Page 1

Router

MODEL RF1100/RF1101

MODEL RD1100/RD1101

INSTRUCTION MANUAL

WARNING:

For your personal safety, READ and UNDERSTAND before using.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

www.makitatools.com

003648

Page 2

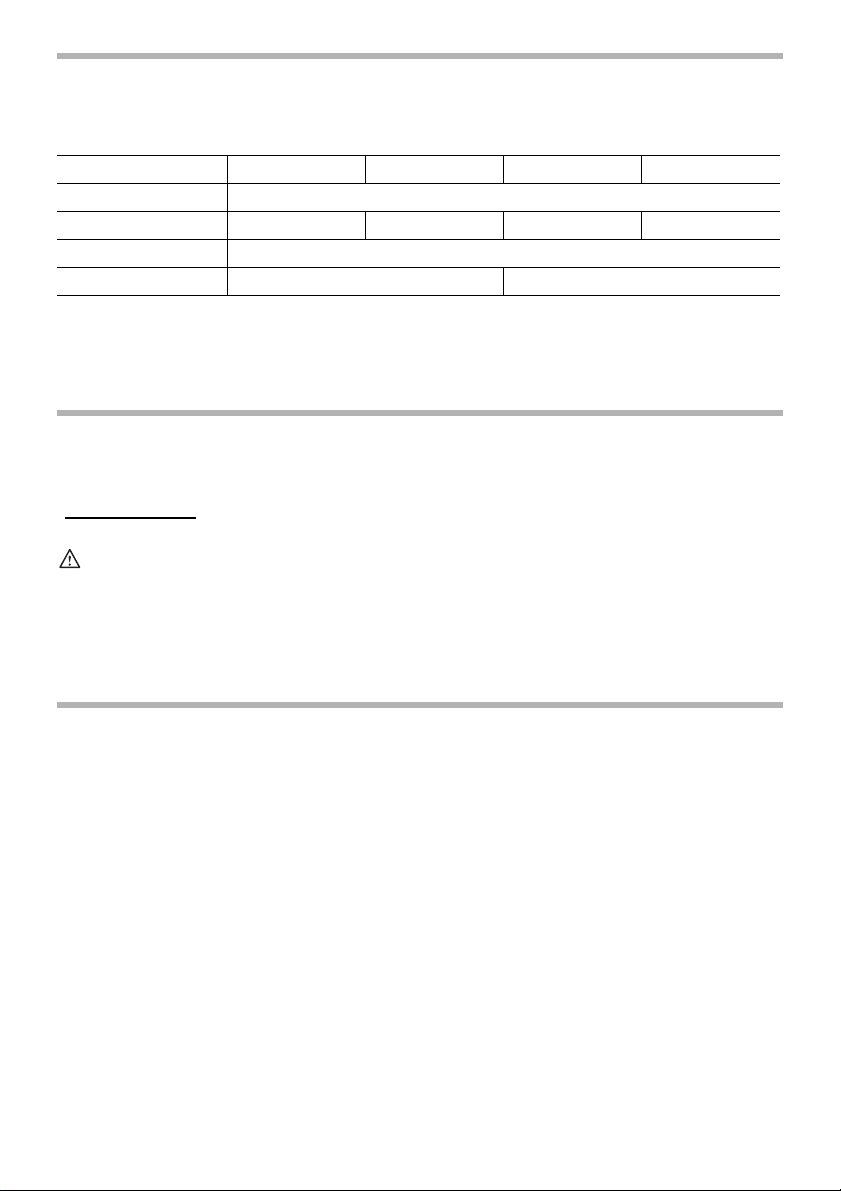

SPECIFICATIONS

Model RF1100 RF1101 RD1100 RD1101

Collet chuck capacity 1/2” and 1/4”

No load speed (RPM) 24,000/min.

Overall height 223 mm (8-3/4”)

Net weight 3.2 kg (7.1 lbs) 3.6 kg (7.9 lbs)

8,000 - 24,000/min.

• Manufacturer reserves the right to change specifications without notice.

• Specifications may differ from country to country.

24,000/min.

8,000 - 24,000/min.

