Page 1

Marmitek X-10

Programming and Measuring Interface

Type PMIX35

Page 2

Introduction

The Programming and Measuring Interface (PMIX35) is a power line communication interface suitable for Marmitek X-10 and

other compatible systems (such as X-10). In addition to supporting the standard and extended protocols of Marmitek X-10,

this interface also measures the quality of various signals. With the supplied PMIX35 software, technical problems in

installations can be quickly localised and resolved, a new installation can be tested for reliability and modules can be quickly

and easily programmed.

Functions

• Sending and receiving commands.

• Measuring the signal level and noise level of incoming

messages.

• Measuring network impedance.

• Sending messages with quick-selection buttons.

• Sending messages with two preset macros.

• Running macros automatically.

• Sending messages with adjustable transmission levels.

• Logging of received and sent messages with error

analysis.

• Easily accessible network diagnostic information.

• Automatic programming of modules at the touch of a

button.

• Network validation measuring method with reporting for

the reliable delivery of new installations (available

starting from software version 1.1).

• Support for the PMIX35 ASCII protocol similar to the

CTX15/35 protocol.

• Support for the CTX15/35 protocol.

Contents

In the PMIX35 box, you should find the following:

• 1x PMIX35

• 1x USB cable

• 1x CD-ROM with:

- PMIX35 software

- PDF operating instructions for the PMIX35

- Quick reference guide

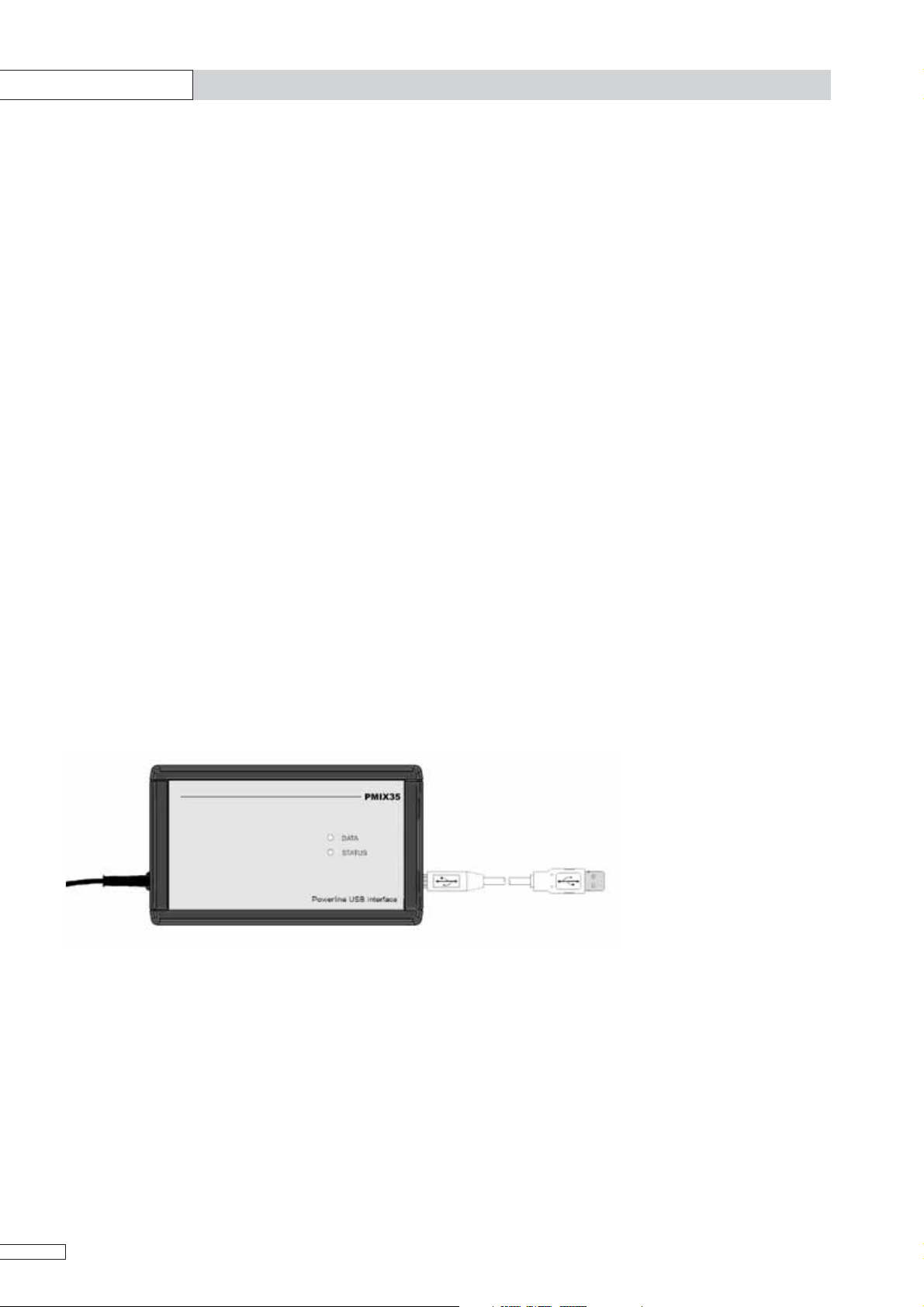

Figure 1: PMIX35

2

Page 3

Software installation

Follow the steps below to install the PMIX35 software.

!

Please note:

Follow the installation procedure below before connecting the PMIX35 to the PC!

1. Place the PMIX35 CD in the CD-ROM drive of the PC.

If the installation does not start automatically, then follow the steps below:

a. Open Windows Explorer and go to the CD-ROM drive in which the PMIX35 CD is located.

b. Click the SETUP.EXE file to start it.

c. Click Run to start the installation.

