Page 1

Twist’R Plus

INSTALLATION AND

OWNER’S MANUAL

Model RSX4000 - Class I

Vehicular Swing Gate Operator

Proven

CGA2K™

TECHNOLOGY!

Serial #:

Date Installed:

Your Dealer:

As of date of manufacture,

Vehicular gate operators

106502

READ THIS MANUAL

CAREFULLY BEFORE

INSTALLATION OR USE

SAVE THESE INSTRUCTIONS

meets all ANSI/UL 325

Safety Requirements for

Page 2

TABLE OF CONTENTS

2

Pre-Installation Notes..............................................3

Operator Class Information .................................3

Section A: Gate System Design/Installation.........4

Section B: Preparing the Site ................................6

The Concrete Operator Pad .................................6

Alternate Post Mount ...........................................6

Placing the Vehicle Detector Loops ....................7

Vehicle Detector Loop Blanking (Shadow) .........8

Electrical Power Requirements ...........................8

Section C: Installing the Operator.........................9

Placing the RSX4000 Pedestal Unit...................10

Optional Photoelectric Thru Beam Sensor........... 11

Optional Photoelectric Retro-Reflective Sensor..12

Optional Electric Edge Sensor............................... 13

Installing the Gate Arm Kit.................................14

Electrical Hookup ...............................................15

Wiring Diagram...................................................15

Lightning Protection ..........................................16

Right/Left Hand Installations.............................16

Synchronous Operation (Master/Slave ............16

Accessory Equipment Hookup.............................17

Terminal Strip Reference Chart ............... 18 & 19

Section D: Starting the Operator .........................19

Setting the Limit Switches ................................19

Setting the Adjustable Torque Drive ................20

Running the RSX4000 Plus ...............................21

Maximum Run Timer..........................................22

Final Setting of Close Timer..............................22

Section E: Auxiliary Equipment ..........................22

Section F: End User Instructions .........................23

Operational Guide for the End User .................23

Safety Guide for the End User ................. 24 & 25

Wiring Diagram ..................................................26

Notes .....................................................................27

RSX4000 Arm Kit Exploded View .........................27

Technical Specifications.......................................28

WARNING HIGH VOLTAGE

Figure 1

ONLY A QUALIFIED TECHNICIAN SHOULD SERVICE THIS GATE OPERATOR

PERIODICALLY TEST SENSITIVITY OF OVERLOAD *** READ MANUAL ***

LOG DATE OVERLOAD TEST

DATE TESTED DATE TESTED DATE TESTED DATE TESTED

READ THESE STATEMENTS CAREFULLY AND FOLLOW THE

INSTRUCTIONS CLOSELY.

The Warning and Caution boxes throughout this manual are there to protect you and your

equipment. Pay close attention to these boxes as you follow the manual.

DATES OPERATOR

SERVICED

WARNING

Indicates a MECHANICAL

hazard of INJURY OR

DEATH. Gives instructions

to avoid the hazard.

CAUTION

Indicates a MECHANICAL hazard

of DAMAGE to your gate, gate

operator, or equipment. Gives

instructions to avoid the hazard.

WARNING

Indicates an ELECTRICAL

hazard of INJURY OR

DEATH. Gives instructions

to avoid the hazard.

CAUTION

Indicates an ELECTRICAL hazard

of DAMAGE to your gate, gate

operator, or equipment. Gives

instructions to avoid the hazard.

Page 3

PRE-INSTALLATION NOTES

3

The Twist’R Plus (Model RSX4000) Vehicular Gate Operator will

provide convenience and assurance to the ultimate users for many

years. It is ruggedly built of the finest materials and has been

thoroughly inspected and tested at the factory. It has many features that

will aid in the installation and testing of the complete gate system. The

RSX4000 has been designed and built to comply with the UL325

Standard For Safety, Fourth Edition, revised March 1, 2000 as

established by Underwriters Laboratory Inc.

NOTICE

BEFORE ATTEMPTING INSTALLATION,

READ THIS MANUAL CAREFULLY SO YOU WILL

BE THOROUGHLY FAMILIAR WITH THE

FEATURES OF THE TWIST'R PLUS AND IT’S

PROPER INSTALLATION PROCEDURES.

The RSX4000 Vehicular Swing Gate Operator is designated a Class

I Vehicular Swing Gate Operator, and is intended to operate a

vehicular swing gate installed on a residential home, maximum of four

single families in the dwelling, or a garage or parking area associated

with that home, or a similar location with respect to the cycle usage (see

below). Gate operators are also manufactured for the three other Class

designations (as defined by UL325); Class II (high cycle usage

commercial location or multi-family home); Class III (Industrial

location not intended to service the general public); and Class IV

(secure or restricted access locations, ie. airports and prisons). The

RSX4000 operator cycle usage is rated at a maximum of 10 cycles per

hour, 50 cycles maximum per day.

Because the RSX4000 (as well as gate operators sold by other

manufacturers) is designed to start and move gates weighing as much as

300 pounds and 16 feet in length. As such, the RSX4000 is capable of

producing high levels of force. It is important in the design of the total

gate system that designers, installers and users be aware of the hazards

that may be associated with the IMPROPER design, installation and

use of Vehicular Gate systems and Gate Operators.

The gate operator is only one part of a complete automatic gate

operating system. As each location and usage is different, a properly

designed system

As the designer and installer of the GATE SYSTEM, you must

advise the purchaser on the proper use of the gate system. You also

have the primary responsibility of insuring that ALL possible

operational hazards have been considered and eliminated.

The RSX4000 CGA2K™ technology provides several features that

can help reduce the hazards of your gate system.

Built-In Adjustable Torque Limiting Drive System

The RSX4000 is provided with a adjustable torque limiting drive

system that may be adjusted to “slip” when an obstruction is

encountered. This system, however, must not be considered as the

primary obstruction sensing system. Consider all available options

(electric leading edges, photoelectric sensors, protective screen mesh,

etc.) to eliminate hazards in your gate system design.

The torque limiting drive system also serves to protect the mechanical

components of the operator.

will include all applicable safety enhancement devices.

The torque limiting drive setting is an adjustable setting that must be

determined at the time of installation. This setting must be tested

periodically to ensure proper operation. The more freely the gate will

move the more sensitive the setting can be made. See Page 17.

ADVISE THE PURCHASER TO CHECK THE SENSITIVITY OF

THE GATE OPERATION PERIODICALLY AND THEN LOG THE

DATE TESTED IN THE TABLE on page 2. (See Figure 1)

NOTICE

THE IMPORTANT SAFEGUARDS AND

INSTRUCTIONS IN THIS MANUAL CANNOT COVER ALL

POSSIBLE CONDITIONS AND SITUATIONS WHICH MAY

OCCUR DURING ITS USE. IT MUST BE UNDERSTOOD

THAT COMMON SENSE AND CAUTION MUST BE

EXERCISED BY THE PERSON(S) INSTALLING,

MAINTAINING AND OPERATING THE EQUIPMENT

DESCRIBED HEREIN. DO NOT USE THIS EQUIPMENT

FOR ANY OTHER THAN ITS INTENDED PURPOSE —

OPERATING A SWING GATE.

Connections for External Entrapment Prevention Sensors

Because all gate system installations are different, the RSX4000 control

panel provides independent connections for Open and Close contact

(edge) sensors and Close non-contact (photoelectric) sensors. In this

way a photoelectric sensor could be utilized to guard the gate area when

closing and an edge sensor would provide the protection when opening.

Depending on the particular application a combination contact and noncontact sensor protection system for the open and close directions may

provide more effective entrapment protection than a single device for

both directions. See pages 4, 5, 11, 12, 13, 17, 19, 23, and 24.

SMART™ Self adjusting MAximum Run Timer

The RSX4000 has a Self adjusting MAximum Run Timer, SMART™.

The amount of time for the first few cycles of operation are registered

and averaged within the motor controller circuitry. After the first few

initial cycles, if the gate is activated and no other command is given or

an end limit (open or close) is not reached in the previously counted

cycle time plus approximately 4 seconds, the operator will be turned

off. See page 22.

OTHER FEATURES

Auto Close Timer: Adjustable from 2 to 60 seconds, provides an

automatic closure of the gate from the full open position. See page 21.

Synchronous Operation (Master/Slave): Two RSX4000 units can be

wired together to operate as one system, with one unit controlling the

movement of both. Additionally, the installer can customize the

installation of the external entrapment protection devices. These

devices can be wired to the controller operator or alternately to the

individual units as the situation dictates or the end user requires. See

Page 16.

Page 4

A: GATE SYSTEM DESIGN / INSTALLATION

4

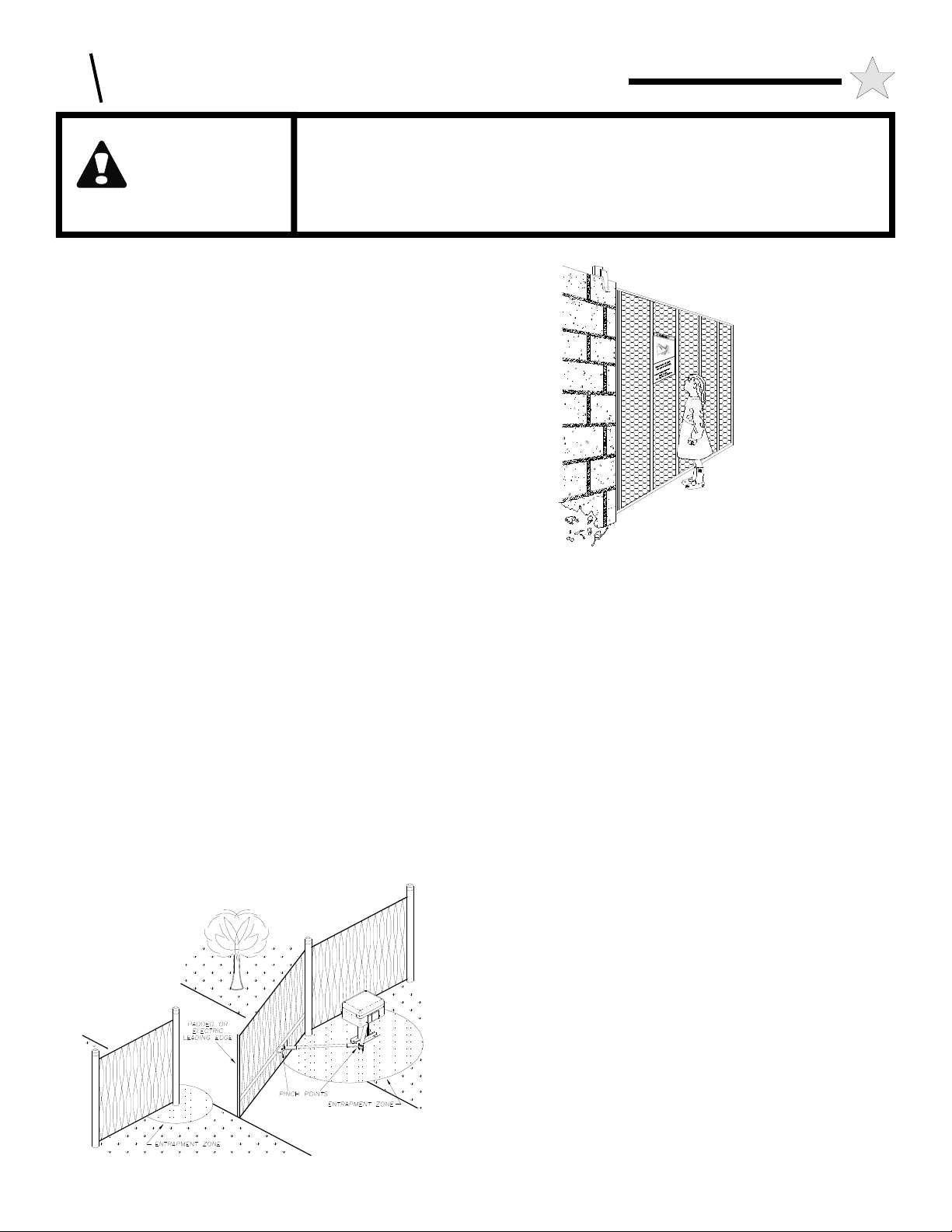

TO REDUCE THE RISK OF SEVERE INJURY

OR DEATH: READ AND FOLLOW ALL

WARNING!

