Makita LS1211 Instruction Manual

Slide

Compound

Saw

305

mm

(12”)

MODEL

LSl21l

Equipped with Electric Brake

INSTRUCTION MANUAL

DOUBLE

INSULATION

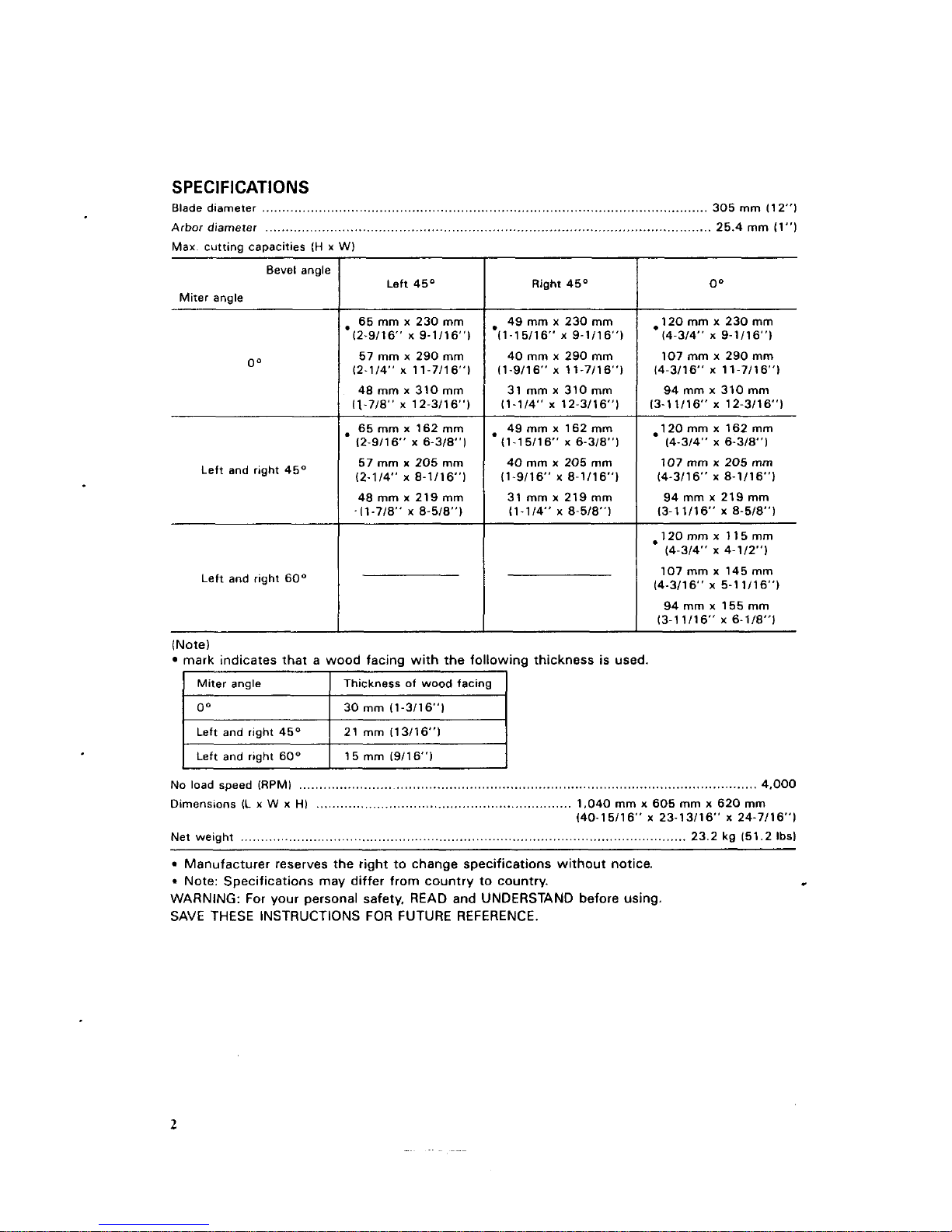

SPECIFICATIONS

Blade diameter ..............................................................................................................

305

mm

11

2")

Arbor diameter ..............................................................................................................

25.4

mm

11")

Max cutting capacities

1H x W)

Left and right

45O

Bevel angle

Left

45"

Right

45"

I

Miter angle

21

mm

113/16"1

.

