Page 1

EN

Cordless Angle Grinder INSTRUCTION MANUAL 8

FR

DE

IT

NL

ES

PT

DA

EL

TR

Meuleuse d’Angle sans Fil MANUEL D’INSTRUCTIONS 25

Akku-Winkelschleifer BETRIEBSANLEITUNG 43

Smerigliatrice angolare a

batteria

Haakse accuslijpmachine GEBRUIKSAANWIJZING 81

Esmeriladora Angular

Inalámbrica

Esmerilhadeira Angular a

Bateria

Ledningsfri vinkelsliber BRUGSANVISNING 135

Φορητός γωνιακός

λειαντήρας

Akülü Avuç Taşlama Makinesi KULLANMA KILAVUZU 171

DGA411, DGA412,

ISTRUZIONI PER L’USO 62

MANUAL DE

INSTRUCCIONES

MANUAL DE INSTRUÇÕES 117

ΕΓΧΕΙΡΙΔΙΟ ΟΔΗΓΙΩΝ 152

99

DGA413, DGA414

DGA461, DGA462,

DGA463, DGA464

DGA511, DGA512,

DGA513, DGA514

Page 2

2

1

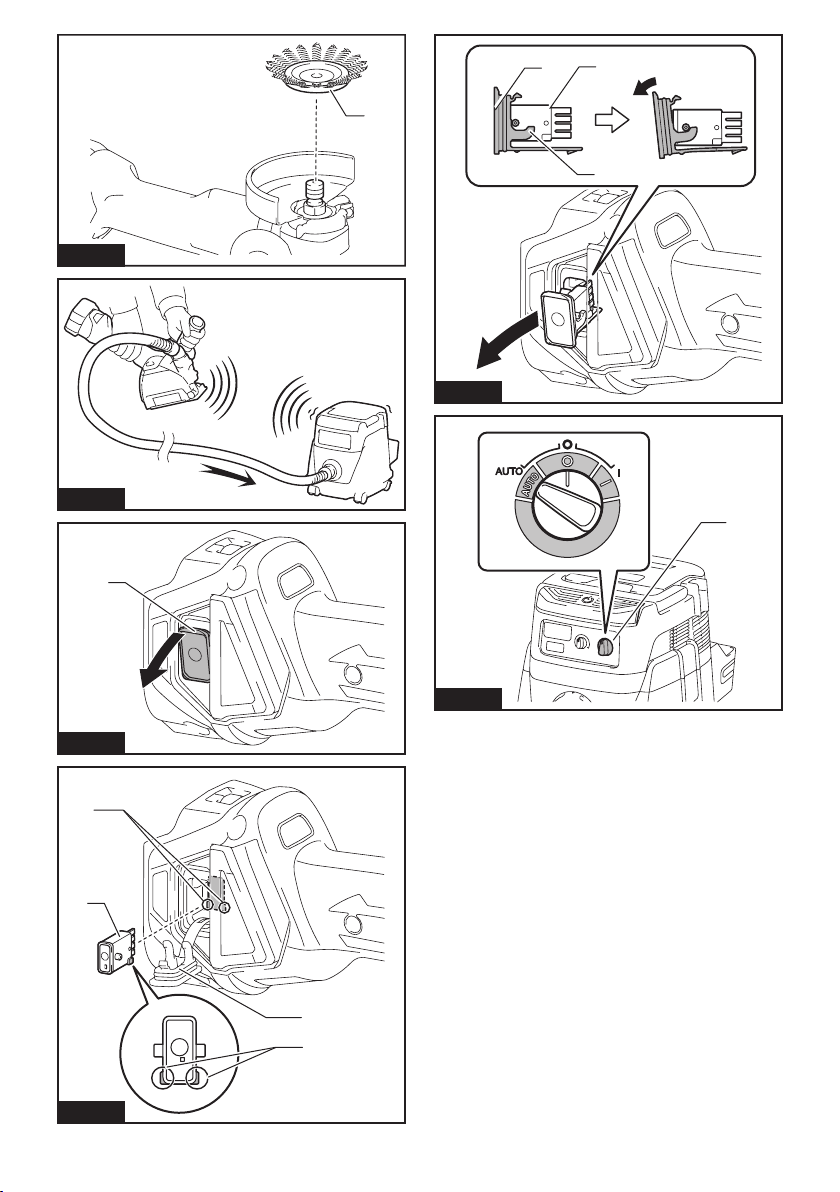

Fig.1

Fig.2

1

Fig.3

3

Fig.5

1

2

Fig.6

1

1

1

Fig.7

Fig.4

1

Fig.8

2

Page 3

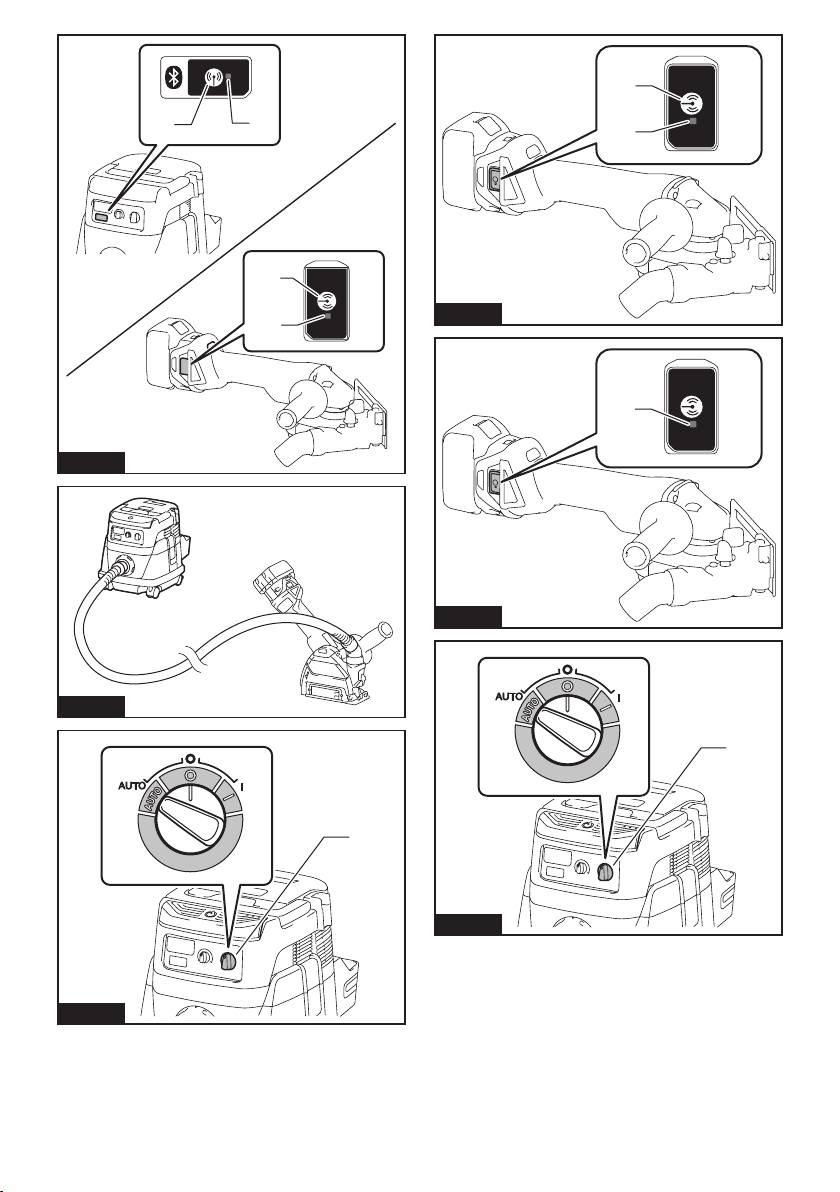

1

1

Fig.9

1

Fig.10

Fig.11

2

3

Fig.13

2

1

2

3

3

4

2

4

2

1

Fig.14

1

2

3

4

Fig.15

1

1

2

3

4

2

Fig.12

3

Fig.16

3

Page 4

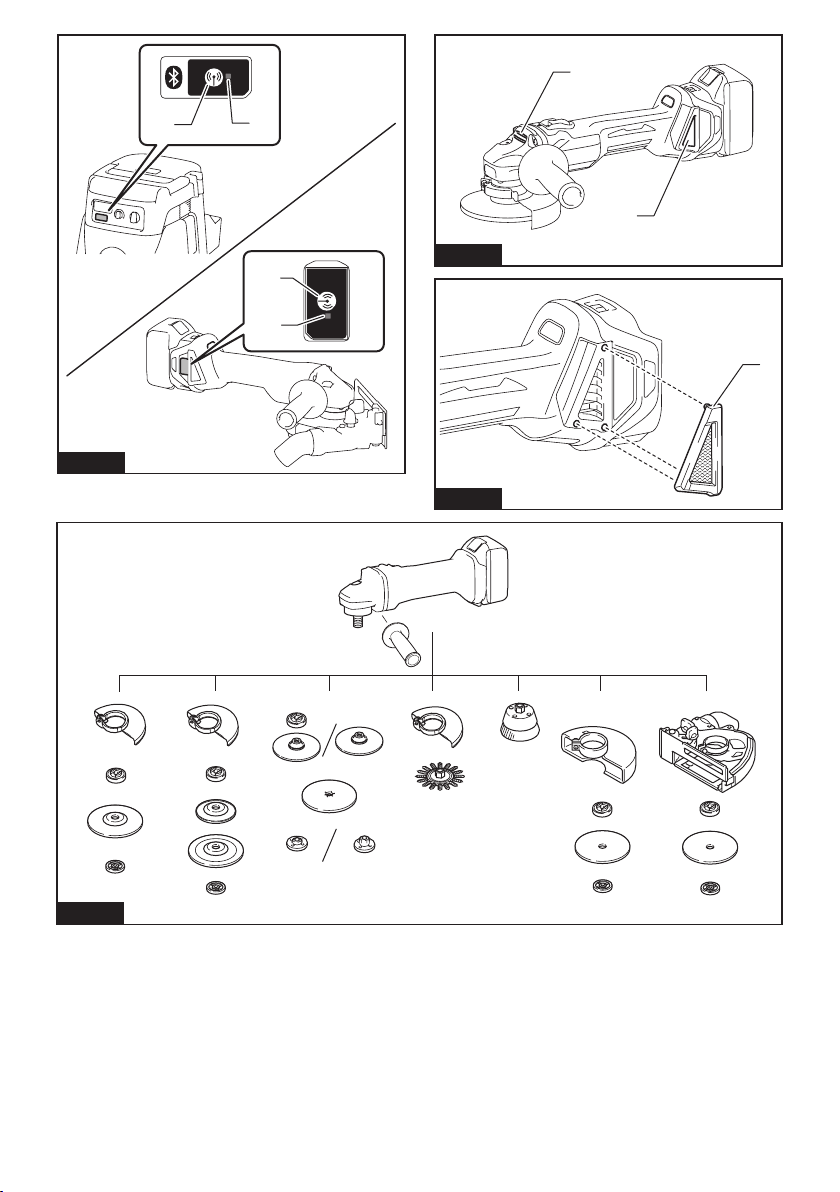

Fig.17

11

23

2

4

4

1

Fig.21

11

23

Fig.18

Fig.19

16 mm (5/8″)

Fig.20

1

2

3

11

23

4

15°

16 mm (5/8″)

4

44

Fig.22

11

23

4

44

Fig.23

1

Fig.24

4

Page 5

Fig.25

Fig.26

1

3

1

2

Fig.29

1

1

Fig.27

4

1

Fig.28

Fig.30

3

2

5

Page 6

1

Fig.31

1

2

2

1

2

Fig.34

1

Fig.35

Fig.32

Fig.33

1

1

Fig.36

6

Page 7

1

Fig.37

1

2

2

Fig.38

1

2

1

Fig.39

1

2

3

4

5

Fig.40

2

8

3

6

7

9

10

2

12

11

5

7

13

3

14

5

15

3

14

5

Page 8

ENGLISH (Original instructions)

