Installation and Maintenance

Instructions

Model SL570

Heavy Duty Slide Gate Operator

Model SL540

Medium Duty Slide Gate Operator

Doc 01-G0685

Rev D

2 Contents

Contents

General Information________________________________________________________ 4

Supplied Parts and Dimensional Outline___________________________________________________ 4

Cycle Rate__________________________________________________________________________ 4

Model Classifications _________________________________________________________________ 5

Specifications _______________________________________________________________________ 5

Safety Information _________________________________________________________ 6

Safety Instructions____________________________________________________________________ 6

Safety Precautions for Open-Roller Gates and Ornamental “Grill Type” Gates ____________________ 8

Pre-Installation Check-List _________________________________________________ 10

Wiring Specifications ________________________________________________________________ 10

Features_________________________________________________________________ 12

Operator Features ___________________________________________________________________ 12

System Features_____________________________________________________________________ 13

Installation ______________________________________________________________ 15

Step 1: Set Up Post or Pad Mounting _____________________________________________________ 15

Step 2: Mounting the Operator__________________________________________________________ 17

Step 3: Gate Brackets_________________________________________________________________ 17

Step 4: Drive Chain __________________________________________________________________ 18

Electrical Disconnect Switch___________________________________________________________ 18

Step 5: Electrical Power Connections ____________________________________________________ 19

Step 6: Limit Switch Adjustments _______________________________________________________ 20

Programming ____________________________________________________________ 21

Switch #1: Operator Programming ______________________________________________________ 21

Switch #2: Timer to Close_____________________________________________________________ 22

Adjustments______________________________________________________________ 23

Step 7: Clutch Adjustment _____________________________________________________________ 23

Step 8: Brake Adjustment _____________________________________________________________ 23

Controls and Accessory Install. ______________________________________________ 24

Troubleshooting __________________________________________________________ 25

1. Power___________________________________________________________________________ 25

Doc 01-G0685

Rev D

Contents 3

2. Accessories ______________________________________________________________________ 26

3. Primary Voltage Circuit ____________________________________________________________ 26

4. Low Voltage Circuit _______________________________________________________________ 27

General Reference Information_________________________________________________________ 28

Features and Program Troubleshooting Review____________________________________________ 28

Required Maintenance – Normal Usage _______________________________________29

SL570/540 Parts List & Drawings ____________________________________________30

Exploded View _____________________________________________________________________ 30

Control Box Exploded View___________________________________________________________ 31

Parts List __________________________________________________________________________ 32

Warranty Policy___________________________________________________________33

Doc 01-G0685

Rev D

4 General Information

2

4

4

2

2

8

8

8

8

4

1

2

1

01-G0685F1

10 ¼”

General Information

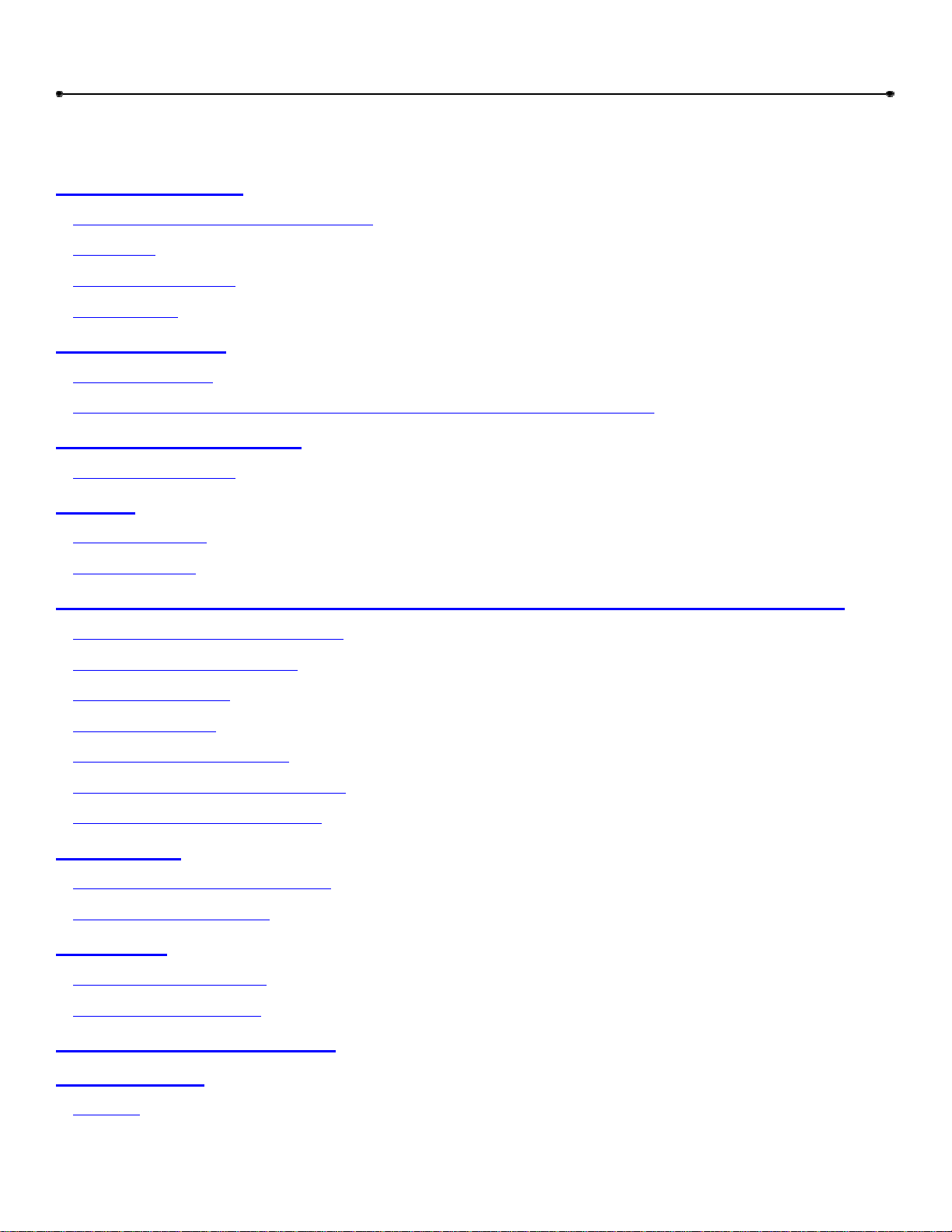

Supplied Parts and Dimensional Outline

SUPPLIED PARTS

Inspect the operator for possible shipping

damage and shortage of parts. Some ordered

accessories may be packed separately.

Part Description Qty.

7/16 Flat Washer

7/16 Spring Lock Washer

7/16 Hex Nut

Gate Bracket

Gate Caution Plate (á)

25/16 Hex Nut

5/16 Spring Lock Washer

3/8 Spring Lock Washer

3/8 Hex Nut

7/16 Set Screw

Roller Chain

Master Link

Stop Button 02-401-sp

Table 1

á Install Gate Caution Plates on both

sides of the gate where they can be

easily seen.

DIMENSIONAL OUTLINE

13 ½”

22”

27 ¼”

Figure 1

16”

15 3/8”

17 3/8”

7 3/8”

2”

8 ½”

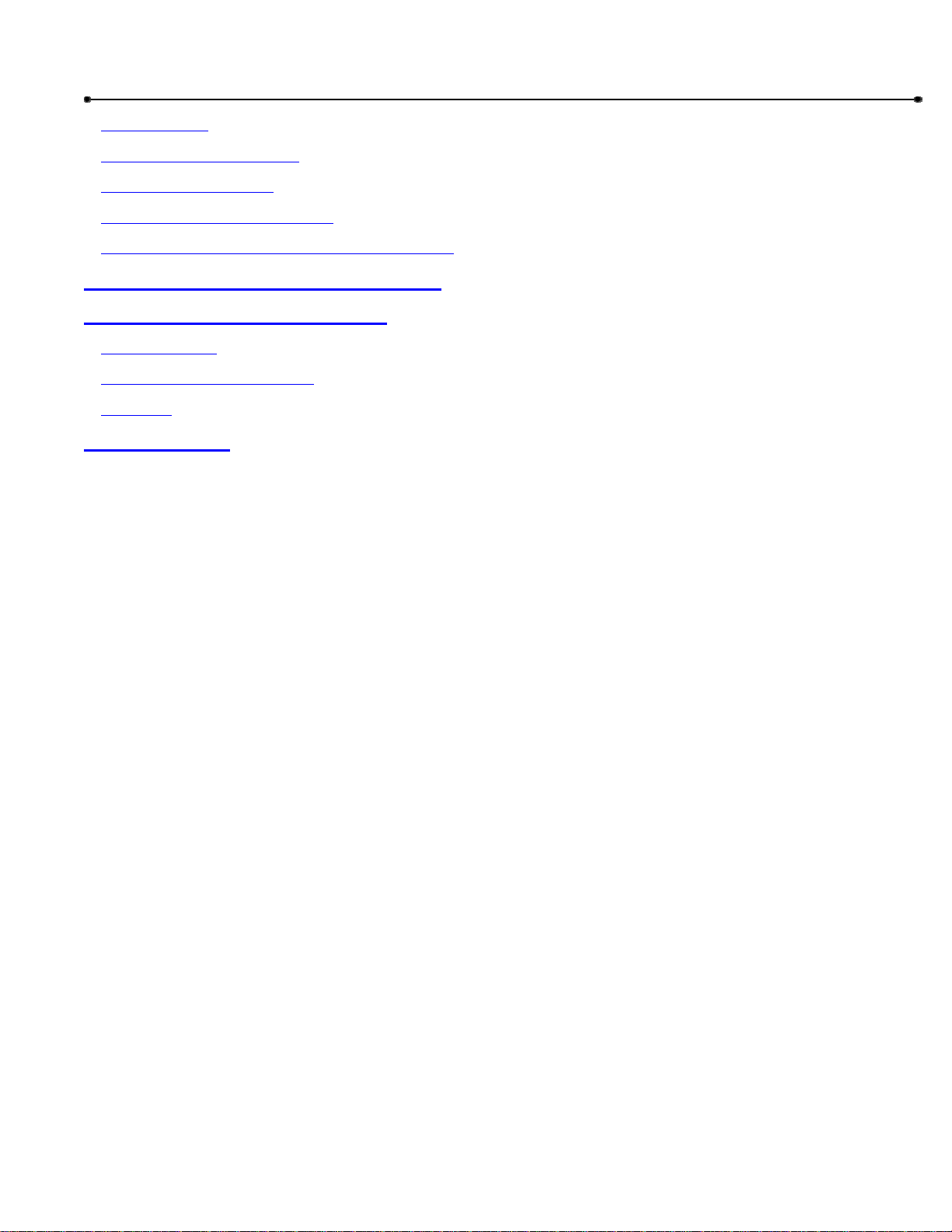

Cycle Rate

NOTE: These figures are maximum and should not be exceeded. When at all possible, try to

