Page 1

®

™

Instruction Manual

™

SL3000UL

HIGH TRAFFIC COMMERCIAL GATE OPERATOR

UL325

compliant

installation instructions and manual book

for architects, general contractors and dealers

© 2005 the chamberlain group, inc. – all rights reserved

UL991

compliant

SERIES

LISTED

Page 2

SL3000UL

9

0

9

8

5

8

Overview

Limit Switch Box

Pg.20

Motor Capacitor

Motor

Interlock Assembly

Cover

Built-In Reset Button

Pg.24

EMERGENCY RELEASE

Crank Tool

Pg.28

Crank Tool Housing

Pg.28

™

Radio Receiver

Pg.27

Gear Reducer

Drive Belt

EMERGENCY RELEASE

Optional Factory

Installed DC2000 Battery

Models DC and DCH Only

Pg.2

Back-Up Motor

Chassis

Radio Receiver Antenna

Limit Switch Chain Sprocket

Limit Switch Chain

Drive Sprocket

Optional Factory

Installed Heater

Models H and DCH Only

Pg.33

Idler Wheels

Optional Factory Installed

DC2000 Battery Back-Up

Controller

Models DC and DCH Only

Pg.30

®

™

N

O

OFF

Operator ON OFF Switch

Control Box

Optional Plug-In

Loop Detectors

4

W

Pg.3

OmniControl™ Board

Surge Suppressor Terminal

Pg.1

UL Alarm

Pg.2

DC2000 Harness

Pg.3

N

al

0 VAC

UTIO

d

n

eutr

u

N

ck 12

CA

o

a

r

e

Bl

G

hit

W

een

r

G

SL Power Wires

Pg.1

LISTED

1

Page 3

TABLE OF CONTENTS

Safety Instructions

Role of Specifiers and Designers

Role of Dealers, Installers and Trained Gate System Technicians

Role of End Users / Home Owners

Horizontal Slide Gate Systems

UL Listings

Warnings and Precautions

Installation

Recommended Setup and Operator Specifications

Gate Post Warning

Mounting Required Warning Signs

Types of Installation

Connecting the Chain

Concrete Pad and Gate Attachment

Gate and Operator Mounting Distance

Optional

How to Connect Power (110 V)

Surge Suppressor Terminal Input Connections (Wiring Optional Equipment)

Choosing Gate Movement Direction (Open Left or Right)

Adjusting Gate Traveling Distance (Limit Switches)

Two-Way Adjustable Reversing Sensor

Adjustable Timer

Master / Second Operators with Timer On

Master / Second Operators with Timer Off

Built-In Reset Button

Table Of Contents

Remove Control Board

Audio Alarm

Solenoid/Maglock J3 Plug Connection

Radio Receiver Programming

Post Mounting Plate

4

4

5

5

6-9

10

11

12

13

14

15

15

16

17

18

19

20

20

21

21

22

23

24

25

25

26

27

EMERGENCY RELEASE

Optional

Emergency Release

28

29

Please DO NOT Touch me!..

Unless you are an Authorized

Service Technician!

© 2005 The Chamberlain Group, Inc.

All Rights Reserved.

For Technical Support: 1-800-528-2806

2

Page 4

TABLE OF CONTENTS

Optional

Optional

Wiring

Wiring

Optional

Optional

Optional

Optional

Optional

Optional

Optional

Optional

Optional

Optional

Factory Installed DC2000 Back-Up Connection. Models DC and DCH Only

Optional

Optional

Devices to DC2000

Safety Devices to DC2000

Factory Installed Heater. Models H and DCH Only

Omni Option Board Description

QCC (Quick Close Circuit)

House Alarm/Proximity Switch Connection

Master/Second Connection

Solenoid Connection

Maglock Connection

3 Push Button Station Connection

Stop Button Alarm Shut-Off Connection

Solenoid/Maglock Connection 38

Optional

Optional

Optional

Single Operator Loop Sizes and Placement

Master/Second Loop Sizes and Placement

Loop Installation and Number of Wire Turns

Plug-In Loop Detectors

External Loop Detectors

Factory Installed Equipment

Optional

Optional

Omni Option Board

Relay Adapter

Loop Detectors and Loop Setup

30

31

32

33

34

34

35

35

36

36

37

37

39

40

41

42

43

Table Of Contents

Optional

Optional

Optional

Optional

Optional

Secondary Entrapment Protection Connection (Non-Contact Sensor)

Safety Photo Electric Sensors Connection (Non-Contact Sensor)

Secondary Entrapment Protection Connection (Contact Sensor)

Safety Edge Sensor Connection (Contact Sensor)

Safety Equipment

44

45

46

47

Troubleshooting

Troubleshooting LED Information

Troubleshooting Table

48

49

Repair Parts

Parts Illustrations

Parts List

50

51

Maintenance

Maintenance 51

Property Owners Checklist of Installation 52

3

Page 5

ROLE OF SPECIFIERS AND DESIGNERS

Specifiers and designers should design an automatic vehicular gate system to:

Incorporate UL 325 compliant equipment.

•

Utilize an operator suited for gate system type, size, frequenc y of use, location and user

•

population. (Refer to UL 325 for usage class definitions)

Separate pedestrian access from vehicle access.

•

Reduce or eliminate pinch points.

•

Reduce risk of entrapment injuries by minimizing all gaps in the gate and enclosing the area of the

•

travel of the gate.

Secure controls from unauthorized use.

•

Locate all controls out of reach from the gate.

•

Allow the user full view of the gate when operating.

•

Consider special populations, such as children or the elderly.

•

Conspicuously display all warnings and instructions.

•

Be consistent with DASMA’s Automatic Gate Opener System Safety Guide.

•

ROLE OF DEALERS, INSTALLERS AND

TRAINED GATE SYSTEM TECHNICIANS

Installers, during the course of the installation proceedings for each job, should:

Confirm that the gate operator being installed is appropriate for the application.

•

Confirm that the gate is designed and built according to current published industry standards.

•

Confirm that all appropriate features and accessory devices are being incorporated, including both

•

primary and secondary entrapment protection devices.

Make sure that the gate works freely before installing the operator.

•

Repair or service worn or damaged gate hardware before installing the operator.

•

Eliminate all gaps in the sliding gate below a 4 foot height that permit a 2 1/4 inch sphere to pass

•

through any location, including the area of the adjacent fence covered when the gate is in the open

position.

Install the gate operator according to the manufacturer’s installation instructions.

•

Adjust the operator clutch or load-sensing device to the minimum force setting that allows reliable

•

gate operation.

Install operator inside fence line (DO NOT install operator on public side of fence line)

•

Install a proper electrical ground to a gate operator.

•

Install keypad controls where users cannot touch, or reach through gate while operating controls.

•

Install controls where user has full view of gate operation.

•

Install all warning signs (In accordance with UL 325) on both sides of the gate to warn persons in

•

the area of potential hazards associated with automatic vehicular gate operation.

Test all features for proper functions before placing the automatic vehicular gate into service.

•

Demonstrat e the basic functions and safety features of the gate system to owners/end

•

users/general contractors, including how to turn off power and how to operate the manual

disconnect feature.

Leave safety instructions, product literature, installation manual and maintenance manual with end

•

user.

Explain to the owners the importance of a service contract that includes a routine re-testing of the

•

entire system including the entrapment protection devices, and explain the need for the owners to

insure that this testing is performed routinely.

Offer the owner/end user a maintenance contract, or contact them regularly to offer maintenance.

4

Page 6

ROLE OF END USERS/HOME OWNER

End users should be made aware that they must:

Contact a trained gate systems technician to maintain and repair the gate system. (End users

•

should never attempt to repair the gate)

Retain and utilize the installation and maintenance manual and safety instructions.

•

Routinely check of all gate operator functions and gate movement.

•

Discontinue use if safety systems operate improperly, the gate is damaged, or the gate is difficult

•

to move.

Never over tighten the operator clutch of load sensing device to compensate for a damaged or stiff

•

operating gate.

Prominently display and maintain warning signs on both sides of the gate.

•

Keep all obstructions clear of the vicinity of the path of the gate system.

•

Actively discourage pedestrian use of the vehicular gate operating system.

•

Prevent anyone from playing near any part of the gate system.

•

Never allow anyone to climb under, over or through a gate or the adjacent fence area.

•

Never allow children to operate gate

•

Keep portable controls out of reach of children.

•

Never allow anyone to install an operating control within reach of the gate.

•

Never allow anyone to install a horizontal slide gate with exposed rollers or openings large enough

•

to allow a sphere of 2 1/4 inches to pass through any portion of the gate below a 4 foot height,

including the area of the adjacent fence covered when the gate is in the open position.

Always be certain that the gate area is clear of pedestrians before operating the gate.

•

HORIZONTAL SLIDE GATE SYSTEMS

Entrapment Zone Hazard - Body parts may become entrapped between a gate and a stationary

•

object when the gate begins to move, which can result in serious injury or death. Pedestrians must

stay clear of the gate path, and any area where gate motion is close to stationary objects.

Pinch Points Hazard - In open rollers gates, hands can get caught between the top of the gate and

•

top rollers, which can result in serious injury. Feet can be injured in the same manner between the

bottom of the gate and bottom rollers. Covers to guard these pinch points should be installed.

Crush Hazard - In picket gates, body parts positioned between the bars can become seriously

•

mutilated when the gate begins to move, which can result in serious injury or death. If any

openings are greater than 2 1/4 inches, a screen should be installed over the gate (in accordance

with the provisions of UL 325) to prevent persons from reaching through and/or passing through

the gate. In like manner, screening should also be applied to the adjacent fence area covered by the

gate when in the fully open position.

Be sure that warning signs are prominently displayed on both sides of the gate and any other place

•

where danger exists.

5

Page 7

UL LISTINGS AND INSTRUCTIONS

Installation Instructions regarding the SL3000UL™

A)

Install the gate operator only when:

1)

The operator is appropriate for the construction and the usage class of the

gate.

2)

All openings of a horizontal slide gate are guarded or screened from the

bottom of the gate to a minimum of 4 feet (1.2 m) above the ground to

prevent a 2 1/4inch (57.15 mm) diameter sphere from passing through the

openings anywhere in the gate, and in that portion of the adjacent fence that

the gate covers in the open position.

3)

All exposed pinch points are eliminated or guarded.

4)

Guarding is supplied for exposed rollers.

B)

The operator is intended for installation only on gates used for vehicles. Pedestrians

must be supplied with a separate access opening.

C)

The gate must be installed in a location so that enough clearance is supplied between

the gate and adjacent structures when opening and closing to reduce the risk of

entrapment. Swinging gates shall not open into public access areas.

D)

The gate must be properly installed and work freely in both directions prior to the

installation of the gate operator. Do not over-tighten the operator clutch to compensate

for a damaged gate.

E)

Controls must be far enough from the gate so that the user is prevented from coming in

contact with the gate while operating the controls. Controls intended to be used to reset

an operator after 2 sequential activations of the entrapment protection device or devices

must be located in the line of sight of the outdoor gate or easily accessible controls

shall have a security feature to prevent unauthorized use.

6

Page 8

UL LISTINGS AND INSTRUCTIONS

F)

G)

H)

See instructions on the placement of non-contact sensor for each type of

application.

Care shall be exercised to reduce the risk of nuisance tripping, such as when

a vehicle trips the sensor while the gate is still moving.

