Page 1

GB

Miter Saw Instruction Manual

F

Scie à Coupe d’Onglet Manuel d’Instructions

D

Gehrungs- und Kappsäge Betriebsanleitung

I

Sega da Banco Istruzioni d’Uso

NL

Afkortzaag Gebruiksaanwijzing

E

Sierra Ingleteadora Manual de Instrucciones

P

Serra de Esquadria Manual de Instruço˜es

DK

Afkorter-geringssav Brugsanvisning

S

Kap- och Geringssåg Bruksanvisning

N

Gjæringssag Bruksanvisning

SF

Jiirisaha Käyttöohje

GR

¢ÈÛÎÔÚ›ÔÓÔ √‰ËÁ›Â˜ ¯Ú‹Ûˆ˜

LS1030

Page 2

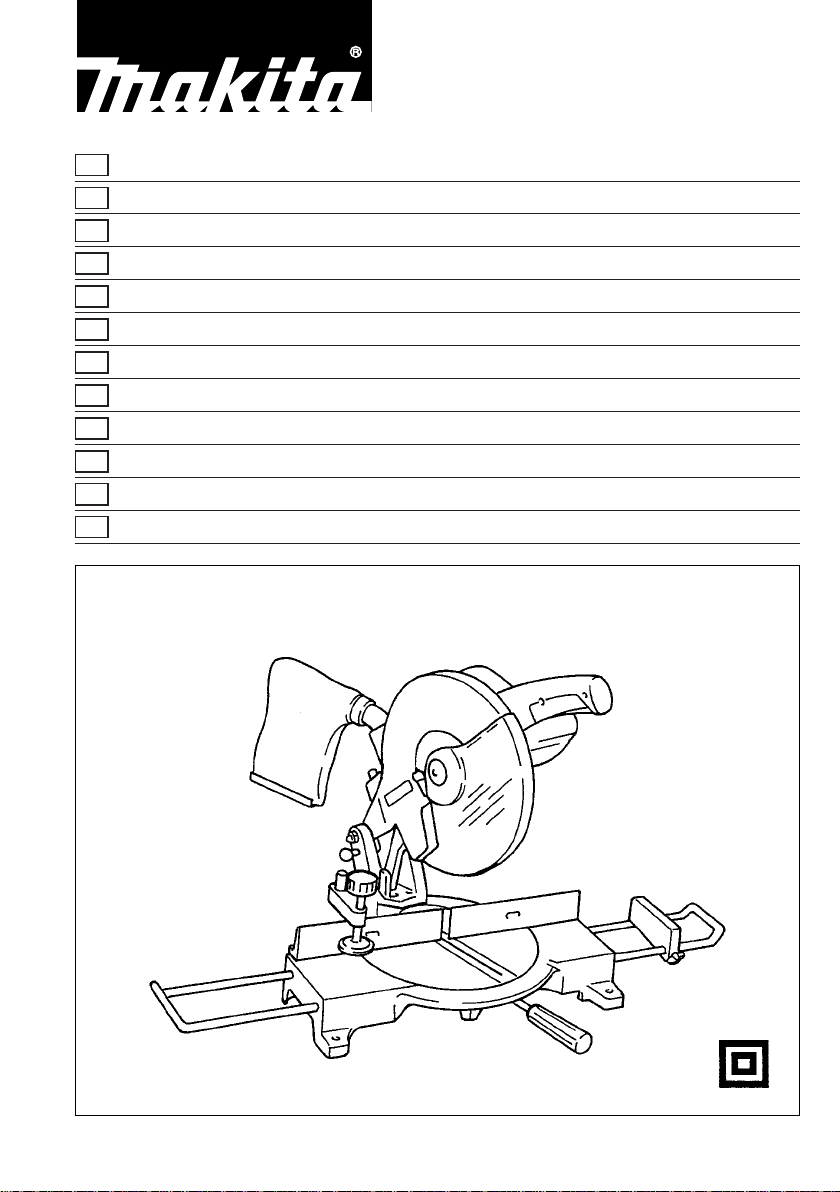

1 2

3 4

5

6 7

2

Page 3

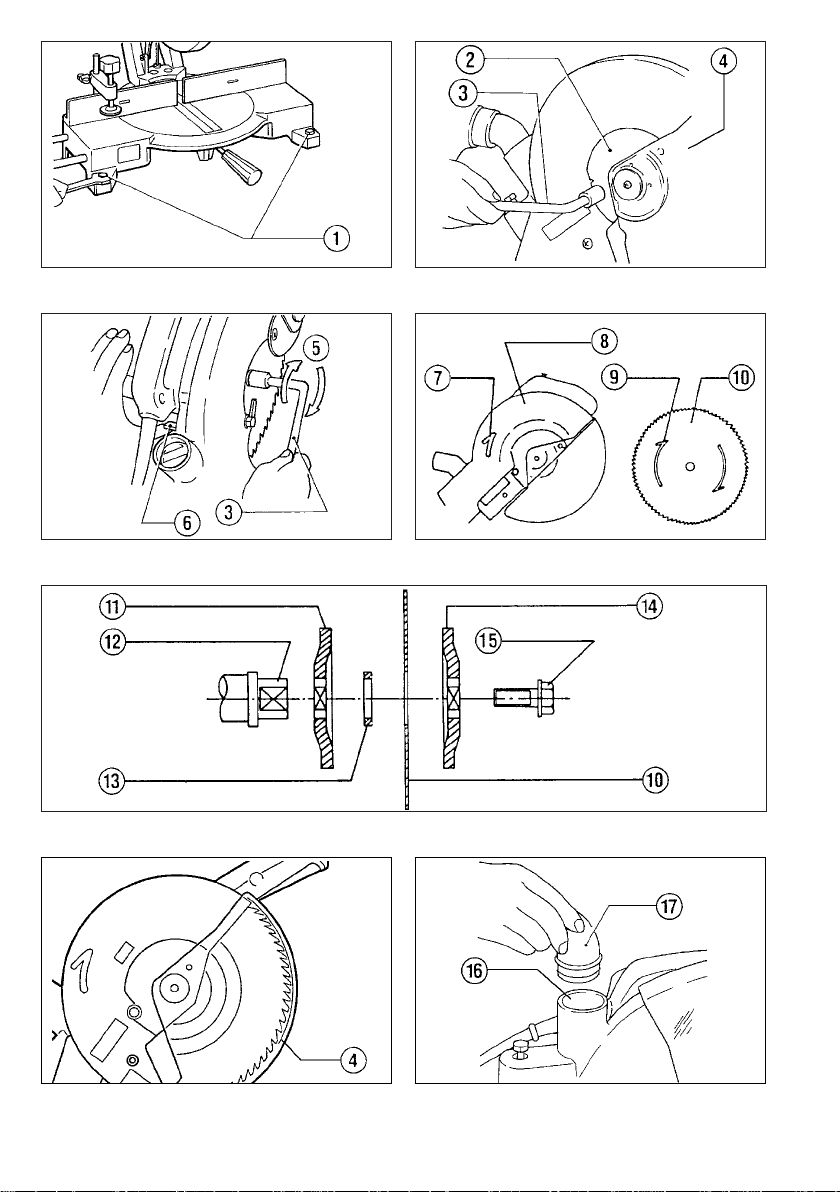

8 9

10 11

12 13

126 mm

14 15

3

Page 4

16 17

18 19

20 21

(4) (3)

