Page 1

OWNER'S MANUAL

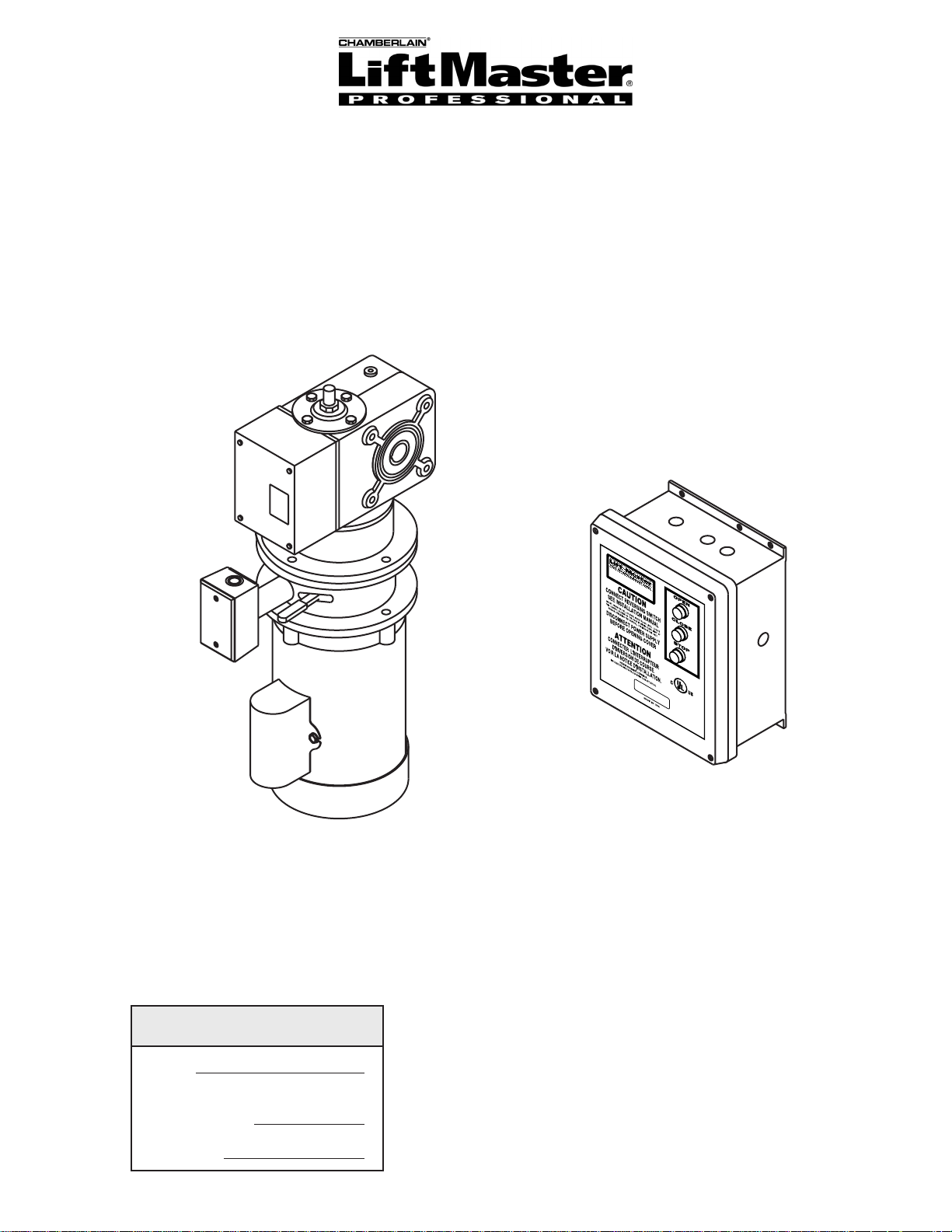

MODEL SJ

SPEED JACKSHAFT OPERATOR

THE

CHA

ELM

M

BER

HUR

LAIN G

ST, ILLIN

RO

OIS 60126

UP, IN

C.

2 YEAR WARRANTY

Serial #

(located on electrical box cover)

Installation Date

41

B6

LIS

PLACE RATING L

TED DOO

R

O

ABEL HERE

PERAT

OR

NOT FOR RESIDENTIAL USE

Wiring Type

Page 2

SPECIFICATIONS

MOTOR

TYPE:....................................AC Synchronous

continuous duty

ENCLOSURE:.......................ODP NEMA 56c face

mount.

HORSEPOWER:...................1 HP

Single or Three phase

SPEED:.................................1725 RPM

VOLTAGE:.............................115 & 230 Single phase

230 & 460 Three phase

575 Three phase

CURRENT:..................................See motor nameplate

DRIVE SYSTEM

CONTINUOUS

POWER RATING: .................260 Ft-Lbs/Sec

GEAR BOX:..........................Worm gear

LUBRICATION:.....................Oil Bath

RATIO: ..................................45:1

OUTPUT SPEED: .................38 rpm

DOOR SPEED:.........................10 - 17" per sec.

depending on door

ELECTRICAL

TRANSFORMER:...............1PH: 120/240 VAC 24VAC

3PH: 240/480 VAC 24VAC

3PH: 575 VAC 24VAC

CONTROL STATION: ........NEMA 4 three button station.

OPEN/CLOSE/STOP

WIRING TYPE: ...................Standard C2 Wiring- Standard

operators are shipped from the factory set for C2 wiring,

which requires momentary contact to open, constant

pressure to close, stop on reverse.

B2 Wiring Option- Dip switch selectable, momentary contact

to open, close and stop. Entrapment protection device must

be included.

Wiring for sensing device to reverse and auxiliary devices to

open and close with open override.

LIMIT ADJUST: ..................Rotary driven, fully

adjustable screw type cams. Adjustable to 30 feet.

ACCESSORY POWER

AVAILABLE:.......................115V & 230V Single Phase -

25VA

230V & 460V Three Phase -

25VA

575V Three Phase - 40VA

DUTY CYCLE: ......................25 Reversing cycles per hour

BRAKE:.................................24VDC electromagnetic disc

EGJ DIMENSIONS

12.36”

4.73”

8.38”

2.76”

SAFETY

SAFETY EYES: ..............Liftmaster CPS-LN4

REVERSING EDGE:.......(Optional) Electric or pneumatic

sensing device attached to the bottom edge of door.

A REVERSING EDGE IS STRONGLY RECOMMENDED

ALL

FOR

REQUIRED

IS OUT OF SIGHT OF DOOR OR ANY OTHER

CONTROL (AUTOMATIC OR MANUAL) IS USED.

3.94”

COMMERCIAL OPERATOR INSTALLATIONS.

WHEN THE 3 BUTTON CONTROL STATION

See Chart

9.13”

1/2” HEX

1” DIA. WITH

1/4” KEYWAY

PHASE

HP

1

1

1

3

DIMENSION

22-3/8”

21-1/8”

2

Page 3

WARNING

CAUTION

WARNING

WARNING

WARNING

IMPORTANT SAFETY NOTES

CAUTION

TO AVOID DAMAGE TO DOOR AND OPERATOR,

MAKE ALL DOOR LOCKS INOPERATIVE. SECURE

LOCK(S) IN "OPEN" POSITION.

