Makita RBC414U, RBC413U, RBC414UG Technical Information

T

ECHNICAL INFORMATION

W

PRODUCT

P 1/ 1

7

Models No.

Description

RBC413U, RBC414U, RBC414UG

Petrol Brushcutter

CONCEPT AND MAIN APPLICATIONS

Model RBC413U is symmetric design bike handle style Petrol brushcutter

powered by 40.2 mL 2-stroke engine.

This product has been developed based on RBC411U, and Diaphragm

carburetor has been employed instead of the float type carburetor of RBC411U.

Other basic features are the same as RBC411U; therefore, the engine for

this model does not comply with well-known exhaust emission regulations.

RBC414U is asymmetric design bike handle style. The handle can be removed

quickly from drive shaft without tool. The others are the same as RBC413U.

RBC414UG is only available in Brazil for use of E25 gasoline (mixture of 25%

anhydrous ethanol and 75% gasoline.)

Specification

RBC414U RBC414UGRBC413U

Type

Displacement: mL

Engine

Max. spindle speed at no load: min.

Compliance with main exhaust

emission regulations; CARB Tier 3,

EPA Phase 2, EU Stage 2

Carburetor

Starting

system

Starting system Recoil starter

Fuel tank capacity: L

Primer pump Yes

Clutch Yes

Spindle thread size

Handle style

Net weight**: kg (lbs)

* 2 cycle engine oil is required in the correct mixture ratio.

** Dry weight, without guard, cutting tool and shoulder harness

Fuel

Max. output: kW (PS) 1.4 (1.9) [at 7,000 min.ˉ¹]

Max. torque (N·m)

ˉ¹ = rpm

Easy start

(Spring-assisted recoil starter)

Decompression valve

Symmetric design

bike handle

Mixed gasoline* Mixed E25 gasoline*

2.2 [at 5,000 min.

Diaphragm

M10x1.25, Left-handed

Asymmetric design bike handle

7.1 (15.7) 7.2 (15.9)

