Page 1

Owner’s and Safety Manual

for Petrol String Trimmer

Manuel d’emploi et de sécurité

de Débroussailleuse Thermique

Manual de empleo y de seguridad

para Desbrozadora

ER2550LH

Important:

Read this instruction manual carefully before putting the Petrol String Trimmer into operation and

strictly observe the safety regulations!

Preserve instruction manual carefully!

Important :

Lisez attentivement les instructions du présent manuel avant de vous servir de la débroussailleuse

thermique pour la première fois, et respectez à la lettre les consignes de sécurité!

Conservez précieusement ce manuel d’instructions!

Importante:

Lea este manual de instrucciones con atención antes de utilizar la desbrozadora y ¡observe

estrictamente las regulaciones de seguridad!

¡Conserve cuidadosamente su manual de instrucciones!

Page 2

English

Thank you very much for purchasing the MAKITA Outdoor Power Equipment.

We are pleased to recommend to you the MAKITA product which is the result of

a long development program and many years of knowledge and experience.

Please read this booklet which refers in detail to the various points that will

demonstrate its outstanding performance. This will assist you to obtain the best

possible result from your MAKITA product.

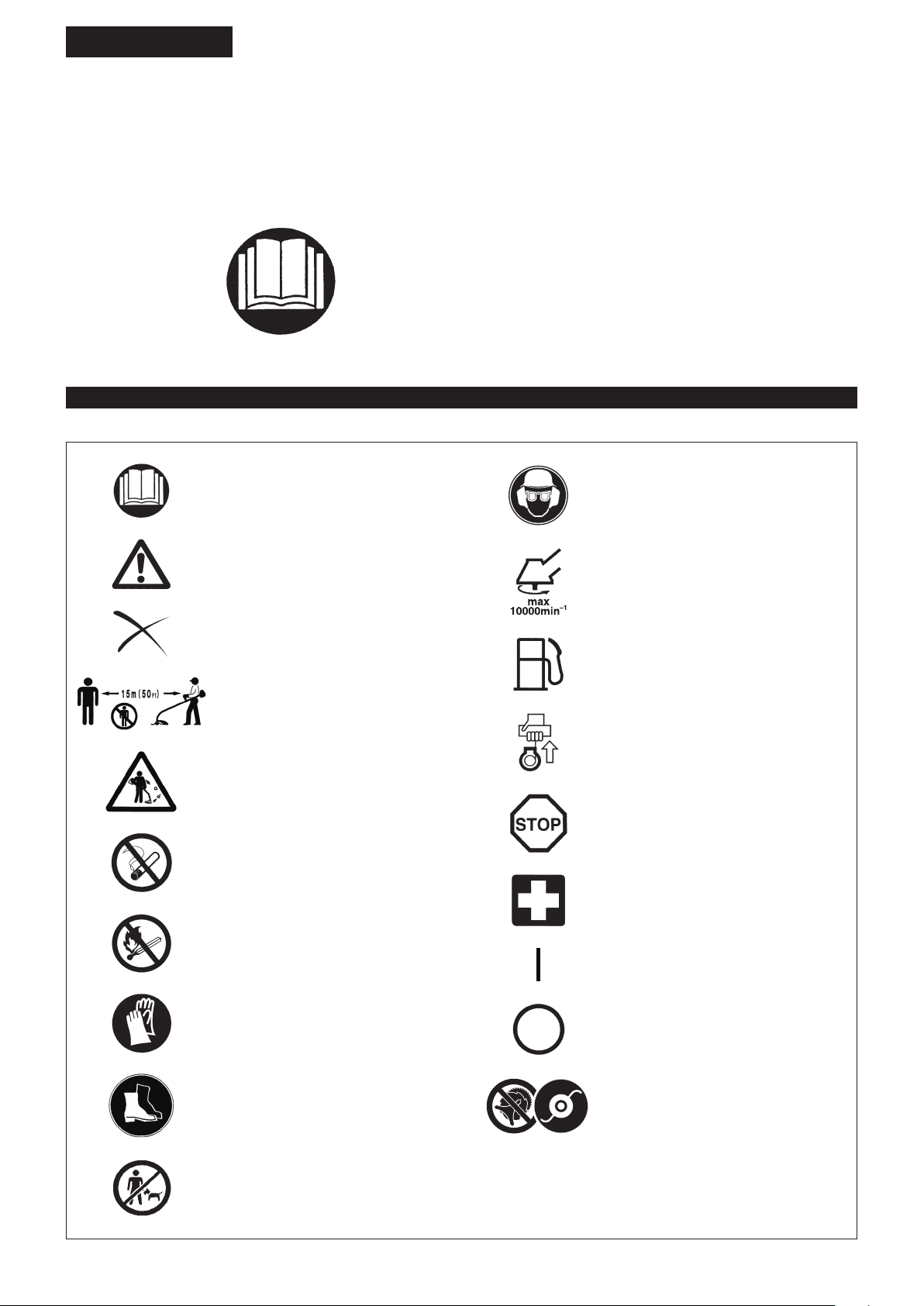

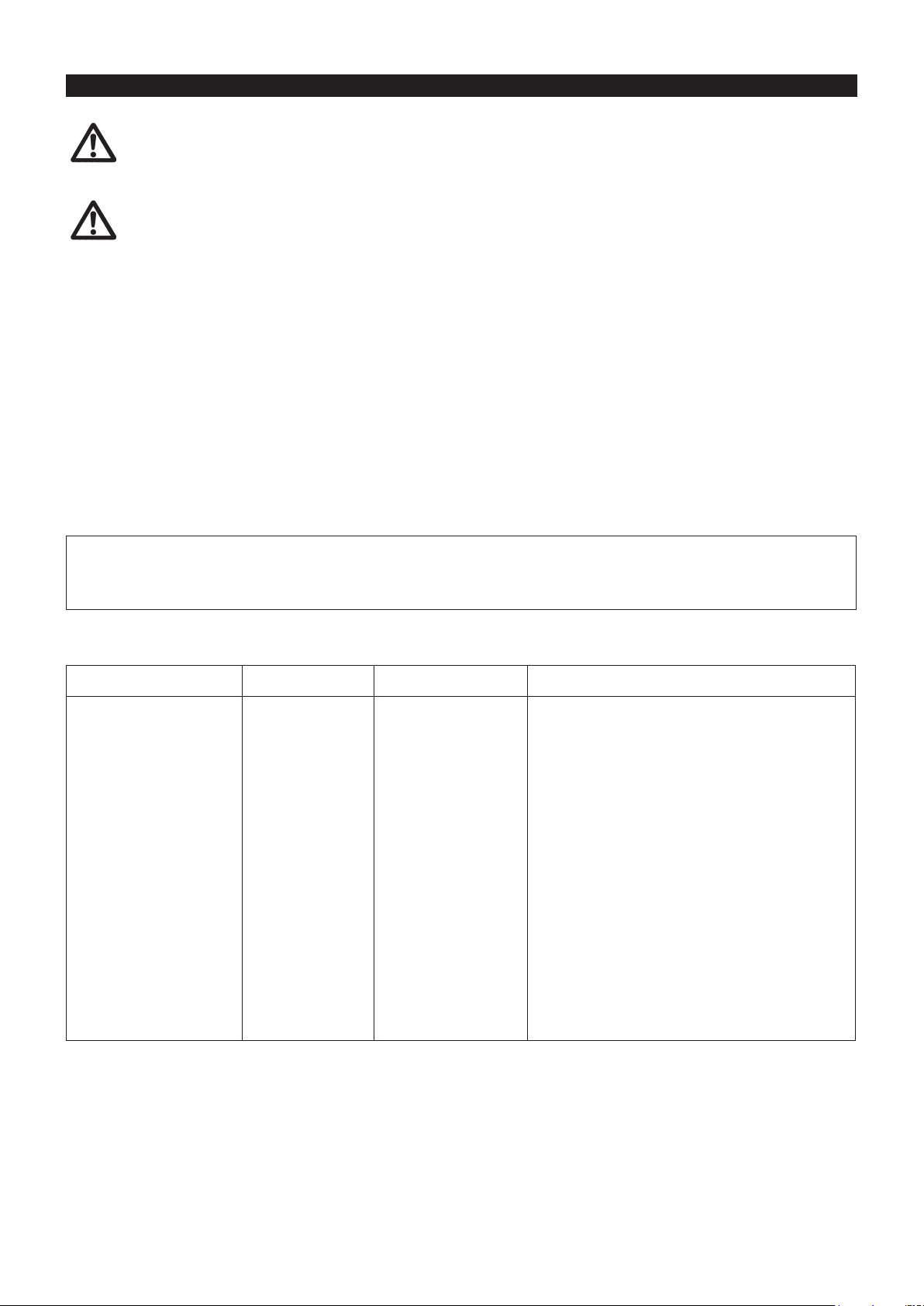

SYMBOLS

You will note the following symbols when reading the instructions manual.

Read instruction manual and follow the

warnings and safety precautions!

Table of Contents Page

Symbols .........................................................................2

Safety instructions .........................................................3

Technical data................................................................6

Designation of parts.......................................................7

Mounting of handle ........................................................8

Mounting of protector.....................................................8

Mounting of nylon cutting head......................................8

Before start of operation ................................................9

Points in operation and how to stop ............................11

The nylon cutting head ................................................12

Servicing instructions...................................................14

Storage ........................................................................17

Wear protective helmet, eye and ear

protection.

Take particular care and attention!

Forbidden!

Keep distance!

Flying object hazard!

No smoking!

No open ame!

Top permissible tool speed

Fuel (Gasoline)

Engine-manual start

Emergency stop

First Aid

ON/START

Protective gloves must be worn!

Wear sturdy boots with nonslip soles.

Steeltoed safety boots are recommended!

Keep the area of operation clear of all

persons and pets!

2

OFF/STOP

Never use metal blades

Page 3

360°

SAFETY INSTRUCTIONS

General Instructions

Read this instruction manual to become familiar with handling of the –

equipment. Users insufciently informed will risk danger to themselves as

well as others due to improper handling.

It is recommended only to lend the equipment to people who have proven to –

be experienced.

Always hand over the instruction manual.

First users should ask the dealer for basic instructions to familiarize oneself –

with the handling of string trimmers.

Children and young persons aged under 18 years must not be allowed to –

operate this equipment. Persons over the age of 16 years may however

use the device for the purpose of being trained while under supervision of a

qualied trainer.

Use with the utmost care and attention. –

Operate only if you are in good physical condition. Perform all work calmly –

and carefully. The user has to accept liability for others.

Never use this equipment after consumption of alcohol or drugs, or if feeling –

tired or ill.

National regulation can restrict the use of the machine. –

Intended use of the machine

This equipment is only intended for cutting grass and light weeds. It should –

not be used for any other purpose such as edging or hedge cutting as this

may cause injury.

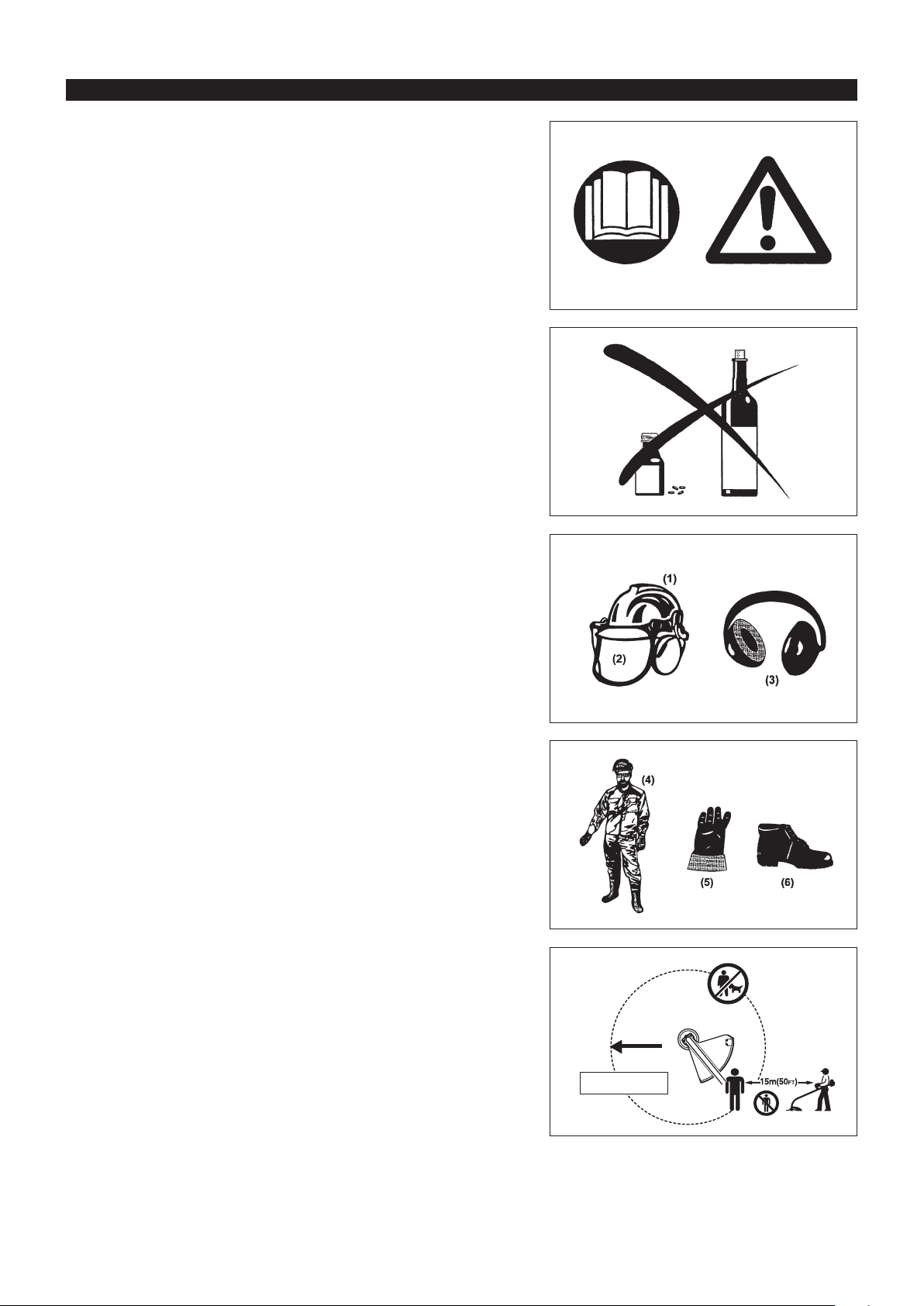

Personal protective equipment

The clothing worn should be functional and appropriate, i.e. it should be tight- –

tting but not cause hindrance. Do not wear either jewelry or clothing which

could become entangled with bushes or shrubs.

