Page 1

®

GRF

400/1600 Getting Started

1.4. Update 2

Part Number: 7820-2035-001

For software version 1.4.20 and later

September, 1999

Page 2

Copyright© 1999 Lucent Technologies. All Rights Reserved.

This material is protected by the copyright laws of the United States and other countries. It may not be reproduced, distributed, or altered in any fashion by an y

entity (either internal or external to Lucent Technologies), except in accordance with applicable agreements, contracts, or licensing, without the express

written consent of Lucent Technologies.

For permission to reproduce or distribute, please contact: Alison Gowan, 1-612-996-6891

Notice

Every effort was made to ensure that the information in this document was complete and accurate at the time of printing. However, information is subject to

change.

Trademarks

GRF is a trademark of Lucent Technologies. Other trademarks and trade names mentioned in this publication belong to their respective owners.

Limited Warranty

Lucent T echnologies pro vides a limited w arranty to this product. See Appendix B, "Limited Warranty," in the GRF 400/1600 Getting Started manual for more

information.

Ordering Information

To order copies of this document, contact your Lucent Technologies representative or reseller.

Support Telephone Numbers

For a menu of support and other services, call (800) 272-3634. Or call (510) 769-6001 for an operator.

Lucent Technologies

Page 3

Customer Service

Customer Service provides a variety of options for obtaining information about Lucent

products and services, software upgrades, and technical assistance.

Finding information and software on the Internet

Visit the Web site at http://www.ascend.com for technical information, product

information, and descriptions of available services.

Visit the FTP site at ftp.ascend.com for software upgrades, release notes, and addenda to

this manual.

Obtaining technical assistance

You can obtain technical assistance by telephone, email, fax, modem, or regular mail, as well

as over the Internet.

Enabling Lucent to assist you

If you need to contact Lucent for help with a problem, make sure that you have the following

information when you call or that you include it in your correspondence:

• Product name and model.

• Software and hardware options.

• Software version.

• Type of computer you are using.

• Description of the problem.

Calling Lucent from within the United States

In the U.S., you can take advantage of Priority Technical Assistance or an Advantage service

contract, or you can call to request assistance.

Priority T echnical Assistance

If you need to talk to an engineer right away, call (900) 555-2763 to reach the Priority Call

queue. The charge of $2.95 per minute does not begin to accrue until you are connected to an

engineer. Average wait times are less than three minutes.

Other telephone numbers

For a menu of Lucent’s services, call (800) 272-363). Or call (510) 769-6001 for an operator.

GRF 400/1600 Getting Started - 1.4 Update 2 iii

Page 4

Calling Lucent from outside the United States

You can contact Lucent by telephone from outside the United States at one of the following

numbers:

Telephone outside the United States (510) 769-8027

Austria/Germany/Switzerland

Benelux

France

Italy

Japan

Middle East/Africa

Scandinavia

Spain/Portugal

UK

For the Asia Pacific Region, you can find additional support resources at

http://apac.ascend.com

(+33) 492 96 5672

(+33) 492 96 5674

(+33) 492 96 5673

(+33) 492 96 5676

(+81) 3 5325 7397

(+33) 492 96 5679

(+33) 492 96 5677

(+33) 492 96 5675

(+33) 492 96 5671

Obtaining assistance through correspondence

Lucent maintains two email addresses for technical support questions. One is for customers in

the United States, and the other is for customers in Europe, the Middle East, and Asia. If you

prefer to correspond by fax, BBS, or regular mail, please direct your inquiry to Lucent’s U.S.

offices. Following are the ways in which you can reach Customer Service:

• Email from within the U.S.—support@ascend.com

• Email from Europe, the Middle East, or Asia—EMEAsupport@ascend.com

• Fax—(510) 814-2312

• Customer Support BBS (by modem)—(510) 814-2302

Write to Lucent at the following address:

Attn: Customer Service

Lucent T echnologies Inc.

1701 Harbor Bay Parkway

Alameda, CA 94502-3002

iv GRF 400/1600 Getting Started - 1.4 Update 2

Page 5

1

2

3

4

5

6

7

8

9

10

11

Important safety instructions

The following safety instructions apply to the GRF router models GRF-4-AC, GRF-4-DC,

GRF-16-AC, and GRF-16-DC except as noted:

Read and follow all warning notices and instructions marked on the product or included in

the manual.

Do not attempt to service this product yourself, as opening or removing covers and/or

components may expose you to dangerous high voltage points or other risks. Refer all

servicing to qualified service personnel.

The maximum recommended ambient temperature for all GRF router models is 104˚

Fahrenheit (40˚ Celsius). Care should be given to allow sufficient air circulation or space

between units when the GRF chassis is installed in a closed or multi-unit rack assembly

because the operating ambient temperature of the rack environment might be greater than

room ambient.

Slots and openings in the GRF cabinet are provided for ventilation. To ensure reliable

operation of the product and to protect it from overheating, maintain a minimum of 4

inches clearance on the top and sides of the GRF 400 router, and a minimum of 6 inches

on the top and sides of the GRF 1600 router.

Installation of the GRF 400 or 1600 in a rack without sufficient air flow can be unsafe.

If a GRF router is installed in a rack, the rack should safely support the combined weight

of all equipment it supports.

- A fully loaded, redundant-power GRF 400 weighs 38.5 lbs (17.3 kg).

- A fully loaded, single-power GRF 400 weighs 32.5 lbs (14.6 kg).

- A four card, redundant-power GRF 1600 weighs 147 lbs (66.2 kg).

- A four card, single-power GRF 1600 weighs 127 lbs (57.2 kg).

The connections and equipment that supply power to GRF routers should be capable of

operating safely with the maximum power requirements of the particular GRF model. In

the event of a power overload, the supply circuits and supply wiring should not become

hazardous.

Models with AC power inputs are intended to be used with a three-wire grounding type

plug - a plug which has a grounding pin. This is a safety feature. Equipment grounding is

vital to ensure safe operation. Do not defeat the purpose of the grounding type plug by

modifying the plug or using an adapter.

Prior to installation, use an outlet tester or a voltmeter to check the AC receptacle for the

presence of earth ground. If the receptacle is not properly grounded, the installation must

not continue until a qualified electrician has corrected the problem. Similarly, in the case

of DC input power, check the DC ground (s).

If a three-wire grounding type power source is not av ailable, consult a qualified electrician

to determine another method of grounding the equipment.

Models with DC power inputs must be connected to an earth ground through the terminal

block Earth/Chassis Ground connectors. This is a safety feature. Equipment grounding is

vital to ensure safe operation.

GRF 400/1600 Getting Started - 1.4 Update 2 v

Page 6

12

13

14

15

Install DC-equipped GRF 400 and 1600 routers only in restricted access areas in

accordance with Articles 110-16, 110-17, and 110-18 of the National Electrical Code,

ANSI/NFPA 70.

