Makita LS1017, LS1017L User Manual

INSTRUCTION MANUAL

MANUEL D'INSTRUCTION

MANUAL DE INSTRUCCIONES

Slide Compound Miter Saw

Scie à Onglet Radiale

Sierra de Inglete Telescópica

LS1017

LS1017L

IMPORTANT: Read Before Using.

IMPORTANT: Lire avant usage.

IMPORTANTE: Leer antes de usar.

010385

DOUBLE INSULATION

DOUBLE ISOLATION

DOBLE AISLAMIENTO

1

ENGLISH (Original instructions)

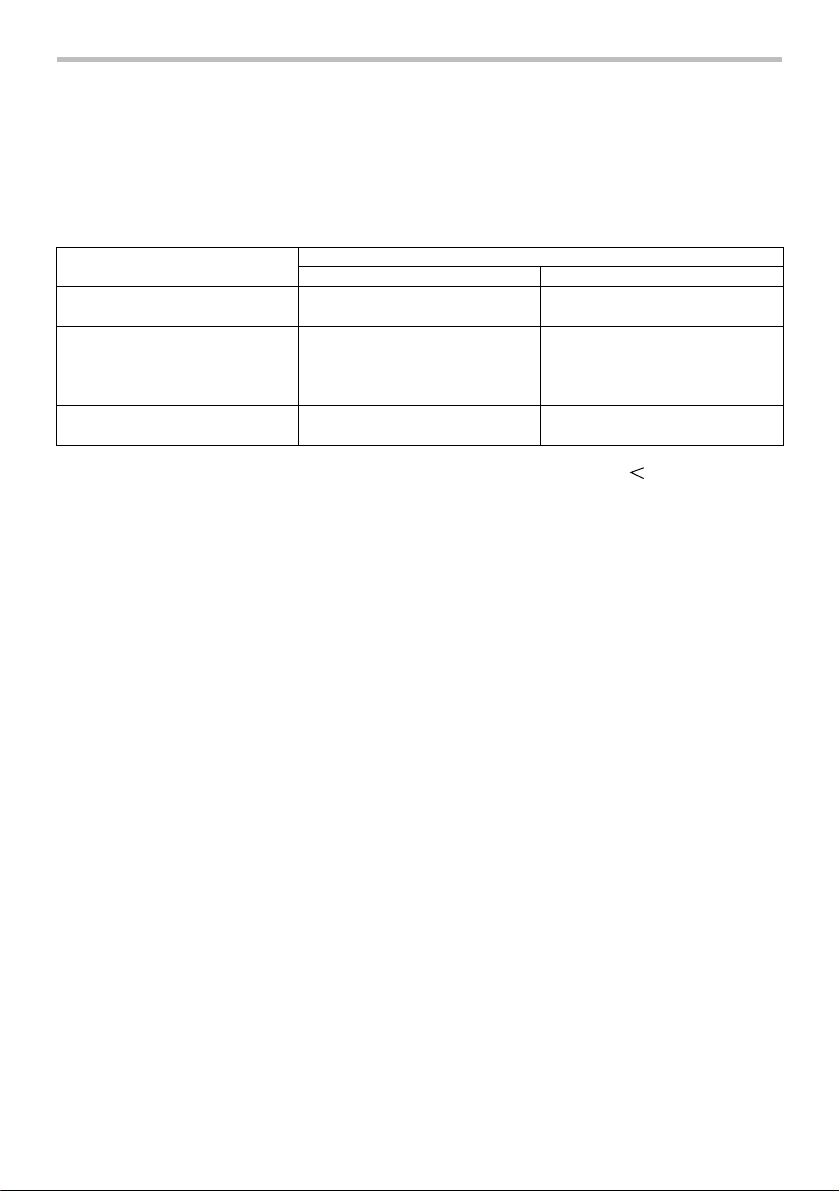

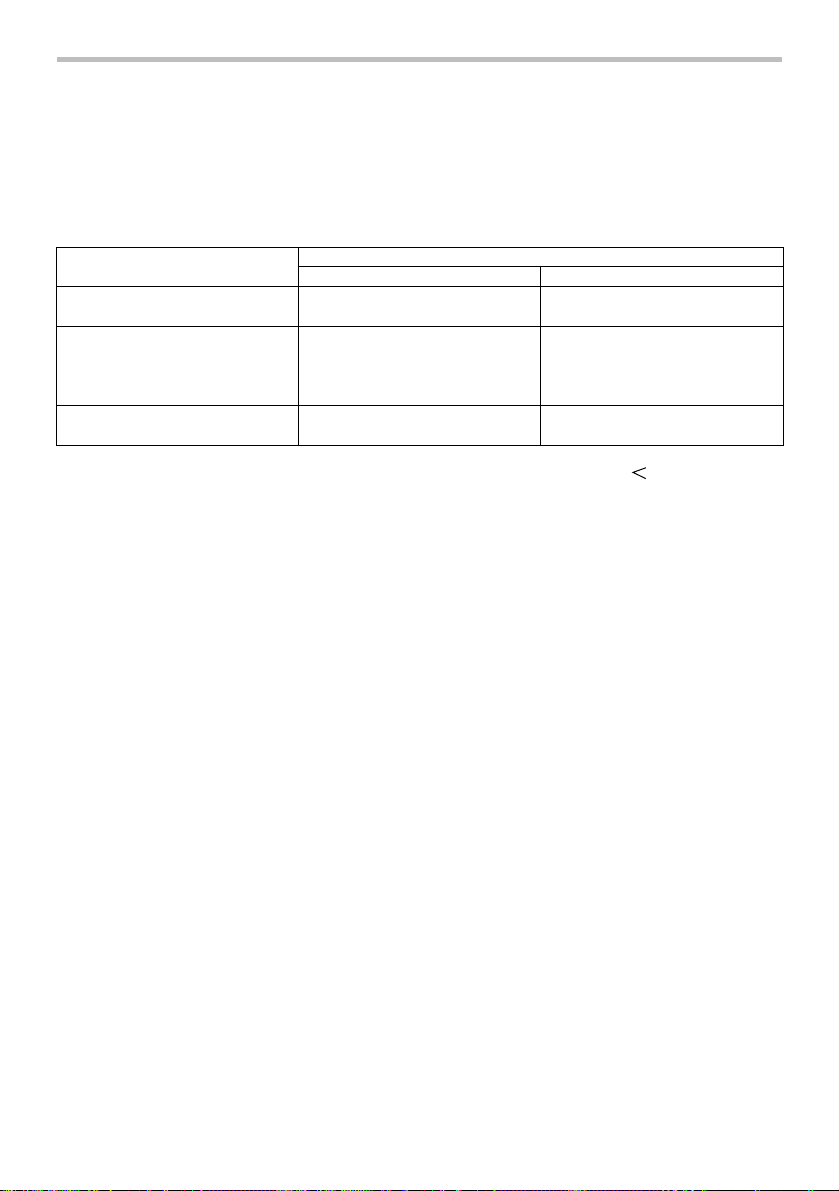

SPECIFICATIONS

Model LS1017 /LS1017L

Blade diameter 255 mm (10")

Hole diameter 15.88 mm (5/8")

Max. Cutting capacities (H x W)

Miter angle

0°

45°

60° (right)

No load speed (RPM) 4,200/min.

Laser Type (LS1017L only) Wavelength 660 nm, Maximum output 1mW (Laser Class II)

Dimensions (L x W x H) 825 mm x 536 mm x 581 mm

(32-1/2" x 21-1/8" x 22-7/8")

Net weight 19.4 kg (42.8 lbs)

• Due to our continuing programme of research and development, the specifications herein are subject to change without notice.

• Specifications may differ from country to country.

• Weight according to EPTA-Procedure 01/2003

45° (left) 0°

50 mm x 305 mm 91 mm x 305 mm

(2" x 12") (3-5/8" x 12")

(left) 50 mm x 200 mm

(2" x 7-7/8") 91 mm x 215 mm

(right) 50 mm x 215 mm (3-5/8" x 8-1/2")

(2" x 8-1/2")

- 91 mm x 150 mm

(3-5/8" x 5-7/8")

USA007-2

5. DO NOT USE IN DANGEROUS ENVIRONMENT.

For Your Own Safety Read

Instruction Manual

Before Operating Tool

Save it for future reference

GENERAL SAFETY

PRECAUTIONS

6. KEEP CHILDREN AWAY. All visitors should be

7. MAKE WORKSHOP KID PROOF with padlocks,

8. DO NOT FORCE TOOL. It will do the job better

9. USE RIGHT TOOL. Do not force tool or

(For All Tools)

1. KNOW YOUR POWER TOOL. Read the owner's

manual carefully. Learn the tool's applications

and limitations, as well as the specific

potential hazards peculiar to it.

2. KEEP GUARDS IN PLACE and in working

order.

3. REMOVE ADJUSTING KEYS AND WRENCHES.

Form habit of checking to see that keys and

adjusting wrenches are removed from tool

before turning it on.

4. KEEP WORK AREA CLEAN. Cluttered areas

and benches invite accidents.

10. WEAR PROPER APPAREL. Do not wear loose

11. ALWAYS USE SAFETY GLASSES. Also use

12. SECURE WORK. Use clamps or a vise to hold

Bevel angle

Do not use power tools in damp or wet

locations, or expose them to rain. Keep work

area well lighted. Do not use tool in presence

of flammable liquids or gases.

kept safe distance from work area.

master switches, or by removing starter keys.

and safer at the rate for which it was designed.

attachment to do a job for which it was not

designed.

clothing, gloves, neckties, rings, bracelets, or

other jewelry which may get caught in moving

parts. Nonslip footwear is recommended.

Wear protective hair covering to contain long

hair.

face or dust mask if cutting operation is dusty.

Everyday eyeglasses only have impact

resistant lenses, they are NOT safety glasses.

work when practical. It's safer than using your

2

hand and it frees both hands to operate tool.

13. DO NOT OVERREACH. Keep proper footing

and balance at all times.

14. MAINTAIN TOOLS WITH CARE. Keep tools

sharp and clean for best and safest

performance. Follow instructions for

lubricating and changing accessories.

15. DISCONNECT TOOLS before servicing; when

changing accessories such as blades, bits,

cutters, and the like.

16. REDUCE THE RISK OF UNINTENTIONAL

STARTING. Make sure switch is in off position

before plugging in.

17. USE RECOMMENDED ACCESSORIES.

Consult the owner's manual for recommended

accessories. The use of improper accessories

may cause risk of injury to persons.

18. NEVER STAND ON TOOL. Serious injury could

occur if the tool is tipped or if the cutting tool

is unintentionally contacted.

19. CHECK DAMAGED PARTS. Before further use

of the tool, a guard or other part that is

damaged should be carefully checked to

determine that it will operate properly and

perform its intended function - check for

alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any

other conditions that may affect its operation.

A guard or other part that is damaged should

be properly repaired or replaced.

20. DIRECTION OF FEED. Feed work into a blade

or cutter against the direction of rotation of

the blade or cutter only.

21. NEVER LEAVE TOOL RUNNING UNATTENDED.

TURN POWER OFF. Do not leave tool until it

comes to a complete stop.

22. REPLACEMENT PARTS. When servicing, use

only identical replacement parts.

23. POLARIZED PLUGS. To reduce the risk of

electric shock, this appliance has a polarized

plug (one blade is wider than the other). This

plug will fit in a polarized outlet only one way.

If the plug does not fit fully in the outlet,

reverse the plug. If it still does not fit, contact

a qualified electrician to install the proper

outlet. Do not change the plug in any way.

VOLTAGE WARNING: Before connecting the tool to

a power source (receptacle, outlet, etc.) be sure the

voltage supplied is the same as that specified on the

nameplate of the tool. A power source with voltage

greater than that specified for the tool can result in

SERIOUS INJURY to the user- as well as damage to

the appliance. If in doubt, DO NOT PLUG IN THE

APPLIANCE. Using a power source with voltage less

than the nameplate rating is harmful to the motor.

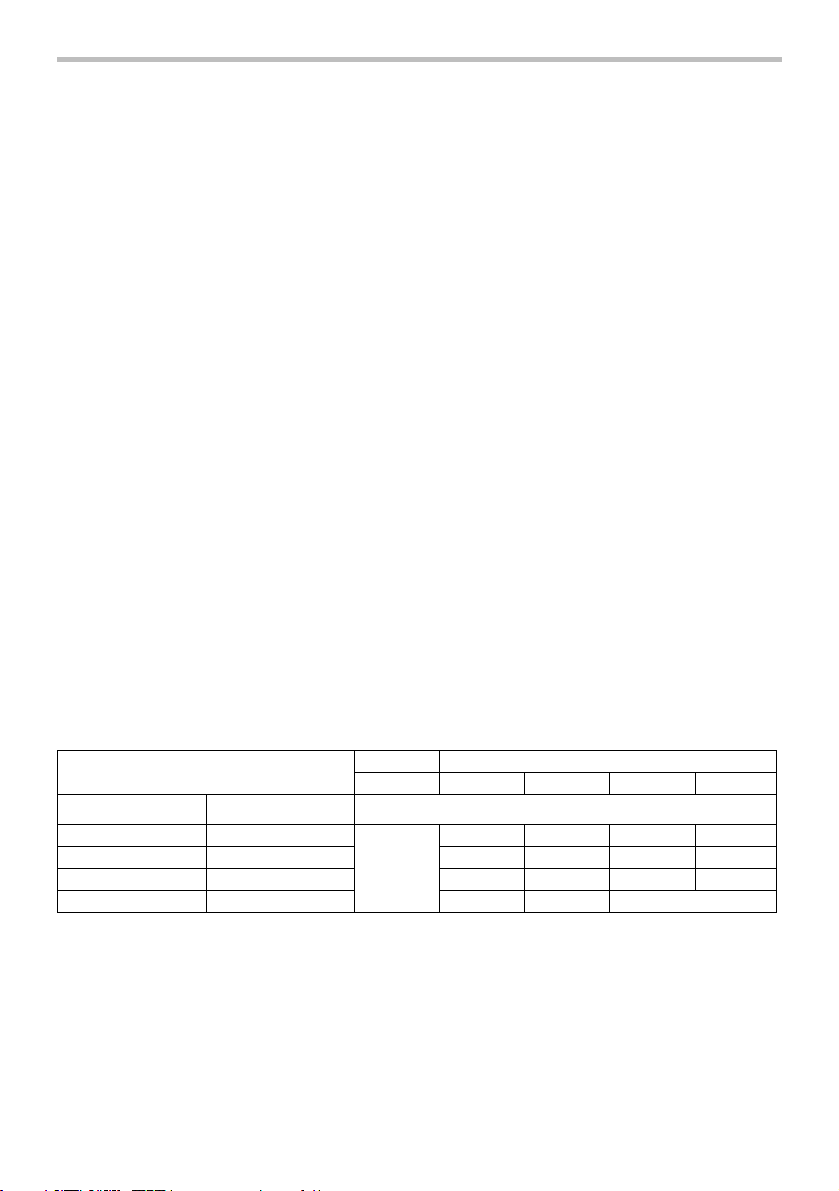

USE PROPER EXTENSION CORD. Make sure your

extension cord is in good condition. When using an

extension cord, be sure to use one heavy enough to

carry the current your product will draw. An

undersized cord will cause a drop in line voltage

resulting in loss of power and overheating. Table 1

shows the correct size to use depending on cord

length and nameplate ampere rating. If in doubt, use

the next heavier gage. The smaller the gage number,

the heavier the cord.

