Page 1

Installation and

Maintenance Manual

Slide Gate Operator

Model SL500-11

Doc 01-20220

Rev D

Page 2

Contents

2

Contents

General Information ____________________________________________ 4

Supplied Parts ___________________________________________________________ 4

Cycle Rate ______________________________________________________________ 4

Specifications ___________________________________________________________ 5

Dimensional Outline ______________________________________________________ 5

Safety Information______________________________________________ 6

Safety Instructions________________________________________________________ 6

Safety Precautions for Open-Roller Gates and Ornamental “Grill Type” Gates ________ 8

Preparing the Installation _______________________________________ 10

Pre-installation Check List ________________________________________________ 10

Wiring Specifications ____________________________________________________ 10

Operator Features _______________________________________________________ 11

Programmable Features___________________________________________________ 14

Led Descriptions ________________________________________________________ 15

Installation___________________________________________________ 16

Step 1: Mounting Legs __________________________________________________ 16

Step 2:

Step 3: Mounting ______________________________________________________ 18

Step 4: Gate Brackets ___________________________________________________ 18

Step 5: Drive Chain_____________________________________________________ 19

Step 6: Chain Guards ___________________________________________________ 19

Step 7: Battery Install___________________________________________________ 20

Step 8: Electrical Power Connections_______________________________________ 21

Step 9: Programming ___________________________________________________ 22

Step 10: Limit Switch Adjustments _________________________________________ 27

Step 11: Preliminary System Check-Out _____________________________________ 28

Pedestal Post (Optional) ___________________________________________ 17

Step 12: Accessory Installation_____________________________________________ 28

Required Maintenance__________________________________________ 30

Doc 01-20220

Rev D

Page 3

Contents

Troubleshooting _______________________________________________31

1. Power ______________________________________________________________ 31

2. Accessories__________________________________________________________ 32

3. Programs/Features ____________________________________________________ 32

4. Operator ____________________________________________________________ 33

General Reference Information_____________________________________________ 34

Warranty _____________________________________________________36

FCC Radio Usage Limitations _____________________________________________ 36

Parts List _____________________________________________________37

3

Doc 01-20220

Rev D

Page 4

4

General Information

General Information

Supplied Parts

Inspect the operator for any possible shipping damage and any shortage of parts.

Please not that if accessories were ordered with this unit, some may be packed

separately.

Part Description QTY.

Roller Chain 1

Chain Bracket 2

Chain Stud 2

Master Link 2

Chain Guard 2

Battery 1

3/8 Flat Washer 4

5/16 Lock Washer 4

5/16 – 16 Hex Nut 4

¼ - 20 Bolt 4

¼ - Lock Washer 4

Gate Caution Sign (!)2

Safety Instructions 1

Wiring Diagram 1

! Install

Gate Caution

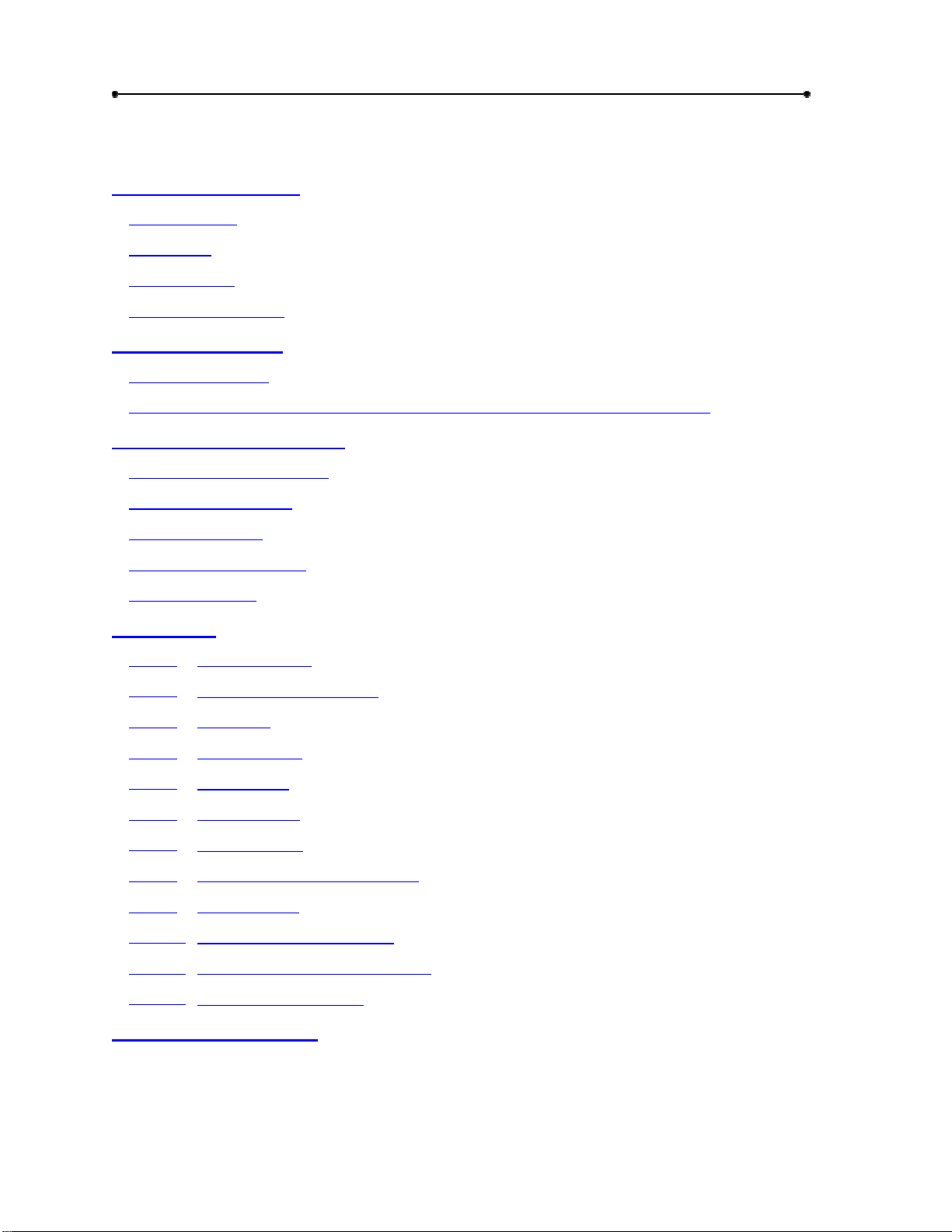

Cycle Rate

Gate opening

in feet

NOTE:

possible, try to keep the cycles per hour at 75% of these figures.

Table 1

signs on both sides of the gate where they can be easily seen.

Frequency of Use - Cycles Per Hour

(cycle equals 1 full open and 1 full close)

Cycles per hour

22 16 13 11 9 8

12

16

20

!

!

!

