Page 1

Service

MD110/F1S / N1S

Manual

STANDBY OPEN

MD110

STANDBY OPEN

DISPLAY

SOURCE

DUBB.

CHARACTER

REC

EDIT

MULTI JOG

PUSH ENTER

REC MODE

MD Deck

TABLE OF CONTENTS

SECTION PAGE

1. TECHNICAL SPECIFICATIONS ........................................................................... 1

2. SERVICE MODE .................................................................................................. 2

3. WIRING DIAGRAM ............................................................................................... 9

4. BLOCK DIAGRAM .............................................................................................. 11

5. SCHEMATIC DIAGRAM ..................................................................................... 13

6. PARTS LOCATION (Pattern Side) ..................................................................... 15

7. IC DATA .............................................................................................................. 21

8. EXPLODED VIEW AND PARTS LIST ................................................................ 27

9. ELECTRICAL PARTS LIST ................................................................................ 32

Please use this service manual with referring to the user guide ( D.F.U. ) without fail.

MD110

R

MD110

325W855010 MIT

3120 785 22730

First Issue 2001.12

Page 2

MARANTZ DESIGN AND SERVICE

MARANTZ AMERICA, INC.

Using superior design and selected high grade components, MARANTZ company has created the ultimate in stereo sound.

Only original MARANTZ parts can insure that your MARANTZ product will continue to perform to the specifications for which

it is famous.

Parts for your

MARANTZ equipment are generally available to our National Marantz Subsidiary or Agent.

ORDERING PARTS :

Parts can be ordered either by mail or by Fax.. In both cases, the correct part number has to be specified.

The following information must be supplied to eliminate delays in processing your order :

1. Complete address

2. Complete part numbers and quantities required

3. Description of parts

4. Model number for which part is required

5. Way of shipment

6. Signature : any order form or Fax. must be signed, otherwise such part order will be considered as null and void.

USA

MARANTZ AMERICA, INC

1100 MAPLEWOOD DRIVE

ITASCA, IL. 60143

USA

PHONE : 630 - 741 - 0300

FAX : 630 - 741 - 0301

AMERICAS

SUPERSCOPE TECHNOLOGIES, INC.

MARANTZ PROFESSIONAL PRODUCTS

2640 WHITE OAK CIRCLE, SUITE A

AURORA, ILLINOIS 60504 USA

PHONE : 630 - 820 - 4800

FAX : 630 - 820 - 8103

AUSTRALIA

QualiFi Pty Ltd,

24 LIONEL ROAD,

MT. WAVERLEY VIC 3149

AUSTRALIA

PHONE : +61 - (0)3 - 9543 - 1522

FAX : +61 - (0)3 - 9543 - 3677

NEW ZEALAND

WILDASH AUDIO SYSTEMS NZ

14 MALVERN ROAD MT ALBERT

AUCKLAND NEW ZEALAND

PHONE : +64 - 9 - 8451958

FAX : +64 - 9 - 8463554

EUROPE / TRADING

MARANTZ EUROPE B.V.

P.O.BOX 80002, BUILDING SFF2

5600 JB EINDHOVEN

THE NETHERLANDS

PHONE : +31 - 40 - 2732241

FAX : +31 - 40 - 2735578

AUSTRALIA

TECHNICAL AUDIO GROUP PTY, LTD

558 DARLING STREET,

BALMAIN, NSW 2041,

AUSTRALIA

PHONE : 61 - 2 - 9810 - 5300

FAX : 61 - 2 - 9810 - 5355

THAILAND

MRZ STANDARD CO.,LTD

746 - 754 MAHACHAI ROAD.,

WANGBURAPAPIROM, PHRANAKORN,

BANGKOK, 10200 THAILAND

PHONE : +66 - 2 - 222 9181

FAX : +66 - 2 - 224 6795

TAIWAN

PAI- YUING CO., LTD.

6 TH FL NO, 148 SUNG KIANG ROAD,

TAIPEI, 10429, TAIWAN R.O.C.

PHONE : +886 - 2 - 25221304

FAX : +886 - 2 - 25630415

BRAZIL

PHILIPS DA AMAZONIA IND. ELET. ITDA

CENTRO DE INFORMACOES AO

CEP 04698-970

SAO PAULO, SP, BRAZIL

PHONE : 0800 - 123123

FAX : +55 11 534. 8988

(Discagem Direta Gratuita)

CANADA

LENBROOK INDUSTRIES LIMITED

633 GRANITE COURT,

PICKERING, ONTARIO L1W 3K1

CANADA

PHONE : 905 - 831 - 6333

FAX : 905 - 831 - 6936

SINGAPORE

WO KEE HONG DISTRIBUTION PTE LTD

130 JOO SENG ROAD

#03-02 OLIVINE BUILDING

SINGAPORE 368357

PHONE : +65 858 5535 / +65 381 8621

FAX : +65 858 6078

MALAYSIA

WO KEE HONG ELECTRONICS SDN. BHD.

SUITE 8.1, LEVEL 8, MENARA GENESIS,

NO. 33, JALAN SULTAN ISMAIL,

50250 KUALA LUMPUR, MALAYSIA

PHONE : +60 3 - 2457677

FAX : +60 3 - 2458180

JAPAN

MARANTZ JAPAN, INC.

Technical

35- 1, 7- CHOME, SAGAMIONO

SAGAMIHARA - SHI, KANAGAWA

JAPAN 228-8505

PHONE : +81 42 748 1013

FAX : +81 42 741 9190

KOREA

MK ENTERPRISES LTD.

ROOM 604/605, ELECTRO-OFFICETEL, 16-58,

3GA, HANGANG-RO, YONGSAN-KU, SEOUL

KOREA

PHONE : +822 - 3232 - 155

FAX : +822 - 3232 - 154

SHOCK, FIRE HAZARD SERVICE TEST :

CAUTION : After servicing this appliance and prior to returning to customer, measure the resistance between either primary AC

cord connector pins ( with unit NOT connected to AC mains and its Power switch ON ), and the face or Front Panel of product and

controls and chassis bottom.

Any resistance measurement less than 1 Megohms should cause unit to be repaired or corrected before AC power is applied, and

verified before it is return to the user/customer.

Ref. UL Standard No. 1492.

In case of difficulties, do not hesitate to contact the Technical

Department at above mentioned address.

010620MIT

Page 3

1. TECHNICAL SPECIFICATIONS

MAIN UNIT (MD110)

Type ........................................................................................................................... MiniDisc Digital Audio System

Laser ......................................................................................................................................... Semiconductor laser

Recording method ............................................................................... Magnetic field modulation overwrite method

RPMs ......................................................................................................... Approximately 400rpm to 900rpm (CLV)

Sampling frequency .....................................................................................................................................44.1 kHz

Frequency characteristics ........................................................................................................ 20 to 20 kHz (± 1 dB)

S/N .................................................................................................................................................. 85 dB or greater

Total Harmonic Distortion ................................................................................................................. 0.005 % or less

Wow and Flutter............................................................................................................ Less than measurable limits

Line output level.......................................................................................................................................... 2.0 Vrms

Analog Input ........................................................................................................................................... 250 mVrms

GENERAL

Power supply ......................................................................................................... AC 100 V 50 / 60 Hz (F version)

AC 230 V 50 Hz (N version)

Power Consumption <Electric Appliance Control Act> ......................................................................................16 W

Maximum external dimensions (W x H x D)............................................................................. 210 x 71.5 x 310 mm

Weight.............................................................................................................................................................. 3.3 kg

ACCESSORIES

Remote Control Transmitter (RC110DRMD/N1S, RC110DRMDF/F1S) ..................................................................1

External dimensions (W x H x D) ........................................................................................ 50.5 x 154.5 x 25 mm

Weight ............................................................................................................................................................. 60 g

AA type batteries ..................................................................................................................................................... 2

Stereo audio cable ............................................................................................................................................ 1 pair

Coaxial cable ........................................................................................................................................................... 1

Remote control cable ............................................................................................................................................... 1

The specifications and external appearance are subject to change without notice.

Some portions of the illustrations that appear in this manual may differ slightly from the actual product.

This product is licensed under U.S. and foreign patents of Dolby Laboratories.

1

Page 4

2. SERVICE MODE

Service Mode

1. While Mains cord is disconnected, press DISPLAY Button on the unit and plug in the Mains cord.

2. Version number of the front micom software is displayed.

3. Turn JOG dial to either direction then Display segment test begins.

4. First all the segments will light and then a segment turns off one by one.

5. Disconnect Mains cord to quit service mode.

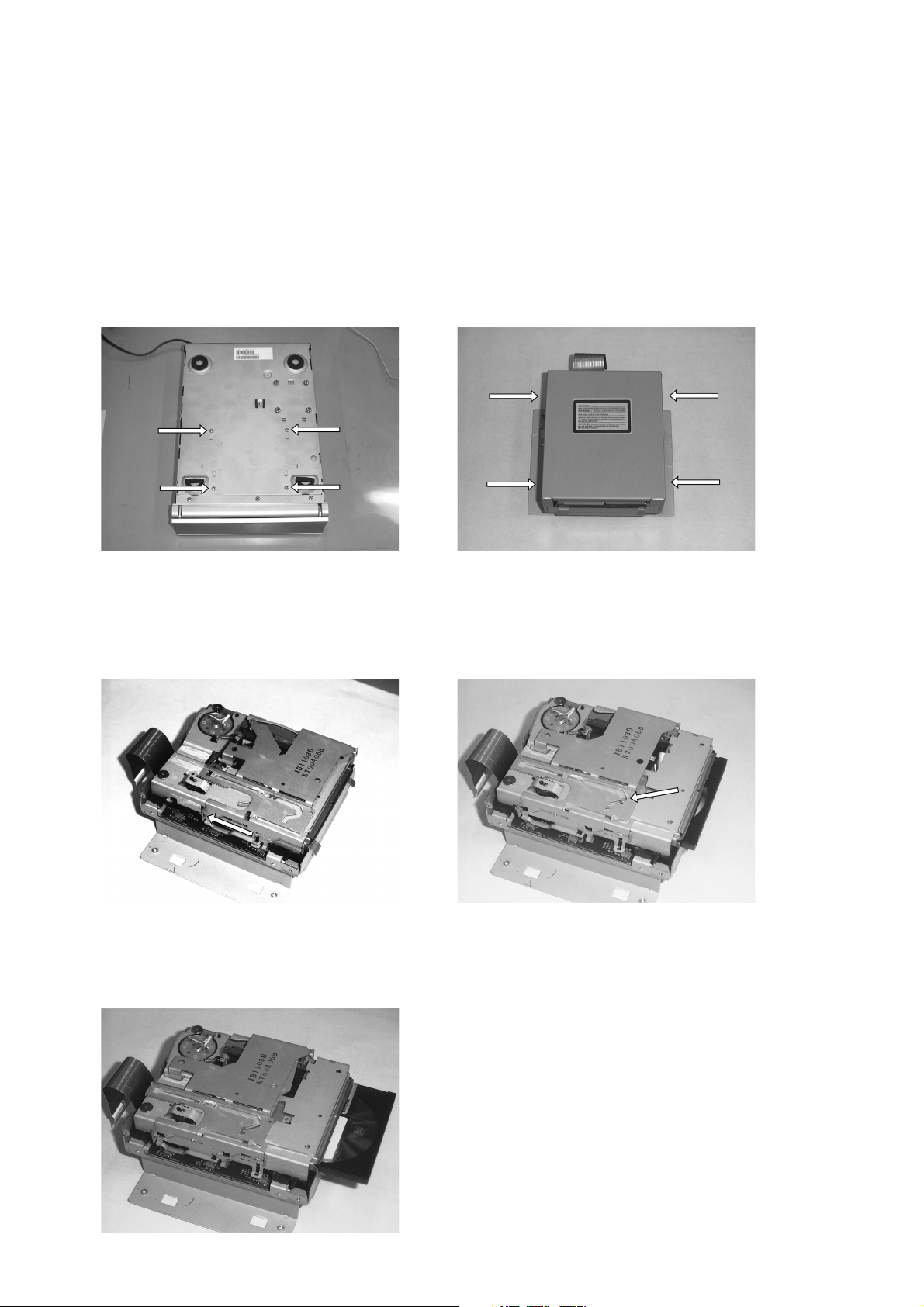

Emargency Eject

1. Remove 5 screws on the top cover and remove 3. Disconnect the flexible wire.

the top cover. 4. Remove the MD mechanism component from the

2. Remove 4 screws on the bottom. (Pointed with unit and remove the 4 screws on the both sides.

the arrows in the picture above.) (Pointed with the arrows in the picture above.)

