Page 1

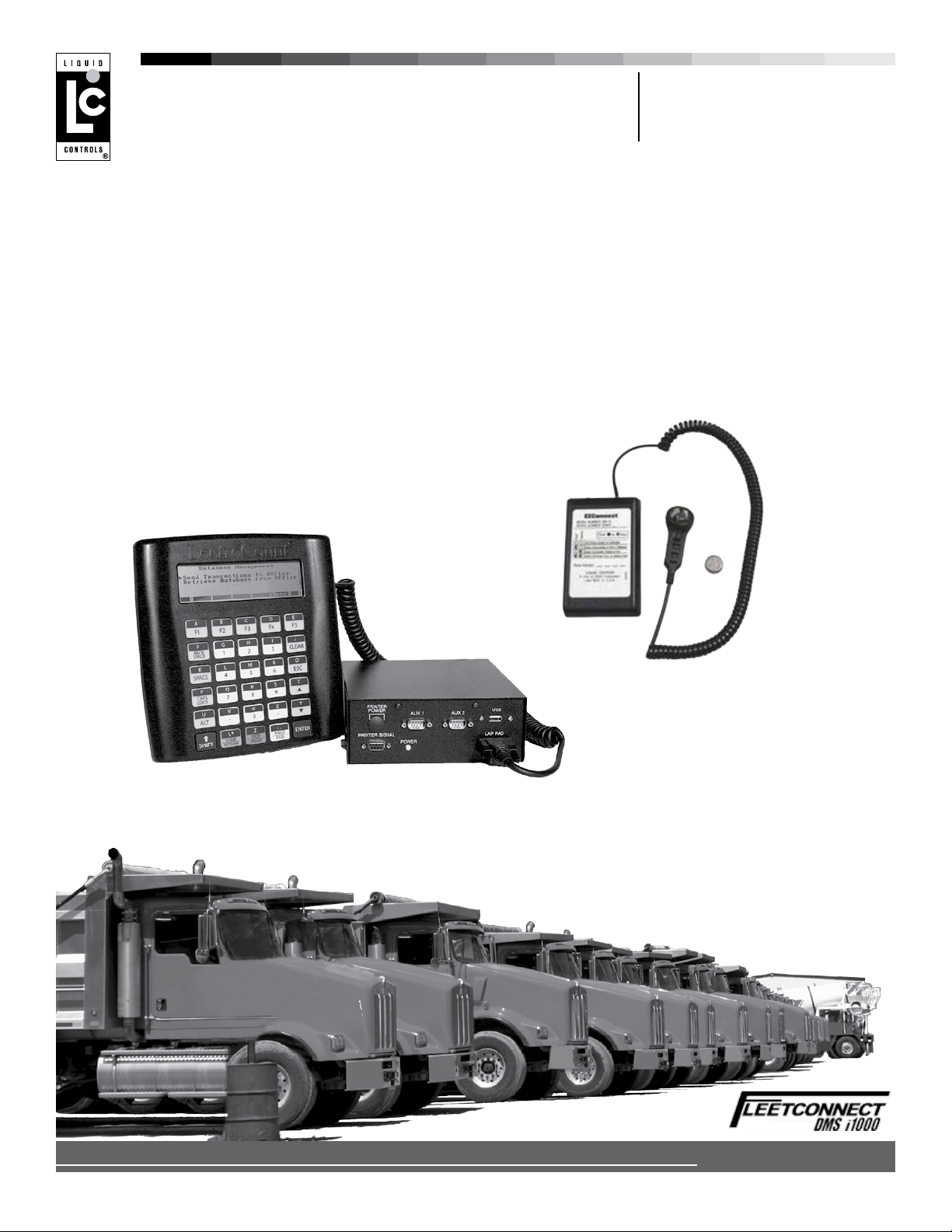

DMS i1000 FleetConnect

Fleet Fueling System

TM

Setup and Operation

Liquid ControLs Group

An IDEX Fluid & Metering Business

Operation: EM200-14

Page 2

TABLE OF CONTENTS

INTRODUCTION

Software License Agreement .................................. 3

DMS i1000 FleetConnect Overview ........................ 4

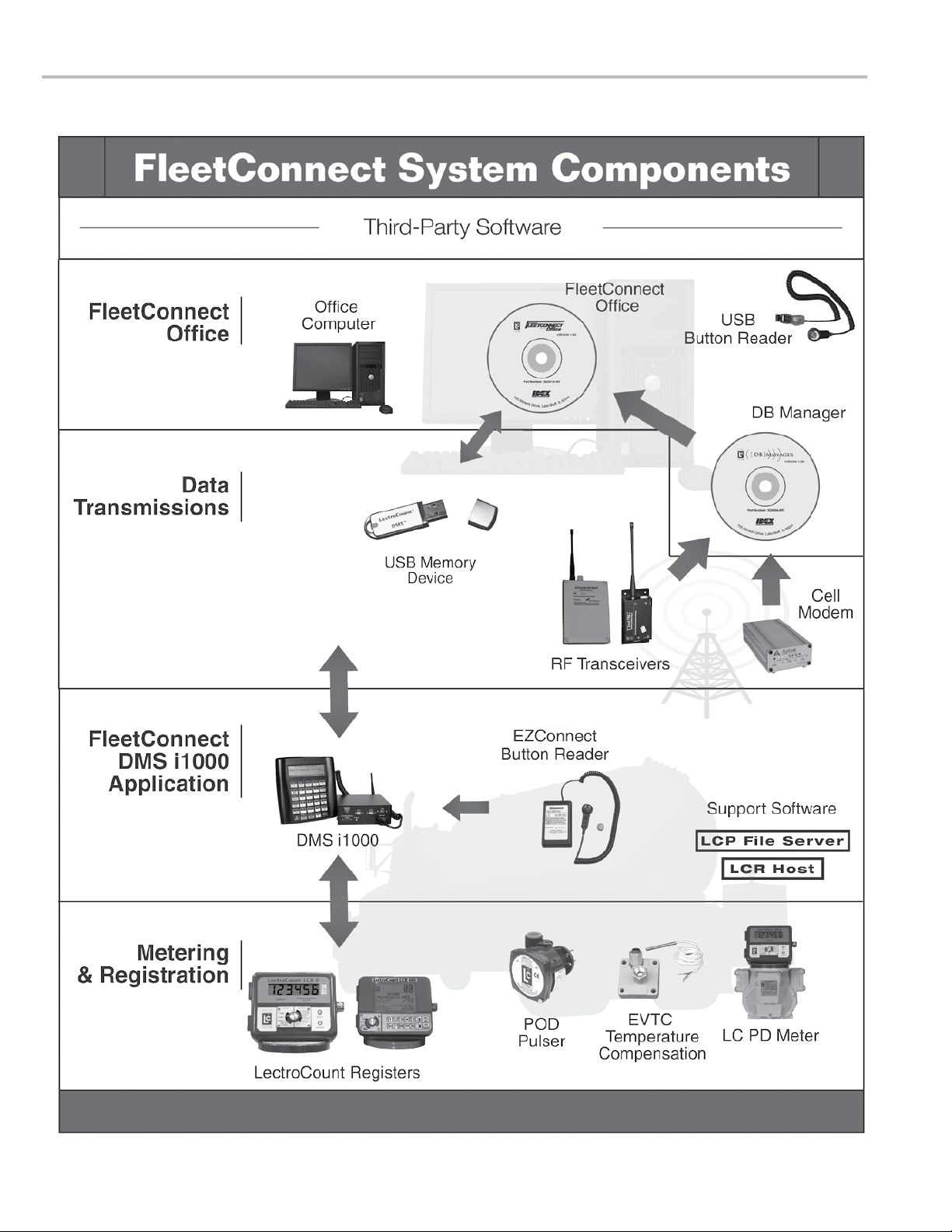

FleetConnect System Components ......................... 5

FleetConnect System Overview ............................... 7

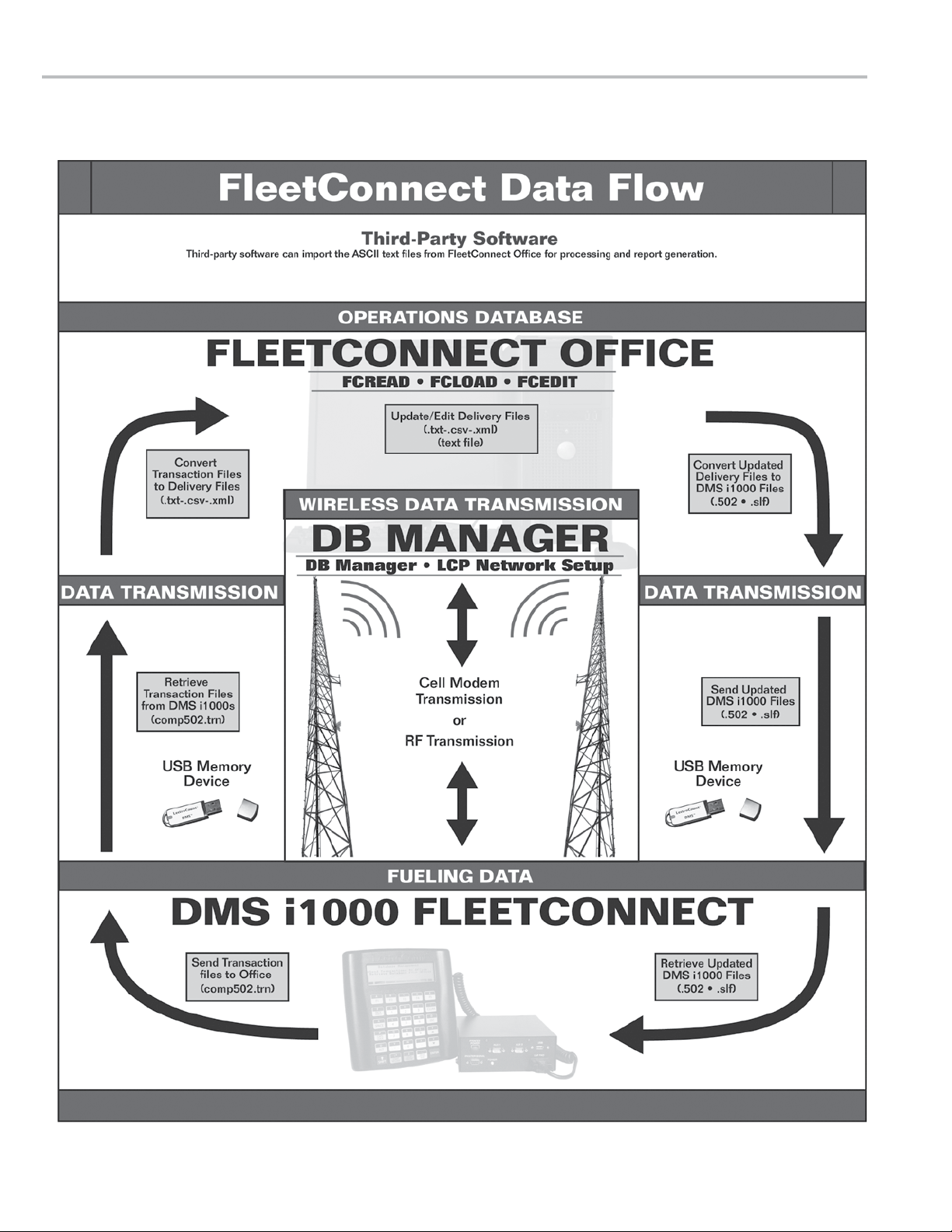

FleetConnect Data Flow ......................................... 10

EZConnect Button Reader ...................................... 12

SETUP

FleetConnect Setup Overview ............................... 13

FleetConnect Security Summary ............................ 13

#1 Loading the FleetConnect Database .................. 14

#2 Launching DMS i1000 FleetConnect ................ 15

#3 Install FleetConnect Antenna for the

EZConnect Button Reader ...................................... 15

Set EZConnect Radio Address .............................. 16

OPERATION

Fueler Logon and Logoff ......................................... 17

Data Transfer .......................................................... 18

Fill Vehicles (Fuel Delivery) ..................................... 19

Miscellaneous Commands (Fueler Logon) ............. 20

Miscellaneous Commands (Fill Vehicles) ................ 21

OPERATION

Setup New Vehicles (Button Mapping) .................... 22

FleetConnect Database Management .................... 24

Add and Delete Records ......................................... 24

Button File ............................................................... 25

Customer File .......................................................... 25

Fueler File ............................................................... 26

Product File ............................................................. 27

System Denitions File ............................................ 27

Truck File ................................................................. 29

Vehicle File .............................................................. 29

Machine Status ....................................................... 30

Printer Status .......................................................... 31

Delivery Status ........................................................ 31

Delivery Code .......................................................... 33

BILL OF MATERIALS

Bill of Materials ........................................................ 34

APPENDIX

Ticket Layouts ......................................................... 35

! WARNING

• Before using this product, read and understand the instructions.

• Save these instructions for future reference.

• All work must be performed by qualied personnel trained in the proper application, installation, and

maintenance of equipment and/or systems in accordance with all applicable codes and ordinances.

• Failure to follow the instructions set forth in this publication could result in property damage, personal injury,

or death from re and/or explosion, or other hazards that may be associated with this type of equipment.

2

Page 3

SOFTWARE LICENSE AGREEMENT

Read this license carefully. You agree that by using the itemized software package, you have

agreed to the software license terms and conditions. This agreement constitutes complete and

entire agreement between you and Liquid Controls with respect to this product.

1. Liquid Controls hereby grants to Licensee a nonexclusive

license to use DMS Menu, LCP File Server, DMS i1000

FleetConnect, FleetConnect Ofce, DB Manager and

LCR Host Software (hereinafter referred to as “Licensed

Software”)

2. Under the License granted herein, Licensee may use the

eldized machine readable (executable code) copy of the

Software, including any subsequent updates which may

be provided. Licensee shall not, without Liquid Controls’

prior written consent, (a) rent, lease, lend, sublease or

otherwise transfer the materials hereunder; (b) remove or

obscure proprietary or copyright notices which may be set

forth on the Licensed Software; or (c) alter, decompile, or

disassemble the program.

3. One (1) copy of the Licensed Software, including any

software distributed on disks may be made for backup

purposes only. No other copies may be made or used

without the written consent of Liquid Controls.

4. Title. No title to ownership of any Licensed Software is

transferred to the Licensee.

5. Upagerades. License upagerades may become available

for the Licensed Software. Any cost associated with such

upagerades will solely be determined by Liquid Controls.

