Page 1

ACCESS PLATFORM

120 AETJ L

150 AETJ C

150 AETJ L

170 AETJ L

547378 EN (01 / 06 / 2006)

BP 249 Z. I.

44158 ANCENIS CEDEX - FRANCE

TEL : 33 (0)2 40 09 10 11

YOUR DEALER

OPERATOR’S MANUAL

THIS INSTRUCTION LEAFLET MUST BE KEPT PERMANENTLY ON THE ACCESS PLATFORM AND BE READ AND

UNDERSTOOD BY THE OPERATORS.

Page 2

PREAMBLE

This instructions manual is designed to

explain how to operate the machine and the maintenance required periodically for the machine to continue to

operate in complete safety.

The platform has been designed and produced to enable you to work at high level in complete

safety.

Before its delivery, MANITOU and the

concessionaire have carefully inspected the platform so

that you receive it in perfect operating condition.

Page 3

THE TEXTS AND ILLUSTRATIONS IN THIS DOCUMENT MUST NOT BE REPRODUCED EITHER WHOLLY OR IN PART.

1 - OPERATING AND SAFETY INSTRUCTIONS

2 - DESCRIPTION

3 - MAINTENANCE

4 - MAINTENANCE HANDBOOK

06/02/2006

01/06/2006

1ST DATE OF ISSUE

UP DATING (2-6 ; 2-7 ; 2-9 ; 3-9)

Page 4

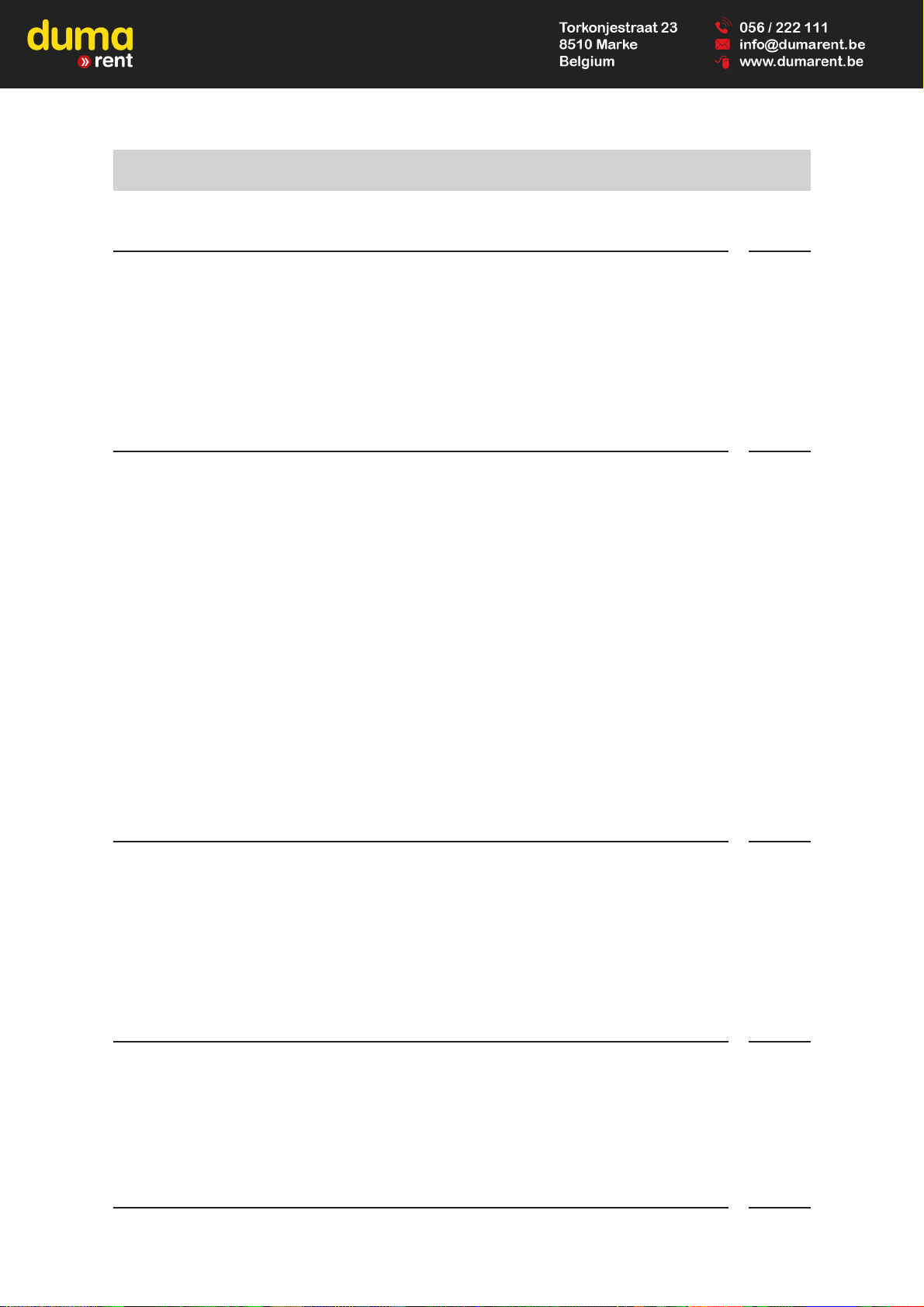

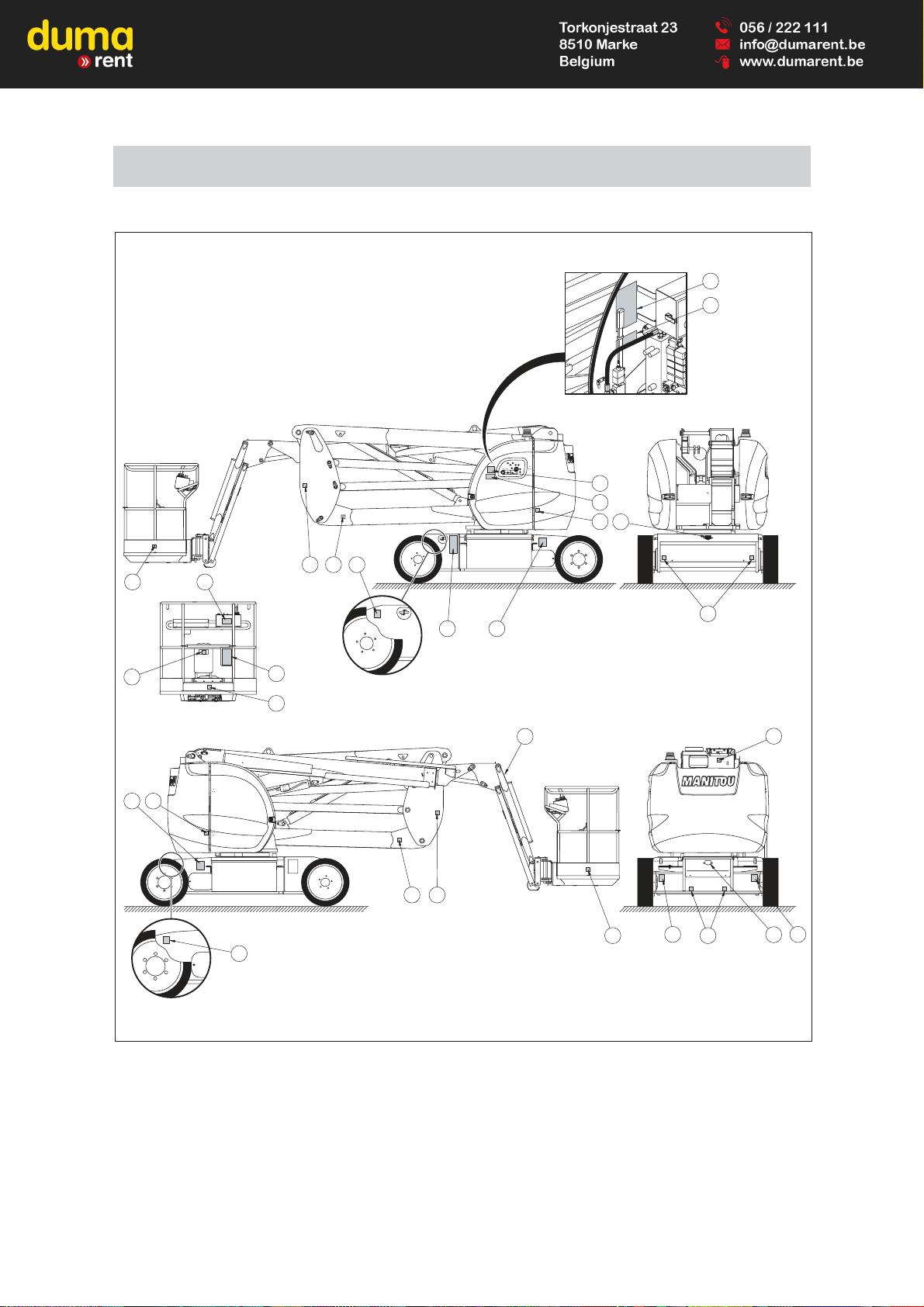

REAR

FRONT

Page 5

1 - OPERATING

AND SAFETY

INSTRUCTIONS

1 - OPERATING

AND SAFETY

INSTRUCTIONS

1 - 1

Page 6

1 - 2

Page 7

1 - 3

TABLE OF CONTENTS

INSTRUCTIONS TO THE COMPANY MANAGER

PREAMBLE

THE OPERATOR

THE PLATFORM

A - THE PLATFORM’S SUITABILITY FOR USE

B - ADAPTING THE PLATFORM TO THE USUAL ENVIRONMENTAL CONDITIONS

C - MODIFYING THE PLATFORM

THE INSTRUCTIONS

THE MAINTENANCE

INSTRUCTIONS FOR THE OPERATOR

PREAMBLE

GENERAL INSTRUCTIONS

A - OPERATOR'S MANUAL

B - AUTHORIZATION FOR USE IN FRANCE

(or see current legislation in other countries).

C - MAINTENANCE

D - MODIFYING THE PLATFORM

E - PLATFORMAXLES

DRIVING INSTRUCTIONS

A - BEFORE STARTING THE PLATFORM

B - DRIVER’S OPERATING INSTRUCTIONS

C - ENVIRONMENT

D - VISIBILITY

E - STARTING THE PLATFORM

F - DRIVING THE PLATFORM

G - STOPPING THE PLATFORM

INSTRUCTIONS FOR WELDING AND BLOW TORCH WORK ON THE EXTERNAL STRUCTURE

A - WITH ELECTRICAL WELDING EQUIPMENT

B - WITH A BLOW TORCH

PLATFORM MAINTENANCE INSTRUCTIONS

GENERAL INSTRUCTIONS

MAINTENANCE

LUBRICANT AND FUEL LEVELS

LEVEL OF ELECTROLYTE IN THE BATTERY

HYDRAULIC

ELECTRICITY

WELDING ON THE ACCESS PLATFORM

WASHING THE PLATFORM

IF THE PLATFORM IS NOT TO BE USED FOR A LONG TIME

INTRODUCTION

PREPARING THE PLATFORM

PROTECTING THE I.C. ENGINE

CHARGING THE BATTERIES

PROTECTING THE PLATFORM

BRINGING THE PLATFORM BACK INTO SERVICE

SAFETY DECALS

1 - 4

1 - 4

1 - 4

1 - 4

1 - 4

1 - 4

1 - 5

1 - 5

1 - 5

1 - 6

1 - 6

1 - 6

1 - 6

1 - 6

1 - 7

1 - 7

1 - 7

1 - 8

1 - 8

1 - 8

1 - 8

1 - 9

1 - 10

1 - 11

1 - 12

1 - 13

1 - 13

1 - 13

1 - 14

1 - 14

1 - 14

1 - 14

1 - 14

1 - 14

1 - 15

1 - 15

1 - 15

1 - 16

1 - 16

1 - 16

1 - 16

1 - 17

1 - 17

1 - 17

1 - 18

Page 8

1 - 4

INSTRUCTIONS TO THE COMPANY MANAGER

PREAMBLE

THE OPERATOR

- Only qualified, authorized personnel can use the platform. This authorization is given in writing by the appropriate person in the establishment with respect to the use of platform and must be carried permanently by the operator.