INSTALLATION INSTRUCTIONS AND GATE

SYSTEM DESIGN PARAMETERS!

GATE SYSTEM DESIGN AND INSTALLATION

SAFETY CHECK LIST:

• The RSX4000 operator may be installed on a Class I Vehicular

Swing Gate. See page 3 for an explanation of the different Class

locations. See the last page of this manual for the operator

specifications (voltage, maximum gate weight & length etc.).

• Make sure that the gate moves freely, all hinges are in good

working order, the gate does not bind in any manner and the gate

swing area is clean and free of irregularities. DO NOT INSTALL

THE OPERATOR UNTIL ALL GATE PROBLEMS HAVE

BEEN CORRECTED.

• Do not increase the built-in overload detector adjustment or

overtighten the torque limiter to compensate for a poorly working

gate. A well maintained gate will ensure easy manual operation (if

needed) and maximum operator obstruction sensitivity.

• Install the operator on the inside of the property/fence line. DO

NOT install an operator on the public side of the fence line or gate.

Outward swinging gates should not open into public areas.

• Make sure the gate operating system is placed far enough back

from the road to eliminate traffic backup. The distance from the

road, size of the gate, usage level and gate cycle/speed must be

taken into consideration to eliminate potential hazards.

• The gate must be installed in a location so that enough clearance is

supplied between the gate and any adjacent structures when

opening and closing to reduce the risk of entrapment.

• For ORNAMENTAL “GRILL TYPE” GATES (or any other type

of open gate where a handhold or toehold may be achieved),

injuries may occur when people put arms through the openings or

children “ride” the gate by standing on the bars and holding on to

106503

Figure 3: Entrapment Zones and Pinch Points

104949

Figure 2

the gate. THIS POTENTIAL HAZARD CAN BE MINIMIZED

BY INSTALLING A MESH SCREEN ON THE GATE. Allstar

strongly recommends the entire gate and adjacent fence area the

gate covers when open be meshed or guarded such that a handhold

or toehold cannot be achieved. See Figure 2.

• The gate operator as described in this manual is a VEHICULAR

GATE OPERATOR and as such is NOT INTENDED FOR

PEDESTRIAN traffic. In installations where pedestrian passage

through the fence is necessary, install a pedestrian access

opening. The pedestrian access opening shall be designed to

promote pedestrian usage. Locate the vehicular gate and the

pedestrian access opening such that persons will not come into

contact with the vehicular gate during the entire path of travel of

the vehicular gate. See page 23 for additional information.

• Install leading edge detectors and/or photocells in your design to

protect system entrapment zones. These devices can be provided

for incorporation in your gate system design.

• Use the illustration at left (Figure 3) and the information and

diagrams on pages 11, 12, and 13 to minimize the risk of injury in

your design of the swing gate operator system. IDENTIFY THE

ENTRAPMENT ZONES AND PINCH POINT AREAS IN

YOUR GATE. Design the gate installation to minimize the risk

of entrapment in these areas. Install additional safety equipment

such as edge sensors and photocells to further minimize risk. All

entrapment zones are required to be protected.

• Entrapment Zones: Design in personal entrapment protection

devices to protect people from entrapment in the zones shown in

Figure 3 and the information and diagrams on pages 11, 12, and

13.

• Pinch Points: Use protective measures (guards, padded edges,

etc.) to protect people from the pinch points shown in Figure 3

and the information and diagrams on pages 11, 12, and 13.

Attach roller guards in cantilevered gate systems to minimize the

risk of hands being caught between the top of the gate and the

roller.

Page 5

A: GATE SYSTEM DESIGN & INSTALLATION

• SWING GATES HAVE THE POTENTIAL HAZARD OF

HANDS AND FINGERS BEING PINCHED between the gate

edge and the post to which the gate is mounted. It is

recommended that the hinges be mounted so that this opening

increases as the gate swings open. PROTECT THIS "PINCH

POINT" SO THIS HAZARD IS MINIMIZED. See Figure 3.

• CONSIDER ALL OTHER "PINCH POINTS" IN YOUR

DESIGN of the gate system. Observe the arm as it opens and the

two arm pieces swing past each other. Use protective measures to

reduce hazards at this location. Restrict access to the arm motion.

See Figure 3.

• DO NOT consider the adjustable torque limiter as the primary

defense system. Consider all options in the gate system design.

• DO NOT connect any auxiliary equipment to the RSX4000

(detectors, card readers, etc.) until the gate operator and all its

functions are fully tested. Only connect one device at a time and

ensure its proper function(s) before moving on to the next device.

• DO NOT locate any control device (key switch, switch, key pad,

card reader, etc.) in a position where it may be activated by a

person reaching through the gate or while touching the gate in any

manner. Locate all control devices a minimum of 10 feet from the

gate when opened or closed.

• Outdoor or easily accessible controls must be of the security type

to prevent unauthorized use of the system.

• Install all devices that will Open, Close or Stop the gate in such a

manner that THE GATE WILL BE IN FULL VIEW WHEN THE

DEVICE IS OPERATED.

• Before activating the "timer to close" option of the RSX4000,

ENSURE THE PERSONAL ENTRAPMENT PROTECTION

DEVICES (operator reversing feature, edges, photocells) ARE

OPERATING and install VEHICLE DETECTOR LOOPS AND

VEHICLE DETECTORS for protection of user vehicles. Read the

manual for information on the installation of these devices. IF

VEHICLE DETECTOR LOOPS HAVE BEEN INSTALLED TO

PREVENT THE GATE FROM CLOSING ON A VEHICLE,

INSTRUCT THE USER TO PERIODICALLY CHECK THE

OPERATION OF THE DETECTORS.

• USE EXTREME CAUTION WHEN WORKING NEAR THE

BELTS AND PULLEYS when the operator cover is removed.

Apply power to the operator only when instructed to do so.

• When the RSX4000 Control Box cover is removed, high voltage

will be exposed. EVEN IF THE RED POWER LIGHT IS NOT

LIGHTED, HIGH VOLTAGE AC MAY STILL BE PRESENT.

NEVER LEAVE THE INSTALLATION WITH THE CONTROL

BOX COVER REMOVED.

• ALWAYS TURN OFF THE POWER BEFORE ATTEMPTING

SERVICE OF EITHER THE ELECTRICAL OR MECHANICAL

SYSTEMS.

• SECURELY ATTACH THE WARNING SIGNS provided with

the RSX4000 on the gate (one on the outside and one on the

inside) where they can be seen by persons in the area of the gate to

alert them of automatic gate operation. The installation of the

warning signs is a requirement of UL325 and as such failure to

install the signs will negate the UL Listing.. If the user refuses to

have the warning signs installed, Allstar recommends that you note

this on your records and have the user sign a disclaimer. See

Figure 4.

5

MOVING GATE

CAN CAUSE

SERIOUS

INJURY OR

DEATH

KEEP CLEAR !

Gate May Move at Any Time.

Do not allow children to play

in gate area or operate gate.

Operate gate only when gate

area is in sight and free of

people and obstructions.

Figure 4

AS THE INSTALLER YOU ARE RESPONSIBLE FOR:

1 ASSURING THAT THE GATE AND OPERATOR

SYSTEM, WHEN FULLY INSTALLED AND OPERABLE,

COMPLIES WITH ALL APPLICABLE REQUIREMENTS

OF UL325: STANDARD FOR SAFETY FOR DOOR,

DRAPERY, GATE, LOUVER AND WINDOW

OPERATORS AND SYSTEMS.

2 ASSURING THAT THE OWNER/END USER OF THE

SYSTEM UNDERSTANDS ITS BASIC OPERATION AND

SAFETY FEATURES. IN PARTICULAR, BE SURE THE

OWNER/END USER UNDERSTANDS THE LOCATION

AND OPERATION OF A MANUAL DISCONNECT

(WHERE PROVIDED) OR HOW TO OPERATE THE

GATE MANUALLY.

3 YOU ALSO HAVE THE PRIMARY RESPONSIBILITY

OF INSURING THAT ALL POSSIBLE OPERATIONAL

HAZARDS HAVE BEEN CONSIDERED AND

ELIMINATED. YOU MUST ADVISE AND WARN THE

PURCHASER AND THE ULTIMATE USER OF ANY

HAZARDS THAT YOU HAVE NOT BEEN ABLE TO

ELIMINATE.

4 POINTING OUT TO THE OWNER/END USER OF THE

GATE SYSTEM THAT CHILDREN OR PETS ARE NOT

ALLOWED TO PLAY ON OR NEAR THE GATE, FENCE

OR ANY PART OF THE SYSTEM, AND THAT THE

SAFETY INSTRUCTIONS SUPPLIED WITH THIS

OPERATOR AND THEIR IMPLEMENTATION ARE

THE RESPONSIBILITY OF THE OWNER/END USER.

5 LEAVING THE INSTALLATION AND MAINTENANCE

MANUAL FOR THIS OPERATOR AS WELL AS ANY

ADDITIONAL SAFETY INFORMATION SUPPLIED

WITH THIS OPERATOR OR OTHER COMPONENTS OF

THE GATE SYSTEM WITH THE OWNER/END USER.

6 NOT PLACING IN SERVICE THIS OPERATOR IF YOU

HAVE ANY QUESTIONS ABOUT THE SAFETY OF THE

GATE OPERATING SYSTEM. CONSULT THE

OPERATOR MANUFACTURER.

