECTRONIQUES ..... 20

GARANTIE ................................................................................ 25

SEGURIDAD DE LA LAVADORA ............................................ 26

ELIMINACION DE LA LAVADORA ......................................... 26

REQUISITOS DE INSTALACION ............................................ 27

Piezas y herramientas ....................................................... 27

Requisitos de ubicaci6n .................................................... 27

Sistema de desagQe ......................................................... 28

Requisitos el_ctricos ......................................................... 28

Sommario

SICUREZZA DELLA LAVATRICE ........................................... 38

L'ELIMINAZIONE DELLA LAVATRICE ................................... 38

REQUISITI D'INSTALLAZIONE .............................................. 39

Attrezzi e componenti ....................................................... 39

Requisiti di posizionamento .............................................. 39

Sistema di scarico ............................................................. 40

Requisiti elettrici ................................................................ 40

INSTRUCCIONES DE INSTALACION .................................... 29

C6mo quitar la correa de embalaje ................................... 29

Conecte las mangueras .................................................... 29

Nivelaci6n de la lavadora .................................................. 30

Complete la instalaci6n ..................................................... 31

Consejos para el funcionamiento ....................................... 31

PROGRAMACION DE LOS CONTROLES

ELECTRONICOS ...................................................................... 32

GARANTIA ................................................................................ 37

ISTRUZlONI D'INSTALLAZlONE ............................................ 41

Rimozione delle fascette d'imballaggio ............................ 41

Collegamento dei tubi ....................................................... 41

Livellamento della lavatrice ............................................... 42

Installazione completa ....................................................... 43

Suggerimenti operativi ...................................................... 43

CONFIGURAZIONE DEI CONTROLLI ELETTRONICI ........... 44

GARANZlA ................................................................................ 52

2

WASHER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen ifthe instructions are not followed.

WASHER DISPOSAL

This appliance is marked according to the European directive 2002/96/EC on Waste Electrical and Electronic Equipment

(WEEE).

By ensuring this product is disposed of correctly, you will help avoid potential negative consequences for the environment and

human health, which could otherwise be caused by inappropriate waste handling of this product.

The symbol on the product, or on the documents accompanying the product, indicates that this appliance may not be treated

as household waste. Instead it shall be handed over to the applicable collection point for the recycling of electrical and

electronic equipment.

Disposal must be carried out in accordance with local environmental regulations for waste disposal.

For more detailed information about treatment, recovery and recycling of this product, please contact your local city office, your

household waste disposal service or the shop where you purchased the product.

INSTALLATION REQUIREMENTS

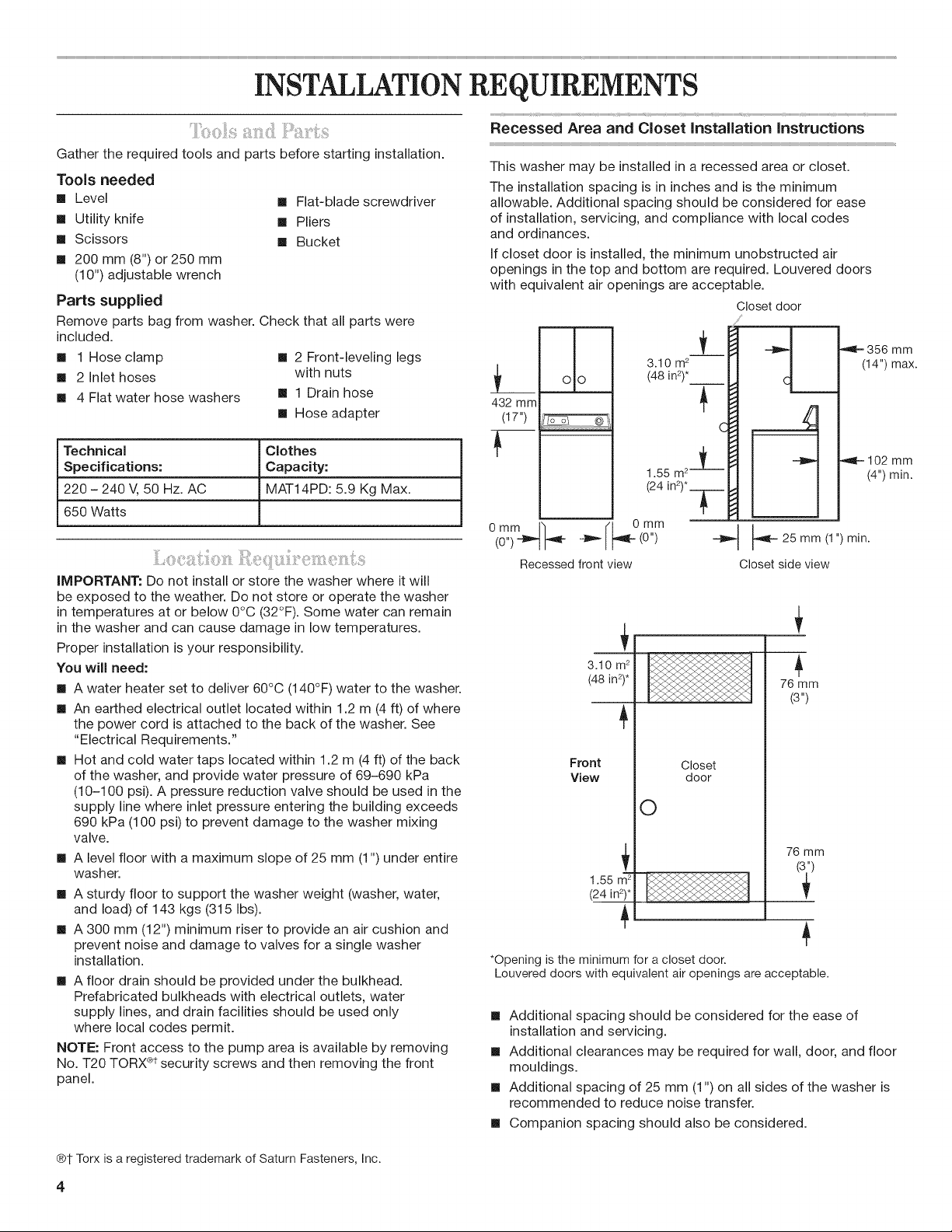

Recessed Area and Closet installation instructions

Gather the required tools and parts before starting installation.

Tools needed

[] Level [] Flat-bladescrewdriver

[] Utility knife [] Pliers

[] Scissors [] Bucket

[] 200 mm (8") or 250 mm

(10") adjustable wrench

Parts supplied

Remove parts bag from washer. Check that all parts were

included.

[] 1 Hose clamp [] 2 Front-leveling legs

[] 2 inlet hoses with nuts

[] 4 Flat water hose washers [] 1 Drain hose

[] Hose adapter

Technical C{othes

Specifications: Capacity:

220 - 240 V, 50 Hz. AC MAT14PD: 5.9 Kg Max.

650 Watts

iMPORTANT: Do not installor store the washer where it will

be exposed to the weather. Do not store or operate the washer

in temperatures at or below 0°C (32°F). Some water can remain

in the washer and can cause damage in low temperatures.

Proper installation is your responsibility.

You wii{ need:

[] A water heater set to deliver 60°C (140°F) water to the washer.

[] An earthed electrical outlet located within 1.2 m (4 ft) of where

the power cord is attached to the back of the washer. See

"Electrical Requirements."

[] Hot and cold water taps located within 1.2 m (4 ft) of the back

of the washer, and provide water pressure of 69-690 kPa

(10-100 psi). A pressure reduction valve should be used in the

supply line where inlet pressure entering the building exceeds

690 kPa (100 psi) to prevent damage to the washer mixing

valve.

[] A level floor with a maximum slope of 25 mm (1") under entire

washer.

[] A sturdy floor to support the washer weight (washer, water,

and load) of 143 kgs (315 Ibs).

[] A 300 mm (12") minimum riser to provide an air cushion and

prevent noise and damage to valves for a single washer

installation.

[] A floor drain should be provided under the bulkhead.

Prefabricated bulkheads with electrical outlets, water

supply lines, and drain facilities should be used only

where local codes permit.

NOTE: Front access to the pump area is available by removing

No. T20 TORX _'_*tsecurity screws and then removing the front

panel.

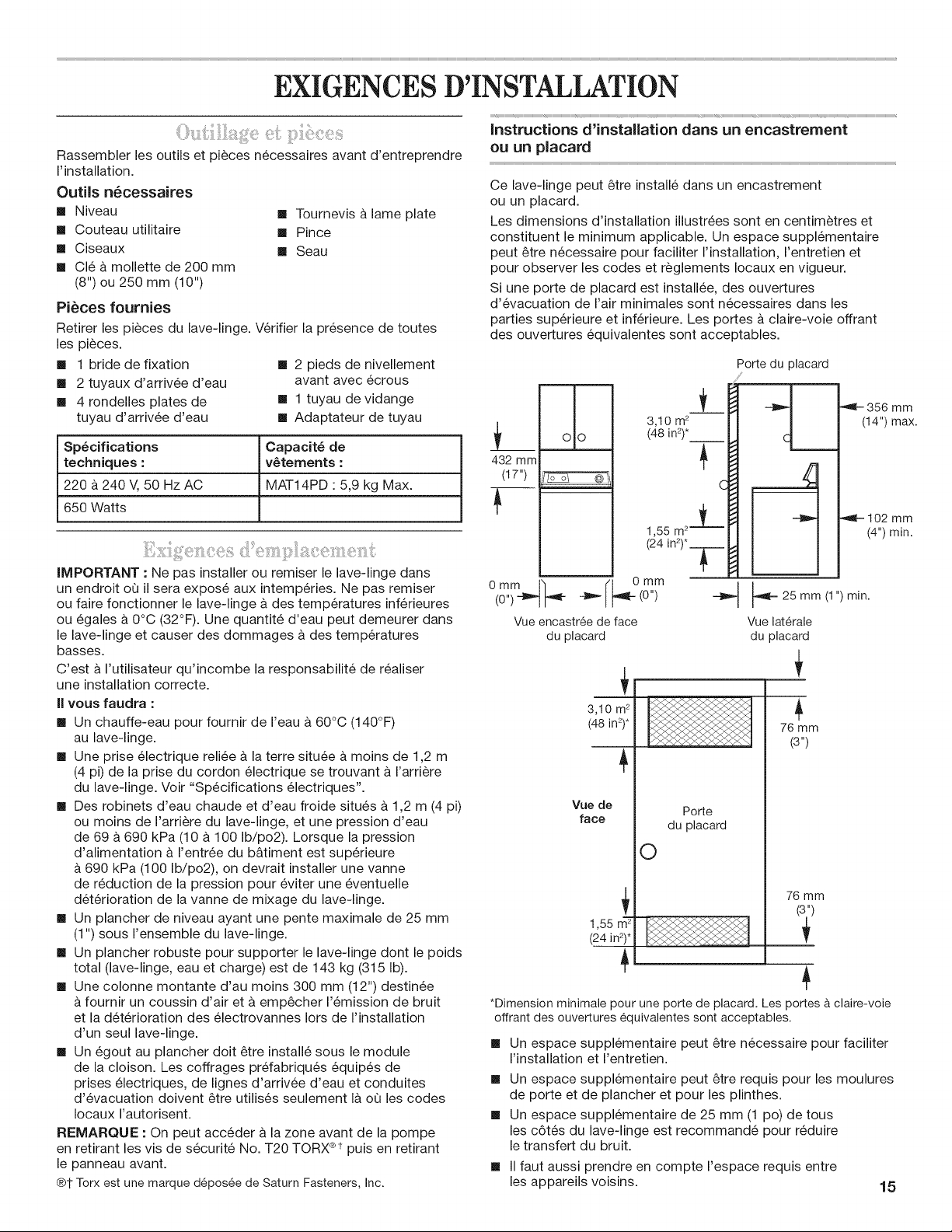

This washer may be installed in a recessed area or closet.

