GB

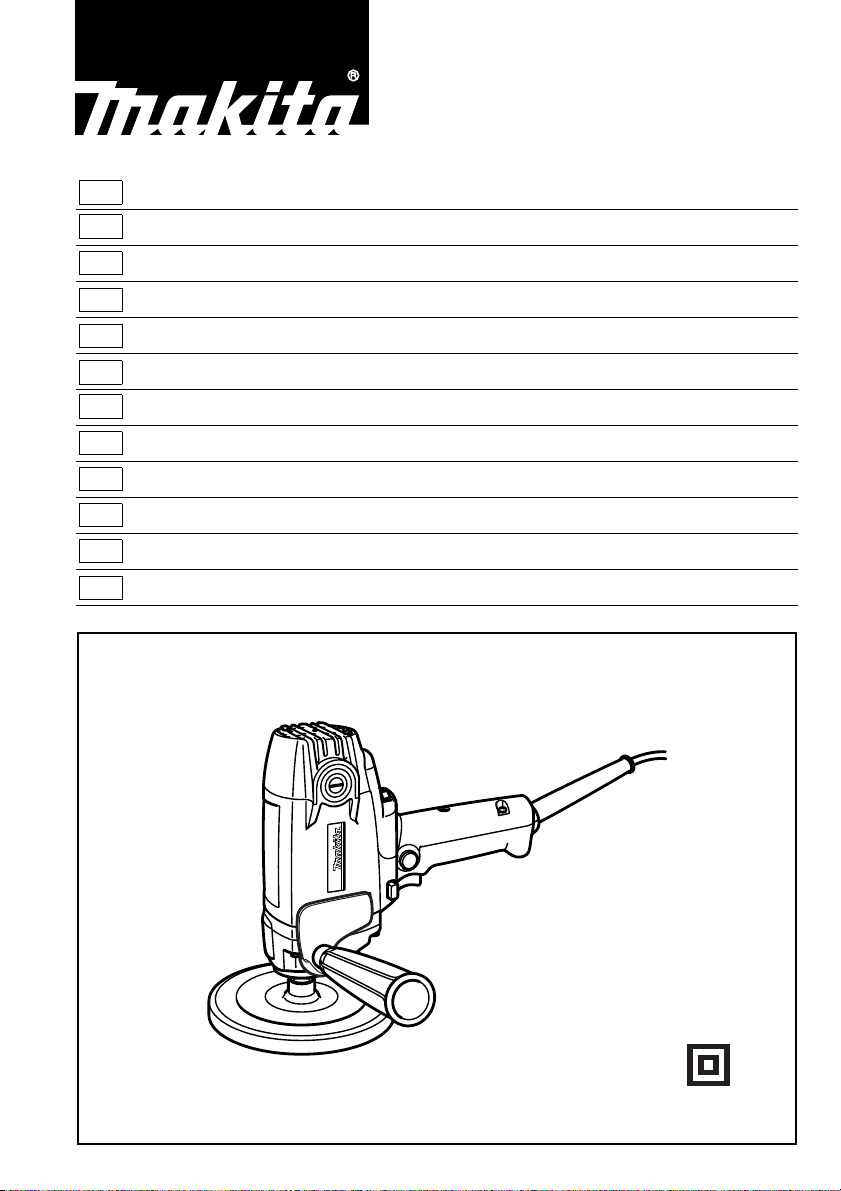

Electronic Polisher Instruction Manual

F

Polisseuse électronique Manuel d’instructions

D

Elektronik-polierer Betriebsanleitung

I

Lucidatrice elettronica Istruzioni per l’uso

NL

Elektronische polijstmachine Gebruiksaanwijzing

E

Pulidora Manual de instrucciones

P

Polidora electrónica Manual de instruções

DK

Elektronisk poleremaskine Brugsanvisning

S

Elektronisk poleringsmaskin Bruksanvisning

N

Elektronisk polermaskin Bruksanvisning

SF

Elektroninen hiomakone Käyttöohje

GR

Ηλεκτρονικς στιλβωτήε Οδηγίες χρήσεως

PV7000C

1

1

2

2

18

3

4

123

2

5

45

6

9

7

8

6

67

10

11

12

13

8

89

2

10 11

15°

12 13

13

15°

11

14

12

7

15°

8

14 15

15

16 17

16

17

3

Symbols

The following show the symbols used for the tool. Be sure that you understand their meaning before use.

Symboles

Nous donnons ci-dessous les symboles utilisés pour l’outil. Assurez-vous que vous en avez bien compris la signification avant d’utiliser l’outil.

Symbole

Die folgenden Symbole werden für die Maschine verwendet. Machen Sie sich vor der Benutzung unbedingt mit ihrer

Bedeutung vertraut.

Symboli

Per questo utensile vengono usati i simboli seguenti. Bisogna capire il loro significato prima di usare l’utensile.

Symbolen

Voor dit gereedschap worden de volgende symbolen gebruikt. Zorg ervoor dat u de betekenis van deze symbolen

begrijpt alvorens het gereedschap te gebruiken.

Símbolos

A continuación se muestran los símbolos utilizados con esta herramienta. Asegúrese de que entiende su significado

antes de usarla.

Símbolos

O seguinte mostra os símbolos utilizados para a ferramenta. Certifique-se de que compreende o seu significado antes

da utilização.

Symboler

Nedenstående symboler er anvendt i forbindelse med denne maskine. Vær sikker på, at De har forstået symbolernes

betydning, før maskinen anvendes.

Symboler

Det följande visar de symboler som används för den här maskinen. Se noga till att du förstår deras innebörd innan

maskinen används.

Symbolene

Følgende viser de symblene som brukes for maskinen. Det er viktig å forstå betydningen av disse før maskinen tas i

bruk.

Symbolit

Alla on esitetty koneessa käytetyt symbolit. Opettele näiden merkitys, ennen kuin käytät konetta.

Σύµβολα

Τα ακλουθα δείχνουν τα σύµβολα που χρησιµοποιούνται για το µηχάνηµα. Βεβαιωθείτε τι καταλαβαίνετε

τη σηµασία τους πριν απ τη χρήση.

❏ Read instruction manual.

❏ Lire le mode d’emploi.

❏ Bitte Betriebsanleitung lesen.

❏ Leggete il manuale di istruzioni.

❏ Lees de gebruiksaanwijzing.

❏ Lea el manual de instrucciones.

❏ DOUBLE INSULATION

❏ DOUBLE ISOLATION

❏ DOPPELT SCHUTZISOLIERT

❏ DOPPIO ISOLAMENTO

❏ DUBBELE ISOLATIE

❏ DOBLE AISLAMIENTO

❏ Wear safety glasses.

❏ Porter des lunettes de protection.

❏ Schutzbrille tragen.

❏ Indossare occhiali di protezione.

❏ Draag een veiligheidsbril.

❏ Póngase gafas de seguridad.

❏ Leia o manual de instruções.

❏ Læs brugsanvisningen.

❏ Läs bruksanvisningen.

❏ Les bruksanvisingen.

❏ Katso käyttöohjeita.

