Page 1

LIPPERTCOMPONENTS, INC.

CENTER POINT SUSPENSION INSTALLATION GUIDE

Installation for the Trailair Center Point suspension system is straight forward and requires replacing the equalizer in the standard tandem(2)

axle suspension system. Trailair strongly recommends the use of shock absorbers in conjuction with Center Point but they are notrequired.

Trailair does not supply shock absorbers because Center Point is not designed structurally to handle shock absorber mountings.If the coach is

not equipped with shock absorbers, please refer to the trailer manufacturer for information on shock absorbers and/or themountings available for

the particular trailer.

1. The first step is to check for fit up and take reference

measurements. Please see the EQUALIZER / HANGER FITUP

ILLUSTRATION which depicts a standard center hanger ,

equalizer (also referred too as a “rocker”) with spring shackles

and the Trailair Center Point Installation Check Template.

Utilize the illustration and a Check T emplate (CP 100001) to

determine if adequate clearance is available under the coach

and which length shackles are required during installation.

Make sure you catalog the “S” dimension measurement for

reference in section 9.

2. For a standard

installation, your coach must

also come equipped with the

standard center hanger shape.

The hanger may vary in

dimension but it must be sized

for a 1 3/4” leaf spring width, be

at least 2.5” from the equalizer

hole to the top of the hanger and be 3” wide or wider. Please

refer to the EQUALIZER / HANGER FIT-UP ILLUSTRA TION

for minimum hanger dimensions. If your coach is not equipped

with this style hanger, you may be able to do a non-standard

installation (See section 8) or you may have to remove the

old hanger from the frame and install the standard center

hanger, which can be acquired from Trailair.

3. After safely

raising the coach to

a level that insures

the tires are off the

ground, properly

position stands to

support the coach.

WARNING: improper raising or lowering of the coach could

result in damage to the coach, injury or death. Insure that

any points of contact for the stands do not result in damage

to any panels or lines under the coach.

4. Remove the tires and

wheels from the coach. The

suspension should be free from

any loads, except it’s own weight

at this point. Place another set of

jack stands under the axles, very

close to the u-bolt plates. This will

provide support to the axles and

insure that they do not swing down during disassembly of the

shackle components. NOTE: allowing the axles to drop could

result in damage to the wiring for the electric brakes.

5. With the coach properly raised on jack stands and

the axles properly supported by additional jackstands, remove

two shackle nuts on the shackle at the rear of the front spring.

NOTE that the bolts are pressed into the shackle plate and

should not turn. However, use a properly sized boxed end

wrench to insure the bolts do not turn. Loosen the nuts only,

to remove these shackle

plates.

6. Once the nuts and

the plate retained by the

nuts are removed, slide the

opposite side shackle plate

out, with the bolts still

pressed into the plate. Also, remove the nut on the cross bolt

for the equalizer. Again, the bolt may be pressed into the

frame hanger and should not be allowed to rotate. After

removing the front spring’s shackle at the equalizer, repeat

the process for the shackle that mates the rear spring to the

equalizer. Then, remove the equalizer.

7. The frame hanger is now ready to receive a Center

Point Sub-assembly. Insure that the clamp plates are

sufficiently loose to allow the retaining tower to slide up into

the frame hanger. Do not remove the clamping plates as

there may not be adequate clearance to reinstall after placing

the tower into the frame hanger. Remove the retaining cross

bolt and nut so the tower will slide into the frame hanger. Do

not misplace these

bolts and nuts after

taking them off the

sub-assembly. If

the hanger has a

cross tube, the

cross tube must be

removed.

STANDARD SUB-ASSEMBL Y

8. It is suggested that a floor jack supports the Center

Point Sub-assembly during this operation. The floor jack

allows mobility along with an ease of slowly raising the Center

point Sub-assembly into position to install the retaining cross

bolt into the frame hanger.

