Page 1

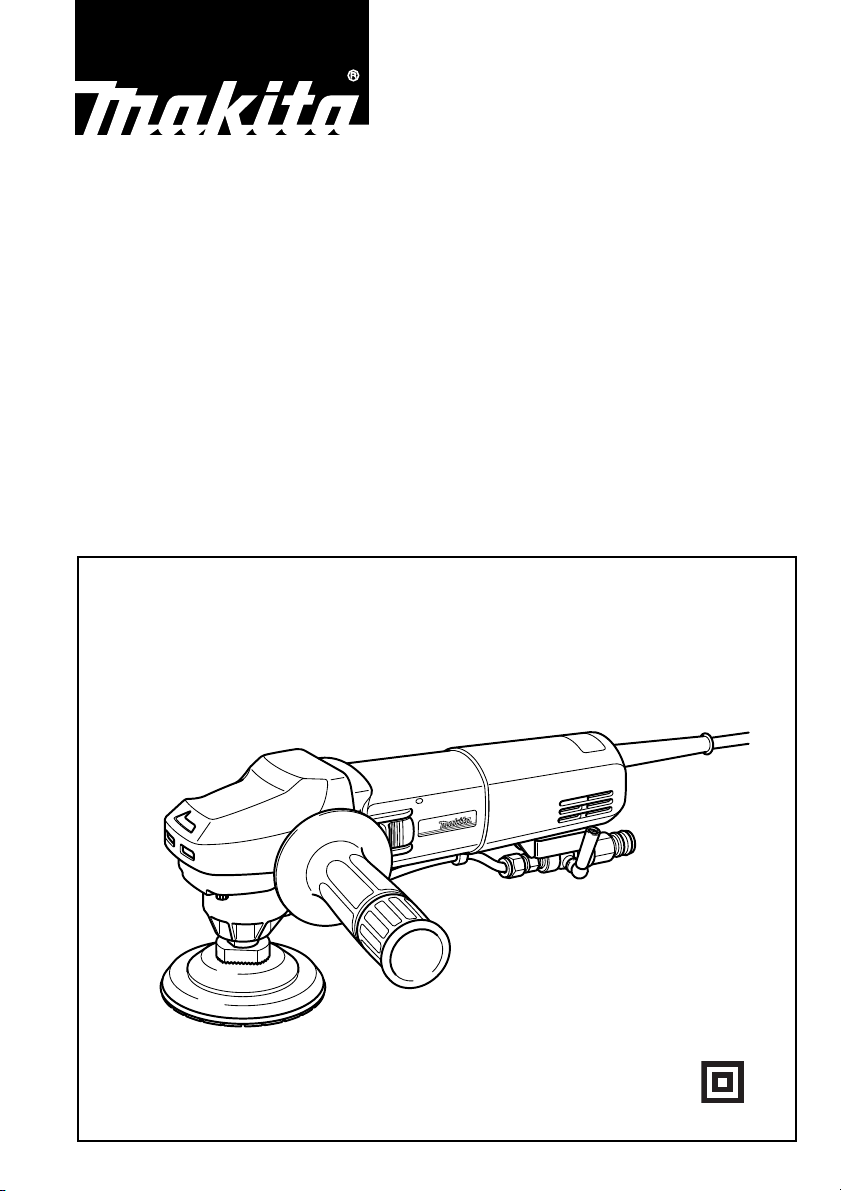

Stone Polisher

Instruction Manual

Steinpolierer

Betriebsanleitung

Polerka do kamieni

Instrukcja obsługi

Шлифовальный станок для камня

Инструкция по эксплуатации

PW5000C

Page 2

1

2

12

5

6

B

3

A

4

34

8

9

7

56

10

11

12

78

2

Page 3

13

14

910

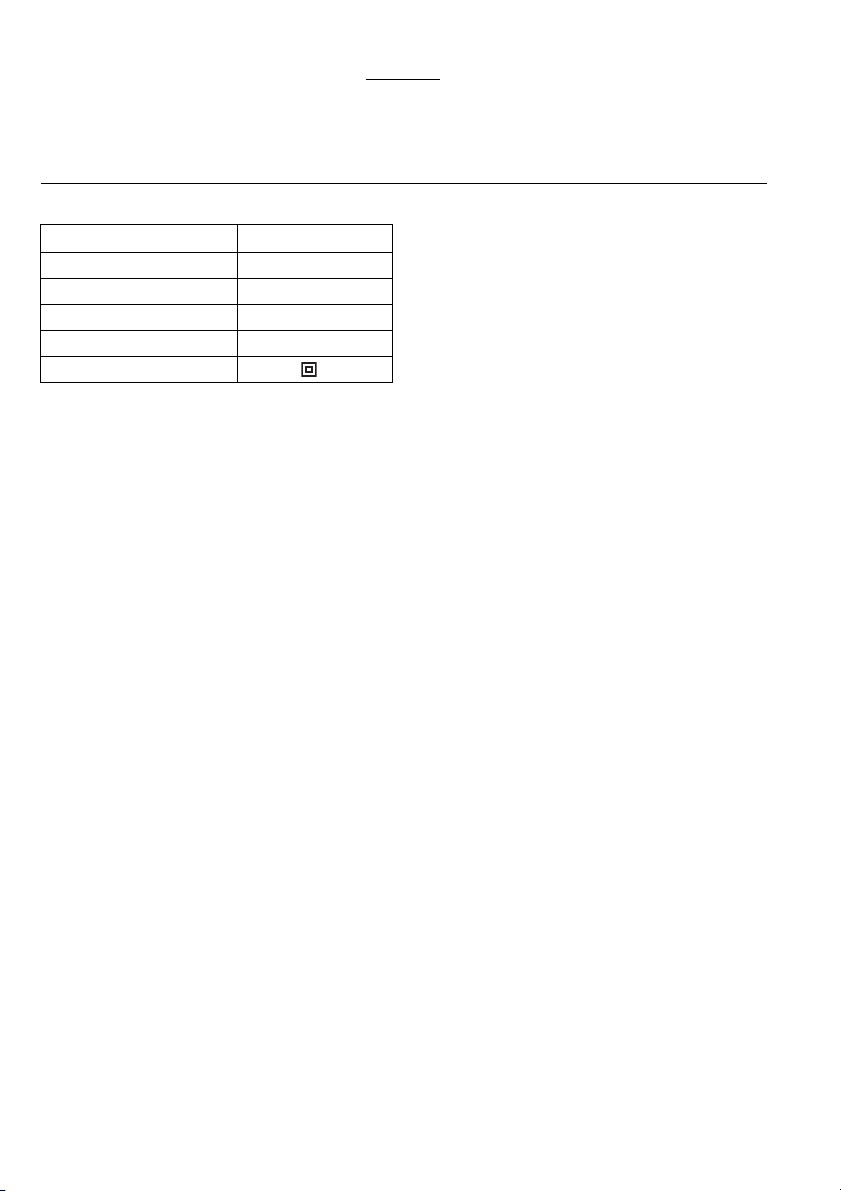

Symbols

The followings show the symbols used for the tool. Be sure that you understand their meaning before use.

Symbole

Die folgenden Symbole werden für die Maschine verwendet. Machen Sie sich vor der Benutzung unbedingt mit ihrer

Bedeutung vertraut.

Symbole

Poniższe symbole używane są do opisu urządzenia. Przed użyciem należy upewnić się, że rozumie się ich znaczenie.

Символы

Следующие объяснения показывают символы, используемые для инструмента. Убедитесь перед

использованием, что Вы понимаете их значение.

❏ Read instruction manual.

❏ Bitte Betriebsanleitung lesen.

❏ Przeczytaj instrukcję obsługi.

❏

Прочитайте инструкцию по эксплуатации.

❏ DOUBLE INSULATION

❏ DOPPELT SCHUTZISOLIERT

❏ PODWÓJNA IZOLACJA

❏

ДВОЙНАЯ ИЗОЛЯЦИЯ

❏ Wear safety glasses.

❏ Schutzbrille tragen.

❏ Noś okulary ochronne.

❏

Одевайте защитные очки.

3

Page 4

ENGLISH

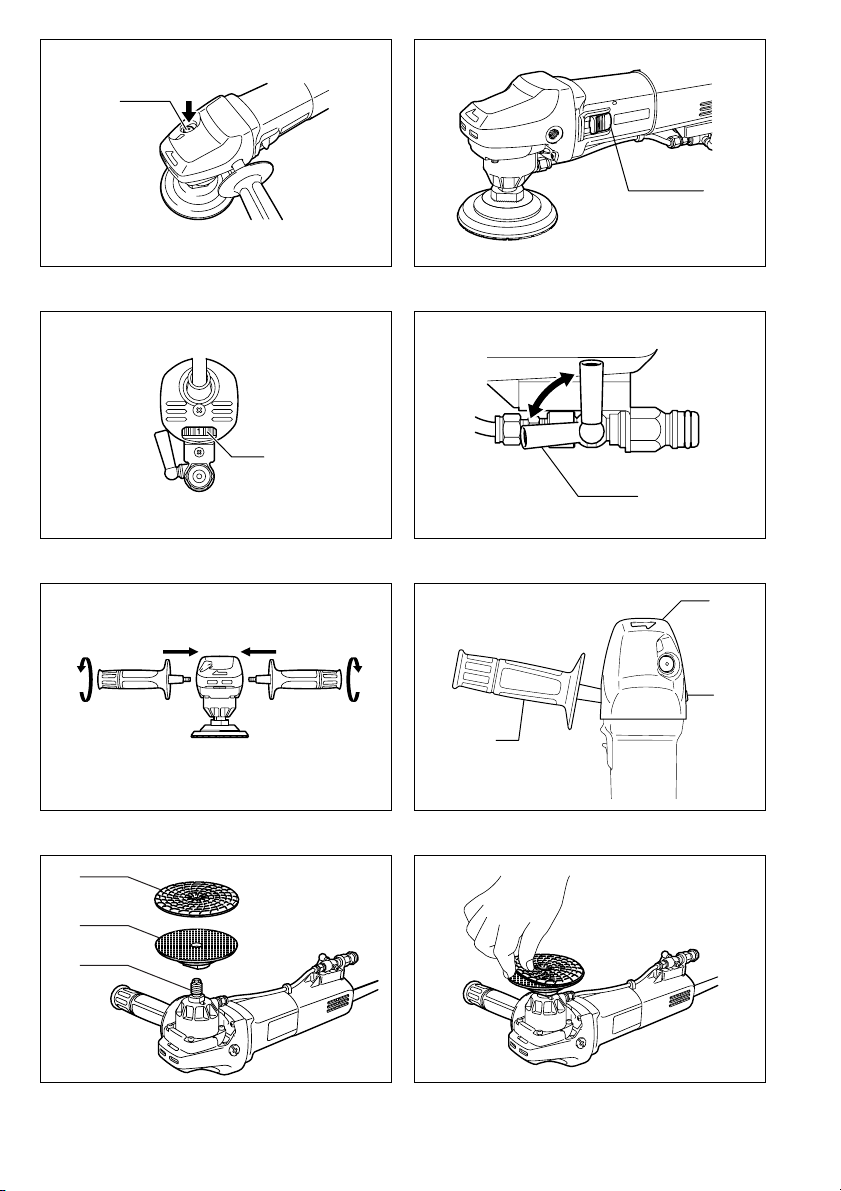

1 Shaft lock

2 Slide switch

3 Speed adjusting dial

4Cock

5 Close

Explanation of general view

6Open

7 Side grip

8 Head cover

9Screw

10 Abrasive disc

11 Pad

12 Spindle

13 Exhaust vent

14 Inhalation vent

SPECIFICATION

Model PW5000C

Pad diameter Max 125 mm

–1

No load speed (min

Overall length 313 mm

Net weight 2.2 kg

Safety class /II

• Due to our continuing program of research and development, the specifications herein are subject to change

without notice.