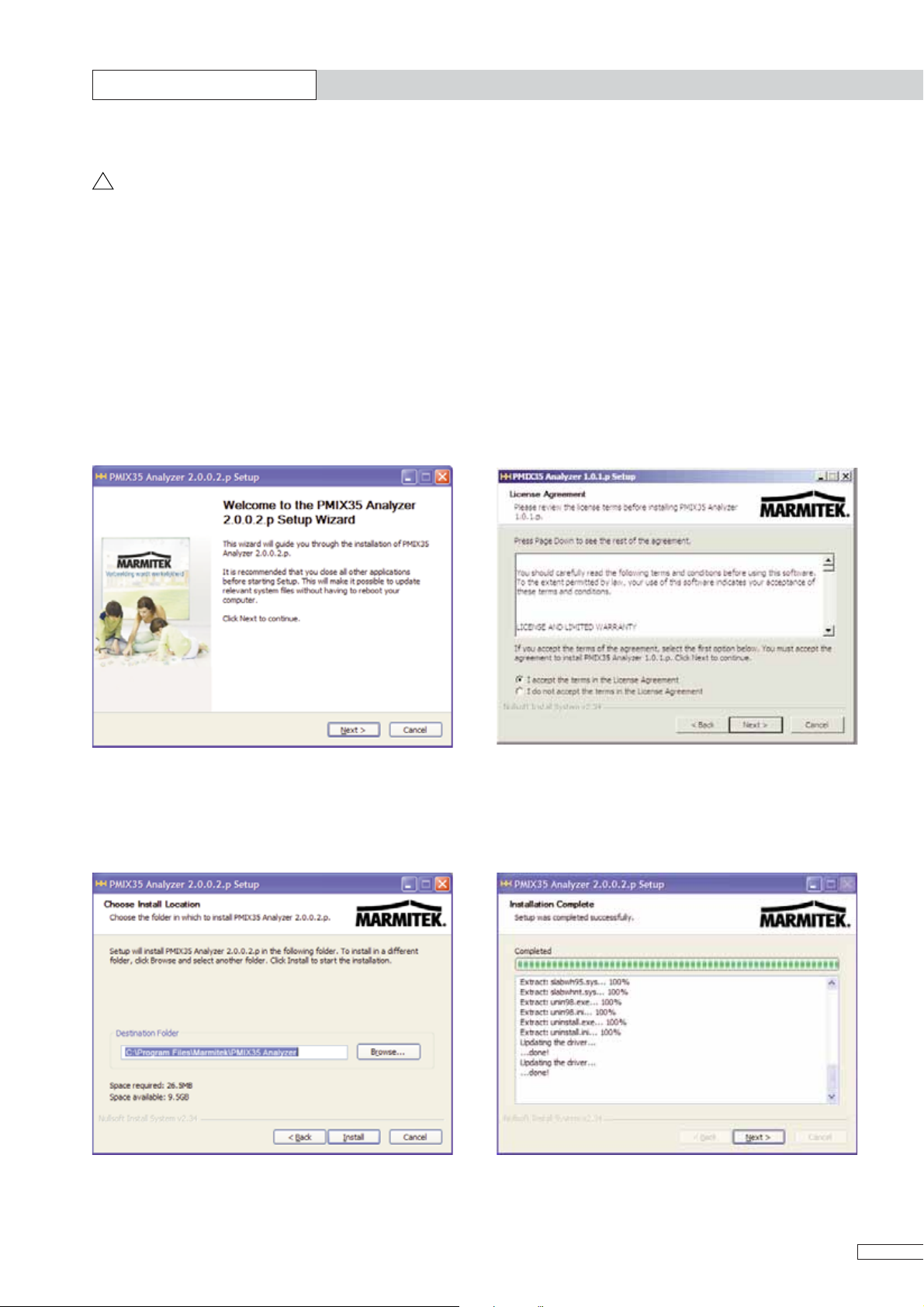

2. Click "Next" in the following screen:

4. Chose a different folder or location, if desired, and click

"Install" in the following screen:

3. Read the terms and conditions and accept them to

continue with the installation process.

5. Wait until the installation is complete.

3

Page 4

Software installation

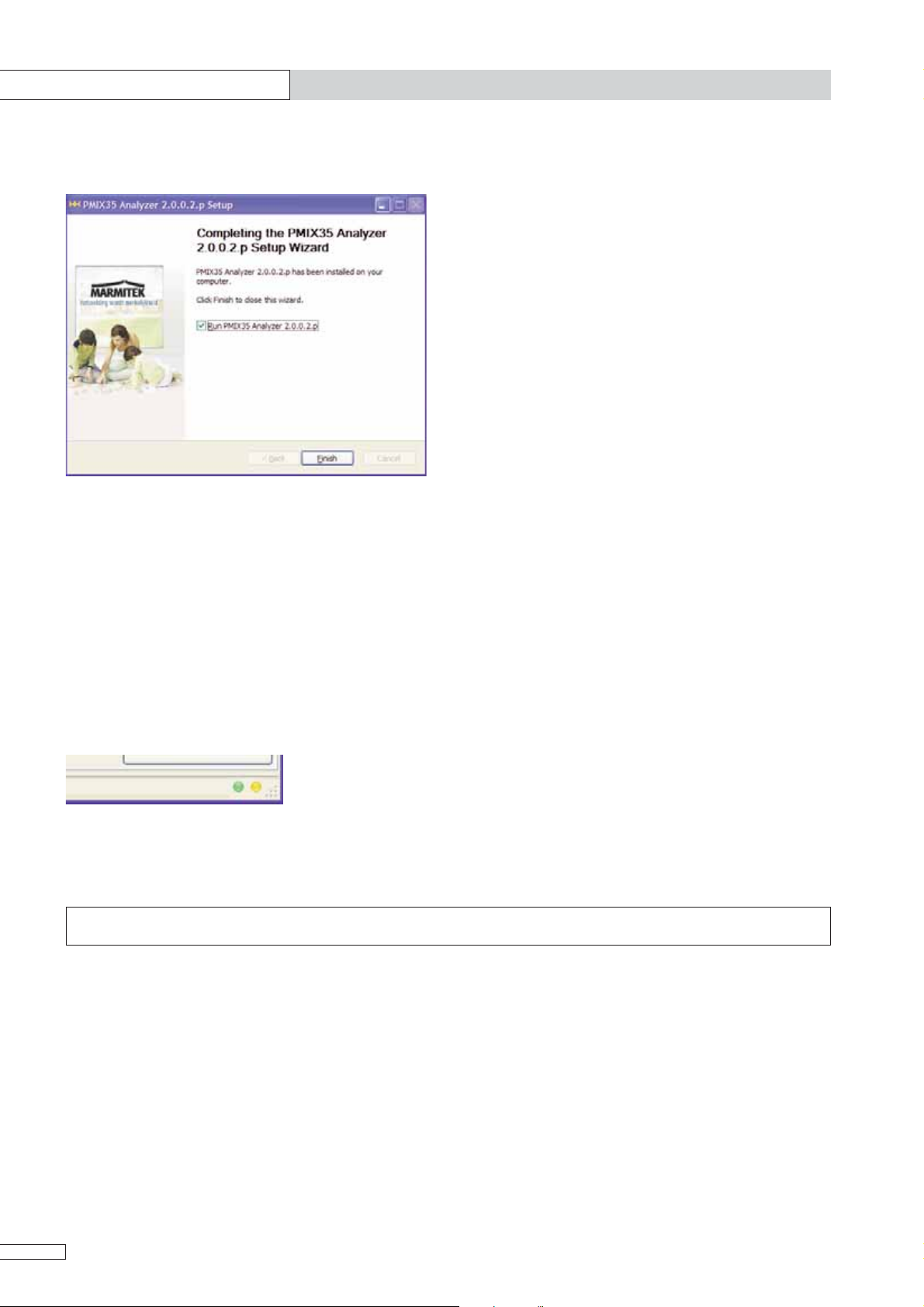

6. Click "Finish" in the following screen:

7. Now connect the USB cable of the PMIX35 to the PC.

8. The PMIX35 is now ready for use.

After starting up, the PMIX35 software will automatically search for the presence of a connected PMIX35 and attempt to

establish a connection. The software verifies whether the correct firmware version is in use. If this is not the case, the

software will load the correct firmware version into the PMIX35. The status of the connection is indicated in the lower right

part of the screen by the following two indicators (see figure 2):

• Yellow: Signals sent to the PMIX35.

• Green: Signals received by the PMIX35.

Figure 2: Connection with PMIX35 indicator

Check www.marmitek.com regularly for new software versions for the PMIX35

4

Page 5

1 Programming and measuring functions

The PMIX35 software can be used for:

• Programming Marmitek X-10 modules.

• Measuring and testing an installation.

For this purpose the PMIX35 software is divided into three tab pages, namely:

1. Programmer

2. Analyzer

3. Network Validation (available via a software update from mid-2008)

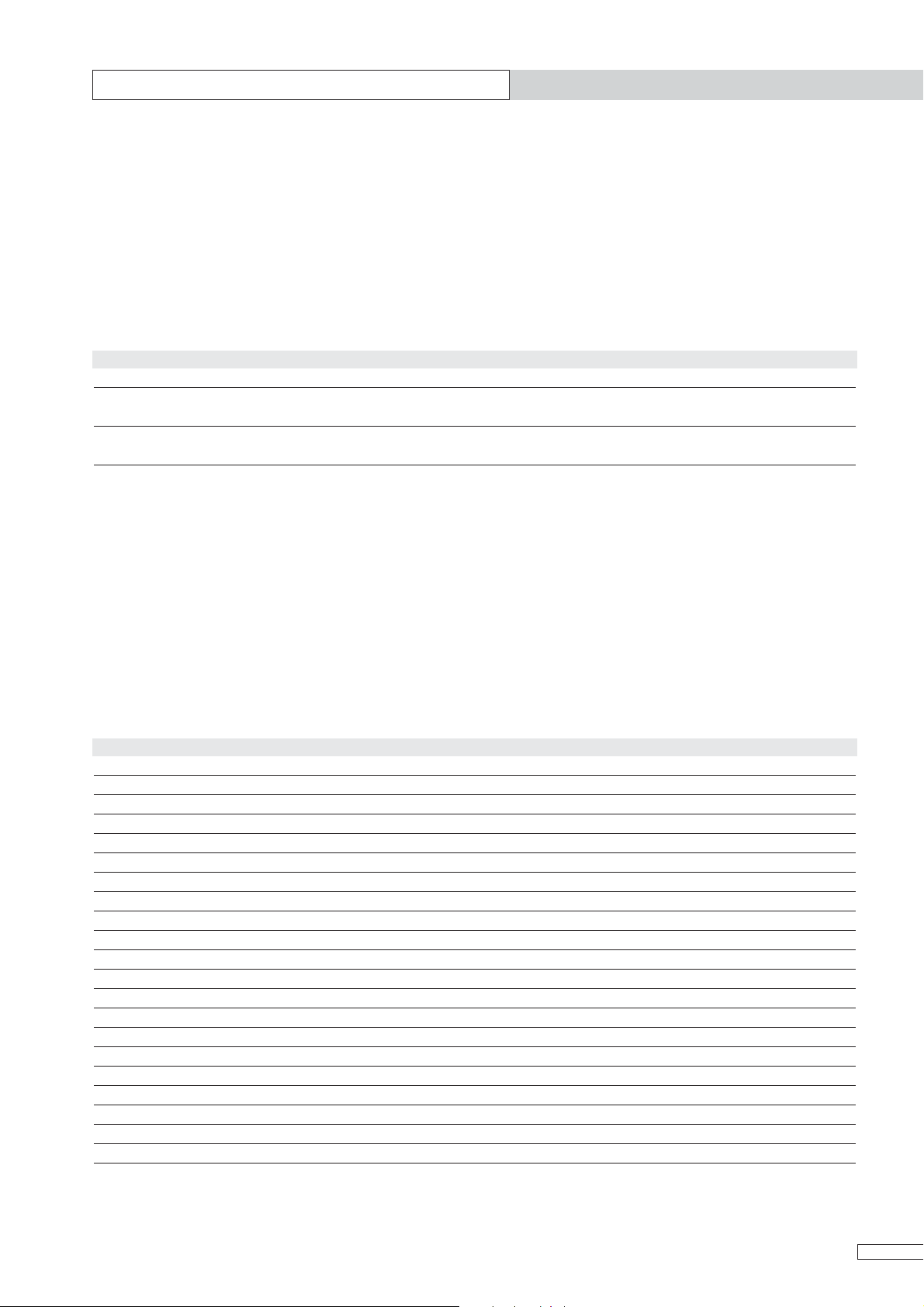

The table below gives an overview of these functions and their applications:

Tab page name Purpose Application

Programmer Programming modules All Marmitek X-10 modules can be easily programmed using this function.

Analyzer Problem analysis

Network Validation Validation of an installation

Table 1 1: Overview of software functions.

In the following chapters each individual tab page with its specific functions will discussed in detail.

Highly specific measurements for analysis can be carried out in a Marmitek X-10

installation using this function.

This function validates the reliability of a new, yet to be delivered Marmitek X-10

installation with a validation report and a final assessment.

1.1 Programmer

The purpose of the Programmer tab page is to allow the simple programming of Marmitek X-10 modules.

The required settings are preset and programmed in the module at the touch of a button.

The latest Marmitek X-10 modules can be automatically placed in program mode (PRG function) without having to remove the

module to press the program button. The module types that support this PRG function can be found in the table below:

Type Description PRG function

IMX10 / TWM4 Programmable interface potential-free inputs Yes

SAIX12 / AWM2P Switch actuator/switch interface 230 V AC inputs Yes

DAIX12 / LWM1P Dimming actuator/dimmer interface 230 V AC inputs Yes

PIOX15 v2 Potential-free input/output interface Yes

SAX15 v2 Switch actuator/switch interface potential-free Yes

SVX10 v2 Signal amplifier Yes

SAIX / AWM2 Switch actuator/witch interface potential-free inputs No

SAX1 Switch actuator No

DAIX10 / LWM1 Dimming actuator/dimmer interface potential-free inputs No

DAX10 Dimming actuator No

AIX / TMA4 Switch interface potential-free inputs No

AIX12 Switch interface 230 V AC inputs No

DIX1 Dimmer interface single-face potential-free inputs No

DIX2 Dimmer interface two-face potential-free inputs No

GIX Group interface potential-free inputs No

SVX10 v1 Signal amplifier No

PIOX15 v1 Potential-free input/output interface No

SAX15 v1 Switch actuator/switch interface potential-free No

SAX35 witch actuator/switch interface potential-free No

VIX10 Fan interface No

ZAX12 / SWM1P Sunscreen interface potential-free No

Table 1 2: Module types.

The following paragraphs describe the programming method for both types of modules.

5

Page 6

1 Programming and measuring functions

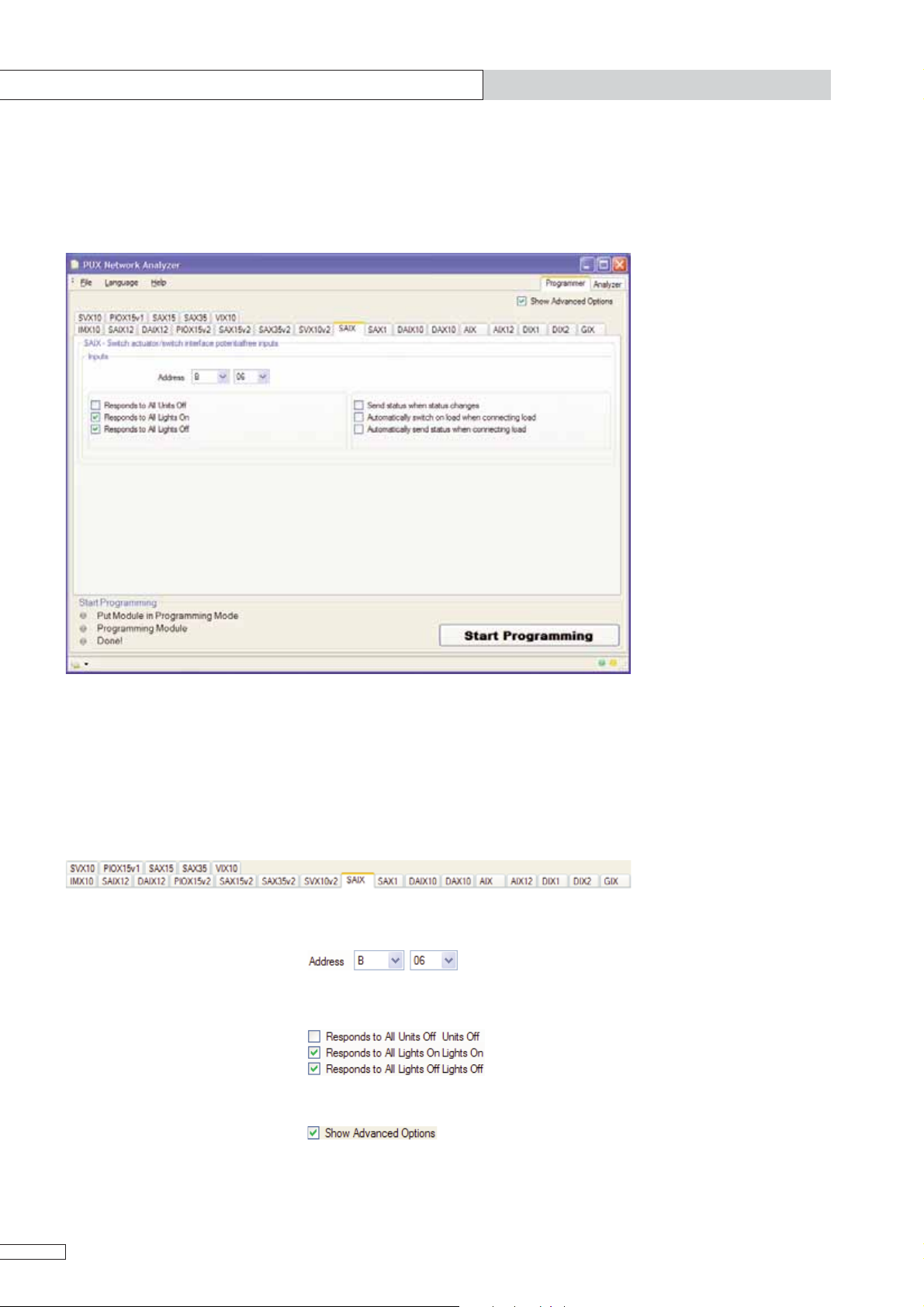

1.1.1 Programming standard modules

Standard modules (without PRG function, see table 1-2) can be easily programmed by selecting the required module settings.