DO NOT REMOVE SIDE CLAMP PLATES

Page 2

NON-STANDARD SUB-ASSEMBL Y

In specific cases where the side clamping plates

cannot be used

with a nonstandard

size

centerhanger,

an alternative

mounting is

possible. If the

CP2 sub-unit

will fit inside the

hanger, and the

hanger is tall enough, the sub-unit may be mounted without

the side clamping plates if (2) crossbolts are used instead of

(1) (An additionial pair of 9/16” x 12 x 3” grade 8 bolts with

nylock nuts will be needed as only one per sub-unit are

provided). The CP2 sub-unit is designed with two crossholes

in the tower to give Center Point an additional inch in height

adjustment. Both holes can be used for mounting cross

bolts(although not needed in a standard installation).The

additional hole in the centerhanger of the coach frame will

need to be drilled and will correspond with the secondary

adjustment hole. A secondary installation is shown with a

hanger that was only 2.5” wide.

If either the side clamping plates or the (2) crossbolt

method cannot be used because of the size and/or shape of

the centerhanger, it is recommended that the frame hanger

first be changed to the standard size hanger.

Once the Center Point Sub-assembly is properly

positioned and the mounting holes are aligned, install the

retaining cross bolt (provided on the tower of each sub-unit).

This bolt will have to be inserted from the outside, inward.

The air spring on the Center Point Sub-assembly prevents

this bolt from being inserted from the under side of the coach.

Y ou may now tighten both the retaining plate bolts and the

cross bolt. T orque these bolts to 100 foot/pounds.

9. T h e

Center Point

S u b assemblies

are preadjusted at

the factory to

insure the

cross shaft

shackle link is parallel to the ground. There are a wide variety

of equalizers being used throughout the industry. Due to the

fact there are so many, it is normally necessary to replace the

original shackles with longer ones. Trailair provides 2 sets of

shackle plates (8 plates each) that offer three different length

settings as well as (8) replacement shackle bolts and (8)

flanged nuts. The check template will give a dimension from

the center of the link eye on the Center Point assembly to the

center of the spring eye on the springs of the coach. Refer to

the EQUALIZER / HANGER FIT-UP ILLUSTRA TION

attachment in step one for the “S” dimension measurement

taken at the beginning of the procedure.

INSERT THE BOLT FROM THIS SIDE

While the slack adjusters allow for adjustment in the

relationship of the spring position to the frame, it is not intended

to offer a latitude great enough to compensate for the necessity

of replacing shackle mounting plates with those that are longer.

This is due to the design of the Center Point system and the

distances from the riser tower cross bolt to the cross shaft’s

shackle link mounting position, while in ideal conditions.

It is important to use the correct replacement shackle

plates so that the height of the coach does not change more

than 1/2”. The “S” dimension

tells us which shackle to use.

If the “S” dimension is 3” or

less, use the CP 100056

shackle plates. If the “S”

dimension is between 3” and

4” use the CP 100046 shackle

plate (which has two settings)

in the short hole set. In the

short setting, be sure that the

end of the shackle plate with

the extra hole is pointed down

to the ground and not up

toward the frame so that it does

not cause interference with the

operation of Center Point. If the

“S” dimension is more than 4”

use the longer setting of holes

in the CP 100046 shackle

plates.

Upon choosing the

correct shackle plates, the

shackles can be assembled

into the spring eyes and into the

cross shaft shackle links. Y ou

must drive the knurled shank

end of the shackle bolt onto the

shackel plate. Use of a standard bottle jack will be of

assistance in positioning the axle to align the two bolts of the

shackle plate. If a bottle jack is utilized, be sure to position it

under the spring mounting plate, below the axle. When the

two bolts on the

shackle plate

will slide easily

into both, the

cross shaft

shackle link

and the spring

eye, place the

other shackle

plate on the

inside and install the nuts to retain the shackle assembly .

Repeat this process on the other spring.

After securing all shackle nuts and bolts to proper

torque levels (50 ft/pounds), the opposite side of the coach

is ready for the same procedures. Repeat the operations 3

through 9 as described above to install the opposite side.

