Page 1

Service

VC8100 /U1B

Manual

PLAY MODE

STANDBY

POWER

ON/STANDBY

DIGITAL VIDEO

DVD CHANGER VC8100

RANDOM DISPLAY INPUT SEARCH

TEXT

SINGLE LOADER

ACCESS PLAY

KEYBOARD

/MOUSE

DISC/CHARADIRECT CUSTOM

PUSH ENTER

CLEAR

CC+1DVDCC+1DVDCC+1DVDCC+1DVDCC+1DVD

CC+1DVDCC+1DVD

CC+1DVDCC+1DVDCC+1DVD

CC+1DVD

CHANGER

CHANGER

CHANGER

CHANGER

CHANGER

CHANGERCHANGERCHANGER

CHANGERCHANGERCHANGER

CHANGERCHANGERCHANGER

CHANGERCHANGERCHANGER

CHANGERCHANGERCHANGER

CHANGERCHANGER

CHANGERCHANGER

CHANGERCHANGER

CHANGERCHANGER

CHANGERCHANGER

CHANGER

CHANGER

CHANGER

CHANGER

CHANGER

123

456

789

AUDIO/VIDEO UPDATE

10

OPEN/CLOSE STOP PLAY PAUSE

DVD Changer

TABLE OF CONTENTS

SECTION PAGE

1. SPECIFICATIONS...................................................................................................................................... 1

2. SAFETY INFORMATION............................................................................................................................ 2

3. SERVICING PRECAUTIONS ..................................................................................................................... 3

4. INFORMATIONS ........................................................................................................................................ 4

5. SERVICING HINT....................................................................................................................................... 5

6. REGIONAL CODES ................................................................................................................................... 6

7. EXPLODED VIEW AND PARTS LIST........................................................................................................ 7

8. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM ................................................................................... 16

9. PCB CONNECTION DIAGRAM ............................................................................................................... 43

10. PCB PARTS LIST..................................................................................................................................... 59

11. ADJUSTMENT.......................................................................................................................................... 66

12. GENERAL INFORMATION ...................................................................................................................... 70

13. PANEL FACILITIES................................................................................................................................ 100

Please use this service manual with referring to the user guide (D.F.U) without fail.

VC8100

R

Printed in Japan

VC8100

296W855010 ACT

First Issue:2000.07

Page 2

MARANTZ DESIGN AND SERVICE

MARANTZ AMERICA, INC.

Using superior design and selected high grade components, MARANTZ company has created the ultimate in stereo sound.

Only original

it is famous.

Parts for your

ORDERING PARTS :

Parts can be ordered either by mail or by Fax.. In both cases, the correct part number has to be specified.

The following information must be supplied to eliminate delays in processing your order :

1. Complete address

2. Complete part numbers and quantities required

3. Description of parts

4. Model number for which part is required

5. Way of shipment

6. Signature : any order form or Fax. must be signed, otherwise such part order will be considered as null and void.

MARANTZ parts can insure that your MARANTZ product will continue to perform to the specifications for which

MARANTZ equipment are generally available to our National Marantz Subsidiary or Agent.

USA

MARANTZ AMERICA, INC

440 MEDINAH ROAD

ROSELLE, ILLINOIS 60172

USA

PHONE : 630 - 307 - 3100

FAX : 630 - 307 - 2687

AMERICAS

SUPERSCOPE TECHNOLOGIES, INC.

MARANTZ PROFESSIONAL PRODUCTS

2640 WHITE OAK CIRCLE, SUITE A

AURORA, ILLINOIS 60504 USA

PHONE : 630 - 820 - 4800

FAX : 630 - 820 - 8103

AUSTRALIA

JAMO AUSTRALIA PTY LTD

1 EXPO COURT, P.O. BOX 350

MT. WAVERLEY VIC 3149

AUSTRALIA

PHONE : +61 - 3 - 9543 - 1522

FAX : +61 - 3 - 9543 - 3677

NEW ZEALAND

WILDASH AUDIO SYSTEMS NZ

14 MALVERN ROAD MT ALBERT

AUCKLAND NEW ZEALAND

PHONE : +64 - 9 - 8451958

FAX : +64 - 9 - 8463554

EUROPE / TRADING

MARANTZ EUROPE B.V.

P.O.BOX 80002, BUILDING SFF2

5600 JB EINDHOVEN

THE NETHERLANDS

PHONE : +31 - 40 - 2732241

FAX : +31 - 40 - 2735578

AUSTRALIA

TECHNICAL AUDIO GROUP PTY, LTD

558 DARLING STREET,

BALMAIN, NSW 2041,

AUSTRALIA

PHONE : 61 - 2 - 9810 - 5300

FAX : 61 - 2 - 9810 - 5355

THAILAND

MRZ STANDARD CO.,LTD

746 - 754 MAHACHAI ROAD.,

WANGBURAPAPIROM, PHRANAKORN,

BANGKOK, 10200 THAILAND

PHONE : +66 - 2 - 222 9181

FAX : +66 - 2 - 224 6795

TAIWAN

PAI- YUING CO., LTD.

6 TH FL NO, 148 SUNG KIANG ROAD,

TAIPEI, 10429, TAIWAN R.O.C.

PHONE : +886 - 2 - 25221304

FAX : +886 - 2 - 25630415

BRAZIL

PHILIP DA AMAZONIA IND. ELET. ITDA

CENTRO DE INFORMACOES AO

CEP 04698-970

SAO PAULO, SP, BRAZIL

PHONE : 0800 - 123123

FAX : +55 11 534. 8988

(Discagem Direta Gratuita)

CANADA

LENBROOK INDUSTRIES LIMITED

633 GRANITE COURT,

PICKERING, ONTARIO L1W 3K1

CANADA

PHONE : 905 - 831 - 6333

FAX : 905 - 831 - 6936

SINGAPORE

WO KEE HONG (S) PTE LTD

WO KEE HONG CENTRE

NO.23, LORONG 8, TOA PAYOH

SINGAPORE 319257

PHONE : +65 2544555

FAX : +65 2502213

MALAYSIA

WO KEE HONG ELECTRONICS SDN. BHD.

SUITE 8.1, LEVEL 8, MENARA GENESIS,

NO. 33, JALAN SULTAN ISMAIL,

50250 KUALA LUMPUR, MALAYSIA

PHONE : +60 3 - 2457677

FAX : +60 3 - 2458180

JAPAN

Technical

MARANTZ JAPAN, INC.

35- 1, 7- CHOME, SAGAMIONO

SAGAMIHARA - SHI, KANAGAWA

JAPAN 228-8505

PHONE : +81 42 748 1013

FAX : +81 42 741 9190

KOREA

MK ENTERPRISES LTD.

ROOM 604/605, ELECTRO-OFFICETEL, 16-58,

3GA, HANGANG-RO, YONGSAN-KU, SEOUL

KOREA

PHONE : +822 - 3232 - 155

FAX : +822 - 3232 - 154

SHOCK, FIRE HAZARD SERVICE TEST :

CAUTION : After servicing this appliance and prior to returning to customer, measure the resistance between either primary AC

cord connector pins ( with unit NOT connected to AC mains and its Power switch ON ), and the face or Front Panel of product and

controls and chassis bottom.

Any resistance measurement less than 1 Megohms should cause unit to be repaired or corrected before A C po w er is applied, and

verified before it is return to the user/customer.

Ref. UL Standard No. 1492.

In case of difficulties, do not hesitate to contact the Technical

Department at above mentioned address.

991207ACT

Page 3

1. SPECIFICATIONS

General

Power requirements ............................................... AC 120 V, 60 Hz

Power consumption ................................................................. 21 W

Power consumption in standby mode ..................... less than 0.9 W

Weight....................................................................8.0 kg (17.6 lbs.)

Dimensions ....................................440 (W) x 434 (D) x 193 (H) mm

(17 5/16 (W) x 17 1/8 (D) x 7 5/8 (H) in.)

Operating temperature ....................+5°C to +35°C

Operating humidity ........................... 5% to 85% (no condensation)

S-Video input/output

Y (luminance) - Output level .......................................1 Vp-p (75 Ω)

C (color) - Output level ........................................286 mVp-p (75 Ω)

Jacks........................................................................... S-VIDEO jack

Video input/output

Output level ................................................................. 1 Vp-p (75 Ω)

Jacks..................................................................................RCA jack

Component video output

(Y, PB, PR)

Output level .......................................................... Y: 1.0 Vp-p (75 Ω)

Jacks..................................................................................RCA jack

(+36°F to +96°F)

PB, PR: 0.7 Vp-p (75 Ω)

Digital output

Optical digital output ..........................................Optical digital jack

Coaxial digital input/output ................................................RCA jack

Control jacks

MASTER-SLAVE....................................................... Minijack (3.5 ø)

REMOTE CONTROL IN/OUT jack...................................... RCA jack

Other jacks

KEYBOARD/MOUSE jack .......................6-pin DIN connection jack

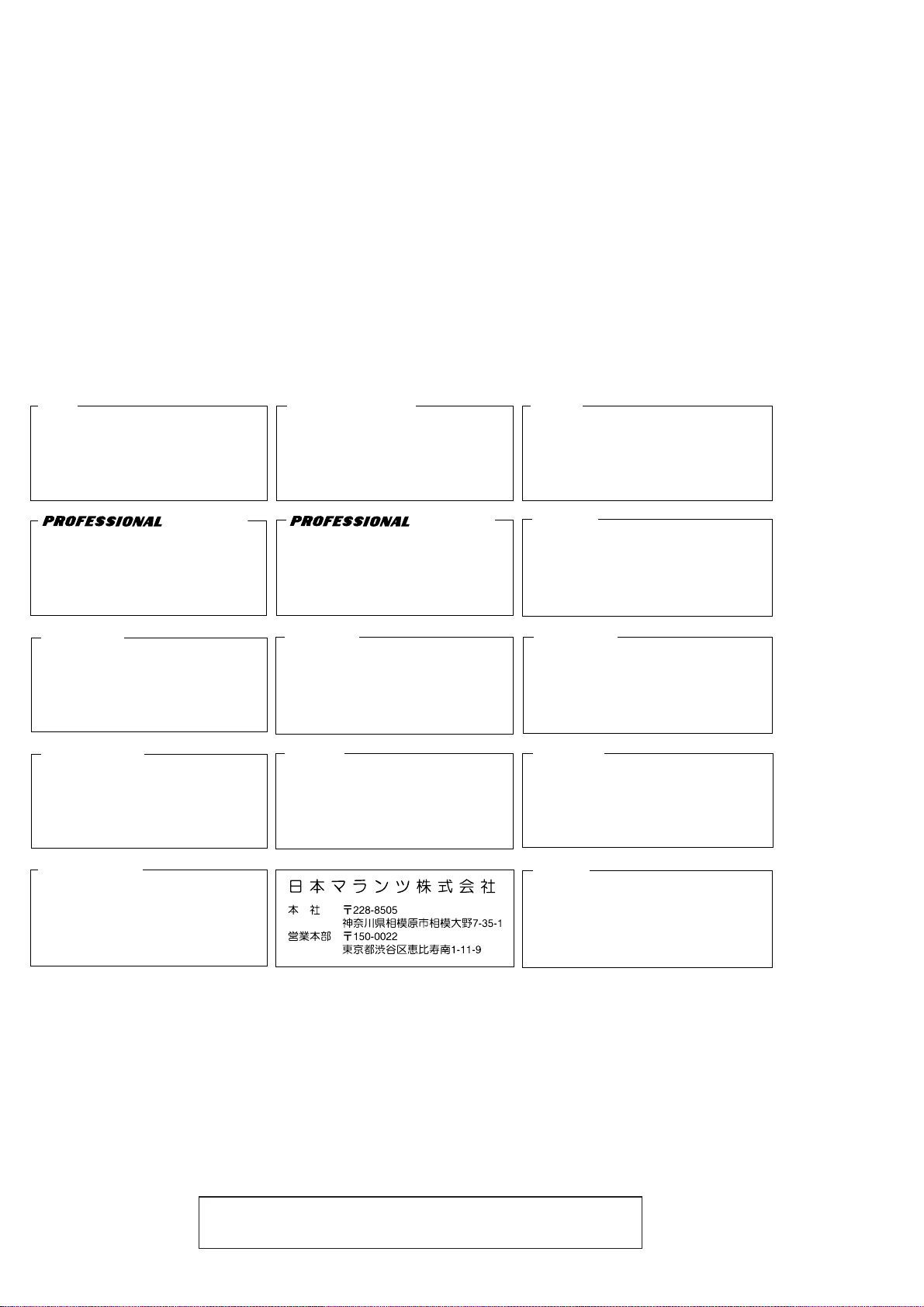

Accessories

Remote control unit .........................................................................1

AA (R6P) dry cell batteries .............................................................2

Audio cord ......................................................................................1

Video cord ......................................................................................1

D-Bus remote cord .........................................................................1

Master-Slave control cord...............................................................1

User guide (English x 1, French x 1) ..............................................2

Warranty Card ............................. (U.S. and Canadian models only)

Note

The specifications and design of this product are subject to change without

notice, due to improvement.

Audio input/output

Output level

During audio output ..............................200 mVrms (1 kHz, –20 dB)

Number of channels .......................................................................2

Jacks..................................................................................RCA jack

Digital audio characteristics

Frequency response..................... 4 Hz to 44 kHz (DVD fs: 96 kHz)

S/N ratio ...............................................................more than 115 dB

Dynamic range .................................................... more than 103 dB

Total harmonic distortion ..................................................... 0.002%

Wow and flutter .............................................. Limit of measurement

(±0.001% W. PEAK) or lower

• Manufactured under license from Dolby Laboratories. “Dolby” and the

double-D symbol are trademarks of Dolby Laboratories. Confidential

unpublished works. © 1992-1997 Dolby Laboratories. All rights

reserved.

• “DTS” is a trademark of Digital Theater Systems, Inc. Manufactured

under license from Digital Theater Systems, Inc.

• TruSurround and the

the United States and selected foreign countries. TruSurround

technology is incorporated under license from SRS Labs, Inc.

symbol are trademarks of SRS Labs, Inc. in

Accessories

Audio Cord (L = 1.5m)

White

Red

Video Cord (L = 1.5m)

Yellow

Master-Slave Control Cord (L = 0.75m)

D-BUS Remote Control Cord

Black

Orenge

Remote Control Unit (RC8100VC)

Dry Cell Battery (R6P, AA)

1

Page 4

2. SAFETY INFORMATION

This service manual is intended for qualified service technicians ; it is not meant for the casual doit-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely,

you should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to

cause cancer, birth defects or other reproductive harm.

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts must

be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les pièces

de remplacement doivent avoir la même désignation.

(FOR USA MODEL ONLY)

Health & Safety Code Section 25249.6 – Proposition 65

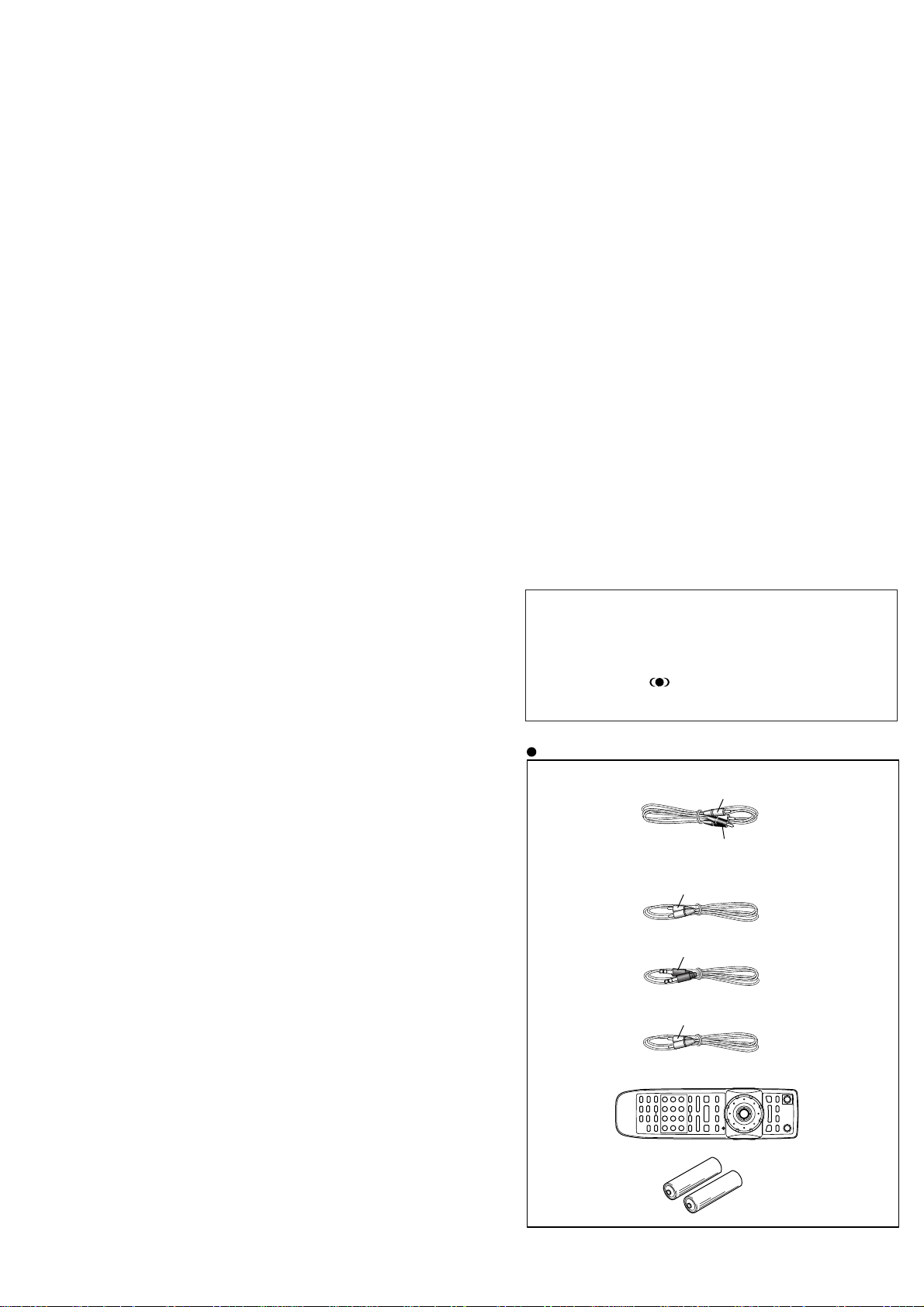

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground (water

pipe, conduit, etc.) by connecting a leakage current tester

such as Simpson Model 229-2 or equivalent between the

earth ground and all exposed metal parts of the appliance

(input/output terminals, screwheads, metal overlays,

control shaft, etc.). Plug the AC line cord of the appliance

directly into a 120V AC 60Hz outlet and turn the AC power

switch on. Any current measured must not exceed 0.5mA.

Reading should

not be above

0.5mA

Earth

ground

Device

under

test

Also test with

plug reversed

(Using AC adapter

plug as required)

AC Leakage Test

Leakage

current

tester

Test all

exposed metal

surfaces

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED

BEFORE RETURNING THE APPLIANCE TO THE

CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance

have special safety related characteristics. These are

often not evident from visual inspection nor the

protection afforded by them necessarily can be obtained

by using replacement components rated for voltage,

wattage, etc. Replacement parts which have these

special safety characteristics are identified in this Service

Manual.

Electrical components having such features are identified

by marking with a

list in this Service Manual.

The use of a substitute replacement component which does

not have the same safety characteristics as the MARANTZ

recommended replacement one, shown in the parts list in

this Service Manual, may create shock, fire, or other

hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current MARANTZ Service

Manual. A subscription to, or additional copies of,

MARANTZ Service Manual may be obtained at a nominal

charge from MARANTZ.

on the schematics and on the parts

2

Page 5

3. SERVICING PRECAUTIONS

CAUTION : Before servicing the DVD covered by this service

data and its supplements and ADDENDUMS, read and follow

the

SAFETY PRECAUTIONS. NOTE

circumstances create conflict between the following servicing

precautions and any of the safety precautions in this

publications, always follow the safety precautions.