(2) (1)

22 23

4

Page 5

24 25

26

5

Page 6

ENGLISH

Explanation of general view

1 Bolt

2 Center cover

3 Socket wrench

4 Safety cover

5 Loosen

6 Shaft lock

7 Arrow

8 Blade case

9 Arrow

0 Saw blade

q Flange

w Spindle

e Ring

r Flange

t Hex bolt

y Dust spout

u Elbow

i Dust bag

o Fastener

p Switch trigger

a Lever

s Turn base

d Kerf board

f Depth adjusting bolt

g Guide fence

h Pointer

j Miter scale

k Grip

l Clamp screw

; Vise arm

z Screw

x Workpiece

c Cutting line

v Groove

b Support

n Screw

m Wood facing

SPECIFICATIONS

Model LS1030

Blade diameter ............................................. 255 mm

Max. cutting capacities (H x W)

Cross cut (90°) .......... 70 x 126mm or 89 x 89 mm

Miter cut (45°) ............. 70 x 89 mm or 89 x 63 mm

No load speed (RPM) ...................................... 4,600

Dimensions (L xWxH)........... 470 x 485 x 510 mm

Net weight ..................................................... 10.6 kg

•

Due to the continuing program of research and

development, the specifications herein are subject

to change without prior notice.

•

Note: Specifications may differ from country to

country.

Power supply

The machine should be connected only to a power

supply of the same voltage as indicated on the

nameplate, and can onlybe operated on single-phase

AC supply. They are double-insulated in accordance

with European Standard and can, therefore, also be

used from sockets without earth wire.

Safety hints

For your own safety, please refer to enclosed safety

instructions.

These symbols mean:

Read instruction manual.

DOUBLE INSULATION

ADDITIONAL SAFETY RULES

1. Wear eye protection.

2. Do not operate saw without guards in place.

3. Don’t use the machine in the presence of

flammable liquids or gases.

4. Check the blade carefully for cracks or dam-

age before operation. Replace cracked or

damaged blade immediately.

5. Use only flanges specified for this machine.

, Aluminum extrusion

. Spacer blocks

/ Bolt

¡ Wrench

™ Hex lock nut

£ Arm

¢ Wrench

∞ Triangular rule

§ Hex bolts

¶ Set plate

• Wing bolt

ª Holder

º Wing bolt

œ Carrying grip

∑ Limit mark

é Screwdriver

® Brush holder cap

† Stopper pin

6. Be careful not to damage the arbor, flanges

(especially the installing surface) or bolt. Damage to these parts could result in blade breakage.

7. Make sure that the turn base is properly

secured so it will not move during operation.

8. For your safety, remove the chips, small

pieces, etc. from the table top before operation.

9. Avoid cutting nails. Inspect for and remove all

nails from the workpiece before operation.

10. Make sure the shaft lock is released before the

switch is turned on.

11. Be sure that the blade does not contact the

turn base in the lowest position.

12. Hold the handle firmly. Be aware that the saw

moves up or down slightly during start-up and

stopping.

13. Do not perform any operation freehand. The

workpiece must be secured firmly against the

turn base and guide fence during all operations.

14. Keep hands out of path of saw blade. Avoid

contact with any coasting blade. It can still

cause severe injury.

15. Never reach around saw blade.

16. Make sure the blade is not contacting the

workpiece before the switch is turned on.

17. Before using the machine on an actual workpiece, let it run for a while. Watch for vibration

or wobbling that could indicate poor installation or a poorly balanced blade.

18. Wait until the blade attains full speed before

cutting.

19. Stop operation immediately if you notice anything abnormal.

20. Do not attempt to lock the trigger in the on

position.

21. Shut off power and wait for saw blade to stop

before servicing or adjusting machine.

6

Page 7

22. Be alert at all times, especially during repetitive, monotonous operations. Don’t be lulled

into a false sense of security. Blades are

extremely unforgiving.

23. Always use accessories recommended in

Makita catalog. Use of improper accessories

such as abrasive wheels may cause an injury.

24. Don’t abuse cord. Never yank cord to disconnect it from the receptacle. Keep cord away

from heat, oil, water and sharp edges.

25. Do not use the saw to cut other than aluminum, wood or similar materials.

26. Connect miter saws to a dust collecting device

when sawing.

27. Select saw blades in relation to the material to

be cut.

28. Take care when slotting.

29. Replace the kerf board when worn.

SAVE THESE INSTRUCTIONS.

OPERATING INSTRUCTIONS

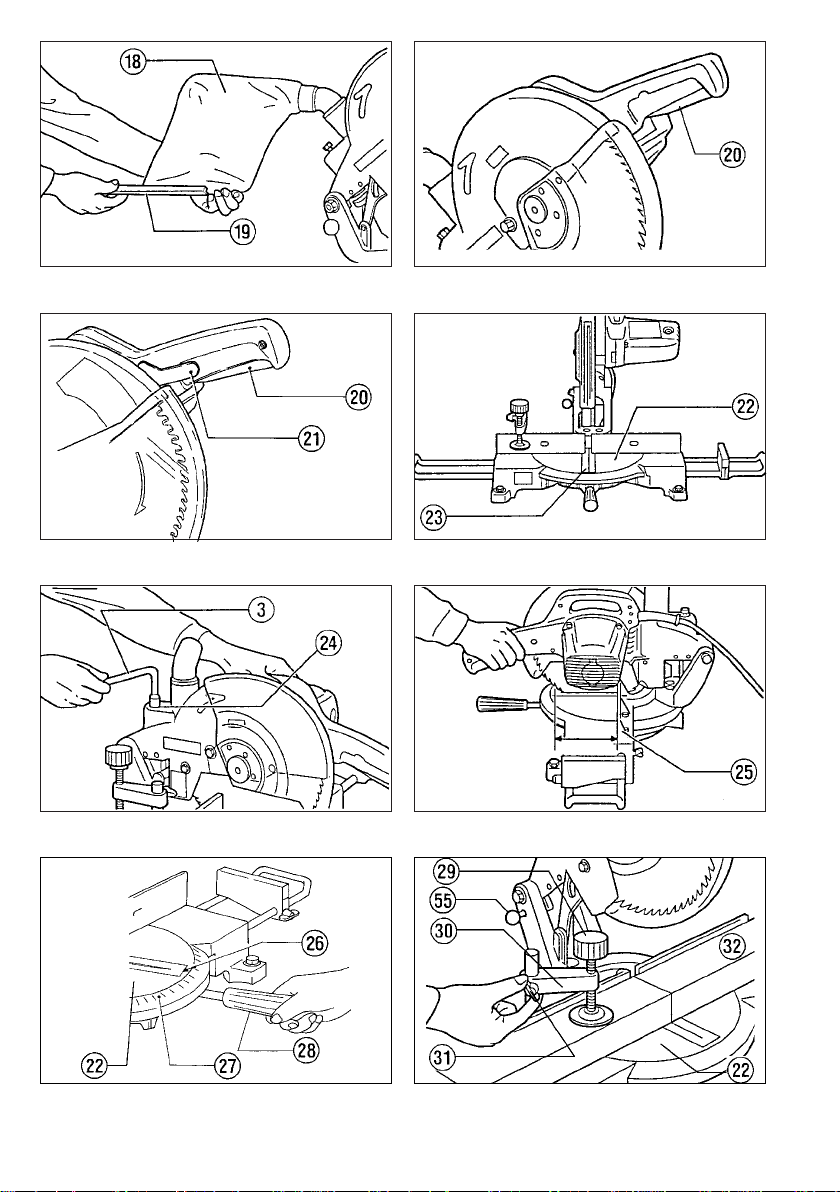

Bench mounting miter saw (Fig. 1)

This machine should be bolted with two bolts to a

level and stable surface using the bolt holes provided

in the machine’s base. This will help prevent tipping

and possible injury.