5. Slide the lever pointed with the arrow to the direction 6. Slide the pin pointed with the arrow to the direction

of the arrow. of the arrow.

7. Disc is ejected.

2

Page 5

TEST MODE

1 How to Setting and Cancel Test Mode

Setting: While pressing the PLAY/PAUSE keys, insert the power cord to the wall outlet.

Cancel: Pull out the power cord.

Key Operation for Adjustment

Key Operation

MULTI JOG Select parameter and mode.

PLAY Fix items. Change of display in every check.

STOP Cancel or back of test mode.

2 Remained Keys Operation

Key Operation

DISPLAY Display changes.

FF Pickup moves outwards when press FF key

FB Pickup moves inwards when press FB key

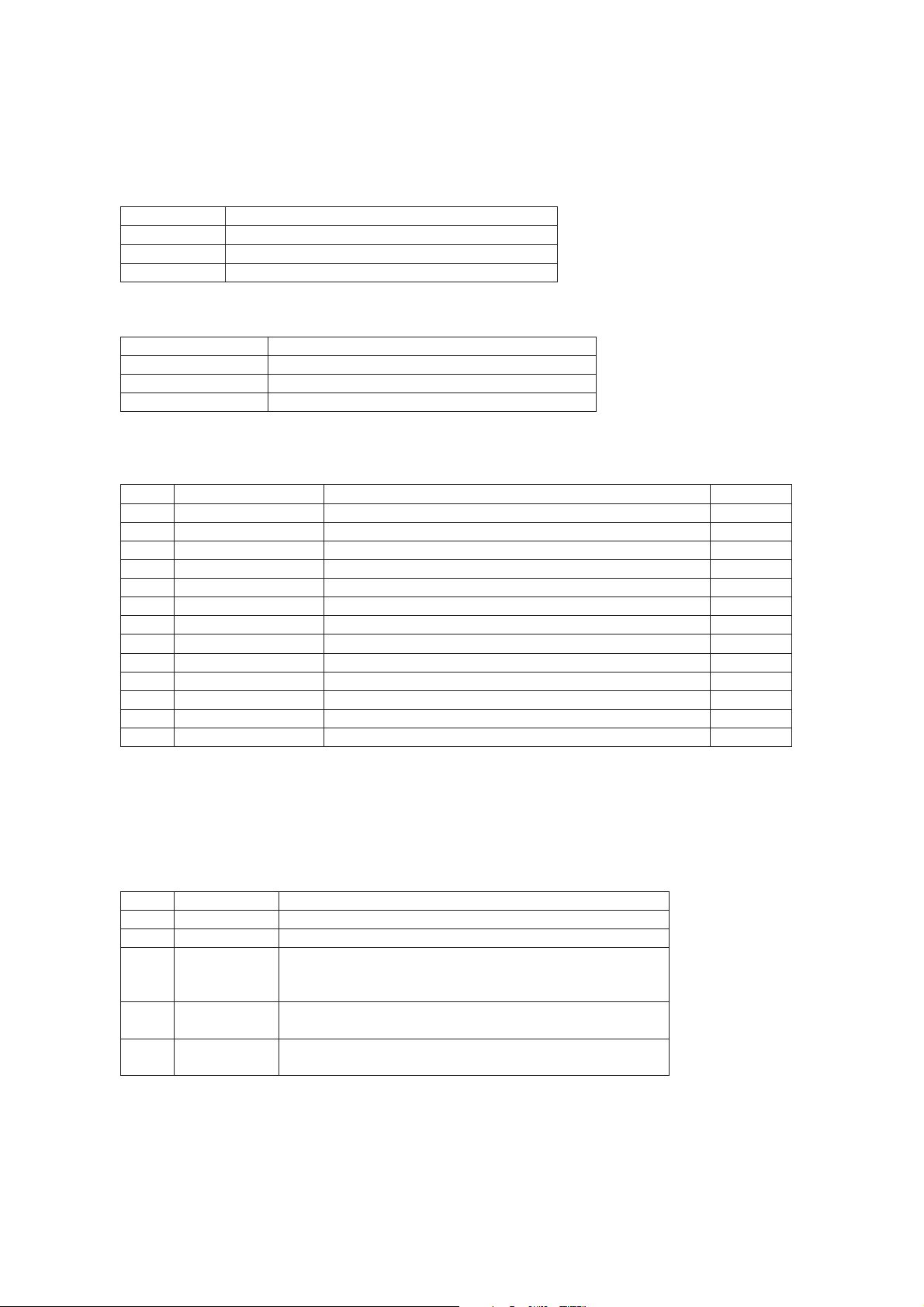

3 Selection of test mode

13 test modes are selected by pressing UPIDOWN keys.

No. Display Description Section

1 TEMP ADJUST The work of adjustment is unnecessary in this mode 6-5

2 LDPWR ADJUST Laser power adjustment 6-6

3 LDPWR CHECK Laser power check 6-6

4 EFBAL ADJUST Traverse adjustment 6-7

5 TE B. ADJUST Automatic EF balance adjustment

6 FBIAS ADJUST Focus bias adjustment 6-8

7 CPLAY MODE Continuous playback mode 5-4

8 CREC MODE Continuous recording mode 5-5

9 STT-LIMIT SW Check the mechanism start limit SW position 10 JUMP MODE Track jump checking mode 11 SRV DAT READ Servo data reading 12 EEP MODE E2PROM data reading or rewrite -

13 EEP INITIAL E2PROM data initializing For more information on each adjustment mode, refer to each section of 6, "Electrical adjustment".

If other adjustment mode has been entered incorrectly, press the STOP key to exit the mode.

*The number 9 -13 are not used for service. If these modes have been entered incorrectly, press the STOP key

immediately to exit the mode. Specially, do not use EEP INITIAL. (E2PROM data has initialized if used it.)

4 continuous Playback Mode

1. Setting of Continuous Playback Mode

No. Key Display/Function

1 MULTI JOG Select [CPLAY MODE]

2 Load disc

3 PL AY [CPLAY MID]

[c=xxxx a=yy] error

(xxxx=C1 error, yy=ADIP error)

4 DISPLAY [CPLAY (zzzz)] CPLAY address

(MID=0300h, OUT=0700h, IN=0030h cluster)

5 DIS PLAY [h****d@@@@] address

(****=current head address, @@@@=ADIP address

In No.5, Display shows [-] if can't read disc.

3

Page 6

2. Change of Playback Points (In continuous playback mode)

No. Key Display/Function

1 PL AY [CPLAY OUT]

2 Carry out No.4 and 5 in the above table

3 PL AY [CPLAY IN]

4 Carry out No.4 and 5 in the above table

5 ST OP [CPLAY MODE]

6 EJECT Disc out

5 Continuous Recording Mode

1. Continuous Recording Setting

No. Key Display/Function

1 MULTI JOG Select [CREC MODE]

2 Load the recordable disc

3 PLAY [CREC MID]

4 PLAY [CREC (zzzz)] CREC address

(0300h cluster = recording start point)

5 DIS PLAY [h****d@@@@] address

6 DISPLAY [c=xxxx a=yy] error

7 DISPLAY [CREC (zzzz)]

8 STOP [c=xxxx a=yy]

2. Change and End of Recording Points

No. Key Display/Function

1 Carry out No.1 to 3 in the above table Select [CREC MID]

2 MULTI JOG [CREC OUT]

3 PLAY [CREC (zzzz)] CREC address

(0700h cluster = recording start point)

Carry out No.5 to 8 in the above table

4 Carry out No.1 to 3 in the above table

5 PL AY Select [CREC MID]

6 MULTI JOG Select [CREC IN]

7 PLAY [CREC (zzzz)] CREC address

(0300h cluster = recording start point)

Carry out No.5 to 8 in the above table

8 EJ ECT Disc out

Starting address is the followings.

IN=30h cluster, MID=300h cluster, OUT=700h cluster

1. The recording start addresses of IN, MID, and OUT are described below.

IN 30H cluster

MID 300H cluster

OUT 700H cluster

2. An erasure prevention control is not detected in the test mode. Be careful not to enter the continuous recording

mode using a disc containing the data that should not be erased.

3. Do not record continuously for more than five minutes.

4. Take care that no vibration is applied during continuous recording.

Electrical adjustment

1 Precaution during confirmation of Laser Diode emission

During adjustment, do not view the emission of a laser diode from lust above for confirmation. This may damage

your eyes.