In order to avoid either head-, eye-, hand- or foot injuries as well as to protect –

your hearing the following protective equipment and protective clothing must

be used during operation.

Always wear a helmet where there is a risk of falling objects. The protective –

helmet (1) is to be checked at regular intervals for damage and is to be

replaced at the latest after 5 years. Use only approved protective helmets.

The visor (2) of the helmet (or alternatively goggles) protects the face from –

ying debris and stones. During operation always wear goggles, or a visor to

prevent eye injuries.

Wear adequate noise protection equipment to avoid hearing impairment (ear –

muffs (3), ear plugs etc.).

The work overalls (4) protect against ying stones and debris. –

We strongly recommend that the user wears work overalls.

Gloves (5) are part of the prescribed equipment and must always be worn –

during operation.

When using the equipment, always wear sturdy shoes (6) with a non-slip –

sole. This protects against injuries and ensures a good footing.

Starting up the Petrol String Trimmer

Please make sure that there are no children or other people within a working –

range of 15 meters (50 ft), also pay attention to any animals in the working

vicinity.

Before use always check the equipment is safe for operation: –

Check the security of the cutting attachment, the throttle lever for easy action

and check for proper functioning of the throttle lever lock.

Rotation of the cutting attachment during idling speed is not allowed. Check –

with your dealer for adjustment if in doubt. Check for clean and dry handles

and test the function of the start/stop switch.

Diagrammatic gure

15 Meters

3

Page 4

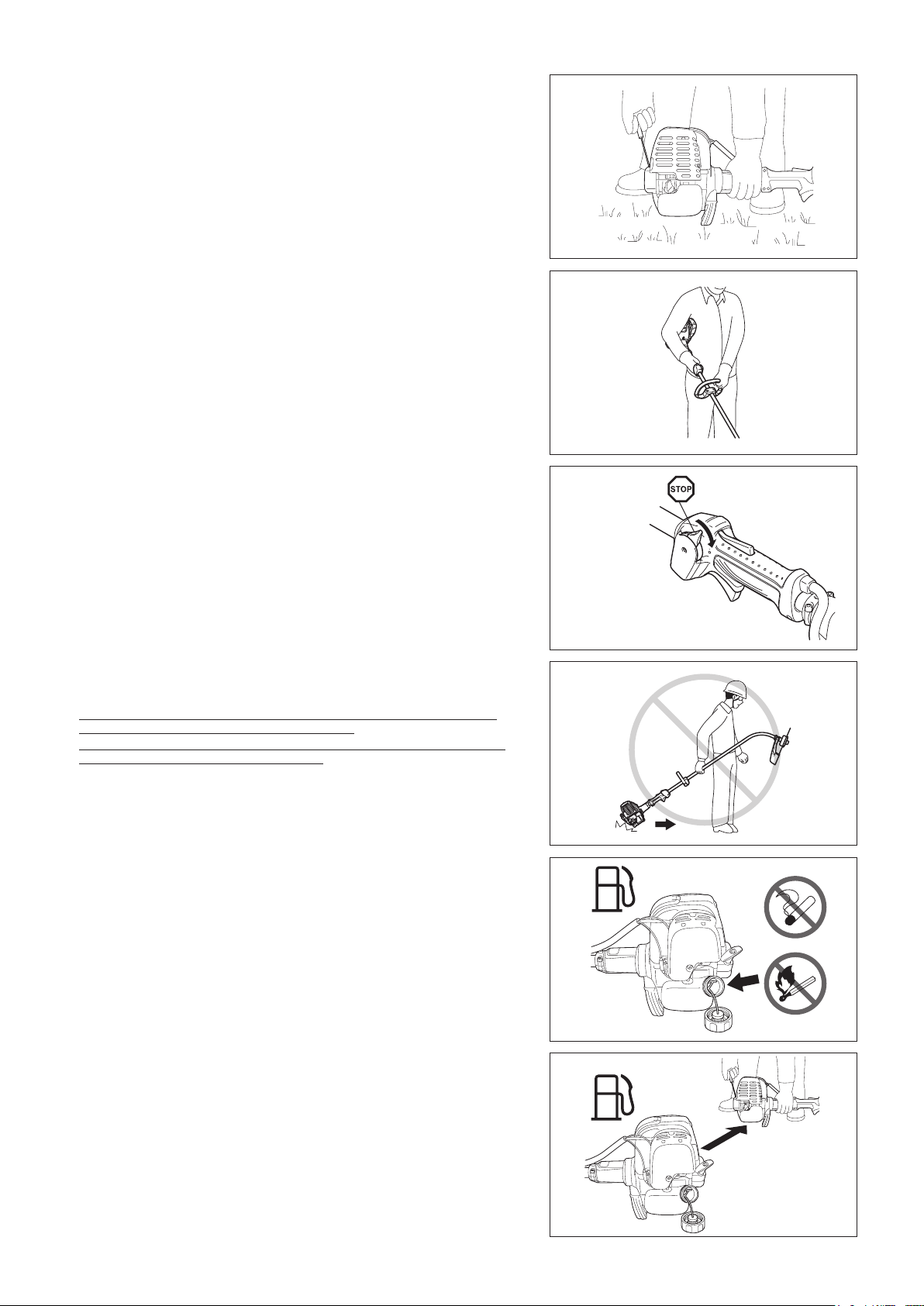

Start the Petrol String Trimmer only in accordance with the instructions. –

Do not use any other methods for starting the engine! –

Use the Petrol String Trimmer and the tools only for such applications as –

specied.

Only start the engine, after the entire assembly is done. Operation of the –

device is only permitted after all the appropriate accessories are attached!

Before starting make sure that the cutting attachment has no contact with –

hard objects such as branches, stones etc. as the cutting attachment will

revolve when starting.

The engine is to be switched off immediately in case of any engine problems. –

Should the cutting attachment hit stones or other hard objects, immediately –

switch off the engine and inspect the cutting attachment.

Inspect the cutting attachment at short regular intervals for damage (detection –

of hairline cracks by means of tapping-noise test).

If the equipment gets heavy impact or fall, check the condition before –

continuing work. Check the fuel system for fuel leakage and the controls

and safety devices for malfunction. If there is any damage or doubt, ask our

authorized service center for the inspection and repair.

During operation always hold the Petrol String Trimmer with both hands. –

Never hold the Petrol String Trimmer with one hand during use.

Always ensure a safe footing.

Operate the equipment in such a manner as to avoid inhalation of the exhaust –

gases. Never run the engine in enclosed rooms (risk of gas poisoning).

Carbon monoxide is an odorless gas.

Switch off the engine when resting and when leaving the equipment –

unattended, and place it in a safe location to prevent danger to others or

damage to the machine.

Never put the hot Petrol String Trimmer onto dry grass or onto any –

combustible materials.

Always install the approved cutting attachment guard onto the equipment –

before starting the engine. Otherwise contact with the cutting attachment may

cause serious injury.

All protective installations and guards supplied with the machine must be –

used during operation.

Never operate the engine with faulty exhaust mufer. –

Shut off the engine during transport. –

Ensure safe position of the equipment during car transportation to avoid fuel –

leakage.

When transporting, ensure that the fuel tank is completely empty. –

When unloading the equipment from the truck, never drop the Engine to the –

ground or this may severely damage the fuel tank.

Except in case of emergency, never drop or cast the equipment to the ground –

or this may severely damage the equipment.

Remember to lift the entire equipment from the ground when moving the –

equipment. Dragging the fuel tank is highly dangerous and will cause damage

and leakage of fuel, possibly causing re.

Resting•

Transport•

Refueling•

Maintenance•

Tool replacement•

Refueling

Shut off the engine during refueling, keep away from open ames and do not –

smoke.

Avoid skin contact with mineral oil products. Do not inhale fuel vapor. Always –

wear protective gloves during refueling. Change and clean protective clothing

at regular intervals.

Take care not to spill either fuel or oil in order to prevent soil contamination –

(environmental protection). Clean the Petrol String Trimmer immediately after

fuel has been spilt.

Avoid any fuel contact with your clothing. Change your clothing instantly if –

fuel has been spilt on it (to prevent clothing catching re).

Inspect the fuel cap at regular intervals making sure that it can be securely –

fastened and does not leak.

Carefully tighten the fuel tank cap. Change location to start the engine (at –

least 3 meters away from the place of refueling).

Never refuel in closed rooms. Fuel vapors accumulate at ground lever (risk of –

explosions).

Only transport and store fuel in approved containers. Make sure the fuel –

stored is not accessible to children.

4

3 meters

Page 5

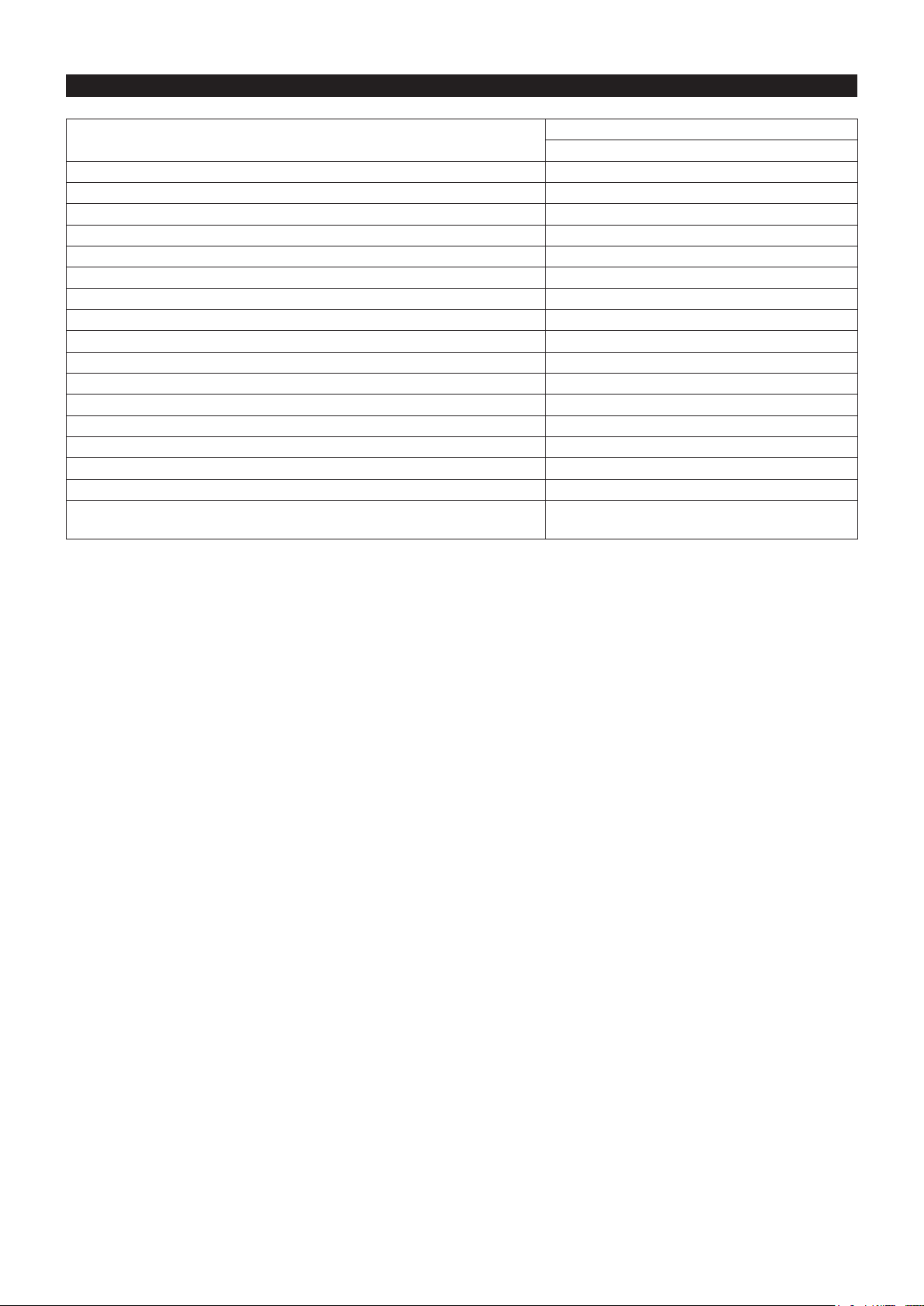

Method of operation

Only use in good light and visibility. During the winter season beware of –

slippery or wet areas, ice and snow (risk of slipping). Always ensure a safe

footing.

Never cut above waist height. –

Never stand on a ladder. –

Never climb up into trees to perform cutting operation. –

Never work on unstable surfaces. –

Remove sand, stones, nails etc. found within the working range. –

Before commencing cutting, the cutting attachment must have reached full –

working speed.

Swing the Petrol String Trimmer evenly. –

If grass or branches get caught between the cutting attachment and guard,

always stop the engine before cleaning. Otherwise unintentional attachment

rotation may cause serious injury.

Take a rest to prevent loss of control caused by fatigue. We recommend to –

take a 10 to 20-minute rest every hour.

Cutting attachments

Never use metal blades including metal multi-piece pivoting chains and ail –

blades. Otherwise blade contact may cause serious injury.

Vibration

People with poor circulation who are exposed to excessive vibration may –

experience injury to blood vessels or the nervous system. Vibration may

cause the following symptoms to occur in the ngers, hands or wrists: “Falling

asleep” (numbness), tingling, pain, stabbing sensation, alteration of skin color

or of the skin. If any of these symptoms occur, see a physician!

To reduce the risk of “white nger disease”, keep your hands warm during –

operation and well maintain the equipment and accessories.

Maintenance instructions

Have your equipment serviced by our authorized service center, always using –

only genuine replacement parts. Incorrect repair and poor maintenance can

shorten the life of the equipment and increase the risk of accidents.

The condition of the equipment, in particular of the cutting attachment of the –

protective devices must be checked before commencing work.

Turn off the engine and remove spark plug connector when replacing cutting –

attachments, and also when cleaning the cutter or cutting attachment.

Pay attention to the environment. Avoid unnecessary throttle operation for –

less pollution and noise emissions. Adjust the carburetor correctly.

Clean the equipment at regular intervals and check that all screws and nuts –

are well tightened.

Never service or store the equipment in the vicinity of naked ames. –

Always store the equipment in locked rooms and with an emptied fuel tank. –

Observe the relevant accident prevention instructions issued by the relevant trade associations and by the insurance companies.

Do not perform any modications to the equipment as this will endanger your safety.

The performance of maintenance or repair work by the user is limited to those activities as described in the instruction manual. All other work is

to be done by an Authorized Service Agent. Use only genuine spare parts and accessories released and supplied by MAKITA.

Use of non-approved accessories and tools means increased risk of accidents.

MAKITA will not accept any liability for accidents or damage caused by the use of non-approved cutting attachments and xing devices of cutting

attachments, or accessories.

