Page 1

INSTRUCTION MANUAL

MANUEL D'INSTRUCTION

MANUAL DE INSTRUCCIONES

Slide Compound Miter Saw

Scie à Onglet Radiale

Sierra de Inglete Telescópica

LS1216

LS1216L

010049

DOUBLE INSULATION

DOUBLE ISOLATION

WARNING:

For your personal safety, READ and UNDERSTAND before using.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

AVERTISSEMENT:

Pour votre propre sécurité, prière de lire attentivement avant l'utilisation.

GARDER CES INSTRUCTIONS POUR RÉFÉRENCE ULTÉRIEURE.

ADVERTENCIA:

Para su seguridad personal, LEA DETENIDAMENTE este manual antes de usar la

herramienta.

GUARDE ESTAS INSTRUCCIONES PARA FUTURA REFERENCIA.

DOBLE AISLAMIENTO

1

Page 2

ENGLISH

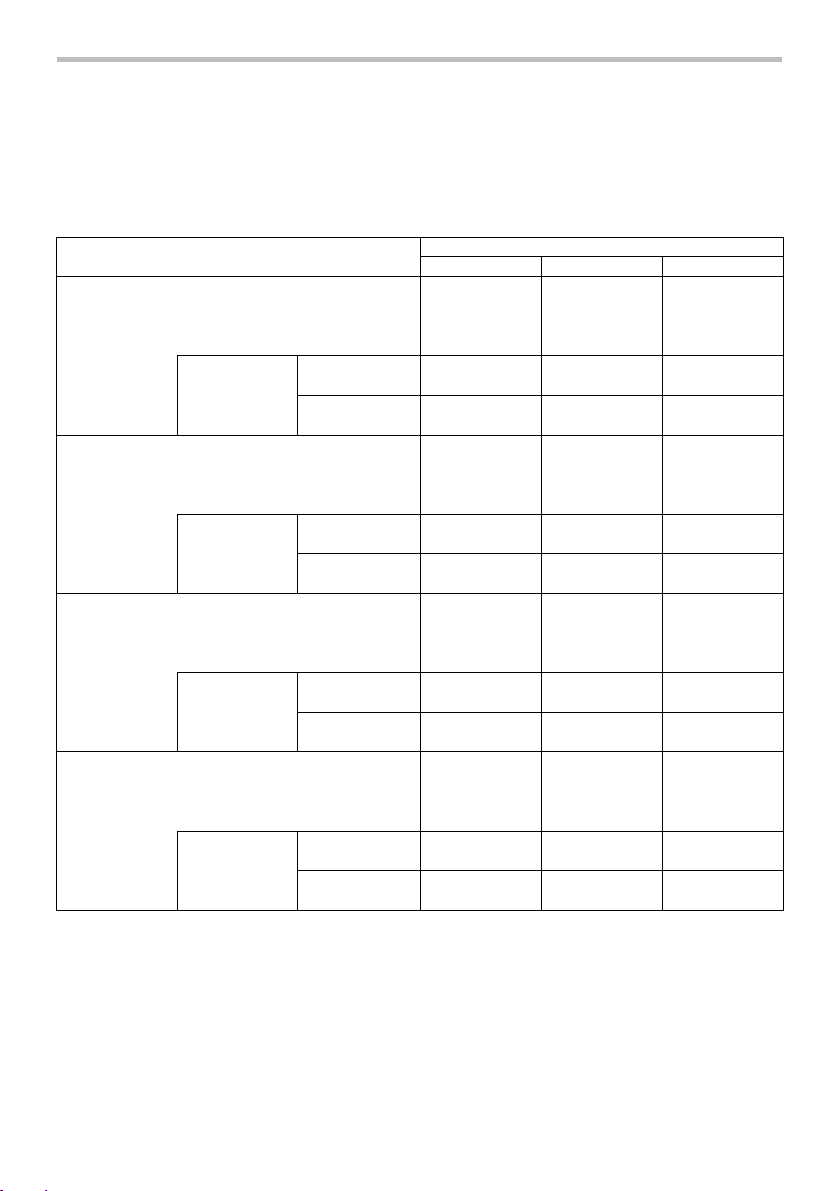

SPECIFICATIONS

Model LS1216/LS1216L

Blade diameter 305 mm (12")

Hole diameter 25.4 mm (1")

Max. Cutting capacities (H x W)

Bevel angle

(4-1/2"×8-15/16")

(4-3/4"×8-3/8")

92mm×233mm

(3-5/8"×9-1/8")

107mm×220mm

(4-1/4"×8-5/8")

(4-1/2"×7-3/4")

(4-3/4"×7-1/8")

92mm×185mm

(3-5/8"×7-1/4")

107mm×178mm

(4-1/4"×7")

(4-1/2"×6-1/8")

(4-3/4"×5-1/2")

―

―

―

―

―

―

―

―

―

―

―

0°

45°(left and right)

52°(left and right)

60°(right)

Miter angle

Thickness of wood

facing

Thickness of wood

facing

Thickness of wood

facing

Thickness of wood

facing

45°(left) 0° 45°(right)

61mm×382mm 92mm×382mm 44mm×382mm

(2-3/8"×15") (3-5/8"×15") (1-3/4"×15")

71mm×363mm 107mm×363mm 54mm×363mm

20mm 78mm×325mm 115mm×325mm 61mm×325mm

(13/16") (3-1/16"×12-3/4") (4-1/2"×12-3/4") (2-3/8"×12-3/4")

38mm 80mm×292mm 120mm×292mm

(1-1/2") (3-1/8"×11-1/2") (4-3/4"×11-1/2")

15mm 115mm×227mm

(9/16")

25mm 120mm×212mm

(1")

15mm 115mm×197mm

(9/16")

25mm 120mm×180mm

(1")

15mm 115mm×155mm

(9/16")

25mm 120mm×140mm

(1")

(2-13/16"×14-1/4") (4-1/4"×14-1/4") (2-1/8"×14-1/4")

61mm×268mm 92mm×268mm 44mm×268mm

(2-3/8"×10-1/2") (3-5/8"×10-1/2") (1-3/4"×10-1/2")

71mm×255mm 107mm×255mm 54mm×255mm

(2-13/16"×10") (4-1/4"×10") (2-1/8"×10")

―

―

―

―

―

―

―

―

―

―

2

Page 3

Special Max. Cutting capacities

Crown molding 45 ゚ type

(with Crown molding stopper used)

Base board (H)

No load speed (RPM) 3,200/min.

Laser Type (LS1216L only)

Dimensions (L x W x H) 806 mm x 640 mm x 721 mm

Net weight (31-3/4" x 25-1/4"x 28-3/8")

26.4 kg (58.2 lbs)

• Due to our continuing programme of research and development, the specifications herein are subject to change without notice.

• Specifications may differ from country to country.

• Weight according to EPTA-Procedure 01/2003

For Your Own Safety Read

Instruction Manual

Before Operating Tool

Save it for future reference

GENERAL SAFETY

PRECAUTIONS

(For All Tools)

1. KNOW YOUR POWER TOOL. Read the owner's

manual carefully. Learn the tool's applications

and limitations, as well as the specific

potential hazards peculiar to it.

2. KEEP GUARDS IN PLACE and in working

order.

3. REMOVE ADJUSTING KEYS AND WRENCHES.

Form habit of checking to see that keys and

adjusting wrenches are removed from tool

before turning it on.

4. KEEP WORK AREA CLEAN. Cluttered areas

and benches invite accidents.

5. DO NOT USE IN DANGEROUS ENVIRONMENT.

Do not use power tools in damp or wet

locations, or expose them to rain. Keep work

area well lighted. Do not use tool in presence

of flammable liquids or gases.

6. KEEP CHILDREN AWAY. All visitors should be

kept safe distance from work area.

(with Horizontal vise used)

USA007-2

Wavelength 655 nm, Maximum output 1mW (Laser Class II)

7. MAKE WORKSHOP KID PROOF with padlocks,

master switches, or by removing starter keys.

8. DO NOT FORCE TOOL. It will do the job better

and safer at the rate for which it was designed.

9. USE RIGHT TOOL. Do not force tool or

attachment to do a job for which it was not

designed.

10. WEAR PROPER APPAREL. Do not wear loose

clothing, gloves, neckties, rings, bracelets, or

other jewelry which may get caught in moving

parts. Nonslip footwear is recommended.

Wear protective hair covering to contain long

hair.

11. ALWAYS USE SAFETY GLASSES. Also use

face or dust mask if cutting operation is dusty.

Everyday eyeglasses only have impact

resistant lenses, they are NOT safety glasses.

12. SECURE WORK. Use clamps or a vise to hold

work when practical. It's safer than using your

hand and it frees both hands to operate tool.

13. DO NOT OVERREACH. Keep proper footing

and balance at all times.

14. MAINTAIN TOOLS WITH CARE. Keep tools

sharp and clean for best and safest

performance. Follow instructions for

lubricating and changing accessories.

15. DISCONNECT TOOLS before servicing; when

changing accessories such as blades, bits,

cutters, and the like.

16. REDUCE THE RISK OF UNINTENTIONAL

STARTING. Make sure switch is in off position

before plugging in.

17. USE RECOMMENDED ACCESSORIES.

Consult the owner's manual for recommended

accessories. The use of improper accessories

may cause risk of injury to persons.

203 mm (8")

165 mm (6-1/2")

3

Page 4

18. NEVER STAND ON TOOL. Serious injury could

occur if the tool is tipped or if the cutting tool

is unintentionally contacted.

19. CHECK DAMAGED PARTS. Before further use

of the tool, a guard or other part that is

damaged should be carefully checked to

determine that it will operate properly and

perform its intended function - check for

alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any

other conditions that may affect its operation.

A guard or other part that is damaged should

be properly repaired or replaced.

20. DIRECTION OF FEED. Feed work into a blade

or cutter against the direction of rotation of

the blade or cutter only.

21. NEVER LEAVE TOOL RUNNING UNATTENDED.

TURN POWER OFF. Do not leave tool until it

comes to a complete stop.

22. REPLACEMENT PARTS. When servicing, use

only identical replacement parts.

23. POLARIZED PLUGS. To reduce the risk of

electric shock, this appliance has a polarized

plug (one blade is wider than the other). This

plug will fit in a polarized outlet only one way.

If the plug does not fit fully in the outlet,

reverse the plug. If it still does not fit, contact

a qualified electrician to install the proper

outlet. Do not change the plug in any way.

VOLTAGE WARNING: Before connecting the tool to

a power source (receptacle, outlet, etc.) be sure the

voltage supplied is the same as that specified on the

nameplate of the tool. A power source with voltage

greater than that specified for the tool can result in

SERIOUS INJURY to the user- as well as damage to

the appliance. If in doubt, DO NOT PLUG IN THE

APPLIANCE. Using a power source with voltage less

than the nameplate rating is harmful to the motor.

USE PROPER EXTENSION CORD. Make sure your

extension cord is in good condition. When using an

extension cord, be sure to use one heavy enough to

carry the current your product will draw. An

undersized cord will cause a drop in line voltage

resulting in loss of power and overheating. Table 1

shows the correct size to use depending on cord

length and nameplate ampere rating. If in doubt, use

the next heavier gage. The smaller the gage number,

the heavier the cord.

Table 1: Minimum gage for cord

Ampere Rating

Volts Total length of cord in feet

120 V 25 ft. 50 ft. 100 ft. 150 ft.

More Than Not More Than AWG

0 6 18 16 16 14

18 16 14 12610

10 12 16 16 14 12

000173

ADDITIONAL SAFETY RULES

DO NOT let comfort or familiarity with product

(gained from repeated use) replace strict adherence

to slide compound saw safety rules. If you use this

tool unsafely or incorrectly, you can suffer serious

personal injury.

1. Wear eye protection.

2. Keep hands out of path of saw blade. Avoid

12 16 14 12

USB036-2

contact with any coasting blade. It can still

cause severe injury.

3. Do not operate saw without guards in place.

Check blade guard for proper closing before

each use. Do not operate saw if blade guard

does not move freely and close instantly.

Never clamp or tie the blade guard into the

open position.

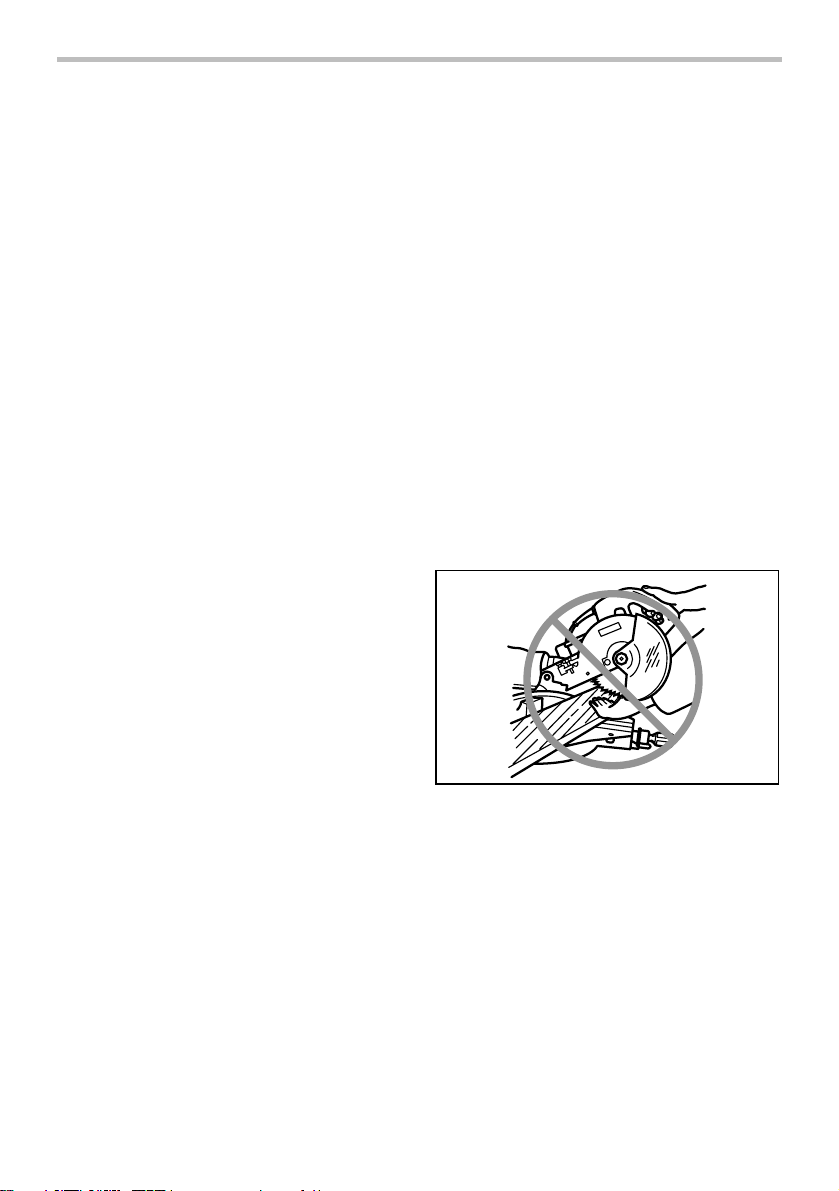

4. Do not perform any operation freehand. The

workpiece must be secured firmly against the

turn base and guide fence with a vise during

all operations. Never use your hand to secure

the workpiece.

5. Never reach around saw blade.

4

Not Recommended

Page 5

6. Turn off tool and wait for saw blade to stop

before moving workpiece or changing

settings.

7. Unplug tool before changing blade or

servicing.

8. To reduce the risk of injury, return carriage to

the full rear position after each crosscut

operation.

9. Always secure all moving portions before

carrying the tool.

10. Stopper pin which locks the cutter head down

is for carrying and storage purposes only and

not for any cutting operations.

11. Do not use the tool in the presence of

flammable liquids or gases.

12. Check the blade carefully for cracks or

damage before operation. Replace cracked or

damaged blade immediately. Gum and wood

pitch hardened on blades slows saw and

increases potential for kickback. Keep blade clean

by first removing it from tool, then cleaning it with

gum and pitch remover, hot water or kerosene.

Never use gasoline to clean blade.