On the basis of experience, there are a number of possible situations in which operating the platform is contra-indicated. Such

foreseeable abnormal uses, the main ones being listed below, are strictly forbidden.

- The foreseeable abnormal behaviour resulting from ordinary neglect, but does not result from any wish to put the

machinery to any improper use.

- The reflex reactions of a person in the event of a malfunction, incident, fault, etc. during operation of the platform.

- Behaviour resulting from application of the "principle of least action" when performing a task.

- For certain machines, the foreseeable behaviour of such persons as : apprentices, teenagers, handicapped persons,

trainees tempted to drive a platform, operator tempted to operate a truck to win a bet, in competition or for their own

personal experience.

The person in charge of the equipment must take these criteria into account when assessing whether or not a person will make a

suitable driver.

OBTAIN INFORMATION ON :

- How to behave when there is a fire.

- The location of the nearest first aid kit and fire extinguisher.

- The emergency telephone numbers for calling (the doctors, ambulance, hospital and fire brigade).

THE PLATFORM

A - THE PLATFORM'S SUITABILITY FOR USE

- MANITOU has ensured that this platform is suitable for use under the standard operating conditions defined in this operator's manual, with an overload test coefficient of 1,25 and an operational test coefficient of 1,1, as stipulated in standardised norm EN 280 for MPLP (Mobile Personnel Lifting Platforms).

- Before commissioning, the company manager must make sure that the platform is appropriate for the work to be done,

and perform certain tests (in accordance with current legislation).

B - ADAPTATING THE PLATFORM TO THE USUAL ENVIRONMENTAL CONDITIONS

- In addition to series equipment mounted on your platform, many options are available, such as : flashing light, working

headlight, etc.

Contact your dealer.

- Take into account climatic and atmospheric conditions of the site of utilisation.

. Protection against frost (see : 3 - MAINTENANCE : LUBRICANTS AND FUEL).

. Adaptation of lubricants (ask your dealer for information).

. I.C. engine filtration (see : 3 - MAINTENANCE : FILTERS CARTRIDGES AND BELTS).

WHENEVER YOU SEE THIS SYMBOL IT MEANS :

WARNING ! BE CAREFUL ! YOUR SAFETY OR THE SAFETY OF THE

PLATFORM IS AT RISK.

Page 9

1 - 5

For operation under average climatic conditions, i.e. : between -15 °C and + 35 °C, correct levels of lubricants in all the circuits are checked

in production. For operation under more severe climatic conditions, before starting up, it is necessary to drain all the circuits, then ensure

correct levels of lubricants using lubricants properly suited to the relevant ambient temperatures. It is the same for the cooling liquid.

- A platform operating in an area without fire extinguishing equipment must be equipped with an individual extinguisher.

There are solutions, consult your dealer.

Your platform is designed for outdoor use under normal atmospheric conditions and indoor use in suitably aerated and ventilated

premises. It is prohibited to use the platform in areas where there is a risk of fire or which are potentially explosive (e.g. Refineries,

fuel or gas depots, stores of inflammable products…). For use in these areas, specific equipment is available (ask your dealer for

information).

C - MODIFYING THE PLATFORM

- For your safety and that of others, you must not change the structure and settings of the various components used in

your platform (hydraulic pressure, calibrating limiters, I.C. engine speed, addition of extra equipment, addition of counterweight, unapproved attachments, alarm systems, etc.) yourself. In this event, the manufacturer cannot be held responsible.

THE INSTRUCTIONS

- The operator's manual must always be in good condition and kept in the place provided on the platform and in the language used by the operator.

- You must necessarily replace the instructions manual, as well as any plates or stickers, if they are no longer legible or

are missing or damaged.

THE MAINTENANCE

- Maintenance or repairs other than those detailed in part : 3 - MAINTENANCE must be carried out by qualified personnel (consult your dealer) and under the necessary safety conditions to maintain the health of the operator and any third

party.

Your patform must be inspected periodically to ensure that it remains in compliance. The frequency of this inspection is

defined by current legislation in the country in which the platform is used.

Page 10

1 - 6

INSTRUCTIONS FOR THE OPERATOR

PREAMBLE

The risk of accident while using, servicing or repairing your platform can be restricted if you follow the safety instructions and safety

measures detailed in these instruction.

- Only the operations and manœuvres described in these operator's manual must be performed. The manufacturer cannot predict all possible risky situations. Consequently, the safety instructions given in the operator's manual and on the

platform itself are not exhaustive.

- At any time, as an operator, you must envisage, within reason, the possible risk to yourself, to others or to the platform

itself when you use it.

Failure to respect the safety and operating instructions, or the instructions for repairing or servicing your platform may lead to serious,

even fatal accident.

GENERAL INSTRUCTIONS

A - OPERATOR’S MANUAL

- Carefully read and understand the operator's manual.

- The operator’s manual must always be kept in the place provided for it on the platform and be written in the language

used by the operator.

- Any operations or manoeuvres not described in the operator’s manual must necessarily be forbidden right from the

start.

- Follow the safety advice and the instructions on the platform.

- Ypu must necessarily replace the operator’s manual, as well as any plates or stickers, if they are no longer legible or

are damaged.

- A second operator must necessaily be present on the ground as a safety measure when using the platform.

- Familiarise yourself with the platform on the terrain it has to travel over.

- The machine must also be used in accordance with good engineering practice.

- Do not use the platform if the wind speed is over 45 km/h. The platform’s arms must not be subjected to a lateral force

of more than 40 kg (platforms for indoor use must not be used outside the building).

B - AUTHORIZATION FOR USE IN FRANCE

(or see current legislation in other countries)

- Only qualified, authorized personnel may use the platform. This authorization is given in writing by the appropriate

person in the company, in charge of using the platform, and must be permanently carried by the operator.

- The operator is not competent to authorise the driving of the platform by another person.

WHENEVER YOU SEE THIS SYMBOL IT MEANS :

WARNING ! BE CAREFUL ! YOUR SAFETY OR THE SAFETY OF THE

PLATFORM IS AT RISK.

Page 11

1 - 7

C - MAINTENANCE

- The operator must immediately advise his superior if his platform is not in good working order or does not comply with

the safety notice.

- The operator is prohibited from carrying out any repairs or adjustments himself, unless he has been trained for this

purpose. He must keep the platform properly cleaned if this is among his responsibilities.

- The operator must carry out daily maintenance (see : 3 - MAINTENANCE : A - DAILY OR EVERY 10 HOURS

SERVICE).

- The operator must ensure tyres are adapted to the nature of the ground (see area of the contact surface of the tyres in

the chapter : 2 - DESCRIPTION : CHARACTERISTICS). There are optional solutions, consult your dealer.

Do not use the platform if the tyres are damaged or excessively worn, because this could put your own safety or that of

others at risk, or cause damage to the platformk itself.

- In the case of electric platforms, the operator must ensure that:

• The batteries are not replaced with lighter ones (compromising stability).

• Safety goggles are always worn when charging the batteries.

• The batteries are not charged in an explosive environment.

• There is no smoking and no naked flame directed towards the batteries whe they are being handled

(during removal, re-installation and checking the levels) .

D - MODIFYING THE PLATFORM

- For your safety and that of others, you must not change the structure and settings of the various components used in

your platform yourself:

• hydraulic pressure,

• calibrating limiters,

• I.C. engine speed,

• addition of extra equipment,

• addition of counterweight,,

• unapproved attachments,

• alarm systems, etc...

In this event, the manufacturer cannot be held responsible.

E - PLATFORM AXLES

- Standard axles:

The chassis is rigid, so the platform can have a ground reach on only three wheels.

- Oscillating axle (if the option is available):

An oscillating axle enables the platform, when in transport position, to have a ground reach on four wheels.

When moving in working position over uneven terrain, the oscillating axle is locked (the chassis is rigid) so the platform

can have a ground reach on only three wheels.

Page 12

1 - 8

DRIVING INSTRUCTIONS

A - BEFORE STARTING THE PLATFORM

- Ensure that the intermediate rail is fully in the locked position before operating the platform from the basket.

- If the platform is new, see the Chapter : BEFORE STARTING THE PLATFORM FOR THE FIRST TIME in Section :

1 - SAFETY ADVICE AND INSTRUCTIONS.

- Carry out daily maintenance (see : 3 - MAINTENANCE : A - DAILY OR EVERY 10 HOURS SERVICE).

- Before starting the platform, check the levels :

• IC PLATFORMS : I • ELECTRIC PLATFORMS :

• IC engine oil I • Hydraulic reservoir oil.

• Hydraulic reservoir oil. I • Battery charge level.

• Fuel. I

• Coolant. I

- Whatever his experience, the operator is advised to familiarize himself with the position and operation of all the controls

and instruments before operating the platform.

- The platform must be in transport position (arms fully folded or scissors in the low position) before you climb onto the

platform.

- Make sure the horn works.

B - DRIVER’S OPERATING INSTRUCTIONS

- Wear suitable clothing for driving the platform, do not wear baggy clothes.

- Make sure you have the appropriate protective equipment for the job to be done.

- Prolonged exposure to high noise levels may cause hearing problems. It is recommended to wear ear muffs to protect

against excessive noise.

- Always pay attention when using the platform. Do not listen to the radio or music using headphones or earphones

- For increased comfort, adopt the correct position in the driver’s cab.

- The operator must always be in his normal position in the driver’s seat : extending arms or legs (or, in general, any part

of the body), outside the basket is forbidden.

- Safety helmets must be worn.

- MANITOU recommends a safety harness in the operator’s size be provided when the platform is in use (for the harness

attachement in the basket , see 2 - DESCRIPTION : INSTRUMENTS AND CONTROLS).

- The control units must never in any event be used for any other than their intended purposes (e.g. climbing onto or

down from the platform, portmanteau, etc.).

- In the case of scissors-type platforms, it is forbidden to use the platform without the guardrails in place.

- Suspending a load under the basket or on any part of the lifting apparatus is strictly forbidden.

- The operator must not climb into or get down from the basket unless it is at ground level (with the lifting system folded).

- The platform must not be fitted with any accessory increasing the machine’s wind profile.

- Do not use a ladder or any improvised constructions in the basket to reach greater heights.

- Do not climb on the sides of the basket to reach greater heights.

C - ENVIRONMENT

- Comply with site safety regulations.

- The platform can be manoeuvred from the ground: ensure that you forbid access.

- If you have to use the platform in a dark area or at night, make sure it is equipped with working lights.

- The platforms may not be used as cranes or elevators for the permanent transport of people or materials, nor as jacks

or supports.

- When operating, ensure that there is no one or anything impeding the platform’s progress ans operation.

- When raising the platform, ensure that no one or anything inpedes the platform’s operation and do not perform any

inappropriate manœuvres.

Page 13

1 - 9

- Do not allow anybody to come near the working area of the platform or pass beneath an elevated load. To do this,

mark your operating area with warning signs.