8. Termination. Liquid Controls may terminate this software

license granted hereunder and require return of the

Licensed Software if Licensee fails to comply with these

license terms and conditions.

9. Licensee acknowledges that it has read this agreement,

understands it, and agrees to be bound by its terms, and

further agrees that this is the complete and exclusive

statement of the agreement between Liquid Controls

and Licensee, which supersedes and merges all prior

proposals, understandings, and all other agreements, oral

or written, between the parties relating to this agreement.

This agreement may not be modied or altered except by

written instrument duly executed by both parties.

10. This Agreement and performance hereunder shall be

construed and interpreted under the laws of the State of

Illinois.

11. If any provision of this agreement is invalid under any

applicable statute or rule of law, it is to that extent to be

deemed omitted.

12. Licensee may not assign or sublicense, without the prior

written consent of Liquid Controls, its rights, duties, or

obligations under this Agreement to any person or entity

in whole or in part.

6. Warranty. Liquid Controls makes and licensee receives

no warranty express or implied and there are expressly

excluded all warranties of merchantability and tness for

a particular purpose.

7. Limitation of Liability. Licensee shall have the sole

responsibility for adequate protection and backup of

its data in connection with the Licensed Software. In

no event shall Liquid Controls be liable for (a) special,

indirect or consequential damages; (b) any damages

whatsoever resulting from loss of use, data, or prots,

product, inaccurate input or work delays, or any direct

property damage arising out of or in connection with this

agreement or the use or performance of the Licensed

Software.

13. The waiver or failure of Liquid Controls to exercise in any

respect any right provided herein shall not be deemed a

waiver of any further right hereunder.

Publication Updates and Translations

The most current English versions of all Liquid Controls publications are available on our web site, www.lcmeter.com. It is the

responsibility of the Local Distributor to provide the most current version of LC Manuals, Instructions, and Specication Sheets in

the required language of the country, or the language of the end user to which the products are shipping. If there are questions

about the language of any LC Manuals, Instructions, or Specication Sheets, please contact your Local Distributor.

3

Page 4

INTRODUCTION

Purpose

The purpose of this document is to explain the setup and operation of DMS i1000 FleetConnect.

DMS i1000 Overview

The DMS i1000 is an in-cab computer with a heavy-duty lap pad interface. The DMS i1000 connects directly

to a LectroCount electronic register that is connected to a ow meter. The DMS i1000 runs application specic

software programs, such as FleetConnent, designed for specic types of fuel delivery companies. These programs

combine metrological data—received from a LectroCount register during fuel deliveries—with pricing, customer, and

operational data to provide detailed accounts of all fueling and shift activity. The collected data can be transferred

from the DMS i1000 to an ofce PC via a USB device, RF communication, or cellular transmission. Every DMS

i1000 comes equipped with two support software programs, LCP File Server and LCR Host. LCP File Server is a le

manager program used to maintain and manage les. LCR Host is used to set up LectroCount register networks and

calibrate the metering system.

DMS i1000 and Lap Pad

DMS i1000 FleetConnect Overview

DMS i1000 FleetConnect is a software application program for the DMS i1000. It is designed for companies that

fuel customers with large eets of vehicles and equipment or for companies that own a large eet of vehicles and

equipment. FleetConnect automatically captures fueling data and records all aspects of each fuel delivery. The

delivery records are organized and saved into a database from where the data can be easily transferred into the

accounting software in your ofces. DMS i1000 FleetConnect has a number of capabilities and features including:

fueler security settings, vehicle identication, delivery start and stop, recording and tracking deliveries, shift reports,

and data transmission to FleetConnect Ofce via USB memory device, RF transmission, or cellular modem.

4

Page 5

LC PD Meter

INTRODUCTION

FleetConnect System Components

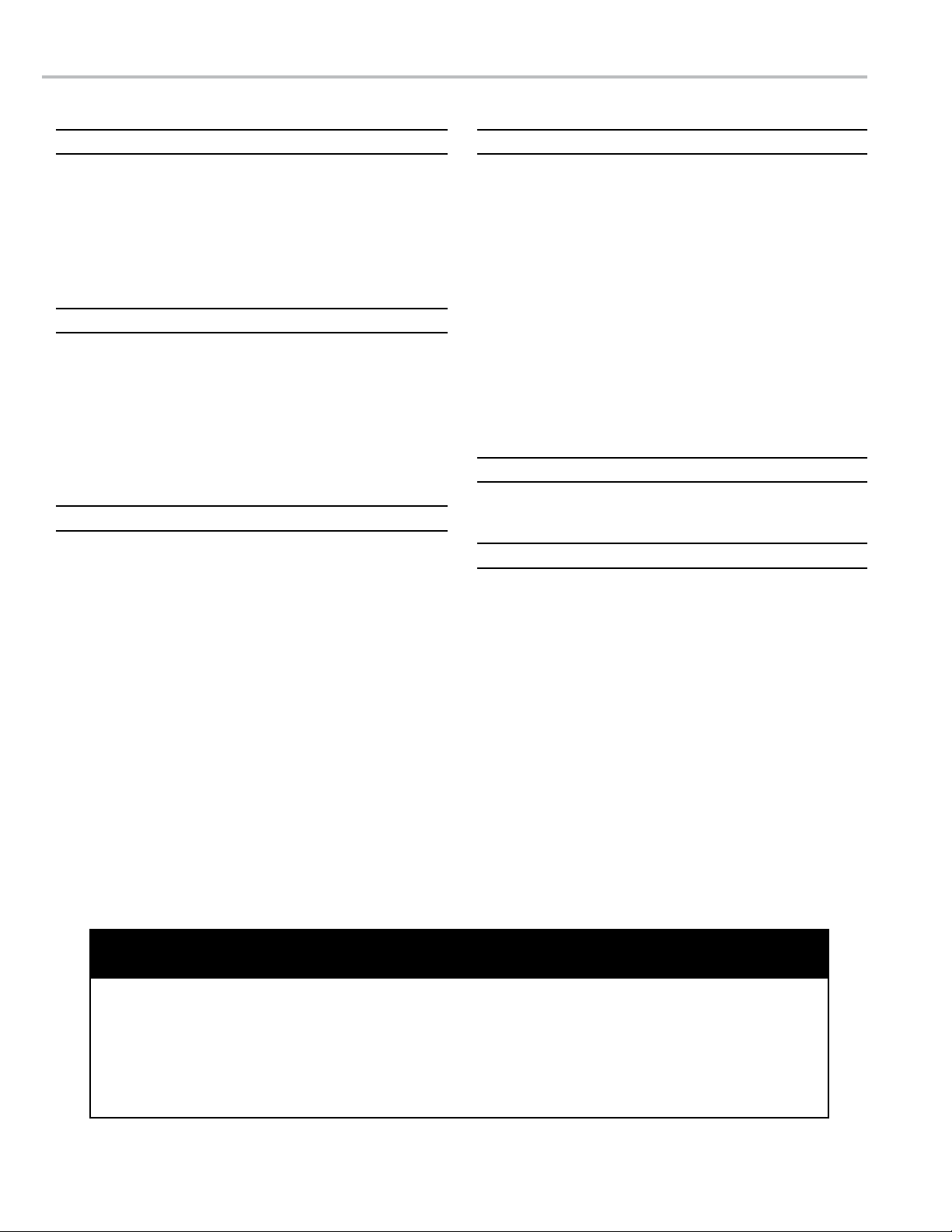

METERING SYSTEM

Typically mounted to the back or side of a delivery

vehicle, the metering system accurately measures,

controls the ow, and preserves the purity of the product.