The installation spacing is in inches and is the minimum

allowable. Additional spacing should be considered for ease

of installation, servicing, and compliance with local codes

and ordinances.

if closet door is installed, the minimum unobstructed air

openings in the top and bottom are required. Louvered doors

with equivalent air openings are acceptable.

Closet door

3.10 m2

__ OO

432mm

(17") _ ................................

0mm "_ 4_

(0")

Recessedfront wew

3.10 m_

(48in_)*

(48 in2)*

(24

0mm

•_- (0">

(4")min.

Closet side view

76 m{

(3")

÷

Front

View

1.55m_

(24in_)*

*Opening is the minimum for a closet door.

Louvered doors with equivalent air openings are acceptable.

[] Additional spacing should be considered for the ease of

installation and servicing.

[] Additional clearances may be required for wall, door, and floor

mouldings.

[] Additional spacing of 25 mm (1") on all sides of the washer is

recommended to reduce noise transfer.

[] Companion spacing should also be considered.

Closet

door

0

76 mm

(3 II

mm

®1 Torx is a registered trademark of Saturn Fasteners, Inc.

4

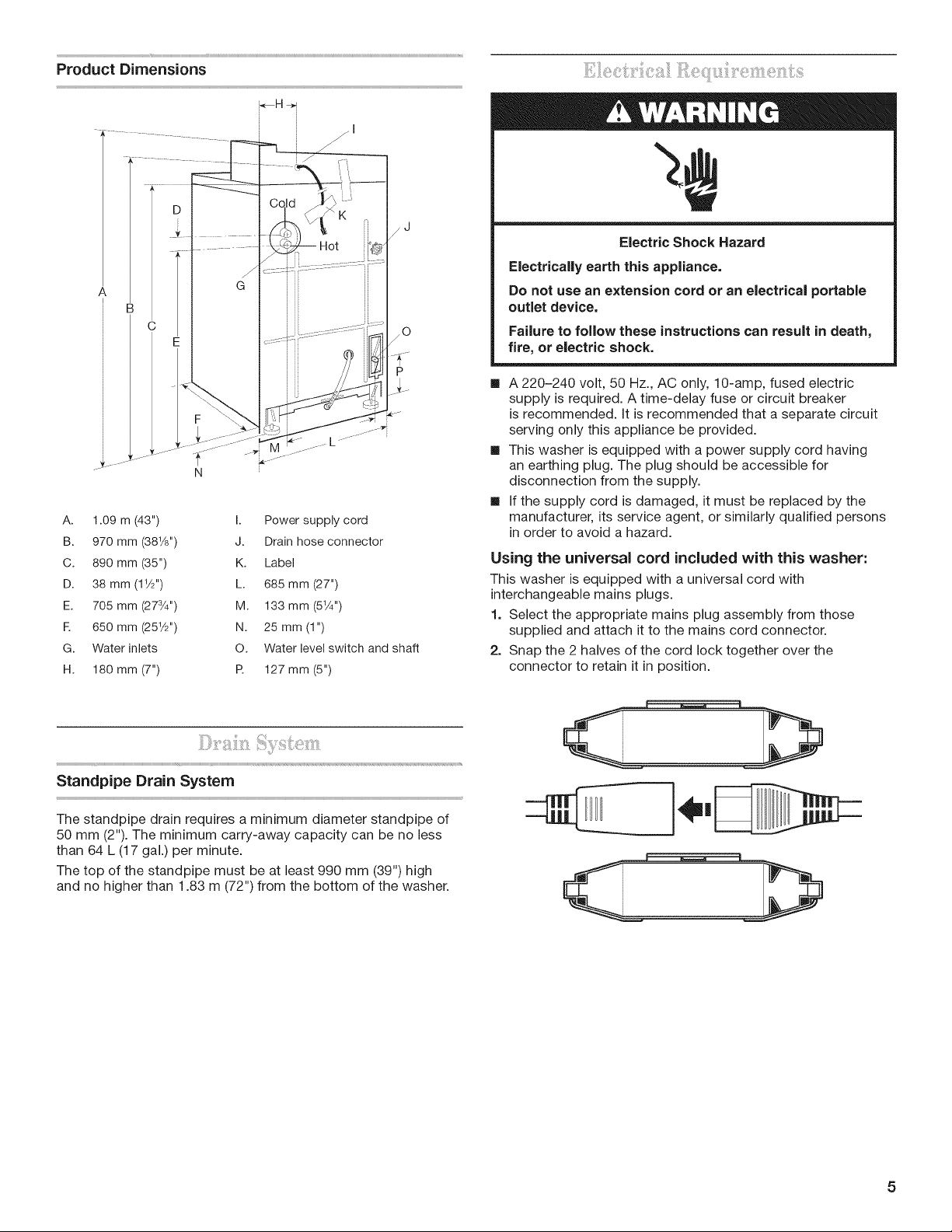

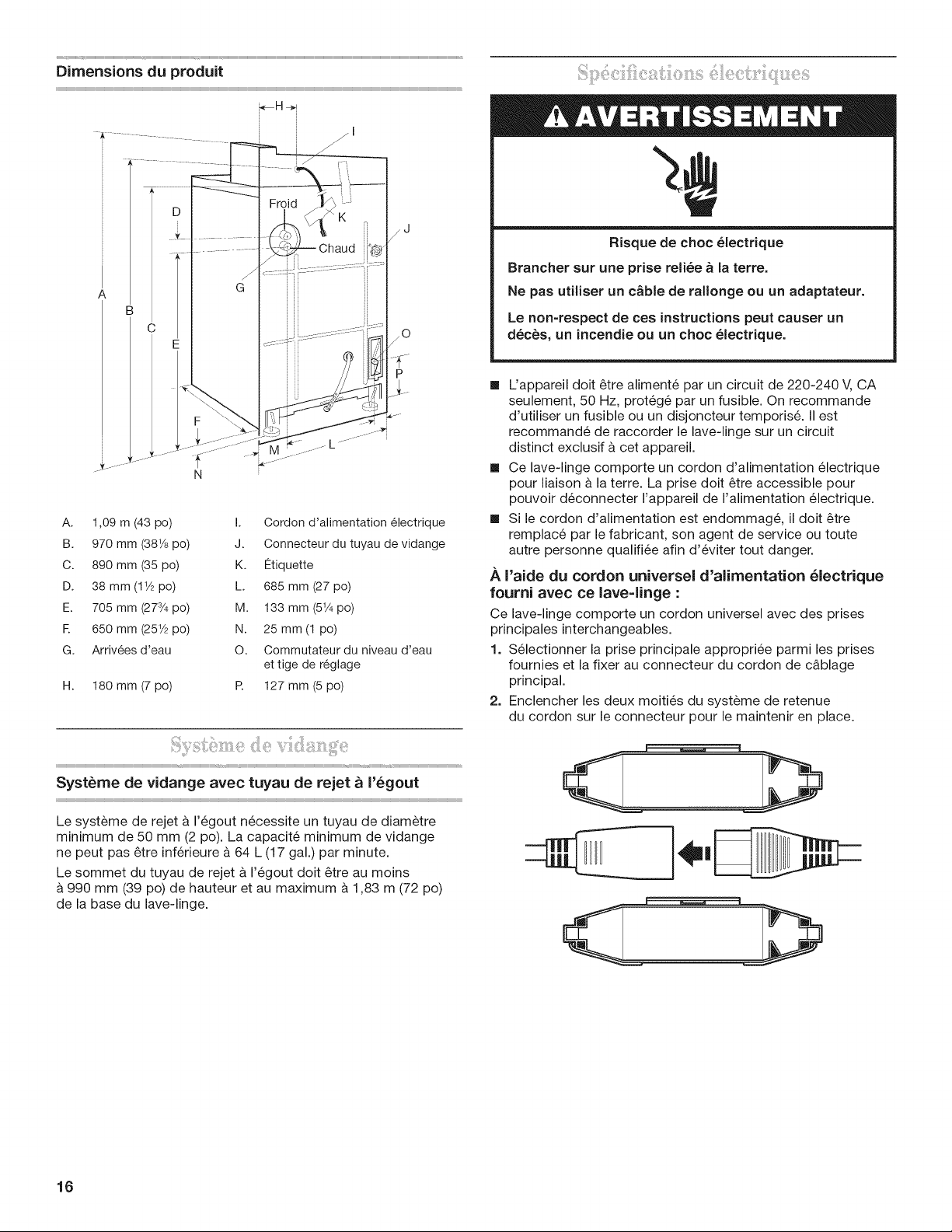

Product Dimensions

_H

A

A. 1.09 m (43") I. Power supply cord

B. 970 mm (38%") J. Drain hose connector

C. 890 mm (35") K. Label

D. 38 mm (11/2'') L. 685 mm (27")

E. 705 mm (27%") M. 133 mm (51/4'')

R 650 mm (251/2'') N. 25 mm (1")

G. Water inlets O. Water level switch and shaft

H. 180 mm (7") R 127 mm (5")

Electric Shock Hazard

Electrically earth this appliance.

Do not use an extension cord or an electrical portable

outlet device,

Failure to follow these instructions can result in death,

fire, or electric shock,

P

[] A 220-240 volt, 50 Hz., AC only, 10-amp, fused electric

supply is required. A time-delay fuse or circuit breaker

is recommended. It is recommended that a separate circuit

serving only this appliance be provided.

[] This washer is equipped with a power supply cord having

an earthing plug. The plug should be accessible for

disconnection from the supply.