Table 1: Minimum gage for cord

Ampere Rating

Volts Total length of cord in feet

120 V 25 ft. 50 ft. 100 ft. 150 ft.

More Than Not More Than AWG

0 6 18 16 16 14

18 16 14 12610

10 12 16 16 14 12

000173

ADDITIONAL SAFETY RULES

DO NOT let comfort or familiarity with product

(gained from repeated use) replace strict adherence

to slide compound saw safety rules. If you use this

tool unsafely or incorrectly, you can suffer serious

personal injury.

1. Wear eye protection.

12 16 14 12

USB036-2

2. Keep hands out of path of saw blade. Avoid

contact with any coasting blade. It can still

cause severe injury.

3. Do not operate saw without guards in place.

Check blade guard for proper closing before

each use. Do not operate saw if blade guard

does not move freely and close instantly.

Never clamp or tie the blade guard into the

open position.

3

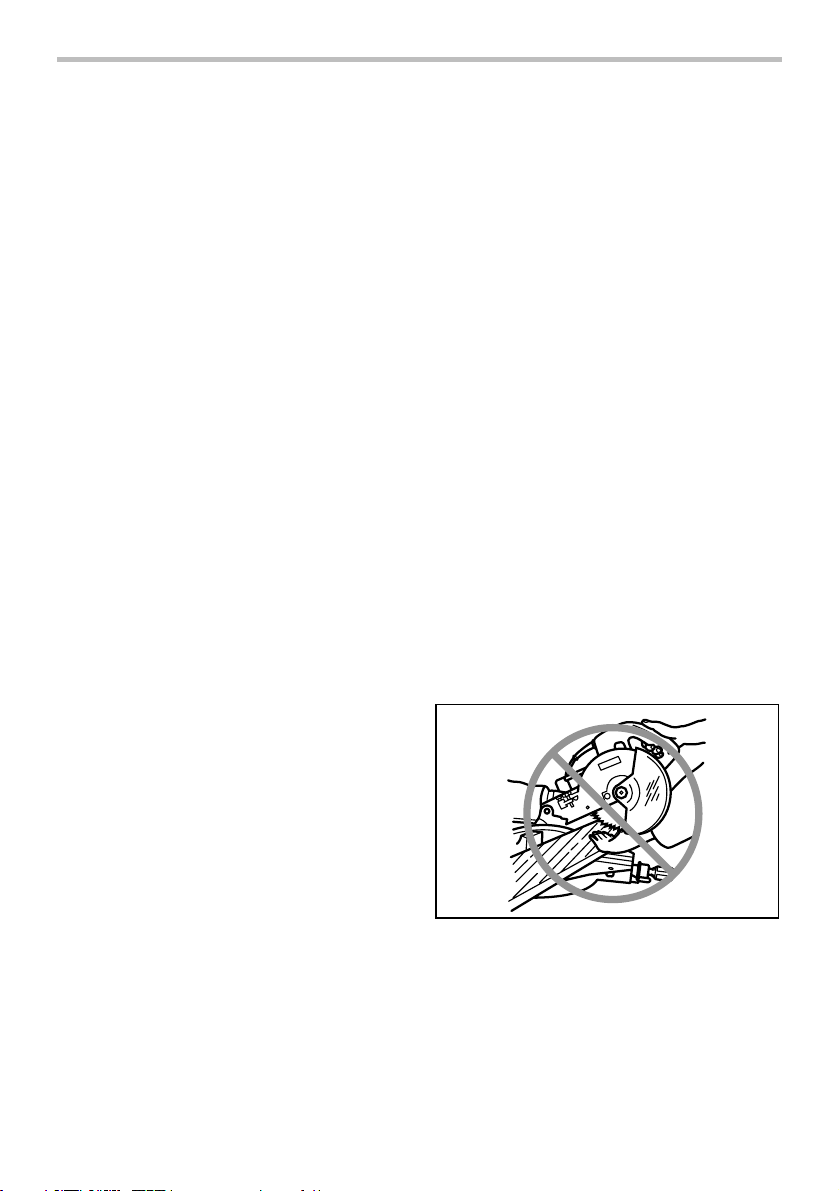

Not Recommended

4. Do not perform any operation freehand. The

workpiece must be secured firmly against the

turn base and guide fence with a vise during

all operations. Never use your hand to secure

the workpiece.

5. Never reach around saw blade.

6. Turn off tool and wait for saw blade to stop

before moving workpiece or changing

settings.

7. Unplug tool before changing blade or

servicing.

8. To reduce the risk of injury, return carriage to

the full rear position after each crosscut

operation.

9. Always secure all moving portions before

carrying the tool.

10. Stopper pin which locks the cutter head down

is for carrying and storage purposes only and

not for any cutting operations.

11. Do not use the tool in the presence of

flammable liquids or gases.

12. Check the blade carefully for cracks or

damage before operation. Replace cracked or

damaged blade immediately. Gum and wood

pitch hardened on blades slows saw and

increases potential for kickback. Keep blade clean

by first removing it from tool, then cleaning it with

gum and pitch remover, hot water or kerosene.

Never use gasoline to clean blade.

13. While making a slide cut, KICKBACK can

occur. KICKBACK occurs when the blade

binds in the workpiece during a cutting

operation and the saw blade is driven back

rapidly towards the operator. Loss of control

and serious personal injury can result. If blade

begins to bind during a cutting operation, do

not continue to cut and release switch

immediately.

14. Use only flanges specified for this tool.

15. Be careful not to damage the arbor, flanges

(especially the installing surface) or bolt.

Damage to these parts could result in blade

breakage.

16. Make sure that the turn base is properly

secured so it will not move during operation.

Use the holes in the base to fasten the saw to

a stable work platform or bench. NEVER use

tool where operator positioning would be

awkward.

17. For your safety, remove the chips, small

pieces, etc. from the table top before

operation.

18. Avoid cutting nails. Inspect for and remove all

nails from the workpiece before operation.

19. Make sure the shaft lock is released before the

switch is turned on.

20. Be sure that the blade does not contact the

turn base in the lowest position.

21. Hold the handle firmly. Be aware that the saw

moves up or down slightly during start-up and

stopping.

22. Make sure the blade is not contacting the

workpiece before the switch is turned on.

23. Before using the tool on an actual workpiece,

let it run for a while. Watch for vibration or

wobbling that could indicate poor installation

or a poorly balanced blade.

24. Wait until the blade attains full speed before

cutting.

25. Stop operation immediately if you notice

anything abnormal.

26. Do not attempt to lock the trigger in the "ON"

position.

27. Be alert at all times, especially during

repetitive, monotonous operations. Do not be

lulled into a false sense of security. Blades are

extremely unforgiving.

28. Always use accessories recommended in this

manual. Use of improper accessories such as

abrasive wheels may cause an injury.

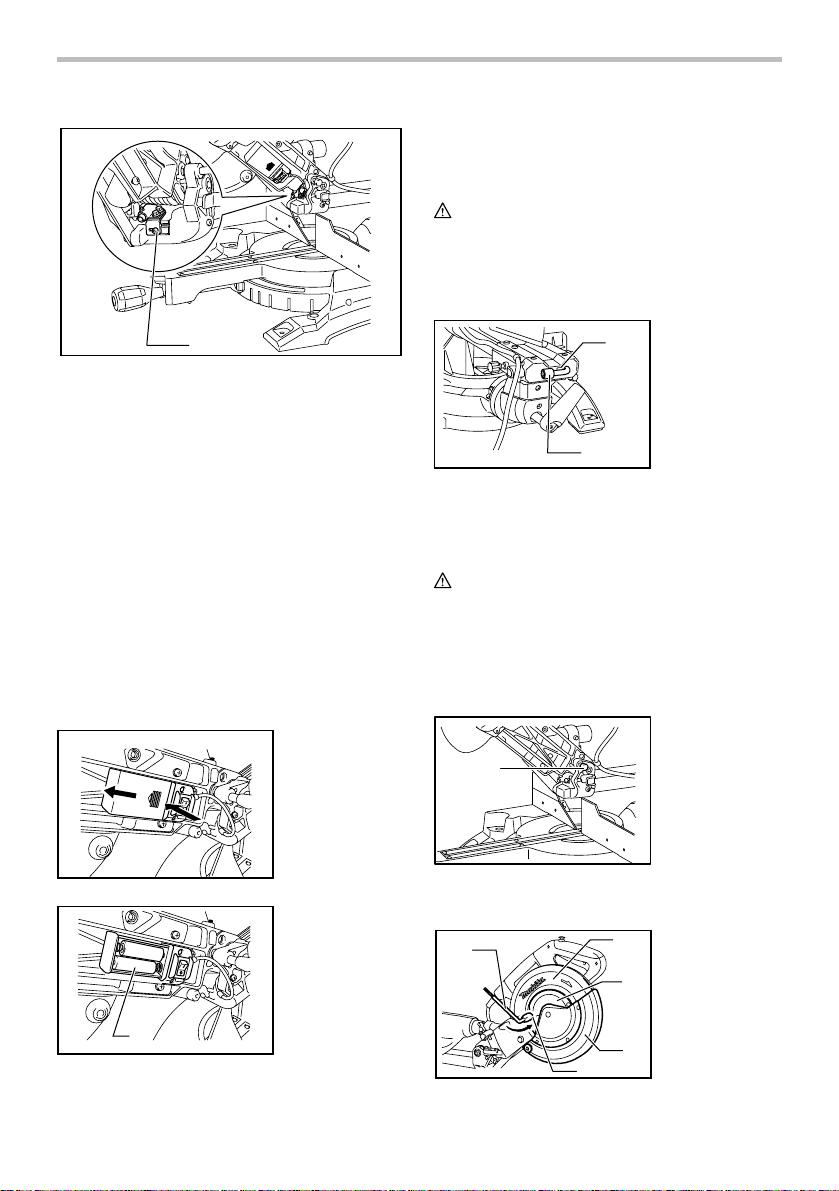

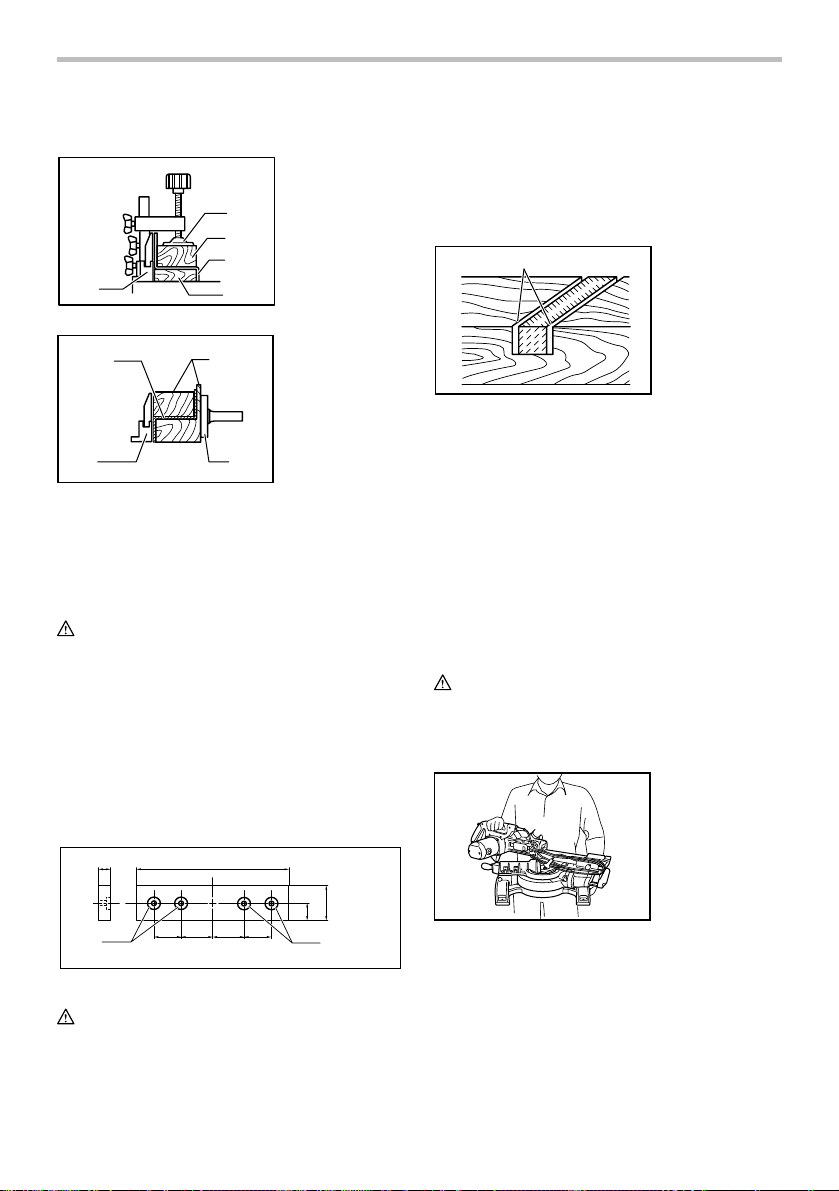

29. NEVER hold workpiece on right side of blade

with left hand or vice versa. This is called

cross-armed cutting and exposes user to risk

of SERIOUS PERSONAL INJURY as shown in

the figure. ALWAYS use vise to secure

workpiece.

000030

30. Do not abuse cord. Never yank cord to

disconnect it from the receptacle. Keep cord

away from heat, oil, water and sharp objects.

31. NEVER stack workpieces on the table top to

speed cutting operations. Cut only one piece

at a time.

32. Some material contains chemicals which may

be toxic. Take caution to prevent dust

inhalation and skin contact. Follow material

4

supplier safety data.

SAVE THESE INSTRUCTIONS.

WARNING:

MISUSE or failure to follow the safety rules stated in

this instruction manual may cause serious personal

injury.