- Travelling on a longitudinal slope :

• Ensure that you adapt the platform’s travelling speed by controlling the speed with the travelling manipulator.

- Take into account the platform’s dimensions and its load before trying to negotiate a narrow or low passageway.

- Never move onto a loading platform without having first checked :

• That it is suitably positioned and made fast.

• That the unit to which it is connected (wagon, lorry, etc.) will not shift.

• That this platform is prescribed for the size and the total weight of the platform.

• That the slope is not greater than the platform’s maximum authorised slope.

- Never move onto a foot bridge, floor or freight lift, without being certain that they are prescribed for the weight and size

of the platform to be loaded and without having checked that they are in sound working order.

- Be careful in the area of loading bays, trenches, scaffolding, soft land and manholes.

- Ensure that the ground or floor under the wheels and/or the stabilizers is stable and firm before raising the basket. If

necessary, add sufficient wedging under the stabilizers.

- Do not attempt any operations outside the plarform’s capabilities.

- Ensure that the materials on the platform (pipes, cables, containers, etc ...) cannot slip off and fall. Do not heap up

these materials to the pint where you have to step over them.

If the basket must remain stationary over a structure for a long period, there is a risk that the basket will rest on this

structure because of the oil cooling in the cylinders or a minor leak in the cylinder locking system.

To eliminate this risk :

- Regularly check the distance between the basket and the structure and re-adjust if necessary.

- If possible use the platform at an oil temperature as close as possible to ambient temperature.

- In the case of work near aerial lines, ensure that the safety distance is sufficient between the working area of the

platform and the aerial line.

You must consult your local electrical agency. You could be electrocuted or seriously injured if you operate or park the platform too

close to power cables.

If the platform comes into contact with electric wires, press the Emergency Stop button.

If you can, jump from the basket without simultaneously being in contact with the basket and the ground.

If not, call for help, wam people not to touch the basket and to switch off the power supply to the wires or have it

switched off.

If the wind is in excess of 45Km/h, do not make any movements putting the platform’s stability at risk.

D - VISIBILITY

- Maintain permanently good visibility throughout the route. To increase your visibility, you can move forwards with the

pendular arm slightly raised (pay attention to the risk of falls in the basket from knocking into a low doorway, overhead

electric wires, travelling cranes, highway bridges, tracks or any obstacle in the area in front of the platform). In reverse,

look directly behind you. In any case, avoid reversing over long distances.

- If visibility of your road is inadequate, ask someone to help, standing outside the area in which the platform will be

moving, and make sure you always have a good view of this person.

Page 14

1 - 10

E - STARTING THE PLATFORM

PLATFORMS WITH IC ENGINES

SAFETY NOTICE

- Never try to start the platform by pushing or towing it. Such operation may cause severe damage to the transmission.

In case of necessity, towing requires the platform to be set for free-wheeling (see : 3 - MAINTENANCE).

- If using an emergency battery for start-up, use a battery with the same characteristics and respect battery polarity

when connecting it. Connect at first the positive terminals before the negative terminals.

Failure to respect polarity between batteries can cause serious damage to the electrical circuit. The electrolyte in the battery may

produce an explosive gas. Avoid flames and generation of sparks close to the batteries.

Never disconnect a battery while it is charging.

INSTRUCTIONS

- Check the closing and locking of the hood(s).

- Turn the ignition key to notch I to switch on the electrical power, which automatically starts the pre-heating system (all

the bars must be displayed), the message “OK” is displayed.

- Check that everything is operating correctly by ensuring that no fault pages are displayed on the screen and no

warning about the fuel level (a pump icon is present on the screen) (see : 2 - DESCRIPTION : INSTRUMENTS AND

CONTROLS).

- Turn the ignition key to notch II to start.

- Release the ignition key and let the engine run at tick-over speed.

NB : In very cold weather (see: 2 - DESCRIPTION : INSTRUMENTS AND CONTROLS).

- Do not engage the starter motor for more than 15 seconds and carry out the preheating for 10 seconds between

unsuccessful attempts.

- Check all control instruments when the I.C. engine is warm and at regular intervals during use, so as to quickly detect

any faults and to be able to correct them without any delay.

- If any faults are displayed on the screen, stop the engine and immediately take the necessary measures.

ELECTRIC PLATFORMS

SAFETY NOTICE

- Do not use the platform if the battery is discharged to the point that movements are slowed down. In certain cases, the

platform may stop (see : 3 - MAINTENANCE : EVERY DAY OR EVERY 5 HOURS FOR OPERATION, for the

minimum permissible charge level).

INSTRUCTIONS

- Set the battery cut-out to the ON position.

- Check the closing and locking of the hood(s).

- Turn the ignition key to the basket position.

- Check that everything is operating correctly by ensuring that no error messages are displayed on the screen and that

the machine maintenance light is not flashing (see : 2 - DESCRIPTION : INSTRUMENTS AND CONTROLS).

NB: For machines not fitted with a display or a maintenance warning light, faults can be identified from the light directly

on the variable speed drive unit (to access: open the cowl on the control size, remove the casing from the variable

speed drive and see whether the light is flashing).

Page 15

1 - 11

- If any error messages are constantly displayed or the machine maintenance light is flashing, return the key to the

neutral position.

- Set the battery cut-off to the OFFposition.

- Immediately take the necessary measures.

F - DRIVING THE PLATFORM

SAFETY NOTICE

Operators should be aware of the risks connected with using the platform, notably:

- Risk of losing control.

- Risk of losing lateral and frontal stability of the platform.

The operator must remain in control of the platform.

- Do not carry out operations which exceed the capacities of your platform.

- Familiarise yourself with the platform on the terrain where it will be used.

- Ensure that the brakes work efficiently when stopping a travelling movement, taking into account the braking distances.

- Drive smoothly at an appropriate speed for the operating conditions (land configuration, load in the basket).

- take extreme care if manoeuvring the platform with the basket in the high position. Ensure you have adequate visibility.

- Take bends slowly.

- In all circumstances make sure you are in control of your speed.

- Travel slowly on damp, slippery or uneven terrain or on truck ramps.

- Always remember that the hydraulic form of steering is very sensitive to movements.

- Never leave the I.C. engine on when the platform is unattended.

- Look where you are going and always make sure you have good visibility along the route.

- Drive round obstacles.

- Never drive on the edge of a ditch or steep slope.

- Whatever your travelling speed, you must reduce the speed as much as possible before stopping.

INSTRUCTIONS

- When moving the platform a long distance, always travel with the arms folded or the scissors in the low position.

- Engage the appropriate gear (see : 2 - DESCRIPTION : INSTRUMENTS AND CONTROLS).

Page 16

1 - 12

G - STOPPING THE PLATFORM

SAFETY NOTICE

- Never leave the ignition key in the platform during the operator's absence.

- Make sure that the platform is not stopped in any position that will interfere with the traffic flow and at less than one

meter from the track of a railway.

- In the event of prolonged parking on a site, protect the platform from bad weather, particularly from frost (check the

level of antifreeze), close and lock all the platform accesses (cowls…).

INSTRUCTIONS

PLATFORMS WITH IC ENGINES

- Before stopping the platform after a long working period, leave the I.C. engine idling for a few moments, to allow the

coolant liquid and oil to lower the temperature of the I.C. engine and transmission

Do not forget this precaution, in the event of frequent stops or warm stalling of the I.C. engine,

or else the temperature of certain parts will rise significantly due to the stopping of the cooling system, with the risk of

badly damaging such parts.

- Stop the I.C. engine with the ignition switch.

- Remove the ignition key.

- Check that all the accesses on the platform are closed and locked (cowls…).

ELECTRIC PLATFORMS

- Remove the ground/platform control selection key.

- Check that all the accesses on the platform are closed and locked (cowls…).

- Set the battery cut-out to the OFF position (ELECTRIC PLATFORM).

Page 17

1 - 13

INSTRUCTIONS FOR WELDING AND BLOW TORCH WORK ON THE EXTERNAL STRUCTURE

Ensure that there are no hydraulic or electrolyte leaks on the platform.

When welding, work in the opposite direction

from the control console to avoid sparks damaging it .

Any welding and cutting (blow torch) work from the basket on a building’s metallic structures requires the following

precautions to be taken:

A - WITH ELECTRIC WELDING EQUIPMENT

- It is essential that the machine has a discharge braid connecting the platform’s chassis to the ground.

- It is also essential that the external structure to be welded is connected to the earth. If the above conditions are

observed, the platform can, in this case, be in contact with the structure or the elements to be welded without

damaging the electronic components.

- The power supply to the welding equipment must be via an earthed socked and any extension required just also be

earthed.

- In all cases, ensure that there are no electrical arcs in the basket or on the platform (contact between the brazing rod or

the torch and the welding equipment’s earth). To ensure this, at any time the welding equipment’s earth must not be

positioned on the platform’s basket but instead only as close as possible to the element to be welded.

- Switch off the welding equipment before disconnecting the earth clamp from the element or elements to be welded.

B - WITH A BLOW TORCH

- Attach the blow torch’s bottles to the basket’s handrails.

- instructions for welding and blow torch work on the external structure

- Do not set the blow torch down on the lip of the basket while it is still operating or point it towards the control console or

its power cables.

Page 18

1 - 141 - 14

GENERAL INSTRUCTIONS

- Ensure the area is sufficiently ventilated before starting the platform.

- Wear clothes suitable for the maintenance of the platform, avoid wearing jewellery and loose clothes. Tie and protect

your hair, if necessary.

- Stop the engine before conducting any work on the platform, remove the ignition key and disconnect the “Minus”

battery terminal.

- Set the battery cut-out to the OFF position (ELECTRIC PLATFORM).

- Read the operator's manual carefully.

- Carry out all repairs immediately, even if the repairs concerned are minor.

- Repair all leaks immediately, even if the leak concerned is minor.

- Make sure that the disposal of process materials and of spare parts is carried out in total safety and in a ecological

way.

- Be careful of the risk of burning and splashing (exhaust, radiator, I.C. engine, etc.).

MAINTENANCE

- Perform the periodic service (see : 3 - MAINTENANCE) to keep your platform in good working conditions. Failure to

perform the periodic service may cancel the contractual guarantee.

LUBRICANT AND FUEL LEVELS

- Use the recommended lubricants (never use contaminated lubricants).

- Do not fill the fuel tank when the I.C. engine is running.

- Only fill up the fuel tank in areas specified for this purpose.

- Do not fill the fuel tank to the maximum level.

- Do not smoke or approach the platform with a flame, when the fuel tank is open or is being filled.

LEVEL OF ELECTROLYTE IN THE BATTERY

- Check the level of the battery or batteries.

When doing this, ensure you take all the safety precautions (See: 3 - MAINTENANCE).

HYDRAULIC

- Make any repairs and fix any leaks, including minor ones, immediately.

- Do not attempt to loosen unions, hoses or any hydraulic component with the circuit under pressure.

BALANCING VALVE : It is dangerous to change the setting and remove the balancing valves or safety valves which

may be fitted to your platform cylinders. These operations must only be performed by

approved personnel (consult your dealer).

PLATFORM MAINTENANCE INSTRUCTIONS

Page 19

1 - 15

Ensure that all consumables and replacement parts are disposed of safety, in an

environmentally friendly manner.

ELECTRICITY

- Do not drop metallic items on the battery (between the “Plus” and “Minus terminals”).

- Disconnect the battery or batteries before working on the electrical circuit.

- The electrical box must only be opened by authorized personnel.

WELDING ON THE ACCESS PLATFORM

- Disconnect the battery or batteries before welding on the platform.