104880

Page 6

6

B: PREPARING THE SITE

111877

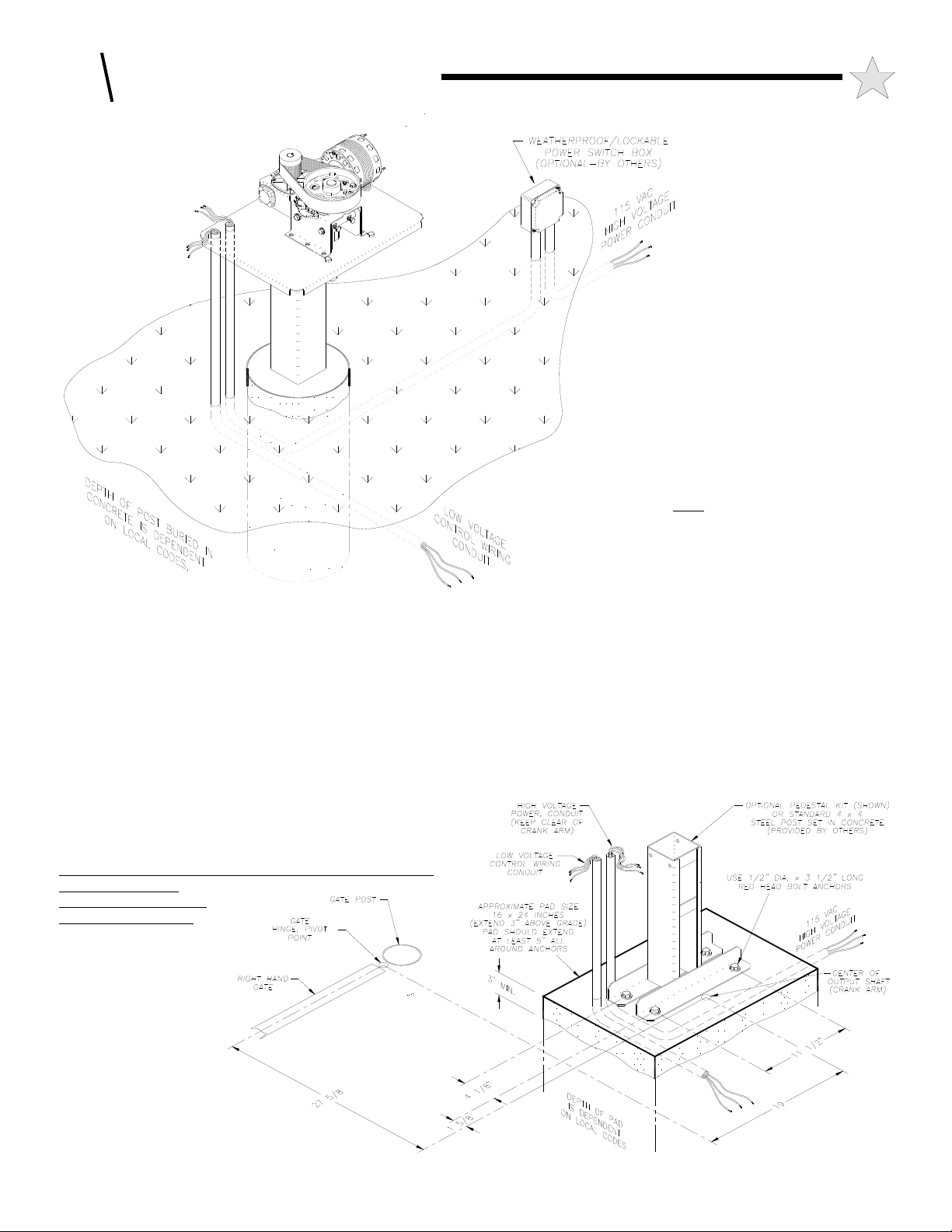

Figure 5: Pad Configuration

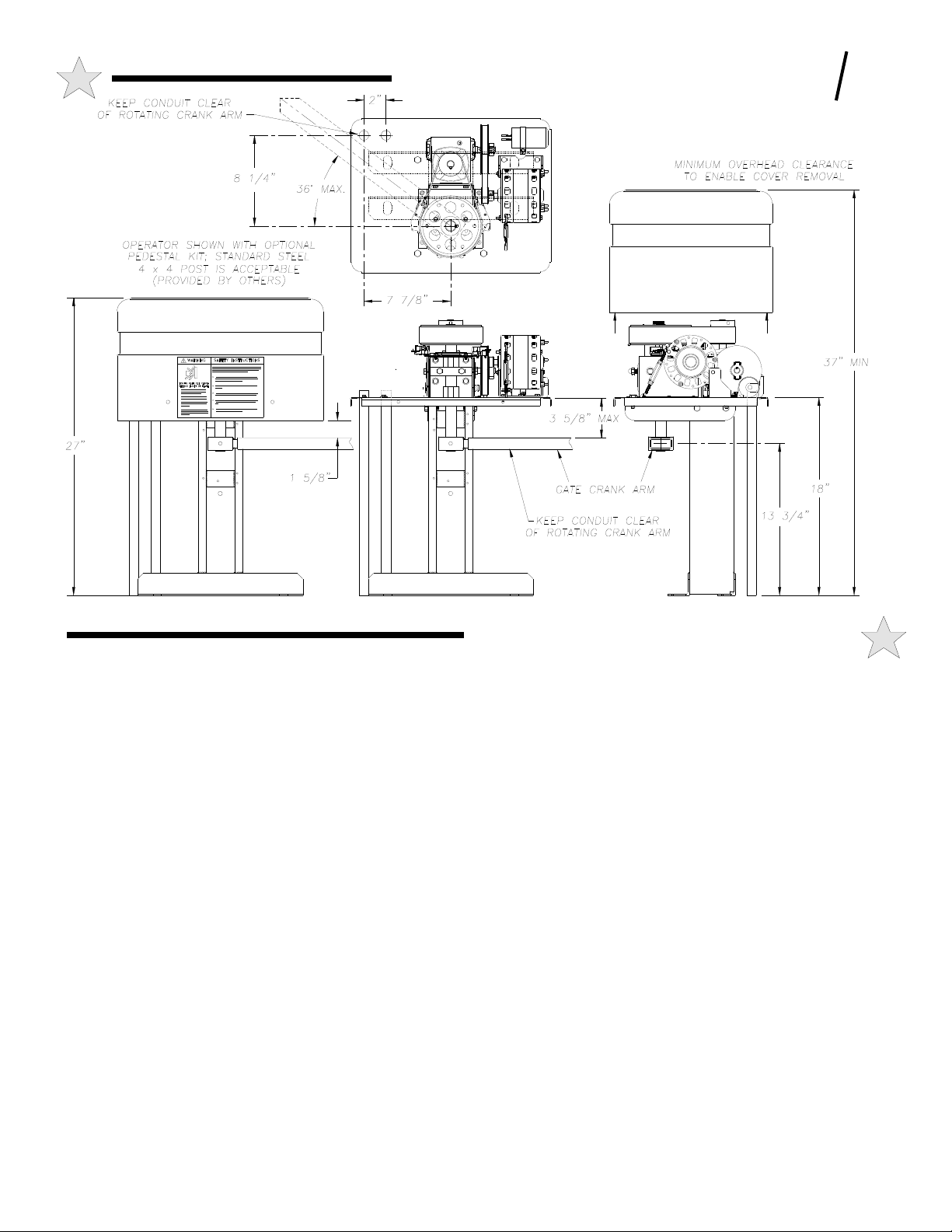

THE CONCRETE PAD

The standard RSX4000 is designed to operate a single leaf gate. Biparting gate systems are possible with the addition of a second

RSX4000 operator. (Consult the factory.) Each RSX4000 has its own

dedicated control board contained within the operator cover. Care

must be taken to provide separate high voltage and low voltage

conduits to each operator. (See Figures 5 and 6.) Care must also be

taken in choosing proper placement of the conduit to avoid

interference with the swinging crank arm which connects to the output

shaft. See Figure 8A for basic dimensions and guidelines. Figure 10

illustrates the full sweeping area which the crank arm will encompass

in a typical gate installation.

If the optional pedestal kit is used, the Installation of the RSX4000

Mechanical Unit will

require a suitable concrete

pad as a mounting base. The

dimensions of the concrete

pad should be sufficient to

allow at least 5" of

clearance from each edge of

the pad to the nearest

pedestal mounting hole. The

top of the pad should be at

least 3" above grade to raise

the operator above any

standing water. The depth of

the pad below grade is

dependent on the weight and

size of the gate and the soil

conditions at the site of the

installation. ALWAYS

FOLLOW LOCAL BUILDING

CODES.

If no suitable concrete base

exists, a pad must be poured. See

Figurez6 for plans for this pad. If

the location of the operator is

such that vehicles have the

potential of hitting the operator,

consideration should be given to

installation of protective posts in

front of the operator.

If a suitable concrete base already exists for

mounting the operator it will be necessary to drill

mounting holes for the RSX4000 operator. 3/4"

mounting holes are located on the front and rear of

the optional pedestal. The bolt pattern is shown in

Figurez6. The mounting bolts should be 1/2"

diameter or larger. "Red head" or wedge anchor

concrete bolts are usually satisfactory.

If mounting anchor bolts are to be installed prior to

pouring the pad, pay particular attention to the bolt

pattern and the location of the mounting holes with respect to

the center line of the gate hinge

operation of the Arm that the center line of the output shaft of

the RSX4000 operator be located exactly as shown on the bolt

pattern drawing, Figure 6.

. It is critical for the proper

ALTERNATE 4 X 4 POST MOUNT

The RSX4000 operator offers an alternative to the optional pedestal

kit for mounting installation. A standard architectural 4 x 4 x 1/8 wall

steel tube may be substituted for the pedestal and installed in a similar

manner to a fence post: Dig a hole of proper diameter (approximately

12”) and suitable depth per local codes, and set the 4ZxZ4 post in

concrete. Make sure the post is plumb and level. The top of the post

should be cut off clean and square and should extend at least 18”

