Page 1

647123EN (09/06/2016)

160 ATJ EURO 3

180 ATJ 2 EURO 3

REPAIR MANUAL

Page 2

2 647123EN

DATE OF ISSUE OBSERVATION

19 / 09 / 2012

19 / 03 / 2013

02 / 05 / 2013

19 / 11 / 2013

23 / 12 / 2015

31 / 05 / 2016

09 / 06 / 2016

1st PUBLICATION DATE

UPDATE ADDITION OF THE 180 ATJ 2 EURO 3

UPDATE ref. CP-NI 547>647, addition ref MR DANA axle som30, modication of

hydraulic diagram 70-02, addition of machine selection 80-04, modication speed

settings 80-04

UPDATE 1004 ENGINE VALUES, 2004 HYDRAULIC VALUES, 2006 HYDROSTATIC

ENGINE REMOVAL, 7002 HYDRAULIC DIAGRAM, 7004 HYDRAULIC VALUES, 80

01 LOCATION AND BUNDLES, 8002 ELECTRIC DIAGRAM, 8004 NEW UPC

UPDATE : Update electric localisation et electric diagrams

UPDATE : separation of V2 and V3 electrical diagrams

UPDATE : ELECTRICAL CONTROL AND ADJUSTMENT (ASSIST)

MANITOU BF S.A Limited liability company with a Board of Directors.

Head oce: 430, Rue de l’Aubinière - 44150 Ancenis - FRANCE

Share capital: 39,548,949 euros

857 802 508 RCS Nantes

Tel: +33 (0)2 40 09 10 11

www.manitou.com

This manual is for information purposes only. Any reproduction, copy, representation, recording, transfer, distribution, or other,

in part or in whole, in any format is prohibited. The plans, designs, views, commentaries and instructions, even the document

organization that are found in this document, are the intellectual property of MANITOU BF. Anyviolation of the aforementioned

may lead to civil and criminal prosecution. The logos as well as the visual identity of the company are the property of MANITOU-BF

and may not be used without express and formal authorization. All rights are reserved.

Page 3

M

(29/09/2011) 00-M173EN

(29/09/2011)00-M173EN

HOW TO USE THIS REPAIR MANUAL ?

647123EN

3

1

GENERAL, CHARACTERISTICS AND SAFETY

ENGINE

TRANSMISSION

AXLE

BRAKE

BOOM

HYDRAULIC

ELECTRIC

DRIVER’S CAB

FRAME - BODY

OPTIONS - ATTACHMENTS

00102030405070808590110

2

GENERAL, CHARACTERISTICS AND SAFETY

- GENERAL INSTRUCTIONS AND SAFETY NOTICE

00

3

GENERAL INSTRUCTIONS AND SAFETY NOTICE

PREAMBLE........................................................................2

MAINTENANCE POSITION .........................................................3

RULES FOR MAINTENANCE ........................................................4

pages

00

4

General instructions and safety

notice4

00

00

RULES FOR MAINTENANCE

Do not carry out any work on the machine unless you have followed

a suitable training course and have the knowledge required for it.

Make sure you have taken into consideration all the indicator plates

on the machine and in the instruction manual.

Be careful not to burn yourself when touching hot liquids or parts

when operations have to be done before the machine has had

time to cool down.

Before carrying out any operation on an electrically powered

1

component, activate the battery cut-o.

If the telehandler does not have a battery isolation device, disconnect

2

the battery connecters then re-assemble them.

Before carrying out any welding operations, think about

ECU

disconnecting computers.

A machine operating in a contaminated environment should be

specifically equipped. Moreover, local safety notices deal with

maintenance and repair work on such machines.

R

547982 : See the repair manual N° 547982.

70 - HYDRAULIC : See the group N° 70 called «Hydraulic».

Page 4

Page 5

GENERAL

ENGINE SPECIFICATION

TRANSMISSION

AXLE

BRAKE

00102030405570808590110

JIB - ACCESS PLATFORM

HYDRAULICS

ELECTRICITY

DRIVER'S CAB

FRAME - BODY

OPTIONS - ATTACHMENTS

Page 6

Page 7

GENERAL

GENERAL INSTRUCTIONS AND SAFETY

NOTICE

GENERAL CONTROL AND ADJUSTMENT

00

Page 8

Page 9

GENERAL INSTRUCTIONS AND SAFETY NOTICE

00

pages

GENERAL INSTRUCTIONS..........................................................2

SPARE PARTS .....................................................................3

TECHNICAL DOCUMENTATION.....................................................4

REPAIR PROCEDURES..............................................................5

HYDRAULICS......................................................................6

SYMBOLS .........................................................................7

SERVICING AND REPAIR EQUIPMENT...............................................8

(02/05/2013) 00-00-M193EN

Page 10

2

00

00

GENERAL INSTRUCTIONS AND SAFETY NOTICE

GENERAL INSTRUCTIONS

This chapter sets out the safety instructions to be followed when carrying out repairs on an access

platform.

