Makita UC3050A, UC3550AP, UC3550A, UC3051A, UC3551A Instruction Manual

...

1

GB

Electric Chain Saw INSTRUCTION MANUAL

SI

Električna verižna žaga NAVODILO ZA UPORABO

AL

Sharra elektrike me zinxhir MANUALI I PËRDORIMIT

BG

Електрически верижен трион

РЪКОВОДСТВО ЗА ЕКСПЛОАТАЦИЯ

HR

Električna motorna pila PRIRUČNIK S UPUTAMA

MK

Електрична моторна пила

У

ПАТСТВО ЗА УПОТРЕБА

RO

Ferăstrău electric cu lanţ MANUAL DE INSTRUCŢIUNI

RS

Електрична ланчана тестера

У

ПУТСТВО ЗА УПОТРЕБУ

RUS

Электрическая Цепная Пила

РУКОВОДСТВО ПО ЭКСПЛУАТАЦИИ

UA

Електрична ланцюгова пила ІНСТРУКЦІЯ З ЕКСПЛУАТАЦІЇ

UC3050A

UC3550A

UC3550AP

UC4050A

UC4550A

UC3051A

UC3551A

UC4051A

UC4551A

2

1 014453

1

2

2 014393

1

3 014515

1

4 014516

1

5 014457

2

1

6 014448

3

1

2

7 014380 8 014454

1

2

9 014394

4

3

1

2

12 014359

1

2

13 014376

14 006921

1

2

15 014386

1

2

3

5

4

1

2

3

5

4

10 014680 11 014682

Reclaimend

oil

3

1

2

3

18 014387

1

32

19 014439

1

20 014517 21 014392

1

22 014389

23 006914

A

B

A

B

24 006915

25 014390

45

o

2 1/

2

45

o

1

26 006917 27 006918

28 006923

1

2

2

3

3

29 009202

30 006924

1

2

3

5

4

16 014680

1

2

3

5

4

17 014682

4

22

1

1

3

1

31 014456

30

30

11

32 014455

33 006927

30

34 006928

35 014344

36 006930

1

2

37 014391

1

38 014513

1

39 001145

1

2

40 014395

5

ENGLISH (Original instructions)

Explanation of general view

2-1. Lever

2-2. Sprocket cover

3-1. Adjusting screw

4-1. Adjusting dial

5-1. Sprocket

6-1. Guide bar

6-2. Hole

7-1. Hook

7-2. Hole

7-3. Pin

9-1. Lever

9-2. Sprocket cover

10-1. Loosen

10-2. Tighten

10-3. Chain adjusting screw

10-4. Guide bar

10-5. Saw chain

11-1. Loosen

11-2. Tighten

11-3. Adjusting dial

11-4. Guide bar

11-5. Saw chain

12-1. Cord hook

12-2. Tool's cord

12-3. Extension cord

12-4. Plug and socket (the shape may

differ from country to country)

13-1. Lock-off button

13-2. Switch trigger

15-1. Oil filler cap

15-2. Strap

16-1. Loosen

16-2. Tighten

16-3. Chain adjusting screw

16-4. Guide bar

16-5. Saw chain

17-1. Loosen

17-2. Tighten

17-3. Adjusting dial

17-4. Guide bar

17-5. Saw chain

18-1. Front hand guard

18-2. Lock

18-3. Unlock

19-1. Front hand guard

19-2. Unlock

19-3. Lock

20-1. Oil level sight

22-1. Spike bumper

26-1. Felling area

29-1. Felling direction

29-2. Danger zone

29-3. Escape route

31-1. Cutting length

31-2. Distance between cutting edge

and depth gauge

31-3. Minimum 3 mm

32-1. Side plate angle

37-1. Oil guide groove

37-2. Oil feed hole

38-1. Sprocket

39-1. Limit mark

40-1. Brush holder cap

40-2. Screwdriver

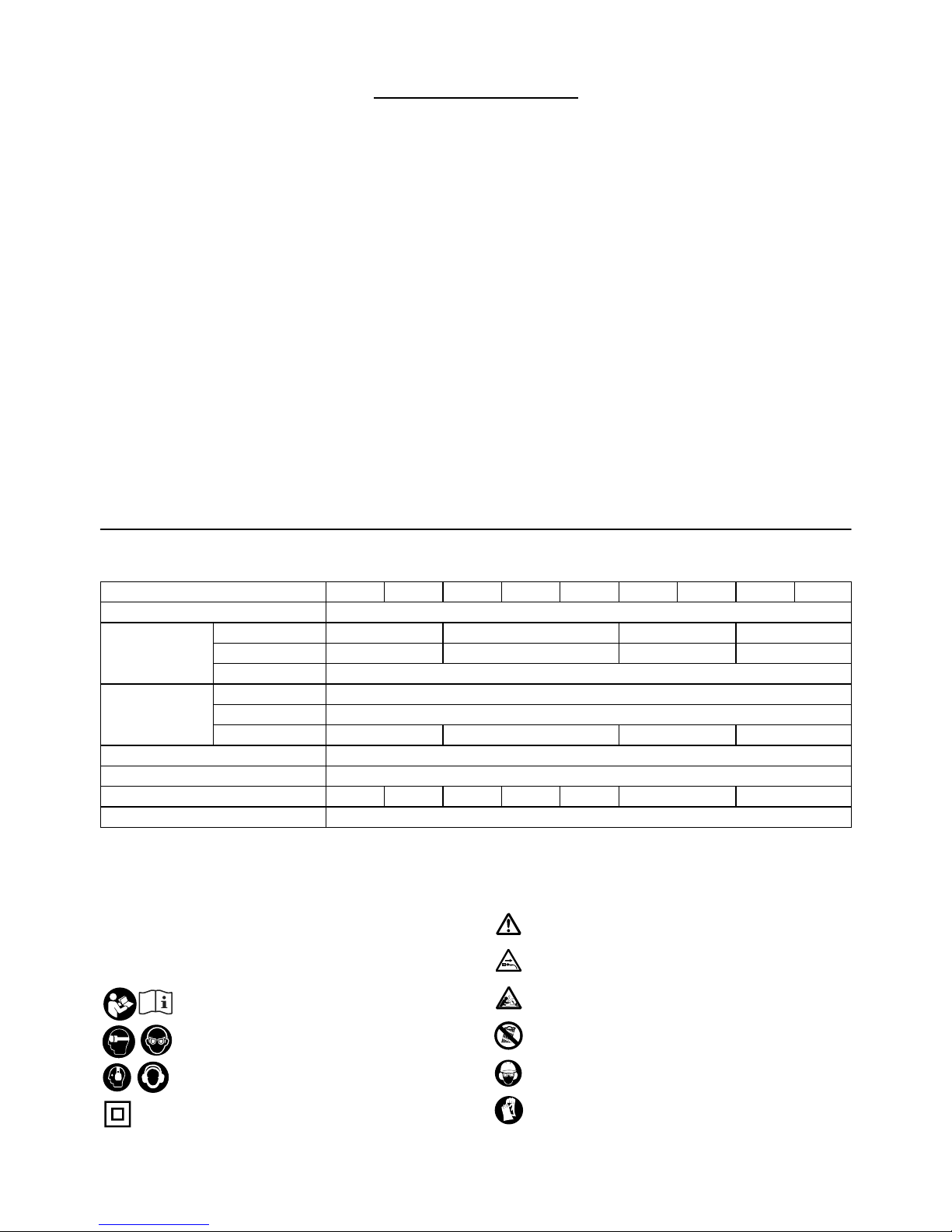

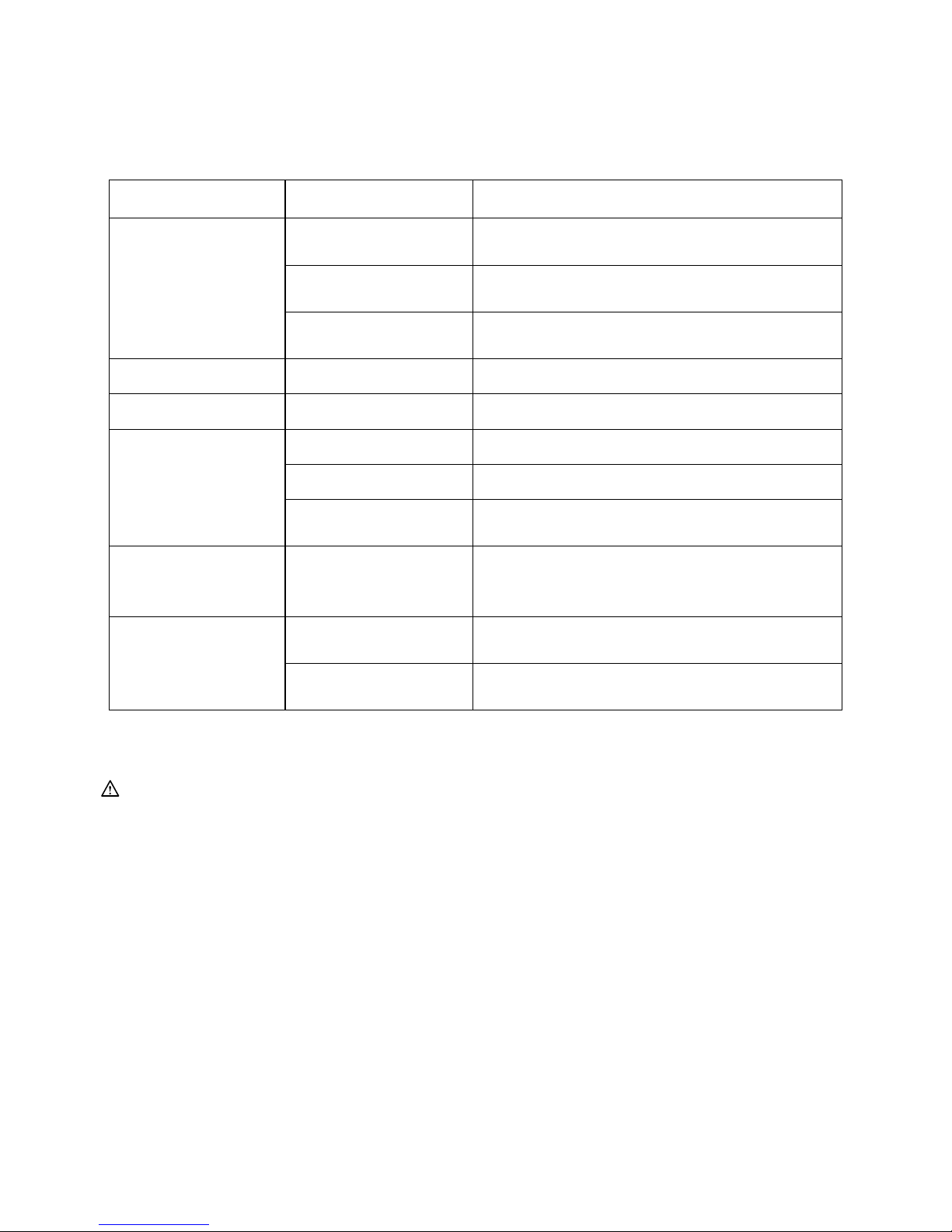

SPECIFICATIONS

Model

UC3050A UC3051A UC3550A

UC3550AP

UC3551A UC4050A UC4051A UC4550A

UC4551A

Max. chain speed 14.5 m/s (870 m/min)

Bar length 300 mm 350 mm 400 mm 450 mm

Cutting length 260 mm 320 mm 355 mm 415 mm

Standard guide

bar

Guide bar type Sprocket nose bar

Type 91PX

Pitch 3/8"

Standard saw

chain

No. of drive links 46 52 56 62

Recommended guide bar length 300 - 450 mm

Overall length (without guide bar) 505 mm

Net weight 5.4 kg 5.5 kg 5.5 kg 5.6 kg 5.5 kg 5.6 kg 5.7 kg

Extension cable (optional) DIN 57282/HO 7RN -F L=30 m max.,3x1.5 mm2

• Due to our continuing program of research and development, the specifications herein are subject to change without notice.

• Specifications may differ from country to country.