2-stroke

40.2

6,800

No

No

No

1.1

RBC413U

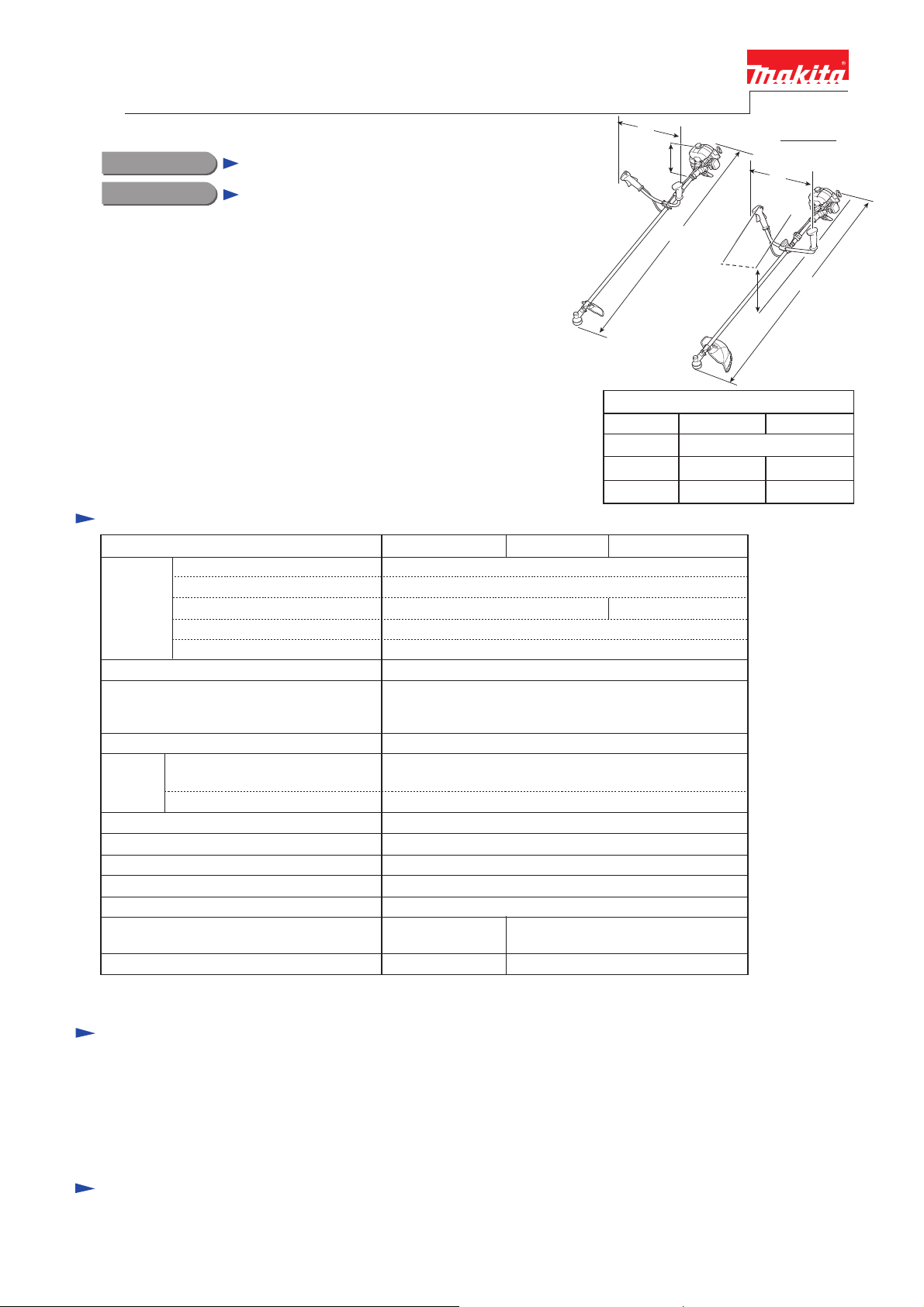

Length (L)

Width (W)

Height (H)

ˉ¹]

H

L

H

Dimensions: mm (")

RBC413U RBC414U

1,710 (67-3/8)

650 (25-5/8)

435 (17-1/8)

W

L

RBC414U,

RBC414UG

630 (24-3/4)

515 (20-1/4)

Standard equipment

Blade or Nylon head .......................................................1

Wrench 17-19 ..................................................................1

Hex wrench 4 ..................................................................1

Hex wrench 5 ..................................................................1

Note: The standard equipment for the tool shown above may vary by country.

Box wrench 17 ................................................................1

Shoulder strap assembly ..................................................1

Accessory bag .................................................................1

Safety goggles (for Slovenia only) ..................................1

Fuel mixture (for Vietnam only) .....................................1

Optional accessories

Double blade 305mm (12"), Triple blade 255mm (10"), Triple blade 305mm (12"), Star blade 230mm (9"),

Star blade 255mm (10"), 8-tooth blade 230mm (9"), 8-tooth blade 255mm (10"), Nylon cutting head (Bump & Feed Z5L),

Nylon cutting head (Ultra Auto 6L), Protector (for cutting blade only), Universal guard (=Protector),

