Liftmaster SL540 User Manual

Installation and Maintenance

Instructions

Model SL570

Heavy Duty Slide Gate Operator

Model SL540

Medium Duty Slide Gate Operator

Doc 01-G0685

Rev D

2 Contents

Contents

General Information________________________________________________________ 4

Supplied Parts and Dimensional Outline___________________________________________________ 4

Cycle Rate__________________________________________________________________________ 4

Model Classifications _________________________________________________________________ 5

Specifications _______________________________________________________________________ 5

Safety Information _________________________________________________________ 6

Safety Instructions____________________________________________________________________ 6

Safety Precautions for Open-Roller Gates and Ornamental “Grill Type” Gates ____________________ 8

Pre-Installation Check-List _________________________________________________ 10

Wiring Specifications ________________________________________________________________ 10

Features_________________________________________________________________ 12

Operator Features ___________________________________________________________________ 12

System Features_____________________________________________________________________ 13

Installation ______________________________________________________________ 15

Step 1: Set Up Post or Pad Mounting _____________________________________________________ 15

Step 2: Mounting the Operator__________________________________________________________ 17

Step 3: Gate Brackets_________________________________________________________________ 17

Step 4: Drive Chain __________________________________________________________________ 18

Electrical Disconnect Switch___________________________________________________________ 18

Step 5: Electrical Power Connections ____________________________________________________ 19

Step 6: Limit Switch Adjustments _______________________________________________________ 20

Programming ____________________________________________________________ 21

Switch #1: Operator Programming ______________________________________________________ 21

Switch #2: Timer to Close_____________________________________________________________ 22

Adjustments______________________________________________________________ 23

Step 7: Clutch Adjustment _____________________________________________________________ 23

Step 8: Brake Adjustment _____________________________________________________________ 23

Controls and Accessory Install. ______________________________________________ 24

Troubleshooting __________________________________________________________ 25

1. Power___________________________________________________________________________ 25

Doc 01-G0685

Rev D

Contents 3

2. Accessories ______________________________________________________________________ 26

3. Primary Voltage Circuit ____________________________________________________________ 26

4. Low Voltage Circuit _______________________________________________________________ 27

General Reference Information_________________________________________________________ 28

Features and Program Troubleshooting Review____________________________________________ 28

Required Maintenance – Normal Usage _______________________________________29

SL570/540 Parts List & Drawings ____________________________________________30

Exploded View _____________________________________________________________________ 30

Control Box Exploded View___________________________________________________________ 31

Parts List __________________________________________________________________________ 32

Warranty Policy___________________________________________________________33

Doc 01-G0685

Rev D

4 General Information

2

4

4

2

2

8

8

8

8

4

1

2

1

01-G0685F1

10 ¼”

