Makita RBC310, RBC311, RBC261, RBC230, RBC260 User Manual

String Trimmer

MODEL RBC230

MODEL

MODEL

MODEL RBC310

MODEL

RBC260

RBC261

RBC311

SPECIFICATIONS

Model

Dimensions

(L

Weight lkg)

Revolution

Gear ratio

Clutch

Engine 1 Starting system

NOTICE:

(mm)

x

W

x

HI

of

nylon cutting

1

Displacement iccl

1

Ignition system

1

Fuel tank

I

Fuel

Specification are subject to change without notice.

i I I

RBC230

1,700 x 225 x 245

(67"

x

8~718" x 9~5/8")

3.9

I

I

I

I

I

I

I

18

6

Ibs)

22.2

11

06

RBC260

/

RBC261 RBC310 / RBC311

x

540 x 350 1,750 x 500

1,700

167"

x

21

lI4" x 13~314") 168~7I8" x 19~1 1/16" x 13~3/4"1

4.6

(10

1

Ibs)

4,000 ~ 6,000

14/18

Automatic centrifugal type

I

I

Mixed qas (Gasoline 2 Cycle

25

4

13

Recoil startet

Solid state ignition

07

EIG

oil

1

I

I

I

=

20 - 25

5 6 112.3

14/20

30.5

15

08

1)

x

350

Ibs)

Thank you very much for your patronage

of and much confident in recommending our MAKITA STRING TRIMMER as the result of our long

t

develop men

This booklet refers to the essence which you should learn

performance.

We wish that you

TRIMMER and make the best use of

and ample know ledge a nd ex per ien ce.

will

have sufficient knowledge from this booklet before operating MAKITA STRING

in

purchasing MAKITA STRING TRIMMER. We are proud

in

order to demonstrate its outstanding

it

for ever.

SAFETY RULES AND PRECAUTIONS

Proper safety precautions must be observed. Like all power equipment this unit must be handled

OR

carefully. DO NOT EXPOSE YOURSELF

1. Always wear safety goggles for eye protection. Dress properly, do not wear loose clothing or jewelry

that could become caught

be worn. Long hair should be tied back.

2. Inspect the entire machine for loose parts (nuts, bolts, screws, etc.) and any damage. Repair or

replace as necessary.

3. DO NOT USE any attachment

manufacturer of the engine. Serious injury to the user or damage to the engine could result.

4.

Keep the handles free of oil and fuel.

5. Always use the proper handle and hanging band when cutting.

6.

Do not smoke while mixing fuel or filling tank.

7.

Do not mix fuel

8. Always mix and store the fuel

9.

Never remove the fuel tank cap while the engine is running.

10. Never start or run the engine inside a closed room or building. Fumes from the exhaust contain

dangerous carbon monoxide.

11. Never attempt to make engine adjustments while the unit is running and strapped to the operator.

Always make engine adjustments

12. Do not use the unit if

13. Inspect the area to be cut and remove all debris that could become entangled

head. Also remove any objects that the

14. Keep children away. Onlookers should be kept at a safe distance from the work area, at least

15. Do not use this unit for any job other than those for which

16. Do not overreach. Keep proper footing and balance at all times. Do not run

on a ladder or any other unstable footing location.

17.

Keep hands and feet clear of the nylon cutting head while unit is in use.

18. Do not run the

rotation at

grass may sometimes become caught

19.

Do not use the unit when you are tired or under the influence of medications, drugs or alcohol.

20.

Use only nylon cutting heads without any damage. In particular, whenever

any other obstacle stop the engine and check the nylon cutting head. A broken, or unbalanced

nylon cutting head must never be used. Follow instructions for changing accessories.

21. Do not store

furnaces, etc. Store

22. Use only replacement parts that are identical to original equipment parts when servicing the

These parts are available from your dealer. The use of any other accessory or attachment may

create a potential hazard, injury to the user and damage to the tool.

23. Clean the machine completely, especially, the fuel tank cap, its surroundings, and the air cleaner.

in

unit

6,000

-

in

a closed area where fuel vapors can reach an open flame from hot water heaters,

in

moving parts of the

with

an enclosed room or near open flames. Assure adequate ventilation.

in

it

is damaged or poorly adjusted.

at

high

speed when not cutting. During operation, be sure to keep the engine

8,000

rpm (rated rotation:

in

a locked, well ventilated area only.

OTHERS TO DANGER. Follow these sample rules.

unit.

Safe, sturdy, nonskid footwear should always

this power head other than those manufactured by the

a properly marked container that is approved for such usage.

with

the

unit

resting on a flat, clear surface.

in

the nylon cutting

unit

may sling during cutting.