One or more non-contact sensors shall be located where the risk of

entrapment or obstruction exists, such as the perimeter reachable by a

moving gate or barrier.

One or more contact sensors shall be located at the leading edge, trailing

edge and post mounted both inside and outside of a vehicular horizontal

slide gate.

A hardwired contact sensor shall be located and its wiring arranged so that

the communication between the sensor and the gate operator is not

subjected to mechanical damage.

A wireless contact sensor such as the one that transmits radio frequency

(RF) signals to the gate operator for entrapment protection functions shall be

located where the transmission of the signals are not obstructed or impeded

by building structures, natural landscaping or similar obstruction. A wireless

contact sensor shall function under the intended end-use conditions.

For a gate operator utilizing a non-contact sensor such as a photo beam:

For a gate operator utilizing a contact sensor such as an edge sensor:

1)

1)

2)

3)

2)

3)

All warning signs and placards must be installed where visible in the area of the gate. A

minimum of two placards installed. A placard is to be installed in the area of each side

of the gate and be visible to persons located on the side of the gate on which the

placard is installed.

7

Page 9

UL LISTINGS AND INSTRUCTIONS

Important Safety Instructions

WARNING

1)

READ AND FOLLOW ALL INSTRUCTIONS.

2)

Never

let children operate or play with gate controls. Keep the remote control away

from children.

3)

Always keep people and objects away from the gate.

- To reduce the risk of injury or death:

NO ONE SHOULD CROSS THE PATH OF THE MOVING GATE.

4)

Test the gate operator monthly. The gate MUST reverse on contact with a rigid object

or stop when an object activates the non-contact sensors. After adjusting the force or

the limit of travel, retest the gate operator, Failure to adjust and retest the gate operator

properly can increase the risk of injury or death.

5)

Use the emergency release only when the gate is not moving. Make sure the power for

the gate operator is off.

6)

KEEP GATES PROPERLY MAINTAINED.

person make repairs to the gate or gate hardware.

Read the manual. Have a qualified service

7)

The entrance is for vehicles only. Pedestrians must use separate entrance.

8)

SAVE THESE INSTRUCTIONS.

8

Page 10

UL LISTINGS AND INSTRUCTIONS

UL Definition of Terms

Gate

– A moving barrier such as a swinging, sliding, raising lowering, rolling, or like, barrier, that is a

stand-alone passage barrier or is that portion of a wall or fence system that controls entrance and/or

egress by persons or vehicles and completes the perimeter of a defined area.

Vehicular horizontal slide-gate operator (or system)

that controls a gate which slides in a horizontal direction that is intended for use for vehicular

entrance or exit to a drive, parking lot, or the like.

– A vehicular gate operator (or system)

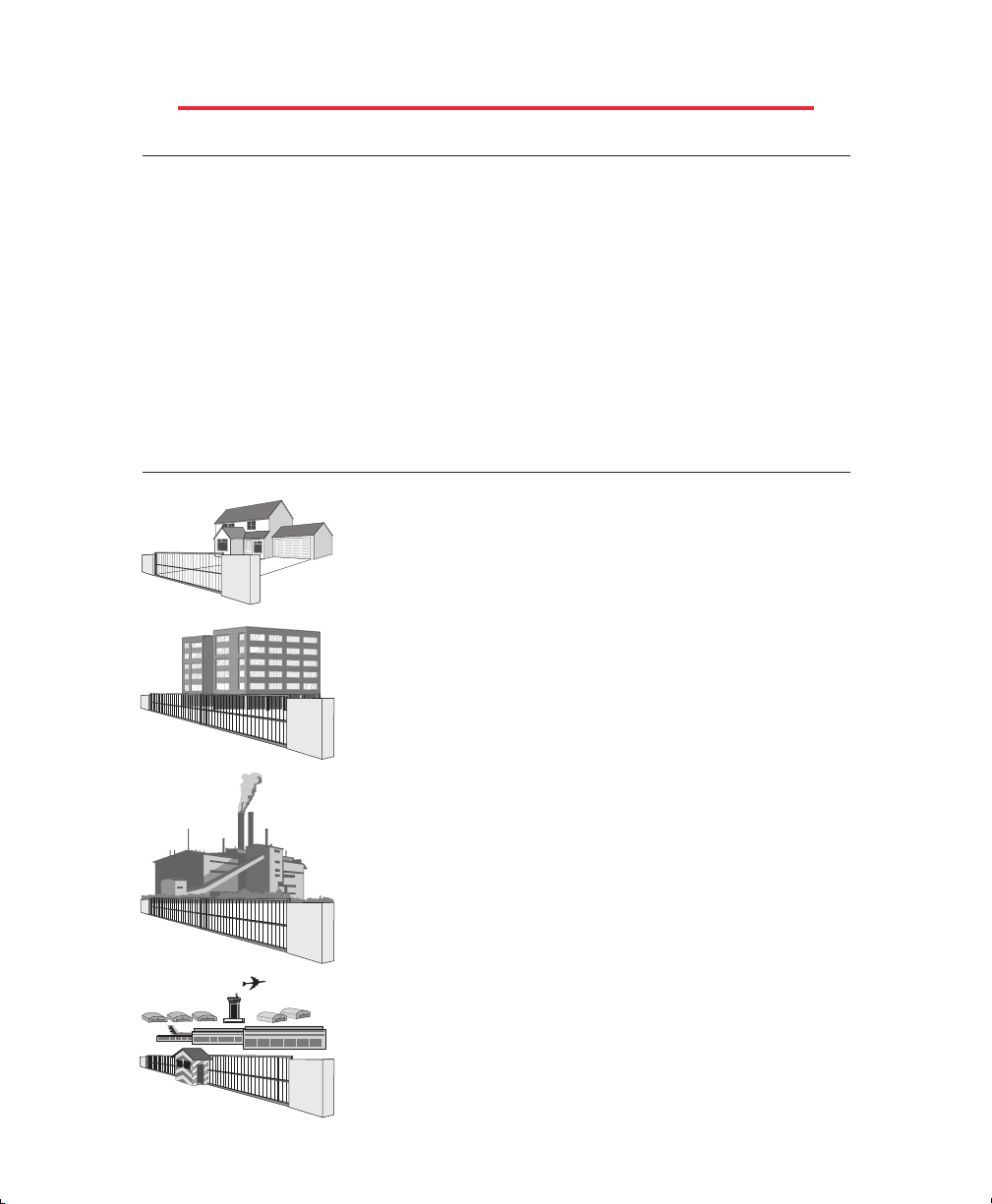

UL Gate Classifications

Class I –

A vehicular gate operator (or system) intended for use in a home of

one-to four single family dwelling, or a garage or parking area

associated therewith.

Class II –

A vehicular gate operator (or system) intended for use in a commercial

location or building such as a multi-family housing unit (five or more

single family units) hotel, garages, retail store or other building

servicing the general public.

Class III –

A vehicular gate operator (or system) intended for use in a industrial

location or building such as a factory or loading dock area or other

locations not intended to service the general public.

Residential vehicular gate operator

Commercial/General access vehicular gate operator

Commercial/General access vehicular gate operator

Class IV –

A vehicular gate operator (or system) intended for use in a guarded

industrial location or building such as an airport security area or other

restricted access locations not servicing the general public, in which

unauthorized access is prevented via supervision by security

personnel.

Restricted access vehicular gate operator

9

Page 11

WARNINGS AND PRECAUTIONS

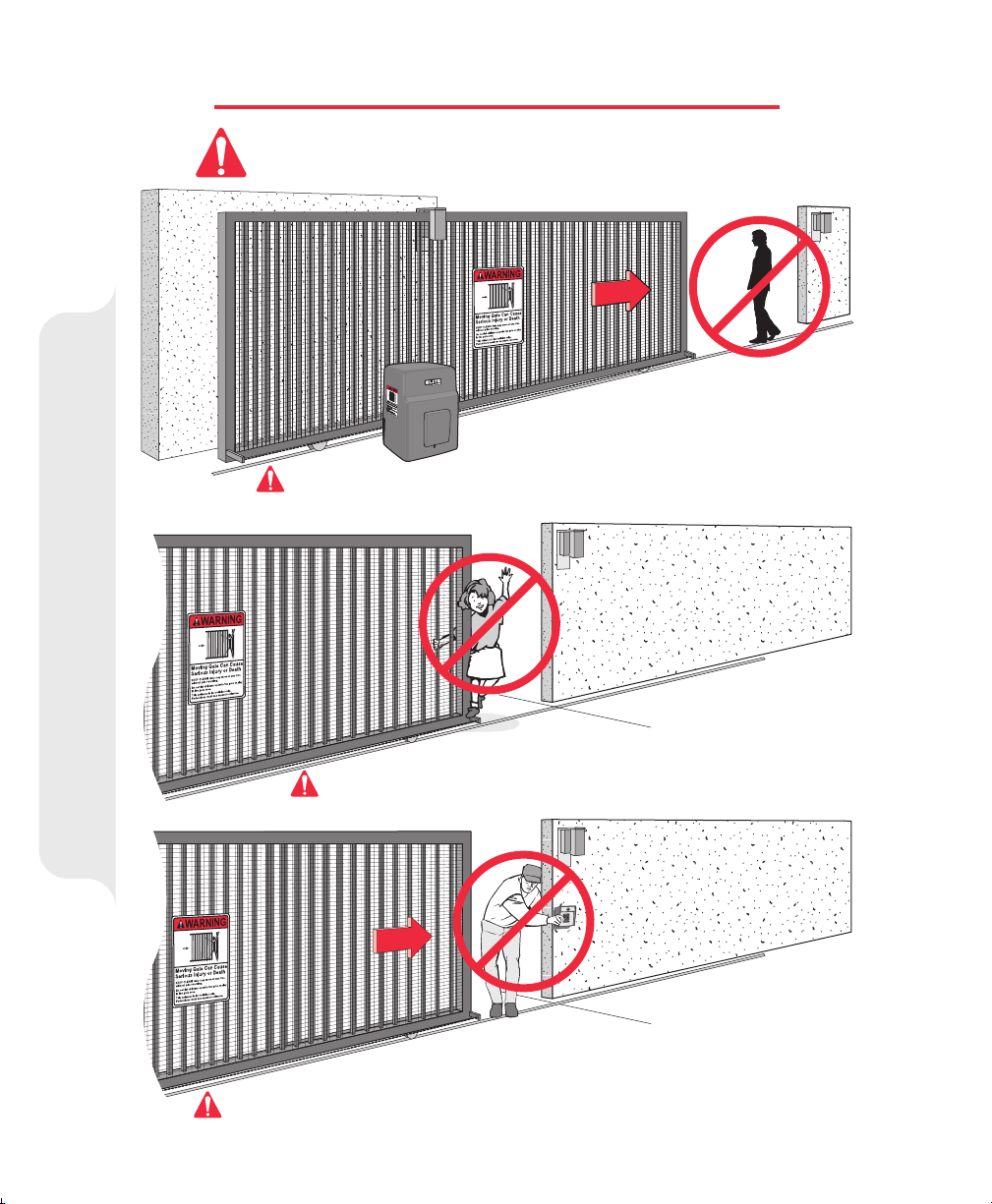

The SL3000UL™ Series is for Vehicular Gate Use Only!

NOT

for Use on Any Pedestrian: Passageways, Doorways or Gateways.

Property owners must never let pedestrians cross the path of a moving gate!

Property owners must never allow anyone to hang or ride on the gate!