GENERAL SAFETY RULES

USA001-2

(For All Tools)

WARNING:

Read and understand all instructions. Failure to follow all

instructions listed below, may result in electric shock, fire and/or

serious personal injury.

SAVE THESE INSTRUCTIONS

Work A re a

1.

Keep your work area clean and well lit.

Cluttered benches and dark areas invite accidents.

2.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases, or dust. Powe r

tools create sparks which may ignite the dust

or fumes.

3.

Keep bystanders, children, and visitors

away while operating a power tool. Distrac-

tions can cause you to lose control.

Electrical Safety

4.

Grounded tools must be plugged into an

outlet properly installed and grounded in

accordance with all codes and ordinances. Never remove the grounding

prong or modify the plug in any way. Do

not use any adaptor plugs. Check with a

qualified electrician if you are in doubt as

to whether the outlet is properly

grounded. If the tools should electrically mal-

function or break down, grounding provides a

low resistance path to carry electricity away

from the user.

2

Page 3

5.

Avoid body contact with grounded surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of

electric shock if your body is grounded.

6.

Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

7.

Do not abuse the cord. Never use the cord

to carry the tools or pull the plug from an

outlet. Keep cord away from heat, oil,

sharp edges or moving parts. Replace

damaged cords immediately. Damaged

cords increase the risk of electric shock.

8.

When operating a power tool outside, use

an outdoor extension cord marked “W-A”

or “W”. These cords are rated for outdoor

use and reduce the risk of electric shock.

Personal Safety

9.

Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use tool while tired or

under the influence of drugs, alcohol, or

medication. A moment of inattention while

operating power tools may result in serious

personal injury.

10.

Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep

your hair, clothing, and gloves away from

moving parts. Loose clothes, jewelry, or long

hair can be caught in moving parts.

11.

Avoid accidental starting. Be sure switch

is off before plugging in. Carrying tools with

your finger on the switch or plugging in tools

that have the switch on invites accidents.

12.

Remove adjusting keys or wrenches

before turning the tool on. A wrench or a

key that is left attached to a rotating part of

the tool may result in personal injury.

13.

Do not overreach. Keep proper footing

and balance at all times. Proper footing and

balance enables better control of the tool in

unexpected situations.

14.

Use safety equipment. Always wear eye

protection. Dust mask, non-skid safety

shoes, hard hat, or hearing protection must

be used for appropriate conditions. Ordinary

eye or sun glasses are NOT eye protection.

Tool Use and Care

15.

Use clamps or other practical way to

secure and support the workpiece to a

stable platform. Holding the work by hand or

against your body is unstable and may lead

to loss of control.

16.

Do not force tool. Use the correct tool for

your application. The correct tool will do the

job better and safer at the rate for which it is

designed.

17.

Do not use tool if switch does not turn it

on or off. Any tool that cannot be controlled

with the switch is dangerous and must be

repaired.

18.

Disconnect the plug from the power

source before making any adjustments,

changing accessories, or storing the tool.

Such preventive safety measures reduce the

risk of starting the tool accidentally.

19.

Store idle tools out of reach of children

and other untrained persons. Tools are

dangerous in the hands of untrained users.

20.

Maintain tools with care. Keep cutting

tools sharp and clean. Properly maintained

tools with sharp cutting edges are less likely

to bind and are easier to control.

21.

Check for misalignment or binding of

moving parts, breakage of parts, and any

other condition that may affect the tools

operation. If damaged, have the tool serviced before using. Many accidents are

caused by poorly maintained tools.

22.

Use only accessories that are recommended by the manufacturer for your

model. Accessories that may be suitable for

one tool, may become hazardous when used

on another tool.

3

Page 4

24.

SERVICE

23.

Tool service must be performed only by

qualified repair personnel. Service or main-

tenance performed by unqualified personnel

could result in a risk of injury.

When servicing a tool, use only identical

replacement parts. Follow instructions in

the Maintenance section of this manual.

Use of unauthorized parts or failure to follow

Maintenance instructions may create a risk of

electric shock or injury.