After that, these settings can be programmed in the module at the touch of a button.

In order to program a module, a number of steps must be followed. These steps are described on the next page.

Figure 3: Example of programming an SAIX.

Programming steps:

1. Select the module to be programmed at the top of the tab page:

2. Select the required address:

3. Select the required options:

4. Select any extra options using:

6

Page 7

1 Programming and measuring functions

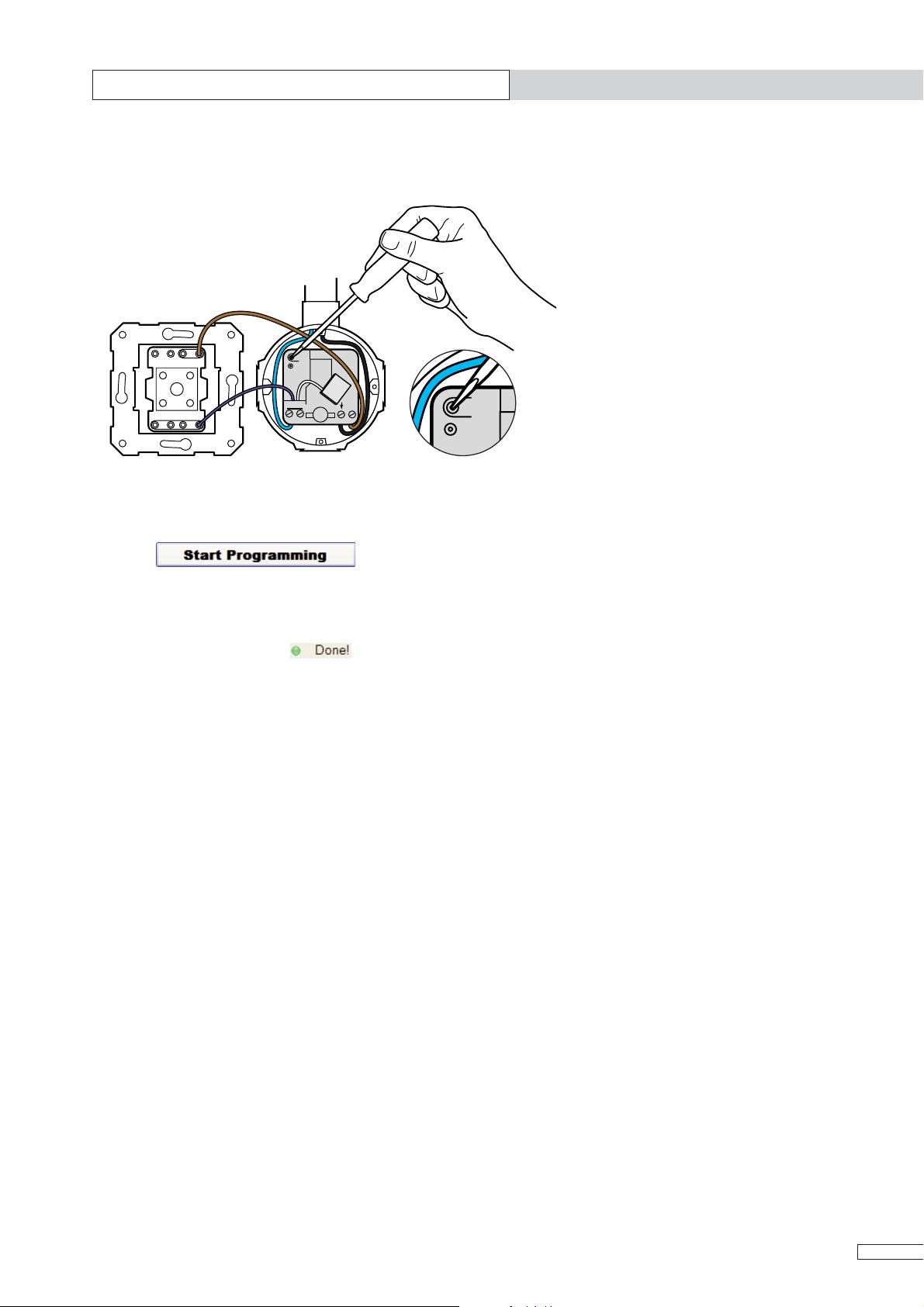

PROG.

5. Switch the module to programming mode by pressing the programming button for 3 seconds.

P

The module LED switches on.

PROG.

SAIX

N

12

L

6. Click:

The module LED will start to flash.

7. Wait for the green indicator:

8. Exit programming mode by pressing the programming button again briefly.

The module LED switches off.