Removing or installing saw blade

Important:

Always be sure that the machine is switched off and

unplugged before removing or installing the blade.

To remove the blade, use the socket wrench to loosen

the hex bolt holding the center cover by turning it

more than three turns counterclockwise. Raise the

safety cover and center cover. (Fig. 2)

Press the shaft lock so that the blade cannot revolve

and use the socket wrench to loosen the hex bolt

clockwise. Then remove the hex bolt, flange and

blade. (Fig. 3)

To install the blade, mount the blade onto the spindle,

making sure that the direction of the arrow on the

surface of the blade matches the direction of the

arrow on the blade case. (Fig. 4)

CAUTION: (Fig 5)

For machines with silver ring factory-installed

between flanges

The silver ring with 25.4 mm outer diameter is factoryinstalled between the flanges. The black ring with

25 mm outer diameter is included as standard equipment. Before mounting the blade onto the spindle,

always be sure that the correct ring for the arbor hole

of the blade you intend to use is installed onto the

spindle.

For machines with black ring factory-installed

between flanges

The black ring with 25 mm outer diameter is factoryinstalled between flanges.

For machines with no ring factory-installed

between flanges

The black ring with 25 mm outer diameter is included

as standard equipment. When using a blade with

25 mm hole diameter, install this ring between

flanges.

Install the flange and hex bolt, and then use the

socket wrench to tighten the hex bolt securely counterclockwise while pressing the shaft lock. Then

tighten the hex bolt clockwise to secure the center

cover.

CAUTION:

Use only the Makita socket wrench provided to install

or remove the blade. Failure to do so may result in

overtightening or insufficient tightening of the hex bolt.

This could cause an injury.

Safety cover (Fig. 6)

When lowering the handle, the safety cover rises

automatically.Thecover returns to its original position

when the cut is completed and the handle is raised.

NEVER DEFEAT OR REMOVE THE SAFETY

COVER. In the interest of your personal safety,

always maintain the safety cover in good condition.

Any irregular operation of the safety cover should be

corrected immediately. NEVER USE THE MACHINE

WITHAFAULTY SAFETY COVER. If the see-through

safety cover becomes dirty, or sawdust adheres to it

in such a way that the blade and/or workpiece is no

longer easily visible, unplug the saw and clean the

cover carefully with a damp cloth. Do not use solvents

or any petroleum-based cleaners on the plastic cover.

Dust bag (Fig.7&8)

The use of the dust bag makes cutting operations

clean and dust collection easy.To attach the dust bag,

insert the elbow into the dust spout on the blade case

and fit the bag’s entry port over the elbow.

When the dust bag is about half full, remove the dust

bag from the machine and pull the fastener out.

Empty the dust bag of its contents, tapping it lightly so

as to remove particles adhering to the insides which

might hamper further collection.

Switch action

CAUTION:

Before plugging in the machine, always check to see

that the switch triggeractuates properly and returnsto

the ‘‘OFF’’ position when released.

For machines without lever (Fig. 9)

To start the machine, simply pull the trigger. Release

the trigger to stop.

For machines with lever (Fig. 10)

To prevent the trigger from being accidentally pulled,

a lock-off button is provided. To start the machine,

press the lever at the side of the handle. The lock-off

button is pressed in by the lever.Then pull the trigger.

Release the trigger to stop.

7

Page 8

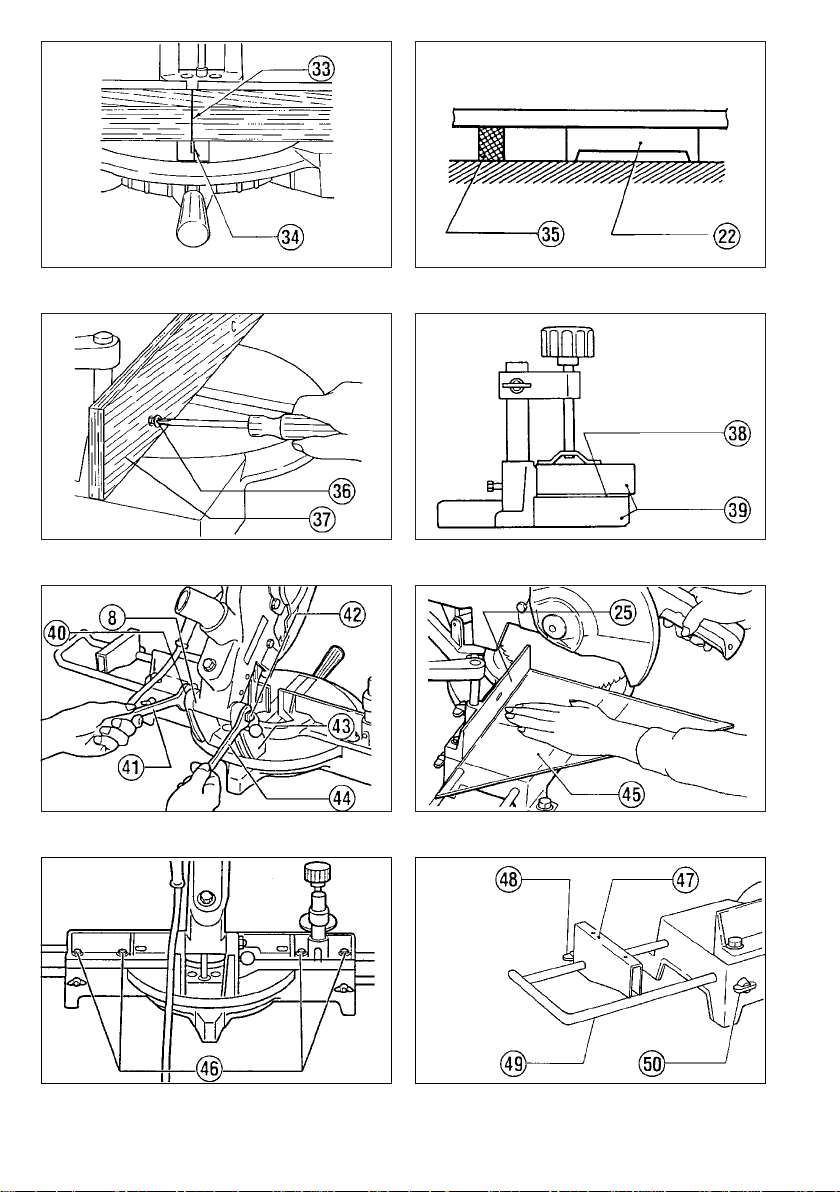

Kerf board (Fig. 11)

This machine is provided with the kerf board in the

turn base. If the kerf groove has not yet been cut in

the kerf board by the factory, you should cut the

groove before actually using the machine to cut a

workpiece. Switch on the machine and lower the

blade gently to cut a groove in the kerf board.