Do not allow anything to rest on the power cord and do not locate the product where

persons will walk on the power cord.

Industry-standard cables are provided with this product. Special cables that may be

required by the regulatory inspection authority for the installation site are the

responsibility of the customer.

When installed in the final configuration, the product must comply with the applicable

Safety Standards and regulatory requirements of the country in which it is installed. If

necessary, consult with the appropriate regulatory agencies and inspection authorities to

ensure compliance.

vi GRF 400/1600 Getting Started - 1.4 Update 2

Page 7

1

2

3

4

5

6

7

8

9

Wichtige Sicherheitshinweise

Die folgenden Sicherheitshinweise gelten für die GRF-Oberfräsenmodelle GRF-4AC,

GRF-4-DC, GRF-16-AC und GRF-16-DC, außer wenn anderweitig angegeben:

Lesen und befolgen Sie alle am Produkt angebrachten und im Handbuch enthaltenen

Warnhinweise und Anleitungen.

Versuchen Sie nicht, dieses Gerät selbst zu warten bzw. die Abdeckung zu öffnen oder

Bauteile zu entfernen. Hochspannungsgefahr. Die Wartung muß durch qualifiziertes

Fachpersonal ausgeführt werden.

Die empfohlene maximale Umgebungstemperatur für alle GRF-Oberfräsenmodelle liegt

bei 40º C. Sorgen Sie für gute Belüftung bzw. ausreichenden Abstand zwischen einzelnen

Geräten, wenn das GRF-Gehäuse in einem Einzel- oder Mehrfach-Einschubrahmen

installiert werden soll, da die Betriebstemperatur in dem Einschubrahmen evtl. höher als

die Raumtemperatur sein kann.

Schlitze und Öffnungen im GRF-Gehäuse dienen zur Belüftung. Um einen einwandfreien

Betrieb des Produktes zu gewährleisten und um Überhitzung vorzubeugen, jeweils oben

und an den Seiten der GRF-400-Oberfräse mindestens 10,16 cm und an der

GRF-1600-Oberfräse mindesten 15,24 cm Freiraum vorsehen.

10

Bei unzureichender Belüftung ist die Installation eines GRF-400 oder 1600 in einem

Einschubrahmen gefährlich.

Bei Installation einer GRF-Oberfräse in einem Einschubrahmen, muß dieser das

Gesamtgewicht aller darin installierten Geräte sicher tragen können.

– Ein komplett bestückter Redundanzstrom-GRF-400 wiegt 17,3 kg.

– Ein komplett bestückter Einzelstrom-GRF-400 wiegt 14,9 kg.

– Ein mit vier Karten bestückter Redundanzstrom-GRF-1600 wiegt 66,2 kg.

– Ein mit vier Karten bestückter Einzelstrom-GRF-1600 wiegt 57,2 kg.

Die Adapter und Geräte, die die GRF-Oberfräsen mit Strom versorgen, sollten auch bei

maximaler Stromanforderung des einzelnen GRF-Modells noch sicher laufen. Im Fall

einer Stromüberlastung sollten die Versorgungskreise und kabel keine Gefahrenquelle

darstellen.

Alle mit Netzeingängen versehenen Geräte müssen mit einem vorschriftsmäßigen Stecker

bestückt sein. Der Stecker bietet die notwendige Erdung und darf in keiner Weise

modifiziert oder mit einem Adapter verwendet werden.

Überprüfen Sie vor der Installation mit Hilfe eines Steckdosentestgerätes oder eines

Voltmeters die Erdung der Netzsteckdose. Sollte die Steckdose nicht ordnungsgemäß

geerdet sein, darf mit der Installation erst fortgefahren werden, wenn ein qualifizierter

Elektriker dieses Problem behoben hat. Handelt es sich um einen Gleichstromeingang ist

dieser in gleicher Weise auf ordnungsgemäße Erdung zu überprüfen.

Ist keine 3polige geerdete Stromquelle vorhanden, beauftragen Sie einen qualifizierten

Elektriker damit, das Gerät auf andere Weise zu erden.

GRF 400/1600 Getting Started - 1.4 Update 2 vii

Page 8

15

11

12

13

14

Bei Modellen mit Gleichstromeingängen muß ein Erdungsdraht entweder an der

Klemmleiste oder an einer Gehäuseschraube angeschlossen werden. Hierbei handelt es

sich um eine Sicherheitseinrichtung. Die Erdung des Gerätes ist eine wichtige

Voraussetzung für den sicheren Betrieb.

Die gleichstromausgerüsteten Oberfräsenmodelle GRF-400- und GRF-1600-Oberfräse

dürfen nur in Bereichen mit beschränktem Zugang, unter Berücksichtigung der

anwendbaren Bestimmungen für Elektroinstallationen sowie der Standards ANSI/NFPA

70 installiert werden.

Keine Gegenstände auf das Netzkabel stellen. Das Kabel so verlegen, daß Personen nicht

versehentlich darauf treten können.

Standardkabel sind im Lieferumfang des Produkts enthalten. Sonderkabel, die evtl. gemäß

den örtlichen Bestimmungen für die Installation erforderlich sind, sind vom Kunden zu

stellen.

Zur Installation in der endgültigen Konfiguration muß das Produkt den am Installationsort

geltenden Sicherheitsstandards und bestimmungen entsprechen. Genauere Informationen

erhalten Sie ggf. bei den zuständigen Behörden.

viii GRF 400/1600 Getting Started - 1.4 Update 2

Page 9

Contents

Contents

Customer Service..................................................................................................................... iii

About This Guide ............................................................................ xix

About 1.4 Update 2................................................................................................................ xix

What is in this guide............................................................................................................... xix

What you should know ............................................................................................................ xx

Documentation conventions................................................................................................... xxi

Documentation set................................................................................................................. xxii

Related publications.............................................................................................................. xxii

Chapter 1 Getting Acquainted with the GRF 400........................................... 1-1

What is the GRF 400?............................................................................................................ 1-2

Which items are included in your system? ....................................................................... 1-2

AC power cord......................................................................................................... 1-2

Site-supplied components ................................................................................................... 1-3

Components you can add....................................................................................................... 1-3

Upgrading system memory.................................................................................................... 1-4

Overview of the GRF 400 base unit....................................................................................... 1-5

Control board .................................................................................................. 1-6

Switch control................................................................................................................. 1-6

System memory ........................................................................................... 1-7

Fans................................................................................................................................. 1-8

Fan “too slow” message........................................................................................... 1-8

Backplane .................................................................................................................. 1-8

Communications bus ....................................................................................... 1-8

Battery............................................................................................................................. 1-8

Power supplies ........................................................................................................ 1-9

Redundant units....................................................................................................... 1-9