65

mm

x

230

mm

12-9/16" x 9-1/16',)

57

mm

x

290

mm

12-1/4" x 11-7/16")

48

mm

x

310

mm

11-7/8" x 12-3/16")

00

.

65

mm

x

162

mm

12-9/16'' X 6-3/8"1

57

mm

x

205

mm

(2-1/4" x 8-1/16',)

Left and right

45O

48

mm

x

219

mm

1

.11-7/8" x 8-5/8")

49

mm

x

230

mm

*11-15/16" x 9-1/16',)

40

mm

x

290

mm

11-9/16" x 11-7/16")

31

mm

x

310

mm

11-1/4" x 12-3/16")

49

mm

x

162

mm

40

mm

x

205

mm

11-9/16" x 8-1/16',)

31

mm

x

219

mm

11-1/4"

x

8-5/8")

11-15/16" x 6-3/8"1

[Note)

mark indicates that a wood facing with the following thickness is used.

Miter angle

I

Thickness of wood facing

I

I

30

mm

11-3/16',)

I

oo

00

.120

mm

x

230

mm

14-3/4" x 9-1/16',)

107

mm

x

290

mm

14-3/16" x 11-7/16")

94

mm

x

310

mm

13-11/16" x 12-3/16")

.120

mm

x

162

mm

(4-3/4" x 6-3/8"1

107

mm

x

205

mm

94

mm

x

219

mm

13-1 1/16" x 8-5/8")

14-3/16"

x

8-1/16")

-120mmx

115mm

(4-3/4"

x

4-112")

107

mm

x

145

mm

14-3/16' x 5-1 1/16',)

94

mm

x

155

mm

13-11/16" x 6-118"l

No

load speed (RPMl

................................................................................................................

4,000

Dimensions (L

x W x

HI

..............................

140-15/16" x 23-13/16" x 24-7/16,')

Net weight

.......................

Manufacturer reserves the right to change specifications without notice.

Note: Specifications may differ from country to country.

WARNING: For your personal safety, READ and UNDERSTAND before using.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

.._.

1,040

mm

x

605

mm

x

620

mm

2

For Your Own Safety Read Instruction

Manual Before Operating

Slide Compound Saw

Save

it

for future reference

GENERAL SAFETY PRECAUTIONS

(For

All

Tools)

1.

KNOW YOUR POWER TOOL. Read the owner’s manual carefully. Learn the

tools applications and limitations, as well as the specific potential hazards

peculiar to

it.

2.

KEEP GUARDS IN PLACE and

in

working order.

3.

REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to

see that keys and adjusting wrenches are removed from tool before turning

it

on.

4.

KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

5.

DON’T USE IN DANGEROUS ENVIRONMENT. Don’t use power tools

in

damp

or wet locations, or expose them to rain. Keep work area well lighted.

Don’t use tool

in

presence of flammable liquids or gases.

6.

KEEP CHILDREN AWAY. All visitors should be kept safe distance from work

area.

7.

MAKE WORKSHOP CHILD PROOF

with

padlocks, master switches, or

by

removing starter keys.

8.

DON‘T FORCE TOOL.

It

will do the job better and safer at the rate for which

it

was designed.

9.

USE RIGHT TOOL. Don’t force tool or attachment

to

do a job for which

it

was not designed.

IO.

WEAR PROPER APPAREL. Wear no loose clothing, gloves, neckties, rings,

bracelets, or other jewelry which may get caught

in

moving parts. Nonslip

footwear is recommended. Wear protective hair covering to contain long hair.

11.

ALWAYS USE SAFETY GLASSES. Also use face or dust mask if cutting

operation is dusty. Everyday eyeglasses only have impact resistant lenses,

they are NOT safety glasses.

12.

SECURE WORK. Use clamps or a vise to hold work when practical. It’s safer

than using your hand and

it

frees both hands to operate tool.

13.

DON‘T OVERREACH. Keep proper footing and balance at all times.

14.

MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for best and

safest performance. Follow instructions for lubricating and changing accessories.

15.

DISCONNECT TOOLS before servicing, when changing accessories such as

blades,

bits,

cutters, and the like.

