Page 1

S Model

Ice Machines

Installation, Use & Care Manual

This manual is updated as new information and models are released.

Visit our website for the latest manual. www.manitowocfsg.com

America’s #1 Selling Ice Machine

Part Number 000000966 10/09

Page 2

Safety Notices

! Warning

!

Caution

Important

!

Caution

Important

! Warning

As you work on Manitowoc equipment, be sure to pay

close attention to the safety notices in this manual.

Disregarding the notices may lead to serious injury and/

or damage to the equipment.

Throughout this manual, you will see the following types

of safety notices:

Text in a Warning box alerts you to a potential

personal injury situation. Be sure to read the

Warning statement before proceeding, and work

carefully.

Text in a Caution box alerts you to a situation in

which you could damage the equipment. Be sure to

read the Caution statement before proc eeding, and

work carefully.

Procedural Notices

As you work on Manitowoc equipment, be sure to read

the procedural notices in this manual. These notices

supply helpful information which may assist you as you

work.

Throughout this manual, you will see the following types

of procedural notices:

Read These Before Proceeding:

Proper installation, care and maintenance are

essential for maximum performance and troublefree operation of your Manitow oc equipment. Read

and understand this manual. It contains valuable

care and maintenance information. If you encounter

problems not covered by this manual, do not

proceed, contact Manitowoc Foodservice Group.

We will be happy to provide assistance.

Routine adjustments and maintenance procedures

outlined in this manual are not covered by the

warranty.

PERSONAL INJURY POTENTIAL

Do not operate equipment that has been misused,

abused, neglected, damaged, or altered/modified

from that of original manufactured specifications.

NOTE: SAVE THESE INSTRUCTIONS.

Text in an Important box provides you with

information that may help you perform a procedure

more efficiently. Disregarding this information will

not cause damage or injury, but it may slow you

down as you work.

NOTE: Text set off as a Note provides you with simple,

but useful, extra information about th e pr oce dur e yo u

are performing.

We reserve the right to make product improvements at any time.

Specifications and design are subject to change without notice.

Page 3

Section 1

General Information

Table of Contents

Model Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

How to Read a Model Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Ice Cube Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Bin Caster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Ice Bagger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Guardian Sachet Packets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Arctic Pure Water Filter System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Manitowoc Cleaner and Sanitizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

AuCS® Automatic Cleaning System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Dispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Model/Serial Number Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Owner Warranty Registration Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Commercial Warranty Coverage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Labor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Exclusions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Authorized Warranty Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Residential Ice Machine Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Section 2

Installation Instructions

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Ice Machine Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Remote Condenser Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Ice Storage Bin Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Large Capacity Ice Storage Bin Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Location of Ice Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Ice Machine Heat of Rejection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Removing Drain Plug and Leveling the Ice Storage Bin . . . . . . . . . . . . . . . . 2-10

Air-Cooled Baffle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Electrical Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

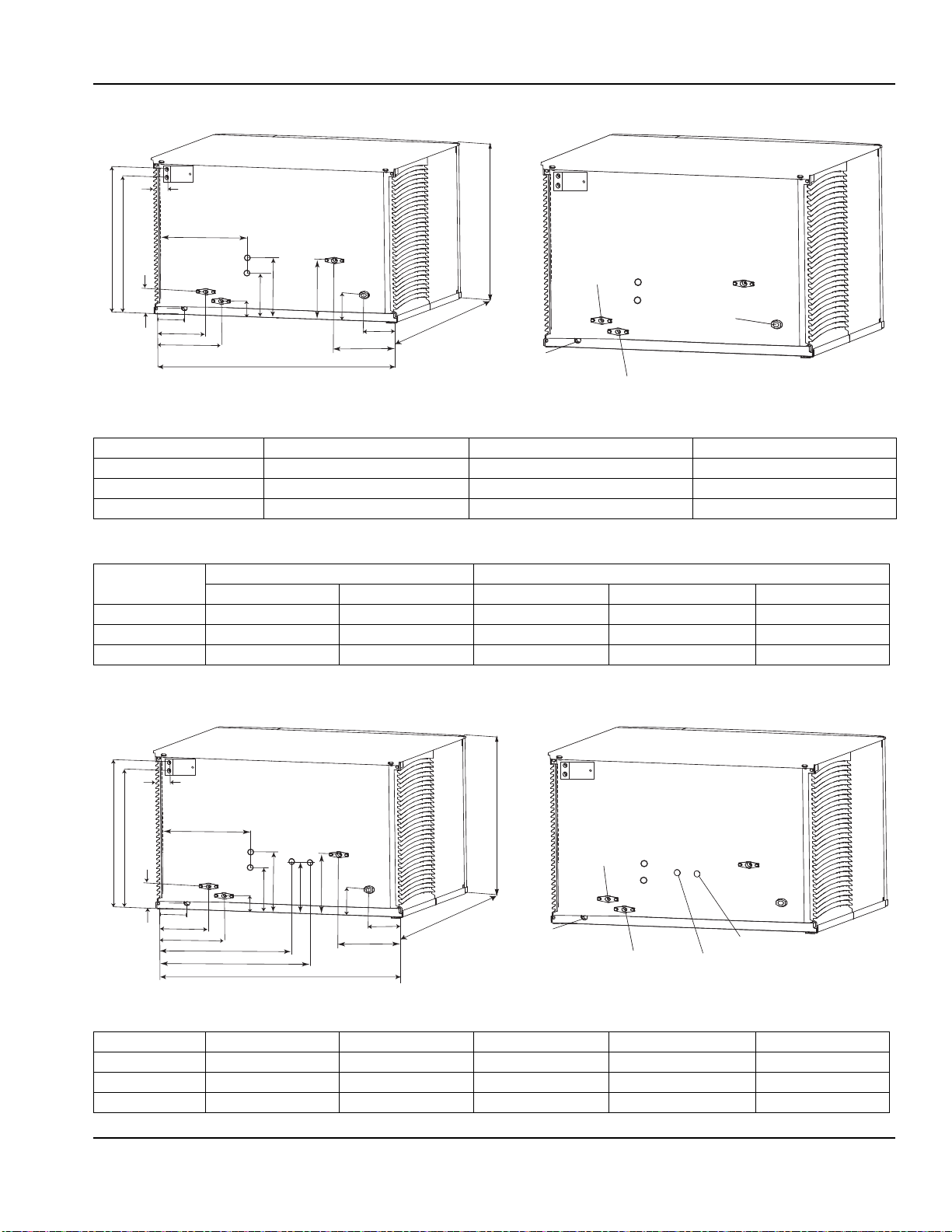

S320/S420 Air and Water-Cooled Ice Machines . . . . . . . . . . . . . . . . . . . . 2-1

S600 Air and Water-Cooled Ice Machines . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

S600 Remote Ice Machines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

S300/S450/S500/S850/S1000/S1200 Air and Water-Cooled Ice Mach ines 2-3

S500/S850/S1000 Remote Ice Machines . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

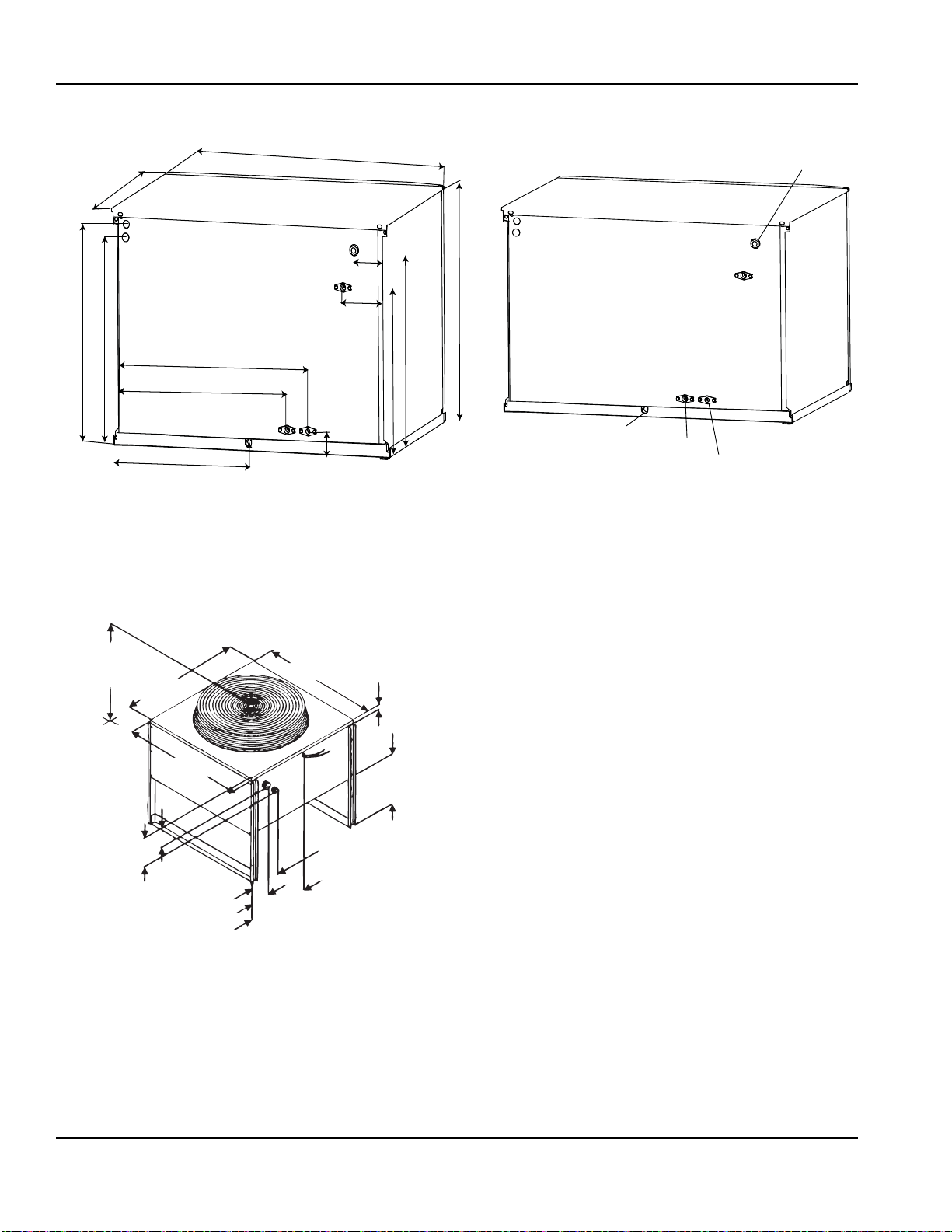

S1400 / S1600 / S1800 Air and Water-Cooled Ice Machines . . . . . . . . . . . 2-5

S1400 / S1600 / S1800 Remote Ice Machines . . . . . . . . . . . . . . . . . . . . . . 2-5

S3300 Water-Cooled Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

JC0495/JC0895/JC1395 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

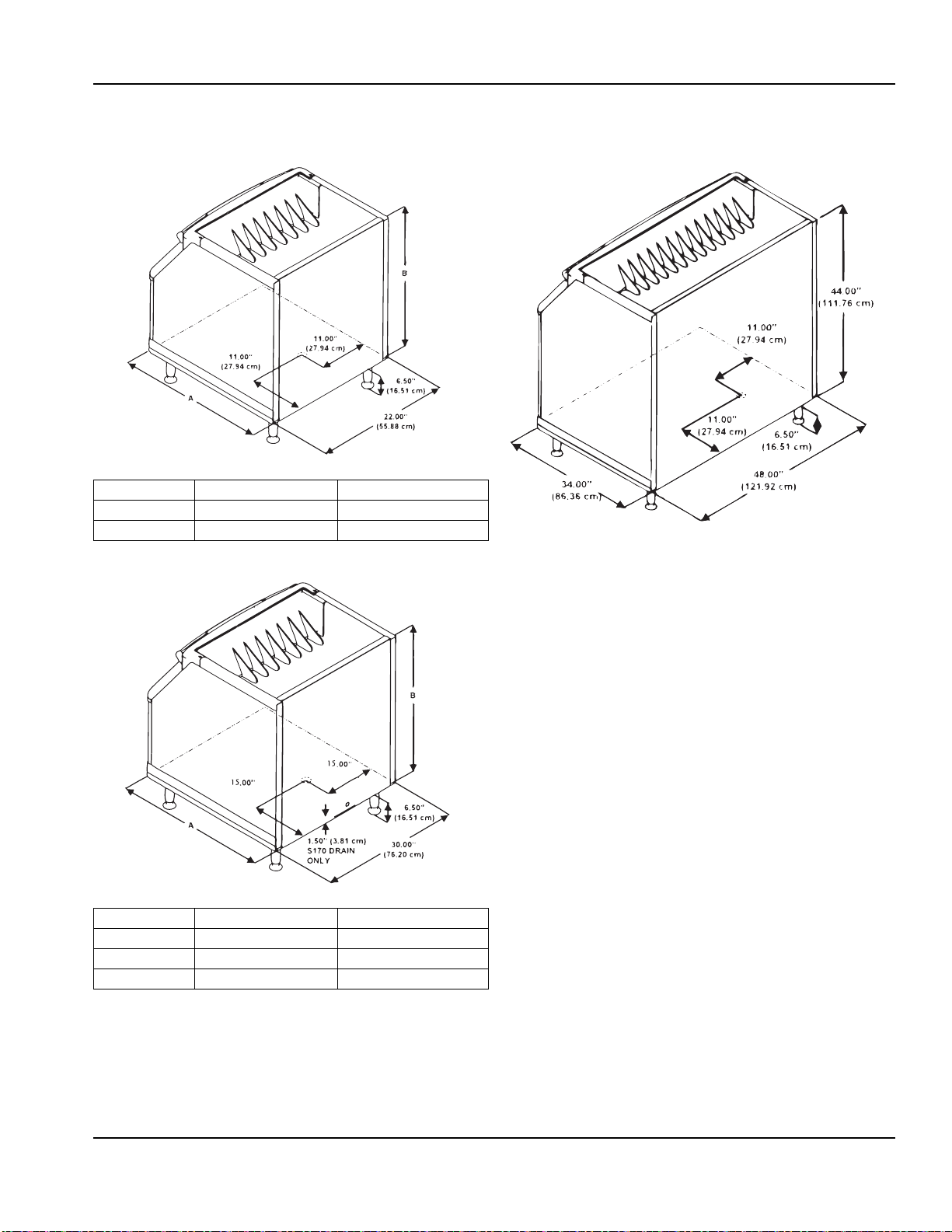

22 Inch (56 cm) Ice Storage Bins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

30 inch (76 cm) Ice Storage Bins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

