Page 1

INSTRUCTION MANUAL

MANUEL D'INSTRUCTION

MANUAL DE INSTRUCCIONES

Metal Cutting Saw

Meule à couper le métal

Sierra Tronzadora

LC1230

003770

DOUBLE INSULATION

DOUBLE ISOLATION

WARNING:

For your personal safety, READ and UNDERSTAND before using.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

AVERTISSEMENT:

Pour votre propre sécurité, prière de lire attentivement avant l'utilisation.

GARDER CES INSTRUCTIONS POUR RÉFÉRENCE ULTÉRIEURE.

ADVERTENCIA:

Para su seguridad personal, LEA DETENIDAMENTE este manual antes de usar la

herramienta.

GUARDE ESTAS INSTRUCCIONES PARA FUTURA REFERENCIA.

DOBLE AISLAMIENTO

1

Page 2

ENGLISH

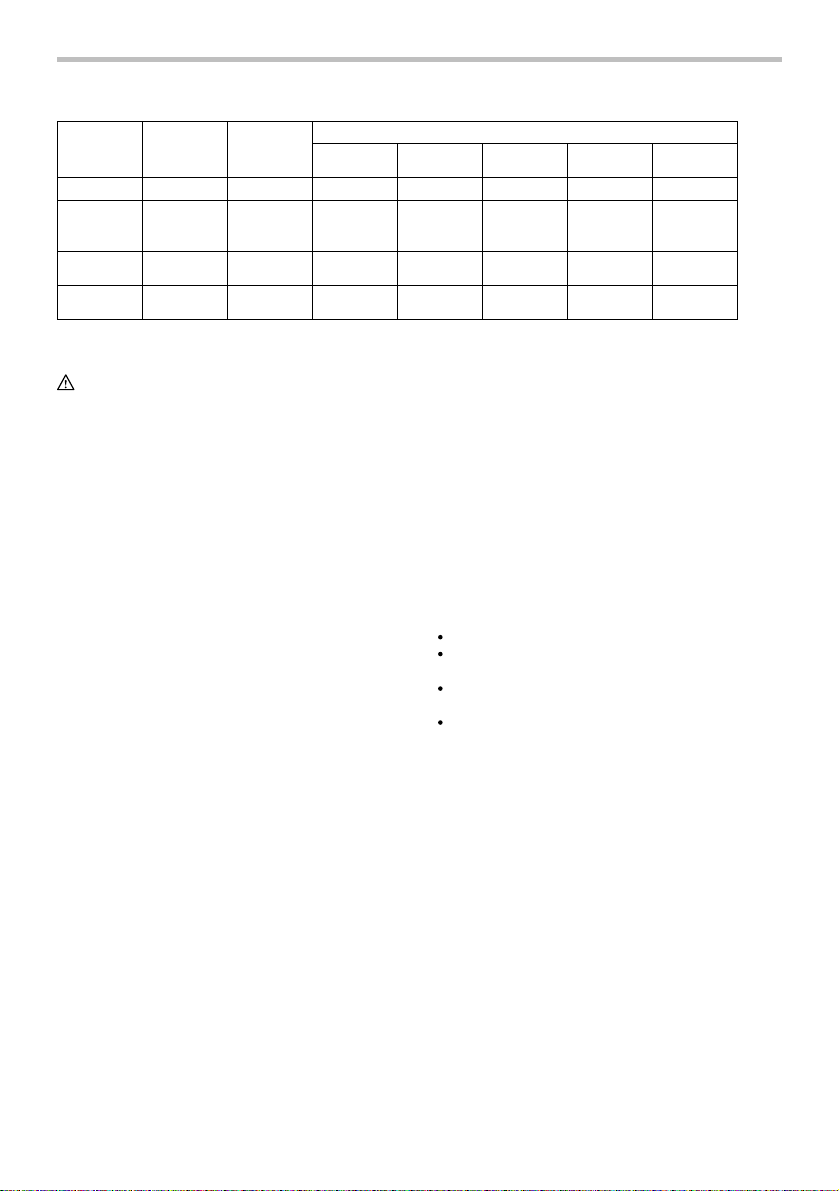

SPECIFICATIONS

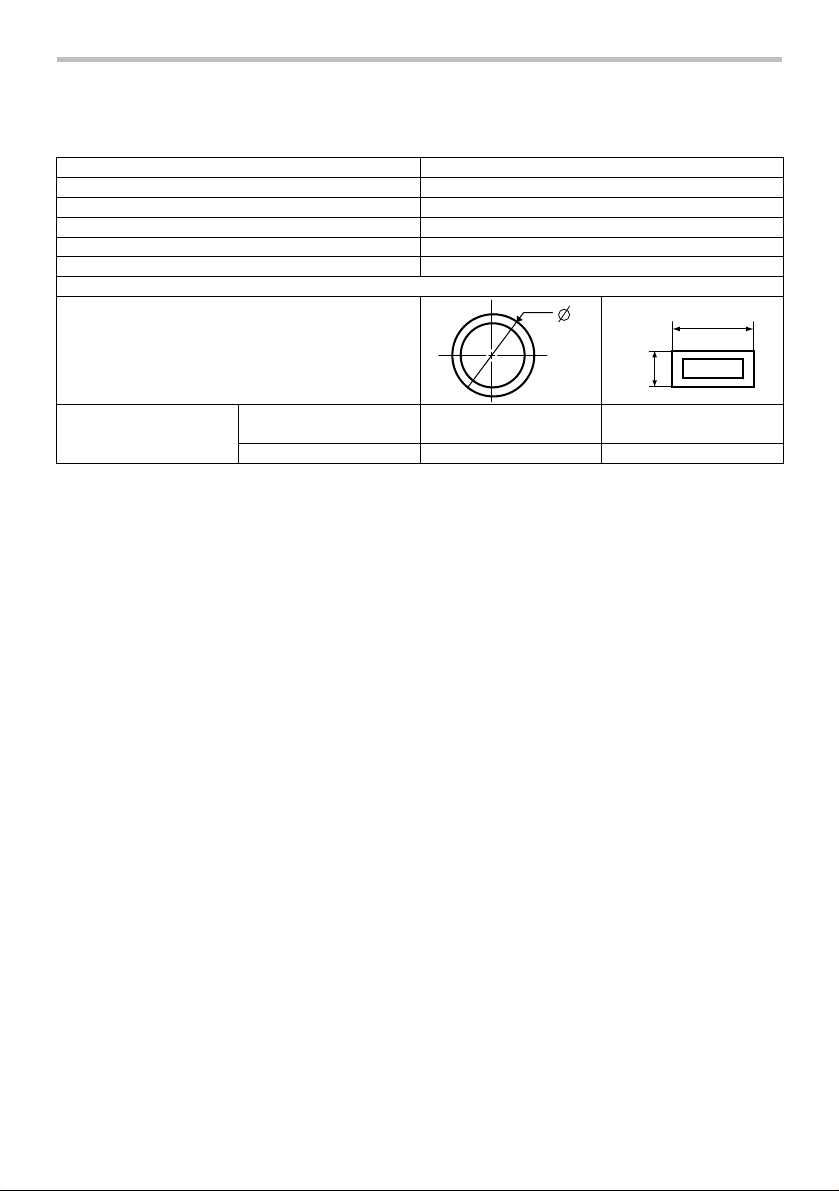

Model LC1230

Blade diameter 305 mm (12")

Hole (arbor) diameter 25.4 mm (1")

No load speed (RPM) 1,300 /min.

Dimensions (L x W x H) 516 mm x 306 mm x 603 mm (20-1/3" x 12" x 23-5/8")

Cutting capacity

Cutting angle

• Due to our continuing programme of research and development, the specifications herein are subject to change without notice.

• Note: Specifications may differ from country to country.

For Your Own Safety Read

Instruction Manual

Before Operating Tool

Save it for future reference

GENERAL SAFETY

PRECAUTIONS

(For All Tools)

1. KNOW YOUR POWER TOOL. Read the owner's

manual carefully. Learn the tool's applications

and limitations, as well as the specific

potential hazards peculiar to it.

2. KEEP GUARDS IN PLACE and in working

order.

3. REMOVE ADJUSTING KEYS AND WRENCHES.

Form habit of checking to see that keys and

adjusting wrenches are removed from tool

before turning it on.

4. KEEP WORK AREA CLEAN. Cluttered areas

and benches invite accidents.

Net weight 19.0kg (41.8 lbs)

A

Workpiece shape

90° 115mm (4-1/2")

45° 90mm (3-1/2")

USA007-2

5. DO NOT USE IN DANGEROUS ENVIRONMENT.

Do not use power tools in damp or wet

locations, or expose them to rain. Keep work

area well lighted. Do not use tool in presence

of flammable liquids or gases.

6. KEEP CHILDREN AWAY. All visitors should be

kept safe distance from work area.

7. MAKE WORKSHOP KID PROOF with padlocks,

master switches, or by removing starter keys.

8. DO NOT FORCE TOOL. It will do the job better

and safer at the rate for which it was designed.

9. USE RIGHT TOOL. Do not force tool or

attachment to do a job for which it was not

designed.

10. WEAR PROPER APPAREL. Do not wear loose

clothing, gloves, neckties, rings, bracelets, or

other jewelry which may get caught in moving

parts. Nonslip footwear is recommended.

Wear protective hair covering to contain long

hair.

11. ALWAYS USE SAFETY GLASSES. Also use

face or dust mask if cutting operation is dusty.

Everyday eyeglasses only have impact

resistant lenses, they are NOT safety glasses.

12. SECURE WORK. Use clamps or a vise to hold

work when practical. It's safer than using your

hand and it frees both hands to operate tool.

13. DO NOT OVERREACH. Keep proper footing

and balance at all times.

2

A X B

A

75 mm x 150 mm (2-15/16" x 5-7/8")

100 mm x 100 mm (3-15/16" x 3-15/16")

85 mm x 85mm (3-5/16" x 3-5/16")

B

Page 3

14. MAINTAIN TOOLS WITH CARE. Keep tools

sharp and clean for best and safest

performance. Follow instructions for

lubricating and changing accessories.

15. DISCONNECT TOOLS before servicing; when

changing accessories such as blades, bits,

cutters, and the like.

16. REDUCE THE RISK OF UNINTENTIONAL

STARTING. Make sure switch is in off position

before plugging in.

17. USE RECOMMENDED ACCESSORIES.

Consult the owner's manual for recommended

accessories. The use of improper accessories

may cause risk of injury to persons.

18. NEVER STAND ON TOOL. Serious injury could

occur if the tool is tipped or if the cutting tool

is unintentionally contacted.

19. CHECK DAMAGED PARTS. Before further use

of the tool, a guard or other part that is

damaged should be carefully checked to

determine that it will operate properly and

perform its intended function - check for

alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any

other conditions that may affect its operation.

A guard or other part that is damaged should

be properly repaired or replaced.

20. DIRECTION OF FEED. Feed work into a blade

or cutter against the direction of rotation of the

blade or cutter only.

21. NEVER LEAVE TOOL RUNNING UNATTENDED.

TURN POWER OFF. Do not leave tool until it

comes to a complete stop.

22. REPLACEMENT PARTS. When servicing, use

only identical replacement parts.

23. POLARIZED PLUGS. To reduce the risk of

electric shock, this appliance has a polarized

plug (one blade is wider than the other). This

plug will fit in a polarized outlet only one way.

If the plug does not fit fully in the outlet,

reverse the plug. If it still does not fit, contact a

qualified electrician to install the proper outlet.

Do not change the plug in any way.

VOLTAGE WARNING: Before connecting the tool to a

power source (receptacle, outlet, etc.) be sure the

voltage supplied is the same as that specified on the

nameplate of the tool. A power source with voltage

greater than that specified for the tool can result in

SERIOUS INJURY to the user- as well as damage to

the appliance. If in doubt, DO NOT PLUG IN THE

APPLIANCE. Using a power source with voltage less

than the nameplate rating is harmful to the motor.

USE PROPER EXTENSION CORD. Make sure your

extension cord is in good condition. When using an

extension cord, be sure to use one heavy enough to

carry the current your product will draw. An

undersized cord will cause a drop in line voltage

resulting in loss of power and overheating. Table 1

shows the correct size to use depending on cord

length and nameplate ampere rating. If in doubt, use

the next heavier gage. The smaller the gage number,

the heavier the cord.

