Marantz DV-6500 Service Manual

Service

DV6500 /N1B/N1S

Manual

STANDBY

POWER ON/STANDBY

SECTION PAGE

TECHNICAL SPECIFICATIONS .............................................................................................. 1-1-1

SERVICE HINTS AND TOOLS ................................................................................................ 1-2-1

WARNING AND LASER SAFETY INSTRUCTIONS ................................................................ 1-2-2

LASER BEAM SAFETY PRECAUTIONS ................................................................................ 1-2-3

IMPORTANT SAFETY PRECAUTIONS .................................................................................. 1-3-1

STANDARD NOTES FOR SERVICING ................................................................................... 1-4-1

CABINET DISASSEMBLY INSTRUCTIONS............................................................................ 1-5-1

TROUBLESHOOTING ............................................................................................................. 1-6-1

BLOCK DIAGRAMS ................................................................................................................. 1-7-1

SCHEMATIC DIAGRAMS / CBA'S AND TEST POINTS .......................................................... 1-8-1

WAVEFORMS .......................................................................................................................... 1-9-1

WIRING DIAGRAMS.............................................................................................................. 1-10-1

FIRMWARE RENEWAL MODE ............................................................................................. 1-11-1

IC PIN FUNCTION DESCRIPTIONS ..................................................................................... 1-12-1

LEAD IDENTIFICATIONS ...................................................................................................... 1-13-1

EXPLODED VIEWS ............................................................................................................... 1-14-1

PARTS LIST ........................................................................................................................... 1-15-1

SUPER AUDIO CD/DVD PLAYER DV6500

Super Audio CD / DVD Player

AUDIO

EX.

TABLE OF CONTENTS

GROUP

P.SCAN

PLAY STOP PAUSE

SACD

DVD A

M

VCD

AUDIO EX.

OPEN/CLOSE

ENTER

MENU

Please use this service manual with referring to the user guide (D.F.U) without fail.

DV6500

DV6500

Part no. 90M13BW855010

First Issue 2004.06

ecm

MARANTZ DESIGN AND SERVICE

Using superior design and selected high grade components, MARANTZ company has created the ultimate in stereo sound.

Only original

MARANTZ parts can insure that your MARANTZ product will continue to perform to the specifications for which

it is famous.

Parts for your

MARANTZ equipment are generally available to our National Marantz Subsidiary or Agent.

ORDERING PARTS :

Parts can be ordered either by mail or by Fax.. In both cases, the correct part number has to be specified.

The following information must be supplied to eliminate delays in processing your order :

1. Complete address

2. Complete part numbers and quantities required

3. Description of parts

4. Model number for which part is required

5. Way of shipment

6. Signature : any order form or Fax. must be signed, otherwise such part order will be considered as null and void.

USA

MARANTZ AMERICA, INC

1100 MAPLEWOOD DRIVE

ITASCA, IL. 60143

USA

PHONE : 630 - 741 - 0300

FAX : 630 - 741 - 0301

AMERICAS

SUPERSCOPE TECHNOLOGIES, INC.

MARANTZ PROFESSIONAL PRODUCTS

2640 WHITE OAK CIRCLE, SUITE A

AURORA, ILLINOIS 60504 USA

PHONE : 630 - 820 - 4800

FAX : 630 - 820 - 8103

AUSTRALIA

QualiFi Pty Ltd,

24 LIONEL ROAD,

MT. WAVERLEY VIC 3149

AUSTRALIA

PHONE : +61 - (0)3 - 9543 - 1522

FAX : +61 - (0)3 - 9543 - 3677

NEW ZEALAND

WILDASH AUDIO SYSTEMS NZ

14 MALVERN ROAD MT ALBERT

AUCKLAND NEW ZEALAND

PHONE : +64 - 9 - 8451958

FAX : +64 - 9 - 8463554

EUROPE / TRADING

MARANTZ EUROPE B.V.

P. O. BOX 8744, BUILDING SILVERPOINT

BEEMDSTRAAT 11, 5653 MA EINDHOVEN

THE NETHERLANDS

PHONE : +31 - 40 - 2507844

FAX : +31 - 40 - 2507860

AUSTRALIA

TECHNICAL AUDIO GROUP PTY, LTD

43-53 Bridge Rd.,

STANMORE NSW 2048

AUSTRALIA

PHONE : +61 - (0)2 - 9519 - 0900

FAX : +61 - (0)2 - 9519 - 0600

THAILAND

MRZ STANDARD CO., LTD

746 - 754 MAHACHAI ROAD.,

WANGBURAPAPIROM, PHRANAKORN,

BANGKOK, 10200 THAILAND

PHONE : +66 - 2 - 222 9181

FAX : +66 - 2 - 224 6795

TAIWAN

PAI- YUING CO., LTD.

6 TH FL NO, 148 SUNG KIANG ROAD,

TAIPEI, 10429, TAIWAN R.O.C.

PHONE : +886 - 2 - 25221304

FAX : +886 - 2 - 25630415

CANADA

MARANTZ CANADA INC.

5-505 APPLE CREEK BLVD.

MARKHAM, ONTARIO L3R 5B1

CANADA

PHONE : 905 - 415 - 9292

FAX : 905 - 475 - 4159

HONG KONG

Jolly ProAudio Broadcast Engineering Ltd.

UNIT 2, 10F, WAH HUNG CENTRE,

41 HUNG TO ROAD, KWUN TONG, KLN.,

HONG KONG

PHONE : 852 - 21913660

FAX : 852 - 21913990

SINGAPORE

WO KEE HONG DISTRIBUTION PTE LTD

No.1 JALAN KILANG TIMOR

#08-03 PACIFIC TECH CENTRE

SINGAPORE 159303

PHONE : +65 6376 0338

FAX : +65 6376 0166

MALAYSIA

WO KEE HONG ELECTRONICS SDN. BHD.

2ND FLOOR BANGUNAN INFINITE CENTRE

LOT 1, JALAN 13/6, 46200 PETALING JAYA

SELANGOR DARUL EHSAN, MALAYSIA

PHONE : +60 - 3 - 7954 8088

FAX : +60 - 3 - 7954 7088

JAPAN

MARANTZ JAPAN, INC.

35- 1, 7- CHOME, SAGAMIONO

SAGAMIHARA - SHI, KANAGAWA

JAPAN 228-8505

PHONE : +81 42 748 1013

FAX : +81 42 741 9190

Technical

KOREA

MK ENTERPRISES LTD.

ROOM 604/605, ELECTRO-OFFICETEL, 16-58,

3GA, HANGANG-RO, YONGSAN-KU, SEOUL

KOREA

PHONE : +822 - 3232 - 155

FAX : +822 - 3232 - 154

SHOCK, FIRE HAZARD SERVICE TEST :

CAUTION : After servicing this appliance and prior to returning to customer, measure the resistance between either primary AC

cord connector pins ( with unit NOT connected to AC mains and its Power switch ON ), and the face or Front Panel of product and

controls and chassis bottom.

Any resistance measurement less than 1 Megohms should cause unit to be repaired or corrected before AC power is applied, and

verified before it is return to the user/customer.

Ref. UL Standard No. 1492.

In case of difficulties, do not hesitate to contact the Technical

Department at above mentioned address.

040401ECM

TECHNICAL SPECIFICATIONS

SIGNAL SYSTEM

PAL color

APPLICABLE DISCS

(1) DVD-Audio/DVD-Video Discs

1-layer 12cm single-sided discs, 2-layer 12cm single-sided

discs, 2-layer 12cm double-sided discs (1 layer per side)

1-layer 8cm single-sided discs, 2-layer 8cm single-sided

discs, 2-layer 8cm double-sided discs (1 layer per side)

(2) Super Audio CD

(3) DVD-R/DVD-RW

(4) Compact discs (CD-DA, Video CD, Super Audio CD)

12cm discs, 8cm discs

(5) CD-R/CD-RW

S-VIDEO OUTPUT

Y output level: 1Vp-p (75 /ohms)

C output level: 0.30Vp-p

Output connectors: S connectors, 1 set

VIDEO OUTPUT

Output level: 1Vp-p (75 /ohms)

Output connector: Pin jacks, 1 set

COMPONENT OUTPUT

Y output level: 1Vp-p (75 /ohms)

B/PB

output level: 0.7Vp-p (75 /ohms)

C

CR/PRoutput level: 0.7Vp-p (75 /ohms)

Output connector: Pin jacks, 1 set

AUDIO/VIDEO

21-pin scart jack

AUDIO OUTPUT

Output level: 2Vrms

2 channel (L, R) output connector: Pin jack, 1 set

Multi channel (FL, FR, C, SW, SL, SR)

output connector: Pin jack, 1 set

AUDIO OUTPUT PROPERTIES

(1) Frequency response

1 DVDs (linear PCM) : 4Hz to 22kHz (48 kHz sampling)

: 4Hz to 44kHz (96 kHz sampling)

: 4Hz to 88kHz (192 kHz sampling)

2 CDs : 4Hz to 20kHz

3 Super Audio CD : 4Hz to 100kHz (192 kHz sampling)

(2) S/N ratio : 115dB

Total harmonic distortion

(3)

(4) Dynamic range : DVD: 100dB

DIGITAL AUDIO OUTPUT

Optical digital output: Optical connector, 1 set

Coaxial digital output: Pin jack, 1 set

POWER SUPPLY

AC 230V, 50Hz

POWER CONSUMPTION

13 W

MAXIMUM EXTERNAL DIMENSIONS

440 (width) x 75 (height) x 211 (depth) mm

MASS

2.2 Kg (4.9 lbs)

REMOTE CONTROL UNIT

RC6500DV

Infrared pulse type

Supply: DC 3V, 2 R6P/AA batteries

: 1kHz CD: 0.0045%

CD: 98dB

2

46

7

135

21

8

15

13

10

1214

11

9

16

1820

1719

Contacts, signal levels and impedances

Contact 1

Audio Output (Right): 2.0Vrms/01k

Contact 3

Audio Output (Left): 2.0Vrms/01k

Contact 4

Audio, Ground

Contact 5

RGB, Ground (Blue)

