Mallory Aluminum Electrolytic Capacitors Application Guide

Application Guide Aluminum Electrolytic Capacitors

This Application Guide

This guide is a full handbook on aluminum electrolytic

capacitors, of course with emphasis on Cornell

Dubilier’s types. It covers construction in depth and

discloses the latest information on performance and

application for the major aluminum electrolytic types

made worldwide. We encourage you to tell us what more

you’d like to know, so we can improve this guide.

Aluminum Electrolytic Capacitor Overview

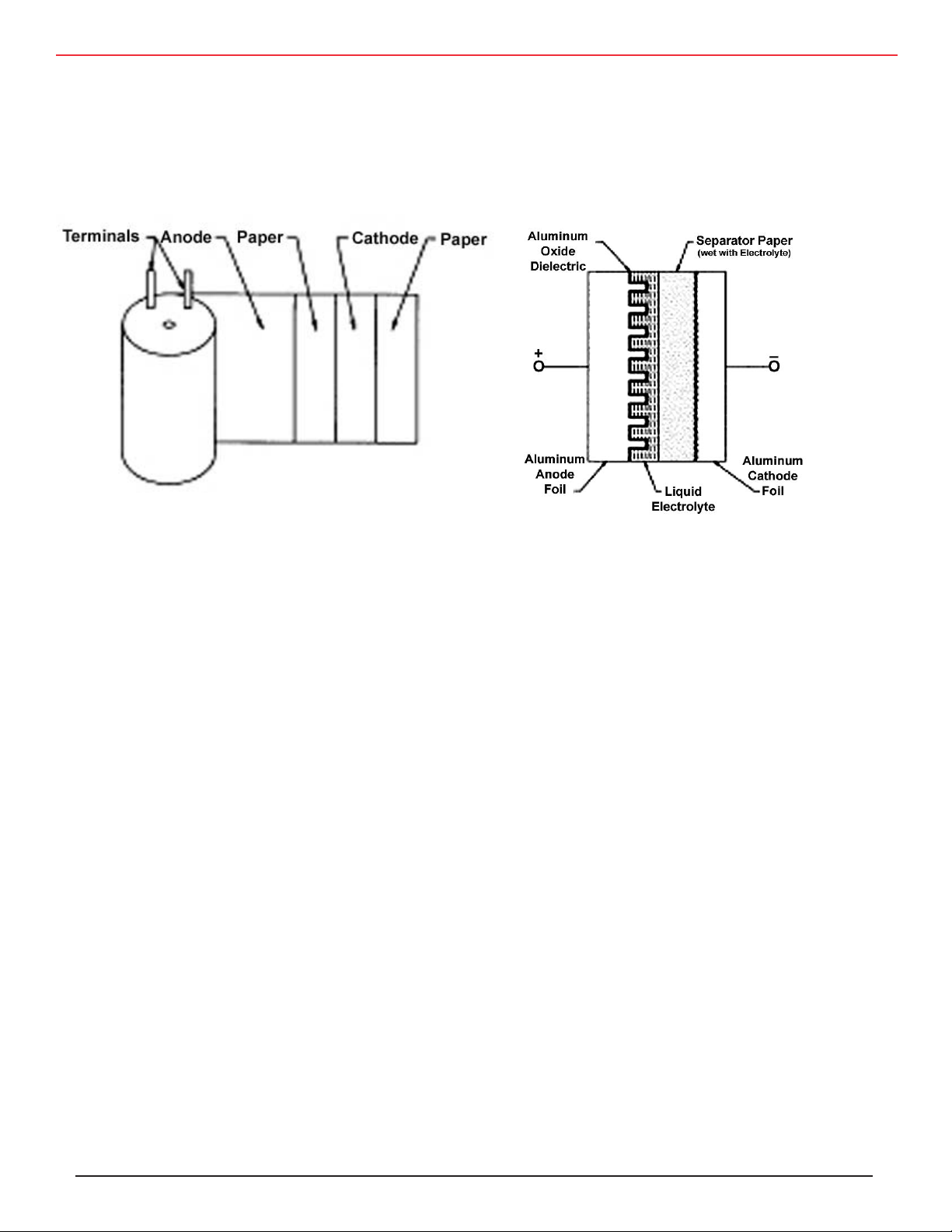

Except for a few surface-mount technology (SMT) aluminum electrolytic capacitor types with solid electro

lyte systems an aluminum electrolytic capacitor con

sists of a wound capacitor element, impregnated with

liquid electrolyte, connected to terminals and sealed in

a can. The element is comprised of an anode foil, paper

separators saturated with electrolyte and a cathode foil.

The foils are high-purity aluminum and are etched with

billions of microscopic tunnels to increase the surface

area in contact with the electrolyte.

While it may appear that the capacitance is between the

two foils, actually the capacitance is between the anode

foil and the electrolyte. The positive plate is the anode

foil; the dielectric is the insulating aluminum oxide on

the anode foil; the true negative plate is the conductive,

liquid electrolyte, and the cathode foil merely connects

to the electrolyte.