• Note: Specifications may differ from country to country.

Intended use

The tool is intended for surface work with natural stone.

Power supply

The tool should be connected only to a power supply of

the same voltage as indicated on the nameplate, and can

only be operated on single-phase AC supply. They are

double-insulated in accordance with European Standard

and can, therefore, also be used from sockets without

earth wire.

) 2,000 – 4,000

SAFETY INSTRUCTIONS

Warning! When using electric tools, basic safety precautions should always be followed to reduce the

risk of fire, electric shock and personal injury, including the following. Read all these instructions before

attempting to operate this product and save these

instructions.

For safe operation:

1. Keep work area clean

Cluttered areas and benches invite injuries.

2. Consider work area environment

Don’t expose power tools to rain. Don’t use power

tools in damp or wet locations. Keep work area well

lit. Don’t use power tools in presence of flammable

liquids or gases.

3. Guard against electric shock

Prevent body contact with grounded surfaces (e.g.

pipes, radiators, ranges, refrigerators).

4. Keep children away

Do not let visitors contact tool or extension cord. All

visitors should be kept away from work area.

5. Store idle tools

When not in use, tools should be stored in dry, high,

or locked-up place, out of the reach of children.

6. Don’t force tool

It will do the job better and safer at the rate for which

it was intended.

7. Use right tool

Don’t force small tools or attachments to do the job

of a heavy duty tool. Don’t use tools for purposes not

intended; for example, don’t use circular saw for cutting tree limbs or logs.

8. Dress properly

Do not wear loose clothing or jewelry. They can be

caught in moving par ts. Rubber gloves and non-skid

footwear are recommended when working outdoors.

Wear protective hair covering to contain long hair.

9. Use safety glasses and hearing protection

Also use face or dust mask if cutting operation is

dusty.

10. Connect dust extraction equipment

If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used.

11. Don’t abuse cord

Never carry tool by cord or yank it to disconnect it

from receptacle. Keep cord from heat, oil and sharp

edges.

12. Secure work

Use clamps or a vise to hold work. It’s safer than

using your hand and it frees both hands to operate

tool.

13. Don’t overreach

Keep proper footing and balance at all times.

14. Maintain tools with care

Keep tools sharp and clean for better and safer performance. Follow instructions for lubricating and

changing accessories. Inspect tool cords periodically and, if damaged, have repaired by authorized

service facility. Inspect extension cords periodically

and replace if damaged. Keep handles dry, clean

and free from oil and grease.

15. Disconnect tools

When not in use, before servicing, and when changing accessories such as blades, bits and cutters.

16. Remove adjusting keys and wrenches

Form the habit of checking to see that keys and

adjusting wrenches are removed from tool before

turning it on.

17. Avoid unintentional star ting

Don’t carry plugged-in tool with finger on switch. Be

sure switch is off when plugging in.

18. Outdoor use extension cords

When tool is used outdoors, use only extension

cords intended for use outdoors and so marked.

19. Stay alert

Watch what you are doing. Use common sense. Do

not operate tool when you are tired.

4

Page 5

20. Check damaged parts

Before further use of the tool, a guard or other part

that is damaged should be carefully checked to

determine that it will operate properly and perform

its intended function. Check for alignment of moving

parts, binding of moving parts, breakage of parts,

mounting, and any other conditions that may affect

its operation. A guard or other part that is damaged

should be properly repaired or replaced by an authorized service center unless otherwise indicated elsewhere in this instruction manual. Have defective

switches replaced by an authorized service center.

Do not use tool if switch does not turn it on and off.

21. Warning

The use of any other accessory or attachment other

than recommended in this operating instruction or

the catalog may present a risk of personal injury.

22. Have your tool repaired by an expert

This electric appliance is in accordance with the relevant safety rules. Repairing of electric appliances

may be carried out only by experts otherwise it may

cause considerable danger for the user.

ADDITIONAL SAFETY RULES FOR TOOL

1. Always use eye and ear protection. Other personal protective equipment such as dust mask,

gloves, helmet and apron should be worn.

2. Always be sure that the tool is switched off and

unplugged before carrying out any work on the

tool.

3. Accessories must be rated for at least the speed

recommended on the tool warning label. Wheels

and other accessories running over rated speed

can fly apart and cause injury.

4. Check the backing pad carefully for cracks, damage or deformity before operation. Replace

cracked, damaged or deformed pad immediately.

5. Check that the workpiece is properly supported.

6. Hold the tool firmly.

7. Keep hands away from rotating parts.

8. Make sure the abrasive disc is not contacting the

workpiece before the switch is turned on.

9. Do not leave the tool running. Operate the tool

only when hand-held.

10. Pay attention that the wheel continues to rotate

after the tool is switched off.

11. Do not touch the workpiece immediately after

operation; it may be extremely hot and could

burn your skin.

12. If working place is extremely hot and humid, or

badly polluted by conductive dust, use a shortcircuit breaker (30 mA) to assure operator safety.

13. Do not use the tool on any materials containing

asbestos.

14. Some material contains chemicals which may be

toxic. Take caution to prevent dust inhalation

and skin contact. Follow material supplier safety

data.

15. Always use the correct dust mask/respirator for

the material and application you are working

with.

16. Ensure that ventilation openings are kept clear

when working in dusty conditions. If it should

become necessary to clear dust, first disconnect

the tool from the mains supply (use non metallic

objects) and avoid damaging internal parts.

ENB078-2

17. For additional protection against electric shock,

be sure to WEAR RUBBER GLOVES AND RUBBER BOOTS during operation.

18. When using the water feed, be careful not to let

water get into the motor. If water runs into the

motor, an electric shock hazard may result.

19. Never use the tool without an isolating transformer.

SAVE THESE INSTRUCTIONS.

Important Notes about Mains Connection for

110 Volts, 50 – 60Hz

Caution! Read and observe these precautions before

using the tool. Non-observance of these precautions may

lead to personal injuries and damage to the tool!

The tool was built according to the European Standards

EN50144-1 (safety of hand-held, motor-driven power

tools; here in particular section 20.19: power tools with

water connection) and EN60309-2 (plugs, receptacles

and couplings for industrial applications). When applying

these standards, the earth contact position of the plug-in

device may only be carried out in “12 o’clock position”.

The tool has a plug-in device with a “12 o’clock” earth

contact position.

However, since the European Standard EN60309-2 does

not provide a differentiation regarding the supply voltage

and this earth contact position, there is the possibility to

confuse the connection to an isolating transformer with

another output voltage (e.g. 230 V). When connecting

the tool to an isolating transformer, make absolutely sure

to use the correct output voltage (110 V, 50

This tool is designed exclusively for connection to an isolating transformer with an output voltage of 110 V. Due to

its use in wet conditions (water connection on the tool),

this tool must never be connected to a power supply without an isolating transformer.

Damages caused by inappropriate tampering with the

plug-in device are not subject to warranty or legal guarantee claims.

Contact your specialist supplier for an isolating transformer suitable for your tool.

–

60 Hz).

FUNCTIONAL DESCRIPTION

CAUTION:

• Always be sure that the tool is switched off and

unplugged before adjusting or checking function on the

tool.

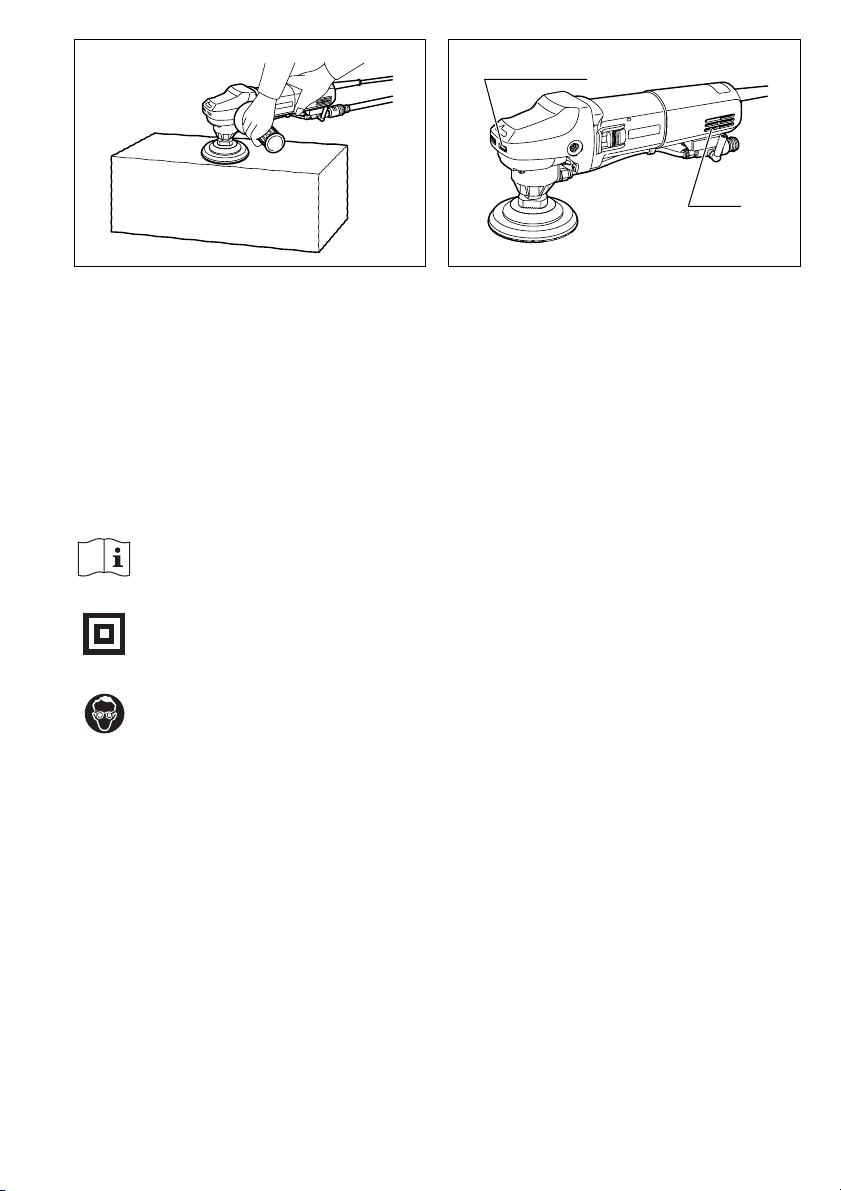

Shaft lock (Fig. 1)

CAUTION:

• Never actuate the shaft lock when the spindle is mov-

ing. The tool may be damaged.

Press the shaft lock to prevent spindle rotation when

installing or removing accessories.

5

Page 6

Switch action (Fig. 2)

CAUTION:

• Before plugging in the tool, always check to see that

the slide switch actuates properly and returns to the “O

(OFF)” position when the rear of the slide switch is

depressed.

• Switch can be locked in “I (ON)” position for ease of

operator comfort during extended use. Apply caution

when locking tool in “I (ON)” position and maintain firm

grasp on tool.

To start the tool, slide the slide switch toward the “I (ON)”

position. For continuous operation, press the front of the

slide switch to lock it.

To stop the tool, press the rear of the slide switch, then

slide it toward the “O (OFF)” position.

Speed adjusting dial (Fig. 3)

The rotating speed can be changed by turning the speed

adjusting dial to a given number setting from 1 to 5.

Higher speed is obtained when the dial is turned in the

direction of number 5. And lower speed is obtained when

it is turned in the direction of number 1.

Refer to the below table for the relationship between the

number settings on the dial and the approximate rotating

speed.

Number RPM (/min)

12,000

22,500

33,000

43,500

54,000

CAUTION:

• If the tool is operated continuously at low speeds for a

long time, the motor will get overloaded and heated up.

• The speed adjusting dial can be turned only as far as 5

and back to 1. Do not force it past 5 or 1, or the speed

adjusting function may no longer work.