Maintaining maximum cutting capacity

(Fig. 12 & 13)

Unplug the machine before any adjustment is

attempted. This machine is factory adjusted to provide the max. cutting capacity for a 255 mm saw

blade. When the diameter of the blade has been

reduced due to sharpening,adjust the depth adjusting

bolt by turning it with the socket wrench. The saw

blade is lowered by turning the depth adjusting bolt

counterclockwise and raised by turning it clockwise.

Adjust so that when the handle is in the fully lowered

position, there will be a distance of about 126 mm

from the front face of the guide fence to the point

where the front edge of the blade enters the kerf. With

the machine unplugged, rotate the blade by hand

while holding the handle all the way down. Be sure

that the blade does not contact any part of the lower

base when the handle is lowered completely.

Positioning for adjusting the miter angle

(Fig. 14)

Loosen the grip by turning counterclockwise. This

allows the turn base to turn freely. When you have

moved the grip to the position where the pointer

indicates the desired angle on the miter scale,

securely tighten the grip clockwise.

CAUTION:

When turning the turn base, be sure to raise the

handle fully.

Securing workpiece (Fig. 15)

WARNING:

It is extremely important to always secure the workpiece properly and tightly with the vise. Failure to do

so can cause the machine to be damaged and/or the

workpiece to be destroyed. PERSONALINJURYMAY

ALSO RESULT. Also, after a cutting operation, DO

NOT raise the blade until the blade has come to a

complete stop.

Secure the turn base firmly at the position of the

desired miter angle. Position the vise arm according

to the thickness and shape of the workpiece and

secure the vise armby tightening the screw.Pressthe

workpiece flat against the guide fence and the turn

base. Position the workpiece at the desired cutting

position and secure it firmly by tightening the clamp

screw.

Operation (Fig. 16 & 17)

When cutting with this machine, the thickness of the

blade is cut out of the workpiece as well. Therefore,

your cutting line should be on either the left or right

side of the groove in the kerf board. Switch on the

machine and wait until the blade attains full speed

before lowering gently into the cut. When the blade

contacts the workpiece, gradually bear down on the

handle to perform the cut. When the cut is completed,

switch off the machine and WAIT UNTIL THE BLADE

HAS COME TOACOMPLETESTOPbeforereturning

the blade to its fully elevated position. A thin piece of

cut off material could otherwise contact the coasting

blade and be thrown around dangerously.

CAUTION:

When cutting long workpieces, use supports that are

as high as the top surface level of the turn base.

Wood facing (Fig. 18)

Use of wood facing helps to assure splinter-free cuts in workpieces. Attach a wood facing to the guide fence

using the holes in the guide fence.

CAUTION:

•

Use straight wood of even thickness as the wood facing.

•

See the figure below concerning the dimensions for a suggested wood facing.

Over

10 mm

Over 460 mm

89 mm

25 mm

117mm 117mm

•

Use screws to attach the wood facing to the guide fence. The screws should be installed so that the screw

heads are below the surface of the wood facing.

•

When the wood facing is attached, do not turn the turn base with the handle lowered. The wood facing will

be damaged.

NOTE:

When the wood facing is attached, the max. cutting capacities in width (126 mm at 0°, 89 mm at 45°) will be

reduced by thickness of the wood facing.

8

Page 9

Cutting aluminum extrusion (Fig. 19)

When securing aluminum extrusions, use spacer

blocks or pieces of scrap as shown in Fig. 19 to

prevent deformation of the aluminum. Use a cutting

lubricant when cutting the aluminum extrusion to

prevent build-up of the aluminum material on the

blade.

CAUTION:

Never attempt to cut thick or round aluminum extrusions. Thick aluminum extrusions may come loose

during operation and round aluminum extrusions cannot be secured firmly with this machine.

Adjusting for smooth handle action (Fig. 20)

The hex lock nut holding together the blade case and

arm has been factory adjusted to assure smooth

handle action up and down and to guarantee precise

cutting. Do not tamper with it.

Should looseness develop at the blade case and arm

connection, tighten the hex lock nut using a wrench

while holding the bolt with another wrench.

After adjusting the hex lock nut, be sure the handle

returns automatically to theinitial, raised position from

any position. If the hex lock nut is too loose, the

cutting accuracy will be affected; if it is too tight, it will

be hard to work the handle up and down. Note that

this is a self locking nut; it is a special type that does

not loosen during normal use. It should not be overtightened or replaced with other types of nuts.

Alignment for squareness (Fig. 21 & 22)

This machine was carefully adjusted and aligned for

squareness of cut at the factory, but rough handling

may have affected the alignment. If your machine is

not aligned properly, perform the following.

Loosen the grip and set the turn base at zero degrees

by turning the turn base. Tighten the grip securely and

loosen the hex bolts on the guide fence. Square the

side of the blade withthe face of the guidefence using

a triangular rule, try-square, etc. by moving the right

side of the guide fence. Then securely tighten the hex

bolts on the guide fence in the order indicated in

Fig. 22.

Installing holders and set plates

(optional accessories) (Fig. 23)

The holders can be installed on either side as a

convenient means of holding workpieces horizontally

or workpieces to be cut repetitively into identical

lengths. Toinstall the holder, insert the holder through

the hole in the set plate with the curved portion of the

holder pointing upwards. Then slip the holder rods

into the holes in the base. Tighten the holders

securely with wing bolts.

Cutting repetitive lengths

When cutting several pieces of stock to the same

length, ranging between 235 – 400 mm, use of the set

plate will facilitate more efficient operation. Align the

cutting line on your workpiece with either the left or

right side of the groove in the kerf board, and while

holding the workpiece form moving, move the set

plate flush against the end of the workpiece. Then

secure the set plate with the wing bolt on the set plate.

Carrying machine (Fig. 15 & 24)

When carrying the machine, lower the handle fully

and press the stopper pin to lock the handle in the

lowered position. Secure the turn base by means of

the grip. The machine can then be conveniently

carried by the carrying grip.

WARNING:

Be sure that the machine is unplugged first.

MAINTENANCE

CAUTION:

Always be sure that the machine is switched off and

unplugged before carrying out any work on the

machine.