7

Page 8

1 Programming and measuring functions

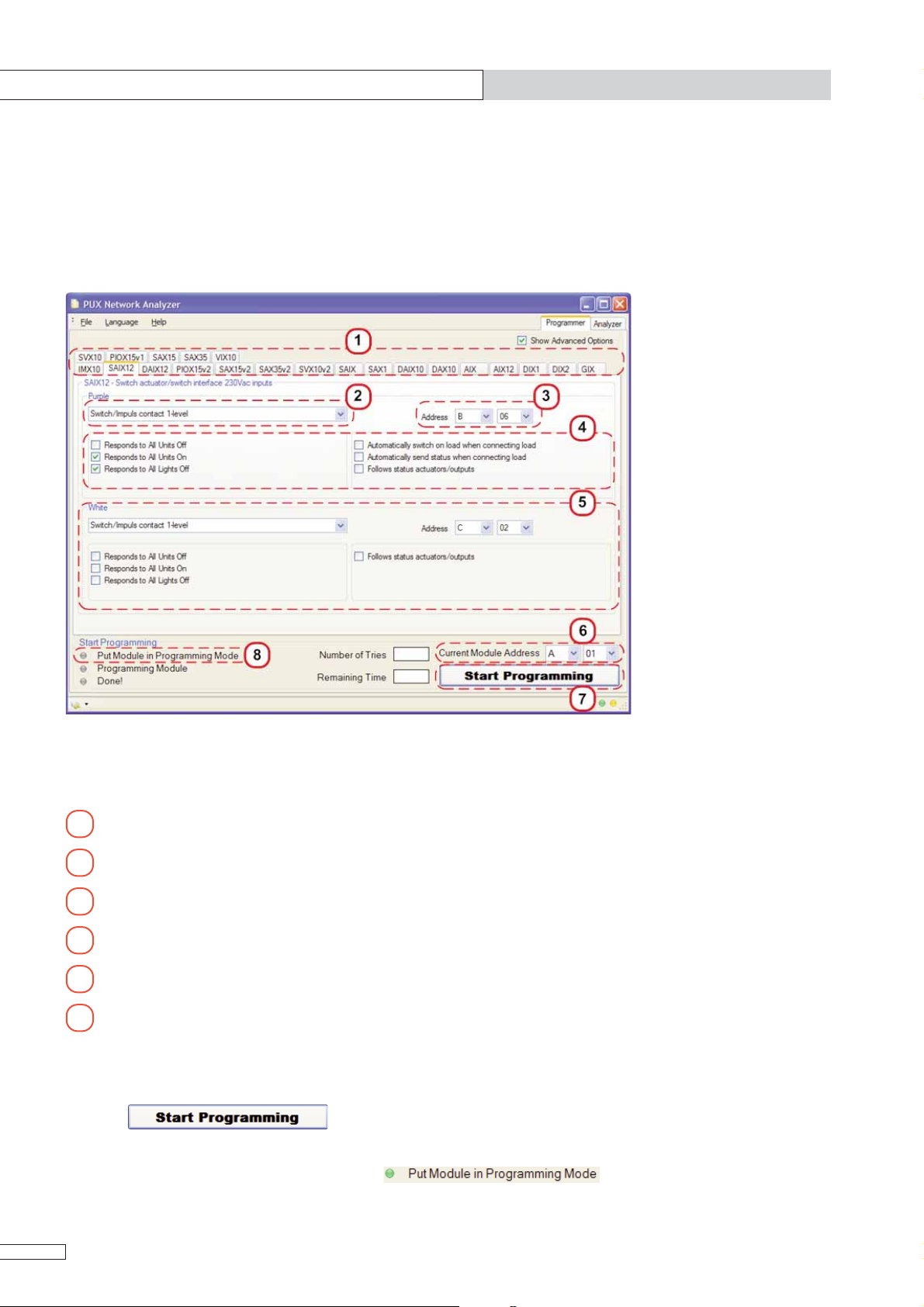

1.1.2 Programming using automatic programming mode

The latest generation of Marmitek X-10 modules can be (re)programmed by means of a special procedure without having to

remove the module. This procedure, which must be followed precisely, is based on interaction between the PMIX35 and the

module. The module can be programmed by operating a switch or pushbutton, or by switching the connected load on and off

(in electrical wall sockets), in combination with the software. The module will not enter the programming mode if any of the

conditions have not been met.

Read through the instructions below carefully and follow them precisely.

Figure 4: Programming steps

The steps for automatic programming mode are as follows:

Select the module type by pressing the tab page.

1

Select the function required for the first input wire.

2

Select the address required for the first input wire.

3

If necessary, select the options for the first input wire.

4

If necessary, select the function, the address and options for the other input wires.

5

Verify whether the current address of the module is selected here. All new modules have the default address A01.

6

This is necessary to activate the PRG function in this module.

1. Click:

2. Wait until the green indicator light is illuminated:

8

Page 9

1 Programming and measuring functions

3. Within 5 seconds, activate the programming mode of the module according to the table below:

Type Activation of programming mode

IMX10 Switch one of the inputs 4 times within 5 seconds using the switch or pushbutton.

SAIX12 Switch one of the inputs 4 times within 5 seconds using a switch or pushbutton or switch the connected load

DAIX12 (wall socket) on and off 4 times within 5 seconds.

The programming starts:

4. Wait for the indicator:

If programming does not start automatically:

• Press: and repeat the instructions above or

• Press the programming button of the module within the time indicated by:

The PMIX35 makes three attempts , before stopping the procedure.

1.2 Analyzer

The purpose of the Analyzer tab page is to measure and analyse the quality of the data transfer over the power line. For a

good analysis, various settings can be made, in many cases requiring specific knowledge. Where in the installation the

measurement is carried out is also important.

All measurements take place via the power cord of the PMIX35.

The explanation of the application of the Analyzer function is divided into a number of practical components. The table below

gives an overview of these components and their possibilities:

Component Possibilities

Measuring signal levels The signal levels of all messages transmitted and received are displayed in the log screen. In this way, unreliable

signal levels are immediately noticeable. By varying the transmission level of the transmitted messages, the

sensitivity of the receiving side of a module can be measured.

Network diagnostics The network diagnostic indicators offer direct insight into possible areas of interest.

Sending and receiving Messages can be sent directly or be placed in a macro before they are sent. The macros can be sent

messages automatically at certain intervals. Messages that are transmitted and received can be found in the log screen.

Logging and viewing The status of the received messages is indicated in the log screen by means of colour shading.

message communication In this way, communication faults are immediately noticeable. The saved log file can be imported into Excel,

for example, for further analysis.

Table 1 3: Analyzer components.

9

Page 10

1 Programming and measuring functions

1.2.1 Measuring signal levels

The measuring of signal levels in Marmitek X-10 installations allows the rapid detection and resolution of problems. A few

examples of this are:

• One or more modules appear to be inaccessible after switching on one module.

• Switching this module On has an affect on various signal levels. The load connected to this module is causing the problem.

• Some of the modules do not work at certain times. The signal levels of some of the modules lie below the required level.

At the times when these modules do not respond, the noise level is shown to be much higher.

The automatic measuring of the signal quality can be performed most simply via the network validation tab page.

See chapter 1.3.

The measuring of signal levels can also be performed for individual modules. This procedure is described below.

1.2.1.1 Signal levels of modules

The signal level and noise level of each message received is measured. These values can be found in the log screen as well

as in the log file next to the received message. These values are reported in mV.

The readings from the two most recently received messages can also be found on the large display fields in order to quickly

gain insight into current events. An important factor in power line communication is network impedance. The value of the

power line impedance is reported in Ohm (see figure 5).

During measuring, always take the following points into account to be able to properly assess

the signal level of a module:

• Before the measuring starts, switch all appliances in the home on. By doing so, the effect of

the switched on appliances is included in the measurement.

• Perform the same measurement at more than one socket in the home.

• Always look at the noise level. The higher the noise level, the more signal is necessary to be

able to function properly. It can happen that an appliance has a negative effect on the noise

level and, therefore, communication. Provide this appliance with a filter.

• Always look at the network impedance. It can happen that an appliance has a negative effect

on the network impedance and, therefore, communication. Provide this appliance with a filter.

Figure 5:

Display of latest readings.

For maximum reliability, the signal levels must comply with the threshold values as indicated in figure 6. If the signal level

falls into the yellow area, it is important to check whether the module continues to function properly in all cases. If the signal

level falls in the red area, action must always be taken to improve the signal quality.

• The network impedance should not be lower than 2 Ω.

Fault Check Good

0 100 mV 200 mV Max

Figure 6: Signal level thresholds for modules.

10

Page 11

1 Programming and measuring functions

1.2.1.2 Sensitivity of modules

The sensitivity of modules can be measured by varying the transmission level of the messages. By doing so, it is possible to

determine at which level the module no longer reacts. To do this, slide the selector from left to right (see figure 7).

Follow the steps below to measure the sensitivity of a module starting from the measurement

site:

1. Enter ON/OFF or Status Request commands in the command lines for controlling the relevant

module (see paragraph 1.2.3.2 Sending several messages simultaneously). For interface

modules, make use of following the status.

Figure 7:

Setting the transmission level.

3. With the selector, find the lowest point at which the module still responds properly. Take the value of the transmission

signal from the display field below.

4. Check where this value falls within the thresholds depicted in the figure below:

Good Check Fault

0 2 V 4 V Max

Figure 8: Sensitivity thresholds of modules.

2. Slide the "Transmit Voltage" selector all the way to the right (maximum) and send several

ON/OFF commands to check the operation of the module. The signal level sent is then

displayed in the large display field underneath.

5. If the signal level falls into the yellow area, it is important to check whether the module continues to function properly in

all cases.

1.2.2 Network diagnostics

The Network Diagnostics indicators and the Counters (see figure 9) offer quick insight into specific events.

Figure 9: Network diagnostics data.

The table on the below gives an overview of the diagnostic indicators and their functions. The indicators are displayed until all

indicators are reset with the button.

Indicator name Diagnostics

Repeater detected Indication that the signal level measured from the 2nd address/command received is higher than the 1st over the

course of several measurements.

Module noise detected Indication that the PMIX35 detects signal interference that disrupts communication.

Lost command detected Indication that a suspect message has been detected in the log screen, indicated by red shading.

Lines shown in this colour require extra attention.

<200 mV detected Indication that a signal lower than 200 mV has been measured.