Table 2

These figures are maximum and should not be exceeded. When at all

Doc 01-20220

Rev D

Page 5

Specifications

General Information 5

MODEL

SL500-11 9” per sec. 150 w. 12.4 amp 20 ft 400 lbs

GATE

SPEED

MOTOR

WATTAGE

FULL LOAD

Table 2

MOTOR

CURRENT

FULL LOAD

MAXIMUM

GATE

OPERNING

MAXIMUM

GATE

WEIGHT

Dimensional Outline

Figure 1

01-20220F1

Doc 01-20220

Rev D

Page 6

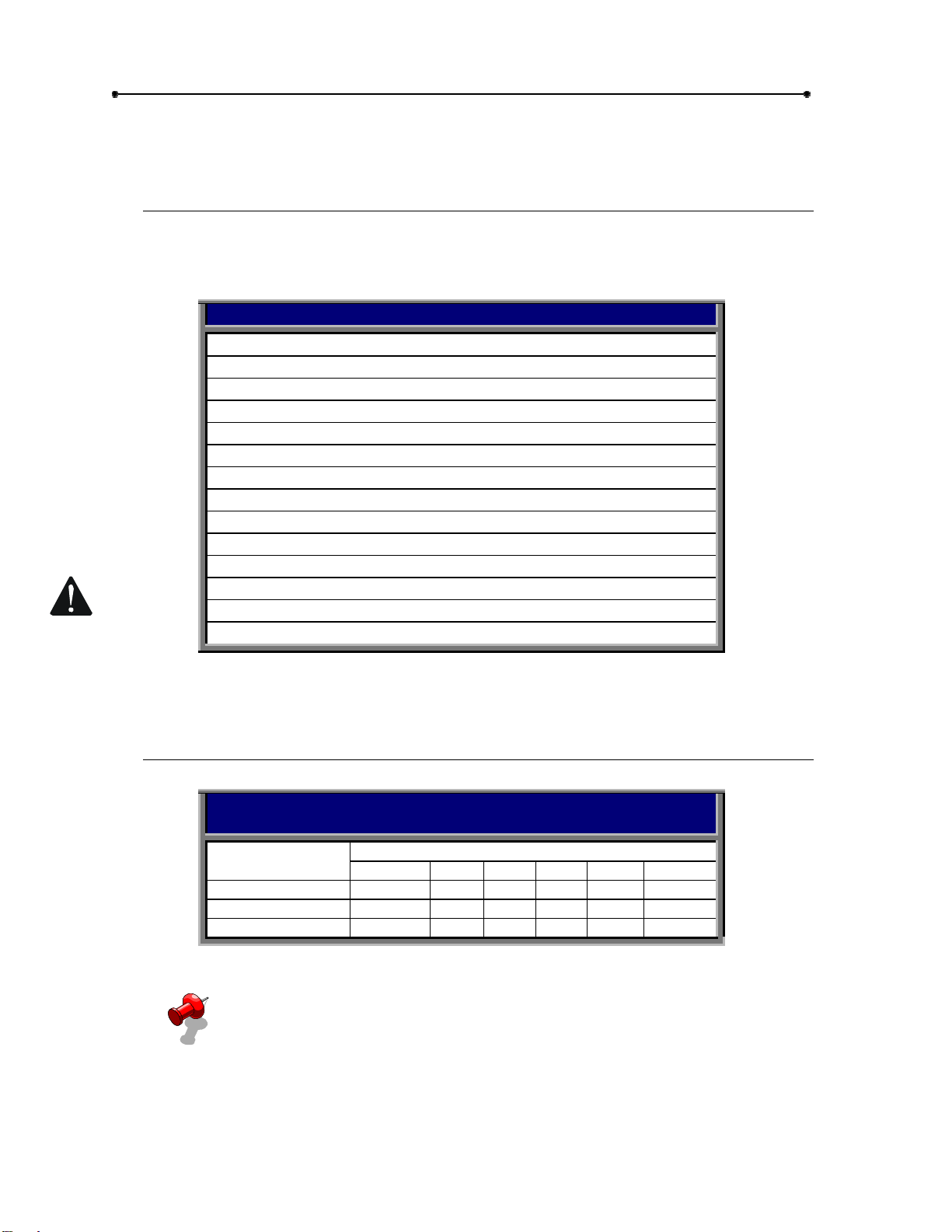

6

Safety Information

Safety Information

Vehicular gate systems provide convenience and security. Gate systems are

comprised of many component parts. The gate operator is only one component. Each

gate system is specifically designed for an individual application.

Gate operating system designers, installers and users must take into account the

possible hazards associated with each individual application. Improperly designed,

installed or maintained systems can create risks for the user as well as the bystander.

Gate systems design and installation must reduce public exposure to potential hazards.

A gate operator can create high levels of force, in its function as a component part of a

gate system. Therefore, safety features must be incorporated into every design.

Specific safety features include:

Gate Edges Enclosed Track Vertical Posts

Guards for exposed

rollers

Screen Mesh

Important instructions follow. These instructions are intended to highlight certain safety

related issues. These instructions are not intended to be comprehensive. Because

each application is unique, it is the responsibility of the purchaser, designer, installer

and end user to ensure that the total gate system is safe for its intended use.

Photo-electric

Sensors

Instructional and

Precautionary Signage

Safety Instructions

Select instructions are highlighted with this precautionary symbol (see left margin).

Failure to follow these selected instructions can result in serious injury or death.

STEP 1: BEFORE INSTALLATION

1

Confirm gate operator model is specified by Installation and Maintenance

Manual for application type, gate size and frequency or use.

2

Confirm ALL appropriate safety features, such as gate edges, photo-electric

sensors, vertical posts and enclosed tracks, are specified.

3

Confirm gate system design reduces pinch points and protects against

entrapment.

4

Confirm gate system design has pedestrian access separate from vehicular

entrance.

5

6

7

8

9

10

Doc 01-20220

Rev D

Confirm gate system design reduces traffic backup.

Confirm warning signage is included in design.

Confirm gate moves freely before installation of operator

Repair or service worn or damaged gate hardware before installation of

operator.

To avoid installation hazards, review the gate system operation and

installation procedures, such as manual disconnect mechanism procedure.

Confirm control design prohibits unauthorized use.

Page 7

STEP 2: DURING INSTALLATION

1

Disconnect power at service panel before making any electrical connection.

2

Avoid pinch points, be aware of all moving parts.

3

Adjust clutch or load sensing device to minimum force setting.

4

Do not over-tighten cutch or adjust force setting above minimum.

5

Install controls where user cannot touch gate while operating controls.

6

Install controls where user has full view of gate operation.

7

Install two or more warning signs on the gate to alert persons in the area of

automatic gate operation. Warning signs must be conspicuous.

8

Install operator inside fence line. DO NOT install operator on public side of

fence line.

9

Secure gate operator cover.

STEP 3: AFTER INSTALLATION

1

Test all safety features.

Safety Information 7

2

Train end user about basic functions and safety features of gate system.

3

Leave Installation and Maintenance Manual and Safety Instructions with

end user.

Doc 01-20220

Rev D

Page 8

8

Safety Information

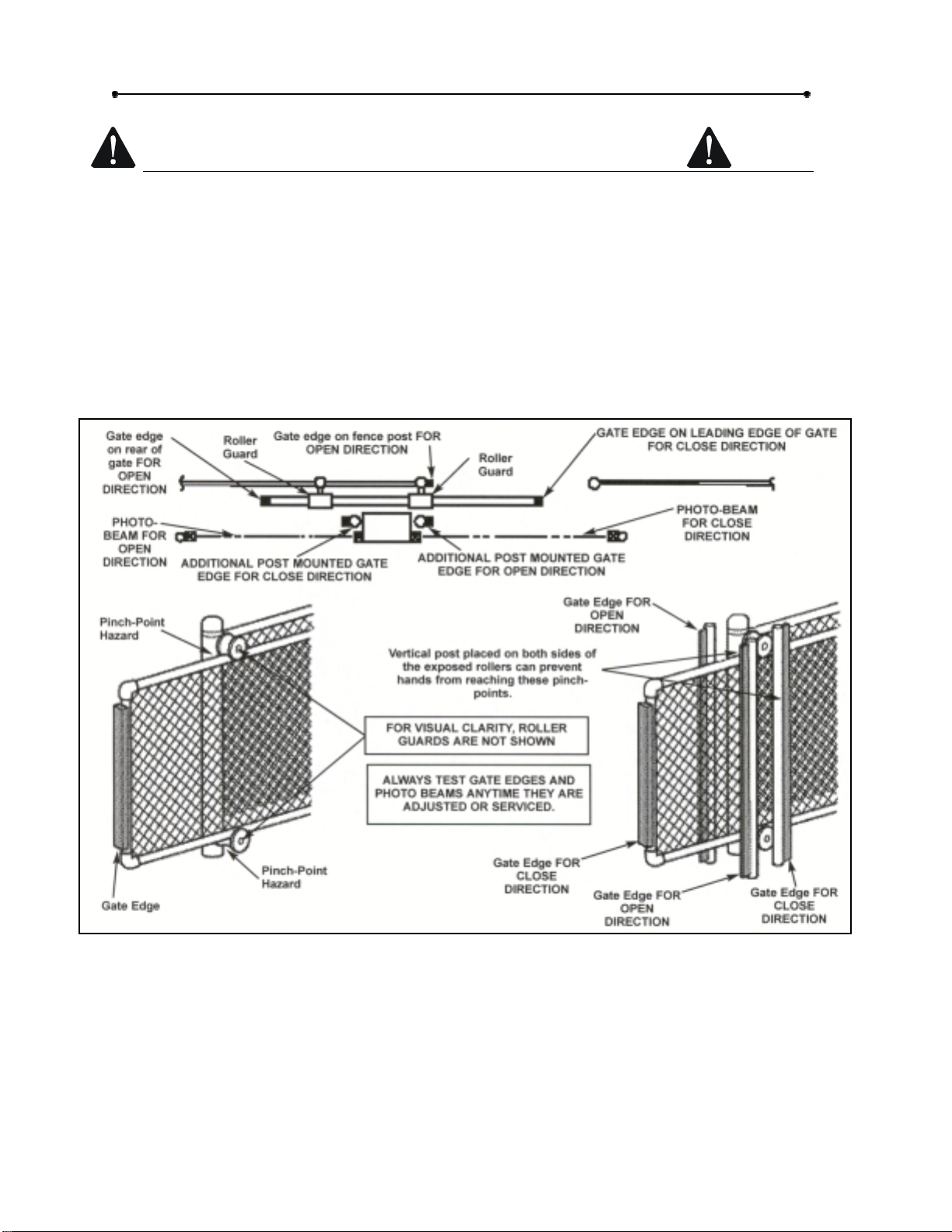

Safety Precautions for Open-Roller Gates and Ornamental “Grill Type” Gates

OPEN-ROLLER GATES

Injuries occur when people get their or feet caught between the top or bottom of the

