Page 1

Service

DV7000 /F1N, /K1G, /S1G, /U1G

F1B, /K1B, /N1B, /U1B

Manual

STANDBY

POWER ON/OFF

SECTION PAGE

1. MAIN UNIT

1.1 TECHNICAL SPECIFICATIONS ......................................................................................................... 1-1

1.2 CONNECTION FACILITIES ................................................................................................................ 1-2

1.3 INFORMATIONS ................................................................................................................................. 1-3

1.4 SERVICING HINT ............................................................................................................................... 1-4

1.5 DISASSEMBLY ................................................................................................................................... 1-5

1.6 REPLACEMENT OF PRINCIPAL COMPONENTS ............................................................................. 1-6

1.7 SERVICE MODE ................................................................................................................................. 1-8

1.8 ELECTRICAL ADJUSTMENT ........................................................................................................... 1-10

1.9 WAVEFORM ..................................................................................................................................... 1-12

1.10 WIRING DIAGRAM ........................................................................................................................... 1-13

1.11 BLOCK DIAGRAM ............................................................................................................................. 1-15

1.12 SCHEMATIC DIAGRAM .................................................................................................................... 1-17

1.13 PARTS LOCATION ........................................................................................................................... 1-27

1.14 EXPLODED VIEW AND PARTS LIST ............................................................................................... 1-32

1.15 ELECTRICAL PARTS LIST ............................................................................................................... 1-35

DVD PLAYER DV7000

VIDEO

OPEN/CLOSE

SURROUND

A-B

REPEAT

TITLE

DTS

SHUFFLE

CHAPTER

SVCD

SHUFFLE

CHAPTER

TITLE

TRACK

SCAN

TRACK

TIME

TOTAL

FTS

TRACK

PBC

SCAN

TABLE OF CONTENTS

DVD Player

PLAY

DIMMER

STOP

LEVEL

PAUSE

PHONES

-

+

2. TKM1000MZ ( DVD MODULE for MARANTZ )

2.1 SCHEMATIC DIAGRAM AND PARTS LOCATION ............................................................................. 2-1

2.2 MICROPROCESSOR AND IC DATA ................................................................................................ 2-15

2.3 EXPLODED VIEW AND PARTS LIST ............................................................................................... 2-28

2.4 ELECTRICAL PARTS LIST ............................................................................................................... 2-30

Printed in Japan

Please use this service manual with referring to the user guide ( D.F.U. ) without fail.

DV7000

R

DV7000

383K855010 MIT

3120 785 22300

First Issue 2000.07

Page 2

MARANTZ DESIGN AND SERVICE

MARANTZ AMERICA, INC.

WILDASH AUDIO SYSTEMS NZ

Using superior design and selected high grade components, MARANTZ company has created the ultimate in stereo sound.

Only original MARANTZ parts can insure that your MARANTZ product will continue to perform to the specifications for which

it is famous.

Parts for your

MARANTZ equipment are generally available to our National Marantz Subsidiary or Agent.

ORDERING PARTS :

Parts can be ordered either by mail or by Fax.. In both cases, the correct part number has to be specified.

The following information must be supplied to eliminate delays in processing your order :

1. Complete address

2. Complete part numbers and quantities required

3. Description of parts

4. Model number for which part is required

5. Way of shipment

6. Signature : any order form or Fax. must be signed, otherwise such part order will be considered as null and void.

USA

MARANTZ AMERICA, INC

440 MEDINAH ROAD

ROSELLE, ILLINOIS 60172

USA

PHONE : 630 - 307 - 3100

FAX : 630 - 307 - 2687

AMERICAS

SUPERSCOPE TECHNOLOGIES, INC.

MARANTZ PROFESSIONAL PRODUCTS

2640 WHITE OAK CIRCLE, SUITE A

AURORA, ILLINOIS 60504 USA

PHONE : 630 - 820 - 4800

FAX : 630 - 820 - 8103

AUSTRALIA

JAMO AUSTRALIA PTY LTD

1 EXPO COURT, P.O. BOX 350

MT. WAVERLEY VIC 3149

AUSTRALIA

PHONE : +61 - 3 - 9543 - 1522

FAX : +61 - 3 - 9543 - 3677

NEW ZEALAND

WILDASH AUDIO SYSTEMS NZ

14 MALVERN ROAD MT ALBERT

AUCKLAND NEW ZEALAND

PHONE : +64 - 9 - 8451958

FAX : +64 - 9 - 8463554

EUROPE / TRADING

MARANTZ EUROPE B.V.

P.O.BOX 80002, BUILDING SFF2

5600 JB EINDHOVEN

THE NETHERLANDS

PHONE : +31 - 40 - 2732241

FAX : +31 - 40 - 2735578

AUSTRALIA

TECHNICAL AUDIO GROUP PTY, LTD

558 DARLING STREET,

BALMAIN, NSW 2041,

AUSTRALIA

PHONE : 61 - 2 - 9810 - 5300

FAX : 61 - 2 - 9810 - 5355

THAILAND

MRZ STANDARD CO.,LTD

746 - 754 MAHACHAI ROAD.,

WANGBURAPAPIROM, PHRANAKORN,

BANGKOK, 10200 THAILAND

PHONE : +66 - 2 - 222 9181

FAX : +66 - 2 - 224 6795

TAIWAN

PAI- YUING CO., LTD.

6 TH FL NO, 148 SUNG KIANG ROAD,

TAIPEI, 10429, TAIWAN R.O.C.

PHONE : +886 - 2 - 25221304

FAX : +886 - 2 - 25630415

BRAZIL

PHILIP DA AMAZONIA IND. ELET. ITDA

CENTRO DE INFORMACOES AO

CEP 04698-970

SAO PAULO, SP, BRAZIL

PHONE : 0800 - 123123

FAX : +55 11 534. 8988

(Discagem Direta Gratuita)

CANADA

LENBROOK INDUSTRIES LIMITED

633 GRANITE COURT,

PICKERING, ONTARIO L1W 3K1

CANADA

PHONE : 905 - 831 - 6333

FAX : 905 - 831 - 6936

SINGAPORE

WO KEE HONG (S) PTE LTD

WO KEE HONG CENTRE

NO.23, LORONG 8, TOA PAYOH

SINGAPORE 319257

PHONE : +65 2544555

FAX : +65 2502213

MALAYSIA

WO KEE HONG ELECTRONICS SDN. BHD.

SUITE 8.1, LEVEL 8, MENARA GENESIS,

NO. 33, JALAN SULTAN ISMAIL,

50250 KUALA LUMPUR, MALAYSIA

PHONE : +60 3 - 2457677

FAX : +60 3 - 2458180

JAPAN

Technical

MARANTZ JAPAN, INC.

35- 1, 7- CHOME, SAGAMIONO

SAGAMIHARA - SHI, KANAGAWA

JAPAN 228-8505

PHONE : +81 42 748 1013

FAX : +81 42 741 9190

KOREA

MK ENTERPRISES LTD.

ROOM 604/605, ELECTRO-OFFICETEL, 16-58,

3GA, HANGANG-RO, YONGSAN-KU, SEOUL

KOREA

PHONE : +822 - 3232 - 155

FAX : +822 - 3232 - 154

SHOCK, FIRE HAZARD SERVICE TEST :

CAUTION : After servicing this appliance and prior to returning to customer, measure the resistance between either primary AC

cord connector pins ( with unit NOT connected to AC mains and its Power switch ON ), and the face or Front Panel of product and

controls and chassis bottom.

Any resistance measurement less than 1 Megohms should cause unit to be repaired or corrected before AC power is applied, and

verified before it is return to the user/customer.

Ref. UL Standard No. 1492.

In case of difficulties, do not hesitate to contact the Technical

Department at above mentioned address.

991207MIT

Page 3

1. TECHNICAL SPECIFICATIONS

Discs played

DVD video disc ............................................... 12 cm single sided, single layer

Compact disc

(CD-DA, Video CD) ......................................... 12 cm, 8 cm

Video system .................................................... PAL (625/50) / NTSC (525/60)

Audio system ................................................... Linear PCM audio

Video output

Line output level .............................................. 1.0 Vp-p / 75 ohms, unbalanced

S1-output level ................................................. Y output: 1.0 Vp-p / 75 ohms unbalanced

Color different output level ............................... Y output: 1.0 Vp-p / 75 ohms unbalanced

R/G/B output .................................................... R/G/B output: 0.7 Vp-p 21-pin SCART connector x 2 (/N1B)

12 cm single sided, double layer

12 cm double sided, single layer

12 cm double sided, double layer (one layer per side)

8 cm single sided, single layer

8 cm single sided, double layer

8 cm double sided, single layer

8 cm double sided, double layer (one layer per side)

MPEG 1/2 audio

Dolby Digital (AC-3)

DTS audio (Digital output only)

RCA pin Jack x 2

C output: 0.3 Vp-p / 75 ohms (PAL)

0.286 Vp-p / 75 ohms (NTSC)

4 pin mini DIN x 1

CB, CR output: 0.7 Vp-p / 75 ohms

RCA pin Jack x 3 (/F1, /K1, /S1, /U1)

Audio output

Line output ....................................................... 2.0 Vrms / 330 ohms

RCA pin Jack x 2 system

Digital audio output

Optical output ................................................... Optical connector x 1

Coaxial output .................................................. 0.5 Vp-p / 75 ohm RCA pin Jack x 1

DVD Iinear audio characteristics

Frequency response ........................................ 4 Hz-22 kHz (Fs = 48 kHz)

S/N ratio ........................................................... More than 110 dB (Fs = 48 kHz / 24 bit PCM)

Dynamic range ................................................. More than 100 dB (Fs = 48 kHz / 24 bit PCM)

Total harmonic distortion ................................. Less than 0.0025% (Fs = 48 kHz / 24 bit PCM)

4 Hz-44 kHz (Fs = 96 kHz)

CD audio characteristics:

Frequency response ........................................ 4 Hz - 20 kHz (EIAJ)

S/N ratio ........................................................... More than 110 dB (EIAJ)

Dynamic range ................................................. More than 100 dB (EIAJ)

Total harmonic distortion ................................. Less than 0.0025% (EIAJ)

Pickup ............................................................... Wavelength: 655 nm (DVD)

Power requirements ........................................ 120V AC, 60 Hz (/U1)

Power consumption ........................................ 22 W (standby mode = approx 5 W, power off = 0 W)

Operation temperature .................................... 5 °C - 35 °C

Operation humidity range ............................... 5% - 90% (no condensation)

Wavelength: 790 nm (CD)

100V AC, 50 / 60 Hz (/F1)

230V AC, 50 Hz (/N1)

220V AC, 50 Hz (/K1)

220 - 230V AC, 50 / 60 Hz (/S1)

Dimensions ....................................................... 440 (W) x 87 (H) x 304 (D) mm (excluding protrusions)

Weight ............................................................... 4.0 kg

Supplied accessories

Auido / Video cable .......................................... x 1

D-BUS remote cable ........................................ x 1

Remote control unit .......................................... x 1

Batteries ........................................................... x 2

• For improvement purposes, specifications and design are subject to change without notice

1-1

Page 4

2. CONNECTION FACILITIES

2.1 Video performance (/N1 only)

135791113151719

21

2. 1. 1 SCART

2 4 6 8 10 12 14 16 18 20

Pin No. TV (OUT) Pin No. AUX (IN)

Pin 1 Audio R out : 2Vrms Pin 1 Audio R out : 2Vrms

Pin 2 Audio R in : 2Vrms Pin 2 Audio R in : 2Vrms

Pin 3 Audio L out : 2Vrms Pin 3 Audio L out : 2Vrms

Pin 4 GND Pin 4 GND

Pin 5 GND Pin 5 GND

Pin 6 Audio L in : 2Vrms Pin 6 Audio L in : 2Vrms

Pin 7 Blue out/C in Pin 7 Blue in/C out

Pin 8 function switching out <2V : TV Pin 8 function switching in<2V : DVD

Pin 9 GND Pin 9 GND

Pin 10 not connected Pin 10 not connected

Pin 11 Green out:0.7Vpp ±0.1V into 75 Ohm *1 Pin 11 Green in:0.7Vpp ±0.1V into 75 Ohm

Pin 12 not connected Pin 12 not connected

Pin 13 GND Pin 13 GND

Pin 14 GND Pin 14 GND

Pin 15 Red/C out Pin 15 Red/C in

Pin 16 fast switching out <0.4V into 75 Ohm=CVBS/S-Video Pin 16 fast switching in <0.4V into 75 Ohm=CVBS/S-Video

1</<3 into 75 Ohm=RGB 1</<3 into 75 Ohm=RGB

Pin 17 GND Pin 17 GND

Pin 18 GND Pin 18 GND

Pin 19 CVBS/Y out : 1Vpp ±0.1V *1 Pin 19 CVBS/Y out : 1Vpp ±0.1V *1

Pin 20 CVBS/Y in : 1Vpp ±0.1V *1 Pin 20 CVBS/Y in : 1Vpp ±0.1V *1

Pin 21 GND Pin 21 GND

Blue : 0.7Vpp ±0.1V into 75 Ohm *1 Blue : 0.7Vpp ±0.1V into 75 Ohm *1

C : 300mVpp ±30 into 75 Ohm *2 C : 300mVpp ±30 into 75 Ohm *2

>5/<8 : asp.ratio 16 : 9 DVD/AUX >5/<8 : asp.ratio 16 : 9 AUX

>9.5/<12 : asp.ratio 4 : 3 DVD/AUX >9.5/<12 : asp.ratio 4 : 3 AUX

Red : 0.7Vpp ±0.1V into 75 Ohm *1 Red : 0.7Vpp ±0.1V into 75 Ohm *1

C : 300mVpp ±30 into 75 Ohm *2 C : 300mVpp ±30 into 75 Ohm *2

*1 : 100% White *2 : Burst Level *3 : color bar(chroma level : 75%)

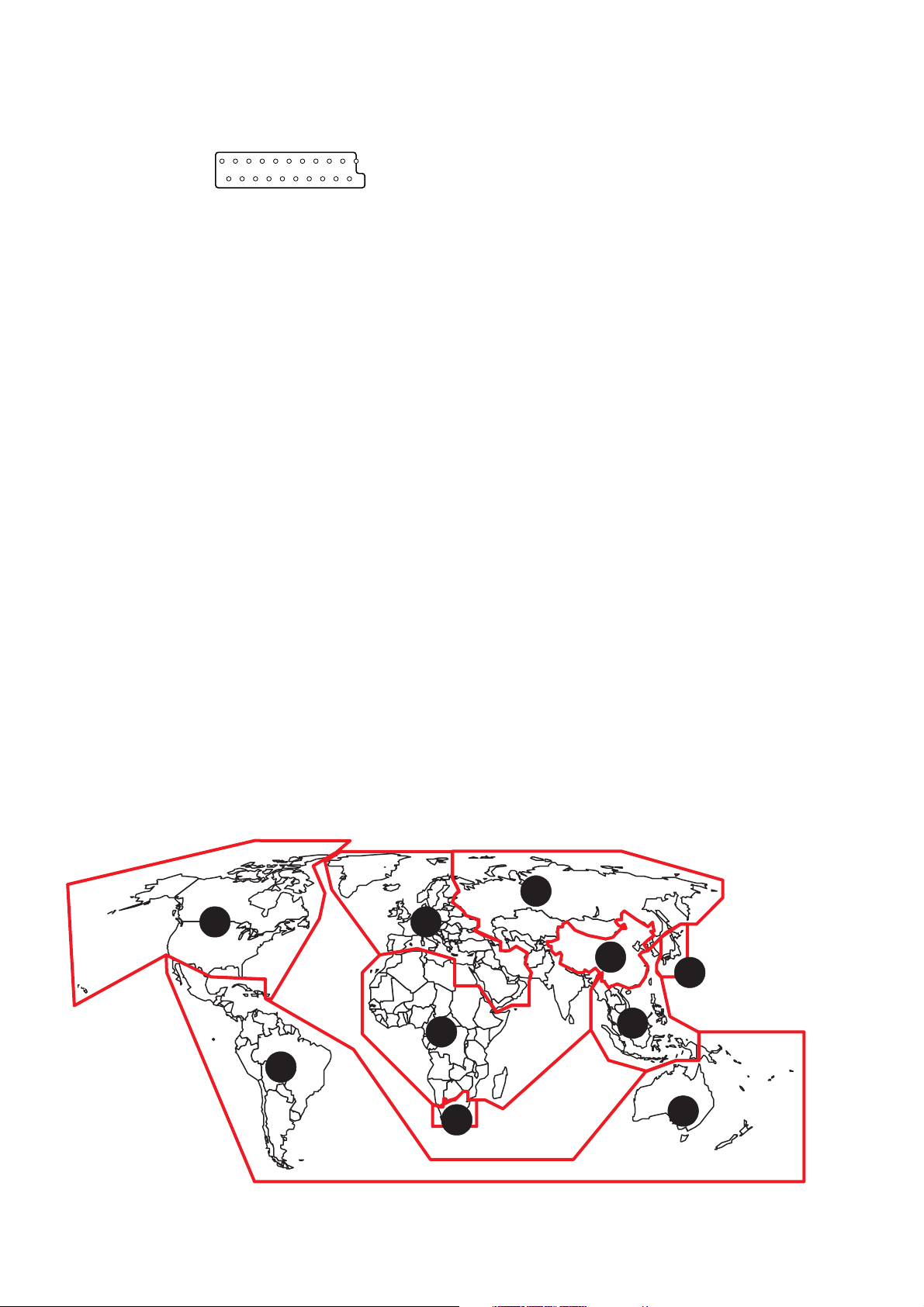

What are "regional codes"?