General Information

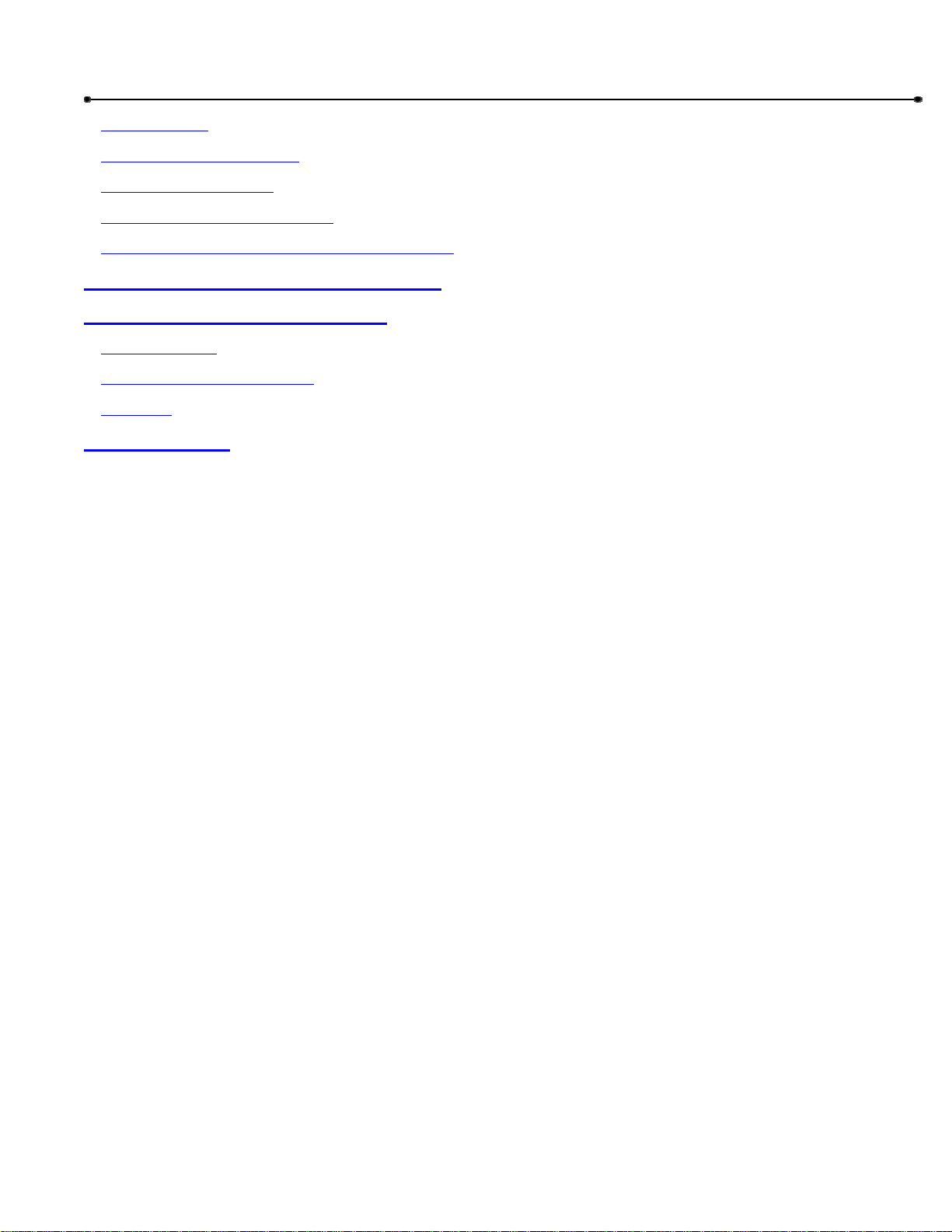

Supplied Parts and Dimensional Outline

SUPPLIED PARTS

Inspect the operator for possible shipping

damage and shortage of parts. Some ordered

accessories may be packed separately.

Part Description Qty.

7/16 Flat Washer

7/16 Spring Lock Washer

7/16 Hex Nut

Gate Bracket

Gate Caution Plate (á)

25/16 Hex Nut

5/16 Spring Lock Washer

3/8 Spring Lock Washer

3/8 Hex Nut

7/16 Set Screw

Roller Chain

Master Link

Stop Button 02-401-sp

Table 1

á Install Gate Caution Plates on both

sides of the gate where they can be

easily seen.

DIMENSIONAL OUTLINE

13 ½”

22”

27 ¼”

Figure 1

16”

15 3/8”

17 3/8”

7 3/8”

2”

8 ½”

