Marantz SR6010 Service Manual

Service

SR6010 /

U1B/N1B/N1SG

Manual

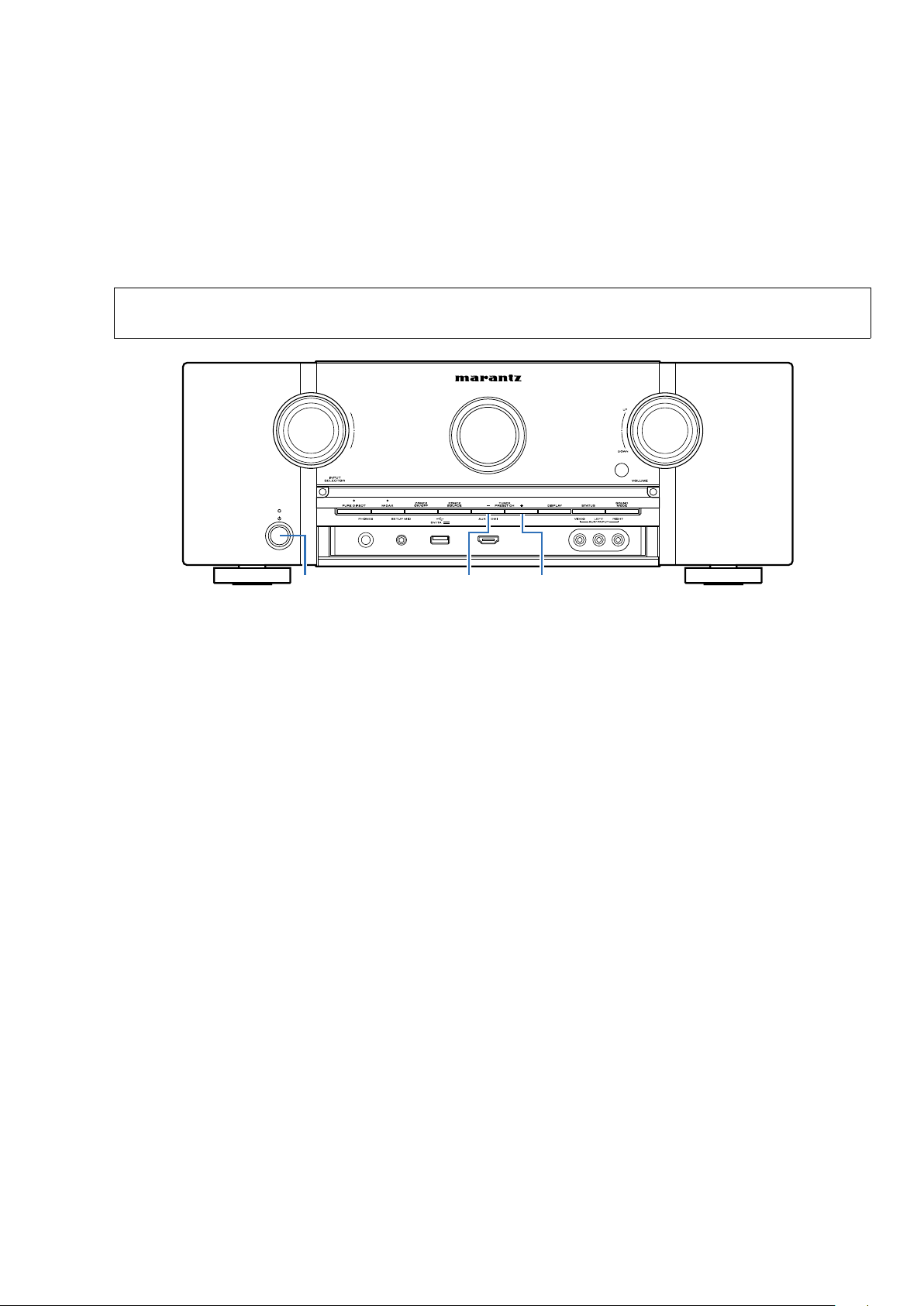

AV SURROUND RECEIVER

For purposes of improvement, specications and design are subject to change without notice.

•

Please use this service manual with referring to the operating instructions without fail.

•

Some illustrations using in this service manual are slightly different from the actual set.

•

SR6010

Copyright 2015-2018 D&M Holdings Inc. All rights reserved.

WARNING: Violators will be prosecuted to the maximum extent possible.

S0172V04DM/DG1801

Ver. 4

Please refer to the

MODIFICATION NOTICE.

Contents

ABOUT THIS MANUAL

What you can do with this manual

Using Adobe Reader (Windows version)

SAFETY PRECAUTIONS

NOTE FOR SCHEMATIC DIAGRAM

NOTE FOR PARTS LIST

Instructions for handling semi-conductors and optical unit

1. Ground for Human Body

2. Ground for Workbench

TECHNICAL SPECIFICATIONS

DIMENSION

CAUTION IN SERVICING

Initializing This Unit

JIG FOR SERVICING

DISASSEMBLY

1. FRONT PANEL ASSY

2. RADIATOR ASSY

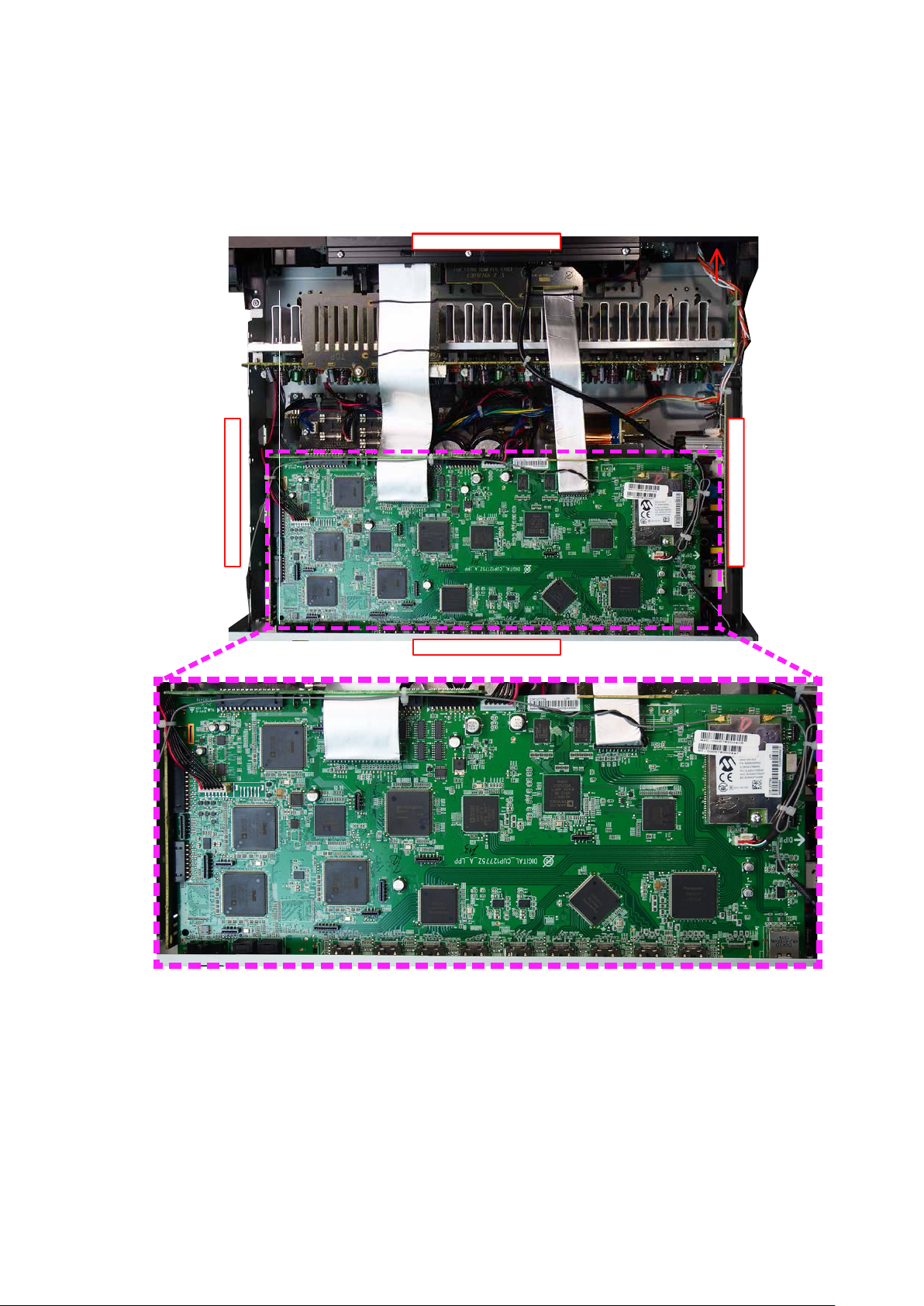

3. DIGITAL PCB

4. VIDEO PCB

5. INPUT HDAM PCB

6. SPK PCB

7. SMPS PCB

8. TRANS POWER

SPECIAL MODE

Special mode setting button

1. Version Display Mode

2. Selecting the Mode for Service-related Operations

PROTECTION DIAGRAM

2-1. DIAGNOSTIC MODE (Service Path Check Mode)

DIAGNOSTIC PATH DIAGRAM

2-2. Protection History Display Mode

2-3. 232C Standby Clear Mode

2-4. Operation Info Mode

2-5. TUNER STEP mode (E2 / E3 only)

3. PANEL / REMOTE LOCK Selection Mode

4. Protection Pass Mode

5. CY920 Reboot Mode

6. CY920 Initialization Mode

JIG FOR SERVICING

Procedure after Replacing the Printed circuit boards.

Procedure after Replacing the Microprocessor, etc.

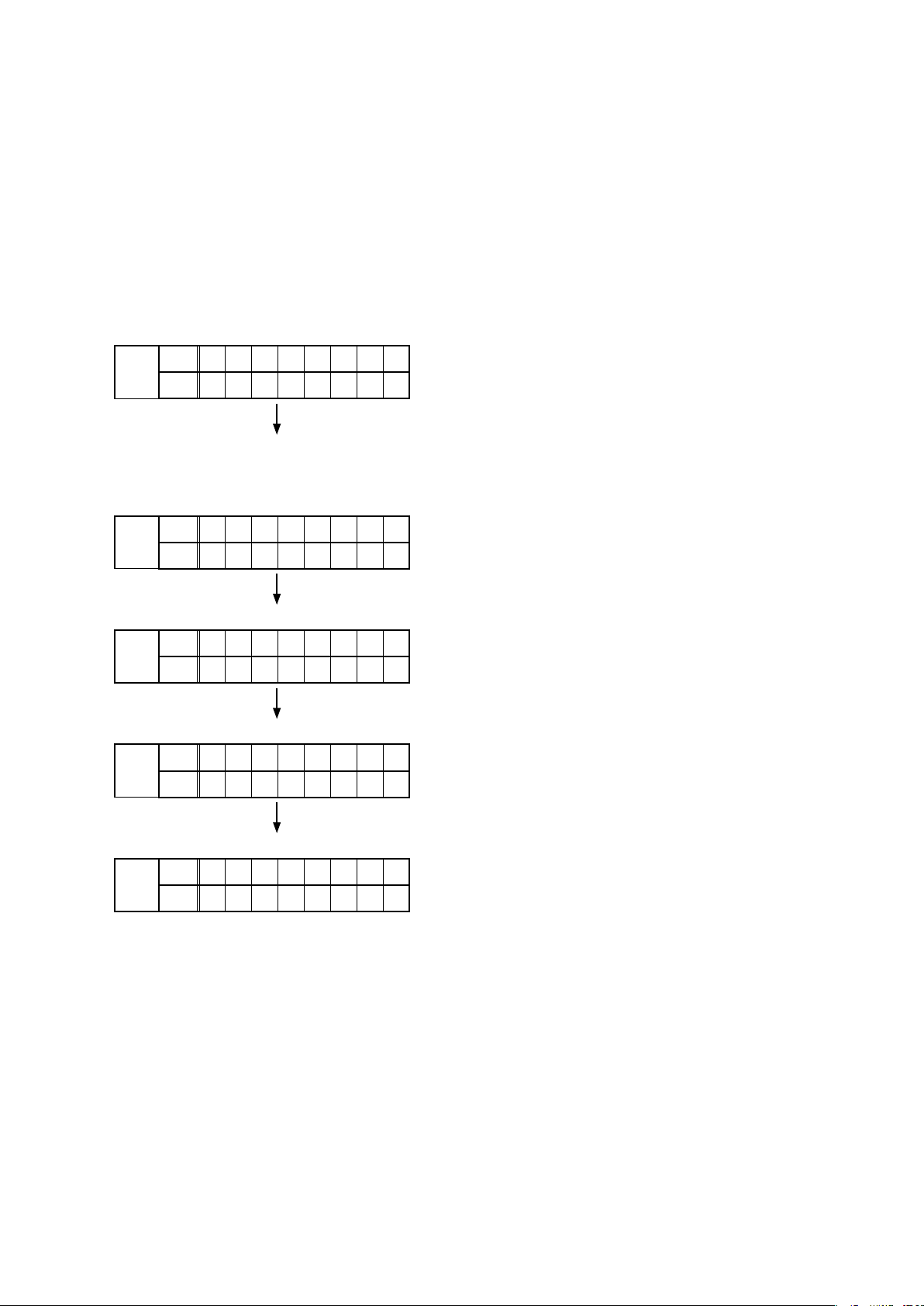

FIRMWARE UPDATE PROCEDURE

1. Updating via USB

2. Updating via DPMS

ADJUSTMENT

SURROUND MODES AND PARAMETERS

TROUBLE SHOOTING

1. POWER

2. Analog video

3. HDMI/DVI

4. AUDIO

5. Network/Bluetooth/USB

6. SMPS

..............................................................................10

..............................................................................17

...............................................................................97

..............................................................................104

................................................................................11 2