Electronic function

Constant speed control

Possible to get fine finish, because the rotating speed is

kept constant even under the loaded condition.

Additionally, when the load on the tool exceeds admissible levels, power to the motor is reduced to protect the

motor from overheating. When the load returns to admissible levels, the tool will operate as normal.

Soft start feature

Soft start because of suppressed starting shock.

Opening or closing of water lever (Fig. 4)

To keep the lever on the tool for water flow open, turn it to

the position A where the water passage will be ready.

Return it to the position B to close.

The amount of water flow can be adjusted by changing

the lever position between the positions A and B.

ASSEMBLY

CAUTION:

• Always be sure that the tool is switched off and

unplugged before carrying out any work on the tool.

Installing side grip (handle)

CAUTION:

• Always be sure that the side grip is installed securely

before operation.

Screw the side grip securely on the position of the tool as

shown in the figure. (Fig. 5)

Remove one of the screws which secure gear housing

and head cover, then screw the side grip on the tool.

(Fig. 6)

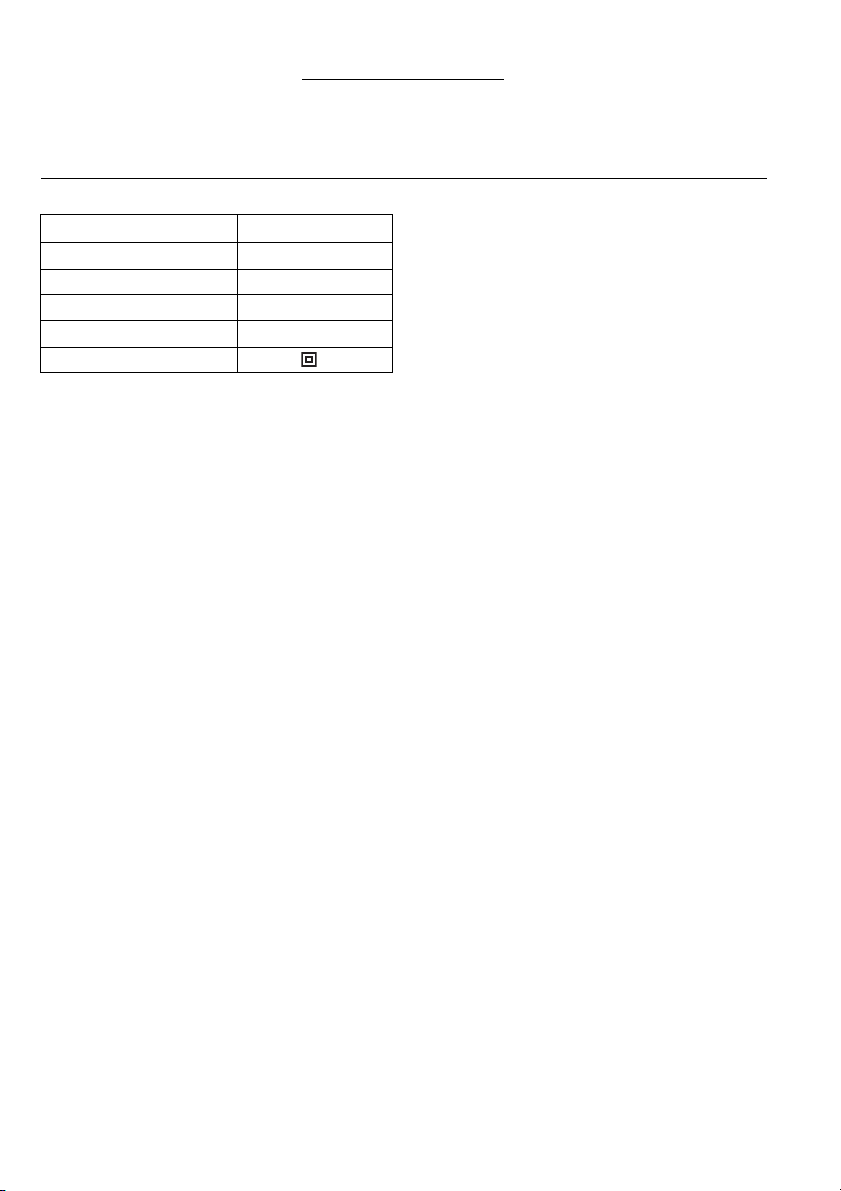

Installing or removing abrasive disc (Fig. 7 & 8)

Remove all dirt or foreign matter from the pad.

Screw the pad onto the spindle with pressing the shaft

lock.

Attach the disc to the pad so carefully that the edges of

disc and pad overlap each other without protruding.

To remove the abrasive disc, pull off its edge from the

pad.

OPERATION

Polishing operation (Fig. 9)

WARNING:

• To reduce the risk of electric shock, check the tool’s

water supply system to ensure there is no damage to

the seals (“o” rings) or hoses. A damaged water supply

system may result in abnormal water flow to the tool,

which could be dangerous.

CAUTION:

• Always wear safety goggles or a face shield during

operation.

• Never switch on the tool when it is in contact with the

workpiece, it may cause an injury to operator.

• Never run the tool without the abrasive disc. You may

seriously damage the pad.

• Be sure to feed water to the abrasive disc during operation. Failure to do so may cause breakage to the tool.

• The temperature of water to be used should be within

the range of 0°C – 40°C (32°F – 104°F). Use of freezing or hot water beyond this range may cause damage

to the tool.

• The maximum permitted pressure of water supply is

7bar.

Make sure that the cock is closed. Connect the hose to

the tool. Make sure that water comes out when the water

lever is opened.

Hold the tool firmly. Turn the tool on and then apply the

abrasive disc to the workpiece.

Apply slight pressure only. Excessive pressure will result

in poor performance and premature wear to abrasive

disc.

6

Page 7

MAINTENA NCE

CAUTION:

• Always be sure that the tool is switched off and

unplugged before attempting to perform inspection or

maintenance.

The tool and its air vents have to be kept clean. Regularly

clean the tool’s air vents or whenever the vents start to

become obstructed. (Fig. 10)

To maintain product SAFETY and RELIABILITY, repairs,

carbon brush inspection and replacement, any other

maintenance or adjustment should be performed by Makita Authorized Service Centers, always using Makita

replacement parts.

ACCESSORIES

CAUTION:

• These accessories or attachments are recommended

for use with your Makita tool specified in this manual.

The use of any other accessories or attachments might

present a risk of injury to persons. Only use accessory

or attachment for its stated purpose.

If you need any assistance for more details regarding

these accessories, ask your local Makita service center.

• Abrasive discs

• Side grip

EC-DECLARATION OF CONFORMITY

We declare under our sole responsibility that this product

is in compliance with the following standards of standardized documents,

HD400, EN50144, EN55014, EN61000

in accordance with Council Directives, 73/23/EEC,

89/336/EEC and 98/37/EC.

Yasuhiko Kanzaki

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

CE 2003

Director

ENH001-1

Noise and Vibration

ENG003-1

The typical A-weighted sound pressure level is 85 dB (A).

The noise level under working may exceed 85 dB (A).

The typical weighted root mean square acceleration

value is not more than 2.5 m/s

– Wear ear protection. –

2

.

7

Page 8

DEUTSCH

1 Spindelarretierung

2 Schiebeschalter

3 Drehzahl-Stellrad

4Hahn

5 Schließen

Übersicht

6 Öffnen

7 Seitengriff

8 Kopfabdeckung

9Schraube

10 Schleifscheibe

11 Schleifteller

12 Spindel

13 Auslassöffnung

14 Einlassöffnung

TECHNISCHE DATEN

Model PW5000C

Schleiftellerdurchmesser Max. 125 mm

Leerlaufdrehzahl (min

Gesamtlänge 313 mm

Nettogewicht 2,2 kg

Sicherheitsklasse /II

• Wir behalten uns vor, Änderungen im Zuge der Entwicklung und des technischen Fortschritts ohne vorherige Ankündigung vorzunehmen.

• Hinweis: Die technischen Daten können von Land zu

Land abweichen.

Vorgesehene Verwendung

Diese Maschine ist für die Oberflächenbearbeitung von

Naturstein vorgesehen.

Stromversorgung

Die Maschine darf nur an die auf dem Typenschild angegebene Spannung angeschlossen werden und arbeitet

nur mit Einphasen-Wechselspannung. Sie ist entsprechend den Europäischen Richtlinien doppelt schutzisoliert und kann daher auch an Steckdosen ohne

Erdungskabel angeschlossen werden.

-1

) 2 000 – 4 000

SICHERHEITSHINWEISE

Achtung! Beim Gebrauch von Elektrowerkzeugen

sind zum Schutz gegen elektrischen Schlag. Verletzungsund Brandgefahr folgende grundsätzlichen Sicherheitsmaßnahmen zu geachten.

Lesen und beachten Sie diese Hinweise, bevor

Sie das Gerät benutzen.

1. Halten Sie Ihren Arbeitsbereich in Ordnung

Unordnung im Arbeitsbereich ergibt Unfallgefahr.

2. Berücksichtigen Sie Umgebungseinflüsse

Setzen sie Elektrowerkzeuge nicht dem Regen aus.

Benützen Sie Elektrowerkzeuge nicht in feuchter

oder nasser Umgebung. Sorgen Sie für gute

Beleuchtung. Benützen Sie Elektrowerkzeuge nicht

in Nähe von brennbaren Flüssigkeiten oder Gasen.

3. Schützen Sie sich vor elektrischem Schlag

Vermeiden Sie Körperberührung mit geerdeten Teilen, zum Beispiel Rohren, Heizkörpern, Herden,

kühlschränken.

4. Halten Sie Kinder fern!

Lassen Sie andere Personen nicht das Werkzeug

oder Kabel berühren, halten Sie sie von Ihrem

Arbeitsbereich fern.

5. Bewahren Sie Ihre Werkzeuge sicher auf

Unbenutzte Werkzeuge sollten in trockenem, verschlossenem Raum und für Kinder nicht erreichbar

aufbewahrt werden.

6. Überlasten Sie Ihr Werkzeug nicht

Sie arbeiten besser und sicherer im angegebenen

Leistungsbereich.

7. Benützen Sie das richtige Werkzeug

Verwenden Sie keine zu schwachen Werkzeuge

oder Vorsatzgeräte für schwere Arbeiten.

Benützen Sie Werkzeuge nicht für Zwecke und

Arbeiten, Wofür sie nicht bestimmt sind; zum Beispiel benützen Sie keine Handkreissäge, um Bäume

zu flällen oder Äste zu schneiden.

8. Tragen Sie geeignete Arbeitskleidung

Tragen Sie keine weite Kleidung oder Schmuck. Sie

können von beweglichen Teilen erfaßt werden. Bei

Arbeiten im Freien sind Gummihandschuhe und

rutschfestes Schuhwerk empfehlenswert. Tragen

Sie bei langen Haaren ein Haarnetz.

9. Schutzbrille und Gehörschutz tragen

Verwenden Sie eine Atemmaske bei stauberzeugenden Arbeiten.

10. Schlleßen Sie eine Staubabsaugvorrichtung an

Wenn Geräte für den Anschluß von Staubabsaugund-sammelvorrichtungen ausgelegt sind, sorgen

Sie dafür, daß Jiese angeschlossen und korrekt

benutzi werden.

11. Zweckentfremden Sie nicht das Kabel

Tragen Sie das Werkzeug nicht am Kabel, und

benützen Sie es nicht, um den Stecker aus der

Steckdose zu ziehen. Schützen Sie das Kabel vor

Hitze, Öl und scharfen Kanten.

12. Sichern Sie das Werkstück

Benützen Sie Spannvorrichtungen oder einen

Schraubstock, um das Werkstück festzuhalten. Es

ist damit sicherer gehalten als mit Ihrer Hand und

ermöglicht die Bedienung der Maschine mit beiden

Händen.