above grade. Two 13/32 diameter holes will need to be drilled on each

side of the 4 x 4 tube. Center each pair of holes on the face of the post

106506

Figure 6: Operator Footprint

Page 7

106508

B : PREPARING THE SITE

7

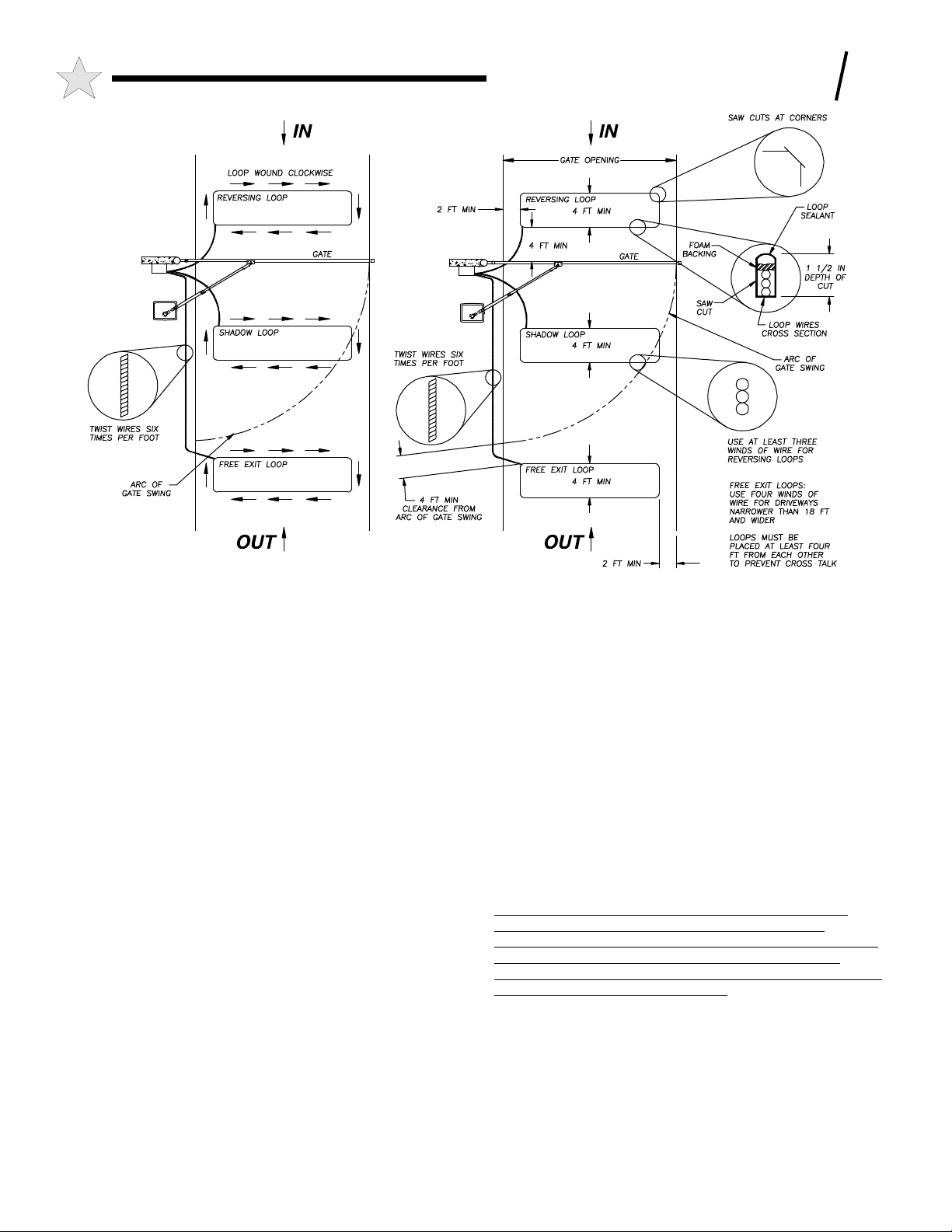

Figure 7: Loop Diagrams

2-5/8” apart and 7/8” down from the top. Each pair of holes is to

align with the pre-drilled holes in the chassis mounting angles of the

RSX4000. See Figure 6 for locating the post relative to the gate,

noting that the center of the output shaft is located 4 5/8” away from

the center of the post, or 2 5/8” away from the face of the 4 x 4 post.

PLACING THE VEHICLE DETECTOR LOOPS

If vehicle detectors are to be used with the RSX4000, the "loops" to

be buried in the drive should be installed during the site preparation

phase of the installation. Proper placement of the vehicle detector

wire loops is critical if the loops are to provide satisfactory, extended

service. THE MOST IMPORTANT CONSIDERATIONS ARE: 1)

PROPER WIRE TYPE AND, 2) GOOD, TIGHT CONNECTIONS

FROM THE LOOP TO THE LOOP TERMINATING

CONNECTOR. The termination of the loop wires will be at the

vehicle detector itself, and not at the RSX4000 terminal panel.

Observe the wiring diagram supplied by the vehicle detector

manufacturer. The vehicle detector may be mounted inside of the

RSX4000 operator cover, provided there is adequate room. The AC

power service delivered to the RSX4000 operator may be tapped to

provide 115 VAC service to the vehicle detector.

Two different types of loop installations will usually be encountered

when placing the loops in the drive: 1) If the driveway material is

already in place. saw cuts will be needed in which to place the loop

wire. 2) For loops where the paving material will be installed after

the loop is positioned, it is necessary to place the loops in Schedule

40 PVC pipe to maintain uniform loop spacing with respect to the

surface of the pavement. The loop should be placed 1.5" below the

surface of the pavement and at least 2" above any reinforcing steel.

The lead-in wires need not be in PVC, but must have at least six (6)

twists per running foot.

THE LOOP WIRES MUST BE CONTINUOUS. NO SPLICES OR

CONNECTIONS IN THE LOOP ARE TO BE PERMITTED

BELOW GROUND. THE ONLY CONNECTION WILL BE AT

THE TERMINATION OF THE WIRE AT THE VEHICLE

DETECTOR. Above ground splices may be used providing the wire

is twisted, soldered and moisture sealed. For best long term results,

do not use wire nuts anywhere in the loop system. Connect to the

vehicle detector harness by soldering.

For saw-cut installations, observe the methods recommended in

Figure 7, above. The saw-cut must be to a depth of 1.5", clean and

with no sharp corners. After placing the wires, it is essential that the

wires be held tightly in place by a foam backing prior to pouring the

sealant. THIS IS ESPECIALLY IMPORTANT WHEN FREEZING

IS LIKELY. No voids should exist that will permit the collection of

water that might freeze and push the loop wires out of the slot. The

sealant used should not be hard setting and should be suitable for

pavement material.

THE WIRE USED FOR THE LOOPS MUST BE HEAT AND

WATER RESISTANT, CROSS-LINK POLYETHYLENE

INSULATED. TYPE XLPE IS BEST. RHW IS O.K. DO NOT USE

ANY PVC INSULATED WIRE. (PVC insulation will absorb

moisture that may affect Detector operation.) WIRE SIZE SHOULD

BE #16 GA. STRANDED OR LARGER.

Page 8

8

B: PREPARING THE SITE

VEHICLE DETECTOR LOOP BLANKING FOR

SWING GATES

The inside loop for a swing gate installation must be located at least

4 feet outside of the arc of the gate. If it is not, the vehicle detector

may detect the gate as it moves over the loop and cause the gate to

reopen. If the gate is large and a single leaf, the arc usually requires

that the loop be a considerable distance from the closed gate position.

This may not be an effective position for the loop. In this case, a

“blanking” or “shadow” loop may be used.

A shadow loop detector is connected to the shadow loop terminal

(#9) and the “common” terminal (#16) of the RSX4000 control

panel.

Now, when the gate is in the fully open or closed position the vehicle

detector will prevent the gate from closing when a vehicle is over the

shadow loop. When the gate is opening or closing, the loop input is

disabled.

ELECTRICAL POWER REQUIREMENTS

The RSX4000 is a 115 Volt AC gate operator. The AWG wire size

for the electrical service is dependant upon the distance from the

operator to the service breaker panel. Refer to Table 1 to determine

the correct wire size to use. A 15 Amp service is required for each

operator unit.

The Nominal Distance column of Table 1 is the maximum

recommended distance from the service breaker panel to the operator

for a given wire size and voltage. The values in the table are valid for

one RSX4000 only. The RSX4000 will operate at a voltage as low as

105 VAC as measured at the input terminals to the operator. This

should be checked as part of the installation procedure.

Class 2 low voltage wiring from external controls such as a key pad,

card reader, telephone entry device, etc. must be brought to the

RSX4000 operator by a separate conduit from the 115 VAC

electrical hook up conduit. Low voltage control wires MUST

NEVER be routed in the same conduit as the HIGH VOLTAGE

power wires.

SERVICE CONDUIT

For new installations the conduit for the High Voltage may be

brought to a junction box near where the RSX4000 operator will be

located or it may be brought directly to the 2 x 4 handy box inside

the operator.

WARNING!

AVOID ELECTROCUTION:

DO NOT ROUTE LOW VOLTAGE WIRES

IN SAME CONDUIT AS HIGH VOLTAGE

WIRES. FOLLOW ALL LOCAL

ELECTRICAL CODES OR THE

NATIONAL ELECTRICAL CODE.

WIRE SIZE NOMINAL DISTANCE

#14 100 FT

#12 150 FT

#10 250 FT

#8 400 FT

#6

#4 1000 FT

#2 1600 FT

600 FT

Table 1

106509

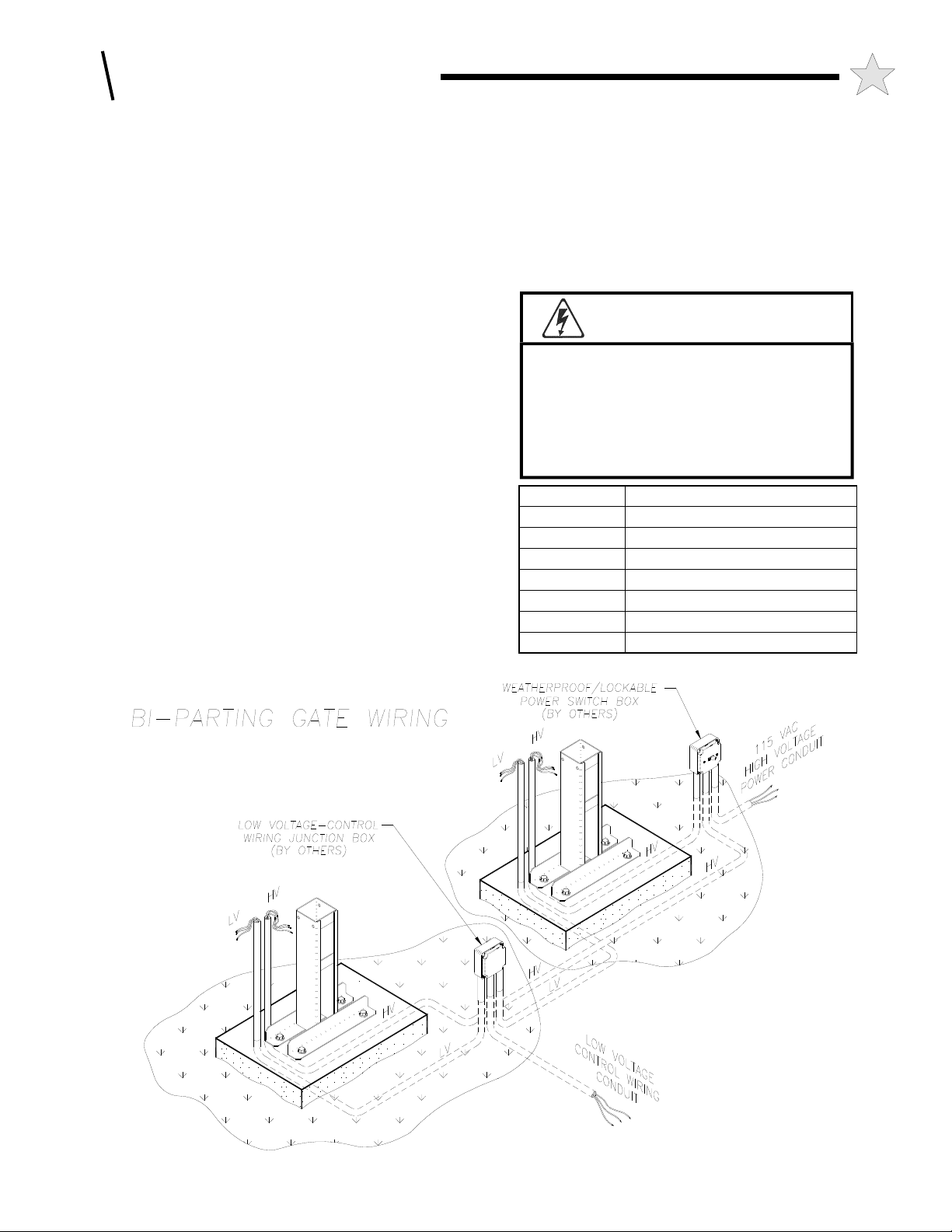

Figure 8: Service

Conduits - Bi-Parting

Page 9

106504

C: INSTALLING THE OPERATOR

9

Figure 8A: Service Conduits

C: INSTALLING THE OPERATOR

TOOLS and MATERIALS REQUIRED

The following tools and materials are required for a proper installation of the Twist'R Plus Model RSX4000.