Universal guard extension, Safety googles, Fuel mixture

P 2/ 17

Repair

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

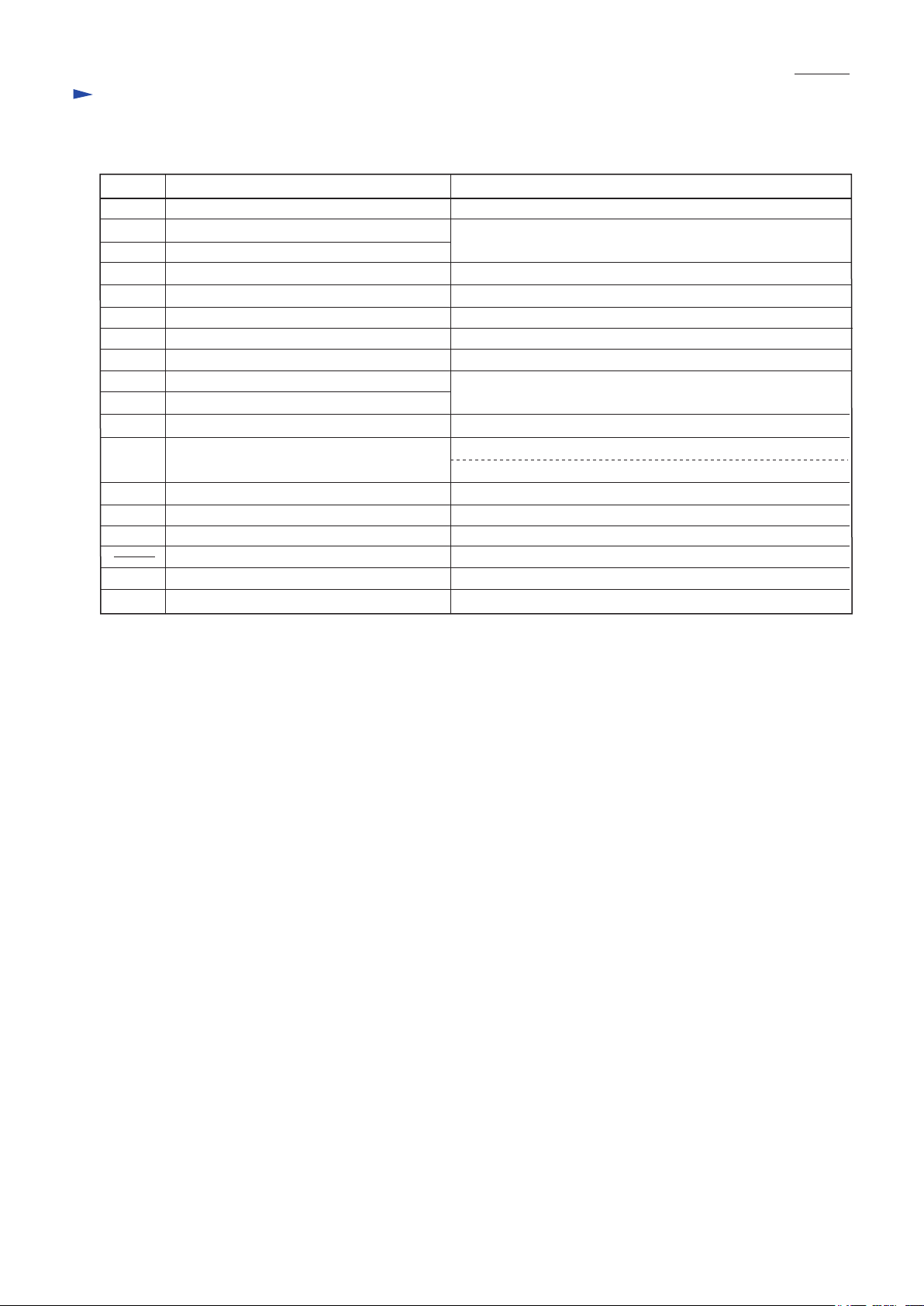

[1] NECESSARY REPAIRING TOOLS

DescriptionCode No. Use for

Retaining ring pliers RT-2E for Internal ring1R006

Bearing plate1R022

Pipe ring1R023

Tachometer1R070 checking rpm of Engine

Crank shaft lock bolt1R155

Ignition checker1R181 checking ignition

1R219

1R269

1R311 Retaining ring pliers with Long bent nails

782235-2

Torque wrench shaft 7-23N·m

Ratchet head 9.5 (for 1R219)1R220

Bearing extractor

Flywheel puller1R364 removing Flywheel

Feeler gauge set1R366 adjusting Ignition coil/ Spark plug

Digital tester1R402 checking the continuity of electrical parts

Wire brush making Spark plug clean

Hex wrench 4 (standard equipment)783223-2

Wrench 17-19 (standard equipment)

removing/ assembling Retaining rings

removing Clutch drum complete from Ball bearing 6003LLU

assembling Ball bearing 6003LLU to Clutch drum completeBearing setting pipe 20-12.21R028

locking Piston (with Crank shaft)

removing Piston pinPiston pin punch1R200

tightening Bolts

removing Ball bearings

removing Fuel tube from nipple of Carburetor

removing Retaining rings R-26 and R-32 in Gear case assembly

removing Clutch drum complete

removing Spark plug

[2] GASKET

Once Gasket is removed:

(1) Replace Gasket with a new one.

(2) Clean up the mating surface where the gasket was installed to maintain its sealing performance.

[3] LUBRICANT/ ADHESIVE APPLICATION

(1) Apply 1g of Makita grease N No. 2 to Spiral spring in Recoil starter.

(2) When the inside of Gear case assembly is cleaned, supply 11g of Makita grease N No. 2 from the grease inlet.

(3) Apply 6g of Makita grease N No. 1 to the entire portion of Shaft complete in Shaft pipe complete.