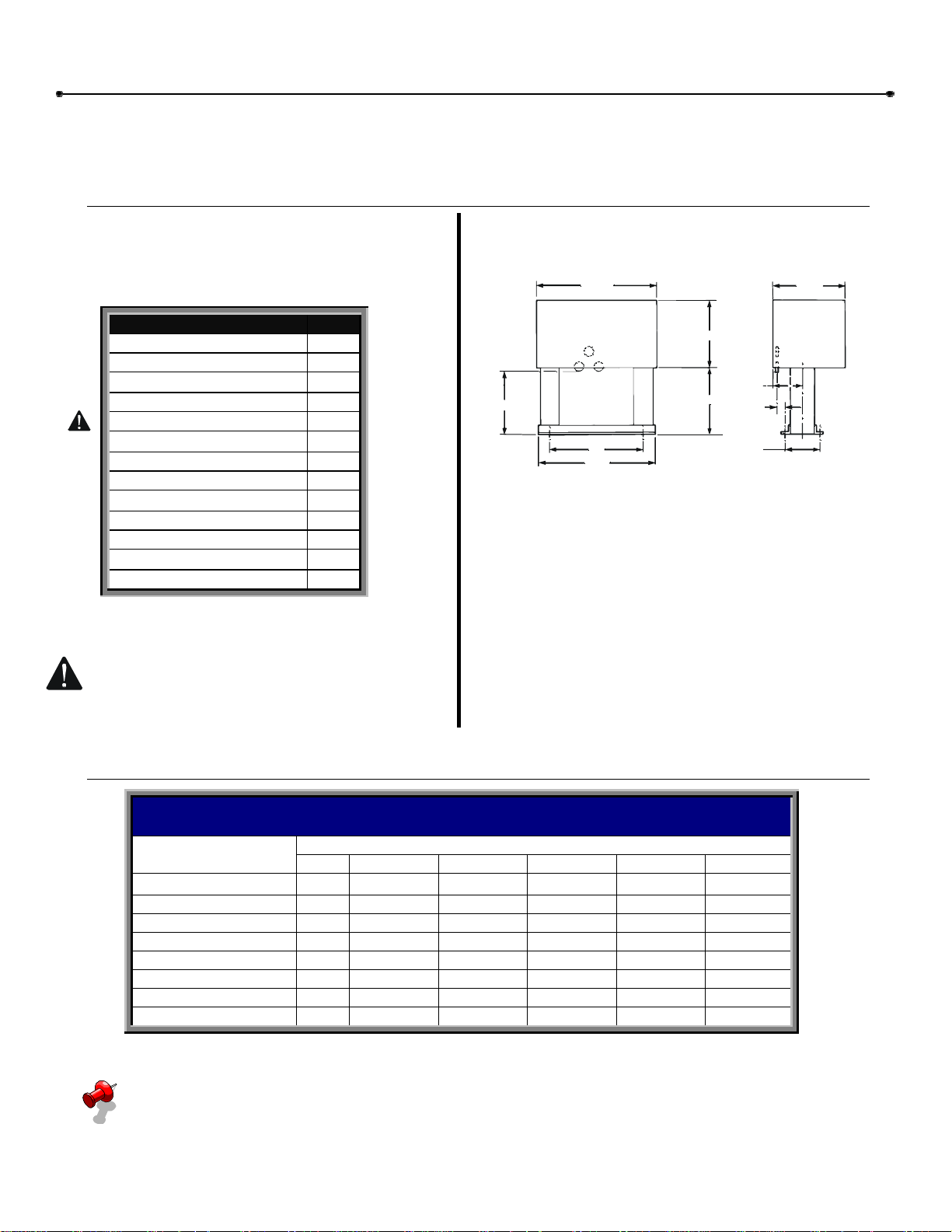

Cycle Rate

NOTE: These figures are maximum and should not be exceeded. When at all possible, try to

keep the cycles per hours at 75% of these figures.

Doc 01-G0685

Rev D

12

16

20

24

30

40

50

60

Frequency of Use – Cycles Per Hour

(cycle equals 1 full open and 1 full close)

Cycles per hourGate opening in feet

30 22 18 15 12 11

â

â

â

â

â

â

â

â

Table 2

General Information 5

Model Classifications

RESIDENTIAL VEHICULAR GATE OPERATOR – CLASS 1

A vehicular gate operator or system intended for use in a home of one to four single family

dwelling or a garage or parking area.

COMMERCIAL/GENERAL ACCESS VEHICULAR GATE OPERATOR – CLASS 2

A vehicular gate operator or system intended for use in a commercial location or building such as

a multi-family housing unit of five or more single family units, hotel, garages, retail store, or other

building servicing the general public.

INDUSTRIAL/LIMITED ACCESS VEHICULAR GATE OPERATOR – CLASS 3

A vehicular gate operator or system intended for use in an industrial location or building such as a

factory or loading dock area or other locations not intended to service the general public.

RESTRICTED ACCESS VEHICULAR GATE OPERATOR – CLASS 4

A vehicular gate operator or system intended for use in a guarded industrial location or building

such as an airport security area or the other restricted access location not servicing the general

public, in which unauthorized access is prevented via supervision by security personal.

MODEL CLASS 1 CLASS 2 CLASS 3 CLASS 4

SL540

SL570

â â â â

â â â â

Table 3

TYPES OF SLIDE GATES

These gate operators are intended t be used with slide gates of the following type: Track

mounted, overhead, cantilever, and track guided v-track.

Specifications

Model H.P. Gate Speed

SL540 .33 12”/sec. 550 lbs. 16 ft. 24 ft. 20 ft.

SL540 .50 12”/sec. 900 lbs. 20 ft. 36 ft. 26 ft.

SL540 .75 12”/sec. 1000 lbs. 25 ft. 40 ft. 30 ft.

SL570 .50 12”/sec. 1200 lbs. 25 ft. 40 ft. 30 ft.

SL570 .75 12”/sec. 1500 lbs. 30 ft. 45 ft. 45 ft.