❏ ∆ιαβάστε τις οδηγίες χρήσης

❏ DUPLO ISOLAMENTO

❏ DOBBELT ISOLATION

❏ DUBBEL ISOLERING

❏ DOBBEL ISOLERING

❏ KAKSINKERTAINEN ERISTYS

❏ ∆ΙΠΛΗ ΜΟΝΩΣΗ

❏ Utilize óculos de segurança.

❏ Bær sikkerhedsbriller.

❏ Bär skyddsglasögon.

❏ Bruk vernebriller

❏ Käytä suojalaseja

❏ Φορέστε γυαλιά ασφαλείας.

4

ENGLISH

1Cover

2 Side grip

3 Switch trigger

4 Lock button

5 Speed adjusting dial

6Pad

Explanation of general view

7 Spindle

8Wrench

9 Sponge pad

10 Wool bonnet

11 Lock nut

12 Rubber pad

13 Lock nut wrench

14 Abrasive disc

15 Limit mark

16 Brush holder cap

17 Screwdriver

18 High-low speed setting button

SPECIFICATIONS

Model PV7000C

Max. capacities

Sponge pad / Wool bonnet .............................. 180 mm

Abrasive disc ................................................... 180 mm

No load speed (min

Overall length ..................................................... 210 mm

Net weight .............................................................. 2.0 kg

• Due to our continuing program of research and devel-

opment, the specifications herein are subject to change

without notice.

• Note: Specifications may differ from country to country.

Power supply

The tool should be connected only to a power supply of

the same voltage as indicated on the nameplate, and can

only be operated on single-phase AC supply. They are

double-insulated in accordance with European Standard

and can, therefore, also be used from sockets without

earth wire.

Safety hints

For your own safety, please refer to the enclosed safety

instructions.

–1

) ...................................600 – 2,000

ADDITIONAL SAFETY RULES

1. Always use eye and ear protection. Other per-

sonal protective equipment such as dust mask,

gloves, helmet and apron should be worn when

necessary. If in doubt, wear the protective equipment.

2. Always be sure that the tool is switched off and

unplugged before carrying out any work on the

tool.

3. Accessories must be rated for at least the speed

recommended on the tool warning label. Wheels

and other accessories running over rated speed

can fly apart and cause injury.

4. Check the backing pad carefully for cracks, dam-

age or deformity before operation. Replace

cracked, damaged or deformed pad immediately.

5. Check that the workpiece is properly supported.

6. Hold the tool firmly.

7. Keep hands away from rotating parts.

8. Make sure abrasive disc or wool bonnet is not

contacting the workpiece before the switch is

turned on.

9. When sanding metal surfaces, watch out for fly-

ing sparks. Hold the tool so that sparks fly away

from you and other persons or flammable materials.

ENB047-3

10. Do not leave the tool running. Operate the tool

only when hand-held.

11. Pay attention that the wheel continues to rotate

after the tool is switched off.

12. Do not touch the workpiece immediately after

operation; it may be extremely hot and could

burn your skin.

13. If working place is extremely hot and humid, or

badly polluted by conductive dust, use a shortcircuit breaker (30 mA) to assure operator safety.

14. Do not use the tool on any materials containing

asbestos.

15. Do not use water or grinding lubricant.

16. Ventilate your work area adequately when you

perform sanding operations.

17. Always use the correct dust mask/respirator for

the material and application you are working

with.

18. Ensure that ventilation openings are kept clear

when working in dusty conditions. If it should

become necessary to clear dust, first disconnect

the tool from the main supply (use non metallic

objects) and avoid damaging internal parts.

SAVE THESE INSTRUCTIONS.

OPERATING INSTRUCTIONS

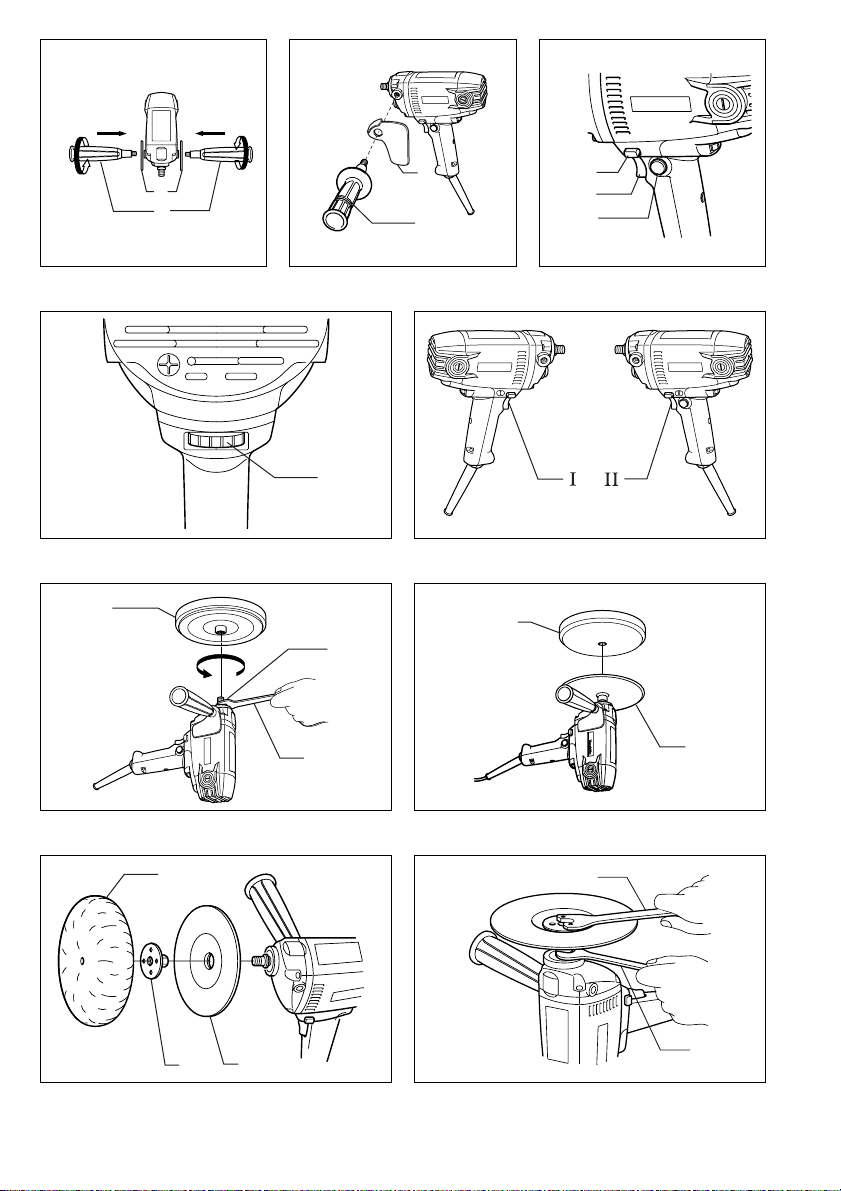

Installing side grip (auxiliary handle) & cover

(Fig. 1 & 2)

CAUTION:

Always be sure that the tool is switched off and

unplugged before installing or removing the side grip.