They are polar devices, having distinct positive and negative terminals, and are offered in an enormous va

-

-

riety of styles which include molded and can-style SMT

devices, axial and radial-leaded can styles, snap-in terminals styles and large-can, screw terminal styles. Rep

resentative capacitance-voltage combinations include

330 µF at 100 V and 6800 µF at 10 V for SMT

devices

100 µF at 450 V, 6,800 µF at 50 V and 10,000

µF at 10 V for miniature-can styles,

1200 µF at 450 V and 39,000 µF at 50 V for

snap-in can styles and

9000 µF at 450 V and 390,000 µF at 50 V for

large-can, screw-terminal styles.

-

-

This construction delivers colossal capacitance because

etching the foils can increase surface area more than

100 times and the aluminum-oxide dielectric is less

than a micrometer thick. Thus the resulting capacitor

has very large plate area and the plates are awfully close

together.

These capacitors routinely offer capacitance values from

0.1 µF to 3 F and voltage ratings from 5 V to 550V.

Capacitor Construction

Rilled

Construction

If two, same-value, aluminum electrolytic capacitors are

connected in series, back-to-back with the positive ter

minals or the negative terminals connected, the result

ing single capacitor is a non-polar capacitor with half

the capacitance. The two capacitors rectify the applied

voltage and act as if they had been bypassed by diodes.

When voltage is applied, the correct-polarity capacitor

gets the full voltage. In non-polar aluminum electrolytic

capacitors and motor-start aluminum electrolyte capaci

tors a second anode foil substitues for the cathode foil to

achieve a non-polar capacitor in a single case.

-

-

-

CDM Cornell Dubilier • 140 Technology Place • Liberty, SC 29657 • Phone: (864)843-2277 • Fax: (864)843-3800 • www.cde.com