................................................................3

...........................................3

...................................4

...............................................................6

..............................................7

................................................................7

......................................................7

........................................................7

.....................................................9

...........................................................11

.................................................................11

..................................................................11

..........................................................................12

............................................................14

.................................................................14

.......................................................................15

..........................................................................16

...............................................................16

...........................................................................17

....................................................................17

.........................................................................18

..................................................18

........................................................19

...........23

.....................................................24

..............25

............................................29

......................................66

................................................67

........................................................68

......................................69

............................70

........................................................71

..........................................................71

..................................................72

..................................................................73

...........76

..............76

............................................77

...............................................................77

............................................................86

...........................................................................93

..................................94

................................................................97

......................................................................98

.........................................................................102

..................................................107

...7

Audio Check PASS

CLOCK FLOW & WAVE FORM IN DIGITAL BLOCK

LEVEL DIAGRAM

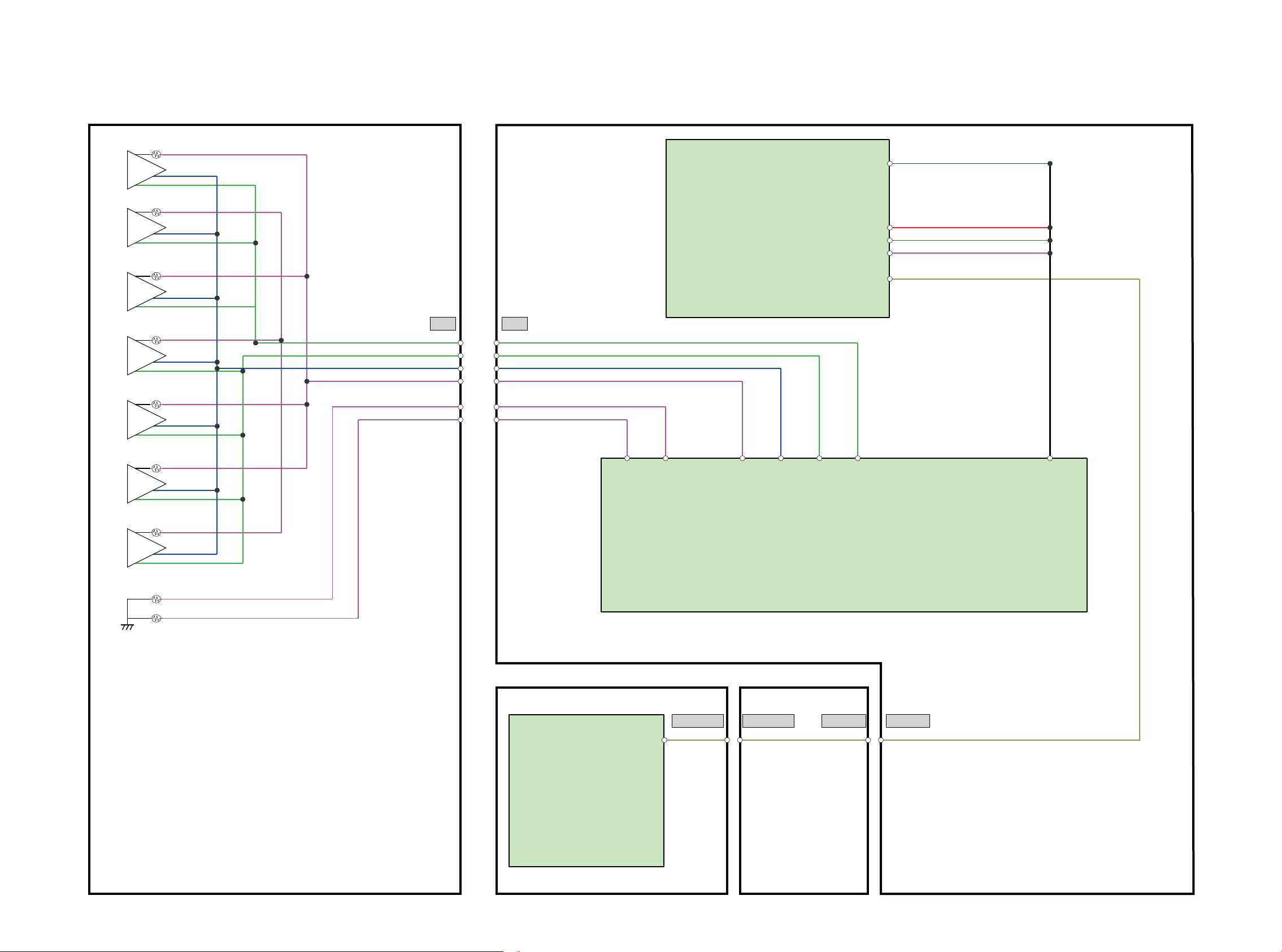

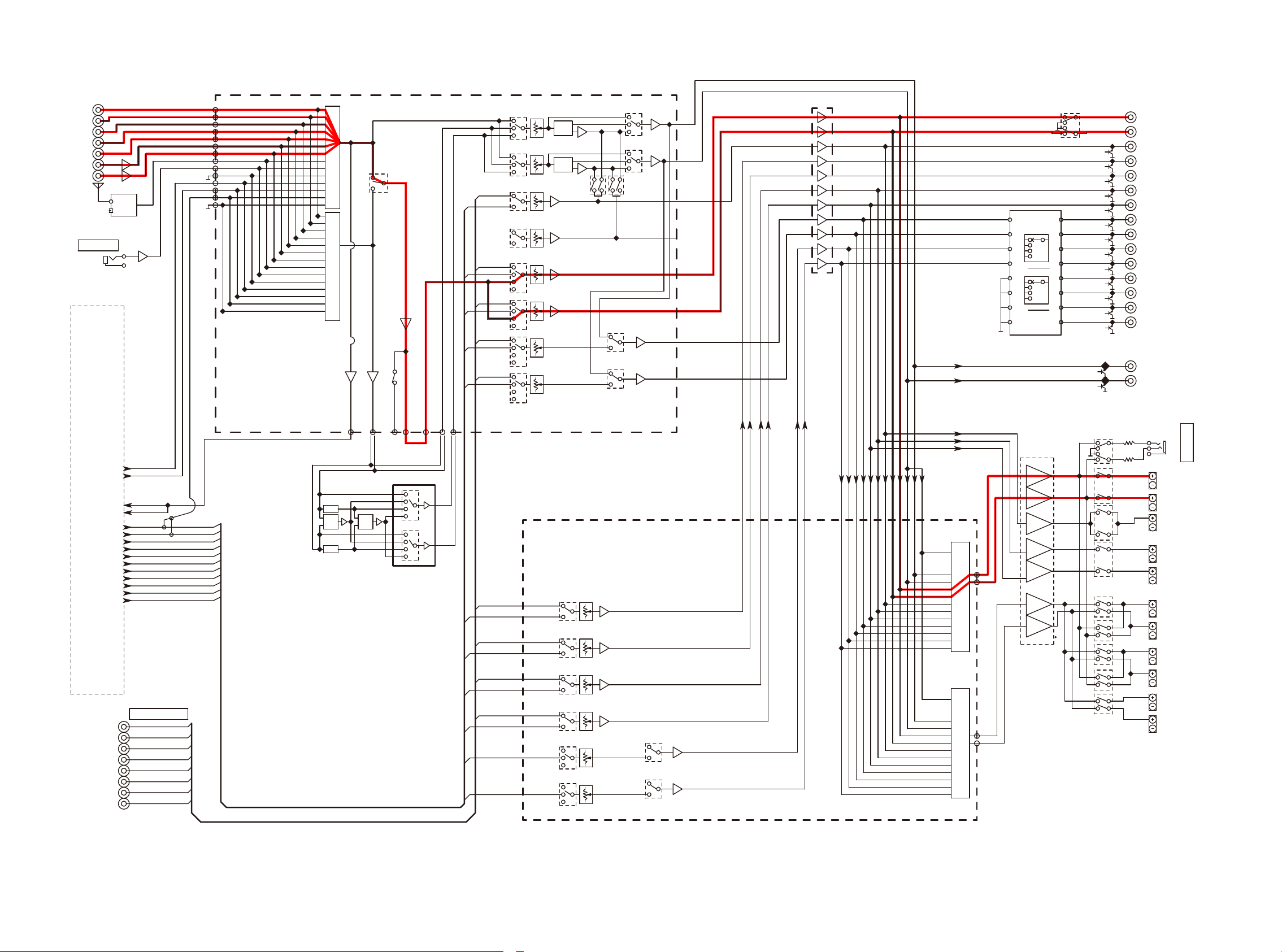

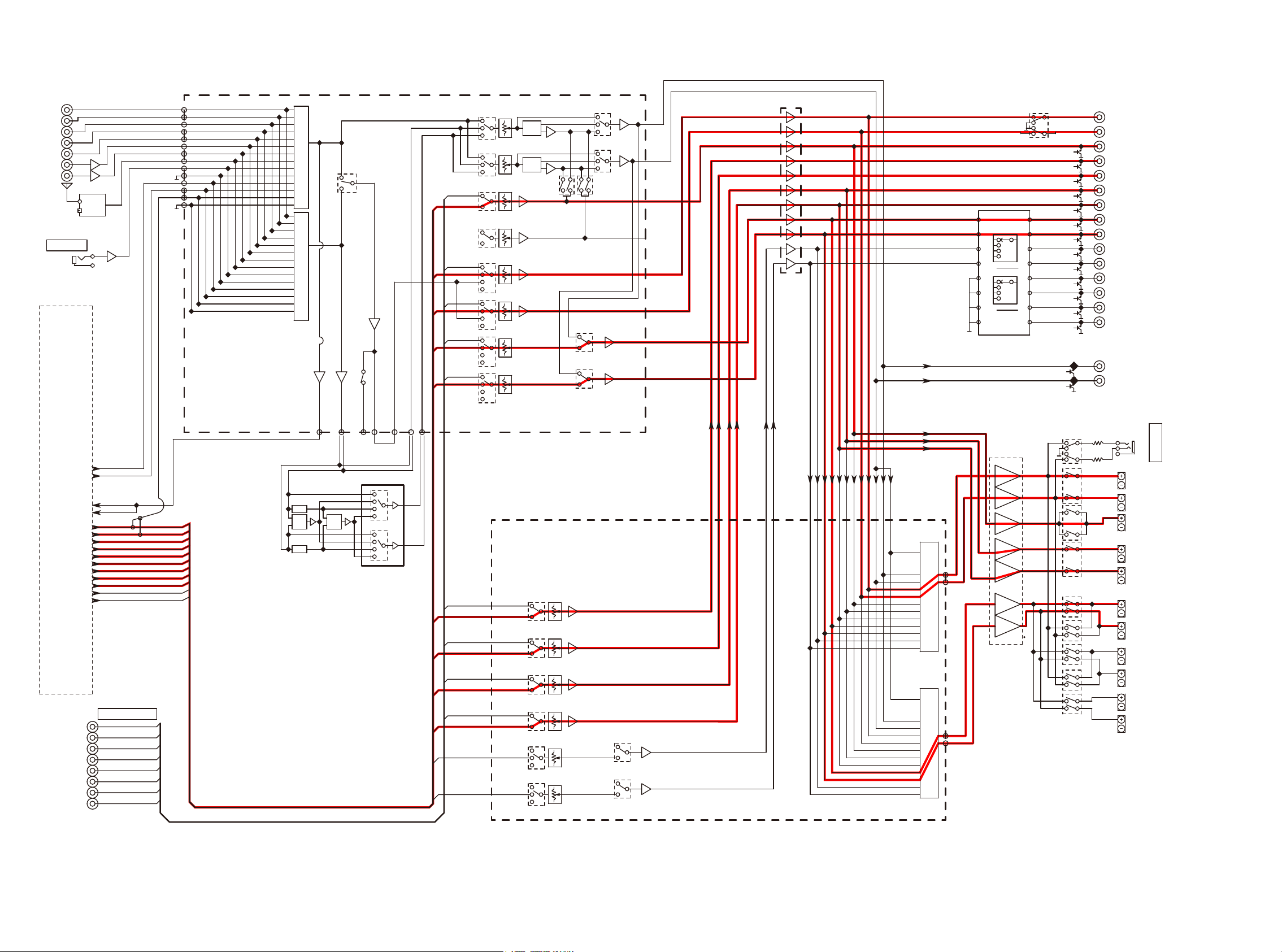

BLOCK DIAGRAM

POWER DIAGRAM

WIRING DIAGRAM

PRINTED CIRCUIT BOARDS

SCHEMATIC DIAGRAMS (01/38)

SCH01_DIGITAL CONNECT

SCH02_DIGITAL POWER

SCH03_MAIN CPU

SCH04_EXPANDER

SCH05_CPU LEVEL CHG

SCH06_DIR

SCH07_AUDIO PLD

SCH08_DSP1

SCH09_DSP2

SCH10_DSP3

SCH11_DSP4

SCH12_ADC

SCH13_ZONE DAC

SCH14_CY920

SCH15_VIDEO DECODER

SCH16_HDMI SW2

SCH17_HDMI SW1

SCH18_VSP & IP & OSD

SCH19_VIDEO PLD

SCH20_HDMI TX & SCALER

SCH21_INPUT

SCH22_PREOUT

SCH23_HDAM CNT & F-HDMI

SCH24_A-VIDEO

SCH25_RC-5

SCH26_RS232C & TRIGGER

SCH27_SIDE CNT

SCH28_FRONT CNT

SCH29_MAIN DAC1

SCH30_MAIN DAC2

SCH31_SPK

SCH32_REGULATOR & TUNER

SCH33_7CH AMP 1

SCH34_7CH AMP 2

SCH35_FRONT

SCH36_HDAM 1

SCH37_HDAM 2

SCH38_SMPS

EXPLODED VIEW

PACKING VIEW

SEMICONDUCTORS

....................................................................................175

1. IC's

2. FL DISPLAY

.................................................................11 4

.....................................................................11 6

...................................................................122

..................................................................126

..................................................................127

....................................................128

.............................................135

....................................................135

........................................................136

.................................................................137

................................................................138

........................................................139

............................................................................140

...............................................................141

.........................................................................142

.........................................................................143

.........................................................................144

.........................................................................145

..........................................................................146

................................................................147

.......................................................................148

.......................................................149

................................................................150

................................................................151

.........................................................152

................................................................153

...................................................154

........................................................................155

.....................................................................156

...............................................157

....................................................................158

..........................................................................159

....................................................160

...................................................................161

...............................................................162

...............................................................163

...............................................................164

............................................................................165

...............................................166

................................................................167

................................................................168

.......................................................................169

....................................................................170

....................................................................171

.........................................................................172

....................................................................173

.......................................................................174

................................................................175

.......................................................................195

...................11 5

2

ABOUT THIS MANUAL

Read the following information before using the service manual.

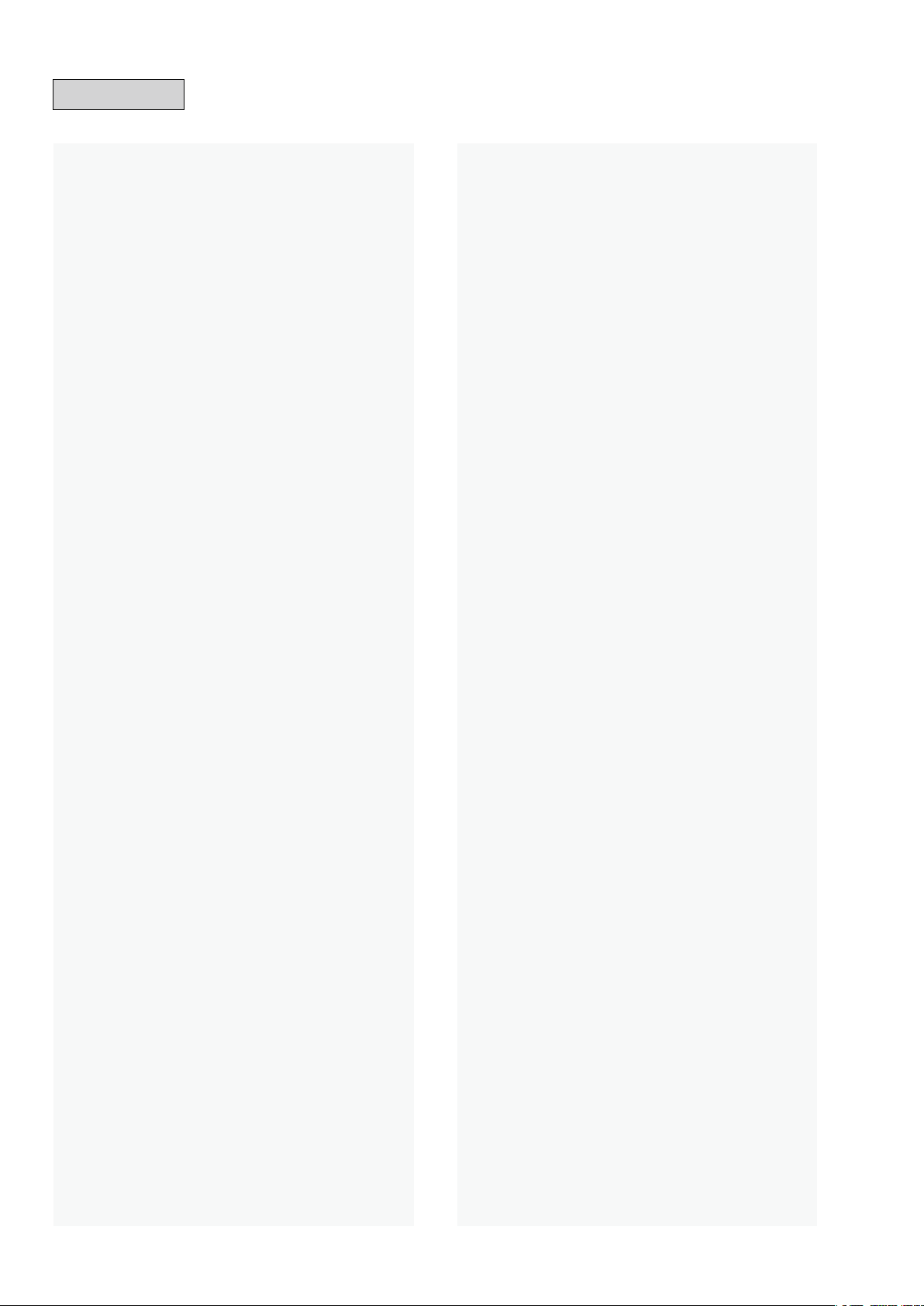

What you can do with this manual

Search for a Ref. No. (phrase)

(Ctrl+Shift+F)

You can use the search function in Acrobat Reader to

search for a Ref. No. in schematic diagrams, printed

wiring circuit diagrams, block diagrams, and parts

lists.

1. Press

• The Search window appears.

2. Enter the Ref. No. you want to search for in the

Search window, and then click the

• A list of search results appears.

Ctrl+Shift+F

Shift

Ctrl

on the keyboard.

F

Search

button.

Jump to the target of a schematic diagram

connector

Click the Ref. No. of the target connector in the red

box around a schematic diagram connector.

•The screen jumps to the target connector.

CP401

v

CP106

3. Click an item on the list.

• The screen jumps to the page for that item, and the

search phrase is displayed.

• Page magnication stays the same as before the

jump.

3

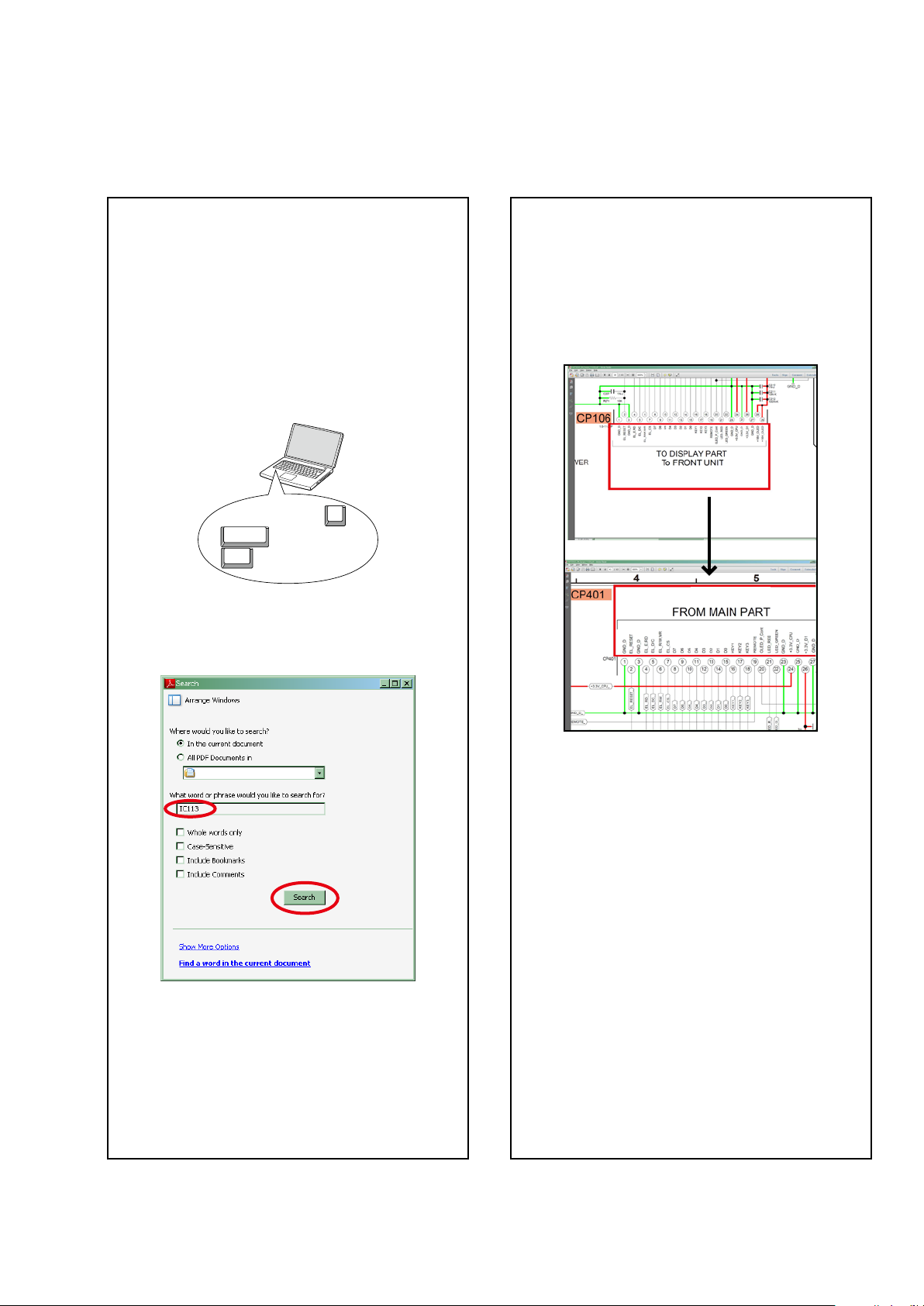

Using Adobe Reader (Windows version)

Add notes to this data (Sign)

The Sign function lets you add notes to the data in

this manual.