A Liquid Controls metering system can include the meter,

LectroCount electronic register, strainer, ETVC probe

(temperature compensation), air eliminator, and control

valve. In FleetConnect systems, in order to safeguard

against misfuelings, the control valve is opened only

when vehicles are identied by the EZConnect button

reader.

LECTROCOUNT REGISTER

LectroCount registers can be Weights & Measures

approved and mounted onto the meter. LectroCount

registers provide metrological data during custody

transfers for the DMS i1000 FleetConnect.

LectroCount Registers

Epson Roll Printer

EZConnect Button Reader

with Button and FleetConnect

Antenna

PRINTER

The printer prints out a record (ticket) of the delivery.

The Epson Roll Printer is ideal for the long tickets

FleetConnect prints at the end of fueler shifts.

EZCONNECT BUTTON READER AND RFID BUTTONS

The EZConnect button reader is a handheld device that

reads the ID number of uniquely-numbered stainless

steel buttons called RFID buttons. During setup, a

vehicle record is created for every fuelable vehicle or

piece of equipment that you fuel. Then, each vehicle

record is then programmed with a RFID button number.

Finally, the RFID buttons are physically attached to the

vehicle they represent in the FleetConnect database.

Before fuel deliveries, fuelers attach the EZConnect

to a vehicle’s RFID button. A RF transceiver inside the

EZConnect transmits the ID number to the DMS i1000.

DMS i1000 FleetConnect pulls the vehicle le with the

RFID button number and records the delivery information

together according to vehicle data.

5

Page 6

INTRODUCTION

FleetConnect System Components

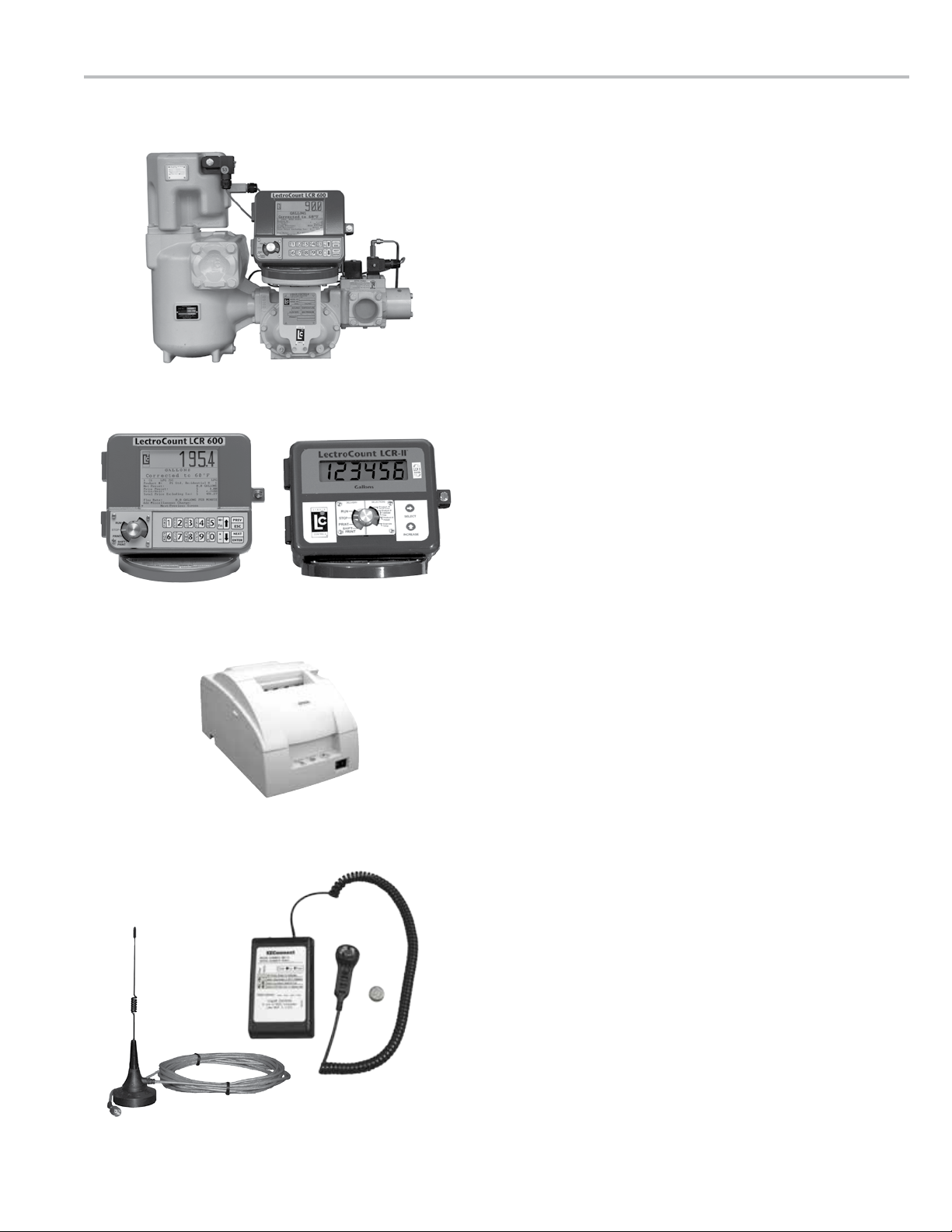

FLEETCONNECT OFFICE

The FleetConnect Ofce contains four executable

programs FCRead.exe, FCEdit.exe, FCLoad.exe and an

installation program for the USB button reader.

FCEdit is a graphical user interface for ofce computers

where users can manage operational data, validate any

changes made in the eld (for example adding a new

customer), congure print tickets, and change system

settings. FCEdit also plays a large role in the setup of a

FleetConnect System by helping map RFID buttons and

populating the FleetConnect database. The USB button

reader plugs into any ofce computer USB port and

reads the ID number of the RFID buttons for FCEdit to

map the RFID buttons.

FleetConnect Ofce

FCRead converts transaction les, created by DMS

i1000s in the eld, into ASCII text les for use in FCEdit

and third party software.

DB MANAGER

DB Manager is used to setup and manage wireless

communication between DMS i1000s in the trucks and

personal computers in your ofce. DB Manager contains

two programs LCPSetup.exe and DBManager.exe. The

rst program, LCPSetup.exe, aligns communication

parameters and conducts testing to conrm wireless

communication between the ofce PC and the DMS

i1000. The second, DBManager.exe, species the DMS

i1000s in the eld, sets the le paths to the ofce PC,

sets a schedule to check for modied FleetConnect

database les and sends those les to the DMS i1000s

in the eld.

CELL MODEM

Cell modems enable long distance wireless data

transmissions between DMS i1000s in the eld and

ofce PCs. Cell modems and service contracts are

purchased separately from a cellular service provider.

USB Button Reader

DB Manager

Cell Modem

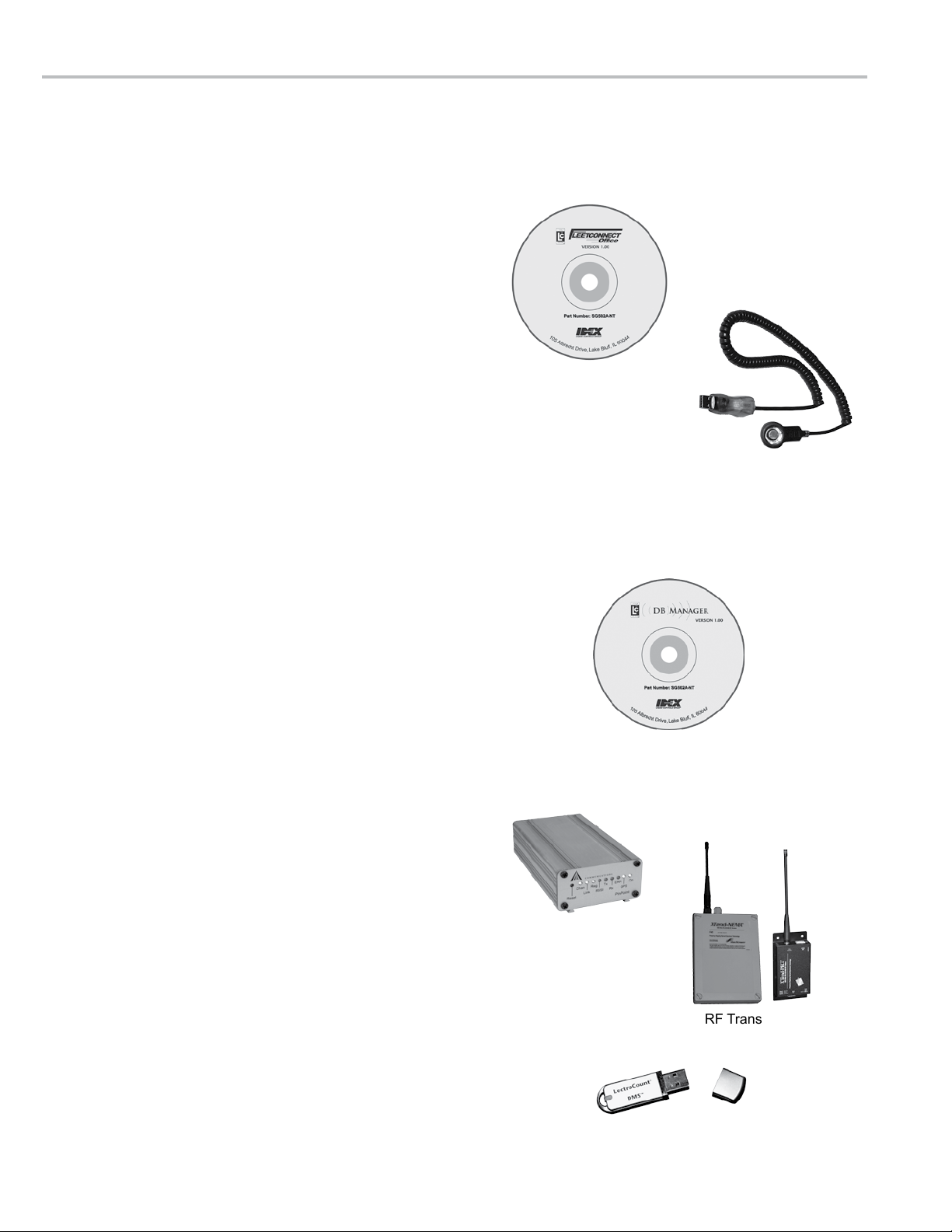

RF TRANSCEIVERS

The RF transceivers are designed for short, line-of-sight

wireless transmissions between DMS i1000s in the eld

and the ofce PC. .

