Page 1

INSTRUCTION MANUAL

MANUEL D'INSTRUCTION

MANUAL DE INSTRUCCIONES

Cordless Screwdriver

Visseuse sans Fil

Atornillador Inalámbrico

DFT022F

DFT044F

DFT084F

DFT126F

IMPORTANT: Read Before Using.

IMPORTANT : Lire avant usage.

IMPORTANTE: Lea antes de usar.

Page 2

ENGLISH (Original instructions)

SPECIFICATIONS

Model DFT022F DFT044F DFT084F DFT126F

Fastening torque Hard joint 0.5 - 2 N·m

Soft joint 0.5 - 2 N·m

No load speed (RPM) 700 /min 950 /min 780 /min 410 /min

Dimensions 200 x 74 x 250 mm (7-7/8" x 2-15/16" x 9-7/8") (with Battery Cartridge BL1430B)

Net weight 1.5 kg (3.4 lbs) (with Battery Cartridge BL1430B)

Rated voltage D.C. 14.4 V

Battery cartridge BL1415NA / BL1430 / BL1430B / BL1460A

(4 - 18 in·lbs)

(4 - 18 in·lbs)

200 x 74 x 235 mm (7-7/8" x 2-15/16" x 9-1/4") (with Battery Cartridge BL1415NA)

• Due to our continuing program of research and development, the specications herein are subject to change without notice.

• Specications and battery cartridge may differ from country to country.

• Weight, with battery cartridge, according to EPTA-Procedure 01/2003

General Power Tool Safety Warnings

WARNING Read all safety warnings and all instruc-

tions. Failure to follow the warnings and instructions may

result in electric shock, re and/or serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to your

mains-operated (corded) power tool or battery-operated

(cordless) power tool.

Work area safety

1. Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

2. Do not operate power tools in explosive atmo-

spheres, such as in the presence of ammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

3. Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

Electrical safety

4.

Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs with

earthed (grounded) power tools. Unmodied plugs and

matching outlets will reduce risk of electric shock.

5. Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of elec-

tric shock if your body is earthed or grounded.

6. Do not expose power tools to rain or wet con-

ditions. Water entering a power tool will increase

the risk of electric shock.

7. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges

or moving parts. Damaged or entangled cords

increase the risk of electric shock.

1 - 4 N·m

(8.9 - 35 in·lbs)

1 - 4 N·m

(8.9 - 35 in·lbs)

1.4 kg (3.0 lbs) (with Battery Cartridge BL1415NA)

8.

When operating a power tool outdoors, use an exten-

3 - 8 N·m

(27 - 71 in·lbs)

3 - 8 N·m

(27 - 71 in·lbs)

5 - 12 N·m

(44 - 106 in·lbs)

5 - 12 N·m

(44 - 106 in·lbs)

sion cord suitable for outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

9. If operating a power tool in a damp location is

unavoidable, use a ground fault circuit interrupter (GFCI) protected supply. Use of an GFCI

reduces the risk of electric shock.

Personal safety

10. Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired or

under the inuence of drugs, alcohol or medication. A moment of inattention while operating

power tools may result in serious personal injury.

11.

Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask, non-

skid safety shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

12. Prevent unintentional starting. Ensure the

switch is in the off-position before connecting

to power source and/or battery pack, picking

up or carrying the tool. Carrying power tools with

your nger on the switch or energising power tools

that have the switch on invites accidents.

13. Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

14. Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

15. Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing, and gloves

away from moving parts. Loose clothes, jewel-

lery or long hair can be caught in moving parts.

16. If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

dust collection can reduce dust-related hazards.

2 ENGLISH

Page 3

Power tool use and care

17. Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at the

rate for which it was designed.

18. Do not use the power tool if the switch does

not turn it on and off. Any power tool that cannot

be controlled with the switch is dangerous and

must be repaired.

19. Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such pre-

ventive safety measures reduce the risk of starting

the power tool accidentally.

20. Store idle power tools out of the reach of chil-

dren and do not allow persons unfamiliar with

the power tool or these instructions to operate

the power tool. Power tools are dangerous in the

hands of untrained users.

21. Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts

and any other condition that may affect the

power tool’s operation. If damaged, have the

power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

22. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

23. Use the power tool, accessories and tool bits

etc. in accordance with these instructions, taking into account the working conditions and

the work to be performed. Use of the power tool

for operations different from those intended could

result in a hazardous situation.

Battery tool use and care

24. Recharge only with the charger specied by

the manufacturer. A charger that is suitable for

one type of battery pack may create a risk of re

when used with another battery pack.

25. Use power tools only with specically desig-

nated battery packs. Use of any other battery

packs may create a risk of injury and re.

26. When battery pack is not in use, keep it away

from other metal objects, like paper clips,

coins, keys, nails, screws or other small metal

objects, that can make a connection from one

terminal to another. Shorting the battery termi-

nals together may cause burns or a re.

27. Under abusive conditions, liquid may be

ejected from the battery; avoid contact. If con-

tact accidentally occurs, ush with water. If

liquid contacts eyes, additionally seek medical

help. Liquid ejected from the battery may cause

irritation or burns.

Service

28. Have your power tool serviced by a qualied

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

29. Follow instruction for lubricating and chang-

ing accessories.

30. Keep handles dry, clean and free from oil and

grease.

CORDLESS SCREWDRIVER

SAFETY WARNINGS

1. Hold power tool by insulated gripping surfaces, when performing an operation where

the fastener may contact hidden wiring.

Fasteners contacting a "live" wire may make

exposed metal parts of the power tool "live" and

could give the operator an electric shock.

2. Always be sure you have a rm footing.

Be sure no one is below when using the tool in

high locations.

3. Hold the tool rmly.

4. Keep hands away from rotating parts.

5. Do not touch the bit or the workpiece immedi-

ately after operation; they may be extremely

hot and could burn your skin.

SAVE THESE INSTRUCTIONS.

WARNING: DO NOT let comfort or famil-

iarity with product (gained from repeated

use) replace strict adherence to safety

rules for the subject product. MISUSE or

failure to follow the safety rules stated in

this instruction manual may cause serious

personal injury.

Symbols

The followings show the symbols used for tool.

volts

direct current

no load speed

revolutions or reciprocation per minute

IMPORTANT SAFETY

INSTRUCTIONS

FOR BATTERY CARTRIDGE

1.

Before using battery cartridge, read all instructions and cautionary markings on (1) battery

charger, (2) battery, and (3) product using battery.

2. Do not disassemble battery cartridge.

3. If operating time has become excessively

shorter, stop operating immediately. It may

result in a risk of overheating, possible burns

and even an explosion.

4. If electrolyte gets into your eyes, rinse them

out with clear water and seek medical attention right away. It may result in loss of your

eyesight.

5. Do not short the battery cartridge:

(1) Do not touch the terminals with any con-

ductive material.

3 ENGLISH

Page 4

(2) Avoid storing battery cartridge in a con-

3

tainer with other metal objects such as

nails, coins, etc.

(3) Do not expose battery cartridge to water

or rain.

A battery short can cause a large current

ow, overheating, possible burns and even a

breakdown.

6. Do not store the tool and battery cartridge in

locations where the temperature may reach or

exceed 50°C (122°F).

7. Do not incinerate the battery cartridge even if

it is severely damaged or is completely worn

out. The battery cartridge can explode in a re.

8. Be careful not to drop or strike battery.

9. Do not use a damaged battery.

10. The contained lithium-ion batteries are subject

to the Dangerous Goods Legislation requirements.

For commercial transports e.g. by third parties,

forwarding agents, special requirement on pack-

aging and labeling must be observed.

For preparation of the item being shipped, consulting an expert for hazardous material is required.

Please also observe possibly more detailed

national regulations.

Tape or mask off open contacts and pack up the

battery in such a manner that it cannot move

around in the packaging.

11. Follow your local regulations relating to dis-

posal of battery.

SAVE THESE INSTRUCTIONS.

CAUTION: Only use genuine Makita batteries.

Use of non-genuine Makita batteries, or batteries that

have been altered, may result in the battery bursting causing res, personal injury and damage. It will

also void the Makita warranty for the Makita tool and

charger.

Tips for maintaining maximum

battery life

1. Charge the battery cartridge before completely

discharged.

Always stop tool operation and charge the battery cartridge when you notice less tool power.

2. Never recharge a fully charged battery cartridge.

Overcharging shortens the battery service life.

3. Charge the battery cartridge with room temperature at 10°C - 40°C (50°F - 104°F). Let a hot

battery cartridge cool down before charging it.

4. Charge the battery cartridge if you do not use

it for a long period (more than six months).

FUNCTIONAL

DESCRIPTION

CAUTION:

• Always be sure that the tool is switched off and

the battery cartridge is removed before adjusting or checking function on the tool.

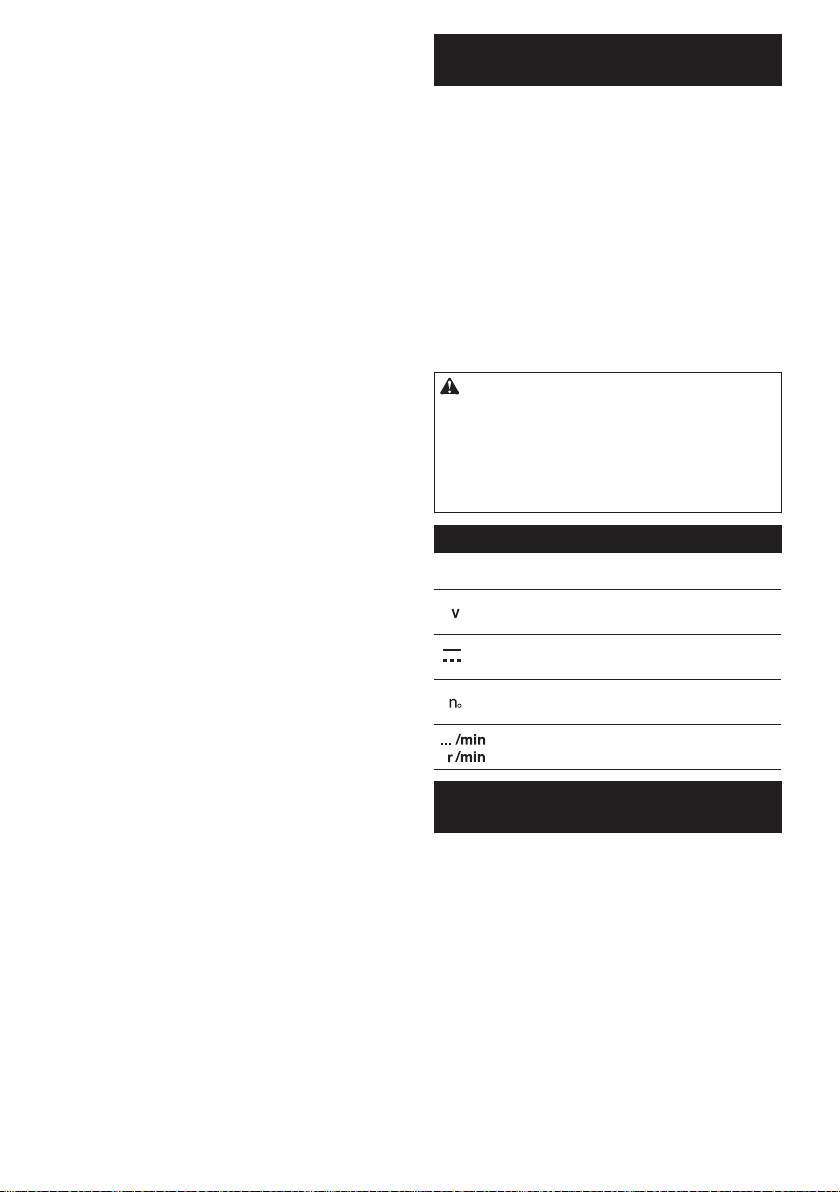

Installing or removing battery

cartridge

1

2

► 1. Red indicator 2. Button 3. Battery cartridge

CAUTION:

• Always switch off the tool before installing or

removing of the battery cartridge.