13. While making a slide cut, KICKBACK can

occur. KICKBACK occurs when the blade

binds in the workpiece during a cutting

operation and the saw blade is driven back

rapidly towards the operator. Loss of control

and serious personal injury can result. If blade

begins to bind during a cutting operation, do

not continue to cut and release switch

immediately.

14. Use only flanges specified for this tool.

15. Be careful not to damage the arbor, flanges

(especially the installing surface) or bolt.

Damage to these parts could result in blade

breakage.

16. Make sure that the turn base is properly

secured so it will not move during operation.

Use the holes in the base to fasten the saw to

a stable work platform or bench. NEVER use

tool where operator positioning would be

awkward.

17. For your safety, remove the chips, small

pieces, etc. from the table top before

operation.

18. Avoid cutting nails. Inspect for and remove all

nails from the workpiece before operation.

19. Make sure the shaft lock is released before the

switch is turned on.

20. Be sure that the blade does not contact the

turn base in the lowest position.

21. Hold the handle firmly. Be aware that the saw

moves up or down slightly during start-up and

stopping.

22. Make sure the blade is not contacting the

workpiece before the switch is turned on.

23. Before using the tool on an actual workpiece,

let it run for a while. Watch for vibration or

wobbling that could indicate poor installation

or a poorly balanced blade.

24. Wait until the blade attains full speed before

cutting.

25. Stop operation immediately if you notice

anything abnormal.

26. Do not attempt to lock the trigger in the "ON"

position.

27. Be alert at all times, especially during

repetitive, monotonous operations. Do not be

lulled into a false sense of security. Blades are

extremely unforgiving.

28. Always use accessories recommended in this

manual. Use of improper accessories such as

abrasive wheels may cause an injury.

29. NEVER hold workpiece on right side of blade

with left hand or vice versa. This is called

cross-armed cutting and exposes user to risk

of SERIOUS PERSONAL INJURY as shown in

the figure. ALWAYS use vise to secure

workpiece.

000030

30. Do not abuse cord. Never yank cord to

disconnect it from the receptacle. Keep cord

away from heat, oil, water and sharp objects.

31. NEVER stack workpieces on the table top to

speed cutting operations. Cut only one piece

at a time.

32. Some material contains chemicals which may

be toxic. Take caution to prevent dust

inhalation and skin contact. Follow material

supplier safety data.

SAVE THESE INSTRUCTIONS.

5

Page 6

WARNING:

MISUSE or failure to follow the safety rules stated in

this instruction manual may cause serious personal

injury.

USB094-1

ADDITIONAL SAFETY RULES

FOR THE LASER

CAUTION:

• LASER RADIATION DO NOT STARE INTO

BEAM.

• AVOID EXPOSURE - LASER RADIATION IS

EMITTED FROM APERTURE.

• USE OF CONTROLS OR ADJUSTMENTS OR

PERFORMANCE OF PROCEDURES OTHER

THAN THOSE SPECIFIED HEREIN MAY

RESULT IN HAZARDOUS RADIATION

EXPOSURE.

Complies with 21CFR

1040.10 and 1040.11

AVOID EXPOSURE-Laser

radiation is emitted from

this aperture

CAUTION

LASER RADIATION

DO NOT STARE INTO BEAM

Maximum Output

<1mW,Wavelength:655nm

CLASS II LASER PRODUCT

009605

INSTALLATION

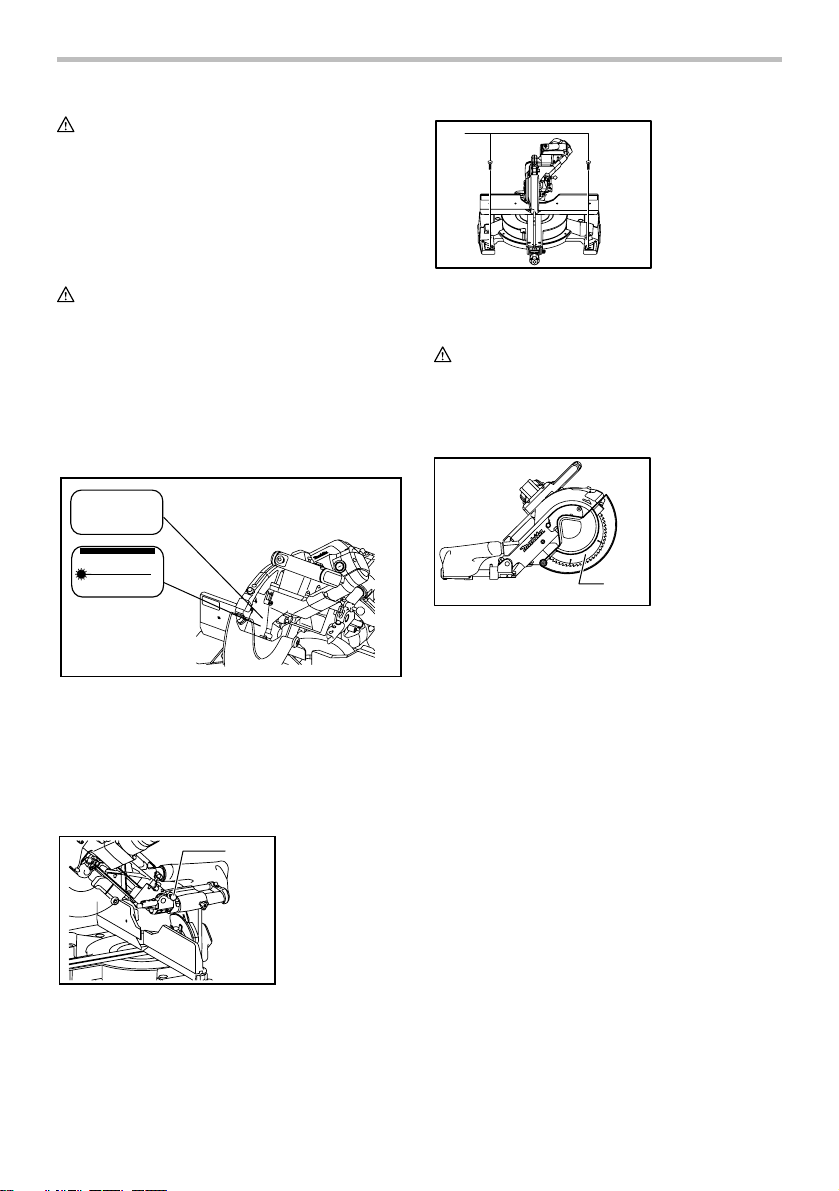

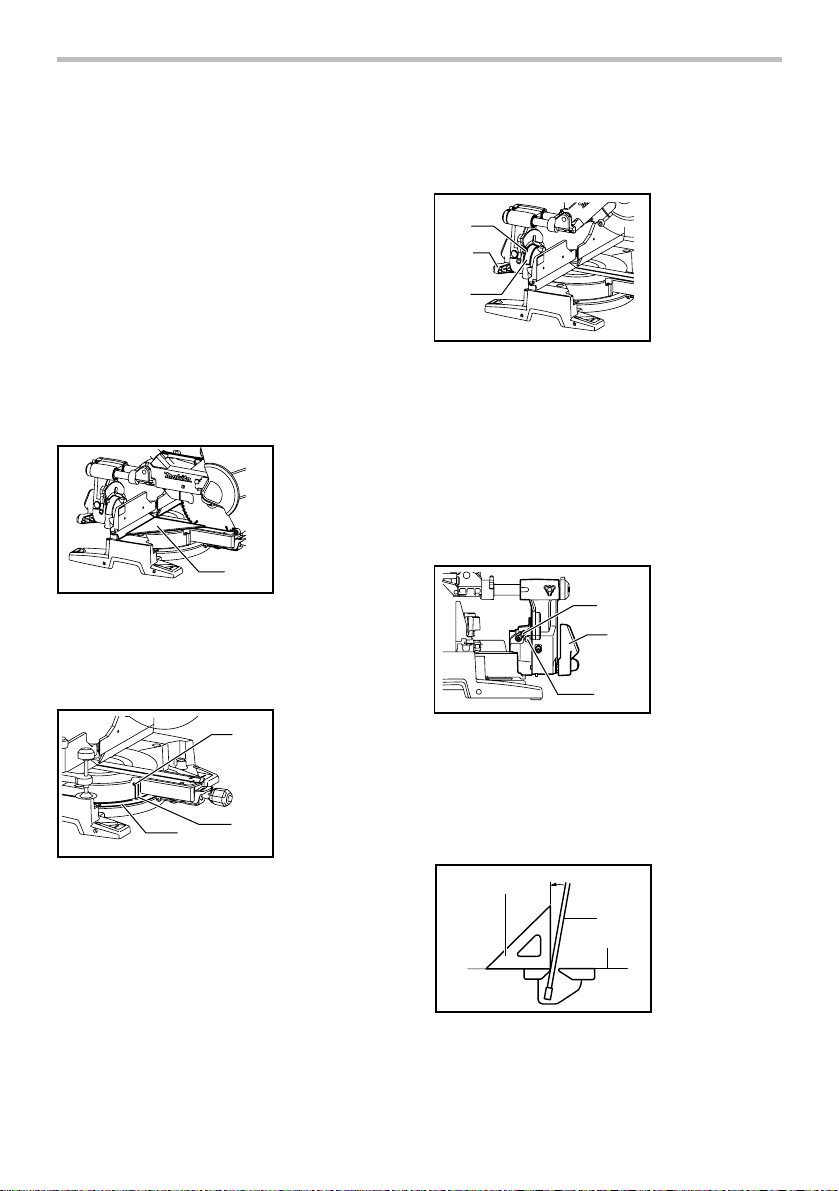

Bench mounting

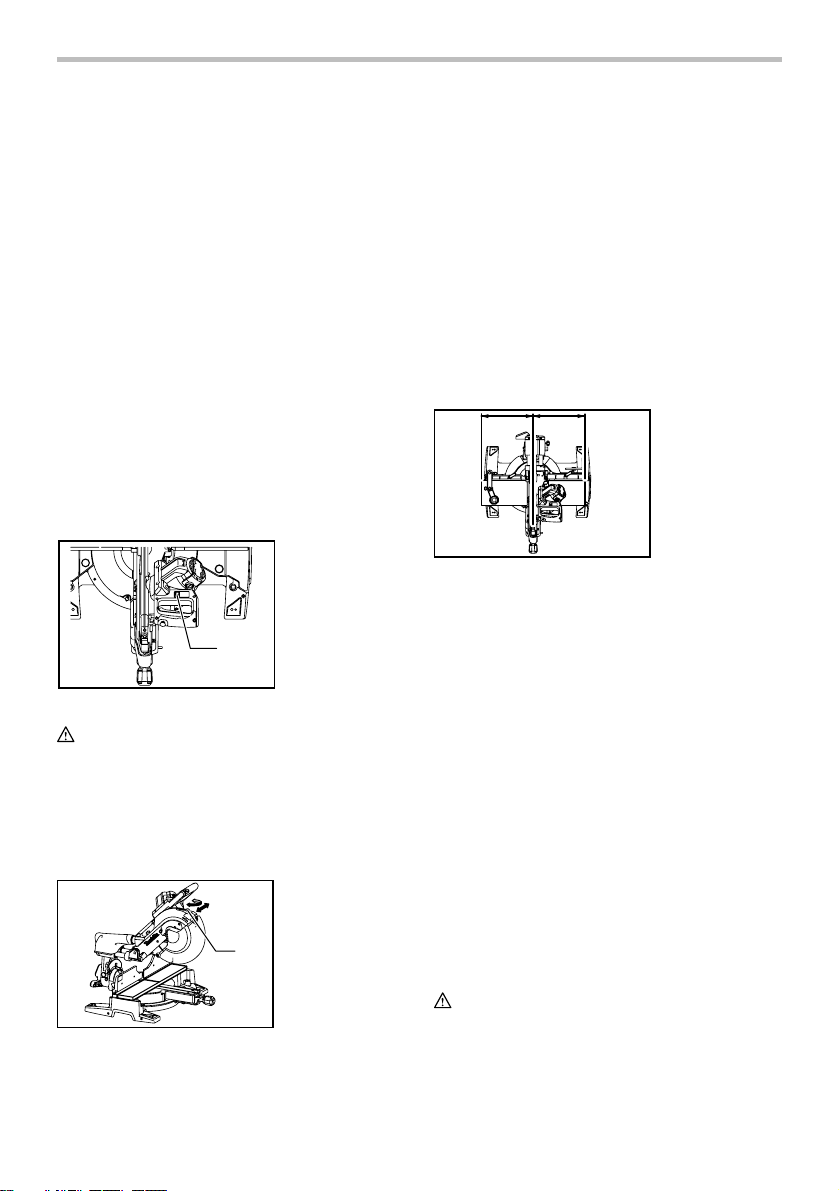

When the tool is shipped, the handle is locked in the

lowered position by the stopper pin. Release the stopper

pin by lowering the handle slightly and pulling the

stopper pin.

1. Stopper pin

1

009483

This tool should be bolted with four bolts to a level and

stable surface using the bolt holes provided in the tool's

base. This will help prevent tipping and possible injury.

1

009484

1. Hex bolt

FUNCTIONAL DESCRIPTION

CAUTION:

• Always be sure that the tool is switched off and

unplugged before adjusting or checking function on

the tool.