IF THE DOOR LOCK NEEDS TO REMAIN

FUNCTIONAL, INSTALL AN INTERLOCK SWITCH.

DO NOT CONNECT ELECTRIC POWER UNTIL

INSTRUCTED TO DO SO.

KEEP DOOR BALANCED. STICKING OR BINDING

DOORS MUST BE REPAIRED. DOORS, DOOR

SPRINGS, CABLES, PULLEYS, BRACKETS AND

THEIR HARDWARE MAY BE UNDER EXTREME

TENSION AND CAN CAUSE SERIOUS PERSONAL

INJURY. CALL A PROFESSIONAL DOOR

SERVICEMAN TO MOVE OR ADJUST DOOR

SPRINGS OR HARDWARE.

WARNING

SITE PREPARATIONS

It is imperative that the wall or mounting surface provide adequate support for the operator. The safety and wear

of the operator will be adversely affected if any of the following requirements are not met.

a) Mounting surface to be rigid to prevent play between operator and door shaft.

b) Provide a level base.

c) Permit the operator to be fastened securely and with the drive shaft parallel to the door shaft.

INSTALLATION INSTRUCTIONS

TYPICAL SHAFT INSTALLATION

1. Slide the shaft collar supplied over the door shaft to

desired position and secure in place.

2. Slide the operator on the door shaft until it contacts the

shaft collar. Insert the 4-1/2” key supplied into the operator

and the door shaft.

3. Slide the second shaft collar on the door shaft until it

contacts the operator and secure in place, this will hold the

4-1/2” key in place.

4. Mount torque arm using 5/16-18 x 1” hex bolt to gear

box as shown in figures 1 & 2.

NOTE: For additional help refer to the illustrations below.

Shaft

Collar

Hex Bolt

Shaft Collar

Hex Bolt

Door

Shaft

4-1/2” Key

T or que Arm

FIGURE 1

Right hand unit shown, hex bolts and

torque arms supplied by others, Door

side plates removed for clarity.

Part of Door

FIGURE 2

Right hand unit shown installed, Door

side plates removed for clarity.

Page 4

ENTRAPMENT PROTECTION ACCESSORIES (OPTIONAL)

SAFETY EYES:

Compatible with Liftmaster CPS-LN4 direct connect failsafe

photoeyes.

SENSING EDGES

All types of sensing edges with an isolated normally open

(N.O.) output are compatible with your operator. This

includes pneumatic and electric edges. If your door does

not have a bottom sensing edge and you wish to purchase

one, contact the supplier of your operator.

If not pre-installed by the door manufacturer, mount the

sensing edge on the door according to the instructions

provided with the edge. The sensing edge may be

electrically connected by either coiled cord or take-up reel.

Refer to the steps below.

Important Notes:

a) Proceed with Limit Switch Adjustments before making

any sensing edge wiring connections to operator as

described below.

b) Electrician must hardwire the junction box to the

operator electrical box in accordance with local codes.

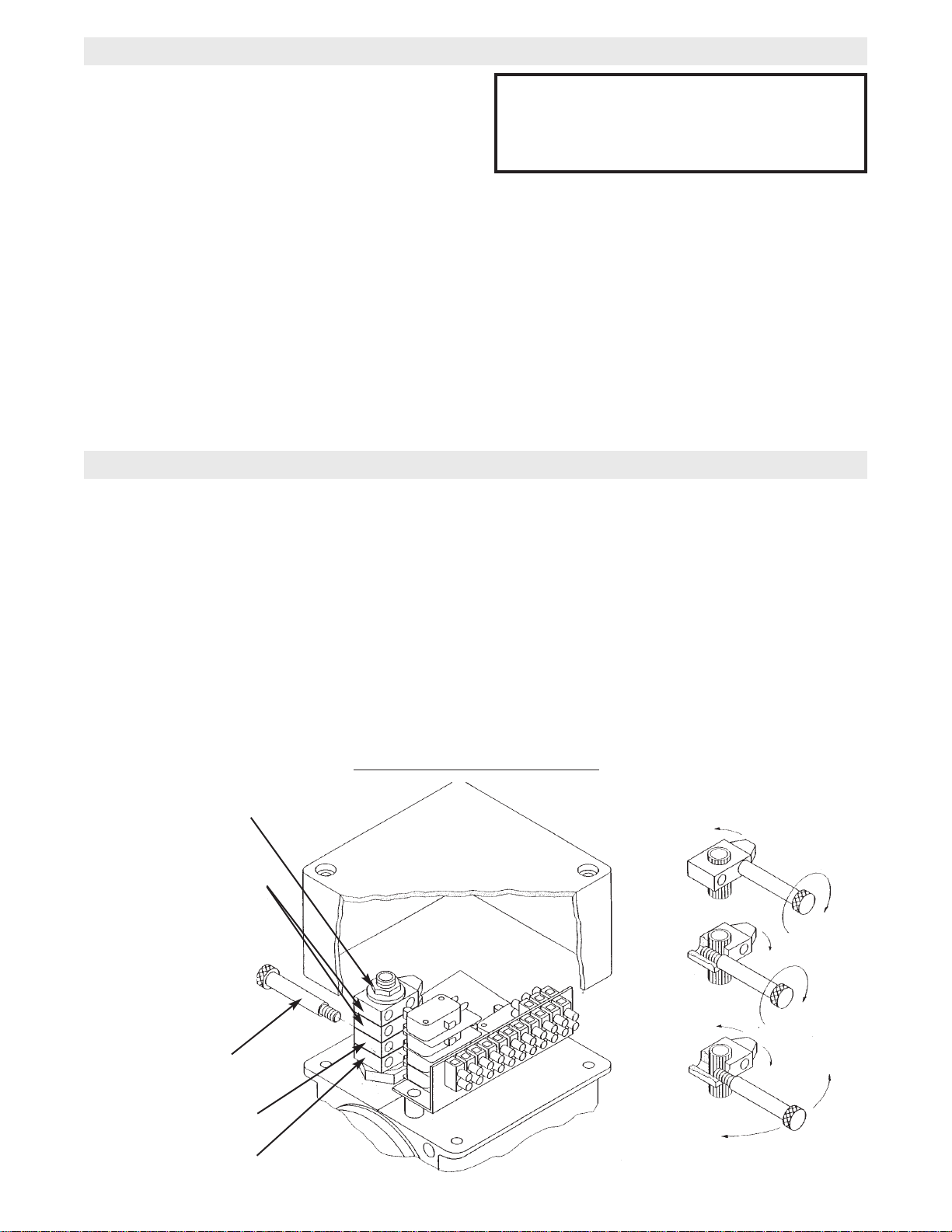

LIMIT SWITCH ADJUSTMENT

THE LIMIT SWITCHES WILL STOP THE DOOR AT EACH

END OF TRAVEL. ADDITIONAL LIMIT SWITCHES CAN

BE USED FOR CONTROL OF OTHER AUTOMATIC

FUNCTIONS.