First Aid

In case of accident make sure that a rst-aid box is available in the vicinity of

the cutting operations. Immediately replace any item taken from the rst aid box.

When asking for help, please give the following

information:

Place of accident –

What happened –

Number of injured persons –

Kind of injuries –

Your name –

5

Page 6

TECHNICAL DATA ER2550LH

Model

Dimensions: length x width x height (without cutting attachment) inch (mm) 64” X 11-3/8” X 18-1/4” (1,623 X 290 X 464)

Cutting diameter inch (mm) 16”-1/4” (412)

Mass (without plastic guard and cutting attachment) lbs (kg) 10.8 (4.9)

Volume (fuel tank) .oz (L) 16.9 (0.5)

Volume (oil reservoir) .oz (L) 2.7 (0.08)

Engine displacement cu.in (cm

Maximum engine performance hp (kw) 1.0 (0.71) at 7,000 rpm

Engine speed at recommended max. spindle speed RPM (1/min) 10,000

Maximum rotational frequency of the spindle RPM (1/min) 7,750

Idling speed RPM (1/min) 3,000

Clutch engagement speed RPM (1/min) 3,750

Carburetor type WALBRO WYL

Ignition system type Solid state ignition

Spark plug type NGK CMR4A

Electrode gap inch (mm) 1/32” (0.7-0.8)

Fuel Automobile gasoline

Engine Oil

(For Canada)

NOTE: This spark ignition system complies with the Canadian standard ICES-002.

3

) 1.49 (24.5)

SAE 10W-30 oil of API Classication,

Class SF or higher (4-stroke engine for automobile)

ER2550LH

Loop handle

6

Page 7

DESIGNATION OF PARTS

15

14

13

10

9

8

7

5

4

11

12

3

17

16

2

1

6

18

19

15

14

13

10

9

8

7

5

4

11

12

ER2550LH

GB DESIGNATION OF PARTS

1 Fuel tank

2 Rewind starter

3 Air cleaner

4 I-O switch (on/off)

5 Spark plug

6 Exhaust mufer

7 Clutch case

8 Rear grip

9 Lock-off lever

10 Handle

11 Throttle lever

12 Control cable

13 Shaft

14 Protector (Cutting attachment guard)

15 Nylon cutting head

16 Fuel tank cap

17 Starter knob

18 Exhaust pipe

19 Oil gauge

7

Page 8

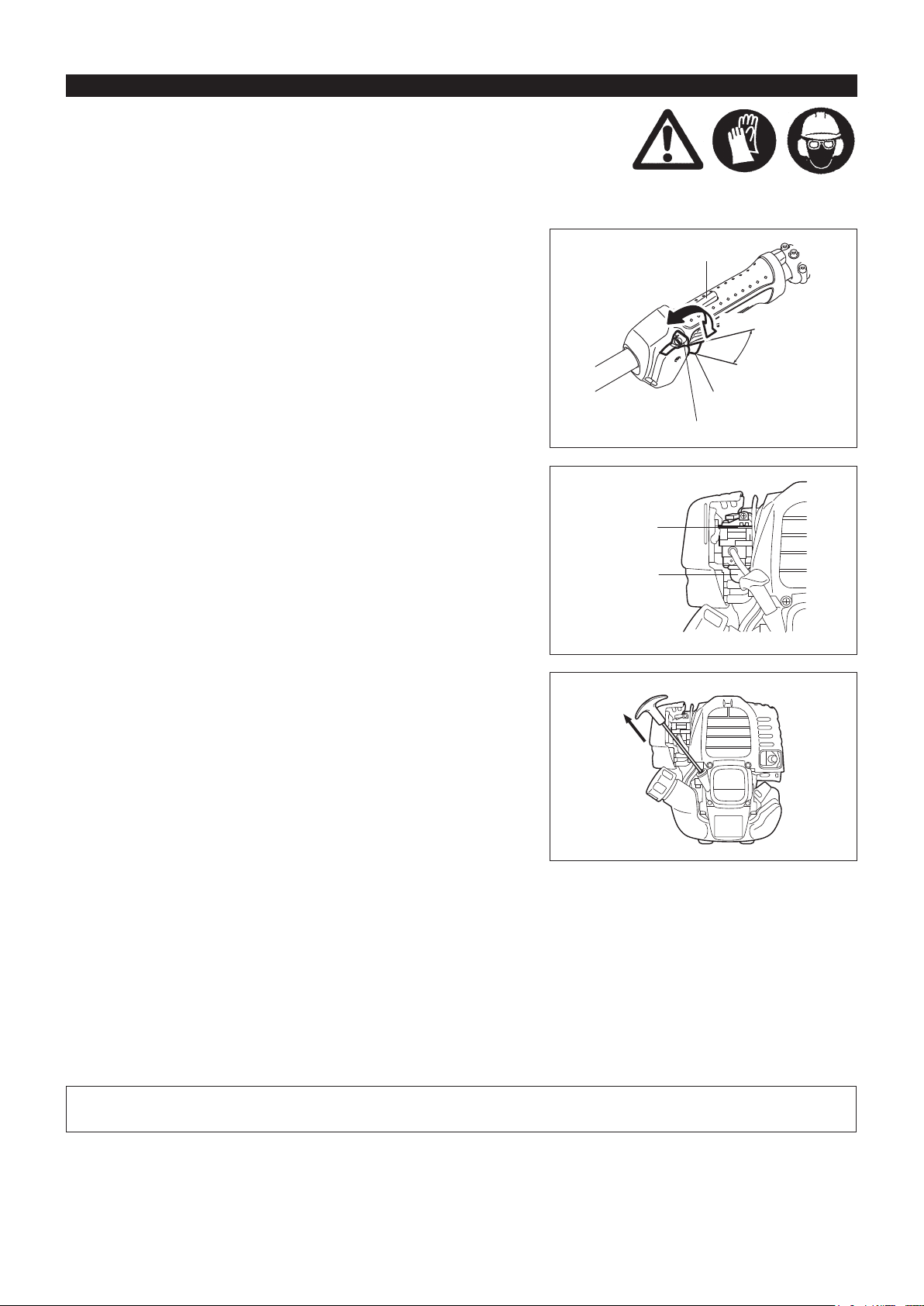

MOUNTING OF HANDLE

CAUTION: Before doing any work on the equipment, always stop the

engine and pull the spark plug connector off the spark plug.

Always wear protective gloves!

CAUTION: Start the engine only after having assembled it completely.

For machines with loop handle

Fix the loop handle on the shaft as shown. –

Make sure that the spacer on the shaft pipe is located between the grip –

assembly and the other grip. Do not remove or shrink the spacer.

NOTE: In some countries, the spacer is not provided with the tool. In that case,

align the handle to further side of the line which is indicated by the

arrow marks.

MOUNTING OF PROTECTOR

To meet the applicable safety provisions, only the tool/protector

combinations as indicated in the table must be used.

CAUTION: Do not touch the cord cutter on the protector. Touching the cord

cutter with bare hands may result in injury.

The protector must be installed to maintain the nylon-cutting-cord length and

protect the operator from thrown stones and debris. Install the protector as the

following steps.

Cord cutter

Protector

1. Set the protector so that the rib on the shaft ts into the groove on the

protector.

2. Tighten two bolts.

MOUNTING OF NYLON CUTTING HEAD

WARNING: Never use cutting blades.

Be sure to use genuine MAKITA nylon cutting head.

If the nylon cutting head hits against a stone during operation, stop the –

engine and check the nylon cutting head immediately.

CAUTION: Do not touch the cord cutter on the protector. Touching the cord

cutter with bare hands may result in injury.

Mount a nylon cutting head as the following steps.

1. Insert the lock key through the hole on the clamp. Rotate them with pushing

the lock key in until they are locked.

2. Screw a nylon cutting head onto the shaft by turning it clockwise. Make sure

that it is mounted securely.

3. Remove the lock key.

To remove the nylon cutting head, turn it counterclockwise.

Bolts

Nylon cutting

head

Clamp

Tighten Loosen

Cord cutter

Lock key

8

Page 9

BEFORE START OF OPERATION

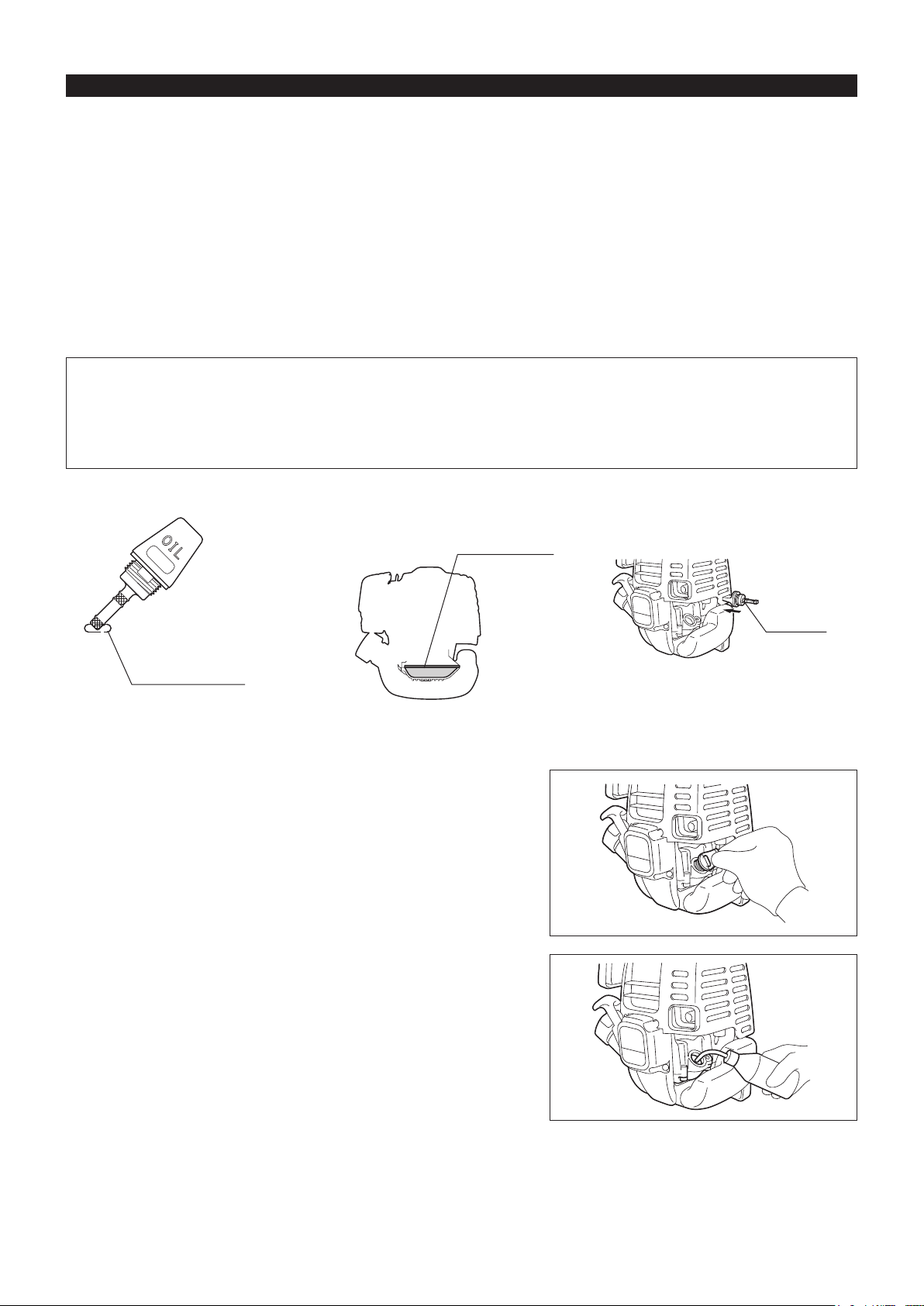

Inspectionandrellofengineoil

Perform the following procedure, with the engine cooled down. –

While keeping the engine level, remove the oil gauge, and conrm that the oil is lled within the upper and lower limit marks. –

When the oil is in short in such a way that the oil gauge touches the oil only by its tip, in particular with the oil gauge remaining inserted in the

crankcase without screwing-in (Fig. 1), rell new oil near the port (Fig. 2).

For reference, the oil rell time is about 10h (10 times or 10 tanks of oil rell). –

If the oil changes in color or mixes with dirt, replace it with new one. (For the interval and method of replacement, refer to P. 14)

Recommended oil: SAE 10W-30 oil of API Classication, Class SF or higher (4-stroke engine for automobile)

Oil volume: Approx. 0.08L

NOTE: If the engine is not kept upright, oil may go into around the engine, and may be relled excessively.

If the oil is lled above the limit, the oil may be contaminated or may catch re with white smoke.

Point 1 in Replacement of oil: “Oil gauge”

Remove dust or dirt near the oil rell port, and detach the oil gauge. –

Keep the detached oil gauge free of sand or dust. Otherwise, any sand or dust adhering to the oil gauge may cause irregular oil circulation –

or wear on the engine parts, which will result in troubles.

As an example to keep the oil gauge clean, it is recommended to insert the oil gauge on its knob side into the engine cover, as shown in –

Fig. 3.

Upper limit (Edge

of oil rell port)

If oil adheres around

this tip, rell new oil.

Fig. 1 Fig. 2 Fig. 3

(1) Keep the engine level, and detach the oil gauge.

(2) Fill oil up to the edge of the oil rell port. (Refer to Fig. 2.)

Feed oil with the lubricant rell container.

Oil gauge

(3) Securely tighten the oil gauge. Insufcient tightening may cause oil leakage.

9

Page 10

Note

Do not replace oil with the engine in a tilted position.•

Filling with oil while engine is tilted leads to overlling which causes oil contamination and/or white smoke.•

Point 2 in Replacement of oil: “If oil spills out”

If oil spills out between the fuel tank and engine main unit, the oil is sucked into through the cooling air intake port, which will contaminate –

the engine. Be sure to wipe out spilt oil before start of operation.

REFUELING

Handling of fuel

It is necessary to handle fuel with utmost care. Fuel may contain substances similar to solvents. Refueling must be performed in a sufciently

ventilated room or in the open air. Never inhale fuel vapor, and keep fuel away from you. If you touch fuel repeatedly or for a long time, the

skin becomes dry, which may cause skin disease or allergy. If fuel enters into the eye, clean the eye with fresh water. If your eye remains still

irritated, consult your doctor.

Storage period of fuel

Fuel should be used up within a period of 4 weeks, even if it is kept in a special container in a well-ventilated shade.

Otherwise, fuel may deteriorate in one day.

STORAGE OF MACHINE AND REFILL TANK

Keep the machine and tank at a cool place free from direct sunshine. –

Never keep the fuel in a car. –

Fuel

The engine is a four-stroke engine. Be sure to use an unleaded automobile gasoline 87 or higher octane ((R+M)/2). It may contain no more than

10% alcohol (E-10).

