Page 1

GB

LS1016

LS1016L

LS1016F

LS1016FL

Slide Compound Miter Saw Instruction Manual

F

Scie à Onglet Radiale Manuel d’instructions

D

Kapp- und Gehrungssäge Betriebsanleitung

I

Sega combinata a slitta Istruzioni per l’uso

NL

Schuifbare afkortverstekzaag Gebruiksaanwijzing

E

Sierra de Inglete Telescópica Manual de instrucciones

P

Serra de Esquadria c/ Braço Telescópico Manual de instruções

DK

Afkorter-geringssav Brugsanvisning

∆ισκοπρίονο σύνθετησ λοξοτοµήσ µήκουσ

GR

ολίσθησησ

Οδηγίεσ χρήσεωσ

Page 2

12

2

2

2

5

6

4

7

8

9

4

3

3

1

34

5

6

2

Page 3

7

10

21

22

20

19

14

17

16

18

12

13

14

15

10

90

8

910

11 12

3

Page 4

13 14

31

92

91

23

24

25

26

24

27

29

30

28

28

29

23

30

10

90

15 16

17 18

19 20

4

Page 5

21 22

AB

33

32

34

32

2

3

37

37

36

5

35

36

2

19

1

23 24

25 26

27 28

2

38

5

41

40

39

5

Page 6

m

53

54

93

23

52

50 51

45

46

47

44

43

42

45

48

48

45

49

2

29 30

31 32

33 34

35 36

6

Page 7

37 38

55

56

57

11

60

11

10

90

58

59

55

39 40

41 42

43 44

7

Page 8

45 46

18

70

68

69

51

66

67

51

64

65

(1)

(2)

(1)

(2)

(2)

(1)

(2)

(1)

(1)

(2)

(3)

(4)

64 65

(1)(2) (3)(4)

61 62

63

52

38

45

45

45

45

18

71

72

73

72

47 48

49 50

51 52

8

Page 9

53 54

75

5

16

78

23

24

27

23

77

11

27

76

75

1

74

55 56

57 58

59 60

9

Page 10

61 62

85

89

88

87

85

86

87

84

82

83

27

79

80

81

77

27

63 64

65 66

67 68

10

Page 11

Symbols

The followings show the symbols used for the equipment. Be sure that you understand their meaning before use.

Symboles

Nous donnons ci-dessous les symboles utilisés pour l’outil. Assurez-vous que vous en avez bien compris la

signification avant d’utiliser l’outil.

Symbole

Die folgenden Symbole werden für die Maschine verwendet. Machen Sie sich vor der Benutzung unbedingt mit ihrer

Bedeutung vertraut.

Symboli

Per questo utensile vengono usati i simboli seguenti. Bisogna capire il loro significato prima di usare l’utensile.

Symbolen

Voor dit gereedschap worden de volgende symbolen gebruikt. Zorg ervoor dat u de betekenis van deze symbolen

begrijpt alvorens het gereedschap te gebruiken.

Símbolos

A continuación se muestran los símbolos utilizados con esta herramienta. Asegúrese de que entiende su significado

antes de usarla.

Símbolos

O seguinte mostra os símbolos utilizados para a ferramenta. Certifique-se de que compreende o seu significado antes

da utilização.

Symboler

Nedenstående symboler er anvendt i forbindelse med denne maskine. Vær sikker på, at De har forstået symbolernes

betydning, før maskinen anvendes.

Σύµβολα

Τα ακλουθα δείχνουν τα σύμβολα που χρησιμοποιούνται για το μηχάνημα. Βεβαιωθείτε τι καταλαβαίνετε

τη σημασία τους πριν απ τη χρήση.

• Read instruction manual. • Lea el manual de instrucciones.

• Lire le mode d’emploi. • Leia o manual de instruções.

• Bitte Bedienungsanleitung lesen. • Læs brugsanvisningen.

• Leggete il manuale di istruzioni. • Διαβάστε τις οδηγίες χρήσης.

• Lees de gebruiksaanwijzing.

•

• DOUBLE INSULATION • DOBLE AISLAMIENTO

• DOUBLE ISOLATION • DUPLO ISOLAMENTO

• DOPPELT SCHUTZISOLIERT • DOBBELT ISOLERET

• DOPPIO ISOLAMENTO •ΔΙΠΛΗ ΜΟΝΩΣΗ

• DUBBELE ISOLATIE

• To avoid injury from flying debris, keep holding the saw head down, after making cuts, until the

blade has come to a complete stop.

• Pour éviter les blessures causées par les objets projetés, maintenez la tête de la scie en position basse une fois la coupe terminée, jusqu’à ce que la lame soit complètement arrêtée.

• Um Verletzungen durch herausgeschleuderte Teile zu vermeiden, halten Sie den Sägekopf

nach Ausführung von Schnitten abgesenkt, bis das Sägeblatt völlig zum Stillstand gekommen

ist.

• Per evitare lesioni dalle schegge volanti, dopo aver eseguito il taglio tenere abbassata la testa

sega finché la lama non si è arrestata completamente.

• Om verwonding door weggeslingerd zaagafval te voorkomen, dient u na het voltooien van een

snede de zaagkop omlaag te houden totdat het zaagblad volledig tot stilstand is gekomen.

• Para evitar sufrir heridas a causa de restos que salen despedidos, siga sujetando la cabeza de

la sierra hacia abajo, al terminar los cortes, hasta que el disco se haya parado completamente.

• Para evitar danos causados por aparas que saltem, mantenha a cabeça da serra para baixo,

depois de terminar os cortes, até que a lâmina esteja completamente parada.

• For at undgå at komme til skade på grund af flyvende affald, skal man holde savhovedet nede

efter skæring, indtil savklingen står helt stille.

• Για να αποφύγετε τραυματισμ απ ιπτάμενα τεμαχίδια, κρατάτε το πρινι με το

κεφάλι προς τα κάτω, αφού κάνετε κοπές, μέχρι η λάμα να σταματήσει τελείως.

11

Page 12

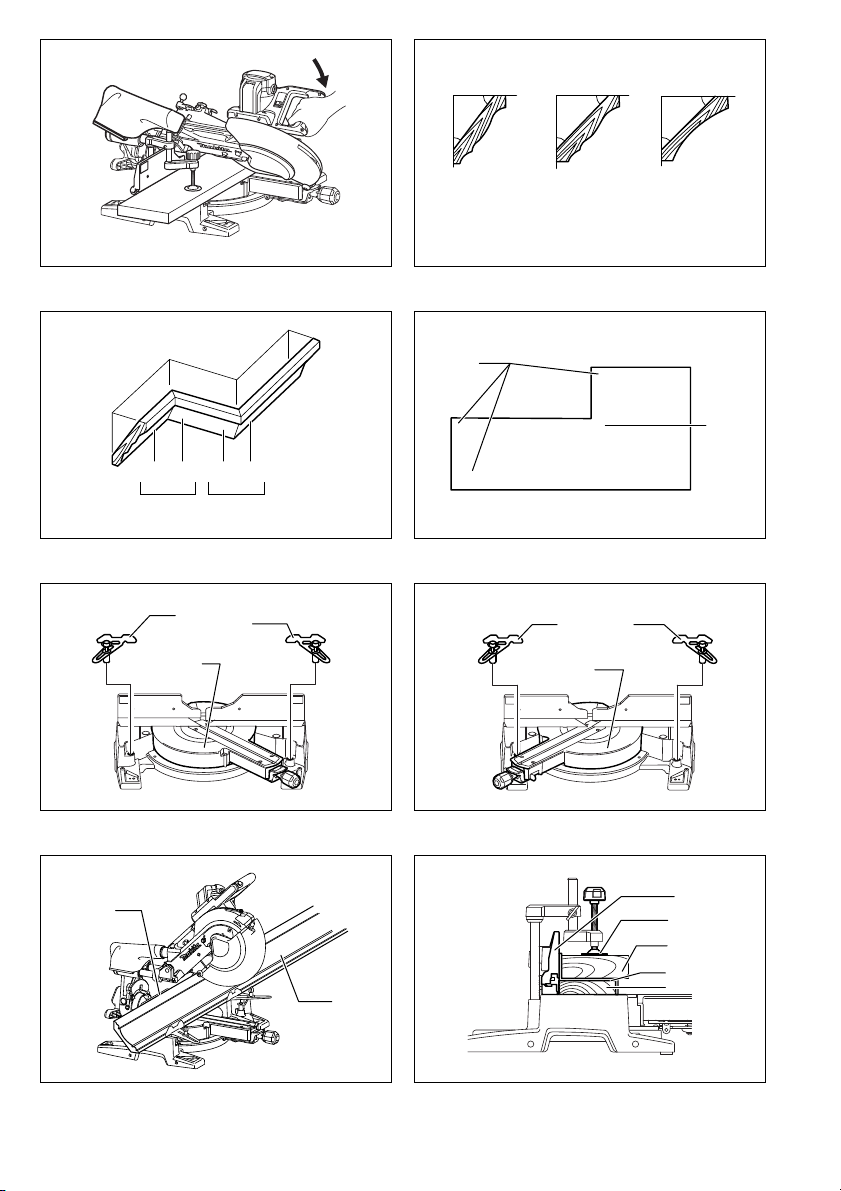

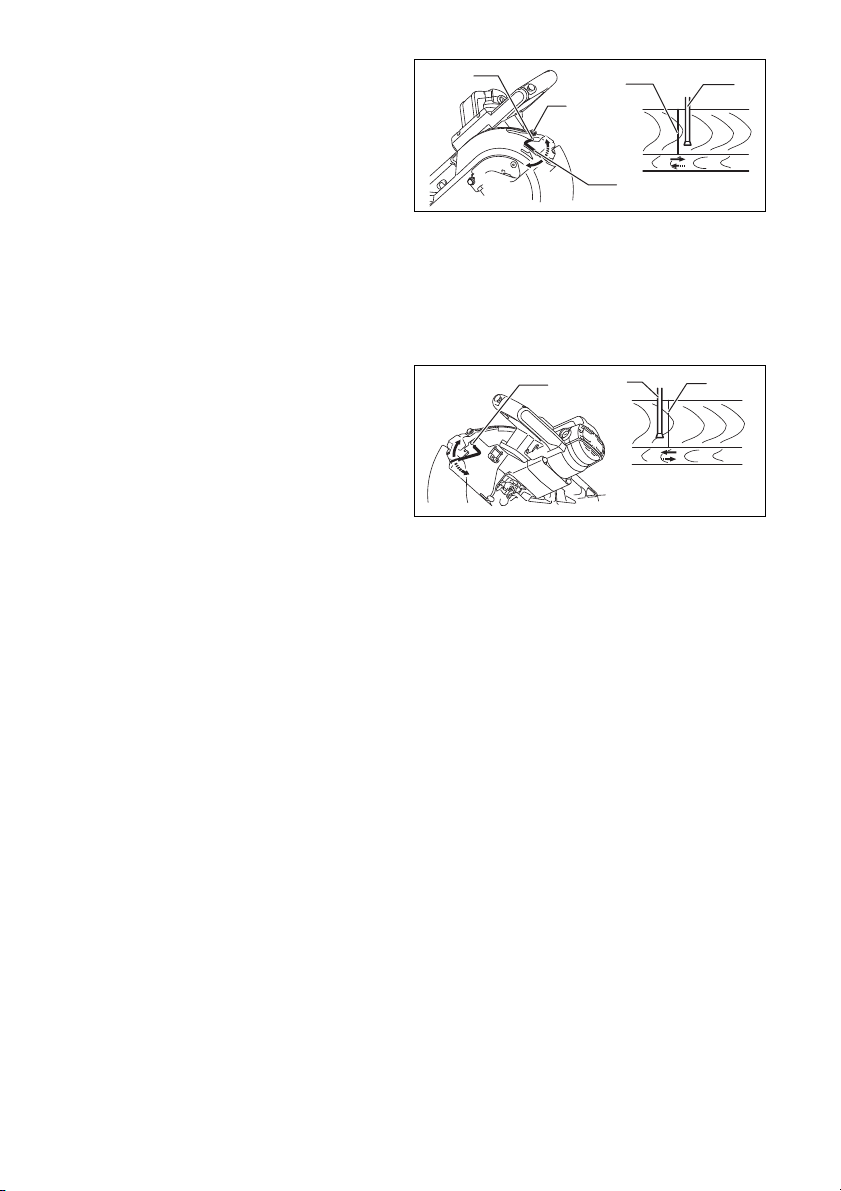

• When performing slide cut, first pull carriage fully and press down handle, then push carriage

1

2

3

toward the guide fence.

• Lorsque vous effectuez une coupe en glissière, tirez d’abord complètement le chariot et abaissez la poignée, puis poussez le chariot vers le guide.

• Ziehen Sie den Schlitten zur Ausführung von Schiebeschnitten zunächst ganz vor, drücken Sie

den Griff nach unten, und schieben Sie dann den Schlitten zum Gehrungsanschlag.

• Per eseguire un taglio di scorrimento, tirare prima completamente il carrello, premere giù il

manico e spingere poi il carrello verso la guida pezzo.

• Bij drukkend (glijdend) zagen, dient u eerst de slede volledig naar u toe te trekken en het handvat omlaag te drukken. Duw daarna de slede naar de geleider toe.

• Cuando haga cortes de deslizamiento, primero tire del carro completamente y presione hacia

abajo la empuñadura, después empuje el carro hacia la guía lateral.

• Quando executa corte corrediço, puxe primeiro o carro completamente e empurre a pega para

baixo e em seguida empurre o carro na direcção da placa guia.

• Når man udfører savning ved gliden, skal man først trække slæden helt og trykke håndtaget

ned og derefter trykke slæden mod anslaget.

• Οταν εκτελείτε ολισθητική κοπή, πρώτα τραβήχτε την κινητή βάση πλήρως και

πατήστε την λαβή κάτω, μετά σπρώχτε την κινητή βάση προς τον φράχτη οδηγ.

• Do not place hand or fingers close to the blade.

• Ne pas placer les mains ou les doigts près de la lame.

• Halten Sie Hände oder Finger vom Sägeblatt fern.

• Non avvicinare le mani o le dita alla lama.

• Kom met uw handen of vingers niet te dicht bij het zaagblad.

• No ponga la mano ni los dedos cerca del disco.

• Não coloque a sua mão ou dedos perto da lâmina.

• Hold hænder og fingre på god afstand af klingen.

• Μη βάζετε το χέρι ή τα δάκτυλα κοντά στην λάμα.

12

• Never look into the laser beam. Direct laser beam may injure your eyes.

• Ne jamais regarder directement la source du faisceau laser. L’exposition directe au faisceau

laser comporte un risque de blessure aux yeux.

• Blicken Sie auf keinen Fall in den Laserstrahl. Der direkte Laserstrahl kann Ihre Augen verletzen.

• Mai guardare direttamente il raggio laser. Il raggio laser può danneggiare gli occhi.

• Kijk nooit in de laserstraal. Een directe laserstraal kan oogletsel veroorzaken.

• No mire nunca directamente al rayo láser. El rayo láser directo puede dañar sus ojos.

• Nunca olhe para o raio laser. Se olhar directamente para o raio laser pode ferir os seus olhos.

• Se aldrig ind i laserstrålen. Direkte udsættelse for laserstråling kan skade dit syn.

• Ποτέ μη κυττάτε απευθείας την ακτίνα λέιζερ. Η απευθείας ακτίνα λέιζερ μπορεί να

προκαλέσει τραυματισμ στα μάτια σας.

