Page 1

T

ECHNICAL INFORMATION

PRODUCT

P 1/ 8

Model No.

Description

BLM430, LM430D

430mm Cordless Lawn Mower

CONCEPT AND MAIN APPLICATIONS

Models LM430D, BLM430, (HML01)*

with rotary blade cutting system.

Its main benefits are:

• Environment-friendly with zero emission and minimum noise pollution

• Compatible with both Makita 36V-2.6Ah Li-ion battery BL3626

and 36V-2.2Ah Li-ion battery BL3622A

• Compatible with Battery converters, BCV01 and BCV02

• Adjustable 13 cutting heights from 20mm to 75mm

• The storage space can be saved by standing the machine on its rear

end (See illustrated right.)

• Handle height is adjustable in 2 stages

This product is available in the variations listed below.

Model No.

LM430DWB

LM430DWBE

BLM430Z

BLM430RD 1 No

BLM430RDE 2BL3626 1

BLM430ZX2C No No

HML01Z*

HML01C1*

Note: All models also include the accessories listed below of "Standard equipment".

Charger

No

DC36RA BL3626

DC36RA

No

1 No NoNoNo No

1 1

Type Quantity

NoLM430DZ

BL3622A 1 NoDC36WA

BL3622A 2 1DC36WA

No

BL3622ADC36WA

1 is Cordless Lawn mower equipped

Battery

Battery

cover

No No

No NoNo NoNo

No

Battery

converter

No

No

No

No

No

BCV02

No