[4] DISASSEMBLY/ ASSEMBLY

[4]-1. Warning

Follow the instructions described below in advance before repairing:

• Wear gloves.

• Remove the cutting tool from the unit, and if it is a saw blade, attach the blade cover to the blade.

• When the engine is hot from use, cool down the engine enough or you can get burned.

• Remove remaining fuel from Fuel tank and Carburetor completely. [FLAMMABLE MATERIAL KEEP FIRE AWAY]

• Remove Spark plug cap from Spark plug.

• Repair the engine on a stable workbench and in a clean workplace kept as free of dust and debris as possible.

• In order to avoid wrong reassembly, draw or write down where and how the parts are assembled, and what are the parts.

• It is also recommended to have boxes ready to keep disassembled parts by group.

• Handle the disassembled parts carefully. Clean and wash them properly.

• If some bolts and screws are too tight, use Impact driver.

• Tighten the bolts and the screws to the specified torque as shown in "[5] Tightening torque specifications".

• Each time after you mounted a main part of the engine such as the piston, check if it moves smoothly

without abnormal noise by manually turning the crankshaft.

• After completion of reassembly, check for loose parts or abnormal noise and vibration by manually turning the crankshaft.

Repair

[4] DISASSEMBLY/ ASSEMBLY

[4]-2. Engine and Shaft

DISASSEMBLING

(1) Remove M6x22 Hex socket head bolt that fastens

Earth terminal to Clutch case.

Disconnect Bullet terminals of Lead wires. (Fig. 1)

Note: If it is difficult to do the above steps, first of all,

remove Fuel tank from Engine.

(2) Remove Inner cable from Swivel of Carburetor,

then separate Control cable

from Adjust screw. (Fig. 2)

(3) Remove the rest of M6x22 Hex socket head bolts to

separate Engine from Clutch case. (Fig. 3)

Fig. 1

M6x22 Hex

socket

head

bolt

Earth terminal

P 3/ 17

Clutch case Fuel tank

Bullet terminals

of Lead wires

Carburetor

ASSEMBLING

Assemble by reversing

the disassembly procedure.

Fig. 2

Inner cable Adjust screw

Swivel

Fig. 3

M6x22 Hex socket

head bolt (with

spring washer)

(3 pcs.)