CP 100046

CP 100056

Page 3

PLUMBING

10. Once both Center Point Sub-assemblies are installed

onto the frame, the air supply lines must be routed. Y ou should

CP 100035

sufficient slack in the air hose, the clip placement (CP 100035)

is critical. The air spring will cycle forward and aft as much as

5 inches, during the operation of the suspension in its reaction

to extreme road conditions. Therefore, the clip must be

secured on the frame with enough slack to allow the movement

necessary. It must also be located so that the hose does not

CP U00020

location, the bulkhead fittings w/ ¼” NPT to push on (CP

U00003) can then be attached to the air hoses. The locking

nut of the bulkhead fitting can be removed from the fitting and

the fitting can be inserted into the mounting clip. Re-install

the locking nut and secure the bulkhead fitting to the clip.

the air gauge panel(CP 5007), the poly air lines may be

installed. A union tee (CP U0000

4) is supplied for joining the

two air lines from the bulkhead fittings. Note that all a ir lines

are DOT approved air brake quality suitable for commercial

industry applications. The poly air lines must be cut square

U00006), self-drilling / self-tapping screws (CP U00020) and

(4) wire ties (CP U00028) provided. Do not drill through any

panels under the coach until assuring there is nothing that

will be damaged. Remember, there are holding tanks, water

location of the air gauge panel (CP

5007) is up to the owner / dealer /

refer to the AIR LINE SCHEMA TIC in the

appendix. Before planning the air hose

routing and placement, verify there is

sufficient clearances for the air spring. The

air springs already have the air hoses

installed and only have to have the loose

end secured. In order to insure there is

contact the air spring to any other moving

parts of the suspension. There are 4 self drilling, self-tapping screws (CP 100020)

provided to attach the clip, two per clip.

11. After attaching the clips in a suitable

This should be done for both sides

of the trailer before installing the

poly air lines.

12. After carefully considering

CP U00003

and true, in order for these fittings to

function properly and retain air

pressure.

13. T o assist in routing the poly

CP U00004

air lines, there are (4) nylon clips (CP

lines and possibly gas lines all mounted

within the frame rails of a coach.

PANEL APPLICATION:

14. The choice of the

CP U00006

the placement and routing of the

air lines to the desired location of

installer. Trailair makes no recommendations other than to

consists of the panel mount plate (CP 100030), the air

pressure gauge (CP U00033) with female connector (CP

U00017) and the access fill valve (CP U00015).

CP U00033 CP U00017 CP U00015

gauge and fill valve acts as a reinforcing plate. The second

option is to mount the air pressure gauge and the access fill

valve directly onto the coach body without utilizing the panel.

Trailair offers both methods and provides sufficient information

for either choice.

PANEL MOUNTING:

The CP 5007 assembly is intended to serve two

functions. One is to provide support for the panel installation

in areas that may not be thick enough to attach fasteners.

The second function is to provide a template to cut an accessmounting

hole. Carefully check to insure there are no

obstacles nor any components that may incur damage while

cutting holes, routing the poly air lines or mounting the panel

mount plate. At this point, mount the female connector to the

air gauge, mount the air gauge and the access fill valve to the

panel mount plate.

Determine the location of the CP 5007 assembly and

mark two holes, 1 3/4” diameter, 3 3/8” apart from each other.

With a suitable tool cut the opening for the air gauge and the

fill valve. Place the CP 5007 assembly into the openings,

level and square the assembly, mark the four hole locations

to mount the panel. Install the assembly using (4) self-tapping

screws (CP U00020), through the holes in the panel.

DIRECT AIR GAUGE MOUNTING:

Once location is determined, use the air gauge

without the bezel and the access air fill valve without the

bulkhead nut as a template to drill the holes needed. Be sure

to check for potential interference and or possible damage to

other components before cutting any access holes. Once

the holes are cut, mount the air gauge with the female

connector attached and the access fill valve to the coach

sidewall.

place it where it will not inhibit

the operation of the system and

will provide an opportunity to

visually check the system

pressure easily. External

mounting is the preferred

method of Trailair, however, the

owner may prefer mounting

CP 5007

within a compartment. CP5007

There are two options for external

installation. The first option is to

install the panel mount plate

provided with the

Page 4

3 - N/A

Page 5

NO LONGER APPLICABLE

Page 6

Direct mounting of air pressure

gauge and access fill valve are

shown.

