Mayser SE 1 TPE Assembly Instructions

Page 1/2

Assembly Instructions SE 1 TPE

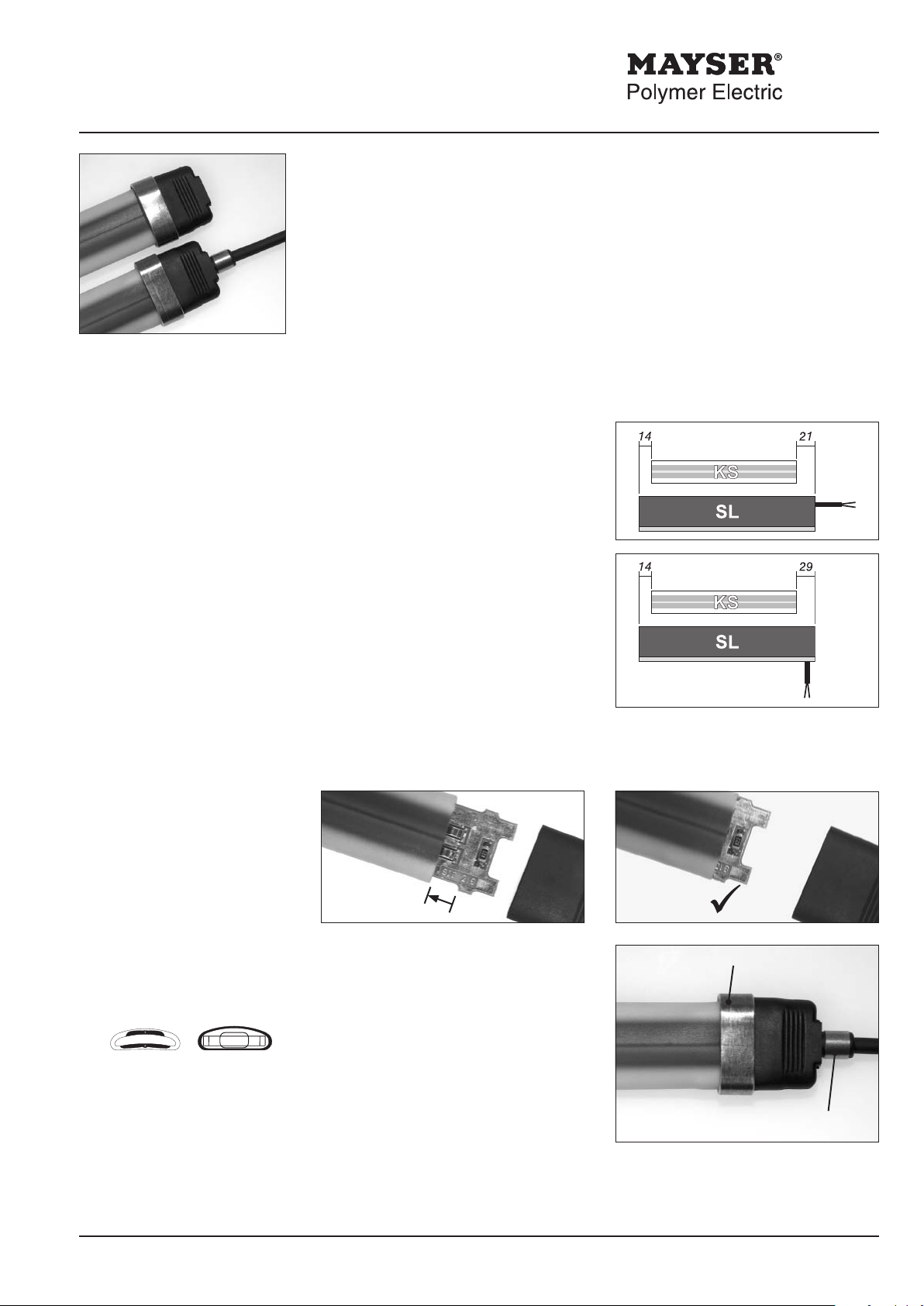

Spring contact

A complete Safety Element SE 1 TPE

in 5 easy steps

These instructions describe cutting of the contact tube to the required length and tting of the end cap on

the resistance side. Fitting is identical on the cable side – apart from the additional sealing ring (round) for

the cable seal.

1. Cut contact tube

2. Assembly

• The contact tube (KS) is always

shorter than the nished Safety Edge

(SL). Measure out required length of

contact tube and mark accordingly.

L

whereby: L

LSL = length of Safety Edge

cable axial: X = 21 mm

cable 90°: X = 29 mm

• Cut to the required length making

sure that the cut edge is straight.

Insert the spring contact PCB into the contact tube as far as the stop position.

= LSL - 14 mm -X

KS

= length of contact tube

KS

2a 2b

3. Position end cap

and sealing ring

contact tube inside of end

cap

Mayser Polymer Electric Postfach 30 48 89020 Ulm GERMANY Tel. +49 731 2061-0 Fax +49 731 2061-222

230412 v1.3 / TNr. 7501801

• Place and position end cap on the

contact tube end. Ensure that the

curvature of the end cap coincides

with the tube curvature (see picture

on left).

Tip: Make a mark 9 mm from the end

of the contact tube. The end cap must

completely cover this mark.