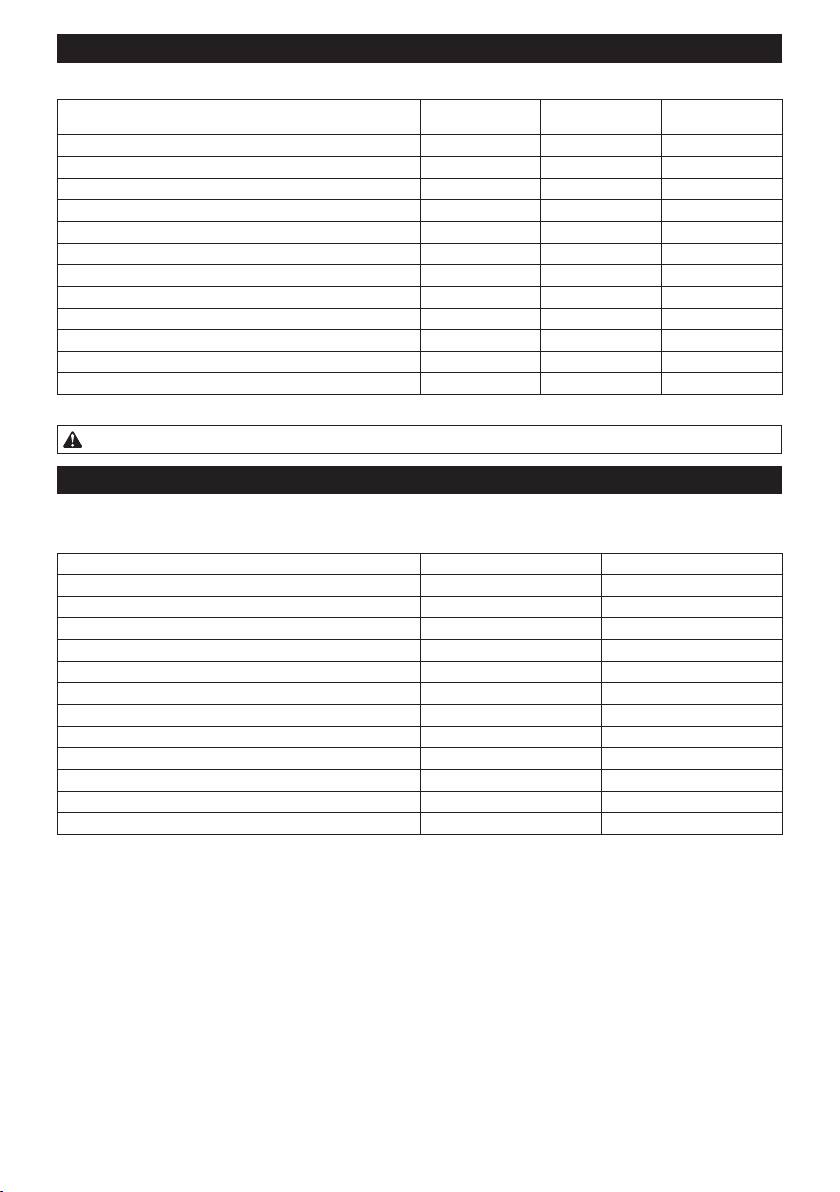

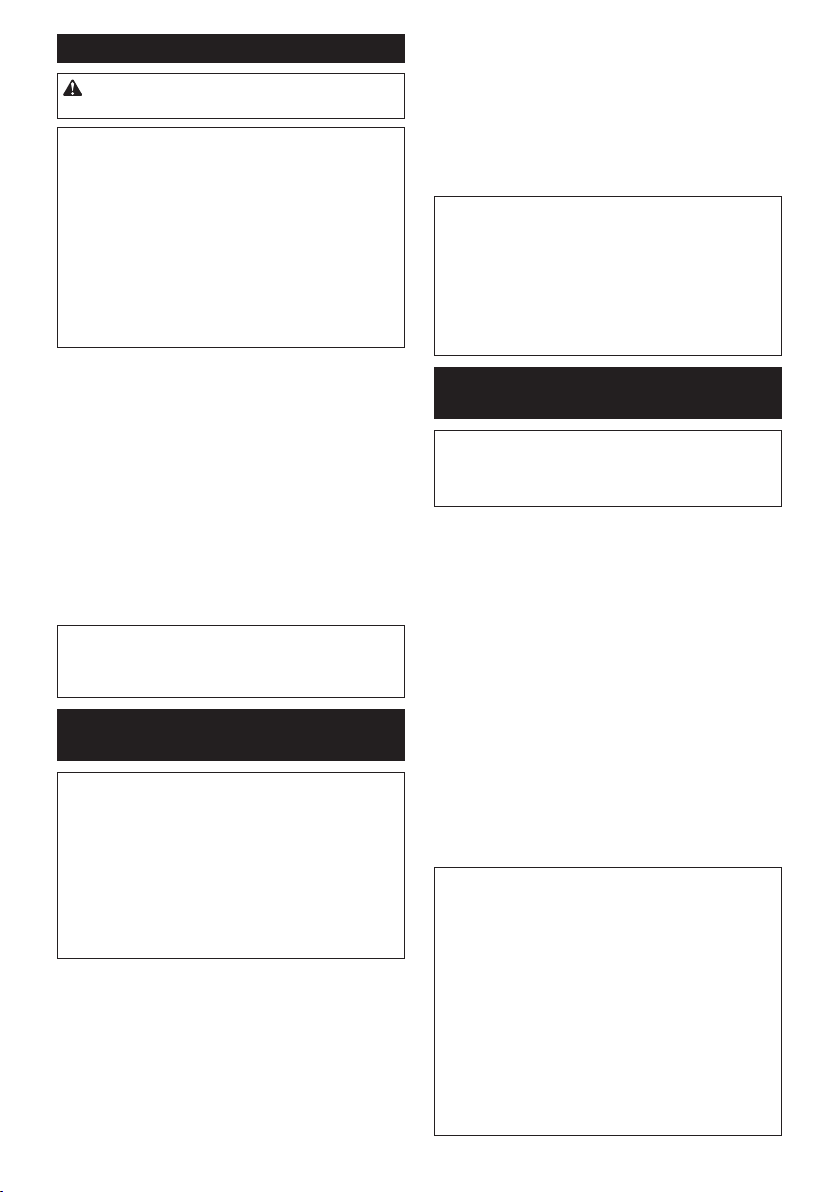

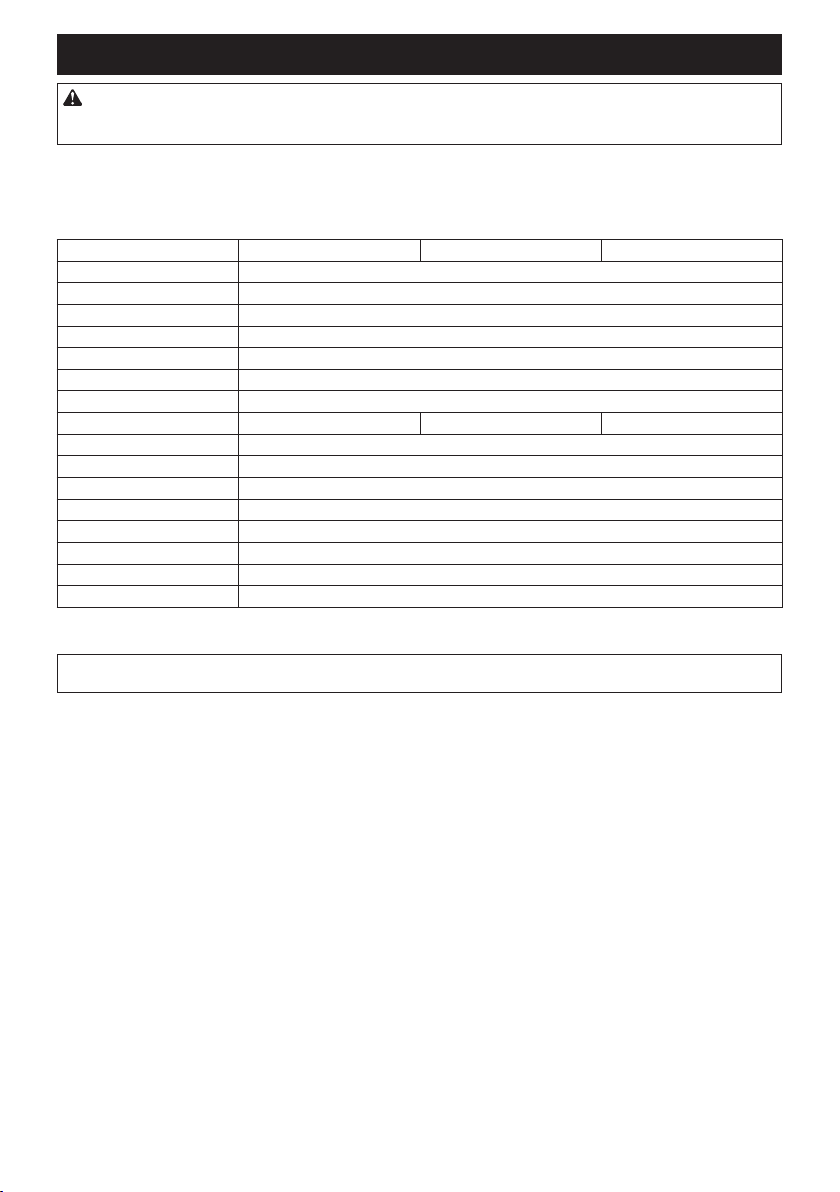

SPECIFICATIONS

Model: DGA411 DGA412 DGA413 DGA414

Wheel diameter 100 mm (4″)

Max. wheel thickness 6.4 mm

Spindle thread M10

Rated speed (n) 8,500 min

Overall length 382 mm

Rated voltage D.C. 18 V

Net weight 2.2 - 2.8 kg

Electric brake -

Wireless activation function - -

Model: DGA461 DGA462 DGA463 DGA464

Wheel diameter 115 mm (4-1/2″)

Max. wheel thickness 7.2 mm

Spindle thread M14 or 5/8″ (country specic)

Rated speed (n) 8,500 min

Overall length 382 mm

Rated voltage D.C. 18 V

Net weight 2.3 - 3.0 kg

Electric brake -

Wireless activation function - -

-1

-1

Model: DGA511 DGA512 DGA513 DGA514

Wheel diameter 125 mm (5″)

Max. wheel thickness 7.2 mm

Spindle thread M14 or 5/8″ (country specic)

Rated speed (n) 8,500 min

Overall length 382 mm

Rated voltage D.C. 18 V

Net weight 2.3 - 3.0 kg 2.4 - 3.0 kg

Electric brake -

Wireless activation function - -

-1

• Due to our continuing program of research and development, the specications herein are subject to change

without notice.

• Specications may differ from country to country.

• The weight may differ depending on the attachment(s), including the battery cartridge. The lightest and heaviest combination, according to EPTA-Procedure 01/2014, are shown in the table.

Applicable battery cartridge

BL1815N / BL1820 / BL1820B / BL1830 / BL1830B / BL1840 / BL1840B / BL1850 / BL1850B / BL1860B

• Some of the battery cartridges listed above may not be available depending on your region of residence.

WARNING: Only use the battery cartridges listed above. Use of any other battery cartridges may cause

injury and/or re.

Intended use

The tool is intended for grinding, sanding and cutting of

metal and stone materials without the use of water.

8 ENGLISH

Page 9

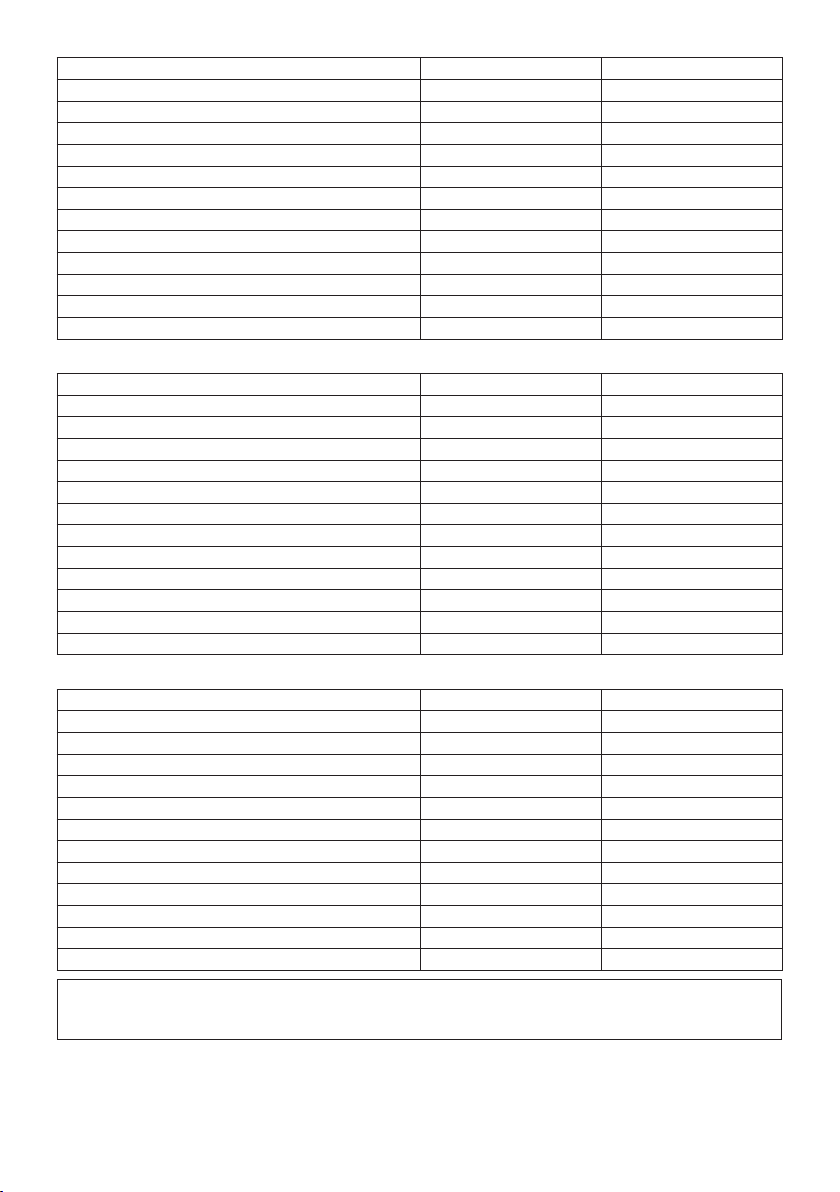

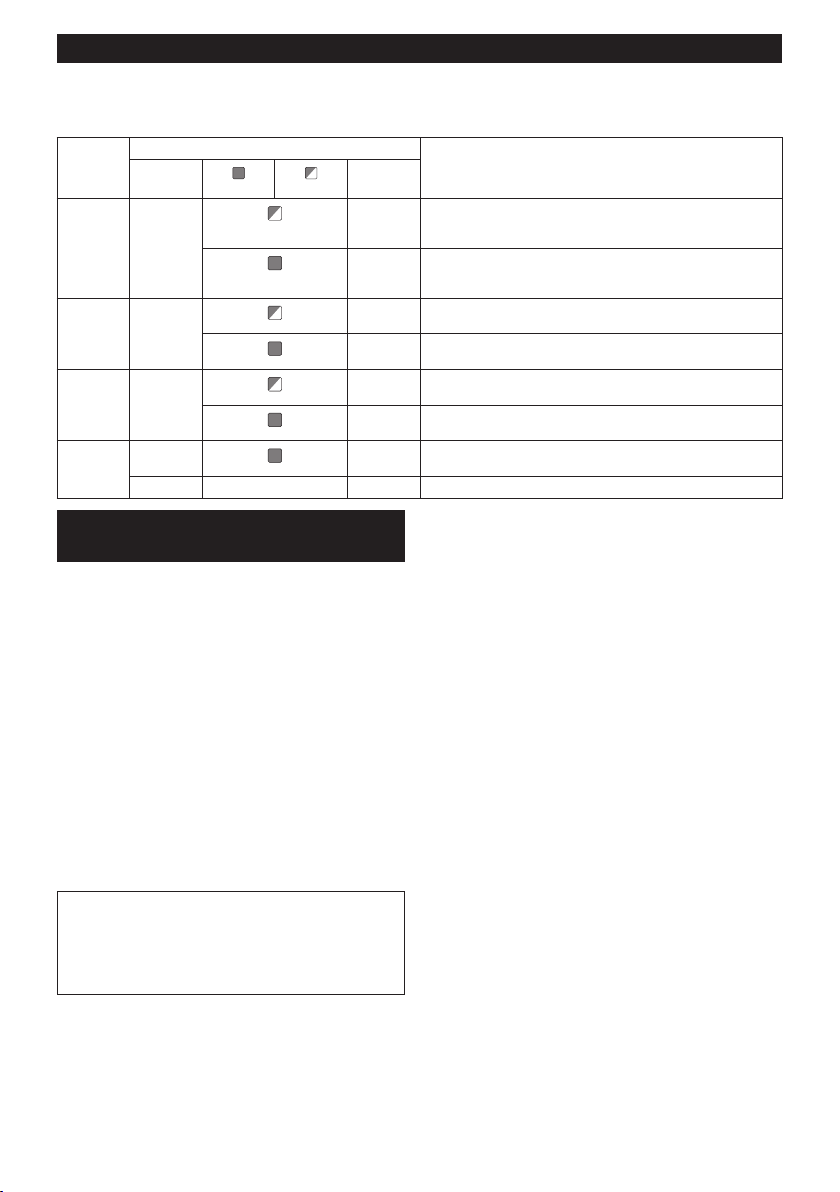

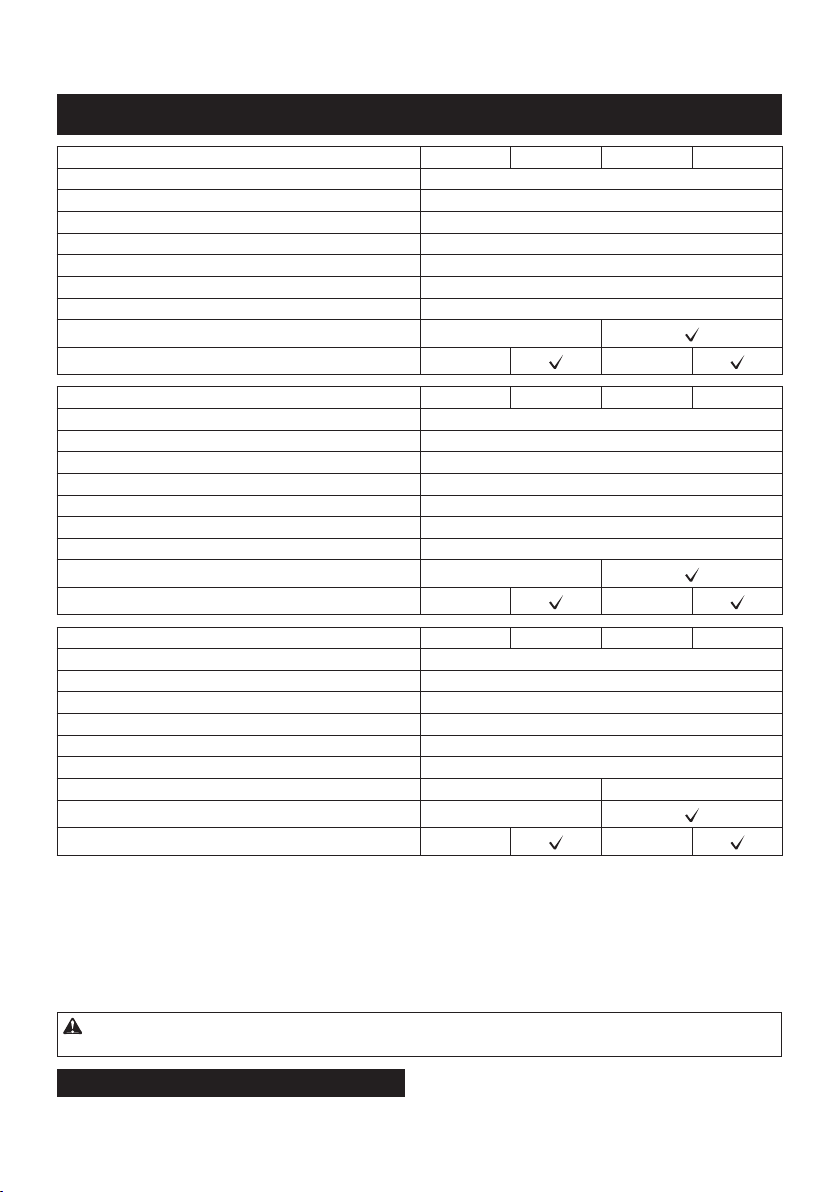

Noise

The typical A-weighted noise level determined according to EN60745:

Model Sound pressure

DGA411 80 - 3

DGA412 80 - 3

DGA413 80 - 3

DGA414 80 - 3

DGA461 79 - 3

DGA462 79 - 3

DGA463 79 - 3

DGA464 79 - 3

DGA511 79 - 3

DGA512 79 - 3

DGA513 79 - 3

DGA514 79 - 3

level (LpA) : (dB(A))

The noise level under working may exceed 80 dB (A).

WARNING: Wear ear protection.

