Makita JV100DZ, JV100DZW, JV100DWE, JV100DW, JV100DWEW Technical Information

...

Jig saw blade No. B-10 .................................. 1

Hex wrench ................................................... 1

Guide rule set (for some countries only) ........ 1

Note: The standard equipment for the tool

shown above may vary by country.

Jig saw blades

Guide rule set

Hose 28

Cover plate

Kerf board set

Charger DC10WA*

2

Li-ion battery BL1013*2

Charger DC10WB*3

Li-ion battery BL1014*3

JV100DZW

JV100DZ

BL1013DC10WA

NoNo

Model No.

type quantity

Charger

No

JV100DWE

1

2

JV100DW

Battery

Makita blue

white

VJ01ZW

VJ01Z

NoNo No

Makita blue

white

Makita blue

JV100DWW white

JV100DWEW white

Makita blue

BL1014DC10WB

No

Yes

No

Yes

VJ01W

2

VJ01 Makita blue

Offered to

white

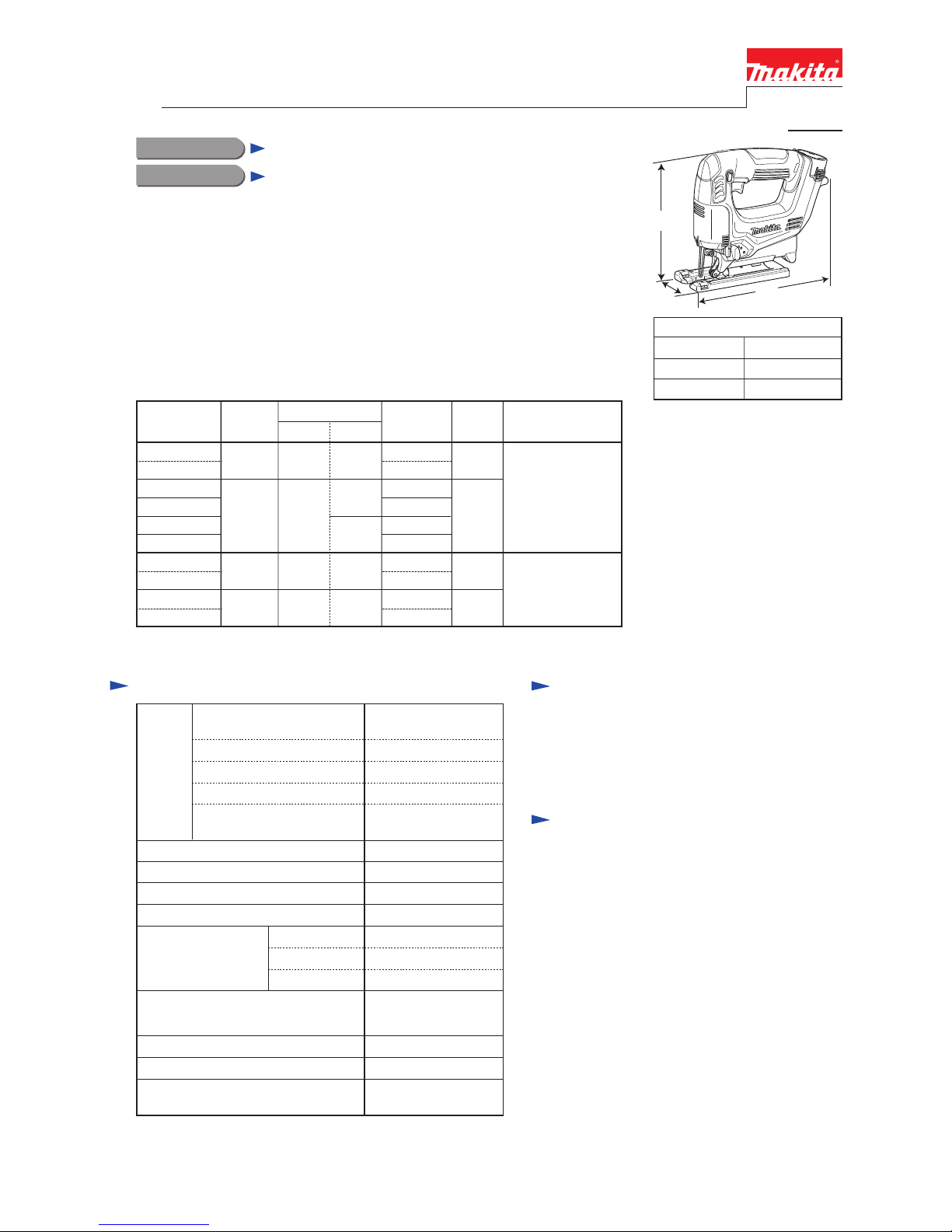

Dimensions: mm (")

Width (W)

Height (H)

Length (L)

231 (9-1/8)

76 (3)

196 (7-3/4)

Model No.