3

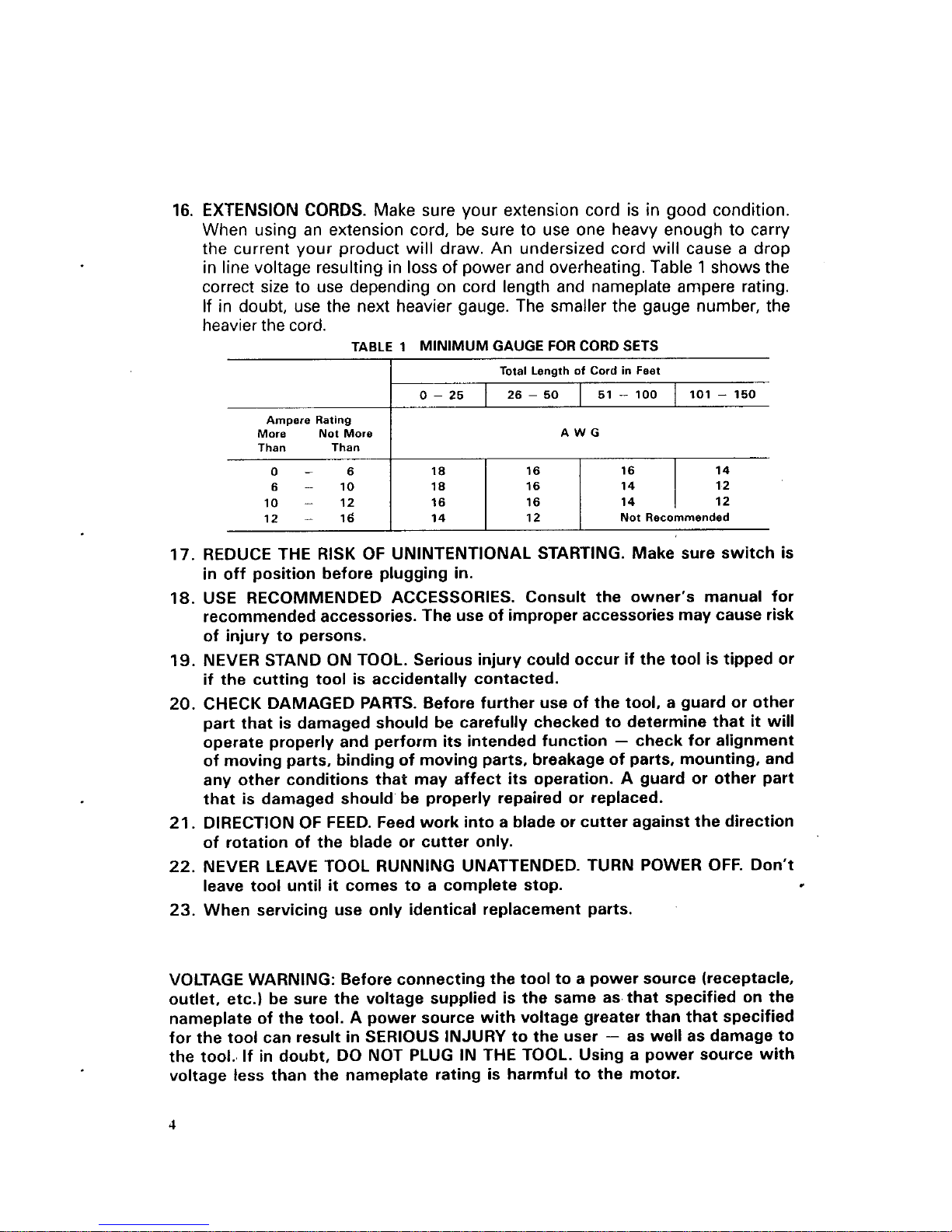

16.

EXTENSION

CORDS.

Make sure your extension cord is in good condition.

When using an extension cord, be sure to use one heavy enough to carry

the current your product will draw. An undersized cord

will

cause a drop

in line voltage resulting in

loss

of

power and overheating. Table 1 shows the

correct size to use depending on cord length and nameplate ampere rating.

If

in doubt, use the next heavier gauge. The smaller the gauge number, the

heavier the cord.

TABLE

1

MINIMUM GAUGE

FOR

CORD

SETS

Total Length

of

Cord

in

Feet

0-

6

6

-

10

10

-

12

12

-

16

I

0

-

25

I

26

-

50

I

51 - 100 I 101

-

150

18 16 14

18 16

16

16 14 12

14

12 Not Recommended

:t

I

12

Ampere Rating

More Not MOW

Than Than

AWG

VOLTAGE WARNING: Before connecting the tool to a power source (receptacle,

outlet, etc.) be sure the voltage supplied is the same as that specified on the

nameplate of the tool. A power source with voltage greater than that specified

for the tool can result in SERIOUS INJURY to the user

-

as well as damage to

the tool. If in doubt, DO NOT PLUG IN THE TOOL. Using a power source with

voltage less than the nameplate rating is harmful to the motor.