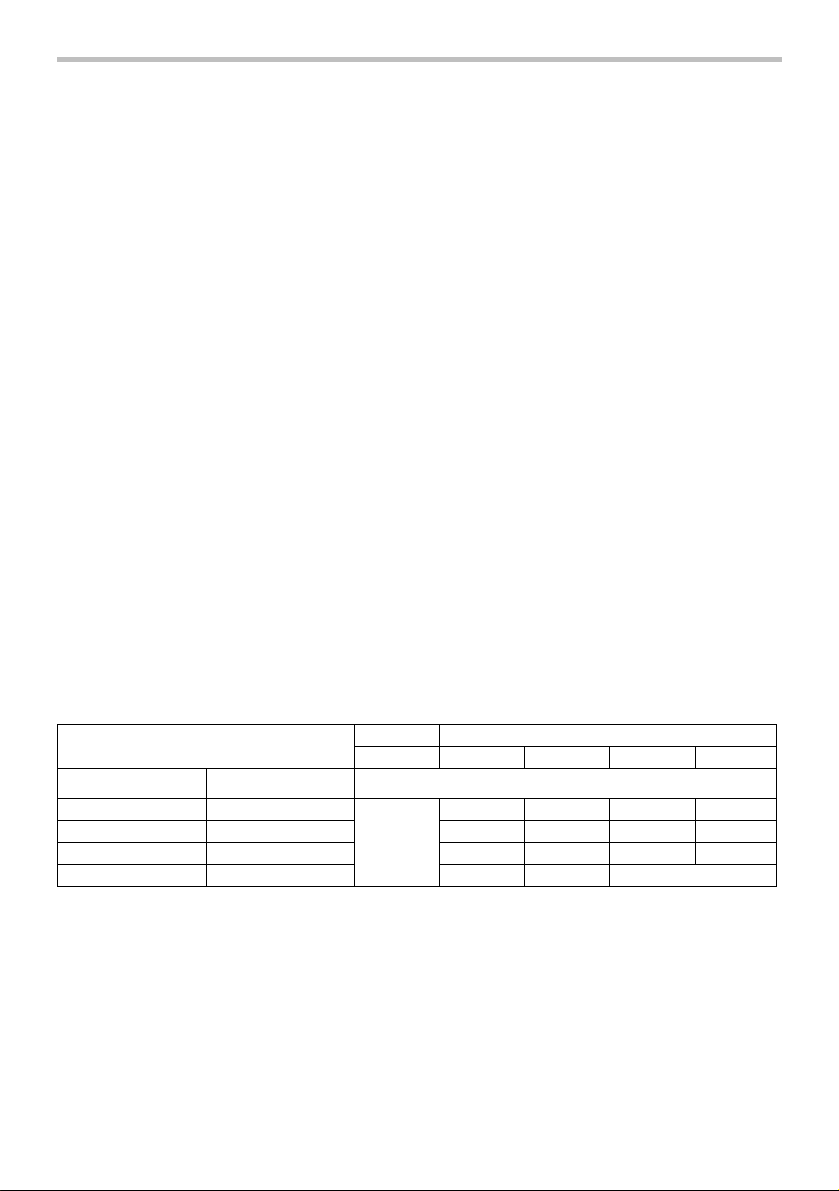

Table 1: Minimum gage for cord

Ampere Rating

Volts Total length of cord in feet

120 V 25 ft. 50 ft. 100 ft. 150 ft.

More Than Not More Than AWG

0 6 18 16 16 14

18 16 14 12610

10 12 16 16 14 12

000173

ADDITIONAL SAFETY RULES

DO NOT let comfort or familiarity with product

(gained from repeated use) replace strict adherence

to metal cutting saw safety rules. If you use this tool

unsafely or incorrectly, you can suffer serious

personal injury.

1. Wear eye protection.

12 16 14 12

USB079-2

2. Keep hands out of path of saw blade. Avoid

contact with any coasting blade. It can still

cause severe injury.

3. Do not operate saw without guards in place.

Check blade guard for proper closing before

each use. Do not operate saw if blade guard

does not move freely and close instantly.

Never clamp or tie the blade guard into the

open position.

3

Not Recommended

Page 4

4. Do not perform any operation freehand. The

workpiece must be secured firmly against the

base with a vise during all operations. Never

use your hand to secure the workpiece.

5. Never reach around saw blade.

6. Turn off tool and wait for saw blade to stop

before moving workpiece or changing

settings.

7. Do not use the tool in the presence of

flammable liquids or gases.

8. Check the blade carefully for cracks or

damage before operation. Replace cracked or

damaged blade immediately.

9. Use only flanges specified for this tool.

10. Be careful not to damage the arbor, flanges

(especially the installing surface) or bolt.

Damage to these parts could result in blade

breakage.

11. Make sure that the base is properly secured so

it will not move during operation. Use the

holes in the base to fasten the saw to a stable

work platform or bench. NEVER use tool

where operator positioning would be

awkward.

12. For your safety, remove the chips, small

pieces, etc. from the table top before

operation.

13. Make sure the shaft lock is released before the

switch is turned on.

14. Be sure that the blade does not contact the

base in the lowest position.

15. Hold the handle firmly. Be aware that the saw

moves up or down slightly during start-up and

stopping.

16. Make sure the blade is not contacting the

workpiece before the switch is turned on.

17. Before using the tool on an actual workpiece,

let it run for a while. Watch for vibration or

wobbling that could indicate poor installation

or a poorly balanced blade.

18. Wait until the blade attains full speed before

cutting.

19. Stop operation immediately if you notice

anything abnormal.

20. Do not attempt to lock the trigger in the "ON"

position.

21. Shut off power and wait for saw blade to stop

before moving workpiece or adjusting tool.

22. Be alert at all times, especially during

repetitive, monotonous operations. Do not be

lulled into a false sense of security. Blades are

extremely unforgiving.

23. Always use accessories recommended in this

manual. Use of improper accessories such as

abrasive wheels may cause an injury.

24. Do not abuse cord. Never yank cord to

disconnect it from the receptacle. Keep cord

away from heat, oil, water and sharp edges.

25. Never attempt to cut workpiece less than 14

gauge (0.08") thick except pipe or workpiece

which cannot be secured firmly with a vise.

The piece cut off may be caught by the blade,

causing dangerous scattering of chips and/or

damage to the carbide-chips. Possible serious

injury may result.

26. Unplug tool before changing blade or

servicing.

SAVE THESE INSTRUCTIONS.

WARNING:

MISUSE or failure to follow the safety rules stated in

this instruction manual may cause serious personal

injury.

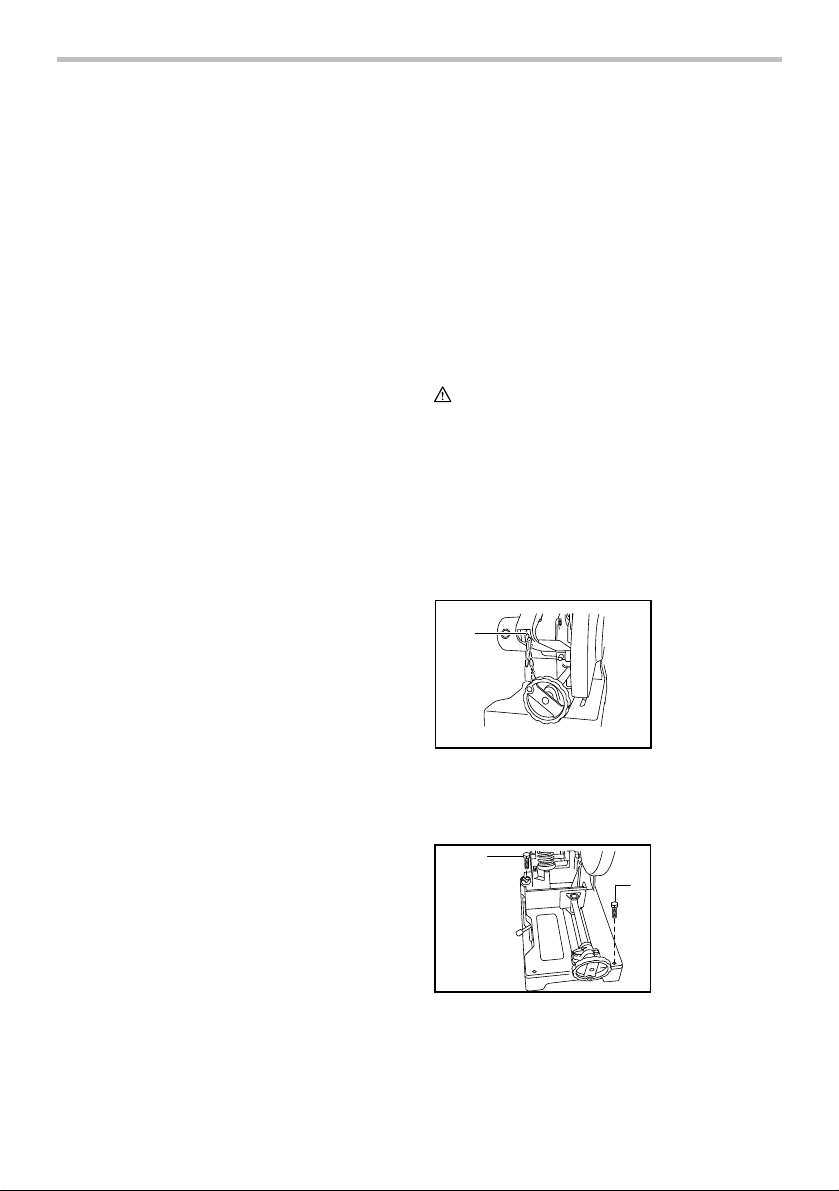

INSTALLATION

Positioning the tool

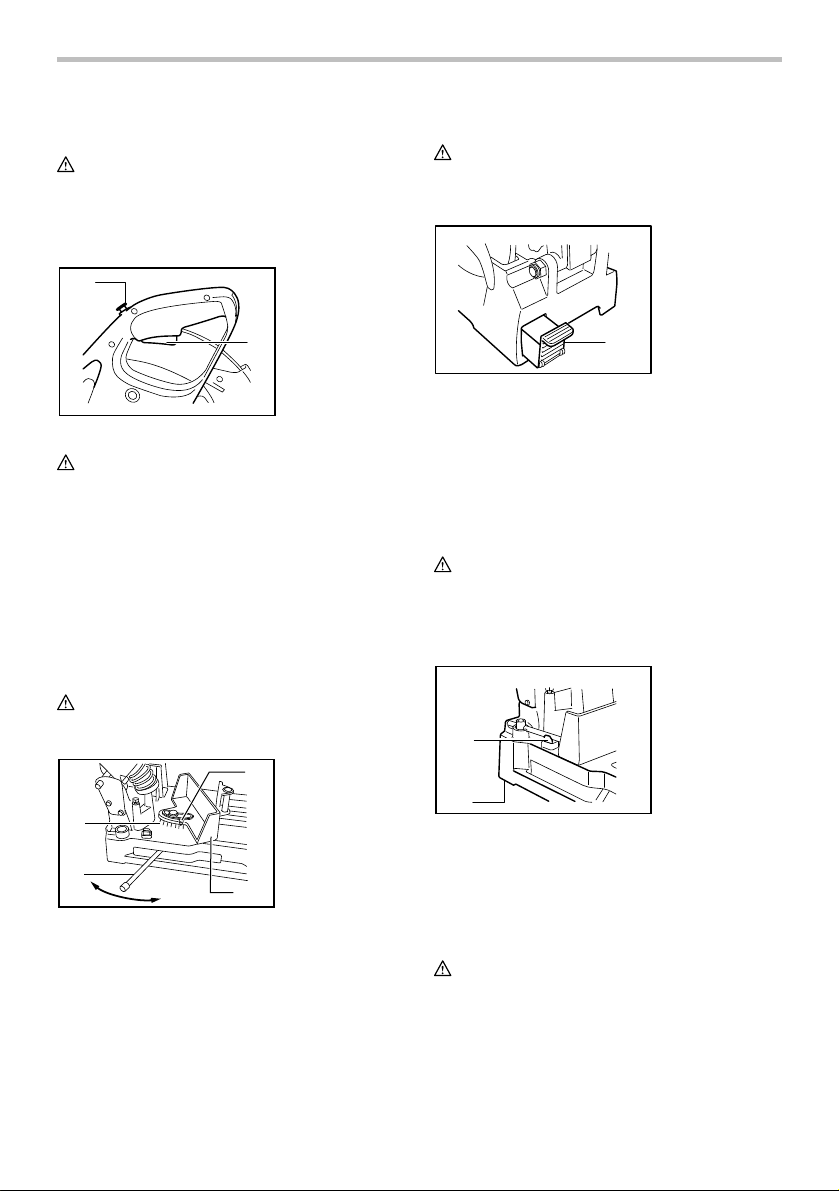

When the tool is shipped from the factory, the handle is

locked in the lowered position. Release the handle from

the lowered position by lowering it slightly and removing

the chain from the hook on the handle.