Maintenance or repairs other than those detailed in part: 3 - MAINTENANCE OF THE OPERATOR’S MANUAL

for the platform, are to be carried out by qualied personnel (consult your dealer) and under optimum

safety conditions to maintain the health of the operator and of others, as well as to avoid damage to

the platform.

Insofar that the platform manufacturer does not directly control maintenance or repair operations,

theoperator and the manager in charge of the establishment shall be responsible for the safety of

these processes.

BEWARE OF LEAKS - Diesel fuel or hydraulic uid escaping under high pressure may pierce the

skin and cause serious injury. In the event of injury due to a pressurised liquid jet, immediately

b

consult a doctor.

FRONT and rear are indicated in the gures for ease of understanding.

For information:

PLATFORM TYPE FRONT REAR

ARTICULATED Counterweight Basket

SCISSOR Steering axle Steps

VERTICAL MAST Counterweight Basket

TRUCK-MOUNTED PLATFORM Driver's cab Basket

TELESCOPIC Basket extension Steps

As our policy is one of constant improvement of our products, our range of access platforms may undergo

certain modications, without obligation for us to advise our customers.

(02/05/2013)00-00-M193EN

Page 11

SPARE PARTS

Our platforms must be serviced using original MANITOU parts.

BY ALLOWING THE USE OF NON ORIGINAL MANITOU PARTS, YOU RISK:

- Legally, to be held responsible in the event of an accident.

- Technically, to cause operating malfunctions or shorten the life of the lift truck.

The use of counterfeit parts or components not approved by the manufacturer, will cause you to loose

the benet of the contractual guarantee. BY USING ORIGINAL MANITOU PARTS FOR MAINTENANCE

OPERATIONS:

YOU BENEFIT FROM OUR KNOW-HOW.

Through its network, MANITOU provides the user with:

GENERAL INSTRUCTIONS AND SAFETY NOTICE

3

00

00

- Know-how and competence.

- The guarantee of high-quality work.

- Original replacement parts.

- Help with preventive maintenance.

- Ecient diagnostic help.

- Improvements due to feedback.

- Operator training.

Only the MANITOU network has detailed knowledge of the design of the access platform and therefore

the best technical ability to provide maintenance.

FOR COMMERCIALLY-AVAILABLE COMPONENTS (CYLINDERS, ELECTRIC PUMP, SPEED CONTROLLER,

CHARGER, ENGINE, ETC.) AND DURING THE PLATFORM GUARANTEE PERIOD:

- Component removal ALLOWED

- Component removal FORMALLY FORBIDDEN AT THE RISK OF INVALIDATING THE GUARANTEE

Original replacement parts are distributed exclusively by MANITOU and its dealer network.

The dealer network list is available on the MANITOU web site: www.manitou.com.

(02/05/2013) 00-00-M193EN

Page 12

4

00

00

GENERAL INSTRUCTIONS AND SAFETY NOTICE

TECHNICAL DOCUMENTATION

READ and UNDERSTAND the contents of the OPERATOR’S MANUAL regarding the platform (this manual

must be stored in the black storage compartment located in the platform basket). COMPLY in particular

with the contents of Chapter 1 - OPERATING AND SAFETY INSTRUCTIONS as well as the sections marked

with a DANGER symbol.

READ and UNDERSTAND the operating and/or safety instructions given by the STICKERS applied to the

platform.

Before starting a procedure given in this REPAIR MANUAL, fully READ it and understand what you have

read.

(02/05/2013)00-00-M193EN

Page 13

REPAIR PROCEDURES

GENERAL:

POSITION the platform within a horizontal working area that is clean, cleared of any objects and mark

it out. If all of these conditions cannot be met (platform on site, in a cold store, etc.), chock the wheels,

mark the platform and familiarise yourself with the hazards associated with the environment.

SWITCH OFF THE PLATFORM by means of the battery cut-o before starting a procedure (unless otherwise

specied).