Application Guide Aluminum Electrolytic Capacitors

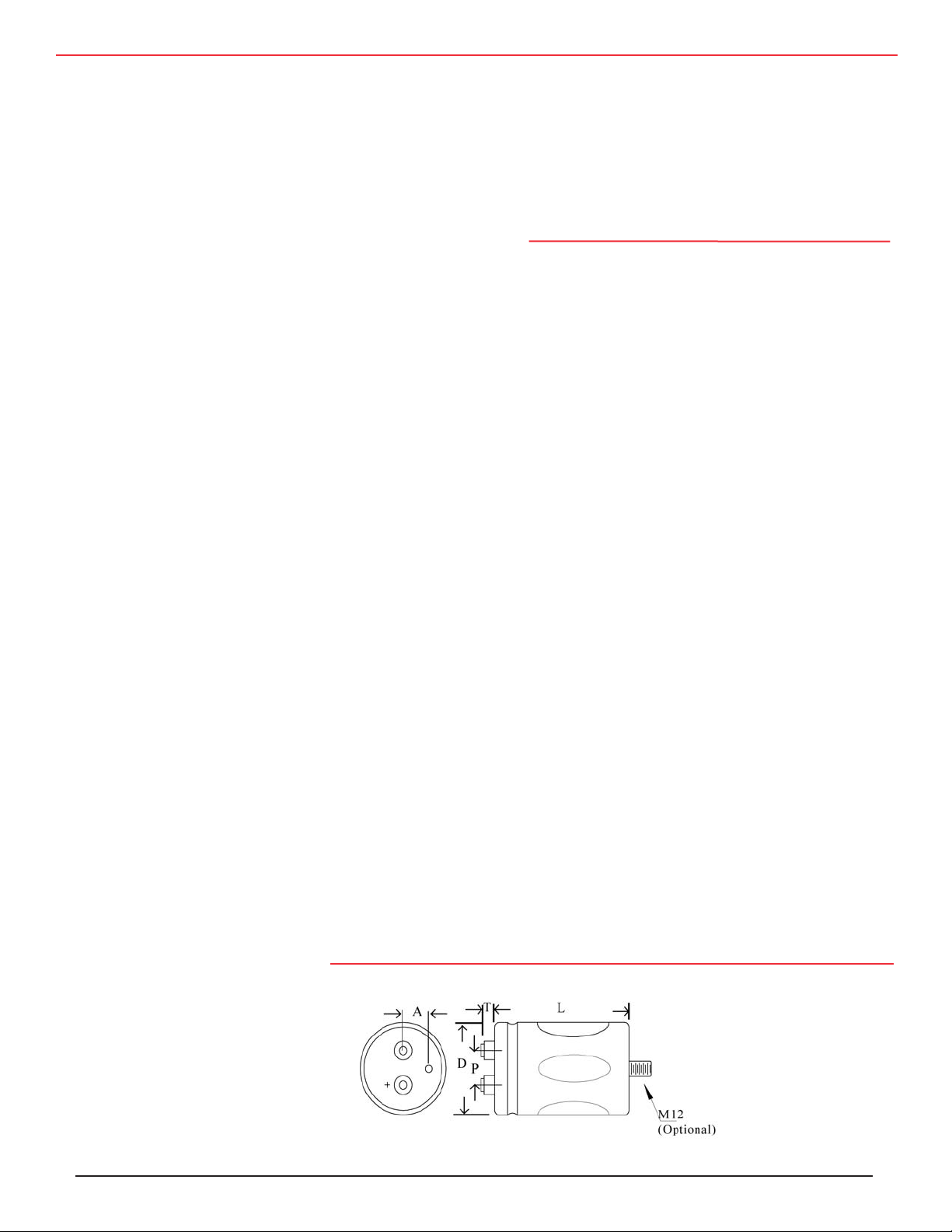

Miniature,

Radial-Leaded T

ype

Snap-in T

ype

Aluminum

Lead Wire

Tabs

Sleeve

Rubber

Can

Capacitor

Element

Terminal

Rubber

Top Disc

Phenolic Disc

Aluminum Tabs

Capacitor Element

Tape

Can

Sleeve

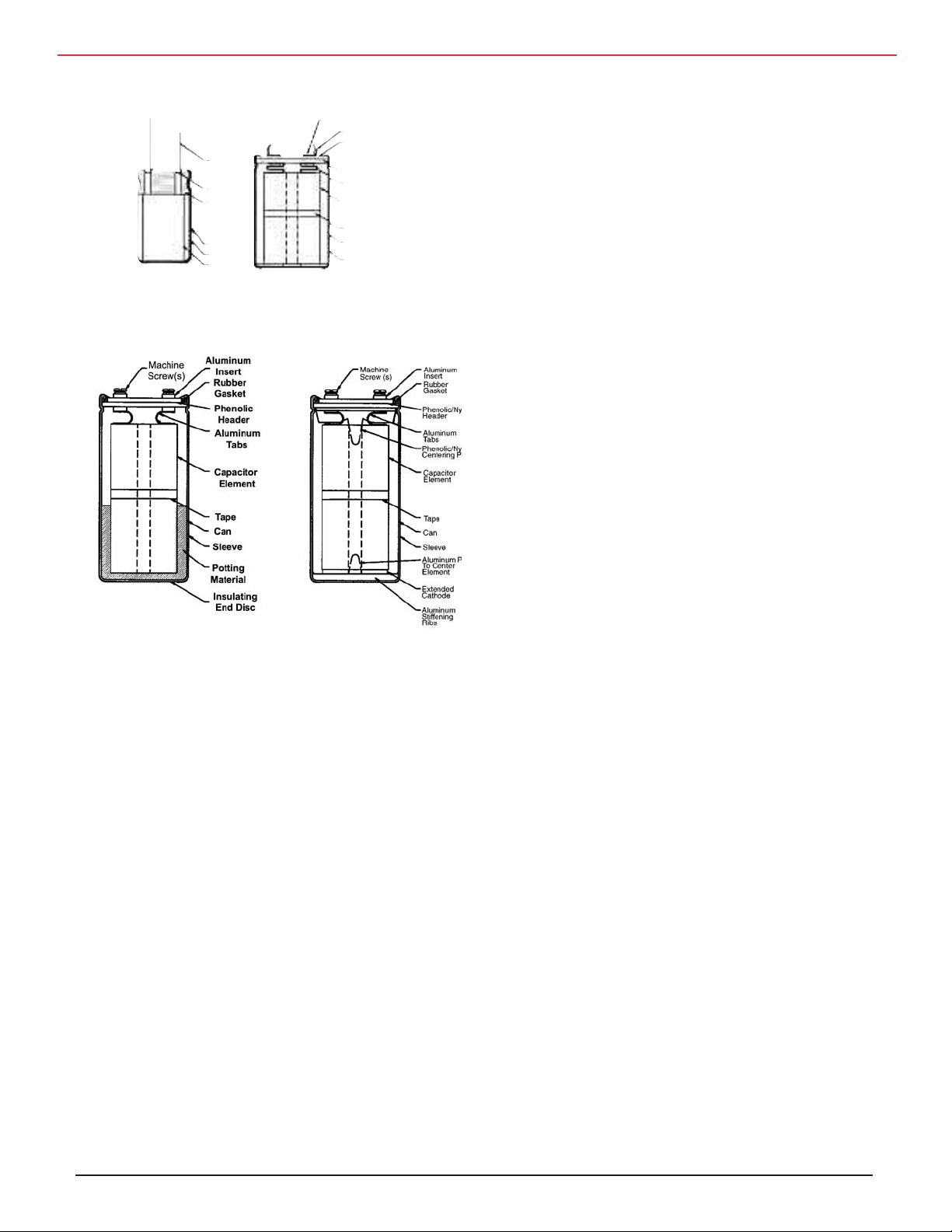

Capacitor Construction

Conventional Cornell Dubilier

Construction Thermal Pak

These figures show typical constructions of the

non-surface-mount aluminum electrolytic capacitors.

Most Cornell Dubilier capacitors use compression-fit

construction so there is no thermoplastic potting com

pound to interfere with safety-vent operation. Thermal

Pak™ and Rilled are Cornell Dubilier’s unique con

structions for computergrade, screw terminal capacitors. Compared to conventional, potted construction,

they operate cooler, provide longer life, withstand

higher shock and vibration, deliver more reliable safe

ty vent operation and are lighter weight.

Etching

The anode and cathode foils are made of high purity,

thin aluminum foil, 0.02 to 0.1 mm thick. To increase

the plate area and the capacitance, the surface area in

contact with the electrolyte is increased by etching the

foils to dissolve aluminum and create a dense network

of billions of microscopic tunnels penetrating through

the foil. Etching involves pulling the aluminum foil on

rollers through a chloride solution while applying an

AC, DC or AC-and-DC voltage between the etch solution and the aluminum foil. Surface area can increase

CDM Cornell Dubilier • 140 Technology Place • Liberty, SC 29657 • Phone: (864)843-2277 • Fax: (864)843-3800 • www.cde.com

as much as 100 times for foil in low-voltage capacitors

and 20 to 25 times for high-voltage capacitors.