• Hold the tool and the battery cartridge rmly

when installing or removing battery cartridge. Failure to hold the tool and the battery

cartridge rmly may cause them to slip off your

hands and result in damage to the tool and

battery cartridge and a personal injury.

To remove the battery cartridge, slide it from the tool

while sliding the button on the front of the cartridge.

To install the battery cartridge, align the tongue on the

battery cartridge with the groove in the housing and slip

it into place. Insert it all the way until it locks in place

with a little click. If you can see the red indicator on the

upper side of the button, it is not locked completely.

CAUTION:

• Always install the battery cartridge fully until the

red indicator cannot be seen. If not, it may accidentally fall out of the tool, causing injury to you

or someone around you.

• Do not install the battery cartridge forcibly. If the

cartridge does not slide in easily, it is not being

inserted correctly.

4 ENGLISH

Page 5

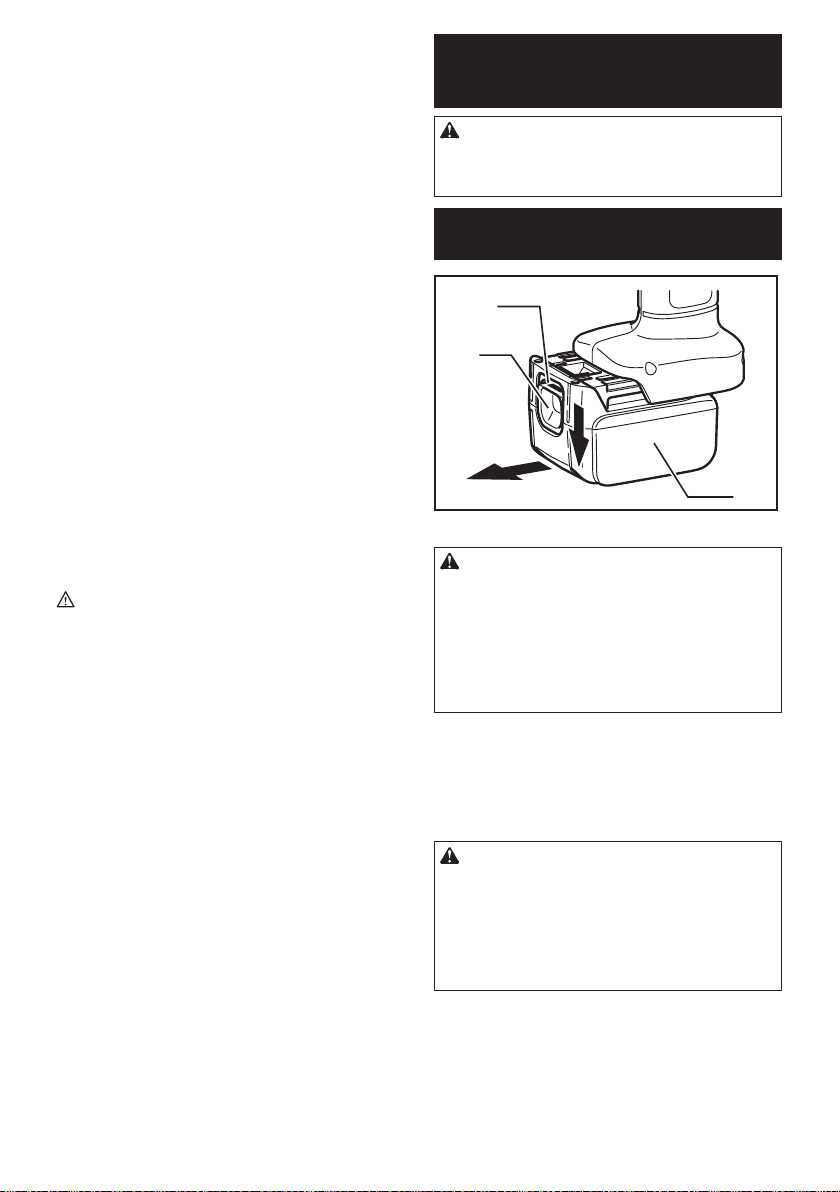

Checking the remaining battery

AB

capacity (BL1460A)

70%-100%

1

50%-70%

35%-50%

If the tool does not start, the battery is overheated. In this situation, let the battery cool

before pulling the switch trigger again.

• Low battery voltage:

When the battery capacity is not enough,

the tool stops automatically and the battery

indicator shows following state. In this case,

remove the battery from the tool and charge

the battery.

BL1460A

2

► 1. Indicator lamps 2. Check button

NOTE: Depending on the conditions of use and the

ambient temperature, the indication may differ slightly

from the actual capacity.

20%-35%

0%-20%

Switch action

When charging

When the charging begins, the rst (far left) indicating lamp

begins to icker. Then, as charging proceeds, the other lamps

light, one after the other, to indicate the battery capacity.

NOTE: If the indicator lamp does not turn on or icker

when charging, the battery may be faulty. In this case,

ask your local service center.

When using

When the tool is switched on, the lamps will light to

indicate the remaining battery capacity. When the tool is

switched off, the light goes out after approx. 5 seconds.

When pushing the check button with the tool switched

off, the indicator lamps turn on for approx. 5 seconds to

show battery capacity.

If the orange lamp ickers, the tool stops because of

little remaining battery capacity (Auto-stop mechanism).

Charge the battery cartridge or use a charged battery

cartridge at this time.

When the tool is used with the battery that has not been

used for a long time and is switched on, no lamps may

light up. The tool stops because of little remaining battery capacity at this time. Charge the battery properly.

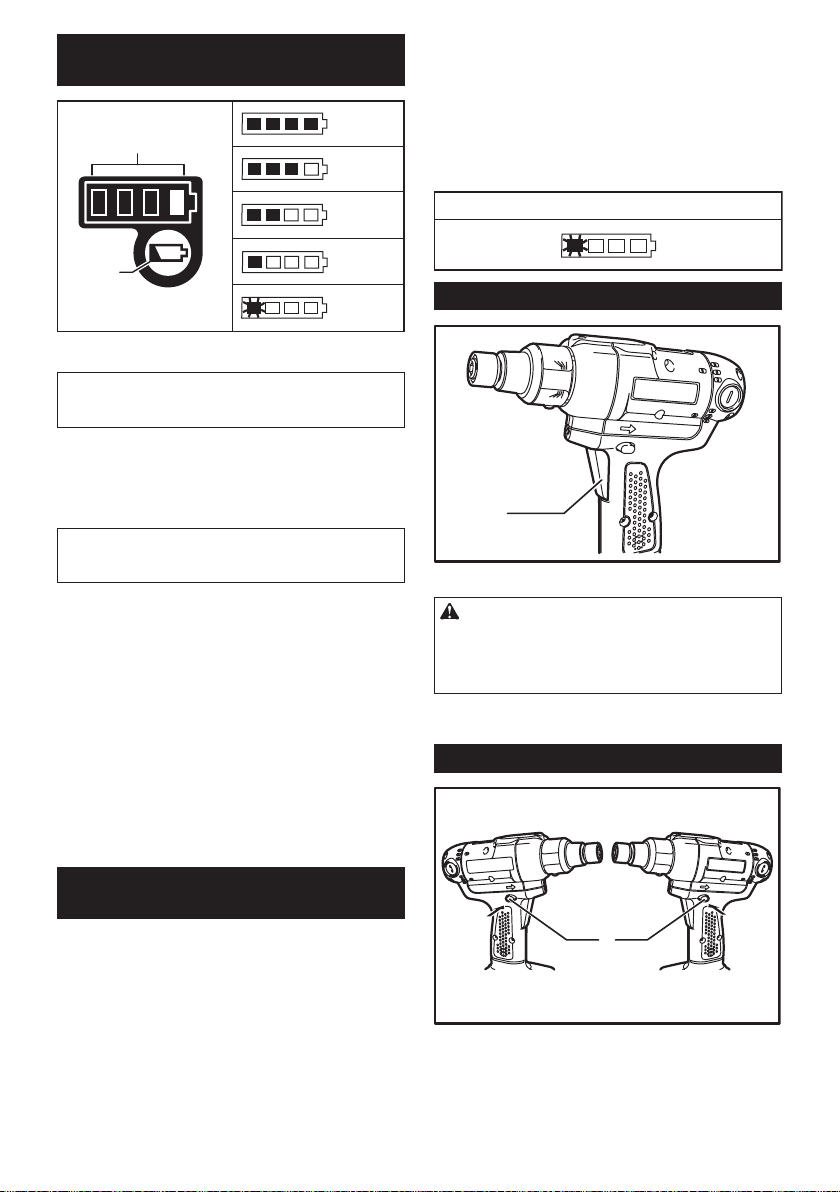

► 1. Switch trigger

To start the tool, simply pull the switch trigger. Release

the switch trigger to stop.

1

CAUTION:

• Before installing the battery cartridge into the

tool, always check to see that the switch trigger

actuates properly and returns to the "OFF"

position when released.

Reversing switch action

Battery protection system

(BL1460A)

The tool is equipped with a battery protection system.

This system automatically cuts off power to the motor to

extend battery life.

The tool will automatically stop during operation if the tool

and/or battery are placed under the following conditions:

• Overloaded:

The tool is operated in a manner that causes

it to draw an abnormally high current.

In this situation, release the switch trigger on

the tool and stop the application that caused

the tool to become overloaded. Then pull the

switch trigger again to restart.

► 1. Reversing switch lever

5 ENGLISH

1

Page 6

CAUTION:

• Always check the direction of rotation before

operation.

• Use the reversing switch only after the tool

comes to a complete stop. Changing the direction of rotation before the tool stops may damage the tool.

• When not operating the tool, always set the

reversing switch lever to the neutral position.

This tool has a reversing switch to change the direction

of rotation. Depress the reversing switch lever from the

A side for clockwise rotation or from the B side for counterclockwise rotation.

When the reversing switch lever is in the neutral position, the switch trigger cannot be pulled.