• Weight according to EPTA-Procedure 01/2003

END218-7

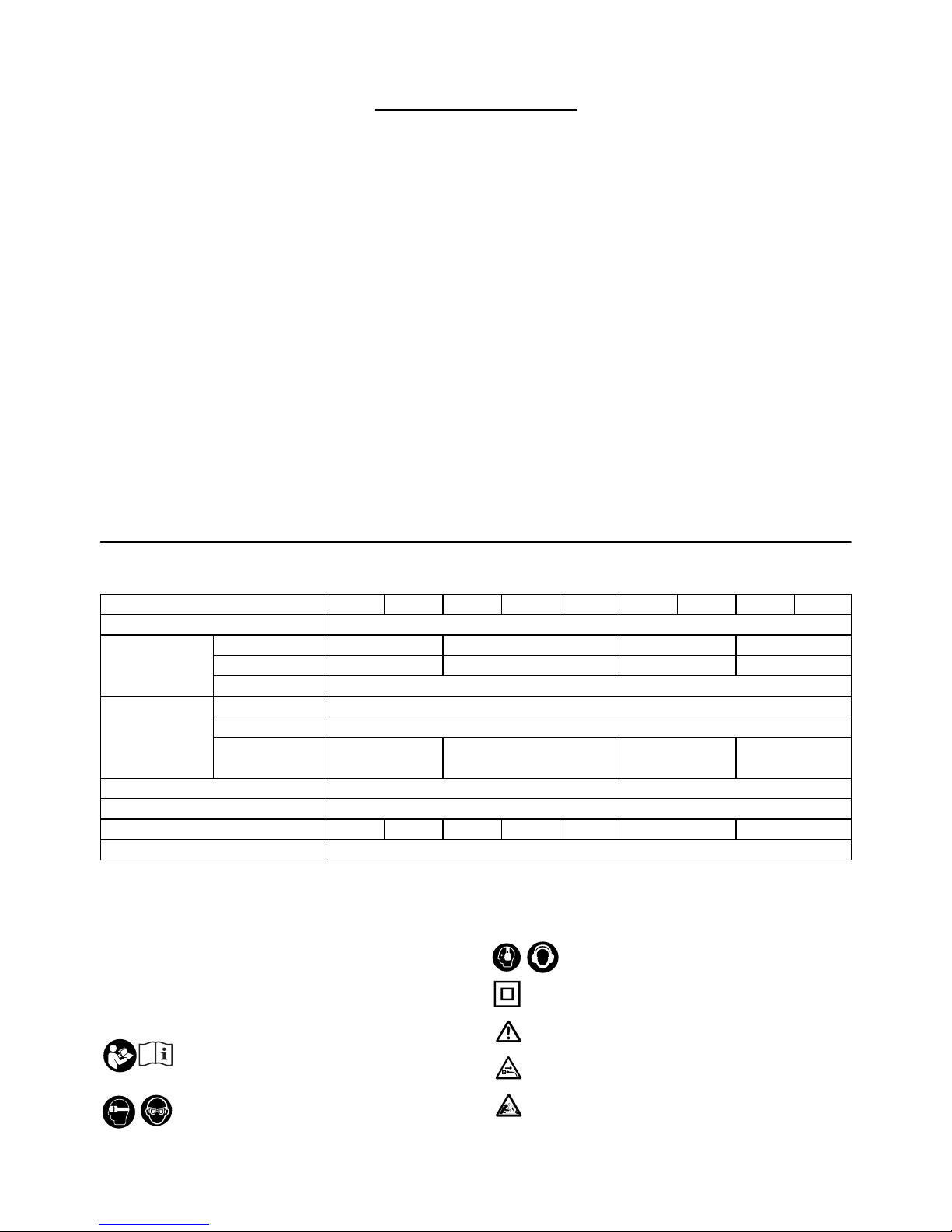

Symbol

The following show the symbols used for the equipment.

Be sure that you understand their meaning before use.

・ Read instruction manual and follow the

warnings and safety instructions.

・ Wear eye protection.

・ Wear ear protection.

・ DOUBLE INSULATION

・ Caution: particular care and attention

required!

・ Caution: withdraw the mains plug

immediately if the cable is damaged!

・ Caution: kickback!

・ Protect against rain and damp!

・ Wear a helmet, goggles and ear

protection!

・ Wear safety gloves!

6

・ Withdraw the mains plug!

・ First aid

・ Maximum permissible length of cut

・ Direction of chain travel

・ Chain oil

・ Chain brake released

・ Chain brake applied

・ Prohibited!

・ Only for EU countries

Do not dispose of electric equipment

together with household waste

material!

In observance of the European

Directive, on Waste Electric and

Electronic Equipment and its

implementation in accordance with

national law, electric equipment that

have reached the end of their life must

be collected separately and returned to

an environmentally compatible

recycling facility.

ENE085-1

Intended use

The tool is intended for cutting lumbers and logs.

ENF002-2

Power supply

The tool should be connected only to a power supply of

the same voltage as indicated on the nameplate, and

can only be operated on single-phase AC supply. They

are double-insulated and can, therefore, also be used

from sockets without earth wire.

ENG905-1

Noise

The typical A-weighted noise level determined

according to EN60745:

Sound pressure level (LpA) : 90.8 dB (A)

Sound power level (L

WA

) : 101.8 dB (A)

Uncertainty (K) : 2.5 dB (A)

Wear ear protection

ENG900-1

Vibration

The vibration total value (tri-axial vector sum)

determined according to EN60745:

Work mode : cutting wood

Vibration emission (a

h

) : 5.2 m/s

2

Uncertainty (K) : 1.5 m/s

2

ENG901-1

•

The declared vibration emission value has been

measured in accordance with the standard test

method and may be used for comparing one tool

with another.

• The declared vibration emission value may also be

used in a preliminary assessment of exposure.

WARNING:

• The vibration emission during actual use of the

power tool can differ from the declared emission

value depending on the ways in which the tool is

used.

• Be sure to identify safety measures to protect the

operator that are based on an estimation of

exposure in the actual conditions of use (taking

account of all parts of the operating cycle such as

the times when the tool is switched off and when it

is running idle in addition to the trigger time).

ENH030-5

For European countries only

EC Declaration of Conformity

Makita declares that the following Machine(s):

Designation of Machine:

Chain Saw

Model No./ Type: UC3050A, UC3550A, UC4050A,

UC4550A, UC3051A, UC3551A, UC3550AP, UC4051A,

UC4551A

Specifications: see "SPECIFICATIONS" table.

Conforms to the following European Directives:

2000/14/EC, 2006/42/EC

They are manufactured in accordance with the following

standard or standardized documents:

EN60745

The EC-Type Examination Certificate

No.5514056.14005

The EC-Type Examination per 2006/42/EC was

performed by:

DEKRA Testing and Certification GmbH

Enderstraße 92b

01277 Dresden

Germany

Identification No. 2140

The technical file in accordance with 2006/42/EC is

available from:

Makita, Jan-Baptist Vinkstraat 2, 3070, Belgium

The conformity assessment procedure required by

Directive 2000/14/EC was in Accordance with annex V.

Measured Sound Power Level: 101.9 dB (A)

Guaranteed Sound Power Level: 103 dB (A)

7

4.9.2014

000331

Yasushi Fukaya

Director

Makita, Jan-Baptist Vinkstraat 2, 3070, Belgium

GEA010-1

General Power Tool Safety

Warnings

WARNING Read all safety warnings and all

instructions.

Failure to follow the warnings and instructions

may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for

future reference.

GEB037-8

Chain saw safety warnings

1.

Keep all parts of the body away from the saw

chain when the chain saw is operating. Before

you start the chain saw, make sure the saw chain

is not contacting anything.

A moment of inattention

while operating chain saws may cause entanglement

of your clothing or body with the saw chain.

2. Always hold the chain saw with your right

hand on the rear handle and your left hand on

the front handle. Holding the chain saw with a

reversed hand configuration increases the risk of

personal injury and should never be done.

3. Hold the power tool by insulated gripping

surfaces only, because the saw chain may

contact hidden wiring or its own cord. Saw

chains contacting a "live" wire may make

exposed metal parts of the power tool "live" and

could give the operator an electric shock.

4.

Wear safety glasses and hearing protection.

Further protective equipment for head, hands,

legs and feet is recommended.

Adequate protective

clothing will reduce personal injury by flying debris or

accidental contact with the saw chain.

5. Do not operate a chain saw in a tree. Operation

of a chain saw while up in a tree may result in

personal injury.

6. Always keep proper footing and operate the

chain saw only when standing on fixed,

secure and level surface. Slippery or unstable

surfaces such as ladders may cause a loss of

balance or control of the chain saw.

7. When cutting a limb that is under tension be

alert for spring back. When the tension in the

wood fibres is released the spring loaded limb

may strike the operator and/or throw the chain

saw out of control.

8. Use extreme caution when cutting brush and

saplings. The slender material may catch the

saw chain and be whipped toward you or pull you

off balance.

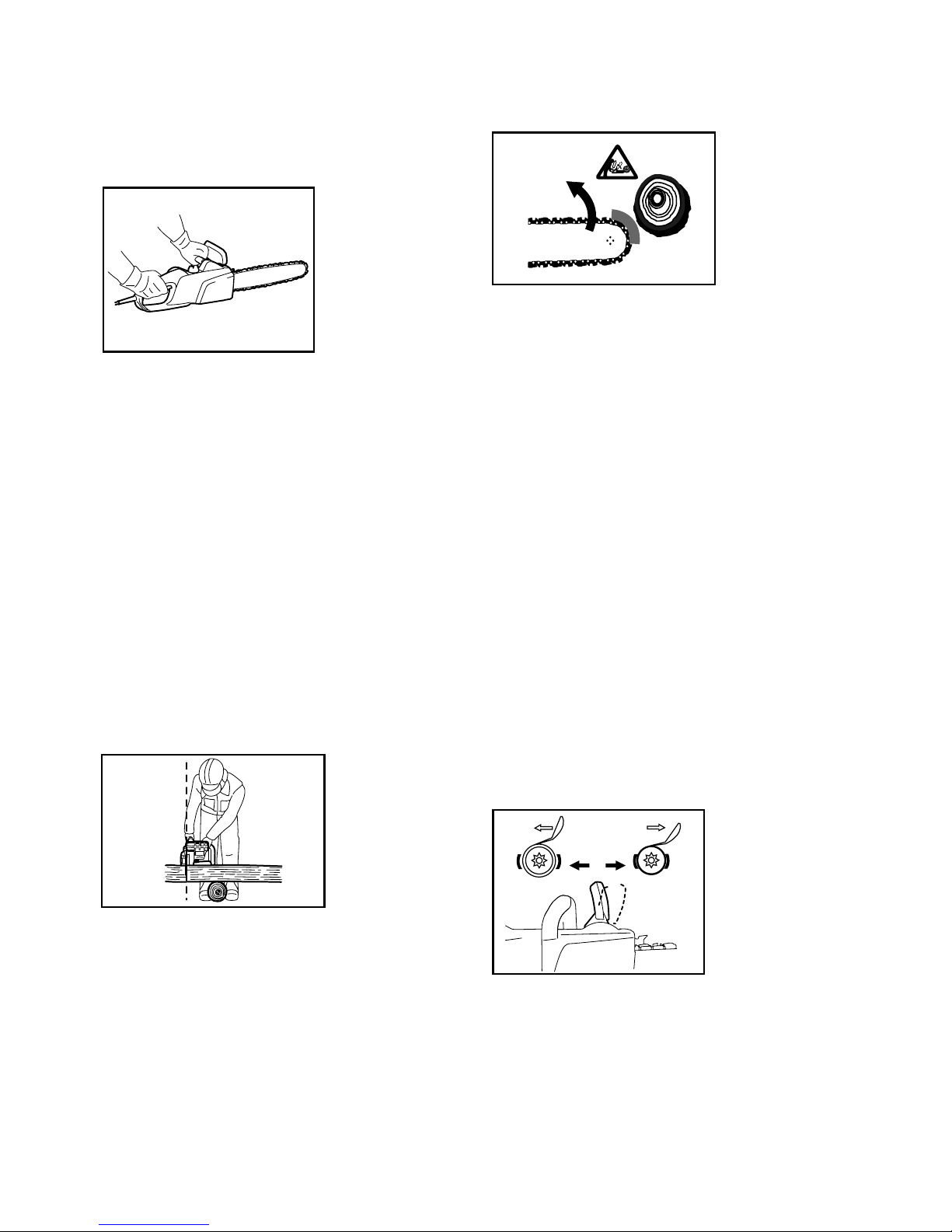

9. Carry the chain saw by the front handle with

the chain saw switched off and away from

your body. When transporting or storing the

chain saw always fit the guide bar cover.

Proper handling of the chain saw will reduce the

likelihood of accidental contact with the moving

saw chain.

10. Follow instructions for lubricating, chain

tensioning and changing accessories.

Improperly tensioned or lubricated chain may

either break or increase the chance for kickback.

11. Keep handles dry, clean, and free from oil and

grease. Greasy, oily handles are slippery causing

loss of control.

12. Cut wood only. Do not use chain saw for

purposes not intended. For example: do not

use chain saw for cutting plastic, masonry or

non-wood building materials. Use of the chain

saw for operations different than intended could

result in a hazardous situation.

13. Causes and Operator Prevention of Kickback:

Kickback may occur when the nose or tip of the

guide bar touches an object, or when the wood

closes in and pinches the saw chain in the cut.

Tip contact in some cases may cause a sudden

reverse reaction, kicking the guide bar up and

back towards the operator.

Pinching the saw chain along the top of the guide

bar may push the guide bar rapidly back towards

the operator.