- When carrying out electric welding work on the platform, connect the negative cable from the equipment directly to the

part being welded, so as to avoid high tension current passing through the alternator or the live ring.

- If the platform is equipped with an electronic control unit, disconnect this before starting to weld, to avoid the risk of

causing irreparable damage to electronic components.

WASHING THE PLATFORM

- Clean the platform or at least the area concerned before any intervention.

- Remember to close and lock all accesses to the platform (cowls…).

- When cleaning with a pressure washer, avoid the articulation joints, and the electrical components and connections.

- If necessary, protect components likely to be damaged, and in particular the electrical components (variable speed

drive, charger) and connections and the injection pump from penetration by water, steam or cleaning products.

- Dry the electrical components.

- Clean the platform of any fuel, oil or grease trace.

- Grease the shafts.

FOR ANY INTERVENTION OTHER THAN REGULAR MAINTENANCE, CONSULT YOUR DEALER.

Page 20

1 - 16

INTRODUCTION

The following recommendations are intended to prevent the platform from being damaged when it is withdrawn from

service for an extended period.

For these operations, we recommend the use of a MANITOU protective product, reference 603726.

Instructions for using the product are given on the packaging.

Procedures to follow if the platform is not to be used for a long time and for starting it up again afterwards must be

performed by your dealership.

PREPARING THE PLATFORM

- Clean the platform thoroughly.

- Check and repair any leakage of fuel, oil, water or air.

- Replace or repair any worn or damaged parts.

- Wash the painted surfaces of the platform in clear and cold water and wipe them.

- Touch up the paintwork if necessary.

- Shut down the platform (see : OPERATING INSTRUCTIONS UNLADEN AND LADEN).

- Make sure the cylinder rods are all in retracted position.

- Release the pressure in the hydraulic circuits.

PROTECTING THE I.C. ENGINE

- Fill the tank with fuel (see : 3 - MAINTENANCE).

- Empty and replace the cooling liquid (see : 3 - MAINTENANCE).

- Leave the I.C. engine running at idling speed for a few minutes, then switch off.

- Replace the I.C. engine oil and oil filter (see : 3 - MAINTENANCE).

- Add the protective product to the engine oil.

- Run the I.C. engine for a short time so that the oil and cooling liquid circulate inside.

- Disconnect the battery and store it in a safe place away from the cold, after charging it to a maximum.

- Remove the injectors and spray the protective product into each cylinder for two seconds with the piston in low neutral

position.

- Turn the crankshaft once slowly and refit the injectors (see I.C. engine REPAIR MANUAL).

- Remove the intake hose from the manifold or turbocharger and spray the protective product into the manifold or

turbocharger.

- Cap the intake manifold hole with waterproof adhesive tape.

- Remove the exhaust pipe and spray the protective product into the exhaust manifold.

- Refit the exhaust pipe and block the outlet with waterproof adhesive tape..

NOTE : The spray time is noted on the product packaging.

- Open the filler plug, spray the protective product around the rocker arm shaft and refit the filler plug.

- Cap the fuel tank using waterproof adhesive tape.

- Remove the drive belts and store them in a safe place.

- Disconnect the engine cut-off solenoid on the injection pump and carefully insulate the connection.

IF THE PLATFORM IS NOT TO BE USED FOR A LONG TIME

Page 21

1 - 17

CHARGING THE BATTERIES

- In the case of electric platforms, in order to preserve the batteries’life and their capacity, check them periodically and

keep the charge level constant (see : 3 - MAINTENANCE).

PROTECTING THE PLATFORM

- Protect cylinder rods which will not be retracted, from corrosion.

- Wrap the tyres.

NOTE : If the platform is to be stored outdoors, cover it with a waterproof tarpaulin.

BRINGING THE PLATFORM BACK INTO SERVICE

- Remove the waterproof adhesive tape from all the holes.

- Refit the intake hose.

- Reconnect the engine cut-off solenoid.

- Refit and reconnect the battery.

- Remove the protection from the cylinder rods.

- Perform the daily service (see : 3 - MAINTENANCE

- Empty and replace the fuel and replace the fuel filter (see : 3 - MAINTENANCE).

- Refit and set the tension in the drive belts (see : 3 - MAINTENANCE).

- Turn the I.C. engine using the starter, to allow the oil pressure to rise.

- Lubricate the platform completely (see : 3 - MAINTENANCE : TABLEAU D'ENTRETIEN).

Make sure the area is adequately ventilated before starting up the platform.

- Start up the platform, following the safety instructions and regulations (see : OPERATING INSTRUCTIONS).

- Carry out all the lifting system’s hydraulic movements right up to the limit switches for each cilinder.

