Page 1

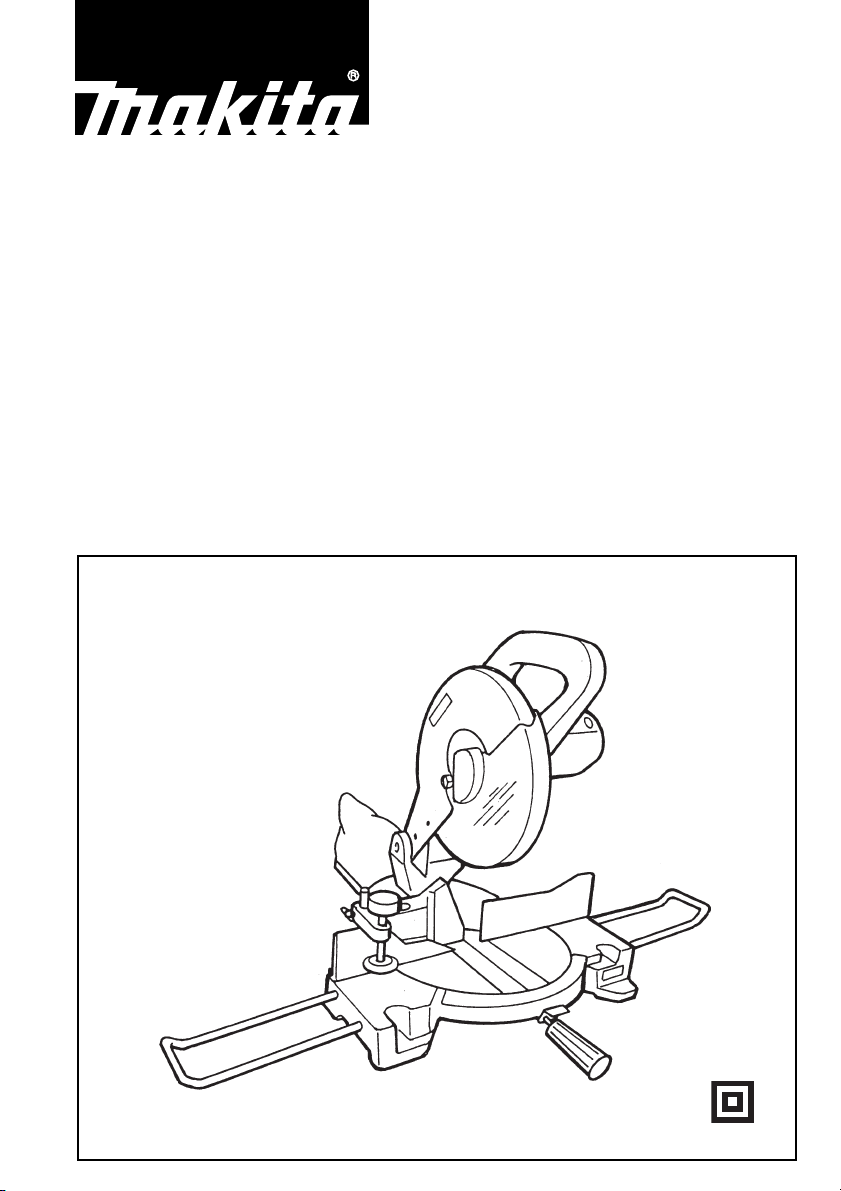

Compound Miter Saw

Gehrungs- und Kappsäge

Пила для составной отрезки

LS1040

Instruction Manual

Betriebsanleitung

Ukośnica

Instrukcja obsługi

Инструкция по эксплуатации

Page 2

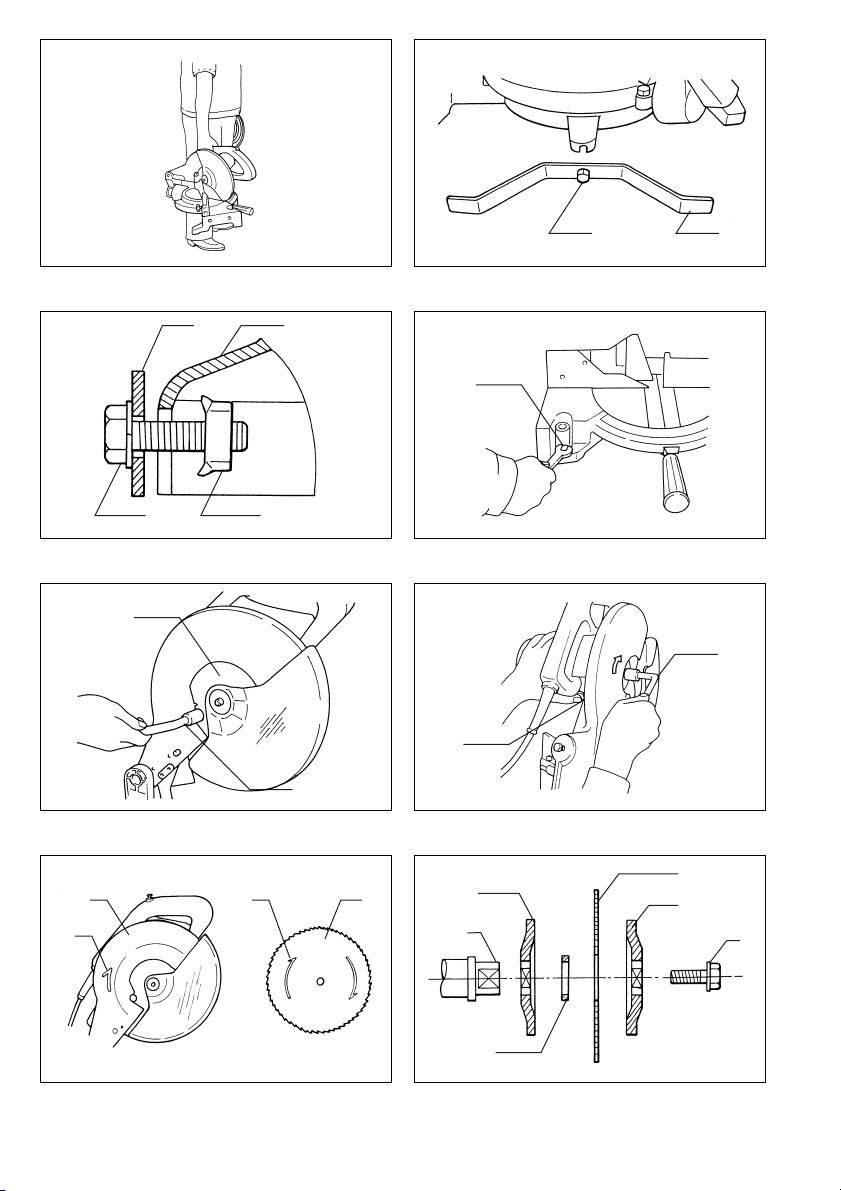

1

2

3

12

13

5

42

34

6

9

8

7

7

56

13

17

18

10

1211

13

15

14

16

78

2

Page 3

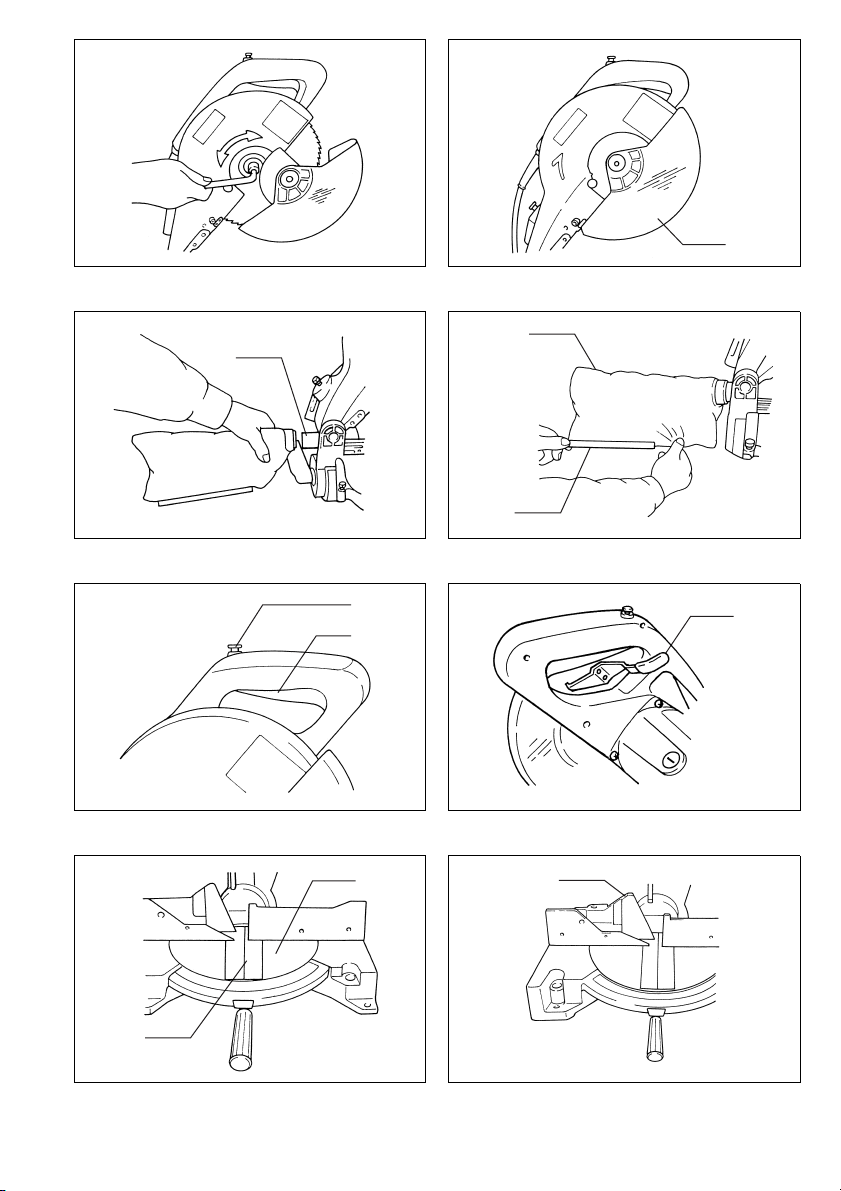

9

19

20

910

22

21

23

11 12

24

25

13 14

27

28

15 16

26

29

3

Page 4

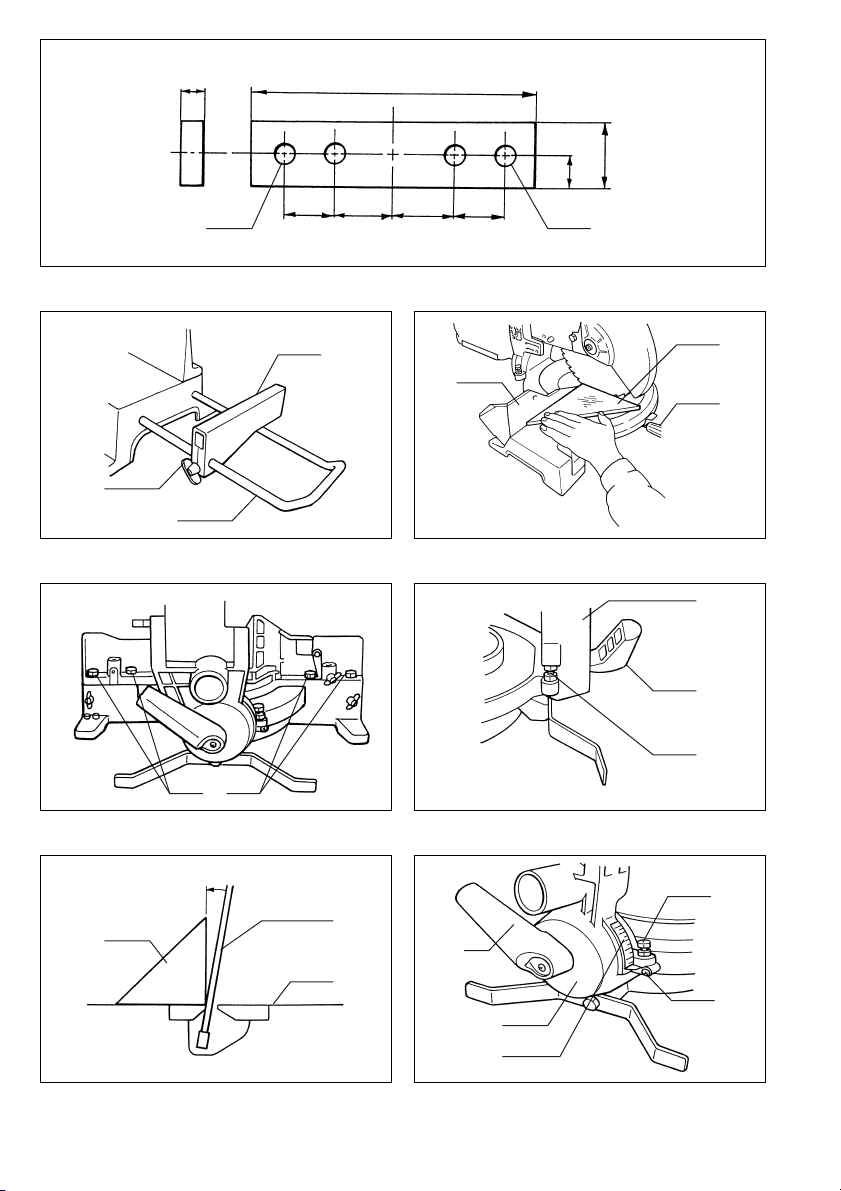

29

17 18

135 mm

19 20

30

7

31

34

32

33

19

9

35

21 22

38

39

40

41

42

27

23 24

4

35

36

37

27 43

Page 5

45

9

44

25 26

47

46

48

49

27 28

51

48

50

52

29 30

53

40

54

55

56

31

5

Page 6

32

57

59

58

90 mm 107 mm 107 mm 90 mm

90 mm

25 mm

59

60

61

46

33 34

(4) (3)

63

(2) (1)

35 36

13

62

66

62

40

34

64

35

65

68

35

37

67

36

37 38

6

Page 7

69

39 40

70

71

7

Page 8

Symbols

The following show the symbols used for the tool. Be sure that you understand their meaning before use.

Symbole

Die folgenden Symbole werden für die Maschine verwendet. Machen Sie sich vor der Benutzung unbedingt

mit ihrer Bedeutung vertraut.

Symbole

Poniższe symbole używane są do opisu urządzenia. Przed użyciem należy upewnić się, że rozumie się ich

znaczenie.

Символы

Следующие объяснения показывают символы, используемые для инструмента. Убедитесь перед

использованием, что Вы понимаете их значение.

❏ Read instruction manual.

❏ Bitte Bedienungsanleitung lesen.

❏ Przeczytaj instrukcję obsługi.

❏ Прочитайте инструкцию по эксплуатации.

❏ DOUBLE INSULATION

❏ DOPPELT SCHUTZISOLIERT

❏ PODWÓJNA IZOLACJA

❏ ДВОЙНАЯ ИЗОЛЯЦИЯ

❏ Do not place hand or fingers close to the blade.

❏ Halten Sie Hände oder Finger vom Sägeblatt fern

❏ Nie zbliżaj rąk i palców do brzeszczotu.

❏ Не помещайте руки или пальцы близко к лезвию.

❏ To avoid injury from flying debris, keep holding the saw head down, after making cuts, until the

blade has come to a complete stop.

❏ Um Verletzungen durch herausgeschleuderte Teile zu vermeiden, halten Sie den Sägekopf nach

Ausführung von Schnitten abgesenkt, bis das Sägeblatt völlig zum Stillstand gekommen ist.

❏ Aby uniknąć zranienia odskakującymi odpadkami, po zakończeniu cięcia trzymaj głowicę piły w

dole, aż do całkowitego zatrzymania się brzeszczotu.

❏ Чтобы избежать травмы от летящих обрезков, удерживайте переднюю часть пилы,

обращенной вниз, после выполнения резки до тех пор, пока лезвие не остановится

полностью.

❏ For your safety, remove chips, small pieces, etc. from the table top before operation.

❏ Zur Sicherheit sollte die Tischplatte vor dem Betrieb von Spänen, Kleinteilen usw. gesäubert wer-

den.

❏ Dla bezpieczeństwa przed przystąpieniem do pracy usuń strużyny, małe odpady itp. z

powierzchni stołu.

❏ Для Вашей безопасности удалите стружки, маленькие куски и т.д. со стола перед

эксплуатацией.

❏ Always set SUB-FENCE to left position when performing left bevel cuts. Failure to do so may cause

serious injury to operator.

❏ Stellen Sie den ZUSATZANSCHLAG bei der Durchführung von Neigungsschnitten immer auf die

linke Position. Anderenfalls kann die Bedienungsperson ernsthaft verletzt werden.