Description

P 1/ 11

JV100D (VJ01

*1)

Cordless Jig Saw

0 - 2,400

18 (11/16)

B-type

65 (2-9/16)

2 (1/16)

Yes

1.7 (3.7)

No load speed: strokes per minute

Battery

Stroke length: mm (")

Shank type

130Max. output: W

Capacities: mm (")

Wood

Mild steel

4 (5/32)Aluminum

Variable speed control by trigger

YesElectric brake

Cut settings

Cell

Voltage: V

Capacity: Ah

Li-ion

Energy capacity: Wh 14

1.3

All models also include the accessories listed below in "Standard equipment".

L

W

H

PRODUCT

*1 Model number for North and Central American countries

except Mexico and Guam

T

ECHNICAL INFORMATION

CONCEPT AND MAIN APPLICATIONS

Model JV100D (VJ01*1) has been developed as the first cordless jig saw

of the 10.8V Li-ion Cordless series.

Its main features are:

• Compact and lightweight design achieved while maintaining the power

enough to perform smooth light duty cutting

• The same mechanical parts and functions as used for AC model 4329

This product is available in the following variations.

Plastic

carrying

case

Housing

color

50 with DC10WA*2,

(DW10WB*3)

10.8*

2,

(10.8/12V max*3)

Charging time

(approx.): min.

3 Orbital settings

+

Straight cutting

Weight according to EPTA-Procedure

01/2003*

4: kg (lbs)

*2 For all countries except North and Central American countries

(Mexico and Guam are included.)

*3 For North and Central American countries except Mexico and Guam

*4 With battery

Standard equipment

Specification

Optional accessories

All countries except

North and Central

American countries

(Mexico and

Guamare included)