USB FLASH MEMORY DEVICE

The USB Flash Memory Device is a data repository used

to transfer data between the DMS i1000 Module and the

ofce PC. A USB Flash Memory Device is included with

the purchase of a DMS i1000.

6

RF Transceivers

USB Flash Memory Device

Page 7

7

Page 8

INTRODUCTION

8

Page 9

INTRODUCTION

FleetConnect Fueling System Overview

FleetConnect is an in-cab fuel delivery and data collection application for the DMS i1000 that spans from the point of

delivery to the ofce PC. FleetConnect is specially designed for businesses who have or fuel customers with large

eets of vehicles and equipment or fuel their own eet. Like other Liquid Control’s data management applications,

FleetConnect runs in conjunction with owmeters equipped with the LectroCount electronic registers.

The main functions of a FleetConnect System include:

• Account management

• Operational data management

• Delivery data tracking

• Data entry interface

• File conversions

• Security settings for fueling access and system conguration

• Print ticket conguration

• Customer equipment identication

• Delivery start and stop

COMPONENTS

There are ve main components unique to a FleetConnect System: DMS i1000 FleetConnect (DMS i1000 software),

FleetConnect Ofce (ofce PC software), the EZConnect button reader, the USB RFID button reader and the RFID

buttons (stainless steel buttons with a unique identication number that can be read by a button reader).

SETUP

During setup, each vehicle (or piece of equipment) to be fueled is assigned a RFID button number. The vehicle

information (name, fuel type, etc.) and the RFID button number are saved together in the FleetConnect database

(in this manual this is referred to as mapping). The RFID buttons are then taken into the eld and fastened to their

respective vehicles. DMS i1000 FleetConnect uses the RFID button numbers to identify vehicles before making a

delivery.

DELIVERIES

To make deliveries, fuelers simply push the EZConnect button reader over the RFID button of the vehicle. The

EZConnect button reader transmits the RFID button number to the DMS i1000. DMS i1000 FleetConnect receives the

transmission from the EZConnect button reader and pulls the vehicle data programmed to the RFID button number.

After FleetConnect conrms the identity of the vehicle, it opens the control valve on the appropriate meter system

allowing the fueler to make the delivery. FleetConnect records the metrological data of the delivery and saves it in a

record with the vehicle data. DMS i1000 FleetConnect transmits all of the transaction data compiled throughout the

shift to the ofce PC via cell modem, RF transmission, or USB memory device.

OFFICE

In the ofce, FleetConnect Ofce converts the data received from each DMS i1000 into ASCII text les. ASCII text

les can be easily transferred to third-party software. The FleetConnect database consists of operational data, like

vehicle, customer, product and fueler data. FleetConnect ofce has a graphical user interface, FCEdit, for ofce

computers where users can manage operational data, congure print tickets, and change system settings. FCEdit

also allows users to verify or reject any changes made to the database by DMS i1000s in the eld—such as new

customers or vehicles—and send the changes, if veried, out to all other DMS i1000 units.

9

Page 10

INTRODUCTION

10

Page 11

FleetConnect Data Flow

INTRODUCTION

DMS i1000 APPLICATIONS TO FLEETCONNECT OFFICE

(Begins at the bottom of the chart on page 10—DMS

i1000 FleetConnect—and ends at the middle top of the

diagram—FleetConnect Ofce.)

DMS i1000

After each delivery, the DMS i1000 compiles the

metrological, transaction, customer, driver, and product

data into transaction les (.trn). The transaction les

are then sent to the ofce PC either wirelessly (RF or

cellular), or they are downloaded to a USB memory

device.

DATA TRANSMISSION (WIRELESS)

If the transaction les are sent wirelessly (RF or cellular)

using the Send Transactions to Ofce

command, DB Manager receives the transaction les

(.trn) and noties FleetConnect Ofce that the les have

been received. Transmissions can be setup to be sent

automatically to the ofce

DATA TRANSMISSION (USB MEMORY DEVICE)

If the transaction les are sent via USB memory

device, when a shift is nished, the fuelers download

the transaction les created during their shift using the

Send Transactions to Ofce command and

return the USB device to the ofce after their shift.

FLEETCONNECT OFFICE SOFTWARE

FCRead converts the transaction les (.trn) into ASCII

text or XML les. The les can then be absorbed into

third party software.

If the les are transferred via a USB memory device,

they must be copied from the USB device and pasted

into the C:/DMS folder. From there, FCRead can convert

them into text or XML les.

THIRD PARTY SOFTWARE

Third-party software imports the ASCII text les

from FleetConnect Ofce for processing and report

generation. If any dispatch data is generated by the

third-party software, it can be converted into ASCII text

les and imported into the FleetConnect database.

FLEETCONNECT OFFICE TO DMS i1000 APPLICATIONS

(Begins at the middle top of the chart on page 10—

FleetConnect Ofce—and ends at the bottom of the

diagram—DMS i1000 FleetConnect.)

FLEETCONNECT OFFICE

FCEdit converts the text les (and any conguration

changes made in third-party software) into .502 and .slf

database les.

DATA TRANSMISSION (WIRELESS)

DB Manager sends modied transaction les to the

DMS i1000s wirelessly. By sending only modied “live”

les, cellular service costs and transmission times are

reduced. DBManager checks newly converted .502 and

.slf database les against a set of “live” les. “Live” les

are the most recent set of database les created by

FleetConnect Ofce. If a new database le is created

that differs from the “live” le, it means the le has been

modied since the last data transmission from the DMS

i1000s.

DATA TRANSMISSION (USB MEMORY DEVICE)

Transferring data via USB memory devices requires the

fuelers to bring the USB devices to the delivery truck

at the beginning of their shift, plug the USB device into

the DMS i1000, and load any new les onto the DMS

i1000 by using the Retrieve Database Updates

command. If the new .502 les have been copied to

the USB memory devices in the ofce, they will simply

rewrite the .502 les on the DMS i1000s when your

fuelers upload them.

DMS i1000

Modied .502 and .slf database les are loaded into

the LCP File Server of a DMS i1000. If a USB memory

device is being used, the Retrieve Database

Updates

les. RF and cellular transmissions can be setup to

automatically load database les every time the DMS

i1000 sends data (this applies to logging on, logging off,

completing a delivery, and editing the database). Any

changes made on the ofce PC and received by the

DMS i1000 are applied to all subsequent deliveries.

command must be used to load the database

11

Page 12

INTRODUCTION

EZConnect Button Reader

The EZConnect button reader is a handheld device that

reads the ID number of uniquely-numbered stainless

steel buttons, called RFID buttons, and radios the

number of the button back to the DMS i1000. Before

delivery, the EZConnect button reader reads the button’s

ID number, and a RF transceiver in the button reader

radios the ID number to an antenna connected to the

DMS i1000. DMS i1000 FleetConnect pulls up the

vehicle data mapped to the RFID button number, records

the metrological data from the delivery, and saves

the vehicle data and delivery data together into the

FleetConnect database.

Time Between Deliveries

If the button reader is pulled from the button, a ten second

window exists in which the button reader must be reattached

to continue the delivery on the same transaction record. This

feature is active only in the By Vehicle setting of the New

LCR Delivery: eld. See FleetConnect Ofce EM200-15.

POWER/RESET BUTTON

RED LIGHT

EZCONNECT BUTTON READER

STATUS LIGHT KEY

YELLOW LIGHT

OFF

ON

FLASH

OPERATION

The thin black button next to the status lights activates

the EZConnect. Press it immediately before or after

attaching the EZConnect to a RFID button. When

attaching the button reader to a RFID button, ensure the

button reader socket completely covers the button and

is not tilted in any manner. When the yellow light blinks,

the RFID number has been received by the DMS i1000.

Other status indications are explained on the right.

STATUSLIGHTS

Red Yellow

Off (press button to activate)

Button disconnected or not in database

Button connected ready to fuel

DMS/LCR/Printer Error or delivery initiation

! WARNING

• To prevent the ignition of a hazardous atmosphere,

batteries must only be replaced with Panasonic

6LR61XWA in a nonhazardous area.

• Only use the EZConnect button reader with the

provided cable and RFID button, as pictured.

12

Conforms to standards ANSI/ISA 82.02.12 (IEC 61010-

1 MOD) (07/12/04) and ANSI/ISA-12.12.01-2007

Class I, Div 2 Group D T4

-20°C (-4°F) ≤ Tamb ≤ +50°C (122°F)

Page 13

SETUP

FleetConnect DMS i1000 Setup Overview

There are four steps that must be completed before fuelers can begin fuel delivery with FleetConnect. The rst

step, Load FleetConnect Database onto the DMS i1000, entails moving data from the ofce PC to the DMS i1000.

The second step, Launch DMS i1000 FleetConnect, includes starting up the DMS i1000 FleetConnect application

software. The third step, Install the FleetConnect Antenna for the EZConnect Button Reader, comprises of installing

an antenna onto the roof of the truck cab and plugging it into the DMS i1000 antenna port. The fourth and nal step,

Set EZConnect Radio Address, requires setting the EZConnects to a unique address so they can transmit without

interference.

DMS I1000 FLEETCONNECT SETUP PREREQUISITES

This manual assumes that FleetConnect Ofce has been setup, the FleetConnect database is loaded onto the ofce

PC, the RFID buttons have been mapped into the database and attached to the vehicles near the fueling point, and

the DB Manager software is installed (if using cellular or RF data transmissions).