4

Page 7

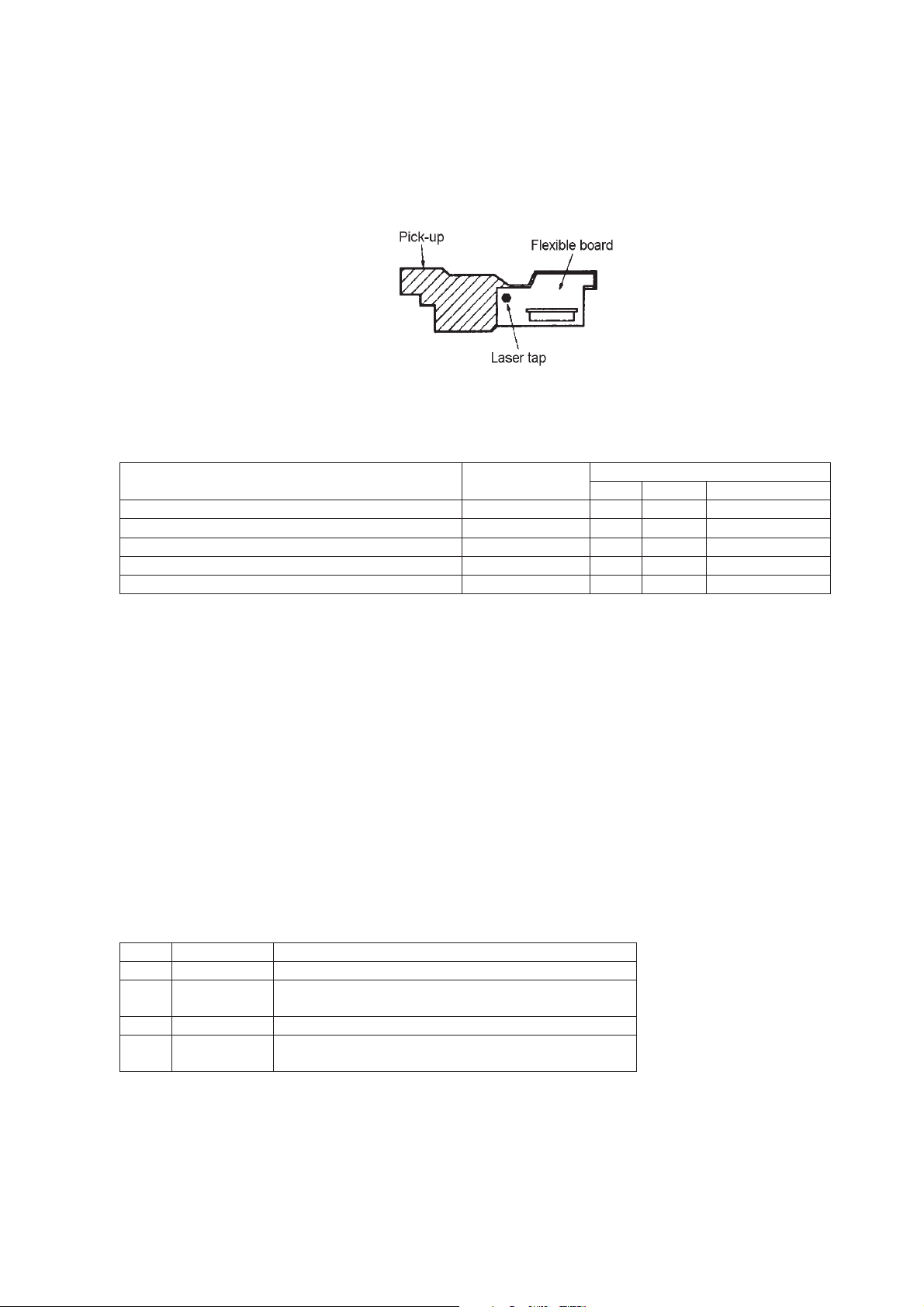

2 Precaution on handling of Optical pick-up (KMS-260B)

The laser diode in an optical pick-up is easy to be subject to electrostatic destruction. Therefore, solder-bridge the

laser tap on the flexible board when handling the optical pick-up.

When removing the flexible board from the connector, make a solder bridge in advance, then remove the board. Be

careful not to remove the solder bridge before inserting the connector. Moreover, take careful measures against

electrostatic destruction. The flexible board is cut easily. Handle the flexible board with care.

3 Precaution during adjustment

1) Perform the adjustment and confirmation marked with "O" in the order shown in the table when the parts below

are replaced.

Optical pick-up

IC6 D101 IC1, IC2, IC10

BD board

1.Temperature compensation offset adjustment X O O O

2. Laser power adjustment O O X O

3.Trtvense adjustment O O X O

4. Focus bias adjustment O O X O

5. Error rate confirmation O O X O

2) In the test mode, perform the adjustment. After adjustment is completed, chancel the test mode.

3) Perform the adjustment in the order described.

4) Use the following tools and measurement equipment.

CD test disc TGYS-1

Laser power meter

Oscilloscope (with bandwidth of more than 40 M Ohms)

(Calibrate the probe before measurement)

Digital voltmeter

Thermometer

5) Take care that VC and GND (ground) are not connected on the oscilloscope when two or more signals are monitored on the oscilloscope. (VC and GND are short-circuited in this case,)

4 Creating the recordable continuous recording disc

This disc is used for focus bias adjustment and error rate confirmation. How to create the recordable continuous

recording disc is 5-5

5 Offset Adjustment

No. Kay Display/Function

1 MULTI JOG Select [TEMP ADJUST]

2 PLAY [TEMP = xx (yy)]

(xx = compensation data, yy = setting temperature

3 MULTI JOG Input "yy" with present temp.

4 PL AY [TEMP=**SAVE]

[TEMP ADJUST] in writing data

5

Page 8

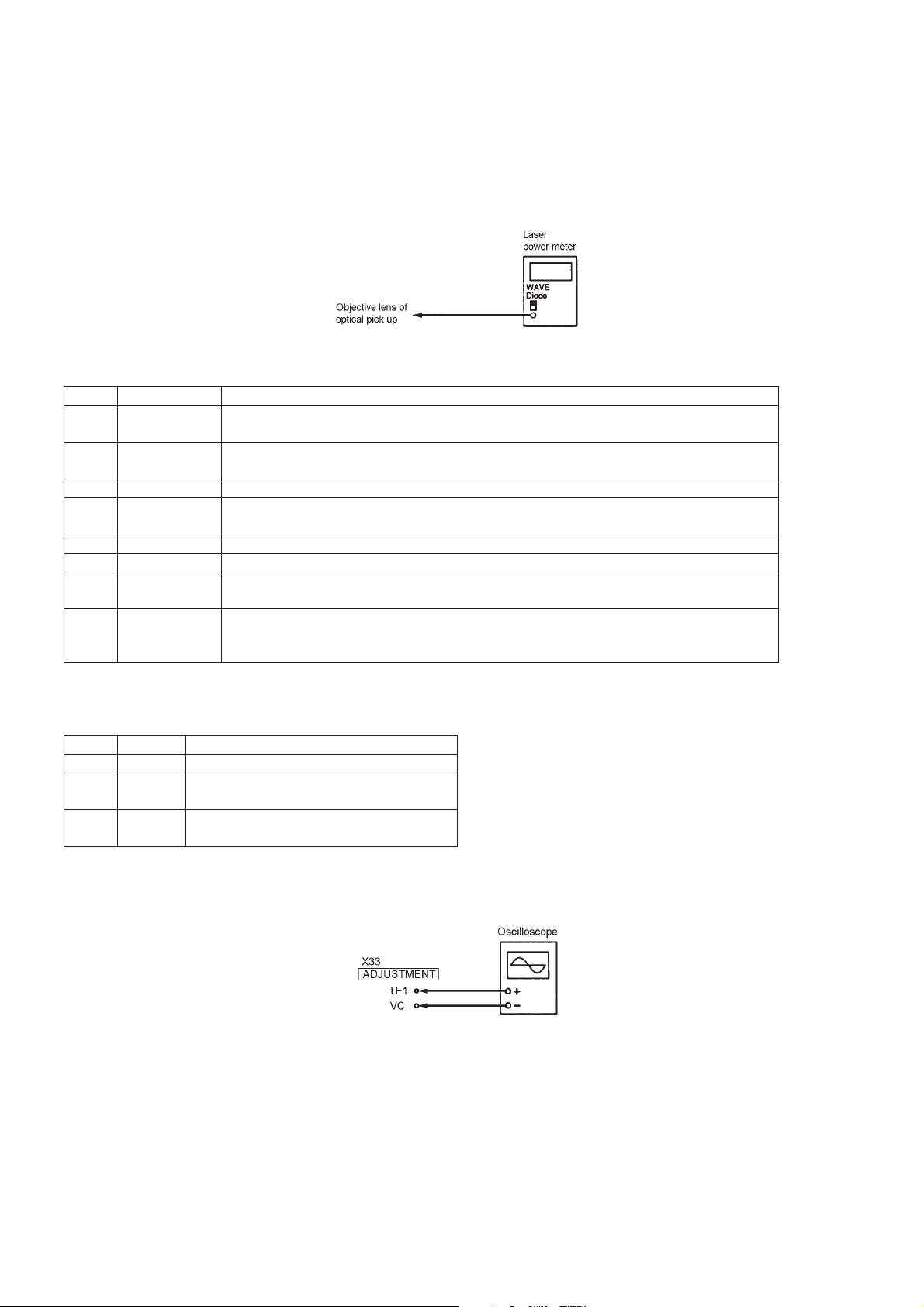

6 Laser Power Check and Adjustment

Laser power setting in playback and recording modes.

Preparation

1. Remove the MD mechanism from the unit

2. Remove the case and bracket.

3. Reconnect the flat cable of MD mechanism to the unit

1. Laser Power Adjustment

No. Key Display/Function

1 MULTI JOG [LDPWR ADJUST]

Load recordable disc

2 Load the disc and laser on [a0.9mW>$xx] read power

(xx = power value)

3 EJECT Unload the disc and laser on

4 FF/FB

(REC)

Move the pickup to check the laser power with laser power meter sensor

(Press the REC key if the pickup is In the proper position)

5 MULTI JOG Adjust “xx” so that the power meter shows 0.9mW.

6 PLAY [a7.0mW>$xx] writing power

7 UPIDOWN Adjust “xx” so that the power meter shows 7.0mW.

This adjustment should be carried out In 15secs.

8 PLAY Laser power off

Display shows [LDPWR ADJUST] after [LDPWR<$xx] to save the data In

E2PROM

Start from No.2 if readjust.

2. Laser Power Check

No. Key Display/Function

1 UP [LDPWR CHECK]

2 PL AY [c0.9mW>$xx]

(xx=0.85 to 0.95mW)