Either of these reactions may cause you to lose

control of the saw which could result in serious

personal injury. Do not rely exclusively upon the

safety devices built into your saw. As a chain saw

user, you should take several steps to keep your

cutting jobs free from accident or injury.

Kickback is the result of tool misuse and/or

incorrect operating procedures or conditions and

can be avoided by taking proper precautions as

given below:

− Maintain a firm grip, with thumbs and

fingers encircling the chain saw handles,

with both hands on the saw and position

your body and arm to allow you to resist

kickback forces. Kickback forces can be

controlled by the operator, if proper

precautions are taken. Do not let go of the

chain saw.

8

014316

− Do not overreach and do not cut above

shoulder height. This helps prevent

unintended tip contact and enables better

control of the chain saw in unexpected

situations.

− Only use replacement bars and chains

specified by the manufacturer. Incorrect

replacement bars and chains may cause

chain breakage and/or kickback.

− Follow the manufacturer’s sharpening

and maintenance instructions for the saw

chain. Decreasing the depth gauge height

can lead to increased kickback.

ADDITIONAL SAFETY RULES

1. Read the instruction manual in order to familiarize

yourself with operation of the chain saw.

2. Before using the chain saw for the first time,

arrange to have instruction in its operation. If this

is not possible, at least practice cutting round

timber on a trestle before beginning work.

3. The chain saw must not be used by children or

young persons under 18 years of age. Young

persons over 16 years of age may be exempted

from this restriction if they are undergoing training

under the supervision of an expert.

4. Working with the chain saw requires a high level

of concentration. Do not work with the saw if you

are not feeling fit and well. Carry out all work

calmly and carefully.

5. Never work under the influence of alcohol, drugs

or medication.

Proper use

1. The chain saw is intended solely for cutting wood.

Do not use it for example to cut plastic or porous

concrete.

2. Only use the chain saw for operations described

in this instruction manual. Do not, for example,

use it to trim hedges or for similar purposes.

3. The chain saw must not be used for forestry work,

i.e. for felling and limbing standing timber. The

chain saw cable does not provide the operator

with the mobility and safety required for such

work.

4. The chain saw is not intended for commercial use.

5. Do not overload the chain saw.

Personal protective equipment

1. Clothing must be close-fitting, but must not

obstruct mobility.

2.

Wear the following protective clothing during work:

• A tested safety helmet, if a hazard is

presented by falling branches or similar;

• A face mask or goggles;

• Suitable ear protection (ear muffs, custom or

mouldable ear plugs). Octave brand analysis

upon request.

• Firm leather safety gloves;

•

Long trousers manufactured from strong fabric;

• Protective dungarees of cut-resistant fabric;

• Safety shoes or boots with non-slip soles,

steel toes, and cut-resistant fabric lining;

• A breathing mask, when carrying out work

which produces dust (e.g. sawing dry wood).

Protection against electric shock

・ The chain saw must not be used in wet

weather or damp environments, as the

electric motor is not waterproof.

1. Only plug the saw into sockets in tested electrical

circuits. Check that the system voltage matches

that on the rating plate. Ensure that a 16 A line

fuse is fitted. Saws used in the open air must be

connected to a residual current-operated circuitbreaker with an operating current no higher than

30 mA.

・ Should the connecting cable be

damaged, withdraw the mains plug

immediately.

Safe working practices

1. Before starting work, check that the chain saw is

in proper working order and that its condition

complies with the safety regulations. Check in

particular that:

• The chain brake is working properly;

• The run-down brake is working properly;

•

The bar and the sprocket cover are fitted correctly;

• The chain has been sharpened and tensioned

in accordance with the regulations;

•

The mains cable and mains plug are undamaged;

Refer to the "CHECKS " section.

2. Always ensure in particular that the extension

cable used is of adequate cross-section (see

"SPECIFICATIONS"). When using a cable reel,

wind the cable completely off the reel. When

using the saw in the open air, ensure that the

cable employed is intended for open-air use and

is rated accordingly.

3. Keep the cord away from the cutting area and to

position cord so that it will not be caught on

branches, and the like, during cutting.

4. Do not operate the chain saw in the vicinity of

flammable dust or gases, as the motor generates

sparks and presents a risk of explosion.

9

5. Work only on firm ground and with a good footing.

Pay particular attention to obstacles (e.g. the

cable) in the working area. Take particular care

where moisture, ice, snow, freshly cut wood or

bark may make surfaces slippery. Do not stand

on ladders or trees when using the saw.

6. Take particular care when working on sloping

ground; rolling trunks and branches pose a

potential hazard.

7. Never cut above shoulder height.

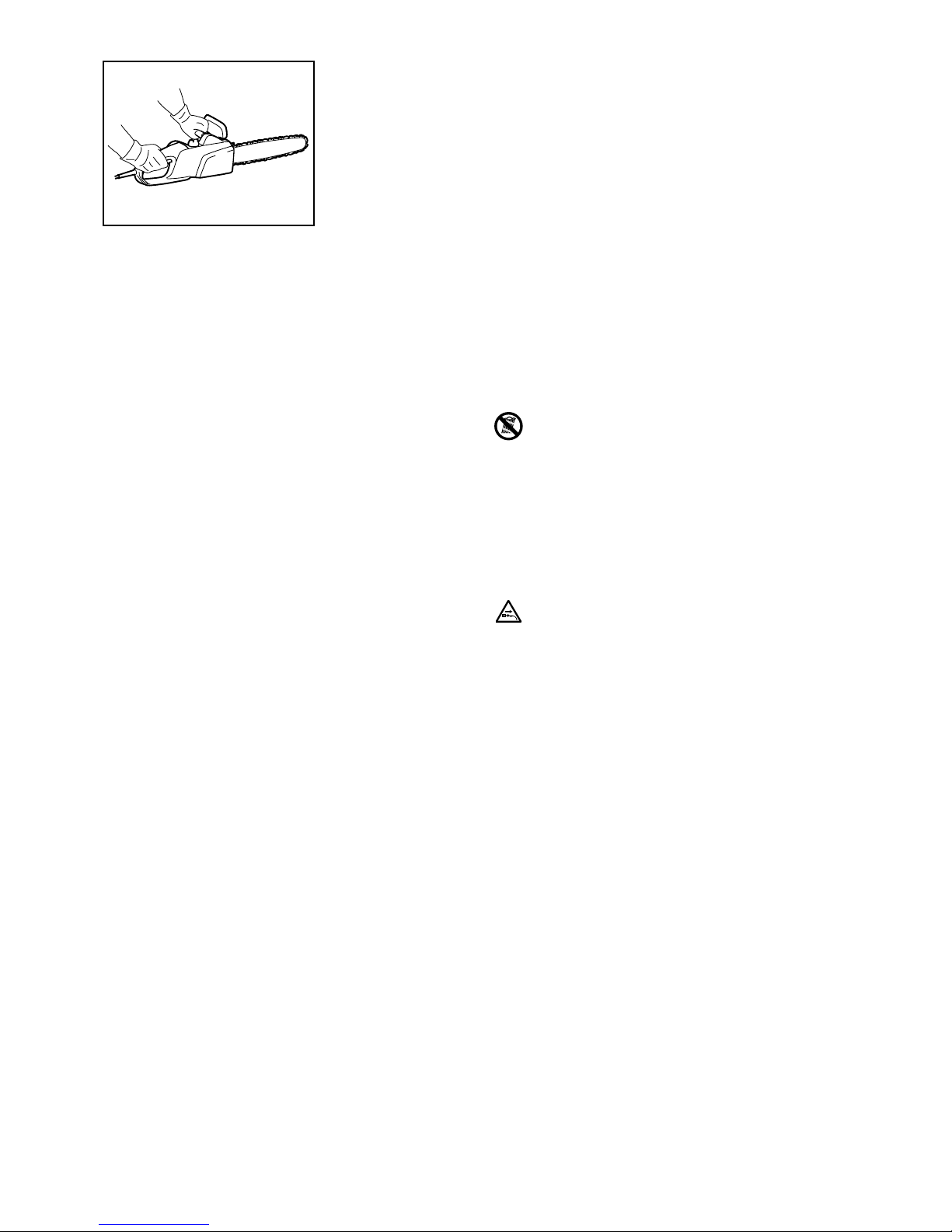

8.

Hold the chain saw with both hands when

switching it on and using it.

Hold the rear handle

with your right hand and the front handle with your

left. Hold the handles firmly with your thumbs. The

bar and the chain must not be in contact with any

objects when the saw is switched on.

014316

9.

Clean the area to be cut of foreign objects such as

sand, stones, nails, wire, etc. Foreign objects damage

the bar and chain, and can lead to dangerous kickback.

10. Take particular care when cutting in the vicinity of

wire fences. Do nut cut into the fence, as the saw

may kick back.

11. Do not cut into the ground.

12.

Cut pieces of wood singly, not in bunches or stacks.

13. Avoid using the saw to cut thin branches and

roots, as these can become entangled in the

chain saw. Loss of balance presents a hazard.

14.

Use a secure support (trestle) when cutting sawn timber.

15. Do not use the chain saw to prise off or brush

away pieces of wood and other objects.

16.

Guide the chain saw such that no part of your body is

within the extended path of the saw chain (see figure).

006909

17. When moving around between sawing operations,

apply the chain brake in order to prevent the

chain from being operated unintentionally. Hold

the chain saw by the front handle when carrying it,

and do not keep your finger on the switch.

18. Withdraw the mains plug when taking breaks or

leaving the chain saw unattended. Leave the

chain saw where it cannot present a hazard.

Kickback

1.

Hazardous kickback may arise during work with the

chain saw. Kickback arises when the tip of the bar (in

particular the upper quarter) comes into contact with

wood or another solid object. This causes the chainsaw

to be deflected in the direction of the operator.

006919

2. In order to avoid kickback, observe the following:

• Never begin the cut with the tip of the bar.

• Never use the tip of the bar for cutting. Take

particular care when resuming cuts which

have already been started.

• Start the cut with the chain running.

•

Always sharpen the chain correctly. In particular,

set the depth gauge to the correct height.

• Never saw through several branches at a time.

• When limbing, take care to prevent the bar

from coming into contact with other branches.

• When bucking, keep clear of adjacent trunks.

Always observe the bar tip.

• Use a trestle.

Safety features

1.

Always check that the safety features are in working

order before starting work. Do not use the chain saw

if the safety features are not working properly.

− Chain brake:

The chain saw is fitted with a chain brake which brings

the saw chain to a standstill within a fraction of a

second. It is activated when the hand guard is pushed

forwards. The saw chain then stops within 0.15 s, and

the power supply to the motor is interrupted.

12

014317

1. Chain brake

applied

2. Chain brake

released

10

− Run-down brake:

The chain saw is equipped with an run down brake

which brings the saw chain to an immediate stop

when the ON/OFF switch is released. This

prevents the saw chain from running on when

switched off, and thus presenting a hazard.

− The front and rear hand guards protect the user

against injury from pieces of wood which may be

thrown backwards, or a broken saw chain.

− The trigger lockout prevents the chain saw from

being switched on accidentally.

− The chain catcher protects the user against injury

should the chain jump or break.

Transport and storage

・ When the chain saw is not in use or is

being transported, withdraw the mains

plug and fit the guide bar cover

supplied with the saw. Never carry or

transport the saw with the saw chain

running.

1. Carry the chain saw by the front handle only, with

the bar pointing backwards.

2. Keep the chain saw in a secure, dry and locked

room out of the reach of children. Do not store the

chain saw outdoors.

MAINTENANCE

1. Withdraw the plug from the socket before carrying

out any adjustments or maintenance.

2. Check the power cable regularly for damage to

the insulation.

3. Clean the chain saw regularly.

4. Have any damage to the plastic housing repaired

properly and immediately.

5. Do not use the saw if the switch trigger is not

working properly. Have it properly repaired.

6. Under no circumstances should any modifications

be made to the chain saw. Your safety is at risk.

7. Do not carry out maintenance or repair work other

than that described in this instruction manual. Any

other work must be carried out by authorized

service centers.

8. Only use genuine replacement parts and

accessories intended for your model of saw. The

use of other parts increases the risk of accident.

9. We accept no responsibility for accidents or

damage should non-approved bars, saw chains

or other replacement parts or accessories be

used.

First aid

・ Do not work alone. Always work within

shouting distance of a second person.

1. Always keep a first-aid box to hand. Replace any

items taken from it immediately.

2. Should you request assistance in the event of an

accident, state the following:

• Where did the accident happen?

• What happened?

• How many persons are injured?

• What injuries do they have?

• Who is reporting the accident?

NOTE:

Individuals with poor circulation who are exposed to

excessive vibration may experience injury to blood

vessels or the nervous system.

Vibration may cause the following symptoms to occur in

the fingers, hands or wrists: "Falling asleep

"(numbness), tingling, pain, stabbing sensation,

alteration of skin colour or of the skin.

If any of these symptoms occur, see a physician!