[] If the supply cord isdamaged, it must be replaced by the

manufacturer, its service agent, or similarly qualified persons

in order to avoid a hazard.

Using the universal cord included with this washer:

This washer is equipped with a universal cord with

interchangeable mains plugs.

1. Select the appropriate mains plug assembly from those

supplied and attach it to the mains cord connector.

2. Snap the 2 halves of the cord lock together over the

connector to retain it in position.

Standpipe Drain System

The standpipe drain requires a minimum diameter standpipe of

50 mm (2"). The minimum carry-away capacity can be no less

than 64 L (17 gal.) per minute.

The top of the standpipe must be at least 990 mm (39") high

and no higher than 1.83 m (72") from the bottom of the washer.

RecommendedEarthingMethod

EARTHING iNSTRUCTiONS

This washer must be earthed. In the event of a malfunction

or breakdown, earthing will reduce the risk of electric

shock by providing a path of least resistance for electric

current. This washer is equipped with a cord having an

equipment-earthing conductor and an earthing plug. The

plug must be plugged into an appropriate outlet that is

properly installed and earthed in accordance with all local

codes and ordinances.

WARNING: Improper connection of the equipment-

earthing conductor can result in a risk of electric shock.

Check with a qualified electrician or serviceman if you are in

doubt as to whether the appliance is properly earthed.

Do not modify the plug provided with the appliance - if it wilt

not fit the outlet, have a proper outlet installed by a qualified

electrician.

INSTALLATION INSTRUCTIONS

Excessive Weight Hazard

Use two or more people to move and install washer.

Failure to do so can result in back or other injury.

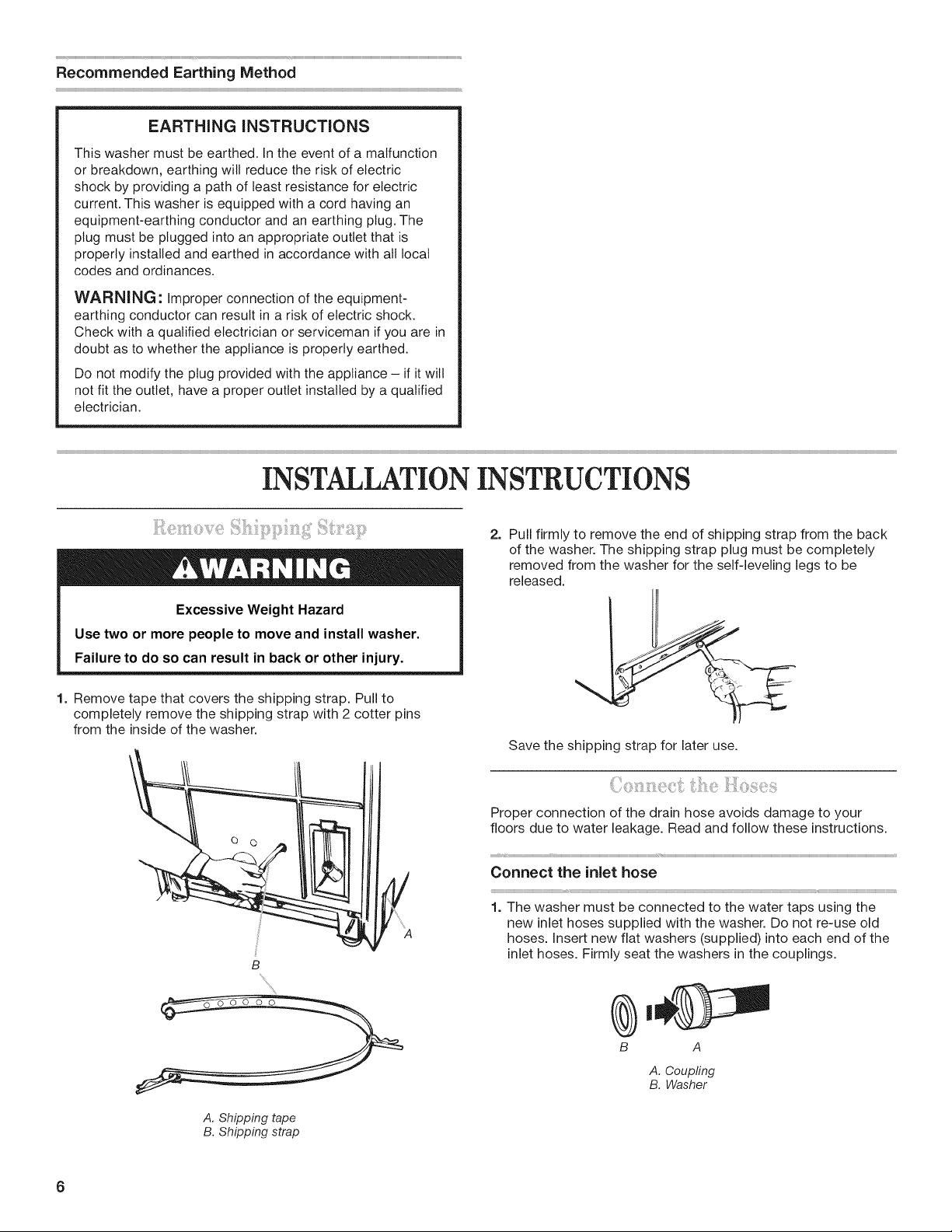

1. Remove tape that covers the shipping strap. Pull to

completely remove the shipping strap with 2 cotter pins

from the inside of the washer.

B

2. Pull firmly to remove the end of shipping strap from the back

of the washer. The shipping strap plug must be completely

removed from the washer for the self-leveling legs to be

released.

Save the shipping strap for later use.

Proper connection of the drain hose avoids damage to your

floors due to water leakage. Read and follow these instructions.

Connect the inlet hose

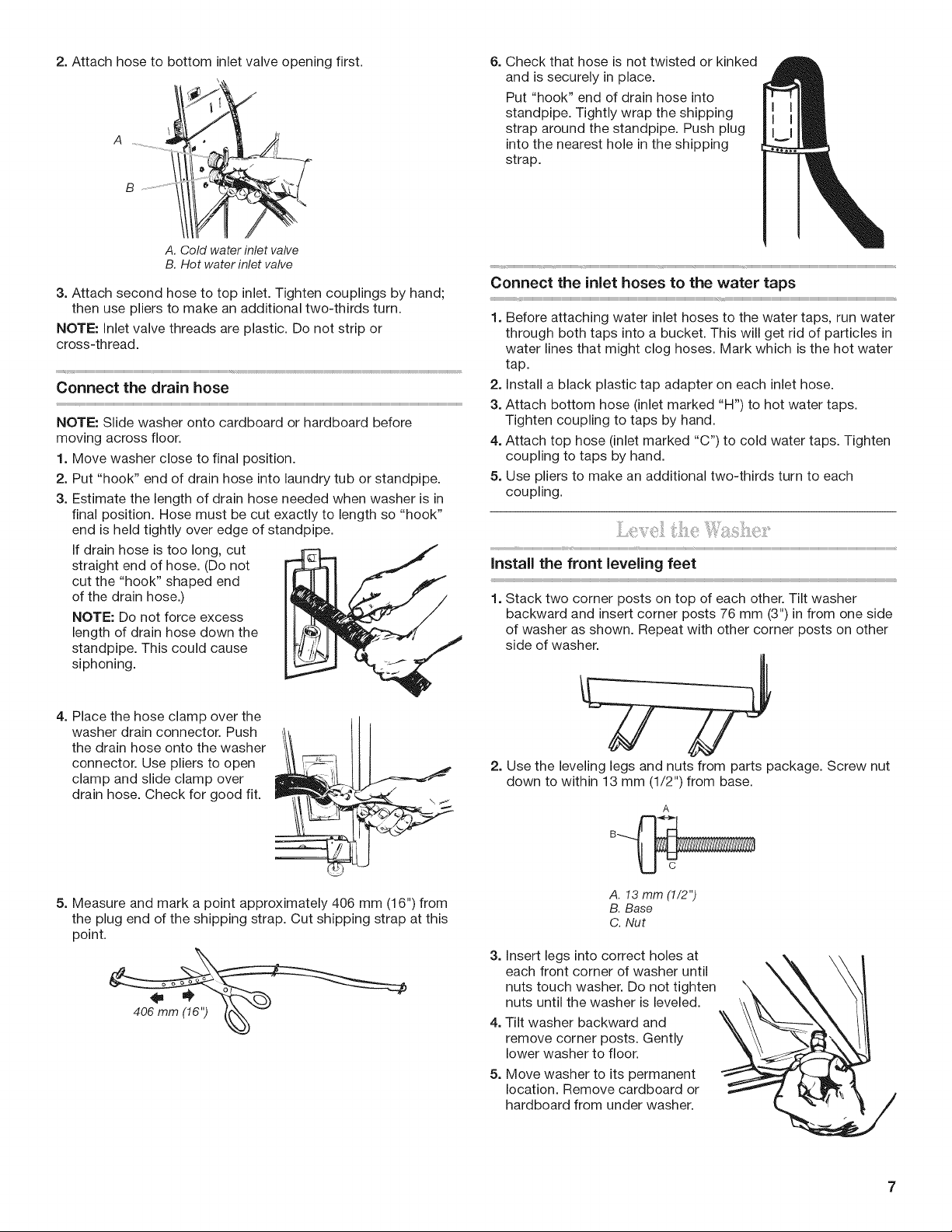

1. The washer must be connected to the water taps using the

A

new inlet hoses supplied with the washer. Do not re-use old

hoses. Insert new flat washers (supplied) into each end of the

inlet hoses. Firmly seat the washers in the couplings.

B A

A. Coupling

B. Washer

A. Shipping tape

B. Shipping strap

6

2. Attach hose to bottom inlet valve opening first.

A

B

A. Cold water inlet valve

B. Hot water inlet valve

3. Attach second hose to top inlet. Tighten couplings by hand;

then use pliers to make an additional two-thirds turn.

NOTE: Inlet valve threads are plastic. Do not strip or

cross-thread.

Connect the drain hose

NOTE: Slide washer onto cardboard or hardboard before

moving across floor.

1. Move washer close to final position.

2. Put "hook" end of drain hose into laundry tub or standpipe.

3. Estimate the length of drain hose needed when washer is in

final position. Hose must be cut exactly to length so "hook"

end is held tightly over edge of standpipe.

if drain hose is too long, cut

straight end of hose. (Do not

cut the "hook" shaped end

of the drain hose.)

NOTE: Do not force excess

length of drain hose down the

standpipe. This could cause

siphoning.

6. Check that hose is not twisted or kinked

and is securely in place.

Put "hook" end of drain hose into

standpipe. Tightly wrap the shipping

strap around the standpipe. Push plug

into the nearest hole in the shipping

strap.