keep the cycles per hours at 75% of these figures.

Doc 01-G0685

Rev D

12

16

20

24

30

40

50

60

Frequency of Use – Cycles Per Hour

(cycle equals 1 full open and 1 full close)

Cycles per hourGate opening in feet

30 22 18 15 12 11

â

â

â

â

â

â

â

â

Table 2

General Information 5

Model Classifications

RESIDENTIAL VEHICULAR GATE OPERATOR – CLASS 1

A vehicular gate operator or system intended for use in a home of one to four single family

dwelling or a garage or parking area.

COMMERCIAL/GENERAL ACCESS VEHICULAR GATE OPERATOR – CLASS 2

A vehicular gate operator or system intended for use in a commercial location or building such as

a multi-family housing unit of five or more single family units, hotel, garages, retail store, or other

building servicing the general public.

INDUSTRIAL/LIMITED ACCESS VEHICULAR GATE OPERATOR – CLASS 3

A vehicular gate operator or system intended for use in an industrial location or building such as a

factory or loading dock area or other locations not intended to service the general public.

RESTRICTED ACCESS VEHICULAR GATE OPERATOR – CLASS 4

A vehicular gate operator or system intended for use in a guarded industrial location or building

such as an airport security area or the other restricted access location not servicing the general

public, in which unauthorized access is prevented via supervision by security personal.

MODEL CLASS 1 CLASS 2 CLASS 3 CLASS 4

SL540

SL570

â â â â

â â â â

Table 3

TYPES OF SLIDE GATES

These gate operators are intended t be used with slide gates of the following type: Track

mounted, overhead, cantilever, and track guided v-track.

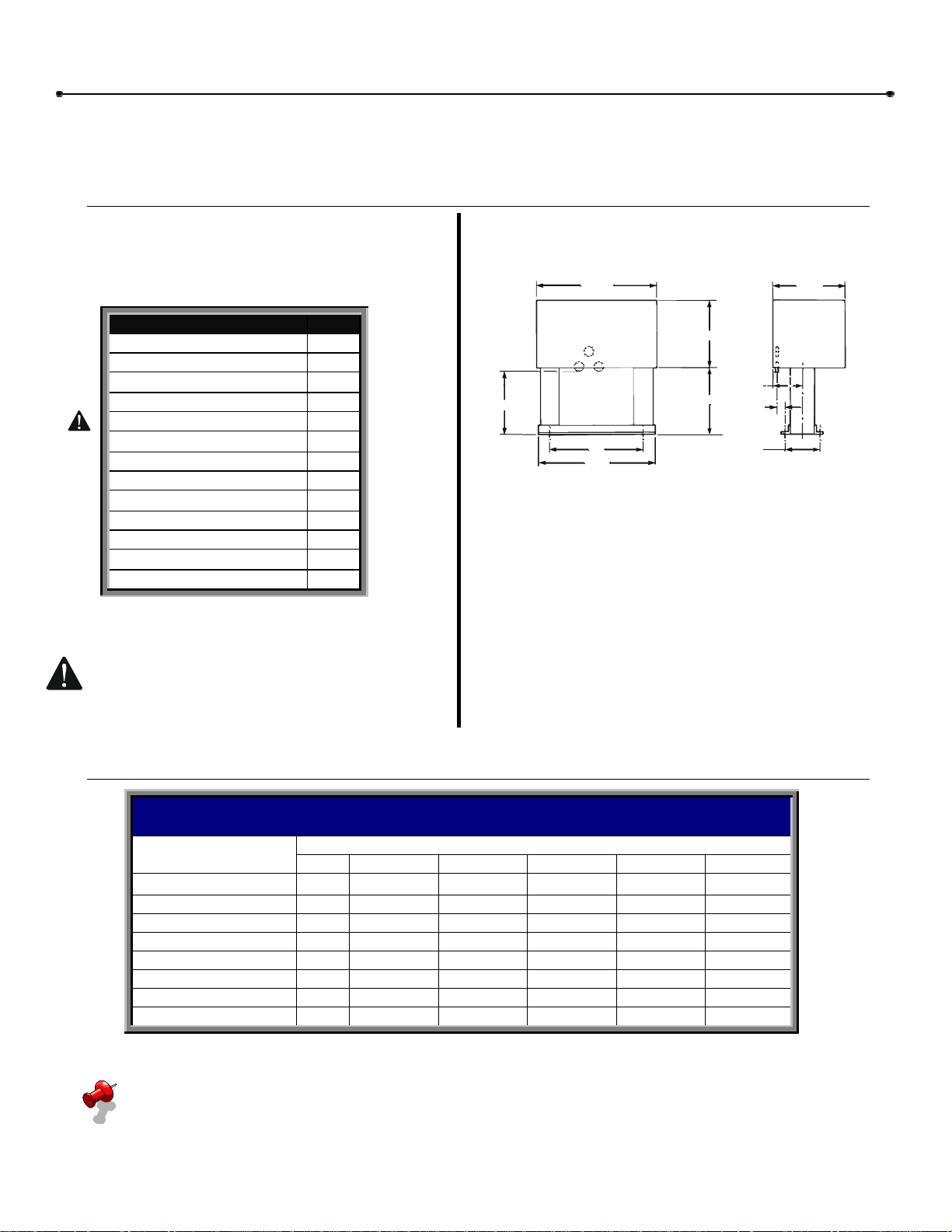

Specifications

Model H.P. Gate Speed

SL540 .33 12”/sec. 550 lbs. 16 ft. 24 ft. 20 ft.

SL540 .50 12”/sec. 900 lbs. 20 ft. 36 ft. 26 ft.

SL540 .75 12”/sec. 1000 lbs. 25 ft. 40 ft. 30 ft.

SL570 .50 12”/sec. 1200 lbs. 25 ft. 40 ft. 30 ft.

SL570 .75 12”/sec. 1500 lbs. 30 ft. 45 ft. 45 ft.

SL570 1.00 12”/sec. 1800 lbs. 32 ft. 50 ft. 48 ft.

Max. Gate

Weight

Max. Cant’l.

Width

Max. O/H

Width

Max. V-Track

Width

Table 4

Doc 01-G0685

Rev D

6 Safety Information

Safety Information

Vehicular gate systems provide convenience and security. Gate systems are comprised of many

component parts. The gate operator is only one component. Each gate system is specifically

designed for an individual application.

Gate operating system designers, installers and users must take into account the possible hazards

associated with each individual application. Improperly designed, installed or maintained systems can

create risks for the user as well as the bystander. Gate systems design and installation must reduce

public exposure to potential hazards.

A gate operator can create high levels of force, in its function as a component part of a gate system.

Therefore, safety features must be incorporated into every design. Specific safety features include:

Gate Edges Enclosed Track Vertical Posts

Guards for exposed

rollers

Screen Mesh

Important instructions follow. These instructions are intended to highlight certain safety related issues.

These instructions are not intended to be comprehensive. Because each application is unique, it is the

responsibility of the purchaser, designer, installer and end user to ensure that the total gate system is

safe for its intended use.

Photo-electric Sensors Instructional and

Precautionary Signage

Safety Instructions

Select instructions are highlighted with this precautionary symbol (see left margin). Failure to follow

these selected instructions can result in serious injury or death.

STEP 1: BEFORE INSTALLATION

1 Confirm gate operator model is specified by Installation and Maintenance Manual for

application type, gate size and frequency or use.

2 Confirm ALL appropriate safety features, such as gate edges, photo-electric sensors,

vertical posts and enclosed tracks, are specified.

3 Confirm gate system design reduces pinch points and protects against entrapment.

4 Confirm gate system design has pedestrian access separate from vehicular entrance.

5 Confirm gate system design reduces traffic backup.

6 Confirm warning signage is included in design.

7 Confirm gate moves freely before installation of operator

8 Repair or service worn or damaged gate hardware before installation of operator.

9 To avoid installation hazards, review the gate system operation and installation

10 Confirm control design prohibits unauthorized use.

Doc 01-G0685

Rev D

procedures, such as manual disconnect mechanism procedure.