Forming

The anode foil carries the capacitor’s dielectric. The di

electric is a thin layer of aluminum oxide, Al

2O3

is chemically grown on the anode foil during a process

called “formation.” Formation is accomplished by pull

ing the anode foil on rollers through an electrolyte bath

and continuously applying a DC voltage between the

bath and the foil. The voltage is 135% to 200% of the

final capacitor’s rated voltage. The thickness of the alu

minum oxide is about 1.4 to 1.5 nm for each volt of

the formation voltage, e.g., the anode foil in a 450 V

capacitor may get a formation voltage in excess of 600

V and have an oxide thickness of about 900 nm. That’s

less than a hundredth the thickness of a human hair.

Formation reduces the effective foil surface area because the microscopic tunnels are partially occluded by

the oxide. The tunnel etch pattern is adjusted by choice

of foil and etching process so that low-voltage anodes

have dense tunnel patterns compatible with thin oxide

and high-voltage anodes have coarse tunnel patterns

compatible with thick oxide. The cathode foil is not

formed and it retains its high surface area and dense

etch pattern.

Slitting

Foil is etched and formed in jumbo rolls of 40 to 50 cm

wide and then slit into various widths according to the

lengths of the final capacitors.

Winding

The capacitor element is wound on a winding machine

with spindles for one-to-four separator papers, the an-

ode foil, another set of one-to-four separator papers and

the cathode foil. These are wound into a cylinder and

wrapped with a strip of pressure-sensitive tape to prevent unwinding. The separators prevent the foils from

touching and shorting, and the separators later hold the

reservoir of electrolyte.

Before or during winding aluminum tabs are attached

to the foils for later connection to the capacitor terminals. The best method is by cold-welding of the tabs to

the foils with tab locations microprocessor controlled

during winding so that the capacitor element’s inductance can be less than 2 nH.

-

, that

-

-

Application Guide Aluminum Electrolytic Capacitors

The older method of attachment is by staking, a process

of punching the tab through the foil and folding down

the punched metal. Cold welding reduces short-circuit

failures and performs better in high-ripple current and

discharge applications in which the individual stakes

may fail from high current like buttons popping off one

at a time from a fat-man’s vest.

Wound Capacitor Elements

Connecting Terminals

conduction. Common solvents are ethylene glycol

(EG), dimethylformamide (DMF) and gammabutyro

lactone (GBL). Common solutes are ammonium borate

and other ammonium salts. EG is typically used for ca

pacitors rated –20 °C or –40 °C. DMF and GBL are

often used for capacitors rated –55 °C.

-

-

In SMT capacitors and miniature capacitors with rub

ber bungs, extensions of the tabs are the capacitor terminals. But in large can capacitors like snap-ins and

screw terminal styles, the tabs are riveted or welded

on the underside of the capacitor tops to terminal inserts. Welding produces the lowest contact resistance

and highest current handling. Both resistive welding

and ultrasonic welding are used. The up to 12 tab pairs

that may be used in large screw terminal capacitors often require more mechanical support during assembly

so the tabs in such capacitors may be both riveted to

post extensions on the terminals and then welded. In an

axial-leaded capacitor the cathode tab is welded to the

can before sealing.

Impregnation

The capacitor element is impregnated with electrolyte

to saturate the paper separators and penetrate the etch

tunnels. The method of impregnation may involve

immersion of the elements and application of vacuumpressure cycles with or without heat or, in the case of

small units, just simple absorption. The electrolyte is

a complex blend of ingredients with different formu

lations according to voltage and operating temperature

range. The principal ingredients are a solvent and a

conductive salt – a solute – to produce electrical

-

Water in the electrolyte plays a big role. It increases

conductivity thereby reducing the capacitor’s resis

tance, but it reduces the boiling point so it interferes

with high temperature performance, and it reduces

shelf life. A few percent of water is necessary because

the electrolyte maintains the integrity of the aluminum

oxide dielectric. When leakage current flows, water is

broken into hydrogen and oxygen by hydrolysis, and

the oxygen is bonded to the anode foil to heal leakage

sites by growing more oxide. The hydrogen escapes by

passing through the capacitor’s rubber seal.

Sealing

The capacitor element is sealed into a can. While most

cans are aluminum, phenolic cans are often used for

motorstart capacitors. In order to release the hydrogen

the seal is not hermetic and it is usually a pressure clo

sure made by rolling the can edge into a rubber gasket,

a rubber end-plug or into rubber laminated to a phenolic board. In small capacitors molded phenolic resin

or polyphenylene sulfide may replace the rubber. Too

-

tight a seal causes pressure build up, and too loose a

seal shortens the life by permitting drying out, loss of

electrolyte.

Capacitor-Element Materials

-

-

CDM Cornell Dubilier • 140 Technology Place • Liberty, SC 29657 • Phone: (864)843-2277 • Fax: (864)843-3800 • www.cde.com

Application Guide Aluminum Electrolytic Capacitors

Aging

Here the capacitor assembly comes full circle. The last

manufacturing step is “aging” during which a DC voltage

greater than the rated voltage but less than the formation

voltage is applied to the capacitor. Usually the voltage is ap

plied at the capacitor’s rated temperature, but other temperatures and even room temperature may be used. This

step reforms the cut edges and any damaged spots on the an

ode foil and covers any bare aluminum with aluminum oxide

dielectric. Aging acts as burn-in and reduces or eliminates

early life failures (infant mortals). Low, initial DC leakage

-

current is a sign of effective aging.