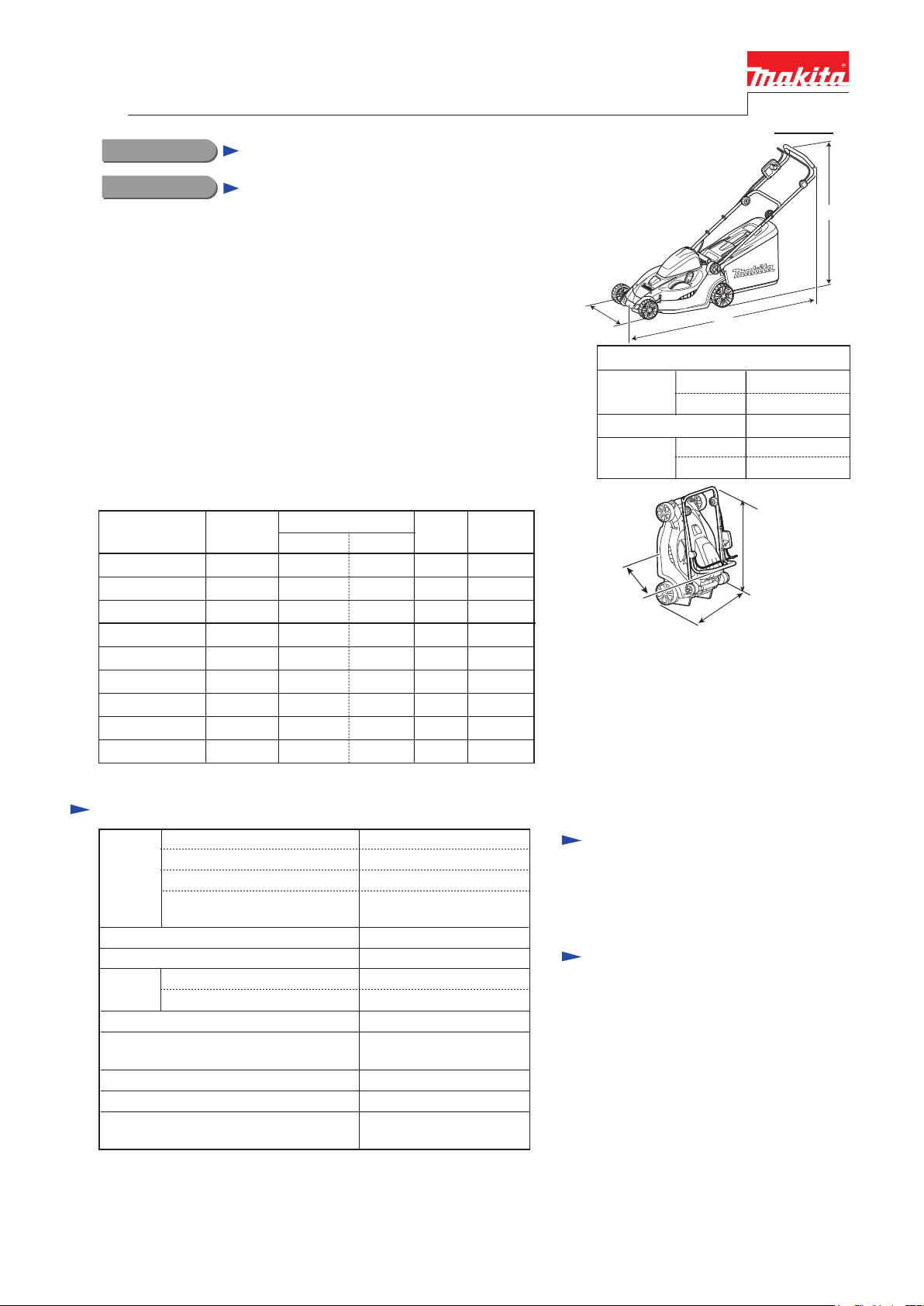

(19-1/4~19-3/4)

W

Length (L)

Width (W)

Height (H)

490~500

L

Dimensions: mm (inch)

minimum

maximum

minimum

maximum

1,450 (57)

1,490 (58-3/4)

460 (18-1/8)

950 (37-1/2)

1,020 (40-1/4)

810 (32)

(without Rear bag)

460 (18-1/8)

H

Specification

Cell

Voltage: V

Battery

Max output (W)

No load speed: min.

Blade

Cutting width: mm (") 430 (17)

Cutting height adjustment range: mm (")

Electric brake Yes

Soft start

Weight according to

EPTA-Procedure 01/2003*

*2: No load speed of the cutting tool

*3: with battery, blade, grass bag

*4: for North and Central American countries

*5: All countries except North and Central American countries

Capacity: Ah

Charging time (approx.): min.

ˉ¹=rpm*2

Type

3: kg (lbs)

Rotary type 2 tooth blade

20 - 75 (13/16 - 2-15/16),

Li-ion

36V

2.2/ 2.6

60 with DC36WA/

22 with DC36RA

580

3,600

24.0 (15/16)Inner diameter: mm (")

13 stages

Yes

18.1 (39.9)*

17.9 (39.4)*5

4,

Standard equipment

Socket wrench ........................................ 1

Blade 430 .............................................. 1

Note: The standard equipment for the tool

shown above may vary by country.

