Page 1

Owner’s and Safety Manual

for Gasoline Chain Saws (page 2 - 32)

Manuel d’emploi et de sécurité

de tronçonneuses thermiques (page 33 - 63)

DCS430, DCS431

DCS520, DCS520i

DCS540

DCS5200, DCS5200i

WARNING!

Read and understand this Manual. Always follow safety precautions in the Owner’s and Safety Manual.

Improper use can cause serious injury!

The engine exhaust from this product contains chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm. Preserve this Manual carefully!

ATTENTION!

Suivez toujours les conseils de sécurité du présent manuel d’emploi et de sécurité. Une utilisation

incorrecte de la tronçonneuse peut entraîner des blessures graves! Conservez avec soin ce manuel!

Les gaz d’échappement émis par ce produit contiennent des produits chimiques connus par l’Etat de

Californie pour provoquer le cancer, des défauts de naissance ou autres dommages de reproduction.

Lisez et comprenez ce manuel.

1

Page 2

EMISSIONS COMPONENT DEFECT WARRANTY COVERAGE

MAKITA U.S.A, Inc warrant to the initial retail purchaser and each subsequent owner, that this utility equipment was designed, built,

and equipped to conform at the time of initial sale to all applicable regulations of the U.S.

Environmental Protection Agency (EPA), and that the engine is free of defects in materials and workmanship which would cause

this engine to fail to conform with EPA regulations during its warranty period.

For the components listed under PARTS COVERED, the service dealer authorized by MAKITA will, at no cost to you, make the

necessary diagnosis, repair, or replacement necessary to ensure that the engine complies with applicable U.S. EPA regulations.

EMISSION COMPONENT DEFECT WARRANTY PERIOD

The warranty period for this engine begins on the date of sale to the initial purchaser and continues for a period of 2 years.

PARTS COVERED

Listed below are the parts covered by the Emission Components Defect Warranty. Some of the parts listed below may require

scheduled maintenance and are warranted up to the first scheduled replacement point for that part.

Fuel Metering System Ignition System

Carburetor and internal parts Spark plugs

Fuel filter, if applicable Flywheel Magneto

Throttle stopper, if applicable Ignition Coil

Choke System, if applicable

Air Induction System Miscellaneous Items Used in Above Systems

Pre filter, if exist Fuel hoses, clamps and sealing gaskets

Air filter, Air cleaner case, Intake manifold

OBTAINING WARRANTY SERVICE

To obtain warranty service, take your engine to the nearest MAKITA Factory Service Center or service Center authorized by

MAKITA. Bring your sales receipts indicating date of purchase for this engine. The dealer of service authorized by MAKITA will

perform the necessary repairs or adjustments within a reasonable amount of time and furnish you with a copy of the repair order.

All parts and accessories replaced under this warranty become the property of MAKITA.

WHAT IS NOT COVERED

• Conditions resulting from tampering, misuse, improper adjustment (unless they were made by the service dealer authorized by

MAKITA during a warranty repair), alteration, accident, failure to use the recommended fuel and oil, or not performing required

maintenance services.

• The replacement parts used for required maintenance services.

• Consequential damages such as loss of time, inconvenience, loss of use of the engine or equipment, etc.

• Diagnosis and inspection charges that do not result in warranty-eligible service being performed.

• Any non-authorized replacement part, or malfunction of authorized parts due to use of non-authorized parts.

OWNER’S WARRANTY RESPONSIBILITIES

As the engine owner, you are responsible for the performance of the required maintenance listed in your owner’s manual.

MAKITA recommends that you retain all receipts covering maintenance on your engine, but MAKITA cannot deny warranty solely

for the lack of receipts or for your failure to ensure the performance of all scheduled maintenance. As the engine owner, you should

however be aware that MAKITA may deny warranty coverage if your engine or a part has failed due to abuse, neglect, improper

maintenance or unapproved modifications.

You are responsible for presenting your engine to the nearest service dealer authorized by MAKITA when a problem exists.

If you have any questions regarding your warranty rights and responsibilities, you should contact the MAKITA Warranty service

Department at 1-888-OPE-PART for the information.

THINGS YOU SHOULD KNOW ABOUT THE EMISSION CONTROL SYSTEM WARRANTY:

MAINTENANCE AND REPAIRS

You are responsible for the proper maintenance of the engine. You should keep all receipts and maintenance records covering the

performance of regular maintenance in the event questions arise. These receipts and maintenance records should be transferred

to each subsequent owner of the engine. MAKITA reserves the right to deny warranty coverage if the engine has not been properly

maintained. Warranty claims will not be denied, however, solely because of the lack of required maintenance or failure to keep

maintenance records.

MAINTENANCE, REPLACEMENT OR REPAIR OF EMISSION CONTROL DEVICES AND SYSTEMS MAY BE PERFORMED BY

ANY REPAIR ESTABLISHMENT OR INDIVIDUAL; HOWEVER, WARRANTY REPAIRS MUST BE PERFORMED BY A SERVICE

DEALER AUTHORIZED BY MAKITA. THE USE OF PARTS THAT ARE NOT EQUIVALENT IN PERFORMANCE AND DURABILITY

TO AUTHORIZED PARTS MAY IMPAIR THE EFFECTIVENESS OF THE EMISSION CONTROL SYSTEM AND MAY HAVE A

BEARING ON THE OUTCOME OF A WARRANTY CLAIM.

If other than the parts authorized by MAKITA are used for maintenance replacements or for the repair of components affecting

emission control, you should assure yourself that such parts are warranted by their manufacturer to be equivalent to the parts

authorized by MAKITA in their performance and durability.

HOW TO MAKE A CLAIM

All repair qualifying under this limited warranty must be performed by a service dealer authorized by MAKITA. In the event that any

emission-related part is found to be defective during the warranty period, you shall notify MAKITA Warranty service Department at

1-888-OPE-PART and you will be advised of the appropriate warranty service dealer or service providers where the warranty repair

can be performed.

2

Page 3

WARNING !

Careless or improper use of this product can cause serious or even fatal injury.

Before operating a chain saw or other MAKITA products it is important that you read, fully understand and

carefully follow the instructions outlined in this owners manual. Kickback may cause severe or fatal injury and

is one of many potential dangers in operating a chain saw. Kickback and other safety related precautions are

described in detail within this owners manual. Additional owners manuals are available from MAKITA U.S.A.,

INC., 14930-C Northam Street, La Mirada, CA 90638-5753, USA, Telephone: (714) 522 80 88 and MAKITA

CANADA INC.,1950 Forbes Street, Whitby, Ontario, L1N 7B7, Canada, Telephone: (905) 571 22 00.

This product complies with: American National Standard Institute B 175.1-1991 chain saw safety standard.

Canadian Standards Association Z62.1-95 chain saw safety standard.

Z62.3-96 chain saw kickback standard.

Society of Automotive Engineers SAEJ 335-Jun 95 „Multiposition small

engine exhaust system fire ignition

suppression”

With the purchase of this chain saw you have chosen a German quality product. Important instructions for the

assembly and operation of this saw are given in this manual. For your own safety, we ask you to read the accident

prevention instructions very carefully before putting your chain saw into operation, as incorrect handling can,

despite all precautions, lead to accidents. With a little care and attention you will have good service and lasting

satisfaction from this first-rate product. The following industrial property rights apply: US 4465440, US 5411382,

EP 0236858, EP 0560201, GBM 8710075, GBM 8809928, GBM 9203378, GBM 29616652.

DCS430, DCS431, DCS520, DCS520i, DCS540, DCS5200, DCS5200i

Contents Page

Delivery inventory 4

Symbols 4

Safety precautions 5-16

Denomination of components 17

Technical data 18

Approved bar and chain combinations 18

Mounting the guide bar and saw chain 19-20

Chain brake 20

Fuel / Refuelling 21-22

Adjusting the chain lubrication 22

Starting the engine 23

Stopping the engine 23

Checking the chain brake 24

Checking the chain lubrication 24

Adjusting the carburetor 24

Working in winter 25

The MAKITA DCS430, DCS431, DCS520, DCS520i, DCS540, DCS5200, DCS5200i will be delivered in a

protective cardboard box to prevent transport damage. Cardboard is a basic raw material and is consequently

reuseable or suitable for recycling (waste paper recycling).

Contents Page

Sharpening the saw chain 25-26

Cleaning the guide bar 26

Cleaning the brake band and sprocket interior 27

Replacing the saw chain 27

Replacing the fuel filter 27

Replacing / cleaning the spark arrester screen 27

Cleaning the air filter 28

Replacing the spark plug 28

Replacing the starter cable 29

Replacing the return spring 29

Mounting the fan housing 29

Instructions for daily and periodic maintenance 30

Service, spare parts and guarantee 30-31

Troubleshooting 31

Extract from the spare parts list 32

Adress list 64

RE Y

3

Page 4

Delivery inventory

3

4

2

1 Chain saw

2 Saw chain

3 Guide bar

4 Chain protection cover

5 Universal wrench

6 Wrench

7 Screw driver for carburetor adjustment

(only in delivery for model DCS5200i, DCS5200)

8 Owner’s and Safety Manual (not shown)

Symbols

You will notice the following symbols on the chain saw and in the Owner’s and Safety Manual:

5

7 6

In case one of the parts listed should not be included in the

delivery inventory, please consult your sales agent.

1

Stop engine!

Wear protective gloves!

Chain brake

Caution, kickback!

Fuel and oil mixture

Carburetor adjustment

Chain oil fill/oil pump

Working in winter

First aid

Recycling

4

Page 5

Safety precautions for chain saw operators

Additional safety precautions

While operating the chain saw please observe the

following rules:

a) Contact of the guide bar nose with any object

should be avoided.

b) Tip contact may cause the guide bar to move

suddenly upward and backward, which may

cause serious or fatal injury.

c) Always operate the chain saw with both hands.

WARNING!

Read and follow all safety precautions in the owner’s

manual. Failure to follow instructions could result

in serious injury. It is recommended to lend the

chain saw only to people who are experienced in

working with chain saws. Always hand over the

Owner’s and Safety Manual.