Save the le once you have nished adding notes.

[Example using Adobe Reader X]

"View"

On the

• The Sign pane appears.

[Example using Adobe Reader 9]

On the

menu, click

"Document"

"Sign"

menu, click

.

"Sign"

.

Magnify schematic / printed circuit board

diagrams - 1

(Ctrl+Space, mouse operation)

Ctrl+Space

Press

mouse to select the area you want to view.

• The selected area is magnied.

• When you want to move the area shown, hold

down

• When you want to show a full page view, press

Ctrl+0

on the keyboard and drag the

0

Ctrl Space

Space

and drag the mouse.

on the keyboard.

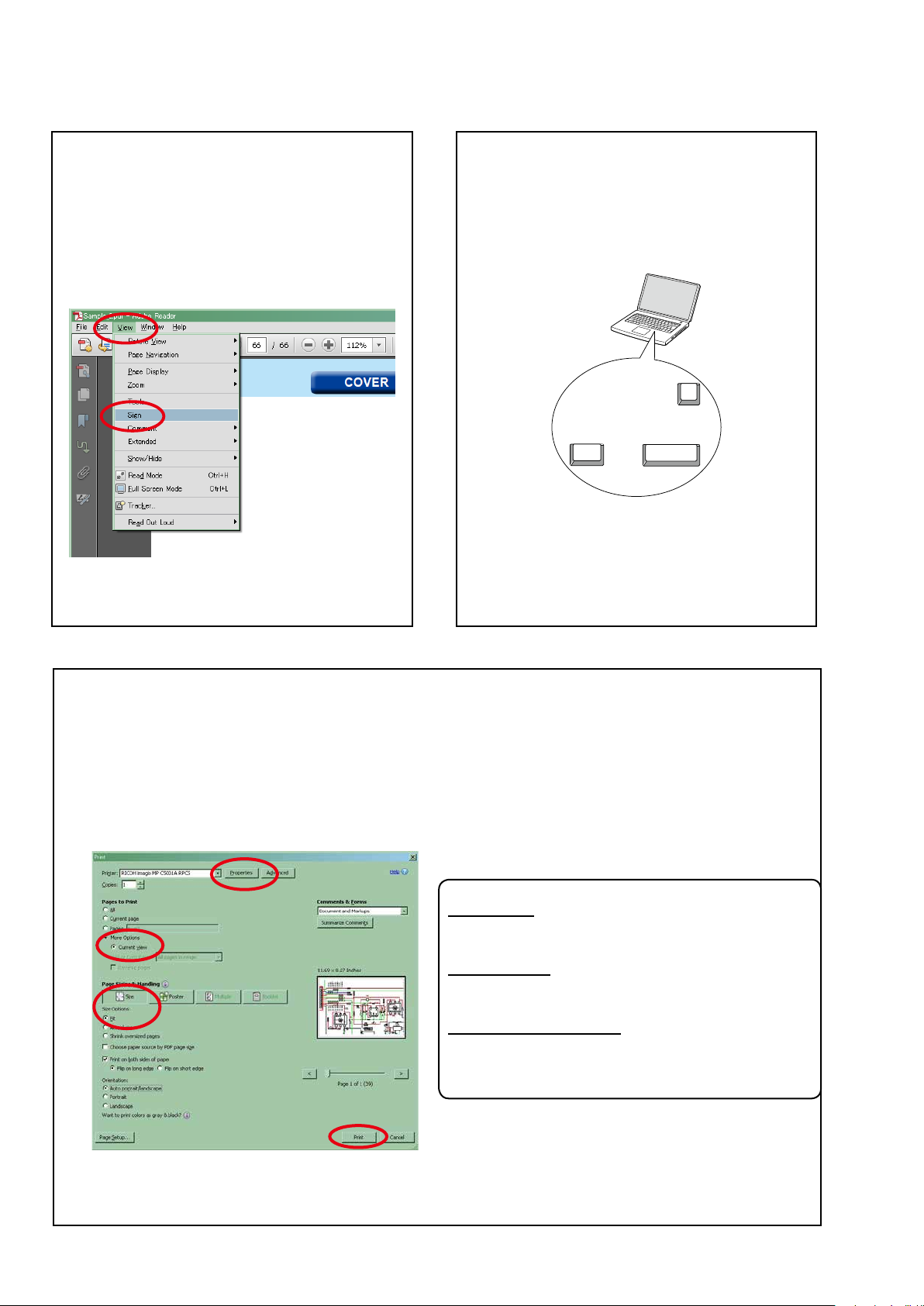

Print a magnied part of the manual

The Properties dialog box and functions will vary depending on your printer.

1. Drag the mouse to magnify the part you want to print.

2. On the

3. Congure the following settings in the Print dialog box.

"File"

menu, click

"Print"

.

• Properties

Click this button and check that the printer is set to a

suitable paper size.

• Page to print

Select the following checkbox.

More Options

"

• Page Sizing & Handling

Select the following checkbox.

Size

"

Size Options

" / "

Current View

" : "

" : "

Fit

"

"

4. Click the

Print

button to start printing.

4

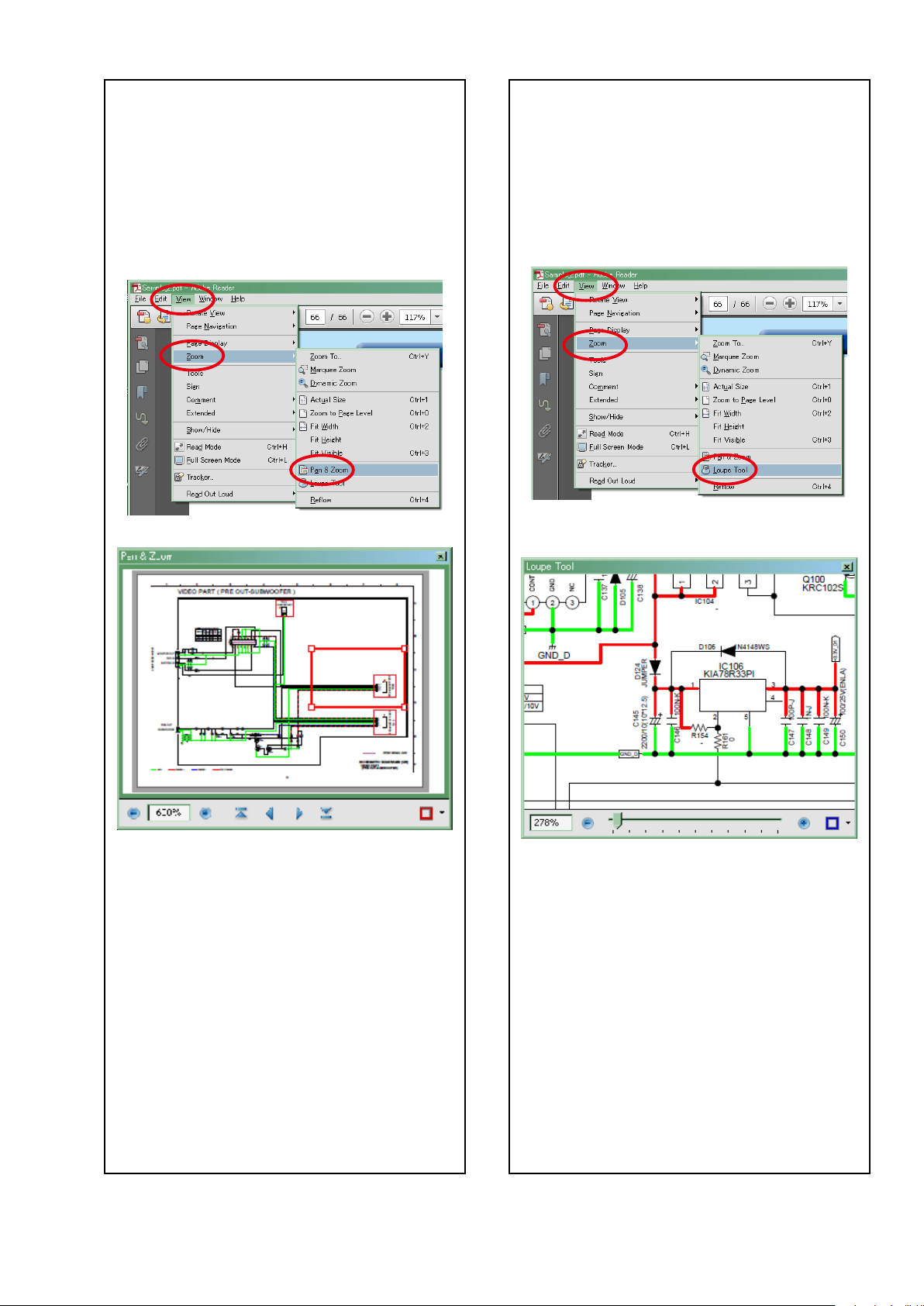

Magnify schematic / printed circuit board

diagrams - 2

(Pan & Zoom function)

The Pan & Zoom function lets you see which part of

a magnied diagram is being shown in a separate

window.

[Example using Adobe Reader X]

"View"

On the

"Pan & Zoom"

click

menu, point to

.

"Zoom"

, and then

Magnify schematic / printed circuit board

diagrams - 3

(Loupe Tool function)

The Loupe Tool function lets you magnify a specic

part of a diagram in a separate window.

[Example using Adobe Reader X]

On the

"Loupe Tool"

click

"View"

menu, point to

.

"Zoom"

, and then

• The Pan & Zoom window appears on the screen.

[Example using Adobe Reader 9]

"Tools"

On the

and then click

menu, point to

"Pan & Zoom Window"

"Select & Zoom"

.

,

• The Loupe Tool window appears on the screen.

[Example using Adobe Reader 9]

"Tools"

On the

and then click

menu, point to

"Loupe Tool Window"

"Select & Zoom"

.

,

5

SAFETY PRECAUTIONS

The following items should be checked for continued protection of the customer and the service technician.

leakage current check

Before returning the set to the customer, be sure to carry out either (1) a leakage current check or (2) a line to chassis

resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the

power cord is less than 460 kohms, the set is defective.

Be sure to test for leakage current with the AC plug in both polarities, in addition, when the set's power is in each state

(on, off and standby mode), if applicable.

CAUTION

Please heed the following cautions and instructions during servicing and

inspection.

◎ Heed the cautions!

Cautions which are delicate in particular for servicing are

labeled on the cabinets, the parts and the chassis, etc. Be

sure to heed these cautions and the cautions described in

the handling instructions.

◎ Cautions concerning electric shock!

(1) An AC voltage is impressed on this set, so if you touch

internal metal parts when the set is energized, you

may get an electric shock. Avoid getting an electric

shock, by using an isolating transformer and wearing

gloves when servicing while the set is energized, or

by unplugging the power cord when replacing parts,

for example.

(2) There are high voltage parts inside. Handle with extra

care when the set is energized.

◎ Caution concerning disassembly and assembly!

Through great care is taken when parts were

manufactured from sheet metal, there may be burrs on

the edges of parts. The burrs could cause injury if ngers

are moved across them in some rare cases. Wear gloves

to protect your hands.

◎ Use only designated parts!

The set's parts have specic safety properties (re

resistance, voltage resistance, etc.). Be sure to use parts

which have the same properties for replacement. The

burrs have the same properties. In particular, for the

important safety parts that are indicated by the z mark

on schematic diagrams and parts lists, be sure to use the

designated parts.

◎ Be sure to mount parts and arrange the wires

as they were originally placed!

For safety seasons, some parts use tapes, tubes or other

insulating materials, and some parts are mounted away

from the surface of printed circuit boards. Care is also

taken with the positions of the wires by arranging them

and using clamps to keep them away from heating and

high voltage parts, so be sure to set everything back as it

was originally placed.

◎ Make a safety check after servicing!

Check that all screws, parts and wires removed or

disconnected when servicing have been put back in

their original positions, check that no serviced parts have

deteriorate the area around. Then make an insulation

check on the external metal connectors and between the

blades of the power plug, and otherwise check that safety

is ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet, disconnect

the antenna, plugs, etc., and on the power. Using a 500V

insulation resistance tester, check that the insulation

resistance value between the inplug and the externally

exposed metal parts (antenna terminal, headphones

terminal, input terminal, etc.) is 1MΩ or greater. If it is

less, the set must be inspected and repaired.

CAUTION

Concerning important safety

parts

Many of the electric and the structural parts used in the

set have special safety properties. In most cases these

properties are difcult to distinguish by sight, and the use

of replacement parts with higher ratings (rated power

and withstand voltage) does not necessarily guarantee

that safety performance will be preserved. Parts with

safety properties are indicated as shown below on the

wiring diagrams and the parts list in this service manual.

Be sure to replace them with the parts which have the

designated part number.

(1) Schematic diagrams Indicated by the z mark.

(2) Parts lists Indicated by the z mark.

The use of parts other than the designated parts could

cause electric shocks, res or other dangerous situations.

6

NOTE FOR SCHEMATIC DIAGRAM

WARNING:

Parts indicated by the z mark have critical characteristics. Use ONLY replacement parts recommended by the manufacturer.

CAUTION:

Before returning the set to the customer, be sure to carry out either (1) a leakage current check or (2) a line to chassis resistance check. If

the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the power cord is less than 460 kohms, the set

is defective.

WARNING:

DO NOT return the set to the customer unless the problem is identied and remedied.

NOTICE:

ALL RESISTANCE VALUES IN OHM. k=1,000 OHM / M=1,000,000 OHM

ALL CAPACITANCE VALUES ARE EXPRESSED IN MICRO FARAD, UNLESS OTHERWISE INDICATED. P INDICATES MICRO-MICRO FARAD. EACH

VOLTAGE AND CURRENT ARE MEASURED AT NO SIGNAL INPUT CONDITION. CIRCUIT AND PARTS ARE SUBJECT TO CHANGE WITHOUT

PRIOR NOTICE.

NOTE FOR PARTS LIST

1. Parts indicated by

2. When ordering a part, make a clear distinction between "1" and "I" (i) to avoid mis-supplying.

3. A part ordered without specifying its part number can not be supplied.

4. Part indicated by " ★ " mark is not illustrated in the exploded view.

WARNING: Parts indicated by the z mark have critical characteristics. Use ONLY replacement parts recommended by the manufacturer.

"nsp"

on this table cannot be supplied.

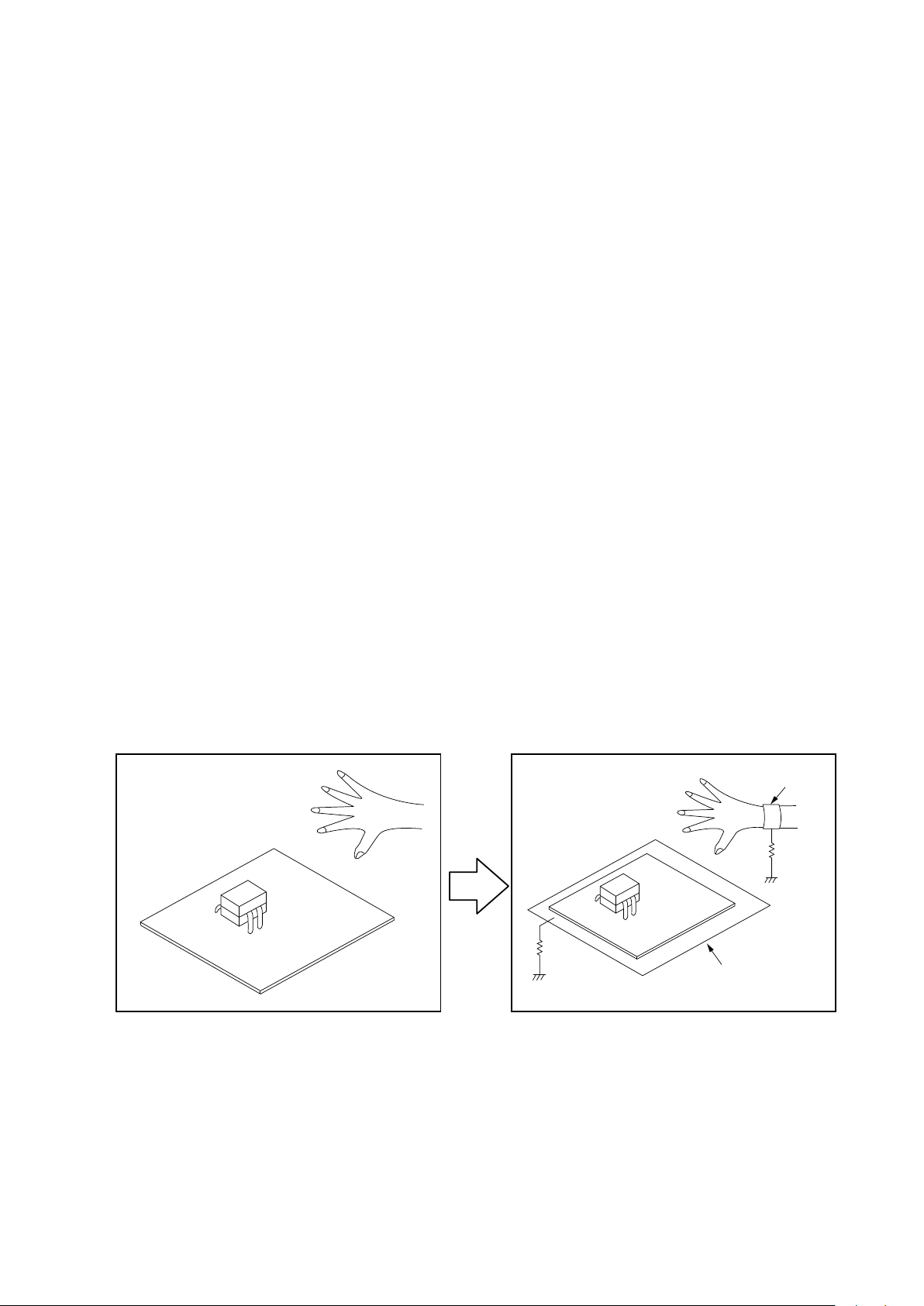

INSTRUCTIONS FOR HANDLING SEMI-CONDUCTORS AND OPTICAL UNIT

Electrostatic breakdown of the semi-conductors or optical pickup may occur due to a potential difference caused by

electrostatic charge during unpacking or repair work.