: if unforeseen

Remember Safety First:

General Servicing Precautions

1. Always unplug the DVD AC power cord from the AC

power source before:

(1) Removing or reinstalling any component, circuit board,

module, or any other assembly.

(2) Disconnection or reconnecting any internal electrical

plug or other electrical connection.

(3) Connecting a test substitute in parallel with an elec-

trolytic capacitor.

Caution : A wrong part substitution or incorrect

polarity installation of electrolytic capacitors may result

in an explosion hazard.

2. Do not spray chemicals on or near this DVD or any of

its assemblies.

3. Unless specified otherwise in this service data, clean

electrical contacts by applying an appropriate contact

cleaning solution to the contacts with a pipe cleaner,

cotton-tipped swab, or comparable soft applicator.

Unless specified otherwise in this service data, lubrication

of contacts is not required.

4. Do not defeat any plug/socket B+ voltage interlocks with

which instruments covered by this service manual might

be equipped.

5. Do not apply AC power to this DVD and/or any of its

electrical assemblies unless all solid-state device heat

sinks are correctly installed.

6. Always connect test instrument ground lead to the

appropriate ground before connection the test instrument

positive lead. Always remove the test instrument ground

lead last.

Insulation Checking Procedure

Disconnect the attachment plug from the AC outlet and turn

the power on. Connect an insulation resistance meter(500V)

to the blades of the attachment plug. The insulation resistance

between each blade of the attachment plug and accessible

conductive parts (Note 1) should be more than 1M-ohm.

Note 1 : Accessible Conductive Parts including Metal panels,

Input terminals, Earphone jacks, etc.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of

typical ES devices are integrated circuits and some field effect

transistors and semiconductor chip components.

The following techniques should be used to help reduce the

incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any

electrostatic charge on your body by touching a known

earth ground. Alternatively, obtain and wear a commercially available discharging wrist strap device, which

should be removed for potential shock reasons prior to

applying power to the unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such

as aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a GROUNDED-tip soldering iron to solder or

unsolder ES devices.

4. Use only an anti-static solder removal device. Some

solder removal devices not classified a “anti-static” can

generate electrical charges sufficient to damage ES

devices.

5. Do not use freon-propelled chemicals. These can

generate electrical charge sufficient to damage ES

devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to

install it. (Most replacement ES devices are packaged with

leads electrically shorted together by conductive foam,

aluminum foil, or comparable conductive material).

7. Immediately before removing the protective material from

the leads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the

device will be installed.

Caution : Be sure no power is applied to the chassis or

circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Normally harmless motion such

as the brushing together of your clothes fabric or the lifting

of your foot from a carpeted floor can generate static electricity sufficient to damage an ES device.)

3

Page 6

4. INFORMATIONS

REGION CODE

VERSION REGION CODE COUNTRY

/UXX 1 USA/CANADA

THE DISCS THAT THE DV8100 CAN HANDLE

The following discs can be played back with a DV8100.

disc mark playback capability size side

DVD Audio/Video

CD Audio

VCD Audio/Video single

Note: The regional code of the discs must meet to the regional

code of the DV8100.

12 cm

12 cm

12 cm

single/double

single

DVD INFORMATION

Below is a glossary of the new terms related to DVD.

Multi-angles:

On some DVDs, scenes have been filmed from different angles

(up to a maximum of 9). On these discs, you can select the

angle that you want to watch. Please refer to the DVD’s manual

to see which scenes have multi-angles.

Parental guide:

Some discs have restriction levels that allow you to cut scenes

or prevent playback of discs that have contents that you do

not want children to watch.

Title:

A disc may have more than one story/movie on it, so each

story/movie is called a “title”.

For example, if there are 2 movies on the disc, they are

separated into Title 1 and Title 2.

Chapter:

A title may also be separated into chapters.

For example, a movie (title) may be separated into 3 scenes

(chapters).

Title 1 Title 2

Chapter1Chapter

Subtitles:

DVDs are recorded with up to 32 different subtitle languages.

If a disc has more than one subtitle language, you can select

the subtitle language that you want to read.

Soundtrack language:

DVDs are recorded with up to 8 different soundtrack languages.

If a disc has more than one language, you can select the

soundtrack language that you want to listen to.

Chapter3Chapter1Chapter2Chapter

2

3

4

Page 7

5. SERVICING HINT

SERVICE HINTS

SERVICE TOOLS

Audio signals disc (SBC429) 4822 397 30184

Disc without errors (SBC444)+

Disc with DO errors, black spots and fingerprints (SBC444A) 4822 397 30245

Disc (65 min 1kHz) without no pause 4822 397 30155

Max. diameter disc (58.0 mm) 4822 397 60141

Torx screwdrivers

Set (straight) 4822 395 50145

Set (square) 4822 395 50132

13th order filter 4822 395 30204

DVD test disc 4822 397 10131

Service tool kit *VC8100JIG

– Test disc (GGV1025)

– Remote control unit for service (GGF1067)

– Interface (GGF1348)

– FFC (VDA1681)

5

Page 8

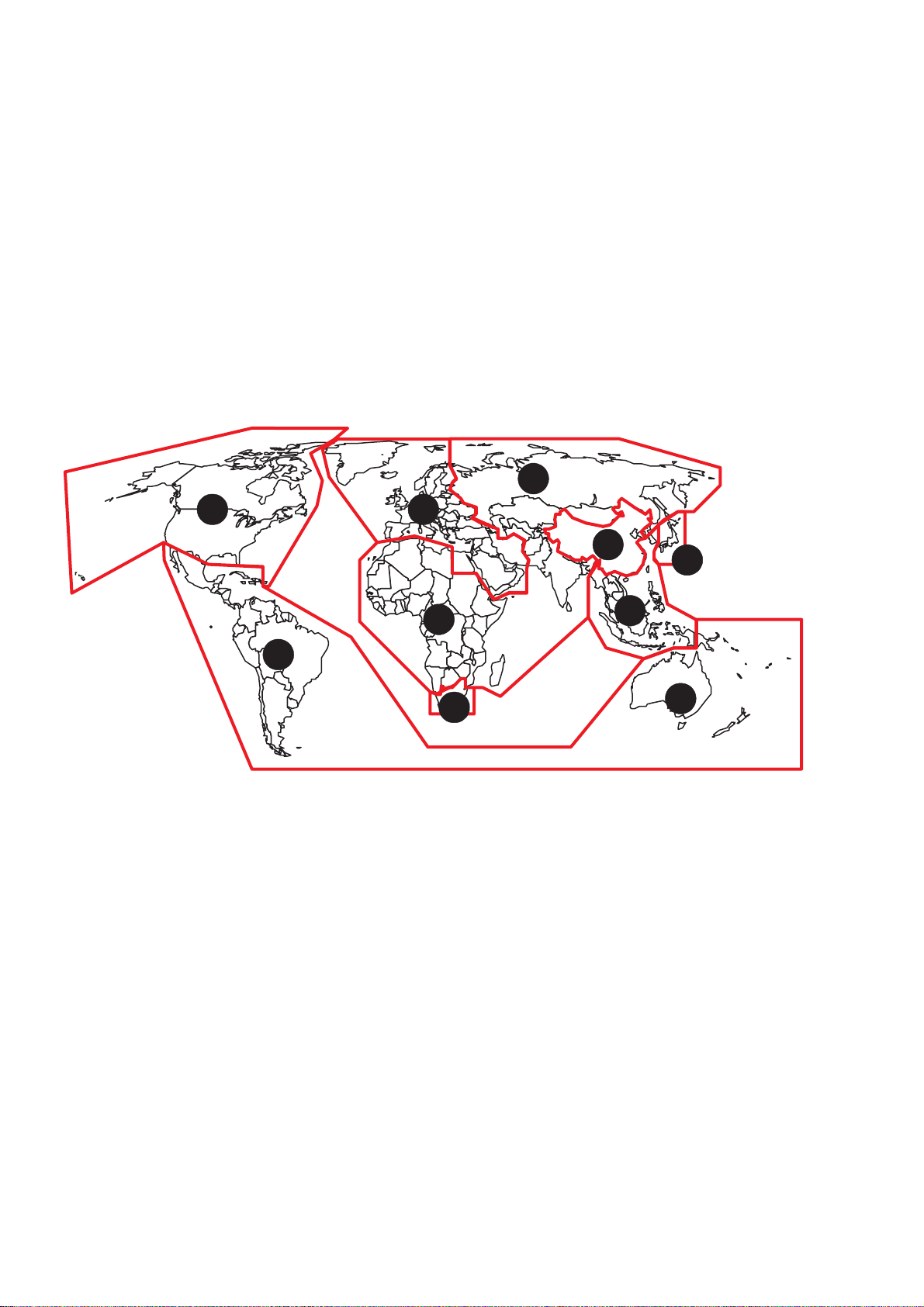

6. REGIONAL CODES

What are "regional codes"?

Motion picture studios want to control the home release of movies in different countries because theater releases arenít

simultaneous (a movie may come out on DVD in the US when itís just hitting screens in Europe). Therefore they have

required that the DVD standard include codes which can be used to lock out the playback of certain discs in certain geographical regions. Players sold in each region will have that regionís code built into the player. The player will refuse to play

these "region coded" discs which are not allowed in the region. However, regional codes are entirely optional. Discs without

codes will play on any player in any country. Some studios have already announced that only their new releases will have

regional codes. There are six regions:

1. United States and Canada

2. Europe and Japan

3. Far East (except Japan & China)

4. South America and Oceania

5. Africa and the Middle East

6. China (except Hong Kong)

5

1 2

6

2

5

3

4

2

Map of DVD Regions

4

6

Page 9

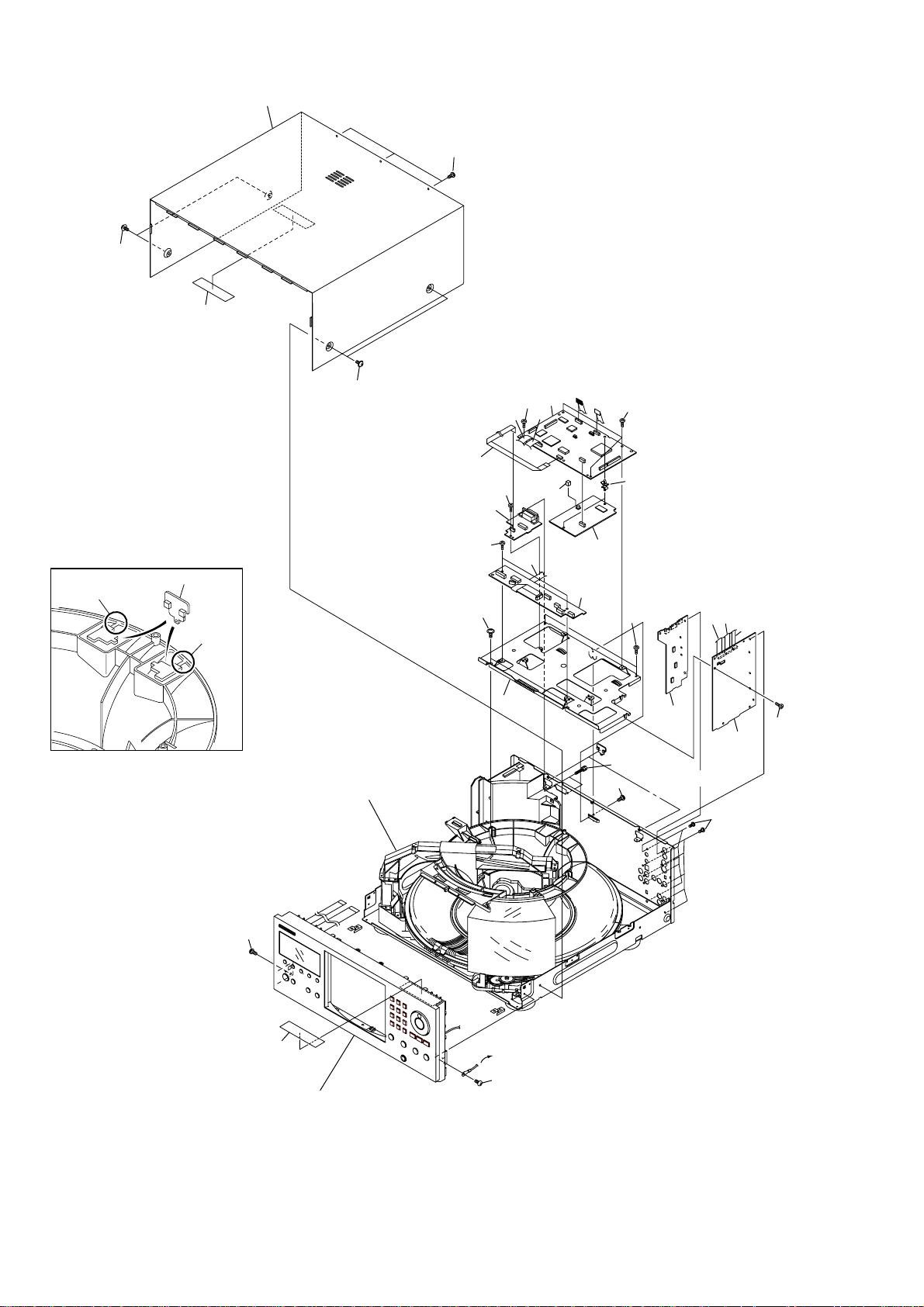

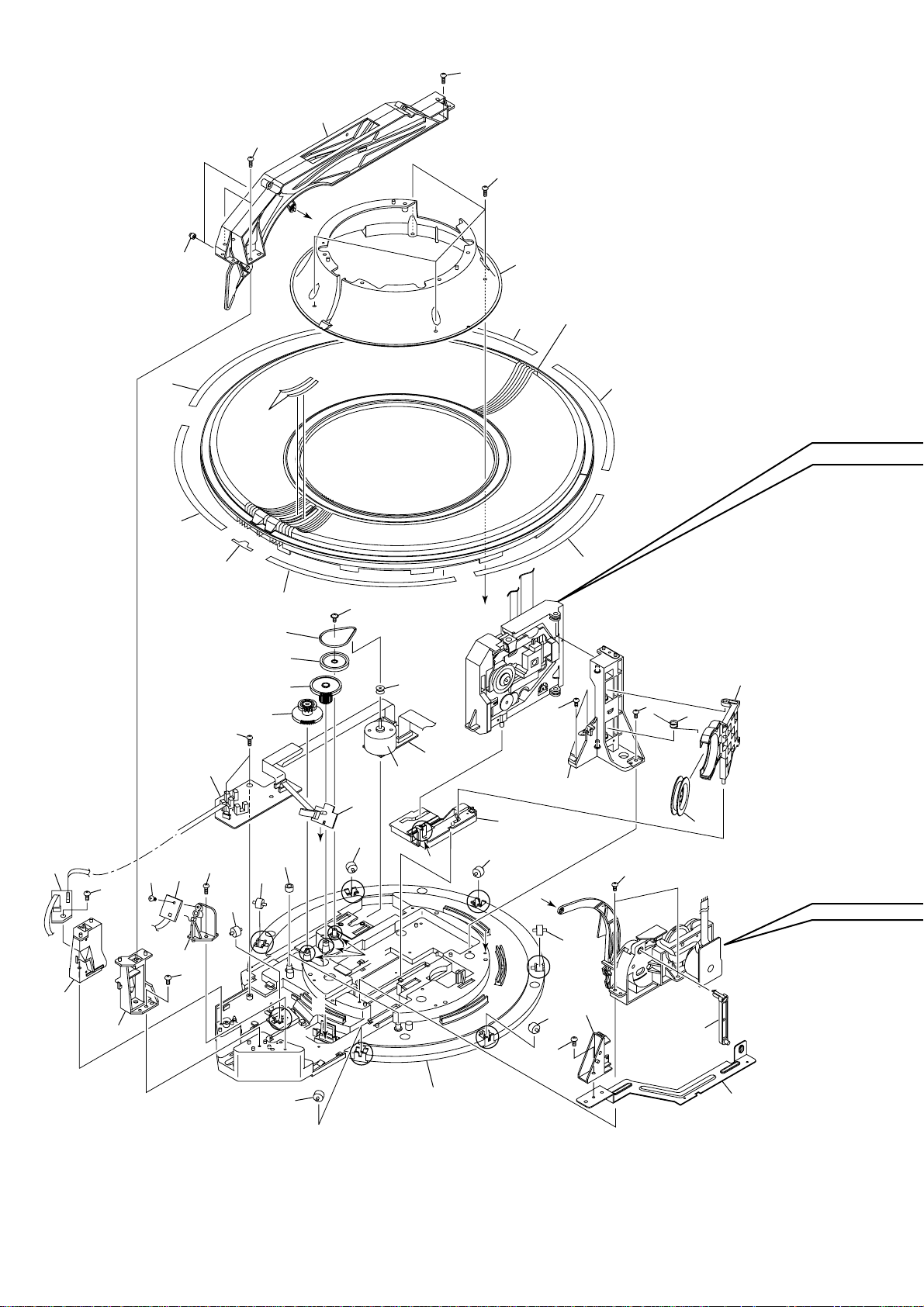

7. EXPLODED VIEWS AND PARTS LIST

NOTES:• Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

•

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on the product are used for disassembly.

•

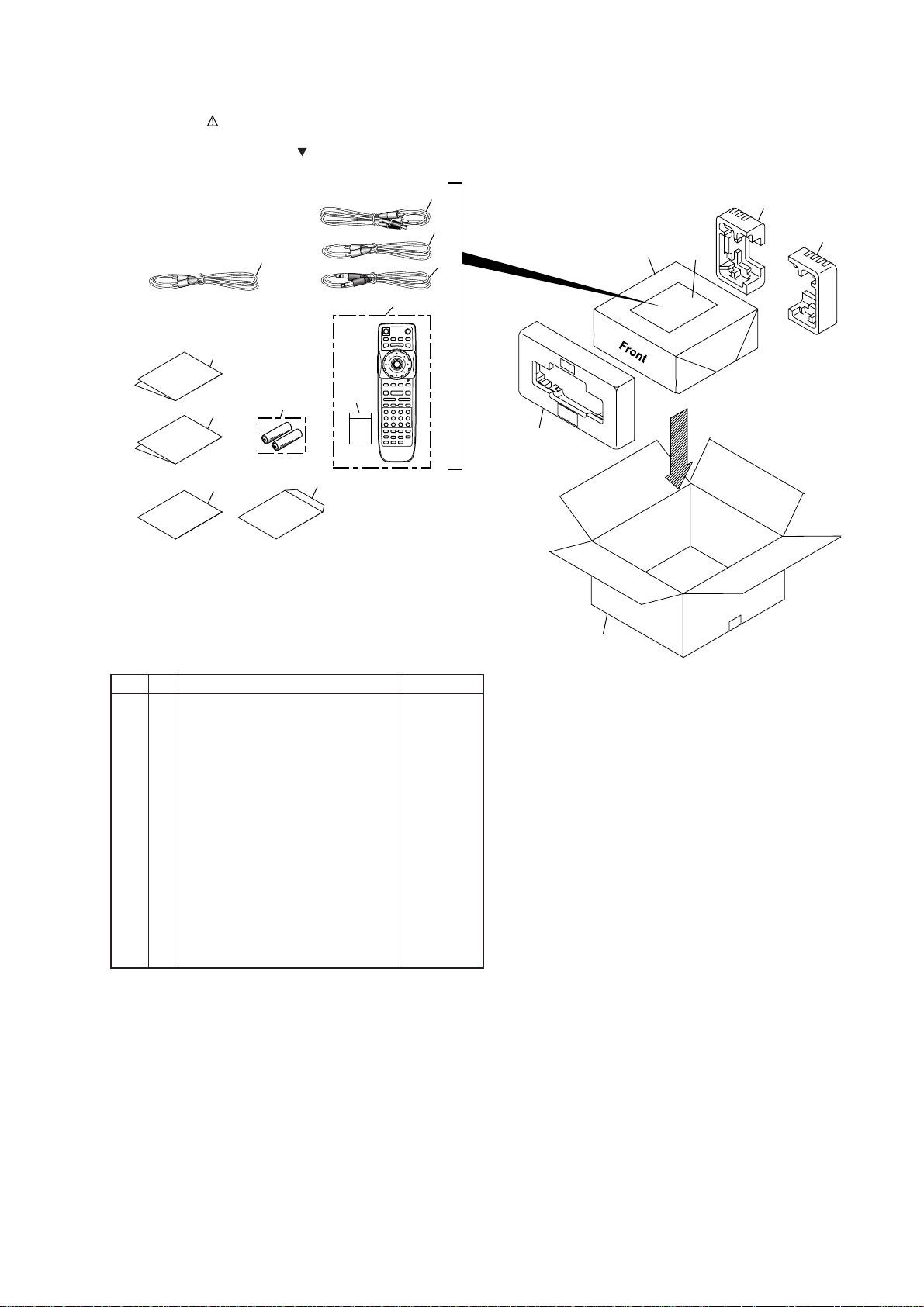

7.1 PACKING

13

15

6

16

(1) PACKING PARTS LIST

12

14

9

10

11

7

8

1

4

3

5

2 (1/2)

2 (2/2)

Mark No. Description Part No.