Contact 7

RGB Output (Blue): 0.7Vp-p/75

Contact 8

Function Select Switching Control

Contact 9

RGB, Ground (Green)

Contact 11

RGB Output (Green): 0.7Vp-p/75

Contact 13

RGB, Ground (Red)

Contact 14

RGB Switching Control, Ground

Contact 15

RGB Output (Red): 0.7Vp-p/75

Contact 16

RGB Switching Control

H: 3.3V DC RGB Mode

Contact 17

Video Output Signal, Ground

Contact 18

Video Input Signal, Ground

Contact 19

Video Output (CVBS): 1.0Vp-p/75

Contact 21

Common Ground (shielding)

L : 0.0~2.0V DC

Power Off

M: 4.5~7.0V DC

Wide-Screen Mode

(16:9)

H: 9.5~12.0V DC

Normal Mode (4:3)

1-1-1

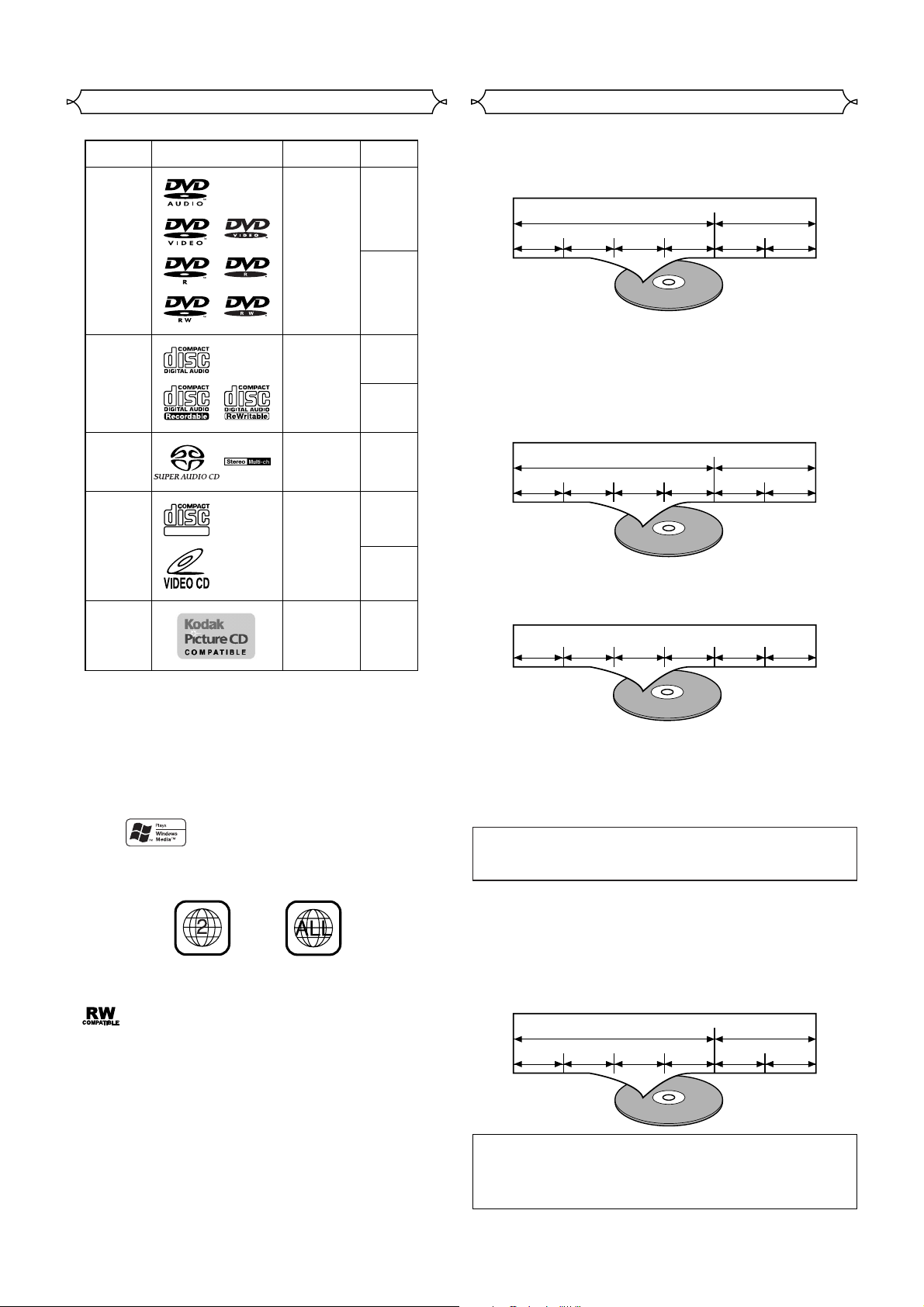

The following discs can be played back on this DVD player.

Track 1 Track 2 Track 5 Track 6Track 3 Track 4

Example

Example

Group 1 Group 2

Track 1 Track 2 Track 5 Track 6Track 3 Track 4

DVD-Video

(NOTE 1)

DVD-Audio

DVD-R

DVD-RW

(NOTE 2, 3)

CD

CD-R

CD-RW

(NOTE 4)

Picture CD

Digital video

(MPEG2)

Digital audio

MP3

WMA

(NOTE 5)

Digital picture

(JPEG)

JPEG

Mark (logo)

Usable

discs

Recorded

signals

Disc Size

12 cm

12 cm

12 cm

8 cm

8 cm

NOTE 1: Some DVD-Video discs do not operate as described in this manual

due to the intentions of the discs’ producers.

NOTE 2: This unit can play DVD-RW discs recorded in DVD video format or

DVD video recording format.

* The disc may not be played back due to recording quality or

properties of the disc, dirt on the disc or the pickup lens, or

condensation on the pickup lens.

NOTE 3: Discs that have not be finalized cannot be played.

Depending on the disc’s recording status, the disc may not be

accepted or may not be played normally (the picture or sound may

not be smooth, etc.).

NOTE 4: Some of CD-R/CD-RW discs may be incompatible because of

“scratch and stain of disc”, “Recording condition”, and “Characteristic

of Recorder”.

NOTE 5: Windows Media and the Windows logo are trademarks

or registered trademarks of Microsoft Corporation in

the United States and/or other countries.

Sound

and

Pictures

12 cm

8 cm

(Singles)

Video

CD

Digital audio 12 cm

Super Audio

CD

DIGITAL VIDEO

Disc TypesPlayable Discs

[DVD-Audio]

DVD-Audios are divided into several large sections called

“groups” and smaller sections called “tracks.” Numbers are

alloted to these sections. These numbers are called “group

numbers” and “track numbers.”

Example

Track 1 Track 2 Track 1 Track 2Track 3 Track 4

[DVD-Video]

Data on a DVD is divided into sections called “titles” and then

into subsections called “chapters” each of which is given a

title or chapter number. Playback conditions are preset on

some DVD-Video discs, and these playback conditions take

priority over user operations on this player. If a function you

selected does not run as desired, refer to the manual accompanying the disc.

Example

Chapter 1 Chapter 2 Chapter 1 Chapter 2Chapter 3 Chapter 4

Group 1 Group 2

Title 1 Title 2

This player conforms to the PAL colour system. Also you can play

discs recorded with the NTSC system via a PAL system TV set.

Some discs include region codes as shown below.

The number inside the symbol refers to a region of the world,

and a disc encoded in a specific region format can only be

played back on DVD players with the same region code.

:

This label indicates playback compatibility with DVD-RW

discs recorded in VR mode (Video Recording Format).

On the following discs, only the sound can be heard

(picture cannot be viewed).

CDV

CD-G

NEVER play back the following discs. Otherwise, mal-

function may result!

DVD-RAM

CD-I

Photo CD

DVD with region codes other than 2 or ALL

DVD-ROM for personal computers

CD-ROM for personal computers

Any other discs without compatibility indications.

[Audio CD, Video CD, Super Audio CD]

Data on Audio CD, Super Audio CD or Video CD is divided

into sections called “tracks,” each of which is given a track

number.

ABOUT THE PBC FUNCTION OF VIDEO CD

This unit conforms to ver.1.1 and ver.2.0 of Video CD

standard, with PBC function.

Ver.1.1 (without PBC function):

You can enjoy playback pic-

ture as well as music CD.

Ver.2.0 (with PBC function):

While using a Video CD with

PBC function, “PBC” appears on the screen and the display.

What is PBC?

“PBC” stands for the Playback Control.

You can play interactive software using menu screens.

Refer to instructions in the Video CD.

NOTE:

When playing Video CDs with PBC function, some operations

(e.g., track search and repeat tracks) cannot be performed

unless the function is cancelled temporarily (Refer to page 16).

[MP3, JPEG, WMA]

Data on an MP3, JPEG or WMA are divided into sections

called “groups” and then into subsections called “tracks” each

of which is given an group or track number.

CAUTION:

• Use caution not to pinch your finger in the disc slot.

• Be sure to remove a disc and unplug the AC power cord

from the outlet before carrying the DVD player.