Optional accessories

Battery 3622A

Battery BL3626

Charger DC36WA

Fast charger DC36RA

Battery converter BCV01

Battery converter BCV02

Page 2

P 2/ 8

Repair

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

[1] NECESSARY REPAIRING TOOLS

DescriptionCode No. Use for

1R285

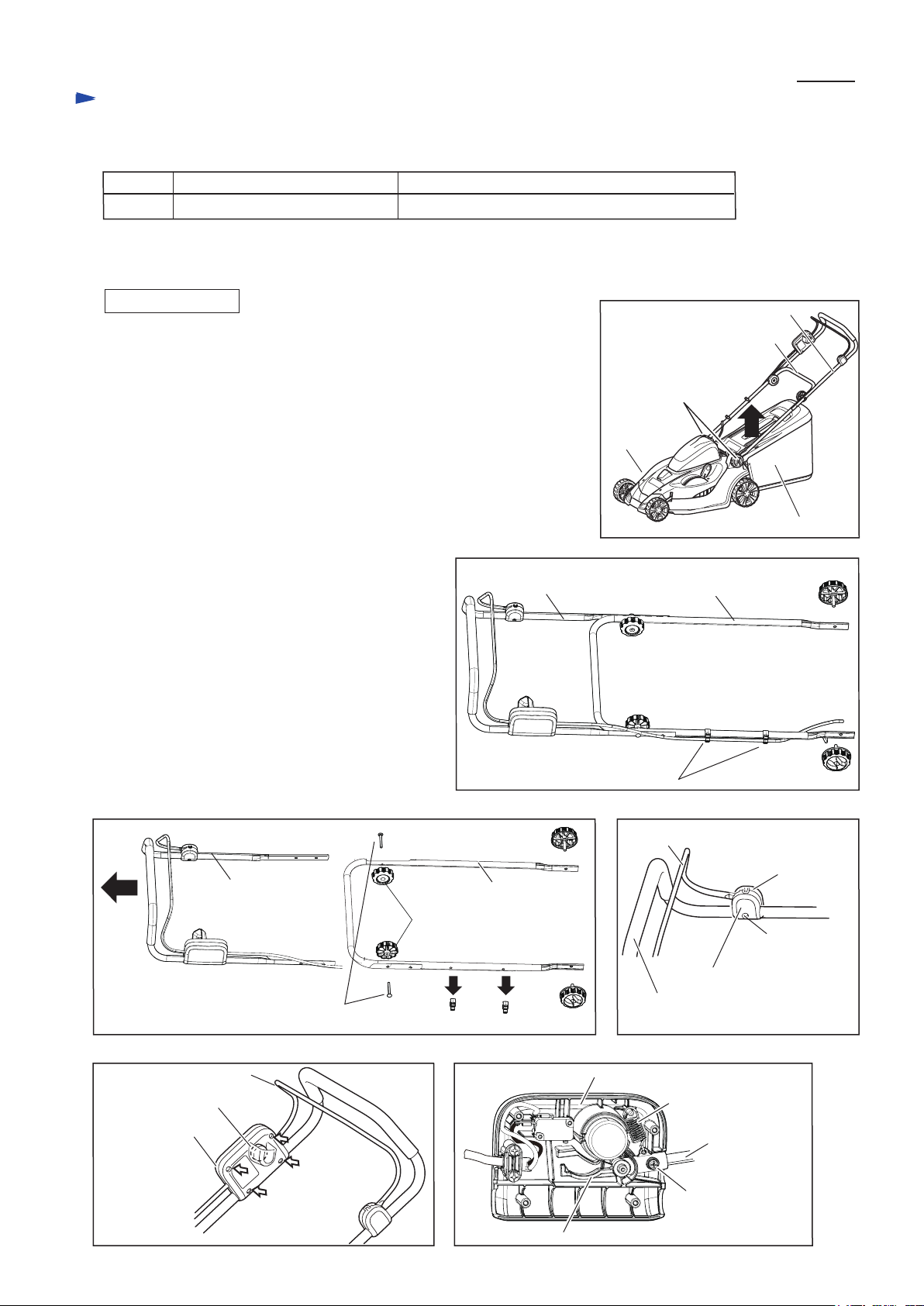

[2] ASSEMBLY/ DISASSEMBLY

[2]-1. Handle section

DISASSEMBLING

(1) Lift and remove Rear bag section from Deck. (Fig. 1)

While holding Handle section (Lower pipe, Upper pipe complete, etc.),

loosen two M6 Thumb screws. (Fig. 1)

Handle section is removed. (Fig. 2)

(2) Remove two Holders 9-19 from Lower pipe.

Remove two M6 Thumb nuts and M6x50 two Cup hex square neck bolts,

and then separate Upper pipe complete from Lower pipe. (Fig. 3)

Lower pipe can be replaced.

(3) Loosen 4x18 Tapping screw, then remove Switch lever case and

Switch lever case cover. (Fig. 4)

(4) Loosen four 4x18 Tapping screws, then remove Switch box cover complete

and Switch box. (Fig. 5)

(5) Remove Tension spring 9, and then separate Lever

and M4x20 Pan head screw with WR (spring washer

and Flat washer) from Switch box and Switch lever.

Upper pipe complete and Lever can be replaced.

(Fig. 6)

Round bar for Arbor 11-50

removing Plane bearing 10 from Front/ Rear wheels

Fig. 1

Upper pipe complete

Lower pipe

M8x35 Thumb screw

(2 pcs.)