Warnings and Precautions

Property owners must never mount any gate operating device near the gate's path!

10

Page 12

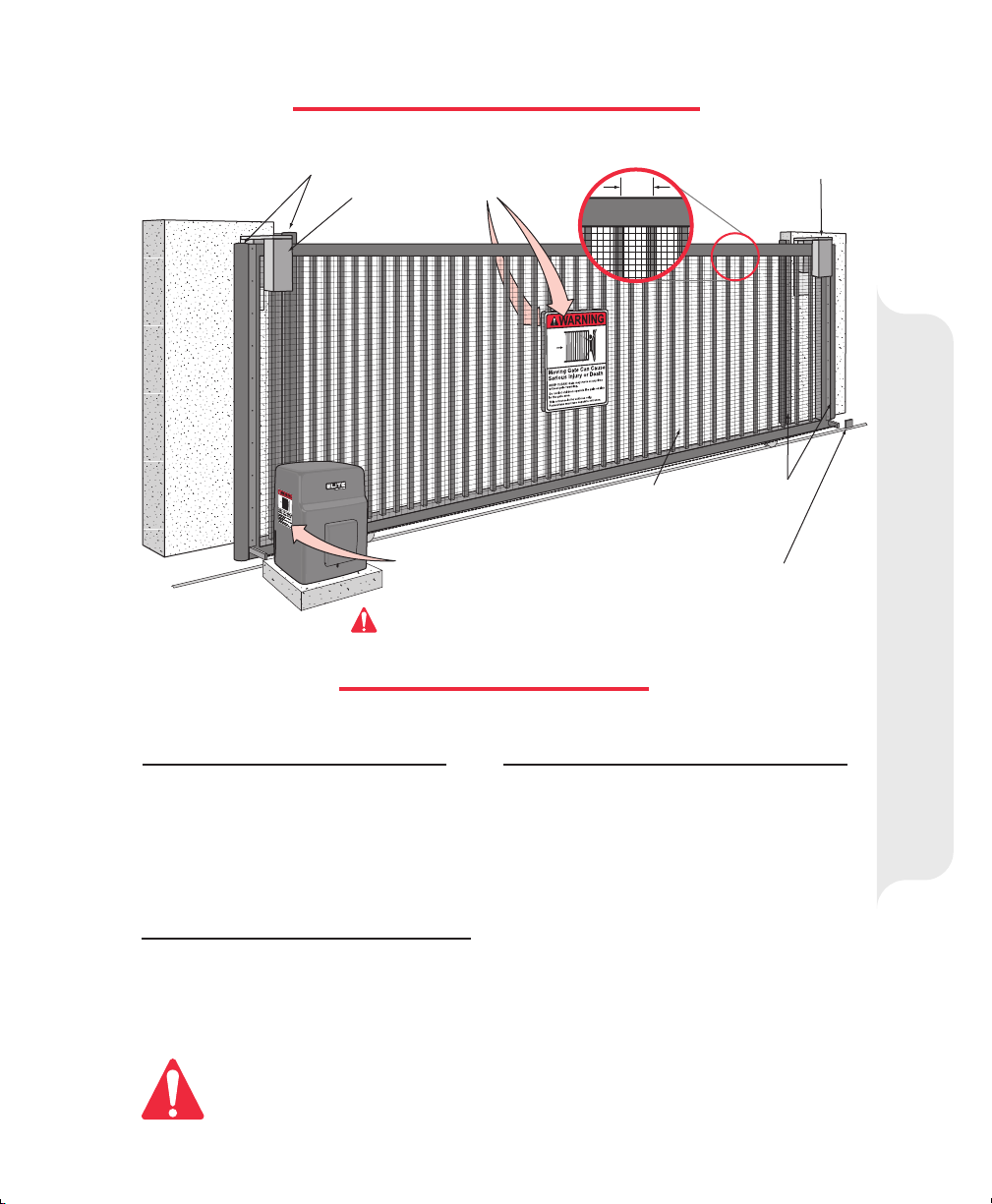

RECOMMENDED SETUP

Sensor Edges

Non-Pinch

Rollers

Warning Signs

Attached on

Both Sides

of Gate

Warning Sign Clearly

Visible on Operator

3" Max. Width of Pickets

Pedestrians Must have a Separate Walkway!

SPECIFICATIONS

(2"x 2" Screen)

Weld Physical Stops on

Both Ends of Gate Rail

Non-Pinch

Rollers

Setup and Specifications

Sensor

Edges

SL3000UL™, SL3000ULDC™

SL3000ULH™, SL3000ULDCH™

1/2 hp Motor, 120 Vac, 4 Amp.

Maximum Gate Length – 37 ft.

Maximum Gate Weight – 1000 lbs.

Maximum Pull – 105 lbs.

SL3000UL1HP™

SL3000UL1HPH™

Two 1/2 hp Motors, 120 Vac, 8.4 Amp.

Maximum Gate Length – 37 ft.

Maximum Gate Weight – 2000 lbs.

Maximum Pull – 180 lbs.

Be sure to read and follow all Chamberlain Elite and UL instructions before installing and

operating any Chamberlain Elite products. the Chamberlain Group, Inc is not responsible

for improper installations or failure to comply with local building codes.

SL3000ULDM™, SL3000ULDMDC™

SL3000ULDMH™, SL3000ULDMDCH™

Two 1/2 hp Motors, 120 Vac, 4.7 Amp.

Maximum Gate Length – 37 ft.

Maximum Gate Weight – 800 lbs.

Maximum Pull – 100 lbs.

DM

- Dual Motor

1HP

- One Horse Power

H

- Factory Installed Heater

DC

- Factory Installed DC2000 Backup System

11

Page 13

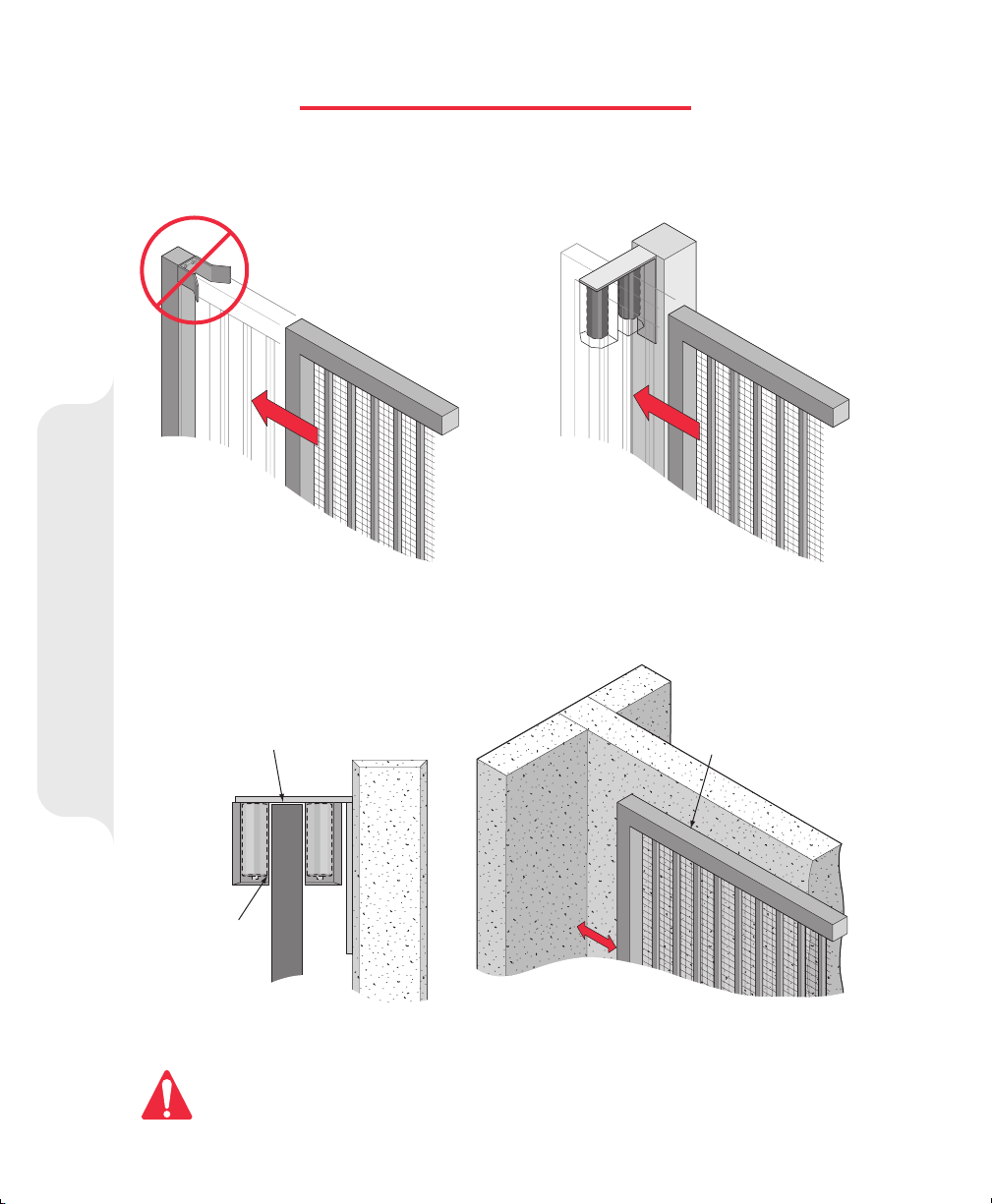

GATE POST WARNING

Because the coasting distance may vary due to changes in temperature, Elite does

installation of a stop or catch post in front of the gates path. To do so will cause the gate to hit the post in certain

instances.

NOT

recommend the

Incorrect Correct

Non-Pinch

Rollers

Important Notice!

Closing

Elite only recommends installation of catch rollers on the side of a catch post or wall with a minimal distance of

half an inch between the rollers and gate. Also when fully open the end of the sliding gate must stop at least five

inches from a wall.

Closing

1/4" Clearance from Top of Gate

Gate Post Warning

Non-Pinch

Rollers

1/2" Clearance

Between Gate

and Rollers

Gate in Fully

Opened Position

Wall

5"

Wall

Gate

For safety reasons, a physical stop must be installed on the gate prior to installation of the gate operator.

This will assure that the gate does not exceed movement limits and derail while opening or closing fully.

Minimum of 5" Clearance Between

Gate and Wall or Other Object

12

Page 14

MOUNTING REQUIRED WARNING SIGNS

Installers are

UL required Warning Signs

view and on both sides of each gate installed. Each

sign is made with fastening holes in each corner and

should be permanently secured in a suitable manner.

Also the warning sticker should be placed on the

operator so it is clearly visible. Installers should keep

photos of signs on gate in their records.

Warning Signs Attached on Both Sides of Gate

required

to adhere to this procedure: The

must

be installed in plain

Important Notice!