ADDITIONAL

SAFETY

RULES

1.

Wear eye protection.

2.

Do

not operate saw without guards

in

place.

3.

Don't use the tool in the presence of flammable liquids or gases.

4.

Check the blade carefully for cracks or damage before operation.

5.

Use only flanges specified for this tool.

6.

Be careful not to damage the arbor, flanges (especially the installing surface)

-

7.

Make sure that the turn base is properly secured

so

it

will not move during

8.

For your safety, remove the chips, small pieces, etc. from the table top before

9.

Avoid cutting nails. Inspect for and remove all nails from the workpiece before

Replace cracked or damaged blade immediately.

or bolt. Damage to these parts could result

in

blade breakage.

operation.

operation.

operation.

IO.

Make sure the shaft lock is released before the switch is turned on.

1

1.

Be sure that the blade does not contact the turn base

in

the lowest position.

12.

Hold the handle firmly. Be aware that the saw moves up or down slightly

during start-up and stopping.

13.

Do not perform any operation freehand. The workpiece must be secured

firmly against the turn base and guide fence with the vise during all

operations. Never use your hand to secure the workpiece.

14.

Keep hands out of path of saw blade. Avoid contact with any coasting blade.

It

can still cause severe injury.

15.

Never reach around saw blade.

16.

Make sure the blade is not contacting

the

workpiece before the switch is

turned on.

17.

Before using the tool on an actual workpiece, let

it

run for a while. Watch

for vibration or wobbling that could indicate poor installation or a poorly

balanced blade.

18.

Wait

until

the blade attains full speed before cutting.

19.

Stop operation immediately if you notice anything abnormal.

20.

Do

not attempt to lock the trigger

in

the on position.

21.

Shut off power and wait for saw blade to stop before servicing or adjusting

tool.

22.

Be alert at all times, especially during repetitive, monotonous operations.

Don't be lulled into a false sense of security. Blades are extremely unforgiving.

23.

Always use accessories recommended in this manual. Use of improper

accessories such as abrasive wheels may cause an injury.

24.

Don't abuse cord. Never yank cord to disconnect

it

from the receptacle. Keep

cord away from heat, oil, water and sharp edges.

SAVE

THESE INSTRUCTIONS.