13. Überdehnen Sie nicht Ihren Standbereich

Vermeiden Sie abnormale Körperhaltung. Sorgen

Sie für sicheren Stand, und halten Sie jederzeit das

Gleichgewicht.

14. Pflegen Sie Ihre Werkzeuge mit Sorgtalt

Halten Sie Ihre Werkzeuge scharf und sauber, um

gut und sicher zu arbeiten. Befolgen Sie die Wartungsvorschriften und die Hinweise für Werkzeugwechsel. Kontrollieren Sie regelmäßig den Stecker

und das Kabel, und lassen Sie diese bei Beschädigung von einem anerkannten Fachmann erneuern.

Kontrollieren Sie Verlängerungskabel regelmäßig

und ersetzen Sie beschädigte. Halten Sie Handgriffe

trocken und frei von Öl und Fett.

8

Page 9

15. Ziehen Sie den Netzstecker

Bei Nichtgebrauch, vor der Wartung und beim Werkzeugwechsel, wie zum Beispiel Sägeblatt, Bohrer

und Maschinenwerkzeugen aller Art.

16. Lassen Sie keine Werkzeugschlüssel stecken

Überprüfen Sie vor dem Einschalten, daß die

Schlüssel und Einstellwerkzeuge entfernt sind.

17. Vermeiden Sie unbeabsichtigten Anlauf

Tragen Sie keine an das Stromnetz angeschlossene

Werkzeuge mit dem Finger am Schalter. Vergewissern Sie sich, daß der Schalter beim Anschluß an

das Stromnetz ausgeschaltet ist.

18. Verlängerungskabel im Freien

Verwenden Sie im Freien nur dafür zugelassene

und entsprechend gekennzeichnete Varlängerungs-

kabel.

19. Seien Sie stets aufmerksam

Beobachten Sie Ihre Arbeit. Gehen Sie vernünftig

vor. Verwenden Sie das Werkzeug nicht, wenn Sie

unkonzentriert sind.

20. Kontrollieren Sie Ihr Gerät auf Beschädigungen

Vor weiterem Gebrauch des Werkzeugs die Schutzeinrichtungen oder leicht beschädigte Teile sorgfäl-

tig auf ihre einwandfreie und bestimmungsgemäße

Funktion überprüfen. Überprüfen Sie, ob die Funktion beweglicher Teile in Ordnung ist, ob sie nicht

klemmen onder ob Teile beschädigt sind. Sämtliche

Teile müssen richtig montiert sein und alle Bedingungen erfüllen, um den einwandfreien Betrieb des

Gerätes zu gewährleisten.

Beschädigte Schutzvorrichtungen und Teile sollen

sachgemäß durch eine Kundendienstwerkstatt repariert oder ausgewechselt werden, soweit nichts

anderes in den Betriebsanleitungen angegeben ist.

Beschädigte Schalter müssen bei einer Kundendienstwerkstatt ersetzt werden. Benutzen Sie keine

Werkzeuge, bei denen sich der Schalter nicht ein

und ausschalten läßt.

21. Achtung!

Zu Ihrer eigenen Sicherheit, benützen Sie nur Zubehör und Zusatzgeräte, die in der Bedienungsanleitung angegeben oder vom Werkzeug-Hersteller

empfohlen oder angegeben werden. Der Gebrauch

anderer als der in der Bedienungsanleitung oder im

Katalog empfohlenen Einsatzwerkzeuge oder Zubehöre kann eine persönliche Verletzungsgefahr für

Sie bedeuten.

22. Reparaturen nur vom Elektrofachmann.

Dieses Elektrowerkzeug entspricht den einschlägi-

gen Sicherheitsbestimmungen. Reparaturen dürfen

nur von einer Elektrofachkraft ausgeführt werden,

andernfalls können Unfälle für den Betreiber entstehen.

ZUSÄTZLICHE

SICHERHEITSBESTIMMUNGEN

1. Tragen Sie stets eine Schutzbrille und Gehörschutz. Das Tragen weiterer Schutzvorrichtungen (Staubmaske, Handschuhe, Helm und

Schürze) wird dringend angeraten.

2. Vergewissern Sie sich vor der Ausführung von

Arbeiten an der Maschine stets, dass sie ausgeschaltet und vom Stromnetz getrennt ist.

3. Das Zubehör muss zumindest für die auf dem

Warnaufkleber der Maschine empfohlene Drehzahl ausgelegt sein. Schleifscheiben und andere

Zubehörteile, die sich schneller als die Nenndrehzahl drehen, können zerbersten und Verletzungen verursachen.

4. Überprüfen Sie den Schleifteller vor dem Betrieb

sorgfältig auf Risse, Beschädigung oder Verformung. Ein gerissener, beschädigter oder verformter Schleifteller muss unverzüglich

ausgewechselt werden.

5. Vergewissern Sie sich, dass das Werkstück

sicher abgestützt ist.

6. Halten Sie die Maschine mit festem Griff.

7. Halten Sie die Hände von rotierenden Teilen fern.

8. Vergewissern Sie sich vor dem Einschalten der

Maschine, dass die Schleifscheibe nicht das

Werkstück berührt.

9. Lassen Sie die Maschine nicht unbeaufsichtigt

laufen. Benutzen Sie die Maschine nur mit Handhaltung.

10. Beachten Sie, dass sich die Schleifscheibe nach

dem Ausschalten der Maschine noch weiterdreht.

11. Vermeiden Sie eine Berührung des Werkstücks

unmittelbar nach der Bearbeitung, weil es dann

noch sehr heiß ist und Hautverbrennungen verursachen kann.

12. Falls der Arbeitsplatz sehr heiß, feucht oder

durch leitfähigen Staub stark verschmutzt ist,

verwenden Sie einen Kurzschlussschalter

(30 mA) zum Schutz des Bedieners.

13. Verwenden Sie diese Maschine nicht zur Bearbeitung von asbesthaltigen Materialien.

14. Manche Materialien können giftige Chemikalien

enthalten. Treffen Sie Vorsichtsmaßnahmen, um

das Einatmen von Arbeitsstaub und Hautkontakt

zu verhüten. Befolgen Sie die Sicherheitsdaten

des Materialherstellers.

15. Verwenden Sie stets die korrekte Staubschutzoder Atemmaske für das jeweilige Material und

die Anwendung.

16. Achten Sie beim Arbeiten unter staubigen Bedingungen darauf, dass die Ventilationsöffnungen

frei gehalten werden. Sollte die Beseitigung von

Staub notwendig sein, trennen Sie die Maschine

zuerst vom Stromnetz (nichtmetallische Gegenstände verwenden), und vermeiden Sie eine

Beschädigung der Innenteile.

17. Als zusätzlichen Schutz gegen elektrische

Schläge sollten Sie beim Betrieb STETS GUMMIHANDSCHUHE UND GUMMISTIEFEL TRAGEN.

18. Achten Sie bei Verwendung der Wasserzufuhr

darauf, dass kein Wasser in den Motor gelangt.

Falls Wasser in den Motor läuft, besteht die

Gefahr eines elektrischen Schlags.

9

Page 10

19. Benutzen Sie die Maschine niemals ohne einen

Tre nn tra fo.

BEWAHREN SIE DIESE HINWEISE

SORGFÄLTIG AUF.

Wichtige Hinweise zum Netzanschluß für

110 Volt, 50 – 60 Hz

Achtung ! Nichtbeachtung dieser Hinweise kann zu Verletzungen und zum Defekt der Maschine führen!

Die Maschine wurde gemäß den europäischen Normen

EN50144-1 (Sicherheit handgeführter motorischer Elektrowerkzeuge; hier im besonderen Abschnitt 20.19: Elektrowerkzeuge mit Wasseranschluß) und EN 60309-2

(Stecker, Steckdosen und Kupplungen für industrielle

Anwendungen) gebaut. Bei Anwendung dieser Normen

darf die Erdkontaktstellung der Steckvorrichtung nur in

„12 Uhr Position“ ausgeführt werden.

Die Maschine verfügt über eine Steckvorrichtung mit der

Erdkontaktstellung in „12 Uhr Position“.

Da die Europäische Norm EN60309-2 jedoch keine Differenzierung im Zusammenhang mit der Versorgungsspannung und dieser Erdkontaktstellung vorsieht, besteht

eine Verwechslungsmöglichkeit des Anschlusses an

einen Trenntransformator mit einer anderen Ausgangsspannung (z.B. 230 Volt) Achten Sie bei Anschluß der

Maschine an einen Trenntransformator unbedingt auf die

richtige Ausgangsspannung (110 Volt, 50 – 60 Hz) .

Diese Maschine ist ausschließlich für den Anschluß an

einen Trenntransformator mit einer Ausgangsspannung

von 110 Volt vorgesehen. Aufgrund der Verwendung im

Naßbetrieb (Wasseranschluß an der Maschine) darf

diese Maschine niemals an eine Stromversorgung ohne

Tenntransformator angeschlossen werden.

Durch nicht fachgerechte Eingriffe in die Steckvorrichtung verursachte Schäden unterliegen nicht der Garantie

bzw. gesetzlichen Gewährleistungsansprüchen.

Einen auf die Maschine angepaßten Trenntransformator

erhalten Sie bei Ihrem Fachhändler.

FUNKTIONSBESCHREIBUNG

VORSICHT:

• Vergewissern Sie sich vor jeder Einstellung oder Funk-

tionsprüfung der Maschine stets, dass sie ausgeschaltet und vom Stromnetz getrennt ist.

Spindelarretierung (Abb. 1)

VORSICHT:

• Betätigen Sie die Spindelarretierung niemals bei rotie-

render Spindel. Die Maschine kann sonst beschädigt

werden.

Drücken Sie die Spindelarretierung, um die Spindel zum

Montieren oder Demontieren von Zubehör zu blockieren.

Schalterfunktion (Abb. 2)

VORSICHT:

• Vergewissern Sie sich vor dem Anschließen der

Maschine stets, dass der Schiebeschalter ordnungsgemäß funktioniert und beim Drücken der Rückseite in

die Stellung „O (AUS)“ zurückkehrt.

• Der Schalter kann zur Arbeitserleichterung bei längerem Einsatz in der Stellung „I (EIN)“ verriegelt werden.

Lassen Sie Vorsicht walten, wenn Sie den Schalter in

der Stellung „I (EIN)“ verriegeln, und halten Sie die

Maschine mit festem Griff.

Zum Einschalten der Maschine den Schalter auf die

Position „I (EIN)“ schieben. Für Dauerbetrieb den Schalter durch Drücken seiner Vorderseite einrasten.

Zum Ausschalten der Maschine die Rückseite des Schiebeschalters drücken, und dann den Schalter auf die Stellung „O (AUS)“ schieben.

Drehzahl-Stellrad (Abb. 3)

Die Drehzahl kann durch Drehen des Drehzahl-Stellrads

auf eine der Stufen von 1 bis 5 geändert werden.

Durch Drehen des Stellrads in Richtung der Stufe 5 wird

die Drehzahl erhöht. Durch Drehen des Stellrads in Richtung der Stufe 1 wird die Drehzahl verringert.

Die ungefähren Drehzahlen für die einzelnen StellradPositionen sind aus der nachstehenden Tabelle ersichtlich.

Nummer RPM (U/min)

12000

22500

33000

43500

54000

VORSICHT:

• Wird die Maschine über längere Zeitspannen im Dauerbetrieb mit niedriger Drehzahl betrieben, wird der

Motor überlastet und überhitzt.

• Das Drehzahl-Stellrad lässt sich nur bis 5 und zurück

auf 1 drehen. Wird es gewaltsam über 5 oder 1 hinaus

gedreht, lässt sich die Drehzahl möglicherweise nicht

mehr einstellen.