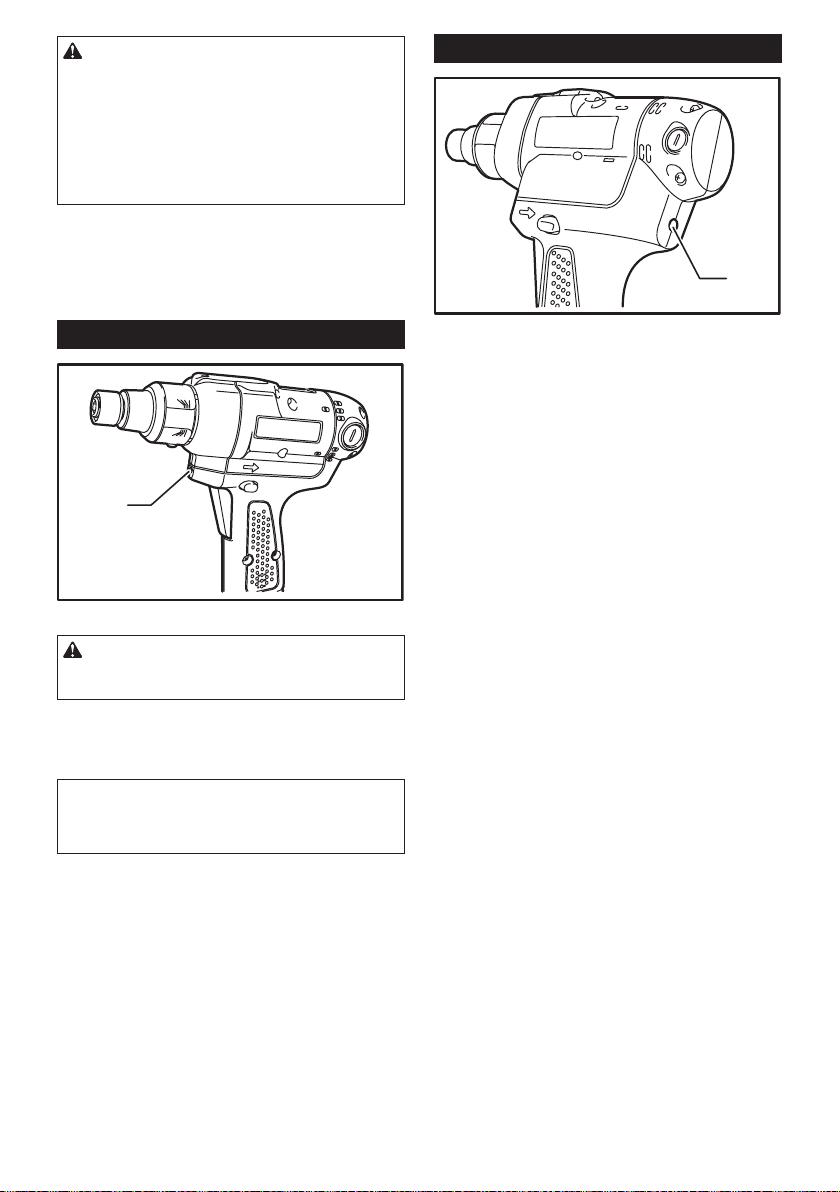

Lighting up the lamps

1

► 1. Front lamp

LED indicator

1

► 1. LED indicator

The LED indicator on the tool shows the following

functions.

CAUTION:

• Do not look in the light or see the source of light

directly.

Pull the switch trigger to light up the lamp. The lamp

keeps on lighting while the switch trigger is being pulled.

The light automatically goes out 10 seconds after the

switch trigger is released.

NOTE:

• Use a dry cloth to wipe the dirt off the lens of

lamp. Be careful not to scratch the lens of lamp,

or it may lower the illumination.

6 ENGLISH

Page 7

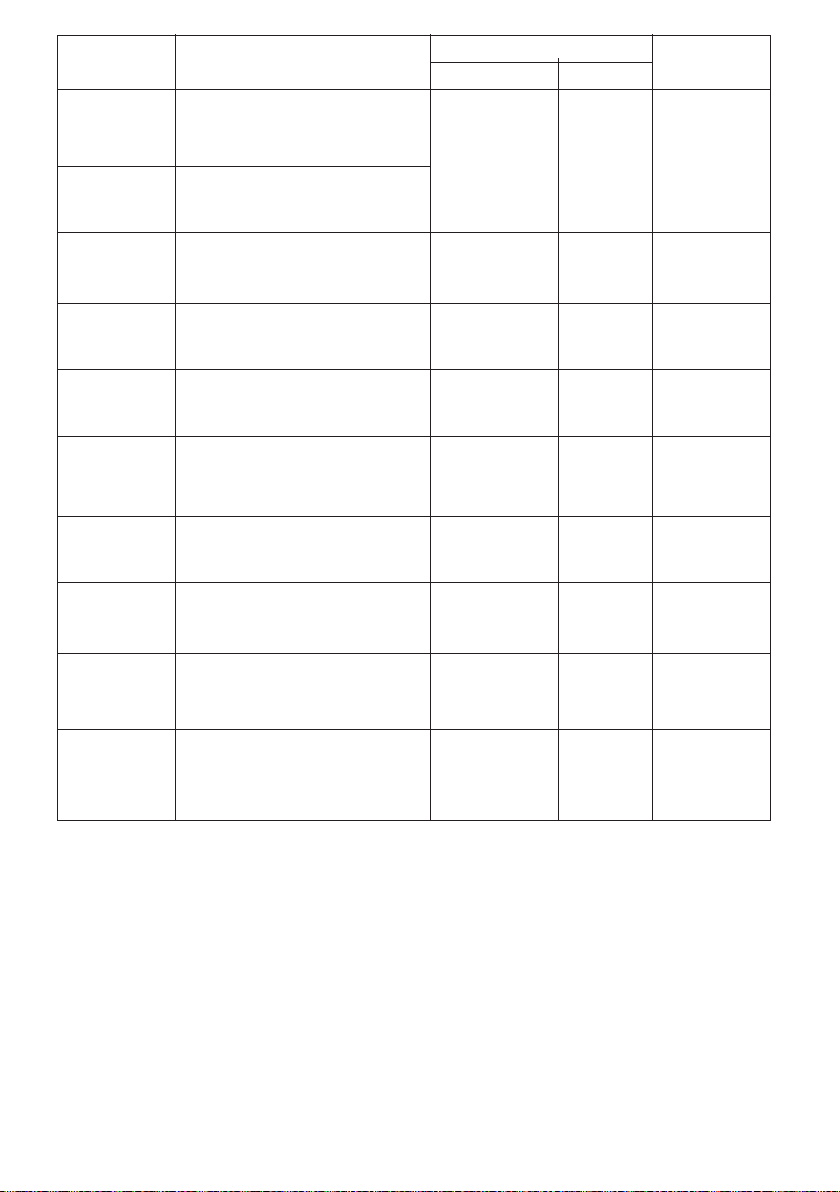

Function Status Action to be taken

--

This function works when the tool has reached

Auto-stop fastening

Delayed re-start

the preset fastening torque and normal

tightening has been completed. This helps

overtightening to be avoided.

For approximately one second after auto-stop

fastening, the tool does not start even if the

switch trigger is pulled.

Status of the LED indicator/beeper

LED indicator Beeper

Lights up in green for

approximately one

second.

Warning against

insufficient fastening

Warning for battery

cartridge capacity

Checking the

remaining battery

capacity, Autostop

Check the LED

indicator, lamp and

beeper operation

Anti-reset of

controller

Overheat

Operation error of

the switch trigger

Warning for limit of

the fastening

capacity

Insufficient fastening has been performed

when the switch trigger has released before

reaching the preset fastening torque.

This indicates the appropriate time to replace

the battery cartridge when the battery power

becomes low.

This function works when the battery power

is almost used up. At this time, tool stops

immediately.

This function works to check the proper

operation of the LED indicator, lamp and

beeper when a battery cartridge has been

inserted into the tool.

This function works when an abnormal drop

of the battery voltage occurs for some reason,

and the tool stops.

This function works when the temperature

of the controller goes up very highly,

and the tool stops.

This function works to avoid the tool's

immediate start upon insertion of battery

cartridge into the tool with the switch trigger

being pulled.

The tool automatically stops without the clutch

working when exceeding the fastening capacity

limit.

Lights up in red. A long beep

Flickers in red slowly.

Lights up in red. A long beep

Lights up first in green,

next red.

(And then the lamp

comes on.)

Flickers in red and

green alternatively.

Flickers in red quickly.

Flickers in red and

green alternatively.

Flickers in red and

green alternatively.

A series of long

beeps

A series of very

short beeps

A series of short

beeps

A series of short

beeps

A series of short

beeps

A series of short

beeps

Retighten the

screw.

Replace the battery

with fully charged

one.

Replace the battery

with fully charged

one.

-

Replace the battery

with fully charged

one.

Remove the battery

cartridge immediately

and cool the tool

down.

Release the switch

trigger.

Remove the battery

cartridge and then

install it again.

Be sure to use the

tool under load within

its capacity.

7 ENGLISH

Page 8

Adjusting the fastening torque

ASSEMBLY

1

2

► 1. Adjusting grip 2. Ring

When you wish to drive machine screws, wood screws,

hex bolts, etc. with the predetermined torque, adjusting

the fastening torque as follows.

1. First remove the battery cartridge from the tool.

2. Loosen and remove the screw that secures ring.

3. Rotate the ring in the front of the tool by hand so

that a hole can be seen below the ring.

4. Place the battery cartridge in place and pull the

switch trigger. Release it so that the adjusting ring

rotates and becomes visible in the hole. And then

remove the battery cartridge.

4

1

2

5

6

CAUTION:

• Always be sure that the tool is switched off and

the battery cartridge is removed before carrying

out any work on the tool.

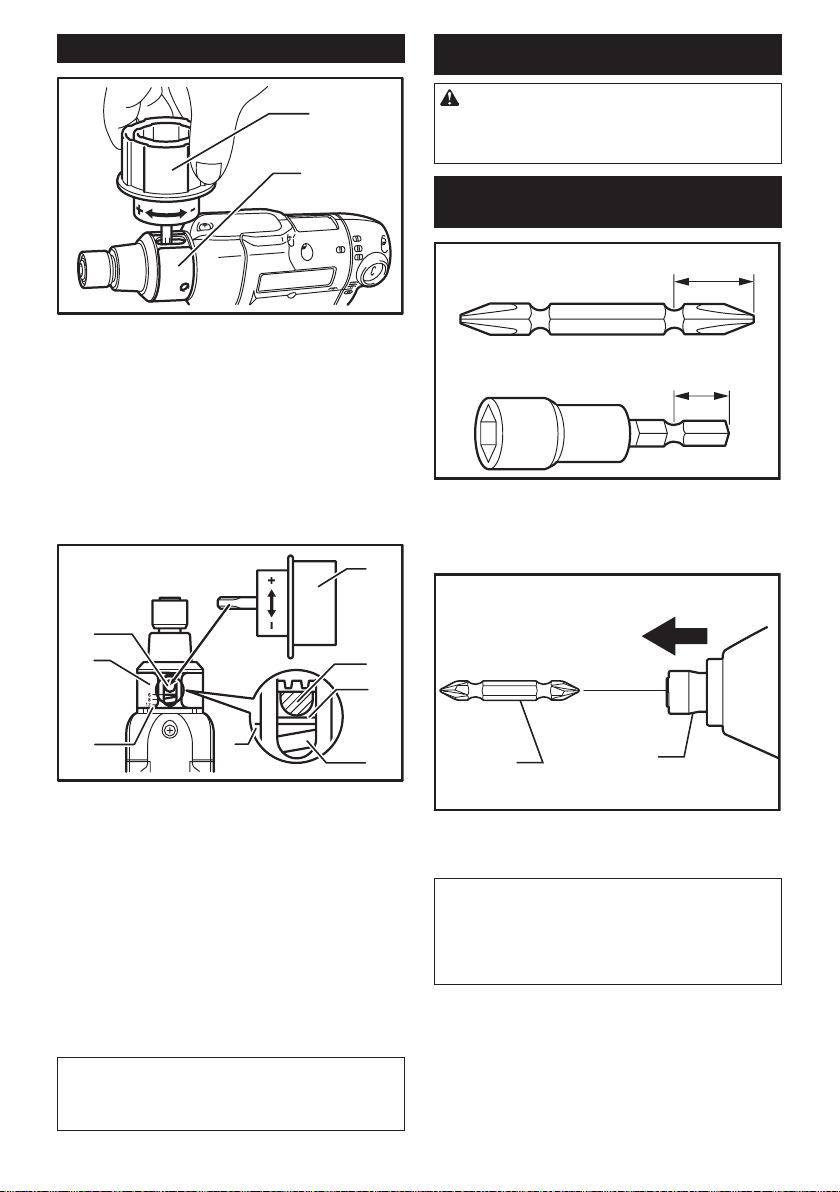

Installing or removing driver bit or

socket bit

12mm(15/32")

9mm(3/8")

Use only the driver bit or socket bit shown in the gure.