❏ Podczas wykonywania cięć pod kątem pionowym lewym zawsze ustaw PROWADNICĘ po lewej

stronie. Niestosowanie się do tego zalecenia może doprowadzić do poważnego zranienia

operatora.

❏ При выполнении левых наклонных разрезов всегда устанавливайте ДОПОЛНИТЕЛЬНЫЙ

ЩИТОК в левое положение. Невыполнение этого условия может привести к серьезной

травме оператора.

8

Page 9

ENGLISH

Explanation of general view

1Base

2Hex bolt

3 Auxiliary plate

4Nut

5Bolt

6Center cover

7 Socket wrench

8 Shaft lock

9Loosen

10 Arrow

11 Blade case

12 Arrow

13 Saw blade

14 Spindle

15 Flange

16 Ring

17 Flange

18 Hex bolt

19 Tighten

20 Safety cover

21 Dust spout

22 Dust bag

23 Fastener

24 Lock-off button

25 Switch trigger

26 Lever

27 Turn base

28 Kerf board

29 Sub-fence

30 Adjusting bolt

31 Pointer

32 Miter scale

33 Latch spring

34 Grip

35 Lever

36 Bevel scale

37 Pointer

38 Vise rod

39 Screws

40 Guide fence

41 Vise arm

42 Clamp screw

43 Support

44 Knob

45 Projection

46 Holder

47 Screw

48 Holder assembly

49 Screw

50 Rod 12

51 Cutting line

52 Groove

53 Vise

54 Spacer block

55 Aluminum extrusion

56 Spacer block

57 Over 10 mm

58 Over 460 mm

59 Hole

60 Set plate

61 Screw

62 Triangular rule

63 Hex bolts

64 Arm

65 Hex bolt (A)

66 Top surface of turn base

67 Arm holder

68 Hex bolt (B)

69 Limit mark

70 Screwdriver

71 Brush holder cap

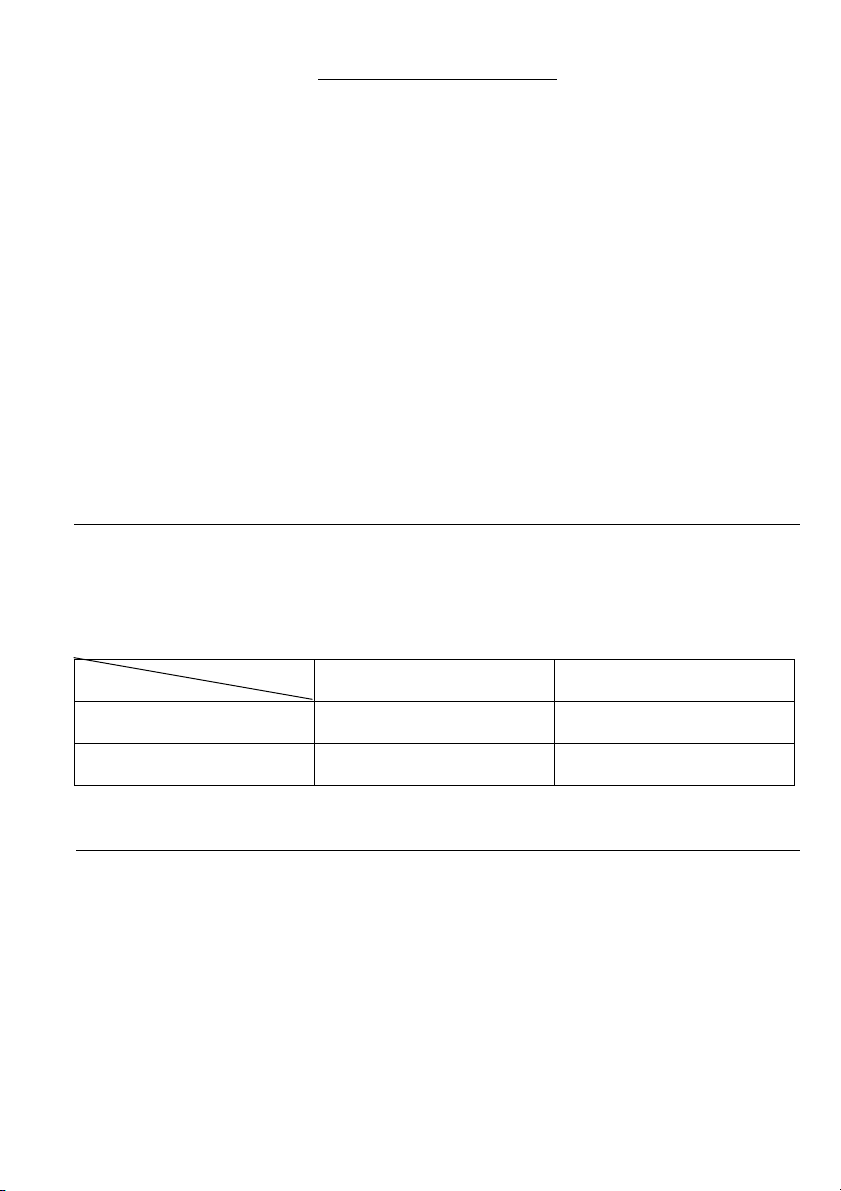

SPECIFICATIONS

Model LS1040

Blade diameter .................................................................................................................................. 255 mm — 260 mm

Hole (arbor) diameter

For all countries other than European countries ........................................................................... 25.4 mm and 25mm

For European countries ......................................................................................................................................30 mm

Max. cutting capacities (H x W) with blade 260 mm in diameter

Miter angle

Bevel angle

0°

45° (left)

No load speed (RPM) ............................................................................................................................................. 4,600

Dimensions (L x W x H) .....................................................................................................530 mm x 476 mm x 532 mm

Net weight .................................................................................................................................................. ............. 11 kg

0° 45° (left and right)

93 mm x 95mm

69 mm x 135 mm

53 mm x 95mm

35 mm x 135 mm

93 mm x 67mm

69 mm x 95mm

49 mm x 67mm

35 mm x 94mm

• Due to our continuing program of research and development, the specifications herein are subject to change

without notice.

• Note: Specifications may differ from country to country.

Intended use

The tool is intended for accurate straight and miter cutting in wood. With appropriate saw blades, aluminum can

also be sawed.

Powe r supply

The tool should be connected only to a power supply of

the same voltage as indicated on the nameplate, and can

only be operated on single-phase AC supply. They are

double-insulated in accordance with European Standard

and can, therefore, also be used from sockets without

earth wire.