Install the cover, then screw the side grip on the tool

securely. The side grip and the cover can be installed on

either side of the tool. Always be sure that they are

installed securely.

Switch action (Fig. 3)

CAUTION:

Before plugging in the tool, always check to see that the

switch trigger actuates properly and returns to the “OFF”

position when released.

To start the tool, simply pull the trigger. Release the trigger to stop. For continuous operation, pull the trigger and

then push in the lock button.

To stop the tool from the locked position, pull the trigger

fully, then release it.

5

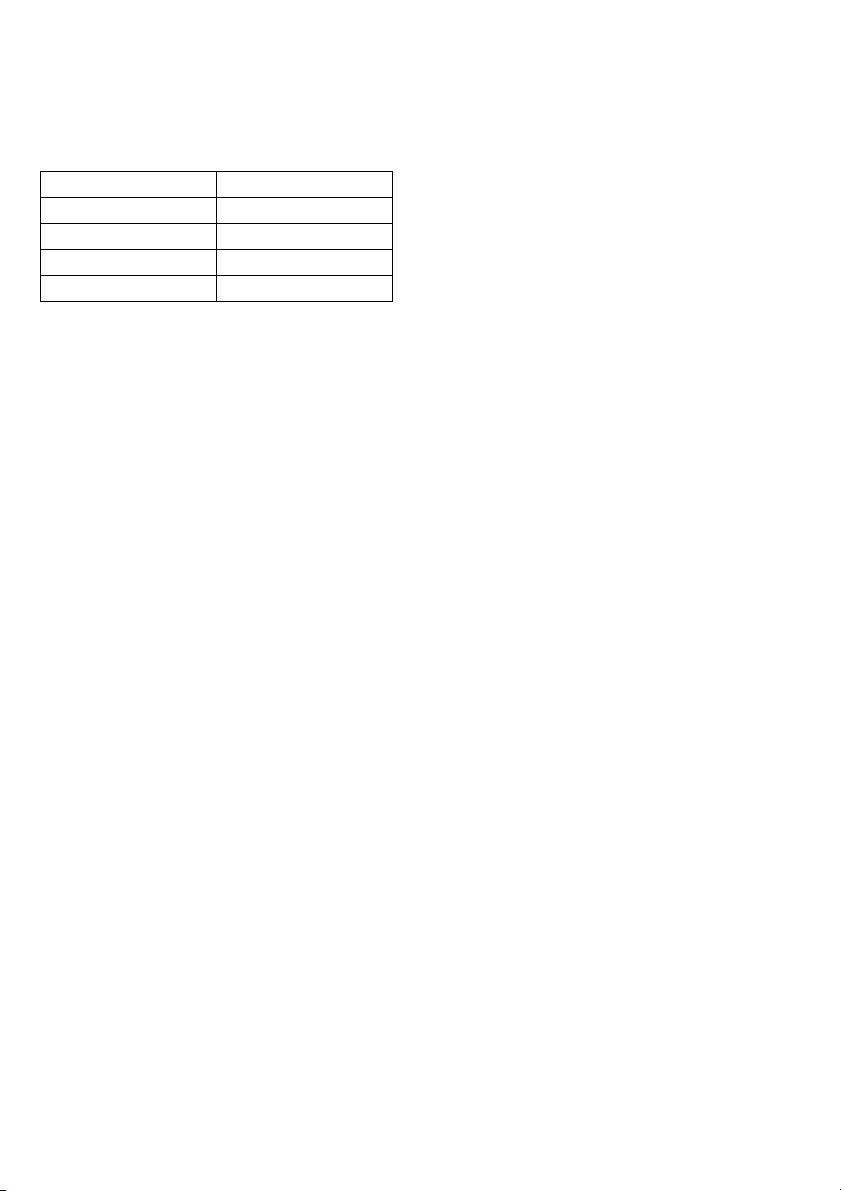

Speed adjusting dial (Fig. 4)

The rotating speed can be changed by turning the speed

adjusting dial to a given number setting from 1 to 5.

Higher speed is obtained when the dial is turned in the

direction of number 5. And lower speed is obtained when

it is turned in the direction of number 1. Refer to the table

below for the relationship between the number settings

on the dial and the approximate rotating speed.

-1

Number min

1–2 600–800

2–3 800–1,300

3–4 1,300–1,800

4–5 1,800–2,000

CAUTION:

• If the tool is operated continuously at low speeds

(speed adjusting dial: 1 – 3), the motor will get overloaded and heated up.

• The speed adjusting dial can be turned only as far as 5

and back to 1. Do not force it past 5 or 1, or the speed

adjusting function may no longer work.

The tools equipped with electronic function are easy to

operate because of the following features.

• Constant speed control Electronic speed control for

obtaining constant speed. Possible to get fine finish,

because the rotating speed is kept constant even under

load condition.

• Soft start feature Safety and soft start because of suppressed starting shock.

High-Low speed setting button (Fig. 3 & 5)

The tool speed can be changed instantly while the tool is

running. Depress the “ I” position for lowest speed and

depress “ II” position for a given number setting. The tool

speed cannot be changed when the button is in “ I ” position, even if you turn the speed adjusting dial. When you

turn the speed adjusting dial, always be sure that the button is depressed in “ II ” position.

(R.P.M.)

FOR USE AS A POLISHER

Installing or removing pad (Fig. 6)

CAUTION:

Always be sure that the tool is switched off and

unplugged before installing or removing the pad.

Hold the spindle with the wrench so that it cannot revolve.

Then screw the pad onto the spindle all the way. (The

pad can be used to install the optional sponge pad.)

To remove the pad, follow the installation procedure in

reverse.

Installing or removing sponge pad (Fig. 7)

CAUTION:

Always be sure that the tool is switched off and

unplugged before installing or removing the sponge pad.

To install the sponge pad, first remove all dirt or foreign

matter from the pad. Install the sponge pad to the pad.

To remove the pad, pull off it from the pad slowly.

Installing or removing the wool bonnet

(Fig. 8, 9 & 10)

CAUTION:

Always be sure that the tool is switched off and

unplugged before installing or removing the wool bonnet.

Mount the rubber pad onto the spindle. Screw the lock

nut onto the spindle. Hold the spindle firmly with the

wrench and tighten the lock nut using the lock nut

wrench. Fit the wool bonnet over the rubber pad. Tie a

bow knot and tuck the knot and any loose strings

between the wool bonnet and the rubber pad.

To remove the wool bonnet, follow the installation procedure in reverse.