NSP 1 VHA1258, Protector F —

NSP 2 VHA1259, Protector R —

NSP 3 RHC1023, Packing Sheet —

NSP 4 VHG1914, Packing Case —

NSP 5 Z21-038, Polyethylene Bag B5 —

6 VRB1254, User Guide (English) 296W851250

7

VXX2709, Remote Control Unit RC8100VC

NSP 8 VNK4423, Battery Cover —

NSP 9 VDE1033, Audio Cord (L = 1.5m) —

NSP 10 VDE1034, Video Cord (L = 1.5m) —

NSP 11

NSP 12

NSP 13

NSP 14

NSP 16 092J854113, Warranty for USA —

RDE1023, Master-Slave Control Cord (L = 0.75m)

VEM-013, Dry Cell Battery (R6P, AA)

ZD00900100, D-BUS Remote control Cord

183J813502, Envelope Kit (Warranty for CANADA)

15 VRC1119, User Guide (French) 296W851260

ZK296W0010

—

—

—

—

7

Page 10

7.2 EXTERIOR SECTION (1/2)

23

28

22

29

Note ∗1

Cut

Part of Center Pole

Cut

28

Refer to

"7.3 EXTERIOR SECTION (2/2)".

8

30

29

1

29

10

9

29

2

17

15

7

29

16

3

6

29

4

∗1

14

29

29

1213

11

29

5

29

21

Refer to

"7.5 FRONT PANEL SECTION".

from PS2B Assy

29

8

Page 11

(1) EXTERIOR SECTION (1/2) PARTS LIST

Mark No. Description Part No.

1 VWS1396, DVDM Assy *ZZ001510R

NSP 2 VWG2201, 232B Assy —

NSP 3 VWV1669, VQEB Assy —

NSP 4 VWG2200, MSJB Assy —

NSP 5 VWV1720, AVJB Assy —

NSP 6 VWG2199, MDRB Assy —

NSP 7 VDA1779, Flexible Cable (12P) —

NSP 8 VDA1777, Flexible Cable (7P) —

NSP 9 VDA1781, Flexible Cable (11P) —

NSP 10 VDA1778, Flexible Cable (12P) —

NSP 11 VDA1782, Flexible Cable (7P) —

NSP 12 VDA1707, Flexible Cable (14P) —

NSP 13 VDA1784, Flexible Cable (15P) —

NSP 14 DBA1078, Screw (#4-40/M2) —

NSP 15 VEC2079, PCB Support Cushion —

NSP 16 VEC2077, PCB Spacer —

NSP 17 VNE2215, Main Holder —

NSP 21 VRW1817, Caution Label 301 —

NSP 22 ARW7050, 65 Label —

NSP 23 VXX2692, Bonnet Case S —

28 RBA1099, Screw 51260408M0

NSP 29 BBZ30P080FZK, Screw —

NSP 30 IPZ30P080FMC, Screw —

9

Page 12

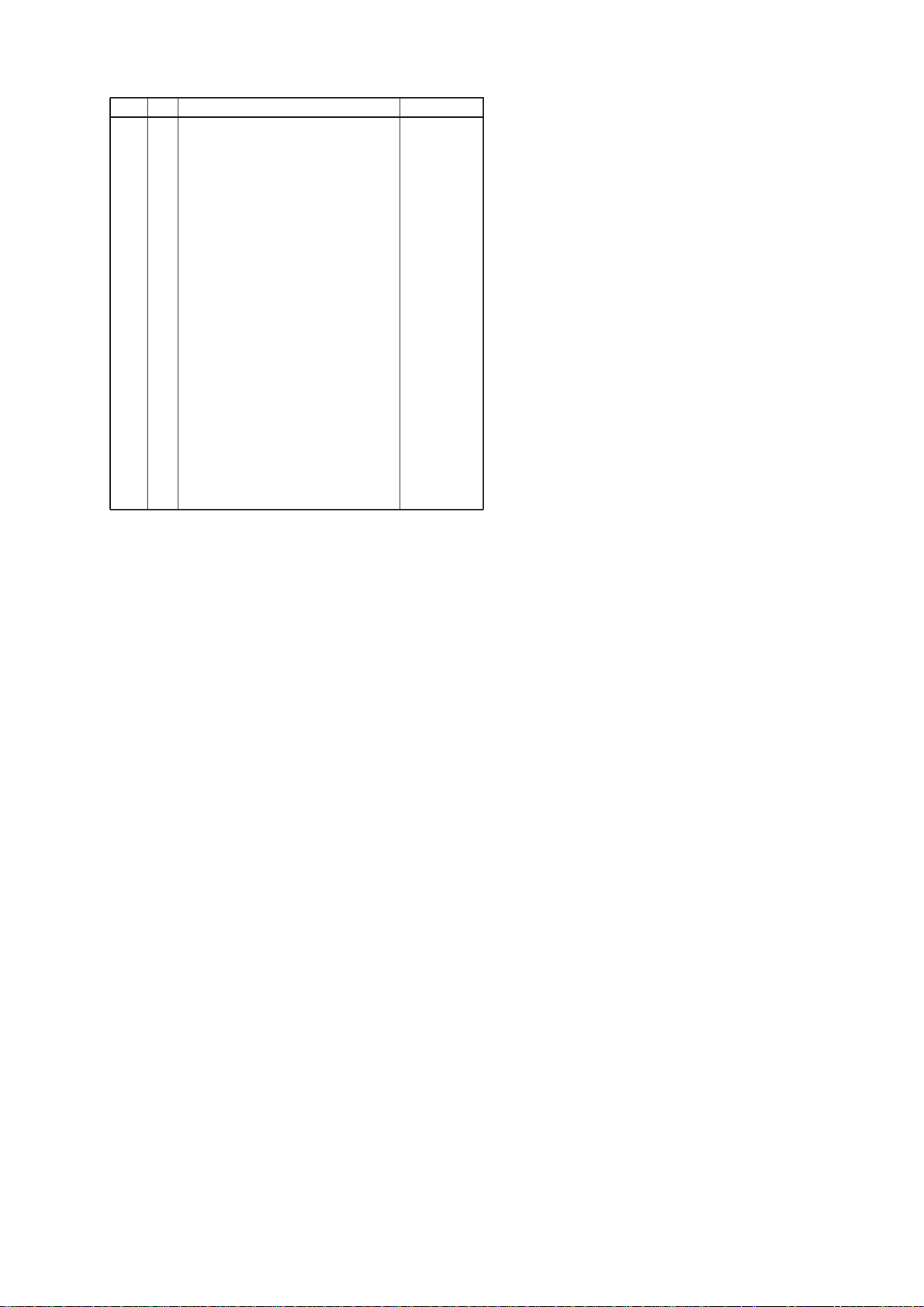

7.3 EXTERIOR SECTION (2/2)

25

15

2

13

Note ∗3 :

KANTO KASEI FROIL PN-397 (for Service) : GYA1001

Note ∗4 :

KANTO KASEI HANARL PN-955R (for Service) : GEM1016

17

∗4

23

18

19

23

4

∗3

21

20

∗4

16

5

3

7

26

10

24

26

1

11

A

12

Refer to

"7.4 DISC RACK SECTION".

Note ∗2 (Screw Cover)

Part of Trans Cover (No.10)

10

Cut

24

24

22

5

26

28

27

27

28

24

14

A

∗2

24

8

9

24

24

10

Page 13

(1) EXTERIOR SECTION (2/2) PARTS LIST

Mark No. Description Part No. Mark No. Description Part No.

1 VWR1317, POWER SUPPLY Assy *ZZ001520R

NSP 2 VWG2197, LEDB Assy —

NSP 3 VWG2194, DOMB Assy —

NSP 4 VWG2195, DOSB Assy —

5 ADG7024, AC Power Cord *ZC000080R

6 VXM1033, Carriage Motor (DOOR) *MM001070R

7 VNK4630, Hood 296W162010

NSP 8 VNA2125, Under Base DVD —

9 PNW2766, Insulator 296W057010

NSP 10 VNK4542, Trans Cover —

NSP 11 VDA1776, Flexible Cable (26P) —

NSP 12 PNW2816, CR Lens —

NSP 13 VEC2113, Dispersion Sheet —

NSP 14 VNA2178, Rear Base —

NSP 15 PNW2792, Center Pole 301 —

16 PNW1634, Motor Pulley 296W262010

NSP 17 PNW2791, Hood Base 301 —

18 PNW2800, Gear M1 296W058010

19 PNW2906, Gear AW 296W058020

20 VNL1662, Gear Pulley 296W058030

21 PEB1300, Belt 296W264010

22 CM-22C, Cord Stopper 296W259010

NSP 23 IPZ20P080FMC, Screw —

NSP 24 BBZ30P080FZK, Screw —

NSP 25 IPZ30P080FMC, Screw —

NSP 26 PBA1106, Screw C —

NSP 27 296W160010, Earth Bracket —

NSP 28 IPZ20P080FMC, Screw —

11

Page 14

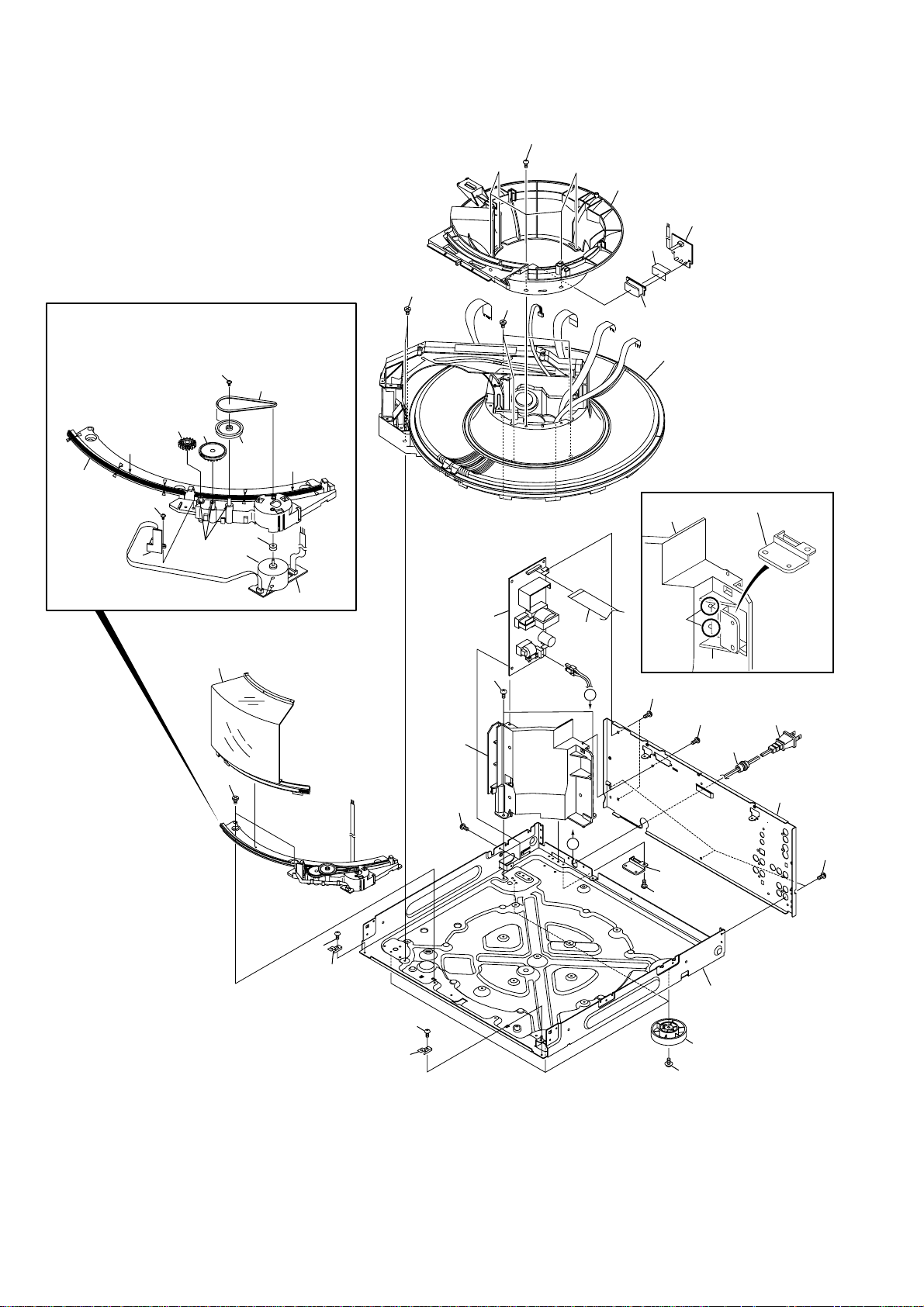

7.4 DISC RACK SECTION

52

53

B

52

Note ∗3 :

KANTO KASEI FROIL PN-397

(for Service) : GYA1001

Note ∗4 :

KANTO KASEI HANARL PN-955R

(for Service) : GEM1016

52

11

44

46

44

45

44

9

10

35

36

52

1

42

32

∗3

∗3

41

55

6

32

50

7

38

52

50

39

51

31

2

43

5

32

C

∗3

∗3

∗4

C

∗3

40

33

44

44

44

A

21

52

52

8

15

28

∗3

32

A

∗3

19

52

B

47

∗3

32

20

32

37

32

12

34

30

Page 15

●

DISC RACK SECTION PARTS LIST

Refer to

"7.6 TRAVERSE MECHANISM ASSY".

13

23

14

27

Note)

Tightening Torque: 2 kg·cm

9

10

49

4

16

a

∗

3

51

48

22

17

Mark No. Description Part No.

NSP 1 VWG2113, SSRB Assy

NSP 2 VWG2114, SEMB Assy

NSP 3 VWG2115, LOMB Assy

NSP 4 VWG2116, LOSB Assy

26

25

∗

3

24

54

51

14

b

29

b

12

a

18

∗

3

31

43

NSP 5 VWG2117, RADB Assy

NSP 6 VWG2118, PHOB Assy

NSP 7 VWG2196, VOLB Assy

8 VBH1318, Clamp Spring 296W115010

9 AEB7029, Loading Belt 296W264020

10 ANW7062, Gear Pulley (B) 296W058040

11 ANW7075, Roller B 296W358010

12 PBH1226, Drive Arm Spring 296W115020

NSP 13 VWT1161, Traverse Mechanism Assy

NSP 14 PED1028, Sheet 301

15 VXA2382, Clamper Assy 301 296W005500

16 PNW2819, Gear 1 296W058050

17 PNW2820, Gear 2 296W058060

NSP 18 PNW2822, Gear Holder

19 PNW2823, Slider Cam 296W054010

20 PNW2826, Clamp Pole” 296W272010

21 PNW2827, Clamper Holder 296W271010

22 PNW2829, Drive Arm 296W002010

23 AEB7063, Float Rubber A 296W130010

NSP 24 VNL1842, Balancer

NSP 25 VDA1785, Flexible Cable (8P)

26 VDA1780, Flexible Cable (24P) *YU000630R

27 VNL1841, Float Base 296W004010

28 PNW2844, Link L 296W121010

29 PNW2873, Drive Cam 296W054020

NSP 30 PNA2438, Lock Plate —

31 PNW1634, Motor Pulley 296W262010

32 PNW2647, Roller 296W358020

33 PNW2790, Disc Rack 296W064010

NSP 34 PNW2835, Rack Base —

35 PNW2836, ST Gear 0.6 296W058070

36 PNW2837, ST Gear 1.0 296W058080

NSP 37 PNW2838, Disc Divider —

NSP 38 PNW2839, Guide Support L —

NSP 39 PNW2840, Guide Support R —

NSP 40 PNW2841, Disc Guard —

NSP 41 PNW2842, Sensor Stay —

42 PNW2843, Guide Roller 296W358030

43

VXM1033, Carriage Motor (SELECT, LOADING)