<100 mV detected Indication that a signal lower than 100 mV has been measured.

Impedance drop detected Indication that the impedance measured changes a specified delta X.

Table 1 4: Network diagnostics indicators.

11

Page 12

1 Programming and measuring functions

The table below gives an overview of the various counters and their functions.

All counters can be set to 0 with the button.

Indicator name Diagnostics

All Addresses Counter value of all addresses received.

All Commands Counter value of all commands received.

DIM/BGT Commands Counter value of all DIM and BRIGHT commands received.

Extended commands Counter value of all extended data received.

Table 1 5: Counters.

1.2.3 Sending and receiving messages

1.2.3.1 Sending messages directly

When sending messages, the required addresses and commands can be sent directly with the buttons available for this

purpose (see figure 10). In this case "Add to command line" must not be selected.

Make use of the address selection buttons to choose another

address. The button is only used for the selection of "Add to command line"

when using macros.

Figure 10: Sending messages directly.

1.2.3.2 Sending several messages simultaneously

When sending several messages simultaneously, the two available command lines can be used (see figure 11).

Figure 11: Sending messages indirectly.

Example:

Follow the steps below for sending a Status Request to the address "A01".

1. Select the option:

2. Select the address:

3. Click the top command line with the mouse.

4. Click twice on , in this example A01A01.

5. Click (there must always be a space between addresses and commands).

6. Click twice on

7. Send the command line using the button next to the entry field.

12

Page 13

1 Programming and measuring functions

1.2.3.3 Sending messages automatically

With the two command lines available, two series of messages can be sent automatically in a specified pattern.

The command lines can be saved in a macro file with the

button. To do this, choose the file name required and save. All

command lines entered and sent can be selected with the arrow

keys. An existing macro can be opened with the button.

Figure 12: Sending messages automatically.

Example:

Follow the steps below to automatically send two command lines to the address "A01".

1. Follow the steps in paragraph 1.2.3.12 to provide both command lines with the required messages.

2. Select the option and the required delay time for the first command line:

3. Select the option and the required delay time for the second command line.

4. Start automatic sending by clicking: (this symbol then becomes: ).

5. The indicator for the command lines indicates in yellow which line is waiting to be sent.

6. Sending can be cancelled by clicking: (this symbol then becomes: ).

1.2.3.4 Receiving messages

As well as messages that are transmitted, messages that are received are also displayed, with their arrival times,

in the and columns in the log window (see figure 13).

Figure 13: Received messages log screen.

According to the X-10 protocol, messages are always sent twice consecutively. The first message always appears in the

column and the second message always appears in the column. If the second message is not

received, the second column will be empty. Single messages occur normally with Phase Couplers and Repeaters.

See the table below for an explanation of the different data colours in the log screen.

Log line Meaning

Received message.

Transmitted message.

Suspect message. Lines shown in this colour require extra attention.

Table 1 6: Log line colour meanings.

13

Page 14

1 Programming and measuring functions

Errors in the log screen are indicated with red shading.

The table below gives several examples of suspect messages:

Suspect messages Description

" "A01" "AONAON

" "A01A01" "AON If one of the double addresses or commands is missing. This does not apply to repeated messages for which the

address and the command consist of only one message.

A01AON If there is no space between two different messages.

A01BDIM

A01B03

AONAOFF

AONBON

A01A[1]031531

AONA[1]031531

A01" "BON If an address is followed by a command with a different letter code.

A01" "B02 If an address is followed by an address with a different letter code.

Table 1 7: Examples of faulty message patterns.

The example of sending a Status Request to the address "A01" from chapter 1.2.3.2 Sending several messages

simultaneously can be found in the log screen as shown below:

Go to the next chapter for more information about the interpretation of log information.

1.2.4 Logging and reading data communication

Information if the log screen can be saved in a log file with the button. To do this, choose the file name required and

save. The log screen can be cleared with the button.

A log file looks like this:

Sample log file: pmix35.log

Date / Time Space Data1 Level1 Noise1 Data2 Level2 Noise2 Status Echo

11/30/2007 12:10:43 PM S A01 555 85 A01 556 83 No Echo

11/30/2007 12:10:43 PM S AOFF 554 89 AOFF 556 86 No Echo

11/30/2007 12:10:46 PM S A01 555 85 A01 556 87 No Echo

11/30/2007 12:10:46 PM S AON 554 89 AON 557 82 No Echo

11/30/2007 12:10:50 PM S A02 563 89 A02 559 93 No Echo

11/30/2007 12:10:51 PM S AOFF 566 98 AOFF 563 89 No Echo

11/30/2007 12:11:01 PM S A01 566 90 A01 564 89 No Echo

11/30/2007 12:11:01 PM S AOFF 544 84 AOFF 555 87 No Echo

11/30/2007 12:11:08 PM S A01 2933 90 A01 2931 95 Echo

11/30/2007 12:11:08 PM S ASRQ 2929 100 ASRQ 2926 92 Echo

11/30/2007 12:11:09 PM S A01 558 83 A01 557 89 No Echo

11/30/2007 12:11:09 PM S ASOF 559 84 ASOF 568 84 No Echo

11/30/2007 12:11:13 PM S A01 3903 90 A01 3898 91 Echo

11/30/2007 12:11:13 PM S AON 3899 90 AON 3892 90 Echo

11/30/2007 12:11:16 PM S A01 3893 86 A01 3890 88 Echo

11/30/2007 12:11:16 PM S ASRQ 3886 93 ASRQ 3887 95 Echo

11/30/2007 12:11:17 PM S A01 564 84 A01 559 83 No Echo

11/30/2007 12:11:17 PM S ASON 564 86 ASON 561 78 No Echo

11/30/2007 12:11:31 PM S A01 550 90 A01 558 83 No Echo

11/30/2007 12:11:48 PM S A01 880 87 Suspicious Echo

11/30/2007 12:11:48 PM S A01 880 87 A01 880 89 Echo

11/30/2007 12:11:48 PM S ASRQ 879 100 ASRQ 876 96 Echo

11/30/2007 12:11:50 PM S A01 561 88 A01 568 84 No Echo

11/30/2007 12:11:50 PM S ASOF 553 84 ASOF 560 80 No Echo

Table 1 8: Log file.

Errors that appear in the log screen with red shading (see table 1-6) are indicated in the log file with the message "Suspicious".

14

Page 15

1 Programming and measuring functions

1.3 Network validation

In this tab page, a quick and simple network analysis can be performed before the delivery of a Marmitek X-10 installation.

By making a selection of the addresses used, the PMIX35 will perform a number of measurements and present a report

which includes the areas of interest of the Marmitek X-10 installation.

1.3.1 Performing network validation

When performing network validation, the tab page "Network validation" must first be selected. Select the letter codes used in

the Marmitek X-10 installation by clicking the relevant boxes, thereby selecting the letter code(s).

In the fields on the top right corner, the name and address details of the customer where the measurement is taking place

can be entered. Any comments can be entered in the remarks field. Once the measurement is complete, this data can be

saved and compared with the data from any subsequent measurements.

!

Please note:

Before validation can be started, it is important to switch on all of the appliances in the home that are connected to the

power line. Switching on means bringing the appliance to working voltage, as opposed to leaving them in stand-by mode.

Appliances such as dishwashers, washing machines, dryers, computer monitors, TVs etc. must be switched on. In this way,

the measurement will be made under the most adverse conditions, so the result gives a good picture of the points that

require attention to guarantee reliable data transfer.

Figure 14: Network validation tab page.

Press "Start Validation" as soon as all appliances in the home have been switched on. The PMIX35 will now begin

transmitting data to and receiving data from the modules that are present in an installation. This process can take up to

10 minutes or so depending on the number of letter codes.

!

Please note: Make sure that no switches are operated during this process and that any motion detectors are not

activated while the measurement is being made. Do not interrupt the test; allow the PMIX35 to run through the entire process.

15

Page 16

1 Programming and measuring functions

1.3.2 Interpreting the network validation data

The PMIX35 software will display the transmission, reception, noise and impedance levels per address.