Vibration

The vibration total value (tri-axial vector sum) determined according to EN60745:

Work mode: surface grinding with normal side grip

Model

DGA411 4.5 1.5

DGA412 4.5 1.5

DGA413 4.5 1.5

DGA414 4.5 1.5

DGA461 6.5 1.5

DGA462 6.5 1.5

DGA463 6.5 1.5

DGA464 6.5 1.5

DGA511 6.5 1.5

DGA512 6.5 1.5

DGA513 6.5 1.5

DGA514 6.5 1.5

Vibration emission (ah, AG) : (m/s2)

Sound power level

(LWA) : (dB(A))

Uncertainty (K) : (m/s2)

Uncertainty (K) :

(dB(A))

9 ENGLISH

Page 10

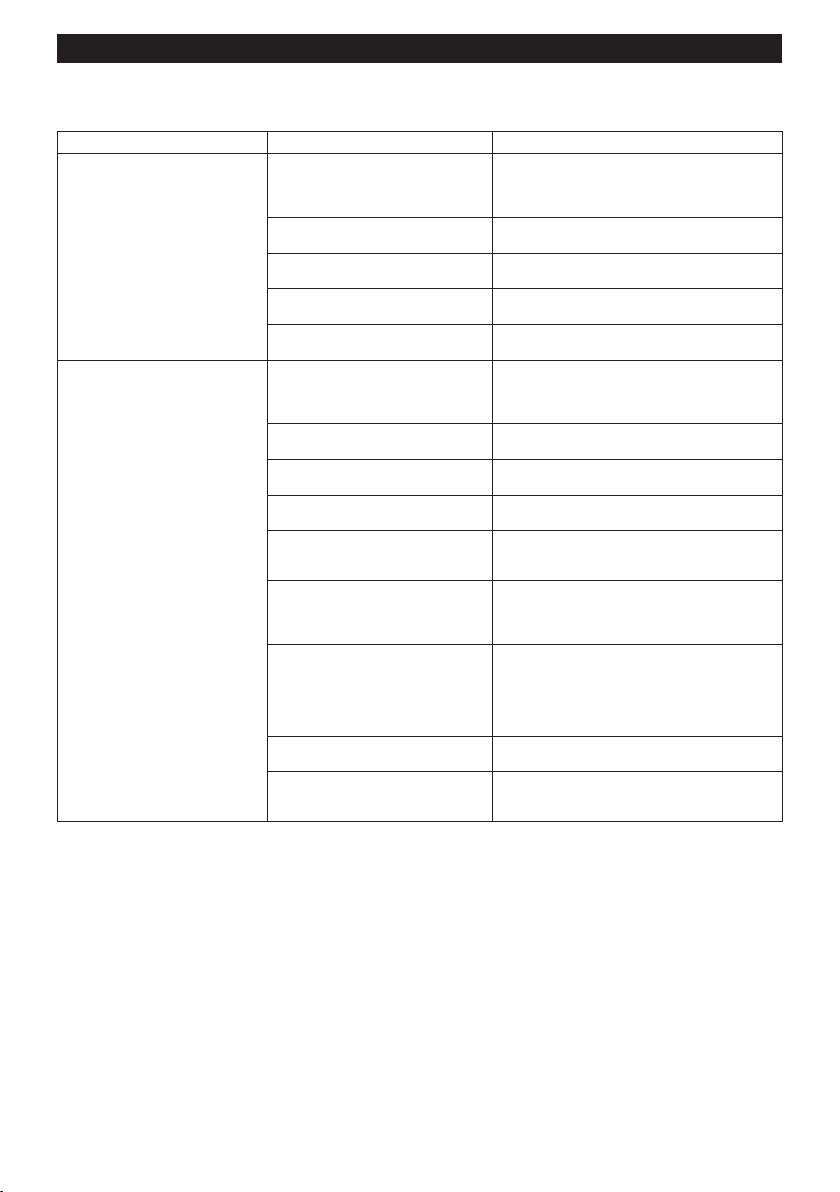

Work mode: surface grinding with anti vibration side grip

Model

DGA411 4.0 1.5

DGA412 4.0 1.5

DGA413 4.0 1.5

DGA414 4.0 1.5

DGA461 6.0 1.5

DGA462 6.0 1.5

DGA463 6.0 1.5

DGA464 6.0 1.5

DGA511 6.0 1.5

DGA512 6.0 1.5

DGA513 6.0 1.5

DGA514 6.0 1.5

Vibration emission (ah, AG) : (m/s2)

Uncertainty (K) : (m/s2)

Work mode: disc sanding with normal side grip

Model

DGA411 2.5 m/s2 or less 1.5

DGA412 2.5 m/s2 or less 1.5

DGA413 2.5 m/s2 or less 1.5

DGA414 2.5 m/s2 or less 1.5

DGA461 2.5 m/s2 or less 1.5

DGA462 2.5 m/s2 or less 1.5

DGA463 2.5 m/s2 or less 1.5

DGA464 2.5 m/s2 or less 1.5

DGA511 2.5 m/s2 or less 1.5

DGA512 2.5 m/s2 or less 1.5

DGA513 2.5 m/s2 or less 1.5

DGA514 2.5 m/s2 or less 1.5

Vibration emission (a

h, DS

) : (m/s2)

Uncertainty (K) : (m/s2)

Work mode: disc sanding with anti vibration side grip

Model

DGA411 2.5 m/s2 or less 1.5

DGA412 2.5 m/s2 or less 1.5

DGA413 2.5 m/s2 or less 1.5

DGA414 2.5 m/s2 or less 1.5

DGA461 2.5 m/s2 or less 1.5

DGA462 2.5 m/s2 or less 1.5

DGA463 2.5 m/s2 or less 1.5

DGA464 2.5 m/s2 or less 1.5

DGA511 2.5 m/s2 or less 1.5

DGA512 2.5 m/s2 or less 1.5

DGA513 2.5 m/s2 or less 1.5

DGA514 2.5 m/s2 or less 1.5

Vibration emission (a

h, DS

) : (m/s2)

Uncertainty (K) : (m/s2)

NOTE: The declared vibration emission value has been measured in accordance with the standard test method

and may be used for comparing one tool with another.

NOTE: The declared vibration emission value may also be used in a preliminary assessment of exposure.

10 ENGLISH

Page 11

WARNING: The vibration emission during actual use of the power tool can differ from the declared emission

value depending on the ways in which the tool is used.

WARNING: Be sure to identify safety measures to protect the operator that are based on an estimation of

exposure in the actual conditions of use (taking account of all parts of the operating cycle such as the times when

the tool is switched off and when it is running idle in addition to the trigger time).

WARNING: The declared vibration emission value is used for main applications of the power tool. However if

the power tool is used for other applications, the vibration emission value may be different.

EC Declaration of Conformity

For European countries only

The EC declaration of conformity is included as Annex A

to this instruction manual.

SAFETY WARNINGS

General power tool safety warnings

WARNING: Read all safety warnings, instruc-

tions, illustrations and specications provided

with this power tool. Failure to follow all instructions

listed below may result in electric shock, re and/or

serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to your

mains-operated (corded) power tool or battery-operated

(cordless) power tool.

Cordless grinder safety warnings

Safety Warnings Common for Grinding, Sanding,

Wire Brushing, or Abrasive Cutting-Off Operations:

1. This power tool is intended to function as a

grinder, sander, wire brush or cut-off tool.

Read all safety warnings, instructions, illus-

trations and specications provided with this

power tool. Failure to follow all instructions listed

below may result in electric shock, re and/or

serious injury.

2. Operations such as polishing are not recommended to be performed with this power

tool. Operations for which the power tool was not

designed may create a hazard and cause personal injury.

3. Do not use accessories which are not speci-

cally designed and recommended by the tool

manufacturer. Just because the accessory can

be attached to your power tool, it does not assure

safe operation.

4. The rated speed of the accessory must be at

least equal to the maximum speed marked on

the power tool. Accessories running faster than

their rated speed can break and y apart.

5. The outside diameter and the thickness of your

accessory must be within the capacity rating

of your power tool. Incorrectly sized accessories

cannot be adequately guarded or controlled.

6. Threaded mounting of accessories must

match the grinder spindle thread. For acces-

sories mounted by anges, the arbour hole of

the accessory must t the locating diameter

of the ange. Accessories that do not match the

mounting hardware of the power tool will run out of

balance, vibrate excessively and may cause loss

of control.

7. Do not use a damaged accessory. Before each

use inspect the accessory such as abrasive

wheels for chips and cracks, backing pad for

cracks, tear or excess wear, wire brush for

loose or cracked wires. If power tool or accessory is dropped, inspect for damage or install

an undamaged accessory. After inspecting and

installing an accessory, position yourself and

bystanders away from the plane of the rotating

accessory and run the power tool at maximum

no-load speed for one minute. Damaged acces-

sories will normally break apart during this test

time.

8. Wear personal protective equipment.

Depending on application, use face shield,

safety goggles or safety glasses. As appropriate, wear dust mask, hearing protectors,

gloves and workshop apron capable of stopping small abrasive or workpiece fragments.

The eye protection must be capable of stopping

ying debris generated by various operations.

The dust mask or respirator must be capable of

ltrating particles generated by your operation.

Prolonged exposure to high intensity noise may

cause hearing loss.

9. Keep bystanders a safe distance away from

work area. Anyone entering the work area

must wear personal protective equipment.

Fragments of workpiece or of a broken accessory

may y away and cause injury beyond immediate

area of operation.

10. Hold the power tool by insulated gripping

surfaces only, when performing an operation

where the cutting tool may contact hidden

wiring. Contact with a "live" wire will also make

exposed metal parts of the power tool "live" and

could give the operator an electric shock.

11. Never lay the power tool down until the acces-

sory has come to a complete stop. The spinning

accessory may grab the surface and pull the

power tool out of your control.

12. Do not run the power tool while carrying it at

your side. Accidental contact with the spinning

accessory could snag your clothing, pulling the

accessory into your body.

13. Regularly clean the power tool’s air vents. The

motor’s fan will draw the dust inside the housing

and excessive accumulation of powdered metal

may cause electrical hazards.

11 ENGLISH

Page 12

14. Do not operate the power tool near ammable

materials. Sparks could ignite these materials.

15. Do not use accessories that require liquid

coolants. Using water or other liquid coolants

may result in electrocution or shock.

Kickback and Related Warnings

Kickback is a sudden reaction to a pinched or snagged

rotating wheel, backing pad, brush or any other accessory. Pinching or snagging causes rapid stalling of the

rotating accessory which in turn causes the uncon-

trolled power tool to be forced in the direction opposite

of the accessory’s rotation at the point of the binding.

For example, if an abrasive wheel is snagged or

pinched by the workpiece, the edge of the wheel that is

entering into the pinch point can dig into the surface of

the material causing the wheel to climb out or kick out.

The wheel may either jump toward or away from the

operator, depending on direction of the wheel’s move-

ment at the point of pinching. Abrasive wheels may also

break under these conditions.

Kickback is the result of power tool misuse and/or

incorrect operating procedures or conditions and can be

avoided by taking proper precautions as given below.

1. Maintain a rm grip on the power tool and

position your body and arm to allow you to

resist kickback forces. Always use auxiliary

handle, if provided, for maximum control over

kickback or torque reaction during start-up.

The operator can control torque reactions or kickback forces, if proper precautions are taken.

2. Never place your hand near the rotating acces-

sory. Accessory may kickback over your hand.

3. Do not position your body in the area where

power tool will move if kickback occurs.

Kickback will propel the tool in direction opposite

to the wheel’s movement at the point of snagging.

4. Use special care when working corners, sharp

edges etc. Avoid bouncing and snagging the

accessory. Corners, sharp edges or bouncing

have a tendency to snag the rotating accessory

and cause loss of control or kickback.

5. Do not attach a saw chain woodcarving blade

or toothed saw blade. Such blades create frequent kickback and loss of control.

Safety Warnings Specic for Grinding and Abrasive

Cutting-Off Operations:

1. Use only wheel types that are recommended

for your power tool and the specic guard

designed for the selected wheel. Wheels for

which the power tool was not designed cannot be

adequately guarded and are unsafe.

2. The grinding surface of centre depressed

wheels must be mounted below the plane of

the guard lip. An improperly mounted wheel that

projects through the plane of the guard lip cannot

be adequately protected.

3. The guard must be securely attached to the

power tool and positioned for maximum safety,

so the least amount of wheel is exposed

towards the operator. The guard helps to protect

the operator from broken wheel fragments, accidental contact with wheel and sparks that could

ignite clothing.

4.

Wheels must be used only for recommended

applications. For example: do not grind with the

side of cut-off wheel. Abrasive cut-off wheels are

intended for peripheral grinding, side forces applied

to these wheels may cause them to shatter.

5. Always use undamaged wheel anges that are

of correct size and shape for your selected

wheel. Proper wheel anges support the wheel

thus reducing the possibility of wheel breakage.

Flanges for cut-off wheels may be different from

grinding wheel anges.

6. Do not use worn down wheels from larger

power tools. Wheel intended for larger power tool

is not suitable for the higher speed of a smaller

tool and may burst.

Additional Safety Warnings Specic for Abrasive

Cutting-Off Operations:

1. Do not “jam“ the cut-off wheel or apply excessive pressure. Do not attempt to make an

excessive depth of cut. Overstressing the wheel

increases the loading and susceptibility to twisting

or binding of the wheel in the cut and the possibil-

ity of kickback or wheel breakage.

2. Do not position your body in line with and

behind the rotating wheel. When the wheel, at

the point of operation, is moving away from your

body, the possible kickback may propel the spinning wheel and the power tool directly at you.

3. When wheel is binding or when interrupting

a cut for any reason, switch off the power

tool and hold the power tool motionless until

the wheel comes to a complete stop. Never

attempt to remove the cut-off wheel from the

cut while the wheel is in motion otherwise

kickback may occur. Investigate and take correc-

tive action to eliminate the cause of wheel binding.

4.

Do not restart the cutting operation in the workpiece. Let the wheel reach full speed and carefully

re-enter the cut. The wheel may bind, walk up or

kickback if the power tool is restarted in the workpiece.

5. Support panels or any oversized workpiece to

minimize the risk of wheel pinching and kickback. Large workpieces tend to sag under their

own weight. Supports must be placed under the

workpiece near the line of cut and near the edge

of the workpiece on both sides of the wheel.

6. Use extra caution when making a “pocket cut”

into existing walls or other blind areas. The

protruding wheel may cut gas or water pipes, electrical wiring or objects that can cause kickback.

Safety Warnings Specic for Sanding Operations:

1. Do not use excessively oversized sanding

disc paper. Follow manufacturers recommendations, when selecting sanding paper. Larger

sanding paper extending beyond the sanding

pad presents a laceration hazard and may cause

snagging, tearing of the disc or kickback.

Safety Warnings Specic for Wire Brushing

Operations:

1. Be aware that wire bristles are thrown by the

brush even during ordinary operation. Do not

overstress the wires by applying excessive

load to the brush. The wire bristles can easily

penetrate light clothing and/or skin.

12 ENGLISH

Page 13

2. If the use of a guard is recommended for wire

brushing, do not allow any interference of the

wire wheel or brush with the guard. Wire wheel

or brush may expand in diameter due to work load

and centrifugal forces.

Additional Safety Warnings:

1. When using depressed centre grinding wheels,

be sure to use only berglass-reinforced

wheels.

2. NEVER USE Stone Cup type wheels with this

grinder. This grinder is not designed for these

types of wheels and the use of such a product

may result in serious personal injury.

3. Be careful not to damage the spindle, the

ange (especially the installing surface) or the

lock nut. Damage to these parts could result in

wheel breakage.

4. Make sure the wheel is not contacting the

workpiece before the switch is turned on.

5. Before using the tool on an actual workpiece,

let it run for a while. Watch for vibration or

wobbling that could indicate poor installation

or a poorly balanced wheel.

6. Use the specied surface of the wheel to per-

form the grinding.

7. Do not leave the tool running. Operate the tool

only when hand-held.

8. Do not touch the workpiece immediately after

operation; it may be extremely hot and could

burn your skin.

9. Observe the instructions of the manufacturer

for correct mounting and use of wheels.

Handle and store wheels with care.

10. Do not use separate reducing bushings or

adaptors to adapt large hole abrasive wheels.

11. Use only anges specied for this tool.

12. For tools intended to be tted with threaded

hole wheel, ensure that the thread in the wheel

is long enough to accept the spindle length.

13. Check that the workpiece is properly

supported.

14. Pay attention that the wheel continues to

rotate after the tool is switched off.

15. If working place is extremely hot and humid,

or badly polluted by conductive dust, use a

short-circuit breaker (30 mA) to assure operator safety.

16. Do not use the tool on any materials containing asbestos.

17. When use cut-off wheel, always work with

the dust collecting wheel guard required by

domestic regulation.

18. Cutting discs must not be subjected to any

lateral pressure.

19. Do not use cloth work gloves during operation.

Fibers from cloth gloves may enter the tool, which

causes tool breakage.

SAVE THESE INSTRUCTIONS.

WARNING: DO NOT let comfort or familiarity

with product (gained from repeated use) replace

strict adherence to safety rules for the subject

product. MISUSE or failure to follow the safety

rules stated in this instruction manual may cause

serious personal injury.

Important safety instructions for

battery cartridge

1. Before using battery cartridge, read all instructions and cautionary markings on (1) battery

charger, (2) battery, and (3) product using

battery.

2. Do not disassemble battery cartridge.

3. If operating time has become excessively

shorter, stop operating immediately. It may

result in a risk of overheating, possible burns

and even an explosion.

4. If electrolyte gets into your eyes, rinse them

out with clear water and seek medical attention right away. It may result in loss of your

eyesight.

5. Do not short the battery cartridge:

(1) Do not touch the terminals with any con-

ductive material.

(2) Avoid storing battery cartridge in a con-

tainer with other metal objects such as

nails, coins, etc.

(3) Do not expose battery cartridge to water

or rain.

A battery short can cause a large current

ow, overheating, possible burns and even a

breakdown.

6. Do not store the tool and battery cartridge in

locations where the temperature may reach or

exceed 50 °C (122 °F).

7. Do not incinerate the battery cartridge even if

it is severely damaged or is completely worn

out. The battery cartridge can explode in a re.

8. Be careful not to drop or strike battery.

9. Do not use a damaged battery.

10. The contained lithium-ion batteries are subject

to the Dangerous Goods Legislation requirements.

For commercial transports e.g. by third parties,

forwarding agents, special requirement on packaging and labeling must be observed.

For preparation of the item being shipped, consult-

ing an expert for hazardous material is required.

Please also observe possibly more detailed

national regulations.

Tape or mask off open contacts and pack up the

battery in such a manner that it cannot move

around in the packaging.

11. Follow your local regulations relating to dis-

posal of battery.

12. Use the batteries only with the products

specied by Makita. Installing the batteries to

non-compliant products may result in a re, excessive heat, explosion, or leak of electrolyte.

SAVE THESE INSTRUCTIONS.

13 ENGLISH

Page 14

CAUTION: Only use genuine Makita batteries.

Use of non-genuine Makita batteries, or batteries that

have been altered, may result in the battery bursting

causing res, personal injury and damage. It will

also void the Makita warranty for the Makita tool and

charger.

Tips for maintaining maximum

battery life

1. Charge the battery cartridge before completely

discharged. Always stop tool operation and

charge the battery cartridge when you notice

less tool power.

2. Never recharge a fully charged battery cartridge. Overcharging shortens the battery

service life.

3. Charge the battery cartridge with room temperature at 10 °C - 40 °C (50 °F - 104 °F). Let

a hot battery cartridge cool down before

charging it.

4. Charge the battery cartridge if you do not use

it for a long period (more than six months).

Important safety instructions for

wireless unit

1. Do not disassemble or tamper with the wireless unit.

2. Keep the wireless unit away from young children. If accidentally swallowed, seek medical

attention immediately.

3. Use the wireless unit only with Makita tools.

4. Do not expose the wireless unit to rain or wet

conditions.

5. Do not use the wireless unit in places where

the temperature exceeds 50°C (122°F).

6. Do not operate the wireless unit in places

where medical instruments, such as heart

pace makers are near by.

7. Do not operate the wireless unit in places

where automated devices are near by. If oper-

ated, automated devices may develop malfunction

or error.

