Mayser SG-RSV 239 User Manual

Polymer Electric

Page 1/4

Control Unit SG-RSV 239 Operating Instructions

Control Unit

according to EN 50155 and

EN 50121‑3‑2

classes TX, S2 in accordance with

EN 50155

for sensors with

1.2 kΩ monitoring resistor

These operating instructions apply to the

following control units:

SG-RSV 239/24 24 V=

SG-RSV 239 50-150 V=

Control

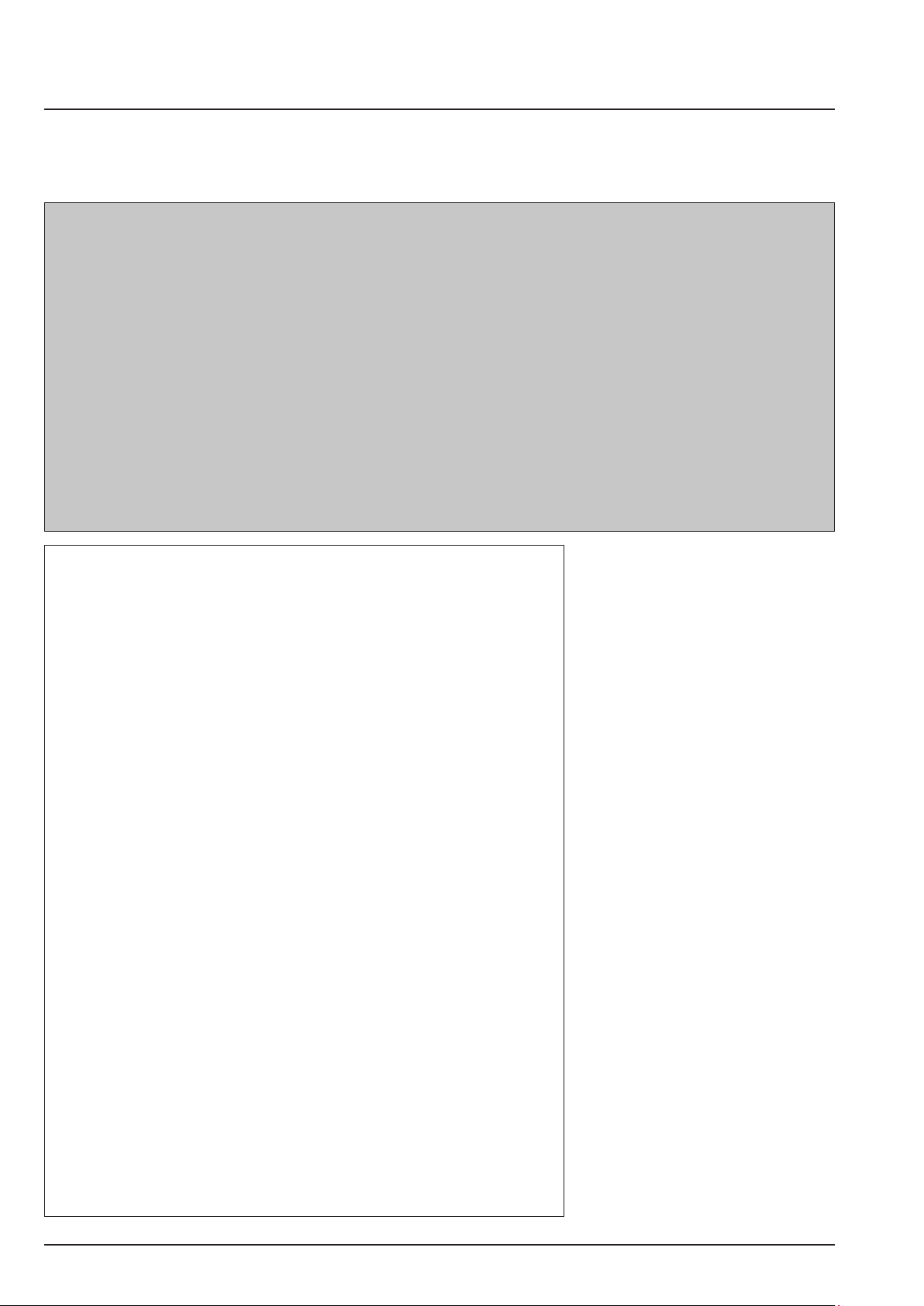

The Control Unit has two monitoring circuits, which operate the output relays.

The electronics monitor the electrical

resistance of the connected sensors

which have a dened zero signal

current.

When the sensors are not activated

(normal operating conditions), the output relays are energised. If the line is

disconnected between the sensor and

the control unit, the relay “fault” is

de-energised.