SL570 1.00 12”/sec. 1800 lbs. 32 ft. 50 ft. 48 ft.

Max. Gate

Weight

Max. Cant’l.

Width

Max. O/H

Width

Max. V-Track

Width

Table 4

Doc 01-G0685

Rev D

6 Safety Information

Safety Information

Vehicular gate systems provide convenience and security. Gate systems are comprised of many

component parts. The gate operator is only one component. Each gate system is specifically

designed for an individual application.

Gate operating system designers, installers and users must take into account the possible hazards

associated with each individual application. Improperly designed, installed or maintained systems can

create risks for the user as well as the bystander. Gate systems design and installation must reduce

public exposure to potential hazards.

A gate operator can create high levels of force, in its function as a component part of a gate system.

Therefore, safety features must be incorporated into every design. Specific safety features include:

Gate Edges Enclosed Track Vertical Posts

Guards for exposed

rollers

Screen Mesh

Important instructions follow. These instructions are intended to highlight certain safety related issues.

These instructions are not intended to be comprehensive. Because each application is unique, it is the

responsibility of the purchaser, designer, installer and end user to ensure that the total gate system is

safe for its intended use.

Photo-electric Sensors Instructional and

Precautionary Signage

Safety Instructions

Select instructions are highlighted with this precautionary symbol (see left margin). Failure to follow

these selected instructions can result in serious injury or death.

STEP 1: BEFORE INSTALLATION

1 Confirm gate operator model is specified by Installation and Maintenance Manual for

application type, gate size and frequency or use.

2 Confirm ALL appropriate safety features, such as gate edges, photo-electric sensors,

vertical posts and enclosed tracks, are specified.

3 Confirm gate system design reduces pinch points and protects against entrapment.

4 Confirm gate system design has pedestrian access separate from vehicular entrance.

5 Confirm gate system design reduces traffic backup.

6 Confirm warning signage is included in design.

7 Confirm gate moves freely before installation of operator

8 Repair or service worn or damaged gate hardware before installation of operator.

9 To avoid installation hazards, review the gate system operation and installation

10 Confirm control design prohibits unauthorized use.

Doc 01-G0685

Rev D

procedures, such as manual disconnect mechanism procedure.

Safety Information 7

STEP 2: DURING INSTALLATION

1 Disconnect power at service panel before making any electrical connection.

2 Avoid pinch points, be aware of all moving parts.

3 Adjust clutch or load sensing device to minimum force setting.

4 Do not over-tighten cutch or adjust force setting above minimum.

5 Install controls where user cannot touch gate while operating controls.

6 Install controls where user has full view of gate operation.

7 Install two or more warning signs on the gate to alert persons in the area of automatic gate

operation. Warning signs must be conspicuous.