USB088-2

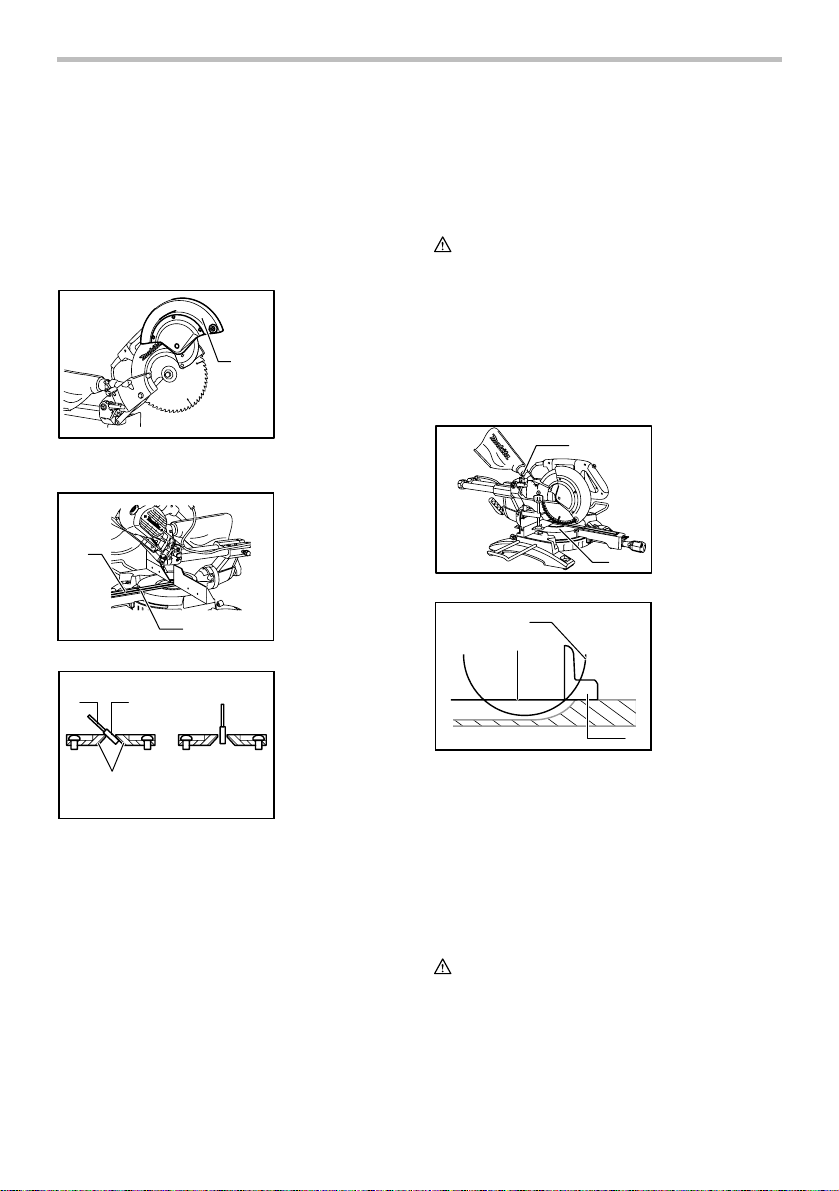

ADDITIONAL SAFETY RULES

FOR THE LASER

CAUTION:

• LASER RADIATION DO NOT STARE INTO

BEAM.

• AVOID EXPOSURE - LASER RADIATION IS

EMITTED FROM APERTURE.

• USE OF CONTROLS OR ADJUSTMENTS OR

PERFORMANCE OF PROCEDURES OTHER

THAN THOSE SPECIFIED HEREIN MAY

RESULT IN HAZARDOUS RADIATION

EXPOSURE.

COMPLIES WITH 21CFR 1040.10 AND

1040.11

AVOID EXPOSURE – LASER RADIATIONS

IS EMITTED FROM THIS APERTURE

CONFORME A 21CFR 1040.10 ET 1040.11

EVITEZ L'EXPOSITION - UN

RAYONNEMENT LASER EST EMIS PAR

CETTE OUVERTURE.

CAUTION/ PRECAUCIÓN

LASER RADIATION DO NOT STARE INTO BEAM

RADIACIÓN LÁSER NO DIRIJA LA

VISTA HACIA EL RAYO LÁSER

Maximum Output

< 1mW, Wavelength : 660 nm

CLASS LASER PRODUCT

010401

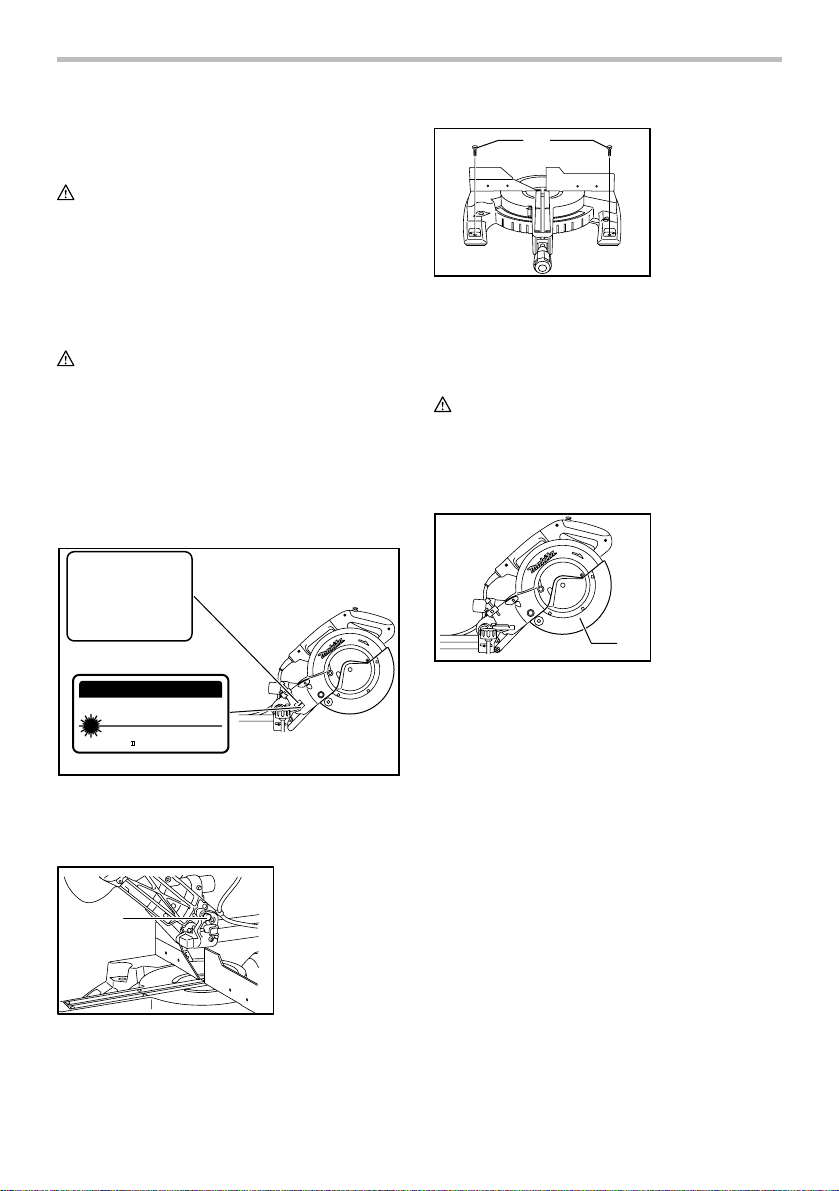

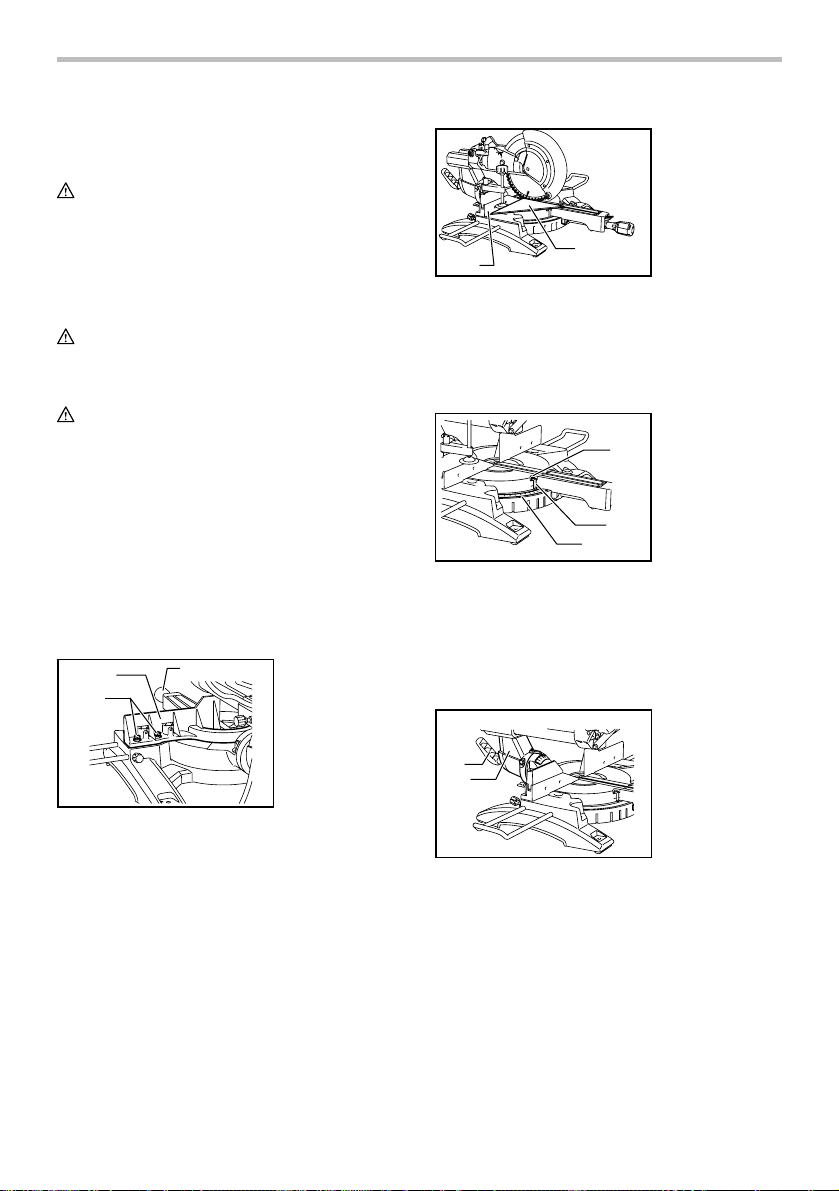

INSTALLATION

Bench mounting

1. Stopper pin

1

010228

When the tool is shipped, the handle is locked in the

lowered position by the stopper pin. Release the stopper

pin by lowering the handle slightly and pulling the stopper

pin.

1

010564

1. Bolt

This tool should be bolted with four bolts to a level and

stable surface using the bolt holes provided in the tool's

base. This will help prevent tipping and possible injury.

FUNCTIONAL DESCRIPTION

CAUTION:

• Always be sure that the tool is switched off and

unplugged before adjusting or checking function on

the tool.