Connect the inlet hoses to the water taps

1. Before attaching water inlet hoses to the water taps, run water

through both taps into a bucket. This will get rid of particles in

water lines that might clog hoses. Mark which isthe hot water

tap.

2. install a black plastic tap adapter on each inlet hose.

3. Attach bottom hose (inlet marked "H") to hot water taps.

Tighten coupling to taps by hand.

4. Attach top hose (inlet marked "C") to cold water taps. Tighten

coupling to taps by hand.

5. Use pliers to make an additional two-thirds turn to each

coupling.

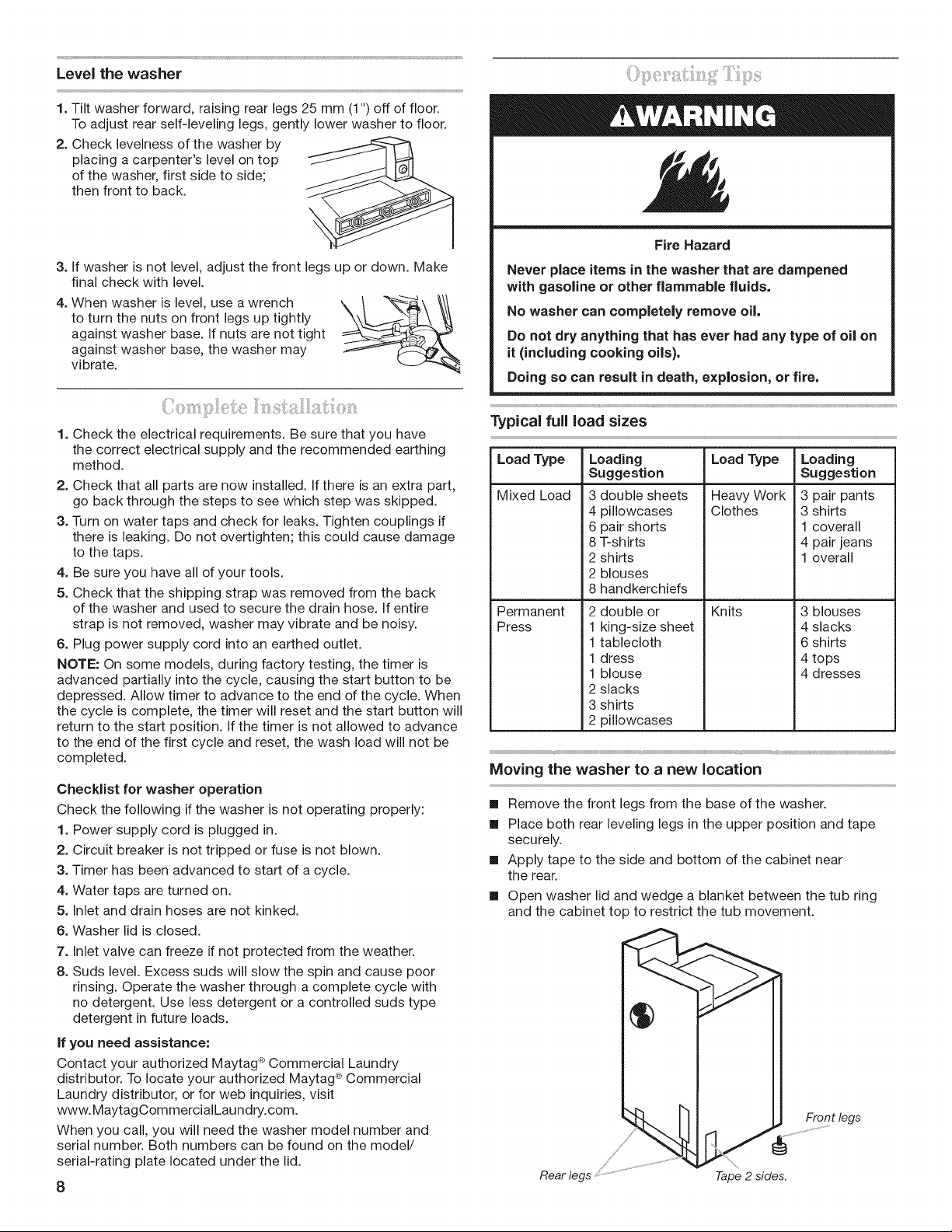

install the front leveling feet

1. Stack two corner posts on top of each other. Tilt washer

backward and insert corner posts 76 mm (3") in from one side

of washer as shown. Repeat with other corner posts on other

side of washer.

4. Place the hose clamp over the

washer drain connector. Push

the drain hose onto the washer

connector. Use pliers to open

clamp and slide clamp over

drain hose. Check for good fit.

5. Measure and mark a point approximately 406 mm (16") from

the plug end of the shipping strap. Cut shipping strap atthis

point.

2. Use the leveling legs and nuts from parts package. Screw nut

down to within 13 mm (1/2") from base.

A

A. 13 mm (1/2 ")

B. Base

C. Nut

3. Insert legs into correct holes at

each front corner of washer until \

nuts touch washer. Do not tighten X

nuts until the washer is leveled.

4. Tilt washer backward and

remove corner posts. Gently

lower washer to floor.

5. Move washer to its permanent

location. Remove cardboard or

hardboard from under washer.

Level the washer

1. Tilt washer forward, raising rear legs 25 mm (1") off of floor.

To adjust rear self-leveling legs, gently lower washer to floor.

2. Check levelness of the washer by __--q---_

placing a carpenter's level on top

of the washer, first side to side;

then front to back.

3. If washer is not level, adjust the front legs up or down. Make

final check with level.

4. When washer is level, useawrench \ _ "_--_\ _\/

to turn the nuts on front legs up tightly

against washer base. if nuts are not tight

against washer base, the washer may

vibrate.

Fire Hazard

Never place items in the washer that are dampened

with gasoline or other flammable fluids.

No washer can completely remove oil.

Do not dry anything that has ever had any type of oil on

it (including cooking oils).

Doing so can result in death, explosion, or fire.

1. Check the electrical requirements. Be sure that you have

the correct electrical supply and the recommended earthing

method.

2. Check that all parts are now installed, if there is an extra part,

go back through the steps to see which step was skipped.

3. Turn on water taps and check for leaks. Tighten couplings if

there is leaking. Do not overtighten; this could cause damage

to the taps.

4. Be sure you have all of your tools.

5. Check that the shipping strap was removed from the back

of the washer and used to secure the drain hose. If entire

strap is not removed, washer may vibrate and be noisy.

6. Plug power supply cord into an earthed outlet.

NOTE: On some models, during factory testing, the timer is

advanced partially into the cycle, causing the start button to be

depressed. Allow timer to advance to the end of the cycle. When

the cycle is complete, the timer will reset and the start button will

return to the start position. If the timer is not allowed to advance

to the end of the first cycle and reset, the wash load will not be

completed.

Checklist for washer operation

Check the following if the washer is not operating properly:

1. Power supply cord is plugged in.

2. Circuit breaker is not tripped or fuse is not blown.

3. Timer has been advanced to start of a cycle.

4. Water taps are turned on.

5. Inlet and drain hoses are not kinked.

6. Washer lid is closed.

7. Inlet valve can freeze if not protected from the weather.

8. Suds level. Excess suds will slow the spin and cause poor

rinsing. Operate the washer through a complete cycle with

no detergent. Use less detergent or a controlled suds type

detergent in future loads.

If you need assistance:

Contact your authorized Maytag _ Commercial Laundry

distributor. To locate your authorized Maytag _'**Commercial

Laundry distributor, or for web inquiries, visit

www. MaytagCommercialLaundry.com.

When you call, you will need the washer model number and

serial number. Both numbers can be found on the model/

serial-rating plate located under the lid.

8

Typical full load sizes

Load Type

Mixed Load

Permanent

Press

Moving the washer to a new location

[] Remove the front legs from the base of the washer.

[] Place both rear leveling legs in the upper position and tape

securely.

[] Apply tape to the side and bottom of the cabinet near

the rear.

[] Open washer lid and wedge a blanket between the tub ring

and the cabinet top to restrict the tub movement.

Loading

Suggestion

3 double sheets

4 pillowcases

6 pair shorts

8 T-shirts

2 shirts

2 blouses

8 handkerchiefs

2 double or

1 king-size sheet

1 tablecloth

1 dress

1 blouse

2 slacks

3 shirts

2 pillowcases

Load Type

Heavy Work

Clothes

Knits

Tape2sides.

Loading

Suggestion

3 pair pants

3 shirts

1 coverall

4 pair jeans

1 overall

3 blouses

4 slacks

6 shirts

4 tops

4 dresses

Front legs

ELECTRONIC CONTROLS SETUP

BASIC OPERATION OF COMMERCIAL WASHER

[] For additional information, see www.MaytagCommercialLaundry.com.

[] This tech sheet is not valid for models prior to series MAT14.

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or

electrical shock.

IMPORTANT

Electrostatic Discharge (ESD)

Sensitive Electronics

ESD problems are present everywhere. ESD may damage

or weaken the electronic control assembly. The new control

assembly may appear to work well after repair is finished,

but failure may occur at a later date due to ESD stress.

[] Use an anti-static wrist strap. Connect wrist strap

to green ground connection point or unpainted metal

in the appliance

-OR-

Touch your finger repeatedly to a green ground connection

point or unpainted metal in the appliance.

[] Before removing the part from its package, touch the

antistatic bag to a green ground connection point or

unpainted metal in the appliance.

[] Avoid touching electronic parts or terminal contacts;

handle electronic control assembly by edges only.

[] When repackaging failed electronic control assembly

in antistatic bag, observe above instructions.

Warm Start (after power failure)

After a delay of up to 8 seconds, the washer is restored to the

state that existed at time of the power failure.

Free Cycles

This is established by setting the cycle price to zero. When this

happens, "SELECT CYCLE" will appear rather than a cycle price.

Debit Card Ready

This washer is debit card "cable" ready. It will accept a variety

of debit card systems, but does NOT come with a debit card

reader. Refer to the debit card reader manufacturer for proper

washer set-up. In models converted to a Generation 1 debit

card system, debit pulses represent the equivalent of one coin

(coin 1).