3 PL AY [c7.0mW>$xx]

Laser power meter: 7.0 + - 1.0mW*

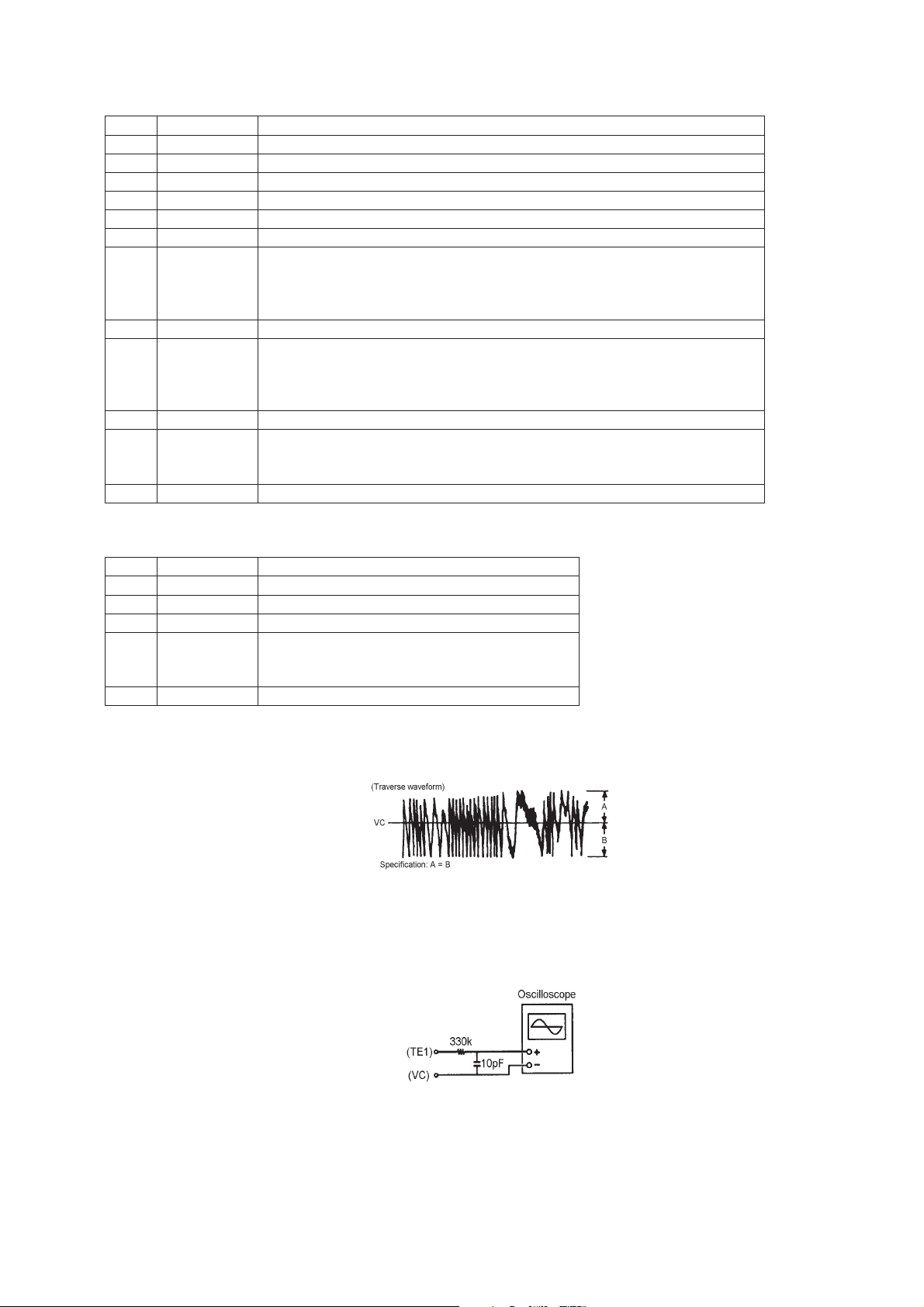

7 Traverse Adjustment

V: 0.5V/div H: 10ms/div

INPUT: DC mode

6

Page 9

FE Balance

1. Recordable Disc

No. Key Display/Function

1 Connect the oscilloscope to TE1 and VC in X33 PCB

2 MULTI JOG Select [EFBAL ADJUST]

3 Load the recordable disc

4 PL AY [EFBAL MO-W]

5 PL AY [EF=$**MOW]

6 MULTI JOG Write adjustment. Adjust the waveform as follows.

7 PLAY Display shows [EF=$**MOR] after [EFB=**xSAVE] to save the data in

E2PROM.

Mode changes write to read

Focus and disc servo are on. Tracking servo off.

8 MULTI JOG Read power adjustment. Adjust the waveform as follows.

9 PL AY

PLAY

Save the data in E2PROM.

Display shows [EFBAL MO-P]

Display shows [EF=$**MOP]

(Pickup travels to search pits and tune the servo to on.)

10 MULTI JOG Adjust the waveform as follows.

11 PLAY Display shows [EFBAL CHANGE] after [EFB=**xSAVE] to save the data

in E2PROM.

Display shows [EFBAL CHANGE] disc motor stops.

12 EJECT Unload disc.

2. PER Master Test Disc (TGYS-1)

No. Key Display/Function

1 Load the disc (TGYS-1).

2 PLAY [EF=$**CD] servo is on

3 MULTI JOG Adjust the waveform as follows.

4 Save the data in E2PROM.

Display shows [EFB=**xSAVE] in brief time.

[EFBAL ADJUST]

5 EJ ECT Unload disc.

During this adjustment, the oscilloscope changes in units of about 2%. Adjust so that the waveform comes nearest to

the specified value. (MO groove read power traverse adjustment)

Notes:

1. Data is erased during MO write when a recorded disc is used for this adjustment

2. If the traverse waveform is difficult to be monitored, connect an oscilloscope as shown in the figure below.

7

Page 10

8 Focus Bias Adjustment

Use the special disc (continuous recorded disc)

No. Key Display/Function

1 MULTI JOG Select [FBIAS ADJUST]

2 Load the disc.

3 PLAY [a=xx yyyy/zz] point a

(xx = focus bias yyyy = C1error)

4 UP Adjust "yyyy" to 220*

5 PLAY [b=xx yyyy/zz] point b

6 DOWN Adjust "yyyy" to 220*

7 PLAY [xx yyyy/zzc=] point c

Check "yyyy" within 50

8 PLAY Display shows [aa bb cc(xx)] focus bias adjust

(aa = point a, bb=b, cc=c )

Notes:

1. The relation between the C1 error and focus bias value is shown in the figure below. Points "a" and "b" in the

figure are detected by the above adjustment. Focal position "C" is automatically obtained from points "a" and “b”

by calculation.

2. The C1 error rate fluctuates. Therefore, perform the adjustment according to the observed mean value.

9 Error Rate Check

1. CD Error Rate

No. Key Display/Function

1 MULTI JOG [CPLAY MODE]

2 Load the test disc (TGYS-1)

3 PLAY Display shows [CPLAY MID]

Access and

[c=xxxx a=yy] xxxx=C1 error (lower 20) yy = AIDP error

4 ST OP [CPLAY MODE]

5 EJ ECT Unload disc.

2. MO Error Rate

No. Key Display/Function

1 MULTI JOG [CPLAY MODE]

2 Load the recordable disc

3 PLAY Display shows [CPLAY MID]

Access and

[c=xxxx a=yy] xxxx=C1 error (lower 50) yy = AIDP error (00)

4 ST OP [CPLAY MODE]

5 EJ ECT Unload disc.

8

Page 11

3. WIRING DIAGRAM

9 10

Page 12

4. BLOCK DIAGRAM

11 12

Page 13

5. SCHEMATIC DIAGRAM

13 14

Page 14

6. PARTS LOCATION (Pattern Side)

REC BOARD

MAIN BOARD

IC12

Q20

IC9

IC8

Q10

Q12

IC7

Q8

Q9

IC11IC10

15 16

Page 15

MAIN BOARD

IC1

IC3

IC2

REC BOARD

Q2

Q1

Q14 Q15

IC4

Q21

Q4L

Q3L

Q4R

Q3R

Q19

Q16-Q18

Q5-Q7

IC13

17 18

Page 16

FRONT BOARD

Q302

Q303 - Q306

Q300

Q301

Q307

19 20

Page 17

7. IC DATA

IC1/3/4:NJM2068

Pin Configuration

IC7:TL431

Pin Assignment

Functional Block Diagram

REF

LP PACKAGE

(TOP VIEW)

CATHODE

V

ref

CATHODE

ANODE

REF

+

_

ANODE

21

Page 18

IC2:KIC9459N

PIN CONNECTION

PIN DESCRIPTION

22

Page 19

Outline 64P2G-A

out puts

out puts

55

54

53

52

51

50

49

48

47

46

45

44

43

42

39

36

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

27

29

30

31

32

41

40

38

37

35

34

64

63

62

61

59

57

56

XOUT

XIN

DIG12/SEG36

DIG13/SEG37

DIG14/SEG38

DIG15/SEG39

input

bidirectional ports

out puts

segment

out puts

PIN CONFIGURATION

RESET

SCK

SDATA

XIN ,

XOUT

P1, P0

Vcc1

Vcc2

Vss

Vp

Symbol

Pin name

Comment

Reset input

CS

Chip select

When "L", M66005 is initialized.

When "L", communication with the MCU is possible.

When "H", any instruction from the MCU is neglected.

Shift clock input

Serial input data is taken and shifted by the positive edge of SCK.

Serial data input

Clock input

Clock output

When use as a CR oscillator, connect external resistor and

capacitor.

When use an external clock, input external clock to XIN, and

XOUT must be opened.

DIG00~

DIG15

Digit output

Connect to digit (grid) pins of VFD.

Connect to segment (anode) pins of VFD. Pins from SEG00 to

SEG39 correspond to segment pins of VFD as shown in the table

below. SEG36~SEG39 pins are common to DIG12~DIG15 pins.

So, when use SEG36~SEG39, the number of digit to be used is

decreased.

Segment output

Universal port

Generally, use this port as the static output port.

This port also operates as the timing IN/OUT port to control

another M66005.

Positive power supply for internal logic.

Positive power supply for DIG and SEG outputs.

GND (0V)

Negative power supply to pull down.

SEG00~

SEG39

P1 : bidirectional

P0 : output

PIN DESCRIPTIONS

IC300:M66005F

1

DIG11

Digit /

2

DIG10

3

DIG09

4

DIG08

60

5

DIG07

Vcc2

SEG00

6

DIG06

Digit

SEG01

58

7

DIG05

SEG02

8

DIG04

SEG03

9

DIG03

SEG05

SEG04

DIG02

DIG01

SEG06

DIG00

SEG07

RESET

Reset input

SEG08

CS

Chip select input

SEG10

SEG09

SCK

SDATA

Serial data

Shift clock input

Segment

SEG12

SEG11

P1

P0

Universal

SEG13

Vcc1

SEG14

Clock output

SEG16

SEG15

Vss

Clock input

SEG17

SEG35

SEG18

SEG34

SEG19

SEG33

SEG20

26

SEG32

Segment

SEG21

SEG31

SEG22

28

SEG30

SEG23

SEG29

SEG24

SEG28

SEG25

SEG27

SEG26

33

Vp

input

23

Page 20

IC13:74HC04

PIN DESCRIPTION

PIN NO. SYMBOL NAME AND FUNCTION

1, 3, 5, 9, 11, 13 1A to 6A data inputs

2, 4, 6, 8, 10, 12 1Y to 6Y data outputs

7 GND ground (0 V)

14 V

CC

positive supply voltage

Fig.1 Pin configuration.

Fig.4 Functional diagram.

24

Fig.5 Schematic diagram

(one inverter).