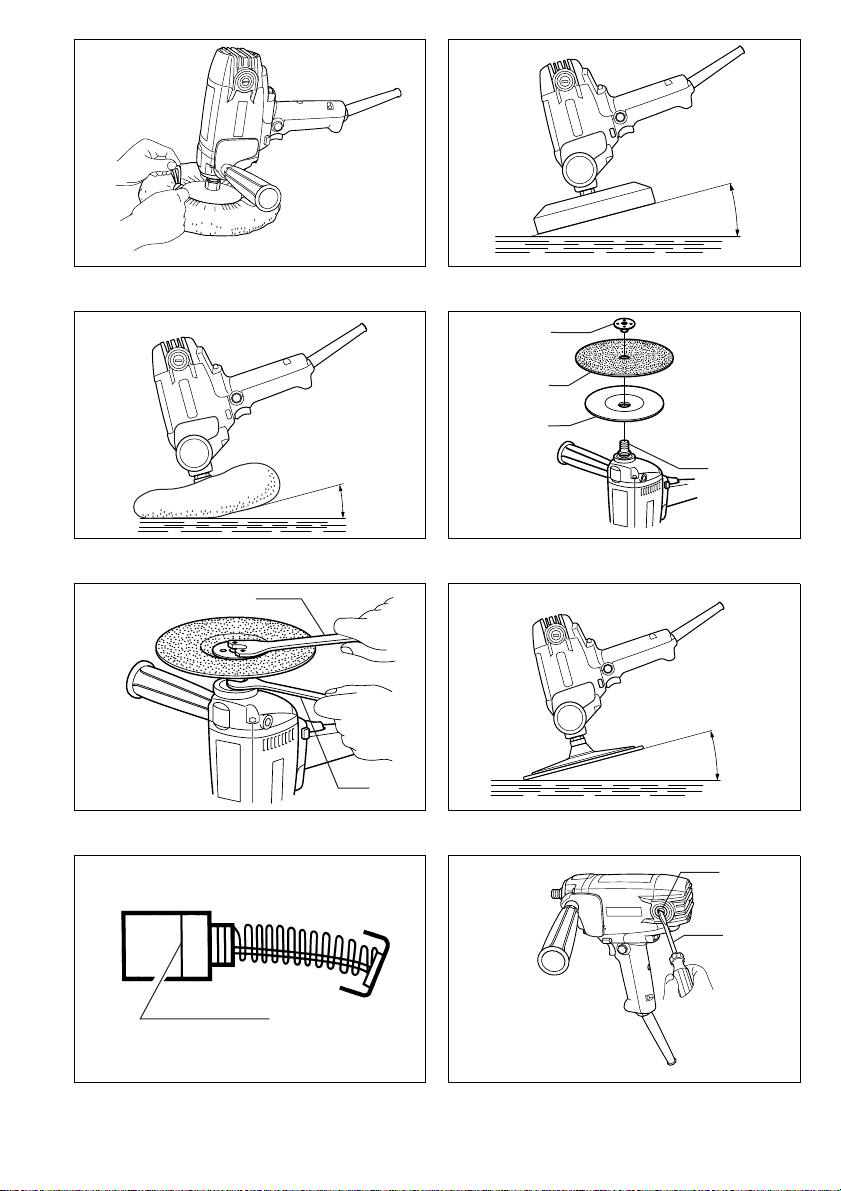

Polishing operation by sponge pad/wool

bonnet (Fig. 11 & 12)

CAUTION:

• Always wear safety glasses or a face shield during

operation.

• Apply slight pressure only. Excessive pressure will

result in poor performance and premature wear to the

sponge pad/wool bonnet.

When polishing, keep the sponge pad/wool bonnet at an

angle of about 15° to the workpiece surface.

FOR USE AS A SANDER

Installing or removing abrasive disc

(Fig. 13 & 14)

CAUTION:

Always be sure that the tool is switched off and

unplugged before installing or removing the abrasive

disc.

Mount the rubber pad onto the spindle. Fit the abrasive

disc on over the rubber pad and screw the lock nut onto

the spindle. Hold the spindle firmly with the wrench and

tighten the lock nut using the lock nut wrench.

To remove the abrasive disc, follow the installation procedure in reverse.

NOTE:

The rubber pad, abrasive disc, lock nut and lock nut

wrench are optional accessories.

Sanding operation (Fig. 15)

CAUTION:

• Always wear safety glasses or a face shield during

operation.

• Apply slight pressure only. Excessive pressure will

result in poor performance and premature wear to the

abrasive disc.

• Never run the tool without the abrasive disc. You may

seriously damage the pad.

Keep the abrasive disc at an angle of about 15° to the

workpiece surface.

6

MAINTENANCE

CAUTION:

Always be sure that the tool is switched off and

unplugged before carrying out any work on the tool.

Replacement of carbon brushes

(Fig. 16 & 17)

Replace carbon brushes when they are worn down to the

limit mark. Both identical carbon brushes should be

replaced at the same time.

To maintain product safety and reliability, repairs, maintenance or adjustment should be carried out by a Makita

Authorized Service Center.

7

NEDERLANDS

1Deksel

2 Zijhandgreep

3 Trekschakelaar

4 Vastzetknop

5 Snelheidsregelknop

6 Steunschijf

7As

Verklaring van algemene gegevens

8 Steeksleutel

9 Schuimrubberschijf

10 Wollen kap

11 Sluitmoer

12 Rubberen steunschijf

13 Nokkensleutel

14 Schuurschijf

15 Limietmarkering

16 Koolborsteldop

17 Schroevedraaier

18 Instelknop voor

hoog/laag toerental

TECHNISCHE GEGEVENS

Model PV7000C

Max. capaciteit

Schuimrubberschijf/Wollen kap ....................... 180 mm

Schuurschijf ..................................................... 180mm

Onbelast toerental (min

Totale lengte ....................................................... 210 mm

Netto gewicht ..........................................................2,0 kg

• In verband met ononderbroken research en ontwikke-

ling behouden wij ons het recht voor bovenstaande

technische gegevens te wijzigen zonder voorafgaande

kennisgeving.

• Opmerking: De technische gegevens kunnen van land

tot land verschillen.

Stroomvoorziening

De machine mag alleen worden aangesloten op een

stroombron van hetzelfde voltage als aangegeven op de

naamplaat, en kan alleen op enkel-fase wisselstroom

worden gebruikt. De machine is dubbel-geïsoleerd volgens de Europese standaard en kan derhalve ook op

een niet-geaard stopkontakt worden aangesloten.

Veiligheidswenken

Voor uw veiligheid dient u de bijgevoegde Veiligheidsvoorschriften nauwkeurig op te volgen.

-1

) ............................. 600–2000

AANVULLENDE

VEILIGHEIDSVOORSCHRIFTEN

1. Draag tijdens het gebruik van het gereedschap

altijd oog- en oorbeschermers. Draag indien

nodig ook andere persoonlijke veiligheidsuitrusting zoals een stofmasker, handschoenen, een

helm en een voorschoot. Draag voor alle zekerheid de veiligheidsuitrusting in geval van twijfel.

2. Zorg er altijd voor dat de machine is uitgescha-

keld en de stekker uit het stopcontact is getrokken alvorens enig onderhoud aan de machine uit

te voeren.

3. Accessoires moeten geschikt zijn voor minstens

het aanbevolen toerental dat op het waarschuwingslabel van de machine is aangeduid. Wielen

en andere accessoires die draaien met een snelheid boven het nominale toerental kunnen van

de machine worden weggeslingerd en verwonding veroorzaken.

4. Controleer de steunschijf zorgvuldig op scheu-

ren, beschadiging of vervorming alvorens de

machine te gebruiken. Vervang een gescheurde,

beschadigde of vervormde schijf onmiddellijk.