Safety Information 7

STEP 2: DURING INSTALLATION

1 Disconnect power at service panel before making any electrical connection.

2 Avoid pinch points, be aware of all moving parts.

3 Adjust clutch or load sensing device to minimum force setting.

4 Do not over-tighten cutch or adjust force setting above minimum.

5 Install controls where user cannot touch gate while operating controls.

6 Install controls where user has full view of gate operation.

7 Install two or more warning signs on the gate to alert persons in the area of automatic gate

operation. Warning signs must be conspicuous.

8 Install operator inside fence line. DO NOT install operator on public side of fence line.

9 Secure gate operator cover.

STEP 3: AFTER INSTALLATION

1 Test all safety features.

2 Train end user about basic functions and safety features of gate system.

3 Leave Installation and Maintenance Manual and Safety Instructions with end user.

Doc 01-G0685

Rev D

8 Safety Information

Safety Precautions for Open-Roller Gates and Ornamental “Grill

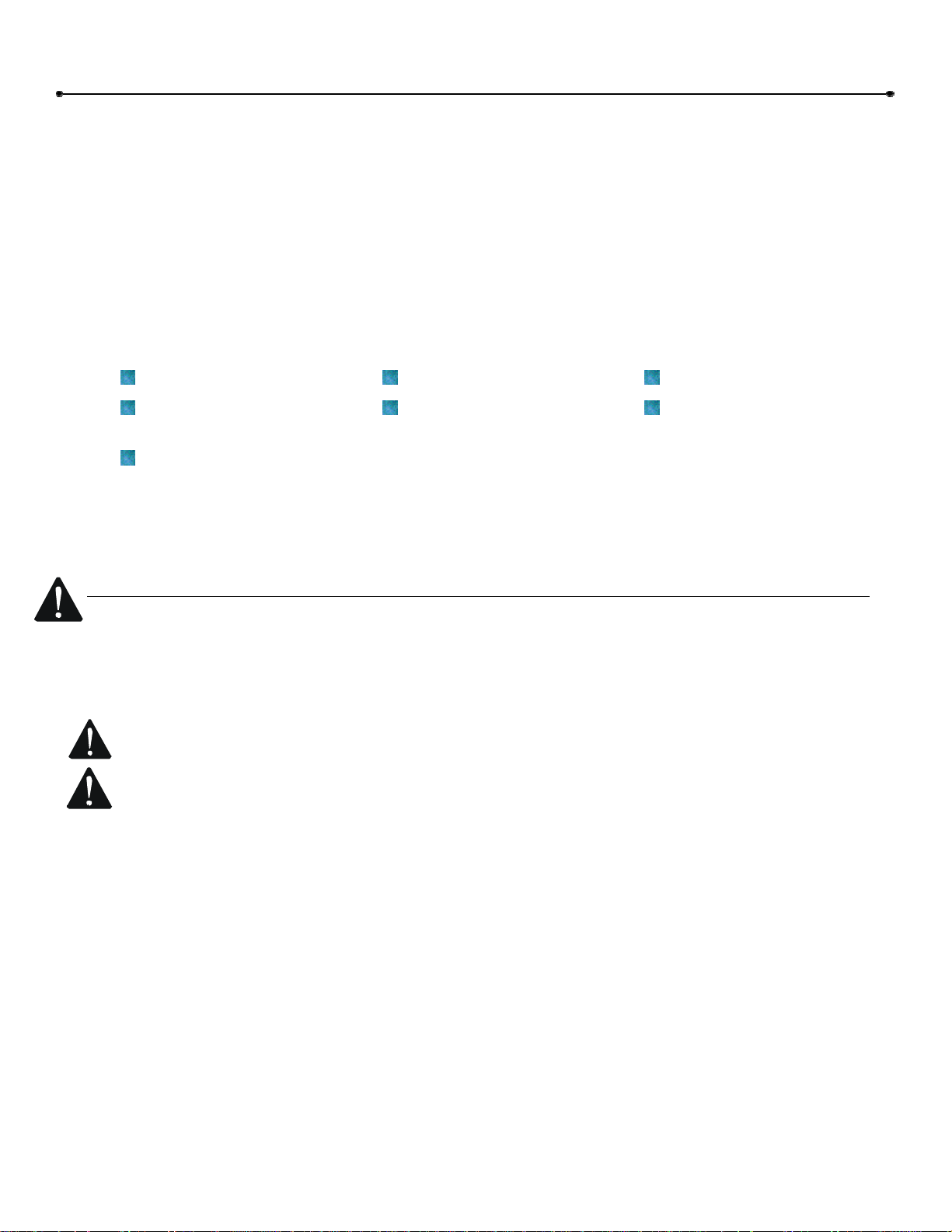

OPEN-ROLLER GATES

Injuries occur when people get their or feet caught between the top or bottom of the gate and the

gate roller. This potential pinch-point should be guarded against at all times. Enclosed style gate

tracks are available for refitting of these rollers from many fence suppliers. Also, roller guards are

available for installing over the rollers.

One more contact sensors shall be located at the leading edge, trailing edge, and post-mounted

both inside and outside of a vehicular horizontal slide gate.

Doc 01-G0685

Rev D

Figure 2

Safety Information 9

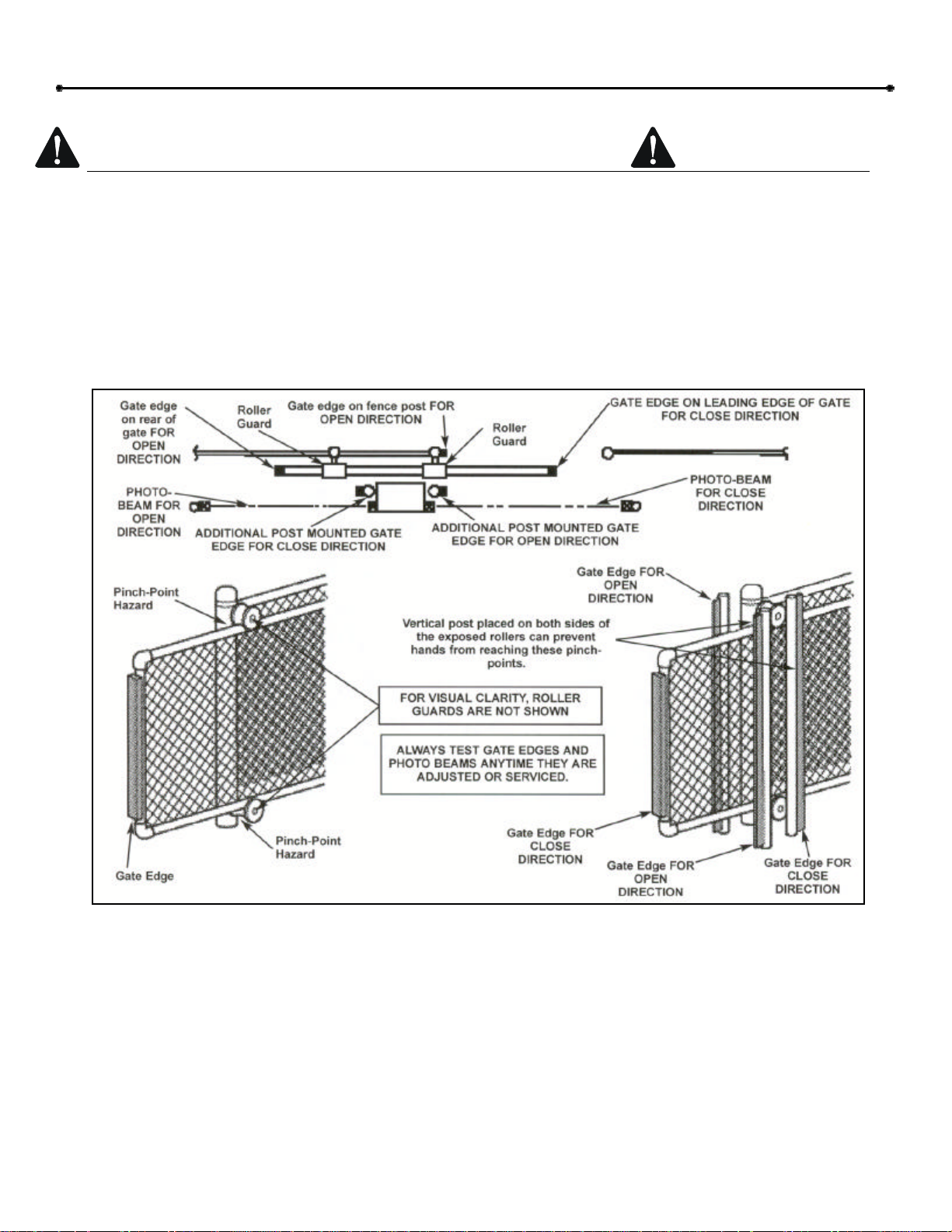

ORNAMENTAL “GRILL TYPE” GATES

Injuries occur when people put their hands and arms through openings in the grill and the gate is

operated. They cannot retract their arm and it gets caught between the moving gate grill and the

stationary fence post or fence. This potential hazard can be averted by placing a 4’ screen mesh

on the gate to prevent access through openings anywhere the gate may travel. See Safety

Brochure for details.