Page 21

IC6:CXP84648

25 A_MUTE OUTPUT A_MUTE ACTIVE LOW O

26 D_MUTE OUTPUT D_MUTE ACTIVE LOW O

27 N.C I/O

28 PO_OFF_CONT OUTPUT FOR RLY ACTIVE HIGH O

29 BACKUP_V I

30 RESET INPUT CPU ACTIVE HIGH I

31 EXTAL OUTPUT FOR 12.288MHZ CRYSTAL O

32 XTAL 12.288MHZ CRYSTAL

33 VSS GND

34 32MHZ CRYSTAL

35 TEX OUTPUT FOR 32MHZ CRYSTAL O

36 AVSS AVSS GND

37 AVREF REFERENC VOLTAGE VDD

38 BACKUP_CH OUTPUT BACKUP CHACK O

39 KEY1 DATA INPUT KEY SCAN CHECK PORT for AD KEY INPUT O

40 KEY2 DATA INPUT KEY SCAN CHECK PORT for AD KEY INPUT O

41 KEY3 DATA INPUT KEY SCAN CHECK PORT for AD KEY INPUT O

42-45 N.C I/O

46 FL_RESET OUTPUT RESET FOR M66005 O

47 FL_CS OUTPUT CS FOR M66005 O

48-54 N.C I/O

55 RC5 SY IN/OUT SYSTEM CONTROL "HIGH": SYSTEM MODE, "LOW": INT MODE O

56 RMC OUTPUT FOR REMOCON DATA O

57-59 N.C O

60 PO_OFF_DET OUTPUT FOR POWER DOWN O

61 N.C I/O

62 N.C I/O

63 RC5_OUT OUTPUT FOR CONTROLING RC-5 O

64 RC5_IN INPUT FOR CONTROLING RC-5 I

65 FL_CLK OUTPUT CLK FOR M66005 O

66 N.C I/O

67 FL_DATA OUTPUT DATA FOR M66005 O

68 ENCODER I

69 ENCODER I

70 BACK/PO_ON OUTPUT TO DRIVE POWER ON(GREEN) ACTIVE HIGH O

71 ST-BY OUTPUT TO DRIVE STBY LED(RED) ACTIVE HIGH O

72 VDD VDD +5V

73 VDD VDD +5V

74 RMC-CONTROL OUTPUT FOR RC-5 ON/OFF O

75-80 N.C I/O

VSS

TX

PIN NO PIN NAME OPERATION DESCRIPTION ASSIGN

PIN ASSIGNMENT

PIN FUNCTION

PIN NO PIN NAME OPERATION DESCRIPTION ASSIGN

1-3 N.C I/O

4 ME_CTXD UART Communication O

5 ME_CRXD UART Communication I/O

6-13 N.C I/O

14 ME_BACK_ON O

15 CE O

16 M E_RESET O

17-19 N.C I/O

20 OPTION PULL-UP(ENG) / PUII-DOWN(JAP) I/O

21 N.C I/O

22 VOL_CLK CLK SIGNAL OUTPUT 9459F ELECTRONIC VOLUME CONTROL O

23 VOL_EN EN SIGNAL OUTPUT 9459F ELECTRONIC VOLUME CONTROL O

24 VOL_DA DA SIGNAL OUTPUT 9459F ELECTRONIC VOLUME CONTROL O

25 26

Page 22

8. EXPLODED VIEW AND PARTS LIST

49

E X2

H

A X2

E

B

2

E X2

46

45

L X4

12

K X7

11

K X2

10

8 X3

PD

9

F X2

23

7 X3

6 X3

5

22 X4

21 X3

20

24

M X2

25

26

K

13

K X2

A

27

14

A

A

A

48

18

47

16

15

A

28

D X4

A X4

38 X2

17

C X7

39 X2

4 X2

3

1

36

TL

29

30

TA X2

31

19

J X3

A1

35

34

H

33

32

PF

I

PC

37

44

43

42

41

40

G

27 28

Page 23

POS.

NO

VERS.

COLOR

PART NO.

(FOR PCS)

DESCRIPTION

PART NO.

(MJI)

POS.

NO

VERS.

COLOR

PART NO.

(FOR PCS)

DESCRIPTION

PART NO.

(MJI)

1 9965 000 11414 PANEL DOOR 325W162010

A nsp SCREW +2S 3x8

2 nsp LABEL LASER CAUTION-CD nsp

3 9965 000 10697 ARM DOOR L 323W002010

B nsp SCREW +2S 3x17

4 9965 000 10698 CUSHION DOOR 323W259010

A1 9965 000 11415 FRONT PANEL SUB ASSY 325W248500

5 nsp PANEL FRONT nsp

6 nsp BUTTON POWER B nsp

7 nsp BUTTON POWER A nsp

8 9965 000 11103 BUTTON DISPLAY 325W270040

9 9965 000 10701 DAMPER GEAR (KIFCO) 323W130010

10 9965 000 10702 BRACKET DOOR C 323W160060

11 nsp P.C.B ASSY FRONT nsp

12 nsp CHASSIS MAIN nsp

13 F nsp POWER TRANS

*TS001340R

100V/50HZ 57x27

13 N 9965 000 11416 POWER TRANS

*TS001330R

C nsp SCREW +2S 3x10

D nsp SCREW +3S 4x8

E nsp SCREW +2S 3x8

F nsp SCREW +2S 2x6 BK/PH nsp

G nsp SCREW +2S 3x8 PI9.5

H nsp SCREW +2S 3x5

I nsp SCREW +3S 3x5 BK/FH nsp

J nsp SCREW +2S 3x6

230V/50HZ 57x27

14 nsp BRACKET SIDE nsp

15 nsp SUPPORTER PCB nsp

16 F nsp CHASSIS BACK nsp

16 N nsp CHASSIS BACK nsp

17 F nsp STOPPER 323W259020

17 N 9965 000 11058 STOPPER 323W259030

18 F nsp MAINS CORD ASSY *YC000560R

18 N 9965 000 10705 MAINS CORD ASSY *YC000570R

K nsp SCREW +2S 3x8 ZNY/PH nsp

L nsp SCREW +3S 2.6x4 ZNW/BH nsp

M nsp SCREW 2PS 3x8Y nsp

PACKING

- N 9965 000 11419 USER GUIDE 325W851310

- F nsp USER GUIDE 325W851110

- N 9965 000 11420 REMOTE CONTROLLER

19 9965 000 11202 KNOB SHUTTLE 325W154010

20 9965 000 10708 BADGE MARANTZ 323W251010

- F nsp REMOTE CONTROLLER

21 9965 000 11109 BUTTON MENU 325W270010

22 9965 000 11110 BUTTON REC 325W270020

23 nsp WINDOW DISPLAY MD nsp

24 9965 000 11417 DOOR MD 325W162100

25 9965 000 11418 SPRING MD 325W115010

26 nsp BRACKET MD DOOR nsp

27 nsp SUPPORTER FLT MD nsp

28 nsp SUPPORTER P.C. nsp

29 9965 000 10709 WINDOW REMOCON B 323W158030

30 9965 000 10713 ARM DOOR R 323W002020

31 9965 000 11111 PLATE EARTH A 323W123010

32 9965 000 10714 SPRING DOOR C 323W115010

33 9965 000 10715 KNOB EJECT 323W154020

34 nsp SUPPORTER EJECT nsp

35 nsp WINDOW REMOCON A nsp

36 9965 000 10716 BRACKET DOOR A 323W160010

37 9965 000 10717 SPRING DOOR A 323W115020

38 9965 000 10718 CUSHION FOOT F 323W057010

39 9965 000 10719 CUSHION FOOT B 323W057020

40 9965 000 10720 HOLDER HINGE B 323W271020

41 9965 000 10721 HOLDER HINGE A 323W271010

42 9965 000 10703 SPRING DOOR B 323W115030

43 9965 000 10722 BRACKET DOOR B 323W160020

44 9965 000 10723 RING 323W353100

45 nsp BRACKET MECHA MD nsp

46 nsp MD MODULE MGM-07000A KPJ 325W304500

47 N nsp P.C.B ASSY MAIN nsp

47 F nsp P.C.B ASSY MAIN nsp

48 N nsp P.C.B ASSY REC nsp

48 F nsp P.C.B ASSY REC nsp

NOT STANDARD SPARE

49 9965 000 11113 CABINET TOP 324W257010

PC nsp PLATE EARTH "C" nsp

PF nsp PLATE EARTH "F" nsp

PD nsp PLATE EARTH "D" nsp

TA nsp TAPE ARM nsp

TL nsp TAPE LENS nsp

- N nsp CARD nsp

- F nsp CARD nsp

- F nsp CARD nsp

- nsp BOX,GIFT 325W801010

- nsp CUSHION,SNOW 323W809010

NOTE : "nsp" PART IS LISTED FOR REFERENCE ONLY, MARANTZ WILL NOT SUPPLY THESE PARTS.

29

B-TYPE ZNY/BH

nsp

nsp

B-TYPE ZNY/BH

nsp

B-TYPE(DOT) BK/BH

nsp

P+S-WASHER ZNY/BH

nsp

B-TYPE CR/BH

nsp

B-TYPE ZNY

nsp

B-TYPE BK/FH

nsp

B-TYPE ZNY/BH

ZK326W0010

RC110DRMD

ZK325W0010

RC110DRMDF

PARTS

Page 24

40

13

39

39

39

39

39

1

31

10

41

40

28

19

45

38

38

38

53

46

49

14

B

18

9

A

44

36

54

47

43

30

36

D

35

15

C

48

6

B

23

2

35

37

16

24

31

3

35

42

35

8

27

21

39

22

27

44

5

29

36

20

41

55

17

27

25

32

26

35

11

7

33

59

58

4

34

30

C

35

56

36

36

51

27

12

36

A

50

52

D

57

35

35

Page 25

POS.

NO

VERS.

COLOR

PART NO.

(FOR PCS)

DESCRIPTION

PART NO.

(MJI)

POS.

NO

VERS.

COLOR

PART NO.

(FOR PCS)

DESCRIPTION

PART NO.

(MJI)

1 nsp A10-3531 CHASSIS(TU) nsp

2 nsp J19-6125 BRACKET ASSY nsp

3 nsp G02-1716

nsp

FLAT SPRING(THRUST)

4 nsp D13-2510 RACK(GEAR) nsp

5 nsp D10-3958 LEVER(LIMIT) nsp

6 nsp A11-1189 SUB CHASSIS ASSY nsp

7 nsp D10-3959 ARM ASSY(MAIN) nsp

8 nsp D10-3961 LEVER ASSY(HEAD) nsp

9 nsp D10-3963 SLIDER(MAIN) nsp

10 nsp D13-2511 GEAR(FINAL) nsp

11 nsp J19-6127 HOLDER ASSY nsp

12 nsp A15-0106 FRAME nsp

13 nsp F11-0503 SHIELDING CASE nsp

15 nsp D10-3982 ROD(SUB) nsp

16 nsp D10-3957 ROD nsp

18 nsp A11-1187

nsp

SUB CHASSIS ASSY(TU)

19 nsp D13-2504 GEAR(LOAD A) nsp

20 nsp D13-2505 GEAR(LOAD B) nsp

21 nsp D13-2516 GEAR(LOAD C) nsp

24 nsp D13-2509 GEAR

nsp

(INTERMEDIATE)

25 nsp D10-3964 SLIDER(LOAD) nsp

26 nsp D10-3965 ARM(LOAD) nsp

27 nsp J02-1492 INSULATOR nsp

28 nsp G01-4230

nsp

TORSION COIL SP(SPM)

29 nsp G01-4231

nsp

EXTENSION COIL SPRING

30 nsp G01-4235

nsp

EXTENSION COIL SPRING

31 nsp G01-4233

nsp

TORSION COIL SPRING

32 nsp G01-4234

nsp

EXTENSION COIL SPRING

33 nsp N39-1745

nsp

MACHINE SCREW 1.7*4.5

34 nsp N09-3104

nsp

MECHINE SCREW 1.7*2

35 nsp N09-3279

nsp

MACHINE SCREW 1.7*3

36 nsp N09-5113

nsp

SCREW 1.7*7 (B-TITE)

37 nsp N09-5229 SCREW 1.4*1.8 nsp

38 nsp N09-5230

nsp

SCREW 1.4*2.2 (S-TITE)

39 nsp N09-5231

nsp

SCREW 1.7*4 (B-TITE)

40 nsp N86-2004

nsp

BIND TAPTITE SC 2*4(S-TITE)

41 nsp N19-0366

nsp

FLAT WASHER 2.1*4*0.5CUT

42 nsp N19-1511

nsp

FLAT WS 2.5*0.9*0.25 CUT

43 nsp N19-1171

nsp

FLAT WS 1.6*3.5*0.25 CUT

44 nsp N09-5285

nsp

MACHINE SCREW(B) 1.7*4.5

45 nsp T42-0983 MOTOR ASSY *MM001170R

47 nsp E35-2689

nsp

WIRING HARNESS(SLED)

49 nsp E35-2690 WIRE HARNESS nsp

50 nsp E35-2691 FLAT CABLE L=80MM *YU000960R

51 nsp E35-2348 FLAT CABLE(PU) 21P *YU000970R

52 nsp X33-1260 PCB ASSY *ZZ001870R

53 nsp T42-0984 MOTOR ASSY(LOAD) *MM001180R

54 nsp T42-0985 MOTOR ASSY(SLED) *MM001190R

55 nsp D13-2506 GEAR ASSY nsp

56 nsp G16-1236 SHEET nsp

57 nsp G11-2825 SOFT TAPE nsp

58 nsp T25-0111-05 PICKUP KMS-260E *ZZ001880R

59 nsp T30-0027-05

*LH400180R

REC HEAD RM-21E

NOTE : "nsp" PART IS LISTED FOR REFERENCE ONLY, MARANTZ WILL NOT SUPPLY THESE PARTS.