1-1-2

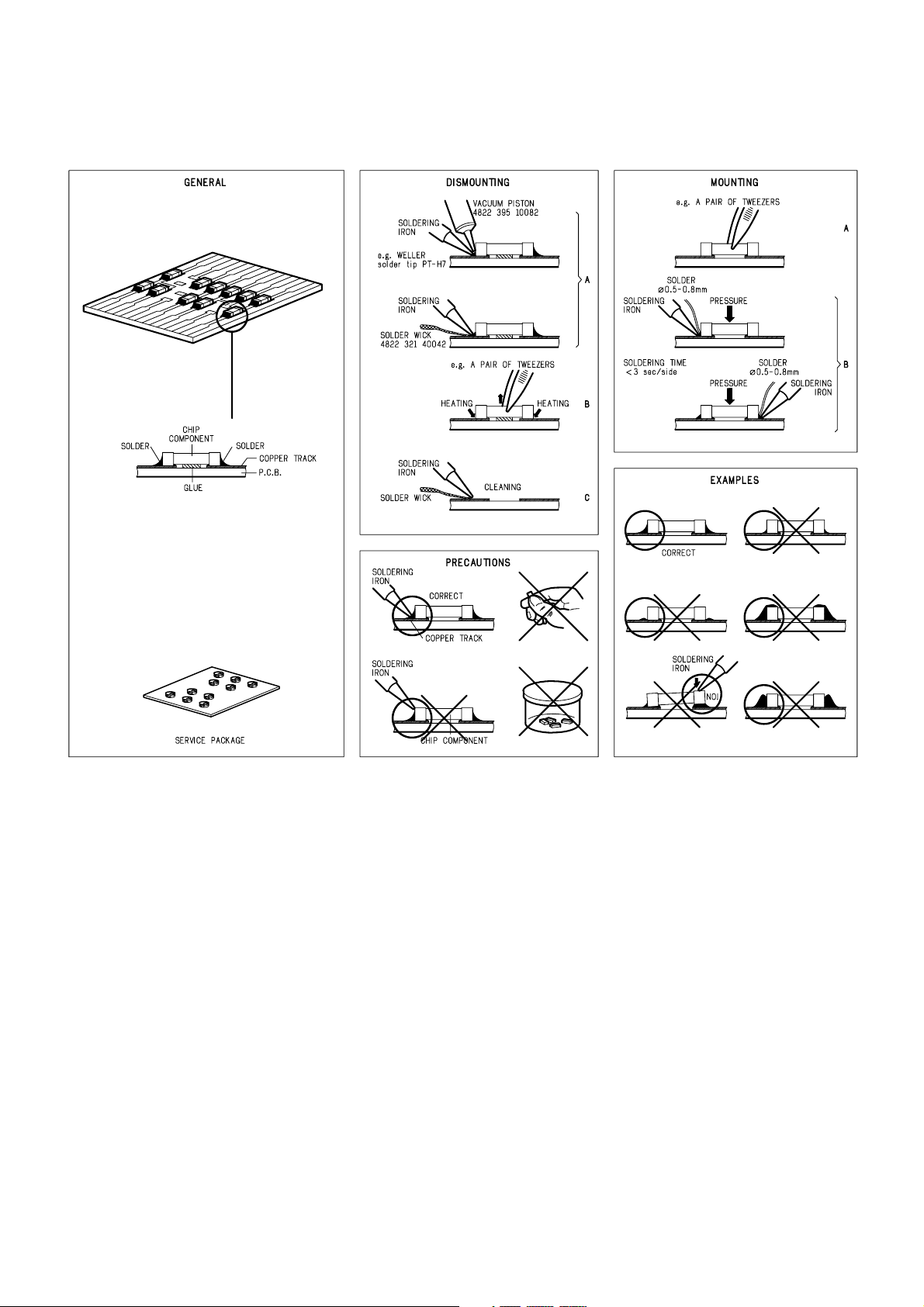

SERVICE HINTS

SERVICE HINTS AND TOOLS

SERVICE TOOLS

Audio signals disc 4822 397 30184

Disc without errors (SBC444)+

Disc with DO errors, black spots and fingerprints (SBC444A) 4822 397 30245

Disc (65 min 1kHz) without no pause 4822 397 30155

Max. diameter disc (58.0 mm) 4822 397 60141

Torx screwdrivers

Set (straight) 4822 395 50145

Set (square) 4822 395 50132

13th order filter 4822 395 30204

DVD test disc (PAL) 4822 397 10131

DVD test disc (NTSC) ALMEDIO TDV-540

1-2-1

WARNING AND LASER SAFETY INSTRUCTIONS

GB

WARNING

All ICs and many other semi-conductors are

susceptible to electrostatic discharges (ESD).

Careless handling during repair can reduce

life drastically.

When repairing, make sure that you are

connected with the same potential as the

mass of the set via a wrist wrap with

resistance.

Keep components and tools also at this

potential.

F

ATTENTION

D

WARNUNG

I

WAARSCHUWING

AVVERTIMENTO

NL

Alle IC’s en vele andere halfgeleiders zijn

gevoelig voor elektrostatische ontladingen

(ESD).

Onzorgvuldig behandelen tijdens reparatie

kan de levensduur drastisch doen

verminderen.

Zorg ervoor dat u tijdens reparatie via een

polsband met weerstand verbonden bent met

hetzelfde potentiaal als de massa van het

apparaat.

Houd componenten en hulpmiddelen ook op

ditzelfde potentiaal.

Tous les IC et beaucoup d’autres semiconducteurs sont sensibles aux décharges

statiques (ESD).

Leur longévité pourrait être considérablement

écourtée par le fait qu’aucune précaution

n’est prise a leur manipulation.

Lors de réparations, s’assurer de bien être

relié au même potentiel que la masse de

l’appareil et enfiler le bracelet serti d’une

résistance de sécurité.

Veiller a ce que les composants ainsi que les

outils que l’on utilise soient également a ce

potentiel.

GB

Safety regulations require that the set be restored to its original condition

and that parts which are identical with those specified be used.

NL

Veiligheidsbepalingen vereisen, dat het apparaat in zijn oorspronkelijke

toestand wordt terug gebracht en dat onderdelen, identiek aan de

gespecifieerde worden toegepast.

Alle IC und viele andere Halbleiter sind

empfindlich gegen elektrostatische

Entladungen (ESD).

Unsorgfältige Behandlung bei der Reparatur

kann die Lebensdauer drastisch vermindern.

Sorgen sie dafür, das Sie im Reparaturfall

über ein Pulsarmband mit Widerstand mit

dem Massepotential des Gerätes verbunden

sind.

Halten Sie Bauteile und Hilfsmittel ebenfalls

auf diesem Potential.

D

Bei jeder Reparatur sind die geltenden Sicherheitsvorschriften zu beachten.

Der Originalzustand des Gerats darf nicht verandert werden.

Fur Reparaturen sind Original-Ersatzteile zu verwenden.

I

Le norme di sicurezza esigono che l’apparecchio venga rimesso nelle

condizioni originali e che siano utilizzati pezzi di ricambiago idetici a quelli

specificati.

Tutti IC e parecchi semi-conduttori sono

sensibili alle scariche statiche (ESD).

La loro longevita potrebbe essere fortemente

ridatta in caso di non osservazione della piu

grande cauzione alla loro manipolazione.

Durante le riparazioni occorre quindi essere

collegato allo stesso potenziale che quello

della massa dell’apparecchio tramite un

braccialetto a resistenza.

Assicurarsi che i componenti e anche gli

utensili con quali si lavora siano anche a

questo potenziale.

F

“Pour votre sécurité, ces documents

doivent être utilisés par des

spécialistes agrées, seuls habilités à

réparer votre appareil en panne.”

Les normes de sécurité exigent que l’appareil soit remis a l’état d’origine et

que soient utilisées les pièces de rechange identiques à celles spécifiées.

LASER SAFETY

This unit employs a laser. Only a qualified service person should remove the cover or attempt to service this

device, due to possible eye injury.

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURE OTHER THAN THOSE

SPECIFIED HEREIN MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

AVOID DIRECT EXPOSURE TO BEAM

WARNING

The use of optical instruments with this product will increase eye hazard.

Repair handling should take place as much as possible with a disc loaded inside the player

WARNING LOCATION: INSIDE ON LASER COVERSHIELD

CAUTION VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID EXPOSURE TO BEAM

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING VED ÅBNING UNDGÅ UDS

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING NÅR DEKSEL Å PNES UNNGÅ EKSPONERING FOR STRÅLEN

VARNING SYNLIG OCH OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD BETRAKTA EJ STRÅLEN

VARO! AVATT AESSA OLET ALTTIINA NÄKYVÄLLE JA NÄKYMÄTTÖMÄLLE LASER SÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN

VORSICHT SICHTBARE UND UNSICHTBARE LASERSTRAHLUNG WENN ABDECKUNG GEÖFFNET NICHT DEM STRAHL AUSSETSEN

DANGER VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID DIRECT EXPOSURE TO BEAM