gate and the gate roller. This potential pinch-point should be guarded against at all

times. Enclosed style gate tracks are available for refitting of these rollers from

many fence suppliers. Also, roller guards are available for installing over the

rollers.

One ore more contact sensors shall be located at the leading edge, trailing edge,

and post-mounted both inside and outside of a vehicular horizontal slide gate.

Doc 01-20220

Rev D

Figure 2

Page 9

Safety Information 9

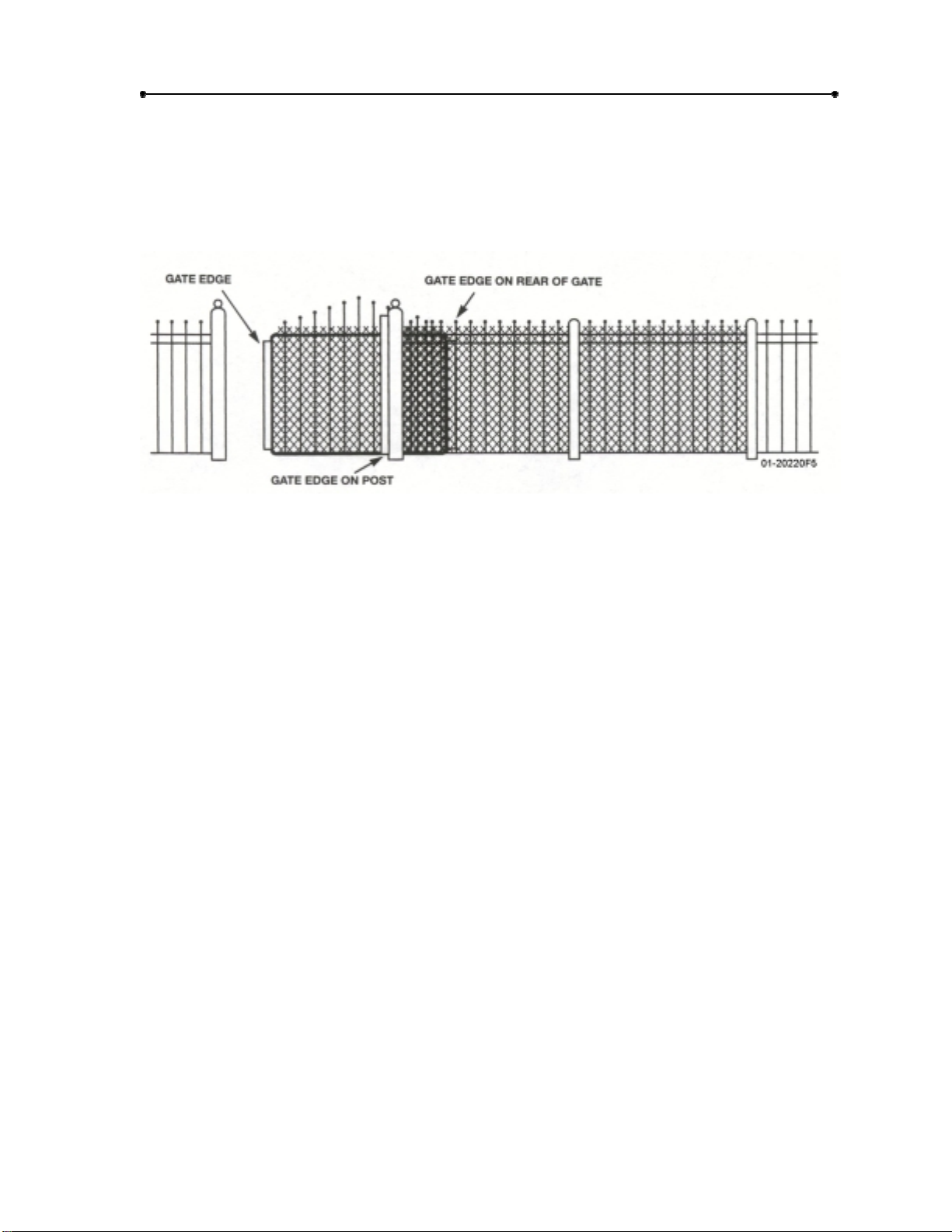

ORNAMENTAL “GRILL TYPE” GATES

Injuries occur when people put their hands and arms through openings in the grill

and the gate is operated. They cannot retract their arms and it gets caught between

the moving gate grill and the stationary fence post or fence. This potential hazard

can be averted by placing a screen mesh on the gate to prevent access through

openings anywhere the gate may travel.

Figure 3

Doc 01-20220

Rev D

Page 10

10

Preparing the Installation

Preparing the Installation

Pre-installation Check List

! Check the gate. It MUST

operate smoothly and freely. If

necessary, lubricate, adjust or

repair the gate prior to operator

installation. The gate MUST be

level and plumb.