WARNING!

This chain saw is capable of severe kickback that

could result in serious injury to the operator. Do not

operate this chain saw unless you have

extraordinary cutting needs and experience in and

special training for dealing with kickback. Chain

saws with significantly reduced kickback potential

are available.

The following additional safety precautions should be

observed by all users of chain saws:

1. Do not operate a chain saw when you are fatigued.

2. Use safety footwear; snug-fitting clothing;

protective gloves; and eye, hearing, and head

protection devices.

3. Use caution when handling fuel. Move the chain

saw at least 10 feet (3 m) from the fueling point

before starting the engine.

4. Do not allow other persons to be near the chain

saw when starting or cutting with the chain saw.

Keep bystanders and animals out of the work

area.

5. Do not start cutting until you have a clear work

area, secure footing, and a planned retreat path

from the falling tree.

6. Keep all parts of your body away from the saw

chain when the engine is running.

7. Before you start the engine, make sure that the

saw chain is not contacting anything.

8. Carry the chain saw with the engine stopped, the

guide bar and saw chain to the rear, and the

muffler away from your body.

WARNING!

Kickback may occur when the nose or tip of the

guide bar touches an object, or when the wood

closes in and pinches the saw chain in the cut. This

contact may abruptly stop the saw chain and in

some cases may cause a lightning fast reverse

reaction, kicking the guide bar up and back towards

the user, or push the guide bar back towards the

operator. Kickback may cause you to lose control

of the saw.

As a chain saw user, you can take several steps to

reduce the risk of a kickback and potential injury.

A. With a basic understanding of kickback, you

can reduce or eliminate the element of surprise.

It is a sudden surprise that contributes to

accidents.

B. Keep a good firm grip on the saw with both

hands, your right hand on the rear grip and

your left hand on the tubular handle, when the

engine is running. Use a firm grip with thumbs

and fingers encircling the chain saw handles.

A firm grip can neutralize kickback and help

you maintain control of the saw. Don’t let go!

C. Make sure that the area in which you are

cutting is free from obstructions. Do not let the

nose of the guide bar contact the log, branch,

or any other obstructions which could be hit

while you are operating the saw.

D. Do not overreach or cut above shoulder height.

E. Follow manufacturer’s sharpening and main-

tenance instructions for the saw chain.

F. Only use replacement bars and chains speci-

fied by the manufacturer or the equivalent.

9. Do not operate a chain saw that is damaged, is

improperly adjusted, or is not completely and

securely assembled. Be sure that the saw chain

stops moving when the throttle control trigger is

released.

10. Shut off the engine before setting it down.

11. Use extreme caution when cutting small size

brush and saplings because slender material may

catch the saw chain and be whipped toward you

or pull you off balance.

12. When cutting a limb that is under tension be alert

for springback so that you will not be struck when

the tension on the wood fibers is released.

13. Keep the handles dry, clean, and free of oil or fuel

mixture.

14. Operate the chain saw only in well-ventilated

areas.

15. Do not operate a chain saw in a tree unless you

have been specifically trained to do so.

16. All chain saw service, other than the items listed in

the owner’s manual maintenance instructions,

should be performed by MAKITA . (For example,

if improper tools are used to remove the flywheel

or if an improper tool is used to hold the flywheel

in order to remove the clutch structural damage to

the flywheel could occur and could subsequently

cause the flywheel to burst.)

17. When transporting your chain saw, use the chain

protection cover.

18. Low kickback bars and low kickback chains are

designed to reduce the risk of kickback injury. Ask

your MAKITA dealer about these devices.

5

Page 6

General Safety Precautions

The use of any chain saw may be hazardous. At full

throttle chain speed can reach 45 mph (20 m/s). It is

important that you read; fully understand and observe

the following safety precautions and warnings. Read

the owner’s manual and the safety instructions

periodically.

WARNING !

Reactive forces, including kickback, can be dangerous. Careless or improper use of any chain saw

may cause serious or fatal injury.

MaximumComputed Kickback Angle

(CKA)* with using the chain brake when

using the recommended bar and chain

combinations (In this example the CKA is 40°).

Have your MAKITA dealer show you how to operate

your chain saw. Observe all applicable local safety

regulations, standards and ordinances.

1

WARNING!

Minors should never be allowed to use a chain

saw.

Bystanders, especially children and animals should

not be allowed in the area where a chain saw is in

use (fig. 1).

Never let the saw run unattended.

Store it in a locked place away from children. Fill

the fuel tank to 7/8 th full (see storing the saw).

Do not lend your chain saw without this owner’s

manual. Be sure that anyone using your saw understands the information given.

Always use two hands when

operating the chain saw!

Reduced Kickback Bar and

Chain combination that has been

XXX.YYY.ZZZ

XXX.YYY.ZZZ

* The Computed Kickback Angle is a calculated value

from energies measured on a test bench.It is not the

angle of the guide bar moved upward in case of a

KICKBACK.

evaluated with the power head

to achieve kickback protection

(according to ANSI and CSA

standards).

The operator

Physical Condition

You must be in good physical condition and mental

health and not under the influence of any substance

(drugs, alcohol), which might impair vision, dexterity

or judgment.

2

Proper use of a chain saw involves

1. the operator

2. the saw

3. the use of the saw.

Discription of symbols used on chain

saws:

Z 62.1-95 and

Z 62.3-96

Class 1A

ANSI B175.1-1991

Chain Saw listed in accordance with

45M6

6

American National Standard Safety

Specifications for Gasoline Powered

Chain Saws (ANSI B 175.1-1991).

Compliance with

CSA -Standards

Compliance with

ANSI -Standards

WARNING !

Prolonged use of chain saws exposing the operator

to vibrations may produce Whitefinger disease

(Raynaud’s phenomenon). This phenomenon

reduces the hand’s ability to feel and regulate

temperature, produces numbness and burning

sensations and may cause nerve and circulation

damage and tissue necrosis.

All MAKITA saws are therefore provided with an

antivibration system which is essential for those

using chain saws on a regular or sustained basis.

Antivibration systems do not guarantee that you will

not sustain Whitefinger disesase, however, they

reduce this danger considerably. Nevertheless,

continual and regular users should observe their

hands and fingers and in case of any abnormal

symptoms, seek medical advice immediately.

Page 7

Proper clothing

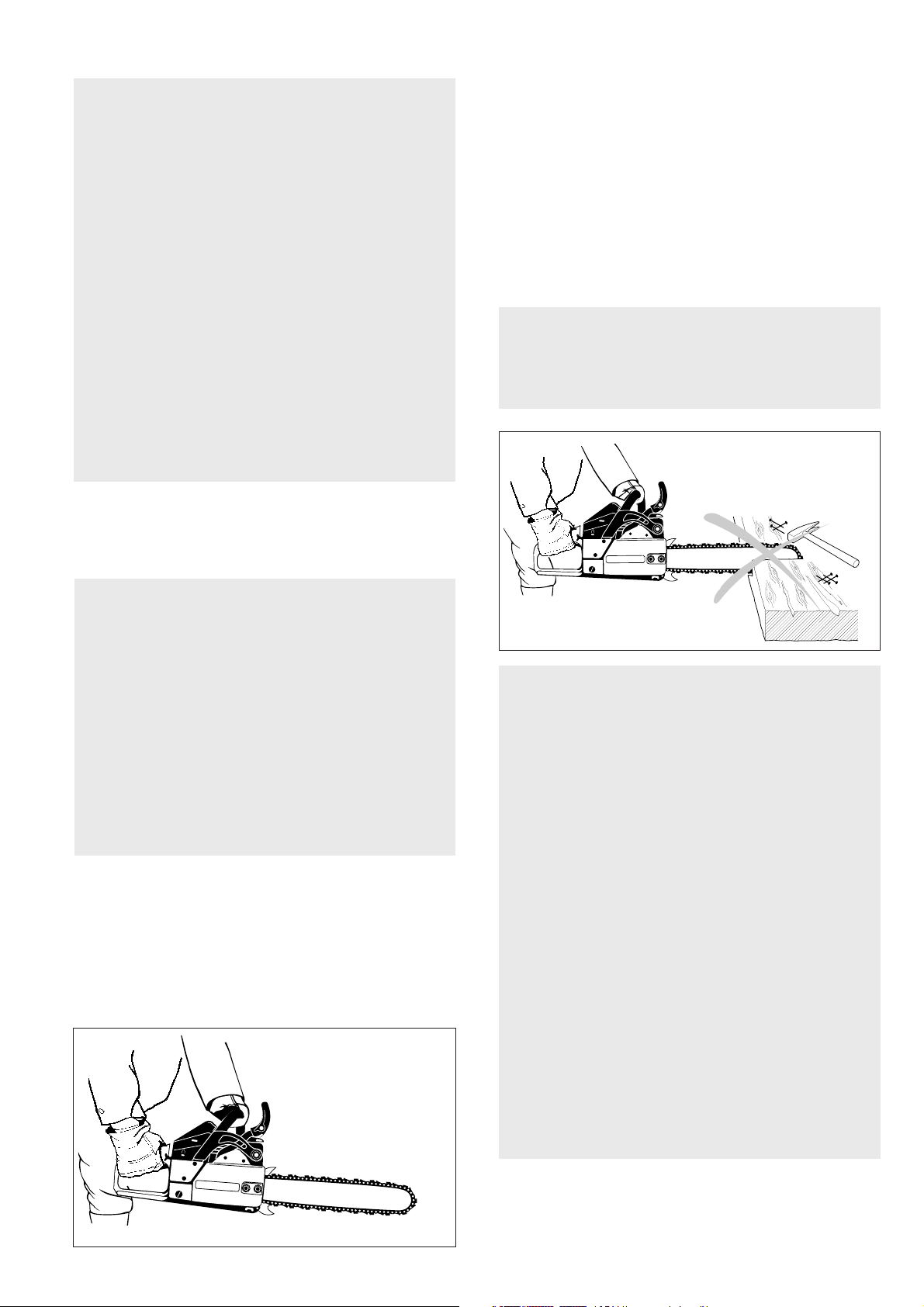

The saw

Clothing must be sturdy and snug-fitting, but allow

complete freedom of movement. Avoid loose-fitting

jackets, scarfs, neckties, jewelry, flared or cuffed pants,

or anything that could become entangled with the saw

or brush. Wear overalls or jeans with a reinforced

cutting resistant insert (fig. 3).