ATTENTION RAYONNEMENT LASER VISIBLE ET INVISIBLE EN CAS D'OUVERTURE EXPOSITION DANGEREUSE AU FAISCEAU

Æ

TTELSE FOR STRÅLING

030804ecm

1-2-2

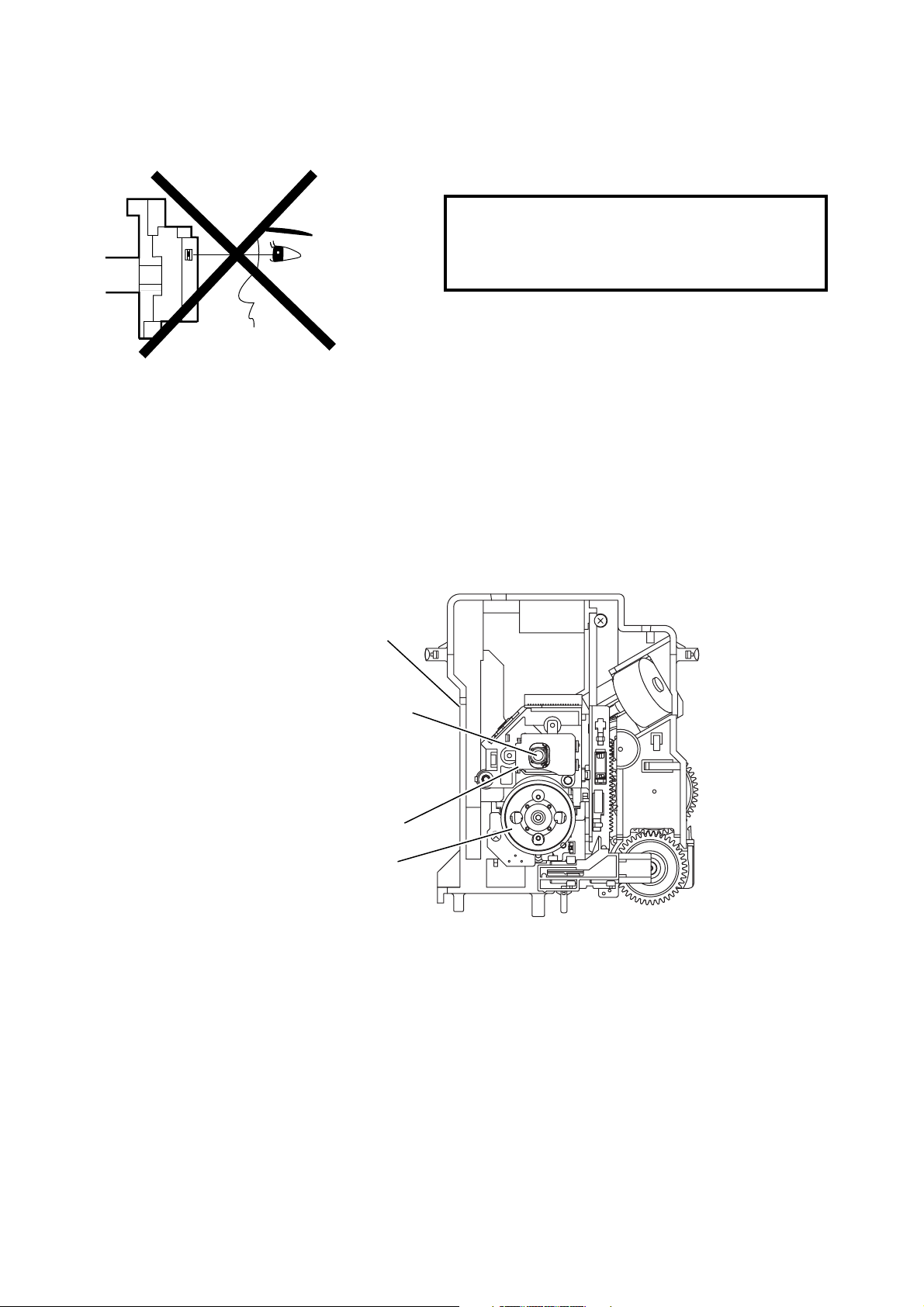

LASER BEAM SAFETY PRECAUTIONS

This DVD player uses a pickup that emits a laser beam.

Do not look directly at the laser beam coming

from the pickup or allow it to strike against your

skin.

The laser beam is emitted from the location shown in the figure. When checking the laser diode, be sure to keep

your eyes at least 30cm away from the pickup lens when the diode is turned on. Do not look directly at the laser

beam.

Caution: Use of controls and adjustments, or doing procedures other than those specified herein, may result in

hazardous radiation exposure.

Drive Mecha Assembly

Laser Beam Radiation

Laser Pickup

Turntable

1-2-3 E5981LBS

IMPORTANT SAFETY PRECAUTIONS

Product Safety Notice

Some electrical and mechanical parts have special

safety-related characteristics which are often not evident from visual inspection, nor can the protection they

give necessarily be obtained by replacing them with

components rated for higher voltage, wattage, etc.

Parts that have special safety characteristics are identified by a ! on schematics and in parts lists. Use of a

substitute replacement that does not have the same

safety characteristics as the recommended replacement part might create shock, fire, and/or other hazards. The Product’s Safety is under review

continuously and new instructions are issued whenever appropriate. Prior to shipment from the factory,

our products are carefully inspected to confirm with

the recognized product safety and electrical codes of

the countries in which they are to be sold. However, in

order to maintain such compliance, it is equally important to implement the following precautions when a set

is being serviced.

Precautions during Servicing

A. Parts identified by the ! symbol are critical for

safety. Replace only with part number specified.

B. In addition to safety, other parts and assemblies

are specified for conformance with regulations

applying to spurious radiation. These must also be

replaced only with specified replacements.

Examples: RF converters, RF cables, noise blocking capacitors, and noise blocking filters, etc.

C. Use specified internal wiring. Note especially:

1)Wires covered with PVC tubing

2)Double insulated wires

3)High voltage leads

D. Use specified insulating materials for hazardous

live parts. Note especially:

1)Insulation tape

2)PVC tubing

3)Spacers

4)Insulators for transistors

E. When replacing AC primary side components

(transformers, power cord, etc.), wrap ends of

wires securely about the terminals before soldering.

F. Observe that the wires do not contact heat produc-

ing parts (heatsinks, oxide metal film resistors, fusible resistors, etc.).

G. Check that replaced wires do not contact sharp

edges or pointed parts.

H. When a power cord has been replaced, check that

5 - 6 kg of force in any direction will not loosen it.

I. Also check areas surrounding repaired locations.

J. Be careful that foreign objects (screws, solder

droplets, etc.) do not remain inside the set.

K. Crimp type wire connector

The power transformer uses crimp type connectors

which connect the power cord and the primary side

of the transformer. When replacing the transformer,

follow these steps carefully and precisely to prevent

shock hazards.

Replacement procedure

1)Remove the old connector by cutting the wires at a

point close to the connector.

Important: Do not re-use a connector. (Discard it.)

2)Strip about 15 mm of the insulation from the ends

of the wires. If the wires are stranded, twist the

strands to avoid frayed conductors.

3)Align the lengths of the wires to be connected.

Insert the wires fully into the connector.

4)Use a crimping tool to crimp the metal sleeve at its

center. Be sure to crimp fully to the complete closure of the tool.

L. When connecting or disconnecting the internal

connectors, first, disconnect the AC plug from the

AC outlet.

1-3-1 DVD_SFNP

Safety Check after Servicing

Examine the area surrounding the repaired location for

damage or deterioration. Observe that screws, parts,

and wires have been returned to their original positions. Afterwards, do the following tests and confirm

the specified values to verify compliance with safety

standards.

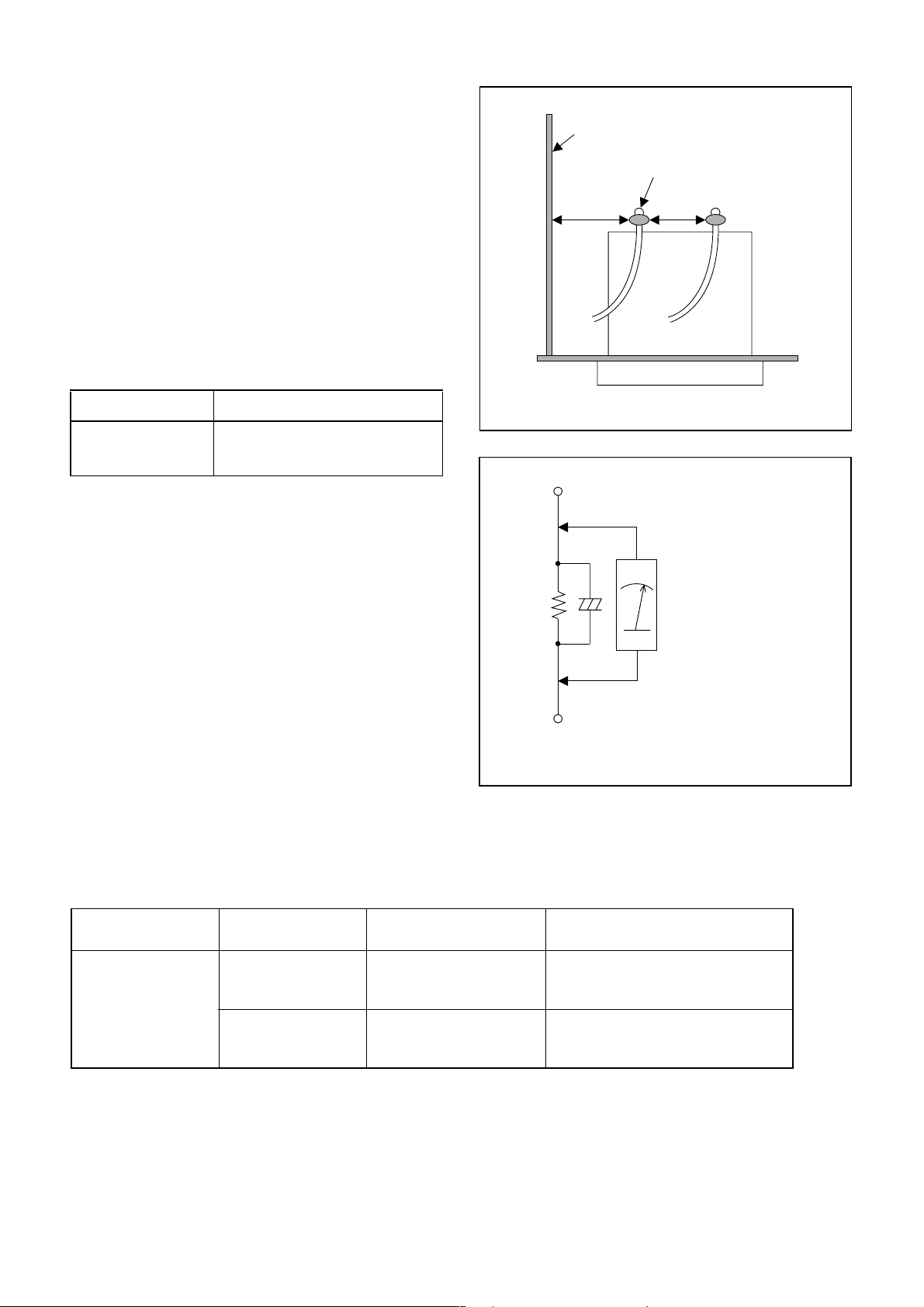

1. Clearance Distance

When replacing primary circuit components, confirm

specified clearance distance (d) and (d’) between soldered terminals, and between terminals and surrounding metallic parts. (See Fig. 1)

Table 1 : Ratings for selected area

AC Line Voltage Clearance Distance (d), (d’)

220 to 240 V

Note: This table is unofficial and for reference only.