Page 13

• Only for EU countries

Do not dispose of electric equipment together with household waste material!

In observance of European Directive 2002/96/EC on waste electrical and electronic equipment and its

implementation in accordance with national law, electric equipment that have reached the end of their

life must be collected separately and returned to an environmentally compatible recycling facility.

• Pour les pays européens uniquement

Ne pas jeter les équipements électriques dans les ordures ménagères !

Conformément à la directive européenne 2002/96/EG relative aux déchets d’équipements électriques

ou électroniques (DEEE), et à sa transposition dans la législation nationale, les équipements électriques doivent être collectés à part et être soumis à un recyclage respectueux de l’environnement.

• Nur für EU-Länder

Werfen Sie Elektrogeräte nicht in den Hausmüll!

Gemäß Europäischer Richtlinie 2002/96/EG über Elektro- und Elektronik-Altgeräte und Umsetzung in

nationales Recht müssen verbrauchte Elektrogeräte getrennt gesammelt und einer umweltgerechten

Wiederverwertung zugeführt werden.

• Solo per Paesi UE

Non gettare le apparecchiature elettriche tra i rifiuti domestici.

Secondo la Direttiva Europea 2002/96/CE sui rifiuti di apparecchiature elettriche ed elettroniche e la

sua attuazione in conformità alle norme nazionali, le apparecchiature elettriche esauste devono

essere raccolte separatamente, al fine di essere riciclate in modo eco-compatibile.

• Alleen voor EU-landen

Geef elektrische apparaten niet met het huisvuil mee!

Volgens de Europese richtlijn 2002/96/EG inzake oude elektrische en elektronische apparaten en de

toepassing daarvan binnen de nationale wetgeving, dient gebruikt elektrische apparaten gescheiden te

worden ingezameld en te worden afgevoerd naar een recycle bedrijf dat voldoet aan de geldende

milieu-eisen.

• Sólo para países de la Unión Europea

¡No deseche los aparatos eléctricos junto con los residuos domésticos!

De conformidad con la Directiva Europea 2002/96/CE sobre residuos de aparatos eléctricos y elec-

trónicos y su aplicación de acuerdo con la legislación nacional, los aparatos eléctricos cuya vida útil

haya llegado a su fin se deberán recoger por separado y trasladar a una planta de reciclaje que cumpla

con las exigencias ecológicas.

• Apenas para países da UE

Não deite ferramentas eléctricas no lixo doméstico!

De acordo com a directiva europeia 2002/96/CE sobre ferramentas eléctricas e electrónicas usadas e

a sua aplicação para as leis nacionais, as ferramentas eléctricas usadas deven ser recolhidas em separado e encaminhadas a uma instalação de reciclagem dos materiais ecológicos.

• Kun for EU-lande

Elværktøj må ikke bortskaffes som almindeligt affald!

I henhold til det europæiske direktiv 2002/96/EF om bortskaffelse af elektriske og elektroniske produk-

ter og gældende national lovgivning skal brugt elværktøj indsamles separat og returneres til miljøgodkendt genindvinding.

• Μνο για τις χώρες της ΕΕ

Μη πετάτε τα είδη ηλεκτρικού εξοπλισμού μαζί με τα οικιακά απορρίμματα.

Σε τήρηση της Eυρωπαϊκής Oδηγίας 2002/96/ΕΚ, περί απορριμμάτων ειδών ηλεκτρικού και

ηλεκτρονικού εξοπλισμού και την εφαρμογή της σύμφωνα με την εθνική νομοθεσία, τα είδη

ηλεκτρικού εξοπλισμού που έχουν φθάσει στο τέλος της ζωής τους πρέπει να συλλέγονται

ξεχωριστά και να επιστρέφονται σε μιά περιβαλλοντικά συμβατή εγκατάσταση ανακύκλωσης.

13

Page 14

ENGLISH (Original instructions)

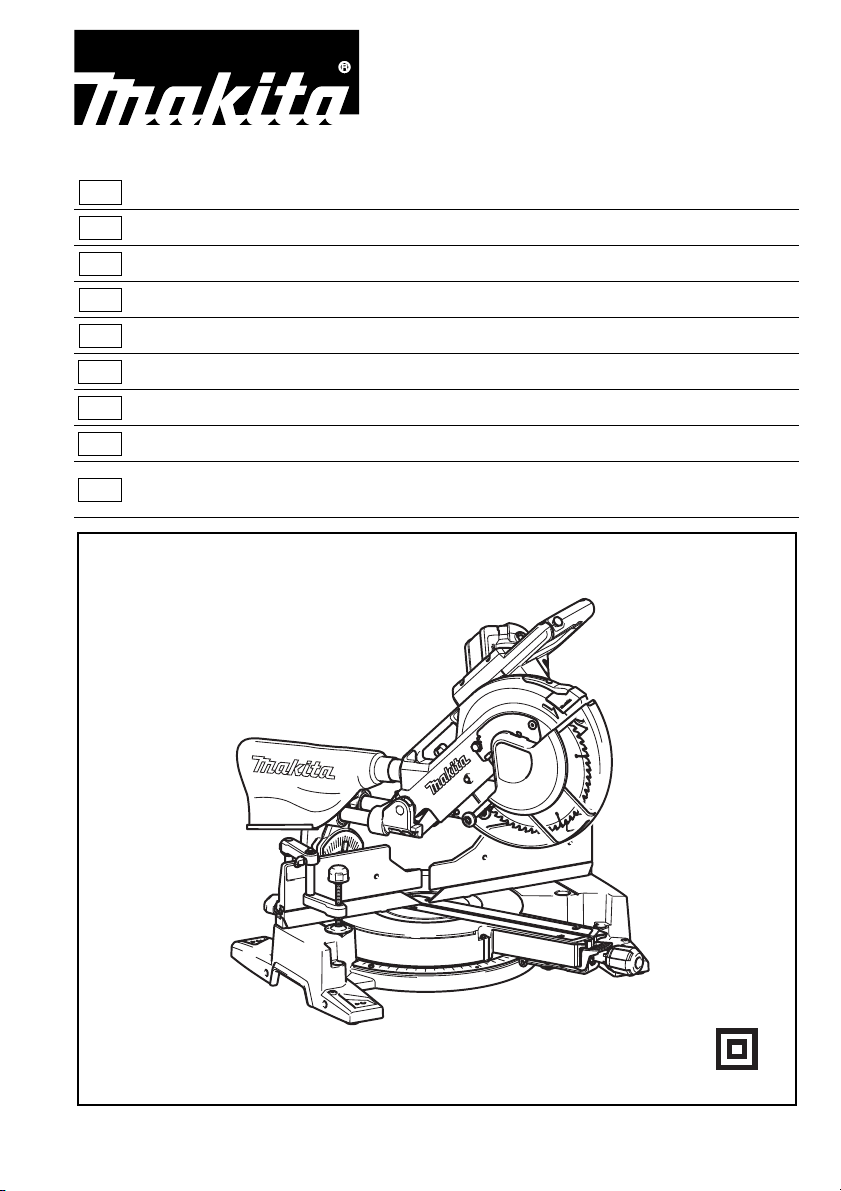

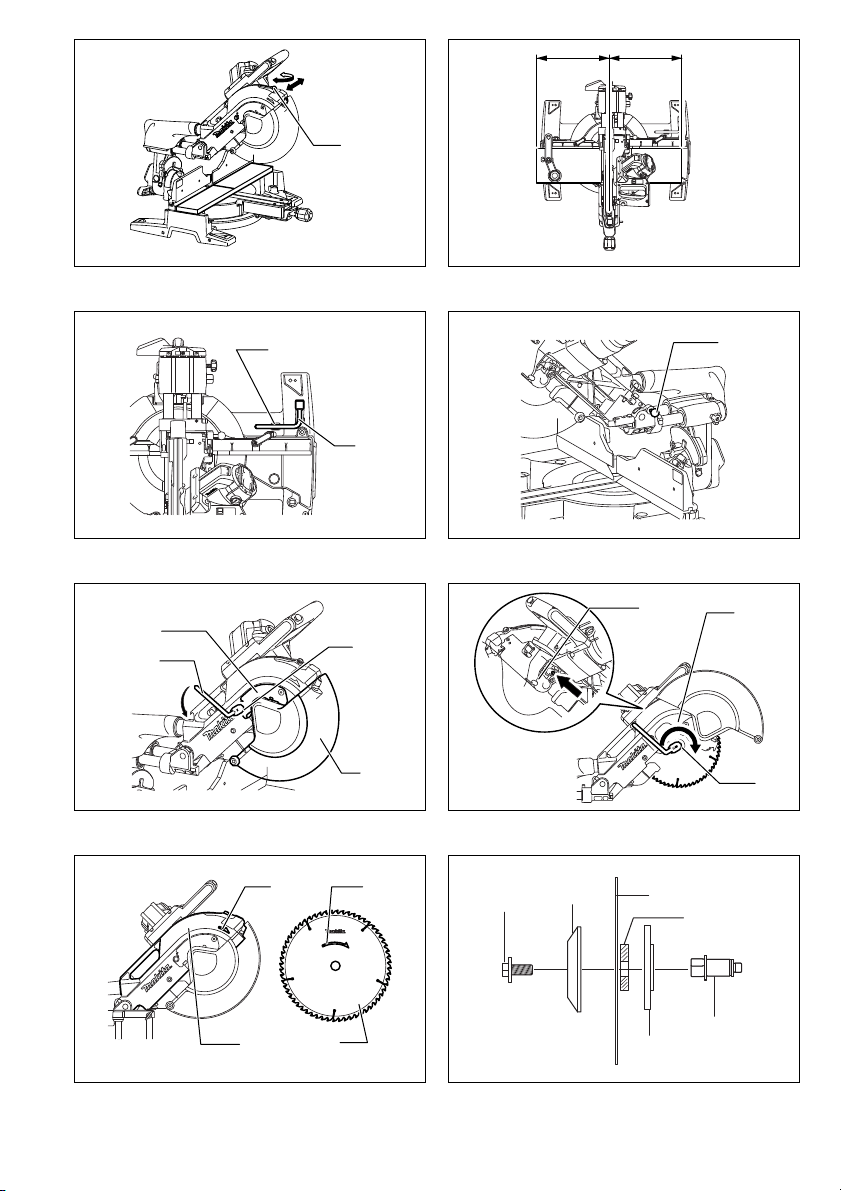

1 Stopper pin

2Hex bolt(s)