44 PAM1770, Rack Label 296W861020

45 PAM1771, S Label 296W861030

46 PRW1507, +1 Label 296W861040

NSP 47 BBZ30P080FZK, Screw —

NSP 48 BMZ26P040FZK, Screw —

NSP 49 BPZ26P060FMC, Screw —

NSP 50 BPZ30P100FCU, Screw —

NSP 51 IPZ20P080FMC, Screw —

NSP 52 PPZ30P080FMC, Screw —

53 PXA1615, Arm Assy 296W002500

54 VBH1319, Float Spring 296W115030

NSP 55 IPZ30P080FMC, Screw —

*MM001070R

3

13

Page 16

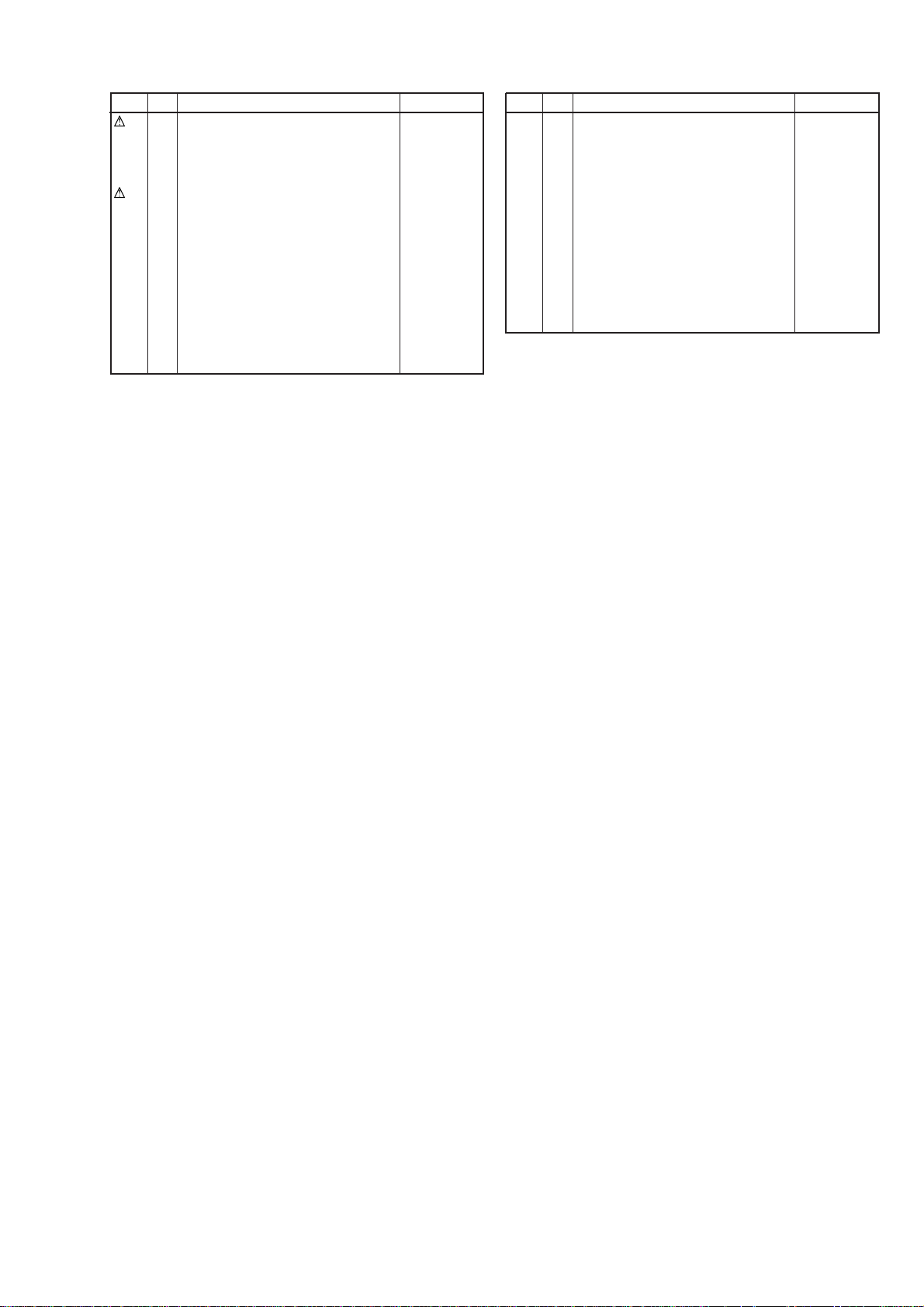

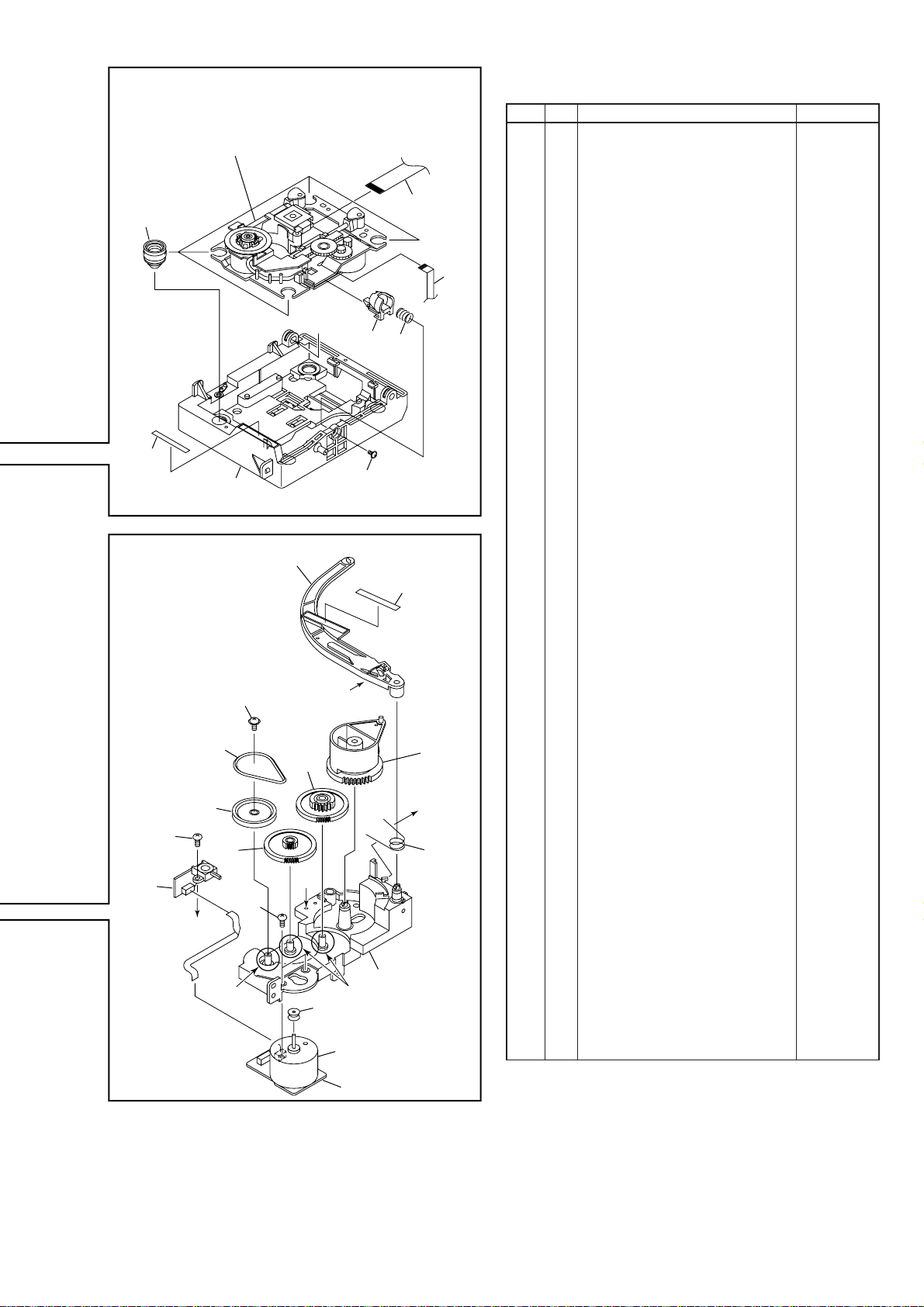

7.5 FRONT PANEL SECTION

10

17

21

6

7

1

21

14

13

23

8

9

11

18

19

20

12

23

15

24

21

4

16

2

21

21

21

22

3

(1) FRONT PANEL SECTION PARTS LIST

Mark No. Description Part No. Mark No. Description Part No.

NSP 1 VWG2192, FLKY Assy —

NSP 2 VWG2193, KEYB Assy —

NSP 3 VWG2198, PS2B Assy —

NSP 4 VDA1839, Flexible Cable (11P) —

NSP 5 VDA1792, Flexible Cable (7P) —

NSP 6 VDA1786, Flexible Cable (7P) —

NSP 7 VDA1775, Flexible Cable (15P) —

8 296W248010, Front Panel 296W248010

9 185J251012, Marantz Badge 185J251010

10 296W158010, Display Window 296W158010

NSP 11 PEC1042, JOG Sheet —

12 296W355010, IR Lens 296W355010

13 PNW2019, LED Lens 296W355020

14 296W105010, Front Chassis 296W105010

15 296W270010, Mode Button 296W270010

16 296W270020, Play Button 296W270020

NSP 17 PNM1324, PCB Cover —

18 PAC1882, JOG Dial 296W067010

19 PBH1228, Enter Spring 296W115040

20 PAC1883, Enter Button 296W270050

NSP 21 PPZ30P080FMC, Screw —

NSP 22 PPZ30P050FMC, Screw —

NSP 23 VBK1128, Contactor —

NSP 24 296W120010, IR Filter —-

14

Page 17

7.6 TRAVERSE MECHANISM ASSY

• Top View

37

18

26

11

25

27

7

29

36

3

22

33

21

33

23

28

10

15

10

5

10

13

37

10

14

7

2

7

18

32

1

35

30

16

*5

31

37

17

24

34

19

8

6

20

12

9

37

4

●

TRAVERSE MECHANISM ASSY PARTS LIST

Mark No. Description Part No. Mark No. Description Part No.

NSP 1 VWG2048, SMEB Assy —

NSP 2 VWG2009, FGSB Assy —

NSP 3 VXM1079, Motor —

NSP 4 VXM1078, Motor —

NSP

5 VWY1055, Pickup Assy —

NSP 6 DEC2040, Table Sheet —

NSP 7 VBA1058, Screw —

NSP 8 VBH1278, Centering Spring —

9 VBH1317, Hook Spring 296W115050

10 VBH1303, Skew Spring 296W115060

11 VBH1308, Gear Spring 296W115070

NSP 12 VEC1959, Reflected Sheet —

NSP 13 VLL1504, Guide Bar —

NSP 14 VLL1505, Sub-guide Bar —

15 VNC1017, Hold Spring 296W115080

NSP 16 VNE2070, Magnet Holder —

NSP 17 VNE2154, Motor Base —

NSP 18 VNE2155, Cover —

NSP 19 VNL1746, Centering Ring —

NSP 20 VNL1747, Disc Table —

21 VNL1770, Hook 296W258010

NSP 22 VNL1802, FFC Holder —

NSP 23 VNL1806, Mechanism Base —

NSP 24 VNL1807, FG Holder —

25 VNL1808, Gear A 296W058090

26 VNL1809, Gear B 296W058100

27 VNL1810, Gear C 296W058110

28 VNL1811, Slider 296W125010

NSP 29 VNL1814, Gear D —

NSP 30 VYM1024, Magnet —

NSP 31 JFZ17P025FZK, Screw —

NSP 32 JGZ17P028FMC, Screw —

NSP 33 VBA1051, Screw —

NSP 34 VXX2507, Magnet Holder Assy —

35 VXX2649, Spindle Motor Assy *ZK000290R

36 VXX2650, Carriage Motor Assy *ZK000300R

NSP 37 PBA1069, Screw —

*5 VXX2653, Traverse Mechanism Assy

(for Service)

*ZK000310R

15

Page 18

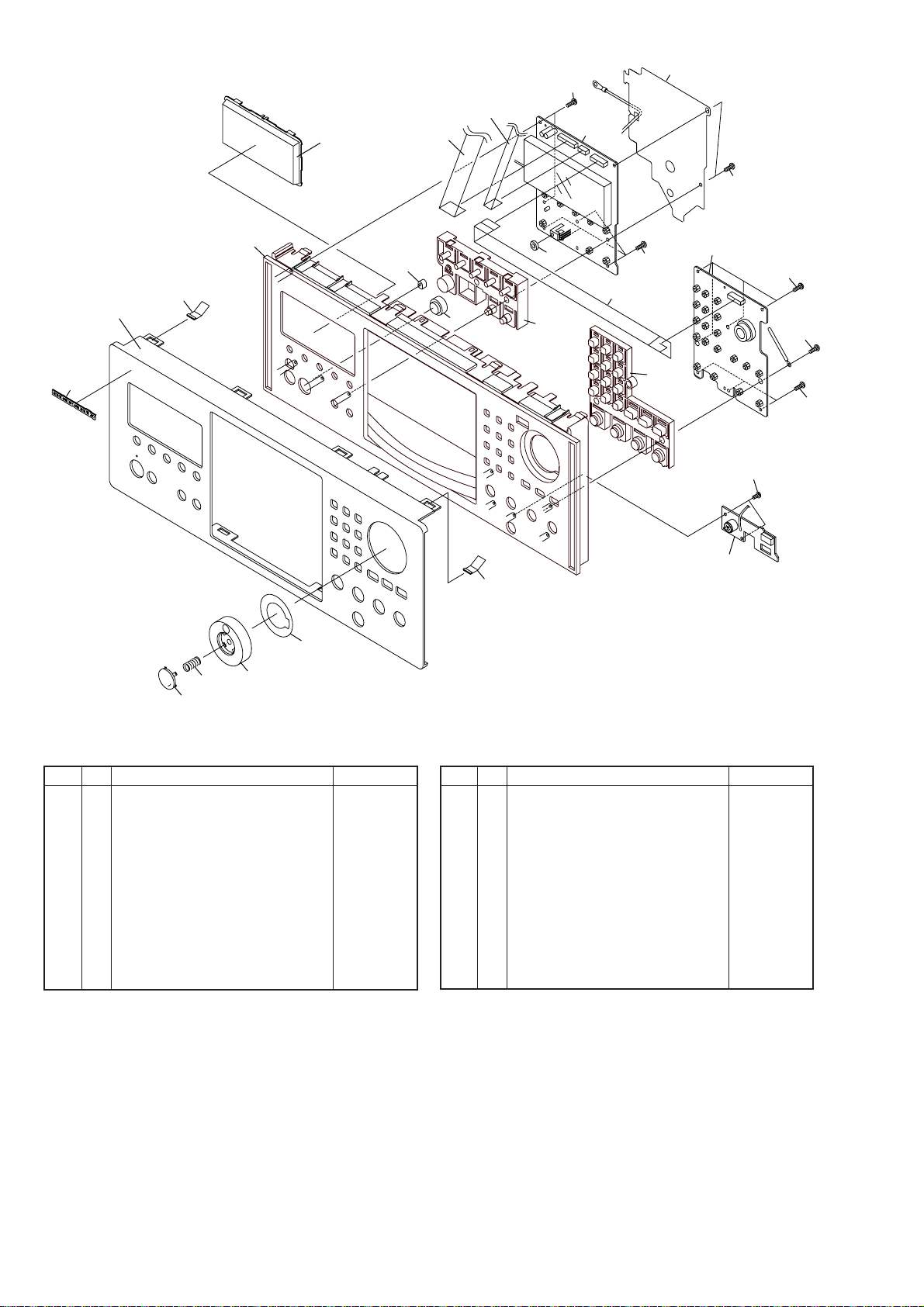

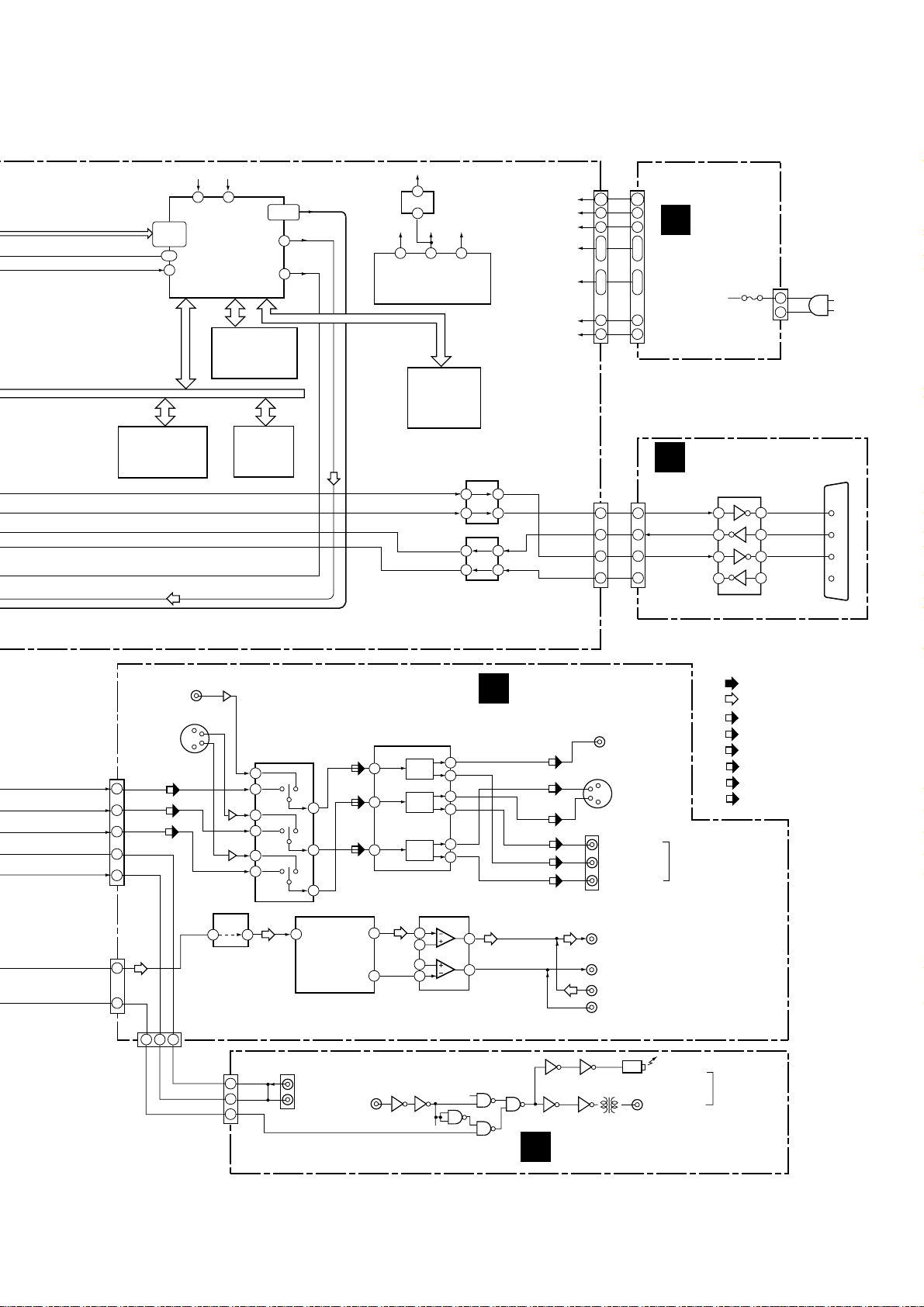

8. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

8.1 BLOCK DIAGRAM

CARRIAGE

MOTOR

LOADING

MOTOR

SELECT

MOTOR

DOOR

MOTOR

M

M

M

M

301 CHANGER

MECHANISM

SPDL

MOTOR

Q

CN303

7

8

5

3

2

1

CN305

(4P)

CN304

8

4

CN307

(9P)

MOTOR DRIVER

OEIC

FCS

TRKG

PICKUP

ASSY

MDRB

ASSY

(8P)

(5P)

14

SELECT DOOR

3

IC301

LA6531

(12P)

CN302

7

9

(24P)

10

7,6,

3,2

21

24

22

23

10

10

12

8

6

4

7

9

F_RTN

F_DRV

T_DRV

T_RTN

(12P)

CN301

SPDL+

SPDL-

SLDR_R

SLDR_F

LOAD+

LOAD-

SRT/

SLT

MCLS/

MOPH

(24P)

CN120

10

7,6,

3,2

21

24

22

23

(12P)

CN1030

5

3

7

9

6

4

(12P)

CN921

3

1

M

B1-B4

13 12 10 9

31

32

14

15

SPDL & FTS

34

35

37

LODDRV

DVDM ASSY

RFRF

3 54

RF IC

6-9

IC101

LA9701M

3

20

17

DRIVER

IC352

M56788FP

28

SLDO

SPDO

8

RFO

DSPRF

46

56

57

42

35

FDO

47

TDO

48

45

46

17

IC610

TC7W53FU

BH

PH

FE

TE

32 33 30 31 39

SERVO DSP

IC201

LC78652W

14

16M

170

Q105

33M 16M

107

4

DVD

DECODER

MY CHIP

IC701

PD4995A

MN414800CSJ-07

SYSTEM

CONTROL CPU

SH1 BASE ASIC

IC601

42

PD3410A

88

57-60

63-66

56

111

4M DRAM

IC702

SD0-SD7

SREQ

CDDATA

118

102

101

117

DTR

TXD

RXD

CTS

PS2B

U

ASSY

JA801

KEYBOARD

/MOUSE

FL TUBE

V701

VAW1052

KEY SW

REMOTE

SENSOR

S

FLKY ASSY

CN801

CN703

KEYB

T

ASSY

1

CN1201

717

1 11

1 11

FL CONTROL

IC701

PE5184A

CN1202

(15P)

CN701

(7P)

CN702

VIDEO ENCODER

(6ch, DNR)

IC101

CN802

CN101

-1/2

-1/2

7

27

(Y0-Y7) D0-D7

DNR

D0-D7

14

34

PM0023AF

25-32

117

115

125

OUTV

OUTY

OUTC

16M SDRAM

IC102

MB811171622A-100FN

(15P)

CN602

SEL IR

IR

SCK0

SB1

1

12

13

14

(7P)

CN903

4

2

SEL IR

IR

CN904

MASTER

CN905

SLAVE

P

MSJB ASSY

(1/2)

15

4

3

2

4

2

7 14

164

IC807

MC74VHCT541ADT

Q541

Q551

Q531

N

FILTER

VQEB

ASSY

VIDEO

F102

Q542

Q552

Q532

CN101

-2/2

2

4

6

(V)

(Y)

(C)

CN802

-2/2

22

24

26

CN901

SEL IR

CN905

7

6

(15P)

V

Y

C

IR

(14P)

ADATA0

ADAI (AC3)

10

12

8

6

5

16

Page 19

149,150,

152-155,

158,159

162

48

WORK SRAM

(1M)

IC604

TC55V1001AF8

27M

36/16M

55 64

MPEG2

DECODER

MITUBISHI

AV-1

IC801

M65773AFP

16M SDRAM

MB811171622A

IC802

-100FN

FLASH

MEMORY

IC603

VYW1701

95-98,

100-103

71

74

YCBR0-7

(Y0-Y7)