1. Hook

1

003771

Bolt the tool with two bolts to a level and stable surface

using the bolt holes provided in the tool base. This will

help prevent tipping and possible injury.

1

003772

1. Bolt

1

4

Page 5

FUNCTIONAL DESCRIPTION

CAUTION:

• Always be sure that the tool is switched off and

unplugged before adjusting or checking function on

the tool.

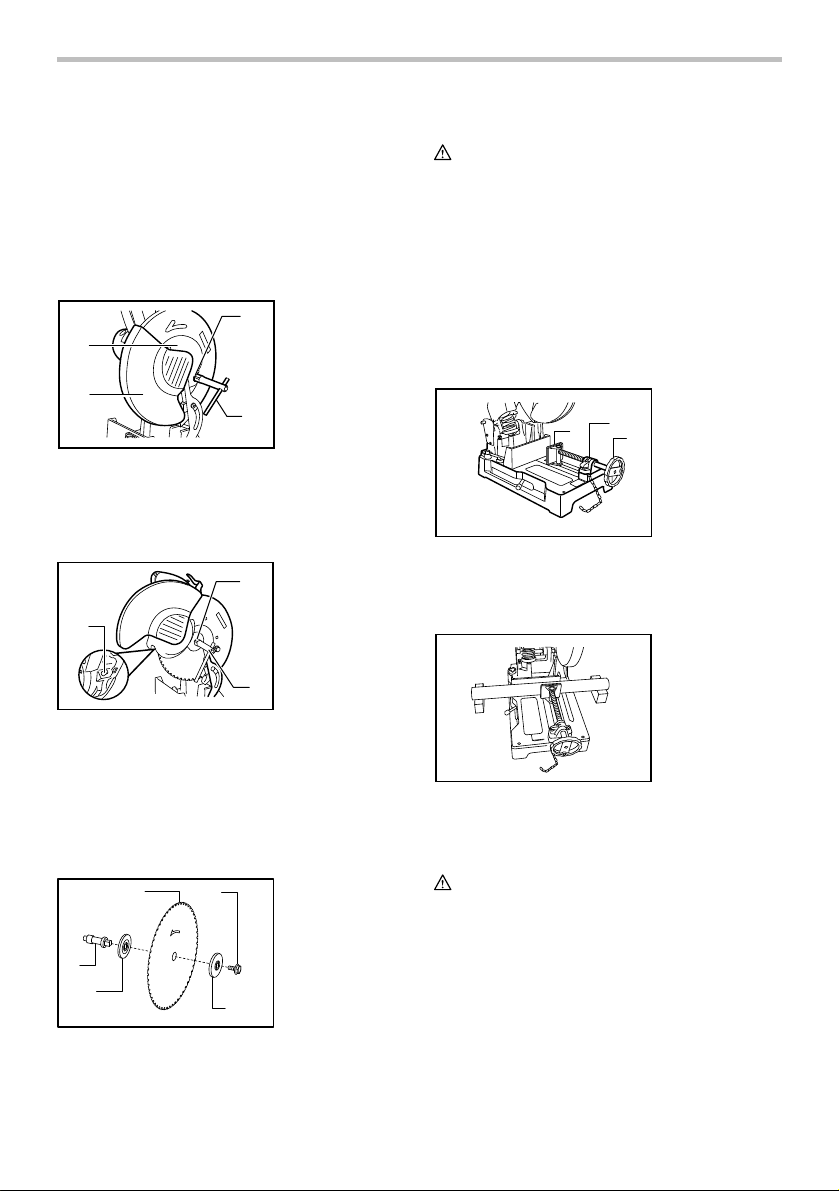

Switch action

1

1. Lock-off button

2. Switch trigger

Dust collection

CAUTION:

• Do not touch any part of the dust box except its

handle immediately after operation; it may be

extremely hot and could burn your skin.

1. Dust box

2

003773

CAUTION:

• Before plugging in the tool, always check to see

that the switch trigger actuates properly and

returns to the "OFF" position when released.

• When not using the tool, remove the lock-off button

and store it in a secure place. This prevents

unauthorized operation.

To prevent the switch trigger from being accidentally

pulled, a lock-off button is provided.

To start the tool, depress the lock-off button and pull the

switch trigger. Release the switch trigger to stop.

Setting for desired cutting angle

CAUTION:

• Always tighten the hex bolt securely after changing

the cutting angle.

1. Graduation

3

2. Lever

3. indicator

1

4. Vise stop

2

4

003774

To change the cutting angle, loosen the lever. Move the

vise stop so that the indicator will point to the desired

graduation. Then tighten the lever to secure the vise

stop.

1

003775

This tool is equipped with the dust box to collect dust

and cut chips. When the dust box is full, hold the handle

of the dust box and raise it slightly. Then pull the dust

box out of the tool base. Empty the dust box of its

contents.

ASSEMBLY

CAUTION:

• Always be sure that the tool is switched off and

unplugged before carrying out any work on the

tool.

Socket wrench storage

1. Wrench holder

2. Base

1

2

003776

The socket wrench is stored as shown in the figure.

When using the socket wrench, pull it out of the wrench

holder. After using the socket wrench, return it to the

wrench holder.

Installing or removing saw blade

CAUTION:

• When mounting the blade, make sure that the

direction of the arrow on the surface of the blade

matches the direction of the arrow on the blade

case.

5

Page 6

• Use only the Makita socket wrench provided to

install or remove the blade. Failure to do so may

result in overtightening or insufficient tightening of

the hex bolt. This could cause a personal injury.

• Do not touch the blade immediately after operation;

it may be extremely hot and could burn your skin.

To remove the blade, use the socket wrench to loosen

the hex bolt holding the center cover by turning it

counterclockwise. Raise the blade guard and center

cover.

1. Center cover

2

2. Hex bolt

1

4

003777

Press the shaft lock to lock the spindle and use the

socket wrench to loosen the hex bolt by turning

counterclockwise. Then remove the hex bolt, outer

flange and blade.

2

003778

To install the blade, mount the inner flange, saw blade,

outer flange and hex bolt onto the spindle in that order.

Tighten the hex bolt by turning clockwise while pressing

the shaft lock. Return the blade guard and center cover

to the original position. Then tighten the hex bolt

clockwise to secure the center cover. Lower the handle

to make sure that the blade guard moves properly.

1

3

4

003801

2

3. Socket wrench

4. Blade guard

3

1. Hex bolt

1

2. Shaft lock

3. Socket wrench

3

1. Carbide-tipped

saw blade

2. Hex bolt

3. Spindle

4. Inner flange

5. Outer flange

5

Securing workpiece

CAUTION:

• Always set the vise nut to the right fully when

securing the workpiece. Failure to do so may result

in insufficient securing of the workpiece. This could

cause the workpiece to be ejected or cause

damage to the blade.

By turning the vise handle counterclockwise and then

flipping the vise nut to the left, the vise is released from

the shaft threads and can be moved rapidly in and out.

To grip workpieces, push the vise handle until the vise

plate contacts the workpiece. Flip the vise nut to the right

and then turn the vise handle clockwise to securely

retain the workpiece.

1. Vise plate

2. Vise nut

2

1

003780

Long workpieces must be supported by blocks of

non-flammable material on either side so that it will be

level with the base top.

003781

3. Vise handle

3

OPERATION

Cutting operation

CAUTION:

• Never attempt to cut workpieces less than 14

gauge (0.08") thick except pipe or workpieces

which cannot be secured firmly with the vise. The

piece cut off may be caught by the blade, causing

dangerous scattering of chips and/or damage to

the carbide-tips. Possible serious injury may result.

• Do not apply excessive pressure on the handle

when cutting. Too much pressure may result in

overload of the motor, decreased cutting efficiency

and/or damage to the carbide-tips or blade itself.

6

Page 7

• Too little pressure on the handle may result in more

sparks and premature blade wear.

• Do not touch the blade, workpiece or cutting chips

immediately after operation; they may be

extremely hot and could burn your skin.

• If the blade stops during operation, makes an odd

noise or begins to vibrate, switch off the tool

immediately. Replace cracked or damaged blade

with a new one.

Hold the handle firmly. Switch on the tool and wait until

the blade attains full speed. Then lower the handle

gently to bring the blade close to the workpiece. When

the blade makes contact, ease into the cut gently at first,

then gradually add pressure as the cutting position

steadies. Your pressure on the handle should be

adjusted to produce the minimum amount of sparks.

When the cut is completed, switch off the tool and WAIT

UNTIL THE BLADE HAS COME TO A COMPLETE

STOP before returning the handle to the fully elevated

position. If the handle is raised while the blade is still

rotating, the piece cut off may be caught by the blade,

causing dangerous scattering of chips. When cutting

only part of the way into a workpiece, raise the handle

while the blade is rotating. Switching off during the cut

may cause damage to the carbide-tips as they contact

the workpiece.

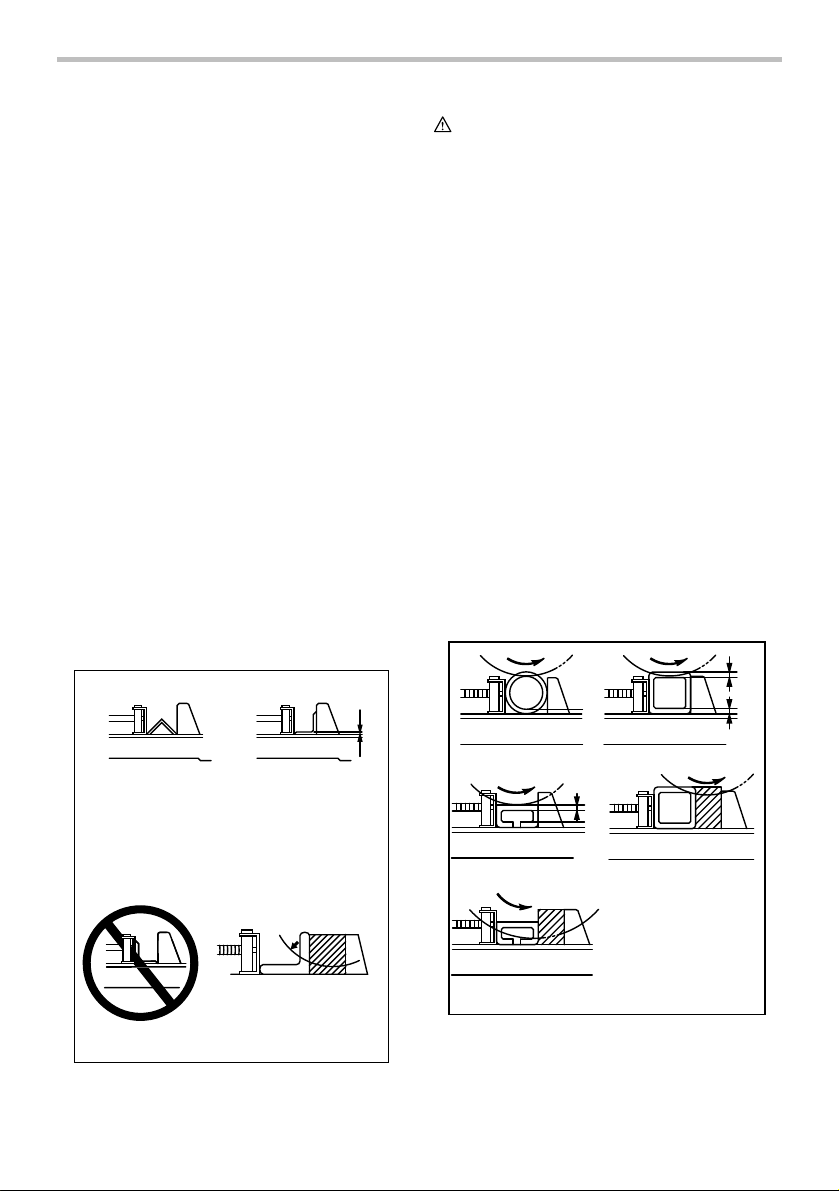

Cutting angles

Secure the workpiece in the vise as shown in the Figure

A and proceed to cut it. The saw blade life will be

shortened if the workpiece is cut as shown in the Fig B.

CAUTION:

• Do NOT cut the workpiece as shown in the Fig. C

since this may cause it to be ejected from the vise,

possibly resulting in injury.

The saw blade is subjected to greater wear when the

area A in the Fig. B is cut. Place a wooden block up

against the workpiece as shown in the Fig. D so that the

saw blade will enter area A at an angle. This will help to

extend the saw blade life.

The allowable cutting dimensions are reduced when a

wooden block is used. Use a wooden block whose

dimensions are equivalent to the maximum allowable

cutting dimensions minus the dimensions of the

workpiece to be cut. This will further minimize the

shortening of the saw blade life.