48 Inch (122 cm) Ice Storage Bins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

30 Inch (76 cm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

48 Inch (122 cm) & 60 Inch (152 cm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Minimum Circuit Ampacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Part Number 000000966 10/09 i

Page 4

Table of Contents (continued)

Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Ground Fault Circuit Interupter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Minimum Power Cord Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Maximum breaker size & Minimum Circuit Amperage Chart . . . . . . . . . . . 2-12

Self-Contained Electrical Wiring Connections . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Self Contained Ice Machine

115/1/60 or 208-230/1/60 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Self Contained Ice Machine

208-230/3/60 or 440-480/3/60 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Self Contained Ice Machine

230/1/50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

For United Kingdom Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Remote Electrical Wiring Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Remote Ice Machine

With Single Circuit Model Condenser

115/1/60 or 208-230/1/60 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Remote Ice Machine

With Single Circuit Model Condenser

208-230/3/60 or 440-480/3/60 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Remote Ice Machine

With Single Circuit Model Condenser

230/1/50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Water Supply and Drain Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Water Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Water Inlet Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Drain Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Cooling Tower Applications

(Water-Cooled Models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

S3300 Condenser Water Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Water Supply and Drain Line Sizing/Connections . . . . . . . . . . . . . . . . . . . . 2-16

Remote Condenser/Line Set Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Remote Ice Machines

Refrigerant Charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Guidelines for Routing Line Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Calculating Remote Condenser Installation Distances . . . . . . . . . . . . . . . . 2-19

Lengthening or Reducing Line Set Lengths . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Connecting A Line Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Remote Receiver Service Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Remote Ice Machine Usage with Non-Manitowoc Multi-Circuit Condensers 2-21

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Head Pressure Control Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Fan Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Internal Condenser Volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Condenser DT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Refrigerant Charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Quick Connect Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Non-Manitowoc Multi-Circuit Condenser Sizing Chart . . . . . . . . . . . . . . . . . 2-22

Installation Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Additional Checks for Remote Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Before Starting the Ice Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

AuCS® Automatic Cleaning System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

ii Part Number 000000966 10/09

Page 5

Section 3

Ice Machine Operation

Section 4

Maintenance

Table of Contents (continued)

Component Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

S Model Single Evaportor Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

S Model Multiple Evaporator Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Sequence Of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Initial Start-Up or Start-Up After Automatic Shut-Off . . . . . . . . . . . . . . . . . . 3-2

Freeze Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Harvest Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Automatic Shut-Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Sequence of Operation Chart Single Evaporator . . . . . . . . . . . . . . . . . . . . 3-3

Sequence of Operation Chart Multiple Evaporators . . . . . . . . . . . . . . . . . . 3-3

Safety Timers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Safety Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Warm Water Rinse Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Operational Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Water Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Ice Thickness Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Harvest Sequence Water Purge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Cleaning and Sanitizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Exterior Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Manitowoc’s Cleaning Technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Cleaning / Sanitizing Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Cleaning Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Parts Removal for Cleaning/Sanitizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Sanitizing Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Procedure to Clean Heavily Scaled Ice Machines . . . . . . . . . . . . . . . . . . . . . 4-7

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Cleaning Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Parts Removal for Cleaning/Sanitizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Sanitizing Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Additional Component Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Ice Machine Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Exterior Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Cleaning the Condenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Water-Cooled Condenser and Water Regulating Valve . . . . . . . . . . . . . . . . . 4-17

AlphaSan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Guardian . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Guardian Sachet Replacement Frequency . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Sachet Installation/Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Clean Up Procedure for Damaged Sachet Packet . . . . . . . . . . . . . . . . . . . 4-18

Removal from Service/Winterization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Self-Contained Air-Cooled Ice Machines . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Water-Cooled Ice Machines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Remote Ice Machines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

AuCS Accessory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Part Number 000000966 10/09 iii

Page 6

Section 5

Before Calling For Service

Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Safety Limit Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Table of Contents (continued)

iv Part Number 000000966 10/09

Page 7

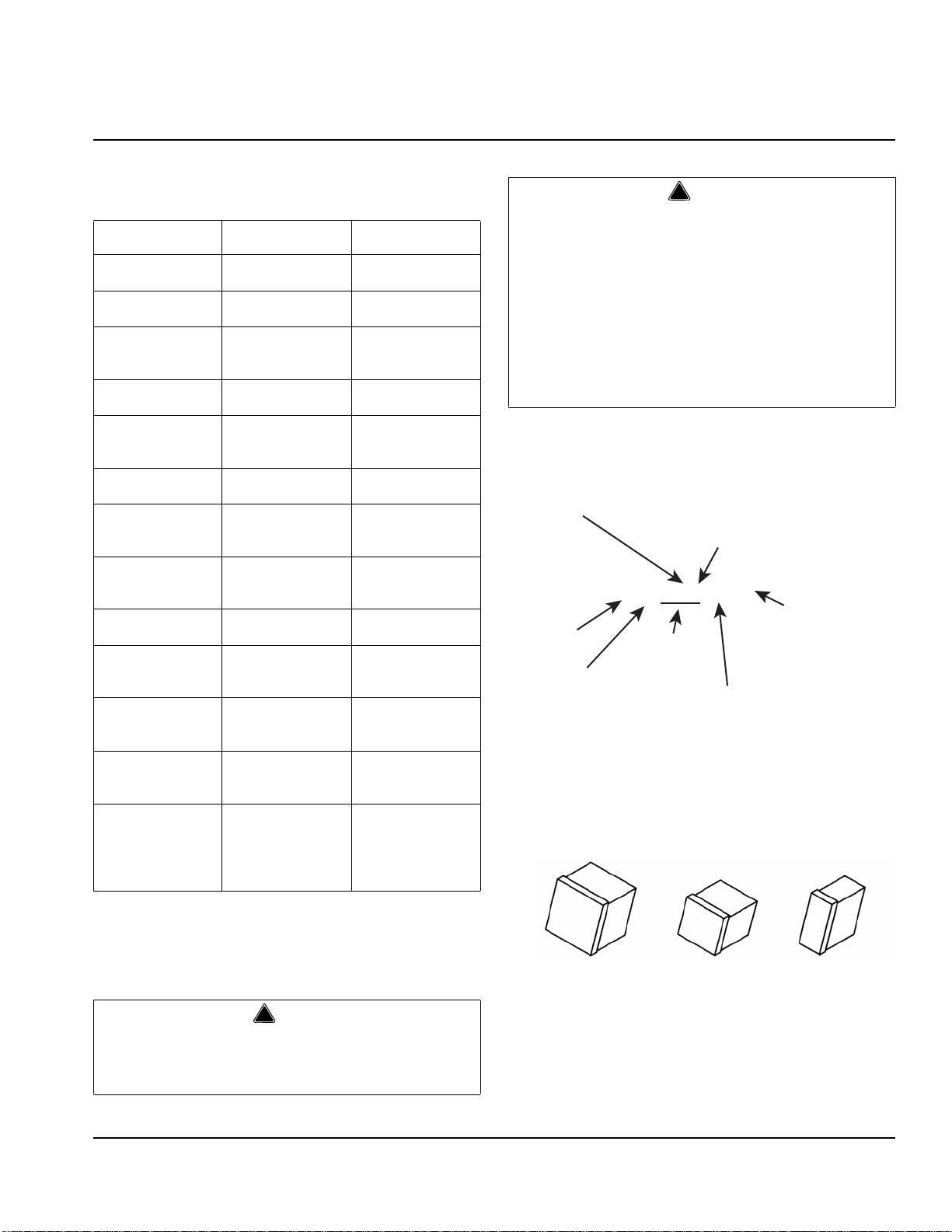

Model Numbers

!

Warning

!

Warning

Section 1

General Information

This manual covers the following models:

Self-Contained

Air-Cooled

SD0302A

SY0304A

SD0322A

SY0324A

SR0420A

SD0422A

SY0424A

SD0452A

SY0454A

SR0500A

SD0502A

SY0504A

SD0602A

SY0604A

SR0850A

SD0852A

SY0854A

SD1002A

SY1004A

SD1202A

SY1204A

SD1402A

SY1404A

SR1600A

SD1602A

SY1604A

SR1800A

SD1802A

SY1804A

----

----

----

----

----

Self-Contained

Water-Cooled

SD0303W

SY0305W

SD0323W

SY0325W

SR0421W

SD0423W

SY0425W

SD0453W

SY0455W

SR0501W

SD0503W

SY0505W

SD0603W

SY0605W

SR0851W

SD0853W

SY0855W

SD1003W

SY1005W

SD1003WM

SD1203W

SY1205W

SD1403W

SY1405W

SD1403WM

SR1601W

SD1603W

SY1605W

SR1801W

SD1803W

SY1805W

SD3303W

SD3303WHP

SY3305W

SY3305WHP

SD3303WM

Remote

----

----

----

----

----

----

----

----

----

SR0590N

SD0592N

SY0594N

SD0692N

SY0694N

SR0890N

SD0892N

SY0894N

SD1092N

SY1094N

---

---

SD1492N

SY1494N

SR1690N

SD1692N

SY1694N

SR1890N

SD1892N

SY1894N

----

----

----

----

----

PERSONAL INJURY POTENTIAL

Do not operate equipment that has been misused,

abused, neglected, damaged, or altered/modified

from that of original manufactured specifications.

This appliance is not intended for use by persons

(including children) with reduced physical, sensory

or mental capabilities, or lack of experience and

knowledge, unless they have been given

supervision concerning use of the appliance by a

person responsible for their safety.

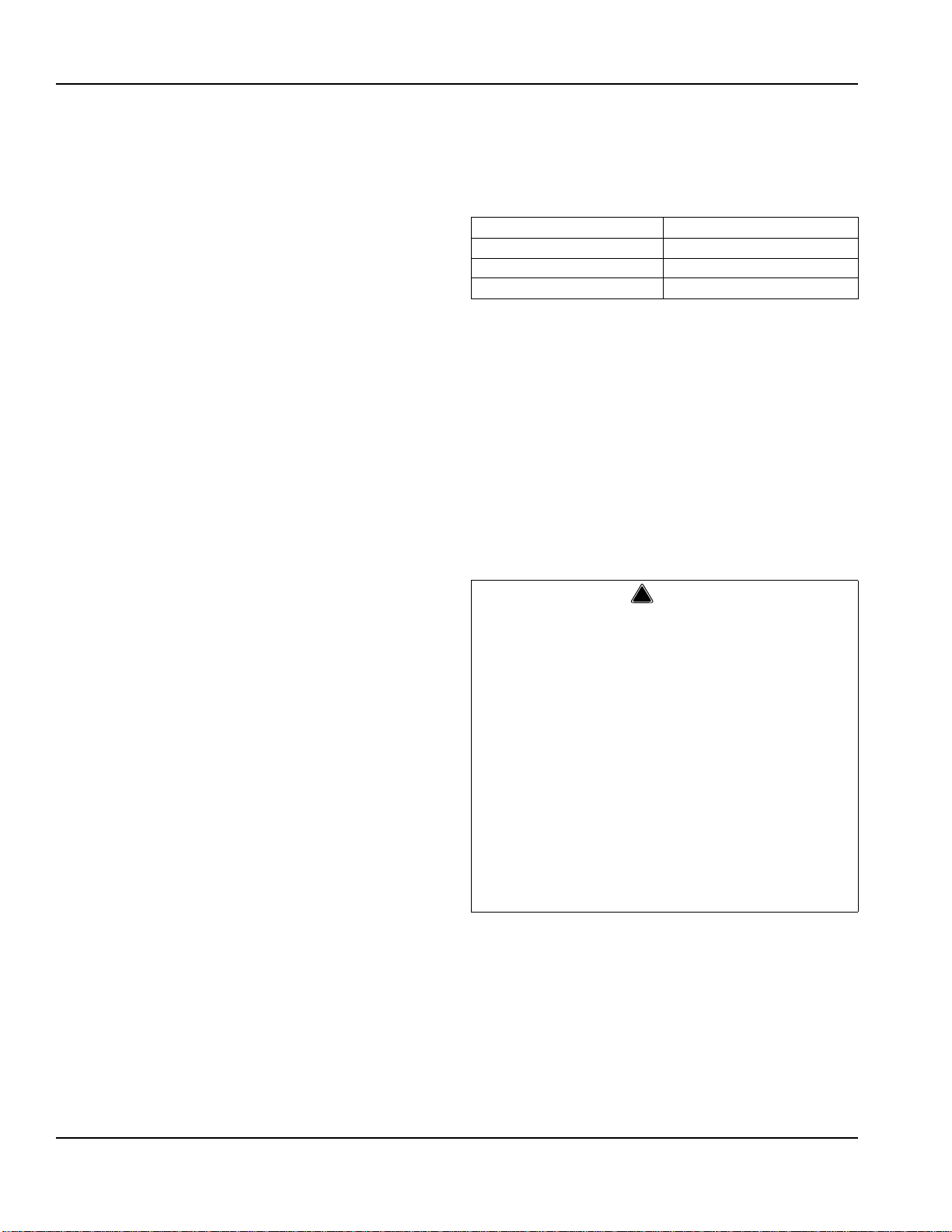

How to Read a Model Number

9 REMOTE

AIR-COOLED

# CUBE SIZE

0 REGULAR

1 REGULAR

2 DICE

3 DICE

4 HALF-DICE

5 HALF-DICE

CONDENSER TYPE

AIR-COOLED

WATER-COOLED

AIR-COOLED

WATER-COOLED

AIR-COOLED

WATER-COOLED

S Y 1094 N SI

ADDITIONAL SPECS

ICE MACHINE

MODEL

ICE CUBE SIZE

R REGULAR

D DICE

Y HALF DICE

ICE MACHINE

SERIES

CONDENSER TYPE

A SELF-CONTAINED AIR-COOLED

W SELF-CONTAINED WATER-COOLED

N REMOTE AIR-COOLED

3 PHASE

M MARINE UNIT

HP HIGH PRESSURE

WATER VALVE

SI AUCS-SI INCLUDED

NOTE: When refering to information in this manul refer

to the Ice Machine Model (letter) and the first number of

the Series followed by zeros. Example: If your model is

SY1094NSI refer to S1000 throughout the manual.