31

Page 26

9. ELECTRICAL PARTS LIST

ASSIGNMENT OF COMMON PARTS CODES.

RESISTORS

R : 1) GD05 × × × 140, Carbon film fixed resistor, ±5% 1/4W

R : 2) GD05 × × × 160, Carbon film fixed resistor, ±5% 1/6W

Examples ;

Resistance value

➀

0.1 Ω .... 001 10 Ω .... 100 1 kΩ .... 102 100 kΩ .... 104

0.5 Ω .... 005 18 Ω .... 180 2.7 kΩ .... 272 680 kΩ .... 684

1 Ω .... 010 100 Ω .... 101 10 kΩ .... 103 1 MΩ .... 105

6.8 Ω .... 068 390 Ω .... 391 22 kΩ .... 223 4.7 MΩ .... 475

Note : Please distinguish 1/4W from 1/6W by the shape of parts

used actually.

CAPACITORS

C : CERAMIC CAP.

3) DD1 × × × × 370, Ceramic capacitor

Examples ;

Tolerance (Capacity deviation)

➁

±0.25 pF .... 0

Tolerance of COMMON PARTS handled here are as follows :

C : CERAMIC CAP.

Examples ;

C : 5) ELECTROLY CAP. ( ), 6) FILM CAP. ( )

Examples ;

0.5 pF 5 pF .... ±0.25 pF

Capacity value

➂

0.5 pF ....005 3 pF .... 030 100 pF .... 101

1.5 pF ....015 47 pF .... 470 560 pF .... 561

4) DK16 × × × 300, High dielectric constant ceramic

Capacity value

➃

100 pF .... 101 1000 pF .... 102 10000 pF ....103

470 pF .... 471 2200 pF .... 222

5) EA × × × × × × 10, Electrolytic capacitor

Capacity value

➄

0.1 µF.... 104 4.7 µF .... 475 100 µF ....107

0.33 µF.... 334 10 µF .... 106 330 µF ....337

Working voltage

➅

{

➂

{

{

➅

Resistance value

Disc type

Temp.coeff.P350 N1000, 50V

Capacity value

Tolerance

capacitor

Disc type

Temp.chara. 2B4, 50V

Capacity value

One-way lead type, Tolerance ±20%

Working voltage

Capacity value

2200 µF ....228

➀

{

➁

±0.5 pF .... 1

±5% .... 5

6 pF 10 pF .... ±0.5 pF

12 pF 560 pF .... ±5%

1 pF .... 010 10 pF .... 100 220 pF .... 221

➃

{

➄

1 µF....105 22 µF .... 226 1100 µF....118

6.3V.... 006 25V .... 025

10V .... 010 35V ....035

16V .... 016 50V ....050

NOTE ON SAFETY FOR FUSIBLE RESISTOR :

The suppliers and their type numbers of fusible resistors

are as follows;

1. KOA Corporation

Part No. (MJI) Type No. (KOA) Description

NH05 × × × 140 RF25S × × × × ΩJ(±5% 1/4W)

NH05 × × × 120 RF50S × × × × ΩJ(±5% 1/2W)

NH85 × × × 110 RF73B2A × × × × ΩJ(±5% 1/10W)

NH95 × × × 140 RF73B2E × × × × ΩJ(±5% 1/4W)

2. Matsushita Electronic Components Co., Ltd

Part No. (MJI) Type No. (MEC) Description

NF05 × × × 140 ERD-2FCJ × × × (±5% 1/4W)

RF05 × × × 140

NF02 × × × 140

RF02 × × × 140

Examples ;

{

Resistance value

ERD-2FCG

{

Resistance value

Resistance value

0.1 Ω .... 001 10 Ω .... 100 1 kΩ .... 102 100 kΩ .... 104

0.5 Ω .... 005 18 Ω .... 180 2.7 kΩ .... 272 680 kΩ .... 684

1 Ω .... 010 100 Ω .... 101 10 kΩ .... 103 1 MΩ .... 105

6.8 Ω .... 068 390 Ω .... 391 22 kΩ .... 223 4.7 MΩ .... 475

{

Resistance value

(0.1 Ω − 10 kΩ)

× × × (±2% 1/4W)

{

Resistance value

ABBREVIATION AND MARKS

ANT. : ANTENNA BATT. : BATTERY

CAP. : CAPACITOR CER. : CERAMIC

CONN. : CONNECTING DIG. : DIGITAL

HP : HEADPHONE MIC. : MICROPHONE

µ-PRO : MICROPROCESSOR REC. : RECORDING

RES. : RESISTOR SPK : SPEAKER

SW : SWITCH TRANSF. : TRANSFORMER

TRIM. : TRIMMING TRS. : TRANSISTOR

VAR. : VARIABLE X’TAL : CRYSTAL

NOTE ON FUSE :

Regarding to all parts of parts code FS20xxx2xx, replace

only with Wickmann-Werke GmbH, Type 372 non glass type

fuse.

6) DF15 × × × 350 Plastic film capacitor

DF15 × × × 310 One-way type, Mylar ±5% 50V

DF16 × × × 310 Plastic film capacitor

Examples ;

Capacity value

➆

0.001 µF (1000 pF) ....... 102 0.1 µF.... 104

0.0018 µF ........................ 182 0.56 µF.... 564

0.01 µF........................ 103 1 µF.... 105

0.015 µF ........................ 153

: 1) The above CODES ( R , R , C , C and

NOTE

C ) are omitted on the schematic diagram in some

case.

2) On the occasion, be confirmed the common parts on

the parts list.

3) Refer to “Common Parts List” for the other common

parts (RI05, DD4, DK4).

➆

{

One-way type, Mylar ±10% 50V

Capacity value

NOTE ON SAFETY :

Symbol Fire or electrical shock hazard. Only original

parts should be used to replaced any part marked with

symbol . Any other component substitution (other

than original type), may increase risk of fire or electrical

shock hazard.

010728MIT

32

Page 27

VERS.

POS.

COLOR

NO

C6L

C6R

C7L

C7R

C8L

C8R

C9L

C9R

C10L

C10R

C11

C12

C13

C14

C15

C16

C17

C18

9965 000 11120 CER.AC(SAFETY),

PART NO.

(FOR PCS)

DESCRIPTION

MAIN CIRCUIT BOARD

MAIN - CAPACITORS

nsp ELECT,22µF-M/16V,5x5-5RE nsp

nsp ELECT,22µF-M/16V,5x5-5RE nsp

nsp FILM,ST-0.0027µF-J/100V-5RE nsp

nsp FILM,ST-0.0027µF-J/100V-5RE nsp

nsp CER.CHIP,220pF-J/50V-1608 nsp

nsp CER.CHIP,220pF-J/50V-1608 nsp

nsp ELECT,22µF-M/16V,5x5-5RE nsp

nsp ELECT,22µF-M/16V,5x5-5RE nsp

nsp CER.CHIP,470pF-J/50V-1608 nsp

nsp CER.CHIP,470pF-J/50V-1608 nsp

nsp CER.CHIP,0.01µF-K/50V-1608 nsp

nsp CER.CHIP,10pF-D/50V-1608 nsp

nsp CER.CHIP,0.1µF-K/50V-1608 nsp

nsp CER.CHIP,22pF-J/50V-1608 nsp

nsp CER.CHIP,0.1µF-K/50V-1608 nsp

nsp CER.CHIP,0.1µF-K/50V-1608 nsp

nsp CER.CHIP,22pF-J/50V-1608 nsp

DE7150-487F 472MVAI

C19

C20

nsp CER.,0.01µF-Z/500V-5RE nsp

nsp ELECT,1000µF-M/25V(SHL),

10x20L-5RE OEMONLY

C21

C22

nsp ELECT,SHL 10000µF 16V M

nsp CER.CHIP,0.01µF-K/50V-1608 nsp

18x35 P=7.5MM

C23

nsp CER.,0.01µF-Z/500V-5RE nsp

C28

C29

C30

C31

C32

C33

C34

C35

C36

C37

C38

C39

C40

C41

C42

9965 000 11128 DOUBLE LAYER(70),

nsp CER.CHIP,0.01µF-K/50V-1608 nsp

nsp CER.CHIP,100pF-J/50V-1608 nsp

nsp ELECT,10µF-M/50V,5x11-5RE nsp

nsp ELECT,100µF-M/50V,8x11.5-5 nsp

nsp ELECT,10µF-M/50V,5x11-5RE nsp

nsp ELECT,2200µF-M/16V,10x20 nsp

nsp ELECT,2200µF-M/16V,10x20 nsp

nsp CER.CHIP,0.01µF-K/50V-1608 nsp

nsp CER.CHIP,27pF-J/50V-1608 nsp

nsp ELECT,470µF-M/10V,6.3x11-5 nsp

nsp CER.CHIP,100pF-J/50V-1608 nsp

nsp ELECT,1000µF-M/10V,10x12.5 nsp

nsp CER.CHIP,0.1µF-K/50V-1608 nsp

0.047F-70UA/5.5V-5RE

C43

C44

C45

C46

C47

C48

9965 000 11120 CER.AC(SAFETY),DE7150-487F

nsp CER.CHIP,0.1µF-K/50V-1608 nsp

nsp CER.CHIP,220pF-J/50V-1608 nsp

nsp CER.CHIP,220pF-J/50V-1608 nsp

nsp ELECT,1µF-M/50V,3x5-5RE nsp

nsp CER.CHIP,0.1µF-K/50V-1608 nsp

472MVAI

C49

C50

9965 000 11120 CER.AC(SAFETY),

nsp ELECT,10µF-M/50V,5x11-5RE nsp

DE7150-487F 472MVAI

C51

C52

C53

9965 000 11128 DOUBLE LAYER(70),

nsp CER.CHIP,27pF-J/50V-1608 nsp

nsp ELECT,2.2µF-M/50V,5x11-5RE nsp

0.047F-70UA/5.5V-5RE

C55

C56

C57

C58

R10

R11

nsp ELECT,47µF-M/16V,5x11-5RE nsp

nsp CER.CHIP,0.1µF-K/50V-1608 nsp

nsp CER.CHIP,18pF-J/50V-1608 nsp

nsp CER.CHIP,18pF-J/50V-1608 nsp

MAIN - RESISTORS

nsp CHIP,3.3K-J,1/16W-1608REEL nsp

nsp CHIP,3.3K-J,1/16W-1608REEL nsp

PART NO.

(MJI)

DK17472840

nsp

nsp

*EX000090R

DK17472840

DK17472840

*EX000090R

POS.

NO

R12

R13L

R13R

R14L

R14R

R15L

R15R

R16L

R16R

R17L

R17R

R18L

R18R

R19L

R19R

R20L

R20R

R21

R22

R23

R24

R25

R26

R27

R28

R29

R30

R31

R32

R33

R34

R37

R38

R39

R40

R41

R42

R43

R44

R45

R46

R47

R48

R49

R50

R51

R52

VERS.

COLOR

N

F

PART NO.