North and Central

American countries

except Mexico

and Guam

P 2/ 11

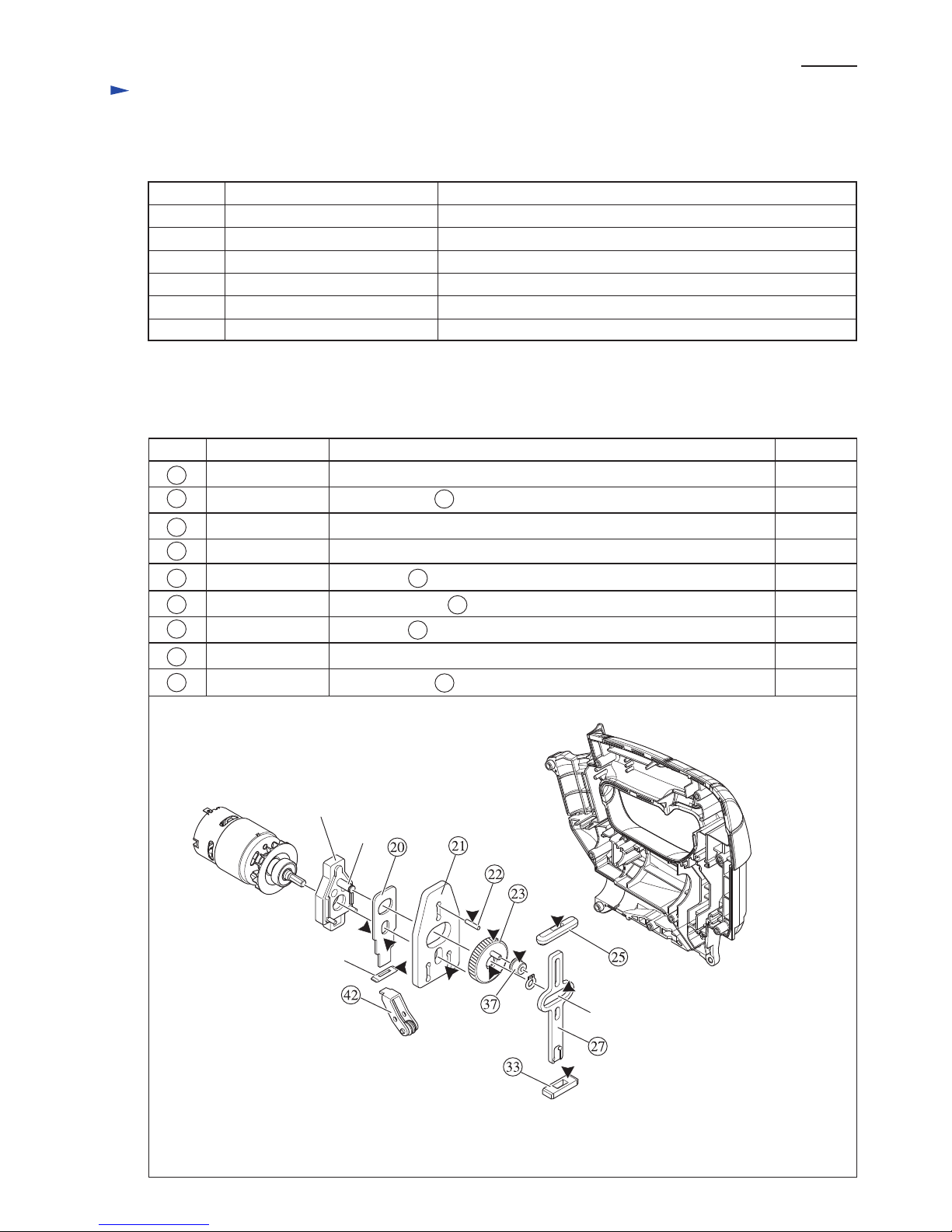

Repair

Apply Makita grease N. No.1 to the following portions designated with the black triangle to protect

parts and product from unusual abrasion.

[1] NECESSARY REPAIRING TOOLS

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

Code No. Description Use for

1R029 Bearing Setting Pipe 23-15.2 Pressing Bearing case complete, when assembling it to DC Motor

1R032 Bearing Setting Plate 8.2 Supporting DC Motor, when assembling it to Bearing case complete

1R258 V Block Supporting DC Motor, when assembling it to Bearing case complete

1R269 Bearing Extractor Separating DC Motor from Bearing case complete

1R291 Retaining Ring S & R Pliers Removing /assembling Retaining ring S-6

1R274 Type 72 Field Insert Jig Supporting DC Motor, when assembling it to Bearing case complete