Ice Cube Sizes

NOTE: Model numbers ending in HP indicate High

Pressure water regulating valve. Standard pressure =

150 psi (10.34 bar) High pressure = 350 psi (24.13 bar)

Regular

1-1/8" x 1-1/8" x 7/8"

2.86 x 2.86 x 2.22 cm

Dice

7/8" x 7/8" x 7/8"

2.22 x 2.22 x 2.22 cm

Half Dice

3/8" x 1-1/8" x 7/8"

0.95 x 2.86 x 2.22 cm

PERSONAL INJURY POTENTIAL

Remove all ice machine panels before lifting and

installing.

Part Number 000000966 10/09 1-1

Page 8

General Information Section 1

!

Warning

Accessories

Contact your Manitowoc distributor for these optional

accessories:

BIN CASTER

Replaces standard legs.

ICE BAGGER

Maximize profits from bagged ice sales with this

convenient accessory. This sturdy unit rests on the bin

door frame, and adapts for left or right side filling.

GUARDIAN SACHET PACKETS

Guardian sachet packets release chlorine dioxide on a

controlled basis to inhibit the growth of bacteria and

slime.

Guardian sachet packets are available through your

local Manitowoc Ice Machine dealer. Not available for

S3300 machines.

ARCTIC PURE WATER FILTER SYSTEM

Engineered specifically for Manitowoc ice machines,

This water filter is an efficient, dependable, and

affordable method of inhibiting scale formation, filtering

sediment, and removing chlorine taste and odor.

MANITOWOC CLEANER AND SANITIZER

Manitowoc Ice Machine Cleaner and Sanitizer are

available in convenient 16 oz. (473 ml) bottles. These

are the only cleaner and sanitizer approved for use with

Manitowoc products.

Cleaner Part Number Sanitizer Part Number

16 ounce Bottle - 94-0546-3 16 ounce Bottle - 94-0565-3

AuCS®-SO - 94-0546-3 AuCS®-SO - 94-0565-3

AuCS®-SI - 40-1326-3 AuCS®-SI - 40-1327-3

AUCS® AUTOMATIC CLEANING SYSTEM

This accessory reduces equipment cleaning expense.

The AuCS® accessory monitors ice making cycles and

initiates cleaning procedures automatically . Not available

for S3300 machines.

DISPENSER

A counter-top dispenser is ideal for cafeterias and many

types of self-service facilities. Manitowoc auto-fill, floorstanding ice dispensers meet the strict sanitary

requirements of the food service, lodging and health

care industries.

All Manitowoc ice machines require the ice storage

system (bin, dispenser, etc.) to incorporate an ice

deflector.

48” wide S Model ice machines require adding

Manitowoc Ice Deflector Kit K00349 when installing

with non-Manitowoc ice storage systems.

30” wide S Model ice machines require adding

Manitowoc Ice Deflector Kit K00347 when installing

with non-Manitowoc ice storage systems.

Prior to using a non-Manitowoc ice storage system

with other Manitowoc ice machines, contact the

manufacturer to assure their ice deflector is

compatible with Manitowoc ice machines.

1-2

Part Number 000000966 10/09

Page 9

Section 1 General Information

FRONT OF

CONTROL BOX

COVER

RIGHT SIDE OF

CONTROL BOX

BACK LEFT

HAND SIDE

SEPARATE BIN

NUMBERS

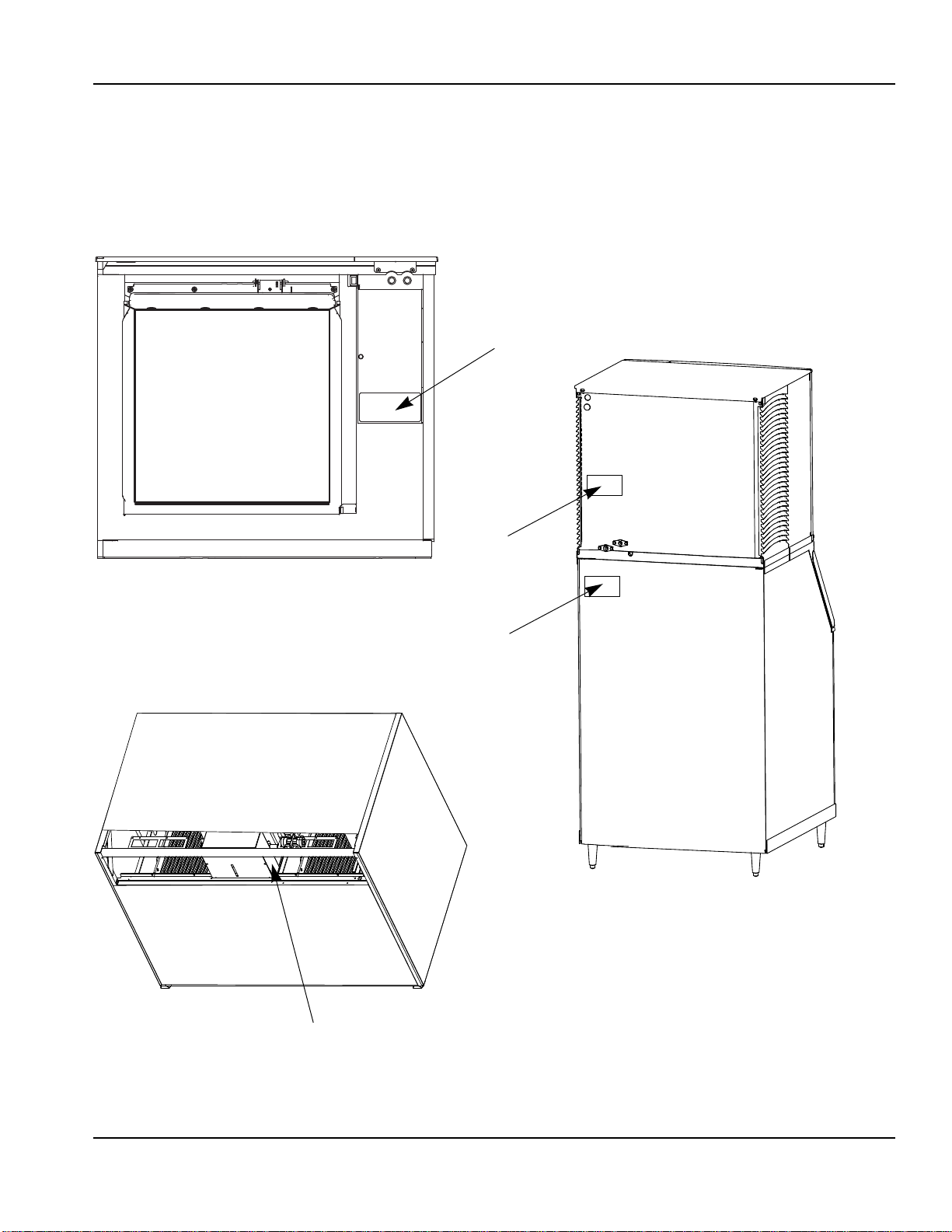

Model/Serial Number Location

These numbers are required when requesting

information from your local Manitowoc distributor, or

Manitowoc Foodservice.

The model and serial number are listed on the MODEL/

SERIAL NUMBER DECAL affixed to the ice machine,

remote condenser and storage bin.

Model/Serial Number Location

Part Number 000000966 10/09 1-3

Page 10

General Information Section 1

Important

Owner Warranty Registration Card

GENERAL

The packet containing this manual also includes

warranty information. Warranty coverage beg ins the day

your new ice machine is installed.

Complete and mail the OWNER WARRANTY

REGISTARATION CARD as soon as possible to

validate the installation date.

If you do not return your OWNER WARRANTY

REGISTRATION CARD, Manitowoc will use the date of

sale to the Manitowoc Distributor as the first day of

warranty coverage for your new ice machine.

Commercial Warranty Coverage

GENERAL

The following Warranty outline is provided for your

convenience. For a detailed explanation, read the

warranty bond shipped with each product.

Contact your local Manitowoc Distributor, Manitowoc Ice,

Inc. or visit our website at www .manitowocice.com if you

need further warranty information.

PARTS

1. Manitowoc warrants the ice machine against defects

in materials and workmanship, under normal use

and service for three (3) years from the date of

original installation.

2. The evaporator and compressor are covered by an

additional two (2) year (five years total) warranty

beginning on the date of the original installation.

LABOR

1. Labor required to repair or replace defective

components is covered for three (3) years from the

date of original installation.

2. The evaporator is covered by an additional two (2)

year (five years total) labor warranty beginning on

the date of the original installation.

EXCLUSIONS

The following items are not

warranty coverage:

1. Normal maintenance, adjustments and cleaning.

2. Repairs due to unauthorized modifications to the

ice machine or use of non-standard parts without

prior written approval from Manitowoc Ice, Inc.

3. Damage caused by improper installation of the ice

machine, electrical supply , water supp ly or drainage,

or damage caused by floods, storms, or other acts of

God.

4. Premium labor rates due to holidays, overtime,

etc.; travel time; flat rate service call charges;

mileage and miscellaneous tools and material

charges not listed on the payment schedule.

Additional labor charges resulting from the

inaccessibility of equipment are also excluded.

5. Parts or assemblies subjected to misuse, abuse,

neglect or accidents.

6. Damage or problems caused by installation,

cleaning and/or maintenance procedures

inconsistent with the technical instructions

provided in this manual.

AUTHORIZED WARRANTY SERVICE

To comply with the provisions of the warranty, a

refrigeration service company qualified and

authorized by a Manitowoc distributor, or a

Contracted Service Representative must perform the

warranty repair.

NOTE: If the dealer you purchased the ice machine from

is not authorized to perform warranty service, contact

your Manitowoc distributor or Manitowoc Ice, Inc. for the

name of the nearest authorized service representative.

Service Calls

Normal maintenance, adjustments and cleaning as

outlined in this manual are not covered by the

warranty. If you have followed the procedures listed on

page 5-1 of this manual, and the ice machine still does

not perform properly, call your authorized service

company.

included in the ice machine’s

1-4

Part Number 000000966 10/09

Page 11

Section 1 General Information

Residential Ice Machine Limited Warranty

WHAT DOES THIS LIMITED WARRANTY COVER?

Subject to the exclusions and limitations below,

Manitowoc Ice, Inc. (“Manitowoc”) warrants to the

original consumer that any new ice machine

manufactured by Manitowoc (the “Product”) shall be

free of defects in material or workmanship for the

warranty period outlined below under normal use and

maintenance, and upon proper installation and start-up

in accordance with the instruction manual supplied with

the Product.

HOW LONG DOES THIS LIMITED WARRANTY

LAST?

Product Covered

Warranty Period

Ice Machine Twelve (12) months

from the sale date

WHO IS COVERED BY THIS LIMITED WARRANTY?

This limited warranty only applies to the original

consumer of the Product and is not transferable.

WHAT ARE MANITOWOC ICE’S OBLIGATIONS

UNDER THIS LIMITED WARRANTY?

If a defect arises and Manitowoc receives a valid

warranty claim prior to the expiration of the warranty

period, Manitowoc shall, at its option: (1) repair the

Product at Manitowoc’s cost, including standard straight

time labor charges, (2) replace the Product with one that

is new or at least as functionally equivalent as the

original, or (3) refund the purchase price for the Pr oduct.

Replacement parts are warranted for 90 days or the

balance of the original warranty period, whiche ve r is

longer. The foregoing constitutes Manitowoc’s sole

obligation and the consumer’s exclusive remedy for any

breach of this limited warranty. Manitowoc’s liability

under this limited warranty is limited to the purchase

price of Product. Additional expenses including, without

limitation, service travel time, overtime or premium labor

charges, accessing or removing the Product, or

shipping are the responsibility of the consumer.

HOW TO OBTAIN WARRANTY SERVICE

To obtain warranty service or information regarding your

Product, please contact us at:

MANITOWOC FOODSERVICE

2110 So. 26th St.

P.O. Box 1720,

Manitowoc, WI 54221-1720

Telephone: 920-682-0161 Fax: 920-683-7585

www.manitowocice.com

WHAT IS NOT COVERED?

This limited warranty does not cover, and you are solely

responsible for the costs of: (1) periodic or routine

maintenance, (2) repair or replacement of the Product

or parts due to normal wear and tear, (3) defects or

damage to the Product or parts resulting from misuse,

abuse, neglect, or accidents, (4) defects or damage to

the Product or parts resulting from improper or

unauthorized alterations, modifications, or changes; and

(5) defects or damage to any Product that has not been

installed and/or maintained in accordance with the

instruction manual or technical instructions provided by

Manitowoc. To the extent that warranty exclusions are

not permitted under some state laws, these exclusions

may not apply to you.

E

XCEPT AS STATED IN THE FOLLOWING SENTENCE, THIS

L

IMITED WARRANTY IS THE SOLE AND EXCLUSIVE

W

ARRANTY OF MANITOWOC WITH REGARD TO THE

P

RODUCT. ALL IMPLIED WARRANTIES ARE STRICTLY

L

IMITED TO THE DURATION OF THE LIMITED WARRANTY

A

PPLICABLE TO THE PRODUCTS AS STATED ABOVE,

I

NCLUDING BUT NOT LIMITED TO, ANY WARRANTY OF

M

ERCHANTABILITY OR OF FITNESS FOR A PARTICULAR

P

URPOSE.

Some states do not allow limitations on how long an

implied warranty lasts, so the above limitation may not

apply to you.

I

N NO EVENT SHALL MANITOWOC OR ANY OF ITS

A

FFILIATES BE LIABLE TO THE CONSUMER OR ANY OTHER

P

ERSON FOR ANY INCIDENTAL, CONSEQUENTIAL OR

S

PECIAL DAMAGES OF ANY KIND (INCLUDING, WITHOUT

L

IMITATION, LOSS PROFITS, REVENUE OR BUSINESS)

A

RISING FROM OR IN ANY MANNER CONNECTED WITH THE

P

RODUCT, ANY BREACH OF THIS LIMITED WARRANTY, OR

A

NY OTHER CAUSE WHATSOEVER, WHETHER BASED ON

C

ONTRACT, TORT OR ANY OTHER THEORY OF LIABILITY.

Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

HOW STATE LAW APPLIES

This limited warranty gives you specific legal rights, and

you may also have rights that vary from state to state or

from one jurisdiction to another.

REGISTRATION CARD

To secure prompt and continuing warranty service, this

warranty registration card must be completed and sent

to Manitowoc within thirty (30) days from the sale date.

Complete the registration card and send it to Manitowoc.

Part Number 000000966 10/09 1-5

Page 12

General Information Section 1

THIS PAGE INTENTIONALLY LEFT BLANK

1-6

Part Number 000000966 10/09

Page 13

Section 2 Installation Instructions

Important

Section 2

Installation Instructions

General

These instructions are provided to assist the qualified

installer. Check your local Yellow Pages for the name of

the nearest Manitowoc distributor, or call Manitowoc

Foodservice for information regarding start-up service s.

Ice Machine Dimensions

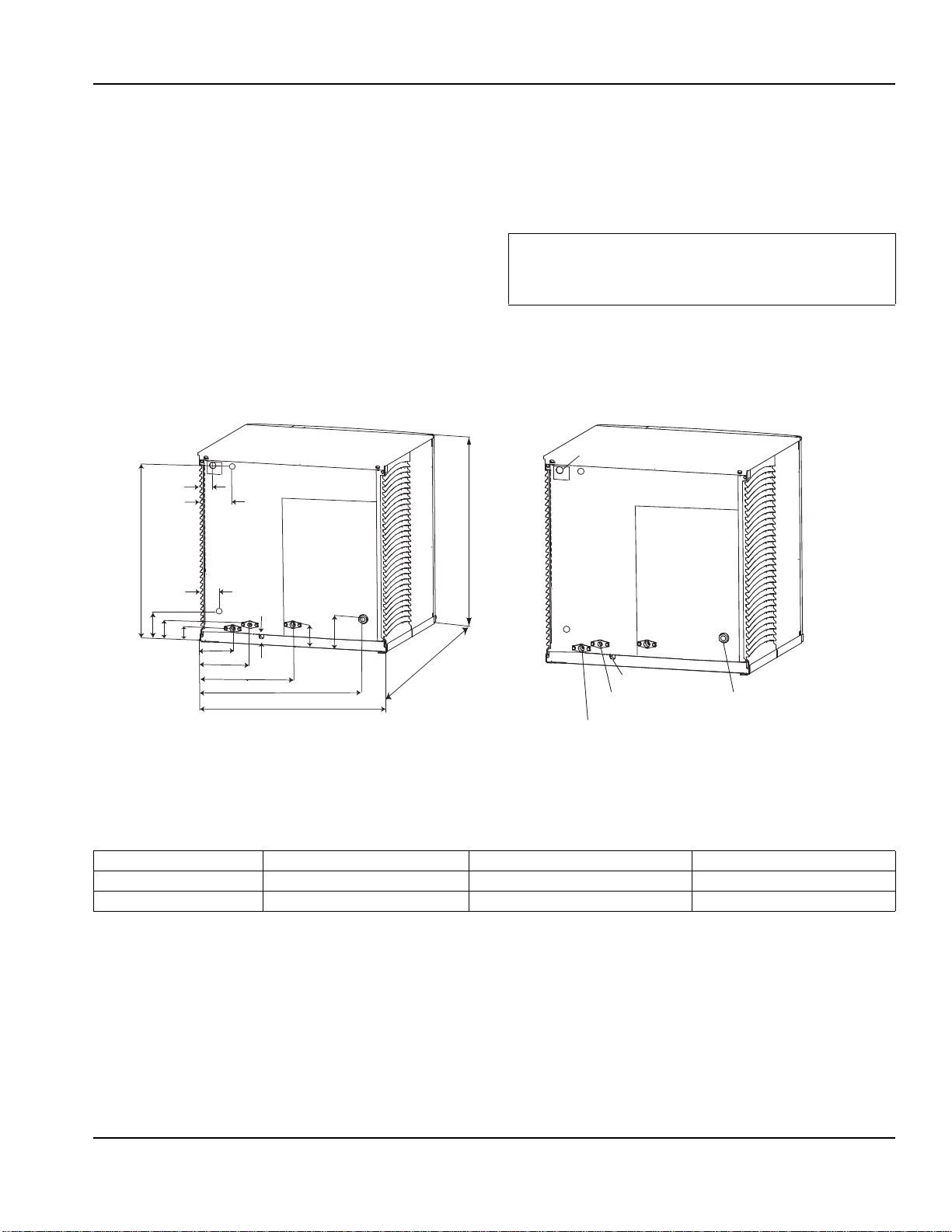

S320/S420 AIR AND WATER-COOLED ICE MACHINES

Failure to follow these installation guidelines may

affect warranty coverage.

ELECTRICAL

2.20" (5.58cm)

5.0" (12.7cm)

AUCS

ELECTRICAL

H

19.3"

(49.0 cm)

4" (10cm)

2.6"

(6.6cm)

1.8"

(4.6cm)

3.25" (8.3cm)

5.06" (12.85cm)

6.68" (16.96cm)

8.49" (21.56cm)

1.1" (2.6cm)

17.0" (43.2cm)

4.21" (10.69cm)

2.85" (7.30cm)

D

W

AUCS

TUBING &

MODULAR

WIRE

DRAIN 1/2"NPTF

CONDENSER WATER

OUTLET 1/2"FPT

(Water-Cooled Only)

AUXILLARY BASE DRAIN

1/2"CPVC SOCKET

WATER INLET

3/8"FPT

CONDENSER WATER

INLET 3/8"FPT

(Water-Cooled Only)

Ice Machine Dimension W Dimension D Dimensio n H

S320 22 in. (55.9 cm) 24.5 in. (62.2 cm) 21.5 in (54.6 cm)

S420 22 in. (55.9 cm) 24.5 in. (62.2 cm) 21.5 in (54.6 cm)

Part Number 000000966 10/09 2-1

Page 14

Installation Instructions Section 2

1.50" (3.81cm)

H

D

W

4.25" (10.81 cm)

17.25" (43.81 cm)

6.68" (16.96cm)

5.06" (12.85cm)

2.85" (7.30cm)

1.81"

(4.59cm)

2.61"

(6.62cm)

A

B

6.50" (16.5cm)

8.50" (21.60cm)

7.75" (19.7 cm)

1.50" (3.81cm)

H

D

W

16.0" (40.64cm)

11.50" (29.21cm)

6.68" (16.96cm)

5.06" (12.85cm)

6.25" (15.88cm)

1.81"

(4.59cm)

2.61"

(6.62cm)

A

B

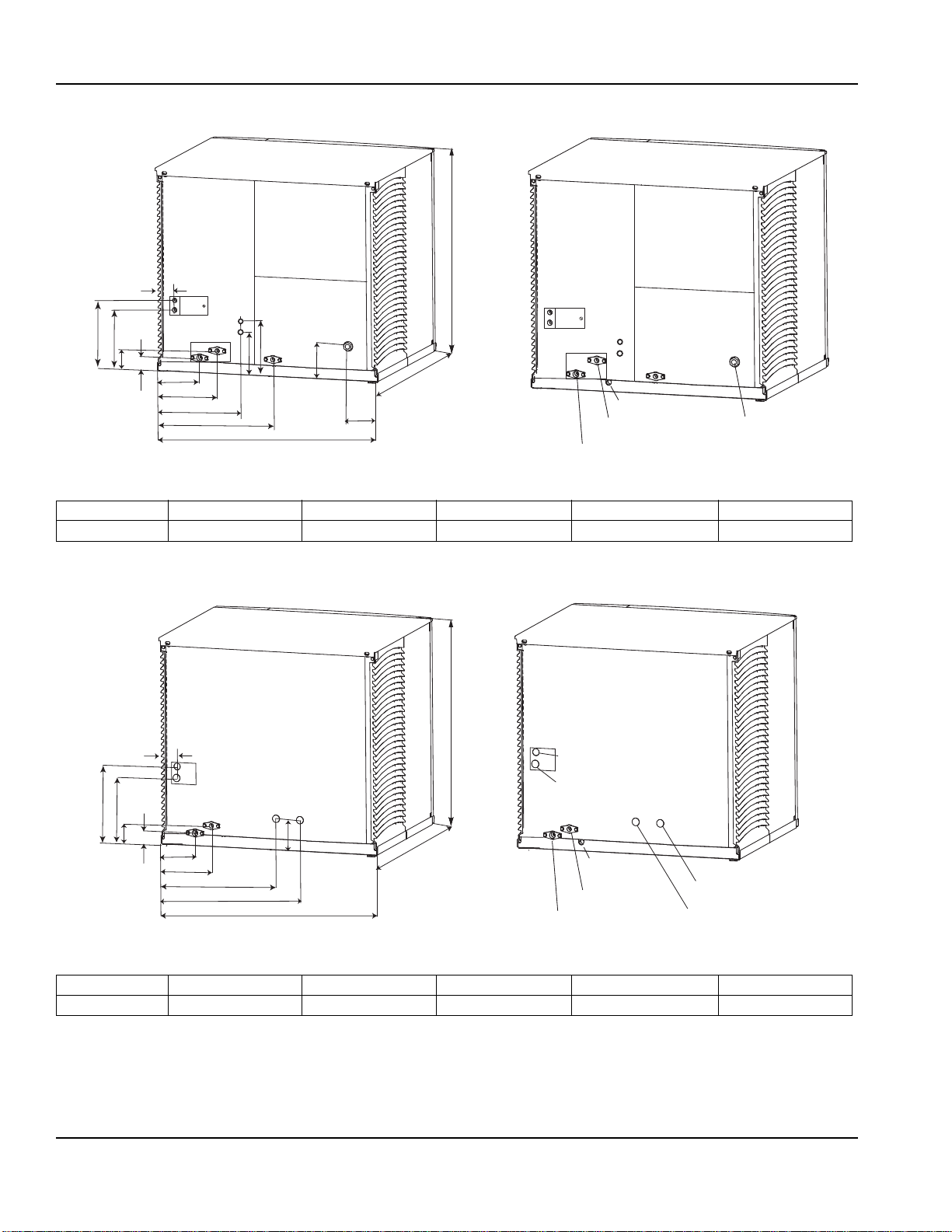

S600 AIR AND WATER-COOLED ICE MACHINES

ELECTRICAL

AUCS

CONNECTIONS

CONDENSER WATER

OUTLET 1/2"FPT

(Water-Cooled Only)

AUXILLARY BASE DRAIN

1/2"CPVC SOCKET

WATER INLET

3/8"FPT

DRAIN 1/2"NPTF

Ice Machine Dimension A Dimension B Dimension W Dimension D Dimension H

S600 11.5 in (29.2 cm) 9.0 in (22.9 cm) 30 in. (76.2 cm) 24.50 in. (62.2 cm) 21.5 in (54.6 cm)

CONDENSER WATER

INLET 3/8"FPT

(Water-Cooled Only)

S600 REMOTE ICE MACHINES

ELECTRICAL

REMOTE CONDENSER

ELECTRICAL

AUXILLARY BASE

DRAIN 1/2"CPVC

SOCKET

WATER INLET

3/8"FPT

DRAIN 1/2"NPTF

Ice Machine Dimension A Dimension B Dimension W Dimension D Dimension H

S600 11.5 in (29.2 cm) 9.0 in (22.9 cm) 30 in. (76.2 cm) 24.50 in. (62.2 cm) 21.5 in (54.6 cm)

REFRIGERANT

LIQUID LINE

REFRIGERANT

DISCHARGE LINE

2-2

Part Number 000000966 10/09

Page 15

Section 2 Installation Instructions

ELECTRICAL

DRAIN 1/2"NPTF

WATER INLET

3/8"FPT

CONDENSER WATER

OUTLET 1/2"FPT

(Water-Cooled Only)

CONDENSER WATER

INLET 3/8"FPT

(Water-Cooled Only)

AUXILLARY BASE

DRAIN 1/2"CPVC

SOCKET

AUCS

CONNECTIONS

2.20" (5.58cm)

H

D

W

25.52" (64.82cm)

8.49" (21.56cm)

6.68" (16.96cm)

5.06" (12.85cm)

1.06 (2.7cm)

2.85" (7.30cm)

4.21" (10.69cm)

1.81"

(4.59cm)

2.61"

(6.62cm)