Page 22

1 - 18

SAFETY DECALS

15

10

14

8

31214

1

13

7

814

12 14

4

5

9

12

714

1011

3

6

14

2

33

13

Page 23

1 - 19

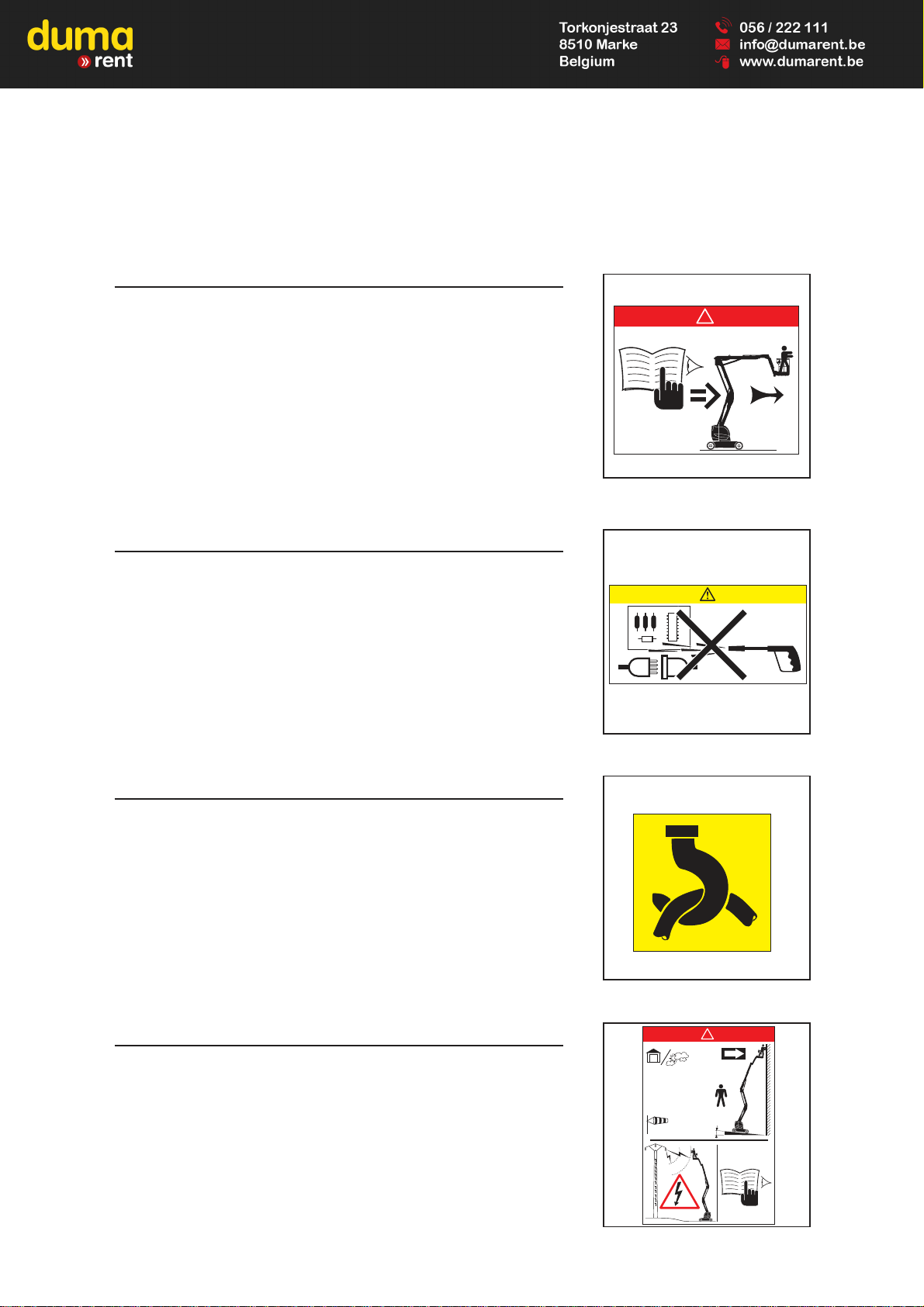

DESCRIPTION

1 - WHITE ARROW

2 - BLACK ARROW

3 - LOAD PER WHEEL

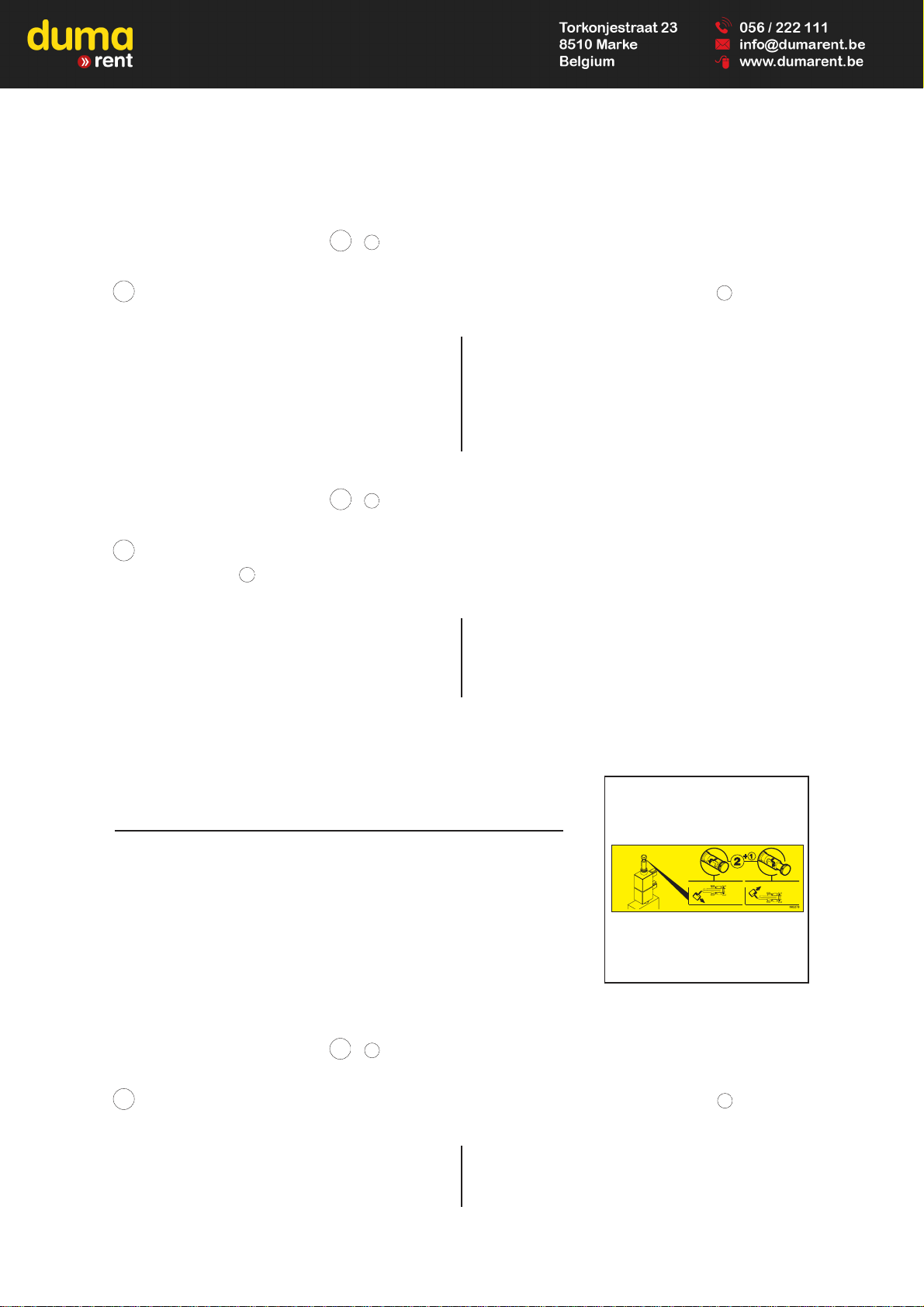

4 - MANUAL CONTROL PROCEDURE

5 - MANUAL CONTROL PROCEDURE FOR ROTATING JIB

6 - BLADE SAFETY INSTRUCTIONS

7 - WASHING RECOMMENDATIONS

8 - ANCHORING HOOK

9 - BASKET INSTRUCTIONS / LOAD CAPACITY

10 - REPLACING THE BATTERIES

11 - BATTERY CUT-OFF / DANGER BATTERY CHARGE / 230 VOLT 16 A SOCKET

12 - DANGER KEEP AWAY

13 - RISK OF SHEARING

14 - RISK OF CRUSHING

15 - POSITION OF THE PLATFORM KEY

Page 24

1 - 20

679307

2

3

2

1

3

1

1

4

MEANING

1. WHITE ARROW

This indicates the direction of travelling when moving forwards.

When the turret assembly, the arms assembly and the basket make a 180°

rotation with respect to the chassis, the travelling controls are reversed.

Identify the forward direction by looking at the arrows on the chassis and on

the basket control console.

2. BLACK ARROW

This indicates the direction of travelling when reversing.

Same: white arrow

NB: As on the basket console and the chassis, the white arrows indicate

forward travelling and the black arrows reverse travelling.

3. LOAD PER WHEEL

This indicates the maximum load on one wheel and the load the wheel will

exert on the ground (see 2 - DESCRIPTION: CHARACTERISTICS for the

piercing value).

Before using the platform, identify the type of ground and find out its ability to

resist being pierced.

NB: The weight must be visible on the platform.

4. MANUAL CONTROL PROCEDURE

This describes the procedure for: lowering or turning the basket, turning the

turret and directing the wheels using the pump and the manual controls.

PROCEDURE :

Thumbnail 1 : Unscrew and remove the protective cover over the indexed

controls.

Thumbnail 2 : Pick up the lever.

Thumbnail 3 : Position the lever on the manual pump.

XXXXXX

XXXX Kg

XXXX Lbs

Page 25

1 - 21

Association of the two operations

2 + 1 :

Depending on the movements desired:

2 - Push in and lock the wheel (left-hand bubble) OR pull out and lock the wheel (right-hand bubble) + 1 - Pump.

This enables you to perform:

Top left column downwards, Top right column downwards,

The five movements below: The five movements below:

- Raise the basket and the pendular arm - Lower the basket and the pendular arm

- Raise the pendular arm (the basket stays horizontal) - Lower the pendular arm (the basket stays horizontal)

- Extend the telescope - Retract the telescope

- Raise the upper arm - Lower the upper arm

- Raise the intermediate arms - Lower the intermediate arms

Association of the two operations

3 + 1 :

Depending on the movements desired:

3 - Push the wheel in and hold it in this position (left-hand bubble) OR pull the wheel out and hold it in this position

(right-hand bubble) + 1 - Pump.

This enables you to perform:

Top left column downwards, Top right column downwards,

The three movements below: The three movements below:

- Basket rotation right - Basket rotation left

- Point wheels left - Point wheels right

- Turret rotation right - Turret rotation left

Thumbnail 4: Screw on the protective cover for the indexed controls.

5. MANUAL CONTROL PROCEDURE FOR ROTATING

JIB (3D PLATFORMS)

This describes the procedure for turning the pendular arm / basket assembly.

PROCEDURE (see sticker N° 4):

Thumbnail 1 : Unscrew and remove the protective cover over the indexed

controls.

Thumbnail 2 : Pick up the lever.

Thumbnail 3 : Position the lever on the manual pump.

Association of the two operations

2 + 1 :

Depending on the movements desired:

2 - Push in and lock the wheel (left-hand bubble) OR pull out and lock the wheel (right-hand bubble) + 1 - Pump.

This enables you to perform:

Left-hand column, Right-hand column,

The movements below: The movements below:

- Rotation of the basket assembly - Rotation of the basket assembly

and pendular arm to the right and pendular arm to the left

Page 26

1 - 22

230 Kg = 70 Kg +

508 Lbs = 155 Lbs +

2

!

12,5 m/s (45 km/h)

3°

400 N

(40 Kg - 90 Lbs)

679309

679311

!

6. BLADE SAFETY INSTRUCTIONS

Take note of the safety and operating instructions before you start the

platform.

7. WASHING RECOMMENDATIONS

It is strictly forbidden to direct a pressure washer’s nozzle over the control

buttons and electrical components.

8. ANCHORING HOOK

This sticker indicates the anchoring points for tying down the platform on the

flatbed of a truck.

9. BASKET INSTRUCTIONS / LOAD CAPACITY

This describes three points:

- The platform’s capabilities for use indoors and out of doors.

- The risk of electric shock.

- An invitation to read the instructions for more detailed information on the

safety instructions.

NB: Each platform has its own capabilities: please refer to this sticker for your

particular platform.

598892 A

598895

XXX

XXX

XXX

XX

Page 27

1 - 23

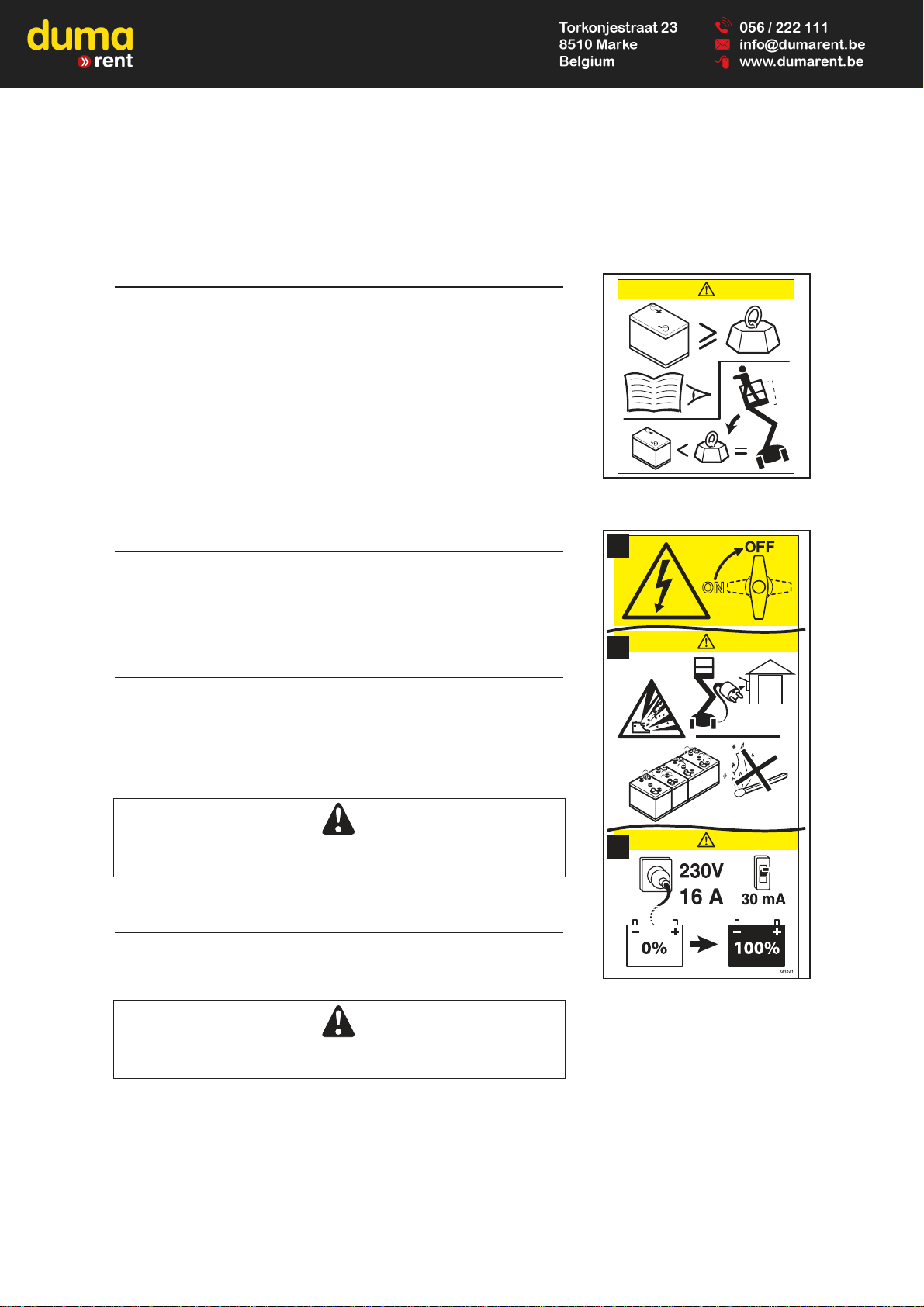

10. REPLACING THE BATTERIES

This indicates that the weight of the new batteries must be greater than or

equal to those you are replacing. If this instruction is not observed, the

platform’s stability will be compromised.

11 A. BATTERY CUT-OFF

This indicates the position of the battery cut-out and its effect:

Position OFF: le courant ne passe pas.

Position ON: le courant passe.

11 B. DANGER BATTERY CHARGE

This describes three points:

- The risk of explosion when batteries are charging.

- Batteries must be charged outside or in a well-ventilated area.

- The risk of explosion during charging, due to a spark, a flame or a schortcircuit.

Do not smoke near the access platform when the batteries are being

charged.

11 C. 230VOLT 16A SOCKET

This informs you that to charge the batteries you must connect the charger to

a socket supplying 230 Volts with an intensity of 16 Amps.

The socket must be protected by a differential circuit breaker

with 30mA protection.