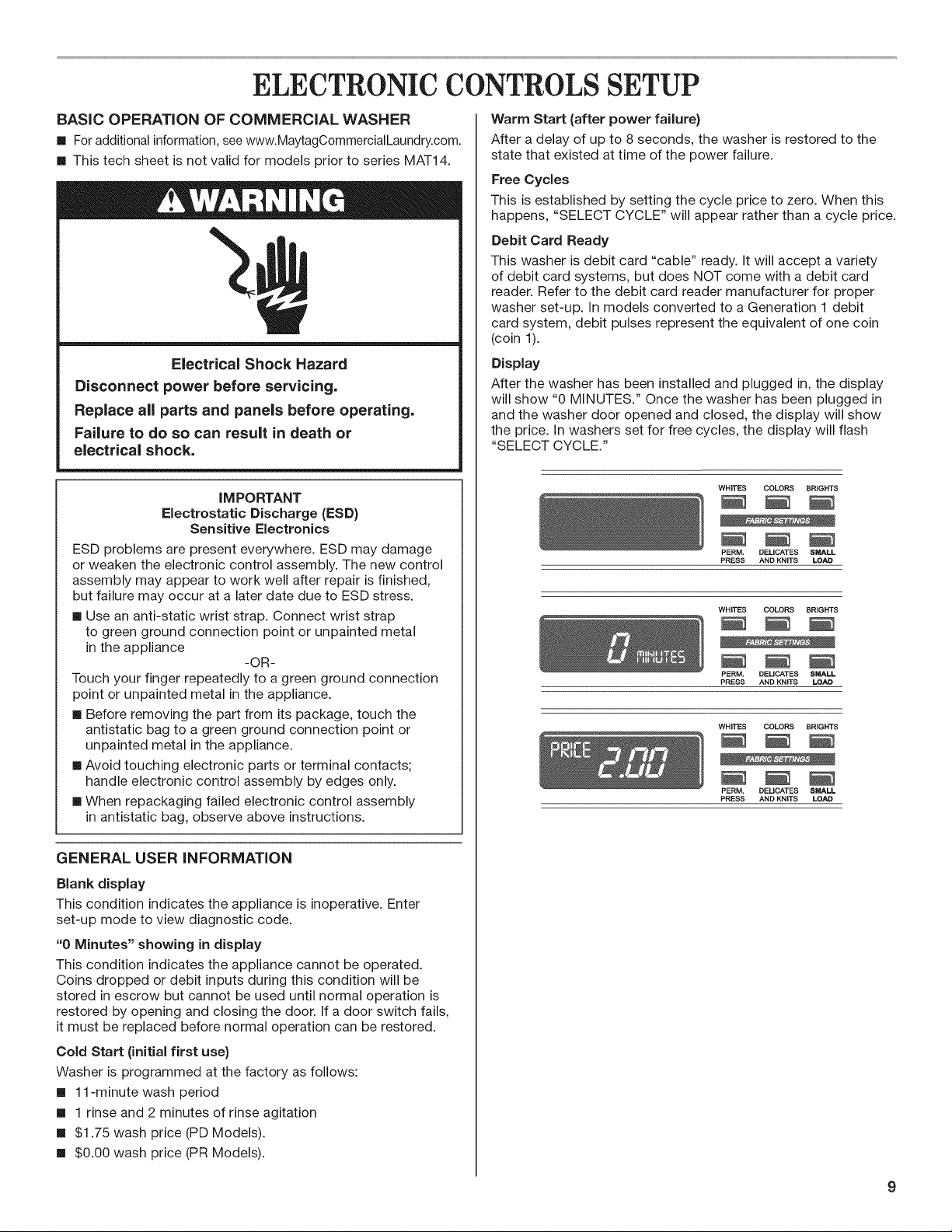

Display

After the washer has been installed and plugged in, the display

will show "0 MINUTES." Once the washer has been plugged in

and the washer door opened and closed, the display will show

the price. Inwashers set for free cycles, the display will flash

"SELECT CYCLE."

WHITES COLORS SRIGHTS

PERM. DEUCATES SMALL

PRESS AND KNITS LOAD

WHITES COLORS SRIGHTS

PERM. DELICATES SMALL

PRESS AND KNITS LOAD

WHITES COLORS 8RIGHTS

PERM. DELICATES SMALL

PRESS AND KNITS LOAD

GENERAL USER INFORMATION

Blank display

This condition indicates the appliance is inoperative. Enter

set-up mode to view diagnostic code.

"0 Minutes" showing in display

This condition indicates the appliance cannot be operated.

Coins dropped or debit inputs during this condition will be

stored in escrow but cannot be used until normal operation is

restored by opening and closing the door. If a door switch fails,

it must be replaced before normal operation can be restored.

Cold Start (initial first use)

Washer is programmed at the factory as follows:

[] 11-minute wash period

[] 1 rinse and 2 minutes of rinse agitation

[] $1.75 wash price (PD Models).

[] $0.00 wash price (PR Models).

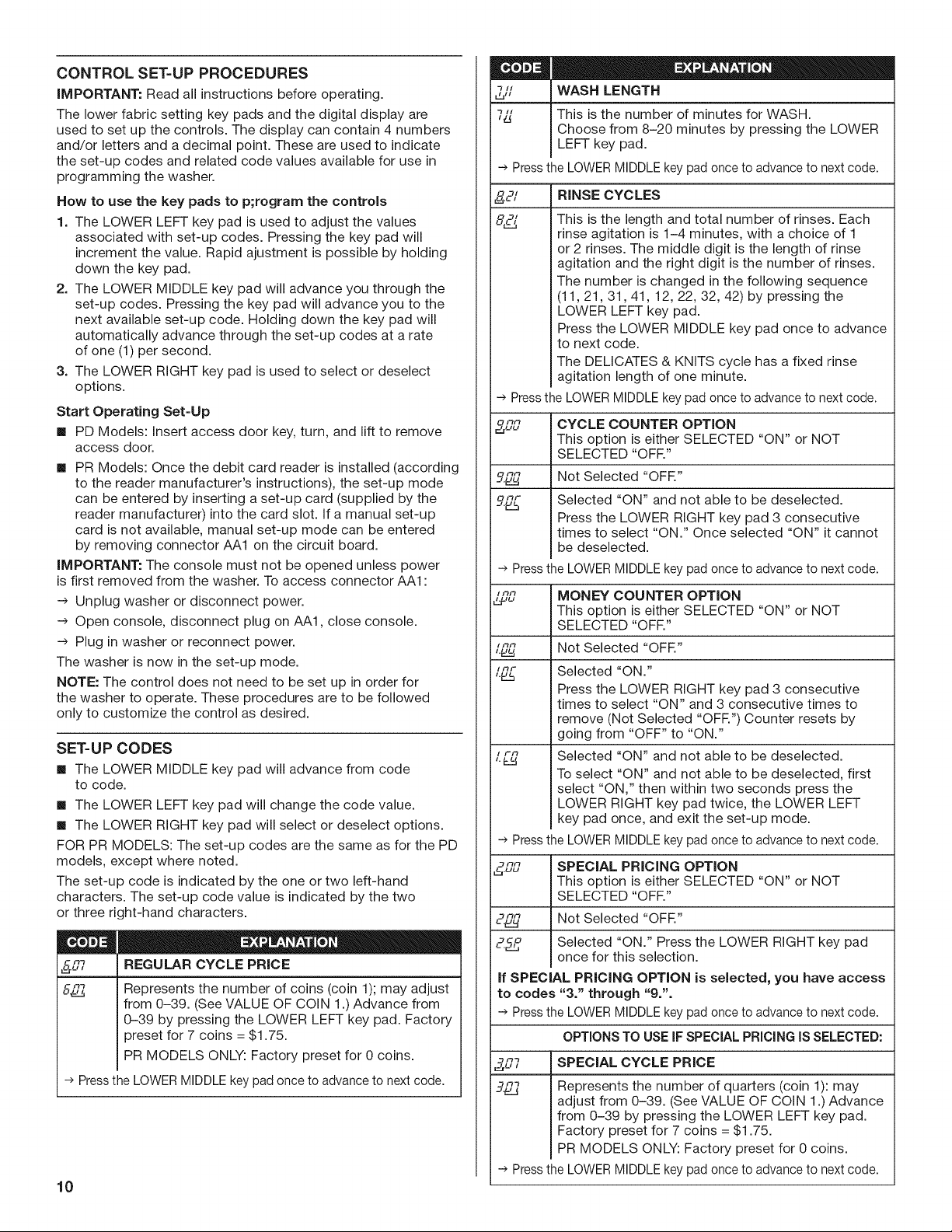

CONTROL SET-UP PROCEDURES

IMPORTANT: Read all instructions before operating.

The lower fabric setting key pads and the digital display are

used to set up the controls. The display can contain 4 numbers

and/or letters and a decimal point. These are used to indicate

the set-up codes and related code values available for use in

programming the washer.

How to use the key pads to p;rogram the controls

1. The LOWER LEFT key pad is used to adjust the values

associated with set-up codes. Pressing the key pad will

increment the value. Rapid ajustment is possible by holding

down the key pad.

2. The LOWER MIDDLE key pad will advance you through the

set-up codes. Pressing the key pad will advance you to the

next available set-up code. Holding down the key pad will

automatically advance through the set-up codes at a rate

of one (1) per second.

3. The LOWER RIGHT key pad is used to select or deselect

options.

Start Operating Set-Up

[] PD Models: insert access door key, turn, and lift to remove

access door.

[] PR Models: Once the debit card reader is installed (according

to the reader manufacturer's instructions), the set-up mode

can be entered by inserting a set-up card (supplied by the

reader manufacturer) into the card slot. If a manual set-up

card is not available, manual set-up mode can be entered

by removing connector AA1 on the circuit board.

IMPORTANT: The console must not be opened unless power

is first removed from the washer. To access connector AA1:

--> Unplug washer or disconnect power.

--> Open console, disconnect plug on AA1, close console.

--> Plug in washer or reconnect power.

The washer is now in the set-up mode.

NOTE: The control does not need to be set up in order for

the washer to operate. These procedures are to be followed

only to customize the control as desired.

SET-UP CODES

[] The LOWER MIDDLE key pad will advance from code

to code.

[] The LOWER LEFT key pad will change the code value.

[] The LOWER RIGHT key pad will select or deselect options.

FOR PR MODELS: The set-up codes are the same as for the PD

models, except where noted.

The set-up code is indicated by the one or two left-hand

characters. The set-up code value is indicated by the two

or three right-hand characters.

m

u I

REGULAR CYCLE PRICE

Represents the number of coins (coin 1); may adjust

from 0-39. (See VALUE OF COIN 1.) Advance from

0-39 by pressing the LOWER LEFT key pad. Factory

preset for 7 coins = $1.75.

PR MODELS ONLY: Factory preset for 0 coins.

-->Press the LOWERMIDDLE keypad once to advance to next code.

10

"1 H

,,,,, WASH LENGTH

"1 H

,_ This is the number of minutes for WASH.

Choose from 8-20 minutes by pressing the LOWER

LEFT key pad.

-->Press the LOWERMIDDLEkey pad once to advance to next code.

_:' RINSE CYCLES

.L I

This is the length and total number of rinses. Each

rinse agitation is 1-4 minutes, with a choice of 1

or 2 rinses. The middle digit is the length of rinse

agitation and the right digit is the number of rinses.