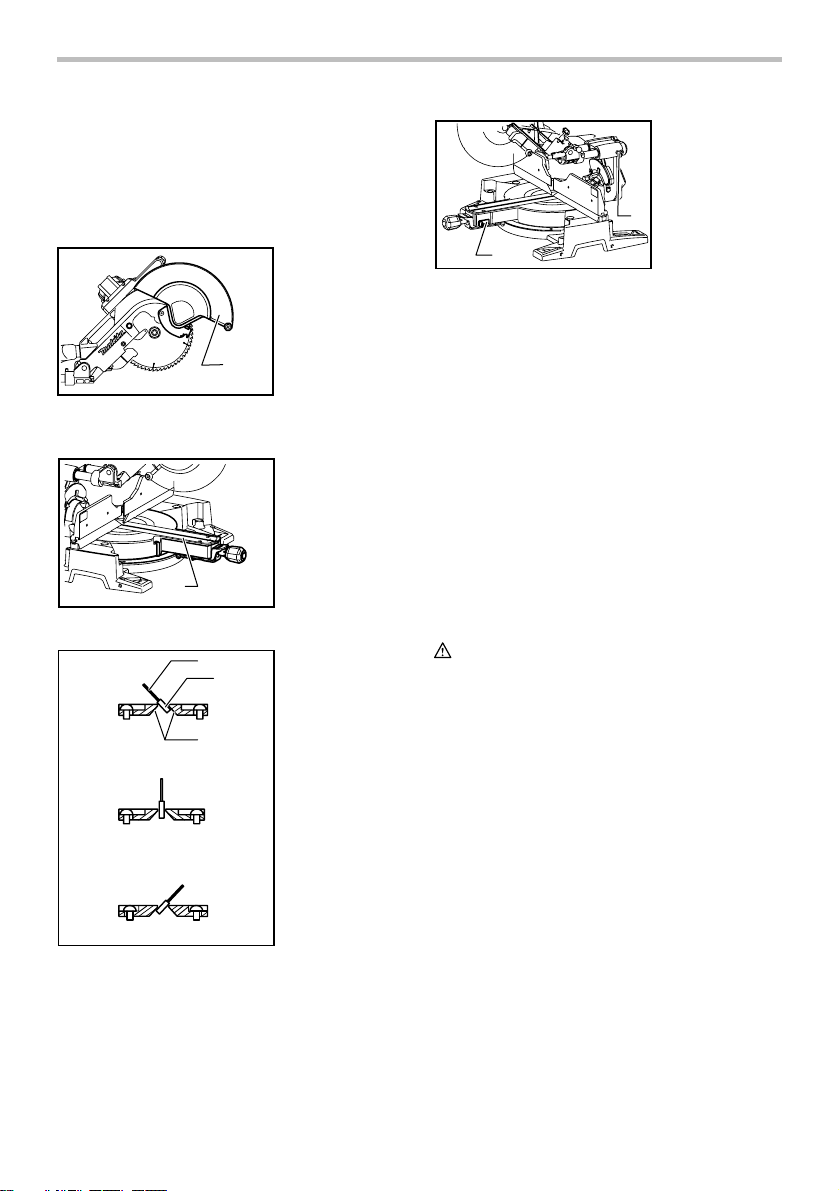

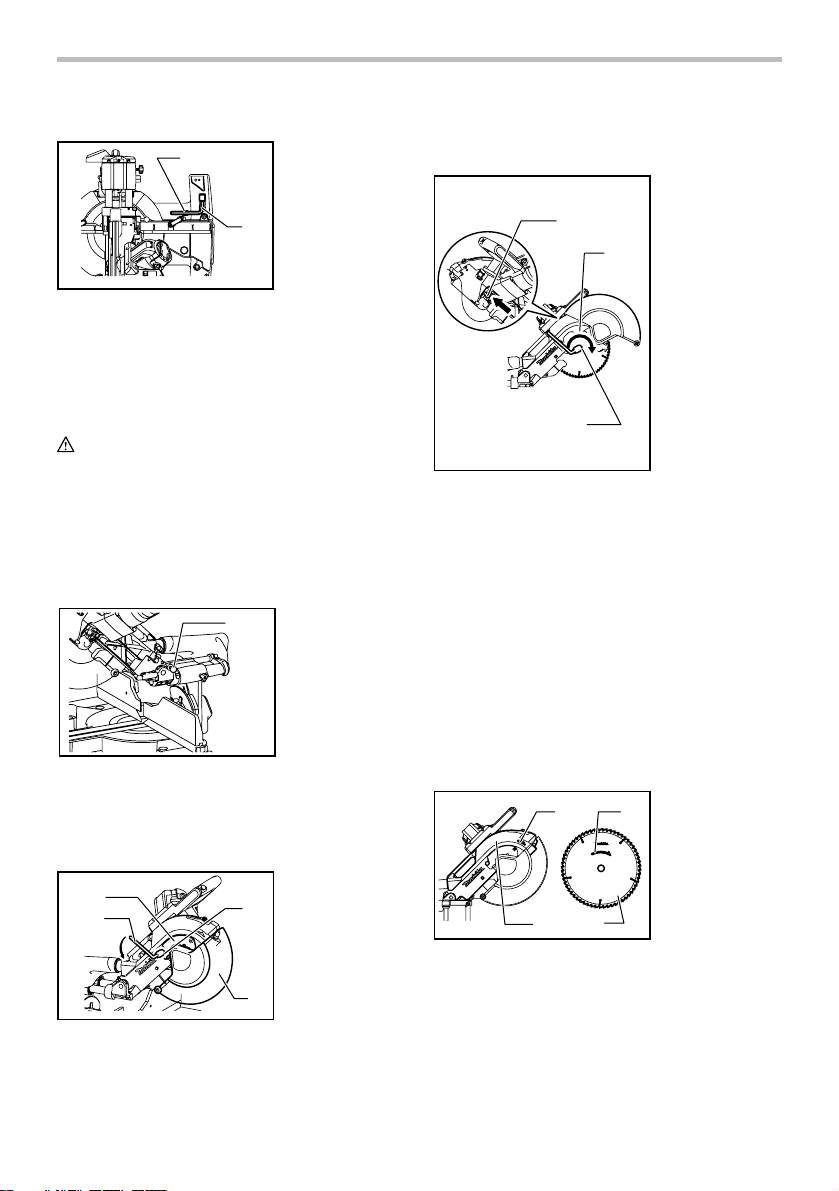

Blade guard

1. Blade guard

1

009485

When lowering the handle, the blade guard rises

automatically. The blade guard returns to its original

position when the cut is completed and the handle is

raised. NEVER DEFEAT OR REMOVE THE BLADE

GUARD OR THE SPRING WHICH ATTACHES TO THE

GUARD.

In the interest of your personal safety, always maintain

the blade guard in good condition. Any irregular

operation of the blade guard should be corrected

immediately. Check to assure spring loaded return

action of guard. NEVER USE THE TOOL IF THE

BLADE GUARD OR SPRING ARE DAMAGED, FAULTY

OR REMOVED. DOING SO IS HIGHLY DANGEROUS

AND CAN CAUSE SERIOUS PERSONAL INJURY.

If the see-through blade guard becomes dirty, or

sawdust adheres to it in such a way that the blade

and/or workpiece is no longer easily visible, unplug the

saw and clean the guard carefully with a damp cloth. Do

not use solvents or any petroleum-based cleaners on

the plastic guard.

If the blade guard is especially dirty and vision through

the guard is impaired, use the supplied socket wrench to

loosen the hex bolt holding the center cover. Loosen the

hex bolt by turning it counterclockwise and raise the

blade guard and center cover. With the blade guard so

6

Page 7

positioned, cleaning can be more completely and

efficiently accomplished. When cleaning is complete,

reverse procedure above and secure bolt. Do not

remove spring holding blade guard. If guard becomes

discolored through age or UV light exposure, contact a

Makita service center for a new guard. DO NOT

DEFEAT OR REMOVE GUARD.

1. Blade guard

1

009486

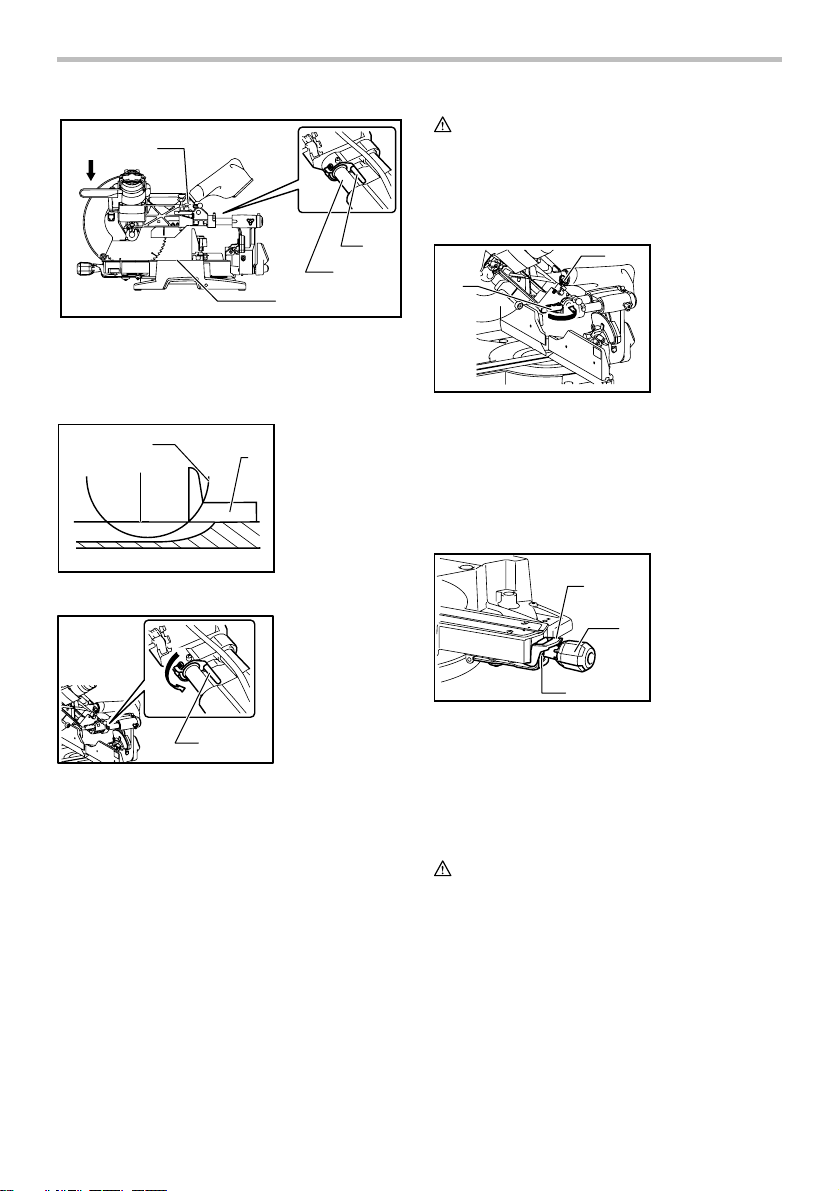

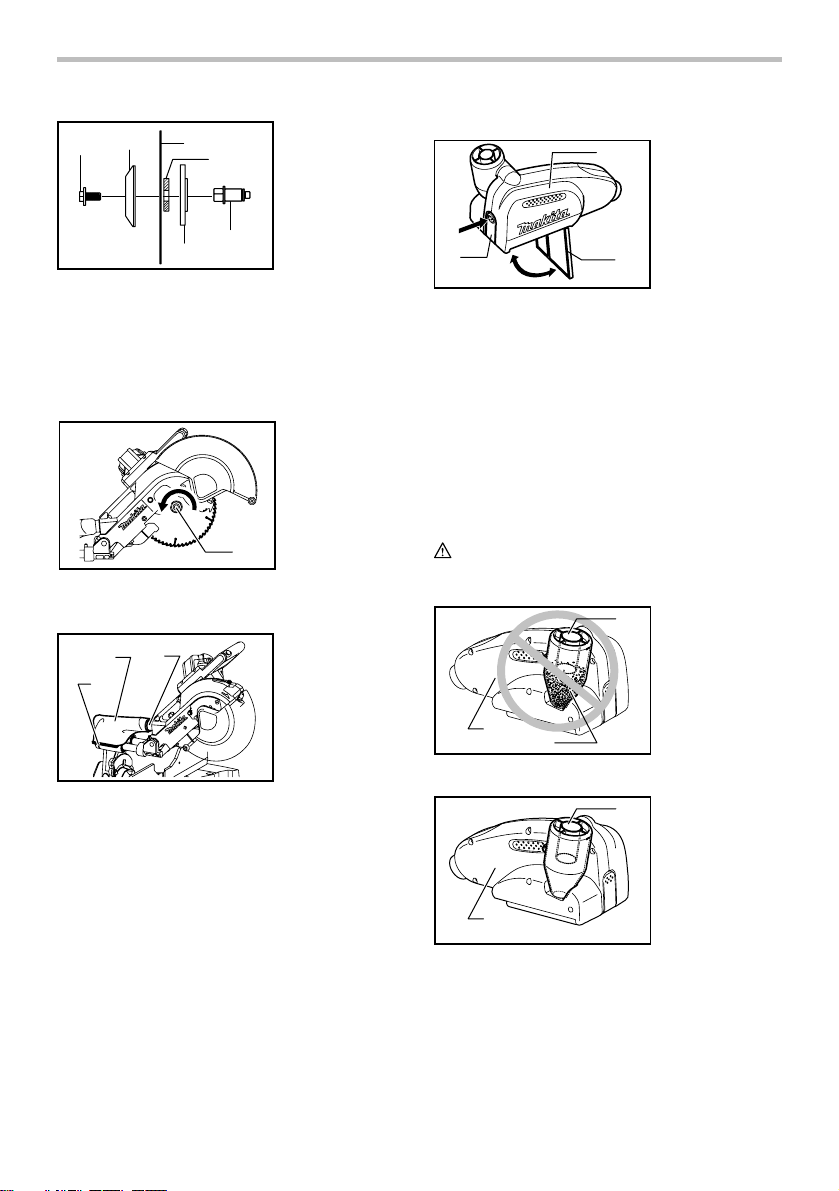

Positioning kerf board

1. Kerf board

1

009488

1

3

4

5

6

001538

This tool is provided with the kerf boards in the turn base

to minimize tearing on the exit side of a cut. The kerf

boards are factory adjusted so that the saw blade does

not contact the kerf boards. Before use, adjust the kerf

boards as follows:

1. Saw blade

2

2. Blade teeth

3. Kerf board

4. Left bevel cut

5. Straight cut

6. Right bevel cut

1. Lock lever

2. Screw

2

009496

First, unplug the tool. Loosen all the screws (3 each on

left and right) securing the kerf boards. Re-tighten them

only to the extent that the kerf boards can still be easily

moved by hand. Lower the handle fully and push in the

stopper pin to lock the handle in the lowered position.

Loosen the locking screw counterclockwise which

secures the upper slide poles and also push forward the

lock lever which secures the lower slide poles. Pull the

carriage toward you fully. Adjust the kerf boards so that

the kerf boards just contact the sides of the blade teeth.

Tighten the front screws (do not tighten firmly). Push the

carriage toward the guide fence fully and adjust the kerf

boards so that the kerf boards just contact the sides of

blade teeth. Tighten the rear screws (do not tighten

firmly).

After adjusting the kerf boards, release the stopper pin

and raise the handle. Then tighten all the screws

securely.

• Before and after changing the bevel angle, always

1

CAUTION:

adjust the kerf boards as described above.

Maintaining maximum cutting capacity

Unplug the tool before any adjustment is attempted. This

tool is factory adjusted to provide the maximum cutting

capacity for a 305 mm (12") saw blade.

When installing a new blade, always check the lower

limit position of the blade and if necessary, adjust it as

follows:

7

Page 8

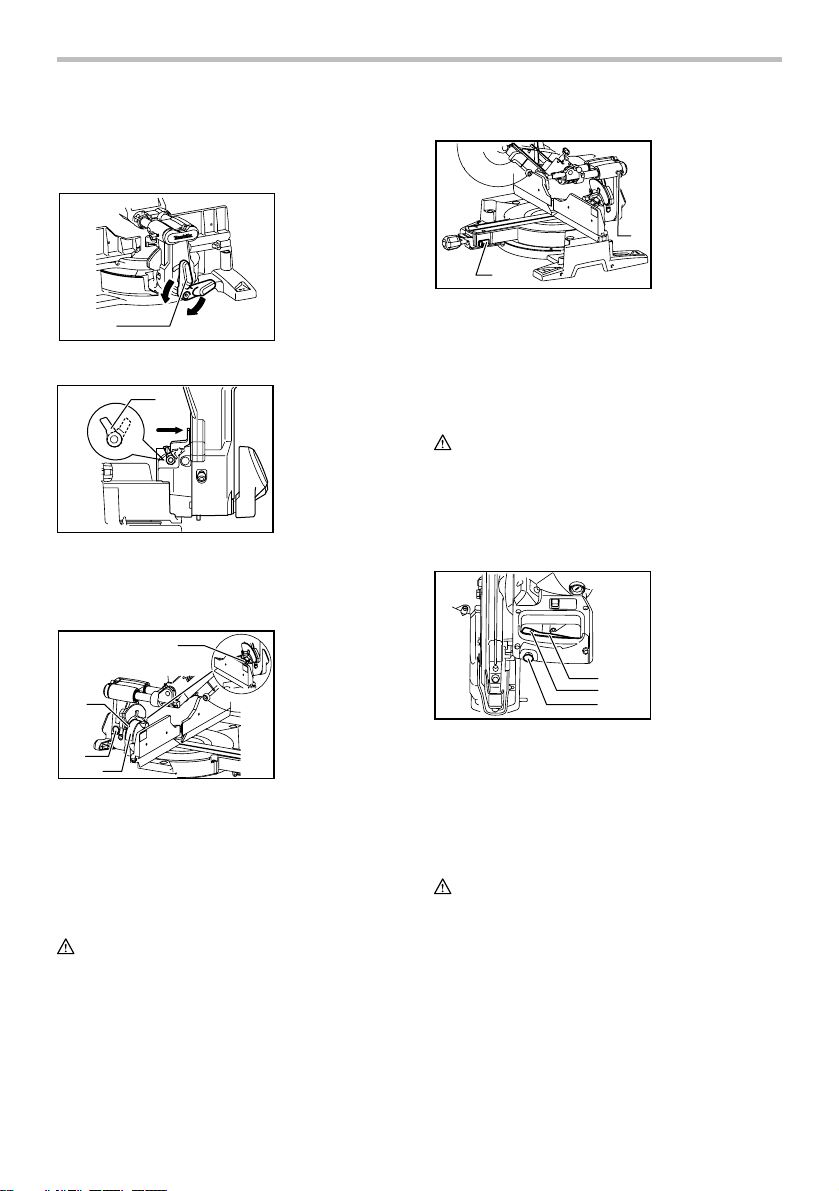

1. Adjusting bolt

2. Turn base

3. Stopper lever

4. Slide pipe

009518

2

1

009737

CAUTION:

1

• After installing a new blade, always be sure that

the blade does not contact any part of the lower

base when the handle is lowered completely.