8 Install operator inside fence line. DO NOT install operator on public side of fence line.

9 Secure gate operator cover.

STEP 3: AFTER INSTALLATION

1 Test all safety features.

2 Train end user about basic functions and safety features of gate system.

3 Leave Installation and Maintenance Manual and Safety Instructions with end user.

Doc 01-G0685

Rev D

8 Safety Information

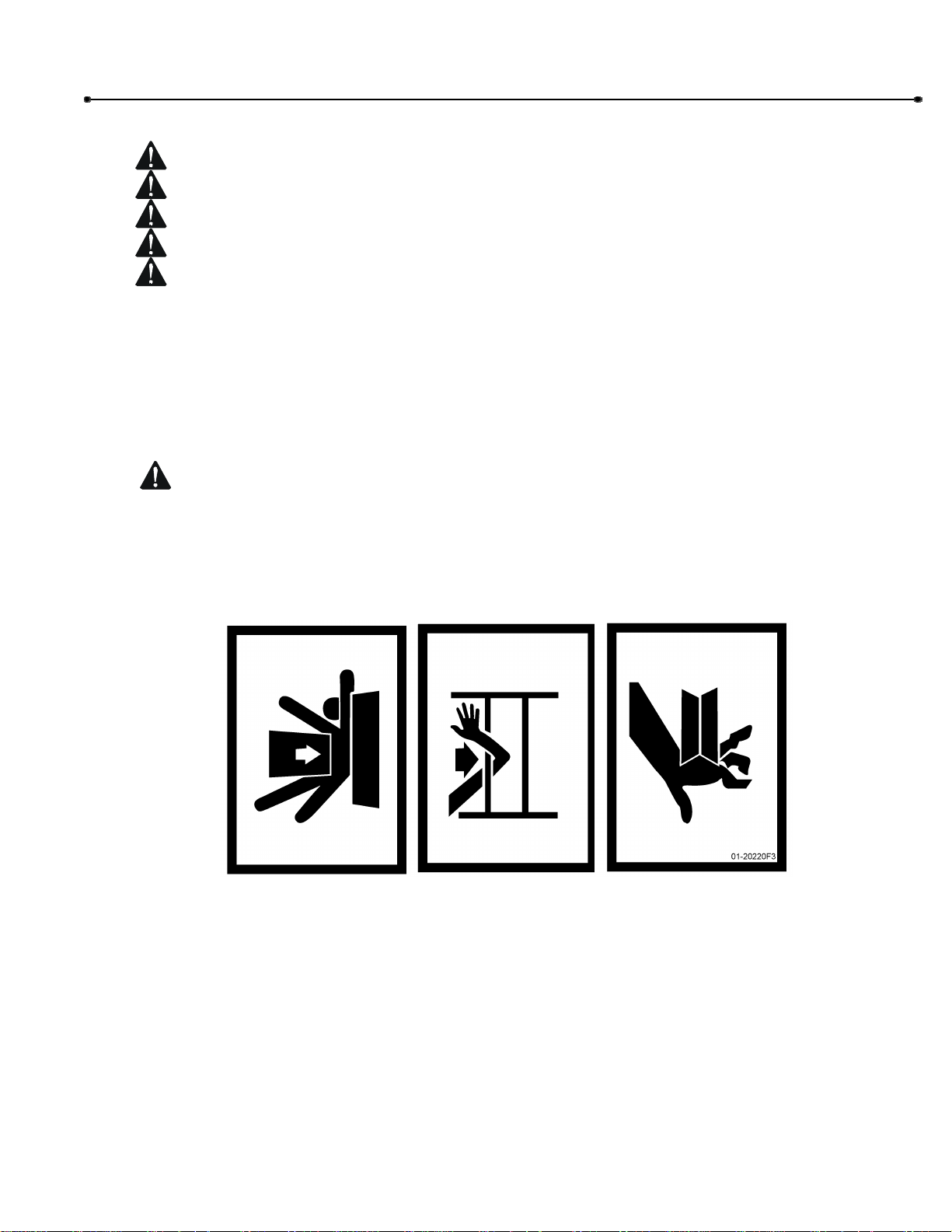

Safety Precautions for Open-Roller Gates and Ornamental “Grill

OPEN-ROLLER GATES

Injuries occur when people get their or feet caught between the top or bottom of the gate and the

gate roller. This potential pinch-point should be guarded against at all times. Enclosed style gate

tracks are available for refitting of these rollers from many fence suppliers. Also, roller guards are

available for installing over the rollers.

One more contact sensors shall be located at the leading edge, trailing edge, and post-mounted

both inside and outside of a vehicular horizontal slide gate.

Doc 01-G0685

Rev D

Figure 2

Safety Information 9

ORNAMENTAL “GRILL TYPE” GATES

Injuries occur when people put their hands and arms through openings in the grill and the gate is

operated. They cannot retract their arm and it gets caught between the moving gate grill and the

stationary fence post or fence. This potential hazard can be averted by placing a 4’ screen mesh

on the gate to prevent access through openings anywhere the gate may travel. See Safety

Brochure for details.

Figure 3

Doc 01-G0685

Rev D

10 Pre-Installation Check-List

01-G0685F2

Pre-Installation Check-List

Φ Check the gate. It must operate smoothly and freely. If necessary, lubricate, adjust, or repair the

gate prior to operate installation. The gate must be level and plumb.