1. Wire cutter, stripper and crimping tools for attaching accessory equipment to the control box.

2. #2 Phillips Head screw driver for general use.

3. Medium standard straight blade screw driver for the terminal strip screws.

4. Very small blade screwdriver for adjusting the potentiometer on the gate control board.

5. Electric arc welder or an electric drill with a 3/8" bit for attaching Arm Bracket to the Gate.

6. Several feet of #18 or #22 gauge insulated multistrand wire for connecting accessory equipment to the control panel.

7. Four 1/2" diameter concrete expansion anchor bolts with hex nuts, flat washers and lock washers for attaching the Twist'R pedestal. (Not Included)

8. Concrete drill and bit to drill mounting holes for concrete bolts.

9. Multimeter to test line voltage and other measurements as necessary.

10. Small level to level the RSX4000 operator at installation.

11. Torque Wrench and 1/2” Socket.

12. 7/16 Socket or Wrench to remove cover bolts.

13. 9/16 Socket or Wrench for post or pedestal mounting bolts.

UNPACKING CHECKLIST

The Twist'R Plus as shipped consists of the components listed below, in two separate shipping boxes. The kits and equipment listed in

the Optional Column can be purchased from your dealer.

BOX #1

• Twist’R Plus Operator, complete with

gate control board

• Hardware Installation Kit, for

pedestal kit or standard 4 x 4 tube

mount

• Instruction Kit, with manual, warranty

and warning signs.

• Swing Arm Kit

Swing Arm

Crank Arm

Crank Arm Extension

Swing Gate Fittings

Swing Arm Bracket

Swing Arm Padlock

• Hardware Package

BOX #2

OPTIONAL

• Pedestal Kit

• Radio Controls

• Electric Edges

• Photoelectric Eyes

• Vehicle Detector Loops

Page 10

10

106513

C: INSTALLING THE OPERATOR

Figure 9: Torque Adjustment

PLACING THE RSX4000 PEDESTAL UNIT

Remove the cover from the RSX4000 operator by removing the four

1/4-20 diameter bolts that secure it to the chassis. Set the cover aside

for the time being.

The recommended procedure for securing the RSX4000 pedestal to

concrete, or fresh concrete pad (for those installations where the

anchor bolts were not previously installed) is to locate and drill the

hole for the mounting bolt nearest to the gate post first. Locate this

hole by referring to the diagram in Figure 6 for the basic dimensions

and gate/operator relationship. After placing a bolt in this pedestal

mounting hole, mark and drill the remaining three mounting holes.

This can be accomplished with the operator in place.

Before inserting the remaining three bolts, check the pedestal to

ensure that it is plumb and level. Flat washers may be used to shim

and elevate a low corner. Snug down all four bolts with nuts and lock

washers when complete.

For previously placed anchor bolts, the procedure is the same except

that the bolts will already be in place. If 1/2" diameter anchor bolts

were set, the 3/4" mounting holes on the RSX4000 pedestal will

allow some adjustment for desired alignment. Washers can be used

under low corners to accurately level the unit as above.

TO REVIEW: Make sure the correct position of the pedestal or post

from the center line of the gate hinge pivot point to the center line of

the RSX4000 output shaft is in accordance with the drawing in

Figurez6.

After the pedestal or post is securely installed, it is time to mount the

RSX4000 operator to it. The RSX4000 operator has two mounting

angles fastened to the bottom of the chassis with two 3/8-16 x 3/4

long bolts, per angle.

Place the RSX4000 operator chassis on top of the pedestal/angle

assembly, aligning the holes in the angles with the holes in the

pedestal. Secure the operator angles to the pedestal with the 3/8-16 x

5 long bolts provided in hardware bag. See Section B for preliminary

work required if a 4 x 4 x 1/8 wall structural steel tube post is used

instead of the pedestal.

Page 11

C: INSTALLING THE OPERATOR

WIRING AND SUGGESTED PLACEMENT OF OPTIONAL NON-CONTACT SENSOR

(PHOTOELECTRIC) SECONDARY ENTRAPMENT PROTECTION DEVICES

THRU BEAM PHOTOELECTRIC WIRING AND SUGGESTED PLACEMENT SHOWN BELOW

B

CLOSE PHOTO

ELECTRIC RECEIVER

E

D

I

S

T

U

O

O

L

C

P

A

R

T

N

E

A

CLOSE PHOTO

ELECTRIC EMMITER

O

S

G

E

N

N

I

S

O

Z

T

N

E

M

O

G

N

I

N

E

P

I

E

D

I

S

N

A B

C

OPEN PHOTO

ELECTRIC RECEIVER

E

D

I

S

T

U

S

N

I

OUTSIDE

E

D

I

OPENING

ENTRAPMENT ZONE

D

ELECTRIC EMMITER

11

113497

OPEN PHOTO

NOTE: THE CLOSE PHOTOELECTRIC

SENSOR IS TO BE MOUNTED NO HIGHER

THAN 27 INCHES OFF THE GROUND AND

NO FURTHER THAN 6 INCHES AWAY FROM

THE GATE MEMBER CENTERLINE WHEN

THE GATE IS FULLY CLOSED.

CLOSE PHOTELECTRIC

(See Note 1) (See Note 1)

A

POWER POWER

IN

21

12

NONC

3

B

IN

5

4

113498

OVERHEAD VIEW

THRU BEAMTHRU BEAM

OPEN PHOTELECTRIC

C D

NC NO

POWER

IN

3

21

5

4

EMMITERRECEIVERRECEIVEREMMITER

POWER

IN

1 2

INSIDE

Note 2

OPERATOR

TERMINAL

STRIP

16

12

11

10

2

COMMON

OPEN

EDGE

REVERSE

CLOSE

PHOTO

24 VAC

C

D

113499

1 - USE A UL RECOGNIZED COMPONENT THAT COMPLIES WITH CURRENT UL 325 REQUIREMENTS,

TERMINAL NUMBERS ABOVE REPRESENT MODEL IR55, WIRING FOR OTHERS SIMILAR

2 - SELECT TERMINAL BASED ON FUNCTION DESIRED, SEE TERMINAL STRIP REFERENCE CHART

24 VAC

1

Page 12

12

C: INSTALLING THE OPERATOR

WIRING AND SUGGESTED PLACEMENT OF OPTIONAL NON-CONTACT SENSOR

(PHOTOELECTRIC) SECONDARY ENTRAPMENT PROTECTION DEVICES

RETRO-REFLECTIVE PHOTOELECTRIC WIRING AND SUGGESTED PLACEMENT SHOWN

B

CLOSE PHOTO

ELECTRIC TRANSCEIVER

E

D

I

S

T

U

O

O

L

C

M

P

A

R

T

N

E

A

ELECTRIC REFLECTOR

CLOSE PHOTO

C

OPEN PHOTO

ELECTRIC TRANSCEIVER

E

D

I

S

T

U

O

S

G

E

N

N

I

S

O

Z

T

N

E

O

G

N

I

N

E

P

I

E

D

I

S

N

A B

OUTSIDE

I

E

D

I

S

N

D

OPEN PHOTO

ELECTRIC REFLECTOR

OPENING

ENTRAPMENT ZONE

113497

NOTE: THE CLOSE PHOTOELECTRIC

113498

SENSOR IS TO BE MOUNTED NO HIGHER

THAN 27 INCHES OFF THE GROUND AND

NO FURTHER THAN 6 INCHES AWAY FROM

OVERHEAD VIEW

THE GATE MEMBER CENTERLINE WHEN

THE GATE IS FULLY CLOSED.

RETRO-REFLECTIVE RETRO-REFLECTIVE

CLOSE PHOTELECTRIC

REFLECTOR TRANSCEIVER TRANSCEIVER REFLECTOR

B

NC NO

POWER

NOCOM COM NO

5

3

4

21

IN

6

C

~~

12

OPEN PHOTELECTRIC

(See Note 1)(See Note 1)

NONC

5

3

6

4

POWER

IN

~~

INSIDE

Note 2

OPERATOR

TERMINAL

STRIP

16

12

11

10

2

COMMON

OPEN

EDGE

REVERSE

CLOSE

PHOTO

24 VAC

C

D

113499

1 - USE A UL RECOGNIZED COMPONENT THAT COMPLIES WITH CURRENT UL 325 REQUIREMENTS,

TERMINAL NUMBERS ABOVE REPRESENT MODEL E3K, WIRING FOR OTHERS SIMILAR

2 - SELECT TERMINAL BASED ON FUNCTION DESIRED, SEE TERMINAL STRIP REFERENCE CHART

1

24 VAC

Page 13

C: INSTALLING THE OPERATOR

WIRING AND SUGGESTED PLACEMENT OF OPTIONAL CONTACT SENSOR

(ELECTRIC EDGE) SECONDARY ENTRAPMENT PROTECTION DEVICES

O

A

S

T

U

CLOSE EDGE

SENSOR

E

D

I

N

I

S

O

L

C

E

M

AP

R

T

N

E

O

S

G

E

N

O

Z

T

N

G

N

I

N

E

P

I

E

D

I

S

N

CLOSE EDGE

A

SENSOR

OUTSIDE

B

INSIDE

13

113497

OPENING

ENTRAPMENT

ZONE

OPEN

B

EDGE

SENSOR

NOTE: USE AN EDGE SENSOR

THAT CAN BE ACTIVATED ON

THREE SIDES

CLOSE EDGE

A B

SENSOR(S)

OPEN EDGE

SENSOR(S)

(SEE NOTES 1 & 3)(SEE NOTES 1 & 3)

113498

A

OVERHEAD VIEW

OUTSIDE

INSIDE

A

Note 2

Note 2

B

OPERATOR

TERMINAL

STRIP

16

13

12

11

113499

COMMON

CLOSE

EDGE

OPEN

EDGE

REVERSE

1 - USE A UL RECOGNIZED COMPONENT THAT COMPLIES WITH CURRENT UL 325 REQUIREMENTS,

AN EDGE SENSOR THAT ACTIVATES ON THREE (3) SIDES SHOULD BE USED

2 - SELECT TERMINAL BASED ON FUNCTION DESIRED, SEE TERMINAL STRIP REFERENCE CHART

3 - MULTIPLE EDGE SENSORS MAY BE CONNECTED IN PARALLEL

Page 14

14

C: INSTALLING THE OPERATOR

CAUTION!