Clutch case

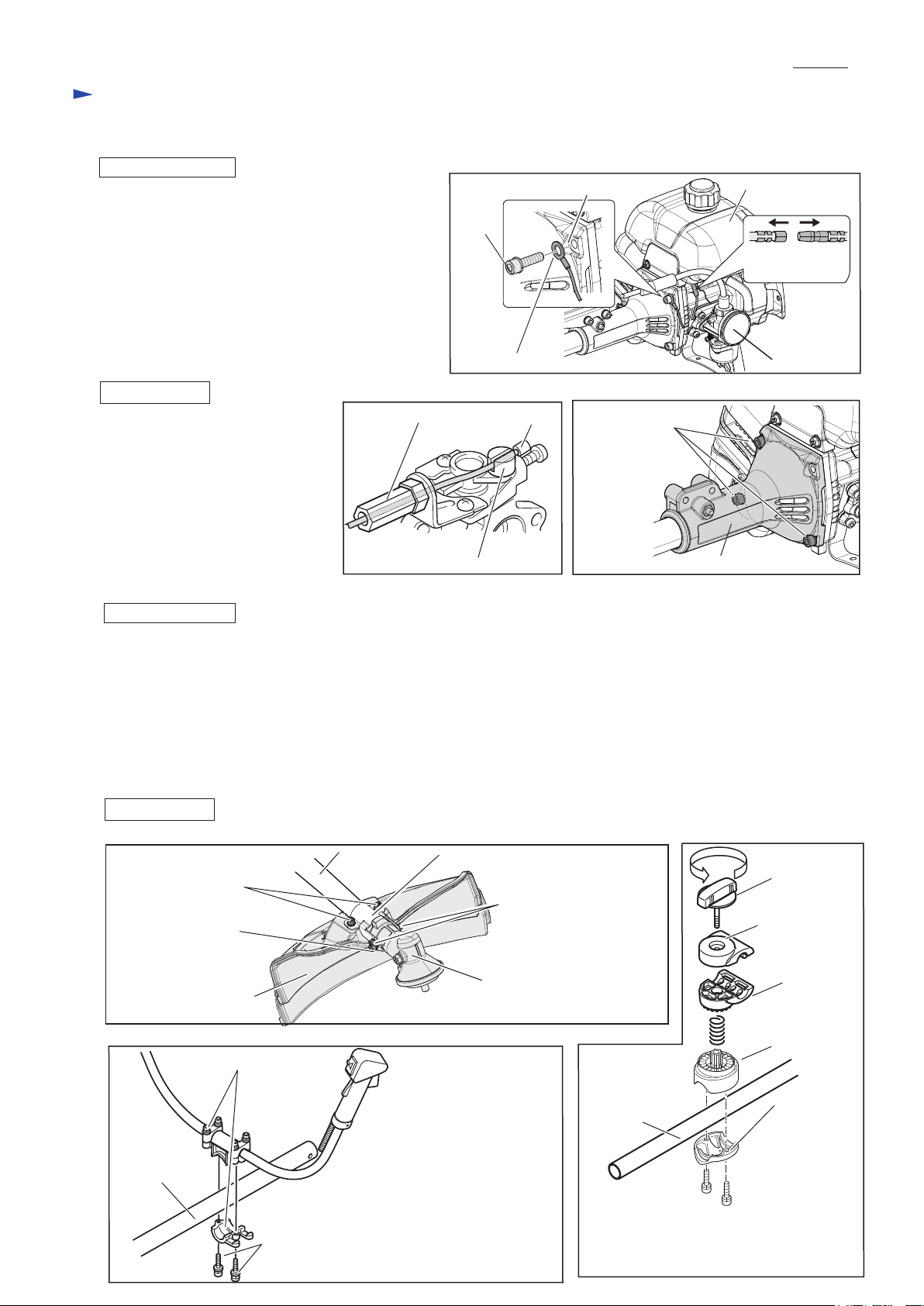

[4]-3. Protector assembly, Bike handle

DISASSEMBLING

(1) Remove two M6x30 Hex head bolts and Protector. (Fig. 4)

(2) Loosen M6x30 Hex socket head bolt on the neck of Gear case assembly, and then remove two M5x14 Hex socket head

screws. Pull out Gear case assembly from the end of Shaft pipe complete.

(3) [For RBC413U only] Remove two M6x30 Hex socket head bolts from Handle holder ass’y to separate Handle section

from Shaft pipe complete. (Fig. 5) Bike handle section can be disassembled.

[For RBC414U and RBC414UG only] Loosen Knob 57 to remove Handle holder from Shaft pipe complete.

Bike handle section can be disassembled.

Remove Pipe clamp from Shaft pipe complete by unscrewing two M6x25 Hex

socket head bolts. (Fig. 6)

ASSEMBLING

Fig. 4

M6x30 Hex socket head screw

(with spring washer and

flat washer) (2 pcs.)

M6x30 Hex socket head bolt

with flat washer and

spring washer

Assemble by reversing the disassembly procedure.

Shaft pipe

complete

Protector

Protector clamp

M5x14 Hex socket head

screw (with spring washer

and flat washer) (2 pcs.)

Gear case assembly

Fig. 6

Knob 57

Handle clamp

Handle holder

Fig. 5

Shaft pipe

complete

Handle holder ass’y

M6x30 Hex socket head bolt (with flat washer

and spring washer) (2 pcs.)

Shaft pipe

complete

Pipe holder

Pipe clamp

M6x25 Hex socket head bolt

(with spring washer) (2 pcs.)

Repair

[4] DISASSEMBLY/ ASSEMBLY

[4]-4. Gear case assembly

DISASSEMBLING

(1) Remove Gear case assembly from Pipe shaft complete. (see Fig. 4 of

the previous page.)

(2) Remove Retaining ring R-26 from the groove in Gear case assembly with

1R311. (Fig. 7)

(3) Remove M8x10 + Hex bolt that is the stopper of Grease inlet on Gear case

assembly. (Fig. 8)

(4) Remove an assembled part of Spiral bevel gear 13*, Ball bearing 6000ZZ,

Ball bearing 6000 and Retaining ring S-10 by tapping Gear case assembly

with Plastic hammer. (Fig. 9)

(5) Remove Retaining ring R-32 from the groove in Gear case assembly with

1R311. (Fig. 10)

(6) Remove an assembled part of Ball bearing 629ZZ, Cutter shaft complete**

and Ball bearing 6201DDU from Gear case assembly. (Fig. 11)

Note: • When it is difficult to remove the assembled part from Gear case

assembly, heat up Gear case assembly with heat gun or like and then

try the step (5)/ (6) again.