[2] LUBRICATION

Item No. Description AmountPortion to lubricate

DC Motor

21 Balance plate The portion that 23 Gear complete contacts

22 Pin 3 Whole portion

23 Gear complete Gear teeth and Armature gear in Bearing case complete and Balance plate

25 Slider guide Hole where 27 Slider reciprocates

27 Slider Elliptic hole where 37 Collar sleeve moves

33 Slider support

Hole where 27 Slider reciprocates

37 Collar sleeve Whole portion

42 Retainer complete The portion that 20 Push plate contacts

Approx. 3 g

Bearing case

complete

Pin

Dust seal

20 Push plate Both side

a little

a little

a little

a little

a little

a little

a little

a little

Repair

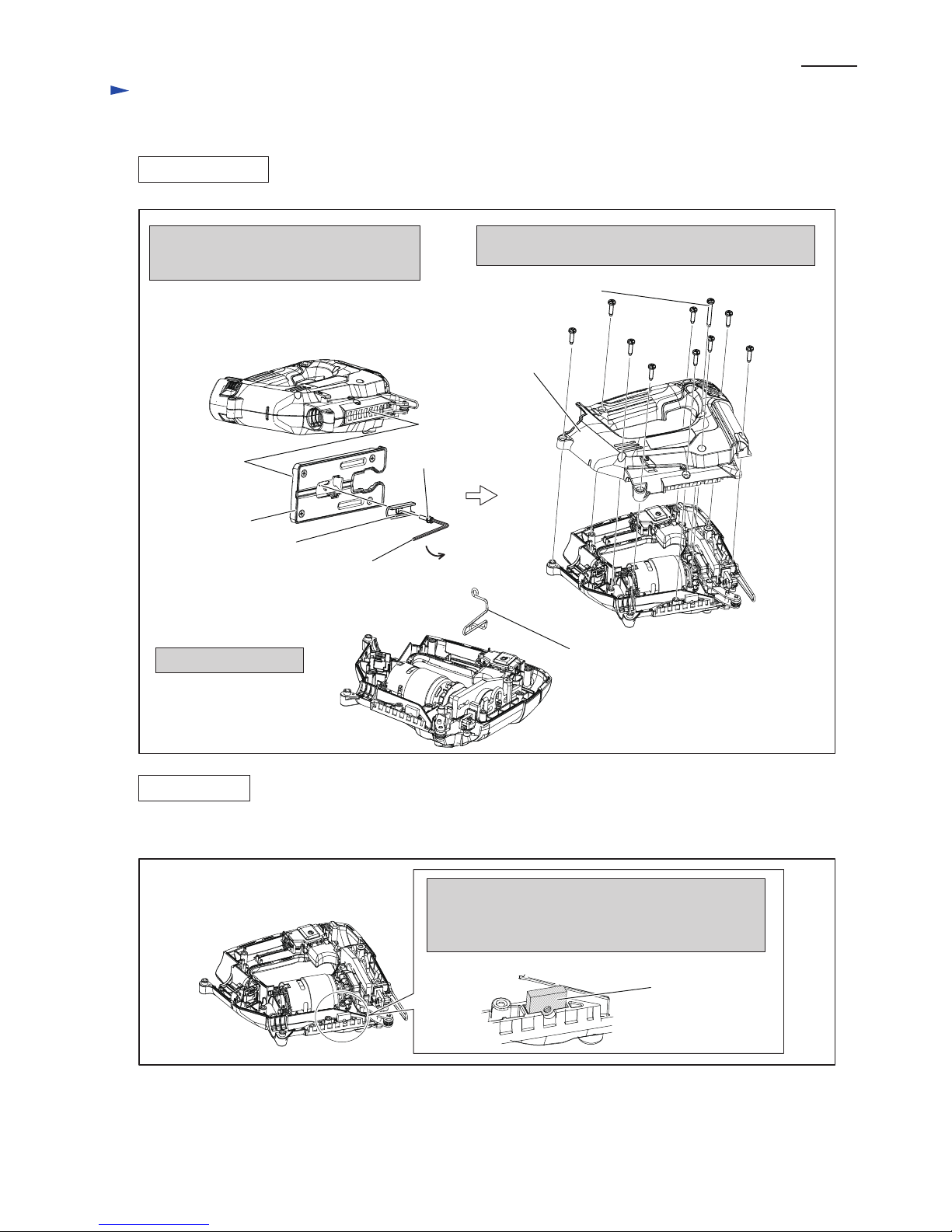

[3] DISASSEMBLY/ASSEMBLY

[3] -1. Housing

DISASSEMBLING

Fig. 2

Fig. 3

4x35 Tapping screw (1 pc.)

Housing R

Clamp plate

Hex wrench 3

(Standard equipment)

M4x16 Hex socket

head bolt

4x18 Tapping screw (9 pc.)

ASSEMBLING

Base

Note;

Before assembling Housing R, make sure that Holder

(with M4 Screw hole) is mounted to Housing L

to fasten Housing set with M4x16 Hex socket head bolt

1. Remove Clamp plate and Base from

Housing set by unscrewing M4x16

Hex socket head bolt with Hex wrench 3.

2. Separate Housing R by unscrewing M4x35

Tapping screw (1pc.) and 4x18 Tapping screws (9pcs).

3. Remove Safety wire.

Holder

(2) Set Safety wire to Housing L (Fig. 2-3).

(3) Assemble Housing R to Housing L (Fig. 2-2).

(4) Assemble Base and Clamp plate to Housing set and tighten them with M4x16 Hex socket head bolt (Fig. 2-1).

(1) Make sure to insert Holder to Housing L (Fig. 3).