30

feet.

it

is intended as described

7,000

rpm). If the rotation goes below this limit,

in

the nylon cutting head, which results

in

this manual.

unit

while standing

in

wear of the clutch.

it

hits at a stone or

unit.

2

24.

Children and Minors should not operate string trimmers with metallic cutting tools, except minors

who are properly training and remain under the supervision of a qualified operator.

25. When refueling, be sure to stop the engine and confirm that it is cooled down. Never refuel when

the engine is running or warmed up. When gasoline spills, be sure to wipe it up completely and

properly dispose of those materials before starting the engine.

26.

Stay clear of other workers.

27.

Whenever approaching an operator of the machine, carefully call his attention and confirm that

the operator stops the engine.

28. Never touch the nylon cutting head whenever the engine is running. If it is necessary to adjust

the protector or nylon cutting head, be sure to stop the engine and confirm that the nylon cutting

head stops running.

29. The engine should be turned off when the string trimmer is moved between working areas.

30.

Be careful not to hit the nylon cutting head against stones, or the ground. Unreasonable operation

will shorten the life of the machine as well as create an unsafe environment for yourself and those

around

31.

Pay attention to loosening and overheating of parts. If there is any abnormality on the machine,

stop operation immediately and check the machine carefully. If necessary, have the machine serviced

by a qualified service facility. Never continue to operate a machine which may be malfunctioning.

32. In startup or during operation of the engine, never touch high-temperature parts such as the muffler,

the high-voltage wire or the spark plug.

33. For a while after the engine is stopped, the muffler is still hot. Never place the machine at any

place where there are flammable materials (dry grass, etc.) or combustible gasses.

34.

Pay special attention to operation in the rain or just after the rain as the ground becomes slippery.

35. If

36. Be careful not to drop the machine or hit

37.

Before proceeding to adjust or repair the machine, be sure to stop the engine and detach the spark

plug cap from the spark plug.

38. When the machine is to be kept

carburetor, clean the parts, move the machine to a safe place and confirm that the engine is cooled

down.

39. Make periodic inspection to always assure safe and efficient operation. If

inspection of your machine, please contact our agent or dealer.

40.

Keep the machine well away from fire or sparks.

41. Warning: The cutter area is still dangerous while the machine is coasting to a stop.

42.

Don't try to tackle a big job

43. Wear a dust mask

44. Wear hearing protection during loud or extended periods

45. Keep guards and protectors

you.

you

slip or fall to the ground or into a hole, return the throttle lever immediately.

it

against obstacles.

in

storage for a long time, drain fuel from the fuel tank and

with

an undersized tool.

in

dusty work conditions.

of

use.

in

place and in working order.

you

need a careful

CAUTION

WHEN MIXING GASOLINE WITH TWO CYCLE ENGINE OIL, USE ONLY GASOLINE WHICH CONTAINS

NO ETHANOL

TO ENGINE FUEL LINES AND OTHER ENGINE PARTS.

SAVE

!

THESE

OR

METHANOL (TYPES

INSTRUCTIONS.

CAU TI 0 N

OF

ALCOHOL), THIS WILL HELP TO AVOID POSSIBLE DAMAGE

!

CAUTION

3

!