5. Controleer of het werkstuk stevig ondersteund

is.

6. Houd de machine stevig vast.

7. Houd uw handen uit de buurt van roterende

onderdelen.

8. Zorg ervoor dat de schuurschijf of de wollen

polijstschijf het werkstuk niet raakt voordat de

schakelaar wordt ingedrukt.

9. Kijk uit voor rondvliegende vonken wanneer u

metalen oppervlakken schuurt. Houd de

machine zo vast dat de vonken wegvliegen van

uzelf en andere personen of van ontvlambare

materialen.

10. Laat de machine niet alleen terwijl deze is ingeschakeld. Laat de machine alleen draaien wanneer u deze vasthoudt.

11. Denk eraan dat de schijf blijft draaien nadat het

gereedschap is uitgeschakeld.

12. Raak het bewerkte oppervlak niet direct na het

schuren (polijsten) aan, aangezien dit zeer heet

kan zijn en brandwonden kan veroorzaken.

13. Indien de werkplaats uiterst heet en vochtig is, of

erg vervuild is door geleidend stof, gebruik dan

een kortsluitschakelaar (30 mA) om een veilige

bediening te verzekeren.

14. Gebruik de machine niet op materialen die

asbest bevatten.

15. Gebruik geen water of slijpolie.

16. Ventileer goed uw werkplaats wanneer u het

gereedschap gebruikt om te schuren.

17. Gebruik altijd het juiste stofmasker/gasmasker

dat nodig is voor het materiaal en de toepassing

waarmee u werkt.

18. Zorg dat de ventilatieopeningen niet geblokkeerd zijn wanneer u in stoffige omgevingen

werkt. Indien stof verwijderd moet worden, trek

dan eerst de stekker uit het stopcontact (gebruik

niet-metalen voorwerpen) en let op dat u geen

interne onderdelen van het gereedschap beschadigt.

BEWAAR DEZE VOORSCHRIFTEN.

BEDIENINGSVOORSCHRIFTEN

Installeren van de zijhandgreep (hulphandgreep) en

het deksel (Fig.1 en 2)

LET OP:

Schakel het gereedschap altijd uit en haal zijn netsnoer

uit het stopcontact alvorens de zijhandgreep te installeren of te verwijderen.

Installeer het deksel en schroef vervolgens de zijhandgreep stevig vast op het gereedschap. De zijhandgreep

en het deksel kunnen aan een van beide zijden van het

gereedschap worden bevestigd. Zorg ervoor dat ze stevig bevestigd worden.

17

Werking van de trekschakelaar (Fig. 3)

LET OP:

Alvorens de machine op netstroom aan te sluiten, dient u

altijd te controleren of de trekschakelaar juist werkt en bij

het loslaten naar de “OFF” positie terugkeert.

Om de machine in te schakelen, drukt u gewoon de trekschakelaar in. Om te stoppen dient u de trekschakelaar

los te laten. Voor continu gebruik, eerst de trekschakelaar en dan de vergrendelknop indrukken.

Om de machine vanuit de vergrendelde stand te stoppen, de trekschakelaar helemaal indrukken en deze dan

loslaten.

Toerentalregelknop (Fig. 4)

U kunt de draaisnelheid veranderen door de toerentalregelknop te draaien en in te stellen op een cijfer van

1 tot 5.

De snelheid verhoogt wanneer u de draaiknop in de richting van het cijfer 5 draait. De snelheid verlaagt wanneer

u deze in de richting van het cijfer 1 draait. Zie de onderstaande tabel voor de verhouding tussen de cijfers op de

draaiknop en de approximatieve draaisnelheid.

-1

Cijfer min

1–2 600–800

2–3 800–1300

3–4 1300–1800

4–5 1800–2000

LET OP:

• Wanneer u het gereedschap (toerentalregelknop: 1 – 3)

achtereen bij een lage snelheid gebruikt, kan de motor

overbelast en oververhit worden.

• De toerentalregelknop kan niet verder dan 5 en niet

verder terug dan 1 worden gedraaid. Forceer de draaiknop niet voorbij 5 of 1, aangezien de toerentalregeling

dan niet meer juist zal werken.

Gereedschappen die voorzien zijn van een elektronische

functie zijn gemakkelijk te bedienen dank zij de volgende

kenmerken.

• Handhaving van een constant toerental Elektronische

toerentalregeling verzekert een constant toerental. U

kunt fijn afwerken, aangezien de draaisnelheid tijdens

belast draaien constant gelijk wordt gehouden.

• Zachte start De aanloopschok wordt onderdrukt zodat

u veilig kunt werken en zacht kunt starten.

Instelknop voor hoog/laag toerental (Fig. 3 en 5)

Het toerental van het gereedschap kan onmiddellijk worden veranderd terwijl het gereedschap draait. Druk de “ I ”

zijde in om het laagste toerental te krijgen, en druk de

“ II ” zijde in om een van de genummerde snelheden te

kiezen. Wanneer de “ I” zijde van de knop is ingedrukt,

kan het toerental niet worden veranderd, zelfs niet wanneer u de toerentalregelknop draait. Als u het toerental

met de toerentalregelknop wilt veranderen, moet u eerst

de “ II” zijde van de knop indrukken.

(RPM)

GEBRUIK ALS EEN POLIJSTMACHINE

Installeren of verwijderen van de steunschijf (Fig. 6)

LET OP:

Schakel het gereedschap altijd uit en haal het netsnoer

uit het stopcontact alvorens de steunschijf te installeren

of te verwijderen.

Houd de as met een sleutel op zijn plaats zodat deze niet

kan draaien. Schroef daarna de steunschijf vast op de

as. (De steunschijf kan worden gebruikt om de los verkrijgbare schuimrubberschijf te installeren.)

Voer de installatieprocedure in de omgekeerde volgorde

uit om de steunschijf te verwijderen.

Installeren of verwijderen van de

schuimrubberschijf (Fig.7)

LET OP:

Schakel het gereedschap altijd uit en haal het netsnoer

uit het stopcontact alvorens de schuimrubberschijf te

installeren of te verwijderen.

Verwijder alle vuil of verontreinigingen van de steunschijf

alvorens de schuimrubberschijf te installeren. Installeer

daarna de schuimrubberschijf op de steunschijf.

Om de schuimrubberschijf te verwijderen, trekt u deze

langzaam van de steunschijf af.

Installeren of verwijderen van de wollen kap

(Fig.8,9en10)

LET OP:

Schakel het gereedschap altijd uit en haal het netsnoer

uit het stopcontact alvorens de wollen kap te installeren

of te verwijderen.

Monteer de rubberen steunschijf op de as. Schroef de

borgmoer op de as. Houd de as goed op zijn plaats met

de sleutel en draai de borgmoer vast met de borgmoersleutel. Monteer de wollen kap over de rubberen steunschijf. Maak een strikknoop en stop de knoop en

eventuele losse touwtjes weg tussen de wollen kap en de

rubberen steunschijf.

Voer de installatieprocedure in de omgekeerde volgorde

uit om de wollen kap te verwijderen.