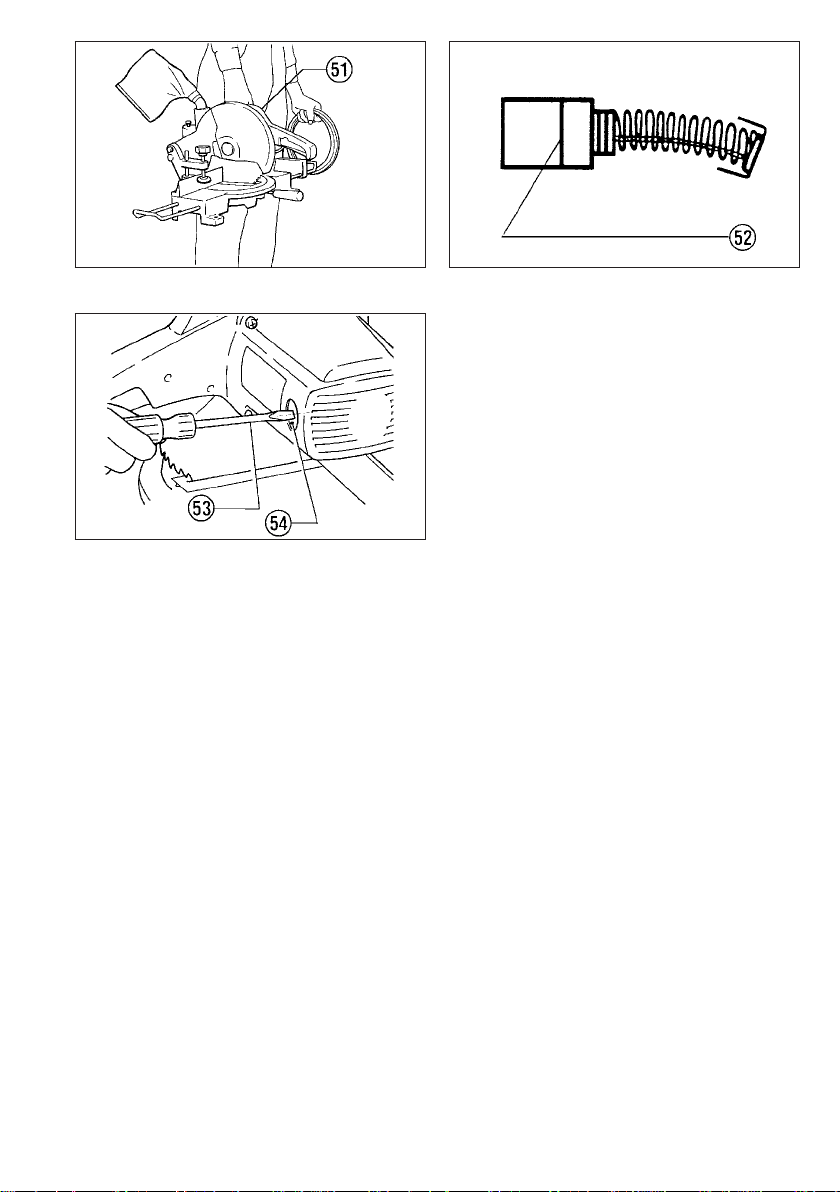

Replacement of carbon brushes (Fig. 25 & 26)

Replace carbon brushes when they are worn down to

the limit mark. Both identical carbon brushes should

be replaced at the same time.

To maintain product safety and reliability, repairs,

maintenance or adjustment should be carried out by

Makita Authorized Service Center.

9

Page 10

NEDERLANDS

Verklaring van algemene gegevens

1 Bout

2 Afdekplaat

3 Dopsleutel

4 Veiligheidskap

5 Losdraaien

6 Asblokkering

7 Pijl

8 Vaste beschermkap

9 Pijl

0 Zaagblad

q Binnen flens

w As

e Vulring

r Buiten flens

t Zeskant bout

y Stofuitlaat

u Verbindingsstuk

i Stofzak

o Sluitstrip

p Trekschakelaar

a Hendel

s Draaibaar voetstuk

d Verstekplaat

f Instelbout

g Aanslag

h Wijzer

j Schaalverdeling

k Instelhendel

l Klemschroef

; Klemarm

z Schroef

x Werkstuk

c Zaaglijn

v Zaagsleuf

b Steun

n Schroef

m Houtbekleding

TECHNISCHE GEGEVENS

Model LS1030

Diameter zaagblad ....................................... 255 mm

Max. zaagkapaciteit (H x B)

Afkorten (90°) ............ 70 x 126 mm of 89 x 89 mm

Verstekzagen (45°) ..... 70 x 89 mm of 89 x 63 mm

Toerental onbelast/min. .................................... 4 600

Afmeting (LxBxH) ................. 470 x 485 x 510 mm

Netto gewicht ................................................ 10,6 kg

•

In verband met ononderbroken research en ontwik-

keling behouden wij ons het recht voor

bovenstaande technische gegevens te wijzigen

zonder voorafgaande kennisgeving.

•

Opmerking: De technische gegevens kunnen van

land tot land verschillen.

Stroomvoorziening

De machine mag alleen worden aangesloten op een

stroombron van hetzelfde voltage als aangegeven op de

naamplaat, en kan alleen op enkel-fase wisselstroom

worden gebruikt. De machine is dubbel-geı¨soleerd volgens de Europese standaard en kan derhalve ook op

een niet-geaard stopcontact worden aangesloten.

Veiligheidswenken

Vooruw veiligheid dient u de bijgevoegde Veiligheidsvoorschriften nauwkeurig op te volgen.

Deze symbolen betekenen:

Lees de gebruiksaanwijzing.

DUBBELE ISOLATIE

AANVULLENDE

VEILIGHEIDSVOORSCHRIFTEN

1. Draag een veiligheidsbril.

2. Verwijder nooit de afdekplaat en de doorzich-

tige beschermkap wanneer u het gereedschap

in gebruik wilt nemen.

3. Gebruik het gereedschap niet in de buurt van

ontvlambare vloeistoffen of gassen.

, Aluminium werkstuk

. Vulblokken

/ Bout

¡ Sleutel

™ Zeskant borgmoer

£ Arm

¢ Sleutel

∞ Driehoek

§ Zeskant bouten

¶ Lengte aanslag

• Vleugelbout

ª Houder

º Vleugelbout

œ Draaghandgreep

∑ Limietaanduiding

é Schroevedraaier

® Koolborsteldop

† Vergrendelpen

4. Kontroleer het zaagblad zorgvuldig op barsten

of beschadiging, alvorens het gereedschap in

te schakelen. Een gebarsten of beschadigd

zaagblad dient onmiddellijk te worden vervangen.

5. Gebruik alleen flenzen die voor dit gereedschap gemaakt zijn.

6. Zorg ervoor dat de as, de flenzen (vooral het

klemoppervlak) of de bout niet worden beschadigd. Beschadiging aan deze delen kan

zaagbladbreuk veroorzaken.

7. Kontroleer of het draaibaar voetstuk goed

vastzit, zodat het tijdens het zagen niet

beweegt.

8. Houd voor uw eigen veiligheid werktafel en

werkplaats schoon. Verwijder zaagsel, kleine

stukken hout enz. alvorens te zagen.

9. Zaag niet in spijkers endergelijke. Verwijder

eventuele spijkers endergelijke van het werkstuk alvorens met zagen te beginnen.

10. Vergeet niet de asblokkering in de vrije stand

te drukken, alvorens in te schakelen.

11. Zorg dat het zaagblad in zijn laagste positie

niet in aanraking komt met het draaibaar voetstuk.

12. Houd de zaaghendel stevig vast. Let op dat bij

het starten en stoppen de zaag even op- en

neergaat.

13. Zaag nooit met het werkstuk in uw hand. Zet

het werkstuk altijd stevig op het draaibaar

voetstuk en tegen de aanslag vast.

14. Houd ten allen tijde uw handen flink uit de

buurt van de zaag. Raak onder geen beding de

draaiende zaag aan, aangezien dit tot ernstige

verwondingen kan leiden.

15. Probeer tijdens het zagen nooit iets vast te

pakken dat achter de zaag ligt.

16. Zorg dat bij inschakelen het zaagblad niet in

kontakt is met het werkstuk.

25

Page 11

17. Laat het gereedschap een tijdje draaien alvorens het te gebruiken. Kontroleer op trillingen

of schommelingen die op onjuiste installatie

of op een slecht gebalanceerd zaagblad kunnen wijzen.