SAVE THESE INSTRUCTIONS.

WARNING:

DO NOT let comfort or familiarity with product

(gained from repeated use) replace strict adherence

to safety rules for the subject product. MISUSE or

failure to follow the safety rules stated in this

instruction manual may cause serious personal

injury.

11

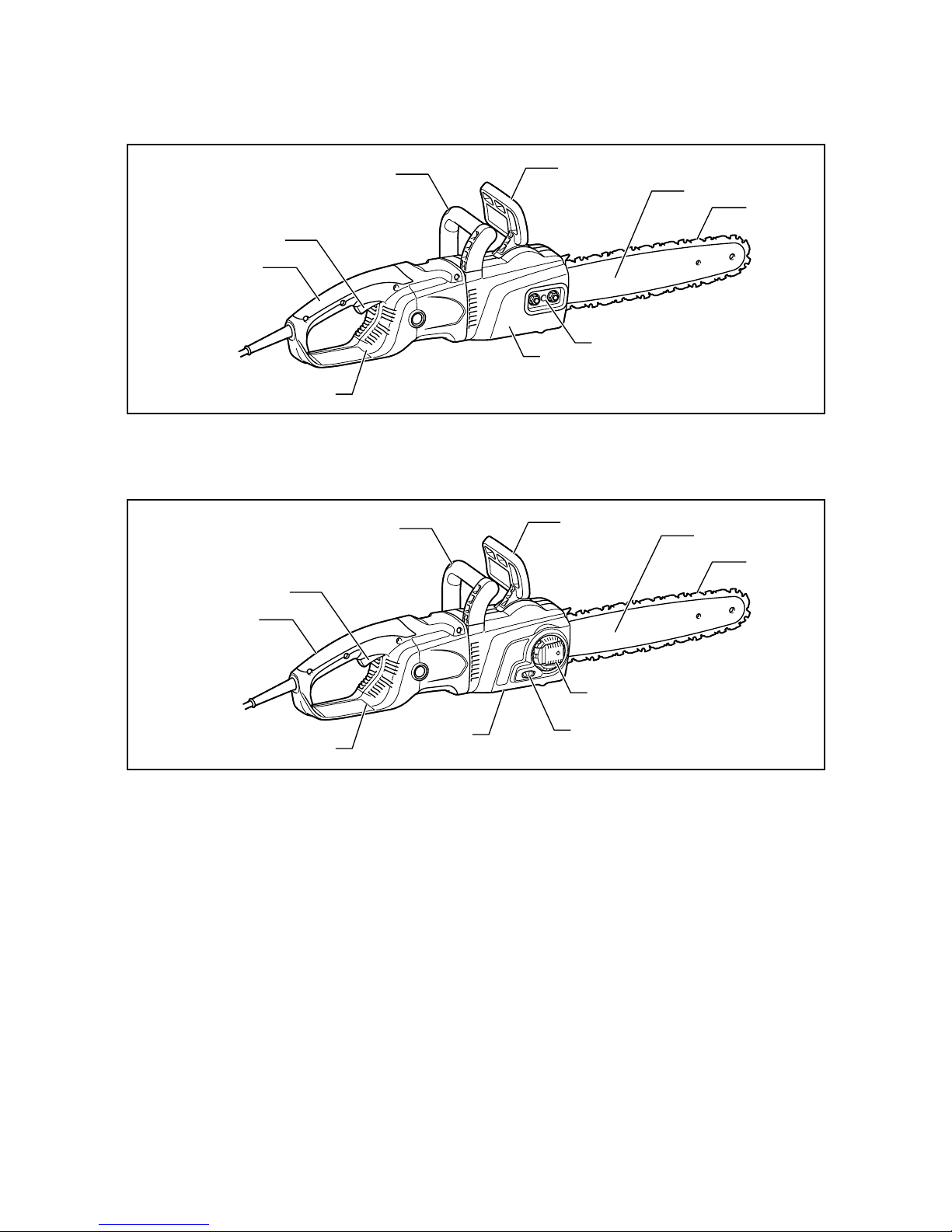

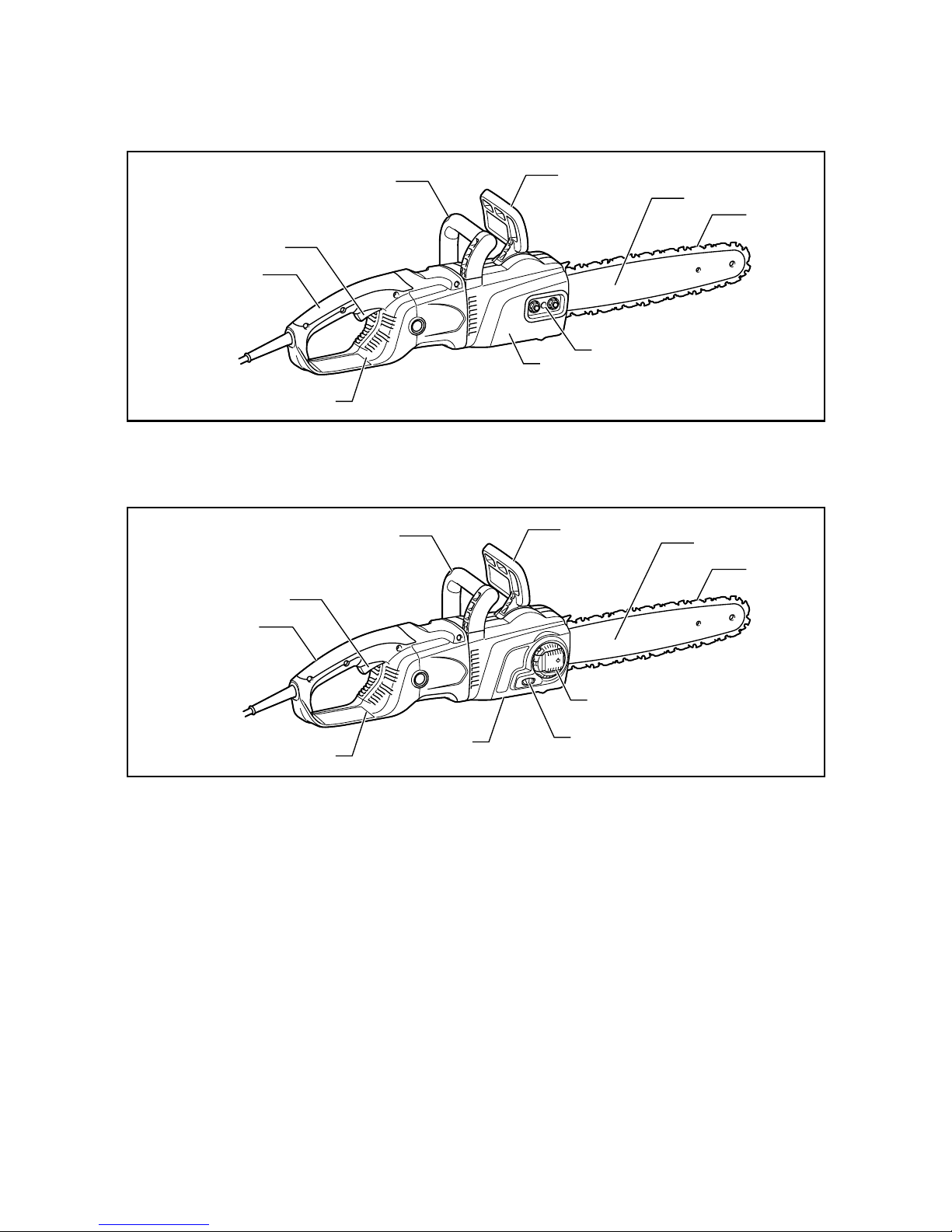

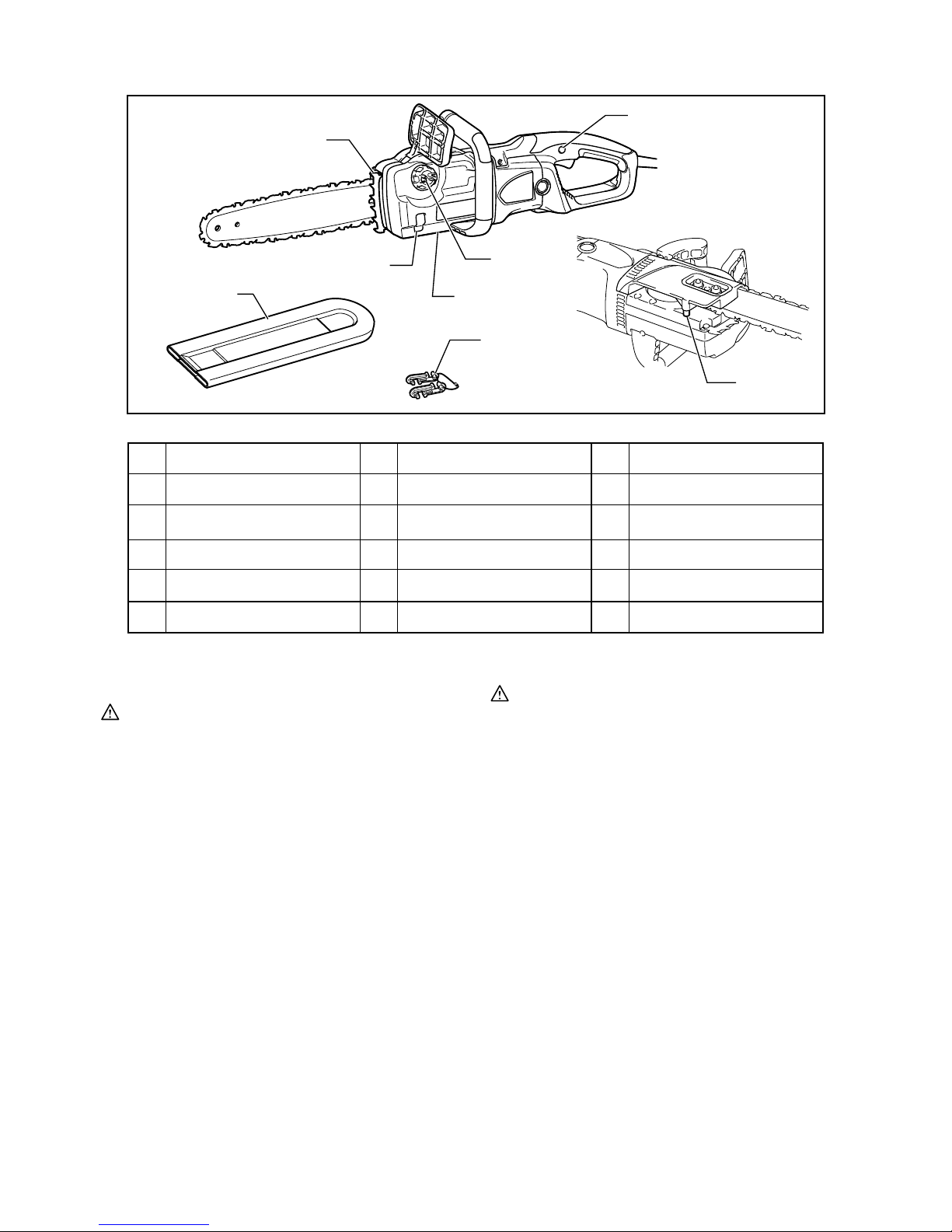

DESIGNATION OF PARTS

(Nut model: the sprocket cover is tightened by nuts.)

For Model UC3050A, UC3550A, UC3550AP, UC4050A,

UC4550A

1

2

3

4

5

6

9

10

8

014372

(Lever model: the sprocket cover is tightened by lever.)