Motion picture studios want to control the home release of movies in different countries because theater releases arenit

simultaneous (a movie may come out on DVD in the US when itis just hitting screens in Europe). Therefore they have

required that the DVD standard include codes which can be used to lock out the playback of certain discs in certain geo-graphical

regions. Players sold in each region will have that regionis code built into the player. The player will refuse to play

these "region coded" discs which are not allowed in the region. However, regional codes are entirely optional. Discs without

codes will play on any player in any country. Some studios have already announced that only their new releases will have

regional codes. There are six regions:

1. United States and Canada 2. Europe and Japan

3. Far East (except Japan & China) 4. South America and Oceania

5. Africa and the Middle East 6. China (except Hong Kong)

5

1 2

6

2

5

3

4

2

Map of DVD Regions

1-2

4

Page 5

3. INFORMATIONS

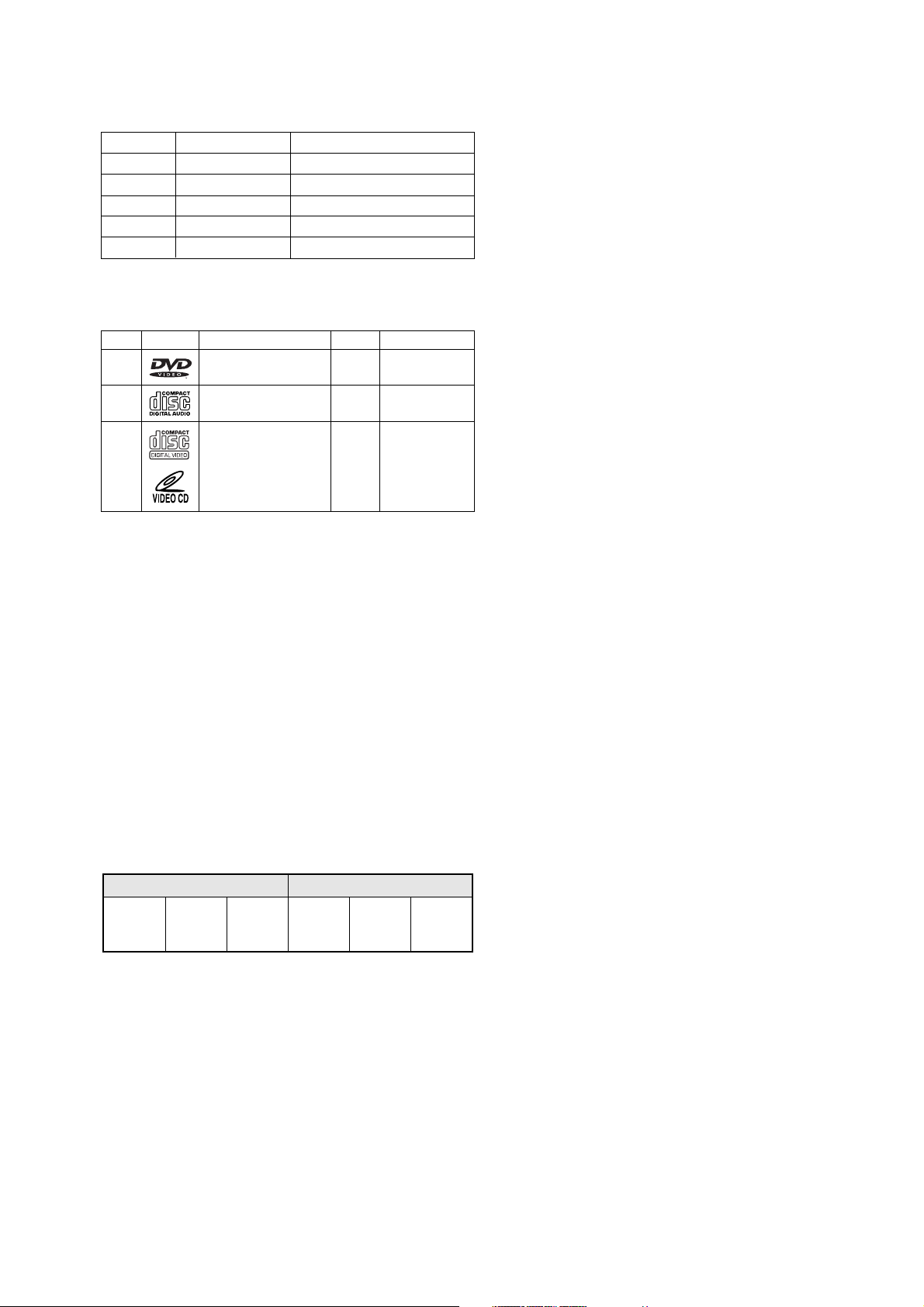

REGION CODE

VERSION REGION CODE COUNTRY

/FXX 2 JAPAN

/KXX 6 CHINA

/NXX 2 EUROPE

/SXX 3 SINGAPORE/HONGKONG

/UXX 1 USA/CANADA

THE DISCS THAT THE DV7000 CAN HANDLE

The following discs can be played back with a DV7000.

disc mark playback capability size side

DVD Audio/Video

CD Audio

VCD Audio/Video single

Note: The regional code of the discs must meet to the regional

code of the DV7000.

12 cm

8 cm

12 cm

8 cm

12 cm

8 cm

single/double

single

Multi-angles:

On some DVDs, scenes have been filmed from different angles

(up to a maximum of 9). On these discs, you can select the

angle that you want to watch. Please refer to the DVD's manual

to see which scenes have multi-angles.

Cancelling password for parental press the DIMMER button

and hold for 10 seconds while the player is stopped.

DVD INFORMATION

Below is a glossary of the new terms related to DVD.

Title:

A disc may have more than one story/movie on it, so each

story/movie is called a

For example, if there are 2 movies on the disc, they are

separated into Title 1 and Title 2.

Chapter:

A title may also be separated into chapters.

For example, a movie (title) may be separated into 3 scenes

(chapters).

Title 1 Title 2

Chapter1Chapter

2

Subtitles:

DVDs are recorded with up to 32 different subtitle languages.

If a disc has more than one subtitle language, you can select

the subtitle language that you want to read.

"title".

Chapter3Chapter1Chapter2Chapter

3

Soundtrack language:

DVDs are recorded with up to 8 different soundtrack languages.

If a disc has more than one language, you can select the

soundtrack language that you want to listen to.

1-3

Page 6

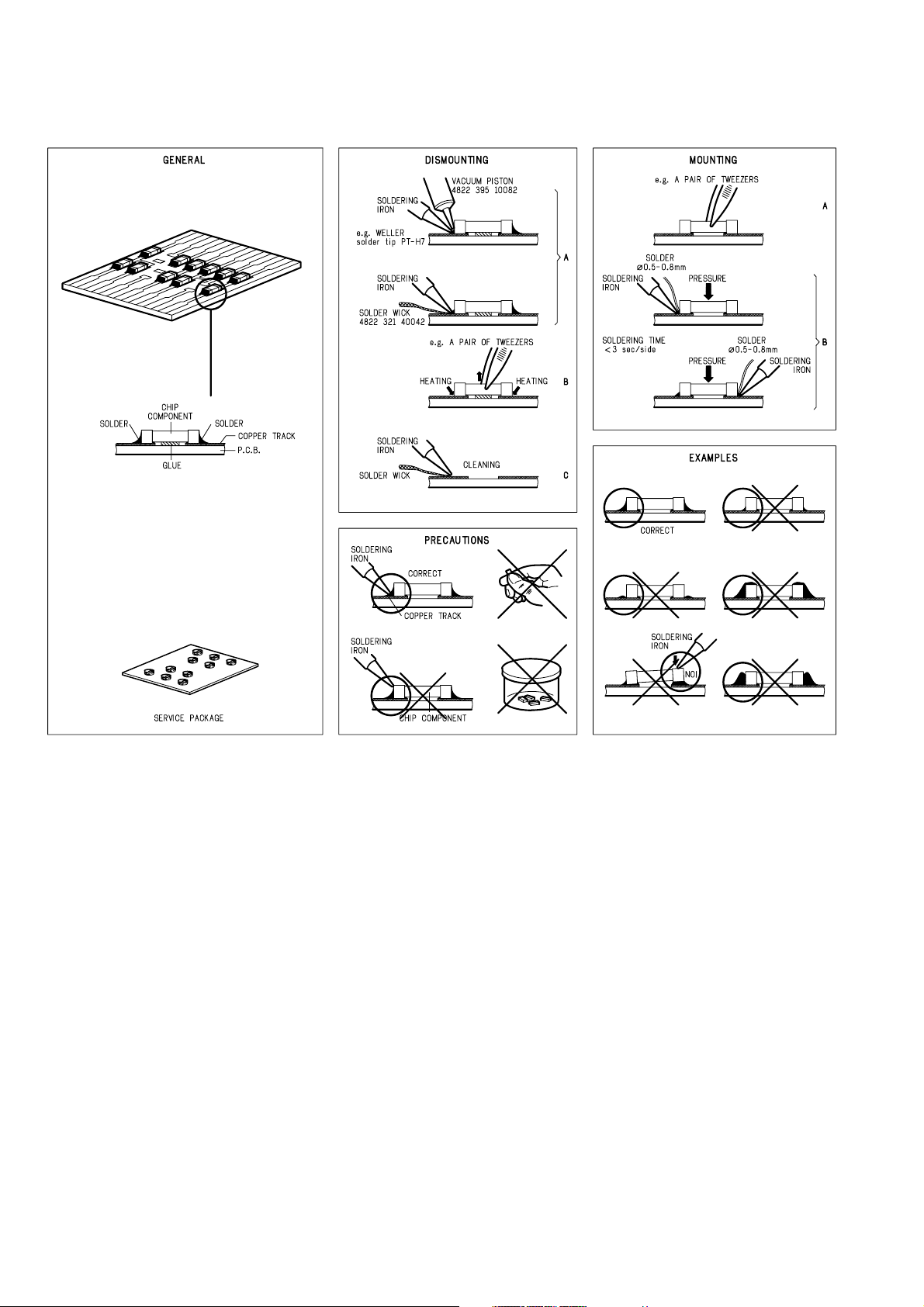

4. SERVICING HINT

SERVICE HINTS

SERVICE TOOLS

Audio signals disc 4822 397 30184

Disc without errors (SBC444)+

Disc with DO errors, black spots and fingerprints (SBC444A) 4822 397 30245

Disc (65 min 1kHz) without no pause 4822 397 30155

Max. diameter disc (58.0 mm) 4822 397 60141

Torx screwdrivers

Set (straight) 4822 395 50145

Set (square) 4822 395 50132

13th order filter 4822 395 30204

DVD test disc (PAL) 4822 397 10131

DVD test disc (NTSC) ALMEDIO TDV-540

1-4

Page 7

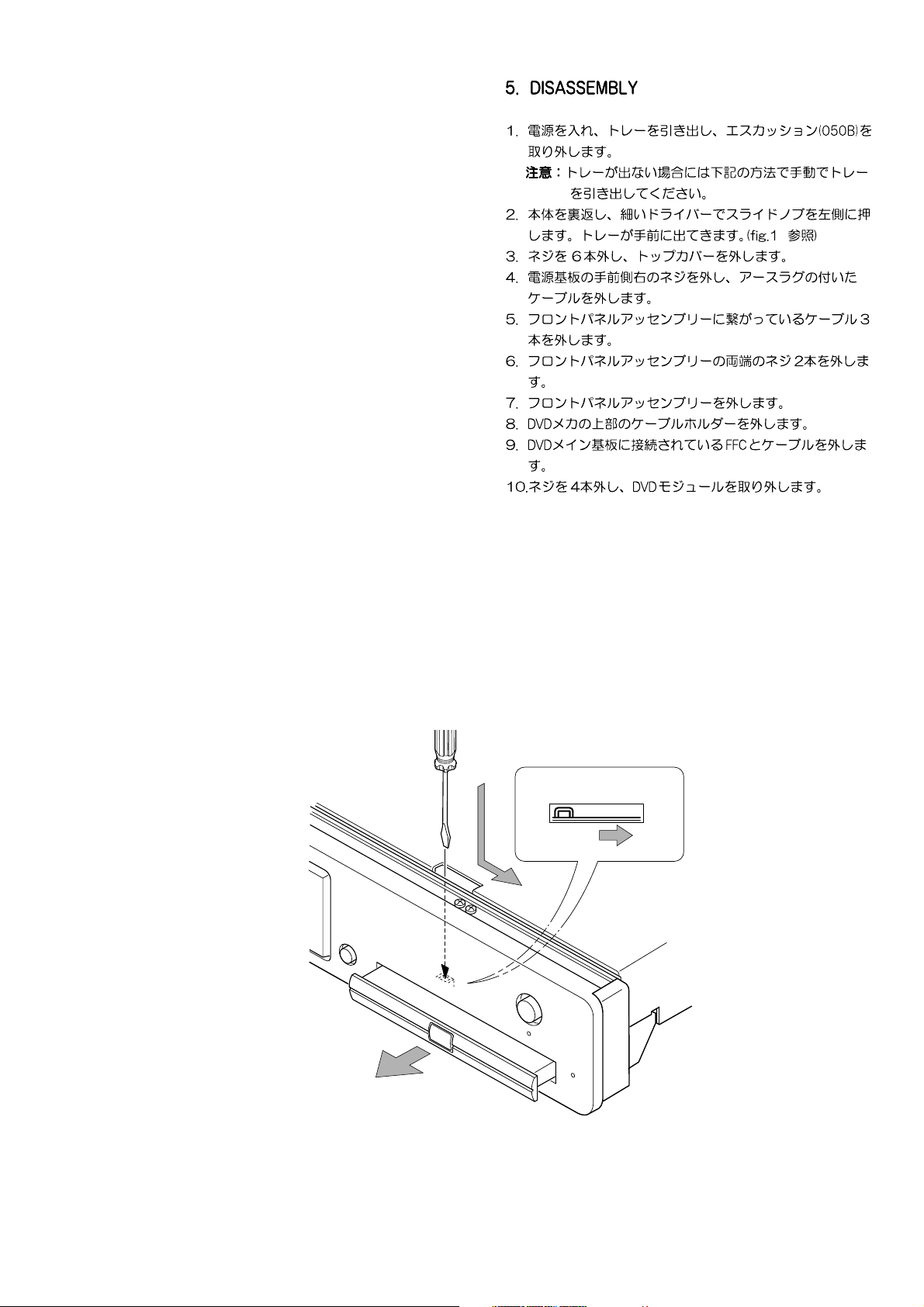

5. DISASSEMBLY

1. Open the tray and remove the escutcheon (050B).

REMARK : If the tray doesn't work, put a small

screwdriver into the hole as shown in picture

and slide the knob. Then the tray comes out.

After the first centimeter it is possible to pull

the tray out by hand. (see fig.1)

2. Remove 6 screws and remove the top cover.

3. Remove a top right side screw on the power supply PCB

and remove the GND lug wire.

4. Remove 3 connectors of the wire harness from (or to )

front panel assembly.

5. Remove 2 screws of left and right side of the front panel

assembly.

6. Remove the front panel assembly.

7. Remove the retainer on the DVD mechanism.

8. Remove FFC and wire harness from the DVD main PCB

which mounted under the DVD mechanism.

9. Remove 4 screws and remove DVD mechanism module.

Fig. 1

1-5

Page 8

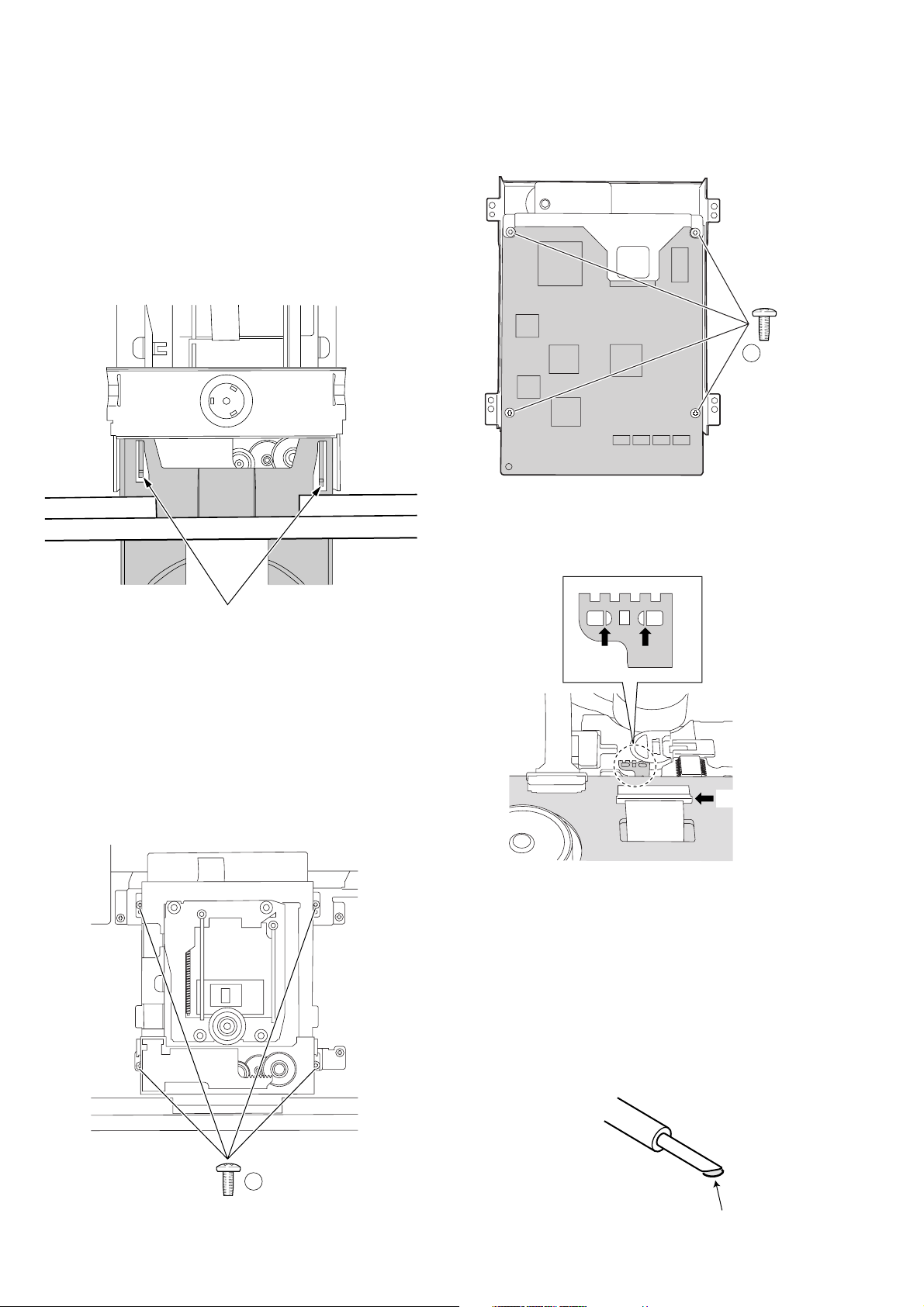

6. REPLACEMENT OF PRINCIPAL COMPONENTS

6-1. Removal of the TRAVERSE MECHA.

6-1-1. Removal of the MECHANISM BLOCK

1) Turn the unit

eject the DISC TRAY.

2) Disconnect the power cord and remove the DISC CLAMPER

BLOCK.

3) Completely remove the DISC TRAY by pulling it outwards

while pulling up both of the stopper tabs alternately.

's power on and press the "EJECT" button to

6-1-2. Removal of the TRAVERSE MECHA.

1) Remove the four b screws on the MAIN PCB and then

disconnect the P800 connector on the MAIN PCB.

B SCREW

Fig. 6-3

2) Short the laser diode protection circuit on the PICK UP

BLOCKÕs flexible cable with solder as shown.

STOPPER TUB

Fig. 6-1

4) Disconnect the two flat cables from the P803 connectors

and one flat cable from the P808 connector on the MAIN

PCB.

5) Disconnect the P807 connector on the MAIN PCB.

6) Remove the four a retaining screws and remove the

MECHANISM BLOCK from the chassis.

P200

Fig. 6-4

Caution

To protect the laser diode from damage caused by high voltage

static electricity, a laser diode protection circuit has to be

shorted before disconnecting the flexible cable (P200 connector

on the MECHANISM PCB). It is recommended that you put

solder on the top of the soldering iron as shown in Fig. 3-5

then short the circuit at once. When you replace the TRAVERSE

MECHA., be sure to connect the P200 connector before

removing the solder at the shorted parts.