TO PREVENT DAMAGE TO THE LIMITS, ETC.,

DURING INSTALLATION OF THE GATE ARM,

REMOVE THE LIMIT TRIGGER PIN PRIOR TO

INSTALLING THE GATE ARM

INSTALLING THE GATE ARM KIT

The gate arm kit can be installed on the RSX4000 only after the

operator has been properly and securely installed, and the correct

gate/operator geometry relationship has been established and

verified. (See Figures 6 and 10.)

Locate the crank arm in the gate arm kit and install it on the output

shaft of the RSX4000 at the underside of the chassis, oriented so the

through hole in the crank arm is aligned with the through hole in the

output shaft. The crank arm is secured to the output shaft with a 5/1618 x 2” long bolt and nylon stopping nut.

Get the crank arm extension from the arm kit and slide it on the crank

arm. This assembly can telescope to various arm lengths depending

on which pair of holes is used. Six length settings are possible: 333/8, 31-7/8, 30-3/8, 28-7/8, 27-3/8 and 25-7/8 inches. Choose the

length that is most appropriate for the gate system. Typically, the

longer the gate, the longer the arm should be to provide more stable

gate handling. Secure the extension to the crank arm with the two

1/4-20 x 1-1/2 inch long bolts, flat washers, lock washers, and nuts

provided.

Next, install a gate arm end piece at each end of the pipe as shown in

Figure 10. The length of this arm is also variable depending on where

the end pieces are snugged down with the four 5/16-18 x 5/8 inch

long square head set screws (two, each end piece). The length of the

gate arm pipe may also be cut to length to suit the needs of the gate

system, although this is not recommended, because a longer arm will

promote more stable gate operation.

Install the gate bracket through the eyelet of the arm end piece and

secure it in place with the 1/2-13 x 2” long bolt as shown in

Figurez10, using the two flat washers and Nylok nut provided.

The RSX4000 operator was designed with an Adjustable Torque

Output Drive. (“ATD”) (See Figure 9.) For initial installation of the

gate arm, the drive should be adjusted to zero torque, so the crank

arm will swing freely. This is accomplished by loosening (do not

remove) the two reducer-slide clamp bolts on each side of the shaft

support tower. To prevent accidental damage to the limits, etc., the

trigger pin should be removed at this time as shown in Figure 18.

The tension on the flat poly-v adjustable torque drive belt can now be

relieved a small amount at a time until the large pulley installed on

the output shaft will just slip when the crank arm is manually rotated.

The tension is increased or decreased by turning the cap-nutted

tensioning bolts as shown in Figure 9. Note: The capnuts have been

permanently installed on the threaded shank and will not loosen or

un-thread).

Next, manually swing the crank arm to the position shown for a

closed gate in Figure 10. Now install the gate arm pipe assembly on

the end of the crank arm by dropping the end piece eyelet over the

protruding sleeve of the crank arm extension, as shown. Swing the

gate arm assembly around until it is straight in line with the crank

arm, and the “elbow” is up against the closed position stop.

Swing this locked arm assembly around until the gate bracket just

meets the gate as shown in Figure 10. Elevate or lower the arm

assembly until it is level, and then temporarily clamp the gate bracket

to the gate. The “elbow” pivot of the gate arm assembly should be

secured with the 1/2-13 x 2-3/4” long bolt, with flat washers and lock

nut, provided.

Now manually move the gate to the fully opened position, moving

cautiously at first, to ensure there is no interference between gate arm

components or the operator/pedestal. Slight adjustments to the gate

bracket location or arm length may be necessary to ensure smooth

operation. Make several trial runs by manually moving the gate from

closed to opened positions, until a smoothly operating gate system is

assured. When satisfied, weld or bolt the gate bracket to the gate and

remove the clamps.

106511

Figure 10: Arm Positions

Page 15

C: INSTALLING THE OPERATOR

15

WARNING!

RISK OF ELECTROCUTION.

DO NOT BEGIN THE ELECTRICAL

CONNECTION PROCEDURES UNTIL THE

POWER IS TURNED OFF AT THE

CIRCUIT BREAKER

CONNECTING THE OPERATOR TO THE

ELECTRICAL SERVICE

It will be necessary to run two conduits to the RSX4000. One will

be used for the A-C power lines and another for the low voltage,

class 2 wiring. See Figure 8. There are cutouts on the bottom of the

Operator Chassis to accept these two conduits.

The high voltage RSX4000 electrical connections are made at the

main power switch / outlet located inside the operator at the rear, left

corner of the control panel. Pigtail wires are connected to the main

power switch / outlet and the operator chassis to facilitate

connection. Conduit should be run from the service breaker panel to

this junction box as discussed in Section B, along with the

appropriate AWG wire (see Table 1). The color code for 115 VAC

is:

black = hot white = neutral green = ground

WARNING!

TO AVOID ELECTRICAL DAMAGE TO THE

OPERATOR DO NOT ALLOW TOTAL WIRE

LENGTH FROM THE SERVICE BREAKER PANEL

TO THE TWIST’R OPERATOR TO EXCEED THE

WIRE LENGTH GIVEN IN TABLEZ1, PAGE 8.

Connections for the 115 VAC service should be made according to

the schematic wiring diagram, Page 25. Service entry is shown in

Figure 11.

Starting at the RSX4000 power switch / outlet proceed as follows:

1. The BLACK

2. The WHITE wire attaches to the 115 VAC NEUTRAL wire,

3. The GREEN wire attaches to the GROUND wire, normally green.

It is good electrical practice to ground the frame of the RSX4000

operator and is required by National and/or local electrical codes.

wire attaches to the 115 VAC HOT wire, normally

black.

normally white.

106507

Figure 11: Service Entry

High Voltage

Power Wiring

Low Voltage

Control Wiring

Page 16

16

C: INSTALLING THE OPERATOR

LIGHTNING PROTECTION

For areas where a high probability of ground lightning strikes exists

(Florida, Georgia, etc.,) additional lightning protection should be

installed in the RSX4000. Although it may not be possible to protect

against all strikes, additional protection will substantially reduce the

occurrence of lightning damage. Allstar’s lightning data indicates

that the most strikes enter the RSX4000 through the power lines.

Effective protection requires that the surge current from the lightning

strike be shunted to ground. This must be done without raising the

potential of the circuitry in the RSX4000, with respect to ground, to

the levels that will damage the solid state circuitry. Lightning strikes

generate enormous currents for very short periods of time.

Unfortunately, the period of time is long enough to damage solid

state components and many times, other components. The key to

success is a very low resistance path from the surge protector to

ground for these currents in addition to a surge protector that will act

fast enough to protect the solid state circuitry. Several manufacturers

offer suitable surge protectors.

WARNING!

TO REDUCE THE RISK OF DAMAGE DUE TO

LIGHTNING, ENSURE A SOLID GROUND

FROM THE TWIST’R GROUND WIRE IN THE

SERVICE ENTRANCE TO THE ELECTRICAL

SERVICE GROUND OR TO A EARTH GROUND

STAKE NEAR THE TWIST’R.

106515 REV D

RIGHT HAND AND LEFT HAND INSTALLATION

The RSX4000 operator is wired at the factory for RIGHT HAND

operation. Right hand operation is described as the gate swinging in

and to the right and where the operator is mounted to the right of the

gate leaf - both as you look at the installation from the inside

(secured side). See Figure 4 for a pictorial example of a right hand

operation.

Left hand operation is described as the gate swinging in and to the

left and where the operator is mounted to the left of the gate leaf both as you look at the installation from the inside (secured side).

Figure 7 diagrams depict gates and operators in a left hand set-up.

Note the different wiring configurations for right-hand installations

and left-hand installations (see Figure 13). To change to a different

handed operation the capacitor wires and limit wires must be

changed. For proper operation, the limits and capacitor must be

wired as shown.

SYNCHRONOUS OPERATION (MASTER/

SLAVE)

Two RSX4000 units in a bi-parting situation (one wired right-hand

and one wired left hand, see above) can be configured to operate in a

synchronous manner. The units can be wired together to operate as

one system, with one unit controlling the movement of both.

Additionally, the installer can customize the installation of the

external entrapment protection devices. These devices can be wired

to the primary (controlling) operator or alternately to the individual

units as the situation dictates or the end user

requires.

When an external entrapment protection

device is wired to the primary unit (such as

would be recommended for a photoelectric

beam across the entire opening) both units

will react to the detection of an obstruction,

regardless of the location of the obstruction.

An edge device (or similar) protecting an

entrapment zone particular to the secondary

unit could be wired to that unit only and

would react individually to the detection of an

obstruction. Synchronous movement would

resume once the obstruction is cleared and an

open or close command is received by the

primary operator.

To obtain synchronous operation (4 Steps):

1. Wire the Primary Operator Terminal #14 to

Terminal #6 in the Secondary Operator.

2. Wire the Primary Operator Terminal #15

to Terminal #7 in the Secondary Operator.

3. Place the Master/Slave Jumper on the

Primary Operator motor control board to the

primary (Master) position. See Figure 19,

Page 21.

4. Place the Master/Slave Jumper on the

Secondary Operator motor control board to

the secondary position. See Figure 19, Page

21.

Figure 13: Left/Right Hand Installation Limit & Motor Wiring Diagram

Page 17

C: INSTALLING THE OPERATOR

17

ACCESSORY EQUIPMENT HOOK-UP

IMPORTANT - remove power from the operator before

attempting to connect an accessory device or control station.

All accessory equipment is connected to the terminal strips

located on the control panel of the RSX4000.

There are 11 command inputs available to the installer on the

RSX4000 in addition to 4 commons. To trigger any of these

inputs, a switch or relay closure to the common terminal for a

duration longer than 100 milliseconds and of a resistance of less

than 100 ohms is necessary. See the INPUT COMMANDS

Reference Chart on Page 19 for an explanation of each of the

inputs.

The RSX4000 has a transformer mounted on the chassis to

power accessory equipment. The maximum power that can be

supplied by this transformer is 5VA or about 1/4 Ampere at

. This is only intended to supply power to a radio

24VAC

receiver. A Separate power supply is required for loop detectors

or card or key pads.

111797

111798

10

9

8

7

6

5

4

3

2

1

A

16

16

16

16

15

14

13

12

11

Figure 14:

C

B

Terminal Strips

WIRING RADIO RECEIVERS

Radio Receivers may be either 3 wire (terminal) or 4 wire units.

THREE TERMINAL RECEIVERS

If a three wire receiver is to be used, the #1 terminal of the receiver is

normally COMMON to both the auxiliary transformer (power input)

and the radio relay. Most radio manufacturers label this terminal as

24 VAC. Connect a wire from the #1 terminal of the radio receiver to

terminal #1 on the operator control panel (24 VAC). The #2 terminal

of the radio receiver is normally the relay contact of the receiver.