Mounting Required Warning Signs

Warning Sign Clearly Visible on Operator

13

Page 15

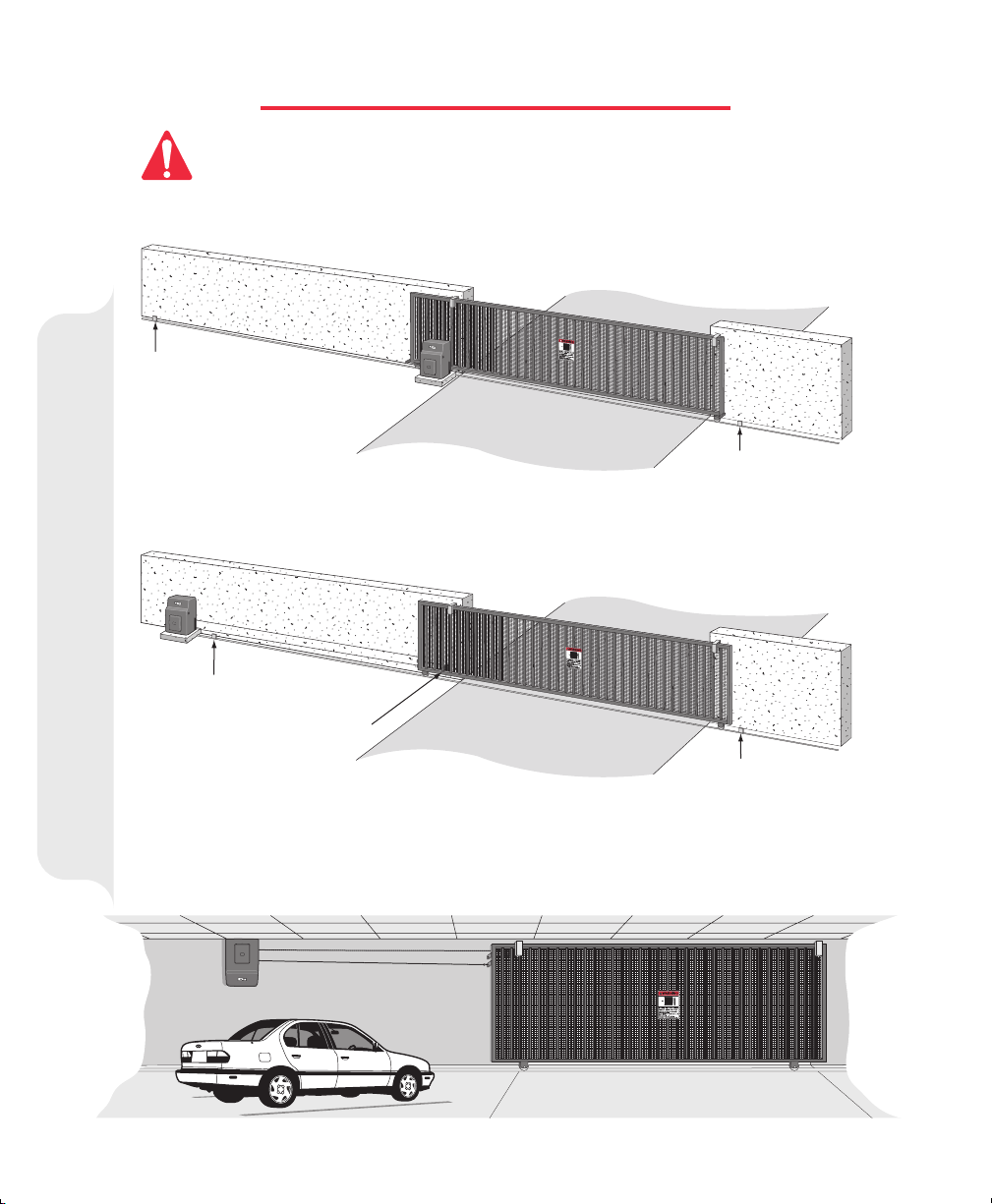

TYPES OF INSTALLATION

It is highly recommended installing over-travel stops at both ends of the gate rail in any type of

installation, to prevent derailing.

Front Installation

Reason: Cost Efficient

Physical Stop

Physical Stop

Rear Installation

Reason: Chain is not visible

Physical Stop

Idler Wheel must have Safety Cover

Types of Installation

Ceiling Mount Installation

Reason: Space Efficient - Chain is not visible

Physical Stop

14

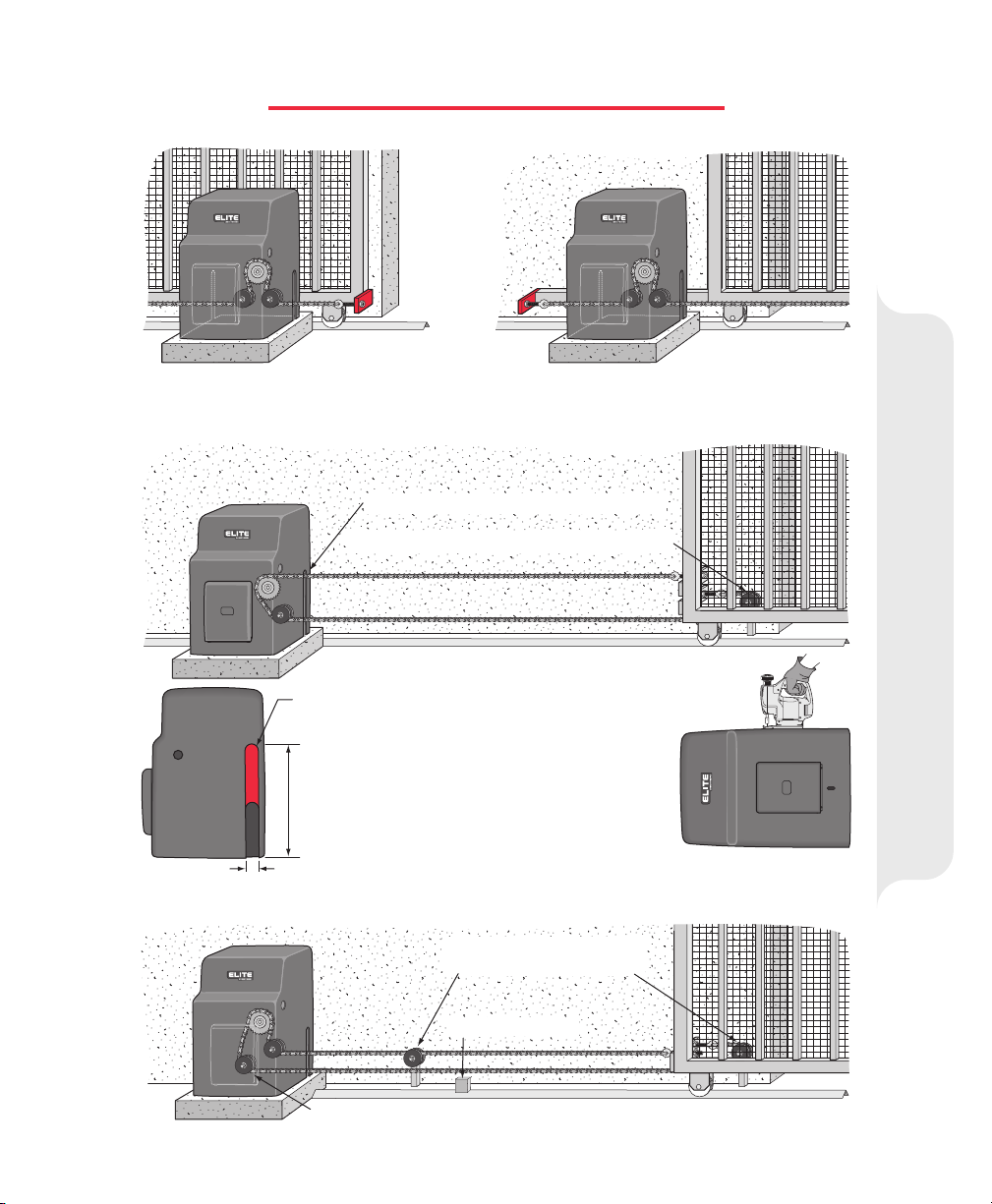

Page 16

17.5"

2"

Cut the chain access slot on the one side

of the cover to the exact specifications.

Important: For safe operation of the gate

opener do not cut the slots any wider or longer

than shown. DO NOT modify the housing in any

way other than specified.

Make sure the idler wheel has a safety cover.

Cut the cover 17 1/2 inches high. (See below)

Rear Installation – Cover Modification

Use lower hole in chassis for the idler wheel.

Make sure additional idler

wheels have safety covers.

Over-Travel Stop

Weld front bracket with gate in open position. Weld rear bracket with gate in closed position.

CONNECTING THE CHAIN

Front Installation

Alternate Rear Installation – Lower Idler Wheel Position

Connecting the Chain

15

Page 17

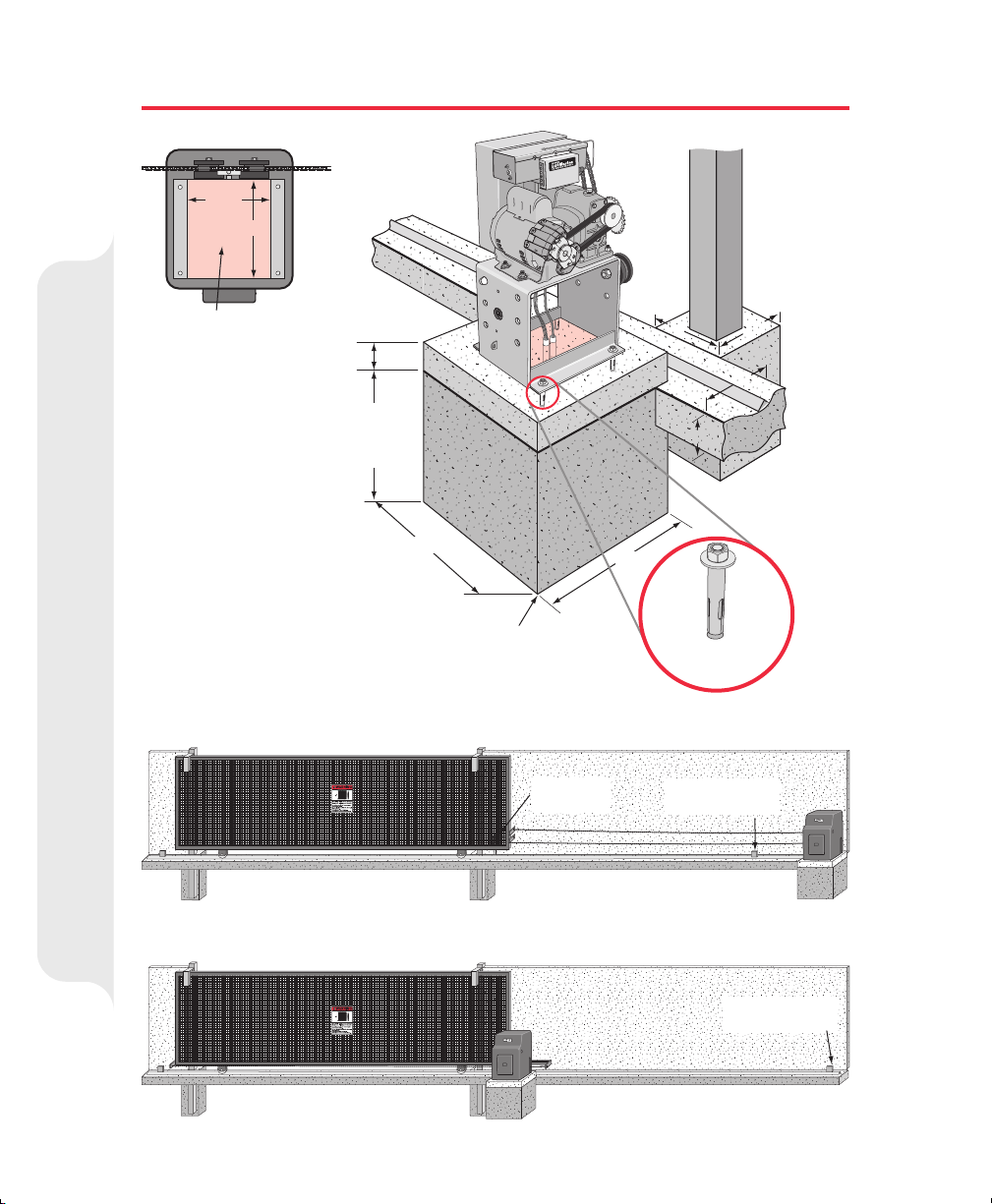

CONCRETE PAD AND GATE ATTACHMENT

Top Inside View

Follow gate

manufacturers

8.25"

13"

specifications

and local

building codes

for setting post.