In the "Result" column, the software displays the result of the measuring process for the relevant address.

There are four possible results, namely:

• Not Found: the address was not found in the installation. The line is coloured white.

• Passed: the results are good. No further action is necessary. The line is coloured green.

• Check: the results give cause to re-examine the situation around the module at this address. The line is coloured orange.

• Failed: the results indicate that under the current circumstances no reliable communication is possible to and/or from this

module. The line is coloured red.

The result is established by an analysis of the software on the basis of the signal level and noise level. As soon as there are

low signal levels, the result is clear. However, it can also occur that the signal levels are good (above the minimal values) but

that there is a very large difference between the signal levels of an ON and an OFF command in a module. The PMIX35

software will also indicate this address as "check".

It is advisable to repeat the validation test for the modules that receive a "check" or a "fail" result. Before repeating the test,

switch off one or more appliances in the vicinity of the module you wish to check. If the repeat validation gives a better

result, this means that the appliances in question have a damping effect on the signal quality. Isolate the appliances with one

or more filters. If the signal levels do not change after switching off the appliances, this can mean that there are other factors

causing the signal strengths to be inadequate. In this situation, a signal amplifier (SVX10) can offer a solution to improve the

signal levels.

The measurement data can be saved by clicking the button. Another possibility is to select the data and copy and paste it into

a spreadsheet program.

16

Page 17

2 The PMIX35 as data interface

The PMIX35 supports the CTX15/35 protocol as standards and, in addition, has a number of extra functions. This means that

the PMIX35 can directly replace the CTX15/35 without having to adapt the software.

2.1 PMIX35 communication driver

The PMIX35 is equipped with a USB connection based on a CP210x virtual COM port. The installation software automatically

installs the CP210x USB to UART Bridge Virtual COM Port (VCP) drivers, so that the PMIX35 can communicate via the USB

port of a PC.

The drivers are available for the following operating systems:

• Windows 2000/XP/Server 2003/Vista

• Macintosh

• Linux

During the installation, the software also checks whether the firmware version which belongs with the installed software is

loaded in the PMIX35. If this is not the case, the software will load the correct firmware version.

2.1.1 Example using Windows 2000/XP driver

After the installation of the USB drivers on the Windows XP operating system, the name of this COM port can be found

under "Device Manager" in the hardware overview in the configuration screen in XP (see figure 15).

Figure 15: Windows XP Device Manager USB Driver.

The COM port number assigned to the PMIX35, COM5 in this case, follows the driver name "CP2101 USB to UART Bridge

Controller". Now, communication with the PMIX35 can occur via this COM port.

17

Page 18

2 The PMIX35 as data interface

2.2 Protocol description

2.2.1 COM port settings

See the figure below for the required COM port settings:

Figure 16: Port settings.

2.2.2 COM port detection

The COM port to which the PMIX35 is connected can be detected by sending the "PX" command. As the PMIX35 will answer

this command, the correct COM port can be automatically selected.

18

Page 19

2 The PMIX35 as data interface

2.2.3 Communication format

All communication is ASCII format. The messages between the PC application and the PMIX35 are equipped with headers.

The PC application always takes the initiative and the PMIX35 answers it. See the table below for the format.

$>9000{message}cs# Communication direction: PC -> PMIX35

$ Start character.

> Communication direction from PC to PMIX35.

9000 PMIX35 address.

{message} Message for PMIX35.

cs Checksum: sum of all characters except the end character.

# End character.

$<9000{bericht}cs# Communication direction: PMIX35 -> PC

$ Start character.

< Communication direction from PMIX35 to PC.

9000 PMIX35 address.

{message} Message for PC.

cs Checksum: sum of all characters except the end character.

# End character.

Table 2 1: Format headers.

There are various types of messages, including messages which contain X-10 traffic. These messages contain not only the X10 format but also the accompanying signal levels. The table below shows the X-10 format:

<L><AA> Address

L 16 letter codes, A to P.

AA 16 addresses, 01 to 16.

<L><CC[C]> Command

L 16 letter codes, A to P.

CC[C] commands: ON, OFF, DIM, BGT, AUF, ALN, ALF, HRQ, HAK, PRG, SON, SOF, SRQ.

<L>[1]<AA><EEEE> Extended

L 16 letter codes, A to P.

AA 16 addresses, 01 to 16.

EEEE Extended code hexadecimal.

" " Space

" " The space character. This corresponds to a specific time between the different messages.

Messages which are different from each other are always separated by a space.

Table 2 2: Format X-10.

19

Page 20

2 The PMIX35 as data interface

2.2.4 Types of messages

The tables below describe the different types of messages. See the next section for an example of a checksum "cs" calculation.

Transmitter Format Description

PC PX PMIX35: "Are you PMIX35" message to ask COM ports whether a PMIX35 is connected to the COM port.

The PMIX35 reacts to this message within 1000 ms with VP.

PMIX35 VP{MMmm} Version PMIX35: This message is sent to the PC application as a response to PX. This also contains the

version number of the PMIX35.

Parameters:

MM - Major Version Number in two-byte decimal ASCII notation.

mm - Minor Number in two-byte decimal ASCII notation.

Example: $<9000VP0131cs#

Corresponds to version 1.31.

Table 2 3: Message: PX (Are you PMIX35).

Transmitter Format Description

PC TV{VVVV} Transmit Voltage: The transmit voltage of the PMIX35 is set with this message.

Parameters:

VVVV - Voltage in two-byte decimal ASCII notation; valid range between 0-5000 mV.

Example: $>9000TV2500cs#

Corresponds to a transmit voltage of 2500 mV.

PMIX35 {s} This message gives an ACK or NACK indicator for the received message.

Parameters:

s - "!" ACK.

"?" NACK transmit again (maximum three times).

Example: $<9000!cs#

Message has been received.

Table 2 4: Message: TV (Transmit Voltage).

Transmitter Format Description

PC SP{D} Send Position: The position of the transmitted data on the mains voltage with respect to the zero crossing

is set with this message.

Parameter:

D - "1" Transmit at: 0 degrees.

"2" Transmit at 30 degrees.

"3" Transmit at 0 and 30 degrees.

"4" Transmit at 60 degrees.

"5" Transmit at 0 and 30 degrees.

"6" Transmit at 0 and 60 degrees.

"7" Transmit at 0, 30 and 60 degrees.

Example: $>9000SP1cs#

Transmit data at 0 degrees.

PMIX35 {s} This message gives an ACK or NACK indicator for the received message.

Parameters:

s - "!" ACK.

"?" NACK transmit again (maximum three times).

Example: $<9000!cs#

Message has been received.

Table 2 5: Message: SP (Send Position).

20

Page 21

2 The PMIX35 as data interface

Transmitter Format Description

PC RQ Data Request: After the connection has been established, a Data Request is made to the PMIX35

with a period of 500 ms. The PMIX35 can answer with the following message types:

ND - Noise detected.

NI - Network Impedance.

LR/LE - Line Read/Line Echo.

? - Message not properly received.

These messages can appear in the answer together or separately.

Example: $>9000RQcs#

PMIX35 ND{SS}

PMIX35 NI{OOOO} Network Impedance: Every 5 seconds, this message is sent along with the other messages.

PMIX35 LR{VVVV}{NNNN}{LL…L}

LE{VVVV}{NNNN}{LL…L} LR/LE - Line Read/Line Echo: Data packet read by the PMIX35 on the circuit, transferred

PMIX35 {s} This message gives a NACK indicator for the received message.

PC ? Nack: After the connection has been established, a Data Request is made to the PMIX35 with a

Module Noise Detected: When changing state, this message is sent along with the other messages.

Parameters:

SS - State in one-byte decimal ASCII notation; 00 = No Noise Detected,

01 = Noise Detected.

Example: $<9000ND01cs#

Corresponds to: There is Module Noise Detected.