Fig. 6-2

A SCREW

SOLDER

Fig. 6-5

1-6

Page 9

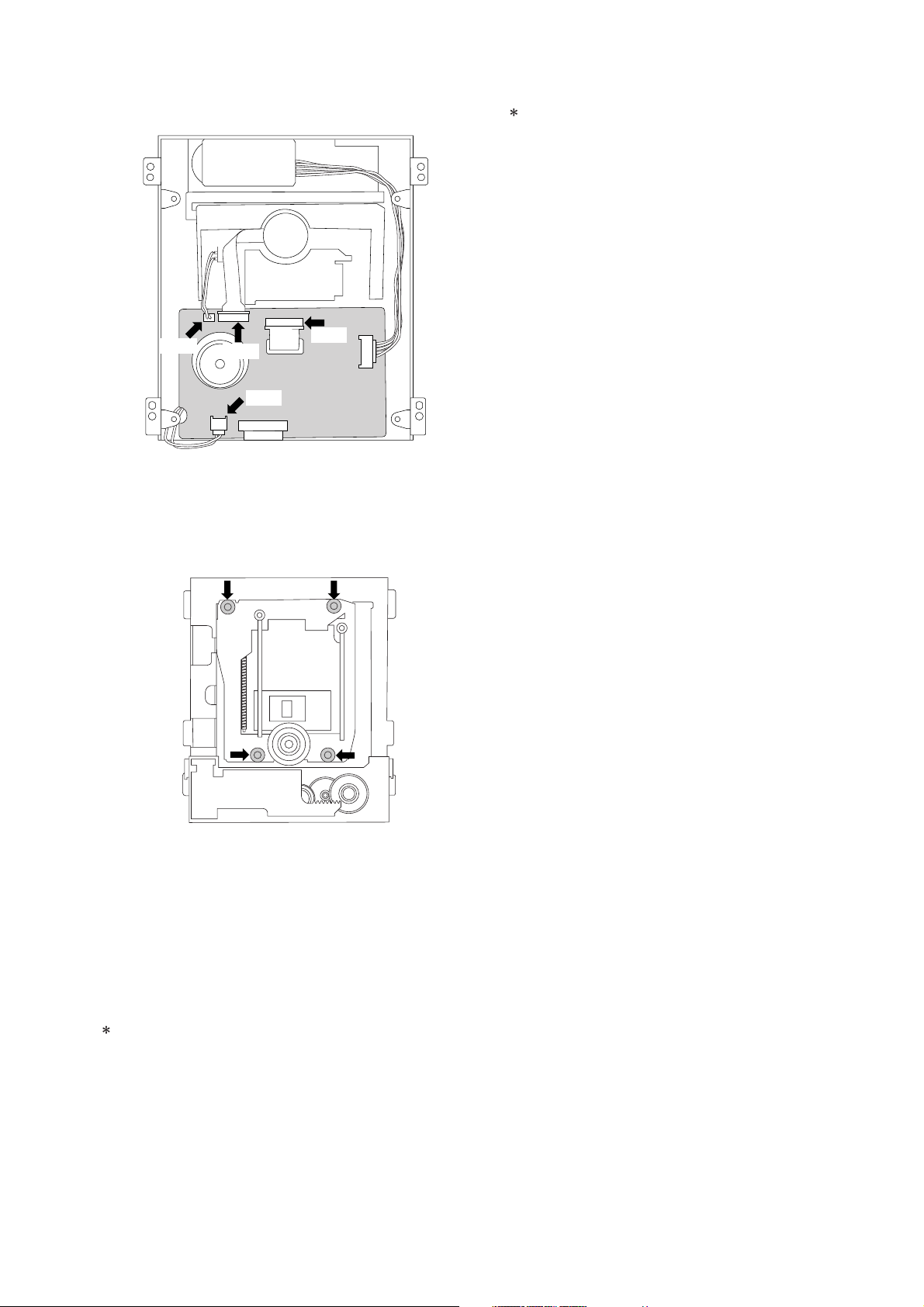

3) Carefully disconnect the two connectors (P500, P600) and

the two flat cables (P200, P300) on the MECHANISM PCB.

6-3. Replacement of the PICK UP BLOCK

Replacement of the PICK UP BLOCK itself is not

recommended because its azimuth adjustment is very

critical and requires a special jig. If PICK UP BLOCK

replacement is necessary, replace with an entire

TRAVERSE MECHANISM only.

P600

P300

P500

P200

Fig. 6-6

4) Using tweezers, release the four retaining HOOKs of the

TRAVERSE MECHA. from the rubber insulators being

careful not to damage the rubber insulators.

Fig. 6-7

5) Remove the TRAVERSE MECHA. from the MECHANISM

BLOCK.

6) Reassemble in the reverse order for installation. Never

remove the solder on the flexible cable before connecting

the P200 connector on the MECHANISM PCB.

6-2. Replacement of the SPINDLE MOTOR

Because the SPINDLE MOTOR position is very critical, jitter

adjustment should be performed after replacement.

1) Disconnect the P300 connector on the MECHANISM PCB.

2) Insert a Philips type screw driver into the hole on the TURN

TABLE of the SPINDLE MOTOR and remove the two

screws.

1-7

Page 10

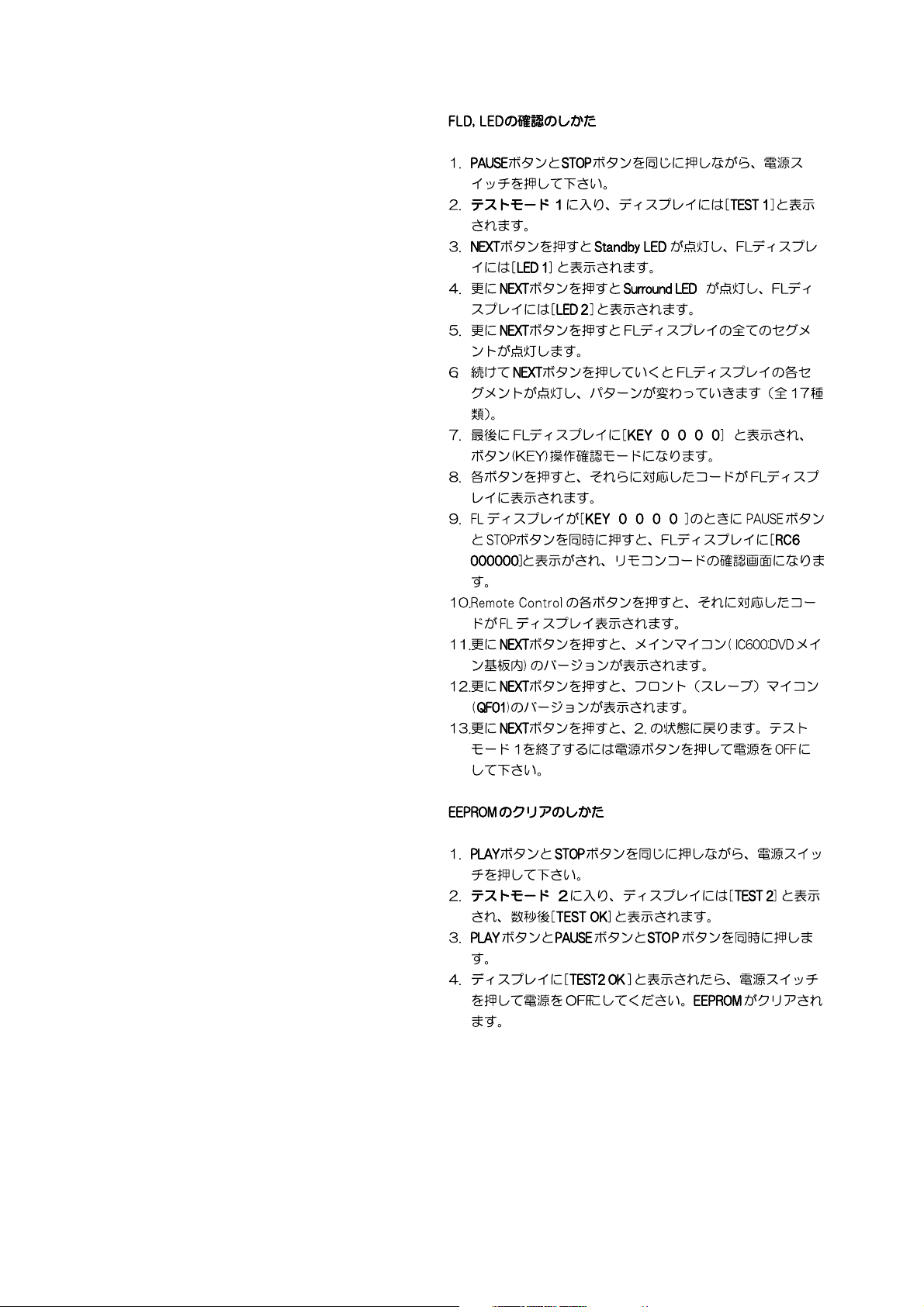

7. SERVICE MODE

FLD, LED TEST

1. Press the mains switch (POWER BUTTON) while

depressing the PAUSE button and STOP button.

2. Status will be on the TEST mode 1 and FL display shows

<TEST 1>.

3. Press the NEXT button, then Standby LED will be light

ON and FLD shows <LED 1>.

4. Press the NEXT button again, then Surround LED will be

light ON and FLD shows <LED 2>.

5. Press the NEXT button again, then all segments of FLD

will be light ON.

6. Press the NEXT button again, then each segments of

FLD will be light ON by press by press. (17 forms)

7. Finally FLD shows <KEY 0 0 0 0>, it will be in

“BUTTON (KEY) TEST MODE”.

8. If press some button on the front panel, FLD shows a

code of that pressed button.

9. If press the PAUSE button and STOP button

simultaneously while FLD shows <KEY 0 0 0 0>. The

status will be in “REMOTE CONTROL TEST MODE” and

FLD shows <RC6 000000>.

10.If press some button on the remote controller, FLD shows

a code of that pressed button.

11.Press the NEXT button again, then the version number of

the main microprocessor (IC600 on the DVD main PCB)

will be shown on the FLD.

12.Press the NEXT button again, then the version number of

the slave microprocessor (QF01 on the front PCB) will be

shown on the FLD.

13.Press the NEXT button again, then the status will be #2.

<TEST 1> mode. In case of finish the <TEST 1> mode,

press the mains switch (POWER BUTTON).

How to EEPROM all clear

1. Press the mains switch (POWER BUTTON) while

depressing the PLAY button and STOP button.

2. Status will be on the TEST mode 2 and FL display shows

<TEST 2>. After a couple of seconds FL display shows

<TEST2 OK>.

3. Press the PLAY button, PAUSE button and STOP button

simultaneously.

4. FL display shows <TEST OK>, then power off the mains

switch (POWER BUTTON). EEPROM should cleared.

1-8

Page 11

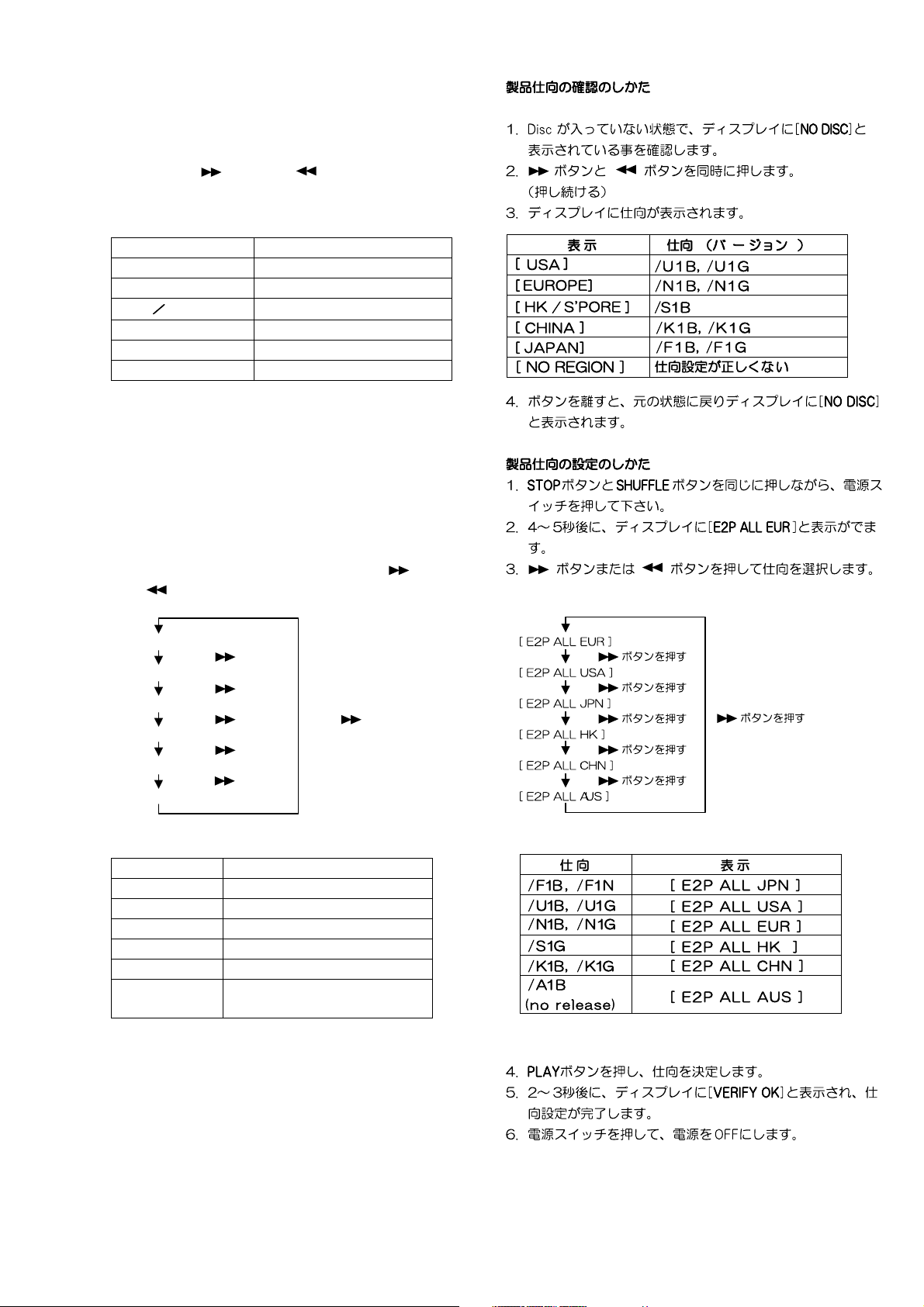

Type version confirmation

1. Power ON the DVD player. The FL display must be

shown <NO DISC>.

2. Pressing the

button and button simultaneously.

3. FL display shows product versions as follows.

DISPLAY VERSIONS

[ USA ]

[ ]

EUROPE

[ HK S ‘PORE ]

[ CHINA ]

[ J A PAN ]

.

[ NO REGION ]

/U1B, /U1G

/N1B, /N1G

/S1G

/K1B, /K1G

/F1B, /F1N

Incorrect setup.

4. Release buttons. Then FL display shows <NO DISC>

and status will be in usual mode.

Type Version setup

1. Press the mains switch (POWER BUTTON) while

depressing the STOP button and SHUFFLE button.

2. The FL display shows <E2P ALL EUR> after a couple of

seconds.

3. Type versions can be changed by pressing

and

button.

button

[ E2P ALL EUR ]

[ E2P ALL USA ]

[ E2P ALL JPN ]

[ E2P ALL HK ]

[ E2P ALL CHN ]

[ E2P ALL AUS ]

VERSIONS DISPLAY

/F1B, /F1N [ E2P ALL JPN ]

/U1B, /U1G [ E2P ALL USA ]

/N1B, /N1G [ E2P ALL EUR ]

/S1G [ E2P ALL HK ]

/K1B, /K1G [ E2P ALL CHN ]

/A1B

(no release)

4. Memorize the version by pressing PLAY button.

5. The FL display shows <VERIFY OK> after a couple of

seconds.

6. Power OFF the mains switch.

Press button

Press button

Press button

Press button

Press button

Press button

[ E2P ALL AUS ]

1-9

Page 12

8. ELECTRICAL ADJUSTMENT

P807

TP201

TP120

VR120

VR121

P800

TP105

TP107

TP300

VR110

P804 P803

JITTER ADJ

SCREW A

VR202

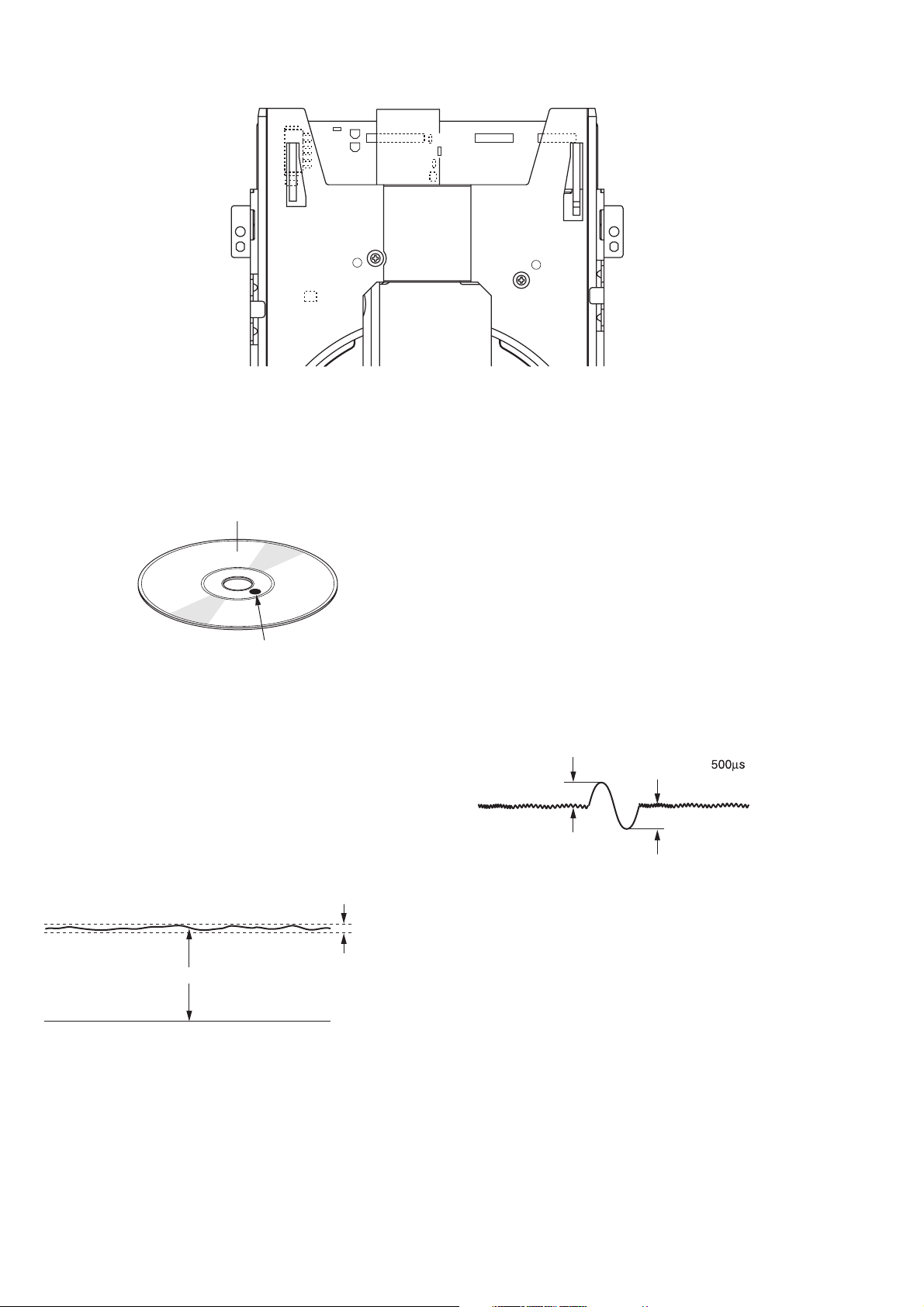

8-1. DVD JITTER ADJUSTMENT

1. Stick the provided small round sticker (0.1 mm thickness) at

the innermost position of a DVD disc as shown and make a

swayed DVD disc.