Sensor 1

Sensor 2

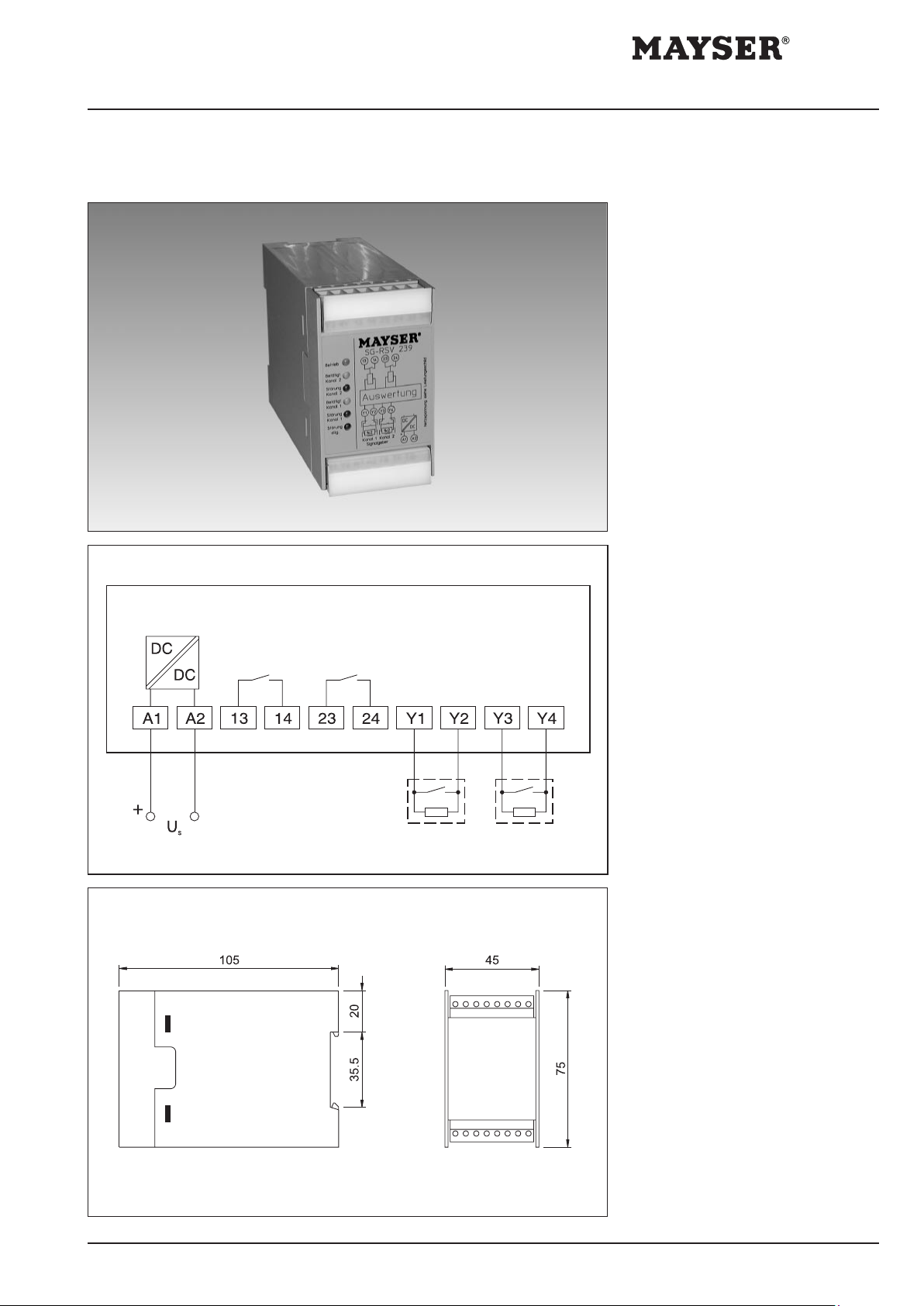

Enclosure

W × H × D (mm) 45 × 75 × 108

Protection class IP20

2 plug-in connectors each 8-channel

Cable clamps max. 2.5 mm

Weight approx 175 g

Parts supplied

‑ Control Unit

Enclosure with electronics module

and plug connections with lift-up lock

release.

‑ Operating Instructions

Mayser Polymer Electric Postfach 30 48 89020 Ulm Germany Tel. +49 731 2061-0 Fax +49 731 2061-222

130707 v1.2

2

Mayser Polymer Electric Postfach 30 48 89020 Ulm Germany Tel. +49 731 2061-0 Fax +49 731 2061-222

130707 v1.2

Page 2/4

Control Unit SG-RSV 239

IMPORTANT NOTES! Please read!

To ensure correct and safe operation

of the unit, it must be properly transported and stored, properly installed

and commissioned, and operated in

accordance with its intended use.

Only persons familiar with the installation, commissioning and operation,

and with the corresponding qualications to prove their skills, may work on

the units.

They must observe the contents of

these instructions, the information

given on the type plate of the unit and

the relevant safety regulations for the

installation and operation of electrical

systems.

This unit is designed in accordance with

EN 50155 and EN 50121-3-2 and left

the factory in a perfectly safe condition.

To maintain this condition, you must

observe the safety regulations marked

WARNING! in these operating instructions. Failure to observe the safety

regulations can lead to death, injury to

personnel, or damage to the unit and

other systems and equipment.

Technical Data

Connecting Voltage US

SG-RSV 239/24 DC 24 V (S2)

Voltage tolerance -30% to +30%

SG-RSV 239 DC 50 to 150 V (S2)

Nominal frequency Frequency tolerance Power consumption < 2 W

Sensor Voltage

max. 12 V DC

Should the information given in these

operating instructions be inadequate

in any way, please contact your local

technical centre, subsidiary or representative. When using the device

outside the European Union, you must

observe the relevant regulations valid

for the country of use.

Important notes:

‑ Supply voltage

must be in accordance with the connecting voltage Us indicated on the

type plate.

‑ Permissible temperature range

maintain sufcient distance from heat

sources if installing in switch cabinet

(min. 2 cm).

‑ Fusing of the relay contacts

due to risk of welding, externally with

1.0 A inert.

Signal Voltage State

Relay Data

Switching current max. 1 A max. 1 A

Switching voltage max. AC 250 V max. DC 150 V

Breaking capacity max. 250 W max. 30 W

(AC 12) (DC 12)

Switching operations

mechanical > 2× 10

electrical > 1× 105 (250 AC V / 1 A)

Operating Conditions

Perm. ambient temperature range -40 °C to +70 °C (T3)

Rel. humidity max. 95%

Endurance limit 5 g in all 3 levels

max. U

s

7

Please note:

When switching inductive loads the user

must be tted out with spark absorbers

(RC-modules).

Loading...

Loading...