Points for fuel

Never use a gasoline mixture which contains engine oil. Otherwise, it will cause excessive carbon accumulation or mechanical troubles. –

Use of deteriorated oil will cause irregular startup. –

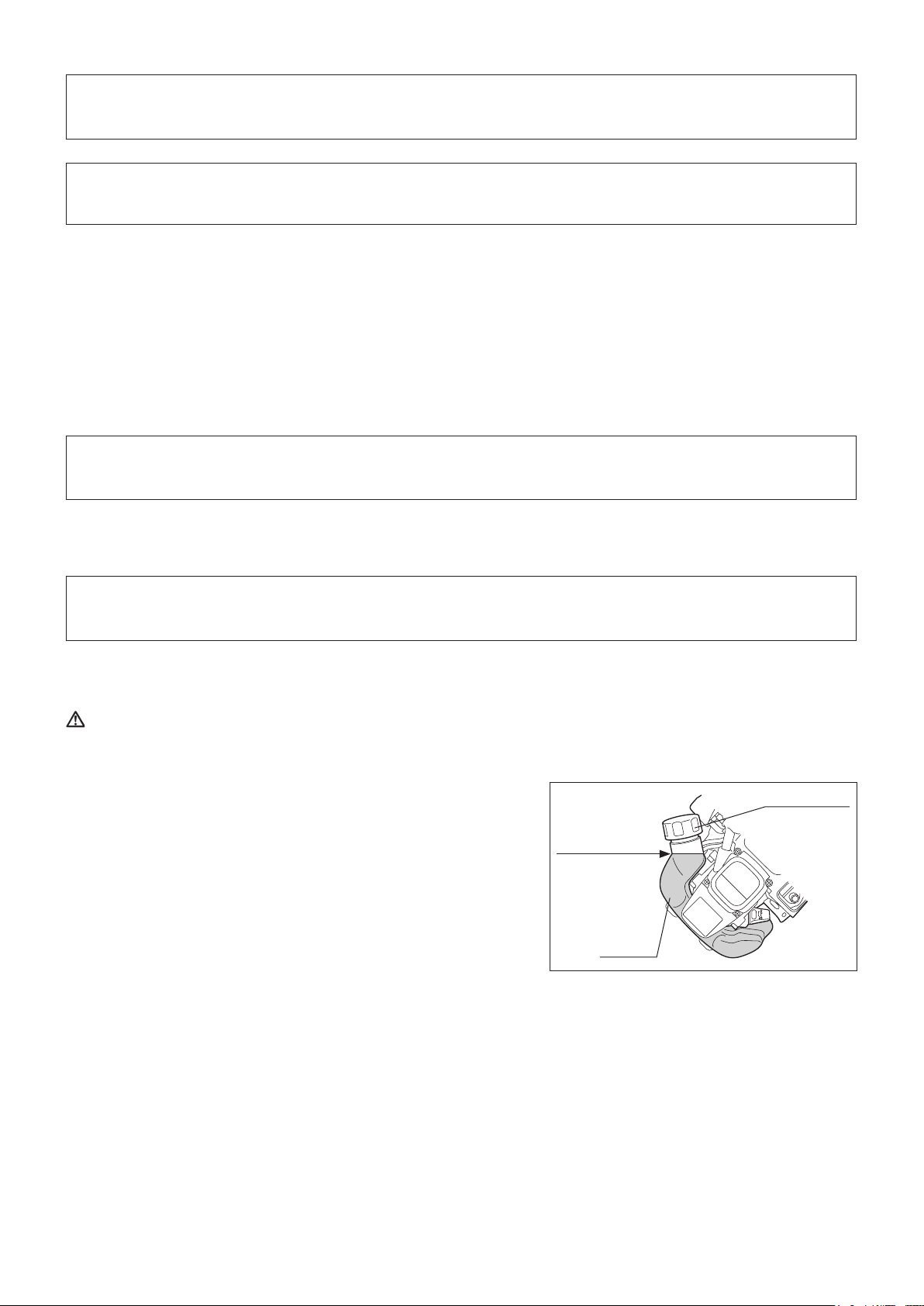

Refueling

WARNING: INFLAMMABLES STRICTLY PROHIBITED

Gasoline used: Unleaded automobile gasoline, 87 or higher octane. No more

than 10% alcohol (E-10).

Loosen the tank cap a little so that there will be no difference in atmospheric –

pressure.

Detach the tank cap, and refuel, discharging air by tilting the fuel tank so –

that the refuel port will be oriented upward. (Never rell fuel full to the oil rell

port.)

Wipe well the periphery of the tank cap to prevent foreign matter from –

entering into the fuel tank.

After refueling, securely tighten the tank cap. –

If there is any aw or damage on the tank cap, replace it.•

The tank cap is consumable, and therefore should be renewed every two to •

three years.

Fuel tank cap

Fuel upper limit

Fuel tank

10

Page 11

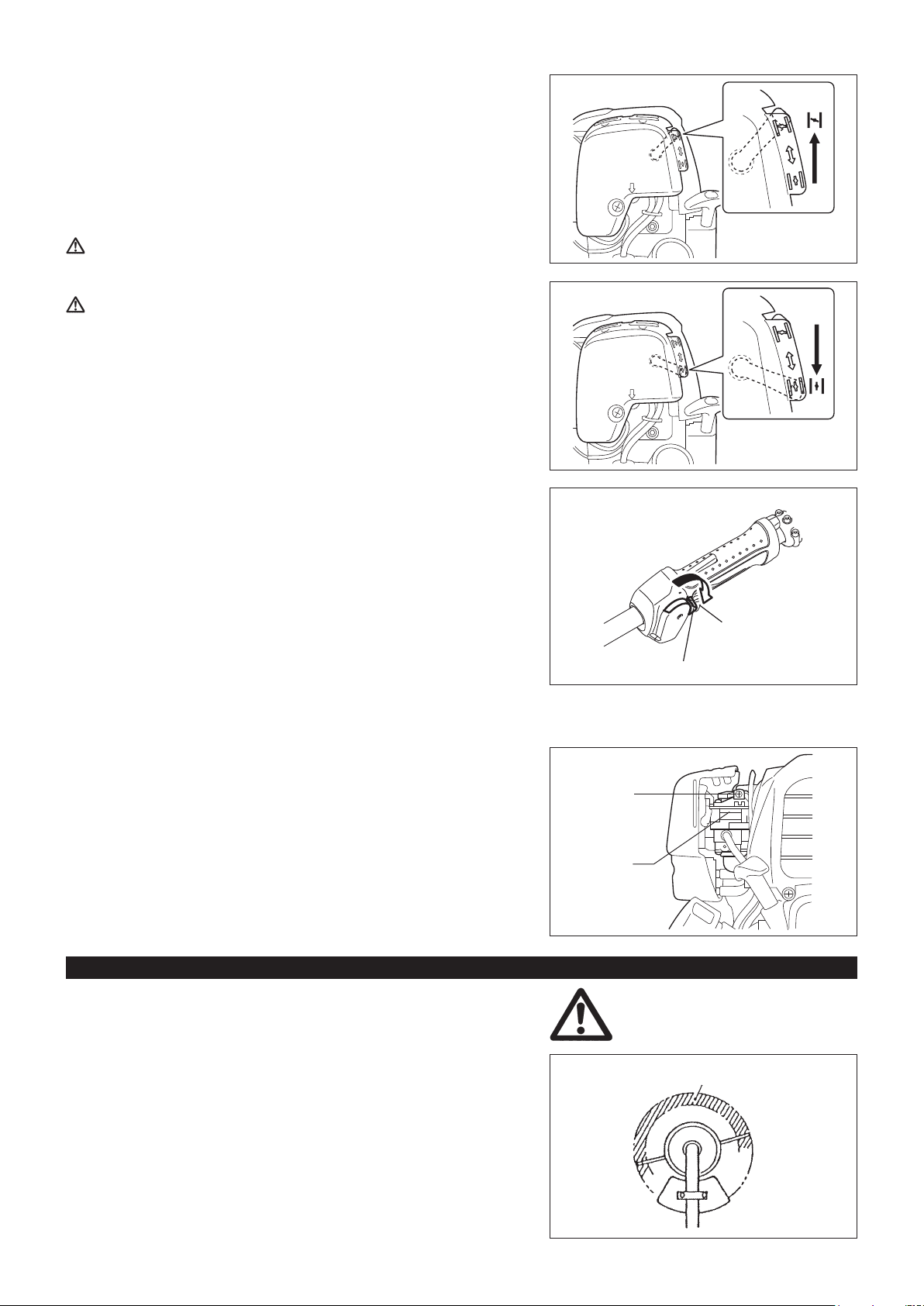

POINTS IN OPERATION AND HOW TO STOP

Observe the applicable accident prevention regulations!

STARTING

Move at least 3 m away from the place of refueling. Place the unit on the ground taking care that the cutting attachment does not come into

contact with the ground or any other objects.

A: Cold start

1) Set this machine on a at space.

2) Set the I-O switch (1) to OPERATION.

3) Primer pump

Continue to push the primer pump until fuel enters into the primer pump. (In

general, fuel enters into the primer pump by 7 to 10 pushes.)

If the primer pump is pushed excessively, an excess of gasoline returns to

the fuel tank.

OPERATION

Carburetor

Lock-off lever

STOP

Throttle lever

(1)

High speed

Low speed

Primer pump

4) Recoil starter

Pull the start knob gently until it is hard to pull (compression point). Then,

return the start knob, and pull it strongly.

Never pull the rope to the full. Once the start knob is pulled, never release

your hand immediately. Hold the start knob until it returns to its original

point.

5) Warm-up operation

Continue warm-up operation for 2 to 3 minutes.

NOTE: In case of excessive fuel intake (ooding), remove the spark plug and pull the starter handle slowly to remove excess fuel. Also, dry the

electrode section of the spark plug.

B: Startup after warm-up operation

1) Push the primer pump repeatedly.

2) Keep the throttle lever at the idling position.

3) Pull the recoil starter strongly.

4) If it is difcult to start the engine, open the throttle by about 1/3.

Attention in Operation

When the engine is operated upside down, white smoke may come out from the mufer.

11

Page 12

At times, such as winter, when starting the engine

is difcult

Operate choke lever with the following procedure when starting engine.

After implementing startup steps 1) to 3), set choke lever to the CLOSE •

position.

Implement startup step 4) and start engine.•

Once engine starts, set choke lever to the OPEN position.•

Implement startup step 5) and complete warm up.•

CLOSE

CAUTION: If a bang (explosive sound) is heard and the engine stops, or

the just-started engine stalls before the choke lever is operated,

return the choke lever to the OPEN position, and pull the starter

knob a few times again to start the engine.

CAUTION: If the choke lever is left in the CLOSE position, and the starter

knob merely pulled repeatedly, too much fuel will be sucked in,

and the engine will become difcult to start.

STOPPING

1) Release the throttle lever (2) fully, and when the engine rpm has lowered,

set the I-O switch to STOP the engine will now stop.

2) Be aware that the cutting head may not stop immediately and allow it to

slow down fully.

OPEN

STOP

(2)

(1)

ADJUSTMENT OF LOW-SPEED ROTATION (IDLING)

When it is necessary to adjust the low-speed rotation (idling), perform it by the carburetor adjusting screw.

CHECKUP OF LOW-SPEED ROTATION

Set the low-speed rotation to 3,000 min –

If it is necessary to change the low speed rotation (idle) speed, use a phillips

head screw driver on the screw illustrated on the right.

Turn the adjusting screw to the right, and the engine rotation will increase. –

Turn the adjusting screw to the left, and the engine rotation will drop.

The carburetor is generally adjusted before shipment. If it is necessary to –

readjust it, please contact Authorized Service Agent.

-1

.

Adjusting

screw

Carburetor

THE NYLON CUTTING HEAD

During operation, use the tip of the nylon cutting cord for cut.

Feeding the nylon cutting cord

As the nylon cutting cord is worn and shortened with the cutting operation, the

operator needs to feed it manually.

Most effective cutting area

To feed the nylon cutting cord, tap the nylon cutting head on the ground while it

rotates around 6,000 min

NOTE: If the nylon cutting cord does not feed out, rewind it.

-1

.

12

Page 13

80 mm

100 mm

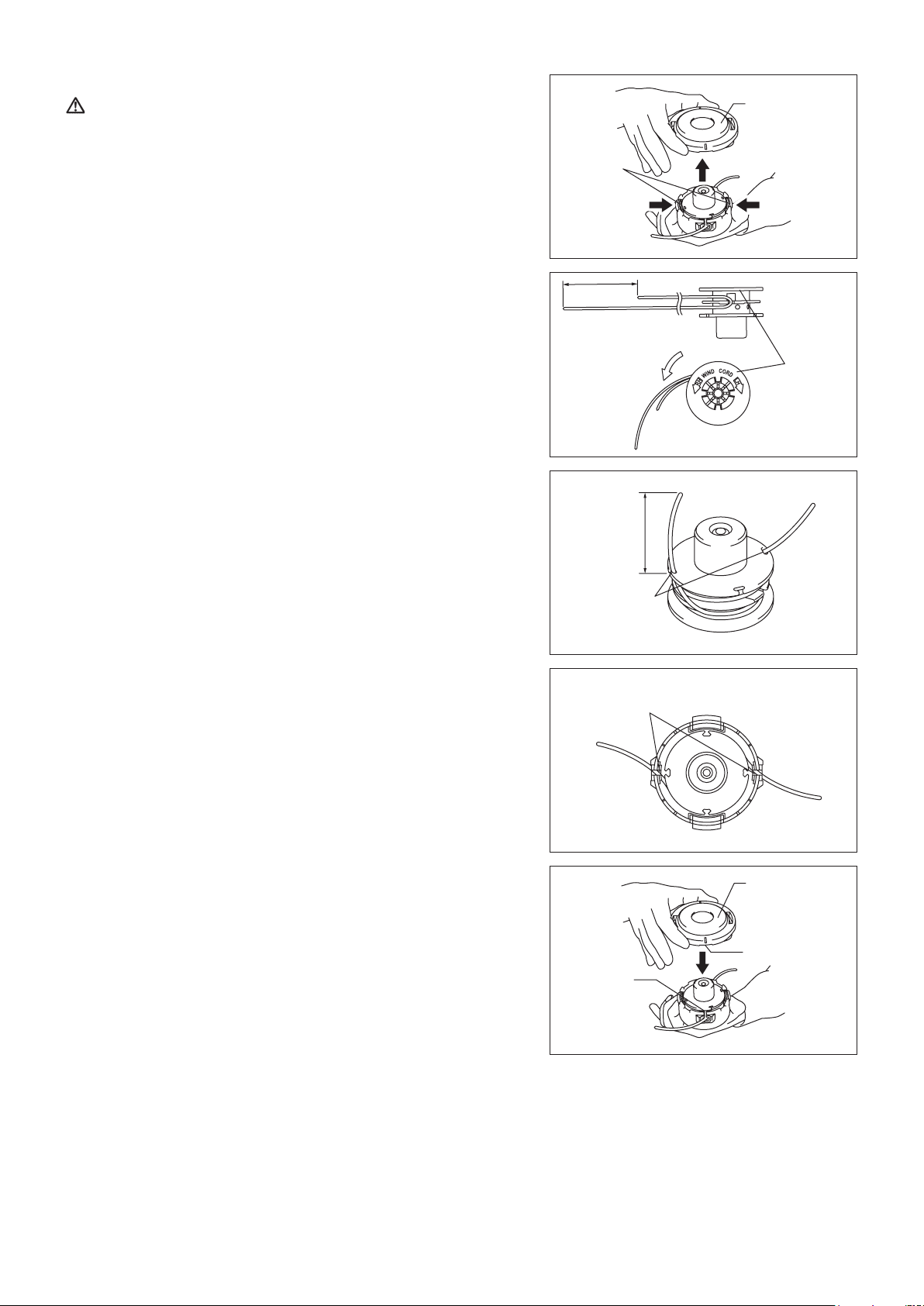

Replacing the nylon cord

WARNING:

Press inward on the housing latches and lift upward to remove the cover.