(FOR PCS)

DESCRIPTION

nsp CHIP,680-J,1/16W-1608REEL nsp

nsp CHIP,4.7K-J,1/16W-1608REEL nsp

nsp CHIP,4.7K-J,1/16W-1608REEL nsp

nsp CHIP,12K-J,1/16W-1608REEL nsp

nsp CHIP,12K-J,1/16W-1608REEL nsp

nsp CHIP,4.7K-J,1/16W-1608REEL nsp

nsp CHIP,4.7K-J,1/16W-1608REEL nsp

nsp CHIP,220-J,1/16W-1608REEL nsp

nsp CHIP,220-J,1/16W-1608REEL nsp

nsp CHIP,220-J,1/16W-1608REEL nsp

nsp CHIP,220-J,1/16W-1608REEL nsp

nsp CHIP,100-J,1/16W-1608REEL nsp

nsp CHIP,100-J,1/16W-1608REEL nsp

nsp CHIP,4.7K-J,1/16W-1608REEL nsp

nsp CHIP,4.7K-J,1/16W-1608REEL nsp

nsp CHIP,4.7K-J,1/16W-1608REEL nsp

nsp CHIP,4.7K-J,1/16W-1608REEL nsp

nsp CHIP,100K-J,1/16W-1608REEL nsp

nsp CHIP,100-J,1/16W-1608REEL nsp

nsp CHIP,75-J,1/16W-1608REEL nsp

nsp CHIP,100K-J,1/16W-1608REEL nsp

nsp CHIP,10K-J,1/16W-1608REEL nsp

nsp CHIP,2.2K-J,1/16W-1608REEL nsp

nsp CHIP,120-J,1/16W-1608REEL nsp

nsp CHIP,120-J,1/16W-1608REEL nsp

nsp 47-J,1/4W-R.REEL nsp

nsp 4.7-J,1/4W,R.REEL nsp

nsp CHIP,2.2K-J,1/16W-1608REEL nsp

nsp 5.6K-J,1/5W-52RE-AX nsp

nsp 22K-J,1/5W-52RE-AX nsp

nsp CHIP,10K-J,1/16W-1608REEL nsp

nsp 150-J,1W-R.REEL nsp

nsp 1.6K-J,1/5W-52RE-AX nsp

nsp 1.5K-J,1/5W-52RE-AX nsp

nsp 4.7K-J,1/5W-52RE-AX nsp

nsp CHIP,100-J,1/16W-1608REEL nsp

nsp CHIP,100K-J,1/16W-1608REEL nsp

nsp CHIP,4.7K-J,1/16W-1608REEL nsp

nsp CHIP,47K-J,1/16W-1608REEL nsp

nsp CHIP,47K-J,1/16W-1608REEL nsp

nsp CHIP,3.9K-J,1/16W-1608REEL nsp

nsp CHIP,1K-J,1/16W-1608REEL nsp

nsp CHIP,2.7K-J,1/16W-1608REEL nsp

nsp CHIP,100K-J,1/16W-1608REEL nsp

nsp CHIP,100K-J,1/16W-1608REEL nsp

nsp CHIP,100-J,1/16W-1608REEL nsp

nsp CHIP,10K-J,1/16W-1608REEL nsp

R57

R58

R59

R60

R65

R66

R67

R68

R69

R70

R71L

R71R

R73

R74

R75

R77

nsp CHIP,12K-J,1/16W-1608REEL nsp

nsp CHIP,12K-J,1/16W-1608REEL nsp

nsp CHIP,12K-J,1/16W-1608REEL nsp

nsp CHIP,47-J,1/16W-1608REEL nsp

nsp CHIP,1K-J,1/16W-1608REEL nsp

nsp CHIP,47-J,1/16W-1608REEL nsp

nsp CHIP,1K-J,1/16W-1608REEL nsp

nsp CHIP,1M-J,1/16W-1608REEL nsp

nsp CHIP,10K-J,1/16W-1608REEL nsp

nsp CHIP,680-J,1/16W-1608REEL nsp

nsp CHIP,680-J,1/16W-1608REEL nsp

nsp 1-J,1/4W-R.TYPE REEL nsp

nsp CHIP,47K-J,1/16W-1608REEL nsp

nsp CHIP,2.2K-J,1/16W-1608REEL nsp

nsp 1-J,1/4W-R.TYPE REEL nsp

PART NO.

(MJI)

NOTE : "nsp" PART IS LISTED FOR REFERENCE ONLY, MARANTZ WILL NOT SUPPLY THESE PARTS.

33

Page 28

VERS.

POS.

COLOR

NO

MAIN - SEMICONDUCTORS

D1

9965 000 11119 D CHIP,1SS355USM *HD201580R

D5

D6

9965 000 10728 DIODE,IN4007 52 1000V 1A *HD201570R

D9

D11

4822 130 32778 DIODE,1SS133T-72-52MM HD20015210

D12

4822 130 83067 D,RECTIFIER BRIDGE,

D13

9965 000 10728 DIODE,IN4007 52 1000V 1A *HD201570R

D20

D23

9965 000 11119 D CHIP,1SS355USM *HD201580R

D24

9965 000 11119 D CHIP,1SS355USM *HD201580R

D27

9965 000 11119 D CHIP,1SS355USM *HD201580R

D28

4822 130 32778 DIODE,1SS133T-72-52MM HD20015210

D29

4822 130 32778 DIODE,1SS133T-72-52MM HD20015210

D30

9965 000 11119 D CHIP,1SS355USM *HD201580R

D31

9965 000 11119 D CHIP,1SS355USM *HD201580R

D32

9965 000 11119 D CHIP,1SS355USM *HD201580R

IC4

5322 209 13406 IC,NJM2068MD-SOP8P *HC107380R

IC7

4822 209 81397 ILINEAR-REGULATOR,

IC8

4822 209 31631 IC,KIA7805PI,

IC9

4822 209 31631 IC,KIA7805PI,

PART NO.

(FOR PCS)

DESCRIPTION

D3SB20/DBF40C 5A-4PIN

TL431CLP 3PIN

20W-TO220IS MOLD

PART NO.

(MJI)

HE20020290

*HC300440R

HC3890509F

HC3890509F

POS.

NO

Q18

Q18

Q18

Q19

Q20

Q21

ZD1

ZD2

ZD3

ZD4

ZD5

CN1

CN2

CN3

20W-TO220IS MOLD

IC10

9965 000 11426 IC,ICP-N15

FU60115020

CN4

T104/PROTEC-REEL

IC11

9965 000 11426 IC,ICP-N15

FU60115020

CN5

T104/PROTEC-REEL

IC12

9965 000 11129 IC,KIA7032P,3.2V/TO92-RELL *HC107390R

IC13

9965 000 10992 IC,INVRTR

MC74HCU04AD SOP14

Q1

9965 000 11427 CHIP TRS.2SA,KRA103S (SOP) *BA001400R

Q2

4822 130 60729 CHIP TRS.2SC,

DTC124EK,0.2W/SMT-REEL

Q3L

9965 000 10744 CHIP TRS.2SC,

KTC2875B 0.15W/LOW-ON-RES

*HC700180R

*BA001080R

*HT300870R

F1

F1

F1L

F1R

GND1

SOT23(RTK)-REEL

Q3R

9965 000 10744 CHIP TRS.2SC,

KTC2875B 0.15W/LOW-ON-RES

SOT23(RTK)-REEL

Q4L

9965 000 10744 CHIP TRS.2SC,

KTC2875B 0.15W/LOW-ON-RES

SOT23(RTK)-REEL

Q4R

9965 000 10744 CHIP TRS.2SC,

KTC2875B 0.15W/LOW-ON-RES

SOT23(RTK)-REEL

Q5

4822 130 60729 CHIP TRS.2SC,

DTC124EK,0.2W/SMT-REEL

Q6

4822 130 60729 CHIP TRS.2SC,

DTC124EK,0.2W/SMT-REEL

Q7

9965 000 11427 CHIP TRS.2SA,KRA103S (SOP) *BA001400R

Q8

4822 130 50437 SEMI,BRT/NPN RC,DTC143ES,

0.3W/TO92M-REEL

Q9

9965 000 10444 SEMI,BRT/NPN RC,KRC107M,

0.4W/TO92M-REEL

Q10

4822 130 11683 SEMI,TR/GE PNP 2SA,

KSA916Y,0.9W/TO92L-REEL

Q12

9965 000 11425 SEMI,TR/GE NPN 2SD,

KTC2026Y TO220IS BULK 2W

Q14

4822 130 60326 CHIP TRS.2SA,

DTA144EK,0.2W/SMT-REEL

Q15

4822 130 60729 CHIP TRS.2SC,

DTC144EK,0.2W/SMT-REEL

Q18

N 9965 000 10753 CHIP TRS.2SC,

*HT300870R

*HT300870R

*HT300870R

*BA001080R

*BA001080R

*BA001300R

*BA001070R

*HT100460R

*HT300780R

*BA001050R

*BA001040R

*BA001220R

J8

J126

JACK1

JACK2

JACK3

JACK4

LT1

RL1

SW1

T1

T1

W1

W2

XTAL1

XTAL2

KRC102S T/P (KEC)

NOTE : "nsp" PART IS LISTED FOR REFERENCE ONLY, MARANTZ WILL NOT SUPPLY THESE PARTS.

34

VERS.

COLOR

N 4822 130 60729 CHIP TRS.2SC,

PART NO.

(FOR PCS)

DESCRIPTION

PART NO.

(MJI)

*BA001040R

DTC144EK,0.2W/SMT-REEL

F 9965 000 10753 CHIP TRS.2SC,

*BA001220R

KRC102S T/P (KEC)

F 4822 130 60729 CHIP TRS.2SC,

*BA001040R

DTC144EK,0.2W/SMT-REEL

9965 000 10753 CHIP TRS.2SC,

*BA001220R

KRC102S T/P (KEC)

4822 130 61227 SEMI,BRT/PNP RA,

*BA001330R

DTA114ES,0.3W/TO92M-REEL

4822 130 90326 CHIP TRS.2SA,

*BA001280R

DTA114TK,0.2W/SMT-REEL

9965 000 11210 D,ZENER,MTZJ20B-0.5W/

*HD301950R

5MA-52MM

4822 130 11627 D,ZENER,MTZJ15B-0.5W/

*HD302000R

5MA-52MM

4822 130 11627 D,ZENER,MTZJ15B-0.5W/

*HD302000R

5MA-52MM

4822 130 10667 D,ZENER,MTZJ4.7B-0.5W/

HD30471000

5MA-52MM

4822 130 80317 D,ZENER,MTZJ5.1B-0.5W/

HD30511000

5MA-52MM

MAIN - MISCELLANEOUS

nsp CN.FPC 1.0MM,

nsp

52806-2610 26P STRAIGHT

nsp CN.WAFER 2.5MM,5267-08A 8P nsp

nsp CN.FPC 1.0MM,

nsp

52806-1910 19P STRAIGHT

nsp CN.WAFER 2.0MM,

nsp

35336-1010 10P

nsp CN.WAFER 2.0MM,

nsp

35336-0510 5P

N 4822 070 31601 FUSE (5.2x20),

*FS000450R

250V-T160MA-S/V/B/R(YARN)

F

nsp FUSE (5.2x20),250V-S1A-U/ *FS000830R

nsp HOLDER,FUSE CLIP,

nsp

PI5.2-REEL

nsp HOLDER,FUSE CLIP,

nsp

PI5.2-REEL

nsp TERMINAL,

nsp

ALL PBST/GND PLATE-REEL

nsp CHIP,0-J,1/8W-3216REEL nsp

9965 000 10734 TER,RCA 4PIN,

*YT002460R

DAERYUNG/JK040131PN

9965 000 11212 MODULE,GP1F37R1/

*YJ002500R

OPTICAL TRANSMITE

9965 000 11127 TER,RCA 1PIN,

*YT002670R

JE010003PN(GND) BLACK

9965 000 11126 TER,RCA 2PIN,JK020130LN

*YJ002490R

(GND PLATE&PIN)/ORINGE

9965 000 11422 COIL,LINE FILTER,

*FN000150R

UU1116 1MH(411B)

9965 000 11424 RELAY,SDT-S-109LMR

*LY000280R

9V 250V/5A

9965 000 10732 SW,SLIDE,SSAF112NA011 *SS000700R

N 9965 000 11027 TRANS ST/BY,230/50 RV5080R

*TS001540R

28x25 Io=22MA 12.5Vx0.1A(DC)

F

nsp TRANS ST/BY,AVC5/

*TS001370R

100V 50HZ 28x15

nsp CN.WAFER 7.92MM,

nsp

YW396-32V 2P

nsp CN.WAFER 3.96MM,35328-0210 nsp

9965 000 11423 CRYSTAL,12.288MHZ,

*JX000890R

HC49U-CL;20pF

9965 000 11124 CRYSTAL,MX-38T(32.768KHZ)

*JX000830R

NDK

Page 29

VERS.