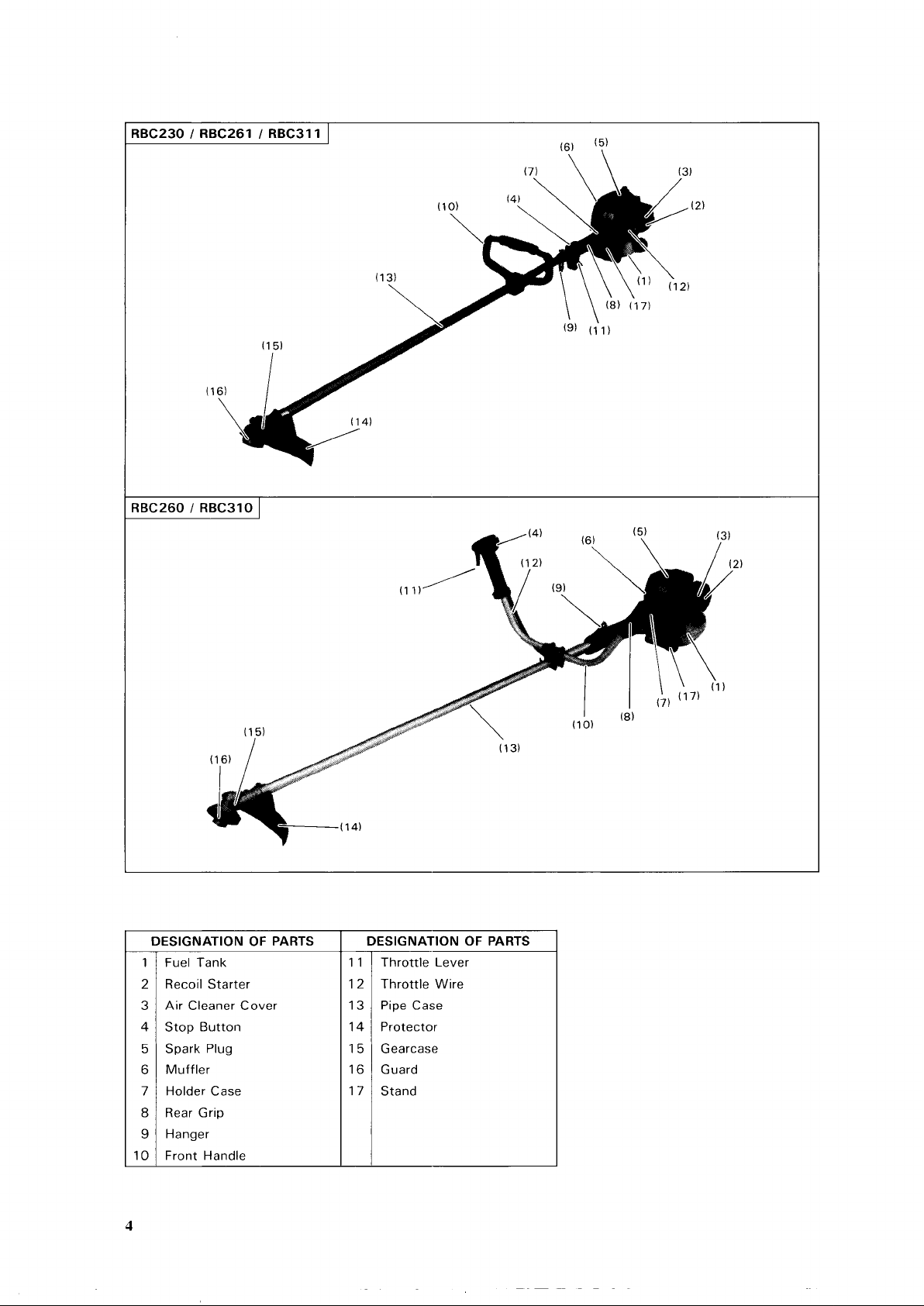

?BC230 I RBC261 I RBC311

(61

‘5)

\\

3BC260 / RBC3lO

I

DESIGNATION

Fuel Tank

Recoil Starter

Air Cleaner Cover

Stop Button

Spark Plug

Muffler

Holder Case

8

Rear Grip

9

Hanger

10

Front Handle

I

OF

PARTS

DESIGNATION

11

Throttle Lever

12

Throttle Wire

Pipe Case

13

14

Protector

Gearcase

15

16

Guard

17

Stand

OF

PARTS

4

ASS

EM

B LY

IN

STR

U

CTI

0

N

S

1.

Assembly

of

engine and pipe case

For RBC230 I RBC261 I RBC311

Remove the protector at the end of the pipe case.

Insert the pipe case into the holder case being sure

to match the splines of the inner shaft to those

inside the holder case.

Match the hole in the pipe case to the hole in the

holder case and fasten the pipe case to the engine

with damper bolt, wave washer and washer.

(Tightening torque:

70

~

100 kg.cm;

5

~ 7

ft.lbs)

11

1

Holder case

151

Wave washer

a0

141

121

Hole

161

Damper bolt

151

171

161

131

Pipe

case

(41

171

Hole

Washer

CAUTION

Securely tighten the damper bolt, which

:

is

one of

the important parts mating the engine and machine

body.

For RBC260 and RBC310

Install the pipe case (the end

with

circular metal

housing) over the clutch assembly and fix with four

socket head bolts and fix tightly with hex wrench.

2.

Mounting of handle

For RBC230 I RBC261 I RBC311

As

shown at right, tighten the loop handle with

three socket head bolts.

Mount the handle

so

that the throttle wire guide

will he oriented to the right, as viewed from the

engine side.

The standard position of the handle

mm

(7-718” ~ 9-718”) from the hanger. Position

is

200

the handle according to a worker’s stature and

working conditions.

to 250

Ill

Pipe case

121

Hex wrench

131

Socket head

bolt

5

Loading...

Loading...