Signal recorded side

STICKER

Fig. 8-2

2. Play back the swayed DVD disc and press the F.F button

repeatedly until the pickup block reaches the outermost

position of its movable range. Next, press the PAUSE button.

3. Set the oscilloscope to the DC input mode and connect it to

the TP201 (HOT) and the TP102 (D.GND) on the MAIN

PCB.

4. Adjust the a screw and b screw alternately so that the AC

and DC level of the waveform is minimum. (DC level should

be less than 1.8 V, AC component should be minimum.)

JITTER ADJ

SCREW B

Fig. 8-1

2. Set the oscilloscope to the DC input mode and connect it to

the TP201 (HOT) and the TP102 (D.GND) on the MAIN

PCB.

3. Adjust the VR202 so that the DC level is minimum. (The DC

level should be less than 1.8 V)

8-3. CD TRACKING BALANCE

1. Set the VR110 at its center position prior to the adjustment.

2. Connect an oscilloscope to the TP150 (TE) on the MAIN

PCB.

3. Play back an ordinary CD-disc and then set it to the PAUSE

mode. If the play mode does not be engage, turn the VR110

at ±15 degrees. If the play mode does still not be engage

even when the VR110 is turned at ±15 degrees, turn the

VR110 at ± 30 degrees and try it again.

4. Observe the waveform and adjust it so that the level A of the

waveform is the same as level B.

A

B

500mV

Fig. 8-4

minimum

Less than 1.8V

Fig. 8-3

NOTE: If the SPINDLE MOTOR is replaced, this jitter

adjustment should be performed for proper performance.

8-2. SLICE LEVEL ADJUSTMENT

1. Play back an ordinary DVD disc (single side, one layer) and

press the F.F button repeatedly until the pickup block reaches

almost the center position of its movable range.

1-10

Page 13

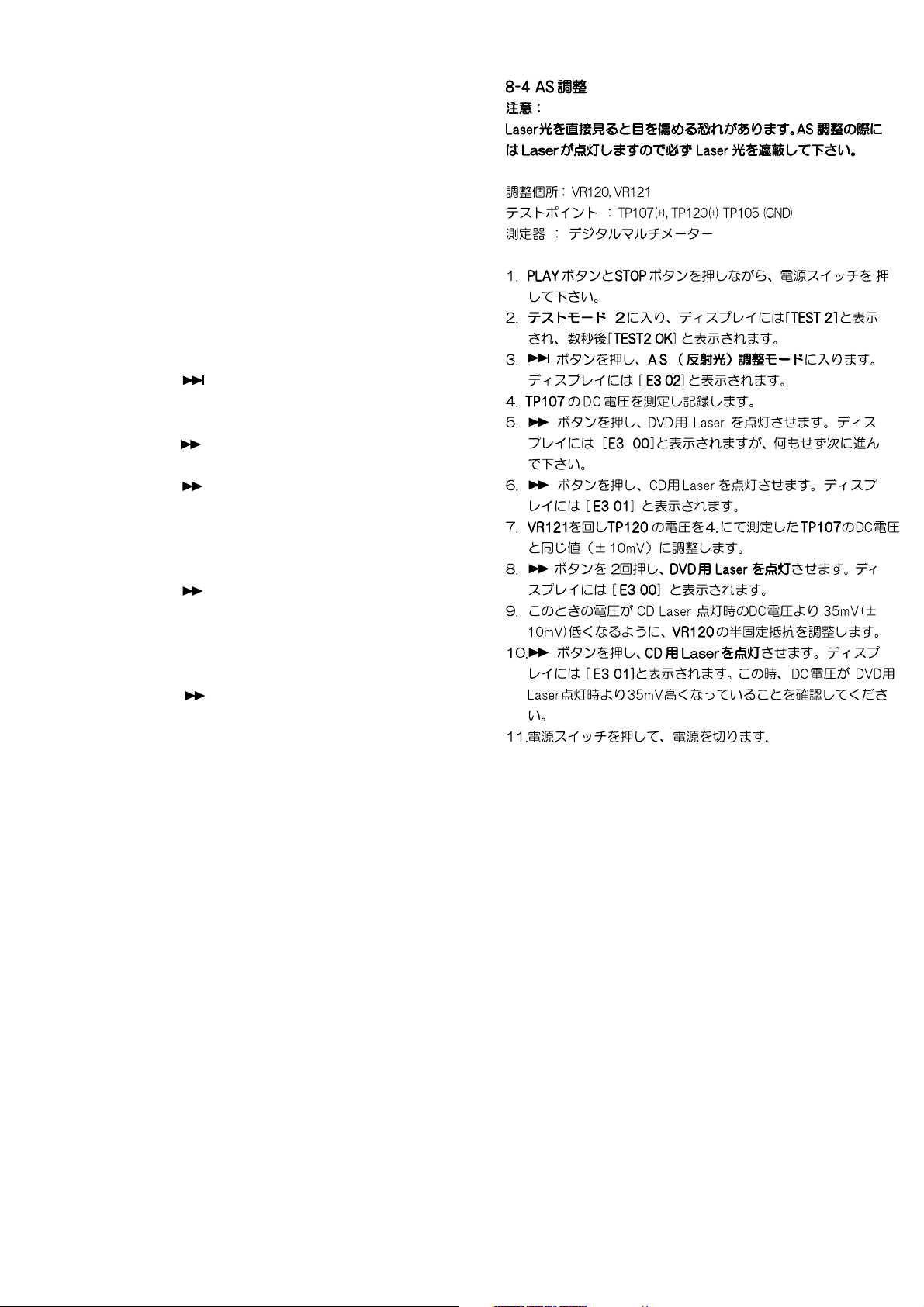

8-4 AS Adjustment

CAUTION :

Do not see the laser pick-up! Cover the laser pick-up unit

while AS adjustment.

Adjustment point : VR120, VR121

Test point : TP107(+), TP120 (+) TP105 (GND)

Equipment : Digital Multi Meter (DC voltage)

1. Press the mains switch (POWER BUTTON) while depressing

the PLAY button and STOP button.

2. Status will be on the TEST mode 2 and FL display shows

<TEST 2>. After a couple of seconds FL display shows

<TEST2 OK>.

3. Press the

and the status will be in AS adjustment mode.

4. Measure the DC voltage at the test point TP107.

5. Press the

and the FL display shows <E3 00>.

6. Press the button again. Then the CD laser will light ON

and the FL display shows <E3 01>.

7. Adjust the voltage at the test point TP120 by VR121, that the

value must be same as TP107 (10mV) value measured on

#4. process.

8. Press the

light ON and the FL display shows <E3 00>.

9. Measure the DC voltage at the status DVD laser light ON.

Adjust the voltage at that status 35mV (±10mV) lower than

“CD laser light ON “ status by the trim resister VR120.

10.Press the

status CD laser light ON.

(DC voltage must be 35mV higher than the status DVD

laser light ON.)

11.Power OFF the mains switch (POWER BUTTON).

button. Then the FL display shows <E3 02>

button again. Then the DVD laser will light ON

button twice of time. Then the DVD laser will

button again. Confirm the DC voltage at the

1-11

Page 14

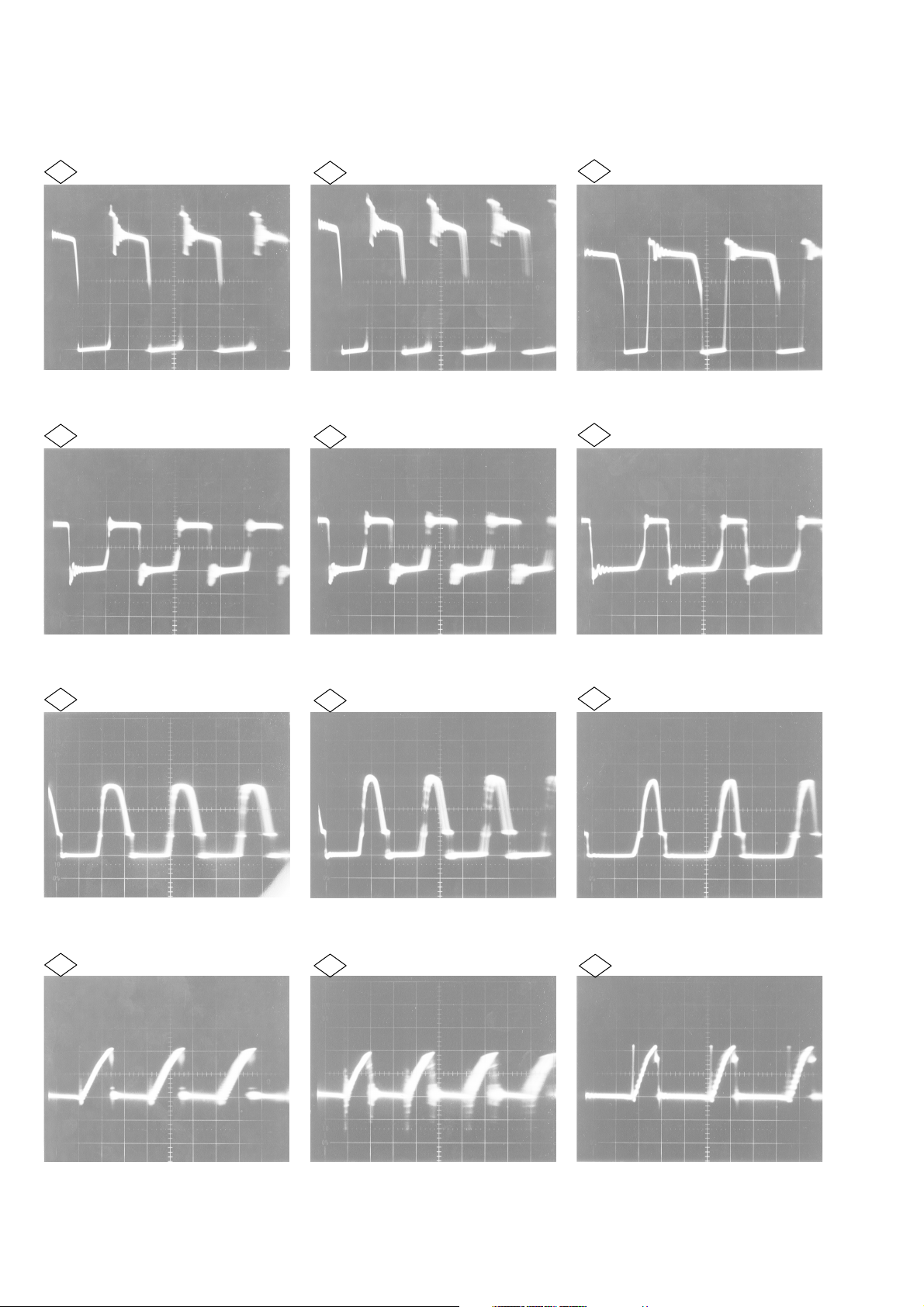

9. WAVEFORM

Power requirements (Refer the circuit diagram page 1-25 and 1-26)