The number is changed in the following sequence

(11, 21,31,41, 12, 22, 32, 42) by pressing the

LOWER LEFT key pad.

Press the LOWER MIDDLE key pad once to advance

to next code.

The DELICATES & KNITS cycle has a fixed rinse

agitation length of one minute.

-->Pressthe LOWERMIDDLE keypad once to advance to next code.

,_,,_, CYCLE COUNTER OPTION

This option is either SELECTED "ON" or NOT

SELECTED "OFR"

-,._,,4 Not Selected "OFE"

_,+,_ Selected "ON" and not able to be deselected.

Press the LOWER RIGHT key pad 3 consecutive

times to select "ON." Once selected "ON" it cannot

be deselected.

->Pressthe LOWERMIDDLEkey pad onceto advanceto next code.

_,,_, MONEY COUNTER OPTION

This option is either SELECTED "ON" or NOT

SELECTED "OFR"

,._-4 Not Selected "OFF."

LHr._

Selected "ON."

Press the LOWER RIGHT key pad 3 consecutive

times to select "ON" and 3 consecutive times to

remove (Not Selected "OFR") Counter resets by

going from "OFF" to "ON."

I FF_

L_r.l

Selected "ON" and not able to be deselected.

To select "ON" and not able to be deselected, first

select "ON," then within two seconds press the

LOWER RIGHT key pad twice, the LOWER LEFT

key pad once, and exit the set-up mode.

-->Press the LOWERMIDDLEkey pad once to advance to next code.

L_j FtFt

.,_,,_, SPECIAL PRICING OPTION

This option is either SELECTED "ON" or NOT

SELECTED "OFR"

2_ Not Selected "OFR"

2._z_ Selected "ON." Press the LOWER RIGHT key pad

once for this selection.

If SPECIAL PRICING OPTION is selected, you have access

to codes "3." through "9.".

-->Press the LOWERMIDDLEkey pad once to advance to next code.

OPTIONS TO USEIF SPECIAL PRICING IS SELECTED:

u I

SPECIAL CYCLE PRICE

Represents the number of quarters (coin 1): may

adjust from 0-39. (See VALUE OF COIN 1.)Advance

from 0-39 by pressing the LOWER LEFT key pad.

Factory preset for 7 coins = $1.75.

PR MODELS ONLY: Factory preset for 0 coins.

-->Press the LOWERMIDDLEkey pad once to advance to next code.

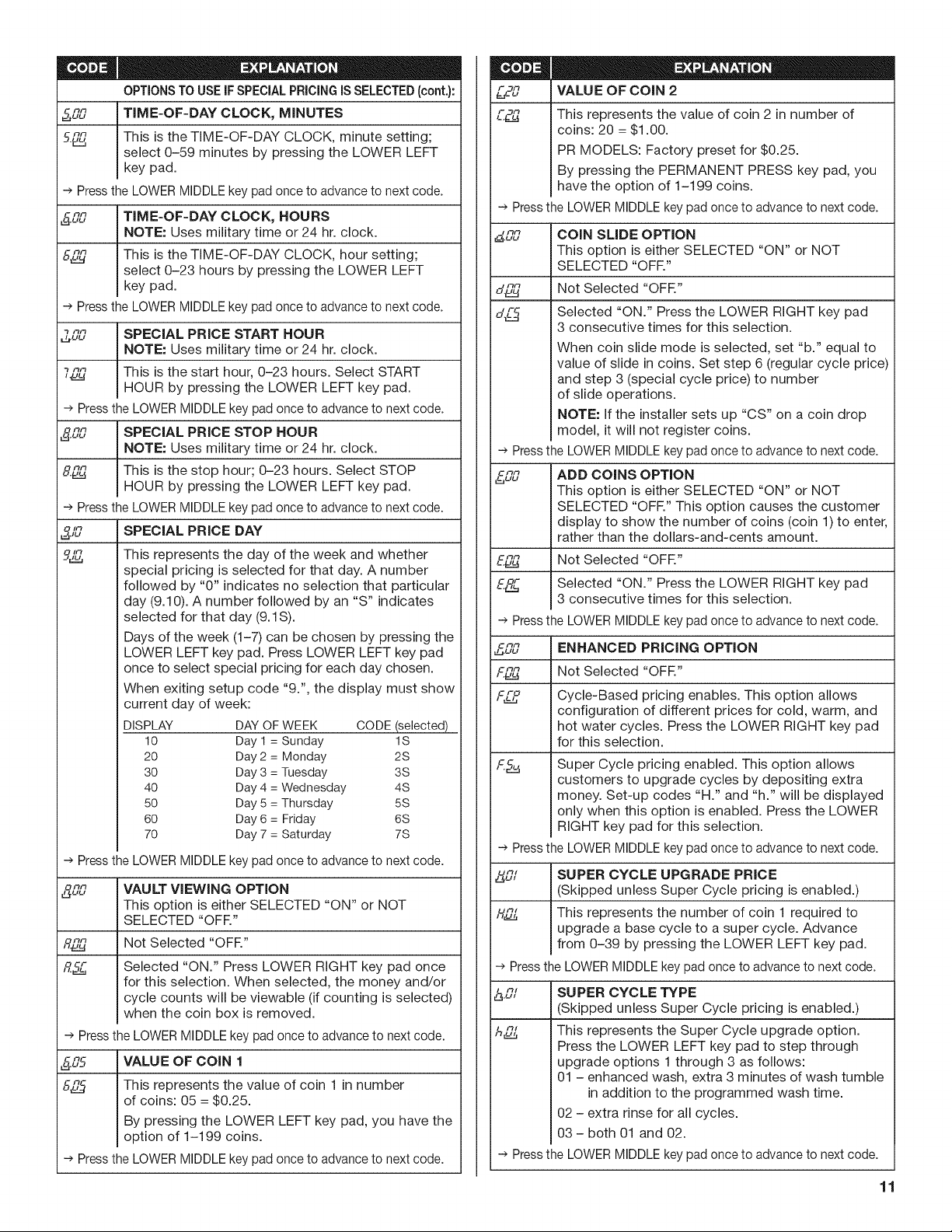

OPTIONSTO USEiFSPECIALPRiCiNGISSELECTED(cont.):

_nn

,_,,_, TIME=OF=DAY CLOCK, MINUTES

C n,'3

-,.F,-,, This is the TIME-OF-DAY CLOCK, minute setting;

->Pressthe LOWERMIDDLE key pad onceto advance to next code.

,,_nn

.,_,,_, TIME-OF-DAY CLOCK, HOURS

b_ This is the TIME-OF-DAY CLOCK, hour setting;

-e Press the LOWERMIDDLE key pad once to advance to next code.

"1/3£7

_,_,,_, SPECIAL PRICE START HOUR

,_u- This is the start hour, 0-23 hours. Select START

-e Pressthe LOWER MIDDLEkey padonce to advance to next code.

_nn

.,_,,_, SPECIAL PRICE STOP HOUR

_nn

.,_u- This is the stop hour; 0-23 hours. Select STOP

-e Pressthe LOWERMIDDLE key pad once to advance to next code.

,O_n

.,,_, SPECIAL PRICE DAY

-e Pressthe LOWER MIDDLEkey padonce to advance to next code.

IL_ f_R

,_,,_, VAULT VIEWING OPTION

R_ Not Selected "OFR"

-e Press the LOWERMIDDLE key pad once to advance to next code.

_.LT__; VALUE OF COIN 1

b_ This represents the value of coin 1 in number

-e Pressthe LOWER MIDDLEkey padonce to advance to next code.

select 0-59 minutes by pressing the LOWER LEFT

key pad.

NOTE: Uses military time or 24 hr. clock.

select 0-23 hours by pressing the LOWER LEFT

key pad.

NOTE: Uses military time or 24 hr. clock.

HOUR by pressing the LOWER LEFT key pad.

NOTE: Uses military time or 24 hr. clock.

HOUR by pressing the LOWER LEFT key pad.

This represents the day of the week and whether

special pricing is selected for that day. A number

followed by "0" indicates no selection that particular

day (9.10). A number followed by an "S" indicates

selected for that day (9.1S).

Days of the week (1-7) can be chosen by pressing the

LOWER LEFT key pad. Press LOWER LEFT key pad

once to select special pricing for each day chosen.

When exiting setup code "9.", the display must show

current day of week:

DISPLAY DAY OF WEEK CODE (selected)

10 Day 1 = Sunday 1S

20 Day 2 = Monday 2S

30 Day 3 = Tuesday 3S

40 Day 4 = Wednesday 4S

50 Day 5 = Thursday 5S

60 Day 6 = Friday 6S

70 Day 7 = Saturday 7S

This option is either SELECTED "ON" or NOT

SELECTED "OFR"

Selected "ON." Press LOWER RIGHT key pad once

for this selection. When selected, the money and/or

cycle counts will be viewable (if counting is selected)

when the coin box is removed.

of coins: 05 = $0.25.

By pressing the LOWER LEFT key pad, you have the

option of 1-199 coins.

VALUE OF COIN 2

,-3,_ This represents the value of coin 2 in number of

L.LL_

coins: 20 = $1.00.

PR MODELS: Factory preset for $0.25.

By pressing the PERMANENT PRESS key pad, you

have the option of 1-199 coins.

-e Pressthe LOWERMIDDLEkey pad once to advanceto next code.

L_ RR

.,_,,_, COIN SLIDE OPTION

This option is either SELECTED "ON" or NOT

SELECTED "OFR"

d_ Not Selected "OFE"

d,___

Selected "ON." Press the LOWER RIGHT key pad

3 consecutive times for this selection.

When coin slide mode is selected, set "b." equal to

value of slide in coins. Set step 6 (regular cycle price)

and step 3 (special cycle price) to number

of slide operations.

NOTE: if the installer sets up "CS" on a coin drop

model, it will not register coins.

-->Pressthe LOWERMIDDLEkey pad once to advance to next code.

LL_CRR

UU

ADD COINS OPTION

This option is either SELECTED "ON" or NOT

SELECTED "OFR" This option causes the customer

display to show the number of coins (coin 1) to enter,

rather than the dollars-and-cents amount.

ERR

.,_zu- Not Selected "OFE"

EP,E, Selected "ON." Press the LOWER RIGHT key pad

3 consecutive times for this selection.

-e Pressthe LOWERMIDDLEkey pad once to advanceto next code.

_nn

,_,,_, ENHANCED PRICING OPTION

ERR

._u Not Selected "OFF."

I-,EI,_ Cycle-Based pricing enables. This option allows

configuration of different prices for cold, warm, and

hot water cycles. Press the LOWER RIGHT key pad

for this selection.