Be sure to confirm the precise values.

≥ 3 mm(d)

≥ 6 mm(d’)

2. Leakage Current Test

Confirm the specified (or lower) leakage current

between B (earth ground, power cord plug prongs)

and externally exposed accessible parts (RF terminals, antenna terminals, video and audio input and

output terminals, microphone jacks, earphone jacks,

etc.) is lower than or equal to the specified value in the

table below.

Measuring Method (Power ON) :

Insert load Z between B (earth ground, power cord

plug prongs) and exposed accessible parts. Use an

AC voltmeter to measure across the terminals of load

Z. See Fig. 2 and the following table.

Chassis or Secondary Conductor

Primary Circuit Terminals

dd'

Exposed Accessible Part

Z

One side of

B

Power Cord Plug Prongs

AC Voltmeter

(High Impedance)

Fig. 1

Fig. 2

Table 2: Leakage current ratings for selected areas

AC Line Voltage Load Z Leakage Current (i)

2kΩ RES.

Connected in

220 to 240 V

Note: This table is unofficial and for reference only. Be sure to confirm the precise values.

parallel

50kΩ RES.

Connected in

parallel

i≤0.7mA AC Peak

i≤2mA DC

i≤0.7mA AC Peak

i≤2mA DC

1-3-2 DVD_SFNP

One side of power cord plug

prongs (B) to:

RF or

Antenna terminals

A/V Input, Output

STANDARD NOTES FOR SERVICING

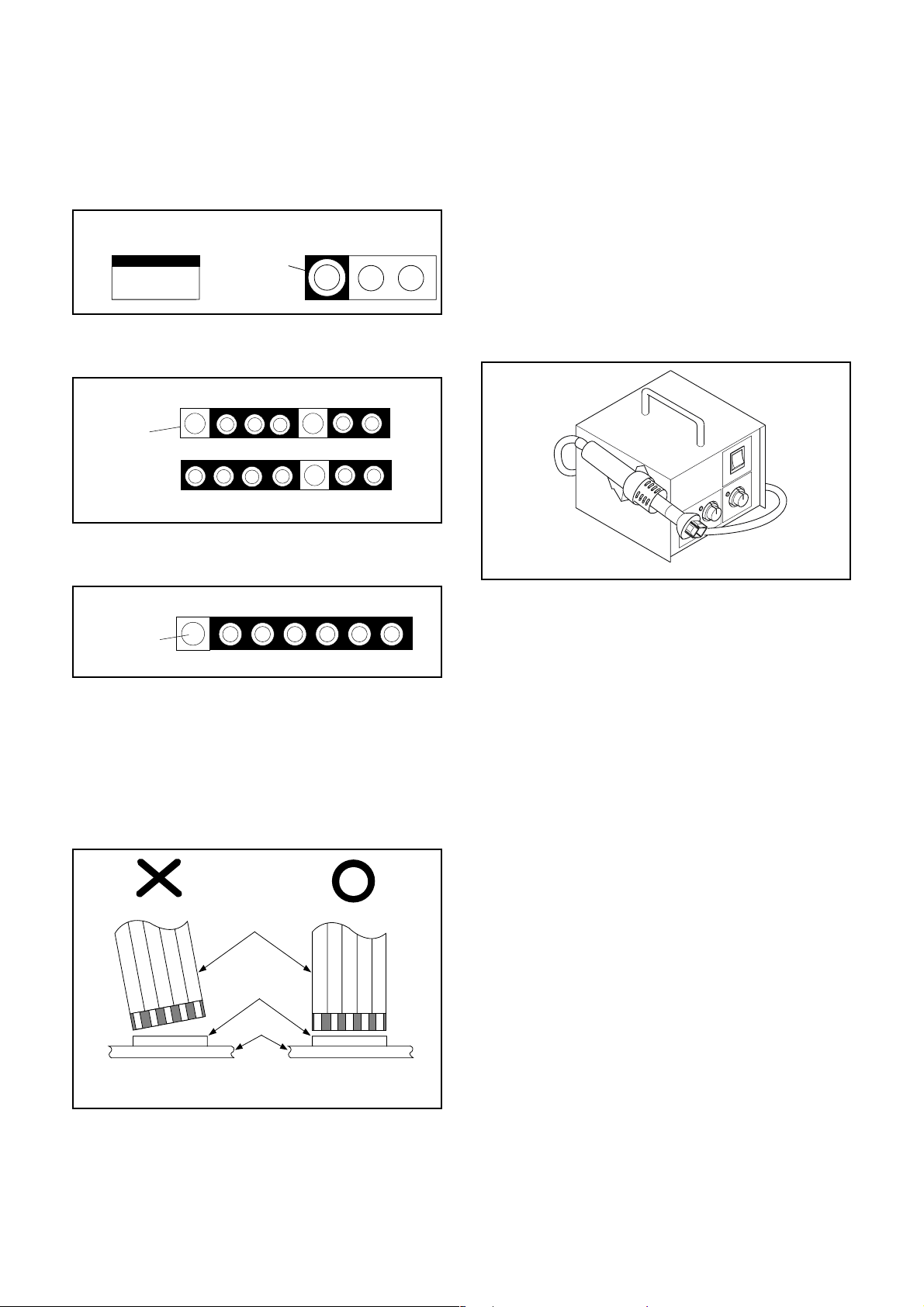

Circuit Board Indications

1. The output pin of the 3 pin Regulator ICs is indicated as shown.

Top View

Input

Out

2. For other ICs, pin 1 and every fifth pin are indicated

as shown.

In

Pin 1

3. The 1st pin of every male connector is indicated as

shown.

Bottom View

5

10

Pb (Lead) Free Solder

When soldering, be sure to use the Pb free solder.

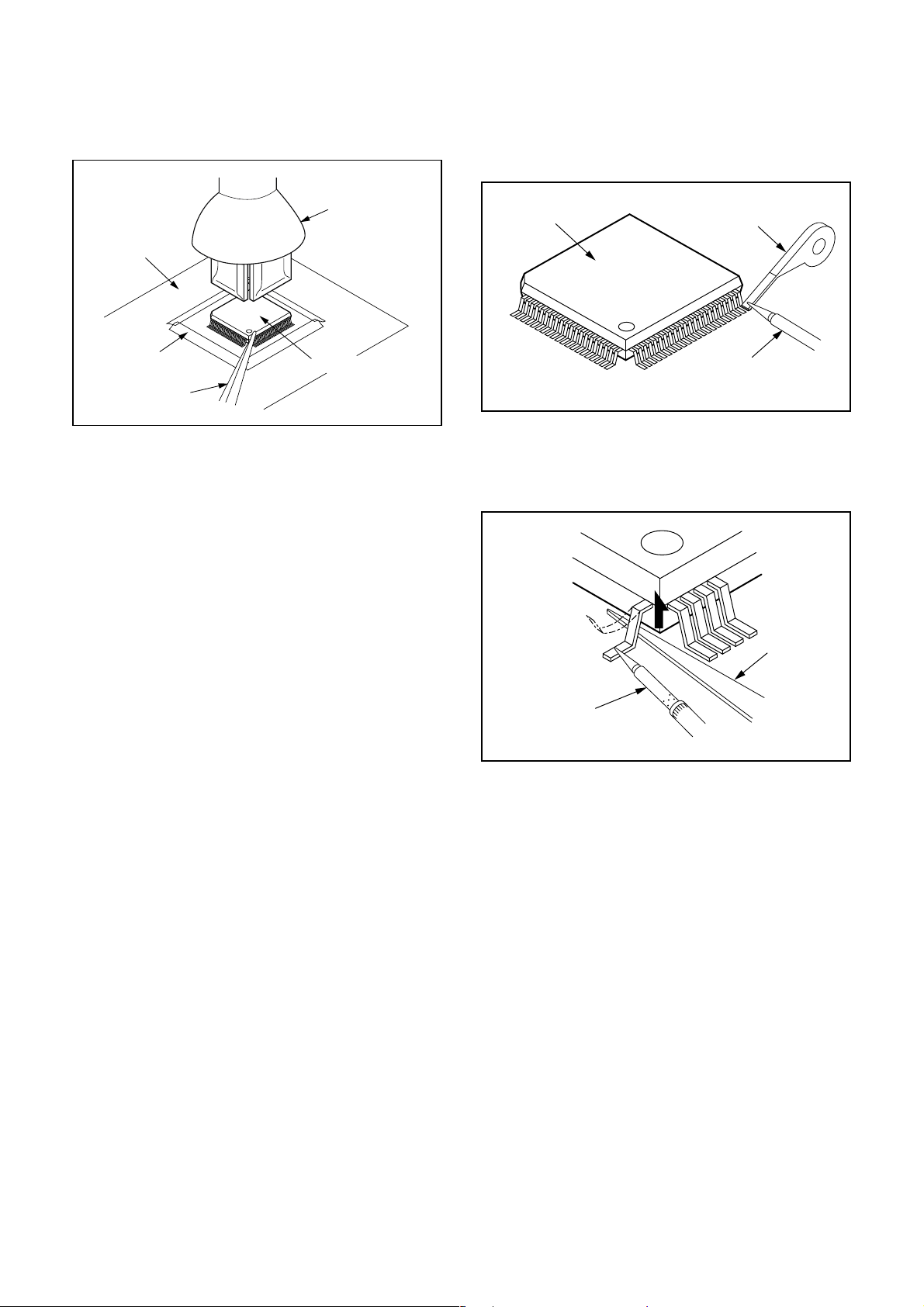

How to Remove / Install Flat Pack-IC

1. Removal

With Hot-Air Flat Pack-IC Desoldering Machine:.