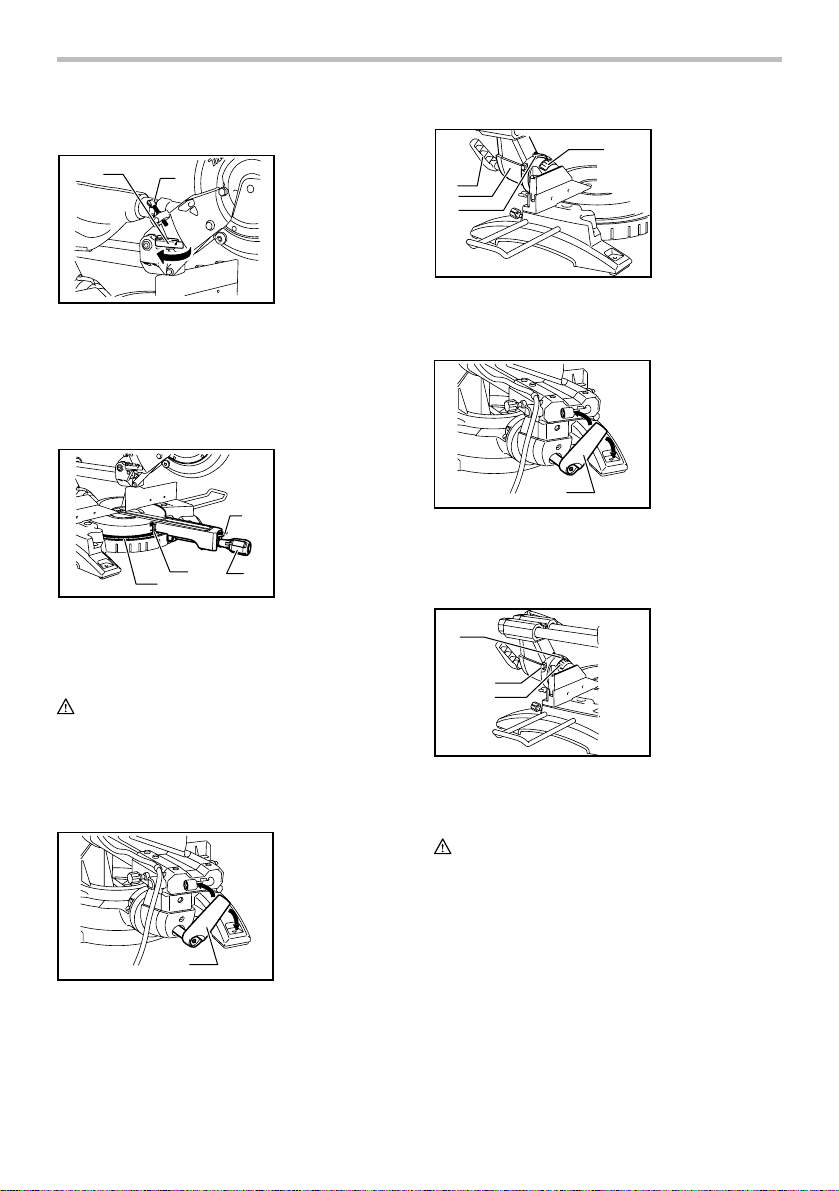

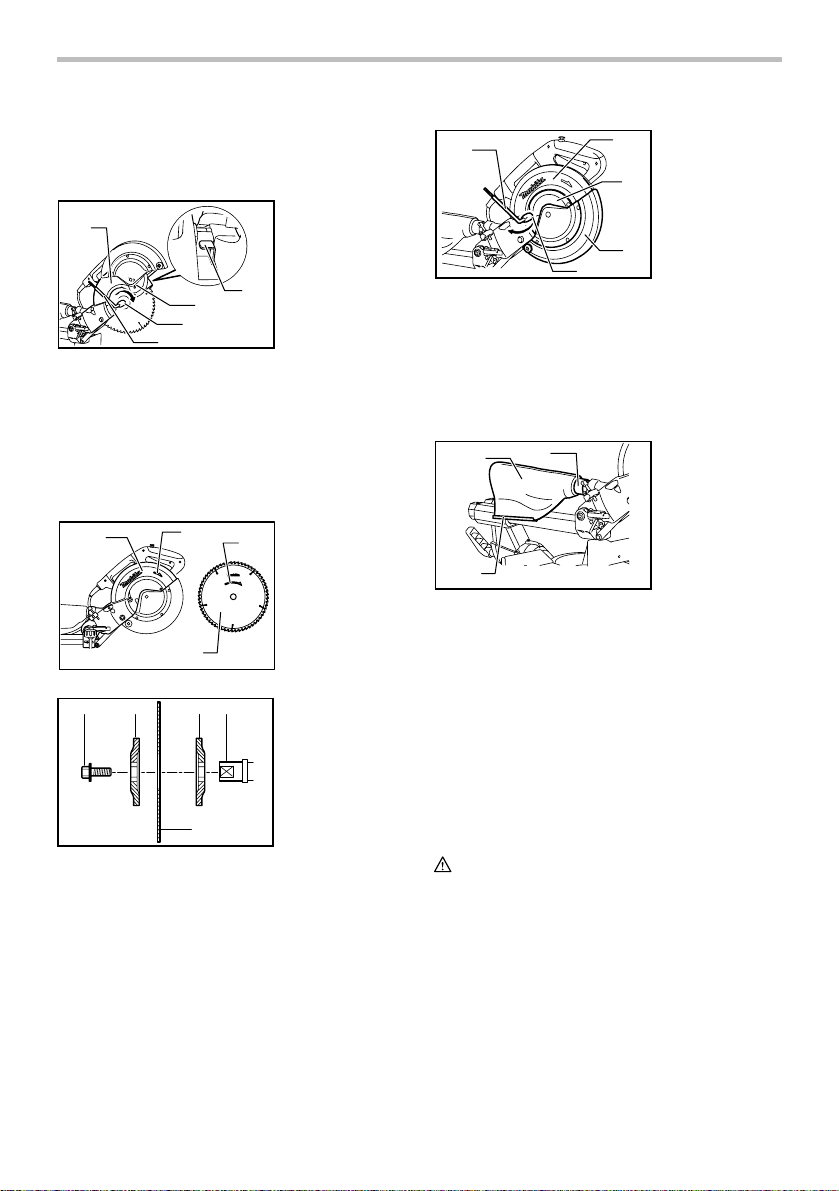

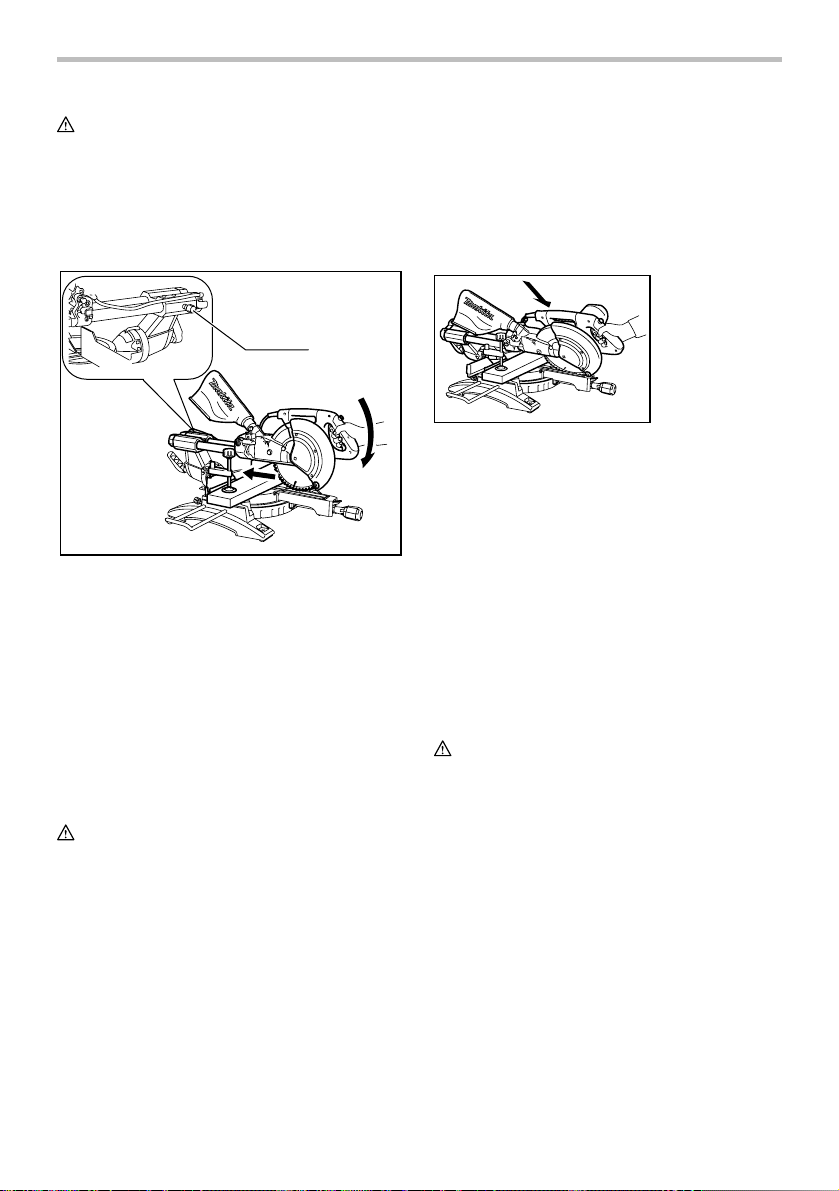

Blade guard

1. Blade guard

1

010386

When lowering the handle, the blade guard rises

automatically. The blade guard returns to its original

position when the cut is completed and the handle is

raised. NEVER DEFEAT OR REMOVE THE BLADE

GUARD OR THE SPRING WHICH ATTACHES TO THE

GUARD.

In the interest of your personal safety, always maintain

the blade guard in good condition. Any irregular

operation of the blade guard should be corrected

immediately. Check to assure spring loaded return action

of guard. NEVER USE THE TOOL IF THE BLADE

GUARD OR SPRING ARE DAMAGED, FAULTY OR

REMOVED. DOING SO IS HIGHLY DANGEROUS AND

CAN CAUSE SERIOUS PERSONAL INJURY.

If the see-through blade guard becomes dirty, or sawdust

adheres to it in such a way that the blade and/or

workpiece is no longer easily visible, unplug the saw and

clean the guard carefully with a damp cloth. Do not use

solvents or any petroleum-based cleaners on the plastic

guard.

If the blade guard is especially dirty and vision through

the guard is impaired, use the supplied socket wrench to

loosen the hex bolt holding the center cover. Loosen the

5

hex bolt by turning it counterclockwise and raise the

blade guard and center cover. With the blade guard so

positioned, cleaning can be more completely and

efficiently accomplished. When cleaning is complete,

reverse procedure above and secure bolt. Do not remove

spring holding blade guard. If guard becomes discolored

through age or UV light exposure, contact a Makita

service center for a new guard. DO NOT DEFEAT OR

REMOVE GUARD.