For public low-voltage distribution systems of

between 220 V and 250 V

Switching operations of electric apparatus cause voltage

fluctuations. The operation of this device under unfavorable mains conditions can have adverse effects to the

operation of other equipment. With a mains impedance

equal or less than 0.30 Ohms it can be presumed that

there will be no negative effects. The mains socket used

for this device must be protected with a fuse or protective

circuit breaker having slow tripping characteristics.

9

Page 10

SAFETY INSTRUCTIONS

Warning! When using electric tools, basic safety precautions should always be followed to reduce the

risk of fire, electric shock and personal injury, including the following. Read all these instructions before

attempting to operate this product and save these

instructions.

For safe operation:

1. Keep work area clean

Cluttered areas and benches invite injuries.

2. Consider work area environment

Don’t expose power tools to rain. Don’t use power

tools in damp or wet locations. Keep work area well

lit. Don’t use power tools in presence of flammable

liquids or gases.

3. Guard against electric shock

Prevent body contact with grounded surfaces (e.g.

pipes, radiators, ranges, refrigerators).

4. Keep children away

Do not let visitors contact tool or extension cord. All

visitors should be kept away from work area.

5. Store idle tools

When not in use, tools should be stored in dry, high,

or locked-up place, out of the reach of children.

6. Don’t force tool

It will do the job better and safer at the rate for which

it was intended.

7. Use right tool

Don’t force small tools or attachments to do the job

of a heavy duty tool. Don’t use tools for purposes not

intended; for example, don’t use circular saw for cutting tree limbs or logs.

8. Dress properly

Do not wear loose clothing or jewelry. They can be

caught in moving parts. Rubber gloves and non-skid

footwear are recommended when working outdoors.

Wear protective hair covering to contain long hair.

9. Use safety glasses and hearing protection

Also use face or dust mask if cutting operation is

dusty.

10. Connect dust extraction equipment

If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used.

11. Don’t abuse cord

Never carry tool by cord or yank it to disconnect it

from receptacle. Keep cord from heat, oil and sharp

edges.

12. Secure work

Use clamps or a vise to hold work. It’s safer than

using your hand and it frees both hands to ope-rate

tool.

13. Don’t overreach

Keep proper footing and balance at all times.

14. Maintain tools with care

Keep tools sharp and clean for better and safer performance. Follow instructions for lubricating and

changing accessories. Inspect tool cords periodically and, if damaged, have repaired by authorized

service facility. Inspect extension cords periodically

and replace if damaged. Keep handles dry, clean

and free from oil and grease.

15. Disconnect tools

When not in use, before servicing, and when changing accessories such as blades, bits and cutters.

16. Remove adjusting keys and wrenches

Form the habit of checking to see that keys and

adjusting wrenches are removed from tool before

turning it on.

17. Avoid unintentional starting

Don’t carry plugged-in tool with finger on switch. Be

sure switch is off when plugging in.

18. Outdoor use extension cords

When tool is used outdoors, use only extension

cords intended for use outdoors and so marked.

19. Stay alert

Watch what you are doing. Use common sense. Do

not operate tool when you are tired.

20. Check damaged parts

Before further use of the tool, a guard or other part

that is damaged should be carefully checked to

determine that it will operate properly and perform

its intended function. Check for alignment of moving

parts, binding of moving parts, breakage of parts,

mounting, and any other conditions that may affect

its operation. A guard or other part that is damaged

should be properly repaired or replaced by an authorized service center unless otherwise indicated elsewhere in this instruction manual. Have defective

switches replaced by and authorized service center.

Do not use tool if switch does not turn it on and off.

21. Warning

The use of any other accessory or attachment other

than recommended in this operating instruction or

the catalog may present a risk of personal injury.

22. Have your tool repaired by an expert

This electric appliance is in accordance with the relevant safety rules. Repairing of electric appliances

may be carried out only by experts otherwise it may

cause considerable danger for the user.

ADDITIONAL SAFETY RULES

1. Wear eye protection.

2. Do not operate saw without guards in place.

3. Don’t use the tool in the presence of flammable

liquids or gases.

4. Check the blade carefully for cracks or damage

before operation. Replace cracked or damaged

blade immediately.

5. Use only flanges specified for this tool.

10

Page 11

6. Be careful not to damage the arbor, flanges

(especially the installing surface) or bolt. Damage to these parts could result in blade breakage.

7. Make sure that the turn base is properly secured

so it will not move during operation.

8. For your safety, remove the chips, small pieces,

etc. from the table top before operation.

9. Avoid cutting nails. Inspect for and remove all

nails from the workpiece before operation.

10. Make sure the shaft lock is released before the

switch is turned on.

11. Be sure that the blade does not contact the turn

base in the lowest position.

12. Hold the handle firmly. Be aware that the saw

moves up or down slightly during start-up and

stopping.

13. Do not perform any operation freehand. The

workpiece must be secured firmly against the

turn base and guide fence with the vise during

all operations. Never use your hand to secure

the workpiece.

14. Keep hands out of path of saw blade. Avoid contact with any coasting blade. It can still cause

severe injury.

15. Never reach around saw blade.

16. Make sure the blade is not contacting the workpiece before the switch is turned on.

17. Before using the tool on an actual workpiece, let

it run for a while. Watch for vibration or wobbling

that could indicate poor installation or a poorly

balanced blade.

18. Wait until the blade attains full speed before cutting.

19. Stop operation immediately if you notice anything abnormal.

20. Do not attempt to lock the trigger in the ON position.

21. Shut off power and wait for saw blade to stop

before servicing or adjusting tool.

22. Be alert at all times, especially during repetitive,

monotonous operations. Don’t be lulled into a

false sense of security. Blades are extremely

unforgiving.

23. Always use accessories recommended in this

manual. Use of improper accessories such as

abrasive wheels may cause an injury.

24. Don’t abuse cord. Never yank cord to disconnect

it from the receptacle. Keep cord away from heat,

oil, water and sharp edges.

25. Do not use the saw to cut other than aluminum,

wood or similar materials.

26. Connect compound miter saws to a dust collecting device when sawing.

27. Select saw blades in relation to the material to be

cut.

28. Take care when slotting.

29. Replace the kerf board when worn.

SAVE THESE INSTRUCTIONS.

OPERATCING INSTRUCTIONS

Carrying tool (Fig. 1)

When carrying the tool, lower the handle fully and press

the stopper pin to lock the handle in the lowered position.

Secure the turn base by means of the grip. The tool can

then be conveniently carried by the carrying grip.

WARNING:

• Be sure that the tool is unplugged first.

• Stopper pin is for carrying purposes only and not for

any cutting operations.

Installing auxiliary plate (Fig.2 & 3)

Install the auxiliary plate using the notch in the tool’s

base and secure it by tightening the hex bolt.

Bench mounting saw (Fig. 4)

This tool should be bolted with two bolts to a level and

stable surface using the bolt holes provided in the tool’s

base. This will help prevent tipping and possible injury.

Installing or removing saw blade

Important:

Always be sure that the tool is switched off and

unplugged before installing or removing the blade.

To remove the blade, use the socket wrench to loosen the

hex bolt holding the center cover by turning it more than

three turns counterclockwise. Raise the safety cover and

center cover. (Fig. 5)

Press the shaft lock so that the blade cannot revolve and

use the socket wrench to loosen the hex bolt clockwise.

Then remove the hex bolt, outer flange and blade.

(Fig. 6)

To install the blade, mount it onto the spindle, making

sure that the direction of the arrow on the surface of the

blade matches the direction of the arrow on the blade

case. (Fig.7)

CAUTION:

• For all countries other than European countries

(Fig.8)

The silver ring 25.4mm in outer diameter is factory-

installed onto the spindle. The black ring 25 mm in

outer diameter is included as standard equipment.

Before mounting the blade onto the spindle, always be

sure that the correct ring for the arbor hole of the blade

you intend to use is installed onto the spindle.

• For European countries (Fig. 8)

The ring 30 mm in outer diameter is factory-installed

onto the spindle.

Install the flange and hex bolt, and then use the socket

wrench to tighten the hex bolt securely counterclockwise

while pressing the shaft lock. Then tighten the hex bolt

clockwise to secure the center cover. (Fig.9)

CAUTION:

Use only the Makita socket wrench provided to install or

remove the blade. Failure to do so may result in overtightening or insufficient tightening of the hex bolt. This could

cause an injury.

11

Page 12

Safety cover (Fig.10)

When lowering the handle, the safety cover rises automatically. The cover returns to its original position when

the cut is completed and the handle is raised. NEVER

DEFEAT OR REMOVE THE SAFETY COVER. In the

interest of your personal safety, always maintain the

safety cover in good condition. Any irregular operation of

the safety cover should be corrected immediately.

NEVER USE THE TOOL WITH A FAULTY SAFETY

COVER. If the see-through safety cover becomes dirty, or

sawdust adheres to it in such a way that the blade and/or

workpiece is no longer easily visible, unplug the saw and

clean the cover carefully with a damp cloth. Do not use

solvents or any petroleum-based cleaners on the plastic

cover.

Dust bag (Fig.11 &12)

The use of the dust bag makes cutting operations clean

and dust collection easy. To attach the dust bag, fit the

bag’s entry port over the dust spout. When the dust bag

is about half full, remove the dust bag from the tool and

pull the fastener out. Empty the dust bag of its contents,

tapping it lightly so as to remove particles adhering to the

insides which might hamper further collection.

Switch action

CAUTION:

• Before plugging in the tool, always check to see that

the switch trigger actuates properly and returns to the

“OFF” position when released.

• When not using the tool, remove the lock-off button and

store it in a secure place. This prevents unauthorized

operation.

• Do not pull the trigger hard without pressing in the lockoff button. This can cause breakage of the switch.

For all countries other than European countries

(Fig. 13)

To prevent the trigger from being accidentally pulled, a

lock-off button is provided. To start the tool, press in the

lock-off button and pull the trigger. Release the trigger to

stop.

For European countries (Fig. 14)

To prevent the trigger from being accidentally pulled, a

lock-off button is provided. To start the tool, push the

lever to the left, press in the lock-off button and then pull

the trigger. Release the trigger to stop.

Kerf board (Fig. 15)

This tool is provided with the kerf board in the turn base.

If the kerf groove has not yet been cut in the kerf board by

the factory, you should cut the groove before actually

using the tool to cut a workpiece. Switch on the tool and

lower the blade gently to cut a groove in the kerf board.

Sub-fence (Fig. 16 &17)

This tool is equipped with the sub-fence which should

ordinarily be positioned as shown in Fig. 16. However,

when performing left bevel cuts, set it to the left position

as shown in Fig. 17.

Maintaining maximum cutting capacity

(Fig. 18 &19)

Unplug the tool before any adjustment is attempted. This

tool is factory adjusted to provide the max. cutting capacity for a 260 mm saw blade. When the diameter of the

blade has been reduced due to sharpening, adjust the

depth adjusting bolt by turning it with the socket wrench.

The saw blade is lowered by turning the depth adjusting

bolt counterclockwise and raised by turning it clockwise.

Adjust so that when the handle is in the fully lowered

position, there will be a distance of about 135 mm from

the front face of the guide fence to the point where the

front edge of the blade enters the kerf. With the tool

unplugged, rotate the blade by hand while holding the

handle all the way down. Be sure that the blade does not

contact any part of the lower base when the handle is

lowered completely.

Positioning for adjusting the miter angle (Fig. 20)

Loosen the grip by turning counterclockwise. Turn the

turn base while pressing down the latch spring. When

you have moved the grip to the position where the pointer

indicates the desired angle on the miter scale, securely

tighten the grip clockwise.

CAUTION:

When turning the turn base, be sure to raise the handle

fully.

Positioning for adjusting the bevel angle

(Fig. 21 &22)

The saw blade tilts up to 45° to the left only when the

sub-fence is set to the left position as shown in Fig. 17.