Protect your hands with gloves when handling saw

and saw chain. Heavy-duty, nonslip gloves improve

your grip and protect your hands.

Parts of the chain saw: illustrations and description of

parts see page 17.

WARNING !

Never modify a chain saw in any way. Only

attachments supplied by MAKITA or expressly

approved by MAKITA for use with the specific saw

are authorized.

WARNING !

Bow guide bars substantially increase the potential

for kickback and severe or fatal injury due to the

greater kickback zone of the bow design. Bow

guide bars are not recommended for use on

MAKITA chain saws nor are they approved by the

ANSI B 175.1-1991 chain saw safety standard.

The use of the saw

Transporting the chain saw

3

Good footing is most important in chain saw work.

Wear sturdy boots with nonslip soles. Steel-toed safety

boots are recommended.

Proper eye protection is a must. Non-fogging, vented

goggles and a face screen is recommended. Their

use reduces the risk of eye and facial injury.

Wear an approved safety hard hat to protect your

head. Chain saw noise may damage your hearing.

Always wear noise protection equipment (ear plugs

or ear muffs) to protect your hearing.

Continual and regular users should have their

hearing checked regularly.

WARNING!

Always stop the engine before putting a chain saw

down or carrying it. Carrying a chain saw with the

en- gine running is extremely dangerous. Accidental

acceleration of the engine can cause the chain to

rotate.

Avoid touching the hot muffler.

4

By hand: When carrying your saw by hand, the

engine must be stopped and the saw must be in the

proper position.

The chain protection cover should be over the

chain and the guide bar must point backwards.

When carrying your saw the bar should be behind

you (fig. 4).

Wear protective helmet,

eye and ear protection!

By vehicle: When transporting in a vehicle, keep

chain and bar covered with the chain guard.

Properly secure your saw to prevent turnover, fuel

spillage and damage to the saw. Make sure the

saw in not exposed to heat or sparks.

7

Page 8

Chain saw operating instructions

For assembly follow the procedure in the appropriate

section "Mounting Guide Bar and Chain" of this manual.

MAKITA chain, guide bar and sprocket must match

each other (see the appropriate section in this manual).

WARNING!

Proper tension of the chain is extremely important.

In order to avoid false setting the tensioning

procedure must be followed as described in this

manual. Always make sure the hexagonal nut(s)

for the sprocket guard is (are) tightened securely

after tensioning the chain. Check chain tension

once more after having tightened the nuts and

thereafter at regular intervals (always before starting

to work). If the chain becomes loose while cutting,

shut off the engine and then tighten. Never try to

tighten the chain while the engine is running!

Fueling

Your MAKITA saw uses on oil-gasoline mixture for fuel

(see chapter "Fuel" of this manual).

Wipe off any spilled fuel before starting your saw and

check for leakage.

Check for fuel leakage while refueling and during

operation. If fuel or oil leakage is found, do not start or

run the engine until leak is fixed and spilled fuel has

been wiped away. Clothing with fuel on it has to be

changed immediately (this is a danger to your life!).

Avoid skin contact with fuel. Never loosen or remove

the cap of the fuel tank while the engine is running.

Starting

Do not drop start. This method is very dangerous because you may lose control of the saw (fig. 6).

5

WARNING!

Gasoline is an extremely flammable fuel. Use

extreme caution when handling gasoline or fuel

mix. Do not smoke or bring any sparks or flame

near the fuel (fig. 5).

Fueling instructions

Fuel your chain saw in well ventilated areas or outdoors. Always shut off the engine and allow it to cool

before refueling. Select bare ground for fueling and

move the chain saw at least 10 feet (3 m) from fueling

spot before starting the engine (fig. 5a).

6

6a

Place the chain saw on firm ground or other solid

surface in an open area. Maintain a good balance and

secure footing. Place your right foot through the rear

handle opening and firmly grasp the front handle with

your left hand (fig. 6a).

Be absolutely sure that guide bar and chain are clear

of you or all other obstructions and objects, including

the ground, because when the engine starts in semithrottle position, engine speed will be fast enough for

the clutch to engage the sprocket and turn the chain

which may cause a kickback.

Never attempt to start the saw when the guide bar is in

a cut or kerf.

When you pull the starter grip, don’t wrap the starter

10 feet

rope around your hands. Do not allow the grip to snap

back, but guide the starter rope slowly back to permit

the rope to rewind properly. Failure to follow this

procedure may result in injury to hand or fingers and

may damage the starter mechanism.

5a

8

Page 9

Important adjustments

WARNING!

At correct idle speed, chain should not turn. For directions to adjust idle speed, see the appropriate

section of this instruction manual.

Do not use a saw with incorrect idle speed adjustment. Adjust the idle speed yourself according to

the appropriate section of this manual.

Have your MAKITA dealer check your saw and

make proper adjustments or repairs.

Check the saw chain tension frequently, especially

just after installing a new chain. New chains may

stretch more during their initial use. A properly

adjusted saw chain can be pulled freely around the

guide bar by hand without sagging. Always stop

the engine and wear gloves when checking or

adjusting the chain tension.

Working conditions

Wrap your fingers tightly around the handles, keeping

the handles cradled between your thumb and forefinger (fig. 7). With your hands in this position, you can

best oppose and absorb the push, pull and kickback

forces of your saw without having it slip out of your

grip (see section of reactive forces). Make sure your

chain saw handle and grip are in good condition and

free of moisture, pitch, oil or grease.

Always start a cut with the chain running at full speed

and the spike bar in contact with the wood.

WARNING!

Never use the saw with one hand. You cannot

control reactive forces (see pages 10 to 12) and

may lose control of the saw.

Operate your chain saw only outdoors. Operate the

saw under good visibility and daylight conditions only.

WARNING!

Take extreme care in wet and freezing weather

(rain, snow, ice). Put off the work when the weather

is windy, stormy or rainfall is heavy. Clear the area

where you are working.

WARNING!

Avoid stumbling on obstacles such as stumps,

roots or rocks and watch out for holes or ditches.

Be extremely cautious when working on slopes or

uneven ground. There is increased danger of slipping on freshly debarked logs.

Cutting instructions

Always hold the saw firmly with both hands when the

engine is running. Place your left hand on the tubular

handle and your right hand on grip and throttle lever.

Left-handers should follow these instructions too.

8

WARNING!

Do not operate your chain saw in semi-throttle

position. Cutting in this position does not permit

the operator proper control of the saw or chain

speed.

WARNING!

Never come too close to a rotating chain with your

hands or body.

WARNING!

Do not cut any material other than wood or

wooden objects.

Use your chain saw for cutting only. It is not

designed for prying or shoveling away limbs, roots

or other objects.

When sawing, make sure that the saw chain does

not touch any foreign materials such as rocks,

nails and the like (fig. 8). Such objects may be flung

off, damage the saw chain or cause the saw to

kickback.

7

9

Page 10

9

In order to keep control of your saw, always maintain

a firm foothold. Never work on a ladder, in a tree or on

any other insecure support. Never use the saw above

shoulder height (fig. 9).

10

Position the chain saw in such a way that your body is

clear of the cutting attachment whenever the engine is

running (fig. 10).

Don’t put pressure on the saw when reaching the end

of a cut. The pressure may cause the bar and rotating

chain to pop out of the cut or kerf, go out of control and

strike the operator or some other object. If the rotating

chain strikes some other object a reactive force (see

pages 11 to 13 ) may cause the chain to strike the

operator.

Reactive forces during the cut, including kickback

WARNING!

Reactive forces, that may occur during any cut are

kickback, pushback and pull-in. Reactive forces

can be dangerous! In any chain saw, the powerful

force used to cut wood can be reversed (and work

against the operator).

If the rotating chain is suddenly stopped by contact

with any solid object like a log or branch or is

pinched, the reactive forces instantly occur. These

reactive forces may result in loss of control which

may, in turn, cause serious or fatal injury. An

understanding of the causes of these reactive

forces may help you avoid loss of control.

The most common reactive forces are

- kickback,

- pushback,

- pull-in.

10

Page 11

Many factors influence the occurence and force of

the kickback reaction. The type of bar and saw chain

you use is a factor in the force of the kickback reaction.

The speed of contact at which the cutter contacts

the object.

Kickback force increase with the rate of impact.

The contact angle between the nose of the bar

and the foreign object (fig. 11).

Kickback is most pronounced in the upper quadrant

of the bar nose.

MAKITA chain types are designed to reduce kickback

forces.

The depth gauges:

Improper lowering of the depth gauges also increases

the risk of a kickback.

13

To avoid kickback

The best protection from personal-injury that may

result from kickback is to avoid kickback situations:

1. Hold the chain saw firmly with both hands and

maintain a secure grip.

Saw chain cutter sharpness:

WARNING!

A dull improperly sharpened chain may increase

the risk of kickback. Always cut with a properly

sharpened chain.

Devices for reducing the risk of kickback injury

MAKITA have developed a special chain brake to

reduce the risk of kickbacks.

This chain brake increases the safety factor on the

job, e.g. when the saw suddenly bucks upwards the

chain stops rotating within a fraction of a second. A

deflection guard on the disengaging lever of the chain

brake and a scoop rear handle ensure that the operator’s hands are fully protected at all times.

Kickback tendency increases as the radius or size of

the guide bar nose increases. MAKITA have developed guide bars with small nose radius, to reduce the

kickback tendency.

WARNING!

No chain brake prevents kickback.

These brakes are designed only to stop the chain,

if activated.

To ensure a proper operation of the chain brake, it

must be properly maintained. Furthermore, there

must be a sufficient distance between the operator

and the bar to ensure that the chain brake has

sufficient time to activate and stop the chain before

potential contact with the operator.

2. Be aware of the location of the guide bar nose at

all times.