Do not use any other driver bit or socket bit.

To install the bit, pull the sleeve in the direction of the

arrow and insert the bit into the sleeve as far as it will

go. Then release the sleeve to secure the bit.

3

3

7

► 1. Adjusting ring 2. Ring 3. Scale 4. Adjusting

grip 5. Hole for adjusting grip 6. Yellow line

7. Compression spring

Use an optional adjusting grip to adjust the fastening

5.

torque. Insert the pin of the adjusting grip into the hole

in the front of the tool. And then, turn the adjusting

grip clockwise to set a greater fastening torque, and

counterclockwise to set a smaller fastening torque.

6. Align the yellow line with your desired number on

the fastening torque scale.

7. Insert the battery cartridge and be sure that a fastening torque has been set up by using a fastening

torque tester.

8. Rotate the ring in front of the tool and then tighten

the screw to secure the ring.

NOTE:

• Numbers on the fastening torque scale is a

guideline to set up your desired fastening

torque.

1

► 1. Bit 2. Sleeve

To remove the bit, pull the sleeve in the direction of the

arrow and pull the bit out rmly.

NOTE:

• If the bit is not inserted deep enough into the

sleeve, the sleeve will not return to its original

position and the bit will not be secured. In this

case, try re-inserting the bit according to the

instructions above.

8 ENGLISH

2

Page 9

OPERATION

Screwdriving operation

Place the point of the driver bit in the screw head and

apply pressure to the tool. Then switch the tool on.

When the clutch cuts in, the motor will stop automatically. Then release the switch trigger.

NOTE:

• Make sure that the driver bit is inserted straight

in the screw head, or the screw and/or bit may

be damaged.

Limits of fastening capacity

Use the tool within the range of the revolution angle up

to 360°. If you use the tool beyond the upper limit of this

range, the clutch does not work. And the tool cannot

deliver enough fastening torque (LED indicator ickers

in red and green alternatively).

NOTE:

• The revolution angle means the angle which

a screw/bolt revolves when the tool attains to

100% from 50% of desired torque.

• Use of a low temperature conditioned battery

cartridge may sometimes give warning for

battery cartridge capacity by warning lamp and

beeper which makes the tool stop immediately.

In this case, the fastening capacity may be

inferior to the specication on this manual even

if a charged battery cartridge is used.

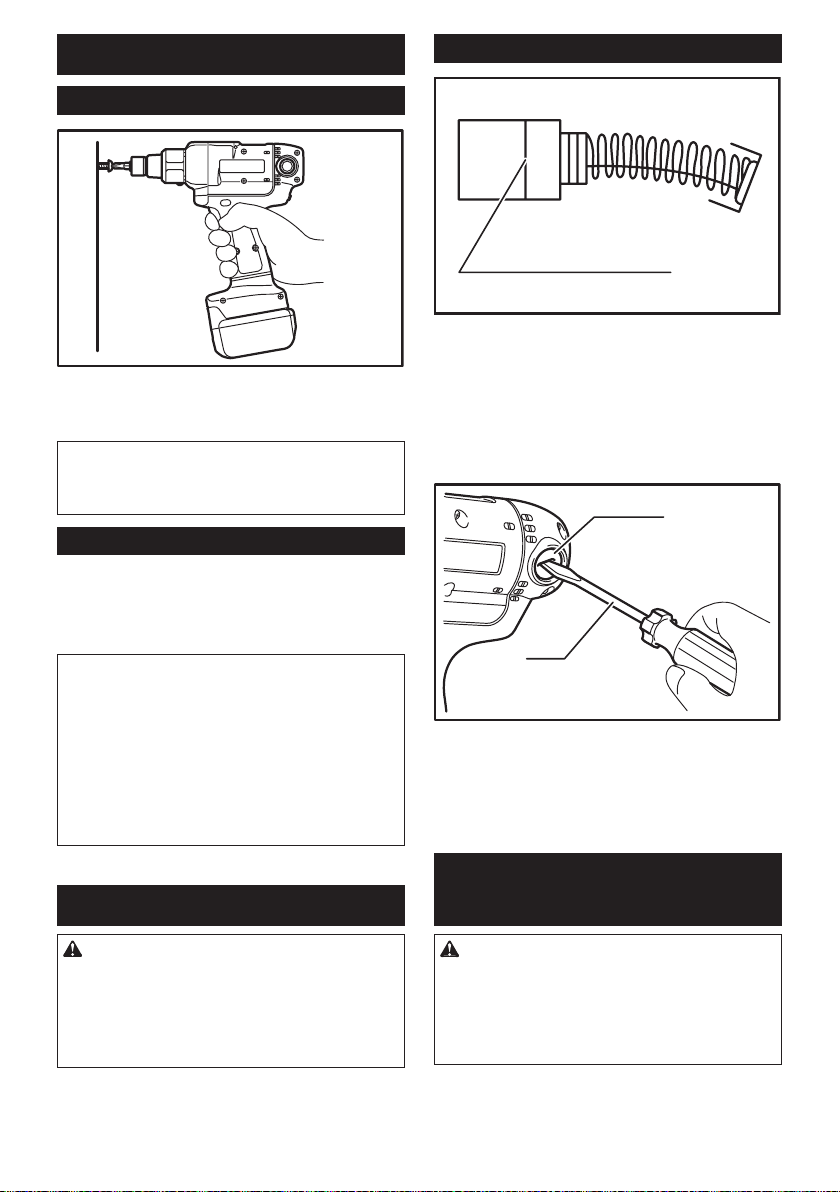

Replacing carbon brushes

1

► 1. Limit mark

Remove and check the carbon brushes regularly.

Replace when they wear down to the limit mark. Keep

the carbon brushes clean and free to slip in the holders.

Both carbon brushes should be replaced at the same

time. Use only identical carbon brushes.

Use a screwdriver to remove the brush holder caps.

Take out the worn carbon brushes, insert the new ones

and secure the brush holder caps.

1

2

► 1. Brush holder cap 2. Screwdriver

To maintain product SAFETY and RELIABILITY,

repairs, any other maintenance or adjustment should

be performed by Makita Authorized or Factory Service

Centers, always using Makita replacement parts.

MAINTENANCE

CAUTION:

• Always be sure that the tool is switched off and

the battery cartridge is removed before attempting to perform inspection or maintenance.

• Never use gasoline, benzine, thinner, alcohol

or the like. Discoloration, deformation or cracks

may result.

OPTIONAL

ACCESSORIES

CAUTION:

• These accessories or attachments are recommended for use with your Makita tool specied

in this manual. The use of any other accessories

or attachments might present a risk of injury to

persons. Only use accessory or attachment for

its stated purpose.

If you need any assistance for more details regard-

ing these accessories, ask your local Makita Service

Center.

9 ENGLISH

Page 10

• Makita genuine battery and charger

• Adjust grip

• Protector

• Grip Base Set

• Grip 37

• Anti kickback head

NOTE:

• Some items in the list may be included in the

tool package as standard accessories. They

may differ from country to country.

MAKITA LIMITED ONE YEAR

WARRANTY

Warranty Policy

Every Makita tool is thoroughly inspected and tested

before leaving the factory. It is warranted to be free of

defects from workmanship and materials for the period

of ONE YEAR from the date of original purchase.

Should any trouble develop during this one year period,

return the COMPLETE tool, freight prepaid, to one

of Makita’s Factory or Authorized Service Centers. If

inspection shows the trouble is caused by defective

workmanship or material, Makita will repair (or at our

option, replace) without charge.

This Warranty does not apply where:

• repairs have been made or attempted by others:

• repairs are required because of normal wear and

tear:

• the tool has been abused, misused or improperly

maintained:

• alterations have been made to the tool.

IN NO EVENT SHALL MAKITA BE LIABLE FOR ANY

INDIRECT, INCIDENTAL OR CONSEQUENTIAL

DAMAGES FROM THE SALE OR USE OF THE

PRODUCT. THIS DISCLAIMER APPLIES BOTH

DURING AND AFTER THE TERM OF THIS

WARRANTY.

MAKITA DISCLAIMS LIABILITY FOR ANY IMPLIED

WARRANTIES, INCLUDING IMPLIED WARRANTIES

OF "MERCHANTABILITY" AND "FITNESS FOR A

SPECIFIC PURPOSE," AFTER THE ONE YEAR TERM

OF THIS WARRANTY.

This Warranty gives you specic legal rights, and you

may also have other rights which vary from state to

state. Some states do not allow the exclusion or lim-

itation of incidental or consequential damages, so the

above limitation or exclusion may not apply to you.

Some states do not allow limitation on how long an

implied warranty lasts, so the above limitation may not

apply to you.

10 ENGLISH

Page 11

FRANÇAIS (Mode d’emploi original)

SPÉCIFICATIONS

Modèle DFT022F DFT044F DFT084F DFT126F

Couple de serrage Joint rigide 0,5 - 2 N·m

Joint souple 0,5 - 2 N·m

Vitesse à vide (RPM) 700 /min 950 /min 780 /min 410 /min

Dimensions 200 x 74 x 250 mm (7-7/8" x 2-15/16" x 9-7/8") (avec la batterie BL1430B)

Poids net 1,5 kg (3,4 lbs) (avec la batterie BL1430B)

Tension nominale C.C. 14,4 V

Batterie BL1415NA / BL1430 / BL1430B / BL1460A

• Étant donné l'évolution constante de notre programme de recherche et de développement, les spécications contenues dans ce manuel sont sujettes à modication sans préavis.

• Les caractéristiques techniques et la batterie peuvent varier suivant les pays.

• Poids, batterie comprise, conforme à la procédure EPTA de 01/2003

(4 - 18 in·lbs)

(4 - 18 in·lbs)

200 x 74 x 235 mm (7-7/8" x 2-15/16" x 9-1/4") (avec la batterie BL1415NA)

Consignes de sécurité générales

pour outils électriques

MISE EN GARDE Veuillez lire toutes les mises en

garde de sécurité et toutes les instructions. L'ignorance

des mises en garde et des instructions comporte un risque

de choc électrique, d'incendie et/ou de blessure grave.

Conservez toutes les mises en

garde et instructions pour référence future.

Le terme « outil électrique » qui gure dans les avertissements fait référence à un outil électrique branché sur

une prise de courant (par un cordon d'alimentation) ou

alimenté par batterie (sans l).

Sécurité de la zone de travail

1. Maintenez la zone de travail propre et bien

éclairée. Les zones de travail encombrées ou

sombres ouvrent grande la porte aux accidents.