Comparison to Other Types of Capacitors

Ceramic Capacitors

Ceramic capacitors have become the preeminent, general

purpose capacitor, especially in SMT chip devices where

their low cost makes them especially attractive. With the

emergence of thinner-dielectric, multilayer units with rated

voltages of less than 10 V capacitance values in the hundreds

of microfarads have become available. This intrudes on the

traditional, high-capacitance province of aluminum electro

lytic capacitors.

Ceramic capacitors are available in three classes according

to dielectric constant and temperature performance. Class 1

(NPO, COG) is suitable for low capacitance, tight tolerance

applications in the range of 1 pF to a few mF. Class 2 (X7R)

has 20 to 70 times as much capacitance per case size, but ca

pacitance typically varies about ± 10% over its –55 to 125 °C

temperature range. The maximum change is +15 % to –25%.

Class 3 (Z5U) with about 5 times the capacitance of Class

2 has wild swings of capacitance with voltage and temperature. The temperature range is –25 °C to 85 °C, and capacitance varies about +20% –65% over the range. Ceramic chip

capacitors are brittle and sensitive to thermal shock, so precautions need to be taken to avoid cracking during mounting,

especially for high-capacitance large sizes.

The typical temperature range for aluminum electrolytic

capacitors is –40 °C to 85 °C or 105 °C. Capacitance var

ies about +5% –40% over the range with the capacitance

loss all at cold temperatures. Capacitors rated –55 °C generally only have –10 % to –20 % capacitance loss at –40 °C.

Cold temperature performance for rated voltages of 300 V

and higher is often worse, and temperature performance var

ies by manufacturer. Thus Class 1 and 2 ceramic capacitors

perform better than aluminum electrolytic capacitors at cold

temperatures, and Class 3 ceramic capacitors perform worse

at all temperatures.

Aluminum electrolytic capacitors readily deliver much

more capacitance. Aluminum electrolytic capacitors give

more capacitance and energy storage per unit volume than

ceramic capacitors for all types except for low-voltage,

Class 3 ceramic SMT chip capacitors. While tolerances of

±5% and ±10% are routine for ceramic capacitors, ± 20%

and –10% +50% are the norms for aluminum electrolytic.

This makes aluminum electrolytics the choice for high capacitance applications like rectification filters and power

holdup where more capacitance is a bonus. Ceramic ca

pacitors are not polarized and therefore can be used in AC

applications. The low DF and high capacitance stability of

Class 1 and 2 are especially suited to AC and RF applica

-

tions. By comparison, aluminum electrolytic capacitors are

polarized and cannot withstand voltage reversal in excess of

1.5 V. While non-polar aluminum electrolytics are available

for momentary-duty AC applications like motor starting and

voltage-reversing applications, the high DF of aluminum

electrolytic capacitors – from 2% to 150% – causes excess

heating and short life in most AC applications.

-

Ceramic capacitors are generally no more reliable than alu

minum electrolytic capacitors because aluminum electrolytics self heal. Since high-capacitance ceramic capacitors may

develop micro-cracks, aluminum electrolytic capacitors are

preferred for high capacitance values. However, small sizes

of aluminum electrolytic capacitors may have limited life

due to dry out, so consider reliability in your choice for applications operating at high temperatures, over 65 °C.

Film Capacitors

Film capacitors offer tight capacitance tolerances, very low

-

leakage currents and small capacitance change with temperature. They are especially suited to AC applications through

their combination of high capacitance and low DF that permits high AC currents. However, they have relatively large

sizes and weights.

-

The popular polymers used for plastic-film dielectric

tors are polyester and polypropylene. The popular polymer

for SMT devices is polyphenylene sulfide (PPS). While film/

foil construction is often used for small capacitance values

– less than 0.01 µF – and for high-current applications, metallized-film is usually preferred because it gives smaller size,

lower cost and is self healing. Film capacitors are generalpurpose capacitors for through-hole applications and have

special uses for tight-tolerance, AC voltage, high voltage and

snubbing.

Polyester film capacitors operate from –55 °C to 85 °C at

-

-

-

-

capaci-

CDM Cornell Dubilier • 140 Technology Place • Liberty, SC 29657 • Phone: (864)843-2277 • Fax: (864)843-3800 • www.cde.com

Application Guide Aluminum Electrolytic Capacitors

rated voltage; +85 °C to 125 °C with linear voltage deratingto 50% rated voltage. The typical capacitance change over

the entire range is less than –5% +15% with ±1% from 0 °C

to 50 °C. Capacitance values are readily available up to 10

µF with special large sections to 100 µF. Generally available

voltages are 50 to 1000 Vdc and 35 to 600 Vac. AC current

handling is limited by polyester’s high temperature DF of

about 1%.