3 Blade guard

4 Kerf board

5 Saw blade

6 Blade teeth

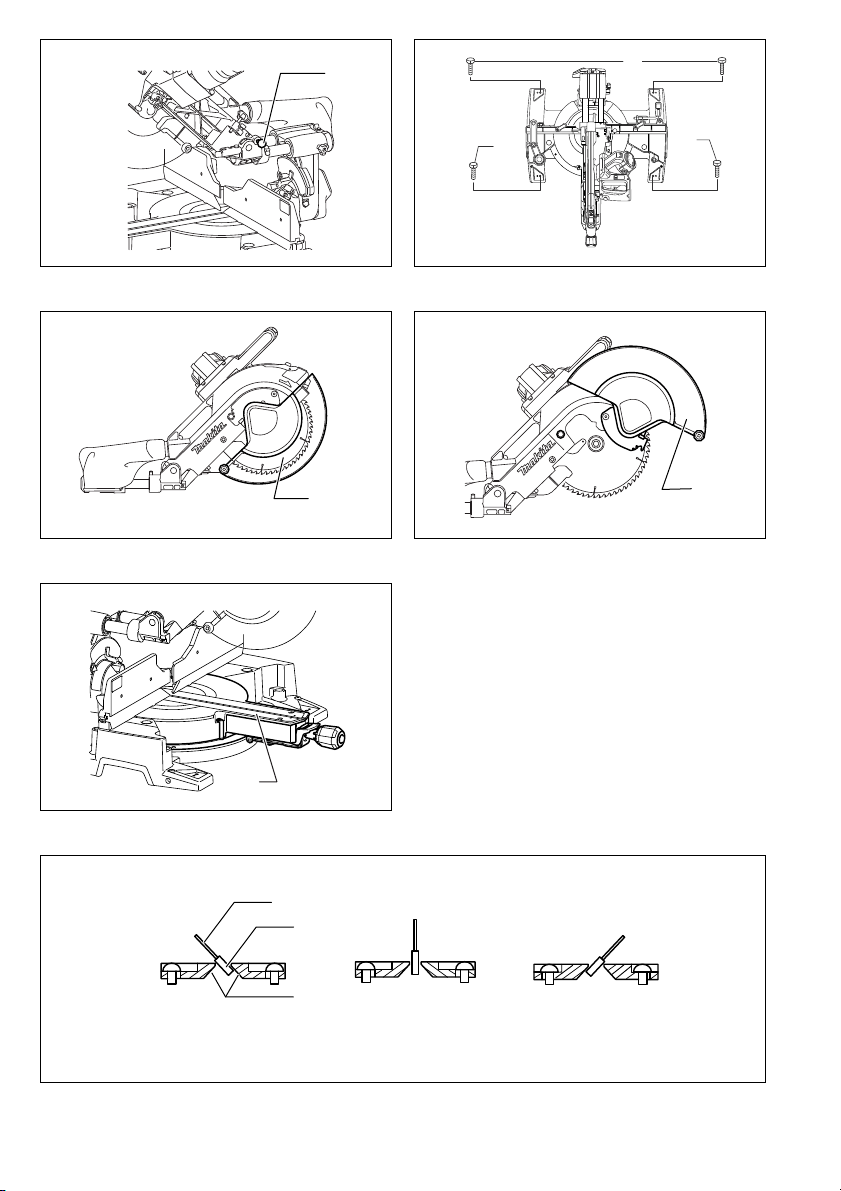

7 Left bevel cut

8 Straight cut

9 Right bevel cut

10 Lock lever

11 Screw

12 Adjusting bolt

13 Turn base

14 Stopper lever

15 Slide pipe

16 Top surface of turn base

17 Periphery of blade

18 Guide fence

19 Adjusting screw

20 Stopper arm

21 Grip

22 Cam

23 Lever(s)

24 Latch lever

25 Scale plate

26 Release button

27 Pointer

28 Lock-off button

29 Switch trigger

30 Hole for padlock

31 Switch for laser

32 Socket wrench

33 Wrench holder

Explanation of general view

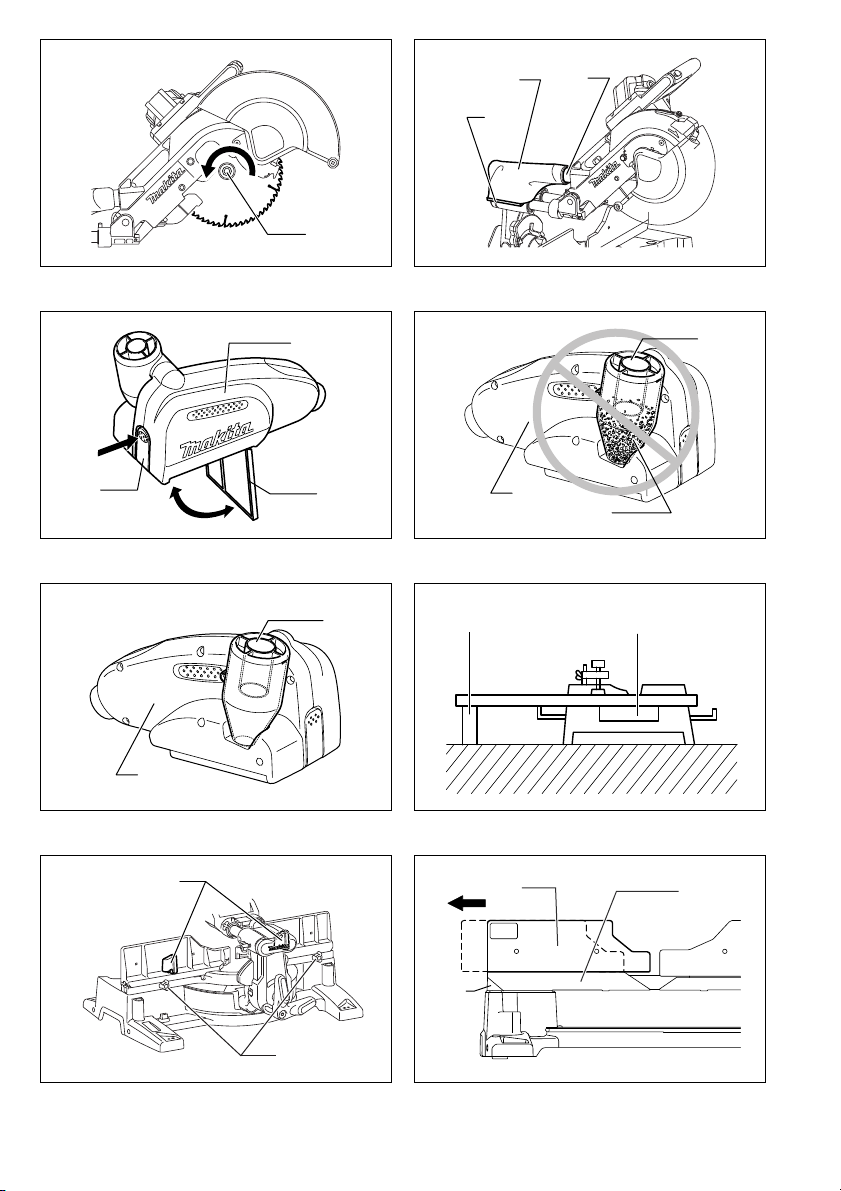

34 Center cover

35 Shaft lock

36 Blade case

37 Arrow

38 Outer flange

39 Inner flange

40 Spindle

41 Ring

42 Dust nozzle

43 Dust bag

44 Fastener

45 Dust box

46 Cover

47 Button

48 Cylinder section

49 Sawdust

50 Support

51 Turn base

52 Clamping screws

53 Upper fence

54 Lower fence

55 Vise knob

56 Vise arm

57 Vise rod

58 Vise plate

59 Vise nut

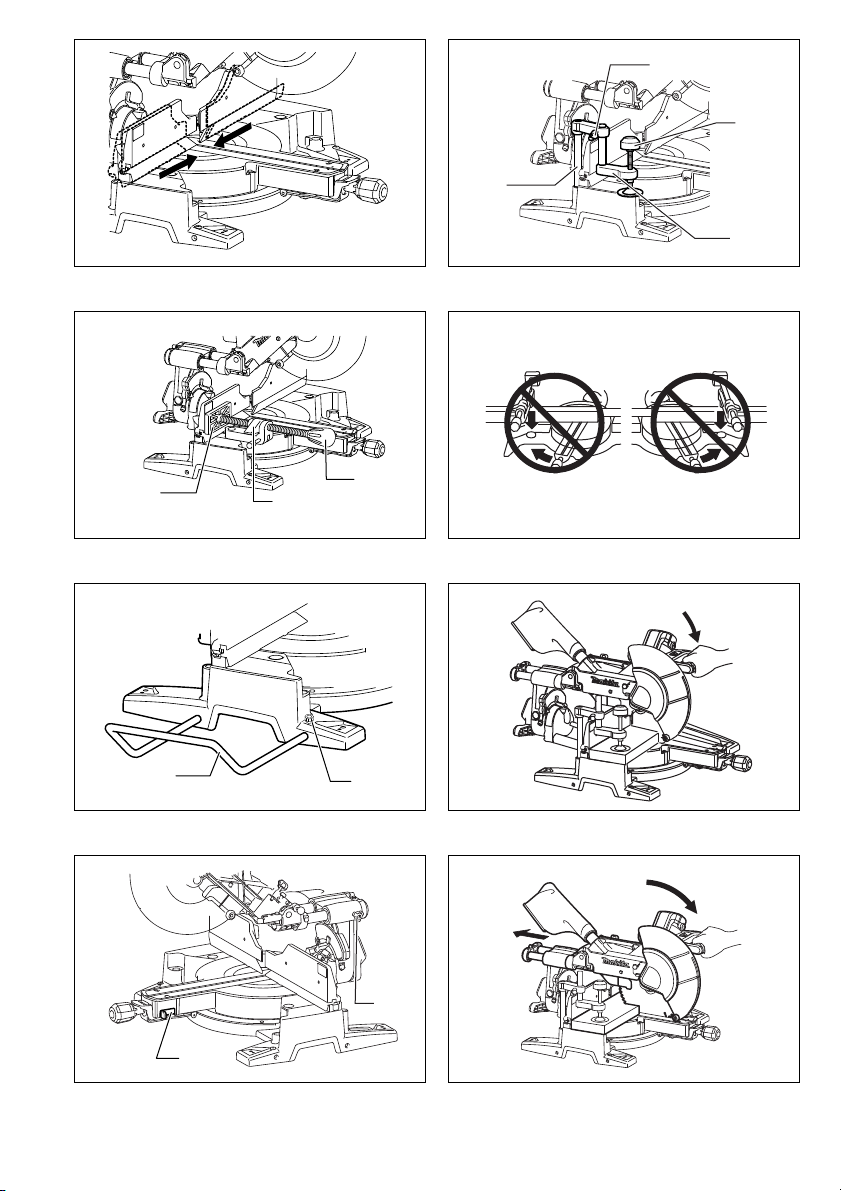

60 Holder

61 52/38° type crown molding

62 45° type crown molding

63 45° type cove molding

64 Inside corner

65 Outside corner

66 Crown molding stopper L

(Optional accessory)

67 Crown molding stopper R

(Optional accessory)

68 Crown molding stopper L

69 Crown molding stopper R

70 Crown molding

71 Vise

72 Spacer block

73 Aluminum extrusion

74 Cut grooves with blade

75 Triangular rule

76 Miter scale

77 Bevel scale plate

78 0° Angle adjusting bolt

79 Scale plate

80 Left 45° bevel angle adjusting

bolt

81 Right 45° bevel angle adjusting

bolt

82 Workpiece

83 Laser line

84 Vertical vise

85 Screwdriver

86 Screw (one piece only)

87 Lens for the laser light

88 Limit mark

89 Brush holder cap

90 Locking screw

91 Switch for light

92 Light

93 Red indicating area

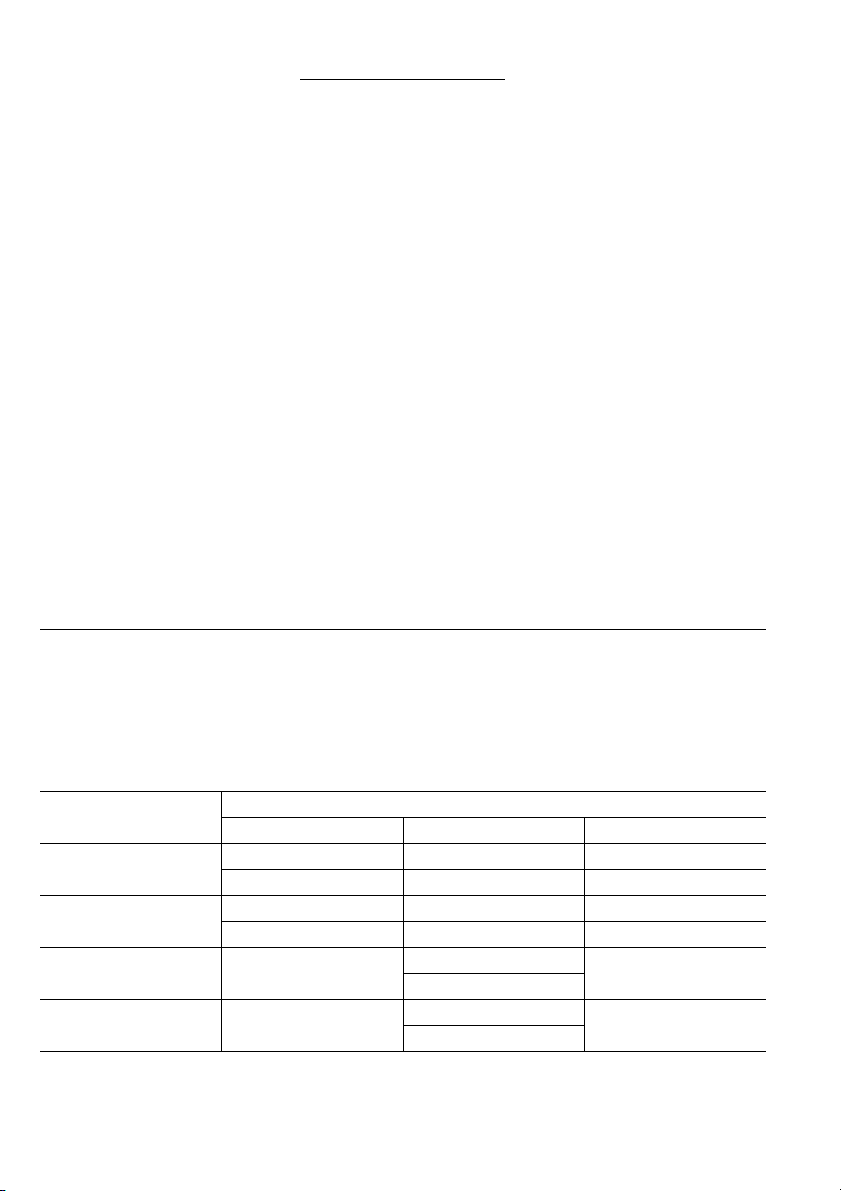

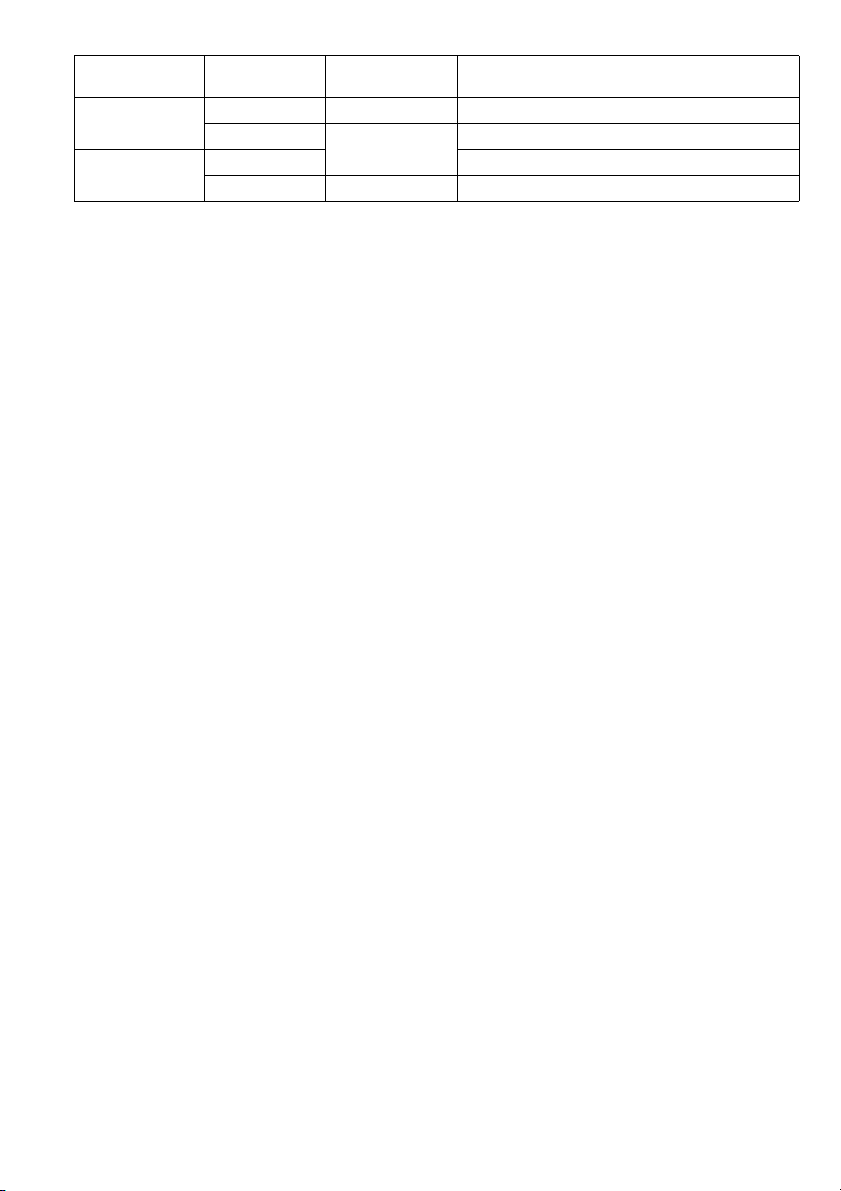

SPECIFICATIONS

Model LS1016/LS1016L/LS1016F/LS1016FL

Blade diameter

For all countries other than European countries ............................................................................. 255 mm – 260 mm

For European countries .................................................................................................................................... 260 mm

Hole diameter

For all countries other than European countries ............................................................................................. 25.4 mm

For European countries ...................................................................................................................................... 30 mm

Max. cutting capacities (H xW) with 260 mm in diameter

Miter angle

0°

45° (right and left)

52° (right and left) –

60° (right) –

45° (left) 0° 45° (right)