AD0

DOUT0

16M

5

IC22

TC7WH74FU

1

27M

33M

36/16M

6

5

1

CLOCK GENERATOR

IC21

CY2081SL-655

EDO DRAM

IC803

M5M4V18165

DTP-6S

IC611

MC74VHCT541ADT

4

16

IC612

MC74VHC541DT

(26P)

CN110

M + 6V

+12V

+12V

+5V

+3.3V

E+5V

– 27V

16

155

4

515

(7P)

CN106

(26P)

CN201

1,2

1,2

5

5

7

7

10

|

POWER

12

SUPPLY

13

|

ASSY

16

22

26

R

(7P)

CN401

7

6

5

4

V

232B ASSY

MAX232EPE

10

9

11

12

IC401

CN101

7

8

14

13

LIVE

1

2

NEUTRAL

JA401

INTERFACE

CONNECTOR

2

3

4

14

AC IN

10

|

12

13

|

16

22

26

TXD

1

RXD

2

DTR

3

CTS

4

COMPOSITE

VIDEO IN

S VIDEO

IN

(15P)

CN501

(V/Cb)

6

4

(C/Cr)

8

10

11

(14P)

CN101

8

AC3/PCM

9

6 3 4

JA504

(2/2)

O

1

7

IC922

AVJB ASSY

JA504

(1/2)

(V)

CN503

(1/2)

(Y)

6

8

(C)

(C/Cr)

(V/Cb)

P

JA505

(Y)

JA201

L

R

L

R

IC901

MSJB ASSY (1/2)

COMPOSITE

VIDEO OUT

S VIDEO

OUT

R

(RED)

P

PB (BLUE)

Y (GREEN)

AUDIO

OUT

AUDIO

IN

ANALOG

COMPONENT

VIDEO

OUT

OPTICAL AC-3/PCM

COAXIAL

CN503

(2/2)

1

3

(Y)

Hi-bit

14 8

PD0236AM

CN502

(7P)

VIDEO

SELECTOR

IC502 BU4551BF

11

12

15

1

6

10

IC241

(7P)

CN902

4

5

2

DIN

JA989

2

(V/Cb)

(C/Cr)

13

14

5

96k,24-bit

2ch DAC

IC201

PE8001A

IN Remote

OUT Control

3IN 6OUT

VIDEO AMP

IC501 LA7135AM

AIN

3

BIN

6

(Y)

CIN

10

VOUTL

16 2

VOUTR

13

COAXIAL

IN

IC931

AMP

AMP

AMP

BA4560F

3

5

6

23

21

19

17

15

13

IC203

DIGITAL

SELECTOR

: RF Signal Route

: Audio Signal Route (L ch)

(V/Cb)

: V Signal Route

(Y)

: Y Signal Route

(C/Cr)

: C Signal Route

(R)

: R Signal Route

(G)

: G Signal Route

(B)

: B Signal Route

DIGITAL

AUDIO

OUT

17

Page 20

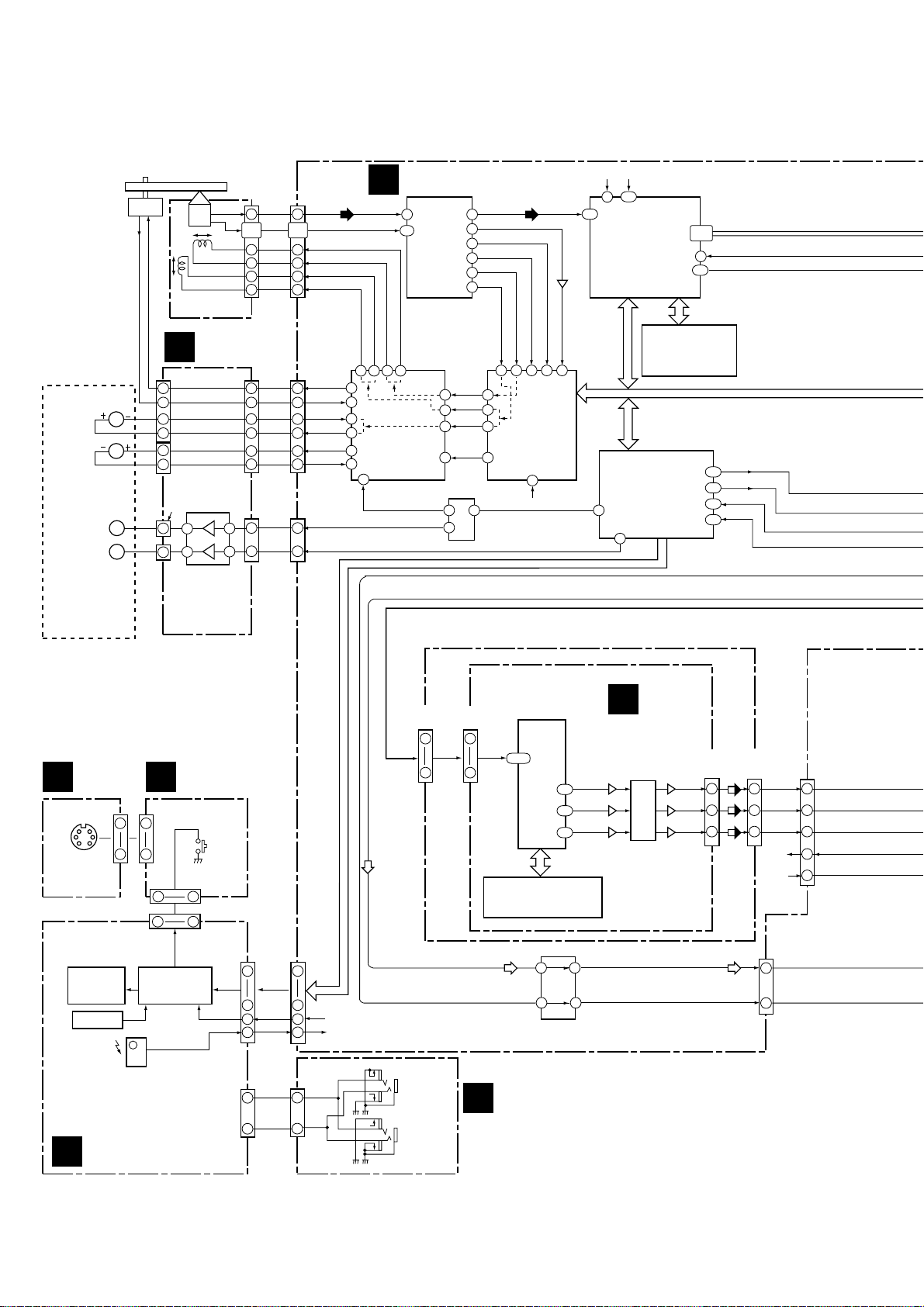

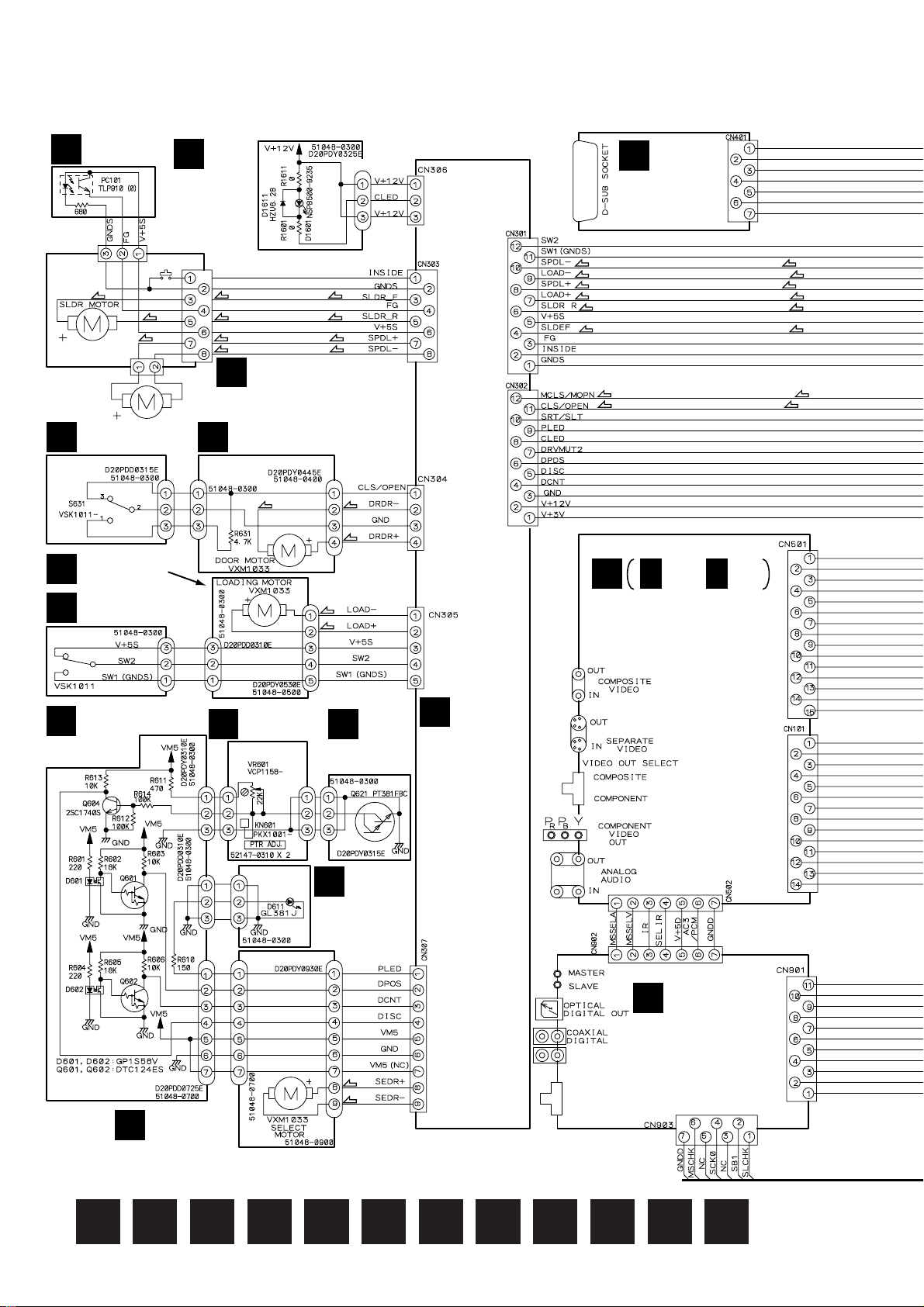

8.2 FGSB, SMEB, SSRB, SEMB, LOMB, LOSB, RADB, PHOB, DOMB, DOSB,

VOLB, LEDB, PICKUP ASSYS and OVERALL WIRING DIAGRAM

FGSB ASSY

A

(VWG2009)

CN201

52044-0345

CARRIAGE

MOTOR

ASSY

VXX2656

CN203

SPINDLE

MOTOR

ASSY

VXX2649

DOSB ASSY

J

(VWG2195)

(S)

LEDB ASSY

(VWG2197)

S201

DSG1016

(S)

(SP)

J632

L

CN202

VKN1212

(S)

(S)

(SP)

(SP)

B

DOMB ASSY

I

(VWG2194)

J632

SMEB ASSY

(VWG2048)

J631

(D)

J1601

(S)

(S)

(SP)

(SP)

(D)

R

232B ASSY

(VWG2201)

(SP)

(L)

(SP)

(L)

(S)

(S)

(D) (D)

(SP)

(SP)

(S)

(S)

(SL)(SL)

(L)

(L)

LOMB ASSY

E

(VWG2115)

LOSB ASSY

F

(VWG2116)

LEAF SW

C

SSRB ASSY

(VWG2113)

J652

VOLB ASSY

K

(VWG2196)

CN605

J605J603

J651

CN604

LED

HOLDER

RNK1795

(D)

(L)

(L)

H

PHOB ASSY

(VWG2118)

J604

G

RADB ASSY

(VWG2117)

J601

Q

MDRB ASSY

(VWG2199)

O 1/2, O 2/2

O

AVJB ASSY

(VWV1720)

P

MSJB ASSY

(VWG2200)

SEMB ASSY

(VWG2114)

D

J602

(SL)

(SL)

ININOUT

OUT

REMOTE

CONTROL

INTERNAL

REMOTE

CONTROL SW

EXTERNAL

A B C D E F G H I J K L

18

Page 21

Note : When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS LIST" or "PCB PARTS LIST".

: RF SIGNAL ROUTE

(F)

: FOCUS SERVO LOOP LINE

(T)

: TRACKING SERVO LOOP LINE

(S)

: SLIDER SERVO LOOP LINE

V

(SP)

: SPINDLE DRIVE SIGNAL ROUTE

(L)

: LOADING DRIVE SIGNAL ROUTE

(D)

: DOOR DRIVE SIGNAL ROUTE

(SL)

: SELECT DRIVE SIGNAL ROUTE

AC POWER CORD

ADG7024

(D)

(SP)

(L)

(SP)

(L)

(S)

(S)

(SL)

M

M 1/4- M 4/4

DVDM ASSY

(VWS1396)

POWER

SUPPLY ASSY

(VWR1317)

CN101

VQEB ASSY

N

(VWV1669)

CN101

(T)

(F)

(F)

(T) (T)

PICKUP

ASSY

(F)

(F)

(T)

(F)

(F)

(T)

(F)

(T)

(T)

(F)

(VWY1055)

(F)

(T)

(T)

(F)

T

KEYB ASSY

(VWG2147)

S

FLKY ASSY

(VWG2192)

U

PS2B ASSY

(VWG2198)

19

Page 22

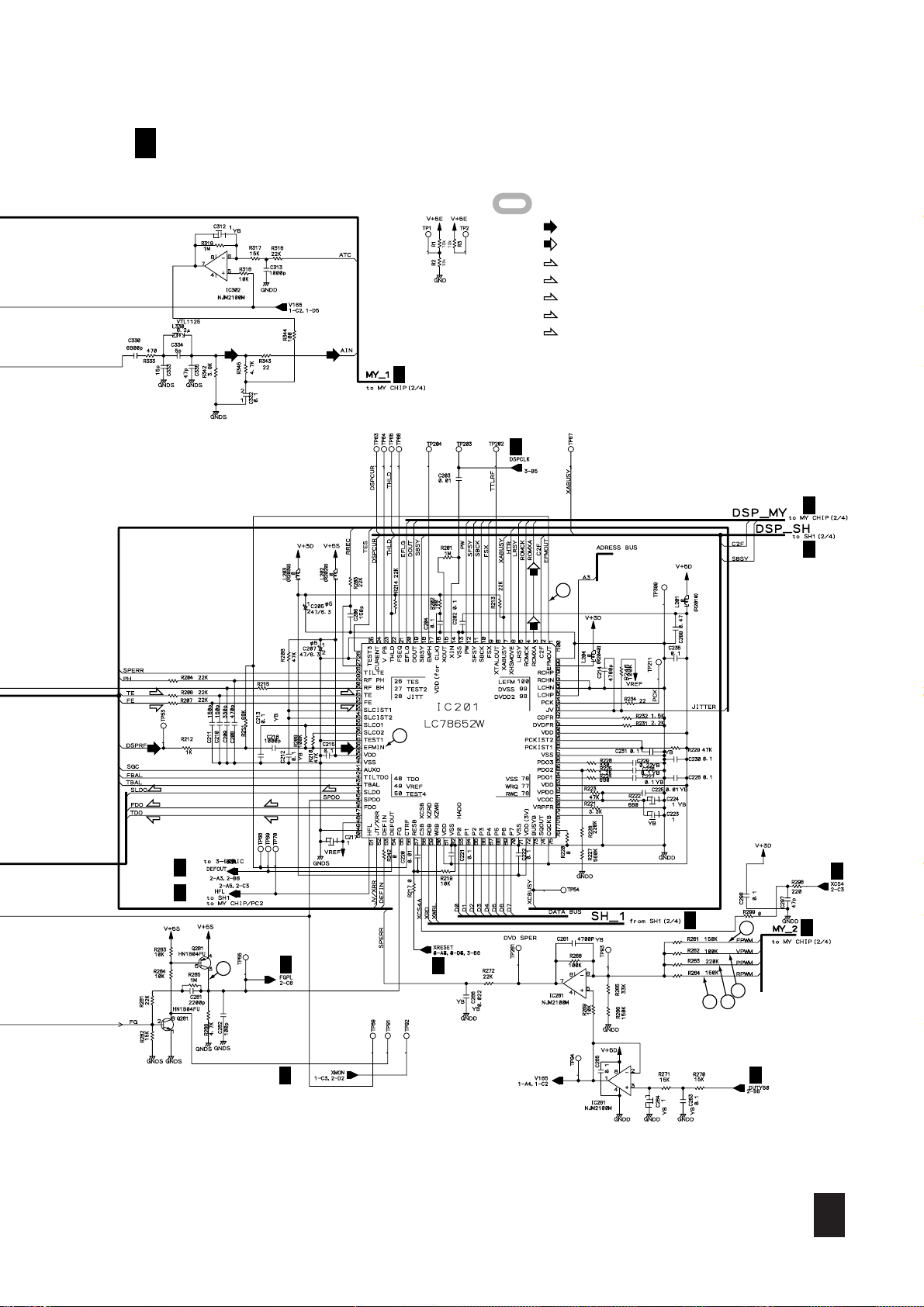

8.3 DVDM ASSY (1/4)

CN110

VKN1479

CN201

V

CN120

VKN1464

1

M

2/4

M

2/4

M

2/4

(F)

(F)

(T)

(T)

(T)

(F)

(F)

M

2/4

1/2

M

2/4

(DVD) (DVD)

CN201

VKN1324

2

M

2/4

(CD)

(DVD)

RF IC

(F)

(F)

(T)

(T)

(CD)

(F) (F)

(F)

(T) (T)

(CD)

4

M

2/4

PICKUP ASSY

CN1030

VKN1471

(L)

(L)

CN301

Q

(F)

(T)

(F)

(SP)

(SP)

M

2/4

M

2/4

M

M

2/4

(F)

(T)

(T)

(F)

M

2/4

SPINDLE & FTS

DRIVER

(S)

(S)

M

2/4

(F)

(F)

(SP)

(SP)

(L)

(L)

(F)

(F)

(T)

(T)

2/4

(T)

(S)

(T)

M

1/4

20

Page 23

M 1/4

DVDM ASSY (VWS1396)

2/2

(DVD) (DVD)

FOR CHECKER

E

2/4

: The power supply is shown with the marked box.