To adjust the bevel angle, loosen the lever at the rear of

the tool. Tilt the blade to the left so that the pointer indicates the desired angle on the bevel scale. Then tighten

the lever firmly to secure the arm.

CAUTION:

When tilting the saw blade, be sure to raise the handle

fully.

Securing workpiece

WARNING:

It is extremely important to always secure the workpiece

properly and tightly with the vise. Failure to do so can

cause the tool to be damaged and/or the workpiece to be

destroyed. PERSONAL INJURY MAY ALSO RESULT.

Also, after a cutting operation, DO NOT raise the blade

until the blade has come to a complete stop.

1. Vertical vise (Fig. 23 &27)

The vertical vise can be installed on the guide

fence or the holder assembly (optional accessory).

Insert the vise rod into the hole in the guide fence or

the holder assembly and tighten the screw to secure

the vise rod. Position the vise arm according to the

thickness and shape of the workpiece and secure

the vise arm by tightening the screw. Press the

workpiece flat against the guide fence and the turn

base. Position the workpiece at the desired cutting

position and secure it firmly by tightening the clamp

screw.

12

Page 13

CAUTION:

The workpiece must be secured firmly against the

turn base and guide fence with the vise during all

operations.

If some part contacts the vise, re-position the vise

arm. Press the workpiece flat against the guide

fence and the turn base. Position the workpiece at

the desired cutting position and secure it firmly by

tightening the clamp screw of the vise.

CAUTION:

When cutting long workpieces, use supports that are

as high as the top surface level of the turn base.

(Fig. 24)

2. Horizontal vise (optional accessory)

(Fig. 25& 26)

The horizontal vise can be installed on either the left

or right side of the base. When performing 15° or

greater miter cuts, install the horizontal vise on the

side opposite the direction in which the turn table is

to be turned. By turning the knob on the vise counterclockwise, the screw is released and the vise

shaft can be moved rapidly in and out. By turning the

knob clockwise, the screw remains secured. To grip

workpieces, turn the knob gently clockwise until the

projection reaches its topmost position, then fasten

securely. If the knob is forced in or pulled out while

being turned clockwise, the projection may stop at

an angle. In this case, turn the knob back counterclockwise until the screw is released, before turning

again gently clockwise.

3. Holders and holder assembly(optional accessories)

The holders and the holder assembly can be

installed on either side as a convenient means of

supporting workpieces horizontally. Install them as

shown in Fig. 27. Then tighten the screws firmly to

secure the holders and the holder assembly.

(Fig. 27)

When cutting long workpieces, use the holder-rod

assembly (optional accessory). It consists of two

holder assemblies and two rods 12. (Fig. 28)

CAUTION:

Always support long workpieces level with the top

surface of the turn base for accurate cuts and to prevent dangerous loss of control of the tool.

Operation

CAUTION:

• Before use, be sure to release the handle from the low-

ered position by pulling the stopper pin.

• Make sure the blade is not contacting the workpiece,

etc. before the switch is turned on.

• Do not apply excessive pressure on the handle when

cutting. Too much force may result in overload of the

motor and/or decreased cutting efficiency.

• Gently press down the handle to perform the cut. If the

handle is pressed down with force or if lateral force is

applied, the blade will vibrate and leave a mark (saw

mark) in the workpiece and the precision of the cut will

be impaired.

When cutting with this tool, the thickness of the blade is

cut out of the workpiece as well. Therefore, your cutting

line should be on either the left or right side of the groove

in the kerf board. Switch on the tool and wait until the

blade attains full speed before lowering gently into the

cut. When the blade contacts the workpiece, gradually

bear down on the handle to perform the cut. When the

cut is completed, switch off the tool and WAIT UNTIL

THE BLADE HAS COME TO A COMPLETE STOP

before returning the blade to its fully elevated position. A

thin piece of cut off material could otherwise contact the

coasting blade and be thrown around dangerously.

(Fig. 29)

1. Miter cutting

Refer to the previously covered “Positioning for

adjusting the miter angle”.

2. Bevel cut (Fig. 30)

• Left 0° –45° bevel cuts can be performed.

• Set the sub-fence to the left position as shown in

Fig. 17. Loosen the lever and tilt the saw blade to

set the bevel angle. Be sure to retighten the lever

firmly to secure the selected bevel angle safely.

Secure the workpiece with the vise. Switch on the

tool and wait until the blade attains full speed.

Then gently lower the handle to the fully lowered

position while applying pressure in parallel with the

blade. When the cut is completed, switch off the

tool and WAIT UNTIL THE BLADE HAS COME TO

A COMPLETE STOP before returning the blade to

its fully elevated position.

CAUTION:

• When performing the bevel cut with the workpiece

secured on the left side of the turn base, it will create a condition where the piece cut off will come to

rest on the blade. If the blade is raised while the

blade is still rotating, this piece may be caught in

the blade, causing fragments to be scattered

around which is dangerous. The blade should be

gently raised only after the blade has come to a

complete stop.

• When pressing down the handle, apply pressure in

parallel with the blade. If a force is applied perpendicularly to the turn base or if the pressure direction is changed during a cut, the precision of the

cut will be impaired.

• Always set the sub-fence to the left position as

shown in Fig. 17 when performing bevel cuts.

3. Compound cutting

Compound cutting can be performed at angle shown

in the table below.

Bevel angle Miter angle

45°

When performing the compound cutting, refer to

“Miter cutting” and “Bevel cut” explanations.

Left and right

0° – 45°

13

Page 14

4. Cutting aluminum extrusion (Fig. 31)

When securing aluminum extrusions, use spacer

blocks or pieces of scrap as shown in Fig. 31 to prevent deformation of the aluminum. Use a cutting

lubricant when cutting the aluminum extrusion to

prevent build-up of the aluminum material on the

blade.

CAUTION:

Never attempt to cut thick or round aluminum extrusions. Thick aluminum extrusions may come loose

during operation and round aluminum extrusions

cannot be secured firmly with this tool.

5. Wood facing (Fig.32)

Use of wood facing helps to assure splinter-free cuts

in workpieces. Attach a wood facing to the guide

fence using the holes in the guide fence.

CAUTION:

• Use straight wood of even thickness as the wood

facing.

•See Fig. 32 concerning the dimensions for a sug-

gested wood facing.

6. Cutting repetitive lengths (Fig. 33)

When cutting several pieces of stock to the same

length, ranging from 240 mm to 400 mm, use of the

set plate (optional accessory) will facilitate more efficient operation. Install the set plate on the holder as

shown in Fig. 33. Align the cutting line on your workpiece with either the left or right side of the groove in

the kerf board, and while holding the workpiece from

moving, move the set plate flush against the end of

the workpiece. Then secure the set plate with the

screw. When the set plate is not used, loosen the

screw and turn the set plate out of the way.

MAINTENANCE

CAUTION:

Always be sure that the tool is switched off and

unplugged before carrying out any work on the tool.

Adjusting the cutting angle

This tool is carefully adjusted and aligned at the factory,

but rough handling may have affected the alignment. If

your tool is not aligned properly, perform the following:

1) Miter angle (Fig. 34& 35)

Loosen the grip and set the turn base at zero

degrees by turning the turn base. Tighten the grip

securely and loosen the hex bolts on the guide

fence. Square the side of the blade with the face of

the guide fence using a triangular rule, try-square,

etc. by moving the right side of the guide fence.

Then securely tighten the hex bolts on the guide

fence in the order indicated in Fig. 35.

2) Bevel angle

i) 0° bevel angle

Loosen the lever at the rear of the tool. Loosen

the hex nut and turn the hex bolt (A) two or three

revolutions clockwise so that the blade tilts to the

right. (Fig. 36)

Lower the handle fully and square the side of the

blade with the top surface of the turn base using

the triangular rule, try-square, etc. by turning the

hex bolt (A) counterclockwise. Then tighten the

hex nut to secure the hex bolt (A). (Fig. 37)

Make sure that the pointer on the arm indicates

0° on the bevel scale on the arm holder. If the

pointer does not indicate 0°, loosen the screw

securing the pointer and adjust the pointer.

(Fig. 38)

ii) 45° bevel angle

Adjust 45° bevel angle only after performing 0°

bevel angle adjustment. To adjust 45° bevel angle,

loosen the lever and tilt the saw blade to the left

fully. Make sure that the pointer on the arm indicates 45° on the bevel scale on the arm holder. If

the pointer does not indicate 45°, turn the hex bolt

(B) on the side of the arm until the pointer indicates 45°. (Fig. 38)

Replacement of carbon brushes

(Fig. 39 &40)

Replace carbon brushes when they are worn down to the

limit mark. Both identical carbon brushes should be

replaced at the same time.

To maintain product safety and reliability, repairs, maintenance or adjustment should be carried out by a Makita

Authorized Service Center.

14

Page 15

Noise and Vibration of Model LS1040

The typical A-weighted noise levels are

sound pressure level: 93 dB (A)

sound power level: 106 dB (A)

The typical weighted root mean square acceleration

value is not more than 2.5 m/s

The undersigned, Yasuhiko Kanzaki, authorized by

Makita Corporation, 3-11-8 Sumiyoshi-Cho, Anjo,

Aichi 446-8502 Japan declares that this product

(Serial No. : series production) manufactured by Makita Corporation in P.R.C is in compliance with the following standards or standardized documents,

in accordance with Council Directives,

73/23/EEC, 89/336/EEC and 98/37/EC.

– Wear ear protection. –

2

.

EC-DECLARATION OF CONFORMITY

EN61029, EN55014, EN61000

Yasuhiko Kanzaki

CE97

Director

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes, Bucks

MK15 8JD, ENGLAND

15

Page 16

DEUTSCH

Übersicht

1 Maschinenfuß

2 Sechskantschraube

3 Kippsicherung

4Mutter

5 Schraube

6 Mittelabdeckung

7 Steckschlüssel

8 Spindelarretierung

9Lösen

10 Drehrichtungspfeil

11 Sägeblattgehäuse

12 Drehrichtungspfeil

13 Sägeblatt

14 Spindel

15 Flansch

16 Reduzierung

17 Flansch

18 Sechskantschraube

19 Anziehen

20 Schutzhaube

21 Staubauslaßstutzen

22 Staubsack

23 Verschlußschiene

24 Einschaltsperre/Einschalt-

Sicherheitsstift

25 Schalter

26 Arretierhebel

27 Drehteller

28 Einlegeplatten

29 Zusatzanschlag

30 Justierschraube

31 Markierungspfeil

32 Einstellskala

33 Sperrhebel

34 Griff

35 Arretierhebel

36 Neigungswinkel-Einstellskala

37 Markierungspfeil

38 Stehbolzen

39 Feststellschrauben

40 Parallelanschlag

41 Schraubzwingenarm

42 Klemmschraube

43 Stütze

44 Drehknopf

45 Sperrhebel

46 Auflageverlängerung

47 Schraube

48 Montagestütze

49 Flügelschraube

50 Führungsstangen

51 Schnittlinie

52 Nut

53 Schraubzwinge

54 Zulagen

55 Dünnwandiger Aluminium

Werkstoff

56 Zulagen

57 Über 10 mm

58 Über 460 mm

59 Bohrung

60 Seitenanschlag

61 Flügelschraube

62 Einstelldreieck

63 Sechskantschrauben

64 Sägekopf

65 Sechskantschraube (A)

66 Werkstückauflagefläche

67 Sägekopf-Drehlager

68 Sechskantschraube (B)

69 Verschleißgrenze

70 Schraubendreher

71 Bürstenhalterkappe

TECHNISCHE DATEN

Modell LS1040

Sägeblattdurchmesser ...................................................................................................................... 255 mm — 260mm

Sägeblattbohrung

Für alle Länder außerhalb Europas ............................................................................................... 25,4mm und 25 mm

Für europäische Länder ..................................................................................................................................... 30 mm

Max. Schnittiefe (H x B) mit 260mm Durchmesser Sägeblatt

Neigungswinkel

Leerlaufdrehzahl ............................................................................................................................................ 4 600 min

Abmessungen (L x B x H) .................................................................................................... 530 mmx 476mm x532 mm

Nettogewicht ............................................................................................................................................................ 11kg

Gehrungswinkel

0°

45° (links)

0° 45° (links und rechts)

93 mm x95 mm

69 mm x 135mm

53 mm x95 mm

35 mm x 135mm

93 mm x 67 mm

69 mm x 95 mm

49 mm x 67 mm

35 mm x 94 mm

-1

• Wir behalten uns vor, Änderungen im Zuge der Ent-

wicklung und des technischen Fortschritts ohne vorherige Ankündigung vorzunehmen.