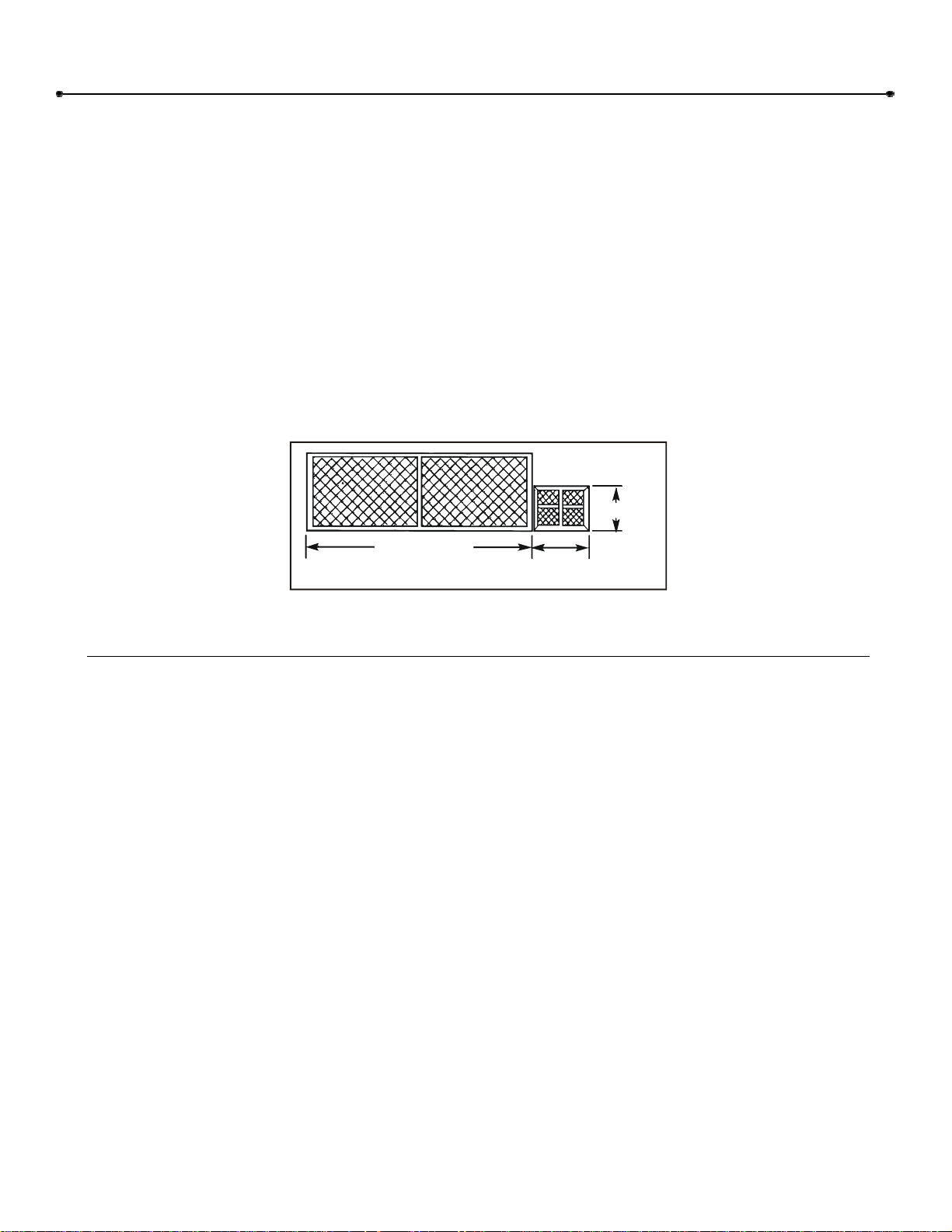

Φ Some gates may only be as wide as the gate opening. They may require a back frame to be

constructed to allow for chain attachments.

Φ Double check the size and weight of the gate to make sure that this operator is proper for this

application.

Φ If wiring has already been installed, check to make sure it meets the following specification and

requirements.