Always do this with the tool unplugged.

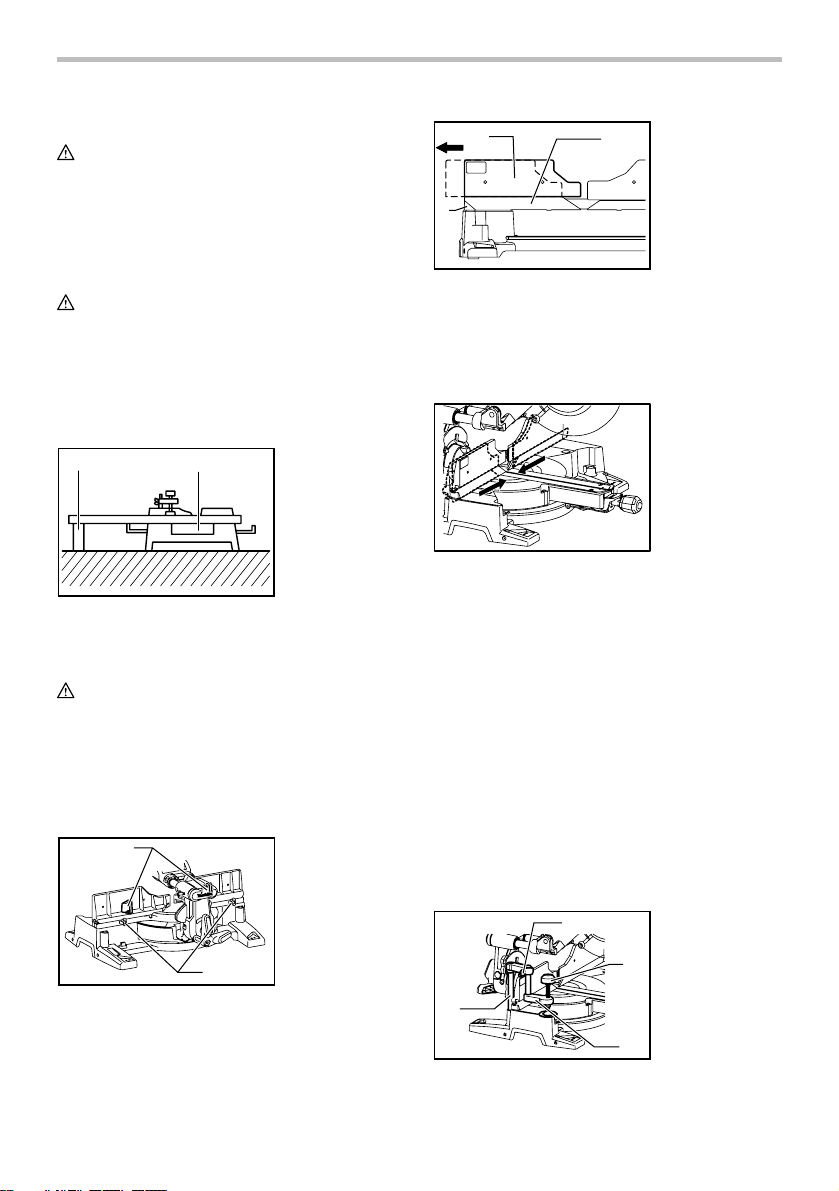

Stopper arm

2

1. Top surface of

turn base

3

2. Periphery of

blade

3. Guide fence

3

4

1

009487

The lower limit position of the blade can be easily

adjusted with the stopper arm. To adjust it, rotate the

stopper arm in the direction of the arrow as shown in the

figure. Adjust the adjusting screw so that the blade stops

at the desired position when lowering the handle fully.

1. Stopper arm

2

2. Adjusting screw

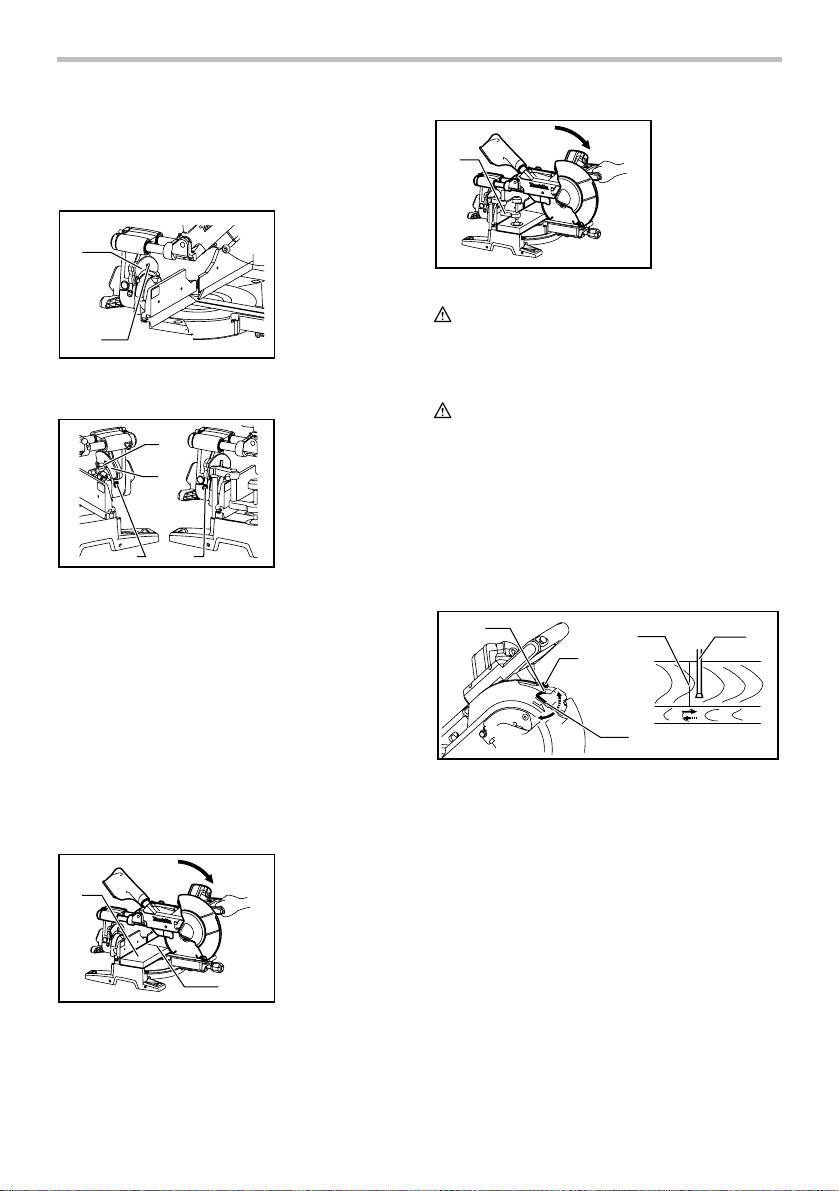

Adjusting the miter angle

2

1. Lock lever

2. Grip

3. Cam

1

1. Stopper lever

1

009736

First, unplug the tool. Lower the stopper lever to position

the saw blade as shown in the figure. Push the carriage

toward the guide fence fully and lower the handle

completely. Use the socket wrench to turn the adjusting

bolt until the periphery of the blade extends slightly

below the top surface of the turn base at the point where

the front face of the guide fence meets the top surface of

the turn base.

With the tool unplugged, rotate the blade by hand while

holding the handle all the way down to be sure that the

blade does not contact any part of the lower base.

Re-adjust slightly, if necessary.

After adjustment, always return the stopper lever to the

original position by turning it counterclockwise.

009517

3

Push the grip so that the cams engages and turn it

clockwise until it stops. Turn the turn base while pressing

down the lock lever. When you have moved the grip to

the position where the pointer points to the desired angle

on the miter scale, turn the grip to 90° counterclockwise

to lock the turn base.

CAUTION:

• When turning the turn base, be sure to raise the

handle fully.

• After changing the miter angle, always secure the

turn base by turning the grip to 90°

counterclockwise.

Adjusting the bevel angle

To adjust the bevel angle, loosen the lever at the rear of

the tool counterclockwise. Push the latch lever forward

as shown in the figure fully while supporting the weight

of the saw head so as to release the pressure on the

lock pin.

8

Page 9

When tilting the carriage to the right, tilt the carriage to

the left slightly after loosening the lever and press the

releasing button. With the releasing button being

pressed, tilt the carriage to the right.

1. Lever

2. Latch lever

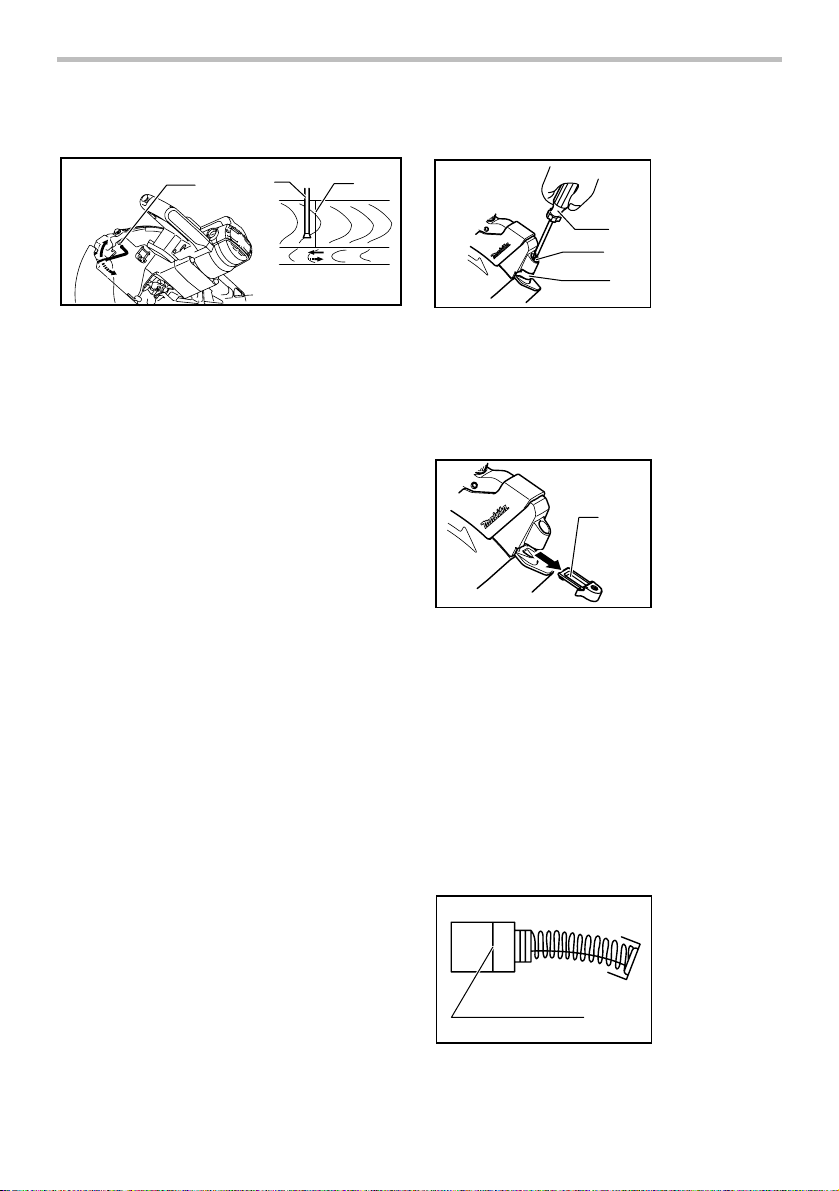

Slide lock adjustment

1. Lock lever

2. Screw

2

1

009489

1

010322

1. Latch lever

Tilt the saw blade until the pointer points to the desired

angle on the bevel scale. Then tighten the lever

clockwise firmly to secure the arm.

1. Scale plate

2. Release button

3. Pointer

4. Latch lever

3

009513

4

2

1

When the latch lever is pulled toward yourself, the saw

blade can be locked using positive stops at the right and

left 22.5 ° and 33.9 ° angle to the base surface.

When the latch lever is pushed forward as shown in the

figure, the saw blade can be locked at an desired angle

within the specified bevel angle range.

CAUTION:

• When tilting the saw blade, be sure to raise the

handle fully.

• After changing the bevel angle, always secure the

arm by tightening the lever clockwise.

• When changing bevel angles, be sure to position

the kerf boards appropriately as explained in the

"Positioning kerf boards" section.

009496

1

To lock the lower slide pole, pull the lock lever toward

yourself.

To lock the upper slide pole, turn the locking screw

clockwise.

Switch action

CAUTION:

• Before plugging in the tool, always check to see

that the switch trigger actuates properly and

returns to the "OFF" position when released.

• Do not pull the switch trigger hard without pressing

in the lock-off button. This can cause switch

breakage.

1. Switch trigger

2. Lock-off button

3. Hole for padlock

1

3

2

009491

To prevent the switch trigger from being accidentally

pulled, a lock-off button is provided. To start the tool,

press in the lock-off button and pull the switch trigger.

Release the switch trigger to stop.

A hole is provided in the switch trigger for insertion of

padlock to lock the tool off.

WARNING:

• Do not use a lock with a shank or cable any

smaller than 6.35 mm (1/4") in diameter.

• NEVER use tool without a fully operative switch

trigger. Any tool with an inoperative switch is

HIGHLY DANGEROUS and must be repaired

before further usage.

• For your safety, this tool is equipped with a lock-off

button which prevents the tool from unintended

starting. NEVER use the tool if it runs when you

simply pull the switch trigger without pressing the

lock-off button. Return tool to a Makita service

9

Page 10

center for proper repairs BEFORE further usage.

• NEVER tape down or defeat purpose and function

of lock-off button.

Electric brake

This tool is equipped with an electric blade brake. If the

tool consistently fails to quickly stop blade after switch

trigger release, have tool serviced at a Makita service

center.

The blade brake system is not a substitute for blade

guard. NEVER USE TOOL WITHOUT A FUNCTIONING

BLADE GUARD. SERIOUS PERSONAL INJURY CAN

RESULT.

Electronic function

Constant speed control

• Possible to get fine finish, because the rotating

speed is kept constantly even under the loaded

condition.

Soft start feature

• Soft start because of suppressed starting shock.

Laser beam action

For model LS1216L only

1. Switch for laser

1

009492

CAUTION:

• LASER RADIATION

Do not stare into beam.

To turn on the laser beam, press the upper position (I) of

the switch. Press the lower position (O) to turn off.

Laser line can be shifted to either the left or right side of

the saw blade by adjusting the adjusting screw as

follows.

009493

1. Adjusting screw

1

1. Loosen the adjusting screw by turning it

counterclockwise.

2. With the adjusting screw loosened, slide the

adjusting screw to the right or left as far as it goes.

3. Tighten the adjusting screw firmly at the position

where it stops sliding.

Laser line is factory adjusted so that it is positioned

within 1 mm (0.04") from the side surface of the blade

(cutting position).

NOTE:

• When laser line is dim and almost or entirely

invisible because of the direct sunlight in the indoor

or outdoor window-by work, relocate the work area

to a place not exposed to the direct sunlight.

Aligning the laser line

AB

009494

Laser line can be shifted to either the left or right side of

the blade according to the applications of cutting. Refer

to explanation titled "Laser beam action" regarding its

shifting method.

NOTE:

• Use wood facing against the guide fence when

aligning the cutting line with the laser line at the

side of guide fence in compound cutting (bevel

angle 45 degrees and miter angle right 45

degrees).

A) When you obtain correct size on the left side of

workpiece

• Shift the laser line to the left of the blade.

B) When you obtain correct size on the right side of

workpiece

• Shift the laser line to the right of the blade.

Align the cutting line on your workpiece with the laser

line.

ASSEMBLY

CAUTION:

• Always be sure that the tool is switched off and

unplugged before carrying out any work on the

tool.

10

Page 11

Socket wrench storage

1

009495

The socket wrench is stored as shown in the figure.

When using the socket wrench, pull it out of the wrench

holder. After using the socket wrench, return it to the

wrench holder.

Installing or removing saw blade

CAUTION:

• Always be sure that the tool is switched off and

unplugged before installing or removing the blade.