The procedure indicates when the weight of a component or an assembly of components exceeds 20kg,

requiring the use of HANDLING EQUIPMENT for removal, insofar as their characteristics (indicated on

the manufacturer's plates or the tare plates) are suitable for the operation to be performed.

For cleaning, use non-ammable solvents approved for that purpose.

GENERAL INSTRUCTIONS AND SAFETY NOTICE

5

00

00

When removing or retting a component, scrupulously follow the procedure step by step. Alwayscomplete

the current stage before commencing the next.

If resistance is felt when removing a component: STOP. Check that the nuts, screws and cables have

been removed and that there is no interference with adjoining components.

The most important factor in the preservation of the working life of the platform is to ensure that its

vital components are kept very clean.

When it is not specied, retting operations consist in performing the removal operations in reverse order.

MECHANICAL COMPONENTS:

Use screws having identical characteristics to the original screws and of an appropriate length.

Insofar that the procedures do not specify the values of the tightening torques to be applied to threaded

fasteners, the appropriate standard values must be used to suit the characteristics of these fasteners.

(02/05/2013) 00-00-M193EN

Page 14

6

00

00

GENERAL INSTRUCTIONS AND SAFETY NOTICE

HYDRAULICS

Certain hydraulic lines ARE UNDER VERY HIGH PRESSURE, even when the platform is not operating.

Inorder to avoid any accidents:

- Follow the hydraulic line decompression procedure before servicing or repairing one of their components.

Certain cylinders are tted with valves that are used to secure the platform the moment the movements

are stopped, by maintaining hydraulic pressure in the chambers of the cylinder. As a result, a chambers of

a cylinder that has been removed might be under VERY HIGH PRESSURE (in excess of 100 bar, inparticular

in the case of the tilt compensation circuit). You should:

- Perform the operations for decompressing the cylinder to be removed.

- Eliminate any pressure from the chambers of a cylinder before it is removed.

Prior to working on a hydraulic component, clean the area immediately around it, provide containers

or rags to recover any uid leakage during removal. Also provide caps and covers to plug openings and

prevent the contamination of the circuit.

Covers, hatches, seals and lters are provided to ensure the purity of the hydraulic uid and prevent

contamination of the circuit. These parts therefore require to be periodically:

- Checked for damage.

- Kept clean.

A cloudy uid indicates a high moisture content, which will lead to oxidation / corrosion of the circuit's

metal components: drain and clean the whole of the circuit, then rell with fresh hydraulic uid.

Should the circuit prove to be contaminated with foreign matter (metal, rubber, etc.), drain and clean

the whole of the circuit then ll with fresh hydraulic uid.

It is not recommended to mix hydraulic uids of dierent types or makes insofar that they cannot be

guaranteed to be of similar composition or viscosity.

Refer to Chapter 3 - MAINTENANCE of the OPERATOR’S MANUAL to select the appropriate oil for the use

of the platform.

(02/05/2013)00-00-M193EN

Page 15

SYMBOLS

GENERAL:

GENERAL HAZARD The associated text must be READ and UNDERSTOOD

ELECTRICAL HAZARD The associated text must be READ and UNDERSTOOD

HIGH TEMPERATURE HAZARD The associated text must be READ and UNDERSTOOD

GENERAL INSTRUCTIONS AND SAFETY NOTICE

before continuing to the next stage of the procedure.

before continuing to the next stage of the procedure.

before continuing to the next stage of the procedure.

7

00

00

HYDRAULIC PRESSURE HAZARD The associated text must be READ and UNDERSTOOD

before continuing to the next stage of the procedure.

MINIMUM WEIGHT Indicated in removal procedures, this sign enables

the selection of the appropriate handling equipment.

647400EN Refer to Operator’s Manual no. 647400EN.

647400 Refer to spare parts catalogue no. 647400.

80-08-M.193EN Refer to Chapter no. 80-08-M.193EN of the current repair manual.

§ B - 1 Refer to paragraph B - 1 of the current chapter.

(A1-1) (Figure A1 - Item 1)

Indicates attachment points or bearing surfaces (for lift truck forks) to be used

during removal operations.

(02/05/2013) 00-00-M193EN

Page 16

8

00

00

GENERAL INSTRUCTIONS AND SAFETY NOTICE

SERVICING AND REPAIR EQUIPMENT

- Tool box.

- MANITOU hydraulic kit: Part no. to be selected from catalogue 647400.