NOTE: Before starting adjustment of the limit switches,

loosen or tighten (if necessary) the lock nut in order to

obtain a convenient adjustment tightness of the cam

wheels. After finishing the adjustments, make sure that the

lock nut is sufficiently tight 1 NM (8”LBS) to retain the cam

wheels securely during operation.

When door is in the fully open position, the green cam

wheel (Open) will be turned into contact with its

corresponding switch. In the same way, just before the

door is in the closed position, the black cam wheel (Closed)

will activate its switch.

IT IS STRONGLY RECOMMENDED THAT A

SENSING EDGE OR OTHER ENTRAPMENT

PROTECTION DEVICE BE USED IN

CONJUNCTION WITH THIS OPERATOR.

WIRING:

For wiring of your sensing device to the operator,

refer to the wiring diagram supplied with your

operator. See field connection terminals identified as

Sensing Device or Safety Edge.

TAKE-UP REEL: Take-up reel should be installed

12" above the top of the door.

COIL CORD: Connect operator end of coil cord to

junction box (not supplied) fastened to the wall

approximately halfway up the door opening.

COARSE ADJUSTMENT

The coarse adjustment of the limit switches can be done by

inserting a rod or a screw driver into one of the adjustment

holes in the cam wheels and by turning each cam wheel

with the rod or screw driver.

FINE ADJUSTMENT

Fine adjustment can be done by screwing the adjustment

screw (supplied) against the cam shaft thread inside each

cam wheel. The screw must be changed from one

adjustment hole into the other for turning the cam wheel in

the opposite direction.

Lock Nut

Auxiliary Limit Switches

(When Supplied)

Adjustment Screw

Close Limit (Black)

Open Limit (Green)

LIMIT BOX ON POWERHEAD

FINE

ADJUSTMENT

CCW

CW

COARSE

ADJUSTMENT

4

Page 5

WARNING

POWER WIRING CONNECTIONS

Remove the cover from the wall mounted starter. Inside this enclosure you will find the wiring diagram(s)

for your unit. Refer to the wiring diagrams for all connections described below. If this diagram is missing,

call the number on the back of this manual. DO NOT INSTALL ANY WIRING OR ATTEMPT TO RUN THIS

OPERATOR WITHOUT CONSULTING THE WIRING DIAGRAM.

POWER WIRING

1. Be sure that the power supply is of the correct

voltage, phase, frequency, and amperage to supply the

operator. Refer to the operator nameplate on the

cover.

2. Drill recommended 7/8” dia. holes at approximate

locations shown below, and bring supply lines to the

wall mounted starter and connect wires to the

terminals indicated on the WIRING CONNECTIONS

DIAGRAM.

IN ORDER TO KEEP NEMA-4 INTEGRITY,

“LIQUIDTITE” CONDUIT CONNECTIONS MUST BE

USED.

DISCONNECT POWER AT THE FUSE BOX BEFORE

PROCEEDING.

OPERATOR MUST BE PROPERLY GROUNDED AND

CONNECTED IN ACCORDANCE WITH LOCAL

ELECTRICAL CODES. NOTE: THE OPERATOR

SHOULD BE ON A SEPARATE FUSED LINE OF

ADEQUATE CAPACITY.

ALL ELECTRICAL CONNECTIONS MUST BE MADE

BY A QUALIFIED INDIVIDUAL.

WARNING

WARNING

DO NOT TURN POWER ON UNTIL YOU HAVE

FINISHED MAKING ALL POWER AND CONTROL

WIRING CONNECTIONS AND HAVE COMPLETED

THE LIMIT SWITCH ADJUSTMENT PROCEDURE.

IMPORTANT: THIS UNIT MUST BE PROPERLY

GROUNDED. A GROUND SCREW IS SUPPLIED IN

THE ELECTRICAL BOX FOR CONNECTION OF

THE POWER SUPPLY GROUND WIRE. FAILURE TO

PROPERLY GROUND THIS UNIT COULD RESULT

IN ELECTRIC SHOCK AND SERIOUS INJURY.

Recommended 7/8” Dia hole for

limit conduit access

THE CHAMBERLAIN GROUP, INC.

ELMHURST, ILLINOIS 60126

41B

6

LIS

P

TED

L

A

C

E

D

R

A

O

T

IN

O

G

R

L

O

A

B

E

P

L

E

H

R

E

R

ATO

E

R

TO AVOID DAMAGE TO DOOR AND OPERATOR,

MAKE ALL DOOR LOCKS INOPERATIVE. SECURE

LOCK(S) IN "OPEN" POSITION.

IF THE DOOR LOCK NEEDS TO REMAIN

FUNCTIONAL, INSTALL AN INTERLOCK SWITCH.

Recommended 7/8” Dia hole for

brake/electrical disconnect conduit access

Recommended 7/8” Dia hole for

motor conduit access

Recommended 7/8” Dia hole for

power conduit access

Recommended 7/8” Dia hole for

photo eyes conduit access

WARNING

Do Not Run Power &

Control Wiring in the

Same Conduit

Recommended 7/8” Dia hole for

safety edge conduit access

5

Page 6

CONTROL WIRING

WARNING

DETERMINE WIRING TYPE

Refer to the wiring diagram located on the inside cover the electrical box to determine the type of control wiring.

SPECIAL CONTROL WIRINGWIRING TYPES

Standard C2 Wiring

Standard operators are shipped from the factory set

for C2 wiring, which requires momentary contact to

open, constant pressure to close, stop on reverse.

If your operator was shipped from the factory with

non-standard control wiring or with optional

accessories that require additional instructions, refer

to the wiring diagram(s) indicated in the special

control wiring data box. When a replacement wiring

B2 Wiring Option

Dip switch selectable, momentary contact to open,

close and stop. Entrapment protection device must

diagram is present, wiring diagrams in this manual

will not apply. Refer only to the replacement wiring

diagram for all connections.

be included.

IMPORTANT NOTE: If your wiring diagram is

missing, or you are unsure of the wiring type for

your operator, contact the customer service

department @ 1-800-528-2806.