POS.

COLOR

NO

FRONT CIRCUIT BOARD

FRONT - CAPACITORS

C300

C301

nsp CER.CHIP,0.01µF-K/50V-1608 nsp

C304

C305

C306

C308

C309

nsp CER.CHIP,0.1µF-K/50V-1608 nsp

C312

C313

C314

C315

C316

C317

R300

R301

R302

R303

R304

R305

R306

R307

R308

R309

R310

R311

R312

R313

R314

R315

R316

R317

R318

R319

R320

R321

R322

R323

R324

R327

R328

R329

FRONT - SEMICONDUCTORS

D300

9965 000 11119 D CHIP,1SS355USM *HD201580R

D301

9965 000 11119 D CHIP,1SS355USM *HD201580R

IC300

9965 000 10762 IC,M66005FP-SOP64P /

Q300

9965 000 10753 CHIP TRS.2SC,KRC102S T/P

Q301

9965 000 10753 CHIP TRS.2SC,KRC102S T/P

Q302

9965 000 10753 CHIP TRS.2SC,KRC102S T/P

Q303

4822 130 60941 CHIP TRS.2SA,DTA114EK,

Q304

9965 000 11131 CHIP TRS.2SC,KRC104S (SOP) *BA001290R

Q305

4822 130 60941 CHIP TRS.2SA,DTA114EK,

Q306

9965 000 11131 CHIP TRS.2SC,KRC104S (SOP) *BA001290R

Q307

9965 000 10753 CHIP TRS.2SC,KRC102S T/P

NOTE : "nsp" PART IS LISTED FOR REFERENCE ONLY, MARANTZ WILL NOT SUPPLY THESE PARTS.

PART NO.

(FOR PCS)

DESCRIPTION

PART NO.

(MJI)

POS.

NO

ZD300

nsp ELECT,100µF-M/10V,6.3x5-5RE nsp

CP3

nsp CER.CHIP,0.1µF-K/50V-1608 nsp

nsp CER.CHIP,100pF-J/50V-1608 nsp

nsp ELECT,100µF-M/10V,6.3x5-5RE nsp

nsp CER.CHIP,220pF-J/50V-1608 nsp

nsp CER.CHIP,220pF-J/50V-1608 nsp

nsp CER.CHIP,220pF-J/50V-1608 nsp

nsp CER.CHIP,0.047µF-Z/50V-1608 nsp

nsp CER.CHIP,0.047µF-Z/50V-1608 nsp

FRONT - RESISTORS

nsp CHIP,1.5K-J,1/16W-1608REEL nsp

nsp CHIP,1.8K-J,1/16W-1608REEL nsp

nsp CHIP,2.2K-J,1/16W-1608REEL nsp

nsp CHIP,2.7K-J,1/16W-1608REEL nsp

FLT300

LED300

LED301

LED302

RM300

SW300

SW301

SW307

SW308

SW309

SW310

nsp CHIP,1.5K-J,1/16W-1608REEL nsp

nsp CHIP,1.8K-J,1/16W-1608REEL nsp

SW311

nsp CHIP,2.2K-J,1/16W-1608REEL nsp

nsp CHIP,1.5K-J,1/16W-1608REEL nsp

SW311

nsp CHIP,1.8K-J,1/16W-1608REEL nsp

nsp CHIP,2.2K-J,1/16W-1608REEL nsp

nsp CHIP,2.7K-J,1/16W-1608REEL nsp

nsp CHIP,47-J,1/16W-1608REEL nsp

nsp CHIP,270-J,1/16W-1608REEL nsp

nsp CHIP,270-J,1/16W-1608REEL nsp

nsp CHIP,270-J,1/16W-1608REEL nsp

nsp CHIP,1K-J,1/16W-1608REEL nsp

nsp CHIP,100-J,1/16W-1608REEL nsp

nsp CHIP,100-J,1/16W-1608REEL nsp

nsp CHIP,10K-J,1/16W-1608REEL nsp

nsp CHIP,27K-J,1/16W-1608REEL nsp

nsp CHIP,4.7K-J,1/16W-1608REEL nsp

nsp CHIP,4.7K-J,1/16W-1608REEL nsp

nsp CHIP,270-J,1/16W-1608REEL nsp

nsp CHIP,4.7K-J,1/16W-1608REEL nsp

nsp CHIP,1K-J,1/16W-1608REEL nsp

nsp CHIP,1K-J,1/16W-1608REEL nsp

nsp CHIP,1K-J,1/16W-1608REEL nsp

nsp CHIP,1.2K-J,1/16W-1608REEL nsp

SW312

C1L

C1R

C2L

C2R

C3L

C3R

C4L

C4R

C5L

C5R

R1L

R1R

R2L

R2R

R3L

FL DRIVER

*HC107180R

*BA001220R

(KEC)

*BA001220R

(KEC)

*BA001220R

(KEC)

BA10023210

0.2W/SMT-REEL

R3R

R4

R5

R6

R72L

R72R

R76L

R76R

R7L

R7R

R8L

0.2W/SMT-REEL

BA10023210

*BA001220R

(KEC)

R8R

R9L

R9R

35

VERS.

COLOR

4822 130 83142 D,ZENER,MTZJ6.2B-0.5W/

PART NO.

(FOR PCS)

DESCRIPTION

PART NO.

(MJI)

HD30621000

5MA-52MM

FRONT - MISCELLANEOUS

nsp CN.FPC 1.0MM,

nsp

52807-1910 19P ANGLE

9965 000 11421 DISPLAY FLT,

*HQ300480R

14-ST-37GN/MD110

9965 000 10758 LED,PI5-RD,

*HI100980R

GR/HLD50RG,DUAL

9965 000 10757 LED,HL-50CDG GREEN MILKY

*HI100970R

RESIN (MAN,5PI,P=2.5)

9965 000 10757 LED,HL-50CDG GREEN MILKY

*HI100970R

RESIN (MAN,5PI,P=2.5)

9965 000 10754 MODULE,REMOCON,

*HW100520R

NJL64H380A

9965 000 10760 SW,TACT, THVH472GAA *SP001150R

9965 000 10761 SW,TACT,SKHV10920A,

*SP001140R

5MM/260G-REEL

9965 000 10760 SW,TACT,THVH472GAA *SP001150R

9965 000 10760 SW,TACT,THVH472GAA *SP001150R

9965 000 10761 SW,TACT,SKHV10920A,

*SP001140R

5MM/260G-REEL

9965 000 11207 SW,ROTARY,

*SR000170R

EC12B24S2033ZZZ/WITHPUSH

9965 000 10761 SW,TACT,SKHV10920A,

*SP001140R

5MM/260G-REEL

9965 000 10761 SW,TACT,SKHV10920A,

*SP001140R

5MM/260G-REEL

REC CIRCUIT BOARD

REC - CAPACITORS

nsp CER.CHIP,100pF-J/50V-1608 nsp

nsp CER.CHIP,100pF-J/50V-1608 nsp

nsp ELECT,22µF-M/16V,5x5-5RE nsp

nsp ELECT,22µF-M/16V,5x5-5RE nsp

nsp ELECT,22µF-M/16V,5x5-5RE nsp

nsp ELECT,22µF-M/16V,5x5-5RE nsp

nsp ELECT,22µF-M/16V,5x5-5RE nsp

nsp ELECT,22µF-M/16V,5x5-5RE nsp

nsp ELECT,1µF-M/50V,3x5-5RE nsp

nsp ELECT,1µF-M/50V,3x5-5RE nsp

REC - RESISTORS

nsp CHIP,1K-J,1/16W-1608REEL nsp

nsp CHIP,1K-J,1/16W-1608REEL nsp

nsp CHIP,100K-J,1/16W-1608REEL nsp

nsp CHIP,100K-J,1/16W-1608REEL nsp

nsp CHIP,100K-J,1/16W-1608REEL nsp

nsp CHIP,100K-J,1/16W-1608REEL nsp

nsp CHIP,1K-J,1/16W-1608REEL nsp

nsp CHIP,1K-J,1/16W-1608REEL nsp

nsp CHIP,1K-J,1/16W-1608REEL nsp

nsp CHIP,270-J,1/16W-1608REEL nsp

nsp CHIP,270-J,1/16W-1608REEL nsp

nsp CHIP,820-J,1/16W-1608REEL nsp

nsp CHIP,820-J,1/16W-1608REEL nsp

nsp CHIP,100K-J,1/16W-1608REEL nsp

nsp CHIP,100K-J,1/16W-1608REEL nsp

nsp CHIP,100-J,1/16W-1608REEL nsp

nsp CHIP,100-J,1/16W-1608REEL nsp

nsp CHIP,1.5K-J,1/16W-1608REEL nsp

nsp CHIP,1.5K-J,1/16W-1608REEL nsp

Page 30

VERS.

POS.

COLOR

NO

REC - SEMICONDUCTORS

IC1

5322 209 13406 IC,NJM2068MD-SOP8P *HC107380R

IC2

9965 000 01373 IC,KIC9459F/SOP24P HC10449050

IC3

5322 209 13406 IC,NJM2068MD-SOP8P *HC107380R

BKT1

PART NO.

(FOR PCS)

DESCRIPTION

REC - MISCELLANEOUS

nsp BRACKET,AVR3300(E3)

(DENON) SPTE 0.8t/SCREW

BKT2

nsp BRACKET,AVR3300(E3)

(DENON) SPTE 0.8t/SCREW

CP4

nsp CN.WAFER 2.0MM,

35237-1010 10P

CP5

nsp CN.WAFER 2.0MM,

35237-0510 5P

J19

nsp CHIP,0-J,1/8W-3216REEL nsp

J109

PART NO.

(MJI)

nsp

nsp

nsp

nsp

NOTE : "nsp" PART IS LISTED FOR REFERENCE ONLY, MARANTZ WILL NOT SUPPLY THESE PARTS.

36

Loading...

Loading...