• Hinweis: Die technischen Daten können von Land zu

Land abweichen.

Vorgesehene Verwendung

Die Maschine ist für genaue Gerad- und Gehrungsschnitte in Holz vorgesehen. Mit entsprechenden Säge-

blättern kann auch Aluminium gesägt werden.

16

Netzanschluß

Die Maschine darf nur an die auf dem Typenschild angegebene Netzspannung angeschlossen werden und

arbeitet nur mit Einphasen-Wechselspannung. Sie ist

entsprechend den Europäischen Richtlinien doppelt

schutzisoliert und kann daher auch an Steckdosen ohne

Erdanschluß betrieben werden.

Page 17

Für öffentliche Niederspannungs-Verteilungssysteme mit einer Spannung zwischen 220 und 250 V

Schaltvorgänge von Elektrogeräten verursachen Spannungsschwankungen. Der Betrieb dieses Gerätes unter

ungünstigen Netzstrombedingungen kann sich nachteilig

auf den Betrieb anderer Geräte auswirken. Bei einer

Netzstromimpedanz von 0,30 Ohm oder weniger ist

anzunehmen, dass keine negativen Effekte auftreten.

Die für dieses Gerät verwendete Netzsteckdose muss

durch eine Sicherung oder einen Schutzschalter mit trä-

gen Auslösungseigenschaften geschützt sein.

SICHERHEITSHINWEISE

Achtung! Beim Gebrauch von Elektrowerkzeugen

sind zum Schutz gegen elektrischen Schlag. Verletzungsund Brandgefahr folgende grundsätzlichen

Sicherheitsmaßnahmen zu geachten.

Lesen und beachten Sie diese Hinweise, bevor Sie

das Gerät benutzen.

1. Halten Sie Ihren Arbeitsbereich in Ordnung

Unordnung im Arbeitsbereich ergibt Unfallgefahr.

2. Berücksichtigen Sie Umgebungseinflüsse

Setzen sie Elektrowerkzeuge nicht dem Regen aus.

Benützen Sie Elektrowerkzeuge nicht in feuchter

oder nasser Umgebung. Sorgen Sie für gute

Beleuchtung. Benützen Sie Elektrowerkzeuge nicht

in Nähe von brennbaren Flüssigkeiten oder Gasen.

3. Schützen Sie sich vor elektrischem Schlag

Vermeiden Sie Körperberührung mit geerdeten Teilen, zum Beispiel Rohren, Heizkörpern, Herden,

kühlschränken.

4. Halten Sie Kinder fern!

Lassen Sie andere Personen nicht das Werkzeug

oder Kabel berühren, halten Sie sie von Ihrem

Arbeitsbereich fern.

5. Bewahren Sie Ihre Werkzeuge sicher auf

Unbenutzte Werkzeuge sollten in trockenem, verschlossenem Raum und für Kinder nicht erreichbar

aufbewahrt werden.

6. Überlasten Sie Ihr Werkzeug nicht

Sie arbeiten besser und sicherer im angegebenen

Leistungsbereich.

7. Benützen Sie das richtige Werkzeug

Verwenden Sie keine zu schwachen Werkzeuge

oder Vorsatzgeräte für schwere Arbeiten.

Benützen Sie Werkzeuge nicht für Zwecke und

Arbeiten, Wofür sie nicht bestimmt sind; zum Beispiel benützen Sie keine Handkreissäge, um Bäume

zu flällen oder Äste zu schneiden.

8. Tragen Sie geeignete Arbeitskleidung

Tragen Sie keine weite Kleidung oder Schmuck. Sie

können von beweglichen Teilen erfaßt werden. Bei

Arbeiten im Freien sind Gummihandschuhe und

rutschfestes Schuhwerk empfehlenswert. Tragen Sie

bei langen Haaren ein Haarnetz.

9. Schutzbrille und Gehörschutz tragen

Verwenden Sie eine Atemmaske bei stauberzeugenden Arbeiten.

10. Schlleßen Sie eine Staubabsaugvorrichtung an

Wenn Geräte für den Anschluß von Staubabsaugund-sammelvorrichtungen ausgelegt sind, sorgen

Sie dafür, daß Jiese angeschlossen und korrekt

benutzi werden.

11. Zweckentfremden Sie nicht das Kabel

Tragen Sie das Werkzeug nicht am Kabel, und

benützen Sie es nicht, um den Stecker aus der

Steckdose zu ziehen. Schützen Sie das Kabel vor

Hitze, Öl und scharfen Kanten.

12. Sichern Sie das Werkstück

Benützen Sie Spannvorrichtungen oder einen

Schraubstock, um das Werkstück festzuhalten. Es

ist damit sicherer gehalten als mit Ihrer Hand und

ermöglicht die Bedienung der Maschine mit beiden

Händen.

13. Überdehnen Sie nicht Ihren Standbereich

Vermeiden Sie abnormale Körperhaltung. Sorgen

Sie für sicheren Stand, und halten Sie jederzeit das

Gleichgewicht.

14. Pflegen Sie Ihre Werkzeuge mit Sorgtalt

Halten Sie Ihre Werkzeuge scharf und sauber, um

gut und sicher zu arbeiten. Befolgen Sie die Wartungsvorschriften und die Hinweise für Werkzeugwechsel. Kontrollieren Sie regelmäßig den Stecker

und das Kabel, und lassen Sie diese bei Beschädi-

gung von einem anerkannten Fachmann erneuern.

Kontrollieren Sie Verlängerungskabel regelmäßig

und ersetzen Sie beschädigte. Halten Sie Handgriffe

trocken und frei von Öl und Fett.

15. Ziehen Sie den Netzstecker

Bei Nichtgebrauch, vor der Wartung und beim Werkzeugwechsel, wie zum Beispiel Sägeblatt, Bohrer

und Maschinenwerkzeugen aller Art.

16. Lassen Sie keine Werkzeugschlüssel stecken

Überprüfen Sie vor dem Einschalten, daß die

Schlüssel und Einstellwerkzeuge entfernt sind.

17. Vermeiden Sie unbeabsichtigten Anlauf

Tragen Sie keine an das Stromnetz angeschlossene

Werkzeuge mit dem Finger am Schalter. Vergewissern Sie sich, daß der Schalter beim Anschluß an

das Stromnetz ausgeschaltet ist.

18. Verlängerungskabel im Freien

Verwenden Sie im Freien nur dafür zugelassene und

entsprechend gekennzeichnete Varlängerungska-

bel.

19. Seien Sie stets aufmerksam

Beobachten Sie Ihre Arbeit. Gehen Sie vernünftig

vor. Verwenden Sie das Werkzeug nicht, wenn Sie

unkonzentriert sind.

17

Page 18

20. Kontrollieren Sie Ihr Gerät auf Beschädigungen

Vor weiterem Gebrauch des Werkzeugs die Schutzeinrichtungen oder leicht beschädigte Teile sorgfältig

auf ihre einwandfreie und bestimmungsgemäße

Funktion überprüfen. Überprüfen Sie, ob die Funktion beweglicher Teile in Ordnung ist, ob sie nicht

klemmen onder ob Teile beschädigt sind. Sämtliche

Teile müssen richtig montiert sein und alle Bedingungen erfüllen, um den einwandfreien Betrieb des

Gerätes zu gewährleisten.

Beschädigte Schutzvorrichtungen und Teile sollen

sachgemäß durch eine Kundendienstwerkstatt repariert oder ausgewechselt werden, soweit nichts

anderes in den Betriebsanleitungen angegeben ist.

Beschädigte Schalter müssen bei einer Kundendienstwerkstatt ersetzt werden. Benutzen Sie keine

Werkzeuge, bei denen sich der Schalter nicht ein

und ausschalten läßt.

21. Achtung!

Zu Ihrer eigenen Sicherheit, benützen Sie nur Zubehör und Zusatzgeräte, die in der Bedienungsanleitung angegeben oder vom Werkzeug-Hersteller

empfohlen oder angegeben werden. Der Gebrauch

anderer als der in der Bedienungsanleitung oder im

Katalog empfohlenen Einsatzwerkzeuge oder Zubehöre kann eine persönliche Verletzungsgefahr für

Sie bedeuten.

22. Reparaturen nur vom Elektrofachmann.

Dieses Elektrowerkzeug entspricht den einschlägi-

gen Sicherheitsbestimmungen. Reparaturen dürfen

nur von einer Elektrofachkraft ausgeführt werden,

andernfalls können Unfälle für den Betreiber entstehen.

ZUSÄTZLICHE

SICHERHEITSBESTIMMUNGEN

1. Tragen Sie während der Arbeit mit der Maschine

stets eine Schutzbrille sowie vorgeschriebene

Arbeitskleidung und, falls erforderlich, persönliche Schutzausrüstung.

2. Vergewissern Sie sich, daß die Schutzvorrich-

tungen vorschriftsmäßig angebracht sind, bevor

Sie das Gerät einschalten.

3. Das Gerät nicht in der Nähe leicht entzündlicher

Flüssigkeiten oder Gase betreiben.

4. Überprüfen Sie das Sägeblatt vor dem Betrieb

sorgfältig auf Risse oder Beschädigung. Wechseln Sie ein gerissenes oder beschädigtes Sägeblatt unverzüglich aus.

5. Verwenden Sie nur die für diese Maschine vorge-

schriebenen Flansche.

6. Achten Sie sorgfältig darauf, daß Welle, Flan-

sche (insbesondere deren Montageflächen) und

Schraube nicht beschädigt werden. Eine

Beschädigung dieser Teile kann zu Schäden am

Sägeblatt führen.

7. Vergewissern Sie sich, daß der Drehteller arre-

tiert ist und sich während des Sägebetriebes

nicht bewegt.

8. Zur Sicherheit des Bedienenden sollten Abfallstücke und Kleinteile vor Beginn der Arbeit aus

dem Arbeitsbereich entfernt werden. Bei der

Bearbeitung können kurze Abschnitte vom

Sägeblatt erfaßt und weggeschleudert werden.

Schmale Abschnitte können zwischen Anschlag

und Sägeblatt eingezogen werden und Verklemmen des Blattes führen.

9. Vor Arbeitsbeginn das zu bearbeitende Werkstück auf evtl. vorhandene Nägel oder Schrauben überprüfen und diese herausziehen. Ein

unbeabsichtigtes Durchschneiden eines mit

Nägeln und Schrauben versehenen Werkstücks

kann zur Beschädigung des Sägeblattes sowie

Verletzungen des Bedienenden führen.

10. Vergewissern Sie sich, daß die Spindelarretierung gelöst ist, bevor Sie das Gerät einschalten.

11. Achten Sie darauf, daß das Sägeblatt in seiner

niedrigsten Position die Drehplatte nicht berührt.

12. Die Säge kann sich während des Anlauf- bzw.

Bremsvorgangs leicht nach oben oder unter

bewegen.