18. Wacht totdat het zaagblad op volle toeren

draait, alvorens het werkstuk te zagen.

19. Stop onmiddellijk met zagen, als u iets abnormaals opmerkt.

20. Zet de trekschakelaar nooit vast.

21. Schakel de spanning altijd uit en wacht totdat

het zaagblad volledig tot stilstand is gekomen,

alvorens het gereedschap een onderhoudsbeurt te geven of bij te stellen.

22. Laat uw aandacht nooit verslappen, vooral

wanneer het werk saai is en uit herhalingen

bestaat. Laat u niet door een vals gevoel van

veiligheid misleiden, aangezien deze zaag

altijd gevaar kan opleveren.

23. Gebruik uitsluitend de accessoires die in de

Makita catalogus worden aanbevolen. Zet bij

voorbeeld geen slijpschijf op het gereedschap

aangezien er anders ongelukken kunnen

gebeuren.

24. Houd het snoer in goede konditie. Verwijder

het van het stopkontakt door de stekker eruit

te trekken. Houd het snoer uit de buurt van

hitte, olie, water en scherpe hoeken.

25. Gebruik de zaag niet voor het zagen van

andere materialen dan aluminium, hout of

gelijksoortige materialen.

26. Sluit afkortzagen tijdens het zagen aan op een

stofvanginrichting.

27. Kies de zaagbladen overeenkomstig het te

zagen materiaal.

28. Wees voorzichtig wanneer u gleuven zaagt.

29. Vervang de verstekplaat wanneer deze versleten is.

BEWAAR DEZE VOORSCHRIFTEN.

BEDIENINGSVOORSCHRIFTEN

Vastzetten van het gereedschap op

de werktafel (Fig. 1)

Het gereedschap dient op een vlak en stevig oppervlak te worden vastgezet met behulp van twee

bouten. De gaten in het voetstuk zijn hiervoor

bedoeld. Hierdoor wordt omkantelen en het daarmee

gepaard gaande gevaar voor verwondingen voorkomen.

Installeren en verwijderen van zaagbladen

Belangrijk:

Kontroleer altijd of het gereedschap is uitgeschakeld

en het netsnoer uit het stopkontakt is getrokken

alvorens het zaagblad te installeren of te verwijderen.

Voor het verwijderen van het zaagblad dient u de

dopsleutel te gebruiken om de zeskant bout, die de

afdekplaat op zijn plaats houdt, los te draaien. Draai

hiervoor de bout driemaal linksom. Licht vervolgens

de doorzichtige beschermkap en de afdekplaat op.

(Fig. 2)

Druk de asblokkering in opdat het zaagblad niet kan

bewegen en draai met een dopsleutel de zeskant

bout naar rechts los. Verwijdervervolgens de zeskant

bout, de flens en het zaagblad. (Fig. 3)

Om het zaagblad te monteren, het zaagblad op de as

plaatsen en ervoor zorgen dat de pijlen op het zaagblad en op de vaste beschermkap naar dezelfde

richting wijzen. (Fig. 4)

LET OP: (Fig. 5)

Voor machines met een vulring die in de fabriek

tussen de flenzen werd gemonteerd

De vulring met een buitendiameter van 25,4 mm werd

in de fabriek tussen de flenzen gemonteerd. De

zwarte ring met een buitendiameter van 25 mm is als

standaard toebehoren meegeleverd. Alvorens het

blad op de as te monteren, altijd ervoor zorgen dat de

juiste ring, voor het asgat van het blad dat u gaat

gebruiken, op de as is gemonteerd.

Voor machines met een zwarte ring die in de

fabriek tussen de flenzen werd gemonteerd

De zwarte ring met een buitendiameter van 25 mm

werd in de fabriek tussen de flenzen gemonteerd.

Voor machines zonder een in de fabriek

gemonteerde ring

De zwarte ring met een buitendiameter van 25 mm is

als standaard toebehoren meegeleverd. Monteer

deze ring tussen de flenzen wanneer u een blad

gebruikt met een gat van 25 mm diameter.

Installeer de flens en de zeskant bout en draai

vervolgens met de dopsleutel de zeskant bout stevig

naar links vast, terwijl u daarbij de asblokkering

ingedrukt houdt. Draai daarna de zeskant bout naar

rechts vast voor het vastzetten van de afdekplaat.

LET OP:

Gebruik voor het installeren of verwijderen van het

zaagblad uitsluitend de bijgeleverde Makita dopsleutel. Doet u dit niet dan kan het gebeuren dat de

zeskante bout te vast of te los komt te zitten hetgeen

verwondingen tot gevolg kan hebben.

Verende beschermkap (Fig. 6)

Wordt de zaaghendel naar beneden gedrukt, dan

gaat de verende beschermkap automatisch naar

boven. De verende beschermkap keert terug naar de

oorspronkelijke stand, wanneer het zagen is beëindigd en de zaaghendel wordt opgeheven. ZET DE

VERENDE BESCHERMKAP NOOIT VAST EN VERWIJDER DE KAP NOOIT. Neem uw persoonlijke

veiligheid in acht en zorg dat de verende beschermkap altijd in goede konditie verkeert. Merkt u dat de

verende beschermkap niet naar behoren funktioneert

dan dient u het gereedschap na te laten kijken.

GEBRUIK HET GEREEDSCHAP NOOIT WANNEER

DE VERENDE BESCHERMKAP NIET IN ORDE IS.

Wanneer de doorzichtige verende beschermkap vuil

is of met zaagsel isbedekt zodat u het zaagbladof het

werkstuk niet meer behoorlijk kunt zien, verwijder dan

de stekker van het stopkontakt en maak de verende

beschermkap zorgvuldig met een vochtig lapje

schoon. Gebruik voor het schoonmaken geen oplossingen of benzinehoudende schoonmaakmiddelen.

26

Page 12

Stofzak (Fig. 7 en 8)

Door de stofzak te gebruiken wordt het zaagsel

opgevangen en houdt u uw werkplaats schoon. Voor

het bevestigen van de stofzak sluit u het verbindingsstuk op de stofuitlaat op de vaste beschermkap

aan, en de stofkap op het andere uiteinde van het

verbindingsstuk.

Wanneer de stofzak halfvol is, verwijdert u deze en

maak de ritssluiting open voor het leeg maken. Geef

de stofzak daarna enige lichte tikken voor het verwijderen van achtergebleven zaagsel.

Werking van de schakelaar

LET OP:

Alvorens de stekker in hetstopkontakt te steken, dient

u altijd te kontroleren of de trekschakelaar in orde is

en bij loslaten naar de ‘‘OFF’’ stand terugkeert.

Voor machines zonder hendel (Fig. 9)

Om de machine te starten, drukt u de trekschakelaar

gewoon in. Laat detrekschakelaar los om demachine

te stoppen.

Voor machines met een hendel (Fig. 10)

Om te voorkomen dat de trekschakelaar per ongeluk

wordt ingedrukt, is deze voorzien van een ontgrendelingsknop. Om de machine te starten, dient de

hendel op de zijkant van het handvat te worden

ingedrukt. De ontgrendelingsknop wordt dan door de

hendel naar binnen gedrukt. Druk daarna de trekschakelaar in. Laat de trekschakelaar los om de

machine te stoppen.