5

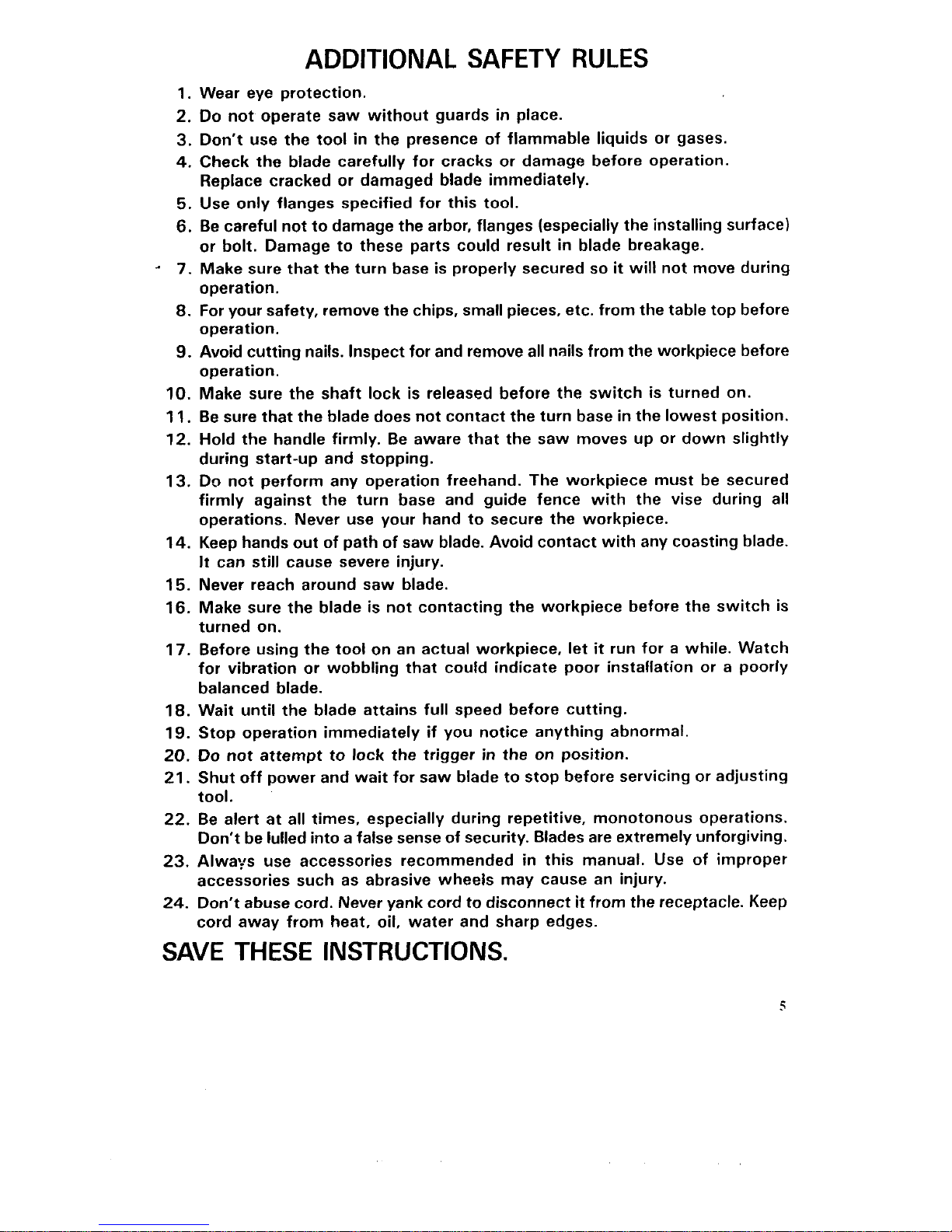

Socket wrench

Store the socket wrench in the wrench

holder

at

the rear of the tool after using

it.

Bench mounting saw

,

When the tool

is

shipped,

the

handle

is

locked in the lowered position. Release the

handle from the lowered position by lowering

it

slightly and removing the chain from

the screw on the motor housing.

I

Wrench holder

1

I

I

Chain

This tool should be bolted with

two

bolts to a

level and stable surface using the bolt holes

provided in the tool’s base. This will help pre-

vent tipping and possible injury.

6

Installing

or

removing

saw

blade

CAUTION

:

Always be sure that the tool

is

switched off and unplugged before installing

or

removing

the blade.

Use the socket wrench to loosen the hex

bolt which secures the center cover

by

turning counterclockwise.

Raise

the safety

cover and the center cover.

Press

the shaft lock to lock the spindle

and use the socket wrench to loosen the

hex bolt by turning it clockwise. Then remove the hex bolt, outer flange and blade.

To

install the blade, mount

it

carefully

onto the spindle, making sure that the

direction of the arrow on the surface of the

blade matches the direction of the arrow

on the blade

case.

Socket wrenc

Hex bolt (left-handed)

Socket wrench

\-Outer

flange

rSpindle

Ring

Inner flange

Saw blade

I--

Hex bolt (left-handed)