15. After installing the

be routed. Make sure the air lines can not rub on the wall of

the coach and create a leak. Install the instructional decal

provided.

ADJUSTMENT INSTRUCTIONS

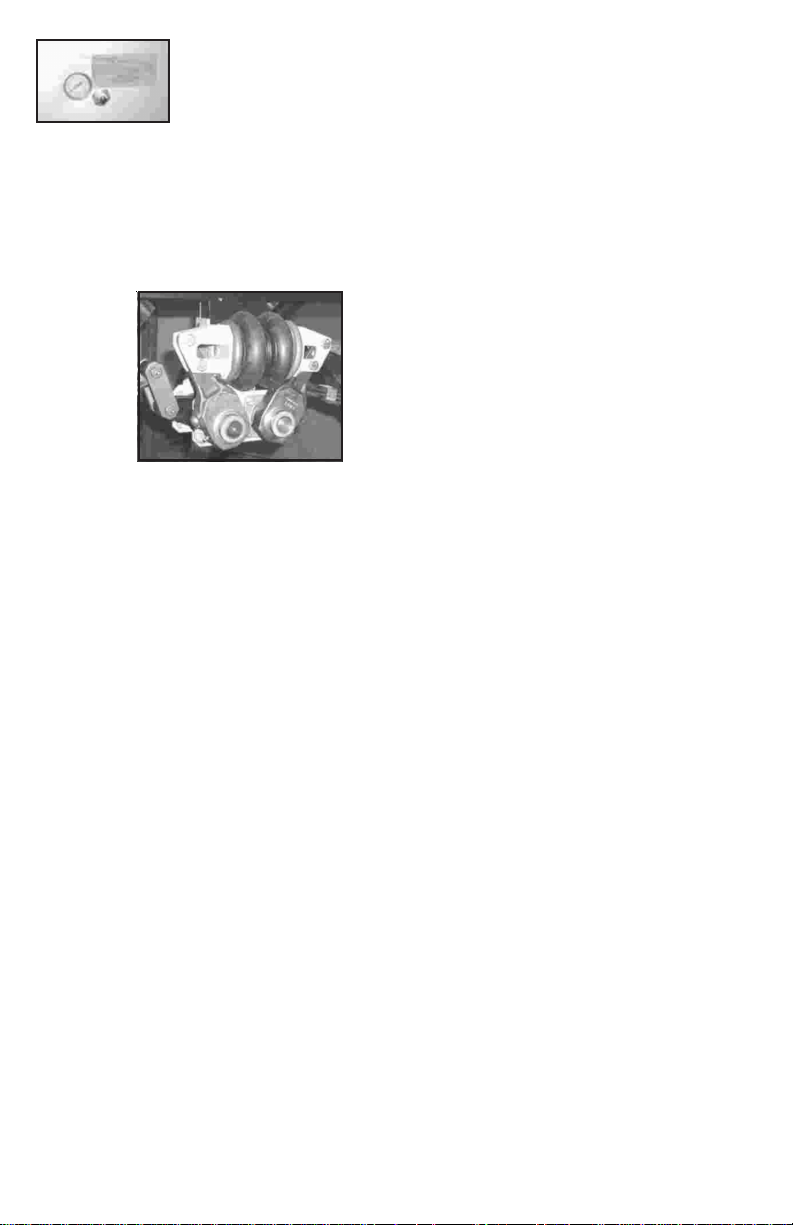

The principle of the Center Point design is to allow

totally independent axle reaction to road conditions and to

also allow adjustability in equalizing coach height, in side-toside

relationship. The sub-units are assembled at the factory

at with the shackle links pre-set. The ride height of the coach

should be acheived with the selection of the shackle, not

adjusting the

shafts. However,

in some cases the

link eyes need to

be adjusted for

c l e a r a n c e

purposes.