BACKFRAME

2 FT.

GATE OPENING

Figure 4

3 FT. MIN.

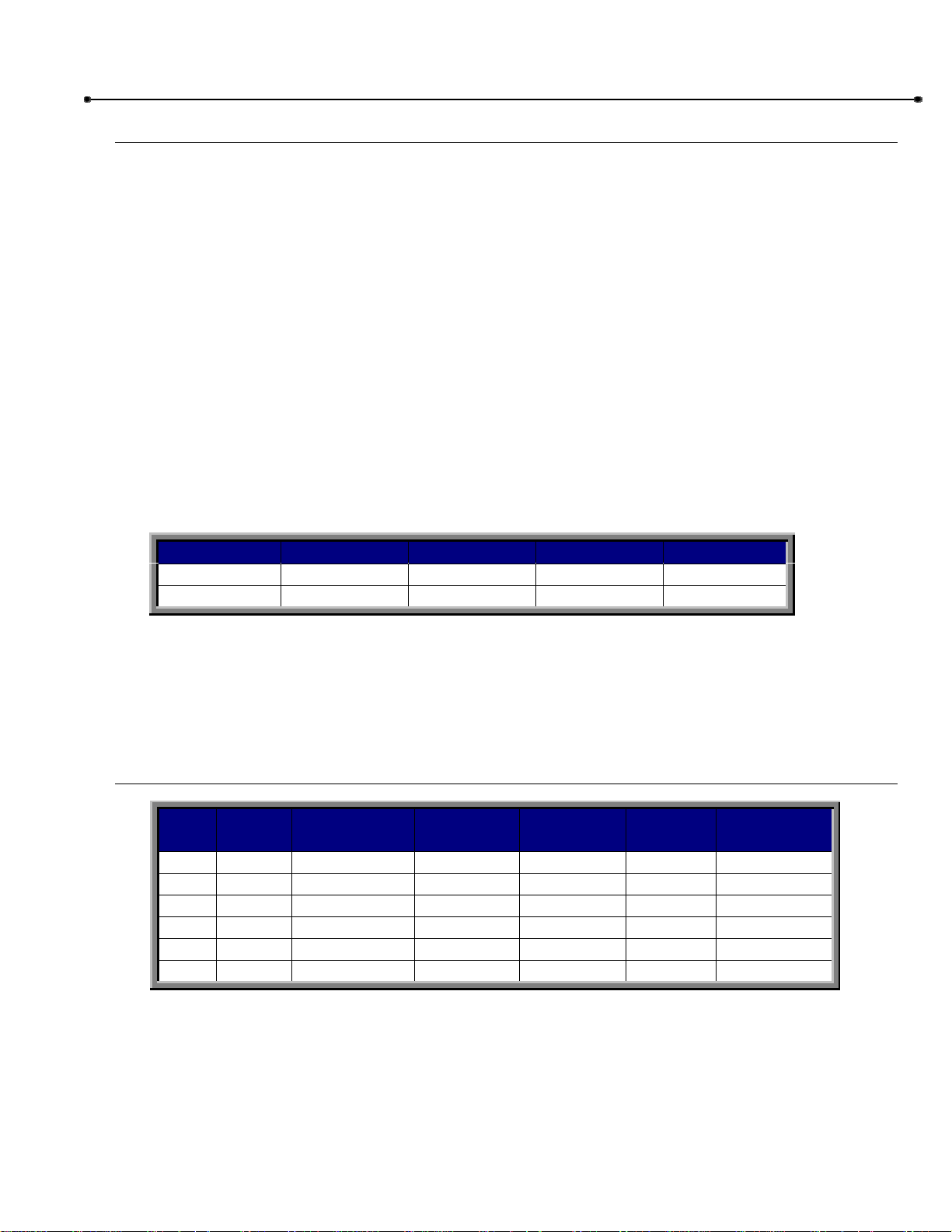

Wiring Specifications

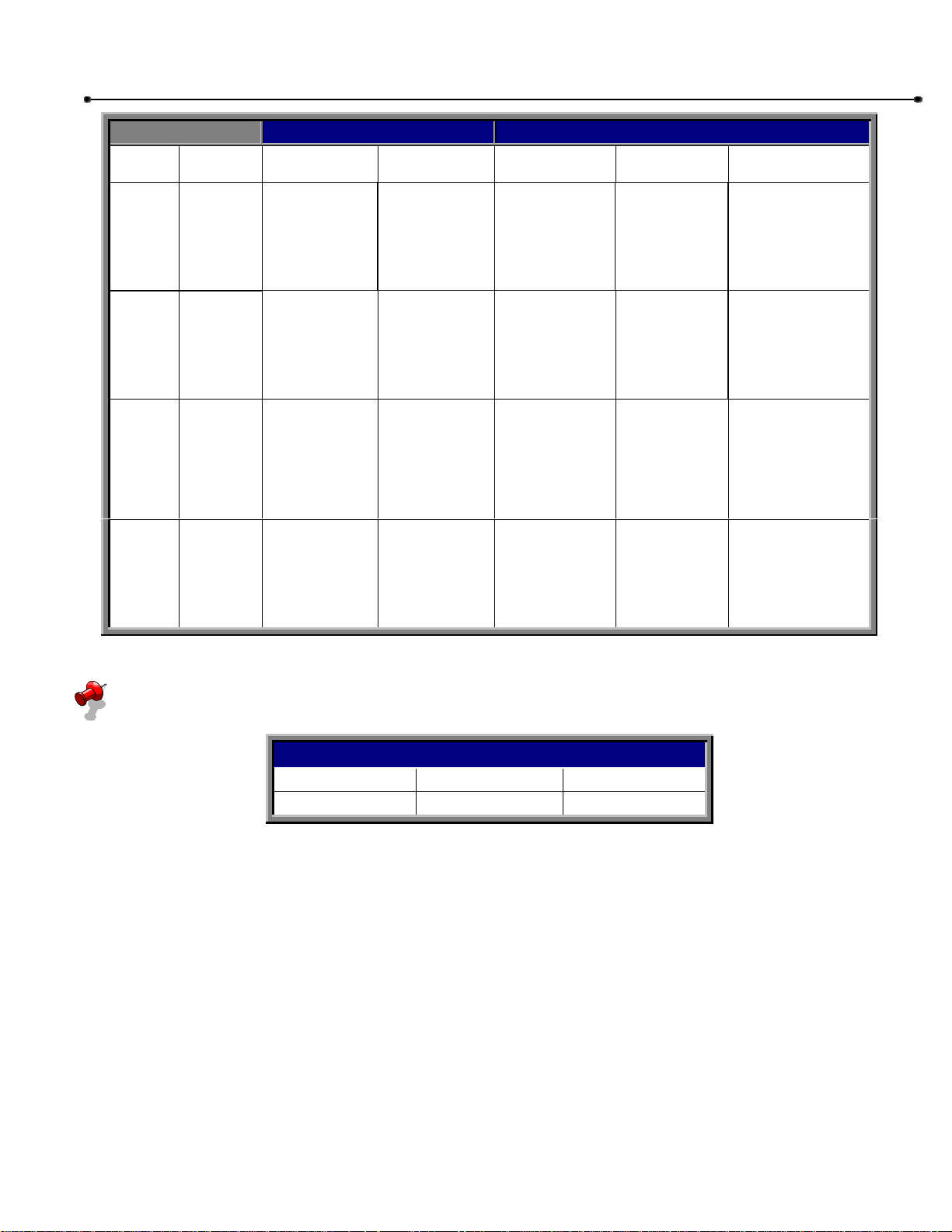

Refer to Table 5.

A. The distances shown in Table 5 are measured in feet from the operator the power source.

B. These calculations are based on the National Electrical Code and allows for a 5% voltage

drop.

C. Supply voltage must be within 10% of the operator’s rating under load conditions.

D. There calculations are based on stranded copper wire.

E. It is highly recommended that only 90% of the distances shown be used; this will allow for a

10% safety factor.

F. For dual units, the distance shown should be cut in half.

G. Permanent wiring is to be employed as required by local codes.

H. All local codes must be strictly adhered to. It is very important that operator is properly

grounded.

I. Do not run control wires in the same conduit with power wires.

Doc 01-G0685

Rev D

J. Do not run multi conductor or parallel conductor cable for controls.

K. All power wiring should be dedicated and protected.

WIRE

GAUGE

6

8

10

12

Pre-Installation Check-List 11

Single Phase 3 Phase