• Use only the Makita socket wrench provided to

install or remove the blade. Failure to do so may

result in overtightening or insufficient tightening of

the hex bolt. This could cause an injury.

Lock the handle in the raised position by pushing in the

stopper pin.

009483

To remove the blade, use the socket wrench to loosen

the hex bolt holding the center cover by turning it

counterclockwise. Raise the blade guard and center

cover.

1

2

009497

1. Wrench holder

2. Socket wrench

2

1. Stopper pin

1

1. Center cover

2. Socket wrench

3

3. Hex bolt

4. Blade guard

4

Press the shaft lock to lock the spindle and use the

socket wrench to loosen the hex bolt clockwise. Then

remove the hex bolt, outer flange and blade.

1. Shaft lock

2. Blade case

1

3. Hex bolt

2

3

009498

NOTE:

• When inner flange is removed mistakenly, be sure

to install it on the spindle with its protrusion facing

the spindle.

• Before mounting the blade onto the spindle,

always be sure that the correct ring for the arbor

hole of the blade you intend to use is installed

between the inner and outer flanges.

To install the blade, mount it carefully onto the spindle,

making sure that the direction of the arrow on the

surface of the blade matches the direction of the arrow

on the blade case.

Install the outer flange and hex bolt, and then use the

socket wrench to tighten the hex bolt (left-handed)

securely counterclockwise while pressing the shaft lock.

1

34

009500

1. Arrow

2

2. Arrow

3. Blade case

4. Saw blade

11

Page 12

2

1

009925

Return the blade guard and center cover to its original

position. Then tighten the hex bolt clockwise to secure

the center cover. Release the handle from the raised

position by pulling the stopper pin. Lower the handle to

make sure that the blade guard moves properly. Make

sure shaft lock has released spindle before making cut.

009524

3

6

4

1. Hex bolt

2. Outer flange

3. Saw blade

4. Inner flange

5. Spindle

6. Ring

5

1. Hex bolt

1

Dust bag

3

2

1

1. Fastener

2. Dust bag

3. Dust nozzle

Dust box (Optional accessory)

1

3

006793

Insert the dust box into the dust nozzle.

Empty the dust box at the earliest possible.

To empty the dust box, open the cover by pushing the

button and throw away sawdust. Return the cover to the

original position and it locks. Dust box can easily be

removed by pulling out while turning it near the dust

nozzle on the tool.

NOTE:

• If you connect a Makita vacuum cleaner to this tool,

more efficient and cleaner operations can be

performed.

CAUTION:

• Empty the dust box before collected sawdust level

reaches the cylinder part.

1. Dust box

2. Cover

3. Button

2

1. Cylinder part

1

2. Dust box

3. Sawdust

009501

The use of the dust bag makes cutting operations clean

and dust collection easy. To attach the dust bag, fit it

onto the dust nozzle.

When the dust bag is about half full, remove the dust

bag from the tool and pull the fastener out. Empty the

dust bag of its contents, tapping it lightly so as to remove

particles adhering to the insides which might hamper

further collection.

NOTE:

If you connect a vacuum cleaner to your saw, more

efficient and cleaner operations can be performed.

12

006792

006794

2

3

2

1. Cylinder part

1

2. Dust box

Page 13

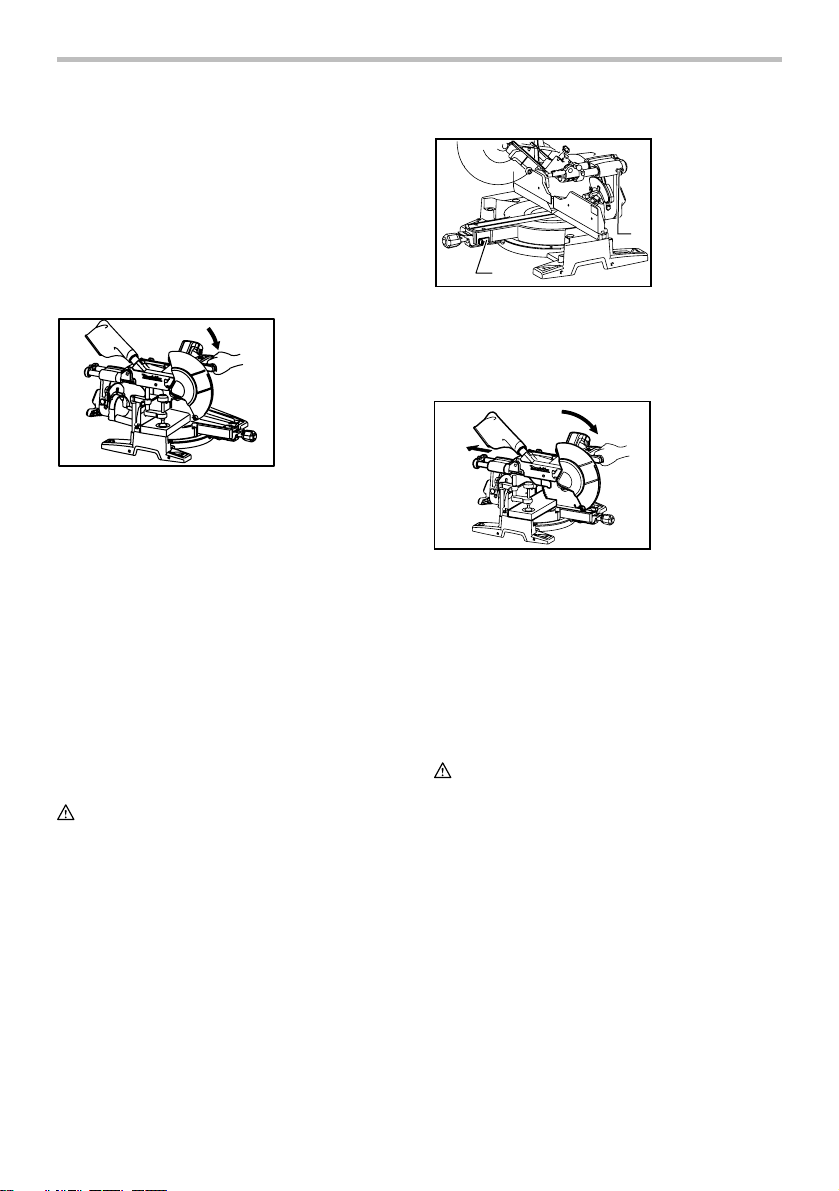

Securing workpiece

WARNING:

• It is extremely important to always secure the

workpiece properly and tightly with the vise. Failure

to do so can cause the tool to be damaged and/or

the workpiece to be destroyed. PERSONAL

INJURY MAY ALSO RESULT. Also, after a cutting

operation, DO NOT raise the blade until the blade

has come to a complete stop.

CAUTION:

• When cutting long workpieces, use supports that

are as high as the top surface level of the turn base.

Do not rely solely on the vertical vise and/or

horizontal vise to secure the workpiece.

Thin material tends to sag. Support workpiece over

its entire length to avoid blade pinch and possible

KICKBACK.

1

2

1. Support

2. Turn base

1

2

1. Upper fence

2. Lower fence

3. Red part

3

009519

Red part appears when lower fences are on the inside

and it does not appear when lower fences are on the

outside.

Upper fences can be moved to the inside and outside by

loosening the levers, and can be removed.

001549

Guide fence (SLIDING FENCES which are

upper and lower fences) adjustment

WARNING:

• Before operating the tool, make sure that the upper

and lower fences are secured firmly.

• Before bevel-cutting, make sure that no part of the

tool, especially blade, contacts the upper and lower

fences when lowering and raising the handle fully

at any position and pulling or pushing the carriage

all the way at the lowest position.

1

2

009508

Lower fences can be moved to the inside and outside by

loosening the clamping screws.

1. Levers

2. Clamping

screws

009611

In case of bevel-cutting, adjust the lower and upper

fences position to be as close to the blade as practical to

provide maximum workpiece support, and make sure

that no part of the tool, especially blade, contacts the

lower and upper fences when lowering and raising the

handle fully at any position and pulling or pushing the

carriage all the way at the lowest position.

Before cutting operations, make a dry run with the saw

turned off and check clearance between fences and

moving parts.

Before cutting operations, firmly secure lower fences by

tightening the clamping screws and upper fences by

tightening the levers.

When bevel-cutting operations are complete, don't

forget to return the upper fences to the original position

and secure it.

Vertical vise

4

3

009502

13

1. Vise knob

2. Vise arm

3. Vise rod

1

4. Screw

2

Page 14

The vertical vise can be installed in two positions on

either the left or right side of the base. Insert the vise rod

into the hole in the base.

Position the vise arm according to the thickness and

shape of the workpiece and secure the vise arm by

tightening the screw. If the screw to secure the vise arm

contacts the carriage, install the screw on the opposite

side of vise arm. Make sure that no part of the tool

contacts the vise when lowering the handle fully and

pulling or pushing the carriage all the way. If some part

contacts the vise, re-position the vise.

Press the workpiece flat against the guide fence and the

turn base. Position the workpiece at the desired cutting

position and secure it firmly by tightening the vise knob.

Turning the vise knob to 90° counterclockwise allows the

vise knob to be moved up and down, facilitating the

quick setting of workpiece. To secure the workpiece after

setting, turn it the vise knob clockwise.

CAUTION:

• The workpiece must be secured firmly against the

turn base and guide fence with the vise during all

operations.

Horizontal vise (optional accessory)

1. Vise plate

2. Vise nut

3. Vise knob

1

009606

The horizontal vise can be installed in two positions on

either the left or right side of the base. When performing

15° or greater miter cuts, install the horizontal vise on

the side opposite the direction in which the turn base is

to be turned.

005232

3

2

By flipping the vise nut to the left, the vise is released,

and rapidly moves in and out. To grip the workpiece,

push the vise knob forward until the vise plate contacts

the workpiece and flip the vise nut to the right. Then turn

the vise knob clockwise to secure the workpiece.

The maximum width of workpiece which can be secured

by the horizontal vise is 215 mm (8-1/2").

CAUTION:

• Always rotate the vise nut to the right fully when

securing the workpiece. Failure to do so may result

in insufficient securing of the workpiece. This could

cause the workpiece to be thrown, cause damage

to the blade or cause the loss of control, which can

result in PERSONAL INJURY.

• When cutting out thin workpiece, such as base

boards, against the fence, always use the

horizontal vise.

Holders (Optional accessory)

1. Holder

2. Screw

1

009607

2

The holders can be installed on either side as a

convenient means of holding workpieces horizontally.

Slip the holder rods into the holes in the base and adjust

their length according to the workpiece to be held. Then

tighten the holders securely with the screws.

CAUTION:

• Always support long workpieces level with the top

surface of the turn base for accurate cuts and to

prevent dangerous loss of control of the tool.

OPERATION

CAUTION:

• Before use, be sure to release the handle from the

lowered position by pulling the stopper pin.

• Make sure the blade is not contacting the

workpiece, etc. before the switch is turned on.

• Do not apply excessive pressure on the handle

when cutting. Too much force may result in

overload of the motor and/or decreased cutting

efficiency. Push down handle with only as much

force as is necessary for smooth cutting and

without significant decrease in blade speed.

14

Page 15

• Gently press down the handle to perform the cut. If

the handle is pressed down with force or if lateral

force is applied, the blade will vibrate and leave a

mark (saw mark) in the workpiece and the

precision of the cut will be impaired.

• During a slide cut, gently push the carriage toward

the guide fence without stopping. If the carriage

movement is stopped during the cut, a mark will be

left in the workpiece and the precision of the cut

will be impaired.

1. Press cutting (cutting small workpieces)

2. Slide (push) cutting (cutting wide workpieces)

1. Lock lever

2. Screw

2

009496

1

Loosen the locking screw counterclockwise and

also push forward the lock lever so that the

carriage can slide freely. Secure the workpiece

with the vise.

009503

Workpieces up to 92 mm (3-5/8") high and 183 mm

(7-1/4") wide can be cut in the following way.

After turning the stopper lever clockwise and

sliding the carriage to your desired position, push

the carriage toward the guide fence fully and

tighten the locking screw clockwise and pull the

lock lever toward yourself to secure the carriage.

Secure the workpiece with the vise. Switch on the

tool without the blade making any contact and wait

until the blade attains full speed before lowering.

Then gently lower the handle to the fully lowered

position to cut the workpiece. When the cut is

completed, switch off the tool and WAIT UNTIL

THE BLADE HAS COME TO A COMPLETE STOP

before returning the blade to its fully elevated

position.

CAUTION:

• Firmly tighten the locking screw clockwise and pull

the lock lever toward yourself so that the carriage

will not move during operation. Insufficient

tightening may cause unexpected kickback of the

blade. Possible serious PERSONAL INJURY may

result.

009504

Pull the carriage toward you fully. Switch on the

tool without the blade making any contact and wait

until the blade attains full speed. Press down the

handle and PUSH THE CARRIAGE TOWARD

THE GUIDE FENCE AND THROUGH THE

WORKPIECE. When the cut is completed, switch

off the tool and WAIT UNTIL THE BLADE HAS

COME TO A COMPLETE STOP before returning

the blade to its fully elevated position.

CAUTION:

• Whenever performing the slide cut, FIRST PULL

THE CARRIAGE TOWARD YOU FULLY and press

down the handle to the fully lowered position, then

PUSH THE CARRIAGE TOWARD THE GUIDE

FENCE. NEVER START THE CUT WITH THE

CARRIAGE NOT FULLY PULLED TOWARD YOU.

If you perform the slide cut without pulling the

carriage fully or if you perform the slide cut toward

your direction, the blade may kickback

unexpectedly with the potential to cause serious

PERSONAL INJURY.

• Never perform the slide cut with the handle locked

in the lowered position by pressing the stopper pin.

• Never loosen the knob which secures the carriage

while the blade is rotating. This may cause serious

injury.

15

Page 16

3. Miter cutting

Refer to the previously covered "Adjusting the

miter angle".

4. Bevel cut

009505

Loosen the lever and tilt the saw blade to set the

bevel angle (Refer to the previously covered

"Adjusting the bevel angle"). Be sure to retighten

the lever firmly to secure the selected bevel angle

safely. Secure the workpiece with a vise. Make

sure the carriage is pulled all the way back toward

the operator. Switch on the tool without the blade

making any contact and wait until the blade attains

full speed. Then gently lower the handle to the fully

lowered position while applying pressure in parallel

with the blade and PUSH THE CARRIAGE

TOWARD THE GUIDE FENCE TO CUT THE

WORKPIECE. When the cut is completed, switch

off the tool and WAIT UNTIL THE BLADE HAS

COME TO A COMPLETE STOP before returning

the blade to its fully elevated position.

CAUTION:

• Always be sure that the blade will move down to

bevel direction during a bevel cut. Keep hands out

of path of saw blade.

• During a bevel cut, it may create a condition

whereby the piece cut off will come to rest against

the side of the blade. If the blade is raised while the

blade is still rotating, this piece may be caught by

the blade, causing fragments to be scattered which

is dangerous. The blade should be raised ONLY

after the blade has come to a complete stop.

• When pressing down the handle, apply pressure in

parallel with the blade. If a force is applied

perpendicularly to the turn base or if the pressure

direction is changed during a cut, the precision of

the cut will be impaired.

• Before bevel-cutting, the adjustment of upper

fence and lower fence is required. Refer to the

section titled "Guide fence adjustment".

5. Compound cutting

Compound cutting is the process in which a bevel

angle is made at the same time in which a miter

angle is being cut on a workpiece. Compound

cutting can be performed at angle shown in the

table.

Miter angle Bevel angle

Left and Right 0 - 45

009713

Left and Right 0 - 45

When performing compound cutting, refer to

"Press cutting", "Slide cutting", "Miter cutting" and

"Bevel cut" explanations.