2.

N'utilisez pas les outils électriques dans les atmosphères explosives, par exemple en présence de

liquides, gaz ou poussières inammables. Les outils

électriques produisent des étincelles au contact desquelles la poussière ou les vapeurs peuvent s'enammer.

3. Assurez-vous qu'aucun enfant ou curieux ne

s'approche pendant que vous utilisez un outil

électrique. Vous risquez de perdre la maîtrise de

l'outil si votre attention est détournée.

Sécurité en matière d'électricité

4. Les ches d'outil électrique sont conçues pour

s'adapter parfaitement aux prises de courant.

Ne modiez jamais la che de quelque façon

que ce soit. N'utilisez aucun adaptateur de

che sur les outils électriques avec mise à

la terre. En ne modiant pas les ches et en les

insérant dans des prises de courant pour lesquelles elles ont été conçues vous réduirez les

risques de choc électrique.

11 FRANÇAIS

1 - 4 N·m

(8,9 - 35 in·lbs)

1 - 4 N·m

(8,9 - 35 in·lbs)

1,4 kg (3,0 lbs) (avec la batterie BL1415NA)

5. Évitez tout contact corporel avec les surfaces

mises à la terre, telles que les tuyaux, radiateurs, cuisinières et réfrigérateurs. Le risque

de choc électrique est plus élevé si votre corps se

trouve mis à la terre.

6. N'exposez pas les outils électriques à la pluie

ou à l'eau. La présence d'eau dans un outil électrique augmente le risque de choc électrique.

7. Ne maltraitez pas le cordon. N'utilisez jamais

le cordon pour transporter, tirer ou débrancher

l'outil électrique. Maintenez le cordon à l'écart

des sources de chaleur, de l'huile, des objets à

bords tranchants et des pièces en mouvement.

Le risque de choc électrique est plus élevé lorsque

les cordons sont endommagés ou enchevêtrés.

8. Lorsque vous utilisez un outil électrique à l'ex-

térieur, utilisez un cordon prolongateur prévu

à cette n. Les risques de choc électrique sont

moindres lorsqu'un cordon conçu pour l'extérieur

est utilisé.

9. Si vous devez utiliser un outil électrique dans

un endroit humide, utilisez une source d'alimentation protégée par un disjoncteur de fuite

à la terre. L'utilisation d'un disjoncteur de fuite à la

terre réduit le risque de choc électrique.

Sécurité personnelle

10. Restez alerte, attentif à vos mouvements et

faites preuve de bon sens lorsque vous utilisez un outil électrique. Évitez d'utiliser un outil

électrique si vous êtes fatigué ou si vous avez

pris une drogue, de l'alcool ou un médicament.

Un moment d'inattention pendant l'utilisation d'un

outil électrique peut entraîner une grave blessure.

11. Portez des dispositifs de protection personnelle. Portez toujours un protecteur pour la

vue. Les risques de blessure seront moins élevés

si vous utilisez des dispositifs de protection tels

qu'un masque antipoussières, des chaussures à

semelle antidérapante, une coiffure résistante ou

une protection d'oreilles.

3 - 8 N·m

(27 - 71 in·lbs)

3 - 8 N·m

(27 - 71 in·lbs)

5 - 12 N·m

(44 - 106 in·lbs)

5 - 12 N·m

(44 - 106 in·lbs)

Page 12

Évitez les démarrages accidentels. Assurez-

12.

vous que l’interrupteur soit en position d'arrêt

avant de brancher l'outil à la prise électrique et/

ou au bloc-piles, avant de prendre ou de transporter l’outil. Vous ouvrez la porte aux accidents

si vous transportez les outils électriques avec le

doigt sur l’interrupteur ou si vous les branchez

alors que l’interrupteur est en position de marche.

13. Retirez toute clé de réglage ou de serrage

avant de mettre l'outil sous tension. Toute clé

laissée en place sur une pièce rotative de l'outil

électrique peut entraîner une blessure.

14. Maintenez une bonne position. Assurez-vous

d'une bonne prise au sol et d'une bonne

position d'équilibre en tout temps. Cela vous

permettra d'avoir une meilleure maîtrise de l'outil

dans les situations imprévues.

15. Portez des vêtements adéquats. Ne portez ni

vêtements amples ni bijoux. Vous devez main-

tenir cheveux, vêtements et gants à l'écart des

pièces en mouvement. Les pièces en mouve-

ment peuvent happer les vêtements amples, les

bijoux et les cheveux longs.

16. Si des accessoires sont fournis pour raccor-

der un appareil d'aspiration et de collecte

de la poussière, assurez-vous qu'ils sont

correctement raccordés et qu'ils sont utilisés

de manière adéquate. L'utilisation d'un appareil

d'aspiration permet de réduire les risques liés à la

présence de poussière dans l'air.

Utilisation et entretien des outils électriques

17. Ne forcez pas l'outil électrique. Utilisez l'outil

électrique adéquat suivant le type de travail à

effectuer. Si vous utilisez l'outil électrique adéquat

et respectez le régime pour lequel il a été conçu,

il effectuera un travail de meilleure qualité et de

façon plus sécuritaire.

18. N'utilisez pas l'outil électrique s'il n'est pas

possible de mettre sa gâchette en position de

marche et d'arrêt. Un outil électrique dont l'inter-

rupteur est défectueux représente un danger et

doit être réparé.

19. Débranchez la che de la source d'alimen-

tation et/ou retirez le bloc-piles de l'outil

électrique avant d'effectuer tout réglage, de

changer un accessoire ou de ranger l'outil électrique. De telles mesures préventives

réduisent les risques de démarrage accidentel de

l'outil électrique.

20. Après l'utilisation d'un outil électrique,

rangez-le hors de portée des enfants et ne

laissez aucune personne l'utiliser si elle n'est

pas familiarisée avec l'outil électrique ou les

présentes instructions d'utilisation. Les outils

électriques représentent un danger entre les

mains de personnes qui n'en connaissent pas le

mode d'utilisation.

21. Veillez à l’entretien des outils électriques.

Assurez-vous que les pièces mobiles ne sont

pas désalignées ou coincées, qu’aucune pièce

n’est cassée et que l’outil électrique n’a subi

aucun dommage affectant son bon fonctionnement. Le cas échéant, faites réparer l'outil

électrique avant de l'utiliser. De nombreux

accidents sont causés par des outils électriques

mal entretenus.

22. Maintenez les outils tranchants bien aiguisés

et propres. Un outil tranchant dont l'entretien est

effectué correctement et dont les bords sont bien

aiguisés risquera moins de se coincer et sera plus

facile à maîtriser.

23. Utilisez l'outil électrique, ses accessoires, ses

embouts, etc., en respectant les présentes

instructions, en tenant compte des conditions

de travail et du type de travail à effectuer.

L'utilisation d'un outil électrique à des ns autres

que celles prévues peut entraîner une situation

dangereuse.

Utilisation et entretien des outils alimentés par

batterie

24. Pour recharger, utilisez uniquement le char-

geur spécié par le fabricant. L'utilisation d'un

chargeur conçu pour un type donné de bloc-piles

comporte un risque d'incendie lorsqu'il est utilisé

avec un autre type de bloc-piles.

25. N'utilisez un outil électrique qu'avec le bloc-

piles conçu spéciquement pour cet outil. Il y a

risque de blessure ou d'incendie si un autre blocpiles est utilisé.

26. Lorsque vous n'utilisez pas le bloc-piles,

rangez-le à l'écart des objets métalliques tels

que trombones, pièces de monnaie, clés,

clous, vis ou autres petits objets métalliques

qui risquent d'établir une connexion entre les

bornes. La mise en court-circuit des bornes de

batterie peut causer des brûlures ou un incendie.

27. Dans des conditions d'utilisation inadéquates

de la batterie, il peut y avoir fuite d'électrolyte;

évitez tout contact avec ce liquide. En cas

de contact accidentel, rincez avec beaucoup

d’eau. Si le liquide pénètre dans vos yeux, il

faut aussi consulter un médecin. L'électrolyte

qui s'échappe de la batterie peut causer des irritations ou des brûlures.

Réparation

28. Faites réparer votre outil électrique par un

réparateur qualié qui utilise des pièces de

rechange identiques aux pièces d'origine. Le

maintien de la sûreté de l'outil électrique sera ainsi

assuré.

29. Suivez les instructions de lubrication et de

changement des accessoires.

30. Maintenez les poignées de l'outil sèches,

propres et exemptes d'huile ou de graisse.

CONSIGNES DE SÉCURITÉ POUR

LE TOURNEVIS SANS FIL

1. Tenez l'outil par ses surfaces de prise isolées

pendant toute opération où l’accessoire de

xation pourrait venir en contact avec un

câblage dissimulé. En cas de contact avec un

conducteur sous tension, les pièces métalliques à

découvert de l'outil pourraient devenir sous tension et risqueraient de transmettre une décharge

électrique à l'utilisateur.

2. Adoptez toujours une position de travail vous

assurant d'un bon équilibre.

Assurez-vous qu'il n'y a personne plus bas

lorsque vous utilisez l'outil en position élevée.

3. Tenez l'outil fermement.

12 FRANÇAIS

Page 13

4. Gardez les mains éloignées des pièces en

rotation.

5. Ne touchez ni la fraise, ni la pièce à travail-

ler immédiatement après l'utilisation ; elles

peuvent être extrêmement chaudes et vous

pourriez vous brûler la peau.

CONSERVEZ CE MODE

D'EMPLOI.

MISE EN GARDE : NE VOUS LAISSEZ

PAS tromper (au l d'une utilisation répétée) par un sentiment d'aisance ou de

familiarité avec le produit en négligeant les

consignes de sécurité qui accompagnent

le produit. L'utilisation non sécuritaire ou

incorrecte de cet outil comporte un risque

de blessure grave.

Symboles

Les symboles utilisés pour l'outil sont indiqués

ci-dessous.

volts

courant continu

vitesse à vide

tours ou alternances par minute

CONSIGNES DE SÉCURITÉ

IMPORTANTES

POUR LA BATTERIE

1. Avant d'utiliser la batterie, lisez toutes les

instructions et précautions relatives (1) au

chargeur de batterie, (2) à la batterie, et (3) à

l'outil utilisant la batterie.

2. Ne démontez pas la batterie.

3. Cessez immédiatement l'utilisation si le temps

de fonctionnement devient excessivement

court. Il y a risque de surchauffe, de brûlures,

voire d'explosion.

4. Si l'électrolyte pénètre dans vos yeux, rincez-les à l'eau claire et consultez immédiatement un médecin. Il y a risque de perte de la

vue.

5. Ne court-circuitez pas la batterie :

(1) Ne touchez les bornes avec aucun maté-

riau conducteur.

(2) Évitez de ranger la batterie dans un

conteneur avec d'autres objets métalliques, par exemple des clous, des pièces

de monnaie, etc.

(3) Évitez d'exposer la batterie à l'eau ou à la

pluie.

Un court-circuit de la batterie pourrait provoquer un fort courant, une surchauffe, parfois

des brûlures et même une panne.

6. Ne rangez pas l'outil ou la batterie dans des

endroits où la température risque d'atteindre

ou de dépasser 50°C (122°F).

7. Ne jetez pas la batterie au feu même si elle est

sérieusement endommagée ou complètement

épuisée. La batterie peut exploser au contact

du feu.