Discard any of the remaining nylon cord.

Hook the middle of the new nylon cord to the notch located at the center of the

spool between the 2 channels provided for the nylon cord. One side of the cord

should be about 80 mm longer than the other side.

Wind both ends rmly around the spool in the direction marked on the head for

right hand direction indicated by RH.

Wind all but about 100 mm of the cords, leaving the ends temporarily hooked

through a notch on the side of the spool.

Make sure that the cover of the nylon cutting head is secured

to the housing properly as described below. Failure to properly

secure the cover may cause the nylon cutting head to y apart

resulting in serious personal injury.

Latches

For right hand

rotation

Cover

PressPress

Spool

Mount the spool in the housing so that the grooves and protrusions on the spool

match up with those in the housing. Now, unhook the ends of the cord from their

temporary position and feed the cords through the eyelets to come out of the

housing.

Align the protrusion on the underside of the cover with the slots of the eyelets.

Then push cover rmly onto the housing to secure it. Make sure the latches fully

spread in the cover.

Notches

Eyelets

Cover

Protrusion

(Not shown)

Slot of

eyelet

13

Page 14

SERVICING INSTRUCTIONS

CAUTION: Before doing any work on the equipment, always stop the engine and pull the plug cap off the spark plug (see “checking the

Always wear protective gloves!

To ensure a long service life and to avoid any damage to the equipment, the following servicing operations should be performed at regular

intervals.

spark plug”).

Daily checkup and maintenance

Before operation, check the machine for loose screws or missing parts. Pay particular attention to the tightness of the nylon cutting head. –

Before operation, always check for clogging of the cooling air passage and the cylinder ns. –

Clean them if necessary.

Perform the following work daily after use: –

Clean the equipment externally and inspect for damage.•

Clean the air lter. When working under extremely dusty conditions, clean the lter the several times a day.•

Check the nylon cutting head for damage and make sure it is rmly mounted.•

Check that there is sufcient difference between idling and engagement speed to ensure that the cutting attachment is at a standstill while •

the engine is idling (if necessary reduce idling speed).

If under idling conditions the tool should still continue to run, consult your nearest Authorized Service Agent.

Check the functioning of the I-O switch, the lock-off lever, the throttle lever, and the lock button. –

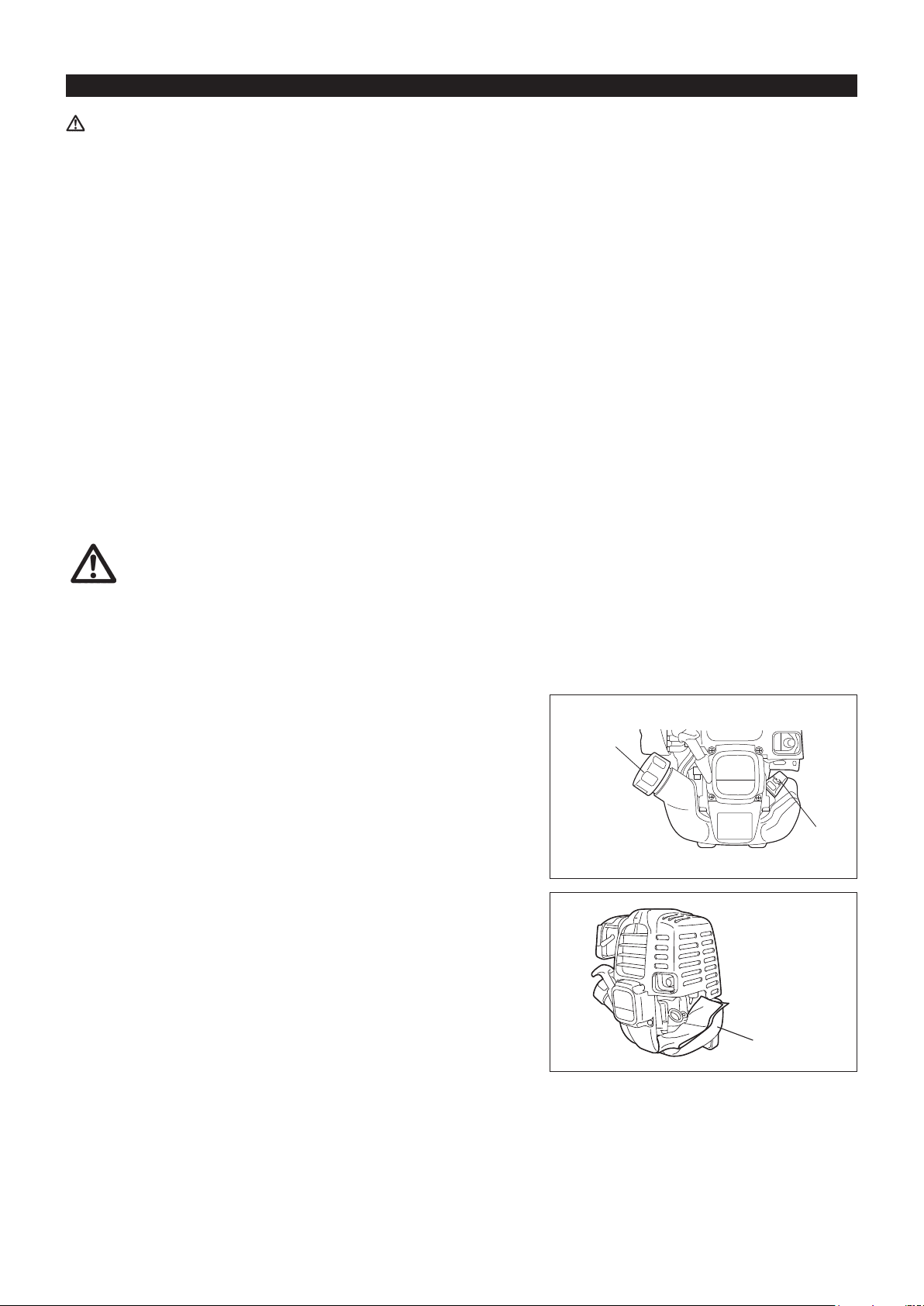

REPLACEMENT OF ENGINE OIL

Deteriorated engine oil will shorten the life of the sliding and rotating parts to a great extent. Be sure to check the period and quantity of

replacement.

ATTENTION: In general, the engine main unit and engine oil still remain hot just after the engine is stopped. In replacement of oil,

conrm that the engine main unit and engine oil are sufciently cooled down. Otherwise, there may remain a risk of

scald.

NOTE:Iftheoillledabovethelimit,itmaybecontaminatedormaycatchrewithwhitesmoke.

Interval of replacement: Initially, every 20 operating hours, and subsequently every 50 operating hours

Recommended oil: SAE10W-30 oil of API Classication SF Class or higher (4-stroke engine oil for automobile)

In replacement, perform the following procedure.

1) Conrm that the tank cap is tightened securely.

2) Detach the oil gauge.

Keep the oil gauge free from dust or dirt.

3) Place waste or paper near the oil rell port.

Fuel tank cap

Oil gauge

Waste or paper

14

Page 15

4) Detach the oil gauge, and drain oil, tilting the main unit toward the oil rell

port.

Drain oil in a container for orderly disposal.

5) Keep the engine level, and feed new oil up to the edge of the oil rell port.

In rell, use a lubricant rell container.

6) After rell, securely tighten the oil gauge. Insufcient tightening of the oil

gauge will lead to oil leakage.

POINTS ON OIL

Never discard replaced engine oil in garbage, earth or sewage ditch. Disposal of oil is regulated by law. In disposal, always follow the –

relevant laws and regulations. For any points remaining unknown, contact Authorized Service Agent.

Oil will deteriorate even when it is kept unused. Perform inspection and replacement at regular intervals (replace with new oil every –

6 months).

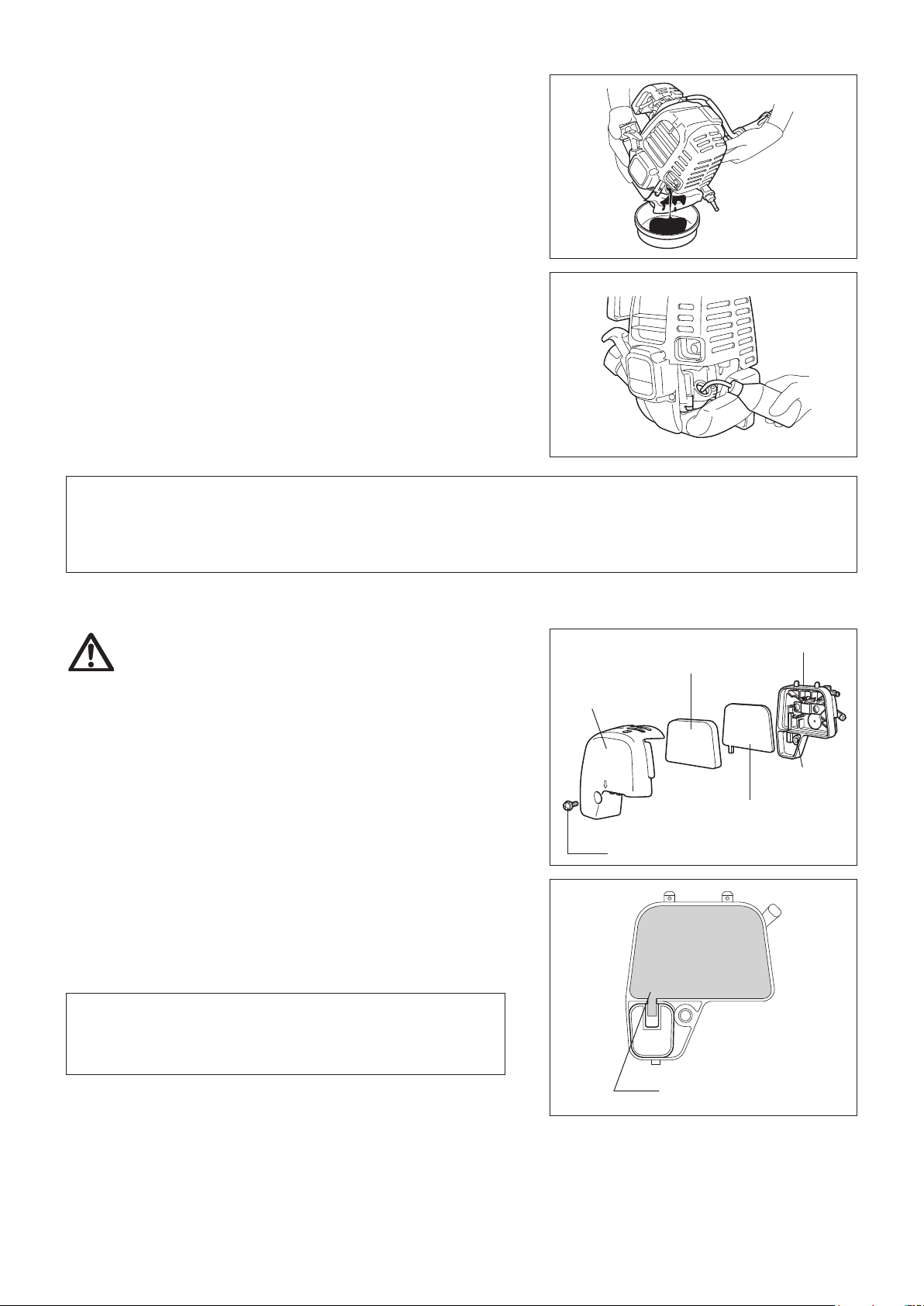

CLEANING OF AIR CLEANER

DANGER: INFLAMMABLES STRICTLY PROHIBITED

Interval of Cleaning and Inspection: Daily (every 10 operating hours)

Turn the choke lever to the full close side, and keep the carburetor off from –

dust or dirt.

Remove the air cleaner cover-xing bolts. –

Pull the cover lower side and detach the air cleaner cover. –

If oil adheres to the element (sponge), squeeze it rmly. –

For heavy contamination: –

1) Remove the element (sponge), immerse it in warm water or in waterdiluted

neutral detergent, and dry it completely.

2) Clean the element (felt) with gasoline, and dry it completely.

Before attaching the element, be sure to dry it completely. Insufcient drying –

of the element may lead to difcult startup.

Wipe out with waste cloth, oil adhering around the air cleaner cover and plate –

breather.

Immediately after cleaning is nished, attach the cleaner cover and tighten it –

with xing bolts. (In remounting, rst place the upper claw, and then the lower

claw.)

Points in Handling Air Cleaner Element

Clean the element several times a day, if excessive dust adheres to it. –

If operation continues with the element remaining not cleared of oil, oil in –

the air cleaner may fall outside, resulting in oil contamination.

Plate

Element (sponge)

Air cleaner cover

Breather part

Element (felt)

Fixing bolt

Pick this part and remove

the element (felt).