Figure 3

Doc 01-G0685

Rev D

10 Pre-Installation Check-List

01-G0685F2

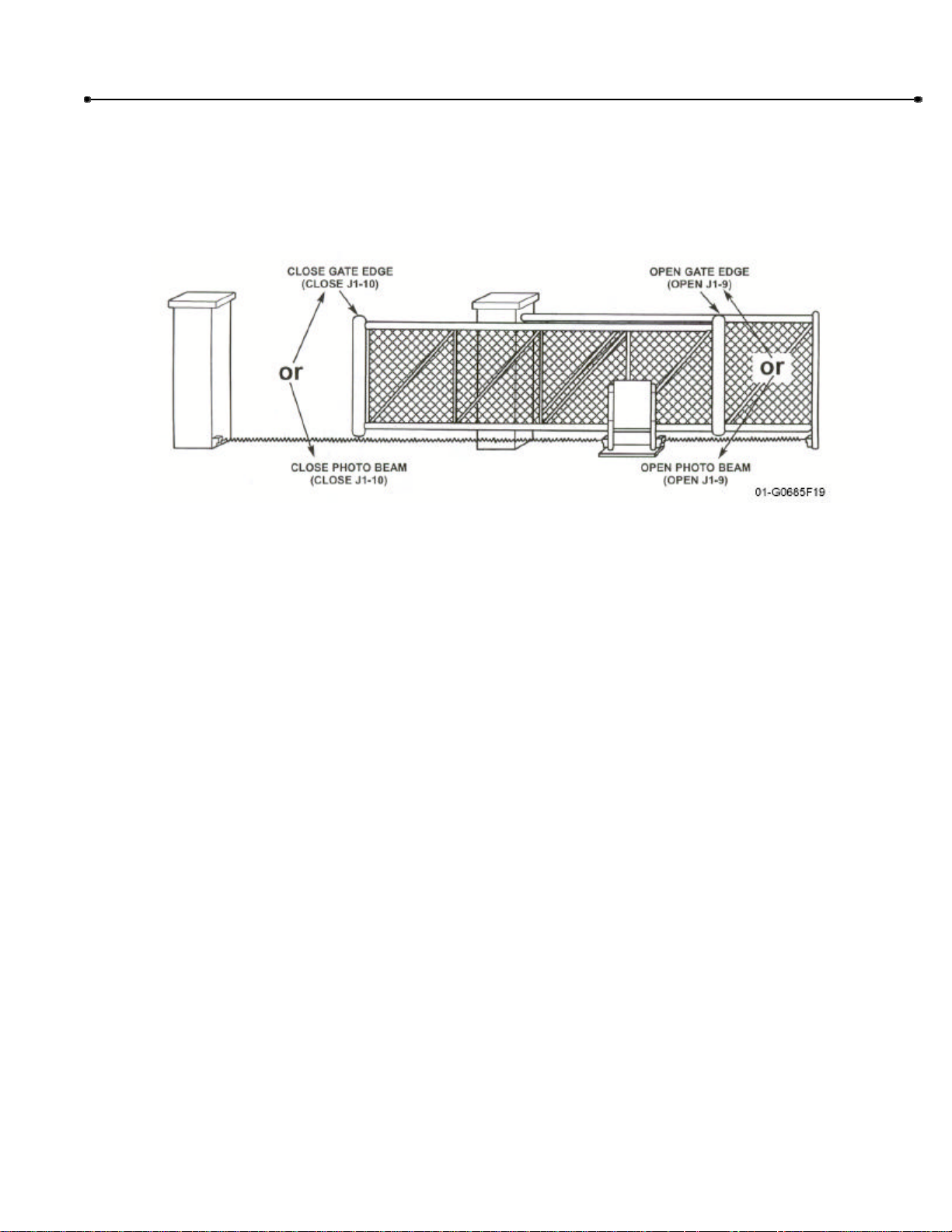

Pre-Installation Check-List

Φ Check the gate. It must operate smoothly and freely. If necessary, lubricate, adjust, or repair the

gate prior to operate installation. The gate must be level and plumb.

Φ Some gates may only be as wide as the gate opening. They may require a back frame to be

constructed to allow for chain attachments.

Φ Double check the size and weight of the gate to make sure that this operator is proper for this

application.

Φ If wiring has already been installed, check to make sure it meets the following specification and

requirements.

BACKFRAME

2 FT.

GATE OPENING

Figure 4

3 FT. MIN.

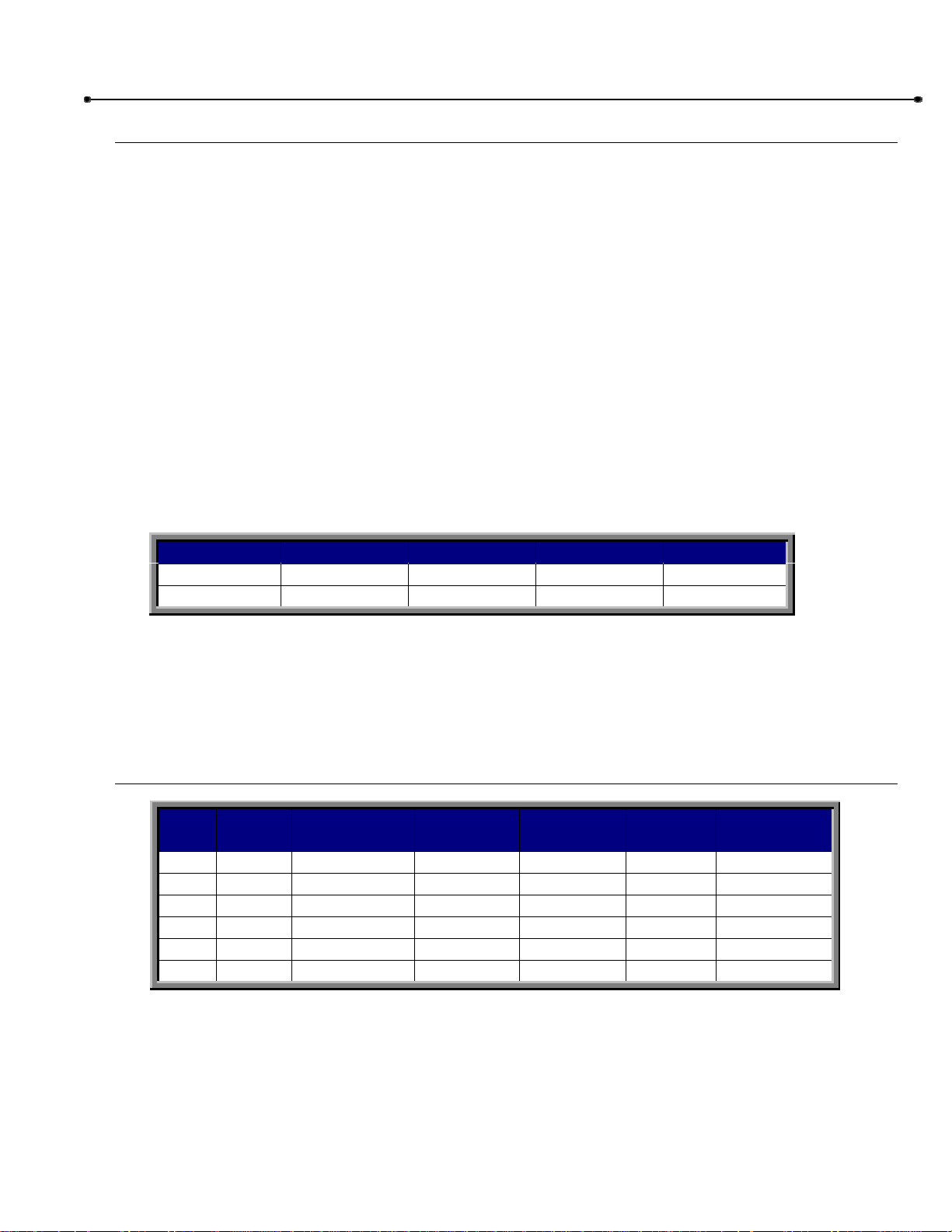

Wiring Specifications

Refer to Table 5.

A. The distances shown in Table 5 are measured in feet from the operator the power source.

B. These calculations are based on the National Electrical Code and allows for a 5% voltage

drop.

C. Supply voltage must be within 10% of the operator’s rating under load conditions.

D. There calculations are based on stranded copper wire.

E. It is highly recommended that only 90% of the distances shown be used; this will allow for a

10% safety factor.

F. For dual units, the distance shown should be cut in half.

G. Permanent wiring is to be employed as required by local codes.

H. All local codes must be strictly adhered to. It is very important that operator is properly

grounded.

I. Do not run control wires in the same conduit with power wires.

Doc 01-G0685

Rev D

J. Do not run multi conductor or parallel conductor cable for controls.

K. All power wiring should be dedicated and protected.

WIRE

GAUGE

6

8

10

12

Pre-Installation Check-List 11

Single Phase 3 Phase

HP 115 VAC 230 VAC 230 VAC 460 VAC 575 VAC

1/3

1/2

3/4

1

1-1/2

2

1/3

1/2

3/4

1

1-1/2

2

1/3

1/2

3/4

1

1-1/2

2

1/3

1/2

3/4

1

1-1/2

2

684

473

324

237

158

-432

299

204

149

100

-271

187

128

94

62

-170

117

80

59

39

--

3,077

2,051

1,231

947

648

437

1,942

1,295

777

597

409

299

1,218

812,

487,

375,

256

187

763

509

305

235

161

117

4,737

2,842

2,030

1,421

947

711

2,990

1,794

1,281

897

589

448

1,876

1,125

804

563

375

281

1,175

705

503

352

235

175

14,211

14,211

7,105

5,684

4,060

2,842

8,969

8,969

4,484

3,587

2,562

1,794

5,627

5,627

2,814

2,251

1,608

1,125

3,524

3,524

1,762

1,410

1,007

705

35,527

17,764

11,842

8,882

5,921

4,441

22,422

11,211

7,474

5,605

3,737

2,803

14,068

7,034

4,689

3,517

2,345

1,758

8,810

4,405

2,937

2,203

1,468

1,101

Table 5

NOTE: Calculated using NEC guidelines. Local codes and conditions must be reviewed for suitability

of wire installation. Master/Slave units must be installed on separate circuits.