(1) Prepare the hot-air flat pack-IC desoldering

machine, then apply hot air to the Flat Pack-IC

(about 5 to 6 seconds). (Fig. S-1-1)

Fig. S-1-1

Pin 1

Instructions for Connectors

1. When you connect or disconnect the FFC (Flexible

Foil Connector) cable, be sure to first disconnect

the AC cord.

2. FFC (Flexible Foil Connector) cable should be

inserted parallel into the connector, not at an angle.

FFC Cable

Connector

CBA

(2) Remove the flat pack-IC with tweezers while apply-

ing the hot air.

(3) Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

(4) Release the flat pack-IC from the CBA using twee-

zers. (Fig. S-1-6)

Caution:

1. The Flat Pack-IC shape may differ by models. Use

an appropriate hot-air flat pack-IC desoldering

machine, whose shape matches that of the Flat

Pack-IC.

2. Do not supply hot air to the chip parts around the

flat pack-IC for over 6 seconds because damage to

the chip parts may occur. Put masking tape around

the flat pack-IC to protect other parts from damage.

(Fig. S-1-2)

* Be careful to avoid a short circuit.

1-4-1 DVD_NOTE

3. The flat pack-IC on the CBA is affixed with glue, so

be careful not to break or damage the foil of each

pin or the solder lands under the IC when removing

it.

Hot-air

Flat Pack-IC

Desoldering

Machine

CBA

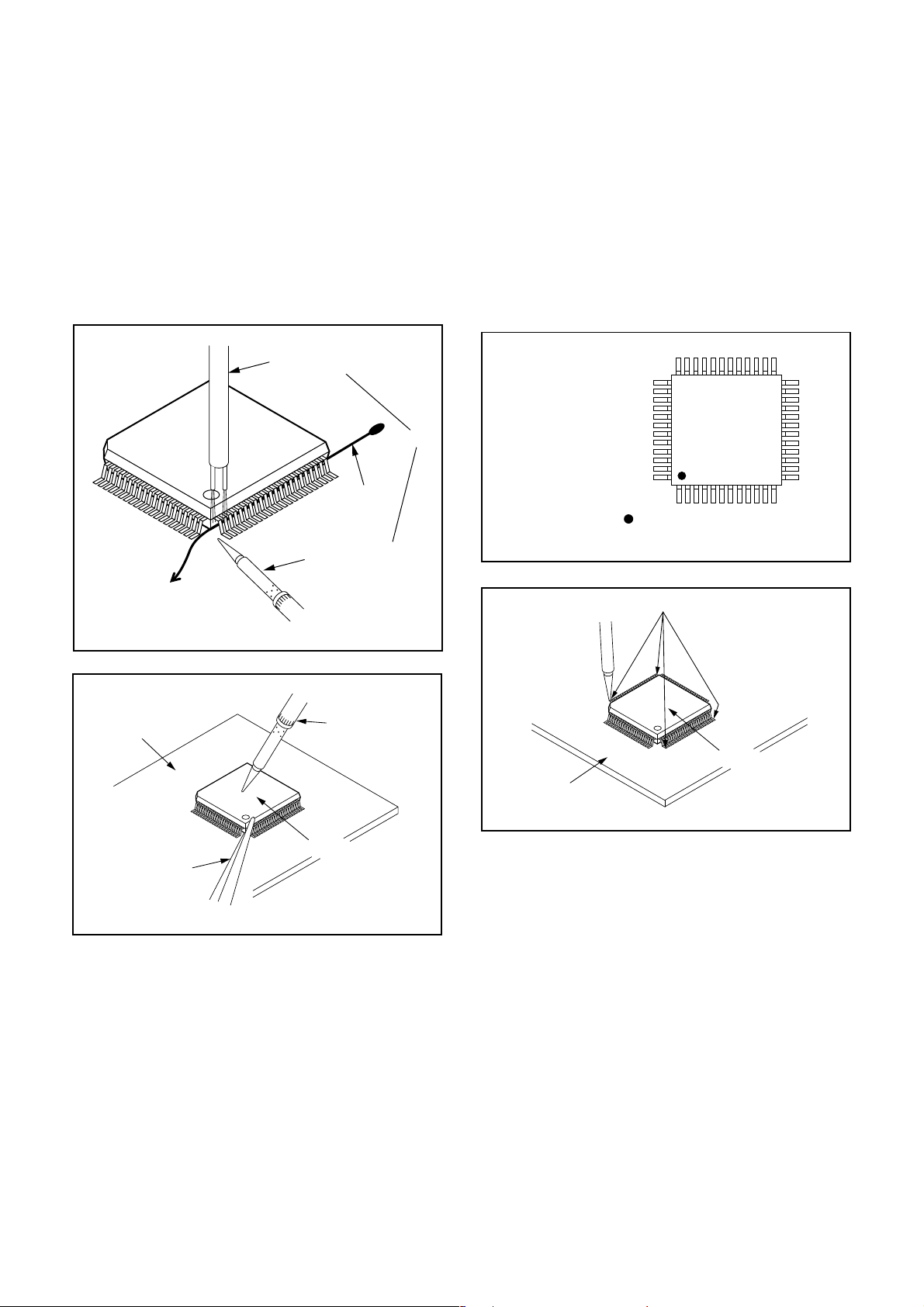

With Soldering Iron:

(1) Using desoldering braid, remove the solder from all

pins of the flat pack-IC. When you use solder flux

which is applied to all pins of the flat pack-IC, you

can remove it easily. (Fig. S-1-3)

Flat Pack-IC

Desoldering Braid

Masking

Tape

Tweezers

Flat Pack-IC

Fig. S-1-2

Soldering Iron

Fig. S-1-3

(2) Lift each lead of the flat pack-IC upward one by

one, using a sharp pin or wire to which solder will

not adhere (iron wire). When heating the pins, use

a fine tip soldering iron or a hot air desoldering

machine. (Fig. S-1-4)

Sharp

Pin

Fine Tip

Soldering Iron

Fig. S-1-4

(3) Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

(4) Release the flat pack-IC from the CBA using twee-

zers. (Fig. S-1-6)

With Iron Wire:

(1) Using desoldering braid, remove the solder from all

pins of the flat pack-IC. When you use solder flux

which is applied to all pins of the flat pack-IC, you

can remove it easily. (Fig. S-1-3)

(2) Affix the wire to a workbench or solid mounting

point, as shown in Fig. S-1-5.

(3) While heating the pins using a fine tip soldering

iron or hot air blower, pull up the wire as the solder

melts so as to lift the IC leads from the CBA contact

pads as shown in Fig. S-1-5

1-4-2 DVD_NOTE

(4) Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

(5) Release the flat pack-IC from the CBA using twee-

zers. (Fig. S-1-6)

Note:

When using a soldering iron, care must be taken

to ensure that the flat pack-IC is not being held by

glue. When the flat pack-IC is removed from the

CBA, handle it gently because it may be damaged

if force is applied.

2. Installation

(1) Using desoldering braid, remove the solder from

the foil of each pin of the flat pack-IC on the CBA so

you can install a replacement flat pack-IC more

easily.

(2) The “I” mark on the flat pack-IC indicates pin 1.

(See Fig. S-1-7.) Be sure this mark matches the 1

on the PCB when positioning for installation. Then

presolder the four corners of the flat pack-IC. (See

Fig. S-1-8.)

(3) Solder all pins of the flat pack-IC. Be sure that none

of the pins have solder bridges.

To Solid

Mounting Point

CBA

Hot Air Blower

Iron Wire

Soldering Iron

Fig. S-1-5

Fine Tip

Soldering Iron

Example :

or

Pin 1 of the Flat Pack-IC

is indicated by a " " mark.