Conduit Area Without

Battery Back-Up

Suggested installation for dirt

ground. The measurements

depend on the type of ground.

(ie., asphalt, cement, dirt)

Check local building codes

before installation.

Above

Ground

Concrete (Reinforced Recommended)

6"

Below the

Frost Line

Check all

Local Codes

Concrete Pad

Optional Post

or

Mounting Plat

(See page 1

e

7

24"

)

Rear Installation

Cover over

Idler Wheel

12"

24"

Red Head Fastener

1/2" x 3 1/2"

Physical Stops on

Both Ends of Rail

12"

10"

8"

Concrete Pad and Gate Attachment

Front Installation

Physical Stops on

Both Ends of Rail

16

Page 18

GATE AND OPERATOR MOUNTING DISTANCE

4"

4" Minimum

Between Gate

and Sprocket

Correct Installation

OPTIONAL POST MOUNTING PLATE

Too Close

to Gate

Too High

Too Low

Incorrect Installation

Mounting Distance

Gate and Operator

Mounting Plate

Optional Post

Part # MPEL

3“ heavy steel posts are U-bolted to

mounting plate and cemented in ground.

Contact your local dealer

for more information.

Op

P

ional

t

duct

ro

Power and control

wiring can be run in

separate conduits.

17

Page 19

HOW TO CONNECT POWER (110V)

OnOn

O

Off

f

.

r

e

f

e

R

f

3

,

2

,

1

s

u

Do Not Use This Outlet Unless You Are

N

O

OFF

An Authorized Service Technician

Suggestion:

Seal all open holes

4

W

of electronic box

with sealant when

finished wiring.

F

N

F

O

O

B

O

Off

f

C

o

n

f

e

r

e

n

c

e

f

R

m

2

,

3

O

Off

C

o

n

f

e

f

r

e

n

c

e

f

R

o

o

m

1

Conference

Room 2

C

om

p

.

S

e

r

ve

2

Air (2)

Conditioner

C

o

m

p

.

S

e

rve

1

Minimum: 20-amp

breaker switch per

OffOff

OnOn

OnOn

OffOff

OnOn

OffOff

f

f

O

Off

operator needed.

Use U.L. Listed Conduit for

Supplying Power to the Unit

Black Wire (110 Vac)

Green Wire (Ground)

White Wire (Neutral)

Gate Operator MUST be Properly Grounded

Important: A factory installed heater must be wired into the power supply. See page 33.

Wire Gauge Requirement for 110 Vac Power Supply

16 Gauge

1/2 HP and Dual Motor

1 HP

Caution: Not responsible for conflicts between the information listed in the above chart and the requirements of your local building codes.

The information is for suggested use only. Check your local codes before installation.

150 Feet

75 Feet

14 Gauge

250 Feet

125 Feet

12 Gauge

400 Feet

200 Feet

10 Gauge

650 Feet

325 Feet

8 Gauge

1000 Feet

500 Feet

4 Gauge

2200 Feet

1100 Feet

Air (1)

Conditioner

Main

Room

SL-3000 (1)

SL-3000

(2

)

Eug. Dept.

Manu. 1 Rm

M

a

i

n

D

e

p

t

.

M

a

n

u

.

2

R

m

Earth Ground Rod Installation

Proper grounding gives an electrical charge, such as from an electrical static

discharge or a near lightning strike, a path from which to dissipate its energy safely

into the earth.

Without this path, the intense energy generated by lightning could be directed

towards the Elite gate operator. Although nothing can absorb the tremendous power

How to Connect Power 110V

of a direct lightning strike, proper grounding can protect the gate operator in most

cases.

Before digging more than 18" deep, contact local underground utility locating companies.

Avoid damaging gas, power, or other underground utility lines.

The earth ground rod must be located within 3 feet from the gate

operator.

The ground wire

Use the proper type earth ground rod for your local area.

must

be a single, whole piece of wire.

Never

splice two

wires for the ground wire. If you should cut the ground wire too short,

break it, or destroy its integrity, replace it with a single wire length.

Not responsible for improper installation or failure to comply with

all necessary local building codes.

18

12 gauge wire

8 ft

Page 20

POW

O

VE

Ground (-)

11

24 DC (+)

13

N

E

P

O

P

O

T

S

E

S

O

L

C

ER

RLOAD

S

M

A

D

E

IN

U

S

A

W4

A

B

G

K

IN

L

S

M

SURGE SUPPRESSOR TERMINAL INPUT CONNECTIONS

SAFETY EXIT

CENTER

SYSTEM

S

EN

SORS

R

M

O

R

S

A

N

L

1

E

A

S

ON

3

D

FIRE

D

E

N

S

DEPT.

A

S

E

M

C

M

O

O

R

C

P

EXIT

LOO

TIM

ER

60

3

1

E

R

S

O

FF

O

R

S

E

N

V

1

3

E

E

S

R

OPEN LEFT

STRIK

E

RADIO

O

PEN

RECEIVER

SAFETY

P

CENTER

LOO

P

LO

3

O

N

OPE

N RIGHT

Output Power

G

ATE

LO

CKED

RESET

OP

M

OT

O

R

GAB

GG

BB

AA

M/S LinkM/S Link

Page 22-23

G

B

A

Master/Second Operator

Page 40

3

4

External “Safety” Loop Detector

®

®

Page 45

11

Ground (-)

13

24 DC (+)

®

+24V

SENSING

COMMON

EDGE

INPUT

INFRARED

BLACK or BROWN

INFRARED

WHITE or BLUE

Photo Electric Sensors (Safety)

®

OmniControl Sur

1 65

43

2

Center

Center

Safety

Safety

Loop

Loop

Loop

Loop

3

4

ge Suppressor

Exit

Exit

Fire D

Fire D

ept

ept

Loop

Loop

Key Sw

Key Sw

itch

itch

P

P

/N

/N

Q

Q

4

4

1

1

0

0

P

P

a

a

te

te

n

n

t P

t P

e

e

n

n

d

d

in

in

g

Strike Open

Strike Open

Push Button

Push Button

g

++

––

R

R

adio

adio

R

R

eceiver

eceiver

7 1312111098

13

11

11

12

Remote NOT Included

Class 2

Class 2

Supply

Supply

o

V

4

o

2

V

4

2

++

24 Volt

––

Neg.

––

Neg.

Com.

10

10

C

D

s

C

l

t

D

s

l

t

DO NOT

let wire insulation

interfere with the removable

terminal connections.

Factory Installed

Radio Receiver

1

2

3

4

Page 27

Card

Reader

9

Push

Button

9

Surge Suppressor Terminal Connections

®

Page 40

5

6

External “Exit” Loop Detector

Important!

Terminals 11 and 12 are the only terminals that will Open and

Close with a single push of a button. All other terminals will only

open with a single push of a button.

19

Phone

10

9

Entry

1

2

3

4

5

6

7

8

9

H

E

L

P

0

Fire or

Any Key

Switch

8

7

Page 21

CHOOSING GATE MOVEMENT DIRECTION

Open to the RightOpen to the Left

OUT

OUT

IN

IN

MER

OFF

60

ON

13

Choosing Gate

OPEN LEFTOPEN LEFT

OPEN RIGHT

Movement Direction

RADIO

ADJUSTING GATE TRAVELING DISTANCE

Push Plate

Limit Nut

Lock Plate

CENTER SAFETY EXIT

W4

GB

A

MS LINK

CENTER SAFETY EXIT

SYSTEM ON

SENSORS

ALARM

SENSOR

MER

OFF

OPEN LEFT

ALARMSENSOR

DC-BACKUP

TIMER

POWER

60

3

OVERLOAD

13

ON

OFF

13

13

SENSOR

REVERSE

OPEN LEFT

FIRE

STRIKE

DEPT.

OPEN

COMMAND

PROCESSED

EXIT

SAFETY

LOOP

LOOP

MADE IN USA

OPEN

OPEN RIGHT

STOPCLOSE

GATE

RADIO

LOCKED

RECEIVER

CENTER

RESET

LOOP

MOTOR

OPEN RIGHTOPEN RIGHT

RADIO

60

ON

13

Nut

Adjusting Gate

Traveling Distance

Before Adjusting, Do the Following:

1. Turn the Power OFF!

2. Push the limit nut lock plate inward.

Roll the nut to the desired location.

Each notch is an estimated 1 inch of gate travel.

3. Place the plate back in a notch.

4. Turn the machine back on.

5. If you need more adjusting,

repeat the process.

20

Page 22

2-WAY ADJUSTABLE REVERSING SENSOR

Adjusted by Qualified Service Personnel

CENTER SAFETY EXIT

ALARMSENSOR

W4

GB

A

MS LINK

CENTER SAFETY EXIT

DO NOT

SYSTEM ON

SENSORS

13

13

ALARM

SENSOR

FIRE

DEPT.

COMMAND

PROCESSED

EXIT

LOOP

TOUCH ALARM SENSOR

DC-BACKUP

TIMER

POWER

60

3

OVERLOAD

13

ON

OFF

SENSOR

REVERSE

OPEN LEFT

STRIKE

RADIO

OPEN

RECEIVER

SAFETY

CENTER

LOOP

LOOP

MADE IN USA

OPEN

OPEN RIGHT

STOPCLOSE

GATE

LOCKED

RESET

MOTOR

CAUTION: If the power supply to the gate

operator is less than 99 volts, adjust the

alarm by turning the alarm adjustment

counter-clockwise enough to actuate the

alarm when obstructed but not sensitive

enough for false triggering to occur.

ADJUSTABLE TIMER

CENTER SAFETY EXIT

Maximum

Sensitivity

3

13

The level of reverse sensitivity depends on the

weight of the gate and the condition of

installation. To make a better gate system, use

SENSOR

REVERSE

Minimum

Sensitivity

any of Chamberlain Elite's power wheels.

Too sensitive = if the gate stops or reverses by itself.

Not sensitive enough = if the gate hits a vehicle and does not stop

or reverse.

Timer ON

TIMERTIMER

OFF

NSOR

OPEN LEFT OPEN RIGHT

60

ONON

3

13

Set Timer

1 to 60 seconds

Reversing Sensor

2-Way Adjustable

Adjustable Timer

ALARMSENSOR

W4

GB

A

MS LINK

CENTER SAFETY EXIT

SYSTEM ON

SENSORS

ALARM

SENSOR

13

13

FIRE

DEPT.

COMMAND

PROCESSED

EXIT

LOOP

Timer can be set from 1 to 60 seconds (Timer ON),

OR for push open/push close type operation (Timer OFF).