- Male and female plug adapters for plugging hydraulic hoses and couplers.

- Calibrator: Part no. according to platform type, see the relevant chapter.

- Multimeter.

(02/05/2013)00-00-M193EN

Page 17

GENERAL CONTROL AND ADJUSTMENT

00

pages

STANDARD TIGHTENING TORQUES.................................................2

(16/04/2012) 00-04-M193EN

Page 18

2

00

00

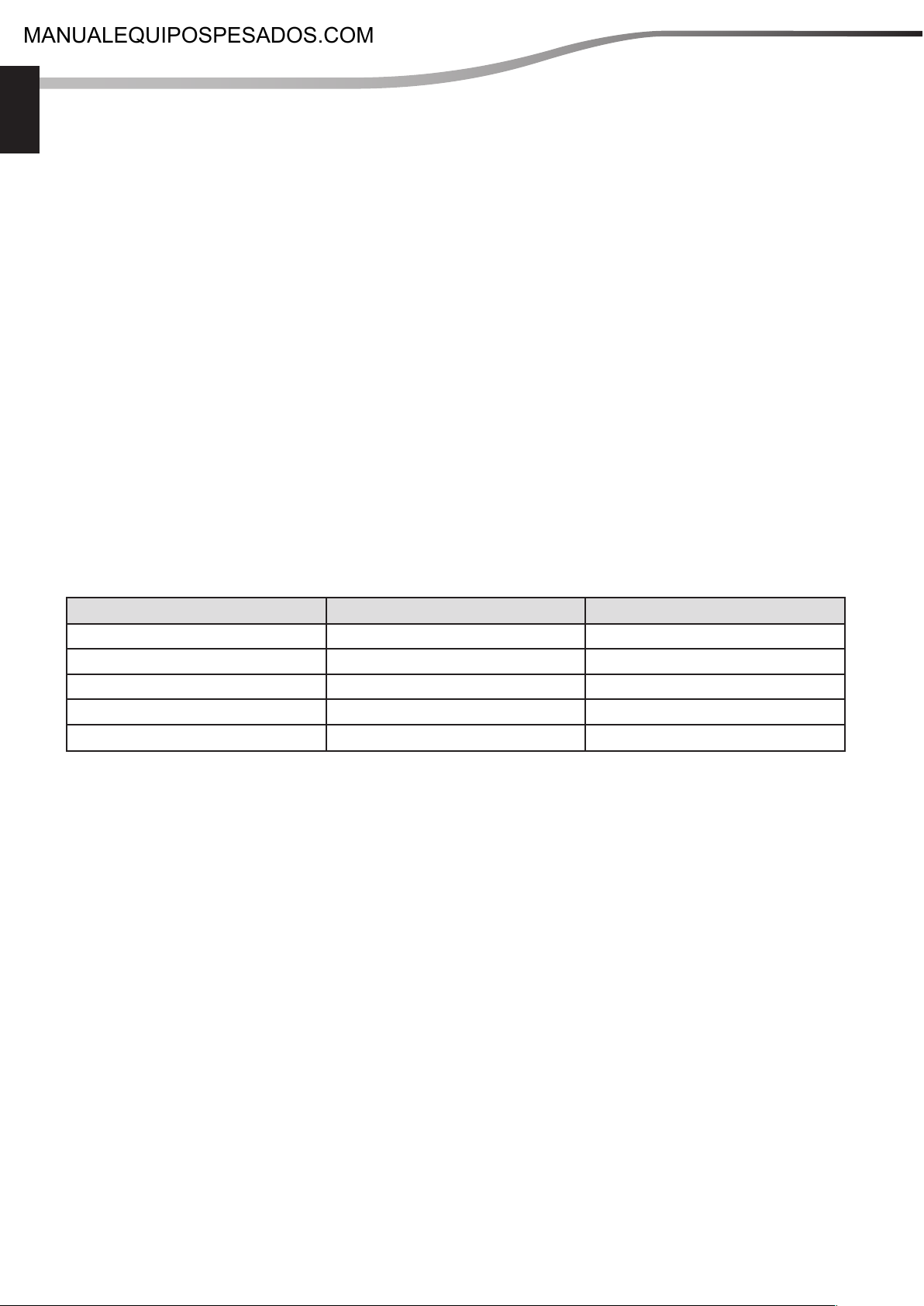

GENERAL CONTROL AND ADJUSTMENT

STANDARD TIGHTENING TORQUES

Standard tightening torque to be used when not otherwise indicated in the removal and refitting

operations:

- The following tightening torques are given for hexagon head screws without flanges and

cylinder head hexagon socket screws.