8. Prenez garde d'échapper ou de heurter la

batterie.

9. N'utilisez pas une batterie si elle est

endommagée.

10. Les batteries au lithium-ion contenues sont

soumises aux exigences des lois applicables

concernant les matières dangereuses.

Pour le transport commercial, p. ex. par des

entreprises de transport tiers, il est nécessaire de

respecter certaines mesures particulières ayant

trait à l'emballage et à l'étiquetage.

L'assistance d'un expert en matières dangereuses

est requise pour la préparation de l'article à

expédier. Veuillez également vous conformer aux

réglementations nationales en vigueur qui pourraient être plus détaillées.

Masquez les contacts découverts ou couvrez-lez

de ruban, et emballez la batterie de façon à ce

qu'elle ne puisse se déplacer à l'intérieur du

paquet.

11. Suivez la réglementation locale concernant la

mise au rebut de la batterie.

CONSERVEZ CE MODE

D'EMPLOI.

ATTENTION : Utilisez uniquement des batteries

Makita d'origine.

L'utilisation de batteries autres que les batteries d'origine Makita ou de batteries qui ont été modiées peut

entraîner l'explosion de la batterie et provoquer des

incendies, blessures et autres dommages. Cela annulerait également la garantie de Makita s'appliquant à

l'outil Makita et au chargeur.

Conseils pour obtenir la durée de

service maximale de la batterie

1. Rechargez la batterie avant qu'elle ne soit

complètement déchargée.

Arrêtez toujours l'outil et rechargez la batterie

quand vous remarquez que la puissance de

l'outil diminue.

2. Ne rechargez jamais une batterie complètement chargée.

La surcharge réduit la durée de service de la

batterie.

3. Rechargez la batterie à une température

ambiante comprise entre 10°C et 40°C (50°F

- 104°F). Si la batterie est chaude, laissez-la

refroidir avant de la recharger.

4. Rechargez la batterie si vous ne l'utilisez pas

pendant une période prolongée (plus de six

mois).

13 FRANÇAIS

Page 14

DESCRIPTION DU

3

FONCTIONNEMENT

ATTENTION :

• Assurez-vous toujours que l'outil est hors

tension et que sa batterie est retirée avant de

l'ajuster ou de vérier son fonctionnement.

Installation ou retrait de la batterie

Vérication du niveau de charge de

la batterie (BL1460A)

70%-100%

1

50%-70%

35%-50%

1

2

► 1. Indicateur rouge 2. Bouton 3. Batterie

ATTENTION :

• Mettez toujours l'appareil hors tension avant

d'installer ou de retirer la batterie.

• Tenez fermement l'outil et la batterie lors de

l'installation ou du retrait de cette dernière.

Sinon, l'outil et la batterie pourraient vous glisser des mains, ce qui risque d'endommager

l'outil et la batterie, ou encore de provoquer des

blessures.

Pour retirer la batterie, faites-la glisser de l'outil tout en

faisant glisser le bouton se trouvant à l'avant.

Pour installer la batterie, alignez sa languette sur la

rainure pratiquée dans le boîtier, et glissez la batterie en

place. Insérez-la à fond jusqu'à ce que vous entendiez

un clic. Si vous pouvez voir l'indicateur rouge situé sur

le dessus du bouton, la batterie n'est pas complètement

verrouillée.

ATTENTION :

• Installez toujours la batterie à fond jusqu’à

ce que vous ne puissiez plus voir l’indicateur

rouge. Dans le cas contraire, elle pourrait tomber de l'outil et entraîner des blessures.

• Ne forcez pas sur la batterie pour l'installer. Si

la batterie ne glisse pas facilement, c'est qu'elle

n'est pas insérée correctement.

2

► 1. Témoins indicateurs 2. Bouton de vérication

NOTE : Suivant les conditions d’utilisation et la

température ambiante, il se peut que l’indication soit

légèrement différente de la charge réelle.

20%-35%

0%-20%

Pendant la charge

Lorsque la charge commence, le premier témoin indicateur (à l'extrême gauche) commence à clignoter. Puis,

à mesure que la batterie se charge, les autres témoins

s'allument un après l'autre pour indiquer le niveau de

charge de la batterie.

NOTE : Si la lampe témoin ne s’allume pas ou ne

clignote pas pendant la charge, il se peut que la batterie soit défectueuse. Le cas échéant, informez-vous

auprès de votre centre de service après-vente local.

Pendant l'utilisation

Lorsque vous allumez l’outil, les témoins s’allument

pour indiquer la charge restante de la batterie. Lorsque

vous éteignez l’outil, la lumière s’éteint au bout d’environ 5 secondes.

Lorsque vous appuyez sur le bouton de vérication

alors que l’outil est éteint, les lampes témoin s’allument

pendant environ 5 secondes pour indiquer la charge de

la batterie.

Si le témoin orange clignote, l’outil s’arrête en raison

de la faible charge restante de la batterie (mécanisme

d’arrêt automatique). Chargez la batterie ou utilisez une

batterie chargée à ce moment.

Si l’outil est utilisé avec une batterie restée longtemps

inutilisée, il se peut que les témoins ne s’allument pas

lorsque vous allumerez l’outil. L’outil s’arrête en raison

de la faible charge restante de la batterie à ce moment.

Chargez la batterie adéquatement.

14 FRANÇAIS

Page 15

Dispositif de protection de la

AB

batterie (BL1460A)

L'outil est équipé d'un système de protection de la

batterie. Ce système coupe automatiquement l'alimentation du moteur pour augmenter la durée de vie de la

batterie.

L’outil s’arrête automatiquement pendant l’utilisation

lorsque l’outil et/ou la batterie sont dans les situations

suivantes :

• En surcharge :

L'outil est utilisé d'une manière entraînant

une consommation anormale de courant.

Dans cette situation, relâchez la gâchette et

arrêtez l'activité qui entraîne une surcharge

de l'outil. Puis appuyez de nouveau sur la

gâchette pour redémarrer.

Si l’outil ne démarre pas, la batterie est en

surchauffe. Dans cette situation, laissez

refroidir la batterie avant d'appuyer de nouveau sur la gâchette.

• Tension de la batterie faible :

Lorsque la charge de la batterie est insuf-

sante, l’outil s’arrête automatiquement et

le voyant de batterie indique l’état suivant.

Dans ce cas, retirez la batterie de l’outil et

chargez-la.

BL1460A

Interrupteur

Inverseur

1

► 1. Levier inverseur

ATTENTION :

• Vériez toujours le sens de rotation avant de

mettre l'outil en marche.

• N'actionnez l'inverseur qu'une fois que l'outil est

complètement arrêté. Si vous changez le sens

de rotation avant l'arrêt de l'outil, vous risquez

de l'endommager.

• Lorsque vous n'utilisez pas l'outil, placez tou-

jours le levier inverseur en position neutre.

L'outil possède un inverseur qui permet de changer le

sens de rotation. Enfoncez le levier inverseur du côté

A pour une rotation dans le sens des aiguilles d'une

montre, ou du côté B pour une rotation dans le sens

inverse des aiguilles d'une montre.

La pression sur la gâchette n'est pas possible lorsque le

levier inverseur se trouve en position neutre.

Allumage de la lampe

1

► 1. Gâchette

ATTENTION :

• Avant d'installer la batterie dans l’outil, vériez

toujours si la gâchette fonctionne correctement

et si elle revient en position « OFF » quand vous

la relâchez.

Pour faire démarrer l'outil, appuyez simplement sur la

gâchette. Pour l'arrêter, relâchez la gâchette.

15 FRANÇAIS

1

► 1. Lampe avant

ATTENTION :

• Evitez de regarder directement le faisceau

lumineux ou sa source.

Appuyez sur la gâchette pour allumer la lampe. La

lampe demeure allumée tant que la pression sur la

gâchette est maintenue. Lorsque vous relâchez la

gâchette, la lumière s'éteint au bout de 10 secondes.

Page 16

NOTE :

• Utilisez un chiffon sec pour essuyer la saleté qui

recouvre la lentille de la lampe. Prenez garde

de rayer la lentille de la lampe, pour éviter une

diminution de l'éclairage.

Témoin DEL

1

► 1. Témoin DEL

Le témoin DEL sur l’outil indique les fonctions

suivantes.

16 FRANÇAIS

Page 17

Fonction État Mesure à prendre

--

Cette fonction s'active lorsque l'outil a atteint le

Serrage à arrêt

automatique

Redémarrage retardé

couple de serrage préréglé et que le serrage

s'est effectué normalement. Cela permet d'éviter

un serrage excessif.

Pendant environ une (1) seconde après le

serrage à arrêt automatique l'outil ne redémarre

pas même si vous appuyez sur la gâchette.

État du témoin DEL / avertisseur sonore

Témoin DEL

S'allume en vert pendant

environ 1 seconde.

Avertisseur sonore

Avertissement de

serrage insuffisant

Avertissement de

faible charge de la

batterie

Vérification de la

charge restante de la

batterie, Arrêt automatique

Vérifiez le fonctionnement

du témoin DEL, de la

lampe et de l'avertisseur

sonore.

Anti-réinitialisation

du contrôleur

Surchauffe

Erreur de fonctionnement

de la gâchette

Avertissement quant à

la limite de capacité

de serrage

Un serrage insuffisant a été exécuté parce que

la gâchette a été relâchée avant que le couple

de serrage préétabli n'ait été atteint.

Indique le temps approprié pour remplacer la

batterie lorsqu'elle devient faible.

Cette fonction s'active également lorsque la

batterie est presque complètement épuisée.

L'outil s'arrête alors immédiatement.

Cette fonction s'active pour demander de

vérifier le bon fonctionnement du témoin DEL,

de la lampe et de l'avertisseur sonore lorsqu'une

batterie vient d'être insérée dans l'outil.

Cette fonction s'active lors d'une baisse

anormale de la tension de la batterie pour une

raison quelconque, et l'outil s'arrête.

Cette fonction s'active lorsque la température

du contrôleur s'élève de manière excessive,

et l'outil s'arrête.

Cette fonction s'active pour empêcher le

démarrage immédiat de l'outil si vous appuyez

sur la gâchette juste après avoir inséré une

batterie dans l'outil.

L’outil s’arrête automatiquement sans

l’activation de l’embrayage si le couple de

serrage limite n’est pas respecté.

S'allume en rouge.

Clignote lentement

en rouge.

S'allume en rouge.

S'allume d'abord en vert,

puis en rouge.

(La lampe s'allume ensuite.)

Clignote alternativement

en rouge et en vert.

Clignote rapidement en

rouge.

Clignote alternativement

en rouge et en vert.

Clignote alternativement

en rouge et en vert.

Long signal sonore

Série de longs

signaux sonores

Long signal sonore

Série de très

courts signaux

sonores

Série de courts

signaux sonores

Série de courts

signaux sonores

Série de courts

signaux sonores

Série de courts

signaux sonores

Resserrer la vis.

Remplacez la batterie

par une autre

complètement chargée.

Remplacez la batterie

par une autre

complètement chargée.

-

Remplacez la batterie

par une autre

complètement chargée.

Retirez immédiatement

la batterie et laissez

refroidir l'outil.

Relâchez la gâchette.

Retirez la batterie, puis

remettez-la en place.

Assurez-vous de

soumettre l’outil à

une charge

correspondant à ses

capacités.