Polypropylene film capacitors operate from –55 °C to 85 °C

at rated voltage; 85 °C to 105 °C with linear voltage derating

to 50% rated voltage. The typical capacitance change over

the entire range is less than +2% –4% with ±1% from –20

°C to 60 °C. Capacitance values are readily available up to

65 µF with special large sections to 1000 µF. Generally avail

able voltages are 100 to 3000 Vdc and 70 to 500 Vac. AC

current handling permits use in motor-run and other continu

ous duty AC applications.

Compared to aluminum electrolytic capacitors, film capaci

tors take teh lead in high voltage, AC voltage and tight toler

ance applications. Aluminum electrolytics excel in capacitance and energy storage.

Solid Tantalum Capacitors

Like aluminum electrolytic capacitors solid tantalum

capacitors are polar devices (1 V maximum reverse voltage),

having distinct positive and negative terminals and are of

fered in a variety of styles. Case styles include both molded

and conformal-coated versions of

radial, axial and surface

mount configurations. Typical capacitance values are from

0.1 µF to 1000 µF in voltage ratings from 2 V to 50 V. Typical maximum capacitance-voltage combinations are approximately 22 µF at 50 V for leaded styles and 22 µF at

35 V for surface mount. Strengths are temperature stability,

volumetric efficiency and compatibility with all automated

assembly systems. Weaknesses are the limited voltage and

capacitance ranges and a short-circuit failure mode accompanied by catching fire.

The operating temperature range is –55 °C to 85 °C at rated

voltage; +85 °C to 125 °C with linear voltage derating to

2/3 rated voltage. The typical capacitance change over the

entire range is less than ±5%. Thus aluminum electrolytic

-

capacitors have a much broader voltage and capacitance

ranges than solid tantalum capacitors but perform worse at

-

cold temperature.

Solid tantalum capacitors are generally considered more re

-

liable than aluminum electrolytic capacitors because solid

-

tantalum capacitors do not wear out. Their failure rate decreases with time, while aluminum electrolytic capacitors

wear out by drying out. As a practical matter, dry-out only

affects the smallest capacitors operating in high-temperature

environments.

Larger aluminum electrolytics do not dry out in the 10 to 20

-

years expected of most applications, and the open-circuit,

dry-out failure is benign compared to solid-tantalum’s short

circuit failure mode.

-

Characterization

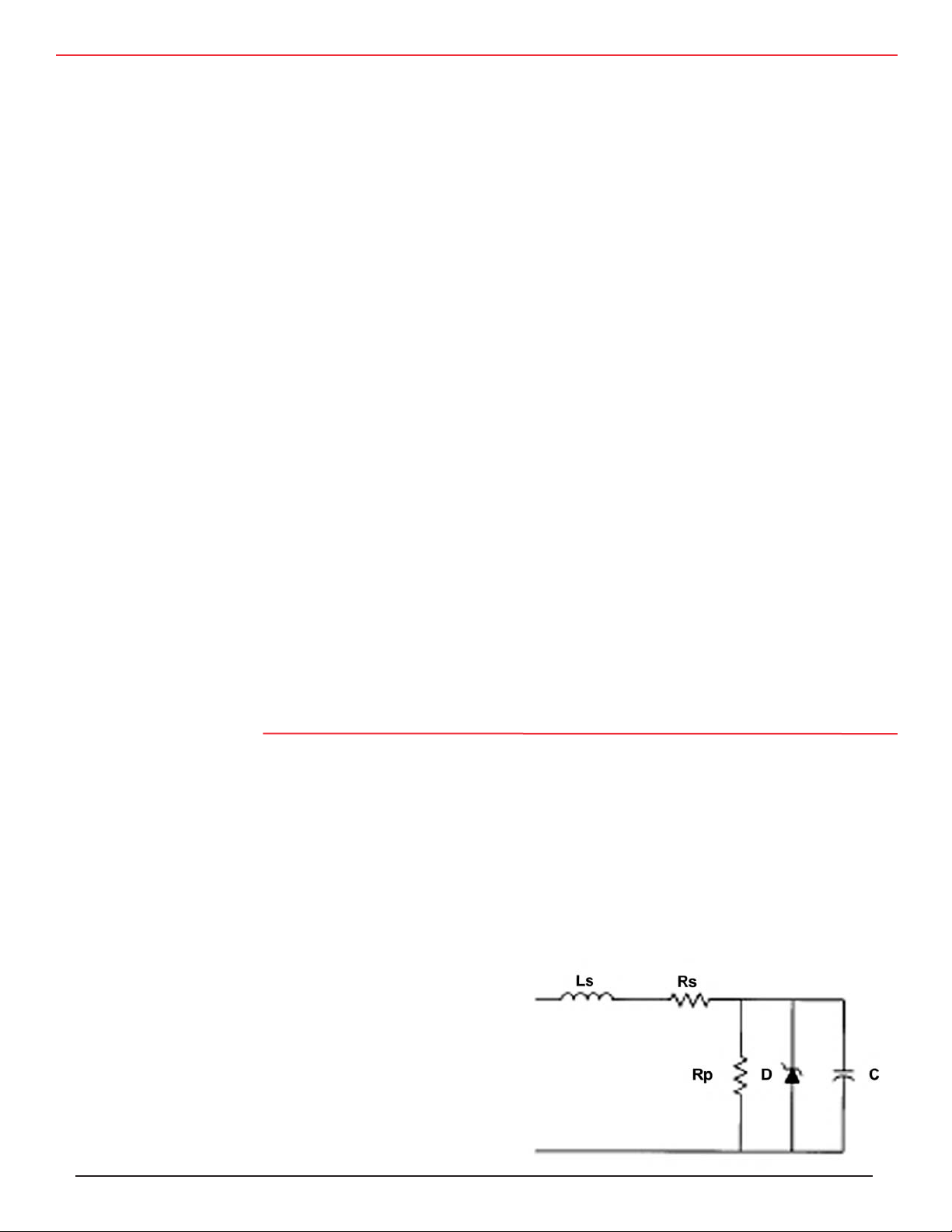

Resistance Rs is the equivalent series resistance, and it

CIRCUIT MODEL

Capacitance occurs when two electrical conductors are separated by an insulator. A capacitor is an electronic component