DC-BACKUP

TIMER

POWER

60

3

OVERLOAD

13

ON

OFF

SENSOR

REVERSE

OPEN LEFT

STRIKE

RADIO

OPEN

RECEIVER

SAFETY

CENTER

LOOP

LOOP

MADE IN USA

OPEN

OPEN RIGHT

STOPCLOSE

GATE

LOCKED

RESET

MOTOR

TIMERTIMER

OFFOFF

NSOR

OPEN LEFT OPEN RIGHT

60

ON

3

13

Timer OFF

Note: When using master/second gates, the gate that takes the longest to open should be set as the master.

21

Page 23

MASTER/SECOND WITH TIMER ON

TIMER

ON

TIMER

ON

Master and Second Boards are InterchangeableMaster Omni Board Primary Control for System

Caution: Never run high voltage and low voltage wires in same conduit

Use low voltage wires in separate conduit to connect gate operators together

Note: The gate that takes the longest to open should be set as the master.

CENTER SAFETY EXIT

Master Omni Board

TIMER

60

3

ALARMSENSOR

W4

GB

A

MS LINK

CENTER SAFETY EXIT

SYSTEM ON

SENSORS

13

13

ALARM

SENSOR

FIRE

DEPT.

COMMAND

PROCESSED

EXIT

LOOP

®

O

C

C

e

e

GG

BB

AA

L

L

n

k

L

i

S

/

M

n

k

L

i

S

/

M

re

p

p

u

S

e

g

r

u

l S

tro

n

o

iC

n

m

n

n

te

te

r

r

S

S

a

a

f

f

e

e

t

t

y

y

E

E

x

x

i

i

F

F

t

t

i

i

r

r

e

e

D

D

e

e

p

p

t

t

o

o

o

o

p

p

L

L

o

o

o

o

p

p

L

L

o

K

K

o

o

e

e

o

p

y

y

p

S

S

w

w

it

it

c

c

h

h

DC-BACKUP

TIMER

OFF

SENSOR

REVERSE

OPEN LEFT

STRIKE

OPEN

SAFETY

LOOP

r

so

s

S

S

t

t

r

r

ik

ik

e

e

P

P

u

u

s

s

h

h

B

B

POWER

60

3

OVERLOAD

13

ON

MADE IN USA

OPEN

OPEN RIGHT

STOPCLOSE

GATE

RADIO

LOCKED

RECEIVER

CENTER

RESET

LOOP

MOTOR

P

P

/

/

N

N

Q

Q

4

4

1

1

0

0

P

P

a

a

t

t

e

e

n

n

t

t

P

P

e

e

n

n

d

d

i

i

n

n

g

g

++

––

s

2

l

s

a

C

s

2

l

s

a

C

S

u

p

p

l

y

S

u

p

p

l

y

O

O

p

p

e

e

n

n

R

R

a

a

d

d

io

io

D

V

o

l

s

C

t

4

D

2

V

o

l

s

C

t

4

2

u

u

t

t

t

t

o

o

R

R

n

n

e

e

c

c

e

e

iv

iv

e

e

r

r

OFF

NSOR

OPEN LEFT OPEN RIGHT

Master Timer “ON”

Use Shielded Twisted Wires

to Connect the Surge

Suppressor of each

Gate Operator Together

g

g

din

din

10

10

4

4

en

en

Q

Q

t P

t P

/N

/N

P

CHASSIS

GROUND

P

Center

Center

AA

BB

aten

aten

GG

P

P

Loop

Loop

k

k

n

n

i

i

L

L

S

S

/

/

M

M

Master / Second with Timer ON

1. Connect G from the master surge suppressor to G of the second surge

suppressor.

2. Connect B from the master surge suppressor to B of the second surge

suppressor.

3. Connect A from the master surge suppressor to A of the second surge

suppressor.

4. Turn timers on BOTH Omni boards to the “ON” position

5. Turn the SECOND Timer adjustment all the way Counterclockwise

6. Use MASTER timer ONLY to select the desired time

ON

CHASSIS

GROUND

13

g

g

in

in

0

0

d

d

1

1

4

4

en

en

Q

Q

t P

t P

n

n

/N

/N

P

P

AA

BB

ate

ate

GG

P

P

k

k

n

n

i

i

L

L

S

S

/

/

M

M

Adjust Time Desired

0 to 60 seconds

Second Omni Board

CENTER SAFETY EXIT

W4

GB

A

MS LINK

CENTERSAFETY EXIT

®

t

n

o

iC

n

m

O

C

e

r

e

n

t

C

e

r

e

n

t

S

S

a

a

f

f

GG

BB AA

L

o

o

p

L

o

o

p

L

L

o

o

k

n

i

L

S

k

n

/

i

L

M

S

/

M

Center

Center

Loop

Loop

MAXIMUM

Counterclockwise

Setting

TIMER

OFF

NSOR

OPEN LEFT OPEN RIGHT

ON

Second Timer “ON”

SYSTEM ON

SENSORS

ALARM

r

y

y

e

e

t

t

o

o

p

p

13

13

SENSOR

FIRE

DEPT.

COMMAND

PROCESSED

EXIT

LOOP

u

S

e

g

r

u

S

l

o

t

i

E

x

t

i

E

x

e

e

r

r

i

i

F

F

L

o

o

p

L

o

o

p

y

y

K

K

e

e

60

TIMER

60

3

13

ON

OFF

SENSOR

REVERSE

OPEN LEFT

OPEN RIGHT

GATE

STRIKE

RADIO

LOCKED

OPEN

RECEIVER

SAFETY

CENTER

RESET

LOOP

LOOP

MOTOR

P

P

/

/

N

N

Q

Q

4

4

1

1

0

0

r

o

s

s

e

r

p

p

P

P

a

a

t

t

e

e

n

n

t

t

P

P

e

e

n

n

d

d

i

i

n

n

g

g

++

––

l

l

C

C

a

a

S

S

u

u

p

p

p

p

e

e

D

t

D

t

n

e

p

n

O

e

p

t

e

O

i

r

k

S

t

e

i

r

k

S

o

R

i

d

o

a

R

i

d

a

o

V

4

2

o

V

4

2

c

c

h

h

t

t

i

i

S

S

w

w

n

o

n

o

t

t

s

P

u

t

h

B

u

s

P

u

t

h

B

u

R

c

i

e

e

v

R

c

e

i

e

e

v

e

r

r

3

13

ALARMSENSOR

DC-BACKUP

POWER

OVERLOAD

MADE IN USA

OPEN

STOPCLOSE

s

s

s

s

2

2

p

p

l

l

y

y

D

C

D

s

l

C

t

s

l

t

22

Page 24

MASTER/SECOND WITH TIMER OFF

TIMER

OFF

TIMER

OFF

Caution: Never run high voltage and low voltage wires in same conduit

Use low voltage wires in separate conduit to connect gate operators together

Master Omni Board Second Omni Board

CENTER SAFETY EXIT

CENTER SAFETY EXIT

Master / Second with Timer OFF

TIMER

ALARMSENSOR

W4

GB

A

MS LINK

CENTERSAFETY EXIT

SYSTEM ON

SENSORS

13

ALARM

SENSOR

COMMAND

®

S

l

o

r

t

n

o

C

i

n

m

O

C

e

r

e

n

t

C

e

r

e

n

t

y

y

S

S

e

e

t

t

a

a

f

f

GG

BB AA

L

o

o

p

L

o

o

p

L

L

o

o

o

o

p

p

k

n

i

L

S

k

n

/

i

L

M

S

/

M

DC-BACKUP

TIMER

POWER

60

3

OVERLOAD

13

ON

OFF

REVERSE

OPEN

LOOP

s

SENSOR

o

s

S

S

t

t

i

i

r

r

s

s

P

P

u

u

OPEN LEFT

RADIO

RECEIVER

CENTER

LOOP

P

P

r

P

P

a

a

t

t

e

e

n

n

t

t

––

O

n

O

n

e

e

p

p

k

k

e

e

n

n

o

o

t

t

t

t

h

h

B

B

u

u

OPEN RIGHT

GATE

LOCKED

RESET

MOTOR

/

/

N

N

Q

Q

4

4

1

1

0

0

P

P

e

e

n

n

d

d

in

in

g

g

++

i

d

o

a

R

i

d

o

a

R

r

e

v

i

e

r

c

e

e

v

R

i

e

c

e

R

MADE IN USA

OPEN

STOPCLOSE

l

l

s

s

s

s

2

2

C

C

a

a

S

S

y

y

u

u

p

p

p

p

l

l

D

C

D

s

l

C

o

t

V

4

s

2

l

o

t

V

4

2

13

FIRE

STRIKE

DEPT.

PROCESSED

EXIT

SAFETY

LOOP

e

r

p

p

u

S

e

g

r

u

t

t

i

i

E

E

x

x

t

p

e

D

e

t

r

p

e

i

F

D

e

r

i

F

L

L

o

o

o

o

p

p

h

c

t

i

S

w

h

y

K

e

c

t

i

S

w

y

K

e

OFF

NSOR

OPEN LEFT OPEN RIGHT

60

ON

3

13

ALARMSENSOR

W4

GB

A

MS LINK

CENTERSAFETY EXIT

SYSTEM ON

SENSORS

13

ALARM

SENSOR

COMMAND

PROCESSED

®

r

u

S

l

o

r

t

n

o

iC

n

m

O

C

e

r

e

n

t

C

e

r

e

n

t

y

y

S

S

e

e

t

t

a

a

f

f

E

E

x

x

GG

BB AA

L

o

o

p

L

o

o

p

L

L

o

o

o

o

p

p

L

L

o

o

o

o

k

n

i

L

S

k

n

/

i

L

M

S

/

M

DC-BACKUP

TIMER

POWER

60

3

OVERLOAD

13

ON

OFF

13

FIRE

STRIKE

DEPT.

OPEN

EXIT

SAFETY

LOOP

LOOP

s

e

r

p

p

u

S

e

g

t

t

i

i

t

p

e

t

D

p

e

e

D

r

i

e

F

r

i

F

p

p

c

h

t

c

i

S

w

h

y

t

K

e

i

S

w

y

K

e

MADE IN USA

SENSOR

OPEN

REVERSE

OPEN LEFT

OPEN RIGHT

STOPCLOSE

GATE

RADIO

LOCKED

RECEIVER

CENTER

RESET

LOOP

MOTOR

P

P

/

/

N

N

Q

Q

4

4

1

1

0

0

r

o

s

P

P

a

a

t

t

e

e

n

n

t

t

P

P

e

e

n

n

d

d

in

in

g

g

++

––

2

2

l

l

s

s

s

s

C

C

a

a

S

S

u

u

p

p

p

p

l

l

y

y

n

e

p

O

k

e

i

r

S

t

n

e

p

O

k

e

i

r

S

t

o

i

d

o

a

i

R

d

a

R

C

D

s

l

C

o

t

V

D

s

l

o

t

V

4

2

4

2

n

o

t

B

u

t

h

s

n

P

u

o

t

B

u

t

h

s

P

u

v

r

c

e

i

e

e

v

R

r

c

e

i

e

e

R

Use Shielded Twisted Wires

to Connect the Surge

Suppressor of each

Gate Operator Together

g

CHASSIS

GROUND

ing

ing

0

0

1

1

4

4

end

end

Q

Q

t P

t P

/N

/N

P

P

Center

Center

AA

aten

aten

GG BB

P

P

Loop

Loop

k

k

n

n

i

i

L

L

S

S

/

/

M

M

CHASSIS

GROUND

g

in

in

0

0

d

d

1

1

4

4

en

en

Q

Q

t P

t P

n

n

/N

/N

P

P

ate

ate

GG BB

P

P

n

n

i

i

L

L

S

S

/

/

M

M

Center

Center

AA

Loop

Loop

k

k

TIMER

OFF

NSOR

60

ON

3

13

OPEN LEFT OPEN RIGHT

1. Connect G from the master surge suppressor to G of the second surge suppressor.

2. Connect B from the master surge suppressor to B of the second surge suppressor.

3. Connect A from the master surge suppressor to A of the second surge suppressor.

4. Turn timers on BOTH Omni boards to the “OFF” position

PARTIAL MASTER/INDIVIDUAL CONTROL

In order for the following operation to occur, follow the instructions.