Failure notification ................................................................................................. 1-9

Description of the AC power supply ........................................................................ 1-10

A note about redundant AC supplies ................................................................... 1-10

Incompatibilities between AC power supply models ................................................ 1-10

Description of the 48V DC power supply ................................................................... 1-12

Redundant DC supply safety considerations ....................................................... 1-12

Installation preview .................................................................................................... 1-13

Chapter 2 Getting Acquainted with the GRF 1600......................................... 2-1

What is the GRF 1600? ............................................................................................. 2-2

Which items are included in your system? ........................................................................ 2-3

AC power cord ...................................................................................................... 2-3

Site-supplied components ................................................................................................... 2-3

Components you can add....................................................................................................... 2-3

Upgrading system memory.................................................................................................... 2-5

Overview of the GRF 1600 base unit ................................................................................... 2-6

Media cards..................................................................................................................... 2-8

Chassis fans ....................................................................................................... 2-8

GRF 400/1600 Getting Started - 1.4 Update 2 ix

Page 10

Contents

Control board .................................................................................................... 2-9

Switch board ................................................................................................................. 2-10

Switch control........................................................................................................ 2-10

Battery........................................................................................................................... 2-10

Backplane ............................................................................................................... 2-10

Communications bus ............................................................................................. 2-10

System memory ......................................................................................... 2-11

Power supply options ...................................................................................... 2-12

Power supply failure notification .......................................................................... 2-12

Description of the AC power supplies ............................................................... 2-13

AC drawer locking tab.................................................................................................. 2-14

How to obtain a clamp........................................................................................... 2-14

AC power supply safety considerations ................................................................... 2-14

Redundant AC supply safety considerations ....................................................... 2-15

Label requirement.................................................................................................. 2-15

Minimum media card load requirement........................................................................ 2-15

Description of the 48VDC power supplies ........................................................ 2-16

DC drawer locking tab........................................................................................... 2-17

DC power supply safety considerations ................................................................... 2-17

Redundant DC supply safety considerations ....................................................... 2-17

Minimum media card load requirement........................................................................ 2-17

Installation preview .................................................................................................... 2-18

Chapter 3 Rack Mount and Power On Procedures........................................ 3-1

Rack mounting the GRF 400 .............................................................................................. 3-2

Servicing clearances .................................................................................................. 3-2

Power and ground requirements ................................................................................ 3-2

Rack-mounting requirements ................................................................................... 3-3

Ventilation requirements................................................................................................. 3-3

What to do next............................................................................................................... 3-3

Inserting a media card............................................................................................................ 3-4

ESD requirements........................................................................................................... 3-5

Insertion procedure ............................................................................................ 3-5

Attaching a VT-100 terminal ................................................................................... 3-6

VT-100 terminal settings .................................................................................... 3-6

Laptop PC ....................................................................................................................... 3-6

What to do next............................................................................................................... 3-6

Powering on the GRF 400...................................................................................................... 3-7

Redundant power supplies.............................................................................................. 3-7

Power supply failure notification ................................................................................. 3-7

Interpreting GRF 400 control board LEDs ........................................................................ 3-8

Applying AC power to the GRF 400 ................................................................................. 3-9

Plug-in steps.................................................................................................................... 3-9

A note about redundant AC supplies ..................................................................... 3-9

Labeling a redundant AC power supply ....................................................................... 3-10

Replacing a redundant AC power supply ................................................................... 3-10

What to do next............................................................................................................. 3-10

Applying DC power to the GRF 400 ............................................................................... 3-11

Site installation requirements .............................................................................. 3-11

DC terminals ...................................................................................................... 3-12

Site alarm option ................................................................................................... 3-12

Wiring procedure.......................................................................................................... 3-13

x GRF 400/1600 Getting Started - 1.4 Update 2

Page 11

Contents

Fuses ............................................................................................................................. 3-13

Redundant DC supply safety considerations ....................................................... 3-14

What to do next............................................................................................................. 3-14

Powering off a GRF 400 .......................................................................................... 3-15

Systems with AC power supplies ................................................................................. 3-15

GRFs with DC power supplies ..................................................................................... 3-15

Rack mounting the GRF 1600 .......................................................................................... 3-16

Servicing clearances ........................................................................................... 3-16

Grounding .............................................................................................................. 3-16

Power requirements ................................................................................................. 3-16

Ventilation requirements............................................................................................... 3-17

Rack depth ................................................................................................ 3-17

Side rails ...................................................................................................... 3-17

Rack-mounting procedure ................................................................................ 3-18

What to do next............................................................................................................. 3-18

Inserting a media card.......................................................................................................... 3-19

ESD requirements......................................................................................................... 3-20

Insertion procedure .......................................................................................... 3-20

Attaching a VT-100 terminal ................................................................................. 3-21

VT-100 terminal settings .................................................................................. 3-21

Laptop PC ..................................................................................................................... 3-21

What to do next............................................................................................................. 3-21

Powering on the GRF 1600 ............................................................... 3-22

Redundant power supplies............................................................................................ 3-22

Power supply failure notification ................................................................................ 3-22

Interpreting GRF 1600 control board LEDs .................................................................... 3-23

Applying AC power to the GRF 1600 .............................................................................. 3-24

Plug-in steps.................................................................................................................. 3-24

Installing a power cord locking clamp ...................................................................... 3-24

Clamp procedure........................................................................................................... 3-25

A note about redundant AC supplies ................................................................... 3-26

Labeling a redundant AC power supply ....................................................................... 3-26

What to do next............................................................................................................. 3-26

Applying DC power to the GRF 1600 ................................................................................. 3-27

Site installation requirements .............................................................................. 3-27

DC terminals................................................................................................................. 3-28

Wiring the DC supply................................................................................................... 3-28

Wire and lug requirements:................................................................................ 3-28

Wiring procedure:............................................................................................... 3-29

Locking tab ................................................................................................................... 3-30

Labeling a redundant DC power supply ....................................................................... 3-31

Powering off a GRF 1600 ........................................................................................ 3-32

Systems with AC power supplies ................................................................................. 3-32

GRFs with DC power supplies ..................................................................................... 3-32

What to do next............................................................................................................. 3-32

Chapter 4 Initial System Set-up....................................................................... 4-1

First communication with the router...................................................................................... 4-2

First-time power on configuration script ................................................. 4-2

Changing the configuration script later ........................................................ 4-3

Logging in as root ........................................................................................................... 4-3

Changing the root password ................................................................................... 4-3

GRF 400/1600 Getting Started - 1.4 Update 2 xi

Page 12

Contents

The de0 interface ....................................................................................... 4-4

grifconfig and netstart de0 addresses must match ................................................ 4-4

Attaching the maintenance interface de0............................................................................... 4-5

Ethernet connection to control board ..................................................................... 4-5