Connect a wire from this #2 terminal of the radio receiver to the #2

terminal (ALTERNATE) on the RSX4000 control panel. The #3

terminal of the radio receiver is usually labeled RADIO POWER and

is connected to 24 VAC. Connect to terminal #2 (24 VAC) of the

RSX4000 control panel.

FOUR WIRE RECEIVERS

Four wire receivers replace the "spade" terminals on the RECEIVER

with 4 wires. These wires are typically color coded. The instructions

with the receiver must be carefully followed to properly connect the

receiver. For any 4 wire receiver, two of the wires will be for power

input and two will be for the relay contacts. Connect the two wires

for the power input to each side of the 24VAC RSX4000 terminals

#1 and #2. Connect one of the two wires for the relay to terminal #16

(COMMON) and the other wire to terminal #3 (ALTERNATE) on

the RSX1000 control panel terminal strip. See Figure 16 for

connecting 4 wire receivers.

TERMINAL

110120

CONNECT TO #3 OR #4 DEPENDING

ON DESIRED FUNCTION (SEE PG.15)

DRY CONTACT

RELAY OUTPUT

24VAC POWER

FOR RECEIVER

Figure 16: Wiring 4-Wire Receiver

WIRING FOUR-WIRE RECEIVER

STRIP

16

4

2

1

COMMON

OPEN6

RADIO OPEN

ALTERNATE3

24 VAC

24 VAC

WIRING A 3-BUTTON STATION

NOTE: THREE BUTTON STATIONS MAY BE ORDERED

WITH THE STOP BUTTON AS NORMALLY OPEN OR

NORMALLY CLOSED. THE RSX4000 WILL OPERATE ONLY

WITH A NORMALLY OPEN STOP BUTTON. See Figure 17 for

instructions on wiring a three button station.

110121

OPEN

CLOSE

STOP

TERMINAL

STRIP

16

COMMON

8

STOP

CLOSE

7

6

OPEN

Figure 17: 3-Button

Station Wiring

WIRING A KEYPAD, CARD READER OR

TELEPHONE ENTRY SYSTEM

These devices activate the RSX4000 by a relay contact closure

within the device. Typically, two wires or terminals are provided by

the device to operate the gate. Follow the manufacturers instructions

on locating these connections. If one of the connections at the device

WARNING!

IMPROPER WIRING COULD CAUSE

ELECTROCUTION OR DAMAGE TO

CIRCUITRY. FOLLOW ALL LOCAL

ELECTRICAL CODES OR THE NATIONAL

ELECTRICAL CODE.

Page 18

18

C: INSTALLING THE OPERATOR

is labeled as COMMON, then connect this to Terminal #16 on the

RSX4000 control panel. Connect the other contact to one of the

following terminals depending on function desired: Terminal #3

(ALTERNATE), Terminal #4 (RADIO OPEN), Terminal #5 (FREE

EXIT), Terminal #6 (OPEN) or Terminal #7 (CLOSE). If no

identification of the connections is noted at the device, then the two

wires may be connected to terminals #1 and one of the terminals

above (again depending on desired function) in any order.

Keypads, Card Readers and Telephone Entry Systems are typically

located remotely from the RSX4000. The wiring used is low voltage

CLASS 2. Be sure to run an independent conduit for this wiring from

the entry device to the RSX4000. The wire size should be 16 or 18

AWG stranded wire for ease of handling.

WIRING VEHICLE DETECTORS

There are three connections that need to be made; 1) the AC power to

the detector, 2) the control connection to the RSX4000, and 3) the

connection to the loop. All these connections will be made at the

vehicle detector connector. Follow the wiring instructions provided

by the vehicle detector manufacturer.

VEHICLE DETECTOR POWER

Vehicle detectors may be ordered for 115 VAC or 24 VAC

operation. Allstar recommends that a 115 VAC Vehicle Detector be

used. The 115 VAC may be obtained from the electrical service to

the RSX4000 operator .

CONNECTING THE VEHICLE DETECTOR TO

THE RSX4000

For a REVERSING LOOP connection of the vehicle detector, the

"relay" or "presence" output of the detector will be connected to

Terminal #11 (REV LOOP) of the RSX4000 and the COMMON

wire will be connected to Terminal #16 (COMMON) of the

RSX4000. As long as a relay closure is present on these two lines,

the RSX4000 will not allow the gate to close. If the gate is opening,

the gate will continue to open. If the signal is removed before the

Timer to Close times out, the gate will close after the Timer to Close

has completed its cycle.

For a FREE EXIT connection of a Vehicle Detector, the RELAY or

PRESENCE output signal will be connected to Terminal #5 (FREE

EXIT) and the RELAY COMMON signal connected to Terminal #16

(COMMON) of the RSX4000. DO NOT CONNECT THE FREE

EXIT OUTPUT SIGNAL TO ANY OTHER TERMINAL, SUCH

AS RADIO RELAY, BECAUSE THE GATE WILL

AFTER REACHING THE OPEN LIMIT AND THE TIMER TO

CLOSE HAS COMPLETED ITS CYCLE, EVEN THOUGH THE

VEHICLE HAS NOT EXITED THE FREE EXIT LOOP.

CLOSE

WARNING!

RISK OF ENTRAPMENT!

TO REDUCE THE RISK OF INJURY OR DEATH:

LOCATE KEYPAD, CARD READER, KEY SWITCH

OR SIMILAR ENTRY DEVICES IN A LOCATION

WHERE A USER CAN NOT REACH THROUGH

THE GATE OR FENCE TO ACTIVATE THE GATE

OPERATOR. THE RECOMMENDED DISTANCE

BETWEEN THE GATE OR FENCE AND

ACCESSORY SWITCH IS 10 FEET.

TERMINAL STRIP REFERENCE CHART

# NAME

1 24 VAC

2 24 VAC

3 ALTERNATE

This input is used for “COMMAND OPEN/COMMAND

CLOSE” applications. The 1st signal will cause the gate to

begin opening. A 2nd signal received during the open cycle

will stop the gate immediately. A 3rd signal will close the gate.

Connect appropriate access control devices to this terminal

and #16 COMMON.

4 RADIO OPEN

Once activated the gate will open fully. Activation while the

gate is closing will cause it to re-open.

5 FREE EXIT

Once activated the gate will open fully. Activation while the

gate is closing will cause it to re-open. Continuous activation

while the gate is open will prevent the Timer-To-Close function

from automatically closing the gate.

6 OPEN

Once activated the gate will open fully. Activation while the

gate is closing will cause it to re-open. Continuous activation

while the gate is open will prevent the Timer-To-Close function

from automatically closing the gate. Continuous signal

required to move the gate when in the alarm mode.

7 CLOSE

Once activated the gate will close fully. Activation while the

gate is opening has no effect. Continuous signal required to

move the gate when in the alarm mode.

8 STOP

Overrides all other signals. Once activated, the gate will

immediately stop and await a new command. If the STOP

input is continuously activated, the gate will not move.

9 SHADOW

LOOP

This input is active only when the gate is at rest in the fully

OPEN position, it has no effect on the gate when fully closed

or when closing or opening. Continuous activation will prevent

the gate from moving in the close direction. When the input is

removed normal operation is resumed. This input is intended

for a vehicle loop detector to sense a vehicle in the gate path.

Connect here and to terminal #16 COMMON. Multiple devices

may be connected in parallel.

DESCRIPTION

Provides maximum 10 VA auxiliary

power for accessories.

Provides maximum 10 VA auxiliary

power for accessories.

Momentary input, must be released

and re-entered to be recognized.

Momentary input, must be released

and re-entered to be recognized.

Momentary or continuous input.

Momentary or continuous signal. On/

Off mode set by Switch #1

Momentary or continuous signal. On/

Off mode set by Switch #1

Momentary or continuous signal.

Momentary or continuous signal.

Page 19

C: INSTALLING THE OPERATOR

TERMINAL STRIP REFERENCE CHART

# NAME

10 CLOSE PHOTO

This input is active only when referenced to the closing

direction, it has no effect on the gate when opening or about to

open. If activated when the gate is closing the gate will stop,

pause and reverse in the open direction for 1/2 second

(approx. 2 inches) and stop. Continuous activation will

prevent the gate from moving in the close direction. When the

input is removed normal operation is resumed. . Continuous

activation while the gate is open will prevent the Timer-ToClose function (if enabled) from automatically closing the gate.

This input is intended for photoelectric eye systems and other

non-contact devices as appropriate. Connect here and to

terminal #16 COMMON. Multiple devices may be connected

in parallel.

11 REV LOOP

This input is active only when the gate is closing or when it’s

fully open and the Close Timer is operative. All stand-alone

vehicle detectors, photo-eyes and active edges should be

connected here and to terminals #3 or #13 COMMON.

Multiple devices may be connected in parallel.

12 OPEN EDGE

This input is active only when referenced to the opening

direction, it has no effect on the gate when closing or about to

close. If activated when the gate is opening the gate will stop,

pause and reverse in the close direction for 1/2 second

(approx. 2 inches) and stop. Continuous activation will prevent

the gate from moving in the open direction. If a second

activation occurs before the limit switch is activated the gate

will stop and a require a renewed, intended input to move in

the open direction and before an automatic activation device

(timer, etc.) will operate. This input is intended for Electric

Gate Edge systems and other minimum-contact devices as

appropriate. Connect here and to terminal #16 COMMON.

Multiple devices may be connected in parallel.

DESCRIPTION

Momentary or continuous signal.

Momentary or continuous signal.

Momentary or continuous signal.

19

# NAME

13 CLOSE EDGE

This input is active only when referenced to the closing direction, it

has no effect on the gate when opening or about to open. If

activated when the gate is closing the gate will stop, pause and

reverse in the open direction for 1/2 second (approx. 2 inches) and

stop. Continuous activation will prevent the gate from moving in

the close direction. Continuous activation while the gate is open

will prevent the Timer-To-Close function (if enabled) from

automatically closing the gate. If a second activation occurs before

the limit switch is activated the gate will stop and a require a

renewed, intended input to move in the close direction and before

an automatic activation device (timer, etc.) will operate. This input

is intended for Electric Gate Edge systems and other minimumcontact devices as appropriate. Connect here and to terminal #16

COMMON. Multiple devices may be connected in parallel.

14 MASTER OPEN

This terminal is used to coordinate two independent systems (two

control box/mechanical unit combinations controlling separate gate

leaves). Connects to terminal #6 (OPEN) in the companion control

box and controls the direction of movement in the companion box

(Switch Jumper Position diagram, Figure 19, Page 18).

15 MASTER CLOSE

This terminal is used to coordinate two independent systems (two

control box/mechanical unit combinations controlling separate gate

leaves).Connects to terminal #7 (CLOSE) in the companion control

box and controls the direction of movement in the companion box

(Switch Jumper Position diagram, Figure 19, Page 18).

16 COMMON

DESCRIPTION

Momentary or continuous signal.

Momentary or continuous signal. Master

(output configuration)

Momentary or continuous signal. Master

(output configuration)

Common connection for low voltage

signal inputs, terminals 3 through 15.