Example: There is a double gate, the entry gate is to be opened with a radio transmitter and the exit gate with a

free exit loop. Only one safety loop system is to open both gates, and a fire department switch should open both

gates at the same time.

1. Connect the radio receiver to entry gate only.

2. Connect the exit loop to exit gate only.

3. Connect the safety loop to both entry and exit gates. (Observe polarity of voltage)

4. Connect the fire department switch to both entry and exit gates. (Observe polarity of both operators)

23

Page 25

BUILT-IN RESET BUTTON

When the gate operator’s audio alarm (See next page) has been tripped, the

operator to function again.

Built-In Reset Button

The

Reset Button

If the audio alarm goes off, always check the gate area for:

Pressing the

operator does

will shut off an activated audio alarm and reset the operator to function again.

• Obstructions in the gate path.

• Damage to the gate and/or gate operator.

Reset Button

NOT

will

stop

need to be reset after doing this.

a moving gate during a normal open/close cycle, like a stop button. The

24

Reset Button

must be pushed for the

Page 26

REMOVE CONTROL BOARD

N

FF

FF

ON

O

O

O

Control Board

W4

4

W

Disconnect wire harnesses from OmniControl board. Unscrew 3 nuts and remove board.

AUDIO ALARM

When one of the following events happens

the Alarm will Sound for 5 minutes!

Press the Built-In Reset Button to Shut Off Alarm

1

The gate is too heavy.

and Reset Operator!

(See previous page)

Twice Consecutively,

Remove

Audio Alarm

2

Debris is on the gate's track such as

mud, rocks, dirt, etc.

4

The gate has one or more broken

wheels.

25

3

The gate is hitting a wall or vehicle.

5

A moving vehicle has hit the gate and

the wheel is off the track.

Page 27

SOLENOID/MAGLOCK J3 CONNECTION

J3J3

1

3

Normally Closed

5

7

Common

9

CENTER SAFETY EXIT

2

4

6

8

10

ALARMSENSOR

W4

GB

A

MS LINK

CENTER SAFETY EXIT

2

4

6

8

10

SYSTEM ON

SENSORS

13

ALARM

SENSOR

1

3

5

7

9

COMMAND

13

SENSOR

REVERSE

FIRE

STRIKE

DEPT.

OPEN

PROCESSED

EXIT

SAFETY

LOOP

LOOP

J3J3

DC-BACKUP

TIMER

OPEN LEFT

OFF

RADIO

RECEIVER

CENTER

LOOP

ON

60

OPEN RIGHT

13

GATE

LOCKED

RESET

MOTOR

POWER

3

OVERLOAD

MADE IN USA

OPEN

STOPCLOSE

Solenoid Lock

#3 Normally Closed

#7 Common

Insert 2 supplied wires

into J3 plug (#3 and #7)

(Motor Harness)

Connection of a Solenoid or Magnetic Lock can be made

using the J3 plug and three wires supplied with the unit.

Solenoid Lock

Ground

Wire Nut

Power

Ground

Magnetic Lock

Solenoid / Maglock J3 Connection

2

4

6

8

10

J3J3

1

3

5

7

9

Insert 2 supplied wires

into J3 plug (#7 and #8)

(Motor Harness)

#7 Common

#8 Normally Open

Ground

Wire Nut

Power

Ground

Normally Open

Relay Contact Rating

0.5 A - 125 Vac

1 A - 24 VDC

Plug-In

Transformer

Magnetic

Lock

Plug-In

Transformer

26

Page 28

RADIO RECEIVER PROGRAMMING

Note: Hand Held

NOT

Remote

with Gate Operator.

Up to 31 Security Plus, Passport

remotes or unlimited dip switch

remotes can be used.

Programming Radio Receiver:

Press and

Within that time, press a desired button on your hand held remote for

to program the radio receiver.

Repeat

Release

the “Learn Button”. LED will light for 30 seconds.

this process for every hand held remote to be used with the gate operator.

Erase ALL Remote Control Codes:

Press and

now erased.

Hold

the “Learn Button” until LED turns off (6 seconds).

Included

3 seconds

All

codes are

Radio Receiver Programming

Mini 3 Button

Part #

970LM

Optional

Part #

Part #

Part #

Part #

Hand Held Remotes

971LM

972LM

Op

Part #

Part #

ional

t

CPT1

CPT2

Products

973LM

974LM

27

Part #

Part #

CPT3

CPT4

Mini 3 Button

Part #

CPTK3

Mini 3 Button with

HID Prox. Sensor

Part #

CPTK3PH

Page 29

EMERGENCY RELEASE

Allen wrench

drill bit size is 5/16"

Crank Tool

Turn the power

OFF!

Push

the crank tool in hole. Safety releases will separate. Turn the crank to open the gate.

Push In

Note:

You may use a cordless

power drill (6”/sec) for quicker

opening in non-emergency

situations.

Emergency Release

28

Page 30

OPTIONAL EMERGENCY RELEASE

Fire Release Box

Part # CP17

Turn the power OFF to the gate operator

and unlock the fire box.

Optional Emergency Release

Op

roduct

P

ional

t

Pull firmly on the “T” Handle

to release the chain.

The chain is held in place by a spring loaded pin.

For More Details,

ask your Local Dealer

29

Page 31

OPTIONAL FACTORY INSTALLED DC2000

Plug in the 12 pin plug into the DC2000 control unit. Make sure the “System ON” and “Charge OK” LEDs are

1

lit. If the “Battery Low” led comes on, the battery needs to charge before it can be used.

2

Make sure “Gate Direction” setting on DC2000 is set the same as the gate operator's setting.

ional

t

Op

duct

ro

P

CLASS I, II, III, IV

s

s

e

n

r

a

H

0

0

0

2

C

D

DO NOT wire 110 Vac power to the DC2000

Important: All devices

wired to the DC2000

be dedicated to it alone.

Normal operation will be

controlled by separate

devices wired to the

OmniControl™ board.

Socket

6

5

4

3

2

1

Motor Safety Wires

DO NOT Remove

System Setup

“Manual” setting: The DC2000 will respond to the input devices wired to the J 20 socket.

This mode can also be used as an emergency override. If 110 Vac power is on, but the system has an electronic

malfunction, the gate can be operated using the DC2000 system with input devices wired to J 20 socket.

“Auto” setting: The DC2000 opens the gate automatically upon 110 Vac power failure and stays open. When 110

Optional Factory Installed DC2000

Vac power is restored, the gate operator will return to normal operation. (The gate can be closed by manual

command)

MUST

7

Manual

Mode

Auto

Mode

110 Vac Power

Failure

Push and Hold to

operate gate

Gate automatically

opens

110 Vac Power On,

OmniControl™ Board Malfunction

Turn the 110 Vac power off then

push and Hold to operate gate

Turn the 110 Vac power off then gate

opens automatically

30

110 Vac Power On,

Emergency Override

Push and Hold to override

the OmniControl™ board

Push and Hold to override

the OmniControl™ board

Page 32

WIRING OPTIONAL DC2000 DEVICES

Important: All devices wired to the DC2000 MUST be dedicated to it alone. Normal operation will be

controlled by separate devices wired to the OmniControl™ board.

If the DC2000 is automatically opening the gate due to a power failure, any manual command such as

“One-Button”, “Three Push Button”, “Key Switch”, “Photo Beam” or “Edge Sensor” will cancel the automatic

mode of the DC2000. After such cancellation, the DC2000 will continue to operate in manual mode until 110 Vac

power is restored.

Manual One-Button

76

5

4

3

2

1

DO Not Remove the

2 Factory Installed

Wires in the

J 20 Socket

ional

t

Op

Products

Part #

AEXITP

Push and

“Hold”

Push again and

to Open

“Hold”

to Close

Wiring Optional DC2000 Devices

Key Switch

1

EMERGENCY OVERRIDE

If 110 Vac power is on, but the

system has an electronic

malfunction, the gate can be

operated using the DC2000

system with

devices shown.

ANY

of these

76

5

4

3

2

Part #

A1KX

Turn and

Turn again and

“Hold”

to Open

“Hold”

to Close

Radio Receivers

76

5

4

3

2

1

12 V

6

5

4

4

Jumper P2:

to Momentary (M)

Jumper P3:

to 12 Volt

1

2

3

4

Three-Button

76

5

4

3

2

1

N.O.

3

N.O.

2

N.O.

1

Com

Com

Com

12 VDC Radio Receiver

Back-Up Operation Only

Part #

412HM

4

Button Two:

Back-Up

Operation

4

(DC2000)

4

Normal Gate Operation

to OmniControl

board

Button Three:

Optional Accessories

®

24 VDC radio receiver to be

used by OmniControl™

Board ONLY

Button One:

Normal Gate Operation

(OmniControl™ Board)

3 Push Button

Part #

02-103

Push and

“Hold”

a Button to operate

Push and

“Hold”

Push again and

31

DC2000 Transmitter Button to Open

“Hold”

DC2000 Transmitter Button to Close

Page 33

CENTER SAFETY EXIT

CENTER SAFETY EXIT

FIRE

DEPT.

13

STRIKE

OPEN

RADIO

RECEIVER

TIMER

SYSTEM ON

EXIT

LOOP

ALARM

SENSOR

REVERSE

SENSOR

OPEN

STOPCLOSE

SAFETY

LOOP

CENTER

LOOP

GATE

LOCKED

60

POWER

OVERLOAD

OFF

W4

OPEN LEFT

DC-BACKUP

ALARMSENSOR

OPEN RIGHT

3

SENSORS

RESET

MOTOR

13

13

COMMAND

PROCESSED

ON

GB

MS LINK

A

MADE IN USA

CLASS I, II, III, IV

1

3

2

7

6

5

4

Part #

AOMRON12V

WIRING OPTIONAL DC2000 SAFETY DEVICES

Edge Sensor

UL Listed 3 Sided Sensor

OmniControl™ Board

Sensor Connection

P

O

W

E

R

O

V

E

R

L

O

A

D

D

C

-B

A

C

K

U

P

ALARM

SENSOR

USE ONLY 12 VDC FAILSAFE PHOTO BEAM SENSORS

FOR THIS SAFETY OPTION

Failsafe Photo Beam: If a photo beam is not working, loses

power or photo beam is blocked, then the photo beam will

stop all gate operation.

Photo Beam Sensor

12 VDC

Power +12 VDC

Power Ground

Important:

DO NOT

remove any existing

attached wires from the

Sensor/Alarm connector.

