Page 1

Introduction

The single station DH300 precision polishing machine provides both

research and production oriented establishments with a high quality,

automated polishing facility. Wafers, lenses, mirrors, prisms or

components consisting of a wide variety of different materials (up to a

maximum of 300mm) can be polished with ease using the Logitech range

of polishing cloths, plates and solutions.

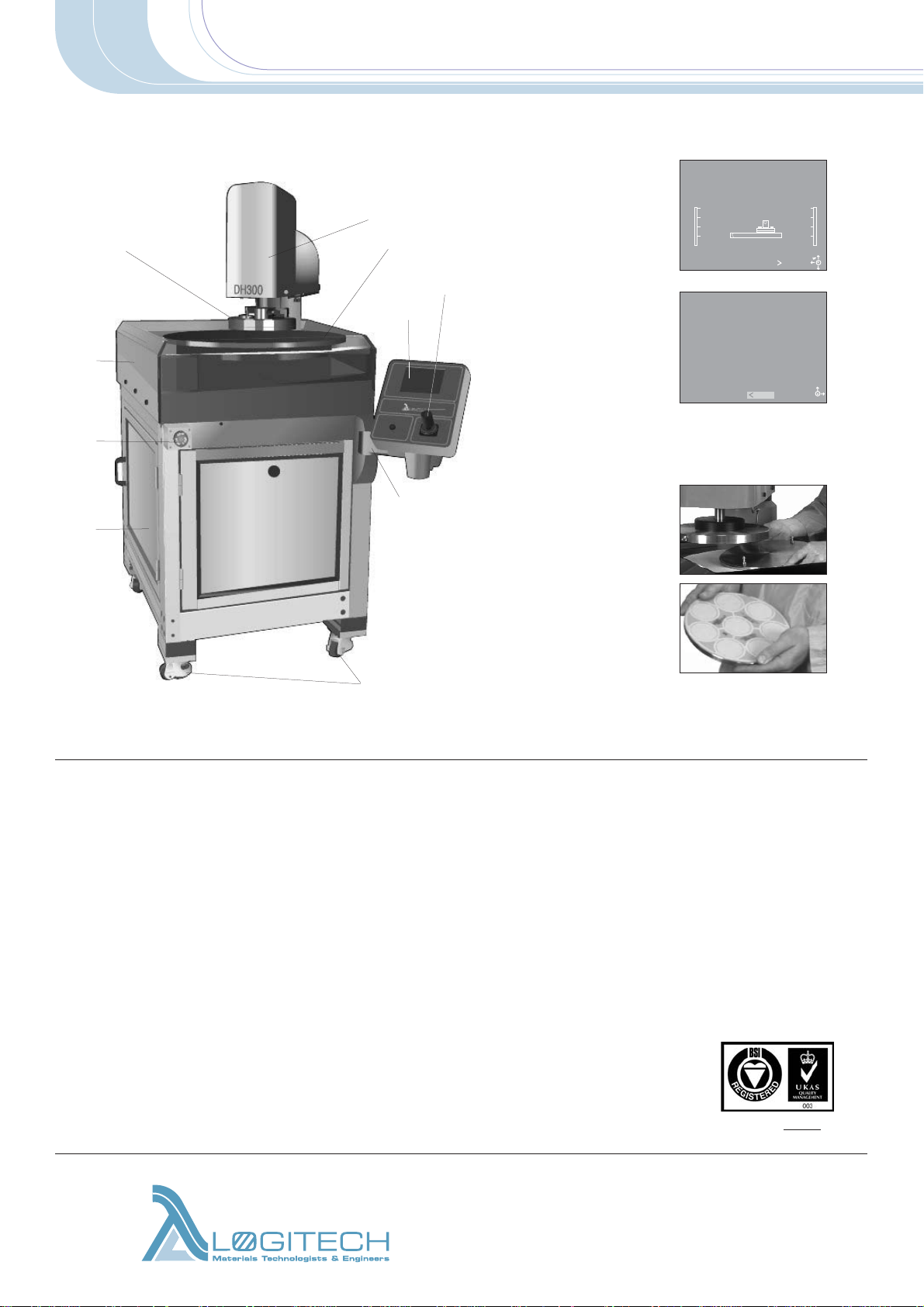

Description

The process area consists of a 560mm (22”) diameter polishing plate, a

single motor driven, sweeping polishing head with a detachable wafer /

component carrier and an integral polishing fluid feed system.