1. Ground for Human Body

Be sure to wear a grounding band (1 MΩ) that is properly grounded to remove any static electricity that may be charged

on the body.

2. Ground for Workbench

Be sure to place a conductive sheet or copper plate with proper grounding (1 MΩ) on the workbench or other surface,

where the semi-conductors are to be placed. Because the static electricity charge on clothing will not escape through the

body grounding band, be careful to avoid contacting semi-conductors with your clothing

<Incorrect>

CBA

<Correct>

1MΩ

Grounding Band

1MΩ

CBA

Conductive Sheet or

Copper Plate

7

Personal notes:

8

TECHNICAL SPECIFICATIONS

nAudio section

• Power amplier

Rated output :

Front :

110 W + 110 W ( 8 Ω, 20 Hz - 20 kHz with 0.08 % T.H.D.)

150 W + 150 W ( 6 Ω, 1 kHz with 0.7 % T.H.D.)

Center :

110 W ( 8 Ω, 20 Hz - 20 kHz with 0.08 % T.H.D.)

150 W ( 6 Ω, 1 kHz with 0.7 % T.H.D.)

Surround :

110 W + 110 W ( 8 Ω, 20 Hz - 20 kHz with 0.08 % T.H.D.)

150 W + 150 W ( 6 Ω, 1 kHz with 0.7 % T.H.D.)

Surround back / Height1 / Front wide :

110 W + 110 W ( 8 Ω, 20 Hz - 20 kHz with 0.08 % T.H.D.)

150 W + 150 W ( 6 Ω, 1 kHz with 0.7 % T.H.D.)

Output connectors : 4 - 16 Ω

nAnalog section

Input sensitivity/Input impedance : 200 mV / 47 kΩ

Frequency response : 10 Hz - 100 kHz — +1, -3 dB (Direct mode)

S/N : 100 dB (IHF-A, Direct mode)

Distortion : 0.005 % (20 Hz – 20 kHz) (Direct mode)

Rated output : 1.2 V

nDigital section

D/A output : Rated output — 2V (at 0 dB playback)

Digital input : Format — Digital audio interface

nPhono equalizer section

Input sensitivity : 2.5 mV

RIAA deviation : ±1 dB (20 Hz to 20 kHz)

S/N ratio : 74 dB (IHF-A)

Distortion factor : 0.03 % (1 kHz, 3 V)

nVideo section

• Standard video connectors

Input/output level and impedance : 1 Vp-p, 75 Ω

Frequency response : 5 Hz - 10 MHz — 0, –3 dB

• Color component video connector

Input/output level and impedance : Y signal — 1 Vp-p, 75 Ω

Frequency response : 5 Hz - 60 MHz — 0, –3 dB

Total harmonic distortion — 0.008 % (1 kHz, 0 dB )

S/N ratio — 102 dB

Dynamic range — 100 dB

PB / CB signal — 0.7 Vp-p, 75 Ω

PB / CB signal — 0.7 Vp-p, 75 Ω

nTuner section

(Note : μV at 75 Ω, 0 dBf = 1 x 10

Reception frequency range : FM 87.5 MHz - 107.9 MHz (for U)

Effective sensitivity : FM 1.2 μV (12.8 dBf)

50 dB sensitivity : MONO ― 2.8 μV (20.2 dBf)

S/N ratio : MONO ― 70 dB (IHF–A weighted, Direct mode)

Distortion : MONO ― 0.7 % (1 kHz)

STEREO ― 67 dB (IHF–A weighted, Direct mode)

FM 87.5 MHz - 108.0 MHz (for N)

AM 520 kHz - 1710 kHz (for U)

AM 522 kHz - 1611 kHz (for N)

AM 18 μV

SRETEO ― 1.0 % (1 kHz)

–15

W)

nWireless LAN section

Network type (wireless LAN standard) : Conforming to IEEE 802.11b

Security : WEP 64 bit, WEP 128 bit

Radio frequency : 2.4 GHz

No. of channels : 1 - 11 ch (for U)

z1 The Wi-Fi® CERTIFIED Logo and the Wi-Fi CERTIFIED On-Product Logo

are registered trademarks of the Wi-Fi Alliance.

WPA/WPA2-PSK (AES)

WPA/WPA2-PSK (TKIP)

1 - 13 ch (for N)

Conforming to IEEE 802.11g

Conforming to IEEE 802.11n

(Wi-Fi® compliant)z1

nBluetooth section

Communications system : Bluetooth Version 2.1 + EDR

Transmission power : Maximum 2.5 mW (Class 2)

Maximum communication range : Approx. 32.8 ft/10 m in line of sightz2

Frequency band : 2.4 GHz band

Modulation scheme : FHSS (Frequency-Hopping Spread Spectrum)

Supported proles : A2DP (Advanced Audio Distribution Prole)1.2

Corresponding codec : SBC, AAC

Transmission range (A2DP) : 20 Hz - 20,000 Hz

z2 The actual communication range varies depending on the inuence of

such factors as obstructions between devices, electromagnetic waves

from microwave ovens, static electricity, cordless phones, reception

sensitivity, antenna performance, operating system, application

software etc.

(Enhanced Data Rate)

AVRCP (Audio Video Remote Control Prole)1.4

nGeneral

Power supply : (for U) : AC 120 V, 60 Hz

Power consumption : 650 W

Power consumption in standby mode : 0.2 W

Power consumption in CEC standby mode : 0.5 W

Power consumption in network standby mode : 2.7 W

For purposes of improvement, specications and design are subject to

change without notice.

(for N) : AC 230 V, 50 Hz / 60 Hz

9

1 3/8

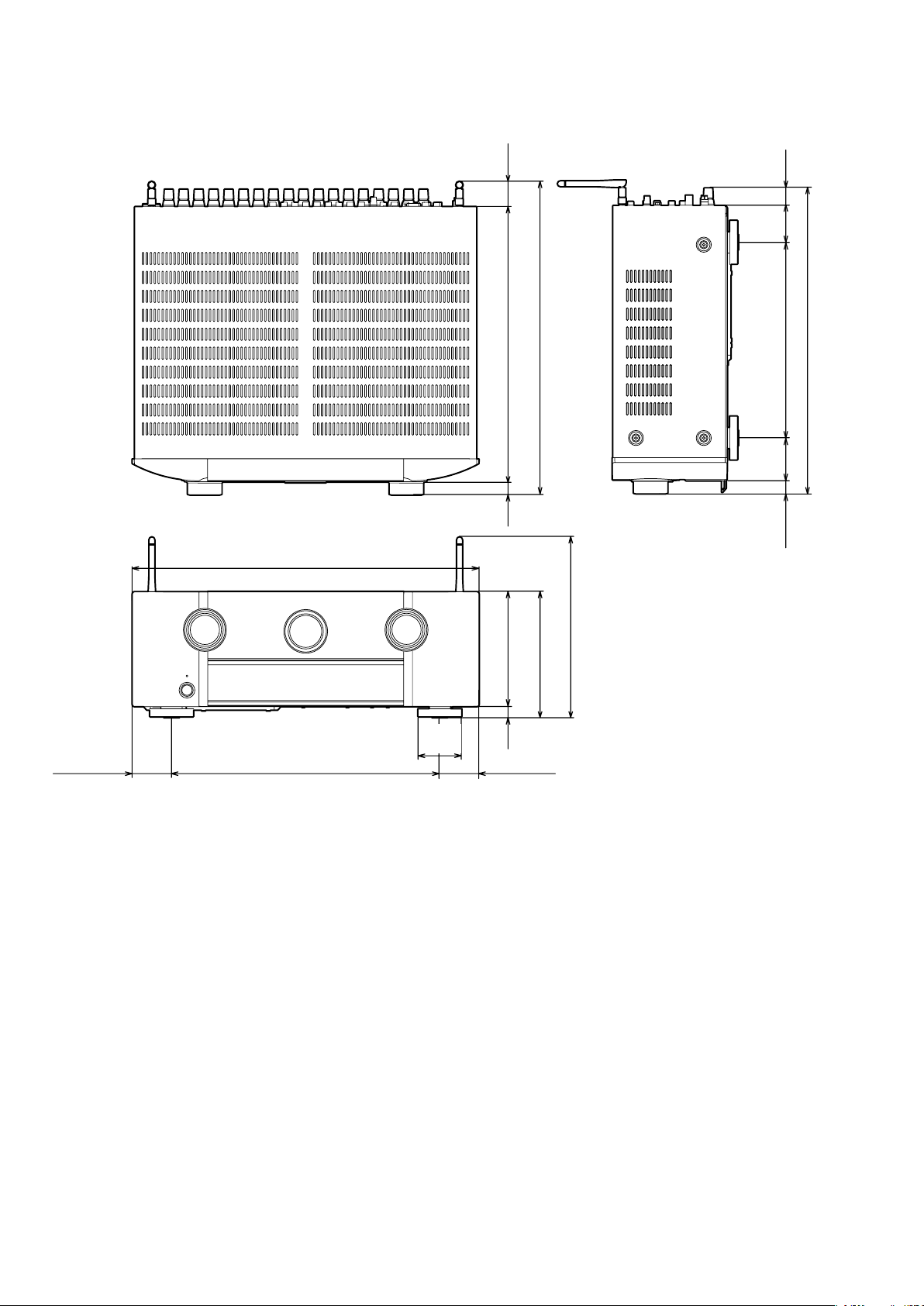

DIMENSION

Unit : in. (mm)

Weight : 25 lbs 9 oz (11.6 kg)

17 3/8 (440)

(32)

13 3/4 (349)

15 3/4 (398)

3/4

(18)

7/8

(22)

(47)

1 7/8

9 7/8 (248)

15 3/8 (388)

(53)

2 1/8

3/4

(18)

2 (50)

2 1/4

(55)

5 7/8 (147)

5/8

(14)

2 (50)13 1/2 (340)

9 1/8 (229)

6 3/8 (161)

10

CAUTION IN SERVICING

Initializing This Unit

Make sure to initialize this unit after replacing the microcomputer or any peripheral equipment, or the digital PCB.

1. Press the power button to turn off the power.

2. While holding down buttons "

to turn on the power.

3. Release the buttons after conrming that the display ashes at 1-second intervals.

* The unit is initialized.

TUNER PRESET -

TUNER PRESET +

" and "

" simultaneously, press the power button

NOTE:

• If the unit fails to enter the service mode in step 3, repeat the procedure from step 1.

• Initializing the device restores the customized settings to the factory settings. Write down your settings in advance and

recongure the settings after initialization.

X

TUNER

PRESET CH -

PRESET CH +

JIG FOR SERVICING

Use the following jigs (extension cable kit) when repairing the PCBs.

Order with your dealer for the jigs your dealer if necessary.

8U-110084S : EXTENSION UNIT KIT : 1Set

8U-110136S : EXTENSION UNIT KIT : 1Set

(See page 73)

TUNER

11

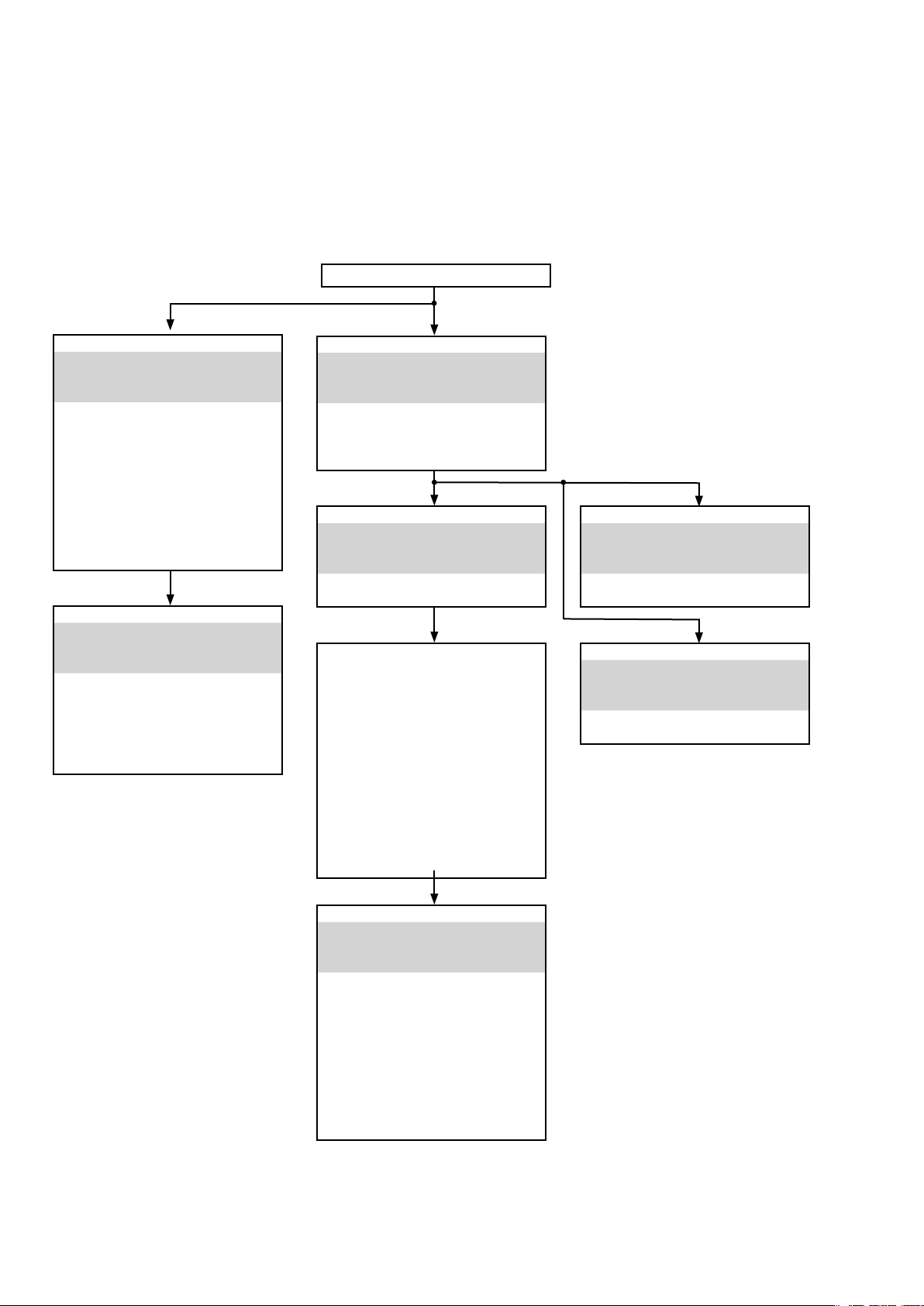

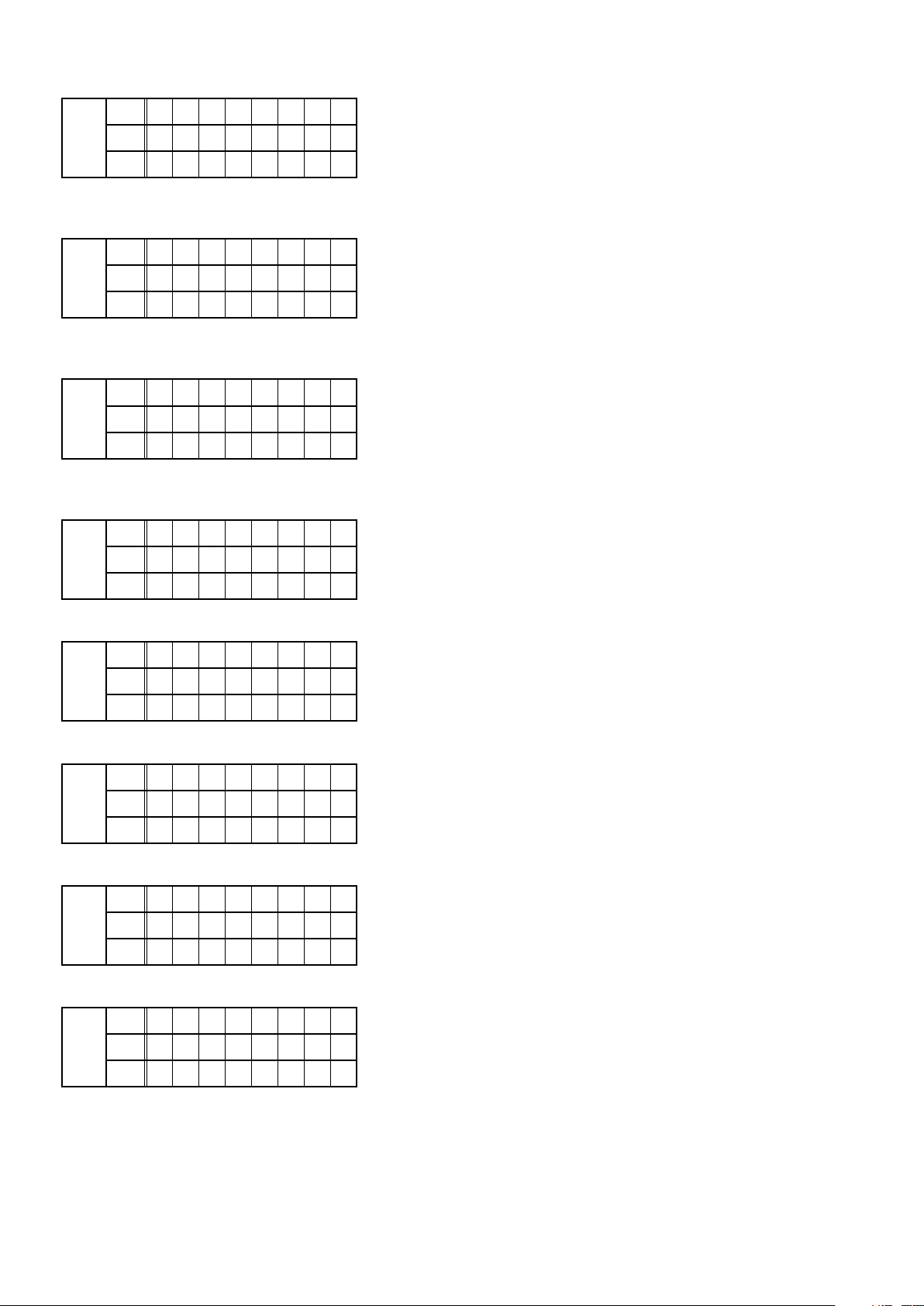

DISASSEMBLY

• Remove each part following the ow below.