100V AC 120V AV 220V AC

50V 5µsec 50V 5µsec 100V 5µsec

1

2

10V 5µsec 10V 5µsec 10V 5µsec

1

2

1

2

5V 5µsec 5V 5µsec 5V 5µsec

3

0.1V 5µsec 0.1V 5µsec 0.1V 5µsec

4

3

4

3

4

1-12

Page 15

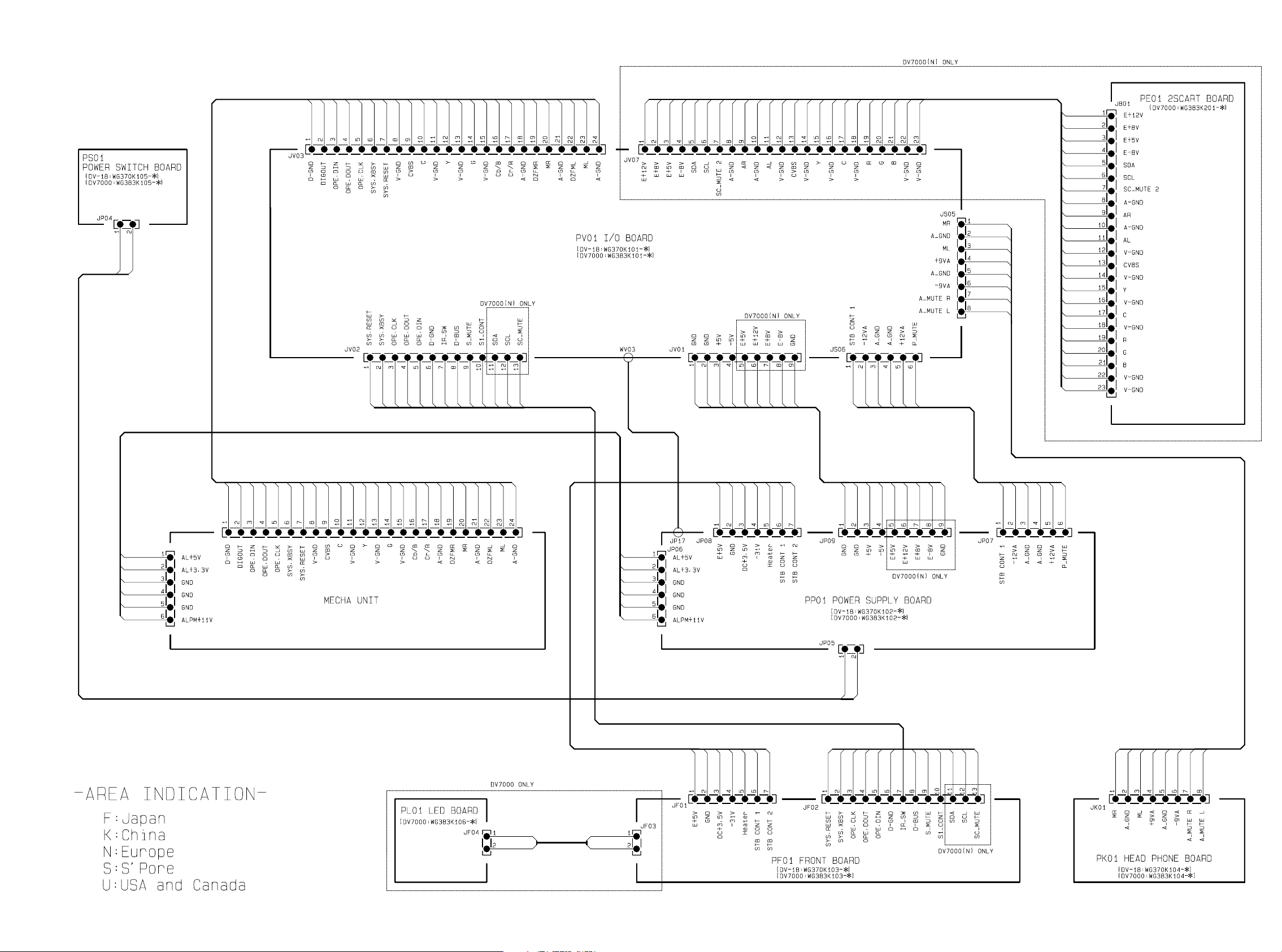

1.10 WARNINGS

1-13 1-14

Page 16

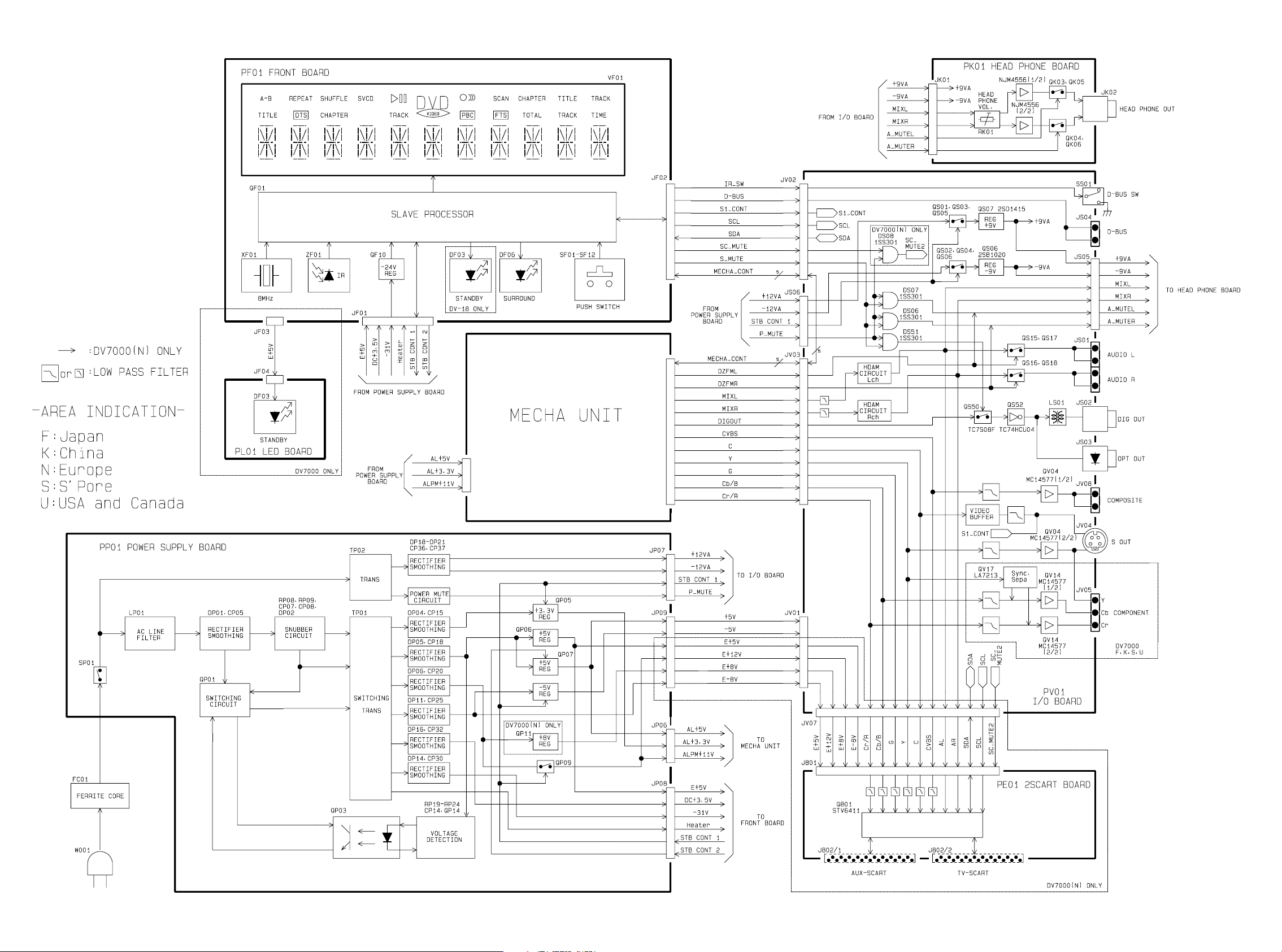

1.11 BLOCK DIAGRAM

1-15 1-16

Page 17

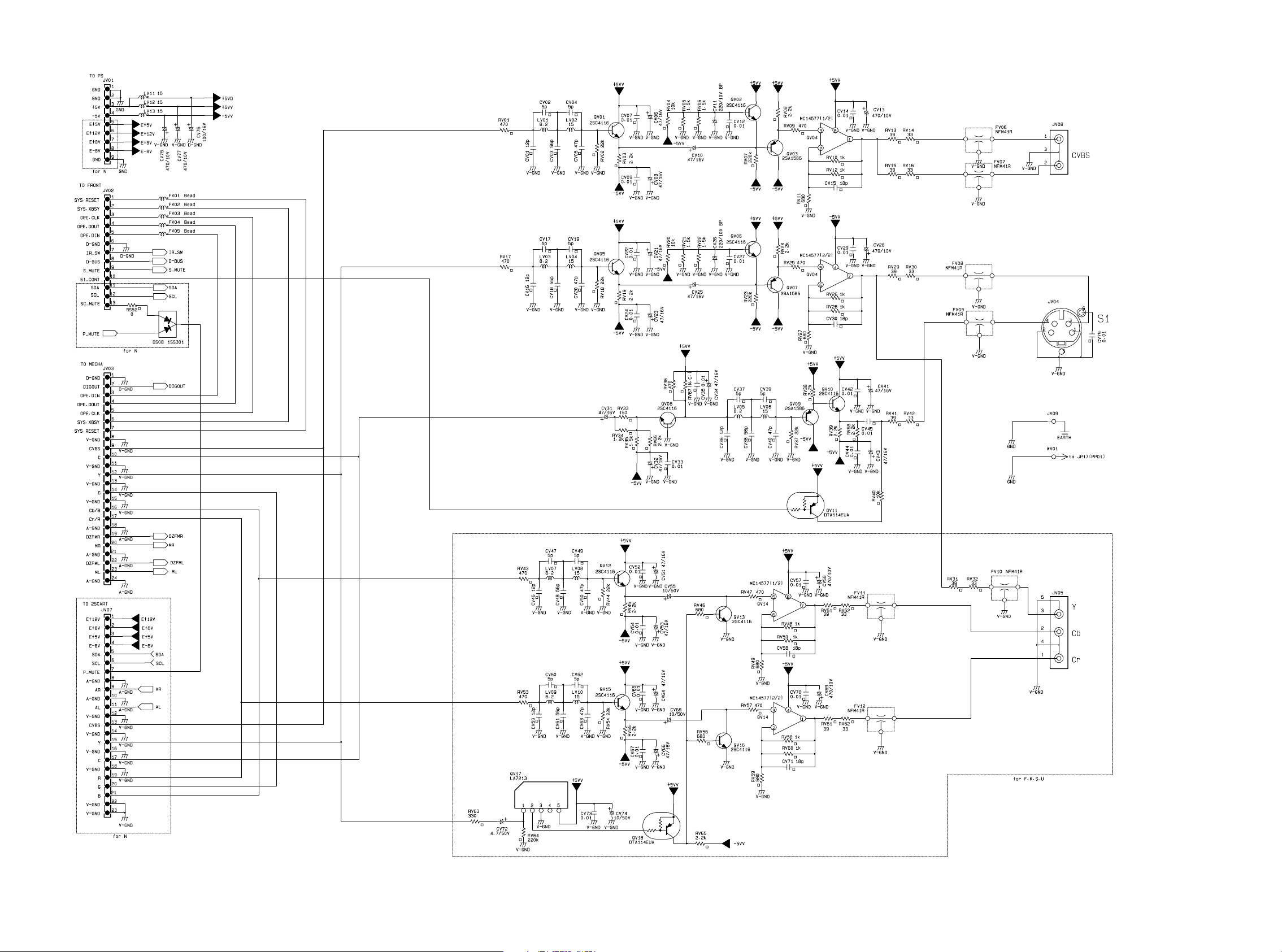

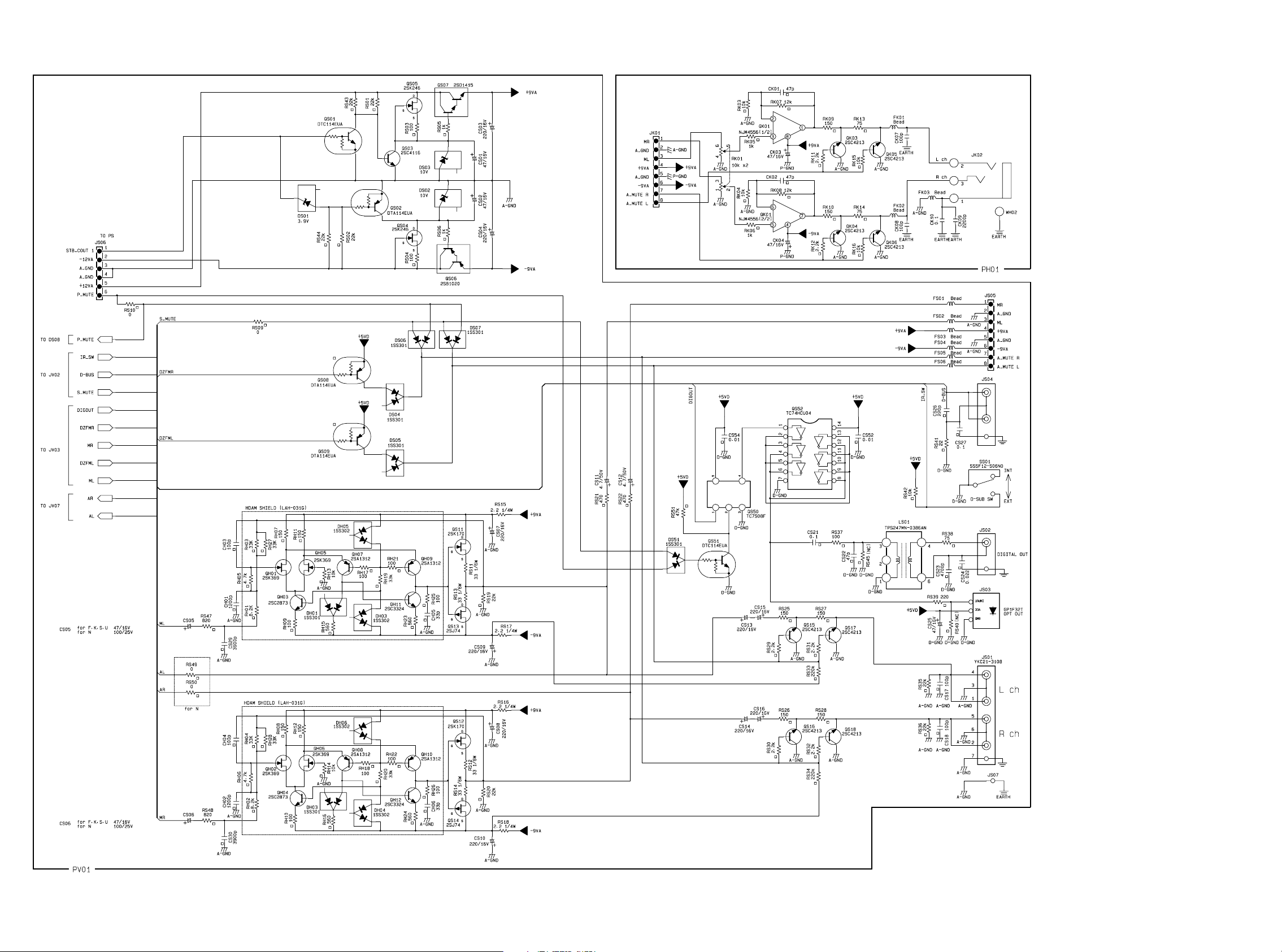

1.12 SCHEMATIC DIAGRAM AND PARTS LOCATION

1-17 1-18

Page 18

1-19 1-20

Page 19

FBIN_ENC

FBIN_VCR

(see Note 1)

BIN_ENC

BIN_VCR

(see Note 1)

GIN_ENC

GIN_VCR

(see Note 1)

RCIN_ENC

RIN_VCR

(see Note 1)

CIN_ENC

CIN_VCR

CIN_TV

CVBSIN_STB

YCVBSIN_ENC

YCVBSIN_TV

YCVBSIN_VCR

YIN_ENC

LIN_ENC

LIN_STB

LIN_TV

LIN_VCR

RIN_TV

RIN_STB

RIN_ENC

RIN_VCR

FB SWITCH

19

18

46

32

44

30

42

28

40

48

54

34

36

52

50

38

45

41

53

49

56

39

43

47

4V

0V

6d

B

RGB SWITCH

B_ENC

B_ENC

B_VCR

G_ENC

G_VCR

R/C_ENC

R_VCR

MUTE

R/C_ENC

C_ENC

C_VCR

MUTE

CVBS/Y_ENC

CVBS/Y_VCR

CVBS_STB

Y_ENC

MUTE

R/C_ENC

C_ENC

C_TV

MUTE

CVBS_STB

CVBS/Y_ENC

CVBS/Y_TV

Y_ENC

MUTE

VCR SWITCH

L_ENC

L_STB

L_TV

R_ENC

R_STB

R_TV

MUTE

TV SWITCH

L_ENC

L_STB

L_VCR

R_VCR

R_STB

R_ENC

MUTE

C SWITCH

Y/CVBS SWITCH

C SWITCH

Y/CVBS SWITCH

-14dB

-14dB

6d

B

6d

B

6dB

TRAP

6dB

6dB

SLOW BLANK,

6dB

0/6dB

0/6dB

I/O MONITOR

I2C BUS

DECODER

0/6dB

0/6dB

STEREO/

MONO

STEREO/

MONO

STV6411A

17

FBOUT_TV

61

BOUT_TV

63

GOUT_TV

1

RCOUT_TV

9

VOUT_RF

11

FILTER

3

YCVBS/OUT_TV

5

COUT_VCR

7

YCVBSOUT_VCR

25

SLB_TV

27

SLB_VCR

21

SCL

22

SDA

59

LOUT_CINCH

58

ROUT_CINCH

62

LOUT_VCR

60

ROUT_VCR

8

AOUT_RF

2

LOUT_TV

64

ROUT_TV

Q801 STV6411

CC3

CC2

NC

GNDV2

V

NC

FILTER

V

16151413121110

17

FBOUT_TV

FBIN_VCR (see Note 1)

RIN_VCR (see Note 1)

GIN_VCR (see Note 1)

BIN_VCR (see Note 1)

18

19

FBIN_ENC

20

ADD

21

SCL

22

SDA

23

V

CC12

NC

24

SLB_TV

25

NC

26

SLB_VCR

27

28

GNDV1

29

30

NC

31

32

333435363738394041424344454647

CC1

NC

NC

V

YIN_ENC

CVBSIN_STB

YCVBSIN_ENC

Pin Number Symbol Description

1 RCOUT_TV Red/chroma Output, to TV Scart

2 LOUT_TV Audio Left Output, to TV Scart

3 YCVBSOUT_TV Y/CVBS Output, to TV scart

4 NC Not Connected

5 COUT_VCR Chroma Output, to VCR Scart

6 NC Not Connected

7 YCVBSOUT_VCR Y/CVBS Output, to VCR Scart

8 AOUT_RF Audio (L+R) Output to RF Modulator

9 VOUT_RF Video (CVBS) Output to RF Modulator

10 GNDV3 Video Switches Ground 3

11 FILTER Chroma Trap Filter

12 V

13 NC Not Connected

14 GNDV2 Video Switches Ground 2

15 NC Not Connected

16 V

17 FBOUT_TV Fast Blanking Output, to TV Scart

18 FBIN_VCR (see Note 1) Fast Blanking Input, from VCR Scart

19 FBIN_ENC Fast Blanking Input, from Encoder

20 ADD I

21 SCL I

22 SDA I

23 V

24 NC Not Connected

25 SLB_TV Slow Blanking Input/Ouput from TV

26 NC Not Connected

27 SLB_VCR Slow Blanking Input/Ouput from VCR

28 RIN_VCR (see Note 1) Red Input, from VCR Scart

29 GNDV1 Video Switches Ground 1

30 GIN_VCR (see Note 1) Green Input, from VCR Scart

31 NC Not Connected

32 BIN_VCR (see Note 1) Blue Input, from VCR Scart

33 V

34 CVBSIN_STB CVBS Input from STB

35 NC Not Connected

36 YCVBSIN_ENC Y/CVBS Input from Encoder

37 NC Not Connected

38 YIN_ENC Y Input, from Encoder

39 RIN_STB Audio Right Input, from STB

40 CIN_ENC Chroma Input, from Encoder

41 LIN_STB Audio Left Input, from STB

42 RCIN_ENC Red/Chroma Input, from Encoder

43 RIN_ENC Audio Right Input, from Encoder

44 GIN_ENC Green Input, from Encoder

45 LIN_ENC Audio Left Input, from Encoder

46 BIN_ENC Blue Input, from Encoder

47 RIN_VCR Audio Right Input, from VCR Scart

48 CIN_VCR Chroma Input, from VCR Scart

49 LIN_VCR Audio Left Input, from VCR

50 YCVBSIN_VCR Y/CVBS Input from VCR Scart

51 V

52 YCVBSIN_TV Y/CVBS Input, from TV Scart

53 LIN_TV Audio Left Input, from TV Scart

54 CIN_TV Chroma Input, from TV Scart

55 V

56 RIN_TV Audio right input, from TV Scart

57 GNDA Audio Switches Ground

58 ROUT_CINCH Audio Right Output, to CINCH

59 LOUT_CINCH Audio Left Output, to CINCH

60 ROUT_VCR Audio Right Output, to VCR sCart

61 BOUT_TV Blue Output, to TV Scart

62 LOUT_VCR Audio Left Output, to VCR Scart

63 GOUT_TV Green Output, to TV Scart

64 ROUT_TV Audio Right Output, to TV Scart

Notes :

1. Pins (xx_VCR) identified as xx_AU X in STV6410A.

2. In application, all unused pins should be left open or high frequency bypassed to ground.

CCV3

CCV2

CC12

CCV1

REF

CCA

NC

COUT_VCR

NC

YCVBSOUT_VCR

AOUT_RF

VOUT_RF

GNDV3

987654321

LIN_STB

LIN_ENC

RIN_STB

RIN_ENC

CIN_ENC

GIN_ENC

RCIN_ENC

Video Switches Supply 3 (8V)

Video Switches Supply 2 (8V)

2

C Bus IC Address Programmation

2

C Bus Clock

2

C Bus Data

Slow Blanking Power Supply (12V)

Video Switches Supply 1 (8V)

Voltage Reference Decoupling

Audio Switches Supply (8V)

RCOUT_TV

LOUT_TV

YCVBSOUT_TV

48

BIN_ENC

RIN_VCR

CIN_VCR

64

ROUT_TV

63

GOUT_TV

62

LOUT_VCR

61

BOUT_TV

60

ROUT_VCR

59

LOUT_CINCH

58

ROUT_CINCH

GNDA

57

RIN_TV

56

V

55

CCA

54

CIN_TV

53

LIN_TV

52

YCVBSIN_TV

51

V

REF

50

YCVBSIN_VCR

49

LIN_VCR

1-21 1-22

Page 20

A-B

TITLE

SHUFFLE

REPEAT

CHAPTER

VCD

TRACK

PBC

SCAN

FTS

TITLE

CHAPTER

TRACK

TOTAL

TRACK

TIME

1-23 1-24

Page 21

1-25 1-26

Page 22

PS01

1.13 PARTS LOCATION

PF01

QF08 QF11 QF01

QF06 QF07 QF05 QF10

QF04

QF09 QF03 QF02 QF12

PL01

PP01

QP18 QP19

QP20 - QP22

QP02

QP01

QP25

QP03

QP24

QP04 QP12 QP14 QP13

QP13 QP11

QP05 QP07

QP09 QP08 QP06

QP10

PK01

QK03 QK05

QK01 QK04 QK06

1-27 1-28

Page 23

QS04 QS02 QS01 QS03 QS05 QS07

QH02 - QH12

(Even number)

QH03 - QH11

(Odd number)

QV10 QV05 QV08 QV15

QV03 QV02

QV07 QV06

QV09 QV10 QV16 QV13

QV12

QV17 QV18

QS08 QS09

QS14 QS12 QS11 QS13QS15 - QS18 QV04 QV11 QV14 QV18 QS51 QS50

QS52

1-29 1-30

Page 24

1.14 EXPLODED VIEW AND PARTS LIST

POS.

NO

VERS.

COLOR

PART NO.

(FOR PCS)

DESCRIPTION

PART NO.