For Model UC3051A, UC3551A, UC4051A, UC4551A

1

2

3

4

5

6

9

10

8

7

014373

12

(For all models)

14

12

11

15

13

17

16

18

014514

Cord hook

1

2

3

4

5

6

7

9

8

10

11

12

13

Spike bumper

18

14

15

16

17

Rear handle

Switch trigger

Oil filler cap

Front handle

Front hand guard

Guide bar

Saw chain

Lever

Adjusting screw/dial

Oil level sight

Rear hand guard

Lock-off button

Chain catcher

Guide bar cover

Adjusting screw for oil pump

(at the bottom)

Sprocket cover

014375

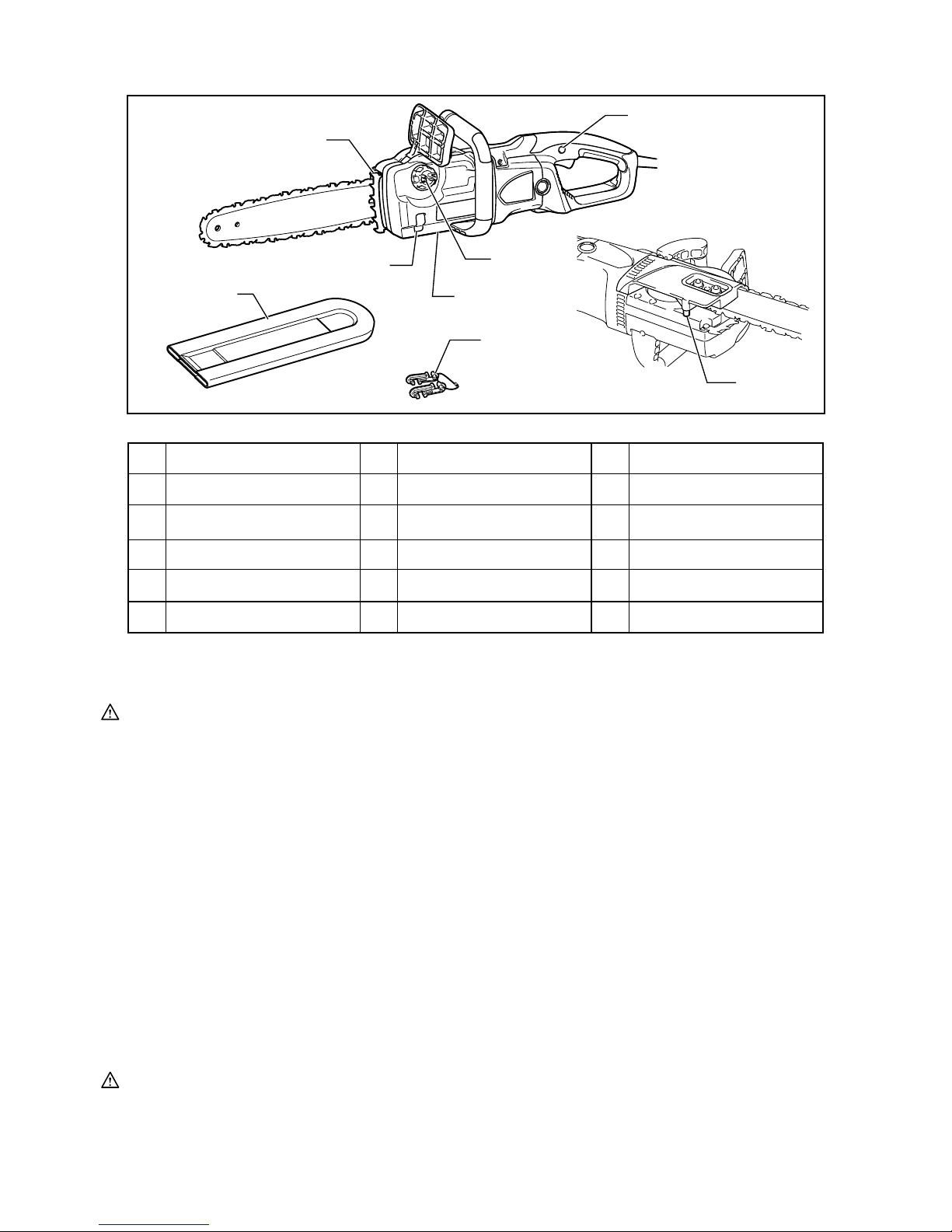

ASSEMBLY

CAUTION:

•

Always be sure that the tool is switched off and

unplugged before carrying out any work on the tool.

Removing or installing sprocket cover

To remove the sprocket cover, perform the following

steps:

(For nut models)

Fig.1

Loosen the nut.

(For lever models)

Fig.2

Press and fully open the lever until it stops.

Turn the lever counterclockwise.

To install the sprocket cover, perform the above steps in

reverse.

Removing or installing saw chain

CAUTION:

• Always wear gloves when installing or removing

the saw chain.

To remove the saw chain, perform the following steps:

1. Loosen the sprocket cover.

2. (For nut models) Turn the chain adjusting screw

counterclockwise to release the saw chain

tension.

(For lever models) Turn the adjusting dial to "-"

direction to loosen the saw chain tension.

Fig.3

Fig.4

3. Remove the sprocket cover.

4. Remove the saw chain and guide bar from the

chain saw.

To install the saw chain, perform the following steps:

5. Make sure the direction of the chain. The arrow

mark on the chain shows the direction of the

chain.

Fig.5

6. Fit in one end of the saw chain on the top of the

guide bar and the other end of it around the

sprocket.

7. Place the guide bar on the chain saw.

8. Align the tension slide with the hole of the guide

bar.

13

Fig.6

9. Holding the guide bar, and turn the chain

adjusting screw / dial to adjust the saw chain

tension.

10. Place the sprocket cover so that the hooks fit

alongside the holes and the pin fits its counterpart

on the sprocket cover.

Fig.7

11. Tighten the sprocket cover.

Fig.8

Fig.9

Adjusting saw chain tension

The saw chain may become loose after many hours of

use. From time to time check the saw chain tension

before use.

1. Loosen the sprocket cover lightly.

2. Lift up the guide bar tip slightly.

3. Turn the adjusting screw / dial to adjust saw chain

tension.

Fig.10

Fig.11

4. Tighten the saw chain until the lower side of the

saw chain fits in the guide bar rail (see circle).

5. Keep holding the guide bar lightly, tighten the

sprocket cover after adjusting the chain tension.

Make sure that the saw chain does not loose at

lower side.

Make sure the saw chain fits snugly against the lower

side of the bar.

CAUTION:

• Do not tighten the saw chain too much.

Excessively high tension of saw chain may cause

breakage of saw chain, wear of the guide bar and

breakage of the adjusting dial.

• A chain which is too loose can jump off the bar,

and therefore presents an accident risk.

• Carry out the procedure of installing or removing

saw chain in a clean place free from sawdust and

the like.

Engaging extension cord

CAUTION:

• Make sure that the extension cord is unplugged to

the mains outlet.

Fig.12

When engaging the extension cord, secure it to the

chain saw's cord with the cord hook.

Attach the cord hook about 100 - 200 mm from the

extension cord connector. This helps prevent

unintentional disconnection.

OPERATION

CAUTION:

• Hold the tool firmly with right hand on the rear

handle and left hand on the front handle when

performing the tool.

Switch action

Fig.13

CAUTION:

•

Always be sure that the tool is switched off and

unplugged before checking function on the switch trigger.

• Before plugging in the tool, always check to see

that the switch trigger actuates properly and

returns to the "OFF" position when released.

To prevent the switch trigger from being accidentally

pulled, a lock-off button is provided.

To start the tool, depress the lock-off button and pull the

switch trigger. Release the switch trigger to stop.

Lubrication

CAUTION:

• Always be sure that the tool is switched off and

unplugged before lubricating the saw chain.

Fig.14

Lubricate the saw chain and bar using biologically

degradable saw chain oil with an adhesion agent. The

adhesion agent in the saw chain oil prevents the oil from

being thrown off the saw excessively quickly. Mineral

oils must not be used, as they are harmful to the

environment.

CAUTION:

• Prevent the oil from coming into contact with the

skin and eyes. Contact with the eyes causes

irritation. In the event of eye contact, flush the

affected eye immediately with clear water, then

consult a doctor at once.

•

Never use waste oil. Waste oil contains carcinogenic

substances. The contaminants in waste oil cause

accelerated wear of the oil pump, the bar and the

chain. Waste oil is harmful to the environment.

• When filling the chain saw with chain oil for the

first time, or refilling the tank after it has been

completely emptied, add oil up to the bottom edge

of the filler neck. The oil delivery may otherwise be

impaired.

Fig.15

To fill the oil, perform the following steps:

1. Clean the area around the oil filler cap thoroughly

to prevent any dirt from entering the oil tank.

2. Unscrew the oil filler cap and add oil up to the

lower edge of the filler neck.

3. Screw the oil filler cap firmly back in place.

4. Wipe away any spilt chain oil carefully.

14

NOTE:

• When the chain saw is used for the first time, it

may take up to two minutes for the saw chain oil to

begin its lubricating effect upon the saw

mechanism. Run the saw without load until it does

so (see "CHECKS ").

CHECKS

Before starting work, carry out the following checks:

Checking the chain tension

WARNING:

• Always withdraw the mains plug before checking

the chain tension, and wear safety gloves.

(For nut models)

Fig.16

(For lever models)

Fig.17

Make sure the saw chain fits snugly against the lower

side of the bar (see circle).

Check the chain tension frequently, as new chains are

subject to elongation.

Excessively high tension of saw chain may cause

breakage of saw chain, wear of the guide bar and

breakage of the adjusting dial.

A chain which is too loose can jump off the bar, and

therefore presents an accident risk.

If the chain is too loose: Refer to the section titled

"Adjusting saw chain tension" and adjust the saw chain

tension again.

Checking the switch action

CAUTION:

Before plugging in the tool, always check to see that the

switch trigger actuates properly and returns to the

"OFF" position when released.

To prevent the switch trigger from being accidentally

pulled, a lock-off button is provided.

To start the tool, depress the lock-off button and pull the

switch trigger. Release the switch trigger to stop.

Do not pull the switch trigger hard without depressing

the lock-off button. This may cause switch breakage.

Checking the chain brake

NOTE:

• If the chain saw fails to start, check whether the

chain brake is released. To release the chain

brake, pull the hand guard backwards firmly until

you feel it engage.

Fig.18

Fig.19

Check the chain brake as follows:

1. Hold the chain saw with both hands when

switching it on. Hold the rear handle with your

right hand, the front handle with your left. Make

sure that the bar and the chain do not contact

with any object.

2. First press the lock-off button, then the switch

trigger. The saw chain starts immediately.

3. Press the front hand guard forwards using the

back of your hand. Make sure that the saw chain

comes to an immediate standstill.

CAUTION:

• If the saw chain does not stop immediately, do not

use the saw under any circumstances. Consult

Makita authorized service centers.

Checking the run-down brake

Switch on the chain saw.

Release the switch trigger completely. Make sure the

saw chain comes to a standstill within a second.

CAUTION:

• If the saw chain does not stop immediately, do not

use the saw under any circumstances. Consult

Makita authorized service centers.

Checking the chain oiler

Before starting work, check the oil level in the tank, and

the oil delivery.

The oil level can be seen in the oil level sight shown in

the figure.

Fig.20

Check the oil delivery as follows:

Start the chain saw.

With the saw running, hold the saw chain approximately

15 cm above a tree trunk or the ground. If lubrication is

adequate, the oil spray will produce a light oil trace.

Observe the wind direction, and do not expose yourself

to the oil spray unnecessarily.

CAUTION:

• If an oil trace is not formed, do not use the saw.

The lifespan of the chain will otherwise be reduced.

Check the oil level. Clean the oil feed groove and

the oil feed hole in the bar (refer to

"MAINTENANCE ").

Adjusting the chain lubrication

Fig.21

You can adjust the oil pump feed rate with the adjusting

screw.

WORKING WITH THE CHAIN SAW

CAUTION:

• Always use a front handle and rear handle and

firmly hold the tool by both front handle and rear

handle during operations.

• Always secure the timber to be cut, otherwise the

cut fragments may cause personal injury.

15

Bucking

Fig.22

For bucking cuts, rest the spike bumper shown in the

figure on the wood to be cut.

With the saw chain running, saw into the wood, using

the rear handle to raise the saw and the front one to

guide it. Use the spike bumper as a pivot.

Continue the cut by applying slight pressure to the front

handle, easing the saw back slightly. Move the spike

bumper further down the timber and raise the front

handle again.

When making several cuts, switch the chain saw off

between cuts.

CAUTION:

• If the upper edge of the bar is used for cutting, the

chain saw may be deflected in your direction if the

chain becomes trapped. For this reason, cut with

the lower edge, so that the saw will be deflected

away from your body.

Fig.23

Cut wood under tension on the pressure side (A) first.

Then make the final cut on the tension side (B). This

prevents the bar from becoming trapped.

Fig.24

Limbing

CAUTION:

•

Limbing may only be performed by trained persons.

A hazard is presented by the risk of kick-back.

When limbing, support the chain saw on the trunk if

possible. Do not cut with the tip of the bar, as this

presents a risk of kickback.

Pay particular attention to branches under tension. Do

not cut unsupported branches from below.

Do not stand on the felled trunk when limbing.

Burrowing and parallel-to-grain cuts

CAUTION:

• Burrowing and parallel-to-grain cuts may only be

carried out by persons with special training. The

possibility of kickback presents a risk of injury.

Fig.25

Perform parallel-to-grain cuts at as shallow an angle as

possible. Carry out the cut as carefully as possible, as

the spike bumper cannot be used.

Felling

CAUTION:

• Felling work may only be performed by trained

persons. The work is hazardous.

Observe local regulations if you wish to fell a tree.

Fig.26

− Before starting felling work, ensure that:

(1) Only persons involved in the felling operation

are in the vicinity;

(2) Any person involved has an unhindered path

of retreat through a range of approximately

45 ° either side of the felling axis. Consider

the additional risk of tripping over electrical

cables;

(3) The base of the trunk is free of foreign

objects, roots and ranches;

(4) No persons or objects are present over a

distance of 2 1/2 tree lengths in the direction

in which the tree will fall.