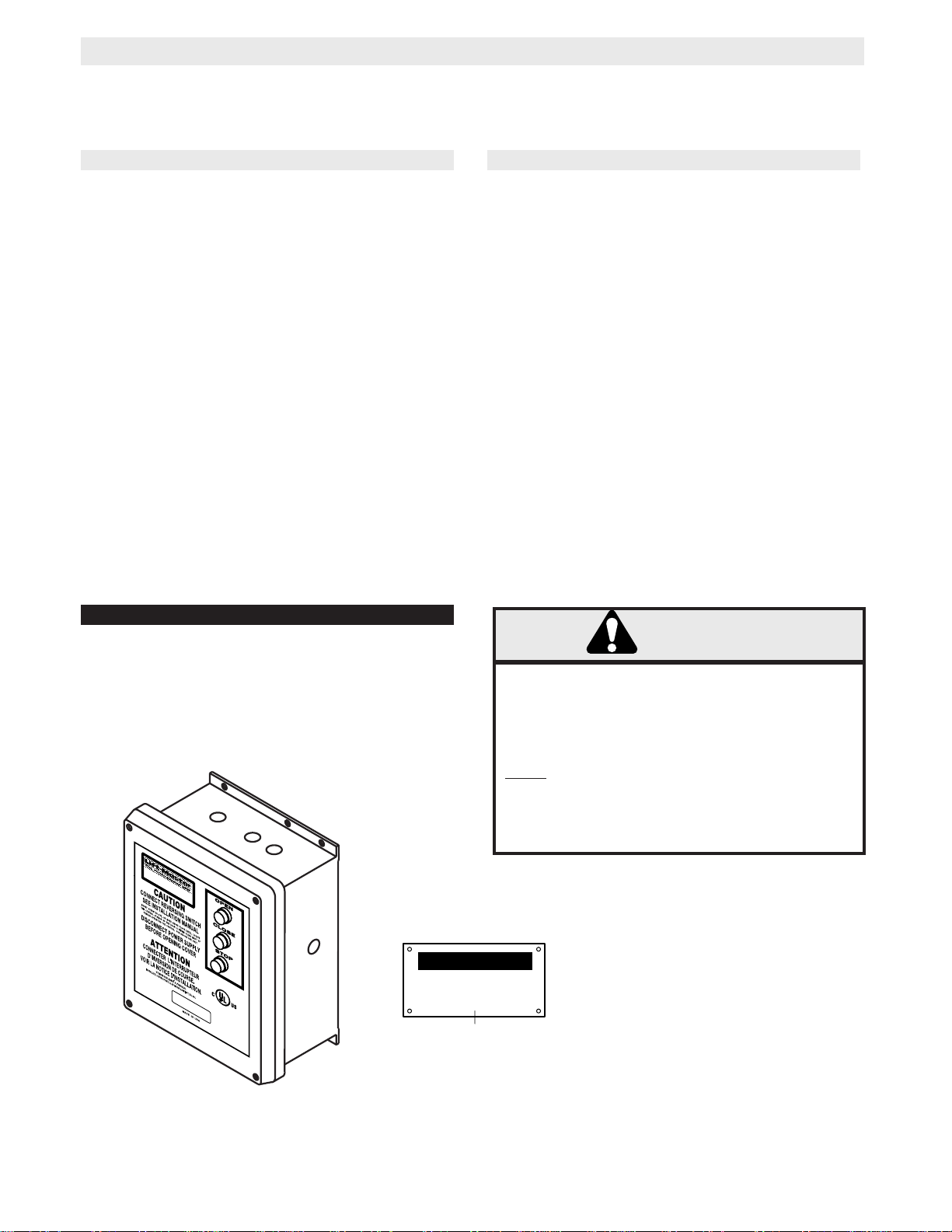

LOCATING THE CONTROL STATION

All operators are supplied with a three button station (OPEN/CLOSE/STOP) incorporated into the wall mounted

starter. Mount the wall mounted starter where the door is visible, but not directly underneath the door, operator, or

mounting hardware.

MOUNT WARNING NOTICE

IMPORTANT: Mount WARNING NOTICE beside or

below the wall mounted starter.

WARNING

THE CHAM

ELMHURST, ILLINO

BERLAIN GROUP, INC

INSTALL THE WALL MOUNTED STARTER WHERE

THE DOOR IS VISIBLE, BUT AWAY FROM THE DOOR

AND ITS HARDWARE. IF STARTER CANNOT BE

INSTALLED WHERE DOOR IS VISIBLE, OR IF ANY

DEVICE OTHER THAN THE CONTROL STATION IS

USED TO A CTIVATE THE DOOR,

MUST

DOOR.

BE INSTALLED ON THE BOTTOM OF THE

FAILURE TO INSTALL A REVERSING EDGE

A REVERSING EDGE

UNDER THESE CIRCUMSTANCES MAY RESULT IN

SERIOUS INJURY OR DEATH TO PERSONS

TRAPPED BENEATH THE DOOR.

IS 60126

.

WARNING

4

1

B

6

L

IS

P

T

L

E

A

C

D

E

D

R

A

O

TING

O

R

L

O

A

BE

P

L

E

H

R

E

R

A

E

T

O

R

TO PREVENT ENTRAPMENT

DO NOT START DOOR DOWNWARD

UNLESS DOORWAY IS CLEAR

WARNING Notice

6

Page 7

CONTROL WIRING (con’t)

WARNING

WARNING

Radio Controls

All radio controls must have dry contact relay

outputs. Power for radio is to be supplied by an

outside source. Do not take power from the

components inside the electrical enclosure.

Additional Access Control Equipment

Locate any additional access control equipment as desired (but so that the door will be in clear sight of the person

operating the equipment), and connect to the terminal block in the electrical enclosure as shown on the FIELD

WIRING CONNECTIONS diagram. Any control with a normally (N.O.) isolated output contact may be connected

in parallel with the OPEN button. More than one device may be connected in this manner. Use 16 gauge wire or

larger for all controls. DO NOT USE THE CONTROL CIRCUIT TRANSFORMER (24VAC) IN THE OPERATOR

TO POWER ANY ACCESS CONTROL EQUIPMENT OTHER THAN A STANDARD RESIDENTIAL TYPE RADIO

RECEIVER.

DO NOT USE RADIO CONTROLS WITH YOUR

OPERATOR UNLESS YOU HAVE INSTALLED

SOME TYPE OF ENTRAPMENT PROTECTION

DEVICE. THE USE OF RADIO CONTROLS

PRESENTS POTENTIAL HAZARDS DUE TO THE

USER’S ABILITY TO OPEN OR CLOSE THE

DOOR WHEN OUT OF SIGHT OF THE DOOR.

WARNING

Manual Release Brake

The operator is equipped with a internal interlock switch mounted to the brake assembly. When the brake is

manually dis-engaged the control circuit will be disabled, thereby preventing electrical operation of the door from

the control devices.

The operator has been pre-wired to accept

WARNING

IF CONTROL STATION CANNOT BE INSTALLED WHERE

DOOR IS VISIBLE, OR IF ANY DEVICE OTHER THAN

THE CONTROL STATION IS USED TO ACTIVATE THE

DOOR,

THE BOTTOM OF THE DOOR.

REVERSING EDGE UNDER THESE CIRCUMSTANCES

MAY RESULT IN SERIOUS PERSONAL INJURY OR

DEA TH TO PERSONS TRAPPED BENEATH THE DOOR.

A REVERSING EDGE MUST BE INSTALLED ON

FAILURE TO INSTALL A

NOTICE:

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference, in which case the user will be required to correct

the interference at his own expense.

connection of a reversing edge device. Connect the

normally open contacts to terminals 5 and 6 located

on the LMPLC board. An auxiliary limit switch (yellow)

will deactivate the safety device during the last few

inches of the door’s downward travel.

7

Page 8

CONTROL WIRING (con’t)

Auxiliary Contacts

Three auxiliary normally open dry contacts will be

available. They will accept a max. of 15 amps, 120V

AC/DC. Terminal Block J2 located on the LMPLC

board is used to access these contacts.

1) Terminal J2-17 and J2-18 will close when the door

is fully closed.