(MJI)

PE01

Q952 - Q955

Q960-Q962

Q956 - Q959 Q823 Q819 - Q821

Q808

Q809

Q801

Q814

Q815 - Q818

Q802 Q803 Q804 Q805 Q806 Q807

001B BLACK 9965 000 05014 FRONT CHASSIS PL(L)BLK 383K105010

001B GOLD 9965 000 05015 FRONT CHASSIS PL(L)GLD 383K105110

002B BLACK 9965 000 05016 FRONT CHASSIS PL(R)BLK 383K105020

002B GOLD 9965 000 05017 FRONT CHASSIS PL(R)GLD 383K105120

003B BLACK 9965 000 05018 FRONT PANEL AL DV7000 BL 383K248010

003B GOLD 9965 000 05019 FRONT PANEL AL DV7000 GL 383K248110

005B BLACK 9965 000 05020 BUTTON FUNCTION BLK 383K270010

005B GOLD 9965 000 05021 BUTTON FUNCTION GLD 383K270110

006B BLACK 9965 000 05022 BUTTON OPEN/CLOSE BLK 383K270020

006B GOLD 9965 000 05023 BUTTON OPEN/CLOSE GLD 383K270120

007B 9965 000 05024 WINDOW DV7000 383K158010

008B 9965 000 05025 BUTTON SUB FUNCTION 386K270090

009B 4822 454 11825 MARANTZ BADGE (BL) 185J251010

010B 9965 000 01393 LENS STANDBY 312J355010

020B BLACK 4822 411 20336 KNOB PHONE BLACK 284T154310

020B GOLD 9965 000 00580 KNOB PHONE GOLD 284T154240

045B BLACK 9965 000 01975 BUTTON POWER BLACK 255W270010

045B GOLD 9965 000 01395 BUTTON POWER GOLD 255W270110

050B BLACK 9965 000 05026 ESCUTCHEON

050B GOLD 9965 000 05027 ESCUTCHEON

051B BLACK 9965 000 05028 DVD BADGE BLK 386K251030

051B GOLD 9965 000 05029 DVD BADGE GLD 386K251130

009G 9965 000 05030 LEG

010G 9965 000 05031 LEG

025G 9965 000 00362 LINK,POWER SW. 349K121010

911G /F BUSHING MAINS CORD 318K259020

911G /K, /S

/N, /U

001A 9965 000 04619 DVD MODULE UNIT

WV01 9965 000 04963 FFC MECHA- AV YU24075510

WV02 /N 9965 000 04965 FFC AV-2SCART YU23135520

W001 /F MAINS CORD 15A 125V

W001 /K1B MAINS CORD

W001 /K1G MAINS CORD CCEE

W001 /S, /N 4822 321 11343 MAINS CORD YC01800790

W001 /U MAINS CORD UL/CSA

PACKING

001T /F USER GUIDE 383K851110

001T /K, /S USER GUIDE 383K851350

001T /N 9965 000 05032 USER GUIDE 383K851320

001T /U USER GUIDE 383K851310

001Z 9965 000 05013 REMOTE COMMANDER

NOT STANDARD SPARE

001S PACKING CASE DV7000 383K801010

002S CUSHION 386K809010

4822 532 60948 BUSHING MAINS CORD 450H259010

TRAY FRONT BLK

TRAY FRONT GLD

(GOLD HOT STAMP) F

(GOLD HOT STAMP) R

DVD MECHA+DIGITAL BOARD

OFC HANAI

FOR BS(MAYOR)

APP.(AC250V 10A)+ VAR2P

NON-INTEGRAL

RC7000DV

PARTS

383K063010

383K063110

383K057010

383K057110

ZK370K0100

YC01800430

YC01800760

YC01800880

YC02000880

ZK383K0010

1-31 1-32

Page 25

NVERSION

SY MBOL ST YL E

5110

5126

5127

5128

5129

54 05

001Z

PA RT S NA ME

+B.H.M.SCREW

+B. H. T AP T I TE SCREW W/WASHER

+ P. H. T AP T I T E SC REW ( B T YPE )

+ B. H. T AP T I T E SC REW ( B T YPE )

+ B. H. T AP T I T E SCREW( W / T . L . WAS HER )

TOOT HE D L OCK WASHERS

T

E

X

T

00 1B

5129

3X8( M)

01 5B x 3

003B

010B

51 2 8

3X8 ( M)

009B

MARK MATERI AL/FINISH

( M) ST EE L / COPPER

(U) STEEL/BLACK

045B

006B

007B

04 1B

025 G

PL01

VF 0 1

00 8B

002B

5126

3X8( M)

055B

056B

005B

PF 0 1

00 1D

05 1 B

001A

050B

02 1B

02 6 G

5126

3x 8( M)

51 28

3x 8( M)

PK0 1

51 2 8

3X8 ( M)

020G

5126

3X8( M)

056 G

02 1 G

003G

007Gx4

51 29

3X8( M)

5128

3x 8( M)

5128

3X8( M)

009G

51 1 0

3x 6 ( M)

PE 0 1

51 28

3x 8 ( M)

5110

3x 6( M)

L002

L

5128

3X8 ( M)

FC0 1

PS0 1

51 10

3x 6( M)

5128

3X8( M)

5129

3X8( M)

990G

UONLY

901G

5110

3x 6( M)

034G

NONLY

L0 04

L003

I

N

V

I

A

V

S

O

I

I

B

D

L

E

D

I

R

L

E

A

C

S

T

E

R

E

X

R

P

O

A

S

D

U

I

R

A

E

T

I

T

O

O

N

B

E

A

M

.

055G x 2

51 2 7

3x 8 ( M)

W001

911G

N, K ONL Y

990G

511 0

3x 6( M)

5127

3x 8( M)

PV0 1

L0 0 5

L001

PP 0 1

031G x 2

5110

3x 8( M)

51 28

3x 8( M)

TP 0 1

54 0 5

3( M)

048G

033G

99 1G

032G x 3

NONLY

043G x 2

035G

00 1 G

W

H

E

N

O

P

E

N

.

036G

002 G

5129

3X8( M)

042G x 2

NONLY

010Gx2

020B

5128

3x 8( M)

1-33 1-34

009G

Page 26

1.15 ELECTRICAL PARTS LIST

ASSIGNMENT OF COMMON PARTS CODES.

RESISTORS

R : 1) GD05 × × × 140, Carbon film fixed resistor, ±5% 1/4W

R : 2) GD05 × × × 160, Carbon film fixed resistor, ±5% 1/6W

Examples ;

Resistance value

➀

0.1 Ω .... 001 10 Ω .... 100 1 kΩ .... 102 100 kΩ .... 104

0.5 Ω .... 005 18 Ω .... 180 2.7 kΩ .... 272 680 kΩ .... 684

1 Ω .... 010 100 Ω .... 101 10 kΩ .... 103 1 MΩ .... 105

6.8 Ω .... 068 390 Ω .... 391 22 kΩ .... 223 4.7 MΩ .... 475

Note : Please distinguish 1/4W from 1/6W by the shape of parts

used actually.

CAPACITORS

C : CERAMIC CAP.

3) DD1 × × × × 370, Ceramic capacitor

Examples ;

Tolerance (Capacity deviation)

➁

±0.25 pF .... 0

Tolerance of COMMON PARTS handled here are as follows :

C : CERAMIC CAP.

Examples ;

C : 5) ELECTROLY CAP. ( ), 6) FILM CAP. ( )

Examples ;

Examples ;

NOTE

0.5 pF 5 pF .... ±0.25 pF

12 pF 560 pF .... ±5%

Capacity value

➂

0.5 pF .... 005 3 pF .... 030 100 pF .... 101

1.5 pF .... 015 47 pF .... 470 560 pF .... 561

4) DK16 × × × 300, High dielectric constant ceramic

Capacity value

➃

100 pF .... 101 1000 pF .... 102 10000 pF .... 103

470 pF .... 471 2200 pF .... 222

5) EA

Capacity value

➄

0.1 µF .... 104 4.7 µF .... 475 100 µF ....107

0.33 µF .... 334 10 µF .... 106 330 µF ....337

Working voltage

➅

6) DF15 × × × 350 Plastic film capacitor

DF15 × × × 310 One-way type, Mylar ±5% 50V

DF16 × × × 310 Plastic film capacitor

Capacity value

➆

0.001 µF (1000 pF) ....... 102 0.1 µF .... 104

0.0018 µF ........................ 182 0.56 µF ....564

0.01 µF ........................ 103 1 µF ....105

0.015 µF ........................ 153

: 1) The above CODES ( R , R , C , C and

C ) are omitted on the schematic diagram in some

case.

2) On the occasion, be confirmed the common parts on

the parts list.

3) Refer to “Common Parts List” for the other common

parts (RI05, DD4, DK4).

{

➀

{

➁

±0.5 pF .... 1

±5% .... 5

6 pF 10 pF .... ±0.5 pF

1 pF .... 010 10 pF .... 100 220 pF .... 221

➃

× × × × ×

{

➄

1 µF....105 22 µF ....226 1100 µF ....118

6.3V .... 006 25V .... 025

10V .... 010 35V .... 035

16V .... 016 50V .... 050

➆

Resistance value

➂

{

➅

{

Disc type

Temp.coeff.P350 N1000, 50V

Capacity value

Tolerance

capacitor

Disc type

Temp.chara. 2B4, 50V

Capacity value

×

10, Electrolytic capacitor

{

One-way lead type, Tolerance ±20%

Working voltage

Capacity value

One-way type, Mylar ±10% 50V

Capacity value

2200 µF ....228

NOTE ON SAFETY FOR FUSIBLE RESISTOR :

The suppliers and their type numbers of fusible resistors

are as follows;

1. KOA Corporation

Part No. (MJI) Type No. (KOA) Description

NH05 × × × 140 RF25S × × × × ΩJ(±5% 1/4W)

NH05 × × × 120 RF50S × × × × ΩJ(±5% 1/2W)

NH85 × × × 110 RF73B2A × × × × ΩJ(±5% 1/10W)

NH95 × × × 140 RF73B2E × × × × ΩJ(±5% 1/4W)

2. Matsushita Electronic Components Co., Ltd

Part No. (MJI) Type No. (MEC) Description

NF05 × × × 140 ERD-2FCJ × × × (±5% 1/4W)

RF05 × × × 140

NF02 × × × 140

RF02 × × × 140

Examples ;

{

Resistance value

ERD-2FCG

{

Resistance value

Resistance value

0.1 Ω .... 001 10 Ω .... 100 1 kΩ .... 102 100 kΩ .... 104

0.5 Ω .... 005 18 Ω .... 180 2.7 kΩ .... 272 680 kΩ .... 684

1 Ω .... 010 100 Ω .... 101 10 kΩ .... 103 1 MΩ .... 105

6.8 Ω .... 068 390 Ω .... 391 22 kΩ .... 223 4.7 MΩ .... 475

{

Resistance value

(0.1 Ω − 10 kΩ)

× × × (±2% 1/4W)

{

Resistance value

ABBREVIATION AND MARKS

ANT. : ANTENNA BATT. : BATTERY

CAP. : CAPACITOR CER. : CERAMIC

CONN. : CONNECTING DIG. : DIGITAL

HP : HEADPHONE MIC. : MICROPHONE

µ-PRO : MICROPROCESSOR REC. : RECORDING

RES. : RESISTOR SPK : SPEAKER

SW : SWITCH TRANSF. : TRANSFORMER

TRIM. : TRIMMING TRS. : TRAMSISTOR

VAR. : VARIABLE X’TAL : CRYSTAL

NOTE ON SAFETY :

Symbol Fire or electrical shock hazard. Only original

parts should be used to replaced any part marked with

symbol . Any other component substitution (other

than original type), may increase risk of fire or electrical

shock hazard.

VERS.

POS.

COLOR

NO

PE01- SCART CIRCUIT

PE01-CAPACITORS

C802 /N 4822 124 90354 ELECT. 100µF M 16V RA-2 OA10701620

C804 /N 4822 124 90354 ELECT. 100µF M 16V RA-2 OA10701620

C806 /N 4822 126 11663 CER. CHIP 12pF ±5% CG 50V DD95120300

C808 /N 4822 122 33782 CER. CHIP 56pF DD95560300

C810 /N 4822 122 33777 CER. CHIP 47pF ±5% CG 50V DD95470300

C812 /N 4822 126 11663 CER. CHIP 12pF ±5% CG 50V DD95120300

C814 /N 4822 122 33782 CER. CHIP 56pF DD95560300

C816 /N 4822 122 33777 CER. CHIP 47pF ±5% CG 50V DD95470300

C819 /N 4822 126 11703 CER. CHIP 0.01µF DK98103300

C821 /N 9965 000 04997 CER. CHIP 5pF ±0.25pF CH DD90050300

C823 /N 4822 122 33741 CER. CHIP 10pF ±0.5pF CH DD91100300

C825 /N 4822 126 11704 CER. CHIP 0.022µF DK98223300

C827 /N 4822 126 11663 CER. CHIP 12pF ±5% CG 50V DD95120300

C829 /N 4822 122 33782 CER. CHIP 56pF DD95560300

C831 /N 4822 126 13956 CER. CHIP 68pF DD95680300

C833 /N 4822 126 11703 CER. CHIP 0.01µF DK98103300

C835 /N 9965 000 04997 CER. CHIP 5pF ±0.25pF CH DD90050300

C836 /N 4822 122 33782 CER. CHIP 56pF DD95560300

C838 /N 4822 126 13956 CER. CHIP 68pF DD95680300

C840 /N 4822 126 11703 CER. CHIP 0.01µF DK98103300

C842 /N 9965 000 04997 CER. CHIP 5pF ±0.25pF CH DD90050300

C844 /N 4822 122 33741 CER. CHIP 10pF ±0.5pF CH DD91100300

C846 /N 5322 124 21731 ELECT. 10µF M 50V RA-2 OA10605020

C848 /N 4822 126 11703 CER. CHIP 0.01µF DK98103300

C850 /N 4822 122 33777 CER. CHIP 47pF ±5% CG 50V DD95470300

C852 /N 4822 126 11703 CER. CHIP 0.01µF DK98103300

C854 /N 4822 126 11704 CER. CHIP 0.022µF DK98223300

C856 /N 4822 126 11703 CER. CHIP 0.01µF DK98103300

C858 /N 4822 126 11703 CER. CHIP 0.01µF DK98103300

C860 /N 4822 126 11703 CER. CHIP 0.01µF DK98103300

C862 /N 4822 126 11703 CER. CHIP 0.01µF DK98103300

C865 /N 4822 126 11703 CER. CHIP 0.01µF DK98103300

C869 /N 4822 126 11703 CER. CHIP 0.01µF DK98103300

C871 /N 4822 126 11703 CER. CHIP 0.01µF DK98103300

C876 /N 4822 126 13883 CER. CHIP 220pF ±5% CG 50V DD95221300

C881 /N 4822 126 13883 CER. CHIP 220pF ±5% CG 50V DD95221300

C884 /N 4822 126 11687 CER. CHIP 0.1µF DK98104200

C887 /N 4822 126 11687 CER. CHIP 0.1µF DK98104200

C951 /N 4822 124 90354 ELECT. 100µF M 16V RA-2 OA10701620

C953 /N 4822 124 80067 ELECT. 4.7µF M 50V RA-2 OA47505020

C956 /N 4822 124 80067 ELECT. 4.7µF M 50V RA-2 OA47505020

C960 /N 4822 124 80067 ELECT. 4.7µF M 50V RA-2 OA47505020

C962 /N 4822 126 13883 CER. CHIP 220pF ±5% CG 50V DD95221300

C964 /N 4822 124 80067 ELECT. 4.7µF M 50V RA-2 OA47505020

C968 /N 4822 124 80067 ELECT. 4.7µF M 50V RA-2 OA47505020

C970 /N 4822 126 13883 CER. CHIP 220pF ±5% CG 50V DD95221300

C972 /N 4822 124 41539 ELECT. 47µF 16V OA47601620

C975 /N 5322 126 11578 CER. CHIP 1000pF DK96102300

C977 /N 5322 126 11578 CER. CHIP 1000pF DK96102300

PE01-RESISTORS

R801 /N 4822 051 30101 CHIP 100Ω ±5% 1/16W NN05101610

R802 /N 4822 051 30681 CHIP 680Ω ±5% 1/16W NN05681610

R803 /N 4822 051 30471 CHIP 470Ω ±5% 1/16W NN05471610

R804 /N 4822 051 30472 CHIP 4.7kΩ ±5% 1/16W NN05472610

R805 /N 4822 051 30101 CHIP 100Ω ±5% 1/16W NN05101610

R806 /N 4822 051 30681 CHIP 680Ω ±5% 1/16W NN05681610

R807 /N 4822 051 30471 CHIP 470Ω ±5% 1/16W NN05471610

R808 /N 4822 051 30472 CHIP 4.7kΩ ±5% 1/16W NN05472610

R809 /N 4822 051 30101 CHIP 100Ω ±5% 1/16W NN05101610

R810 /N 4822 051 30681 CHIP 680Ω ±5% 1/16W NN05681610

R811 /N 4822 051 30471 CHIP 470Ω ±5% 1/16W NN05471610

R812 /N 4822 051 30472 CHIP 4.7kΩ ±5% 1/16W NN05472610

R813 /N 4822 051 30101 CHIP 100Ω ±5% 1/16W NN05101610

R814 /N 4822 051 30681 CHIP 680Ω ±5% 1/16W NN05681610

PART NO.

(FOR PCS)

DESCRIPTION

BOARD [ /N VERSION ]

PART NO.

(MJI)

1-35 1-36

VERS.

POS.