Cutting pipes, squares and channels

The saw blade is subjected to greater wear when the

areas A and B in figure F and figure G are cut. Place a

wooden block up against the workpiece as shown in

figure H and figure I so that the saw blade will enter

areas A and B at an angle. This will help to minimize the

shortening of the saw blade life.

The allowable cutting dimensions are reduced when a

wooden block is used. Use a wooden block whose

dimensions are equivalent to the maximum allowable

cutting dimensions minus the dimensions of the

workpiece to be cut. This will further minimize the

shortening of the saw blade life.

A

003782

Fig. A Fig. B

Fig. C

Fig. D

B

A

Fig. E Fig. F

A

Fig. G

Fig. H

Fig. I

003783

7

Page 8

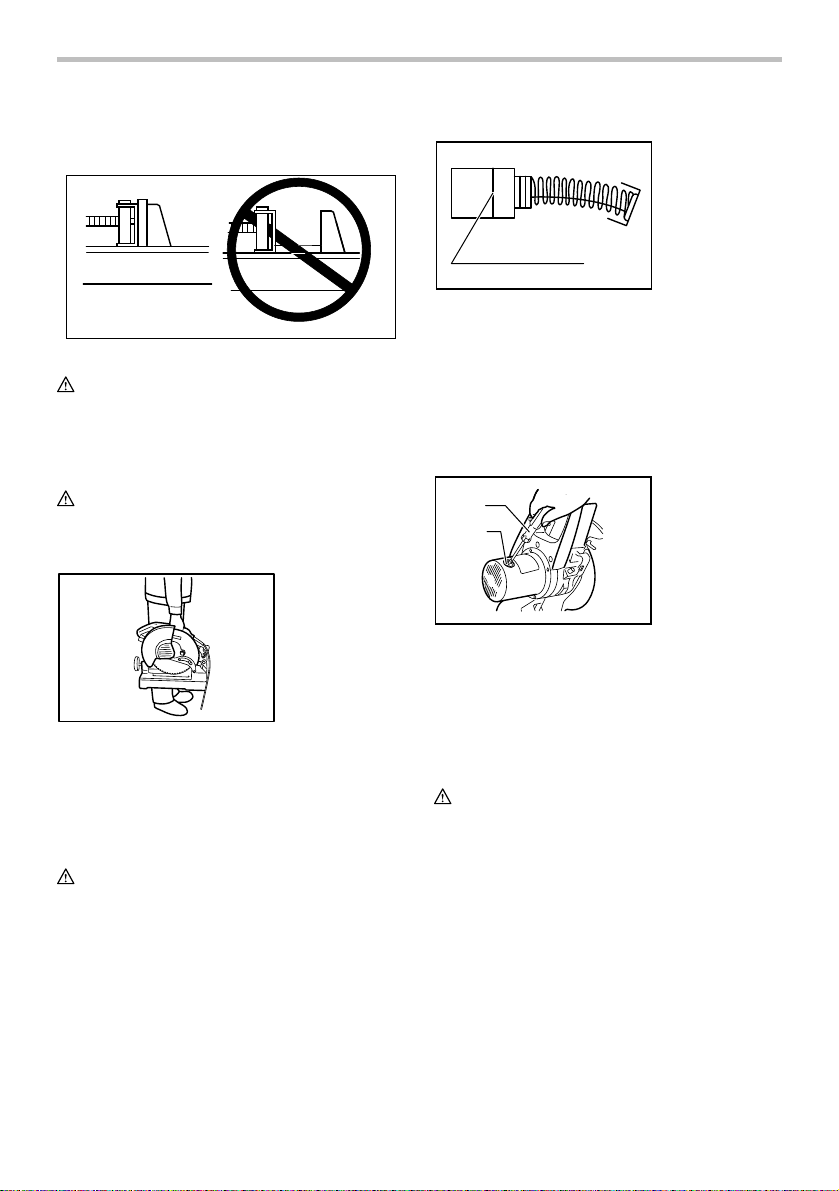

Cutting rectangles

Secure the workpiece in the vise as shown in figure J,

and proceed to cut it.

Fig. J

003784

CAUTION:

• Do NOT cut the workpiece as shown in figure K

since this may cause it to be ejected from the vise,

possibly resulting in injury.

Carrying tool

CAUTION:

• The chain for transportation shall be adjusted to

minimize the accessible zone of the saw blade

before transporting the tool.

Fig. K

Replacing carbon brushes

1. Limit mark

1

001145

Remove and check the carbon brushes regularly.

Replace when they wear down to the limit mark. Keep

the carbon brushes clean and free to slip in the holders.

Both carbon brushes should be replaced at the same

time. Use only identical carbon brushes.

Use a screwdriver to remove the brush holder caps.

Take out the worn carbon brushes, insert the new ones

and secure the brush holder caps.

1

2

1. Screwdriver

2. Brush holder

cap

003785

Fold down the tool head to the position where you can

attach the chain to the hook on the handle. Grasp the

carrying grip when carrying the tool.

MAINTENANCE

CAUTION:

• Always be sure that the tool is switched off and

unplugged before attempting to perform inspection

or maintenance.

Replacing saw blade

Continuing to use a dull and worn blade may cause

motor overload and decreased cutting efficiency.

Replace with a new blade as soon as it is no longer

effective.

003786

To maintain product SAFETY and RELIABILITY, repairs,

any other maintenance or adjustment should be

performed by Makita Authorized or Factory Service

Centers, always using Makita replacement parts.

ACCESSORIES

CAUTION:

• These accessories or attachments are

recommended for use with your Makita tool

specified in this manual. The use of any other

accessories or attachments might present a risk of

injury to persons. Only use accessory or

attachment for its stated purpose.

If you need any assistance for more details regarding

these accessories, ask your local Makita Service Center.

• Socket wrench 17

• Safety goggle

• Lock-off button (Switch button)

• Carbide-tipped saw blade

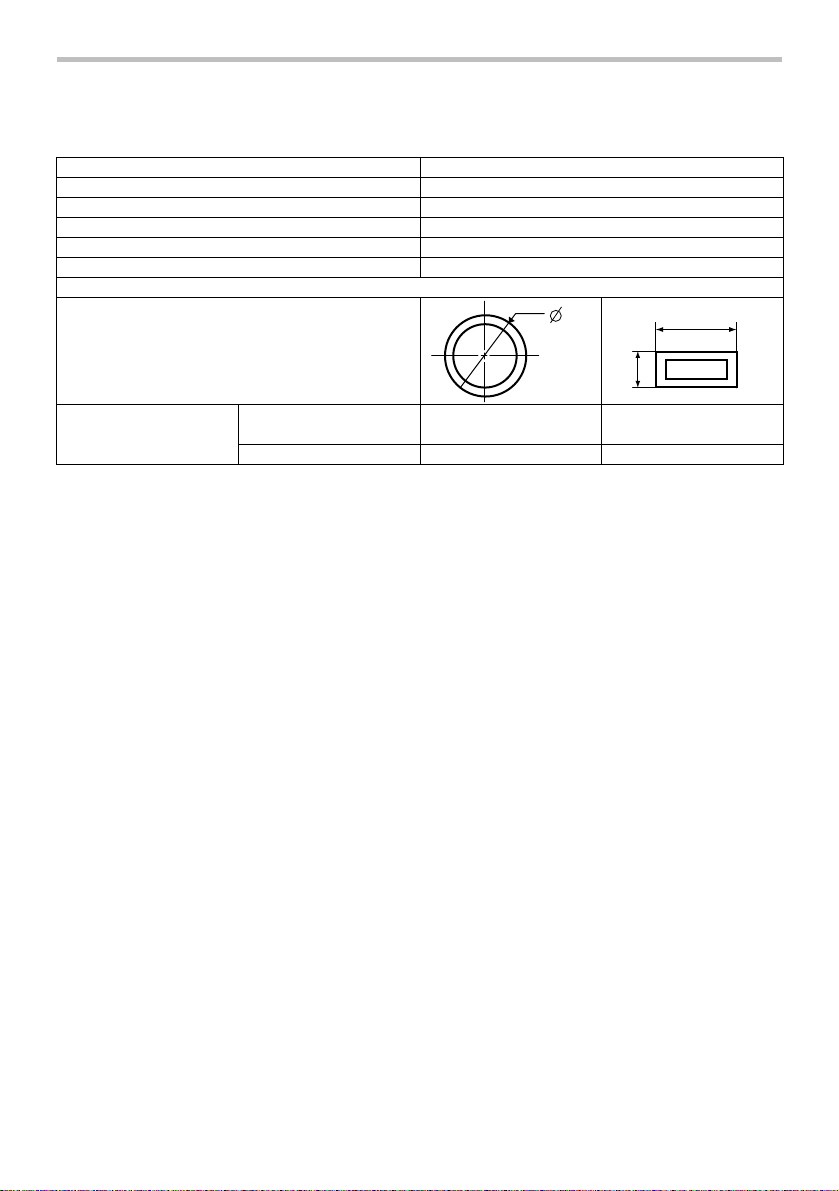

• 305 mm (12") Carbide-tipped saw blade &

workpiece ranges

8

Page 9

Part No.

A-90532

A-90722

A-90875

A-90847

006943

Number

of teeth

60 Mild Steel 5/32" or more 1/8"-13/64" 5/32" or more

60

78

78

application

Mild Steel

(Lessened

Noise Type)

Thin Mild

Steel

Stainless

Steel

Angles Pipes Channels

5/32" or more 1/8"-13/64" 5/32" or more

1/8"-15/64"

CAUTION:

• Always use carbide-tipped saw blades appropriate

for your job. Do not cut aluminum, wood, plastics,

concrete, tiles, etc.

• Carbide-tipped saw blades for metal cutting saw

are not to be re-sharpened.

Applicable workpiece & thickness range

3/64"-13/64"

3/64"-13/64"

5/64" or more1/8"-15/64"

5/32" or more

Stainless

Pipes

NA

NA

NA

3/64"-13/64"

Stainless

Angles

NA

NA

NA

1/8"-5/32"

(NA.......Not applicable)

MAKITA LIMITED ONE YEAR WARRANTY

Warranty Policy

Every Makita tool is thoroughly inspected and tested

before leaving the factory. It is warranted to be free of

defects from workmanship and materials for the period

of ONE YEAR from the date of original purchase.

Should any trouble develop during this one year period,

return the COMPLETE tool, freight prepaid, to one of

Makita’s Factory or Authorized Service Centers. If

inspection shows the trouble is caused by defective

workmanship or material, Makita will repair (or at our

option, replace) without charge.

This Warranty does not apply where:

repairs have been made or attempted by others:

repairs are required because of normal wear and

tear:

the tool has been abused, misused or improperly

maintained:

alterations have been made to the tool.

IN NO EVENT SHALL MAKITA BE LIABLE FOR ANY

INDIRECT, INCIDENTAL OR CONSEQUENTIAL

DAMAGES FROM THE SALE OR USE OF THE

PRODUCT. THIS DISCLAIMER APPLIES BOTH

DURING AND AFTER THE TERM OF THIS

WARRANTY.

MAKITA DISCLAIMS LIABILITY FOR ANY IMPLIED

WARRANTIES, INCLUDING IMPLIED WARRANTIES

OF "MERCHANTABILITY" AND "FITNESS FOR A

SPECIFIC PURPOSE," AFTER THE ONE YEAR TERM

OF THIS WARRANTY.

This Warranty gives you specific legal rights, and you

may also have other rights which vary from state to

state. Some states do not allow the exclusion or

limitation of incidental or consequential damages, so

the above limitation or exclusion may not apply to you.

Some states do not allow limitation on how long an

implied warranty lasts, so the above limitation may not

apply to you.

EN0006-1

9

Page 10

FRANÇAIS

SPÉCIFICATIONS

Modèle LC1230

Diamètre de la lame 305 mm (12")

Diamètre de l'orifice (alésage) 25.4 mm (1")

Vitesse à vide (T/MIN) 1,300 /min.

Dimensions (L x L x H) 516 mm x 306 mm x 603 mm (20-1/3" x 12" x 23-5/8")

Capacité de coupe

Poids net 19.0kg (41.8 lbs)

A

Forme de la pièce

A X B

A

B

Angle de coupe

• Étant donné l'évolution constante de notre programme de recherche et de développement, les spécifications contenues dans ce

manuel sont sujettes à modification sans préavis.

• Note : Les spécifications peuvent varier suivant les pays.

