Page 1

TECHNICAL INFORMATION

Models No.

UC3510A

New Tool

Description

300mm, 350mm, 400mm chain saw

CONCEPTION AND MAIN APPLICATIONS

These models are home use chain saws that correspond to the functions

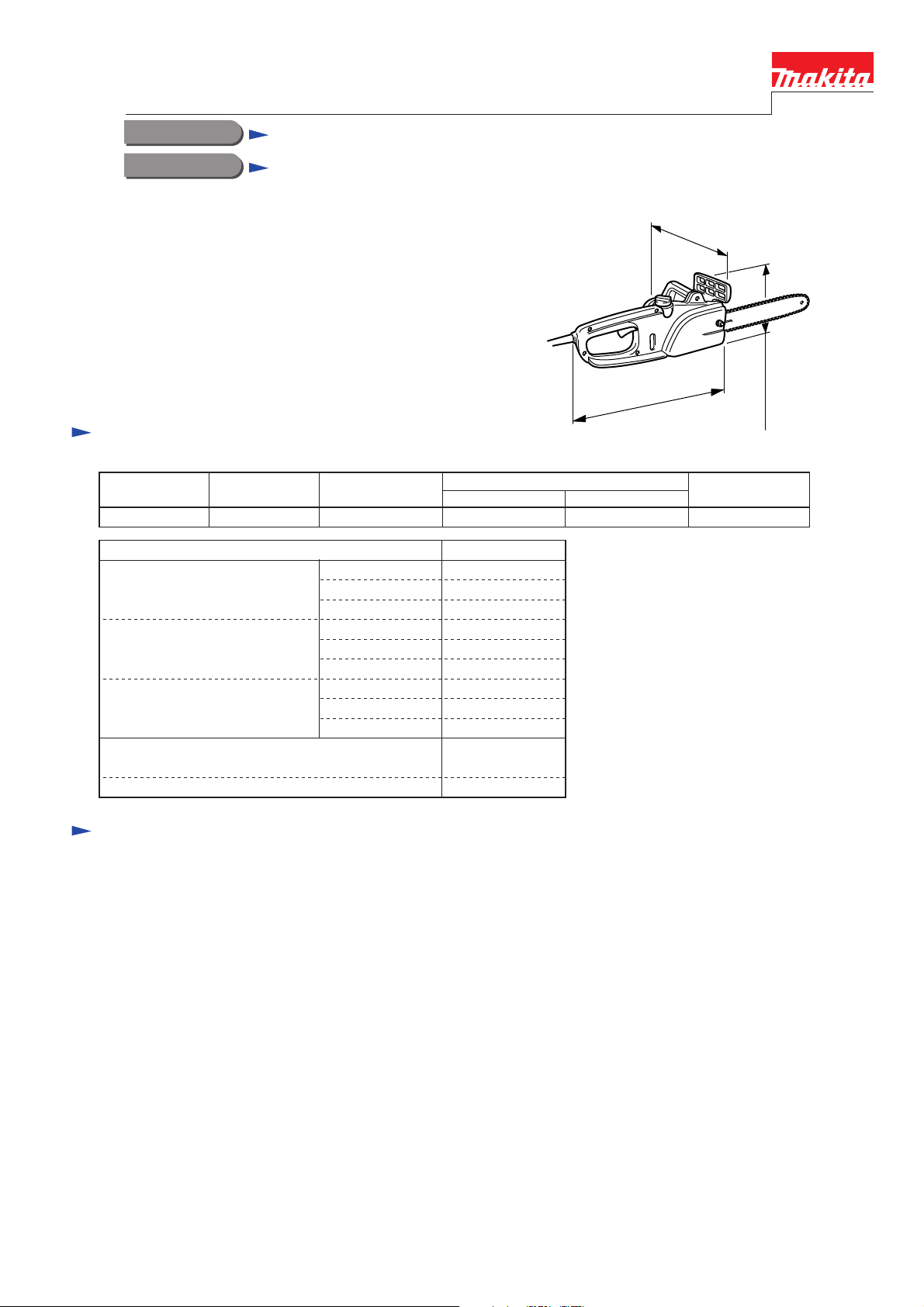

Specifications

Voltage (V) Current (A) Cycle (Hz)

220-240

Chain speed

7.0 50/60 1500 780 2000

Continuous Rating (W)

Input Output

800m/min.

221mm

(8-11/16")

410mm(16-1/8")

180mm(7-3/32")

Max.

Output(W)

Saw chain

Standard equipment

Chain cover

Universal wrench

--------------------------- 1 pc.

-------------------- 1 pc.

Type

Pitch

Gauge

90SG

3/8"

0.042"

Page 2

Repair

1. Replacement of carbon

1)

Loosen three tapping screws 4x18 that fix front handle and remove front handle to replace the carbon.

2)

Secure lead wires to the lead holder.

Tapping screw 4x18 (3 pcs.)