15

Page 16

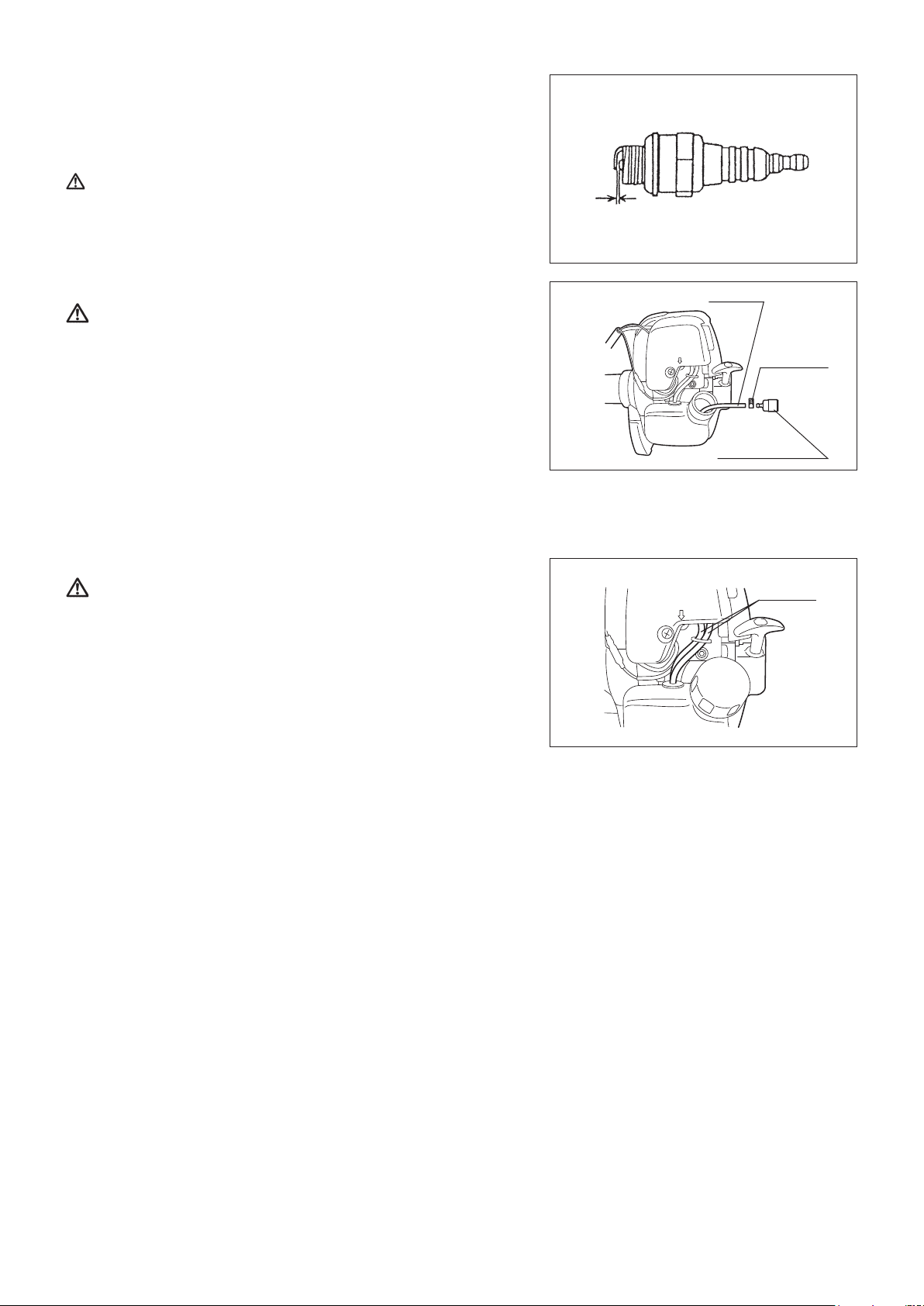

CHECKING THE SPARK PLUG

Only use the supplied universal wrench to remove or to install the spark plug. –

The gap between the two electrodes of the spark plug should be 0.7 - 0.8 mm –

(0.028” - 0.032”). If the gap is too wide or too narrow, adjust it. If the spark

plug is clogged or contaminated, clean it thoroughly or replace it.

CAUTION: Never touch the spark plug connector while the engine is

running (danger of high voltage electric shock).

CLEANING OF FUEL FILTER

WARNING: INFLAMMABLES STRICTLY PROHIBITED

Interval of Cleaning and Inspection: Monthly (every 50 operating hours)

Suction head in the fuel tank

The fuel lter (1) of the suction head is used to lter the fuel required by the –

carburetor.

A periodical visual inspection of the fuel lter is to be conducted. For that –

purpose open the tank cap, use a wire hook and pull out the suction head

through the tank opening. Filters found to have hardened, been polluted or

clogged up are to be replaced.

Insufcient fuel supply can result in the admissible maximum speed being –

exceeded. It is therefore important to replace the fuel lter at least quarterly to

ensure satisfactory fuel supply to the carburetor.

REPLACEMENT OF FUEL PIPE

CAUTION: INFLAMMABLES STRICTLY PROHIBITED

Interval of Cleaning and Inspection: Daily (every 10 operating hours)

Replacement: Annually (every 200 operating hours)

Replace the fuel pipe every year, regardless of operating frequency. Fuel

leakage may lead to re.

If any leakage is detected during inspection, replace the fuel pipe immediately.

0.7 mm - 0.8 mm

(0.028” - 0.032”)

Fuel pipe

Hose clamp

Fuel lter (1)

Fuel pipe

INSPECTION OF BOLTS, NUTS AND SCREWS

Retighten loose bolts, nuts, etc. –

Check for fuel and oil leakage. –

Replace damaged parts with new ones for safety operation. –

CLEANING OF PARTS

Keep the engine always clean. –

Keep the cylinder ns free of dust or dirt. Dust or dirt adhering to the ns will –

cause piston seizure.

REPLACEMENT OF GASKETS AND PACKINGS

In reassembling after the engine is dismounted, be sure to replace the gaskets and packings with new ones.

Any maintenance of adjustment work that is not included and described in this manual is only to be performed by Authorized Service Agents.

16

Page 17

STORAGE

WARNING: When draining the fuel, be sure to stop the engine and make sure that the engine

cools down.

Just after stopping the engine, it may still be hot with possibility of burns,

inammabilityandre.

ATTENTION: When the machine is kept out of operation for a long time, drain up all fuel from the

fuel tank and carburetor, and keep it at a dry and clean place.

Drain fuel from the fuel tank and carburetor according to the following procedure: –

1) Remove the fuel tank cap, and drain fuel completely.

If there is any foreign matter remaining in the fuel tank, remove it completely.

2) Pull out the fuel lter from the rell port using a wire.

3) Push the primer pump until fuel is drained from there, and drain fuel coming into the fuel tank.

4) Put the lter to the fuel tank, and securely tighten the fuel tank cap.

5) Then, continue to operate the engine until it stops.

Remove the spark plug, and drip several drops of engine oil through the spark plug hole. –

Gently pull the starter handle so that engine oil will spread over the engine, and attach the spark plug. –

During storage, keep the rod horizontal or keep the machine upright with the cutting attachment side oriented upward. (In this case, pay full –

attention to prevent the machine from falling.)

Never store the machine with the cutting attachment side oriented downward. Lubricating oil may spill out.

Keep the drained fuel in a special container in a well-ventilated shade. –

Attention after long-time storage

Before startup after long-time shutdown, be sure to replace oil (refer to P 14). Oil will deteriorate while the machine is kept out of –

operation.

Fault location

Fault System Observation Cause

Engine not starting or with

difculty

Warm start problems Tank lled ignition spark

Engine starts but dies Fuel supply Tank lled Incorrect idling adjustment, carburetor contaminated

Insufcient performance Several systems may

Ignition system Ignition spark O.K. Fault in fuel supply or compression system, mechanical

defect

No ignition spark STOP-switch operated, wiring fault or short circuit, spark

plug or connector defective, ignition module faulty

Fuel supply Fuel tank lled Incorrect choke position, carburetor defective, fuel supply

line bent or blocked, fuel dirty

Compression No compression when

pulled over

Mechanical fault Starter not engaging Broken starter spring, broken parts inside of the engine

existing

Engine idling poor Air lter contaminated, carburetor contaminated, mufer

simultaneously be

affected

Cylinder bottom gasket defective, crankshaft seals

damaged, cylinder or piston rings defective or improper

sealing of spark plug

Carburetor contaminated, have it cleaned

Fuel tank vent defective, fuel supply line interrupted,

cable or STOP-switch faulty

clogged, exhaust duct in the cylinder clogged

17

Page 18

Item

Operating time

Before

operation

After

lubrication

Daily

(10h)

30h 50h 200h

Shutdown/

rest

Corres-

ponding P

Engine oil

Inspect/clean

Replace

Tightening parts

(bolt, nut)

Inspect

Clean/inspect

Fuel tank

Drain fuel

Throttle lever Check function

Stop switch Check function

Cutting attachment Inspect

Low-speed rotation Inspect/adjust

Air cleaner Clean

Ignition plug Inspect

Cooling air inlet Clean/inspect

Inspect

Fuel pipe

Replace

Fuel lter Clean/replace

9

1

*

14

16

—

3

*

17

—

12

8

12

15

16

16

16

2

*

—

16

Clearance between air intake

valve and air discharge valve

Adjust

Engine overhaul

Carburetor Drain fuel

*1 Perform initial replacement after 20h operation.

*2 For the 200 operating hour inspection, request Authorized Service Agent or a machine shop.

*3 After emptying the fuel tank, continue to run the engine and drain fuel in the carburetor.

2

*

2

*

3

*

—

—

17

18

Page 19

TROUBLESHOOTING

Before making a request for repairs, check for trouble by yourself. If any abnormality is found, control your machine according to the description

of this manual. Never tamper or dismount any part contrary to the description. For repairs, contact Authorized Service Agent or local dealership.

State of abnormality Probable cause (malfunction) Remedy

Failure to operate primer pump Push 7 to 10 times

Low pulling speed of starter rope Pull strongly

Lack of fuel Feed fuel

Clogged fuel lter Clean

Broken fuel tube Straighten fuel tube

Deteriorated fuel Deteriorated fuel makes starting more difcult.

Replace with new fuel. (Recommended

replacement: 1 month)

Excessive suction of fuel Set throttle lever from medium speed to high

speed, and pull starter handle until engine

starts. Once engine starts, nylon cutting

Engine does not start

Detached plug cap Attach securely

Contaminated spark plug Clean

Abnormal clearance of spark plug Adjust clearance

Other abnormality of spark plug Replace

Abnormal carburetor Make request for inspection and maintenance.

Starter rope cannot be pulled Make request for inspection and maintenance.

Abnormal drive system Make request for inspection and maintenance.

Insufcient warm-up Perform warm-up operation

Choke lever is set to “CLOSE” although

Engine stops soon

Engine speed does not increase

The cutting attachment does not rotate.

Stop engine immediately!

The unit vibrates abnormally.

Stop engine immediately!

The cutting attachment does not stop.

Stop engine immediately!

Engine does not stop

Run engine at idling, and set choke lever

to CLOSE

The nylon cutting cord does not feed. The cord is used up or tangled in the spool. Rewind the cord.

The nylon cutting cord is not cut off at the

correct length.

When the engine does not start after warm-up operation:

If there is no abnormality found for the check items, open the throttle by about 1/3 and start the engine.

engine is warmed up.

Clogged fuel lter Clean

Contaminated or clogged air cleaner Clean

Abnormal carburetor Make request for inspection and maintenance.

Abnormal drive system Make request for inspection and maintenance.

The cutting attachment is not tightened

securely.

A twig is caught between the cutting

attachment and the protector.

The drive system does not work properly. Ask Makita authorized service center to

The cutting attachment is broken. Replace the cutting attachment with new one.

The cutting attachment is not tightened

securely.

One end of nylon cutting cord has been

broken and the nylon cutting head got

unbalanced.

The drive system does not work properly. Ask Makita authorized service center to

The power unit does not work properly. Refer to the instruction manual of the power

Detached connector Attach securely

Abnormal electric system Make request for inspection and maintenance.

The cord cutter on the protector is damaged

or missing.

The cord extends past the protector. Rewind the cord.

head starts rotating. Pay full attention to

nylon cutting head.

If engine will not start still, remove spark plug,

make electrode dry, and reassemble them as

they originally are. Then, start as specied.

Set to “OPEN”

Tighten the cutting attachment securely.

Remove the foreign matter.

inspect and repair it.

Tighten the cutting attachment securely.

Feed the nylon cutting cord with tapping the

nylon cutting head on the ground.

inspect and repair it.

unit.

Ask Makita authorized service center to

replace the cord cutter.

19

Page 20

Français

Merci d’avoir acheté l’équipement de jardinage motorisé MAKITA. Nous

sommes heureux de vous recommander ce produit MAKITA qui est le fruit

d’un long programme de développement et de nombreuses années de

connaissances et d’expérience.

Veuillez lire ce document, il décrit en détail les performances remarquables de

cette machine. Il vous aidera à obtenir les meilleurs résultats possibles de votre

produit MAKITA.

PICTOGRAMMES

Vous verrez les pictogrammes suivants en lisant le manuel d’instructions.

Lire le manuel d’instructions et respecter

les avertissements et mesures de

sécurité!

Table des matières Page

Pictogrammes..............................................................20

Consignes de sécurité .................................................21

Données techniques ....................................................24

Désignation des pièces ...............................................25

Montage de la poignée ................................................26

Montage du protecteur ................................................26

Montage de la tête à ls nylon .....................................26

Avant utilisation ...........................................................27

Remarques concernant le fonctionnement

et l’arrêt de la machine ................................................29

Tête à ls nylon ...........................................................30

Instructions d’entretien ................................................32

Entreposage ................................................................35

Casque de protection, protections oculaire

et auditive obligatoires.

Faites particulièrement attention!

Interdit!

Ne pas s’approcher!

Danger de projections!

Défense de fumer!

Flamme nue interdite!

Vitesse d’outil maximale autorisée

Carburant (essence)

Démarrage manuel du moteur

Arrêt d’urgence

Premiers soins

MARCHE/DÉMARRAGE

Gants de protection obligatoires!

Portez des chaussures solides avec

semelle antidérapante.

Il est conseillé de porter des chaussures

avec embout de sécurité!

Zone de travail interdite aux individus et

aux animaux!

20

ARRÊT/COUPURE MACHINE

N’utilisez jamais de lames métalliques

Page 21

360°

CONSIGNES DE SÉCURITÉ

Consignes générales

Lisez ce manuel d’instructions an de vous familiariser avec le –

fonctionnement de l’équipement. S’ils ne sont pas sufsamment informés, les

utilisateurs qui manipulent la machine de façon incorrecte représentent un

danger pour eux-mêmes comme pour les autres.

Il est recommandé de prêter l’équipement seulement à des personnes l’ayant –

déjà utilisé.

Remettez toujours le manuel d’instructions avec la machine.

Les utilisateurs inexpérimentés doivent demander des instructions de –

base au vendeur an de se familiariser avec la manipulation d’une

débroussailleuse.