Pour votre propre sécurité,

veuillez lire le manuel

d'instructions

Avant d'utiliser l'outil

Conservez-le pour référence

ultérieure

PRÉCAUTIONS GÉNÉRALES

(POUR TOUS LES OUTILS)

1. VOUS DEVEZ CONNAÎTRE VOTRE OUTIL

ÉLECTRIQUE. Lisez attentivement le manuel

d'instructions. Familiarisez-vous avec les

applications et limites de l'outil, ainsi qu'avec

les risques potentiels qui lui sont spécifiques.

2. MAINTENEZ LES PROTECTEURS EN PLACE

et en bon état de fonctionnement.

3. RETIREZ LES CLÉS DE RÉGLAGE ET DE

SERRAGE. Prenez l'habitude de vous assurer

que les clés de réglage et de serrage ont été

retirées de l'outil avant de le mettre sous

tension.

90° 115mm (4-1/2")

45° 90mm (3-1/2")

USA007-2

4. MAINTENEZ LA ZONE DE TRAVAIL PROPRE.

Les zones de travail et les établis encombrés

ouvrent grande la porte aux accidents.

5. ÉVITEZ L'UTILISATION DANS UN

ENVIRONNEMENT DANGEREUX. N'utilisez

pas les outils électriques dans les endroits

humides ou mouillés, et ne les exposez pas à

la pluie. Maintenez un éclairage adéquat dans

la zone de travail. Ne vous servez pas de votre

outil en présence de liquides ou gaz

inflammables.

6. MAINTENEZ LES ENFANTS À L'ÉCART. Toute

autre personne que l'utilisateur de l'outil doit

se tenir à une distance sûre de l'aire de travail.

7. FAITES EN SORTE QUE L'ATELIER SOIT

SANS DANGER POUR LES ENFANTS, en y

posant des cadenas, un interrupteur principal,

ou en retirant des équipements leurs clés de

démarrage.

8. NE FORCEZ PAS L'OUTIL. Il effectuera un

travail de meilleure qualité et plus sécuritaire

s'il est utilisé au régime pour lequel il a été

conçu.

9. UTILISEZ LE BON OUTIL. Ne forcez pas un

outil ou accessoire à effectuer un travail pour

lequel il n'a pas été conçu.

10. PORTEZ DES VÊTEMENTS ADÉQUATS. Ne

portez ni vêtements ni gants amples, ni

cravate, anneaux/bagues, bracelets ou autres

bijoux susceptibles d'être happés par les

pièces mobiles de l'outil. Le port de

75 mm x 150 mm (2-15/16" x 5-7/8")

100 mm x 100 mm (3-15/16" x 3-15/16")

85 mm x 85mm (3-5/16" x 3-5/16")

10

Page 11

chaussures antidérapantes est recommandé.

Portez un filet de protection pour envelopper

les cheveux longs.

11. PORTEZ TOUJOURS DES LUNETTES DE

SÉCURITÉ. Si le travail de coupe dégage de la

20. SENS D'ALIMENTATION. Vous devez faire

poussière, portez également un écran facial ou

un masque antipoussières. Les lunettes

ordinaires ne sont munies que de lentilles

résistances aux chocs ; elles ne constituent

21. NE LAISSEZ JAMAIS SANS SURVEILLANCE

PAS des lunettes de sécurité.

12. FIXEZ BIEN LA PIÈCE. Lorsque cela est

possible, fixez la pièce à travailler à l'aide de

dispositifs de serrage ou d'un étau. Cela est

22. PIÈCES DE RECHANGE. Seules des pièces de

plus sécuritaire que l'utilisation de la main et

libère les deux mains pour le maniement de

l'outil.

23. FICHES POLARISÉES. Pour réduire les

13. MAINTENEZ UNE BONNE POSITION.

Assurez-vous d'une bonne prise au sol et

d'une bonne position d'équilibre en tout

temps.

14. PRENEZ SOIN DES OUTILS. Maintenez les

outils bien aiguisés et propres pour assurer

une performance sécuritaire et optimale.

Suivez les instructions de lubrification et de

changement des accessoires.

15. DÉBRANCHEZ LES OUTILS avant tout travail

de réparation ou avant de changer les

accessoires tels que lames,

embouts/forets/fraises et couteaux.

16. RÉDUISEZ LES RISQUES DE MISE EN

MARCHE ACCIDENTELLE. Assurez-vous que

l'interrupteur est en position d'arrêt avant de

brancher l'outil.

17. UTILISEZ LES ACCESSOIRES

RECOMMANDÉS. Consultez le manuel de

l'utilisateur pour savoir quels sont les

accessoires recommandés. L'utilisation

d'accessoires non adéquats peut comporter

un risque de blessure.

18. NE VOUS APPUYEZ JAMAIS SUR L'OUTIL.

Vous courez un risque de blessure grave si

l'outil bascule ou si vous touchez

accidentellement l'outil tranchant.

19. VÉRIFIEZ S'IL Y A DES PIÈCES

ENDOMMAGÉES. Avant d'utiliser l'outil, tout

protecteur ou dispositif endommagé doit être

vérifié soigneusement afin de s'assurer qu'il

fonctionne adéquatement et peut remplir la

fonction pour laquelle il est conçu. Vérifiez si

les pièces mobiles sont bien alignées et bien

fixées, vérifiez la présence de pièces brisées,

vérifiez que l'outil est bien monté et

MISE EN GARDE RELATIVE À LA TENSION : avant

de brancher l'outil sur une source d'alimentation

(prise ou autre dispositif), assurez-vous que la

tension du circuit correspond à celle qui est

spécifiée sur la plaque signalétique de l'outil.

L'utilisation d'une source d'alimentation dont la

tension est supérieure à celle spécifiée pour l'outil

peut entraîner une GRAVE BLESSURE et

endommager l'outil. En cas de doute, NE

BRANCHEZ PAS L'OUTIL. L'utilisation d'une source

d'alimentation dont la tension est inférieure à la

valeur indiquée sur la plaque signalétique

endommagera le moteur.

UTLISEZ UN CORDON PROLONGATEUR ADÉQUAT.

Assurez-vous que le cordon prolongateur est en bon

état. Lors de l'utilisation d'un cordon prolongateur,

utilisez sans faute un cordon assez gros pour

conduire le courant que l'outil nécessite. Un cordon

trop petit provoquera une baisse de tension de

secteur, résultant en une perte de puissance et une

surchauffe. Le Tableau 1 indique la dimension

appropriée de cordon selon sa longueur et selon

l'intensité nominale indiquée sur la plaque

signalétique. En cas de doute sur un cordon donné,

utilisez le cordon suivant (plus gros). Plus le numéro

de gabarit indiqué est petit, plus le cordon est gros.

assurez-vous que rien ne peut entraver son

bon fonctionnement. Un protecteur ou tout

autre dispositif endommagé doit être

adéquatement réparé ou remplacé.

avancer la pièce à l'encontre de la lame ou de

l'outil tranchant, non la faire progresser dans

le même sens.

UN OUTIL EN MARCHE. COUPEZ LE CONTACT.

Attendez que l'outil se soit complètement

arrêté avant de le quitter.

rechange identiques aux originales doivent

être utilisées lors des réparations.

risques de choc électrique, cet appareil est

muni d'une fiche polarisée (une des lames est

plus large que l'autre). Cette fiche ne peut être

insérée dans une prise polarisée que dans un

seul sens. Si la fiche ne s'insère pas à fond

dans la prise, insérez-la en sens inverse. Si

elle ne s'insère toujours pas à fond, contactez

un technicien qualifié pour faire installer une

prise appropriée. N'apportez aucune

modification à la fiche.

11

Page 12

Tableau 1. Gabarit minimum du cordon

Intensit

é nominale

Volts Longueur totale du cordon en pieds

120 V 25 pi 50 pi 100 pi 150 pi

Plus de Pas plus de Calibre am

0 6 18 16 16 14

10 12 16 16 14 12

000173

12 16 14 12

USB079-2

10. Prenez garde d'endommager l'arbre, les

RÈGLES DE SÉCURITÉ

SUPPLÉMENTAIRES

NE vous laissez PAS tromper (au fil d'une utilisation

répétée) par un sentiment d'aisance et de familiarité

avec l'outil, en négligeant le respect rigoureux des

règles de sécurité qui accompagnent la scie à métal.

Si vous n'utilisez pas cet outil de façon sûre et

adéquate, vous courez un risque de blessure grave.

1. Portez un protecteur pour la vue.

2. Maintenez les mains hors de la ligne de coupe

de la lame. Évitez tout contact avec la lame

lorsqu'elle continue de tourner après la mise

hors tension de l'outil. Elle peut alors quand

même causer de graves blessures.

3. N'utilisez jamais la scie sans les protections

en place. Assurez-vous avant chaque

utilisation que le protecteur de lame se

referme bien. N'utilisez pas la scie si le

protecteur de lame ne se déplace pas

librement et ne se referme pas instantanément.

Ne fixez ou n'attachez jamais le protecteur de

lame en position ouverte.

4. Ne sciez jamais à la volée. La pièce doit être

fixée fermement contre la base avec un étau

lors de toutes les opérations. Ne tenez jamais

la pièce simplement avec la main, sans étau.

5. N'approchez jamais les mains de la lame.

6. Coupez le contact et attendez l'arrêt de la lame

avant de déplacer la pièce ou de modifier les

réglages.

7. N'utilisez pas l'outil en présence de liquides ou

gaz inflammables.

8. Avant l'utilisation, assurez-vous que la lame

ne comporte aucune fissure et qu'elle n'est

pas endommagée. Remplacez immédiatement

toute lame fissurée ou endommagée.

9. Utilisez exclusivement les flasques spécifiés

pour cet outil.

11. Assurez-vous que la base est bien fixée, afin

12. Pour votre sécurité, retirez les copeaux et

13. Assurez-vous que le blocage de l'arbre est

14. Assurez-vous que la lame ne touche pas la

15. Tenez la poignée fermement. N'oubliez pas

16. Assurez-vous que la lame n'entre pas en

17. Avant d'utiliser l'outil sur la pièce, laissez-le

18. Attendez que la lame atteigne sa pleine vitesse

19. Arrêtez immédiatement votre outil dès que

20. N'essayez pas de verrouiller la gâchette en

21. Coupez l’alimentation et attendez l'arrêt de la

12

éricain des fils

18 16 14 12610

Non recommand

flasques (tout particulièrement leur surface

d'installation) ou le boulon.

L'endommagement de ces pièces peut causer

une cassure de la lame.

qu'elle ne risque pas de se déplacer pendant le

sciage. Utilisez les orifices de la base pour

fixer la scie à une surface de travail ou à un

établi stable. N'utilisez JAMAIS l'outil si vous

vous trouvez dans une position qui n'assure

pas une pleine liberté de mouvement.

autres petites pièces présentes sur la table

avant de commencer le travail.

libéré avant de mettre le contact.

base quand elle est abaissée au maximum.

que la scie se déplace légèrement vers le haut

ou le bas au démarrage et à l'arrêt.

contact avec la pièce avant de mettre l'outil

sous tension.

tourner à vide un instant. Soyez attentif à toute

vibration ou sautillement pouvant indiquer

que la lame n'est pas bien installée ou est mal

équilibrée.

avant de procéder à la coupe.

vous observez quelque chose d'anormal.

position de marche.

lame avant de déplacer la pièce ou de régler

l’outil.

é

Page 13

22. Demeurez attentif en tout temps, et tout

particulièrement lors des travaux répétitifs et

monotones. Ne vous laissez pas emporter par

un sentiment de sécurité trompeur. Les lames

ne pardonnent pas.

23. Utilisez toujours les accessoires

recommandés dans le présent manuel.

L'utilisation d'accessoires inadéquats, tels

que les meules abrasives par exemple, peut

entraîner une blessure.

24. Ne maltraitez pas le cordon. Ne tirez jamais

directement sur le cordon pour le débrancher

de la prise de courant. Maintenez le cordon à

l'écart de la chaleur, de l'eau, de l'huile et des

objets à bords tranchants.

25. N'essayez jamais de couper des pièces d'une

épaisseur inférieure à 14 jauges (0,08 po), à

l'exception des tuyaux et pièces qu'il n'est pas

possible d'immobiliser fermement avec un

étau. La pièce détachée peut être happée par la

lame et causer la projection de copeaux

dangereux et/ou l'endommagement des

pointes de carbure de tungstène. Il y a risque

de grave blessure.

26. Débranchez l'outil avant le changement de

lame ou la réparation.

CONSERVEZ CE MODE

D'EMPLOI.

AVERTISSEMENT:

Une MAUVAISE UTILISATION de l'outil ou

l'ignorance des consignes de sécurité du présent

manuel d'instructions peuvent entraîner une grave

blessure.

Pose

Préparation de l'outil

À sa sortie d'usine, l'outil est expédié avec la poignée

verrouillée en position abaissée. Libérez la poignée de

sa position abaissée en l'abaissant légèrement et en

retirant la chaîne du crochet sur la poignée.