• Reassemble the removed parts in the reverse order.

• Read "Precautions During Work" before reassembling the removed parts.

• If wire bundles are removed or moved during adjustment or part replacement, reshape the wires after completing

the work. Failure to shape the wires correctly may cause problems such as noise.

TOP COVER

FRONT PANEL ASSY

See "DISASSEMBLY"

1. FRONT PANEL ASSY

and "EXPLODED VIEW"

FRONT PCB

Ref. No. of EXPLODED VIEW : C1

GUIDE TOP PCB

Ref. No. of EXPLODED VIEW : C10

FRONT CONT FFC PCB

Ref. No. of EXPLODED VIEW : C4

F_HDMI PCB

Ref. No. of EXPLODED VIEW : C5

HP PCB

Ref. No. of EXPLODED VIEW : C45

RADIATOR ASSY

See "DISASSEMBLY"

2. RADIATOR ASSY

and "EXPLODED VIEW"

GUIDE L PCB

Ref. No. of EXPLODED VIEW : C7

AMP PCB

Ref. No. of EXPLODED VIEW : C8

HEATSINK

Ref. No. of EXPLODED VIEW : M14

DIGITAL PCB ASSY

See "DISASSEMBLY"

3. DIGITAL PCB ASSY

and "EXPLODED VIEW"

DIGITAL PCB

Ref. No. of EXPLODED VIEW : C21

CY920 MODULE ASSY

Ref. No. of EXPLODED VIEW : C22

VIDEO PCB ASSY

See "DISASSEMBLY"

4. VIDEO PCB ASSY

and "EXPLODED VIEW"

VIDEO PCB

Ref. No. of EXPLODED VIEW : C20

INPUT HDAM PCB ASSY

See "DISASSEMBLY"

5. INPUT HDAM PCB ASSY

and "EXPLODED VIEW"

INPUT PCB

Ref. No. of EXPLODED VIEW : C39

CONNECT-2 PCB

Ref. No. of EXPLODED VIEW : C44

CONNECT-3 PCB

Ref. No. of EXPLODED VIEW : C43

CONNECT-4 PCB

Ref. No. of EXPLODED VIEW : C42

HDAM PCB

Ref. No. of EXPLODED VIEW : C41

SMPS PCB

See "DISASSEMBLY"

7. SMPS PCB

and "EXPLODED VIEW"

SMPS PCB

Ref. No. of EXPLODED VIEW : C11

MAIN TRANS

See "DISASSEMBLY"

8. MAIN TRANS

and "EXPLODED VIEW"

MAIN TRANS

Ref. No. of EXPLODED VIEW : C19

SPK PCB ASSY

See "DISASSEMBLY"

6. SPK PCB ASSY

and "EXPLODED VIEW"

SPK PCB

Ref. No. of EXPLODED VIEW : C29

SPK FW PCB

Ref. No. of EXPLODED VIEW : C@@

FUSE PCB

Ref. No. of EXPLODED VIEW : C27

FRT CNT PCB

Ref. No. of EXPLODED VIEW : C26

SIDE CONT PCB

Ref. No. of EXPLODED VIEW : C28

12

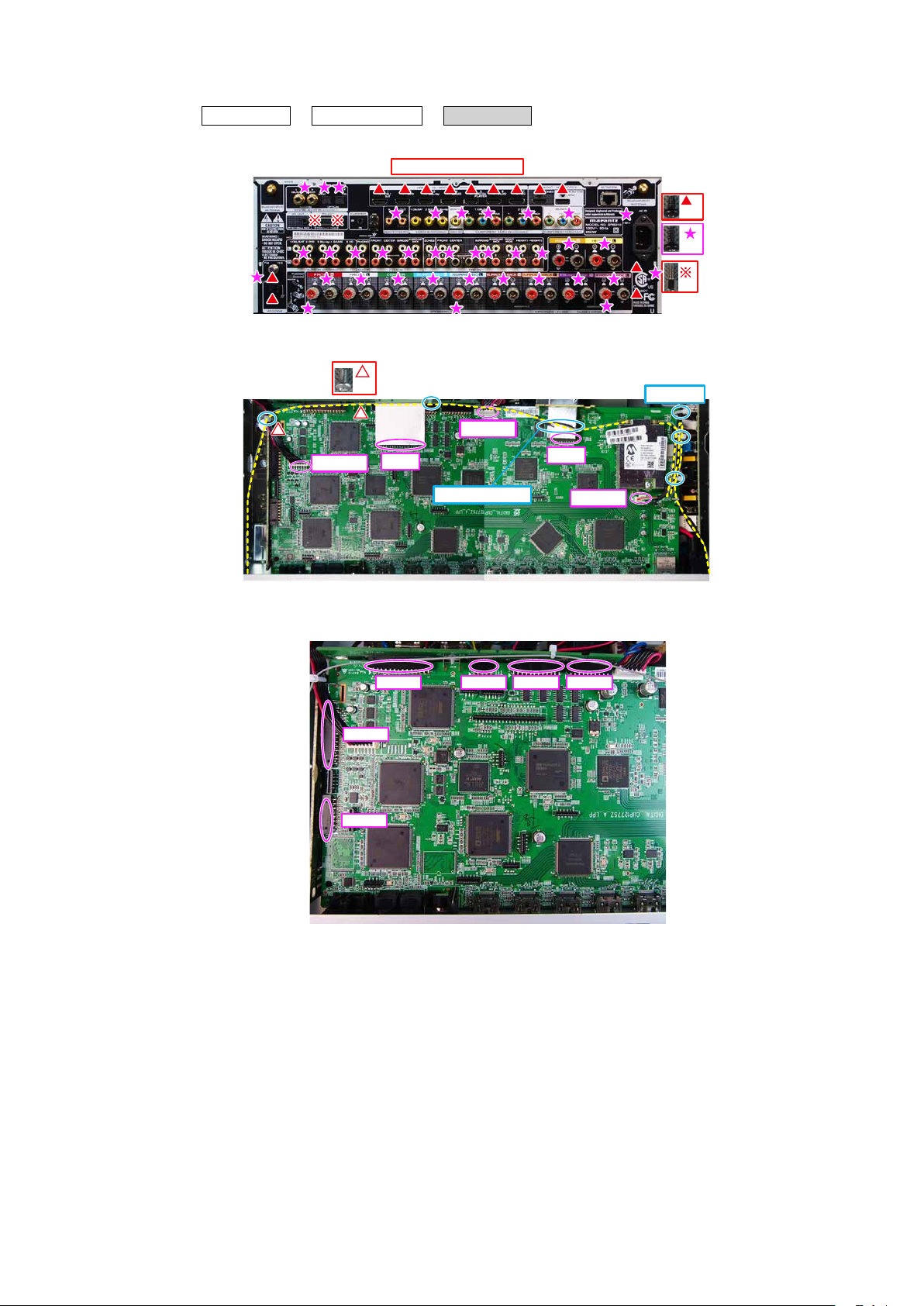

Explanatory Photos for DISASSEMBLY

• For the shooting direction of each photos used in this manual, see the photo below.

• A, B, C and D in the photo below indicate the shooting directions of photos.

• The photographs with no shooting direction indicated were taken from the top of the unit.

• Photos of SR6010 U are used in this manual.

The viewpoint of each photograph

(Shooting direction : X) [View from the top]

↓Shooting direction: B↓

↓Shooting direction: D↓

↑Shooting direction: A↑

Front side

↑Shooting direction: C↑

13

1. FRONT PANEL ASSY

Proceeding : TOP COVER

(1) Remove the screws.

(2) Remove the screws. Cut the wire clamp, then remove the connector. Remove the FFC.

FRONT PANEL ASSY

→

x5

View from the bottom

CN102

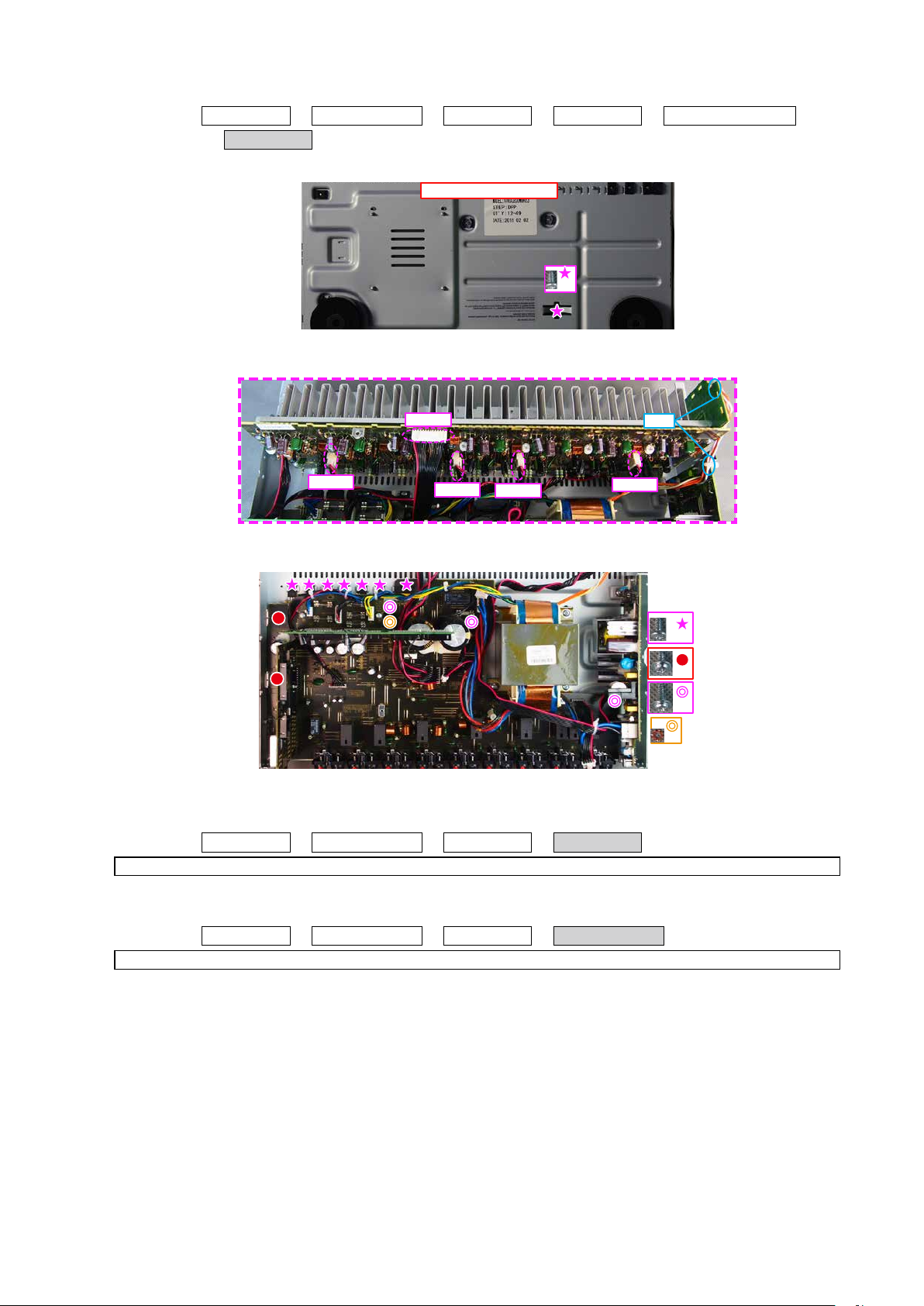

2. RADIATOR ASSY

Proceeding : TOP COVER

(1) Remove the screws.

x1

FFC

FRONT PANEL ASSY→RADIATOR ASSY

→

Shooting direction: A

x3

CUT x4

FFC

CN104

(2) Cut the wire clamp, then remove the connector wire. Remove the screws.

CUT

CN461

x2 x2

↑Shooting direction: D↑

CN701 CN702 CN704

CN703

↑Shooting direction: C↑

CUT

CN704

14

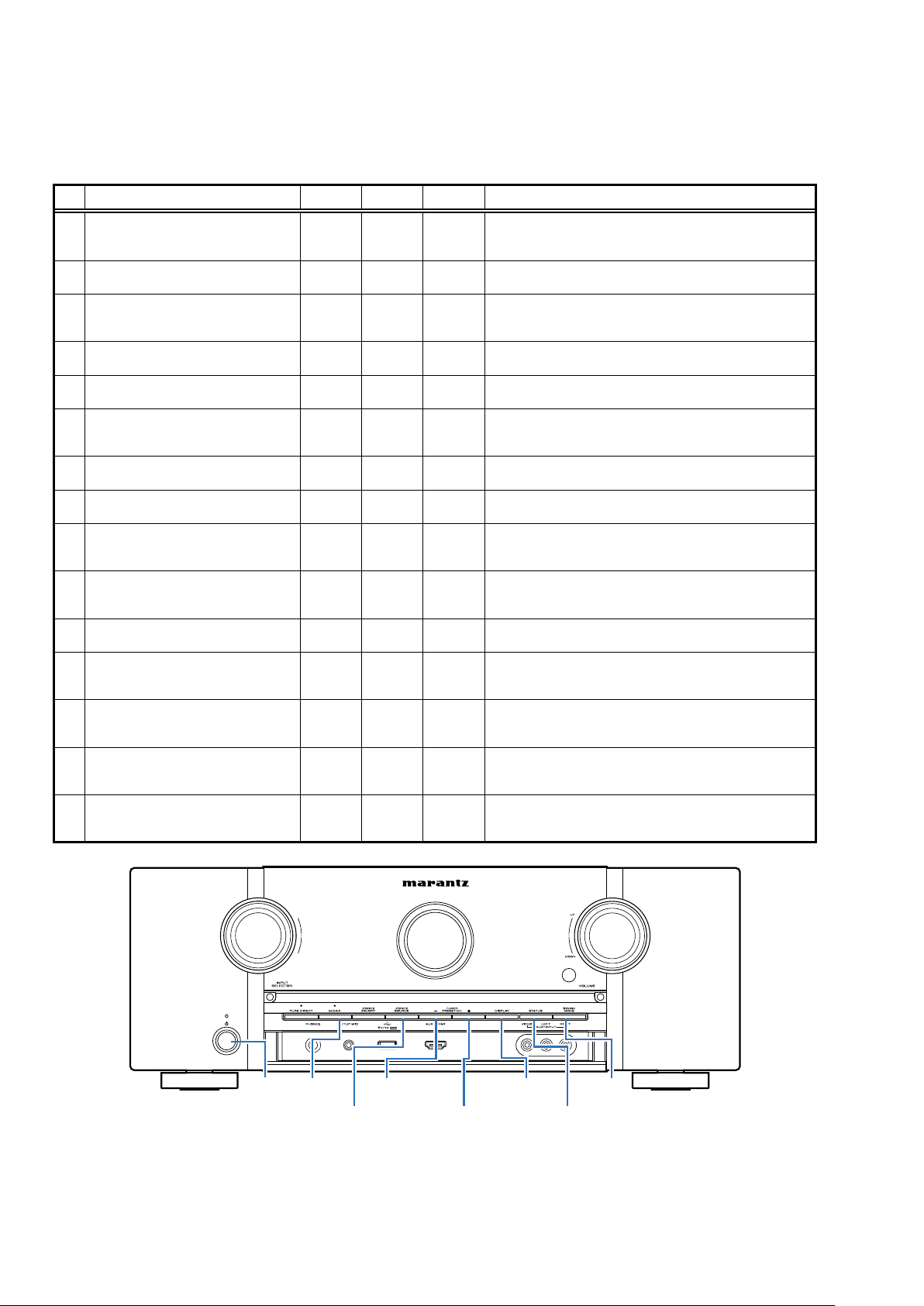

3. DIGITAL PCB

Proceeding : TOP COVER

(1) Remove the screws.