optimized to deliver capacitance. The capacitance in pF is

C = 0.08855(n-1) ε A/d

Where n is the number of plates for electrodes, ε is the

dielectric constant, A is the plate surface area in cm

is the thickness of the dielectric between the plates in cm.

Dielectric constant is the multiplier increase in capacitance

that the dielectric delivers compared to a vacuum. The

dielectric constant for aluminum oxide is about 8.

The circuit at the right models the aluminum electrolytic

capacitor’s normal operation as well as overvoltage and

reverse-voltage behavior. Capacitance C is the equivalent

capacitance and it decreases with increasing frequency.

Common values range from

CDM Cornell Dubilier • 140 Technology Place • Liberty, SC 29657 • Phone: (864)843-2277 • Fax: (864)843-3800 • www.cde.com

1 µF to 1 F, a six-decade range.

2

and d

decreases with increasing frequency and temperature. It increases with rated voltage. Typical values range from 10 m�

to 1 Ω , and Rs is inversely proportional to capacitance for a

given rated voltage.

Inductance Ls is the equivalent series inductance, and it is

relatively independent of both frequency and temperature.

Typical values range from 10 nH to 30 nH for radial-leaded

types, 20 to 50 nH for screw-terminal types, and up to 200

nH for axial-leaded types. It increases with terminal spacing.

Equivalent Circuit

Application Guide Aluminum Electrolytic Capacitors

Resistance Rp is the equivalent parallel resistance and accounts for leakage current in the capacitor. It increases with

increasing capacitance, temperature and voltage, and it de

creases with time. Typical values are on the order of 100/C

MΩ with C in µF.

Zener diode D models overvoltage and reverse voltage be

havior. Application of overvoltage on the order of 50 V be

yond the capacitor’s surge voltage rating causes high leak

age current and a constant-voltage operating mode quite like

the reverse conduction of a zener diode.

Parameter Unit Symbol Formula Approximately

Capacitance farads (F) C

Capacitive reactance

ohms (Ω)

Current amperes (A) I C(dV/dt), Vz/Z

Dissipation factor none DF

Energy

Equivalent series resistance

joules (J) E ½CV²

ohms (Ω)

Frequency hertz (Hz) f

Impedance

ohms (Ω)

Inductance henries (H) Ls

Inductive reactance

ohms (Ω)

Loss angle degrees (°)

Phase angle degrees (°)

Power watts (W) P I²Rs, I²XcDF,(VA)(PF)

Power factor none PF

Quality factor none Q

Self-resonant frequency hertz (Hz)

Voltage

volts (V) V Vc=IXc, Vz=IZ

Volt-amperes V-A VA

Application of reverse voltage much beyond 1.5 V causes

high leakage current quite like the forward conduction of a

diode. Neither of these operating modes can be maintained

-

for long because hydrogen gas is produced by the capaci

tor, and the pressure build up will cause failure. In terms

of parameters in the next section, Rated Capacitance is C,

Dissipation Factor is 2

-

is Rs, Impedance is

-

-

and Inductance is Ls. The table below expresses these and

other parameters in terms of the equivalent-circuit model.

[(Rs)2 + (1/(2πfC) – 2πfLs)2 ]

Xc

Rs/Xc, 2πfCRs, tan δ, cot θ

Rs

Z [Rs²+ (Xc–XL)²]

X

L

δ

θ

Rs/Z, sin δ, cos θ

Xc/Rs, 1/DF, cot

ω

o

πfCRs, Equivalent Series Resistance

1⁄2

1/(2πfC)

PF

DF/(2πfC)

½

Xc

2πfLs

tan-1 DF

cot-1 DF

DF

δ, tan θ

1/PF

1/[2π(LC)½]

Z

IVz, I²Z

-

Parameters

TEMPERATURE RANGE

Operating Temperature Range

The Operating Temperature Range is the temperature range

over which the part will function, when electrified, within

the limits given in the specification. It is the range of ambient

temperatures for which the capacitor has been designed to

operate continuously. Largely the formation voltage sets the

high-temperature limit. Higher formation voltages permit

higher operating temperatures but reduce the capacitance.

The low-temperature limit is set largely by the cold resistivity of the electrolyte. The higher cold resistivity increases

the capacitor’s ESR 10 to 100 fold and reduces the available

capacitance.

CDM Cornell Dubilier • 140 Technology Place • Liberty, SC 29657 • Phone: (864)843-2277 • Fax: (864)843-3800 • www.cde.com

Typical temperature ranges are –20 °C to 55 °C, –25 °C

to 85 °C, –40 °C to 85 °C, –55 °C to 85 °C, –40 °C to

105 °C, –55 °C to 105 °C and –55 °C to 125 °C.