USE PROPER EXTENSION CORD: Use only three-wire extension cords that have threeprong grounding-type plugs and three-pole receptacles that accept the tool’s plug. Make

sure your extension cord is in good condition. Replace or repair damaged or worn cord

immediately. When using an extension cord, be sure to use one heavy enough to carry the

current your product will draw. An undersized cord will cause a drop in line voltage resulting

in loss of power and overheating. Table 1 shows the correct size to use depending on cord

length and nameplate ampere rating. If in doubt, use the next heavier gage. The smaller the

gage number, the heavier the cord.

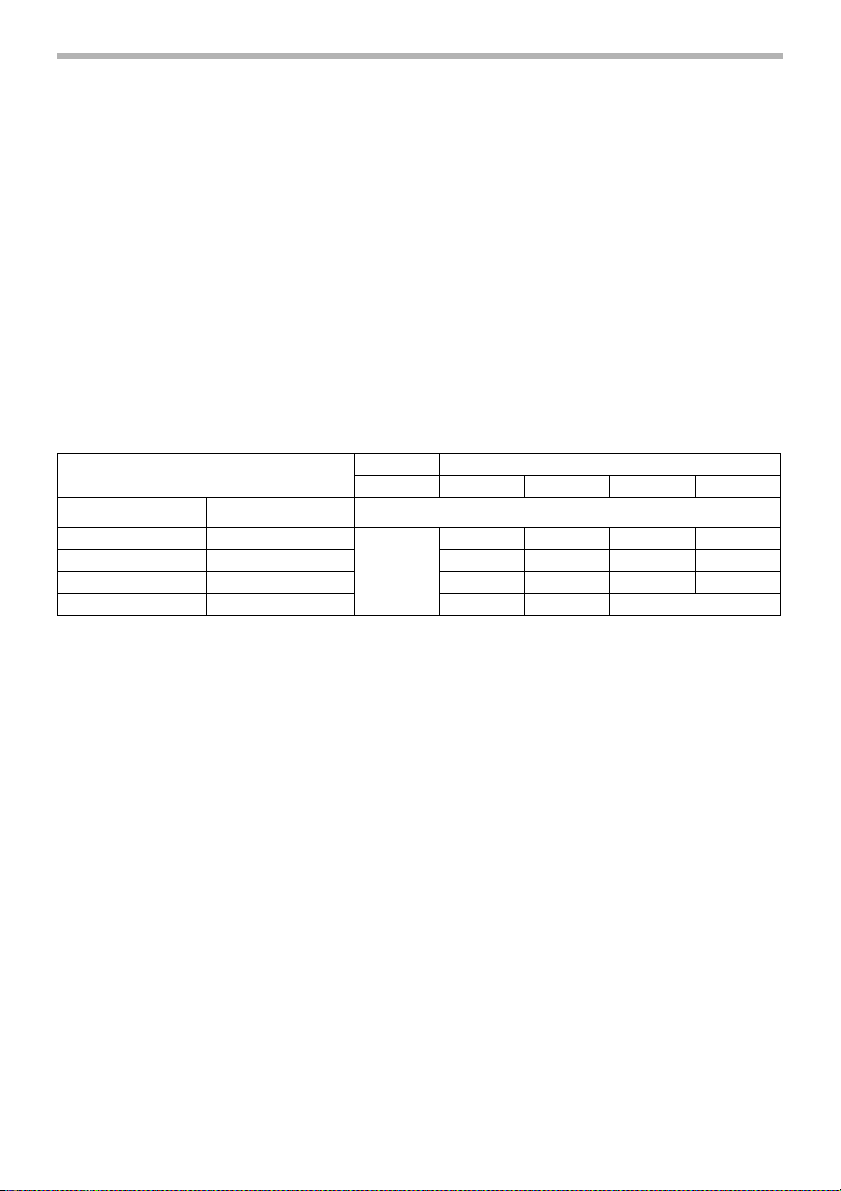

Table 1: Minimum gage for cord

Ampere Rating

More Than Not More Than AWG

0 6 18 16 16 14

6 10 18161412

10 12 16 16 14 12

12 16 14 12 Not Recommended

Volts Total length of cord in feet

120 V 25 ft. 50 ft. 100 ft. 150 ft.

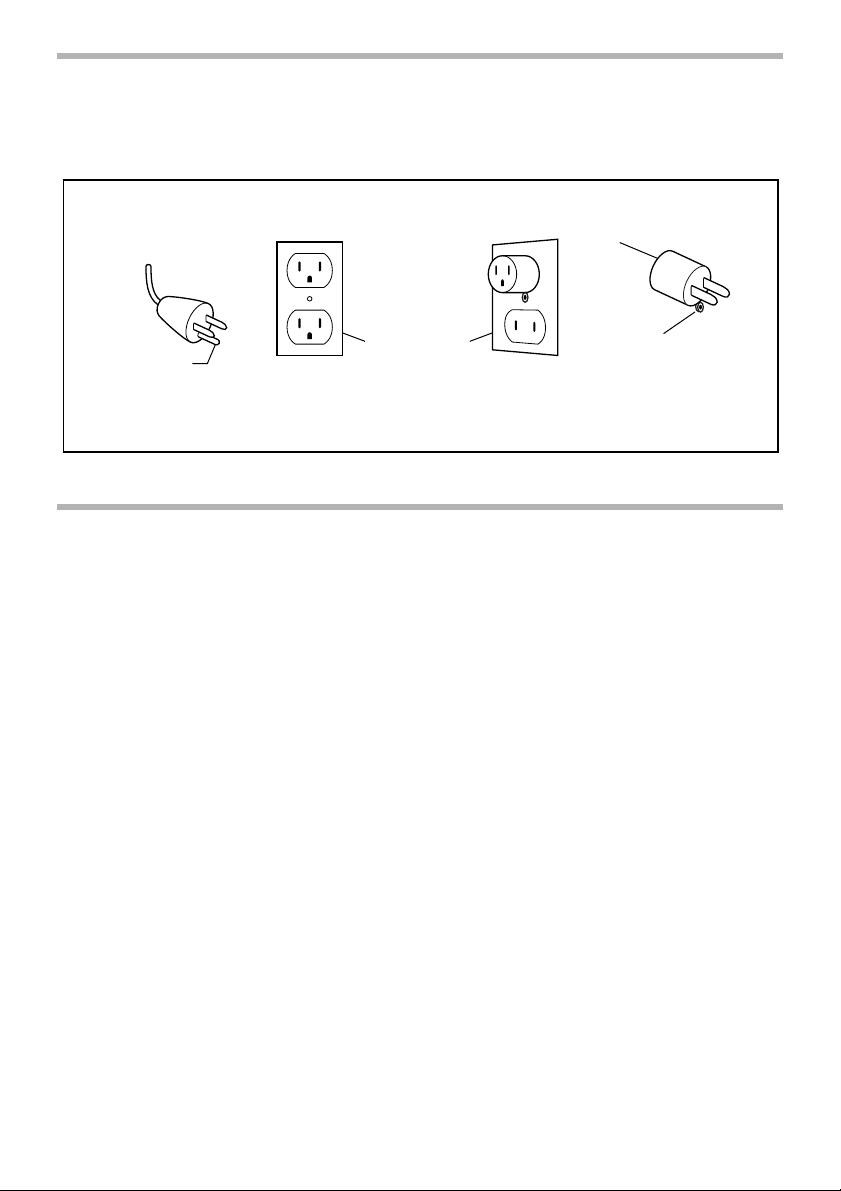

GROUNDING INSTRUCTIONS

This tool should be grounded while in use to protect the operator from electric shock. The

tool is equipped with a three-conductor cord and three-prong grounding type plug to fit the

proper grounding type receptacle. The green (or green and yellow) conductor in the cord is

the grounding wire. Never connect the green (or green and yellow) wire to a live terminal.

Your unit is for use on 120 volts and has a plug that looks like Fig. “A”.

4

Page 5

An adapter Fig. “B” and “C” is available for connecting Fig. “A” type plugs to two- prong

receptacles. The green-colored rigid ear, lug, etc., extending from the adapter must be connected to a permanent ground, such as a properly grounded outlet box.

Adapter

Grounding Means

Grounding

Blade

Cover of Grounded

Outlet Box

Fig. A Fig. B Fig. C

SPECIFIC SAFETY RULES

USB013-3

DO NOT let comfort or familiarity with product (gained from

repeated use) replace strict adherence to router safety rules. If

you use this tool unsafely or incorrectly, you can suffer serious

personal injury.