3. Never bring the nose of the guide bar in contact

with any object. Do not cut limbs with the nose of

the guide bar. Be especially careful with small,

tough limbs, small size brush and saplings which

may easily catch the chain.

4. Don’t overreach.

5. Don’t cut above shoulder height.

6. Begin cutting and continue at full throttle.

7. Cut only one log at a time.

8. Use extreme caution when re-entering a previous

cut.

9. Do not attempt plunge cuts (see page 14) if you

are not experienced with these cutting techniques.

10. Be alert for shifting of the log or other forces that

may cause the cut to close and pinch the chain.

11. Maintain saw chain properly. Cut with a correctly

sharpened, properly tensioned chain at all times.

12. Stand to the side of the cutting path of the chain

saw.

11

Page 12

12

Page 13

45°

1

2

2

45°

= cutting down area

17

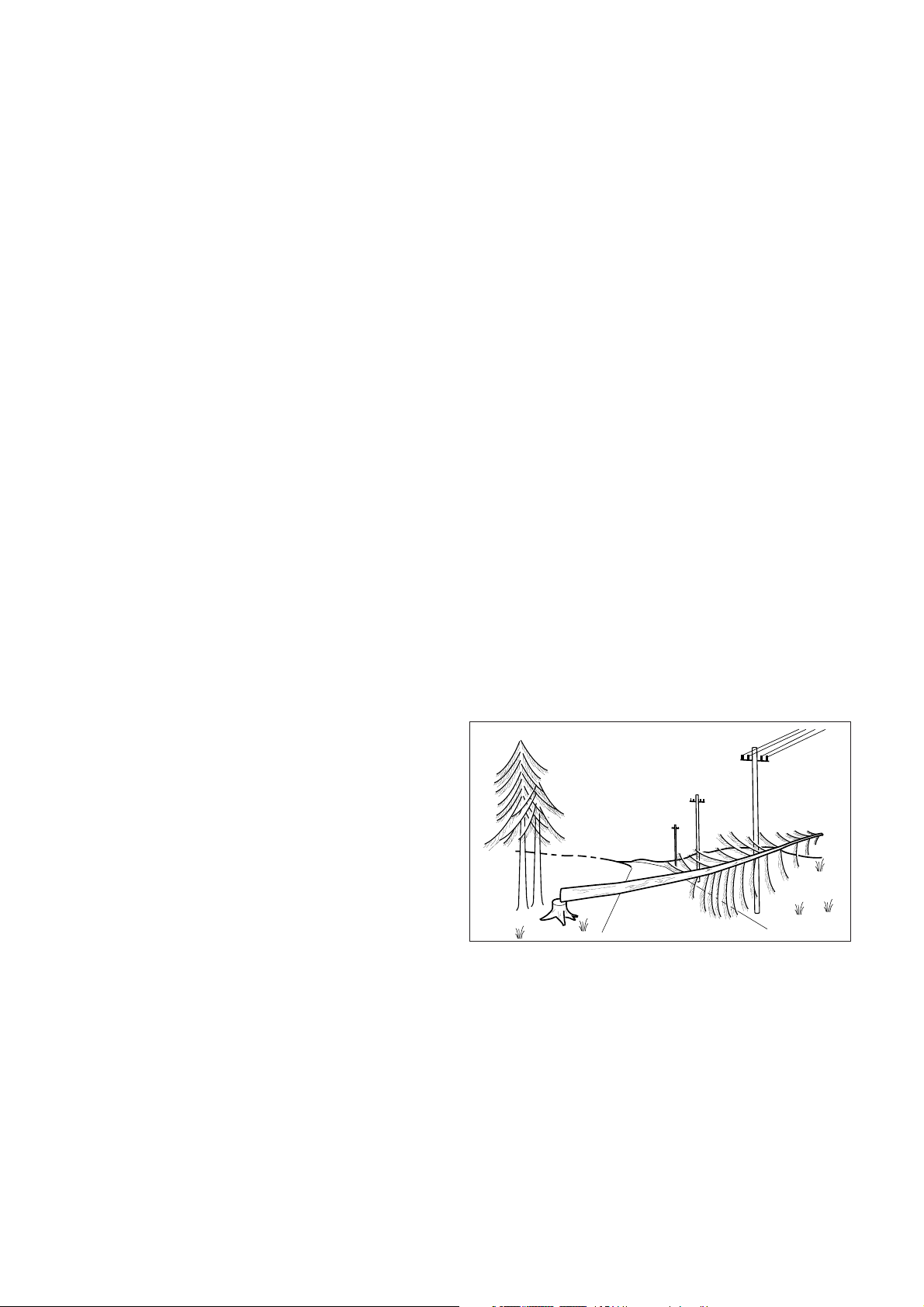

When felling, maintain a distance of at least 2 1/2 tree

lengths from the nearest person (see fig. 17)

.

Note:

The noise of your engine may drown any warning call.

Felling instructions:

First cut

Second cut

20

If the tree has large buttress roots, cut into the largest

buttresses vertically first (horizontally next) and remove (fig. 20).

Direction of fall

21

18

First clear the tree base and work area from interfering limbs and brush and clean its lower portion an

axe (see fig. 18).

45°

19

Then, establish a path of escape and remove all

obstacles. This path should be opposite to the planned

direction of the fall of the tree and at a 45° angle (fig.

19). An alternate path must also be selected. Place all

tools and equipment a safe distance away from the

tree, but not on the escape path.

Felling cut

1

"

/

(4cm)

1

2

1/10∅

Hinge

Felling notch

1/5∅

22

Felling notch

Hinge

23

Then, determine the placement of the felling notch

(fig. 21). The felling notch when properly placed determines the direction in which the tree will fall. It is

made perpendicular to the line of fall and should be as

close to the ground as possible. Cut the felling notch to

a depth of about one-fifth to one-fourth of the trunk

diameter (fig. 22). It should be in no case higher than

it is deep. Make the felling notch very carefully.

13

Page 14

Begin the felling cut slighty higher than the felling

notch and on the opposite side of the tree (fig. 22).

Then cut horizontally through towards the felling notch.

Apply the chain saw with its spikes directly behind the

uncut portion of wood and cut toward the notch (fig.

23). Leave approximately 1/10 of the tree diameter

uncut! This is the hinge (fig. 23). Do not cut through the

hinge because you could lose control of the direction

of the fall. Drive wedges into the felling cut where

necessary to control the direction of the fall. Wedges

should be of wood, light alloy or plastic - never of steel,

which can cause kickback and damage to the chain.

Always keep to the side of the falling tree. When the

tree starts to fall, shut off the engine, withdraw the bar

and walk away on the pre-planned escape path.

Watch out for falling limbs.

WARNING!

Be extremely careful with partially fallen trees which

are poorly supported.

Plunge-Cut Method

Timber having a diameter more than twice the length

of the guide bar reauires the use of the plunge-cut

method before making the felling cut.

First, cut a large, wide notch. Make a plunge cut in the

center of the notch.

The plunge cut is made with the guide bar nose. Begin

the plunge cut by applying the lower portion of the

guide bar nose to the tree at an angle (fig. 25). Cut until

depth of the kerf is about the same as the width of the

guide bar (fig. 26). Next, align the saw in the direction

When the tree hangs or for some other reason does

not fall completely, set the saw aside and pull the

tree down with a cable winch, block and tackle or

tractor. If you try to cut it down with your saw, you

may be injured.

Sectioning Method

WARNING!

Felling a tree that has a diameter greater than the

length of the guide bar requires use of either the

sectioning or plunge-cut method. These methods

are extremely dangerous because they involve the

use of the nose of the guide bar and can result in

kickback. Only properly trained professionals

should attempt these techniques.

1

25

in which the recess is to be cut. With the saw at full

throttle, insert the guide bar in the trunk (fig. 27).

Enlarge the plunge cut as shown in illustration (fig. 28)

26

23

24

For the sectioning method (fig. 24) make the first cut

with the guide bar fanning in toward the hinge. Then,

using the bumper spike as a pivot, reposition the saw

for the next cut. Avoid repositioning the saw more than

necessary. When repositioning for the next cut, keep

the guide bar fully engaged in the kerf to keep the

felling cut straight. If the saw begins to pinch, insert a

wedge to open the cut. On the last cut, do not cut

the hinge.

14

27

28

Page 15

29

WARNING!

There is an extreme danger of kickback at this

point. Extra caution must be taken to maintain

control of the saw. To make the felling cut, follow

the sectioning method described previously (fig.

29). If you are inexperienced with a chain saw

plunge-cutting should not be attempted. Seek the

help of a professional.

Limbing

Limbing is removing the branches from a fallen tree.

Bucking

Bucking is cutting a log into sections.

WARNING!

There is an extreme danger of kickback during the

limbing operation. Do not work with the nose of the

bar. Be extremely cautious and avoid contacting

the log or other limbs with the nose of the guide bar.

Do not stand on a log while limbing it - you may slip

or the log may roll.

30

Start limbing by leaving the lower limbs to support

the log off the ground (fig. 30). Always cut from the

top of the limb. Do not underbuck freely hanging

limbs. A pinch may result or the limb may fall,

causing loss of control. If a pinch occurs, stop the

engine and remove the saw, by lifting the limb.

WARNING!

Be extremely cautious when cutting limbs under

tension. The limbs could spring back toward the

operator and cause loss of control of the saw or

injury to the operator.