HP 115 VAC 230 VAC 230 VAC 460 VAC 575 VAC

1/3

1/2

3/4

1

1-1/2

2

1/3

1/2

3/4

1

1-1/2

2

1/3

1/2

3/4

1

1-1/2

2

1/3

1/2

3/4

1

1-1/2

2

684

473

324

237

158

-432

299

204

149

100

-271

187

128

94

62

-170

117

80

59

39

--

3,077

2,051

1,231

947

648

437

1,942

1,295

777

597

409

299

1,218

812,

487,

375,

256

187

763

509

305

235

161

117

4,737

2,842

2,030

1,421

947

711

2,990

1,794

1,281

897

589

448

1,876

1,125

804

563

375

281

1,175

705

503

352

235

175

14,211

14,211

7,105

5,684

4,060

2,842

8,969

8,969

4,484

3,587

2,562

1,794

5,627

5,627

2,814

2,251

1,608

1,125

3,524

3,524

1,762

1,410

1,007

705

35,527

17,764

11,842

8,882

5,921

4,441

22,422

11,211

7,474

5,605

3,737

2,803

14,068

7,034

4,689

3,517

2,345

1,758

8,810

4,405

2,937

2,203

1,468

1,101

Table 5

NOTE: Calculated using NEC guidelines. Local codes and conditions must be reviewed for suitability

of wire installation. Master/Slave units must be installed on separate circuits.

Control Wiring

Volt Max. Dist. (Ft.) Wire Gage

24 1000 18

Table 6

Doc 01-G0685

Rev D

Loading...

Loading...