1.

Hold tool by insulated gripping surfaces

when performing an operation where the

cutting tool may contact hidden wiring or

its own cord. Contact with a “live” wire will

make exposed metal parts of the tool “live”

and shock the operator.

2.

Wear hearing protection during extended

period of operation.

3.

Handle the bits very carefully.

4.

Check the bit carefully for cracks or damage before operation. Replace cracked or

damaged bit immediately.

5.

Avoid cutting nails. Inspect for and

remove all nails from the workpiece

before operation.

6.

Hold the tool firmly with both hands.

7.

Keep hands away from rotating parts.

8.

Make sure the bit is not contacting the

workpiece before the switch is turned on.

9.

Before using the tool on an actual workpiece, let it run for a while. Watch for

vibration or wobbling that could indicate

improperly installed bit.

10.

Be careful of the bit rotating direction and

the feed direction.

11.

Do not leave the tool running. Operate the

tool only when hand-held.

12.

Always switch off and wait for the bit to

come to a complete stop before removing

the tool from workpiece.

5

Page 6

13.

Do not touch the bit immediately after

operation; it may be extremely hot and

could burn your skin.

14.

Always lead the power supply cord away

from the tool towards the rear.

15.

Do not smear the tool base carelessly with

thinner, gasoline, oil or the like. They may

cause cracks in the tool base.

16.

Draw attention to the need to use cutters

of the correct shank diameter and suitable

for the speed of the tool.

17.

Some material contains chemicals which

may be toxic. Take caution to prevent dust

inhalation and skin contact. Follow material supplier safety data.

SAVE THESE INSTRUCTIONS

WARNING:

MISUSE or failure to follow the safety rules stated in this

instruction manual may cause serious personal injury.

SYMBOLS

The followings show the symbols used for tool.

V .......................volts

A ....................... amperes

Hz .....................hertz

6

USD101-2

................alternating current

....................no load speed

n

˚

.../min................revolutions or reciprocation per

minute

Page 7

FUNCTIONAL

DESCRIPTION

1

3

4

4

1

5

8

8

3

1

2

5

1. Motor unit housing

2. Index line

3. Scale ring

4. Graduation

5. Lock lever

0

ON

OFF

1. Switch lever

CAUTION:

• Always be sure that the tool is switched off and

unplugged before adjusting or checking function on the

tool.

003653

Adjusting the depth of cut

2

Place the tool on a flat wood surface. Open the lock lever.

Turn the motor unit until the bit just touches the flat surface.

3

Close the lock lever.

4

Rotate the scale ring until the zero-line is on the index line on

the motor unit. One graduation on the scale ring means the

cutting edge of the bit is exposed 1/64” below the base.

While holding up the base slightly, open the lock lever and

turn the motor unit clockwise until the index line on the motor

unit reaches the desired depth indicated on the scale ring.

Close the lock lever firmly.

Switch action

003661

For RF1100 and RF1101

1

CAUTION:

• Before plugging in the tool, always check to see that the

tool is switched off.

• Switch can be locked in “ON” position for ease of

operator comfort during extended use. Apply caution

when locking tool in “ON” position and maintain firm

grasp on tool.

To start the tool, move the switch lever to the I (ON) position.

To stop the tool, move the switch lever to the O (OFF) position.

7

Page 8

1. Motor unit cord

2. Outlet

3. Lock button

4. Switch trigger

003663

For RD1100 and RD1101

1

CAUTION:

• Before plugging in the tool, always check to see that the

2

3

4

switch trigger actuates properly and returns to the “OFF”

position when released.

• Switch can be locked in “ON” position for ease of

operator comfort during extended use. Apply caution

when locking tool in “ON” position and maintain firm

grasp on tool.

After connecting the motor unit cord to the outlet in the handle, move the switch lever to the “ON” position.

To start the tool, simply pull the switch trigger. Release the

switch trigger to stop.

For continuous operation, pull the switch trigger and then

push in the lock button.

To stop the tool from the locked position, pull the switch trigger fully, then release it.