7

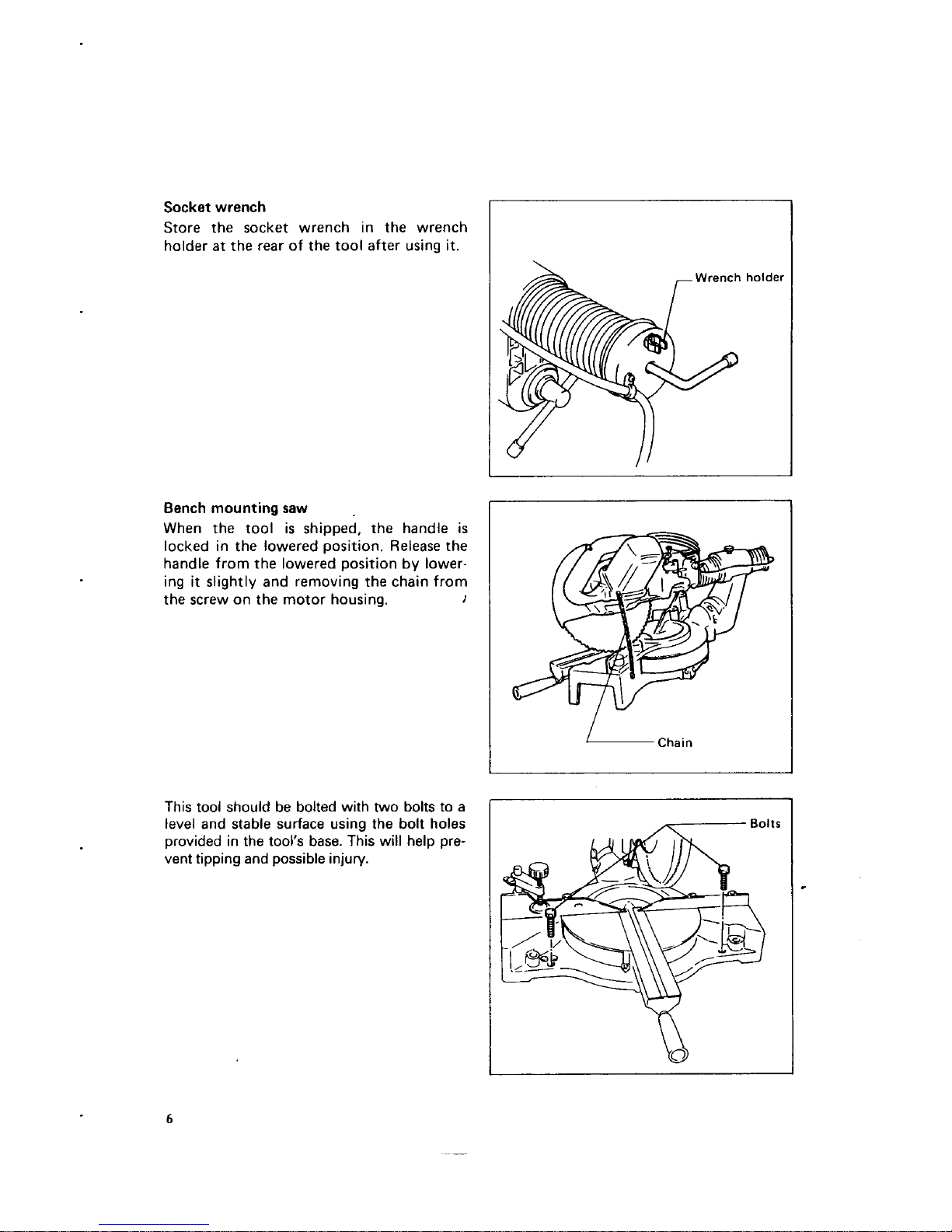

Install the outer flange and hex bolt, and

then use the socket wrench to tighten the

hex bolt securely by turning

it

counter-

clockwise while pressing the shaft lock.

Return the safety cover and the center

cover to the original position. Then tighten

the hex bolt to secure the center cover.

Lower the handle to make sure that the

safety cover moves properly.

I

/-Safety

cover

I

-Socket

wrench

CAUTION:

Use only the Makita socket wrench provided to install or remove the blade. Failure to do

so

may result in overtightening or insufficient tightening of the hex bolt. This could cause

serious injury to operator or others in the general vicinity of the tool.