A

B

C

E

F

SV3143

SV3143B

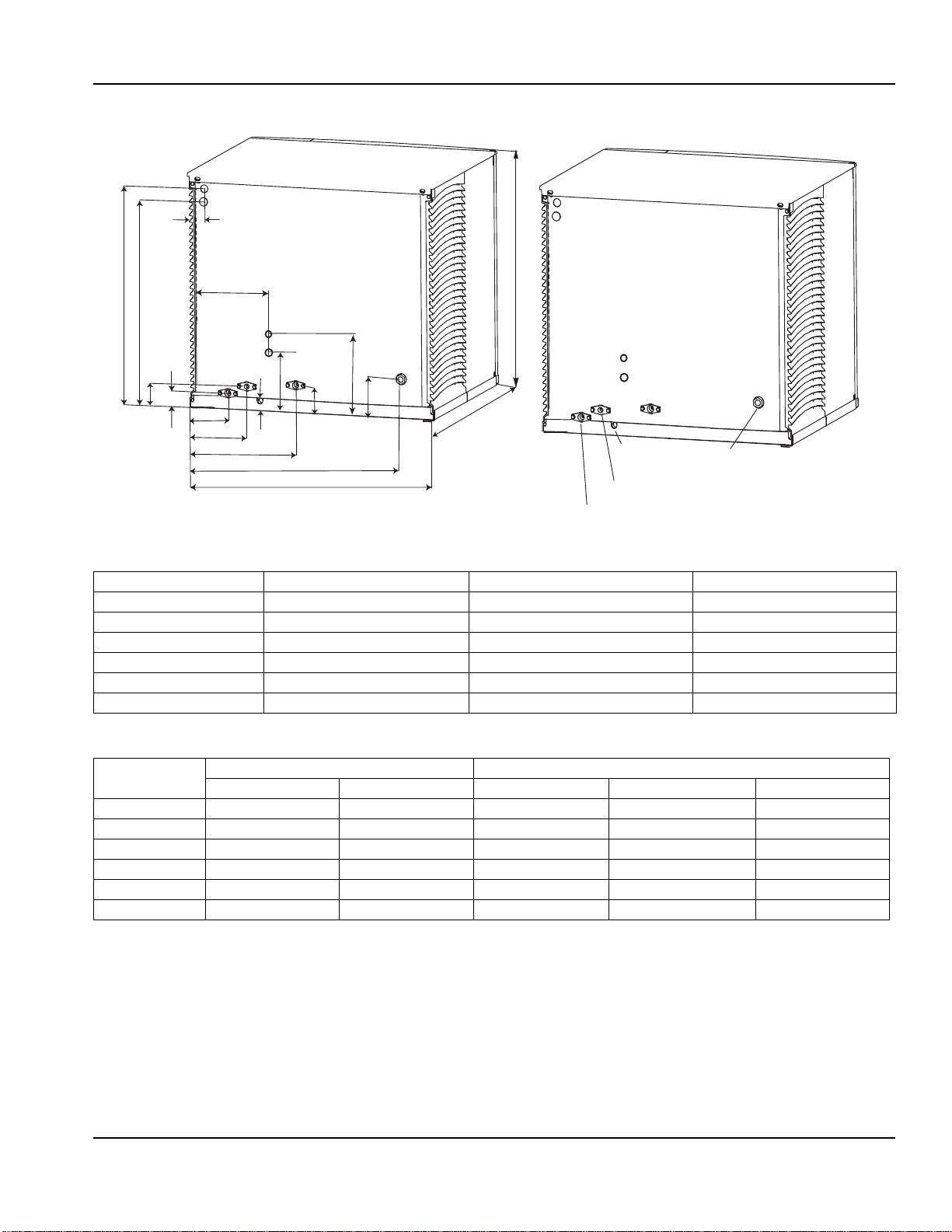

S300/S450/S500/S850/S1000/S1200 AIR AND WATER-COOLED ICE MACHINES

Width, Depth, and Height Dimensions

Ice Machine Dimension W Dimension D Dimension H

S300 30 in. (76.2 cm) 24.50 in. (62.2 cm) 16.5 in (41.9 cm)

S450 30 in. (76.2 cm) 24.50 in. (62.2 cm) 21.5 in (54.6 cm)

S500 30 in. (76.2 cm) 24.50 in. (62.2 cm) 21.5 in (54.6 cm)

S850 30 in. (76.2 cm) 24.50 in. (62.2 cm) 26.5 in (67.3 cm)

S1000 30 in. (76.2 cm) 24.50 in. (62.2 cm) 26.5 in (67.3 cm)

S1200 30 in. (76.2 cm) 24.50 in. (62.2 cm) 29.5 in (74.9cm)

Electrical and AuCS Dimensions

Ice Machine

Dimension A Dimension B Dimension C Dimension E Dimension F

S300 14.00 in (35.6 cm) NA 10.0 in (25.4 cm) 6.0 in (15.24 cm) 4.0 in (10.16 cm)

S450 19.25 in (48.9 cm) 17.5 in (44.45 cm) 8.5 in (21.6 cm) 8.5 in (21.6 cm) 6.5 in (16.5 cm)

S500 19.25 in (48.9 cm) 17.5 in (44.45 cm) 8.5 in (21.6 cm) 8.5 in (21.6 cm) 6.5 in (16.5 cm)

S850 23.82 in (60.5 cm) 22.32 in (56.69 cm) 8.5 in (21.6 cm) 8.5 in (21.6 cm) 6.5 in (16.5 cm)

S1000 23.82 in (60.5 cm) 22.32 in (56.69 cm) 8.5 in (21.6 cm) 8.5 in (21.6 cm) 6.5 in (16.5 cm)

S1200 27.0 in (68.6 cm) 25.25 in (54.1 cm) 8.5 in (21.6 cm) 8.5 in (21.6 cm) 6.5 in (16.5 cm)

Electrical AuCS

Part Number 000000966 10/09 2-3

Page 16

Installation Instructions Section 2

DRAIN 1/2"NPTF

WATER INLET

3/8"FPT

REFRIGERANT

LIQUID LINE

REFRIGERANT

DISCHARGE LINE

ELECTRICAL

REMOTE CONDENSER

ELECTRICAL

S500/S850/S1000 REMOTE ICE MACHINES

2.20" (5.58cm)

A

B

1.81"

(4.59cm)

1.06 (2.69cm)

6.12" (15.54cm)

H

2.61"

(6.62cm)

5.06" (12.85cm)

6.68" (16.96cm)

12.26" (42.27cm)

16.64" (64.82cm)

D

W

Ice Machine Dimension A Dimension B Dimension W Dimension D Dimension H

S300 14.00 i n (35.6 cm) NA 30 in. (76.2 cm) 24.50 in. (62.2 cm) 16.5 in (41.9 cm)

S450 19.25 i n (48.9 cm) 17.5 in (44.45 cm) 30 in. (76.2 cm) 24.50 in. (62.2 cm) 21.5 in (54.6 cm)

S500 19.25 i n (48.9 cm) 17.5 in (44.45 cm) 30 in. (76.2 cm) 24.50 in. (62.2 cm) 21.5 in (54.6 cm)

S850 23.82 i n (60.5 cm) 22.32 in (56.69 cm) 30 in. (76.2 cm) 24.50 in. (62.2 cm) 26.5 in (67.3 cm)

S1000 23.82 in (60.5 cm) 22.32 in (56.69 cm) 30 in. (76.2 cm) 24.50 in. (62.2 cm) 26.5 in (67.3 cm)

2-4

Part Number 000000966 10/09

Page 17

Section 2 Installation Instructions

2.50" (6.35cm)

H

D

W

11.0" (27.9cm)

10.25" (26.0cm)

2.0" (5.1cm)

5.75" (14.6cm)

4.0"

(10.2cm)

A

B

3.0" (7.6cm)

3.75" (9.5cm)

11.0" (27.9cm)

7.8" (19.8cm)

1.1" (2.8cm)

C

E

F

2.50" (6.35cm)

H

D

W

11.0" (27.9cm)

10.25" (26.0cm)

2.0" (5.1cm)

5.75" (14.6cm)

4.0"

(10.2cm)

A

B

3.0" (7.6cm)

3.75" (9.5cm)

11.0" (27.9cm)

7.8" (19.8cm)

1.1" (2.8cm)

C

E

F

8.0"

(20.3cm)

23.75" (60.3cm)

28.25" (71.8cm)

ELECTRICAL

CONDENSER WATER

OUTLET 1/2"FPT

(Water-Cooled Only)

DRAIN 1/2"NPTF

CONDENSER WATER

INLET 1/2"FPT

(Water-Cooled Only)

AUXILLARY BASE DRAIN

1/2"CPVC SOCKET

WATER INLET

3/8"FPT

AuCS

Connections

REFRIGERANT

LIQUID LINE

REFRIGERANT

DISCHARGE LINE

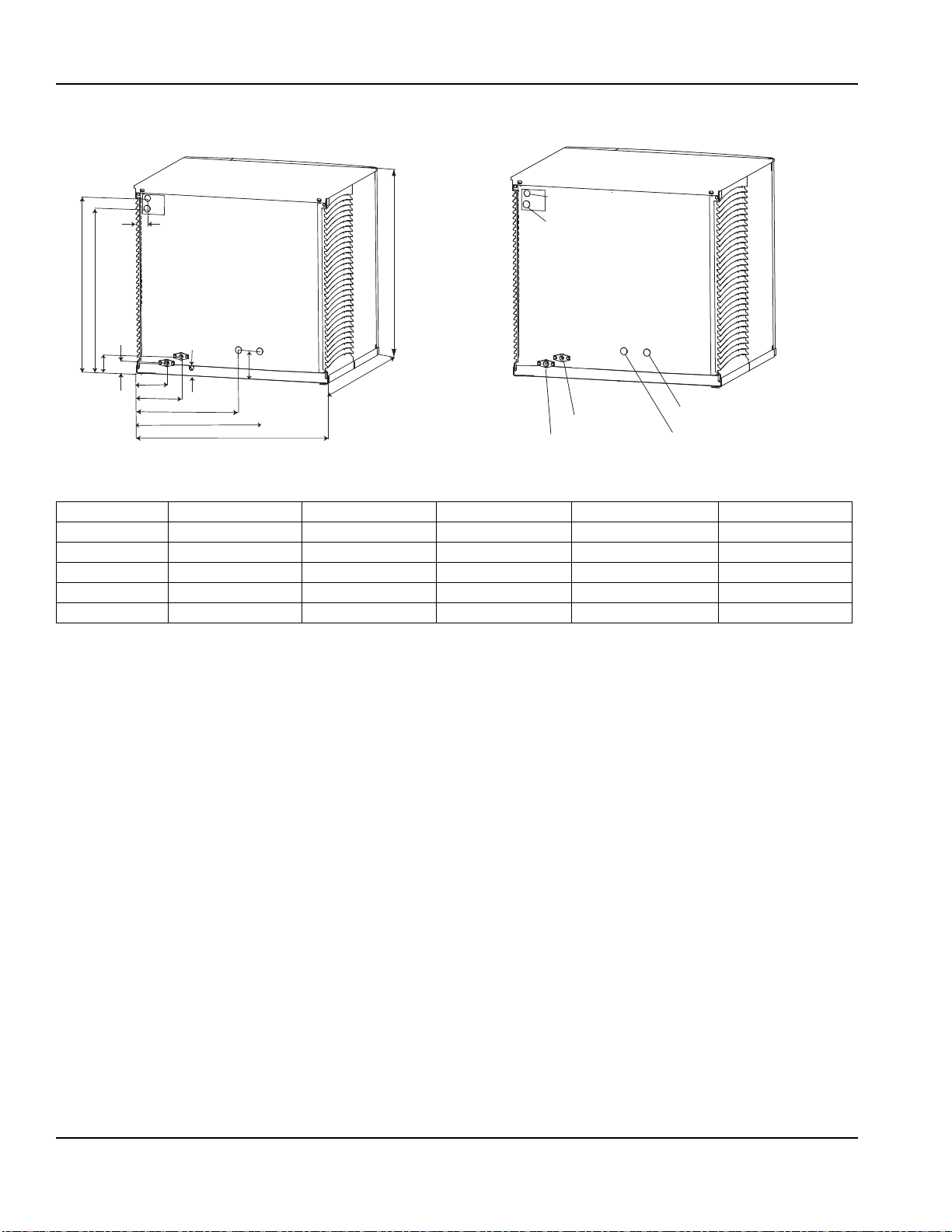

S1400 / S1600 / S1800 AIR AND WATER-COOLED ICE MACHINES

ELECTRICAL

CONDENSER WATER

OUTLET 1/2"FPT

(Water-Cooled Only)

CONDENSER WATER

INLET 1/2"FPT

(Water-Cooled Only)

WATER INLET

3/8"FPT

AUXILLARY BASE DRAIN

1/2"CPVC SOCKET

AuCS

Connections

DRAIN 1/2"NPTF

Width, Depth, and Height Dimensions

Ice Machine Dimension W Dimension D Dimension H

S1400 48 in. (121.9 cm) 24.5 in. (62.2 cm) 29.5 in (74.9 cm)

S1600 48 in. (121.9 cm) 24.5 in. (62.2 cm) 29.5 in (74.9 cm)

S1800 48 in. (121.9 cm) 24.5 in. (62.2 cm) 29.5 in (74.9 cm)

Electrical and AuCS Dimensions

Ice Machine

Dimension A Dimension B Dimension C Dimension E Dimension F

S1400 22.75 in (57.8 cm) 22.25 in (56.5 cm) 14.0 in (35.6 cm) 9.5 in (24.1 cm) 7.5 in (19.1 cm)

S1600 22.75 in (57.8 cm) 22.25 in (56.5 cm) 14.0 in (35.6 cm) 9.5 in (24.1 cm) 7.5 in (19.1 cm)

S1800 22.75 in (57.8 cm) 22.25 in (56.5 cm) 14.0 in (35.6 cm) 9.5 in (24.1 cm) 7.5 in (19.1 cm)

Electrical AuCS

S1400 / S1600 / S1800 REMOTE ICE MACHINES

Ice Machine Dimension A Dimension B Dimension W Dimension D Dimension H

S1400 22.75 in (57.8 cm) 22.25 in (56.5 cm) 48 in. (121.9 cm) 24.5 in. (62.2 cm) 29.5 in (74.9 cm)

S1600 22.75 in (57.8 cm) 22.25 in (56.5 cm) 48 in. (121.9 cm) 24.5 in. (62.2 cm) 29.5 in (74.9 cm)

S1800 22.75 in (57.8 cm) 22.25 in (56.5 cm) 48 in. (121.9 cm) 24.5 in. (62.2 cm) 29.5 in (74.9 cm)

Part Number 000000966 10/09 2-5

Page 18

Installation Instructions Section 2

ELECTRICAL

DRAIN 1"FPT

WATER INLET

1/2"FPT

CONDENSER WATER

OUTLET 1"FPT

(Water-Cooled Only)

CONDENSER WATER

INLET 1"FPT

(Water-Cooled Only)

BASE DRAIN

1"FPT

34.00

32.50

32.50

29.50

24.00

8.00

7.00

23.00

36.00

8.25

1.50

30.00

48.00

36.00

OPTIONAL

38.0” (96.5 CM)

34.0” (86.4 CM)

OPTIONAL

20.0” (50.8 CM)

16.0” (40.6 CM)

29.5”

(74.3 CM)

27.9”

(71.0 CM)

1.5”

(3.6 CM)

6.5”

(16.5 CM)

14.6”

(37.1 CM)

4.0”

(10.2 CM)

3.5”

(8.9 CM)

6.0”

(15.2 CM)

29.2”

(74.1 CM)

S3300 WATER-COOLED MODEL

Remote Condenser Dimensions

JC0495/JC0895/JC1395

2-6

Part Number 000000966 10/09

Page 19

Section 2 Installation Instructions

B970

Ice Storage Bin Dimensions

22 INCH (56 CM) ICE STORAGE BINS

Bin Model Dimension A Dimension B

B320 34.0 in (86.3 cm) 32.0 in (81.3 cm)

B420 34.0 in (86.3 cm) 44.0 in (111.7 cm)

30 INCH (76 CM) ICE STORAGE BINS

48 INCH (122 CM) ICE STORAGE BINS

Bin Model Dimension A Dimension B

B170 29.5 in (74.9 cm) 19.1 in (48.5 cm)

B400 34.0 in (86.3 cm) 32.0 in (81.3 cm)

B570 34.0 in (86.3 cm) 44.0 in (111.7 cm)

Part Number 000000966 10/09 2-7

Page 20

Installation Instructions Section 2

!