Elektronikfunktionen

Konstantdrehzahlregelung

Feines Finish wird ermöglicht, weil die Drehzahl selbst

unter Belastung konstant gehalten wird. Wenn die Belastung der Maschine das zulässige Maß überschreitet, wird

außerdem die Motorleistung reduziert, um den Motor vor

Überhitzung zu schützen. Sobald die Belastung auf

zulässige Werte abfällt, arbeitet die Maschine wieder

normal.

10

Page 11

Soft-Start-Funktion

Diese Funktion gewährleistet ruckfreies Anlaufen durch

Anlaufstoßunterdrückung.

Öffnen und Schließen des Wasserhahns (Abb. 4)

Um das Ventil für die Wasserzufuhr zu öffnen, drehen Sie

den Hebel an der Maschine auf die Stellung A. Drehen

Sie den Hebel auf die Stellung B zurück, um das Ventil

zu schließen.

Die Wasserdurchflussmenge kann durch Umstellen des

Hebels zwischen den Positionen A und B reguliert werden.

MONTAGE

VORSICHT:

• Vergewissern Sie sich vor der Ausführung von Arbeiten

an der Maschine stets, dass sie ausgeschaltet und vom

Stromnetz getrennt ist.

Montieren des Seitengriffs (Zusatzgriffs)

VORSICHT:

• Vergewissern Sie sich vor dem Betrieb stets, dass der

Seitengriff einwandfrei montiert ist.

Schrauben Sie den Seitengriff an der in der Abbildung

gezeigten Position fest an die Maschine. (Abb 5)

Entfernen Sie eine der Befestigungsschrauben von

Getriebegehäuse und Kopfabdeckung, und schrauben

Sie dann den Seitengriff an der Maschine fest. (Abb. 6)

Montage und Demontage der Schleifscheibe

(Abb. 7 und 8)

Den Schleifteller von jeglichem Schmutz oder Fremdkör-

pern säubern.

Den Schleifteller bei gedrückter Spindelarretierung auf

die Spindel schrauben.

Die Schleifscheibe sorgfältig am Schleifteller anbringen,

dass sich die Kanten von Schleifscheibe und Schleifteller

decken, ohne überzustehen.

Zum Entfernen der Schleifscheibe ziehen Sie ihre Kante

vom Schleifteller ab.

BETRIEB

Polierbetrieb (Abb. 9)

WARNUNG:

• Um die Gefahr eines elektrischen Schlags zu reduzieren, überprüfen Sie die Wasserversorgung der

Maschine, um sicherzustellen, dass die Dichtungen (ORinge) oder Schläuche nicht beschädigt sind. Eine

beschädigte Wasserversorgung kann zu einem anormalen Wasserfluss zur Maschine führen, der gefährlich

sein könnte.

VORSICHT:

• Tragen Sie bei der Arbeit stets eine Schutzbrille und

einen Gesichtsschutz.

• Schalten Sie die Maschine niemals ein, wenn sie mit

dem Werkstück in Berührung ist, weil sonst Verletzungsgefahr für die Bedienungsperson besteht.

• Benutzen Sie die Maschine niemals ohne Schleifscheibe. Der Schleifteller könnte sonst schwer beschä-

digt werden.

• Führen Sie der Schleifscheibe während der Arbeit

unbedingt Wasser zu. Anderenfalls kann die Maschine

beschädigt werden.

• Die Wassertemperatur sollte innerhalb des Bereichs

von 0°C – 40°C liegen. Wasser, dessen Temperatur

unter oder über diesem Bereich liegt, kann eine

Beschädigung der Maschine verursachen.

• Der höchstzulässige Druck der Wasserversorgung

beträgt 7 bar.

Vergewissern Sie sich, dass der Hahn geschlossen ist.

Schließen Sie den Schlauch an die Maschine an. Vergewissern Sie sich, dass Wasser herauskommt, wenn der

Wasserhahn geöffnet wird.

Halten Sie die Maschine mit festem Griff. Schalten Sie

die Maschine ein, und setzen Sie dann die Schleifscheibe an das Werkstück an.

Üben Sie nur leichten Druck aus. Übermäßiger Druck

führt zu schlechter Schleifleistung und vorzeitigem Verschleiß der Schleifscheibe.

WARTUNG

VORSICHT:

• Denken Sie vor der Durchführung von Überprüfungen

oder Wartungsarbeiten stets daran, die Maschine auszuschalten und vom Stromnetz zu trennen.

Halten Sie die Maschine und ihre Ventilationsöffnungen

stets sauber. Reinigen Sie die Ventilationsöffnungen der

Maschine regelmäßig oder im Anfangsstadium einer Verstopfung. (Abb. 10)

Um die SICHERHEIT und ZUVERLÄSSIGKEIT dieses

Produkts aufrechtzuerhalten, sollten Reparaturen, Über-

prüfung und Austausch der Kohlebürsten und andere

Wartungs- oder Einstellarbeiten nur von Makita-Kundendienstzentren unter ausschließlicher Verwendung von

Makita-Originalersatzteilen ausgeführt werden.

ZUBEHÖR

VORSICHT:

• Die folgenden Zubehör teile oder Vorrichtungen werden

für den Einsatz mit der in dieser Anleitung beschriebenen Makita-Maschine empfohlen. Die Verwendung

anderer Zubehörteile oder Vorrichtungen kann eine

Verletzungsgefahr darstellen. Verwenden Sie Zubehör-

teile oder Vorrichtungen nur für ihren vorgesehenen

Zweck.

Wenn Sie weitere Einzelheiten bezüglich dieser Zubehörteile benötigen, wenden Sie sich bitte an Ihre MakitaKundendienststelle.

• Schleifscheiben

• Seitengriff

11

Page 12

CE-KONFORMITÄTSERKLÄRUNG

Hiermit erklärt wir unter unserer alleinigen Verantwor-

ENH001-1

tung, daß dieses Produkt gemäß den Ratsdirektiven 73/

23/EWG, 89/336/EWG und 98/37/EG mit den folgenden

Normen von Normendokumenten übereinstimmen:

HD400, EN50144, EN55014, EN61000.

Yasuhiko Kanzaki

CE 2003

Direktor

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

Geräusch- und Vibrationsentwicklung

Der typische A-bewertete Schalldruckpegel beträgt

85 dB (A).

Der Lärmpegel kann während des Betriebs 85 dB (A)

überschreiten.

– Gehörschutz tragen. –

Der gewichtete Effektivwert der Beschleunigung beträgt

nicht mehr als 2,5 m/s

2

.

ENG003-1

12

Page 13

POLSKI

Wyjaśnienia dotyczące urządzenia i jego użycia

1 Blokada wałka

2 Włącznik przesuwny

3 Pokrętło regulacji prędkości

4Kurek

5 Zamykanie

6Otwieranie

7 Uchwyt przesuwny

8Pokrywa głowicy

9Śruba

10 Tarcza ścierna

DANE TECHNICZNE

Model PW5000C

Średnica podkładki Maks. 125 mm

Prędkość bez obciążenia (min

Całkowita długość 313 mm

Ciężar netto 2,2 kg

Klasa bezpieczeństwa /II

• Ze względu na prowadzony program udoskonaleń i

badań, podane dane techniczne mogą zostać

zmienione bez uprzedzenia.

• Uwaga: Dane techniczne mogą się różnić w zależności

od kraju.

Przeznaczenie

Urządzenie jest przeznaczone do szlifowania

powierzchni kamieni naturalnych.

Zasilanie

Urządzenie to, powinno być podłączone tylko do źródła

zasilania o takim samym napięciu jak pokazano na

tabliczce znamionowej i może być używane tylko dla

zmiennego prądu jednofazowego. Zgodnie ze

standardami Unii Europejskiej zastosowano podwójną

izolację i dlatego też możliwe jest zasilanie z gniazda bez

uziemienia.

–1

) 2 000 – 4000

INSTRUKCJE BEZPIECZEŃSTWA

Ostrzeżenie! Używając urządzeń elektrycznych

podstawowe środki ostrożności muszą być zawsze

zachowane, aby zmniejszyć ryzyko ognia, porażenia

prądem i uszkodzenia ciała, włączając poniższe.

Przeczytaj wszystkie podane instrukcje przed próbą

użycia tego produktu i zachowaj je do wglądu.

Dla bezpiecznego użycia:

1. Utrzymuj miejsce pracy w czystości

Zabałaganione miejsca i stoły warsztatowe

sprzyjają wypadkom.

2. Zastanów się nad warunkami pracy

Nie wystawiaj urządzeń elektrycznych na deszcz.

Nie używaj urządzeń elektrycznych w wilgotnych

lub mokrych miejscach. Utrzymuj miejsce pracy

dobrze oświetlone. Nie używaj urządzeń

elektrycznych w obecności łatwopalnych płynów

lub gazów.

3. Chroń się przed porażeniem prądu.

Zapobiegaj kontaktom ciała z uziemionymi

powierzchniami (np. rurami, grzejnikami,

kuchenkami, lodówkami).

11 Podkładka

12 Wrzeciono

13 Otwór wydechowy

14 Otwór zasysający

4. Nie pozwalaj zbliżać się dzieciom

Nie pozwalaj wizytującym osobom dotykać

urządzenia lub przedłużacza. Wszystkie wizytujące

osoby nie powinny zbliżać się do miejsca pracy.

5. Zachowaj nieczynne urządzenia.

Nieużywane urządzenia powinny być

przechowywane w suchych, wysokich lub

zamykanych miejscach tak, aby były niedostępne

dla dzieci.

6. Nie przeciążaj urządzenia.

Wykona ono pracę lepiej i bezpieczniej, pracując w

sposób, dla którego zostało ono zaprojektowane.

7. Używaj poprawnego urządzenia.

Nie nadużywaj małych lub dodatkowych urządzeń

do wykonania pracy urządzeń do dużej pracy. Nie

używaj urządzeń do celów, do których nie zostały

przeznaczone; na przykład, nie używaj piły

tarczowej do przecinania gałęzi lub kłód drzew.

8. Ubierz się odpowiednio

Nie noś luźnych ubrań lub biżuterii. Mogą one

zostać zahaczone o ruchome części. Gumowe

rękawiczki i przeciwpoślizgowe buty są wskazane

przy pracy na dworze. Zaleca się noszenie ochrony

na głowę przytrzymującej długie włosy.

9. Użyj okularów ochronnych i ochraniaczy uszu.

Użyj masek na twarz lub masek przeciwpyłowych

jeżeli czynność cięcia wytwarza pyły.

10. Podłącz urządzenie usuwające pył.

Jeżeli urządzenia posiadają podłączenia do

urządzeń do usuwania i składowania pyłu, upewnij

się, że są one poprawnie podłączone i użyte.

11. Uważaj na przewód sieciowy

Nigdy nie noś urządzenia trzymając za przewód i

nie odłączaj go od gniazda przez pociągnięcie

przewodu. Chroń przewód przed ciepłem, olejem i

ostrymi krawędziami.

12. Pewnie mocuj cięte elementy.

Użyj ścisków lub imadła do zamocowania ciętych

elementów. Jest to bezpieczniejsze niż używanie

rąk, a dodatkowo zwalnia obie ręce do

obsługiwania piły.

13. Używając piłę, nie oddalaj jej zbytnio od siebie.

Cały czas trzymaj dobrze ustawione nogi i

równowagę.

14. Pamiętaj o dobrej konserwacji urządzenia.

Utrzymuj urządzenie ostre i czyste dla jego lepszego

i bezpieczniejszego działania. Wykonaj podane

instrukcje w celu smarowania lub wymiany

elementów wyposażenia. Regularnie sprawdzaj

przewody urządzenia, i jeżeli są uszkodzone, oddaj

je do naprawy do autoryzowanego serwisu.

Regularnie sprawdzaj przewody przedłużające i

wymień je, jeżeli są uszkodzone. Utrzymuj uchwyty

suche, czyste i nie zabrudzone olejem lub smarem.