The following installation and setup must be completed prior to setup of the DMS i1000 FleetConnect:

1. Meter system installed

2. LectroCount Register(s) Installation (EM100-10 or EM150-10)

3. LectroCount Register(s) Setup (EM100-10 or EM150-11)

4. DMS i1000 Installation (EM200-10)

5. DMS i1000 Setup (EM200-11)

6. DB Manager (EM200-21) optional

7. FleetConnect Ofce Setup (EM200-14)

DMS I1000 FLEETCONNECT SETUP

After all of the setup prerequisites are fullled, only four steps are required before FleetConnect DMS i1000 is ready

for daily use.

STEP 1 Load the FleetConnect database onto the DMS i1000 (Retrieve Database from Ofce).

This step is also documented in the FleetConnect Ofce Setup (EM200-14)

STEP 2 Launch DMS i1000 FleetConnect.

STEP 3 Install the FleetConnect Antenna for the EZConnect Button Reader.

STEP 4 Set the EZConnect button readers radio addresses so that they are all unique.

This step is only required if more than one EZConnect button reader is operating in close proximity to another.

DMS i1000 FleetConnect Security

FleetConnect provides three sets of security checks: the fueler logon password, the database management password,

and the LCRHost and LCP File Server password. The fueler logon password protects access to FleetConnect’s

fuel delivery functions (see FleetConnect Ofce manual EM200-15). The database management password protects

access to the FleetConnect database. The LCRHost and LCP File Server password protects access to network setup,

calibration, and le management functions (see DMS Setup and Operation Manual EM200-12).

13

Page 14

SETUP

#1 -Load FleetConnect Database

onto the DMS i1000

Liquid Controls recommends using a USB memory

device for the initial loading of the FleetConnect

database because of the large amount of data to be

uploaded. Transmitting a large amount of data wirelessly

can be time consuming and, for cellular transmissions,

costly.

To transfer the latest FleetConnect Ofce

database to the DMS i1000s via USB device:

1. Using the ofce PC, name a USB memory device DMS_

USB and create a folder named DMS in it. (USB memory

devices from Liquid Controls are precongured with

these settings.)

2. Copy the .502 and .slf les from the C:\DMS folder into

the D:\DMS_USB\DMS folder on the USB memory

device.

.502 and .slf les are created during FleetConnect

Ofce setup.

3. Remove the USB memory device from the ofce

computer and plug it into a DMS i1000.

4. On the DMS i1000 lap pad, push ALT and ESC

simultaneously to open the DMS Application

List.

5. Press F5 (Data) to open Database Management.

6. Press F3 (USB) to boot the USB Drive.

7. Move the pointer to Retrieve Entire Database

and push Enter.

8. Move the pointer to USB Memory Device as

the Receive Mechanism and press Enter. The

Retrieving Database screen will appear while the

database loads onto the DMS i1000.

Util (F1) opens System Utilities (1/3) See page 12 EM200-11

Data (F5) opens Database Management screen

While the DMS i1000 displays the DMS Application List

screen, it is disabled from the LectroCount register(s).

When the DMS i1000 is disabled, deliveries can be made

with the register’s RUN and PRINT settings.

USB (F3) activates the USB memory device

Done (F5) opens Fueler Logon or Fill Vehicles screen, or DMS

Application List screen

9. Press Enter upon successful retrieval of the database

les.

10. Repeat steps 3-9 until all trucks equipped with DMS

i1000s are loaded with the FleetConnect database.

These instructions are also included in the

FleetConnect Ofce Setup (EM200-14) manual.

Every DMS i1000 is supplied with a USB Flash

Memory Device congured for immediate use.

14

Transfer Database Wirelessly

After initial setup, choose Retrieve Database Updates to

update only those les that have changed. Follow the same

procedure as above, but for step 8, select the Radio option,

instead of USB Memory Device, then press Enter.

The Retrieve Database Updates command inside

the DMS i1000 FleetConnect program will not

upload the whole database, only .502 and .slf les.

Page 15

SETUP

#2 -Launch DMS i1000

FleetConnect

The DMS Application List is the launch point for DMS

i1000 FleetConnect software.

To open FleetConnect:

1. Press ALT+ESC.

2. Move the pointer to select FleetConnect and press

Enter.

#3 -Install the FleetConnect

Antenna for the EZConnect Button

Reader

When the EZConnect button reader is attached to a

RFID button, a RF transceiver inside the EZConnect

transmits the RFID button number to the DMS i1000.

In order to receive the RF signal, the DMS i1000 must

be equipped with the FleetConnect antenna. The

FleetConnect antenna plugs into the back of the DMS

i1000 and is easily afxed to the roof of the truck cab.

FleetConnect Antenna

DMS i1000 Antenna Port

To install the FleetConnect antenna:

1. There is a heavy magnet in the bottom of the

FleetConnect antenna. Find a high spot on the delivery

truck, preferably the top of the truck cab, and set the

antenna down so the magnet sticks securely to the

surface.

2. Find a pathway for the antenna cable into the inside

of the cab and the DMS i1000 antenna port. If a more

convenient option isn’t apparent, use the same hole as

the LCR-II cables.

3. Run the antenna cord tight to the truck. Secure it so there

is no slack along the pathway. Tie off any excess cord in

the cab next to the DMS i1000.

4. Screw the antenna cable into the DMS i1000 antenna

port.

Liquid Controls recommends using split loom for

the antenna wire. It protects the wire and is easier

to ziptie to the truck.

15

Page 16

SETUP

#4 -Set EZConnect Radio Address

If you are running more than one DMS i1000

FleetConnect in close proximity to another, the

EZConnect button readers will not be able to transmit

data on the same radio address without interference.

The Set EZConnect Radio Address function

can set a unique address where the DMS i1000 unit and

the EZConnect can communicate without interference.

To change the radio address of an EZConnect

device:

1. Turn off all of the EZConnect devices except the one you

want to congure.

2. From the DMS Application List, select FleetConnect.

3. If the Fueler Logon screen does not appear, logoff

the fueler. See page 17.

4. Press F4 (Misc) to open Miscellaneous

Commands list box window.

4. Move the pointer to Setup DMS/EZConnect Link

and press Enter.

5. Select DMS Radio Address and enter a unique 1-4

digit hexadecimal code in DMS Radio Address. See

box to the right.

6. Move the pointer to Set EZConnect Radio

Address and press Enter.

7. Turn on the EZConnect. Wait until the red light stops

blinking.

8. Take a small screwdriver and touch the small metal disc

and the metal around the inside the socket of the button

reader extension at the same time until both EZConnect

lights turn on.

9. While both lights are on, press Enter on the lap pad. A

successful message will appear on the lap pad.

Done (F5) opens Fueler Logon screen

If the DMS Radio Address is displayed as

dashes, the DMS i1000 is not responding to

FleetConnect. Select Done (F5) and repeat the

directions from the beginning. If the problem persists,

call the Liquid Controls Service Department.

16

Page 17

OPERATION

Fueler Logon and Logoff

The Fueler Logon screen allows operators to logon

and logoff the DMS i1000 FleetConnect system. If the

previous fueler has logged off, the Fueler Logon

screen is the rst screen displayed when the DMS i1000

is turned on. If the previous fueler has not logged off,

the Fill Vehicles screen is the rst screen displayed.

To access the Fueler Logon screen from the Fill

Vehicles

Miscellaneous Commands screen. See below.

screen, log off the previous fueler using the

All (F2) opens each eld on the screen in succession

Misc (F4) opens Fueler Logon Miscellaneous list

Fwd (F5) opens Fill Vehicle screen

Before logging on, retrieve any les that have been

sent from the ofce. See Send Transactions page 20.

To logon and begin a shift:

1. Move the pointer to

2. Select your name from the list of fuelers and press Enter.

3. Press F5 (Fwd) to open the Fill Vehicles screen.

To logon with a RFID button:

1. Attach the EZConnect button reader to your designated

RFID button. Press EZConnect’s power button. When the

DMS i1000 receives the RFID number, the yellow light

will begin to blink and your Fueler information will appear

on the lap pad display.

2. Press F5 (

The Password: and Odometer: elds are optional.

The Password: option can be activated in the Fueler

File of FleetConnect Ofce or DMS i1000 FleetConnect,

and the Odometer: option can be activated in the

System Denitions File of FleetConnect Ofce or DMS

i1000 FleetConnect.

FUELER LOGOFF

Complete the following procedure to logoff from any

DMS i1000 screen.

Fwd) to open the Fill Vehicles screen.

Fueler #: and press Enter.

Examples of the End-of-Shift tickets are on page 35.

To logoff at the end of a shift:

1. From the Fill Vehicles screen, press F4 (Misc)

to

open the

window.

2. Select Logoff and press Enter to open the End-of-

Shift Ticket list box.

3. Select Detailed, None, or Summary and press

Enter. The lap pad will return to the Fueler Logon screen.

Miscellaneous Commands

list box

17

Page 18

OPERATION

Data Transfer

FleetConnect systems transfer data between the

DMS i1000 and your ofce PC via a USB memory

device or wirelessly using a cell modem. FleetConnect

systems transferring data via USB devices require no

additional setup outside of DMS i1000 FleetConnect

and FleetConnect Ofce. Systems using cell modems

require additional conguration and Liquid Controls’ DB

Manager software. See DB Manager Installation and

Setup Manual EM200-21.

CELL MODEM

FleetConnect systems setup for cell modem

transmissions send and retrieve data each time a record

is created. Every time a fueler logs on, logs off, delivers

fuel, edits the database, or enters a load truck command

from the DMS i1000 lap pad, the DMS i1000 sends new

data to and checks for new data from the ofce PC.

USB MEMORY DEVICE

If you have a FleetConnect system that relies on USB

memory devices to transfer data, the USB devices

must be physically moved between the trucks’ DMS

i1000s and the ofce PC at the beginning and end of

each shift. In the ofce, the transaction data from the

DMS i1000s must be copied from each USB memory

device and pasted into the C:\DMS folder on the ofce

PC. Database updates for the DMS i1000s must be

copied from the C:\DMS folder and pasted onto the

USB memory stick. In the eld, fuelers can manually

retrieve data from and manually save data to the

USB memory device before or after logon using the

Retrieve Database Updates and the Send

Transactions to Ofce

commands.

DMS Application List Screen

A small up arrow appears in the top line to the left of the

time when there are transactions to send to the USB

memory stick or ofce PC via cellular transmission.

Fueler Logon Miscellaneous Command Screen

The Retrieve Database Updates and the Send

Transactions to Ofce

by pressing the Data (F5) button in the DMS Application

List screen, pressing the Misc (F5) button in the Fueler

Logon screen, or pressing the Misc (F5) button in the

Fill Vehicles screen. The Send Transactions to

Ofce

i1000 onto the USB memory device for transfer to the

ofce PC.