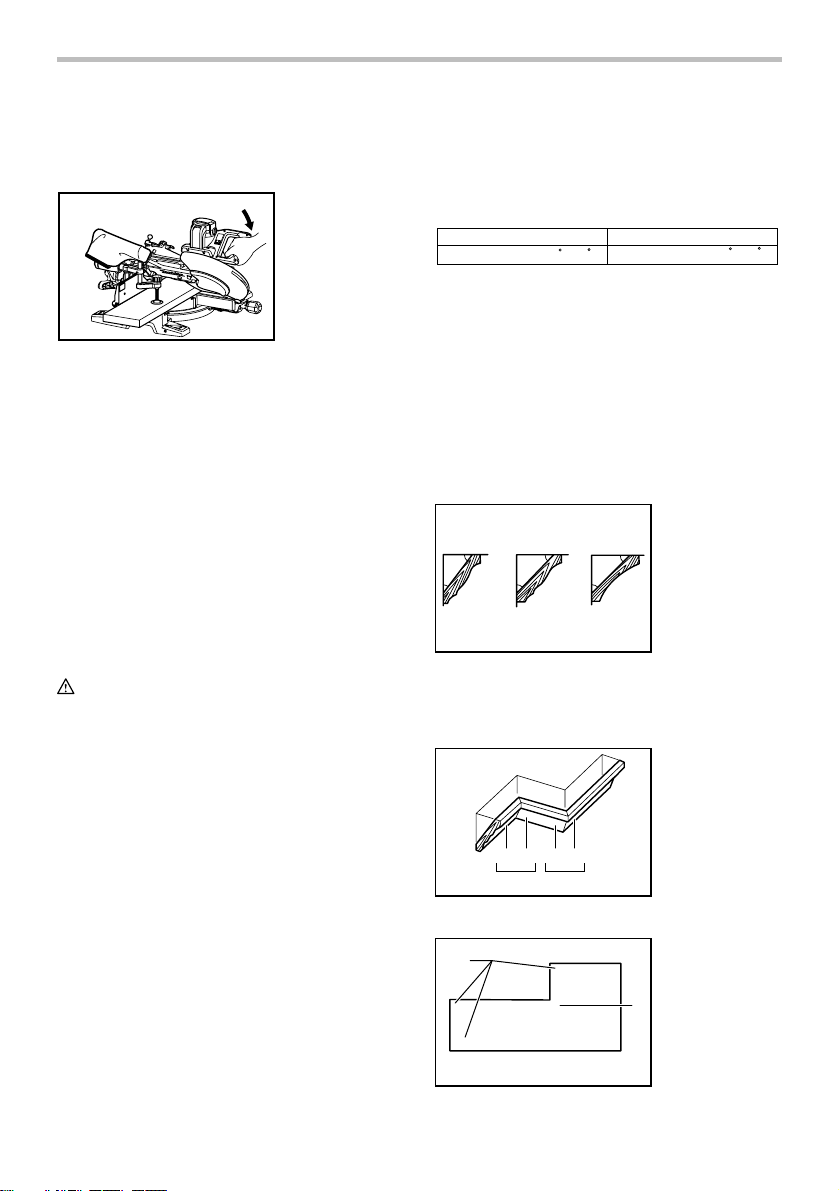

6. Cutting crown and cove moldings

Crown and cove moldings can be cut on a

compound miter saw with the moldings laid flat on

the turn base.

There are two common types of crown moldings

and one type of cove moldings; 52/38° wall angle

crown molding, 45° wall angle crown molding and

45° wall angle cove molding. See illustrations.

1. 52/38 ゚ type

52

38

45

45

45

45

2. 45 ゚ type crown

3. 45 ゚ type cove

123

001555

There are crown and cove molding joints which are

made to fit "Inside" 90° corners ((1) and (2) in Fig.

A) and "Outside" 90° corners ((3) and (4) in Fig. A).

1. Inside corner

2. Outside corner

(1) (2) (3)(4)

Fig.A

001556

1 2

1. Inside corner

2. Outside corner

(2)

2

(1)

(1)

(2)

001557

1

(2)

(1)

(1)

(2)

(1)

(4)

(3)

(2)

16

crown molding

molding

molding

Page 17

Measuring

Measure the wall length and adjust workpiece on

table to cut wall contact edge to desired length.

Always make sure that cut workpiece length at the

back of the workpiece is the same as wall length.

Adjust cut length for angle of cut. Always use

several pieces for test cuts to check the saw

angles.

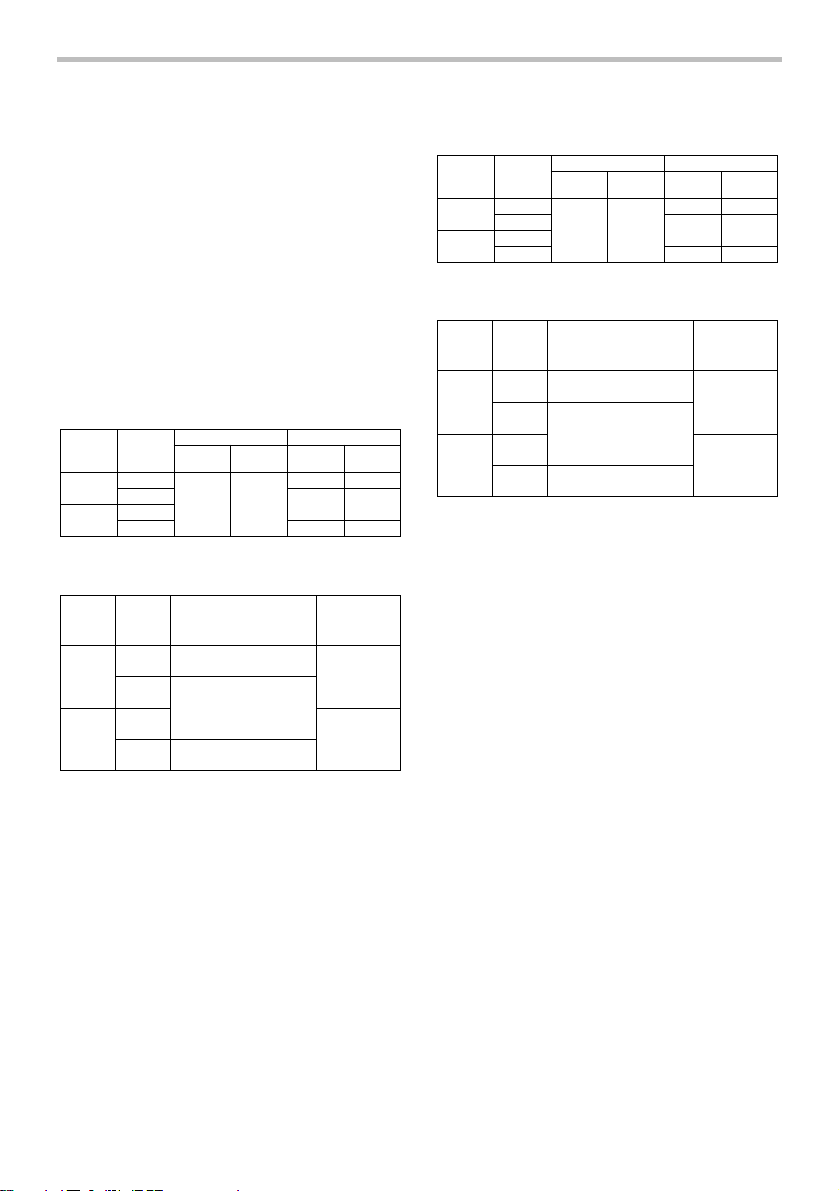

When cutting crown and cove moldings, set the

bevel angle and miter angle as indicated in the

table (A) and position the moldings on the top

surface of the saw base as indicated in the table

(B).

In the case of left bevel cut

Table (A)

Bevel angleMiter angle

52/38° type 45° type

Left 33.9° Left 30°

52/38° type

Right 31.6°

Left 31.6°Left 35.3°

For inside

corner

For outside

corner

006361

Molding

position in

Fig. A

(1)

(2)

(3)

(4)

Table (B)

Molding

Molding edge against

For inside

corner

For

outside

corner

006362

position in

guide fence

Fig. A

Ceiling contact edge should

(1)

be against guide fence.

(2)

Wall contact edge should be

against guide fen

(3)

Ceiling contact edge should

(4)

be against guide fence.

ce.

Finished piece

Finished piece

will be on the

Left side of

blade.

Finished piece

will be on the

Right side of

blade.

Example:

In the case of cutting 52/38° type crown

molding for position (1) in Fig. A:

• Tilt and secure bevel angle setting to

33.9° LEFT.

• Adjust and secure miter angle setting to

31.6° RIGHT.

• Lay crown molding with its broad back

(hidden) surface down on the turn base

with its CEILING CONTACT EDGE

against the guide fence on the saw.

• The finished piece to be used will

always be on the LEFT side of the blade

after the cut has been made.

45° type

Right 35.3°

Right 35.3°Right 31.6°

In the case of right bevel cut

Molding

position in

Fig. A

For inside

corner

For outside

corner

006363

(1)

(2)

(3)

(4)

Molding

position in

Fig. A

For inside

corner

For

outside

corner

006364

(1)

(2)

(3)

(4)

Example:

In the case of cutting 52/38° type crown

molding for position (1) in Fig. A:

• Tilt and secure bevel angle setting to

33.9° RIGHT.

• Adjust and secure miter angle setting to

31.6° RIGHT.

• Lay crown molding with its broad back

(hidden) surface down on the turn base

with its WALL CONTACT EDGE against

the guide fence on the saw.

• The finished piece to be used will

always be on the RIGHT side of the

blade after the cut has been made.

Table (A)

Bevel angleMiter angle

52/38° type 45° type

Right 33.9° Right 30°

52/38° type

Right 31.6°

Left 31.6°Left 35.3°

Table (B)

Molding edge against

guide fence

Wall contact edge should b

against guide fence.

Ceiling contact edge should

be against guide fence.

Wall contact edge should be

against guide fence.

Finished piece

e

Finished piece

will be on the

Right side of

blade.

Finished piece

will be on the

Left side of

blade.

45° type

Right 35.3°

Right 35.3°Right 31.6°

17

Page 18

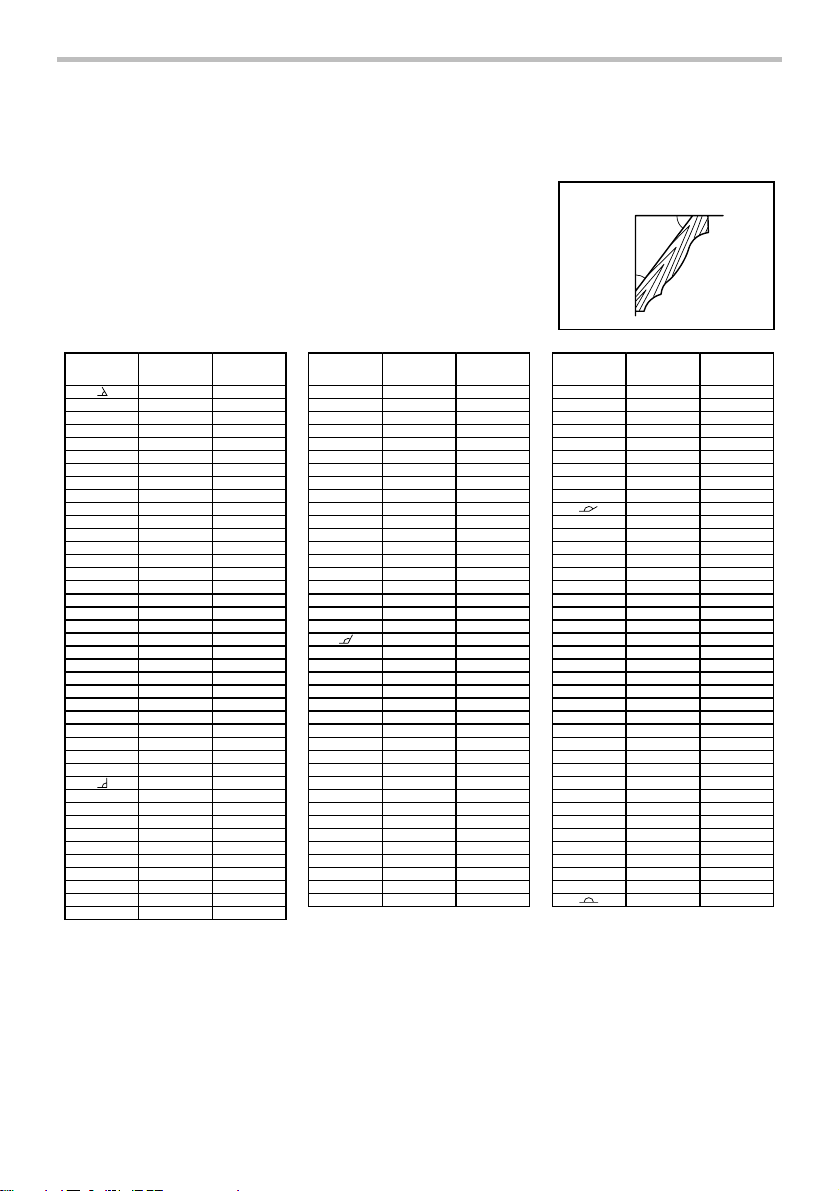

Compound Miter Saw

Miter and Bevel Angle Settings

Ceiling

52°

38°

Wall

Wall to Crown Molding Angle: 52/38 degrees

Wall Angle

(deg.)

EN0002-1

Bevel Angle

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

(deg.)

43.0

42.8

42.5

42.2

41.9

41.7

41.4

41.1

40.8

40.5

40.2

39.9

39.6

39.3

39.0

38.7

38.4

38.1

37.8

37.4

37.1

36.8

36.5

36.2

35.8

35.5

35.2

34.9

34.5

34.2

33.9

33.5

33.2

32.8

32.5

32.2

31.8

31.5

31.1

30.8

30.4

Miter Angle

(deg.)

46.8

46.3

45.7

45.1

44.6

44.0

43.5

42.9

42.4

41.9

41.3

40.8

40.3

39.8

39.2

38.7

38.2

37.7

37.2

36.8

36.3

35.8

35.3

34.8

34.4

33.9

33.4

33.0

32.5

32.1

.6

31

31.2

30.7

30.3

29.9

29.4

29.0

28.6

28.2

27.7

27.3

Wall Angle

(deg.)

Bevel Angle

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

(deg.)

30.1

29.7

29.4

29.0

28.7

28.3

28.0

27.6

27.2

26.9

26.5

26.1

25.8

25.4

25.0

24.7

24.3

23.9

23.6

23.2

22.8

22.5

22.1

21.7

21.3

21.0

20.6

20.2

19.8

19.5

19.1

18.7

18.3

17.9

17.6

17.2

16.8

16.4

16.0

15.6

Miter Angle

(deg.)

26.9

26.5

26.1

25.7

25.3

24.9

24.5

24.1

23.7

23.3

22.9

22.6

22.2

21.8

21.4

21.0

20.7

20.3

19.9

19.6

19.2

18.8

18.5

18.1

17.8

17.4

17.1

.7

16

16.4

16.0

15.7

15.3

15.0

14.6

14.3

14.0

13.6

13.3

13.0

12.8

000031

Wall Angle

(deg.)

141

142

143

144

1

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

177

178

179

180

Bevel Angle

(deg.)

45

15.3

14.9

14.5

14.1

13.7

13.3

12.9

12.5

12.2

11.8

11.4

11.0

10.8

10.2

9.8

9.4

9.0

8.6

8.3

7.9

7.5

7.1

6.7

6.3

5.9

5.5

5.1

4.7

4.3

3.9

3.5

3.2

2.8

2.4

2.0

1.6

1.2

0.8

0.4

0.0

Miter Angle

(deg.)