8. The wireless unit can produce electromagnetic

elds (EMF) but they are not harmful to the

user.

9. The wireless unit is an accurate instrument. Be

careful not to drop or strike the wireless unit.

10. Avoid touching the terminal of the wireless

unit with bare hands or metallic materials.

11. Always remove the battery on the tool when

installing the wireless unit.

12. When opening the lid of the slot, avoid the

place where dust and water may come into the

slot. Always keep the inlet of the slot clean.

13. Always insert the wireless unit in the correct

direction.

14. Do not press the wireless activation button

on the wireless unit too hard and/or press the

button with an object with a sharp edge.

15. Always close the lid of the slot when

operating.

16. Do not remove the wireless unit from the slot

while the power is being supplied to the tool.

Doing so may cause a malfunction of the wireless

unit.

17. Do not remove the sticker on the wireless unit.

18. Do not put any sticker on the wireless unit.

19. Do not leave the wireless unit in a place where

static electricity or electrical noise could be

generated.

20. Do not leave the wireless unit in a place subject to high heat, such as a car sitting in the

sun.

21. Do not leave the wireless unit in a dusty or

powdery place or in a place corrosive gas

could be generated.

22. Sudden change of the temperature may bedew

the wireless unit. Do not use the wireless unit

until the dew is completely dried.

23. When cleaning the wireless unit, gently wipe

with a dry soft cloth. Do not use benzine, thinner, conductive grease or the like.

24. When storing the wireless unit, keep it in the

supplied case or a static-free container.

25. Do not insert any devices other than Makita

wireless unit into the slot on the tool.

26. Do not use the tool with the lid of the slot damaged. Water, dust, and dirt come into the slot may

cause malfunction.

27. Do not pull and/or twist the lid of the slot more

than necessary. Restore the lid if it comes off

from the tool.

28. Replace the lid of the slot if it is lost or

damaged.

SAVE THESE INSTRUCTIONS.

14 ENGLISH

Page 15

FUNCTIONAL

DESCRIPTION

CAUTION: Always be sure that the tool is

switched off and the battery cartridge is removed

before adjusting or checking function on the tool.

Installing or removing battery cartridge

CAUTION: Always switch off the tool before

installing or removing of the battery cartridge.

CAUTION:

rmly when installing or removing battery cartridge.

Failure to hold the tool and the battery cartridge rmly may

cause them to slip off your hands and result in damage to

the tool and battery cartridge and a personal injury.

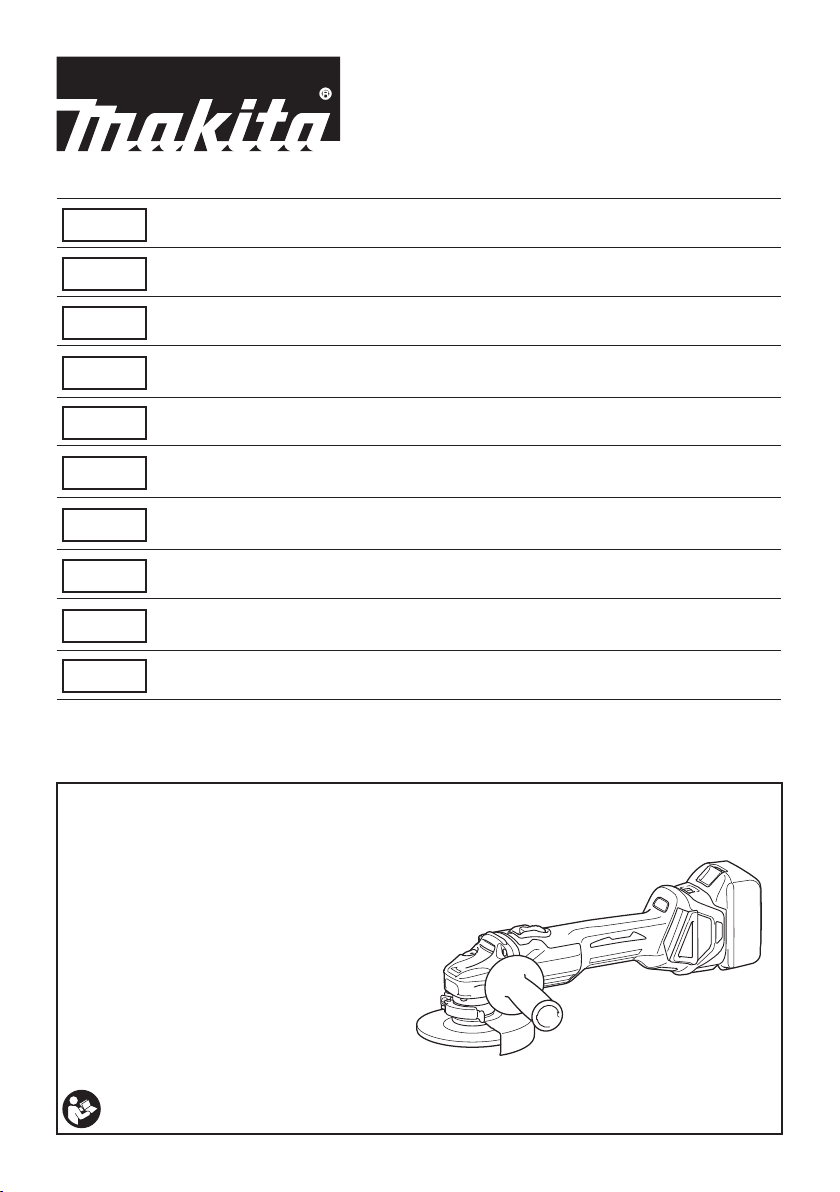

► Fig.1: 1. Red indicator 2. Button 3. Battery cartridge

To remove the battery cartridge, slide it from the tool

while sliding the button on the front of the cartridge.

To install the battery cartridge, align the tongue on the

battery cartridge with the groove in the housing and slip

it into place. Insert it all the way until it locks in place

with a little click. If you can see the red indicator on the

upper side of the button, it is not locked completely.

CAUTION:

until the red indicator cannot be seen. If not, it may accidentally

fall out of the tool, causing injury to you or someone around you.

CAUTION: Do not install the battery cartridge

forcibly. If the cartridge does not slide in easily, it is

not being inserted correctly.

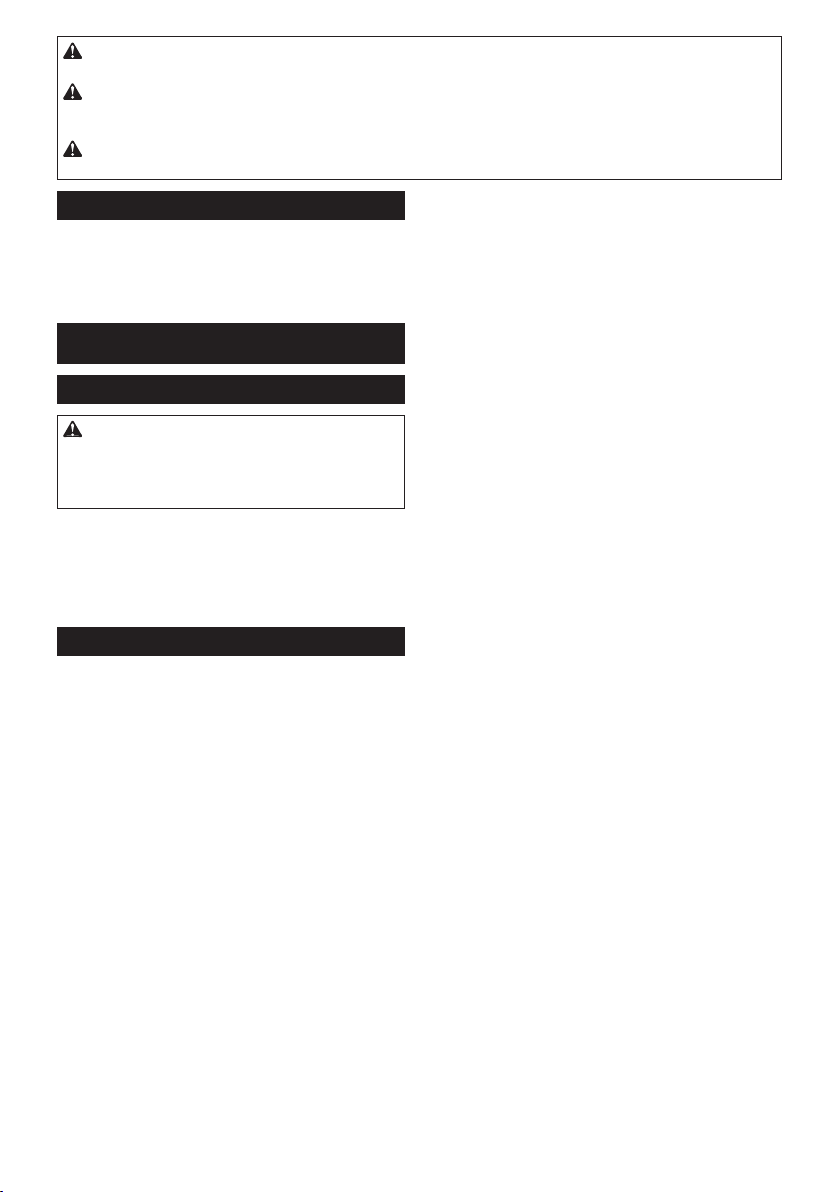

Indicating the remaining battery capacity

Only for battery cartridges with the indicator

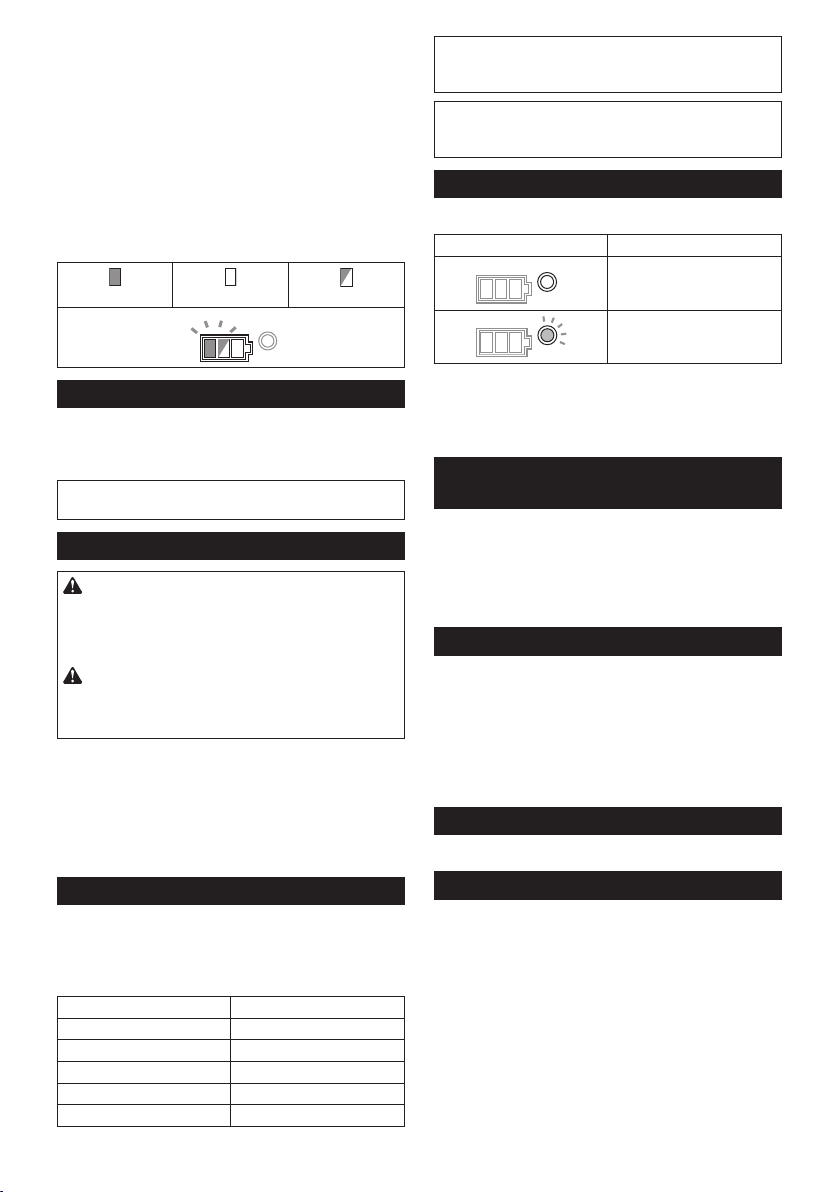

► Fig.2: 1. Indicator lamps 2. Check button

Press the check button on the battery cartridge to indi-

cate the remaining battery capacity. The indicator lamps

light up for a few seconds.

Lighted Off Blinking

Hold the tool and the battery cartridge

Always install the battery cartridge fully

Indicator lamps Remaining

capacity

75% to 100%

50% to 75%

25% to 50%

NOTE: Depending on the conditions of use and the

ambient temperature, the indication may differ slightly

from the actual capacity.

Indicating the remaining battery

capacity

Country specic

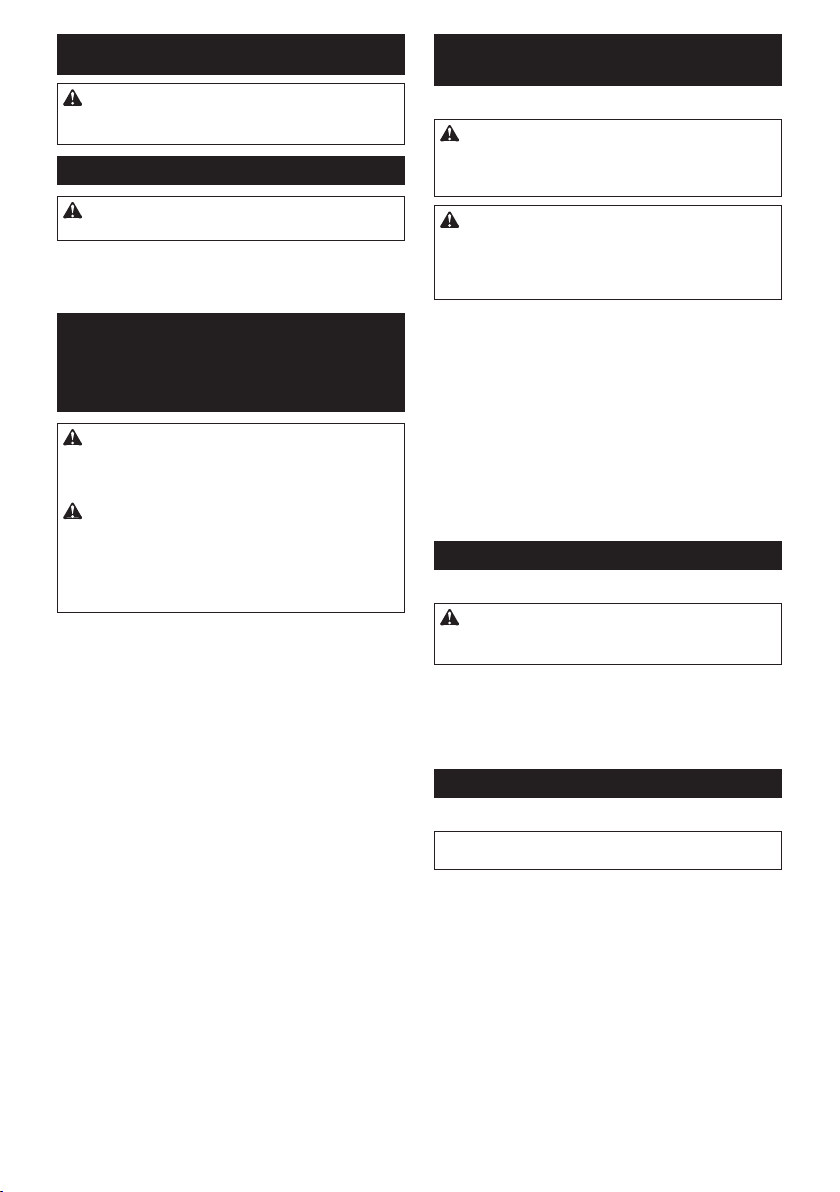

When you turn the tool on, the battery indicator shows

the remaining battery capacity.

► Fig.3: 1. Battery indicator

The remaining battery capacity is shown as the follow-

ing table.

Battery indicator status Remaining

On

Off

Blinking

battery

capacity

50% to 100%

20% to 50%

0% to 20%

Charge the

battery

Tool / battery protection system

The tool is equipped with a tool/battery protection system. This system automatically cuts off power to the

motor to extend tool and battery life. The tool will automatically stop during operation if the tool or battery is

placed under one of the following conditions:

Overload protection

When the tool is operated in a manner that causes it to

draw an abnormally high current, the tool automatically

stops without any indication. In this situation, turn the

tool off and stop the application that caused the tool to

become overloaded. Then turn the tool on to restart.

Overheat protection

When the tool is overheated, the tool stops automati-

cally and the battery indicator shows following state. In

this situation, let the tool cool before turning the tool on

again.

0% to 25%

Charge the

battery.

The battery

may have

malfunctioned.

On

If the tool does not start, the battery may be overheated.

In this situation, let the battery cool before starting the

tool again.

15 ENGLISH

Blinking

Page 16

Overdischarge protection

When the battery capacity is not enough, the tool stops

automatically. In this case, remove the battery from the

tool and charge the battery.

Releasing protection lock

When the protection system works repeatedly, the tool is

locked and the battery indicator shows the following state.

In this situation, the tool does not start even if turning

the tool off and on. To release the protection lock,

remove the battery, set it to the battery charger and wait

until the charging nishes.

On

Off

Blinking

Shaft lock

Press the shaft lock to prevent spindle rotation when

installing or removing accessories.

► Fig.4: 1. Shaft lock

NOTICE: Never actuate the shaft lock when the

spindle is moving. The tool may be damaged.