POWER WIRING

POWER WIRING CONNECTIONS

1. Connect power wires to the J1 terminal block

located on the Printed Circuit Board (shown below).

(See wiring diagram page 11, 13, and 15)

2) Terminal J2-19 and J2-20 will close when the door

is stopped at any position other than fully closed.

3) Terminal J2-21 and J2-22 will close when the door

is in motion.

Single button control is available as an optional

device and is wired to terminals J2-11 and J2-12 on

the LMPLC board.

CONTROL STATION WIRING

CONTROL WIRING CONNECTIONS

1. Connect control wires to the J2 terminal block

located on the Printed Circuit Board (shown below).

(See wiring diagram page 11, 13 and 15)

GROUND WIRING

1. Connect earth ground to chassis ground screw in the

electrical box enclosure marked with the label shown

below.

40-10033B

2. Use same conduit entry into the electrical box as the

power wiring.

(See wiring diagram page 11, 13 and 15)

2. Apply power to the operator. Press OPEN push

button and observe direction of door travel and then

Press the STOP button.

If door did not move in the correct direction, check for

improper wiring at the control station or between

operator and control station.(See page 19)

8

Page 9

OPTIONAL CONTROL SETTINGS

NOTE: All functions are independent of each other and do not require other control settings to be set at any

certain configuration. For dip switch location refer to illustration below. All switches are factory preset to the “OFF”

position.

SI-1 WIRING TYPE - B2 wiring in the OFF position and C2 wiring in the ON position.

SI-2 NOT USED

SI-3 NOT USED

SI-4 INFRARED EYES STATE - The operator will support Chamberlain (CPS LN4) Infrared Eyes when

enabled, and ignore IR inputs when disabled.

TERMINAL

BLOCK (J1)

ON (C2)

1 2 3 4

OFF (B2)

DIP SWITCH (S1)

TERMINAL

BLOCK (J2)

ON (IR'S ENABLED)

1 2 3 4

OFF (IR'S DISABLED)

NOTICE:

This equipment has been tested and found to

comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide

reasonable protection against harmful

interference when the equipment is operated

in a commercial environment. This equipment

generates, uses, and can radiate radio

frequency energy and, if not installed and used

in accordance with the instruction manual,

may cause harmful interference to radio

communications. Operation of this equipment

in a residential area is likely to cause harmful

interference, in which case the user will be

required to correct the interference at his own

expense.

HEAT SINK

9

Page 10

TEST THE SYSTEM

WARNING

Turn on power. Test all controls and safety devices to

make sure they are working properly. It will be

necessary to refer back to page 4 for fine adjustment

of the limit switches.

IMPORTANT NOTES:

Do not leave operator power on unless all safety

and entrapment protection devices have been

tested and are working properly.

Be sure you have read and understand all Safety

Instructions included in this manual.

Be sure the owner or person(s) responsible for

operation of the door have read and understand

the Safety Instructions, know how to electrically

operate the door in a safe manner, and know how

to use the manual disconnect operation of the

door operating system.

WARNING

DO NOT PLACE HANDS OR TOOLS IN OR NEAR

THE OPERATOR WHEN THE POWER IS ON OR

WHEN TESTING CONTROL OR SAFETY

DEVICES. ALWAYS DISCONNECT POWER

BEFORE SERVICING OR ADJUSTING THE

OPERATOR.

10

Page 11

115V - 208/230V 1 PHASE SCHEMATIC DIAGRAM

02264-1

T1

T2

T3

T4

115 VOLT - 1 PHASE

MOTOR CONNECTION

OUTPUTS

CLOSED WHEN DOOR IS IN

MOTION

CLOSED WHEN THE DOOR IS

STOPPED AT ANY POSITION

OTHER THAN FULLY CLOSED

CLOSED WHEN THE DOOR IS

FULLY CLOSED

ACCESSORY POWER 25VA

INTERNAL TIMER

DEFEAT SWITCH

(RD)

EXTERNAL

TIMER

(RD)

GY

BL

YE

PU

3

1

8

5

4

2

J14

J13

T2- NOT USED

J15

(RD)

R1

J12

J9

J8

14 15 16 17 18 19 20 21 22 23 24

13

12345 67 8 9101112

GY

T1

YE

T3

PU

T4

1

2

8

BL

5

4

208/230 VOLT - 1 PHASE

MOTOR CONNECTION

AX

CL

OP

(BL)(RD)(YE)

J3

(WH)

(RD)

(BL)

(BR)

(OR)

7

4

1

(BL)

J30

J4

ZILOG PROCESSOR

3

B1

S1

J2

AUXILARY CLOSE

LIMIT SWITCH

(YELLOW)

CLOSE LIMIT

SWITCH

(BLACK)

OPEN LIMIT

SWITCH

(GREEN)

(WH)

DC BRAKE

(WH)

WIRE NUTWIRE NUT

B2

(BL/BK)(BL/BK)

J17

J16

J19

J18

NOTES:

1) TO REVERSE MOTOR DIRECTION: REVERSE

PURPLE AND GREY MOTOR WIRES (T1 AND T4).

2) USE 16 GAUGE OR HEAVIER WIRE, FOR ALL

CONTROL CIRCUIT WIRING.

3) SEE OWNERS MANUAL FOR DIP SWITCH

FUNCTIONS AND PROGRAMMING PROCEDURES.

8

5

2

J27

INTERNAL

INTERLOCK

J21

J22

J26

(BK)

(BK)

J5

(YE)

(BL)

(RD)

J1

L1 L2 L3

WIRE NUT

CM

ED2

(YE)

J24

J23

J6

J7

(OR)

J25

J28

J20

J29

(GY)

(PU)

(BL)

ED1

(RD)

CHASSIS

GROUND

T3

T1

T4

T2

CPS LN4

PHOTO EYES

(BR)

R1

REVERSE

EDGE

(BR)

11

OPEN

CLOSE

STOP

(YE)

(PU)

(RD)

(OR)

24V

TRANSFORMER

BRAKE

AND

BOARD

SECONDARY

(BK)

1PH.

(BK)

POWER IN

OVERLOAD

SINGLE BUTTON CONTROL

RADIO 412HM

COM

PRIMARY LINE VOLTAGE

PRIMARY

(WH)

CHASSIS

GROUND

(BK)

Page 12

115V - 208/230V 1 PHASE FIELD CONNECTION DIAGRAM

WALL MOUNTED

STARTER

CPS LN4

PHOTO EYES

SAFTEY EDGE

SINGLE BUTTON CONTROL

RADIO 412HM

DOOR IS FULLY OPEN

WHEN THE DOOR IS

STOPPED AT ANY POSITION

OTHER THAN FULLY OPEN

DOOR IS IN MOTION

POWERHEAD

LIMIT BOX

1

2

3

4

THESE TERMINALS ARE

5

LOCATED ON THE LMPLC

BOARD

6

7

8

9

10

11

12

17

*

18

19

*

20

21

*

22

DRY CONTACTS ONLY. NORMALLY

*

OPEN 15 AMPS 120V AC/DC MAX.