COLOR

NO

R815 /N 4822 051 30471 CHIP 470Ω ±5% 1/16W NN05471610

R816 /N 4822 051 30472 CHIP 4.7kΩ ±5% 1/16W NN05472610

R817 /N 4822 051 30101 CHIP 100Ω ±5% 1/16W NN05101610

R818 /N 4822 051 30681 CHIP 680Ω ±5% 1/16W NN05681610

R819 /N 4822 051 30471 CHIP 470Ω ±5% 1/16W NN05471610

R820 /N 4822 051 30472 CHIP 4.7kΩ ±5% 1/16W NN05472610

R821 /N 4822 051 30101 CHIP 100Ω ±5% 1/16W NN05101610

R822 /N 4822 051 30681 CHIP 680Ω ±5% 1/16W NN05681610

R823 /N 4822 051 30471 CHIP 470Ω ±5% 1/16W NN05471610

R824 /N 4822 051 30472 CHIP 4.7kΩ ±5% 1/16W NN05472610

R825 /N 4822 051 30101 CHIP 100Ω ±5% 1/16W NN05101610

R826 /N 4822 051 30101 CHIP 100Ω ±5% 1/16W NN05101610

R827 /N 4822 051 30472 CHIP 4.7kΩ ±5% 1/16W NN05472610

R828 /N 4822 051 30472 CHIP 4.7kΩ ±5% 1/16W NN05472610

R829 /N 4822 051 30222 CHIP 2.2kΩ ±5% 1/16W NN05222610

R830 /N 4822 051 30472 CHIP 4.7kΩ ±5% 1/16W NN05472610

R831 /N 4822 051 30472 CHIP 4.7kΩ ±5% 1/16W NN05472610

R832 /N 4822 117 13632 CHIP 100kΩ ±5% 1/16W NN05104610

R833 /N 4822 051 30561 CHIP 560Ω ±5% 1/16W NN05561610

R834 /N 4822 051 30562 CHIP 5.6kΩ ±5% 1/16W NN05562610

R835 /N 4822 051 30102 CHIP 1kΩ ±5% 1/16W NN05102610

R836 /N 4822 116 82487 CHIP 0Ω ±5% 1/16W NN05000610

R837 /N 4822 117 12925 CHIP 47kΩ ±5% 1/16W NN05473610

R838 /N 4822 051 30471 CHIP 470Ω ±5% 1/16W NN05471610

R839 /N 4822 051 30121 CHIP 120Ω ±5% 1/16W NN05121610

R840 /N 4822 051 30151 CHIP 150Ω ±5% 1/16W NN05151610

R841 /N 4822 051 30102 CHIP 1kΩ ±5% 1/16W NN05102610

R842 /N 4822 051 30151 CHIP 150Ω ±5% 1/16W NN05151610

R843 /N 4822 051 30221 CHIP 220Ω ±5% 1/16W NN05221610

R844 /N 4822 051 30102 CHIP 1kΩ ±5% 1/16W NN05102610

R845 /N 4822 051 30472 CHIP 4.7kΩ ±5% 1/16W NN05472610

R846 /N 4822 051 30102 CHIP 1kΩ ±5% 1/16W NN05102610

R847 /N 4822 051 30472 CHIP 4.7kΩ ±5% 1/16W NN05472610

R849 /N 4822 117 13632 CHIP 100kΩ ±5% 1/16W NN05104610

R850 /N 4822 051 30561 CHIP 560Ω ±5% 1/16W NN05561610

R851 /N 4822 051 30562 CHIP 5.6kΩ ±5% 1/16W NN05562610

R852 /N 4822 051 30472 CHIP 4.7kΩ ±5% 1/16W NN05472610

R853 /N 4822 116 82487 CHIP 0Ω ±5% 1/16W NN05000610

R854 /N 4822 117 12925 CHIP 47kΩ ±5% 1/16W NN05473610

R855 /N 4822 051 30471 CHIP 470Ω ±5% 1/16W NN05471610

R856 /N 4822 051 30121 CHIP 120Ω ±5% 1/16W NN05121610

R857 /N 4822 051 30151 CHIP 150Ω ±5% 1/16W NN05151610

R858 /N 4822 051 30472 CHIP 4.7kΩ ±5% 1/16W NN05472610

R859 /N 4822 051 30151 CHIP 150Ω ±5% 1/16W NN05151610

R860 /N 4822 051 30221 CHIP 220Ω ±5% 1/16W NN05221610

R861 /N 4822 117 11817 CHIP 1.2kΩ ±5% 1/16W NN05122610

R862 /N 4822 117 11817 CHIP 1.2kΩ ±5% 1/16W NN05122610

R863 /N 4822 051 30471 CHIP 470Ω ±5% 1/16W NN05471610

R864 /N 4822 051 30101 CHIP 100Ω ±5% 1/16W NN05101610

R865 /N 4822 051 30471 CHIP 470Ω ±5% 1/16W NN05471610

R866 /N 4822 051 30121 CHIP 120Ω ±5% 1/16W NN05121610

R867 /N 4822 051 30151 CHIP 150Ω ±5% 1/16W NN05151610

R868 /N 4822 051 30101 CHIP 100Ω ±5% 1/16W NN05101610

R869 /N 4822 051 30471 CHIP 470Ω ±5% 1/16W NN05471610

R870 /N 4822 051 30121 CHIP 120Ω ±5% 1/16W NN05121610

R871 /N 4822 051 30151 CHIP 150Ω ±5% 1/16W NN05151610

R872 /N 4822 051 30101 CHIP 100Ω ±5% 1/16W NN05101610

R873 /N 4822 051 30471 CHIP 470Ω ±5% 1/16W NN05471610

R874 /N 4822 051 30151 CHIP 150Ω ±5% 1/16W NN05151610

R875 /N 4822 051 30221 CHIP 220Ω ±5% 1/16W NN05221610

R876 /N 4822 051 30221 CHIP 220Ω ±5% 1/16W NN05221610

R877 /N 4822 051 30101 CHIP 100Ω ±5% 1/16W NN05101610

R878 /N 4822 051 30471 CHIP 470Ω ±5% 1/16W NN05471610

R879 /N 4822 051 30121 CHIP 120Ω ±5% 1/16W NN05121610

R880 /N 4822 051 30151 CHIP 150Ω ±5% 1/16W NN05151610

R881 /N 4822 051 30181 CHIP 180Ω ±5% 1/16W NN05181610

R882 /N 4822 051 30151 CHIP 150Ω ±5% 1/16W NN05151610

PART NO.

(FOR PCS)

DESCRIPTION

PART NO.

(MJI)

Page 27

POS.

NO

VERS.

COLOR

PART NO.

(FOR PCS)

DESCRIPTION

PART NO.

(MJI)

POS.

NO

VERS.

COLOR

PART NO.

(FOR PCS)

DESCRIPTION

PART NO.

(MJI)

R883 /N 4822 051 30471 CHIP 470Ω ±5% 1/16W NN05471610

R884 /N 4822 117 12925 CHIP 47kΩ ±5% 1/16W NN05473610

R885 /N 4822 051 30181 CHIP 180Ω ±5% 1/16W NN05181610

R886 /N 4822 051 30151 CHIP 150Ω ±5% 1/16W NN05151610

R887 /N 4822 051 30181 CHIP 180Ω ±5% 1/16W NN05181610

R888 /N 4822 051 30151 CHIP 150Ω ±5% 1/16W NN05151610

R889 /N 4822 116 83829 CHIP 270Ω ±5% 1/16W NN05271610

R890 /N 4822 116 83829 CHIP 270Ω ±5% 1/16W NN05271610

R891 /N 4822 051 30221 CHIP 220Ω ±5% 1/16W NN05221610

R892 /N 4822 051 30101 CHIP 100Ω ±5% 1/16W NN05101610

R893 /N 4822 051 30471 CHIP 470Ω ±5% 1/16W NN05471610

R894 /N 4822 051 30121 CHIP 120Ω ±5% 1/16W NN05121610

R895 /N 4822 051 30151 CHIP 150Ω ±5% 1/16W NN05151610

R896 /N 4822 051 30181 CHIP 180Ω ±5% 1/16W NN05181610

R897 /N 4822 051 30151 CHIP 150Ω ±5% 1/16W NN05151610

R898 /N

R903 /N

R904 /N 4822 051 30102 CHIP 1kΩ ±5% 1/16W NN05102610

R905 /N 4822 051 30102 CHIP 1kΩ ±5% 1/16W NN05102610

R906 /N

R909 /N

R951 /N 4822 051 30474 CHIP 470kΩ ±5% 1/16W NN05474610

R952 /N 4822 051 30471 CHIP 470Ω ±5% 1/16W NN05471610

R953 /N 4822 051 30471 CHIP 470Ω ±5% 1/16W NN05471610

R954 /N 4822 117 12925 CHIP 47kΩ ±5% 1/16W NN05473610

R955 /N 4822 117 12925 CHIP 47kΩ ±5% 1/16W NN05473610

R956 /N 4822 051 30151 CHIP 150Ω ±5% 1/16W NN05151610

R957 /N 4822 051 30151 CHIP 150Ω ±5% 1/16W NN05151610

R958 /N 4822 051 30222 CHIP 2.2kΩ ±5% 1/16W NN05222610

R959 /N 4822 051 30222 CHIP 2.2kΩ ±5% 1/16W NN05222610

R960 /N 4822 051 30151 CHIP 150Ω ±5% 1/16W NN05151610

R961 /N 4822 051 30151 CHIP 150Ω ±5% 1/16W NN05151610

R962 /N 4822 051 30222 CHIP 2.2kΩ ±5% 1/16W NN05222610

R963 /N 4822 051 30222 CHIP 2.2kΩ ±5% 1/16W NN05222610

R964 /N 4822 051 30223 CHIP 22kΩ ±5% 1/16W NN05223610

R965 /N 4822 051 30223 CHIP 22kΩ ±5% 1/16W NN05223610

R968 /N 4822 051 30471 CHIP 470Ω ±5% 1/16W NN05471610

R969 /N 4822 051 30471 CHIP 470Ω ±5% 1/16W NN05471610

R970 /N 4822 117 12925 CHIP 47kΩ ±5% 1/16W NN05473610

R971 /N 4822 117 12925 CHIP 47kΩ ±5% 1/16W NN05473610

R972 /N 4822 051 30151 CHIP 150Ω ±5% 1/16W NN05151610

R973 /N 4822 051 30151 CHIP 150Ω ±5% 1/16W NN05151610

R974 /N 4822 051 30222 CHIP 2.2kΩ ±5% 1/16W NN05222610

R975 /N 4822 051 30222 CHIP 2.2kΩ ±5% 1/16W NN05222610

R976 /N 4822 051 30151 CHIP 150Ω ±5% 1/16W NN05151610

R977 /N 4822 051 30151 CHIP 150Ω ±5% 1/16W NN05151610

R978 /N 4822 051 30222 CHIP 2.2kΩ ±5% 1/16W NN05222610

R979 /N 4822 051 30222 CHIP 2.2kΩ ±5% 1/16W NN05222610

R980 /N 4822 051 30223 CHIP 22kΩ ±5% 1/16W NN05223610

R981 /N 4822 051 30223 CHIP 22kΩ ±5% 1/16W NN05223610

R984 /N 4822 051 30471 CHIP 470Ω ±5% 1/16W NN05471610

R985 /N 4822 051 30471 CHIP 470Ω ±5% 1/16W NN05471610

R986 /N 4822 117 12925 CHIP 47kΩ ±5% 1/16W NN05473610

R987 /N 4822 117 12925 CHIP 47kΩ ±5% 1/16W NN05473610

R988 /N 4822 051 30103 CHIP 10kΩ ±5% 1/16W NN05103610

R989 /N 4822 051 30222 CHIP 2.2kΩ ±5% 1/16W NN05222610

R990 /N 4822 051 30103 CHIP 10kΩ ±5% 1/16W NN05103610

PE01-SEMICONDUCTORS

D801 /N 4822 130 83715 CHIP DIODE 1SS301 DAN202U HZ21005000

D802 /N 4822 130 80346 CHIP DIODE 02CZ8.2 HZ30004050

D803 /N 4822 130 80346 CHIP DIODE 02CZ8.2 HZ30004050

D805 /N 4822 130 80346 CHIP DIODE 02CZ8.2 HZ30004050

D807 /N 4822 130 80346 CHIP DIODE 02CZ8.2 HZ30004050

D808 /N 4822 130 80346 CHIP DIODE 02CZ8.2 HZ30004050

D809 /N 4822 130 80346 CHIP DIODE 02CZ8.2 HZ30004050

/N 4822 051 30221 CHIP 220Ω ±5% 1/16W NN05221610

/N 4822 051 30151 CHIP 150Ω ±5% 1/16W NN05151610

D810 /N 4822 130 80346 CHIP DIODE 02CZ8.2 HZ30004050

Q801 /N 9965 000 05001 IC STV6411A

Q802

Q807 2SA1576 (Q R)

Q808 /N 4822 130 60669 CHIP TRS. 2SC4081 (Q R)

Q809 /N 4822 130 60669 CHIP TRS. 2SC4081 (Q R)

Q810 /N 4822 130 10698 CHIP TRS. 2SA1586 (Y GR)

Q811

Q814 2SC4116 (Y GR)

Q815 /N 4822 130 10698 CHIP TRS. 2SA1586 (Y GR)

Q816

Q823 2SC4116 (Y GR)

Q952

Q959

Q960 /N 4822 130 60669 CHIP TRS. 2SC4081 (Q R)

Q961 /N 4822 130 60669 CHIP TRS. 2SC4081 (Q R)

Q962 /N 4822 130 61903 DIG.TRS. DTA114EU BA10026210

PE01-MISCELLANEOUS

F801 /N 9965 000 04998 EMI FILTER NFM41R01C221 FM31221020

F802 /N 4822 051 30121 CHIP 120Ω ±5% 1/16W NN05121610

F803

F808

F809 /N 4822 051 30121 CHIP 120Ω ±5% 1/16W NN05121610

F810

F814

F952 /N 4822 051 30471 CHIP 470Ω ±5% 1/16W NN05471610

F953 /N 4822 051 30471 CHIP 470Ω ±5% 1/16W NN05471610

F954 /N 4822 051 30121 CHIP 120Ω ±5% 1/16W NN05121610

F955 /N 4822 051 30121 CHIP 120Ω ±5% 1/16W NN05121610

F956 /N 4822 051 30471 CHIP 470Ω ±5% 1/16W NN05471610

F957 /N 4822 051 30471 CHIP 470Ω ±5% 1/16W NN05471610

F958 /N 4822 051 30121 CHIP 120Ω ±5% 1/16W NN05121610

F959 /N 4822 051 30121 CHIP 120Ω ±5% 1/2W NN05121610

J801 /N 9965 000 04999 JACK FFC 23FMN-BTRK(ST) YJ07019470

J802 /N 9965 000 05000 TERMINAL YKF41-5019

L801

L804 COIL 15µH J%

L805 /N 9965 000 00458 CHOKE COIL 8.2µH EL0405 LC18223900

L806 /N 4822 157 60445 CHOKE COIL 15µH J% LC11533900

L807 /N 9965 000 00458 CHOKE COIL 8.2µH EL0405 LC18223900

L808 /N 4822 157 60445 CHOKE COIL 15µH J% LC11533900

L809 /N 9965 000 00458 CHOKE COIL 8.2µH EL0405 LC18223900

L810 /N 4822 157 60445 CHOKE COIL 15µH J% LC11533900

L811 /N 9965 000 00458 CHOKE COIL 8.2µH EL0405 LC18223900

L812 /N 4822 157 60445 CHOKE COIL 15µH J% LC11533900

L813 /N 9965 000 00458 CHOKE COIL 8.2µH EL0405 LC18223900

L814 /N 4822 157 60445 CHOKE COIL 15µH J% LC11533900

L815 /N 9965 000 00458 CHOKE COIL 8.2µH EL0405 LC18223900

L816 /N 4822 157 60445 CHOKE COIL 15µH J% LC11533900

L951 /N 4822 157 60445 CHOKE COIL 15µH J% LC11533900

/N 4822 130 10698 CHIP TRS. 2SA1586 (Y GR) HX100012A0

/N 4822 130 60669 CHIP TRS. 2SC4081 (Q R) HX300012A0

/N 4822 130 60669 CHIP TRS. 2SC4081 (Q R) HX300012A0

/N 4822 130 63601 CHIP TRS. 2SC4213 HX342132A0

/N 9965 000 04998 EMI FILTER NFM41R01C221 FM31221020

/N 9965 000 04998 EMI FILTER NFM41R01C221 FM31221020

/N 4822 157 60445 CHOKE COIL SUBSTITUDE LC11533900

A/V SWITCH MATRIX

2SC4116 (Y GR)

2SC4116 (Y GR)

2SA1576A (Q R)

2SA1576A (Q R)

2SC4116 (Y GR)

2SC4116 (Y GR)

EUROCONNECTOR(21X2)

HC10008540

HX300012A0

HX300012A0

HX100012A0

HX100012A0

HX300012A0

HX300012A0

YT02420010

37

Page 28

POS.

NO

VERS.

COLOR

PART NO.

(FOR PCS)

DESCRIPTION

PART NO.

(MJI)

POS.

NO

VERS.

COLOR

PART NO.

(FOR PCS)

DESCRIPTION

PART NO.

(MJI)

PF01-FRONT CIRCUIT BOARD

PF01-CAPACITORS

CF01

CF11

CF12 4822 124 23056 ELECT CAP. 47µF 10V EJ47601010

CF13 9965 000 01912 CER. CHIP 0.047µF DK98473300

CF14 9965 000 01912 CER. CHIP 0.047µF DK98473300

CF15 9965 000 01912 CER. CHIP 0.047µF DK98473300

CF16 /N 4822 122 31765 CER. CHIP 100pF ±5% CG 50V DD95101300

CF17 /N 4822 122 31765 CER. CHIP 100pF ±5% CG 50V DD95101300

CF19 9965 000 01912 CER. CHIP 0.047µF DK98473300

CF21 4822 124 23056 ELECT CAP. 47µF 10V EJ47601010

CF22 4822 126 11703 CER. CHIP 0.01µF DK98103300

CF23 4822 126 11703 CER. CHIP 0.01µF DK98103300

CF24 4822 122 33752 CER. CHIP 15pF ±5% CG 50V DD95150300

CF25 4822 122 33752 CER. CHIP 15pF ±5% CG 50V DD95150300

CF31 9965 000 01912 CER. CHIP 0.047µF DK98473300

CF32

CF36

CF37 /N 4822 122 31765 CER. CHIP 100pF ±5% CG 50V DD95101300

CF39 4822 122 31765 CER. CHIP 100pF DD95101300

CF40 4822 122 31765 CER. CHIP 100pF DD95101300

CF41 4822 126 11687 CER. CHIP 0.1µF

CF42

CF45 GRM39F104Z16

PF01-RESISTORS

RF01 4822 051 20129 CHIP 12Ω ±5% 10W NI05120110

RF02 4822 051 30102 CHIP 1kΩ ±5% 1/16W NN05102610

RF03 4822 051 30103 CHIP 10kΩ ±5% 1/16W NN05103610

RF04 4822 051 30102 CHIP 1kΩ ±5% 1/16W NN05102610

RF05 4822 051 30103 CHIP 10kΩ ±5% 1/16W NN05103610

RF06 /N 4822 051 30101 CHIP 100Ω ±5% 1/16W NN05101610

RF07 /N 4822 051 30101 CHIP 100Ω ±5% 1/16W NN05101610

RF10 4822 117 12925 CHIP 47kΩ ±5% 1/16W NN05473610

RF11 4822 051 30101 CHIP 100Ω ±5% 1/16W NN05101610

RF12 4822 051 30101 CHIP 100Ω ±5% 1/16W NN05101610

RF13 4822 051 30103 CHIP 10kΩ ±5% 1/16W NN05103610

RF14 4822 051 30103 CHIP 10kΩ ±5% 1/16W NN05103610

RF15 4822 051 30103 CHIP 10kΩ ±5% 1/16W NN05103610

RF16 4822 051 30472 CHIP 4.7kΩ ±5% 1/16W NN05472610

RF17 4822 051 30103 CHIP 10kΩ ±5% 1/16W NN05103610

RF18 4822 051 30222 CHIP 2.2kΩ ±5% 1/16W NN05222610

RF19 4822 116 83829 CHIP 270Ω ±5% 1/16W NN05271610

RF20 4822 051 30103 CHIP 10kΩ ±5% 1/16W NN05103610

RF23 4822 116 82487 CHIP 0Ω ±5% 1/16W NN05000610

RF28

RF31

RF32 4822 051 30472 CHIP 4.7kΩ ±5% 1/16W NN05472610

RF33 4822 051 30472 CHIP 4.7kΩ ±5% 1/16W NN05472610

RF34 4822 051 30472 CHIP 4.7kΩ ±5% 1/16W NN05472610

RF35 4822 117 12925 CHIP 47kΩ ±5% 1/16W NN05473610

RF36 4822 117 12925 CHIP 47kΩ ±5% 1/16W NN05473610

RF37 4822 051 30103 CHIP 10kΩ ±5% 1/16W NN05103610

RF38 4822 051 30103 CHIP 10kΩ ±5% 1/16W NN05103610

RF39 4822 051 20129 CHIP 12Ω ±5% 1/10W NI05120110

RF40 4822 051 30102 CHIP 1kΩ ±5% 1/16W NN05102610

RF41 4822 117 12925 CHIP 47kΩ ±5% 1/16W NN05473610

RF42 4822 051 30101 CHIP 100Ω ±5% 1/16W NN05101610

RF43

RF46

RF49 4822 051 30101 CHIP 100Ω ±5% 1/16W NN05101610

RF50 4822 116 83829 CHIP 270Ω ±5% 1/16W NN05271610

4822 122 31765 CER. CHIP 100pF ±5% CG 50V DD95101300

4822 122 31765 CER. CHIP 100pF DD95101300

DK98104200

GRM39F104Z16

4822 126 11687 CER. CHIP 0.1µF DK98104200

4822 051 30101 CHIP 100Ω ±5% 1/16W NN05101610

4822 051 30101 CHIP 100Ω ±5% 1/16W NN05101610

RF51 4822 051 30103 CHIP 10kΩ ±5% 1/16W NN05103610

RF52 4822 051 30152 CHIP 1.5kΩ ±5% 1/16W NN05152610

RF53 4822 051 30101 CHIP 100Ω ±5% 1/16W NN05101610

RF54 4822 117 12864 CHIP 82kΩ ±5% 1/16W NN05823610

PF01-SEMICONDUCTORS

DF02 4822 130 83715 CHIP DIODE 1SS301 DAN202U HZ21005000

DF04 9965 000 04970 CHIP DIODE 02CZ3.3X HZ30014050

DF05 9965 000 04971 CHIP DIODE 02CZ3.9X HZ30024050

DF06 9965 000 04972 L.E.D. SEL4117R TP2 RED HI10036080

QF01 9965 000 04870 Microprocessor *HU7000DV1

QF02 4822 130 10698 CHIP TRS. 2SA1586 (Y GR)