Switch action

CAUTION: Before installing the battery car-

tridge into the tool, always check to see that the

slide switch actuates properly and returns to the

"OFF" position when the rear of the slide switch

is depressed.

CAUTION: Switch can be locked in "ON" posi-

tion for ease of operator comfort during extended

use. Apply caution when locking tool in "ON"

position and maintain rm grasp on tool.

To start the tool, slide the slide switch toward the “I

(ON)” position by pushing the rear of the slide switch.

For continuous operation, press the front of the slide

switch to lock it.

To stop the tool, press the rear of the slide switch, then

slide it toward the “O (OFF)” position.

► Fig.5: 1. Slide switch

Speed adjusting dial

The rotation speed of the tool can be changed by turning

the speed adjusting dial. The table below shows the num-

ber on the dial and the corresponding rotation speed.

► Fig.6: 1. Speed adjusting dial

Number Speed

1 3,000 min

2 4,500 min

3 6,000 min

4 7,500 min

5 8,500 min

-1

-1

-1

-1

-1

NOTICE: If the tool is operated continuously at

low speed for a long time, the motor will get overloaded, resulting in tool malfunction.

NOTICE: When changing the speed dial from "5"

to "1", turn the dial counterclockwise. Do not turn

the dial clockwise forcibly.

Automatic speed change function

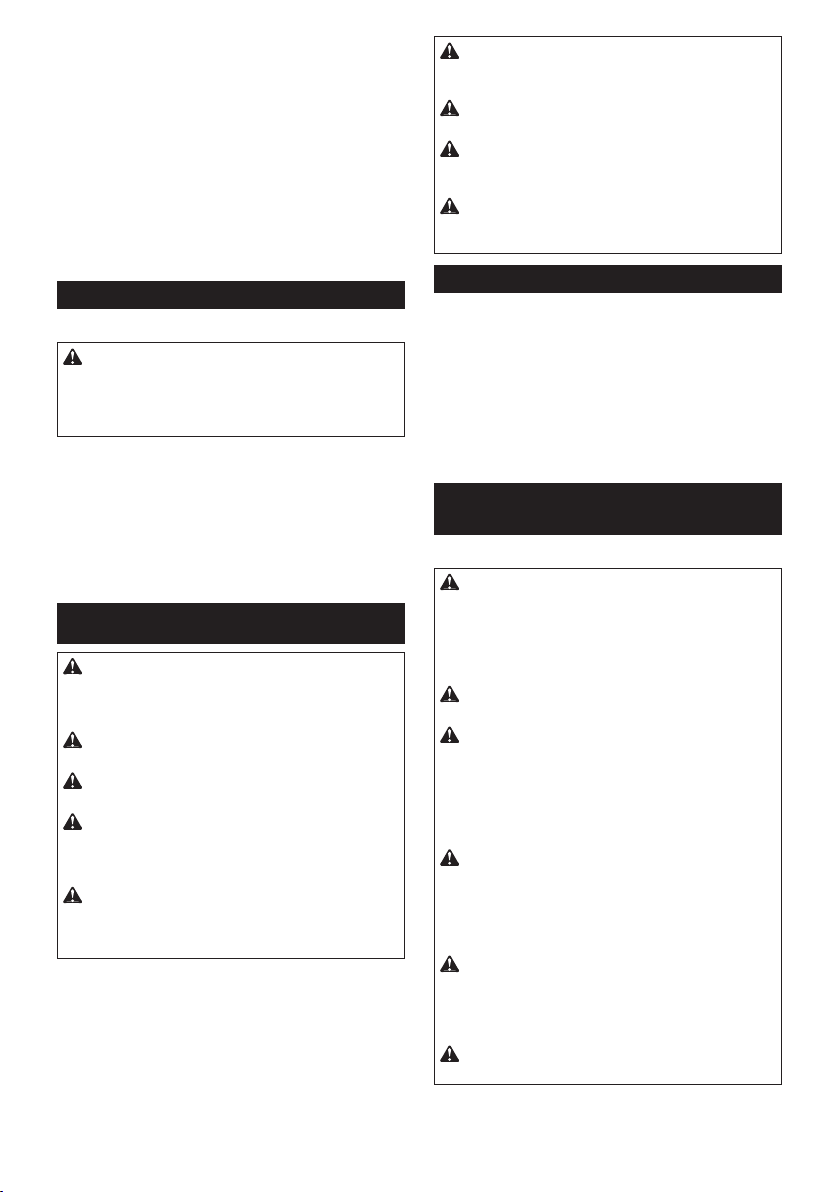

► Fig.7: 1. Mode indicator

Mode indicator status Operation mode

High speed mode

High torque mode

This tool has "high speed mode" and "high torque

mode". It automatically changes operation mode

depending on the work load. When mode indicator

lights up during operation, the tool is in high torque

mode.

Accidental re-start preventive

function

Even if the battery cartridge is installed on the tool with

the slide switch in the "I (ON)" position, the tool does

not start.

To start the tool, rst slide the slide switch toward the

"O (OFF)" position and then slide it toward the "I (ON)"

position.

Electronic torque control function

The tool electronically detects situations where the

wheel or accessory may be at risk to be bound. In the

situation, the tool is automatically shut off to prevent

further rotation of the spindle (it does not prevent

kickback).

To restart the tool, switch off the tool rst, remove the

cause of sudden drop in the rotation speed, and then

turn the tool on.

Soft start feature

Soft start feature reduces starting reaction.

Electric brake

For model DGA413/DGA414/DGA463/DGA464/

DGA513/DGA514 only

Electric brake is activated after the tool is switched off.

The brake does not work when the power supply is shut

down, such as the battery is removed accidentally, with

the switch still on.

16 ENGLISH

Page 17

ASSEMBLY

CAUTION: Always be sure that the tool is

switched off and the battery cartridge is removed

before adjusting or checking function on the tool.

Installing side grip (handle)

CAUTION: Always be sure that the side grip is

installed securely before operation.

Screw the side grip securely on the position of the tool

as shown in the gure.

► Fig.8

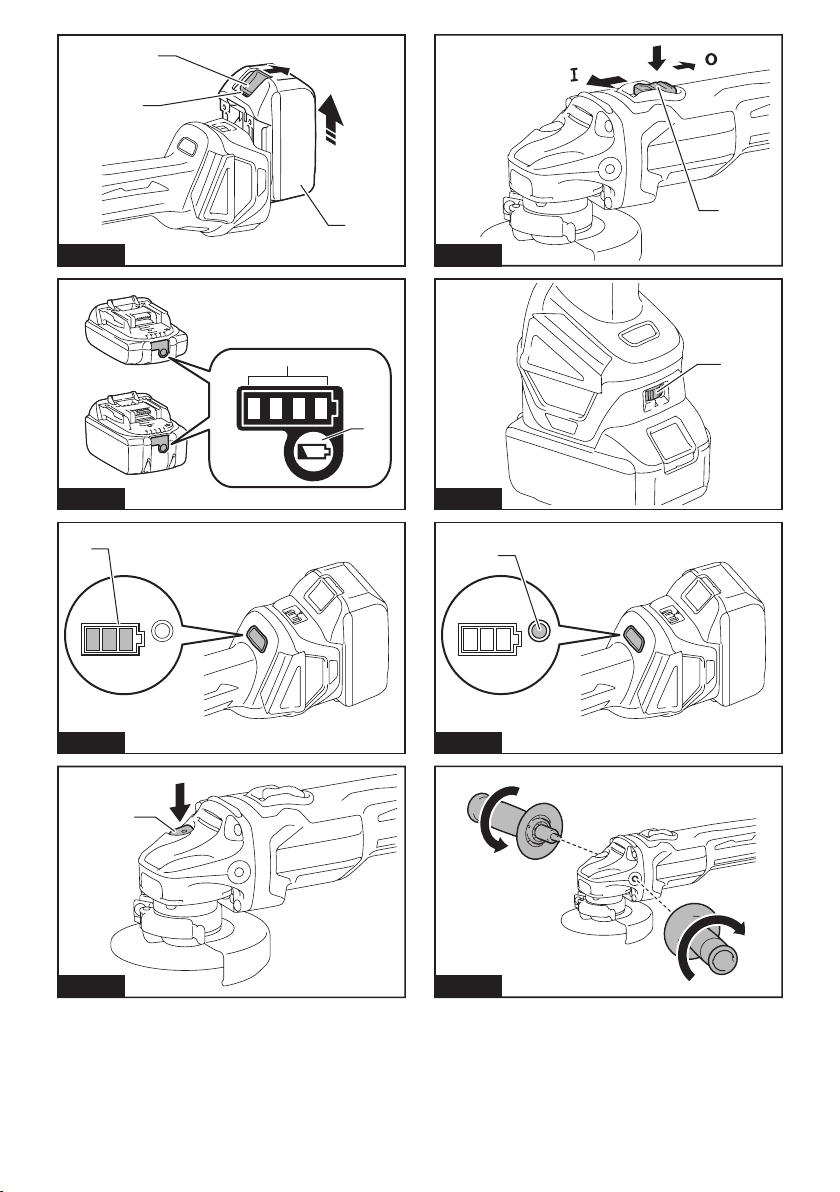

Installing or removing wheel guard

(For depressed center wheel, ap disc,

ex wheel, wire wheel brush / abrasive

cut-off wheel, diamond wheel)

WARNING:

ap disc, ex wheel or wire wheel brush, the wheel

guard must be tted on the tool so that the closed side

of the guard always points toward the operator.

WARNING: When using an abrasive cut-off

/ diamond wheel, be sure to use only the special

wheel guard designed for use with cut-off wheels.

(In some European countries, when using a diamond

wheel, the ordinary guard can be used. Follow the

regulations in your country.)

For tool with locking screw type

wheel guard

Mount the wheel guard with the protrusions on the

wheel guard band aligned with the notches on the bear-

ing box. Then rotate the wheel guard to such an angle

that it can protect the operator according to work. Be

sure to tighten the screw securely.

To remove wheel guard, follow the installation proce-

dure in reverse.

► Fig.9: 1. Wheel guard 2. Bearing box 3. Screw

For tool with clamp lever type wheel

guard

Loosen the screw, and then pull the lever in the direction

of the arrow. Mount the wheel guard with the protrusions

on the wheel guard band aligned with the notches on

the bearing box. Then rotate the wheel guard to such an

angle that it can protect the operator according to work.

► Fig.10: 1. Wheel guard 2. Bearing box 3. Screw

Pull the lever in direction of the arrow. Then tighten the

wheel guard with fastening the screw. Be sure to tighten

the screw securely. The setting angle of the wheel

guard can be adjusted with the lever.

► Fig.11: 1. Screw 2. Lever

To remove wheel guard, follow the installation proce-

dure in reverse.

When using a depressed center wheel,

4. Lever

Installing or removing depressed

center wheel or ap disc

Optional accessory

WARNING: When using a depressed center

wheel or ap disc, the wheel guard must be tted

on the tool so that the closed side of the guard

always points toward the operator.

CAUTION: Make sure that the mounting part

of the inner ange ts into the inner diameter of

the depressed center wheel / ap disc perfectly.

Mounting the inner ange on the wrong side may

result in the dangerous vibration.

Mount the inner ange onto the spindle.

Make sure to t the dented part of the inner ange onto

the straight part at the bottom of the spindle.

Fit the depressed center wheel / ap disc on the inner

ange and screw the lock nut onto the spindle.

► Fig.12: 1. Lock nut 2. Depressed center wheel

3. Inner ange 4. Mounting part

To tighten the lock nut, press the shaft lock rmly so

that the spindle cannot revolve, then use the lock nut

wrench and securely tighten clockwise.

► Fig.13: 1. Lock nut wrench 2. Shaft lock

To remove the wheel, follow the installation procedure

in reverse.

Installing or removing ex wheel

Optional accessory

WARNING: Always use supplied guard when

ex wheel is on tool. Wheel can shatter during use

and guard helps to reduce chances of personal injury.

► Fig.14: 1. Lock nut 2. Flex wheel 3. Back up pad

4. Inner ange

Follow instructions for depressed center wheel but also

use back up pad over wheel. See order of assembly on

accessories page in this manual.

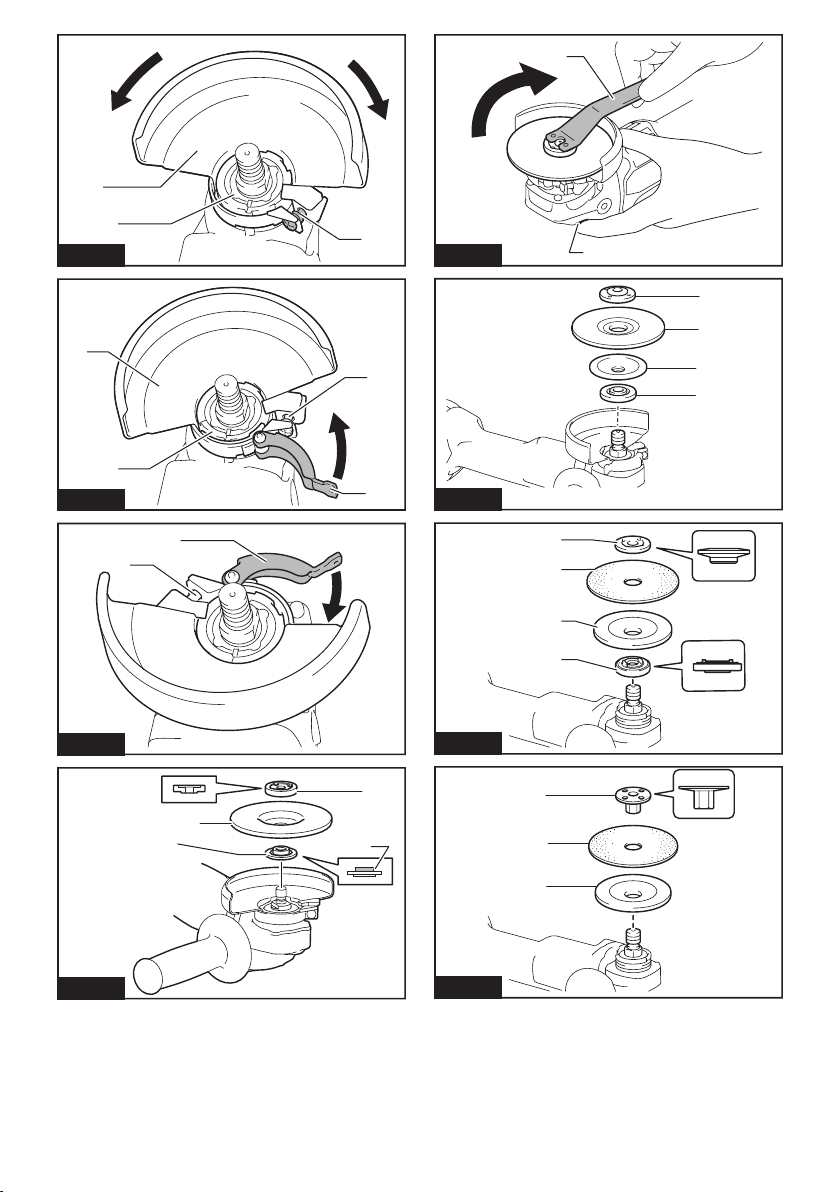

Installing or removing abrasive disc

Optional accessory

NOTE: Use sander accessories specied in this manual. These must be purchased separately.

For 100 mm (4″) model

► Fig.15: 1. Sanding lock nut 2. Abrasive disc

3. Rubber pad 4. Inner ange

1. Mount the inner ange onto the spindle.

2. Mount the rubber pad onto the spindle.

3. Fit the disc on the rubber pad and screw the sand-

ing lock nut onto the spindle.

4. Hold the spindle with the shaft lock, and securely

tighten the sanding lock nut clockwise with the lock nut

wrench.

To remove the disc, follow the installation procedure in

reverse.

17 ENGLISH

Page 18

For 115 mm (4 - 1/2″) / 125 mm (5″)

model

► Fig.16: 1. Sanding lock nut 2. Abrasive disc

3. Rubber pad

1. Mount the rubber pad onto the spindle.

2. Fit the disc on the rubber pad and screw the sand-

ing lock nut onto the spindle.

3. Hold the spindle with the shaft lock, and securely

tighten the sanding lock nut clockwise with the lock nut

wrench.

To remove the disc, follow the installation procedure in

reverse.

Connecting a vacuum cleaner

Optional accessory

WARNING: Never vacuum metal particles

created by grinding/cutting/sanding operation.

Metal particles created by such operation are so hot

that they ignite dust and the lter inside the vacuum

cleaner.

To avoid dusty environment caused by masonry cutting, use a dust collecting wheel guard and a vacuum

cleaner.

Refer to the instruction manual attached to the dust

collecting wheel guard for assembling and using it.

► Fig.17: 1. Dust collecting wheel guard 2. Hose of

the vacuum cleaner

OPERATION

WARNING: It should never be necessary to

force the tool. The weight of the tool applies ade-

quate pressure. Forcing and excessive pressure

could cause dangerous wheel breakage.

WARNING: ALWAYS replace wheel if tool is

dropped while grinding.

WARNING: NEVER bang or hit grinding disc

or wheel onto work.

WARNING: Avoid bouncing and snagging

the wheel, especially when working corners,

sharp edges etc. This can cause loss of control and

kickback.

WARNING: NEVER use tool with wood cutting

blades and other saw blades. Such blades when

used on a grinder frequently kick and cause loss of

control leading to personal injury.

CAUTION: Never switch on the tool when it

is in contact with the workpiece, it may cause an

injury to operator.

CAUTION: Always wear safety goggles or a

face shield during operation.

CAUTION: After operation, always switch off

the tool and wait until the wheel has come to a

complete stop before putting the tool down.

CAUTION: ALWAYS hold the tool rmly with

one hand on housing and the other on the side

grip (handle).