Using telnet..................................................................................................................... 4-5

Administrative log on ........................................................................................................... 4-6

CLI and UNIX passwords .............................................................................. 4-6

Overview of GRF user interface components........................................................................ 4-7

Configuration tasks - shell or CLI ? .......................................................................... 4-7

Command Line Interface (CLI)...................................................................................... 4-7

UNIX shell...................................................................................................................... 4-8

maint commands............................................................................................................. 4-8

What to do next........................................................................................................ 4-8

About GRF logs and dumps ................................................................................................ 4-9

Logs ............................................................................................................................... 4-9

Accessing a log file................................................................................................ 4-10

Dumps........................................................................................................................... 4-10

System dump .................................................................................................. 4-10

Media card dumps ................................................................................................. 4-10

Panic dumps sent to external storage .................................................................. 4-10

Option 1: Log and dump to a PCMCIA device .............................................. 4-11

List of devices............................................................................................................... 4-11

PCMCIA slot commands.............................................................................................. 4-11

Installing a PCMCIA device ........................................................................................ 4-12

iflash command - caution ! ........................................................................................... 4-15

Option 2: Set up a syslog server ................................................... 4-16

Option 3: Use an NFS-mounted file system ............................................................ 4-18

Setting up NFS on the GRF.......................................................................................... 4-18

Option: Attaching a modem to the GRF ........................................................... 4-19

Installing a PCMCIA modem ....................................................................................... 4-19

Configuration procedure ............................................................................................ 4-19

Powering off a GRF ................................................................................................. 4-21

Systems with AC power supplies ................................................................................. 4-21

Systems with DC power supplies ................................................................................. 4-21

What to do next.................................................................................................................... 4-22

Chapter 5 Cabling and Verifying Media Cards............................................... 5-1

ESD requirements........................................................................................................... 5-1

Returning a media card to Lucent ....................................................................... 5-2

Get an RMA number....................................................................................................... 5-2

Package your board properly.......................................................................................... 5-2

Ship via FedEx................................................................................................................ 5-3

Inserting a media card into the GRF ................................................................................ 5-4

ESD requirements........................................................................................................... 5-4

Minimum load requirement ............................................................................................ 5-4

On-card connectors......................................................................................................... 5-4

Chassis insertion procedure ............................................................................................ 5-5

Hot swapping media cards ..................................................................................... 5-6

Q cards ...................................................................................................................... 5-6

Burning in media card flash memory ................................................................... 5-6

Cabling the media cards .............................................................................................. 5-7

ESD requirements........................................................................................................... 5-7

xii GRF 400/1600 Getting Started - 1.4 Update 2

Page 13

Contents

Blank face plates............................................................................................................. 5-7

Cable specifications........................................................................................................ 5-7

Differences in media card loading .................................................................... 5-8

Reset GRF when all cables are attached ...................................................................... 5-8

ATM OC-3c (ATM/Q) media card ..................................................................................... 5-9

LEDs ..................................................................................................................... 5-9

Laser safety ............................................................................................................. 5-10

ATM OC-12c media card ................................................................................................. 5-11

LEDs ................................................................................................................... 5-11

Laser safety ............................................................................................................. 5-12

Attaching ATM media cables ................................................................................... 5-13

FDDI/Q media cards ......................................................................................................... 5-15

LEDs ................................................................................................................... 5-15

Attaching FDDI/Q media cables ......................................................................... 5-16

FDDI connector keys ......................................................................................... 5-17

Connector key types...................................................................................................... 5-17

FDDI attachment options ................................................................................................. 5-18

Attachment summary.................................................................................................... 5-18

SAS and DAS attachments ........................................................................................... 5-18

Single attach - M and S interfaces ................................................................................ 5-19

Dual attach - A and B interfaces................................................................................... 5-19

Installing a FDDI optical bypass ................................................................................. 5-20

Manual enable/disable ............................................................................................... 5-20

HIPPI media card ............................................................................................................. 5-21

Attaching HIPPI media cables...................................................................................... 5-21

HIPPI card LEDs ................................................................................................... 5-23

HSSI media card ................................................................................................................ 5-24

Attaching HSSI media cables ....................................................................................... 5-24

Problems with bad HSSI cables ................................................................................. 5-25

HSSI card LEDs ...................................................................................................... 5-25

Ethernet media cards .................................................................................................... 5-26

Attaching 10/100Base-T media cables ............................................................ 5-26

Ethernet card LEDs ....................................................................................... 5-27

SONET OC-3c media card ............................................................................................... 5-28

Laser safety ............................................................................................................... 5-28

Attaching SONET media cables ............................................................................... 5-29

SONET card LEDs ............................................................................................. 5-30

Media card reset and checkout ........................................................................................... 5-31

Verify media card operation using ping .................................................... 5-31

Check media card status using grcard ................................................................ 5-32

Media card states ................................................................................................ 5-32

Reset media card using grreset ..................................................................... 5-33

Rebooting the system........................................................................................................... 5-34

Rebooting from the VT 100 terminal - grms ..................................................... 5-34

Rebooting from a remote workstation - shutdown ................................................. 5-34

Running media card hardware diagnostics .......................................................................... 5-35

Special login.................................................................................................................. 5-35

Running grdiag.............................................................................................................. 5-35

Activity during testing .................................................................................................. 5-37

Testing completes ......................................................................................................... 5-37

If a card fails... .............................................................................................................. 5-38

Error reporting .............................................................................................................. 5-39

GRF 400/1600 Getting Started - 1.4 Update 2 xiii

Page 14

Contents

Stopping or halting grdiag ............................................................................................ 5-39

What to do next............................................................................................................. 5-40

Appendix A GRF Specifications......................................................................... A-1

General specifications and environmental requirements ............................................. A-1

GRF 400 chassis specifications ............................................................ A-2

GRF 1600 chassis specifications .......................................................... A-3

DC power requirements ............................................................................................... A-4

GRF 400 control board specifications ........................................................................ A-5

GRF 1600 control board specifications ...................................................................... A-5

Cable types ......................................................................................................................... A-6

Media card specifications...................................................................................................... A-7

FDDI specifications ................................................................................................ A-7

ATM OC-3c specifications ......................................................................................... A-8

ATM OC-12c specifications ....................................................................................... A-9

10/100Base-T specifications ..................................................................................... A-10

HSSI specifications ................................................................................................... A-10

HIPPI specifications .................................................................................................. A-11

SONET OC-3c specifications ................................................................................... A-12

Appendix B Warranty .......................................................................................... B-1

Product warranty.................................................................................................................... B-1

Warranty repair............................................................................................................... B-1

Out-of warranty repair .................................................................................................... B-2

FCC Part 15 Notice................................................................................................................ B-2

Appendix C GRF 400 Agency Notices ............................................................... C-1