• Spiral bevel gear 13* and Cutter shaft complete** cannot be supplied

individually. Order “Cutter shaft set” from us.

(7) Disassemble their assembled parts by using 1R269 and Arbor press.

Fig. 9

Ball bearing 6000

Ball bearing

6000ZZ

Spiral bevel gear 13* (The component of Cutter shaft set)

P 4/ 17

Fig. 7

Groove in Gear

case assembly

Retaining ring

R-26

Fig. 8

M8x10

+ Hex bolt

Grease inlet

Fig. 10

Groove in Gear

case assembly

Retaining

ring R-32

Retaining

ring S-10

Fig. 11

Ball bearing 629ZZ

ASSEMBLING

Assemble by reversing the disassembly procedure.

Note: • Receive Gear case assembly with the U-shape table of

Arbor press, then press down Ball bearing 6201DDU

with 1R031 to set Cutter shaft complete in place.

(Fig. 12)

• Ball bearing 6000ZZ must be close to Retaining ring

S-10. (See Fig. 9)

• When the gear room is cleaned up, apply 11g Makita

grease N No.2 into Gear case assembly from the grease

inlet. (See Fig. 8)

Cutter shaft complete**

(The component of Cutter shaft set)

Ball bearing 6201DDU

Fig. 12

Arbor press

Cutter shaft complete

Gear case assembly

U-shape table

of Arbor press

Ball bearing

6201DDU

1R031

Ball bearing

629ZZ

P 5/ 17

Repair

[4] DISASSEMBLY/ ASSEMBLY

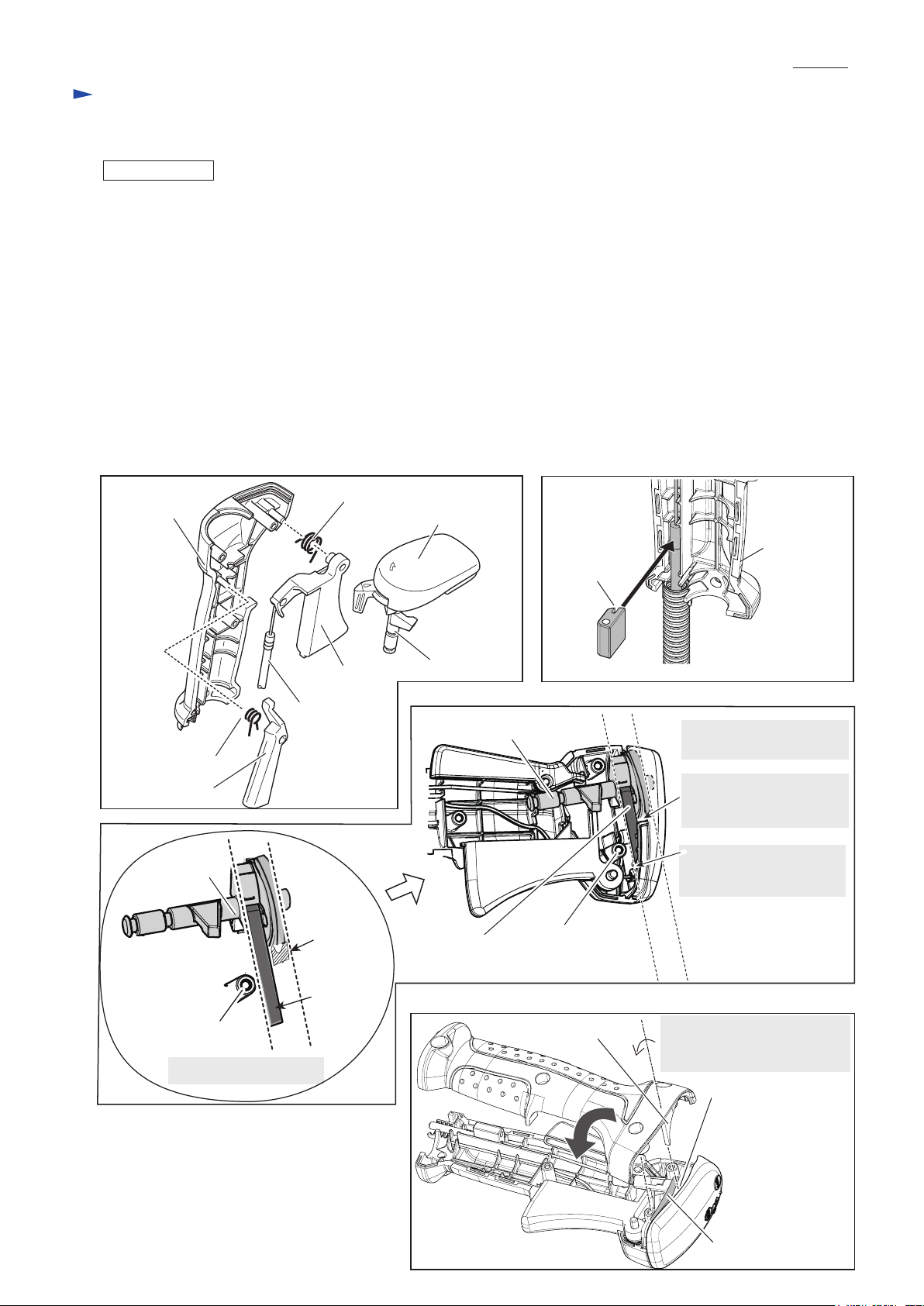

[4]-5. Control lever assembly

ASSEMBLING

See Fig. 13.

(1) Hook Control cable to Throttle lever.

Assemble Switch lever and Leaf spring to Switch cover.

(2) Assemble Throttle lever, Lock off lever and Switch cover to Lever case L in order while setting the following parts