1. Blade guard

1

010387

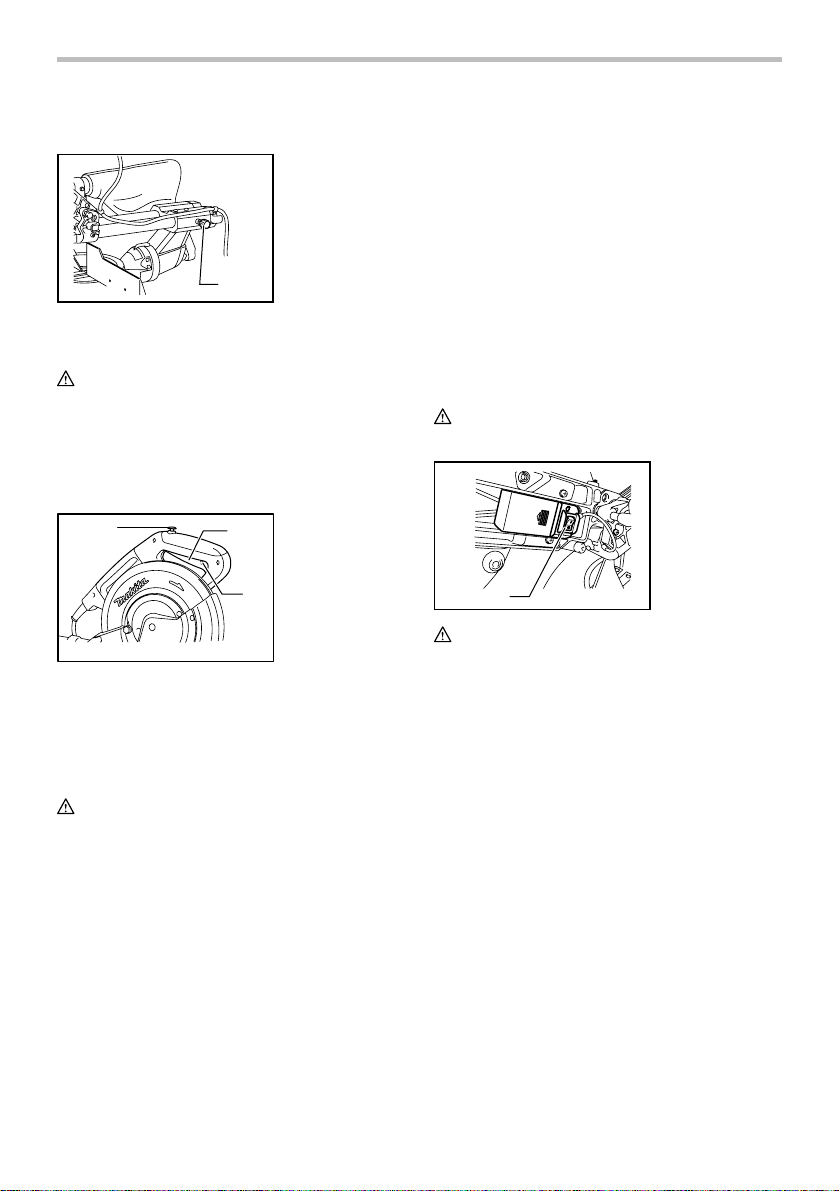

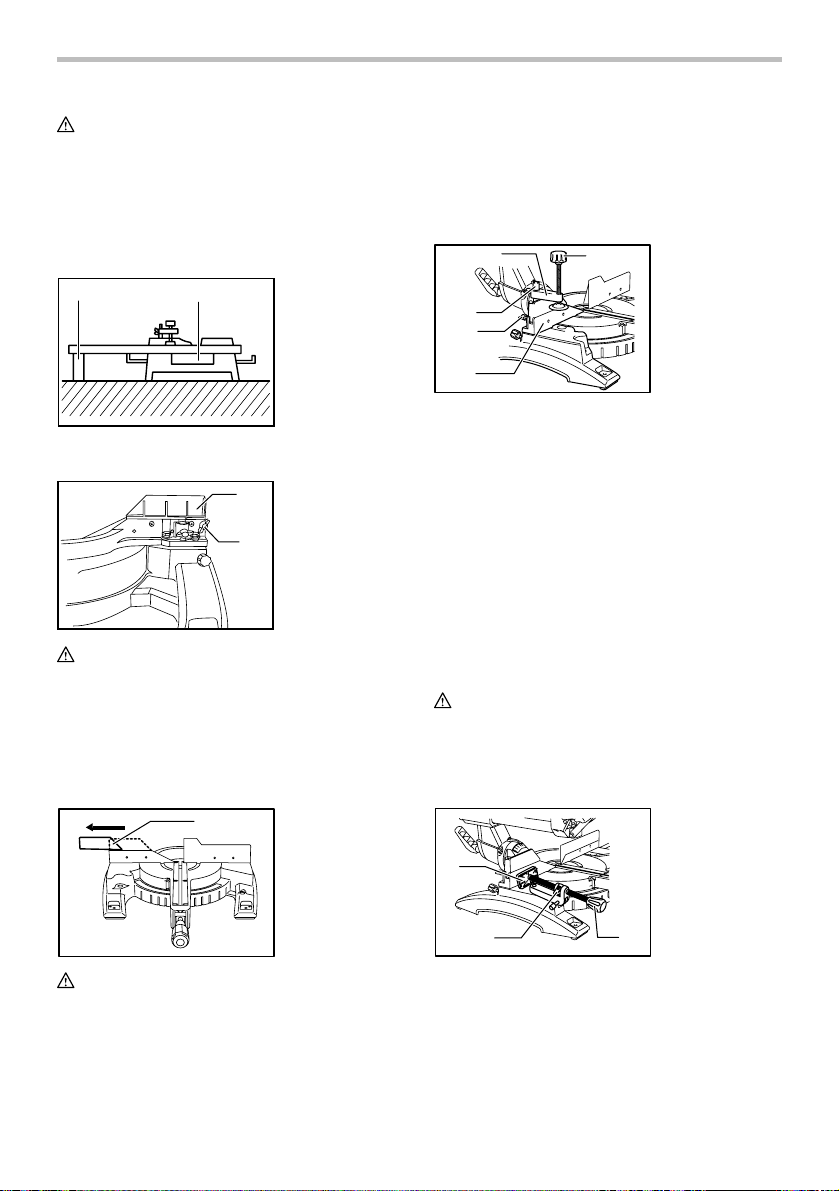

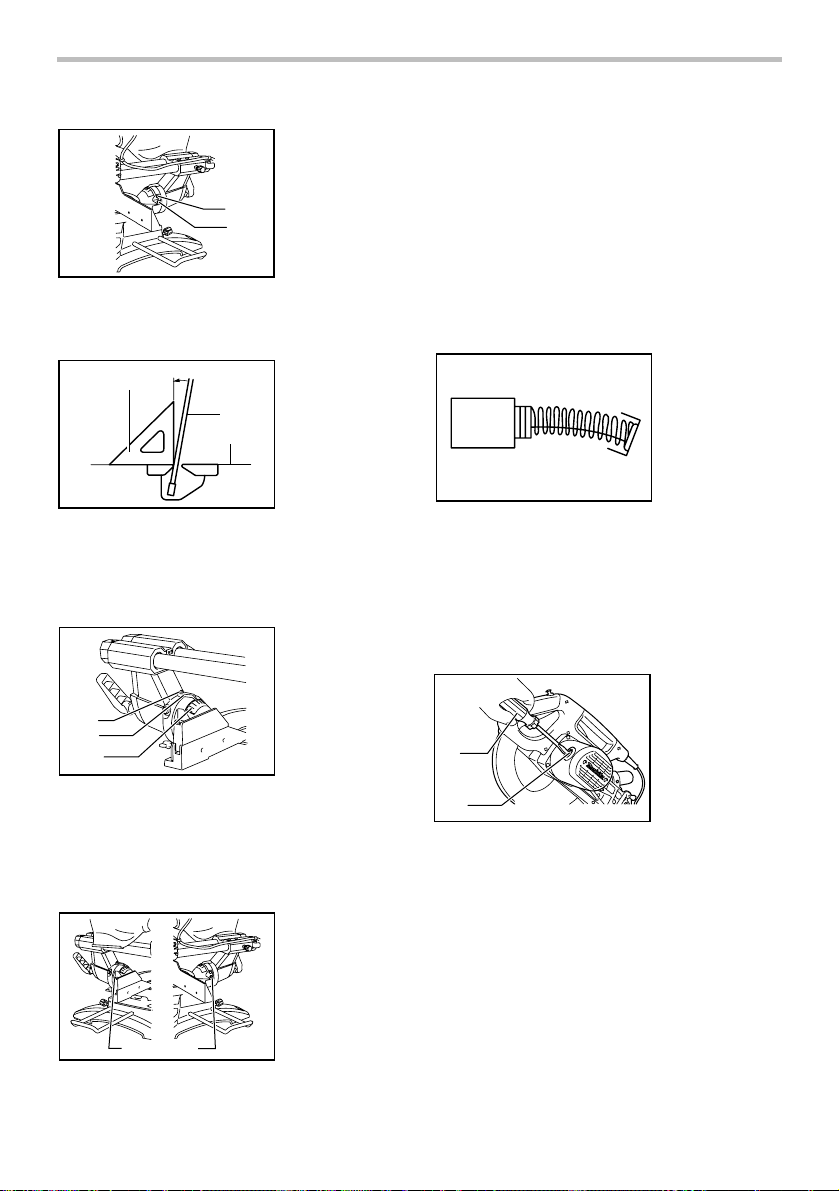

Positioning kerf board

1. Kerf board

2. Screw

boards so that the kerf boards just contact the sides of

blade teeth. Tighten the rear screws (do not tighten

firmly).

After adjusting the kerf boards, release the stopper pin

and raise the handle. Then tighten all the screws

securely.

CAUTION:

• Before and after changing the bevel angle, always

adjust the kerf boards as described above.

Maintaining maximum cutting capacity

Unplug the tool before any adjustment is attempted. This

tool is factory adjusted to provide the maximum cutting

capacity for a 255 mm (10") saw blade.

When installing a new blade, always check the lower limit

position of the blade and if necessary, adjust it as follows:

1

1. Adjusting bolt

2. Turn base

1

010384

2

12

3

45

001800

This tool is provided with the kerf boards in the turn base

to minimize tearing on the exit side of a cut. The kerf

boards are factory adjusted so that the saw blade does

not contact the kerf boards. Before use, adjust the kerf

boards as follows:

First, unplug the tool. Loosen all the screws (3 each on

left and right) securing the kerf boards. Re-tighten them

only to the extent that the kerf boards can still be easily

moved by hand. Lower the handle fully and push in the

stopper pin to lock the handle in the lowered position.

Loosen the screw which secures the slide poles. Pull the

carriage toward you fully. Adjust the kerf boards so that

the kerf boards just contact the sides of the blade teeth.

Tighten the front screws (do not tighten firmly). Push the

carriage toward the guide fence fully and adjust the kerf

1. Saw blade

2. Blade teeth

3. Kerf board

4. Left bevel cut

5. Straight cut

2

010402

2

1

001540

First, unplug the tool. Push the carriage toward the guide

fence fully and lower the handle completely. Use the hex.

wrench to turn the adjusting bolt until the periphery of the

blade extends slightly below the top surface of the turn

base at the point where the front face of the guide fence

meets the top surface of the turn base.

With the tool unplugged, rotate the blade by hand while

holding the handle all the way down to be sure that the

blade does not contact any part of the lower base.

Re-adjust slightly, if necessary.

CAUTION:

• After installing a new blade, always be sure that the

blade does not contact any part of the lower base

when the handle is lowered completely. Always do

this with the tool unplugged.

1. Top surface of

turn base

2. Periphery of

blade

3. Guide fence

3

6

Stopper arm

1

1. Lever

4

2

1. Stopper arm

2. Adjusting screw

1

2

3

2. Arm

3. Pointer

4. Bevel scale

010233

The lower limit position of the blade can be easily

adjusted with the stopper arm. To adjust it, move the

stopper arm in the direction of the arrow as shown in the

figure. Adjust the adjusting screw so that the blade stops

at the desired position when lowering the handle fully.

Adjusting the miter angle

1. Miter scale

2. Pointer

3. Lock lever

4. Grip

3

4

2

1

010234

Loosen the grip by turning counterclockwise. Turn the turn base

while pressing down the lock lever. When you have moved the

grip to the position where the pointer points to the desired angle

on the miter scale, securely tighten the grip clockwise.

CAUTION:

• When turning the turn base, be sure to raise the

handle fully.

• After changing the miter angle, always secure the

turn base by tightening the grip firmly.

Adjusting the bevel angle

1. Lever

1

010236

To adjust the bevel angle, loosen the lever at the rear of

the tool counterclockwise. Unlock the arm by pushing the

handle somewhat strongly in the direction that you intend

to tilt the saw blade.

010235

Tilt the saw blade until the pointer points to the desired

angle on the bevel scale. Then tighten the lever

clockwise firmly to secure the arm.

1

010236

When tilting the carriage to the right, tilt the carriage to

the left slightly after loosening the lever and press the

releasing button. With the releasing button being pressed,

tilt the carriage to the right.

1

2

3

010430

Tilt the saw blade until the pointer points to the desired

angle on the bevel scale. Then tighten the lever

clockwise firmly to secure the arm.

CAUTION:

• When tilting the saw blade, be sure to raise the

handle fully.

• After changing the bevel angle, always secure the

arm by tightening the lever clockwise.

• When changing bevel angles, be sure to position

the kerf boards appropriately as explained in the

"Positioning kerf boards" section.

1. Lever

1. Pointer

2. Release button

3. Bevel scale

7

Slide lock adjustment

1. Locking screw

1

010428

To lock the slide pole, turn the locking screw clockwise.

Switch action

CAUTION:

• Before plugging in the tool, always check to see

that the switch trigger actuates properly and returns

to the "OFF" position when released.

• Do not pull the switch trigger hard without pressing

in the lock-off button. This can cause switch

breakage.

1

1. Lock-off button

2

2. Switch trigger

3. Hole for padlock

Electric brake

This tool is equipped with an electric blade brake. If the

tool consistently fails to quickly stop blade after switch

trigger release, have tool serviced at a Makita service

center.

The blade brake system is not a substitute for blade

guard. NEVER USE TOOL WITHOUT A FUNCTIONING

BLADE GUARD. SERIOUS PERSONAL INJURY CAN

RESULT.

Electronic function

Soft start feature

• Soft start because of suppressed starting shock.

Laser beam action

For model LS1017L only

CAUTION:

• When not in use, be sure to turn off the laser

1. Switch for laser

3

010388

To prevent the switch trigger from being accidentally

pulled, a lock-off button is provided. To start the tool,

press in the lock-off button and pull the switch trigger.

Release the switch trigger to stop.

A hole is provided in the switch trigger for insertion of

padlock to lock the tool off.

WARNING:

• Do not use a lock with a shank or cable any smaller

than 6.35 mm (1/4") in diameter.

• NEVER use tool without a fully operative switch

trigger. Any tool with an inoperative switch is

HIGHLY DANGEROUS and must be repaired

before further usage.

• For your safety, this tool is equipped with a lock-off

button which prevents the tool from unintended

starting. NEVER use the tool if it runs when you

simply pull the switch trigger without pressing the

lock-off button. Return tool to a Makita service

center for proper repairs BEFORE further usage.

• NEVER tape down or defeat purpose and function

of lock-off button.

010257

1

CAUTION:

• LASER RADIATION

Do not stare into beam.

• Before shifting the laser line or performing

maintenance adjustment, be sure to unplug the

tool.

To turn on the laser beam, press the upper position (I) of

the switch. Press the lower position (O) to turn off.

Laser line can be shifted to either the left or right side of

the saw blade by loosening the screw holding the laser

unit box and shifting it in the desired direction. After

shifting, be sure to tighten the screw.

8

1

x

1. Screw holding the laser unit bo

010389

Laser line is factory adjusted so that it is positioned within

1 mm (0.04") from the side surface of the blade (cutting

position).

Cleaning of the lens for the laser light

If the lens for the laser light becomes dirty, or sawdust

adheres to it in such a way that the laser line is no longer

easily visible, unplug the saw and remove and clean the

lens for the laser light carefully with a damp, soft cloth.

Do not use solvents or any petroleum-based cleaners on

the lens.

NOTE:

• When laser line is dim and almost or entirely

invisible because of the direct sunlight in the indoor

or outdoor window-by work, relocate the work area

to a place not exposed to the direct sunlight.

Replacing the dry cells for laser unit

new ones as shown in the figure. After replacing, return

the lid to cover it.

ASSEMBLY

CAUTION:

• Always be sure that the tool is switched off and

unplugged before carrying out any work on the tool.

Storage of socket wrench with hex wrench on

its other end

1. Socket wrench

2

1

010240

The socket wrench is stored as shown in the figure. When

using the socket wrench, pull it out of the wrench holder.

After using the socket wrench, return it to the wrench holder.

Installing or removing saw blade

CAUTION:

• Always be sure that the tool is switched off and

unplugged before installing or removing the blade.

• Use only the Makita socket wrench provided to

install or remove the blade. Failure to do so may

result in overtightening or insufficient tightening of

the hex bolt. This could cause an injury.

with hex wrench

on its other end

2. Wrench holder

1. Stopper pin

010399

1

010259

Remove the lid for the dry cells for laser unit by sliding

while pressing it. Take out the old dry cells and put the

1. Dry cell

1

010228

Lock the handle in the raised position by pushing in the

stopper pin.

1

010390

9

4

2

1. Socket wrench

2. Blade case

3. Center cover

3

4. Hex bolt

5. Blade guard

5

To remove the blade, use the socket wrench to loosen

the hex bolt holding the center cover by turning it

counterclockwise. Raise the blade guard and center

cover.

1. Blade case

2. Socket wrench

3. Hex bolt

4. Arrow

5. Shaft lock

5

010391

1

4

3

2

Press the shaft lock to lock the spindle and use the

socket wrench to loosen the hex bolt clockwise. Then

remove the hex bolt, outer flange and blade.

NOTE:

• When inner flange is removed mistakenly, be sure

to install it on the spindle with its protrusion facing

the spindle.

1

010392

12 435

001786

2

4

1. Blade case

3

2. Arrow

3. Arrow

4. Saw blade

1. Hex bolt

2. Outer flange

3. Saw blade

4. Inner flange

5. Spindle

To install the blade, mount it carefully onto the spindle,

making sure that the direction of the arrow on the surface

of the blade matches the direction of the arrow on the

blade case.

Install the outer flange and hex bolt, and then use the

socket wrench to tighten the hex bolt (left-handed)

securely counterclockwise while pressing the shaft lock.

2

1. Socket wrench

2. Blade case

3. Center cover

3

4. Hex bolt

5. Blade guard

5

010560

1

4

Return the blade guard and center cover to its original

position. Then tighten the hex bolt clockwise to secure

the center cover. Release the handle from the raised

position by pulling the stopper pin. Lower the handle to

make sure that the blade guard moves properly. Make

sure shaft lock has released spindle before making cut.

Dust bag (accessory)

2

3

010245

1

The use of the dust bag makes cutting operations clean

and dust collection easy. To attach the dust bag, fit it onto

the dust nozzle.

When the dust bag is about half full, remove the dust bag

from the tool and pull the fastener out. Empty the dust

bag of its contents, tapping it lightly so as to remove

particles adhering to the insides which might hamper

further collection.

NOTE:

If you connect a vacuum cleaner to your saw, more

efficient and cleaner operations can be performed.

Securing workpiece

WARNING:

• It is extremely important to always secure the

workpiece properly and tightly with the vise. Failure

to do so can cause the tool to be damaged and/or

the workpiece to be destroyed. PERSONAL

INJURY MAY ALSO RESULT. Also, after a cutting

operation, DO NOT raise the blade until the blade

has come to a complete stop.

1. Dust nozzle

2. Dust bag

3. Fastener

10

CAUTION:

• When cutting long workpieces, use supports that

are as high as the top surface level of the turn base.

Do not rely solely on the vertical vise and/or

horizontal vise to secure the workpiece.

Thin material tends to sag. Support workpiece over

its entire length to avoid blade pinch and possible

KICKBACK.

1

2

1. Support

2. Turn base

However, when performing left bevel cuts, set it to the left

position as shown in the figure if the tool head contacts it.

When bevel-cutting operations are complete, don't forget

to return the sliding fence to the original position and

secure it by firmly tightening the clamping screw.