Speed adjusting dial

For model RF1101 and RD1101 only

The tool speed can be infinitely adjusted between 8,000 and

24,000 rpm by turning the speed adjusting dial on the top of

the tool. Higher speed is obtained when the dial is turned in

the direction of number 6; lower speed is obtained when it is

turned in the direction of number 1.

This allows the ideal speed to be selected for optimum material processing, i.e. the speed can be correctly adjusted to

suit the material and bit diameter.

CAUTION:

• If the tool is operated continuously at low speeds for a

long time, the motor will get overloaded, resulting in tool

malfunction.

• The speed adjusting dial can be turned only as far as 6

and back to 1. Do not force it past 6 or 1, or the speed

adjusting function may no longer work.

8

Page 9

ASSEMBLY

1. Lock lever

1. Wrench

2. Router bit

CAUTION:

• Always be sure that the tool is switched off and

unplugged before carrying out any work on the tool.

Installing or removing the bit

CAUTION:

• Do not tighten the collet chuck without inserting a bit, or

the collet chuck will break.

• When using bit of bigger than 1-1/4” in diameter, install

base plate with center hole diameter 2-1/2”, replacing

the original base plate.

003672

First, remove the motor unit from the base as follows.

1

003673

1

2

1. Open the lock lever.

2. While holding the base, turn the motor unit counterclockwise.

3. Turn it until the pin in the base is disengaged from the

groove in the motor unit. Lift the motor unit free from the

base.

Insert the bit all the way into the collet cone and tighten the

collet nut securely with the two wrenches.

These routers accommodate the bits with 1/2” diameter

shank. When using the 1/4” diameter shank bit, replace the

equipped collet chuck with the one for 1/4” diameter shank

bit which is provided as the standard accessory.

To remove the bit, follow the installation procedure in reverse.

1. Pin

003674

Reinstall the motor unit

1

Install the motor unit into the base as follows.

1. Open the lock lever.

2. While holding the base, insert the motor unit into the

base aligning the pin with the groove in the base.

3. Confirm that the pin and the groove are aligning. Rotate

the motor unit clockwise into the base.

4. Close the lock lever.

9

Page 10

1. Motor unit cord

2. Outlet

For equipped with switch-in-handle

003675

For model RD1100 and RD1101 only

1

Connect the motor unit cord to the outlet in the handle.

2

OPERATION

2

1

1. Feed direction

2. Bit revolving direction

3. Workpiece

4. Straight guide

Set the tool base on the workpiece to be cut without the bit

making any contact. Then turn the tool on and wait until the

bit attains full speed. Move the tool forward over the workpiece surface, keeping the tool base flush and advancing

smoothly until the cutting is complete.

When doing edge cutting, the workpiece surface should be

on the left side of the bit in the feed direction.

001984

2

1

2

1. Workpiece 2. Bit revolving direction

3. View from the top of the tool 4. Feed direction

001985

NOTE:

3

• Moving the tool forward too fast may cause a poor

4

3

4

quality of cut, or damage to the bit or motor. Moving the

tool forward too slowly may burn and mar the cut. The

proper feed rate will depend on the bit size, the kind of

4

workpiece and depth of cut. Before beginning the cut on

the actual workpiece, it is advisable to make a sample

cut on a piece of scrap lumber. This will show exactly

how the cut will look as well as enable you to check

dimensions.

• When using the straight guide, be sure to install it on the

right side in the feed direction. This will help to keep it

flush with the side of the workpiece.

10

Page 11

1

2

1. Hex socket bolts

2. Guide bar

3. Straight guide

003678

Straight guide (optional accessory)

The straight guide is effectively used for straight cuts when

chamfering or grooving.

003682

To install the straight guide, insert the guide bars into the

holes in the tool base. Adjust the distance between the bit

and the straight guide. At the desired distance, tighten the

hex socket bolts to secure the straight guide in place.

When cutting, move the tool with the straight guide flush with

the side of the workpiece.

3

003689

Templet guide (optional accessory)

The templet guide provides a sleeve through which the bit

passes, allowing use of the tool with templet patterns.

1

2

1. Lock nut

2. Templet guide

3. Base plate

4. Router bit

003693

To install the templet guide, insert the templet guide in center

hole in the base plate and secure in place with the lock nut.