1. Crochet

1

003771

Boulonnez l'outil avec deux boulons sur une surface

horizontale et stable, à l'aide des orifices à boulon

prévus sur la base de l'outil. L'outil risquera moins de

basculer et de causer des blessures.

1

003772

1. Boulon

1

DESCRIPTION DU

FONCTIONNEMENT

ATT EN TI ON :

• Assurez-vous toujours que l'outil est hors tension

et débranché avant de l'ajuster ou de vérifier son

fonctionnement.

Interrupteur

1

003773

ATT EN TI ON :

• Avant de brancher l'outil, assurez-vous toujours

que la gâchette fonctionne correctement et revient

en position d'arrêt une fois relâchée.

• Lorsque vous avez terminé d'utiliser l'outil, retirez

le bouton de sécurité et rangez-le dans un endroit

sûr. Cela évitera l'utilisation de l'outil sans

autorisation.

Un bouton de sécurité est fourni pour prévenir la

pression accidentelle sur la gâchette.

Pour mettre l'outil en marche, enfoncez le bouton de

sécurité puis appuyez sur la gâchette. Pour l'arrêter,

relâchez la gâchette.

Réglage de l'angle de coupe

ATT EN TI ON :

• Serrez toujours le boulon hexagonal fermement

après avoir changé l'angle de coupe.

1. Bouton de

sécurité

2. Gâchette

2

13

Page 14

1. Graduation

3

2. Levier

3. indicateur

1

4. Butée de l'étau

2

4

003774

Pour changer l'angle de coupe, desserrez le levier.

Déplacez la butée de l'étau de sorte que l'indicateur

pointe sur la graduation désirée. Serrez ensuite le levier

pour immobiliser la butée de l'étau.

Collecte des poussières

ATT EN TI ON :

• Après la coupe, ne touchez aucune partie de la

boîte à poussières à l'exception de sa poignée ;

ces parties peuvent être très chaudes et vous

brûler la peau.

1. Boîtier collecteur

de poussière

1

003775

Cet outil est équipé d'une boîte à poussières pour la

collecte des poussières et des copeaux. Lorsque la

boîte à poussières est pleine, saisissez-la par sa

poignée et soulevez-la légèrement. Tirez ensuite pour

retirer la boîte à poussières de la base de l'outil. Videz la

boîte à poussières.

ASSEMBLAGE

ATT EN TI ON :

• Avant d'effectuer toute intervention sur l'outil,

assurez-vous toujours qu'il est hors tension et

débranché.

Rangement de la clé à douille

1. Support à clé

2. Base

1

2

003776

Le rangement de la clé à douille s'effectue de la façon

indiquée sur l'illustration. Pour utiliser la clé à douille,

retirez-la du support à clé. Après avoir utilisé la clé à

douille, remettez-la dans le support à clé.

Pose et retrait de la lame de scie

ATT EN TI ON :

• Lorsque vous montez la lame, assurez-vous que le

sens indiqué par la flèche sur la surface de la lame

correspond à celui de la flèche du porte-lame.

• Utilisez exclusivement la clé à douille Makita

fournie pour installer ou retirer la lame. Sinon, le

boulon hexagonal risque d'être trop ou pas assez

serré. Cela comporte un risque de blessure.

• Ne touchez jamais la lame juste après la coupe ;

elle peut être extrêmement chaude et risque de

vous brûler la peau.

Pour retirer la lame, utiliser la clé à douille pour

desserrer le boulon hexagonal qui retient le couvercle

central, en tournant dans le sens inverse des aiguilles

d'une montre. Soulevez le protecteur de lame et le

couvercle central.

1

4

003777

Appuyez sur le blocage de l'arbre pour verrouiller l'axe

et desserrez le boulon hexagonal en tournant vers la

gauche. Retirez ensuite le boulon hexagonal, le flasque

extérieur et la lame.

1. Couvercle

2

central

2. Boulon

hexagonal

3. Clé à douille

4. Protecteur de

lame

3

14

Page 15

1. Boulon

1

hexagonal

2. Verrouillage de

2

l'arbre

3. Clé à douille

3

003778

Pour poser la lame, montez le flasque intérieur, la lame,

le flasque extérieur et le bouton hexagonal sur l'axe,

dans cet ordre. Serrez le boulon hexagonal en tournant

vers la droite tout en appuyant sur le blocage de l'arbre.

Remettez le protecteur de lame et le capot central en

position initiale. Vissez ensuite le boulon hexagonal en

le tournant vers la droite pour fixer le capot central.

Abaissez la poignée pour vous assurer que le protecteur

de lame se déplace adéquatement.

1

2

3

4

1. Lame à dents de

carbure

2. Boulon

hexagonal

3. Axe

4. Bague interne

5. Bague externe

5

003801

Immobilisation de la pièce

ATT EN TI ON :

• Lorsque vous immobilisez la pièce, tournez

toujours l'écrou de l'étau complètement vers la

droite. Faute de cette précaution, la pièce risque

de ne pas être suffisamment serrée. Cela peut

causer l'éjection de la pièce ou l'endommagement

de la lame.

Vous pouvez dégager l'étau des filages de l'arbre et le

déplacer rapidement vers l'intérieur et l'extérieur en

tournant la poignée de l'étau dans le sens inverse des

aiguilles d'une montre et en basculant l'écrou de l'étau

vers la gauche. Pour serrer la pièce à travailler, poussez

sur la poignée de l'étau jusqu'à ce que la plaque de

l'étau entre en contact avec la pièce. Basculez l'écrou de

l'étau vers la droite puis tournez la poignée de l'étau

dans le sens des aiguilles d'une montre pour immobiliser

solidement la pièce à travailler.

1. Plaque de l'étau

1

003780

3. Poignée de

3

l'étau

2. Écrou de l'étau

2

Les longues pièces à travailler doivent être soutenues

de chaque côté par des blocs en matériau ininflammable

placés au même niveau que le dessus de la base.

003781

UTILISATION

Coupe

ATT EN TI ON :

• N'essayez jamais de couper des pièces d'une

épaisseur inférieure à 14 jauges (0,08 po), à

l'exception des tuyaux et pièces qu'il n'est pas

possible d'immobiliser fermement dans l'étau. La

pièce détachée peut être happée par la lame et

causer la projection de copeaux dangereux et/ou

l'endommagement des pointes de carbure de

tungstène. Il y a risque de BLESSURE grave.

• Pendant la coupe, n'appliquez pas une pression

excessive sur la poignée. Une pression trop

grande peut entraîner une surcharge du moteur,

réduire l'efficacité de coupe et/ou endommager les

pointes de carbure de tungstène ou la lame

elle-même.

• Une pression insuffisante sur la poignée peut

provoquer des étincelles et l'usure rapide de la

lame.

• Ne touchez jamais la lame, la pièce ou les

copeaux juste après la coupe ; ils peuvent être

extrêmement chauds et risquent de vous brûler la

peau.

• Si la lame s'arrête pendant la coupe, émet un bruit

anormal ou se met à vibrer, éteignez

immédiatement l'outil. Remplacez la lame fissurée

ou endommagée par une neuve.

15

Page 16

Tenez la poignée fermement. Mettez l'outil sous tension

et attendez que la lame atteigne sa pleine vitesse.

Abaissez ensuite doucement la poignée pour approcher

la lame de la pièce. Lorsque la lame entre en contact

avec la pièce, faites-la d'abord pénétrer légèrement

dans sa ligne de coupe, puis augmentez graduellement

la pression à mesure que la position de la lame se

stabilise. Vous devez ajuster votre pression sur la

poignée de façon à produire un minimum d'étincelles.

Lorsque la coupe est terminée, coupez le contact de

l'outil et ATTENDEZ QUE LA LAME SE SOIT

COMPLÈTEMENT ARRÊTÉE avant de ramener la

poignée en position complètement relevée. Si vous

soulevez la poignée alors que la lame tourne encore, la

pièce détachée peut être happée par la lame et causer

la projection de copeaux dangereux. Pour couper une

pièce en partie seulement, soulevez la poignée alors

que la lame tourne encore. En coupant le contact

pendant la coupe vous risqueriez d'endommager les

pointes de carbure de tungstène en contact avec la

pièce.

Angles de coupe

Immobilisez la pièce dans l'étau, tel qu'indiqué sur la

figure A, puis coupez-la. La durée de service de la lame

sera réduite si vous coupez la pièce en procédant

comme à la figure B.

La lame s'use plus rapidement lors de la coupe de la

zone A indiquée sur la figure B. Posez un bloc de bois

contre la pièce, tel qu'indiqué sur la figure D, de sorte

que la lame entre dans la zone A avec un angle. Cela

favorisera une usure moins rapide de la lame.

Les dimensions de coupe permises diminuent lors de

l'utilisation d'un bloc de bois. Utilisez un bloc de bois

dont les dimensions correspondent aux dimensions de

coupe permises maximales, moins celles de la pièce à

couper. Cela favorisera davantage l'allongement de la

durée de vie de la lame.

Coupe des tuyaux, carrés (profils pleins) et

profilés en U

La lame s'use plus rapidement lors de la coupe des

zones A et B indiquées sur les figures F et G. Posez un

bloc de bois contre la pièce, tel qu'indiqué sur les figures

H et I, de sorte que la lame entre dans les zones A et B

avec un angle. Cela aidera à allonger la durée de vie de

la lame.

Les dimensions de coupe permises diminuent lors de

l'utilisation d'un bloc de bois. Utilisez un bloc de bois

dont les dimensions correspondent aux dimensions de

coupe permises maximales, moins celles de la pièce à

couper. Cela favorisera davantage l'allongement de la

durée de vie de la lame.

A

A

Fig. A Fig. B

Fig. C

003782

ATT EN TI ON :

• NE PAS couper la pièce en procédant comme à la

figure C, car elle risquerait d'être éjectée de l'étau

et de causer une blessure.

Fig. D

Fig. E Fig. F

A

Fig. G

Fig. I

003783

Fig. H

Coupe des rectangles

Immobilisez la pièce dans l'étau, tel qu'indiqué sur la

figure J, puis coupez-la.

16

B

Page 17

Remplacement des charbons

1. Trait de limite

d'usure

Fig. J

003784

Fig. K

ATT EN TI ON :

• NE PAS couper la pièce en procédant comme à la

figure K, car elle risquerait d'être éjectée de l'étau

et de causer une blessure.

Transport de l'outil

ATT EN TI ON :

• Avant de transporter l'outil, vous devez vous

assurer que la chaîne de transport est ajustée pour

réduire le plus possible la zone exposée de la

lame.

003785

Repliez la tête de l'outil vers le bas jusqu'à la position qui

permet de fixer la chaîne au crochet de la poignée.

Saisissez l'outil par sa poignée de transport pour le

transporter.

ENTRETIEN

ATT EN TI ON :

• Assurez-vous toujours que l'outil est hors tension

et débranché avant d'y effectuer tout travail

d'inspection ou d'entretien.

Changement de lame

Il y a risque de surcharge du moteur et de coupes moins

efficaces si vous continuez d'utiliser une lame émoussée

ou usée. Remplacez la lame par une neuve dès qu'elle

ne coupe plus bien.

1

001145

Retirez et vérifiez régulièrement les charbons.

Remplacez-les lorsqu'ils sont usés jusqu'au trait de

limite d'usure. Maintenez les charbons propres et en état

de glisser aisément dans les porte-charbon. Les deux

charbons doivent être remplacés en même temps.

N'utilisez que des charbons identiques.

Utilisez un tournevis pour retirer les bouchons de

porte-charbon. Enlevez les charbons usés, insérez-en

de nouveaux et revissez solidement les bouchons de

porte-charbon.

1. Tournevis

1

2

003786

2. Bouchon de

porte-charbon

Pour maintenir la SÉCURITÉ et la FIABILITÉ du produit,

les réparations, tout autre travail d'entretien ou de

réglage doivent être effectués dans un centre de service

Makita agréé ou un centre de service de l'usine Makita,

exclusivement avec des pièces de rechange Makita.

ACCESSOIRES

ATT EN TI ON :

• Ces accessoires ou pièces complémentaires sont

recommandés pour l'utilisation avec l'outil Makita

spécifié dans ce mode d'emploi. L'utilisation de

tout autre accessoire ou pièce complémentaire

peut comporter un risque de blessure. N'utilisez les

accessoires ou pièces qu'aux fins auxquelles ils

ont été conçus.

Si vous désirez obtenir plus de détails concernant ces

accessoires, veuillez contacter le centre de service

après-vente Makita le plus près.