42 mm x 310 mm 68 mm x 310 mm 29 mm x 310 mm

58 mm x 279 mm 91 mm x 279 mm 43 mm x 279 mm

42 mm x 218 mm 68 mm x 218 mm 29 mm x 218 mm

58 mm x 197 mm 91 mm x 197 mm 43 mm x 197 mm

Bevel angle

68 mm x 190 mm

91 mm x 171 mm

68 mm x 155 mm

91 mm x 139 mm

–

–

14

Page 15

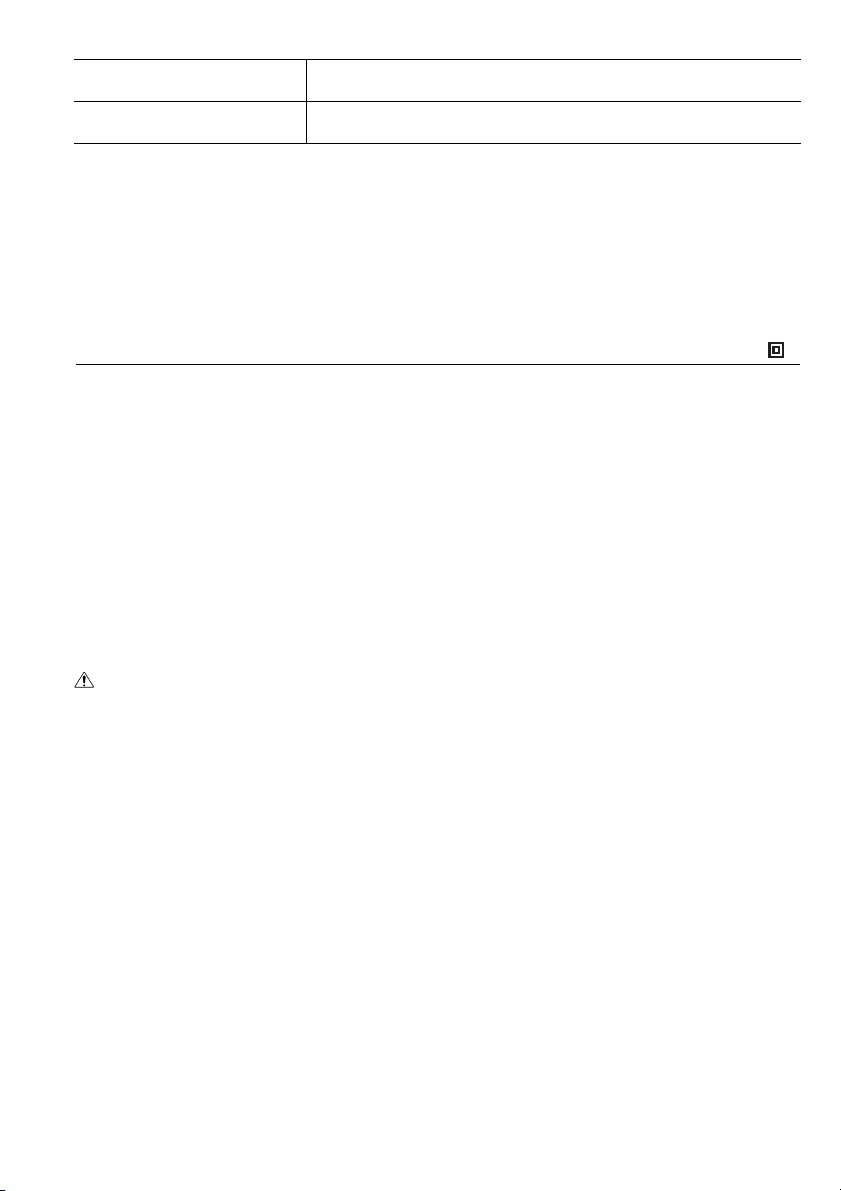

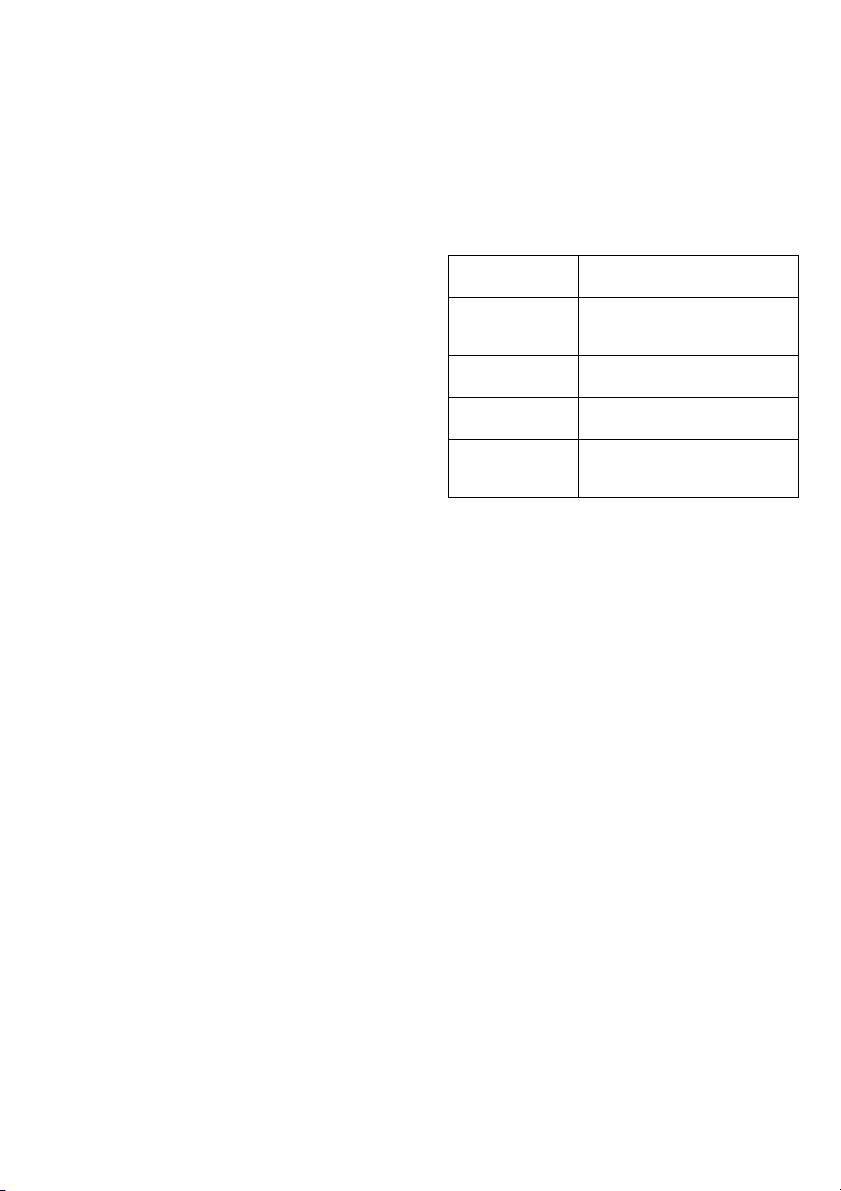

Special Max. Cutting capacities

Crown molding 45° type

(with Crown molding stopper used)

Base board (H)

(with Horizontal vise used)

–1

No load speed (min

Laser Type (LS1016L, LS1016FL)...........................................................Red Laser 650 nm, <1.6mW (Laser Class 2M)

Dimensions (L x W x H) .....................................................................................................718 mm x 640 mm x 671 mm

) ............................................................................................................................................ 3,200

168 mm

120 mm

Net weight

For all countries other than European countries

LS1016 .............................................................................................................................................................. 23.6 kg

LS1016L/LS1016F............................................................................................................................................. 23.7 kg

LS1016FL .......................................................................................................................................................... 23.8 kg

For European countries

LS1016 .............................................................................................................................................................. 24.1 kg

LS1016L/LS1016F............................................................................................................................................. 24.2 kg

LS1016FL .......................................................................................................................................................... 24.3 kg

Safety class ............................................................................................................................................................. /II

• Due to our continuing program of research and development, the specifications herein are subject to change

without notice.

• Specifications may differ from country to country.

• Weight according to EPTA-Procedure 01/2003

Intended use

The tool is intended for accurate straight and miter cutting in wood. With appropriate saw blades, aluminum can

also be sawed.

Power supply

The tool should be connected only to a power supply of

the same voltage as indicated on the nameplate, and can

only be operated on single-phase AC supply. They are

double-insulated in accordance with European Standard

and can, therefore, also be used from sockets without

earth wire.

GEA010-1

General Power Tool Safety Warnings

WARNING Read all safety warnings and all

instructions. Failure to follow the warnings and

instructions may result in electric shock, fire and/or

serious injury.

Save all warnings and instructions for future reference.

ENB034-6

ADDITIONAL SAFETY RULES FOR TOOL

1. Wear eye protection.

2. Keep hands out of path of saw blade. Avoid con-

tact with any coasting blade. It can still cause

severe injury.

3. Do not operate saw without guards in place.

Check blade guard for proper closing before

each use. Do not operate saw if blade guard

does not move freely and close instantly. Never

clamp or tie the blade guard into the open position.

4. Do not perform any operation freehand. The

workpiece must be secured firmly against the turn

base and guide fence with the vise during all operations. Never use your hand to secure the workpiece.

5. Never reach around saw blade.

6. Turn off tool and wait for saw blade to stop

before moving workpiece or changing settings.

7. Unplug tool before changing blade or servicing.

8. Always secure all moving portions before carrying the tool.

9. Stopper pin which locks the cutter head down is

for carrying and storage purposes only and not

for any cutting operations.

10. Do not use the tool in the presence of flammable

liquids or gases. The electrical operation of the tool

could create an explosion and fire when exposed to

flammable liquids or gases.

11. Check the blade carefully for cracks or damage

before operation.

Replace cracked or damaged blade immediately.

12. Use only flanges specified for this tool.

13. Be careful not to damage the arbor, flanges

(especially the installing surface) or bolt. Damage to these parts could result in blade breakage.

14. Make sure that the turn base is properly secured

so it will not move during operation.

15. For your safety, remove the chips, small pieces,

etc. from the table top before operation.

16. Avoid cutting nails. Inspect for and remove all

nails from the workpiece before operation.

17. Make sure the shaft lock is released before the

switch is turned on.

18. Be sure that the blade does not contact the turn

base in the lowest position.

19. Hold the handle firmly. Be aware that the saw

moves up or down slightly during start-up and

stopping.

20. Make sure the blade is not contacting the workpiece before the switch is turned on.

21. Before using the tool on an actual workpiece, let

it run for a while. Watch for vibration or wobbling

that could indicate poor installation or a poorly

balanced blade.

22. Wait until the blade attains full speed before cutting.

23. Stop operation immediately if you notice anything abnormal.

24. Do not attempt to lock the trigger in the on position.

25. Be alert at all times, especially during repetitive,

monotonous operations. Don’t be lulled into a

false sense of security. Blades are extremely

unforgiving.

15

Page 16

26. Always use accessories recommended in this

manual. Use of improper accessories such as

abrasive wheels may cause an injury.

27. Do not use the saw to cut other than wood, aluminum or similar materials.

28. Connect miter saws to a dust collecting device

when sawing.

29. Select saw blades in relation to the material to

be cut.

30. Take care when slotting.

31. Replace the kerf board when worn.

32. Do not use saw blades manufactured from high

speed steel.

33. Some dust created from operation contains

chemicals known to cause cancer, birth defects

or other reproductive harm. Some examples of

these chemicals are:

• lead from lead-based-painted material and,

• arsenic and chromium from chemically-treated

lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: work

in a well ventilated area and work with approved

safety equipment, such as those dust masks

that are specially designed to filter out microscopic particles.

34. To reduce the emitted noise, always be sure that

the blade is sharp and clean.

35. The operator is adequately trained in the use,

adjustment and operation of the machine.

36. Use correctly sharpened saw blades. Observe

the maximum speed marked on the saw blade.

37. Refrain from removing any cut-offs or other

parts of the workpiece from the cutting area

whilst the tool is running and the saw head is not

in the rest position.

38. Use only saw blades recommended by the

manufacturer which conform to EN847-1.

39. Wear gloves for handling saw blade (saw blades

shall be carried in a holder wherever practicable)

and rough material.

40. When fitted with laser, no exchange with different type of laser is permitted. Repairs shall only

be carried out correctly.

SAVE THESE INSTRUCTIONS

INSTALLATION

Bench mounting

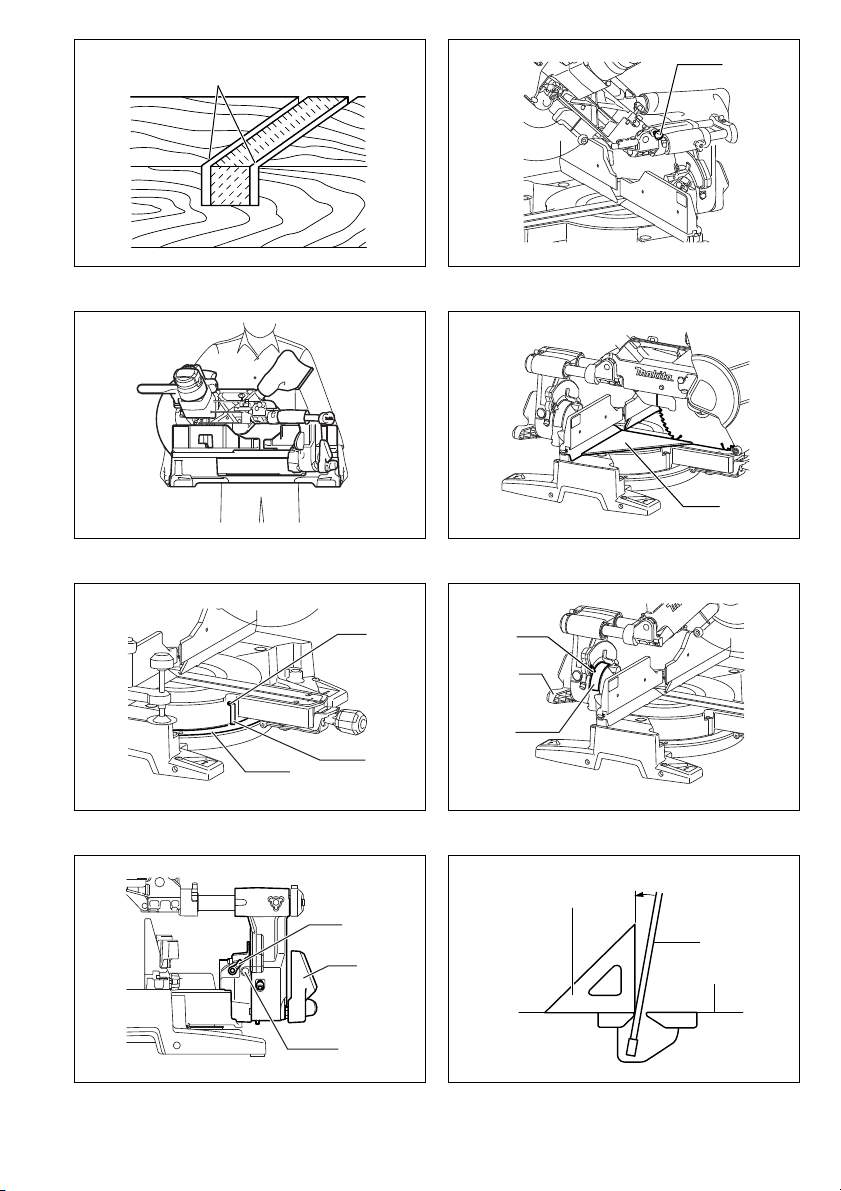

When the tool is shipped, the handle is locked in the lowered position by the stopper pin. Release the stopper pin

by simultaneously applying a slight downward pressure

on the handle and pulling the stopper pin. (Fig. 1)

WARNING:

• Ensure that the tool will not move on the support-

ing surface. Movement of the miter saw on the sup-

porting surface while cutting may result in loss of

control and serious personal injury.

This tool should be bolted with four bolts to a level and

stable surface using the bolt holes provided in the tool’s

base. This will help prevent tipping and possible injury.

(Fig. 2)

FUNCTIONAL DESCRIPTION

WARNING:

•

Always be sure that the tool is switched off and

unplugged before adjusting or checking function on

Failure to switch off and unplug the tool may

the tool.

result in serious personal injury from accidental start-up.

Blade guard (Fig. 3 & 4)

When lowering the handle, the blade guard rises automatically. The blade guard returns to its original position

when the cut is completed and the handle is raised.

WARNING:

• Never defeat or remove the blade guard or the

spring which attaches to the guard. An exposed

blade as a result of defeated guarding may result in

serious personal injury during operation.

In the interest of your personal safety, always maintain

the blade guard in good condition. Any irregular operation of the blade guard should be corrected immediately.