Polijsten met de schuimrubberschijf/wollen kap

(Fig. 11 en 12)

LET OP:

• Draag tijdens het werk altijd een veiligheidsbril of een

gezichtsbescherming.

• Oefen alleen lichte dr uk uit. Overmatige druk zal

slechte prestaties en vroegtijdige slijtage van de

schuimrubberschijf/wollen kap veroorzaken.

Houd de schuimrubberschijf/wollen kap tijdens het polijsten onder een hoek van ongeveer 15° vanaf het werkstukoppervlak.

18

GEBRUIK ALS EEN SCHUURMACHINE

Installeren of verwijderen van de schuurschijf

(Fig. 13en 14)

LET OP:

Schakel het gereedschap altijd uit en haal het netsnoer

uit het stopcontact alvorens de schuurschijf te installeren

of te verwijderen.

Monteer de rubberen steunschijf op de as. Monteer de

schuurschijf over de rubberen steunschijf en schroef de

borgmoer op de as. Houd de as goed op zijn plaats met

de sleutel en draai de borgmoer vast met de borgmoersleutel.

Voer de installatieprocedure in de omgekeerde volgorde

uit om de schuurschijf te verwijderen.

OPMERKING:

De rubberen steunschijf, de schuurschijf, de borgmoer en

de borgmoersleutel zijn los verkrijgbare accessoires.

Schuren (Fig.15)

LET OP:

• Draag tijdens het werk altijd een veiligheidsbril of een

gezichtsbescherming.

• Oefen alleen lichte druk uit. Overmatige druk zal

slechte prestaties en vroegtijdige slijtage van de

schuurschijf veroorzaken.

• Schuur nooit met het gereedschap zonder de schuurschijf. Als u dit doet, kan de steunschijf ernstig beschadigd raken.

Houd de schuurschijf tijdens het schuren onder een hoek

van ongeveer 15° vanaf het werkstukoppervlak.

ONDERHOUD

LET OP:

Zorg er altijd voor dat de machine is uitgeschakeld en de

stekker uit het stopcontact is verwijderd alvorens onderhoud aan de machine uit te voeren.

Vervangen van koolborstels (Fig. 16en 17)

Vervang de borstels wanneer ze tot aan de aangegeven

limiet zijn afgesleten. Beide koolborstels dienen tegelijkertijd te worden vervangen.

Opdat het gereedschap veilig en betrouwbaar blijft, dienen alle reparaties, onderhoud of afstellingen te worden

uitgevoerd bij een erkend Makita service centrum.

19

GB ACCESSORIES

CAUTION:

These accessories or attachments are recommended for

use with your Makita tool specified in this manual. The

use of any other accessories or attachments might

present a risk of injury to persons. The accessories or

attachments should be used only in the proper and

intended manner.

F ACCESSOIRES

AT T E N TI O N :

Ces accessoires ou ces fixations sont recommandés

pour l’utilisation de l’outil Makita spécifié dans ce manuel.

L’utilisation d’autres accessoires ou fixations peut

présenter un risque de blessures. Les accessoires ou les

fixations ne devront être utilisés que dans le but et de la

manière prévus.

P ACESSÓRIOS

PRECAUÇÃO:

Estes acessórios ou acoplamentos são os

recomendados para uso na ferramenta MAKITA

especifidada neste manual. A utilização de qualquer

outro acessórios ou acoplamento poderá ser perigosa

para o operador. Os acessórios ou acoplamentos devem

ser utilizados de maneira adequada e apenas para os

fins a que se diestinam.

DK TILBEHØR

ADVARSEL:

Dette udstyr og tilbehør bør anvendes sammen med

Deres Makita maskine, sådan som det er beskrevet i

denne vejledning. Anvendelse af andet udstyr eller

tilbehør kan medføre personskade. Tilbehøret bør kun

anvendes til det, det er beregnet til.

D ZUBEHÖR

VORSICHT:

Das mitgelieferte Zubehör ist speziell für den Gebrauch

mit dem in dieser Betriebsanleitung angegebenen

Makita-Elektrowerkzeug vorgesehen. Bei Verwendung

von Fremdzubehör in Verbindung mit dieser Maschine

besteht Verletzungsgefahr.

I ACCESSORI

ATTENZIONE:

Gli accessori o raccordi seguenti sono raccomandati per

l’uso con l’utensile Makita specificato in questo manuale.

L’uso di qualsiasi altro accessorio o raccordo potrebbe

causare pericoli di ferite alle persone. Gli accessori o

raccordi devono essere usati soltanto nel modo corretto

e specificato.

NL ACCESSOIRES

LET OP:

Deze accessoires of hulpstukken zijn aanbevolen voor

gebruik met uw Makita gereedschap dat in deze

gebruiksaanwijzing is beschreven. Het gebruik van

andere accessoires of hulpstukken kan gevaar voor

persoonlijke verwondingen opleveren. De accessoires of

hulpstukken dienen alleen op de juiste en

voorgeschreven manier te worden gebruikt.

E ACCESORIOS

PRECAUCIÓN:

Estos accesorios o acoplamientos están recomendados

para usar con la herramienta Makita especificada en

este manual. Con el uso de cualquier otro accesorio o

acoplamiento se podría correr el riesgo de producir

heridas a personas. Los accesorios o acoplamientos

deberán usarse solamente de la manera apropiada y

para la que han sido designados.

S TILLBEHÖR

FÖRSIKTIGHET:

Dessa tillbehör eller tillsatser rekommenderas endast för

användning tillsammans med din Makita maskin som

specifieras i denna bruksanvisning. Användning av andra

tillbehör eller tillsatser kan medföra risk för personskador.

Tillbehören och tillsatserna får endast användas på

lämpligt och där för avsett sätt.

N TILBEHØR

NB!

Dette tilbehøret eller utstyret anbefales til å brukes

sammen med din Makita maskin som er spesifisert i

denne bruksanvisningen. Bruk av annet tilbehør eller

utstyr kan medføre en risiko for personskader. Tilbehør

og utstyr må bare brukes som spesifisert og bare til det

det er beregnet til.

SF LISÄVARUSTEET

VA RO :

Tässä käyttöohjeessa mainitun Makita-koneen kanssa

suositellaan seuraavien lisälaitteiden ja -varusteiden

käyttöä. Minkä tahansa muun lisälaitteen tai -varusteen

käyttäminen saattaa aiheuttaa loukkaantumisvaaran.

Lisälaitteita ja -varusteita tulee käyttää ainoastaan niille

sopivalla tavalla.

GR ΕΞΑΡΤΗΜΑΤΑ

ΠΡΟΣΟΧΗ:

Αυτά τα εξαρτήµατα ή προσαρτήµατα συνιστώνται

για χρήση µε το µηχάνηµα της Μάκιτα που

περιγράφεται στο εγχειρίδιο αυτο. Η χρήση άλλων

εξαρτηµάτων ή προσαρτηµάτων µπορεί να είναι

επικίνδυνη για τραυµατισµ% ατ%µων. Τα εξαρτήµατα

ή προσαρτήµατα πρέπει να χρησιµοποιούνται µ%νο

µε το σωστ% και προτιθέµενο τρ%πο.