The Retrieve Entire Database command is

typically used only when setting up the DMS i1000 unit.

It can be found in the the Database Management screen

(the screen that opens with the Data (F5) button)

retrieves the entire database from the USB memory

device onto the DMS i1000.

command is used to save data from the DMS

commands can be found

18

Fill Vehicles Miscellaneous Command Screen

Database Management Screen

Page 19

Fueler Logon Miscellaneous Command Screen

OPERATION

Miscellaneous Commands (Fueler

Logon)

In the Fueler Logon screen, the Misc (F4) opens a

Miscellaneous Commands list box that includes access

to the Database Management menu, the Reprint

Shift Ticket

commands (Retrieve Database Updates and

Send Transactions), and the Setup DMS/

EZConnect Link

DATABASE MANAGEMENT

The Database Management screen provides access to

the FleetConnect database les for viewing and editing

purposes. See page 24.

command, two data transfer

screen.

Shift Ticket Date Screen

Shift Ticket Type

Not to be confused with the Database Management

screen on page 14

REPRINT SHIFT TICKET

The Reprint Shift Ticket command opens

a list box, Shift Ticket Date, with a list of

previously printed shift tickets. To reprint a shift ticket,

move the pointer to the date and time of the ticket you

want reprinted and press Enter. After selecting the

specic shift ticket, a Shift Ticket Type list box

will open. Select Detailed or Summary. An example

of a detailed and summary shift ticket is on page 35.

RETRIEVE DATABASE UPDATES

The Retrieve Database Updates command,

when selected, brings up a list box to conrm the

command. Select Yes to send retrieve updates to les

from the ofce. Click No to cancel the command.

The Retrieve Database Updates command

manually retrieves updates from the FleetConnect

Ofce database on the ofce computer. This command

requires wireless communication through DB Manager.

This option is especially helpful when wireless

connection is intermittent or if the system is not set up to

send updates automatically.

Retrieve Database Updates

DMS/EZConnect Link

SEND TRANSACTIONS

The Send Transactions command, when

selected, opens up a list box to conrm the Send

Transactions

transaction les to the ofce. Click No to cancel the

command.

SETUP DMS/EZCONNECT LINK

The Setup DMS/EZConnect Link

command. Select Yes to send

command

opens a screen with the means to set the radio addresses

of EZConnect button readers. See page 16.

19

Page 20

OPERATION

Fill Vehicles (Fuel Delivery)

Fill Vehicles is the lap pad screen from which fuelers can

activate fuel deliveries. It appears on the lap pad display

immediately after logging on. When the EZConnect

reads an RFID button, the button ID, product type,

delivery quantities, and account information will appear

on in the Fill Vehicles screen. They will remain on the

screen until the EZConnect is removed from the button.

To make a delivery:

1. Attach the EZConnect button reader onto the RFID

button.

2. Press the power button on the EZConnect.

3. Open the nozzle and deliver the fuel

3. Remove the button reader from the RFID button to

deactivate the delivery.

If the button reader is pulled from the button, a ten second

window exists in which the button reader must be reattached

to continue the delivery on the same transaction record. This

feature is active only in the By Vehicle setting of the New

LCR Delivery: eld in System Denitions.

When the delivery is completed, the roll printer prints the

transaction information, the DMS i1000 FleetConnect

records the delivery information into the FleetConnect

database, and the Fill Vehicles screen displays the

Waiting to start a new LCR delivery.

message.

FleetConnect can be set to save delivery les to the

USB device automatically. In the System Denitions

File, set the Transaction Target to “USB”. See page 28.

Status (F3) opens Machine Status (1/2) screen

Misc (F4) opens Fill Vehicles Miscellaneous Commands list

Status (F3) opens Machine Status (1/2) screen

Misc (F4) opens Fill Vehicles Miscellaneous Commands list

FILL VEHICLES MESSAGES

There are certain conditions in which FleetConnect can

not or will not permit a delivery. FleetConnect will display

a message at the bottom of the DMS i1000 screen when

a delivery is prohibited. These include:

No button ID is being read.

The EZConnect button reader is not reading a RFID

button.

Unkown button ID.

The button ID is not in the FleetConnect database.

The customer record for the button does

not exist.

The customer record assigned to the button is not in

the FleetConnect database.

20

The vehicle record for the button does

not exist.

The vehicle record assigned to the button is not in the

FleetConnect database.

Vehicle xxxxxx does not have an assigned

product code.

A product code has not been specied for the vehicle

The Distallate product type is not

available on the truck.

The LCR(s) on the truck are not calibrated to deliver the

product type.

The LCR Red switch must be in the RUN

position before a new delivery can be

started.

The selector switch on the LectroCount LCR register(s) is

not in the RUN position. Fuel can not be delivered.

Page 21

Fill Vehicles Screen

Find (F3) search for les

PageDn (F4) opens second Miscellaneous Vehicles screen

End (F5) opens Fill Vehicles screen

OPERATION

Miscellanous Commands (Fill

Vehicles)

The Fill Vehicles screen also has a Miscellaneous

Commands menu. Press the Misc (F4) button on lap

pad to open the Miscellaneous Commands list box.

The Duplicate Ticket command reprints the

last delivery ticket. The Print Account Summary

command prints a summary of completed deliveries

to a specic customer’s account over the course of

the current shift. And the Logoff command logs off

the current fueler and prints a shift ticket. To select

a command from the list, move the pointer to the

command and press Enter on the DMS lap pad.

DUPLICATE TICKET

To print an exact copy of the last ticket printed, move the

pointer to Duplicate Ticket and press Enter.

LOAD TRUCK

The Load Truck command opens a screen where

fuelers can manually enter loading information after the

delivery truck is loaded with fuel. The roll printer prints

the loading information after it is entered and later, at log

off, onto the shift ticket.

LOGOFF

To logoff from a shift, move the pointer to Logoff and

press Enter. The End-of-Shift Ticket list box

will open. Select Detailed, None, or Summary

and press Enter. The lap pad will then return to the

Fueler Logon screen.

Back (F1) opens Fill Vehicles screen

All (F2) opens each eld on the screen in succession

Save (F5) saves entered data and opens Fill Vehicles screen

Setup New Vehicle Screen

PRINT ACCOUNT SUMMARY

The Print Account Summary prints a list of the

deliveries that have been made during the current shift.

RETRIEVE DATABASE UPDATES/SEND TRANSACTIONS

See page 20.

SETUP NEW VEHICLE

The Setup New Vehicle feature allows fuelers to

add new vehicles and customers to the FleetConnect

database and map them to a RFID button. For

instructions, see page 22.

21

Page 22

OPERATION

Setup New Vehicle

The Setup New Vehicle screen allows fuelers to add

new vehicles to the FleetConnect database, so that

when fuelers encounter a vehicle that doesn’t exist in

the FleetConnect database, they can enter it into the

FleetConnect database and fuel the vehicle on-the-spot

in the eld.

The fueler will need a RFID button to map in the DMS

i1000 and then attach to the new vehicle. It’s a good

practice to carry a bag of RFID buttons in the delivery

truck so they are on hand. To attach a RFID button to a

vehicle, nd a convenient spot near the fueling point on

the vehicle, clean it thoroughly, and stick the RFID button

onto the vehicle using double-sided tape.

To map a button using a customer account

and vehicle le that exists in the FleetConnect

database:

1. Press Misc (F4) in Fill Vehicles screen.

2. Press PgDn (F4) to scroll the Miscellaneous

Commands

Command.

list down to the Setup New Vehicles

Add (F1) creates a Button File record of the displayed data

All (F2) opens each eld on the screen in succession

New (F3) opens Customer File (Account #:) or Vehicle File

(Vehicle #:)

Done (F5) opens Fill Vehicle screen

DO NOT CREATE BUTTON RECORDS IN THE BUTTON

FILE. Liquid Controls does not recommend creating or

editing les in the Button File. It is for viewing only.

3. Move the pointer to Setup New Vehicles and press

Enter.

4. Attach the EZConnect button reader to the RFID button

and press the power button. The RFID number will

appear in the iButton eld of the Setup New Vehicles

screen.

5. Select Account # to open the Customer File screen.

6. Select Account # to open a list box of customer

accounts in the FleetConnect database.

7. Move the pointer to a customer account and press Enter.

8. Select Vehicle # to open the Vehicle File screen.

9. Select Vehicle # to open a list box of vehicles

programmed to the selected customer.

10. Move the pointer to a vehicle and press Enter.

11. Press Add (F1).

12. Press Done (F5).

Next (F1) opens Customer File (2/2)

New (F3) creates new Customer File record

Del (F4) deletes displayed Customer File record

Exit (F5) opens Database Management (1/2)

22

Selecting a Vehicle

Page 23

Home (F1) returns cursor to rst space

← (F2) moves cursor back one space

Ins (F3) allows text to be inserted above cursor

→ (F4) moves cursor ahead one space

End (F5) moves cursor to the end space

OPERATION

To map a button for a new customer and a new

vehicle that does not exist in the FleetConnect

database:

1. Press Misc (F4) in Fill Vehicles screen.

2. Press PgDn (F4) to scroll the Miscellaneous

Commands

Command.

3. Move the pointer to Setup New Vehicles and

press Enter.

4. Attach the EZConnect button reader to the RFID button

and press the power button. The RFID number will

appear in the iButton eld of the Setup New Vehicles

screen.

If the customer exists but the vehicle is new skip to step 9.

list down to the Setup New Vehicles

If Customer File or Vehicle File records currently exist in

the database, choosing Account #: brings up a list box

window of existing records. Editing the options inside the

existing records will change that customer’s records.

Home (F1) returns cursor to rst space

← (F2) moves cursor back one space

Ins (F3) allows text to be inserted above cursor

→ (F4) moves cursor ahead one space

End (F5) moves cursor to the end space

5. In the Setup New Vehicles screen, move the pointer to

Account # and press New (F3) to open the Customer

File screen.

6. In the Customer File screen, move the pointer to

Account # and press New (F3). Enter the new

account number into the eld edit box.

7. Enter the customer information for the new account into

both screens of the Customer File.

8. Press Exit (F5) to return to the Setup New Vehicles

screen.

9. In the Setup New Vehicles screen, move the pointer

to Vehicle # and press New (F3). Enter the new

account number.

10. In the Vehicle File screen, move the pointer to Vehicle

and press New (F3).

#

11. The Account # list box will open. Select a customer

account for the vehicle.

12. A Vehicle # eld edit box will open next. Enter the new

vehicle number and press Enter.