I-,%_ Super Cycle pricing enabled. This option allows

customers to upgrade cycles by depositing extra

money. Set-up codes "H." and "h." will be displayed

only when this option is enabled. Press the LOWER

RIGHT key pad for this selection.

-e Pressthe LOWERMIDDLEkey pad once to advanceto next code.

,IL_R t

,_,, SUPER CYCLE UPGRADE PRICE

(Skipped unless Super Cycle pricing is enabled.)

y,_ This represents the number of coin 1 required to

upgrade a base cycle to a super cycle. Advance

from 0-39 by pressing the LOWER LEFT key pad.

-e Pressthe LOWERMIDDLE key pad onceto advanceto nextcode.

L_Rt

.,_,, SUPER CYCLE TYPE

(Skipped unless Super Cycle pricing is enabled.)

h R, This represents the Super Cycle upgrade option.

Press the LOWER LEFT key pad to step through

upgrade options 1 through 3 as follows:

01 - enhanced wash, extra 3 minutes of wash tumble

in addition to the programmed wash time.

02 - extra rinse for all cycles.

03 - both 01 and 02.

-e Pressthe LOWERMIDDLEkey pad once to advanceto next code.

11

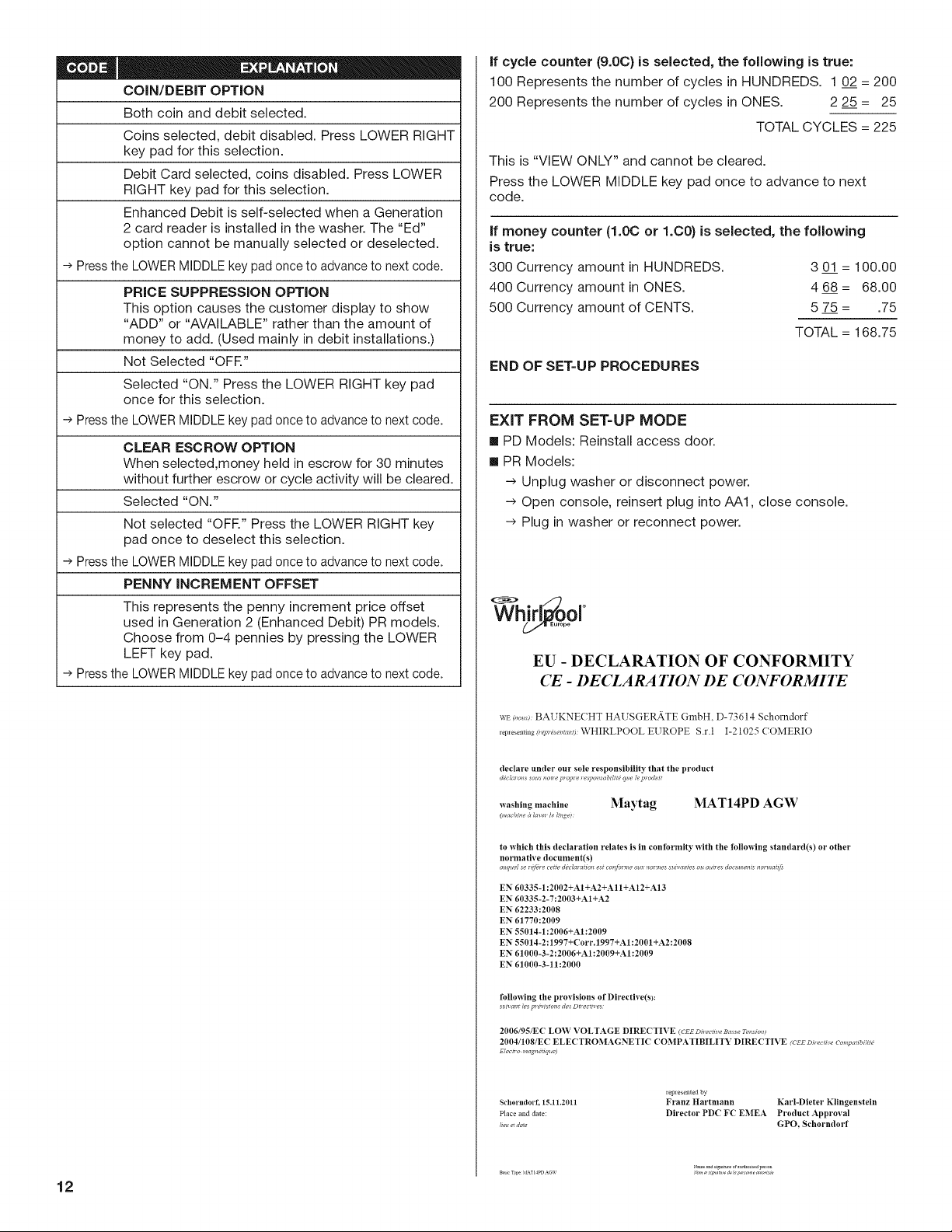

COIN/DEBIT OPTION

Both coin and debit selected.

Coins selected, debit disabled. Press LOWER RIGHT

key pad for this selection.

Debit Card selected, coins disabled. Press LOWER

RIGHT key pad for this selection.

Enhanced Debit is self-selected when a Generation

2 card reader is installed in the washer. The "Ed"

option cannot be manually selected or deselected.

->Pressthe LOWERMIDDLE key pad onceto advance to next code.

PRICE SUPPRESSION OPTION

This option causes the customer display to show

"ADD" or "AVAILABLE" rather than the amount of

money to add. (Used mainly in debit installations.)

Not Selected "OFE"

Selected "ON." Press the LOWER RIGHT key pad

once for this selection.

->Pressthe LOWERMIDDLE key pad onceto advance to next code.

CLEAR ESCROW OPTION

When selected,money held in escrow for 30 minutes

without further escrow or cycle activity will be cleared.

Selected "ON."

Not selected "OFR" Press the LOWER RIGHT key

pad once to deselect this selection.

-e Press the LOWERMIDDLE key pad once to advance to next code.

PENNY INCREMENT OFFSET

This represents the penny increment price offset

used in Generation 2 (Enhanced Debit) PR models.

Choose from 0-4 pennies by pressing the LOWER

LEFT key pad.

-e Press the LOWERMIDDLE key pad once to advance to next code.

If cycle counter (9.0C} is selected, the following is true:

100 Represents the number of cycles in HUNDREDS. 1 02 = 200

200 Represents the number of cycles in ONES. 2 25 = 25

TOTAL CYCLES = 225

This is "VIEW ONLY" and cannot be cleared.

Press the LOWER MIDDLE key pad once to advance to next

code.

If money counter (1o0Cor 1.C0} is selected, the following

is true:

300 Currency amount in HUNDREDS. 3 01 = 100.00

400 Currency amount in ONES. 4 68 = 68.00

500 Currency amount of CENTS. 5 7.5 = .75

TOTAL = 168.75

END OF SET=UP PROCEDURES

EXIT FROM SET=UP MODE

[] PD Models: Reinstall access door.

[] PR Models:

Unplug washer or disconnect power.

Open console, reinsert plug into AA1, close console.

Plug inwasher or reconnect power.

EU - DECLARATION OF CONFORMITY

CE- DECLARATION DE CONFORMITE

WE0,o.;) BAUKNE(HT HAUSGERATE GmbH. D-73614 Schorndorf

_p_*nm_g#_p_,,t_,,,t)WHIRLPOOL EUROPE S.r.1 1-21025 (OMERIO

declare under our sole responsibility that the product

dgclaTo_Tssam _otTe ]_ opTe _e_po,_ bllitd que lep_ oduit

washingmachine Maytag MAT14PD AGW

(machh_ 0 lave7 le li_*g_)

to which this declaration relates is in conformity with the following standard(s) or other

normative document(s)

_uqu_l se 7eJ_ e eerie decla_ atio_ e_t co_fuT m_ _ ,1_noTm_s suivcmt_s o_ _ *mes documem_ _ormat_

EN 60335-1:2002+Al+A2+A11+A12+A13

EN 60335-2-7:2003+Al+A2

EN 62233:2008

EN 61770:2009

EN 55014-1:2006+A1:2009

EN 55014-2:1997+Corr,1997+Al:2001+A2:2008

EN 61000-3-2:2006+Al:2009+Al:2009

EN 61000-3-11:2000

following the provisions of Directive(s):

suivanr les p_e, hfon_ de_ Df__cm'es

2006/95/EC LOW VOLTAGE DIRECTIVE (c_E Di_ectM,e Basse T{,n*io_*l

2004/108/EC ELECTROMAGNETIC COMPATIBILITY DIRECTIVE (CEEDilectil'e Compatibilite

Elect_ o mag_etiqu_)

Schorndorf, 15.11.2011

Place and date:

!_e. etdate

leplesemed by

Franz Hartmann Karl-Dieter Klingenstein

Director PDC FC EMEA Product Approval

GPO, Sehorndorf

12

MAYTAG ® COMMERCIAL SINGLE-LOAD AND VENDED

MULTkLOAD WASHER AND DRYER

WARRANTY

LiMiTED WARRANTY ON PARTS

For the first five years from the date of purchase, when this commercial appliance is installed, maintained and operated according to the

instructions attached to or furnished with the product, Maytag brand of Whirlpool Corporation (thereafter "Maytag") will pay for factory

specified parts or original equipment manufacturer parts to correct defects in materials or workmanship. Proof of original purchase date

is required to obtain service under this warranty.

ITEMS MAYTAG WILL NOT PAY FOR

1. All other costs including labor, transportation, or custom duties.

2. Service calls to correct the installation of your commercial appliance, to instruct you how to use your commercial appliance, to

replace or repair fuses, or to correct external wiring or plumbing.

3. Repairs when your commercial appliance is used for other than normal, commercial use.

4. Damage resulting from improper handling of product during delivery, theft, accident, alteration, misuse, abuse, fire, flood, acts of

God, improper installation, installation not in accordance with local electrical or plumbing codes, or use of products not approved

by Maytag.

5. Pickup and Delivery. This commercial appliance is designed to be repaired on location.

6. Repairs to parts or systems resulting from unauthorized modifications made to the commercial appliance.

7. The removal and reinstallation of your commercial appliance if it is installed in an inaccessible location or is not installed in

accordance with published installation instructions.