13. Führen Sie keine Freihandarbeiten aus. Das

Werkstück muß bei allen Arbeiten festgespannt

werden und am Parallelanschlag sowie am Drehteller anliegen.

14. Vermeiden Sie jede Berührung des Sägeblattes

bei laufender Maschine. Auch seitliche Berührung kann zu schweren Verletzungen führen.

15. Fassen Sie nie um das Sägeblatt herum.

16. Vor dem Einschalten darf das Sägeblatt nicht mit

dem Werkstück in Berührung kommen.

17. Überprüfen Sie vor der eigentlichen Bearbeitung

eines Werkstücks den einwandfreien Rundlauf

des Sägeblattes. Schalten Sie dazu die Maschine

ein und achten Sie auf eventuelle Vibrationen

oder Taumelbewegungen des Sägeblattes, die

Anzeichen für falsche Montage oder Unwucht

des Sägeblattes sein können.

18. Beginnen Sie erst dann mit dem Bearbeitungsvorgang, wenn die Maschine ihre volle Drehzahl

erreicht hat.

19. Bei Auftreten von Störungen den Betrieb sofort

unterbrechen.

20. Versuchen Sie nicht, den Schalter in der EINStellung zu arretieren.

21. Schalten Sie die Maschine aus und warten Sie,

bis das Sägeblatt völlig zum Stillstand gekommen ist, bevor Sie Wartungs- oder Einstellarbeiten an der Maschine ausführen.

22. Die Maschine wurde unter Beachtung aller

Sicherheitsvorkehrungen konstruiert. Trotzdem

gehen von der Maschine Restrisiken aus. Das

Sägeblatt läuft bei dem Bearbeitungsvorgang

unabgedeckt. Daher muß darauf geachtet werden, daß niemals Körperteile das Sägeblatt

berühren.

18

Page 19

23. Verwenden Sie nur die in dieser Anleitung empfohlenen Zubehörteile. Die Verwendung ungeeigneter Zubehörteile, wie z.B. Schleifscheiben,

kann zu Verletzungen führen.

24. Behandeln Sie das Netzkabel sorgfältig. Ziehen

Sie das Netzkabel niemals gewaltsam aus der

Steckdose heraus. Halten Sie das Netzkabel von

Wärmequellen, Öl, Wasser und scharfen Kanten

fern.

25. Bestimmungsgemäße Verwendung: Diese Gehrungs- und Kappsäge ist bestimmt zum Schneiden von Massivholz, Holzwerkstoffen,

Kunststoffen und Leichtmetall-Hohlprofilen. Bei

Massivholz und Holz gleichzusetzenden Werkstoffen nur Sägeblätter mit positivem Spanwinkel verwenden. Kunststoffe und Leichtmetalle

sind mit einem Sägeblatt mit negativem Spanwinkel und Zahnform (Trapez/Flachzahn) zu

schneiden. Jede darüber hinausgehende Verwendung gilt als nicht bestimmungsgemäß und

bedarf der schriftlichen Zustimmung und Genehmigung des Herstellers.

26. Bei längerem Bearbeiten von Holz bzw. holzähnlichen Werkstoffen oder gewerblichen Einsatz

von Materialien, bei denen gesundheitsgefährdende Stäube entstehen, ist das Elektrowerkzeug an eine geeignete externe

Absaugeinrichtung anzuschließen.

27. Bei der Herstellung von Nuten besonders aufmerksam und umsichtig vorgehen.

28. Wechseln Sie die Einlegeplatte bei Abnutzung

aus.

BEWAHREN SIE DIESE HINWEISE

SORGFÄLTIG AUF.

BEDIENUNGSHINWEISE

Tragen der Maschine (Abb.1)

Zum Tragen der Maschine senken Sie den Sägekopf vollständig und drücken den Verriegelungsknopf, um den

Sägekopf in der abgesenkten Stellung zu arretieren.

Sichern Sie den Drehteller durch Festdrehen des Griffes.

Danach kann die Maschine bequem am Tragegriff getragen werden.

WARNUNG:

• Vergewissern Sie sich vor allen Arbeiten an der

Maschine stets, daß der Netzstecker gezogen ist.

• Der Anschlagstift ist lediglich zum Tragen der Maschine

vorgesehen; beim Sägebetrieb wird er nicht verwendet.

Montage der Kippsicherung (Abb. 2u. 3)

Montieren Sie die Kippsicherung am Maschinenfuß und

ziehen Sie die Sechskantschraube fest an.

Befestigung der Säge auf einer Werkbank

(Abb. 4)

Diese Maschine sollte mit zwei Schrauben auf einer ebenen und stabilen Oberfläche befestigt werden. Verwenden Sie dazu die Befestigungsbohrungen im

Maschinenfuß. Sie erreichen dadurch hohe Standfestigkeit und größtmögliche Sicherheit während des Bearbeitungsvorgangs.

Montage bzw. Demontage des Sägeblattes

Wichtig:

Vergewissern Sie sich vor der Montage bzw. Demontage

des Sägeblattes stets, daß die Maschine abgeschaltet

und der Netzstecker gezogen ist.

Bei der Demontage benutzen Sie den Steckschlüssel,

um die Sechskantschraube, die die Mittelabdeckung hält,

durch mehr als drei Umdrehungen linksdrehend zu

lösen. Danach heben Sie die Schutzhaube und die Mittelabdeckung an. (Abb. 5) Drücken Sie auf die Spindelarretierung, damit sich das Sägeblatt nicht drehen kann,

und benutzen Sie den Steckschlüssel, um die Sechskantschraube durch Rechtsdrehung zu lösen. Dann entfernen Sie die Sechskantschraube, den Flansch und das

Sägeblatt. (Abb. 6)

Zur Montage des Sägeblattes setzen Sie dieses auf die

Spindel, wobei Sie darauf achten, daß die Drehrichtungspfeile auf dem Sägeblatt mit der Richtung der Drehrichtungspfeile auf dem Sägeblattgehäuse übereinstimmen.

(Abb.7)

VORSICHT:

• Für alle Länder außerhalb Europas (Abb.8) Werk-

seitig ist ein silberner Reduzierring mit 25,4 mm Außen-

durchmesser auf der Spindel montiert. Der schwarze

Reduzierring mit 25 mm Außendurchmesser gehört

zum Lieferumfang der Maschine. Bevor Sie das Säge-

blatt auf der Spindel montieren, vergewissern Sie sich

immer, daß der für die Bohrung des Sägeblattes richtige Reduzierring auf der Spindel angebracht ist.

• Für europäische Länder (Abb. 8)

Werkseitig ist der Reduzierring mit 30 mm Außendurch-

messer auf der Spindel montiert.

Montieren Sie den Flansch und die Sechskantschraube.

Benutzen Sie dazu den Steckschlüssel, um die Sechskantschraube durch Linksdrehung anzuziehen. Dabei

drücken Sie die Spindelarretierung. Anschließend die

Sechskantschraube für die Mittelabdeckung rechtsdrehend wieder festziehen. (Abb. 9)

VORSICHT:

Benutzen Sie ausschließlich den von Makita gelieferten

Steckschlüssel, um die Sechskantschraube anzuziehen.

Andernfalls kann es zu einem zu starken oder zu schwachen Anziehen der Sechskantschraube kommen. Dies

könnte zu Verletzungen führen. Der Hebelweg dieses

Schlüssels ist auf das Drehmoment der Sechskantschraube abgestimmt.

19

Page 20

Schutzhaube (Abb. 10)

Wenn Sie den Griff senken und den Arretierhebel der

Feststelleinrichtung seitlich bis zum Anschlag gedrückt

haben, hebt sich die Schutzhaube automatisch. Die

Schutshaube kehrt in die Ausgangsstellung zurück, wenn

der Bearbeitungsvorgang beendet ist und der Griff wieder angehoben wird. NIEMALS DIE SCHUTZHAUBE

ENTFERNEN. Im Interesse Ihrer eigenen Sicherheit sollten Sie die Schutzhaube stets in ordnungsgemäßem

Zustand halten. Störungen im Betrieb der Schutzhaube

müssen sofort behoben werden. BENUTZEN SIE DAS

GERÄT NIE MIT EINER FEHLERHAFTEN SCHUTZHAUBE. Wenn die transparente Schutzhaube verschmutzt ist oder soviel Sägemehl an ihr haftet, daß das

Sägeblatt und/oder das Werkstück nicht mehr ohne weiteres sichtbar sind, sollten Sie den Netzstecker ziehen

und die Schutzhaube mit einem feuchten Tuch sorgfältig

reinigen. Benutzen Sie keine Lösungsmittel oder Reinigungsmittel auf Petroleumbasis wie Reinigungsbenzin.

Staubsack (Abb.11 u.12)

Den Staubsack auf den Staubauslaßstutzen der

Maschine befestigen. Wenn der Staubsack etwa zur

Hälfte gefüllt ist, nehmen Sie ihn von der Maschine und

ziehen die Verschlußschiene heraus. Leeren Sie den

Inhalt des Staubsacks und klopfen Sie den Staubsack

leicht aus. Die an den Innenflächen heftenden Staubpartikel, die den weiteren Staubsammelvorgang beeinträch-

tigen können, werden so entfernt. Für staubarmes

Arbeiten kann ein Makita-Absauggerät an die Maschine

mit Hilfe des Absaugadapters angeschlossen werden.

Bei längerem Bearbeiten von Holz oder gewerblichen

Einsatz von Materialien, bei denen gesundheitsgefähr-

dende Stäube entstehen, ist das Elektrowerkzeug an

eine geeignete externe Absaugeinrichtung anzuschließen. Die nationalen Bestimmungen (TRK-Werte) müssen eingehalten werden.

Schalterfunktion

VORSICHT:

• Vor dem Anschließen der Maschine an das Stromnetz

stets überprüfen, ob der Schalter ordnungsgemäß

funktioniert und beim Loslassen in die AUS-Position

zurückkehrt.

• Wenn Sie die Maschine nicht benutzen, entfernen Sie

den Einschaltsicherheitsstift und bewahren sie ihn an

einem sicheren Ort auf. Dadurch wird unerlaubte

Benutzung verhindert.

• Den Schalter nicht ohne vorherige Betätigung der Einschaltarretierung gewaltsam drücken. Hierdurch kann

der Schalter beschädigt werden.

Für alle Länder außerhalb Europas (Abb.13)

Um versehentliche Betätigung des Schalters zu verhindern, verfügt die Maschine über eine Einschaltarretierung. Zum Einschalten der Maschine

Einschaltarretierung und danach Schalter drücken. Zum

Ausschalten der Maschine den Schalter loslassen.

Für europäische Länder (Abb. 14)

Um versehentliche Betätigung des Schalters zu verhindern, verfügt die Maschine über eine Einschaltarretie-

rung. Zum Einschalten der Maschine den Arretierhebel

nach links schieben, Einschaltarretierung und danach

Schalter drücken. Zum Ausschalten der Maschine den

Schalter loslassen.

Einlegeplatten (Abb. 15)

Diese Maschine ist mit Einlegeplatten im Drehteller versehen. Wenn der Einschnitt nicht bereits werkseitig ausgeführt wurde, muß er vom Bedienenden in die Platte

eingesägt werden, bevor das Gerät erstmalig in Betrieb

genommen wird. Dazu schalten Sie die Maschine ein

und senken das Sägeblatt langsam in die Einlegeplatte.

Zusatzanschlag (Abb. 16 u.17)

Diese Maschine ist mit einem Zusatzanschlag ausgestattet, der entsprechend Abb. 16 zu positionieren ist. Bei

linksseitiger Neigungswinkeleinstellung ist der Zusatzanschlag in der, wie in Abb.17 gezeigten, Position zu verwenden.