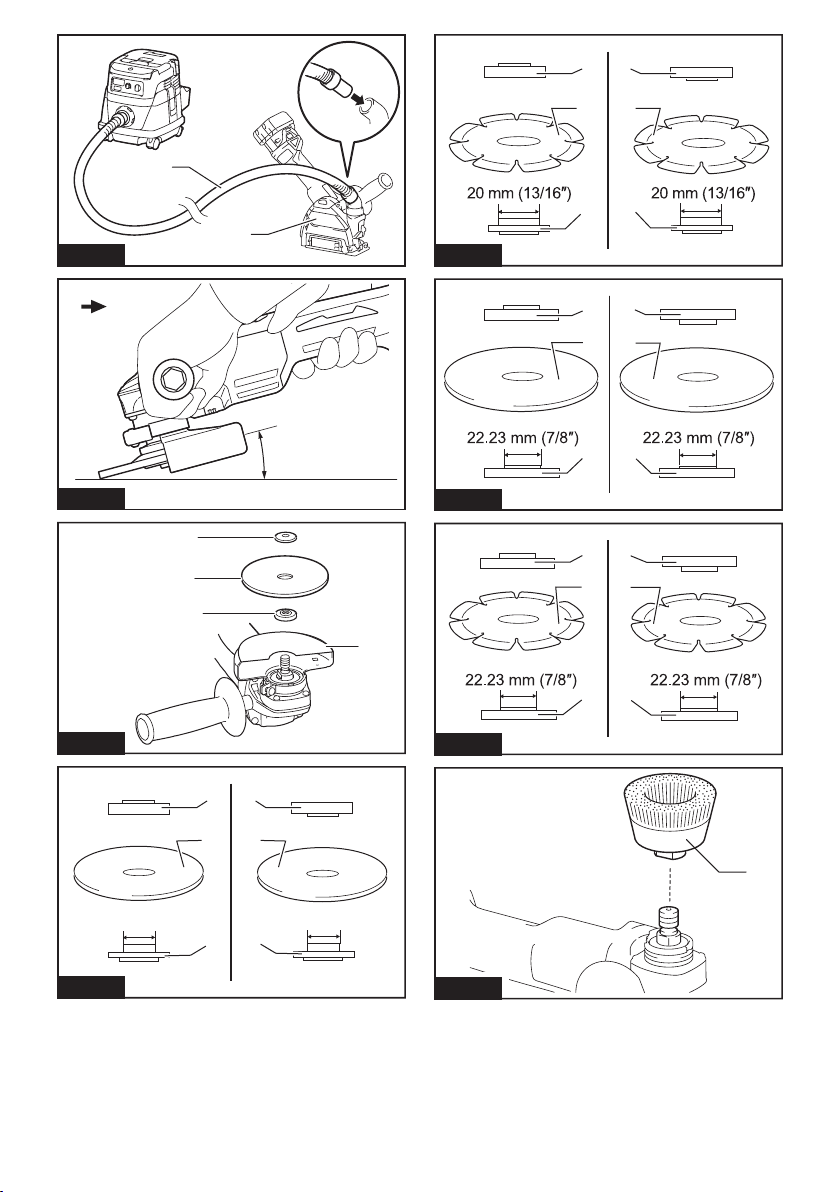

Grinding and sanding operation

► Fig.18

Turn the tool on and then apply the wheel or disc to the

workpiece.

In general, keep the edge of the wheel or disc at an

angle of about 15° to the workpiece surface.

During the break-in period with a new wheel, do not

work the grinder in forward direction or it may cut into

the workpiece. Once the edge of the wheel has been

rounded off by use, the wheel may be worked in both

forward and backward direction.

Operation with abrasive cut-off /

diamond wheel

Optional accessory

WARNING: When using an abrasive cut-off

/ diamond wheel, be sure to use only the special

wheel guard designed for use with cut-off wheels.

(In some European countries, when using a diamond

wheel, the ordinary guard can be used. Follow the

regulations in your country.)

WARNING: NEVER use cut-off wheel for side

grinding.

WARNING: Do not "jam" the wheel or apply

excessive pressure. Do not attempt to make an

excessive depth of cut. Overstressing the wheel

increases the loading and susceptibility to twisting

or binding of the wheel in the cut and the possibility

of kickback, wheel breakage and overheating of the

motor may occur.

WARNING: Do not start the cutting operation

in the workpiece. Let the wheel reach full speed

and carefully enter into the cut moving the tool

forward over the workpiece surface. The wheel

may bind, walk up or kickback if the power tool is

started in the workpiece.

WARNING: During cutting operations, never

change the angle of the wheel. Placing side pres-

sure on the cut-off wheel (as in grinding) will cause

the wheel to crack and break, causing serious per-

sonal injury.

WARNING: A diamond wheel shall be oper-

ated perpendicular to the material being cut.

18 ENGLISH

Page 19

► Fig.19: 1. Lock nut 2. Abrasive cut-off wheel / dia-

mond wheel 3. Inner ange 4. Wheel guard

for abrasive cut-off wheel / diamond wheel

As for the installation, follow the instructions for

depressed center wheel.

The direction for mounting the lock nut and the

inner ange varies by wheel type and thickness.

Refer to the following gures.

For 100 mm (4″) model

When installing the abrasive cut-off wheel:

► Fig.20: 1. Lock nut 2. Abrasive cut-off wheel

(Thinner than 4mm (5/32")) 3. Abrasive cutoff wheel (4mm (5/32") or thicker) 4. Inner

ange

When installing the diamond wheel:

► Fig.21: 1. Lock nut 2. Diamond wheel (Thinner

than 4mm (5/32″)) 3. Diamond wheel (4mm

(5/32″) or thicker) 4. Inner ange

For 115 mm (4 - 1/2″) / 125 mm (5″)

model

When installing the abrasive cut-off wheel:

► Fig.22: 1. Lock nut 2. Abrasive cut-off wheel

(Thinner than 4mm (5/32")) 3. Abrasive cutoff wheel (4mm (5/32") or thicker) 4. Inner

ange

When installing the diamond wheel:

► Fig.23: 1. Lock nut 2. Diamond wheel (Thinner

than 4mm (5/32″)) 3. Diamond wheel (4mm

(5/32″) or thicker) 4. Inner ange

Operation with wire cup brush

Optional accessory

CAUTION: Check operation of brush by run-

ning tool with no load, insuring that no one is in

front of or in line with brush.

CAUTION: Do not use brush that is damaged,

or which is out of balance. Use of damaged brush

could increase potential for injury from contact with

broken brush wires.

► Fig.24: 1. Wire cup brush

Remove the battery cartridge from the tool and place it

upside down allowing easy access to spindle.

Remove any accessories on spindle. Thread wire cup

brush onto spindle and tighten with supplied wrench.

NOTICE: Avoid applying too much pressure

which causes over bending of wires when using

brush. It may lead to premature breakage.

Operation with wire wheel brush

Optional accessory

CAUTION: Check operation of wire wheel

brush by running tool with no load, insuring that

no one is in front of or in line with the wire wheel

brush.

CAUTION: Do not use wire wheel brush that

is damaged, or which is out of balance. Use of

damaged wire wheel brush could increase potential

for injury from contact with broken wires.

CAUTION: ALWAYS use guard with wire

wheel brushes, assuring diameter of wheel ts

inside guard. Wheel can shatter during use and

guard helps to reduce chances of personal injury.

► Fig.25: 1. Wire wheel brush

Remove the battery cartridge from the tool and place it

upside down allowing easy access to spindle.

Remove any accessories on spindle. Thread wire wheel

brush onto spindle and tighten with the wrenches.

NOTICE: Avoid applying too much pressure

which causes over bending of wires when

using wire wheel brush. It may lead to premature

breakage.

WIRELESS ACTIVATION

FUNCTION

For DGA412/DGA414/DGA462/DGA464/DGA512/

DGA514 only

What you can do with the wireless

activation function

The wireless activation function enables clean and comfortable operation. By connecting a supported vacuum

cleaner to the tool, you can run the vacuum cleaner

automatically along with the switch operation of the tool.

► Fig.26

To use the wireless activation function, prepare following items:

• A wireless unit

• A vacuum cleaner which supports the wireless

activation function

The overview of the wireless activation function

setting is as follows. Refer to each section for detail

procedures.

1. Installing the wireless unit

2. Tool registration for the vacuum cleaner

3. Starting the wireless activation function

19 ENGLISH

Page 20

Installing the wireless unit

CAUTION: Place the tool on a at and stable

surface when installing the wireless unit.

NOTICE: Clean the dust and dirt on the tool

before installing the wireless unit. Dust or dirt

may cause malfunction if it comes into the slot of the

wireless unit.

NOTICE: To prevent the malfunction caused by

static, touch a static discharging material, such

as a metal part of the tool, before picking up the

wireless unit.

NOTICE: When installing the wireless unit,

always be sure that the wireless unit is inserted

in the correct direction and the lid is completely

closed.

1. Open the lid on the tool as shown in the gure.

► Fig.27: 1. Lid

2. Insert the wireless unit to the slot and then close

the lid.

When inserting the wireless unit, align the projections

with the recessed portions on the slot.

► Fig.28: 1. Wireless unit 2. Projection 3. Lid

4. Recessed portion

When removing the wireless unit, open the lid slowly.

The hooks on the back of the lid will lift the wireless unit

as you pull up the lid.

► Fig.29: 1. Wireless unit 2. Hook 3. Lid

After removing the wireless unit, keep it in the supplied

case or a static-free container.

NOTICE: Always use the hooks on the back of

the lid when removing the wireless unit. If the

hooks do not catch the wireless unit, close the lid

completely and open it slowly again.

Tool registration for the vacuum

cleaner

NOTE: A Makita vacuum cleaner supporting the

wireless activation function is required for the tool

registration.

NOTE: Finish installing the wireless unit to the tool

before starting the tool registration.

NOTE: During the tool registration, do not pull the

switch trigger or turn on the power switch on the

vacuum cleaner.

NOTE: Refer to the instruction manual of the vacuum

cleaner, too.

If you wish to activate the vacuum cleaner along with

the switch operation of the tool, nish the tool registra-

tion beforehand.

1. Install the batteries to the vacuum cleaner and the

tool.

2. Set the stand-by switch on the vacuum cleaner to

"AUTO".

► Fig.30: 1. Stand-by switch

3. Press the wireless activation button on the vac-

uum cleaner for 3 seconds until the wireless activation

lamp blinks in green. And then press the wireless activation button on the tool in the same way.

► Fig.31: 1. Wireless activation button 2. Wireless

If the vacuum cleaner and the tool are linked success-

fully, the wireless activation lamps will light up in green

for 2 seconds and start blinking in blue.

NOTE: The wireless activation lamps nish blinking

in green after 20 seconds elapsed. Press the wireless

activation button on the tool while the wireless activation lamp on the cleaner is blinking. If the wireless

activation lamp does not blink in green, push the wire-

less activation button briey and hold it down again.

NOTE: When performing two or more tool registra-

tions for one vacuum cleaner, nish the tool registration one by one.

activation lamp

Starting the wireless activation

function

NOTE: Finish the tool registration for the vacuum

cleaner prior to the wireless activation.

NOTE: Refer to the instruction manual of the vacuum

cleaner, too.

After registering a tool to the vacuum cleaner, the

vacuum cleaner will automatically runs along with the

switch operation of the tool.

1. Install the wireless unit to the tool.

Connect the hose of the vacuum cleaner with the tool.

2.

► Fig.32

3. Set the stand-by switch on the vacuum cleaner to

"AUTO".

► Fig.33: 1. Stand-by switch

4. Push the wireless activation button on the tool

briey. The wireless activation lamp will blink in blue.

► Fig.34: 1. Wireless activation button 2. Wireless

5. Pull the switch trigger of the tool. Check if the

vacuum cleaner runs while the switch trigger is being

pulled.

To stop the wireless activation of the vacuum cleaner,

push the wireless activation button on the tool.

NOTE: The wireless activation lamp on the tool will

stop blinking in blue when there is no operation for

2 hours. In this case, set the stand-by switch on the

vacuum cleaner to "AUTO" and push the wireless

activation button on the tool again.

NOTE: The vacuum cleaner starts/stops with a delay.

There is a time lag when the vacuum cleaner detects

a switch operation of the tool.

NOTE: The transmission distance of the wireless unit

may vary depending on the location and surrounding

circumstances.

NOTE: When two or more tools are registered to one

vacuum cleaner, the vacuum cleaner may start running even if you don't pull the switch trigger because

an other user is using the wireless activation function.