: RF SIGNAL ROUTE

: ROM DATA SIGNAL ROUTE

(F)

: FOCUS SERVO LOOP LINE

(T)

: TRACKING SERVO LOOP LINE

(S)

: SLIDER SERVO LOOP LINE

(SP)

: SPINDLE DRIVE SIGNAL ROUTE

(L)

: LOADING DRIVE SIGNAL ROUTE

M

3/4

M

M

6

2/4

2/4

(CD)

2/4

2/4

(T)

(F)

(CD)

(S)

5

DSP IC

M

2/4

M

2/4

M

2/4,4/4

2/2

1/2

8

9

1011

M

2/4

M

2/4

(T)

(F)

(S)

(F)

(T)

M

2/4

M

2/4

7

(F)

(T)

M

M

21

M

1/4

Page 24

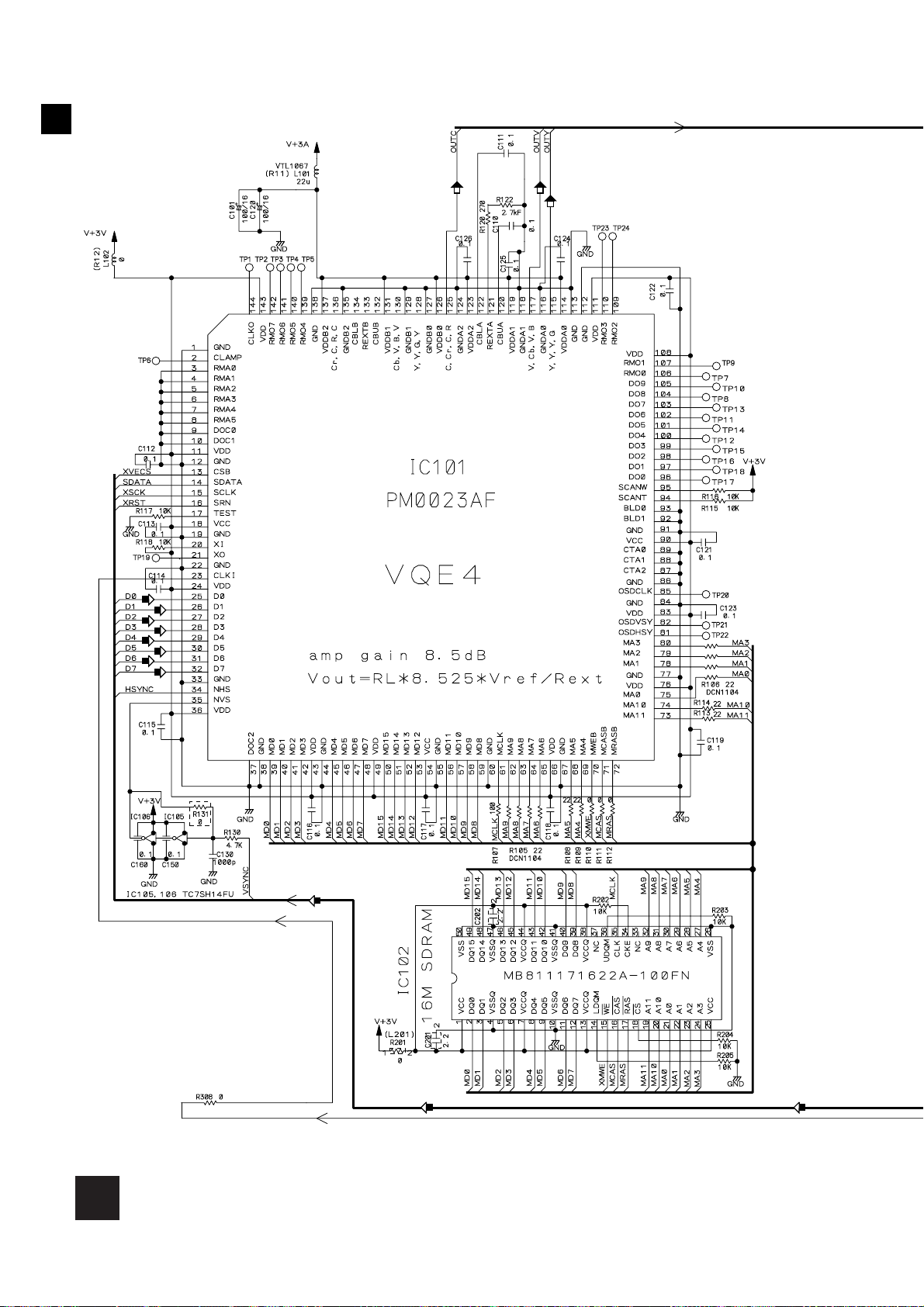

8.4 DVDM ASSY (2/4)

PGM 16M FLASH MEMORY

IC603

VYW1701

M 2/4

DVDM ASSY (VWS1396)

WORK SRAM

IC604

TC55V1001FAF8

M

M

4/4

4/4

M

1/4

M

3→5 CONVERTER

5→3 CONVERTER

CN106

VKN1299

1/4

M

3/4

CN401

R

M

M

M

M

4/4

3/4

M

1/4

M

3/4,4/4

3/4

1/4

M

1/4

M

1/4

SH1 BASE ASIC

(D)

M

1/4

4/4

(SL)

M

M

M

1/4

4/4

M

1/4

M

4/4

M

4/4

M

3/4

M

1/4

M

4/4

CN107

VKN1575

M

M

1/4,3/4

1/4

M

2/4

22

Page 25

M

3/4

MN414800CSJ-07

4M DRAM

IC702

(MY CHIP ES2)

DVD ENCODER

: The power supply is shown with the marked box.

: AUDIO SIGNAL ROUTE

: ROM DATA SIGNAL ROUTE

(D)

: DOOR DRIVE SIGNAL ROUTE

(SL)

: SELECT DRIVE SIGNAL ROUTE

M

1/4

M

4/4

M

3/4

M

4/4

M

1/4

M

1/4

M

M

M

1/4

1/4

1/4

M

M

3/4

3/4

CN602

VKN1474

S

CN701

M

4/4

3→5 CONVERTER

M

3/4

3

M

1/4

M

1/4

23

M

2/4

Page 26

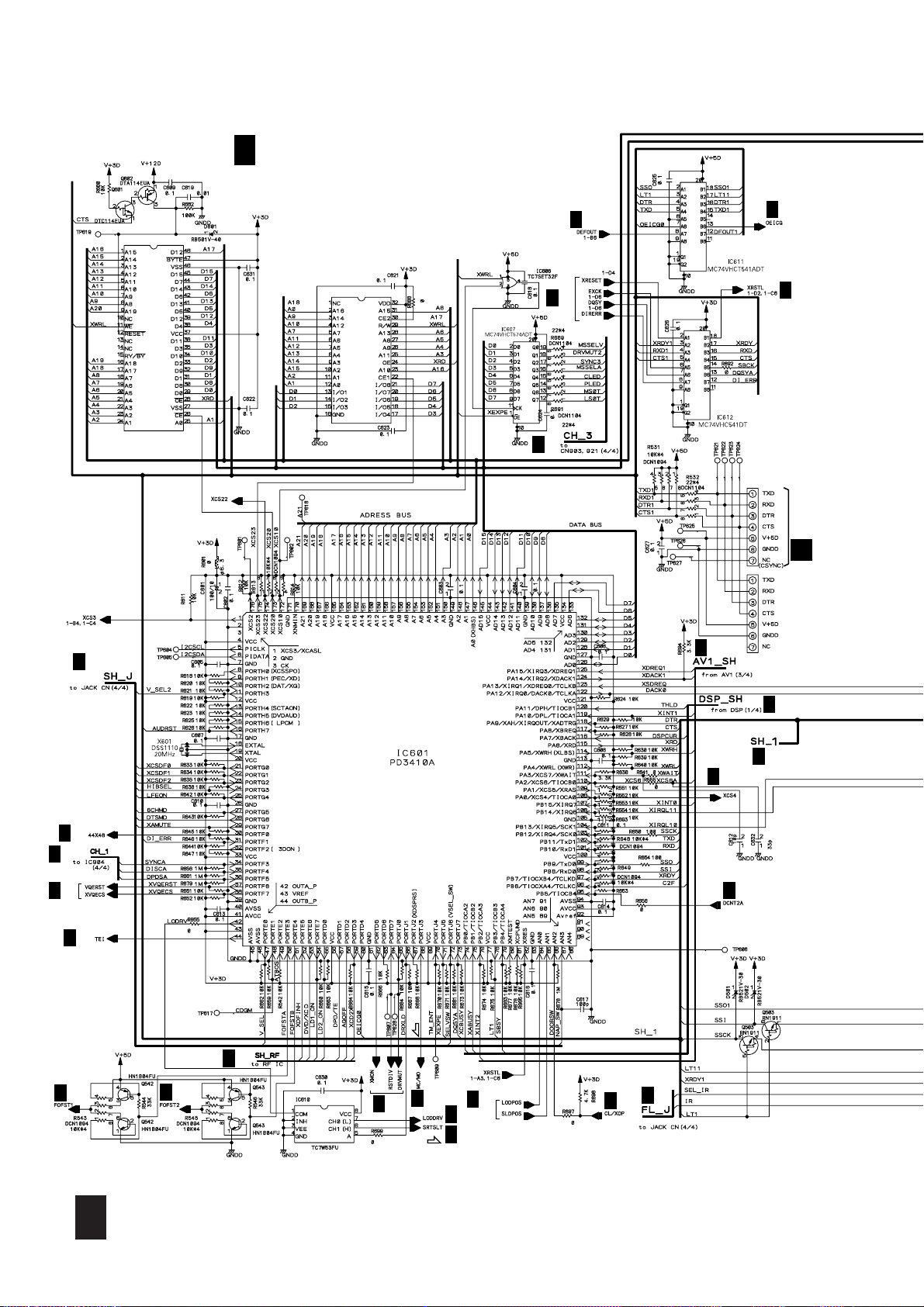

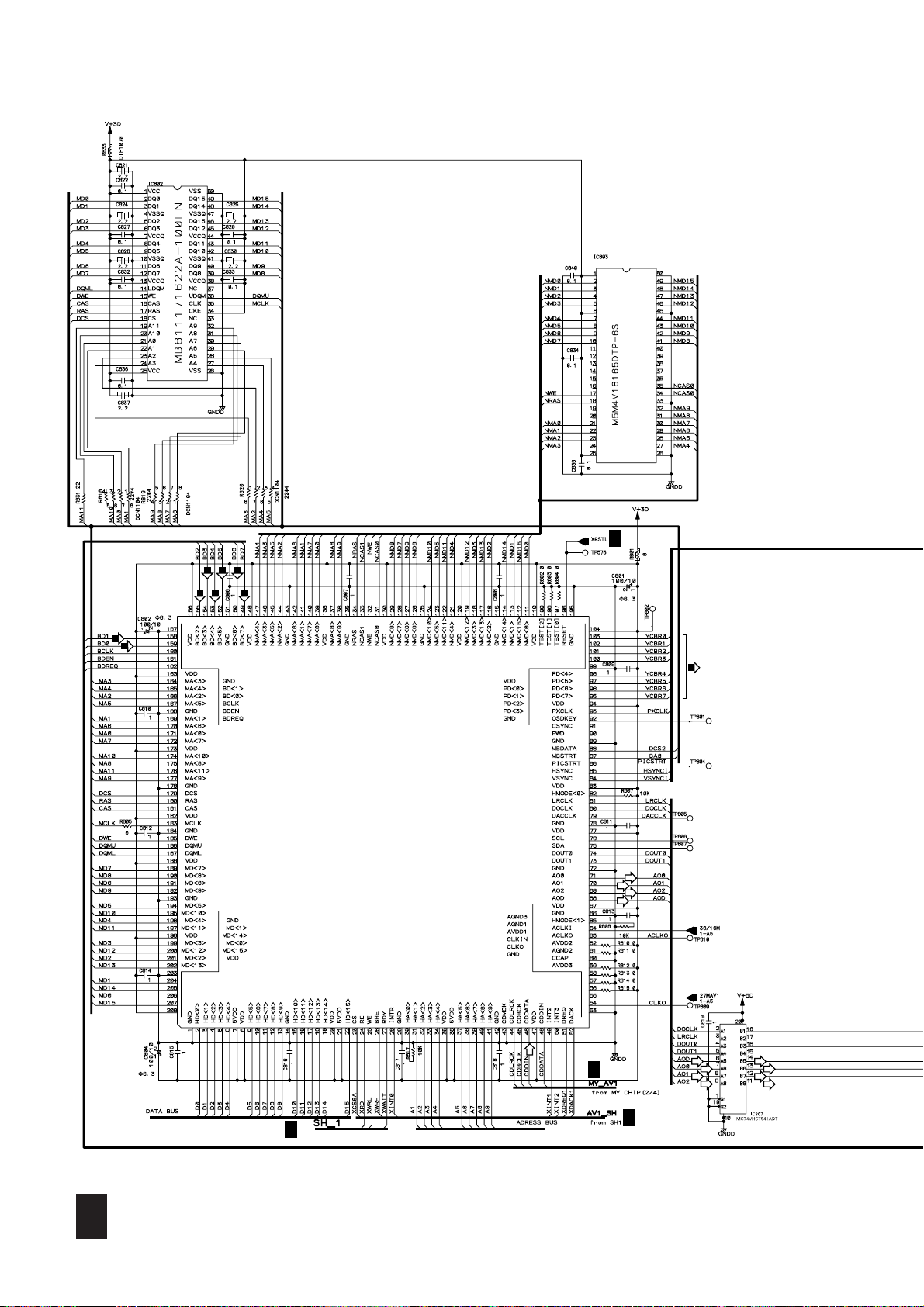

8.5 DVDM ASSY (3/4)

16M SDRAM

1M × 16 EDO DRAM (TSOP)

IC801

M65773AFP

AV1

MPEG2 ENCODER

M

2/4

3→5 CONVERTER

M

3/4

M

2/4

24

M

2/4

M

2/4

Page 27

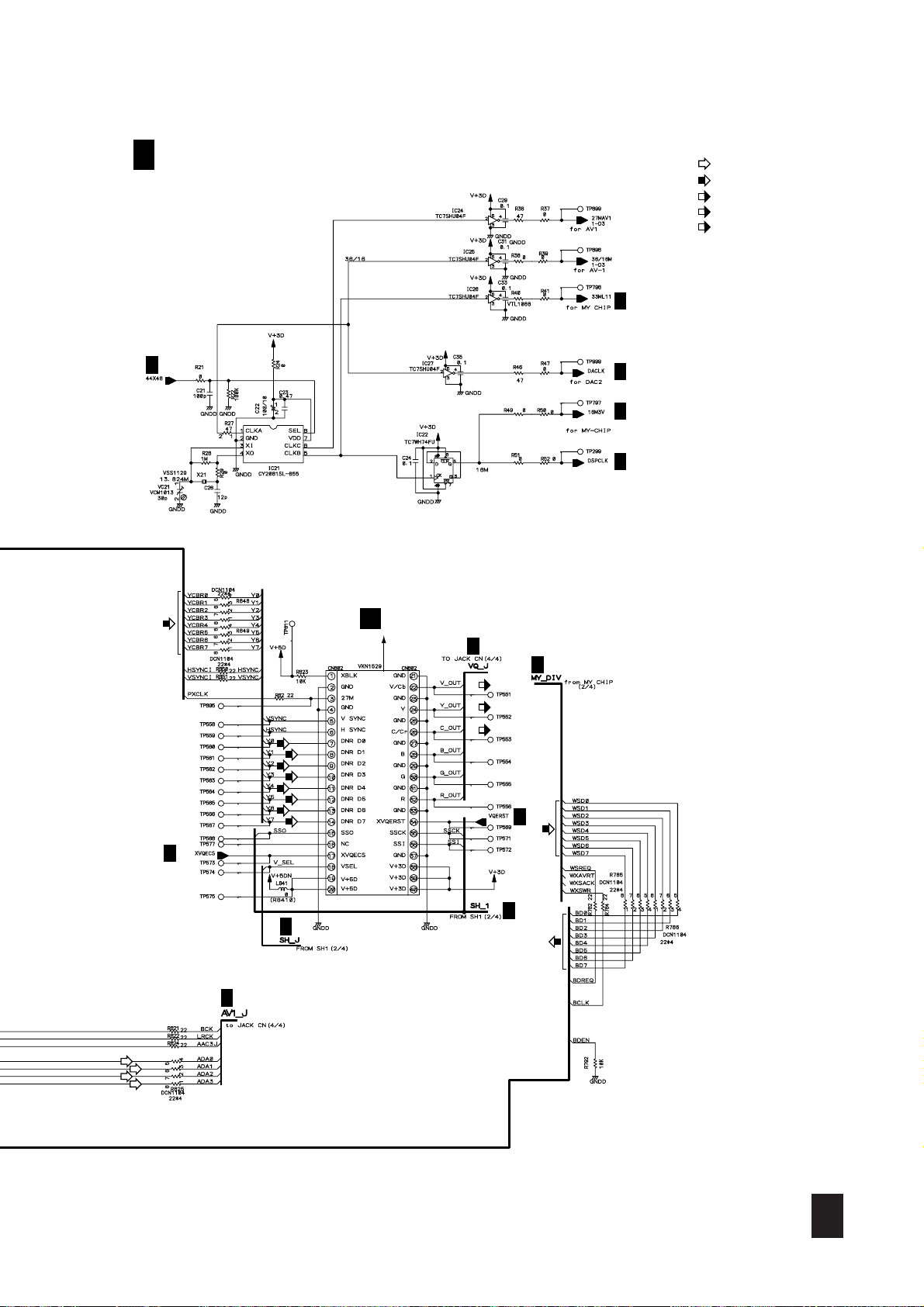

M 3/4

M

2/4

DVDM ASSY (VWS1396)

CLOCK GEN. BLOCK

M

2/4

M

4/4

M

2/4

M

FOR SERVO DSP

1/4

: AUDIO SIGNAL ROUTE

: ROM DATA SIGNAL ROUTE

(V)

: VIDEO SIGNAL ROUTE

(Y)

: Y SIGNAL ROUTE

(C)

: C SIGNAL ROUTE

M

2/4

M

4/4

M

2/4

N

CN101

M

4/4

M

M

M

2/4

2/4

2/4

(V)

(Y)

(C)

25

M

3/4

Page 28

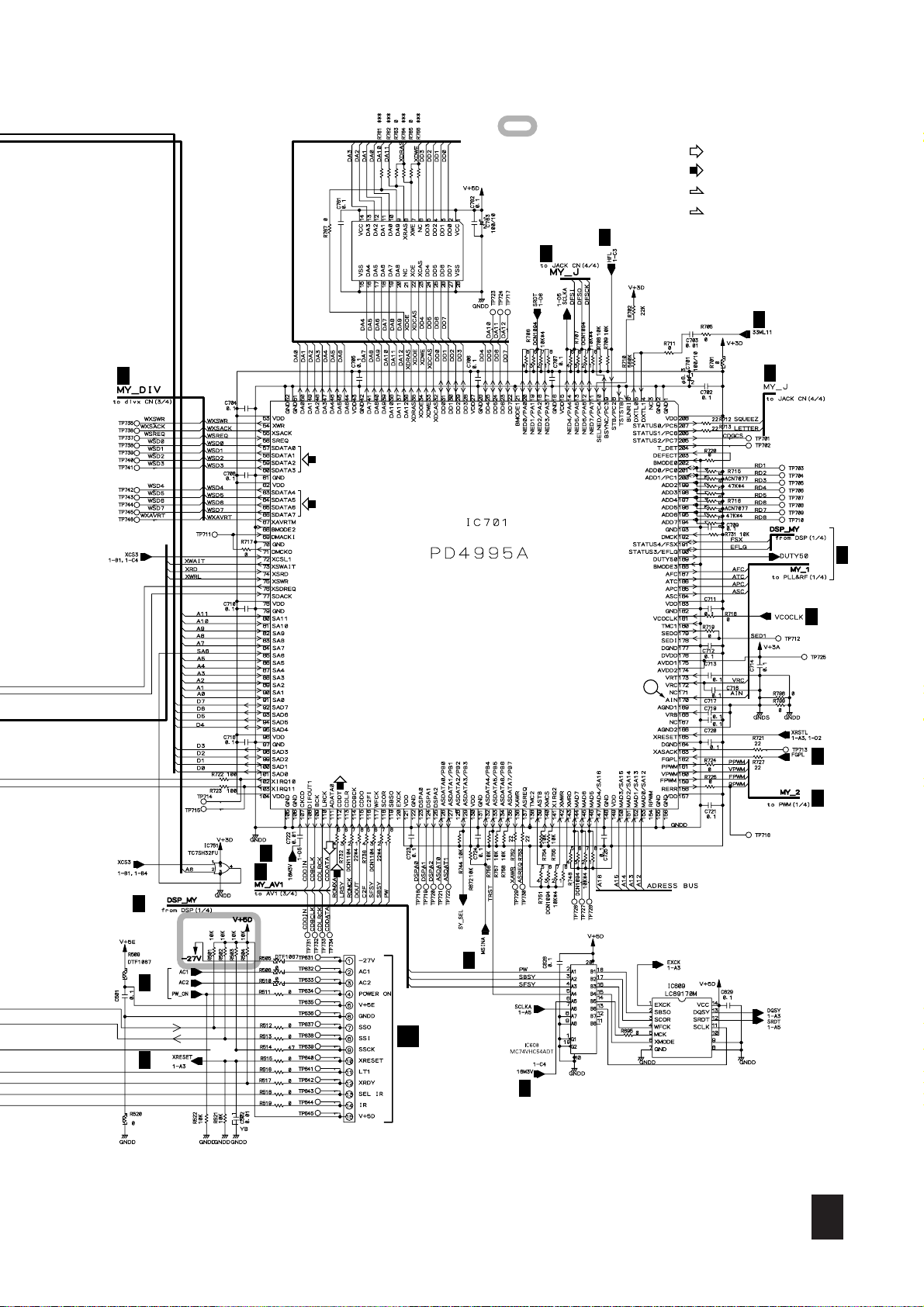

8.6 DVDM ASSY (4/4)

M 4/4

M

2/4

DVDM ASSY (VWS1396)

5→3 CONVERTER

M

2/4

M

2/4

M

2/4

M

2/4

M

3/4

3→5 CONVERTER

M

2/4

M

2/4

CN905

VKN1473

(D)

(SL)

CN921

VKN1471

CN903

VKN1497

(V)

(Y)

(C)

(D)

(SL)

CN302

Q

CN901

P

: AUDIO SIGNAL ROUTE

: VIDEO SIGNAL ROUTE

: Y SIGNAL ROUTE

: C SIGNAL ROUTE

: DOOR DRIVE SIGNAL ROUTE

: SELECT DRIVE SIGNAL ROUTE

M

4/4

M

M

1/4, 2/4

2/4

M

2/4

M

3/4

26

(Y)

(V)

(C)

CN901

VKN1474

O1/2

CN101

O2/2

CN501

Page 29

27

Page 30

8.7 VQEB ASSY

VQEB ASSY (VWV1669)

N

(C) (V)

(6 ch, DNR) VIDEO ENCODER

(Y)

N

28

Page 31

: The power supply is shown with the marked box.