15

Page 16

16

Page 17

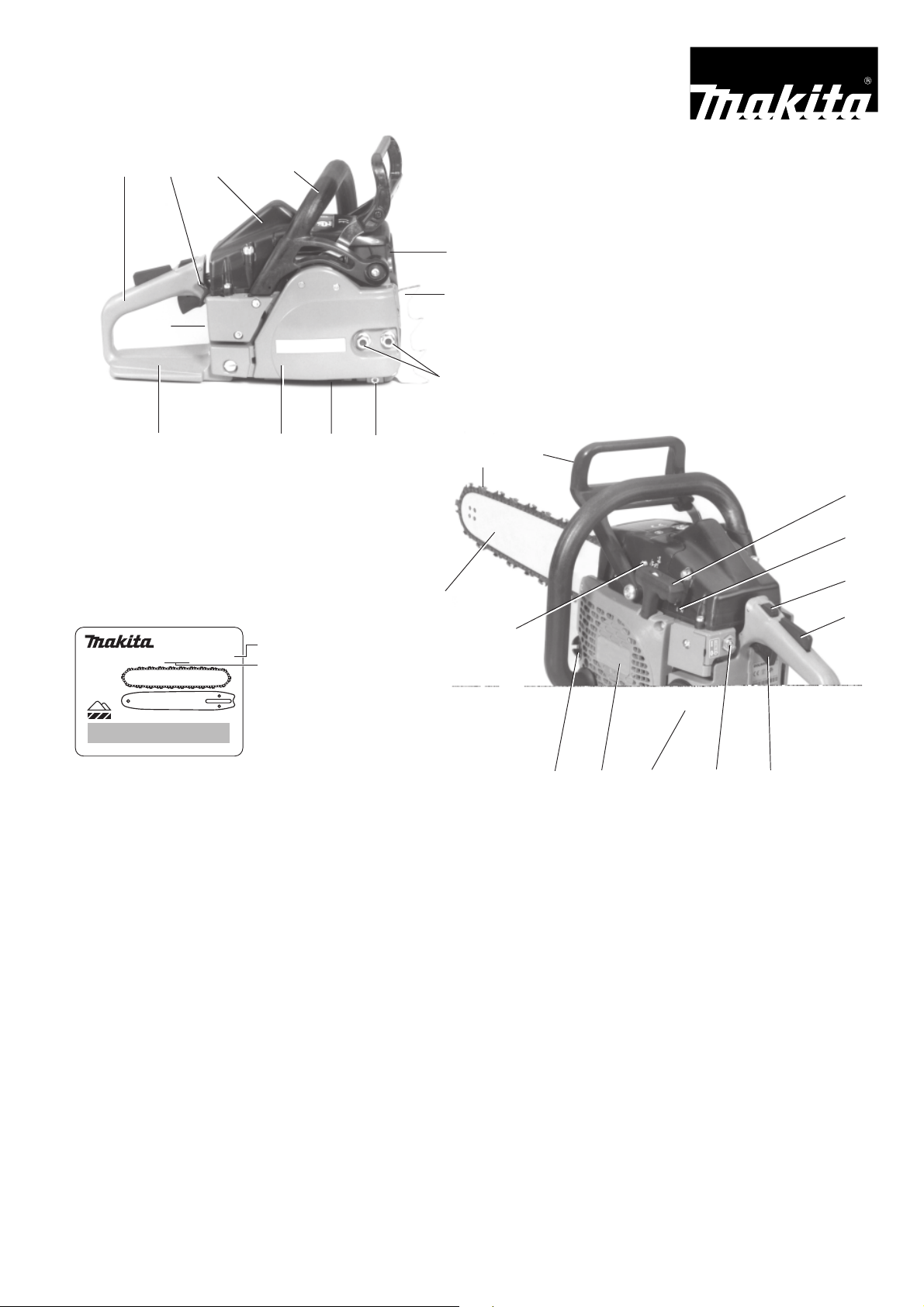

Denomination of components

1

32

11

12

Identification plate

(example model DCS5200)

21" (530mm)

DCS5200

0405 123456

523.102.672

443.053.661

22045 Hamburg,Germany

4

10

Serial no.

Year of manufacture

5

7

6

9

8

14

15

16

17

19

13

20

25

027.100. 653

Indicate when ordering spare parts!

1 Handle

2 Choke

3 Filter cover

4 Tubular handle

5 Muffler

6 Retaining nuts

7 Spike bar

(toothed stop for holding saw steady against wood)

8 Chain catch

9 Adjusting screw for oil pump (bottom side)

10 Sprocket guard

11 Identification plate

12 Hand guard

24

13 Guide bar

14 Chain

15 Hand guard (release for chain brake)

16 Starter grip

17 Adjusting screws "S-L-H" for carburetor

18 I/STOP-switch

19 Stop knob for halfway throttle

20 Throttle stopper

21 Throttle lever

22 Fuel tank cap

23 Fan housing with starting assembly

24 Oil tank cap

25 Decompression valve (only DCS431)

2223

18

21

17

Page 18

Technical data

Stroke volume cu. in 2.7 (43 cm3) 3.2 (52 cm3) 3.3 (54 cm3) 3.2 (52 cm3)

Bore inch 1.57 (40 mm) 1.73 (44 mm) 1.77 (45 mm) 1.73 (44 mm)

Stroke inch 1.34 (34 mm) 1.34 (34 mm) 1.34 (34 mm) 1.34 (34 mm)

Max. power at speed kW / rpm 2.0 / 9,000 2.4 / 9,000 2.2 / 9,000 2.7 / 9,000

Max. torque at speed Nm / rpm 2.4 / 6,000 2.9 / 6,000 3.0 / 6,000 3.1 / 6,000

Idling speed rpm 2,500 2,500 2,500 2,500

Coupling speed rpm 3,600 3,600 3,600 3,600

Sound Pressure Level at the operator’s ear

at full load according to ANSI B 175.1 db(A) 102 102 102 102

Sound Pressure Level at the bystander’s position

(50ft/15 m distance) according to ANSI B 175.1

Carburetor (for CANADA) Type Walbro WT 465

Carburetor (for USA) Type Walbro WT 465

Ignition system Type electronic electronic electronic electronic

Spark plug Type BOSCH WSR 6F BOSCH WSR 6F BOSCH WSR 6F BOSCH WSR 6F

Electrode gap inch .020 .020 .020 .020

or spark plug Type NGK BPMR 7A NGK BPMR 7A NGK BPMR 7A NGK BPMR 7A

Fuel consumption at max. load kg/h 0.90 1.08 1.30 1.21

Specific consumption at max. load g/kWh 450 450 590 450

Fuel tank capacity oz 18.6 18.6 18.6 18.6

Chain oil tank capacity oz 9.3 9.3 9.3 9.3

Mixture ratio (fuel/two-stroke oil) see chapter "Fuel"

Chain brake Engages manually or in case of kickback.

Weight

1)

(fuel tank empty, without chain and guide bar) 10 lbs 10 lbs 10 lbs 2 oz 10 lbs 2 oz

DCS5200 = Walbro WT 465 / DCS5200i = TILLOTSON HU 116

db(A) 75 75 75 75

DCS430 / 431

DCS520 / 520i DCS540 DCS5200 / 5200i

TILLOTSON HU 116

TILLOTSON HU 116

Walbro WT 465

Walbro WT 465

1)

1)

Approved bar and chain combinations

"Low-kickback saw chain is a chain which has met the kickback performance requirements of ANSI B 175.1-1991

(American National Standard for Power Tools-Gasoline-Powered Chain Saws-Safety Requirements) when tested on the

representative sample of chain saws below 3.8 c.i.d. specifed in ANSI B 175.1-1991". The approved bar and chain

combinations are low kickback chains according to ANSI B 175.1-1991 and also meet the kickback requirements of

CSA Z62.3-96 for chains saws below 80 cm3.

WARNING

Do not use other replacement bars and chains unless they have been designated as meeting the ANSI B 175.1-1991

(for USA) and CSA Z62.3-96 (for Canada) kickback performance requirements on that specific powerhead, or has

been designated as "low kickback" saw chain in accordance with the ANSI B 175.1-1991 (for USA) and CSA

Z62.3-96 (for Canada) standard.

Guide bar and saw chain combinations meeting kickback requirements of ANSI B 175.1-1991 for the use

in the USA

Models DCS430, DCS431

GUIDE BAR SAW CHAIN

length pitch part no. part no.

15" (38 cm) .325" 445 038 631 523 085 664

16" (40 cm) .325" 445 040 631 523 085 666

18" (45 cm) .325" 445 045 631 523 085 672

Drive link gauge: .058", Chain sprocket: 8 teeth

Guide bar and saw chain combinations meeting kickback requirements of CSA Z62.3-96 for the use in

CANADA

Models DCS430, 431, 520, 520i, 540 and DCS5200, 5200i

GUIDE BAR SAW CHAIN

length pitch part no. part no.

15" (38 cm) .325" 445 038 631 523 085 664

16" (40 cm) .325" 445 040 631 523 085 666

18" (45 cm) .325" 445 045 631 523 085 672

Drive link gauge: .058", Chain sprocket: 8 teeth

15" (38 cm) 3/8" 443 038 651 522 094 656

Models DCS520, DCS520i, DCS540, DCS5200, DCS5200i

GUIDE BAR SAW CHAIN

length pitch part no. part no.