Deck

Fig. 2

Lower pipeUpper pipe complete

Rear bag complete

M8x35 Thumb

screw

Fig. 3

Upper pipe complete

M6x50 Cup hex square neck bolt

Fig. 5 Fig. 6

Switch lever

Switch box cover complete

Switch box

4x18 Tapping

screw (4 pcs.)

Lower pipe

M6 Thumb nut

(2 pcs.)

Holder 9-19 (2 pcs.)

Holder 9-19 (2 pcs.)

Switch box

Lever

M8x35

Thumb screw

Fig. 4

Switch lever

Switch lever case

4x18 Tapping

screw

Switch lever case cover

Upper pipe complete

Tension spring 9

Switch lever

M4x20 Pan head

screw with WR

Page 3

P 3/ 8

Repair

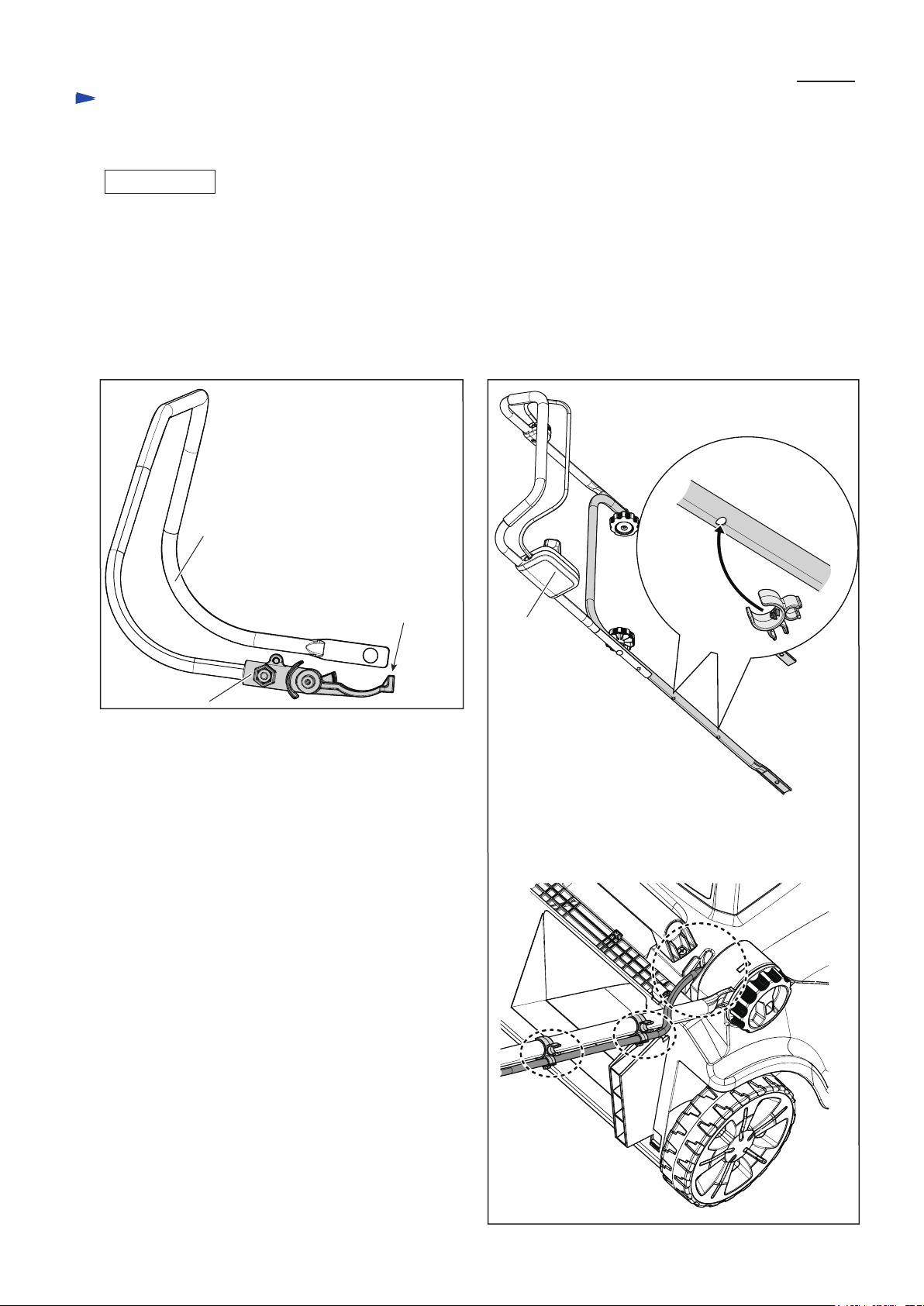

[2] ASSEMBLY/ DISASSEMBLY

[2]-1. Handle section (cont.)

ASSEMBLING

Assemble Handle section in the reverse order of disassembly.

Note: • Face the top of Lever to the upper side when assembling Lever to Switch lever. (Fig. 7)

While holding the insert nut on lever so as not to separate, assemble Lever to Switch lever with M4x20 Pan head

screw with WR.

• Be careful to the direction of Compression spring 9. Refer to Fig. 6 in the previous page.

• Assemble Lower pipe to Upper pipe complete so that the two holes of Lower pipe come to Switch box side. (Fig. 8)

• Route Power supply cord along Lower pipe, and fix it in the lower holders of two Holders 9-19, then pass it over

Lower pipe near the hinge. (Fig. 8)

Fig. 7 Fig. 8

Switch lever

LeverInsert nut

The top of Lever

faces the upper side.

Switch box

The holes of Lower pipe

to attach Holders 9-19

Holder 9-19

Page 4

P 4/ 8

Repair

[2] ASSEMBLY/ DISASSEMBLY

[2]-2. Motor section

REPLACING

(1) Remove Blade.

(2) Pull Lock lever to release the locking of Battery cover complete, and then open Battery cover complete. (Fig. 11)

Remove the hinge of one side carefully, and separate it from Cowling. (Fig. 12)

And then, remove the other hinge in the same way.