• Position sealing ring (oval) until it is

ush with the end cap.

• On the cable end also position the

sealing ring (round) in the middle.

sealing ring (oval)

sealing ring (round)

Page 2/2

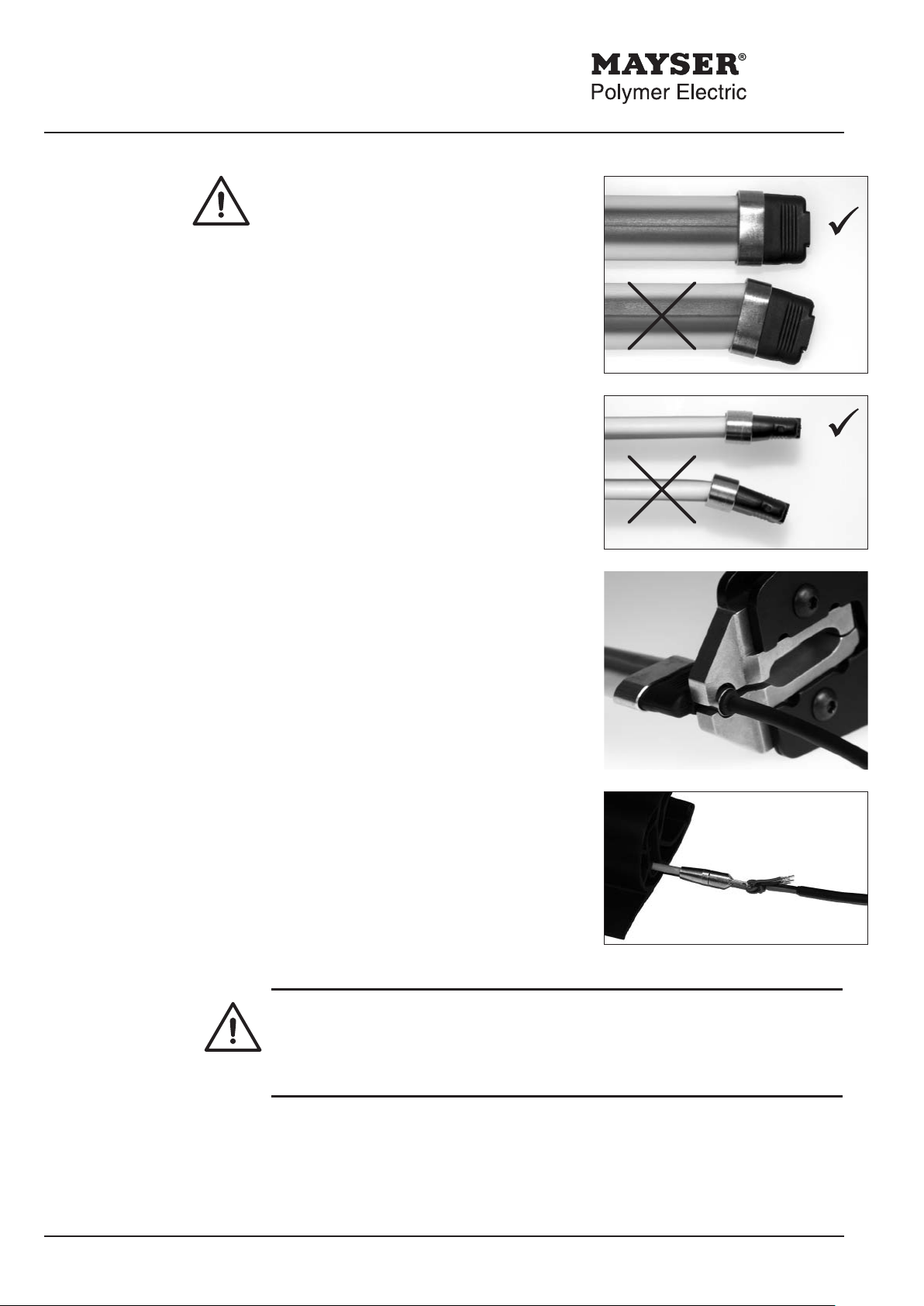

4. Close tool

Prior to closing the tool, ensure that the

contact tube, end cap and sealing ring

are correctly positioned!

If

• the contact tube and end cap are on

the same horizontal

and

• the contact tube and end cap are on

the same vertical line,

then

• close the tool around the sealing ring

(oval). In addition, use the tool on the

the sealing ring (round) at the cable

end – for direction, see picture.

5. Position and test

• Connect up the SE 1 TPE and test for

function.

• Carefully position the complete Safety

Element in the rubber prole of the Safety

Edge.

Tip: The cable pulling device Kati

®

Blitz is

suitable for aiding insertion of the Safety

Element in the rubber prole.

The Safety Element may be irreparably damaged!

Ä Max. permissible pulling force on cable: 30 N

Ä No pressure may be exerted on the contact tube in non-operative mode.

• If necessary, seal both rubber prole ends.

Tip: See "Assembly Instructions for Safety Edges" for the next assembly process.

Mayser Polymer Electric Postfach 30 48 89020 Ulm GERMANY Tel. +49 731 2061-0 Fax +49 731 2061-222

230412 v1.3 / TNr. 7501801

Loading...

Loading...