Control Wiring

Volt Max. Dist. (Ft.) Wire Gage

24 1000 18

Table 6

Doc 01-G0685

Rev D

12 Features

01-G0685F3

CLUTCH

SYSTEM

Features

Operator Features

SOLENOID ACTIVATED, CALIPER DISC

BRAKE

The brake minimizes over travel caused by gate

coasting. An added feature of the brake is to

assist in preventing backdriving of the gate. The

brake is spring applied whenever the motor is not

running. Anytime the motor is running, the

electric solenoid physically releases the brake.

Important: periodically check and adjust the

brake mechanism. See page 29.

MOTORS

The SL540 & SL570 utilize a 56 frame, base

mounted, dual voltage, TEFC (totally enclosed

fan cooled) motor. The single phase motors also

incorporate a start switch. The family

incorporates motor H.P. from 1/3 to 1 and single

phase voltages 115 and 230. The 3-phase

voltages are 230, 460 and 575.

PRESSURE TYPE SLIPPING CLUTCH

The operator clutch mechanism works similar to

that of a clutch in a car. It allows the operator to

gradually start the gate moving, rather than trying

to instantaneously start moving the gate. This

clutch mechanism must be adjusted properly.

When it left the factory, it was purposely loosened

so that it will not operate the gate. You must

tighten the clutch spring lock nut so it is tight

enough to operate the gate, yet loose enough so

that if the gate meets an obstruction, the clutch

will slip easily. This clutch system will require

periodic maintenance. See page 29.

CALIPER DISC

BRAKE ASSY.

MECHANICAL

DISCONNECT

BRAKE SOLENOID

MOTOR (SINGLE PHASE SHOWN)

Figure 5

01-G0685F20

WARNING

This friction clutch system is not an automatic reversing device. It only serves to minimize

damage to the gate operator and gate, and also to hopefully minimize vehicle damage. If you

need an external automatic obstruction sensing device, items such as gate edges and photo

beams are available to help protect pedestrians.

Doc 01-G0685

Rev D

Figure 6

Features 13

01-G0685F4

01-G0685F5

MECHANICAL DISCONNECT

Refer to Figure 6. The operator can be disconnected from the gate, so the gate can be manually

opened or closed. The manual disconnect lever is located on the side of the operator. Simply pull

the lever outwards away from the frame and the operator is now disconnected. To re-engage the

operator to the gate, push the lever back towards the frame. The operator, when electrically

operated will automatically re-engage with the gate.

System Features

ACTIVITY LED

Steady indication when gate is at either open

or close limit.

1 flash per second when gate is off a limit in

normal operation

2 flashes per second when entrapment level

one has occurred.

AUDIBLE WARNING DEVICE

If the operator should have a second inherent

obstruction in sequence with the first; i.e. back to

back, the sounder will activate for 5 minutes then shut

off. Also the sounder can be programmed to come

on 2 seconds prior to gate movement and stay on

during gate movement.

Figure 7

THREE BUTTON CONTROL (SEQUENCE OF

OPERATION)

Open, stop, close, close id programmable. Stop will

override all other functions. If closing, open will

cause the operator to stop and reverse to full open.

Will close from open limit or midstop only. If SW1 pin

1 is on three button station will only close the

operator from the open limit or from mid-stop. If SW1

pin 1 is off, the input will work as a single button

(open, close, stop).

SWITCH #1

Figure 8

SINGLE BUTTON CONTROL (SEQUENCE OF OPERATION)

Open to open limit, close open. If power has been interrupted, will always open with first

activation.

CLOSE SINGLE BUTTON SELECT

The single button (programmable) control can be programmed to either function as a single button

control or to function as a close button only.

Doc 01-G0685

Rev D

14 Features

DIGITAL MICROPROCESSOR

This is the main circuit board for the operator. It contains all the logic and intelligence for the

system. All the system programming is done on this circuit board. All solid state, with an

emergency back-up system that works even if the processor is missing.

INHERENT OBSTRUCTION PROTECTION

The limit shaft is equipped with an R.P.M. sensor. When the gate meets an obstruction, the loss

of r.p.m’s. will cause the gate to reverse. A second obstruction will cause the gate to stop. A

renewed wired input will restart the gate.

EXTERNAL OBSTRUCTION CIRCUIT

This circuit can be used with either a gate edge or a photo beam system. When either of the two

devices mentioned are activated, the operator will react in a similar manner to the inherent

obstruction described above.

SPECIAL NOTE ABOUT OBSTRUCTION SENSING FROM EITHER INTERNAL OR

EXTERNAL SYSTEMS

The operator will stop if it senses two sequential obstructions. If will not activate form any

automatic system, including the built in time delay to close. Either a manual device such as a

pushbutton within site of the gate and operator, or the stop button supplied with the operator must

be activated to resume the operator back to its normal operation.

NOTE: If external entrapment protection is required by the class of operator, both an open

and closed protection device must be used.

OPEN ONLY CIRCUIT

Separate open circuits for line-of sight devices and out-of-sight devices such as open loops or

radio controls.

LOOP CONTROL CIRCUITS

Vehicle control devices such as opening or security loop detectors are connected to this circuit

TIME DELAY TO REVERSE CIRCUIT

Allows the gate to come to a complete stop before reversing direction. Approximately ½ second

between stop and reverse.

NOTE: This feature is defeated when either the inherent or external obstruction circuits

are activated.

Doc 01-G0685

Rev D

Installation 15

01-G0685F21

Installation

Please note that there are two basic types of power unit mounting, concrete pad or post mounting.

Choose the proper mounting for your application. The installation illustrations shown are for right hand

units; for left hand units, everything will be just the opposite.

If there is existing concrete at the area of power unit mounting, use the dimensioning procedure called

out in pad mounting instructions. It is suggested that ½” threaded anchors (not supplied) be used to

secure the unit. If needed, shim the unit to ensure that it is level and parallel with the gate.

Step 1: Set Up Post or Pad Mounting

STEP 1A: CONCRETE PAD

1 Layout concrete pad as detailed.

2 Locate electrical conduit, as required, prior to pouring concrete.

3 Pour concrete, insuring that pad is level and above the ground line.

4 Locate four (4) 1/2:” threaded anchors, not supplied, as detailed. Important: Anchors

must be positioned accurately and securely in concrete.

5 Allow concrete to set for at least two days before installing power unit.

REAR OF GATE

OR BACKFRAME

7”

FENCE LINE

3”

22”

36”

CONDUIT

AS REQ’D.

1”

18”

4” MIN.

DEPTH AS

REQUIRED BY

LOCAL CODES

OR BELOW

FROST LINE

5”

8 ½”

1/2” MOUNTING

BOLTS OR

ANCHORS

1” MIN.

2”- 4”

Figure 9

Doc 01-G0685

Rev D

16 Installation

01-G0685F6

REAR OF GATE

OR BACKFRAME

STEP 1B: POST MOUNTING

1 Locate and secure two posts, 3” O.D.

2 Remove the mounting angles from base of power unit. Unit the angles to maintain the

proper distance between posts. Secure the angles to the posts using U-bolts.

3 Check that:

4 Locate conduit, as required.

5 Allow concrete to set at least two days before installing power unit.

ü Each post is the same distance from the gate.

ü That the distance between the posts is 26”.

ü The post height is at least 14” from the ground.

ü Tops of posts are level with each other.

FENCE LINE

DEPTH AS

REQUIRED

BY LOCAL

CODES OR

BELOW

FROST

LINE

7 - ¾”

6”

3” U-BOLTS

Figure 10

26”

3” O.D.

14” MIN.

Doc 01-G0685

Rev D

Step 2: Mounting the Operator

01-G0685F22

01-G0685F7

01-G0685F8

WITH LOCK-

STEP 2A: MOUNTING TO PAD

Carefully secure the power unit to the

concrete pad with the drive and idler

sprockets facing the gate. It is very

important that the unit is level and parallel

to the gate.

STEP 2B: MOUNTING TO POST

Remove the angle braces and carefully

secure the power unit to the posts with drive

and idler sprockets facing the gate. It is

very important that the power unit is level

and parallel to the gate.

Installation 17

Figure 11

Step 3: Gate Brackets

Secure gate bracket to the vertical front and rear

posts of the gate.

NOTE: If a back frame was added, then

secure rear gate bracket to the back frame.

Important: The large slotted holes in gate

brackets must be level and in line with the bottom

of the idler sprockets and each other. Slide the

gate to the full open and full closed positions t

check alignments.

GATE

GATE

BRACKET

SETSCREW

Figure 12

“OUTSIDE”

“INSIDE”

MASTER LINK

ASSSEMBLY

2” U-BOLTS

WASHERS &

NUTS

EYEBOLT WITH FLAT WASHERS,

LOCKWASHERS, & HEX NUTS

Figure 13

Doc 01-G0685

Rev D

18 Installation

01-G0685F9

Step 4: Drive Chain

Important: Operator must be disengaged. Refer to Mechanical Disconnect on page 13. Also, refer

to Figure 13 as you perform the steps below.

1 Connect both threaded eye bolts to each of drive chain. Then attach one eye bolt to the rear

gate bracket.