Vertical vise

1

2

3

4

1. Vise arm

2. Vise knob

3. Vise rod

4. Screw

5. Guide fence

001549

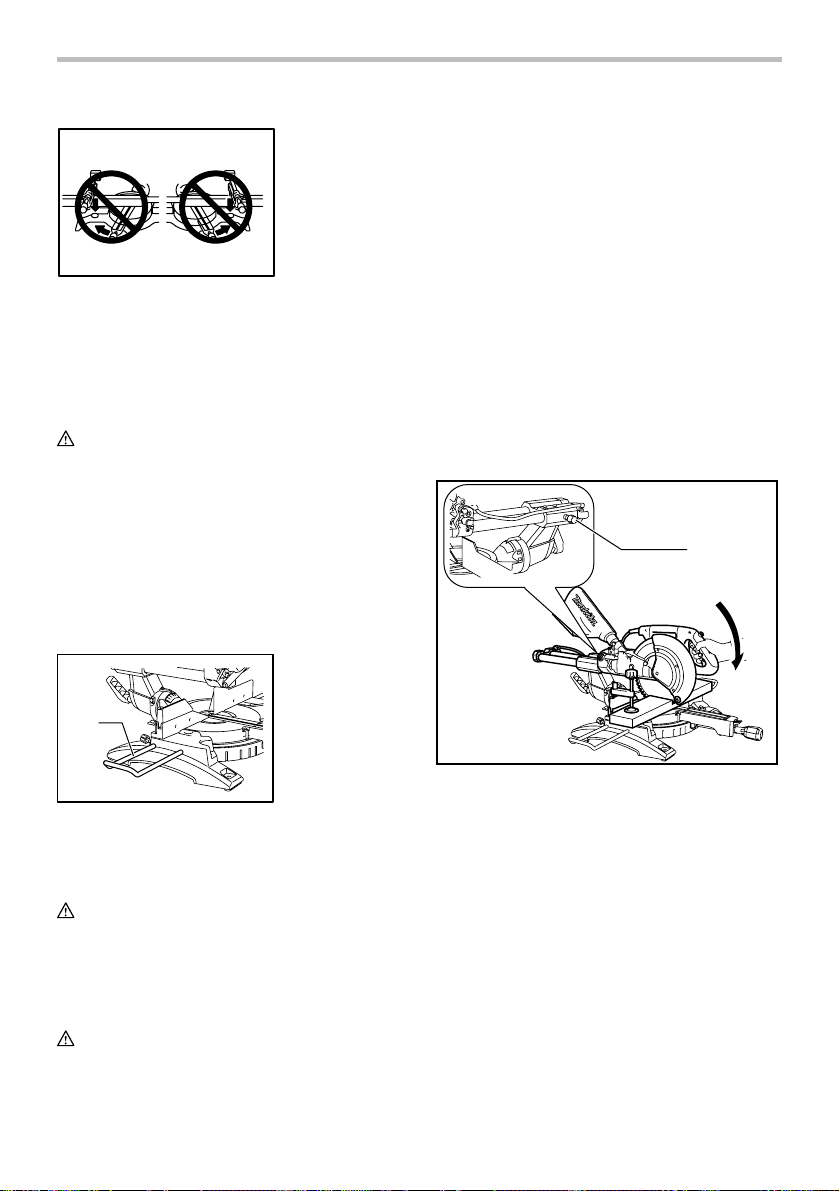

Sliding fence adjustment

1. Sliding fence

1

2. Clamping screw

2

010480

WARNING:

• Before operating the tool, make sure that the sliding

fence is secured firmly.

• Before bevel-cutting, make sure that no part of the

tool contacts the sliding fence when lowering and

raising the handle fully at any position and pulling or

pushing the carriage all the way at the lowest

position..

1

010407

CAUTION:

• When performing bevel cuts, slide the sliding fence

to the left and secure it as shown in the figure.

Otherwise, it will contact the blade or a part of the

tool, causing possible serious injury to the operator.

This tool is equipped with the sliding fence which should

ordinarily be positioned as shown in the figure.

1. Sliding fence

5

010393

The vertical vise can be installed on either the left or right

side of the guide fence. Insert the vise rod into the hole in

the guide fence and tighten the screw on the back of the

guide fence to secure the vise rod.

Position the vise arm according to the thickness and

shape of the workpiece and secure the vise arm by

tightening the screw. If the screw to secure the vise arm

contacts the guide fence, install the screw on the

opposite side of vise arm. Make sure that no part of the

tool contacts the vise when lowering the handle fully and

pulling or pushing the carriage all the way. If some part

contacts the vise, re-position the vise.

Press the workpiece flat against the guide fence and the

turn base. Position the workpiece at the desired cutting

position and secure it firmly by tightening the vise knob.

CAUTION:

• The workpiece must be secured firmly against the

turn base and guide fence with the vise during all

operations.

Horizontal vise (optional accessory)

1. Vise plate

2. Vise nut

1

2

010299

The horizontal vise can be installed in two positions on

either the left or right side of the base. When performing

10° or greater miter cuts, install the horizontal vise on the

side opposite the direction in which the turn base is to be

turned.

11

3. Vise knob

3

005232

By flipping the vise nut to the left, the vise is released,

and rapidly moves in and out. To grip the workpiece,

push the vise knob forward until the vise plate contacts

the workpiece and flip the vise nut to the right. Then turn

the vise knob clockwise to secure the workpiece.

The maximum width of workpiece which can be secured

by the horizontal vise is 215 mm (8-1/2").

CAUTION:

• Always rotate the vise nut to the right fully when

securing the workpiece. Failure to do so may result

in insufficient securing of the workpiece. This could

cause the workpiece to be thrown, cause damage

to the blade or cause the loss of control, which can

result in PERSONAL INJURY.

• When cutting out thin workpiece, such as base

boards, against the fence, always use the

horizontal vise.

Holders

1. Holder

• Make sure the blade is not contacting the

workpiece, etc. before the switch is turned on.

• Do not apply excessive pressure on the handle

when cutting. Too much force may result in

overload of the motor and/or decreased cutting

efficiency. Push down handle with only as much

force as is necessary for smooth cutting and

without significant decrease in blade speed.

• Gently press down the handle to perform the cut. If

the handle is pressed down with force or if lateral

force is applied, the blade will vibrate and leave a

mark (saw mark) in the workpiece and the precision

of the cut will be impaired.

• During a slide cut, gently push the carriage toward

the guide fence without stopping. If the carriage

movement is stopped during the cut, a mark will be

left in the workpiece and the precision of the cut will

be impaired.

1. Press cutting (cutting small workpieces)

1

1

010255

The holders can be installed on either side as a

convenient means of holding workpieces horizontally.

Slip fully the holder rods into the holes in the base. Then

tighten the holders securely with the screws.

CAUTION:

• Always support long workpieces level with the top

surface of the turn base for accurate cuts and to

prevent dangerous loss of control of the tool.

OPERATION

CAUTION:

• Before use, be sure to release the handle from the

lowered position by pulling the stopper pin.

1. Locking screw

010394

Workpieces up to 91 mm (3-5/8") high and 70 mm

(2-3/4") wide can be cut in the following way.

Push the carriage toward the guide fence fully and

tighten the locking screw clockwise to secure the

carriage. Secure the workpiece with the vise.

Switch on the tool without the blade making any

contact and wait until the blade attains full speed

before lowering. Then gently lower the handle to

the fully lowered position to cut the workpiece.

When the cut is completed, switch off the tool and

WAIT UNTIL THE BLADE HAS COME TO A

COMPLETE STOP before returning the blade to its

fully elevated position.

12

CAUTION:

• Firmly tighten the knob clockwise so that the

carriage will not move during operation. Insufficient

tightening may cause unexpected kickback of the

blade. Possible serious PERSONAL INJURY may

result.

2. Slide (push) cutting (cutting wide workpieces)

1

• Never loosen the locking screw which secures the

carriage while the blade is rotating. This may cause

serious injury.

3. Miter cutting

Refer to the previously covered "Adjusting the miter

angle".

4. Bevel cut

1. Locking screw

010395

Loosen the locking screw counterclockwise so that

the carriage can slide freely. Secure the workpiece

with the vise. Pull the carriage toward you fully.

Switch on the tool without the blade making any

contact and wait until the blade attains full speed.

Press down the handle and PUSH THE

CARRIAGE TOWARD THE GUIDE FENCE AND

THROUGH THE WORKPIECE. When the cut is

completed, switch off the tool and WAIT UNTIL

THE BLADE HAS COME TO A COMPLETE STOP

before returning the blade to its fully elevated

position.

CAUTION:

• Whenever performing the slide cut, FIRST PULL

THE CARRIAGE TOWARD YOU FULLY and press

down the handle to the fully lowered position, then

PUSH THE CARRIAGE TOWARD THE GUIDE

FENCE. NEVER START THE CUT WITH THE

CARRIAGE NOT FULLY PULLED TOWARD YOU.

If you perform the slide cut without pulling the

carriage fully or if you perform the slide cut toward

your direction, the blade may kickback

unexpectedly with the potential to cause serious

PERSONAL INJURY.

• Never perform the slide cut with the handle locked

in the lowered position by pressing the stopper pin.

010396

Loosen the lever and tilt the saw blade to set the

bevel angle (Refer to the previously covered

"Adjusting the bevel angle"). Be sure to retighten

the lever firmly to secure the selected bevel angle

safely. Secure the workpiece with a vise. Make sure

the carriage is pulled all the way back toward the

operator. Switch on the tool without the blade

making any contact and wait until the blade attains

full speed. Then gently lower the handle to the fully

lowered position while applying pressure in parallel

with the blade and PUSH THE CARRIAGE

TOWARD THE GUIDE FENCE TO CUT THE

WORKPIECE. When the cut is completed, switch

off the tool and WAIT UNTIL THE BLADE HAS

COME TO A COMPLETE STOP before returning

the blade to its fully elevated position.

CAUTION:

• Always be sure that the blade will move down to

bevel direction during a bevel cut. Keep hands out

of path of saw blade.

• During a bevel cut, it may create a condition

whereby the piece cut off will come to rest against

the side of the blade. If the blade is raised while the

blade is still rotating, this piece may be caught by

the blade, causing fragments to be scattered which

is dangerous. The blade should be raised ONLY

after the blade has come to a complete stop.

• When pressing down the handle, apply pressure in

parallel with the blade. If a force is applied

perpendicularly to the turn base or if the pressure

direction is changed during a cut, the precision of

the cut will be impaired.

• Always slide the sliding fence so that it does not

interfere any part of the carriage when performing

bevel cuts.

13

5. Compound cutting

Compound cutting is the process in which a bevel

angle is made at the same time in which a miter

angle is being cut on a workpiece. Compound

cutting can be performed at angle shown in the

table.

Miter angle Bevel angle

Left and Right 0 - 45

010340

Left 0 - 45

When performing compound cutting, refer to "Press

cutting", "Slide cutting", "Miter cutting" and "Bevel

cut" explanations.

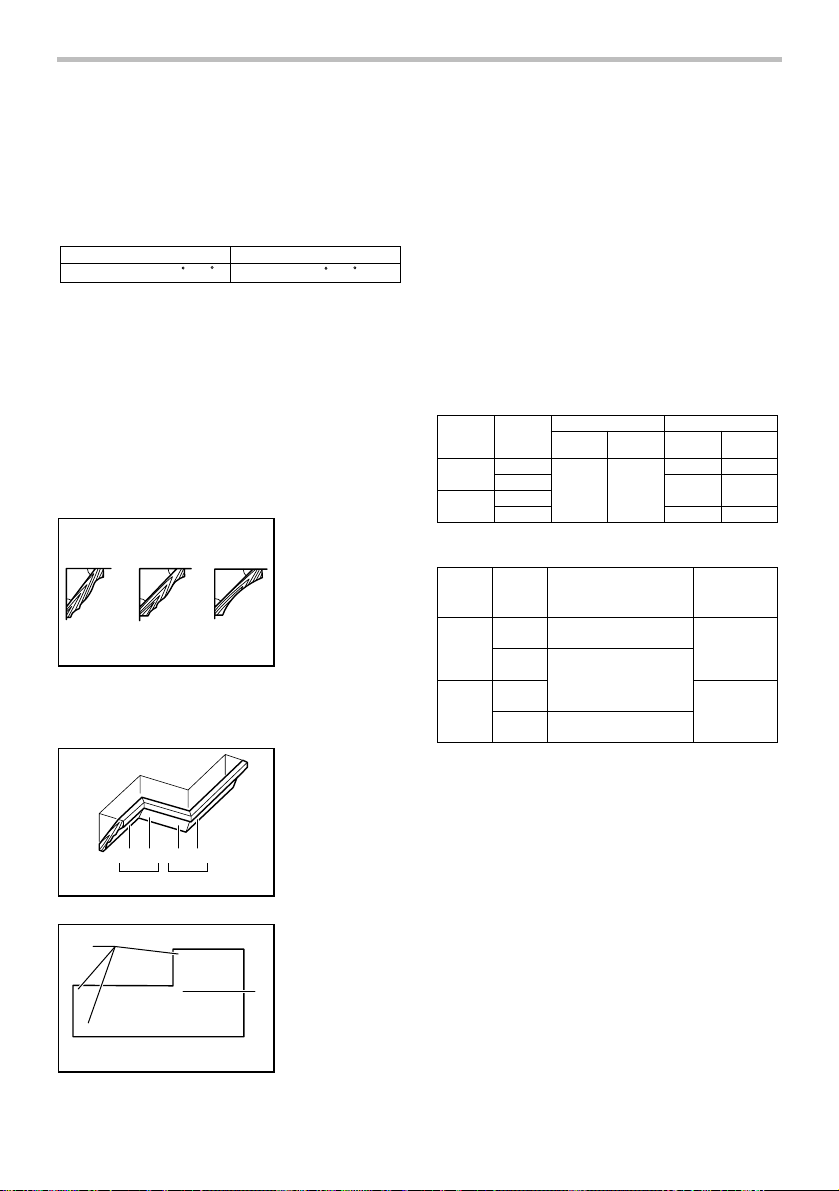

6. Cutting crown and cove moldings

Crown and cove moldings can be cut on a

compound miter saw with the moldings laid flat on

the turn base.

There are two common types of crown moldings

and one type of cove moldings; 52/38° wall angle

crown molding, 45° wall angle crown molding and

45° wall angle cove molding. See illustrations.

1. 52/38 ゚ type

crown molding

52

38

45

45

45

45

2. 45 ゚ type crown

molding

3. 45 ゚ type cove

molding

123

001555

There are crown and cove molding joints which are

made to fit "Inside" 90° corners ((1) and (2) in Fig.

A) and "Outside" 90° corners ((3) and (4) in Fig. A).

1. Inside corner

2. Outside corner

(1) (2) (3) (4)

Fig.A

001556

(1)

(2)

1 2

1

(2)

(1)

(2)

(1)

(4)

(3)

1. Inside corner

(2)

2

(1)

2. Outside corner

(1)

(2)

Measuring

Measure the wall length and adjust workpiece on

table to cut wall contact edge to desired length.

Always make sure that cut workpiece length at the

back of the workpiece is the same as wall length.

Adjust cut length for angle of cut. Always use

several pieces for test cuts to check the saw

angles.

When cutting crown and cove moldings, set the

bevel angle and miter angle as indicated in the

table (A) and position the moldings on the top

surface of the saw base as indicated in the table

(B).

In the case of left bevel cut

Molding

position in

Fig. A

For inside

corner

For outside

corner

006361

For inside

corner

For

outside

corner

006362

(1)

(2)

(3)

(4)

Molding

position in

Fig. A

(1)

(2)

(3)

(4)

Example:

In the case of cutting 52/38° type crown

molding for position (1) in Fig. A:

• Tilt and secure bevel angle setting to

• Adjust and secure miter angle setting to

• Lay crown molding with its broad back

• The finished piece to be used will

Table (A)

Bevel angleMiter angle

52/38° type 45° type

Left 33.9° Left 30°

52/38° type

Right 31.6°

45° type

Right 35.3°

Left 31.6° Left 35.3°

Right 35.3°Right 31.6°

Table (B)

Molding edge against

guide fence

Ceiling contact edge should

be against guide fence.