(3) Remove Grip A by unscrewing two 5x25 Tapping screws. (Fig. 13)

(4) Remove six 4x18 Tapping screws. Shift Change lever to the position of Cutting height between 40 and 60mm. (Fig. 14)

(5) Pass Terminal housing through the square hole of Cowling without disconnecting the lead wires as drawn in Fig. 15.

Cowling can be removed toward the upper direction. (Fig. 15)

(6) Remove three M6x30 Pan head screws. DC motor can be replaced. (Fig. 16)

Fig. 11

Fig. 12

Battery cover complete

Fig. 13

5x25 Tapping screw

2

1

Grip A

hinges of Cowling with

Battery cover complete

Fig. 15

Terminal housing

Cowling

Fig. 14

4x18 Tapping

screw (6 pcs.)

Change lever

Terminal

housing

Square hole

of Cowling

Fig. 16

DC motor

M6x30 Pan head

screw with WR

(3 pcs.)

Page 5

Repair

[2] ASSEMBLY/ DISASSEMBLY

[2]-3. Change lever section

DISASSEMBLING

(1) Remove Cowling. (Refer to the previous page.)

(2) Shift Change lever to the position of grass cutting height 75mm.

(3) Detach the hook of Tension spring 16 from the projection of Deck using long-nose pliers. (Fig. 17)

(4) Put a wood under Deck to raise Wheels from the ground. (Fig. 18)

(5) Unscrew two 4x18 Tapping screws, and separate the pin of Connecting rod from the hole of Change lever,

and then remove Change lever section from Deck toward DC motor side. (Fig. 19)

(6) Remove Change lever cover, and then separate screws, bolt and nut as drawn in Fig. 20.

ASSEMBLING

Assemble Change lever section in the reverse order of disassembly.

Note: Lift Connecting rod and insert the pin into the hole of Connecting rod. (Fig. 21)

Fig. 17

Change lever

Fig. 19

P 5/ 8

hook of

Tension

spring 16

Fig. 18

Long-nose

pliers

projection of Deck

Adjust plate

Fig. 20

Flat washer 4

4x18 Tapping

screw

M6 Hex nut

Change lever

Compression spring 9

Flat washer 9

4x18 Tapping screw

(2 pcs.)