Warning

!

Caution

A

34” (86.4 cm)

25.25”

(64.1 cm)

6”

(15.2 cm)

B

43.6”

(110.81 cm)

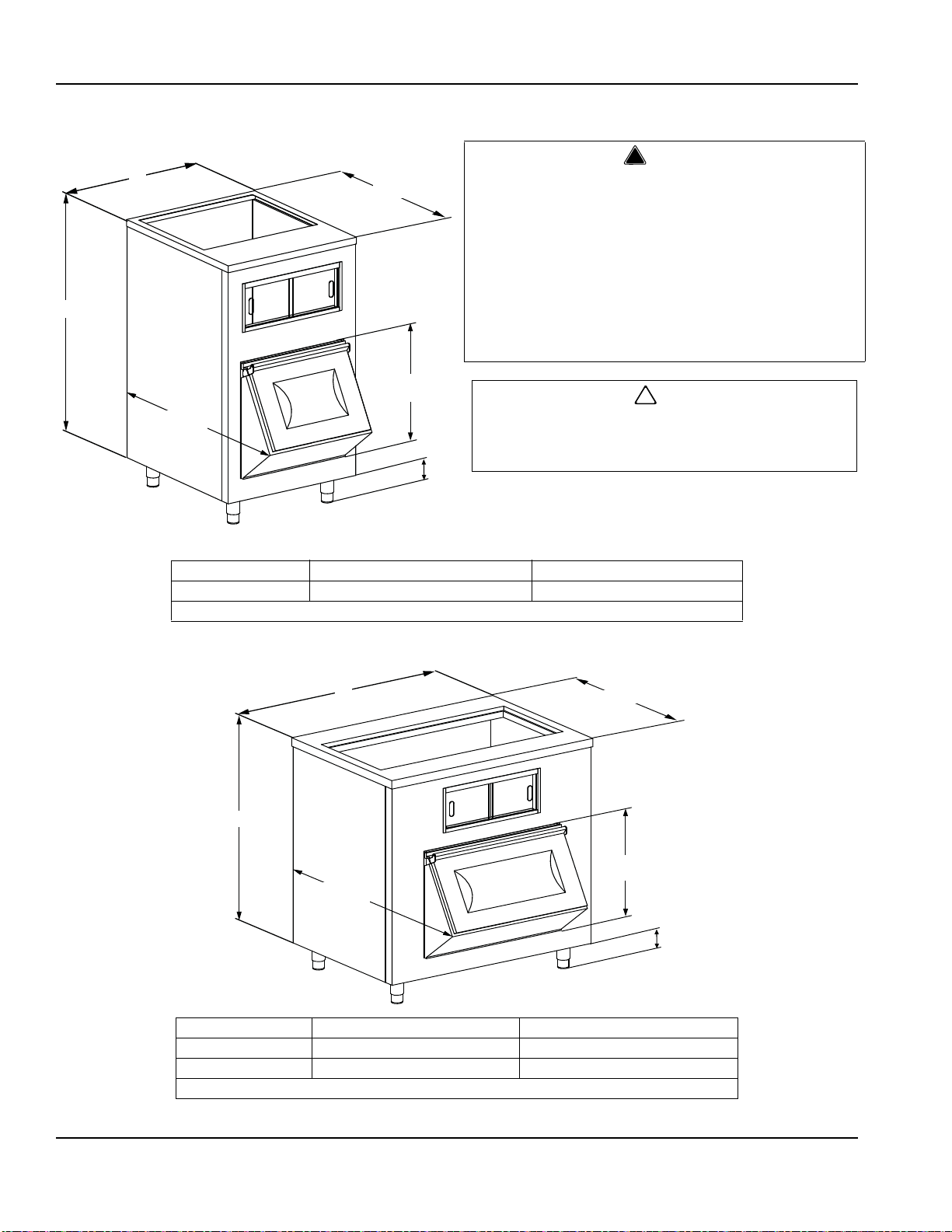

Large Capacity Ice Storage Bin Dimensions

30 INCH (76 CM)

A

34” (86.4 cm)

All Manitowoc ice machines require the ice storage

system (bin, dispenser, etc.) to incorporate an ice

deflector.

The S600, S850, S1000 ice machines re quire adding

Manitowoc Ice Deflector Kit K00347 when installing

with non-Manitowoc ice storage systems.

Prior to using a non-Manitowoc ice storage system

B

with other Manitowoc ice machines, contact the

manufacturer to assure their ice deflector is

compatible with Manitowoc ice machines.

25.25”

(64.1 cm)

43.6”

(110.81 cm)

30” large capacity ice storage bins must be

attached to the wall with the bracket provided with

the bin.

6”

(15.2 cm)

Bin Model Dimension A (Width) Dimension B (Height)

B750 30 in. (76.2 cm.) 58 in. (147.3 cm.)

The bin drain is exactly in the center of the bin.

48 INCH (122 CM) & 60 INCH (152 CM)

Bin Model Dimension A (Width) Dimension B (Height)

B1 100/B1100-00 48.0 in. (121.9 cm.) 55.0 in. (139.7 cm.)

B1400/B1400-00 60.0 in. (152.4 cm.) 55.0 in. (139.7 cm.)

The bin drain is exactly in the center of the bin.

2-8

Part Number 000000966 10/09

Page 21

Section 2 Installation Instructions

!

Caution

Location of Ice Machine

The location selected for the ice machine must meet the

following criteria. If any of these criteria are not met,

select another location.

• The location must be free of airborne and other

contaminants.

• The air temperature must be at least 35°F (1.6°C),

but must not exceed 110°F (43.4°C).

• Remote air cooled - The air temperature must be at

least -20°F (-29°C), but must not exceed 120°F

(49°C)

• The location must not be near heat-gen erating

equipment or in direct sunlight and must be protected

from weather.

• The location must not obstruct air flow through or

around the ice machine. Refer to the chart below for

clearance requirements.

S320/S450/S500/

S600/S850/S1000

Top/Sides 12" (30.5 cm) 8" (20.3 cm)

S1400/S1600/S1800

S300

Top/Sides 16" (40.6 cm) 8" (20.3 cm)

Back 5" (12.7 cm) 5" (12.7 cm)

Top/Sides 8" (20.3 cm) 8" (20.3 cm)

Back 5" (12.7 cm) 5" (12.7 cm)

S420

Back 5" (12.7 cm) 5" (12.7 cm)

S1200

Top 8" (20.3 cm) 8" (20.3 cm)

Sides 12" (30.5 cm) 8" (20.3 cm)

Back 5" (12.7 cm) 5" (12.7 cm)

Top/Sides 24" (61.0 cm) 8" (20.3 cm)

Back 12" (30.5 cm) 5" (12.7 cm)

Self-Contained

Air-Cooled

Self-Contained

Air-Cooled

Self-Contained

Air-Cooled

Self-Contained

Air-Cooled

Self-Contained

Air-Cooled

Self-Contained

Water-Cooled

Water-Cooled and

Remote*

Water-Cooled and

Remote*

Water-Cooled and

Remote*

Water-Cooled

and Remote*

The ice machine must be protected if it will be

subjected to temperatures below 32°F (0°C).

Failure caused by exposure to freezing

temperatures is not covered by the warranty. See

“Removal from Service/Winterization”.

Ice Machine Heat of Rejection

Series

Ice Machine

Air Conditioning

Heat of Rejection

S300 5000 6000

S320 3800 6000

S420 5900 6900

S450 5900 6900

S500 6100 6900

S600 9000 13900

S850 13000 16000

S1000 17700 21000

S1200 20700 24500

S1400 23500 27000

S1600 21000 31000

S1800 30000 35000

S3300 45000 51000

B.T.U./Hour

Because the heat of rejection varies during the ice making cycle,

the figure shown is an average.

Ice machines, like other refrigeration equipment, reject

heat through the condenser. It is helpful to know the

amount of heat rejected by the ice machine when sizing

air conditioning equipment where self -c on tained air cooled ice machines are installed.

This information is also necessary when evaluating the

benefits of using water-cooled or remote condensers to

reduce air conditioning loads. The amount of heat added

to an air conditioned environment by an ice machine

using a water-cooled or remote condenser is negligible.

Knowing the amount of heat rejected is also important

when sizing a cooling tower for a water-cooled

condenser. Use the peak figure for sizing the cooling

tower.

Peak

S3300** Water-Cooled

Top/Sides 8" (20.3 cm)

Back 24" (61.0 cm)

*There is no minimum clearance required for water-cooled or remote ice

machines. This value is recommended for efficient operation and servicing

only.

**S3300 - 24” on all sides is recommended to allow access without moving the

bin/ice machine.

Part Number 000000966 10/09 2-9

Page 22

Installation Instructions Section 2

!

Caution

THREAD LEVELING

LEG INTO BASE OF

CABINET

AIR

BAFFLE

SCREWS

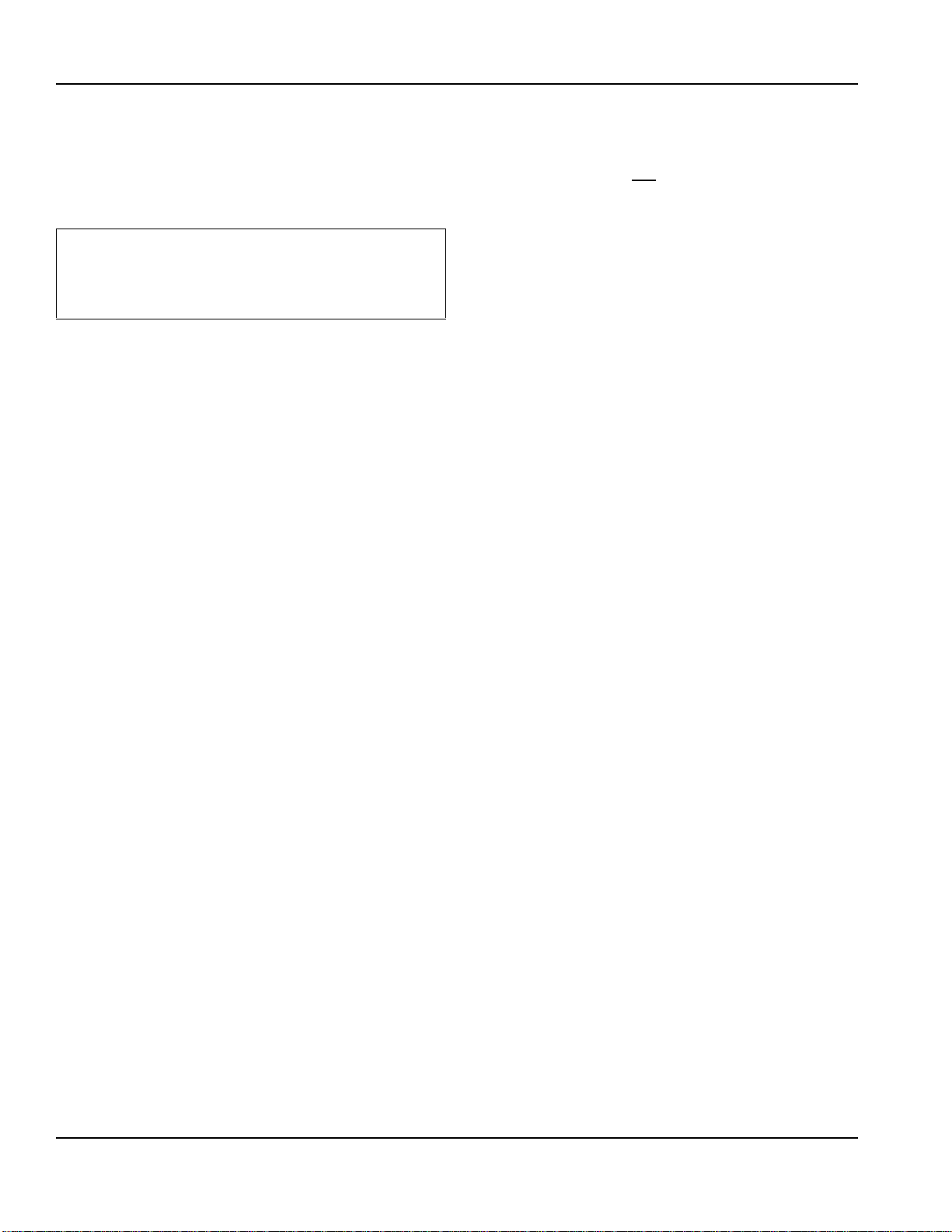

Removing Drain Plug and Leveling the Ice

Storage Bin

1. Remove threaded plug from drain fitting.

2. Screw the leveling legs onto the bottom of the bin.

3. Screw the foot of each leg in as far as possible.

The legs must be screwed in tightly to prevent them

from bending.

4. Move the bin into its final position.

5. Level the bin to assure that the bin door closes and

seals properly . Use a level on top of the bin. T urn the

base of each foot as necessary to level the bin.

6. Inspect bin gasket prior to ice machine installation.

(Manitowoc bins come with a closed cell foam

gasket installed along the top surface of the bin.)

7. Remove all panels from ice machine before lifting.

Remove both front panels, top cover, left and right

side panels.

8. Install ice machine on bin.

Air-Cooled Baffle

SELF-CONTAINED AIR-COOLED ONLY

The air-cooled baffle prevents condenser air from

recirculating. To install:

1. Remove the back panel screws next to the

condenser.

2. Align the mounting holes in the air baffle with the

screw holes and reinstall the screws.

2-10

Leveling Leg and Foot

Air Baffle

Part Number 000000966 10/09

Page 23

Section 2 Installation Instructions

!

Warning

!

Warning

Important

Electrical Service

GENERAL

All wiring must conform to local, state and national

codes.