- The torques are given for a friction coecient μ = 0,20 corresponding to dry-tted zinc-plated

fasteners and for torque tools having a ± 20% class C tightening torque accuracy (equivalent

to pneumatic screwdrivers).

NF E25-030-1 Screw / Nut connection:

Tightening torque in N.m (±20%)

Ø x "coarse" pitch Grade 8.8 Grade 10.9 Ø x “ne” pitch Grade 8.8 Grade 10.9

M3 x 0,5 1 1,5 - - -

M4 x 0,7 2,4 3,5 - - -

M5 x 0,8 4,8 7,1 - - -

M6 x 1 8,2 12,1 - - -

M8 x 1,25 20 30 M8 x 1 22 32

M10 x 1,5 40 59

M12 x 1,75 69 102

M14 x 2 111 163 M14 x 1,5 123 181

M16 x 2 175 256 M16 x 1,5 190 279

M18 x 2,5 240 352 M18 x 1,5 279 410

M20 x 2,5 341 501 M20 x 1,5 391 574

M22 x 2,5 470 691 M22 x 1,5 531 780

M24 x 3 588 864 M24 x 2 659 967

M27 x 3 874 1284 M27 x 2 965 1418

M30 x 3,5 1181 1735 M30 x 2 1351 1984

M33 x 3,5 1614 2371 M33 x 2 1821 2674

M36 x 4 2068 3037 - - -

M10 x 1,25 43 63

M10 x 1 46 68

M12 x 1,5 74 108

M12 x 1,25 78 115

For hexagon screws with anges:

Apply a torque of accuracy + 10%.

b

(16/04/2012)00-04-M193EN

Page 19

ENGINE

- ENGINE COMPONENTS LOCATION

- ENGINE CONTROL AND ADJUSTMENT

- ENGINE REMOVAL

10

- ENGINE CHARACTERISTICS AND

SPECIFICATIONS

- ENGINE IDENTIFICATION

- INSPECTION & MAINTENANCE

- SPECIFIC TOOLING

M

R

(KUBOTA V1505 ENGINE)

647124EN

Page 20

Page 21

ENGINE COMPONENTS LOCATION

10

pages

ENGINE ...........................................................................2

(22/02/2013) 10-03-M193EN

Page 22

2

ENGINE COMPONENTS LOCATION

ENGINE

10

Starter

Air lter

Engine accelerator block

Radiator

Alternator

Exhaust

Starter

Oil lter

Alternator

Fuel lter

Thermostat

Belt

Injection pump

Fuel pump

Accelerator

(22/02/2013)10-03-M193EN

Page 23

ENGINE CONTROL AND ADJUSTMENT

10

pages

PROPORTIONAL ENGINE SPEED BLOCK REMOVAL ..................................2

PROPORTIONAL ENGINE SPEED BLOCK ADJUSTMENT ..............................4

(02/10/2013) 10-04-M193EN

Page 24

2

ENGINE CONTROL AND ADJUSTMENT

10

FRONT

FRONT

A

PROPORTIONAL ENGINE SPEED BLOCK REMOVAL

1

B

2

3

1

From the base console, raise arms 1/2 until the upper hinge

(A-1) is one meter above the counterweight.

Climb onto the frame, remove the lock nut, manually raise the

maintenance support arm (B-2) and place the strut (B-3).

From the base console, lower arms 1-2 until the upper hinge

(B-1) comes into contact with the maintenance support arm,

then release the controls.

Switch o the engine.

FRONT

1

FRONT

C

D

1

Remove the battery cover (C-1).

Remove the engine inspection cover (D-1).

(02/10/2013)10-04-M193EN

Page 25

ENGINE CONTROL AND ADJUSTMENT

3

E

Locate the proportional engine speed block (E-1) on the right-hand

side of the engine.

3

1

Disconnect the power supply harness from the accelerator (E-2).

10

2

F

3

4

1

2

5

6

Disconnect the two hydraulic hoses (F-1) and (F-2) an mark

them for easy ret.

Place the plugs on the hoses.

Remove the accelerator cable (E-3) by removing its pin.

Remove the return spring (F-3).

G

1

2

H

Remove the link rod by undoing the two screws (G-1) and (G-2).

Remove the connecting rods (H-1) and (H-2) with a pin drift.