18" (45 cm) 3/8" 443 045 651 522 094 664

21" (53 cm) 3/8" 443 053 651 522 094 672

Drive link gauge: .058", Chain sprocket: 7 teeth

15" (38 cm) .325" 445 038 631 523 085 664

16" (40 cm) .325" 445 040 631 523 085 666

18" (45 cm) .325" 445 045 631 523 085 672

Drive link gauge: .058", Chain sprocket: 8 teeth

18" (45 cm) 3/8" 443 045 661 523 102 664

21" (53 cm) 3/8" 443 053 661 523 102 672

Drive link gauge: .050", Chain sprocket: 7 teeth

18

Page 19

PUTTING INTO OPERATION

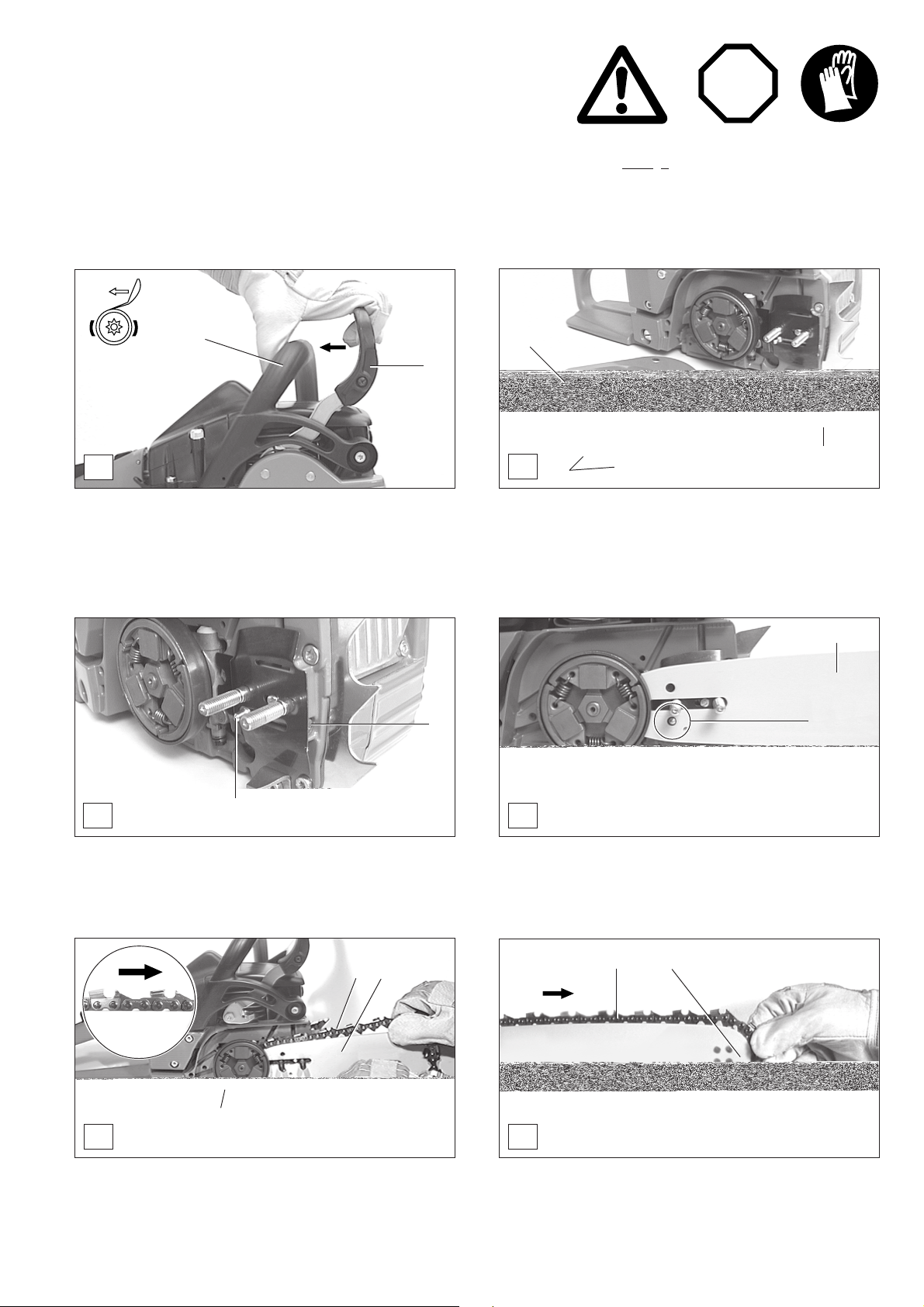

Mounting the guide bar and saw chain

STOP

Use the universal wrench delivered with the chain saw for the

following work.

Put the chain saw on a stable surface and carry out the

following steps for mounting the guide bar and chain:

2

1

A

- Always release the chain brake before removing or

replacing the sprocket guard (B/4). To do so, pull the hand

guard (A/1) towards the tubular handle (A/2) until you feel

it catch.

CAUTION: Before doing any work on the guide bar or

chain, always switch off the engine and pull

the plug cap off the spark plug (see "Replacing

the spark plug"). Always wear protective gloves!

CAUTION: Start the chain saw only after having assem-

bled it completely and inspected!

4

5

B

3

- Unscrew retaining nuts (B/3).

- Pull off the sprocket guard (B/4).

- Remove the plastic transport cover (B/5) and dispose of

properly.

6

C D

- Turn the chain adjusting screw (C/6) to the left (counterclockwise) until the pin (C/7) is at the left stop.

7

10

8

8

9

- Position the guide bar (D/8). Make sure that the pin (D/9)

of the chain tightener is in the hole (circled) on the guide

bar.

10

12

11

E

- Lift the chain (E/10) over the clutch drum and onto the

sprocket (E/11). Using your right hand, guide the chain

into the top guide groove on the guide bar (E/8).

NOTE: The cutting edges along the top of the chain must

point in the direction of the arrow!

F

- Lead the chain (F/10) around the sprocket nose (F/12) of

the guide bar.

NOTE: The chain should be easy to pull in the direction of

the arrow.

19

Page 20

6

G

- Turn the chain tightener (G/6) to the right (clockwise)

until the chain engages the guide groove of the bottom side

of the bar (see circle). Press the guide bar against the

housing with your left hand.

6

I

Tightening the saw chain

- Slightly lift the end of the guide bar and turn the chain

adjusting screw (I/6) to the right (clockwise) until the chain

rests against the bottom side of the guide bar.

- While still holding up the tip of the guide bar, tighten the

retaining nuts (H/3) with the universal wrench.

Chain brake

H

- Replace the sprocket guard (H/4).

- Manually tighten the retaining nuts (H/3).

Checking the chain tension

J

- The tension of the chain is correct if the chain rests against

the bottom side of the guide bar and can still be easily

turned by hand. While doing so the chain brake must be

released.

- Every new chain has to be broken in for about 2 to 3

minutes. Ample chain lubrication is essential during this

period. After breaking in, check chain tension and adjust, if

necessary.

- When checking the chain tension the engine must be

switched off.

NOTE: Check the chain tension frequently - chains tend to

get longer during use! If this is not done, there is a risk of the

chain jumping off the bar. It is recommended to use 2-3

chains alternatively.

In order to guarantee uniform wear of the guide bar the bar

should be turned over whenever replacing the chain.

4

3

STOP

20

2

1

3

K

L

Engaging the chain brake (braking)

If the kickback is strong enough the sudden acceleration of

the guide bar combined with the inertia of the hand guard

(L/3) will automatically actuate the chain brake.

To engage the chain brake manually, simply push the hand guard

(L/3) forward (towards the tip of the saw) with your left hand (arrow 1).

Releasing the chain brake

Pull the hand guard (L/3) towards you (arrow 2) until you feel

it catch. The brake is now released.

Page 21

Fuel / Refuelling

Gasoline

1.0 Us-gal. (3.7 l)

2.5 Us-gal. (9.4 l)

5.0 Us-gal. (18.9 l)

40:1

other oil MAKITA oil MAKITA oil

OIL

+

3.2 floz.(94 cm3) 2.5 floz.(75 cm3) 1.3 floz.(38 cm3)

8.0 floz.(236 cm3) 6.4 floz.(189 cm3) 3.2 floz.(94 cm3)

16.0 floz.(473 cm3) 12.8 floz.(378 cm3) 6.4 floz.(189 cm3)

50:1

OIL

50:1

100:1

HP 100

Fuel mixture

The engine of the chain saw is a high-efficiency two-stroke engine.

It runs on a mixture of gasoline and two-stroke engine oil.

The engine is designed for unleaded regular gasoline with a min.

octane value of 91 ROZ. In case no such fuel is available, you can

use fuel with a higher octane value. This will not affect the engine.

In order to obtain an optimum engine output and to protect

your health and the environment use unleaded fuel only.

Gasoline which contens alcohol should not used in MAKITA

products.

For lubricating the engine use a high-performance two-stroke

engine oil (quality grade JASO FC or ISO EGD specifications),

which is added to the fuel. The engine has been designed for

use of MAKITA HP 100 high-performance two-stroke engine oil

and a mixture ratio of only 100:1 to protect the environment. In

addition, a long service life and reliable operation with a minimum

emission of exhaust gases are ensured.

MAKITA HP 100 high-performance two-stroke engine oil is available in the following sizes:

0.5 l order number 980 008 609

MAKITA high-performance two-stroke engine oil is available in

the following sizes to suit your individual requirements:

1 l order number 980 008 607

100 ml order number 980 008 606

In case MAKITA high-performance two-stroke engine oil is not

available, it is urgently recommended to use a mixture ratio of 40:1

with other two-stroke engine oils, as otherwise optimum operation

of the engine cannot be guaranteed.

The correct mixture ratio:

50:1 when using MAKITA high-performance two-stroke engine

oil, i. e. mix 50 parts gasoline with 1 part oil.

100:1 when using MAKITA HP 100 high-performance two-stro-

ke engine oil, i. e. mix 100 parts gasoline with 1 part oil.

40:1 when using other two-stroke engine oils, i. e. mix 40 parts

gasoline with 1 part oil.

Handling and storage

Utmost care is required when handling with fuel. Fuel can contain

substances which have a behavior similar to that of solvents. Fill

the tank only outside or ventilated rooms. Do not inhale vapors,

avoid any fuel contact with your skin. For preparing the fuel-oil

mixture first mix the entire oil quantity with half of the fuel required,

then add the remaining fuel. Thoroughly shake the mixture before

filling it into the chain saw tank.

It is not wise to add more engine oil than specified to ensure safe

operation. This will only result in a higher production of combustion residues which will pollute the environment and clog the

exhaust channel in the cylinder as well as the muffler. In addition,

fuel consumption will rise and performance will decrease.

Fuel cannot be stored for an unlimited period of time. Buy only as

much as will be consumed in 4 weeks. Use only approved and

marked containers for transport and storage.

B

Chain oil

Use an oil with adhesive additive for lubricating the chain and

guide bar. The adhesive additive prevents the oil from being

flung off the chain too quickly.

We recommend the use of chain oil which is bio-degradable in

order to protect the environment. The use of bio-degradable oil

may even be required by local regulations.

The chain oil BIOTOP sold by MAKITA is made of special

vegetable oils and is 100% bio-degradable. BIOTOP has been

granted the "blue angel" (Blauer Umweltschutz-Engel) for

being particularly environment-friendly (RAL UZ 48).

BIOTOP chain oil is available in the following sizes:

1 l order number 980 008 610

5 l order number 980 008 611

Bio-degradable oil is stable only for a limited period of time. It

should be used within 2 years from the date of manufacture

(printed on the container).