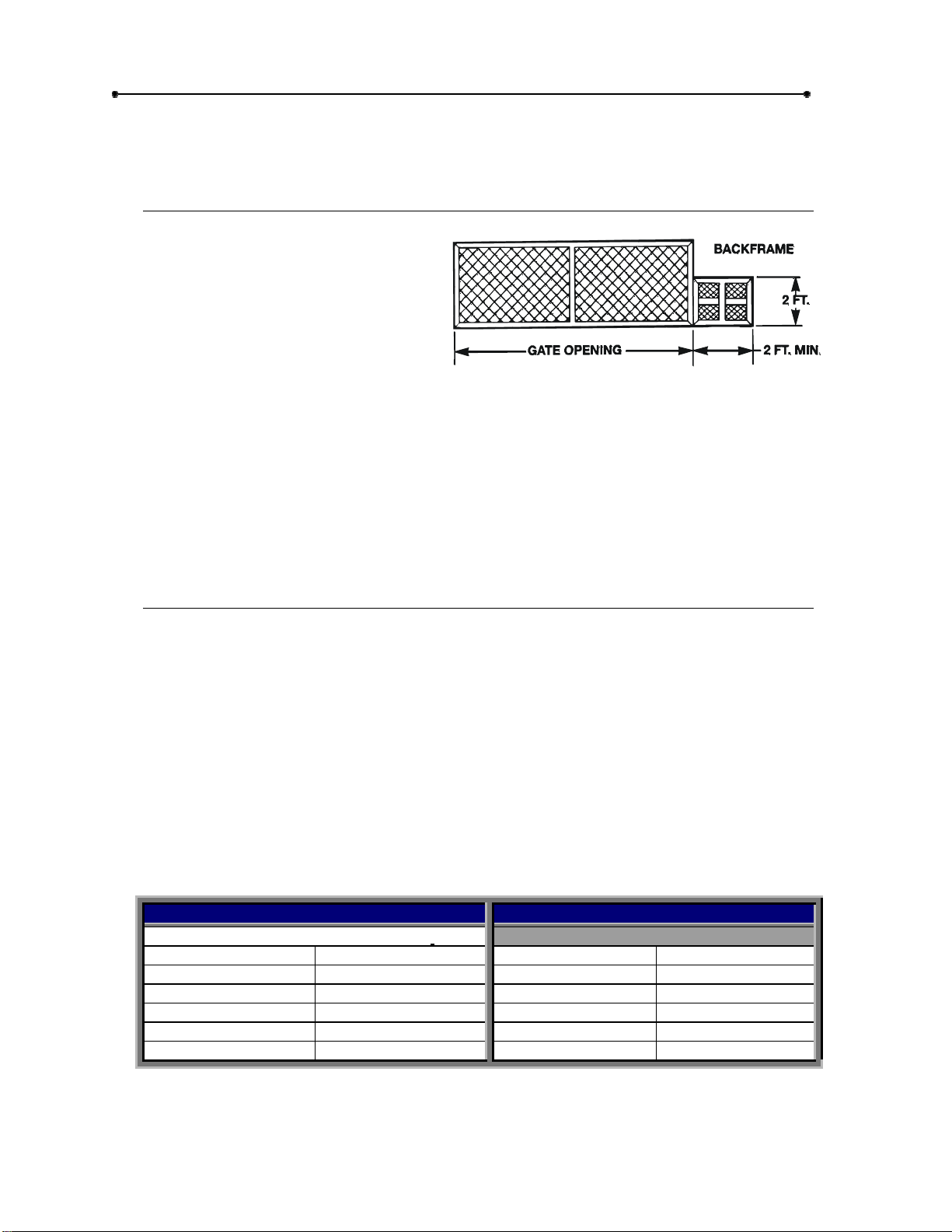

! Some gates may only be as

wide as the gate opening. They

may require a backframe to be

constructed to allow for chain

attachments. See Figure 4.

! Double check the size and weight of the gate to make sure that this operator is

proper for this application.

! If wiring has already been installed, check to make sure it meets the following

specifications and requirements.

01-20220F6

Figure 4

Wiring Specifications

A.

The distances shown are measured in feet

from the operator to the power source.

B.

These calculations are based on the

National Electrical Code and allows fro a

5% voltage drop.

C.

Supply voltage must be within 10% of the

operator’s rating under load conditions.

D.

These calculations are based on stranded

copper wire.

E.

It is highly recommended that only 90% of

the distances shown be used; this will allow

for a 10% safety factor.

F.

For dual units, the distance shown

should be cut in half.

G.

When wire larger than 12 gauge is

used , a separate junction box will

be required for operator power

connections. Not supplied .

H.

All local codes must be strictly

adhered to.

I.

Do not run control wires in the

same conduit with power wires.

J.

Do not run or parallel conductor

cable for controls.

Single Phase – 120 Vac. – 60 HZ.

One Way Distance Wire Gauge One Way Distance Wire Gauge

145ft. 14 1200 ft. 16

225 ft. 12 2000 ft. 14

360 ft. 10

602 ft. 8

Doc 01-20220

Rev D

POWER WIRING CONTROL WIRING

90 ft. 16 800 ft. 18

Table 3

Page 11

Preparing the Installation 11

g

DO NOT RUN OPERATOR UNTIL INSTRUCTED!

OPERATOR MUST BE PROGRAMMED BEFORE OPERATION.

Operator Features

Internal Obstruction Sensin

on Circuit Board

Motor

Brake

Power DisconnectEmergency Stop

Battery

01-20220F7

Figure 5

Circuit

Breaker

BATTERY BACK-UP

Should there be a power failure, the model SL500-11 will automatically switch over

to battery back up to run the gate. If battery is fully charged, it should be able to

run a standard size gate many complete cycles, (cycle = one full open and one full

close). The number may vary depending on idle time and weather conditions.

Battery specifications – Type = Sealed lead acid. Amp hours = 6.5 Max. charging

volt. = 13.7 BATTERY PRECAUTIONS:

NEVER place battery near or in fire.

NEVER short the terminals.

NEVER disassemble the battery.

If dilute sulfuric acid contacts skin or clothes, wash immediately with water

and contact a doctor.

Doc 01-20220

Rev D

Page 12

12

Preparing the Installation

.

INTERNAL OBSTRUCTION SENSING

Built-in motor current monitor. Will automatically “Learn” the current that the motor

is using to open and close the gate. During gate operation, should the current rise

above the learned setting (because of gate obstruction), the model SL500-11 will

react. See program settings for more details.

POWER DISCONNECT SWITCH/EMERGENCY STOP

This switch will turn power (120 vac.) off at the operator. Will also act as an

emergency stop. When turned off, the operator will immediately stop if it was

running.

SPRING APPLIED, ELECTRICALLY RELEASED BRAKE

The purpose of the brake is to minimize overtravel caused by gate coasting. An

added feature of the brake is to assist in preventing backdriving of the gate. The

brake is spring applied whenever the motor is not running. Anytime the motor is

running, 12 v.d.c. is sent to the brake to electrically release it.

MOTOR (12 V.D.C. / 150 WATTS)

The motor used in the model SL500-11 is a PMDC (permanent magnet direct

current) gearmotor. The nominal characteristics of the motor are – 1/8 horsepower,

19:1 gear ratio (with all steel gears), no lkoad r.p.m. = 111, full load r.p.m. = 75, no

load amps = 2.2, full load amps = 12.4, full load torque = 75 lb. in., starting torque =

90 lb. in., and it is rated for intermediate duty.

CIRCUIT BREAKER

15 amp. circuit breaker, with manual reset. Protects the secondary circuit (d.c.

side) of the operator.

NOTE:

unit is operating from the batter, and then turned back on, the unit will NOT

work. It will only work when 120 volts are re-applied.

If the power disconnect/emergency stop switch is turned off while the

MAXIMUM RUN SHUT OFF CIRCUIT

This is a self learning circuit. It will take the average amount of time between the

opening cycle and the closing cycle and add 5 seconds to it. If this time should be

reached during operation, then this circuit will shut of the operator.

REVERSAL DELALY CIRCUIT

Will not allow the operator to instantly reverse the gate, there will be a 1-1/2 second

delay prior to operator reversing direction.

AUDIBLE WARNING

Built in sounder will activate four seconds prior to and during gate movement.

Sound level is adjustable.

DIGITAL MICROPROCESSOR CONTROL BOARD

This circuit board contains all the logic, inputs and outputs for the system. It

contains all the L.E.D.’s the programming button and displays. All input and output

Doc 01-20220

Rev D

Page 13

Preparing the Installation 13

wire connections are made to it. It is protected from voltage spikes and surges by a

“State-of –the-art” voltage clamping circuitry (See Figure 6).

01-20220F8

Figure 6

MID OPEN CIRCUIT

When a control device is wired into this circuit, it will open the gate to position

slightly greater than ½ way from the full closed position or if gate is less than ½

open. If the gate should be more than ½ way open, then the control device will

open the gate to the full open position. If the time delay to close is enabled, the

operator will automatically close from the “mid-open” position.

VEHICLE REVERSE CIRCUIT

If this circuit is energized while gate is closing, gate will stop and reverse to full

open position. If energized while gate is at full open or stopped between limits, it

will not allow the gate to be closed.

VEHICLE OPEN CIRCUIT

A device connected to this circuit will only open the gate. If gate is closing, it will

cause the gate to stop and reverse to the full open position.

EXTERNAL WARNING CIRCUIT

An external signaling system can be connected to this circuit that will activate

anytime the sounder in the operator is active, (4 seconds prior to and during gate

movement).

THREE BUTTON CONTROL CIRCUIT

Sequence of operation is, open/stop/close. Stop will override all other functions. If

closing, open will cause operator to stop and reverse to full open. If opening, close

will cause operator to stop and reverse to full open. If opening, close will cause

operator to stop and reverse to full close position.

ONE BUTTON CONTROL CIRCUIT

Sequence of operation is – open, stop, close, stop. If power has been interrupted,

will always open with first activation.

Doc 01-20220

Rev D

Page 14

14

Preparing the Installation

Programmable Features

PROG.1

(R.H./L.H.): Will automatically set up motor rotation, limit switch functions and

directional logic for the operator.

PROG. 2

(MASTER/SLAVE): Will set up two (2) operators to act as one, using common

controls.

PROG. 3

(CURRENT SENSOR): This program will set the current sensor for different

sensitivities of obstruction force required to make the system react.

PROG. 4

(OBSTRUCTION SENSING CLOSE): Will determine the response the operator will

make when the gate meets an obstruction while closing.