Change lever

Change

lever

cover

Sleeve 6

Wood

4x18 Tapping

screw (2 pcs.)

Fig. 21

hole of Change lever

Connecting rod

Adjust plate

pin of Connecting rod

M6x30

Hex bolt

Page 6

Repair

[2] ASSEMBLY/ DISASSEMBLY

[2]-4. Wheels

DISASSEMBLING

(1) Pull Front wheel caps straight out of Front wheels. (Fig. 22) Remove Rear wheel caps in the same way.

(2) Remove M8 Collared hex nuts and Front wheels from Front shaft. (Fig. 23)

Separate Rear wheels from Rear shaft in the same way.

(3) Tap the edge of each wheel with plastic hammer. Ball bearings 6200ZZ in the wheels are removed. (Fig. 24)

(4) Press each Plane bearing 10 out of the wheels with 1R285 as drawn in Fig. 25.

ASSEMBLING

Assemble each wheel section in the reverse order of disassembly. Refer to Fig. 26.

Fig. 22

Front wheel cap

Front

wheel

Fig. 23 Fig. 24

M8 Collared

hex nut

Front wheel

Ball bearing

6200ZZ

P 6/ 8

Fig. 25 Fig. 26

Arbor press

1R285

Ball bearing

6200ZZ

Front wheel

Plane bearing 10

M8 Collared hex nut

Front wheel cap

[2]-5. Connecting rod, Shafts

DISASSEMBLING

(1) Remove the assembled part of Lower pipe and Upper pipe complete.

(Refer to [2]-1. Handle section.)

(2) Remove Cowling. (Refer to [2]-2. Motor section.)

(3) Remove the assembled part of Change lever and Adjust plate.

(Refer to [2]-3. Change lever section.)

(4) Remove Front wheels and Rear wheels. (Refer to [2]-4. Wheels.)

As for the specifications for North America, remove two 4x18

Tapping screws and Protective shield. (Fig. 27)

(5) Loosen two M5-8 Hex lock nut and remove Connecting rod. (Fig. 28)

(6) Loosen six 4x18 Tapping screws. Front shaft and Rear shaft can be

removed. (Fig. 29)

Fig. 27

Fig. 28

M5-8 Hex lock nut (2 pcs.)

on Connecting rod

Fig. 29

4x18 Tapping screw (4 pcs.)

Front shaft

4x18 Tapping

screw (2 pcs.)

[ North America only]

Proactive

shield

Rear shaft

4x18 Tapping screw (2 pcs.)

Page 7

P 7/ 8

Repair

[2] ASSEMBLY/ DISASSEMBLY

[2]-5. Connecting rod, Shafts (cont.)

ASSEMBLING

Assemble each wheel section in the reverse order of disassembly.

Distinguish Front shaft from Rear shaft by the white paint. (Fig. 30)

Circuit diagram

Fig. D-1

Color index of lead wire’s sheath

Black Orange

White

Red Yellow

Blue

Lock key

Lead unit

Fig. 30

Rear shaft

Front shaft

white paint

Switch

Line filter

Terminal

Wiring diagram

Fig. D-2

Connect Lead wires as drawn below.

Pass them through the square hole of Cowling.

Controller

Route Lead wires in Switch box as drawn below so as not to

be pinched between ribs / bosses.

DC motor

Tension spring 9

Switch lever

Power

supply

cord

M4x20 Pan

head screw

Lever

Page 8

Wiring diagram (cont.)

Fig. D-3

To Switch

Lead unit

P 8/ 8

Terminal

Fix Lead wires (black, white) in

these Lead wire holders.

Connect Flag

receptacles as

drawn above.

Be careful to

the directions.

Controller

Fix Lead wires (red, blue) in

these Lead wire holders.

Fix Lead wires (red) in

these Lead wire holders.

Fix Lead wires (blue) in

these Lead wire holders.

DC motor

All Connectors, Line filters and Controller must be set in place using ribs on Deck as drawn above.

Be careful not to put any Lead wires on ribs drawn above.

Loading...

Loading...