677856

A

B

C

Page 28

1 - 24

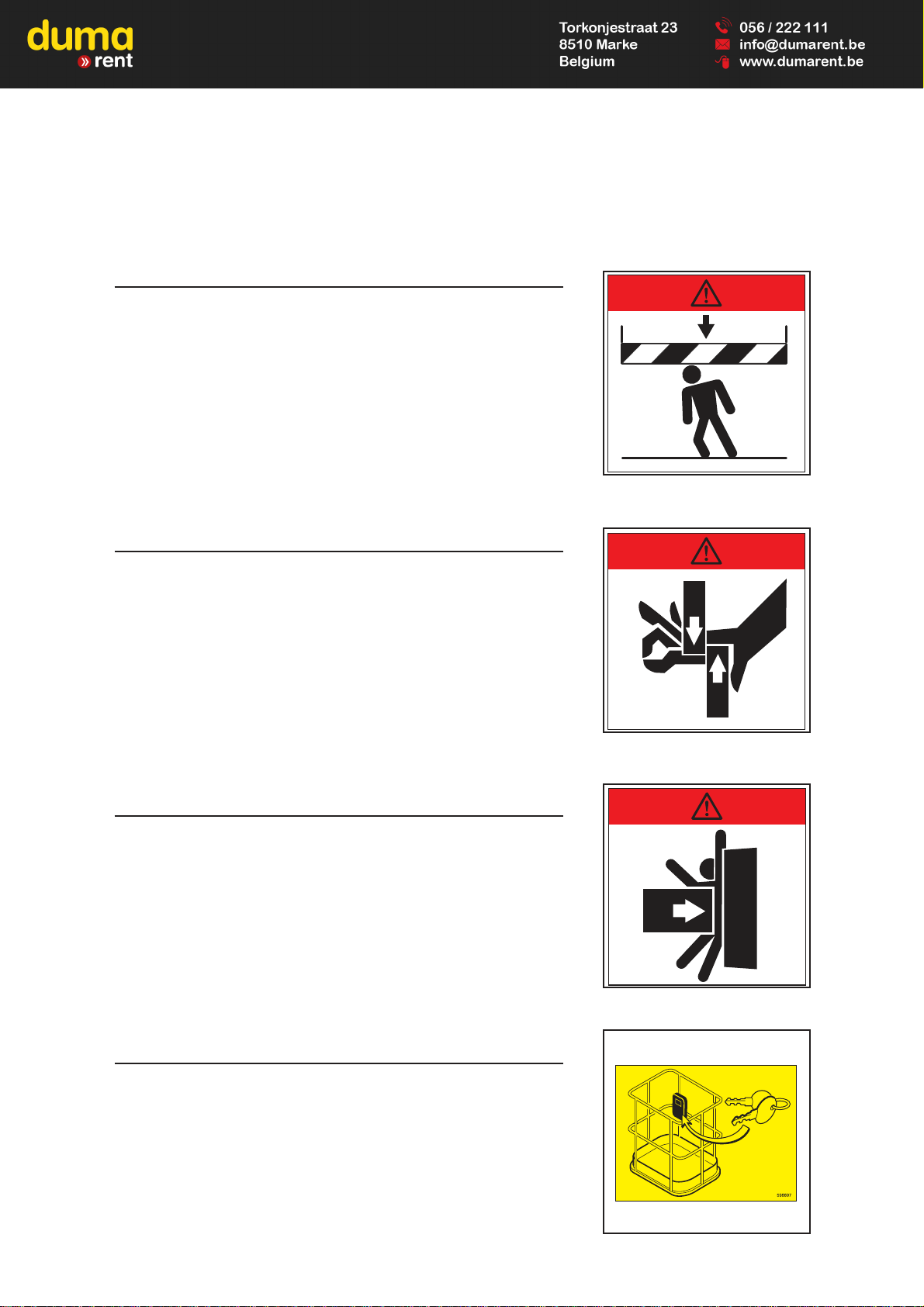

12. DANGER : KEEP AWAY

It is strictly forbidden to cross under or park under the structure (arms,

scissors, pendular arm, basket, etc.) and in the area over which the platform

operates.

13. RISK OF SHEARING

It is strictly forbidden to place your fingers, or any other part of the body, in

the parts of the lifting system (arms, scissors, pendular arm, etc.): risk of

being cut or crushed.

14. RISK OF CRUSHING

It is strictly forbidden to park in this area when the platform is moving

(rotating, etc.). The elements on which the stickers are affixed could collide

with you, with the risk of crushing you.

15. POSITION OF THE PLATFORM KEY

The spare keys for the access platform (ignition key, control selector key, key

for locking casings...) are stored in the place provided for the purpose.

679452

679451

679450

Page 29

2 - 1

2 - DESCRIPTION

2 - DESCRIPTION

Page 30

2 - 2

Page 31

2 - 3

CONTENTS

PLATFORM IDENTIFICATION

CHARACTERISTICS

DIMENSIONS 120 AETJ L

DIMENSIONS 150 AETJ C

DIMENSIONS 150 AETJ L

DIMENSIONS 170 AETJ L

PLATFORM OPERATION

CONTROL INSTRUMENTATION

GROUND BACKUP AND MAINTENANCE STATION

BASKET COMMAND AND CONTROL STATION

USE OF THE PLATFORM

RESCUE PROCEDURE

2 - 4

2 - 5

2 - 10

2 - 12

2 - 14

2 - 16

2 - 19

2 - 22

2 - 26

2 - 33

2 - 37

2 - 41

Page 32

2 - 4

It is our policy to improve our products constantly. Certain modifications may

be made to our range of platforms without our being required to advise our

customers.

On any order for replacement parts or for any technical information, please

always specify:

NB: To be able to provide all these numbers more easily, we recommend that

you write them down in the locations provided for this on receipt of the

platform.

PLATFORM MANUFACTURER’S PLATE (FIG. A)

- Type

- Serial No.

- Year of manufacture

LOCATION OF THE MANUFACTURER’S PLATE (FIG. B)

The manufacturer’s plate is fastened to the rear of the chassis on the lefthand side.

PLATFORM IDENTIFICATION

A

B

Page 33

2 - 5

ELECTRIC PUMP

- Power supply 48 V

- Power 3,6 KW

- Cubic capacity 4,8 cm3

- Pressure 200 bar

ELECTRICAL WHEELS MOTORS

- Type T 17 - 2 KW

ELECTRICAL CIRCUIT

- Battery 48 V - 300 Ah(150AETJC - 150AETJL -

170AETJL)

48 V - 240 Ah (120AETJL)

- Charger 45 Ah (Mono)

FUSES

- Main card (Base control box ): 5 A (1 Fig A) and 15 A (2 Fig A)

- Power (Contactor plate): 325 A (3 Fig B)

- Electric pump (Variable speed drive plate): 100 A (4 Fig C)

CHARACTERISTICS

3

4

1

2

A

B

C

Page 34

2 - 6

TYRES

Wheel nut tightening torque ; front wheels 34 daNm

Wheel nut tightening torque ; rear wheels 22 daNm

120 AETJ L

SPECIFICATIONS

- Use Indoors and Outdoors

- Capacity 200 Kg including 2 people

- Maximum authorized wind speed 45 Km/h

- Control system Hydro-electric

- Turret rotation 355°

- Working speed 0,6 km/h

- Speed in transport 5 km/h

- Working height 11950 mm

- Height of floor 9950 mm

- Max. offset 6870 mm

- Weight of the access platform

• Unloaded 5050 kg

• In nominal load 5250 kg

- Number of speed 2

- Negotiable slope 30%

- Max. permissible tilt 5% or 3°

LOAD PER WITH MAX. LOAD

CONTACT SURFACE

DIMENSIONS TYPE

TYRE UNLADEN

+ D

OFF-CENTRING ON 1 WHEEL

OF 1 WHEEL WITH GROUND

STAMPING

FRONT REAR FRONT / REAR

600 X 190 TYRE

2370 KG 2680 KG 2800 KG - CM

2

- DAN/CM

2

Page 35

2 - 7

TYRES

Wheel nut tightening torque ; front wheels 34 daNm

Wheel nut tightening torque ; rear wheels 22 daNm

150 AETJ C

SPECIFICATIONS

- Use Indoors and Outdoors

- Capacity 200 Kg including 2 people

- Maximum authorized wind speed 45 Km/h

- Control system Hydro-electric

- Turret rotation 355°

- Working speed 0,6 km/h

- Speed in transport 5 km/h

- Working height 14990 mm

- Height of floor 12990 mm

- Max. offset 7600 mm

- Weight of the access platform

• Unloaded 6700 kg

• In nominal load 6900 kg

- Number of speed 2

- Negotiable slope 23%

- Max. permissible tilt 5% or 3°

LOAD PER WITH MAX. LOAD

CONTACT SURFACE

DIMENSIONS TYPE

TYRE UNLADEN+ OFF-CENTRING ON 1 WHEEL

OF 1 WHEEL WITH GROUND

STAMPING

FRONT REAR FRONT / REAR

600 X 190 TYRE

2930 KG 3770 KG 3600 KG - CM

2

- DAN/CM

2

Page 36

TYRES

Wheel nut tightening torque ; front wheels 34 daNm

Wheel nut tightening torque ; rear wheels 22 daNm

2 - 8

150 AETJ L

SPECIFICATIONS

- Use Indoors and Outdoors

- Capacity 230 Kg including 2 people

- Maximum authorized wind speed 45 Km/h

- Control system Hydro-electric

- Turret rotation 355°

- Working speed 0,6 km/h

- Speed in transport 5 km/h

- Working height 15280 mm

- Height of floor 13280 mm

- Max. offset 7810 mm

- Weight of the access platform

• Unloaded 5910 kg

• In nominal load 6140 kg

- Number of speed 2

- Negotiable slope 26%

- Max. permissible tilt 5% or 3°

LOAD PER WITH MAX. LOAD

CONTACT SURFACE

DIMENSIONS TYPE

TYRE UNLADEN

+ D

OFF-CENTRING ON 1 WHEEL

OF 1 WHEEL WITH GROUND

STAMPING

FRONT REAR FRONT / REAR

600 X 190 TYRE

1240 KG 1715 KG 3600 KG 283 CM

2

12,5 DAN/CM

2

Page 37

2 - 9

TYRES

Wheel nut tightening torque ; front wheels 34 daNm

Wheel nut tightening torque ; rear wheels 22 daNm

170 AETJ L

SPECIFICATIONS

- Use Indoors and Outdoors

- Capacity 200 Kg including 2 people

- Maximum authorized wind speed 45 Km/h

- Control system Hydro-electric

- Turret rotation 355°

- Working speed 0,6 km/h

- Speed in transport 5 km/h

- Working height 16910 mm

- Height of floor 14910 mm

- Max. offset 9430 mm

- Weight of the access platform

• Unloaded 6910 kg

• In nominal load 7110 kg

- Number of speed 2

- Negotiable slope 22%

- Max. permissible tilt 5% or 3°

LOAD PER WITH MAX. LOAD

CONTACT SURFACE

DIMENSIONS TYPE

TYRE UNLADEN+ OFF-CENTRING ON 1 WHEEL

OF 1 WHEEL WITH GROUND

STAMPING

FRONT REAR FRONT / REAR

600 X 190 TYRE

1520 KG 1935 KG 4200 KG - CM

2

- DAN/CM

2

Page 38

2 - 10

DIMENSIONS 120AETJ L

D

E

B

C

F

H

G

I

A1A1

C1

A

A 5520

A1 3930

B 2000

C 1995

C1 2210

D 1500

E 153

F 2640

G 1870

H 3960

I 4520

Page 39

2 - 11

G1

G2

H2 H1

G3

H3

G4

H4

12

11

10

9

8

7

6

5

4

3

2

1

4567

13

3210123

52332 674

G1 2350

G2 3105

G3 6370

G4 5640

H1 9950

H2 8795

H3 4775

H4 545

Page 40

2 - 12

DIMENSIONS 150AETJ C

D

E

F

H

G

I

B

C1

A1

C

A

A 6050

A1 4400

B 2000

C 1965

C1 2080

D 1500

E 143

F 2640

G 1870

H 3960

I 4820

Page 41

2 - 13

G1

G2

H2 H1

G3

H3

G4

H4

897

12

11

10

9

8

7

6

5

4

3

2

1

456789

16

15

14

13

3210123

2332

G1 2665

G2 3425

G3 7105

G4 6300

H1 12985

H2 11835

H3 7165

H4 235

Page 42

D

E

FH

G

I

B

A1

A

C

C1

2 - 14

DIMENSIONS 150AETJ L

A 5960

A1 4400

B 2000

C 1970

C1 2080

D 1750

E 143

F 2880

G 1970

H 4270

I 4890

Page 43

G1

G2

H2 H1

G3

H3

G4

H4

89

12

11

10

9

8

7

6

5

4

3

2

1

456789

16

15

14

13

3210123

52332

2 - 15

G1 2660

G2 3420

G3 7310

G4 6500

H1 13275

H2 12120

H3 7165

H4 205

Page 44

D

E

FH

G

I

B

A1

A

C

C1

2 - 16

DIMENSIONS 170AETJ L

A 6840

A1 5120

B 2000

C 1970

C1 2040

D 1750

E 143

F 2890

G 2005

H 4300

I 5600

Page 45

G1

G2

H2 H1

G4

910

10

12

11

10

9

8

7

6

5

4

3

2

1

456789

16

17

15

14

13

3210123

2332 64

H4

G3

H3

2 - 17

G1 2840

G2 3600

G3 8930

G4 8130

H1 14910

H2 13750

H3 7160

H4 270

Page 46

2 - 18

Page 47

2 - 19

PLATFORM OPERATION

DESCRIPTION

- This machine is a mobile platform for lifting people. It consists of a work platform fastened to the end of a pendular arm,

itself fastened to the end of a telescopic arm and the whole assembly is fastened to an articulated arm structure.