1PH

POWER IN

GROUND

GROUND

L1

L2

L3

T1

T2

T3

T4

T1

T3

T4

ED2

ED1

B1

B2

OP

CM

CL

AX

WIRE NUTS

115V 1 PHASE

MOTOR

208/230V 1PH

MOTOR

(WH)

(WH)

1

4

7

DC BRAKE

(GREEN)

(BLACK)

(YELLOW)

INTERNAL

INTERLOCK

2

5

8

OPEN LIMIT SWITCH

CLOSE LIMIT SWITCH

AUXILIARY CLOSE

LIMIT SWITCH

12

Page 13

208/230V - 460V 3 PHASE SCHEMATIC DIAGRAM

02264-3

T1

T2

T3

OUTPUTS

CLOSED WHEN DOOR IS IN

MOTION

CLOSED WHEN THE DOOR IS

STOPPED AT ANY POSITION

OTHER THAN FULLY CLOSED

CLOSED WHEN THE DOOR IS

FULLY CLOSED

ACCESSORY POWER 25VA

INTERNAL TIMER

DEFEAT SWITCH

(RD)

GY

PUR

YEL

1

2

3

7

4

85

9

6

208/230 VOLT - 3 PHASE

MOTOR CONNECTION

J14

(RD)

J8

GY

T1

PUR

T2

YEL

T3

1

2

3

7

4

85

9

6

460 VOLT - 3 PHASE

MOTOR CONNECTION

AUXILARY CLOSE

LIMIT SWITCH

AX

CL

J3 J4

J15

J13

J12

J9

13 14 15 16 17 18 19 20 21 22 23 24

(WH)

(RD)

(BL)

(BR)

OP

(BL)(BL)(RD)(YE)

ZILOG PROCESSOR

7

4

1

(YELLOW)

CLOSE LIMIT

SWITCH

(BLACK)

OPEN LIMIT

SWITCH

(GREEN)

(WH)

(WH)

WIRE NUTWIRE NUT

B1

B2

(BL/BK)(BL/BK)

J17

J30

J19

J18

S1

J2

DC BRAKE

J16

INTERNAL

INTERLOCK

J21

NOTES:

1) TO REVERSE MOTOR DIRECTION: REVERSE

PURPLE AND GREY MOTOR WIRES (T1 AND T2).

2) USE 16 GAUGE OR HEAVIER WIRE, FOR ALL

CONTROL CIRCUIT WIRING.

3) SEE OWNERS MANUAL FOR DIP SWITCH

FUNCTIONS AND PROGRAMMING PROCEDURES.

8

5

2

WIRE NUT

(BK)

(BK)

CM

J5

J23

(RD)

J20

ED1

ED2

(YE)

J24

(PU)

J6

(GY)

J7

(BK)

J25

(BK)

J28

(RD)

CHASSIS

GROUND

T3

T2

T1

EXTERNAL

TIMER

(RD)

R1

12345 67 8 9101112

(OR)

OPEN

CPS LN4

PHOTO EYES

R1

REVERSE

EDGE

(OR)

CLOSE

STOP

(YE)

(PU)

(RD)

J22

J26

J27

(BL)

SINGLE BUTTON CONTROL

RADIO 412HM

J1

L1 L2 L3

3PH

POWER IN

(BK)

J29

(BK)

(BR)

(BR)

(BK)

(BK)

T3

L3

T2

L2

L1

T1

95

96

TRANSFORMER

(WH)

(BK)

(BR)

24V

SECONDARY

BRAKE

AND

BOARD

COM

PRIMARY LINE VOLTAGE

PRIMARY

13

Page 14

208/230V - 460V 3 PHASE FIELD CONNECTION DIAGRAM

WALL MOUNTED

STARTER

CPS LN4

PHOTO EYES

SAFTEY EDGE

SINGLE BUTTON CONTROL

RADIO 412HM

DOOR IS FULLY OPEN

WHEN THE DOOR IS

STOPPED AT ANY POSITION

OTHER THAN FULLY OPEN

DOOR IS IN MOTION

POWERHEAD

LIMIT BOX

1

2

3

4

5

6

7

8

9

10

11

12

17

*

18

19

*

20

21

*

22

THESE TERMINALS ARE

LOCATED ON THE LMPLC

BOARD

DRY CONTACTS ONLY. NORMALLY

*

OPEN 15 AMPS 120V AC/DC MAX.

3PH

POWER IN

GROUND

L1

L2

L3

T1

T2

T3

ED2

ED1

B1

B2

OP

CM

CL

AX

WIRE NUTS

208/230V - 460V

3 PHASE MOTOR

(WH)

(WH)

1

4

7

DC BRAKE

(GREEN)

(BLACK)

(YELLOW)

INTERNAL

INTERLOCK

2

5

8

OPEN LIMIT SWITCH

CLOSE LIMIT SWITCH

AUXILIARY CLOSE

LIMIT SWITCH

14

Page 15

575V 3 PHASE SCHEMATIC DIAGRAM

02264-53

OUTPUTS

CLOSED WHEN DOOR IS IN

MOTION

CLOSED WHEN THE DOOR IS

STOPPED AT ANY POSITION

OTHER THAN FULLY CLOSED

CLOSED WHEN THE DOOR IS

FULLY CLOSED

INTERNAL TIMER

DEFEAT SWITCH

(RD)

EXTERNAL

TIMER

(RD)

R1

(RD)

AX

CL

J14

J8

CPS LN4

PHOTO EYES

J13

J12

J9

J3 J4

J15

(RD)

(BR)

13 14 15 16 17 18 19 20 21 22 23 24

12345 678 9101112

(OR)

R1

(BR)

OP

(WH)

REVERSE

EDGE

(OR)

7

4

1

(BL)(BL)(RD)(YE)

J30

ZILOG PROCESSOR

OPEN

(YE)

CLOSE

(PU)

(RD)

STOP

B1

S1

J2

24V

AUXILARY CLOSE

LIMIT SWITCH

(YELLOW)

CLOSE LIMIT

SWITCH

(BLACK)

OPEN LIMIT

SWITCH

(GREEN)

(WH)

DC BRAKE

(WH)

WIRE NUTWIRE NUT

B2

(BL/BK)(BL/BK)

J17

J16

J19

J18

TRANSFORMER

BRAKE

AND

BOARD

SECONDARY

8

5

2

INTERNAL

INTERLOCK

J21

J22

J26

J27

(BL)

SINGLE BUTTON CONTROL

RADIO 412HM

575V

PRIMARY

(BK)

(BK)

J5

(RD)

L1 L2 L3

575V 3PH.

POWER IN

NOTES:

1) TO REVERSE MOTOR DIRECTION: REVERSE

PURPLE AND GREY MOTOR WIRES (T1 AND T2).

2) USE 16 GAUGE OR HEAVIER WIRE, FOR ALL

CONTROL CIRCUIT WIRING.

3) SEE OWNERS MANUAL FOR DIP SWITCH

FUNCTIONS AND PROGRAMMING PROCEDURES.