Fig. S-1-7

Presolder

Flat Pack-IC

CBA

Fig. S-1-8

Tweezers

Flat Pack-IC

Fig. S-1-6

1-4-3 DVD_NOTE

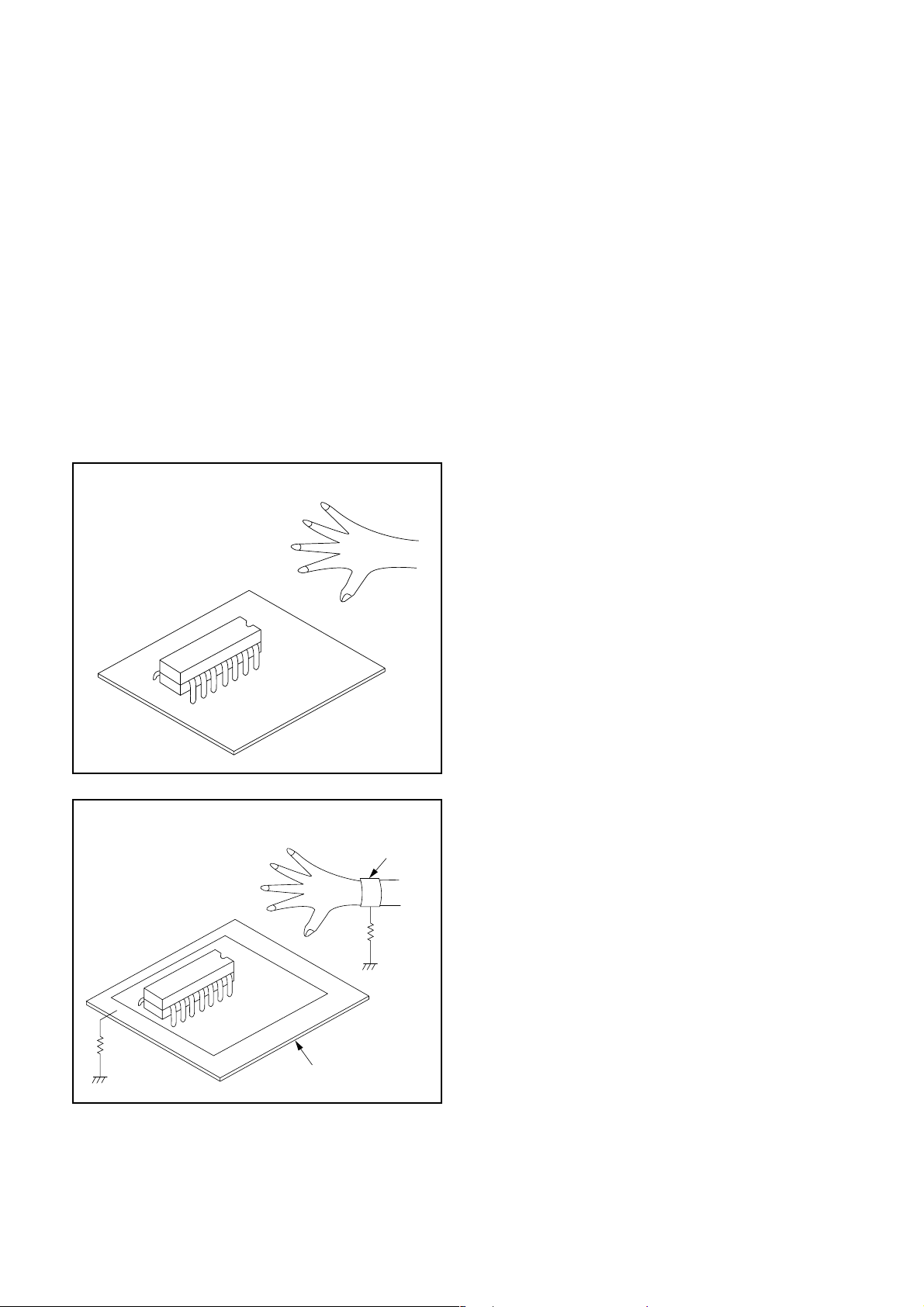

Instructions for Handling

Semi-conductors

Electrostatic breakdown of the semi-conductors may

occur due to a potential difference caused by electrostatic charge during unpacking or repair work.

1. Ground for Human Body

Be sure to wear a grounding band (1MΩ) that is properly grounded to remove any static electricity that may

be charged on the body.

2. Ground for Workbench

(1) Be sure to place a conductive sheet or copper plate

with proper grounding (1MΩ) on the workbench or

other surface, where the semi-conductors are to be

placed. Because the static electricity charge on

clothing will not escape through the body grounding band, be careful to avoid contacting semi-conductors with your clothing.

< Incorrect >

< Correct >

1MΩ

CBA

Grounding Band

1MΩ

CBA

Conductive Sheet or

Copper Plate

1-4-4 DVD_NOTE

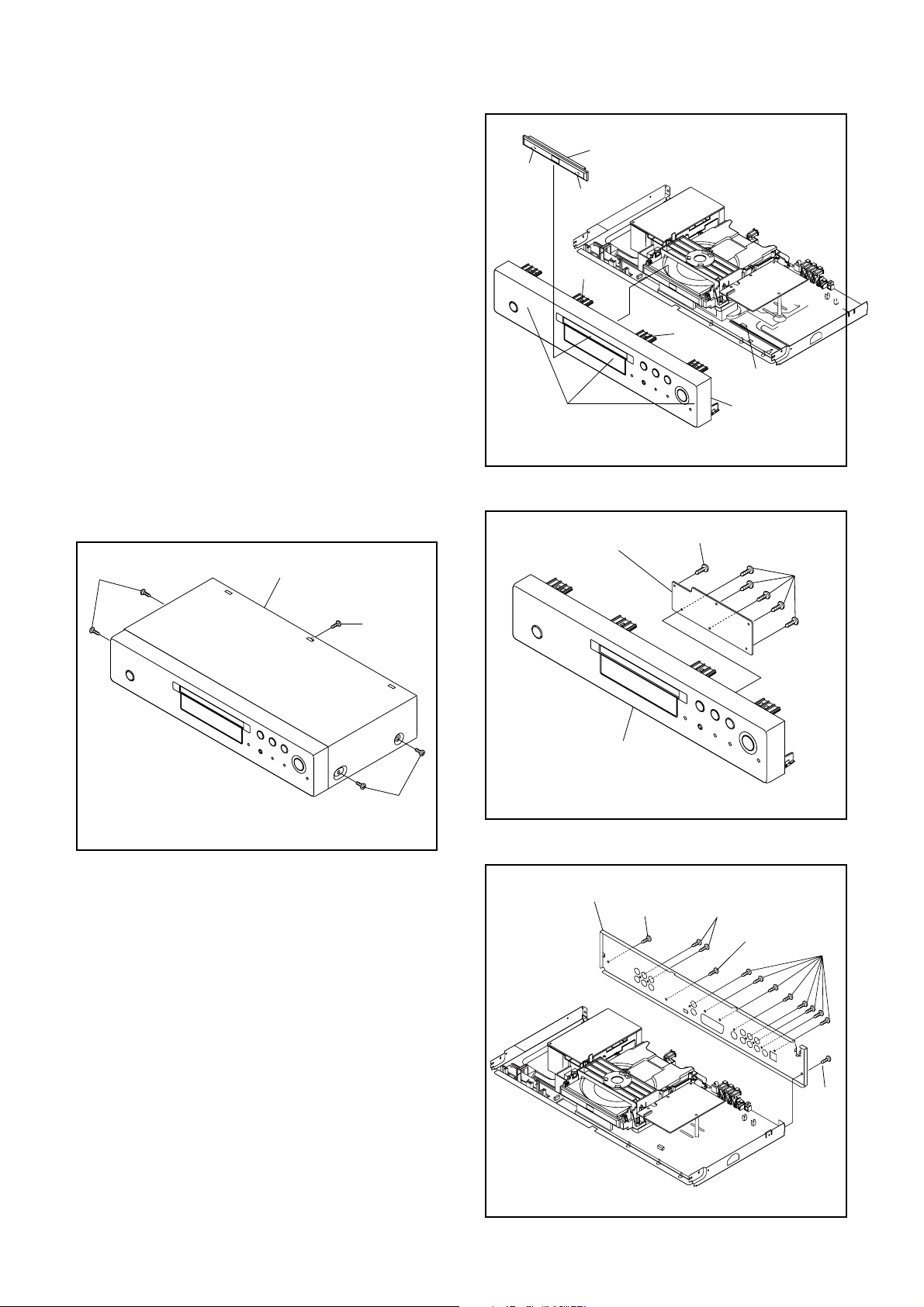

CABINET DISASSEMBLY INSTRUCTIONS

1. Disassembly Flowchart

This flowchart indicates the disassembly steps to gain

access to item(s) to be serviced. When reassembling,

follow the steps in reverse order. Bend, route, and

dress the cables as they were originally.

[14] Stopper Bracket

[1] Top Cover

[2] Front Unit

[5] Rear Panel [6] DVD Main CBA Unit

[10] AV CBA

[11] LED CBA

[12] Power PCB Holder

[8] JackPCB Holder

[7] DVD Audio CBA

[3] Function CBA

[4] Front Assembly

[9] DVD Mecha

[13] Loader Base

2. Disassembly Method

ID/

LOC.

No.

[1] Top Cover D1 5(S-1) -

[2] Front Unit D2

[3]

[4]

[5] Rear Panel D4 10(S-3), 3(S-4) -

[6]

[7]

[8]

[9] DVD Mecha

PAR T

Function

CBA

Front

Assembly

DVD Main

CBA Unit

DVD Audio

CBA

Jack PCB

Holder

Fig.

No.

D3 6(S-2) -

D3 ---------- -

D5

D6 (S-6), *CN7101 -

D6 2(S-7), *2(L-4) -

D5

D7

REMOVAL

REMOVE/*UNHOOK/

UNLOCK/RELEASE/

UNPLUG/DESOLDER

*2(L-1), Tray Panel,

*2(L-2), *3(L-3),

*CN2081

2(S-5A), (S-5B),

*CN201, *CN301,

*CN401, *CN601,

*CNS01

4(S-8)

Note

1

1-1

1-2

1-3

1-4

1-5

1-6

1-7

2

2-1

2-2

2

3

ID/

LOC.

No.

[10] AV CBA D8

[11] LED CBA D8 2(S-11) -

[12]

[13] Loader Base D9 4(S-12) -

[14]

↓

(1)

(1): Identification (location) No. of parts in the figures

(2): Name of the part

(3): Figure Number for reference

(4): Identification of parts to be removed, unhooked,

(5): Refer to “Reference Notes.”

PART

Power PCB

Holder

Stopper

Bracket

↓

(2)

unlocked, released, unplugged, unclamped, or

desoldered.

P=Spring, L=Locking Tab, S=Screw,

CN=Connector

*=Unhook, Unlock, Release, Unplug, or Desolder

e.g. 2(S-2) = two Screws (S-2),

2(L-2) = two Locking Tabs (L-2)

Fig.

No.

D8 ---------- -

D9 ---------- -

↓

(3)

REMOVAL

REMOVE/*UNHOOK/

UNLOCK/RELEASE/

UNPLUG/DESOLDER

3(S-9), (S-10),

*CN2101

↓

(4)

Note

-

↓

(5)

About tightening screws

When tightening screws, tighten them with the following torque.

Screws Torque

(S-1), (S-2), (S-3), (S-4),

(S-5A), (S-6), (S-7), (S-8),

(S-9), (S-10), (S-11), (S-12)

(S-5B) 0.38 ± 0.04 N·m

0.45 ± 0.05 N·m

Reference Notes

CAUTION 1: Locking Tabs (L-1), (L-2) and (L-3) are

fragile. Be careful not to break them.

1-1. Connect the wall plug to an AC outlet and press

the [OPEN/CLOSE] button to open the tray.

1-2. Remove the Tray Panel by releasing two locking

tabs (L-1).

1-3. Press the [OPEN/CLOSE] button again to close

the tray.

1-4. Press the [POWER] button to turn the power off.

1-5. Unplug an AC cord.

1-6. Disconnect connector CN2081.

1-5-1 E59M7DC

1-7. Release two Locking Tabs (L-2). Then release

three Locking Tabs (L-3), and remove the Front

Unit.