PROG. 5

(OBSTRUCTION SENSING OPEN): Will determ ine the response the operator will

make when the gate meets an obstruction while opening.

PROG. 6

(EXTERNAL REVERSE DEVICE): Will program the system to accept either a

normally open or normally closed contact type external obstruction sensing device.

PROG. 7 & 8

(TIME DELALY TO CLOSE): These two independent programs will allow the gate

to automatically close from the full open or mid open position after a programmed

amount of time.

PROG. 9

(GATE LOCK): This program will allow the use of different types of gate locks to be

used with the system.

Doc 01-20220

Rev D

Page 15

Preparing the Installation 15

Led Descriptions

Color Name Description

Green Program “On when in program mode, “OFF” when in operational mode

Red

Red

Red

Red

Red Gate

Red Gate

Red Power

External

Reverse

Maximum

Run

Current

Sensor

Right

Hand/Left

Hand

Closing

Closing

“ON” when an external reverse device was activated, “OFF” with next

input

“ON” when maximum run circuit shut operator off, “OFF” with next input

“ON” when current sensor circuit caused an operator reaction, “OFF”

with next input

“ON” when operator is programmed R.H., “OFF” when operator is

programmed L.H., “BLINKS” when operator has not been programmed

for either

“ON” anytime sounder is activated prior to and during closing

“ON” anytime sounder is activated prior to and during opening

“ON” when operator electrical power is on. “OFF” when the operator

has no power. “BLINKS” when the control voltage of the operator drops

below 10.5 VAC. See not below.

NOTE:

PROGRAM 2 (MASTER/SLAVE)

When setting up a master/slave system, both operators MUST be programmed

independently.

IMPORTANT:

IMPORTANT:

NOTE:

Table 4

The following is for a standard master/slave system.

The following is for a standard master/slave system.

Program 1:

Program 2:

Program 3:

Program 4 through 9:

One operator will be set to #1 the other will be set to #2.

One operator will be set to #1 the other will be set to #2.

Set each operator as required.

Both operators will have the same settings..

When the battery is fully charged, the red power L.E.D. will “flicker”.

Doc 01-20220

Rev D

Page 16

16

Installation

Installation

Please note that there are two basic types of power unit mounting shown here.

Mounting, using the operators two mounting legs on a concrete pad or pedestal post

mounting (pedestal post is an optional item). The installation shown here is for right

hand units (when looking outside, unit is right side). For left hand units everything is the

same, just opposite.

If there is existing concrete at the area of power unit mounting, use dimensioning

procedure called out. It is suggested that ½” threaded anchors (not supplied), be used

to secure the unit. If needed, shim the unit to

the gate!

ensure that it is level and parallel with

Step 1:

1

2

3

4

5

Mounting Legs

Layout concrete pad as detailed. See Figure 7.

Locate electrical conduit, as required, prior to

pouring concrete.

Pour concrete, ensuring that pad is level and

above the ground line.

Locate four (4) ½” threaded anchors (not

supplied) as detailed.

Allow concrete to set for at least two days

before installing power unit.

IMPORTANT: Anchors must be

positioned accurately and secure

in concrete.

Doc 01-20220

Rev D

01-20220F9

Figure 7: Typical Mounting

Page 17

Installation 17

Step 2:

1

2

3

4

5

Pedestal Post (Optional)

Layout concrete pad as detailed. See Figure 8.

Locate electrical conduit, as required, prior to

pouring concrete.

Pour concrete, ensuring that pad is level and

above the ground line.

Locate four (4) ½” threaded anchors (not

supplied) as detailed.

Allow concrete to set at least two days

before installing pedestal post and power

unit.

Part number

49425

IMPORTANT: Anchors must be

positioned accurately and secure

in concrete.

12”

01-20220F10

Figure 8: Pedestal Post (Optional)

NOTE

Figure 7 and Figure 8 display two possible ways of mounting the unit; there are

others which you may prefer.

IMPORTANT:

It is extremely important that you

double check the distance from the mounting leg to the lowest chain point.

must

You

insure that the gate itself is low enough at the bottom to reach this chain

dimension.

Doc 01-20220

Rev D

Page 18

18

Installation

Step 3:

Mounting

STEP 3A: MOUNTING TO PAD

Carefully secure the power unit the concrete pad with the drive and idler sprockets

facing the gate. It is

very important

that the unit is level and parallel to the gate.

01-20220F11

Figure 9

STEP 3B: MOUNTING TO POST

Carefully secure the power unit to the pedestal with the drive and idler sprocket

facing the gate. It is

very important

that the unit is level and parallel to the gate.

Pedestal Post

Part #49425

Figure 10

Step 4:

Secure gate bracket to the vertical front and rear posts of the gate.

Doc 01-20220

Rev D

NOTE

If a back frame was added, then secure rear gate bracket to the back frame.

IMPORTANT:

of the drive sprocket and with the bottom of the idler sprocket. Slide the gate to the

full open and full closed positions to check alignments.

Gate Brackets

The large slotted holes in gate brackets

01-20220F12

must

be level with the top

Page 19

Installation 19

Step 5:

Before proceeding, it is suggested that the gate be positioned at the half way point.

1

2

3

4

Drive Chain

Using a master link assembly, connect one of the threaded

eye bolts to each end of the drive chain. Then attach this

eyebolt to one of the gate brackets.

Thread chain around drive and idler sprockets.

If required, cut chain to proper length, then attach the

remaining eyebolt to the chain.

Attach this eyebolt to the remaining gate bracket and take

out the chain slack, using both eyebolts evenly. The

suggested amount of chain slack is no more than 1 inch of

slack for every 10 feet of chain length.

tighten chain!

Double check alignments of chain and brackets. It is

suggested that after chain is installed and adjusted, the

gate brackets be welded to the gate.

Do not over-

See Figure 11.

Gate

Bracket

Chain Guard (2)

Chain

Drive

Idler Sprocket

Chain

Sprocket

Viewed from Outside of Gate - Looking In

Figure 11

Step 6:

Using ¼” bolts and lock washers, attach both chain guards to the sprocket shield (see

Figure 11).

Chain Guards

01-20220F13

Doc 01-20220

Rev D

Page 20

20

y

Installation

OPTIONAL POST MOUNTING

If necessary, the model SL500-11 can be post mounted. Requirements are (2) two

2” x 2” posts and mounting hardware. You will need to remove the battery bracket

and the tow mounting legs to install the posts and u-bolts. After installing, replace

batter bracket.

6 1/2”

5.68”

2.73”

01-20220F14

U-Bolts

Figure 12

Step 7:

Locate the two battery wires and connect them to the battery.

Battery Install

IMPORTANT:

The red

wire MUST go to the (+) positive terminal and black wire MUST go to the (-) negative

terminal. Install battery into unit.

Batter

01-20220F15

Figure 13

NOTE:

It is highly suggested that the battery be charged before using operator.

Due to stocking inventory, installation date and weather conditions, we cannot

guarantee that the battery will be completely charged.

Doc 01-20220

Rev D

Page 21

Installation 21

Step 8:

Electrical Power Connections

Panel Box Shown

With Cover Off

01-20220F16

GRD.

Power Conduit

Switch Has Seal

Boot Over It

Figure 14

Emergency

Stop

ON

Disconnect

OFF

Electrical

Switch

CAUTION

Make sure power is disconnected at the main power source and at the

operator’s electrical disconnect switch before proceeding!

Secure the electrical power connection inside panel box. Use electrical diagram

supplied with operator. The 120 vac., single phase, 60 hz. will have – L1 (neutral), L2

(hot) and a ground lead.

The disconnect switch can also be used as an emergency stop switch, if

needed. By turning this switch “OFF”, the gate and operator will stop if

they are opening or closing.

Doc 01-20220

Rev D

Page 22

22

Installation

Step 9:

Programming

This gate controller has (9) nine programmable options which must be set prior to gate

operation. To program the controller, press and hold the “FUNCTION” select

pushbutton for 2 seconds. When the board enters the program mode, the green

program LED will turn on and the two display panels will become active.

When the controller enters the program mode and the program LED turns on, the

“FUNCTION” display panel will display “0” (zero) and the “OPTION” display panel will

display “0” (zero). To exit the program mode, at any time, press and hold the

“FUNCTION” select pushbutton for 2 seconds. The program LED will turn off, indicating

that you a re out of the program mode. The board will reset as if first powered on.