GRF 400 agency regulatory notices....................................................................................... C-2

Agency status.................................................................................................................. C-2

Canadian notice............................................................................................................... C-2

European Union notice ................................................................................................... C-2

Federal Communications Commission notice................................................................ C-3

VCCI Class 1 notice........................................................................................................ C-3

Non-telecommunication port.......................................................................................... C-4

EC declaration: GRF-4-AC............................................................................................ C-5

EC declaration: GRF-4-DC............................................................................................ C-6

Appendix D GRF 1600 Agency Notices ............................................................. D-1

GRF 1600 agency regulatory notices.................................................................................... D-2

Agency status................................................................................................................. D-2

Canadian notice.............................................................................................................. D-2

European Union notice .................................................................................................. D-2

Federal Communications Commission notice............................................................... D-3

VCCI Class 1 notice....................................................................................................... D-3

Non-telecommunication port......................................................................................... D-4

EC declaration: GRF-16-AC......................................................................................... D-5

EC declaration: GRF-16-DC......................................................................................... D-6

Index.......................................................................................... Index-1

xiv GRF 400/1600 Getting Started - 1.4 Update 2

Page 15

Figures

Figure 1-1 Expandable area of system memory............................................................. 1-4

Figure 1-2 GRF 400 base unit and component (front view) ......................................... 1-5

Figure 1-3 Cable panel view of GRF 400 ...................................................................... 1-5

Figure 1-4 Media card and control board stack with slots numbered ............................ 1-5

Figure 1-5 Memory components and options on the control board ............................... 1-7

Figure 1-6 Front of Astec AC power supply drawer.................................................... 1-11

Figure 1-7 Front of Artesyn AC power supply drawer. ............................................... 1-11

Figure 1-8 Front of -48V power supply drawer. .......................................................... 1-12

Figure 2-1 Expandable area of system memory............................................................. 2-5

Figure 2-2 GRF 1600 base unit and component areas (front view) .............................. 2-6

Figure 2-3 Rear panel view of GRF 1600 ................................................................. 2-7

Figure 2-4 Top view of GRF 1600 chassis with slots numbered ................................... 2-8

Figure 2-5 Memory components and options on the control board ............................. 2-11

Figure 2-6 Front of GRF 1600 AC power supply drawer and locking tab................... 2-13

Figure 2-7 Warning label required for redundant supplies .......................................... 2-15

Figure 2-8 Front panel of GRF 1600 DC power supply............................................... 2-16

Figure 3-1 Air intake and exhaust areas of the GRF 400............................................... 3-3

Figure 3-2 Media card components................................................................................ 3-4

Figure 3-3 Connectors on a control board...................................................................... 3-6

Figure 3-4 GRF 400 control board faceplate and LEDs................................................. 3-8

Figure 3-5 Warning label required for redundant AC supplies.................................... 3-10

Figure 3-6 Front of -48V power supply drawer. .......................................................... 3-12

Figure 3-7 Air intake and exhaust areas of the GRF 1600........................................... 3-17

Figure 3-8 Diagram of proper way to move GRF 1600 into rack................................ 3-18

Figure 3-9 Media card components.............................................................................. 3-19

Figure 3-10 Connectors on a control board.................................................................... 3-21

Figure 3-11 GRF 1600 control board faceplate and LEDs............................................. 3-23

Figure 3-12 AC power supply with a power cord locking clamp installed.................... 3-25

Figure 3-13 Warning label required for redundant supplies .......................................... 3-26

Figure 3-14 Terminal pairs on GRF 1600 DC power supply......................................... 3-29

Figure 3-15 DC supply wires attached to GRF 1600 DC terminal pairs........................ 3-30

Figure 3-16 Warning label required for redundant DC power supply cover ................. 3-31

Figure 4-1 Point-to-point Ethernet connector on the control board ............................... 4-5

Figure 5-1 Media card components................................................................................ 5-4

Figure 5-2 ATM OC-3c single mode media card faceplate ........................................... 5-9

Figure 5-3 Faceplate of an ATM OC-12c (version 1) single mode media card........... 5-11

Figure 5-4 Faceplate of an ATM OC-12c (version 2) single mode media card........... 5-11

Figure 5-5 Single and multi-mode ATM cable ends.................................................... 5-13

Figure 5-6 FDDI/Q media card faceplate..................................................................... 5-15

GRF 400/1600 Getting Started - 1.4 Update 2

October, 1998 xv

Page 16

Figures

Figure 5-7 FDDI/Q media card faceplate and LEDs.................................................... 5-15

Figure 5-8 FDDI optic cable connector and keys......................................................... 5-17

Figure 5-9 Types of FDDI connector keys................................................................... 5-17

Figure 5-10 DAS and SAS connection options.............................................................. 5-18

Figure 5-11 FDDI media cards used as single and dual attachment nodes.................... 5-18

Figure 5-12 Single attach FDDI interface using master / slave keys ............................. 5-19

Figure 5-13 Dual attach FDDI interface using A / B keys............................................. 5-19

Figure 5-14 Optical bypass switch attachments............................................................. 5-20

Figure 5-15 HIPPI media card faceplate ........................................................................ 5-21

Figure 5-16 Cabling a HIPPI media card ....................................................................... 5-21

Figure 5-17 HIPPI 100-pin connector............................................................................ 5-22

Figure 5-18 HIPPI media card faceplate and LEDs....................................................... 5-23

Figure 5-19 HSSI media card faceplate.......................................................................... 5-24

Figure 5-20 HSSI 50-pin connector end......................................................................... 5-24

Figure 5-21 HSSI media card faceplate and LEDs ........................................................ 5-25

Figure 5-22 Ethernet 8-port media card faceplate.......................................................... 5-26

Figure 5-23 Ethernet 4-port media card faceplate.......................................................... 5-26

Figure 5-24 Cable connector for a 10/100Base-T interface........................................... 5-26

Figure 5-25 Ethernet media card faceplate and LEDs.................................................... 5-27

Figure 5-26 SONET OC-3c single mode media card faceplate ..................................... 5-28

Figure 5-27 Single and multi-mode SONET cable ends................................................ 5-29

Figure 5-28 SONET OC-3c single mode media card faceplate and LEDs.................... 5-30

xvi October, 1998

GRF 400/1600 Getting Started - 1.4 Update 2

Page 17

Tables

Table 3-1 Descriptions of GRF 400 control board LEDs ............................................. 3-8

Table 3-2 Descriptions of GRF 1600 control board LEDs ......................................... 3-23

Table 5-1 Media card cable specifications.................................................................... 5-7

Table 5-2 ATM OC-3c LEDs........................................................................................ 5-9

Table 5-3 ATM OC-3c single mode laser information............................................... 5-10

Table 5-4 ATM OC-12c LEDs.................................................................................... 5-11