− Consider the following with respect to each tree:

• Direction of lean;

• Loose or dry branches;

• Height of the tree;

• Natural overhang;

• Whether or not the tree is rotten.

− Consider the wind speed and direction. Do not

carry out felling work if the wind is gusting strongly.

− Trimming of root swellings: Begin with the largest

swellings. Make the vertical cut first, then the

horizontal cut.

Fig.27

− Cut a scarf: The scarf determines the direction in

which the tree will fall, and guides it. It is made on

the side towards which the tree is to fall. Cut the

scarf as close to the ground as possible. First

make the horizontal cut to a depth of 1/5 -1/3 of

the trunk diameter. Do not make the scarf too

large. Then make the diagonal cut.

− Cut any corrections to the scarf across its entire

width.

Fig.28

− Make the back cut a little higher than the base cut

of the scarf. The back cut must be exactly

horizontal. Leave approximately 1/10 of the trunk

diameter between the back cut and the scarf.

The wood fibers in the uncut trunk portion act as a

hinge. Do not cut right through the fibers under

any circumstances, as the tree will otherwise fall

unchecked. Insert wedges into the back cut in time.

− Only plastic or aluminum wedges may be used to

keep the back cut open. The use of iron wedges is

prohibited.

− Stand to the side of the falling tree. Keep an area

clear to the rear of the falling tree up to an angle of

45 ° either side of the tree axis (refer to the " felling

area " figure). Pay attention to falling branches.

− An escape path should be planned and cleared as

necessary before cuts are started. The escape

path should extend back and diagonally to the rear

of the expected line of fall as illustrated in figure.

Fig.29

16

MAINTENANCE

CAUTION:

• Always be sure that the tool is switched off and

unplugged before attempting to perform inspection

or maintenance.

• Always wear gloves when performing any

inspection or maintenance.

• Never use gasoline, benzine, thinner, alcohol or

the like. Discoloration, deformation or cracks may

result.

Carry out the maintenance work described below at

regular intervals. Warranty claims will be accepted only

if these operations have been performed regularly and

properly.

Only maintenance work described in this instruction

manual may be performed by the user. Any other work

must be carried out by MAKITA authorized service

centers.

Cleaning the chain saw

Clean the saw regularly with a clean rag. The handles,

in particular, must be kept free of oil.

Checking the plastic housing

Carry out regular visual inspections of all parts of the

housing. If any parts are damaged, have them repaired

immediately and properly in MAKITA authorized service

centers.

Sharpening the saw chain

CAUTION:

• Always withdraw the mains plug and wear safety

gloves when performing work on the saw chain.

Fig.30

Sharpen the saw chain when:

− Mealy sawdust is produced when damp wood is

cut;

− The chain penetrates the wood with difficulty, even

when heavy pressure is applied;

− The cutting edge is obviously damaged;

− The saw pulls to the left or right in the wood. The

reason for this behavior is uneven sharpening of

the saw chain, or damage to one side only.

Sharpen the saw chain frequently, but remove only

a little material each time.

Two or three strokes with a file are usually sufficient for

routine resharpening. When the saw chain has been

resharpened several times, have it sharpened in

MAKITA authorized service center.

Sharpening criteria:

− All cutter length must be equal. Cutters of differing

length prevent the chain from running smoothly,

and may cause the chain to break.

− Do not sharpen the chain once a minimum cutter

length of 3 mm has been reached. A new chain

must then be fitted.

− The chip thickness is determined by the distance

between the depth gauge (round nose) and the

cutting edge.

− The best cutting results are obtained with following

distance between cutting edge and depth gauge.

Chain blade 91PX: 0.65 mm

Fig.31

WARNING:

• An excessive distance increases the risk of kick-

back.

− The sharpening angle of 30 ° must be the same on

all cutters. Differences in angle cause the chain to

run roughly and unevenly, accelerate wear, and

lead to chain breaks.

− The side plate angle of the cutter is determined by

the depth of penetration of the round file. If the

specified file is used properly, the correct side

plate angle is produced automatically.

− Side plate angle for each saw chain are as follows:

Chain blade 91PX: 80 °

Fig.32

File and file guiding

− Use a special round file (optional accessory) for

saw chains to sharpen the chain. Normal round

files are not suitable.

− Diameter of the round file for each saw chain is as

follows:

Chain blade 91PX: 4.0 mm

− The file should only engage the cutter on the

forward stroke. Lift the file off the cutter on the

return stroke.

− Sharpen the shortest cutter first. Then the length

of this shortest cutter becomes the standard for all

other cutters on the saw chain.

Fig.33

− Guide the file as shown in the figure.

− The file can be guided more easily if a file holder

(optional accessory) is employed. The file holder

has markings for the correct sharpening angle of

30 ° (align the markings parallel to the saw chain)

and limits the depth of penetration (to 4/5 of the

file diameter).

Fig.34

− After sharpening the chain, check the height of the

depth gauge using the chain gauge tool (optional

accessory).

Fig.35

− Remove any projecting material, however small,

with a special flat file (optional accessory).

− Round off the front of the depth gauge again.

17

Cleaning the guide bar and lubricating the

return sprocket

CAUTION:

• Always wear safety gloves for this task. Burrs

present a risk of injury.

Fig.36

Check the running surfaces of the bar regularly for

damage. Clean using a suitable tool, and remove burrs

if necessary.

If the chain saw receives frequent use, lubricate the

return sprocket bearing at least once a week. Before

adding new fresh grease, carefully clean the 2 mm hole

on the tip of the guide bar, then force a small quantity of

multi-purpose grease (optional accessory) into the hole.

Cleaning the oil guide

Fig.37

− Clean the oil guide groove and the oil feed hole in

the bar at regular intervals.

New saw chains

Use two or three saw chains alternately, so that the saw

chain, sprocket and running surfaces of the bar wear

evenly.

Turn the bar over when changing the chain so that the

bar groove wears evenly.

CAUTION:

• Only use chains and bars which are approved for

this model of saw (refer to "SPECIFICATIONS").

Fig.38

Before fitting a new saw chain, check the condition of

the sprocket.

CAUTION:

• A worn sprocket damages a new saw chain. Have

the sprocket replaced in this case.

Always fit a new locking ring when replacing the

sprocket.

Maintaining the chain and run-down brakes

The braking systems are very important safety features.

Like any other component of the chain saw, they are

subject to a certain degree of wear. They must be

inspected regularly by MAKITA authorized service

centers. This measure is for your own safety.

Replacing carbon brushes

Fig.39

Remove and check the carbon brushes regularly.

Replace when they wear down to the limit mark. Keep

the carbon brushes clean and free to slip in the holders.

Both carbon brushes should be replaced at the same

time. Use only identical carbon brushes.

Fig.40

Use a screwdriver to remove the brush holder caps.

Take out the worn carbon brushes, insert the new ones

and secure the brush holder caps.

After replacing brushes, plug in the tool and break in

brushes by running tool with no load for about 10

minutes.

Storing tool

Biologically degradable saw chain oil can only be kept

for a limited period. Beyond two years after manufacture,

biological oils begin to acquire an adhesive quality, and

cause damage to the oil pump and components in the

lubricating system.

− Before taking the chain saw out of service for a

longer period, empty the oil tank and fill it with a

small quantity of engine oil (SAE 30).

− Run the chain saw briefly to flush all residue of the

biological oil out of the tank, lubricating system

and saw mechanism.

NOTE:

• When the chain saw is taken out of service, small

quantities of chain oil leaks from it for some time

afterwards. This is normal, and is not a sign of a

fault.

Store the chain saw on a suitable surface.

Before returning the chain saw to service, fill up with

fresh BIOTOP saw chain oil.

To maintain product SAFETY and RELIABILITY, repairs,

any other maintenance or adjustment should be

performed by Makita Authorized Service Centers,

always using Makita replacement parts.

18

TROUBLE SHOOTING

Before asking for repairs, conduct your own inspection

first. If you find a problem that is not explained in the

manual, do not attempt to dismantle the tool. Instead,

ask Makita Authorized Service Centers.

No oil on the chain.

Chain does not stop

even the chain brake is

engaged.

The tool vibrates

abnormally.

Malfunction status

Possible cause Remedy

The chain saw does not

start.

Chain does not run.

Insufficient performance.

Cable defective.

Chain brake is engaged.

Carbon brush worn down.

Oil tank is empty.

Oil guide groove is dirty.

Oil pump adjusting screw

incorrectly adjusted.

Brake

band worn down.

Loose guide bar or saw

chain.

No power supply.

Release chain brake.

Ask your local authorized service center for repair.

Fill the oil tank.

Clean the groove.

Adjust the oil pump feed rate.

Adjust the guide bar and

saw chain tension.

Tool malfunction.

Tool malfunction.

Connect to the power supply.

Check the power supply.

Stop using the tool immediately, and ask your local

authorized service center.

Stop using the tool immediately, and ask your local

author

ized service center.

Stop using the tool immediately, and ask your local

authorized service center.

Stop using the tool immediately, and ask your local

authorized service center.

014314

OPTIONAL ACCESSORIES

CAUTION:

• These accessories or attachments are

recommended for use with your Makita tool

specified in this manual. The use of any other

accessories or attachments might present a risk of

injury to persons. Only use accessory or

attachment for its stated purpose.

If you need any assistance for more details regarding

these accessories, ask your local Makita Service Center.

• Saw chain

• Guide bar cover

• Guide bar

• Saw chain oil

NOTE:

• Some items in the list may be included in the tool

package as standard accessories. They may differ

from country to country.

19

SLOVENŠČINA (izvirna navodila)

Razlaga splošnega pogleda

2-1. Ročica

2-2. Pokrov zobca kolesa

3-1. Nastavitveni vijak

4-1. Nastavljalna številčnica

5-1. Vskočnik

6-1. Meč

6-2. Odprtina

7-1. Kljuka

7-2. Odprtina

7-3. Zatič

9-1. Ročica

9-2. Pokrov zobca kolesa

10-1. Zrahljati

10-2. Priviti

10-3. Prilagoditveni vijak verige

10-4. Meč

10-5. Veriga žage

11-1. Zrahljati

11-2. Priviti

11-3. Nastavljalna številčnica

11-4. Meč

11-5. Veriga žage

12-1. Kavelj za kabel

12-2. Kabel orodja

12-3. Kabelski podaljšek

12-4. Vtič in vtičnica (oblika se lahko

med posameznimi državami

razlikuje)

13-1. Sprostilni gumb

13-2. Sprožilno stikalo

15-1. Kapica nastavka za dolivanje olja

15-2. Jermen

16-1. Zrahljati

16-2. Priviti

16-3. Prilagoditveni vijak verige

16-4. Meč

16-5. Veriga žage

17-1. Zrahljati

17-2. Priviti

17-3. Nastavljalna številčnica

17-4. Meč

17-5. Veriga žage

18-1. Sprednji ščitnik za roko

18-2. Zakleni

18-3. Odkleni

19-1. Sprednji ščitnik za roko

19-2. Odkleni

19-3. Zakleni

20-1. Kontrola nivoja olja

22-1. Ostroga

26-1. Območje podiranja

29-1. Smer podiranja

29-2. Nevarno območje

29-3. Pot izhoda

31-1. Dolžina reza

31-2. Razdalja med rezalnim robom in

merilnikom globine

31-3. Najmanj 3 mm

32-1. Čelni kot

37-1. Utor vodila za olje

37-2. Odprtina za dolivanje olja

38-1. Vskočnik

39-1. Meja obrabljenosti

40-1. Pokrov krtačke

40-2. Izvijač

TEHNIČNI PODATKI

Model

UC3050A UC3051A UC3550A

UC3550AP

UC3551A UC4050A UC4051A UC4550A

UC4551A

Maks. hitrost verige 14,5 m/s (870 m/min)

Dolžina meča 300 mm 350 mm 400 mm 450 mm

Dolžina reza 260 mm 320 mm 355 mm 415 mm

Standardni meč

Tip meča Konica verižnika meča

Tip 91PX

Naklon 3/8"

Standardna

veriga žage

Št. pogonskih

povezav

46 52 56 62

Priporočena dolžina meča 300 - 450 mm

Skupna dolžina (brez meča) 505 mm

Neto teža 5,4 kg 5,5 kg 5,5 kg 5,6 kg 5,5 kg 5,6 kg 5,7 kg

Podaljšek kabla (izbirno) DIN 57282/HO 7RN -F D=30 m maks.,3x1,5 mm2

• Zaradi našega nenehnega programa raziskav in razvoja si pridržujemo pravico do spremembe tehničnih podatkov brez obvestila.

• Tehnični podatki se lahko razlikujejo od države do države.

• Teža je v skladu z EPTA-postopkom 01/2003

END218-7

Simbol

Naslednji simboli se uporabljajo v povezavi s strojem.