CHASSIS

WIRE NUT

CM

ED2

J24

J23

J6

J7

J25

J28

J20

J1

J29

(BK)

(BK)

(BR)

(BR)

(WH)

(BK)

GROUND

ED1

(RD)

(YE)

A1

T3

T1

T2

(BK)

(BK)

(BK)

(BK)

13

5

3

1

(WH) (WH)

A1

13

5

3

1

(YE)

T3

MOTOR

T1

(WH)

(BK)

L3

L2

L1

(GY)

(PU)

T2

T3

T2

T1

95

96

(WH)

575V

(WH)

(WH)

(WH) (WH)

TRANSFORMER

MOTOR

PRIMARY

A2

14

6

(BL)

4

2

A2

14

6

4

2

(BL)

24V

(BL)

SECONDARY

ACCESSORY

POWER

40VA

15

24V

ACCESSORY

TRANSFORMER

SECONDARY

PRIMARY

(BK)

575V

(WH)

Page 16

575V 3 PHASE FIELD CONNECTION DIAGRAM

WALL MOUNTED

STARTER

CPS-LN4

PHOTO EYES

SAFTEY EDGE

SINGLE BUTTON CONTROL

RADIO 412HM

DOOR IS FULLY OPEN

WHEN THE DOOR IS

STOPPED AT ANY POSITION

OTHER THAN FULLY OPEN

DOOR IS IN MOTION

POWERHEAD

LIMIT BOX

1

2

3

4

5

6

7

8

9

10

11

12

17

*

18

19

*

20

21

*

22

THESE TERMINALS ARE

LOCATED ON THE LMPLC

BOARD

DRY CONTACTS ONLY. NORMALLY

*

OPEN 15 AMPS 120V AC/DC MAX.

575V 3PH

POWER IN

GROUND

L1

L2

L3

T1

T2

T3

ED2

ED1

B1

B2

OP

CM

CL

AX

WIRE NUTS

575V 3 PHASE MOTOR

(WH)

(WH)

1

4

7

DC BRAKE

(GREEN)

(BLACK)

(YELLOW)

INTERNAL

INTERLOCK

2

5

8

OPEN LIMIT SWITCH

CLOSE LIMIT SWITCH

AUXILIARY CLOSE

LIMIT SWITCH

16

Page 17

MAINTENANCE SCHEDULE

Check at the intervals listed in the following chart.

EVERY EVERY EVERY

ITEM PROCEDURE 3 MONTHS 6 MONTHS 12 MONTHS

Drive Chain Check for excessive slack.

Check & adjust as required.

Lubricate.*

Sprockets Check set screw tightness

ll

ll

P

P

Fasteners Check & tighten as required

Manual Disconnect Check & Operate

Bearings & Shafts Check for wear & lubricate

☛☛

Use SAE 30 Oil (Never use grease or silicone spray).

nn

Repeat ALL procedures.

nn

Do not lubricate motor. Motor bearings are rated for continuous operation.

nn

Inspect and service whenever a malfunction is observed or suspected.

nn

CAUTION: BEFORE SERVICING, ALWAYS DISCONNECT OPERA TOR FROM POWER SUPPLY.

ll

ll

ll

P

P

P

MOTOR OPERATOR MAINTENANCE

Operators require practically no special maintenance other than periodic checking to see that mechanical parts

where necessary are lubricated and the electrical compartments are clear of dirt.

Service technicians should familiarize themselves with the proper sequence of operation and all related controls.

Power to operator must be disconnected when removing or replacing covers on electrical components, making

adjustments, or performing maintenance.

1. Check wire connections for tightness and wire insulation for defects of abrasions.

2. Check to see that all conduit connections are secure.

3. Check wires to safety edge, or infrared safety eyes, if unit is equipped with a safety to reverse feature.

4. Inspect operation of brake.

5. Inspect gearbox for leaks.

6. Inspect roller chain and drive sprockets. Align, lubricate the sprockets, and tighten the set screws.

7. Generally inspect the motor mounting, and tighten the fasteners and bracing.

8. Verify that all conduit connections are tight and have no exposed wires.

9. Inspect the electrical enclosure for debris, arching and moisture. Check for and tighten loose wiring connections.

10. Test motor operation through all control stations.

11. Check limit switch settings.

12. Examine safety edge, coil cord and take-up reel for damage.

13. Test the operation of the safety edge.

14. Check motor amperage draw for a full open and close cycle. Compare readings to those listed on the motor

nameplate

.

17

Page 18

MOTOR OPERATOR TROUBLE SHOOTING GUIDE

SYMPTOM

Motor does not run when OPEN or

CLOSE button is pushed.

Motor runs but door does not

move.

Motor hums but does not run.

Operator runs in wrong direction

and limits do not function.

POSSIBLE CAUSE

Circuit breaker tripped or power fuse

blown.

Thermal overload tripped.

External interlock open. (if supplied)

Sprocket key missing or drive chain

broken.

Intermediate shaft or key damaged.

Door jammed. Drive train jammed.

Dead phase in 3 phase system.

Brake does not release.

Open motor winding.

On 3 phase operators power supply is out

of phase.

Note: All units are checked for proper rotation at factory. Limit switch adjustment

instructions in electrical enclosure indicates proper direction of travel for OPEN and

CLOSE limit nuts.

Check circuit breaker, power fuses, safety

switch; check cause.

Reset; check cause.

Close interlocks.

Check drive train for operation

Close & lock off door, remove motor and

inspect; check cause.

Check door. Try to operate manually.

Check power supply.

Check power to brake coil.

Check all motor connections.

Interchange any 2 wires in 3O

REPAIR

Limit switches do not hold their

settings.

Door ‘drifts’ when motor shuts off.

Operator does not shut off at full

OPEN or at full CLOSE position.

Operator Functions Erratically

Limit nut loose.

Brake inoperative or worn.

Limits not adjusted properly.

Defective limit switch

Low line voltage

Bad ground

“Noise” on electrical line

Adjust nut to proper torque.

Check brake operation.

Adjust

Operate limit switch manually to determine.

Check line voltage at operator. Low voltage,

check cause.

Check circuit for high current draws.

Eliminate all other units from the circuit.

Check ground connections.

18

Page 19

ILLUSTRATED PARTS – MODEL SJ

Refer to the parts lists below for replacement kits available for your operator. If optional modifications and/or

accessories are included with your operator, certain components may be added or remove from these lists.

Individual components of each kit may not be available. Please consult a parts and service representative

regarding availability of individual components. Refer to page 24 for all repair part ordering information.