Carbon brush

Lead holders (4 locations)

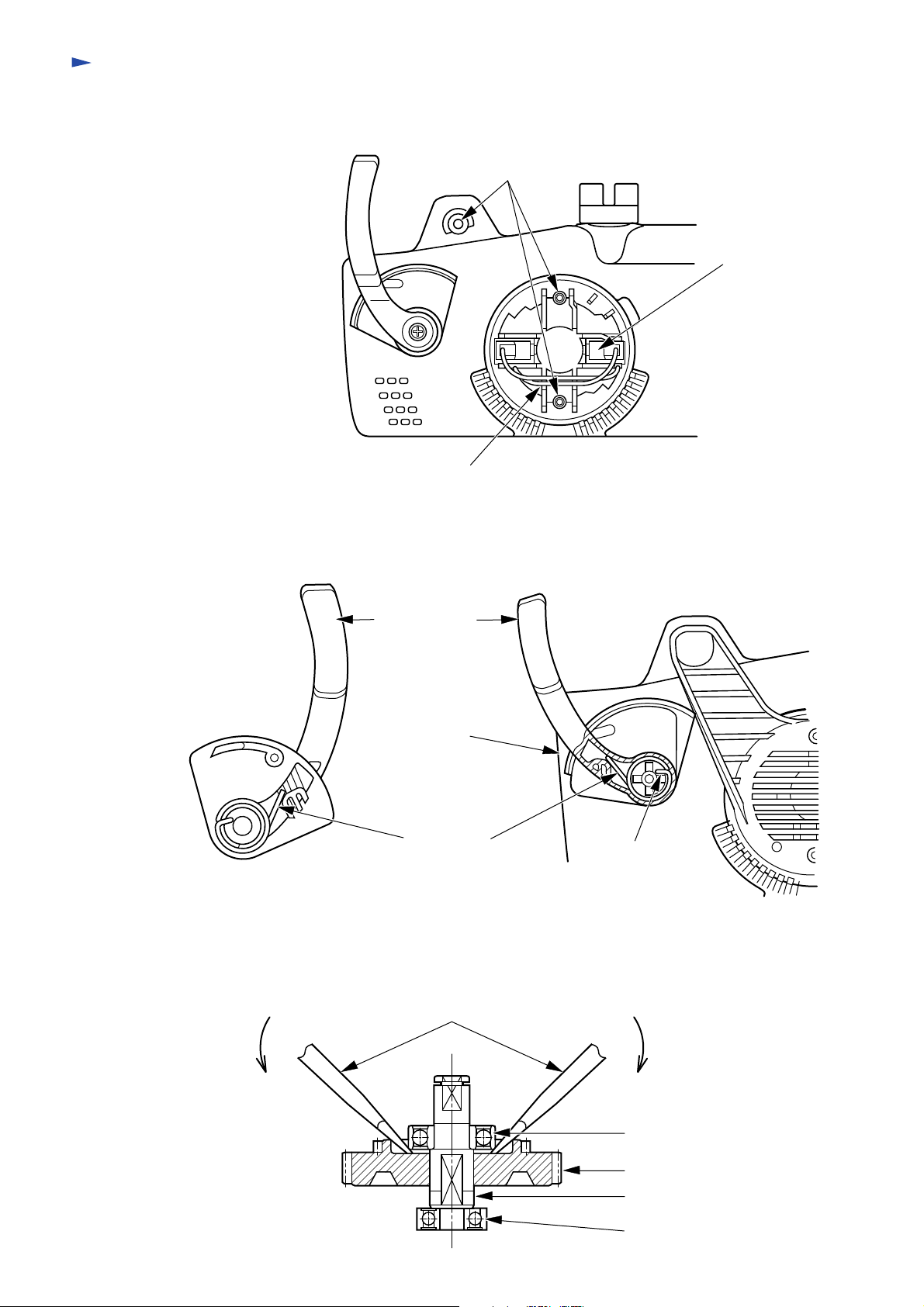

2. Replacement of front hand guard

1)

Put down front hand guard forward and replace it while actuating a kick-back brake.

2)

Mount torsion spring 20 on the front hand guard as shown in the figure below.

3)

Mount the front hand guard to the housing L at an angle as shown below. At this time hook the torsion spring to the

boss of the housing L.

Front hand guard

Housing L

Torsion spring 20 Hook here

3. Replacement of bearing

Replace bearing #6001LLB by using two flat head screwdrivers as shown below.

Flat head screwdriver

Bearing #6001LLB

Spur gear 55

Spindle

Bearing #608ZZ

Page 3

4. Replacement of oil pump complete

1)

Loosen tapping screw 3.5x10 and remove holder.

2)

Remove oil pump complete together with oil bezel.

3)

Secure pipe 6 on the groove of the bearing holder and the pipe holder.

4)

Insert flat washer 5 between bearing holder and spur gear 39.

Tapping screw 3.5x10

Oil pump

complete

Oil bezel

Flat washer 5

Groove

Holder

Bearing holder

Pipe holder

Pipe 6

5. Replacement of armature

1)

Before replacement release kick-back brake by following the instruction manual.

2)

Remove carbon by following the procedures of "1. Replacement of carbon."

3)

When pulling out/putting on armature from/to bearing holder, hook a rod to the bearing holder and release the kickback brake.

4)

Use two flat head screwdrivers to replace the bearing #6000LLB.

Rod

Hook here

Bearing holder

Flat head screwdriver

#6000LLB

6. Replacement of brake band

1)

Release the brake as the same procedures as 5-1 above.

2)

Before replacing the brake band, insert rink plate complete to the brake band hole and mount it on the bearing holder.

3)

Confirm that the claws of the brake band and those of the brake ring are positioned as shown in the figure below.

Brake ring

Link plate complete

Brake band

Page 4

Wiring diagram

Orange

Power supply cord

P1

P2

Mains switch

Details of wiring

Sub-switch

1

4

Black

5

4

3

2

Noise

suppressor

Black

Brush holder

(Rear handle side)

Connect receptacle as shown in the figure.

Support complete

Black White

Brush holder

(Front handle side)

Receptacle

Receptacle

Fix lead wires by the lead holders.

Contain noise suppressor as shown in the figure.

Noise suppressor

Loading...

Loading...