Check to assure spring loaded return action of guard.

WARNING:

• Never use the tool if the blade guard or spring are

damaged, faulty or removed. Operation of the tool

with a damaged, faulty or removed guard may result in

serious personal injury.

If the see-through blade guard becomes dirty, or sawdust

adheres to it in such a way that the blade and/or workpiece is no longer easily visible, unplug the saw and

clean the guard carefully with a damp cloth. Do not use

solvents or any petroleum-based cleaners on the plastic

guard because this may cause damage to the guard.

If the blade guard becomes dirty and needs to be

cleaned for proper operation follow the steps below:

With the tool switched off and unplugged, use the supplied socket wrench to loosen the hex bolt holding the

center cover. Loosen the hex bolt by turning it counterclockwise and raise the blade guard and center cover.

With the blade guard so positioned, cleaning can be

more completely and efficiently accomplished. When

cleaning is complete, reverse procedure above and

secure bolt. Do not remove spring holding blade guard. If

guard becomes damaged through age or UV light exposure, contact a Makita service center for a new guard.

DO NOT DEFEAT OR REMOVE GUARD.

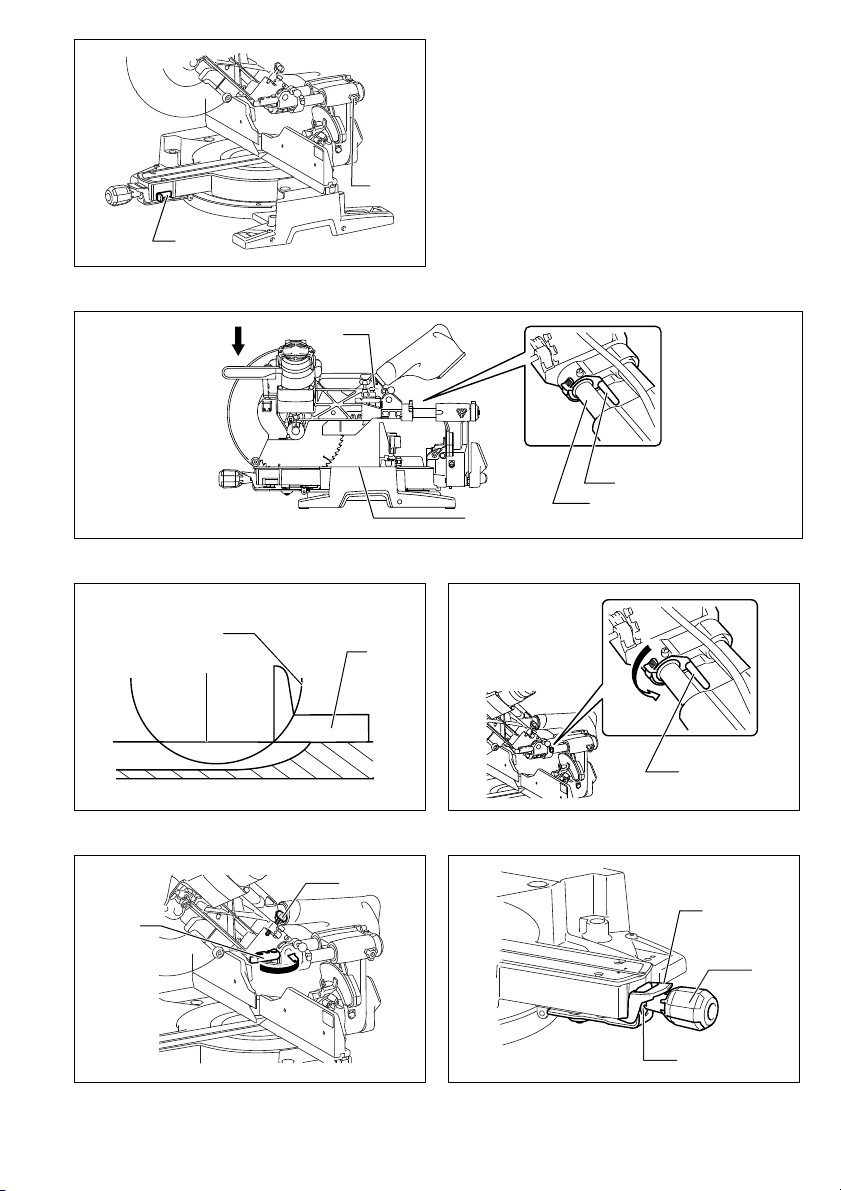

Positioning kerf board (Fig. 5, 6 & 7)

This tool is provided with the kerf boards in the turn base

to minimize tearing on the exit side of a cut. The kerf

boards are factory adjusted so that the saw blade does

not contact the kerf boards. Before use, adjust the kerf

boards as follows:

First, unplug the tool. Loosen all the screws (2 each on

left and right) securing the kerf boards. Re-tighten them

only to the extent that the kerf boards can still be easily

moved by hand. Lower the handle fully and push in the

stopper pin to lock the handle in the lowered position.

Loosen the locking screw counterclockwise which

secures the upper slide poles and also push forward the

lock lever which secures the lower slide poles. Pull the

carriage toward you fully. Adjust the kerf boards so that

the kerf boards just contact the sides of the blade teeth.

Tighten the front screws (do not tighten firmly). Push the

carriage toward the guide fence fully and adjust the kerf

boards so that the kerf boards just contact the sides of

blade teeth. Tighten the rear screws (do not tighten

firmly).

16

Page 17

After adjusting the kerf boards, release the stopper pin

and raise the handle. Then tighten all the screws

securely.

NOTICE:

• After setting the bevel angle ensure that the kerf

boards are adjusted properly. Correct adjustment of

the kerf boards will help provide proper support of the

workpiece minimizing workpiece tear out.

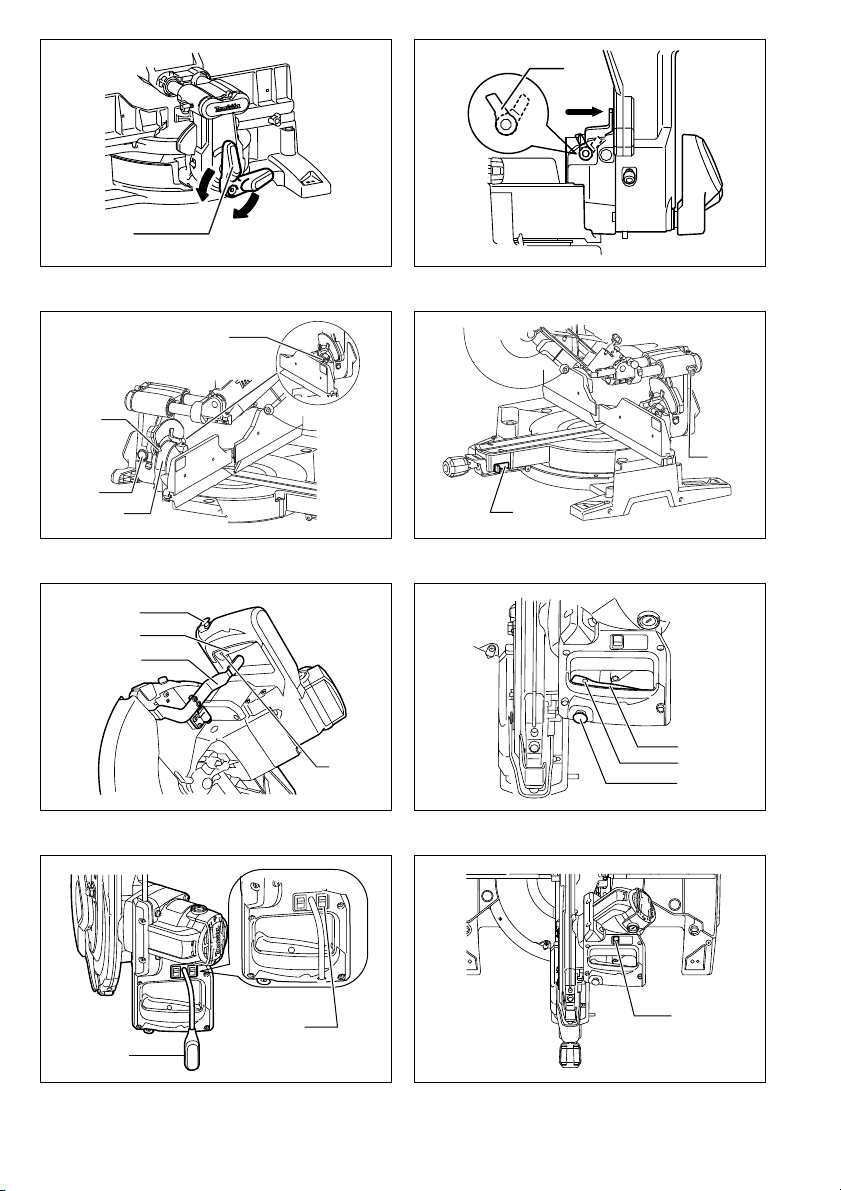

Maintaining maximum cutting capacity

(Fig. 8, 9 & 10)

This tool is factory adjusted to provide the maximum cutting capacity for a 260 mm saw blade.

Unplug the tool before any adjustment is attempted.

When installing a new blade, always check the lower limit

position of the blade and if necessary, adjust it as follows:

First, unplug the tool. Lower the stopper lever to position

the saw blade as shown in the figure. Push the carriage

toward the guide fence fully and lower the handle completely. Use the socket wrench to turn the adjusting bolt

until the periphery of the blade extends slightly below the

top surface of the turn base at the point where the front

face of the guide fence meets the top surface of the turn

base.

With the tool unplugged, rotate the blade by hand while

holding the handle all the way down to be sure that the

blade does not contact any part of the lower base. Readjust slightly, if necessary.

After adjustment, always return the stopper lever to the

original position by turning it counterclockwise.

WARNING:

• After installing a new blade and with the tool

unplugged, always be sure that the blade does not

contact any part of the lower base when the handle

is lowered completely. If a blade makes contact with

the base it may cause kickback and result in serious

personal injury.

Stopper arm (Fig. 11)

The lower limit position of the blade can be easily

adjusted with the stopper arm. To adjust it, rotate the

stopper arm in the direction of the arrow as shown in the

figure. Adjust the adjusting screw so that the blade stops

at the desired position when lowering the handle fully.

Adjusting the miter angle (Fig. 12)

Push the grip so that the cams engages and turn it clockwise until it stops. Turn the turn base while pressing

down the lock lever. When you have moved the grip to

the position where the pointer points to the desired angle

on the miter scale, turn the grip 90° counterclockwise to

lock the turn base.

CAUTION:

• After changing the miter angle, always secure the turn

base by turning the grip 90° counterclockwise.

NOTICE:

• When turning the turn base, be sure to raise the handle

fully.

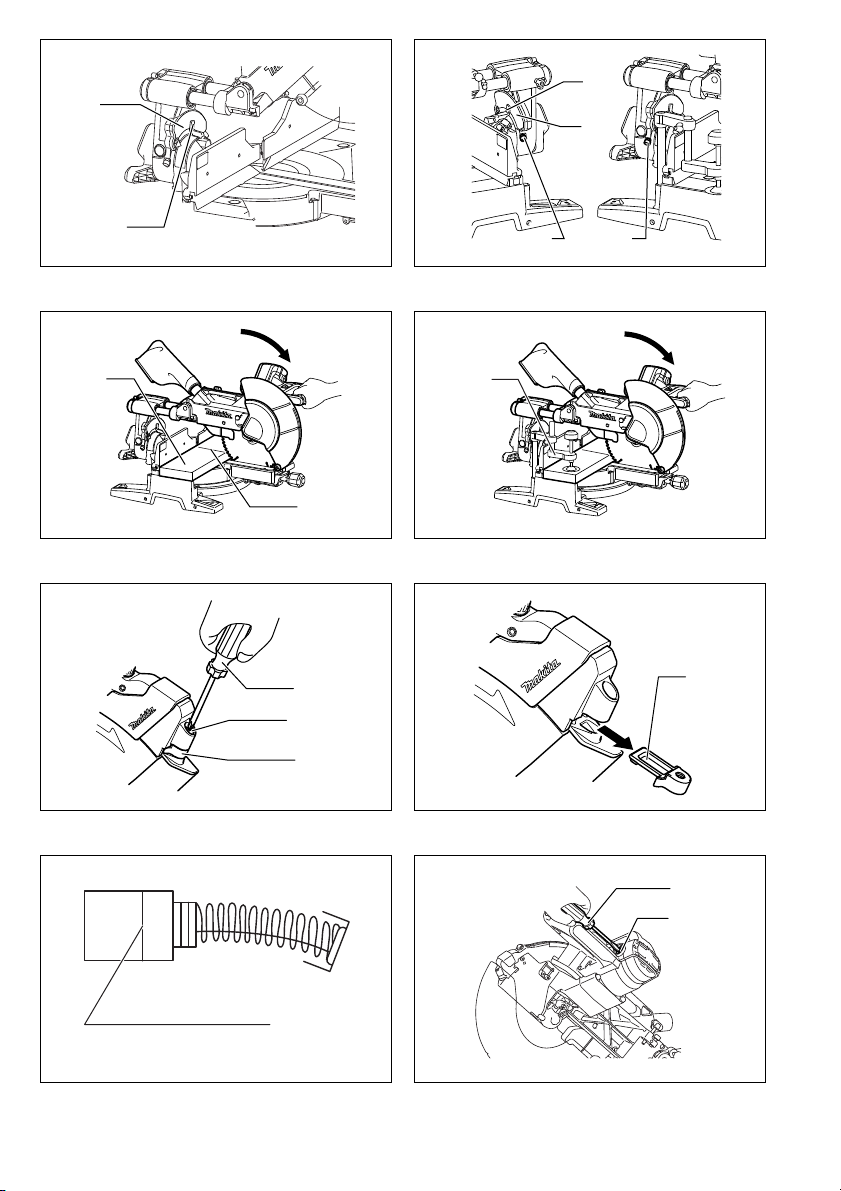

Adjusting the bevel angle (Fig. 13, 14 & 15)

To adjust the bevel angle, loosen the lever at the rear of

the tool counterclockwise. Push the latch lever forward as

shown in the figure fully while supporting the weight of

the saw head so as to release the pressure on the lock

pin.

When tilting the carriage to the right, tilt the carriage to

the left slightly after loosening the lever and press the

releasing button. With the releasing button being

pressed, tilt the carriage to the right.

Tilt the saw blade until the pointer points to the desired

angle on the bevel scale. Then tighten the lever clockwise firmly to secure the arm.

When the latch lever is pulled towards the front of the

saw, the saw blade can be locked using positive stops at

the right and left 22.5 ° and 33.9 ° angle to the base surface.

When the latch lever is pushed to the back of the saw as

shown in the figure, the saw blade can be locked at any

desired angle within the specified bevel angle range.

CAUTION:

• After changing the bevel angle, always secure the arm

by tightening the lever clockwise.

NOTICE:

• When tilting the saw blade be sure the handle is fully

raised.

• When changing bevel angles, be sure to position the

kerf boards appropriately as explained in the “Positioning kerf board” section.

Slide lock adjustment (Fig. 16)

To lock the lower slide pole, pull the lock lever towards

the front of the saw.

To lock the upper slide pole, turn the locking screw clockwise.