Schnittiefeneinstellung

(nur bei gezogenem Netzstecker!)

(Abb. 18 u.19)

Diese Maschine ist werkseitig so eingestellt, daß mit

einem Sägeblattdurchmesser von 260 mm die maximale

Schnittiefe erzielt wird. Wenn der Durchmesser des

Sägeblattes durch Nachschärfen verringert wurde, stellen Sie die Justierschraube mit dem Steckschlüssel folgendermaßen ein:

Das Sägeblatt wird gesenkt, indem Sie die Schraube im

Uhrzeigersinn drehen; es wird gehoben, indem Sie die

Schraube gegen den Uhrzeigersinn drehen. Dabei muß

der Abstand zwischen Anschlagleiste und dem Eintauchpunkt des Sägeblattes in die Einlegeplatte bei voll abgesenktem Sägeblatt ca. 135 mm betragen. Das Sägeblatt

darf nach der Einstellung bei abgesenktem Sägekopf

keine Teile im unteren Sägetischbereich berühren. Dies

Prüfen Sie durch manuelles Drehen des Sägeblattes.

Einstellung des Gehrungswinkels (Abb. 20)

Lösen Sie den Griff durch Linksdrehung. Zur Verstellung

des Drehtellers drücken Sie den Sperrhebel nach unten.

Bewegen Sie den Griff, bis der Pfeil auf den gewünsch-

ten Winkel der Gehrungswinkelskala zeigt, und ziehen

Sie dann den Griff durch Rechtsdrehung fest.

VORSICHT:

Zur Verstellung des Drehtellers den Sägekopf vollständig

anheben.

20

Page 21

Einstellung des Neigungswinkels (Abb. 21 u.22)

Der Sägekopf kann um 45° nach links geneigt werden,

sofern sich der Zusatzanschlag wie in Abb. 17 gezeigt in

der linken Stellung befindet. Zur Neigungswinkel-Einstellung lösen Sie den Arretierhebel auf der Rückseite der

Maschine. Neigen Sie das Sägeblatt nach links, bis der

Pfeil auf den gewünschten Winkel der NeigungswinkelEinstellskala zeigt. Ziehen Sie den Arretierhebel fest, um

den Sägekopf zu sichern.

VORSICHT:

Neigen Sie den Sägekopf nur in der vollständig angehobenen Position.

Werkstückspanneinrichtung

WARNUNG:

Das Werkstück muß vor dem Schnittvorgang fest und

unverrückbar mit der Schraubzwinge gesichert werden.

Bei nicht ordnungsgemäß gesichertem Werkstück

besteht VERLETZUNGSGEFAHR. Ebenfalls können

Maschine und/oder Werkstück beschädigt werden. Das

Werkstück erst nach Stillstand des Sägeblattes aus der

gesicherten Position herausnehmen.

1. Vertikalschraubzwinge (Abb. 23 u. 27)

Die Vertikalschraubzwinge kann auf dem Parallelanschlag oder Seitenanschlag (Sonderzubehör) montiert werden. Setzen Sie den Stehbolzen in die

Bohrung des Parallelanschlags oder Seitenanschlags und ziehen Sie die Flügelschraube zur

Sicherung des Stehbolzens fest. Stellen Sie den

Schraubzwingenarm auf die Abmessungen des

Werkstücks ein und sichern Sie ihn mit der Flügelschraube. Drücken Sie das Werkstück flach gegen

Parallelanschlag und Drehteller. Bringen Sie das

Werkstück in die gewünschte Schnittposition und

sichern Sie es durch Festziehen der Feststellschraube.

VORSICHT:

Das Werkstück muß bei allen Arbeiten mit der

Schraubzwinge so gesichert werden, daß es sowohl

auf dem Drehteller als auch am Parallelanschlag

anliegt.

Falls Maschinenteile mit der Schraubzwinge in

Berührung kommen, ändern Sie die Position des

Schraubzwingenarms. Anschließend das Werkstück, wie zuvor beschrieben, ordnungsgemäß

sichern.

VORSICHT:

Wenn Sie lange Werkstücke schneiden, benutzen

Sie zusätzliche Stützen, die ebenso hoch sind wie

die Drehplattenoberfläche (Abb. 24)

2. Horizontalschraubzwinge (Sonderzubehör)

(Abb. 25u. 26)

Die Horizontalschraubzwinge kann rechts oder links

am Maschinentisch montiert werden. Bei Gehrungsschnitten ≥15° montieren Sie die Horizontalschraubzwinge auf der Drehtellerdrehrichtung

entgegengesetzten Seite.

Die Horizontalschraubzwinge ist mit einer Schnellverstellung ausgerüstet. Den Drehknopf linksdrehend lösen und die Schraubstockspindel vor oder

zurückziehen. Den Sperrhebel durch Rechtsdrehung des Drehknopfes kurz vor Anlage der Schraubstockplatte am Werkstück in die obere Position

bringen. Das Werkstück kann jetzt mit dem Drehknopf gesichert werden. Sollte sich der Sperrhebel

durch gewaltsames Vorgehen nicht in der oberen

Position befinden, den Drehknopf lösen und wieder

festziehen.

3. Auflageverlängerung und Montagestütze

(Sonderzubehör)

Die Auflageverlängerung und Montagestütze können zur waagerechten Werkstückauflage rechts und

links am Maschinentisch befestigt werden. Zur Montage, wie in Abb. 27 gezeigt, die Teile montieren und

anschließend mit den Flügelschrauben sichern. Bei

längeren Werkstücken die Führungsstangen mit

Montagestütze montieren (Sonderzubehör).

(Abb. 28)

VORSICHT:

Beim Schneiden von langen Werkstükken stets das

Werkstück mit Stützen gleicher Höhe wie die Drehtelleroberfläche abstützen. Die gewährleistet eine

hohe Schnittgenauigkeit und sicheres Arbeiten mit

der Maschine.

Betrieb

VORSICHT:

• Vor dem Betrieb den Sägekopf durch Herausziehen

des Verriegelungsstiftes entriegeln.

• Vergewissern Sie sich vor der Betätigung des Schal-

ters, daß eine Berührung des Sägeblatts mit dem

Werkstück oder Teilen der Maschine ausgeschlossen

ist.

•Üben Sie beim Schneiden keinen übermäßigen Druck

auf den Sägekopf aus. Zu starker Druck kann zu Über-

lastung des Motors und/oder verminderter Schnittleistung führen.

• Zum Erreichen der höchsten Schnittgenauigkeit den

Sägekopf nur mit gemäßigtem Vorschubdruck nach

unten bewegen. Bei zu großem Vorschub oder seitlicher Krafteinwirkung auf den Sägekopf kann das Säge-

blatt in Schwingung versetzt werden und dadurch

zusätzlich Sägespuren am Werkstück hinterlassen.

• Die Schnittlinie sollte rechts oder links von der Nut der

Einlegeplatten verlaufen. Der Materialverlust wird

durch die Sägeblattstärke bestimmt.

21

Page 22

Schalten Sie die Maschine ein und warten Sie, bis sie

ihre volle Drehzahl erreicht hat. Erst dann drücken Sie

den Arretierhebel der Feststelleinrichtung und senken

den Griff vorsichtig. Sobald das Sägeblatt das Werkstück

berührt, drücken Sie langsam auf den Griff, um den

Schnitt auszuführen. Wenn der Schnitt beendet ist,

schalten Sie das Gerät aus und WARTEN, BIS DAS

SÄGEBLATT VOLLSTÄNDIG ZUM STILLSTAND

GEKOMMEN IST, bevor Sie den Sägekopf in die obere

Position bringen. Andernfalls könnten kleine Abschnitte

vom Sägeblatt erfaßt und weggeschleudert werden.

(Abb. 29)

1. Gehrungsschnitte

Siehe Abschnitt “Einstellung des Gehrungswinkels”.

2. Neigungsschnitte (Abb. 30)

• Linksseitige Neigungsschnitte können in einem

Neigungswinkel von 0°–45° durchgeführt werden.

• Bringen Sie den Zusatzanschlag in die in Abb. 17

gezeigte linke Stellung. Lösen Sie den Arretierhebel und stellen den Sägekopf auf den gewünsch-

ten Neigungswinkel ein. Achten Sie darauf, den

Hebel wieder fest anzuziehen, um den Griff im eingestellten Schrägstellungswinkel zu sichern.

Sichern Sie das Werkstück mit der Werkstücks-

panneinrichtung. Schalten Sie die Maschine ein.

Nach Erreichen der max. Drehzahl den Sägekopf

in das Werkstück eintauchen und den Schnittvorgang unter paralleler Druckausübung zum Säge-

blatt mit einer Schubbewegung des Sägekopfes in

Richtung des Parallelanschlags durchführen. Nach

Beendigung des Schnittvorgangs Maschine ausschalten UND DEN STILLSTAND DES SÄGE-

BLATTS ABWARTEN, bevor Sie den Sägekopf in

die Ausgangsposition zurückschwenken.

VORSICHT:

• Bei Neigungsschnitten kann das Sägeblatt auf

dem Werkstückabschnitt seitlich aufliegen. Durch

Anheben des Sägekopfes bei laufender Maschine

kann das Werkstück erfaßt und herausgeschleudert werden und Verletzungen verursachen. Säge-

kopf immer nur bei Sägeblattstillstand anheben.

•Üben Sie den Druck auf den Sägekopf immer nur

parallel zum Sägeblatt in radialer Kraftrichtung

aus. Axiale Krafteinwirkung verschlechtert die

Bearbeitungsgenauigkeit.

• Achten Sie bei Neigungsschnitten stets darauf,

den Zusatzanschlag, wie in Abb. 17 gezeigt, in die

linke Stellung zu bringen.

3. Doppelgehrungsschnitte (Schifterschnitte)

Unter Doppelgehrungsschnitten versteht man den

Bearbeitungsvorgang mit gleichzeitiger Neigungswinkel- und Gehrungswinkeleinstellung. Die Kombinationsmöglichkeiten entnehmen Sie

nachstehender Tabelle.

Neigungswinkel Gehrungswinkel

45°

Zum Doppelgehrungsschnitt beachten Sie außer-

dem die Hinweise unter “Gehrungsschnitt” und “Nei-

gungsschnitt”.

4. Schneiden von dünnwandigen

Leichtmetallprofilen (Abb. 31)

Zur Werkstücksicherung verwenden Sie – wie in

Abb.31 gezeigt – Zulagen aus Hartholz o.ä., um

Verformungen des Materials während des Schneidvorgangs zu vermeiden. Benutzen Sie beim Schneiden von dünnwandigen Aluminium-Werkstoffen eine

Schneidflüssigkeit, damit sich keine AluminiumRückstände am Sägeblatt ansammeln.

VORSICHT:

Vollmaterialien mit großem Querschnitt und Rundmaterial dürfen nicht bearbeitet werden. Beim Säge-

vorgang kann sich das Material lösen bzw.

Rundmaterial kann nicht sicher befestigt werden.

5. Zwischenbrett (Abb.32)

Durch das Benutzen eines Zwischenbretts können

Sie die Werkstücke ausrißfrei sägen. Die Bohrungen

im Parallelanschlag dienen als Befestigungshilfe für

ein Zwischenbrett.

VORSICHT:

• Benutzen Sie glatt gehobeltes Holz gleichmäßiger

Dicke als Zwischenbrett.

• Beachten Sie die Abmessungen gem. Abb. 32.

6. Verwendung des Seitenanschlags (Abb.33)

Der Seitenanschlag erlaubt wiederholt, längenglei-

che Schnitte zwischen 240 und 400 mm. Montieren

Sie den Seitenanschlag an der Auflageverlänge-

rung, wie in Abb. 33 gezeigt.