20 ENGLISH

activation lamp

Page 21

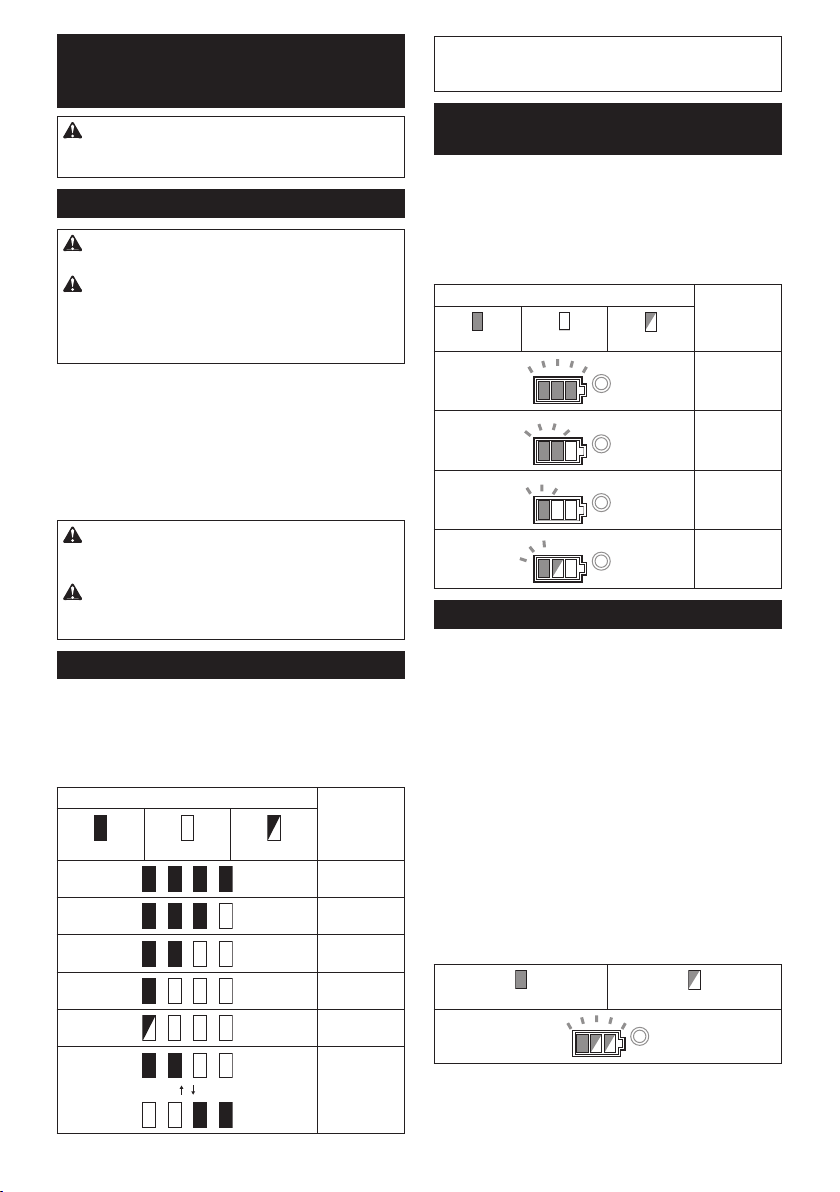

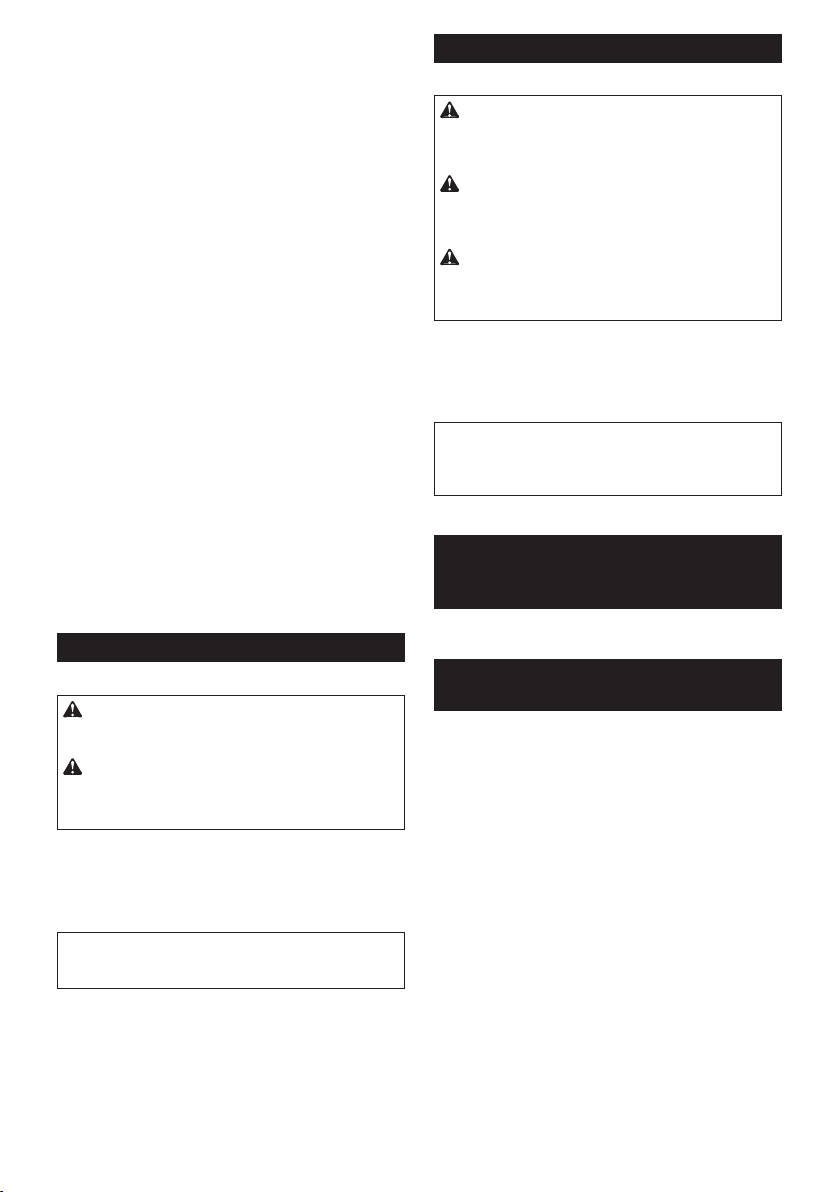

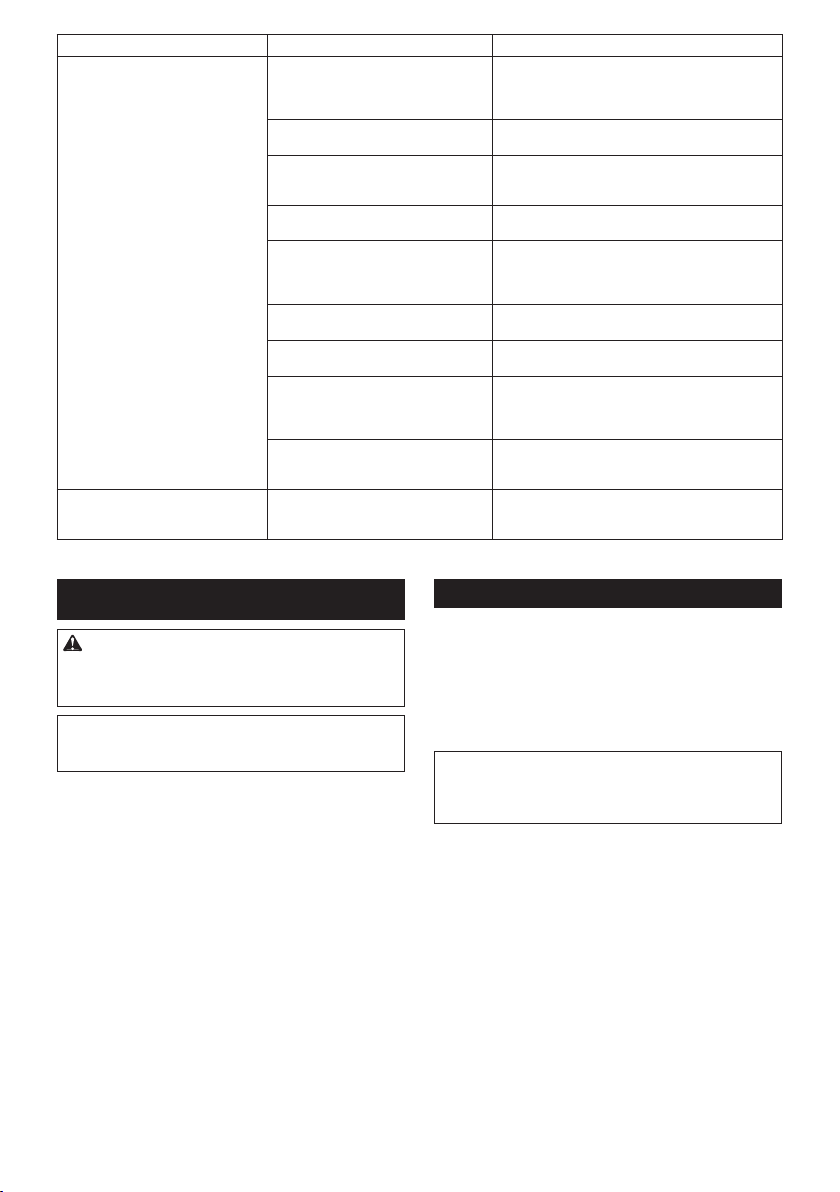

Description of the wireless activation lamp status

► Fig.35: 1. Wireless activation lamp

The wireless activation lamp shows the status of the wireless activation function. Refer to the table below for the

meaning of the lamp status.

Status Wireless activation lamp Description

Duration

2 hours The wireless activation of the vacuum cleaner is available. The

the tool is

running.

20 seconds Ready for the tool registration. Waiting for the registration by the

2 seconds The tool registration has been nished. The wireless activation

20 seconds Ready for the cancellation of the tool registration. Waiting for the

2 seconds The cancellation of the tool registration has been nished. The

3 seconds The power is supplied to the wireless unit and the wireless activa-

lamp will automatically turn off when no operation is performed

for 2 hours.

When

The wireless activation of the vacuum cleaner is available and the

tool is running.

vacuum cleaner.

lamp will start blinking in blue.

cancellation by the vacuum cleaner.

wireless activation lamp will start blinking in blue.

tion function is starting up.

Standby Blue

Tool

registration

Cancelling

tool

registration

Others Red

Color

Green

Red

Off - - The wireless activation of the vacuum cleaner is stopped.

On

Blinking

Cancelling tool registration for the

vacuum cleaner

Perform the following procedure when cancelling the

tool registration for the vacuum cleaner.

1. Install the batteries to the vacuum cleaner and the

tool.

2. Set the stand-by switch on the vacuum cleaner to

"AUTO".

► Fig.36: 1. Stand-by switch

3. Press the wireless activation button on the vac-

uum cleaner for 6 seconds. The wireless activation

lamp blinks in green and then become red. After that,

press the wireless activation button on the tool in the

same way.

► Fig.37: 1. Wireless activation button 2. Wireless

If the cancellation is performed successfully, the wire-

less activation lamps will light up in red for 2 seconds

and start blinking in blue.

NOTE: The wireless activation lamps nish blinking in

red after 20 seconds elapsed. Press the wireless activation button on the tool while the wireless activation

lamp on the cleaner is blinking. If the wireless activation lamp does not blink in red, push the wireless

activation button briey and hold it down again.

activation lamp

21 ENGLISH

Page 22

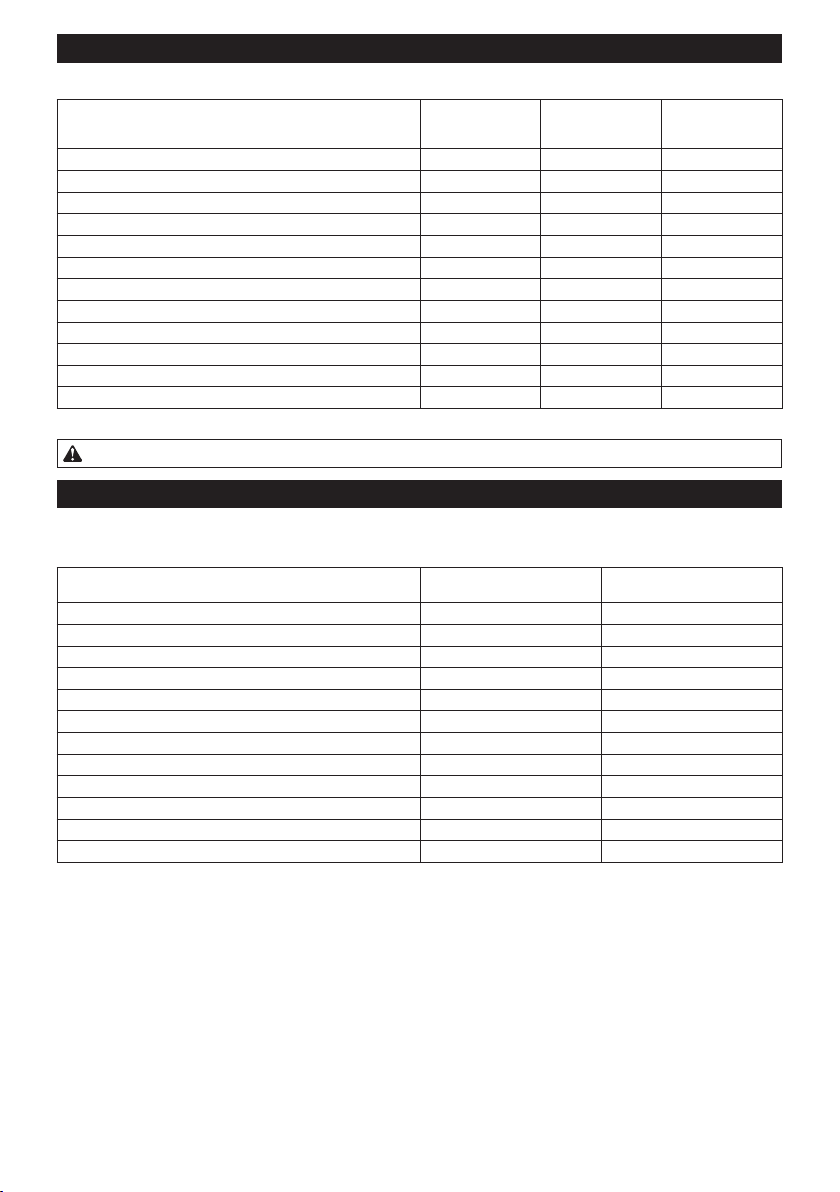

Troubleshooting for wireless activation function

Before asking for repairs, conduct your own inspection rst. If you nd a problem that is not explained in the manual,

do not attempt to dismantle the tool. Instead, ask Makita Authorized Service Centers, always using Makita replace-

ment parts for repairs.

State of abnormality Probable cause (malfunction) Remedy

The wireless activation lamp does

not light/blink.

Cannot nish tool registration / cancelling tool registration successfully.

The wireless unit is not installed into

the tool.

The wireless unit is improperly installed

into the tool.

The terminal of the wireless unit and/or

the slot is dirty.

The wireless activation button on the

tool has not been pushed.

The stand-by switch on the vacuum

cleaner is not set to "AUTO".

No power supply Supply the power to the tool and the vacuum

The wireless unit is not installed into

the tool.

The wireless unit is improperly installed

into the tool.

The terminal of the wireless unit and/or

the slot is dirty.

The stand-by switch on the vacuum

cleaner is not set to "AUTO".

No power supply Supply the power to the tool and the vacuum

Incorrect operation Push the wireless activation button briey and

The tool and vacuum cleaner is away

from each other (out of the transmission

range).

Before nishing the tool registration/

cancellation;

- the switch trigger on the tool is pulled

or;

- the power button on the vacuum

cleaner is turned on.

The tool registration procedures for the

tool or vacuum cleaner has not nished.

Radio disturbance by other appliances

which generate high-intensity radio

waves.

Install the wireless unit correctly.

Gently wipe off dust and dirt on the terminal of the

wireless unit and clean the slot.

Push the wireless activation button on the tool

briey.

Set the stand-by switch on the vacuum cleaner to

"AUTO".

cleaner.

Install the wireless unit correctly.

Gently wipe off dust and dirt on the terminal of the

wireless unit and clean the slot.

Set the stand-by switch on the vacuum cleaner to

"AUTO".

cleaner.

perform the tool registration/cancellation procedures

again.

Get the tool and vacuum cleaner closer to each

other. The maximum transmission distance is

approximately 10 m however it may vary according

to the circumstances.

Push the wireless activation button briey and

perform the tool registration/cancellation procedures

again.

Perform the tool registration procedures for both the

tool and the vacuum cleaner at the same timing.

Keep the tool and vacuum cleaner away from the

appliances such as Wi-Fi devices and microwave

ovens.

22 ENGLISH

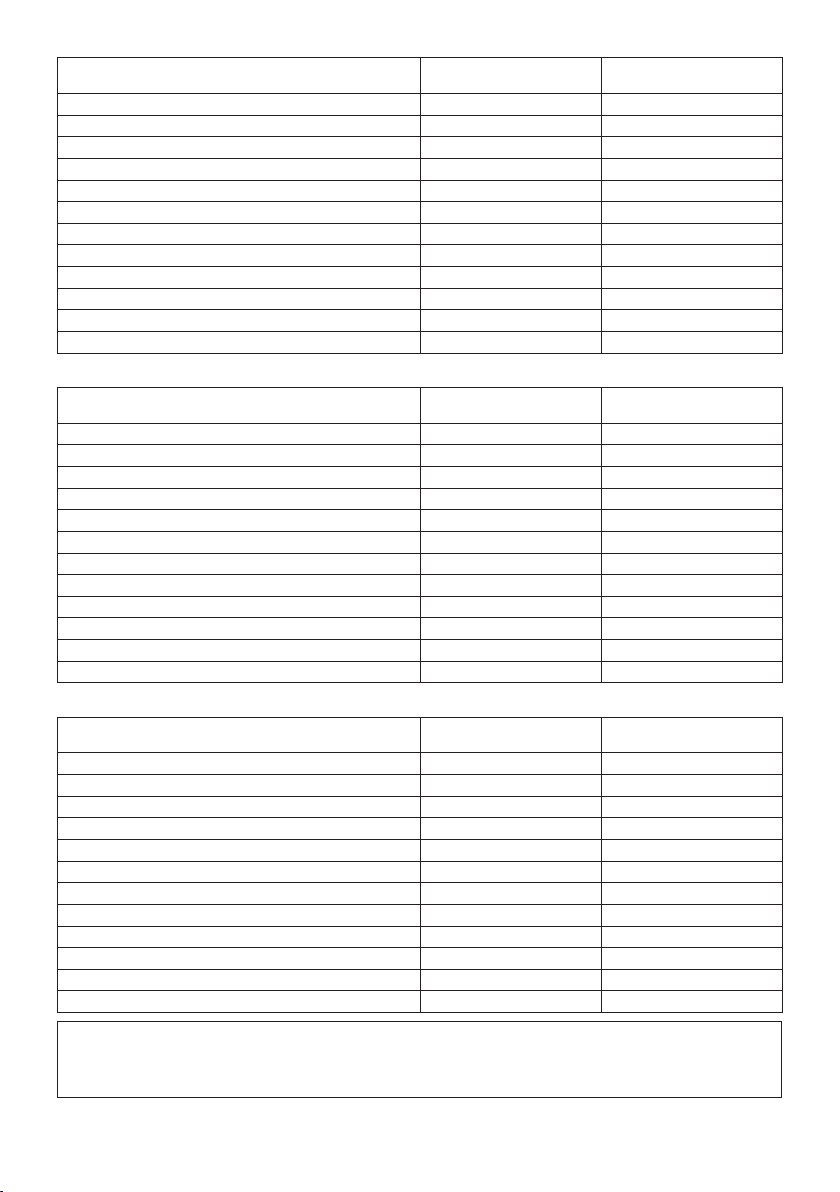

Page 23

State of abnormality Probable cause (malfunction) Remedy

The vacuum cleaner does not run

along with the switch operation of

the tool.

The vacuum cleaner runs while the

tool's switch trigger is not pulled.

The wireless unit is not installed into

the tool.

The wireless unit is improperly installed

into the tool.

The terminal of the wireless unit and/or

the slot is dirty.

The wireless activation button on the

tool has not been pushed.

The stand-by switch on the vacuum

cleaner is not set to "AUTO".

More than 10 tools are registered to the

vacuum cleaner.

The vacuum cleaner erased all tool

registrations.

No power supply Supply the power to the tool and the vacuum

The tool and vacuum cleaner is away

from each other (out of the transmission

range).

Radio disturbance by other appliances

which generate high-intensity radio

waves.

Other users are using the wireless

activation of the vacuum cleaner with

their tools.

Install the wireless unit correctly.

Gently wipe off dust and dirt on the terminal of the

wireless unit and clean the slot.

Push the wireless activation button briey and make

sure that the wireless activation lamp is blinking

in blue.

Set the stand-by switch on the vacuum cleaner to

"AUTO".

Perform the tool registration again.

If more than 10 tools are registered to the vacuum

cleaner, the tool registered earliest will be cancelled

automatically.

Perform the tool registration again.

cleaner.

Get the tool and vacuum cleaner closer each other.

The maximum transmission distance is approximately 10 m however it may vary according to the

circumstances.

Keep the tool and vacuum cleaner away from the

appliances such as Wi-Fi devices and microwave

ovens.

Turn off the wireless activation button of the other

tools or cancel the tool registration of the other

tools.

MAINTENANCE

CAUTION: Always be sure that the tool is

switched off and the battery cartridge is removed

before attempting to perform inspection or

maintenance.

NOTICE: Never use gasoline, benzine, thinner,

alcohol or the like. Discoloration, deformation or

cracks may result.

Air vent cleaning

The tool and its air vents have to be kept clean.

Regularly clean the tool's air vents or whenever the

vents start to become obstructed.

► Fig.38: 1. Exhaust vent 2. Inhalation vent

Remove the dust cover from inhalation vent and clean it

for smooth air circulation.

► Fig.39: 1. Dust cover

NOTICE: Clean out the dust cover when it is

clogged with dust or foreign matters. Continuing

operation with a clogged dust cover may damage the

tool.