• Clé à douille 17

• Lunettes de sécurité

• Bouton de sécurité (interrupteur)

17

Page 18

• Lame à dents de carbure de tungstène

• Les lames à dents de carbure de tungstène de 305

mm (12 po) et les dimensions de pièce permises

N° de pièce

A-90532

A-90722

A-90875

A-90847

006943

Nombre de

dents

60 Acier doux 5/32" ou plus 1/8"-13/64" 5/32" ou plus

60

78

78

Application

Acier doux

(de type réducteur

de bruit)

Acier doux

mince

Acier

inoxydable

Angles Tuyaux Tubes

5/32" ou plus 1/8"-13/64" 5/32" ou plus

1/8"-15/64"

ATT EN TI ON :

• Utilisez toujours des lames à dents de carbure de

tungstène qui conviennent au travail à effectuer.

Ne coupez pas l'aluminium, le bois, le plastique, le

béton, la tuile, etc.

• Les lames à dents de carbure de tungstène pour

scie à métal n'ont pas besoin d'être réaffûtées.

Type de pièce à couper et plage d'épaisseur

Tuyaux en

acier inoxydable

SO

SO

3/64"-13/64"

3/64"-13/64"

5/64" ou plus1/8"-15/64"

5/32" ou plus

SO

3/64"-13/64"

Angles en acier

inoxydable

SO

SO

SO

1/8"-5/32"

(SO.......Sans objet)

18

Page 19

GARANTIE LIMITÉE D’UN AN MAKITA

A

À

A

Politique de garantie

Chaque outil Makita est inspecté rigoureusement et

testé avant sa sortie d’usine. Nous garantissons qu’il

sera exempt de défaut de fabrication et de vice de

matériau pour une période d’UN AN à partir de la date

de son achat initial. Si un problème quelconque devait

survenir au cours de cette période d’un an, veuillez

retourner l’outil COMPLET, port payé, à une usine ou à

un centre de service après-vente Makita. Makita

réparera l’outil gratuitement (ou le remplacera, à sa

discrétion) si un défaut de fabrication ou un vice de

matériau est découvert lors de l’inspection.

Cette garantie ne s’applique pas dans les cas où:

des réparations ont été effectuées ou tentées par

un tiers:

des réparations s’imposent suite à une usure

normale:

l’outil a été malmené, mal utilisé ou mal entretenu:

l’outil a subi des modifications.

MAKITA DÉCLINE TOUTE RESPONSABILITÉ POUR

TOUT DOMMAGE ACCESSOIRE OU INDIRECT LIÉ À

LA VENTE OU À L’UTILISATION DU PRODUIT. CET

VIS DE NON-RESPONSABILITÉ S’APPLIQUE À LA

FOIS PENDANT ET APRÈS LA PÉRIODE COUVERTE

PAR CETTE GARANTIE.

MAKITA DÉCLINE TOUTE RESPONSABILITÉ QUANT

TOUTE GARANTIE TACITE, INCLUANT LES

GARANTIES TACITES DE “QUALITÉ MARCHANDE”

ET “ADÉQUATION À UN USAGE PARTICULIER”

PRÈS LA PÉRIODE D’UN AN COUVERTE PAR

CETTE GARANTIE.

Cette garantie vous donne des droits spécifiques

reconnus par la loi, et possiblement d’autres droits, qui

varient d’un État à l’autre. Certains États ne permettant

pas l’exclusion ou la limitation des dommages

accessoires ou indirects, il se peut que la limitation ou

exclusion ci-dessus ne s’applique pas à vous. Certains

États ne permettant pas la limitation de la durée

d’application d’une garantie tacite, il se peut que la

limitation ci-dessus ne s’applique pas à vous.

EN0006-1

19

Page 20

ESPAÑOL

ESPECIFICACIONES

Especificaciones eléctricas en México 120 V 15 A 50/60 Hz

Revoluciones por minuto (r.p.m.) 1 300 /min.

Capacidad de corte

Modelo LC1230

Diámetro del disco 305 mm (12")

Diámetro del orificio (eje ) 25,4 mm (1")

Dimensiones (L x A x A) 516 mm x 306 mm x 603 mm (20-1/3" x 12" x 23-5/8")

Peso neto 19,0kg (41,8 lbs)

A

A X B

Forma de la pieza de trabajo

A

B

Ángulo de corte

• Debido a nuestro programa continuo de investigación y desarrollo, las especificaciones aquí dadas están sujetas a cambios sin

previo aviso.

• Nota: Las especificaciones pueden ser diferentes de país a país.

Por su propia seguridad lea el

Manual de Instrucciones

Antes de utilizar la herramienta

Guarde las instrucciones para

referencia futura

PRECAUCIONES DE

SEGURIDAD GENERALES

(Para todas las herramientas)

1. CONOZCA SU HERRAMIENTA ELÉCTRICA.

Lea el manual del usuario atentamente.

Conozca las aplicaciones y limitaciones de la

herramienta, así como también los riesgos

potenciales específicos propios de la misma.

2. NO QUITE LOS PROTECTORES y

manténgalos en buen estado de

funcionamiento.

90° 115mm (4-1/2")

45° 90mm (3-1/2")

USA007-2

3. RETIRE LAS LLAVES DE AJUSTE Y DE

APRIETE. Adquiera el hábito de comprobar y

ver que las llaves de ajuste y de apriete estén

retiradas de la herramienta antes de ponerla

en marcha.

4. MANTENGA EL ÁREA DE TRABAJO LIMPIA.

Las áreas y bancos de trabajo desordenados y

amontonados hacen que los accidentes sean

propensos.

5. NO LAS UTILICE EN AMBIENTES

PELIGROSOS. No utilice las herramientas

eléctricas en lugares húmedos o mojados, ni

las exponga a la lluvia. Mantenga el área de

trabajo bien iluminada. No utilice la

herramienta en presencia de líquidos o gases

inflamables.

6. MANTENGA ALEJADOS A LOS NIÑOS. Todos

los visitantes deberán ser mantenidos a una

distancia segura del área de trabajo.

7. MANTENGA EL TALLER A PRUEBA DE NIÑOS

con candados, interruptores maestros, o

quitando las llaves de encendido.

8. NO FORCE LA HERRAMIENTA. La herramienta

realizará la tarea mejor y de forma más segura

a la potencia para la que ha sido diseñada.

9. UTILICE LA HERRAMIENTA APROPIADA. No

force la herramienta ni los accesorios

realizando con ellos un trabajo para el que no

han sido diseñados.

20

75 mm x 150 mm (2-15/16" x 5-7/8")

100 mm x 100 mm (3-15/16" x 3-15/16")

85 mm x 85mm (3-5/16" x 3-5/16")

Page 21

10. PÓNGASE INDUMENTARIA APROPIADA. No

se ponga ropa holgada, guantes, corbata,

anillos, pulseras, ni otro tipo de alhajas que

puedan engancharse en las partes móviles. Se

recomienda utilizar calzado antiderrapante.

Recójase el cabello o si lo tiene largo o

cúbralo para su protección.

11. UTILICE SIEMPRE GAFAS DE SEGURIDAD.

Utilice también careta contra el polvo si la

operación de corte es polvorienta. Las gafas

de uso diario para la vista sólo tienen lentes

que pueden proteger contra pequeños

impactos, NO son gafas de seguridad.

12. SUJETE LA PIEZA DE TRABAJO. Utilice

mordazas o un tornillo de banco para sujetar

la pieza de trabajo cuando resulte práctico. Es

más seguro que utilizar la mano y además

dispondrá de ambas manos para manejar la

herramienta.

13. NO UTILICE LA HERRAMIENTA DONDE NO

ALCANCE. Mantenga los pies sobre suelo

firme y el equilibrio en todo momento.

14. DÉ MANTENIMIENTO A SUS HERRAMIENTAS.

Mantenga las herramientas afiladas y limpias

para obtener de ellas un mejor y más seguro

rendimiento. Siga las instrucciones para

lubricarlas y cambiar los accesorios.

15. DESCONECTE LAS HERRAMIENTAS antes de

darles mantenimiento; cuando cambie

accesorios tales como discos, brocas,

cuchillas, y otros por el estilo.

16. REDUZCA EL RIESGO DE PUESTAS EN

MARCHA INVOLUNTARIAS. Asegúrese de que

el interruptor esté en posición desactivada

antes de conectar la herramienta.

17. UTILICE ACCESORIOS RECOMENDADOS.

Consulte el manual del propietario para ver los

accesorios recomendados. La utilización de

accesorios no apropiados podría ocasionar un

riesgo de heridas a personas.

18. NO SE PARE NUNCA ENCIMA DE LA

HERRAMIENTA. Si se tropieza y enciende la

herramienta, o si se toca sin querer el disco de

corte podrá ocasionar graves heridas.

19. COMPRUEBE LAS PARTES DAÑADAS. Si un

protector u otra parte están dañados, antes de

seguir utilizando la herramienta deberá

verificarlos cuidadosamente para cerciorarse

de que van a funcionar debidamente y realizar

la función para la que han sido previstos compruebe la alineación de las partes móviles,

la sujeción de las partes m'viles, si hay partes

rotas, el montaje y cualquier otra condición

que pueda afectar su operación. Un protector

u otra parte que esté dañada deberá ser

reparada o debidamente cambiada.

Si el cordón de alimentación es dañado, éste

deberá ser reemplazado por un cordón

especial o ensamble disponible por parte del

fabricante o su centro de sercvicio.

20. DIRECCIÓN DE AVANCE. Avance la pieza de

trabajo hacia el disco o cuchilla solamente a

contra dirección del giro de los mismos.

21. NO DESCUIDE NI DEJE NUNCA LA

HERRAMIENTA MIENTRAS ESTÉ EN MARCHA.

DESCONECTE LA ALIMENTACIÓN. No deje la

herramienta hasta que haya detenido

completamente.

22. PIEZAS DE REPUESTO. Cuando se dé el

servicio a la herramienta (mantenimiento),

utilice solamente piezas de repuesto

idénticas.

23. CLAVIJAS POLARIZADAS. Para reducir el

riesgo de descargas eléctricas, este equipo

tiene una clavija polarizada (un borne es más

ancho que el otro.) Esta clavija encajará en

una toma de corriente polarizada en un

sentido solamente. Si la clavija no encaja

totalmente en la toma de corriente, invierta la

clavija. Si aún así no encaja, póngase en

contacto con un electricista cualificado para

que le instale la toma de corriente apropiada.

No modifique la clavija de ninguna forma.

ADVERTENCIA SOBRE EL VOLTAJE: Antes de

conectar la herramienta a una toma de corriente

(enchufe, fuente de alimentación, etc.), asegúrese de

que la tensión suministrada es igual a la

especificada en la placa de características de la

herramienta. Una toma de corriente con un voltaje

mayor que el especificado para la herramienta podrá

resultar en HERIDAS GRAVES al usuario -así como

también daños a la herramienta. Si no está seguro,

NO CONECTE LA HERRAMIENTA. La utilización de

una toma de corriente con una voltaje menor al

nominal indicado en la placa de características es

dañino para el motor.

UTILICE CABLES DE EXTENSIÓN APROPIADOS.

Asegúrese de que su cable de extensión esté en

buenas condiciones. Cuando utilice un cable de

extensión, asegúrese de utilizar uno del calibre

suficiente para conducir la corriente que demande el

producto. Un cable de calibre inferior ocasionará

una caída en la tensión de línea que resultará en una

pérdida de potencia y sobrecalentamiento. La Tabla

1 muestra el tamaño correcto a utilizar dependiendo

de la longitud del cable y el amperaje nominal

indicado en la placa de características. Si no está

seguro, utilice el siguiente calibre más potente.

Cuanto menor sea el número de calibre, más potente

será el cable.

21

Page 22

Tabla 1. Calibre mínimo para el cable

Amperaje nominal

Volts Longitud total del cable en metros

120 V~

7,6 m (25 ft) 15,2 m (50 ft) 30,4 m (100 ft) 45,7 m (150 ft)

Más de No más de Calibre del cable (AWG)

0 A 6 A 18161614

18 16 14 126 A 10 A

10 A 12 A 16 16 14 12

000173

NORMAS DE SEGURIDAD

ADICIONALES

Advertencias y precauciones

NO deje que la comodidad o familiaridad con el

producto (a base de utilizarlo repetidamente)

sustituya la estricta observancia de las normas de

seguridad para la sierra cortadora de metal. Si utiliza

esta herramienta de forma no segura o incorrecta,

podrá sufrir graves heridas personales.