Table 5-5 ATM OC-12c csingle mode laser information ........................................... 5-13

Table 5-6 FDDI/Q media card LEDs.......................................................................... 5-15

Table 5-7 HIPPI media card LEDs.............................................................................. 5-23

Table 5-8 HSSI media card LEDs............................................................................... 5-25

Table 5-9 Ethernet media card LEDs.......................................................................... 5-27

Table 5-10 SONET OC-3c single mode laser information........................................... 5-29

Table 5-11 SONET OC-3c LEDs.................................................................................. 5-30

Table A-1 GRF 400 chassis characteristics................................................................... A-2

Table A-2 GRF 1600 chassis characteristics................................................................. A-3

Table A-3 DC power requirement per individual components..................................... A-4

Table A-4 Characteristics of the GRF 400 control board ............................................. A-5

Table A-5 Characteristics of the GRF 1600 control board ........................................... A-5

Table A-6 Media card cable specifications................................................................... A-6

Table A-7 FDDI media card specifications................................................................... A-7

Table A-8 ATM OC-3c media card specifications ....................................................... A-8

Table A-9 ATM OC-12c media card specifications ..................................................... A-9

Table A-10 10/100Base-T media card specifications................................................... A-10

Table A-11 HSSI media card specifications................................................................. A-10

Table A-12 HIPPI media card specifications................................................................ A-11

Table A-13 SONET OC-3c media card specifications ................................................. A-12

GRF 400/1600 Getting Started - 1.4 Update 2

October, 1998 xvii

Page 18

Tables

xviii October, 1998

GRF 400/1600 Getting Started - 1.4 Update 2

Page 19

About This Guide

About 1.4 Update 2

The 1.4 GRF manual set is updated to include new features added since software release

1.4.12. This manual describes the full set of features for GRF units running software version

1.4.20 and later. Some features might not be available with earlier versions of the software.

What is in this guide

The GRF 400/1600 Getting Started guide contains these chapters:

• Chapter 1, “Getting Acquainted with the GRF 400,” describes the GRF 400 system

components and operating environment.

• Chapter 2, “Getting Acquainted with the GRF 1600,” describes the GRF 1600 system

components and operating environment.

• Chapter 3, “Rack Mount and Power On Procedures,” describes the rack mounting

procedure for each GRF model, and provides power on procedures for AC and DC power

supplies.

• Chapter 4, “Initial System Set-up,” explains the first-time configuration script, the

Command-line Interface (CLI), and system set up for logging, PCMCIA devices, and

other system tasks that bring the GRF to an operational state, ready for media card cabling

and verification.

• Chapter 5, “Cabling and Verifying Media Cards,” describes the set of available IP media

cards, their LED activity, and provides the cable requirements for each card.

• Appendix A, “GRF Specifications,” lists technical specifications for the GRF routers and

the IP media cards.

• Appendix B, “Warranty,” contains the product warranty information.

• Appendix C, “GRF 400 Agency Notices,” contains the GRF 400 agency information.

• Appendix D, “GRF 1600 Agency Notices,” contains the GRF 1600 agency information.

The guide also includes an index.

GRF 400/1600 Getting Started - 1.4 Update 2 October, 1998 xix

Page 20

About This Guide

What you should know

What you should know

Configuring and monitoring the GRF requires that a Network Administrator have experience

with and an understanding of UNIX systems, and the ability to navigate in a UNIX

environment. Knowledge of UNIX, its tools, utilities, and editors is useful, as is experience

with administering and maintaining a UNIX system.

Configuring the GRF requires network experience and familiarity with:

– UNIX systems and commands

– IP protocol and routing operations

– IP internetworking

The Network Administrator must understand how TCP/IP internetworks are assembled; what

interconnections represent legal topologies; how networks, hosts, and routers are assigned IP

addresses and configured into operation; and how to determine and specify route table

(routing) information about the constructed internetwork(s). Although not required, a

high-level understanding of SNMP is useful.

xx October, 1998

GRF 400/1600 Getting Started - 1.4 Update 2

Page 21

Documentation conventions

Ascend uses standard documentation conventions, which are as follows:

Convention Meaning

Monospace text Represents text that appears on your computer’s screen, or

that could appear on your computer’s screen.

Boldface t Represents characters that you enter exactly as shown (unless

the characters are also in italics—see Italics, below). If you

could enter the characters but are not specifically instructed

to, they do not appear in boldface.

Italics Represent variable information. Do not enter the words

themselves in the command. Enter the information they

represent. In ordinary text, italics are used for titles of

publications, for some terms that would otherwise be in

quotation marks, and to show emphasis.

[ ] Square brackets indicate an optional argument you might add

to a command. To include such an argument, type only the

information inside the brackets. Do not type the brackets

unless they appear in bold type.

| Separates command choices that are mutually exclusive.

Key1-Key2 Represents a combination keystroke. To enter a combination

keystroke, press the first key and hold it down while you

press one or more other keys. Release all the keys at the same

time. (For example, Ctrl-H means hold down the Control ke y

and press the H key.)

Note:

Introduces important additional information.

About This Guide

Documentation conventions

!

Caution:

Warning:

GRF 400/1600 Getting Started - 1.4 Update 2 October, 1998 xxi

Warns that a failure to follow the recommended procedure

could result in loss of data or damage to equipment.

Warns that a failure to take appropriate safety precautions

could result in physical injury.

Page 22

About This Guide

Documentation set

Documentation set

The GRF 1.4 Update 2 documentation set consists of the following manuals:

• GRF 400/1600 Getting Started 1.4 Update 2 (this manual)

• GRF Configuration and Management - 1.4 Update 2

• GRF Reference Guide - 1.4 Update 2

• GRF GateD - 1.4 Update 2

Related publications

Here are some related publications that you may find useful:

• Internetworking with TCP/IP, Volume 1 and 2, by Douglas E. Comer, and David L.

Stevens. Prentice-Hall,

• TCP/IP Illustrated, Volumes 1 and 2, by W. Richard Stevens. Addison-Wesley, 1994.

• Interconnections, Radia Perlman. Addison-Wesley, 1992. Recommended for information

about routers and bridging.

• Routing in the Internet, by Christian Huitema. Prentice Hall PTR, 1995. Recommended

for information about IP, OSPF, CIDR, IP multicast, and mobile IP.

• TCP/IP Network Administration, by Craig Hunt. O’Reilly & Associates, Inc. 1994.

Recommended for network management information.

• Essential System Administration, Æleen Frisch. O’Reilly & Associates, Inc. 1991.

Recommended for network management information.

xxii October, 1998 GRF 400/1600 Getting Started - 1.4 Update 2

Page 23

Getting Acquainted with the GRF 400

This chapter describes the components in a GRF 400 router that you need to be familiar with as

you set up and install the equipment.