: ROM DATA SIGNAL ROUTE

(V)

: VIDEO SIGNAL ROUTE

(Y)

: Y SIGNAL ROUTE

(C)

: C SIGNAL ROUTE

3 6

,

(C)

1 4

,

(V)

2 5

,

(Y)

Q531, Q532, Q541, Q542, Q551, Q552 : 2PB709A (QR)

F102 : VTF1155

M3/4

CN802

(V)

(C)

(V)

(Y)

(Y)

(C)

29

N

Page 32

8.8 AVJB ASSY (1/2)

O 1/2

M4/4

CN905

AVJB ASSY (VWV1720)

O

2/2

CN101

VKN1190

IC201

PE8001A

DAC

O

2/2

Hi-Bit

O

1/2

30

Page 33

: The power supply is shown with the marked box.

1/2

2/2

O

2/2

: AUDIO SIGNAL ROUTE

JA201

VKB1133

31

O

1/2

Page 34

8.9 AVJB ASSY (2/2)

CN501

VKN1191

O

1/2

M4/4

CN901

P

CN902

CN502

VKN1183

(V)

JA504 (2/2)

VKB1135

(V/PB)

(C/PR)

O

(Y)

1/2

(Y)

(V/PB)

(C/PR)

O

1/2

(V/PB)

(C/PR)

(Y)

(Y)

(C/PR)

(C)

(Y)

(Y)

(Y)

(V/P

(Y)

B)

B)

(V/P

(C/PR)

O

CN503 (2/2)

AKP7023

2/2

(Y)

(C)

(C)

(C)

VIDEO

SELECTOR

32

Page 35

O 2/2

(V/PB)

(C/PR)

(Y)

AVJB ASSY (VWV1720)

: The power supply is shown with the marked box.

VIDEO AMP

(V/PB)

(C/PR)

(Y)

(V)

(PB)

(C)

(PR)

(Y)

(VPB)

(Y)

(C/PR)

(V) (V)

(Y)

(C)

: VIDEO/PB SIGNAL ROUTE

: Y SIGNAL ROUTE

: C/PR SIGNAL ROUTE

JA504 (1/2)

VKB1135

CN503 (1/2)

AKP7023

JA505

VKB1152

(PR)

(Y)

(PB)

(Y)

(PR)

(PB)

(Y)

33

O

2/2

Page 36

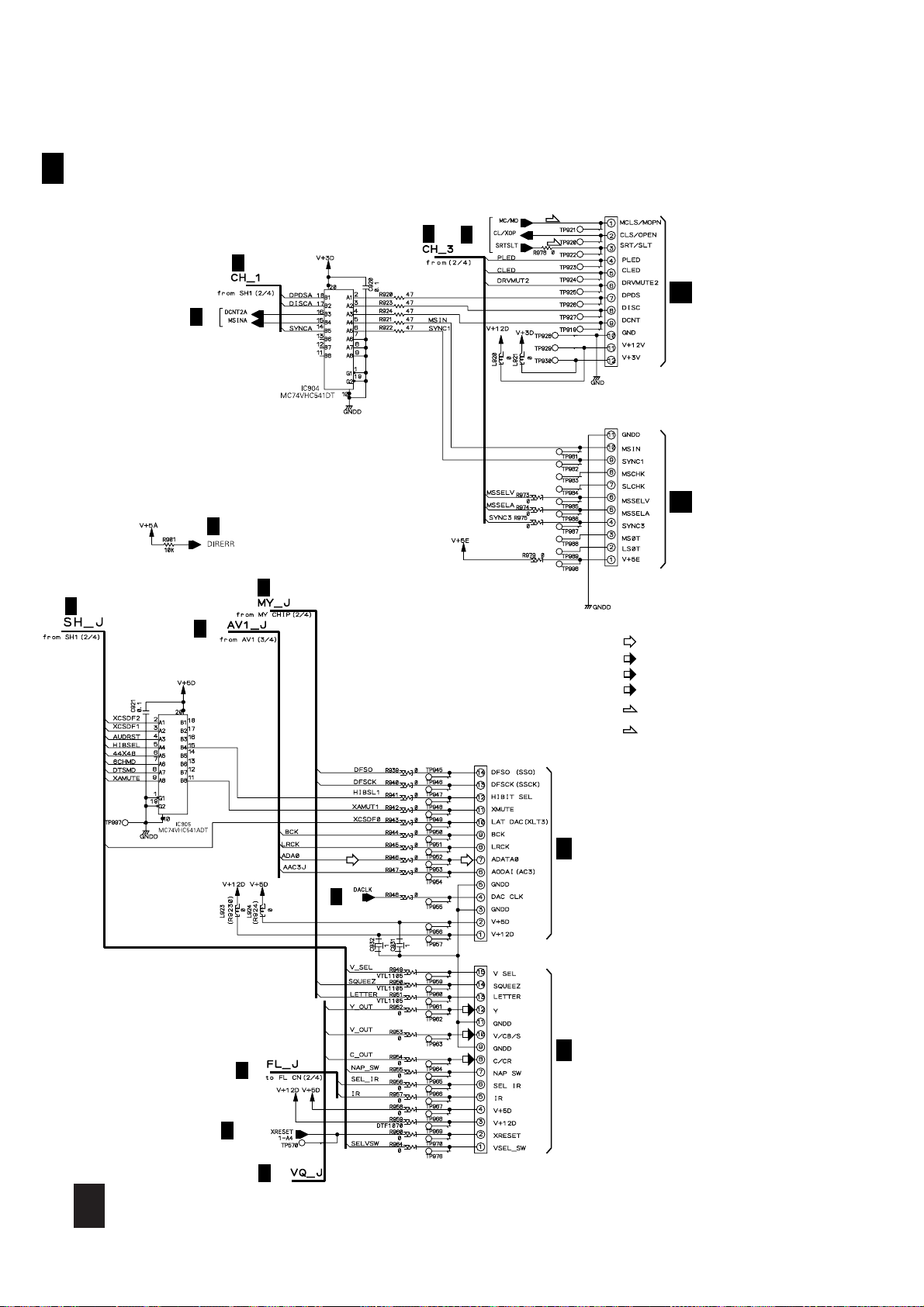

8.10 MSJB ASSY

MSJB ASSY (VWG2200)

P

CN903

VKN1267

S

CN702

MSCHK, SLCHK

Normal : Low

Plug in : High

R997

300

R989

300

R998

300

CN904

AKN1028

CN905

AKN1028

M4/4

CN903

O2/2

CN502

JA989

VKB1149-

C989

0.1

R992

10K

10K

R990

Q991

47µ/10

R995

R996

2SC2412K (QRS)

47k

Q990

2SC2412K (QRS)

R994

22

R991

4.7K

R993

47k

18K

R968

CN901

VKN1271

CN902

VKN1267

(D) (D) (D)

0

R967

0

R991

0.1

R990

Q989

2SA1037K (QRS)

D989

1SS355

0

R999

S901

VSH1009-

6

5

4

Remote Control

3

External

2

Internal

1

P

34

Page 37

: The power supply is shown with the marked box.

(D)

: DIGITAL AUDIO SIGNAL ROUTE

JA902

GP1F32T

(D)

(D)

(D)

(D) (D)

(D) (D) (D)

(D)

(D)(D)(D)

JA909

VKB1148

(D)

(D) (D)

(D)

P

35

Page 38

8.11 MDRB ASSY

MDRB ASSY (VWG2199)

Q

CN306

52147-0310

L

J1601

CN303

VKN1239

CN202

B

CN301

VKN1243

J631

I

J651

E

J601

D

CN304

52147-0410

CN305

52147-0510

CN307

52147-0910

CN302

VKN1243

CN1030

M1/4

CN921

M4/4

Q

36

Page 39

8.12 232B ASSY (DV-F07 ONLY)

232B ASSY (VWG2201)

R

M2/4

CN106

CN401

VKN1238

37

R

Page 40

8.13 FLKY, KEYB and PS2B ASSYS

FLKY ASSY

S

(VWG2192)

M2/4

CN701

VKN1246

CN602

S

38

Page 41

CN702

VKN1238

MSCHK, SLCHK

Normal : Low

Plug in : High

CN903

P

: The power supply is shown with the marked box.

KEYB ASSY (VWG2193)

T

CN703

HLEM11S-1

FLKY ASSY

S701 : STYANDBY/ON

S702 : ACCESS

S703 : PLAY

S704 : PLAYMODE

S705 : RANDOM

S706 : DISPLAY

S707 : INPUT

S708 : SEARCH

KEYB ASSY

S1200 : DISC CHARA (MULTI JOG)

S1201 : PUSH ENTER

S1202 : CLEAR

S1203 : 41

S1204 : ¡¢

S1205 : 8 (PAUSE)

S1206 : 7 (STOP)

S1207 : 3

S1208 : 2

S1209 : 1

S1210 : 4

S1211 : 5

S1212 : 6

S1213 : 9

S1214 : 8

S1215 : 7

S1216 : 10

S1217 : AUDIO/VIDEO

S1218 : UPDATE

S1219 : 3(PLAY)

S1220 : 0(OPEN/CLOSE)

SINGLE LOADER

TEXT

DIRECT CUSTOM

CN1202

HLEM11S-1

U

PS2B ASSY (VWG2198)

CN801

VKN1267

CN1201

VKN1267

39

UTS

Page 42

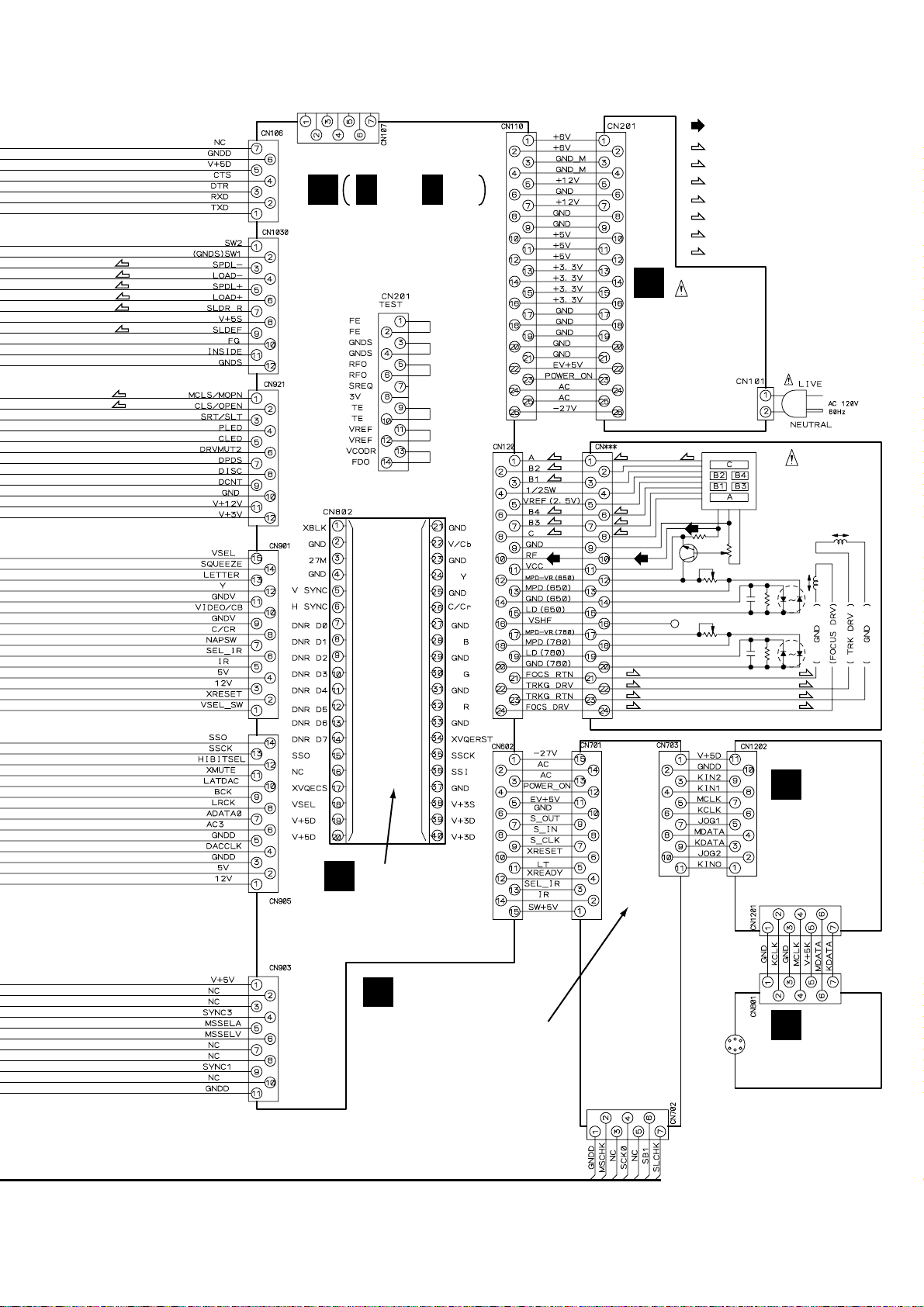

8.14 POWER SUPPLY ASSY

POWER SUPPLY ASSY (VWR1317)

V

R110

T101

TRANS

D201

R101

C102

C104 C103

L101

C101

Z101

D102 D101

D103 D104

C105

C106

PC102

C109

R121

C123

R130

R113

Q103

R114

D110

Q102

R109

PC101

R102

R103

R112

R122

R123

D109

R104

D105

D106

C111

L102

D108

D107

C108

C107

C110

R107 R106

R115

Q101

T102

TRANS

D202

D203

D204

D206

D205

L207 P202

D301

R206

10

C204

3300/10

C205

100/35

REK1078

2A/125V

CN101

AC IN

V

F101

GND

Q121

R124

Q122

C122

C121

R128

PC121

40

R127

D121

R129

R126R125

D302

C301

470/10

Page 43

NOTE OF SPARE PARTS IN POWER SUPPLY (SYPS) ASSY

• In case of repairing, use the described parts only to prevent an accident.

• Please write the red mark on the board when the primary section of POWER SUPPLY (SYPS) Assy is repaired.

• Please take care to keep the space, not touching other parts when replacing the parts.

• NOTE FOR FUSE REPLACEMENT

CAUTION -

C201

1000/16

C202

1000/16

R201

47

PC101

C203

2200/10

IC201

R301

470

R302

PC121

R305

C303

1k

IC301

1k

0.1

FOR CONTINUED PROTECTION AGAINST RISK OF FIRE.

REPLACE WITH SAME TYPE AND RATINGS ONLY.

L201

R205

R303

2.2k

R304

2.7k

0.1/25

1k

R208

5.6k

R209

5.6k

VR301

1k

R202

1k

C213

L301

20µH

R203

3.3k

R204

2.7k

D207

VR201

1k

L205

20µH

20µH

L202

20µH

C302

100/16

C206

100/16

C207

100/16

C210

33/50

IC203

AEK7064

1A

R306

1k

PC102

Q301

C211

100/16

P201

P203

IC202

AEK7066

1.6A

R307

270

R211

R216

1k

100

R215

100

VR202

200

R214

100

C212

100/16

CN201

VKN1202

+M6.0V

1

+M6.0V

2

3

GND

4

GND

5

+12V

6

GND

7

+12V

8

GND

9

GND

10

+5V

11

+5V

12

+5V

13

+3.3V

14

+3.3V

15

+3.3V

16

+3.3V

17

GND

18

GND

19

GND

20

GND

21

GND

22

E+5.0V

23

P. CONT

24

FLAC-A

25

FLAC-B

26

-27V

CN110

1/4

M

41

V

Page 44

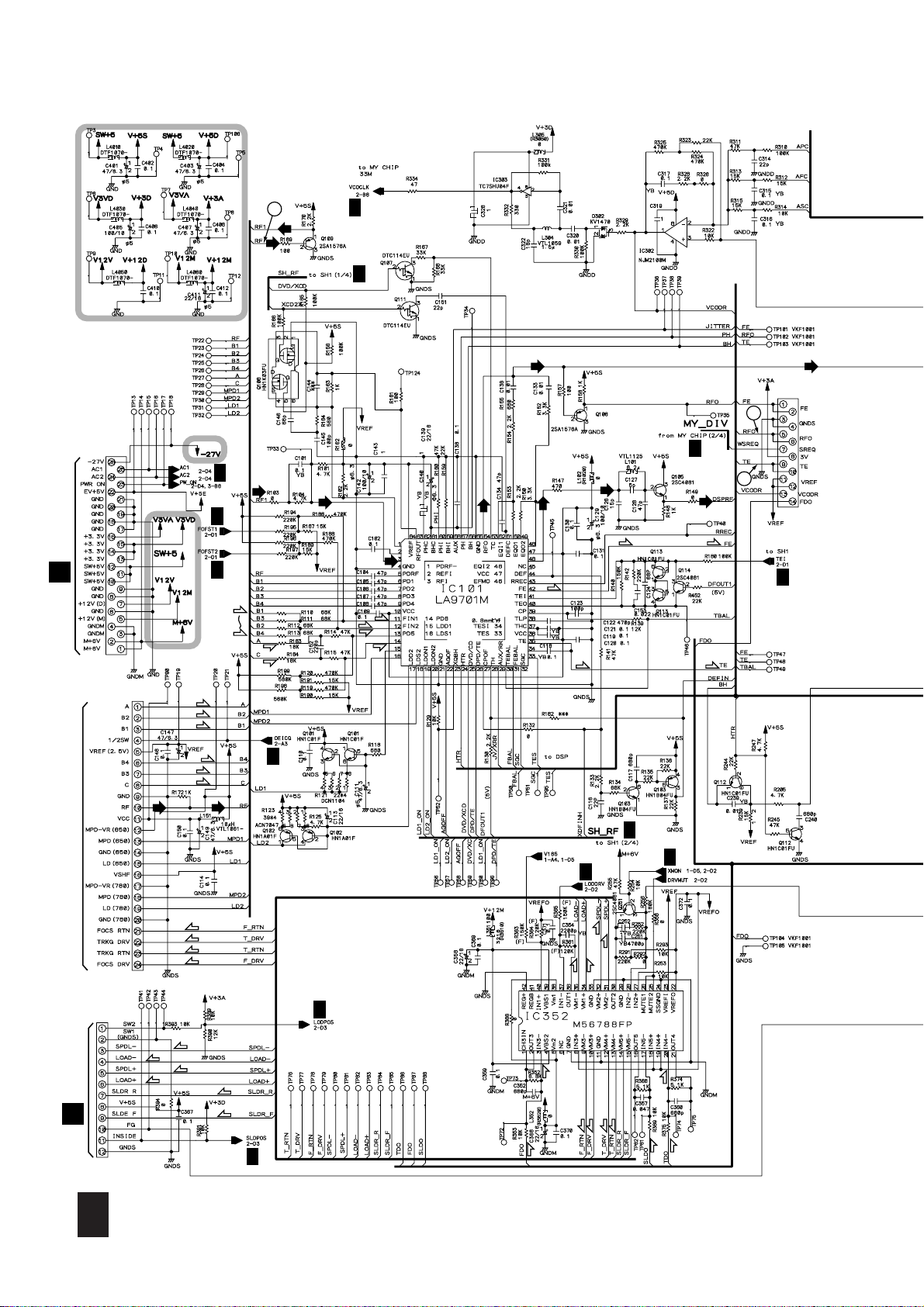

WAVEFORMS

Note : The encircled numbers denote measuring point in the schematic diagram.