12.3

12.0

11.6

11.3

11.0

10.7

10.3

10.0

9.7

9.4

9.0

8.7

8.4

8.1

7.8

7.5

7.1

6.8

6.5

6.2

5.9

5.6

5.3

4.9

4.6

4.3

4.0

3.7

3.4

3.1

2.8

2.5

2.2

1.8

1.5

1.2

0.9

0.6

0.3

0.0

18

Page 19

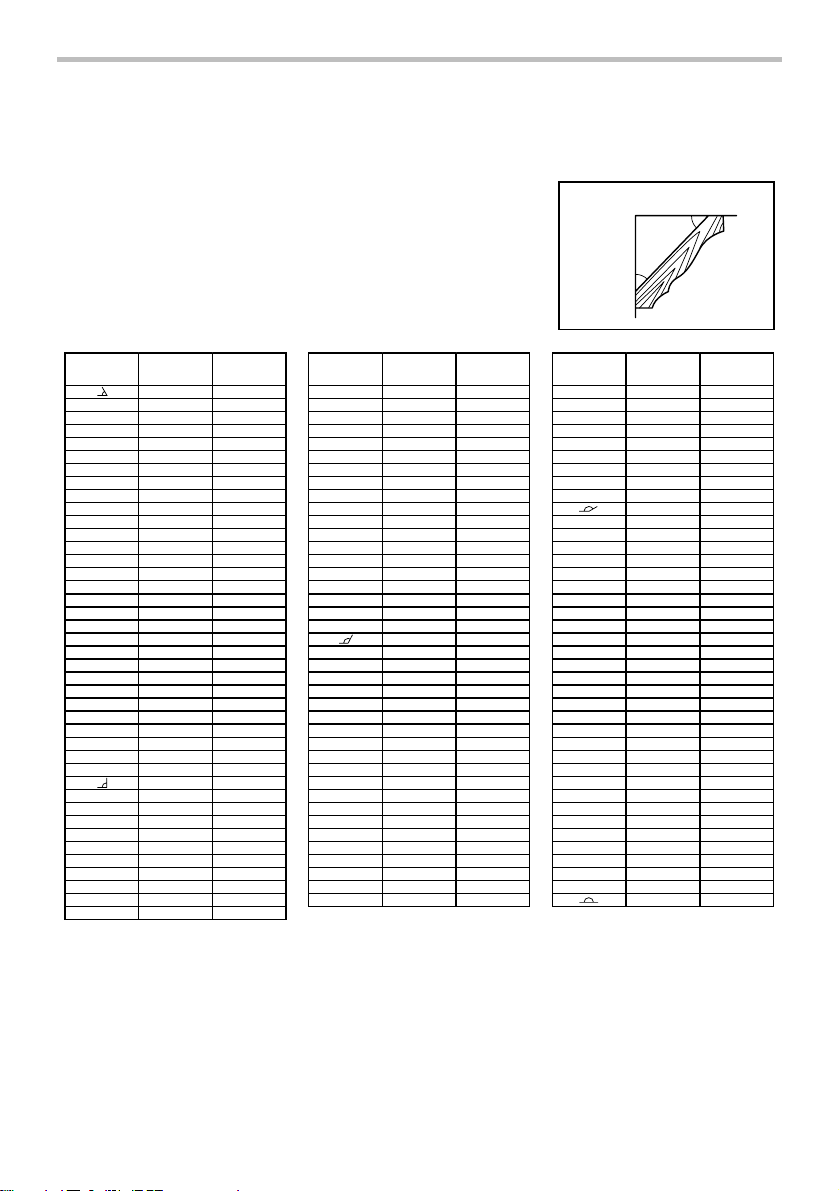

Compound Miter Saw

Miter and Bevel Angle Settings

Ceiling

45°

45°

Wall

Wall to Crown Molding Angle: 45 degrees

Wall Angle

EN0003-1

(deg.)

Bevel Angle

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

(deg.)

37.8

37.5

37.3

37.1

36.8

36.6

36.4

36.1

35.9

35.6

35.4

35.1

34.9

34.6

34.4

34.1

33.9

33.6

33.3

33.1

32.8

32.5

32.3

32.0

31.7

31.4

31.1

30.9

30.6

30.3

30.0

29.7

29.4

29.1

28.8

28.5

28.2

27.9

27.6

27.3

27.0

Miter Angle

(deg.)

50.8

50.2

49.6

49.1

48.5

48.0

47.4

46.9

46.4

45.8

45.3

44.8

44.2

43.7

43.2

42.7

42.1

41.6

41.1

40.6

40.1

39.6

39.1

38.6

38.1

37.7

37.2

36.7

36.2

35.7

35.3

34.8

34.3

33.9

33.4

32.9

32.5

32.0

31.6

31.1

30.7

Wall Angle

(deg.)

Crown molding stoppers (optional accessories)

allow easier cuts of crown molding without tilting

the saw blade. Install them on the base as shown

in the figures.

Bevel Angle

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

(deg.)

26.7

26.4

26.1

25.8

25.5

25.2

24.9

24.6

24.2

23.9

23.6

23.3

23.0

22.7

22.3

22.0

21.7

21.4

21.0

20.7

20.4

20.0

19.7

19.4

19.1

18.7

18.4

18.1

17.7

17.4

17.1

16.7

16.4

16.0

15.7

15.4

15.0

14.7

14.3

14.0

Miter Angle

(deg.)

30.2

9.8

2

29.4

28.9

28.5

28.1

27.6

27.2

26.8

26.3

25.9

25.5

25.1

24.7

24.3

23.8

23.4

23.0

22.6

22.2

21.8

21.4

21.0

20.6

20.2

19.8

19.4

19.0

18.6

18.2

17.9

17.5

17.1

16.7

16.3

15.9

15.6

15.2

14.8

14.4

000032

Wall Angle

(deg.)

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

177

178

179

180

Bevel Angle

(deg.)

13.7

13.3

13.0

12.6

12.3

11.9

11.6

11.2

10.9

10.5

10.2

9.8

9.5

9.2

8.8

8.5

8.1

7.8

7.4

7.1

6.7

6.4

6.0

5.6

5.3

4.9

4.6

4.2

3.9

3.5

3.2

2.8

2.5

2.1

1.8

1.4

1.1

0.7

0.4

0.0

Miter Angle

(deg.)

14.1

13.7

13.3

12.9

12.6

12.2

11.8

11.5

.1

11

10.7

10.4

10.0

9.6

9.3

8.9

8.5

8.2

7.8

7.5

7.1

6.7

6.4

6.0

5.7

5.3

5.0

4.6

4.3

3.9

3.5

3.2

2.8

2.5

2.1

1.8

1.4

1.1

0.7

0.4

0.0

19

Page 20

1. Crown molding

stopper L

(Optional

accessory)

2. Crown molding

stopper R

(Optional

accessory)

3. Turn base

009521

1

2

3

1. Crown molding

stopper L

2. Crown molding

stopper R

3. Turn base

009522

2

1

3

Fig. B: At right 45° miter angle

Fig. C: At left 45° miter angle

Position crown molding with its WALL CONTACT

EDGE against the guide fence and its CEILING

CONTACT EDGE against the crown molding

stoppers as shown in the figure. Adjust the crown

molding stoppers according to the size of the

crown molding. Tighten the screws to secure the

crown molding stoppers. Refer to the table (C) for

the miter angle.

1. Guide fence

1

2. Crown molding

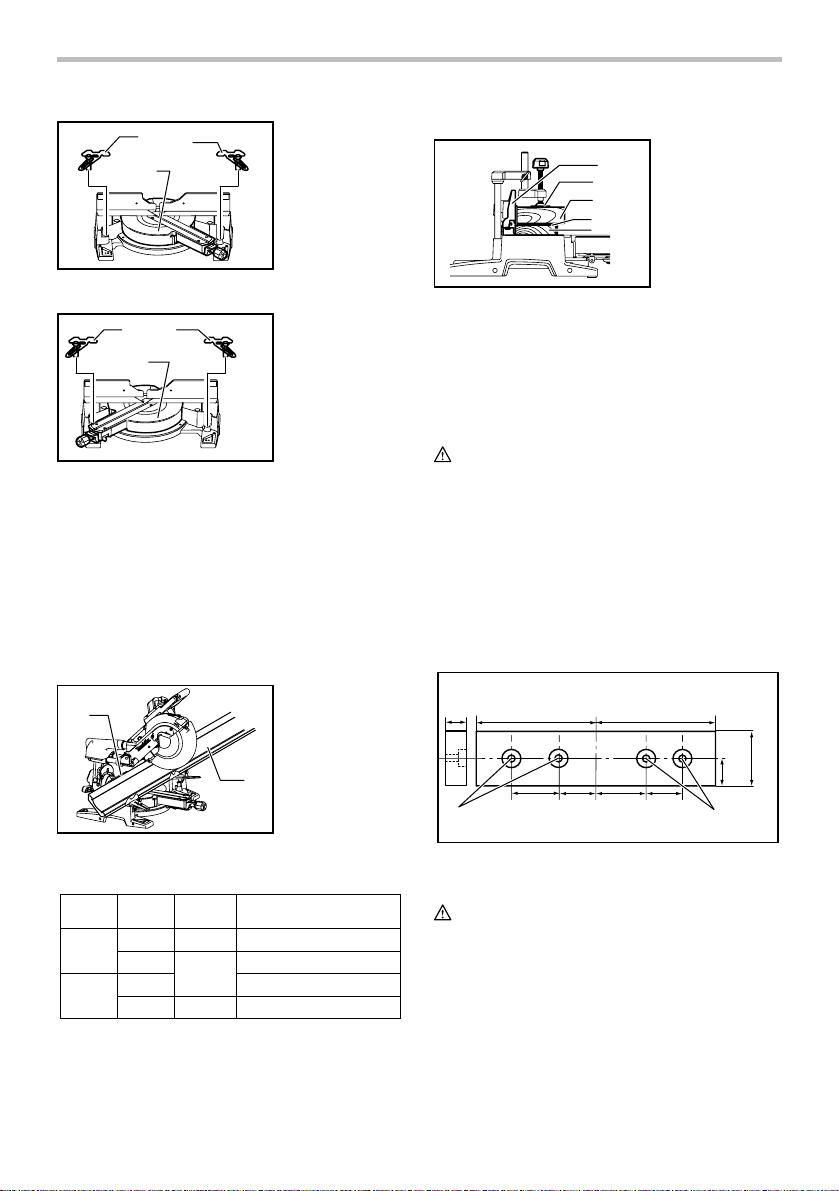

7. Cutting aluminum extrusion

1. Guide fence

2. Vise

3. Spacer block

4. Aluminum

extrusion

5. Spacer block

009523

1

2

3

4

5

When securing aluminum extrusions, use spacer

blocks or pieces of scrap as shown in the figure to

prevent deformation of the aluminum. Use a

cutting lubricant when cutting the aluminum

extrusion to prevent build-up of the aluminum

material on the blade.

CAUTION:

• Never attempt to cut thick or round aluminum

extrusions. Thick aluminum extrusions may come

loose during operation and round aluminum

extrusions cannot be secured firmly with this tool.

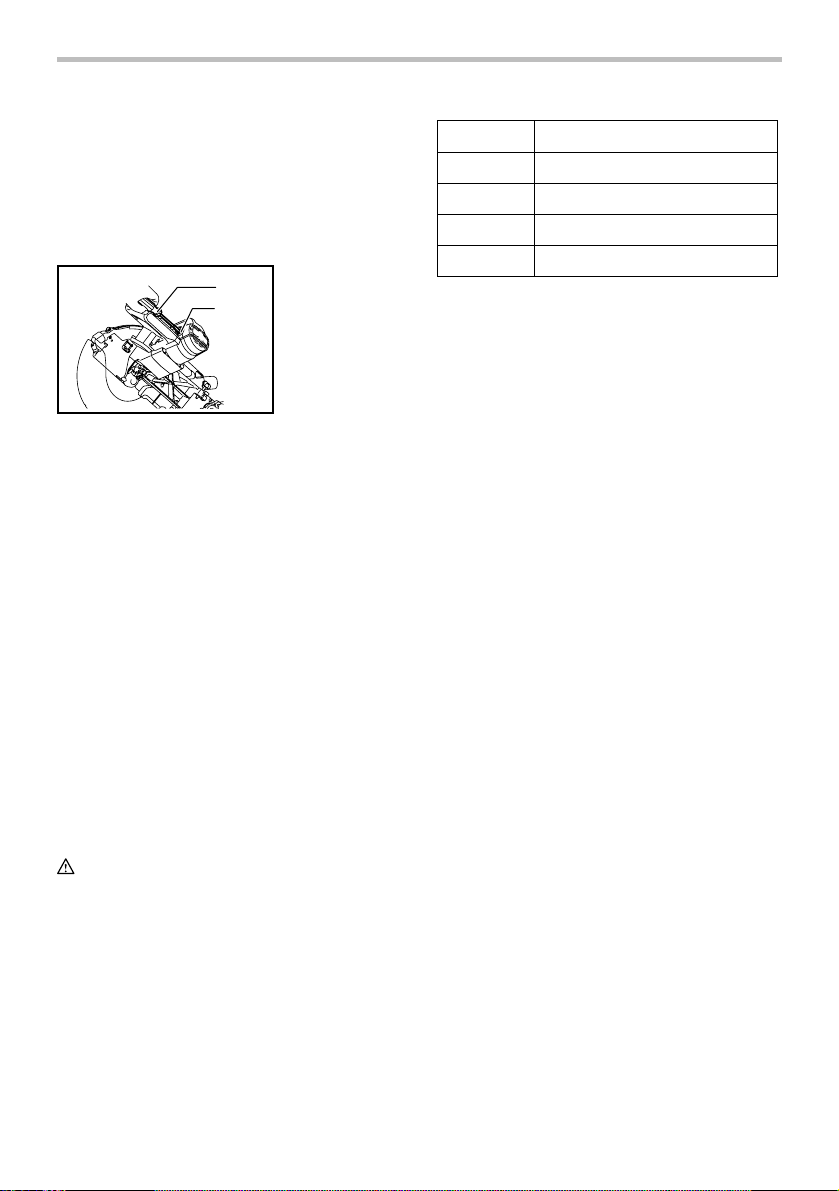

8. Wood facing

Use of wood facing helps to assure splinter-free

cuts in workpieces. Attach a wood facing to the

guide fence using the holes in the guide fence and

6 mm (1/4") screws.

See the figure concerning the dimensions for a

suggested wood facing.

Over

15mm(9/16”)

Over 290mm(11-3/8”)

Over 340mm(13-3/8”)

009520

For inside

corner

For outside

corner

006365

2

Table (C)

Position in

Miter angle Finished piece

Fig. A

(1) Right 45° Save the right side of blade

(2) Save the left side of blade

Left 45°

(3) Save the right side of blade

(4) Right 45° Save the left side

of blade

135mm

1

1. Hole

010047

106mm 116mm 180mm

(5-5/16”)

(4-3/16”) (7-1/8”)(4-9/16”)

CAUTION:

• Use straight wood of even thickness as the wood

facing.

• When cutting workpieces from 107 mm (4 -1/4") to

120 mm (4 - 3/4") high, use a wood facing to

prevent a portion of the workpiece near the guide

fence from being left uncut.

20

(3-1/8”)

80mm

(4-1/2” - 4-3/4”)

115 - 120mm

1

Page 21

Example:

When cutting workpieces 115 mm (4-1/2")

and 120 mm (4 - 3/4") high, use a wood

facing with the following thickness.

Thickness of wood facing

115 mm (4-1/2") 120 mm (4-3/4")

15 mm (9/16")

15 mm (9/16")

15 mm (9/16")

38 mm (1-1/2")

25 mm (1")

25 mm (1")

25 mm (1")

Left and Right 45°

Left and Right 52°

010050

Miter angle

0° 20 mm (13/16")

Right 60°

CAUTION:

• Use screws to attach the wood facing to the guide

fence. The screws should be installed so that the

screw heads are below the surface of the wood

facing.

• When the wood facing is attached, do not turn the

turn base with the handle lowered. The blade

and/or the wood facing will be damaged.