3

4

11

Page 12

003696

Secure the templet to the workpiece. Place the tool on the

1

2

3

6

templet and move the tool with the templet guide sliding

along the side of the templet.

4

1. Router bit

2. Base

3. Templet

4. Workpiece

5. Templet guide

6. Lock nut

MAINTENANCE

1

1. Limit mark

1. Brush holder cap

2. Screwdriver

5

CAUTION:

• Always be sure that the tool is switched off and

unplugged before attempting to perform inspection or

maintenance.

001145

Replacing carbon brushes

Remove and check the carbon brushes regularly. Replace

when they wear down to the limit mark. Keep the carbon

brushes clean and free to slip in the holders. Both carbon

brushes should be replaced at the same time. Use only identical carbon brushes.

003703

Use a screwdriver to remove the brush holder caps. Take out

the worn carbon brushes, insert the new ones and secure

the brush holder caps.

1

2

To maintain product SAFETY and RELIABILITY, repairs, any

other maintenance or adjustment should be performed by

Makita Authorized or Factory Service Centers, always using

Makita replacement parts.

12

Page 13

ACCESSORIES

CAUTION:

• These accessories or attachments are recommended for

use with your Makita tool specified in this manual. The

use of any other accessories or attachments might

present a risk of injury to persons. Only use accessory

or attachment for its stated purpose.

If you need any assistance for more details regarding these

accessories, ask your local Makita service center.

• Straight & groove forming bits

• Edge forming bits

• Laminate trimming bits

• Straight guide

• Templet guides

• Lock nut

• Clear base plate (Center hole 2-1/2”)

• Wrench 27

13

Page 14

Memo

14

Page 15

Memo

15

Page 16

Memo

16

Page 17

Cut

Makita U.S.A., Inc.

14930 Northam Street

La Mirada, CA 90638-5753

Fold

First-Class

Postage

Required

Post Office will

not deliver

without proper

postage.

17

Page 18

MAIL THIS PORTION

Your answers to the following questions are appreciated.

1. This product was purchased from:

Home Center

Hardware/Lumber Store

Tool Distributor

Industrial Supply

Construction Supply

2. Use of the product is intended for:

Construction Trade

Industrial Maintenance

Home Maintenance

Hobby

Other ( )

5. Any comments:

DATE PURCHASED MODEL NO.

MONTH DAY YEAR

INTL. LAST NAME / COMPANY NAME

Other ( )

3. How did you learn about this product:

4. Most favored points are:

SERIAL NO.

Magazine

From Dealer

Newspaper

Store Display

Catalog

Design

Features

Size

Price

Makita Brand

Radio

Exhibition

From Friend

Previous Usage

Other ( )

Repair Service

Durability

Powe r

Other ( )

STATUS

Married

Single

SEX

MF

STREET ADRESS

CITY

AREA

S TATE

AGE:

BE SURE TO COMPLETE THE CUSTOMER’S PORTION OF THIS FORM AND RETAIN FOR YOUR RECORDS.

Paste Paste Paste Paste Paste Paste

18

Please return this portion by facsimile or mail.