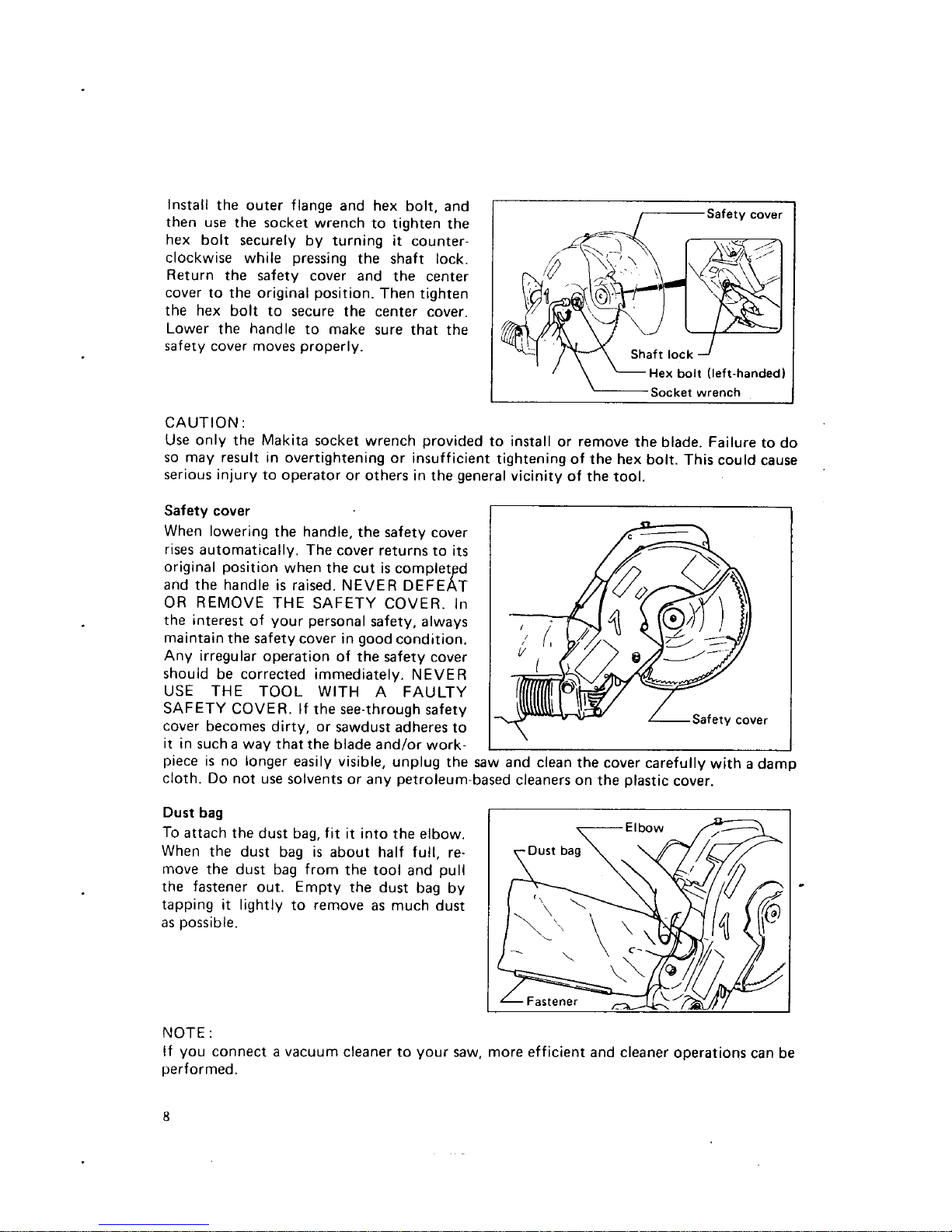

Safety cover

When lowering the handle, the safety cover

rises automatically. The cover returns to

its

original position when the cut is complet d

and the handle

is

raised. NEVER DEFE&T

OR

REMOVE THE SAFETY COVER. In

the interest

of

your personal safety, always

maintain the safety cover in good condition.

Any irregular operation of the safety cover

should be corrected immediately. NEVER

USE THE TOOL WITH A FAULTY

SAFETY COVER. If the see-through safety

cover becomes dirty, or sawdust adheres to

it

in sucha way that the blade and/or work-

--

~~

piece is no longer easily visible, unplug the saw and clean the cover carefully with a damp

cloth.

Do

not use solvents or any petroleum-based cleaners on the plastic cover.

Dust

bag

To attach the dust bag,

fit

it into the elbow.

When the dust bag

is

about half full, remove the dust bag from the tool and pull

the fastener out. Empty the dust bag by

tapping

it

lightly to remove

as

much dust

as

possible.

NOTE

:

If

you

connect a vacuum cleaner to your saw, more efficient and cleaner operations can be

performed.