in place:

• Torsion spring 11 to Throttle lever

• Torsion spring 7 to Lock off lever

(3) Fix Control cable in Cable holder when setting Control cable in place as drawn in Fig. 14.

(4) If Lever case R is assembled straight to Lever case L, Leaf spring will be hooked with the bosses of Lever cases L/R

or the curve rib of the Lever case L. Therefore, do the following steps. as drawn in Figs. 15 and 16.

1. Set Leaf spring horizontal to the round shape of Switch lever so as to place the spring to the bottom of Lever case L

between Boss of Lever case L and the curve rib installation position. (Fig. 15)

2. While retaining Leaf spring in between the curve rib and Boss, turn Lever case R counterclockwise carefully to

mate it with Lever case L without pinching. (Fig. 16)

Fig. 13

Lever case L

Torsion spring 7

Lock off lever

Switch lever

Torsion spring 11

Throttle lever

Control cable

Switch cover

Switch lever

Fig. 15

Switch lever

Fig. 14

Lever case L

Cable holder

Set Leaf spring horizontal

to Switch lever.

Insert the curve rib of

Lever case R here so as

not to pinch Leaf spring.

Insert the end portion of

Leaf spring firmly to the

bottom of Lever case L.

Boss of Lever case L

Leaf spring position

Curve rib

installation

position

Leaf spring

Leaf spring

Fig. 16

Boss

Position of Leaf spring

Curve rib

Round shape of

Switch lever

While turning Lever case R

along with this axis, assemble

to Lever case L carefully.