Pred uporabo proizvoda se obvezno seznanite z

njihovim pomenom.

・ Preberite navodila za uporabo in

upoštevajte opozorila in varnostna

navodila.

・ Uporabljajte zaščito za oči.

・ Uporabljajte zaščito za sluh.

・ DVOJNA IZOLACIJA

・ Pozor: zahtevana posebna nega in

pozornost!

・ Pozor: če je kabel poškodovan, takoj

izvlecite električni vtič!

・ Pozor: povratni udarec!

20

・ Zaščitite pred dežjem in vlago!

・ Nosite čelado, očala in zaščito za sluh!

・ Uporabljajte zaščitne rokavice!

・ Izvlecite električni vtič!

・ Prva pomoč

・ Največja dovoljena dolžina reza

・ Smer premika verige

・ Verižno olje

・ Zavora verige sproščena

・ Zavora verige pritisnjena

・ Prepovedano!

・ Le za države EU

Električnega orodja ne odlagajte skupaj

z gospodinjskimi odpadki!

V skladu z Evropsko direktivo o odpadni

električni in elektronski opremi in z njenim

izvajanjem v skladu z državno zakonodajo

se mora električna oprema, ki je prišla do

konca svojega življenjskega cikla, zbirati

ločeno in se vrniti v okoljsko združljivo

ustanovo za recikliranje.

ENE085-1

Namenska uporaba

Orodje je namenjeno za rezanje lesa in hlodov.

ENF002-2

Priključitev na električno omrežje

Napetost električnega omrežja se mora ujemati s

podatki na tipski ploščici. Stroj deluje samo z enofazno

izmenično napetostjo. Stroj je po evropskih smernicah

dvojno zaščitno izoliran, zato se ga lahko priključi tudi

na vtičnice brez ozemljitvenega voda.

ENG905-1

Hrup

Tipični, z A ocenjeni vrednosti hrupa glede na EN60745:

Raven zvočnega tlaka (LpA): 90,8 dB (A)

Raven zvočne moči (L

WA

): 101,8 dB (A)

Odstopanje (K): 2,5 dB (A)

Uporabljajte zaščito za sluh

ENG900-1

Vibracije

Skupne vrednosti vibracij (vektorska vsota treh osi) po

EN60745:

Delovni način: rezanje lesa

Oddajanje tresljajev (a

h

): 5,2 m/s

2

Odstopanje (K): 1,5 m/s

2

ENG901-1

•

Navedena vrednost oddajanja vibracij je bila

izmerjena v skladu s standardnimi metodami

testiranja in se lahko uporablja za primerjavo orodij.

• Navedena vrednost oddajanja vibracij se lahko

uporablja tudi pri predhodni oceni izpostavljenosti.

OPOZORILO:

•

Oddajanje vibracij med dejansko uporabo električnega

orodja se lahko razlikuje od navedene vrednosti

oddajanja, odvisno od načina uporabe orodja.

•

Upravljavec mora za lastno zaščito poznati varnostne

ukrepe, ki temeljijo na oceni izpostavljenosti v

dejanskih pogojih uporabe (upoštevajoč celoten

delovni proces v trenutkih, ko je orodje izključeno in

ko deluje v prostem teku z dodatkom časa sprožitve).

ENH030-5

Samo za evropske države

ES Izjava o skladnosti

Družba Makita izjavlja, da je/so naslednji stroj/-i:

Oznaka stroja:

Verižna žaga

Št. modela / tip: UC3050A, UC3550A, UC4050A,

UC4550A, UC3051A, UC3551A, UC3550AP, UC4051A,

UC4551A

Tehnični podatki: glejte tabelo "TEHNIČNI PODATKI".

Je skladen z naslednjimi evropskimi direktivami:

2000/14/ES, 2006/42/ES

Izdelan v skladu z naslednjim standardom ali

standardiziranimi dokumenti:

EN60745

Potrdilo o pregledu tipa ES št.5514056,14005

Pregled tipa ES v skladu z 2006/42/ES je izvedel:

DEKRA Testing and Certification GmbH

Enderstraße 92b

01277 Dresden

Nemčija

Identifikacijska št. 2140

Tehnična dokumentacija v skladu z direktivo

2006/42/ES je na voljo na:

Makita, Jan-Baptist Vinkstraat 2, 3070, Belgija

Postopek za ugotavljanje skladnosti, ki ga predpisuje

direktiva 2000/14/ES, je v skladu s prilogo V.

Izmerjena stopnja jakosti zvoka: 101,9 dB (A)

Zajamčena stopnja jakosti zvoka: 103 dB (A)

4.9.2014

000331

Yasushi Fukaya

Direktor

Makita, Jan-Baptist Vinkstraat 2, 3070, Belgija

21

GEA010-1

Splošna varnostna opozorila za

električno orodje

OPOZORILO Preberite vsa varnostna opozorila in

navodila.

Neupoštevanje opozoril in navodil lahko vodi do

električnega udara, požara, in/ali hudih telesnih poškodb.

Shranite vsa opozorila in navodila za

kasnejšo uporabo.

GEB037-8

Varnostna opozorila za uporabo

verižne žage

1. Med delovanjem verižne žage ne približujte

delov telesa verigi. Preden zaženete verižno

žago se prepričajte, da se veriga ničesar ne

dotika. Trenutek nepazljivosti pri delu z verižnimi

žagami lahko povzroči zapletanje vaših oblačil ali

telesa v verigo žage.

2. Vedno držite verižno žago z desno roko za

zadnji ročaj in z levo za sprednji ročaj. Obratno

držanje verižne žage poveča tveganje za osebne

poškodbe in ga nikoli ne smete izvesti.

3. Električno orodje držite samo na izoliranih

držalnih površinah, saj se lahko veriga žage

dotakne skritih žic ali lastnega kabla. Ob stiku

verige žage z vodniki pod napetostjo dobijo

napetost vsi neizolirani kovinski deli električnega

orodja, zaradi česar lahko uporabnik utrpi

električni udar.

4. Uporabljajte zaščitna očala in zaščito za sluh.

Priporočena je dodatna zaščita za glavo, roke,

noge in stopala. Zadostna zaščitna obleka bo

zmanjšala telesne poškodbe zaradi letečih

ostankov ali nenamernega stika z verigo žage.

5. Ne uporabljajte verižne žage na drevesu.

Uporaba verižne žage na drevesu lahko povzroči

telesne poškodbe.

6. Vedno uporabljajte ustrezno obutev in

uporabljajte verižno žago samo, če stojite na

trdni, varni in ravni površini. Drseča ali

nestabilna površina, kot so lestve, lahko povzroči

izgubo ravnotežja ali nadzora nad verižno žago.

7. Kadar režete napeto vejo, bodite pozorni, ko

odskoči nazaj. Ko se napetost lesnih vlaken

sprosti, lahko veja udari upravljavca in/ali

povzroči nenadzorovano premikanje verižne žage.

8. Bodite izjemno previdni pri rezanju mladik in

sadik. Vitek material lahko ujame verigo žage in

jo vrže proti vam ali povzroči izgubo ravnotežja.

9.

Verižno žago nosite tako, da jo izklopljeno držite

za sprednji ročaj in obrnjeno stran od telesa.

Kadar nosite ali shranjujete verižno žago, vedno

namestite pokrivalo meča.

Ustrezno ravnanje z

verižno žago bo zmanjšalo verjetnost nenamernega

stika s premikajočo se verigo.

10. Upoštevajte navodila glede mazanja,

napetosti verige in menjave pripomočkov.

Nepravilno napeta ali namazana veriga se lahko

strga ali poveča možnost povratnega udarca.

11. Ročaji morajo biti suhi, čisti in brez olja ter

masti. Mastni, naoljeni ročaji so drseči in

povzročijo izgubo nadzora.

12. Režite samo les. Verižne žage ne uporabljajte

v nepredvidene namene. Na primer: verižne

žage ne uporabljajte za rezanje plastike, zidov

ali nelesenih gradbenih elementov. Uporaba

verižne žage, ki ni v skladu z namensko uporabo,

lahko povzroči nevarno situacijo.

13. Vzroki in preprečevanje povratnega udarca s

strani upravljavca:

Povratni udarec se lahko pojavi, če se konica

meča dotakne kakšnega predmeta ali ko se les

zapre in uklešči verigo v reži.

Stik konice lahko v nekaterih primerih povzroči

nenadno obratno reakcijo, ki vrže meč navzgor in

nazaj proti upravljavcu.

Zagozditev verige žage na vrhu meča lahko hitro

potisne meč nazaj proti upravljavcu.

Katera koli izmed teh reakcij lahko povzroči izgubo

nadzora nad žago, kar lahko povzroči hude telesne

poškodbe. Ne zanašajte se izključno na zaščitne

naprave, vgrajene v vašo žago. Kot uporabnik

verižne žage morate izvesti nekaj korakov, da

preprečite nesreče ali poškodbe med delom.

Povratni udarec je posledica nestrokovnega

ravnanja z orodjem in/ali neugodnih okoliščin.

Preprečite ga lahko z upoštevanjem spodaj

navedenih opozoril.

− Trdno držite žago, tako da s sklenjenimi

prsti držite ročaja, imate obe roki na žagi

in namestite telo ter roki tako, da boste

lahko prestregli sile povratnega udarca.

Sile povratnega udarca lahko upravljavec

nadzoruje, če izvede pravilne previdnostne

ukrepe. Ne izpustite verižne žage.

014316

− Ne segajte previsoko in ne režite nad

višino ramen. S tem boste preprečili

nenameren stik konice in omogočili boljši

nadzor nad verižno žago v nepredvidenih

situacijah.

22

− Uporabljajte samo nadomestne meče in

verige, ki jih je določil proizvajalec.

Nepravi nadomestni meči in verige lahko

povzročijo strganje verige in/ali povratni

udarec.

− Upoštevajte navodila proizvajalca za

brušenje in vzdrževanje verige žage.

Zmanjšanje višine merilnika globine lahko

povzroči povečano možnost povratnega

udarca.

DODATNA VARNOSTNA

PRAVILA

1. Preberite navodila za uporabo, da se spoznate z

obratovanjem verižne žage.

2. Preden prvič uporabite verižno žago uredite, da

boste imeli uvajanje v delovanje. Če to ni mogoče,

pa pred začetkom dela vadite na okroglem lesu

na stojalu.

3. Verižne žage ne smejo uporabljati otroci ali mlajši

od 18 let. Mladoletniki, starejši od 16 let, so lahko

izvzeti iz te omejitve, če se usposabljajo pod

nadzorom strokovnjaka.

4. Delo z verižno žago zahteva visoko stopnjo

koncentracije. Ne delajte z verižno žago, če se ne

počutite dobro. Vsa dela opravljajte mirno in

previdno.

5. Nikoli ne delajte pod vplivom alkohola, drog ali

zdravil.

Pravilna uporaba

1. Verižna žaga je namenjena izključno rezanju lesa.

Ne uporabljajte je za rezanje plastike ali

poroznega betona.

2. Verižno žago uporabljajte samo za dela, opisana

v teh navodilih za uporabo. Ne, na primer,

uporabljajte je za rezanje žive meje ali v podobne

namene.

3. Verižne žage ni dovoljeno uporabljati za

gozdarska dela, torej za podiranje in klestenje

stoječega lesa. Kabel verižne žage ne omogoča

upravljavcu premičnosti in varnosti, ki je potrebna

za takšna dela.

4. Verižna žaga ni namenjena za komercialno

uporabo.

5. Ne preobremenjujte verižne žage.

Osebna zaščitna oprema

1. Obleka se mora tesno prilegati, vendar ne sme

ovirati gibljivosti.

2. Med delom nosite naslednja zaščitna oblačila:

• Atestirano zaščitno čelado, če obstaja

nevarnost padajočih vej ali podobna;

• Obrazno masko ali očala;

• Ustrezno zaščito sluha (čepki za ušesa,

običajni ali uliti ušesni čepki). Analiza znamke

Octave na zahtevo.

• Zaščitne rokavice iz trdega usnja;

• Dolge hlače iz močne tkanine;

• Zaščitne delovne hlače iz tkanine, odporne na

reze;

• Zaščitne čevlje ali škornje z nedrsečimi

podplati, jeklenim prstnim delom in oblogo iz

tkanine, odporne na reze;

• Dihalno masko, kadar delate v prašnem

okolju (npr. žaganje suhega lesa).

Zaščita pred električnim udarom

・ Verižne žage ne smete uporabljati pri

mokrem vremenu ali v vlažnem okolju,

saj električni motor ni vodoodporen.

1. Žago vključite samo v vtičnice preverjenega

tokokroga. Preverite, ali se napetost sistema

ujema s tisto na tipski ploščici. Prepričajte se, ali

je nameščena 16 A varovalka. Žage, ki jih

uporabljate na prostem, je treba priključiti na

odklopnik na diferenčni tok z delovnim tokom, ki

ne presega 30 mA.