Wall contact edge should be

against guide fence

Ceiling contact edge should

be against guide fence

.

.

Finished piece

Finished piece

will be on the

Left side of

blade.

Finished piece

will be on the

Right side of

blade.

33.9° LEFT.

31.6° RIGHT.

(hidden) surface down on the turn base

with its CEILING CONTACT EDGE

against the guide fence on the saw.

always be on the LEFT side of the blade

after the cut has been made.

001557

14

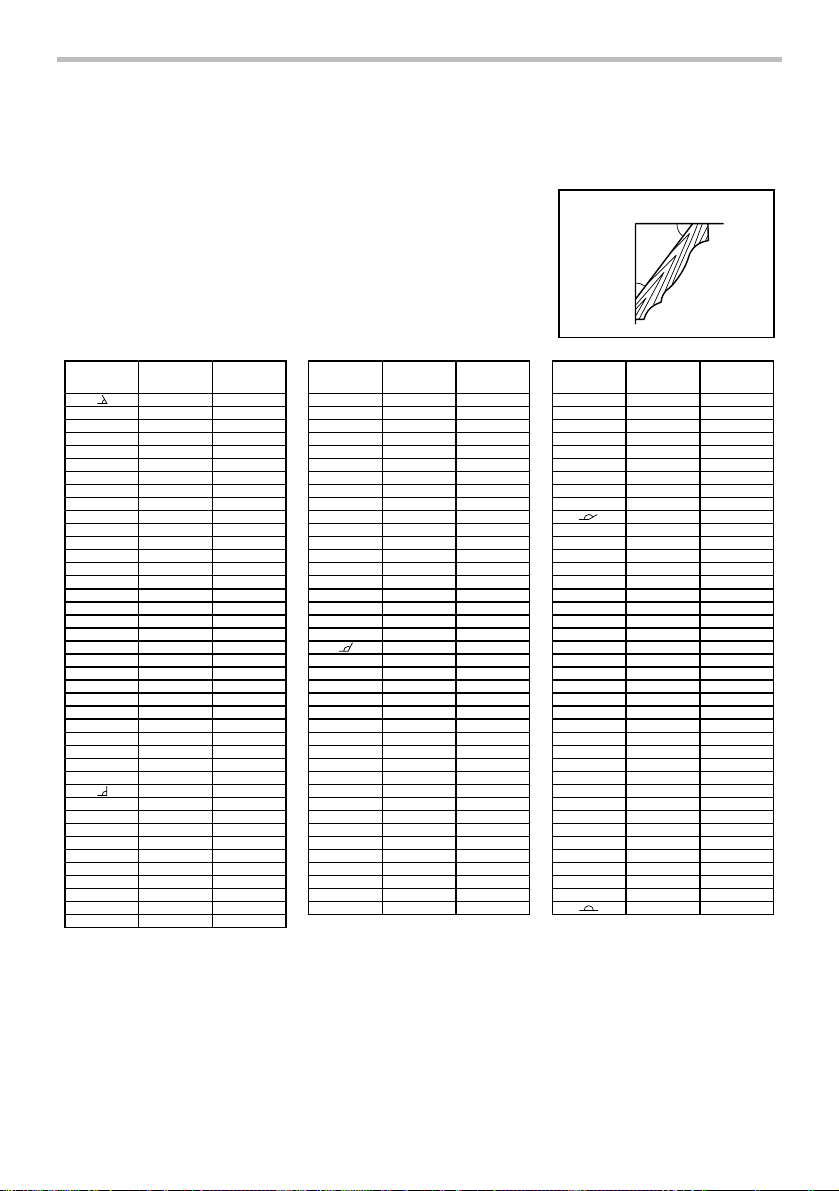

Compound Miter Saw

Miter and Bevel Angle Settings

Ceiling

52°

38°

Wall

Wall to Crown Molding Angle: 52/38 degrees

Wall Angle

(deg.)

EN0002-1

Bevel Angle

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

(deg.)

43.0

42.8

42.5

42.2

41.9

41.7

41.4

41.1

40.8

40.5

40.2

39.9

39.6

39.3

39.0

38.7

38.4

38.1

37.8

37.4

37.1

36.8

36.5

36.2

35.8

35.5

35.2

34.9

34.5

34.2

33.9

33.5

33.2

32.8

32.5

32.2

31.8

31.5

31.1

30.8

30.4

Miter Angle

(deg.)

46.8

46.3

45.7

45.1

44.6

44.0

43.5

42.9

42.4

41.9

41.3

40.8

40.3

39.8

39.2

38.7

38.2

37.7

37.2

36.8

36.3

35.8

35.3

34.8

34.4

33.9

33.4

33.0

32.5

32.1

31.6

31.2

30.7

30.3

29.9

29.4

29.0

28.6

28.2

27.7

27.3

Wall Angle

(deg.)

Bevel Angle

101

102

103

4

10

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

(deg.)

30.1

29.7

29.4

29.0

28.7

28.3

28.0

27.6

27.2

26.9

26.5

26.1

25.8

25.4

25.0

24.7

24.3

23.9

23.6

23.2

22.8

22.5

22.1

21.7

21.3

21.0

20.6

20.2

19.8

19.5

19.1

18.7

18.3

17.9

17.6

17.2

16.8

16.4

16.0

15.6

Miter Angle

(deg.)

26.9

26.5

26.1

25.7

25.3

24.9

24.5

24.1

23.7

23.3

22.9

22.6

22.2

21.8

21.4

21.0

20.7

20.3

19.9

19.6

19.2

18.8

18.5

18.1

17.8

17.4

17.1

16.7

16.4

16.0

15.7

15.3

15.0

14.6

14.3

14.0

13.6

13.3

13.0

12.8

000031

Wall Angle

(deg.)

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

177

178

179

180

Bevel Angle

(deg.)

15.3

14.9

14.5

14.1

13.7

13.3

12.9

12.5

12.2

11.8

11.4

11. 0

10.8

10.2

9.8

9.4

9.0

8.6

8.3

7.9

7.5

7.1

6.7

6.3

5.9

5.5

5.1

4.7

4.3

3.9

3.5

3.2

2.8

2.4

2.0

1.6

1.2

0.8

0.4

0.0

Miter Angle

(deg.)

12.3

12.0

11.6

11.3

11. 0

10.7

10.3

10.0

9.7

9.4

9.0

8.7

8.4

8.1

7.8

7.5

7.1

6.8

6.5

6.2

5.9

5.6

5.3

4.9

4.6

4.3

4.0

3.7

3.4

3.1

2.8

2.5

2.2

1.8

1.5

1.2

0.9

0.6

0.3

0.0

15

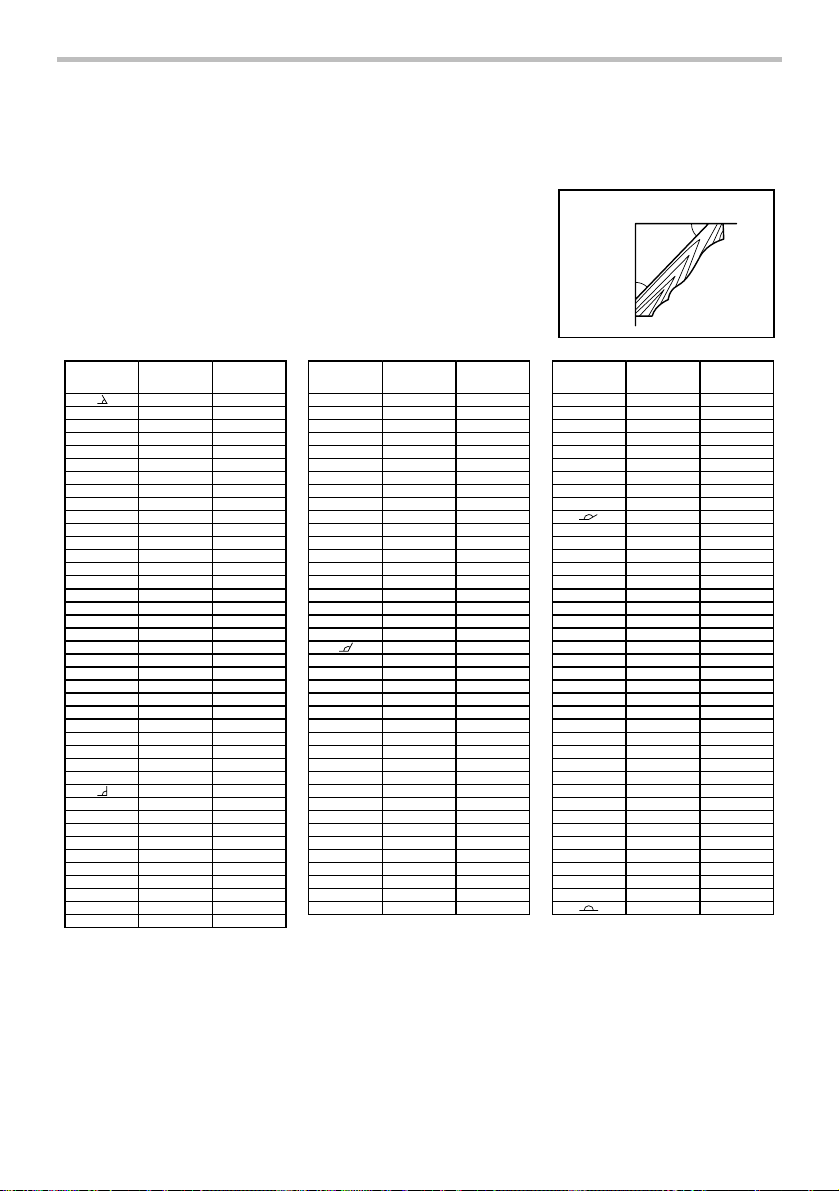

Compound Miter Saw

Miter and Bevel Angle Settings

Ceiling

45°

45°

Wall

Wall to Crown Molding Angle: 45 degrees

Wall Angle

EN0003-1

(deg.)

Bevel Angle

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

(deg.)

37.8

37.5

37.3

37.1

36.8

36.6

36.4

36.1

35.9

35.6

35.4

35.1

34.9

34.6

34.4

34.1

33.9

33.6

33.3

33.1

32.8

32.5

32.3

32.0

31.7

31.4

31.1

30.9

30.6

30.3

30.0

29.7

29.4

29.1

28.8

28.5

28.2

27.9

27.6

27.3

27.0

Miter Angle

(deg.)

50.8

50.2

49.6

49.1

48.5

48.0

47.4

46.9

46.4

45.8

45.3

44.8

44.2

43.7

43.2

42.7

42.1

41.6

41.1

40.6

40.1

39.6

39.1

38.6

38.1

37.7

37.2

36.7

36.2

35.7

35.3

34.8

34.3

33.9

33.4

32.9

32.5

32.0

31.6

31.1

30.7

Wall Angle

(deg.)

101

102

103

104

105

106

107

1

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

Bevel Angle

(deg.)

08

26.7

26.4

26.1

25.8

25.5

25.2

24.9

24.6

24.2

23.9

23.6

23.3

23.0

22.7

22.3

22.0

21.7

21.4

21.0

20.7

20.4

20.0

19.7

19.4

19.1

18.7

18.4

18.1

17.7

17.4

17.1

16.7

16.4

16.0

15.7

15.4

15.0

14.7

14.3

14.0

Miter Angle

(deg.)

30.2

29.8

29.4

28.9

28.5

28.1

27.6

27.2

26.8

26.3

25.9

25.5

25.1

24.7

24.3

23.8

23.4

23.0

22.6

22.2

21.8

21.4

21.0

20.6

20.2

19.8

19.4

19.0

18.6

18.2

17.9

17.5

17.1

16.7

16.3

15.9

15.6

15.2

14.8

14.4

000032

Wall Angle

(deg.)

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

1

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

177

178

179

180

Bevel Angle

(deg.)

58

13.7

13.3

13.0

12.6

12.3

11. 9

11. 6

11. 2

10.9

10.5

10.2

9.8

9.5

9.2

8.8

8.5

8.1

7.8

7.4

7.1

6.7

6.4

6.0

5.6

5.3

4.9

4.6

4.2

3.9

3.5

3.2

2.8

2.5

2.1

1.8

1.4

1.1

0.7

0.4

0.0

Miter Angle

(deg.)

14.1

13.7

13.3

12.9

12.6

12.2

11. 8

11. 5

11. 1

10.7

10.4

10.0

9.6

9.3

8.9

8.5

8.2

7.8

7.5

7.1

6.7

6.4

6.0

5.7

5.3

5.0

4.6

4.3

3.9

3.5

3.2

2.8

2.5

2.1

1.8

1.4

1.1

0.7

0.4

0.0

16

7. Cutting aluminum extrusion

1. Guide fence

2. Vise

3. Spacer block

2

4. Aluminum

extrusion

5. Spacer block

1. Aluminum

extrusion

2. Guide fence

3. Spacer block

4. Horizontal vise

(optional

accessory)

010404

010469

3

4

1

1

2

5

3

4

When securing aluminum extrusions, use spacer

blocks or pieces of scrap as shown in the figure to

prevent deformation of the aluminum. Use a cutting

lubricant when cutting the aluminum extrusion to

prevent build-up of the aluminum material on the

blade.

CAUTION:

• Never attempt to cut thick or round aluminum

extrusions. Thick aluminum extrusions may come

loose during operation and round aluminum

extrusions cannot be secured firmly with this tool.

8. Wood facing

Use of wood facing helps to assure splinter-free

cuts in workpieces. Attach a wood facing to the

guide fence using the holes in the guide fence.

See the figure concerning the dimensions for a

suggested wood facing.

screw heads are below the surface of the wood

facing.

• When the wood facing is attached, do not turn the

turn base with the handle lowered. The blade

and/or the wood facing will be damaged.

9. Groove cutting

1

001563

1. Cut grooves with

blade

A dado type cut can be made by proceeding as

follows:

Adjust the lower limit position of the blade using the

adjusting screw and the stopper arm to limit the

cutting depth of the blade. Refer to "Stopper arm"

section described previously.

After adjusting the lower limit position of the blade,

cut parallel grooves across the width of the

workpiece using a slide (push) cut as shown in the

figure. Then remove the workpiece material

between the grooves with a chisel. Do not attempt

to perform this type of cut using wide (thick) blades

or with a dado blade. Possible loss of control and

injury may result.

CAUTION:

• Be sure to return the stopper arm to the original

position when performing other than groove cutting.