Safety wire

P 3/ 11

Repair

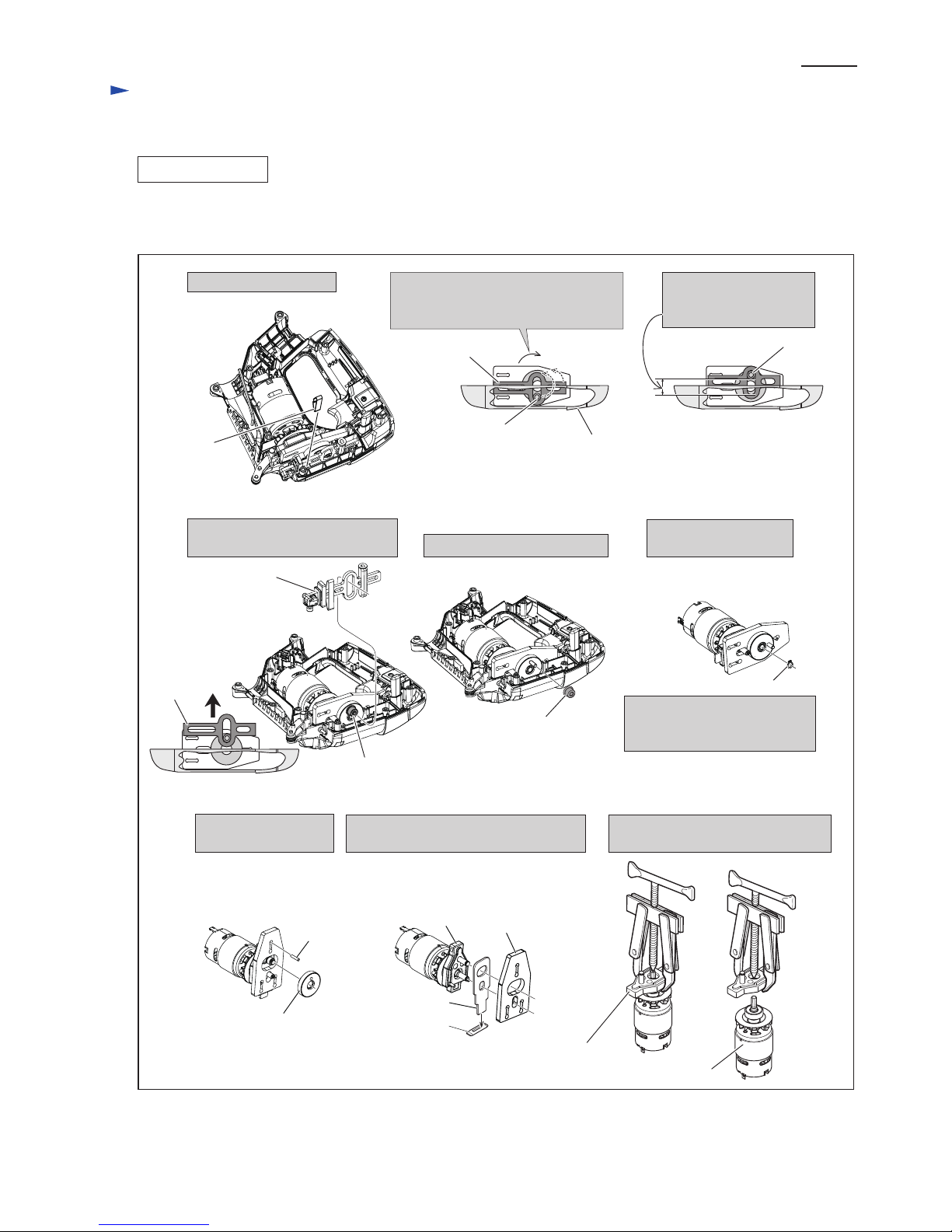

[3] DISASSEMBLY/ASSEMBLY

[3] -2. Reciprocating Mechanism

DISASSEMBLING

2. Turn DC motor shaft to move

Collared sleeve 4 up to the top

position of Slider’s elliptical hole.

4. Remove Slider section from the

Collared sleeve 4.

5 . Remove Collared sleeve 4.

7. Now, remove Gear

complete and Pin 3.

8. Remove Balance plate and Push plate

from Bearing case complete.

9. Remove DC motor from Bearing

case complete with 1R269.

Slider

Collared

sleeve 4

Collared

sleeve 4

Housing L

3. A space for removing

Slider from Collared

sleeve 4 is secured.

Slider

Collared sleeve 4

Slider section

Leaf spring

Gear complete

Push plate

Dust seal

Balance plate

Bearing case

complete

Pin 3

Retaining ring S-6

6 . Remove Retaining

ring S-6 with 1R291.

Note;

Retaining ring S-6 is deformed

in this step. Do not re-use it.

Bearing case

complete

DC motor

(1) Separate Housing R from Housing L (Fig. 2).

(2) Now, Reciprocating mechanism can be disassembled (Fig. 4).

Fig. 4

Collared sleeve 4

1. Remove Leaf spring.

P 4/ 11

Loading...

Loading...