2 Thread chain around drive and idler sprockets and pull towards the front gate bracket.

3 If required, cut chain to proper length, then attach the front eye bolt to the front gate bracket.

4 Carefully check the alignment of gate brackets to the idler sprockets in both the vertical and

horizontal directions.

5 Adjust the nuts on eye bolts t remove excessive chain slack. Important: The suggested

amount of chain slack is no more than 1” of chain slack for every 10 ft. to total chain length.

Do not over tighten chain.

NOTE: It is suggested that after the drive chain is properly installed and adjusted, the

gate brackets be welded to the gate.

SUGGESTION

It is recommended that for gates over 20 feet in length, some type of chain support be added to

the gate to prevent excessive chain sag. Please not that chain supports must be located a

minimum of ¾” below the idler sprocket shield and must note exceed ¾” beyond the centerline of

the chain.

NOTE ABOUT SOME TYPES OF CANTILEVER GATES

With some cantilever gates over 20 feet long, you may need to add a brace along the length of the

gate to prevent the gate from bowing with chain is tightened. This may also be required on some

styles of gates that are constructed out of aluminum. Note that if positioned properly, this brace

can also be used as a chain support.

BEFORE PROCEEDING PLEASE READ THIS

Electrical Disconnect Switch

Throughout the course of installation

you will be required to disconnect

electrical power.

This can be done by locating the

electrical power disconnect switch on

the control panel and placing it in the

desired position, as shown on the label

near it.

ELECTRICAL DISCONNECT SWITCH

Doc 01-G0685

Rev D

Figure 14

Installation 19

01-G0685F16

Step 5: Electrical Power Connections

CAUTION

Make sure power is disconnected at the main power source and at the operator’s electrical

disconnect switch before proceeding.

Secure all electrical power connections inside the power wiring compartment located on the outside

end of control panel. Use the electrical wiring supplied with this unit.

All single phase operators will have – L1 (neutral), L2 (hot) and ground.

All three phase operators will have – L1, L2, L3 and ground.

It is very important that operator is properly grounded.

NOTE: Permanent wiring is to be employed as required by local codes.

Important: On the phase operators the power connections must be properly phased. If they are

phased wrong the gate operator will run backwards. To correct this situation, disconnect power at

main power source and at the operator’s electrical disconnect switch. Then, reverse any two of the

three power leads.

WIRING

COMPARTMENT

WIRING COMPARTMENT

COVER

Figure 15

“POWER”

Doc 01-G0685

Rev D

20 Installation

01-G0685F11

CLOSE WHEN R.H.

CLOSE WHEN R.H.

Step 6: Limit Switch Adjustments

1 By using the mechanical disconnect, manually open the gate to its full open position.

2 Remove control panel cover and locate the rotary limit switch assembly. Disengage the

detent plate from the limit nuts, as shown.

3 Depending on “hand” of the operator, rotate the open limit nut until it makes contact with the

open limit switch lever and trips the open limit switch activation button.

4 Adjust the other limit nut so that it is near the open limit nut but not touching.

5 Manually close the gate to its full closed position.

6 Disengage the detent plate and rotate the close limit nut until it makes contact with the close

limit switch lever and trips the close switch.

7 Re-engage the detent plate into both limit nuts and also re-engage the mechanical

disconnect.

R.P.M. SENSOR

LIMIT NUT

CLOSE WHEN L.H.

OPEN WHEN R.H.

LIMIT SWITCH

CLOSE WHEN L.H.

OPEN WHEN R.H.

DETENT PLATE

LIMIT NUT

OPEN WHEN L.H.

LIMIT SWITCH

OPEN WHEN L.H.

DO NOT RUN OPERATOR UNTIL INSTRUCTED!

OPERATOR MUST BE PROGRAMMED BEFORE OPERATION

Doc 01-G0685

Rev D

Figure 16

Programming

01-G0610F13

Programming 21

Figure 17

Switch #1: Operator Programming

POLE #1: SINGLE/CLOSE BUTTON

ON = Close button only

OFF = Open/Close button

POLE #2: RIGHT HAND / LEFT HAND

ON = Left Hand (gate will open to the left)

OFF = Right Hand (gate will open to the right—inside of

fence looking out)

POLE #3: WARNING DEVICE

ON = Warning device will turn on 3 seconds before gate

starts to move in either direction.

OFF = Warning device disabled.

POLE #4: MASTER/SLAVE – SINGLE UNIT

ON = Master or Single Unit

OFF = Slave Unit

RED LED INFORMATION

Figure 18

RED LED INFORMATION

Continuous ON = Unit is on a limit.

Blinking 1 flash per second = Normal operation (gate travel or midstop).

Blinking 2 flashes per second = Entrapment level 1 (operator reverse to limit).to limit).

Doc 01-G0685

Rev D

22 Programming

01-G0610F14

TOTAL TIME

POLE #1 POLE #2 POLE #3 POLE #4

ON ON ON ON DISABLED DISABLED

OFF ON ON ON 1 SEC. 4 SEC.

ON OFF ON ON 13 SEC. 16 SEC.

OFF OFF ON ON 26 SEC. 2 SEC.

ON ON OFF ON 40 SEC. 43 SEC.

OFF ON OFF ON 52 SEC. 55 SEC.

ON OFF OFF ON 65 SEC. 68 SEC.

OFF OFF OFF ON 78 SEC. 81 SEC.

ON ON ON OFF 104 SEC. 107 SEC.

OFF ON ON OFF 117 SEC. 120 SEC.

ON OFF ON OFF 129 SEC. 132 SEC.

OFF OFF ON OFF 141 SEC. 144 SEC.

ON ON OFF OFF 155 SEC. 158 SEC.

OFF ON OFF OFF 167 SEC. 170 SEC.

ON OFF OFF OFF 180 SEC. 183 SEC.

OFF OFF OFF OFF 194 SEC. 197 SEC.

WARNING

DEVICE

DISABLED

TOTAL TIME

WARNING

DEVICE

ENABLED

Table 7

Switch #2: Timer to Close

Timer to close is locked out at the factory. To activate the timer to close, follow steps below:

Figure 19

1 Move safety jumper from bottom two pins to top two pins. Then set time per the chart

2 During normal operation, if the operator stops on a limit, or mid travel, the operator will time

out per the chart below and automatically close.

3 To lock the timer to close program and disable, simply return the jumper to the bottom two

pins, or turn on all pins of SW#2.

IMPORTANT NOTE: When using master/slave, only set the time for the master operator.

The slave operator must be set to disabled position (all poles on).

Doc 01-G0685

Rev D

Adjustments

BRAKE LEVER SHOULD BE

WHEN MOTOR IS RUNNING

BRAKE LEVER SHOULD BE

Step 7: Clutch Adjustment

The clutch left the factory completely loosened. In

this position, it will not allow the operator to move

the gate, so it must be adjusted. Due to the internal

speed sensor, you may get obstruction sensing

reaction during the clutch adjustment procedure.

You must adjust the clutch so that it produces just

enough force to move the gate, but yet will easily

slip when the gate meets with an obstruction. To

adjust the clutch mechanism, either tighten or

loosen the lock nut on the end of the intermediate

shaft, as shown in Figure 20.

CAUTION

The friction clutch is not an automatic reversing device. It minimizes damage to the gate operator

and gate. It can also limit major vehicle damage, if adjusted properly. This operator incorporates

an internal obstruction sensor system, but it is highly recommended that external obstruction

sensing devices such as gate edges or photo beams systems be incorporated into the gate

system to aid in the protection of any possible pedestrian traffic. Periodic inspection of the clutch

system and all internal and external sensor systems is required to ensure their proper operation.

Adjustments 23

CLUTCH

ADJUSTMENT

LOCK NUT

01-G0685F10

Figure 20

Step 8: Brake Adjustment

To minimize limit overtravel, this operator incorporates a solenoid activated caliper type brake

system. It has been factory set but will require periodical checks and possible adjustments. To

adjust:

1 Tighten lock nut on brake lever until

CLOSE TO HORIZONTAL

brake lever is horizontal.

2 Loosen lock nut until brake lever drops

1/8” TO 3/8”

1/8” to 3/8”.

3 Operate gate briefly and check lever

position. If the 1/8” to 3/8” dimension is

not maintained in the power off

position, tighten or loosen the lock nut

as required.

AS SHOWN HERE WHEN

MOTOR IS NOT RUNNING

01-G0685F23

Figure 21

NOTE: Do not over tighten the brake. Operator should run freely with the brake lever in the

horizontal position.

Doc 01-G0685

Rev D

24 Controls and Accessory Install.

GATE LOCK

SECURITY LOOP

provide UL secondary safety for persons. This

OPEN BUTTON

Note, on a second inherent obstruction, this

5

7

5

4

SAFETY OPEN

9

10

CLOSE

3

5

13

14

11

11

12

12

01-G0610F16

Controls and Accessory Install.

See wiring diagram for more information. See p. 10 for wiring distances and wire gauge

information.

All inputs are normally open and momentary, except the stop (NC), and emergency close and

emergency open (constant pressure). The following instructions are based upon UL 325, dated March

of 1999 and include recommendations for significant increase in safety.

We strongly recommend that you follow the UL guidelines presented throughout the manual.

Installation device instructions – always follow the instructions provided by the manufacturer when

installing and adjusting any control device. If these instructions are contrary to the advice given here,

call for assistance.

5 6

WIRELESS OPEN BUTTON

Caution - Only wired devices in sight of the

gate may be used with this input.

Any device can be used here and the radio

(R2) Is wired here internally by the factory.

input will not function (disabled).

CLOSE/SINGLE BUTTON

OPEN

5

Will reverse (close) the gate if active. If struck

again during a reversal the gate will stop.