17 FRANÇAIS

Page 18

Réglage du couple de serrage

1

NOTE :

• Les numéros inscrits sur l'échelle du couple

de serrage permettent d'effectuer un réglage

approximatif sur le couple de serrage désiré.

2

► 1. Poignée de réglage 2. Bague

Pour serrer des vis à machine, des vis à bois, des

boulons hexagonaux, etc., avec un couple de serrage

donné, procédez au réglage du couple de serrage de la

façon suivante.

1. Retirez d'abord la batterie de l'outil.

2. Desserrez puis retirez la vis qui retient l'anneau.

3. Tournez manuellement l'anneau à l'avant de l'outil

de sorte que l'orice soit visible sous l'anneau.

4. Mettez la batterie en place et appuyez sur la

gâchette. Relâchez-la de sorte que l'anneau de

réglage tourne et devienne visible dans l'orice.

Retirez ensuite la batterie.

4

1

2

5

6

ASSEMBLAGE

ATTENTION :

• Assurez-vous toujours que l'outil est hors tension et que sa batterie est retirée avant d'effec-

tuer tout travail dessus.

Installation ou retrait de l'embout ou

l'embout à douille

12mm(15/32")

9mm(3/8")

Utilisez exclusivement l'embout ou l'embout à douille du

modèle indiqué sur la gure.

Pour installer l'embout, tirer le manchon dans le sens

de la èche et introduire l'embout dans le manchon

jusqu'au fond. Lâchez alors le manchon pour immobiliser l'embout.

3

3

7

► 1. Bague de réglage 2. Bague 3. Échelle 4. Poignée

de réglage 5. Orice pour la poignée de réglage

6. Ligne jaune 7. Ressort de compression

5. Utilisez la poignée de réglage en option pour

régler le couple de serrage. Insérez la broche de

la poignée de réglage dans l'orice à l'avant de

l'outil. Tournez ensuite la poignée de réglage dans

le sens des aiguilles d'une montre pour augmenter

le couple de serrage, et dans le sens inverse pour

le réduire.

6. Alignez la ligne jaune sur le numéro désiré de

l'échelle du couple de serrage.

7. Insérez la batterie et assurez-vous que le couple

de serrage est bien réglé, au moyen d'un testeur

de couple de serrage.

8. Serrez les vis pour xer le couvercle de la lampe,

puis faites tourner l'anneau à l'avant de l'outil

jusqu'à ce qu'il se verrouille.

1

► 1. Embout 2. Manchon

Pour enlever l'embout, tirez le manchon dans la direction de la èche et tirez fermement l'embout.

NOTE :

• Si l'embout n'est pas inséré assez profondément dans le manchon, celui-ci ne revient pas

à sa position d'origine et l'embout ne se trouve

pas bien assuré. En ce cas, insérez à nouveau

l'embout comme il est dit ci-dessus.

18 FRANÇAIS

2

Page 19

UTILISATION

Vissage

Placez la pointe de l'embout dans la tête de vis et appliquez une pression sur l'outil. Mettez ensuite l'outil sous

tension. Lorsque l'embrayage s'active, le moteur s'arrête automatiquement. Relâchez ensuite la gâchette.

NOTE :

• Assurez-vous que l'embout est inséré bien droit

dans la tête de vis, sinon la vis et/ou l'embout

risque d'être endommagé.

Remplacement des charbons

1

► 1. Trait de limite d'usure

Retirez et vériez régulièrement les charbons.

Remplacez-les lorsqu'ils sont usés jusqu'au trait de

limite d'usure. Maintenez les charbons propres et en

état de glisser aisément dans les porte-charbon. Les

deux charbons doivent être remplacés en même temps.

N'utilisez que des charbons identiques.

Utilisez un tournevis pour retirer les bouchons de

porte-charbon. Enlevez les charbons usés, insérez-en

de nouveaux et revissez solidement les bouchons de

porte-charbon.

Limites de capacité de serrage

Utilisez l’outil à l’intérieur de la plage d’angle de révolution avec au maximum 360°. Si vous utilisez l’outil

au-delà de la limite supérieure de cette plage, l'embrayage ne s’activera pas. En outre, l'outil ne parviendra pas à fournir le couple de serrage requis (le témoin

DEL clignote en rouge ou en vert).

NOTE :

• L'angle de rotation fait référence à l'angle sur

lequel une vis ou un boulon tourne lorsque l'outil

passe de 50% à 100% du couple désiré.

• L'utilisation d'une batterie pour basses températures peut indiquer la capacité de la cartouche

avec un témoin d'alerte et un avertisseur sonore

qui arrêtent immédiatement l'outil. Dans ce cas,

la capacité de serrage peut être inférieure aux

spécications de ce manuel même si une batterie chargée est utilisée.

ENTRETIEN

ATTENTION :

• Assurez-vous toujours que l'outil est hors tension et que la batterie est retirée avant d'y effectuer tout travail d'inspection ou d'entretien.

• N'utilisez jamais d'essence, de benzine, de

solvant, d'alcool ou d'autres produits similaires.

Une décoloration, une déformation, ou la formation de ssures peuvent en découler.

1

2

► 1. Bouchon de porte-charbon 2. Tournevis

Pour maintenir la SÉCURITÉ et la FIABILITÉ du produit, les réparations, tout autre travail d'entretien ou

de réglage doivent être effectués dans un centre de

service Makita agréé ou un centre de service de l'usine

Makita, exclusivement avec des pièces de rechange

Makita.

19 FRANÇAIS

Page 20

ACCESSOIRES EN

OPTION

ATTENTION :

• Ces accessoires ou pièces complémentaires

sont recommandés pour l'utilisation avec

l'outil Makita spécié dans ce mode d'emploi.

L'utilisation de tout autre accessoire ou pièce

complémentaire peut comporter un risque de

blessure. N'utilisez les accessoires ou pièces

qu'aux ns auxquelles ils ont été conçus.

Si vous désirez obtenir plus de détails concernant ces

accessoires, veuillez contacter le centre de service

après-vente Makita le plus près.

• Chargeur et batterie authentiques Makita

• Poignée de réglage

• Protecteur

• Ensemble poignée

• Poignée 37

• Tête anti-retour

NOTE :

• Certains éléments de la liste peuvent être inclus

avec l'outil comme accessoires standard. Ils

peuvent varier suivant les pays.

GARANTIE LIMITÉE D’UN AN DE

MAKITA

Politique de garantie

Tous les outils Makita sont soigneusement inspectés et

mis à l’essai avant de quitter l’usine. Ils sont garantis

contre les vices de fabrication et de matériau pour une

période d’UN AN suivant la date de l’achat original. Si

un problème survient pendant cette période d’un an,

retournez l’outil COMPLET, fret payé d’avance, à une

usine ou un centre de service après-vente autorisé

Makita. S’il ressort de l’inspection que le problème est

dû à un vice de fabrication ou de matériau, Makita réparera (ou remplacera, à son gré) l’outil gratuitement.

Cette garantie ne s’applique pas dans les cas où :

• des réparations ont été effectuées ou tentées par

un tiers;

• des réparations sont nécessaires en raison de

l’usure normale;

• l’outil a été malmené, mal utilisé ou non adéquate-

ment entretenu;

• l’outil a subi des modications.

MAKITA NE SERA EN AUCUN CAS RESPONSABLE

DE TOUS DOMMAGES INDIRECTS, ACCESSOIRES

OU CONSÉCUTIFS DE LA VENTE OU DE

L’UTILISATION DU PRODUIT. CET AVIS DE NONRESPONSABILITÉ S’APPLIQUE PENDANT ET

APRÈS LA PÉRIODE COUVERTE PAR CETTE

GARANTIE.

MAKITA DÉCLINE TOUTE RESPONSABILITÉ QUANT

À TOUTES GARANTIES IMPLICITES, Y COMPRIS

LES GARANTIES DE « QUALITÉ MARCHANDE »

OU D’« ADAPTATION À UN USAGE PARTICULIER »

APRÈS LA PÉRIODE DE GARANTIE D’UN AN.

Cette garantie vous donne des droits légaux spéciques, et vous pouvez également avoir d’autres droits

qui varient d’une province à l’autre. Certaines provinces

n’autorisant pas l’exclusion ou la restriction des dom-

mages accessoires ou consécutifs, il se peut que la

restriction ou l’exclusion ci-dessus ne s’applique pas à

vous. Certaines provinces n’autorisant pas de restric-

tion quant à la durée des garanties implicites, il se peut

que la restriction ci-dessus ne s’applique pas à vous.

20 FRANÇAIS

Page 21

ESPAÑOL (Instrucciones originales)

ESPECIFICACIONES

Modelo DFT022F DFT044F DFT084F DFT126F

Par de fuerza de

apriete

Velocidad sin carga (RPM) 700 r/min 950 r/min 780 r/min 410 r/min

Dimensiones 200 mm x 74 mm x 250 mm (7-7/8" x 2-15/16" x 9-7/8") (con cartucho de batería

Peso neto 1,5 kg (3,4 lbs) (con cartucho de batería BL1430B)

Tensión nominal 14,4 V c.c.

Cartucho de batería BL1415NA / BL1430 / BL1430B / BL1460A

• Debido a nuestro programa continuo de investigación y desarrollo, las especicaciones aquí dadas están sujetas a

cambios sin previo aviso.

• Las especicaciones y el cartucho de la batería pueden variar de país a país.

• Peso de acuerdo al procedimiento de EPTA-01/2003 incluyendo el cartucho de la batería

Advertencias de seguridad

generales para herramientas

eléctricas

ADVERTENCIA: lea todas las advertencias de segu-

ridad e instrucciones. Si no sigue todas las advertencias

e instrucciones indicadas a continuación, podrá ocasionar

una descarga eléctrica, un incendio y/o lesiones graves.

Guarde todas las advertencias

e instrucciones para su futura

referencia.

El término "herramienta eléctrica" se reere, en todas

las advertencias que aparecen a continuación, a su

herramienta eléctrica de funcionamiento con conexión

a la red eléctrica (con cableado eléctrico) o herramienta

eléctrica de funcionamiento a batería (inalámbrica).

Seguridad en el área de trabajo

1. Mantenga el área de trabajo limpia y bien iluminada. Las áreas oscuras o desordenadas son

propensas a accidentes.

2. No utilice las herramientas eléctricas en

atmósferas explosivas, tal como en la presen-

cia de líquidos, gases o polvo inamables. Las

herramientas eléctricas crean chispas que pueden

prender fuego al polvo o los humos.

3. Mantenga a los niños y curiosos alejados

mientras utiliza una herramienta eléctrica. Las

distracciones le pueden hacer perder el control.

Seguridad eléctrica

4.

Las clavijas de conexión de las herramientas

eléctricas deberán encajar perfectamente en la

toma de corriente. No modique nunca la clavija

de conexión de ninguna forma. No utilice ninguna

clavija adaptadora con herramientas eléctricas

que tengan conexión a tierra (puesta a tierra). La

Unión fuerte 0,5 N·m - 2 N·m

Unión suave 0,5 N·m - 2 N·m

(4 in·lbs - 18 in·lbs)

(4 in·lbs - 18 in·lbs)

200 mm x 74 mm x 235 mm (7-7/8" x 2-15/16" x 9-1/4") (con cartucho de batería

1,4 kg (3,0 lbs) (con cartucho de batería BL1415NA)

21 ESPAÑOL

1 N·m - 4 N·m

(8,9 in·lbs - 35 in·lbs)

1 N·m - 4 N·m

(8,9 in·lbs - 35 in·lbs)

utilización de clavijas no modicadas y que encajen

perfectamente en la toma de corriente reducirá el

riesgo de que se produzca una descarga eléctrica.