23 ENGLISH

Page 24

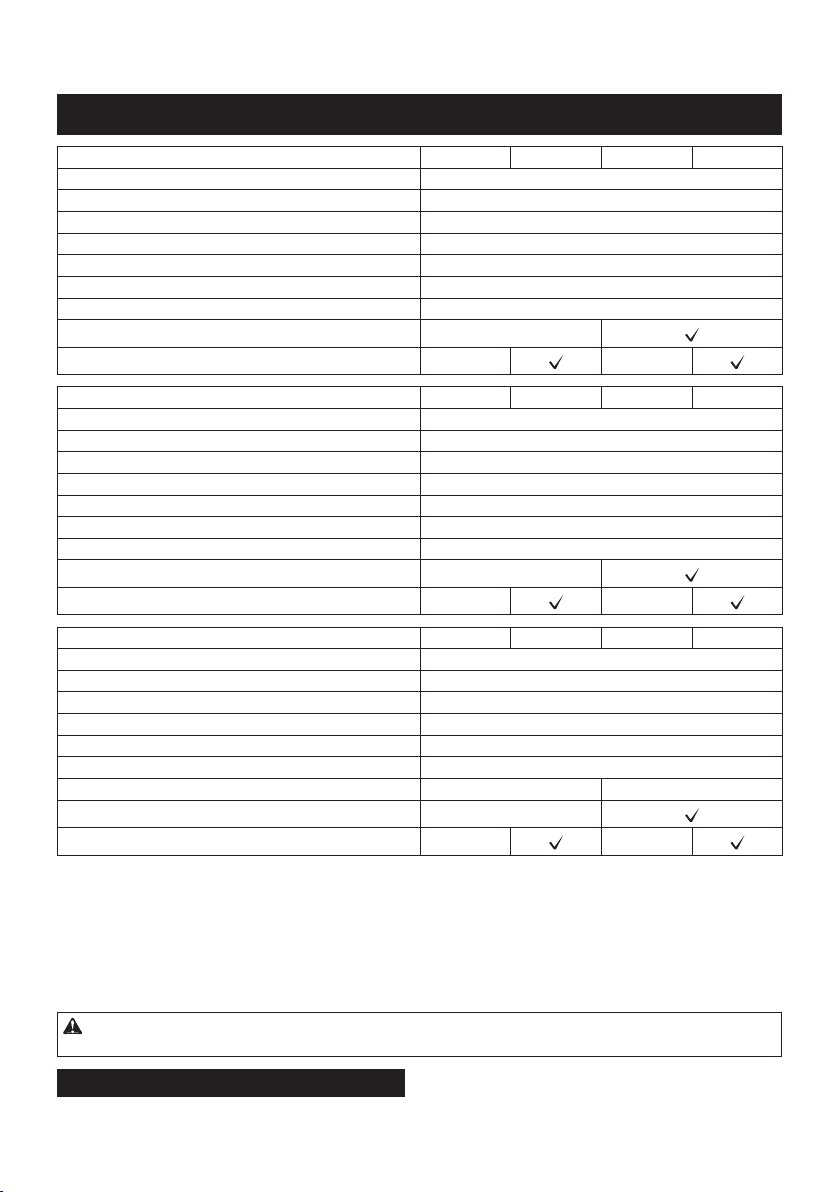

OPTIONAL ACCESSORIES

CAUTION: These accessories or attachments are recommended for use with your Makita tool spec-

ied in this manual. The use of any other accessories or attachments might present a risk of injury to persons.

Only use accessory or attachment for its stated purpose.

If you need any assistance for more details regarding these accessories, ask your local Makita Service Center.

• Makita genuine battery and charger

• Wireless unit (For models with wireless activation function)

► Fig.40

- 100 mm (4″) model 115 mm (4-1/2″) model 125 mm (5″) model

1 Grip 36

2 Wheel Guard (for grinding wheel)

3 Inner ange

4 Depressed center wheel / Flap disc

5 Lock nut

6 Back up pad

7 Flex wheel

8 Inner ange and rubber pad 76 Rubber pad 100 Rubber pad 115

9 Abrasive disc

10 Sanding lock nut

11 Wire wheel brush

12 Wire cup brush

13 Wheel Guard (for cut-off wheel) *1

14 Abrasive cut-off wheel / Diamond wheel

15 Dust collecting wheel guard

- Lock nut wrench

NOTE: *1 In some European countries, when using a diamond wheel, the ordinary guard can be used instead of the

special guard covering the both side of the wheel. Follow the regulations in your country.

NOTE: Some items in the list may be included in the tool package as standard accessories. They may differ from

country to country.

24 ENGLISH

Page 25

FRANÇAIS (Instructions originales)

SPÉCIFICATIONS

Modèle : DGA411 DGA412 DGA413 DGA414

Diamètre de meule 100 mm (4″)

Épaisseur max. de la meule 6,4 mm

Filetage de l’axe M10

Vitesse nominale (n) 8 500 min

Longueur totale 382 mm

Tension nominale 18 V CC

Poids net 2,2 à 2,8 kg

Frein électrique -

Fonction d’activation sans l - -

Modèle : DGA461 DGA462 DGA463 DGA464

Diamètre de meule 115 mm (4-1/2″)

Épaisseur max. de la meule 7,2 mm

Filetage de l’axe M14 ou 5/8″ (selon le pays)

Vitesse nominale (n) 8 500 min

Longueur totale 382 mm

Tension nominale 18 V CC

Poids net 2,3 à 3,0 kg

Frein électrique -

Fonction d’activation sans l - -

-1

-1

Modèle : DGA511 DGA512 DGA513 DGA514

Diamètre de meule 125 mm (5″)

Épaisseur max. de la meule 7,2 mm

Filetage de l’axe M14 ou 5/8″ (selon le pays)

Vitesse nominale (n) 8 500 min

Longueur totale 382 mm

Tension nominale 18 V CC

Poids net 2,3 à 3,0 kg 2,4 à 3,0 kg

Frein électrique -

Fonction d’activation sans l - -

-1

• Étant donné l’évolution constante de notre programme de recherche et de développement, les spécications

contenues dans ce manuel sont sujettes à modication sans préavis.

• Les spécications peuvent varier suivant les pays.

• Le poids peut être différent selon les accessoires, notamment la batterie. Les associations la plus légère et la

plus lourde, conformément à la procédure EPTA 01/2014, sont indiquées dans le tableau.

Batterie applicable

BL1815N / BL1820 / BL1820B / BL1830 / BL1830B / BL1840 / BL1840B / BL1850 / BL1850B / BL1860B

• Certaines batteries répertoriées ci-dessus peuvent ne pas être disponibles selon la région où vous résidez.

AVERTISSEMENT : N’utilisez que les batteries répertoriées ci-dessus. L’utilisation de n’importe quelle

autre batterie peut provoquer des blessures et/ou un incendie.

Utilisations

L’outil est conçu pour le meulage, le ponçage et la coupe

de matériaux en métal ou en pierre sans utiliser d’eau.

25 FRANÇAIS

Page 26

Bruit

Niveau de bruit pondéré A typique, déterminé selon EN60745 :

Modèle

DGA411 80 - 3

DGA412 80 - 3

DGA413 80 - 3

DGA414 80 - 3

DGA461 79 - 3

DGA462 79 - 3

DGA463 79 - 3

DGA464 79 - 3

DGA511 79 - 3

DGA512 79 - 3

DGA513 79 - 3

DGA514 79 - 3

Niveau de pression

sonore (L

) : (dB (A))

pA

sance sonore (LWA)

Le niveau de bruit en fonctionnement peut dépasser 80 dB (A).

AVERTISSEMENT : Portez un serre-tête antibruit.

Vibrations

Valeur totale de vibrations (somme de vecteur triaxial) déterminée selon EN60745 :

Mode de travail : meulage de surfaces avec poignée latérale normale

Modèle

DGA411 4,5 1,5

DGA412 4,5 1,5

DGA413 4,5 1,5

DGA414 4,5 1,5

DGA461 6,5 1,5

DGA462 6,5 1,5

DGA463 6,5 1,5

DGA464 6,5 1,5

DGA511 6,5 1,5

DGA512 6,5 1,5

DGA513 6,5 1,5

DGA514 6,5 1,5

Émission de vibrations (ah, AG) :

(m/s

2

)

Niveau de puis-

: (dB (A))

Incertitude (K) :

(dB (A))

Incertitude (K) : (m/s2)

26 FRANÇAIS

Page 27

Mode de travail : meulage de surfaces avec poignée latérale anti-vibration

Modèle

DGA411 4,0 1,5

DGA412 4,0 1,5

DGA413 4,0 1,5

DGA414 4,0 1,5

DGA461 6,0 1,5

DGA462 6,0 1,5

DGA463 6,0 1,5

DGA464 6,0 1,5

DGA511 6,0 1,5

DGA512 6,0 1,5

DGA513 6,0 1,5

DGA514 6,0 1,5

Émission de vibrations (ah, AG) :

(m/s

2

)

Incertitude (K) : (m/s2)

Mode de travail : ponçage au disque avec poignée latérale normale

Modèle

DGA411 2,5 m/s2 ou moins 1,5

DGA412 2,5 m/s2 ou moins 1,5

DGA413 2,5 m/s2 ou moins 1,5

DGA414 2,5 m/s2 ou moins 1,5

DGA461 2,5 m/s2 ou moins 1,5

DGA462 2,5 m/s2 ou moins 1,5

DGA463 2,5 m/s2 ou moins 1,5

DGA464 2,5 m/s2 ou moins 1,5

DGA511 2,5 m/s2 ou moins 1,5

DGA512 2,5 m/s2 ou moins 1,5

DGA513 2,5 m/s2 ou moins 1,5

DGA514 2,5 m/s2 ou moins 1,5

Émission de vibrations (a

(m/s

2

)

h, DS

) :

Incertitude (K) : (m/s2)

Mode de travail : ponçage au disque avec poignée latérale anti-vibration

Modèle

DGA411 2,5 m/s2 ou moins 1,5

DGA412 2,5 m/s2 ou moins 1,5

DGA413 2,5 m/s2 ou moins 1,5

DGA414 2,5 m/s2 ou moins 1,5

DGA461 2,5 m/s2 ou moins 1,5

DGA462 2,5 m/s2 ou moins 1,5

DGA463 2,5 m/s2 ou moins 1,5

DGA464 2,5 m/s2 ou moins 1,5

DGA511 2,5 m/s2 ou moins 1,5

DGA512 2,5 m/s2 ou moins 1,5

DGA513 2,5 m/s2 ou moins 1,5

DGA514 2,5 m/s2 ou moins 1,5

Émission de vibrations (a

(m/s

2

)

h, DS

) :

Incertitude (K) : (m/s2)

NOTE : La valeur d’émission de vibrations déclarée a été mesurée conformément à la méthode de test standard

et peut être utilisée pour comparer les outils entre eux.

NOTE : La valeur d’émission de vibrations déclarée peut aussi être utilisée pour l’évaluation préliminaire de

l’exposition.

27 FRANÇAIS

Page 28

AVERTISSEMENT : L’émission de vibrations lors de l’usage réel de l’outil électrique peut être différente de

la valeur d’émission déclarée, suivant la façon dont l’outil est utilisé.

AVERTISSEMENT : Les mesures de sécurité à prendre pour protéger l’utilisateur doivent être basées sur

une estimation de l’exposition dans des conditions réelles d’utilisation (en tenant compte de toutes les compo-

santes du cycle d’utilisation, comme par exemple le moment de sa mise hors tension, lorsqu’il tourne à vide et le

moment de son déclenchement).

AVERTISSEMENT : La valeur d’émission de vibrations déclarée est utilisée pour les applications principales

de l’outil électrique. Toutefois si l’outil électrique est utilisé pour d’autres applications, la valeur d’émission de

vibrations peut être différente.

Déclaration de conformité CE

Pour les pays européens uniquement

La déclaration de conformité CE est fournie en Annexe

A à ce mode d’emploi.

CONSIGNES DE

SÉCURITÉ

Consignes de sécurité générales

pour outils électriques

AVERTISSEMENT :

de sécurité, instructions, illustrations et spécications

qui accompagnent cet outil électrique. Le non-respect de

toutes les instructions indiquées ci-dessous peut entraîner

une électrocution, un incendie et/ou de graves blessures.

Conservez toutes les mises en

garde et instructions pour référence ultérieure.

Le terme « outil électrique » dans les avertissements

fait référence à l’outil électrique alimenté par le secteur

(avec cordon d’alimentation) ou à l’outil électrique fonctionnant sur batterie (sans cordon d’alimentation).

Consignes de sécurité pour

meuleuse sans l

Consignes de sécurité communes aux travaux de meulage,

ponçage, brossage métallique ou tronçonnage abrasif :

1.

Cet outil électrique est conçu pour être utilisé

en tant que meuleuse, ponceuse, brosse métallique ou outil de tronçonnage. Veuillez lire les

consignes de sécurité, instructions, illustrations

et spécications qui accompagnent cet outil

électrique. Le non-respect de toutes les instructions indiquées ci-dessous peut entraîner une électrocution, un incendie et/ou de graves blessures.

2.

Il est déconseillé d’effectuer des travaux de polissage avec cet outil électrique. Il y a risque de danger

et de blessure si l’outil électrique est utilisé pour exécuter des travaux pour lesquels il n’a pas été conçu.

3. N’utilisez pas d’accessoires qui n’ont pas été

conçus spéciquement et recommandés par le

fabricant de l’outil. Même si un accessoire peut

être xé sur l’outil électrique, cela ne garantit pas

qu’il fonctionnera de manière sûre.

Veuillez lire les consignes

4. La vitesse nominale de l’accessoire doit être

au moins égale à la vitesse maximum inscrite

sur l’outil électrique. Les accessoires tournant

plus vite que leur vitesse nominale peuvent se

casser et voler en éclats.

5. Le diamètre extérieur et l’épaisseur de l’ac-

cessoire ne doivent pas dépasser la capacité

nominale de l’outil électrique. Les accessoires

de taille incorrecte ne peuvent être protégés ou

contrôlés adéquatement.

6. Le letage des accessoires à monter doit

correspondre à celui de l’axe de la meuleuse.

Pour les accessoires montés à l’aide de

asques, la taille de l’alésage de l’accessoire

doit correspondre au diamètre du asque.

Les accessoires qui ne sont pas bien adaptés à

la taille de la pièce où ils sont montés sur l’outil

électrique se déséquilibreront, vibreront trop et

pourront entraîner une perte de maîtrise de l’outil.

7.

N’utilisez jamais un accessoire endommagé.

Avant chaque utilisation, assurez-vous que la

meule abrasive est exempte de copeaux et ssures, que la semelle n’est pas ssurée, déchi-

rée ou trop usée, ou que la brosse métallique est

exempte de ls métalliques lâches ou cassés. Si

vous lâchez l’outil électrique ou un accessoire,

assurez-vous qu’il n’est pas endommagé ou bien

remplacez l’accessoire endommagé. Après avoir

vérié et posé un accessoire, assurez-vous que

personne, y compris vous-même, ne se trouve

dans la trajectoire de l’accessoire en rotation et

faites tourner l’outil électrique à vitesse à vide

maximale pendant une minute. Les accessoires

endommagés se brisent généralement au cours de

cette période d’essai.

8.

Portez un équipement de protection individuelle.

Suivant le type de travail à effectuer, utilisez

un écran facial, des lunettes à coques ou des

lunettes de sécurité. Si nécessaire, portez un

masque anti-poussière, des protège-tympans,

des gants et un tablier de travail pouvant arrêter

les particules abrasives ou les fragments de

pièce. La protection oculaire doit pouvoir arrêter les

débris volants produits par les diverses opérations.

Le masque anti-poussières ou le masque ltrant doit

pouvoir ltrer les particules générées lors des tra-

vaux. Une exposition prolongée à un bruit d’intensité

élevée peut entraîner une perte auditive.

9. Assurez-vous que les passants demeurent à

une distance sûre de la zone de travail. Toute

personne pénétrant dans la zone de travail

doit porter un équipement de protection individuelle. Des fragments de pièce ou un accessoire

cassé peuvent être éjectés et blesser les personnes au-delà de la zone immédiate de travail.

28 FRANÇAIS

Page 29

10. Tenez l’outil électrique uniquement par ses

surfaces de prise isolées, lors d’une opération au cours de laquelle l’outil de coupe peut

entrer en contact avec un l caché. Le contact

avec un l « sous tension » mettra également «

sous tension » les parties métalliques exposées

de l’outil électrique, pouvant ainsi causer un choc

électrique chez l’utilisateur.

11. Ne déposez jamais l’outil électrique avant que

l’accessoire ne se soit parfaitement arrêté.

L’accessoire en rotation peut accrocher la surface

et projeter l’outil électrique de telle sorte que vous

en perdiez la maîtrise.

12. Ne transportez pas l’outil électrique tout en le

laissant tourner. En cas de contact accidentel

avec l’accessoire en rotation, ce dernier risque

d’accrocher vos vêtements et d’être entraîné vers

votre corps.

13. Nettoyez régulièrement les orices d’aération

de l’outil électrique. Le ventilateur du moteur

aspire la poussière à l’intérieur du carter, ce qui

présente un danger électrique en cas d’accumulation excessive de poussières métalliques.

14. N’utilisez pas l’outil électrique près de maté-

riaux inammables. Les étincelles risqueraient

d’enammer ces matériaux.

15. N’utilisez pas d’accessoires nécessitant un

liquide de refroidissement. L’utilisation d’eau

ou d’un liquide de refroidissement comporte un

risque d’électrocution ou de choc électrique.

Mises en garde concernant le choc en retour et

autres dangers

Le choc en retour est une réaction soudaine qui survient lorsque la meule, la semelle, la brosse ou un autre

accessoire en rotation se coince ou accroche. Lorsque

l’accessoire en rotation se coince ou accroche, il s’ar-

rête soudainement et l’utilisateur perd alors la maîtrise

de l’outil électrique projeté dans le sens contraire de sa

rotation au point où il se coince dans la pièce.

Par exemple, si une meule abrasive accroche ou se

coince dans la pièce, son tranchant introduit au point

de pincement risque d’y creuser la surface du matériau,

entraînant la sortie ou le déchaussement de la meule.

La meule peut alors dévier de sa trajectoire, vers l’utilisateur ou dans le sens opposé, selon la direction du

mouvement de la meule au point de pincement. Dans

ces conditions, la meule abrasive risque également de

se briser.

Le choc en retour est le résultat d’une utilisation

incorrecte de l’outil électrique et/ou de l’inobservation

des procédures ou conditions d’utilisation. Il peut être

évité en prenant les précautions adéquates indiquées

ci-dessous.

1. Maintenez une poigne ferme sur l’outil élec-