5

This input is for vehicles only and does not

functions as an wireless open unless on the

close limit where it is defeated - thus preventing

vehicles from entering.

1 2 3

RADIO

RECEIVER

8

R1

R2

R3

TERMINAL STRIP

ON SIDE OF

CONTROL PANEL

SECONDARY SAFETY

It is recommended that secondary

safeties always be used for both

the open and close directions.

Use safety edges. In

the device must sense people.

Loops cannot be used.

3

These are constant pressure inputs that

bypasses the processor and may be used in

an emergency even if the processor fails.

Note left/right switch effects direction.

C

A

V

4

2

MASTER/SLAVE

Use shielded twisted pair.

do not run with power wiring.

any case,

E- OPEN

2

E- CLOSE

1

5

SAFETY CLOSE

Will reverse (open) the gate if active. If stuck

again during a reversal the gate will stop.

May defeat the timer to close.

STOP BUTTON

- REQUIRED -

This is a normally closed input and the operator

will not run unless this is installed!

POWER

USE POWER TO MATCH GATE LOCK

REQUIREMENTS, NOT TO EXCEED

115V 10A.

For warning devices,

call the factory

Figure 22

NOTE: Numbers shown inside a box are on the J1 terminal strip on the circuit board.

Connections shown here are field connections. The radio receiver may be ordered factory

installed.

Doc 01-G0685

Rev D

Troubleshooting 25

Troubleshooting

When troubleshooting, one of the first things to do is try to isolate the problem area. The four (4) main

areas to check out are:

Power

Accessories

Operator’s Primary Voltage

Operator’s Low Voltage

1. Power

Always use extreme caution! Some possible symptoms of power problems include:

The obvious one is – the operator will not run.

The operator runs slow.

Circuit breakers or fuses keep tripping.

Motor overload keeps tripping.

Operator starts but then stops..

1A.

Using a V.O.M. take a voltage reading at the control transformer’s primary terminals. You should

get a reading as follows:

Nominal Volt. Min. Max.

120v. 108 132

230v. 207 253

Table 8

If you get a reading that does not fall into the minimum/maximum area, then check out your main

power supply. Also, make sure that the operator was ordered with the proper voltage and phase.

Another item to check is the wire run from the power supply to the operator. Double check the

gauge of the wire versus the distance.

1B.

If the voltage reading is O.K. from 1A, then take the same voltage reading with the operator

running. If voltage drops below the minimum with this reading, then there could be an excessive

current draw somewhere.

1C.

In some cases, power drops can occur at only specific times during the day or night. This can be

caused by increased power demands in a general area at a specific time.

Doc 01-G0685

Rev D

26 Troubleshooting

2. Accessories

Add-on accessories can create many of the problems that are credited to the operator. Many

applications have more than one accessory item attached to the operator and some of these items

even draw their power from the operator.

Some of the symptoms that can show up because of accessories:

The operator won’t close.

The operator won’t open.

The operator will not run.

The operator begins to run then stops or reverses.

2A.

Whenever the problem is thought to be an accessory and there are more than one connected to

the operator, always disconnect one accessory at a time and then test the system. This will

hopefully isolate which item is causing the problem.

2B.

If an accessory item is being used as an access control device (used to open or close), falls in the

closed position or sends out a continuous signal. The operator will hold the gate in one position

until the signal from the accessory is removed.

2C.

In some applications, the gate may begin to move then either stop or stop and reverse within a

couple of seconds. This can be caused by an external obstruction device that has failed.

2D.

If there are many accessories attached to and powered by the operator, there may be too much

current draw for the operator’s control transformer. This operator can only supply approximately 2

amps @ 24 vac. Double check all accessories for their current requirements.

3. Primary Voltage Circuit

Use extreme caution when troubleshooting the primary voltage circuit! There are three (5) items

in this circuit that could be causing trouble, and they are:

Motor

Transformer

Brake solenoid

Contactor

Power disconnect switch

3A.

The first thing to check is the incoming power. Is it there at the incoming side of the power

disconnect switch?

Doc 01-G0685

Rev D

Troubleshooting 27

3B.

If there is power, then check for it at the transformer primary terminals. If there is voltage at the

switch and none at the transformer, then you probably have a bad power disconnect and it should

be replaced.

3C.

If 3A and 3B check out O.K., then manually disconnect the operator from the gate. Very

carefully, using a screwdriver with an insulated handle, press down on the open side of the

contactor. Then, do the same to the close side of the contactor. Then, do the same to the close

side of the contactor. Did the operator run in both directions? If it did, the problem may be in the

low voltage control circuit, if it did not, then the problem is either in the contactor or the motor.

NOTE: Some motors have the overload built into the motor itself, while other units have a

separate overload in the controller.

3D.

If the contactor is suspected to be causing the problem, first carefully check all wiring connections

at the contacts. DISCONNECT POWER! USING A V.O.M. take continuity readings across the

contacts of the contactor. Place one probe on 1 and the other on 2. You should get NO

continuity, now press down on the contactor, you should get a continuity reading. Repeat this on

all the of the contactor’s contact points.

Figure 23

4. Low Voltage Circuit

4A.

The first thing to check is the circuit breaker.

4B.

The secondary voltage must be between 22 and 30 vac. This voltage can be checked at the

circuit board at terminals J1-3 & J1-11.

4C.

The contactor coils receive 24 vac. to activate the motor in either the open or close direction.

There are two contactor coils (one for open and one for close).

4D.

The limit switches are S.P.D.T. (single pole, double throw). These limit switches are what tells the

operator to shut off at either the full open or full close position.

Doc 01-G0685

Rev D

28 Troubleshooting

4E.

The R.P.M. Sensor is counting the r.p.m ‘s of the wheel that is attached to the shaft. There are no

repairable parts for the sensor of wheel. The only thing that should be checked is the wire

harness. Make sure that the wires are crimpled and fully seated into the housing. Also make sure

that the housing is fully seated into the circuit board.

4F.

The circuit board is the “brains” of the entire system. It is a non-repairable item. In many cases,

un-awareness of the different programs and their functions can make it look like there is a

problem when in actuality it is just a missed or wrong program setting. Make sure that all the

connections wires on the “J1” terminal board are installed correctly. There MUST also be a stop

button connected to J1-3 and J1-5.

General Reference Information

THE GATE

Double check the gate and its related hardware. Does the gate move freely? If it doesn’t, this can

affect the internal obstruction sensor.

WIRING DIAGRAM

Always reference the wiring diagram that was supplied with the operator. Note that some of the

accessory items may have their own wiring diagram.

If you cannot correct the problem or if you feel you will require technical assistance, contact your

local distributor or dealer. If you do not have a distributor or dealer, then contact us for technical

assistance. Please when calling for assistance, make sure you have the gate operator model

number, voltage, phase, horsepower and a list of all accessories that are attached to the operator.

Features and Program Troubleshooting Review

The internal obstruction sensor (r.p.m. sensor) will cause the operator to either stop or reverse if it

senses a slow down in gate speed. A damaged or poorly working gate can trip the sensor and cause

“phantom” reversing or stopping. Also if the operator’s clutch is slipping too much, this can cause the

same situation.

Doc 01-G0685

Rev D

Required Maintenance – Normal Usage 29

Complete Check Out

Required Maintenance – Normal Usage

Check at least once every

Month intervals 1 3 6 12

Internal speed

sensor

External safety

systems

Gate caution signs

Clutch systemá

Brake system Check & adjust if required

Manual disconnect Check & operate

Drive chain (D) (E)

Sprockets & pulleys

Gate Inspect for wear or damage

Check for proper operation

Check for proper operation

Make sure they are present

Check & adjust if required

Check for excessive slack &

lubricate

Check for excessive slack &

lubricate

á

á

á

á

á

á

á

á

á

Accessories Check all for proper operation

Electrical Inspect all wire connections

Frame bolts Check for tightness

Total unit Inspect for wear or damage

á

á

á

Table 9

áá Important: A clutch that is set too loose will give false, inherent entrapment and reverse or

stop the gate.

NOTES:

A. Caution: When servicing, always

disconnect operator from electrical power

supply.

B. Severe or high cycle usage will require

more frequent maintenance checks.

C. Inspection and service should always be

performed anytime a malfunction is

observed or suspected.

D. Limit switches may have to be reset after

any major drive chain adjustments.

E. If lubrication chain, use only a proper chain

lub spray or a lightweight motor oil. Never

use grease or silicone spray.

F. When servicing, please do some “home

cleaning” of the operator an the area around

the operator. Pick up any debris in the area.

Clean the operator if needed.

G. It is suggested that while you are at the site,

you take some voltage readings of the

operator. Using a VOM, double check the

incoming voltage to the operator to make sure

it is within ten percent of the operator’s rating.

H. While you are at the site, now would be a

good time to let the owner or manager know

about any new items available or any safety

items that could and should be added to the

site.