Wiring Optional DC2000 Safety Devices

DO Not Remove the

2 Factory Installed Wires

in the J 20 Socket

Contact your local dealer

for more information.

4

6

Part #s

G65MGO20

G65MGR20

G65MGS20

Op

t

ional

Products

32

Page 34

OPTIONAL FACTORY INSTALLED HEATER

TOUCH

DON’T

Connect the black, white and ground wire from the heater to the 110 Vac power supply as shown. When the

heater switch is left in the “ON” position, the heater will turn on and off automatically when needed.

Switch should

remain in the

“ON” position.

4

W

Power Supply

(110 Vac)

N

FF

O

O

S

L

P

o

Gr

White N

Bla

C

e

e

AUT

c

n Gro

k

120 VAC

eu

und

ION

t

ral

DON’T

TOUCH

Heater may be

HOT when the

switch is “ON”!

ional

t

Op

duct

ro

P

Green Wires

w

e

r

W

i

r

e

s

(Ground)

Black Wires

(110 Vac)

Optional Factory Installed Heater

33

White Wires

(Neutral)

Page 35

Q

C

C

A

B

O

P

E

N

S

T

O

P

C

L

O

S

EM

A

G

L

O

C

K

A

L

A

R

M

A

R

M

E

D

M

/S

L

IN

K

+

QCC Access Socket

+

QCC Access ID (Top Positive)

Q

C

C

A

B

O

PEN STO

P

CLO

SE

M

AGLO

CK ALARM

ARM

ED

M

/S

LINK

Mode of Operation Switch

CENTER SAFETY EXIT

CENTER SAFETY EXIT

FIRE

DEPT.

13

STRIKE

OPEN

RADIO

RECEIVER

TIMER

SYSTEM ON

EXIT

LOOP

ALARM

SENSOR

REVERSE

SENSOR

OPEN

STOPCLOSE

SAFETY

LOOP

CENTER

LOOP

GATE

LOCKED

60

POWER

OVERLOAD

OFF

W4

OPEN LEFT

DC-BACKUP

ALARMSENSOR

OPEN RIGHT

3

SENSORS

RESET

MOTOR

13

13

COMMAND

PROCESSED

ON

GB

MS LINK

A

MADE IN USA

QCC

AB

OPEN STOP CLOSE MAGLOCK ALARM

ARMED

M/S LINK

QCC

AB

OPEN STOP CLOSE MAGLOCK ALARM

ARMED

M/S LINK

2 3 4 5 6 7 8 9 10 11 12 13 14 15116

QCC socket with QCC access ID inserted

QCC “Mode of Operation” switch

Omni Option Board Part # OOMNIEXB

QCC Access ID Part # OQCCOMNI

Gnd

Gnd

Gnd

Gnd

Gnd

B

A

N.O.

N.O.

N.O.

N.O.

N.C.

N.C.

N.C.

Com

Com

QCC is designed for slide gate operators only!

OPTIONAL OMNI OPTION BOARD DESCRIPTION

OPTIONAL QCC (QUICK CLOSE CIRCUIT)

Optional Omni Option

Board Description

Optional QCC

Quick Close Circuit

– Open Command

– Stop Command

– Close Command

– Common

– Normally Closed

– Normally Open

Maglock

1

& 2

3 & 4

5 & 6

7

8

9

Master/

Second

or

RS485

– Burglar Alarm Output

– Burglar Alarm Input

– Ground

– B

– A

10

& 11

12

& 13

14

15

16

Solenoid

Op

t

ional

P

ro

duct

Op

t

ional

Products

Omni Option Board

Part # OOMNIEXB

Mode A (switch OFF)

If the gate is closing while a car is driving over the safety loop, the QCC will stop the gate

for a second then open the gate while the car is over the safety loop detector. As soon as the car leaves the safety

loop, the QCC will resume closing the gate.

Mode B (switch ON)

If the gate is closing, and a vehicle drives over the safety loop, the QCC will stop the gate. It will not open the gate.

After the vehicle leaves the safety loop, the QCC will close the gate.

The QCC can operate in two different modes. The mode of operation will depend

on the switch setting on the Omni Option Board.

34

Page 36

OPTIONAL HOUSE ALARM/PROXIMITY SWITCH WITH OMNI OPTION BOARD

Omni Option Board

Part # OOMNIEXB

CENTER SAFETY EXIT

QCC

W4

AB

OPEN STOP CLOSE MAGLOCK ALARM

M/S LINK

GB

A

ARMED

MS LINK

CENTER SAFETY EXIT

SYSTEM ON

SENSORS

13

13

ALARM

SENSOR

FIRE

DEPT.

COMMAND

PROCESSED

EXIT

LOOP

QCC

AB

OPEN STOP CLOSE MAGLOCK ALARM

ARMED

M/S LINK

10 11 12 13

ALARMSENSOR

DC-BACKUP

TIMER

POWER

60

3

OVERLOAD

13

OFF

ON

MADE IN USA

SENSOR

OPEN

REVERSE

OPEN LEFT

OPEN RIGHT

GATE

STRIKE

RADIO

LOCKED

OPEN

RECEIVER

SAFETY

CENTER

RESET

LOOP

LOOP

MOTOR

Use Low Voltage

STOPCLOSE

Wire 20 AWG

Alarm

10 – Common

11 – Normally Open

Armed

12 – Normally Closed

13 – Ground

OmniControl™ Board

12VDC

House Alarm System

Dry Contact

2"

M

ax

.

ional

t

House Alarm

Op

Products

Proximity Switch

Part # APRS

OPTIONAL MASTER / SECOND WITH OMNI OPTION BOARD

Omni Option Board

Part # OOMNIEXB

ED

M/S LIN

M/S L IN K

Optional House Alarm /Proximity

Switch with Omni Option Board

Optional Master / Second

with Omni Option Board

CENTER SAFETY EXIT

QCC

W4

AB

GB

A

MS LINK

OPEN STOP CLOSE MAGLOCK ALARM

CENTER SAFETY EXIT

BAG

ALARMSENSOR

DC-BACKUP

ARMED

SENSORS

ALARM

13

SENSOR

SYSTEM ON

M/S LINK

COMMAND

PROCESSED

FIRE

DEPT.

EXIT

LOOP

13

TIMER

OFF

SENSOR

REVERSE

OPEN LEFT

STRIKE

RADIO

OPEN

RECEIVER

SAFETY

CENTER

LOOP

LOOP

60

ON

OPEN RIGHT

LOCKED

MOTOR

13

GATE

RESET

POWER

3

OVERLOAD

MADE IN USA

OPEN

STOPCLOSE

Use this socket (M/S LINK) if the Omni

Option Board is being used, and

Master/Second option is needed.

Op

ro

P

ional

t

duct

35

Page 37

OPTIONAL SOLENOID CONNECTION WITH OMNI OPTION BOARD

7 – Common

8 – Normally Closed

SE MAGLOCKMAGLOCK AL

9 – Normally Open

CENTER SAFETY EXIT

ALARMSENSOR

60

13

ON

OPEN RIGHT

RADIO

GATE

RECEIVER

LOCKED

CENTER

RESET

LOOP

MOTOR

0.5 A - 125 Vac

1 A - 24 VDC

DC-BACKUP

POWER

3

OVERLOAD

MADE IN USA

OPEN

STOPCLOSE

QCC

W4

AB

GB

A

MS LINK

OPEN STOP CLOSE MAGLOCK ALARM

with Omni Option Board

CENTER SAFETY EXIT

ARMED

Optional Solenoid Connection

Omni Option Board

M/S LINK

Op

SYSTEM ON

SENSORS

ALARM

SENSOR

P

13

13

FIRE

STRIKE

DEPT.

OPEN

COMMAND

PROCESSED

EXIT

SAFETY

ional

LOOP

LOOP

t

roduct

TIMER

OFF

SENSOR

REVERSE

OPEN LEFT

Relay Contact Rating

Part # OOMNIEXB

OPTIONAL MAGLOCK CONNECTION WITH OMNI OPTION BOARD

SE MAGLOCKMAGLOCK AL

CENTER SAFETY EXIT

Solenoid Lock

7

8

9

Ground

Plug-In

Transformer

Power

Ground

7 – Common

8 – Normally Closed

9 – Normally Open

ALARMSENSOR

60

13

ON

OPEN RIGHT

RADIO

GATE

RECEIVER

LOCKED

CENTER

RESET

LOOP

MOTOR

0.5 A - 125 Vac

1 A - 24 VDC

DC-BACKUP

POWER

3

OVERLOAD

MADE IN USA

OPEN

STOPCLOSE

QCC

W4

AB

GB

A

MS LINK

OPEN STOP CLOSE MAGLOCK ALARM

with Omni Option Board

CENTER SAFETY EXIT

ARMED

Optional Maglock Connection

M/S LINK

Op

SYSTEM ON

SENSORS

ALARM

SENSOR

P

13

13

FIRE

STRIKE

DEPT.

OPEN

COMMAND

PROCESSED

EXIT

SAFETY

LOOP

LOOP

ional

t

roduct

TIMER

OFF

SENSOR

REVERSE

OPEN LEFT

Relay Contact Rating

Omni Option Board

Part # OOMNIEXB

36

7 9

8

Ground

Magnetic

Lock

Plug-In

Transformer

Power

Ground

Page 38

OPTIONAL THREE PUSH BUTTON STATION

Omni Option Board

Omni Option Board Needed to Preform This Function

Part # OOMNIEXB

OPENOPEN STOPSTOP CLOSECLOSE

3 Push Button

02-103

Part #

N.O.

N.C.

N.O.

Com

Com

Com

Three Push Button System

351

642

W4

(OPEN-STOP-CLOSE)

Step 1 - Cut jumper wire #W4.

Step 2 - Install Omni option board.

Step 3 - Connect OPEN push button to 1 & 2 .

Step 4 - Connect STOP push button to 3 & 4 .

Step 5 - Connect CLOSE push button to 5 & 6 .

iona

t

Op

o

Pr

CENTER SAFETY EXIT

l

ts

uc

d

QCC

W4

AB

GB

A

MS LINK

OPEN STOP CLOSE MAGLOCK ALARM

CENTER SAFETY EXIT

SYSTEM ON

M/S LINK

ARMED

SENSORS

13

13

ALARM

SENSOR

FIRE

DEPT.

COMMAND

PROCESSED

EXIT

SAFETY

LOOP

DC-BACKUP

TIMER

60

3

13

OFF

ON

SENSOR

REVERSE

OPEN LEFT

OPEN RIGHT

GATE

STRIKE

RADIO

LOCKED

OPEN

RECEIVER

RESET

CENTER

MOTOR

LOOP

LOOP

Note: If using the Master/Second board

configuration, unplug the Master/Second

link plug on main board and connect it into

the Omni option board M/S link socket.

Caution: Make sure each push button is dry

contact and there are no jumper wires

between them.

POWER

OVERLOAD

OPEN

STOPCLOSE

ALARMSENSOR

MADE IN USA

Important! The Stop button must be ”Normally Closed”. 2, 4 and 6

are common on Omni Option Board for a 4 wire installation.

OPTIONAL STOP BUTTON ALARM SHUT-OFF

Omni Option Board

Part # OOMNIEXB

OPEN STOPSTOP CLOSE

Omni Option Board Needed to perform this function.

Optional Three Push

Button Station

Optional Stop Button

3 - N.C.

Stop Button

Part #

AEXITP

3

12

4

34

56

4 - Com

Install the stop button in a