ADJUSTMENT FOR AUDIBLE

WARNING SOUND LEVEL

AUDIBLE WARNING SOUNDER

PROGRAM

EXT. REV.

01-20220f17

MAX. RUN

OBSTRUCTION

RIGHT HAND

CLOSING

OPENING

POWER

FUNCTION & OPTION

PROGRAMMING BUTTONS

INDICATOR L.E.D.s

(Light Emitting Diode)

FUNCTION & OPTION

DISPLAY PANELS

Doc 01-20220

Rev D

Figure 15

Page 23

Installation 23

PROGRAM 1 – RIGHT HAND/LEFT HAND OPERATION

Program 1 determines whether the operator is “right handed” or “left handed”. To

determine which type your gate controller needs to be set to, observe the

installation from the operator side of the gate.

0 = NOT SELECTED – OPERATOR WILL NOT FUNCTION IN THIS MODE

1 = RIGHT HANDED – OPERATOR WILL MOVE GATE FROM LEFT TO

RIGHT TO OPEN

2 = LEFT HANDED – OPERATOR WILL MOVE GATE FROM RIGHT TO

LEFT TO OPEN

If the operator is on the right side of the opening, the operator is “right

handed”.

If the operator is on the left side of the opening, it is “left handed”.

1

Press the FUNCTION select button to set

the function to “1”.

The option display will show

a “0”, “1” or “2”.

Option “0” is the factory setting and does not

allow gate movement.

2

Pressing the ”OPTION” button will change

the option between “1” and “2”.

When the correct option for your application

is indicated, press the “FUNCTION” select

button to save this selected option and to

step to the next program.

This option must be changed

to either a “1” for right hand

or “2” for left hand.

PROGRAM 2 – MASTER/SLAVE OPERATION

Program 2 selects whether the installation is a single operator or dual operators

with common controls.

0 = SINGLE GATE OPERATOR INSTALLATION

1 = MASTER GATE OPERATOR

2 = SLAVE GATE OPERATOR

1

If the “FUNCTION” display shows “2”,

proceed on as follows.

If it does not show “2” then

press the “FUNCTION” select

button to set the display to “2”.

2

The “OPTION” display will indicate a “0”,

“1” or “2”. The “0” option is the factory

setting and is for single operator gates.

3

Press the “OPTION” select button to

change the option between “0”, “1” or “2”,

where option “1” is for master operation.

The “0” option can be changed

to “1” or “2” for dual gate

operators.

Doc 01-20220

Rev D

Page 24

24

Installation

IMPORTANT:

Once all programming is completed for the master operator, you

must then program all features for the slave operator. All nine (9) programs

should be the same except for – Program 1 (R.H./L.H.). In most cases one

unit will be right handed and the other will be left hand. Program 3 (Gate

obstruction sensitivity). In some cases the two gates will require different

settings.

NOTE – MASTER/SLAVE OPERATION:

The two operators must have the 3

interconnection wires in place between the two operators for the master/slave

system to work. Reference the wiring diagram supplied with units.

PROGRAM 3 – GATE OBSTRUCTION SENSITIVITY SELECT

Program 3 selects the force required to make the internal speed sensor react.

0 = MINIMUM FORCE SETTING

1 = MODERATE FORCE SETTNG

2 = MEDIUM FORCE SETTING

3 = MAXIMUM FORCE SETTING

1

If the “FUNCTION” display shows “3”,

proceed on as follows.

The “OPTION” display indicates a “0”, “1”, “2”

or “3”. The “0” option is the factory setting.

If it does not show “3” then

press the “FUNCTION”

select button to set the

display to “3”.

2

Press the “OPTION” select button to change

this setting to ei th e r”1”, “2” or “3”.

Option “0” is the most sensitive setting. It will

only take a small amount of force to make

the sensor react.

Option “3” is the least sensitive setting, in this

setting. It will take the most force at the gate

to make the sensor react.

IMPORTANT:

Always select the lowest option number that will function

properly with your gate application.

NOTE:

After you have completed all programming and are testing out the

system, you may have to come back to this program and make some

refinements for proper gate operation. Press the “FUNCTION” select button

to save this selected option and to step to the next program.

PROGRAM 4 – REVERSE WHEN CLOSING

Program 4 determines the response of the gate operator to an obstruction from

either the internal sensor or an external obstruction signal while closing.

0 = REVERSE FOR 2 SECONDS THEN STOP

1 = REVERSE TO FULL OPEN POSITION

With “FUNCTION” display showing “4”, press the “OPTION” select button to select

either “0” or “1”. The factory setting is “1”.

Doc 01-20220

Rev D

Page 25

Installation 25

PROGRAM 5 - REVERSE WHEN OPENING

Program 5 determines the response of the gate operator to an obstruction from

either the internal sensor or the external obstruction circuit, (#6 on wiring diagram),

while opening.

0 = REVERSE FOR 2 SECONDSTHEN STOP

1 = STOP

With “FUNCTION” display showing “5”, press the “OPTION” select button to choose

either “0” or “1”. The factory setting is “1”.

IMPORTANT:

Programs 4 and 5 are only for the internal sensor and for the

external obstruction device (adaption #6 on wiring diagram). Note that

adaption #5, shown on wiring diagram (vehicle reverse device), will always

stop and reverse a closing gate to the full open position. Adaption # 7 will only

react in the closing direction.

PROGRAM 6 – EXTERNAL REVERSE DEVICE SELECT

This program determines which polarity of signal on the external obstruction device

will cause the gate operator to react.

0 = EXTERNAL REVERSE DEVICE WITH NORMALLY CLOSED CONTACTS

1 = EXTERNAL REVERSE DEVICE WITH NORMALLY OPEN CONTACTS

If a device with normally open contacts is used, then this option should be set to

“1”. If a device with normally closed contacts then this option should be set to “0”.

The factory setting is “1”.

When the correct option is displayed, press the “FUNCTION” select button to save

the choice and to step to the next program.

PROGRAM 7 – TIME DELAY TO CLOSE ENABLE/DISABLE

This program enables or disables the automatic time delay to close option.

0 = TIME DELAY TO CLOSE “OFF”

1 = TIME DELAY TO CLOSE “ON”

When the correct option is displayed, press the “FUNCTION” select button to save

the choice and to step to the next program.

NOTE:

If the timer to close option is set to disable, you will not need to do

program 8. By pressing the “FUNCTION” select button twice you will go to

program 9.

Doc 01-20220

Rev D

Page 26

26

Installation

PROGRAM 8 – TIME DELAY TO CLOSE “TIME”

This program sets the time from when the gate is fully open to the time when it will

automatically begin to close.

0 = 2 seconds

1 = 15 seconds

2 = 30 seconds

3 = 60 seconds (1min.)

4 = 90 seconds (1- ½ min.)

5 = 120 seconds (2 min.)

6 = 180 seconds (3 min.)

7 = 240 seconds (4 min.)

1

By pressing the “OPTION” select button, choose the time that

will be required for this gate application.

2

Once the selection has been made, press the “FUNCTION”

select button to save this selection and to step to the next

program.

PROGRAM 9 – GATE LOCK TYPE SELECT

If gate lock is to be used with the operator, this program determines the state of the

built-in lock relay contacts and how they will turn on and off.

0 = LOCK OUTPUT NORMALLY “OFF”

1 = LOCK OUTPUT NORMALLY “ON”

By pressing the “OPTION select button, choose either option “0” or “1”.

Option “0” would normally be selected if you are using a solenoid activated type

lock system. The built-in lock relay’s contacts will be open when gate is closed.

They will close for one second before the gate begins to open, and open up two

seconds after the gate has begun moving.

Option “1” would normally be selected if you are using a magnetic type lock system.

The built-in lock relay’s contacts will be closed while the gate is closed. They will

open up one second before the gate begins to open and remain open.

With either selection the contacts will be closed when the gate begins to close.

NOTE:

For wiring information see electrical diagram supplied with operator. If no lock

system is to be used, it does not matter which option is shown in the display.

This was the last programming option. To exit program mode, press and hold the

“FUNCTION” select button for 2 seconds. The green program LED will turn off.

Doc 01-20220

Rev D

Page 27

Installation 27

Step 10:

Limit Switch Adjustments

IMPORTANT:

1

Remove operator top cover and locate limit

switch assembly.