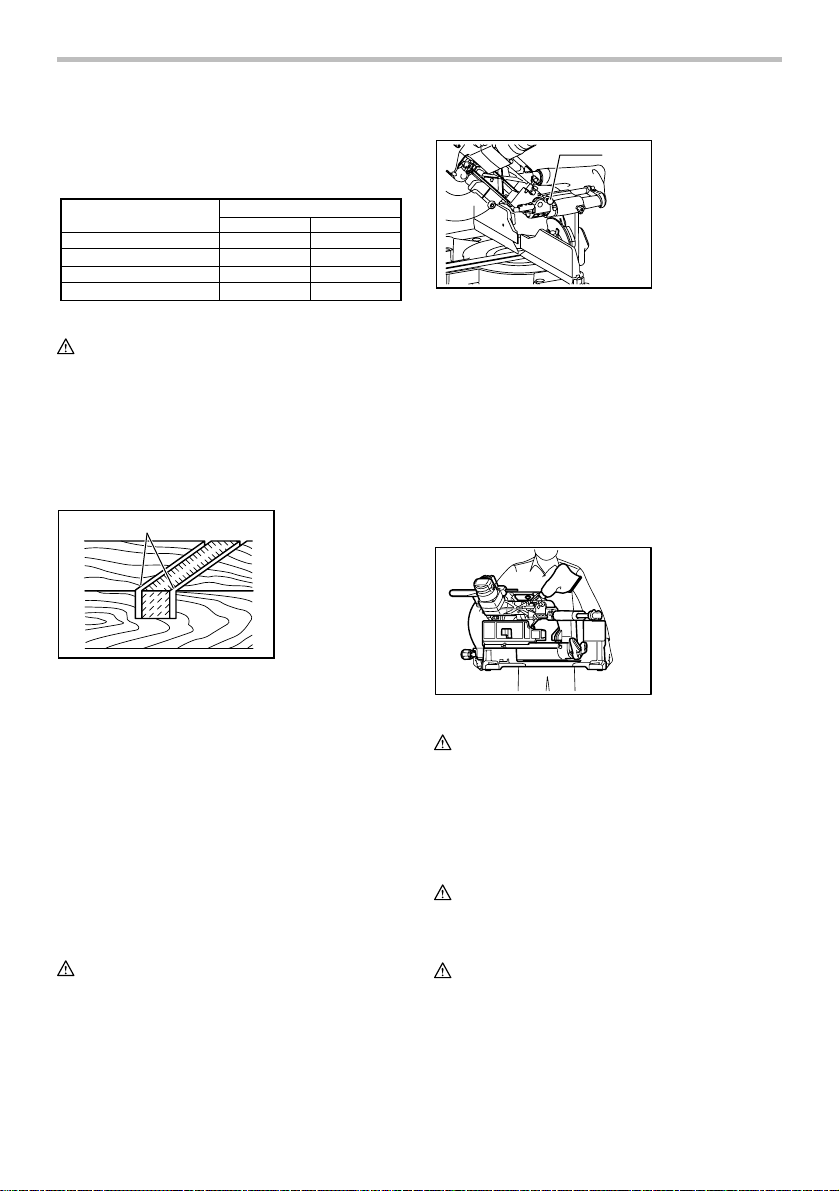

9. Groove cutting

1

1. Cut grooves with

blade

Carrying tool

1. Stopper pin

1

009483

Make sure that the tool is unplugged. Secure the blade

at 0° bevel angle and the turn base at right miter angle

fully. Secure the slide poles so that the lower slide pole

is locked in the position of the carriage fully pulled to

operator and the upper poles are locked in the position

of the carriage fully pushed forward to the guide fence

(refer to the section titled "Slide lock adjustment ".)

Lower the handle fully and lock it in the lowered position

by pushing in the stopper pin.

Carry the tool by holding both sides of the tool base as

shown in the figure. If you remove the holders, dust bag,

etc., you can carry the tool more easily.

001563

A dado type cut can be made by proceeding as

follows:

Adjust the lower limit position of the blade using

the adjusting screw and the stopper arm to limit the

cutting depth of the blade. Refer to "Stopper arm"

section described previously.

After adjusting the lower limit position of the blade,

cut parallel grooves across the width of the

workpiece using a slide (push) cut as shown in the

figure. Then remove the workpiece material

between the grooves with a chisel. Do not attempt

to perform this type of cut using wide (thick) blades

or with a dado blade. Possible loss of control and

injury may result.

CAUTION:

• Be sure to return the stopper arm to the original

position when performing other than groove

cutting.

009506

CAUTION:

• Always secure all moving portions before carrying

the tool.

• Stopper pin is for carrying and storage purposes

only and not for any cutting operations.

MAINTENANCE

CAUTION:

• Always be sure that the tool is switched off and

unplugged before attempting to perform inspection

or maintenance.

WARNING:

• Always be sure that the blade is sharp and clean

for the best and safest performance.

Adjusting the cutting angle

This tool is carefully adjusted and aligned at the factory,

but rough handling may have affected the alignment. If

your tool is not aligned properly, perform the following:

21

Page 22

1. Miter angle

Push the carriage toward the guide fence and

tighten the locking screw clockwise and pull the

lock lever toward yourself to secure the carriage.

Turn the grip counterclockwise which secures the

turn base. Turn the turn base so that the pointer

points to 0° on the miter scale. Then turn the turn

base slightly clockwise and counterclockwise to

seat the turn base in the 0° miter notch. (Leave as

it is if the pointer does not point to 0°.) Loosen the

hex sockets bolts securing the guide fence using

the socket wrench.

Lower the handle fully and lock it in the lowered

position by pushing in the stopper pin. Square the

side of the blade with the face of the guide fence

using a triangular rule, try-square, etc. Then

securely tighten the hex socket bolts on the guide

fence in the order from the right side.

1. Triangular rule

1

009509

Make sure that the pointer points to 0° on the miter

scale. If the pointer does not point to 0°, loosen the

screw which secures the pointer and adjust the

pointer so that it will point to 0°.

3

009525

1. Screw

2. Pointer

1

3. Miter scale

2

2. Bevel angle

Push the latch lever forward fully to release the positive

stops.

(1) 0° bevel angle

1. Pointer

1

2

3

009512

Push the carriage toward the guide fence and

tighten the locking screw clockwise and pull

the lock lever toward yourself to secure the

carriage. Lower the handle fully and lock it in

the lowered position by pushing in the

stopper pin. Loosen the lever at the rear of

the tool.

Turn the hex socket bolt on the right side of

the arm holder two or three revolutions

counterclockwise to tilt the blade to the right.

3

1

009511

Carefully square the side of the blade with

the top surface of the turn base using the

triangular rule, try-square, etc. by turning the

hex socket bolt on the right side of the arm

holder clockwise. Then tighten the lever

securely.

1

2

001819

22

2. Lever

3. Bevel scale

plate

1. 0 ゚ Angle

adjusting bolt

2. Lever

3. Latch lever

2

1. Triangular rule

2. Saw blade

3. Top surface of

3

turn base

Page 23

Make sure that the pointers on the arm holder

point to 0° on the bevel scale plate on the

arm. If they do not point to 0°, loosen the

screws which secure the pointers and adjust

them so that they will point to 0°.

1. Bevel scale

plate

1

2

009490

(2) 45° bevel angle

009608

3

Adjust the 45° bevel angle only after

performing 0° bevel angle adjustment. To

adjust left 45° bevel angle, loosen the lever

and tilt the blade to the left fully. Make sure

that the pointer on the arm holder points to

45° on the bevel scale on the arm. If the

pointer does not point to 45°, turn the left 45°

bevel angle adjusting bolt on the side of the

arm until the pointer points to 45°.

To adjust right 45° bevel angle, perform the

same procedure described above.

1

2

4

2. Pointer

1. Pointer

2. Scale plate

3. Left 45 ゚ bevel

angle adjusting

bolt

4. Right 45 ゚ bevel

angle adjusting

bolt

Adjusting the position of laser line

For model LS1216L only

1. Workpiece

1

2

009526

2. Laser line

1. Vertical vise

1

009527

WARNING:

• As the tool is plugged when adjusting the position

of laser line, take a full caution especially at switch

action. Pulling the switch trigger accidentally cause

an accidental start of the tool and personal injury.

CAUTION:

• Never look into the laser beam directly. Direct laser

beam causes damage to your eyes.

• LASER RADIATION

Do not stare into beam.

• Never apply a blow or impact to the tool. A blow or

impact causes the incorrect position of laser line,

damage to the laser beam emitting part or a short

life of the tool.

When adjusting the laser line appears on the left

side of the saw blade

1

2

1. Screw to change the movable range of the adjusting

screw

2. Adjusting screw

3. Hex wrench

4. Laser line

5. Saw blade

009514

4

3

5

23

Page 24

When adjusting the laser line appears on the right

side of the saw blade

3

1. Adjusting screw

2. Saw blade

3. Laser line

009515

2

1

For both adjustments, do as follows.

1. Make sure that the tool is unplugged.

2. Draw the cutting line on the workpiece and place it

on the turn table. At this time, do not secure the

workpiece with a vise or similar securing device.

3. Lower the blade by lowering the handle and just

check to see where the cutting line and the

position of the saw blade is. (Decide which

position to cut on the line of cut.)

4. After decision the position to be cut, return the

handle to the original position. Secure the

workpiece with the vertical vise without shifting

the workpiece from the pre-checked position.

5. Plug the tool and turn on the laser switch.

6. Adjust the position of laser line as follows.

The position of laser line can be changed as the

movable range of the adjusting screw for the laser is

changed by turning two screws with a hex wrench. (The

movable range of laser line is factory adjusted within 1

mm (0.04") from the side surface of blade.)

To shift the laser line movable range further away from

the side surface of blade, turn the two screws

counterclockwise after loosening the adjusting screw.

Turn these two screws clockwise to shift it closer to the

side surface of the blade after loosening the adjusting

screw.

Refer to the section titled "Laser line action" and adjust

the adjusting screw so that the cutting line on your

workpiece is aligned with the laser line.

NOTE:

• Check the position of laser line regularly for

accuracy .

• Have the tool repaired by Makita authorized

service center for any failure on the laser unit.

Cleaning of the lens for the laser light

For model LS1216L only

1. Screwdriver

2. Screw (one

piece only)

3. Lens for the

1

2

3

009609

laser light

If the lens for the laser light becomes dirty, or sawdust

adheres to it in such a way that the laser line is no longer

easily visible, unplug the saw and remove and clean the

lens for the laser light carefully with a damp, soft cloth.

Do not use solvents or any petroleum-based cleaners on

the lens.

1. Lens for the

laser light

1

009610

To remove the lens for the laser light, remove the saw

blade before removing the lens according to the

instructions in the section titled "Installing or removing

saw blade".

Loosen but do not remove the screw which secures the

lens using a screwdriver.

Pull out the lens as shown in the figure.

NOTE:

• If the lens does not come out, loosen the screw

further and pull out the lens again without removing

the screw.

Replacing carbon brushes

1. Limit mark

1

001145

24

Page 25

Remove and check the carbon brushes regularly.

Replace when they wear down to the limit mark. Keep

the carbon brushes clean and free to slip in the holders.

Both carbon brushes should be replaced at the same

time. Use only identical carbon brushes.

Use a screwdriver to remove the brush holder caps.

Take out the worn carbon brushes, insert the new ones

and secure the brush holder caps.

1

2

009516

1. Screwdriver

2. Brush holder

cap

After replacing brushes, plug in the tool and break in

brushes by running tool with no load for about 10

minutes. Then check the tool while running and electric

brake operation when releasing the switch trigger. If

electric brake is not working well, ask your local Makita

service center for repair.

After use

• After use, wipe off chips and dust adhering to the

tool with a cloth or the like. Keep the blade guard

clean according to the directions in the previously

covered section titled "Blade guard". Lubricate the

sliding portions with machine oil to prevent rust.

• When storing the tool, pull the carriage toward you

fully so that the slide pole is thoroughly inserted

into the turn base.

To maintain product SAFETY and RELIABILITY, repairs,

any other maintenance or adjustment should be

performed by Makita Authorized or Factory Service

Centers, always using Makita replacement parts.

ACCESSORIES

CAUTION:

• These accessories or attachments are

recommended for use with your Makita tool

specified in this manual. The use of any other

accessories or attachments might present a risk of

injury to persons. Only use accessory or

attachment for its stated purpose.

If you need any assistance for more details regarding

these accessories, ask your local Makita Service Center.

• Steel & Carbide-tipped saw blades

Miter saw blades

Combination

Crosscutting

Fine cross cuts For sand-free cuts cleanly against the grain.

Non-ferrous metals

miter saw blades

006526

For smooth and precise cutting in various materials.

General purpose blade for fast and smooth rip,

crosscuts and miters.

For smoother cross grain cuts. Slices cleanly

against the grain.

For miters in aluminum, copper, brass, tubing,

and other non-ferrous metals.

• Vise assembly (Horizontal vise)

• Vertic al vi se

• Socket wrench 13

• Holder

• Dust bag

• Crown molding stopper set

• Triangular rule

• Dust box

• Hex wrench (for LS1216L)

25

Page 26

MAKITA LIMITED ONE YEAR WARRANTY

Warranty Policy

Every Makita tool is thoroughly inspected and tested

before leaving the factory. It is warranted to be free of

defects from workmanship and materials for the period

of ONE YEAR from the date of original purchase.

Should any trouble develop during this one year period,

return the COMPLETE tool, freight prepaid, to one of

Makita’s Factory or Authorized Service Centers. If

inspection shows the trouble is caused by defective

workmanship or material, Makita will repair (or at our

option, replace) without charge.

This Warranty does not apply where:

repairs have been made or attempted by others:

repairs are required because of normal wear and

tear:

the tool has been abused, misused or improperly

maintained:

alterations have been made to the tool.

IN NO EVENT SHALL MAKITA BE LIABLE FOR ANY

INDIRECT, INCIDENTAL OR CONSEQUENTIAL

DAMAGES FROM THE SALE OR USE OF THE

PRODUCT. THIS DISCLAIMER APPLIES BOTH

DURING AND AFTER THE TERM OF THIS

WARRANTY.

MAKITA DISCLAIMS LIABILITY FOR ANY IMPLIED

WARRANTIES, INCLUDING IMPLIED WARRANTIES

OF "MERCHANTABILITY" AND "FITNESS FOR A

SPECIFIC PURPOSE," AFTER THE ONE YEAR TERM

OF THIS WARRANTY.

This Warranty gives you specific legal rights, and you

may also have other rights which vary from state to

state. Some states do not allow the exclusion or

limitation of incidental or consequential damages, so

the above limitation or exclusion may not apply to you.

Some states do not allow limitation on how long an

implied warranty lasts, so the above limitation may not

apply to you.

EN0006-1

26

Page 27

FRANÇAIS

SPÉCIFICATIONS

Modèle LS1216/LS1216L

Diamètre de la lame 305 mm (12")

Diamètre de l'orifice 25,4 mm (1")

Capacités de coupe maximales (H x P)

Angle de coupe en biseau

―

―

―

―

―

―

―

―

―

―

(4-1/2"×8-15/16")

(4-3/4"×8-3/8")

92mm×233mm

(3-5/8"×9-1/8")

107mm×220mm

(4-1/4"×8-5/8")

(4-1/2"×7-3/4")

(4-3/4"×7-1/8")

92mm×185mm

(3-5/8"×7-1/4")

107mm×178mm

(4-1/4"×7")

(4-1/2"×6-1/8")

(4-3/4"×5-1/2")

―

―

―

―

―

―

―

―

―

―

―

0°

45°(Gauche et droite)

52°(Gauche et droite)

60°(droite)

Angle de coupe d'onglet

Épaisseur de

parement en bois

Épaisseur de

parement en bois

Épaisseur de

parement en bois

Épaisseur de

parement en bois

45°(gauche) 0° 45°(droite)

61mm×382mm 92mm×382mm 44mm×382mm

(2-3/8"×15") (3-5/8"×15") (1-3/4"×15")

71mm×363mm 107mm×363mm 54mm×363mm

(2-13/16"×14-1/4") (4-1/4"×14-1/4") (2-1/8"×14-1/4")

20mm 78mm×325mm 115mm×325mm 61mm×325mm

(13/16") (3-1/16"×12-3/4") (4-1/2"×12-3/4") (2-3/8"×12-3/4")

38mm 80mm×292mm 120mm×292mm

(1-1/2") (3-1/8"×11-1/2") (4-3/4"×11-1/2")

61mm×268mm 92mm×268mm 44mm×268mm

(2-3/8"×10-1/2") (3-5/8"×10-1/2") (1-3/4"×10-1/2")

71mm×255mm 107mm×255mm 54mm×255mm

(2-13/16"×10") (4-1/4"×10") (2-1/8"×10")

15mm 115mm×227mm

(9/16")

25mm 120mm×212mm

(1")

15mm 115mm×197mm

(9/16")

25mm 120mm×180mm

(1")

15mm 115mm×155mm

(9/16")

25mm 120mm×140mm

(1")

27

Page 28

Capacités spéciales de coupe max

Moulure couronnée du type 45 ゚

(avec l'utilisation de la butée de moulure couronnée)