Remove the proportional engine speed block by undoing the

three fastening screws (F-4), (F-5) and (F-6).

PROPORTIONAL ENGINE SPEED BLOCK REFIT

2

1

Perform the removal operations described above in reverse order

then check the proportional engine speed block adjustment

setting.

(02/10/2013) 10-04-M193EN

Page 26

4

ENGINE CONTROL AND ADJUSTMENT

10

I

PROPORTIONAL ENGINE SPEED BLOCK ADJUSTMENT

1

Check the tension of the accelerator cable (I-1). Adjust if necessary

with the adjustment screw located on the proportional engine

speed block.

Turn the block so that the accelerator cable (I-1) is slightly

tensioned by moving the block in the direction of the arrow (J).

Start the access platform and check that the engine speed is

at 1000 ± 50 rpm.

J

If not, turn the proportional engine speed block until the desired

value is reached.

Set the dierent engine speed thresholds in accordance with

the procedure described below.

This procedure is to be performed only on a "hot" machine,

withthe hydraulic uid at a temperature exceeding 40°C.

A tolerance of ± 50 rpm. shall apply to each threshold.

Press the Menu key (K-4), position yourself over the padlock

K

B2

1

2

3

4

5

L

B2

1

using the </> keys (K-1) then press OK (K-3).

Enter the code "****" using the +/- keys (K-2), and confirm

bypressing OK after each number.

Go to the "Calibration" icon (L-1) using the arrow keys.

Select the "Calibration accél. Moteur" (Engine accel. Calibration)

group with the +/- keys (K-2) then conrm.

Check the cable tension by setting the max. engine speed to 3050 rpm.

If threshold 5 cannot be set, check and modify the accelerator

cable tension.

Next set the values of each threshold to obtain the desired

results to within +/- 20 rpm.

Between each threshold, press OK to cut-o acceleration then

press OK again to initialize.

When calibration is completed, leave the "Calibration accél.

Moteur" (Engine accel. Calibration) menu by pressing Exit (K-5).

Enter the "Sauvegarde des paramètres" (Save parameters) menu

to record the values.

(02/10/2013)10-04-M193EN

Page 27

GENERATOR BLOCK

2

3

P

HYDRAULIC CHARACTERISTICS AND

SPECIFICATIONS

Values present (as an indication)

ROLE :

– Run the generator

– Cut the pressure according to the electrical

instructions.

1

LEGEND :

1 - NC proportional hydraulic slide valve

2 - HP restrictor

1

1

3

2

200 b

240 b

P

2

2

T

70

2

2

Note :

(18/04/2014) F70-3-0072EN

Page 28

2

HYDRAULIC CHARACTERISTICS AND

SPECIFICATIONS

Values present (as an indication)

70

(18/04/2014)F70-3-0072EN

Page 29

VARIABLE CAPACITY PUMP A10VG

HYDRAULIC CHARACTERISTICS AND

SPECIFICATIONS

Values present (as an indication)

ROLE :

– Enables the machine to translate

(forward / reverse movement)

1

LEGEND :

1 - Proportional distributor (Forward / reverse

movement)

2 - DR valve

3 - HP valve

4 - Force-feed pressure restrictor

5 - Servo-control piston

1

b

T

1

a

5

1

45cm3

365 b

365 b

26 b

70

S

P

G

Fe

BM

8,4cm3

2

A

2

1

X

3

2

X

3

G

4

AM

S

Note :

(02/05/2013) F70-3-0073EN

B

Page 30

2

HYDRAULIC CHARACTERISTICS AND

SPECIFICATIONS

Values present (as an indication)

2

70

1

3

4

5

3

(02/05/2013)F70-3-0073EN

Page 31

ELECTRICAL SPECIFIC TOOLING

pages

KIT BOITIERS ÉCLATEURS ..........................................................2

ADAPTATION SOLÉNOÏDE .........................................................2

80

(13/01/2016) 80-09-M193EN

Page 32

2

ELECTRICAL SPECIFIC TOOLING

BREAKOUT BOX KIT

Breakout box (DT connectors)

Breakout box (DTM connectors)

Breakout box kit ..........................................................785503

Consisting of:

1. 1 breakout box (DT connectors).................................... 785504

2. 1 breakout box (DTM connectors)..................................785505

80

ELECTROVALVE ADAPTER

Electrovalve adapter ......................................................662196

(13/01/2016)80-09-M193EN

Loading...

Loading...