Polishing process parameters such as the plate speed, carrier speed,

direction, down pressure and polishing fluid fow rate can all be set using

the automated control panel. Each of these parameters can be selected,

changed and saved using the control panel joystick. Situated to the front

of the DH300, the control panel unit can be swivelled to either the left or

right hand sides of the machine as desired. An umbilical link also allows

the panel to be detached from the main body of the DH300 and moved to

a distance of 2m (6.56ft) away.

The polishing plate and wafer / component carrier can both be

programmed to rotate in clockwise or anti-clockwise directions

independently and at speeds of up to 160rpm and 125rpm respectively.

This allows a wide variety of individual polishing techniques to be catered

for whilst making use of the Logitech polishing plate, cloth and fluid range

to produce repeatable process results.

The polishing arm can also be programmed to sweep the wafer /

component carrier across the polishing plate surface. The level of sweep

can be controlled from the control panel, as can the level of down force

exerted on the carrier (1-5psi sample pressure). This combination of

sweep and down force allows particularly hard optical materials such as

sapphire and silicon carbide, to be polished with ease.

Loading and unloading of the carrier arm is again controlled from the

control panel and no heavy lifting is required as the carrier simply clicks

into place.

The polishing solution feed system is regulated from the automated

control panel and brings fluid through a peristaltic pump to the polishing

plate. This system ensures a continuous supply of polishing fluid

throughout the polishing process.

Applications

The DH300 can be used for polishing wafers, prisms, mirrors, lenses or

components of virtually any optical or semiconductor material. Automated

controls and independently adjustable process parameters make this

single station unit ideal for those seeking to quickly polish wafers to an

epitaxy ready surface. This versatility is heightened by the unit’s ability to

work with wafers / components of differing diameters and up to a

maximum of 300mm.

DH300

• Single motor driven sweeping polishing

head

• Variable plate speed (0-160rpm)

• Plate diameter of 560mm (22”)

• Process 1 x 300mm or 12 x 2”Ø wafers

• SiC, GaN, AlN, Sapphire, Nd:YAG

Driven Head Precision Polishing Machine

Page 2

Technical Data

Specifications:

Power supply:

Fuse rating:

Plate speed:

Plate direction:

Plate size:

Carrier speed:

Carrier direction:

Machine capacity:

Height:

Width:

Depth:

Single Phase 220-230V

13A

0-160rpm

Clockwise & counter clockwise

560mm (22”)

125rpm

Clockwise & counter clockwise

12 x 2” wafers per run

1800mm

700mm

950mm

Logitech Limited

Erskine Ferry Road, Old Kilpatrick, Glasgow G60 5EU, Scotland, U.K.

Tel: +44 (0) 1389 875444

Fax: +44 (0) 1389 890956

e-mail: info@logitech.uk.com

www.logitech.uk.com

Distributed by:

Due to a continuous programme of development, Logitech reserves the right to change specifications without prior notice.

Certificate No. FM12025

Ordering Data:

1DH31

1DHS1-0100

1DHS1-0200

1DHS1-0300

DH300 Driven Head Precision Polishing Machine (220-230V)

Standard complete wafer / component carrier

Carrier plate for the wafer / component carrier

Standard sample polishing template (12 x 2ӯ wafers)

DH300/7/04

The Automated Control Panel:

From this control screen it is

possible to set the following

process parameters:

• Plate & carrier rotation speed

• Polishing solution feed rate

• Carrier Sweep

• Start / stop the polishing

process

From the second control screen

it is possible to set the following

process parameters:

• Plate rotational direction

• Carrier rotational direction

• Carrier down pressure

Polishing Templates:

Avariety of different templates

are available to suit individual

requirements. The carrier head

has a lightweight removable

baseplate for fixing templates to

as shown on the right.

Each template allows wafers /

components to be held securely

throughout the polishing process

and work equally well with

multiple groupings of wafers /

components (see right) or single

large diameter wafers up to

300mm.

Polishing plate

Polishing arm

Wafer /

component

carrier

Emergency

stop button

Joystick

control

Perspex

spray shield

Lockable wheels

Access to

motor

1/4 VGA

Graphical

interface

MANUAL CONTROL

Timer: 00:00 mm:ss

RESET START STOP

Carrier

021 rpm

FlushONSlurry

400 ml/m

Plate

003 rpm

40

80

120

160

40

80

120

160

50%Sweep Frequency:

50%Sweep Amplitude:

PAGE EXIT

MANUAL CONTROL

Timer: 00:26 mm:ss

Plate Direction:

Carrier Direction:

Pressure Units:

CW

CCW

PSI

EXITPAGE

Movable

arm

Loading...

Loading...