13

Page 14

15. Odłącz urządzenia

Przed konserwacją urządzenia lub zmianą

wyposażenia takiego jak tarcze, noże do struga i

noże do frezowania, gdy nie jest ono używane.

16. Wyjmij klucze regulacyjne

Nabierz zwyczaju sprawdzania czy klucze

regulacyjne są usunięte z urządzenia przed jego

użyciem.

17. Unikaj przypadkowych uruchomień.

Nie noś podłączonego urządzenia z palcem na

włączniku. Upewnij się, że urządzenie jest

wyłączone, gdy je podłączasz do zasilania.

18. Zastosuj przedłużacz używając urządzenia na

dworze.

Gdy urządzenie używane jest na dworze, stosuj

tylko przedłużacze przeznaczone i oznaczone do

pracy na dworze.

19. Bądź uważny

Patrz co robisz. Bądź rozsądny. Nie używaj

urządzenia, gdy jesteś zmęczony.

20. Sprawdzaj uszkodzone części.

Przed dalszym użyciem urządzenia, osłona lub inne

części, które są uszkodzone, muszą być uważnie

sprawdzone, aby upewnić się, że będą poprawnie

działać i wykonywać przeznaczone im funkcje.

Sprawdzaj ustawienia ruchomych części, oprawy

ruchomych części, pęknięcia części, zamocowania,

i jakiekolwiek inne warunki, które mogą wpływać na

działanie. Osłona lub inne części, które są

uszkodzone, powinny być naprawione lub

wymienione przez autoryzowany serwis, jeżeli w

instrukcji nie podano inaczej. Uszkodzone

przełączniki powinny być wymienione przez

autoryzowany serwis. Nie używaj urządzenia, jeżeli

włącznik nie może go włączyć lub wyłączyć.

21. Ostrzeżenie

Użycie jakiegokolwiek innego wyposażenia lub

części dodatkowych innych niż zalecane w tej

instrukcji obsługi lub katalogu, może stworzyć

ryzyko uszkodzenia ciała.

22. Naprawy urządzenia powinny być wykonywane

tylko przez specjalistę.

To urządzenie jest wykonane zgodnie z

odpowiednimi zasadami bezpieczeństwa. Naprawa

urządzeń elektrycznych może być wykonana

wyłącznie przez specjalistę, gdyż w przeciwnym

wypadku może ono stanowić zagrożenie dla

użytkownika.

D O D AT K O W E Z A S A D Y B E Z P I E C Z E Ń S T W A

1. Zawsze używaj ochrony oczu i uszu. Należy też

zakładać inne osobiste wyposażenie ochronne,

takie jak maska przeciwpyłowa, rękawice, kask i

fartuch.

2. Przed wykonywaniem jakiejkolwiek pracy nad

urządzeniem zawsze upewnij się, czy jest ono

wyłączone i odłączone od zasilania.

3. Wyposażenie musi mieć prędkość znamionową

nie mniejszą niż prędkość zalecana podana na

tabliczce ostrzegawczej urządzenia. Tarcze i

inne wyposażenie pracujące z prędkością

wyższą od znamionowej mogą rozpaść się i

spowodować wypadek.

4. Przed przystąpieniem do pracy sprawdź

dokładnie tylną podkładkę, czy nie jest

popękana, uszkodzona lub wypaczona. Wymień

natychmiast popękaną, uszkodzoną lub

wypaczoną podkładkę.

5. Sprawdź, czy szlifowany przedmiot jest

prawidłowo podparty.

6. Trzymaj urządzenie pewnie.

7. Trzymaj ręce z daleka od obracających się

części.

8. Upewnij się, czy tarcza ścierna nie dotyka

obrabianego przedmiotu przed włączeniem

urządzenia.

9. Nie odchodź od pracującego urządzenia.

Korzystaj z urządzenia tylko wtedy, jeżeli

trzymasz je w rękach.

10. Zwróć uwagę, że tarcza obraca się nadal po

wyłączeniu urządzenia.

11. Nie dotykaj obrabianego przedmiotu

natychmiast po zakończeniu pracy; może on być

bardzo gorący i poparzyć skórę.

12. Jeżeli miejsce pracy jest bardzo gorące lub

wilgotne albo zanieczyszczone przewodzącym

pyłem, używaj bezpiecznika

przeciwzwarciowego (30 mA), aby zapewnić

bezpieczną pracę.

13. Nie używaj urządzenia do żadnych materiałów

zawierających azbest.

14. Niektóre materiały zawierają substancje, które

mogą być toksyczne. Podejmij środki

zapobiegające wdychaniu pyłu i kontaktowi ze

skórą. Postępuj zgodnie z zaleceniami

producenta materiału.

15. Zawsze używaj właściwej dla obrabianego

materiału i wykonywanej pracy maski

przeciwpyłowej/respiratora.

16. Podczas pracy w miejscu zapylonym upewnij

się, czy otwory wentylacyjne są czyste. Jeżeli

trzeba będzie oczyścić pył, najpierw odłącz

urządzenie od zasilania (użyj niemetalowego

przedmiotu) i unikaj uszkodzenia części

wewnętrznych.

17. W celu dodatkowego zabezpieczenia przed

porażeniem prądem podczas pracy ZAKŁADAJ

GUMOWE RĘKAWICE I GUMOWE BUTY.

18. W przypadku korzystania ze strumienia wody

uważaj, aby woda nie dostała się do silnika.

Jeżeli woda dostanie się do silnika, może dojść

do porażenia prądem.

19. Nigdy nie używaj urządzenia bez transformatora

izolującego.

ZACHOWAJ INSTRUKCJĘ OBSŁUGI.

14

Page 15

Ważne uwagi dotyczące podłączenia do zasilania

–

110 V, 50

Uwaga: Przed użyciem urządzenia przeczytaj, a potem

stosuj następujące środki bezpieczeństwa.

Niestosowanie się do tych zaleceń może doprowadzić

do obrażeń i uszkodzenia urządzenia!

Urządzenie jest zbudowane zgodnie z Normą

Europejską EN50144-1 (bezpieczeństwo pracy z

urządzeniami elektrycznymi obsługiwanymi ręcznie,

zasilanymi silnikiem; zwłaszcza rozdział 20.19:

urządzenia elektryczne podłączone do wody) i

EN60309-2 (wtyczki, gniazda i podłączenia dla

zastosowań przemysłowych). W przypadku stosowania

tych norm położenie uziemienia urządzenia do

podłączania musi być w położeniu „godziny 12”.

Urządzenie wyposażone jest w urządzenie do

podłączania z położeniem uziemienia „na godzinę 12”.

Ponieważ jednak Norma Europejska EN60309-2 nie

rozróżnia napięcia zasilania i tego położenia uziemienia,

powstaje możliwość pomylenia podłączenia do

transformatora izolującego o innym napięciu

wyjściowym (np. 230 V). W przypadku podłączania

urządzenia do transformatora izolującego sprawdź

bardzo dokładnie, czy daje on właściwe napięcie

wyjściowe (110 V, 50 – 60 Hz).

Urządzenie jest zaprojektowane wyłącznie do

podłączenia do transformatora izolującego o napięciu

wyjściowym 110 V. Ze względu na używanie w mokrych

warunkach (podłączenie urządzenia do wody)

urządzenia nie wolno nigdy podłączać do zasilania bez

transformatora izolującego.

Uszkodzenia spowodowane niewłaściwym

przerabianiem urządzenia do podłączania nie podlegają

gwarancji i naprawom gwarancyjnym.

Po transformator izolujący właściwy dla niniejszego

urządzenia zwróć się do dostawcy urządzeń

specjalistycznych.

60 Hz

OPIS DZIAŁANIA

UWAGA:

• Przed regulacją lub sprawdzaniem działania

urządzenia zawsze upewnij się, czy jest ono

wyłączone i odłączone od zasilania.

Blokada wałka (Rys. 1)

UWAGA:

• Nigdy nie włączaj blokady wałka, kiedy wrzeciono

obraca się. Urządzenie może zostać uszkodzone.

Podczas zakładania lub zdejmowania wyposażenia

naciśnij blokadę wałka, aby zapobiec obracaniu się

wrzeciona.

Działanie włącznika (Rys. 2)

UWAGA:

• Przed podłączeniem urządzenia do zasilania zawsze

sprawdź, czy włącznik przesuwny działa prawidłowo i

powraca do położenia „O (OFF)” po naciśnięciu jego

tylnej części.

• Podczas długiej, nieprzerwanej pracy dla wygody

operatora można zablokować włącznik w położeniu „I

(ON)”. W przypadku blokowania włącznika w

położeniu „I (ON)” zachowaj ostrożność i trzymaj

pewnie urządzenie.

Aby uruchomić urządzenie, przesuń włącznik przesuwny

do położenia „I (ON)”. Dla zapewnienie pracy ciągłej

naciśnij przednią część włącznika przesuwnego, aby go

zablokować.

Aby zatrzymać urządzenie, naciśnij tylną część

włącznika przesuwnego, a następnie przesuń go do

położenia „O (OFF)”.

Pokrętło regulacji prędkości (Rys. 3)

Prędkość obrotową można zmienić obracając pokrętło

regulacji prędkości na określone ustawianie oznaczone

liczbą od 1 do 5.

Wyższą prędkość uzyskuje się obracając pokrętło w

stronę liczby 5. Niższą prędkość uzyskuje się obracając

w stronę liczby 1.

Zależność pomiędzy liczbą ustawioną na pokrętle a

przybliżoną prędkością obrotową podana jest w

poniższej tabeli.

Liczba Liczba obrotów na minutę

12000

22500

33000

43500

54000

UWAGA:

• Jeżeli urządzenie będzie pracowało długo z niską

prędkością, silnik może zostać przeciążony i

przegrzany.

• Pokrętło regulacji prędkości można obrócić tylko do 5 i

z powrotem do 1. Nie obracaj go na siłę poza 5 lub 1,

bo funkcja regulacji prędkości może przestać działać.

Funkcje elektroniczne

Kontrola stałej prędkości

Umożliwia uzyskanie dokładnego wykończenia, dzięki

utrzymywaniu stałej prędkości obrotowej nawet pod

obciążeniem.

Ponadto, kiedy obciążenie urządzenia przekroczy

dopuszczalny poziom, moc silnika zostanie

ograniczona, aby chronić go przed przegrzaniem. Kiedy

obciążenie powróci do dopuszczalnego poziomu,

urządzenie będzie pracowało dalej normalnie.

Funkcja łagodnego startu

Łagodny start dzięki złagodzeniu szoku towarzyszącego

rozpoczęciu pracy.

Otwieranie lub zamykanie dźwigni dopływu wody

(Rys. 4)

Aby dźwignia urządzenia sterująca dopływem wody była

stale otwarta, obróć ją do położenia A, gdzie tor wody

jest otwarty. Obróć z powrotem do położenia B, aby

zamknąć dopływ.

Natężenie strumienia wody można regulować zmieniając

położenie dźwigni pomiędzy A i B.

15

Page 16

SKŁADANIE

UWAGA:

• Przed wykonywaniem jakiejkolwiek pracy nad

urządzeniem zawsze sprawdź, czy jest ono wyłączone

i odłączone od zasilania.

Zakładanie uchwytu bocznego

UWAGA:

• Przed przystąpieniem do pracy zawsze sprawdź, czy

uchwyt boczny jest pewnie zamocowany.

Przykręć pewnie uchwyt boczny we właściwym miejscu

do urządzenia, w sposób pokazany na rysunku. (Rys. 5)

Wyjmij jedną ze śrub mocujących obudowę przekładni i

pokrywę głowicy, a następnie przykręć uchwyt boczny

do urządzenia. (Rys. 6)

Zakładanie lub zdejmowanie tarczy ściernej

(Rys. 7 i 8)

Oczyść podkładkę z brudu i ciał obcych.