Switch action

For European countries (Fig. 17)

To prevent the switch trigger from being accidentally

pulled, a lock-off button is provided. To start the tool,

push the lever to the left, press in the lock-off button and

then pull the switch trigger. Release the switch trigger to

stop.

WARNING:

• Before plugging in the tool, always check to see

that the switch trigger actuates properly and

returns to the “OFF” position when released. Do

not pull the switch trigger hard without pressing in

the lock-off button. This can cause switch breakage. Operating a tool with a switch that does not actu-

ate properly can lead to loss of control and serious

personal injury.

A hole is provided in the switch trigger for insertion of

padlock to lock the tool off.

For all countries other than European countries

(Fig. 18)

To prevent the switch trigger from being accidentally

pulled, a lock-off button is provided. To start the tool,

press in the lock-off button and pull the switch trigger.

Release the switch trigger to stop.

WARNING:

• Before plugging in the tool, always check to see

that the switch trigger actuates properly and

returns to the “OFF” position when released. Do

not pull the switch trigger hard without pressing in

the lock-off button. This can cause switch breakage. Operating a tool with a switch that does not actu-

ate properly can lead to loss of control and serious

personal injury.

A hole is provided in the switch trigger for insertion of

padlock to lock the tool off.

17

Page 18

WARNING:

• Do not use a lock with a shank or cable any smaller

than 6.35 mm in diameter. A smaller shank or cable

may not properly lock the tool in the off position and

unintentional operation may occur resulting in serious

personal injury.

• NEVER use tool without a fully operative switch

trigger. Any tool with an inoperative switch is HIGHLY

DANGEROUS and must be repaired before further

usage or serious personal injury may occur.

• For your safety, this tool is equipped with a lock-off button which prevents the tool from unintended starting.

NEVER use the tool if it runs when you simply pull the

switch trigger without pressing the lock-off button. A

switch in need of repair may result in unintentional

operation and serious personal injury. Return tool to a

Makita service center for proper repairs BEFORE further usage.

• NEVER defeat the lock-off button by taping down or

some other means. A switch with a defeated lock-off

button may result in unintentional operation and serious

personal injury.

Lighting up the lamps (Fig. 19)

For Models LS1016F and LS1016FL only

CAUTION:

• This is not a rainproof light. Do not wash the light in

water or use it in a rain or a wet area. Such a conduct

can cause an electric shock and fume.

• Do not touch the lens of the light, as it is very hot while

it is lighted or shortly after it is turned off. This may

cause a burn to a human body.

• Do not apply impact to the light, which may cause damage or shorted service time to it.

• Do not keep casting the beam of the light to your eyes.

This can cause your eyes to be hurt.

• Do not cover the light with clothes, carton, cardboard or

similar objects while it is lighted, which can cause a fire

or an ignition.

To turn on the light, press the upper position (I) of the

switch. To turn off the light, press the lower position (O) of

the switch.

Move the light to shift an area of lighting.

NOTE:

• Use a dry cloth to wipe the dirt off the lens of lamp. Be

careful not to scratch the lens of light, or it may lower

the illumination.

Electronic function

Constant speed control

• The tool is provided with an electronic speed control

which helps maintain a constant blade rotation speed

even under load. A constant blade rotation speed will

result in a very smooth cut.

Soft start feature

• This function allows the smooth start-up of the tool by

limiting the start-up torque.

Laser beam action

For Models LS1016L and LS1016FL only

CAUTION:

• Never look into the laser beam. Direct laser beam may

injure your eyes.

• LASER RADIATION, DO NOT STARE INTO THE

BEAM OR VIEW DIRECTLY WITH OPTICAL INSTRUMENTS, CLASS 2M LASER PRODUCT.

To turn on the laser beam, press the upper position (I) of

the switch. To turn off the laser beam, press the lower

position (O) of the switch. (Fig. 20)

Laser line can be shifted to either the left or right side of

the saw blade by adjusting the adjusting screw as follows. (Fig. 21)

1. Loosen the adjusting screw by turning it counterclockwise.

2. With the adjusting screw loosened, slide the adjusting screw to the right or left as far as it goes.

3. Tighten the adjusting screw firmly at the position

where it stops sliding.

Laser line is factory adjusted so that it is positioned within

1 mm from the side surface of the blade (cutting position).

NOTE:

• When laser line appears dim and hard to see because

of direct sunlight, relocate the work area to a place

where there is less direct sunlight.

Aligning the laser line (Fig. 22)

Laser line can be shifted to either the left or right side of

the blade according to the applications of cutting. Refer

to explanation titled “Laser beam action” regarding its

shifting method.

NOTE:

• Use wood facing against the guide fence when aligning

the cutting line with the laser line at the side of guide

fence in compound cutting (bevel angle 45 degrees and

miter angle right 45 degrees).

A) When you obtain the correct size on the left side of

workpiece

• Shift the laser line to the left of the blade.

B) When you obtain the correct size on the right side

of workpiece

• Shift the laser line to the right of the blade.

Align the cutting line on your workpiece with the laser

line.

ASSEMBLY

WARNING:

• Always be sure that the tool is switched off and

unplugged before working on the tool. Failure to

switch off and unplug the tool may result in serious personal injury.

Socket wrench storage (Fig. 23)

The socket wrench is stored as shown in the figure.

When the socket wrench is needed it can be pulled out of

the wrench holder.

After using the socket wrench it can be stored by returning it to the wrench holder.

Installing or removing saw blade

WARNING:

• Always be sure that the tool is switched off and

unplugged before installing or removing the blade.

Accidental start up of the tool may result in serious personal injury.

• Use only the Makita socket wrench provided to

install or remove the blade. Failure to use the wrench

may result in overtightening or insufficient tightening of

the hex bolt and serious personal injury.

Lock the handle in the raised position by pushing in the

stopper pin. (Fig. 24)

18

Page 19

To remove the blade, use the socket wrench to loosen

the hex bolt holding the center cover by turning it counterclockwise. Raise the blade guard and center cover.

(Fig. 25)

Press the shaft lock to lock the spindle and use the

socket wrench to loosen the hex bolt clockwise. Then

remove the hex bolt, outer flange and blade. (Fig. 26)

NOTE:

• If the inner flange is removed be sure to install it on the

spindle with its protrusion facing away from the blade. If

the flange is installed incorrectly the flange will rub

against the machine.

WARNING:

• Before mounting the blade onto the spindle, always

be sure that the correct ring for the blade's arbor

hole you intend to use is installed between the

inner and the outer flanges. Use of the incorrect

arbor hole ring may result in the improper mounting of

the blade causing blade movement and severe vibration resulting in possible loss of control during operation and in serious personal injury.

To install the blade, mount it carefully onto the spindle,

making sure that the direction of the arrow on the surface

of the blade matches the direction of the arrow on the

blade case.

Install the outer flange and hex bolt, and then use the

socket wrench to tighten the hex bolt (left-handed)

securely counterclockwise while pressing the shaft lock.

(Fig. 27 & 28)

Return the blade guard and center cover to its original

position. Then tighten the hex bolt clockwise to secure

the center cover. Release the handle from the raised

position by pulling the stopper pin. Lower the handle to

make sure that the blade guard moves properly. Make

sure the shaft lock has released spindle before making

cut. (Fig. 29)

Dust bag (Fig. 30)

The use of the dust bag makes cutting operations

cleaner and dust collection easier. To attach the dust

bag, fit it onto the dust nozzle.

When the dust bag is about half full, remove the dust bag

from the tool and pull the fastener out. Empty the dust

bag of its contents, tapping it lightly so as to remove particles adhering to the insides which might hamper further

collection.

NOTE:

• If you connect a vacuum cleaner to your saw, cleaner

operations can be performed.

Dust box (optional accessory) (Fig. 31, 32 & 33)

Insert the dust box into the dust nozzle.

Empty the dust box when necessary.

To empty the dust box, open the cover by pushing the

button and dispose of the sawdust. Return the cover to

the original position and lock it in place. Dust box can

easily be removed by pulling it out while turning it near

the dust nozzle on the tool.

NOTE:

• If you connect a Makita vacuum cleaner to this tool,

cleaner operations can be performed.

NOTICE:

• Empty the dust box before collected sawdust level

reaches the cylinder section.

Securing workpiece

WARNING:

• It is extremely important to always secure the workpiece correctly with the proper type of vise or

crown molding stoppers. Failure to do so may result

in serious personal injury and cause damage to the tool

and/or the workpiece.

• After a cutting operation do not raise the blade

until it has come to a complete stop. The raising of a

coasting blade may result in serious personal injury

and damage to the workpiece.

• When cutting a workpiece that is longer than the

support base of the saw, the material should be

supported the entire length beyond the support

base and at the same height to keep the material

level. Proper workpiece support will help avoid blade

pinch and possible kickback which may result in serious personal injury. Do not rely solely on the vertical

vise and/or horizontal vise to secure the workpiece.

Thin material tends to sag. Support workpiece over its

entire length to avoid blade pinch and possible KICKBACK. (Fig. 34)

Guide fence (SLIDING FENCES which are upper

and lower fences) adjustment

WARNING:

• Before operating the tool, make sure that the upper and

lower fences are secured firmly.

• Before bevel-cutting, make sure that no part of the

tool, especially the blade, contacts the upper and

lower fences when fully lowering and raising the

handle in any position and while moving the carriage through its full range of travel. If the tool or

blade makes contact with the fence this may result in

kickback or unexpected movement of the material and

serious personal injury.

The lower fences can be moved inward and outward by

loosening the clamping screws. (Fig. 35)

A red indicating area will appear as the lower fences are

moved inward and will disappear as the lower fences are

moved outward.

The upper fences can be removed or moved inward and

outward by loosening the levers. (Fig. 36)

In case of bevel-cutting, adjust the lower and upper fence

positions to be as close to the blade as practical to provide maximum workpiece support, and make sure that no

part of the tool, especially the blade, contacts the lower

and upper fences when lowering and raising the handle

fully at any position and pulling or pushing the carriage all

the way at the lowest position. (Fig. 37)

Before cutting operations, make a dry run with the saw

turned off and unplugged, then check clearance between

fences and moving parts.

Before cutting operations, firmly secure lower fences by

tightening the clamping screws and upper fences by

tightening the levers.

When bevel-cutting operations are complete, don’t forget

to return the upper fences to the original position and

return it.

Vertical vise (Fig. 38)

The vertical vise can be installed in two positions on

either the left or right side of the base. Insert the vise rod

into the hole in the base.

19

Page 20

Position the vise arm according to the thickness and

shape of the workpiece and secure the vise arm by tightening the screw. If the screw to secure the vise arm contacts the carriage, install the screw on the opposite side

of vise arm. Make sure that no part of the tool contacts

the vise when lowering the handle fully and pulling or

pushing the carriage all the way. If some part contacts

the vise, re-position the vise.

Press the workpiece flat against the guide fence and the

turn base. Position the workpiece at the desired cutting

position and secure it firmly by tightening the vise knob.

Turning the vise knob to 90° counterclockwise allows the

vise knob to be moved up and down, facilitating the quick

setting of workpiece. To secure the workpiece after setting, turn the vise knob clockwise.

WARNING:

• The workpiece must be secured firmly against the

turn base and guide fence with the vise during all

operations. If the workpiece is not properly secured

against the fence the material may move during the

cutting operation causing possible damage to the

blade, causing the material to be thrown and loss of

control resulting in serious personal injury.

Horizontal vise (optional accessory) (Fig. 39 & 40)

The horizontal vise can be installed in two positions on

either the left or right side of the base.

When performing 15° or greater miter cuts, install the

horizontal vise on the side opposite the direction in which

the turn base is to be turned.

By flipping the vise nut counterclockwise, the vise is

released, and rapidly moves in and out. To grip the workpiece, push the vise knob forward until the vise plate contacts the workpiece and flip the vise nut clockwise. Then

turn the vise knob clockwise to secure the workpiece.

The maximum width of workpiece which can be secured

by the horizontal vise is 215 mm.

WARNING:

• Always rotate the vise nut clockwise until the workpiece is properly secured. If the workpiece is not

properly secured the material may move during the cutting operation causing possible damage to the blade,

causing the material to be thrown and loss of control

resulting in serious personal injury.

• When cutting a thin workpiece, such as base boards,

against the fence, always use the horizontal vise.

Holders (optional accessory) (Fig. 41)

The holders can be installed on either side as a convenient means of holding workpieces horizontally. Slip the

holder rods into the holes in the base and adjust their

length according to the workpiece to be held. Then

tighten the holders securely with the screws.

WARNING:

• Always support a long workpiece so it is level with

the top surface of the turn base for an accurate cut

and to prevent dangerous loss of tool control.

Proper workpiece support will help avoid blade pinch

and possible kickback which may result in serious personal injury.

OPERATION

NOTICE:

• Before use, be sure to release the handle from the lowered position by pulling the stopper pin.

• Do not apply excessive pressure on the handle when

cutting. Too much force may result in overload of the

motor and/or decreased cutting efficiency. Push down

handle with only as much force as is necessary for

smooth cutting and without significant decrease in

blade speed.

• Gently press down the handle to perform the cut. If the

handle is pressed down with force or if lateral force is

applied, the blade will vibrate and leave a mark (saw

mark) in the workpiece and the precision of the cut will

be impaired.

• During a slide cut, gently push the carriage toward the

guide fence without stopping. If the carriage movement

is stopped during the cut, a mark will be left in the workpiece and the precision of the cut will be impaired.

WARNING:

• Make sure the blade is not contacting the workpiece, etc. before the switch is turned on. Tu r ning

the tool on with the blade in contact with the workpiece

may result in kickback and serious personal injury.

1. Press cutting (cutting small workpieces)

(Fig. 42)

Workpieces up to 68 mm high and 160 mm wide can be

cut in the following manner.

After turning the stopper lever clockwise and sliding the

carriage to your desired position, push the carriage

toward the guide fence fully and tighten the locking screw

clockwise and pull the lock lever towards the front of the

saw to secure the carriage. Secure the workpiece correctly with the proper type of vise or crown molding stoppers.

Switch on the tool without the blade making any contact

and wait until the blade attains full speed before lowering.

Then gently lower the handle to the fully lowered position

to cut the workpiece. When the cut is completed, switch

off the tool and WAIT UNTIL THE BLADE HAS COME

TO A COMPLETE STOP before returning the blade to its

fully elevated position.

WARNING:

• Firmly tighten the locking screw clockwise and pull

the lock lever towards the front of the saw so that

the carriage will not move during operation. Insuffi-

cient tightening of the locking screw may cause possible kickback which may result in serious personal

injury.

2. Slide (push) cutting (cutting wide workpieces)

(Fig. 43 & 44)

Loosen the locking screw counterclockwise and also

push forward the lock lever so that the carriage can slide

freely. Secure the workpiece with the proper type of vise.

Pull the carriage toward you fully. Switch on the tool without the blade making any contact and wait until the blade

attains full speed. Press the handle down and PUSH

THE CARRIAGE TOWARD THE GUIDE FENCE AND

THROUGH THE WORKPIECE. When the cut is completed, switch off the tool and WAIT UNTIL THE BLADE

HAS COME TO A COMPLETE STOP before returning

the blade to its fully elevated position.

20

Page 21

WARNING:

• Whenever performing a slide cut, first pull the carriage full towards you and press the handle all the

way down, then push the carriage toward the guide

fence. Never start the cut with the carriage not

pulled fully toward you. If you perform the slide cut

without the carriage pulled fully toward you unexpected

kickback may occur and serious personal injury may

result.