Parameters:

OOOO - Impedance in two-byte decimal ASCII Notation;

valid range between 0-9999 10th of an Ohm.

Example: $<9000NI0047cs#

Corresponds to a Network Impedance of 4.7 Ohm.

transparently to the PC application. The voltage and noise that the message was received with

are also provided. The "LE" indicates that the data packet received had been sent by the

PMIX35 itself.

Parameters:

VVVV - Voltage in two-byte decimal ASCII notation; valid range between 0-6000 mV.

NNNN - Noise Level in two-byte decimal ASCII notation; valid range between 0-6000 mV.

LL..L - Line in variable length ASCII notation.

Description:

Example 1: $<9000LR35000300A01cs#

Received: A01 with 3500 mV and 300 mV noise.

Example 2: $<9000LE35000300AOFFcs#

Received echo: AOFF with 3500 mV and 300 mV noise.

Example 3: $<9000LR35000300 A01cs#

Received: A01 preceded by a space with 3500 mV and 300 mV noise.

Parameters:

s - "?" NACK transmit again (maximum three times).

Example: $<9000?cs#

Message not properly received.

period of 500 ms. The PMIX35 can answer with the following message types:

ND - Noise detected.

NI - Network Impedance.

LR/LE - Line Read/Line Echo.

These messages can appear in the answer together or separately.

Example: $>9000?cs#

Examples of combined messages. Only one of each type can appear in these messages.

The LR/LE messages are always at the end of the line.

$<9000NI0047LR35000300A01cs#

$<9000ND01NI0047LE35000300 AOFFcs#

$<9000ND01LR35000300 A01cs#

Table 2 6: Message: RQ (Data Request).

21

Page 22

2 The PMIX35 as data interface

Transmitter Format Description

PC LW{LLL..L} Line Write: With this message, the PC application commands the PMIX35 to transfer data transparently

on the circuit.

Parameters:

LL..L - Line in variable length ASCII notation. Corresponds to the data entered in the

"Macro entry fields". See item 4 Fout! Verwijzingsbron niet gevonden.

Example: $>9000LW A01A01 AONAONcs#

Corresponds to switching on everything on A01.

PMIX35 {s} This message gives an ACK or NACK indicator for the received message.

Parameters:

s - "!" ACK.

"?" NACK transmit again (maximum three times).

Example: $<9000!cs#

Message has been received.

Table 2 7: Message: LW (Line Write).

22

Page 23

2 The PMIX35 as data interface

2.2.4.1 Sample checksum calculation

To receive data from the PMIX35, a request must be sent to the PMIX35.

This request is described in

$>9000RQcs#

To calculate the checksum "cs", the hexadecimal values of all of the previous characters must be added together

hexadecimally. These values can be found in the ASCII table below:

Hex Code Hex Code Hex Code Hex Code Hex Code Hex Code

20 (Space) 30 0 40 @ 50 P 60 ` 70 p

21 ! 31 1 41 A 51 Q 61 a 71 q

22 " 32 2 42 B 52 R 62 b 72 r

23 # 33 3 43 C 53 S 63 c 73 s

24 $ 34 4 44 D 54 T 64 d 74 t

25 % 35 5 45 E 55 U 65 e 75 u

26 & 36 6 46 F 56 V 66 f 76 v

27 ' 37 7 47 G 57 W 67 g 77 w

28 ( 38 8 48 H 58 X 68 h 78 x

29 ) 39 9 49 I 59 Y 69 i 79 y

2A * 3A : 4A J 5A Z 6A j 7A z

2B + 3B ; 4B K 5B [ 6B k 7B {

2C , 3C < 4C L 5C \ 6C l 7C |

2D - 3D = 4D M 5D ] 6D m 7D }

2E . 3E > 4E N 5E ^ 6E n 7E ~

2F / 3F ? 4F O 5F _ 6F o

Table 2 8: ASCII table.

Table 2 6: Message: RQ (Data Request) and looks like this:

With the values from the table, the calculation is made as follows:

Character: $>9000RQ

Hex value: 24 + 3E + 39 + 30 + 30 + 30 + 52 + 51 = 1CE

cs: =CE

Use only the last two hexadecimal numbers for the checksum.

A Data Request looks like this:

$>9000RQCE#

Examples of answers which can be expected from the PMIX35:

$<900029#

$<9000ND001B#

$<9000NI001687# (Network Impedance is: 1.6 Ohm)

(No Module Noise Detected)

The LR and LE data types are also included in the data received.

23

Page 24

2 The PMIX35 as data interface

2.3 Technical data

Marmitek X-10 home automation

Rated voltage 230 Vac, 50 Hz

Total power consumption Max. 2.5 W

Signal transmission Adjustable from 0 to 5 Vpp (per 25 mV) in 5 Ω at 120 kHz according to EN 50065-1, EN 50065-2-1, EN 50065-4-1

Transmission regulation: Transmission level adjusts itself automatically to the power line impedance.

The maximum adjustable level is 5 Vpp.

Transmission synchronisation 1 pulse burst at 0°/ 30°/ 60°/ 90°/ 120°/ 150° selectable

Signal sensitivity 25 mVpp-6 Vpp at 120 kHz ± 4 kHz

Signal/noise ratio 1.35 : 1

Minimum ambient temperature 0°C

Maximum ambient temperature 40°C (*)

Atmospheric pressure 86 pkA - 106 pkA

Relative humidity (non condensing) 30 to 90%

Standards NEN-EN-IEC 60669-2-1, NEN-EN-IEC 60669-2-2

Marking

Subject to technical changes without prior notice.

(*) Marmitek X-10 modules are suitable for use in homes where the ambient temperature in the living area is not higher that 35°C under normal circumstances, or may

(exceptionally) reach a maximum of 40°C.

Undisturbed functioning of Marmitek X-10 automation

Electrical equipment and systems can be sensitive to signals from other equipment, which causes electro magnetic

disturbance. In the European Union, countries agreed upon laws for the immunity (sensitivity) of signals of other equipment

as well as equipment emission (disturbance). When equipment or applications in a certain surrounding comply with the valid

standards, they will not disturb each other's operations (they are called "Electro Magnetic Compatible").

For residential surroundings, where the home automation system Marmitek X-10 is being applied, the European standard for

immunity is standardised in EN 61000-6-1. Equipment that complies with this standard is resistant to electro magnetic

emission of other equip ment, which complies with the European standard EN 61000-6-3 for residential surroundings.

Experience has shown that in domestic surroundings, equipment is being used which has an EMC-emission level that is

above the levels stated in EN 61000-6-3. This equip ment can disturb the correct functioning of the Marmitek X-10 modules.

The immunity of the Marmitek X-10 built-in modules is therefore revaluated and equivalent to EN 61000-6-2 (the more severe

European standard for immunity in industrial surroundings).

Nevertheless, the application area for Marmitek X-10 will remain restricted to residential areas.

Marmitek X-10 is therefore not responsible for the disfunctioning of the Marmitek X-10 system as a consequence of

equipment in the building with emission levels that exceed the maximum allowed levels set as standard for residential,

commercial and semi-industrial surroundings stated in EN 61000-6-3.

Application area Valid European Standard Marmitek X-10-home automation*

Immunity of equipment Emission of equipment Immunity and emission standards

Residential 61000-6-1 61000-6-3 Compatible/meets the requirements

Commercial

Semi-industrial

* Condition is that the total Marmitek X-10-system is installed in accordance with valid instructions supplied by a certified and trained Marmitek X-10 dealer.

24

Page 25

Marmitek is a trademark of Pattitude B.V., PMIX35™ is a trademark of Marmitek B.V. All rights reserved. Copyright and all other proprietary rights in the content (including but not limited

to model numbers, software, audio, video, text and photographs) rests with Marmitek B.V. Any use of the Content, but without limitation, distribution, reproduction, modification, display or

transmission without the prior written consent of Marmitek is strictly prohibited. All copyright and other proprietary notices shall be retained on all reproductions.

Copyrights

20317 - 20100928

Loading...

Loading...