VOLTAGE

The maximum allowable voltage variation is ±1 0% of the

rated voltage at ice machine start-up (when the electrical

load is highest).

The ice machine must be grounded in accordance

with national and local electrical codes.

All electrical work, including wire routing and grounding,

must conform to local, state and national electrical

codes. The following precautions must be observed:

• The ice machine must be grounded.

• A separate fuse/circuit breaker must be provided for

each ice machine.

• A qualified electrician must determine proper wire

size dependent upon location, materials used and

length of run (minimum circuit ampacity can be used

to help select the wire size).

• The maximum allowable voltage variation is +/-10 of

the rated voltage at ice machine start-up (when the

electrical load is highest).

• Check all gre en ground screws in the control box and

verify they are tight before starting the ice machine.

Observe correct polarity of incoming line voltage.

Incorrect polarity can lead to erratic ice machine

operation and a safety issue. This is especially critical o n

230 volt / 50 cycle ice machines.

Fuse/Circuit Breaker

A separate fuse/circuit breaker must be provided for

each ice machine. Circuit breakers must be H.A.C.R.

rated (does not apply in Canada).

MINIMUM CIRCUIT AMPACITY

The minimum circuit ampacity is used to help select the

wire size of the electrical supply. (Minimum circuit

ampacity is not the ice machine’s running amp load.)

The wire size (or gauge) is also dependent upon

location, materials used, length of run, etc., so it must be

determined by a qualified electrician.

ELECTRICAL REQUIREMENTS

Refer to Ice Machine Model/Serial Plate for voltage/

amperage specifications.

GROUND FAULT CIRCUIT INTERUPTER

Ground Fault Circuit Interupter (GFCI/GFI) protection is

a system that shuts down the electric circuit (opens it)

when it senses an unexpected loss of power,

presumably to ground. Manitowoc Ice does not

recommend the use of a GFCI/GFI circuit protection with

our equipment. If code requires the us e of a GF CI /G FI

then you must follow the local code. The circuit must be

dedicated, sized properly and there must be a panel

GFCI/GFI breaker. We do not recommend GFCI/GFI

outlets as they are known for more intermittent nuisance

trips than panel breakers.

MINIMUM POWER CORD SPECIFICATIONS

Maximum

Breaker Size

15 amp 14 gauge 6 feet (1.83 m)

20 amp 12 gauge 6 feet (1.83 m)

30 amp 10 gauge 6 feet (1.83 m)

40 amp 8 gauge 6 feet 1(.83 m)

If a power cord is used the wire size to the receptacle is

dependant upon location, materials used, length of run, etc., so

it must be determined by a qualified electrician. Local, state or

national requirements will supersede our minimum

requirements.

Part Number 000000966 10/09 2-11

Minimum

Wire Size

Maximum Length of

Power Cord

Page 24

Installation Instructions Section 2

Important

Important

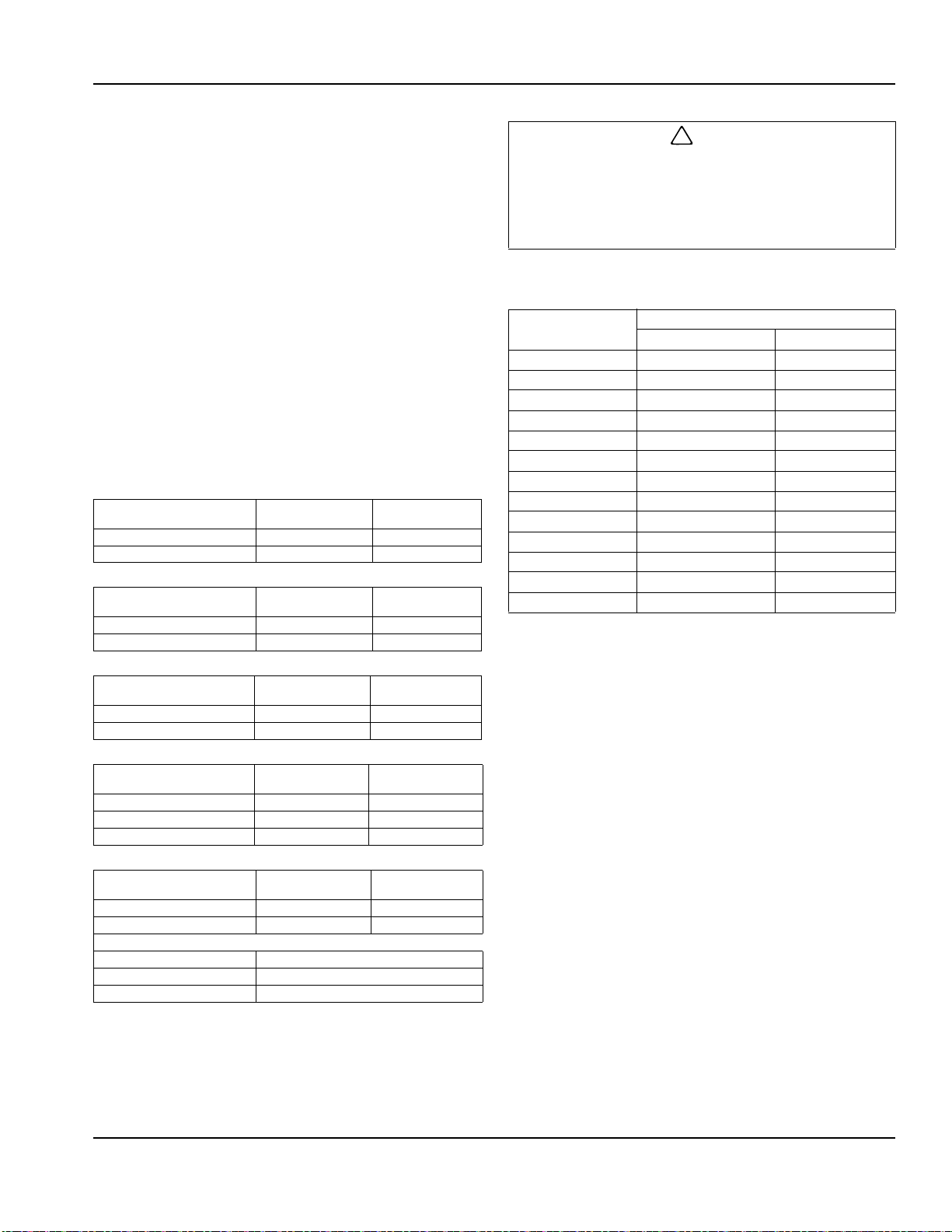

MAXIMUM BREAKER SIZE & MINIMUM CIRCUIT AMPERAGE CHART

Due to continuous improvements, this information is for reference only.

Please refer to the ice machine serial number tag to verify electrical data.

Serial tag information overrides information listed on this p age.

Air-Cooled Water Cooled Remote

Maximum

Breaker

Minimum

Circuit Amps

Ice Machine

Voltage

Phase

Cycle

Fuse/Circuit

115/1/60 25 15.6 25 14.8 N/A N/A

S300

230/1/50 15 7.4 15 6.9 N/A N/A

230/1/60 15 6.7 15 6.3 N/A N/A

115/1/60 15 11.3 15 10.5 N/A N/A

S320

208-230/1/60 15 6.0 15 5.6 N/A N/A

230/1/50 15 6.0 15 5.6 N/A N/A

115/1/60 20 14.2 20 13.5 N/A N/A

S420/S450

208-230/1/60 15 6.1 15 5.7 N/A N/A

230/1/50 15 7.1 15 6.8 N/A N/A

115/1/60 20 20.0 20 13.5 25 20.0

S500

208-230/1/60 15 6.1 15 5.7 15 8.3

230/1/50 15 7.1 15 6.8 15 6.7

S600

208-230/1/60 15 8.3 15 7.9 15 8.9

230/1/50 15 6.7 15 6.1 15 7.1

208-230/1/60 20 11.9 20 10.9 20 11.9

S850

208-230/3/60 15 9.2 15 8.2 15 9.2

230/1/50 20 10.8 20 9.4 15 10.4

S1000

S1200

208-230/1/60

208-230/3/60 15 10.6 15 9.6 15 10.6

230/1/50

460/3/60

208-230/1/60

208-230/3/60

230/1/50

30 17.3 30 16.3 25 15.7

20 12.7 20 11.3 20 12.3

N/A N/A 15 4.5 N/A N/A

35 25.0 35 25.0 N/A N/A

20 16.0 20 16.0 N/A N/A

30 20.0 30 20.0 N/A N/A

208-230/1/60 30 18.3 30 16.9 30 17.9

S1400

208-230/3/60 20 13.2 20 11.8 20 12.8

230/1/50 30 15.1 30 13.7 30 14.7

440-480/3/60 N/A N/A 15 6.4 N/A N/A

208-230/1/60 30 19.8 30 18.4 30 19.4

S1600

208-230/3/60 20 13.5 20 12.1 20 13.1

230/1/50 30 16.7 30 15.3 30 16.3

S1800

208-230/1/60

208-230/3/60

230/1/50

40 23.8 40 22.4 40 23.4

25 15.4 25 14.0 25 15.0

40 21.9 40 20.5 40 21.5

440-480/3/60 N/A N/A 15 6.5 N/A N/A

S3300

208-230/1/60

208-230/3/60

230/1/50 N/A N/A N/A N/A N/A N/A

440-480/3/60

N/A N/A N/A N/A N/A N/A

N/A N/A 30 30 N/A N/A

N/A N/A 15 9.9 N/A N/A

S3300 Only - Verify the direction of rotation correct is correct on

the 3ph scroll compressor. The ice machine will have high suction

pressure, low discharge pressure and will be noticeably loud.

Reverse any two incoming power leads to reverse rotation.

Maximum

Fuse/Circuit

Breaker

Minimum

Circuit Amps

Maximum

Fuse/Circuit

Breaker

Minimum

Circuit Amps

.

2-12

Part Number 000000966 10/09

Page 25

Section 2 Installation Instructions

!

Warning

L

1

L

1

N=115V

OR

L2=208-230V

GROUND

GROUND

ICE MACHINE

CONNECTIONS

TO SEPARATE

FUSE/BREAKER

L

1

L

1

GROUND

GROUND

ICE MACHINE

CONNECTIONS

TO SEP ARATE

FUSE/BREAKER

L

2

L

3

L

2

L

3

L

1

L

1

N

N

GROUND

GROUND

ICE MACHINE

CONNECTIONS

TO SEPARATE

FUSE/BREAKER.

DISCONNECT ALL

POLES.

Self-Contained Electrical Wiring Connections

SELF CONTAINED ICE MACHINE

These diagrams are not intended to show proper

wire routing, wire sizing, disconnects, etc., only the

correct wire connections.

All electrical work, including wire routing and

grounding, must conform to local, state and national

electrical codes.

Though wire nuts are shown in the drawin gs, th e ice

machine field wiring connections may use either

wire nuts or screw terminals.

SELF CONTAINED ICE MACHINE

115/1/60 OR 208-230/1/60

208-230/3/60 OR 440-480/3/60

SELF CONTAINED ICE MACHINE

230/1/50

For United Kingdom Only

As the colors of the wires in the mains lead of the appliance may not correspond with the colored markings

identifying the terminals in your plug, proceed as follows:

• The wire which is colored green and yellow

the letter E or by the earth ground symbol or colored green or green and yellow.

• The wire colored blue

• The wire colored brown

Part Number 000000966 10/09 2-13

must be connected to the terminal which is marked with the letter N or colored black.

must be connected to the terminal which is marked with the letter L or colored red.

must be connected to the terminal in the plug which is marked with

Page 26

Installation Instructions Section 2

!

Warning

Important

L

1

NOTE:

CONDENSER FAN

MOTOR VOL TAGE

MATCHES ICE

MACHINE

VOLTAGE (115V

OR 208-230V)

GROUND

SINGLE

CIRCUIT

REMOTE

CONDENSER

ICE

MACHINE

SV1255

L

2

L

1

L

2

GROUND

TO SEPARATE

FUSE/BREAKER

GROUND

L

1

L

2

F

2

F

1

N=115V OR L2=208-230V

GROUND

ICE

MACHINE

SV1199

L

3

L

1

L

2

GROUND

TO SEPARATE

FUSE/BREAKER

GROUND

L

3

L

1

L

2

F

2

F

1

NOTE: FAN

MOTOR IS

208-230V

L

1

L

2

SINGLE

CIRCUIT

REMOTE

CONDENSER

SINGLE CIRCUIT

REMOTE

CONDENSER

L

1

L

2

NOTE: FAN

MOTOR IS

220-240V

L

1

N

F

2

F

1

ICE

MACHINE

GROUND

L

1

N

GROUND

TO SEPARATE

FUSE/BREAKER

(220-240).

DISCONNECT ALL

POLES.

SV1256

Remote Electrical Wiring Connections

These diagrams are not intended to show proper

wire routing, wire sizing, disconnects, etc., only the

correct wire connections.

All electrical work, including wire routing and

grounding, must conform to local, state and national

electrical codes.

Though wire nuts are shown in the drawin gs, th e ice

machine field wiring connections may use either

wire nuts or screw terminals.

F2 wire is located in the compressor compartment

behind the control box. The wire is labeled F2 and

capped with a wire nut.

REMOTE ICE MACHINE

WITH SINGLE CIRCUIT MODEL CONDENSER

115/1/60 OR 208-230/1/60

REMOTE ICE MACHINE

WITH SINGLE CIRCUIT MODEL CONDENSER

208-230/3/60 OR 440-480/3/60

2-14

REMOTE ICE MACHINE

WITH SINGLE CIRCUIT MODEL CONDENSER

230/1/50

Part Number 000000966 10/09

Page 27

Section 2 Installation Instructions

Important

!

Caution

Water Supply and Drain Requirements

WATER SUPPLY

Local water conditions may require treatment of the

water to inhibit scale formation, filter sediment, and

remove chlorine odor and taste.

If you are installing a Manitowoc Arctic Pure water

filter system, refer to the Installation Instructions

supplied with the filter system for ice making water

inlet connections.

WATER INLET LINES

Follow these guidelines to install water inlet lines:

• Do not connect the ice machine to a hot water

supply. Be sure all hot water restrictors installed for

other equipment are working. (Check valves on sink

faucets, dishwashers, etc.)