• Never attempt to perform a slide cut by pulling the

carriage towards you. Pulling the carriage towards

you while cutting may cause unexpected kickback

resulting in possible serious personal injury.

• Never perform the slide cut with the handle locked in

the lowered position.

• Never loosen the knob which secures the carriage

while the blade is rotating. A loose carriage while cutting may cause unexpected kickback resulting in possible in serious personal injury.

3. Mitre cutting

Refer to the previously covered “Adjusting the miter

angle”.

4. Bevel cut (Fig. 45)

Loosen the lever and tilt the saw blade to set the bevel

angle (Refer to the previously covered “Adjusting the

bevel angle”). Be sure to retighten the lever firmly to

secure the selected bevel angle safely. Secure the workpiece with a vise. Make sure the carriage is pulled all the

way back toward the operator. Switch on the tool without

the blade making any contact and wait until the blade

attains full speed. Then gently lower the handle to the

fully lowered position while applying pressure in parallel

with the blade and PUSH THE CARRIAGE TOWARD

THE GUIDE FENCE TO CUT THE WORKPIECE. When

the cut is completed, switch off the tool and WAIT UNTIL

THE BLADE HAS COME TO A COMPLETE STOP

before returning the blade to its fully elevated position.

WARNING:

• After setting the blade for a bevel cut, before operating the tool ensure that the carriage and blade

will have free travel throughout the entire range of

the intended cut. Interruption of the carriage or blade

travel during the cutting operation may result in kickback and serious personal injury.

Measuring

Measure the wall length and adjust workpiece on table to cut wall contact edge to desired length. Always make sure

that cut workpiece length at the back of the workpiece is the same as wall length. Adjust cut length for angle of cut.

Always use several pieces for test cuts to check the saw angles.

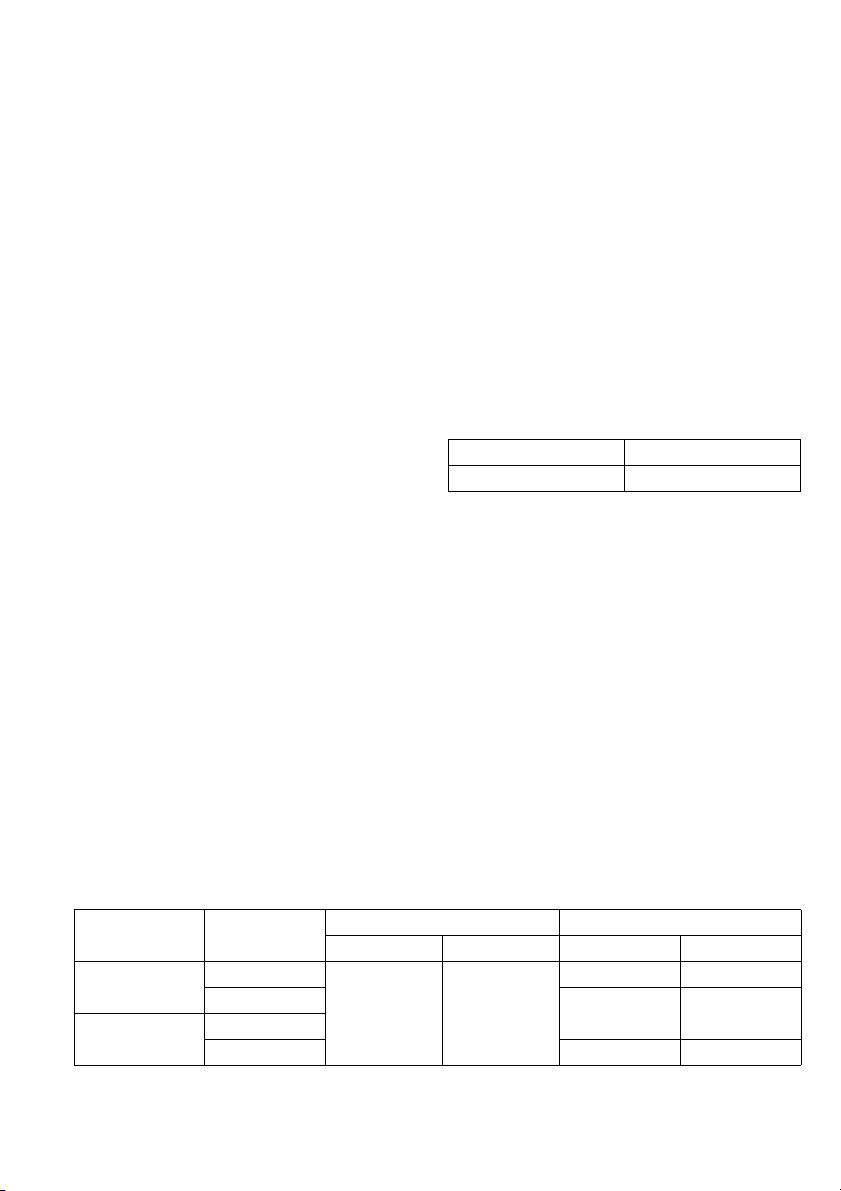

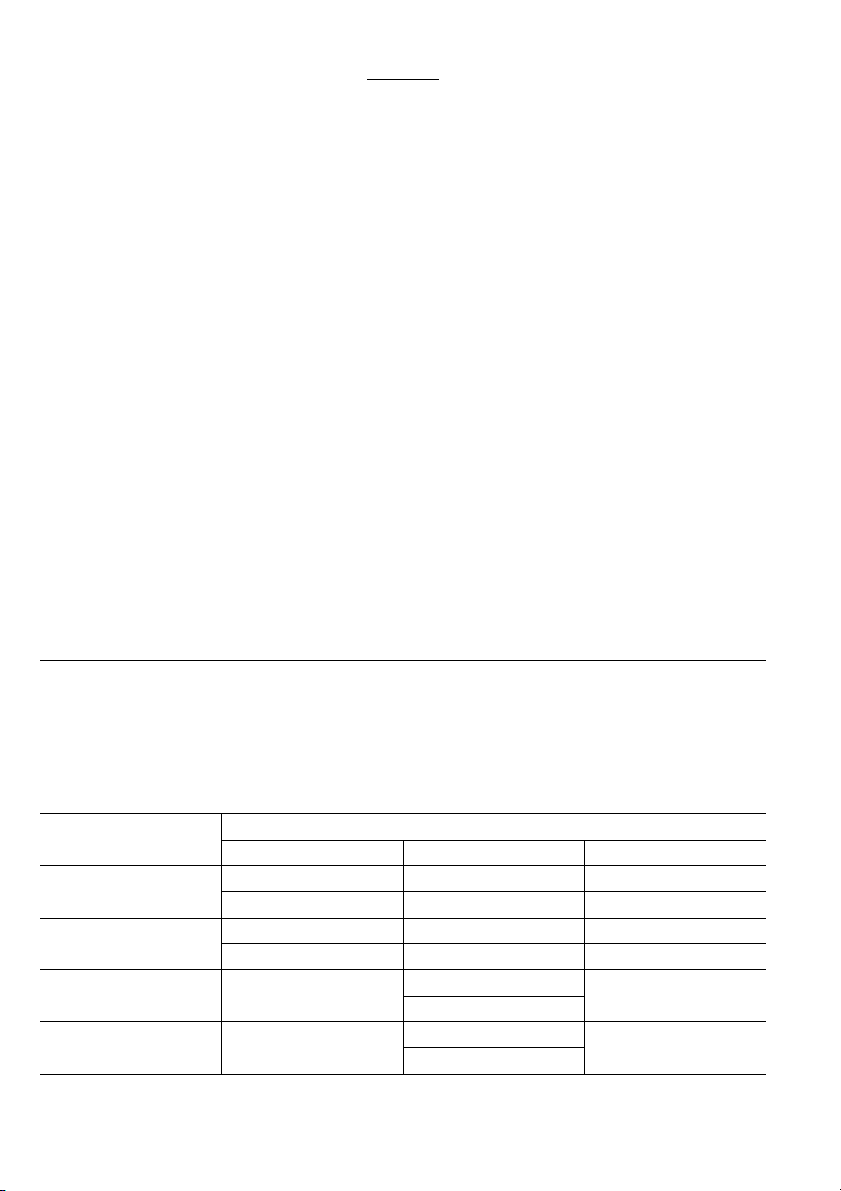

When cutting crown and cove moldings, set the bevel angle and miter angle as indicated in the table (A) and position

the moldings on the top surface of the saw base as indicated in the table (B).

In the case of left bevel cut

Tab l e (A )

Molding position

For inside corner

For outside corner

in Fig. 47 & 48

(1)

(2)

(3)

(4) Right 31.6° Right 35.3°

52/38° type 45° type 52/38° type 45° type

Left 33.9° Left 30°

• While making a bevel cut keep hands out of the

path of the blade. The angle of the blade may confuse

the operator as to the actual blade path while cutting

and contact with the blade will result in serious personal injury.

• The blade should not be raised until it has come to

a complete stop. During a bevel cut the piece cut off

may come to rest against the blade. If the blade is

raised while it is rotating the cut-off piece maybe

ejected by the blade causing the material to fragment

which may result in serious personal injury.

NOTICE:

• When pressing down the handle, apply pressure in parallel with the blade. If a force is applied perpendicularly

to the turn base or if the pressure direction is changed

during a cut, the precision of the cut will be impaired.

• Before bevel-cutting, an adjustment of the upper fence

and lower fence maybe required. Refer to the section

titled “Guide fence adjustment”.

5. Compound cutting

Compound cutting is the process in which a bevel angle

is made at the same time in which a miter angle is being

cut on a workpiece. Compound cutting can be performed

at the angle shown in the table.

Miter angle Bevel angle

Left and Right 0° – 45° Left and Right 0° – 45°

When performing compound cutting, refer to “Press cutting”, “Slide cutting”, “Miter cutting” and “Bevel cut” explanations.

6. Cutting crown and cove moldings

Crown and cove moldings can be cut on a compound

miter saw with the moldings laid flat on the turn base.

There are two common types of crown moldings and one

type of cove moldings; 52/38° wall angle crown molding,

45° wall angle crown molding and 45° wall angle cove

molding. See illustrations. (Fig. 46)

There are crown and cove molding joints which are made

to fit “Inside” 90° corners ((1) and (2) in Fig. 47 & 48) and

“Outside” 90° corners ((3) and (4) in Fig. 47 & 48).

Bevel angle Miter angle

Right 31.6° Right 35.3°

Left 31.6° Left 35.3°

21

Page 22

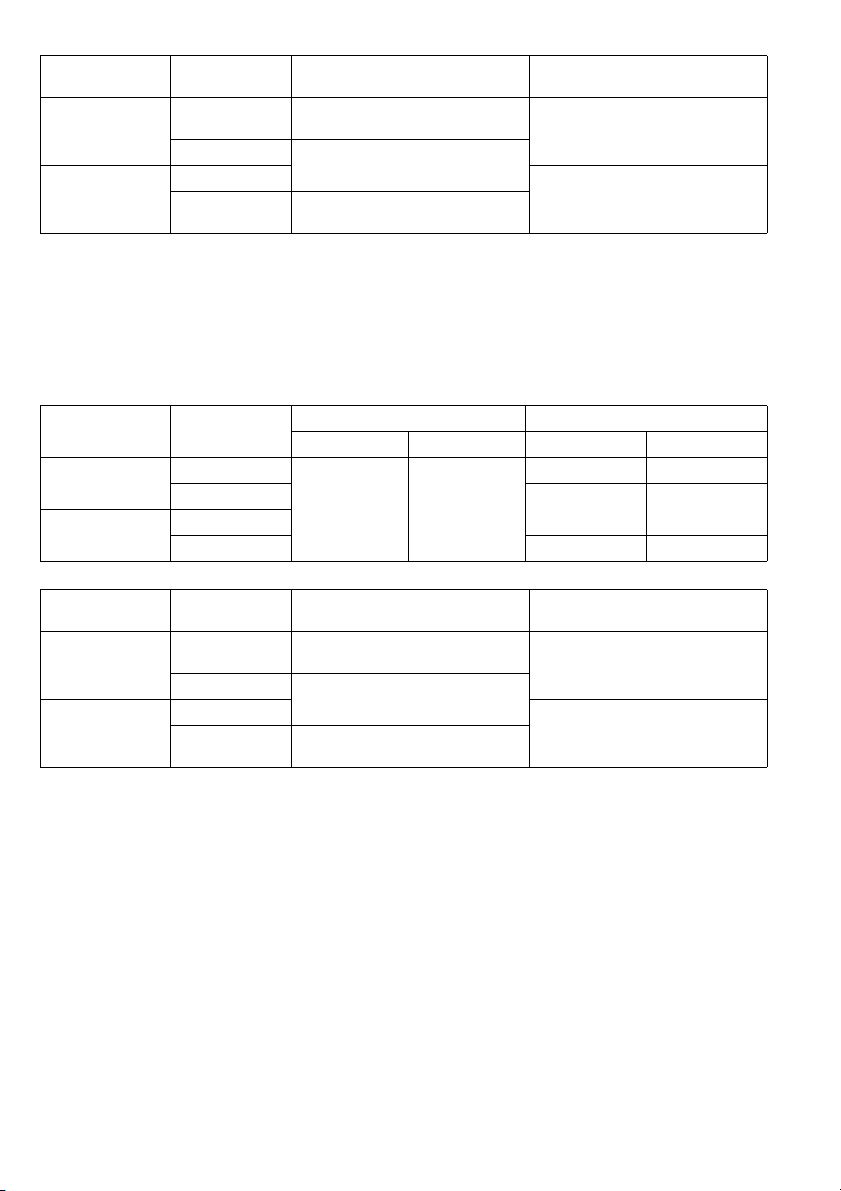

Table (B )

Molding position

in Fig. 47 & 48

For inside corner

For outside corner

Example:

In the case of cutting 52/38° type crown molding for position (1) in Fig. 47 & 48:

• Tilt and secure bevel angle setting to 33.9° LEFT.

• Adjust and secure miter angle setting to 31.6° RIGHT.

• Lay crown molding with its broad back (hidden) surface down on the turn base with its CEILING CONTACT EDGE

against the guide fence on the saw.

• The finished piece to be used will always be on the LEFT side of the blade after the cut has been made.

In the case of right bevel cut

Table (A )

For inside corner

For outside corner

Table (B )

For inside corner

For outside corner

Example:

In the case of cutting 52/38° type crown molding for position (1) in Fig. 47 & 48:

• Tilt and secure bevel angle setting to 33.9° RIGHT.

• Adjust and secure miter angle setting to 31.6° RIGHT.

• Lay crown molding with its broad back (hidden) surface down on the turn base with its WALL CONTACT EDGE

against the guide fence on the saw.

• The finished piece to be used will always be on the RIGHT side of the blade after the cut has been made.

Crown molding stoppers (optional accessories) allow easier cuts of crown molding without tilting the saw blade. Install

them on the base as shown in the figures. (Fig. 49 & 50)

Fig. 49: At right 45° miter angle

Fig. 50: At left 45° miter angle

Position crown molding with its WALL CONTACT EDGE against the guide fence and its CEILING CONTACT EDGE

against the crown molding stoppers as shown in the figure (Fig. 51). Adjust the crown molding stoppers according to

the size of the crown molding. Tighten the screws to secure the crown molding stoppers. Refer to the table (C) for the

miter angle.