2

Attach activation device such as a three button

station to control terminal strip.

3

With power on and gate a the mid way point,

activate operator to open.

After unit shuts off, press detent down and adjust

open limit nut until full open position is obtained.

Operator must be programmed before operation!

Reference wiring diagram or

control wiring section further

on in this manual.

Note direction of limit nuts.

Repeat this procedure for the

full close direction.

Figure 16

01-20220F18

Doc 01-20220

Rev D

Page 28

28

Installation

Step 11:

Before adding any options, accessories or adaptions, it is highly recommended that

you check out the system and its programs. If you have not already done so, .…

! Temporarily connect a 3 button station to the control terminal strip, see next

! Test for proper open, stop and closing of gate.

! Test the internal sensor system.

! Test for proper operation of all programs that were programmed into the

! Once everything checks out okay, then proceed to adding on the accessory

Step 12:

See Figure 17 for more information.

Refer to

Preliminary System Check-Out

page or wiring diagram supplied with operator.

system.

items for this job site.

NOTE:

one is attached check it for proper operation before adding the next.

We recommend that, if more than one accessory item is used, after each

Accessory Installation

Wiring Specifications

on p. 10 for wiring distance and wire gauge information.

WARNING

Make sure that the two (2) gate caution signs are secured to the gate: one on the

inside and one on the outside. They must be easily visible. If exterior controls such

as keyswitch, card reader or pushbutton station are to be incorporated into this

system, make sure the controls are installed where the user cannot touch the gate

while operating controls. Install the controls where the user has full view of gate

operation.

Doc 01-20220

Rev D

Page 29

Installation 29

Figure 17

Doc 01-20220

Rev D

Page 30

30

p

Required Maintenance

Required Maintenance

Normal Usage

Check at least once every

MONTH INTERVALS

Internal sensor Check for proper operation

External safety systems Check for proper operation

Com

Gate caution signs Make sure they are present

Brake system Check for proper operation

lete Check Out

Drive chain (D) (E) Check for excessive slack & lubricate

Drive sprockets Check for set screw tightness

Battery back-up Disconnect power and test battery

Gate Inspect for wear or damage

Accessories Check all for proper operation

Electrical Inspect all wire connections

Frame bolts Check for tightness

Total unit Inspect for wear or damage

13612

!

!

!

!

!

!

!

!

!

!

!

Table 5

NOTES

A.

CAUTION -

When servicing, always disconnect operator from electrical power

supply.

B. Severe or high cycle usage will require more frequent maintenance checks.

C. Inspection and service should always be performed anytime a malfunction is

observed or suspected.

D. Limit switches may have to be reset after any major drive chain adjustments.

E. If lubricating chain, use only a proper chain lube spray or a lightweight motor

oil. Never use grease or silicone spray.

F. When servicing, please do some “house cleaning” of the operator and the area

around the operator. Pick up any debris in the area. Clean the operator if

needed.

G. It is suggested that while you are at the site, you take some voltage readings of

the operator. Using a VOM, double check the incoming voltage to the operator

is

to make sure it

within ten percent of the operator’s rating.

H. While you are at the site, now would be a good time to let the owner or

manager know about any new items available or any safety items that could

and should be added to the site.

IMPORTANT:

I.

Please leave this manual at the job site, preferably with the end

user or facility manager.

Doc 01-20220

Rev D

Page 31

Troubleshooting

Troubleshooting

When troubleshooting, one of the first things to do is try to isolate the problem area. The

four (4) main areas to check out are:

POWER

ACCESSORIES

PROGRAMMING

OPERATOR

1. Power

Always use extreme caution! Some possible symptoms of power problems include:

! The obvious one – the operator will not run.

! The operator runs slow.

! Circuit breakers or fuses keep tripping.

31

! Operator starts but then stops.

1A.

Using a V.O.M. take a voltage reading at the control transformer’s primary

terminals. You should get a reading as follows:

Nominal volt. Min. Max.

120v 108 132

If you get a reading that does not fall into the minimum/maximum area, then check

out your main power supply. Check the wire run from the power supply to the

operator. Double check the gauge of the wire versus the distance.

1B.

If the voltage reading is O.K. from 1 a, then take the same voltage reading with the

operator running. If voltage drops below the minimum with this reading, then there

could be an excessive current draw somewhere.

1C.

In some cases, power drops can occur at only specific times during the day or

night. This can be caused by increased power demands in a general area at a

specific time.

Doc 01-20220

Rev D

Page 32

32

Troubleshooting

2. Accessories

Add-on accessories can create many of the problems that are credited to the operator.

Many applications have more than one accessory item attached to the operator and

some of these items even draw their power from the operator. So, before we start

blaming the operator, let’s take a look at all the add-on’s first.

Some of the symptoms that can show up because of accessories include:

! The operator won’t close.

! The operator won’t open.

! The operator will not run.

! The operator begins to run then stops or reverses.

2A.

Whenever the problem is thought to be an accessory and there are more than one

connected to the operator, always disconnect one accessory at a time and then test

the system. This will hopefully isolate which item is causing the problem.

2B.

If an accessory

close), fails in the closed position or sends out a continuous signal. The operator

will hold the gate in one position until the signal from the accessory is removed.

item

is being used as an access control device (used to open or

2C.

In some applications, the gate may begin to move then either stop or stop and

reverse within a couple of seconds. This can be caused by an external obstruction

device that has failed.

3. Programs/Features

In many cases, unawareness of the programs and their functions can make it look like

in

there is a problem when

Before you start tearing things apart, please review pages 8, 12, 13 & 14.

Always use the LE.D.’s that are on the circuit board. They will normally lead you to the

particular area to check out.

3A.

PROGRAM 1 - R.HJLH.: If not programmed for either one, the operator will not

work. Check LE.D.

3B.

PROGRAM 2- MASTER/SLAVE: If you have a single unit and have the program

set for master, the operator will not work. It MUST be set to #0. When programming

for master/slave, both operators MUST be programmed individually.

actuality it is just missed or wrong program mode setting.

Doc 01-20220

Rev D

Page 33

Troubleshooting 33

3C.

PROGRAM 3- CURRENT SENSOR: A damaged or poorly working gate can trip

the sensor and cause what is called, “phantom reversal or stopping”. Also,

excessive wind loads can cause the sensor to react. Double check the sensor

settings.

3D.

PROGRAMS 4 & 5- OBSTRUCTION REACTION SETTINGS: Please review these

programs.

3E.

PROGRAMS 6- EXTERNAL REVERSE DEVICE: If this program is set the opposite

from what the device is, the gate will not move.

3F.

PROGRAMS 7, 8 & 9: Please review these programs.

3G.

When in the program mode (green LE.D. on), the operator will not work.

3H.

The operator will automatically exit the program mode if no button (function or

option) is pressed within five minutes.

3I.

MAXIMUM RUN SHUT OF CIRCUIT: This is a built in self learning circuit. It will

automatically shut off the operator after the amount of time to open plus 5 seconds.

LED will indicate activation.

3J.

Mid open circuit. If terminals #4 and #6 are activated, operator will only open to

approximately the 1/2 way position.

4. Operator

4A.

The transformer is: 120 vac,. input /1 2vac. output / 100 Va. If the transformer is

suspected, check for proper voltages.

4B.

If the motor sounds like it’s running but the gate is not moving, there is a possibility

that there is a broken gear tooth inside the gear box. To test for this, carefully while

try

the motor is running,

broken tooth or two.

pushing the gate. If it starts to move then there might be a

Doc 01-20220

Rev D

Page 34

34

Troubleshooting

4C.

To check the brake. First take a V.O.M. reading at the terminals where the two

brake leads are connected at the circuit board. You should get 12 vdc. there when

the motor is running. If not, then the circuit board should be replaced. Second, with

try

gate either opened or closed,

to move. If it is very easy to move then the brake has mostly likely failed and the

entire gear motor should be replaced.

manually moving the gate. It should be

very

hard

4D.

If unit will not run, double check the circuit breaker on side of operator. Push button

on circuit breaker.

4E.

wires.

run

from the battery. First check the battery for voltage and current.

see

12 vdc. at

If unit does not

Second, remove the two wires from the battery and using V.O.M. take a voltage

reading from the two wires. When 120 vac. is active you should

these

two

4F.