・ Če je priključni kabel poškodovan, takoj

izvlecite električni vtič.

Varne delovne prakse

1. Pred začetkom dela preverite, ali verižna žaga

pravilno deluje in ali se njeno stanje sklada s

predpisi za varnost. Še posebej preverite:

• ali zavora verige pravilno deluje,

• ali zavora izteka pravilno deluje,

• ali sta meč in pokrov zobca kolesa pravilno

nameščena,

• ali je veriga naostrena in napeta v skladu s

pravili,

• ali sta električni kabel in vtič nepoškodovana;

Glejte razdelek "PREGLEDI".

2. Vedno zagotovite uporabo podaljškov kablov z

zadostnim prečnim prerezom (glejte "TEHNIČNI

PODATKI"). Pri uporabi navitja kabla v celoti

odvijte kabel. Kadar uporabljate žago na prostem,

zagotovite, da je uporabljeni kabel namenjen za

uporabo na prostem in ima ustrezne specifikacije.

3. Kabla ne približujte območju rezanja in namestite

kabel tako, da se med rezanjem ne bo zataknil v

veje ali podobno.

4. Ne uporabljajte verižne žage v bližini vnetljivega

prahu ali plinov, saj motor ustvarja iskre in

predstavlja nevarnost eksplozije.

5. Delajte samo na trdni podlagi z dobro obutvijo.

Posebno pozornost namenite oviram (npr. kablu)

v delovnem območju. Še posebej bodite pozorni

na območjih, kjer je zaradi vlage, ledu, snega,

sveže narezanega lesa ali lubja podlaga drseča.

Med uporabo žage ne stojte na lestvah ali

drevesih.

6. Bodite še posebej previdni pri delu na pobočjih;

kotaleča se debla in veje predstavljajo morebitno

nevarnost.

7. Nikoli ne režite nad višino ramen.

23

8. Med vklopom in uporabo držite verižno žago z

obema rokama. Zadnji ročaj držite z desno,

sprednjega pa z levo roko. Ročaja trdno držite z

obema palcema. Meč in veriga ne smeta biti v

stiku z nobenim predmetom, kadar je žaga

vključena.

014316

9. Iz območja rezanja odstranite tujke, kot so pesek,

kamni, žeblji, žice itd. Tujki poškodujejo meč in

verigo in lahko povzročijo nevaren povratni

udarec.

10. Bodite še posebej previdni pri rezanju v bližini

žičnih ograj. Ne zarežite v ograjo, saj lahko to

povzroči povratni udarec žage.

11. Ne zarežite v tla.

12. Režite posamezne kose lesa in ne svežnjev ali

kupov.

13. Izogibajte se uporabi žage za rezanje tankih vej

in korenin, saj se lahko zataknejo v verigo žage.

Izguba ravnotežja predstavlja tveganje.

14. Pri žaganju lesa uporabljajte varno podporo

(stojalo).

15. Ne uporabljajte verižne žage za dviganje ali

odstranjevanje kosov lesa in drugih predmetov.

16. Vodite verižno žago tako, da se noben del telesa

ne nahaja znotraj podaljšane poti verige žage

(glejte sliko).

006909

17. Pri premikanju med žaganjem uporabite zavoro

verige, da preprečite nenameren zagon verige.

Med nošenjem držite verižno žago za sprednji

ročaj in ne imejte prsta na sprožilcu.

18. Med odmori ali puščanjem nenadzorovane

verižne žage izvlecite električni vtič. Puščajte

verižno žago tam, kjer ne predstavlja nevarnosti.

Povratni udarec

1. Med delom z verižno žago lahko pride do

nevarnega povratnega udarca. Do povratnega

udarca pride, ko konica meča (še posebno

zgornja četrtina) pride v stik z lesom ali drugim

trdnim predmetom. To povzroči odboj verižne

žage v smeri upravljavca.

006919

2. Da boste preprečili povratni udarec, upoštevajte

naslednje:

• Nikoli ne začnite žagati s konico meča.

• Nikoli ne uporabljajte konice meča za žaganje.

Bodite še posebej previdni pri nadaljevanju

rezov.

• Začnite z rezom, ko veriga deluje.

• Vedno pravilno naostrite verigo. Še posebej

pravilno nastavite merilnik globine na pravilno

višino.

• Nikoli ne žagajte več vej hkrati.

• Pri klestenju bodite previdni, da preprečite stik

meča z drugimi vejami.

• Pri luženju se ne približujte sosednjim deblom.

Vedno glejte konico meča.

• Uporabite stojalo.

Varnostne funkcije

1. Pred začetkom dela vedno preverite, ali

varnostne funkcije delujejo. Ne uporabljajte

verižne žage, če varnostne funkcije ne delujejo

pravilno.

− Zavora verige:

Verižna žaga je opremljena z zavoro verige, ki

zaustavi verigo žage v delčku sekunde. Aktivira se,

ko potisnete ščitnik roke naprej. Veriga žage se nato

ustavi v 0,15 s, napajanje motorja pa se prekine.

12

014317

− Zavora izteka:

Veriga žage je opremljena z zavoro izteka, ki

nemudoma zaustavi verigo žage, ko spustite

stikalo za VKLOP/IZKLOP. To prepreči nevarnost

zagona verige, ko je žaga izklopljena.

− Sprednji in zadnji ščitniki rok ščitijo uporabnika

pred poškodbami zaradi letečih kosov lesa ali

strgane verige.

1. Pritisnjena zavora

verige

2. Sproščena zavora

verige

24

− Sprožilni zaklep preprečuje nenamerni vklop

verižne žage.

− Lovilnik verige ščiti uporabnika pred poškodbami,

če veriga odskoči ali se strga.

Prenašanje in hramba

・ Kadar verižne žage ne uporabljate ali

med prenašanjem, izvlecite električni

vtič in namestite pokrov meča, ki je

priložen žagi. Nikoli ne prenašajte ali

prevažajte žage z delujočo verigo.

1. Verižno žago nosite samo za sprednji ročaj, meč

pa mora biti obrnjen nazaj.

2. Verižno žago hranite v varnem, suhem in

zaklenjenem prostoru izven dosega otrok. Ne

hranite verižne žage na prostem.

VZDRŽEVANJE

1. Pred izvajanjem prilagoditev ali vzdrževanjem

izvlecite vtič iz vtičnice.

2. Redno preverjajte napajalni kabel glede

poškodovane izolacije.

3. Redno čistite verižno žago.

4. Morebitne poškodbe plastičnega ohišja je treba

ustrezno in takoj popraviti.

5. Ne uporabljajte žage, če sprožilno stikalo ne

deluje pravilno. Ustrezno ga popravite.

6. V nobenem primeru ni dovoljeno spreminjanje

verižne žage. Vaša varnost je ogrožena.

7. Ne izvajajte drugih vzdrževalnih del ali popravil

kot samo tiste, ki so opisani v teh navodilih za

uporabo. Vsakršno drugo delo mora izvesti

pooblaščeni servis.

8. Uporabljajte samo originalne nadomestne dele in

pripomočke, ki so namenjeni za vaš model žage.

Uporaba drugih delov poveča nevarnost nesreče.

9. Ne prevzemamo odgovornosti za nesreče ali

poškodbe, če se uporabljajo neodobreni meči,

verige ali drugi nadomestni deli ali pripomočki.

Prva pomoč

・ Ne delajte sami. Vedno delajte znotraj

slišne razdalje do druge osebe.

1. Vedno imejte pri roki škatlo za prvo pomoč. Takoj

nadomestite vse predmete, ki ste jih uporabili.

2. Če potrebujete pomoč v primeru nesreče,

navedite naslednje:

• Kje se je nesreča zgodila?

• Kaj se je zgodilo?

• Koliko oseb je poškodovanih?

• Kakšne vrste poškodb imajo?

• Kdo poroča o nesreči?

OPOMBA:

Pri posameznikih s slabo prekrvavitvijo, ki so

izpostavljeni čezmernim vibracijam, lahko pride do

poškodb krvnih žil ali živčnega sistema.

Vibracije lahko povzročijo naslednje simptome, ki se

pojavijo v prstih, dlaneh ali zapestjih: "Spanje"

(odrevenelost), mravljinci, bolečina, občutek zbadanja,

spremembe barve kože ali kože same.

Če opazite kateri koli izmed teh pojavov, poiščite

zdravniško pomoč!

SHRANITE TA NAVODILA.

OPOZORILO:

NE dopustite si, da bi zaradi udobnejšega dela ali

poznavanja izdelka (pridobljenega z večkratno

uporabo) opustili striktno upoštevanje varnostnih

pravil pri uporabi stroja. ZLORABA ali

neupoštevanje varnostnih pravil v teh navodilih za

uporabo lahko povzroči hude telesne poškodbe.

25

OZNAKA DELOV

(Model matice: pokrov verižnika se zategne z maticami.)

Za model UC3050A, UC3550A, UC3550AP, UC4050A,

UC4550A

1

2

3

4

5

6

9

10

8

014372

(Model ročice: pokrov verižnika se zategne z ročico.)

Za model UC3051A, UC3551A, UC4051A, UC4551A

1

2

3

4

5

6

9

10

8

7

014373

26

(Za vse modele)

14

12

11

15

13

17

16

18

014514

Kavelj za kabel

1

2

3

4

5

6

7

9

8

10

11

12

13

Ostroga

18

14

15

16

17

Zadnji ročaj

Sprožilno stikalo

Kapica nastavka za dolivanje olja

Sprednji ročaj

Sprednji ščitnik za roko

Meč

Veriga žage

Ročica

Prilagoditveni vijak/številčnica

Kontrola nivoja olja

Zadnji ščitnik za roko

Sprostilni gumb

Lovilnik verige

Pokrov meča

Prilagoditveni vijak črpalko za olje

(na dnu)

Pokrov zobca kolesa

014375

MONTAŽA

POZOR:

• Pred vsakim posegom v orodje se prepričajte, da

je le to izključeno in ločeno od električnega

omrežja.

Odstranjevanje ali nameščanje pokrova

verižnika

Za odstranjevanje pokrova verižnika izvedite naslednje

korake:

(Za modele z matico)

Sl.1

Odvijte matico.

(Za modele z ročico)

Sl.2

Pritisnite in v celoti odprite vzvod, dokler se ne ustavi.

Obrnite ročico v nasprotni smeri urinega kazalca.

Za nameščanje pokrova verižnika izvedite zgornje

korake v obratnem vrstnem redu.

Odstranjevanje ali nameščanje verige žage

POZOR:

• Pri nameščanju in odstranjevanju verige žage

vedno uporabljajte zaščitne rokavice.

Za odstranjevanje verige žage izvedite naslednje

korake:

1. Zrahljajte pokrov verižnika.

2. (Za modele z matico) Obrnite prilagoditveni vijak

verige v nasprotni smeri urinega kazalca, da

sprostite napetost verige žage.

(Za modele z ročico) Obrnite prilagoditveno

številčnico v smeri „-“, da sprostite napetost

verige žage.

Sl.3

Sl.4

3. Odstranite ščitnik verižnega koluta.

4. Odstranite verigo žage in meč z verižne žage.

Za namestitev verige žage izvedite naslednje korake:

5. Preverite smer verige. Puščična oznaka na verigi

kaže smer delovanja verige.

Sl.5

6. Namestite en konec verige na zgornjo stran meča,

drugega pa okrog verižnika.

27

7. Namestite meč na verižno žago.

8. Poravnajte napetostni drsnik z luknjo na meču.

Sl.6

9. Medtem ko držite meč, obrnite prilagoditveni vijak

verige/številčnico za nastavitev napetosti verige

žage.

10. Namestite pokrov verižnika tako, da se kavlji

prilegajo vzdolž luknje in da se zatiči prilegajo v

dvojnike v pokrovu verižnika.

Sl.7

11. Zategnite pokrov verižnika.

Sl.8

Sl.9

Nastavitev napetosti verige

Veriga se po več delovnih urah lahko sprosti. Zato pred

zagonom občasno preverjajte napetost verige.

1. Rahlo zrahljajte pokrov verižnika.

2. Rahlo dvignite konico meča.

3. Obrnite prilagoditveni vijak/številčnico, da

sprostite napetost verige žage.

Sl.10

Sl.11

4. Zategujte verigo žage, dokler se spodnja stran

verige žage ne prilega v vodilo meča (glejte krog).

5. Še vedno rahlo držite meč, nato pa po

nastavljanju napetosti verige zategnite pokrov

verižnika. Prepričajte se, ali se morda veriga žage

na spodnji strani ne zrahlja.

Prepričajte se, ali se veriga žage dobro prilega na

spodnjo stran meča.

POZOR:

• Verige žage ne zategnite preveč. Če je veriga

preveč napeta, lahko pride do poškodbe verige,

prezgodnje obrabe meča ali zloma nastavljalne

številčnice.

• Preohlapna veriga lahko odskakuje in predstavlja

nevarnost nesreče.