(2) Cut the wire clamp, then remove the connector. Remove the FFC.

BACK CHASSIS

→

DIGITAL PCB

→

Shooting direction: A

x13

x37

x2

(3) Remove the connector.

CN704

BN23A

BN27A

x2

CN903

FFC

FFC

STYLE PIN

BN24A BN26A BN25A BN21A

CUTx5

CN321

15

4. VIDEO PCB

Proceeding : TOP COVER

(1) Cut the wire clamp, then remove the connector. PCB HOLDER を外します。

BACK CHASSIS

→

BN28B

BN27B

DIGITAL PCB

→

BN21B

VIDEO PCB

→

PCB HOLDER

5. INPUT HDAM PCB

Proceeding : TOP COVER

(1) Remove the screws. Remove the connector.

BACK CHASSIS

→

DIGITAL PCB

→

VIDEO PCB

→

From AMP PCB

CUT x4

INPUT HDAM PCB

→

x1

BN24C

BN64C

BN23C

BN26C

STYLE PIN

CN706

16

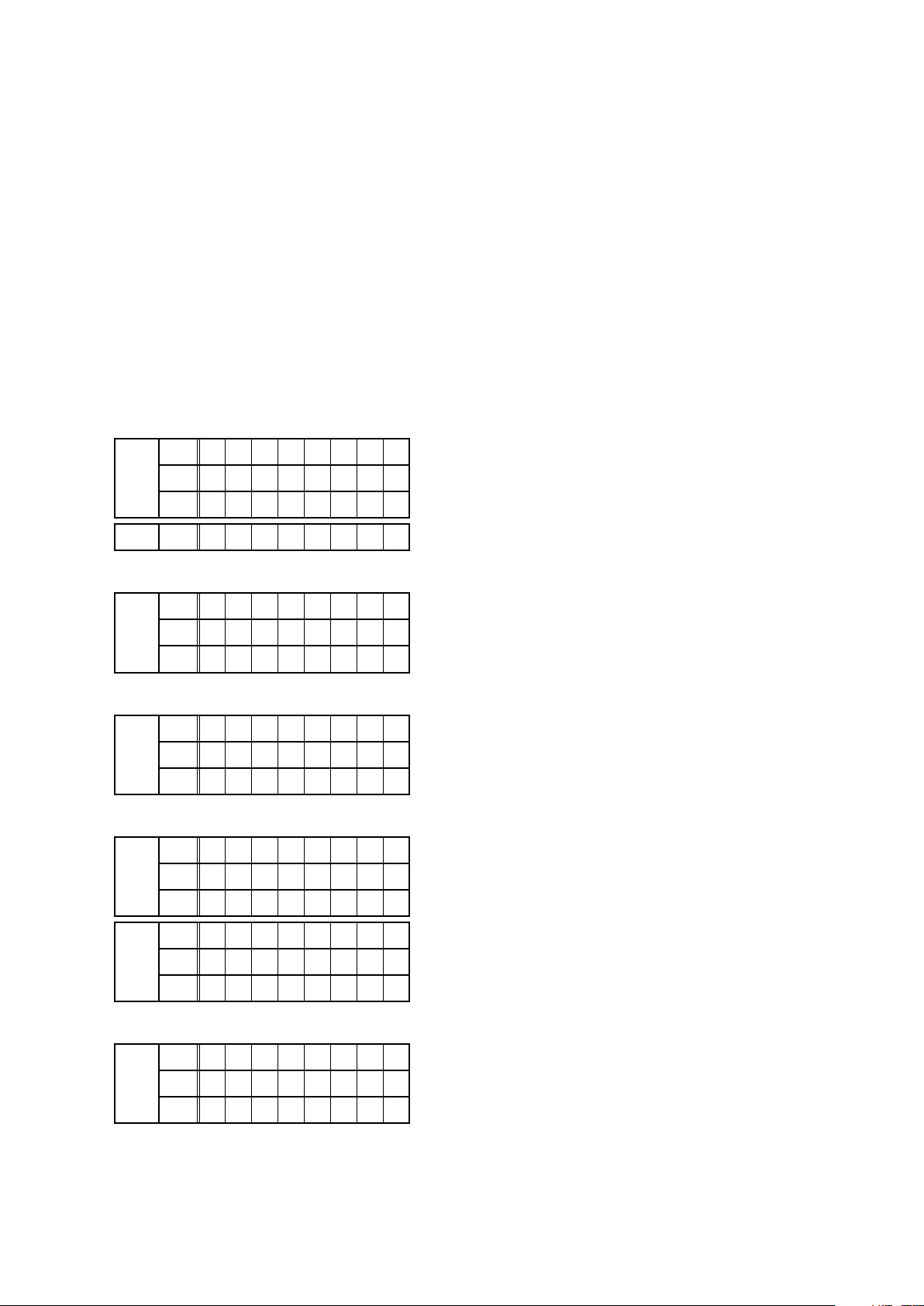

6. SPK PCB

Proceeding : TOP COVER

SPK PCB

→

(1) Remove the screws.

(2) Cut the wire clamp, then remove the connector.

BACK CHASSIS

→

DIGITAL PCB

→

View from the bottom

→

VIDEO PCB

x1

INPUT HDAM PCB

→

(3) Remove the screws.

7. SMPS PCB

Proceeding : TOP COVER

CN461

CN701

BACK CHASSIS

→

See "EXPLODED VIEW" for instructions on removing the SMPS PCB.

CN703

DIGITAL PCB

→

CN702

→

SMPS PCB

CUT

CN704

x1

x7

x2

x3

8. TRANS POWER

Proceeding : TOP COVER

See "EXPLODED VIEW" for instructions on removing the transformer (TRANS).

BACK CHASSIS

→

DIGITAL PCB

→

17

TRANS POWER

→

SPECIAL MODE

Special mode setting button

ABC

b

AB

b

AB

b

No. Mode Button A Button B Button C Descriptions

f

X

M-DAX

SOURCE

TUNER

PRESET CH -

PRESET CH +

TUNER

DIMMER SOUND

MODE

STATUSZONE2

1. Version Display Mode

1.1. Actions

Version information is displayed when the device is started in this mode.

1.2. Starting up

While holding down buttons "DIMMER" and "

then press the "STATUS" button to display the information in section 1.3 on the display.

The version list is also displayed on GUI while the version is displayed on the display.

b

1.3. Display Order

Error information("See "1.4. Error display") → q Model destination information, Serial Number

→ w Firmware Package Version → e Main µ-com, Main 1st Boot Loader Version → r DSP1/2/3/4 ROM

→ t Audio, Video PLD → y GUI SFLASH → u Ethernet 1st Boot Loader, Hardware ID

→ i Ethernet 2nd Boot Loader, Rhapsody Flag → o Ethernet IMAGE → Q0 Ethernet MAC ADDRESS information

→ Q1 BT MAC ADDRESS information → Q2 MultEQ Pro APP (Displayed when Audyssey Pro is complete)

→ Q3 MultEQ Pro ICL (Displayed when Audyssey Pro is complete)

Model destination information, Serial Number:

q

L1

S R 6 0 1 0 U

FLD

L2

L3

S N - * * * *

* * * * * *

STATUS

" simultaneously, press the power button to turn on the power.

FLD L1

Firmware Package Version:

w

FLD

Main µ-com, Main 1st Boot Loader Version:

e

FLD

DSP1/2/3/4 ROM :

r

FLD

FLD

S R 6 0 1 0 N

L1

P A C K A G E

L2

L3

L1

M A i n

L2

L3

B L - * * . * *

L1

D 1

L2

L3

D 2

L1

D 3

L2

L3

D 4

* * * *

* * * *

–

* * . * *

–

* * . * *

–

* * . * *

–

* * . * *

Audio, Video PLD :

t

L1

A . P L D

FLD

L2

L3

* * . * *

19

GUI SFLASH :

y

L1

G U I

FLD

L2

@ @ $ \ * * * *

L3

@ : Model code, $ : Brand code, \ : Region code (U=1, N=2, K=5, F=4)

Ethernet 1st Boot Loader, Hardware ID :

u

L1

N E T F B L

FLD

L2

* * * * * * * *

L3

AA : Hardware ID

Ethernet 2nd Boot Loader, Rhapsody Flag :

i

L1

N E T S B L

FLD

L2

* * * * * * * *

L3

* * * * * - B B

BB : Rhapsody Flag

Ethernet IMAGE :

o

L1

N E T I M G

FLD

L2

* * * * * * * *

L3

* * * * *

- A A

Ethernet MAC ADDRESS information:

Q0

L1

N E T M A C

FLD

L2

L3

BT MAC ADDRESS information:

Q1

L1

B T M A C

FLD

L2

L3

MultEQ Pro APP :

Q2

L1

E Q A P P

FLD

L2

* * . * * . * *

L3

MultEQ Pro ICL :

Q3

L1

E Q I C L

FLD

L2

* * . * * . * *

L3

* * * * * *

- * * * * * *

* * * * * *

- * * * * * *

. * * * *

. * * * *

20

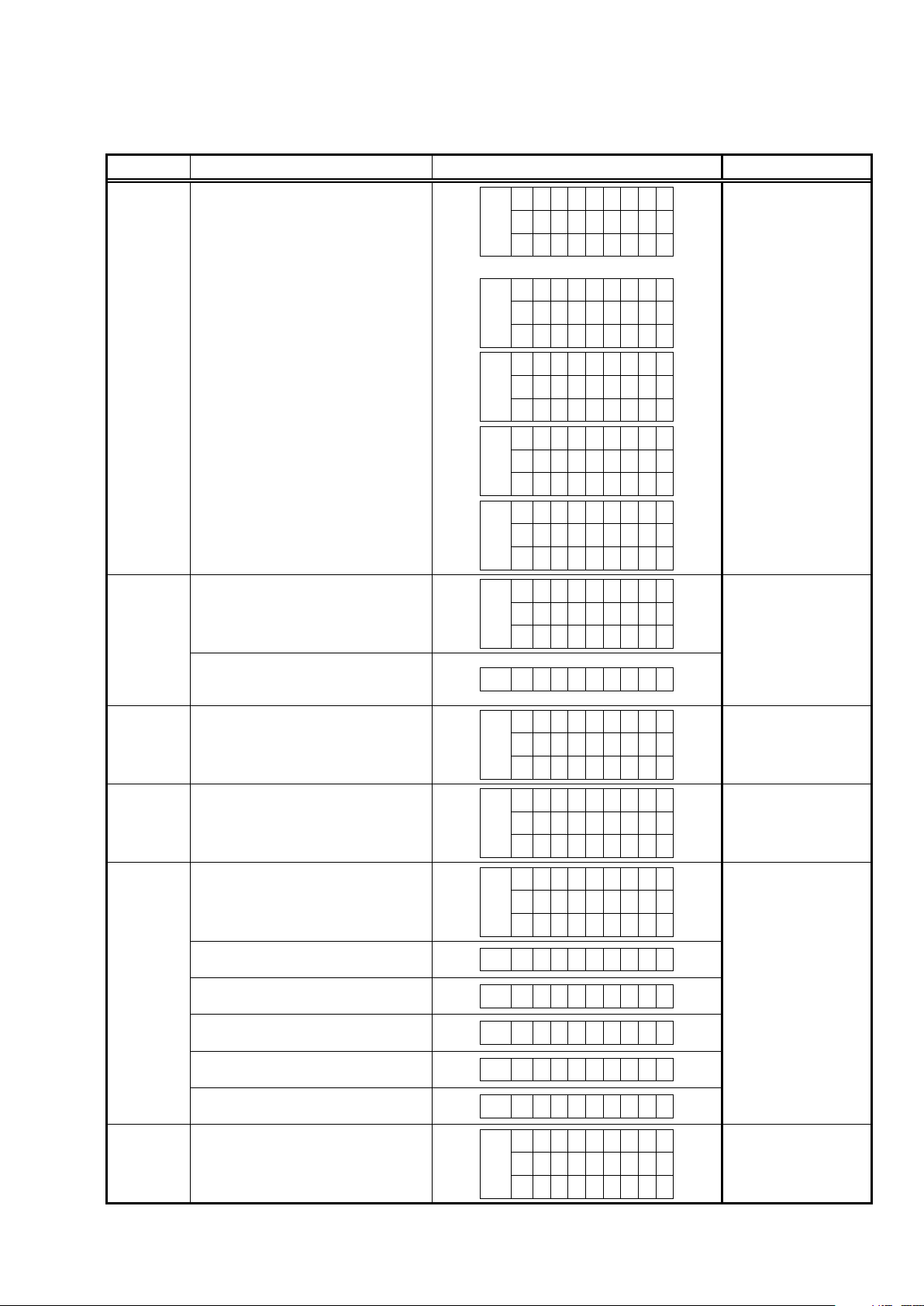

1.4. Error display

See the table below for descriptions of the displayed errors and countermeasures for these.

If multiple errors occur, only one item is displayed.

The priority order is w, e, r, t, y, q.

Condition States Display TROUBLE SHOOTING

L1

F I R M

FLD

L2

E R R O R

L3

q

Firm Check

NG

(*:1/2/3/4)

w

IP SCALER

NG

e

GUI Serial

Flash NG

The model name, brand name and region

information written in the rmware are

compared to the region settings in the

PCB. This error is displayed if the information does not match.

" ▲ " or " ▼ " is displayed as the rst character if the rmware is not correct (see the

illustrations on the right).

An error occurs in Loopback Test of the

DDR memory which is performed during

the initial setting of i/p Scaler (ADV8003).

During the initial setting of i/p Scaler (

ADV8003 ) , there is not the reply of the

Loopback Test result of the DDR memory .

If the Main CPU version is not supported

by the GUI Serial Flash (ADV8003),

" ▼ " is displayed as the rst character of

the GUI rmware version.

L1

FLD

L2

L3

L1

FLD

L2

L3

L1

FLD

L2

L3

L1

FLD

L2

L3

L1

FLD

L2

L3

FLD L3

L1

L2

FLD

L3

M A I N

* * * * * * * *

B L - * * . * *

D S P *

* * . * *

A . P L D

* * . * *

G U I

* * . * *

I P

S C A L E R

E R R 0 1

E R R 0 2

G U I V E R

E R R O R

–

• Check the resistor for

–

setting the region

(R1589/R1590 DIGITAL

PCB).

• Write the rmware for

the correct region.

–

–

•Check the circuits

around the IP SCALER

(IC401, DIGITAL PCB)

and DDR2 (IC402/IC403).

If there appear to be

no problems, IC401 or

IC402/IC403 is faulty.

.

• Check the rmware

version.

r

DIR NG

t

DSP* NG

(*:1/2/3/4)

y

EEPROM

NG

This error is displayed if there is no response from the DIR.

The DSP* FLAG0 port does not enter "Hi"

status while booting a DSP code even

after resetting DSP.

The DSP* FLAG0 port does not enter "Hi"

status before issuing a DSP command.

Setting WRITE to "Lo" does not set ACK to

"Hi" during DSP* data reading.

Setting REQ to "Lo" does not set ACK to

"Lo" during DSP* data reading.

Setting WRITE to "Hi" does not set ACK to

"Hi" during DSP* data writing.

Setting REQ to "Lo" does not set ACK to

"Lo" during DSP* data writing.

An error occurred in a checksum of the

EEPROM(*** is a block address number).

L1

FLD

L2

L3

L1

L2

FLD

L3

FLD L3

FLD L3

FLD L3

FLD L3

FLD L3

L1

FLD

L2

L3

D I R

E R R O R

D S P *

E R R O R

E 2 P R O M

E R R O R

* * *

0 1

0 1

0 2

0 3

0 4

0 5

0 6

• Check the DIR (IC202,

DIGITAL PCB) and surrounding circuits.

• Check the DSP (IC251/

IC261/IC271/IC281, DIGITAL PCB) and surrounding circuits.