Verstekplaat (Fig. 11)

Dit apparaat is voorzien van een verstekplaat in de

draaibare basis. Als de verstekgroef nog niet in de

fabriek in de verstekplaat is gezaagd, dient u de

verstekgroef eerst te zagen alvorens het apparaat te

gebruiken voor het zagen van werkstukken. Schakel

het apparaat in en breng het zaagblad langzaam

omlaag voor het zagen van een groef in de verstekplaat.

Op peil houden van zaagkapaciteit

(Fig. 12 en 13)

Verwijder de stekker van het gereedschap alvorens

het gereedschap een onderhoudsbeurt te geven. Het

gereedschap is in de fabriek ingesteld voor het

leveren van maximale zaagkapaciteit met een

255 mm zaagblad. Wanneer de diameter van het

zaagblad wegens herhaald aanscherpen is geslonken, dient de instelbout te worden afgesteld, door

deze met de dopsleutel te draaien. Door de instelbout

naar links om te draaien, wordt het zaagblad lager

ingesteld en door de bout naar rechts om te draaien

hoger ingesteld. U dient zo af te stellen dat wanneer

u de zaaghendel volledig neerdrukt, de afstand tussen de aanslag en de voorkant van het zaagblad (het

punt waar deze in de spleet van het zaagvlak is

gezakt) ongeveer 126 mm bedraagt. Draai met de

hand het zaagblad rond (met de stekker uit het

stopkontakt!) terwijl u de zaaghendel volledig ingedrukt houdt, en kontroleer dat het zaagblad met niets

in aanraking komt.

Instellen van de verstekhoek (Fig. 14)

Draai de instelhendel naar links los. U kunt dan het

draaibaar voetstuk verdraaien. Stel de hendel in op

de gewenste hoek, hetgeen wordt aangegeven door

de wijzer en draai de hendel vervolgens weer stevig

vast.

LET OP:

Voor het verdraaien van het draaibaar voetstuk dient

u de schakelhandgreep in de hoogste stand te plaatsen.

Vastzetten van werkstukken (Fig. 15)

WAARSCHUWING:

Het is van vitaal belang dat u met de klem het

werkstuk behoorlijk en stevig vastzet. Wanneer u dit

nalaat kan het gereedschap beschadiging oplopen en

het werkstuk worden vernield. OOK KAN PERSOONLIJK LETSEL HET GEVOLG ZIJN. Wanneer het

zagen is beëindigd, dient u de zaag NIET op te tillen

alvorens deze volledig tot stilstand is gekomen.

Zet het draaibaar voetstuk vast nadat de verstekhoek

is ingesteld. Zet de arm van de klem in de stand, die

overeenkomt met de dikte en vorm van het werkstuk,

en zet vervolgens de arm vast door de schroef vast te

draaien. Druk het werkstuk tegen de aanslag en het

draaibaar voetstuk. Zet het werkstuk in de gewenste

snijpositie, en zet het vervolgens stevig vast door de

klemschroef vast te draaien.

Bediening (Fig. 16 en 17)

Wanneer u met dit gereedschap zaagt, bedenk dat

wat feitelijk wordt afgezaagd ook afhangt van de dikte

van het zaagblad. U dient derhalve de zaaglijn te

laten samenvallen met de linker- of rechterkant van

de zaagspleet. Schakel vervolgens het gereedschap

in tot het op volletoeren is gekomen en laatdaarna de

zaag voorzichtig op het werkstuk neerzakken. Wanneer de zaag in kontakt komt met het werkstuk, dient

u voldoende druk op de zaag uit te oefenen. Is het

zagen beëindigd, schakel dan het gereedschap uit en

WACHT TOTDAT DE ZAAG VOLLEDIG TOT STILSTAND IS GEKOMEN alvorens de zaag in z’n

hoogste positie terug te zetten. Dit is om te voorkomen dat de draaiende zaag een afgezaagd stuk grijpt

en het naar u toe slingert.

LET OP:

Wilt u lange werkstukken zagen, dan dient u deze te

ondersteunen, zodat het werkstuk volledig horizontaal ligt.

27

Page 13

Houten hulpstuk (Fig. 18)

Door een houten hulpstuk te gebruiken voorkomt u dat het werkstuk splintert. Bevestig het hulpstuk tegen de

aanslag met behulp van de gaten in de aanslag.

LET OP:

•

Gebruik als hulpstuk een recht stuk hout van gelijke dikte.

•

Zie onderstaand figuur voor de afmetingen van het hulpstuk.

Meer dan

10 mm

Meer dan 460 mm

89 mm

25 mm

117mm 117mm

•

Bevestig het houten hulpstuk tegen de aanslag met behulp van schroeven ervoor zorgend dat de

schroefkoppen er niet uitsteken.

•

Verdraai het ronde draaibare voetstuk na het bevestigen van het houten hulpstuk niet met de schakelhandgreep naar beneden, aangezien anders het houten hulpstuk wordt beschadigd.

OPMERKING:

Wanneer u met een houten hulpstuk zaagt, dient u het maximale bereik van de zaag (126 mm bij 0°, 89 mm

bij 45°) te verminderen met de dikte van het houten hulpstuk.

Zagen van aluminium werkstukken (Fig. 19)

Gebruik voor het vastzetten van aluminium werkstukken, vulblokken of afgedankte blokstukken, zoals

afgebeeld in Fig. 19, om te voorkomen dat het werkstuk wordt vervormd. Gebruik daarbijook zaagolie om

te voorkomen dat aluminium zaagsel zich op het

zaagblad ophoopt.

LET OP:

Probeer nooit dikke of ronde aluminium werkstukken

te zagen. Dikke aluminium werkstukken kunnen

tijdens het zagen losraken en ronde aluminium werkstukken kunnen op dit gereedschap niet worden

vastgezet.

Soepele bediening van de schakelhandgreep

(Fig. 20)

hl;5De zeskant borgmoer die de vaste beschermkap

en de arm aaneen houdt is in de fabriek ingesteld

voor maximaal soepele bediening van de schakelhandgreep. Ook maakt de instelling nauwkeurig

zagen mogelijk. Doe dus geen pogingen om de

instelling te wijzigen.

Raakt de vaste beschermkap losservan de arm, draai

dan de zeskant borgmoer met een sleutel vast terwijl

u met een andere sleutel de bout vasthoudt.

Kontroleer na het vastdraaien van de borgmoer of de

schakelhandgreep vanuit iedere neergedrukte stand,

automatisch naar de oorspronkelijke opgeheven

stand terugkeert. Zit de borgmoer te los, dan is

nauwkeurig zagen niet meer mogelijk; zit de borgmoer daarentegen te vast, dan is soepel bedienen

van de schakelhandgreep niet mogelijk. Let op dat de

borgmoer een zelfborgende moer is en dus bij normaal gebruik van het gereedschap niet kan losraken.

De moer mag niet te vast zitten en niet door een

ander type moer worden vervangen.

Instelling voor van rechte hoeken zagen

(Fig. 21 en 22)

In de fabriek is het gereedschap ook ingesteld voor

het nauwkeurig zagen van rechte hoeken. Wanneer

door ruwe behandeling van het gereedschap de

instelling ongedaan is gemaakt, doe dan het volgende.