To adjust

the link eye on the

cross shafts, use

a 9/16” wrench to

turn the worm

gear in the slack adjuster. If lowering the coach, it may not be

necessary to have the weight off the the axles. However, if

raising the coach height the weight of the coach will have to

be lifted off the axles to turn the worm gear in the slack adjuster.

ADJUSTMENT POINT

Angles of 30 degrees or less from a horizontal position

are acceptable, in compensating for differences in height. Both

arms on a sub-unit should be equal when adjusting coach

height. Do not exceed 30 degrees of adjustment. Angles

greater than 30 degrees require using different shackle plate

lengths. Do not use a shackle longer than the CP 100056

shackle provided by Trailair.

SETTING AIR PRESSURE

Air pressure levels should be 5 PSI per 1,000 pounds

of coach weight at 70 degrees ambient temperature. This

will vary according to individual personal belongings and

effects that the owner wishes to place in the coach. Once a

satisfactory air pressure (yielding a compliant ride for the

coach) is established, the air pressure gauge will allow quick

and easy verification of operating pressure levels. Always

make sure the fill valve cap is secure so that the seal in the

cap will function properly and assist in sealing the system.

Keep in mind that three natural factors will effect the

air pressure in a self contained air system. The following

conditions will cause the air pressure reading in the gauge to

components, the poly air lines can

fluctuate more than 2-3 psi up or down from the conditions

the coach is set at upon installation; A change in altitude of

3000 to 4000 feet or more, a change in temperature of 50

degrees or more and 500 pounds or more of weight differential.

What does that mean? If one or more of these conditions

change for a prolonged period after the initial installation, an

adjustment to the air pressure may be required. If these are

temporary fluctuations, changes in the air pressure are most

likely not needed.

Note that once the coach is moved, the air spring

may return to a position other than centered. This is not

abnormal. It only illustrates the fact that the axles are reacting

to torque of acceleration, deceleration or turning input. The

only way to return to an absolute centered position of the air

spring is to lift the coach and allow the axles to seek a neutral

condition, having no residual torque input.

HELPFUL HINTS

If the system is leaking, add air to 100psi and begin

trouble shooting at the fitting connections with soapy water. If

the leak cannot be traced to a fitting connection, the air gauge

and the fill valve are the most likely pnuematic parts to leak.

The most unlikely component to leak is the air bags themselves

and Trailair recommends checking those last upon a fresh

installation. If the leak cannot be found and fixed, call Trailair

for assistance. Once the leak is found, reset the air pressure to

the setting for your coach.

There is no lubrication required for CenterPoint as it is

designed to perform best dry. The only maintenance would be

for the brass in the link-eyes of the shafts and standard

maintenance required for the spring eyes of the standard

suspension.

For clarity purposes, Center Point is shown in the

manual without the mechanical bag stops that are standard on

the sub-units. This allows Center Point to be operated on your

coach without air in cases where travel is necessary. So if you

have an air leak or a complete loss of air in the system, you can

still travel. It should be noted that prolonged use in this condition

can potentially accelerate the wear of the stop plates. The parts

are easily replaced if overly worn.

A full listing of all replacement parts can be found on

page 5 of the manual on the air line schematic print. Please

contact Trailair for all your replacement parts needs.

TECHNICAL SERVICE:

Direct any and all technical service questions to:

Trailair, Inc Corporate Office.

409 Vandiver West, Bldg 6-201

Columbia, MO 65202

800/998-4238 email: info@trailair.com

573/446-1086 (fax) www.trailair.com

Page 7

Page 8

The Leader in RV Air-Ride Technology

Trailair’s National sales and business office in Goshen, IN is your location to place orders, order literature,

follow up on orders and other inventory maintenance issues.

Contact information:

LIPPERTCOMPONENTS, INC.

Service & Warranty; Plant #39

2703 College Ave.

Goshen, IN 46528

Toll Free: (866) 524-7821

Phone: (574) 537-8900

Fax: (574) 534-7161

www.lci1.com

email: warranty@lci1.com

Product information and photography are as accurate as possible at the time of publication. Colors and finishes

are photographic representations and may appear different from actual materials.

rev021612

Loading...

Loading...