21

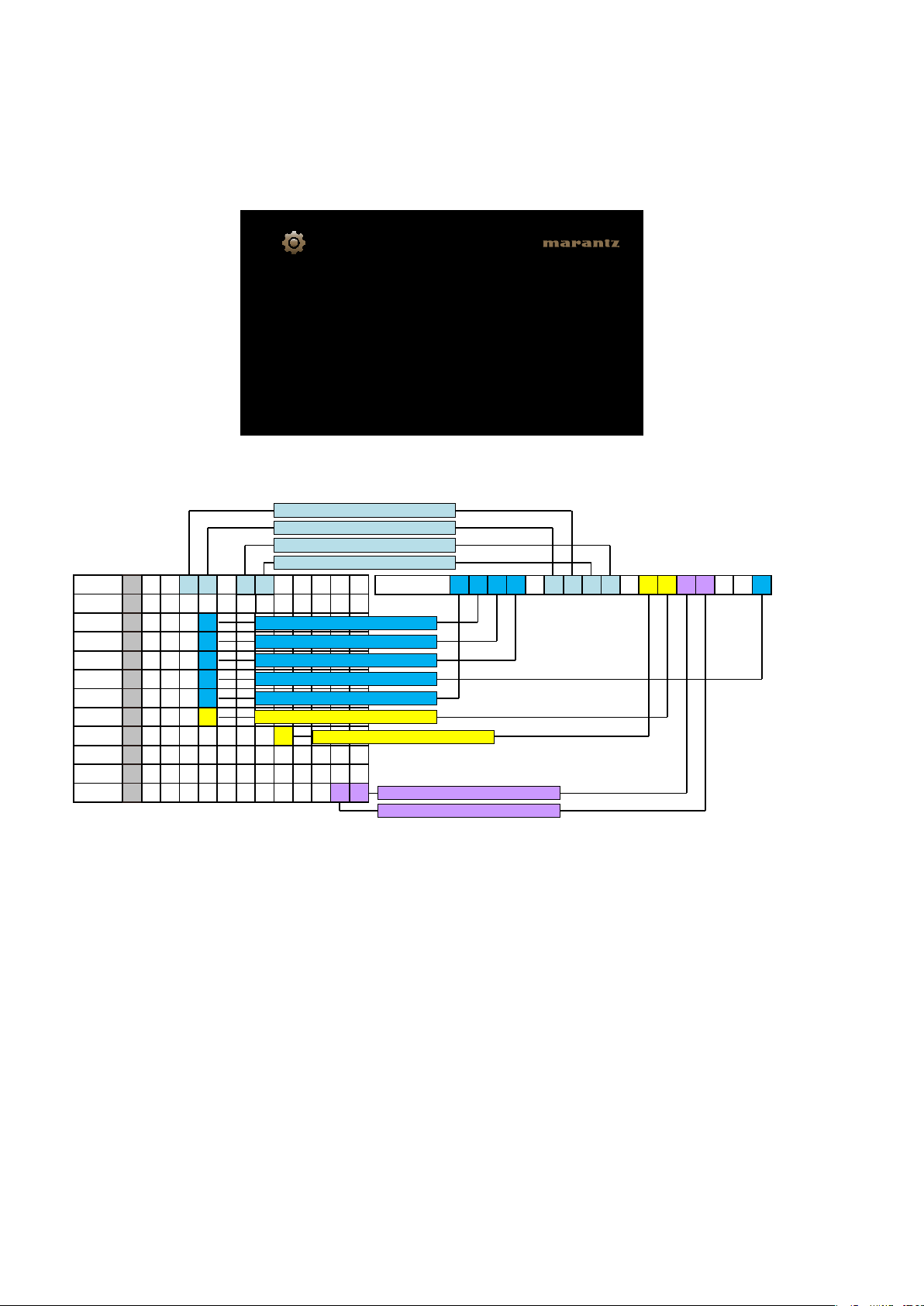

1.5. Version Display in the Setup Menu

Follow the steps below to display the rmware information.

(1) Press the "

SETUP

" button on the remote control.

(2) Select "General - Information - Firmware".

The version information is displayed as a 14-digit number as shown in the screenshot below.

General/Firmware

Version

Displays system information

XXXX-XXXX-XXXX-XX

GUI Image

This 14-digit number comprises a part of the version number of each device and module.

These version numbers correspond to the 14-digit number as shown below.

The 2nd digit from the right for Main

The 1th digit from the right for Main

The 2nd digit from the right for Sub

The 1st digit from the right for Sub

Main

M.FBL

DSP1

DSP2

DSP3

DSP4

A.PLD

V.PLD

GUI

E.FBL

E.SBL

E.IMG

X X X X XXX X

X X X

X X X

X X X

X X X

X X X

X X X

X X X X 0 0 1 6

X X X X X X

XB X X X X X X X X X X X

XI X X X X X X X 0 0 3 7

2 8X

8X 3 8- 3 8 21

2

3

4

5

1

7

The 1st digit from the right for DSP1

The 1st digit from the right for DSP2

The 1st digit from the right for DSP3

The 1st digit from the right for DSP4

The 1st digit from the right for A.PLD

The 1st digit from the right for V.PLD

The 1st digit from the right for GUI

Info display 2 3 4 - 6 7 7 3 - 0 5

The 1st digit from the right for IMG

The 2nd digit from the right for IMG

The rmware version numbers and this 14-digit version information are written in the Service Information.

b

22

2. Selecting the Mode for Service-related Operations

2.1. Actions

Select diagnostic mode (service path check mode), protection history display mode, or 232C standby clear mode.

2.2. Starting up

While holding down buttons "

power.

Select the desired mode using the "

ZONE2 SOURCE

TUNER PRESET CH+/-

2.3. Displaying and Selecting Each Mode

The information shown on the display switches each time the "

Press the "

q

FLD

Service Path Check Mode:

The Video and Audio paths can be checked.

This function is convenient for conrming problem paths in the product and checking

w

FLD

The protection history can be checked.

STATUS

L1

L2

L1

L2

" button to set the currently displayed mode and restart the device.

1 S E R V I C E

C H E C K

the paths after repairing.

2 P R O T E C T

" and "

STATUS

" simultaneously, press the power button to turn on the

" button, then press the "

TUNER PRESET CH+/-

STATUS

" button to conrm.

" button is pressed.

e

L1

FLD

Switches from 232C standby mode to normal standby mode.

r

FLD

Operation Info for the unit can be checked.

t

FLD

Enables reception STEP of the ANALOG TUNER to be changed.

3 R S 2 3 2 C

L2

L1

L2

L1

L2

R E S E T

4 O P I N F O

5 T U N E R

F R E Q

2.3. Canceling the selected mode

Press the power button to turn off the power.

23

PROTECTIONDIAGRAM

TR_THERMAL

FL

TR_THERMAL

FR

TR_THERMAL

C

TR_THERMAL

SL

TR_THERMAL

SR

TR_THERMAL

ASO

DC

ASO

DC

ASO

DC

ASO

DC

ASO

DC

PAMP PCB

BN710 CN704

DC_DET2

DC_DET1

ASO_DET

THERMAL_DETA

THERMAL_DETE

THERMAL_DETF

DIGITAL PCB

DC_DET2

DC_DET1

ASO_DET

THERMAL_DETA

THERMAL_DETE

THERMAL_DETF

uCOM

PROTECTION LOGIC

DC ⇒ L_activeshutdown

ASO ⇒ L_activeshutdown

THER PROTF ⇒ L_activeshutdown

THER PROTA ⇒ L_activeshutdown

CURRENT (After 90sec )

Over 1.0V & Low B & THERMAL E = Low ⇒ shutdown

Over 2.0V ⇒ shutdown

DC/ASO PROT 125pin/AN105

THER_PROT_E 161pin/P91

THER_PROT_F 163pin/P90

THER_PROT_A 159pin/P93

CURRENT_DET 166pin/AN006

SBL

TR_THERMAL

SBR

HEATSINK_THERMAL

HEATSINK_THERMAL

ASO

DC

ASO

DC

SPEAKER PCB FRONT CNT PCB

CURRENT DETECT PART

CPU LEVEL CHG PART

BN25D 15pinCN25D 15pin

CURRENT DET

CN25A 9pin

CURRENT DET

BN25A 9pin

CURRENT DET CURRENT DET

24

2-1. DIAGNOSTIC MODE (Service Path Check Mode)

2-1.1. Actions

This function is convenient for conrming problem paths in the product and checking the paths after repairing.

The Video and Audio paths can be checked.

The backup data is not rewritten.

2-1.2. Starting up

While holding down buttons "

1.SERVICE CHECK

Select "

The "

TUNED

STEREO

", "

ZONE2 SOURCES

", then press the "

RDS

" and "

" segments are lit in this mode.

STATUS

2-1.3. Canceling diagnostic mode

Press the power button to turn off the power.

2-1.4. Selecting items to check

Press the q button to switch between video items and audio items.

Press the w or e button to select the previous or next item.

The unit Remote control unit

Actions

Button DIMMER TUNER PRESET CH- TUNER PRESET CH+ SLEEP CURSOR

q w e q w e

Audio ⇔ Video PREVIOUS NEXT Audio ⇔ Video PREVIOUS NEXT

2-1.5. Audio system conrmation items

See the block diagram g.XXth.

STATUS

" and "

" simultaneously, press the power button to turn on the power.

" button to activate the diagnostic mode.

0

CURSOR

1

Analog

(MAIN ZONE)

1

Digital

(MAIN)

2

Digital

(ZONE2)

3

HDMI

4

Paths to be conrmed Display Settings What to conrm

g.01

g.02a

g.02b

g.03a

g.03b

g.03c

g.04a

g.04b

g.04c

L1

A 0 1 A N L G

L2

* * * . * d B

L1

A 0 2 D I G .

L2

* * * . * d B

L1

A 0 3 Z 2 D I G

L2

* * * . * d B

L1

A 0 5 H D M I

L2

* * * . * d B

Input Source : CBL/SAT

Input Mode : Analog (xed)

Sound mode : DIRECT

Amp assign : 7.1ch

Floor Layout : 5ch&SB

Height Sp : 2ch

Dolby Sp : None

Height Layout : Front Height

MAIN ZONE : ON

ZONE2 : OFF

Input Source : CBL/SAT

Input Mode : DIGITAL (xed)

Sound mode : MULTI CH STEREO

Amp assign : 7.1ch

Floor Layout : 5ch&SB

Height Sp : 2ch

Dolby Sp : None

Height Layout : Front Height

Speaker Select : Floor

Speaker Cong ALL Speaker = Small / SW = Yes(2ch)

MAIN ZONE : ON

ZONE2 : OFF

Input Source : Online Music

Input Mode : Auto

Sound mode : STEREO

Amp assign : 5.1ch + ZONE2

MAIN ZONE : ON

ZONE2 : ON

Input Source : CBL/SAT

Input Mode : HDMI (xed)

Sound mode : STEREO

Amp assign : 7.1ch

Floor Layout : 5ch&SB

Height Sp : 2ch

Dolby Sp : None

Height Layout : Front Height

MAIN ZONE : ON

ZONE2 : OFF

・Analog input ⇒ Speaker output (Front L/R)

・Analog input ⇒ Preout output (Front L/R)

(b The input source can be switched to any source except CBL/SAT.)

・Digital input ⇒ Speaker output (Front L/R, Center, Surround L/R, Surround Back L/R)

・Digital input ⇒ Pre output (Front L/R, Center, Surround L/R, Surround Back L/R, Subwoofer)

(b The input source can be switched to any source except CBL/SAT.)

・Digital(PCM) input ⇒ Amp Assign Speaker (Surround Back L/R → ZONE2 L/R)

・Digital(PCM) input ⇒ Preout output (ZONE2 L/R)

(b The input source can be switched to any source except Online Music.)

・HDMI input ⇒ Speaker output (Front L/R)

・HDMI input ⇒ Preout output (Front L/R)

(b The input source can be switched to any source except CBL/SAT.)

25

Paths to be conrmed Display Settings What to conrm

Analog A/D

(MAIN ZONE)

5

Analog Amp Assign

(Amp Assign:ZONE2)

6

Amp Assign

(Bi-Amp)

7

Front Height

8

Front Wide

9

Ext.In

10

Front Amp>>Front Wide

11

g.05a

g.05b

g.06

g.07a

g.07b

g.08a

g.08b

g.09a

g.09b

g.10

g.11a

g.11b

L1

A 0 6 A D

L2

* * * . * d B

L1

A 0 7 Z 2 A S S

L2

* * * . * d B

L1

A 1 1 B i A M P

L2

* * * . * d B

L1

A 1 4 F H

L2

* * * . * d B

L1

A 1 5 F W

L2

* * * . * d B

L1

A 1 9 7 . 1 I N

L2

* * * . * d B

L1

A 2 1 F W 2

L2

* * * . * d B

Input Source : CBL/SAT

Input Mode : Analog (xed)

Sound mode : MULTI CH STEREO

Amp assign : 7.1ch

Floor Layout : 5ch&SB

Height Sp : 2ch

Dolby Sp : None

Height Layout : Front Height

Speaker Select : Floor

Speaker Cong ALL Speaker = Small/SW = Yes(2ch)

MAIN ZONE : ON

ZONE2 : OFF

Input Source : CBL/SAT

Input Mode : Auto

Sound mode : STEREO

Z2 Source : Source

Amp assign : 5.1ch + ZONE2

MAIN ZONE : ON

ZONE2 : ON

Input Source : CBL/SAT

Input Mode : Auto

Sound mode : MULTI CH STEREO

Amp assign : 5.1ch + Bi-Amp

MAIN ZONE : ON

ZONE2 : OFF

Input Source : CBL/SAT

Input Mode : Auto

Sound mode : MULTI CH STEREO

Amp assign : 7.1ch

Floor Layout : 5ch

Height Sp : 2ch

Dolby Sp : None

Height Layout : Front Height

Speaker Select : Floor & Height

MAIN ZONE : ON

ZONE2 : OFF

Input Source : CBL/SAT

Input Mode : Auto

Sound mode : MULTI CH STEREO

Amp assign : 7.1ch

Floor Layout : 5ch&FW

Height Sp : None

Dolby Sp : None

Speaker Select : Front

MAIN ZONE : ON

ZONE2 : OFF

Input Source : CBL/SAT

Input Mode : 7.1ch IN

SURROUND mode : 7.1ch In

Amp assign : 7.1ch

Floor Layout : 5ch&SB

Height Sp : None

Dolby Sp : None

MAIN ZONE : ON

ZONE2 : OFF

Input Source : CBL/SAT

Input Mode : Auto

SURROUND mode : Multi ch STEREO

Amp assign : 9.1ch

Floor Layout : 5ch&SB&FW

Height Sp : None

Dolby Sp : None

Pre-out Channel : Front

Speaker Select : Floor

MAIN ZONE : ON

ZONE2 : OFF

・Analog input ⇒ Speaker output (Front L/R, Center, Surround L/R, Surround Back L/R)

・Analog input ⇒ Preout output, SW(20Hz) (Front L/R, Center, Surround L/R, Surround Back L/R)

(b The input source can be switched to any source except CBL/SAT.)

(b Volume -20dB is the value when Relative settings are used. The value is 60 when Absolute settings are used)

・Analog input ⇒ Speaker input (Surround Back L/R → ZONE2 L/R)

・Analog input ⇒ Preout input (ZONE2 L/R)

(b The input source can be switched to any source except CBL/SAT.)

(b Volume -20dB is the value when Relative settings are used. The value is 60 when Absolute settings are used)

・Analog input ⇒ Speaker output (Surround Back L/R → Front L/R)

(b The input source can be switched to any source except CBL/SAT.)

(b Volume -20dB is the value when Relative settings are used. The value is 60 when Absolute settings are used)

・Analog input ⇒ Speaker output (Height1 L/R → Front Height)

・Analog input ⇒ Preout output (Height1 L/R → Front Height)

(b The input source can be switched to any source except CBL/SAT.)

・PREOUT output

(b Volume -20dB is the value when Relative settings are used. The value is 60 when Absolute settings are used)

・Analog input ⇒ Speaker output (Front Wide L/R)

・Analog input ⇒ Preout output (Front Wide L/R)

(b The input source can be switched to any source except CBL/SAT.)

・PREOUT output

(b Volume -20dB is the value when Relative settings are used. The value is 60 when Absolute settings are used)

・7.1ch input ⇒ Speaker output (Front L/R, Center, Surround L/R, Surround Back L/R)

・7.1ch input ⇒ Pre output (Front L/R, Center, Surround L/R, Surround Back L/R, Subwoofer)

・Analog input ⇒ Speaker output (Front Wide L/R)

・Analog input ⇒ Preout output (Front Wide L/R)

(b The input source can be switched to any source except CBL/SAT.)

(b Volume -20dB is the value when Relative settings are used. The value is 60 when Absolute settings are used)

26

Paths to be conrmed Display Settings What to conrm

Front Amp>>Surround Back

12

Height

13

g.12a

g.12b

g.13a

g.13b

L1

A 2 2 S B 2

L2

* * * . * d B

L1

A 2 4 H E I G

L2

* * * . * d B

Input Source : CBL/SAT

Input Mode : Auto

SURROUND mode : Multi ch STEREO

Amp assign : 9.1ch

Floor laytou : 5ch&SB

Height Sp : 2ch

Dolby Sp : None

Height Layout : Front Height

Pre-out Channel : Front

Speaker Select : Floor & Height

MAIN ZONE : ON

ZONE2 : OFF

Input Source : CBL/SAT

Input Mode : Auto

Sound mode : MULTI CH STEREO

Amp assign : 9.1ch

Floor Layout : 5ch

Height Sp : 4ch

Dolby Sp : None

Height Layout : Top Front & Top Rear

Pre-out Channel : Top Rear

Speaker Select : Floor & Height

MAIN ZONE : ON

ZONE2 : OFF

・Analog input ⇒ Speaker output (Surround Back L/R)

(b The input source can be switched to any source except CBL/SAT.)

(b Volume -20dB is the value when Relative settings are used. The value is 60 when Absolute settings are used)

・Analog input ⇒ Preout output (Height1 L/R → Top Front) (Height2 → Top Rear)

(b The input source can be switched to any source except CBL/SAT.)

・PREOUT output

(b Volume -20dB is the value when Relative settings are used. The value is 60 when Absolute settings are used)

27

2-1.6. Conrmation items for the video system

See the block diagram g.XXth.

Paths to be conrmed Display Settings What to conrm

Analog Video

1

Video Convert

(Analog or HDMI ⇒ HDMI)

2

HDMI pass

3

(MAIN ZONE)

HDMI CEC

4

HDMI Audio

(Audio :AVR)

5

HDMI Audio

(Audio :TV)

6

GUI

7

HDMI

(ZONE2)

8

g.14

g.15a

g.15b

g.16

g.17

g.18a

g.18b

g.18c

g.19a

g.19b

g.20

g.21

L1

V 0 1 V I D E O

L2

* * * . * d B

L1

V 0 2 C O N V

L2

* * * . * d B

L1

V 0 3 H D M I

L2

* * * . * d B

L1

V 0 4 C E O

L2

* * * . * d B

L1

V 0 5 H - A V R

L2

* * * . * d B

L1

V 0 6 H - T V

L2

* * * . * d B

L1

V 0 7 M E N U

L2

* * * . * d B

L1

V 0 8 Z 2 H D

L2

* * * . * d B

Input Source : CBL/SAT

Video Convert (IP Scaler) : OFF, All sources

MAIN ZONE : ON

ZONE2 : ON

Input Source : CBL/SAT

Video Convert (IP Scaler) : ON, All sources

IP Scaler : "Analog & HDMI", All sources

Resolution : "Auto", All sources

MAIN ZONE : ON

ZONE2 : OFF

Input Source : CBL/SAT

Video Convert (IP Scaler): OFF MAIN ZONE : ON, All sources

ZONE2 : OFF

Input Source : CBL/SAT

HDMI Control : ON

MAIN ZONE : ON

ZONE2 : OFF

Input Source : CBL/SAT

HDMI Control : OFF

HDMI Audio : AVR (if checking the audio output from AVR)

Input Source : CBL/SAT

HDMI Control : OFF

HDMI Audio : AVR (if checking the audio output from AVR)

Input Source : CBL/SAT

Video Convert (IP Scaler) : ON, All sources

IP Scaler : "Analog & HDMI", All sources

Resolution : "AUTO", All sources

Setup Menu : ON

MAIN ZONE : ON

ZONE2 : OFF

Input Source : CBL/SAT

ZONE2 Source : Source

MAIN ZONE : ON

ZONE2 : ON

・Component input ⇒ Component output

・CVBS input ⇒ CVBS output

(b The input source can be switched to any source except CBL/SAT.)