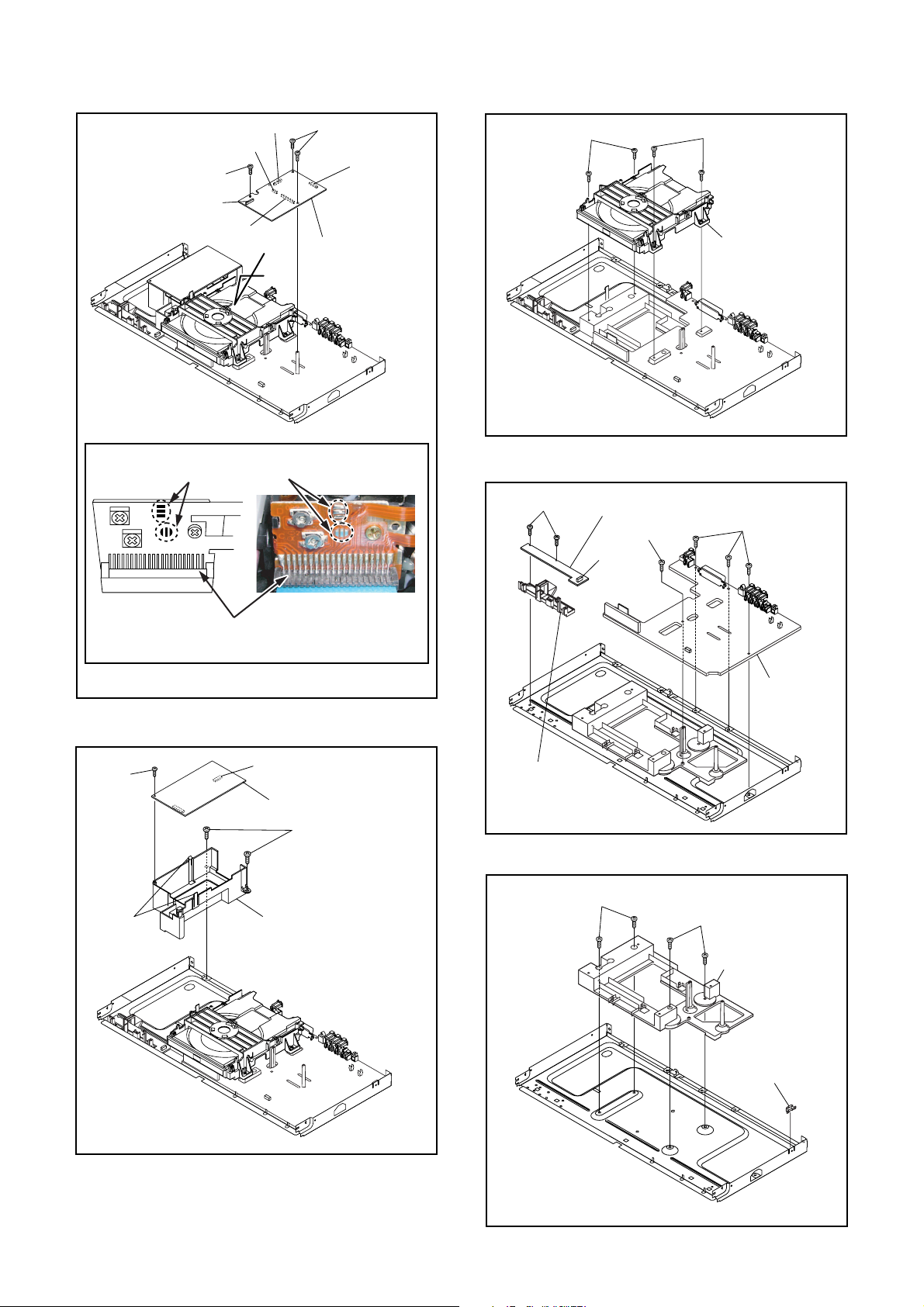

CAUTION 2: Electrostatic breakdown of the laser

diode in the optical system block may occur as a

potential difference caused by electrostatic charge

accumulated on cloth, human body etc, during

unpacking or repair work.

To avoid damage of pickup follow next procedures.

2-1. Short the three short lands of FPC cable with sol-

der before removing the FFC cable (CN201) from

it. If you disconnect the FFC cable (CN201), the

laser diode of pickup will be destroyed. (Fig. D4)

2-2. Disconnect Connectors (CN301), (CN401),

(CN601) and (CNS01). Remove three Screws

(S-5A) and (S-5B) and lift the DVD Main CBA

Unit. (Fig. D5)

CAUTION 3: When reassembling, confirm the FFC

cable (CN201) is connected completely. Then remove

the solder from the three short lands of FPC cable.

(Fig. D5)

(L-1)

(L-3)

Tray Panel

(L-1)

(L-2)

(L-2)

CN2081

[2] Front Unit

Fig. D2

(S-1)

[1] Top Cover

(S-1)

(S-1)

Fig. D1

[3] Function CBA

[4] Front Assembly

[5] Rear Panel

(S-4)

(S-2)

(S-3)

(S-4)

(S-2)

Fig. D3

(S-3)

(S-4)

Fig. D4

1-5-2 E59M7DC

CN201

CN301

(S-5B)

CNS01

CN401

A

(S-5A)

CN601

[6] DVD Main

CBA Unit

Short the three short lands by soldering.

(Either of two places.)

(S-8)

(S-8)

[7] DVD Mecha

Fig. D7

(S-6)

(L-4)

Connector

View for A

CN7101

[7] DVD Audio CBA

[8] Jack PCB Holder

(S-7)

Fig. D5

(S-11)

[11] LED CBA

[12] Power

PCB Holder

(S-12)

(S-10)

CN2101

(S-9)

[10] AV CBA

Fig. D8

(S-12)

[13] Loader

Base

Fig. D6

[14] Stopper

Bracket

Fig. D9

1-5-3 E59M7DC

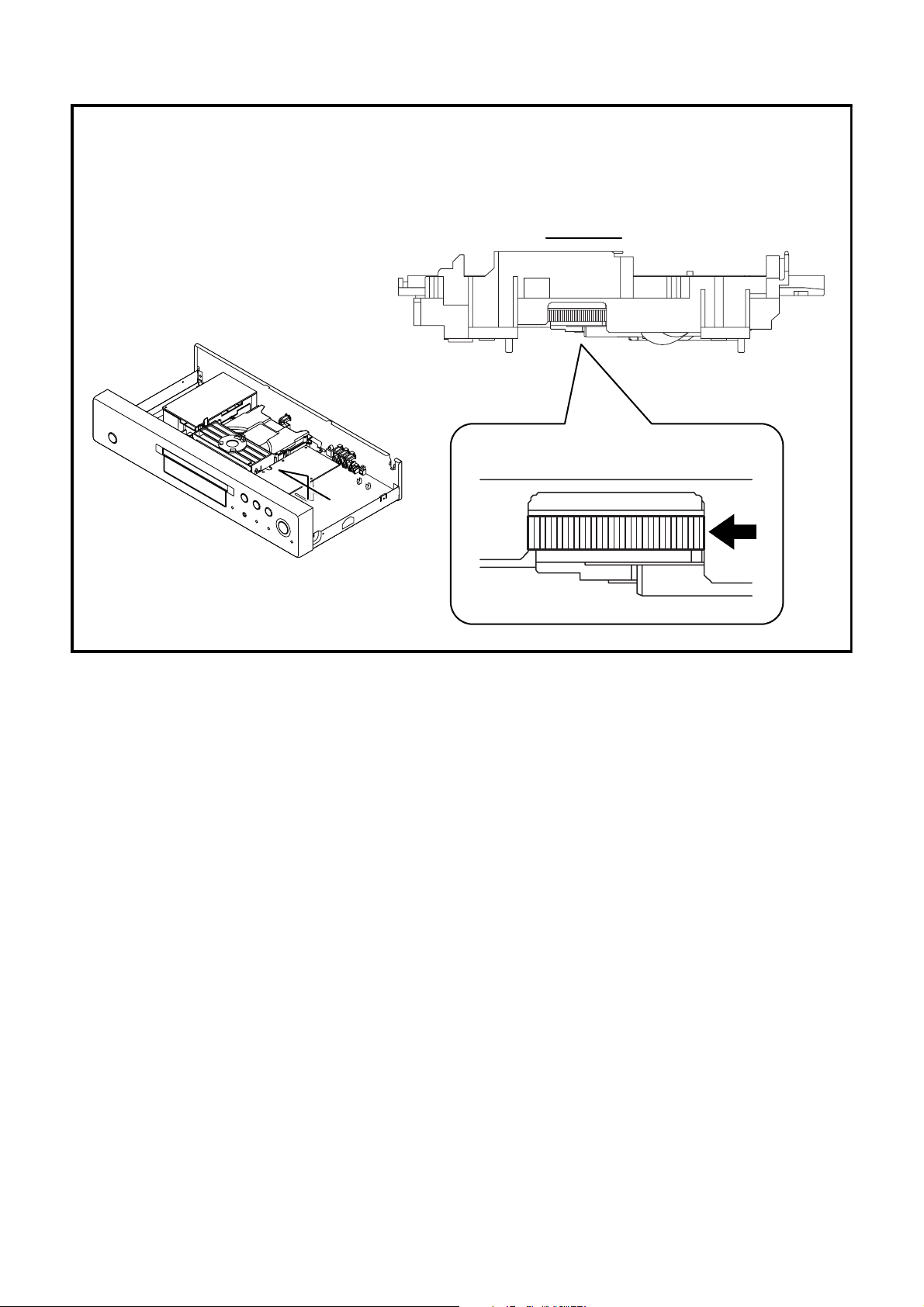

HOW TO EJECT MANUALLY

1. Remove the Top Cover.

2. Rotate the roulette in the direction of the arrow as shown

below.

Rotate this roulette in

the direction of the arrow

A

View for A

1-5-4 E59M7DC

Loading...

Loading...