SETTING THE LIMIT SWITCHES

Once the gate arm has been installed to the gate and operator, the

limit switches can be adjusted and set. BE CERTAIN TO TURN

THE MAIN POWER SWITCH TO THE OPERATOR “OFF”

BEFORE PROCEEDING.

The instructions in this manual describe a right hand gate installation,

as shown in Figure 10. A right hand gate installation is defined as a

gate which swings inward and to the right to an open position, with

the operator on the right, as viewed from inside of the gate area

facing out. The RSX4000 as shipped is configured for a right hand

installation. If a left hand installation is required, the limit switch

wires and motor wires must be swapped. This is fully defined in the

right hand/left hand wiring schematic illustrated in Figure 13.

Assuming a right hand gate installation, swing the gate to position it a

few inches short of the fully closed position. In this right hand

installation, the “closed” gate limit will be located on the left side of

the output shaft (see Figure 18).

WARNING!

RISK OF ELECTROCUTION

DO NOT BEGIN TO SET THE FOLLOWING

ADJUSTMENTS UNTIL THE POWER IS

TURNED OFF AT THE TWIST’R CONTROL BOX

The limit mechanism consists of a spring loaded flipper toggle which

activates a micro switch. These are installed on a bracket which

pivots around the output shaft. A trigger pin, installed on the large

output pulley, is used to flip the toggle and thus activate or deactivate the micro switch. With this mechanical combination, the

switching action is positive and precise. This accuracy is not

diminished by repeated operations of the gate.

Identify the small trigger pin mounting hole closest to the “close”

limit located toward the front

and “close” limit brackets. Manually swing the gate open until this

side of the pulley between the “open”

Page 20

20

Figure 18: Limit Adjustments

C: INSTALLING THE OPERATOR

111879

mounting hole is positioned directly above the clearance notch

provided in the shaft support tower (see Figure 18). This notch

provides the appropriate clearance to install the limit trigger pin with

the bolt and washers provided. Install the trigger pin firmly in place.

Flip the toggle open so it is positioned to receive the trigger pin.

Swing the gate to a position that is just a few inches short of the fully

closed position. Now swing the “close” limit bracket

output shaft toward the trigger pin until the toggle just trips to

“close” the micro switch.

The limit brackets are provided with a slot so that they can slide

freely about the limit clamp screw. It may be necessary to relocate

this clamp screw to bring this slot within the range of the trigger pin.

Alternate clamp screw locations have been provided for this purpose.

Flip the “open” limit toggle toward the trigger pin so that it is ready

to receive. Manually swing the gate to a position that is just short of

the fully “open” position. Now swing the “open” limit bracket

around the output shaft toward the trigger pin until the toggle just

trips to “close” the micro switch.

Lock the positions of the limit brackets by gently snugging the limit

clamp screws in place.

NOTE: These are the rough settings for the “open” and “close”

limits. Final adjustment will be made after the Adjustable

Torque Drive system has been set.

around the

SETTING ADJUSTABLE TORQUE DRIVE

The RSX4000 operator incorporates an Adjustable Torque Drive to

limit the amount of force that the gate arm can exert. This provides

the additional flexibility to fine tune the output of the gate system

BEFORE BEGINNING THIS PROCESS, BE SURE THE MAIN

POWER SWITCH TO THE OPERATOR IS

Output torque can be increased by turning the belt tensioning bolts in

a clockwise direction. To decrease torque, reduce the belt tension by

turning the tensioning bolts in a counter-clockwise direction. This

allows a controlled slipping action to occur between the flat Poly-V

OFF.

.

belt and the large output pulley, similar to that of a clutch

mechanism.

Before turning the tensioning bolts, it is necessary to loosen the four

(4) reducer slide clamp bolts (two each side of the shaft support

tower), and the motor mount clamp nut (see Figure 9). Loosening the

motor mount clamp nut allows the motor/pulley to pivot. Gravity will

tension the V-Belt as the reducer slide moves in and out of the shaft

support tower.

BE SURE POWER IS STILL OFF!

Tension the Poly-V belt by small increments by turning the

tensioning bolts as a balanced pair. After tensioning the Poly-V belt,

test the grip between the belt and drive pulley by applying manual

pressure against the gate and estimating the resistance by the operator

before slipping occurs.

When the desired resistance is achieved, tighten the four reducer

slide clamp bolts. Evaluate the motor drive belt tension by applying a

moderate downward pressure on the belt midway between the two

pulleys. If an excessive amount of deflection occurs, loosen the

clamp nut slightly and apply a slight downward pressure to the

motor. The motor drive belt can be further tensioned by turning

the body nut of the turnbuckle. Turn clockwise to increase belt

tension. Do not over tension. This turnbuckle will also help to

maintain motor belt tension and facilitate easy re-adjustment

should the belt stretch with age. Re-tighten the motor clamp nut.

Additional adjustments may be necessary after the RSX4000

operator has been powered up and is fully operable.

Now that the Adjustable Torque Drive has been set, limit settings

obtained in the previous section must be fine tuned. Move the limit

brackets a degree at time while cycling the operator. Note the gate’s

actual stopping position. Continue to adjust the limit brackets

small increments while cycling the operator until the exact stopping

position desired is reached. Lock the limit brackets in place by

snugging the limit clamp screws. Test and adjust the Torque Drive

setting on a regular basis (at least once per month).

by very

Page 21

D: STARTING THE OPERATOR

21

TIMER TO CLOSE SETTING

The Timer to Close is controlled by the setting of the “AUTO

CLOSE TIMER” potentiometer on the control board, see Figure 19.

When the pot is adjusted fully counter-clockwise the Timer-To-Close

is disabled. Turning the pot approximately 1/4 turn clockwise will

enable the Timer To Close function with a delay of approximately 2

seconds between the gate reaching the full open position and

automatically closing. To increase the time delay continue to turn

the pot in the clockwise direction to a maximum delay of 60 seconds

(one minute).

IT IS HIGHLY RECOMMENDED THAT AUXILIARY

ENTRAPMENT PROTECTION DEVICES BE INSTALLED

WHENEVER THE TIMER TO CLOSE OPTION IS

ENABLED.

APPLYING POWER TO THE OPERATOR

PRE-POWER CHECK LIST

Before applying power to the RSX4000 operator for the first time, go

through the following check list to ensure that all is in order before

the application of power.

1. Check that the RSX4000 power switch is off.

2. Check that the breaker at the power panel

is on.

3. With a voltmeter on the proper scale,

check that the line voltage at the input to

the RSX4000 is the voltage that is

expected. Connection of a 115 VAC

RSX4000 to an unexpected 230 VAC line

is a common occurrence. This will cause

readily identifiable board failure that

WILL NOT BE COVERED UNDER

WARRANTY.

4. Manually move the gate to the center of

the gate opening.

5. Make sure the adjustable torque drive

(ATD) is properly set to just

load of slight to moderate force applied to

the gate. Follow the procedures outlining

the ATD on Page 17, Section C, if

readjustment is necessary.

6. The proper Left-or Right-hand or BiParting wiring has been completed.

7. The Limit Switch brackets have been

preliminarily set.

8. No other auxiliary devices should be

connected to the terminal strip until the

powering-up procedures are completed.

overcome a

Synchronous Operation

Switch

1 2 3

Move Jumper to Pins

1 & 2 for Slave Mode

LOCATION OF AUTOCLOSE TIMER

ADJUSTMENT AND SYNCHRONOUS

OPERATION SWITCH

RUNNING THE RSX4000

Turn ON the main power switch. The gate should not move. If the

gate moves in either direction or continues to run, turn off the power

and call Factory Service for assistance. Follow the instructions

below for first time commands and the Basic Operation Guide on the

following page for ongoing operation.

1. Give the RSX4000 a command to open by touching a jumper wire

connected to Terminal #16 (COMMON) to Terminal #6 (OPEN).

The gate should move to the fully open position.

2. If the TIMER TO CLOSE option has been enabled, the timer will

activate the gate to close within the set time parameter on the

potentiometer. If not give the RSX4000 a command to open by

touching a jumper wire connected to Terminal #16 (COMMON)

to Terminal #7 (CLOSE).

3. Allow the gate to close and note the position of the gate.

If the gate stops short of the desired fully open or closed position

or if it bangs against the end stops, TURN OFF THE MAIN

POWER and reset the appropriate Limit Switch. After you have

attained the final adjustment, run the RSX4000 open and closed

several times to ensure that the positions set will be retained.

110478

Edge of

Board

Figure 19: Timer Adjustment and Synchronous Switch Location

Page 22

22

D: STARTING THE OPERATOR

MAXIMUM RUN TIMER

SMART™ Self adjusting MAximum Run Timer (Patent

Pending)

The RSX4000 has a Self adjusting MAximum Run Timer,

SMART™ (patent pending). The amount of time for the first few

cycles of operation are registered and averaged within the motor

controller circuitry. After the first few initial cycles, if the gate is

activated and no other command is given or an end limit (open or

close) is not reached in the previously counted cycle time plus

approximately 4 seconds, the operator will be turned off.

E: INSTALLATION NOTES FOR AUXILIARY EQUIPMENT

You are now ready to install and connect the auxiliary

equipment. INSTALLATION STEPS DETAILED IN

SECTIONS A, B, C AND D MUST BE COMPLETE

BEFORE PROCEEDING.

1. Vehicle Detectors: If a Vehicle Detector (Safety Loop)

is to be a part of this installation, start with this first.

Connect the Vehicle Detector to AC power and the Loop

in accordance with the Manufacturer's instructions and

the information contained in this manual. Do not

connect to the terminal strip of the RSX4000 at this

time. Test the Vehicle Detector independently using the

presence lamp on the front panel of the detector and a

metal plate over the loop. When you are satisfied that

the Detector is working properly, connect the output

wires to the "REVERSING" terminal on the control

panel of the RSX4000.

Give the gate an open command and allow the Timer to

Close to start the gate to close. Place the metal plate

over the Loop and observe that the gate reopens.

FINAL SETTING OF THE CLOSE TIMER

To alter the amount of time that the Close Timer will hold the gate

open, adjust the timer potentiometer located on the control board.

See Figure 19.

The Close Timer is adjustable from 2 to approximately 60 seconds.

Turning the potentiometer clockwise increases the delay; turning it

counterclockwise decreases the delay.

2. Shadow Loop: See Section B regarding Vehicle

Detector Loop Blanking for Swing Gates.

3. Free Exit: If a "FREE EXIT" Detector is installed, connect the

output wires of this Detector to the Terminal #5 (FREE EXIT).

It is acceptable to have more than one device connected to the

same Terminal. Place the metal plate over the FREE EXIT

LOOP and observe that the gate opens to the fully open

position. Leave the metal plate on the loop for at least one

minute. Observe that the gate does not close. Remove the plate

from the Loop and observe that the gate closes. (Some Vehicle

Detectors will "tune out" a constant obstruction to the loop after

15 to 30 minutes.)

4. Installing other entry devices: After you are satisfied that all

the loops are functioning properly, proceed with the installation

of the additional devices, such as a Radio Receiver, Telephone

Entry or Key Pad. Connect the Radio Receiver to the Radio

Terminal. Observe the precautions regarding radio receivers