39

• Rubber pad

• Plateau caoutchouc

• Elastischer Schleifteller

• Platorello di gomma

• Rubberen steunschijf

• Almohadilla de goma

• Disco de borracha

• Gummibagskive

• Gummiplatta

• Gummipute

• Kumilevy

• Ελαστικ% υπ%θεµα

• Sponge pad

• Coussinet-éponge

• Schaumstoffkissen

• Tampone di spugna

• Schuimrubberschijf

• Boina de esponja

• Almofada esponjosa

• Svampepude

• Svampdyna

• Skumgmmipute

• Vaahtokumityyny

• Σπογγοειδές πέλµα

• Wool bonnet

• Peau de mouton

• Polierhaube

• Cuffia di lana

• Wollen kap

• Caperuza de lana

• Baina de lã

• Polerhætte

• Lammullshättan

• Ullhette

• Villakansi

• Μάλλινο κάλυµµα

• Abrasive disc

• Disque abrasif

• Fiberscheibe

• Disco abrasivo

• Schuurschijf

• Disco abrasivo

• Disco abrasivo

• Slibeskive

• Sliprondell

• Slipeskive

• Hiomalaikka

• Λειαντικ%ς δίσκος

• Lock nut

•Écrou

• Flanschmutter

• Flangia esterna

•Sluitmoer

• Tuerca de fijación

• Contraporca

• Sikringsmøtrik

• Låsmutter

• Låsemutter

• Lukkomutteri

• Κοχλίας κλειδώµατος

Grid: 16, 20, 24, 30, 50, 80, 100, 120

40

• Lock nut wrench

• Clé à ergots

• Stirnlochschlüssel

• Chiave per controdadi

• Nokkensleutel

• Llave para la tuerca de fijación

• Chave de pinos

• Tapnøgle

• Låsmutternyckel

• Skrunøkkel til låsemutter

• Lukkomutterin avain

• Κλειδί κοχλία κλειδώµατος

•Wrench

• Clés

• Gabelschlüssel

•Chiave

•Sleutel

•Llave

•Chave

•Nøgle

• Skruvnyckel

• Skrunøkkel

• Kiintoavain

•Κλειδί

41

ENGLISH

EC-DECLARATION OF CONFORMITY

The undersigned, Yasuhiko Kanzaki, authorized by

Makita Corporation, 3-11-8 Sumiyoshi-Cho, Anjo, Aichi

446-8502 Japan declares that this product

manufactured by Makita Corporation in Japan is in compliance with the following standards or standardized documents,

in accordance with Council Directives, 73/23/EEC,

89/336/EEC and 98/37/EC.

(Serial No. : series production)

HD400, EN50144, EN55014, EN61000

FRANÇAISE

DÉCLARATION DE CONFORMITÉ CE

Je soussigné, Yasuhiko Kanzaki, mandaté par Makita Corporation, 3-11-8 Sumiyoshi-Cho, Anjo, Aichi 446-8502

Japan, déclare que ce produit

fabriqué par Makita Corporation au Japon, est conformes

aux normes ou aux documents normalisés suivants,

HD400, EN50144, EN55014, EN61000

conformément aux Directives du Conseil, 73/23/CEE,

89/336/CEE et 98/37/EG.

(No. de série: production en série)

DEUTSCH

Hiermit erklärt der Unterzeichnete, Yasuhiko Kanzaki,

Bevollmächtigter von Makita Corporation, 3-11-8

Sumiyoshi-Cho, Anjo, Aichi 446-8502 Japan, daß dieses

von der Firma Makita Corporation in Japan hergestellte

Produkt

gemäß den Ratsdirektiven 73/23/EWG, 89/336/EWG

und 98/37/EG mit den folgenden Normen bzw. Normendokumenten übereinstimmen:

CE-KONFORMITÄTSERKLÄRUNG

(Serien-Nr.: Serienproduktion)

HD400, EN50144, EN55014, EN61000.

ITALIANO

DICHIARAZIONE DI CONFORMITÀ

CON LE NORME DELLA COMUNITÀ EUROPEA

Il sottoscritto Yasuhiko Kanzaki, con l’autorizzazione

della Makita Corporation, 3-11-8 Sumiyoshi-Cho, Anjo,

Aichi 446-8502 Japan, dichiara che questo prodotto

(Numero di serie: Produzione in serie)

fabbricato dalla Makita Corporation in Giappone è conformi alle direttive europee riportate di seguito:

HD400, EN50144, EN55014, EN61000

secondo le direttive del Consiglio 73/23/CEE,

89/336/CEE e 98/37/CE.

NEDERLANDS

EG-VERKLARING VAN CONFORMITEIT

De ondergetekende, Yasuhiko Kanzaki, gevolmachtigd

door Makita Corporation, 3-11-8 Sumiyoshi-Cho, Anjo,

Aichi 446-8502 Japan verklaart dat dit produkt

vervaardigd door Makita Corporation in Japan voldoet

aan de volgende normen of genormaliseerde documenten,

in overeenstemming met de richtlijnen van de Raad

73/23/EEC, 89/336/EEC en 98/37/EC.

(Serienr. : serieproduktie)

HD400, EN50144, EN55014, EN61000

ESPAÑOL

DECLARACIÓN DE CONFORMIDAD DE LA CE

El abajo firmante, Yasuhiko Kanzaki, autorizado por

Makita Corporation, 3-11-8 Sumiyoshi-Cho, Anjo, Aichi

446-8502 Japan, declara que este producto

(Número de serie: producción en serie)

fabricado por Makita Cor poration en Japón cumple las

siguientes normas o documentos normalizados,

HD400, EN50144, EN55014, EN61000

de acuerdo con las directivas comunitarias, 73/23/EEC,

89/336/EEC y 98/37/CE.

42

Yasuhiko Kanzaki

Director Amministratore

Directeur Directeur

Direktor Director

CE 2000

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

PORTUGUÊS

DECLARAÇÃO DE CONFORMIDADE DA CE

O abaixo assinado, Yasuhiko Kanzaki, autorizado pela

Makita Corporation, 3-11-8 Sumiyoshi-Cho, Anjo, Aichi

446-8502 Japan, declara que este produto

(N. de série: produção em série)

fabricado pela Makita Corporation no Japão obedece às

seguintes normas ou documentos normalizados,

HD400, EN50144, EN55014, EN61000

de acordo com as directivas 73/23/CEE, 89/336/CEE e

98/37/CE do Conselho.

DANSK

EU-DEKLARATION OM KONFORMITET

Undertegnede, Yasuhiko Kanzaki, med fuldmagt fra

Makita Corporation, 3-11-8 Sumiyoshi-Cho, Anjo, Aichi

446-8502 Japan, erklærer hermed, at dette produkt

(Løbenummer: serieproduktion)

fremstillet af Makita Corporation i Japan, er i overensstemmelse med de følgende standarder eller normsættende dokumenter,

HD400, EN50144, EN55014, EN61000

i overensstemmelse med Rådets Direktiver 73/23/EEC,

89/336/EEC og 98/37/EC.