Die Schnittlinie auf dem Werkstück an der Nut der

Einlegeplatten rechts oder links ausrichten, den Seitenanschlag am Werkstückende anlegen und mit der

Flügelschraube sichern. Für längere Abschnitte

kann der Seitenanschlag bei Nichtgebrauch nach

vorne umgeklappt werden.

Links und rechts

0° – 45°

22

Page 23

WARTUNG

VORSICHT:

Vor Arbeiten an der Maschine vergewissern Sie sich, daß

sich der Schalter in der “AUS-” Position befindet und der

Netzstecker gezogen ist.

Schnittwinkeleinstellung

Diese Maschine wurde werkseitig eingestellt und justiert.

Die Einstellungen können jedoch durch Transporteinflüsse oder unsachgemäße Behandlung beeinträchtigt

werden. Nachfolgend beschriebene Korrekturen können

an ihrer Maschine durchgeführt werden.

1) Gehrungswinkel (Abb. 34u. 35)

Lösen Sie den Griff durch Linksdrehung und drehen

Sie den Drehteller bis zur 0°-Position. Ziehen Sie

den Griff wieder fest und lösen Sie die Sechskantschrauben zur Befestigung des Parallelanschlags.

Den Parallelanschlag unter Verwendung eines Dreiecks, Anschlagwinkels o.ä. zum Sägeblatt bei abgesenktem Sägekopf rechtwinklig ausrichten. Dabei

die rechte Seite des Parallelanschlags verschieben.

Die Sechskantschrauben des Parallelanschlags in

der Reihenfolge nach Abb. 35 festziehen.

2) Neigungswinkel

i) 0° Neigungswinkel

Lösen Sie den Arretierhebel, die Sechskantmutter

und drehen Sie die Sechskantschraube (A) um 2 –

3 Umdrehungen linksdrehend heraus. Der Säge-

kopf wird nach rechts geneigt. (Abb. 36) Den

Sägekopf absenken und den rechten Winkel zwischen Sägeblatt und Drehtelleroberfläche unter

Verwendung eines Dreiecks, Anschlagwinkels o.ä.

durch Drehen der Sechskantschraube (A) einstellen. Zur Sicherung der Sechskantschraube (A) die

Sechskantmutter festziehen. (Abb. 37)

Der Markierungspfeil ist nach der orrekten

0°-Einstellung des Sägekopfs auf die 0°-Markie-

rung der Neigungswinkeleinstellskala auszurichten. (Abb. 38)

ii) 45° Neigungswinkel

Die 45° Neigungswinkeleinstellung kann erst nach

erfolgreicher 0° Neigungswinkeleinstellung durchgeführt werden. Zum Einstellen den Arretierhebel

lösen und den Sägekopf bis zum Anschlag in die

45° Position neigen. Falls der Markierungspfeil

nicht auf die 45° Markierung der Neigungswinkeleinstellskala zeigt, die Sechskantschraube (B) entsprechend drehen. (Abb.38)

Auswechseln der Kohlebürsten (Abb.39 u.40)

Wechseln Sie die Kohlebürsten aus, wenn sie bis zur

Verschleißgrenze abgenutzt sind. Die beiden identischen

Kohlebürsten sollten gleichzeitig ausgewechselt werden.

Um die Sicherheit und Zuverlässigkeit dieses Gerätes zu

gewährleisten, sollten Reparatur-, Wartungs-, und Einstellarbeiten nur von Makita autorisierten Werkstätten

oder Kundendienstzentren unter ausschließlicher Verwendung von Makita-Originalersatzteilen ausgeführt

werden.

23

Page 24

Geräusch- und Vibrationsentwicklung des Modells LS1040

Die typischen A-bewerteten Geräuschpegel betragen:

Der gewichtete Effektivwert der Beschleunigung beträgt nicht

mehr als 2,5m/s

Schalldruckpegel:93 dB (A)

Schalleistungspegel:106 dB (A)

– Gehörschutz tragen. –

2

.

CE-KONFORMITÄTSERKLÄRUNG

Hiermit erklärt der Unterzeichnete, Yasuhiko Kanzaki, Bevollmäch-

tigter von Makita Corporation, 3-11-8 Sumiyoshi-Cho, Anjo, Aichi,

446-8502 Japan, daß dieses von der Firma Makita Corporation in

der Volksrepublik China hergestellte Produkt

gemäß den Ratsdirektiven 73/23/EWG, 89/336/EWG und

98/37/EG mit den folgenden Normen bzw. Normendokumenten

übereinstimmen:

(Serien-Nr.: Serienproduktion)

EN61029, EN55014, EN61000.

24

Yasuhiko Kanzaki

CE97

Direktor

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes, Bucks

MK15 8JD, ENGLAND

Page 25

POLSKI

Wyjaśnienia dotyczące urządzenia i jego użycia

1 Podstawa

2 Śruba sześciokątna

3 Płyta pomocnicza

4Nakrętka

5Śruba

6Pokrywa środkowa

7 Klucz nasadkowy

8 Blokada wałka

9 Odkręcanie

10 Strzałka

11 Obudowa brzeszczotu

12 Strzałka

13 Brzeszczot

14 Trzpień obrotowy

15 Kołnierz

16 Pierścień

17 Kołnierz

18 Śruba sześciokątna

19 Zakręcanie

20 Pokrywa zabezpieczająca

21 Dysza na pył

22 Torba na pył

23 łącznik

24 Przycisk blokady

25 Spust włącznika

26 Dźwignia

27 Podstawa obrotowa

28 Płyta z nacięciem

29 Prowadnica

30 Śruba regulacyjna

31 Wskaźnik

32 Podziałka kąta poziomego

33 Sprężyna zatrzaskowa

34 Uchwyt

35 Dźwignia

36 Podziałka kąta pionowego

37 Wskaźnik

38 Drążek zacisku

39 Śruby

40 Osłona prowadząca

41 Ramię zacisku

42 Śruba zaciskowa

43 Podpórka

44 Gałka

45 Występ

46 Uchwyt

47 Śruba

48 Układ mocowania

49 Śruba

50 Pręt 12

51 Linia cięcia

52 Bruzda

53 Zacisk

54 Klocek rozporowy

55 Kształtownik aluminiowy

56 Klocek rozporowy

57 Ponad 10 mm

58 Ponad 460 mm

59 Otwór

60 Ogranicznik regulowany

61 Śruba

62 Ekierka

63 Śruby sześciokątne

64 Ramię

65 Śruba sześciokątna (A)

66 Górna powierzchnia podstawy

obrotowej

67 Uchwyt ramienia

68 Śruba sześciokątna (B)

69 Oznaczenie limitu

70 Śrubokręt

71 Pokrywa pojemnika na

szczoteczki

DANE TECHNICZNE

Model LS1040

Średnica brzeszczotu ........................................................................................................................255 mm— 260mm

Średnica otworu (wałka)

Wszystkie kraje pozaeuropejskie ...................................................................................................... 25,4 mm i 25 mm

Kraje europejskie ................................................................................................................................................30 mm

Maksymalna zdolność cięcia (wys.x szer.) brzeszczotem o średnicy 260mm

Kąt poziomy

Kąt pionowy

0˚

45˚ (lewy)

0˚ 45˚ ( lewy i prawy)

93 mm x95 mm

69 mm x135 mm

53mm x 95mm

35 mm x135 mm

93 mm x67 mm

69 mm x95 mm

49 mm x67 mm

35 mm x94 mm

Prędkość bez obciążenia (obr./min) ....................................................................................................................... 4.600

Wymiary (dług. x szer. x wys.) ........................................................................................... 530 mm x 476 mm x 532 mm

Ciężar netto ............................................................................................................................................................ 11 kg

• W związku z ciągłym programem badawczorozwojowym podane dane techniczne mogą ulec

zmianie bez uprzedzenia.

• Uwaga: Dane techniczne mogą różnić się w zależności

od kraju.

Przeznaczenie

Narzędzie przeznaczone jest do dokładnego cięcia

prostego i ukośnego elementów drewnianych. Stosując

odpowiednie tarcze, można przy jego użyciu również

ciąć aluminium.

Zasilanie

Urządzenie powinno być podłączane wyłącznie do

źródła zasilania o takim samym napięciu jak podane na

tabliczce znamionowej urządzenia i może pracować

tylko przy zasilaniu jednofazowym prądem zmiennym.

Posiada ono podwójna izolację zgodną Normą

Europejską i dlatego może być również podłączane do

gniazdek bez uziemienia.

25

Page 26

Publiczne sieci niskiego napięcia od 220 V do

250 V

Włącznie i wyłączanie urządzeń elektrycznych powoduje

fluktuacje napięcia. Posługiwanie się urządzeniem przy

niekorzystnych parametrach sieci zasilania może mieś

niekorzystny wpływ na działanie innych urządzeń. Przy

impedancji sieci zasilania mniejszej lub równej 0,30 W

można założyć, że niekorzystne efekty nie wystąpią.

Gniazdo zasilania używane do podłączenia tego

urządzenia musi być zabezpieczone bezpiecznikiem

topikowym lub przerywaczem o wolno wzrastającej

charakterystyce.

INSTRUKCJE BEZPIECZEŃSTWA

Ostrzeżenie! Używając urządzeń elektrycznych

podstawowe środki ostrożności muszą być zawsze

zachowane, aby zmniejszyć ryzyko ognia, porażenia

prądem i uszkodzenia ciała, włączając poniższe.

Przeczytaj wszystkie podane instrukcje przed próbą

użycia tego produktu i zachowaj je do wglądu.

Dla bezpiecznego użycia:

1. Utrzymuj miejsce pracy w czystości

Zabałaganione miejsca i stoły warsztatowe

sprzyjają wypadkom.

2. Zastanów się nad warunkami pracy

Nie wystawiaj urządzeń elektrycznych na deszcz.

Nie używaj urządzeń elektrycznych w wilgotnych

lub mokrych miejscach. Utrzymuj miejsce pracy

dobrze oświetlone. Nie używaj urządzeń

elektrycznych w obecności łatwopalnych płynów

lub gazów.

3. Chroń się przed porażeniem prądem

Zapobiegaj kontaktom ciała z uziemionymi

powierzchniami (np. rurami, grzejnikami,

kuchenkami, lodówkami).

4. Nie pozwalaj zbliżać się dzieciom

Nie pozwalaj wizytującym osobom dotykać

urządzenia lub przedłużacza. Wszystkie wizytujące

osoby nie powinny zbliżać się do miejsca pracy.

5. Zachowaj nieczynne urządzenia

Nieużywane urządzenia powinny być

przechowywane w suchych, wysokich lub

zamykanych miejscach tak, aby były niedostępne

dla dzieci.

6. Nie przeciążaj urządzenia

Wykona ono pracę lepiej i bezpieczniej, pracując w

sposób, dla którego zostało ono zaprojektowane.

7. Używaj poprawnego urządzenia

Nie nadużywaj małych lub dodatkowych urządzeń

do wykonania pracy urządzeń do dużej pracy. Nie

używaj urządzeń do celów, do których nie zostały

przeznaczone; na przykład, nie używaj piły

tarczowej do przecinania gałęzi lub kłód drzew.

8. Ubierz się odpowiednio

Nie noś luźnych ubrań lub biżuterii. Mogą one

zostać zahaczone o ruchome części. Gumowe

rękawiczki i przeciwpoślizgowe buty są wskazane

przy pracy na dworze. Zaleca się noszenie ochrony

na głowę przytrzymującej długie włosy.

9. Użyj okularów ochronnych i ochraniaczy uszu

Użyj masek na twarz lub masek przeciwpyłowych

jeżeli czynność cięcia wytwarza pyły.

10. Podłącz urządzenie usuwające pył

Jeżeli urządzenia posiadają podłączenia do