Facsimile No: (714) 522-8133

ZIP CODE PHONE

Under 19 20-29 30-39 40-49 50-60 Over 60

CODE

Paste Paste Paste Paste Paste Paste Paste Paste

Paste Paste Paste Paste Paste Paste

Page 19

FACTORY SERVICE CENTERS

1-800-4-MAKITA

RETAIN THIS PORTION FOR YOUR RECORDS

ARIZONA

3707 E. Broadway Rd., Ste. 6

Phoenix, AZ 85040

(602) 437-2850

CALIFORNIA

41850 Christy St.

Fremont, CA 94538-5107

(510) 657-9881

14930 Northam St.

La Mirada, CA 90638-5753

(714) 522-8088

1970 Fulton Avenue

Sacramento, CA 95825

(916) 482-5197

7674 Clairemont Mesa Blvd.

San Diego, CA 92111

(858) 278-4471

16735 Saticoy St., Ste. 105

Van Nuys, CA 91406

(818) 782-2440

COLORADO

11839 E. 51st Ave.

Denver, CO 80239-2709

(303) 371-2850

FLORIDA

750 East Sample Road

Pompano Beach, FL 33064

(954) 781-6333

GEORGIA

4680 River Green Parkway NW

Duluth, GA 30096

(770) 476-8911

ILLINOIS

1450 Feehanville Dr.

Mt. Prospect, IL 60056-6011

(847) 297-3100

MARYLAND

7397 Washington Boulevard,

Suite 104 Elkridge, MD 21075

(410) 796-4401

MASSACHUSETTS

232 Providence Hwy.

Westwood, MA 02090

(781) 461-9754

MINNESOTA

6427 Penn Ave. South

Richfield, MN 55423

(612) 869-5199

MISSOURI

9876 Watson Road

St. Louis, MO 63126-2221

(314) 909-9889

NEBRASKA

4129 S. 84th St.

Omaha, NE 68127

(402) 597-2925

NEVADA

3375 S. Decatur Blvd.

Suites. 22 - 24

Las Vegas, NV 89102

(702) 368-4277

NEW JERSEY

251 Herrod Blvd.

Dayton, NJ 08810-1539

(609) 655-1212

NEW YORK

4917 Genessee Street

Cheektowaga, NY 14225

(716) 685-9503

OREGON

828 19th Avenue, N.W.

Portland, OR 97209

(503) 222-1823

PENNSYLVANIA

1704 Babcock Blvd.

Pittsburgh, PA 15209

(412) 822-7370

PUERTO RICO

200 Guayama St.

Hato Rey, PR 00917

(787) 250-8776

TENNESSEE

1120 Elm Hill P.

Suile 170 Nashville, TN 372

(615) 248-3321

TEXAS

12801 Stemmons Fwy Ste. 809

Farmers Branch, TX 75234

(972) 243-1150

12701 Directors Dr.

Stafford, TX 77477-3701

(281) 565-8665

3453 IH-35 North, Ste. 101

San Antonio, TX 78219

(210) 228-0676

WISCONSIN

Lincoln Plaza Shopping Ctr.

2245 S. 108th St. West Allis, WI

53227

(414) 541-4776

CUSTOMER’S RECORD

When you need service: Send

complete tool (prepaid) to one

of the Makita Factory Service

Centers listed, or to an Authorized

Makita Service Center. Be sure

to attach a letter to the outside of

the carton detailing the problem

with your tool.

Date Purchased

Dealer’s Name & Address

Model No.

Serial No.

19

Page 20

WARNING

Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to the State of California

to cause cancer, birth defects or other reproductive harm. Some examples

of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this

type of work. To reduce your exposure to these chemicals: work in a well

ventilated area, and work with approved safety equipment, such as those

dust masks that are specially designed to filter out microscopic particles.

MAKITA LIMITED ONE YEAR WARRANTY

Warranty Policy

Every Makita tool is thoroughly inspected and tested before leaving the factory. It is warranted to be free of

defects from workmanship and materials for the period of ONE YEAR from the date of original purchase.

Should any trouble develop during this one year period, return the COMPLETE tool, freight prepaid, to one of

Makita’s Factory or Authorized Service Centers. If inspection shows the trouble is caused by defective

workmanship or material, Makita will repair (or at our option, replace) without charge.

This Warranty does not apply where:

• repairs have been made or attempted by others:

• repairs are required because of normal wear and tear:

• the tool has been abused, misused or improperly maintained:

• alterations have been made to the tool.

IN NO EVENT SHALL MAKITA BE LIABLE FOR ANY INDIRECT, INCIDENTAL OR CONSEQUENTIAL

DAMAGES FROM THE SALE OR USE OF THE PRODUCT. THIS DISCLAIMER APPLIES BOTH DURING

AND AFTER THE TERM OF THIS WARRANTY.

MAKITA DISCLAIMS LIABILITY FOR ANY IMPLIED WARRANTIES, INCLUDING IMPLIED WARRANTIES OF

“MERCHANTABILITY” AND “FITNESS FOR A SPECIFIC PURPOSE,” AFTER THE ONE YEAR TERM OF THIS

WARRANTY.

This Warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you. Some states do not allow limitation on how long an implied

warranty lasts, so the above limitation may not apply to you.

884304C068

Makita Corporation of America

2650 Buford Hwy., Buford, GA 30518

Loading...

Loading...