13. Complete the remaining elds in the Vehicle File screen.

Next (F1) opens Vehicle File (2/2)

New (F3) creates new Vehicle File record

Del (F4) deletes displayed Vehicle File record

Exit (F5) opens Database Management (2/2)

14. Press Exit (F5) to return to the Setup New Vehicles

screen.

15. Press Add (F1).

16. Press Done (F5).

23

Page 24

OPERATION

FleetConnect Database

Management

FleetConnect’s Database Management is DMS i1000

FleetConnect’s interface for managing customer and

operational data in the FleetConnect database. Using

eld edit and list box windows in one of the seven

Database Management les, fuelers can create new

les and edit existing les. When the DMS i1000

FleetConnect sends transactions to the ofce PC, any

changes to the database les made by the DMS i1000

will be sent as well. Database changes can be validated

by ofce personnel in FleetConnect Ofce, added to the

FleetConnect database, and transferred to other DMS

i1000s.

To access the Database Management window

perform the following:

1. From the Fueler Logon screen press Misc (F4).

2. From the Miscellaneous Commands list box, move

the pointer to Database Manager and press Enter.

Next (F1) opens Database Management (2/2)

Vers (F4) opens About Screen (Software Version Information)

Dlvy (F5) opens Fueler Logon screen

A password can be created in the Systems Denition le to

limit access to the features in Database Management.

Add and Delete Records

When a le is open, records can be added or deleted.

ADD A NEW RECORD

To add a new record, perform the following:

1. From the Database Management screen, move the

pointer to one of the le types and press Enter.

2. Press New (F3) to create a new record.

3. Enter information for the new record into an edit or list

box for each eld in the record

4. Press Exit (F5) to save the new record.

DELETE A RECORD

To delete a record, perform the following:

1. From the Database Management screen, move the

pointer to one of the le types and press Enter.

2. Open the record you would like to delete.

3. Press Del (F4) to delete the record.

4. From the Delete list box move the pointer to Yes and

press Enter.

Prev (F2) opens Database Management (1/2)

Dlvy (F5) opens Fueler Logon screen

Although data can be entered in the eld with the lap

pad, it is much easier to enter large amounts of data using

FleetConnect Ofce.

5. Press Exit (F5) to exit.

24

Customer File Screen

Page 25

New (F3) creates new Button File record

Del (F4) deletes displayed Button File record

Exit (F5) opens Database Management (1/2)

OPERATION

Button File

The Button File allows you to view the account number

and vehicle number mapped to a RFID button and to

delete a RFID button from the database.

Please use the Setup New Vehicles command

to add a RFID button and a vehicle. Adding buttons

in the Button File is not recommended.

ID: (LB)

The ID of the RFID button.

Account #: (LB)

The account associated with the RFID button.

Vehicle: (LB)

The vehicle associated with the RFID button.

Customer File

The Customer File allows you to view, create, edit or

delete customer accounts and contact information.

Next (F1) opens Customer File (2/2)

New (F3) creates new Customer File record

Del (F4) deletes displayed Customer File record

Exit (F5) opens Database Management (1/2)

Prev (F2) opens Customer File (1/2)

New (F3) creates new Customer File record

Del (F4) deletes displayed Customer File record

Exit (F5) opens Database Management (1/2)

If Customer File records exist in the database,

choosing Account #: brings up a list box window

of existing records. Changing the options inside the

existing records will edit that customer’s records.

Account: (LB)

The customer account number.

Name: (FE)

The customer name. 35 alphanumeric characters

maximum.

Phone: (FE)

The customer phone number. 14 alphanumeric

characters maximum.

Address 1: (FE)

The rst line of the customer address. 35

alphanumeric characters maximum.

Address 2: (FE)

The second line of the customer address. 35

alphanumeric characters maximum.

Zip: (FE)

The zip code of the customer address. 10

alphanumeric characters maximum.

City: (FE)

The city of the customer address. 19 alphanumeric

characters maximum.

State: (FE)

The state of the customer address. Two alphanumeric

characters maximum.

Field Type

FE - Field Edit Box

LB - List Box

25

Page 26

OPERATION

Fueler File

The Fueler File allows you to view, create, edit or delete

information for all drivers in the FleetConnect database.

Fueler records can be created by manually entering

a Fueler # or with RFID buttons. Using a RFID button

allows fuelers to logon by attaching the EZConnect

button reader to a personally designated fueler RFID

button.

To add a fueler with a RFID button:

1. Attach the EZConnect button reader to a RFID button

and press the power button. The button ID number will

appear in the ID: eld.

2. Enter the fueler information in the remaining elds. Press

Add (F2) to save fueler to the FleetConnect database.

If Fueler File records exist in the database,

choosing Fueler #: brings up a list box window

of existing records. Changing the options inside the

existing records will edit that customer’s records.

Fueler #: (LB)

The fueler number. 16 alphanumeric characters

maximum.

Password: (FE)

The fueler password. 10 alphanumeric characters

maximum.

ID: (FE)

The fueler ID. 16 alphanumeric characters maximum.

Full Name: (FE)

The fueler full name. 35 alphanumeric characters

maximum.

First Name: (FE)

The fueler rst name. 17 alphanumeric characters

maximum.

Last Name: (FE)

The fueler last name. 17 alphanumeric characters

maximum.

Security: (FE)

The security level of the fueler. Three numeric

characters maximum.

Applications: (FE)

The applications that can be run by the fueler. Five

numeric characters maximum.

Language: (LB)

The language associated with the fueler DMS i1000

Lap Pad display.

Next (F1) opens Fueler File (2/2)

New (F3) creates new Fueler File record

Del (F4) deletes displayed Fueler File record

Exit (F5) opens Database Management (1/2)

Field Type

FE - Field Edit Box

LB - List Box

Prev (F2) opens Fueler File (1/2)

New (F3) creates new Fueler File record

Del (F4) deletes displayed Fueler File record

Exit (F5) opens Database Management (1/2)

Product File

The Product File allows you to view, create, edit or

delete information that maps the product back to the

LCR, labels the product on the ticket, and designates a

product code.

26

New (F3) creates new Product File record

Del (F4) deletes displayed Product File record

Exit (F5) opens Database Management (1/2)

Page 27

New (F3) creates new Product File record

Del (F4) deletes displayed Product File record

Exit (F5) opens Database Management (1/2)

If Product File records exist in the database, choosing

Product Code: brings up a list box window of

existing records. Changing the options inside the

existing records will edit that customer’s records.

Field Type

FE - Field Edit Box

LB - List Box

Next (F1) opens System Denitions File (2/6)

Exit (F5) opens Database Management (1/2)

Next (F1) opens System Denitions File (3/6)

Prev (F2) opens System Denitions File (1/6)

Exit (F5) opens Database Management (1/2)

OPERATION

Product File (cont.)

Product Code: (LB)

The product number in the LectroCount register that

is calibrated for delivery of a product type.

Name: (FE)

The product names. 24 alphanumeric characters

maximum.

LCR Device Address: (FE)

The node address of the LCR electronic register that

will deliver the product. Value to match node address

programmed into the LectroCount register. Numeric

characters between 1 and 250.

LCR Product Number: (LB)

The calibration number in the LCR electronic register

of the product. The value can be changed using the

drop-down box.

LCR Product Type: (LB)

The product type. Must match product type on the

LectroCount register. The value can be changed

using the drop-down box.

System Denitions File

The System Denitions le denes the contact

information and system properties of your fueling

operation.

Name: (FE)

The name of the fueling operation. 35 alphanumeric

characters maximum.

Address 1: (FE)

35 alphanumeric characters maximum.

Address 2: (FE)

35 alphanumeric characters maximum.

Zip: (FE)

10 alphanumeric characters maximum.

City: (FE)

19 alphanumeric characters maximum.

State: (FE)

Two alphanumeric characters maximum.

Owner ID: (FE)

Four alphanumeric characters maximum.

Phone: (FE)

The phone number of the fueling operation. 14

alphanumeric characters maximum.

Database Password: (FE)

Password for Database Management access on

the DMS i1000 unit. 10 alphanumeric characters

maximum.

New LCR Delivery: (LB)

DMS i1000 begins a new LCR Delivery begins at

each change of Account, Product, or Vehicle.

Map Product by LCR Node: (LB)

Product selected using the LCR by node address and

calibration # instead of by product type.

27

Page 28

OPERATION

System Denitions File

Print LCR Header? (LB)

LCR Header printed onto delivery tickets.

Print Account Header? (LB)

Account Header printed onto delivery tickets.

Print Vehicle Header? (LB)

Vehicle Header printed onto delivery tickets.

Print Vehicle Footer? (LB)

Vehicle Footer printed onto delivery tickets.

Print Account Footer? (LB)

Account Footer printed onto delivery tickets.

Print LCR Footer? (LB)

LCR Footer printed onto delivery tickets.

DOT Usage: (LB)

Enables DOT check at logons and logoffs

Both • Logoff • Logon • Never

Prompt for Odometer: (LB)

Asks for odometer reading at logon.

Shared Printer Port: (LB)

Allows DMS to communicate directly to printer without

LCR.

Print GPS Coordinates: (LB)

GPS coordinate elds printed onto delivery tickets.

GMT Offset: (FE)

Location’s offset from Greenwich Mean Time. Three

alphanumeric characters maximum.

Transactions Format: (LB)

The current le format of FCRead output. .

CompTran • ASR • XML

Transactions Target: (LB)

The current target of FCRead output. .

Local • USB • Ofce

Ticket Footer 1: (FE)

The footer comment option 1 for elds printed

onto delivery tickets. 35 alphanumeric characters

maximum.

Ticket Footer 2: (FE)

The footer comment option 2 for elds printed

onto delivery tickets. 35 alphanumeric characters

maximum.

Automatic Updates: (LB)

When the current transactions update method will

occur.

Always • Both • Logoff • Logon • Never

Disable Truck DB Access: (LB)

Truck access to database management on the DMS

i1000 units.

Preset by Tank Size: (LB)

Tank size preset on the DMS i1000 units.

Next (F1) opens System Denitions File (4/6)

Prev (F2) opens System Denitions File (2/6)

Exit (F5) opens Database Management (1/2)

Next (F1) opens System Denitions File (5/6)

Prev (F2) opens System Denitions File (3/6)

Exit (F5) opens Database Management (1/2)

Next (F1) opens System Denitions File (6/6)

Prev (F2) opens System Denitions File (4/6)

Exit (F5) opens Database Management (1/2)

28

Prev (F2) opens System Denitions File (5/6)

Exit (F5) opens Database Management (1/2)

Page 29

New (F3) creates new Truck File record

Del (F4) deletes displayed Truck File record

Exit (F5) opens Database Management (1/2)

The LCR Unit ID: eld in LCRHost’s

General Setup (1/5) screen must match

LCR Unit ID: eld in the Truck File of the

FleetConnect database. See manual EM200-11.