- MANITOU lifting platforms are solely for use for bringing people, and their tools and supplies (within the authorised

weight limit, please refer to the paragraph “SPECIFICATIONS”), to a desired working height, to reach hard-to-access

locations over installations and buildings.

- The lifting platform is equipped with a control station in the basket. From this, the operator can drive or move the

machine forwards or backwards. He can raise or lower all the arms, extend or retract the telescopic arm and turn the

turret or the basket right or left. The basket, arms and turret assembly can rotate within an angle of 355 degrees, noncontinuously, to the right and the left of its folded position.

- The lifting platform is also equipped with a ground backup and maintenance station which can control all lifting

functions except travelling The base controls are only to be used in an emergency to bring the operator back to ground

level if he is incapable of doing this himself.

- The ground backup and maintenance station and the basket control station must be checked by the operator every day

to ensure that they work properly.

The characteristics, safety instructions and rescue procedure stickers are affixed to the machine.

The operator must take note of these and understand their contents. To avoid any risk of misinterpreting

the pictograms, please refer to the Paragraph “SAFETY STICKERS” in Chapter 1 – SAFETY ADVICE AND

INSTRUCTIONS.

- The lifting platform’s movements are powered by a hydraulic pump, operated by a battery-powered electric motor. The

hydraulic components are controlled by electro-valves actuated by contactors and the manipulator.

- The base or basket console’s controls are via changeover contactors and are either in “Run” or “Stop” mode.

- The base console is equipped with a so-called “Dead Man’s” push button. This must be pressed in at the same

time a contactor is switched over. Releasing it stops the movement.

- The lifting platform is a two-wheel drive machine driven by an electric motor on each wheel. The drive wheels have

spring-operated, hydraulically released brakes. These brakes tighten automatically as soon as the travelling

manipulator is returned to the neutral position.

- The lifting platform can lift up to the limit of its capacities (seer “SPECIFICATIONS” in this Chapter). Having a maximum

capacity load or less in the basket will still enable you to move in any position, provided that the machine on ground

with a slope of no more than 3°.

GENERAL

- In the following pages, you will find all the information required for using the machine, including the platform’s

operating, driving, parking, loading and transport instructions.

Page 48

2 - 20

SAFETY

SLOPE

When the access platform has reached the maximum authorised

inclination (see chapter : CHARACTERISTICS), the LED 23* on the

basket console flashes regularly. Furthermore, the beeper 33* in the

basket also sounds intermittently.

All "AGGRAVATING" movements - raising the arms, extending the

telescope movements are prohibited for safety reasons .

To restore these functions, only perform "disaggravating" movements :

- Return to safe position by retracting the telescope and lowering the arms:

then position the platform on a more horizontal surface so that you can

raise the arms and extend the telescope.

OVERLOAD

When the access platform has reached the maximum authorised weight (see

chapter : CHARACTERISTICS) in the basket. The overload LED at the

ground backup and maintenance station 3* and the basket console 22* flash

regularly. The beeper 33* in the basket sounds constantly. All movements are

prohibited for safety reasons.

To restore these functions :

- Lighten the basket by removing the item(s) causing the overload,

OR,

- Ask someone at ground level to lower the basket under manual control

(see “RESCUE PROCEDURE” in this Chapter and “SAFETY STICKERS”

in Chapter 1 “SAFETY ADVICE AND INSTRUCTIONS”).

* : the above references are the same as those used in the description

of these components in the following pages.

22

23

33

3

Page 49

2 - 21

NB :

INCOHERENCE of OVERLOAD SENSORS,

LOW ARM position and TELESCOPE extension

/ retraction.

This memo is to inform you that the slope and overload LEDs

may, in certain situations, be activated intermittently and the

beeper may sound constantly, for reasons other than excessive slope position or overloaded basket.

For your safety, the access platform is equipped with two overload

sensors. If only one sensor is activated, the access platform is blocked, the display (see Ref. 7 on the following pages) displays fault

code "F02004". At the same time :

on the basket console : on the base console :

- Beeper 33* sounds constantly. - LED 3* flashes regularly.

- LED 22* flashes in sets of 5 flashes - LED 4* flashes in sets of 5 flashes

every 2 seconds. every 2 seconds.

For your safety, the access platform is equipped with two sensors for the low arm position and two for telesco-

pe extension / retraction. If only one sensor is activated in either of these functions, the display (see Ref. 7

on the next page) displays fault code "F02005". At the same time :

on the basket console : on the base console :

- Beeper 33* remains silent. - LED 4* flashes in sets of 5 flashes

- LED 22* flashes in sets of 5 flashes every 2 seconds.

every 2 seconds.

If the fault continues to be displayed, immobilise the platform and make the necessary repairs.

Consult your dealer.

* : the above references are the same as those used in the description of these components in the following

pages.

4

Page 50

2 - 22

CONTROL INSTRUMENTATION

A- GROUND BACKUP AND MAINTENANCE STATION

17

16

18

19

20

15

8

10

14

3

4

5

6

9

11

12

13

1

2

7

Page 51

2 - 23

A- GROUND BACKUP AND MAINTENANCE STATION

1 - EMERGENCY STOP

2 - KEY-OPERATED CONTROL SELECTOR SWITCH AT GROUND LEVEL OR IN THE

BASKET

3 - OVERLOAD LAMP

4 - "MAINTENANCE MACHINE" LAMP

5 - "STATE OF CHARGE OF THE BATTERY" LAMP

6 - "DEAD MAN" BUTTON

7 - BATTERY CHARGE INDICATOR AND THE HORAMETER

8 - PLATFORM ROTATION CONTACTOR

9 - RAISE AND LOWER CONTACTOR OF THE EXTENSION ARM

10 - ROTATION CONTACTOR FOR ROTATED JIB (OPTION 3D)

11 - TELESCOPE OUTPUTS AND INPUTS CONTACTOR

12 - RAISE AND LOWER CONTACTOR OF THE SUPERIOR ARM

13 - RAISE AND LOWER CONTACTOR OF THE INFERIOR ARM

14 - TURRET ROTATION CONTACTOR

15 - INCLINATION CONTACTOR OF THE PLATFORM

16 - BATTERY SWITCH

17 - FLASHING LIGHT (OPTION)

18 - SLOPE SENSOR

19 - SOUND ALARM HORN

20 - BLOCKAGE OF THE TURRET ROTATION

Page 52

2 - 24

CONTROL INSTRUMENTATION

B - BASKET COMMAND AND CONTROL STATION

25

27

28

26

24

34

34

29

30

22

23

33

31

21

32

35

Page 53

2 - 25

B - BASKET COMMAND AND CONTROL STATION

21 - EMERGENCY STOP

22 - OVERLOAD LAMP AND VARIATOR DEFECTS

23 - SLOPE LAMP

24 - SOUND ALARM HORN

25 - CONTROL SWITCH

26 - CONTACTOR OF SELECTION OF ROTATION

27 - PLATFORM INCLINATION CONTACTOR

28 - EXTENSION ARM LIFTING / LOWERING CONTACTOR

29 - TELESCOPE OUTPUTS / INPUTS CONTACTOR

30 - SUPERIOR ARM LIFTING / RAISING CONTACTOR

31 - INFERIOR ARM LIFTING / RAISING CONTACTOR

32 - TRAVELLING CONTACTOR

33 - ALARM BUZZER

34 - SAFETY HARNESS ATTACHMENT POINTS

35 - CONSOLE PROTECTIVE COVER

NB: The terms RIGHT-LEFT-FRONT-REAR apply to a user on the nacelle platform in the transportation position

and looking straight ahead.

Page 54

2 - 26

1 - EMERGENY STOP

This red mushroom-head switch cuts off all the machine’s movements in the

event of any anomalies or danger.

- Press the knob to stop the machine’s movements.

- Turn the knob a quarter of a turn to the right to restore the power (the switch

automatically returns to its initial position).

This command takes priority in all circumstances, even when control is swit-

ched to the access platform.

If the Emergency Stop is pressed,

movements may stop very abruptly.

2 - KEY-OPERATED CONTROL SELECTOR SWITCH AT

GROUND LEVEL OR IN THE BASKET

This 3-position BASKET / BASE control station, with the Stop position in the

centre, powers the basket control console when it is set in the PLATFORM

position. When the selector is in the BASE position, power to the console in

the BASKET is cut off and only the base controls can be used.

A : - Functions are controlled from the basket command and control sta-

tion.

B : - Neutral position : the platform controls are idle (remove the key in

this position)

C : - Functions are controlled from the ground backup and maintenance

station.

3 - O

VERLOAD LAMP

If the basket is overloaded, the LED flashes intermittently (See : ACCESS

PLATFORM OPERATION– SAFETY INSTRUCTIONS ).

GROUND BACKUP AND MAINTENANCE STATION

B

C

A

1

2

3

Page 55

2 - 27

4 - “MAINTENANCE MACHINE” LAMP

- THIS LAMP HAS TWO FUNCTIONS:

1 This lamp is controlled by a timer, which brings it on every 50 hours

worked (Counting of the number of hours the hydraulic pump has

operated).

When the lamp is on (fixed LED), this mean that the machine must be

serviced (see chapter "MAINTENANCE TABLE").

NB: To deactivate this light, see 7 “Battery charge and timer indicator

lights”.

2 In the event of a fault, the number of flashes indicates the type of fault

detected by the variator:

- 1 flash : Variator parameter defect

- 2 flashes : Command activated before the use

- 3 flashes : Variator in short-circuit

- 4 flashes : Defect contactors of power

- 5 flashes : Sensor synchronisation fault

- 6 flashes : Accelerator, control switch, potentiometer or wire of speed

sensor

- 7 flashes : Battery discharged

- 8 flashes : Variator temperature over high

- 9 flashes : Bobbin contactor in short-circuit

-12 flashes : Defect bus connection.

If the LED flashes permanently, stop the access platform.

Consult your dealer

5 - “STATE OF CHARGE OF THE BATTERY” LAMP

The lamp changes of colors according to the state of the battery charge:

The red led:

- The charger is on the initial phase of charge.

The yellow led:

- The battery is charged at 80% of charge.

The green led:

- The battery is charged.