The two limit switches used are S.RD.T. (single pole double throw). Each has two

wires attached to it, one on the common and one on the normally open side (N.O.).

The limit switch designations are LS-1 and LS-2. LS-1 is the open switch when the

and

operator is programmed for “right hand”

switches are opposite when the unit is programmed for “left hand”.

LS-2 is the closed switch. The two

4G.

If a three button station or a normally closed (N.C.) stop button is not used, there

MUST be a jumper placed between terminals #2 and #4 (stop & common). If a

three button station or stop button is used, then this jumper MUST be removed. If

wire is not there when it should be, the operator will not work. If it is there when it

should not be, the operator will not stop when the stop button is pressed.

4H.

ALWAYS double check the wire connections at the terminal strips. Make sure that

the wire itself, not the insulation of the wire is being clamped down on. Also check

for a loose wire connection.

General Reference Information

THE GATE

Double check the gate and its related hardware. Does the gate move freely? If it

does not, this can and will affect the unit’s internal obstruction sensor.

WIRING DIAGRAM

Always reference the wiring diagram for this operator. Note that some accessory

items may have their own wiring diagram.

Doc 01-20220

Rev D

Page 35

Troubleshooting 35

COMPONENT DESCRIPTIONS

A. GEAR MOTOR WITH BRAKE -12 v.d.c. permanent magnet, rated horsepower

1/8, no load r.p.m.

=

12.4, gearbox ratio = 19 to 1, duty cycle = intermittent, brake is spring activated

12 v.d.c. to release.

B. POWER DISCONNECT SWITCH - Rocker style, triple pole single throw

(T.P.S.T.), cont ac t ratings

C. TRANSFORMER - Primary voltage

100 v.a., class B insulation, built in thermal overload.

D. LIMIT SWITCH - Single pole double throw (S.RD.T.), 15 amp. @250 vac.

E. CI RCUIT BREAKER - 15 amp. © 125 v.a.c./50 v.d.c. with manual reset.

F. BRIDGE RECTIFIER - Full wave, 12 v.a.c. to 12 v.d.c., reverse voltage

volt. mm., rectified current

=

111, no load amps = 2.2, full load r.p.m. = 75, full load amps

=

15 amp. © 125 v.a.c./10 amp. ©

=

120 v.a.c., secondary voltage~ = 12 v.a.c.,

=

50

=

25 amp. m m .

G. BATTERY -

13.7, battery storage info = 6 months c~ 68 degrees F = 80% voltage, 12 months

© 68 c~rees F

hours, or 1/2 amp. for 13 hours, etc.

NOTE

No attempt at service or repair should be made on the battery!

Type = sealed lead acid, amp. hour = 6.5, maximum charging volts

=

63% voltage. Amp hours = Battery will supply 1 amp, for 6 1/2

=

Doc 01-20220

Rev D

Page 36

36

Warranty

Warranty

LIMITED ONE-YEAR WARRANTY

LiftMaster gate operators are warranted against deficiencies in material and workmanship for a period of one

(1) year from date of purchase, providing recommended installation, and maintenance procedures are

followed. This warranty is in lieu of all other warranties expressed or implied (some states do not allow

limitations on how long an Implied warranty lasts, so this limitation may not apply to you) and shall be

considered void if damage was due to improper installation or use, connection to improper power source, or if

damage was caused by fire, flood or lightning. The manufacturer will not be responsible for any labor charges

Incurred in the removal or replacement of deficient parts.

In case of failure due to deficiencies in material or workmanship during the warranty period, the complete

gate operator will be repaired or replaced at the manufacturers option. New or factory rebuilt replacements

will be used. Replacement parts are warranted for the remaining portion of the original warrant period.

LiftMaster will pay freight on our return of repaired or replaced items in warranty.

This warranty give you specific rights, and you may also have other rights which vary from state to state.

FCC Radio Usage Limitations

CAUTION:

Federal Communications Standards for part 15 radio devices. Operation of this device

is subject to the following conditions: (1) This device may not cause harmful

interference; (2) This device must accept any interference that my be received,

including interference that may cause undesired operation; (3) Changes or

modifications not expressly approved by LiftMaster could void the authority of users to

operate this equipment.

The gate operator and all accessory equipment has been designed to

Doc 01-20220

Rev D

Page 37

Parts List

1/4 - 20 X 1/2

HEX BOLT W/

LOCK WASHER

Parts List

10-32 X 1/4 SELFTAP SCREWS

W/LOCK WASHER

37

01-20220F20

10-32 X 3/8 MACH.

SCREW W/WASHER

10-24 X ¾ MACH.

SCREW W/LOCK

WASHER & NUT

REF. NO. PART NO. DESCRIPTION/NOTES

1 49429 COMPLETE PANEL BOX

2 & 3 49430 KIT, 3-R BOX & COVER

4 310.2047 TRANSFORMER ONLY

5 310.2045 RECTIFIER ONLY

6 310.1990 DISCONNECT SWITCH ONLY

7 310.2048 SWITCH COVER ONLY

8 49433

9 --- GROMMET

10 410.1457 THRU-BUSHING ONLY

STAND-OFF KIT (OPTION), FOR

OPTIONAL RADIO RECEIVER

Table 6

Figure 18

Doc 01-20220

Rev D

Page 38

38

Parts List

10-24 SCREW,

WASHER & NUT

6-32

SCREW

1/4-20 BOLT

WASHER & NUT

1/4-20 BOLT

WASHER & NUT

5/16-18 BOLT

& WASH.

10-32 SCREW

& WASHER

01-20220F21

1/4-20 BOLT

WASHER & NUT

5/16-18 BOLT,

NUT, WASHER

8-32 SCREW

& WASHER

Doc 01-20220

Rev D

Figure 19

Page 39

01-20220F22

Parts List 39

Figure 20

Ref. No. Part No. Descriptions/Notes Ref. No. Part No. Description/Notes

1

2

3

4 510.1024 Motor/Gearbox 20 645.0002 Woodruff Key

5

6

7

8 49426

9

10 23-10041 Limit Sw 26 520.0874-T

11 49427

12 49428 Stand-Off Kit - Incl: (5) 28

13 204001 Cir c uit Bd. 29

14 310.2042

15 310.2043

16 310.2044

510.1021-T

510.1022

510.1023

310.1113

520.0868 Bearing Plate Assy.

510.1027 Detent Plate

510.1029

Housing 17 310.2045 Rectifier

Mounting Angle 18 310.2046 Circuit Breaker

Battery Bracket 19 49431

Limit Nut 21 520.0870

Spring Kit - Ncl: Scr’s,

Washers, Nuts

Limit Switch Bracket 25

Limit Sw. Scr. Kit - Incl:

(2) Scr’s.

Circuit Bd. Connector -3

Pole

Circuit Bd. Connector -4

Pole

Circuit Bd. Connector -6

Pole

Drive Sprkt

Sprocket Shield Assy -

Incl: Shield & Bearing

22 625.0058 Idler Bolt

23 510,1032

24 520.0871

510.1036-T

27 49056

410.1322

310.0241 Chai n Stud Not Sh o wn

30

31 410.1457 Bushing (For Limit Brkt)

49425 Pedestal Not Shown

Support Tube

Idler Sprocket Assy -

Incl: Sprk~ & Bearing

Cover Kit. Incl: Co ver

W/Labels

Chain Guard Assy - Incl:

Guard W/Caution Tape

Battery

Chain Bracket Not

Shown

Table 7

Doc 01-20220

Rev D

Page 40

COPYRIGHT 2001

ALL RIGHTS RESERVED

This document is protected by copyright and may not be copied or adapted without the prior written

consent of LiftMaster. This documentation contains information proprietary to LiftMaster and such

information may not be distributed without the prior written consent of LiftMaster. The software and

firmware included in the LiftMaster product as they relate to this documentation are also protected by

copyright and contain information proprietary to LiftMaster.

FOR TECHNICAL SUPPORT

Call our toll free numbers:

(800) 323-2276

(800) 998-9197

Installation and service information is

available six days a week.

TO ORDER REPAIR PARTS

Call our toll free numbers:

(800) 528-2806

(800) 998-9197

Prepare to provide the following

information when ordering repair parts:

Part Number

"

Part Name

"

Model Number

"

Loading...

Loading...