5. Evite tocar con el cuerpo supercies conec-

tadas a tierra o puestas a tierra tales como

tubos, radiadores, cocinas y refrigeradores. Si

su cuerpo es puesto a tierra o conectado a tierra

existirá un mayor riesgo de que sufra una descarga eléctrica.

6. No exponga las herramientas eléctricas a la

lluvia ni a condiciones húmedas. La entrada de

agua en una herramienta eléctrica aumentará el

riesgo de que se produzca una descarga eléctrica.

7. No jale el cable. Nunca utilice el cable para

transportar, jalar o desconectar la herramienta

eléctrica. Mantenga el cable alejado del calor,

aceite, objetos cortantes o piezas móviles. Los

cables dañados o atrapados aumentan el riesgo

de sufrir una descarga eléctrica.

8.

Cuando utilice una herramienta eléctrica en

exteriores, utilice un cable de extensión apropiado para uso en exteriores. La utilización de un

cable apropiado para uso en exteriores reducirá el

riesgo de que se produzca una descarga eléctrica.

9. Si no es posible evitar usar una herramienta

eléctrica en condiciones húmedas, utilice un

alimentador protegido con interruptor de circuito de falla en tierra (ICFT). El uso de un ICFT

reduce el riesgo de descarga eléctrica.

Seguridad personal

10. Manténgase alerta, preste atención a lo que

está haciendo y utilice su sentido común

cuando opere una herramienta eléctrica. No

utilice la herramienta eléctrica cuando esté

cansado o bajo la inuencia de drogas, alcohol o medicamentos. Un momento de distracción

mientras opera la máquina puede dar como resultado heridas personales graves.

3 N·m - 8 N·m

(27 in·lbs - 71 in·lbs)

3 N·m - 8 N·m

(27 in·lbs - 71 in·lbs)

BL1430B)

BL1415NA)

5 N·m - 12 N·m

(44 in·lbs - 106 in·lbs)

5 N·m - 12 N·m

(44 in·lbs - 106 in·lbs)

Page 22

11. Use equipo de protección personal. Póngase

siempre protección para los ojos. El equipo

protector tal como máscara contra el polvo, zapatos de seguridad antiderrapantes, casco rígido y

protección para oídos utilizado en las condiciones

apropiadas reducirá las heridas personales.

12.

Impida el encendido accidental. Asegúrese de

que el interruptor esté en la posición de apagado antes de conectar a la alimentación eléctrica y/o de colocar el cartucho de la batería, así

como al levantar o cargar la herramienta. Cargar

las herramientas eléctricas con su dedo en el interruptor o enchufarlas con el interruptor encendido

hace que los accidentes sean propensos.

13.

Retire cualquier llave de ajuste o llave de apriete

antes de encender la herramienta. Una llave

de ajuste o llave de apriete que haya sido dejada

puesta en una parte giratoria de la herramienta

eléctrica podrá resultar en heridas personales.

14. No utilice la herramienta donde no alcance.

Mantenga los pies sobre suelo rme y el equilibrio en todo momento. Esto permite un mejor

control de la herramienta eléctrica en situaciones

inesperadas.

15.

Use vestimenta apropiada. No use ropas sueltas

ni joyas. Mantenga el cabello, la ropa y los guantes alejados de las piezas móviles. Las prendas

de vestir holgadas, las joyas y el cabello suelto

podrían engancharse en estas piezas móviles.

16. Si dispone de dispositivos para la conexión de

equipos de extracción y recolección de polvo,

asegúrese de conectarlos y utilizarlos debidamente. La utilización de estos dispositivos reduce

los riesgos relacionados con el polvo.

Mantenimiento y uso de la herramienta eléctrica

17.

No fuerce la herramienta eléctrica. Utilice la

herramienta eléctrica correcta para su aplicación.

La herramienta eléctrica adecuada hará un trabajo

mejor a la velocidad para la que ha sido fabricada.

18. No utilice la herramienta eléctrica si el inte-

rruptor no la enciende y apaga. Cualquier

herramienta eléctrica que no pueda ser controlada con el interruptor es peligrosa y debe ser

reemplazada.

19. Desconecte la clavija de la fuente de energía

y/o la batería de la herramienta eléctrica antes

de realizar ajustes, cambiar accesorios o guardar las herramientas eléctricas. Dichas medidas

de seguridad preventivas reducen el riesgo de

que la herramienta se inicie accidentalmente.

20. Guarde la herramienta eléctrica que no use

fuera del alcance de los niños y no permita

que las personas que no están familiarizadas

con ella o con las instrucciones la operen. Las

herramientas eléctricas son peligrosas en manos

de personas que no saben operarlas.

21. Realice el mantenimiento a las herramientas

eléctricas. Compruebe que no haya partes

móviles desalineadas o estancadas, piezas

rotas y cualquier otra condición que pueda

afectar al funcionamiento de la herramienta

eléctrica. Si la herramienta eléctrica está

dañada, haga que se la reparen antes de

utilizarla. Muchos accidentes son ocasiona-

dos por herramientas eléctricas con un mal

mantenimiento.

22. Mantenga las herramientas de corte limpias

y losas. Si recibe un mantenimiento adecuado

y tiene los bordes alados, es probable que la

herramienta se atasque menos y sea más fácil

controlarla.

23. Utilice la herramienta eléctrica, así como acce-

sorios, piezas, brocas, etc. de acuerdo con

estas instrucciones y de la manera establecida

para cada tipo de unidad en particular; tenga

en cuenta las condiciones laborales y el trabajo a realizar. Si utiliza la herramienta eléctrica

para realizar operaciones distintas de las indica-

das, podrá presentarse una situación peligrosa.

Uso y cuidado de la herramienta a batería

24. Realice la recarga sólo con el cargador espe-

cicado por el fabricante. Un cargador que es

adecuado para un solo tipo de batería puede

generar riesgo de incendio al ser utilizado con otra

batería.

25. Utilice las herramientas eléctricas solamente

con las baterías designadas especícamente

para ellas. La utilización de cualquier otra batería

puede crear un riesgo de heridas o incendio.

26. Cuando no se esté usando el cartucho de la

batería, manténgalo alejado de otros objetos

metálicos, como sujetapapeles (clips), monedas, llaves, clavos, tornillos u otros objetos

pequeños de metal los cuales pueden actuar

creando una conexión entre las terminales de

la batería. Cerrar el circuito de las terminales de

la batería puede causar quemaduras o incendios.

27. En condiciones abusivas, podrá escapar

líquido de la batería; evite tocarlo. Si lo toca

accidentalmente, enjuague con agua. Si hay

contacto del líquido con los ojos, acuda por

ayuda médica. Puede que el líquido expulsado

de la batería cause irritación o quemaduras.

Servicio de mantenimiento

28. Haga que una persona calicada repare la

herramienta utilizando sólo piezas de repuesto

idénticas. Esto asegura que se mantenga la

seguridad de la herramienta eléctrica.

29. Siga las instrucciones para la lubricación y

cambio de accesorios.

30. Mantenga las agarraderas secas, limpias y sin

aceite o grasa.

ADVERTENCIAS DE SEGURIDAD

DEL ATORNILLADOR

INALÁMBRICO

1. Sujete la herramienta eléctrica por las supercies de agarre aisladas al realizar una operación en la que el porta útil pueda entrar en

contacto con cables ocultos. Si el porta útil

entra en contacto con un cable con corriente, las

piezas metálicas expuestas de la herramienta

eléctrica se cargarán también de corriente y el

operario puede recibir una descarga.

2.

Asegúrese siempre de que pisa sobre suelo rme.

Asegúrese de que no haya nadie debajo

cuando utilice la herramienta en lugares altos.

3. Sostenga la herramienta con rmeza.

4. Mantenga las manos alejadas de las piezas

giratorias.

22 ESPAÑOL

Page 23

No toque la broca o la pieza de trabajo inme-

5.

diatamente después de utilizarla; podrían estar

muy calientes y producirle quemaduras de piel.

GUARDE ESTAS

INSTRUCCIONES.

ADVERTENCIA: NO DEJE que la como-

didad o familiaridad con el producto (a

base de utilizarlo repetidamente) sustituya

la estricta observancia de las normas de

seguridad para dicho producto. El MAL

USO o el no seguir las normas de seguridad establecidas en este manual de instrucciones puede ocasionar graves lesiones personales.

Símbolos

A continuación se muestran los símbolos utilizados

para la herramienta.

volts o voltios

corriente directa o continua

velocidad en vacío o sin carga

revoluciones o alternaciones por minuto,

frecuencia de rotación

INSTRUCCIONES IMPORTANTES

DE SEGURIDAD

PARA CARTUCHO DE BATERÍA

1. Antes de utilizar el cartucho de batería, lea

todas las instrucciones e indicaciones de precaución sobre (1) el cargador de baterías, (2) la

batería, y (3) el producto con el que se utiliza la

batería.

2. No desarme el cartucho de batería.

3. Si el tiempo de operación se ha acortado en

exceso, deje de operar de inmediato. Podría

correrse el riesgo de sobrecalentamiento,

posibles quemaduras e incluso explosión.

4. En caso de que ingresen electrolitos en sus

ojos, enjuáguelos bien con agua limpia y consulte de inmediato a un médico. Podría perder

la visión.

5. No cortocircuite el cartucho de batería:

(1) No toque las terminales con ningún mate-

rial conductor.

(2) Evite guardar el cartucho de batería en un

cajón junto con otros objetos metálicos,

tales como clavos, monedas, etc.

(3) No exponga la batería de cartucho a la

lluvia o nieve.

Un corto circuito en la batería puede causar un

ujo grande de corriente, sobrecalentamiento,

posibles quemaduras y aún descomposturas.

6. No guarde la herramienta ni el cartucho de

batería en lugares donde la temperatura pueda

alcanzar o exceder los 50°C (122°F).

7. Nunca incinere el cartucho de batería incluso

en el caso de que esté dañado seriamente o

ya no sirva en absoluto. El cartucho de batería

puede explotar si se tira al fuego.

8. Tenga cuidado de no dejar caer ni golpear el

cartucho de batería.

9. No use una batería dañada.

10. Las baterías incluidas están sujetas a cum-

plir con los requisitos de la Legislación de

Insumos Peligrosos.

Para transportes comerciales, p.ej. por entidades

terceras como agencias de envío de paquetería,

se requiere de un empacado con el etiquetado

correspondiente.

Para la preparación del artículo a ser enviado, se

requiere de la asesoría de un experto con sus-

tancias peligrosas. Por favor también asegúrese

de cumplir con las posibles normas nacionales

detalladas.

Cubra con cinta adhesiva o coloque una barrera

en los contactos que estén expuestos y empaque

la batería de tal manera que no pueda moverse

dentro del paquete.

11. Siga las regulaciones locales relacionadas al

desecho de las baterías.

GUARDE ESTAS

INSTRUCCIONES.

PRECAUCIÓN: Use solo baterías auténticas de

Makita.

El uso de baterías no auténticas de Makita, o baterías

que hayan sido alteradas, puede que resulte en la

explosión de la batería, originando un incendio, así

como lesiones al usuario y daños. También anulará la

garantía de Makita para la herramienta y el cargador

Makita.