• If water pressure exceeds the maximum

recommended pressure (80 psi), obtain a water

pressure regulator from your Manitowoc distributor.

• Contact your distributor if your water pressure is

greater than 150 psig (10.34 bar). A special order

condensing unit is available that allows water

pressure up to 350 psig (24.13 bar).

• Install a water shut-off valve for both the ice making

and condenser water lines.

• Insulate water inlet lines to prevent condensation.

Do not apply heat to water valve inlet fitting. This will

damage plastic water inlet connection.

DRAIN CONNECTIONS

Follow these guidelines when installing drain lines to

prevent drain water from flowing back into the ice

machine and storage bin:

• Drain lines must have a 1.5 inch drop per 5 feet of

run (2.5 cm per meter), and must not create traps.

• The floor drain must be large enough to

accommodate drainage from all drains.

• Run separate bin and ice machine drain lines.

Insulate them to prevent condensatio n.

• Vent the bin and ice machine drain to the

atmosphere. Do not vent the condenser drain on

water-cooled models.

• S3300 requires base drain connection (1” FPT).

Cooling Tower Applications

(Water-Cooled Models)

A water cooling tower installation does not require

modification of the ice machine. The water regulator

valve for the condenser continues to control the

refrigeration discharge pressure.

It is necessary to know the amount of heat rejectio n, and

the pressure drop through the condenser and water

valves (inlet and outlet) when using a cooling tower on

an ice machine.

• Water entering the condenser must not exceed

90°F (32.2°C).

• Water flow through the condenser must not exceed

5 gallons (19 liters) per minute.

• Allow for a pressure drop of 7 psi (0.5 bar) between

the condenser water inlet and the outlet of the ice

machine.

• Water exiting the condenser must not exceed

110°F (43.3°C).

S3300 CONDENSER WATER PRESSURE

Water pressure at the condenser cannot exceed 150

psig (10.34 bar) with the standard water-regulating

valve. Contact your distributor if your water pressure is

greater than 150 psig (10.34 bar). A special order

condensing unit is available that allows water pressure

up to 350 psig (24.13 bar).

IMPORTANT

The Commonwealth of Massachusetts requires that all

water-cooled models must be connected only to a closed

loop, cooling tower system.

Part Number 000000966 10/09 2-15

Page 28

Installation Instructions Section 2

!

Caution

ELECTRICAL ENTRANCE

18” (46 CM) VENT TUBE

AIR GAP

1/2” (1.3 CM) MIN

DRAIN ID

1/2” DRAIN CONNECTION

PLASTIC FITTING ON OPPOSITE

SIDE DO NOT APPLY HEAT

OPEN, TRAPPED AND

VENTED DRAIN

DO NOT TRAP DRAIN LINE,

LEAVE AIR GAP BETWEEN

DRAIN TUBE AND DRAIN

3/8” FPT ICE MAKING WATER INLET FITTING,

PLASTIC FITTING ON OPPOSITE SIDE DO NOT

APPLY HEAT

1/2” FPT CONDENSER WATER DRAIN

(WATER COOLED UNITS ONLY)

3/8” FPT CONDENSER WATER INLET

(WATER COOLED UNITS ONLY

1/2” CPVC SOCKET AUXILLARY BASE

DRAIN

WATER SUPPLY AND DRAIN LINE SIZING/CONNECTIONS

Plumbing must conform to state and local codes.

Location

Ice Making

Water Inlet

Ice Making

Water Drain

Condenser

Water Inlet

Condenser

Water Drain

Bin Drain

Large Capacity

Bin Drain

Refer to “Ice Machine Dimensions” at the beginning of Section 2 for the exact locations of inlets and drains for the model you are working on.

Water

Temperature

35°F (1.6°C) Min.

90°F (32.2°C) Max.

--- ---

90°F (32.2°C) Max.

--- ---

--- ---

--- ---

Water Pressure Ice Machine Fitting

20 psi (1.4 bar) Min.

80 psi (5.52 bar) Max.

Standard

20 psi (1.4 bar) Min.

150 psi (10.34 bar) Max.

High Pressure Option

20 psi (1.4 bar) Min.

350 psi (24.1 bar) Max.

3/8" Female Pipe Thread

1/2” FPT S3300 Only

1/2" Female Pipe Thread

1” FPT S3300 Only

1” FPT Base Drain S3300 Only

1” Female Pipe Thread S3300 Only

1/2" Female Pipe Thread

1” FPT S3300 Only

3/4" Female Pipe Thread 3/4" (1.91 cm) minimum inside

1” Male Pipe Thread

3/8" Female Pipe Thread

Tubing Size Up to Ice Machine

Fitting

3/8" (.95 cm) min inside diameter

1/2” (1.27 cm) S3300 Only

1/2" (1.27 cm) min inside diameter

1” (2.54 cm) S3300 Only

1/2" (1.27 cm) min inside diameter

1” (2.54 cm) S3300 Only

diameter

1” (2.54 mm) min. inside diameter

2-16

Typical Water Supply Drain Installation

Part Number 000000966 10/09

Page 29

Section 2 Installation Instructions

Important

!

Warning

!

Caution

Remote Condenser/Line Set Installation

Remote Single

Ice Machine

S500 JC0495

S600/S800/S1000 JC0895

S1400/S1600/

S1800

*Line Set Discharge Line Liquid Line

RT 1/2" (1.27 cm) 5/16" (.79 cm)

RL 1/2" (1.27 cm) 3/8" (.95 cm)

Air Temperature Around the Condenser

Minimum Maximum

-20°F (-29°C) 120°F (49°C)

Circuit

Condenser

JC1395

Line Set*

RT-20-R404A

RT-35-R404A

RT-50-R404A

RT-20-R404A

RT-35-R404A

RT-50-R404A

RL-20-R404A

RL-35-R404A

RL-50-R404A

REMOTE ICE MACHINES

REFRIGERANT CHARGE

Each remote ice machine ships from the factory with a

refrigerant charge appropriate for installation with line

sets of up to 50' (15.25 m). The serial tag on the ice

machine indicates the refrigerant charge.

Additional refrigerant may be required for installations

using line sets between 50' and 100’ (15.25-30.5 m)

long. If additional refrigerant is required, refer to the

chart below for the correct amount to be added.

IMPORTANT

EPA CERTIFIED TECHNICIANS

If remote line set length is between 50' and 100' (15.25-

30.5 m), add

Refer to the Installation Instructions in Installation Use and

Care Manual for the model being worked on.

Tubing length: ______________________________

Refrigerant added to nameplate: ________________

New total refrigerant charge: ___________________

additional refrigerant to the nameplate charge.

Typical Additional Refrigerant Label

Manitowoc remote systems are only approved and

warranted as a complete new package. Warranty on

the refrigeration system will be void if a new ice

machine head section is connected to pre-existing

(used) tubing or remote condensers.

Ice Machine

S500 6 lb. (96 oz.) 1.5 lb. (24 oz.) 7.5 lb. (120 oz.)

S600 6.5 lb.(104 oz) 1.5 lb. (24 oz.) 8 lb. (128 oz.)

S850 8.5 lb. (136 oz.) 2 lb. (32 oz.) 10.5 lb. (168 oz.)

S1000 8.5 lb. (136 oz.) 2 lb. (32 oz.) 10.5 lb. (1 68 oz.)

S1400 11 lb. (176 oz.) 2 lb. (32 oz.) 13 lb. (208 oz.)

S1600 11.5 lb (184 oz.) 2 lb. (32 oz.) 13.5 lb. (216 oz.)

S1800 12.5 lb. (200 oz.) 1 lb. (16 oz.) 13.5 lb. (216 oz.)

Nameplate Charge

(Charge Shipped in Ice Machine)

Potential Personal Injury Situation

The ice machine contains refrigerant charge.

Installation of the line sets must be performed by a

properly trained and EPA certified refrigeration

technician aware of the dangers of dealing with

refrigerant charged equipment.

Never add more than nameplate charge to the

refrigeration system for any application.

Refrigerant to be Added for

50'-100' Line Sets

Maximum System Charge

(Never Exceed)

Part Number 000000966 10/09 2-17

Page 30

Installation Instructions Section 2

!

Caution

1

2

3

1

2

3

DOWNWARD

HORIZONTAL

SPIRAL

GENERAL

Condensers must be mounted horizontally with the fan

motor on top with nothing obstructing it. There must be

at least a 16” clearance from the bottom for air intake.

The front coupling panel & one other panel (back or

side) must also be unobstructed.

Remote condenser installations consist of vertical and

horizontal line sets between the ice machine and the

condenser. When co mbined, they must fit within

approved specifications. The following guidelines,

drawings and calculation methods must be followed to

verify a proper remote condenser installation.

The 60 month compressor warranty (including the

36 month labor replacement warranty) will not apply

if the remote ice machine is not installed according

to specifications.

This warranty also will not apply if the refrigeration

system is modified with a condenser, heat reclaim

device, or other parts or assemblies not

manufactured by Manitowoc Ice unless specifically

approved in writing by Manitoc Ice.

2-18

Routing Line Sets

Part Number 000000966 10/09

Page 31

Section 2 Installation Instructions

!

Caution

H

R

Combination of a Rise and a

Horizontal Run

Combination of a Drop and a

Horizontal Run

Combination of a Rise, a Drop

and a Horizontal Run

SV1196 SV1195 SV1194

CALCULATING REMOTE CONDENSER

INSTALLATION DISTANCES

Line Set Length

The maximum length is 100' (30.5 m).

The ice machine compressor must have the proper oil

return. The receiver is designed to hold a char ge

sufficient to operate the ice machine in ambient

temperatures between -20°F (-29°C) and 120°F (49°C),

with line set lengths of up to 100' (30.5 m).

Line Set Rise/Drop

The maximum rise is 35' (10.7 m).

The maximum drop is 15' (4.5 m).

If a line set has a rise followed by a drop, another

rise cannot be made. Likewise, if a line set has a

drop followed by a rise, another drop cannot be

made.

Calculated Line Set Distance

The maximum calculated distance is 150' (45.7 m).

Line set rises, drops, horizontal ru ns (or combinations of

these) in excess of the stated maximums will exceed

compressor start-up and design limits. This will cause

poor oil return to the compressor.

Make the following calculations to make sure the line set

layout is within specifications.

1. Insert the measured rise into the formula below.

Multiply by 1.7 to get the calculated rise.

(Example: A condenser located 10 feet above the

ice machine has a calculated rise of 17 feet.00)

2. Insert the measured drop into the formula below.

Multiply by 6.6 to get the calculated drop.

(Example. A condenser located 10 feet below the

ice machine has a calculated drop of 66 feet.)

3. Insert the measured horizontal distance into the

formula below. No calculation is necessary.

4. Add together the calculated rise, calculated drop,

and horizont al distance to get the total calculated

distance. If this total exceeds 150' (45.7 m), move

the condenser to a new location and perform the

calculations again.

Maximum Line Set Distance Formula

Step 1. Measured Rise (35' [10.7 m] Maximum) ______ x 1.7 = _______ Calculated Rise

Step 2. Measured Drop (15' [4.5 m] Maximum) ______ x 6.6 = _______ Calculated Drop

Step 3. Measured Horizontal Distance (100' [30.5 m] Maximum) _______ Horizontal Distance

Step 4. T otal Calculated Distance 150' (45.7 m) _______ Total Calculated Distance

H

D

H

R

D

Part Number 000000966 10/09 2-19

Page 32

Installation Instructions Section 2

SV1603

REMOVE FRONT, TOP,

AND LEFT SIDE PANEL

FOR ACCESS TO

RECEIVER VALVE

TURN

COUNTERCLOCKWISE

TO OPEN

RECEIVER SERVICE

VALVE CAP (TURN

COUNTERCLOCKWISE

TO REMOVE)

LENGTHENING OR REDUCING LINE SET LENGTHS

In most cases, by routing the line set properly,

shortening will not be necessary. When shortening or

lengthening is required, do so before connecting the line

set to the ice machine or the remote condenser. This

prevents the loss of refrigerant in the ice machine or

condenser.

The quick connect fittings on the line sets are equipped

with Schraeder valves. Use these valves to recover any

vapor charge from the line set. When lengthening or

shortening lines follow good refrigeration practices,

purge with nitrogen and insulate all tubing. Do not

change the tube sizes. Evacuate the lines and place

about 5 oz (143g) of vapor refrigerant charge in each

line.

CONNECTING A LINE SET

1. Remove the dust caps from the line set, condenser

and ice machine.

2. Apply refrigeration oil to the threads on the quick

disconnect couplers before connecting them to the

condenser.

3. Carefully thread the female fitting to the condenser

or ice machine by hand.

4. Tighten the couplings with a wrench until they

bottom out.

REMOTE RECEIVER SERVICE VALVE

The receiver service valve is closed during shipment.

Open the valve prior to starting the ice machine.

1. Remove the top and left side panels.

2. Remove the receiver service valve cap.

3. Backseat (open) the valve.

4. Reinstall the cap and panels.

5. Turn an additional 1/4 turn to ensure proper brassto-brass seating. Torque to the following

specifications:

Liquid Line Discharge Line

10-12 ft lb.

(13.5-16.2 N•m)

35-45 ft lb.

(47.5-61.0 N•m)

6. Check all fittings and valve caps for leaks.

7. Make sure Schraeder cores are seated and

Schraeder caps are on and tight.

Backseating the Receiver Service Valve

2-20

Part Number 000000966 10/09

Page 33

Section 2 Installation Instructions

Important

!

Caution

!

Caution

Remote Ice Machine Usage with Non-Manitowoc Multi-Circuit Condensers

WARRANTY

The sixty (60) month compressor warranty, including

thirty six (36) month labor replacement warranty, shall

not apply when the remote ice machine is not installed

within the remote specifications. The foregoing warranty

shall not apply to any ice machine installed and/or

maintained inconsistent with the technical instructions

provided by Manitowoc Ice, Inc. Performance may vary

from Sales specifications. S-Model ARI certified

standard ratings only apply when used with a Manitowoc

remote condenser.

If the design of the condenser meets the specifications,

Manitowoc’s only

to be extended to the Manitowoc manufactured part of

the system. Since Manitowoc does not

condenser in conjunction with the ice machine,

Manitowoc will not endorse, recommend, or approve the