Wkręć podkładkę na wrzeciono, naciskając blokadę

wałka.

Załóż starannie tarczę na podkładkę tak, aby brzegi

tarczy i podkładki przylegały do siebie i nie wystawały.

Aby zdjąć tarczę ścierną, podnieś jej brzeg z podkładki.

POSTĘPOWANIE

Polerowanie (Rys. 9)

OSTRZEŻENIE:

• Aby ograniczyć niebezpieczeństwo porażenia prądem,

sprawdź system doprowadzania wody do urządzenia,

aby upewnić się, czy uszczelki (pierścienie okrągłe) nie

są uszkodzone. Uszkodzony system doprowadzania

wody może spowodować nienormalny dopływ wody

do urządzenia, co może być niebezpieczne.

UWAGA:

• Podczas pracy zawsze zakładaj okulary ochronne lub

osłonę na twarz.

• Nigdy nie włączaj urządzenia, jeżeli dotyka ono

obrabianego przedmiotu, ponieważ może to

spowodować obrażenia u operatora.

• Nigdy nie uruchamiaj urządzenia bez tarczy ściernej.

Może to doprowadzić do poważnego uszkodzenia

podkładki.

• Koniecznie dostarczaj wodę do tarczy ściernej

podczas pracy. Niestosowanie się do tego zalecenia

może spowodować uszkodzenie urządzenia.

• Temperatura używanej wody powinna być w zakresie

0˚C – 40˚C (32˚F – 104˚F). Używanie bardzo zimnej lub

gorącej wody poza tym zakresem temperatur może

spowodować uszkodzenie urządzenia.

• Maksymalne dopuszczalne ciśnienie dopływu wody

wynosi 7 barów.

Upewnij się, czy kurek jest zamknięty. Podłącz wąż do

urządzenia. Upewnij się, czy woda płynie po otwarciu

dźwigni dopływu wody.

Chwyć pewnie urządzenie. Włącz je, a następnie zetknij

tarczę ścierną z obrabianym przedmiotem.

Wywieraj tylko lekki nacisk. Nadmierny nacisk może

doprowadzić do słabej wydajności i przedwczesnego

zużycia tarczy ściernej.

KONSERWACJA

UWAGA:

• Przed przystąpieniem do przeglądu urządzenia lub

jego konserwacji należy upewnić się, że zostało ono

wyłączone i odłączone od zasilania.

Urządzenie i jego otwory wentylacyjne należy

utrzymywać w czystości. Czyść regularnie otwory

wentylacyjne urządzenia lub kiedy tylko zaczną się

blokować. (Rys. 10)

W celu zachowania poziomu BEZPIECZEŃSTWA i

NIEZAWODONOŚCI wyrobu, wszelkie naprawy, innego

rodzaju prace konserwacyjne lub regulacje powinny być

przeprowadzane przez autoryzowany punkt serwisowy

narzędzi Makita, zawsze z użyciem części zamiennych

Makita.

WYPOSAŻENIE

UWAGA:

• Niniejsze wyposażenie i nakładki są zalecane do

używania wraz z urządzeniem Makita określonym w tej

instrukcji obsługi. Używanie jakiegokolwiek innego

wyposażenia lub nakładek może spowodować

niebezpieczeństwo zranienia osób. Używaj

wyposażenia i nakładek wyłącznie w celu, który

podano.

Jeżeli potrzebujesz pomocy związanej z dalszymi

szczegółami dotyczącymi niniejszego wyposażenia,

zwróć się do miejscowego punktu usługowego Makita.

• Tarcze ścierne

• Uchwyt boczny

UE-DEKLARACJA ZGODNOŚCI

Oświadczamy, biorąc za to wyłączną odpowiedzialność,

że niniejszy wyrób jest zgodny z następującymi

standardami standardowych dokumentów:

HD400, EN50144, EN55014, EN61000,

zgodnie z Zaleceniami Rady: 73/23/EEC i 89/336/EEC i

98/37/EC.

Yasuhiko Kanzaki

CE 2003

Dyrektor

ENH001-1

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

Szumy i drgania

ENG003-1

Typowy A-ważony poziom ciśnienia dźwięku wynosi

85 dB (A).

Poziom szumów w trakcie pracy może przekroczyć

85 dB (A).

Typowa wartość ważonej średniej kwadratowej

przyspieszenia nie jest większa niż 2,5 m/s

– Noś ochraniacze uszu. –

2

.

16

Page 17

РУССКИЙ ЯЗЫК

Объяснения общего плана

1 Фиксатор вала

2 Ползунковый переключатель

3 Регулятор скорости

4 Кран

5 Открыть

6 Закрыть

7 Боковой захват

8 Крышка передней части

9Винт

10 Шлифовальный диск

11 Подушка

12 Шпиндель

ТЕХНИЧЕСКИЕ ХАРАКТЕРИСТИКИ

Модель PW5000C

Диаметр подушки Макс. 125 мм

Скорость в незагруженном

состоянии (мин

–1

)

2000

–

4000

Общая длина 313 мм

Вес нетто 2,2 кг

Класс безопасности /II

• Вследствие нашей продолжающейся программы

поиска и разработок технические характеристики

могут быть изменены без уведомления.

• Примечание: Технические характеристики могут

различаться в зависимости от страны.

Предназначенное использование

Инструмент предназначен для поверхностной

обработки натурального камня.

Источник питания

Инструмент должен быть подсоединен только к

источнику питания с напряжением, указанным в

табличке номиналов, и может функционировать

только от однофазного источника питания

переменного тока. В соответствии с Европейским

стандартом имеется двойная изоляция,

следовательно, возможно использование с

розетками без провода заземления.

13 Выходные вентиляционные

отверстия

14 Входные вентиляционные

отверстия

ИНСТРУКЦИИ ПО МЕРАМ

БЕЗОПАСНОСТИ

Предостережение! При использовании

электрических инструментов следует всегда

соблюдать основные меры безопасности для

уменьшения опасности пожара, поражения

электрическим током и персональных травм,

включая следующие.

Прочитайте эти инструкции перед тем, как

пытаться управлять этим изделием, и сохраните

эти инструкции.

Для безопасного функционирования:

1. Поддерживайте чистоту на рабочем месте

Захламленные места и подставки могут

привести к травмам.

2. Учитывайте рабочую окружающую среду

Не подвергайте инструменты с электроприводом

воздействию дождя. Не используйте инструменты с

электроприводом в сырых или влажных местах.

Поддерживайте хорошее освещение на рабочем

месте. Не используйте инструменты с

электроприводом в присутствии возгораемых

жидкостей или газов.

3. Предохраняйтесь от поражения

электрическим током

Предотвращайте контакт тела с заземленными

поверхностями (например, трубами, радиаторами,

батареями, холодильниками).

4. Держитесь подальше от детей

Не позволяйте посетителям прикасаться к

инструменту или шнуру-удлинителю. Все

посетители должны находиться подальше от

рабочей области.

5. Правильно храните неработающие

инструменты

Если инструменты не используются, они должны

храниться в сухом, высоком или закрытом

месте, вне достижения детей.

6. Не прилагайте усилие к инструменту

Он будет выполнять работу лучше и безопаснее

при скорости, для которой он предназначен.

7. Используйте правильный инструмент

Не пытайтесь прилагать усилие к маленьким

инструментам или присоединениям для

выполнения работы инструмента тяжелого

назначения. Не используйте инструменты для

непредназначенных целей; например, не

используйте дисковую пилу для резки веток или

корней деревьев.

171717

Page 18

8. Одевайтесь правильно

Не одевайте свисающую одежду или украшения.

Они могут попасть в движущиеся части. При

работе на улице рекомендуется одевать

резиновые перчатки и нескользящую обувь.

Одевайте предохранительный головной убор для

убирания длинных волос.

9. Используйте защитные очки и

предохранительные приборы для слуха.

Если работа по резке является пыльной,

используйте также маску для лица или

пылезащитную маску

10. Подсоедините пылевсасывающее

оборудование

Если имеются подсоединения устройств для

всасывания и сбора пыли, убедитесь в том, что

они подсоединены и используются правильно.

11. Не прилагайте усилие к шнуру

Никогда не носите инструмент за шнур и не

дергайте за него для отсоединения его из

розетки. Держите шнур подальше от жарких

мест, масла и острых краев.

12. Закрепите рабочее изделие

Используйте зажимы или тиски для крепления

рабочего изделия. Это является более

безопасным, чем использование Вашей руки, и

при этом освобождаются две руки для

управления инструментом.

13. Не заходите слишком далеко

Сохраняйте правильную стойку и баланс все

время.

14. Осторожно обращайтесь с инструментами

Держите инструменты острыми и чистыми для

более лучшей и безопасной работы. Следуйте

инструкциям для смазки и смены

принадлежностей. Периодически проверяйте

шнуры инструмента, и, если они повреждены,

обращайтесь относительно ремонта в

уполномоченный центр по техобслуживанию.

Периодически проверяйте шнуры-удлинители и

заменяйте, если они повреждены. Держите ручки

сухими чистыми и свободными от масла или

смазки.

15. Отсоединяйте инструменты

Если не используются, перед техобслуживанием, и

при смене принадлежностей, таких, как лезвия,

резцы и резаки.

16. Убирайте регулировочные ключи и гаечные

ключи

Сформируйте привычку проверять, что

регулировочные ключи и гаечные ключи убраны

с инструмента перед его включением.

17. Избегайте случайных запусков

Не носите подсоединенный к сети инструмент с

пальцем, находящемся на переключателе. Перед

подсоединением инструмента к сети убедитесь,

что переключатель находится в положении

“выкл”.

18. Шнуры-удлинители для использования на

улице

Когда инструмент используется на улице,

используйте только шнуры-удлинители,

предназначенные для использования на улице с

указанием этого.

19. Будьте бдительны

Наблюдайте за тем, что Вы делаете. Используйте

разумный подход. Не управляйте инструментом,

если Вы устали.

20. Проверяйте поврежденные части

Перед дальнейшим использованием

инструмента, предохранитель или другая часть

должны быть тщательно проверены для

определения того, что они будут

функционировать правильно и выполнять

предназначенную функцию. Проверьте на

предмет совмещения движущихся частей,

соединения движущихся частей, поломки

частей, монтажа и других условий, которые

могут повлиять не их функционирование.

Предохранитель или другая часть должны быть

правильно отремонтированы или заменены в

уполномоченном центре по техобслуживанию,

если только не указано другое в этой

инструкции по эксплуатации. Дефектные

переключатели должны быть заменены в

уполномоченном центре по техобслуживанию.

Не используйте инструмент, если невозможно

его включение и выключение с помощью

переключателя.

21. Предостережение

Использование любой другой принадлежности

или присоединения, отличного от рекомендуемого

в этой инструкции по эксплуатации или каталоге,

может привести к опасности персональной

травмы.

22. Используйте для ремонта услуги

специалиста

Это электрическое оборудование соответствует

относящимся к нему правилам безопасности.

Ремонт электрического оборудования может

проводиться только специалистами, в

противном случае, он может вызвать

существенную опасность для пользователя.

ДОПОЛНИТЕЛЬНЫЕ ПРАВИЛА

БЕЗОПАСНОСТИ

1. Всегда используйте защиту для глаз и ушей.

Также должно использоваться другое

индивидуальное защитное оборудование

такое, как пылезащитная маска, перчатки,

шлем, фартук.

2. Следует всегда быть уверенным, что

инструмент выключен и отключен от сети

перед проведением любых работ с

инструментом.

3. Принадлежности должны быть рассчитаны,

по крайней мере, на скорость,

рекомендованную на предупреждающей

этикетке инструмента. Диски и другие

принадлежности, работающие на скорости

выше, чем номинальная скорость, могут

отлететь в сторону и причинить травму.