Draai de hendel voor het instellen van de verstekhoek

los en zet het ronde draaibare voetstuk op 0°. Draai

de instelhendel vervolgens vast en draai de zeskant

bouten op de aanslag los. Stel de aanslag met behulp

van een rechthoekige driehoek of iets dergelijks

haaks in ten opzichte van het zaagblad door de

rechterkant van de aanslag te verschuiven. Draai

vervolgens de zeskant bouten op de aanslag weer

stevig vast zoals in de Fig. 22 aangegeven volgorde.

28

Page 14

Installeren van houders en lengteaanslagen

(los verkrijgbare accessoires) (Fig. 23)

U kunt aan beide zijdenvan het gereedschap houders

aanbrengen. Met behulp van de houders kunt u dan

het werkstuk horizontaal houden of afzagen in gelijke

lengten. Voor het installeren van de houder steekt u

deze door de gaten in de lengteaanslag en vervolgens in de gaten in het voetstuk. Het omgebogen

gedeelte van de houder dient naar boven te wijzen.

Zet vervolgens de houders stevig met vleugelbouten

vast.

Afzagen in gelijke lengten

Wilt u stukken zagen van gelijke lengten (tussen

235 – 400 mm), dan wordt dit met behulp van de

lengteaanslag ten zeerste vergemakkelijkt. Laat de

zaaglijn met de linker of rechterzijde van de spleet in

het zaagvlak samenvallen. Houdt daarna het werkstuk vast en schuif delengteaanslag er tegen aan. Zet

de lengteaanslag vervolgens vast met behulp van de

vleugelbout.

Dragen van het gereedschap (Fig. 15 en 24)

Wanneer u het gereedschap wilt verplaatsen, druk

dan de schakelhandgreep naar beneden en vergrendel deze vervolgens door de vergrendelpen in te

drukken. Zet het draaibare voetstuk vast met behulp

van de instelhendel. U kunt dan het gereedschap

gemakkelijk dragen door de voor dit doel aangebrachte handgreep vast te pakken.

WAARSCHUWING:

Kontroleer tevoren of de stekker van het stopkontakt

is verwijderd.

ONDERHOUD

LET OP:

Zorg er altijd voor dat de machine is uitgeschakeld en

de stekker uit het stopcontact is verwijderd alvorens

onderhoud aan de machine uit te voeren.

Vervangen van koolborstels (Fig. 25 en 26)

Vervang de borstels wanneer ze tot aan de aangegeven limiet zijn afgesleten. Beide koolborstels

dienen tegelijkertijd te worden vervangen.

Opdat het gereedschap veilig en betrouwbaar blijft,

dienen alle reparaties, onderhoud of afstellingen te

worden uitgevoerd bij een erkend Makita service

centrum.

296667

Page 15

Page 16

Page 17

Page 18

Page 19

Page 20

AUS TRI A

Makita Werkzeug

Gesellschaft m.b.H.

Kolpingstraße 13, A 1232 Wien

Phone: (01) 6162730

Fax: (01) 616273040

Telex: 136384 MAKITA A

BELGIUM

S.A. Makita N.V.

Mechelsesteenweg 323,

1800 Vilvoorde

Phone: (02) 253-1234

Fax: (02) 253-0101

CZECH REPUBLIC

Makita S.R.O.

Pražákova 51

CZ- 61900, Brno

Tel: (05) 432-16944

Fax: (05) 432-16946

DENMARK

Denmark office

Sandøvej 11, 8700 Horsens

Phone: 75 601133

Fax: 75 601958

ΕΛΛΑ∆Α

ΠΑΝΑΓΙΩΤΗΣ ΜΙΧΟΣ

ΜΕΝΑΝ∆ΡΟΥ, 85

ΑΘΗΝΑ 10438

ΤΗΛ: (01) 522.6390

FAX: (01) 555.6392

ΚΟΥΡΟΣ Α.Β.Ε.Ε

ΛΕΓΑΚΙ 8,

ΑΓ. ΙΩΑΝΝΗΣ ΡΕΝΤΗΣ

ΠΕΙΡΑΙΑΣ 182 33

ΤΗΛ: (01) 345.9573

FAX: (01) 345.6766

ΠΑΡΤΣΑΛΙ∆ΗΣ ΓΕΩΡΓΙΟΣ

ΜΕΡΚΟΥΡΙΟΥ 1 (ΝΤΕΝΩ)

ΘΕΣ/ΝΙΚΗ

ΤΗΛ: (031) 411.592

FAX: (031) 411.592

FINLAND

ESSVE FINLAND OY

ELANNONTIE 5: 01510

VANTAA ASIAKASPAVELU

Puh.: 09-8575 830

Puh.: 09-857 880

Fax.: 09-8578 8211

FRANCE

Makita France S.A.

Head office

2, Allée des performances,

Zone Industrielle des Richardets,

(B.P. 119) 93162 Noisy-Le-Grand

Cedex

Phone: (0) 149326200

Fax: (0) 143059913

Telex: 235337 MAKITA F

GERMANY

Makita Werkzeug GmbH

Head office

Keniastraße 20, 47269 Duisburg

Phone: (0203) 9757-0

Fax: (0203) 9757-129

HUNGARY

Makita kft.

8000, Székesfehérvár,

Seregélyesi út 96

Phone: (22) 327-025

Fax: (22) 348-092

IRELAND

Tuck & Co (Ireland) LTD

77 Upper Gardiner street.

DUBLIN 1, Ireland

Phone: 00 353 1 8749851

ITALY

Makita S.p.A.

Via Sempione 269A,

20028 S. Vittore Olona (Ml)

Phone: (0331) 524111

Fax: (0331) 421580

NORWAY

ESSEVE BYGG OG INDUSTRIAS

Grenseveien 86 C

Postboks 6399

Etterstad 0604 Oslo

Telefon: 22 88 40 40

Telefax: 22 65 16 16

Direkte innv.: 22 88 40 43

Telefon privat: 67 53 61 32

POLAND

Makita Sp. Z.O.O.

UL, Straźacka 81,

PL43-382

Bielsko-Biala

Phone: (9030) 7354

Fax: (033) 184059

PORTUGAL

FIXANCO

SEDE:

Rua Vale Formoso,

94 - 2.° Esq. – 1900 Llsaoa

Tel: (01) 861 0530

Fax: 868 73 06

SPAIN

Makita S.A.

C/JUAN DE LA CIERVA, 7-11

28820 COSLADA (MADRID)

Tfno.: 671 1262

Fax.: 671 8293

SWEDEN

ESSVE Produkter AB

Box 770

Sidensvansvägen 10

19127 Sollentuna

Tel vxl: 08-623 61 00

Fax: 08-92 68 65

SWITZERLAND

Hebor SA

Route de Genges 6

Z.I. En Carouge

CH-1027 LONAY/Morges

Tél.: 021/803 07 51

Téléfax: 021/801 12 82

THE NETHERLANDS

Makita Benelux B.V.

Ekkersrijt 4086,

5692 DA, Son

Phone: 0499-460045

Fax: 0499-460096

UNITER KINGDOM

Makita (U.K.) Ltd.

Michigan Drive, Tongwell,

Milton Keynes,

Bucks MK15 8JD

Phone: (01908) 211678

Fax: (01908) 211400

Makita Corporation

Anjo, Aichi, Japan

Made in Japan

883722D978

Loading...

Loading...