1. Utilice protección para los ojos.

2. Mantenga las manos alejadas de la trayectoria

3. No utilice la sierra sin los protectores puestos.

4. No realice ninguna operación directamente

5. No acerque nunca las manos alrededor del

6. Apague la herramienta y espere hasta que el

7. No utilice la herramienta en presencia de

8. Inspeccione el disco cuidadosamente para ver

9. Utilice solamente las bridas especificadas

12 A 16 A 14 12

USB079-2

del disco. Evite el contacto con cualquier

disco que esté girando por inercia. Aún puede

ocasionarle heridas graves.

Verifique el protector de disco para confirmar

que se cierra debidamente antes de cada uso.

No utilice la sierra si el protector de disco no

se mueve libremente y se cierra

instantáneamente. No sujete ni ate el protector

de disco en la posición abierta.

con la mano. La pieza de trabajo debe estar

firmemente asegurada con una prensa contra

la base durante todas las operaciones. Nunca

asegure la pieza de trabajo con la mano.

disco.

disco de sierra pare antes de mover la pieza

de trabajo o cambiar los ajustes.

líquidos o gases inflamables.

si tiene grietas o daños antes de comenzar la

operación. Reemplace el disco

inmediatamente si está agrietado o dañado.

para esta herramienta.

10. Tenga cuidado de no dañar el eje, bridas

(especialmente la cara de instalación) ni el

perno. Los daños en estas piezas podrían

provocar la ruptura del disco.

11. Asegúrese de que la base esté correctamente

fijada para que no se mueva durante el

funcionamiento. Utilice los orificios de la base

para asegurar la sierra a una plataforma o

banco de trabajo estable. NUNCA utilice la

herramienta si la posición del operador es

incómoda.

12. Para su seguridad, quite todas las astillas,

pequeñas piezas, etc. de la mesa de trabajo

antes de utilizar la herramienta.

13. Asegúrese de que el bloqueo del eje esté

suelto antes de activar el interruptor.

14. Asegúrese de que el disco no haga contacto

con la base en su posición más baja.

15. Sostenga firmemente la empuñadura. Tenga

en cuenta que la sierra se mueve levemente

hacia arriba o hacia abajo al iniciar y al

finalizar el funcionamiento.

16. Asegúrese de que el disco no esté haciendo

contacto con la pieza de trabajo antes de

activar el interruptor.

17. Antes de utilizar la herramienta en una pieza

de trabajo definitiva, déjela funcionar durante

un rato. Observe para ver si hay vibración o

bambamboleo que pueda indicar una

incorrecta instalación o un desequilibrio del

disco.

18. Espere hasta que el disco alcance plena

velocidad antes de cortar.

19. Pare la operación inmediatamente si nota algo

anormal.

20. No intente bloquear el gatillo en la posición

activada (ON).

21. Corte el suministro eléctrico y espere a que la

hoja de la sierra se detenga antes de mover la

pieza de trabajo o de hacer ajustes en la

herramienta.

22

No se recomienda

Page 23

22. Esté alerta en todo momento, especialmente

durante las operaciones repetitivas y

monótonas. No se deje llevar por una falsa

sensación de seguridad. Los discos no

perdonan nunca.

23. Utilice los accesorios recomendados en este

manual. La utilización de accesorios no

apropiados, tales como discos abrasivos,

podría ocasionarle heridas.

24. No jale el cable. Nunca jale el cable para

desconectarlo desde la toma de corriente.

Mantenga el cable alejado del calor, aceite,

agua o bordes cortantes.

25. Nunca intente cortar la pieza de trabajo menos

de 14 (0.08″) de grosor de calibre, salvo el

conducto o la pieza de trabajo que no puede

fijarse firmemente con una prensa. La pieza

cortada podría quedar atrapada por la hoja y

causar el corte peligroso de astillas y/o dañar

las astillas de carburo. Se podrían ocasionar

heridas de gravedad.

26. Desconecte la herramienta del tomacorriente

antes de cambiar la hoja o realizar cualquier

arreglo.

GUARDE ESTAS

INSTRUCCIONES.

ADVERTENCIA:

El USO INCORRECTO o el no seguir las normas de

seguridad que se declaran en este instructivo podría

resultar en lesiones personales graves.

INSTALACIÓN

Ubicación de la herramienta

Cuando la herramienta es transportada desde la fábrica,

la empuñadura se traba en la posición inferior. Libere la

empuñadura de la posición inferior bajándolo levemente

y quitando la cadena del gancho de la empuñadura.

1. Gancho

1

003771

Asegure la herramienta con dos pernos sobre una

superficie plana y estable, utilizando los orificios de los

pernos que se encuentran en la base de la herramienta.

Esto ayudará a evitar vuelcos y posibles heridas.

1

003772

1. Tornillo

1

DESCRIPCIÓN DEL

FUNCIONAMIENTO

PRECAUCIÓN:

• Asegúrese siempre de que la herramienta esté

apagada y desconectada antes de ajustar o

comprobar cualquier función en la misma.

Accionamiento del interruptor

1

003773

PRECAUCIÓN:

• Antes de conectar la herramienta, compruebe

siempre que el gatillo interruptor se acciona

debidamente y que vuelve a la posición "OFF"

(apagado) cuando lo suelta.

• Cuando no utilice la herramienta, extraiga el botón

lock-off y guárdelo en un lugar seguro. Esto evitará

el uso no autorizado de la herramienta.

La herramienta posee un botón traba a fin de evitar que

el gatillo interruptor se accione accidentalmente.

Para encender la herramienta, pulse este botón y

accione el gatillo. Para detener la herramienta, suelte el

gatillo interruptor.

Ajuste del ángulo de corte deseado

PRECAUCIÓN:

• Ajuste siempre el perno hexagonal antes de

cambiar el ángulo de corte.

1. Botón lock-off

(bloqueador)

2. Gatillo

interruptor

2

23

Page 24

1. Graduación

3

2. Palanca

3. indicador

1

4. Tope de la

prensa

2

4

003774

Para cambiar el ángulo de corte, afloje la palanca.

Mueva el tope de la prensa de modo tal que el indicador

señale la graduación deseada. Luego ajuste la palanca

para asegurar el tope de la prensa.

Recolección de polvo

PRECAUCIÓN:

• Inmediatamente después de la operación, no

toque ninguna parte de la caja de polvo salvo la

empuñadura ya que puede estar extremadamente

caliente y podría quemar su piel.

1. Bolsa para polvo

1

003775

Esta herramienta está equipada con la caja recolectora

de polvo que recoge polvo y astillas. Cuando la caja

recolectora de polvo está llena, sostenga la

empuñadura de la caja y elévela ligeramente. Luego

retire la caja recolectora de polvo de la base de la

herramienta. Vacíe el contenido de la caja recolectora

de polvo.

ENSAMBLE

PRECAUCIÓN:

• Asegúrese siempre de que la herramienta esté

apagada y desconectada antes de realizar

cualquier trabajo en la misma.

Almacenamiento de la llave tubo

1. Portallaves

2. Base

1

2

003776

La llave de tubo se almacena tal como se muestra en la

figura. Retírela del portallave cuando la utilice y vuelva a

colocarla allí cuando termine.

Instalación o extracción del disco de sierra.

PRECAUCIÓN:

• Cuando monte la hoja, asegúrese de que la

dirección de la flecha sobre la superficie de la hoja

coincida con la de la cubierta de la hoja.

• Para instalar o extraer la hoja, sólo utilice la llave

tubo Makita provista. Si no lo hace, se podría

ajustar demasiado o no lo suficiente el perno

hexagonal. Esto podría provocar heridas

personales.

• No toque la hoja inmediatamente después de

operar la herramienta, puesto que puede estar

extremadamente caliente y quemarle la piel.

Para desmontar el disco, utilice la llave de tubo para

aflojar el perno hexagonal que sujeta la cubierta central

girándolo en el sentido contrario a las agujas del reloj.

Suba el protector de disco y la cubierta central.

1

4

003777

Pulse la traba para trabar el eje y utilice la llave tubo

para aflojar el perno hexagonal girando en sentido

contrario a las agujas del reloj. Luego retire el perno

hexagonal, la brida exterior y la hoja.

24

1. Cubierta central

2

2. Tornillo

hexagonal

3. Llave de tubo

4. Protector de

disco

3

Page 25

1. Tornillo

1

hexagonal

2. Bloqueo del eje

2

3. Llave de tubo

3

003778

Para instalar la hoja monte la brida interior, la hoja de

sierra, la brida exterior y el perno hexagonal en ese

orden sobre el eje. Ajuste el perno hexagonal girando en

el sentido de las agujas del reloj al tiempo que presiona

la traba. Regrese la protección de la hoja y la cubierta

central a la posición original. Luego ajuste el perno

hexagonal en el sentido de las agujas del reloj para

asegurar la cubierta central. Baje la empuñadura para

asegurarse de que la protección de la hoja se mueva

correctamente.

1. Disco de sierra

con punta de

carburo

2. Tornillo

hexagonal

3. Eje

4. Brida interior

5. Brida exterior

5

3

003801

1

2

4

Aseguramiento de la pieza

PRECAUCIÓN:

• Siempre coloque la tuerca de la prensa

completamente hacia la derecha cuando asegure

la pieza de trabajo. El no hacerlo puede resultar en

la falta de sujeción de la pieza de trabajo. Esto

podría causar que la pieza de trabajo salga

despedida o dañe la hoja.

Girando la empuñadura de prensa en el sentido

contrario a las agujas del reloj y luego volver la tuerca

de la prensa hacia la izquierda, ésta se libera de las

roscas del eje y se puede mover rápidamente hacia

adentro y hacia afuera. Para sujetar la pieza, empuje la

empuñadura hasta que la placa de la prensa haga

contacto con dicha pieza. Vuelva la tuerca de la prensa

hacia la derecha y luego gire la empuñadura en el

sentido de las agujas del reloj para que la pieza quede

sujetada con firmeza.

1. Placa de la

mordaza

2. Tuerca de la

3

mordaza

3. Empuñadura de

la prensa

003780

2

1

Las piezas largas deben estar sujetadas de ambos

lados por bloques de material no inflamable, de manera

tal que estén nivelados con la parte superior de la base.

003781

OPERACIÓN

Operación de corte

PRECAUCIÓN:

• Nunca intente cortar piezas de un calibre inferior a

14 (0,08") de ancho excepto tubos o piezas de

trabajo que no puedan asegurarse firmemente con

la prensa. La pieza cortada podría quedar

atrapada por la hoja y causar el corte peligroso de

astillas y/o dañar las puntas de carburo. Se

podrían ocasionar heridas de gravedad.

• No ejerza demasiada presión sobre la

empuñadura al cortar. El exceso de presión

podría resultar en una sobrecarga del motor, en

una disminución de la eficacia de cortado y/o daño

en las puntas de carburo o en la misma hoja.

• Muy poca presión sobre la empuñadura puede

ocasionar más chispas y un prematuro desgaste

de la hoja.

• No toque la hoja, chispas, o la pieza de trabajo

inmediatamente después de operar la herramienta,

puesto que pueden estar extremadamente caliente

y quemarle la piel.

• Si la hoja se detiene durante la operación, hace un

ruido extraño o comienza a vibrar apague la

herramienta de inmediato. Reemplace

inmediatamente la hoja cuando ésta se encuentre

rota o dañada.

25

Page 26

Sostenga la empuñadura con firmeza. Encienda la

herramienta y espere hasta que la hoja alcance plena

velocidad. Luego baje la empuñadura suavemente para

acercar la hoja a la pieza de trabajo. Cuando la hoja

haga contacto, primero mueva con cuidado dentro del

corte; luego en forma gradual inserte presión a medida

que la posición de corte se estabilice. La presión que

usted ejerza sobre la empuñadura debe ajustarse para

producir la mínima cantidad de chispas.

Cuando se completa el corte, apague la herramienta y

ESPERE HASTA QUE LA HOJA SE HAYA DETENIDO

POR COMPLETO antes de regresar la empuñadura a la

posición completamente elevada. Si se levantara la

empuñadura mientras la hoja sigue girando, la pieza

cortada podría quedar atrapada por la hoja, lo que

causaría una peligrosa dispersión de astillas. Cuando

sólo se corte una parte de la pieza de trabajo, levante la

empuñadura mientras la hoja sigue rotando. El apagado

durante el corte puede dañar las puntas de carburo al

hacer contacto con la pieza de trabajo.

Corte de ángulos

Asegure la pieza de trabajo en la prensa como se ilustra

en la Figura A y proceda a cortarla. La duración de la

hoja de la sierra disminuirá si la pieza se corta como en

la Figura B.

La hoja de la sierra se gastará más cuando se corte el

área A de la Figura B. Coloque un tope de madera

contra la pieza como se ilustra en la Fig. D de modo tal

que la hoja de la sierra entre en el área A con ángulo.

Esto ayudará a que se prolongue la vida útil de la hoja.