Les enfants et les mineurs ne doivent pas être autorisés à utiliser cet –

équipement. Les individus âgés de plus de 16 ans peuvent toutefois utiliser

la machine en vue d’apprentissage, mais toujours sous la surveillance d’une

personne qualiée.

Utilisez l’équipement avec le maximum de soin et d’attention. –

Utilisez l’équipement seulement si vous êtes en bonne forme physique. –

Manipulez délicatement et soigneusement la machine. L’utilisateur doit

endosser la responsabilité du fait d’autrui.

N’utilisez jamais cet équipement après avoir consommé de l’alcool ou de la –

drogue, ou encore si vous vous sentez fatigué ou malade.

Les réglementations nationales peuvent limiter l’utilisation de la machine. –

Utilisation normale de la machine

Cet équipement est conçu pour couper de l’herbe. Il ne doit en aucun cas –

être utilisé dans un autre but, comme le dressage de bordures ou la taille de

haies. Cela représente un risque de blessure.

Équipement de protection personnel

La tenue portée doit être fonctionnelle et appropriée, autrement dit elle doit –

être ajustée et ne pas entraver les mouvements. Ne portez pas de bijoux ni

de vêtements qui pourraient s’accrocher dans les buissons ou les arbustes.

An d’éviter les blessures à la tête, aux yeux, aux mains ou aux pieds et –

de protéger votre ouïe, vous devez porter l’équipement et les vêtements de

protection indiqués ci-dessous lorsque vous utilisez l’équipement.

Portez toujours un casque s’il y a un risque de chute d’objets. Le casque de –

protection (1) doit être inspecté fréquemment en vue d’éventuels dommages

et doit être remplacé au moins tous les 5 ans. Utilisez uniquement des

casques de protection homologués.

La visière-écran (2) du casque (ou à défaut les lunettes étanches) protège le –

visage des projections de débris et de pierres. Portez toujours des lunettes

étanches ou une visière lorsque vous utilisez l’équipement, an de prévenir

les blessures aux yeux.

Portez un équipement anti-bruit adéquat an d’éviter une perte auditive –

(protège-oreilles (3), bouchons d’oreilles, etc.).

La combinaison de travail (4) vous protège des projections de débris et de –

pierres.

Il est vivement conseillé à l’utilisateur de porter une combinaison de travail.

Les gants (5) font partie de l’équipement réglementaire et doivent toujours –

être portés lors de l’utilisation de l’équipement.

Lorsque vous utilisez l’équipement, portez toujours des chaussures (6) –

robustes dotées d’une semelle antidérapante. Cela vous préservera des

blessures et vous assurera une bonne stabilité.

Démarrage de la débroussailleuse thermique

Veillez à éloigner les enfants ou toute autre personne dans un périmètre de –

travail de 15 mètres (50 pieds) et faites également attention aux animaux

présents dans cette zone.

Assurez-vous toujours que l’équipement est en bonne condition avant de –

l’utiliser.

Vériez la sécurité du dispositif de coupe, ainsi que le bon fonctionnement du

levier d’accélérateur et de son verrouillage.

La rotation du dispositif de coupe en fonctionnement de ralenti est –

impossible. Vériez le réglage auprès de votre vendeur en cas de doute.

Vériez que les poignées sont propres et sèches, et testez le fonctionnement

du commutateur marche/arrêt.

Schéma de

représentation

15 mètres

21

Page 22

Suivez strictement les instructions pour démarrer la débroussailleuse –

thermique.

Ne démarrez pas le moteur d’une autre façon. –

N’utilisez la débroussailleuse thermique et ses outils que pour l’utilisation à –

laquelle ils sont destinés.

Ne démarrez le moteur qu’une fois que la machine est totalement montée. Le –

fonctionnement de la machine n’est possible qu’une fois tous les accessoires

correctement xés!

Avant le démarrage, veillez à ce que le dispositif de coupe ne soit pas en –

contact avec des objets durs tels que des branches, des pierres, etc., étant

donné qu’il amorcera la rotation au démarrage.

Vous devez couper immédiatement le moteur s’il présente un –

dysfonctionnement.

Si le dispositif de coupe heurte des pierres ou des objets durs, coupez –

immédiatement le moteur et inspectez le dispositif de coupe.

Inspectez fréquemment le dispositif de coupe en vue d’éventuels dommages –

(détection de craquelures grâce à un test de bruit de battement).

Si l’équipement tombe ou heurte violemment une surface, vériez son –

état avant de poursuivre l’utilisation. Recherchez une éventuelle fuite du

système d’alimentation et un éventuel dysfonctionnement des dispositifs de

commande et de sécurité. En cas de dommage avéré ou suspecté, adressezvous à un centre de services agréé pour une inspection et une réparation.

Tenez toujours la débroussailleuse thermique avec les deux mains en cours –

de fonctionnement.

Ne tenez jamais la débroussailleuse thermique d’une seule main lorsqu’elle

est en marche.

Assurez-vous toujours de votre stabilité.

Utilisez l’équipement de manière à éviter l’inhalation des gaz d’échappement. –

Ne faites jamais fonctionner le moteur dans une pièce fermée (risque

d’asphyxie au gaz). Le monoxyde de carbone est un gaz inodore.

Coupez le moteur lorsque vous cessez l’utilisation et que vous laissez –

l’équipement sans surveillance, puis rangez la machine dans un endroit sûr

an de ne pas l’endommager ni blesser qui que ce soit.

Ne placez jamais la débroussailleuse thermique chaude sur de l’herbe sèche –

ou sur tout matériau combustible.

Installez toujours le dispositif de protection du dispositif de coupe sur –

l’équipement avant de lancer le moteur. Si vous ne le faites pas, un contact

avec le dispositif de coupe peut entraîner des blessures graves.

Toutes les installations et dispositifs de protection fournis avec la machine –

doivent être utilisés au cours du fonctionnement.

Ne faites jamais tourner le moteur avec un silencieux d’échappement défectueux. –

Coupez le moteur durant le transport. –

Assurez-vous que l’équipement est positionné correctement lors du transport –

en voiture pour éviter toute fuite d’essence.

Lors du transport, assurez-vous que le réservoir d’essence est complètement vide. –

Lors du déchargement de l’équipement du camion, ne laissez jamais tomber –

le moteur sur le sol car cela pourrait endommager sérieusement le réservoir

d’essence.

Sauf en cas d’urgence, ne faites jamais tomber l’équipement ou ne le lancez –

pas par terre; cela risquerait de provoquer des dommages graves.

Ne traînez pas l’équipement sur le sol lorsque vous le transportez. Il est très –

dangereux de faire traîner le réservoir d’essence, cela pourrait l’endommager,

provoquer une fuite d’essence, voire même déclencher un incendie.

Pause•

Transport•

Remplissage•

Entretien•

Remplacement d’outil•

Remplissage

Coupez le moteur pendant le remplissage du réservoir, éloignez-vous de –

toute amme et ne fumez pas.

Évitez tout contact des produits pétroliers avec la peau. N’inhalez pas les –

vapeurs d’essence. Portez toujours des gants de protection pendant le

remplissage du réservoir. Changez et nettoyez souvent les vêtements de

protection.

Veillez à ne pas renverser l’essence ou l’huile an de ne pas contaminer les –

sols (protection de l’environnement). Nettoyez la débroussailleuse thermique

immédiatement si de l’essence a été renversée.

Évitez les projections d’essence sur vos vêtements. Changez immédiatement vos –

vêtements en cas de projection d’essence (pour éviter qu’ils ne s’enamment).

Inspectez régulièrement le bouchon du réservoir d’essence pour vous –

assurer qu’il se ferme correctement et qu’il ne fuit pas.

Serrez bien le bouchon du réservoir d’essence. Déplacez-vous pour démarrer –

le moteur (à au moins 3 mètres du lieu de remplissage du réservoir).

Ne remplissez jamais le réservoir dans une pièce fermée. Les vapeurs –

d’essence s’accumulent au ras du sol (risque d’explosions).

Ne transportez et ne conservez l’essence que dans des conteneurs –

appropriés. Veillez à conserver l’essence hors de portée des enfants.

22

3 mètres

Page 23

Mode de fonctionnement

Utilisez l’équipement seulement avec un bon éclairage et dans de bonnes –

conditions de visibilité. En hiver, faites attention aux sols glissants et aux

zones humides, à la glace et à la neige (risque de glissade). Assurez-vous

toujours de votre stabilité.

Ne réalisez jamais de coupe en tenant la machine plus haut que votre taille. –

Ne montez jamais sur une échelle. –

Ne réalisez jamais de coupe en étant perché dans un arbre. –

Ne travaillez pas sur des surfaces instables. –

Retirez le sable, les pierres, les clous, etc. qui se trouvent dans la zone –

d’utilisation de la machine.

Avant de commencer la coupe, le dispositif de coupe doit avoir atteint sa –

pleine vitesse de travail.

Balancez la débroussailleuse thermique régulièrement. –

Si de l’herbe ou des branches sont coincées entre le dispositif de coupe et

son dispositif de protection, coupez toujours le moteur avant de procéder au

nettoyage. Si vous ne le faites pas, une rotation accidentelle du dispositif peut

entraîner des blessures graves.

Faites des pauses an de ne pas perdre le contrôle à cause de la fatigue. Nous –

vous recommandons de vous reposer 10 à 20 minutes toutes les heures.

Dispositifs de coupe

N’utilisez jamais des lames métalliques, y compris les chaines multiples –

pivotantes métalliques et les lames à éaux. Si vous le faites, un contact

avec la lame peut entraîner des blessures graves.

Vibrations

Des détériorations au niveau des vaisseaux sanguins ou du système nerveux –

peuvent se produire chez des personnes souffrant de troubles circulatoires et

trop souvent soumises à des vibrations. Les symptômes pouvant apparaître

à la suite de vibrations au niveau des doigts, des mains ou des articulations

sont les suivants : engourdissement des membres, chatouillements, douleurs,

points et altération de la peau (notamment, le changement de couleur). Si

ces symptômes apparaissent, consultez un médecin.

Pour éviter le phénomène du « doigt mort », assurez-vous de garder vos –

mains au chaud durant l’utilisation de l’outil et de préserver le bon état de

l’outil et de ses accessoires.

Consignes d’entretien

Faites réparer votre équipement par nos centres de services agréés, –

qui n’utilisent que des pièces de rechange d’origine. Des réparations

mal exécutées et un mauvais entretien peuvent réduire la durée utile de

l’équipement et accroître les risques d’accident.

Vous devez vérier l’état de l’équipement, plus particulièrement du dispositif –

de coupe et des protections, avant de commencer à travailler.

Coupez le moteur et retirez le connecteur de la bougie d’allumage lorsque vous –

remplacez les dispositifs de coupe, et également lorsque vous les nettoyez.

Faites attention à l’environnement. Évitez tout fonctionnement inutile du –

papillon des gaz an de limiter la pollution et les nuisances sonores. Réglez

correctement le carburateur.

Nettoyez l’équipement à intervalles réguliers et vériez que toutes les vis et –

tous les écrous sont bien serrés.

Ne réparez ou n’entreposez jamais l’équipement à proximité de ammes nues. –

Entreposez toujours l’équipement dans une pièce fermée à clé avec le –

réservoir d’essence vide.

Respectez les consignes de prévention des accidents fournies par les associations professionnelles ainsi que par les compagnies d’assurance

concernées.

N’apportez aucune modication à l’équipement, cela vous mettrait en danger.

L’entretien ou les réparations réalisables par l’utilisateur sont ceux décrits dans le manuel d’instructions. Tout autre travail doit être réalisé par un

technicien agréé. N’utilisez que des pièces de rechange et accessoires fabriqués et vendus par MAKITA.

L’utilisation d’accessoires et outils non agréés accroît le risque d’accidents.

MAKITA décline toute responsabilité en cas d’accidents ou de dommages du fait de l’utilisation de dispositifs de coupe, de dispositifs de xation

de dispositifs de coupe ou d’accessoires non agréés.

Premiers soins

En cas d’accident, veillez à avoir une trousse de premiers soins non loin de

la zone de travail. Remplacez sans délai tout article utilisé dans la trousse de

premiers soins.

Si vous demandez de l’aide, veillez à donner les

informations suivantes :

Lieu de l’accident; –

Les conditions de l’accident; –

Le nombre de personnes blessées; –

Le type de blessure; –

Votre nom. –

23

Page 24

DONNÉES TECHNIQUES ER2550LH

Modèle

Dimensions : longueur x largeur x hauteur

(hors dispositif de coupe)

Diamètre de coupe pouce (mm) 16”-1/4” (412)

Poids

(hors dispositif de protection plastique et dispositif de coupe)

Volume (réservoir d’essence) oz liq (l) 16,9 (0,5)

Volume (réservoir d’huile) oz liq (l) 2,7 (0,08)

Cylindrée pouce cube (cm

Rendement maximal du moteur hp (kW) 1,0 (0,71) à 7 000 tr/min

Vitesse moteur à la vitesse de broche maximale recommandée TR/MIN (1/min) 10 000

Fréquence de rotation maximale de la broche TR/MIN (1/min) 7 750

Vitesse au ralenti TR/MIN (1/min) 3 000

Vitesse d’embrayage TR/MIN (1/min) 3 750

Carburateur type WALBRO WYL

Système d’allumage type Allumage transistorisé

Bougie d’allumage type NGK CMR4A

Distance entre les électrodes pouce (mm) 1/32” (0,7-0,8)

Carburant Essence automobile

Huile moteur

(Pour le Canada)

NOTE : Ce système d’allumage par étincelle de véhicule est conforme à la norme NMB-002 du Canada.

pouce (mm) 64” X 11-3/8” X 18-1/4” (1 623 X 290 X 464)

lb (kg) 10,8 (4,9)

3

) 1,49 (24,5)

SAE 10W-30 huile de classication API,

(moteur automobile à 4 temps)

ER2550LH

Poignée arceau

classe SF ou supérieure

24

Page 25

DÉSIGNATION DES PIÈCES

15

14

13

10

9

8

7

5

4

11

12

3

17

16

2

1

6

18

19

15

14

13

10

9

8

7

5

4

11

12

ER2550LH

F DÉSIGNATION DES PIÈCES

1 Réservoir d’essence

2 Démarreur à rappel

3 Filtre à air

4 Commutateur (marche/arrêt)

5 Bougie d’allumage

6 Silencieux d’échappement

7 Carter d’embrayage

8 Poignée arrière

9 Levier de sécurité

10 Poignée

11 Levier d’accélérateur

12 Câble de commande

13 Axe

Protecteur

14

(Dispositif de protection du

dispositif de coupe)

15 Tête à ls nylon

16 Bouchon du réservoir d’essence

17 Poignée de démarrage

18 Tuyau d’échappement

19 Jauge d’huile

25

Page 26

MONTAGE DE LA POIGNÉE

ATTENTION : Avant de manipuler l’équipement, coupez toujours le moteur

et retirez le connecteur de la bougie d’allumage.