Curve rib

installation

position

Leaf spring

Repair

[4] DISASSEMBLY/ ASSEMBLY

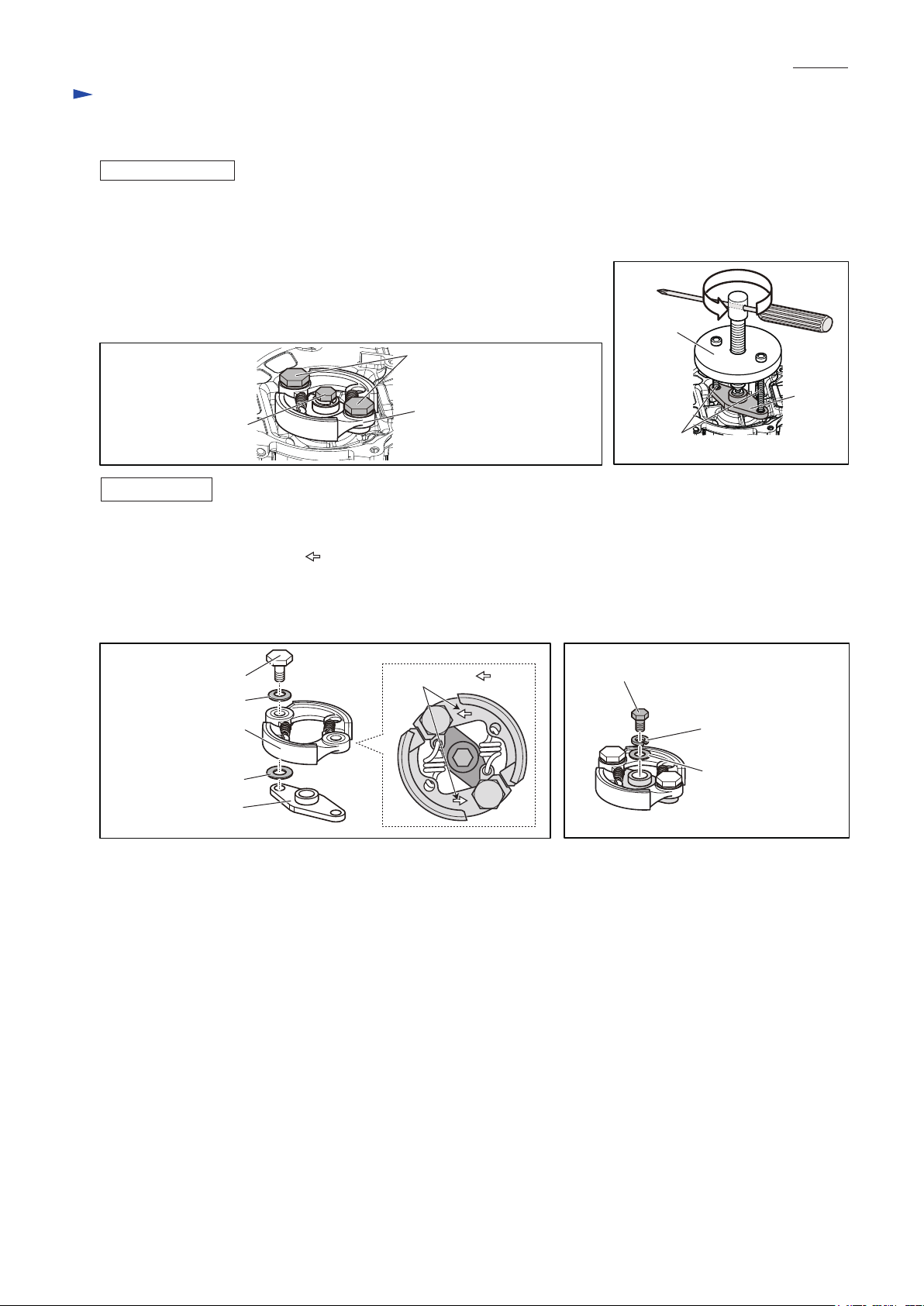

[4]-6. Clutch

DISASSEMBLING

Note: • Clutch can be easily removed with Impact driver without holding the piston.

• Do not remove Spark plug as compressed air resistance has to be used for the disassembling.

• Plug cap with Plug cap spring has to be removed from Spark plug.

(1) Remove the clutch section by unscrewing two M8 shoulder hex bolts.

Then, remove M6x14 Hex head bolt with Impact driver. (Fig. 17)

(2) Install 1R364 on Holder then screw two bolts into Holder as drawn in Fig. 18

instead of M8 Shoulder hex bolts. Holder is removed from Engine.

Fig. 17

M8 Shoulder hex bolt (2pcs.)

Fig. 18

P 6/ 17

1R364

M6x14 Hex head bolt

ASSEMBLING

(1) After putting the clutch section (two Clutch shoes and two Springs), two Wave washers 10 and two Flat washers 8

on Holder, tighten them with two M8 shoulder hex bolts. (Fig. 19)

Note: Face the marking of “ ” to the outside as drawn in Fig. 19A.

(2) Put the assembled part, Flat washer 6, Spring washer 6 and M6x14 Hex head bolt on the crank shaft of Engine,

then tighten the bolt to 12 N·m with 1R219, 1R220 while inserting 1R155 into Spark plug hole to lock Piston

to prevent the rotation of the crank shaft. (Fig. 20)

Fig. 19

M8 Shoulder hex bolt

Wave washers 10

Clutch section

Flat washers 8

Holder

Clutch section

Fig. 19A

marking of “ ”

M8 bolts

(the components of 1R364)

Fig. 20

M6x14 Hex head bolt

Spring washer 6

Flat washer 6

Holder

Loading...

Loading...