QF03 4822 130 60669 CHIP TRS. 2SC4081 (Q R)

QF04 4822 209 15921 IC RESET IC S-806D-Z SEIKO HC10077530

QF05 4822 130 60669 CHIP TRS. 2SC4081 (Q R)

QF06 4822 130 60669 CHIP TRS. 2SC4081 (Q R)

QF07 4822 130 10698 CHIP TRS. 2SA1586 (Y GR)

QF08 4822 130 10698 CHIP TRS. 2SA1586 (Y GR)

QF09 4822 130 61903 DIG.TRS. DTA114EUA BA10026210

QF10 9965 000 04975 IC NJM79L24A -24V 100MA HC39124090

QF11 4822 130 10698 CHIP TRS. 2SA1586(Y.GR)

QF12 /N 4822 130 61903 DIG.TRS. DTA114EUA BA10026210

PF01-MISCELLANEOUS

JF01 9965 000 04973 JACK S7B-PH-K-S YJ06006470

JF02 /F, /K,

JF02 /N 4822 265 20556 JACK S13B-PH-K-S YJ06006530

JF03 9965 000 04974 JACK S2B-PH-K-S YJ06006420

SF01

SF12 SKQNAE H/5MM 160GF

VF01 9965 000 04976 DISPLAY UNIT FL DISPLAY

XF01 9965 000 04977 SERAMIC VIB. CSTS MG 8MHz FQ08004060

ZF01 4822 130 11494 PHOTO UNIT RPM6936-V4

PK01-HEAD PHONE

PK01-CAPACITORS

CK01 4822 122 33777 CER. CHIP 47pF ±5% CG 50V DD95470300

CK02 4822 122 33777 CER. CHIP 47pF ±5% CG 50V DD95470300

CK03 4822 124 41539 ELECT. 47µF M 16V RA-2 OA47601620

CK04 4822 124 41539 ELECT. 47µF M 16V RA-2 OA47601620

CK07 4822 122 31765 CER. CHIP 100pF ±5% CG 50V DD95101300

CK08 4822 122 31765 CER. CHIP 100pF ±5% CG 50V DD95101300

CK09 4822 126 12339 CER. CHIP 2200pF DK96222300

CK10 4822 126 11687 CER. CHIP 0.1µF

PBK01-RESISTORS

RK01 9965 000 00602 VARIABLE RESIST RK09L12B0

RK03 4822 051 30103 CHIP 10kΩ ±5% 1/16W NN05103610

RK04 4822 051 30103 CHIP 10kΩ ±5% 1/16W NN05103610

RK05 4822 051 30102 CHIP 1kΩ ±5% 1/16W NN05102610

RK06 4822 051 30102 CHIP 1kΩ ±5% 1/16W NN05102610

RK07 4822 051 30123 CHIP 12kΩ ±5% 1/16W NN05123610

RK08 4822 051 30123 CHIP 12kΩ ±5% 1/16W NN05123610

RK09 4822 051 30151 CHIP 150Ω ±5% 1/16W NN05151610

/S, /U

4822 276 13732 PUSH SWITCH SP01013310

2SA1576A (Q R)

2SC4116 (Y GR)

2SC4116 (Y GR)

2SC4116 (Y GR)

2SA1576A (Q R)

2SA1576A (Q R)

2SA1576A(Q.R)

JACK S10B-PH-K-S YJ06006500

11-BT-174 GNK

(IR SENSOR)

CIRCUIT BOARD

GRM39F104Z16

10K B(D-CUT REVERSE)

HX100012A0

HX300012A0

HX300012A0

HX300012A0

HX100012A0

HX100012A0

HX100012A0

HQ31110410

HW10004210

DK98104200

RM01031170

38

Page 29

POS.

NO

VERS.

COLOR

PART NO.

(FOR PCS)

DESCRIPTION

PART NO.

(MJI)

POS.

NO

VERS.

COLOR

PART NO.

(FOR PCS)

DESCRIPTION

PART NO.

(MJI)

RK10 4822 051 30151 CHIP 150Ω ±5% 1/16W NN05151610

RK11 4822 051 30222 CHIP 2.2kΩ ±5% 1/16W NN05222610

RK12 4822 051 30222 CHIP 2.2kΩ ±5% 1/16W NN05222610

RK13 4822 051 30759 CHIP 75Ω ±5% 1/16W NN05750610

RK14 4822 051 30759 CHIP 75Ω ±5% 1/16W NN05750610

RK15 4822 051 30222 CHIP 2.2kΩ ±5% 1/16W NN05222610

RK16 4822 051 30222 CHIP 2.2kΩ ±5% 1/16W NN05222610

PK01- SEMICONDUCTORS

QK01 4822 209 31378 IC NJM4556 HC10045090

QK03

QK06

PK01-MISCELLANEOUS

FK01 4822 157 10416 EMIFILTER BLM11B102S FN31010030

FK02 4822 157 10416 EMIFILTER BLM11B102S FN31010030

FK03 4822 157 10416 EMIFILTER BLM11B102S FN31010030

JK01 9965 000 04978 JACK B8B-PH-K-S YJ06006280

JK02 BLACK 9965 000 01662 H.P JACK HLJ0540-01-410 BLK YJ01003870

JK02 GOLD 4822 267 31692 H.P JACK HLJ0540-01-430 GRY YJ01003880

PL01-LED CIRCUIT BOARD

DF03 4822 130 80326 L.E.D. LT3D8B RED 3O HI10062320

JF04 9965 000 04974 JACK S2B-PH-K-S YJ06006420

RF21 4822 051 30222 CHIP 2.2kΩ ±5% 1/16W NN05222610

4822 130 63601 CHIP TRS. 2SC4213 HX342132A0

PP01-POWER SUPPLY

CIRCUIT BOARD

PP01-CAPACITORS

CP01 9965 000 04979 FILM CAP. 0.1µF

ECQU2A104MLA AC250V

CP02 9965 000 04979 FILM CAP. 0.1µF

ECOU2A104MLA AC250V

CP03 /F, /N,/U9965 000 04980 CER. 470pF

DE0910 B 471K -KX 250V

CP03 /K, /S CER. 220pF

DE0910 B 221K -KX 250V

CP04 /F, /N,/U9965 000 04980 CER. 470pF

DE0910 B 471K -KX 250V

CP04 /K, /S CER. 220pF

DE0910 B 221K -KX 250V

DF17104630

DF17104630

DK17471520

DK17221520

DK17471520

DK17221520

CP25 9965 000 01318 ELECT. 220µF M 10V RA-2 OA22701020

CP26 4822 124 41539 ELECT. 47µF M 16V RA-2 OA47601620

CP27 4822 124 90351 ELECT. 0.1 µF M 50V RA-2 OA10405020

CP28 4822 124 90353 ELECT. 100µF M 10V RA-2 OA10701020

CP29 /N 4822 124 90353 ELECT. 100µF M 10V RA-2 OA10701020

CP30 4822 124 22276 ELECT. 47µF M 50V RA-2 OA47605020

CP31 4822 124 22276 ELECT. 47µF M 50V RA-2 OA47605020

CP32 9965 000 01318 ELECT. 220µF M 10V RA-2 OA22701020

CP33 4822 122 30043 CER. 0.01µF Z 50V DK18103310

CP34 4822 122 30043 CER. 0.01µF Z 50V DK18103310

CP36 4822 124 40723 ELECT. 2200µF 16V OA22801620

CP37 4822 124 40723 ELECT. 2200µF 16V OA22801620

CP38 4822 124 40723 ELECT. 2200µF 16V OA22801620

CP39 4822 124 90351 ELECT. 0.1µF M 50V RA-2 OA10405020

CP40 4822 124 90352 ELECT. 10µF M 16V RA-2 OA10601620

PP01-RESISTORS

RP01 /F, /U 330kΩ K 1/2W ERC12GK334C RC10334120

RP01 /K, /N/S9965 000 00502 1MΩ ±5% 1W RCR60 L15 RC05105010

RP02

4822 051 30334 CHIP 330kΩ ±5% 1/16W NN05334610

RP07

RP08 4822 116 82107 METAL 68kΩ ±5% 3W NK05683030

RP09 4822 116 82107 METAL 68kΩ ±5% 3W NK05683030

RP10 /F, /U METAL 0.47Ω ±5% 2W NL05472020

RP10 /K, /N/S9965 000 04992 METAL 0.82Ω ±5% 2W NL05822020

RP11 4822 051 30105 CHIP 1MΩ ±5% 1/16W NN05105610

RP12 4822 051 30221 CHIP 220Ω ±5% 1/16W NN05221610

RP13 /F, /U METAL 220Ω ±5% 2W NK05221020

RP13 /K, /N/S9965 000 04993 METAL 470Ω ±5% 2W NK05471020

RP14 /F, /U METAL 1kΩ ±5% 1W NK05102010

RP14 /K, /N/S4822 117 12712 METAL 2.2kΩ ±5% 1W NK05222010

RP16 4822 051 30103 CHIP 10kΩ ±5% 1/16W NN05103610

RP17 /F, /U 4822 051 30102 CHIP 1kΩ ±5% 1/6W NN05102610

RP17 /K, /N/S4822 051 30681 CHIP 680Ω ±5% 1/16W NN05681610

RP18 /F, /U 4822 051 30102 CHIP 1kΩ ±5% 1/16W NN05102610

RP18 /K, /N/S4822 051 30681 CHIP 680Ω ±5% 1/16W NN05681610

CP05 /F ELECT CAP. 220µF 200V RJ EA227200P0

CP05 /K, /S ELECT CAP. 82µF RE2-400V EA82640010

CP05 /N 9965 000 04981 ELECT CAP. 120µF

CP05 /U ELECT CAP. 82µF

CP06 4822 124 80493 ELECT CAP. 1µF 250V 105ΩC EA10525020

CP07 4822 126 13091 FILM CAP. 0.047µF 250V

CP08 9965 000 04982 CER. 150P DE0405-1B151K2K

CP11 /F CER. 0.01µF

CP11 /K, /S

/U

CP11 /N 9965 000 04983 CER. 4700pF

CP15 9965 000 04984 ELECT. 1000µF 10V M RA-2 OA10801020

CP16 9965 000 01318 ELECT. 220µF M 10V RA-2 OA22701020

CP17 9965 000 01318 ELECT. 220µF M 10V RA-2 OA22701020

CP18 9965 000 04984 ELECT. 1000µF 10V M RA-2 OA10801020

CP19 9965 000 01318 ELECT. 220µF M 10V RA-2 OA22701020

CP20 4822 124 22722 ELECT. 1000µF M 16V RA-2 OA10801620

CP21 4822 124 22722 ELECT. 1000µF M 16V RA-2 OA10801620

CP22 /N 4822 124 12404 ELECT. 220µF M 16V RA-2 OA22701620

CP24 /N 4822 124 90353 ELECT. 100µF M 10V RA-2 OA10701020

RE3-400V121MK9 400V

RA3-200V82µF 200V

ECQE2473KF

2KV SHORT

DE1607F103M-KH 250V

CER. 220pF

DE0910 B 221K -KX 250V

DE1610 E 472K-KX 250V

EA12740070

EA82620070

DF16473640

DK16151910

DK17103860

DK17221520

DK17472520

RP19 /F CHIP 820Ω ±5% 1/16W NN05821610

RP19 /K, /N,

RP20 4822 051 30472 CHIP 4.7kΩ ±5% 1/16W NN05472610

RP21 4822 116 82487 CHIP 0Ω ±5% 1/16W NN05000610

RP22 4822 051 30681 CHIP 680Ω ±5% 1/16W NN05681610

RP23 4822 051 30562 CHIP 5.6kΩ ±5% 1/16W NN05562610

RP24 4822 051 30392 CHIP 3.9kΩ ±5% 1/16W NN05392610

RP25 4822 051 30222 CHIP 2.2kΩ ±5% 1/16W NN05222610

RP26 4822 051 30222 CHIP 2.2kΩ ±5% 1/16W NN05222610

RP27 4822 051 30471 CHIP 470Ω ±5% 1/16W NN05471610

RP28 4822 051 30471 CHIP 470Ω ±5% 1/16W NN05471610

RP29 4822 051 30103 CHIP 10kΩ ±5% 1/16W NN05103610

RP31 4822 051 30223 CHIP 22kΩ ±5% 1/16W NN05223610

RP32 4822 051 30152 CHIP 1.5kΩ ±5% 1/16W NN05152610

RP33 4822 051 30681 CHIP 680Ω ±5% 1/16W NN05681610

RP34 4822 051 30681 CHIP 680Ω ±5% 1/16W NN05681610

RP35 4822 051 30123 CHIP 12kΩ ±5% 1/16W NN05123610

RP36 4822 051 30393 CHIP 39kΩ ±5% 1/16W NN05393610

RP38 4822 051 30103 CHIP 10kΩ ±5% 1/16W NN05103610

RP47 4822 051 30102 CHIP 1kΩ ±5% 1/16W NN05102610

RP48 4822 051 30223 CHIP 22kΩ ±5% 1/16W NN05223610

RP49 9965 000 03193 CHIP 3.3MΩ ±5% 1/16W NN05335610

RP50 4822 117 12925 CHIP 47kΩ ±5% 1/16W NN05473610

RP51 4822 051 30223 CHIP 22kΩ ±5% 1/16W NN05223610

4822 051 30681 CHIP 680Ω ±5% 1/16W NN05681610

/S, /U

39

Page 30

POS.

NO

VERS.

COLOR

PART NO.

(FOR PCS)

DESCRIPTION

PART NO.

(MJI)

POS.

NO

VERS.

COLOR

PART NO.

(FOR PCS)

DESCRIPTION

PART NO.

(MJI)

RP52 4822 051 30223 CHIP 22kΩ ±5% 1/16W NN05223610

RP53 4822 051 30103 CHIP 10kΩ ±5% 1/16W NN05103610

RP54 4822 051 30103 CHIP 10kΩ ±5% 1/16W NN05103610

RP55 4822 116 82487 CHIP 0Ω ±5% 1/16W NN05000610

RP56 4822 117 11462 METAL 4.7Ω ±5% 1W NK05047010

RP57 4822 117 11462 METAL 4.7Ω ±5% 1W NK05047010

RP58 4822 117 12925 CHIP 47kΩ ±5% 1/16W NN05473610

RP59 4822 051 30103 CHIP 10kΩ ±5% 1/16W NN05103610

RP64 4822 051 30152 CHIP 1.5kΩ ±5% 1/16W NN05152610

RP65 4822 117 12925 CHIP 47kΩ ±5% 1/16W NN05473610

RP66 4822 117 12925 CHIP 47kΩ ±5% 1/16W NN05473610

RP68 4822 116 82487 CHIP 0Ω ±5% 1/16W NN05000610

RP80 9965 000 04994 METAL 68Ω ±5% 2W NK05680020

RP81 /F METAL 33Ω ±5% 2W NK05330020

RP81 /U1 METAL 33Ω ±5% 2W NK05330020

RP82 4822 051 30681 CHIP 680Ω ±5% 1/16W NN05681610

RP83 4822 051 30681 CHIP 680Ω ±5% 1/16W NN05681610

PP01-SEMICONDUCTORS

DP01 4822 130 81248 DIODE S1WB(A)60 30A 600V HD20031290

DP02 4822 130 81244 DIODE ERA22-10 STRAICHT HD20008130

DP03 4822 130 83715 CHIP DIODE 1SS301 DAN202U HZ21005000

DP04 4822 130 11074 DIODE RK46(SBD)60V 3.5A HD20050080

DP05 4822 130 11074 DIODE RK46(SBD)60V 3.5A HD20050080

DP06 4822 130 11074 DIODE RK46(SBD)60V 3.5A HD20050080

DP08 9965 000 04985 CHIP DIODE ZENER 02CZ13Y HZ31301050

DP09 4822 130 83715 CHIP DIODE 1SS301 DAN202U HZ21005000

DP10 4822 130 83715 CHIP DIODE 1SS301 DAN202U HZ21005000

DP11 4822 130 82019 CHIP DIODE SFPL-52

200V/0.9A

DP12 4822 130 11514 CHIP DIODE ZENER 02CZ4.7Z HZ30017050

DP13 9965 000 04970 CHIP DIODE ZENER 02CZ3.3X

3.3V

DP14 4822 130 82019 CHIP DIODE SFPL-52

DP16 4822 130 82019 CHIP DIODE SFPL-52

DP18

9965 000 04986 CHIP DIODE U1BC44 1A 100V HZ20032050

DP25

DP26 4822 130 83715 CHIP DIODE 1SS301 DAN202U HZ21005000

DP27 4822 130 83715 CHIP DIODE 1SS301 DAN202U HZ21005000

DP28 4822 130 81672 CHIP DIODE 02CZ5.6X HZ30020050

QP01 /F, .U F.E.T. 2SK3200 500V 10A HF23200000

QP01 /K, /N,/S9965 000 00395 F.E.T. 2SK2943 900V 3A HF22943000

QP02 4822 130 61441 TRS. 2SD1862 TV-2 NPN Q R HT418622A0

QP03 4822 130 10431 PHOTO UNIT PC-123F2

QP04 4822 209 62759 IC NJM431 SHUNT REG. HC33136090

QP05 9965 000 00399 IC SI-3033C

QP06 9965 000 00400 IC SI-3050N +5.0V 1A HC36905080

QP07 9965 000 04991 IC SI-3050C