Portez toujours des gants de protection!

ATTENTION : Ne démarrez le moteur qu’après l’avoir entièrement

assemblé.

Pour les machines avec poignée arceau

Fixez la poignée arceau sur l’axe comme indiqué. –

Assurez-vous que la pièce d’écartement de l’axe se trouve entre l’ensemble –

de la poignée et l’autre poignée. Ne réduisez pas et ne tassez pas la pièce

d’écartement.

REMARQUE : Dans certains pays, la pièce d’écartement n’est pas fournie avec

l’outil. Dans ce cas, alignez la poignée plus loin du côté de la

ligne indiquée par les èches.

MONTAGE DU PROTECTEUR

An de respecter les consignes de sécurité en vigueur, vous ne devez utiliser

que les ensembles outil/protecteur indiqués dans le tableau.

ATTENTION : Ne touchez pas le coupe-l du protecteur. Vous pourriez

vous blesser en touchant le coupe-l à mains nues.

Le protecteur doit être installé de façon à maintenir la longueur du l en nylon et

à protéger l’opérateur des projections de pierres et débris. Installez le protecteur

de la façon suivante.

Coupe-l

Protecteur

1. Placez le protecteur de sorte que les nervures de l’axe correspondent à la

rainure du protecteur.

2. Serrez les deux boulons.

MONTAGE DE LA TÊTE À FILS NYLON

AVERTISSEMENT : N’utilisez jamais de lames de coupe.

Assurez-vousd’utiliserunetêteàlsdenylonMAKITA

d’origine.

Si la tête à ls nylon heurte une pierre en cours de fonctionnement, coupez le –

moteur et vériez immédiatement l’état de la tête à ls nylon.

ATTENTION : Ne touchez pas le coupe-l du protecteur. Vous pourriez

vous blesser en touchant le coupe-l à mains nues.

Montez une tête à ls nylon de la façon suivante.

1. Insérez la clavette de verrouillage dans le trou du collier de xation. Faites-

les pivoter en enfonçant la clavette de verrouillage jusqu’à la butée.

2. Vissez une tête à ls nylon sur l’axe en tournant dans le sens horaire.

Veillez à ce qu’elle soit solidement montée.

3. Retirez la clavette de verrouillage.

Boulons

Tête à ls

nylon

Fixation

Serrer Desserrer

Coupe-l

Clavette de

verrouillage

Pour retirer la tête à ls nylon, tournez-la dans le sens antihoraire.

26

Page 27

AVANT UTILISATION

Inspection et remplissage de l’huile moteur

Procédez comme suit, une fois le moteur refroidi. –

Maintenez le moteur de niveau, retirez la jauge d’huile et assurez-vous que le niveau d’huile se trouve entre les limites supérieure et –

inférieure.

Lorsqu’il n’y a pas sufsamment d’huile et que seule l’extrémité de la jauge peut atteindre l’huile, notamment si la jauge est insérée dans le

carter du moteur sans être vissée (Fig. 1), rajoutez de l’huile par l’orice (Fig. 2).

Pour informations, le temps de remplissage de l’huile est d’environ 10 heures (10 remplissages ou un remplissage de 10 réservoirs d’huile). –

Si l’huile change de couleur ou se mélange à des impuretés, changez-la. (Pour connaître la fréquence et la méthode de remplacement,

reportez-vous à la page 32)

Huile recommandée : SAE 10W-30 huile de classication API, classe SF ou supérieure (moteur automobile à 4 temps)

Quantité d’huile : Environ 0,08 l

REMARQUE : Si le moteur n’est pas de niveau, l’huile peut se répandre dans le moteur et le remplissage peut être excessif.

Si vous mettez trop d’huile, elle peut être souillée ou s’enammer en dégageant une fumée blanche.

Remarque 1 concernant le changement d’huile : « Jauge d’huile »

Retirez la poussière ou les impuretés au niveau de l’orice de remplissage d’huile, puis détachez la jauge d’huile. –

Veillez à ce que la jauge d’huile n’entre pas en contact avec du sable ou de la poussière. Le sable ou la poussière adhérant à la jauge –

d’huile pourrait perturber la circulation de l’huile ou entraîner une usure des pièces moteur, provoquant des problèmes.

Pour garantir la propreté de la jauge d’huile, il est recommandé de l’insérer dans le couvercle du moteur en la tenant par sa poignée, –

comme indiqué sur la Fig. 3.

Limite supérieure

(Bord de l’orice de

remplissage d’huile)

Si de l’huile adhère

à cette extrémité,

rajoutez de l’huile.

Fig. 1 Fig. 2 Fig. 3

(1) Maintenez le moteur de niveau et détachez la jauge d’huile.

Jauge d’huile

(2) Versez de l’huile jusqu’au bord de l’orice de remplissage. (Reportez-vous à

la Fig. 2).

Versez l’huile à l’aide du acon de remplissage de lubriant.

(3) Serrez bien la jauge d’huile. Un bouchon d’huile insufsamment serré peut

fuir.

27

Page 28

Remarque

Ne versez pas d’huile lorsque le moteur est incliné.•

Verser de l’huile alors que le moteur est incliné entraîne un remplissage excessif, causant une contamination de l’huile et/ou une fumée •

blanche.

Remarque 2 concernant le changement d’huile : « Si l’huile déborde »

Si l’huile déborde entre le réservoir d’essence et le corps du moteur, elle sera aspirée par l’orice d’admission d’air de refroidissement et –

contaminera le moteur. Veillez à essuyer l’excédent d’huile avant de démarrer la machine.

REMPLISSAGE

Manipulation de l’essence

Vous devez manipuler l’essence avec une extrême précaution. L’essence peut contenir des substances telles que des solvants. Vous devez

procéder au remplissage dans une pièce sufsamment ventilée ou en plein air. Tenez-vous éloigné de l’essence et évitez d’en inhaler les

vapeurs. Si l’essence entre en contact plusieurs fois ou pendant longtemps avec votre peau, vous pourriez souffrir de sécheresse cutanée,

entraînant maladies de peau ou allergies. En cas de projection d’essence dans les yeux, rincez à l’eau claire. Si vos yeux restent irrités,

consultez un médecin.

Entreposage de l’essence

Vous devez utiliser l’essence dans un délai de 4 semaines, même si vous la conservez dans un conteneur spécial, dans un endroit ombragé et

bien ventilé.

Sinon, la qualité de l’essence pourrait être altérée.

ENTREPOSAGE DE LA MACHINE ET REMPLISSAGE DU RÉSERVOIR

Entreposez la machine et son réservoir dans un endroit frais non soumis à la lumière directe du soleil. –

Ne conservez jamais l’essence dans une voiture. –

Carburant

Le moteur est un moteur à quatre temps. Veillez à utiliser de l’essence automobile sans plomb, indice d’octane 87 ou plus ((R+M)/2). Elle ne

doit pas contenir plus de 10 % d’alcool (E-10).

Remarques concernant l’essence

N’utilisez jamais une essence mélangée avec de l’huile moteur. Cela pourrait entraîner une accumulation excessive de carbone ou des –

problèmes mécaniques.

L’utilisation d’une huile usagée entraînera un démarrage difcile. –

Remplissage

AVERTISSEMENT : PRODUITS INFLAMMABLES STRICTEMENT

Essence utilisée : Essence automobile sans plomb, indice d’octane 87 ou

Dévissez légèrement le bouchon du réservoir an qu’il n’y ait aucune –

différence de pression atmosphérique.

Retirez le bouchon du réservoir, remplissez ce dernier et évacuez l’air en –

inclinant le réservoir d’essence pour que l’orice de remplissage soit orienté

vers le haut. (Ne remplissez jamais à ras bord.)

Essuyez bien le pourtour du bouchon du réservoir pour éviter que des –

substances étrangères ne pénètrent à l’intérieur du réservoir d’essence.

Après le remplissage, veillez à bien serrer le bouchon du réservoir. –

Si le bouchon du réservoir présente un défaut ou est endommagé, •

remplacez-le.

Le bouchon du réservoir est un produit consommable, il doit donc être •

remplacé tous les deux ou trois ans.

INTERDITS

plus. Pas plus de 10 % d’alcool (E-10).

Bouchon

du réservoir

d’essence

Limite supérieure

d’essence

Réservoir

d’essence

28

Page 29

REMARQUES CONCERNANT LE FONCTIONNEMENT ET L’ARRÊT DE LA MACHINE

Respectez la réglementation en vigueur sur la prévention des accidents.

DÉMARRAGE

Allez à au moins 3 mètres du lieu de remplissage du réservoir. Placez la machine sur le sol en veillant à ce que le dispositif de coupe n’entre

pas en contact avec le sol ou tout autre objet.

A : démarrage à froid

1) Posez la machine sur une surface plane.

2) Basculez le commutateur marche/arrêt (1) sur FONCTIONNEMENT.

3) Pompe d’amorçage

Continuez à appuyer sur la pompe d’amorçage jusqu’à ce que l’essence

pénètre à l’intérieur. (En général, l’essence pénètre dans la pompe

d’amorçage au terme de 7 à 10 pressions.)

Si vous appuyez trop sur la pompe d’amorçage, un excédent d’essence

retourne dans le réservoir.

FONCTIONNEMENT

Carburateur

d’amorçage

Levier de sécurité

ARRÊT

Vitesse élevée

Vitesse basse

Levier

d’accélérateur

(1)

Pompe

4) Lanceur à rappel

Tirez délicatement sur la poignée de démarrage jusqu’à ce que cela

devienne difcile (point de compression). Relâchez la poignée de

démarrage puis tirez dessus fermement.

Ne tirez jamais la corde à fond. Une fois la poignée de démarrage tirée, ne

la relâchez pas immédiatement. Raccompagnez la poignée de démarrage

jusqu’à sa position d’origine.

5) Réchauffage

Poursuivez le réchauffage pendant 2 à 3 minutes.

REMARQUE : En cas d’admission d’essence excessive (noyage du moteur), retirez la bougie d’allumage et tirez lentement sur la poignée de

démarrage an de supprimer l’excédent d’essence. Vous pouvez aussi sécher l’électrode de la bougie d’allumage.

B : démarrage après le réchauffage

1) Appuyez plusieurs fois sur la pompe d’amorçage.

2) Maintenez le levier d’accélérateur en fonctionnement de ralenti.

3) Tirez fermement sur le lanceur à rappel.

4) Si le démarrage du moteur se révèle difcile, ouvrez l’étrangleur d’environ 1/3.

Attention lors de l’utilisation

Lorsque le moteur est utilisé sens dessus dessous, de la fumée blanche peut sortir du silencieux.

29

Page 30

Pendant les périodes, telles que l’hiver, où

démarrer le moteur est difcile

Actionnez le levier d’étrangleur de la manière suivante lorsque vous démarrez

le moteur.

Après avoir effectué les étapes de démarrage 1) à 3), basculez le levier •

d’étrangleur sur FERMER.

Effectuez l’étape de démarrage 4) et démarrez le moteur.•

Une fois le moteur démarré, basculez le levier d’étrangleur sur OUVRIR.•

Effectuez l’étape de démarrage 5) et terminez le réchauffage.•

FERMER

ATTENTION : Si le bruit d’une explosion retentit et le moteur s’arrête,

ou si le moteur à peine démarré cale avant que le

levier d’étrangleur ne soit actionné, rebasculez le levier

d’étrangleur sur OUVRIR et tirez de nouveau sur la poignée

de démarrage quelques fois pour démarrer le moteur.

ATTENTION : Si le levier d’étrangleur est laissé sur la position FERMER

et la poignée de démarrage seulement tirée plusieurs fois,

une quantité excessive d’essence est aspirée et le moteur

devient difcile à démarrer.

ARRÊT

1) Relâchez complètement le levier d’accélérateur (2), puis une fois que le

régime moteur a baissé, basculez le commutateur marche/arrêt sur ARRÊT,

cela coupe le moteur.

2) La tête de coupe peut ne pas s’arrêter immédiatement, attendez qu’elle

s’arrête complètement.

RÉGLAGE DE LA ROTATION À FAIBLE VITESSE (RALENTI)

Si vous devez régler la rotation à faible vitesse (ralenti), utilisez la vis de réglage du carburateur.

OUVRIR

ARRÊT

(2)

(1)

VÉRIFICATION DE LA ROTATION À FAIBLE VITESSE

Réglez la rotation à faible vitesse sur 3 000 min –

Si vous devez régler la rotation à faible vitesse (ralenti), utilisez un tournevis

cruciforme sur la vis illustrée à droite.

Pour augmenter la rotation du moteur, tournez la vis de réglage vers la droite. –

Pour diminuer la rotation du moteur, tournez la vis de réglage vers la gauche.

Le carburateur est réglé généralement à l’usine. S’il est nécessaire de le –

réajuster, contactez votre technicien agréé le plus proche.

-1

.

TÊTE À FILS NYLON

Pendant l’utilisation, utilisez l’extrémité du l en nylon pour la coupe.

Alimentation du l en nylon

Lorsque le l en nylon s’use et se raccourcit à cause de la coupe, l’opérateur

doit procéder manuellement à l’alimentation.

Pour l’alimentation du l en nylon, tapotez la tête à ls nylon sur le sol pendant

qu’elle tourne à environ 6 000 min

REMARQUE : Si le l en nylon ne sort pas, rembobinez-le.

-1

.

Vis de réglage

Carburateur

Zone de coupe la plus efcace

30

Page 31

80 mm

100 mm

Remplacementdulnylon

AVERTISSEMENT :

Pour retirer le couvercle, appuyez sur les ergots de verrouillage du boîtier et

relevez-le. Jetez le l nylon restant.

Accrochez le milieu du l nylon neuf dans l’entaille au centre de la bobine, entre

les deux canaux prévus pour le l nylon. Un côté du l doit dépasser l’autre

d’environ 80 mm.

Enroulez fermement les deux extrémités autour de la bobine, dans le sens

indiqué sur la tête par les lettres RH.

Laissez environ 100 mm de l non enroulés, les extrémités dépassant

temporairement des entailles sur le côté de la bobine.

Assurez-vous que le cache de la tête à ls nylon est

solidement installé dans le logement, comme décrit ci-

dessous. Si vous ne xez pas le cache correctement,

la tête à ls nylon peut être projetée, entraînant des

blessures corporelles graves.

Ergots de

verrouillage

Pour rotation

vers la droite

Cache

AppuyerAppuyer

Bobine

Montez la bobine dans le logement de sorte que les rainures et les saillies de

la bobine correspondent à celles du logement. Enn, retirez les extrémités du l

nylon de leur position temporaire et engagez-les dans les œillets pour que le l

nylon sorte du logement.

Alignez la saillie de la partie inférieure du cache avec les encoches des œillets.