8

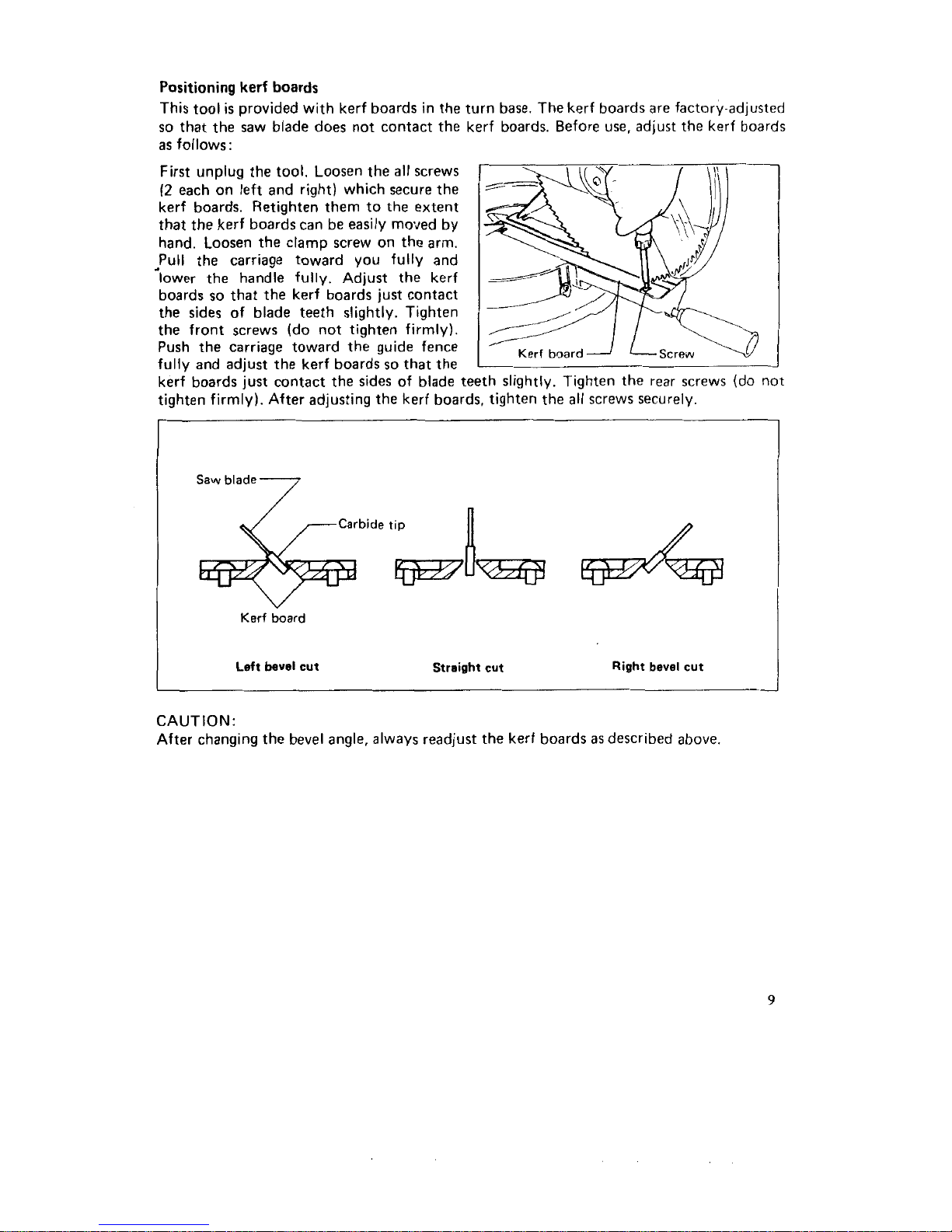

Positioning

kerf

boards

This tool

is

provided with kerf boards in the turn base. The kerf boards are factory-adjusted

so

that the saw blade does not contact the kerf boards. Before use, adjust the kerf boards

as

follows:

First unplug the tool. Loosen the

all

screws

(2

each on left and right) which secure the

kerf boards. Retighten them to the extent

that the

kerf boards can be easily moved by

hand. Loosen the clamp screw on the arm.

Pull the carriage toward

you

fully and

lower the handle

fully.

Adjust the kerf

boards

so

that the kerf boards just contact

the sides of blade teeth slightly. Tighten

the front screws (do not tighten firmly).

Push the carriage toward the guide fence

fully and adjust the kerf boards

so

that the

kerf boards just contact the sides of blade teeth slightly. Tighten the rear screws (do not

tighten firmly). After adjusting the kerf boards, tighten the

all

screws securely.

1

Kerf

board

Left

bevel

cut

Straight

cut

Right

bevel

cut

CAUTION:

After changing the bevel angle, always readjust the kerf boards

as

described above.

9

Loading...

Loading...