At the end of this chapter is a one-page preview of the tasks to set up and install the GRF.

Please read through the list, the tasks are described in subsequent chapters.

After you have completed this introduction to the GRF 400, go to chapter 3. It contains

information for rack-mounting the GRF 400 and procedures you use to power on AC and DC

systems.

Chapter 1 covers these topics:

What is the GRF 400? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Which items are included in your system? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Site-supplied components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Components you can add. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Upgrading system memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Overview of the GRF 400 base unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1

Description of the AC power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Description of the 48V DC power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Installation preview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Note: The GRF 400 has hardware that integrates the router management hardware pre viously

contained in the RMS node with components on the GRF 400 control board. A GRF 400

system currently using an RMS node can be upgraded by replacing its control board (optional)

and installing 1.4 software.

GRF 400/1600 Getting Started - 1.4 Update 2 October, 1998 1-1

Page 24

Getting Acquainted with the GRF 400

What is the GRF 400?

What is the GRF 400?

The GRF 400 is a high-performance IP switch designed for high-volume, large-scale public

and private backbone applications. It has these main features:

• Performs Layer-3 switching across 4 gigabits/second aggregate bandwidth

• Supports large suite of routing protocols

• Accommodates 1–4 media cards, available media are ATM OC-3c, ATM OC-12c,

10/100Base-T Ethernet (4- and 8-port), HSSI, HIPPI, SONET OC-3c, and FDDI

• Provides advanced dynamic routing, basic filtering, OSPF multicast, SNMP v1, IPv4

• Accommodates redundant, hot swappable power supplies

• Supports a 400W AC power supply unit

• Supports a -48VDC power supply (negative 48V)

• Manages 150K-entry route tables, batch updating with 20 routes per second

The GRF 400 chassis can be mounted in a standard 19” rack unit or on a table. The chassis

weighs between 26 and 40 pounds (11.9–18.2 kg), depending upon the number of media cards

and power supplies installed.

Which items are included in your system?

This section helps you confirm the items in your system.

• Each system includes a GRF 400 base unit.

• Base unit components vary depending upon the type/number of media cards and power

supplies ordered.

• Software is pre-installed at the factory.

AC power cord

If you ordered the GRF with one (two) A C power supply , make sure the shipping box contains:

• one (two) AC power cords

If your GRF 400 has a redundant AC power supply, you should have two power cords.

AC power cord requirements

Use only the AC power cord included with your product or an equivalent cord:

• North America: UL listed, CSA certified, type SJT or SVT, 3-conductor,

18AWG minimum

• outside of North America: Agency-approved for the country of use, cord type

H05VVF3G1.0, 3-conductor, 1.0mm2, rated 250V, 10A,

plug type suitable for country of use.

1-2October, 1998 GRF 400/1600 Getting Started - 1.4 Update 2

Page 25

Site-supplied components

To boot the GRF 400, you must attach a VT100-compatible terminal directly to the control

board, and you must supply:

• a standard RS-232 null modem cable and the terminal

Optionally, if you later want to directly connect the GRF to a site LAN, you must supply:

• a cross-over 10Base-T Ethernet cable to connect the LAN to a receptacle on the control

board

Components you can add

In addition to media cards, options you can order from Lucent include:

• 400W AC power supplies

• negative 48V DC power supplies

• upgrades to system memory (control board RAM)

The GRF 400 ships with a base of 128MB of RAM. Sites can upgrade to a maximum of

512MB in increments of 128MB, as pairs of 64MB SIMMs.

Memory upgrades may only be obtained from Lucent, do not use other sources.

• ATA disk devices in a PCMCIA slot for system logging and backup

Lucent certifies the following ATA-compliant devices for GRF operation:

Getting Acquainted with the GRF 400

Site-supplied components

– Kingston Datapak 520MB, P/N CT520RM

– Sandisk 175MB Flash, P/N SDP3B

– Sandisk 85MB Flash, P/N SDP3B-85-101

– Aved 85MB Flash, P/N AVEF385MB25ATA501

Lucent offers only the 85 MB Flash directly (GRF-AC-FLASH). Customers may purchase

the other devices through an external source.

• PCMCIA modems

– US Robotics/MegaHertz 56K PC Card Modem, model xj5560

GRF 400/1600 Getting Started - 1.4 Update 2 October, 1998 1-3

Page 26

Getting Acquainted with the GRF 400

Upgrading system memory

Upgrading system memory

Figure 1-1 shows the area of system memory (control board RAM) that can be expanded to

meet site requirements. Memory upgrades are made in 128MB increments up to 512MB.

expandable to -->

- system software

- config files

- GateD binary

- log files

- route tables

- ATMP tunnels

- kernel runs

- GateD runs

256MB

RAM

212MB

= expandable area of RAM

--> 384MB

RAM

340MB

--> 512MB

RAM

468MB

Memory

size and

organization

128MB RAM

32MB

(fixed size)

84MB

8-12MB

(fixed size)

Figure 1-1. Expandable area of system memory

This chart provides general guidelines for memory required in different routing environments.

Although the figures assume BGP peers with 50K route entries, additional memory may be

required for higher average numbers of routes per BGP peer.

If the GRF is to support dynamic routing or ATMP home agents and mobile nodes, upgrade to

at least 256MB. In environments where large numbers of routes are advertised, upgrade to

512MB.

Customer

profile

Amount of

control

board

memory

needed

Space for

dynamic

routing,

ATMP

tables

Route

entries

on

media

card

Route

entries in

dynamic

routing

database

Typical

numbe

r of

peer

sessions

Static routing:

(in high-performance

environment)

Small POP 256MB 212MB 150K Typical

128MB 84MB 150K Typical

number:

35,800

0

3

number:

199,000

Medium POP /

ISP backbone

384MB 340MB 150K Typical

number:

9

362,000

Large POP /

Exchange point /

Route reflection server

512MB 468MB 150K Typical

number:

521,000

12

1-4October, 1998 GRF 400/1600 Getting Started - 1.4 Update 2

Page 27

Getting Acquainted with the GRF 400

Overview of the GRF 400 base unit

Figure 1-2 shows the GRF 400 base unit from the front. The rack-mountable chassis is 5.25”

high and 19” wide. When you install the GRF, you must provide six to ten inches of side

clearance for ambient air intake and heated air exhaust. All ventilation is to the sides.