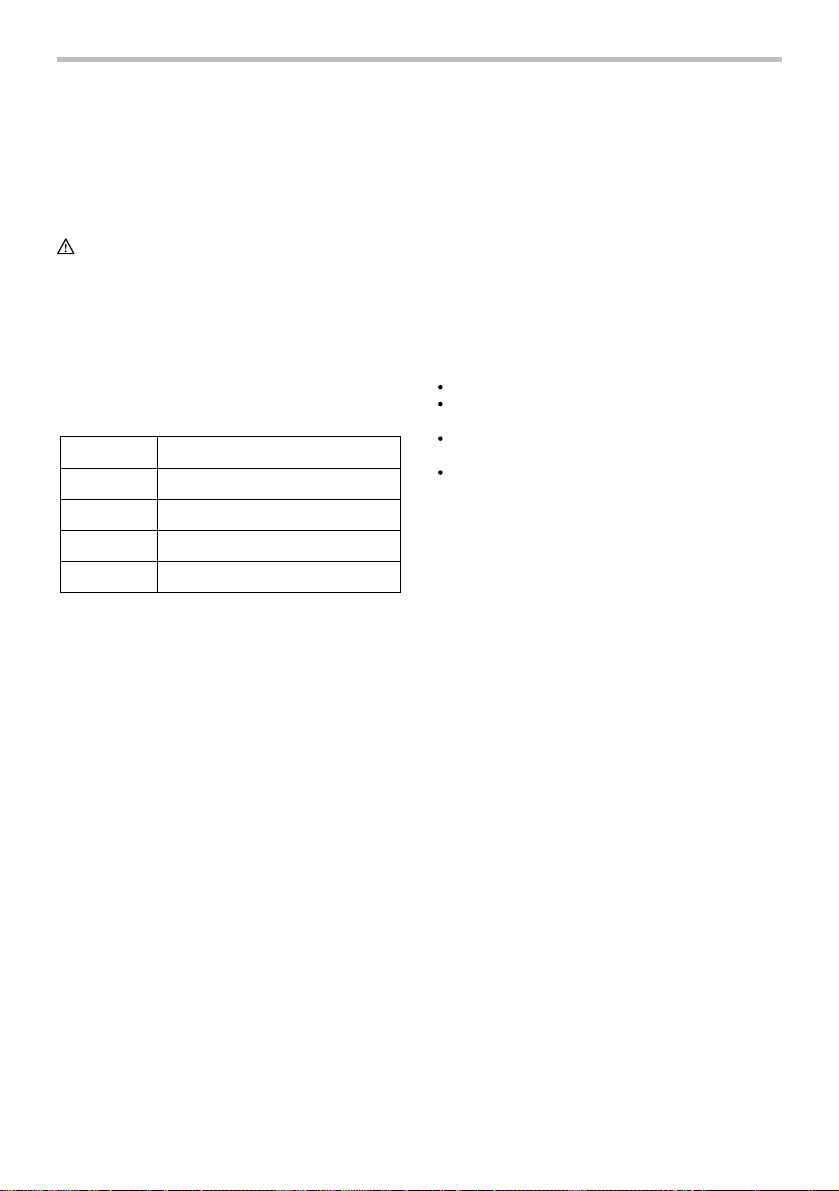

Carrying tool

15mm (9/16") Over 500 mm (19-3/4")

80mm-90mm

(3-1/8"-3-1/2")

1

1. Holes

010535

68mm

(2-11/16")

121mm

(4-3/4")

121mm

(4-3/4")

68mm

(2-11/16")

24 mm (15/16")

1

CAUTION:

• Use straight wood of even thickness as the wood

facing.

• Use screws to attach the wood facing to the guide

fence. The screws should be installed so that the

010397

Make sure that the tool is unplugged. Secure the blade at

0° bevel angle and the turn base at right miter angle fully.

Secure the slide poles after pulling the carriage toward

you fully. Lower the handle fully and lock it in the lowered

position by pushing in the stopper pin.

Wind the power supply cord using the cord rests.

Carry the tool by holding the tool base as shown in the

figure. If you remove the holders, dust bag, etc., you can

carry the tool more easily.

17

Carry the tool by holding both sides of the tool base as

shown in the figure. If you remove the holders, dust bag,

etc., you can carry the tool more easily.

CAUTION:

• Always secure all moving portions before carrying

the tool.

• Stopper pin is for carrying and storage purposes

only and not for any cutting operations.

MAINTENANCE

CAUTION:

• Always be sure that the tool is switched off and

unplugged before attempting to perform inspection

or maintenance.

WARNING:

• Always be sure that the blade is sharp and clean for

the best and safest performance.

NOTICE:

• Never use gasoline, benzine, thinner, alcohol or the

like. Discoloration, deformation or cracks may

result.

Adjusting the cutting angle

This tool is carefully adjusted and aligned at the factory,

but rough handling may have affected the alignment. If

your tool is not aligned properly, perform the following:

1. Miter angle

1

3

2

010251

Push the carriage toward the guide fence and

tighten the locking screw to secure the carriage.

Loosen the grip which secures the turn base. Turn

the turn base so that the pointer points to 0° on the

miter scale. Then turn the turn base slightly

clockwise and counterclockwise to seat the turn

base in the 0° miter notch. (Leave as it is if the

pointer does not point to 0°.) Loosen the hex

sockets bolts securing the guide fence using the

socket wrench.

1. Guide fence

2. Hex bolts

3. Grip

1. Guide fence

2. Triangular rule

2

010398

1

Lower the handle fully and lock it in the lowered

position by pushing in the stopper pin. Square the

side of the blade with the face of the guide fence

using a triangular rule, try-square, etc. Then

securely tighten the hex socket bolts on the guide

fence in the order from the right side.

1. Screw

2. Pointer

1

3. Miter scale

2

3

010432

Make sure that the pointer points to 0° on the miter

scale. If the pointer does not point to 0°, loosen the

screw which secures the pointer and adjust the

pointer so that it will point to 0°.

2. Bevel angle

(1) 0° bevel angle

1. Lever

2. Arm

1

2

010260

Push the carriage toward the guide fence and

tighten the locking screw to secure the

carriage. Lower the handle fully and lock it in

the lowered position by pushing in the stopper

pin. Loosen the lever at the rear of the tool.

18

010482

1. 0 ゚ adjusting

bolt

2. Left 45 ゚ bevel

angle adjusting

1

2

bolt

Turn the hex bolt on the right side of the arm

two or three revolutions counterclockwise to

tilt the blade to the right.

1

2

3

1. Triangular rule

2. Saw blade

3. Top surface of

turn base

Adjust the 45° bevel angle only after

performing 0° bevel angle adjustment. To

adjust left 45° bevel angle, loosen the lever

and tilt the blade to the left fully. Make sure

that the pointer on the arm points to 45° on

the bevel scale on the arm holder. If the

pointer does not point to 45°, turn the 45°

bevel angle adjusting bolt on the right side of

the arm holder until the pointer points to 45°.

To adjust the right 5° bevel angle, perform

the same procedure as that described above.

Replacing carbon brushes

001819

010261

010483

Carefully square the side of the blade with the

top surface of the turn base using the

triangular rule, try-square, etc. by turning the

hex bolt on the right side of the arm clockwise.

Then tighten the lever securely.

1

2

3

Make sure that the pointer on the arm point to

0° on the bevel scale on the arm holder. If

they do not point to 0°, loosen the screw

which secure the pointer and adjust it so that

it will point to 0°.

(2) 45° bevel angle

1

1. Screw

2. Pointer

3. Bevel scale

007834

Remove and check the carbon brushes regularly.

Replace when they wear down to 3 mm in length. Keep

the carbon brushes clean and free to slip in the holders.

Both carbon brushes should be replaced at the same

time. Use only identical carbon brushes.

Use a screwdriver to remove the brush holder caps. Take

out the worn carbon brushes, insert the new ones and

secure the brush holder caps.

1

1. Screwdriver

2. Brush holder

cap

2

010256

After replacing brushes, plug in the tool and break in

brushes by running tool with no load for about 10 minutes.

Then check the tool while running and electric brake

operation when releasing the switch trigger. If electric

1. Right 5 ゚ bevel

angle adjusting

bolt

2. Left 45 ゚ bevel

angle adjusting

bolt

2

brake is not working well, ask your local Makita service

center for repair.

After use

• After use, wipe off chips and dust adhering to the

tool with a cloth or the like. Keep the blade guard

clean according to the directions in the previously

covered section titled "Blade guard". Lubricate the

sliding portions with machine oil to prevent rust.

• When storing the tool, pull the carriage toward you

fully.

19

To maintain product SAFETY and RELIABILITY, repairs,

any other maintenance or adjustment should be

performed by Makita Authorized or Factory Service

Centers, always using Makita replacement parts.

ACCESSORIES

CAUTION:

• These accessories or attachments are

recommended for use with your Makita tool

specified in this manual. The use of any other

accessories or attachments might present a risk of

injury to persons. Only use accessory or

attachment for its stated purpose.

If you need any assistance for more details regarding

these accessories, ask your local Makita Service Center.

• Steel & Carbide-tipped saw blades

Miter saw blades

Combination

Crosscutting

Fine cross cutsFor sand-free cuts cleanly against

Non-ferrous metals

miter saw blades

006526

Vise assembly (Horizontal vise)

•

• Ve rtical vise

• Socket wrench with hex wrench on its other end

• Holder

• Dust bag

• Elbow

• Triangular rule

For smooth and precise cutting in various materials.

General purpose blade for fast and smooth rip,

crosscuts and miters.

For smoother cross grain cuts. Slices cleanly

against the grain.

the grain.

For miters in aluminum, copper, brass, tubing,

and other non-ferrous metals.

MAKITA LIMITED ONE YEAR WARRANTY

Warranty Policy

Every Makita tool is thoroughly inspected and tested

before leaving the factory. It is warranted to be free of

defects from workmanship and materials for the period

of ONE YEAR from the date of original purchase.

Should any trouble develop during this one year period,

return the COMPLETE tool, freight prepaid, to one of

Makita’s Factory or Authorized Service Centers. If

inspection shows the trouble is caused by defective

workmanship or material, Makita will repair (or at our

option, replace) without charge.

This Warranty does not apply where:

repairs have been made or attempted by others:

repairs are required because of normal wear and

tear:

the tool has been abused, misused or improperly

maintained:

alterations have been made to the tool.

IN NO EVENT SHALL MAKITA BE LIABLE FOR ANY

INDIRECT, INCIDENTAL OR CONSEQUENTIAL

DAMAGES FROM THE SALE OR USE OF THE

PRODUCT. THIS DISCLAIMER APPLIES BOTH

DURING AND AFTER THE TERM OF THIS

WARRANTY.

MAKITA DISCLAIMS LIABILITY FOR ANY IMPLIED

WARRANTIES, INCLUDING IMPLIED WARRANTIES

OF "MERCHANTABILITY" AND "FITNESS FOR A

SPECIFIC PURPOSE," AFTER THE ONE YEAR TERM

OF THIS WARRANTY.

This Warranty gives you specific legal rights, and you

may also have other rights which vary from state to

state. Some states do not allow the exclusion or

limitation of incidental or consequential damages, so

the above limitation or exclusion may not apply to you.

Some states do not allow limitation on how long an

implied warranty lasts, so the above limitation may not

apply to you.

EN0006-1

20

FRANÇAIS (Mode d’emploi original)

SPÉCIFICATIONS

Modèle LS1017 /LS1017L

Diamètre de la lame 255 mm (10")

Diamètre de l'orifice 15,88 mm (5/8")

Capacités de coupe maximales (H x P)

Angle de coupe d'onglet

0°

45°

60° (droite)

Vitesse à vide (T/MIN) 4 200/min.

Type de laser (LS1017L uniquement) Longueur d'ondes 660 nm, sortie maximale 1mW (Laser Classe II)

Dimensions (L x P x H) 825 mm x 536 mm x 581 mm

(32-1/2" x 21-1/8" x 22-7/8")

Poids net 19,4 kg (42,8 lbs)

• Étant donné l'évolution constante de notre programme de recherche et de développement, les spécifications contenues dans ce

manuel sont sujettes à modification sans préavis.

• Les spécifications peuvent varier suivant les pays.

• Poids conforme à la procédure EPTA du 01/2003

45° (gauche) 0°

50 mm x 305 mm 91 mm x 305 mm

(2" x 12") (3-5/8" x 12")

(gauche) 50 mm x 200 mm

(2" x 7-7/8") 91 mm x 215 mm

(droite) 50 mm x 215 mm (3-5/8" x 8-1/2")

(2" x 8-1/2")

USA007-2

Pour votre propre sécurité,

veuillez lire le manuel

d'instructions

Avant d'utiliser l'outil

Conservez-le pour référence

ultérieure

PRÉCAUTIONS GÉNÉRALES

(POUR TOUS LES OUTILS)

1. VOUS DEVEZ CONNAÎTRE VOTRE OUTIL

ÉLECTRIQUE. Lisez attentivement le manuel

d'instructions. Familiarisez-vous avec les

applications et limites de l'outil, ainsi qu'avec

les risques potentiels qui lui sont spécifiques.

2. MAINTENEZ LES PROTECTEURS EN PLACE

et en bon état de fonctionnement.

3. RETIREZ LES CLÉS DE RÉGLAGE ET DE

SERRAGE. Prenez l'habitude de vous assurer

que les clés de réglage et de serrage ont été

Angle de coupe en biseau

- 91 mm x 150 mm

(3-5/8" x 5-7/8")

retirées de l'outil avant de le mettre sous

tension.

4. MAINTENEZ LA ZONE DE TRAVAIL PROPRE.

Les zones de travail et les établis encombrés

ouvrent grande la porte aux accidents.

5. ÉVITEZ L'UTILISATION DANS UN

ENVIRONNEMENT DANGEREUX. N'utilisez

pas les outils électriques dans les endroits

humides ou mouillés, et ne les exposez pas à

la pluie. Maintenez un éclairage adéquat dans

la zone de travail. Ne vous servez pas de votre

outil en présence de liquides ou gaz

inflammables.

6. MAINTENEZ LES ENFANTS À L'ÉCART. Toute

autre personne que l'utilisateur de l'outil doit

se tenir à une distance sûre de l'aire de travail.

7. FAITES EN SORTE QUE L'ATELIER SOIT

SANS DANGER POUR LES ENFANTS, en y

posant des cadenas, un interrupteur principal,

ou en retirant des équipements leurs clés de

démarrage.

8. NE FORCEZ PAS L'OUTIL. Il effectuera un

travail de meilleure qualité et plus sécuritaire

s'il est utilisé au régime pour lequel il a été

conçu.

21

Loading...

Loading...