Field Type

FE - Field Edit Box

LB - List Box

OPERATION

Truck File

The Truck File is used for viewing, creating, editing, or

deleting truck ID information, aligning FleetConnect with

the LCR Unit ID, selecting the network number used

by the truck, and names and numbers of the truck. All

fueling trucks will have a unique ID. The Truck Unit ID

must match the value in the Unit ID of the LectroCount

register on the truck.

If Truck File records exist in the database, choosing

LCR Unit ID: brings up a list box window of

existing records. Changing the options inside the

existing records will edit that customer’s records.

LCR Unit ID: (LB)

The LectroCount register unit ID code. 10

alphanumeric characters maximum.

Name: (FE)

The truck name. 16 alphanumeric characters

maximum.

Number: (FE)

The truck number. 10 numeric characters maximum.

Network #: (LB)

The truck network. Five numeric characters

maximum.

Vehicle File

The Vehicle File species the customer account and

product type for the vehicle mapped to a button.

Next (F1) opens Vehicle File (2/2)

New (F3) creates new Vehicle File record

Del (F4) deletes displayed Vehicle File record

Exit (F5) opens Database Management (2/2)

Vehicle File (2/2)

If Vehicle File records exist in the database, choosing

Account #: or Vehicle #: brings up a list box

window of existing records. Changing the options inside

the existing records will edit that customer’s records.

Account: (LB)

The account number for the fuelable vehicle

(customer).

Vehicle: (LB)

The number of the fuelable vehicle. 12 alphanumeric

characters maximum.

Name: (FE)

The name of the fuelable vehicle’s owner. 12

alphanumeric characters maximum.

Product Code: (LB)

The code of the fueling product. 8 alphanumeric

characters maximum.

Department: (FE)

The department that will be billed for fueling the

vehicle. 16 numeric characters maximum.

Tank Size: (FE)

The size of the fuelable vehicle’s tank. 10 numeric

characters maximum.

On-Road: (LB)

Whether or not the vehicle is an “on road” vehicle.

29

Page 30

OPERATION

Machine Status

The Machine Status screens display information

regarding system status. There are two Machine Status

screens. The Status (F3) key on the Fill Vehicles

screen opens the Machine Status (1/2) screen. From the

Machine Status (2/2) screen, you can open the Printer

Status, Delivery Status, and Delivery Code screens.

These screens display the current conditions of the

FleetConnect system. These status screens are helpful

for troubleshooting and maintenance purposes. For

more information, see manual EM200-11.

Security: Display Only

A description of the active security level.

Idle • Unlocked Idle • Delivery Paused

• Delivery Active • W&M Idle • Factory

Idle

Switch: Display Only

The position of the selector switch.

Run • Stop • Print • Shift Print •

Calibrate

State: Display Only

The current processing activity of the LCR 600.

Run • Stop • End Delivery • Auxiliary •

Shift • Calibrate • Waiting for No-Flow

• Unknown

Next (F1) opens Machine Status (2/2)

Diag (F3) opens list box to print a diagnostic ticket

LCR# (F4) opens list box to switch to another active LCR

Exit (F5) opens Fill Vehicles screen

Printing? Display Only

Is the printer currently printing?

Other Errors? Display Only

Are there any other errors being reported by the

LCR?

Printer Status

Select this eld to open the Printer Status screen..

Delivery Status

Select this eld to open the Delivery Status screen.

Delivery Code

Select this eld to open the Delivery Code screen.

Prev(F2) opens Machine Status (1/2)

Diag (F3) opens list box to print a diagnostic ticket

LCR# (F4) opens list box to switch to another active LCR

30

Page 31

Next (F1) opens Printer Status screen 2/2

Status (F3) opens Machine Status screen 1/2

OPERATION

Printer Status

The Printer Status screen displays the current print/ticket

conditions of the FleetConnect system. It is non-editable.

The Printer Status screen is helpful for troubleshooting

and maintenance purposes. There are two Printer Status

screens. The Printer Status screens are accessible

through the Machine Status (2/2) screen.

Delivery Ticket? Display Only

Has a delivery ticket been requested?

Shift Ticket? Display Only

Has a shift ticket been requested?

Diagnostic Ticket? Display Only

Has a diagnostic ticket been requested?

Pass-Through Print? Display Only

Is text from the host in the LCR print buffer?

Printer Error? Display Only

Has an error been detected with the printer?

Printer Busy? Display Only

Has the print processor began to print a ticket?

Prev (F2) opens Printer Status screen 1/2

Status (F3) opens Machine Status screen 1/2

Next (F1) opens Delivery Status screen 2/4

Status (F3) opens Machine Status screen 2/2

Delivery Status

The Delivery Status screen displays the current delivery

conditions of the FleetConnect system. It is non-editable.

The Delivery Status screen is helpful for troubleshooting

and maintenance purposes. There are four Delivery

Status screens. The Delivery Status screens are

accessible through the Machine Status (2/2) screen.

Delivery Status (1/4)

ROM Check Sum? Display Only

Has a delivery not started due to the checksum of the

LectroCount program code space failing?

Temperature? Display Only

Has the current delivery not started (or was

terminated) due to an error with the temperature

reading hardware?

Watchdog? Display Only

Was the processor reset due to a LectroCount

watchdog time out error?

VCF Setup? Display Only

Was there an error setting up the volume

compensation factor for the current product?

31

Page 32

OPERATION

Delivery Status

Delivery Status (2/4)

VCF Domain? Display Only

Did the temperature of the product go outside the

valid range for the compensation type of the product?

Meter Calibration? Display Only

Did an error occur while setting up the meter

calibration for the current delivery?

Pulser Failure? Display Only

Did the current delivery terminate due to too many

pulser faults?

Preset Stop? Display Only

Was the gross or net preset volume reached?

Delivery Status (3/4)

No-Flow Stop? Display Only

Was the current delivery stopped due to no-ow being

detected through the meter for a specied amount of

time?

Stop/Pause Request? Display Only

Was a stop activated by the selector switch during an

active delivery?

Print/End Request? Display Only

Was a print activated by the selector switch during an

active delivery?

Power Failure? Display Only

Did a delivery end due to a power fail condition for

more than 15 seconds?

Delivery Status (4/4)

Preset Error? Display Only

Did a delivery end due to an error condition while

attempting to set up a gross or net preset?

RS-232 Lap Pad? Display Only

Did the last delivery end due to the Lap Pad being

removed after the delivery started.

Printer? Display Only

Does the current delivery require a printed ticket but

the printer is off-line or busy?

Next (F1) opens Delivery Status screen 3/4

Prev (F2) opens Delivery Status screen 1/4

Status (F3) opens Machine Status screen 2/2

Next (F1) opens Delivery Status screen 4/4

Prev (F2) opens Delivery Status screen 2/4

Status (F3) opens Machine Status screen 2/2

Data Access? Display Only

Did a data access error occur during the delivery

which was critical to the delivery?

32

Prev (F2) opens Delivery Status screen 3/4

Status (F3) opens Machine Status screen 2/2

Page 33

Next (F1) opens Delivery Code screen 2/4

Status (F3) opens Machine Status screen 2/2

Next (F1) opens Delivery Code screen 3/4

Prev (F2) opens Delivery Code screen 1/4

Status (F3) opens Machine Status screen 2/2

Next (F1) opens Delivery Code screen 4/4

Prev (F2) opens Delivery Code screen 2/4

Status (F3) opens Machine Status screen 2/2

Prev (F2) opens Delivery Code screen 3/4

Status (F3) opens Machine Status screen 2/2

OPERATION

Delivery Code

The Delivery Code screen allows operators to review the

operating status of the currently connected device. There

are four Delivery Code screens. The Delivery Code

screens are accessible through the Machine Status (2/2)

screen.

Delivery Code (1/4)

Delivery Ticket? Display Only

Is a delivery ticket is pending? A new delivery cannot

be started until this eld is cleared by successfully

printing the last delivery ticket.

Shift Ticket? Display Only

Has a shift ticket been requested and waiting to be

printed?

Flow Active? Display Only

Is the ow active during a delivery? This eld

changes with the Delivery Active? eld, but it

also turns off when a delivery is paused and turned

on when the delivery is resumed.

Delivery Active? Display Only

Is a delivery active?

Delivery Code (2/4)

Gross Preset Active? Display Only

Is the current delivery a gross preset?

Net Preset Active? Display Only

Is the current delivery a net preset?

Stop/Gross Preset? Display Only

Has the current delivery been stopped by reaching a

gross preset value?

Stop/Net Preset? Display Only

Has the current delivery been stopped by reaching a

net preset value?

Delivery Code (3/4)

VCF Active? Display Only

Is the volume of the current delivery compensated

according to temperature?

S1 Closed? Display Only

Is the S1 solenoid closed? During preset deliveries,

the S1 solenoid should be open at full product ow

and closed at dwell ow.

Delivery Beginning? Display Only

Is a delivery in the process of being started?

New Delivery Queued? Display Only

Has a new delivery has been queued in the LCR

600?

Delivery Code (4/4)

Init Warning? Display Onlyy

Did a warning condition occur during the initialization

of the current delivery.

Cong Event? Display Only

Did a conguration event occur.

Calib Event? Display Only

Did a calibration event occur.

33

Page 34

BILL OF MATERIALS

EZConnect Button Reader with RFID Button Reader Cable E4363

RFID Button and Mounting Kit (Qty. 10) 82696

Roll Printer Kit without Cable, without RS232 & Power, without Reel E49005

Description Part Number

USB Button Reader Adapter 71707

USB Button Reader Cable 71395

USB Flash Memory Device 82684

FleetConnect Ofce CD ROM SG502CD

DB Manager CD ROM SH252CD

EZConnect Button Reader with RFID Button Reader Cable

USB Flash Memory Device

USB Button Reader Adapter with Cable

DB Manager CD ROM

34

Epson Roll Printer

FleetConnect Ofce CD ROM

Page 35

LOAD TICKET

Appendix

Ticket Layouts

DETAILED SHIFT TICKETDELIVERY TICKET

SUMMARY SHIFT TICKET

SHIFT TICKET

35

Page 36

105 Albrecht Drive

Lake Bluff, IL 60044-2242

1.800.458.5262 • 847.295.1050

Fax: 847.295.1057

www.lcmeter.com

© 2010 Liquid Controls

Pub. No. 500351

(06/2010)

Loading...

Loading...