SVENSKA

EG-DEKLARATION OM ÖVERENSSTÄMMELSE

Undertecknad, Yasuhiko Kanzaki, auktoriserad av Makita

Corporation, 3-11-8 Sumiyoshi-Cho, Anjo, Aichi 446-8502

Japan deklarerar att denna produkt

tillverkad av Makita Corporation i Japan, uppfyller kraven

i följande standard eller standardiserade dokument,

HD400, EN50144, EN55014, EN61000

i enlighet med EG-direktiven 73/23/EEC, 89/336/EEC

och 98/37/EC.

(serienummer: serieproduktion)

NORSK

Undertegnede, Yasuhiko Kanzaki, med fullmakt fra

Makita Corporation, 3-11-8 Sumiyoshi-Cho, Anjo, Aichi

446-8502 Japan bekrefter herved at dette produktet

fabrikert av Makita Corporation, Japan, er i overensstemmelse med følgende standarder eller standardiserte

dokumenter:

i samsvar med Råds-direktivene, 73/23/EEC,

89/336/EEC og 98/37/EC.

EUs SAMSVARS-ERKLÆRING

(Serienr. : serieproduksjon)

HD400, EN50144, EN55014, EN61000,

SUOMI

VAKUUTUS EC-VASTAAVUUDESTA

Makita Corporation, 3-11-8 Sumiyoshi-Cho, Anjo, Aichi

446-8502 Japan valtuuttamana allekirjoittanut, Yasuhiko

Kanzaki, vakuuttaa että tämä tämä tuote

valmistanut Makita Corporation Japanissa vastaa seu-

(Sarja nro : sarjan tuotantoa)

raavia standardeja tai stardardoituja asiakirjoja

HD400, EN50144, EN55014, EN61000

neuvoston direktiivien 73/23/EEC, 89/336/EEC ja

98/37/EC mukaisesti.

ΕΛΛΗΝΙΚΑ

Ο υπογράφων, Yasuhiko Kanzaki, εξουσιοδοτηµένος

απ% την εταιρεία Makita Corporation, 3-11-8

Sumiyoshi-Cho, Anjo, Aichi 446-8502 Japan, δηλώνει

%τι αυτ% το προϊ%ν

κατασκευασµένο απ% την Εταιρεία Makita στην

Ιαπωνία, βρίσκεται σε συµφωνία µε τα ακ%λουθα

πρ%τυπα ή τυποποιηµένα έγγραφα,

σύµφωνα µε τις Οδηγίες του Συµβουλίου,

73/23/EEC, 89/336/EEC και 98/37/ΚE.

∆ΗΛΩΣΗ ΣΥΜΜΟΡΦΩΣΗΣ ΕΚ

(Αύξων Αρ.: παραγωγή σειράς)

HD400, EN50144, EN55014, EN61000

Yasuhiko Kanzaki

Director Direktor

DirektørJohtaja

CE 2000

Direktör ∆ιευθυντής

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

43

ENGLISH

The typical A-weighted sound pressure level is 82 dB (A).

The noise level under working may exceed 85 dB (A).

The typical weighted root mean square acceleration value is

not more than 2.5 m/s

Noise and Vibration

– Wear ear protection. –

2

.

PORTUGUÊS

O nível normal de pressão sonora A é 82 dB (A).

O nível de ruído durante o trabalho pode exceder 85 dB (A).

O valor médio da aceleração é inferior a 2,5 m/s

Ruído e vibração

– Utilize protectores para os ouvidos –

2

.

FRANÇAISE

Le niveau de pression sonore pondéré A type est de 82 dB (A).

Le niveau de bruit en fonctionnement peut dépasser 85 dB (A).

L’accélération pondérée ne dépasse pas 2,5 m/s

Bruit et vibrations

– Porter des protecteurs anti-bruit. –

2

.

DEUTSCH

Geräusch- und Vibrationsentwicklung

Der typische A-bewertete Schalldruckpegel beträgt 82 dB (A).

Der Lärmpegel kann während des Betriebs 85 dB (A) überschreiten.

Der gewichtete Effektivwert der Beschleunigung beträgt nicht

mehr als 2,5 m/s

– Gehörschutz tragen. –

2

.

ITALIANO

Il livello di pressione sonora pesata secondo la curva A è di

82 dB (A).

Il livello di rumore durante il lavoro potrebbe superare gli

85 dB (A).

Il valore quadratico medio di accellerazione non supera i

2

2,5 m/s

Rumore e vibrazione

– Indossare i paraorecchi. –

.

NEDERLANDS

Het typische A-gewogen geluidsdrukniveau is 82 dB (A).

Tijdens het werken kan het geluidsniveau 85 dB (A) overschrijden.

De typische gewogen effectieve versnellingswaarde is niet

meer dan 2,5 m/s

Geluidsniveau en trilling

– Draag oorbeschermers. –

2

.

ESPAÑOL

El nivel de presión sonora ponderada A es de 82 dB (A).

El nivel de ruido en condiciones de trabajo puede que sobrepase los 85 dB (A).

El valor ponderado de la aceleración no sobrepasa los

2

.

2,5 m/s

Ruido y vibración

– Póngase protectores en los oídos. –

DANSK

Det typiske A-vægtede lydtryksniveau er 82 dB (A).

Støjniveauet under arbejde kan overstige 85 dB (A).

Den vægtede effektive accelerationsværdi overstiger ikke

2

.

2,5 m/s

Lyd og vibration

– Bær høreværn. –

SVENSKA

Den typiska-A-vägda ljudtrycksnivån är 82 dB (A).

Bullernivån under pågående arbete kan överstiga 85 dB (A).

Det typiskt vägda effektivvärdet för acceleration överstiger

inte 2,5 m/s

Buller och vibration

– Använd hörselskydd –

2

.

NORSK

Det vanlige A-belastede lydtrykksnivå er 82 dB (A).

Under bruk kan støynivået overskride 85dB (A).

Den vanlig belastede effektiv-verdi for akselerasjon overskrider ikke 2,5 m/s

Støy og vibrasjon

– Benytt hørselvern. –

2

.

SUOMI

Tyypillinen A-painotettu äänenpainetaso on 82 dB (A).

Melutaso työpaikalla saattaa ylittää 85 dB (A).

Tyypillinen kiihtyvyyden painotettu tehollisarvo ei ylitä

2

.

2,5 m/s

Melutaso ja tärinä

– Käytä kuulosuojaimia. –

ΕΛΛΗΝΙΚΑ

Η τυπική Α-µετρούµενη ηχητική πίεση είναι 82 dB (A).

Η ένταση ήχου υπο συνθήκες εργασίας µπορεί να

µπερβεί τα 85 dB (A).

Η τυπική αξία της µετρούµενης ρίζας του µέσου

τετραγώνου της επιτάχυνσης δεν ξεπερνά τα 2,5 m/s

Θρυβος και κραδασµς

– Φοράτε ωτοασπίδες. –

2

.

44

454647

Makita Corporation

Anjo, Aichi, Japan

Made in Japan

884356D994

Loading...

Loading...