8. Chemical damage is excluded from all warranty coverage.

9. Changes to the building, room, or location needed in order to make the commercial appliance operate correctly.

10. Repairs made by a non-Whirlpool authorized service technician.

DiSCLAiMER OF iMPLiED WARRANTIES; LiMiTATiONS OF REMEDIES

CUSTOMER'S SOLE AND EXCLUSIVE REMEDY UNDER THiS LIMITED WARRANTY SHALL BE PRODUCT REPAIR AS PROVIDED

HEREIN. IMPLIED WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABiLiTY OR FITNESS FOR A PARTICULAR PURPOSE,

ARE LIMITED TO ONE YEAR OR THE SHORTEST PERIOD ALLOWED BY LAW. WHIRLPOOL SHALL NOT BE LIABLE FOR

INCIDENTAL OR CONSEQUENTIAL DAMAGES. SOME STATESAND PROVINCES DO NOT ALLOW THE EXCLUSION OR LIMITATION

OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, OR LIMITATIONS ON THE DURATION OF iMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS, SO THESE EXCLUSIONS OR LIMITATIONS MAY NOT APPLY TO YOU. THIS WARRANTY GIVES

YOU SPECIFIC LEGAL RIGHTS AND YOU MAY ALSO HAVE OTHER RIGHTS, WHICH VARY FROM STATE TO STATE OR PROVINCE

TO PROVINCE.

If you need service, please contact your authorized Maytag ®Commercial Laundry distributor. To locate your authorized Maytag ®

Commercial Laundry distributor, or for web inquiries, visit www.MaytagCommercialLaundry.com.

3/10

For written correspondence:

Maytag ®Commercial Laundry Service Department

Benton Harbor, Michigan 49022 USA

2000 M-63 North

13

SECURITE DU LAVE.LINGE

Votre sdcuritd et celle des autres est tr_s irnportante.

Nous donnons de nombreux messages de securit_ importants dans ce manue} et sur votre apparei{ m_nager. Assurez-vous de

toujours {iretous {es messages de securite et de vous y conformer.

Voici {e symbo{e d'a{erte de s6curit&

Ce symbo{e d'a{erte de s_curite vous signa{e {es dangers potentie{s de d_c_s et de b{essures graves & vous

et &d'autres.

Tous {es messages de s_curite suivront {e symbo{e d'alerte de s_curit_ et {e mot "DANGER" ou

"AVERTiSSEMENT". Ces mots signifient :

Risque possible de ddc_s ou de biessure grave si vous ne

suivez pas immddiatement les instructions,

Risque possible de ddc_s ou de blessure grave si vous

ne suivez pas les instructions.

Tousles messages de securite vous diront que} est {e danger potentie{ et vous disent comment r_duire {erisque de b{essure et

ce qui peut se produire en cas de non-respect des instructions.

ELIMINATION DU LAVE.LINGE

Le marquage de {'appareil est conforme & {a directive europeenne 2002/96/EC sur {es _quipements d{ectroniques et

_{ectriques, pour gestion des d6chets.

En veiHant h }'elimination correcte de ce produit, vous eviterez d'eventueHes consequences nefastes pour I'environnement et {a

sant_ humaine qui peuvent _tre associ_es au traitement inapproprid de ce produit {orsqu'i{ a _t_ mis au rebut.

Le symbo{e figurant sur {e produit ou darts }es documents qui accompagnent }e produit indique que cet apparei{ ne doit pas _tre

traitd comme ddchet m_nager; on doit plut6t {e remettre & un centre de coHecte sp_cialis_ pour {e recyc{age des 6quipements

_{ectriques et _lectroniques.

L'elimination de ce produit apres mise au rebut doit _tre effectuee conformement aux prescriptions de la reglementation locale

de protection de {'environnement.

Pour {'information ddtaiH_e concernant le traitement, {e recyc}age et la r_cupdration de ce produit, contacter {a municipalit_

{oca{e, {e service d'_{imination des d_chets m_nagers, ou {e commergant qui a vendu {e produit.

14

EXIGENCES D'INSTALLATION

Rassembler les outils et pieces n6cessaires avant d'entreprendre

I'installation.

Outils n6cessaires

[] Niveau [] Tournevis & lame plate

[] Couteau utilitaire [] Pince

[] Ciseaux [] Seau

[] CI6 a mollette de 200 mm

(8") ou 250 mm (10")

Pi_ces fournies

Retirer les pieces du lave-linge. V6rifier la pr6sence de toutes

les pieces.

[] 1 bride de fixation [] 2 pieds de nivellement

[] 2 tuyaux d'arriv6e d'eau avant avec 6crous

[] 4 rondelles plates de [] 1 tuyau de vidange

tuyau d'arriv6e d'eau [] Adaptateur de tuyau

Specifications Capacit_ de

techniques : v_tements :

220 a 240 V,50 Hz AC MAT14PD : 5,9 kg Max.

650 Watts

instructions d'installation darts un encastrement

ou un placard

Ce lave-linge peut _tre install_ dans un encastrement

ou un placard.

Les dimensions d'installation illustr_es sont en centimetres et

constituent le minimum applicable. Un espace suppl_mentaire

peut _tre n_cessaire pour faciliter I'installation, I'entretien et

pour observer les codes et reglements Iocaux en vigueur.

Si une porte de placard est install_e, des ouvertures

d'_vacuation de I'air minimales sont n_cessaires dans les

parties sup_rieure et inf_rieure. Les portes a claire-vole offrant

des ouvertures _quivalentes sont acceptables.

Portedu placard

j'

3,10 m2

!

432mm

(17")

O0

(48 in_)*

(24

mm

(4")min.

iMPORTANT : Ne pas installer ou remiser le lave-linge dans

un endroit oQ il sera expos6 aux intemp6ries. Ne pas remiser

ou faire fonctionner le lave-linge a des temp6ratures inf6rieures

ou 6gales a 0°C (32°F). Une quantit6 d'eau peut demeurer dans

le lave-linge et causer des dommages a des temp6ratures

basses.

C'est a I'utilisateur qu'incombe la responsabilit6 de r6aliser

une installation correcte.

II vous faudra :

[] Un chauffe-eau pour fournir de I'eau a 60°C (140°F)

au lave-linge.

[] Une prise 61ectrique reli6e a la terre situ6e a moins de 1,2 m

(4 pi) de la prise du cordon _lectrique se trouvant a I'arriere

du lave-linge. Voir "Specifications _lectriques".

[] Des robinets d'eau chaude et d'eau froide situ_s a 1,2 m (4 pi)

ou moins de I'arriere du lave-linge, et une pression d'eau

de 69 a 690 kPa (10 a 100 Ib/po2). Lorsque la pression

d'alimentation a I'entr_e du b&timent est sup_rieure

690 kPa (100 Ib/po2), on devrait installer une vanne

de r_duction de la pression pour _viter une _ventuelle

d_t_rioration de la vanne de mixage du lave-linge.

[] Un plancher de niveau ayant une pente maximale de 25 mm

(1") sous I'ensemble du lave-linge.

[] Un plancher robuste pour supporter le lave-linge dont le poids

total (lave-linge, eau et charge) est de 143 kg (315 Ib).

[] Une colonne montante d'au moins 300 mm (12") destin_e

fournir un coussin d'air eta emp_cher I'_mission de bruit

et la d_t_rioration des _lectrovannes Iors de I'installation

d'un seul lave-linge.

[] Un _gout au plancher dolt _tre install_ sous le module

de la cloison. Les coffrages pr_fabriqu_s _quip_s de

prises _lectriques, de lignes d'arriv_e d'eau et conduites

d'_vacuation doivent _tre utilis_s seulement la oQ les codes

Iocaux I'autorisent.

REMARQUE : On peut acceder & la zone avant de la pompe

en retirant les vis de s_curit_ No. T20 TORX _'_*tpuis en retirant

le panneau avant.

®1Torx est une marqued_pos_e de Saturn Fasteners,Inc.

0mm

3,10 m_

(48in_)*

Vue de

face

,_- (o")

76 m_

(3")

Porte

du placard

Omm '_

(0")

Vue encastr_e de face

du placard

O

76 mm

1,55m-'T

(24in_)*

*Dimension minimale pour uneporte de placard. Les portes & claire-vole

offrant des ouvertures _quivalentes sont acceptables.

[] Un espace suppl_mentaire peut _tre n_cessaire pour faciliter

I'installation et I'entretien.

[] Un espace suppl_mentaire peut _tre requis pour les moulures

de porte et de plancher et pour les plinthes.

[] Un espace suppl_mentaire de 25 mm (1 po) de tous

les c6t_s du lave-linge est recommand_ pour r_duire

le transfert du bruit.

[] II faut aussi prendre en compte I'espace requis entre

les appareils voisins.

(3"

15

Dimensions du produit

i< H

/I

X J

A

P

A. 1,09 m (43 po) I. Cordon d'alimentation _lectrique

B. 970 mm (381/8po) J. Connecteur du tuyau de vidange

C. 890 mm (35 po) K. Etiquette

D. 38 mm (11/2po) L. 685 mm (27 po)

E. 705 mm (27% po) M. 133 mm (51/4po)

R 650 mm (25V2 po) N. 25 mm (1 po)

G. Arriv_es d'eau O. Commutateur du niveau d'eau

et tige de r_giage

H. 180 mm (7 po) R 127 mm (5 po)

Risque de choc e}ectrique

Brancher sur une prise re{iee & {a terre.

Ne pas uti{}ser un c&ble de ra{{onge ou un adaptateur.

Le non=respect de ces instructions peut causer un

deces, un incend{e ou un choc electrique.

[] Uappareil doit _tre aliment_ par un circuit de 220-240 V, CA

seulement, 50 Hz, prot_g_ par un fusible. On recommande

d'utiliser un fusible ou un disjoncteur temporis_. IIest

recommand_ de raccorder le lave-linge sur un circuit

distinct exclusif a cet appareil.

[] Ce lave-linge comporte un cordon d'alimentation _lectrique

pour liaison a la terre. La prise doit #.tre accessible pour

pouvoir d_connecter I'appareil de I'alimentation _lectrique.

[] Si le cordon d'alimentation est endommag_, il doit _tre

remplac_ par le fabricant, son agent de service ou toute

autre personne qualifi_e afin d'_viter tout danger.

I'aide du cordon universel d'alimentation _lectrique

fourni avec ce lave-linge :

Ce lave-linge comporte un cordon universel avec des prises

principales interchangeables.

1. S_lectionner la prise principale appropri_e parmi les prises

fournies et la fixer au connecteur du cordon de c&blage

principal.

2. Enclencher les deux moiti_s du systeme de retenue

du cordon sur le connecteur pour le maintenir en place.

Syst_me de vidange avec tuyau de rejet _ I'_gout

Le systeme de rejet a I'_gout n_cessite un tuyau de diametre

minimum de 50 mm (2 po). La capacit_ minimum de vidange

ne peut pas #.tre inf_rieure a 64 L (17 gal.) par minute.

Le sommet du tuyau de rejet a I'_gout doit #.tre au moins

990 mm (39 po) de hauteur et au maximum a 1,83 m (72 po)

de la base du lave-linge.

16

Loading...

Loading...