Important note on bio-degradable chain oils:

If you are not planning to use the saw again for an extended

period of time (longer than the expiration date of the chain oil),

empty the oil tank and put in a small amount of regular engine

oil (SAE 30), and then run the saw for a time. This is necessary

to flush out all remaining bio-degradable oil from the oil tank,

oil-feed system, chain and guide bar, as many such oils tend

to leave sticky residues over time, which can cause damage

to the oil pump or other parts.

The next time you use the saw, fill the tank with BIOTOP chain

oil again.

waste oil

C

NEVER USE WASTE OIL

Waste oil is very dangerous for the environment.

Waste oil contains high amounts of carcinogenic substances.

Residues in waste oil result in a high degree of wear and tear

at the oil pump and the sawing device.

In case of damage caused by using waste oil or unappropriate

chain oil the product guarantee will be null and void.

Your salesman will inform you about the use of chain oil.

21

Page 22

AVOID SKIN AND EYE CONTACT

D

Refuelling

STOP

FOLLOW THE SAFETY PRECAUTIONS ON PAGE 7!

Be careful and cautious when handling fuels.

The engine must be switched off!

Mineral oil products degrease your skin. If your skin comes in

contact with these substances repeatedly and for an extended

period of time, it will desiccate. Various skin deseases may

result. In addition, allergic reactions are known to occur.

Eyes can be irritated by contact with oil. If oil comes into your

eyes, immediately wash them with clear water.

If your eyes are still irritated, see a doctor immediately!

- Thoroughly clean the area around the caps, to prevent dirt

from getting into the fuel or oil tank.

- Unscrew the cap and fill the tank with fuel (fuel/oil mixture)

or chain oil as the case may be. Fill up to the bottom edge

of the filler neck. Be careful not to spill fuel or chain oil!

- Tightly screw on the cap.

After refuelling, clean screw cap, tank and check for

lekages.

STOP

Adjusting the chain lubrication

2

1

E

chain oil fuel mixture

Lubricating the chain

During operation there must always be sufficient chain oil in

the chain-oil tank to provide good chain lubrication. One filling

is sufficient for about one half-hour of continuous operation.

While working make sure there is enough chain oil in the tank.

If necessary, add oil. The engine must be switched off!

3

F

The engine must be switched off.

You can adjust the oil pump feed rate with the adjusting screw

(F/1). The adjusting screw is located in the housing underneath

the sprocket guard (F/2). It is accessible from below.

The oil pump comes factory-set to a medium feed rate.

Note: To set from minimum to maximum oil supply, turn

the adjusting screw (F/1 with adjustment markings) max.

a 1/4-turn.

22

G

To ensure troublefree operation of the oil pump the oil guide

groove at the crank case (G/3) and the oil inlet bore in the guide

bar (G/4) must be cleaned regularly.

To change the feed quantity use the universal wrench and

adjust the adjusting screw (F/1) in the following way:

- Turn to the right to reduce the feed rate.

- Turn to the left to increase the feed rate.

Note: After the saw has been turned off it is normal for residual

chain oil to drip from the oil feed system, the guide bar and the

chain for a time. This does

Place the saw on a suitable surface.

4

not constitute a defect!

Page 23

Starting the engine

2

1

DCS431

A

3

5

2

1

B

4

1

Cold-starting the DCS430, 431, 520, 540, 5200:

The carburetors of these saws have a choke valve for cold

starting (mixture enrichment).

To make it easier to start, the chain saw DCS431 is equipped

with a semi-automatic decompression valve (B/5). Pushing

this valve in reduces the amount of compression effort needed,

so that it is easier to bring the engine up to starting speed when

pulling the starter cable. The high pressure increase in the

combustion chamber that results from the first ignitions will

automatically close the decompression valve (button pops

back out).

Model DCS430, DCS520 and DCS5200 do not have a

decompression valve. Starting and carburetor adjustment

are as for model DCS 431 except without the instruction

"Push the decompression valve".

- Put the short-circuit ignition switch in the "I" position (B/1).

- Pull out the choke (B/2).

- Depress the half-throttle lock button (B/3) half-way and hold.

- Depress the throttle (B/4) and half-throttle lock button (B/3)

all the way. Release the throttle - it will now be held at

half-throttle by the lock button.

- Push the decompression valve (B/5) (only DCS431).

- Slowly pull out the starter cable until you notice resistance

(the piston is positioned before the top dead center).

- Now pull the starter cable with a fast and forceful

movement until you hear the first ignition.

CAUTION: Do not pull out the starter cable more than approx.

50 cm, and lead it back by hand.

- When you hear the first ignition, push the choke (B/2) in.

Push the decompression valve again (only DCS431) and

pull the starter cable. As soon as the engine is running, press

the throttle (B/4) to release the half-throttle lock (B/3),

allowing the engine to idle.

CAUTION: As soon as the engine is started it must be put in

idle to prevent the chain brake from being damaged.

- Now release the chain brake.

2

- Move at least 10 feet (3 m) away from the place where you

fuelled the saw.

- Make sure you have a good footing, and place the saw on the

ground in such a way that the chain is not touching anything.

- Engage the chain brake (lock).

- Hold the tubular handle tightly with one hand and press the

chain saw to the ground.

- Steady the rear handle by standing in the hand guard.

Cold-starting the DCS520i and DCS5200i:

The carburetors of these saws have a fuel-injection system

(injection carburetor) for cold starting (mixture enrichment).

These two cold-starting systems work differently.

- Put the short-circuit ignition switch in the "I" position (B/1).

- Pull out the choke (B/2) (opens the injection valve).

- Depress the half-throttle lock button (B/3) half-way and hold.

- Depress the throttle (B/4) and half-throttle lock button (B/3)

all the way. Release the throttle - it will now be held at

half-throttle by the lock button.

Note: If the temperature is below -15° C (5° F) start at full

throttle.

- Slowly pull out the starter cable until you notice resistance

(the piston is positioned before the top dead center).

- Now pull the starter cable with a fast and forceful

movement until you hear the first ignition.

CAUTION: Do not pull out the starter cable more than approx.

50 cm, and lead it back by hand.

- Push in the choke (B/2) when the engine starts, or after

the first audible ignitions.

- If the engine has not yet started, keep pulling the starter

cable until it does.

As soon as the engine is running, press the throttle (B/4) to

release the half-throttle lock (B/3), allowing the engine to idle.

CAUTION: As soon as the engine is started it must be put in

idle to prevent the chain brake from being damaged.

- Now release the chain brake.

Warm starting (all models):

- As described above for cold starting, but without using

the choke (B/2). Keep the choke in.

Starting under special conditions

(MAKITA DCS520i and DCS5200i only):

In conditions of high ambient temperature and when the engine

has been stopped for only a short period following full-load

operation, if a fuel with a low boiling point is used (winter fuel), and

at high altitudes especially, the heat could prevent the engine from

starting immediately. If this happens, proceed as follows:

- Pull out the choke (B/2) and start the engine at half-throttle,

as described for cold starting.

- When the engine has started, release the chain brake

immediately and gun the engine all the way several times

until it runs smoothly.

- Now push in the choke (B/2).

If the engine won’t start:

If the engine refuses to start even after a number of tries, check

the spark plug (see the section on "Replacing the spark plug").

Stopping the engine

- Put the short-circuiting switch (B/1) in position "O" (STOP).

STOP

23

Page 24

Checking the chain brake

Do not work with the chain saw without first checking the

chain brake!

- Start the engine as described (make sure you have a good

footing, and place the chain saw on the ground in such a

way that the guide bar is free of contact).

- Grasp the tubular handle

grip with the other.

- With the engine running at moderate speed, press the hand

guard (C/1) in the direction of the arrow

y

our hand until the chain brake engages. The chain should

stop immediately.

- Immediately release the throttle and release the chain

brake.

IMPORTANT: If the chain does not stop immediately when

you test the chain brake, do NOT use the chain saw. Take

the chain saw to a MAKITA service center for repair.

firmly with one hand and hold the

with the back of

Adjusting the carburetor

24

Page 25

Working in winter

In order to prevent carburetor icing in conditions of low temperature combined with high humidity, and in order to get up to

operating temperature faster in subfreezing temperatures,

heated air can be taken from the cylinder.

At temperatures above freezing the carburetor must NOT be

fed heated air.

Failure to follow these instructions can lead to damage

to the cylinder and piston!

- Remove the filter cover and air filter (see "Cleaning the air

filter").

- To enable hot-air induction from the cylinder, remove the

plug (A/1) using the universal wrench.

NOTE:

Keep the plug in the saw’s tool kit. You must put the plug back

in at temperatures above 0° C / 32° F.

- Reinstall the air filter and filter cover.

MAINTENANCE

Sharpening the saw chain

CAUTION:

Before doing any work on the guide bar or chain,

switch off the engine and pull the plug cap off the spark

plug (see "Replacing the spark plug"). Always wear protective gloves!

C

The chain needs sharpening when:

- The sawdust produced when sawing damp wood looks like

wood flour.

- The chain penetrates the wood only under great pressure.

- The cutting edge is visibly damaged.

- The saw is pulled to the left or right when sawing. This is

caused by uneven sharpening of the chain.

Important: Sharpen frequently, but without removing too

much metal!

Generally, 2 or 3 strokes of the file will be enough.

Have the chain resharpened at a service center when you

have already sharpened it yourself several times.

always

D

Proper sharpening:

CAUTION:

Use only chains and guide bars designed for this saw

(see the Extract from the spare-parts list)!

- All cutters must be of the same length (dimension a).

Cutters with different lengths result in rough running of the

chain and can cause cracks in the chain.

- Minimum cutter length: 0.11" (3 mm). Do not resharpen the

chain when the minimum cutter length has been reached;

at this point, the chain must be replaced (see the Extract

from the spare-parts list and "Replacing the saw chain").

- The depth of the cut is determined by the difference in

height between the depth limiter (round nose) and the

cutting edge.

- The best results are obtained with a depth-limiter depth of

.025" (chain: 085 / .325") or .030" (chain: 094, 102 / 3/8").