Overview of the GRF 400 base unit

Intake

Back plane

Media card

and

IP switch control board

stack

Power

supplies

Exhaust

vents

fans

GRF 400

Lucent Technolo gies

(g0002)

Figure 1-2. GRF 400 base unit and component (front view)

Figure 1-3 shows the chassis from the cable panel. Power supplies are on the left. The control

board is on the top of the card stack to the right, the four media cards are in the slots below:

B A

PCMCIA

RESET

POWER

100/10

LINK OK

ACTIVE

RECEIVE

TRANSMIT

FAULT

STATUS

PS2-OK

PS1-OK

100

RS232

COM1

RCV ACT

XMT ACT

SM-4MB

ATM-3-Q

4MB

FDDI-Q

4MB

HSSI

4MB-TX

10/100-Q

PWR

PWR ON

FAULT

STAT 0

0

PWR

TAT

S

PWR ON

FAULT

STAT 0

7

RCV ACT

XMT ACT

LINK OK

STAT1

RCV ACT

XMT ACT

LINK OK

LASER

HSSI

A

TRX

0

B

A

5

4

0

A

ACTIVE

STATUS

6

1

STAT 1

STAT 2

LASER

B

TRX

1

A

STATUS

ACTIVE

3

B

2

1

SM

ATM

OC-3c

1

B

0

Figure 1-3. Cable panel view of GRF 400

The GRF 400 has four media card slots, 0–3. Slots are numbered top to bottom as shown in

Figure 1-4, the control board is always 66:

Backplane

66

3

Control board

2

1

0

Media card slot numbers

(in decimal)

(g0009)

Figure 1-4. Media card and control board stack with slots numbered

GRF 400/1600 Getting Started - 1.4 Update 2 October, 1998 1-5

Page 28

Getting Acquainted with the GRF 400

Overview of the GRF 400 base unit

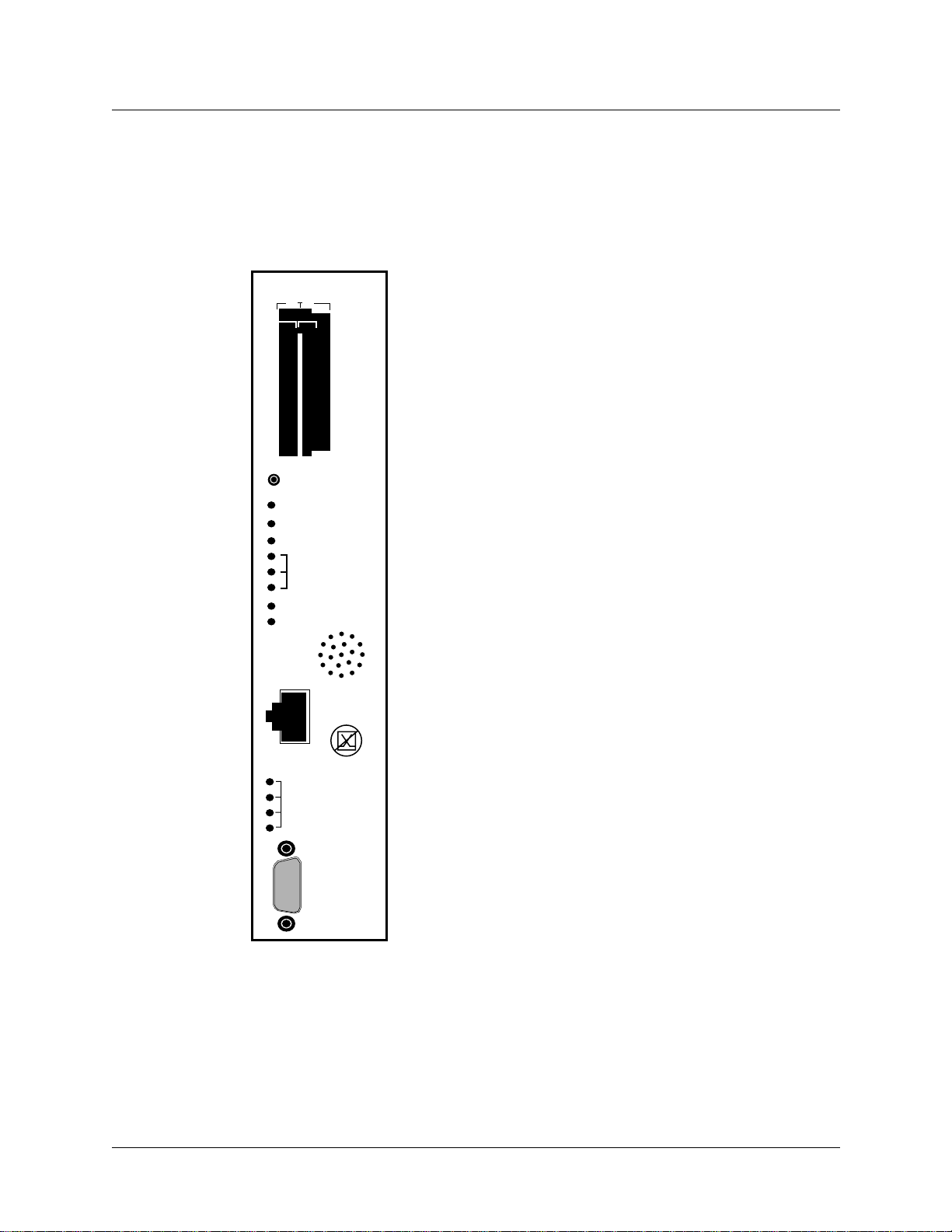

Control board

GRF 400 control board hardware runs the router management software (RMS). RMS is the

communications and control software for the media cards. Other control board components are

the system RAM, internal flash memory, switch hardware, Ethernet connector, and PCMCIA

device slots. The control board is field-replaceable, but not hot swappable.

PCMCIA

B A

RESET

POWER

FAULT

STATUS

ACTIVE

TRANSMIT

RECEIVE

COM BUS

PS1-OK

PS2-OK

100/10

LINK OK

100

XMT ACT

ETHERNET

RCV ACT

•

•

•

•

•

•

•

•

•

RS232

COM1

A hardware reset button, receptacles for Ethernet and RS-232

connections, and power, status and fault LEDs are on the control

board’s faceplate, shown left.

PCMCIA slots can contain an external flash memory device and a

PCMCIA modem attachment.

The system can be reset by depressing the reset button, but a

software command reset is preferable since it saves files and

leaves the system in order.

LEDs provide status for control board and chassis components.

The faceplate speaker functions as a typical PC speaker , it chimes

during system boot, for example. The control board has another

component that sounds an audible alarm when the operating

temperature level is exceeded.

The control board has temperature monitoring (sensor) and

reporting (alarm) capabilities. The router management software

provides a command (temp) to check the current board-surface

operating temperature. If excessive temperature levels are

reached, the router management software triggers the control

board’s audible alarm. If levels are exceeded, the management

software will shut the system down. The management software

also monitors the power supply units, issuing power failure

warnings to the user interface via grconslog if power problems

are detected. The LEDs do not reflect the actual location of power

supplies in the chassis: power supply 2 is on top, power supply 1

is on the bottom.

A 10/100 megabit Ethernet receptacle (autosensing) supports a