Storage Temperature Range

The Storage Temperature Range is the temperature range to

which the part can be subjected unbiased, and retain conformance to specified electrical limits. It is the range of ambient

temperatures over which the capacitor may be stored without

damage for short periods. For long periods of storage keep

capacitors at cool room temperatures and in an atmosphere

free of halogen gases like chlorine and fluorine that can corrode aluminum. Storage temperature ranges are from –55

°C to the upper limit of the operating-temperature ranges.

Application Guide Aluminum Electrolytic Capacitors

CAPACITANCE

The rated capacitance is the nominal capacitance and it is

specified at 120 Hz and a temperature of 25 °C. The rated

capacitance is also the capacitance marked on the unit.

here DF is a unit-less number express in percent, test fre

quency f is

i

n Hz, capacitance C

is in µF and ESR is in

Ω.

-

Capacitance Tolerances

Capacitance tolerance is the permitted minimum and maxi

mum capacitance values expressed as the percentage decrease and increase from the rated capacitance, ΔC/C. Typical capacitance tolerances are ±20%, –10% +50%, and –10%

+75%.

Tighter tolerances are more readily available in high volt

age capacitors, e.g., above 150 V, but tolerances tighter than

±10% are generally not available. Note that tighter tolerance

parts may meet other tolerance requirements and are readily

substitutable. The capacitance varies with temperature and

frequency. This variation itself is also dependent on the rated

voltage and capacitor size.

Capacitance Measurement

For aluminum electrolytic capacitors, capacitance is mea

sured as the capacitance of the equivalent series circuit at 25

°C in a measuring bridge supplied by a 120 Hz source free of

harmonics with maximum AC signal voltage of 1 V rms and

no forward-bias voltage.

DF Measurement

The measurement of DF is carried out at +25 °C, 120 Hz,

and no voltage bias, with a maximum 1 Vac rms signal volt

age free of harmonics. The value of DF is temperature and

frequency dependent.

DF Temperature Characteristics

The dissipation factor decreases with increasing temperature.

DF declines about 50% from 25 °C to the high-temperature

limit, but increases more than 10 fold at the low temperature

limit. The DF of the better devices rated –55 °C increases

less than 5 times at –40 °C.

DF

defined in the next paragraph, varies little with tem-

lf,

perature and ESR

, also in the next paragraph, increases 10

hf

to 100 times from 25 °C to the low-temperature limit. The

increase in DF at cold temperatures is set by the ESRhf.

-

DF Frequency Characteristics

The dissipation factor varies with frequency at high frequen

cies. DF can be modeled as below:

-

-

Capacitance Temperature Characteristics

The capacitance varies with temperature. This variation it

self is dependent to a small extent on the rated voltage and

capacitor size. Capacitance increases less than 5% from 25

ºC to the high-temperature limit. For devices rated –40 °C

capacitance typically declines 20% at –40 °C for low-volt

age units and up to 40% for high-voltage units. Most of the

decline is between –20 °C and –40 °C. For devices rated

–55 °C capacitance typically declines less than 10% at –40

°C and less than 20% at –55 °C.

Capacitance Frequency Characteristics

The effective capacitance decreases as frequency increases.

Self-resonance is typically below 100 kHz depending on capacitance. At self-resonance the device is resistive and be

yond it is inductive. The termination style (i.e., axial, radial,

screw-terminal) will influence the inductive characteristics.

Small radial-leaded capacitors have inductance of less than

20 nH. Larger capacitors have more inductance according to

terminal spacing.

DISSIPATION FACTOR (DF)

Dissipation factor is the measurement of the tangent of the

loss angle (tan

δ) expressed as a percentage. It is also the ratio

of the ESR to the capacitive reactance and is thus related to

ESR by this equation:

DF = 2πfC(ESR)/10,000

DF = DFlf + 2πfC(ESRhf)/10,000

Where DF is a the total dissipation factor in percent, DF

the low-frequency dissipation factor in percent, ESR

high-frequency ESR in

C is the capacitance in µF at the test frequency. DF

-

Ω, f is the test frequency in Hz and

hf

results

lf

from the power lost by the applied electric field in orienting he molecules of the aluminum oxide dielectric. ESR

results from the resistive losses in the foils, connections and

the electrolyte/separator pad. The electrolyte/ separator pad

resistance usually dominates and its resistance varies little

with frequency. DF

ranges from about 1.5% to 3%. ESRhf

lf

ranges from 0.002 to 10 and decreases with temperature.

The DF equation above shows that DF is constant for low fre

quencies and crosses over to increasing-DF, constant ESR, at

a crossover frequency inversely proportional to capacitance.

Since high-capacitance capacitors have low crossover fre

quencies, DF increases more with increasing frequency than

for lower-capacitance capacitors.

EQUIVALENT SERIES RESISTANCE (ESR)

The equivalent series resistance (ESR) is a single resistance

representing all of the ohmic losses of the capacitor and con

nected in series with the capacitance.

is

lf

is the

hf

-

-

-

CDM Cornell Dubilier • 140 Technology Place • Liberty, SC 29657 • Phone: (864)843-2277 • Fax: (864)843-3800 • www.cde.com

Loading...

Loading...