BATTERY AUTONOMY

- The following functions will be switched off when you reach 20% of

load, in working or transport speed position, at the ground backup and

maintenance control station or basket command and control station :

• Raise intermediate arms

• Raise upper arm

• Extend telescope

6 - “DEAD MAN” BUTTON

As a safety measure, this button must be held down constantly to activate the

various lifting and rotation functions.

6

4

5

Page 56

2 - 28

7 - BATTERY CHARGE INDICATOR AND THE

HORAMETER

A - BATTERY CHARGE INDICATOR

· BATTERY CHARGED

- All the bars are displayed (dark).

· BBATTERY DISCHARGED

- Only two bars are still displayed, meaning that you must proceed to

recharge the batteries (See the Chapter "MAINTENANCE INTERVALS").

NB: You must not drop below a battery charge level of 20%; otherwise the

batteries can deteriorate rapidly.

The following 2 timers are displayed on startup, but only the counter

with the "T" symbol is on during normal operation :

B - DAILY HORAMETRE INDICATOR

It indicates the total number of hours for all the movements made and can be

reset to zero.

C - PUMP AND TRACTION HORAMETRE INDICATOR

It indicates the total number of hours for all the movements made

D - FAULT DISPLAY

If the machine breaks down, a fault number is displayed (it will be stored in

memory and can be analysed) and the “machine maintenance” light 4 comes

on (flashing after faults have occurred).

If the fault continues to be displayed, immobilise the platform and make the

necessary repairs.

NB: For the descriptions and frequencies of the faults detected, see this

machine’s REPAIRS MANUAL.

Consult your dealer.

D

B

C

A

Page 57

2 - 29

RESETTING THE DAILY HORAMETRE TIMER TO ZERO

Proceed as follows:

- The platform must be in transport position (arms and telescope

completely folded),

- The platform must not be sloping,

- The platform must be in "Ground backup and maintenance station"

position, using selector 2 "key-operated control selector at ground level

or in the basket " and wait for the initialisation "Beep".

- Press 6, the "dead man button" and at the same time the two contactors

: 9 "contactor for raising and lowing the pendular arm" and 15 "basket

tilt contactor", until the counter is reset to zero.

NB: This operation should be done during the few seconds following

restoration of power to the electrical circuit.

RESET THE TIMER TO ZERO EVERY 50 HOURS OF OPERATION

This must be done after performing the maintenance described in the

Chapter: MAINTENANCE “EVERY 50 HOURS OF OPERATION”.

Proceed as follows:

- The platform must be in transport position (arms and telescope

completely folded),

- The platform must not be sloping,

- The platform must be in "Ground backup and maintenance station"

position, using selector 2 "key-operated control selector at ground level

or in the basket " and wait for the initialisation "Beep".

- Simultaneously press the “Dead Man’s” button 6 and contactors No. 12

(“upper arm raising and lowering contactor”) and 13 (“lower arm raising

and lowering contactor” until the MACHINE MAINTENANCE light 4

goes out (the timer is reset to zero).

NB: This operation should be done during the few seconds following

restoration of power to the electrical circuit.

6

2

12

9

15

13

4

Page 58

2 - 30

8 - PLATFORM ROTATION CONTACTOR

- This contactor is used to rotate the platform.

RIGHT ROTATION

- Place the base/basket switch in the base position, keep the "dead man"

button pushed and push the switch 8 to the right.

LEFT ROTATION

- Place the base/basket switch in the base position, keep the "dead man"

button pushed and push the switch 8 to the left.

9 - RAISE AND LOWER CONTACTOR OF THE EXTENSION ARM

- This contactor is used to raise or lower the extension arm.

LIFTING OF THE EXTENSION ARM

- Place the base/basket switch in the base position, keep the "dead man" button pushed and push the switch 9 upwards.

LOWERING OF THE EXTENSION ARM

- Place the base/basket switch in the base position, keep the "dead man" button pushed and push the switch 9

downwards.

10 - ROTATION CONTACTOR FOR ROTATED JIB (OPTION 3D)

- This contactor enables you to rotate the pendular arm.

RIGHT ROTATION

- Place the base/basket switch in the base position, keep the "dead man"

button pushed and push the switch 10 to the right.

LEFT ROTATION

- Place the base/basket switch in the base position, keep the "dead man"

button pushed and push the switch 10 to the left.

11 - TELESCOPE OUTPUTS AND INPUTS CONTACTOR

- This contactor enables you to extend and retract the telescope.

TELESCOPE EXTENSION

-

Place the base/basket switch in the base position, keep the "dead man"

button pushed and push the switch 11 to the left.

TELESCOPE RETRACTION

-

Place the base/basket switch in the base position, keep the "dead man" button

pushed and push the switch 11 to the right.

12 - RAISE AND LOWER CONTACTOR OF THE SUPERIOR ARM

- This contactor is used to raise or lower the superior arm.

LIFTING OF THE SUPERIOR ARM

-

Place the base/basket switch in the base position, keep the "dead man" button pushed and push the switch 12 upwards.

LOWERING OF THE SUPERIOR ARM

-

Place the base/basket switch in the base position, keep the "dead man" button pushed and push the switch 12 downwards.

10

8

9

11

12

Page 59

2 - 31

13 - RAISE AND LOWER CONTACTOR OF THE

INFERIOR ARM

- This contactor is used to raise and lower the inferior arm.

LIFTING OF THE SUPERIOR ARM

- Place the base/basket switch in the base position, keep the "dead man"

button pushed and push the switch 13 upwards.

LOWERING OF THE INFERIOR ARM

- Place the base/basket switch in the base position, keep the "dead man"

button pushed and push the switch 13 downwards.

14 - TURRET ROTATION CONTACTOR

- This contactor is used to rotate the turret.

RIGHT ROTATION

- Place the base/basket switch in the base position, keep the "dead man"

button pushed and push the switch 14 to the right.

LEFT ROTATION

- Place the base/basket switch in the base position, keep the "dead man"

button pushed and push the switch 14 to the left.

15 - INCLINATION CONTACTOR OF THE PLATFORM

- This contactor is used for the correction of the horizontality of the platform or

the complete re-folding of the platform in the transportation position.

CORRECTION OF THE PLATFORM UPWARD

- Place the base/basket switch in the base position, keep the "dead man"

button pushed and push the switch 15 upwards.

CORRECTION OF THE PLATFORM DOWNWARD

- Place the base/basket switch in the base position, keep the "dead man"

button pushed and push the switch 15 downwards.

16 - BATTERY SWITCH

The battery cut-out switch is located on the chassis on the ground backup

and maintenance station side.

IN THE ON POSITION

Turn the handle a quarter of a turn: current flows.

IN THE OFF POSITION

Turn the handle a quarter of a turn: current stops flowing.

Always set the battery cut-out to the OFF position when you are not using the

platform.

The sound alarm (see 19 - SOUND ALARM HORN) will come on if the

battery cut-out is left ON when the batteries are being charged.

15

16

14

13

Page 60

2 - 32

17 - FLASHING LIGHT (OPTION)

- The flashing alarm lamp turns on automatically when the platform is

travelling, or if a movement is carried out (Lifting, rotation,...).

18 - SLOPE SENSOR

- This sensor checks the platform’s inclination. When the platform

reaches the maximum authorised inclination (See the Chapter:

CHARACTERISTICS), the buzzer (33) sounds intermittently and all the

“AGGRAVATING” movements – raising the arms, extending the

telescope – are blocked. The LED (23) on the platform is lit.

NB: SLOPE TEST; set the platform on a flat surface in base control

position (see 2 – KEY-OPERATED CONTACTOR). Press the sensor

“PRESS TO TEST”, the buzzer should sound and the LED light up.

If the buzzer does not sound and the LED does not light, immobilise the

platform and make the necessary repairs.

19 - SOUND ALARM HORN

This sound alarm horn (fixed to the turret above the ground backup and

maintenance station box) is activated by pressing button 24.

The alarm will be activated if the BATTERY CUT-OUT is left on the ON

position when charging the batteries (see 16 – BATTERY CUT-OUT).

20 - BLOCKAGE OF THE TURRET ROTATION

- Put the spindle in the space foreseen for this effect.

- This spindle is used to lock the turret rotation when she is in position.

- She must be used when the access platform is transported by truck or by

another transport (train ...).

Do not forget to remove its during the use of the access platform.

NB: Releasing the pin; you may have to rotate the turret right or left to

free the pin to extract it from its location.

17

18

19

20

Page 61

2 - 33

21 - EMERGENCY STOP

This red mushroom-head switch cuts off all the machine’s movements in the

event of any anomalies or danger.

- Press the knob to stop the machine’s movements.

- Turn the knob a quarter of a turn to the right to restore the power (the switch

automatically returns to its initial position).

In any case, this control has priority, unless movements are controlled by the

ground backup and maintenance station.

If the Emergency Stop is pressed, movements may stop very abruptly.

22 - OVERLOAD LAMP AND VARIATOR DEFECTS

- THIS LAMP HAS TWO FUNCTIONS :

1 If the basket is overloaded, the LED flashes intermittently (See :

ACCESS PLATFORM OPERATION – SAFETY INSTRUCTIONS).

2 In case of fault, the number of flashes indicates the type of fault detected

by the variator (See: 4 - Lamp“MAINTENANCE MACHINE” p 2-17).

23 - SLOPE LAMP

When the access platform has reached the maximum authorised slope

the LED flashes intermittently See : ACCESS PLATFORM OPERATION

– SAFETY INSTRUCTIONS).

24 - SOUND ALARM HORN

- When button 24 is pressed, it activates the sound alarm horn 19 located on

the turret.

BASKET COMMAND AND CONTROL STATION

22

23

24

21

Page 62

2 - 34

25 - CONTROL SWITCH

NB: This control switch is progressive control, and gives a very high approa-

ch accurancy. Its use should be smooth and free of jerkes.

SAFETY TRIGGER

- This trigger (item A) of control control switch 25 must be continually

pushed in to perform movements from the operating of the access

platform.

26 - CONTACTOR OF SELECTION OF ROTATION

This contactor (26) has three positions. Switch it over to the movements

you desire and then use the manipulator (25).

PLATFORM ROTATION

- Switch the contactor 26 to the left (position I).

- Incline to the right or to the left the control switch 25 to orientate on the right

or on the left respectively.

TURRET ROTATION

- Switch the contactor 26 to vertical (position II).

- Incline to the right or to teh left the control switch 25 to orientate on the right

or on the left respectively.

ROTATION OF ROTATED JIB (3D PLATFORMS)

- Switch the contactor 26 to the right (position III).

- Incline to the right or to the left the contactor 25 in order to rotate on the right

or on the left respectively.

Before you make any rotation manoeuvres, check that there is enough space

between the platform or the turret and the various walls and installations.

I

II

III

I

II

III

26

26

I

II

III

26

A

25

Page 63

2 - 35

27 - 28 - 29 - 30 - 31 - 32 - MOVEMENT SELECTION

CONTACTOR

27 PLATFORM INCLINATION CONTACTOR

- Select the movement by pressing button 27; the movement remains

selected while the LED is lit (8 seconds).

- Push (forward) or pull (backward) the switch control 25 to raise or lower.

NB : The basket can only be tilted when the machine is in transport position.

(see USING THE ACCESS PLATFORM).

28 EXTENSION ARM LIFTING / LOWERING CONTACTOR

- Select the movement by pressing button 28; the movement remains

selected while the LED is lit (8 seconds).

- Push (forward) or pull (backward) the switch control 25 to raise or lower.

29 TELESCOPE OUTPUTS / INPUTS CONTACTOR