4. Тщательно проверьте нижнюю подушку

перед началом эксплуатации на предмет

наличия трещин, повреждения или

деформации. Немедленно замените

треснувшую, поврежденную или

деформированную подушку.

5. Проверьте, что рабочее изделие правильно

закреплено.

6. Крепко удерживайте инструмент.

181818

Page 19

7. Держите руки подальше от вращающихся

частей.

8. Убедитесь в том, что шлифовальный диск не

контактирует с рабочим изделием перед тем,

как включать инструмент.

9. Не оставляйте работающий инструмент.

Эксплуатируйте инструмент только тогда,

когда он удерживается руками.

10. Обратите внимание на то, что режущий диск

продолжает вращаться после того, как

инструмент выключается.

11. Не прикасайтесь к рабочему изделию сразу

же после эксплуатации; оно может быть

очень горячим и обжечь Вашу кожу.

12. Если рабочее место является чрезмерно

жарким или влажным, или сильно

загрязнено проводящей пылью, используйте

прерыватель цепи (30 мА), чтобы обеспечить

безопасность эксплуатации.

13. Не используйте инструмент ни с какими

материалами, содержащими асбест.

14. Некоторые материалы содержат химикаты,

которые могут быть токсичными. Примите

меры, чтобы предотвратить вдыхание пыли

и контакт с кожей. Выполняйте указания по

безопасности поставщика материала.

15. Всегда используйте правильную

пылезащитную маску/респиратор для

материала и способа обработки, которые Вы

используете.

16. Убедитесь в том, что при работе в пыльных

условиях вентиляционные отверстия

содержатся в чистоте. Если становится

необходимым очистить пыль, сначала

отсоедините инструмент от сетевой розетки

(используйте неметаллический предмет), и

избегайте повреждения внутренних частей.

17. Для дополнительной защиты от поражения

электрическим током обязательно

ИСПОЛЬЗУЙТЕ РЕЗИНОВЫЕ ПЕРЧАТКИ И

РЕЗИНОВУЮ ОБУВЬ во время работы.

18. Во время подачи воды будьте внимательны,

чтобы не позволить воде попасть в мотор.

Если вода попадет в мотор, может

возникнуть опасность поражения

электрическим током.

19. Никогда не используйте инструмент без

разделительного трансформатора.

СОХРАНИТЕ ЭТУ ИНСТРУКЦИЮ.

Важные примечания относительно

сетевого подсоединения для 110 Вольт,

50 – 60 Гц

Предупреждение! Прочитайте и соблюдайте эти

предписания перед использованием инструмента.

Несоблюдение этих предписаний может привести к

травмам и повреждению инструмента!

Инструмент изготовлен в соответствии с

Европейскими Стандартами EN50144-1

(безопасность ручного электромеханического

инструмента; в частности раздел 20.19:

электрические инструменты, использующие воду) и

EN60309-2 (штепселя, штепсельные розетки и

соединения для промышленного инструмента). При

использовании этих стандартов позиция контакта

заземления устройства подсоединения может быть

выполнена только в положении “12 часов”.

Этот инструмент имеет устройство подсоединения с

позицией контакта заземления “12 часов”.

Однако, так как в Европейском Стандарте EN603092 не существует различия относительно напряжения

питания и позиции этого контакта заземления, то

имеется вероятность ошибочного подсоединения к

разделительному трансформатору с другим

выходным напряжением (например, 230 В). При

подсоединении инструмента к разделительному

трансформатору следует быть абсолютно

уверенным, чтобы использовать правильное

выходное напряжение (110 В, 50 – 60 Гц).

Этот инструмент разработан исключительно для

подсоединения к разделительному трансформатору

с выходным напряжением 110 В. Так как этот

инструмент используется во влажных условиях

(подача воды в инструмент), то он никогда не должен

подсоединяться к электрической сети без

разделительного трансформатора.

Повреждения, вызванные неправильным

обращением с устройством подсоединения, не

покрываются гарантией и не являются случаем

гарантийной претензии.

Обращайтесь к специалисту Вашего поставщика за

разделительным трансформатором, походящим для

Вашего инструмента.

ОПИСАНИЕ ФУНКЦИОНИРОВАНИЯ

ПРЕДУПРЕЖДЕНИЕ:

• Следует всегда быть уверенным, что инструмент

выключен и отключен от сети перед настройкой

или проверкой функционирования инструмента.

Фиксатор вала (Рис. 1)

ПРЕДУПРЕЖДЕНИЕ:

• Никогда не приводите в действие фиксатор вала,

когда шпиндель движется. Инструмент может быть

поврежден.

Нажмите фиксатор вала, чтобы предотвратить

вращение шпинделя во время установки или

удаления принадлежностей.

191919

Page 20

Операция переключения (Рис. 2)

ПРЕДУПРЕЖДЕНИЕ:

• Перед подсоединением инструмента всегда

проверяйте, чтобы видеть, что ползунковый

переключатель действует правильно и

возвращается в положение “O (OFF)” (выкл.) после

высвобождения задней стороны ползункового

переключателя.

• Пусковой механизм может быть заблокирован в

положении “I (ON)” (вкл.) для удобства работы

оператора при длительном использовании. Будьте

внимательны при блокировке инструмента в

положении “I (ON)” (вкл.) и крепко удерживайте

инструмент.

Для запуска инструмента передвиньте ползунковый

переключатель в направлении положения “I (ON)”.

Для непрерывного функционирования нажмите

переднюю сторону ползункового переключателя,

чтобы зафиксировать его.

Для остановки инструмента нажмите заднюю

сторону ползункового переключателя, а затем

передвиньте его в направлении положения “O (OFF)”.

Регулятор скорости (Рис. 3)

Скорость вращения может быть изменена с

помощью поворота регулятора скорости на номер

нужной установки от 1 до 5.

Более высокая скорость достигается, когда

регулятор поворачивается в направлении номера 5.

И более медленная скорость достигается, когда он

поворачивается в направлении номера 1.

Обращайтесь к таблице внизу относительно

соотношения между номером, установленным на

регуляторе, и приблизительной скоростью

вращения.

Номер Оборотов в мин. (/мин)

12000

22500

33000

43500

54000

ПРЕДУПРЕЖДЕНИЕ:

• Если инструмент непрерывно функционирует на

маленькой скорости в течение длительного

времени, то мотор перегрузится и нагреется.

• Регулятор скорости может поворачиваться только

до значения 5 и обратно до значения 1. Не

прилагайте силу, чтобы повернуть его дальше 5 или

1, или же регулятор скорости может больше не

работать.

Электронная функция

Регулирование постоянной скорости

Это дает возможность аккуратно завершить

операцию, т.к. скорость вращения сохраняется

постоянной даже в режиме нагрузки.

К тому же при превышении нагрузки инструмента

допустимого уровня, мощность питания мотора

уменьшается, чтобы предохранить мотор от

перегрева. Когда нагрузка возвратится к

допустимому уровню, инструмент будет работать в

нормальном режиме.

Функция плавного запуска

Плавный старт возможен из-за сдерживания удара

при запуске.

Открытие или закрытие водяного крана

(Рис. 4)

Чтобы сохранять кран на инструменте открытым для

тока воды, поверните его в положение А, где водоток

будет в состоянии готовности. Чтобы закрыть его,

верните в положение В.

Скорость подачи воды может регулироваться

изменением положения крана между положением А

и В.

СБОРКА

ПРЕДУПРЕЖДЕНИЕ:

• Следует всегда быть уверенным, что инструмент

выключен и отключен от сети перед проведением

любых работ с инструментом.

Установка бокового захвата (ручки)

ПРЕДУПРЕЖДЕНИЕ:

• Перед началом эксплуатации следует всегда быть

уверенным, что боковой захват установлен

надежно.

Привинтите боковой захват в таком положении на

инструменте, как показано на рисунке. (Рис. 5)

Удалите один из винтов, которые крепят корпус

механизма и крышку передней части, затем

привинтите боковой захват на инструмент. (Рис. 6)

Установка или удаление шлифовального

диска (Рис. 7 и 8)

Удалите всю грязь и посторонние предметы с

подушки.

Нажимая фиксатор вала, привинтите подушку на

шпиндель.

Аккуратно прикрепите диск на подушку так, чтобы

края диска и подушки перекрывали друг друга без

выступов.

Чтобы удалить шлифовальный диск, снимите за его

угол с подушки.

202020

Page 21

ЭКСПЛУАТАЦИЯ

Операция шлифования (Рис. 9)

ПРЕДОСТЕРЕЖЕНИЕ:

• Для уменьшения риска поражения электрическим

током, проверьте систему подачи воды, чтобы

удостовериться, что уплотнения (уплотнительные

кольца) и шланги не повреждены. Повреждение

системы подачи воды может привести к

ненормальному току воды на инструменте, что

может быть опасным.

ПРЕДУПРЕЖДЕНИЕ:

• Всегда носите защитные очки или защитную маску

во время работы.

• Никогда не включайте инструмент, когда он

контактирует с рабочим изделием, так как это

может привести к травме оператора.

• Никогда не запускайте инструмент без

шлифовального диска. Вы можете серьезно

повредить подушку.

• Во время эксплуатации обязательно подавайте

воду на шлифовальный диск. Невыполнение этого

условия может привести к поломке инструмента.

• Температура используемой воды должна быть в

диапазоне 0°C – 40°C. Использование замерзшей

или горячей воды вне этого диапазона может

привести к повреждению инструмента.

• Максимально допустимое давление подачи воды

составляет 7 бар.

Убедитесь в том, что кран закрыт. Подсоедините

шланг к инструменту. Убедитесь в том, что вода

льется, когда кран открыт.

Крепко удерживайте инструмент. Включите

инструмент, а затем приложите шлифовальный диск

к рабочему изделию.

Прилагайте только небольшое давление. Излишнее

давление приведет к ухудшению

производительности и преждевременному износу

шлифовального диска.

ОБСЛУЖИВАНИЕ

ПРЕДУПРЕЖДЕНИЕ:

Следует всегда быть уверенным, что инструмент

выключен и отсоединен от сети перед выполнением

проверки или обслуживания.

Инструмент и его вентиляционные отверстия

должны поддерживаться чистыми. Регулярно

очищайте вентиляционные отверстия инструмента

или всякий раз, когда вентиляционные отверстия

начинают засоряться. (Рис. 10)

Для поддержания БЕЗОПАСНОСТИ и

ДОЛГОВЕЧНОСТИ изделия ремонт, любое другое

обслуживание и регулировка должны проводиться в

уполномоченном центре по техобслуживанию Makita,

всегда используя сменные части Makita.

ПРИНАДЛЕЖНОСТИ

ПРЕДУПРЕЖДЕНИЕ:

• Эти принадлежности или приспособления

рекомендуются для использования с Вашим

инструментом Makita, указанном в руководстве.

Использование любых других принадлежностей

или приспособлений может вызвать риск

причинения травмы. Используйте принадлежности

или приспособления только для указанных целей.

Если Вам необходима какая-либо помощь

относительно дальнейших подробностей об этих

принадлежностях, обращайтесь в Ваш местный

центр по техобслуживанию Makita.

• Шлифовальные диски

• Боковой захват

ЕС ДЕКЛАРАЦИЯ СООТВЕТСТВИЯ

Мы заявляем под свою собственную

ответственность, что этот продукт находится в

соответствии со следующими стандартами

документов по стандартизации:

HD400, EN50144, EN55014, EN61000,

согласно сборникам директив 73/23EEC, 89/336/EEC

и 98/37/EC.

Ясухико Канзаки

Директор

CE 2003

ENH001-1

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

Шум и вибрация

ENG003-1

Типичный А-взвешенный уровень звукового

давления составляет 85 дБ (А).

Уровень шума при работе может превышать

85 дБ (А).

Типичное взвешенное значение квадратного корня

ускорения составляет не более чем 2,5 м/с