Measurement condition : No. 1 to 4 and 6 to 11 : Disc MA1, Title 1-chp 1

No. 5 : CD, ABEX-784 Track 1

No. 12 to 14 : MJK1, Title 1-chp 4 or T2-1

No. 15 to 17 : MJK1, Title 1-chp 5 or T2-19

No. 18 to 20 : T2-19, Color-bar (WY and WV Types only)

DVDM ASSY

Foot of R169 (RF)

1

V: 100mV/div. H: 0.2µsec/div.

CN201 - pin 5, 6 (RFO)

2

V: 500mV/div. H: 0.1µsec/div.

IC701 - pin 170 (MY CHIP input)

3

V: 1V/div. H: 0.2µsec/div.

GND

GND

GND

Q281 - Collector (FG)

7

V: 1V/div. H: 5msec/div.

Foot of R261 (FPWM)

8

V: 1V/div. H: 5msec/div.

Foot of R262 (VPWM)

9

V: 1V/div. H: 5msec/div.

GND

GND

GND

VQEB ASSY

Q541 Base (Composite Video output)

1

V: 0.1V/div. H: 10µsec/div.

Q551 Base (Y output)

2

V: 0.1V/div. H: 10µsec/div.

Q531 Base (C output )

3

V: 0.1V/div. H: 10µsec/div.

GND

GND

GND

CN201 - pin 9, 10 (Tracking Error)

4

(AI-Inner Tracking Off)

V: 500mV/div. H: 2msec/div.

IC201 - pin 39 (EFM before slice)

5

V: 1V/div. H: 1µsec/div.

IC201 - pin 1 (EFM)

6

V: 1V/div. H: 0.2µsec/div.

GND

GND

Foot of R263 (PPWM)

10

V: 1V/div. H: 5msec/div.

Foot of R264 (RPWM)

11

V: 1V/div. H: 5msec/div.

GND

GND

B

Q541 Base (C

4

color difference output)

V: 0.1V/div. H: 10µsec/div.

Q551 Base (Y output when selecting

5

color difference output)

V: 0.1V/div. H: 10µsec/div.

Q531 Base (CR output when selecting

6

color difference output)

V: 0.1V/div. H: 10µsec/div.

output when selecting

GND

GND

42

Page 45

NOTE FOR PCB DIAGRAMS :

1. Part numbers in PCB diagrams match those in the schematic

diagrams.

2. A comparison between the main parts of PCB and schematic

diagrams is shown below.

3. The parts mounted on this PCB include all necessary parts for

several destinations.

For further information for respective destinations, be sure to

check with the schematic diagram.

4. View point of PCB diagrams.

Symbol In PCB

Diagrams

Symbol In Schematic

Diagrams

Part Name

BCE

D

DGGSS

BCE

BCE

DGS

BCEBCE

BCE

Transistor

Transistor

with resistor

Field effect

transistor

Resistor array

3-terminal

regulator

Capacitor

Connector

P.C.Board

Chip Part

SIDE A

SIDE B

9. PCB CONNECTION DIAGRAM

43

Page 46

9.1FGSB, SMEB, SSRB, SEMB, LOMB, LOSB, RADB, PHOB,DOMB, DOSB,

VOLB and LEDB ASSYS

FGSB ASSY

A

PC101

R101

SSRB ASSY

C

VOLB

K

ASSY

VR601

Q603

Q601Q602

(VNP1778-A)

Q604

(VNP1661-B)

Q621

(VNP1727-B)

PHOB

H

ASSY

(VNP1727-B)

SMEB

B

ASSY

D

Q

CN306

CARRIAGE

SEMB

ASSY

M

MOTOR

Q

CN303

Q

CN307

(VNP1695-A)

SELECT MOTOR

(VNP1727-B)

G

(VNP1727-B)

L

M

SPINDLE

MOTOR

M

RADB

ASSY

LEDB

ASSY

DOMB ASSY

I

Q

CN304

LOMB ASSY

E

Q

CN305

SIDE A

LOADING

MOTOR

M

(VNP1727-A)

LOSB ASSY

F

(VNP1727-B)

M

DOOR

MOTOR

(VNP1778-A)

DOSB

J

ASSY

(VNP1778-A)

A B C D E F G H I J K L

(VNP1778-A)

44

Page 47

SEMB ASSY

D

(VNP1727-B)

RADB

G

ASSY

LEDB

L

ASSY

(VNP1727-B)

H

PHOB

ASSY

SSRB ASSY

C

(VNP1727-B)

(VNP1727-B)

VOLB ASSY

K

(VNP1778-A)

(VNP1778-A)

LOSB ASSY

F

(VNP1727-B)

DOMB ASSY

I

LOMB ASSY

E

DOSB

J

ASSY

(VNP1727-B)

SIDE B

(VNP1778-A)

(VNP1778-A)

C D E F G H I J K L

45

Page 48

9.2 DVDM ASSY

• This PCB is a four-layered board.

PICKUP

ASSY

DVDM ASSY

M

O

CN101

O

CN501

CN401

R

VR851

VC21

IC23

IC26

IC31

Q810 Q808

IC25

IC54

Q809 Q807 Q811

IC21

IC801

IC807

IC22

IC903

IC261

IC302

Q812

IC806

IC303

IC702

Q

CN301

CN201

V

CN701

S

CN901

P

(VNP1706-B)

Q

Q112

IC101 IC601

Q102

Q281

IC352 IC603

CN302

IC610

Q111

Q107

IC761

IC606

Q601

Q602

M

SIDE A

46

Page 49

N

CN101

DVDM ASSY

M

• This PCB is a four-layered board.

IC905

IC803

IC27

IC805

IC802

IC73

IC201

IC701

Q542

IC608

Q106

IC299

Q543

IC904

IC609

IC611

IC612

IC751

IC792

IC604

IC607

IC231

Q179

Q105 Q237

Q113

Q114

Q101

Q103

IC791

Q106

Q251

SIDE B

47

(VNP1706-B)

M

Page 50

9.3 AVJB ASSY

AVJB ASSY

O

Q120

IC203

IC206

IC202

IC201

IC241

IC150

Q150

Q588

IC501

IC502

Q589

Q592

Q591

Q586

Q587

Q590

O

M

CN901

CN905

M

SIDE A

48

P

(VNP1725-B)

CN902

Page 51

AVJB ASSY

O

Q201

Q257

Q277

Q281

Q151

Q202

(VNP1725-B)

Q582

Q584

Q561

Q583

Q581

Q585

SIDE B

49

O

Page 52

9.4 VQEB ASSY

VQEB ASSY

N

SIDE A

SIDE B

VQEB ASSY

N

VR102

VR101

Q551 Q541

Q531

Q521 Q511

Q501

IC103

(VNP1696-B)

IC106IC1

IC105

N

M

Q1

CN802

Q502 Q512

Q522 IC104

Q532 Q542

Q552

(VNP1696-B)

IC102

50

Page 53

9.5 MSJB ASSY

MSJB ASSY

P

(VNP1778-A)

S

M

O

CN702

CN903

CN502

MSJB ASSY

P

IC921 IC922 IC931 IC901

Q990

Q989

SIDE A

(VNP1778-A)

SIDE B

51

P

Page 54

9.6 MDRB ASSY

MDRB ASSY

Q

I

J631

E

J651

L

J1601

M

CN921

M

CN1030

MDRB ASSY

Q

Q301

Q302

IC301

Q

VR301

Q303

B

CN202

D

J601

(VNP1778-A)

SIDE A SIDE B

52

Page 55

9.7 232B ASSY (DV-F07 ONLY)

232B ASSY

R

M

CN106

IC401

232B ASSY

R

(VNP1778-A)

SIDE A

SIDE B

53

(VNP1778-A)

R

Page 56

9.8 FLKY, KEYB and PS2B ASSYS

FLKY ASSY

S

P

CN903

M

CN602

S

IC701

IC702

SIDE A

54

(VNP1778-A)

Page 57

IC1251

IC1201

KEYB ASSY

T

U

(VNP1778-A)

PS2B

ASSY

(VNP1778-A)

UT

55

Page 58

KEYB ASSY

T

(VNP1778-A)

UT

56

(VNP1778-A)

U

PS2B

ASSY

Page 59

FLKY ASSY

S

SIDE B

57

(VNP1778-A)

Q701Q702

S

Page 60

9.9 POWER SUPPLY ASSY

POWER SUPPLY ASSY

V

AC IN

Q103

Q102

Q101

Q122

Q121

M

CN110

SIDE A

VR201

VR301

VR202

IC201

IC203 IC202

IC301

Q301

V

58

Page 61

10. PCB PARTS LIST

NOTES:•Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

•

Therefore, when replacing, be sure to use parts of identical designation.

When ordering resistors, first convert resistance values into code form as shown in the following examples.

•

Ex.1 When there are 2 effective digits (any digit apart from 0), such as 560 ohm and 47k ohm (tolerance is shown by J=5%,

and K=10%).

560 Ω→56 × 10

47k Ω→47 × 10

0.5 Ω→R50 ..................................................................................... RN2H

1 Ω→1R0 ..................................................................................... RS1P 1 R 0 K

Ex.2 When there are 3 effective digits (such as in high precision metal film resistors).

5.62k Ω→ 562 × 10

1

→ 561 ........................................................RD1/4PU 5 6 1 J

3

→ 473 ........................................................RD1/4PU 4 7 3 J

R 5 0

1

→ 5621 ...................................................... RN1/4PC 5 6 2 1 F

K

A

FGSB ASSY

Mark No. Description Part No.

SEMICONDUCTOR

PC101 TLP910(O) *HW100480R

RESISTORS

NSP All Resistors RS1/10SxxxJ —

B

SMEB ASSY

Mark No. Description Part No.

SWITCH

S201 DSG1016 *SP001020R

OTHERS

NSP CN201 52044-0345,

3P FFC CONNECTOR —

NSP CN202 VKN1212, 8P

FFC CONNECTOR —

NSP —

C

SSRB ASSY

Mark No. Description Part No.

Q604 2SC1740S HT317402F0

Q601,Q602 DTC124ES BA20003000

D601,D602 GP1S58V HW10036320

NSP All Resistors RD1/4PUxxxJ —

VNP1695, PC BOARD SMEB

SEMICONDUCTORS

RESISTORS

—

E

LOMB ASSY

Mark No. Description Part No.

OTHERS

NSP —

NSP —

NSP J652

NSP J651

F

LOSB ASSY

Mark No. Description Part No.

— VSK1011, LEAF SWITCH *SM000340R

NSP —

G

RADB ASSY

Mark No. Description Part No.

D611 GL381J *HI100870R

NSP —

NSP — RNK1795, LED HOLDER —

H

PHOB ASSY

Mark No. Description Part No.

Q621 PT381FBC *HF000050R

51048-0300, 3P CABLE HOLDER

51048-0500, 5P CABLE HOLDER

D20PDD0310E, JUMPER WIRE 3P

D20PDY0530E, JUMPER WIRE 5P

SWITCH

OTHERS

51048-0300, 3P CABLE HOLDER

SEMICONDUCTOR

OTHERS

51048-0300, 3P CABLE HOLDER

SEMICONDUCTOR

—

—

—

—

—

—

OTHERS

NSP —

NSP —

NSP J603

NSP J602

NSP J605

D

SEMB ASSY

Mark No. Description Part No.

NSP —

NSP —

NSP J601

51048-0300, 3P CABLE HOLDER

51048-0700, 7P CABLE HOLDER

D20PDD0310E, JUMPER WIRE 3P

D20PDD0725E, JUMPER WIRE 7P

D20PDY0310E, JUMPER WIRE 3P

OTHERS

51048-0700, 7P CABLE HOLDER

51048-0900, 9P CABLE HOLDER

D20PDY0930E, JUMPER WIRE 9P

—

—

—

—

—

—

—

—

OTHERS

NSP —

NSP J604

I

DOMB ASSY

Mark No. Description Part No.

NSP All Resistors RS1/10SxxxJ —

NSP —

NSP —

NSP J631

59

51048-0300, 3P CABLE HOLDER

D20PDY0315E, JUMPER WIRE 3P

RESISTORS

OTHERS

51048-0300, 3P CABLE HOLDER

51048-0400, 4P CABLE HOLDER

D20PDY0445E, JUMPER WIRE 4P

—

—

—

—

—

Page 62

J

DOSB ASSY

Mark No. Description Part No.

SWITCH

S631 VSK1011, LEAF SWITCH *SM000340R

OTHERS

NSP —

NSP J632

K

VOLB ASSY

Mark No. Description Part No.

VR601 VCP1158 (22kW) *RA000970R

NSP CN604,CN605 52147-0310, 3P

NSP KN601

L

LEDB ASSY

Mark No. Description Part No.

D1611 HZU6.2B *HZ300030R

D1601 NSPB500-9235 *HI100880R

NSP All Resistors RS1/10SxxxJ —

NSP — 51048-0300, 3P

NSP J1601 D20PDY0325E,

M

DVDM ASSY

Mark No. Description Part No.

IC21 CY2081SL-655 *HC105840R

IC101 LA9701M *HC105850R

IC201 LC78652W *HC105860R

IC609 LC89170M HC10390030

IC352 M56788FP *HC105870R

IC801 M65773AFP *HC105880R

IC802 MB811171622A-100FN *HC105890R

IC803 M5M4V18165DTP-6S *HC106040R

IC612,IC904 MC74VHC541DT *HC700230R

IC608,IC611,

IC807,IC905 MC74VHCT541ADT *HC700240R

IC607 MC74VHCT574ADT *HC700250R

IC702 MN414800CSJ-07 *HC105900R

IC261,IC302 NJM2100M HC10085090

IC601 PD3410A *HU100400R

IC701 PD4995A *HU100410R

IC604 TC55V1001AF8 *HC105910R

IC606 TC7SET32F *HC105920R

IC751 TC7SH32FU *HC105930R

IC24-IC27,IC303

IC610 TC7W53FU HC007105K0

IC22 TC7WH74FU *HC105950R

IC603 VYW1701 *HC105960R

Q106,Q109 2SA1576A HX100012A0

Q105,Q114,Q251

Q602 DTA114EUA *BA000900R

Q107,Q111,Q601

51048-0300, 3P CABLE HOLDER

D20PDD0315E, JUMPER WIRE 3P

RESISTOR

OTHERS

JUMPER CONNECTOR —

PKX1001, JUMPER TERMINAL

SEMICONDUCTORS

RESISTORS

OTHERS

CABLE HOLDER —

JUMPER WIRE 3P —

SEMICONDUCTORS

TC7SHU04F *HC105940R

2SC4081 HX300012A0

DTC114EUA *BA000910R

—

—

—

Mark No. Description Part No.

Q102 HN1A01F BA10011050

Q103,Q281,

Q542,Q543 HN1B04FU *BA000920R

Q101 HN1C01F *BA000930R

Q112,Q113 HN1C01FU *BA000940R

Q108 HN1K03FU *BA000950R

Q503 RN1911 *BA000960R

D302 KV1470 *HZ400010R

D601 RB501V-40 *HZ200100R

D501,D502 RB521S-30 *HZ200110R

COILS AND FILTERS

F5050,F5090 DTF1067, CHIP BEAD *FC900220R

F4010,F4020,

F4030,F4040,

F4050 DTF1070, CHIP BEAD *FC900230R

F4060,F8330,

F9590 DTF1070, CHIP BEAD *FC900230R

NSP L304

L151

L47 VTL1084, CHIP BEAD *FC900240R

L1400 VTL1088, CHIP BEAD *FC900250R

L9490,L9500,

L9510 VTL1105, CHIP BEAD

NSP L101,L330

NSP C612 CCSRCH100D50 —

NSP

C123,C145,C21,

C282,C617 CCSRCH101J50 —

NSP C26 CCSRCH120J50 —

NSP C126,C333 CCSRCH150J50 —

NSP

C206,C210,C211

NSP C322 CCSRCH180J50 —

NSP

C116,C151,C314

NSP C152 CCSRCH221J50 —

NSP C632 CCSRCH330J50 —

NSP C209 CCSRCH331J50 —

NSP

C104-C108,

C128,C134,C297

NSP C335 CCSRCH470J50 —

NSP C122,C208 CCSRCH471J50 —

NSP C127,C334 CCSRCH5R0C50 —

NSP C124,C146 CCSRCH680J50 —

NSP C117,C240,

C352,C360 CCSRCH681J25 —

NSP

C129,C142,

C22,C405,C601

NSP

C701,C763,

C801,C802,C804

NSP

C113,C139,

C358,C368,C411

NSP

C111,C147,

C149,C205,C207

NSP

C401,C403,C407

NSP C502 CKSQYB103K50 —

NSP

C140,C223,

C224,C252,C264

NSP C312 CKSQYB105K10 —

NSP C229 CKSQYB224K16 —

NSP C217 CKSQYF105Z16 —

NSP C216,C313 CKSRYB102K50 —

NSP

C133,C136,

C203,C220,C225

NSP

C239,C320,

C321,C619,C703

NSP C722 CKSRYB103K50 —

VTL1059, CHIP COIL (1.5mH)

VTL1061, CHIP COIL (10mH)

VTL1125, CHIP COIL (8.2mH)

CAPACITORS

CCSRCH151J50 —

CCSRCH220J50 —

CCSRCH470J50 —

CEV101M10 —

CEV101M10 —

CEV220M16 —

CEV470M6R3 —

CEV470M6R3 —

CKSQYB105K10 —

CKSRYB103K50 —

CKSRYB103K50 —

—

*LU000130R

*FC900260R

—

60

Page 63

Mark No. Description Part No.

NSP

C101,C102,

C114,C118,C119

NSP

C121,C130,

C138,C204

NSP

C212,C213,

C227,C228,C231

NSP

C24,C263,

C315-C317,C332

NSP C281,C354 CKSRYB222K50 —

NSP C153,C266 CKSRYB223K25 —

NSP

C214,C251,C261

NSP C357 CKSRYB473K16 —

NSP C330 CKSRYB682K50 —

NSP

C109,C110,

C120,C131,C148

NSP

C150,C202,

C215,C221,C222

NSP

C226,C230,

C235,C265,C29

NSP

C31,C33,

C35,C359,C367

NSP

C369-C372,

C402,C404,C406

NSP C408,C410,

C412,C501 CKSRYF104Z16 —

NSP

C602-C611,

C613-C616,C618

NSP

C621-C631,

C702,C704-C714

NSP C716-C721,

C723-C725 CKSRYF104Z16 —

NSP

C761,C762,

C822,C827,C829

NSP

C832,C833,

C836,C920,C921

NSP

C834,C838,C840

NSP C143,C319,

C806-C819 CKSRYF105Z10 —

NSP

C328,C821,

C824,C825,C828

NSP C830,C837 VCG1030 (2.2mF) —

NSP C23,C299 VCG1032 (0.47mF) —

NSP VC21 VCM1013 (30pF) —

NSP R123 ACN7047 (39W±4) —

NSP R715,R716 ACN7077 (47W±4) —

NSP R531,R543,

R545,R613 DCN1094 (10kW±4) —