INDIVIDUAL PARTS

ITEM PART # DESCRIPTION QTY

1

13-10465

2

80-13713

3

82-HN38-16

4

85-LS-38

5

TVR5

6

See Page 20

7

See Pages 21-23

8

80-10025

1

SHAFT COLLAR

KEY, 1/4” X 4-1/2” LONG

HEX BOLT 3/8-16” X 1” LONG

LOCKWASHER 3/8”

LIMIT GEAR REDUCER

MOTOR

WALL MOUNTED STARTER

SHIM WASHER

5

2

2

1

8

8

1

1

1

8

1

BRAKE KIT, K76-17265

ITEM PART # DESCRIPTION QTY

B1

08-16114-1

B2

11-16112-1

B3

36-16803

B4

80-16113

B5

82-NH10-04

B6

82-SH10-06S

HOUSING (REWORKED)

EXTENSION SHAFT

BRAKE WITH DISCONNECT

STEP KEY

SET SCREW #10-32 X 1/4” LONG

SOCKET HEAD SCREW #10-32

1

1

1

1

4

4

MOUNTING BOX KIT, K75-17264

ITEM PART # DESCRIPTION QTY

M1

M2

M3

27-17190

28-3003

28-3004

1/2” NIPPLE X 3” LONG

MULBERRY MOUNTING BOX

1 GANG BLANK COVER

1

1

1

B1

B5

5

B3

B6

6

B2

B4

8

B5

3

4

M1

M2

M3

7

19

Page 20

REPAIR PARTS KITS - STARTER FOR MODELS SJ1011, 1021, 1023, 1043

Below are replacement kits available for your operator. For replacement of wall mounted starter and or motor kit be sure to

match model number of your unit to kit number below to ensure proper voltage requirements. Optional modifications and/or

accessories included with your operator may add or remove certain components from these lists. Please consult a parts and

service representative regarding availability of individual components of kits specified below. Refer to page 24 for all repair

part ordering information.

Complete Electrical Box Replacement Kits

To order a complete electrical box replacement kit, add a K-

prefix to the model number of your operator. For example:

SJ1011 (Operator) = K-SJ1011 (Elec. Box Kit)

Motor Kits

K20-1100C-2 Models SJ1011 & SJ1021

K20-3100C-4 Models SJ1023 & SJ1043

K20-3100M-5 Models SJ1053

Item

10-17291

1

21-XXXXX

2

25-XXXX

3

25-3000K

4

30-100-2

5

30-111-2

6

30-112-2

7

30-310-2

8

30-301-2

9

42-114

10

44-17258

11

75-13705

12

79-13493

13

82-PX08-04T

14

82-PX08-10T

15

82-PX06-12

16

82-PX06-08T

17

10-17268

18

23-3001

19

24-24-1

20

26-438

21

* COMPLETE ELECTRICAL BOX KITS

P/N

Description

E-BOX SUB PANEL, EGJ

(SEE VARIABLE CHART)

(SEE VARIABLE CHART)

(SEE VARIABLE CHART)

PBO NEMA 4

BLACK BUTTON FC-BK NEMA

RED BUTTON NEMA 1, 12

N.O. CONTACT CB-NO (GREEN)

CBNC CONTACT N.C. (RED)

TERMINAL BLOCK, 14 POSITION

ENCLOSURE ASSEMBLY, 10 X 12

STANDOFF ASSEMBLY

LOGIC BOARD ASSEMBLY

#8-32 PH PH SELF-TAPPED SCREW

#8-32 PH PH SELF-TAPPED SCREW

#6-32 X 3/4” PH HD SCREW

#6-32 PH PH SELF-TAPPED SCREW

SWITCH L-BRACKET

SWITCH, DPST ON/OFF TAG

RELAY, 24V DPDT

ARTISAN TIMER

Qty

1

1

1

1

3

2

1

2

1

1

1

8

1

8

2

1

2

1

1

1

1

Item

2

3

4

P/N

21-16699

21-16698

25-2020

25-2015

25-4004-K

25-4002-5K

25-3000K

Description

TRANSFORMER, 115/208/230-24V

TRANSFORMER, 208/230/460-24V

OVERLOAD, 115V 1PH

OVERLOAD, 230V 1PH

OVERLOAD, 230V 3PH

OVERLOAD, 460V 3PH

OVERLOAD BRACKET

20

SJ1011

SJ1021

SJ1023

SJ1043

Page 21

ILLUSTRATED PARTS- STARTER FOR MODELS SJ1011, 1021, 1023, 1043

10

15

16

13

12

1

20

14

18

14

21

17

19

14

2

14

3

11

4

3

8

9

5

7

5

6

21

Page 22

REPAIR PARTS KITS-WALL MOUNTED STARTER FOR MODEL SJ1053

INDIVIDUAL PARTS

ITEM PART # DESCRIPTION QTY

1

03-8024K

2

10-17172

3

21-5575

4

25-3000K

5

25-4001-8K

6

30-100-2

7

30-111-2

8

30-112-2

9

30-310-2

10

30-301-2

11

42-114

12

44-1614-HWPL

13

75-13705

14

79-13493

15

82-PX06-08T

16

82-PX08-04T

17

82-PX08-10T

18

82-PX06-12

19

10-17257

20

23-3001

21

24-24-1

22

26-438

K LINE CONTACTOR

E-BOX SUB PANEL, MODELSJ1053

TRANSFORMER 575V-24V

OVERLOAD BRACKET

OVERLOAD 575V 3PH

PBO NEMA 4

BLACK BUTTON FC-BK NEMA

RED BUTTON NEMA 1, 12

N.O. CONTACT CB-NO (GREEN)

CBNC CONTACT N.C. (RED)

TERMINAL BLOCK, 14 POSITION

ENCLOSURE ASSEMBLY, 14 X 16

STANDOFF ASSEMBLY

LOGIC BOARD ASSEMBLY

#6-32 PH PH SELF-TAPPED SCREW

#8-32 PH PH SELF-TAPPED SCREW

#8-32 PH PH SELF-TAPPED SCREW

#6-32 X 3/4” PH HD SCREW

SWITCH BRACKET

SWITCH, DPST ON/OFF TAG

RELAY, 24V DPDT

ARTISAN TIMER

1

1

3

1

1

3

2

1

2

1

1

1

8

1

4

12

2

1

1

1

1

1

22

Page 23

ILLUSTRATED PARTS – WALL MOUNTED STARTER FOR MODEL SJ1053

18

13

16

14

11

4

17

5

10

16

3

15

22

2

9

16

19

6

8

6

7

20

3

16

16

3

15

1

16

21

23

12

Page 24

CONTROL CONNECTION DIAGRAM

IMPORTANT NOTES:

The 3-Button Control Station provided must be connected for operation.

3 BUTTON STATION

SENSING DEVICE TO REVERSE

J2

LOCATED ON

LMPLC BOARD

6 7 8

Open

9 10 11 12

LOCATED ON

LMPLC BOARD

Close

Stop

HOW TO ORDER REPAIR PARTS

OUR LARGE SERVICE ORGANIZATION

SPANS AMERICA

INSTALLATION AND SERVICE INFORMATION

ARE AVAILABLE 6 DAYS A WEEK

CALL OUR TOLL FREE NUMBER - 1-800-528-2806

HOURS 7:00 TO 3:30 p.m. (Mountain Std. Time)

MONDAY Through SATURDAY

5

J2

Sensing Device

6

01-17192C

WHEN ORDERING REPAIR PARTS

PLEASE SUPPLY THE FOLLOWING INFORMATION:

PART NUMBER DESCRIPTION MODEL NUMBER

ADDRESS ORDER TO:

THE CHAMBERLAIN GROUP, INC.

Electronic Parts & Service Dept.

2301 N. Forbes Blvd., Suite 104

Tucson, AZ 85745

c

2000, The Chamberlain Group, Inc.

All rights Reserved

Loading...

Loading...