・CVBS input ⇒ IP Scaler ⇒ HDMI output.

・Component input ⇒ IP Scaler ⇒ HDMI output.

・HDMI input ⇒ IP Scaler ⇒ HDMI output.

・ETHERNET input ⇒ IP Scaler ⇒ HDMI output.

(b The input source can be switched to any source except CBL/SAT.)

・HDMI input ⇒ HDMI output(MAIN)

(b The input source can be switched to any source except CBL/SAT.)

・ When the power supply of a TV is put in the standby mode, make sure that the power supply of this unit is also put in the

standby mode.

・The ARC path can also be checked (check this using the TV input source).

(b The input source can be switched to any source except CBL/SAT.)

・HDMI input (PCM, DolbyDigital, DTS) ⇒ Speaker output.

・HDMI input(HD audio) ⇒ Speaker output.

(b The input source can be switched to any source except CBL/SAT.)

・HDMI input(PCM, DolbyDigital, DTS) ⇒ HDMI output (audio output from connected TV)

(b The input source can be switched to any source except CBL/SAT.)

・GUI display ⇒ HDMI output.

(b The input source can be switched to any source except CBL/SAT.)

・HDMI input ⇒ HDMI output (ZONE2)

(b The input source can be switched to any source except CBL/SAT.)

28

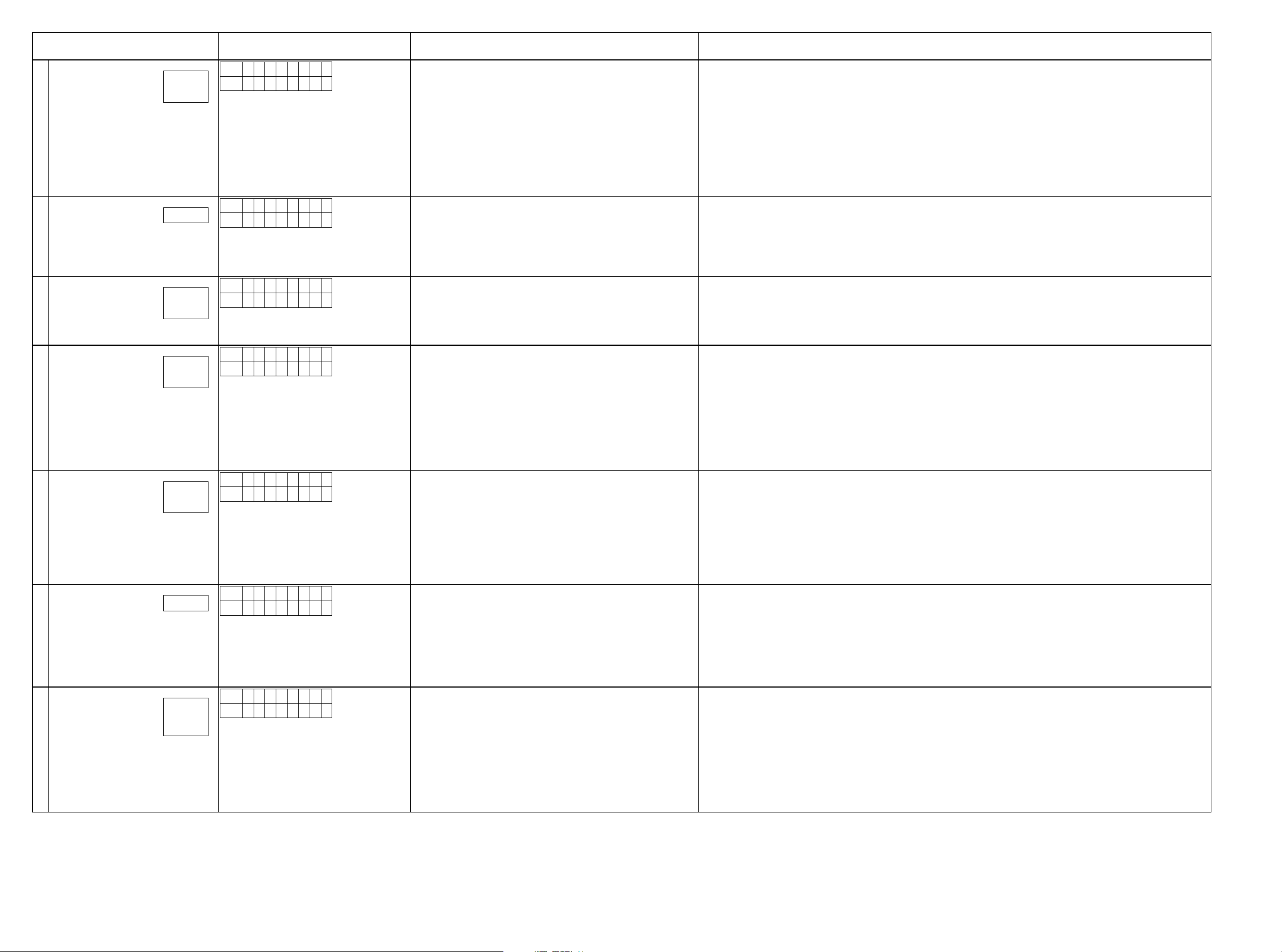

DIAGNOSTICPATHDIAGRAM

SR6010 ANALOG AUDIO BLOCK

DAC_F

70,71

72.73

74,75

76,77

78,79

82,83

64,65

66,67

62,63

68.69

60,61

58,59

56,57

84,85

CBL/SAT

Blu-Ray

Media

PHONO

V.AUX

(FRONT)

DVD

CD

TUNER

TUNER(FM /AM)

MIC

fig.01

Z2R_VO L_OUT

HDAM

Z2L_VO L_OUT

R2A15220

Z2 IN1

Z2 IN2( HPF/MONO)

TONE

19,20

FL_VOL _OU

FR_VOL_ OUT

T

C_VO L_OUT

TONE

MAIN ZONE SWZONE2 SW

MAIN_Fron t

ADC

SUB_1

EXT_C

DAC

EXT_FL

DAFL

ANA_L

EXT_FR

DAFR

ANA_R

EXT_SBL

DAASSIGN1L

(SB1/FH1/FW1 )

EXT_SBR

DAASSIGN1R

(SB1/FH1/FW1 )

22,23

16

7,8

10,11

99,100

2,3

SW1_VOL_O UT

SW2_VOL_O UT

SL_VO L_OUT

SR_VOL _OUT

ASSIGN1L_ VOL_OU T

ASSIGN1R_V OL_OU T

ASSIGN2L_ VOL_OU T

ASSIGN2R_V OL_OU T

ASSIGN2L

ASSIGN2R

CSLSR

ASSIGN1L

ASSIGN1R

FLFRZ2L

Z2R

PREOUT _FL

PREOUT _FR

PREOUT _C

PREOUT _SW1

PREOUT _SW2

PREOUT _SL

SR

PREOUT _

PREOUT _ASS1L

PREOUT _ASS1R

PREOUT _ASS2L

PREOUT _ASS2R

InA1

InB1

InA2

InB2

SW-A x 4

InA3

InB3

InA4

SW-B x 4

InB4

NJU72751V

Z2L

Z2R

OutA1

OutB1

OutA2

OutB2

OutA3

OutB3

OutA4

OutB4

FL

FR

C

SW1

SW2

SL

SR

SBL

SBR

FW_L

FW_R

H1_L

H1_R

H2_L

H2_R

ZONE2 OUT

ZONE2 OUT

DIGITAL AUDIO BLOCK_C1

SW

SR

SBL

SBR

FL

FR

C

SL

DAZ2

DAZ3

ADINL

ADINR

DAFL

DAFR

DAC

DASW1

DASW2

DASL

DASR

DAASSIGN1L

DAASSIGN1R

DAASSIGN2L

DAASSIGN2R

7.1ch EXT . IN

HPF

MONO

MIX

HPF

53,54

46,47

ZONE2

MONO

MIX

88,89

1

7

3

5

2

8

4

6

80,81

BD3841F

34,35

42,43

90,91

ZONE2

ZONE2

26

FLFRZ2L

ASSIGN1L

ASSIGN1R

ASSIGN2L

ASSIGN2L_ VOL_OU T

SW1_VOL_O UT

SW2_VOL_O UT

SL_VO L_OUT

SR_VOL _OUT

15

ZONE2

25

EXT_SW

DASW1

EXT_SW

DASW2

EXT_SL

DASL

EXT_SR

DASR

DAASSIGN2L

(SB2/FH2/ FW2)

DAASSIGN2R

(SB2/FH2/ FW2)

39

38

40

41

36

37

17911

R2A15218

ASSIGN2R_V OL_OU T

3

5

ASSIGN2R

78

696871

70

Z2R

CSLSR

79

72,73

Z2_MONO

61

636267

66

C

SL

SR

POWER AMP PA RT

29dB

29dB

29dB

29dB

46

SUB

47

29dB

29dB

29dB

RY921

RY922

RY923

RY924

RY927

RY925

ATT.

FL

FR

C

SL

SR

SBL

SBR

HPL

HPR

GND

H/P O UT

FW_L

RY928

RY926

FW_R

H_L

91

REC3

90

H_R

SB AMP Select Front AMP Select

29

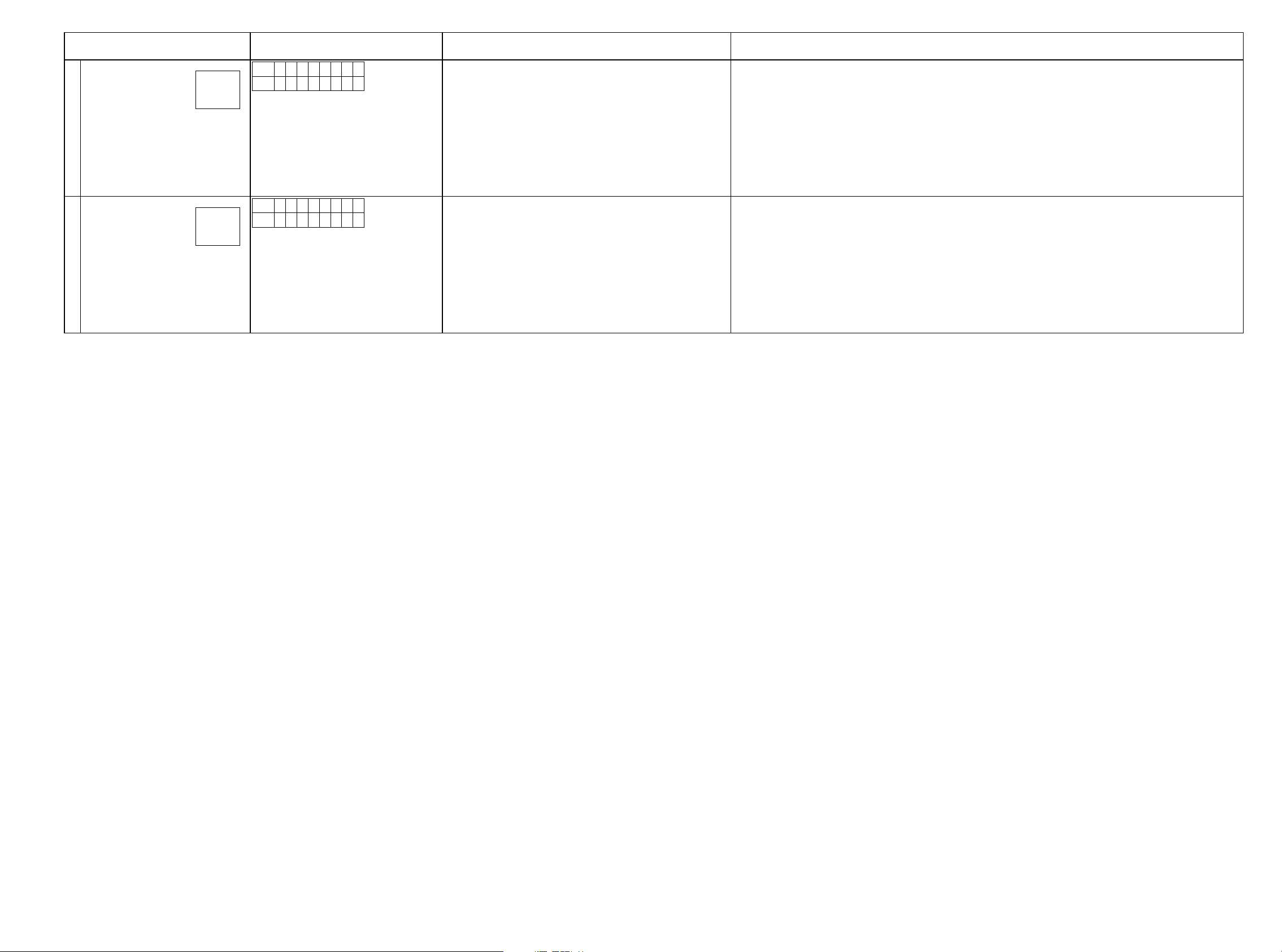

SR6010 ANALOG AUDIO BLOCK

DAC_F

70,71

72.73

74,75

76,77

78,79

82,83

64,65

66,67

62,63

68.69

60,61

58,59

56,57

84,85

CBL/SAT

DVD

Blu-Ray

Media

PHONO

V.AUX

(FRONT)

CD

TUNER

TUNER(FM /AM)

MIC

fig.02a

Z2R_VO L_OUT

HDAM

Z2L_VO L_OUT

R2A15220

Z2 IN1

Z2 IN2( HPF/MONO)

TONE

19,20

FL_VOL _OU

FR_VOL_ OUT

T

C_VO L_OUT

TONE

MAIN ZONE SWZONE2 SW

MAIN_Fron t

ADC

SUB_1

EXT_C

DAC

EXT_FL

ANA_L

EXT_FR

DAFR

ANA_R

EXT_SBL

DAASSIGN1L

(SB1/FH1/FW1 )

EXT_SBR

DAASSIGN1R

(SB1/FH1/FW1 )

DAFL

22,23

16

7,8

10,11

99,100

2,3

SW1_VOL_O UT

SW2_VOL_O UT

SL_VO L_OUT

SR_VOL _OUT

ASSIGN1L_ VOL_OU T

ASSIGN1R_V OL_OU T

ASSIGN2L_ VOL_OU T

ASSIGN2R_V OL_OU T

ASSIGN2L

ASSIGN2R

CSLSR

ASSIGN1L

ASSIGN1R

FLFRZ2L

Z2R

PREOUT _FL

PREOUT _FR

PREOUT _C

PREOUT _SW1

PREOUT _SW2

PREOUT _SL

SR

PREOUT _

PREOUT _ASS1L

PREOUT _ASS1R

PREOUT _ASS2L

PREOUT _ASS2R

InA1

InB1

InA2

InB2

SW-A x 4

InA3

InB3

InA4

SW-B x 4

InB4

NJU72751V

Z2L

Z2R

OutA1

OutB1

OutA2

OutB2

OutA3

OutB3

OutA4

OutB4

FL

FR

C

SW1

SW2

SL

SR

SBL

SBR

FW_L

FW_R

H1_L

H1_R

H2_L

H2_R

ZONE2 OUT

ZONE2 OUT

DIGITAL AUDIO BLOCK_C1

SW

SBL

SBR

FL

FR

C

SL

SR

DAZ2

DAZ3

ADINL

ADINR

DAFL

DAFR

DAC

DASW1

DASW2

DASL

DASR

DAASSIGN1L

DAASSIGN1R

DAASSIGN2L

DAASSIGN2R

7.1ch EXT . IN

HPF

MONO

MIX

HPF

53,54

46,47

ZONE2

MONO

MIX

88,89

1

7

3

5

2

8

4

6

80,81

BD3841F

34,35

42,43

90,91

ZONE2

ZONE2

26

FLFRZ2L

ASSIGN1L

ASSIGN1R

ASSIGN2L

ASSIGN2L_ VOL_OU T

SW1_VOL_O UT

SW2_VOL_O UT

SL_VO L_OUT

SR_VOL _OUT

15

ZONE2

25

EXT_SW

DASW1

EXT_SW

DASW2

EXT_SL

DASL

EXT_SR

DASR

DAASSIGN2L

(SB2/FH2/ FW2)

DAASSIGN2R

(SB2/FH2/ FW2)

39

38

40

41

36

37

17911

R2A15218

ASSIGN2R_V OL_OU T

3

5

ASSIGN2R

78

696871

70

Z2R

CSLSR

79

72,73

Z2_MONO

61

636267

66

C

SL

SR

POWER AMP PA RT

29dB

29dB

29dB

29dB

46

SUB

47

29dB

29dB

29dB

RY921

RY922

RY923

RY924

RY927

RY925

ATT.

FL

FR

C

SL

SR

SBL

SBR

HPL

HPR

GND

H/P O UT

FW_L

RY928

RY926

FW_R

H_L

91

REC3

90

H_R

SB AMP Select Front AMP Select

30

Loading...

Loading...