CAUTION:

Excessive depth increases

the risk of kickback!

25

Page 26

- The sharpening angle α must be identical for all cutters!

Different angles result in a roughly, irregularly running

chain, increase wear and tear and cause chain beakage.

- The front rake β of the cutter results from the cut depth of

the round file. If the proper file is used in the right manner,

the correct front rake will be obtained automatically.

F

Cleaning the guide bar

CAUTION:

Protective gloves must be worn.

J

Regularly inspect the bearing surfaces of the guide bar for

damage, and clean them with a suitable tool.

26

Page 27

Cleaning the brake band and sprocket interior

STOP

Replacing the saw chain

CAUTION:

Use only chains and guide bars designed for this saw

(see the Extract from the spare-parts list and page 18)!

6

7

1

A

CAUTION: Before doing any work on the guide bar or

chain, always switch off the engine and pull

the plug cap off the spark plug (see "Replacing

the spark plug"). Always wear protective gloves!

CAUTION: Start the chain saw only after having assem-

bled it completely and inspected!

- Remove the sprocket guard (A/1) (See "PUTTING INTO

OPERATION" figs. A and B).

- Turn the chain tightener screw (A/2) to the left (counterclockwise) until you feel resistance.

- Remove the chain (A/3) and guide bar (A/4).

- Clean the interior with a brush, in particular the brake-band

area (A/5).

NOTE:

Make sure that no residue or contaminants remain in the oil

guide groove (A/6) and the chain tightener (A/7).

- For replacing the guide bar, chain, and sprocket see

"PUTTING INTO OPERATION".

NOTE:

The chain brake is a very important safety device and like

any other component subject to normal wear and tear.

Regular inspection and maintenance are important for

your own safety and must be done by a MAKITA service

center.

5

2

3

4

1

B

Check the sprocket (B/1) before mounting a new chain.

The sprocket is located underneath the clutch drum (B/2).

CAUTION:

Worn out sprockets (C) may damage the new chain and must

therefore be replaced. If the wear marks on the teeth are very

pronounced (about 0,5 mm /0.02” deep), the sprocket should

be replaced.

Do not attempt to replace the sprocket yourself. Sprocket

replacement requires special training and tools and must be

done at a MAKITA service center.

2

C

Replacing/cleaning the spark arrester screen

Replacing the fuel filter

D

The felt filter (D/1) of the fuel filter can become clogged. It is

recommended to replace the fuel filter once every three months

in order to ensure unimpeded fuel flow to the carburetor.

To remove the fuel filter for replacement, pull it out through the

tank filler neck using a piece of wire bent at one end to

form a hook.

1

2

1

E

The spark arrester screen should be checked and cleaned

regularly.

- Loosen the 3 screws (E/1) and remove the spark arrester

screen (E/2).

- Reassembly the spark arrester screen and tighten the

screws. The two long screws must be tigthed with a torque

of 6,3 ft. lb.(8,5 Nm).

CAUTION:

Do not use sharp or pointed objects for screen cleaning.

Damaged or misformed screen wires may result.

27

Page 28

Cleaning the air filter

1

2

4

3

STOP

F

- Remove the filter cover (F/1) (2 screws).

- Loosen the screws on the air filter (F/2) and remove from

intake manifold.

- Loosen the screw on the prefilter cover (F/3) and remove.

- Remove prefilter (F/4).

IMPORTANT:

Cover the intake opening with a clean cloth to prevent dirt

particles from getting into the carburetor.

- Pry apart the top and bottom of the air filter as shown in

Figure G.

CAUTION:

To prevent injury to the eyes, do NOT blow out dirt parti-

cles!

Do not use fuel to clean the air filter and prefilter.

G

- Clean the air filter and prefilter with a soft brush.

- If the filter is very dirty, clean it in lukewarm water with

dishwashing detergent.

- Let the air filter dry completely.

- Put the top and bottom sections back together.

- Before reinstalling the air filter, check the intake opening

and remove any dirt particles. If there are any, remove them

with a brush.

Clean frequently (several times a day) when working in very

dusty or dirty conditions. Full engine power is possible only with

a clean air filter and prefilter!

CAUTION: If the air filter or prefilter becomes damaged,

replace immediately!

Pieces of cloth or large dirt particles can destroy the

engine!

Replacing the spark plug

STOP

1

H

CAUTION:

Do not touch the spark plug or plug cap if the engine is

running (high voltage).

Switch off the engine before starting any maintenance

work.

A hot engine can cause burns. Wear protective gloves!

The spark plug must be replaced in case of damage to the

insulator, electrode erosion (burn) or if the electrodes are very

dirty or oily.

- Remove the filter cover (see "Cleaning the air filter").

- Pull the plug cap (H/1) off the spark plug. Use only the

combination wrench supplied with the saw to remove the

spark plug.

CAUTION: Use only the following spark plugs:

BOSCH WSR 6F or NGK BPMR 7A.

28

.020" (0,5 mm)

I

Electrode gap

The electrode gap must be .020" (0.5 mm).

Checking the ignition spark

- Press the loosened spark plug with the ignition cable firmly

connected against the cylinder using insulated pliers (not

near the spark plug opening).

- ON/OFF switch in the "I" (ON) position.

- Pull the starter cable hard.

If the function is correct, an ignition spark must be visible near

the electrodes.

Page 29

Replacing the starter cable

STOP

A

- Unscrew the four screws (A/1) holding down the fan housing (A/2). Lift the housing slightly, pull in the direction of the

arrow, and remove.

- Remove all pieces of cable.

Replacing the return spring

- Thread in a new cable (4 mm/.16" dia. x 1000 mm/39" long)

as shown in Figure B and tie the ends as shown.

- Pull knot (B/1) into the cable pulley (B/3).

- Pull knot (B/2) into the cable grip (B/4).

- Wind the cable around the pulley in the direction shown by

the arrow. Pull the cable out from the pulley by the grip, then

hold the pulley firmly and wrap the cable around it another

three times.

CAUTION: Danger of injury! Secure the cable grip when

pulled out! It will whip back if the cable pulley is released

by accident.

NOTE: With the cable pulled all the way out, it must still be

possible to turn the pulley another 1/4 turn against the return

spring.

- Remove the fan housing (see above under "Replacing the

starter cable").

- Take off the circlip (C/1) and washer (C/2) (circlip pliers, see

"Accessories").

- Remove the cable pulley (C/3).

- Unscrew screws (C/4) and carefully remove spring housing

(C/5) with spring.

CAUTION: Danger of injury! If the spring is broken it may

pop out!

Mounting the fan housing

NOTE:

The old spring and spring housing should be recycled.

Replacement springs come already installed in a new spring

housing. Before installing, grease the spring lightly with

multi-purpose grease, order No. 944 360 000.

- Assemble in reverse order. When putting the cable pulley

back on, turn it slightly until you feel it catch.

- Wind on the starter cable as described above under "Replacing the starter cable."

- Push the tab (D/1) extending out from the edge of the fan

housing (D/3) under the hood (D/2).

- Position the screw holes.

- Push the fan housing (D/3) gently and pull the starter grip

until the starter catches.

- Screw in the four fastening screws tightly.

29

Page 30

Instructions for daily and periodic maintenance

To ensure long life, prevent damage and ensure the full functioning of the safety features the following maintenance must be

performed regularly. Guarantee claims can be recognized only if this work is performed regularly and properly. Failure to perform

the prescribed maintenance work can lead to accidents!

Perform the following servicing work daily after use. Make a habit of it, it does not require much time and your saw will always

function properly.

Possibly hidden faults can be detected in this manner before causing expensive and annoying interruptions of your work. In case

you should detect a fault in the safety equipment when performing daily servicing, the saw must not be used before elimination

of the fault. The user of the chain saw must not perform maintenance work which is not described in the instruction manual. All such

work must be carried out by a MAKITA service center.

Page

General Chain saw Clean exterior, check for damage. In case of damage,

Saw chain Sharpen regulary, replace in good time 25-26

Chain brake Have inspected regularly at an authorized service center

Guide bar Turn over to ensure even wear of bearing surfaces

Before each start Saw chain Inspect for damage and sharpness 25

Guide bar Check for damage

Chain lubrication Functional check 24

Chain brake Functional check 20

Chain catch Check for damage

OFF switch,

Throttle stopper,

Throttle lever Functional check 23-24

Fuel/oil tank

cap Check for tightness and lekages

Dayli servicing Air filter, prefilter Clean (more often if necessary) 28

Chain brake Clean, check for visible damage or cracks 27

Guide bar Clean, in particular the oil guide groove 22

Guide bar support Check for damage, clean oil intake bore 22, 27

Idle speed Check that a sufficient difference is existing between

have repaired by a qualified service center immediately

Replace in good time 20

Check chain tension 20

idlind speed and engaging speed, to ensure that the chain

is in standstill while the engine is idling. 24

Every week Fan housing Clean to ensure proper air cooling 29

Starter cable Check for damage 29

Carburetor interior Clean (remove filter cover for access) 28

Chain brake Clean the brake band (sawdust, oil) 27

Spark plug Check and replace if necessary 28

Muffler Check tightness of mounting, clean spark arrester screen 27

Chain guide Check 26

Every 3 months Fuel filter Replace 27

Fuel, oil tanks Clean 22

Annually Chain saw Check at an authorized service center

Storage Chain saw Clean exterior, check for damage. In case of damage,

Guide bar/chain Demount, clean and oil slightly

Fuel, oil tanks Empty and clean

Carburetor Run empty

have repaired by a qualified service center immediately

Clean the guide groove 26

Service, spare parts and guarantee

Maintenance and repair

The maintenance and repair of modern engines as well as all safety devices require qualified technical training and a special

workshop equipped with special tools and testing devices.

We therefore recommend that you consult a MAKITA service center for all work not described in this instruction manual.

The MAKITA service centers have all the necessary equipment and skilled and experienced personnel, who can work out cost-

effective solutions and advise you in all matters.

Please contact the general agent or importer indicated on the back cover of this Instruction Manual, who will gladly provide you with

the address of your nearest MAKITA service center.

30