(1)

(2)

(3)

(4)

Molding position

in Fig. 47 & 48

(1)

(2)

(3)

(4) Right 31.6° Right 35.3°

Molding position

in Fig. 47 & 48

(1)

(2)

(3)

(4)

Molding edge against guide fence Finished piece

Ceiling contact edge should be

against guide fence.

Wall contact edge should be against

guide fence.

Ceiling contact edge should be

against guide fence.

Bevel angle Miter angle

52/38° type 45° type 52/38° type 45° type

Right 33.9° Right 30°

Molding edge against guide fence Finished piece

Wall contact edge should be against

guide fence.

Ceiling contact edge should be

against guide fence.

Wall contact edge should be against

guide fence.

Finished piece will be on the Left

side of blade.

Finished piece will be on the Right

side of blade.

Right 31.6° Right 35.3°

Left 31.6° Left 35.3°

Finished piece will be on the Right

side of blade.

Finished piece will be on the Left

side of blade.

22

Page 23

Tab l e (C )

Molding position

in Fig. 47 & 48

For inside corner

For outside corner

7. Cutting aluminum extrusion

When securing aluminum extrusions, use spacer blocks

or pieces of scrap as shown in Fig. 52 to prevent deformation of the aluminum. Use a cutting lubricant when

cutting the aluminum extrusion to prevent build-up of the

aluminum material on the blade.

WARNING:

• Never attempt to cut thick or round aluminum

extrusions. Thick or round aluminum extrusions can

be difficult to secure and may work loose during the

cutting operation which may result in loss of control and

serious personal injury.

8. Groove cutting (Fig. 53)

A dado type cut can be made by proceeding as follows:

Adjust the lower limit position of the blade using the

adjusting screw and the stopper arm to limit the cutting

depth of the blade. Refer to “Stopper arm” section

described previously.

After adjusting the lower limit position of the blade, cut

parallel grooves across the width of the workpiece using

a slide (push) cut as shown in the figure. Then remove

the workpiece material between the grooves with a

chisel.

WARNING:

• Do not attempt to perform this type of cut by using

a wider type blade or dado blade. Attempting to

make a groove cut with a wider blade or dado blade

could lead to unexpected cutting results and kickback

which may result in serious personal injury.

• Be sure to return the stopper arm to the original

position when performing other than groove cutting. Attempting to make cuts with the stopper arm in

the incorrect position could lead to unexpected cutting

results and kickback which may result in serious personal injury.

Carrying tool

Make sure that the tool is unplugged. Secure the blade at

0° bevel angle and the turn base at the full right miter

angle position. Secure the slide poles so that the lower

slide pole is locked in the position of the carriage fully

pulled to operator and the upper poles are locked in the

position of the carriage fully pushed forward to the guide

fence (refer to the section titled “Slide lock adjustment”.)

Lower the handle fully and lock it in the lowered position

by pushing in the stopper pin. (Fig. 54)

Carry the tool by holding both sides of the tool base as

shown in the figure. If you remove the holders, dust bag,

etc., you can carry the tool more easily. (Fig. 55)

(1) Right 45° Save the right side of blade

(2)

(3) Save the right side of blade

(4) Right 45° Save the left side of blade

Miter angle Finished piece

Left 45°

Save the left side of blade

WARNING:

• Stopper pin is only for carrying and storage purposes and should never be used for any cutting

operations. The use of the stopper pin for cutting oper-

ations may cause unexpected movement of the saw

blade resulting in kickback and serious personal injury.

CAUTION:

• Always secure all moving portions before carrying the

tool. If portions of the tool move or slide while being

carried loss of control or balance may occur resulting in

personal injury.

MAINTENANCE

WARNING:

• Always be sure that the tool is switched off and

unplugged before attempting to perform inspection

or maintenance. Failure to unplug and switch off the

tool may result in accidental start up of the tool which

may result in serious personal injury.

• Always be sure that the blade is sharp and clean for

the best and safest performance. Attempting a cut

with a dull and/or dirty blade may cause kickback and

result in a serious personal injury.

NOTICE:

• Never use gasoline, benzine, thinner, alcohol or the

like. Discoloration, deformation or cracks may result.

Adjusting the cutting angle

This tool is carefully adjusted and aligned at the factory,

but rough handling may have affected the alignment. If

your tool is not aligned properly, perform the following:

1. Miter angle

Push the carriage toward the guide fence and tighten the

locking screw clockwise and pull the lock lever towards

the front of the saw to secure the carriage.

Turn the grip counterclockwise which secures the turn

base. Turn the turn base so that the pointer points to 0°

on the miter scale. Then turn the turn base slightly clockwise and counterclockwise to seat the turn base in the 0°

miter notch. (Leave as it is if the pointer does not point to

0°.) Loosen the hex socket bolts securing the guide fence

using the socket wrench.

Lower the handle fully and lock it in the lowered position

by pushing in the stopper pin. Square the side of the

blade with the face of the guide fence using a triangular

rule, try-square, etc. Then securely tighten the hex

socket bolts on the guide fence in order starting from the

right side. (Fig. 56)

Make sure that the pointer points to 0° on the miter scale.

If the pointer does not point to 0°, loosen the screw which

secures the pointer and adjust the pointer so that it will

point to 0°. (Fig. 57)

23

Page 24

2. Bevel angle

Push the latch lever forward fully to release the positive

stops.

1) 0° bevel angle

Push the carriage toward the guide fence and

tighten the locking screw clockwise and pull the lock

lever towards the front of the saw to secure the carriage. Lower the handle fully and lock it in the lowered position by pushing in the stopper pin. Loosen

the lever at the rear of the tool. (Fig. 58)

Turn the hex socket bolt on the right side of the arm

holder two or three revolutions counterclockwise to

tilt the blade to the right. (Fig. 59)

Carefully square the side of the blade with the top

surface of the turn base using the triangular rule, trysquare, etc. by turning the hex socket bolt on the

right side of the arm holder clockwise. Then tighten

the lever securely. (Fig. 60)

Make sure that the pointers on the arm holder point

to each 0° on the bevel scale on the arm. If they do

not point to 0°, loosen the screws which secure the

pointers and adjust them so that they will point to 0°.

(Fig. 61)

2) 45° bevel angle (Fig. 62)

Adjust the 45° bevel angle only after performing 0°

bevel angle adjustment. To adjust left 45° bevel

angle, loosen the lever and tilt the blade to the left

fully. Make sure that the pointer on the arm holder

points to 45° on the bevel scale on the arm. If the

pointer does not point to 45°, turn the left 45° bevel

angle adjusting bolt on the side of the arm until the

pointer points to 45°.

To adjust right 45° bevel angle, perform the same

procedure described above.

Adjustment of the laser line position (Fig. 63 & 64)

For models LS1016L and LS1016FL only

WARNING:

• Since the tool must be plugged in while adjusting

the laser line, special care must be taken to not

switch on the tool. Accidental start up of the tool may

result in serious personal injury.

CAUTION:

• Never look directly into the laser beam. Direct eye

exposure to the beam could cause serious damage to

the eyes.

• LASER RADIATION

Do not stare into beam.

NOTICE:

• Beware that impacts to the tool may cause the laser

line to be misaligned or may cause damage to the

laser, shortening its life.

Adjusting the laser line for the left side of the blade.

1

4

5

2

3

1 Screw to change the movable range of the adjusting

screw

2 Adjusting screw

3 Hex wrench

4 Laser line

5 Saw blade

Adjusting the laser line for the right side of the

blade.

1

1 Adjusting screw

2 Saw blade

3 Laser line

For both adjustments, do as follows.

1. Make sure that the tool is unplugged.

2. Draw the cutting line on the workpiece and place it

on the turn table. At this time, do not secure the

workpiece with a vise or similar securing device.

3. Lower the blade by lowering the handle and just

check to see where the cutting line and the position

of the saw blade is. (Decide which position to cut on

the line of cut.)

4. After deciding the correct position of the line in rela-

tion to the blade, return the handle to the original

position. Secure the workpiece with the vertical vise

without shifting the workpiece from the pre-checked

position.

5. Plug the tool and turn on the laser switch.

6. Adjust the position of laser line as follows.

The position of laser line can be changed as the movable

range of the adjusting screw for the laser is changed by

turning two screws with a hex wrench. (The movable

range of laser line is factory adjusted within 1 mm from

the side surface of blade.)

2

3

24

Page 25

To shift the laser line movable range further away from

the side surface of blade, turn the two screws counterclockwise after loosening the adjusting screw. Turn these

two screws clockwise to shift it closer to the side surface

of the blade after loosening the adjusting screw.

Refer to the section titled “Laser beam action” and adjust

the adjusting screw so that the cutting line on your workpiece is aligned with the laser line.

NOTE:

• Check the position of laser line regularly for accuracy.

• Have the tool repaired by a Makita authorized service

center for any failure on the laser unit.

Cleaning the laser light lens (Fig. 65 & 66)

For models LS1016L and LS1016FL only

If the lens for the laser light becomes dirty, or sawdust

adheres to it in such a way that the laser line is no longer

easily visible, unplug the saw and remove and clean the

lens for the laser light carefully with a damp, soft cloth.

Do not use solvents or any petroleum-based cleaners on

the lens.

To remove the lens for the laser light, remove the saw

blade before removing the lens according to the instructions in the section titled “Installing or removing saw

blade”.

Loosen but do not remove the screw which secures the

lens using a screwdriver.

Pull out the lens as shown in the figure.

NOTE:

• If the lens does not come out, loosen the screw further

and pull out the lens again without removing the screw.

Replacing carbon brushes (Fig. 67 & 68)

Remove and check the carbon brushes regularly.

Replace when they wear down to the limit mark. Keep

the carbon brushes clean and free to slip in the holders.

Both carbon brushes should be replaced at the same

time. Use only identical carbon brushes.

Use a screwdriver to remove the brush holder caps. Take

out the worn carbon brushes, insert the new ones and

secure the brush holder caps.

After replacing brushes, plug in the tool and break in

brushes by running tool with no load for about 10 minutes. Then check the tool while running and electric

brake operation when releasing the switch trigger. If the

electric brake is not working correctly, have the tool

repaired by a Makita service center.

After use

• After use, wipe off chips and dust adhering to the tool

with a cloth or the like. Keep the blade guard clean

according to the directions in the previously covered

section titled “Blade guard”. Lubricate the sliding portions with machine oil to prevent rust.

• When storing the tool, pull the carriage toward you fully

so that the slide pole is thoroughly inserted into the turn

base.

To maintain product SAFETY and RELIABILITY, repairs,

any other maintenance or adjustment should be performed by Makita Authorized Service Centers, always

using Makita replacement parts.

ACCESSORIES

WARNING:

• These accessories or attachments are recommended for use with your Makita tool specified in

this manual. The use of any other accessories or

attachments may result in serious personal injury.

• Only use the Makita accessory or attachment for its

stated purpose. Misuse of an accessory or attachment may result in serious personal injury.

If you need any assistance for more details regarding

these accessories, ask your local Makita Service Center.

• Steel & Carbide-tipped saw blades

Miter saw blades

Combination

Crosscutting

Fine cross cuts

Non-ferrous metals

miter saw blades

• Vise assembly (Horizontal vise)

• Vertical vise

• Socket wrench 13

• Holder

• Dust bag

• Crown molding stopper set

• Triangular rule

• Dust box

• Hex wrench (For LS1016L and LS1016FL)

For smooth and precise cutting in

various materials.

General purpose blade for fast

and smooth rip, crosscuts and

miters.

For smoother cross grain cuts.

Slices cleanly against the grain.

For sand-free cuts cleanly against

the grain.

For miters in aluminum, copper,

brass, tubing, and other non-ferrous metals.

25

Page 26

FRANÇAIS (Instructions originales)

Descriptif

1 Broche d’arrêt

2 Boulon(s) hexagonal(aux)

3 Protecteur de lame

4 Plateau de découpe

5 Lame de scie

6 Dents de lame

7 Coupe en biseau à gauche

8 Coupe droite

9 Coupe en biseau à droite

10 Levier de verrouillage

11 Vis

12 Boulon de réglage

13 Plateau tournant

14 Levier de butée

15 Tuyau de glissement

16 Face supérieure du plateau

tournant

17 Périphérie de la lame

18 Guide

19 Vis de réglage

20 Bras de blocage

21 Poignée

22 Came

23 Levier(s)

24 Levier de fermeture

25 Secteur angulaire

26 Bouton de libération

27 Index

28 Bouton de déverrouillage

29 Gâchette

30 Orifice pour cadenas

31 Interrupteur du laser

32 Clé à douille

33 Support à clé

34 Capot central

SPECIFICATIONS

Modèle LS1016/LS1016L/LS1016F/LS1016FL

Diamètre de la lame

Pour tous les pays à l’exception de l’Europe .................................................................................. 255 mm et 260 mm

Pour l’Europe.................................................................................................................................................... 260 mm

Diamètre de l’orifice

Pour tous les pays à l’exception de l’Europe ................................................................................................... 25,4 mm

Pour l’Europe...................................................................................................................................................... 30 mm

Capacités de coupe maximales (H x P) avec une lame d’un diamètre de 260 mm

Angle d’onglet

0°

45° (droite et gauche)

52° (droite et gauche) –

60° (droite) –

35 Blocage de l’arbre

36 Carter de lame

37 Flèche

38 Flasque extérieur

39 Flasque intérieur

40 Axe

41 Bague

42 Raccord à poussières

43 Sac à poussière

44 Fermeture

45 Boîte à poussières

46 Couvercle

47 Bouton

48 Section cylindrique

49 Sciure de bois

50 Cale

51 Plateau tournant

52 Vis de serrage

53 Guide supérieur

54 Guide inférieur

55 Poignée de l’étau

56 Bras de l’étau

57 Tige de l’étau

58 Plaque d’étau

59 Ecrou de l’étau

60 Servante

61 Moulure couronnée du type

52/38°

62 Moulure couronnée du type 45°

63 Moulure concave du type 45°

64 Coin intérieur

65 Coin extérieur

66 Butée de moulure couronnée de

gauche (Accessoire en option)

Angle de biseau

45° (gauche) 0° 45° (droite)

42 mm x 310 mm 68 mm x 310 mm 29 mm x 310 mm

58 mm x 279 mm 91 mm x 279 mm 43 mm x 279 mm

42 mm x 218 mm 68 mm x 218 mm 29 mm x 218 mm

58 mm x 197 mm 91 mm x 197 mm 43 mm x 197 mm

68 mm x 190 mm

91 mm x 171 mm

68 mm x 155 mm

91 mm x 139 mm

67 Butée de moulure couronnée de

droite (Accessoire en option)

68 Butée de moulure couronnée de

gauche

69 Butée de moulure couronnée de

droite

70 Moulure couronnée

71 Étau

72 Cale d’écartement

73 Profilé d’aluminium

74 Coupe de rainures avec la lame

75 Règle triangulaire

76 Secteur

77 Plaque graduée de coupe en

biseau

78 Boulon de réglage d’angle 0°

79 Secteur angulaire

80 Boulon de réglage de l’angle

de biseau de 45° à gauche

81 Boulon de réglage de l’angle

de biseau de 45° à droite

82 Pièce à travailler

83 Ligne laser

84 Étau vertical

85 Tournevis

86 Vis (une pièce seulement)

87 Lentille du laser

88 Repère d’usure

89 Bouchon de porte-charbon

90 Vis de verrouillage

91 Interrupteur de lampe