Doc 01-G0685

Rev D

30 SL570/540 Parts List & Drawings

01-G0685F14

SL570/540 Parts List & Drawings

Exploded View

46

51

80

Doc 01-G0685

Rev D

Figure 24

Control Box Exploded View

01-G0685F15

79

72

SL570/540 Parts List & Drawings 31

74

78

76

81

71

77

73

75

Figure 25

Doc 01-G0685

Rev D

32 SL570/540 Parts List & Drawings

Parts List

Ref. # Part # Description Ref. # Part # Description

1 MG24732 BRAKE/CLUTCH PLATE KIT 32 MG3101990 POWER SWITCH

3 MG24734 40B-11T TIMER SPROCKET 33 76-G0537 ALARM ASSY.

4 MG9200040 SL540 OUTPUT 41B-17T SPROCKET KIT 34 MG4100316-P SIDE PLATE (PULLEY SIDE)

5 MG24736 SL570 OUTPUT 50B-15T SPROCKET KIT 35 10-G0571-P END CHANNEL

6 MG24740-T OUTER COVER ASSY. KIT 36 MG4100621-P MOUNTING ANGLE

7A 25-2006 6A OVERLOAD FUSE, 1-PH 37 MG4100639 BRAKE LEVER

7B 25-2008 8A OVERLOAD FUSE, 1-PH 38 MG4100932-P BELT SHIELD

7C 25-2010 10A OVERLOAD FUSE, 1-PH 39 MG4100933-P CHAIN & SPROCKET SHIELD

7D 25-2015 15A OVERLOAD FUSE, 1-PH 40 MG4100966 LIMIT DETENT

7E 25-2020 20A OVERLOAD FUSE, 1-PH 41 MG4100967 LIMIT DENT SPRING

7F 25-4001 1A OVERLOAD FUSE, 3-PH 42 MG4100977 LIMIT SUPPORT BRACKET

7G 25-4001-5 1.5A OVERLOAD FUSE, 3-PH 43 MG4101051-P COVER STOP

7H 25-4002-5 2.5A OVERLOAD FUSE, 3-PH 44 23-10041 LIMIT SWITCH

7I 25-4004 4A OVERLOAD FUSE, 3-PH 45 MG4101349-P SIDE PLATE (DRIVE SIDE)

9 MG49157 41A-48T SPROCKET KIT 46 MG4101498 INTERMEDIATE SHAFT

10 MG49158 DISCONNECT SPRING KIT 47 21-3260 50VA TRANSFORMER

11 MG49159 BRAKE LINK KIT 48 21-10298 100VA TRANSFORMER

12 MG49161 48B-11T TIMER SPROCKET KIT 49 69-G2000 S3 PCB

13 MG49162 41B-9T SPROCKET KIT 50 MG4101507 OUTPUT SHAFT

14 MG49163 DISCONNECT PLATE KIT 51 10-G0546 CONTROL BOX MOUNTING PLATE

15 MG49164 CLUTCH SPRING KIT 52 MG4101513 SOLENOID LINK LINER

16 MG49165 OUTPUT SHAFT CLIP RING KIT 53 MG4200311 BRAKE PUCK AND LEVER ASSY.

17 MG49166 IDLER SHAFT KIT 54 MG4200349 LIMIT SWITCH BRACKET ASSY.

18 MG49167 SL540 41B-15T IDLER SPROCKET KIT 55 MG4200350 LIMIT PLATE AND BEARING ASSY.

19 MG49169 SL570 50B-12T IDLER SPROCKET KIT 56 MG4200400 COVER HINGE

20 MG49171 IDLER SHAFT CLIP RING KIT 57 MG4200789 DISCONNECT ARM ASSY.

21 MG49146 #41 ROLLER CHAIN KIT 58 MG4200843 FRAME AND NUTSERT ASSY.

22A 20-3050-5T MOTOR - 1/2HP 575V 3PH 59 MG4200902 SL540 PULLEY ASSY.

22B 20-3075-5T MOTOR - 3/4HP 575V 3PH 60 MG4201093 SL570 PULLEY ASSY.

22C MG1010022 MOTOR - 1/2HP 115V 1PH 61 MG4200913

22D MG1010023 MOTOR - 3/4HP 115V 1PH 62 MG4200915

22E MG1010024 MOTOR - 1/2HP 208/230V 1PH 63 MG4200914

22F MG1010025 MOTOR - 3/4HP 208/230V 1PH 64 MG4200916

22G MG1010026 MOTOR - 1/3HP 115V 1PH 65 MG4200947 SL540 INTERMEDIATE SHAFT ASSY.

22H MG1010027 MOTOR - 1/3HP 208/230V 1PH 66 MG4201129 SL570 INTERMEDIATE SHAFT ASSY.

22I MG1010028 MOTOR - 1HP 208/230V 1PH 67 MG8230002 THRUST WASHER

22J MG1010029 MOTOR - 1HP 115V 1PH 68 MG8260018

22K MG1030002 MOTOR - 1/2HP 208/230/460V 3PH 69 MG49177 LIMIT CHAIN KIT

22L MG1030004 MOTOR - 3/4HP 208/230/460V 3PH 70 K-73SL540-3311 CONTROL BOX ASSY.

22M MG1030007 MOTOR - 1HP 208/230/460V 3PH 71 MG4101510 BRAKE SOLENOID LINK

22N MG1030013 MOTOR - 1HP 575V 3PH 72 13-10024 LIMIT NUTS

23 MG3100374 MOTOR PULLEY 73 29-18163 16 POLE MAGNET

24 22-120 120V BRAKE SOLENOID 74 10-G0470 LIMIT ASSY. END PLATE

25 22-240 240V BRAKE SOLENOID 75 12-G0506 FLANGE BEARING IN LIMIT ASSY.

26 22-575-1 575V BRAKE SOLENOID 76 74-G0487-M HALL EFFECT SENSOR ASSY.

27 MG3100742 CLUTCH FACING 77 74-G0504 LIMIT SHAFT ASSY.

28 03-8024 24V CONTACTOR 78 10-G0483 HALL SENSOR MOUNTING BRACKET

29 MG3600942 5/8" SET COLLAR 79 MG49283 LIMIT SWITCH ASSY. KIT

30 MG3601049 SL570 COGGED V-BELT 80 MG8260014 5/8" BORE RADIAL BEARING

31 MG4101526 SL540 SOLID V-BELT 81 MG49284 U-NUT KIT

SL540 BEARING PLATE ASSY. (DRIVE

SIDE)

SL570 BEARING PLATE ASSY. (DRIVE

SIDE)

SL540 BEARING PLATE ASSY.

(PULLEY SIDE)

SL570 BEARING PLATE ASSY.

(PULLEY SIDE)

SL570 FLANGETTE BEARING

NOTE: SL540 BEARINGS ARE BRONZE

AND PRESSED IN TO THE SIDE

PLATES. IT IS RECOMMENDED THAT

THE ENTIRE SIDE PLATE ASSY. BE

ORDERED.

Doc 01-G0685

Rev D

Warranty Policy 33

Warranty Policy

Seller warrants that the goods are free from defect in materials and/or workmanship for a period of one

year from the date of shipment from the F.O.B. point. Goods returned to Seller for warranty repair

within the warranty period, which upon receipt by Seller are confirmed to be defective and covered by

this limited warranty, will be repaired or replaced (at Seller’s sole option) at no cost and returned prepaid. Defective parts will be repaired or replaced with new or factory-rebuilt parts at Seller’s sole

option. Authorization instructions for the return of any goods must be obtained by Buyer from Seller

before returning the goods. The goods must be returned with complete identification, freight prepaid,

and in accordance with Seller’s instructions or they will not be accepted. In no event will Seller be

responsible for goods returned without proper authorization or identification.

THIS LIMITED WARRANTY IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE, OR OTHERWISE, AND OF ANY OTHER OBLIGATIONS OR LIABILITY

ON SELLER’S PART. THIS LIMITED WARRANTY DOES NOT COVER NON-DEFECT DAMAGE,

DAMAGE CAUSED BY IMPROPER INSTALLATION, OPERATION OR CARE (INCLUDING, BUT

NOT LIMITED TO ABUSE, MISUSE, FAILURE TO PROVIDE REASONABLE AND NECESSARY

MAINTENANCE, OR ANY ALTERATIONS TO THIS PRODUCT), LABOR CHARGES FOR

DISMANTLING OR REINSTALLING A REPAIRED OR REPLACED UNIT, OR REPLACEMENT

BATTERIES. UNDER NO CIRCUMSTANCES SHALL SELLER BE LIABLE FOR CONSEQUENTIAL,

INCIDENTAL OR SPECIAL DAMAGES ARISING IN CONNECTION WITH THE USE, OR INABILITY

TO USE, THIS PRODUCT. IN NO EVENT SHALL SELLER’S LIABILITY FOR BREACH OF

WARRANTY, BREACH OF CONTRACT, NEGLIGENCE OR STRICT LIABILITY EXCEED THE COST

OF THE PRODUCT COVERED HEREBY. NO PERSON IS AUTHORIZED TO ASSUME FOR US

ANY OTHER LIABILITY IN CONNECTION WITH THE SALE OF THIS PRODUCT. Some states do

not allow the exclusion or limitation of consequential, incidental or special damages, so the above

limitation or exclusion may not apply to you. This limited warranty gives you specific legal rights, and

you may also have other rights which vary from state to state.

Doc 01-G0685

Rev D

COPYRIGHT 2001

ALL RIGHTS RESERVED

This document is protected by copyright and may not be copied or adapted without the prior written

consent of LiftMaster. This documentation contains information proprietary to LiftMaster and such

information may not be distributed without the prior written consent of LiftMaster. The software and

firmware included in the LiftMaster product as they relate to this documentation are also protected by

copyright and contain information proprietary to LiftMaster.

FOR TECHNICAL SUPPORT

Call our toll free numbers:

(800) 323-2276

(800) 998-9197

Installation and service information is

available six days a week.

TO ORDER REPAIR PARTS

Call our toll free numbers:

(800) 528-2806

(800) 998-9197

Prepare to provide the following

information when ordering repair parts:

— Part Number

— Part Name

— Model Number

Loading...

Loading...